Page 1

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware

Installation Guide

First Published: 2015-04-07

Last Modified: 2017-06-16

Americas Headquarters

Cisco Systems, Inc.

170 West Tasman Drive

San Jose, CA 95134-1706

USA

http://www.cisco.com

Tel: 408 526-4000

800 553-NETS (6387)

Fax: 408 527-0883

Text Part Number: Online Only

Page 2

THE SPECIFICATIONS AND INFORMATION REGARDING THE PRODUCTS IN THIS MANUAL ARE SUBJECT TO CHANGE WITHOUT NOTICE. ALL STATEMENTS,

INFORMATION, AND RECOMMENDATIONS IN THIS MANUAL ARE BELIEVED TO BE ACCURATE BUT ARE PRESENTED WITHOUT WARRANTY OF ANY KIND,

EXPRESS OR IMPLIED. USERS MUST TAKE FULL RESPONSIBILITY FOR THEIR APPLICATION OF ANY PRODUCTS.

THE SOFTWARE LICENSE AND LIMITED WARRANTY FOR THE ACCOMPANYING PRODUCT ARE SET FORTH IN THE INFORMATION PACKET THAT SHIPPED WITH

THE PRODUCT AND ARE INCORPORATED HEREIN BY THIS REFERENCE. IF YOU ARE UNABLE TO LOCATE THE SOFTWARE LICENSE OR LIMITED WARRANTY,

CONTACT YOUR CISCO REPRESENTATIVE FOR A COPY.

The Cisco implementation of TCP header compression is an adaptation of a program developed by the University of California, Berkeley (UCB) as part of UCB's public domain version

of the UNIX operating system. All rights reserved. Copyright©1981, Regents of the University of California.

NOTWITHSTANDING ANY OTHER WARRANTY HEREIN, ALL DOCUMENT FILES AND SOFTWARE OF THESE SUPPLIERS ARE PROVIDED “AS IS" WITH ALL FAULTS.

CISCO AND THE ABOVE-NAMED SUPPLIERS DISCLAIM ALL WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT LIMITATION, THOSE OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT OR ARISING FROM A COURSE OF DEALING, USAGE, OR TRADE PRACTICE.

IN NO EVENT SHALL CISCO OR ITS SUPPLIERS BE LIABLE FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL, OR INCIDENTAL DAMAGES, INCLUDING, WITHOUT

LIMITATION, LOST PROFITS OR LOSS OR DAMAGE TO DATA ARISING OUT OF THE USE OR INABILITY TO USE THIS MANUAL, EVEN IF CISCO OR ITS SUPPLIERS

HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Any Internet Protocol (IP) addresses and phone numbers used in this document are not intended to be actual addresses and phone numbers. Any examples, command display output, network

topology diagrams, and other figures included in the document are shown for illustrative purposes only. Any use of actual IP addresses or phone numbers in illustrative content is unintentional

and coincidental.

Cisco and the Cisco logo are trademarks or registered trademarks of Cisco and/or its affiliates in the U.S. and other countries. To view a list of Cisco trademarks, go to this URL: http://

www.cisco.com/go/trademarks. Third-party trademarks mentioned are the property of their respective owners. The use of the word partner does not imply a partnership

relationship between Cisco and any other company. (1110R)

©

2015-2017 Cisco Systems, Inc. All rights reserved.

Page 3

CONTENTS

CHAPTER 1

CHAPTER 2

Overview 1

About the ASA 5506-X, ASA 5506W-X, and ASA 5506H-X 1

Package Contents 4

Front Panel 5

Rear Panel 6

LEDs 8

Network Ports 11

Console Ports 11

Internal and External Flash Storage 12

Solid State Drive 12

Power Supply Modules 13

Hardware Specifications 13

Power Cord Specifications 14

Installation Preparation 23

Installation Warnings 23

Position the ASA 24

Mount and Deployment Preparation for the ASA 5506W-X 25

Safety Recommendations 25

Maintain Safety with Electricity 26

Prevent Electrostatic Discharge Damage 26

Site Environment 26

Site Considerations 27

Power Supply Considerations 27

Equipment Rack Configuration Considerations 27

CHAPTER 3

Mount and Connect 29

Desktop Mount the ASA 29

Online Only iii

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

Page 4

Contents

Wall Mount the ASA 30

Rack Mount the ASA 32

Install the ASA 5506H-X in a DIN Rail 34

Connect Cables, Turn on Power, and Verify Connectivity 37

Connect to a Console Terminal or PC 39

Connect to the Console Port with Microsoft Windows 39

Connect to the Console Port with Mac OS X 42

Connect to the Console Port with Linux 43

CHAPTER 4

Maintenance and Upgrades 45

Connect the DC Adapter for the 5506H-X 45

Install the Adjustable Power Supply Retainer 47

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

iv Online Only

Page 5

CHAPTER 1

Overview

This chapter describes the hardware features of the Cisco ASA 5506-X series of security appliances, and

contains the following sections:

About the ASA 5506-X, ASA 5506W-X, and ASA 5506H-X, page 1

•

Package Contents, page 4

•

Front Panel, page 5

•

Rear Panel, page 6

•

LEDs, page 8

•

Network Ports, page 11

•

Console Ports, page 11

•

Internal and External Flash Storage, page 12

•

Solid State Drive, page 12

•

Power Supply Modules, page 13

•

Hardware Specifications, page 13

•

Power Cord Specifications, page 14

•

About the ASA 5506-X, ASA 5506W-X, and ASA 5506H-X

The Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X adaptive security appliances are part of the ASA

5500-X of next-generation mid-range ASAs and are built on the same security platform as the rest of the ASA

family.

Note

Online Only 1

Your ASA 5506-X ships with either ASA or Firepower Threat Defense software preinstalled. To reimage

your device, see Reimage the Cisco ASA or Firepower Threat Defense Device.

This next-generation ASA delivers unprecedented levels of defense against threats to the network with deeper

web inspection and flow-specific analysis, improved secure connectivity via end-point security posture

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

Page 6

About the ASA 5506-X, ASA 5506W-X, and ASA 5506H-X

validation, and voice and video over VPN support. It also provides enhanced support for intelligent information

networks through improved network integration, resiliency, and scalability.

This ASA is a smaller form-factor chassis, intended primarily for desktop or wall-mounting, although one or

two can be mounted in a single rack shelf. The ASA has a standard 1 RU chassis. See Cisco ASA 5500-X

Series Next-Generation Firewalls to compare the performance metrics and capabilities of the 5500-X ASAs.

Overview

Caution

Do not stack the ASA chassis on top of another ASA chassis. If you stack the units, they will overheat,

which causes the units to power cycle.

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

2 Online Only

Page 7

Overview

About the ASA 5506-X, ASA 5506W-X, and ASA 5506H-X

ASA 5506W-X Wireless Features

The ASA 5506W-X supports two high-performing spatial stream rates over a deployable distance with

high reliability when serving clients. The ASA 5506W-X contains two simultaneous dual-band radios

(2.4-GHz and 5-GHz 802.11n MIMO radios) in a controller-based mode or autonomous mode. It has

integrated internal antennas that support full inter-operability with leading 802.11n clients. The radio

hardware supports Unified, FlexConnect, and Monitor-mode.

The ASA 5506W-X has the following processor features:

128 MB NAND flash size

•

1 MB NOR flash size

•

128 MB DDR2 memory bus, x32

•

The 2.4 GHz and 5 GHz 802.11n radios have the following features:

802.11n standard compliant

•

A-MPDU TX

•

HT Duplicate Mode

•

2TX x 2RX

•

2-spatial streams, 300 Mbps PHY rate

•

Maximal ratio combining (MRC)

•

Cyclic Shift Diversity (CSD)

•

MCS0-MCS15; Short or Long Guard Intervals

•

DFS for UNII-2 and UNII-2 Extended channels, including 0.5us radar pulse detection

•

The ASA 5506W-X is configured with four single-band, inverted-F antennas (two 2.4-GHz and two

5-GHz), which are evenly spaced inside the top of the chassis. Peak gains are approximately 3 dBi in

the 2.4-GHz band and 5 dBi in the 5-GHz band.

ASA 5506H-X Features

The ASA 5506H-X is a hardened version of the 5506-X with a ruggedized chassis, power supply, SSD,

and four ports instead of eight. It is ruggedized because it supports a much wider industrial operational

temperature range (-20C to 60C), meets the harsh EMI and environmental criteria for the IEC1613 and

IEC 61850-3 power substation standards, and meets IEC60529 IP40 for ingress protection.

The ASA 5506H-X ships with a ruggedized 5V-5.3V barrel power supply that provides 22 W. Or you

can order an optional DC power supply that supplies 24V DC (part number PWR2-20W-24VDC) or

20W 20-60V DC (part number PWR2-22W-20-60VDC).

Note

Before beginning any of the procedures described in this book, be sure to read the Regulatory Compliance

and Safety Information for the Cisco ASA 5506-X series and follow proper safety procedures.

