Page 1

Cisco BPX 8600 Series

Installation and Configuration

Release 9.2

July 2001

Corporate Headquarters

Cisco Systems, Inc.

170 West Tasman Drive

San Jose, CA 95134-1706

USA

http://www.cisco.com

Tel:

408 526-4000

800 553-NETS (6387)

Fax: 408 526-4100

Customer Order Number: DOC-786325=

Text Part Number: 78-6325-04 Rev. B0

Page 2

TTHE SPECIFICATIONS AND INFORMATION REGARDING THE PRODUCTS IN THISMANUAL ARE SUBJECT TO CHANGE WITHOUT

NOTICE. ALLSTATEMENTS, INFORMATION, AND RECOMMENDATIONS IN THIS MANUAL ARE BELIEVED T O BE ACCURATE BUTARE

PRESENTED WITHOUT WARRANTY OF ANY KIND, EXPRESS OR IMPLIED. USERS MUST TA KE FULL RESPONSIBILITY FOR THEIR

APPLICATION OF ANY PRODUCTS.

THE SOFTWARE LICENSE AND LIMITED WARRANTYFOR THE ACCOMPANYING PRODUCT ARE SET FORTH IN THE INFORMATION

PACKET THAT SHIPPED WITH THE PRODUCT AND ARE INCORPORATED HEREIN BY THIS REFERENCE. IF YOUARE UNABLE TO

LOCATE THE SOFTWARE LICENSE OR LIMITED WARRANTY, CONTACT YOUR CISCO REPRESENTATIVE FOR A COPY.

The following information is for FCC compliance of Class Adevices: This equipment hasbeen tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial en vironment. This equipment generates, uses, and can radiate radio-frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential areais

likely to cause harmful interference, in which case users will be required to correct the interference at their own expense.

The following information is for FCC compliance of Class B devices: The equipment described in this manual generates and may radiate radio-frequency

energy.If it isnot installed inaccordance with Cisco’s installation instructions, it maycause interferencewith radioand television reception. This equipment

has been tested and found to comply with the limits for a Class B digital device in accordance with the specifications in part 15 of the FCC rules. These

specifications are designed to provide reasonable protection against such interference in a residential installation. However, there is no guarantee that

interference will not occur in a particular installation.

Modifying the equipment without Cisco’s written authorization mayresult in the equipment no longer complying with FCC requirements for Class Aor

Class B digital devices. In that event, your right to use the equipment may be limited by FCC regulations, and you may be required to correct any interference

to radioor televisioncommunicationsat your own expense.

You candetermine whether your equipment is causinginterference byturning it off. If the interference stops, it was probably caused by the Cisco equipment

or one of its peripheral devices. If the equipmentcauses interference to radio or television reception, try to correct the interference by using o ne ormoreof

the following measures:

• Turn the television or radio antenna until the interference stops.

• Move theequipmentto one side or the other of thetelevisionor radio.

• Move the equipment farther away from the television or radio.

• Plug the equipment into an outlet that is on a different circuit from the television or radio. (That is, make certain the equipment and the television orradio

are on circuits controlled by different circuit breakers or fuses.)

Modificationsto this product not authorizedby Cisco Systems, Inc.could void theFCC approvaland negate your authorityto operatethe product.

The Cisco implementationof TCP header compression is an adaptation of a program developed by the University of California, Berkeley (UCB ) as part of

UCB’spublic domainversion of the UNIX operating system. All rights reserved. Copyright© 1981, Regentsof the University of California.

NOTWITHSTANDING ANY OTHER WARRANTY HER EIN, ALL DOCUMENT FILES AND SOFTWARE OF THESE SUPPLIERS ARE

PROVIDED “AS IS” WITH ALL FAULTS. CISCOAND THE ABOVE-NAMED SUPPLIERS DISCLAIM ALL WARRANTIES, EXPRESSED

OR IMPLIED, INCLUDING, WITHOUT LIMITATION, THOSE OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND

NONINFRINGEMENT OR ARISING FROM A COURSE OF DEALING, USAGE, OR TRADE PRAC TICE.

IN NO EVENT SHALL CISCO OR ITS SUPPLIERS BE LIABLE FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL, OR INCIDENTAL

DAMAGES, INCLUDING, WITHOUT LIMITATION, LOST PROFI TS OR LOSS OR DAMAGE TO DATA ARISING OUT OF THE USE OR

INABILITY TOUSE THISMANUAL, EVEN IF CISCO OR ITS SUPPLIERS HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAM AGES.

AccessPath, AtmDirector, Browse with M e, CCIP, CCS I, CD-PAC, CiscoLink,theCiscoPowered N e twork logo, Cisco Syst ems Networking

Academy, the Cisco Systems Networking Academy logo, Fast Step, Follow Me Browsing, FormShare, FrameS har e, GigaStack, IGX, I nterne t

Quotient, IP/VC, iQ Breakthrough, iQ Expertise, iQ FastTrack, the iQ Logo, iQ Net Re adine ss Scorecard, MGX, the Networkers logo, Packet,

RateMUX, Sc riptBu ilde r, ScriptShare, SlideCast, S MAR Tn et, TransPath, Unity, Voic e LAN, Wavelength Rout er, and WebViewer are trademarks

of Cisco Systems, Inc.; Changing the Way We Work, Live, Play, and Learn, Dis co ver Al l That ’s P ossible , and Empowering the Intern e t Ge nerat ion ,

are service marks of Cisco Systems, Inc.; and Aironet, ASIST, BPX , Catalyst, CCDA, CCDP, CCIE, CCNA, CCNP, Cisco, the Cisco Certified

Internetwork Expert logo, Cisco IOS, the Cisco IOS logo, Cisco Systems, Cisco Systems Capital, the Cisco Systems logo, Enterprise/Solver,

EtherChannel, Eth erSw itc h, FastHub, FastSwitch, IOS, I P/TV, LightStream, MICA, Network Regis trar, P IX, Post-Routing, Pre-Routing, Re gi s trar,

StrataView Plus,Stratm, SwitchProbe, TeleRouter, andVCO are registered trademarks of CiscoSystems, Inc.and/or its affiliatesin the U.S. and

certain other countries.

All other trademarks mentioned in this document or Web site are t he pr oper ty of theirresp ective owners. The use of the word partner does not imply

a partnershi p relationship between Ci s co and any other c ompany. (0106R)

Cisco BPX 8600 SeriesInstallation and Configuration, Release 9.2

Copyright © 2001 Cisco Systems, Inc.

All rightsreserved.

Page 3

Feedback on the

Documentation Response Card

Cisco BPX 8600

Series Installation

and Configuration

Release 9.2, July 2001

Part No. 78-6325-04 Rev .B0

Thank you for taking the time

to fill out this r esponse card.

Your input is important to us and

helps us to provide you with

better documentation.

If you have comments about

this document, please complete

this self-addressedresponse

card and mail it to us.

Feedback on the Cisco BPX 8600 Series Installation and Configuration, Release

9.2, July 2001, Part No. 78-6325-04 Rev. B 0

Please respond to the following statements by checking a number from 1 to 5:

5 Strongly agree

4 Somewhat agree

3 Neutral

2 Somewhat disagree

1 Strongly disagree

Overall, I am satisfied with this document.

Strongly agree 5 4321Strongly disagree

This document is accurate and free of errors.

Strongly agree

54321Strongly disagree

I can find the information I need in this document.

Strongly agree

54321Strongly disagree

This document is complete and offers enough relevant information for me to do my job.

Strongly agree

54321Strongly disagree

This document is written at the correct level of complexity for the subject m atter.

Strongly agree

54321Strongly disagree

This document is useful to me in doing my job.

Strongly agree

54321Strongly disagree

Would you like us to contact you? Yes No

Additional Feedback

Wealso encourage you to make

copies of this blank response

card to complete and send to us

wheneveryou have comments

about this document. You can

mail copies of this card to:

Cisco Systems, Inc.

Attn: Central

Documentation Services

170 West Tasman Drive

San Jose, CA 95134-9883

You can also send us your

commentsby e-mail to

bug-doc@cisco.com, or fax your

comments to us at (408) 527-8089.

Y ou can also submit comments

electronically on the World Wide

Web. Click Feedback in thetoolbar

and select Documentation.After

you complete theform, click

Submit to send it to Cisco.

We appreciate your comments.

Mailing Information

Date

Company Name

Contact Name

Mailing Address

City State/Province

Zip/Postal Code Country

Phone ( ) Extension

Fax ( ) E-mail

Page 4

BUSINESS REPLY MAIL

FIRST-CLASS MAIL PERMIT NO. 4631 SAN JOSE CA

POSTAGE WILL BE PAID BY ADDRESSEE

ATTN CENTRAL DOCUMENTATION SERVICES

CISCO SYSTEMS INC

170 WEST TASMAN DRIVE

SAN JOSE CA 95134-9883

NO POSTAGE

NECESSARY

IF MAILED

IN THE

UNITED STATES

Page 5

About This Manual xxix

Documentation CD-ROM xxix

Objectives xxix

Audience xxix

Cisco WAN Switching Product Name Change xxix

Organization xxx

Related Documentation xxxiv

Conventions xxxiv

PART 1 Introduction

Chapter 1 Introduction 1-1

PART 2 Quickstart

TABLE OF CONTENTS

Chapter 2 Quickstart Installation and Configuration 2-1

Introduction 2-1

Installation Sequence 2-1

Finishing the Installation and Initial Power-Up 2-1

Configuration 2-2

Configuration, Lines, T runks, and Connections 2-2

Configuration, ATM Connections 2-2

Configuration, PVCs, SVCs, and SPVCs 2-3

ASI SVC Resource Partitioning 2-3

BXM SVC Resource Partitioning 2-3

BNI TrunkSVC Partitioning (NNI) 2-3

BXM TrunkSVC Resource Partitioning 2-3

Configuration Virtual Trunks 2-3

Configuration, VSI 2-3

Configuration, SONET APS 2-3

Configuration, Multicasting PVCs, Adding Connections 2-4

Configuration, MPLS 2-4

Customer Support 2-4

PART 3 Installation

Chapter 3 Installation Summary 3-1

Introduction 3-1

Table of Contents iii

Page 6

Installation Sequence 3-1

Support 3-3

Chapter 4 Installation, Preliminary 4-1

Site Preparation 4-1

Parts Checklist 4-2

Safety Requirements 4-4

Laser Sa fety Guidelines 4-4

Maintaining Safety with Electricity 4-4

Basic Guidelines 4-5

Power and Grounding 4-6

CEPT Requirements 4-6

EMI Requirements 4-6

Mechanical Installation 4-7

Installing a B PX Switch Shelf, Preliminary Steps 4-10

Chapter 5 Installation with Cisco Cabinets including 7000 Series Routers 5-1

Installing a BPX Switch in a Cisco Cabinet 5-1

Preliminary Procedure: 5-3

Installing a 7200 or 7500 Router in a BPX 8650 Cabinet or Rack 5-7

Installing Router Assemblyin a Cisco Cabinet 5-9

Installing Router Assembly in a 19-Inch Open Rack 5-10

Installing Router Assembly in a 23-Inch Open Rack 5-11

Chapter 6 Installation with Customer Cabinet 6-1

Installing a BPX Switch, Rear Rail Setback at 30-Inch 6-1

Preliminary Procedure: 6-1

Chapter 7 Installation, DC Shelf Initial Setup 7-1

DC Power Input Connections 7-1

Card Slot Fuses 7-4

Fan Power Fuses 7-4

Chapter 8 Installation, AC Shelf Initial Setup 8-1

Installing an AC Power Supply Tray 8-1

Installing an AC Power Supply 8-8

AC Power Input Connections 8-10

Card Slot Fuses 8-13

Fan Power Fuses 8-13

Chapter 9 Finishing the Installation

and Power-Up 9-1

Installing the BPXSwitch Cards 9-2

iv CiscoBPX 8600 Series Installation and Configuration, Release 9.2, July 2001, Part No. 78-6325-04 Rev. B0

