Page 1

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

May 2013

Americas Headquarters

Cisco Systems, Inc.

170 West Tasman Drive

San Jose, CA 95134-1706

USA

http://www.cisco.com

Tel: 408 526-4000

800 553-NETS (6387)

Fax: 408 527-0883

Text Part Number: OL-26701-02

Page 2

THE SPECIFICATIONS AND INFORMATION REGARDING THE PRODUCTS IN THIS MANUAL ARE SUBJECT TO CHANGE WITHOUT NOTICE. ALL

STATEMENTS, INFORMATION, AND RECOMMENDATIONS IN THIS MANUAL ARE BELIEVED TO BE ACCURATE BUT ARE PRESENTED WITHOUT

WARRANTY OF ANY KIND, EXPRESS OR IMPLIED. USERS MUST TAKE FULL RESPONSIBILITY FOR THEIR APPLICATION OF ANY PRODUCTS.

THE SOFTWARE LICENSE AND LIMITED WARRANTY FOR THE ACCOMPANYING PRODUCT ARE SET FORTH IN THE INFORMATION PACKET THAT

SHIPPED WITH THE PRODUCT AND ARE INCORPORATED HEREIN BY THIS REFERENCE. IF YOU ARE UNABLE TO LOCATE THE SOFTWARE LICENSE

OR LIMITED WARRANTY, CONTACT YOUR CISCO REPRESENTATIVE FOR A COPY.

The following information is for FCC compliance of Class A devices: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio-frequency energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference, in which case users will be required

to correct the interference at their own expense.

The following information is for FCC compliance of Class B devices: The equipment described in this manual generates and may radiate radio-frequency energy. If it is not

installed in accordance with Cisco’s installation instructions, it may cause interference with radio and television reception. This equipment has been tested and found to

comply with the limits for a Class B digital device in accordance with the specifications in part 15 of the FCC rules. These specifications are designed to provide reasonable

protection against such interference in a residential installation. However, there is no guarantee that interference will not occur in a particular installation.

Modifying the equipment without Cisco’s written authorization may result in the equipment no longer complying with FCC requirements for Class A or Class B digital

devices. In that event, your right to use the equipment may be limited by FCC regulations, and you may be required to correct any interference to radio or television

communications at your own expense.

You can determine whether your equipment is causing interference by turning it off. If the interference stops, it was probably caused by the Cisco equipment or one of its

peripheral devices. If the equipment causes interference to radio or television reception, try to correct the interference by using one or more of the following measures:

• Turn the television or radio antenna until the interference stops.

• Move the equipment to one side or the other of the television or radio.

• Move the equipment farther away from the television or radio.

• Plug the equipment into an outlet that is on a different circuit from the television or radio. (That is, make certain the equipment and the television or radio are on circuits

controlled by different circuit breakers or fuses.)

Modifications to this product not authorized by Cisco Systems, Inc. could void the FCC approval and negate your authority to operate the product.

The Cisco implementation of TCP header compression is an adaptation of a program developed by the University of California, Berkeley (UCB) as part of UCB’s public

domain version of the UNIX operating system. All rights reserved. Copyright © 1981, Regents of the University of California.

NOTWITHSTANDING ANY OTHER WARRANTY HEREIN, ALL DOCUMENT FILES AND SOFTWARE OF THESE SUPPLIERS ARE PROVIDED “AS IS” WITH

ALL FAULTS. CISCO AND THE ABOVE-NAMED SUPPLIERS DISCLAIM ALL WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT

LIMITATION, THOSE OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT OR ARISING FROM A COURSE OF

DEALING, USAGE, OR TRADE PRACTICE.

IN NO EVENT SHALL CISCO OR ITS SUPPLIERS BE LIABLE FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL, OR INCIDENTAL DAMAGES, INCLUDING,

WITHOUT LIMITATION, LOST PROFITS OR LOSS OR DAMAGE TO DATA ARISING OUT OF THE USE OR INABILITY TO USE THIS MANUAL, EVEN IF CISCO

OR ITS SUPPLIERS HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Cisco and the Cisco logo are trademarks or registered trademarks of Cisco and/or its affiliates in the U.S. and other countries. To view a list of Cisco trademarks, go to this

URL: www.cisco.com/go/trademarks. Third-party trademarks mentioned are the property of their respective owners. The use of the word partner does not imply a partnership

relationship between Cisco and any other company. (1110R)

Any Internet Protocol (IP) addresses used in this document are not intended to be actual addresses. Any examples, command display output, and figures included in the

document are shown for illustrative purposes only. Any use of actual IP addresses in illustrative content is unintentional and coincidental.

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

© 2013 Cisco Systems, Inc. All rights reserved.

Page 3

Preface vii

CONTENTS

CHAPTER

1 Preparing for Installation 1-1

Cisco ASR 9001 Router 1

Cisco ASR 9001-S Router 1

Safety Guidelines 1-2

General Safety Guidelines 1-2

Compliance and Safety Information 1-3

Laser Safety 1-3

Energy Hazard 1-3

Preventing Electrostatic Discharge Damage 1-4

Lifting Guidelines 1-4

Site Requirement Guidelines 1-5

Site Layout and Equipment Dimensions 1-5

Site Wiring Guidelines 1-7

Chassis Air Flow Guidelines 1-7

Rack-Mounting and Air Flow Clearance Guidelines 1-8

Telco 2-Post Rack 1-9

Open 4-Post Rack 1-10

Enclosed Rack with Perforated Sides 1-10

Air Flow Guidelines for Enclosed Rack Installation 1-11

Temperature and Humidity Guidelines 1-12

Power Connection Guidelines 1-12

AC Powered Routers 1-13

AC Power Cord Illustrations 1-13

DC Powered Router 1-17

NEBS Supplemental Unit Bonding and Grounding Guidelines 1-20

OL-26701-02

Cisco ASR 9001 Router Port Connection Guidelines 1-21

Console Port and Auxiliary Port Connection Guidelines 1-23

Console Port Signals 1-23

Auxiliary Port Signals 1-24

Management LAN Ports Connection Guidelines 1-24

Management LAN Port LED Indicators 1-25

Management LAN RJ-45 Cabling 1-25

Sync Ports Connection Guidelines 1-26

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

iii

Page 4

Contents

SYNC Port LED Indicators 1-26

RP External USB Port 1-27

CHAPTER

CHAPTER

2 Unpacking and Installing the Chassis 2-1

Pre-Installation Considerations and Requirements 2-1

Installation Overview 2-1

Required Tools and Equipment 2-2

Unpacking the Cisco ASR 9001 Router 2-2

Positioning the Router 2-3

Rack-Mounting the Router Chassis 2-4

Verifying Rack Dimensions 2-4

Installing the Chassis in a 2-Post Rack 2-4

Installing the Chassis in a 4-post Rack 2-7

Supplemental Bonding and Grounding Connections 2-7

3 Installing Modules and Cables in the Chassis 3-1

Fixed 4x10-Gigabit Ethernet Ports 3-1

Modular Port Adapters 3-2

20-Port Gigabit Ethernet Modular Port Adapter 3-2

4-Port 10 Gigabit Ethernet Modular Port Adapter 3-3

2-Port 10 Gigabit Ethernet Modular Port Adapter 3-4

Installing and Removing Modular Port Adapters 3-5

Handling Modular Port Adapters (MPAs) 3-6

Online Insertion and Removal 3-6

Modular Port Adapter (MPA) Installation and Removal 3-7

Optical Device Installation and Removal 3-8

Cleaning Optical Devices 3-8

Checking the Installation 3-8

Verifying the Installation 3-8

Using show Commands to Verify Modular Port Adapter (MPA) Status 3-9

Using show Commands to Display Modular Port Adapter (MPA) Information 3-10

Using the ping Command to Verify Network Connectivity 3-10

Installing and Removing SFP Modules 3-11

Installing and Removing XFP Modules 3-11

Cable Management 3-12

Cable Management Tray 3-12

Installing a Cable Management Tray 3-12

Removing a Cable-Management Tray 3-13

iv

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

OL-26701-02

Page 5

Cable Management Bracket 3-14

Installing a Cable Management Bracket 3-14

Removing a Cable-Management Bracket 3-15

Connecting Route Processor Cables 3-16

Connecting to the RP Console Port 3-17

Connecting to the RP Auxiliary Port 3-17

Connecting to the RP Ethernet Management Ports 3-17

Connecting Power to the Router 3-18

Connecting Power to an AC-Powered Router 3-18

Connecting Power to a DC-Powered Router 3-20

Powering on the Router 3-21

Contents

CHAPTER

4 Troubleshooting the Installation 4-1

Troubleshooting Overview 4-1

Troubleshooting Using a Subsystem Approach 4-1

Normal Router Startup Sequence 4-2

Identifying Startup Issues 4-2

Troubleshooting the Power Subsystem 4-3

Troubleshooting the AC-Input Power Subsystem 4-3

Troubleshooting the DC-Input Power Subsystem 4-5

Troubleshooting a DC Power Module 4-5

Additional Power Subsystem Troubleshooting Information 4-6

Hardware and Software Identification 4-6

Obtaining Temperature and Environmental Information 4-6

Troubleshooting the Power Distribution System 4-8

Troubleshooting the Route Processor Subsystem 4-9

Route Processor Overview 4-9

RP Front Panel Indicators 4-10

Ethernet Ports and Status LEDs 4-11

Auxiliary and Console Ports 4-11

Monitoring Critical, Major, and Minor Alarm Status 4-12

OL-26701-02

Troubleshooting the Line Card 4-12

Initial Boot Process 4-12

Status LEDs 4-12

Configuring and Troubleshooting Line Card Interfaces 4-13

Configuration Parameters 4-13

Line Card Interface Address 4-14

Using Configuration Commands 4-14

Basic Line Card Configuration 4-14

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

v

Page 6

Contents

Verifying the Transceiver Modules 4-15

Advanced Line Card Troubleshooting 4-17

Troubleshooting the Cooling Subsystem 4-18

Fan Tray Operation 4-18

Power Module Fans 4-18

Over-temperature Conditions 4-19

Isolating Cooling Subsystem Problems 4-19

CHAPTER

APPENDIX

APPENDIX

5 Replacing Cisco ASR 9001 Router Components 5-1

Prerequisites and Preparation 5-1

Field Replaceable Units 5-1

Online Insertion and Removal 5-2

Powering Off the Router 5-2

Removing and Replacing the Fan Tray 5-2

Removing and Replacing AC or DC Power System Components 5-3

Power Module Replacement Guidelines 5-4

Removing and Replacing an AC or DC Power Module 5-4

Removing an AC or DC Power Module 5-4

Installing an AC or DC Power Module 5-5

Removing a Chassis from the Equipment Rack 5-5

Installing a Replacement Chassis in the Equipment Rack 5-6

Packing a Chassis for Shipment 5-6

A Technical Specifications A-1

B Site Log B-1

I

NDEX

vi

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

OL-26701-02

Page 7

Preface

This Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide preface contains these

sections:

• Changes to This Document, page vii

• Audience, page vii

• Purpose, page vii

• Document Organization, page viii

• Document Conventions, page viii

• Obtaining Documentation and Submitting a Service Request, page ix

Changes to This Document

Table 1 lists the technical changes made to this document since it was first developed.

Table 1 Changes to This Document

Revision Date Change Summary

OL-26701-02 May 2013 Added information about Cisco ASR 9001-S Router.

OL-26701-01 June 2012 Initial release of this document.

Audience

This Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide is written for

hardware installers and system administrators of Cisco routers.

These users must have a substantial background in installing and configuring router and switch-based

hardware. Also, they should be familiar with electronic circuitry and wiring practices, and have

experience as an electronic or electromechanical technician.

Purpose

OL-26701-02

This installation guide contains procedures for installing the router hardware, creating a basic startup

configuration file, and powering the router on for the first time.

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

vii

Page 8

Document Organization

This installation guide is organized into these chapters and appendixes:

• Chapter 1, “Preparing for Installation,” describes safety considerations, required tools and

equipment, an overview of the installation, and procedures to perform before installation.

• Chapter 2, “Unpacking and Installing the Chassis,” provides instructions for installing the chassis

into a rack.

• Chapter 3, “Installing Modules and Cables in the Chassis,” provides instructions for installing the

cards and modules into the chassis after it is mounted in a rack, and for connecting external network

interface cables.

• Chapter 4, “Troubleshooting the Installation,” provides guidelines for troubleshooting the router

hardware installation.

• Chapter 5, “Replacing Cisco ASR 9001 Router Components,” provides removal and replacement

procedures for primary router components and field-replaceable units (FRUs).

• Appendix A, “Technical Specifications,” provides a summary of physical, electrical, and

environmental specifications for the router.

• Appendix B, “Site Log,” provides a sample site log that can be used to record actions relevant to the

operation and maintenance of the router.

Preface

Document Conventions

This publication uses these conventions:

• Ctrl represents the key labeled Control. For example, the key combination Ctrl-Z means hold down

the Control key while you press the Z key.

Command descriptions use these conventions:

• Examples that contain system prompts denote interactive sessions, indicating the commands that

you should enter at the prompt. For example:

RP/0/RSP0/CPU0:router#

• Commands and keywords are in bold font.

• Arguments for which you supply values are in italic font.

• Elements in square brackets ([ ]) are optional.

• Alternative but required keywords are grouped in braces ({ }) and separated by vertical bars (|).

Caution Means be careful. You are capable of doing something that might result in equipment damage or loss of

data.

Note Means take note. Notes contain helpful suggestions or references to materials not contained in this

manual.

viii

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

OL-26701-02

Page 9

Preface

Timesaver Means the described action saves time. You can save time by performing the action described in the

paragraph.

Warning

This warning symbol means danger. You are in a situation that could cause bodily injury. Before you

work on any equipment, be aware of the hazards involved with electrical circuitry and be familiar

with standard practices for preventing accidents. To see translations of the warnings that appear in

this publication, see the Regulatory Compliance and Safety Information document that accompanied

this device.

Obtaining Documentation and Submitting a Service Request

For information on obtaining documentation, submitting a service request, and gathering additional

information, see the monthly What’s New in Cisco Product Documentation, which also lists all new and

revised Cisco technical documentation, at:

http://www.cisco.com/en/US/docs/general/whatsnew/whatsnew.html

Subscribe to the What’s New in Cisco Product Documentation as a Really Simple Syndication (RSS) feed

and set content to be delivered directly to your desktop using a reader application. The RSS feeds are a free

service and Cisco currently supports RSS Version 2.0.