Online Only 3

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

Page 8

Package Contents

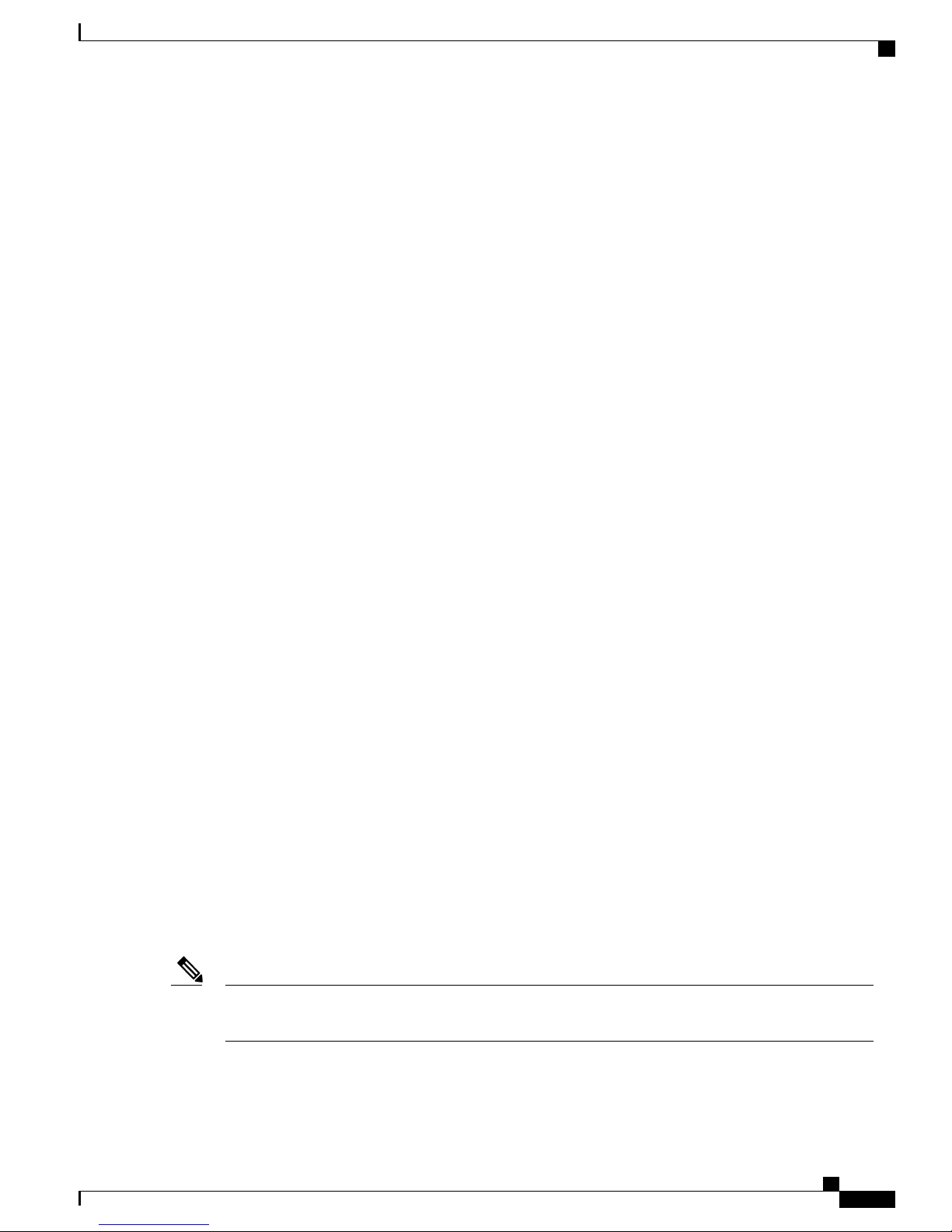

Package Contents

The following figure shows the package contents for the ASA 5506-X and ASA 5506W-X. Note that the

contents are subject to change and your exact contents might contain additional or fewer items.

Figure 1: ASA 5506-X and 5506W-X Package Contents

Overview

USB Console Cable (Type A to Type B)2Chassis1

Brick power supply4Power cord3

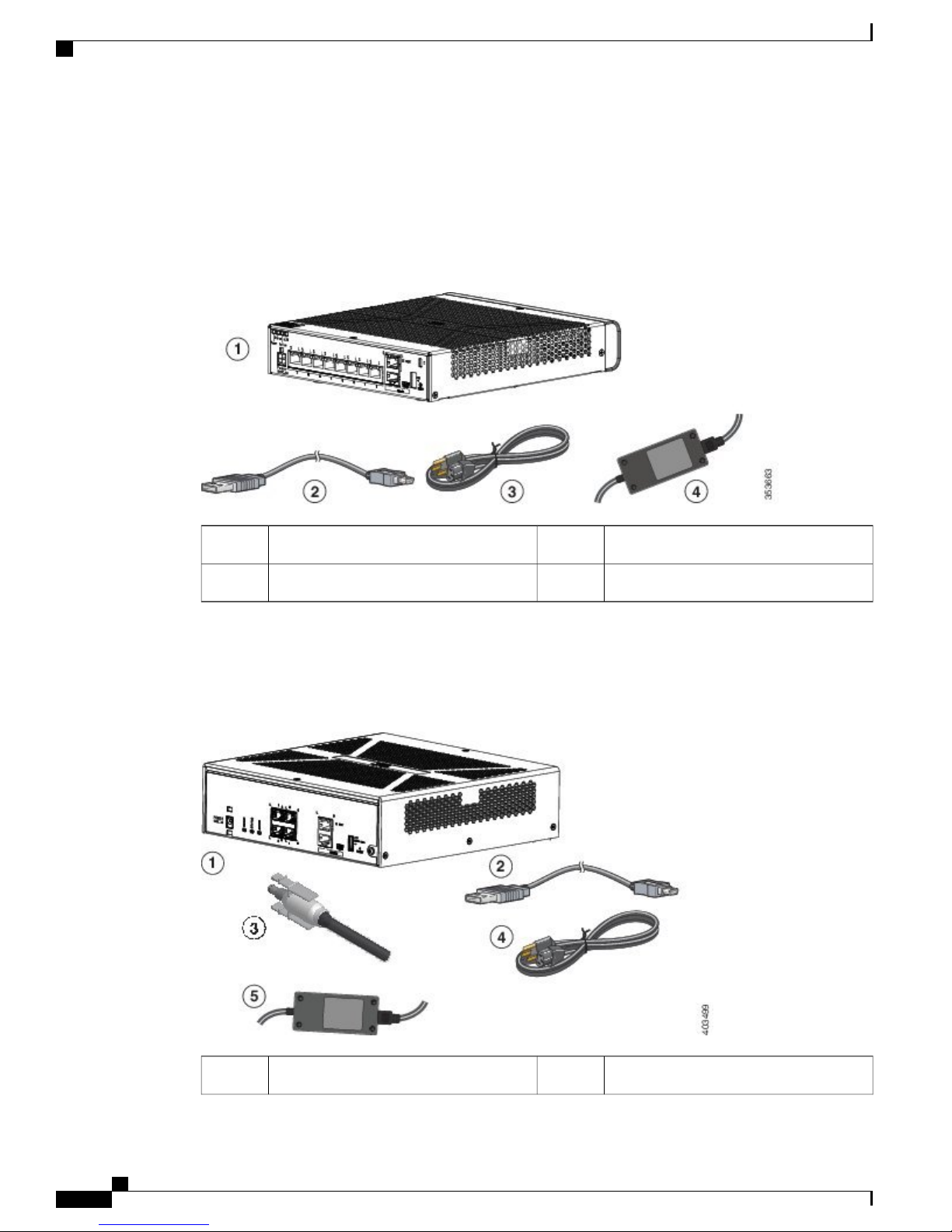

The following figure shows the package contents for the ASA 5506H-X. Note that the contents are subject

to change and your exact contents might contain additional or fewer items.

Figure 2: ASA 5506H-X Package Contents

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

4 Online Only

USB Console Cable (Type A to Type B)2Chassis1

Page 9

Overview

Front Panel

Front Panel

Power cord4Power cord retention lock3

Power supply5

The following figure shows the front panel of the ASA 5506-X. The ASA 5506W-X has an identical front

panel. Note that there are no connectors or LEDs on the front panel.

Figure 3: 5506-X and 5506W-X Front Panel

The following figure shows the front panel of the ASA 5506H-X. Note that there are no connectors or LEDs

on the front panel.

