Cisco AS5400HPX, 5428 - SN Router, SN5420-FCM-GEM - SN 5420 Router, AS5400 Installation Manual

Page 1

Cisco AS5400 Universal Gateway

Chassis Installation Guide

Corporate Headquarters

Cisco Systems, Inc.

170 West Tasman Drive

San Jose, CA 95134-1706

USA

http://www.cisco.com

Tel: 408 526-4000

800 553-NETS (6387)

Fax: 408 526-4100

Text Part Number: OL-2847-02 0A

Page 2

THE SPECIFICATIONS AND INFORMATION REGARDING THE PRODUCTS IN THIS MANUAL ARE SUBJECT TO CHANGE WITHOUT NOTICE. ALL

STATEMENTS, INFORMATION, AND RECOMMENDATIONS IN THIS MANUAL ARE BELIEVED TO BE ACCURATE BUT ARE PRESENTED WITHOUT

WARRANTY OF ANY KIND, EXPRESS OR IMPLIED. USERS MUST TAKE FULL RESPONSIBILITY FOR THEIR APPLICATION OF ANY PRODUCTS.

THE SOFTWARE LICENSE AND LIMITED WARRANTY FOR THE ACCOMPANYING PRODUCT ARE SET FORTH IN THE INFORMATION PACKET THAT

SHIPPED WITH THE PRODUCT AND ARE INCORPORATED HEREIN BY THIS REFERENCE. IF YOU ARE UNABLE TO LOCATE THE SOFTWARE LICENSE

OR LIMITED WARRANTY, CONTACT YOUR CISCO REPRESENTATIVE FOR A COPY.

The following information is for FCC compliance of Class A devices: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio-frequency energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference, in which case users will be required

to correct the interference at their own expense.

The following information is for FCC compliance of Class B devices: The equipment described in this manual generates and may radiate radio-frequency energy. If it is not

installed in accordance with Cisco’s installation instructions, it may cause interference with radio and television reception. This equipment has been tested and found to

comply with the limits for a Class B digital device in accordance with the specifications in part 15 of the FCC rules. These specifications are designed to provide reasonable

protection against such interference in a residential installation. However, there is no guarantee that interference will not occur in a particular installation.

Modifying the equipment without Cisco’s written authorization may result in the equipment no longer complying with FCC requirements for Class A or Class B digital

devices. In that event, your right to use the equipment may be limited by FCC regulations, and you may be required to correct any interference to radio or television

communications at your own expense.

You can determine whether your equipment is causing interference by turning it off. If the interference stops, it was probably caused by the Cisco equipment or one of its

peripheral devices. If the equipment causes interference to radio or television reception, try to correct the interference by using one or more of the following measures:

• Turn the television or radio antenna until the interference stops.

• Move the equipment to one side or the other of the television or radio.

• Move the equipment farther away from the television or radio.

• Plug the equipment into an outlet that is on a different circuit from the television or radio. (That is, make certain the equipment and the television or radio are on circuits

controlled by different circuit breakers or fuses.)

Modifications to this product not authorized by Cisco Systems, Inc. could void the FCC approval and negate your authority to operate the product.

The Cisco implementation of TCP header compression is an adaptation of a program developed by the University of California, Berkeley (UCB) as part of UCB’s public

domain version of the UNIX operating system. All rights reserved. Copyright © 1981, Regents of the University of California.

NOTWITHSTANDING ANY OTHER WARRANTY HEREIN, ALL DOCUMENT FILES AND SOFTWARE OF THESE SUPPLIERS ARE PROVIDED “AS IS” WITH

ALL FAULTS. CISCO AND THE ABOVE-NAMED SUPPLIERS DISCLAIM ALL WARRANTIES, EXPRESSED OR

LIMITATION, THOSE OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT OR ARISING FROM A COURSE OF

DEALING, USAGE, OR TRADE PRACTICE.

IN NO EVENT SHALL CISCO OR ITS SUPPLIERS BE LIABLE FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL, OR INCIDENTAL DAMAGES, INCLUDING,

WITHOUT LIMITATION, LOST PROFITS OR LOSS OR DAMAGE TO DATA ARISING OUT OF THE USE OR INABILITY TO USE THIS MANUAL, EVEN IF CISCO

OR ITS SUPPLIERS HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

IMPLIED, INCLUDING, WITHOUT

CCSP, the Cisco Square Bridge logo, Follow Me Browsing, and StackWise are trademarks of Cisco Systems, Inc.; Changing the Way We Work, Live, Play, and Learn, and iQuick

Study are service marks of Cisco Systems, Inc.; and Access Registrar, Aironet, ASIST, BPX, Catalyst, CCDA, CCDP, CCIE, CCIP, CCNA, CCNP, Cisco, the Cisco Certified

Internetwork Expert logo, Cisco IOS, Cisco Press, Cisco Systems, Cisco Systems Capital, the Cisco Systems logo, Cisco Unity, Empowering the Internet Generation,

Enterprise/Solver, EtherChannel, EtherFast, EtherSwitch, Fast Step, FormShare, GigaDrive, GigaStack, HomeLink, Internet Quotient, IOS, IP/TV, iQ Expertise, the iQ logo, iQ

Net Readiness Scorecard, LightStream, Linksys, MeetingPlace, MGX, the Networkers logo, Networking Academy, Network Registrar, Pa cke t, PIX, Post-Routing, Pre-Routing,

ProConnect, RateMUX, ScriptShare, SlideCast, SMARTnet, StrataView Plus, SwitchProbe, TeleRouter, The Fastest Way to Increase Your Internet Quotient, TransPath, and VCO

are registered trademarks of Cisco Systems, Inc. and/or its affiliates in the United States and certain other countries.

All other trademarks mentioned in this document or Website are the property of their respective owners. The use of the word partner does not imply a partnership relationship

between Cisco and any other company. (0501R)

Cisco AS5400 Universal Gateway Chassis Installation Guide

Copyright © 2000-2004, Cisco Systems, Inc.

All rights reserved.

Page 3

Preface vii

Document Organization vii

Document Conventions viii

Obtaining Documentation x

World Wide Web x

Documentation CD-ROM xi

Ordering Documentation xi

Documentation Feedback xi

Obtaining Technical Assistance xi

Cisco.com xii

Technical Assistance Center xii

Related Documentation xiii

CONTENTS

CHAPTER

CHAPTER

New Hardware Features xiii

1 Overview 1-1

Chassis Components 1-1

Dial Feature Cards (DFCs) 1-2

Power Supply 1-3

Specifications 1-3

2 Preparing to Install 2-1

Safety Recommendations 2-1

Maintaining Safety with Electricity 2-2

Preventing Electrostatic Discharge Damage 2-3

Required Tools and Equipment 2-3

Preparing to Connect to a Network 2-3

Network Specifications 2-4

Ethernet Connections 2-5

Console and Auxiliary Ports 2-5

2T Serial Ports 2-6

Alarm Port 2-6

BITS Port 2-6

Power Supply Considerations 2-7

OL-2847-02 0A

Cisco AS5400 Universal Gateway Chassis Installation Guide

iii

Page 4

Contents

CHAPTER

CHAPTER

3 Installing the Cisco AS5400 and Cisco AS5400HPX Universal Gateways 3-1

Setting Up the Chassis 3-2

Setting the Chassis on a Desktop 3-2

Rack-Mounting the Chassis 3-3

Connecting to the Network 3-5

Connecting to an Ethernet Network 3-6

Connecting to a WAN 3-7

Connecting the Console Terminal and Modem 3-9

Connecting to the Console Port 3-9

Connecting a Modem to the Auxiliary Port 3-10

Connecting to the BITS Port 3-11

Connecting to the Alarm Port 3-12

Supplying Power 3-13

Connecting the AC Power Cord 3-14

Wiring the DC Power Supply 3-14

Where to Go Next 3-16

4 Troubleshooting 4-1

APPENDIX

LEDs 4-1

Mixing WAN DFCs 4-3

Environment Monitoring 4-4

Displaying Environment Status 4-5

Using the Bantam Jacks for Test Port Functionality 4-7

Monitoring Mode for the T1, E1, and T3 DFCs 4-7

Drop and Insert Mode for the CT3 DFC 4-7

Troubleshooting Network Interfaces 4-8

Flash Memory Installation 4-8

Cisco AS5400HPX Images 4-8

Getting Help 4-9

A Replacing Memory Components A-1

Removing the Chassis Cover A-1

Required Tools A-1

Safety Recommendations A-1

Chassis Cover Removal A-2

Replacing the Boot ROM A-5

Required Tools and Equipment A-5

Cisco AS5400 Universal Gateway Chassis Installation Guide

iv

OL-2847-02 0A

Page 5

Boot ROM Replacement A-5

Replacing SDRAM DIMMs A-7

Required Tools and Equipment A-7

SDRAM DIMM Replacement A-7

Replacing Flash Memory SIMMs A-9

Flash Memory Identification A-10

Required Tools and Equipment A-11

Flash Memory SIMM Replacement A-11

Replacing the Chassis Cover A-13

Required Tools and Equipment A-13

Chassis Cover Replacement A-13

Contents

APPENDIX

APPENDIX

B Replacing the Power Supply B-1

Safety Recommendations B-1

Required Tools and Equipment B-2

Removing the Chassis Cover B-3

Removing the Power Supply B-5

Installing the Power Supply B-11

Replacing the Chassis Cover B-18

Verifying the Status of the Redundant Power Supply B-21

Configuring the Power Supply Alarm B-21

Verify Alarm Configuration B-22

C Cabling Specifications C-1

Console and Auxiliary Port Cables and Pinouts C-1

Identifying a Rollover Cable C-2

Console Port Cables and Pinouts C-2

Auxiliary Port Signals and Pinouts C-4

Ethernet Port Pinouts C-4

BITS Cable and Port Pinouts C-5

Alarm Port Pinouts C-5

Bantam Jack Port Pinouts C-6

INDEX

OL-2847-02 0A

Cisco AS5400 Universal Gateway Chassis Installation Guide

v

Page 6

Contents

Cisco AS5400 Universal Gateway Chassis Installation Guide

vi

OL-2847-02 0A

Page 7

Preface

This preface describes the objectives and organization of this document and explains how to find

additional information on related products and services. This chapter contains the following sections:

• Document Organization, page vii

• Document Conventions, page viii

• Obtaining Documentation, page x

• Obtaining Technical Assistance, page xi

• Related Documentation, page xiii

• New Hardware Features, page xiii

Document Organization

This publication is designed for people who have some experience installing networking equipment such

as routers, hubs, servers, and switches. The person installing the server should be familiar with electronic

circuitry and wiring practices and have experience as an electronic or electromechanical technician.