OL-26701-02

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

ix

Page 10

Preface

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

x

OL-26701-02

Page 11

Cisco ASR 9001 Router

CHAP T ER

1

Preparing for Installation

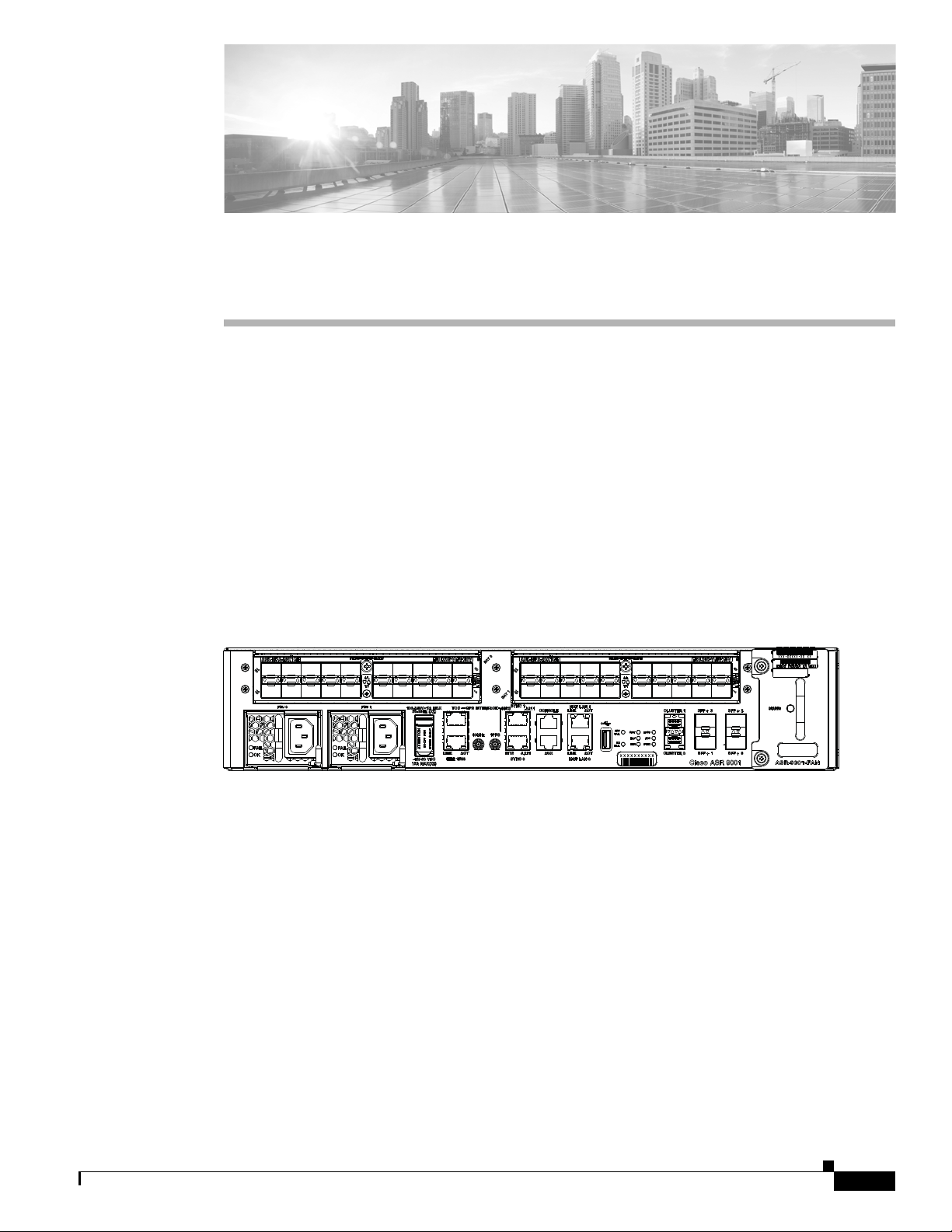

The Cisco ASR 9001 Router is a compact high-capacity provider edge (PE) router that delivers 120

Gbps of non-blocking, full-duplex fabric capacity in a two-rack-unit (2RU) form factor. Similar to other

routers in the Cisco ASR 9000 Series, running Cisco IOS XR software images, the

Cisco ASR 9001 Router delivers the features and services found on the ASR 9000 Series platforms,

allowing customers to standardize on the same Cisco IOS XR image. The Cisco ASR 9001 Router has

an integrated route processor (RP) and two modular bays that support 1 GE and 10 GE modular port

adapters (MPAs). The base chassis has four integrated 10 GE enhanced small form-factor pluggable

(SFP+) ports, a GPS input for stratum-1 clocking, building integrated timing supply (BITS) ports, and

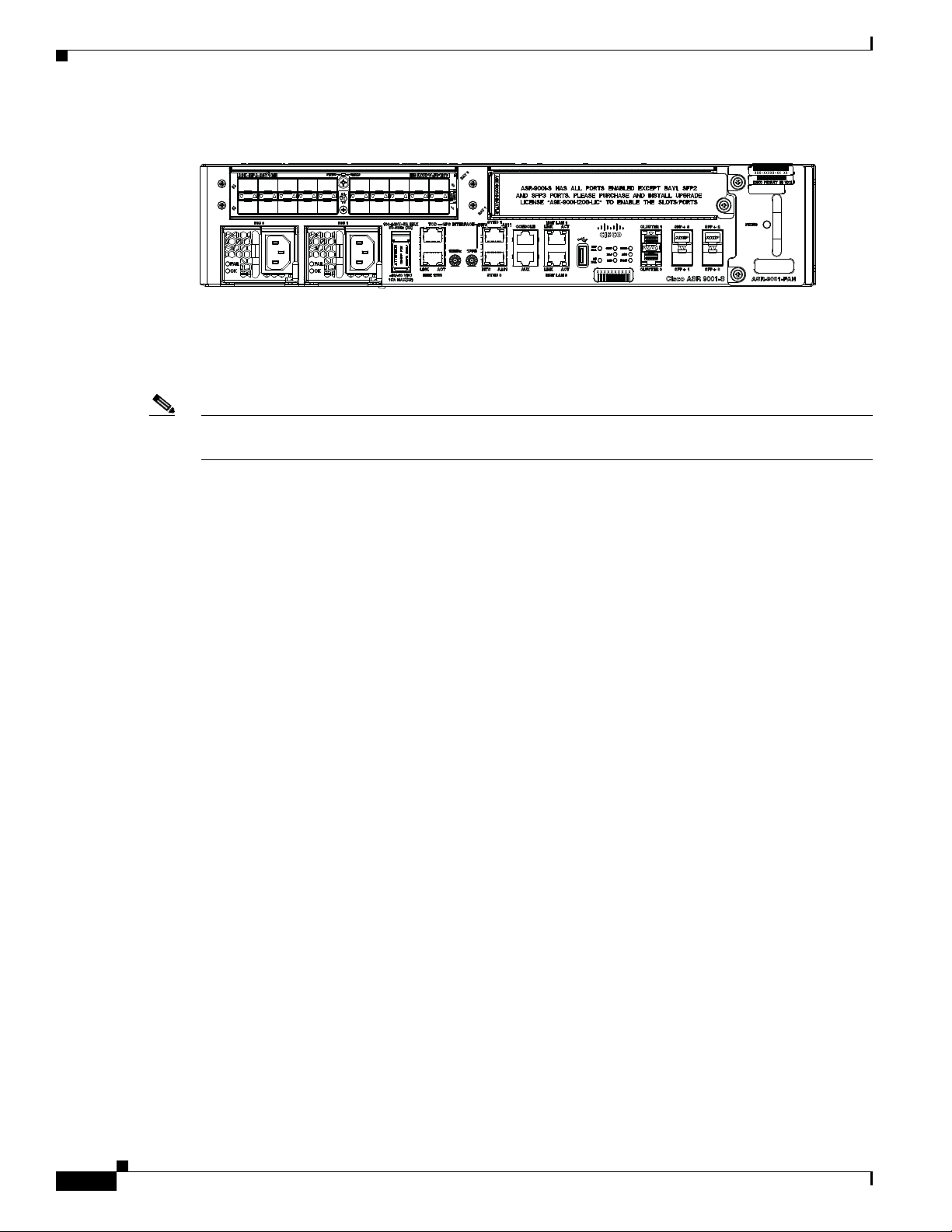

management ports. Figure 1-1 shows the front panel of the Cisco ASR 9001 Router.

Figure 1-1 Front Panel of the Cisco ASR 9001 Router

Cisco ASR 9001-S Router

The Cisco ASR 9001-S Router is a 60 Gbps variant of the Cisco ASR 9001 Router. Similar to other

routers in the Cisco ASR 9000 Series, running Cisco IOS XR software images, the

Cisco ASR 9001-S Router delivers the features and services found on the ASR 9000 Series platforms,

allowing customers to standardize on the same Cisco IOS XR image. The Cisco ASR 9001-S Router

comes standard with one modular bay (BAY 0) that supports either a 1 GE, 10 GE, or 40 GE modular

port adapters (MPAs). The chassis also comes usable with two fixed SFP+ ports (SFP+0 and SFP+1).

The second MPA slot (BAY 1) and other two SFP+ ports (SFP+2 and SFP+3) are disabled and covered

with dust caps by default. It supports the same set of features and scaling for each NPU as does the

Cisco ASR 9001 Router. Figure 1-2 shows the front panel of the Cisco ASR 9001-S Router.

OL-26701-02

360033

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

1-1

Page 12

Safety Guidelines

360032

Note The Cisco ASR 9001-S Router follows the same hardware installation procedure as the procedure for the

Chapter 1 Preparing for Installation

Figure 1-2 Front Panel of the Cisco ASR 9001-S Router

In order to achieve the full bandwidth of 120 Gbps and to enable the disabled ports, a Cisco license can

be obtained. Once the license is obtained and installed, the Cisco ASR 9001-S Router must be reloaded

to bring up the full 120 Gbps capacity. For information on configuring the Cisco license for

Cisco ASR 9001-S Router, refer to the Cisco ASR 9001-S 120G Upgrade License Configuration Guide.

Cisco ASR 9001 Router, described in this document.

This chapter guides you through the process of preparing for router installation.

Before installing your Cisco ASR 9001 Router, you must consider these requirements:

• power and cabling requirements must be in place at your installation site

• special equipments must be available for installing the router

• the environmental conditions that your installation site must meet to maintain normal operation

The shipping package for the router is engineered to reduce chances of product damage that may result

from routine material handling during shipment:

• Keep the router in the shipping container until you have determined the installation site.

• The router should always be transported or stored in its shipping package in the upright position.

Inspect all items for shipping damage. If an item appears damaged, contact a Cisco customer service

representative immediately.

This chapter contains these installation topics:

• Safety Guidelines, page 1-2

• Site Requirement Guidelines, page 1-5

• Cisco ASR 9001 Router Port Connection Guidelines, page 1-21

Safety Guidelines

Before you perform any procedure in this publication, you must review the safety guidelines in this

section to avoid injuring yourself or damaging the equipment.

Note that this section contains guidelines, and do not include every potentially hazardous situation.

When you install a router, always use caution and common sense.

General Safety Guidelines

• Never attempt to lift an object that might be too heavy for you to lift by yourself.

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

1-2

OL-26701-02

Page 13

Chapter 1 Preparing for Installation

• Always disconnect the power source and unplug all power cables before lifting, moving, or working

on the router.

• Keep the work area clear and dust free during and after installation.

• Keep tools and router components away from walkways and equipment rack aisles.

• Do not wear loose clothing, jewelry (including rings and chains), or other items that could get caught

in the router.

• Fasten your tie or scarf and sleeves.

• Operate Cisco equipment safely by using it in accordance with its electrical ratings and product

usage instructions.

• Do not work alone if potentially hazardous conditions exist.

• Always unplug power cables when performing maintenance or working on the router, unless the

replacement part is hot swappable and designed for online insertion and removal (OIR).

• Ensure that the installation of the router is in compliance with national and local electrical codes: in

the United States, National Fire Protection Association (NFPA) 70, United States National

Electrical Code; in Canada, Canadian Electrical Code, part I, CSA C22.1; in other countries,

International Electrotechnical Commission (IEC) 364, part 1 through part 7.

Safety Guidelines

Compliance and Safety Information

Both the Cisco ASR 9001 Router and the Cisco ASR 9001-S Router are designed to meet the regulatory

compliance and safety approval requirements. See Regulatory Compliance and Safety Information for

Cisco 12000 Series Routers.

Laser Safety

The line card ports in Cisco ASR 9001 Router are equipped with lasers. The lasers emit invisible

radiation. Do not stare into open line card ports. Observe this warning to prevent eye injury:

Warning

Because invisible laser radiation may be emitted from the aperture of the port when no cable is

connected, avoid exposure to laser radiation and do not stare into open apertures.

Energy Hazard

The Cisco ASR 9001 Router can be configured for a DC power source. Do not touch terminals while

they are live. Observe this warning to prevent injury.

Warning

Hazardous voltage or energy may be present on power terminals. Always replace cover when

terminals are not in service. Be sure uninsulated conductors are not accessible when cover is in

place.

Statement 1086

Statement 70

OL-26701-02

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

1-3

Page 14

Safety Guidelines

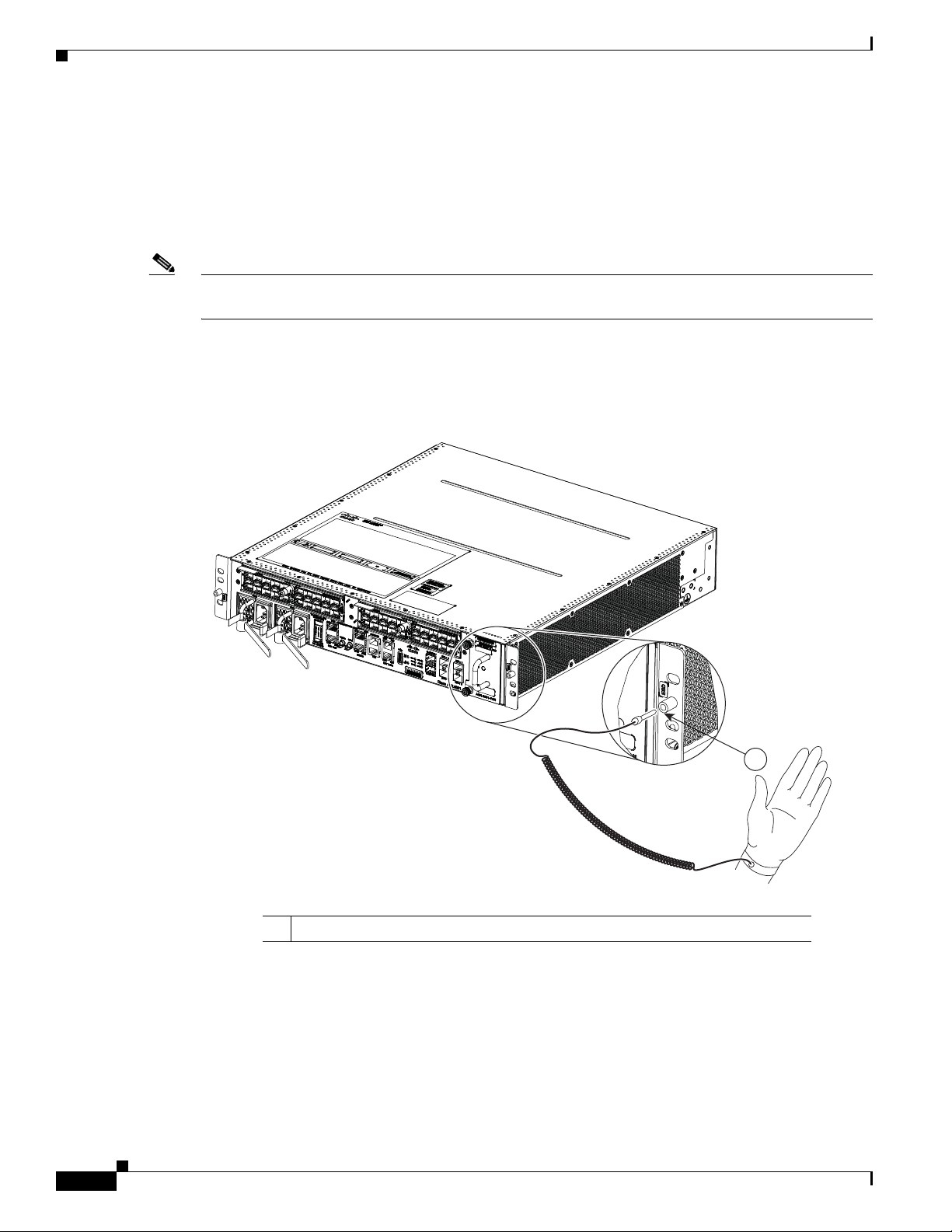

Preventing Electrostatic Discharge Damage

Many router components can be damaged by static electricity. Not exercising the proper electrostatic

discharge (ESD) precautions can result in intermittent or complete component failures. To minimize the

potential for ESD damage, always use an ESD-preventive antistatic wrist strap (or ankle strap) and

ensure that it makes good skin contact.

