Cisco Firepower 2120, Firepower 2110, Firepower 2140, Firepower 2130 Hardware Installation Manual

Page 1

Cisco Firepower 2100 Series Hardware Installation Guide

First Published: 2017-05-25

Last Modified: 2017-06-20

Americas Headquarters

Cisco Systems, Inc.

170 West Tasman Drive

San Jose, CA 95134-1706

USA

http://www.cisco.com

Tel: 408 526-4000

800 553-NETS (6387)

Fax: 408 527-0883

Page 2

THE SPECIFICATIONS AND INFORMATION REGARDING THE PRODUCTS IN THIS MANUAL ARE SUBJECT TO CHANGE WITHOUT NOTICE. ALL STATEMENTS,

INFORMATION, AND RECOMMENDATIONS IN THIS MANUAL ARE BELIEVED TO BE ACCURATE BUT ARE PRESENTED WITHOUT WARRANTY OF ANY KIND,

EXPRESS OR IMPLIED. USERS MUST TAKE FULL RESPONSIBILITY FOR THEIR APPLICATION OF ANY PRODUCTS.

THE SOFTWARE LICENSE AND LIMITED WARRANTY FOR THE ACCOMPANYING PRODUCT ARE SET FORTH IN THE INFORMATION PACKET THAT SHIPPED WITH

THE PRODUCT AND ARE INCORPORATED HEREIN BY THIS REFERENCE. IF YOU ARE UNABLE TO LOCATE THE SOFTWARE LICENSE OR LIMITED WARRANTY,

CONTACT YOUR CISCO REPRESENTATIVE FOR A COPY.

The Cisco implementation of TCP header compression is an adaptation of a program developed by the University of California, Berkeley (UCB) as part of UCB's public domain version

of the UNIX operating system. All rights reserved. Copyright©1981, Regents of the University of California.

NOTWITHSTANDING ANY OTHER WARRANTY HEREIN, ALL DOCUMENT FILES AND SOFTWARE OF THESE SUPPLIERS ARE PROVIDED “AS IS" WITH ALL FAULTS.

CISCO AND THE ABOVE-NAMED SUPPLIERS DISCLAIM ALL WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT LIMITATION, THOSE OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT OR ARISING FROM A COURSE OF DEALING, USAGE, OR TRADE PRACTICE.

IN NO EVENT SHALL CISCO OR ITS SUPPLIERS BE LIABLE FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL, OR INCIDENTAL DAMAGES, INCLUDING, WITHOUT

LIMITATION, LOST PROFITS OR LOSS OR DAMAGE TO DATA ARISING OUT OF THE USE OR INABILITY TO USE THIS MANUAL, EVEN IF CISCO OR ITS SUPPLIERS

HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Any Internet Protocol (IP) addresses and phone numbers used in this document are not intended to be actual addresses and phone numbers. Any examples, command display output, network

topology diagrams, and other figures included in the document are shown for illustrative purposes only. Any use of actual IP addresses or phone numbers in illustrative content is unintentional

and coincidental.

Cisco and the Cisco logo are trademarks or registered trademarks of Cisco and/or its affiliates in the U.S. and other countries. To view a list of Cisco trademarks, go to this URL: http://

www.cisco.com/go/trademarks. Third-party trademarks mentioned are the property of their respective owners. The use of the word partner does not imply a partnership

relationship between Cisco and any other company. (1110R)

©

2017 Cisco Systems, Inc. All rights reserved.

Page 3

CONTENTS

CHAPTER 1

CHAPTER 2

Overview 1

Cisco Firepower 2100 Series Features 1

Deployment Options 3

Package Contents 4

Serial Number Location 6

Front Panel 6

Front Panel LEDs 9

Rear Panel 14

Network Modules 15

Power Supply Modules 17

Fans 20

SSDs 20

Supported SFP/SFP+ Transceivers 20

Hardware Specifications 23

Installation Preparation 27

CHAPTER 3

Installation Notes and Warnings 27

Safety Recommendations 30

Maintain Safety with Electricity 30

Prevent Electrostatic Discharge Damage 31

Site Environment 31

Site Considerations 31

Power Supply Considerations 31

Equipment Rack Configuration Considerations 32

Mount and Connect 33

Rack-Mount the Chassis 33

Ground the Chassis 38

Cisco Firepower 2100 Series Hardware Installation Guide

iii

Page 4

Contents

Connect Cables, Turn on Power, and Verify Connectivity 39

CHAPTER 4

Maintenance and Upgrades 43

Remove and Replace the Network Module 43

Remove and Replace the SSD 45

Remove and Replace the Power Supply Module 46

Connect the DC Power Supply Module 48

Secure the Power Cord on the Power Supply Module 51

Remove and Replace the Fan Tray 54

Install the Optional Cable Management Brackets 55

Cisco Firepower 2100 Series Hardware Installation Guide

iv

Page 5

CHAPTER 1

Overview

This chapter describes the hardware features of the Cisco Firepower 2100 security appliance, and contains

the following sections:

Cisco Firepower 2100 Series Features, page 1

•

Deployment Options, page 3

•

Package Contents, page 4

•

Serial Number Location, page 6

•

Front Panel, page 6

•

Front Panel LEDs, page 9

•

Rear Panel, page 14

•

Network Modules, page 15

•

Power Supply Modules, page 17

•

Fans, page 20

•

SSDs, page 20

•

Supported SFP/SFP+ Transceivers, page 20

•

Hardware Specifications, page 23

•

Cisco Firepower 2100 Series Features

The Cisco Firepower 2100 series security appliance is a standalone modular security services platform. The

series includes the Firepower 2110, 2120, 2130, and 2140.