Page 7

Installing Front Cards 9 -4

Installing Back Cards 9-6

Verifying 9.6 or 19.2 Gbps Backplane 9-7

Upgrading to BCC-4 Cards 9-8

Installation of APS Redundant Frame Assembly and Backcards 9-9

APS 1:1 Redundancy Installation 9-9

APS 1+1 Redundancy Installation 9-10

Making T3 or E3 Connections 9-14

Making an ASI-155 or BNI-155 Connection 9-17

Making a BXM OC-3 or OC-12 Connection 9-17

Making a BXM T3/E3 Connection 9-19

Setting up the BME OC-12 Port Loop 9-21

Alarm Output Connections 9-22

Attaching Peripherals 9-23

Temporarily Connecting a terminal or NMS to the Control Port 9-23

LAN Connection for the Network Management Station 9-27

Connecting a Network Printer to the BPX Switch 9-28

Connecting Modems 9-29

Making External Clock Connections 9-31

Initial Power-Up of the BPX Switch 9-33

BPX Switch Startup Diagnostic 9-33

Provisioning the BPX Switch 9-34

Configuration 9-34

Chapter 10 T3/E3 Cable Management Tray 10-1

Installation of Cable Management Tray 10-2

Installing Tray Brackets 10-2

Installing Tray 10-3

RaisingTrayforAccesstoPEMs 10-5

Installing BXM T3/E3 Cable Bracket 10-6

Connecting Cables to BXM T3/E3 Cards 10-7

Routing Cables from Cards through Cable Management Tray 10-9

Tray Raised with Cables in Place 10-10

Table of Contents v

Page 8

PART 4 Configuration, General

Chapter 11 Configuration, Introduction 11-1

Introduction 11-1

ConfigurationProcedures 11-1

Chapter 12 Configuration, Initial Setup 12-1

BPX Switch Management 12-1

Initial Node Configuration Summary 12-2

Adding Nodes, AddingTrunks, Shelves, etc. 12-2

IP Setup and IP Relay Configuration 12-4

Installing Cisco WAN Manager and Associated Applications 12-5

Configuring the Cisco WAN Ma nager Workstation (example) 12-5

Configuring the LAN Port 12-6

Configuring the MGX 8220 for Cisco WAN Manager NMS Operation (example) 12-10

Adding Virtual Trunks using BXM Cards 12-11

Adding Virtual Trunks using BNI and ASI Cards 12-11

Chapter 13 Configuration, ATM Connections 13-1

ATM Connection Services 13-1

SVCs 13-2

Traffic Management Overview 13-3

Standard ABR notes: 13-4

VSVD Description 13-4

BXM Connections 13-4

ForeSight Congestion Control 13-5

ATM Connection Requirements 13-5

Connection Routing 13-6

addcon Command Syntax 13-6

addcon Example 13-7

ATM Connection Flow 13-9

ATM Connection Flow through the BPX 13-9

Advanced CoS Management 13-10

Connection Flow Example 13-10

Ingress from CPE 1 to BXM 3 13-11

Egress to Network via BXM 10 13-11

Ingress from Network via BXM 5 13-11

Egress from BXM 11 to CPE 2 13-11

Traffic Shaping for CBR, rt-VBR, nrt-VBR, and UBR 13-12

Traffic Shaping Rates 13-13

Configuration 13-13

rt-VBR and nrt-VBR Connections 13-16

Connection Criteria 13-17

Connection Management 13-17

vi Cisco BPX 8600 Series Installation and Configuration, Release 9.2, July 2001, Part No. 78-6325-04 Rev. B0

Page 9

Configuring Resources 13-18

Trunk Queues for rt-VBR and nrt-VBR 13-18

Port Queues for rt-VBR and nrt-VBR 13-19

Related Switch Software Commands 13-19

Related Documentation 13-19

ATM Connection C onfiguration 13-20

CBR Connections 13-26

rt-VBR and nrt-VBR Connections 13-27

ABR Notes 13-29

ABR Connections 13-29

ABRSTD Connections 13-30

ABRFST Connections 13-32

UBR Connections 13-33

Network and Service Interworking Notes 13-34

ATFR Network Interworking Connections 13-36

ATFST Network Interworking Connection 13-37

ATFT Transparent Service Interworking Connections 13-38

ATFTFST Transparent Service Interworking Connections 13-39

ATFX Translational Service InterworkingConnections 13-40

ATFXFST Translational Service Interworking Connections 13-41

Traffic Policing Examples 13-42

Dual-Leaky Bucket (An Analogy) 13-42

CBR Traffic Policing E xamples 13-42

VBR Dual-Leaky Bucket Policing Examples 13-45

Leaky Bucket 1 13-47

Leaky Bucket 2 13-47

Examples 13-48

ABR Connection Policing 13-54

UBR Connection Policing 13-54

Leaky Bucket 1 13-54

Leaky Bucket 2 13-54

LMI and ILMI Parameters 13-56

LMI and ILMI Enhancements on BXM 13-56

Early Abit Notification with Configurable T imer on IL MI/LMI Interface 13-56

Chapter 14 Configuration BXM: PVCs, SVCs, and SPVCs 14-1

Label Switching 14-1

Dynamic Resource Partitioning for SPVCs 14-1

BXM Cards 14-2

User Commands 14-5

Connection Provisioning 14-5

Diagnostics 14-5

Test 14-5

Statistics 14-5

Configuring Connections 14-6

Configuration Management 14-6

Table of Contents vii

Page 10

Command Line Interface Examples 14-8

Configuring the BPX Switch LAN and IP Relay 14-17

Configuring the MGX 8220 14-17

Resource Partitioning 14-18

MPLS 14-18

Dynamic Re source Partitioning for SPVCs 14-18

Summary 14-18

BXM SVC Resource Partitioning 14-19

NNI Trunk SVC Resource Partitioning 14-20

BXM Trunk SVC Resource Partitioning 14-20

Chapter 15 Configuration, BXM Virtual Trunks 15-1

Overview 15-1

Typical ATM Hybrid Networkwith Virtual Trunks 15-2

Features 15-3

Functional Description 15-4

Virtual Interfaces 15-4

VSI Virtual Trunks and AutoRoute Virtual Trunks 15-5

Virtual Trunk Example 15-5

Virtual Trunk Transmit Queuing 15-6

Connection Management 15-7

Cell Header Formats 15-7

Routing with Virtual Trunks 15-9

Virtual Trunk Bandwidth 15-9

Virtual Trunk Connection Channels 15-9

Cell Transmit Address Translation 15-9

Cell Receive Address Lookup 15-9

Selection of ConnectionIdentifier 15-9

Routing VPCs over Virtual Trunks 15-10

Primary Configuration Criteria 15-10

VPC Configuration with the ATM Cloud 15-11

Virtual Trunk Interfaces 15-12

Virtual Trunk Traffic Classes 15-12

Virtual Trunk Cell Addressing 15-12

BXM/UXM Two Stage Queueing 15-12

Configuration 15-13

Virtual Trunk Example 15-13

Trunk Redundancy 15-15

Networking 15-16

Virtual Trunk Configuration 15-16

ILMI 15-16

Blind Addressing 15-16

VPC Failure Within the ATM Cloud 15-16

Trunk Statistics 15-17

Trunk Alarms 15-19

viii Cisco BPX 8600 SeriesInstallation and Configuration, Release9.2, July 2001, Part No. 78-6325-04 Rev. B0