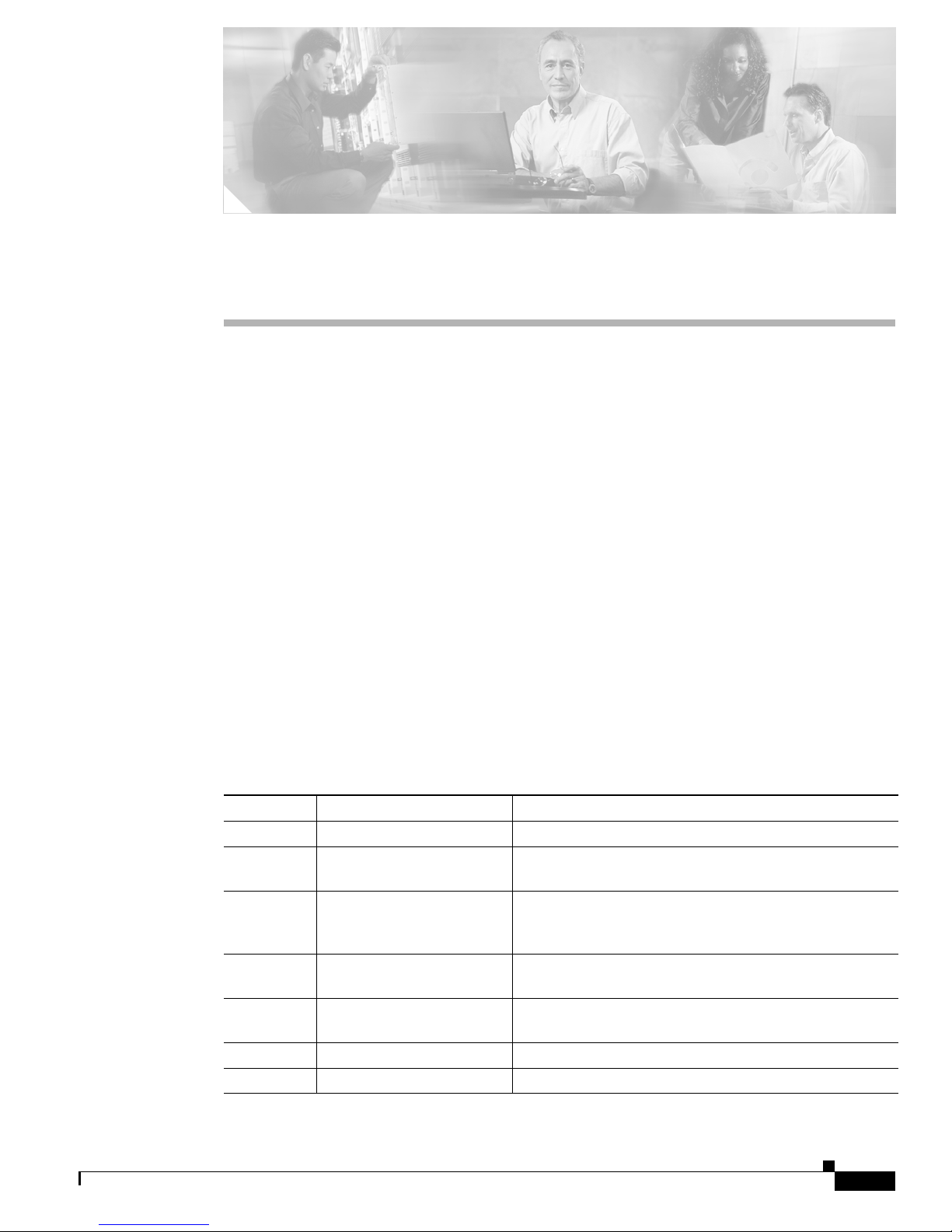

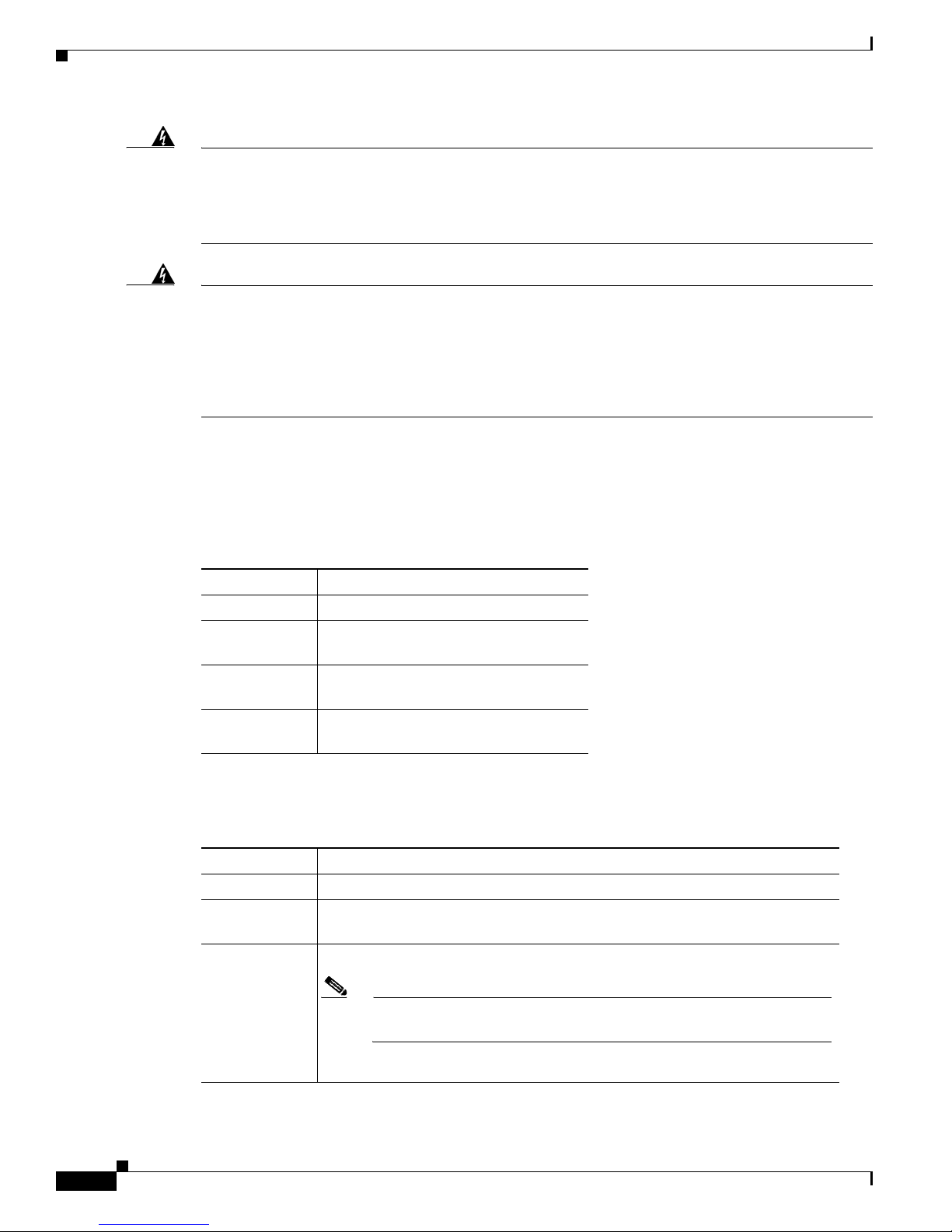

Table 1 describes the contents of each chapter in this document.

Ta b l e 1 Organization

Chapter Title Description

Chapter 1 Overview Overview of the Cisco AS5400 universal gateway.

Chapter 2 Preparing to Install Describes the tasks you must perform before you begin to

Chapter 3 Installing the Cisco AS5400

and Cisco AS5400HPX

Universal Gateways

Chapter 4 Troubleshooting Describes how to troubleshoot the chassis by referring to

Appendix A Replacing Memory

Components

Appendix B Replacing the Power Supply Describes how to replace the power supply.

Appendix C Cabling Specifications Describes cabling and pinout information for the chassis.

install the chassis.

Describes the tasks you must perform to install the

Cisco

AS5400 and Cisco AS5400HPX chassis.

the chassis LEDs.

Describes how to replace memory chips in the chassis

field-replaceable units.

OL-2847-02 0A

Cisco AS5400 Universal Gateway Chassis Installation Guide

vii

Page 8

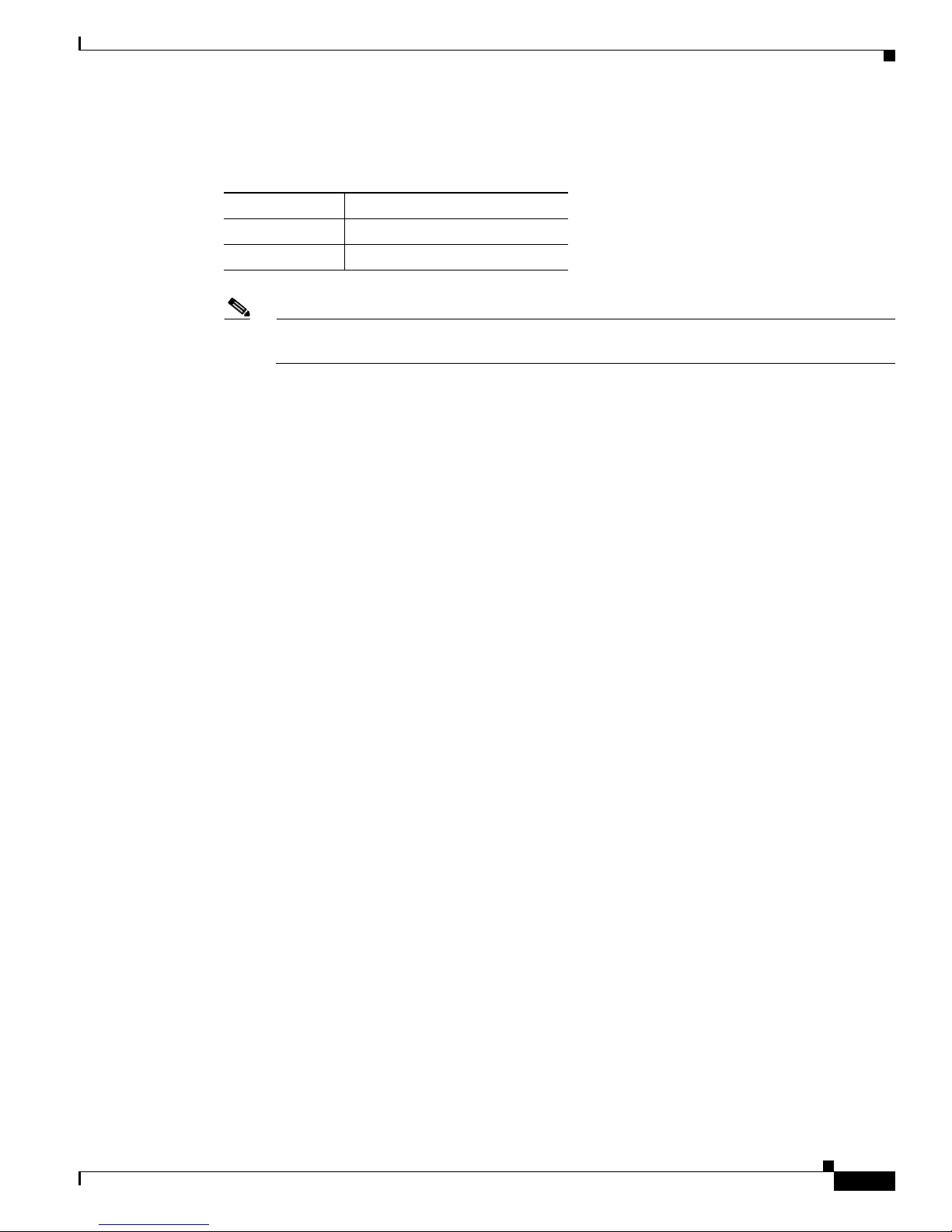

Document Conventions

Document Conventions

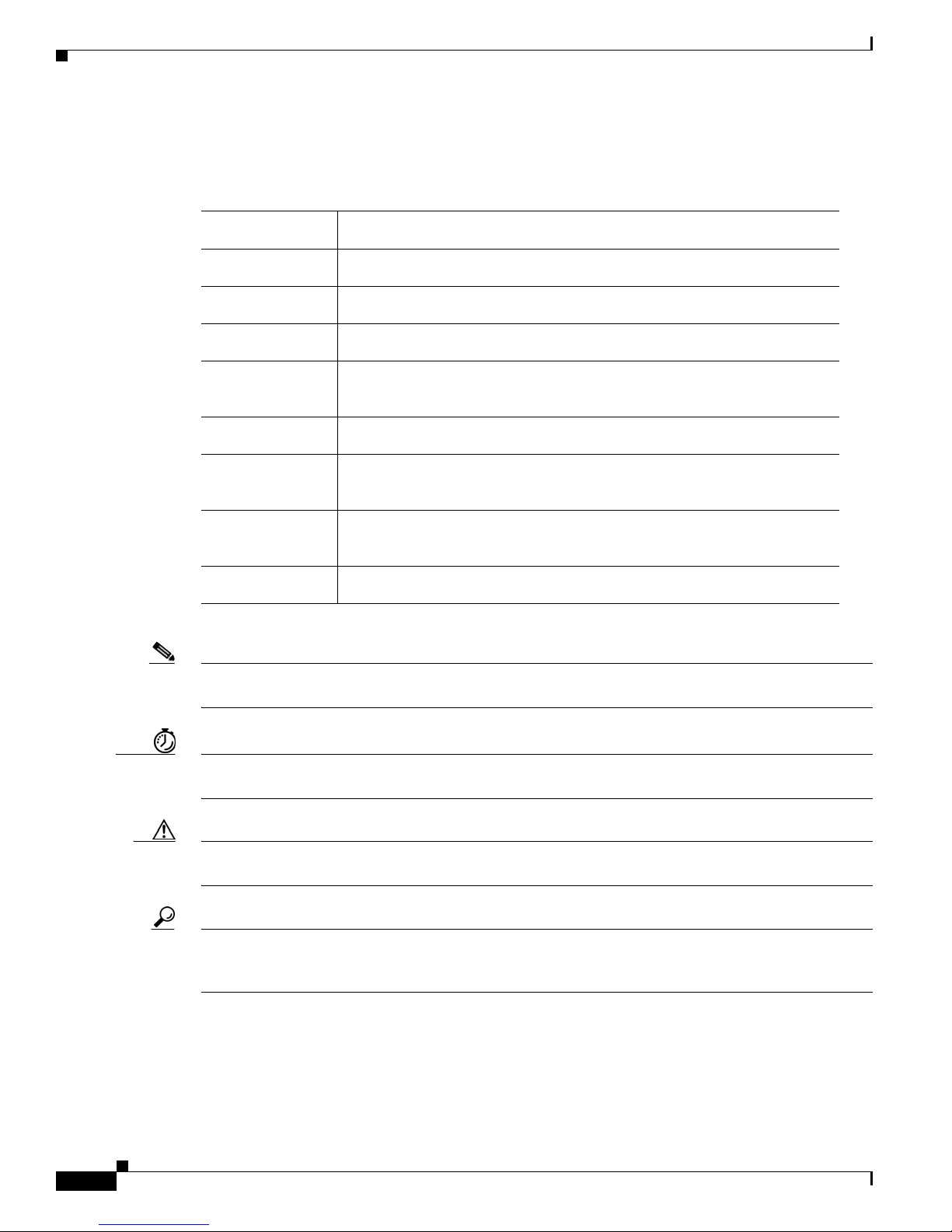

This publication uses the following conventions to convey instructions and information.