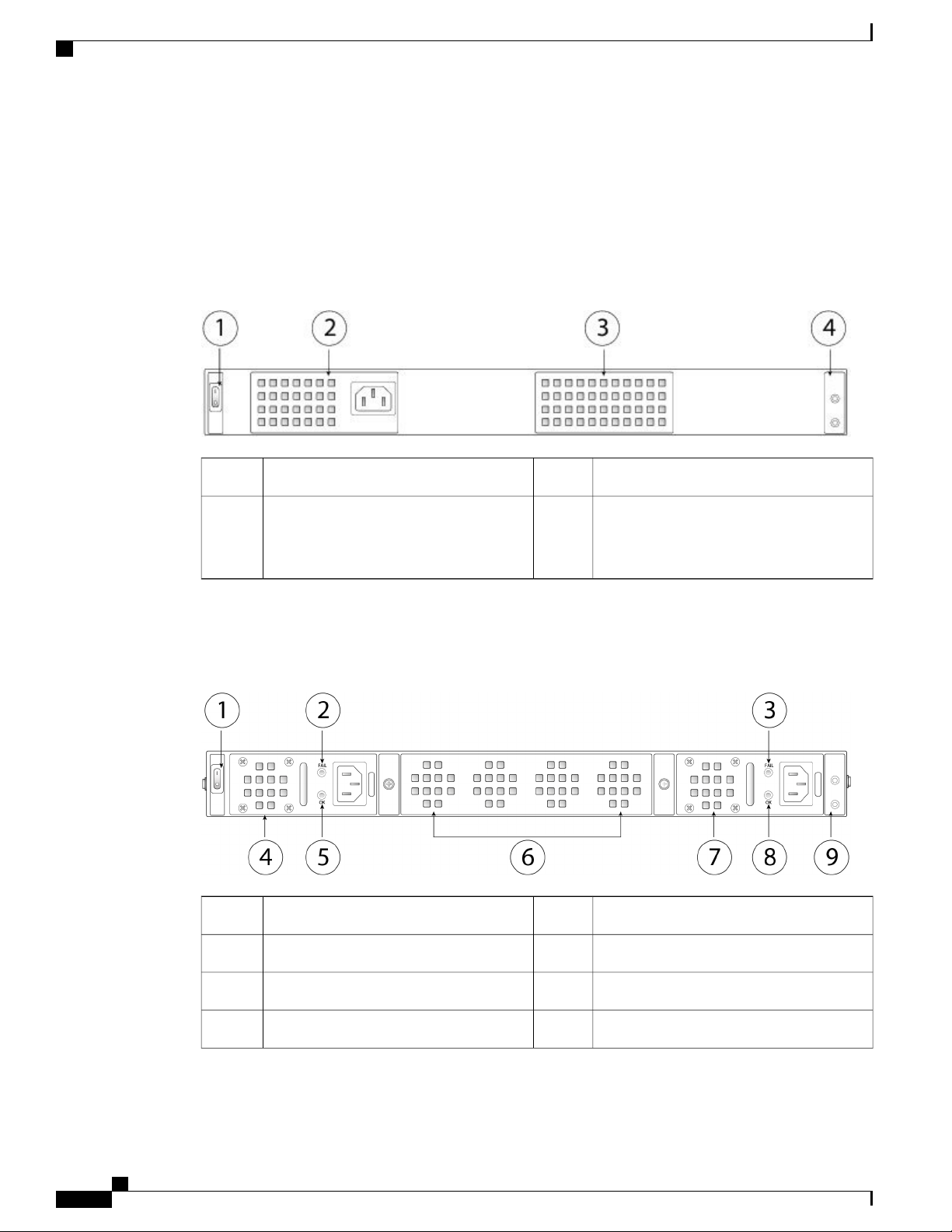

Figure 1: Firepower 2110/2120 and Firepower 2130/2140

Cisco Firepower 2100 Series Hardware Installation Guide

1

Page 6

Cisco Firepower 2100 Series Features

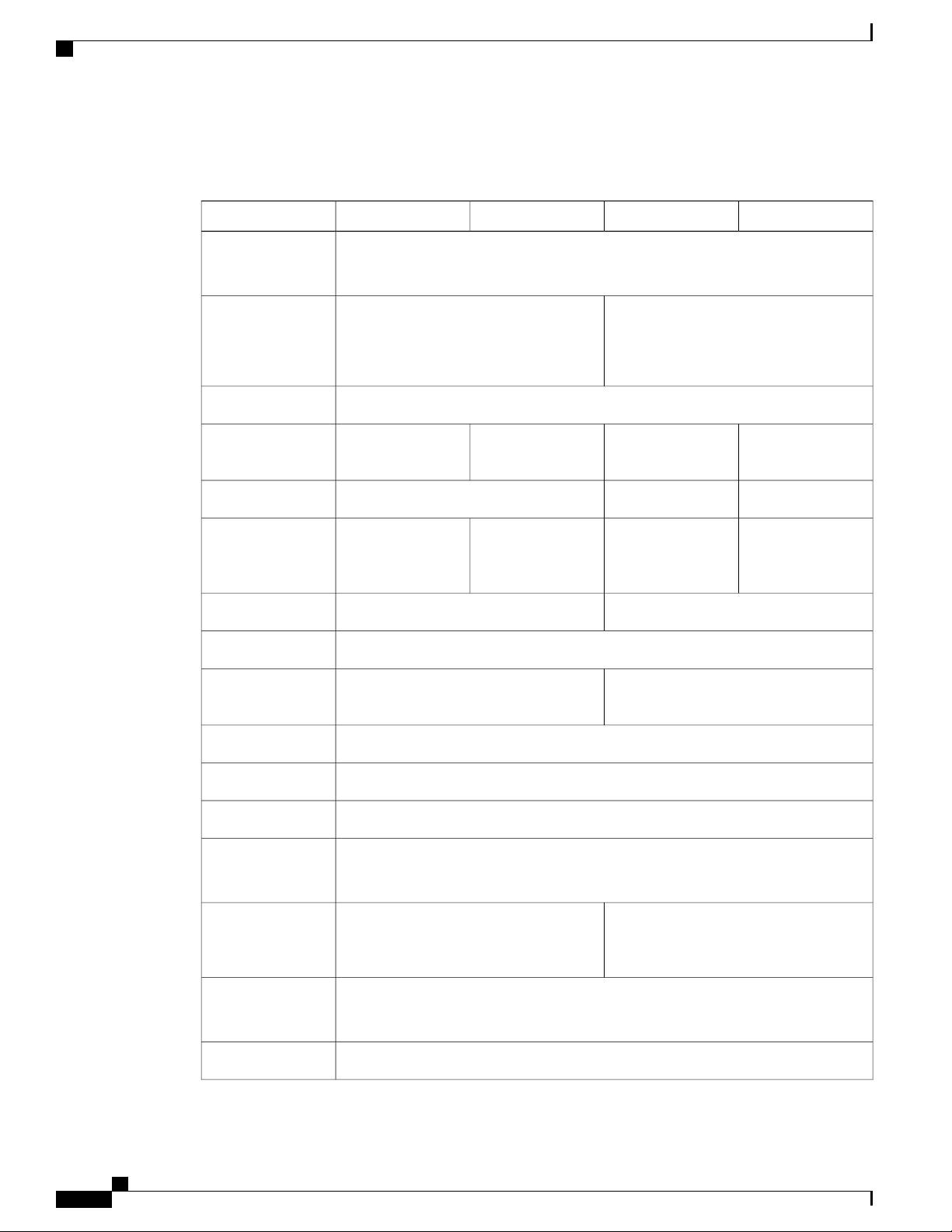

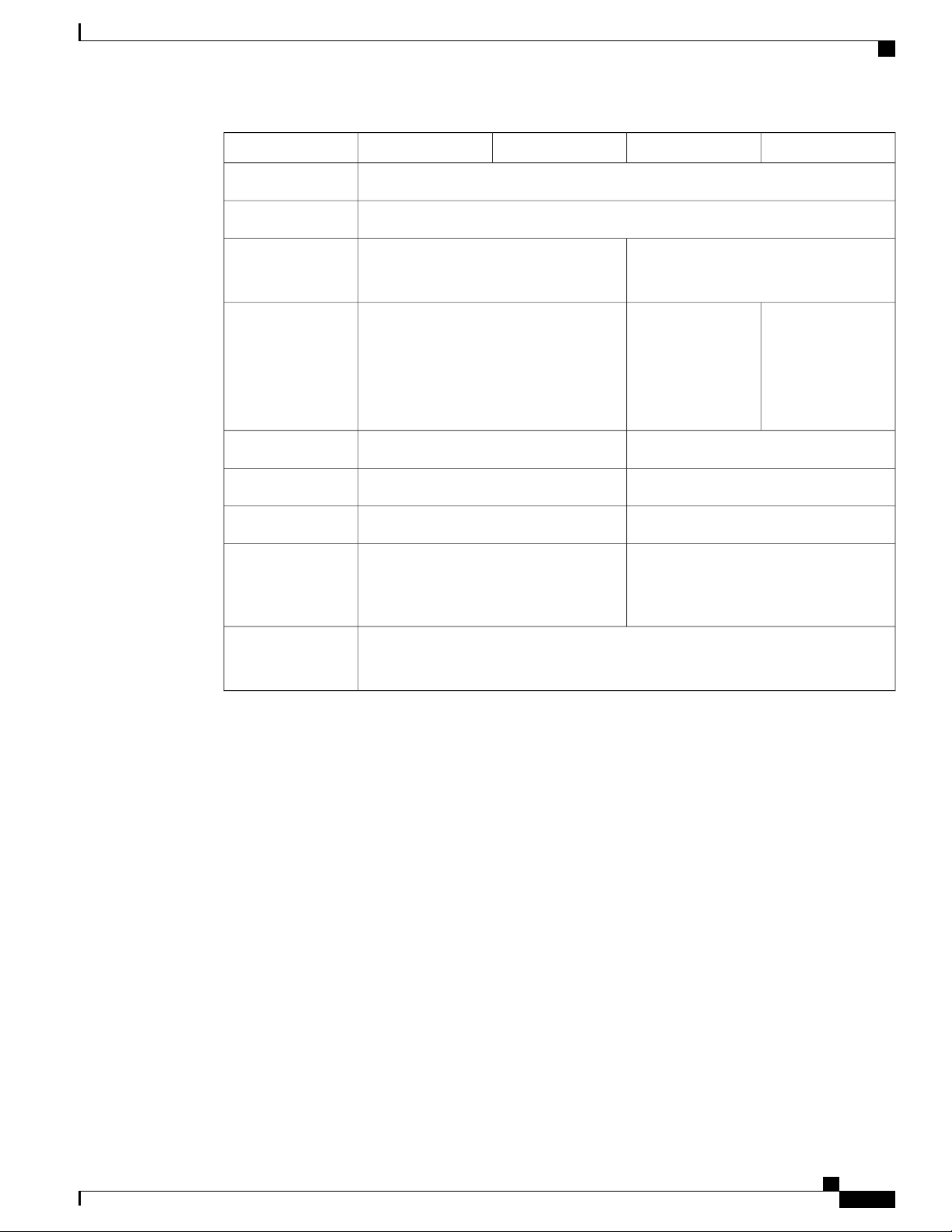

The following table lists the features for the Firepower 2100 series.

Table 1: Cisco Firepower 2100 Series Features

Overview

2140213021202110Feature

Form factor

Rack mountable

Intel x86 processor

Cavium Network

Processor Unit

(NPU)

of interfaces

1 RU

Fits standard 19-in (48.3-cm) square-hole rack.

Yes

2 two-post mount brackets

(Optional) 4-post EIA-310-D rack

Yes

4-post EIA-310-D rack

(Optional) 2-two-post mount brackets

Front to rear (cold aisle to hot aisle)Airflow

Single 4-core at

1.8G

Single 6-core at

1.2G

Single 6-core at

1.9G

Single 8-core at

1.2G

Single 8-core at

2.0G

Single 12-core at

1.2G

16G8GCavium NPU RAM

8G (nominal)Flash

2416Maximum number

Single 16-core at

1.3G

64 GB32 GB16 GBIntel x86 memory

Single 16-core at

1.8G

1 Gigabit Ethernet (10M/100M/1G Base-T)Management port

RJ-45 serial portConsole port

Type A 2.0 (500mA)USB port

Network ports

12 fixed RJ-45 1G/100M/10M ports

Named Ethernet 1/1 through 1/12

4 fixed 1G/10G SFP+ ports4 fixed 1G SFP portsSmall Form-Factor

Pluggable (SFP)

ports

Pull-out label card

Yes

Displays serial number.

YesGrounding lug

Cisco Firepower 2100 Series Hardware Installation Guide

2

Page 7

Overview

Deployment Options

2140213021202110Feature

YesLocator beacon

YesPower switch

Storage

Malware Storage

Pack (MSP)

NoNetwork modules

1 fixed AC power supply moduleAC power supply

Two SSD slots (100GB )

Ships with one 100GB SSD installed in

slot 1.

Yes

You can install the MSP in the SSD slot 2.

1 network module slot

NOT hot swappable

2 power supply slots

Ships with one

400W AC power

supply

Hot swappable

Yes (optional)NoDC power supply

YesNoRedundant power

1 hot-swappable fan tray with 4 fans4 fixed fansFan

Two SSD slots (200GB )

Ships with one 200GB SSD installed in

slot 1.

2 power supply slots

Ships with two

400W AC power

supplies

Hot swappable

Deployment Options

You can deploy the Firepower 2100 in the following ways:

As a firewall:

•

At the enterprise Internet edge deployed in a high availability configuration

◦

At branch offices in either an HA pair or standalone

◦

As a device that provides additional application control, URL filtering, or IPS/threat-centric capabilities:

•

Behind an enterprise Internet edge firewall in an inline in a transparent bump-in-the-wire

◦

configuration or as a standalone (requires hardware fail open network module support)

Deployed passively off a SPAN port on a switch or a tap on a network, or standalone

◦

As a VPN device:

•

For remote access VPN

◦

Cisco Firepower 2100 Series Hardware Installation Guide

3

Page 8

Package Contents

For site-to-site VPN

◦

Package Contents

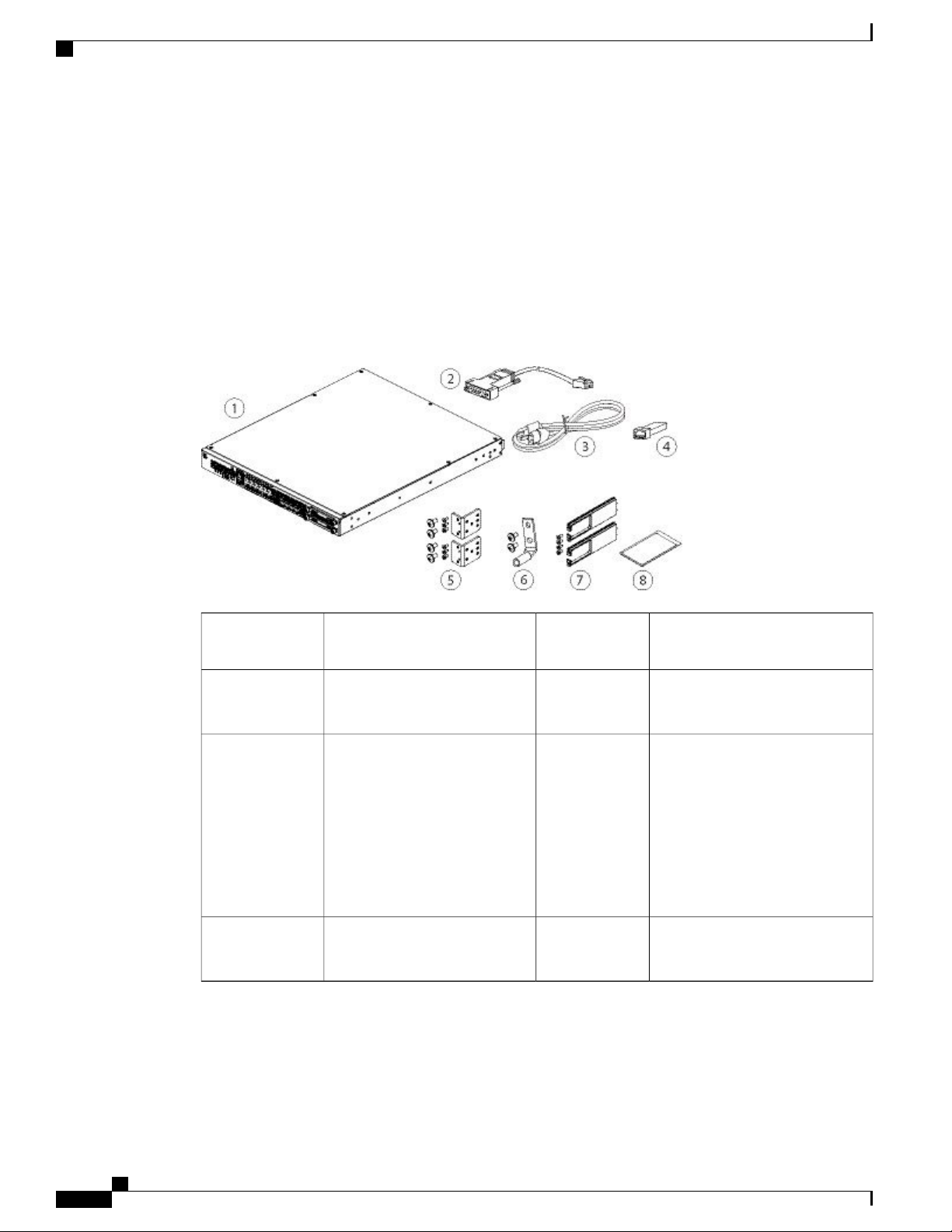

The following illustration shows the package contents for the Firepower 2110 and 2120. The contents are

subject to change and your exact contents will contain additional or fewer items depending on whether you

order the optional parts.

Figure 2: Firepower 2110 and 2120 Package Contents

Overview

2Firepower 2110 or 2120 chassis1

3

(country-specific)

5

screws:

Six 8-32, 0.281#

•

Four 12-24, 0.75#

•

Four 10-32, 0.75#

•

Four M6, 19mm

•

7

(Optional; in package if ordered)

4One power cord

62 rack-mount brackets and

8Two cable management brackets

Blue console cable PC terminal

adapter

SFP transceiver

(Optional; in package if ordered)

One ground lug kit

#6 AWG lug, two 10-32 x .38"

screws

Useful Links Cisco Firepower 2100

Series

Cisco Firepower 2100 Series Hardware Installation Guide

4

Page 9

Overview

Package Contents

The following illustration shows the package contents for the Firepower 2130 and 2140. The contents are

subject to change and your exact contents will contain additional or fewer items depending on whether you

order the optional parts.