Figure 4: 5506H-X Front Panel

Online Only 5

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

Page 10

Rear Panel

Rear Panel

Overview

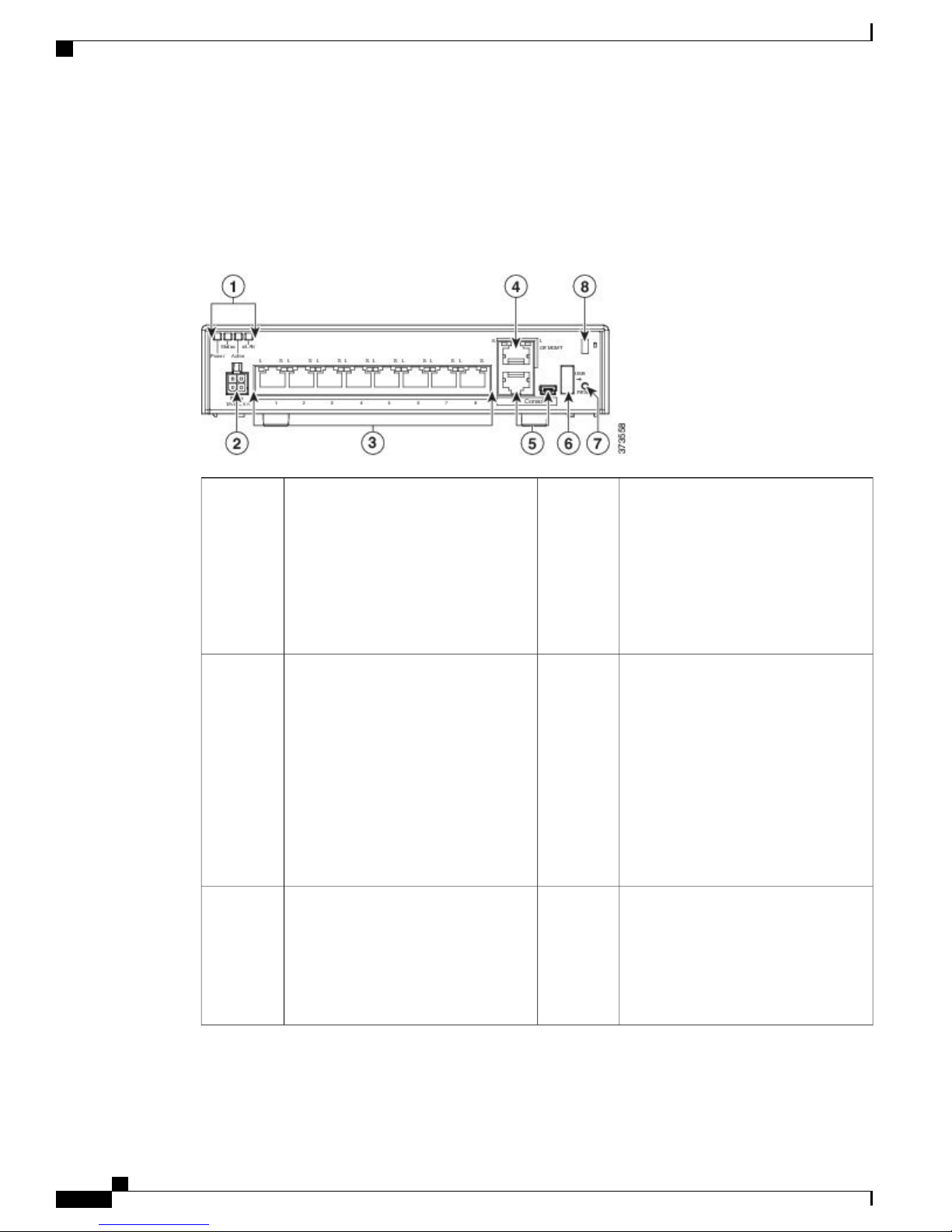

The following figure shows the rear panel of the ASA 5506-X. The 5506W-X has an identical rear panel.

Figure 5: ASA 55-6-X and 5506W-X Rear Panel

1

2Status LEDs

The locations and meanings of the status

LEDs are described in LEDs, on page

8.

Power cord socket

The chassis power-supply socket. See

Power Supply Modules, on page 13 for

more information about the chassis

power supply.

Note

The ASA is powered on when

you plug in the AC power

supply.

3

Network data ports

Eight Gigabit Ethernet RJ-45 (8P8C)

network I/O interfaces. The ports are

numbered (from left to right) 1, 2, 3, 4,

5, 6, 7, 8. Each port includes a pair of

LEDs, one each for connection status

4

Management port

A Gigabit Ethernet interface restricted

to network management access only.

Connect with an RJ-45 cable.

and link status. The ports are named and

numbered Gigabit Ethernet 1/1 through

Gigabit Ethernet 1/8. See Network

Ports, on page 11 for additional

information.

5

6Console ports

Two serial ports, a mini USB Type B,

and a standard RJ-45 (8P8C), are

provided for management access via an

external system. See Console Ports, on

page 11 for additional information.

USB port

A standard USB Type A port is

provided that allows the attachment of

an external device, such as mass storage.

See Internal and External Flash Storage,

on page 12 for additional information.

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

6 Online Only

Page 11

Overview

Rear Panel

7

8Reset button

A small recessed button that if pressed

for longer than three seconds resets the

ASA to its default “as-shipped” state

Lock slot

The slot accepts a standard Kensington

T-bar locking mechanism for securing

the ASA.

following the next reboot. Configuration

variables are reset to factory default.

However, the flash is not erased and no

files are removed.

Note

You can use the service

sw-reset-button to disable the

reset button. The default is

enabled.

Note

Pressing the reset button on the

ASA 5506W-X does not affect

the AP configuration, but it

causes any unsaved AP

configuration to be lost,

because the system has

rebooted. After the system

reboots, if you want a default

AP configuration, use the

hw-module module wlan

recover configuration

command to recover the AP

configuration.

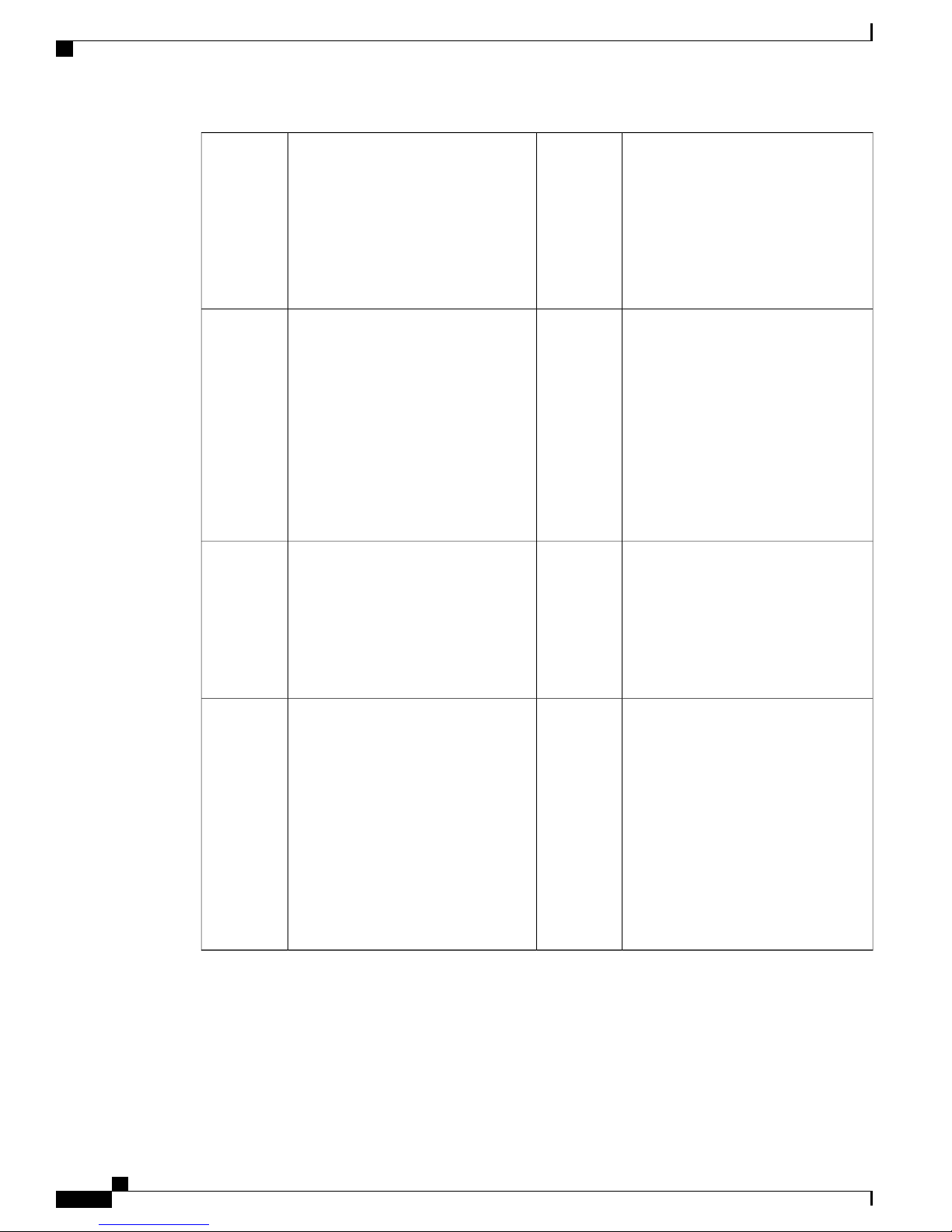

The following figure shows the rear panel of the 5506H-X.