Convention Description

boldface font Commands and keywords.

italic font Variables for which you supply values.

[ ] Keywords or arguments that appear within square brackets are optional.

{x | y | z} A choice of required keywords appears in braces separated by vertical bars.

Preface

You must select one.

screen font

boldface screen

Examples of information displayed on the screen.

Examples of information you must enter.

font

< > Nonprinting characters, for example passwords, appear in angle brackets in

contexts where italic font is not available.

[ ] Default responses to system prompts appear in square brackets.

Note Means reader take note. Notes contain helpful suggestions or references to additional

information and material.

Timesaver This symbol means the described action saves time. You can save time by performing the

action described in the paragraph.

Caution This symbol means reader be careful. In this situation, you might do something that could

result in equipment damage or loss of data.

Tips This symbol means the following information will help you solve a problem. The tips

information might not be troubleshooting or even an action, but could be useful

information, similar to a Timesaver.

Cisco AS5400 Universal Gateway Chassis Installation Guide

viii

OL-2847-02 0A

Page 9

Preface

Document Conventions

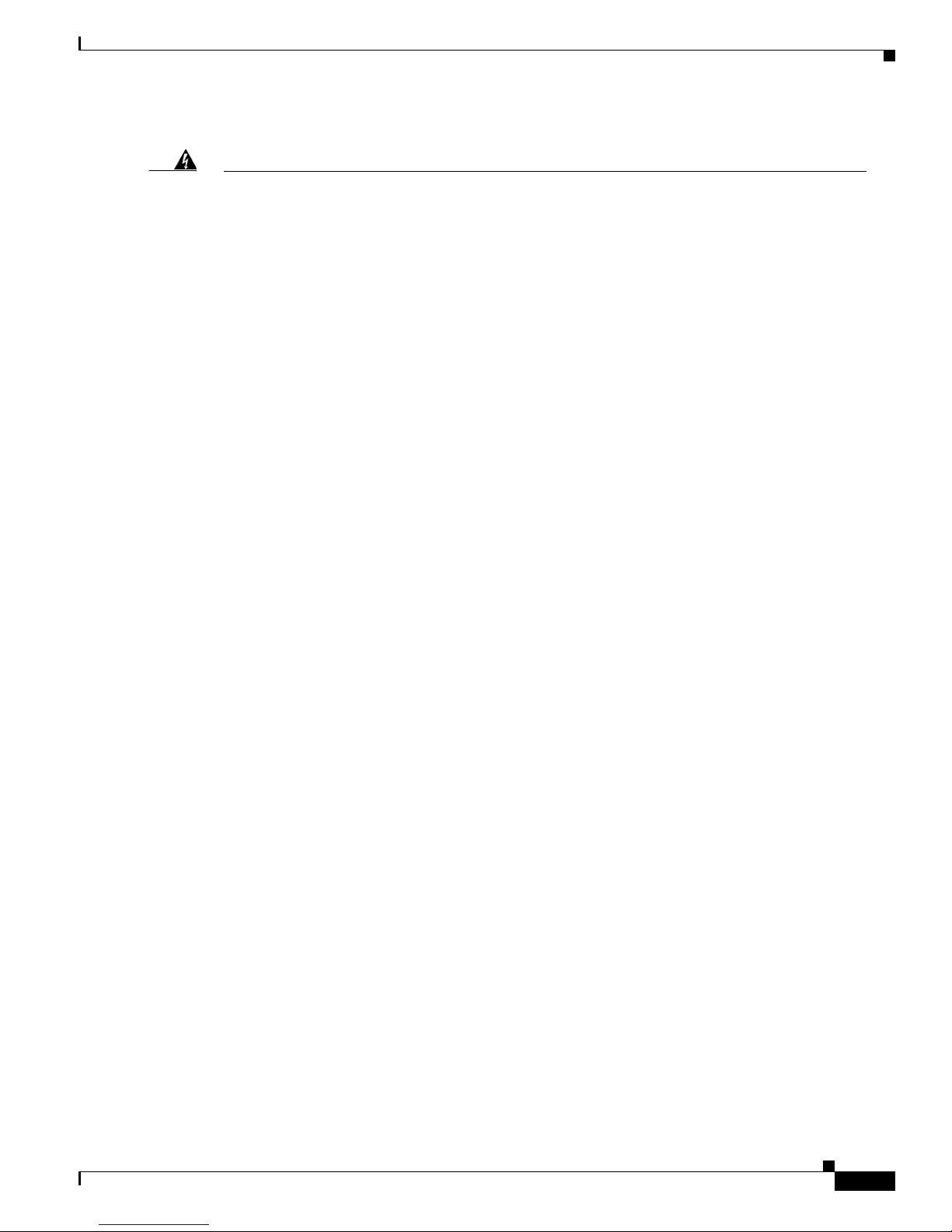

Warning

Waarschuwing

Varoitus

Attention

This warning symbol means danger. You are in a situation that could cause bodily

injury. Before you work on any equipment, be aware of the hazards involved with

electrical circuitry and be familiar with standard practices for preventing

accidents. To see translations of the warnings that appear in this publication, refer

to the Regulatory Compliance and Safety Information document that accompanied

this device.

Dit waarschuwingssymbool betekent gevaar. U verkeert in een situatie die

lichamelijk letsel kan veroorzaken. Voordat u aan enige apparatuur gaat werken,

dient u zich bewust te zijn van de bij elektrische schakelingen betrokken risico's en

dient u op de hoogte te zijn van standaard maatregelen om ongelukken te

voorkomen. Voor vertalingen van de waarschuwingen die in deze publicatie

verschijnen, kunt u het document Regulatory Compliance and Safety Information

(Informatie over naleving van veiligheids- en andere voorschriften) raadplegen dat

bij dit toestel is ingesloten.

Tämä varoitusmerkki merkitsee vaaraa. Olet tilanteessa, joka voi johtaa

ruumiinvammaan. Ennen kuin työskentelet minkään laitteiston parissa, ota selvää

sähkökytkentöihin liittyvistä vaaroista ja tavanomaisista onnettomuuksien

ehkäisykeinoista. Tässä julkaisussa esiintyvien varoitusten käännökset löydät

laitteen mukana olevasta Regulatory Compliance and Safety Information -kirjasesta

(määräysten noudattaminen ja tietoa turvallisuudesta).

Ce symbole d'avertissement indique un danger. Vous vous trouvez dans une situation

pouvant causer des blessures ou des dommages corporels. Avant de travailler sur un

équipement, soyez conscient des dangers posés par les circuits électriques et

familiarisez-vous avec les procédures couramment utilisées pour éviter les

accidents. Pour prendre connaissance des traductions d’avertissements figurant

dans cette publication, consultez le document Regulatory Compliance and Safety

Information (Conformité aux règlements et consignes de sécurité) qui accompagne

cet appareil.

Warnung

Avvertenza

OL-2847-02 0A

Dieses Warnsymbol bedeutet Gefahr. Sie befinden sich in einer Situation, die zu

einer Körperverletzung führen könnte. Bevor Sie mit der Arbeit an irgendeinem Gerät

beginnen, seien Sie sich der mit elektrischen Stromkreisen verbundenen Gefahren

und der Standardpraktiken zur Vermeidung von Unfällen bewußt. Übersetzungen der

in dieser Veröffentlichung enthaltenen Warnhinweise finden Sie im Dokument

Regulatory Compliance and Safety Information (Informationen zu behördlichen

Vorschriften und Sicherheit), das zusammen mit diesem Gerät geliefert wurde.

Questo simbolo di avvertenza indica un pericolo. La situazione potrebbe causare

infortuni alle persone. Prima di lavorare su qualsiasi apparecchiatura, occorre

conoscere i pericoli relativi ai circuiti elettrici ed essere al corrente delle pratiche

standard per la prevenzione di incidenti. La traduzione delle avvertenze riportate in

questa pubblicazione si trova nel documento Regulatory Compliance and Safety

Information (Conformità alle norme e informazioni sulla sicurezza) che accompagna

questo dispositivo.

Cisco AS5400 Universal Gateway Chassis Installation Guide

ix

Page 10

Obtaining Documentation

Preface

Advarsel

Aviso

¡Advertencia!

Varning!

Dette varselsymbolet betyr fare. Du befinner deg i en situasjon som kan føre til

personskade. Før du utfører arbeid på utstyr, må du vare oppmerksom på de

faremomentene som elektriske kretser innebærer, samt gjøre deg kjent med vanlig

praksis når det gjelder å unngå ulykker. Hvis du vil se oversettelser av de advarslene

som finnes i denne publikasjonen, kan du se i dokumentet Regulatory Compliance

and Safety Information (Overholdelse av forskrifter og sikkerhetsinformasjon) som

ble levert med denne enheten.

Este símbolo de aviso indica perigo. Encontra-se numa situação que lhe poderá

causar danos físicos. Antes de começar a trabalhar com qualquer equipamento,

familiarize-se com os perigos relacionados com circuitos eléctricos, e com

quaisquer práticas comuns que possam prevenir possíveis acidentes. Para ver as

traduções dos avisos que constam desta publicação, consulte o documento

Regulatory Compliance and Safety Information (Informação de Segurança e

Disposições Reguladoras) que acompanha este dispositivo.

Este símbolo de aviso significa peligro. Existe riesgo para su integridad física.

Antes de manipular cualquier equipo, considerar los riesgos que entraña la

corriente eléctrica y familiarizarse con los procedimientos estándar de prevención

de accidentes. Para ver una traducción de las advertencias que aparecen en esta

publicación, consultar el documento titulado Regulatory Compliance and Safety

Information (Información sobre seguridad y conformidad con las disposiciones

reglamentarias) que se acompaña con este dispositivo.

Denna varningssymbol signalerar fara. Du befinner dig i en situation som kan leda

till personskada. Innan du utför arbete på någon utrustning måste du vara medveten

om farorna med elkretsar och känna till vanligt förfarande för att förebygga skador.

Se förklaringar av de varningar som förkommer i denna publikation i dokumentet

Regulatory Compliance and Safety Information (Efterrättelse av föreskrifter och

säkerhetsinformation), vilket medföljer denna anordning.

Obtaining Documentation

These sections explain how to obtain documentation from Cisco Systems.

World Wide Web

You can access the most current Cisco documentation on the World Wide Web at this URL:

http://www.cisco.com

Translated documentation is available at this URL:

http://www.cisco.com/public/countries_languages.shtml

Cisco AS5400 Universal Gateway Chassis Installation Guide

x

OL-2847-02 0A

Page 11

Preface

Documentation CD-ROM

Cisco documentation and additional literature are available in a Cisco Documentation CD-ROM

package, which is shipped with your product. The Documentation CD-ROM is updated monthly and may

be more current than printed documentation. The CD-ROM package is available as a single unit or

through an annual subscription.

Ordering Documentation

You can order Cisco documentation in these ways:

• Registered Cisco.com users (Cisco direct customers) can order Cisco product documentation from

the Networking Products MarketPlace:

http://www.cisco.com/cgi-bin/order/order_root.pl

• Registered Cisco.com users can order the Documentation CD-ROM through the online Subscription

Store:

http://www.cisco.com/go/subscription

• Nonregistered Cisco.com users can order documentation through a local account representative by

calling Cisco Systems Corporate Headquarters (California, U.S.A.) at 408

in North America, by calling 800

Obtaining Technical Assistance

526-7208 or, elsewhere

553-NETS (6387).