Figure 3: Firepower 2130 and 2140 Package Contents

3

5

9

11

(country-specific)

Left and right slide rails, two

M3X6mm wafer head screws

Two cable management brackets

and four 8-32 x 0.375" screws

(Optional; in package if ordered)

Power supply module tie wrap

and clamp

2Firepower 2130 or 2140 chassis1

Blue console cable PC terminal

adapter

4One or two power cords

SFP transceiver

(Optional; in package if ordered)

6Slide rail kit

Six 8-32 x .25" slide rail locking

bracket screws

8Two slide rail locking brackets7

One ground lug kit

#6 AWG lug, two 10-32 x .38"

screws

10Cable management bracket kit

Useful Links Cisco Firepower 2100

Series

Cisco Firepower 2100 Series Hardware Installation Guide

5

Page 10

Serial Number Location

Serial Number Location

The serial number for the Firepower 2100 series chassis is located on the pull-out label card on the front panel.

Figure 4: Serial Number on 2100 Chassis

Overview

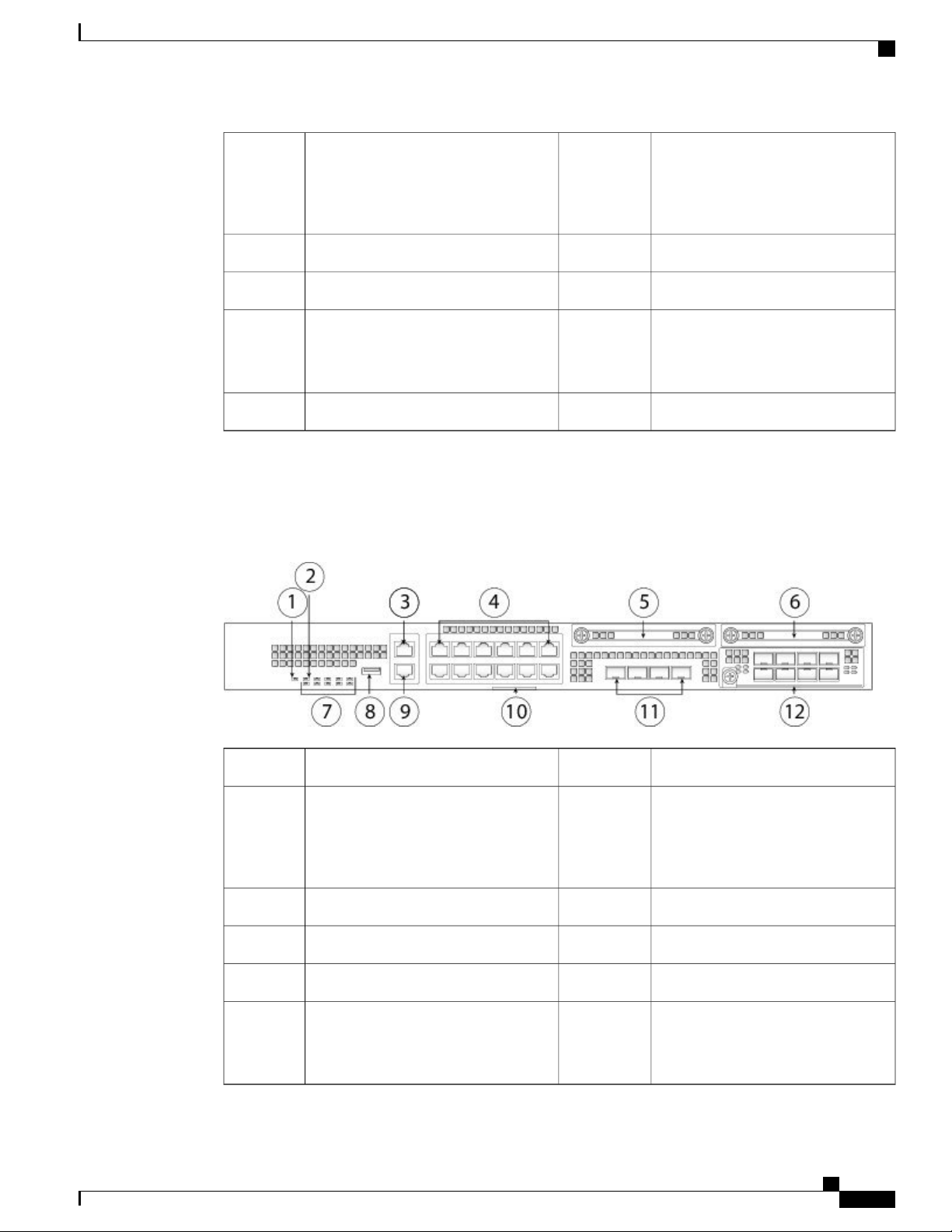

Front Panel

The following figure shows the front panel of the Firepower 2110 and 2120 security appliances. See Front

Panel LEDs, on page 9 for a description of the LEDs.

Figure 5: Firepower 2110 and 2120 Front Panel

2Power LED1

Gigabit Ethernet management port

Management 0 (also referred to as

Management 1/1 and Diagnostic 1/1)

Cisco Firepower 2100 Series Hardware Installation Guide

6

Page 11

Overview

Front Panel

3

SSD (slot 1)4Twelve RJ-45 1G/100M/10M auto

duplex/auto MDI-X Base-T ports

Ethernet 1/1 through 1/12 labeled top to

bottom, left to right

System LEDs6Locator beacon5

RJ-45 console port8Type A USB 2.0 port7

10Pull-out label card9

4 fixed SFP (1G) ports

Fiber ports 1/13 through 1/16 labeled

left to right

SSD (slot 2)11

The following figure shows the front panel of the Firepower 2130 and 2140 security appliance. See Front

Panel LEDs, on page 9 for a description of the LEDs.

Figure 6: Firepower 2130 and 2140 Front Panel

3

11

Management 0 (also referred to as

Management 1/1 and Diagnostic 1/1)

Fiber ports 13 through 16 labeled left to

right

Cisco Firepower 2100 Series Hardware Installation Guide

Locator beacon2Power LED1

4Gigabit Ethernet management port

Twelve RJ-45 1G/100M/10M auto

duplex/auto MDI-X Base-T ports

Ethernet 1/1 through 1/12 labeled top

to bottom, left to right

SSD 26SSD 15

Type A USB 2.0 port8System LEDs7

Pull-out label card10RJ-45 console port9

124 fixed SFP+ (1G/10G) ports

Network Module (network module slot

1)

7

Page 12

Front Panel

Overview

Management Port

The Firepower 2100 chassis has an RJ-45 copper management port.

RJ-45 Console Port

The Firepower 2100 chassis has a standard RJ-45 console port. You can use the command-line interface

(CLI) to configure your 2100 through the RJ-45 serial console port by using a terminal server or a

terminal emulation program on a computer.

The RJ-45 (8P8C) port supports RS-232 signaling to an internal UART controller. The console port

does not have any hardware flow control, and does not support a remote dial-in modem. The baud rate

is 9600. You can use the standard cable found in your accessory kit to convert the RJ45 to DB9 if

necessary.

Type A USB Port

You can use the external Type A USB port to attach a data-storage device. The external USB drive

identifier is disk1:. The Type A USB port supports the following:

OIR

•

USB drive formatted with FAT32

•

Boot kickstart image from ROMMON for discovery recovery purposes

•

Copy files to and from workspace:/ and volatile:/ within local-mgmt. The most relevant files are:

•

Core files

◦

Ethanalyzer packet captures

◦

Tech-support files

◦

Security module log files

◦

Platform bundle image upload using download image usbA:

•

The Type A USB port does NOT support Cisco Secure Package (CSP) image upload support.

Network Ports

The Firepower 2100 chassis has 12 fixed RJ-45 1G/100M/10M) ports. They are numbered from top to

bottom, left to right starting with 1 and are named Ethernet 1/1 through Ethernet 1/12.

The 2110 and 2120 also have four fixed SFP (1G) ports, and the 2130 and 2140 have four fixed SFP+

(1G/10G) ports. They are fiber ports numbered left to right (1/13 through 1/16).

Each port has LEDs that represent Link/Activity status.

Cisco Firepower 2100 Series Hardware Installation Guide

8

Page 13

Overview

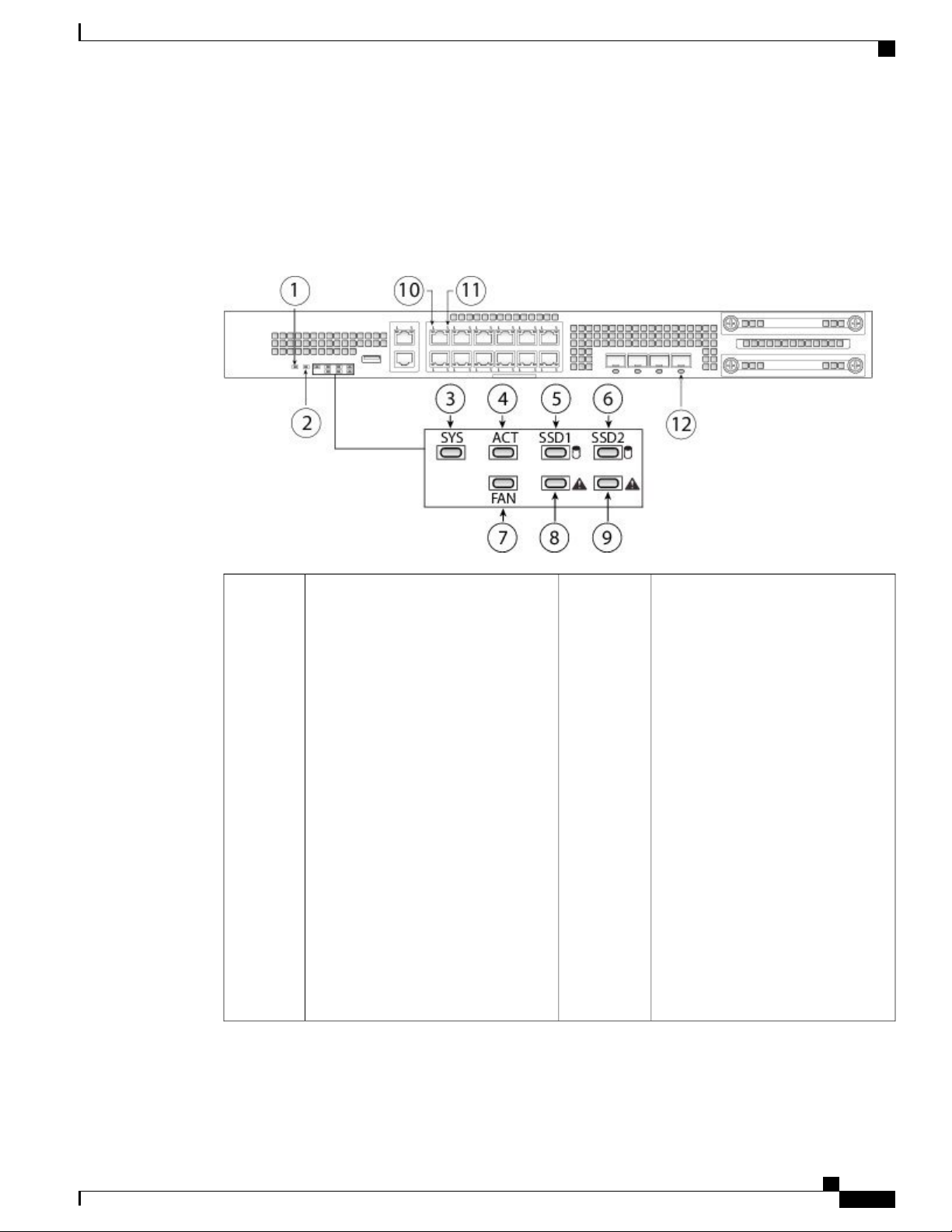

Front Panel LEDs

The following figure shows the Firepower 2110 and 2120 front panel LEDs.

Figure 7: Firepower 2110 and 2120 Front Panel LEDs

Front Panel LEDs

1

• Unlit – Input power is not

detected. Standby power is off.

• Blinking green – The system has

detected a power switch toggle

event, and initiated the shutdown

sequence. If the power switch is

in the OFF position, the system

powers off after shutdown is

completed. Do not remove the AC

or DC power source while this

LED is blinking so that the system

has time to perform a graceful

shutdown.

• Solid amber – The system is

powering up (before the BIOS

boots). This takes one to five

seconds at most.

• Solid green – The system is fully

powered up.

2PWR

Locator Beacon

• Unlit – Locate is off.