Figure 6: ASA 5506H-X Rear Panel

Online Only 7

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

Page 12

LEDs

Overview

1

2Power cord socket.

The chassis power-supply socket. See

Power Supply Modules, on page 13

for more information about the chassis

Status LEDs

The locations and meanings of the

status LEDs are described in LEDs, on

page 8.

power supply.

Note

The ASA is powered on when

you plug in the AC power

supply.

3

4Network data ports

Four Gigabit Ethernet RJ-45 (8P8C)

network I/O interfaces. The ports are

numbered (from top to bottom) 1, 2, 3,

Management port

A Gigabit Ethernet interface restricted

to network management access only.

Connect with an RJ-45 cable.

4,. Each port includes a pair of LEDs,

one each for connection status and link

status. The ports are named and

numbered Gigabit Ethernet 1/1 through

Gigabit Ethernet 1/4. See Network

Ports, on page 11 for additional

information.

5

6Console ports

Two serial ports, a standard RJ-45

(8P8C), and a mini USB Type B, are

provided for management access via

an external system. See Console Ports,

on page 11 for additional information.

USB port

A standard USB Type A port is

provided that allows the attachment of

an external device, such as mass

storage. See Internal and External Flash

Storage, on page 12 for additional

information.

LEDs

7

Reset button

A small recessed button that if pressed

for longer than three seconds resets the

ASA to its default “as-shipped” state

following the next reboot.

Configuration variables are reset to

factory default. However, the flash is

not erased and no files are removed.

Note

You can use the service

sw-reset-button to disable the

reset button. The default is

enabled.

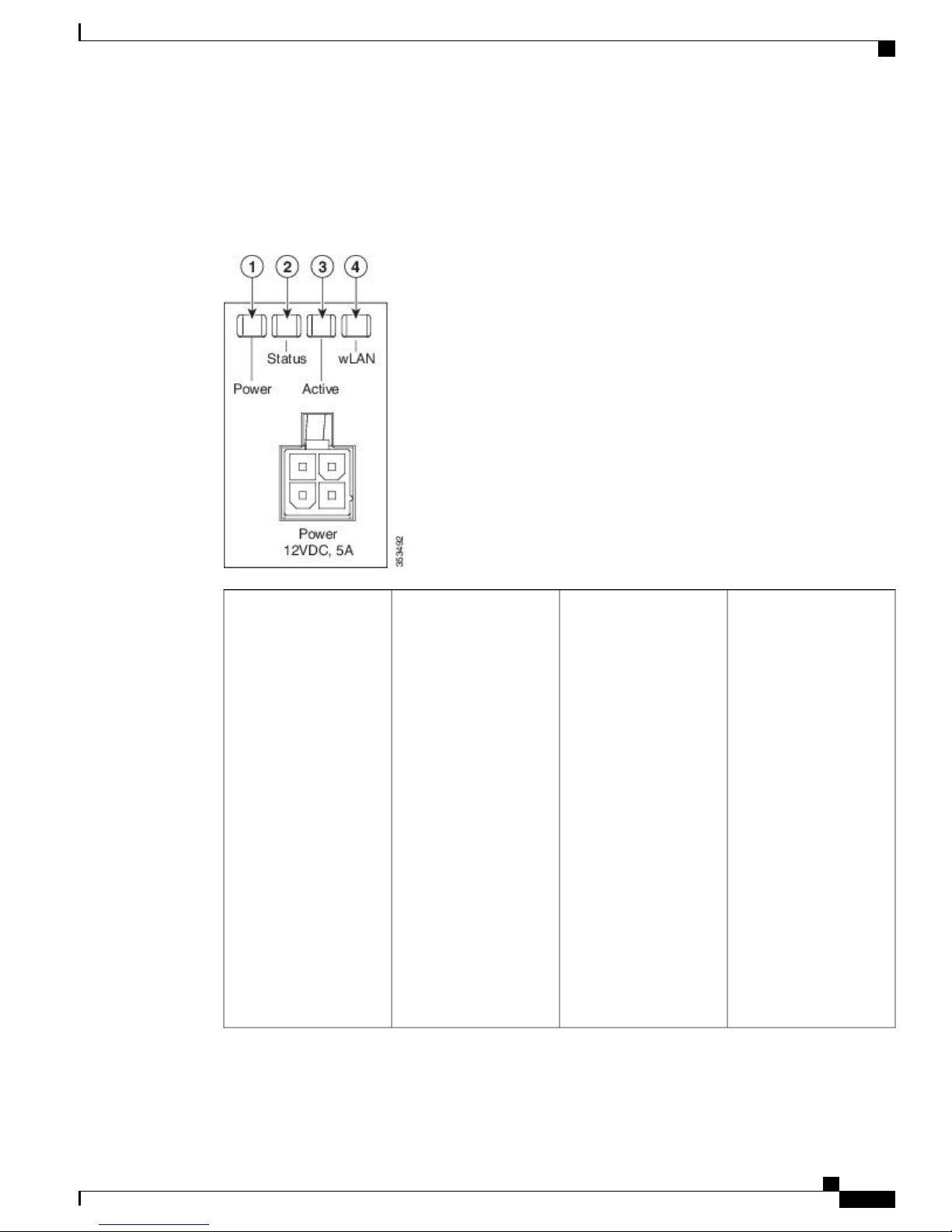

Facing the rear of the ASA 5506-X and ASA 5506W-X chassis, the LEDs are located on the top left edge

(facing the front of the chassis, they are in the back right corner of the top). Facing the rear of the ASA

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

8 Online Only

Page 13

Overview

LEDs

5506H-X, the LEDs are located on the bottom left of the chassis. The network port LEDs are at the top sides

of each network port. See Rear Panel, on page 6 for more information.

The following figure shows the LEDs on the top left edge.

Figure 7: LEDs

1

2Power

Power supply status:

• Unlit – Power

supply off.

• Solid green – Power

supply on.

Status

System operating status:

• Green – Normal

system function.

• Amber – Critical

alarm indicating one

or more of the

See Power Supply

Modules, on page 13 for

additional power

information specific to

your specific ASA.

following:

Major failure

•

of a hardware

or software

component.

Over-temperature

•

condition.

Power voltage

•

outside the

tolerance

range.

Online Only 9

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

Page 14

LEDs

Overview

3

4Active

Status of the failover pair:

• Solid green –

Failover pair

operating normally.

The LED is green

always unless the

ASA in an HA pair.

• Amber – When the

ASA is in an HA

pair, the LED is

amber for the

Standby unit.

• Unlit – Failover is

not operational.

wLAN

Not in use on the ASA

5506-X or the ASA

5506-H.

Association status of the

wireless connection on

the ASA 5506W-X:

• Chirping green –

Normal operating

condition, but no

wireless client is

present.

• Green – Normal

operating condition,

at least one wireless

client is associated.

• Blinking amber –

Software upgrade in

progress.

Green, red, amber

•

sequence –

Discovery/join

process in progress.

• Blinking red –

Ethernet link not

operational.

• Unlit – Wireless is

not operational.

Network Port Status

On the rear panel of the ASA 5506-X and ASA 5506W-X, a pair of LEDs (link status and connection status)

for each of the eight Gigabit Ethernet network ports, and the Gigabit Ethernet management port.

On the rear panel of the ASA 5506H-X, a pair of LEDs (link status and connection status) for each of the four

Gigabit Ethernet network ports, and the Gigabit Ethernet Management port.

Link status (L):

• Unlit – No link, or port is not in use.

• Solid green – Link established.

• Flashing green – Link activity.

Connection-speed status (S):

• One blink every three seconds – 10 Mbps.

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

10 Online Only

Page 15

Overview

• Two rapid blinks – 100 Mbps.

• Three rapid blinks – 1000 Mbps.

Network Ports

There are eight 10/100/1000 baseT Ethernet network ports on the ASA 5506-X and ASA 5506W-X. Each

RJ-45 (8P8C) copper port supports auto MDI/X as well as auto-negotiation for interface speed, duplex, and

other negotiated parameters, and are MDI/MDIX compliant.

In addition, the ASA 5506W-X has a Gigabit Ethernet 1/9 port that is internal and connects to the WLAN

module.

The ASA 5506H-X has four 10/100/1000 baseT Ethernet network ports. Each RJ-45 (8P8C) copper port

supports auto MDI/X as well as auto-negotiation for interface speed, duplex, and other negotiated parameters,

and are MDI/MDIX compliant.

Looking at the rear of the ASA 5506-X and ASA 5506W-X, where the ports are located, port 1 is on the left,

and port 8 is on the right, next to the console and management ports. Each port is accompanied by a pair of

LEDs, one each for link status (L) and connection status (S). The ports are named and numbered Gigabit

Ethernet 1/1 through Gigabit Ethernet 1/8. The ports are named and numbered Gigabit Ethernet 1/1 through

Gigabit Ethernet 1/4.

The four ports on the ASA 5506H-X are numbered differently. Looking at the rear of the ASA 5506H-X

where the ports are located, ports 1 and 3 are at the top from left to right. Ports 2 and 4 are on the bottom from

left to right. The ports are between the Status LEDs and the console and management ports. The ports are

named and numbered Gigabit Ethernet 1/1 through Gigabit Ethernet 1/4.