Note Check the resistance value of the ESD-preventive strap periodically. The measurement should be

between 1 and 10 megohms.

Before you perform any procedure in this guide, attach an ESD-preventive strap to your wrist and

connect the leash to the chassis as shown in Figure 1-3.

Figure 1-3 Connecting an ESD-Preventive Wrist Strap to the Cisco ASR 9001 Router Chassis

Chapter 1 Preparing for Installation

Lifting Guidelines

A fully-configured Cisco ASR 9001 Router can weigh as much as 37.91 pounds (17.2 kg). These

systems are not intended to be moved frequently. Before you install the router, ensure that you have

planned the installation and migration of the router into your network so that you can avoid having to

move the router later to accommodate power sources and network connections.

Use these lifting guidelines to avoid injury to yourself or damage to the equipment:

331880

1

1 Location of chassis socket for ESD strap on the Cisco ASR 9001 Router

1-4

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

OL-26701-02

Page 15

Chapter 1 Preparing for Installation

• Do not lift equipment alone; have another person help you to lift the equipment.

• Ensure that your footing is solid; balance the weight of the object between your feet.

• Lift the equipment slowly; never move suddenly or twist your body as you lift.

• Keep your back straight and lift with your legs, not your back. When bending down to lift

equipment, bend at the knees (not at the waist), to reduce the strain on your lower back muscles.

Site Requirement Guidelines

Warning

To prevent injury and equipment damage, never attempt to lift or tilt the router chassis using the

handles on the fan tray or on line cards. These handles do not support the weight of the chassis.

Site Requirement Guidelines

These sections contain the site requirement guidelines that you should be familiar with before installing

the router:

• Site Wiring Guidelines, page 1-7

• Rack-Mounting and Air Flow Clearance Guidelines, page 1-8

• Chassis Air Flow Guidelines, page 1-7

• Temperature and Humidity Guidelines, page 1-12

• Power Connection Guidelines, page 1-12

• NEBS Supplemental Unit Bonding and Grounding Guidelines, page 1-20

Site Layout and Equipment Dimensions

To help maintain trouble-free operation, adhere to these precautions and guidelines when planning your

rack installation:

• Install the system in a restrictive access location with means for a permanent grounding.

OL-26701-02

• Ensure the site of the rack includes provisions for source AC or DC power, grounding, and network

interface cables.

• Allow sufficient space to work around the rack during the installation. You need at least 3 feet (91.44

cm) adjacent to the rack to move, align, and insert the chassis.

• Maintain at least 24 inches (61 cm) of clearance in front of, and behind the chassis for maintenance

after installation.

• To mount the router between two posts or rails, the usable aperture (the width between the inner

edges of the two mounting flanges) must be at least 17.75 inches (45.09 cm) for the

Cisco ASR 9001 Router.

• Height of the Cisco ASR 9001 Router is 3.47 inches (8.8 cm).

• When fully populated with cards, the router can weigh as much as 37.91 pounds (17.2 kg). To

maintain equipment rack stability and to ensure your safety, the rack is provided with stabilizing

devices. Make sure you install the stabilizers before installing the router.

• If you use a telco-style rack, the weight of the chassis is cantilevered off the two rack posts. Make

sure that:

–

Weight of the router does not make the frame unstable.

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

1-5

Page 16

Site Requirement Guidelines

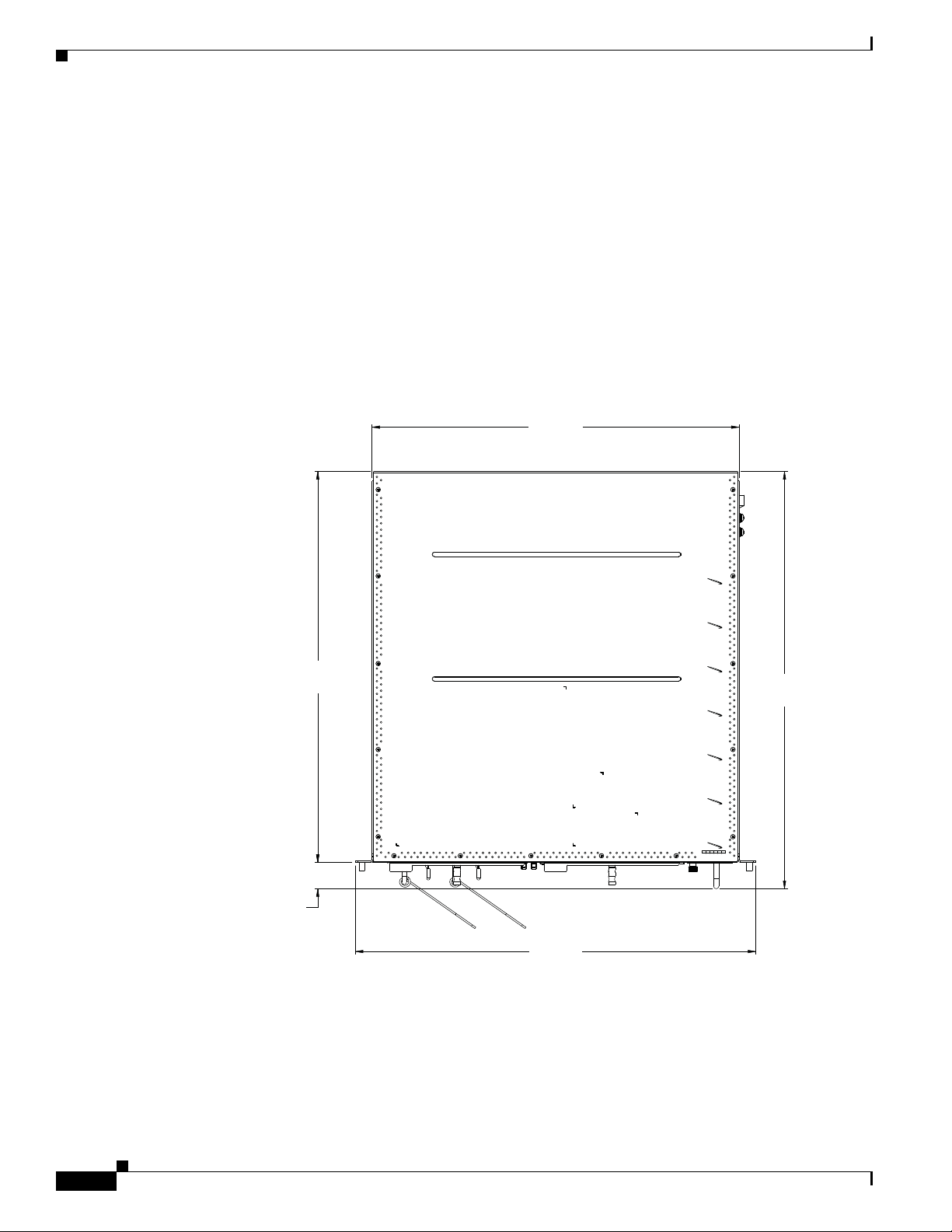

Rear of chassis

Front of chassis

19 inch

(48.3 cm)

17.42 Inch

(44.2 cm)

18.54 Inch

(47.1 cm)

19.79 inch

(50.3 cm)

1.25 inch

(3.2 cm)

• When mounting the router in a telco-style rack or 4-post rack, be sure to use all the screws provided

• Install the cable-management brackets included with the router to keep cables organized. Be sure to

• To avoid noise interference in network interface cables, do not route them directly across or along

Figure 1-4 shows the top-down view chassis dimensions of the Cisco ASR 9001 Router.

Figure 1-4 Cisco ASR 9001 Router Chassis Footprint and Dimensions—Top View

Chapter 1 Preparing for Installation

–

Frame is bolted to the floor and is secured to the building structure using either wall brackets or

overhead brackets.

to secure the chassis to the rack posts.

use appropriate strain-relief methods to protect cables and equipment connections.

power cables.

1-6

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

OL-26701-02

Page 17

Chapter 1 Preparing for Installation

Site Wiring Guidelines

When planning the location of the router, consider distance limitations for signaling, electromagnetic

interference (EMI), and connector compatibility. If the wiring is run for any significant distance in an

electromagnetic field, interference can occur between the field and the signals on the wires. Poor wiring

can cause:

• Radio interference emanating from the wires.

• Strong EMI, especially when caused by lightning or radio transmitters. EMI can destroy the signal

drivers and receivers in the router, and can even create an electrical hazard by conducting power

surges through lines and into equipment.

Note To predict and remedy strong EMI, you may need to consult with radio frequency interference

(RFI) experts.

Site wiring is unlikely to emit radio interference if you use twisted-pair cable with good distribution of

grounding conductors. Use a high-quality twisted-pair cable with one ground conductor for each data

signal, when applicable.

Give special consideration to the effect of lightning strikes in your vicinity, especially if the wiring

exceeds recommended distances, or if it passes between buildings. The electromagnetic pulse (EMP)

caused by lightning or other high-energy phenomena can easily induce enough energy into unshielded

conductors, and destroy electronic devices. If you have experienced EMP problems in the past, you may

want to consult experts in electrical surge suppression and shielding.

Most data centers cannot resolve infrequent, but potentially catastrophic, problems without pulse meters

and other special equipment. In addition, these problems can take a great deal of time to identify and

resolve. We recommend that you take the necessary precautions to avoid these problems by providing a

properly grounded and shielded environment, with special attention to issues of electrical surge

suppression.

Site Requirement Guidelines

Chassis Air Flow Guidelines

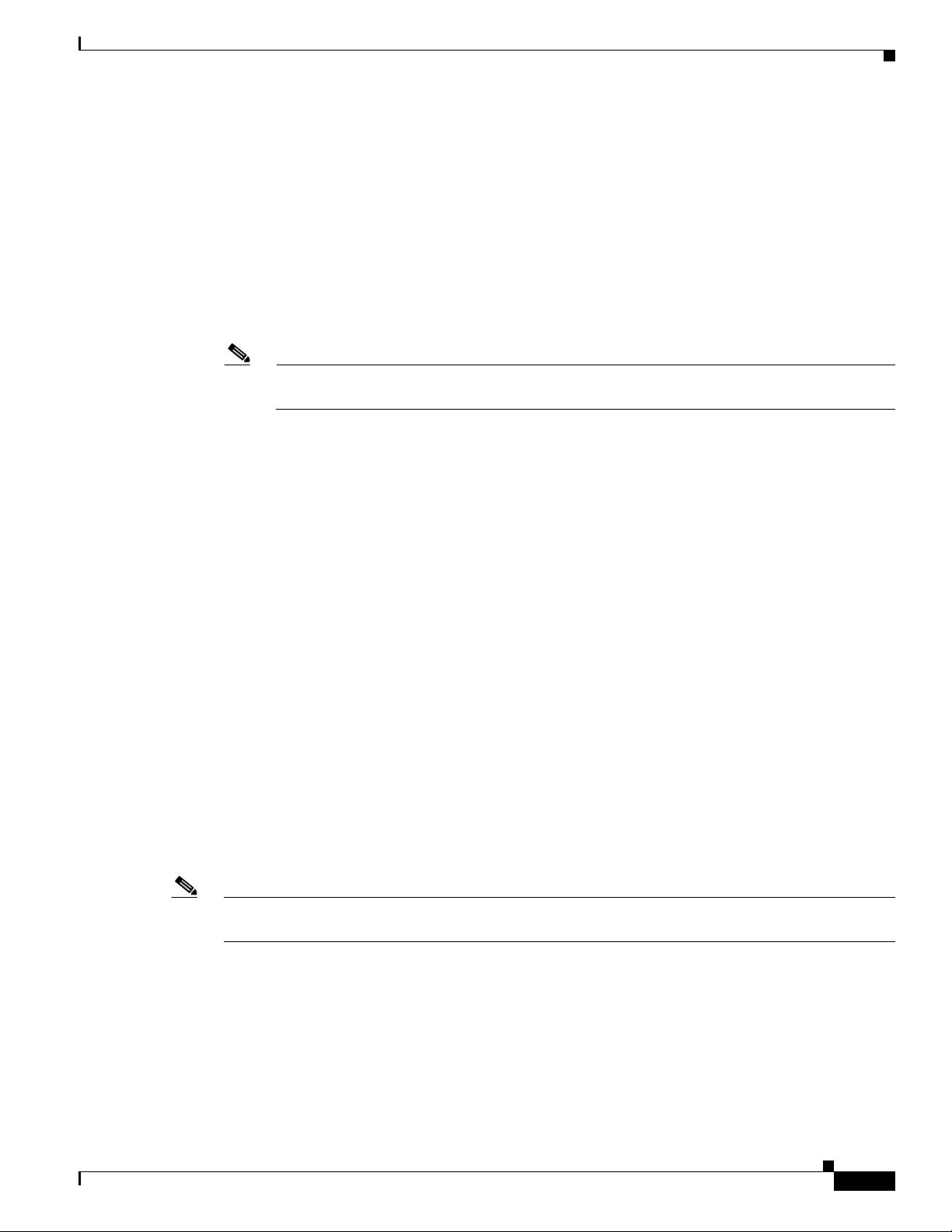

Cool air is circulated through the Cisco ASR 9001 Router by one fan tray located along the right side of

the router (see Figure 1-5).

The fan tray maintains acceptable operating temperatures for the internal components by drawing in cool

air through the vents, and circulating the air through the chassis. Each power supply is also equipped

with fans that draw cool air into the front of the power supply and force warm air out of the air exhaust.

Note See the “Rack-Mounting and Air Flow Clearance Guidelines” section on page 1-8 section for details on

air flow clearance requirements for installation in an enclosed 4-post rack.

OL-26701-02

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

1-7

Page 18

Site Requirement Guidelines

Figure 1-5 Air Flow Path through the Cisco ASR 9001 Router

Chapter 1 Preparing for Installation

Air exhaust

When selecting a site to install the router, observe these guidelines:

• Dust free area—Site should be as dust free as possible. Dusty environments can clog the power

supply intake vents, reducing the cooling air flow through the router. Clogged filters and vents can

cause an over-temperature condition in the router.