• Solid blue – Locate is on.

Note

The Locator beacon helps

you locate a unit that needs

physical service attention.

This feature is activated in

the software.

Cisco Firepower 2100 Series Hardware Installation Guide

9

Page 14

Front Panel LEDs

Overview

3

4SYS (Health)

• Unlit – The system has not booted

up yet.

• Blinking green – The system is

booting up or in bootloader stage.

• Solid green – The system has fully

booted.

ACT (Active)

• Unlit – The system in standby

mode.

• Green – The system is active.

The status is updated every 10

seconds.

• Amber – Not in use at this time.

• Solid amber – The system boot up

has failed.

• Blinking amber – Alarm

condition, system needs service or

attention and may not boot

properly.

5

6SSD1 ACT

• Unlit – SSD is not present.

• Solid green – SSD is present; no

activity.

• Blinking green – SSD is active.

SSD2 ACT

• Unlit – SSD is not present.

• Solid green – SSD is present; no

activity.

• Blinking green – SSD is active.

7

8FAN

• Unlit – The environmental

subsystem is not active yet.

SSD1 Alert Status

• Unlit – SSD has normal activity.

• Solid amber – SSD failure.

• Solid green—The fans are running

normally. It may take up to one

minute for the LED status to turn

green after power is on.

• Solid amber—One fan has failed.

The system can continue to

operate normally, but fan service

is required.

• Blinking amber—Two or more

fans have failed, or the fan tray has

been removed from the system.

Immediate attention is required.

9

10SSD2 Alert Status

• Unlit – SSD has normal activity.

• Solid amber – SSD failure.

Ethernet Link

• Solid green – The link partner is

detected; no activity.

• Blinking green – Network

activity is detected.

Cisco Firepower 2100 Series Hardware Installation Guide

10

Page 15

Overview

Front Panel LEDs

11

12Ethernet Speed

• Blinking green – The number of

blinks determines link speed; 1

blink=10Mbit, 2=100Mbit,

3=1Gbit.

Fiber Port

• Solid green – Port is enabled, the

link partner is detected.

• Solid amber – Port is enabled,

but the link partner is not

detected.

• Blinking green – Port is enabled;

network activity is detected.

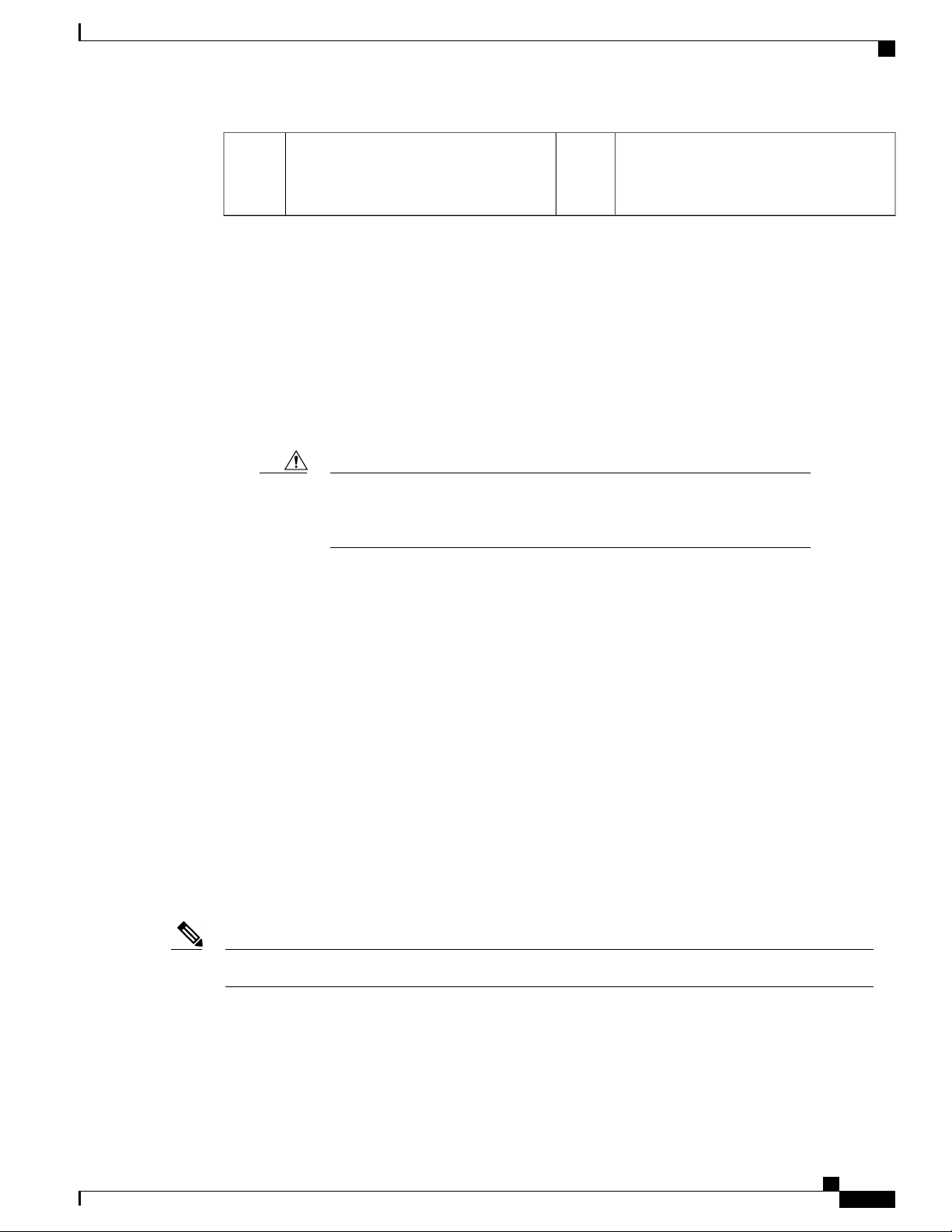

The following figure describes the Firepower 2130 and 2140 front panel LEDs.

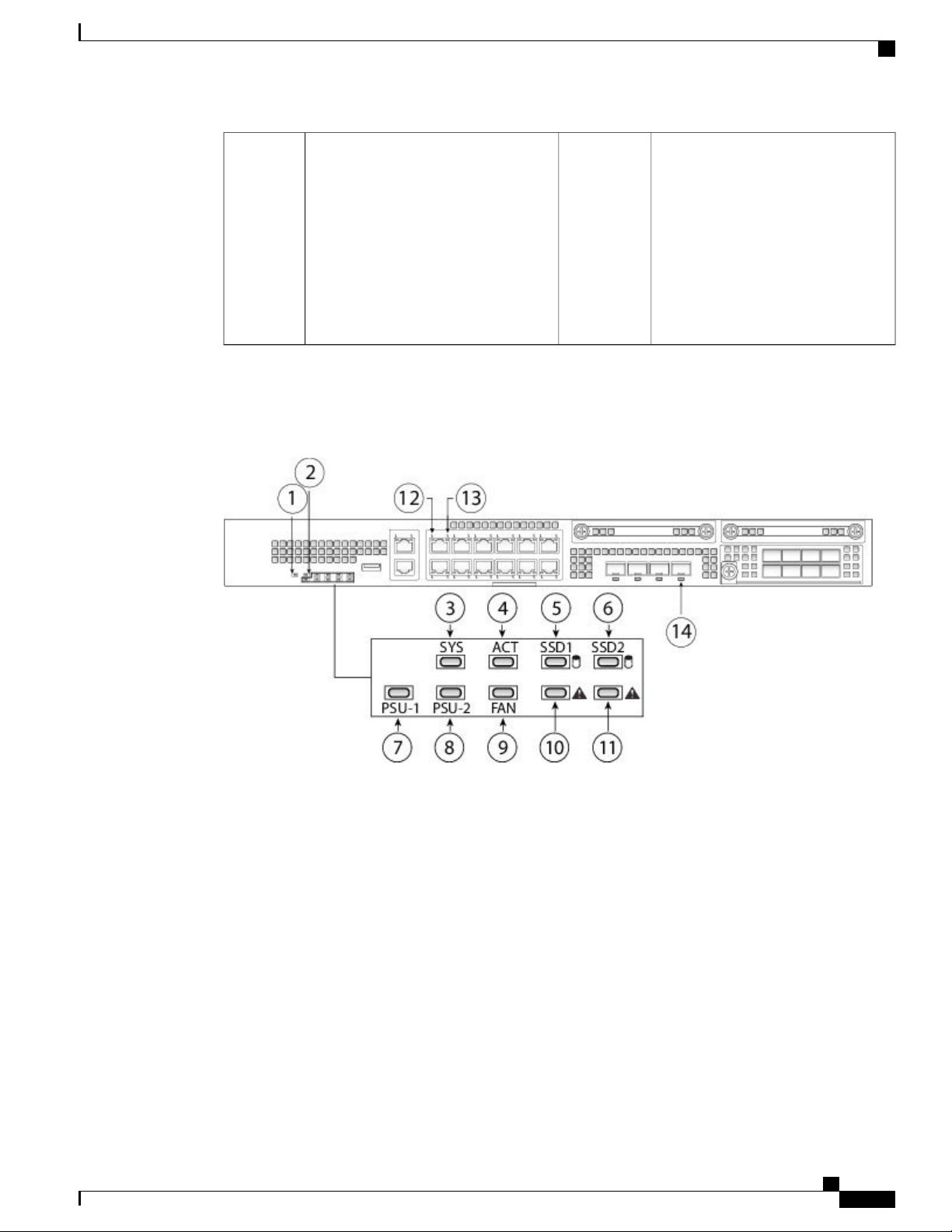

Figure 8: Firepower 2130 and 2140 Front Panel LEDs

Cisco Firepower 2100 Series Hardware Installation Guide

11

Page 16

Front Panel LEDs

Overview

1

2Power

• Unlit – Input power is not

detected. Standby power is off.

Locator LED

• Unlit – Locate is off.

• Solid blue – Locate is on.

• Blinking green – The system has

detected a power switch toggle

event, and initiated the shutdown

sequence. If the power switch is

in the OFF position, the system

powers off after shutdown is

Note

The Locator beacon helps

you locate a unit that needs

physical service attention.

This feature is activated in

the software.

completed. Do not remove the AC

or DC power source while this

LED is blinking so that the system

has time to perform a graceful

shutdown.

• Solid amber – The system is

powering up (before the BIOS

boots). This takes one to five

seconds at most.

• Solid green – The system is fully

powered up.

3

4SYS (Health)

ACT (Active)

• Unlit – The system has not booted

up yet.

• Blinking green – The system is

booting up or in bootloader stage.

• Solid green – The system has fully

booted.

• Unlit – The system in standby

mode.

• Green – The system is active.

The status is updated every 10

seconds.

• Amber – Not in use at this time.

• Solid amber – The system boot up

has failed.

• Blinking amber – Alarm

condition, system needs service or

attention and may not boot

properly.

5

6SSD1 ACT

• Unlit – The SSD is not present.

• Solid green – The SSD is present;

no activity.

• Blinking green – The SSD is

active.

SSD2 ACT

• Unlit – The SSD is not present.

• Solid green – The SSD is

present; no activity.

• Blinking green – The SSD is

active.