Page 11

Logical T runk Alarms 15-19

Physical Trunk Alarms 15-19

Physical and Logical Trunk Alarm Summary 15-19

Event Logging 15-20

Error messages 15-21

Command Reference 15-22

Virtual Trunk Commands 15-22

Virtual Trunks Commands Common to BXM and UXM 15-22

Virtual Trunk UXM Commands 15-23

Virtual Trunk BXM/BNI Commands 15-24

cnfrsrc 15-25

cnftrk 15-26

cnftrkparm 15-29

dspload 15-31

dsprts 15-32

dsptrkcnf 15-33

dsptrks 15-34

Chapter 16 Configuration, BXM VSIs 16-1

Virtual Switch Interfaces 16-1

VSI Controller 16-1

Virtual Interfaces 16-1

VSIMasterandSlaves 16-2

Partitioning 16-4

Class of Service Templates 16-6

Functional Description 16-6

Structure 16-7

Downloading Service Templates 16-9

Assignment of a Se rvice Template to an interface 16-9

Card Qbin Configuration 16-9

Qbin dependencies 16-9

Extended Services Types Support 16-10

Connection Admission Control 16-10

Supported Service Types 16-12

VC Descriptors 16-13

VC Descriptor Parameters 16-17

Chapter 17 SONET APS, Configuration 17-1

Introduction 17-1

Automatic Operation 17-2

Manual Operation 17-2

Operation Criteria 17-3

APS Front Card Displays 17-3

APS 1+1 LED Displays 17-4

APS 1+1 (Card and Line Redundancy) 17-5

APS +1 Redundancy Criteria 17-7

Application Notes for APS 1+1 17-8

Table of Contents ix

Page 12

Using switchcdred/switchyred command 17-8

Other Notes: 17-9

Some switchapsln Notes 17-9

Configuration Procedure, APS 1+1 17-10

APS 1:1 (Line Redundancy) 17-11

General Criteria 17-12

Configuration Criteria 17-12

Configuration Procedure, APS 1:1 17-12

APS 1 +1 Annex B Card and Line Redundancy 17-13

General Criteria 17-13

Configuration Procedure, APS 1+1 Annex B 17-13

Test Loops 17-14

Notes on APS Messages 17-14

APS Alarms 17-14

Statistical Alarms 17-14

APS K1 Command Precedence 17-17

Command Reference 17-19

APS Command Summary 17-19

addapsln/delapsln 17-20

addcdred 17-21

cnfapsln 17-23

cnfcdaps 17-24

dspapsln 17-25

dsplog/dspalms 17-26

switchapsln 17-27

switchcdred/switchyred 17-28

Other Notes: 17-29

Troubleshooting Notes 17-30

Introduction 17-30

APS Configuration Problems 17-31

Not Able to Correctly Set Up APS 1+1 Line Redundancy Configuration 17-31

Description 17-31

Workaround 17-31

Unable to set up APS 1:1 line redundancy configuration 17-31

Description 17-31

Initial Investigation 17-32

Workaround 17-32

Detailed Debugging 17-32

Operator information about APS architectures 17-32

Work Arounds 17-32

Operational Problems 17-33

What the various APS switches mean 17-33

Description 17-33

Unable to perform APS external switch after forced or manual APS switch. 17-33

Description 17-33

Investigation 17-34

x Cisco BPX 8600 SeriesInstallation and Configuration, Release9.2, July 2001, Part No. 78-6325-04 Rev. B0

Page 13

APS manual switch to a line does not occur right away. 17-34

Description 17-34

Explanation 17-34

Switch occurs after lockout issued. 17-34

Description 17-34

Investigation 17-34

APS switch made to a linein alarm. 17-34

17-34

Investigation 17-35

Reverse switch 17-35

Description 17-35

Investigation 17-35

APS switch occurs at the same time as a yred switch. 17-35

Description 17-35

Explanation 17-35

APSswitchoccursafterissuinganAPSclearswitch. 17-36

Description 17-36

Explanation 17-36

APS Switch Occurs even though APS F orced switch in effect. 17-36

Description 17-36

Explanation 17-36

APS line is failing to switch 17-36

Description 17-36

Investigation 17-36

Large cell loss when performing a front card switchover 17-37

Description 17-37

Investigation 17-37

APS service switch description 17-37

Description 17-37

Investigation 17-37

APS line does not seem to switch and active line is in alarm 17-37

Description of problem 17-37

Initial Investigation 17-37

Work Around 17-38

BXM backcard LED green and yellow indications 17-38

Description 17-38

Explanation 17-38

BXM Port LED states 17-38

Scenario 17-38

Explanation 17-39

Alarms 17-39

What do APS Alarms Represent. 17-39

Description 17-39

Initial Investigation 17-39

Chapter 18 Configuration, BME Multicasting 18-1

Introduction 18-1

Standards 18-2

Multicasting Benefits 18-2

Table of Contents xi

Page 14

Multicasting Overview 18-2

BME Features: 18-2

BME Requirements 18-2

BME Restrictions 18-3

Address C riteria 18-3

Connection Management Criteria 18-3

Connection Management with Cisco WAN Manager 18-3

BME Operation 18-4

BME Cell Replication 18-4

Cell Replication Stats 18-5

Adding Connections 18-5

Multi-Segment Multicast Connections 18-6

Multicast Statistics 18-6

Policing 18-7

Alarms 18-7

OAM cells 18-7

AIS cells 18-8

Hot Standby Backup 18-8

Configuration 18-9

Connection Diagnostics 18-9

List of Terms 18-9

Related Documents 18-9

ConfigurationManagement 18-9

PART 5 Configuration, MPLS

Chapter 19 Configuration General,

MPLS on BPX Switch 19-1

Introduction 19-2

MPLS/Tag Terminology 19-2

Label Switching Benefits 19-3

Label Switching Overview 19-3

Elements in a Label Switching Network 19-4

Label Switching Operation at Layer 3 19-4

Forwarding 19-4

Control 19-5

Label Switching in an ATM WAN 19-5

Forwarding 19-5

Control 19-6

Label Switching and the BPX 8650 19-8

xii Cisco BPX 8600 SeriesInstallation and Configuration, Release9.2, July 2001, Part No. 78-6325-04 Rev. B0

Page 15

Virtual Switch Interfaces 19-10

Label Switching Resource Configuration Parameters 19-12

Summary 19-12

Configuring VSI LCNS 19-13

Useful Default Allocations 19-14

Details of More Rigorous Allocations 19-15

Requirements 19-16

List of Terms 19-16

Related Documents 19-17

ConfigurationManagement 19-17

ConfigurationCriteria 19-18

The cnfqbin Command 19-18

The cnfrsrc Command 19-18

ConfigurationExample 19-20

Checking and Troubleshooting 19-27

Provisioning and Managing Connections 19-31

Statistics 19-31

Command Reference 19-32

BPX Switch Commands 19-32

LSC Commands 19-32

addshelf 19-33

cnfqbin 19-37

cnfrsrc 19-39

Useful Default Allocations 19-41

Details of More Rigorous Allocations 19-42

Example 1, 8-Port OC-3BXM Configured in Trunk Mode 19-43

Example 2, 8-Port OC-3BXM Configured in Port Mode 19-46

dspcd 19-49

dspcds 19-50

dspnode 19-53

dspqbin 19-55

dsprsrc 19-57

dsptrks 19-58

resetcd 19-60

upport 19-62

uptrk 19-64

Chapter 20 Configuring the BPX Switch, 7200, and 7500 Routers for MPLS 20-1

Introduction 20-2

Table ofContents xiii

Page 16

MPLS/Tag Terminology 20-3

Equipment and Software Requirements 20-4

ConfigurationPreview 20-4

Initial Setup of MPLS Switching 20-6

Configuration for BPX switch portions of the BPX 8650 ATM-LSRs 20-7

Command Syntax Summary for BPX Portion of MPLS Configuration 20-8

Configurationfor BPX 1 Portion of ATM-LSR-1 20-8

Configurationfor BPX 2 portion of ATM-LSR-2 20-10

Configuration for LSC 1 and LSC 2 portions of the BPX 8650 20-12

Configurationfor LSC1portion of ATM-LSR-1 20-13

Configurationfor LSC2portion of ATM-LSR-2 20-14

Configuration for Edge Label Switch Routers, LSR-A and LSR-B 20-15

Configurationof Cisco7500 as an Edge Router, Edge LSR-A 20-15

Configurationof Cisco7500 as an Edge Router, Edge LSR-C 20-16

Routing Protocol Configures LVCs via MPLS 20-17

Testing the MPLS Network Configuration 20-18

Useful LSC Commands 20-18

Checking the BPX Extended ATM Interfaces 20-18

Basic Router Configuration 20-23

Accessing the Router Command-Line Interface 20-23

Booting the Router for the First Time 20-23

Configuring the Router for the First Time 20-23

Using the System Configuration Dialog 20-24

Configuring Port Adapter Interfaces 20-27

Preparing to Configure Port Adapter Interfaces 20-27

Identifying Chassis Slot, Port AdapterSlot, a nd Interface Port Numbers 20-27

Cisco 7200 or 7500 Port Adapter Interface Ports 20-27

Configuring ATM Interfaces 20-28

Other Router Interfaces 20-29

Checking the Configuration 20-30

Using Show Commands to Verify the New Interface Status 20-30

Using Show Commands to Display Interface Information 20-30

Using the ping Command 20-32

Using Configuration Mode 20-33

Cisco IOS Software Basics 20-34

Cisco IOS Modes of Operation 20-34

Getting Context-Sensitive Help 20-35

Saving Configuration Changes 20-36

Chapter 21 MPLS CoS with BPX 8650,

Configuration 21-1

MPLS CoS Summary 21-1

Related Features andTechnologies 21-2

xiv Cisco BPX8600 SeriesInstallation and Configuration, Release9.2, July 2001, Part No. 78-6325-04 Rev. B0

Page 17

Related Documents 21-2

Prerequisites 21-2

List of Terms and Acronyms 21-3

MPLS CoS with IP+ATM Overview 21-4

MPLS CoS in an IP+ATM Network 21-5

ATM CoS Service Templates and Qbins on the BPX 8650 21-7

Initial Setup of LVCs 21-8

Structure 21-8

MPLS CoS over IP+ATM Operation 21-10

ConfigurationExample 21-11

Configuration 21-12

Chapter 22 MPLS VPNS with BPX 8650, Configuration 22-1

Introduction 22-1

MPLS VPN Benefits Summary 22-3

MPLS VPN Features 22-4

MPLS VPN Description 22-5

New Business Opportunities for Service Providers 22-6

Intranet and Extranet VPNs 22-6

List of Terms 22-6

Related Features andTechnologies 22-8

Related Documents 22-8

Prerequisites 22-8

MPLS Labeling Criteria 22-9

MPLS VPNs over IP+ATM Backbones Description 22-9

MPLS-Enabled Virtual Private Networks 22-10

Built-In VPN Visibility 22-11

BGP Protocol 22-11

MPLS VPN Operation 22-14

VRFs 22-14

VPN Route Target Communities 22-14

IBGP Distribution of VPN Routing Information 22-14

Label Forwarding 22-15

Quality of Service 22-15

Security 22-16

Manageability 22-16

Scalability 22-16

Configuration, E xample, and Commands 22-17

Configuring the BPX 8650 ATM LSR 22-17

Configuring VRFs 22-17

Table of Contents xv

Page 18

Configuring BGPs 22-18

Configuring Import and Export Routes 22-18

Verifying VPN Operation 22-18

PART 6 Operation andManagement

Chapter 23 Cisco WAN Manager 23-1

Chapter 24 CiscoView 24-1

PART 7 Upgrades

Chapter 25 Upgrading MPLS Networks to Switch SW Rel. 9.2 and BXM FW Rel. E 25-1

Introduction 25-2

Upgrade Steps Required 25-2

Upgrading from 9.1 to 9.2 25-2

VSI Configuration Upgrade 25-3

Compatibility 25-3

Capabilities 25-4

PART 8 Reference

Appendix A Cisco Cabinet Di mensions A-1

Cisco Cabinet and Component Heights A-2

Cisco Cabinet A-3

Cable Management A-4

Examples of BPX 8600 Series Switch Configurations A-6

Examples of IGX 8400 Series Switch Configurations A-13

Appendix B BPX Switch Cabling Summary B-1

Trunk Cabling B-1

Power Cabling B-1

AC Powered Nodes B-1

DC Powered Nodes B-2

LM-BCC Cabling B-2

Auxiliary and Control Port Cabling B-2

LAN Port Cabling B-3

Modem Cabling B-3

External Clock Input Cabling B-4

xvi Cisco BPX8600 SeriesInstallation and Configuration, Release9.2, July 2001, Part No. 78-6325-04 Rev. B0