Network Ports

Console Ports

The ASA has two external console ports, a standard RJ-45 port and a Mini USB Type B serial port. Only one

console port can be active at a time. When a cable is plugged into the USB console port, the RJ-45 port

becomes inactive. Conversely, when the USB cable is removed from the USB port, the RJ-45 port becomes

active. The console ports do not have any hardware flow control. You can use the command-line interface

(CLI) to configure your ASA through either serial console port by using a terminal server or a terminal

emulation program on a computer.

In addition, the AP module inside the ASA 5506W-X has a console port, which is accessible by sessioning

to the module's console via the session wlan console command in the ASA CLI.

See Connect to a Console Terminal or PC, on page 39 for the procedure to install a console terminal.

RJ-45 Port

The RJ-45 (8P8C) port supports RS-232 signaling to an internal UART controller. The RJ-45 console

port does not support a remote dial-in modem. You can use a standard management cable (Cisco part

number 72-3383-01) to convert the RJ45-to-DB9 connection if necessary.

Online Only 11

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

Page 16

Internal and External Flash Storage

Mini USB Type B Port

The Mini USB Type B port lets you connect to a USB port on an external computer. For Linux and

Macintosh systems, no special driver is required. For Windows systems, you must download and install

a USB driver (available on software.cisco.com). You can plug and unplug the USB cable from the

console port without affecting Windows HyperTerminal operations. We recommend shielded USB

cables with properly terminated shields. Baud rates for the USB console port are 1200, 2400, 4800,

9600, 19200, 38400, 57600, and 115200 bps.

Overview

Note

For Windows operating systems, you must install a Cisco Windows USB Console Driver on any PC

connected to the console port before using the USB console port. See Connect to the Console Port with

Microsoft Windows, on page 39 for information on installing the driver.

Internal and External Flash Storage

The ASA contains one internal USB flash drive, and a standard USB Type A port that you can use to attach

an external device. The USB port can provide output power of 5 volts, up to a maximum of 500 mA (5 USB

power units).

Internal USB Device

An embedded eUSB device is used as the internal flash; it is identified as disk0.

External USB Drive (Optional)

You can use the external Type A USB port to attach a data-storage device. The external USB drive

identifier is disk1. When the ASA is powered on, a connected USB drive is mounted as disk1 and is

available for you to use. Additionally, the file-system commands that are available to disk0 are also

available to disk1, including copy, format, delete, mkdir, pwd, cd, and so on.

If you insert a USB drive with more than one partition, only the first partition is mounted.

FAT-32 File System

The ASA only supports FAT-32-formatted file systems for the internal eUSB and external USB drives.

If you insert an external USB drive that is not in FAT-32 format, the system mounting process fails,

and you receive an error message. You can enter the command format disk1: to format the partition

to FAT-32 and mount the partition to disk1 again; however, data might be lost.

Solid State Drive

The ASA 5506-X and ASA 5506W-X ship with an SSD installed that provides storage support. The SSD has

50 GB of useable space and is not field-replaceable. You must return the entire ASA to Cisco for drive

replacement. The SSD is used by the software; there is no user access to the SSD.

The ASA 5506H-X ships with a ruggedized SSD installed that provides storage support. The SSD is an

industrial-rated part so that it operates over the extended temperature range that the ASA 5506H-X supports.

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

12 Online Only

Page 17

Overview

The SSD has 50 GB of useable space and is not field-replaceable. You must return the entire ASA to Cisco

for drive replacement. The SSD is used by the software; there is no user access to the SSD.

Power Supply Modules

The ASA 5506-X and ASA 5506W-X ship with a 12V brick power supply that provides 60 W.

The ASA 5506H-X ships with a ruggedized 5V-5.3V barrel power supply that provides 22 W. The power

supply supports an extended temperature range of -25°C to 60°C. Or you can order an optional DC power

supply that supplies 24V DC (part number PWR2-20W-24VDC) or 20W 20-60V DC (part number

PWR2-22W-20-60VDC).

Hardware Specifications

The following table contains hardware specifications for the ASA.

Power Supply Modules

Mounting

Dimensions

Weight

Desk mountable; see Desktop Mount the ASA, on page 29 for more

•

information.

Caution

Rack mountable in a rack tray. You can place two chassis side by side. See

•

Rack Mount the ASA, on page 32 for more information.

Note

Wall mountable (ASA 5506-X and ASA 5506W-X only); see Wall Mount

•

the ASA, on page 30 for more information.

DIN rail mountable (ASA 5506H-X only); the DIN rail is available for

•

order from Cisco Systems. See Install the ASA 5506H-X in a DIN Rail,

on page 34.

7.87 x 9.23 x 1.94 in (19.99 x 23.44 x 4.93 cm) including the feet (ASA 5506-X

and ASA 5506W-X).

9.1 x 9.1 x 2.8 in (23.11 x 23.11 x 7.11 cm) including the feet (ASA 5506H-X).

4 lb (ASA 5506-X and ASA 5506W-X)

6.7 lb (ASA 5506H-X)

Do not stack the ASA chassis on top of another ASA chassis.

If you stack the units, they will overheat, which causes the units

to power cycle.

One ASA 5506H-X fits in the rack tray. See Rack Mount the ASA,

on page 32 for more information.

DRAM

Online Only 13

Total: 4 GB

Allotted to FW/VPN: 1.8 GB

Allotted to Module: 2.2 GB

8 GBInternal flash

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

Page 18

Power Cord Specifications

Overview

Power

60 W (ASA 5506-X and ASA 5506W-X)

22 W (5506H-X)

Temperature

Operating: 32°F to 104°F (0°C to 40°C) (ASA 5506-X and ASA 5506W-X)

-4°F to 140°F (-20°C to 60°C) (ASA 5506H-X)

Nonoperating: -13°F to 158°F (-25°C to 70°C) (ASA 5506-X and ASA 5506W-X)

-40°F to +185°F (-40° C to +85° C) (ASA 5506H-X)

Relative humidity

Operating: 90% (ASA 5506-X and ASA 5506W-X)

Operating: 95% (ASA 5506H-X)

Nonoperating: 10% to 90%

Maximum altitude

Operating: 10,000 ft (3048 m)

Nonoperating: 15,000 ft (4572 m)

IP40 per IEC60529 (ASA 5506H-X)IP rating

IEEE1613, IEC60068-2, IEC 61850-3 (ASA 5506H-X)Extended vibe and shock

1

Derate the maximum operating temperature 1.5 degrees C per 1000 ft above sea level.

2

Derate the maximum operating temperature 1.5 degrees C per 1000 ft above 6,000 feet elevation.

1

2

Power Cord Specifications

This section applies only to the ASA 5506-X and ASA 5506W-X. It does NOT apply to the ASA 5506H-X.Note

Each power supply has a separate power cord. Standard power cords are available for connection to the security

appliance.

If you do not order the optional power cord with the system, you are responsible for selecting the appropriate

power cord for the product. Using a non-compatible power cord with this product may result in electrical

safety hazard. Orders delivered to Argentina, Brazil, and Japan must have the appropriate power cord ordered

with the system.

Only the approved power cords provided with the security appliance are supported. The following table lists

the supported power cords.

Table 1: Supported Power Cords

AC power cord

(Europe)

ConnectorPlugVoltageAmperageDescription

IEC 60320/C13CEE 7 VII250V10ACAB-ACE

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

14 Online Only

Page 19

Overview

Power Cord Specifications

IEC 60320/C13NEMA 5-15P125V10ACAB-AC

AC power cord

(North America)

IEC 60320/C13A.S. 3112250V10ACAB-ACA

AC power cord

(Australia)

IEC 60320/C13CE123-16-VII250V10ACAB-ACI

AC power cord

(Italy)

IEC 60320/C13IRAM 2073250V10ACAB-ACR

AC power cord

(Argentina)

IEC 60320/C13SEV 1011250V10ACAB-ACS

AC power cord

(Switzerland)

AC power cord

(United Kingdom)

Power cord 3PIN

(Japan)

AIR line cord

(South Africa)

Power cord (China)

Power cord (India)

AC power cord

(Brazil)

IEC 60320/C13BS1363a/SS145250V10ACAB-ACU

IEC 60320/C13JIS C8303125V12ACAB-JPN-3PIN

IEC 60320/C13SABS 1661250V10AAIR-PWR-CORD-SA

IEC 60320/C13GB2009.1-2008250V10ACAB-ACC

IEC 60320/C13IS 6538-1971250V10ACAB-IND-10A

IEC 60320/C13NBR 14136250V10ACAB-C13-ACB

AC power cord

(Korea)

Online Only 15

IEC 60320/C13KSC8305250V10ACAB-AC-C13-KOR

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

Page 20

Power Cord Specifications

AC power cord

(Taiwan)

The following illustrations show the cord, connector, and plug for each country listed in the table above.