Cisco Firepower 2100 Series Hardware Installation Guide

12

Page 17

Overview

Front Panel LEDs

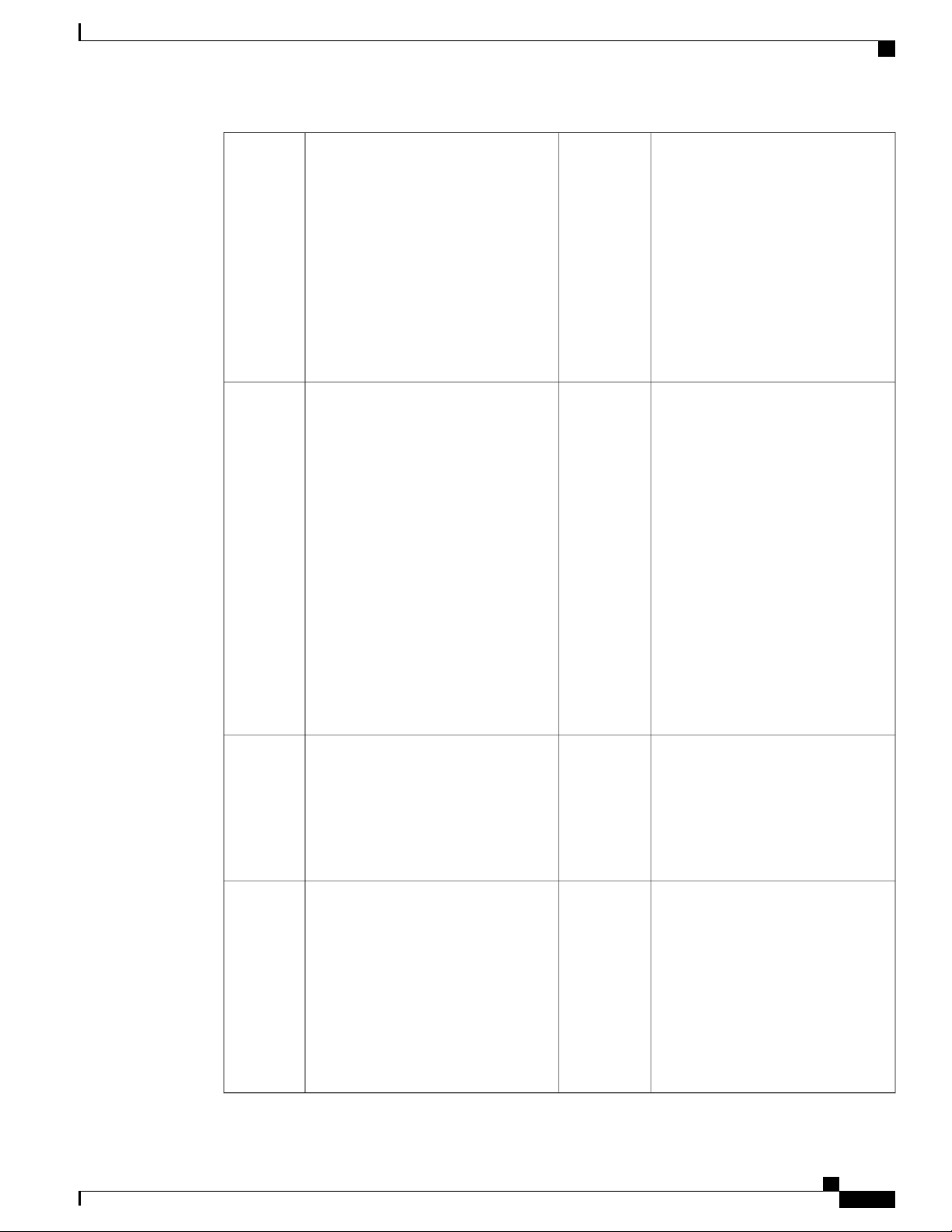

7

8PSU-1

• Unlit – The power supply module

is not present or not detected.

• Solid green – The power supply

module is present and working

properly.

• Solid amber – The power supply

module is present but a fault or

problem has been detected.

PSU-2

• Unlit – The power supply

module is not present or not

detected.

• Solid green – The power supply

module is present and working

properly.

• Solid amber – The power supply

module is present but a fault or

problem has been detected.

9

10FAN

• Unlit – The environmental

subsystem is not active yet.

SSD1 Alert Status

• Unlit – SSD has normal activity.

• Solid amber – SSD failure.

• Solid green—The fans are running

normally. It may take up to one

minute for the LED status to turn

green after power is on.

• Solid amber—One fan has failed.

The system can continue to

operate normally, but fan service

is required.

11

13

• Blinking amber—Two or more

fans have failed, or the fan tray has

been removed from the system.

Immediate attention is required.

• Unlit – SSD has normal activity.

• Solid amber – SSD failure.

• Blinking green – The number of

blinks determines link speed; 1

blink=10Mbit, 2=100Mbit,

3=1Gbit.

12SSD2 Alert Status

Ethernet Link

• Solid green – The link partner is

detected; no activity.

• Blinking green – Network

activity is detected.

14Ethernet Speed

Fiber Port

• Solid green – Port is enabled, the

link partner is detected.

• Solid amber – Port is enabled,

but the link partner is not

detected.

• Blinking green – Port is enabled;

network activity is detected.

Cisco Firepower 2100 Series Hardware Installation Guide

13

Page 18

Rear Panel

Rear Panel

Overview

The following figure shows the rear panel of the Firepower 2110 and 2120.

Figure 9: Firepower 2110 and 2120 Rear Panel

Fixed power supply module2Power on/off switch1

4Fixed fans3

The following figure shows the rear panel of the Firepower 2130 and 2140.

Figure 10: Firepower 2130 and 2140 Rear Panel

Two-post grounding lug

Note

Power supply module 1 FAIL LED2Power on/off switch1

Power supply module 14Power supply module 2 FAIL LED3

The two-post grounding lug is

included in the accessory kit.

Fan tray6Power supply module 1 OK LED5

Power supply module 2 OK LED8Power supply module 27

Cisco Firepower 2100 Series Hardware Installation Guide

14

Page 19

Overview

Network Modules

9

Power Switch

For More Information

Two-post grounding lug

Note

The power switch is located to the left of power supply module 1 on the rear of the chassis. It is a toggle

switch that controls power to the system. If the power switch is in standby position, only the 3.3V

standby power is enabled from the power supply module and the 12V main power is OFF. When the

switch is in the ON position, the 12V main power is turned on and the system boots.

Before you move the power switch to the OFF position, use the shutdown commands so that the system

can perform a graceful shutdown. This may take several minutes to complete. After the graceful shutdown

is completed, the front panel power LED is unlit and the console displays Power Down. See the FXOS

Configuration Guide for more information on using these commands.

Caution

The two-post grounding lug is

included in the accessory kit.

If you move the power switch to the OFF position before the shutdown

command sequence has completed or if you remove the system power cords

before the graceful shutdown is complete, disk corruption can occur.

See Remove and Replace the Power Supply Module, on page 46 for the procedure for removing and

•

replacing the power supply module in the Firepower 2130 and 2140.

See Remove and Replace the Fan Tray, on page 54 for the procedure for removing and replacing the

•

fan tray in the Firepower 2130 and 2140.

See Ground the Chassis, on page 38 for the procedure for using the grounding lug to ground the chassis.

•

See Power Supply Modules, on page 17 for a description of the power supply module LEDs.

•

See Front Panel LEDs, on page 9 for a description of the fan LEDs.

•

Network Modules

The Firepower 2130 and 2140 contain one network module slot that provides optical or electrical network

interfaces. Network modules are optional, removable I/O modules that provide either additional ports or

different interface types. The Firepower network module plugs into the chassis on the front panel.

The network module is NOT hot swappable.Note

The Firepower 2130 and 2140 support the Firepower 8-port 10G Network Module single-wide

(FPR-NM-8X10G SFP+). The 10 Gigabit Ethernet network module ports are numbered from top to bottom,

left to right.

Cisco Firepower 2100 Series Hardware Installation Guide

15

Page 20

Network Modules

Overview

The following figure shows the front panel view of the 10G network module.

Figure 11: Firepower Network Module 10G

Ethernet 2/12Captive screw/handle1

Ethernet 2/54Ethernet 2/33

Ethernet 2/26Ethernet 2/75

Ethernet 2/68Ethernet 2/47

10Ethernet 2/89

Network activity LEDs

• Unlit – No connection or port is not

in use.

• Solid amber – No link or network

failure.

• Solid green – Link up.

• Blinking green – Network activity.

For More Information

See Supported SFP/SFP+ Transceivers, on page 20 for a list of supported SFPS.

•

See Remove and Replace the Network Module, on page 43 for the procedure for removing and replacing

•

network modules.

Cisco Firepower 2100 Series Hardware Installation Guide

16

Page 21

Overview

Power Supply Modules

The Firepower 2110 and 2120 have one fixed AC power supply. If the power supply fails, you must send

your Firepower 2110 or 2120 for RMA.

The Firepower 2130 and 2140 support two AC power supply modules so that dual power supply redundancy

protection is available. The Firepower 2130 ships with one AC power supply and the Firepower 2140 ships

with two AC power supplies. You can also install DC power supply modules rather than AC power on the

2130 and 2140. Facing the back of the chassis, the power supply modules are numbered left to right, for

example, PSU1 and PSU2.

You CANNOT mix AC and DC power supply modules in the chassis.Note

The power supply module is hot swappable.Note

Power Supply Modules

Note

Note

The system power requirements are lower than the power supply module capabilities. See the following

table.

Make sure that one power supply module is always active.Attention

AC Power Supply

The dual power supplies can supply up to 800W power across the input voltage range. The load is shared

when both power supply modules are plugged in and running at the same time.

The system does not consume more than the capacity of one power supply module, so it will always

operate in full redundancy mode (2130 and 2140 only) when two power supply modules are installed.

Table 2: AC Power Supply Module Hardware Specifications

2140213021202110

100 to 240V ACInput voltage

6.3A (at 100V AC)4A (at 100V AC)Maximum current

power

400W250WMaximum output

Cisco Firepower 2100 Series Hardware Installation Guide

17

Page 22

Power Supply Modules

Overview

2140213021202110

Maximum

—

800W

redundancy output

power

Redundancy

—

1+1 redundancy

50 to 60HzFrequency

89%Efficiency at 50%

load

DC Power Supply

The power supplies can supply up to 350W power across the input voltage range. The load is shared when

both power supply modules are plugged in and running at the same time.

Table 3: DC Power Supply Module Hardware Specifications

21402130

-48 to -60V DCInput voltage

Maximum current

15A (at -48V DC)

Note

The power supply module is rated at 15A but the system power

is limited to 6.1A. See Hardware Specifications, on page 23

for more system specifications.

350WMaximum output power

1+1 redundancyRedundancy

92%Efficiency at 50% load

Cisco Firepower 2100 Series Hardware Installation Guide

18

Page 23

Overview

Power Supply Modules

Power Supply Module LEDs

The following figure shows the bicolor power supply LEDs on the power supply module. The figure shows

the AC power supply module. The DC power supply module has the same LEDs.

Figure 12: Power Supply Module LEDs

Green OK LED2Amber FAIL LED1

The following describes the power module supply LEDs.

Green LED (OK Status)

• Unlit – Input power not present.

• Blinking green – Input power present, but system is not powered up (power switch is off).

• Solid green – The power supply module is enabled and running.

Amber LED (Fail Status)

• Unlit – No fault detected.

• Blinking amber – Fault warning, power supply may still work but could fail due to high temperature,

failing fan, or over current.

• Solid amber – Fault detected; power supply not working properly. Includes over voltage, over current,

over temperature, and fan failure.

For More Information

See Remove and Replace the Power Supply Module, on page 46 for the procedure for removing and

•

replacing the power supply module in the Firepower 2130 and 2140.

Cisco Firepower 2100 Series Hardware Installation Guide

19

Page 24

Fans

Fans

SSDs

Overview

The Firepower 2110 and 2120 have 4 fixed fans.

The Firepower 2130 and 2140 have a removable fan tray with three + one redundant fans that are hot swappable.

The fan tray is installed in the rear of the chassis. Any one fan can fail indefinitely and the system continues

to function. When a fan fails, the remaining fans automatically spin up to full speed.

The fan LED is located on the front of the chassis.

For More Information

See Front Panel LEDs, on page 9 for the location and description of the fan LED.

•

See Remove and Replace the Fan Tray, on page 54 for the procedure for removing and replacing the

•

fan tray.

Caution

Note

The Firepower 2110 and 2120 have two SSD slots. These models ship with one 100-GB SSD installed in slot

1. The Firepower 2130 and 2140 have two SSD slots. These models ship with one 200-GB SSD installed in

slot 1.

You can use the second SSD slot to upgrade to the MSP. The MSP MUST be installed in the second slot. The

MSP stores threat detection results for use in future analysis. It supports the Advanced Malware Protection

(AMP) software feature. It is used as both storage and as the Malware application repository. RAID is not

supported.

You cannot swap SSDs between different Firepower platforms. For example, you cannot use a 4100 series

SSD in a 2100 series security appliance.

The 100-GB SSD is restricted to the 2110 and 2120 models. The 200-GB SSD is restricted to the 2130

and 2140 models. Do not mix them.

Although the hardware supports hot swapping for the SSDs, the software does not, so you must power down

the chassis before removing and replacing them.

For More Information

See Front Panel, on page 6 for the location and description of the SSD LEDs on the front panel.