• Unrestricted air flow—Allow sufficient air flow by maintaining a minimum of 6 inches (15.24 cm)

of clearance at both the inlet and exhaust openings on the chassis and the power modules. If the air

flow is blocked or restricted, or if the inlet air is too warm, an over-temperature condition can occur

within the router. Under extreme conditions, the environmental monitoring system powers off the

router to protect the components.

See “Rack-Mounting and Air Flow Clearance Guidelines” for details on air flow clearance requirements

for installation in an enclosed 4-post rack.

Rack-Mounting and Air Flow Clearance Guidelines

The router can be mounted in most 2-post, 4-post, or telco-style 19-inch equipment racks that comply

with the Electronics Industries Association (EIA) standard for equipment racks (EIA-310-D). The rack

must have at least two posts with mounting flanges to mount the router chassis. The distance between

the center lines of the mounting holes on the two mounting posts must be 18.31 inches ± 0.06 inch

(46.50 cm ± 0.15 cm).

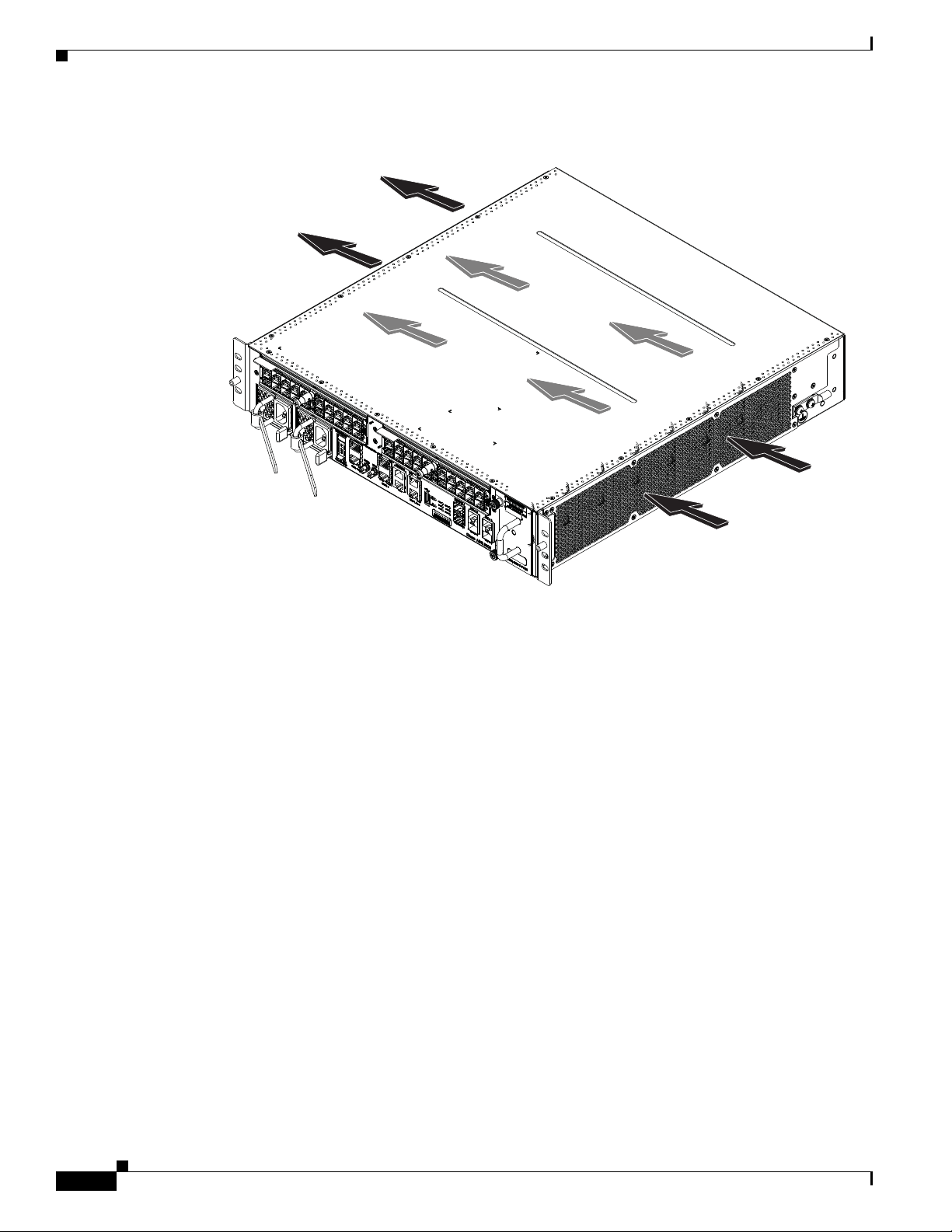

Figure 1-6 shows examples of typical 2-post, 4-post, and telco-type equipment racks.

Room air

331882

1-8

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

OL-26701-02

Page 19

Chapter 1 Preparing for Installation

243453

a b c

Figure 1-6 Equipment Rack Types

Site Requirement Guidelines

Telco 2-Post Rack

Note The mounting brackets on the Cisco ASR 9001 Router chassis have a pair of holes at the top and bottom

a Telco-style rack b Free-standing, 4-post open

rack with two mounting

posts in the front, two

mounting posts in the back

c Free-standing enclosed rack

with perforated sides and

two mounting posts in the

front

or along each side

Item a in Figure 1-6 shows a telco-style rack. The telco-style rack is an open frame consisting of two

posts tied together by a cross-bar at the top and a floor-stand at the bottom.

This type of rack is usually secured to the floor, and sometimes to an overhead structure or wall for

additional stability. The router chassis can be installed in the telco-style rack only in a front-mounted

position.

In the front-mounted position, you secure the chassis rack-mounting brackets directly to the rack posts

(see Figure 1-7 as an example of a Cisco ASR 9001 Router rack mounting). Two rear mounting brackets

are provided for mounting the Cisco ASR 9001 Router in a 2-post rack.

of each bracket; the remaining openings in the brackets are slots. If the Cisco ASR 9001 Router is to be

mounted in a 2-post 19-inch rack, you must first use the holes to locate and position the brackets on the

rack. Insert screws through the bracket holes into the rack before inserting screws through the bracket

slots.

OL-26701-02

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

1-9

Page 20

Site Requirement Guidelines

331928

Figure 1-7 Cisco ASR 9001 Router Mounted in a 2-Post Rack

Chapter 1 Preparing for Installation

Open 4-Post Rack

Item b in Figure 1-6 shows a free-standing, 4-post open rack with two mounting posts in the front and

two mounting posts in the back or along the side. The mounting posts in this type of rack are often

adjustable so that you can position the rack-mounted unit within the depth of the rack rather than

flush-mount it with the front of the rack.

Two rear mounting brackets are provided for mounting the Cisco ASR 9001 Router in a 4-post rack.

Enclosed Rack with Perforated Sides

Item c in Figure 1-6 shows a free-standing 4-post enclosed rack with perforated sides and two mounting

posts in the front.

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

1-10

OL-26701-02

Page 21

Chapter 1 Preparing for Installation

Caution Do not install the Cisco ASR 9001 Router in any type of fully-enclosed rack that does not have the

required perforated sides or doors; the router requires an unobstructed flow of cooling air to maintain

acceptable operating temperatures for its internal components. Installing the router in any type of

fully-enclosed rack without proper perforation could disrupt the air flow, trap heat next to the chassis,

and cause an over-temperature condition inside the router.

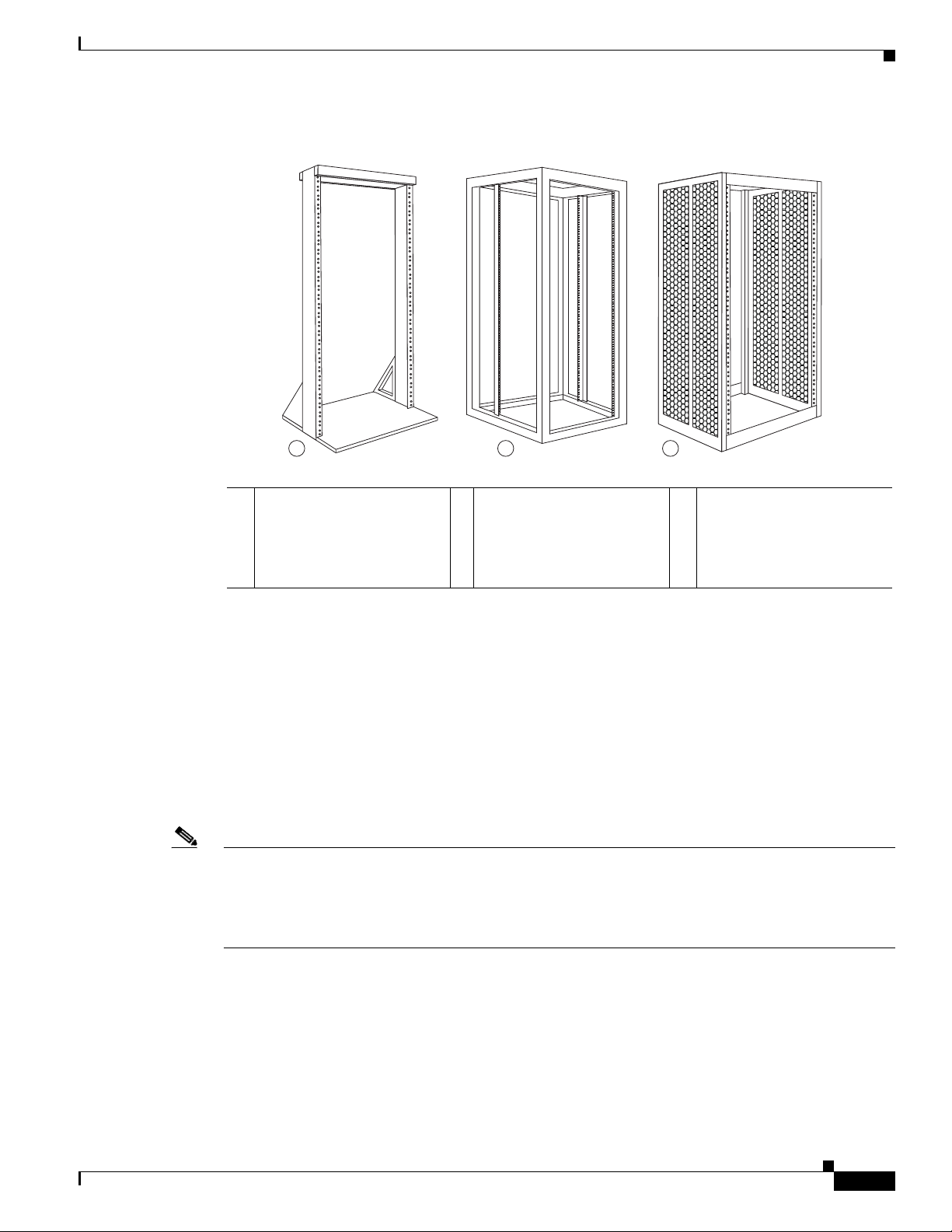

Air Flow Guidelines for Enclosed Rack Installation

To install a Cisco ASR 9001 Router in a 4-post enclosed cabinet, the front and rear doors of the cabinet

must be removed or be perforated with a minimum of 65% open area (70% for ETSI 800mm racks).

If you are mounting the chassis in a 4-post enclosed cabinet, ensure that you have these clearances aound

the chassis:

• Rear: Minimum of 3.15 inches (8.00 cm) of clearance

• Sides: Minimum of 6 inches (15.24 cm) of clearance on each side of the chassis.

Figure 1-8 shows the side and rear chassis air flow clearance requirements for mounting the

Cisco ASR 9001 Router in a 4-post enclosed rack.

Site Requirement Guidelines

OL-26701-02

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

1-11

Page 22

Site Requirement Guidelines

Figure 1-8 ASR 9001 Clearance Requirements for an Enclosed 4-Post Rack Installation

Chapter 1 Preparing for Installation

Rear of chassis

6 Inches

152.0 mm

Temperature and Humidity Guidelines

Front of chassis

3.25 Inches

82.55 mm

6 Inches

152.0 mm

331929

The operating and nonoperating environmental site requirements are listed in Tab l e A-2. The router

normally operates within the ranges listed in Tab le A-3; however, if a temperature measurement is

approaching a minimum or maximum parameter, it indicates a potential problem. Maintain normal

operation by anticipating and correcting environmental anomalies before they approach critical values,

by properly planning and preparing your site before you install the router.

Power Connection Guidelines

You can configure the router with either an AC-input or DC-input power subsystem, so the site power

source requirements differ depending on the power subsystem in your router. Ensure all power

connection wiring conforms to the rules and regulations in the National Electrical Code (NEC) as well

as local codes.

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

1-12

OL-26701-02

Page 23

Chapter 1 Preparing for Installation

Caution Each Cisco ASR 9001 Router is powered by only one type of input: AC or DC. A hybrid (AC+DC)

power configuration is not supported.

Caution Proper grounding is necessary to avoid damage from lightning and power surges. See the “NEBS

Supplemental Unit Bonding and Grounding Guidelines” section on page 1-20 for grounding

requirements.

AC Powered Routers

AC power modules operate in the input range of 100 VAC to 240 VAC, 50 to 60 Hz and require a

minimum service of:

• 15 A for operation in North America and Japan

• 10 A for international operation

• 13 A for operation in the UK

Site Requirement Guidelines

Each of the AC power inputs requires a separate dedicated branch circuit. For a list of the nominal and

acceptable value ranges for source AC power, see Tab le A-5.