Page 19

T1 Clock Cabling B-4

E1 Clock Cabling B-5

External Alarm Cabling B-6

Standard BPX Switch Cables B-6

Redundancy “Y” Cable B-7

Appendix C BPX Switch Peripherals C-1

Network Management C-1

StrataView Plus Terminal C-1

Control Port, Local Control C-1

Printer C -2

DIP Switch Settings for Okidata 184 C-2

Modems, Dial-In and Dial-Out C-4

Motorola V.34R BPX S witch Dial-In Configuration C-4

BPX Switch Auto-Answer (Dial-In to BPX switch) C-4

IPX Auto-Dial to Customer Service C-6

Index

Table of Contents xvii

Page 20

xviii Cisco BPX 8600 SeriesInstallation and Configuration, Release9.2, July 2001, Part No. 78-6325-04 Rev. B0

Page 21

LIST OF FIGURES

Figure 3-1 Installation Sequence 3-3

Figure 4-1 Laser Information Label 4-4

Figure 4-2 Cabinet Mounting Options for the BPX Shelf 4-8

Figure 4-3 BPX Shelf and T-Rail (Open Rack) or Equivalent Mounting Options 4-9

Figure 4-4 Rack Mounting Dimensions, DC Powered Shelf 4-11

Figure 4-5 Rack Mounting Dimensions, AC Powered Shelf 4-12

Figure 4-6 Removing an Air Intake Grille 4-13

Figure 4-7 Temporary Spacer Bar and Support BracketsInstallation 4-13

Figure 4-8 BPX Switch Shelf Aligned with Temporary Support Bra ckets and Bar 4-14

Figure 5-1 Location of DC Power Entry Module(s), Cabinet Rear View 5-2

Figure 5-2 BPX Shelf Aligned with Temporary Support Bracketsand Bar 5-3

Figure 5-3 BPX Shelf with Rear Rail Mounting at Setbackof 19.86 inches 5-5

Figure 5-4 Rear Mounting Brackets, with 19.86 Inch Rear Rail Setback (DC Systems) 5-6

Figure 5-5 Rear Mounting Brackets, 19.86 Inch Rear Rail Setback (AC-Systems) 5-6

Figure 5-6 Assembly of Router in Router Enclosure 5-8

Figure 5-7 Installing the Router Enclosure Assembly in the Cisco BPX 7650 Cabinet 5-9

Figure 5-8 Installing the Router Enclosure Assembly in a 19-inch Open Rack 5-10

Figure 5-9 Installing the Router Enclosure Assembly in a 23-inch Open Rack 5-11

Figure 6-1 BPX Switch Aligned with Temporary Support Brackets and Spacer Bar 6-2

Figure 6-2 BPX Switch with Rear Rail Mountingat Setback of 30 Inches 6-3

Figure 6-3 Rear Mounting Brackets, Detail 6-3

Figure 6-4 Rear Mounting Brackets, with 30 Inch Rear Rail Setback (DC Systems) 6-4

Figure 6-5 Rear Mounting Brackets, 30 Inch Rear Rail Setback (AC-Powered S ystems) 6-4

Figure 7-1 DC Power 7-2

Figure 7-2 DC Power Connections—With Conduit Box 7-3

Figure 7-3 DC Power Connections—Without Conduit Box 7-4

Figure 8-1 Temporary Spacer Bracket and Support Bracket Installation 8-2

Figure 8-2 Power Supply Tray aligned with Temporary Support Bracketsand Bar 8-3

Figure 8-3 Removing an Air Intake Grille 8-4

Figure 8-4 Securing AC P ower Supply Tray, 30-Inch Rail Setback 8-5

Figure 8-5 Securing an AC Power Supply Tray, 19.86 inch Rear Rail Setback 8-6

Figure 8-6 AC Power Supply Tray with Redundant AC Inputs(view from rear) 8-7

Figure 8-7 Removing an Air Intake Grille 8-8

Figure 8-8 AC Power Supply Installation 8-9

List of Figures xix

Page 22

Figure 8-9 AC Power Supply Connections (Dual and Single Versions Shown) 8-11

Figure 8-10 AC Power 8-12

Figure 9-1 BPX Shelf (front view) 9-3

Figure 9-2 BPX Shelf (rear view, DC shelf shown) 9-3

Figure 9-3 Removing an Air Intake Grille 9-5

Figure 9-4 Laser Information Label 9-6

Figure 9-5 Installing a Back Card 9-7

Figure 9-6 APS 1:1 Redundancy 9-9

Figure 9-7 APS 1+1 Redundancy 9-10

Figure 9-8 APS Redundant Frame Assembly 9-11

Figure 9-9 BPX Shelf, Rear View 9-12

Figure 9-10 Installing APS Redundant Frame Assembly and Backcards into Place 9-13

Figure 9-11 Connecting T3 Cables to BPX LM-T3 (BNI T3 backcard) 9-15

Figure 9-12 Connecting Y-Cable Adapters to a T3 Port 9-16

Figure 9-13 Connecting Y-Cables to an OC-3-SMF Backcard 9-18

Figure 9-14 BXM T3/E3 Cable Connector Detail 9-19

Figure 9-15 Y-Cable for BXM T3/E3 Cards 9-20

Figure 9-16 Looping Ports 1 and 2 for BME on OC-12 Backcard 9-21

Figure 9-17 Alarm Output Connector 9-22

Figure 9-18 Temporary Connections to Bring up a New Node, LM-BCC Backcard Shown 9-25

Figure 9-19 Temporary Connections to Bring up a New Node, LM-BCCs Shown 9-26

Figure 9-20 LAN Connectionsto BCC Backcards, LM-BCCs Shown 9-27

Figure 9-21 Connections to a Network Printer, LM-BCC Shown 9-29

Figure 9-22 Connecting Modems to the BPX Switch, LM-BCC Shown 9-30

Figure 9-23 External Clock Source Connections to Backcards for BCCs 9-32

Figure 10-1 Installation of Cable Management Tray Brackets 10-2

Figure 10-2 Sliding Cable Management Tray over Brackets 10-3

Figure 10-3 Cable Management Tray in Lowered Home Position 10-4

Figure 10-4 Cable Management Tray in Raised Position 10-5

Figure 10-5 Installing BXM T3/E3 Cable Bracket 10-6

Figure 10-6 Connecting C ables to T3/E3 Card 10-7

Figure 10-7 T3/E3 SMB Connector Detail 10-8

Figure 10-8 Cables Routed through Cable Management Tray in Lowered Position 10-9

Figure 10-9 Tray Raised with Cables in Place 10-10

xx Cisco BPX8600 SeriesInstallation and Configuration, Release9.2, July 2001, Part No. 78-6325-04 Rev. B0

Page 23

Figure 11-1 Configuration Sequence 11-2

Figure 12-1 Cisco WAN Manager Physical LAN andIP Relay Network 12-4

Figure 12-2 Cisco WAN Manager LAN Connection via Gateway Router to a BPX S witch 12-8

Figure 12-3 Cisco WAN Manager L AN Connection to a BPX Switch (no gateway) 12-9

Figure 12-4 Virtual Trunks across a Cisco Wan Switching ATM Cloud 12-12

Figure 13-1 ATM Connections over a BPX Switch Network 13-2

Figure 13-2 ABR VSVD Flow Control Diagram 13-5

Figure 13-3 ATM Connection Flow via BPX Switches 13-12

Figure 13-4 Traffic Shaping Example 13-13

Figure 13-5 CBR Connection Prompt Sequence 13-26

Figure 13-6 rt-VBR and nrt-VBR Connection Prompt Sequence 13-27

Figure 13-7 ABR Standard Connection Prompt Sequence 13-30

Figure 13-8 Meaning of VSVD and Flow Control External Segments 13-31

Figure 13-9 ABR ForeSight Connection Prompt Sequence 13-32

Figure 13-10 UBR Connection Prompt Sequence 13-33

Figure 13-11 Frame Relay to ATM Network Interworking 13-35

Figure 13-12 Frame Relay to ATM Service Interworking 13-35

Figure 13-13 ATFR Connection Prompt Sequence 13-36

Figure 13-14 ATFST Connection Prompt Sequence 13-37

Figure 13-15 ATFT Connection Prompt Sequence 13-38

Figure 13-16 ATFTFST ConnectionPrompt Sequence 13-39

Figure 13-17 ATFX Connection Prompt Sequence 13-40

Figure 13-18 ATFXFST Connection Prompt Sequence 13-41

Figure 13-19 CBR Connection, UPC Overview 13-43

Figure 13-20 CBR.1 Connection with Bucket Compliant 13-44

Figure 13-21 CBR.1 Connection, withBucket D iscarding non-Compliant Cells 13-44

Figure 13-22 VBR Connection, UPC Overview 13-46

Figure 13-23 VBR Connection, Policing = 4, Leaky Bucket 1 Compliant 13-48

Figure 13-24 VBR Connection, Policing = 4, Leaky Bucket 1 Non-Compliant 13-49

Figure 13-25 VBR.2 Connection, Policing = 2, with Buckets 1 and 2 Compliant 13-50

Figure 13-26 VBR.2 Connection, Leaky Bucket 2 Discarding CLP (0) Cells 13-51

Figure 13-27 VBR.1 Connection, Policing = 1, with Buckets 1 and 2 Compliant 13-52