•

See Remove and Replace the SSD, on page 45 for the procedure for removing and replacing the SSD.

•

Supported SFP/SFP+ Transceivers

Take note of the following warnings:

Cisco Firepower 2100 Series Hardware Installation Guide

20

Page 25

Overview

Supported SFP/SFP+ Transceivers

Warning

Warning

Warning

Warning

Statement 1053—Class 1M Laser Radiation

Class 1M laser radiation when open. Do not view directly with optical instruments.

Statement 1055—Class I and Class 1M Laser

Class I (CDRH) and Class 1M (IEC) laser products.

Statement 1056—Unterminated Fiber Cable

Invisible laser radiation may be emitted from the end of the unterminated fiber cable or connector. Do not

view directly with optical instruments. Viewing the laser output with certain optical instruments (for

example, eye loupes, magnifiers, and microscopes) within a distance of 100 mm may pose an eye hazard.

Statement 1057—Hazardous Radiation Exposure

Use of controls or adjustments or performance of procedures other than those specified may result in

hazardous radiation exposure.

The SFP/SFP+ transceiver is a bidirectional device with a transmitter and receiver in the same physical

package. It is a hot-swappable optical interface that plugs into the SFP/SFP+ ports on the fixed ports and the

network module ports, and provides Ethernet connectivity.

Figure 13: SFP

Bail clasp2Dust plug1

Transmit optical bore4Receive optical bore3

Cisco Firepower 2100 Series Hardware Installation Guide

21

Page 26

Supported SFP/SFP+ Transceivers

Overview

Warning

Note

Caution

Use appropriate electrostatic discharge (ESD) procedures when inserting the transceiver. Avoid touching

the contacts at the rear, and keep the contacts and ports free of dust and dirt. Keep unused transceivers in

the ESD packing that they were shipped in.

The 1G transceivers are limited to 1GB operation only (no auto-negotiation support). 100M/10M modes

are not supported.

Although non-Cisco SFPs are allowed, we do not recommend using them because they have not been

tested and validated by Cisco. Cisco TAC may refuse support for any interoperability problems that result

from using an untested third-party SFP transceiver.

The following table lists the supported transceivers.

Table 4: Supported SFPs

Ports SupportedPIDOptics Type

SFP 1G

GLC-SX-MMD1G-SX

GLC-LH-SMD1G-LH

Ports 13 through 16

Ports 1 though 8 of the 8X10G network

module (available only on the 2130 and 2140)

SFP+ 10G

GLC-EX-SMD1G-EX

GLC-ZX-SMD1G-ZX

Cisco Firepower 2100 Series Hardware Installation Guide

22

Page 27

Overview

Hardware Specifications

H10GB-CU 1M, 1.5M, 2M,

2.5M, 3M, 5M

SFP-10G-SR10G-SR

SFP-10G-LR10G-LR

SFP-10G-LRM10G-LRM

SFP-10G-ER10G-ER

SFP-10G-SR-S10G-SR-S

SFP-10G-LR-S10G-LR-S

SFP-10G-ZR-S10G-ZR-S

SFP-10G-ER-S10G-ER-S

SFP-H10GB-CU1M

SFP-H10GB-CU1-5M

SFP-H10GB-CU2M

SFP-H10GB-CU2-5

SFP-H10GB-CU3M

SFP-H10GB-CU5M

Ports 13 through 16

Ports 1 though 8 of the 8X10G network

module (available only on the 2130 and 2140)

H10GB-ACU 7M, 10M

10G-AOC 1M, 2M, 3M, 5M,

7M, 10M

Hardware Specifications

The following table contains hardware specifications for the Firepower 2100 series security appliance.

Physical

Form factor

1 RU

Fits standard 19-in (48.3-cm) square-hole rack.

SFP-H10GB-ACU7M

SFP-H10GB-ACU10M

SFP-10G-AOC1M

SFP-10G-AOC2M

SFP-10G-AOC3M

SFP-10G-AOC5M

SFP-10G-AOC7M

SFP-10G-AOC10M

2140213021202110Specification

Cisco Firepower 2100 Series Hardware Installation Guide

23

Page 28

Hardware Specifications

Overview

2140213021202110Specification

Rack mountable

x D)

Storage

SSD

MSP

Memory

Power

Yes

Fixed 2 two-post mount brackets

Optional: 4-post EIA-310-D mount rails

1.73 x 16.90 x 19.76 in (4.4 x 42.9 x 50.2 cm)Dimensions (H x W

100 GB

Note

The storage SSD must be

installed in slot 1.

800 GB

Note

The MSP SSD must be installed in slot

2.

Yes

4-post EIA-31-D mount rails

Optional: 2 two-post mount brackets

21 lb (9.52 kg)19.4 lb (8.79 kg)16.1 lb (7.3 kg)Weight

200 GB

Note

The storage SSD must be

installed in slot 1.

64 GB32 GB16 GBDDR4 DRAM

System power

module

Environmental

Temperature

Humidity

Altitude

100/240VAC 1.9A (at 100VAC), 50 to 60

Hz

Note

The power supply module is rated

at 4A, but the system power is

limited to 1.9A.

100/240VAC 2.9A (at 100VAC), 50 to 60

Hz

Note

The power supply module is rated

at 6.3A, but the system power is

limited to 2.9A.

AC or DCACPower supply

YesNoRedundant power

Operating: 32⁰ to 104⁰F (0⁰ to 40⁰C)

Nonoperating: -40⁰ to 149°F (-40⁰ to 65°C) maximum altitude is 40,000 ft

Operating: 10 to 85 percent noncondensing

Nonoperating: 5 to 95 percent noncondensing

Operating: 10,000 ft maximum

Nonoperating: 40,000 ft maximum

Cisco Firepower 2100 Series Hardware Installation Guide

24

Page 29

Overview

Hardware Specifications

2140213021202110Specification

Acoustic Noise

Sound pressure

Sound power

47.3 dBA (typical)

73.4 dBA (maximum)

60.2 (typical)

85.1 (maximum)

Front to backAir flow

55.7 dBA (typical)

76.7 dBA (maximum)

66 (typical)

84.5 (maximum)

Cisco Firepower 2100 Series Hardware Installation Guide

25

Page 30

Hardware Specifications

Overview

Cisco Firepower 2100 Series Hardware Installation Guide

26

Page 31

CHAPTER 2

Installation Preparation

This chapter prepares you to install the Firepower 2100 security appliance, and contains the following

sections:

Installation Notes and Warnings, page 27

•

Safety Recommendations, page 30

•

Maintain Safety with Electricity , page 30

•

Prevent Electrostatic Discharge Damage , page 31

•

Site Environment , page 31

•

Site Considerations, page 31

•

Power Supply Considerations, page 31

•

Equipment Rack Configuration Considerations, page 32

•

Installation Notes and Warnings

Be sure to read the Regulatory Compliance and Safety Information document before installing the security

appliance.

Take note of the following warnings:

Warning

Statement 1071—Warning Definition

IMPORTANT SAFETY INSTRUCTIONS

This warning symbol means danger. You are in a situation that could cause bodily injury. Before you

work on any equipment, be aware of the hazards involved with electrical circuitry and be familiar with

standard practices for preventing accidents. Use the statement number provided at the end of each warning

to locate its translation in the translated safety warnings that accompanied this device.

SAVE THESE INSTRUCTIONS

Cisco Firepower 2100 Series Hardware Installation Guide

27

Page 32

Installation Notes and Warnings

Installation Preparation

Warning

Warning

Warning

Warning

Statement 1015—Battery Handling

There is the danger of explosion if the battery is replaced incorrectly. Replace the battery only with the

same or equivalent type recommended by the manufacturer. Dispose of used batteries according to the

manufacturer's instructions.

Statement 12—Power Supply Disconnection Warning

Before working on a chassis or working near power supplies, unplug the power cord on AC units; disconnect

the power at the circuit breaker on DC units.

Statement 43—Jewelry Removal Warning

Before working on equipment that is connected to power lines, remove jewelry (including rings, necklaces,

and watches). Metal objects will heat up when connected to power and ground and can cause serious burns

or weld the metal object to the terminals.

Statement 94—Wrist Strap Warning

During this procedure, wear grounding wrist straps to avoid ESD damage to the card. Do not directly

touch the backplane with your hand or any metal tool, or you could shock yourself.

Warning

Warning

Warning

Warning

Statement 1004—Installation Instructions

Read the installation instructions before connecting the system to the power source.

Statement 1007—TN and IT Power Systems

This equipment has been designed for connection to TN and IT power systems.

Statement 1017—Restricted Area

This unit is intended for installation in restricted access areas. A restricted access area can be accessed

only through the use of a special tool, lock and key, or other means of security.

Statement 1021—SELV Circuit

To avoid electric shock, do not connect safety extra-low voltage (SELV) circuits to telephone-network

voltage (TNV) circuits. LAN ports contain SELV circuits, and WAN ports contain TNV circuits. Some

LAN and WAN ports both use RJ-45 connectors. Use caution when connecting cables.

Cisco Firepower 2100 Series Hardware Installation Guide

28

Page 33

Installation Preparation

Installation Notes and Warnings

Warning

Warning

Warning

Warning

Statement 1024—Ground Conductor

This equipment must be grounded. Never defeat the ground conductor or operate the equipment in the

absence of a suitably installed ground conductor. Contact the appropriate electrical inspection authority

or an electrician if you are uncertain that suitable grounding is available.

Statement 1028—More Than One Power Supply

This unit might have more than one power supply connection. All connections must be removed to

de-energize the unit.

Statement 1029—Blank Faceplates and Cover Panels

Blank faceplates and cover panels serve three important functions: they prevent exposure to hazardous

voltages and currents inside the chassis; they contain electromagnetic interference (EMI) that might disrupt

other equipment; and they direct the flow of cooling air through the chassis. Do not operate the system

unless all cards, faceplates, front covers, and rear covers are in place.

Statement 1030—Equipment Installation

Only trained and qualified personnel should be allowed to install, replace, or service this equipment.

Warning

Warning

Warning

Warning

Statement 1040—Product Disposal

Ultimate disposal of this product should be handled according to all national laws and regulations.

Statement 1073—No User-Serviceable Parts

No user-serviceable parts inside. Do not open.

Statement 1045—Short-circuit Protection

This product requires short-circuit (overcurrent) protection to be provided as part of the building installation.

Install only in accordance with national and local wiring regulations.

Statement 1074—Comply with Local and National Electrical Codes

Installation of the equipment must comply with local and national electrical codes.

Cisco Firepower 2100 Series Hardware Installation Guide

29

Page 34

Safety Recommendations

Safety Recommendations

Use the information in the following sections to help ensure your safety and to protect the chassis. This

information may not address all potentially hazardous situations in your working environment, so be alert and

exercise good judgment at all times.

Observe these safety guidelines:

Keep the area clear and dust-free before, during, and after installation.

•

Keep tools away from walkways, where you and others might trip over them.

•

Do not wear loose clothing or jewelry, such as earrings, bracelets, or chains that could get caught in the

•

chassis.

Wear safety glasses if you are working under any conditions that might be hazardous to your eyes.

•

Do not perform any action that creates a potential hazard to people or makes the equipment unsafe.

•

Never attempt to lift an object that is too heavy for one person.

•

Installation Preparation

Maintain Safety with Electricity

Before working on a chassis, be sure the power cord is unplugged.Warning

Be sure to read the document before installing the security appliance.

Follow these guidelines when working on equipment powered by electricity:

Before beginning procedures that require access to the interior of the chassis, locate the emergency

•

power-off switch for the room in which you are working. Then, if an electrical accident occurs, you can

act quickly to turn off the power.

Do not work alone if potentially hazardous conditions exist anywhere in your work space.

•

Never assume that power is disconnected; always check.

•

Look carefully for possible hazards in your work area, such as moist floors, ungrounded power extension

•

cables, frayed power cords, and missing safety grounds.

If an electrical accident occurs:

•

Use caution; do not become a victim yourself.

◦

Disconnect power from the system.

◦

If possible, send another person to get medical aid. Otherwise, assess the condition of the victim,

◦

and then call for help.

Determine whether the person needs rescue breathing or external cardiac compressions; then take

◦

appropriate action.

Use the chassis within its marked electrical ratings and product usage instructions.