Figure 8: CAB-ACE (Europe)

Overview

IEC 60320/C13CNS10917250V10ACAB-ACTW

Connector: IEC 60320/C133

Figure 9: CAB-AC (North America)

Connector: IEC 60320/C133

Cord set rating: 10A, 250V2Plug: CEE 7 VII1

Cord set rating: 10A, 125V2Plug: NEMA 5-15P1

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

16 Online Only

Page 21

Overview

Power Cord Specifications

Figure 10: CAB-ACA (Australia)

Cord set rating: 10A, 250V2Plug: A.S. 31121

Connector: IEC 60320/C133

Figure 11: CAB-ACI (Italy)

Connector: IEC 60320/C133

Cord set rating: 10A, 250V2Plug: CE123-16-VII1

Online Only 17

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

Page 22

Power Cord Specifications

Figure 12: CAB-ACR (Argentina)

Overview

Cord set rating: 10A, 250V2Plug: IRAM 20731

Connector: IEC 60320/C133

Figure 13: CAB-ACS (Switzerland)

Connector: IEC 60320/C133

Cord set rating: 10A, 250V2Plug: SEV 10111

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

18 Online Only

Page 23

Overview

Power Cord Specifications

Figure 14: CAB-ACU (United Kingdom)

Connector: IEC 60320/C133

Figure 15: CAB-JPN-3PIN (Japan)

Connector: IEC 60320/C133

Cord set rating: 10A, 250V2Plug: BS1363a/SS1451

Cord set rating: 12A, 125V2Plug: JIS C83031

Online Only 19

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

Page 24

Power Cord Specifications

Figure 16: AIR-PWR-CORD-SA (South Africa)

Overview

Connector: IEC 60320/C133

Figure 17: CAB-ACC (China)

Connector: IEC 60320/C133

Cord set rating: 10A, 250V2Plug: SABS 16611

Cord set rating: 10A, 250V2Plug: GB2009.1-20081

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

20 Online Only

Page 25

Overview

Power Cord Specifications

Figure 18: CAB-IND-10A (India)

Connector: IEC 60320/C133

Figure 19: CAB-C13-ACB (Brazil)

Cord set rating: 10A, 250V2Plug: IS 6538-19711

Cord set rating: 10A, 250V2Plug: NBR 141361

Connector: IEC 60320/C133

Online Only 21

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

Page 26

Power Cord Specifications

Figure 20: CAB-AC-C13-KOR (Korea)

Overview

Cord set rating: 10A, 250V2Plug: KSC83051

Connector: IEC 60320/C133

Figure 21: CAB-ACTW (Taiwan)

Connector: IEC 60320/C133

Cord set rating: 10A, 250V2Plug: CNS109171

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

22 Online Only

Page 27

Installation Preparation

This chapter prepares you to install your ASA, and contains the following sections:

Installation Warnings, page 23

•

Position the ASA, page 24

•

Mount and Deployment Preparation for the ASA 5506W-X, page 25

•

Safety Recommendations, page 25

•

Site Environment , page 26

•

Installation Warnings

Be sure to read the Regulatory Compliance and Safety Information document before installing the ASA.

Take note of the following warnings:

CHAPTER 2

Read the installation instructions before connecting the system to the power source.Warning

Warning

Warning

Warning

Online Only 23

Before working on a chassis or working near power supplies, unplug the power cord on AC units; disconnect

the power at the circuit breaker on DC units.

Before working on equipment that is connected to power lines, remove jewelry (including rings, necklaces,

and watches). Metal objects will heat up when connected to power and ground and can cause serious burns

or weld the metal object to the terminals.

During this procedure, wear grounding wrist straps to avoid ESD damage to the card. Do not directly

touch the backplane with your hand or any metal tool, or you could shock yourself.

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

Page 28

Position the ASA

Installation Preparation

Warning

Warning

Warning

This product requires short-circuit (overcurrent) protection to be provided as part of the building installation.

Install only in accordance with national and local wiring regulations.

To avoid electric shock, do not connect safety extra-low voltage (SELV) circuits to telephone-network

voltage (TNV) circuits. LAN ports contain SELV circuits, and WAN ports contain TNV circuits. Some

LAN and WAN ports both use RJ-45 connectors. Use caution when connecting cables.

This equipment must be grounded. Never defeat the ground conductor or operate the equipment in the

absence of a suitably installed ground conductor. Contact the appropriate electrical inspection authority

or an electrician if you are uncertain that suitable grounding is available.

Ultimate disposal of this product should be handled according to all national laws and regulations.Warning

Installation of the equipment must comply with local and national electrical codes.Warning

The device is designed to work with TN power systems.Warning

Position the ASA

Whether positioning the ASA on a desktop, on a non-rack closet shelf, or mounting it on a wall, consider the

following:

Caution

Do not stack the ASA chassis on top of another ASA chassis. If you stack the units, they will overheat,

which causes the units to power cycle.

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

24 Online Only

Page 29

Installation Preparation

Mount and Deployment Preparation for the ASA 5506W-X

Be sure to choose an area where the ASA is out of the way to make sure it is not bumped or accidentally

•

dislodged. The appliance has “feet” on the bottom so it does not sit flush where placed, thus allowing

proper air circulation through and around it. Make sure that the appliance is not tightly enclosed or

crowded by other objects that might impede proper circulation.

Choose a location that lets you easily bring the power cord and Ethernet and console cables to the ASA,

•

with plenty of slack and yet tucked away, so they cannot be inadvertently unplugged.

Mount and Deployment Preparation for the ASA 5506W-X

Before you mount and deploy the ASA 5506W-X, we recommend that you perform a site survey (or use the

site planning tool) to determine the best location to install your wireless ASA.

Make sure you have the following information about your wireless network available:

ASA 5506W-X locations

•

ASA 5506W-X mounting options (see Position the ASA, on page 24 for mounting options)

•

ASA 5506W-X power options

•

Note

We recommend that you make a site map showing the ASA 5506W-X locations so you can record the

device MAC addresses from each location and provide them to the person who is planning or manage

your wireless network.

Safety Recommendations

Use the information in the following sections to help ensure your safety and to protect the chassis. This

information may not address all potentially hazardous situations in your working environment, so be alert and

exercise good judgment at all times.

Observe these safety guidelines:

Keep the area clear and dust-free before, during, and after installation.

•

Keep tools away from walkways, where you and others might trip over them.

•

Do not wear loose clothing or jewelry, such as earrings, bracelets, or chains that could get caught in the

•

chassis.

Wear safety glasses if you are working under any conditions that might be hazardous to your eyes.

•

Do not perform any action that creates a potential hazard to people or makes the equipment unsafe.

•

Never attempt to lift an object that is too heavy for one person.

•

Online Only 25

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

Page 30

Maintain Safety with Electricity

Maintain Safety with Electricity

Before working on a chassis, be sure the power cord is unplugged.Warning

Follow these guidelines when working on equipment powered by electricity:

Before beginning procedures that require access to the interior of the chassis, locate the emergency

•

power-off switch for the room in which you are working. Then, if an electrical accident occurs, you can

act quickly to turn off the power.

Do not work alone if potentially hazardous conditions exist anywhere in your work space.

•

Never assume that power is disconnected; always check.

•

Look carefully for possible hazards in your work area, such as moist floors, ungrounded power extension

•

cables, frayed power cords, and missing safety grounds.

If an electrical accident occurs:

•

Installation Preparation

Use caution; do not become a victim yourself.

◦

Disconnect power from the system.

◦

If possible, send another person to get medical aid. Otherwise, assess the condition of the victim,

◦

and then call for help.

Determine whether the person needs rescue breathing or external cardiac compressions; then take

◦

appropriate action.

Use the chassis within its marked electrical ratings and product usage instructions.

•

Prevent Electrostatic Discharge Damage

Electrostatic discharge (ESD) occurs when electronic components are improperly handled, and it can damage

equipment and impair electrical circuitry, resulting in intermittent or complete failure.

Always follow ESD-prevention procedures when removing and replacing components. Ensure that the chassis

is electrically connected to an earth ground. Wear an ESD-preventive wrist strap, ensuring that it makes good

skin contact. Connect the grounding clip to an unpainted surface of the chassis frame to safely ground ESD

voltages. To properly guard against ESD damage and shocks, the wrist strap and cord must operate effectively.

If no wrist strap is available, ground yourself by touching the metal part of the chassis.

For safety, periodically check the resistance value of the antistatic strap, which should be between one and

10 megohms.

Site Environment

You can place the chassis on a desktop, mount it on a wall, or on a rack shelf. The location of the chassis and

the layout of the equipment rack or wiring room are extremely important for proper system operation. Placing

equipment too close together with inadequate ventilation and inaccessible panels can cause system malfunctions

and shutdowns. Improper placement can also make it difficult for you to access the chassis for maintenance.

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

26 Online Only

Page 31

Installation Preparation

Site Considerations

Warning

Under no circumstances should you stack more than one chassis on top of one another. This disrupts

cooling air flow to the ASAs and causes damage to the hardware.

See Hardware Specifications, on page 13 for information about physical specifications.