Figure 13-28 VBR.3 Connection, Policing = 3, with Bucket 2 non-compliant 13-53

Figure 13-29 UBR Connection, UPC Overview 13-55

List of Figures xxi

Page 24

Figure 14-1 A BPX Switch Network with BXM Cards 14-2

Figure 15-1 Typical ATM Hybrid Network using Virtual Trunks 15-2

Figure 15-2 Virtual and Physical Trunks on a BXM 15-4

Figure 15-3 BXM Egress VIrtual Interfaces and Qbins 15-5

Figure 15-4 Virtual Trunks across a Public ATM Network 15-6

Figure 15-5 ATM Virtual Trunk Header Types 15-8

Figure 15-6 Addition of Virtual Trunks across a Public ATM Network 15-14

Figure 16-1 BXM Virtual Interfaces and Qbins 16-2

Figure 16-2 VSI, Controller and Slave VSIs 16-3

Figure 16-3 VSI Master and VSI Slave Example 16-3

Figure 16-4 Cross Connects and Links between Switches 16-4

Figure 16-5 Graphical View of Resource Partitioning, Autoroute and vsi 16-5

Figure 16-6 Service Template Overview 16-7

Figure 16-7 Service Template and Associated Qbin Selection 16-8

Figure 17-1 APS 1+1 Redundancy 17-3

Figure 17-2 APS 1:1 Redundancy 17-3

Figure 17-3 APS 1+1 Redundancy, Installing APS Backcards in AP S Redundant Backplane 17-6

Figure 17-4 SONET APS 1+1 Detail 17-7

Figure 17-5 SONET APS 1:1 Detail 17-11

Figure 18-1 Replication of a Root Connection into Three Leaves 18-4

Figure 18-2 Example of T raffic, One Root and Two Leaves 18-5

Figure 18-3 Adding Multicasting Connections 18-6

Figure 18-4 Multi-Segment Multicast Connections 18-6

Figure 18-5 Statistics Collection 18-7

Figure 18-6 OAM Cells 18-7

Figure 18-7 Alarms 18-8

Figure 19-1 Label Forwarding Information Base (LFIB) in an IP Packet Environment 19-5

Figure 19-2 Label Forwarding Information Base (LFIB) in an ATM Environment 19-6

Figure 19-3 Downstream on Demand Label Allocation, Conservative Mode Shown 19-7

Figure 19-4 BPX Label Switching 19-9

Figure 19-5 BPX Switch VSI Interfaces 19-10

Figure 19-6 Connection Setup, End Points on same VSI Slave 19-11

Figure 19-7 Connection Setup, End Points on Different VSI Slaves 19-11

Figure 19-8 Port VSI Partition LCN Allocation Elements 19-15

xxii Cisco BPX 8600 Series Installation and Configuration,Release 9.2, July 2001, Part No. 78-6325-04 Rev. B0

Page 25

Figure 19-9 BPX Label Switching Router with BXM in Slot 4 19-20

Figure 19-10 Port VSI Partition LCN Allocation Elements 19-42

Figure 19-11 LCN Allocations for Ports 1-4, Ports Configured in Trunk Mode Example 19-45

Figure 19-12 LCN Allocationsfor Ports 1-4, Ports Configured in Port Mode Example 19-48

Figure 20-1 High-Level View of Configuration of an MPLS Network 20-5

Figure 20-2 Label Swapping Detail 20-6

Figure 20-3 Simplified Example of Configuring an MPLS network. 20-7

Figure 20-4 Example of L VCs in an MPLS Switched Network 20-17

Figure 21-1 Multiple LVCs for IP QoS Services 21-6

Figure 21-2 Example of Multiple LVCs CoS with BPX 8650s 21-7

Figure 21-3 Service Template and Associated Qbin Selection 21-9

Figure 21-4 MPLS CoS over IP+ ATM with BPX 8650 LSRs 21-10

Figure 21-5 MPLS CoS with BPX 8650 LSRs, Configuration Example 21-12

Figure 22-1 VPN Network 22-2

Figure 22-2 Benefits of MPLS Labels 22-9

Figure 22-3 MPLS VPNs in Cisco IP+ATM Network 22-10

Figure 22-4 VPN-IP Address Format 22-11

Figure 22-5 VPN with Service Provider Backbone 22-12

Figure 22-6 Using MPLS to Build VPNs 22-13

Figure A-1 Back View of Empty Cisco Cabinet A-3

Figure A-2 Typical Cable Management, IGX-32 Switch in Cisco Cabinet A-5

Figure A-3 Single BPX Switch, DC and AC Systems A-6

Figure A-4 Single BPX Switch and MGX 8220, DC and AC Systems A-7

Figure A-5 BPX Switch, MGX 8220, and ESP, DC and AC Systems A-8

Figure A-6 BPXSwitchWith2ESPand3MGX8220,DCSystem A-9

Figure A-7 Six MGX 8220, DC System A-10

Figure A-8 BPX Switch with Three MGX 8220s, DC System A-11

Figure A-9 Mounting Brackets (BPX switch), Standard Configuration A-12

Figure A-10 IGX 8430 Switch, DC and AC Systems A-13

Figure A-11 Single IGX 8420 Switch, DC and AC Systems A-14

Figure A-12 Single IGX 8410 switch, DC or AC System A-15

Figure C-1 Dial-Modem Cabling for Auto Answer (Dial-In to BPX) C-5

Figure C-2 Dial Modem Cabling for Auto Dial (dial-out to customer service) C-7

List of Figures xxiii

Page 26

xxiv Cisco BPX8600 SeriesInstallation and Configuration, Release9.2, July 2001, Part No. 78-6325-04 Rev. B0

Page 27

LIST OF TABLES

Table 9-1 BXM SONET APS 9-9

Table 13-1 Standard ATM Traffic Classes 13-3

Table 13-2 Standard ATM Type a nd addcon 13-9

Table 13-3 ATM to Frame Relay Network and Service Interworking 13-9

Table 13-4 Traffic Shaping Rates 13-13

Table 13-5 Traffic Policing Definitions 13-21

Table 13-6 Connection Parameters with Default Settings a nd Ranges 13-21

Table 13-7 Connection Parameter Descriptions 13-23

Table 13-8 CBR Policing Definitions 13-26

Table 13-9 VBR Policing Definitions 13-28

Table 13-10 UBR Policing Definitions 13-33

Table 13-11 ILMI P arameters 13-56

Table 14-1 BXM T3/E3, BXM-155, and BXM 622 Front Card Options 14-3

Table 14-2 BXM-T3/E3, BXM-155, and BXM-622 Back Cards 14-4

Table 15-1 Virtual Trunk Criteria 15-3

Table 15-2 Virtual Trunk Traffic Types 15-6

Table 15-3 Bit Shifting for Virtual Trunking 15-8

Table 15-4 VPI Ranges 15-11

Table 15-5 Maximum Connection IDs (LCNs) 15-11

Table 15-6 Trunk Statistics 15-17

Table 15-7 Physical and Logical Trunk Alarms 15-19

Table 15-8 IGX Log Messaging for Activating and Adding VT 15-21

Table 15-9 BPX Log Messaging for Activating and Adding VT 15-21

Table 15-10 Virtual Trunk Error Messages 15-21

Table 15-11 Virtual Trunk Commands Common to BXM and UXM (IGX) 15-22

Table 15-12 Virtual Trunk UXM Commands 15-23

Table 15-13 Virtual Trunk Commands BXM/BNI 15-24

Table 16-1 ifci Parameters (Virtual Switch Interface) 16-4

Table 16-2 Partition Criteria 16-5

Table 16-3 Service Template Qbn Parameters 16-10

Table 16-4 Service Category Listing 16-12

Table 16-5 VSI Special Service Types 16-13

Table 16-6 ATM Forum Service Types, CBR, UBR, and ABR 16-14

Table 16-7 ATM Forum VBR Service Types 16-15

List of Tables xxv

Page 28

Table 16-8 MPLS Service Types 16-16

Table 16-9 Connection Parameter Descriptionsand Ranges 16-17

Table 17-1 BXM SONET APS 17-2

Table 17-2 BXM Front Card LED Display 17-4

Table 17-3 BXM Back Card for APS 1+1 LED Display 17-4

Table 17-4 APS Alarms 17-15

Table 17-5 K1 Switching Conditions 17-17

Table 17-6 APS Commands 17-19

Table 17-7 addcdred–Parameters 17-21

Table 17-8 Possible APS System Architectures 17-32

Table 19-1 BXM Port Groups 19-13

Table 19-2 Port Connection Allocations 19-14

Table 19-3 Port Connection Allocations, Useful Default Values 19-14

Table 19-4 cnfrsrc Parameter Summary 19-19

Table 19-5 Label Swi tching Parameters—addshe lf 19-34

Table 19-6 Interface Shelf Parameters—addshelf 19-35

Table 19-7 Port Connection Allocations, Useful Default Values 19-41

Table 19-8 LCN A llocations for 8-port OC-3 BXM, Ports Configured in Trunk Mode 19-45

Table 19-9 LCN A llocations for 8-Port OC-3 BXM, Ports Configured in Port Mode 19-48

Table 20-1 Cisco IOS Operating Modes 20-34

Table 21-1 CoS Services and Features 21-2

Table 21-2 Type of Service and RelatedCoS 21-6

Table 21-3 Class of Service and Relative Bandwidth We ighting 21-11

Table 21-4 Class of Service and Relative Bandwidth We ighting Setup 21-11

Table 25-1 MPLS Template Service Class to Qbin Mapping 25-3

Table 25-2 Summary of Firmware and Switch Software Capabilities 25-4

Table A-1 Table of Cisco Cabinet and Component Heights A-2

Table B-1 Trunk Cables B-1

Table B-2 AC Power Cables B-2

Table B-3 DC Power Wiring B-2

Table B-4 Auxiliary and ControlPort Cabling B-2

Table B-5 Auxiliary and ControlPort Pin Assignments B-3

Table B-6 LAN Port Cabling B-3

Table B-7 LAN Port Pin Assignments B-3

xxvi Cisco BPX8600 SeriesInstallation and Configuration, Release9.2, July 2001, Part No. 78-6325-04 Rev. B0

Page 29

Table B-8 External Clock Cabling B-4

Table B-9 T1 Connection to XFER TMG on BCC-bc B-4

Table B-10 T1 Connection to EXT TMG on BCC-bc B-4

Table B-11 T1 Connection to EXT 1 or EXT 2 on BCC-3-bc B-4

Table B-12 E1 Connector Pin Assignments for External Clock B-5

Table B-13 E1 Connection 75 Ohm to E XT TMG on BCC-bc or BCC-3-bc B-5

Table B-14 E1 Connection 100/120 Ohm to EXT TMG on BCC-bc B-5

Table B-15 E1 Connection 100/120 Ohm to EXT 1 or EXT 2 on BCC-3-bc B-5

Table B-16 External Alarm Cabling B-6

Table B-17 Network Alarm Pin Assignments B-6

Table B-18 Standard Cables Available from Cisco B-7

Table B-19 RedundancyY-Cables B-7

Table C-1 Control Port Parameters for Local Control (pc or workstation) C-2

Table C-2 Auxiliary Port Parameters for OkiData 184 Printer C-2

Table C-3 Switch A Settings —Okidata 184 Printer C-2

Table C-4 Switch 1 Settings—Okidata 184 Printer C-3

Table C-5 Switch 2 Settings—Okidata 184 Printer C-3

Table C-6 Modem Interface Requirements C-4

Table C-7 V.34R Modem Configuration for Auto-Answer (Dial-in to BPX) C-5

Table C-8 V.34R Auto-Dial Configuration (dial-out to customer service)* C-6

Table C-9 V.34R with talk/data, Auto-Dial Configuration (dial-out to customer service) C-7

List of Tables xxvii

Page 30

xxviii Cisco BPX 8600 Series Installation and Configuration, Release9.2, July 2001, Part No. 78-6325-04 Rev. B0

Page 31

About This Manual

This publication provides installation procedures and related information for the installation of the

BPX 8600 Series wide-area switches which include the BPX8620 switch and theBPX 8650 MPLS

switch.