Documentation Feedback

You can submit comments electronically on Cisco.com. In the Cisco Documentation home page, click

the Fax or Email option in the “Leave Feedback” section at the bottom of the page.

You can e-mail your comments to bug-doc@cisco.com.

You can submit your comments by mail by using the response card behind the front cover of your

document or by writing to the following address:

Cisco Systems

Attn: Document Resource Connection

170 West Tasman Drive

San Jose, CA 95134-9883

We appreciate your comments.

Obtaining Technical Assistance

Cisco provides Cisco.com as a starting point for all technical assistance. Customers and partners can

obtain online documentation, troubleshooting tips, and sample configurations from online tools by using

the Cisco Technical Assistance Center (TAC) Web Site. Cisco.com registered users have complete access

to the technical support resources on the Cisco TAC Web Site.

OL-2847-02 0A

Cisco AS5400 Universal Gateway Chassis Installation Guide

xi

Page 12

Obtaining Technical Assistance

Cisco.com

Preface

Cisco.com is the foundation of a suite of interactive, networked services that provides immediate, open

access to Cisco information, networking solutions, services, programs, and resources at any time, from

anywhere in the world.

Cisco.com is a highly integrated Internet application and a powerful, easy-to-use tool that provides a

broad range of features and services to help you with these tasks:

• Streamline business processes and improve productivity

• Resolve technical issues with online support

• Download and test software packages

• Order Cisco learning materials and merchandise

• Register for online skill assessment, training, and certification programs

If you want to obtain customized information and service, you can self-register on Cisco.com. To access

Cisco.com, go to this URL:

http://www.cisco.com

Technical Assistance Center

The Cisco Technical Assistance Center (TAC) is available to all customers who need technical assistance

with a Cisco product, technology, or solution. Two levels of support are available: the Cisco TAC

Web

Site and the Cisco TAC Escalation Center.

Cisco TAC inquiries are categorized according to the urgency of the issue:

• Priority level 4 (P4)—You need information or assistance concerning Cisco product capabilities,

product installation, or basic product configuration.

• Priority level 3 (P3)—Your network performance is degraded. Network functionality is noticeably

impaired, but most business operations continue.

• Priority level 2 (P2)—Your production network is severely degraded, affecting significant aspects

of business operations. No workaround is available.

• Priority level 1 (P1)—Your production network is down, and a critical impact to business operations

will occur if service is not restored quickly. No workaround is available.

The Cisco TAC resource that you choose is based on the priority of the problem and the conditions of

service contracts, when applicable.

Cisco TAC Web Site

You can use the Cisco TAC Web Site to resolve P3 and P4 issues yourself, saving both cost and time.

The site provides around-the-clock access to online tools, knowledge bases, and software. To access the

Cisco TAC Web Site, go to this URL:

http://www.cisco.com/tac

All customers, partners, and resellers who have a valid Cisco service contract have complete access to

the technical support resources on the Cisco TAC Web Site. The Cisco TAC Web Site requires a

Cisco.com login ID and password. If you have a valid service contract but do not have a login ID or

password, go to this URL to register:

http://www.cisco.com/register/

Cisco AS5400 Universal Gateway Chassis Installation Guide

xii

OL-2847-02 0A

Page 13

Preface

If you are a Cisco.com registered user, and you cannot resolve your technical issues by using the Cisco

TAC Web Site, you can open a case online by using the TAC Case Open tool at this URL:

http://www.cisco.com/tac/caseopen

If you have Internet access, we recommend that you open P3 and P4 cases through the Cisco TAC

Web

Site.

Cisco TAC Escalation Center

The Cisco TAC Escalation Center addresses priority level 1 or priority level 2 issues. These

classifications are assigned when severe network degradation significantly impacts business operations.

When you contact the TAC Escalation Center with a P1 or P2 problem, a Cisco TAC engineer

automatically opens a case.

To obtain a directory of toll-free Cisco TAC telephone numbers for your country, go to this URL:

http://www.cisco.com/warp/public/687/Directory/DirTAC.shtml

Before calling, please check with your network operations center to determine the level of Cisco support

services to which your company is entitled: for example, SMARTnet, SMARTnet Onsite, or Network

Supported Accounts (NSA). When you call the center, please have available your service agreement

number and your product serial number.

Related Documentation

Related Documentation

This guide describes how to install and maintain the Cisco AS5400 universal gateway chassis. You will

also need the following publications to configure the universal gateway:

• Refer to the Cisco AS5400 Universal Gateway Regulatory Compliance and Safety Information guide

to familiarize yourself with safety guidelines.

• Use the Cisco AS5350 and Cisco AS5400 Universal Gateway Card Installation Guide to install,

replace, and troubleshoot cards and modules.

• Refer to the Cisco AS5350 and Cisco AS5400 Universal Gateway Software Configuration Guide for

basic software configuration instructions.

• Refer to the appropriate Cisco IOS software configuration guides, command reference publications,

Dial Solutions Configuration Guide, and the Dial Solutions Command Reference for more advanced

configuration topics. These publications are available on the Documentation CD-ROM that came

with your universal gateway, on the World Wide Web from Cisco’s home page, or you can order

printed copies.

New Hardware Features

A description of new hardware features available after the release of this document can be found at the

following URL:

http://www.cisco.com/univercd/cc/td/doc/product/access/acs_serv/as5400/index.htm

OL-2847-02 0A

Cisco AS5400 Universal Gateway Chassis Installation Guide

xiii

Page 14

New Hardware Features

Preface

Cisco AS5400 Universal Gateway Chassis Installation Guide

xiv

OL-2847-02 0A

Page 15

CHA P TER

Overview

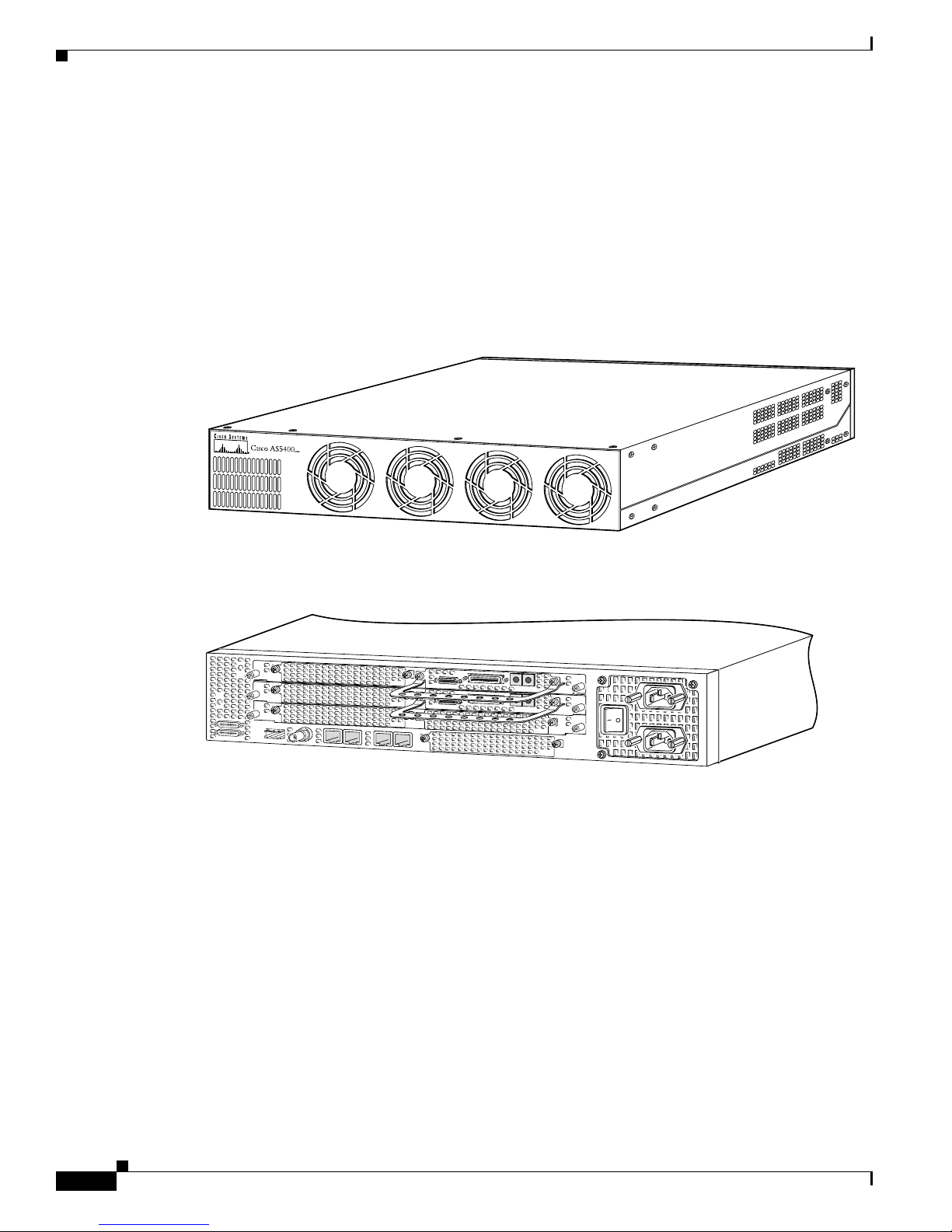

This chapter provides an overview of the Cisco AS5400 and Cisco AS5400HPX universal gateways, a

versatile voice and data communications platform that provides high performance, high density, and hot

swappability in only two rack units. (See

The Cisco AS5400 and Cisco AS5400HPX are intended for large companies and service providers who

require dense and scalable solutions to create new multi-service access networks, replace existing

hardware, or expand and enhance their current access offering. The Cisco AS5400HPX provides

enhanced performance for processor-intensive voice and fax applications. The Cisco

Cisco

AS5400HPX provide you with a cost-effective platform for deploying the widest range of IP based

services.

Note Unless specifically noted, all references to the Cisco AS5400 also apply to the

Cisco AS5400HPX.

This chapter includes the following sections:

• Chassis Components, page 1-1

• Dial Feature Cards (DFCs), page 1-2

Figure 1-1 and Figure 1-2.)

1

AS5400 and

• Power Supply, page 1-3

• Specifications, page 1-3

Chassis Components

The Cisco AS5400 universal gateway chassis has a system board, high-speed backplane, and seven slots

for dial feature cards (DFCs). The chassis includes four backplane slots. Three backplane slots accept

DFC carrier cards and the other backplane slot accepts one DFC. Each DFC carrier card accepts two

DFCs which allow online insertion and removal (OIR).

Tips To help identify your universal gateway, starting with Cisco IOS Release 12.2(11)T, the

show version and show diag commands will identify the universal gateway as an AS5400

or AS5400HPX. Prior to this release, these commands showed the universal gateway as an

AS5400, even if it was an AS5400HPX.

OL-2847-02 0A

Cisco AS5400 Universal Gateway Chassis Installation Guide

1-1

Page 16

Dial Feature Cards (DFCs)

Chapter 1 Overview

The chassis consists of the following components:

• One Building Integrated Timing System (BITS) interface port

• One alarm port

• Two Fast Ethernet (2FE) LAN ports

• Two T serial ports for backhaul WAN support

• One fast console port for local administrative access

• An integral redundant AC or DC power supply, with two power input lines

Figure 1-1 Cisco AS5400 Front Panel

29023

Figure 1-2 Cisco AS5400 Rear Panel

Dial Feature Cards (DFCs)

Each DFC is a 5.1 by 13 inch PCI-based interface board. The following is a brief description of the trunk

types supported:

• North American robbed-bit signaling (RBS) is supported on T1 trunks, including a variety of North

American RBS protocol, framing, and encoding types on these trunks.

• CAS is supported for E1 trunks, with R2 signaling.

• Many countries require an E1 R2 variant. Per-country defaults are provided for supervisory and

inter-register signaling.

• The CT3 DFC provides physical line termination for a channelized T3 ingress trunk line, and it uses

an onboard multiplexer to multiplex 28 channelized T1 lines into a single channelized T3 line.

29024

• Universal access (analog modem or digital calls) is supported when an interface is configured for

ISDN PRI signaling. PRI signaling is available for both T1 and E1 trunks.

Cisco AS5400 Universal Gateway Chassis Installation Guide

1-2

OL-2847-02 0A

Page 17

Chapter 1 Overview

In any single DFC slot, you can install your choice of:

• One T1 dial feature card

• One E1 dial feature card

• One T3 dial feature card

Note The Cisco AS5400 supports only one type of WAN DFC at a time. For more information,

see the “Mixing WAN DFCs” section on page 4-3.