•

Cisco Firepower 2100 Series Hardware Installation Guide

30

Page 35

Installation Preparation

Prevent Electrostatic Discharge Damage

Electrostatic discharge (ESD) occurs when electronic components are improperly handled, and it can damage

equipment and impair electrical circuitry, resulting in intermittent or complete failure.

Always follow ESD-prevention procedures when removing and replacing components. Ensure that the chassis

is electrically connected to an earth ground. Wear an ESD-preventive wrist strap, ensuring that it makes good

skin contact. Connect the grounding clip to an unpainted surface of the chassis frame to safely ground ESD

voltages. To properly guard against ESD damage and shocks, the wrist strap and cord must operate effectively.

If no wrist strap is available, ground yourself by touching the metal part of the chassis.

For safety, periodically check the resistance value of the antistatic strap, which should be between one and

10 megohms.

Site Environment

See Hardware Specifications, on page 23 for information about physical specifications.

When planning the site layout and equipment locations, consider the information in the next sections to help

avoid equipment failures and reduce the possibility of environmentally caused shutdowns. If you are currently

experiencing shutdowns or unusually high error rates with your existing equipment, these considerations may

help you isolate the cause of failures and prevent future problems.

Prevent Electrostatic Discharge Damage

Site Considerations

Considering the following helps you plan an acceptable operating environment for the chassis, and avoid

environmentally caused equipment failures.

Electrical equipment generates heat. Ambient air temperature might not be adequate to cool equipment

•

to acceptable operating temperatures without adequate circulation. Ensure that the room in which you

operate your system has adequate air circulation.

Ensure that the chassis cover is secure. The chassis is designed to allow cooling air to flow effectively

•

within it. An open chassis allows air leaks, which may interrupt and redirect the flow of cooling air from

the internal components.

Always follow the ESD-prevention procedures described previously to avoid damage to equipment.

•

Damage from static discharge can cause immediate or intermittent equipment failure.

Power Supply Considerations

See Power Supply Modules, on page 17 for more detailed information about the power supply modules for

your model.

When installing the chassis, consider the following:

• Check the power at the site before installing the chassis to ensure that it is “clean” (free of spikes and

noise). Install a power conditioner, if necessary, to ensure proper voltages and power levels in the

appliance input voltage.

Cisco Firepower 2100 Series Hardware Installation Guide

31

Page 36

Equipment Rack Configuration Considerations

Install proper grounding for the site to avoid damage from lightning and power surges.

•

The chassis does not have a user-selectable operating range. Refer to the label on the chassis for the

•

correct appliance input-power requirement.

Several styles of AC-input power supply cords are available; make sure that you have the correct style

•

for your site.

Install an uninterruptible power source for your site, if possible.

•

If you are using dual redundant (1+1) power supplies, we recommend that you use independent electrical

•

circuits for each power supply.

Equipment Rack Configuration Considerations

Consider the following when planning an equipment-rack configuration:

If you are mounting a chassis in an open rack, make sure that the rack frame does not block the intake

•

or exhaust ports.

Installation Preparation

Be sure enclosed racks have adequate ventilation. Make sure that the rack is not overly congested as

•

each chassis generates heat. An enclosed rack should have louvered sides and a fan to provide cooling

air.

In an enclosed rack with a ventilation fan in the top, heat generated by equipment near the bottom of

•

the rack can be drawn upward and into the intake ports of the equipment above it in the rack. Ensure

that you provide adequate ventilation for equipment at the bottom of the rack.

Baffles can help to isolate exhaust air from intake air, which also helps to draw cooling air through the

•

chassis. The best placement of the baffles depends on the airflow patterns in the rack. Experiment with

different arrangements to position the baffles effectively.

Cisco Firepower 2100 Series Hardware Installation Guide

32

Page 37

Mount and Connect

This chapter describes how to rack-mount the Cisco Firepower 2100 security appliance, and how to connect

the cords and cables. It contains the following sections:

Rack-Mount the Chassis, page 33

•

Ground the Chassis, page 38

•

Connect Cables, Turn on Power, and Verify Connectivity, page 39

•

Rack-Mount the Chassis

Take note of the following warnings:

CHAPTER 3

Warning

Warning

Statement 1006—Chassis Warning for Rack-Mounting and Servicing

To prevent bodily injury when mounting or servicing this unit in a rack, you must take special precautions

to ensure that the system remains stable. The following guidelines are provided to ensure your safety:

This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

•

When mounting this unit in a partially filled rack, load the rack from the bottom to the top with the

•

heaviest component at the bottom of the rack.

If the rack is provided with stabilizing devices, install the stabilizers before mounting or servicing

•

the unit in the rack.

Statement 1024—Ground Conductor

This equipment must be grounded. Never defeat the ground conductor or operate the equipment in the

absence of a suitably installed ground conductor. Contact the appropriate electrical inspection authority

or an electrician if you are uncertain that suitable grounding is available.

Cisco Firepower 2100 Series Hardware Installation Guide

33

Page 38

Rack-Mount the Chassis

Mount and Connect

Warning

Statement 1047—Overheating Prevention

To prevent the system from overheating, do not operate it in an area that exceeds the maximum

recommended ambient temperature of: 40°C

This procedure describes how to install the Firepower 2100 series in a rack using the rack kit. It applies to all

models of the 2100 series. For the 2110/2120, you install 3 screws on the chassis to secure the slide rail. For

the 2130/2140, you install use the pegs on the chassis to secure the slide rail.

Before You Begin

You need the following to install the Firepower 2100 in a rack (4-post EIA-310-D rack):

#1 Phillips Head screwdriver

•

Firepower 2100 kit that contains the following:

•

One slide rail set

◦

Two brackets with captive screws

◦

Six 8-32 0.25" screws

◦

Two M3x6mm screws

◦

Six 8-32" shoulder screws

◦

Cisco Firepower 2100 Series Hardware Installation Guide

34

Page 39

Mount and Connect

Rack-Mount the Chassis

Slide rail assemblies work with four-post racks and cabinets with square slots, round 7.1mm holes, #10-32

threaded holes, and #12-24 threaded holes on the rack post front. The slide rail works with front to back

spacing of rack posts from 24 to 36 inches.

Step 1

Attach a rack mount bracket to each side of the chassis using the six 8-32 x .375" countersink Phillip head screws (three

per side) provided in the kit.

Figure 14: Attaching the Rack Mount Bracket to the Side of the Chassis

Step 2

3

8-32 x 0.25" countersink Phillip head screws

(3 per side)

Attach the inner rails to the sides of the chassis:

a) Remove the inner rails from the slide rail assemblies.

b) Align an inner rail with each side of the chassis:

Rack mount bracket2Chassis1

Cisco Firepower 2100 Series Hardware Installation Guide

35

Page 40

Rack-Mount the Chassis

For the 2110/2120, install the three 8-32" screws into each side of the chassis, and align the inner rail so that

•

the three slots on the rail line up with the screws on the chassis.

Figure 15: Installing the Screws on the 2110/2120 Chassis and Lining up the Inner Rail

Mount and Connect

Inner rail28-32" screw1

M3X6mm screw (1 per side)3

For the 2130/2140, align the inner rail so that the three slots on the rail line up with the three pegs on the side

•

of the chassis.

Figure 16: Lining up the Inner Rail with the Pegs on the 2130/2140 Chassis

Inner rail2Mounting peg on the chassis for the keyed slot1

M3X6mm screw (1 per side)3

c) Set the keyed slots over the screws/pegs, and then slide the rail toward the front to lock it in place on the screw/pegs.

The rear key slot has a metal clip that locks over the screw/peg.

d) Using one M3X6mm screw, secure the inner rail to the side of the chassis to prevent sliding.

Cisco Firepower 2100 Series Hardware Installation Guide

36

Page 41

Mount and Connect

e) Install the second inner rail to the opposite side of the chassis and secure with the other M3X6mm screw.

Rack-Mount the Chassis

Step 3

Open the front securing plate on both slide-rail assemblies. The front end of the slide-rail assembly has a spring-loaded

securing plate that must be open before you can insert the mounting pegs into the rack-post holes.

On the outside of the assembly, push the green arrow button toward the rear to open the securing plate.

Figure 17: Front Securing Mechanism Inside the Front End

1

Note

Works with square slots,

2Front mounting pegs

Securing plate shown pulled back to open

position

7.1mm holes, and 10-32

threaded holes.

Step 4

Step 5

Rack post3

Install the slide rails into the rack:

a) Align one slide-rail assembly front end with the front rack-post holes that you want to use.

The slide rail front-end wraps around the outside of the rack post and the mounting pegs enter the rack-post holes

from the outside-front.

Note

The rack post must be between the mounting pegs and the open securing

plate.

b) Push the mounting pegs into the rack-post holes from the outside-front.

c) Press the securing plate release button marked 'PUSH.' The spring-loaded securing plate closes to lock the pegs in

place.

d) Adjust the slide-rail length, and then push the rear mounting pegs into the corresponding rear rack-post holes. The

slide rail must be level front-to-rear.

The rear mounting pegs enter the rear rack-post holes from the inside of the rack post.

e) Attach the second slide-rail assembly to the opposite side of the rack. Make sure that the two slide-rail assemblies

are at the same height with each other and are level front-to-back.

f) Pull the inner slide rails on each assembly out toward the rack front until they hit the internal stops and lock in place.

Insert the chassis into the slide rails.

Cisco Firepower 2100 Series Hardware Installation Guide

37

Page 42

Mount and Connect

Ground the Chassis

a) Align the rear of the inner rails that are attached to the chassis sides with the front ends of the empty slide rails on

the rack.

b) Push the inner rails into the slide rails on the rack until they stop at the internal stops.

c) Slide the release clip toward the rear on both inner rails, and then continue pushing the chassis into the rack until the

mounting brackets meet the front of the slide rail.

Figure 18: Inner Rail Release Clip

Step 6

Use the captive screws on the front of the mounting brackets to fully secure the chassis to the rack.

What to Do Next

Continue with Ground the Chassis, on page 38 and Connect Cables, Turn on Power, and Verify Connectivity,

on page 39.

Ground the Chassis

Warning

Statement 1024—Ground Conductor

This equipment must be grounded. Never defeat the ground conductor or operate the equipment in the

absence of a suitably installed ground conductor. Contact the appropriate electrical inspection authority

or an electrician if you are uncertain that suitable grounding is available.

Inner rail attached to chassis2Inner rail release clip1

Cisco Firepower 2100 Series Hardware Installation Guide

38

Page 43

Mount and Connect

Connect Cables, Turn on Power, and Verify Connectivity

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Step 7

Warning

Statement 1046—Installing or Replacing the Unit

When installing or replacing the unit, the ground connection must always be made first and disconnected

last.

Warning

Statement 1025—Use Copper Conductors Only

Use copper conductors only.

Caution

Grounding the chassis is required, even if the rack is already grounded. A grounding pad with two threaded

M4 holes is provided on the chassis for attaching a grounding lug. The ground lug must be NRTL-listed.

In addition, a copper conductor (wires) must be used and the copper conductor must comply with NEC

code for ampacity.

Use a wire-stripping tool to remove approximately 0.75 inches (19 mm) of the covering from the end of the grounding

cable.

Insert the stripped end of the grounding cable into the open end of the grounding lug.

Use the crimping tool to secure the grounding cable in the grounding lug.

Remove the adhesive label from the grounding pad on the chassis.

Place the grounding lug against the grounding pad so that there is solid metal-to-metal contact, and insert the two M4

screws with washers through the holes in the grounding lug and into the grounding pad.

Make sure that the lug and cable do not interfere with other equipment.

Prepare the other end of the grounding cable and connect it to an appropriate grounding point in your site to ensure

adequate earth ground.

Connect Cables, Turn on Power, and Verify Connectivity

Take note of the following warnings:

Warning

Statement 1005—Circuit Breaker

This product relies on the building's installation for short-circuit (overcurrent) protection. Ensure that the

protective device is rated not greater than:

Rated 120 V, 15 A (US), 250 V, 16A (EU)

Cisco Firepower 2100 Series Hardware Installation Guide

39

Page 44

Connect Cables, Turn on Power, and Verify Connectivity

Mount and Connect

Warning

Warning

Warning

Warning

Warning

Statement 1007—TN and IT Power Systems

This equipment has been designed for connection to TN and IT power systems.

Statement 1002—DC Power Supply

When stranded wiring is required, use approved wiring terminations, such as closed-loop or spade-type

with upturned lugs. These terminations should be the appropriate size for the wires and should clamp both

the insulation and conductor.