Refer to 9.2 Re lease Notes for supported features.

Documentation CD-ROM

Ciscodocumentationandadditionalliteratureareavailablein a CD-ROM package, whichshipswith

your product. The DocumentationCD-ROM, a member of theCiscoConnectionFamily, is updated

monthly.Therefore,itmightbe more current than printed documentation.Toorderadditionalcopies

of the Documentation CD-ROM, contact your local sales representative or call customer service.

The CD-ROM package is available a s a single package or as an annual subscription. You can also

access Cisco documentation on the WorldWide Web at http://www.cisco.com,

http://www-china.cisco.com, or http://www-europe.cisco.com.

If you arereadingCiscoproduct documentation on theWorld WideWeb, you can submitcomm ents

electronically. Click Feedback in the toolbar and select Documentation. After you complete the

form, click Submit to send it to Cisco. We appreciate your comments.

Objectives

This publication provides informationforthe installationand initial startup and configuration of the

BPX 8600 series.

Audience

This publication is intended for persons installing the BPX 8600 series. The installers should be

familiar with electronic circuity and electrical wiring practices and should ha ve experience as an

electronic or electromechanical technician. It is also intended for the network administrator

performing initial BPX configuration. Both the installers andthe network administrator should be

familiar with BPX network operation and with the WAN Manager Network Management System.

Cisco WAN Switching Product Name Change

The Cisco WAN Switching products have new names. Any switch in the BPXswitch family (Cisco

BPX® 8620 broadband sw itch and Cisco BPX® 8650 broadband switch) is now called a Cisco

BPX® 8600 series broadband switch. The BPXServiceNodeswitchis now called the Cisco BPX®

About This Manual xxix

Page 32

Organization

Organization

8620 broadband switch. The BPX switch as a Tag s witch controller is now called theCisco BPX®

8650 broadband switch. The AXIS shelf is now called the Cisco MGX™ 8220 edge concentrator.

Any switch in the IGX switch family (IGX 8, IGX16, andIGX32 wide-area switches)isnow called

the Cisco IGX™ 8400 series multiband s witch. The IGX 8 switch is now called the Cisco IGX™

8410 multiband switch.The IGX 16 switch is now called the Cisco IGX™ 8430 multiband sw itch.

Cisco StrataView Plus® is now called Cisco WAN Manager® (CWM).

This publication is organized as follows:

PART 1 Introduction

Chapter 1 Introduction

Provides a brief introduction tothe document, including a flow diagram that

shows which procedures are applicable to thevariousoptions,Cisco Cabinet

or Customer Cabinet, ac cabinet or dc cabinet

PART 2 Quickstart

Chapter 2 Quickstart Installation and Configuration

Provides a summary of the contents of the major parts of the manual.

PART 3 Installation

Chapter 3 Installation Summary

Provides a summary of the procedures anda flow diagram showing the

overall installation tasks in PART 1.

Chapter 4 Installation, P reliminary

Includes preliminary instructions including site preparation information,

parts checklist, and safety re quirements.

Chapter 5 Installation with Cisco Cabinetsincluding 7000 Series Routers

Provides installationsteps forthe mechanical placement of a BPX switch in

a standard Cisco cabinet. This cabinet provides rear rails at a 19.86 inch

(50.5 cm) setback from the front of the cabinet.

Chapter 6 Installation with Customer Cabinet

Provides installationsteps forthe mechanical placement of a BPX switch in

a standard 19-inchwide customer supplied equipment cabinet or rack witha

rear rail setback at 30 inches.

Chapter 7 Installation, DC Shelf Initial Setup

Describes how to m ake the DC power connections.

Chapter 8 Installation, AC Shelf Initial Setup

Explains how to install the AC power supply tray, power supplies, and make

AC power connections.

xxx Cisco BPX 8600 Series Installationand Configuration, Release 9.2, July 2001, Part No. 78-6325-04 Rev. B0

Page 33

Chapter 9 Finishing the Installation and Power-Up

Explains how to install the BPX switch cards, connect the line and trunk

cables, connect peripherals, connect to a network management station, and

initial power-up.

Chapter 10 T3/E3 Cable Management Tray

Provides instructions for the installation of the optional cable management

tray that may be used to route cables in an open rack non-redundant

configuration.

PART 4 Configuration, General

Chapter 11 Configuration, Introduction

Provides a brief introduction to BPX switch configuration, including a flow

diagram showing the applicable procedures.

Chapter 12 Configuration, Initial Setup

Provides initial BPX switch configuration information.

Organization

Chapter 13 Configuration,ATMConnections

Provides general ATM description and ATM connection parameter

information for CBR, VBR, UBR, and ABR connections.

Chapter 14 Configuration BXM: PVCs, SVCs, and SP VCs

Provides a brief description of BXM switch functions and describes

command line interface commands for configuring the BXM and for

configuring resource partitions for PVCsand SVCs. Refersto other chapters

in this m anual and to other documents, as applicable, for tag switching and

SVCs and SPVCs.

Chapter 15 Configuration, BXM Virtual Trunks

Provides a brief overview of BXM Virtual Trunks and configuration

procedures.

Chapter 16 Configuration, BXM VSIs

Provides a brief overview of Vitual Switch Interface features and resources

and c onfiguration procedures.

Chapter 17 SONET APS, Configuration

Provides a descriptionand configuration information for the SONET

Automatic Protection System (APS) which may be used to provide line and

card redundancy for SMF and SMF LR BXM OC3 and OC12 cards.

Chapter 18 Configuration, BME Multicasting

Provides a brief overview of BME multicastingand provides configuration

examples.

About This Manual xxxi

Page 34

Organization

PART 5 Configuration, MPLS

Chapter 19 ConfigurationGeneral, MPLS on BPX Switch

Provides a brief overview of MultiProtocol L abel Switching (MPLS) and

configuration procedures for MPLS on the BPX switch.

Chapter 20 Configuring the BPX Switch, 7200, and 7500 Routers for MPLS

Provides a summary overview of MPLS with respect to both the MPLS

router controlling function and the BPX node slave switching function and

an example of an integrated MPLS configuration procedures.

Chapter 21 MPLS CoSwith BPX 8650, Configuration

Provides a description of MPLS CoS with the use of the BPX 8650 ATM

Label Switch Router (ATM LSR). It also contains a summary example for

configuring BPX 8650 LSRs, their associated LSCs (7200 or 7500 series,

and Label Edge Routers

Chapter 22 MPLS VPNS with BPX 8650, Configuration

Provides a description of MPLS VPNs with the use of the BPX 8650 ATM

Label Switch Router (ATM LSR).It also contains a summaryexample of the

configuration of IOS to support VPNs, and references to relevantIOS

documentation. Refer to 9.2 Release notes for supported features

PART 6 Operation and Management

Chapter 23 Cisco WAN Manager

Provides a brief overview of network management of the BPX switch and

associated equipment by the Cisco WAN Manager, also referred to as CWM,

and formerly known a s StrataView Plus.

Chapter 24 CiscoView

Provides a brief overview of network management of the BPX switch and

associated equipment by Cisco View

PART 7 Upgrades

Chapter 25 Upgrading MPLS Networks to Switch SW Rel. 9.2 and BXM FW Rel. E

Provides procedures to upgrade MPLS networks from BPX switch software

Release 9.1 and BXM firmware Release C, to switch software Release 9.2.x

and B XM Firmware Release E.

PART 8 Reference

Provides procedures to upgrade MPLS networks from BPX switch software

Release 9.1 and BXM firmware Release C, to switch software Release 9.2.x

and B XM Firmware Release E.

Appendix A Cisco Cabinet Dimensions

Illustrates typical cable management and space requirements for various

system configurations in the Ciscocabinet. It also lists the height of

components in inches, centimeters, and rack-mount units (RMUs).

xxxii Cisco BPX 8600 Series Installation and Configuration, Release 9.2, July 2001, Part No. 78-6325-04 Rev. B0

Page 35

Appendix B B PX Switch Cabling Summary

Provides details on the cabling required to install the BPX switch.

Appendix C BPX Switch Peripherals

Provides details on the peripherals used with the BPX switch including

printers and modems.

Organization

About This Manual xxxiii

Page 36

Related Documentation

Related Documentation

The following Cisco publications contain a dditional information related to the operation of the

BPXswitchandassociatedequipmentinaCiscoWANswitchingnetwork:

• Cisco WAN Manager Operations document providing for procedures for using the Cisco WAN

Manager network management system.

• Cisco WAN Design Tools User Guide provides procedures for modeling networks.

• Cisco WAN Service Node Extended Services Processor Installation and Operation Release 2.2

provides detailed information about the Extended S ervices Processor (ESP).

• Release 9.2 of the IGX/BPX documentation set, including:

— CiscoBPX 8600 Series Referenceprovides a ge neral descriptionand technical details of the

BPX broadband switch.

— CiscoIGX 8400 SeriesReference provides a general description and technical details of the

IGX multiband switch.

— Cisco IGX 8400 Series Installation and Configuration provides installation instructions for

the IGX multiband switch.

— Cisco MGX 8220 Reference provides a general description and technical details of the

MGX 8220.

Conventions

— Cisco MGX 8220 Command Reference provides detailed information for MGX 8220

command line usage.

— Cisco WAN Switching Command Reference provides detailedinformation on operating the

BPX, IGX, and IPX systems through their command line interfaces.

— Cisco WAN Switching SuperUser Command Reference provides detailed information on

their command line interfaces s pecial commands requiring S uperUser access authorization.