Power Supply

The power system is comprised of a fully redundant switching power supply with two AC (or DC) inputs

to the main power modules. Each input and output is 100 percent fully redundant, with dual fans for

added reliability.

The output of each power module is rated at 300 watts (nonredundant mode), and is composed of four

independent output voltages: 3.3V, 5V, 12V and -12V. AC input units have power factor correction, and

low harmonic distortion. Units that are in redundant mode run at one-half the power capability. If a

power supply failure occurs, these units are capable of powering the complete system either at the input

side or the DC load side. Power failures are reported through environmental monitoring software.

Power Supply

Specifications

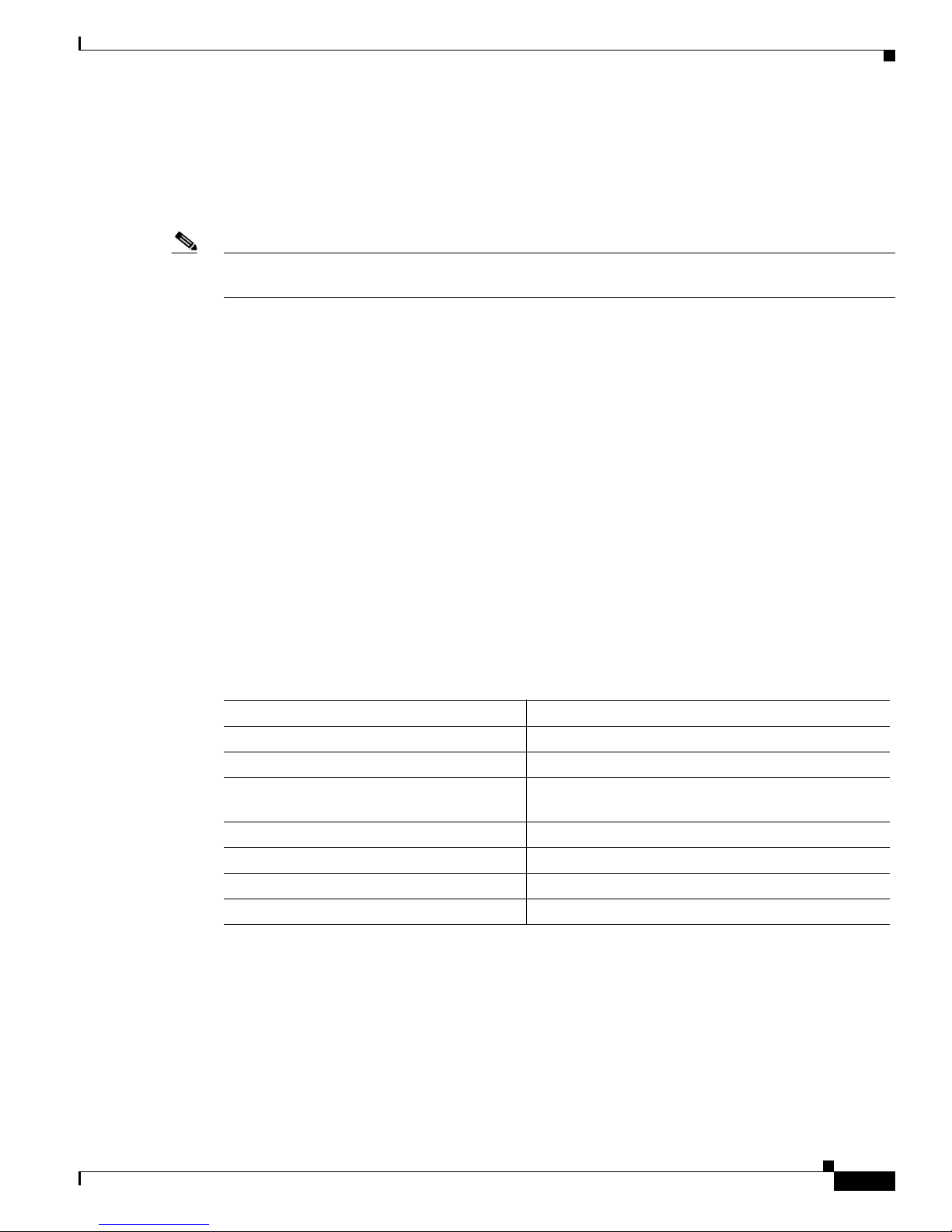

Table 1-1 provides system specifications for the Cisco AS5400.

Ta b l e 1-1 Specifications

Description Specification

Dimensions (H x W x D) 3.5 x 17.5 x 18.25 in. (8.89 x 44.45 x 46.36 cm)

Weight 35 lb maximum (15.8 kg)

Processor 250 MHz (Cisco AS5400)

Operating environment 32 to 104° F (0 to 40° C)

Nonoperating temperature –40 to 185° F (–40 to 85° C)

Operating humidity 5 to 95%, noncondensing

Noise level 70 dB1 @ 3 ft (0.914 m)

390 MHz (Cisco AS5400HPX)

OL-2847-02 0A

Cisco AS5400 Universal Gateway Chassis Installation Guide

1-3

Page 18

Specifications

Chapter 1 Overview

Table 1-1 Specifications (continued)

Description Specification

Input voltage, AC power supply

Current

Frequency

Power factor

Input AC power

Input voltage, DC power supply

Maximum input current

Typical input current

Efficiency

Input DC power

WAN interface options T1, E1, T3

Serial interfaces (for backhaul WAN support) 2 serial line interfaces

LAN interface options Fast Ethernet 10/100BASE-T (RJ-45)

Console and auxiliary ports Asynchronous serial (RJ-45)

Regulatory compliance See the Regulatory Compliance and Safety

1. dB = decibels.

2. VAC = volts alternating current.

3. VDC = volts direct current.

100 to 240 VAC2; -10%, +6% tolerance

5 to 2A

50/60 Hz

0.80 to 0.95

200 to 400W (maximum)

–48 to –60 VDC3; -10%, +6% tolerance

9.0A

2.0 to 4.0A

63%

200 to 400W (maximum)

Information guide that came with your gateway.

Cisco AS5400 Universal Gateway Chassis Installation Guide

1-4

OL-2847-02 0A

Page 19

Preparing to Install

This chapter describes the tasks you must perform before you begin to install the universal gateway and

includes the following sections:

• Safety Recommendations, page 2-1

• Required Tools and Equipment, page 2-3

• Preparing to Connect to a Network, page 2-3

Note Unless specifically noted, all references to the Cisco AS5400 also apply to the

Cisco AS5400HPX.

Safety Recommendations

CHA P TER

2

Warning

Any device that uses electricity must be handled carefully; follow these guidelines to ensure general

safety:

• Keep the chassis area clear and dust-free during and after installation.

• Put the removed chassis cover in a safe place.

• Keep tools away from walk areas where you and others could fall over them.

• Do not wear loose clothing that could get caught in the chassis. Fasten your tie or scarf and roll up

your sleeves.

• Wear safety glasses if you are working under any conditions that might be hazardous to your eyes.

• Do not perform any action that creates a potential hazard to people or makes the equipment unsafe.

Ultimate disposal of this product should be handled according to all national laws and

regulations. To see translations of the warnings that appear in the publication, refer to

the Regulatory Compliance and Safety Information document that accompanied this

device.

OL-2847-02 0A

Cisco AS5400 Universal Gateway Chassis Installation Guide

2-1

Page 20

Safety Recommendations

Maintaining Safety with Electricity

Chapter 2 Preparing to Install

Warning

Warning

Before working on equipment that is connected to power lines, remove jewelry

(including rings, necklaces, and watches). Metal objects will heat up when connected

to power and ground and can cause serious burns or can weld the metal object to the

terminals. To see translations of the warnings that appear in the publication, refer to the

Regulatory Compliance and Safety Information document that accompanied this device.

Follow these guidelines when you work on equipment powered by electricity.

• Locate the emergency power-OFF switch for the room in which you are working. Then, if an

electrical accident occurs, you can act quickly to turn OFF the power.

• Before working on the system, unplug the power cord.

• Disconnect all power before doing the following:

–

Installing or removing a chassis

–

Working near power supplies

When installing the unit, the ground connection must always be made first and

disconnected last. Do not work alone if potentially hazardous conditions exist. To see

translations of the warnings that appear in this publication, refer to the Regulatory

Compliance and Safety Information document that accompanied this device.

• Never assume that power is disconnected from a circuit. Always check.

Warning

Warning

Read the installation instructions before you connect the system to its power source. To

see translations of the warnings that appear in the publication, refer to the Regulatory

Compliance and Safety Information document that accompanied this device.

• Look carefully for possible hazards in your work area, such as moist floors, ungrounded power

extension cables, frayed power cords, and missing safety grounds.

• If an electrical accident occurs, proceed as follows:

–

Use caution; do not become a victim yourself.

–

Turn OFF power to the system.

–

If possible, send another person to get medical aid. Otherwise, assess the condition of the victim

and then call for help.

–

Determine if the person needs rescue breathing or external cardiac compressions; then take

appropriate action.

This product relies on the building’s installation for short-circuit (overcurrent)

protection. Ensure that a fuse or circuit breaker no larger than 120 VAC, 15A U.S.

VAC, 10A international) is used on the phase conductors (all current-carrying

(240

conductors). To see translations of the warnings that appear in the publication, refer to

the Regulatory Compliance and Safety Information document that accompanied this

device.

Cisco AS5400 Universal Gateway Chassis Installation Guide

2-2

OL-2847-02 0A

Page 21

Chapter 2 Preparing to Install

Preventing Electrostatic Discharge Damage

Electrostatic discharge (ESD) can damage equipment and impair electrical circuitry. ESD damage occurs

when electronic components are improperly handled and can result in complete or intermittent failures.

Always follow ESD-prevention procedures when you remove and replace components. Ensure that the

chassis is electrically connected to earth ground. Wear an ESD-preventive wrist strap, ensuring that it

makes good skin contact. Connect the grounding clip to an unpainted surface of the chassis frame to

safely ground unwanted ESD voltages. To guard against ESD damage and shocks, the wrist strap and

cord must operate properly. If no wrist strap is available, ground yourself by touching the metal part of

the chassis.

Caution For safety, periodically check the resistance value of the antistatic strap, which should be

between 1 and 10 megohm (Mohm).

Required Tools and Equipment

Required Tools and Equipment

The following items are included with the universal gateway:

• 19- and 24-inch rack-mount kits

• Rubber feet for desktop installation

• RJ-45-to-DB-9 female DTE adapter (labeled TERMINAL)

• RJ-45-to-DB-25 female DTE adapter (labeled TERMINAL)

• RJ-45-to-DB-25 male DCE adapter (labeled MODEM)

• RJ-45-to-RJ-45 rollover console cable

• ESD-preventive wrist strap

• Nylon cable tie

• Cable tie holder

• Grounding lug

You might need the following equipment, which is not included:

• Straight-through RJ-45-to-RJ-45 cable for an Ethernet connection

• Ethernet hub or PC with a network interface card for Ethernet LAN connections

• One breakout cable consisting of a 36-pin connector connected to eight RJ-45 adapters for CT1/CE1

connections

• 75-ohm coaxial cable for a CT3 connection

• PC running terminal emulation software for local administrative access

• Modem for remote administrative access

Preparing to Connect to a Network

When you set up the chassis, consider distance limitations and potential electromagnetic interference

(EMI) as defined by the Electronic Industries Association

OL-2847-02 0A

(EIA).

Cisco AS5400 Universal Gateway Chassis Installation Guide

2-3

Page 22

Preparing to Connect to a Network

Chapter 2 Preparing to Install

Warning

Warning

Hazardous network voltages are present in WAN ports regardless of whether power to

the router is OFF or ON. To avoid electric shock, use caution when working near WAN

ports. When detaching cables, detach the end away from the router first. To see

translations of the warnings that appear in the publication, refer to the Regulatory

Compliance and Safety Information document that accompanied this device.

The ISDN connection is regarded as a source of voltage that should be inaccessible to

user contact. Do not attempt to tamper with or open any public telephone operator

(PTO)-provided equipment or connection hardware. Any hardwired connection (other

than by a nonremovable, connect-one-time-only plug) must be made only by PTO staff or

suitably trained engineers. To see translations of the warnings that appear in the

publication, refer to the Regulatory Compliance and Safety Information document that

accompanied this device.