When planning the site layout and equipment locations, consider the information in the next section to help

avoid equipment failures and reduce the possibility of environmentally caused shutdowns. If you are currently

experiencing shutdowns or unusually high error rates with your existing equipment, these considerations may

help you isolate the cause of failures and prevent future problems.

Site Considerations

Considering the following helps you plan an acceptable operating environment for the chassis, and avoid

environmentally caused equipment failures.

Electrical equipment generates heat. Ambient air temperature might not be adequate to cool equipment

•

to acceptable operating temperatures without adequate circulation. Ensure that the room in which you

operate your system has adequate air circulation.

Ensure that the chassis cover is secure. The chassis is designed to allow cooling air to flow effectively

•

within it. An open chassis allows air leaks, which may interrupt and redirect the flow of cooling air from

the internal components.

Always follow the ESD-prevention procedures described previously to avoid damage to equipment.

•

Damage from static discharge can cause immediate or intermittent equipment failure.

Power Supply Considerations

When installing the chassis, consider the following:

• Check the power at the site before installing the chassis to ensure that it is “clean” (free of spikes and

noise). Install a power conditioner, if necessary, to ensure proper voltages and power levels in the

appliance input voltage.

Install proper grounding for the site to avoid damage from lightning and power surges.

•

The chassis does not have a user-selectable operating range. Refer to the label on the chassis for the

•

correct appliance input-power requirement.

Install an uninterruptible power source for your site, if possible.

•

Equipment Rack Configuration Considerations

Consider the following when planning an equipment-rack configuration:

If you are mounting a chassis in an open rack, make sure that the rack frame does not block the intake

•

or exhaust ports.

Online Only 27

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

Page 32

Equipment Rack Configuration Considerations

Be sure enclosed racks have adequate ventilation. Make sure that the rack is not overly congested as

•

each chassis generates heat. An enclosed rack should have louvered sides and a fan to provide cooling

air.

In an enclosed rack with a ventilation fan in the top, heat generated by equipment near the bottom of

•

the rack can be drawn upward and into the intake ports of the equipment above it in the rack. Ensure

that you provide adequate ventilation for equipment at the bottom of the rack.

Baffles can help to isolate exhaust air from intake air, which also helps to draw cooling air through the

•

chassis. The best placement of the baffles depends on the airflow patterns in the rack. Experiment with

different arrangements to position the baffles effectively.

Installation Preparation

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

28 Online Only

Page 33

Mount and Connect

CHAPTER 3

Note

Do not remove the rubber feet included with the ASA because they are needed for proper cooling for all

mounting orientations.

This chapter describes how to rack-mount the ASA, and how to connect the cords and cables. It contains the

following sections:

Desktop Mount the ASA, page 29

•

Wall Mount the ASA, page 30

•

Rack Mount the ASA, page 32

•

Install the ASA 5506H-X in a DIN Rail, page 34

•

Connect Cables, Turn on Power, and Verify Connectivity, page 37

•

Connect to a Console Terminal or PC, page 39

•

Desktop Mount the ASA

You can mount the ASA on a desktop by placing it on a desk in a horizontal position. Make sure there are no

blockages or obstructions within one inch of the top of the ASA or within .5 inch of the sides and back, so

that nothing interferes with cooling. Do not remove the rubber feet included with the ASA. They are also

needed for proper cooling.

Online Only 29

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

Page 34

Wall Mount the ASA

Mount and Connect

Caution

Do not stack the ASA chassis on top of another ASA chassis. If you stack the units, they will overheat,

which causes the units to power cycle.

Wall Mount the ASA

Follow these steps to mount your ASA on a wall. You can purchase a wall mount kit. The part number for

the wall mount kit is ASA5506-WALL-MNT= .

Step 1

Step 2

Step 3

Choose a location on the desired wall for the ASA.

Use the two Cisco-provided screws and anchors from the optional wall-mount kit.

If you are mounting the ASA onto something other than drywall, such as wood or sheet metal, anchors may not be

required.

Use a pencil, ruler, and level to mark locations for the two mounting screws.

The width and length of the ASA are 7.87 x 9.23 inches ( 20 x 23.44 cm). The mounting holes in the chassis are in the

middle length-wise (that is, 6.372 inches from front and back), while the holes are inset from the opposite edges 0.75

inches (1.9 cm).

Thus, you need to make two level marks 6.37, or approximately 6-3/8, inches (16.18 cm) apart.

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

30 Online Only

Page 35

Mount and Connect

Figure 22: Marking the Locations of the Two Mounting Screws

Wall Mount the ASA

Online Only 31

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

Page 36

Rack Mount the ASA

Mount and Connect

Step 4

Step 5

Step 6

Step 7

Drill a hole into the wall at each mark.

These holes should be slightly smaller in diameter than your anchors. The recommended drill hole size is 3/16".

Insert the anchors into the holes and be sure they are properly seated.

Fasten each screw into its anchor until it protrudes about 1/4 inch.

Pick up the ASA, align the screws in the anchors with the holes in the bottom of the chassis, move the ASA toward the

wall until the screw heads are in the chassis, and then slide the ASA down until it rests on the screws.

You can only mount the chassis with the front panel oriented toward either the ceiling or the floor. Wall mounting in

other orientation is not supported.

What to Do Next

You can now install the cables and power cord, as described in Connect Cables, Turn on Power, and Verify

Connectivity, on page 37.

Rack Mount the ASA

Follow these steps to mount the ASA to a rack-mount shelf.

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

32 Online Only

Page 37

Mount and Connect

Rack Mount the ASA

Step 1

Step 2

Step 3

Step 4

Note

You mount only one ASA 5506H-X in the rack-mount shelf.

The dimensions of the ASA 5506H-X are 3.46 in. x 18.3 in. x 19.5 in. (8.79 cm x 46.48 cm x 49.52 cm).

The PID is asa5506h-rack-mnt=.

Place the ASA upside down on a large, stable work area. If you are installing two ASAs in the shelf, place the second

ASA beside the first, also upside down.

Invert the sliding trays and position the ASA(s) on top of them such that the front of the device(s) and the front of the

tray are in the same direction.

Adjust the position of the first ASA and the tray until the three mounting holes in the dimples in the bottom of the shelf

are aligned with the mounting holes in the bottom of the ASA.

Tighten the captive tray screws into the shelf to lock it into place.

Figure 23: ASA 5506-X and ASA 5506W-X in the Rack-Mount Shelf

Figure 24: ASA 5506H-X in the Rack-Mount Shelf

Online Only 33

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

Page 38

Install the ASA 5506H-X in a DIN Rail

Mount and Connect

Step 5

Carefully turn the tray right-side up and slide it into the rack-mounted shelf.

What to Do Next

You can now install the cables and power cord, as described in Connect Cables, Turn on Power, and Verify

Connectivity, on page 37.

Install the ASA 5506H-X in a DIN Rail

You can use the 7.5-mm thick 45mm wide top hat DIN rail for the ASA 5506H-X. Secure the DIN rail to the

mounting surface approximately every 7.8 inches (200 mm) and use end-anchors appropriately.

We recommend that you install the ASA 5506H-X on a steel DIN rail for extra stability.Note

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

34 Online Only

Page 39

Mount and Connect

Install the ASA 5506H-X in a DIN Rail

To attach the ASA 5506H-X to a 35-mm wide DIN rail, follow these steps:

Step 1

Attach the DIN rail bracket to the back of the chassis using the four screws provided.

Figure 25: Attaching the DIN Rail Bracket to the ASA 5506H-X

Online Only 35

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

Page 40

Install the ASA 5506H-X in a DIN Rail

Mount and Connect

Step 2

Step 3

Step 4

Step 5

Step 6

Locate the plastic tab on the end of the DIN rail bracket that extends past the chassis. Press the tab in and slide the plastic

latch piece out while the tab is pressed down to put it into the locked position.

Turn the chassis sideways so that the power connector is near the top.

Position the rear edge of the chassis directly in front of the DIN rail making sure that the DIN rail fits in the space between

the plastic latch and the metal hook.

Position the chassis so that the hook on the DIN rail bracket hooks onto the top edge of the DIN rail. The weight of the

chassis can rest on the hook temporarily while the DIN rail bracket latches are secured.

Push the DIN rail bracket latch up when the chassis is over the DIN rail to secure it. This snaps the latch into the closed

position which locks it onto the DIN rail.

Figure 26: ASA 5506H-X Installed with the DIN Rail

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

36 Online Only

Page 41

Mount and Connect

Connect Cables, Turn on Power, and Verify Connectivity

The chassis is now installed in the DIN rail.

What to Do Next

See Connect Cables, Turn on Power, and Verify Connectivity, on page 37 to finish setting up your ASA.

Connect Cables, Turn on Power, and Verify Connectivity

After positioning or mounting the ASA, follow these steps to connect cables, turn on power, and verify

connectivity:

Step 1

Connect the network cables:

a)

Management interface – Using this Management 1/1 Gigabit Ethernet port, you can connect a management computer

directly with an Ethernet cable, or you can connect the computer and the ASA to the same management network. Be

sure the PC is configured to obtain an IP address using DHCP.