This publication uses the following conventions to convey instructions and information.

Command descriptions use these conventions:

• Commands and keywords are in boldface.

• Arguments for which you supply values are in italics.

• Elements in square brackets ([ ]) a re optional.

• Alternative but required keywords are grouped in braces({ })and are separatedby vertical bars

(|).

Examples use these conventions:

• Terminal sessions and information the system displays are in screen font.

• Information you enter is i n boldface screen font.

• Nonprinting characters, such as passwords, a re in angle brackets (< >).

• Default responses to system prompts are in square brackets ([ ]).

Note Means reader take note. Notes contain helpful suggestions or references to materials not

contained in this manual.

xxxiv Cisco BPX 8600 Series Installation and Configuration, Release 9.2, July 2001, Part No. 78-6325-04 Rev. B0

Page 37

Conventions

Caution Means reader be careful. In this situation, you might do something that could result i n

equipment damageor loss ofdata.

Warning This warning symbol means danger. You arein a situation that could cause bodily injury.

Before you work on any equipment, you must be aware of the hazards involved with electrical

circuitryand familiar with standardpracticesfor preventingaccidents.(Tosee translatedversionsof

this warning, refer to the Regulatory Compliance and Safety Information that accompanied your

equipment.)

Waarschuwing Dit waarschuwingssymbool betekent gevaar. U verkeert in een situatie die

lichamelijkletselka n veroorzaken. Voordatu aanenigeapparatuurgaat werken, dient u zich bewust

te zijn van de bij elektrische schakelingen betrokken risico's en dient u op de hoogte te zijn van

standaard maatregelen om ongelukken te voorkomen.

Varoitus Tämä varoitusmerkki merkitsee vaaraa. O let tilanteessa, joka voi johtaa

ruumiinvammaan. Ennen kuin työskentelet minkään laitteiston parissa, ota selvää

sähkökytkentöihin liittyvistä vaaroista ja tavanomaisista onnettomuuksien ehkäisykeinoista.

Attention Ce symbole d'avertissement indique un danger. Vous vous trouvez dans une situation

pouvant causer des blessures ou des dommages corporels. Avant de travailler sur un équipement,

soyez conscient des dangers posés par les circuits électriques et familiarisez-vous avec les

procédures couramment utilisées pour éviter les accidents.

12

93

6

Warnung Dieses Warnsymbol bedeutet Gefahr. Sie befinden sich in einer Situation, die zu einer

Körperverletzung führen könnte. BevorSie mit der Arbeit an irgendeinem Gerät beginnen,seienSie

sich der mit elektrischen Stromkreisen verbundenen Gefahren und derStandardpraktiken zur

Vermeidung von Unfällen bewußt.

Avvertenza Questo simbolo di avvertenza indica un pericolo. La situazione potrebbe causare

infortuni alle persone.Prima di lavorare su qualsiasi apparecchiatura, occorre conoscere i pericoli

relativiaic ircuitielettricied esserealcorrentedelle pratichestandardperlaprevenzione di incidenti.

Advarsel Dette varselsymbolet betyr fare. Du befinner deg i en situasjon som kan føre til

personskade. Før du utfører arbeid på utstyr, m å du vare oppmerksom på de faremomentene som

elektriskekretser innebærer,samt gjøre deg kjent med vanligpraksisnårdetgjelderåunngåulykker.

Aviso Este símbolo de aviso indica perigo. Encontra-se numa situação que lhe poderá causar danos

físicos. Antes de começar a trabalhar com qualquer equipamento, familiarize-se com os perigos

relacionados com circuitos eléctricos, e com quaisquer práticas comuns que possam prevenir

possíveis acidentes.

¡Atención! Este símbolode aviso significa peligro. Existe riesgo para su integridad física. Antes

de manipular cualquier equipo, considerar los riesgos que entraña la corriente eléctrica y

familiarizarse con los procedimientos estándar de prevención deaccidentes.

Varning! Denna varningssymbol signalerar fara. Du befinner dig i en situation som kan leda till

personskada. Innan du utför arbete på någon utrustning måste du vara medveten om farorna med

elkretsar och känna till vanligt förfarande för att förebygga skador.

Timesaver Means the described action saves time. You can save time with this action.

About This Manual xxxv

Page 38

Conventions

xxxvi Cisco BPX 8600 Series Installation and Configuration, Release 9.2, July 2001, Part No. 78-6325-04 Rev. B0

Page 39

PART 1

Introduction

Page 40

Page 41

CHAPTER

Introduction

This document provides installation andconfiguration instructions for the BPX 8600 Series

wide-areaswitches.It is divided intoa number of parts. Thisisthefirstpartthattellsyou very briefly

what’sin the document. If you see textor a reference underlined in this document, you can click on

it to go to the linked area.

• PART 1, Introduction—Summarizeswhat’s in this document.

• PART 2, Quickstart—Provides a quick start guide to installation and an abbreviated

configuration guide. Detailed installation andconfiguration procedures a re provided in their

separate sections of this document.

1

• PART 3, Installation—Provides detailed installation instructions.

• PART 4, Configuration, General—Provides detailed configuration examples.

• PART 5, Configuration, MPLS—Provides detailed configuration examples.

• PART 6, Operation and Management—Provides Ope ration and Management and NMS

information.

• PART 7, — Provides proceduresto upgrade MPLS networks from BPX switch software Release

9.1 and BXM firmware Release C, to switch software Release 9.2.x and BXM Firmware Release

E.

• PART 8, Reference—Provides reference information, cabling, i.e.

Introduction 1-1

Page 42

1-2 Cisco BPX8600 SeriesInstallation and Configuration, Release9.2, July 2001, Part No. 78-6325-04 Rev. B0

Page 43

PART 2

Quickstart

Page 44

Page 45

Introduction

CHAPTER

Quickstart Installation and Configuration

This section provides a summary of configuration procedures for the BPX. Detailed procedures are

provided in later chapters of this manual.

For additional information on the BPX switch, including card descriptions and additional

informationon configuration, refer to t he CiscoBPX 8600 Series Reference.Foradescriptionofthe

commandsused to operate a BPX switch, refer to the Cisco WAN Switch Command Reference and

Cisco WAN Switch SuperUser Command Reference. Refer tothe Cisco WAN Manager manuals for

information on network management.

2

Installation Sequence

A summary of the installation sequence for the BPX follows:

Step 1 Safety... refer to Chapter 4, Installation, Preliminary

Step 2 Site Preparation...refer to Chapter 4, Installation, Preliminary

Step 3 Unpacking... refer to Chapter 4, Installation, Preliminary

Step 4 Installing shelf in cabinet or rack... refer to Chapter 4, Installation, Preliminary

Step 5 Installing a Cisco 7200 or 7500 router on a BPX 8650... refer to Chapter 5, Installation

with Cisco Cabinets including 7000 Series Routers.

Step 6 OptionalCable Management Tray... refer to Chapter10, T3/E3 Cable Management Tray.

Finishing the Installation and Initial Power-Up

A summary of these procedures is as follows:

Power-Up and Initial Configuration... refer to:

Step 1 Installing the BPX Switch Cards

Step 2 Verifying 9.6or 19.2 Gbps Backplane

Step 3 Upgrading to BCC-4 C ards

Step 4 Installation of APS Redundant Frame Assembly and Backcards

Step 5 Making T 3 or E3 Connections

Step 6 Making an ASI-155 or BNI-155 Connection

Step 7 Making a BXM OC3 or OC12 Connection

Quickstart Installation and Configuration 2-1

Page 46

Configuration

Step 8 Making a BXM T3/E3 Connection

Step 9 Setting up the BME OC-12 Port Loop

Step 10 Alarm OutputConnections

Step 11 Attaching Peripherals

Step 12 LAN Connection for the Network Management Station

Step 13 Connecting a Network Printer tothe BPX Switch

Step 14 Connecting Modems

Step 15 Making External Clock Connections

Step 16 Initial Power-Up of the BPX Switch

Step 17 Provisioning the BPX Switch

Step 18 Configuration

Configuration

The following providesa summary of the procedures to configure various functions of the BPX. For

more detailedinformation,you arereferredto specific chaptersinthis manual, or to other associated

Cisco Documents, as applicable.

Configuration, Lines, Trunks, and Connections

Lines a nd Trunks can be added and c onfigured in many cases using the Cisco WAN Manager

Equipment Manager. Inother cases, the command line interface (CLI) is used. For additional

information, refer to the Cisco WAN Switch Command Reference.

Configuration, ATM Connections

Connections are typically added using the Cisco WAN Manager Connection Manager. In other

cases, the command line interface is used.

Toadd an ATM connection, for example, the following CLI command may be used:

addcon local_addr node remote_addr traffic type ...extended parameters

For example, for an abr connection:

at bpx 1, addcon 4.1.30.30 bpx23.1.40.40 abr ...extended parameters

For additional information, refer to Chapter 13, Configuration, ATM Connections.

Cisco BPX 8600 Series Installation and Configuration, Release 9. 2, July 2001, Part No. 78-6325-04 Rev. B02-2

Page 47

Configuration, PVCs, SVCs, and SPVCs

Upping andconfiguring trunks. For additional information, refer to Chapter 14, Configuration

BXM: PVCs, SVCs, and SPVCs. Some of the applicable CLI commands are:

uptrk 4.1

addtrk 4.1

upln 3.3

cnfln 3.3

cnfport 3.3

cnfportq 3.3

upport 3.3

cnfcls 1

cnfcls 2

addcon 3.1.105.55 bpx1 3.2.205.65 v ............

cnfcon 3.1.105.55

addcon 3.1.104.54 bpx1 3.2.204.64 abr ............

cnfcon 3.1.104.54

cnfabrparm 3

dsplns

dsptrks

ASI SVC Resource Partitioning

cnfport 2.1

Configuration, PVCs, SVCs, and SPVCs

cnfportq 2.1

BXM SVC Resource Partitioning

cnfport 13.1

cnfportq 13.1

BNI Trunk SVC Partitioning (NNI)

cnftrk5.1

cnftrkparm 5.1

BXM Trunk SVC Resource Partitioning

cnftrk3.1

cnftrkparm 3.1

Configuration Virtual Trunks

Refer to the c onfiguration information in Chapter 15, Configuration, BXM Virtual Trunks.

Configuration, VSI

Refer to the configuration information in Chapter 16, Configuration, BXM VSIs.

Configuration, SONET APS

Refer to the configuration information in Chapter 17, SONET AP S, Configuration.

