Page 1

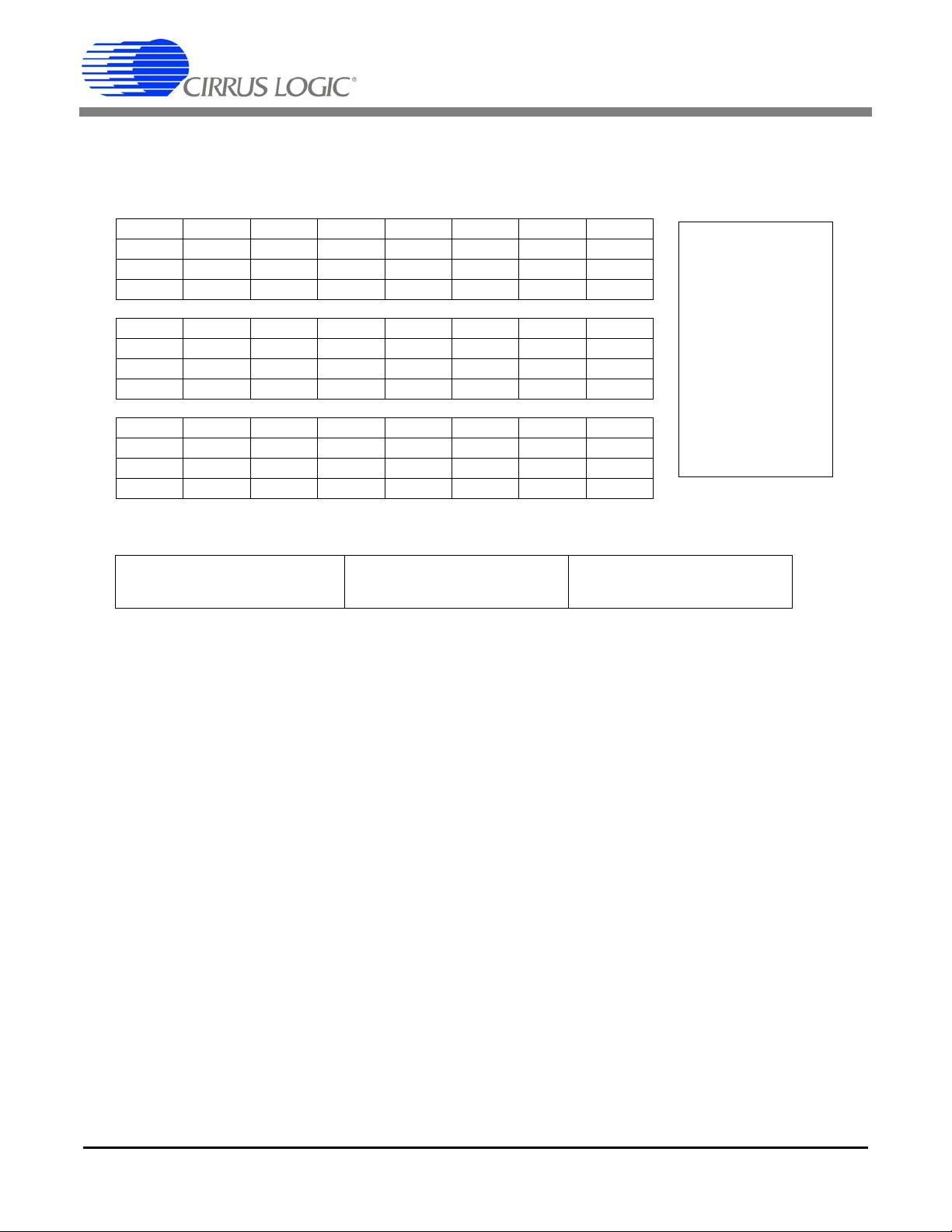

CS5378

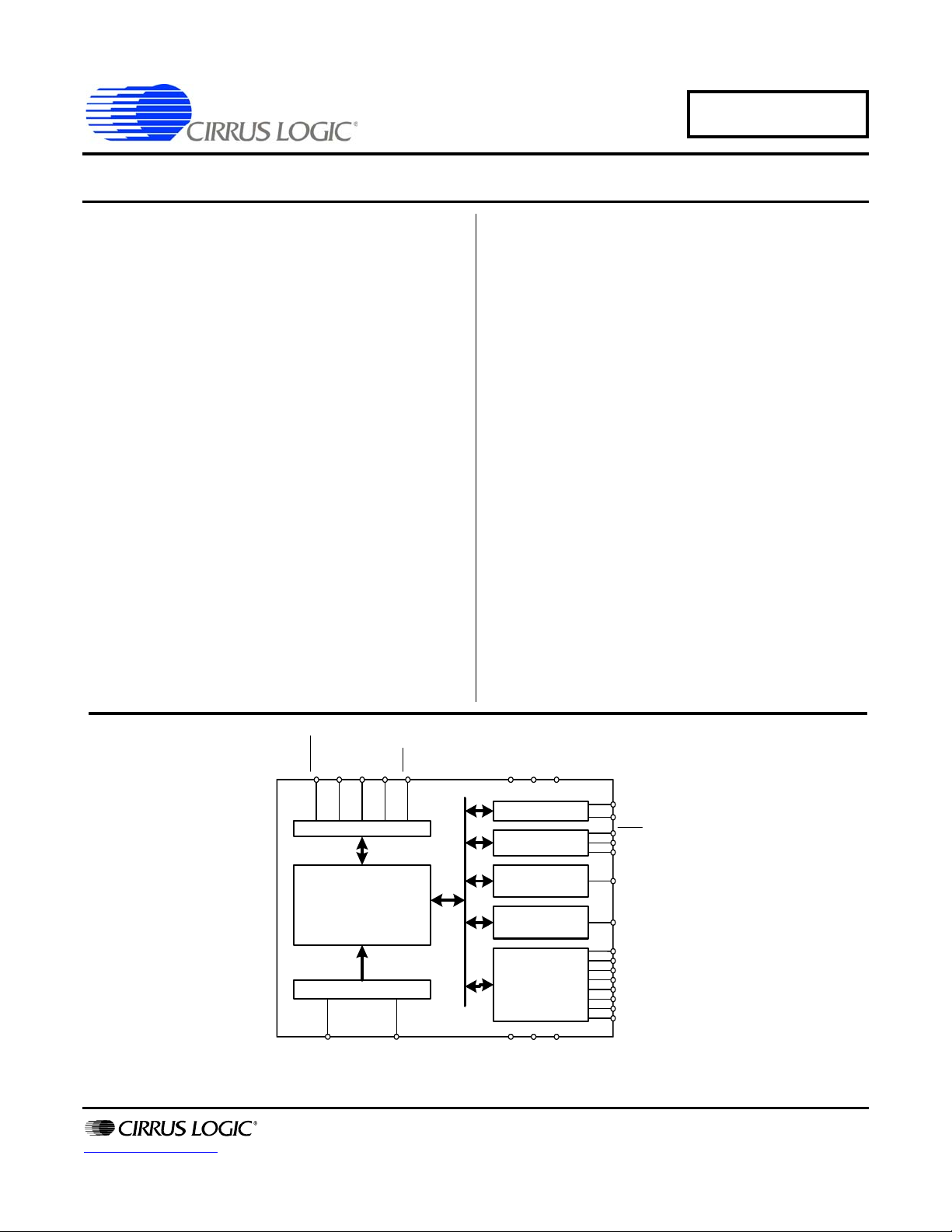

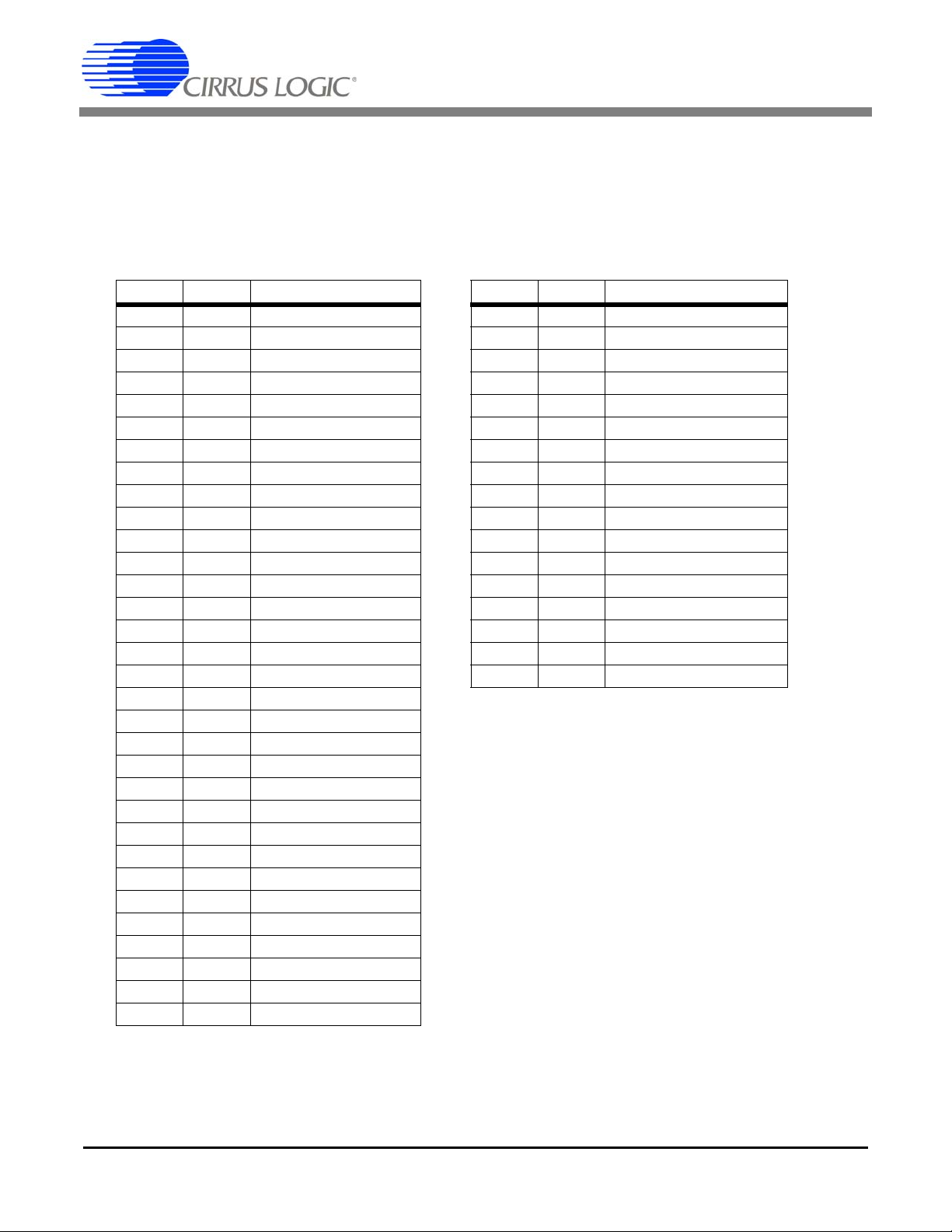

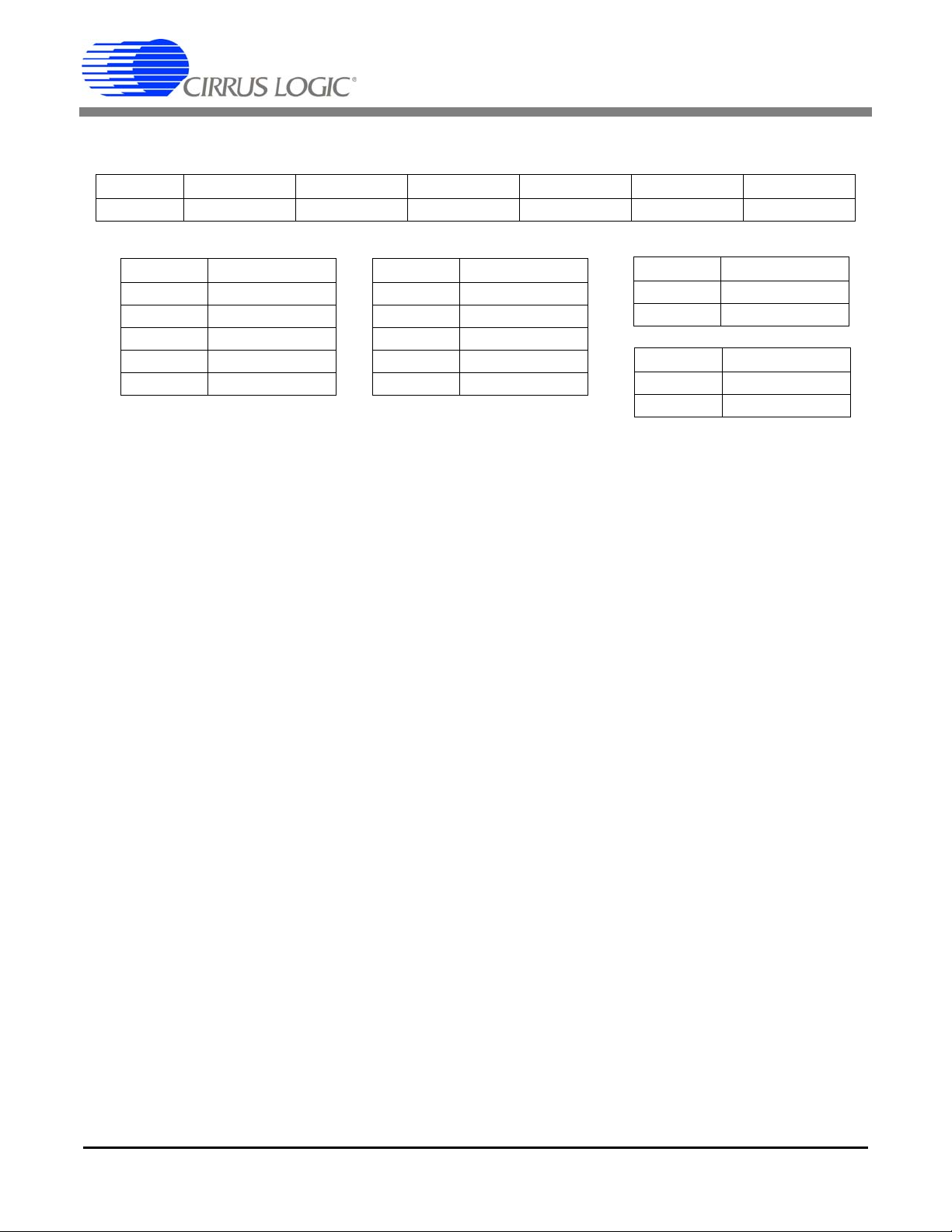

Serial Interface

Decimation and

Filtering Engine

Mod u lator Data Inte r fa c e

Test Bit Stream

Con tr o lle r

Reset, Synchronization

TBSD ATA

Time Break Controller

GPIO

General Purpose I/O

SCK

MOSI

VDDPAD

VDDPLL

VDDCORE

SYNC

MSYNC

TIME B

GPIO5:PLL1