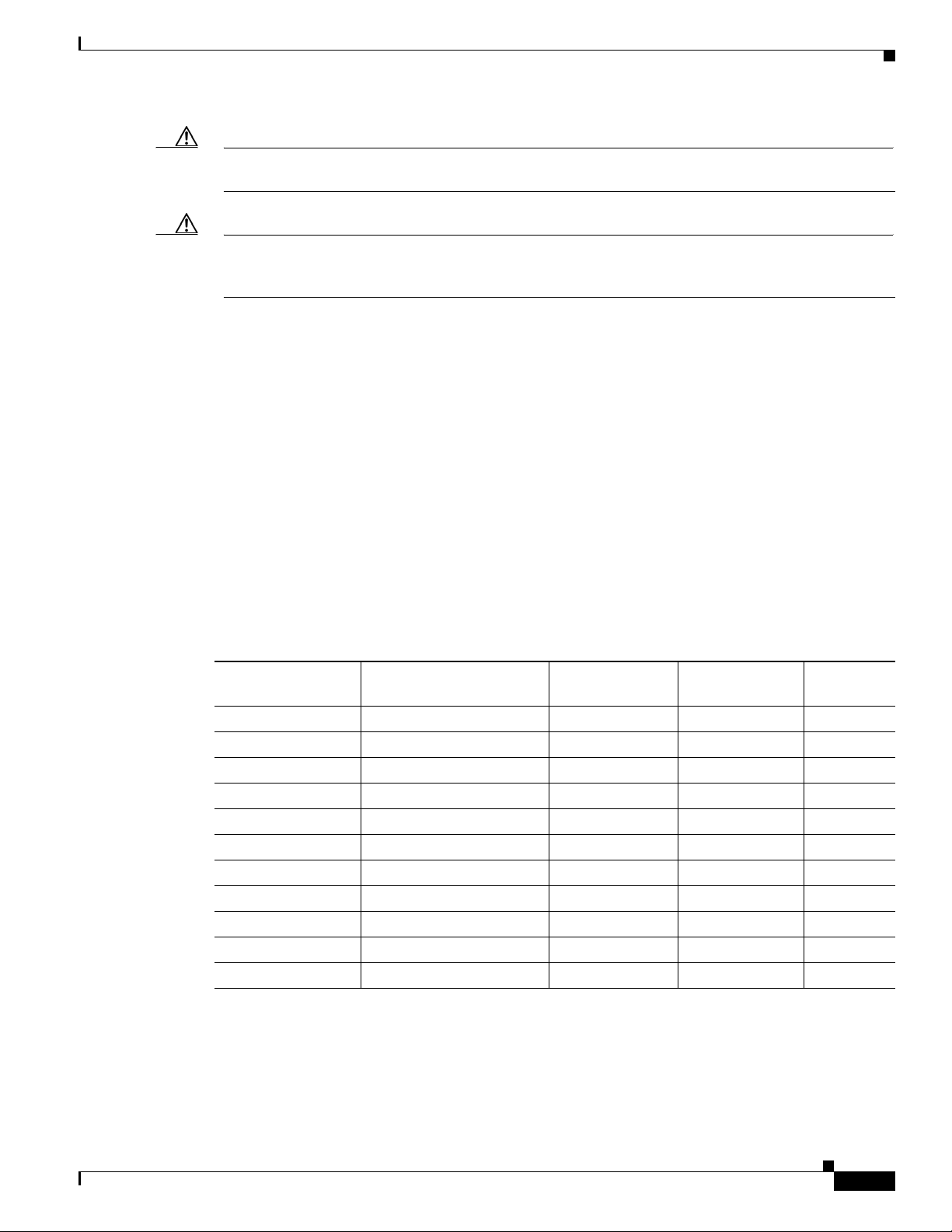

Table 1-1 lists the AC-input power cord options, specifications, and Cisco product numbers for the

AC-input power supply modules. Tab le 1-1 also references power cord illustrations. For more

information on Cisco product numbers (PIDs) and their detailed description of power cords, refer to

Dynamic Configuration Tool.

Table 1-1 AC-Input Power Cord Options for ASR 9001 Router

Locale Part Number Length

Power Cord

Rating

Reference

Illustration

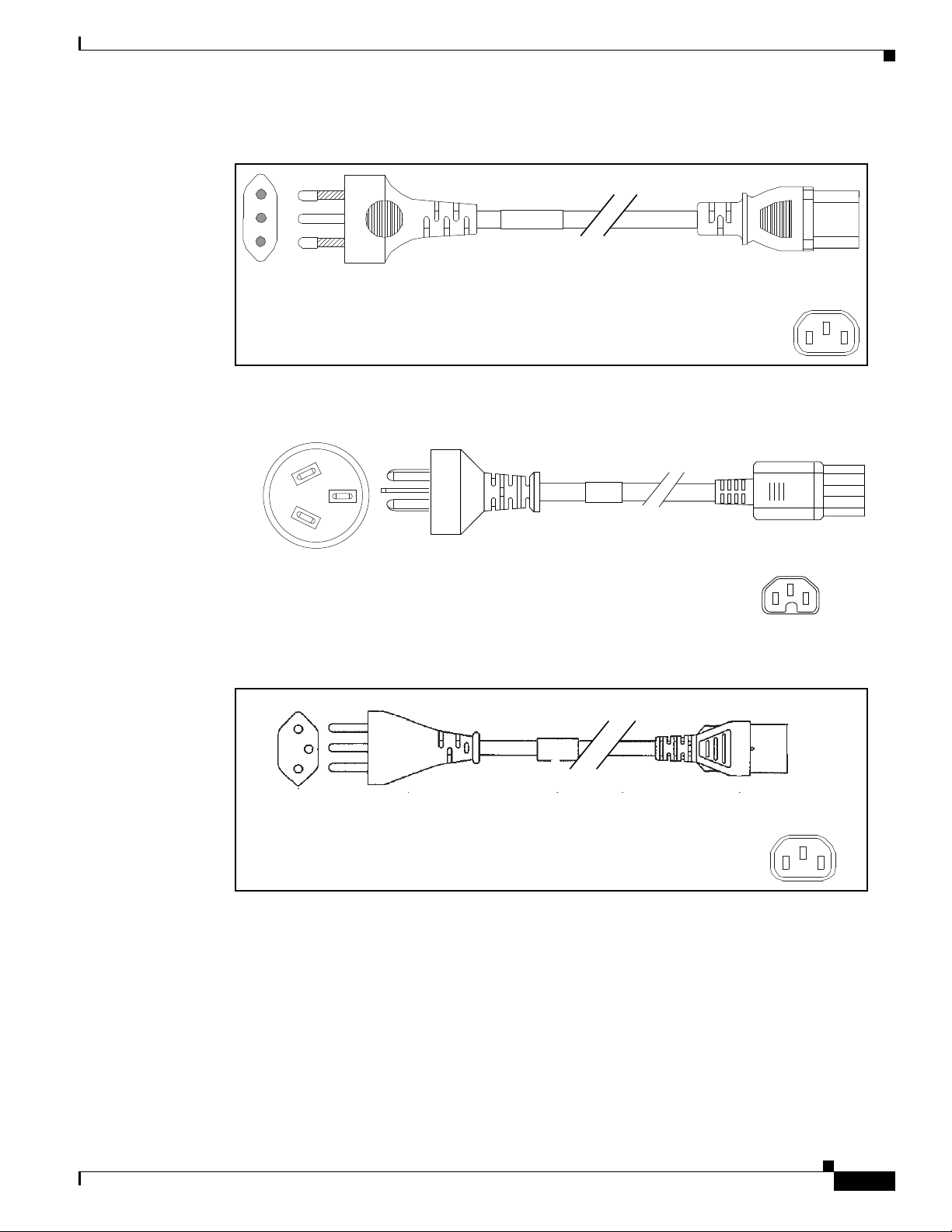

USA CAB-AC 8.2 feet (2.5 m) 15 A, 250 V Figure 1-9

Japan CAB-L620P-C13-JPN 8.2 feet (2.5 m) 15 A, 250 V Figure 1-10

Australia CAB-ACA 8.2 feet (2.5 m) 10 A, 250 V Figure 1-11

Italy CAB-ACI 8.2 feet (2.5 m) 10 A, 250 V Figure 1-12

Argentina CAB-ACR 8.2 feet (2.5 m) 10 A, 250 V Figure 1-13

Switzerland CAB-ACS 8.2 feet (2.5 m) 10 A, 250 V Figure 1-14

UK CAB-ACU 8.2 feet (2.5 m) 13 A, 250 V Figure 1-15

China CAB-ACC 8.2 feet (2.5 m) 10 A, 250 V Figure 1-16

South Africa/India CAB-ACSA 8.2 feet (2.5 m) 10 A, 250 V Figure 1-17

Europe CAB-9K10A-EU 8.2 feet (2.5 m) 10 A, 250 V Figure 1-18

Israel SFS-250V-10A-IS 8.2 feet (2.5 m) 10 A, 250 V Figure 1-19

AC Power Cord Illustrations

This section contains the AC power cord illustrations, as described in Table 1-1. Note that an AC power

cord may be used with several power supplies.

OL-26701-02

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

1-13

Page 24

Site Requirement Guidelines

Cordset rating: 15 A, 250 V

Length: 8 ft 2 in. (2.5 m)

Connector: WS 002

Plug: NEMA L6-20P

332009

Figure 1-9 AC Power Cord CAB-AC

Figure 1-10 AC Power Cord CAB-L620P-C13-JPN

Plug: EL701B

Chapter 1 Preparing for Installation

Cordset rating: 15 A, 250 V

Length: 8 ft 2 in. (2.5 m)

Connector: IEC 60320 C13

332012

1-14

Figure 1-11 AC Power Cord CAB-ACA

Cordset rating: 10 A, 250 V

Length: 8 ft 2 in. (2.5 m)

Plug: NEMA L6-20

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

Connector: IEC 60320 C13

332013

OL-26701-02

Page 25

Chapter 1 Preparing for Installation

Cordset rating: 10 A, 250 V

Length: 8 ft 2 in. (2.5 m)

Connector: IEC 60320 C13

Plug: CEI 23-16

332008

Cordset rating: 10 A, 250 V

Length: 8 ft 2 in. (2.5 m)

Connector: WS 002

Plug: NEMA L6-20P

332011

Figure 1-12 AC Power Cord CAB-ACI

Figure 1-13 AC Power Cord CAB-ACR

Site Requirement Guidelines

Plug: EL 219 (IRAM 2073)

Figure 1-14 AC Power Cord CAB-ACS

Cordset rating: 10 A/250 V

Length: 8 ft 2 in. (2.5 m)

Connector: IEC 60320 C13

285303

OL-26701-02

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

1-15

Page 26

Site Requirement Guidelines

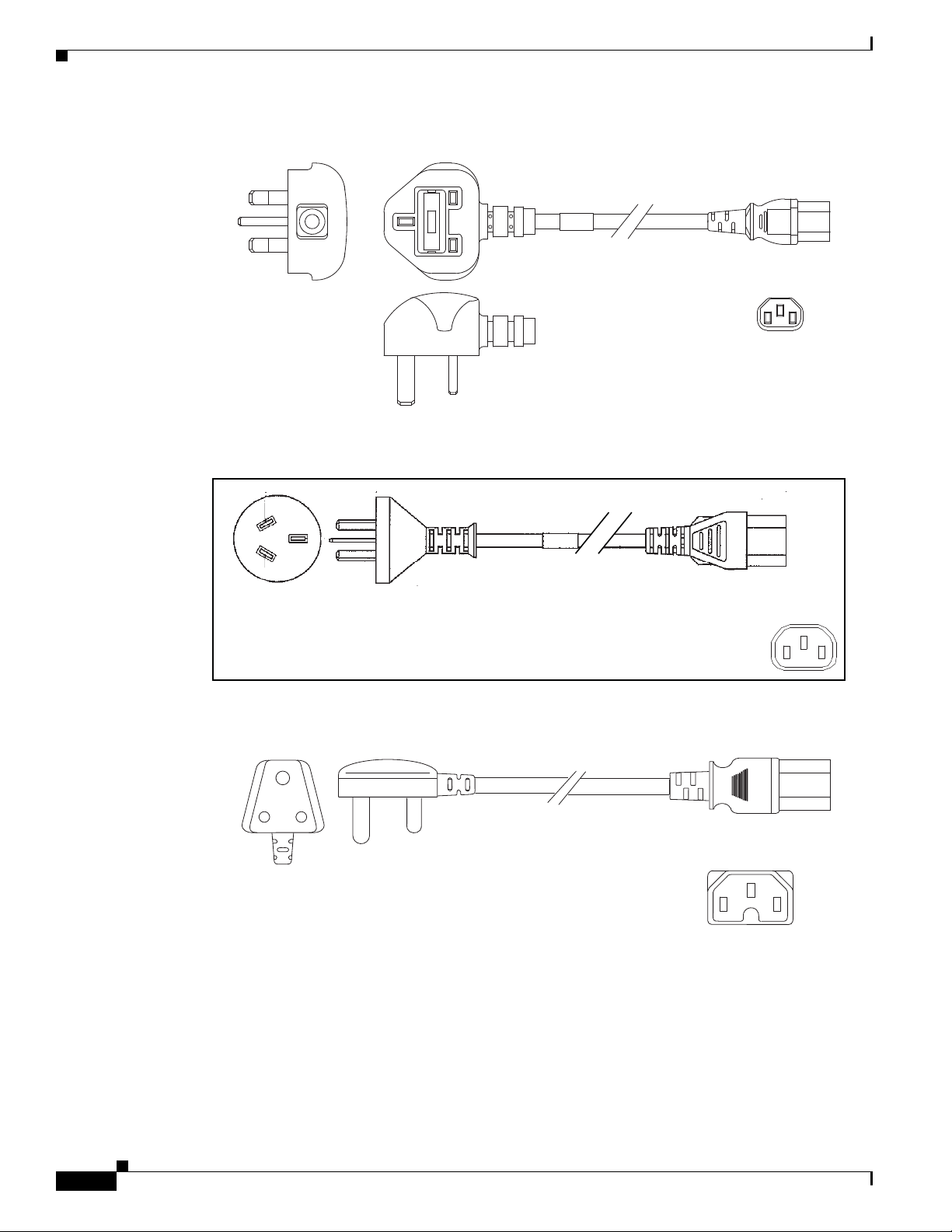

Cordset rating: 10 A, 250 V

Length: 8 ft 2 in. (2.5 m)

Connector: WS 002

Plug: NEMA L6-20P

332010

285302

Connector: IEC 60320 C15

Plug: EL 208

(SABS 164-1)

Cordset rating: 10 A, 250 V

Length: 8 ft 2 in. (2.5 m)

Figure 1-15 AC Power Cord CAB-ACU

Figure 1-16 AC Power Cord CAB-ACC

Chapter 1 Preparing for Installation

Cordset rating: 13 A, 250 V

Length: 8 ft 2 in. (2.5 m)

Plug: BSI 1363

Connector: IEC 60320 C13

285301

1-16

Figure 1-17 AC Power Cord CAB-ACSA

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

OL-26701-02

Page 27

Chapter 1 Preparing for Installation

Connector: WS 002

Cordset rating: 10A, 250 V

Length: 8 ft 2 in. (2.5 m)

Plug:

M2511

Figure 1-18 AC Power Cord CAB-9K10A-EU

Figure 1-19 AC Power Cord SFS-250V-10A-IS

Site Requirement Guidelines

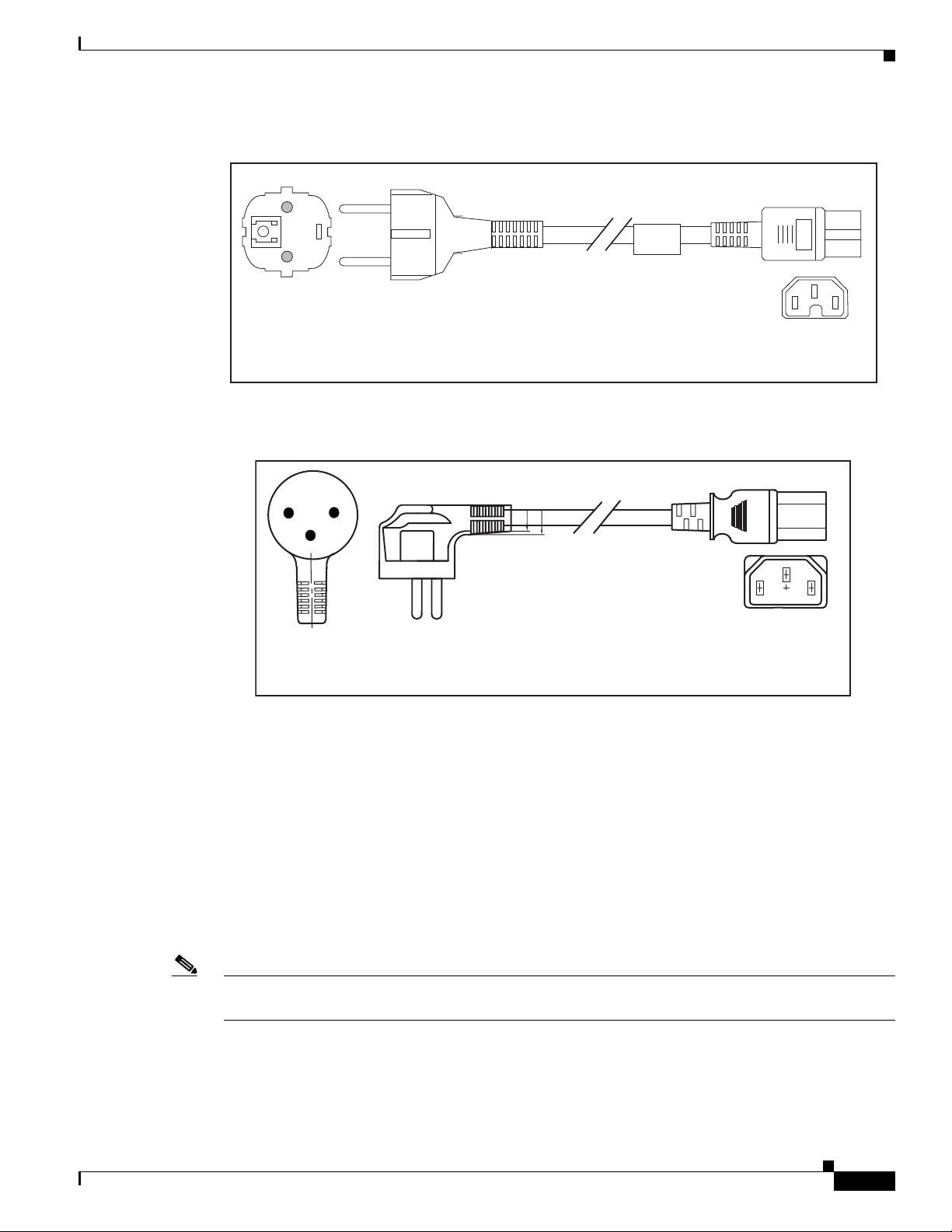

DC Powered Router

Connections to DC power modules are rated at 20 A maximum. The system accepts a nominal input voltage

of –48 VDC with an operational tolerance range of –48 VDC to –60 VDC. One dedicated, commensurately

rated DC power source is required for each power module connection.

Power connections to the each DC power module requires two cables: one source cable and one return

cable.

For DC power cables, we recommend that you use 20-A-rated, high-strand-count copper wire cables.

The length of the cables depends on your router location from the source power.

Note DC power cables are not available from Cisco, but they are available from external commercial cable

vendors.

Cordset rating: 10 A, 250V

Length: 8 ft 2 in. (2.5 m)

Connector: WS 002

Plug:

EL 212

(SI-32)

332624

OL-26701-02

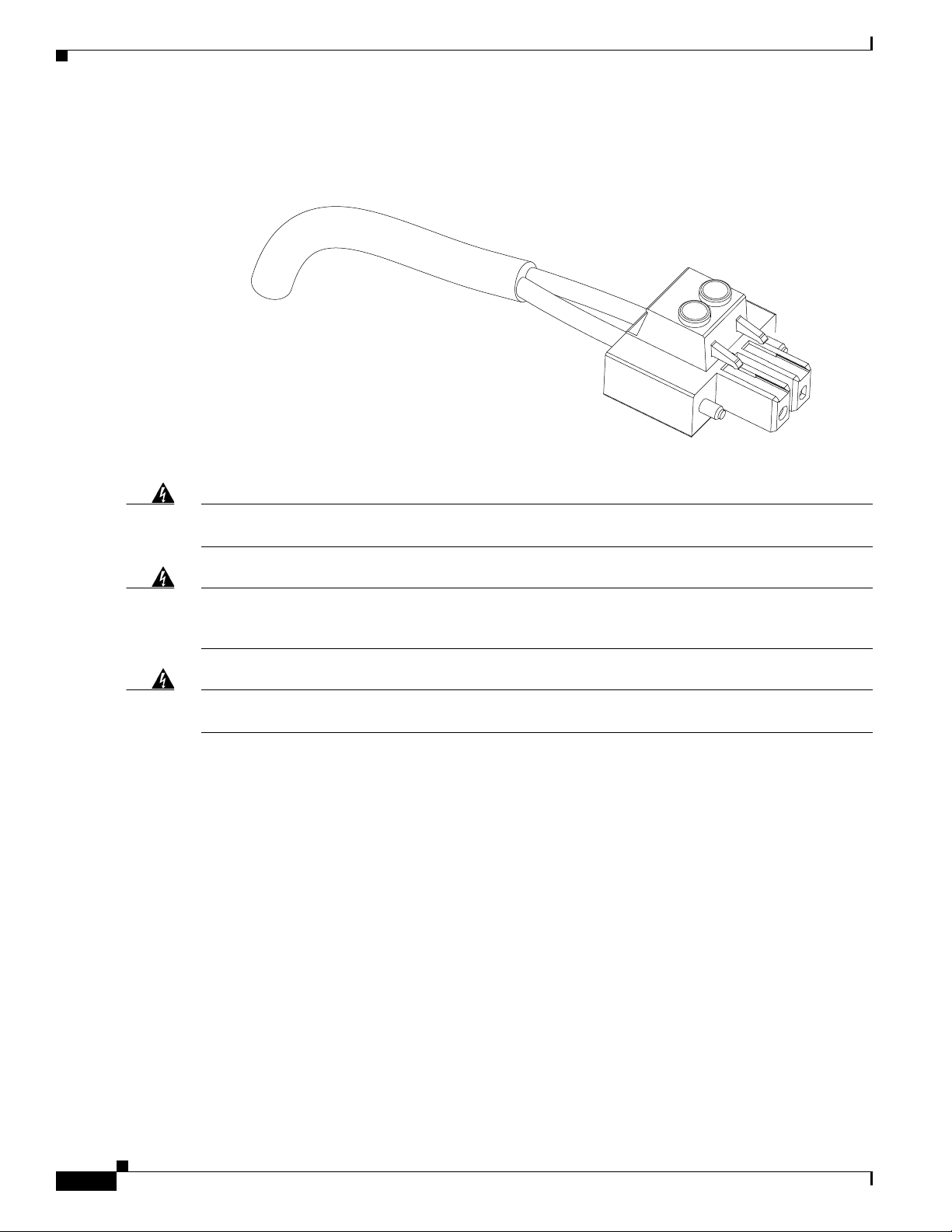

You must terminate DC power cables using terminal blocks. The terminal blocks are supplied along with

the DC power supply modules from Cisco. The terminal block part number is PC 5/2-STF-7.62 BD:+,from Phoenix contact.

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

1-17

Page 28

Site Requirement Guidelines

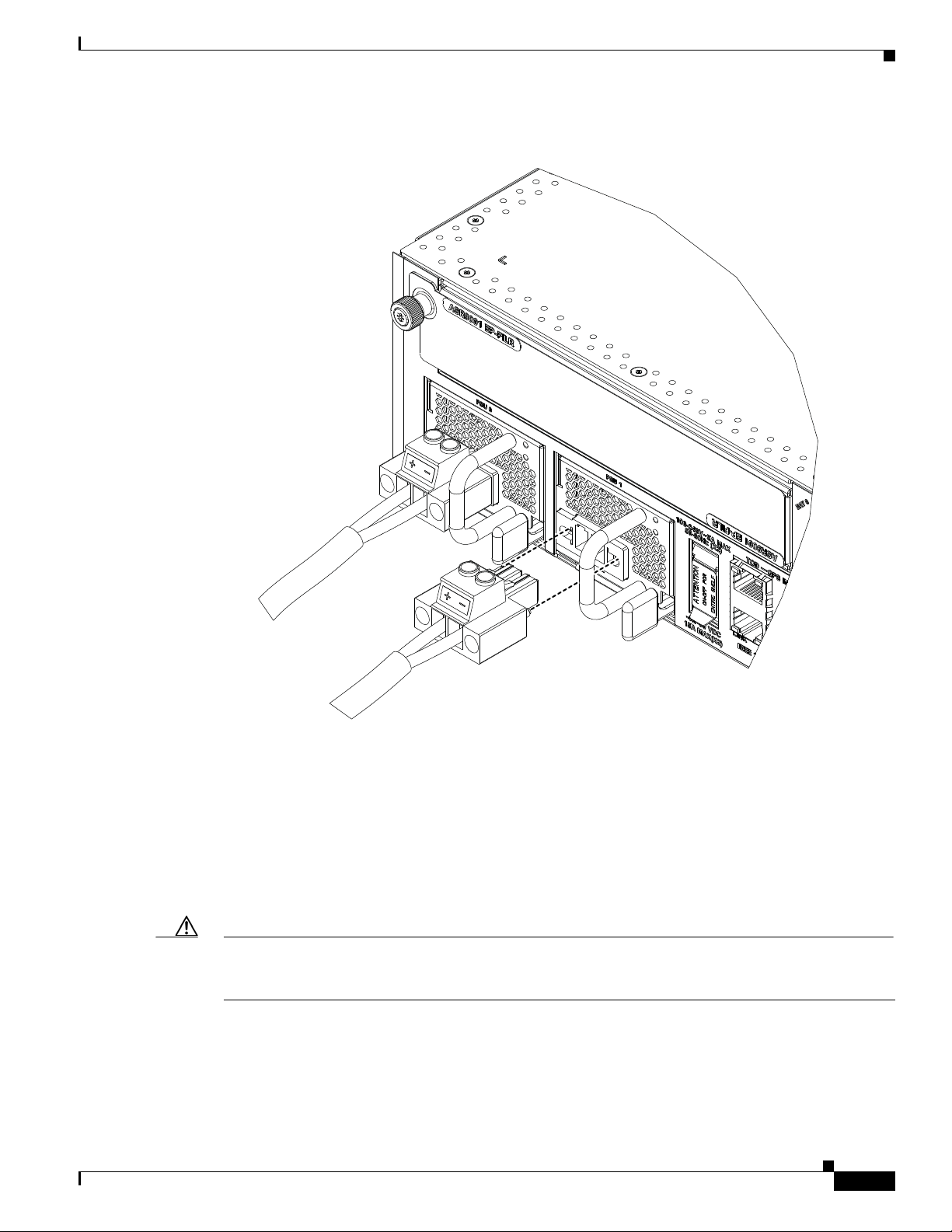

Figure 1-20 shows the type of terminal block required for DC-input cable connections.

Figure 1-20 DC Power Cable Terminal Block

Figure 1-21 shows DC power source cable connections for single DC power module.

Chapter 1 Preparing for Installation

Warning

Warning

Warning

To avoid shock hazard, be sure to apply shrink wrap tubing around the wire entry area of the terminal

block.

Hazardous voltage or energy may be present on power terminals. Always replace cover when

terminals are not in service. Be sure uninsulated conductors are not accessible when cover is in

place.

Statement 1086

Only trained and qualified personnel should be allowed to install, replace, or service this equipment.

Statement 1030

1-18

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

OL-26701-02

Page 29

Chapter 1 Preparing for Installation

Figure 1-21 DC Power Source Cabling Scheme for a Single DC Power Module

Site Requirement Guidelines

331933

The color coding of the source DC power cable leads depends on the color coding of the site DC power

source. Because there is no color code standard for source DC wiring, be sure that power source cables

are connected to the power modules using the proper positive (+) and negative (–) polarity:

• In some cases, the source DC cable leads might have a positive (+) or a negative (–) label. This is a

relatively safe indication of the polarity, but you must also verify the polarity by measuring the

voltage between the DC cable leads. Be sure that the positive (+) and negative (–) cable leads match

the positive (+) and negative (–) labels on the power module when making the measurement.

• Green (or green and yellow) cable typically indicates that it is a ground cable.

Caution DC power modules contain reverse voltage protection circuitry to prevent damage to the power module

if it detects a reverse polarity condition. No damage should occur from reverse polarity, but you should

correct a reverse polarity condition immediately.

For a list of the nominal and acceptable value ranges for source DC power, see Table A-4 on page A-3.

OL-26701-02

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

1-19

Page 30

Chapter 1 Preparing for Installation

Site Requirement Guidelines

NEBS Supplemental Unit Bonding and Grounding Guidelines

Although the router chassis requires a safety earth ground connection as part of the power cabling to

power modules, you must permanently connect the central office ground system or interior equipment

grounding system to the supplemental bonding and grounding connection on the side of the router

chassis to meet network equipment building system (NEBS) requirements as well as safety compliance

requirements. These grounding points are referred to as the NEBS bonding and grounding points.

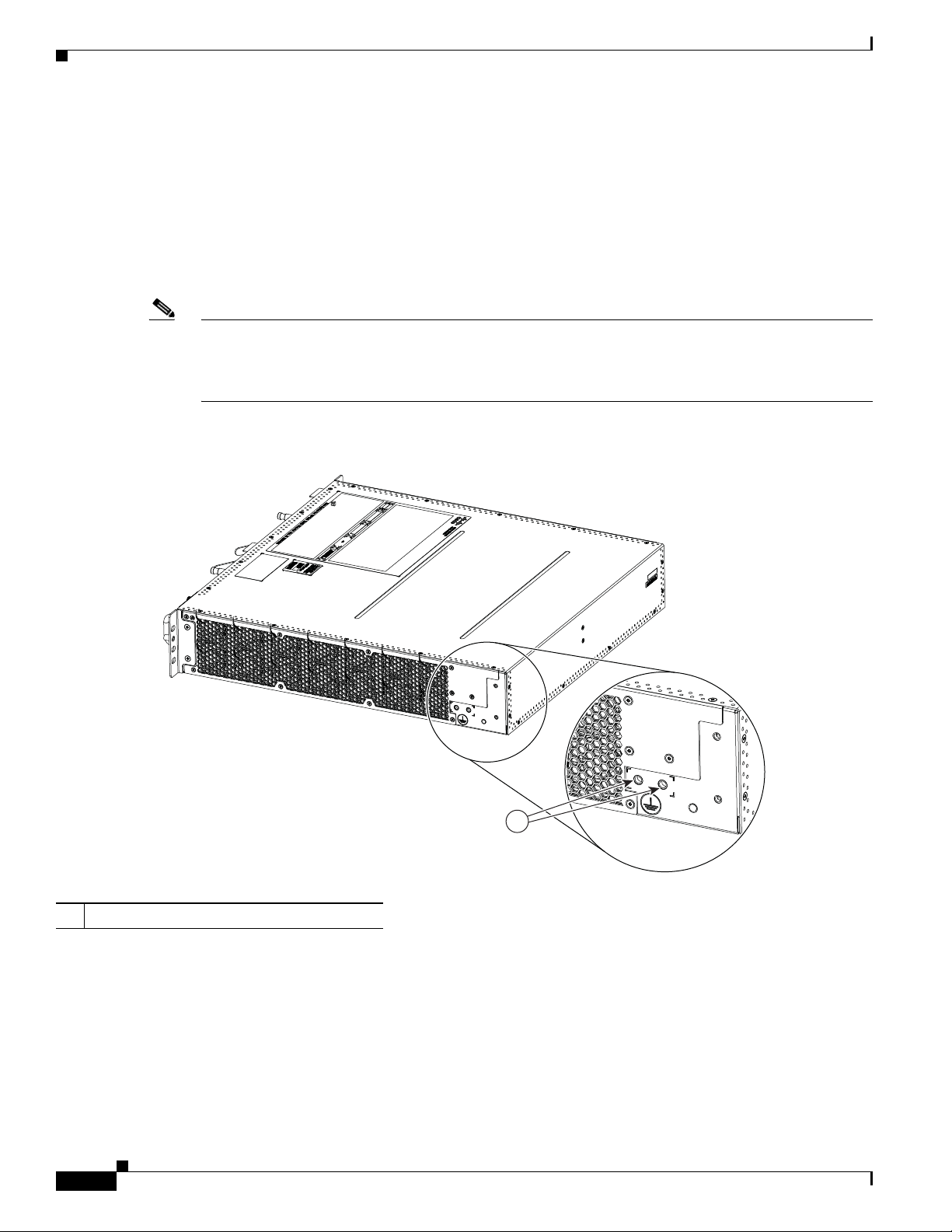

Figure 1-22 shows the NEBS grounding locations for the Cisco ASR 9001 Router.