Statement 1003—DC Power Disconnection

Before performing any of the following procedures, ensure that power is removed from the DC circuit.

Statement 1046—Installing or Replacing the Unit

When installing or replacing the unit, the ground connection must always be made first and disconnected

last.

Statement 1022—Disconnect Device

A readily accessible two-poled disconnect device must be incorporated in the fixed wiring.

Step 1

Step 2

Warning

Statement 1025—Use Copper Conductors Only

Use copper conductors only.

After rack mounting the Firepower 2100 series security appliance, follow these steps to connect cables, turn

on power, and verify connectivity.

Connect the console port.

Using a serial console cable, connect a computer or terminal server to the RJ-45 serial console port (baud rate is 9600)

so that you can use the Firepower Device Manager or the CLI (and then continue configuration using the Firepower

Management Center ) to initially set up the Firepower 2100.

Connect the management interface.

Install the management cable that was provided in the Firepower 2100 accessory kit in the Management port,

Cisco Firepower 2100 Series Hardware Installation Guide

40

Page 45

Mount and Connect

Figure 19: Connecting the Cables to the Firepower 2100 Security Appliance

Connect Cables, Turn on Power, and Verify Connectivity

1

Console port (RJ-45)2Gigabit Ethernet Management interface (RJ-45)

Management 0 (also referred to as Management

1/1 and Diagnostic 1/1)

3

4Twelve fixed-port Gigabit Ethernet data

interfaces for SFP+ transceivers

Four fixed-port Gigabit Ethernet data interfaces

for SFP+ transceivers

Flip the SFP+ over to connect in the upper

ports.

Ethernet 1/1 through Ethernet 1/12

Note

The Ethernet 1/1 (WAN) port is

configured by default for internet

access. Connect your DHCP enabled

cable modem (internet) to this port.

Note

The Ethernet 1/2 (inside) port is

configured by default for inside

access. Firepower 2100 bootstrapping

is only supported on Ethernet 1/2 or

on Management 0.

5

Eight fixed port Gigabit Ethernet data interfaces

for SPF+ transceivers.

Step 3

Install the SFP/SFP+ transceivers.

Install SFP/SFP+/ transceivers in the Ethernet network interfaces in the fixed ports or in the network modules you have

installed taking care not to touch the contacts in the rear.

Flip the SFP+ over to connect in the upper ports. The SFP+ connects in the normal way in the lower ports. The sockets

on the upper row face up and the sockets on the lower row face down.

Warning

Do not force an SFP transceiver into a socket. This can jam the transceiver and can cause permanent damage

to the transceiver, the chassis, or both.

Caution

Although non-Cisco SFPs are allowed, we do not recommend using them because they have not been tested

and validated by Cisco. Cisco TAC may refuse support for any interoperability problems that result from

using an untested third-party SFP transceiver. See Supported SFP/SFP+ Transceivers, on page 20 for a list

of supported Cisco transceivers.

Cisco Firepower 2100 Series Hardware Installation Guide

41

Page 46

Connect Cables, Turn on Power, and Verify Connectivity

Mount and Connect

Step 4

Step 5

Step 6

Step 7

Step 8

Step 9

Note

Use appropriate electrostatic discharge (ESD) procedures when inserting the transceiver. Avoid touching the

contacts at the rear, and keep the contacts and ports free of dust and dirt. Store unused SPFs in their ESD

packaging.

Connect the Ethernet interfaces.

Use the proper cable to connect the SFP/SFP+ transceivers in the fixed ports or in the network modules you have installed.

Note

The Ethernet 1/1 (WAN) port is configured by default for internet access. Connect your DHCP enabled cable

modem (internet) to this port.

Note

The Ethernet 1/2 (inside) port is configured by default for inside access. Firepower 2100 bootstrapping is only

supported on Ethernet 1/2 or on Management 0.

Attach the power cable to the appliance and connect it to an electrical outlet.

Press the power switch on the rear panel.

Check the PWR LED on the front panel. Solid green indicates that the appliance is powered on.

Check the SYS LED on the front panel. Solid green indicates that the system has passed power-on diagnostics.

Note

When you toggle the power switch from ON to OFF, it takes several seconds for the system to power off. During

this time, the PWR LED on the front panel blinks green. Do not remove the power cable until the PWR LED

is completely off. See Rear Panel, on page 14 for more information on the power switch.

See the quick start guide for your operating software to configure the Firepower 2100 series security appliance.

Cisco Firepower Threat Defense for the Firepower 2100 Series Using Firepower Device Manager Quick Start

•

Guide

Cisco Firepower Threat Defense for the Firepower 2100 Series Using Firepower Management Center Quick Start

•

Guide

Cisco Firepower 2100 Series Hardware Installation Guide

42

Page 47

CHAPTER 4

Maintenance and Upgrades

This chapter contains procedures for maintaining and upgrading the Firepower 2100 security appliance, and

contains the following sections:

Remove and Replace the Network Module, page 43

•

Remove and Replace the SSD, page 45

•

Remove and Replace the Power Supply Module, page 46

•

Connect the DC Power Supply Module, page 48

•

Secure the Power Cord on the Power Supply Module, page 51

•

Remove and Replace the Fan Tray, page 54

•

Install the Optional Cable Management Brackets, page 55

•

Remove and Replace the Network Module

Take note of the following warnings:

Warning

Warning

Statement 1030—Equipment Installation

Only trained and qualified personnel should be allowed to install, replace, or service this equipment.

Statement 1073—No User-Serviceable Parts

No user-serviceable parts inside. Do not open.

You can remove and replace the network module in the Firepower 2130 and 2140. Although the hardware

supports removing and replacing the network module while the system is running, the software does not

Cisco Firepower 2100 Series Hardware Installation Guide

43

Page 48

Remove and Replace the Network Module

currently support hot swapping. You must power down the chassis to remove and replace network modules.

See Network Modules, on page 15 for more information about Firepower network modules.

Maintenance and Upgrades

Step 1

Step 2

Step 3

Save your configuration.

Power down the security appliance by moving the power switch to the OFF position. See Rear Panel, on page 14 for

more information about the power switch.

To remove a network module, loosen the captive screw on the lower left side of the network module and pull out the

handle that is connected to the screw. This mechanically ejects the network module from the slot.

Figure 20: Removing the Network Module from the Firepower 2130 and 2140

Step 4

Step 5

Step 6

Step 7

44

If the slot is to remain empty, install a blank faceplate to ensure proper airflow and to keep dust out of the chassis;

otherwise, install another network module.

To replace a network module, hold the network module in front of the network module slot on the right of the chassis

and pull the network module handle out.

Slide the network module into the slot and push it firmly into place until the handle is flush with the front of the network

module.

Tighten the captive screw on the lower left side of the network module.

Power on the chassis so that the new network module is recognized.

What to Do Next

Follow the procedures in the FXOS Configuration Guide to connect to the network module and make sure

that it has been discovered correctly by the security appliance.

Cisco Firepower 2100 Series Hardware Installation Guide

Page 49

Maintenance and Upgrades

Remove and Replace the SSD

Take note of the following warnings:

Remove and Replace the SSD

Warning

Warning

Note

Statement 1030—Equipment Installation

Only trained and qualified personnel should be allowed to install, replace, or service this equipment.

Statement 1073—No User-Serviceable Parts

No user-serviceable parts inside. Do not open.

Although the hardware supports removing and replacing SSDs while the system is running, the software does

not currently support hot swapping. You must power down the chassis to remove and replace SSDs.

The 100-GB SSD is restricted to the 2110 and 2120 models. The 200-GB SSD is restricted to the 2130

and 2140 models. Do not mix them.

You can install a Malware Storage Pack (MSP) in slot 2. The MSP stores threat detection data for use in future

analysis. It supports the Advanced Malware Protection (AMP) software feature. It is used as both storage and

as the Malware application repository. RAID is not supported.

Cisco Firepower 2100 Series Hardware Installation Guide

45

Page 50

Remove and Replace the Power Supply Module

Maintenance and Upgrades

Step 1

Step 2

Step 3

Caution

Save your configuration.

Power down the chassis by moving the power switch to the OFF position. See Rear Panel, on page 14 for more information

on the power switch.

To remove the SSD in slot 1, face the front of the chassis, loosen the two captive screws on the SSD, and gently pull it

out of the chassis.

Figure 21: Removing the SSD

Do not switch the two SSDs. You MUST install the MSP in slot 2. If you remove it and install it in slot

1, all stored capture data are lost.

Step 4

Step 5

Step 6

Step 7

Step 8

To replace the SSD in slot 1, make sure the power switch is still in the OFF position, and then hold the SSD in front of

slot 1 and push it in gently until it is seated.

To install the MSP SSD, make sure the power switch is still in the OFF position, and then remove the blank faceplate

in Slot 2 by loosening the captive screws on either side of the faceplate.

Hold the MSP SSD in front of slot 2 and push it in gently until it is seated.

Caution

Tighten the captive screws on either side of the SSD.

Check the SSD LED to make sure the SSD is operative. See Front Panel LEDs, on page 9 for a description of the SSD

LEDs.

Do not switch the two SSDs. The MSP MUST be installed in slot 2. If you remove it and install it in slot 1,

all stored file capture data are lost.

Remove and Replace the Power Supply Module

Take note of the following warnings:

Cisco Firepower 2100 Series Hardware Installation Guide

46

Page 51

Maintenance and Upgrades

Remove and Replace the Power Supply Module

Warning

Warning

Warning

Warning

Statement 1002—DC Power Supply

When stranded wiring is required, use approved wiring terminations, such as closed-loop or spade-type

with upturned lugs. These terminations should be the appropriate size for the wires and should clamp both

the insulation and conductor.

Statement 1003—DC Power Disconnection

Before performing any of the following procedures, ensure that power is removed from the DC circuit.

Statement 1015—Battery Handling

There is the danger of explosion if the battery is replaced incorrectly. Replace the battery only with the

same or equivalent type recommended by the manufacturer. Dispose of used batteries according to the

manufacturer's instructions.

Statement 1022—Disconnect Device

A readily accessible two-poled disconnect device must be incorporated in the fixed wiring.

Warning

Warning

Warning

Warning

Statement 1025—Use Copper Conductors Only

Use copper conductors only.

Statement 1030—Equipment Installation

Only trained and qualified personnel should be allowed to install, replace, or service this equipment.

Statement 1046—Installing or Replacing the Unit

When installing or replacing the unit, the ground connection must always be made first and disconnected

last.

Statement 1073—No User-Serviceable Parts

No user-serviceable parts inside. Do not open.

Cisco Firepower 2100 Series Hardware Installation Guide

47

Page 52

Connect the DC Power Supply Module

Power supply modules are hot swappable. You can remove and replace power supply modules while the

system is running.

Maintenance and Upgrades

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Step 7

Step 8

Unplug the power supply cable before removing the power supply module. You cannot disengage the power supply

module latch without first removing the cable.

To remove a power supply module, face the back of the chassis and grasp the handle.

Press the latch found on the middle of the power supply to disengage the power supply.

Place your other hand under the power supply module to support it while you slide it out of the chassis.

Figure 22: Removing the Power Supply Module

If the slot is to remain empty, install a blank faceplate to ensure proper airflow and to keep dust out of the chassis;

otherwise, install another power supply module.

To replace a power supply module, hold the power supply module with both hands and slide it into the power supply

module bay.

Push in the power supply module gently until you hear the latch engage and it is seated.

Plug in the power supply cable.

Check the LED on the power supply to make sure the power supply is operative. See Power Supply Modules, on page

17

Connect the DC Power Supply Module

Take note of the following warnings:

Warning

Cisco Firepower 2100 Series Hardware Installation Guide

48

Statement 1030—Equipment Installation

Only trained and qualified personnel should be allowed to install, replace, or service this equipment.

Page 53

Maintenance and Upgrades

Connect the DC Power Supply Module

Warning

Statement 1073—No User-Serviceable Parts

No user-serviceable parts inside. Do not open.

For the Cisco 2130 and 2140, the input connector and plug must be UL recognized under UL 486 for field

wiring. The connection polarity is from left to right: negative (–), positive (+), and ground.

Use the handle on the power supply installation and removal. You must support the module with one hand

because of its length.

Figure 23: Firepower 2100 DC Power Supply Module

FAIL and OK LEDs2Handle1

Ejector latch4DC power connector3

Before You Begin