GPIO4:PLL0

GPIO3

GPIO2

GPIO1

GNDPAD

GNDCORE

GNDPLL

MDATA

MFLAG

GPIO0

GPIO6:PLL2

GPIO7:BOOT

DRDY

MISO

SS:EECS

RESET

CLK

MCLK

PLL, Clock Generation

Low-power Single-channel Decimation Filter

Features

Single-channel Digital Decimation Filter

Multiple On-chip FIR and IIR Coefficient Sets

Programmable Coefficients for Custom Filters

Synchronous Operation

Integrated PLL for Clock Generation

1.024 MHz, 2.048 MHz, or 4.096 MHz Input

Standard Clock or Manchester Input

Selectable Output Word Rate

4000, 2000, 1000, 500, 333, 250 SPS

200, 125, 100, 50, 40, 25, 20, 10, 5, 1 SPS

Digital Gain and Offset Corrections

Test DAC Bit-stream Generator

Digital Sine Wave Output

Time Break Controller, General-purpose I/O

Microcontroller or EEPROM Configuration

Small-footprint, 28-pin SSOP Package

Low Power Consumption

16 mW at 500 SPS OWR

Flexible Power Supplies

I/O Interface and PLL: 3.3 V or 5.0 V

Digital Logic Core: 2.5 V, 3.3 V or 5.0 V

I

Description

The CS5378 is a multi-function digital filter utilizing a lowpower signal processing architecture to achieve efficient

filtering for a delta-sigma-type modulator. By combining

the CS537 8 with a CS33 01A/02A di fferential a mplifier

and a CS5373A modulator + test DAC, a synchronous

high-resolution, self- testing, sin gle-channel m easurement system can be designed quickly and easily.