Network Specifications

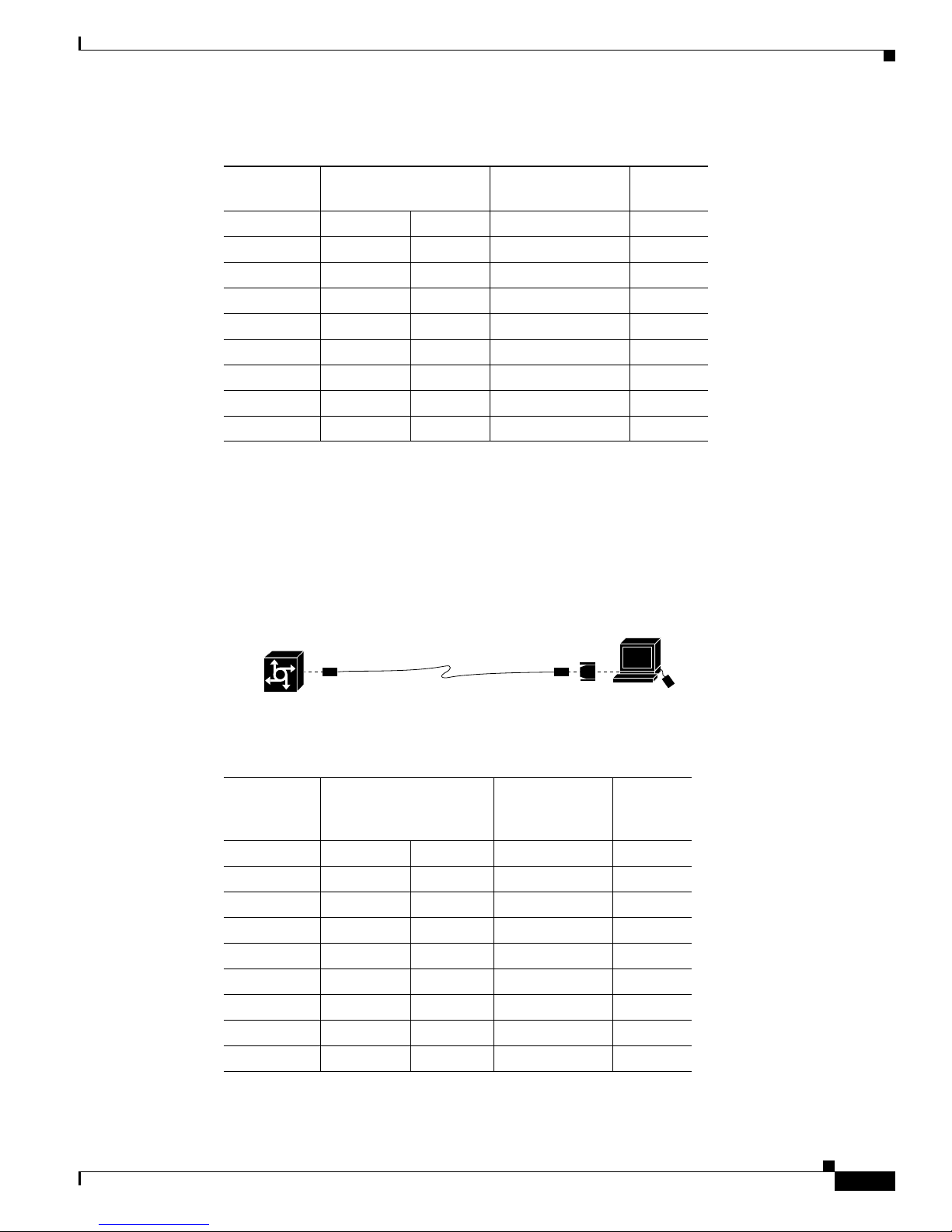

Table 2-1 lists the network specifications to consider before connecting a T1 DFC to a network.

Ta b l e 2-1 T1 Network Specifications

Description Specification

Line rate 1.544 Mbps

Data rates (per

port)

Standards AT&T Pub. 62411, 54016, and 43081,

Input

impedance

number x 56 or number x 64 kbps, where

number = 1 to 24

and ANSI T1.403

100-ohms per port

Table 2-2 lists the network specifications to consider before connecting an E1 DFC to a network.

Ta b l e 2-2 E1 Network Specifications

Description Specification

Line rate 2.048 Mbps

Data rate (per

port)

Input

impedance

Cisco AS5400 Universal Gateway Chassis Installation Guide

2-4

number x 56 or number x 64 kbps, where number = 1 to 31.

75 or 120-ohms per port

Note The factory default setting for the E1 ports is 120 ohm. Use a software

command to change the impedance.

OL-2847-02 0A

Page 23

Chapter 2 Preparing to Install

Table 2-3 lists the network specifications to consider before connecting a T3 DFC to a network.

Ta b l e 2-3 T3 Network Specifications

Description Specification

Line rate 44.736 Mbps

Data rates 672 DS0 channels at 64 Kbps

Note For information on installing and removing dial feature cards, refer to the

Cisco AS5350 and Cisco AS5400 Universal Gateway Card Installation Guide.

Ethernet Connections

Two Fast Ethernet (FE) ports are RJ-45 ports located on the rear panel of the chassis: FE0 and FE1

(selectable). To configure the Ethernet ports, refer to the Cisco

Gateway Software Configuration Guide. Both ports use unshielded twisted-pair (UTP) cable and require

Category 5 cable. The maximum segment distance is 328 feet (100 meters). UTP cables look like the

cables used for ordinary telephones; however, UTP cables meet certain electrical standards that

telephone cables do not. Cables are not included.

Preparing to Connect to a Network

AS5350 and Cisco AS5400 Universal

Console and Auxiliary Ports

The chassis includes an asynchronous serial console port and an auxiliary port. The console and

auxiliary ports provide access either locally (with a console terminal) or remotely (with a modem). This

section discusses important cabling information to consider before connecting a console terminal (an

ASCII terminal or PC running terminal emulation software) to the console port or modem to the

auxiliary port.

Console Port

The chassis includes an EIA/TIA-232 asynchronous serial console port (RJ-45). Depending on the cable

and the adapter used, this port appears as a data terminal equipment (DTE) or data communications

equipment (DCE) device at the end of the cable. Your chassis arrives with cables and adapters to connect

a console terminal (an ASCII terminal or PC running terminal emulation software) to the console port.

To connect an ASCII terminal to the console port, use the RJ-45 rollover cable with the female

RJ-45-to-DB-25 adapter (labeled TERMINAL).

To connect a PC running terminal emulation software to the console port, use the RJ-45 rollover cable

with the female RJ-45-to-DB-9 adapter (labeled TERMINAL). The default parameters for the console

port are 9600 baud, 8

flow control.

For detailed information about installing a console terminal, see Chapter 3, “Installing the Cisco AS5400

and Cisco AS5400HPX Universal Gateways.” See Appendix C, “Cabling Specifications” for cable and

port pinouts.

data bits, no parity, and 2 stop bits. The console port does not support hardware

OL-2847-02 0A

Cisco AS5400 Universal Gateway Chassis Installation Guide

2-5

Page 24

Preparing to Connect to a Network

Auxiliary Port

2T Serial Ports

Chapter 2 Preparing to Install

The chassis includes an EIA/TIA-232 asynchronous serial auxiliary port (RJ-45) that supports flow

control. Depending on the cable and the adapter used, this port will appear as a DTE or DCE device at

the end of the cable. Your chassis arrives with a cable and an adapter to connect a modem to the auxiliary

port. To connect a modem to the auxiliary port, use the RJ-45 rollover cable with the male

RJ-45-to-DB-25 adapter (labeled MODEM).

For detailed information about connecting devices to the auxiliary port, see Chapter 3, “Installing the

Cisco AS5400 and Cisco AS5400HPX Universal Gateways.” See Appendix C “Cabling Specifications”

for cable and port pinouts.

Two high-speed 12-in-1 serial ports on the rear panel of the chassis provide backhaul WAN and IP

support.

The following types of serial interface standards (in DTE/DCE) are supported:

• EIA/TIA-232

Alarm Port

• EIA/TIA-449

• EIA/TIA-530

• EIA/TIA-530A

• EIA/TIA-X.21

• CCITT V.35

Each port supports up to 8 Mbps.

For detailed information about connecting devices to the serial ports, see Chapter 3, “Installing the

Cisco AS5400 and Cisco AS5400HPX Universal Gateways.” See Appendix C “Cabling Specifications”

for cable and port pinouts.

The three pins on the alarm port are connected to the output of a relay. This relay is controlled by system

software. With the alarm ports connected and configured, Cisco

detect the failure events that are configured and turns ON the alarm when it detects any failure event.

For detailed information about connecting devices to the alarm port, see Chapter 3, “Installing the

Cisco AS5400 and Cisco AS5400HPX Universal Gateways.” See Appendix C “Cabling Specifications”

for cable and port pinouts.

IOS software polls every one second to

BITS Port

The BITS port is a coaxial interface that provides external synchronized clocking through a Timing

Signal Generator (TSG).

For detailed information about connecting devices to the BITS port, see Chapter 3, “Installing the

Cisco AS5400 and Cisco AS5400HPX Universal Gateways.” See Appendix C “Cabling Specifications”

for cable and port pinouts.

Cisco AS5400 Universal Gateway Chassis Installation Guide

2-6

OL-2847-02 0A

Page 25

Chapter 2 Preparing to Install

Power Supply Considerations

Check the power at your site to ensure that you are receiving “clean” power (free of spikes and noise).

Install a power conditioner if necessary.

Preparing to Connect to a Network

Warning

The device is designed to work with TN power systems. To see translations of the

warnings that appear in the publication, refer to the Regulatory Compliance and Safety

Information document that accompanied this device.

The universal gateway AC power supply includes the following features:

• Full range operation—100 to 240 VAC.

• All units include a 6-foot (1.8-m) electrical power cord. (A label near the power cord indicates the

correct voltage, frequency, and current draw for the unit.)

For detailed information about connecting power, see Chapter 3, “Installing the Cisco AS5400 and

Cisco AS5400HPX Universal Gateways.” For information on replacing the power supply see

Appendix B, “Replacing the Power Supply”

Warning

Caution In a DC power supply installation, do not connect the 48 VDC Return to chassis ground at

This product relies on the building’s installation for short-circuit (overcurrent)

protection. Ensure that a fuse or circuit breaker no larger than 120

VAC, 10A international) is used on the phase conductors (all current-carrying

(240

conductors). To see translations of the warnings that appear in the publication, refer to

the Regulatory Compliance and Safety Information document that accompanied this

device.

VAC, 15A U.S.

the Cisco AS5400. A single-point ground is recommended at the power distribution rack.

OL-2847-02 0A

Cisco AS5400 Universal Gateway Chassis Installation Guide

2-7

Page 26

Preparing to Connect to a Network

Chapter 2 Preparing to Install

Cisco AS5400 Universal Gateway Chassis Installation Guide

2-8

OL-2847-02 0A

Page 27

CHA P TER

3

Installing the Cisco AS5400 and

Cisco AS5400HPX Universal Gateways

This chapter guides you through the installation of the Cisco AS5400 and Cisco AS5400HPX universal

gateways and includes the following sections:

• Setting Up the Chassis, page 3-2

• Connecting to the Network, page 3-5

• Connecting the Console Terminal and Modem, page 3-9

• Connecting to the BITS Port, page 3-11

• Connecting to the Alarm Port, page 3-12

• Supplying Power, page 3-13

• Where to Go Next, page 3-16

Note Unless specifically noted, all references to the Cisco AS5400 also apply to the

Cisco AS5400HPX.

Warning

Warning

Warning

Only trained and qualified personnel should be allowed to install or replace this

equipment. To see translations of the warnings that appear in the publication, refer to the

Regulatory Compliance and Safety Information document that accompanied this device.

To see translations of the warnings that appear in the publication, refer to the Regulatory

Compliance and Safety Information document that accompanied this device.

This equipment is intended to be grounded. Ensure that the host is connected to earth

ground during normal use. To see translations of the warnings that appear in the

publication, refer to the Regulatory Compliance and Safety Information document that

accompanied this device.

Incorrect connection of this or connected equipment to the general purpose outlet could

result in a hazardous situation. To see translations of the warnings that appear in the

publication, refer to the Regulatory Compliance and Safety Information document that

accompanied this device.