Quickstart Installation and Configuration 2-3

Page 48

Customer Support

Configuration, Multicasting PVCs, Adding Connections

The following is a short summary example of multicasting commands.

Group 2.1.70.x Action Command

atbpxswitch_F, addinputtoroot addcon2.1.70.0 bpxswitch_A1.1.80.100c500***

atbpxswitch_F, addleaf1 addcon2.2.70.101 bpxswitch_D6.1.100.50c500***

atbpxswitch_F, addleaf2 addcon2.2.70.100 bpxswitch_C4.3.50.60c500***

atbpxswitch_F, addleaf3 addcon2.2.70.102 bpxswitch_G3.4.55.75c500***

Group 2.2.80.x

at bpx switch_F, add input t o root addcon 2.2.80.0 bpx switch_B 10.1.233.400 v 4000***

atbpxswitch_F, addleaf1 addcon2.1.80.201 bpxswitch_E13.1.78.900v4000***

at bpx switch_F, add leaf 2 addcon2.1.80.100 bpx switch_E 14.1.100.40v 4000 * * *

For additional configuration i nformation, refer to Chapter 18, Configuration, BME Multicasting.

Configuration, MPLS

Referto the MPLS c onfiguration proceduresin Chapter 20,Configuring the BPX S witch, 7200, and

7500 Routers for MPLS. For additional information, refer to Chapter 19, Configuration General,

MPLS on BPX Switch.

For MPLS CoS Configuration information, refer to Chapter 21, MPLS CoS with BPX 8650,

Configuration.

For MPLS VPN Configuration information, refer to Chapter 22, MPLS VPNS with BPX 8650,

Configuration

Customer Support

Contact your local Cisco sales office for Customer Service information.

Cisco BPX 8600 Series Installation and Configuration, Release 9. 2, July 2001, Part No. 78-6325-04 Rev. B02-4

Page 49

PART 3

Installation

Page 50

Page 51

Introduction

CHAPTER

Installation Summary

This part of the manual providesinstallation and power-up instructions for the BPX 8600 Series

wide-areaswitches.This chapter provides a summary of the procedures and a flow diagram showing

the overall installation tasks covered in PART 3 of this m anual.

• Installation instructions are provided in this part, PART 3.

• Configuration information, except for MPLS, is provided in PART 4.

• Configuration information specific to MPLS and MPLS VPNs is provided in PART 5 .

3

• References to Cisco WAN Manager and CiscoView are provided inPAR T 6.

• Reference information, such as cabling, and specificationsis provided inPAR T 8.

For additional information on the BPX switch, including card descriptions and additional

informationon configuration, refer to t he CiscoBPX 8600 Series Reference.Foradescriptionofthe

commandsused to operate a BPX switch, refer to the Cisco WAN Switching Command Reference.

Refer to the Cisco WAN Manager manuals for information on network management.

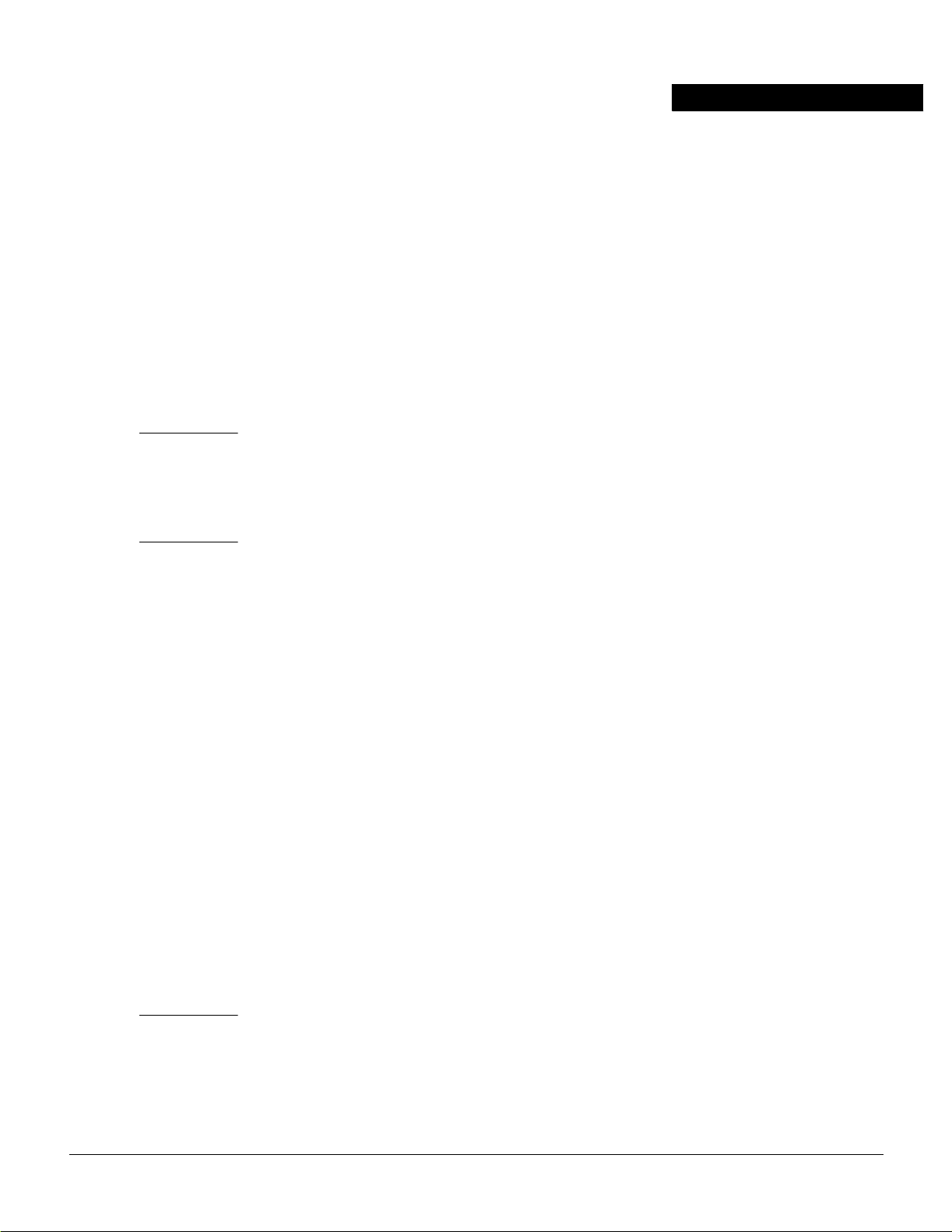

Installation Sequence

Figure 3-1 shows the sequence of operationsfollowed during the installation of the BPX switch.A

summary of this s equence is as follows:

• Chapter 4,Installation, Preliminary,providespreliminary setup instructions for the mechanical

installationof a BPX switch shelf. Depending on the type of rack or cabinet, the installer is then

directed to either:

— Chapter 5, Installation with Cisco Cabinets including 7000 Series Routers with rear rail

setback at 19.86 inches, or

— Chapter 6,Installationwith Customer Cabinet that is 19 incheswidewitha rear rail setback

of 30 inches.

— Otherwise, the installation is non-standardand requires that Customer Servicebe contacted.

The BPX switch shelves are either AC or DC powered. At the completion of the procedures in

Chapter 5 or Chapter 6, the installer is directed to the appropriate power setup and connection

chapter:

• Chapter 7, Installation, DC Shelf Initial Setup,or

• Chapter 8, Installation, AC Shelf Initial Setup.

Installation Summary 3-1

Page 52

Installation Sequence

The remaining installation procedures are common andthe installer is directed to the final setup and

configuration procedures in:

• Chapter 9, Finishing the Installation and Power-Up

An optional cable management tray and optional BXM T3/E3 cable management brackets are

availablefor usewith T3/E3 BXM cards.Thebracketsareforusewithcardssetupasnon-redundant

(single cables rather than Y-cabling). The tray is designed primarily for use in a mid-mountopen

rack c onfiguration. Instructions for installing t he optional tray are provided in:

• Chapter 10, T3/E3 Cable Management Tray

Following the completion of these installation procedures, the BPX switch can be configured.

Configuration procedures a re provided in PART 4, Configuration, General.

3-2 Cisco BPX8600 SeriesInstallation and Configuration, Release9.2, July 2001, Part No. 78-6325-04 Rev. B0

Page 53

Figure 3-1 Installation Sequence

Chapter 4

Installation,

Preliminary

Support

Cisco

cabinet?

Yes

Chapter 5

Installation with

Cisco cabinet.

Rear rail setback

at 19.86 inches.

Is BPX switch

a DC shelf?

Yes

Chapter 7

Installation,

DC shelf,

Initial setup

No

Standard 19-inch

customer cabinet

or rack?

Chapter 6

Installation with standard

19-inch wide customer

cabinet or rack. Rear rail

setback at 30 inches.

No

Chapter 8

Installation,

AC shelf,

Initial setup

Yes

No

Special installation.

Contact customer service.

Support

Chapter 9

Finishing the

installation

and powerup

Proceed to

Part 4 of this

document,

Configuration

Chapter 10,

Optional T3/E3

cable tray

28808

Contact your local Cisco sales office for Customer Service information.

Installation Summary 3-3

Page 54

Support

3-4 Cisco BPX8600 SeriesInstallation and Configuration, Release9.2, July 2001, Part No. 78-6325-04 Rev. B0

Page 55

CHAPTER

Installation, Preliminary

This chapter provides preliminary installation steps for the BPX switch, including the mechanical

installationof the BPX switch shelf in a Cisco cabinet or vendor supplied standard 19 inch

(48.25 cm) equipment rack.

This chapter contains the following sections:

• Site Preparation

• Parts Checklist

• Safety Requirements

4

• Mechanical Installation

Warning Installation should be performed by authorized personnel only.

Site Preparation

The BPX switch has the following site preparation requirements.

• Location

The BPX switchis to be installed only in a RESTRICTED ACCESS LOCATION.

• Space

EachBPXswitchshelfrequires floorspaceof22inches(55.9cm) wide and 80 inches (203.2 cm)

deep to assure sufficient clearance around the cabinet to allow access to the front and back of the

unit.

• Power

An ACor DCpower source must be available within 6feet (2 m.) of the rearof theBPX switch

shelf. A maximum configuration for an AC powered BPX switch may require up to 2333 VA

(13 Aat 180 VAC, 10 A at 230 VAC). A maximum configurationfora DCpoweredBPX switch

may require up to 1680 Watts (40 A at –42 VDC, 35 A at -48 VDC).

• Uninterruptible Power Source