Note These bonding and grounding connections satisfy the Telcordia NEBS requirements for supplemental

bonding and grounding connections. If you are not installing the router in a NEBS environment, you can

choose to bypass these guidelines and rely on the safety earth ground connections to the AC or DC power

modules.

Figure 1-22 NEBS Bonding and Grounding Points on the Cisco ASR 9001 Router

1 NEBS grounding point on side of chassis

To ensure a satisfactory supplemental ground connection to the router, use these parts:

• One grounding lug, which has two M6 bolt holes with 0.625- to 0.75-inch (15.86- to 19.05-mm)

spacing between them, and a wire receptacle large enough to accept a six AWG or larger, multistrand

copper wire. For four AWG cable, use Panduit part number LCD4-14AF-L; for six AWG, use

Panduit part number LCD6-14AF-L.

• Two 10-32 round-head screws and two locking washers (nickel-plated brass is ideal).

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

1-20

1

332017

OL-26701-02

Page 31

Chapter 1 Preparing for Installation

1 3 4 5 6 687

332426

92

Cisco ASR 9001 Router Port Connection Guidelines

• One grounding wire. Although we recommend at least six AWG multistrand copper wire, the wire

diameter and length depend on your router location and site environment.

Note These parts are not available from Cisco, but they are available from external commercial vendors.

Cisco ASR 9001 Router Port Connection Guidelines

This section contains detailed cabling and signal information for all interface and port connections to the

RP. It also provides information for Ethernet routing and equipment.

Caution Ports labeled Ethernet, SYNC, CONSOLE, and AUX are safety extra-low voltage (SELV) circuits. SELV

circuits should only be connected to other SELV circuits.

Note In Cisco ASR 9001-S Router, two 10 GE fixed SFP+ ports (SFP+2 and SFP+3) are disabled by default,

and can be enabled by a license upgrade.

Figure 1-23 shows all the port connections on the front panel of the Cisco ASR 9001 Router.

Figure 1-23 Cisco ASR 9001 Router Front Panel Ports

1 Service LAN and ToD ports 6 External USB port

2 10MHz and 1PPS indicators 7 Eight discrete LED indicators

3 SYNC (BITS/J.211) ports 8 CLUSTER ports

4 CONSOLE and AUX ports 9 Fixed SFP+ ports

5 Management LAN ports

OL-26701-02

Table 1-2 lists the Cisco ASR 9001 Router front panel ports description.

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

1-21

Page 32

Cisco ASR 9001 Router Port Connection Guidelines

Port Name Connector Type Description

TOD Port RJ45 Time of Day Input/Output Port along with 1PPS

Service LAN Port (IEEE

1588)

10MHz Connector SMB 10MHz Input for GPS Synchronization. This signal

1PPS Connector SMB 1PPS Input for GPS Synchronization. This signal can

SYNC Ports (SYNC

0/SYNC 1)

CONSOLE Port RJ45 Local Craft Terminal for connecting the box with PC.

AUX Port RJ45 Local Craft Terminal with modem handshaking

Management LAN Ports

(MGT LAN 0/1)

USB Port USB TYPE-A

Chapter 1 Preparing for Installation

Table 1-2 Cisco ASR 9001 Router Front Panel Ports Description

Signal. Signal type is RS422.

RJ45 A 10/100Mbps Ethernet Port for IEEE1588 Grand

Master Connection through CAT5 cable. Signal type is

MLT3.

can provide 10MHz output as well from Cisco ASR

9001 Router. Signal type is sinusoidal.

provide output as well from Cisco ASR 9001 Router.

Signal type is square wave.

RJ45 Used as BITS or DTI (one at a time) Input/Output Port

based on the configuration used. CAT5 ethernet cable

can be used for DTI. In DTI mode link resembles an

Ethernet (802.3) 10BaseT link. Signal type depends

on the mode such as B8ZS for T1, HDB3 for E1,

Manchester Coded Data for DTI, Sinusoidal for

6.3128 Out.

Used to command the CPU and to collect CPU log.

This console port operates at default 115200 baud rate

however other standard baud rates can be configured

through confreg setting at Rommon. Signal type is

RS232.

signals. This port operates at default 115200 baud rate

however other standard baud rates can be configured

through confreg setting at Rommon. The hardware has

design option (through IMIO FPGA) to connect the

AUX port with RP CPU or LC CPU. This can be used

as console port for the LC CPU. Signal type is RS232.

RJ45 Management Port for TFTP boot. It is a tri speed

(10/100/1000 Mbps) Ethernet port with auto

negotiation enabled. Connection through CAT5E

cable. Signal type is 8B/10B for 1G, MLT3 for 100

Mbps, Manchester coded for 10 Mbps.

For connecting USB Device. This port can be used to

Receptacle

upload installable modules, temporary binaries,

scripts etc through USB disk. Also, it can be used to

transfer router log from the internal eUSB to the

external memory stick. Signal type is NRZI.

1-22

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

OL-26701-02

Page 33

Chapter 1 Preparing for Installation

Cisco ASR 9001 Router Port Connection Guidelines

Table 1-2 Cisco ASR 9001 Router Front Panel Ports Description

Port Name Connector Type Description

CLUSTER Ports (0/1) SFP For Cascading two Cisco ASR 9001 Router systems.

The pinout and signal level is as per the SFP standard.

This supports copper/optical SFP modules.

Fixed SFP+ Ports (0/1/2/3) SFP+ Fixed ports include 4X10G SFP+ ports and supports

20X1G, 4X10G and 2X10G ports through Ethernet

Plugs.

Console Port and Auxiliary Port Connection Guidelines

The RP has two EIA/TIA-232 (formerly RS232) serial RJ-45 connection ports (see Figure 1-23):

• Console port—RJ-45 interface for connecting a data terminal device to the router, which you need

to perform the initial configuration of the router.

• Auxiliary port—RJ-45 interface for connecting a modem.

Note The console and auxiliary ports are asynchronous serial ports. Ensure that devices connected to

Console Port Signals

The RP console port is an RJ-45 interface for connecting a terminal to the router. The console port does

not support modem control or hardware flow control and requires a straight-through RJ-45 cable.

Before connecting a terminal to the console port, check the terminal setting for the data transmission

rate, in bits per second (bps). The terminal transmission rate setting must match the default rate of the

RP console port, which is 115200 bps. Set the terminal to these operational values: 115200 bps, 8 data

bits, no parity, 1 stop bits (115200 8N1).

Table 1-3 lists the signals used on the RP console port.

Table 1-3 RP Console Port Signals

Console Port Pin Signal Input/Output Description

these ports are capable of asynchronous transmission.

1 RTS Output Request to Send

2 — — (Not connected)

3 TxD Output Transmit data

4 GND — Signal ground

5 GND — Signal ground

6 RxD Input Receive data

7 — — (Not connected)

8 CTS Input Clear to Send

OL-26701-02

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

1-23

Page 34

Cisco ASR 9001 Router Port Connection Guidelines

Auxiliary Port Signals

The RP Auxiliary (AUX) port is a RJ-45 interface for connecting a modem or other data communication

equipment (DCE) device (such as another router) to the RP. The AUX port supports hardware flow

control and modem control.

Table 1-4 lists the signals used on the Auxiliary port.

Table 1-4 RP AUX Port Signals

AUX Port Pin Signal Input/Output Description

1 RTS Output Request to send

2 DTR Output Data terminal ready

3 TxD Output Transmit data

4 GND — Signal ground

5 GND — Signal ground

6 RxD Input Receive data

7 DSR Input Data set ready

8 CTS Input Clear to send

Chapter 1 Preparing for Installation

Management LAN Ports Connection Guidelines

The RP has two RJ45 media-dependent interface (MDI) Ethernet management LAN ports: MGT LAN 0

and MGT LAN 1 (see Figure 1-23).

These ports are used for IEEE 802.3 10BASE-T (10 Mbps), IEEE 802.3u 100BASE-TX (100 Mbps), or

1000BASE-T (1000 Mbps) Ethernet connections.

The transmission speed of the management LAN ports is not user-configurable. The transmission speed

is set through an auto-sensing scheme on the RP; the speed is determined by the network to which that

the Ethernet port is connected. The combined total input rate of both MGT LAN 0 and MGT LAN 1 is

about 12 Mbps.

Management port characteristics are:

• Maximum transmission unit (MTU) is fixed at 1514 and cannot be configured.

• Flow control is disabled and cannot be configured.

• Input unicast packets with an unknown destination address are filtered and dropped.

• Autonegotiation of port speed (10/100/1000) and duplex (full/half) is supported. Autonegotiation

cannot be disabled.

Table 1-5 lists the signals used on the Management LAN ports.

Table 1-5 RP Management LAN Port Signals

MGT LAN Port Pin 10Base-T, 100Base-TX Signal 1000Base-T Signal

1 Transmit+ BI_DA+

2 Transmit– BI_DA–

3 Receive+ BI_DB+

1-24

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

OL-26701-02

Page 35

Chapter 1 Preparing for Installation

332427

Table 1-5 RP Management LAN Port Signals (continued)

MGT LAN Port Pin 10Base-T, 100Base-TX Signal 1000Base-T Signal

4— BI_DC+

5— BI_DC–

6 Receive– BI_DB–

7— BI_DD+

8— BI_DD–

Management LAN Port LED Indicators

The Management LAN connectors have integral LED indicators (see Figure 1-24). When lit, these LEDs

indicate:

• Green (LINK)—Connection is alive.

• Amber (ACT)—Connection is active.

Cisco ASR 9001 Router Port Connection Guidelines

Figure 1-24 RP Management LAN Port LED Indicators

Management LAN RJ-45 Cabling

When connecting the RJ-45 port to a hub, repeater, or switch, use the straight-through cable pinout

shown in Figure 1-25.

Note To comply with the intra-building lightning surge requirements of Telecordia GR-1089-CORE, Issue II,

Revision 01, February 1999, you must use a shielded cable when connecting the management LAN ports

on the RP card. The shielded cable is terminated by shielded connectors on both ends, with the cable

shield material tied to both connectors.

OL-26701-02

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

1-25

Page 36

Cisco ASR 9001 Router Port Connection Guidelines

MDI-X wiringMDI wiring

1 TxD+

2 TxD–

3 RxD+

6 RxD–

1 RxD+

2 RxD–

3 TxD+

6 TxD–

H11007

PRP

1 TxD+

2 TxD–

3 RxD+

6 RxD–

1 TxD+

2 TxD–

3 RxD+

6 RxD–

75431

PRP

Figure 1-25 Straight-Through Cable Pinout to a Hub, Repeater or Switch

When connecting to a router, use the crossover cable pinout shown in Figure 1-26.

Figure 1-26 Crossover Cable Pinout Between RP

Chapter 1 Preparing for Installation

Sync Ports Connection Guidelines

The SYNC 0 and SYNC 1 ports are timing synchronization ports. They can be configured as Building

Integrated Timing Supply (BITS) ports or J.211 ports (see Figure 1-23).

Note Both ports must be configured to be in the same mode. It is not possible to use external BITS and J.211

sources at the same time.

When configured as BITS ports, they provide connections for an external synchronization source. Such

connections are for establishing precise frequency control at multiple network nodes, if required for your

application. The RP card contains a synchronous equipment timing source (SETS) that can receive a

frequency reference from an external BITS timing interface or from a clock signal recovered from any

incoming Gigabit Ethernet or 10-Gigabit Ethernet interface. The RP SETS circuit filters the received

timing signal and uses it to drive outgoing Ethernet interfaces.

The BITS input can be T1, E1 or 64K 4/. The BITS output can be T1, E1 or 6.312M 5/.

When configured as J.211 ports, they can be used as Universal Timing Interface (UTI) ports to

synchronize timing across multiple routers by connecting to an external timing source.

SYNC Port LED Indicators

The SYNC port connector has integral LED indicators (see Figure 1-27). When lit, these LEDs indicate:

• in BITS mode:

–

Green — Connection is alive.

–

Amber — A fault has occurred.

1-26

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

OL-26701-02

Page 37

Chapter 1 Preparing for Installation

332428

12345678

• in J.211 mode:

–

–

Figure 1-27 SYNC Port Connector

Cisco ASR 9001 Router Port Connection Guidelines

Green — DTI is operating in normal mode.

Amber — DTI is operating in fast mode.

Table 1-6 BITS/J.211 Connector Pinout

Pin Signal Note

1 DTI_P/BITS_RX_P Bi-direction for DTI, T1/E1/64K Input

2 DTI_P/BITS_RX_N Bi-direction for DTI, T1/E1/64K Input

3— —

4 BITS_TX_P* T1/E1/6.321M Output

5 BITS_TX_N* T1/E1/6.321M Output

6— —

7— —

8 — —

RP External USB Port

The Cisco ASR 9001 Router RP card has an external USB Type A slot accessible on the front panel. The

front panel USB slot accepts widely available USB thumb drives. The only restriction on devices you

can plug into the front panel external USB slot is that they need to be USB 2.0 devices. These devices

can be formatted with FAT16, FAT32 or QNX4 file systems.

The mount point /disk1: is reserved for the front panel USB device.

OL-26701-02

Note Do not connect a USB hub device to the front panel USB port.

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

1-27

Page 38

Cisco ASR 9001 Router Port Connection Guidelines

Chapter 1 Preparing for Installation

1-28

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

OL-26701-02

Page 39

CHAP T ER

Unpacking and Installing the Chassis

This chapter contains the procedures for installing the router in a rack. The installation is presented in

these sections:

• Pre-Installation Considerations and Requirements, page 2-1

• Installation Overview, page 2-1

• Unpacking the Cisco ASR 9001 Router, page 2-2

• Rack-Mounting the Router Chassis, page 2-4

• Supplemental Bonding and Grounding Connections, page 2-7

Pre-Installation Considerations and Requirements

Before you perform any procedures in this chapter, review these sections:

• Safety Guidelines, page 1-2

• Site Requirement Guidelines, page 1-5

2

In particular, observe the guidelines for preventing electrostatic discharge (ESD) damage described in

the “Preventing Electrostatic Discharge Damage” section on page 1-4. Use Figure 1-3 as a reference in

locating and using the ESD sockets on the front of the router chassis.