OL-2847-02 0A

Cisco AS5400 Universal Gateway Chassis Installation Guide

3-1

Page 28

Setting Up the Chassis

Setting Up the Chassis

You can set the chassis on a desktop or install it in a rack. Use the procedure in this section that best

meets the needs of your network:

• Setting the Chassis on a Desktop

• Rack-Mounting the Chassis

Chapter 3 Installing the Cisco AS5400 and Cisco AS5400HPX Universal Gateways

Warning

Warning

When installing the unit, the ground connection must always be made first and

disconnected last. To see translations of the warnings that appear in the publication,

refer to the Regulatory Compliance and Safety Information document that accompanied

this device.

This unit is intended for installation in restricted access areas. A restricted access area

is where access can only be gained by service personnel through the use of a special

tool, lock and key, or other means of security, and is controlled by the authority

responsible for the location. To see translations of the warnings that appear in the

publication, refer to the Regulatory Compliance and Safety Information document that

accompanied this device.

Setting the Chassis on a Desktop

The location of the chassis is extremely important for proper operation. Equipment placed too close

together, inadequate ventilation, and inaccessible panels can cause malfunctions and shutdowns, and can

make maintenance difficult. The following information will help you to plan the location of the chassis:

• Plan for access to both front and rear panels of the chassis.

• Ensure that the room where the chassis operates has adequate ventilation. Remember that electrical

equipment generates heat. Ambient air temperature may not cool equipment to acceptable operating

temperatures without adequate ventilation.

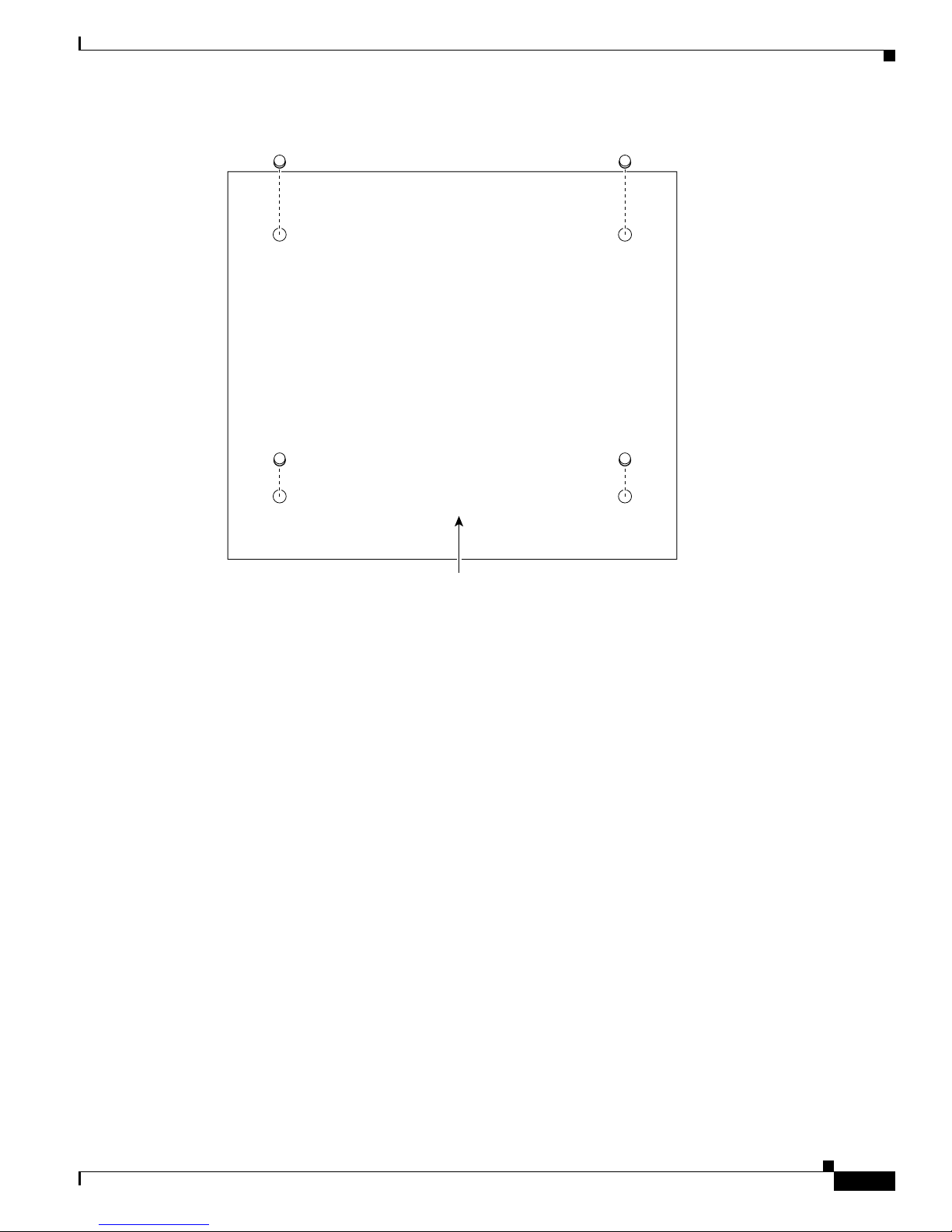

Attach the rubber feet as shown in Figure 3-1. Rubber feet are included in the accessory kit that shipped

with your universal gateway.

Cisco AS5400 Universal Gateway Chassis Installation Guide

3-2

OL-2847-02 0A

Page 29

Chapter 3 Installing the Cisco AS5400 and Cisco AS5400HPX Universal Gateways

Figure 3-1 Attaching the Rubber Feet

Setting Up the Chassis

Rack-Mounting the Chassis

This section describes how to rack-mount the chassis. The universal gateway arrives with 19-inch

rack-mount brackets and larger brackets for use with a 23- or 24-inch rack. (See

The following information will help you plan your equipment rack configuration:

• Enclosed racks must have adequate ventilation. Ensure that the rack is not congested, because each

unit generates heat. An enclosed rack should have louvered sides and a fan to provide cooling air.

Heat generated by equipment near the bottom of the rack can be drawn upward into the intake ports

of the equipment above.

• When mounting a chassis in an open rack, ensure that the rack frame does not block the intake or

exhaust ports. If the chassis is installed on slides, check the position of the chassis when it is seated

in the rack.

• Baffles can isolate exhaust air from intake air, which also helps to draw cooling air through the

chassis. The best placement of the baffles depends on the airflow patterns in the rack, which can be

found by experimenting with different configurations.

• When equipment installed in a rack (particularly in an enclosed rack) fails, try operating the

equipment by itself, if possible. Power OFF other equipment in the rack (and in adjacent racks) to

allow the unit under test a maximum of cooling air and clean power.

• Install the chassis and external devices to which it will connect in a contiguous stack.

37208

Universal gateway

chassis bottom

Figure 3-2.)

OL-2847-02 0A

Cisco AS5400 Universal Gateway Chassis Installation Guide

3-3

Page 30

Setting Up the Chassis

k

Chapter 3 Installing the Cisco AS5400 and Cisco AS5400HPX Universal Gateways

Warning

Before working on a chassis or working near power supplies, unplug the power cord on

AC units; disconnect the power at the circuit breaker on DC units. To see translations of

the warnings that appear in the publication, refer to the Regulatory Compliance and

Safety Information document that accompanied this device.

Required Tools and Equipment

You need the following tools and equipment to rack-mount the chassis:

• Number 2 Phillips screwdriver (not included)

• Screws for attaching the chassis to the rack (not included)

• Standard rack-mount brackets (included)

Figure 3-2 Standard Rack-Mount Brackets

Bracket for 19-inch rack

H6028

Bracket for 23- or 24-inch rac

Installing in a Rack

Step 1 To install the chassis in a rack, attach the brackets as follows:

• With the standard brackets on the side panels of the universal gateway and the front panel forward

Figure 3-3 Standard Bracket Installation—Front Panel Forward

or rear panel forward, as shown in

Figure 3-3 and Figure 3-4.

H10643

Cisco AS5400 Universal Gateway Chassis Installation Guide

3-4

OL-2847-02 0A

Page 31

Chapter 3 Installing the Cisco AS5400 and Cisco AS5400HPX Universal Gateways

Figure 3-4 Standard Bracket Installation—Rear Panel Forward

Note: The second bracket attaches to the other side of the chassis.

Caution Do not use the handles on the dial feature cards to assist in lifting the chassis.

Step 2 After the brackets are secured to the chassis, and using the screws that you provide, attach the chassis to

the rack as shown in

Figure 3-5.

Connecting to the Network

30860

Figure 3-5 Attaching the Chassis to the 19-Inch Rack—Rear Panel Forward

Note: The second bracket attaches to the rack at the other side

of the chassis. The brackets can also be installed with the

front panel forward.

Connecting to the Network

This section describes how to connect the universal gateway to your network. The cables required to

connect to a network are not provided. For ordering information, contact customer service (see the

“Obtaining Technical Assistance” section on page -xi in the Preface) or see Appendix C, “Cabling

Specifications” for cable and port pinouts.

29034

OL-2847-02 0A

Cisco AS5400 Universal Gateway Chassis Installation Guide

3-5

Page 32

Connecting to the Network

Chapter 3 Installing the Cisco AS5400 and Cisco AS5400HPX Universal Gateways

Warning

To avoid electric shock, do not connect safety extra-low voltage (SELV) circuits to

telephone-network voltage (TNV) circuits. LAN ports contain SELV circuits, and WAN

ports contain TNV circuits. Some LAN and WAN ports use both RJ-45 connectors. Use

caution when connecting cables. To see translations of the warnings that appear in the

publication, refer to the Regulatory Compliance and Safety Information document that

accompanied this device.

Warning

Do not work on the system or connect or disconnect cables during periods of lightning

activity. To see translations of the warnings that appear in the publication, refer to the

Regulatory Compliance and Safety Information document that accompanied this device.

Caution If the universal gateway is configured with fewer than seven DFCs, make sure that a blank

slot cover is installed over each open slot to ensure proper airflow.

Note The universal gateway arrives with all carrier cards and DFCs already installed, unless you

order a card separately as a spare. Refer to the Cisco

Gateway Card Installation Guide for card installation instructions.

Connecting to an Ethernet Network

AS5350 and Cisco AS5400 Universal

You can connect the universal gateway to an Ethernet network by using a straight-through

RJ-45-to-RJ-45 Ethernet cable to connect the Fast Ethernet port to an Ethernet hub. (See

Figure 3-6 Connecting to an Ethernet Hub (10/100BASE-T Shown)

FE1

10/100BASE-T port

(RJ-45)

Ethernet hub

8

7

Straight-through

Ethernet cable

1

Figure 3-6.)

30849

Cisco AS5400 Universal Gateway Chassis Installation Guide

3-6

OL-2847-02 0A

Page 33

Chapter 3 Installing the Cisco AS5400 and Cisco AS5400HPX Universal Gateways

30848

Connecting to a WAN

Connecting to the Network

Warning

Warning

Warning

Warning

The telecommunications lines must be disconnected 1) before unplugging the main

power connector and/or 2) while the housing is open. To see translations of the warnings

that appear in the publication, refer to the Regulatory Compliance and Safety Information

document that accompanied this device.

Hazardous network voltages are present in WAN ports regardless of whether power to

the router is OFF or ON. To avoid electric shock, use caution when working near WAN

ports. When detaching cables, detach the end away from the router first. To see

translations of the warnings that appear in the publication, refer to the Regulatory

Compliance and Safety Information document that accompanied this device.

This equipment is to be installed and maintained by service personnel only as defined by

AS/NZS

3260 Clause 1.2.14.3 Service Personnel. To see translations of the warnings that

appear in the publication, refer to the Regulatory Compliance and Safety Information

document that accompanied this device.

To reduce the risk of fire, use only No. 26 AWG or larger telecommunication line cord. To

see translations of the warnings that appear in the publication, refer to the Regulatory

Compliance and Safety Information document that accompanied this device.

You can connect the universal gateway to a WAN in the following ways:

• Use a breakout cable and straight-through RJ-45-to-RJ-45 cable for CT1 connections. (See

Figure 3-7.)

Figure 3-7 Connecting to an RJ-45C (T1) Jack

0

1

2

P

T1/E1 8 PRI

P

P

P

connector

3

4

5

6

P

7

P

P

P

Straight-through

RJ-45-to-RJ-45 cable

RJ-45 jack

OL-2847-02 0A

Cisco AS5400 Universal Gateway Chassis Installation Guide

3-7

Page 34

Connecting to the Network

• Use an E1 cable to connect each E1/PRI port to an E1 channel service unit (CSU) or data service

Note If you choose a port with 75-ohm input impedance, use an RJ-45-to-75-ohm

Chapter 3 Installing the Cisco AS5400 and Cisco AS5400HPX Universal Gateways

unit (DSU). (See

coaxial cable adapter and plug it into that port. Use software commands to choose

a particular port and the line termination on that port. For information on software

commands, refer to the Cisco

Software Configuration Guide.