You can configure any of the Gigabit Ethernet interfaces to be a management-only interface using the

management-only command. However, you cannot disable management-only mode on the Management 1/1 interface.

The following figure shows how to connect the network cables.

Figure 27: ASA 5506-X and ASA 5506W-X Cabling

Online Only 37

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

Page 42

Connect Cables, Turn on Power, and Verify Connectivity

Management 1/1 interface (RJ-45)3

Figure 28: ASA 5506H-X Cabling

Mount and Connect

Console port (RJ-45 or Mini USB Type B)2Gigabit Ethernet data interface (RJ-45)1

Management 1/1 interface (RJ-45)3

b)

(Optional) Console port – For use with the CLI. Connect a computer or terminal server using a serial console cable

to either the RJ-45 or Mini USB Type B port.

Only one console port can be active at a time. When a cable is plugged into the USB console port, the RJ-45 port

becomes inactive. Conversely, when the USB cable is removed from the Mini USB Type B port, the RJ-45 port

becomes active. See Connect to a Console Terminal or PC, on page 39 for specific instructions for connecting the

console port.

c)

Gigabit Ethernet ports – For the network interfaces; use standard RJ-45 Ethernet cables.

Step 2

Connect the power cord to the ASA, and plug the other end to your power source.

Note

The ASA 5506-X, 5506W-X, and ASA 5506H-X do not have an on/off switch; the device powers on when you

plug it into a power source.

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

38 Online Only

Console port (RJ-45 or Mini USB Type B)2Gigabit Ethernet data interface (RJ-45)1

Page 43

Mount and Connect

Connect to a Console Terminal or PC

Step 3

Step 4

Check the Status LED on the ASA chassis.

When it is solid green, the ASA has passed power-on diagnostics.

See the Cisco ASA 5506-X Series Quick Start Guide to continue setting up your ASA.

Note

Your ASA ships with either ASA or Firepower Threat Defense software preinstalled. To reimage your device,

see Reimage the Cisco ASA or Firepower Threat Defense Device.

Connect to a Console Terminal or PC

The serial ports provide administrative access to the ASA either with a console terminal or a PC. To configure

the ASA through the CLI, you must establish a connection between the ASA console port and either a terminal

or a PC.

This section describes how to connect to a console terminal or a PC, and contains the following topics:

Connect to the Console Port with Microsoft Windows

You must install a USB device driver the first time a Microsoft Windows-based PC is connected to the USB

serial port on the ASA, otherwise the connection fails.

To uninstall the driver, use the Add Remove Programs utility or the Setup-exe program.

Online Only 39

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

Page 44

Connect to the Console Port with Microsoft Windows

Disconnect the ASA console terminal before uninstalling the driver.Note

Mount and Connect

Step 1

Step 2

Step 3

Obtain the appropriate driver (Cisco_usbconsole_driver_X_X_zip, where X is a revision number) for your ASA model

from the Cisco Download Software site, USB Console Software category.

Install the driver.

Connect a USB 5-pin Mini USB Type B to the USB console port as shown in the following figure.

Figure 29: ASA 5506-X and ASA 5506W-X Console Port Connection

USB Type A3

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

40 Online Only

2Mini USB Type B console port1

Mini USB Type B to USB Type A

console cable

Page 45

Mount and Connect

Figure 30: ASA 5506H-X Console Port Connection

Connect to the Console Port with Microsoft Windows

USB Type A3

Step 4

Connect the end of the cable with the DB-9 connector (or USB Type A) to the terminal or PC. If your terminal or PC

has a console port that does not accommodate a DB-9 connector, you must provide an appropriate adapter for that port.

Online Only 41

2Mini USB Type B console port1

Mini USB Type B to USB Type A

console cable

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

Page 46

Connect to the Console Port with Mac OS X

The LED for the console port turns green and within a few moments the Found New Hardware Wizard appears.

Step 5

Step 6

Follow the instructions to complete the driver installation.

To communicate with the ASA, start a terminal emulator application. This software should be configured with the

following parameters:

9600 baud

•

8 data bits

•

no parity

•

1 stop bit

•

no flow control

•

Mount and Connect

Connect to the Console Port with Mac OS X

Follow these steps to connect a Mac OS X system USB port to the console using the built in OS X Terminal

utility, or alternatively you can use a separate terminal emulator application.

Step 1

Step 2

Step 3

Step 4

Step 5

Use the Finder to go to Applications > Utilities > Terminal.

Connect the OS X USB port to the ASA.

Enter the following commands to find the OS X USB port number:

Example:

macbook:user$ cd /dev

macbook:user$ ls -ltr /dev/*usb*

crw-rw-rw- 1 root wheel 9, 66 Apr 1 16:46 tty.usbmodem1a21

DT-macbook:dev user$

Connect to the USB port with the following command followed by the ASA USB port speed:

Example:

macbook:user$ screen /dev/tty.usbmodem1a21 9600

Enter Ctrl-z followed by Ctrl-\ to disconnect the OS X USB console from the Terminal window.

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

42 Online Only

Page 47

Mount and Connect

Connect to the Console Port with Linux

Follow these steps to connect a Linux system USB port to the console using the built-in Linux Terminal utility.

Connect to the Console Port with Linux

Step 1

Step 2

Step 3

Step 4

Step 5

Open the Linux Terminal window.

Connect the Linux USB port to the ASA.

Enter the following commands to find the Linux USB port number:

Example:

root@usb-suse# cd /dev

root@usb-suse /dev# ls -ltr *ACM*

crw-r--r-- 1 root root 188, 0 Jan 14 18:02 ttyACM0

root@usb-suse /dev#

Connect to the USB port with the following command followed by the ASA USB port speed

Example:

root@usb-suse /dev# screen /dev/ttyACM0 9600

To disconnect the Linux USB console from the Terminal window, enter Ctrl-a followed by : then quit.

Online Only 43

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

Page 48

Connect to the Console Port with Linux

Mount and Connect

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

44 Online Only

Page 49

CHAPTER 4

Maintenance and Upgrades

This chapter contains procedures for maintaining and upgrading your ASA, and contains the following

sections:

Connect the DC Adapter for the 5506H-X, page 45

•

Install the Adjustable Power Supply Retainer, page 47

•

Connect the DC Adapter for the 5506H-X

You can order an optional DC power supply that supplies 24V DC (part number PWR2-20W-24VDC) or

20W 20-60V DC (part number PWR2-22W-20-60VDC).

Step 1

Warning

Warning

Connect the black and white lead wires to a 12 VDC source.

This product relies on the building's installation for short-circuit (overcurrent) protection. Ensure that the

protective device is rated not greater than 36 VDC, 5A. Statement 1005

This product requires short-circuit (overcurrent) protection to be provided as part of the building installation.

Install only in accordance with national and local wiring regulations.

The device is designed to work with TN power systems.Warning

To connect the DC power on your 5506H-X, follow these steps:

Online Only 45

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

Page 50

Maintenance and Upgrades

Connect the DC Adapter for the 5506H-X

The black lead is negative or ground and the white lead is positive. The output cable is 1.3 meters and the input cable is

1 meter in length.

Figure 31: DC Power Adapter

Step 2

Step 3

White wire (positive)2Black wire (negative)1

Adapter3

Plug the adapter cord into the ASA.

Note

The power adapters have 18 AWG wires for the input connection. Tinned bare wires are used for the input

connection because there is no standard established for connector type. Screw terminal blocks are most often

used.

Power on the ASA and check that it has power. See LEDs, on page 8 for information on the power LED.

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

46 Online Only

Page 51

Maintenance and Upgrades

Install the Adjustable Power Supply Retainer

Install the Adjustable Power Supply Retainer

You can install an adjustable power supply retainer for the Delta and LiteOn power supplies in the rack-mount

tray. The bracket kit contains the bracket, 2 M3 screws, and washers. The following figure shows the adjustable

retainer.

Figure 32: ASA Bracket Assembly

Step 1

Step 2

1

from high to low bracket

Slide the rack-mount shelf containing the ASA(s) out of the rack.

At the back of the rack-mount shelf behind the power supplies, install the adjustable retainer.

a) Loosen the 2 top screws (item 1 in the figure above) slightly to adjust the bracket for each power supply.

The Delta power supply uses the bracket extended to its tallest configuration. This configuration has item 1 shifted

to the bottom of the slot on the bracket over the power supply. The LiteOn power supply uses the bracket extended

to its shortest configuration. This configuration has item 1 shifted to the top of the slot on the bracket over the power

supply.

b) Install the bracket over the power supply and screw the 2 bottom M3 captive screws (item 2 in the figure above) on

each side of the bottom of the bracket into the rack-mount tray.

2Two screws to loosen to change

Two captive screws to attach to

rack-mount tray

Online Only 47

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

Page 52

Install the Adjustable Power Supply Retainer

The following figure shows the installed power supply retainer.

Figure 33: Installed Power Supply Retainer

Maintenance and Upgrades

Cisco ASA 5506-X, ASA 5506W-X, and ASA 5506H-X Hardware Installation Guide

48 Online Only

Loading...

Loading...