For additional safety and compliance information, see the Regulatory Compliance and Safety

Information for the Cisco ASR 9000 Series Aggregation Services Routers document that accompanied

your router.

Warning

This router is not designed to be installed as a shelf-mounted or a free-standing router. The router

must be installed in a rack that is secured to the building structure. You must install the router in

either a telco-style frame or a 4-post equipment rack.

Installation Overview

A fully-equipped router with two power modules can weigh as much as 37.91 pounds (17.2 kg); an

empty chassis weighs 24.69 pounds (11.2 kg). The chassis is designed to be lifted by two persons.

OL-26701-02

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

2-1

Page 40

Unpacking the Cisco ASR 9001 Router

Required Tools and Equipment

Before you begin the rack-mount installation, you must read and understand the information in the

“Rack-Mounting and Air Flow Clearance Guidelines” section on page 1-8 and have these tools and

equipment:

• ESD-preventive wrist strap

• Number 1 and number 2 Phillips screwdrivers

• 1/4-inch (6.35-mm) and 3/16-inch (4.5-mm) flat-blade screwdrivers

• Tape measure

• Level (optional)

• Minimum of 10 slotted binderhead screws (usually provided with the rack) to secure the chassis to

the mounting flanges (also called rails) in the rack. Three screws should be installed on each side of

the chassis.

Unpacking the Cisco ASR 9001 Router

Chapter 2 Unpacking and Installing the Chassis

Follow these unpacking steps to unpack the Cisco ASR 9001 Router from its shipping container (see

Figure 2-1).

Step 1 Cut the packaging tape and open the cardboard shipping container.

Step 2 Remove the accessory box.

Step 3 Remove the packaging material (see Figure 2-1).

a. Remove the foam packaging material from the top of the router.

b. Remove cardboard caps from both sides.

c. Remove the router from the bag.

Step 4 Save the packaging materials in case the router needs repackaging or shipping.

2-2

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

OL-26701-02

Page 41

Chapter 2 Unpacking and Installing the Chassis

Figure 2-1 Unpacking the Cisco ASR 9001 Router from the Shipping Container

3

Unpacking the Cisco ASR 9001 Router

2

4

5

5

6

1

1 Cardboard packaging container 4 Bag containing router

2 Accessory box 5 Cardboard caps

3 Foam packaging material- top caps 6 Foam packaging material - bottom cap

332150

Positioning the Router

Use a safety hand truck to move the router to the location where it is being installed in a rack.

OL-26701-02

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

2-3

Page 42

Rack-Mounting the Router Chassis

Rack-Mounting the Router Chassis

The router chassis is installed in a front-mounted position, as shown in Figure 1-7 for the

Cisco ASR 9001 Router chassis.

In a front-mounted position, the chassis rack-mounting flanges are secured directly to the rack posts.

The PID of the rack mounting kit for Cisco ASR 9001 Router and Cisco ASR 9001-S Router is

ASR-9001-2P-KIT=.

Verifying Rack Dimensions

Before you install the chassis, measure the space between the vertical mounting flanges (rails) on your

equipment rack to verify that the rack conforms to the measurements shown in Figure 2-2.

Step 1 Mark and measure the distance between two holes on the left and right mounting rails.

The distance should measure 18.31 inches ± 0.06 inches (46.5 cm ± 0.15 cm).

Chapter 2 Unpacking and Installing the Chassis

Note Measure the distance for pairs of holes near the bottom, middle and top of the equipment rack

to ensure that the rack posts are parallel.

Step 2 Measure the space between the inner edges of the left front and right front mounting flanges on the

equipment rack.

The space must be at least 17.7 inches (45 cm) to accommodate the chassis, which is approximately

17.45 in. (44.32 cm) wide, and fits between the mounting posts on the rack.

Figure 2-2 Verifying Equipment Rack Dimensions

Mounting flanges

Minimum usable

aperture 17.7 inches

(45.0 cm)

Hole centerline

to hole centerline

18.31 inches ± 0.06 inches

(46.5 cm ± 0.15 cm)

247170

Installing the Chassis in a 2-Post Rack

Two people must lift the router chassis using the handles on the sides. To accommodate racks with

different hole patterns in their mounting flanges, the chassis rack-mounting flanges have three oblong

screw holes on each side.

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

2-4

OL-26701-02

Page 43

Chapter 2 Unpacking and Installing the Chassis

332151

1

1

This section describes how to install the chassis in a 2-post telco-style rack.

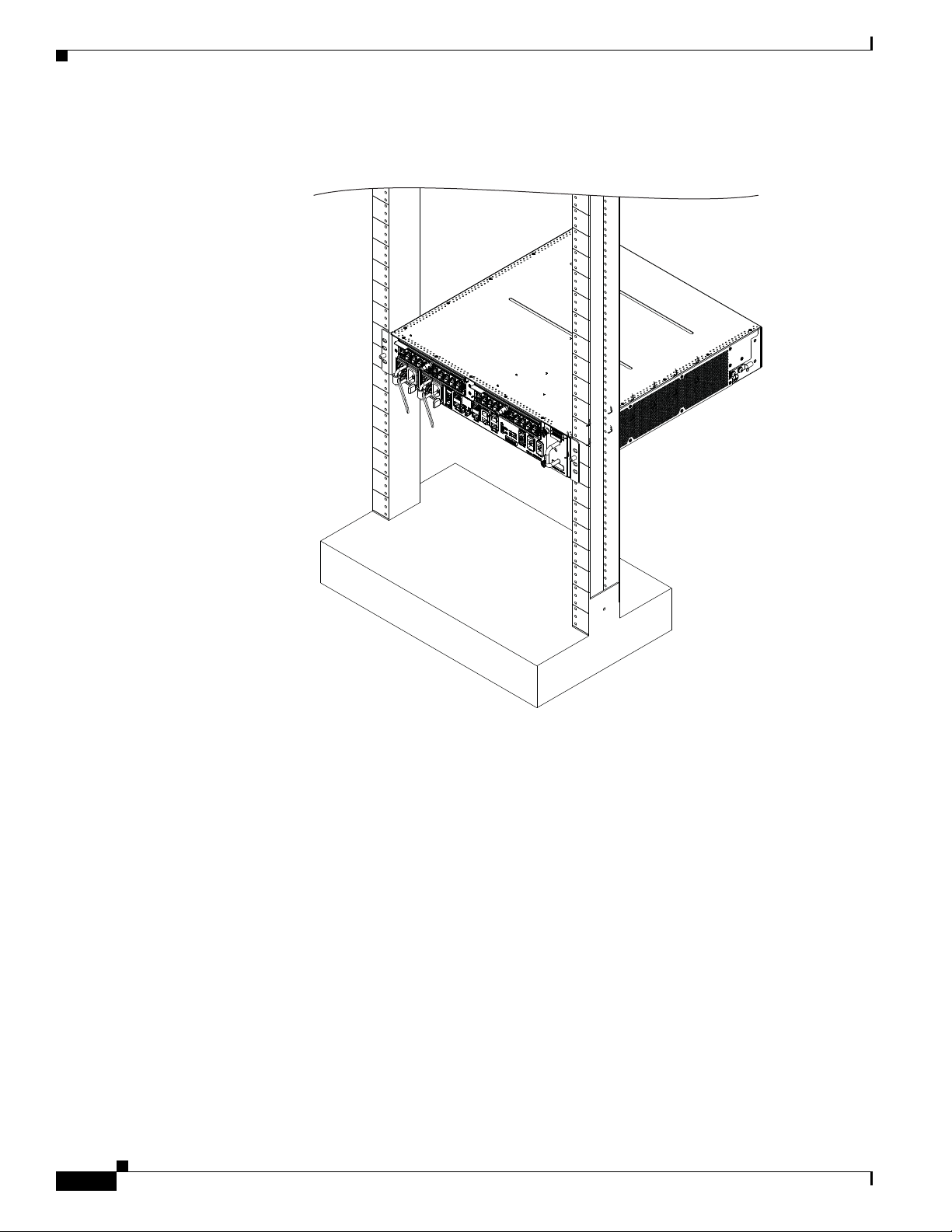

Figure 2-3 shows the orientation of the Cisco ASR 9001 Router chassis to the rack posts and

components used in the installation.

Figure 2-3 Installing the Cisco ASR 9001 Router Chassis in a 2-Post Rack

Rack-Mounting the Router Chassis

1 Three screws on each side (minimum two) to attach the router chassis to the

rack

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

OL-26701-02

2-5

Page 44

Rack-Mounting the Router Chassis

Use this procedure to install the chassis in the equipment rack:

Step 1 With two people’s aid, lift the chassis into the rack holding top and bottom of the chassis (see

Figure 2-4).

Figure 2-4 Correct Lifting Positions

Chapter 2 Unpacking and Installing the Chassis

Caution Do not grasp air inlet or exhaust when lifting the router chassis.

Step 2 Position the chassis until the rack-mounting flanges are flush against the mounting rails on the rack.

Step 3 Hold the chassis in position against the mounting rails while the second person finger-tightens a screw

to the rack rails on each side of the chassis.

Step 4 Finger-tighten two more screws to the rack rails on each side of the chassis. Space the screws evenly

between the top and bottom of the chassis.

Step 5 Attach the side brackets to the left and right side of the chassis by finger-tightening two screws through

each bracket into the chassis.

Step 6 Attach the side bracket front flanges to the rack by finger-tightening two screws through each bracket

flange into the front mounting rails of the rack.

Step 7 Fully tighten both the screws on the chassis mounting flanges on each side to secure the chassis to the

rack rails.

Step 8 Fully tighten the two screws on each side bracket to secure the brackets to the chassis.

Step 9 Fully tighten the two screws on each side bracket flange to secure the brackets to the rack rails.

2-6

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

OL-26701-02

Page 45

Chapter 2 Unpacking and Installing the Chassis

Installing the Chassis in a 4-post Rack

To mount the Cisco ASR 9001 Router chassis in a 4-post open rack, two side brackets must be attached

to the chassis and the rear posts (see Figure 2-5).

Figure 2-5 Installing the Cisco ASR 9001 Router Chassis in a 4-Post Rack

Supplemental Bonding and Grounding Connections

Supplemental Bonding and Grounding Connections

Before you power on the router for the first time, we recommend that you connect the central office

ground system or Network Equipment Building System (NEBS) to the threaded supplemental bonding

and grounding receptacles on the router. For more information on supplemental bonding and grounding

cable requirements, see the “NEBS Supplemental Unit Bonding and Grounding Guidelines” section on

page 1-20.

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

OL-26701-02

332153

2-7

Page 46

Supplemental Bonding and Grounding Connections

Use this procedure to attach a grounding cable lug to the router:

Step 1 Insert the grounding screws through the locking washers, and into the threaded grounding receptacle on

the Cisco ASR 9001 Router chassis as shown in Figure 2-6.

Step 2 Tighten the grounding screws securely to the receptacles.

Step 3 Prepare the other end of the grounding wire, and connect it to the appropriate grounding point at your

site to ensure an adequate earth ground.

Figure 2-6 NEBS Bonding and Grounding for the Cisco ASR 9001 Router

Chapter 2 Unpacking and Installing the Chassis

2-8

332154

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

OL-26701-02

Page 47

CHAP T ER

3

Installing Modules and Cables in the Chassis

This chapter contains the procedures for installing cards and modules into the chassis, after it has been

installed in a rack. It also describes how to connect cables to the ports and RP.

The installation is presented in these sections:

• Fixed 4x10-Gigabit Ethernet Ports, page 3-1

• Modular Port Adapters, page 3-2

• Installing and Removing Modular Port Adapters, page 3-5

• Installing and Removing SFP Modules, page 3-11

• Installing and Removing XFP Modules, page 3-11

• Cable Management, page 3-12

• Connecting Route Processor Cables, page 3-16

• Connecting Power to the Router, page 3-18

• Powering on the Router, page 3-21

Fixed 4x10-Gigabit Ethernet Ports

The Cisco ASR 9001 Router has four integrated 10 GE small form-factor pluggable (SFP+) ports that

operate at a rate of 10 Gbps.

Each fixed SFP+ port has an adjacent Link LED visible on the front panel. The Link LED indicates the

status of the associated SFP+ port.

Note In Cisco ASR 9001-S Router, two 10 GE fixed SFP+ ports (SFP+2 and SFP+3) are disabled by default,

and can be enabled by a license upgrade.

Figure 3-1 shows the front panel of the chassis and connectors of the fixed 4x10-Gigabit Ethernet ports.

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

OL-26701-02

3-1

Page 48

Modular Port Adapters

1 3 4 5 6 687

92

Figure 3-1 .4x10-Gigabit Ethernet SFP+ Ports

9 Fixed 10 GE SFP+ ports

Modular Port Adapters

Chapter 3 Installing Modules and Cables in the Chassis

The Cisco ASR 9001 Router has two ethernet pluggable ports that support these Modular Port Adapters

(MPAs):

• 20-Port GE MPA

• 4-Port 10-GE MPA

• 2-Port 10-GE MPA

Note In Cisco ASR 9001-S Router, one ethernet pluggable port (MPA1) is disabled by default, and can be

enabled by license upgrade.

20-Port Gigabit Ethernet Modular Port Adapter

The 20-Port Gigabit Ethernet modular port adapter provides 10 double-stacked SFP (20 total) cages that

support either fiber-optic or copper Gigabit Ethernet transceivers.

Each SFP cage on the Gigabit Ethernet modular port adapter has an adjacent Link LED visible on the

front panel. The Link LED indicates the status of the associated SFP port, as described in Table 4-4.

Refer to Figure 3-2 for an example of the 20-Port Gigabit Ethernet Modular Port Adapter.

3-2

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

OL-26701-02

Page 49

Chapter 3 Installing Modules and Cables in the Chassis

Figure 3-2 20-Port Gigabit Ethernet Modular Port Adapter

Modular Port Adapters

330784

Table 3-1 describes the 20-Port Gigabit Ethernet modular port adapter LEDs.

Table 3-1 20-Port Gigabit Ethernet Modular Port Adapter LEDs

LED Label Color State Meaning

A/L Off Off Port is not enabled.

Green On Port is enabled and the link is up. The MPA A/L LED will

blink green when there is traffic activity.

Amber On Port is enabled and the link is down.

STATUS Off Off Modular port adapter power is off.

Green On Modular port adapter is ready and operational.

Amber On Modular port adapter power is on and good, and modular

port adapter is being configured.

4-Port 10 Gigabit Ethernet Modular Port Adapter

The 4-Port 10 Gigabit Ethernet modular port adapter provides four cages for XFP Ethernet optical

interface modules that operate at a rate of 10 Gbps. The four XFP modules can be 10-Gigabit Ethernet

multimode or single mode connections.

Each XFP cage on the 4-Port 10 Gigabit Ethernet modular port adapter has an adjacent Link LED visible

on the front panel. The Link LED indicates the status of the associated XFP port, as described in

Table 4-4.

Refer to Figure 3-3 for an example of the 4-Port 10 Gigabit Ethernet modular port adapter.

OL-26701-02

Cisco ASR 9001 and Cisco ASR 9001-S Routers Hardware Installation Guide

3-3

Page 50

Modular Port Adapters

330784