Figure 3-8.)

AS5350 and Cisco AS5400 Universal Gateway

Warning

The E1 interface card may only be installed in an ACA-permitted customer equipment or

a Data Terminal Equipment (DTE) that is exempted from ACA’s permit requirements. The

customer equipment must only be housed in a cabinet that has screw-down lids to stop

user access to overvoltages on the customer equipment. The customer equipment has

circuitry that may have telecommunications network voltages on them. To see

translations of the warnings that appear in the publication, refer to the Regulatory

Compliance and Safety Information document that accompanied this device.

Figure 3-8 Connecting to an RJ-45 Jack

0

1

2

P

T1/E1 8 PRI

connector

3

P

4

P

5

P

6

P

7

P

P

P

E1 cable

RJ-45 jack

30847

Cisco AS5400 Universal Gateway Chassis Installation Guide

3-8

OL-2847-02 0A

Page 35

Chapter 3 Installing the Cisco AS5400 and Cisco AS5400HPX Universal Gateways

• Use a serial transition cable to connect one of the two synchronous serial ports to a modem or a

CSU/DSU. (See

Figure 3-9 Connecting to a CSU/DSU

Synchronous serial

port (DB-26)

Figure 3-9.)

Connecting the Console Terminal and Modem

30846

Internet

Serial

transition

cable

EIA/TIA-232, EIA/TIA-449, EIA/TIA-530A,

EIA/TIA-530, V.35, or X.21 connector

Note For cable and port pinouts for specific dial feature cards, refer to Appendix C,

CSU/DSU or

other DCE or DTE

“Cabling Specifications” in the Cisco AS5350 and Cisco AS5400 Universal

Gateway Card Installation Guide.

Connecting the Console Terminal and Modem

Use the console terminal for local administrative access to the universal gateway. You can only connect

a terminal to the console port. You can use the auxiliary port to connect a terminal or a modem for remote

access.

Connecting to the Console Port

To connect a terminal (an ASCII terminal or a PC running terminal emulation software) to the console

port, follow these steps:

Step 1 Connect the terminal using an RJ-45 rollover cable and an RJ-45-to-DB-25 or RJ-45-to-DB-9 adapter.

The adapters provided are labeled TERMINAL. Other types of adapters are not included. (See

Figure 3-10.)

OL-2847-02 0A

Cisco AS5400 Universal Gateway Chassis Installation Guide

3-9

Page 36

Connecting the Console Terminal and Modem

Figure 3-10 Connecting the Console Terminal

Chapter 3 Installing the Cisco AS5400 and Cisco AS5400HPX Universal Gateways

Console port

(RJ-45)

RJ-45-to-RJ-45

rollover cable

RJ-45

Note For additional information on rollover cable pinouts, see Appendix C “Cabling

PC (laptop)

30845

Specifications.”

Step 2 Configure your terminal or PC terminal emulation software for 9600 baud, 8 data bits, no parity, and

2

stop bits. To configure the console port, refer to the Cisco AS5350 and Cisco AS5400 Universal

Gateway Software Configuration Guide.

Connecting a Modem to the Auxiliary Port

To connect a modem to the auxiliary port, follow these steps:

Step 1 Connect a modem to the auxiliary port using an RJ-45 rollover cable with an RJ-45-to-DB-25 adapter.

The adapter provided is labeled MODEM. (See

Cisco AS5400 Universal Gateway Chassis Installation Guide

3-10

Figure 3-11.)

OL-2847-02 0A

Page 37

Chapter 3 Installing the Cisco AS5400 and Cisco AS5400HPX Universal Gateways

Figure 3-11 Connecting a Modem to the Auxiliary Port

Connecting to the BITS Port

Auxiliary port

0

1

2

P

P

P

T1/E1 8 PRI

connector

3

4

5

P

6

P

7

P

P

P

RJ-45-to-RJ-45

rollover cable

(RJ-45)

Step 2 Make sure that your modem and the auxiliary port on the universal gateway are configured for the same

transmission speed (38400 baud is typical) and hardware flow control with Data Carrier Detect (DCD)

and Data Terminal Ready (DTR) operations.

Connecting to the BITS Port

Use a coaxial cable to connect a Timing Signal Generator (TSG) to the BITS port. The BITS port is used

for external clocking. (See

Figure 3-12 Connecting to the BITS Port

Figure 3-12.)

30850

Modem

RJ-45-to-DB-25 adapter

(labeled MODEM)

Timing signal

generator

OL-2847-02 0A

Satellite global

positioning system

Coaxial cable

52503

Universal gateway

Cisco AS5400 Universal Gateway Chassis Installation Guide

3-11

Page 38

Connecting to the Alarm Port

Connecting to the Alarm Port

Connect to the alarm port as follows:

Step 1 Insert the three-pin alarm port connector into the alarm port terminal block. (See Figure 3-13.)

Figure 3-13 Connecting to the Alarm Port

Chapter 3 Installing the Cisco AS5400 and Cisco AS5400HPX Universal Gateways

Alarm port

connector

Cable ties

Note Connect the alarm port only to a safety extra-low voltage (SELV) source using 22

#1#2#3

35145

AWG, or thicker, copper wire. SELV ratings are maximum 30 Volts AC (RMS),

maximum 60 Volts DC, and maximum 50

VA Power. The alarm port is rated for 2.0

Amp maximum current.

Step 2 Strip a minimum 1/4 in. (0.625 cm) off the wire insulation to connect the stranded wires to the alarm

connector. The maximum insulation strip length is 0.31 in. (0.78 cm).

Step 3 Secure the wires to the alarm connector with screws.

Caution The maximum tightening torque on the screws is 7 in.-lb (0.79 N-m).

Step 4 Connect the wires to strain relief clamps that are inserted into the holes in the ventilation grid.

Note See Appendix C “Cabling Specifications” for alarm port cable assembly and port

pinouts.

Cisco AS5400 Universal Gateway Chassis Installation Guide

3-12

OL-2847-02 0A

Page 39

Chapter 3 Installing the Cisco AS5400 and Cisco AS5400HPX Universal Gateways

Supplying Power

The power system is comprised of a fully redundant switching power supply with two AC (or two DC)

inputs to the main power modules. Each input and output is 100 percent fully redundant, with dual fans

for added reliability.

The output of each power module is rated at 300 watts (nonredundant mode), and is composed of four

independent output voltages: 3.3V, 5V, 12V, and -12V. AC input units have power factor correction,

and low Total Harmonic Distortion. Units that are in redundant mode run at one-half the power

capability. If a power supply failure occurs, these units are capable of powering the complete system

either at the input side or the DC load side. Power failures are reported through software SNMP alarm

traps.

Check the power at your site to ensure that you are receiving “clean” power (free of spikes and noise).

Install a power conditioner if necessary.

The universal gateway AC power supply includes the following features:

• Full range operation—100 to 240 VAC.

• All units include two 6-foot (1.8-meter) electrical power cords. (A label near the power inlets

indicates the correct voltage, frequency, current draw, and power dissipation for the unit.)

Supplying Power

Caution In a DC power supply installation, do not connect the 48 VDC Return to chassis ground at

the Cisco AS5400. A single-point ground is recommended at the power distribution rack.

Warning

Warning

Warning

Do not touch the power supply when the power cord is connected. For systems with a

power switch, line voltages are present within the power supply even when the power

switch is off and the power cord is connected. For systems without a power switch, line

voltages are present within the power supply when the power cord is connected. To see

translations of the warnings that appear in the publication, refer to the Regulatory

Compliance and Safety Information document that accompanied this device.

This product relies on the building’s installation for short-circuit (overcurrent)

protection. Ensure that a fuse or circuit breaker no larger than 120

VAC, 10A international) is used on the phase conductors (all current-carrying

(240

conductors). To see translations of the warnings that appear in the publication, refer to

the Regulatory Compliance and Safety Information document that accompanied this

device.

The device is designed to work with TN power systems. To see translations of the

warnings that appear in the publication, refer to the Regulatory Compliance and Safety

Information document that accompanied this device.

VAC, 15A U.S.

OL-2847-02 0A

Cisco AS5400 Universal Gateway Chassis Installation Guide

3-13

Page 40

Supplying Power

Connecting the AC Power Cord

To connect the power cord, follow these steps:

Step 1 Connect one end of each power cord to the power connectors on the rear panel. (See Figure 3-14.)

Figure 3-14 Connecting the AC Power Cord

Chapter 3 Installing the Cisco AS5400 and Cisco AS5400HPX Universal Gateways

Power switch

30851

Step 2 Latch the clips provided on the power supply of the chassis to each power cord.

Step 3 Connect the other end of the power cords to the power outlets.

Warning

Step 4 Power ON the universal gateway.

The plug-socket combination must be accessible at all times because it serves as the

main disconnecting device. To see translations of the warnings that appear in the

publication, refer to the Regulatory Compliance and Safety Information document that

accompanied this device.

The internal power supply fan should power on.

Wiring the DC Power Supply

If you ordered the universal gateway with a DC power supply, follow the procedure in this section to

wire the terminal block.

Warning

A readily accessible two-poled disconnect device must be incorporated in the fixed

wiring. To see translations of the warnings that appear in the publication, refer to the

Regulatory Compliance and Safety Information document that accompanied this device.

Cisco AS5400 Universal Gateway Chassis Installation Guide

3-14

OL-2847-02 0A

Page 41

Chapter 3 Installing the Cisco AS5400 and Cisco AS5400HPX Universal Gateways

Supplying Power

Warning

Before performing any of the following procedures, ensure that power is removed from

the DC circuit. To ensure that all power is OFF, locate the circuit breaker on the panel

board that services the DC circuit, switch the circuit breaker to the OFF position, and

tape the switch handle of the circuit breaker in the OFF position. To see translations of

the warnings that appear in the publication, refer to the Regulatory Compliance and

Safety Information document that accompanied this device.

Note This product is intended for installation in restricted access areas and is approved for

connection using 12 or 14 AWG copper conductors only. The installation must comply with

all applicable codes.

Refer to Figure 3-15 and follow these steps to wire the terminal blocks:

Step 1 Note the orientation of the DC power supply. The power supply cord should have three wires: 48 VDC

Return, -48 VDC, and a safety ground (green wire).

Warning

The illustration shows the DC power supply terminal block. Wire the DC power supply

using the appropriate wire terminations at the wiring end, as illustrated. The proper

wiring sequence is ground to ground, return to return, and negative to negative. Note that

the ground wire should always be connected first and disconnected last. To see

translations of the warnings that appear in the publication, refer to the Regulatory

Compliance and Safety Information document that accompanied this device.

Figure 3-15 DC Power Supply Connections

Mounting screws

Terminal block

J2

IN OK

LEDs

LEDs

DC

OTF

IN OK

DC

OTF

J1

Terminal block

Mounting screw

On/off switch

146407

OL-2847-02 0A

Cisco AS5400 Universal Gateway Chassis Installation Guide

3-15

Page 42

Where to Go Next

Caution In a DC power supply installation do not connect the 48 VDC Return to chassis ground at

Step 2 Strip off a quarter of an inch (1/4 in. [0.625 cm]) of insulation on the safety ground, 48 VDC Return, and

Step 3 Install the safety grounds (green wire) into the terminal block ground connectors and tighten the locking

Note For central office installations, we recommend using a copper 6 AWG green ground wire

Caution Do not overtorque the terminal block contact screws. The recommended torque is

Chapter 3 Installing the Cisco AS5400 and Cisco AS5400HPX Universal Gateways

the Cisco AS5400. A single-point ground is recommended at the power distribution rack.

-48

VDC input wires.

screws. Ensure that no bare wire is exposed.

with one end connected to reliable earth. The other end of the wire should be crimped onto

the double-hole lug provided in the installation pack. The lug should be secured to the

mating holes on either side of the chassis with the two screws included in the accessory

pack.

5.0 in.-lb (0.56 N-m).

Step 4 Insert both 48 VDC Return wires into the terminal block positive connectors (+) and tighten the locking

screws. Ensure that no bare wire is exposed.

Step 5 Insert both -48 VDC wires into the terminal block negative connectors (-) and tighten the locking screws.

Ensure that no bare wire is exposed.

Step 6 Secure the power supply cords to the cable strain-relief clamps on the DC power supply with cable ties.

(See

Figure 3-15.)

Warning

Step 7 Power ON the universal gateway.