Digital filter coefficients for the CS5378 FIR and IIR filters

are included on-chip for a simple setup, or they can be

programmed for custom ap plications. Selectable digital

filter decimation ratios produce output wor d rates from

4000 SPS to 1 SPS, resulting in measurement bandwidths ra nging fro m 16 00 Hz down to 400 mHz whe n

using the on-chip coefficient sets.

The CS5378 includes integrated peripherals to simplify

system d esign: a low- jitter PL L for standard clo ck or

Manchester inpu ts, offset and gain co rrections, a test

DAC bit stream generator, a tim e break controller, and

eight general-purpose I/O pins.

ORDERING INFORMATION

See page 86.

http://www.cirrus.com

Copyright Cirrus Logic, Inc. 2010

(All Rights Reserved)

2&7 ‘10

DS639F3

Page 2

TABLE OF CONTENTS

1. General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.1. Digital Filter Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.2. Integrated Peripheral Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.3. System Level Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.4. Configuration Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2. Characteristics and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 12

Specified Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Thermal Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Digital Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Power Consumption. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Switching Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3. System Design with CS5378. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.1. Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.2. Reset Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.3. PLL and Clock Generation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.4. Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.5. System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.6. Digital Filter Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.7. Data Collection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.8. Integrated peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4. Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.1. Pin Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.2. Bypass Capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.3. Power Consumption. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

5. Reset Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

5.1. Pin Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

5.2. Reset Self-Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

5.3. Boot Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

6. PLL and Clock Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.1. Pin Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

6.2. PLL Mode Select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

6.3. Synchronous Clocking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

6.4. Master Clock Jitter and Skew. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

7. Synchronization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.1. Pin Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

7.2. MSYNC Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

7.3. Digital Filter Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

7.4. Modulator Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

7.5. Test Bit Stream Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

8. Configuration By EEPROM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.1. Pin Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

8.2. EEPROM Hardware Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

8.3. EEPROM Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

8.4. EEPROM Configuration Commands . . . . . . . . . . . . . . . . . . . . . . . . . . .27

8.5. Example EEPROM Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

9. Configuration By Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . 30

CS5378

DS639F3 2

Page 3

9.1. Pin Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

9.2. Microcontroller Hardware Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

9.3. Microcontroller Serial Transactions . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

9.4. Microcontroller Configuration Commands . . . . . . . . . . . . . . . . . . . . . . .33

9.5. Example Microcontroller Configuration . . . . . . . . . . . . . . . . . . . . . . . . .35

10. Modulator Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10.1. Pin Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

10.2. Modulator Clock Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

10.3. Modulator Synchronization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

10.4. Modulator Data Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

10.5. Modulator Flag Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

11. Digital Filter Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

11.1. Filter Coefficient Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

11.2. Filter Configuration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

12. SINC Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

12.1. SINC1 Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

12.2. SINC2 Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

12.3. SINC3 Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

12.4. SINC Filter Synchronization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

13. FIR Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

13.1. FIR1 Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

13.2. FIR2 Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

13.3. On-Chip FIR Coefficients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

13.4. Programmable FIR Coefficients. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

13.5. FIR Filter Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

14. IIR Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

14.1. IIR Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

14.2. IIR1 Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

14.3. IIR2 Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

14.4. IIR3 Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

14.5. On-Chip IIR Coefficients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

14.6. Programmable IIR Coefficients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

14.7. IIR Filter Synchronization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

15. Gain and Offset Correction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

15.1. Gain Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

15.2. Offset Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

15.3. Offset Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

16. Serial Data Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

16.1. Pin Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

16.2. Serial Data Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

16.3. Serial Data Transactions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

17. Test Bit Stream Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

17.1. Pin Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

17.2. TBS Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

17.3. TBS Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

17.4. TBS Data Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

17.5. TBS Sine Wave Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

17.6. TBS Loopback Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

CS5378

DS639F3 3

Page 4

17.7. TBS Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

18. Time Break Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

18.1. Pin Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

18.2. Time Break Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

18.3. Time Break Delay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

19. General Purpose I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

19.1. Pin Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

19.2. GPIO Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

19.3. GPIO Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

19.4. GPIO Input Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

19.5. GPIO Output Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

20. Register Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

20.1. SPI Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

20.2. Digital Filter Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

21. Pin Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

22. Package Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

23. Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

24. Environmental, Manufacturing, & Handling Information. . . . . . . 86

25. Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

CS5378

LIST OF FIGURES

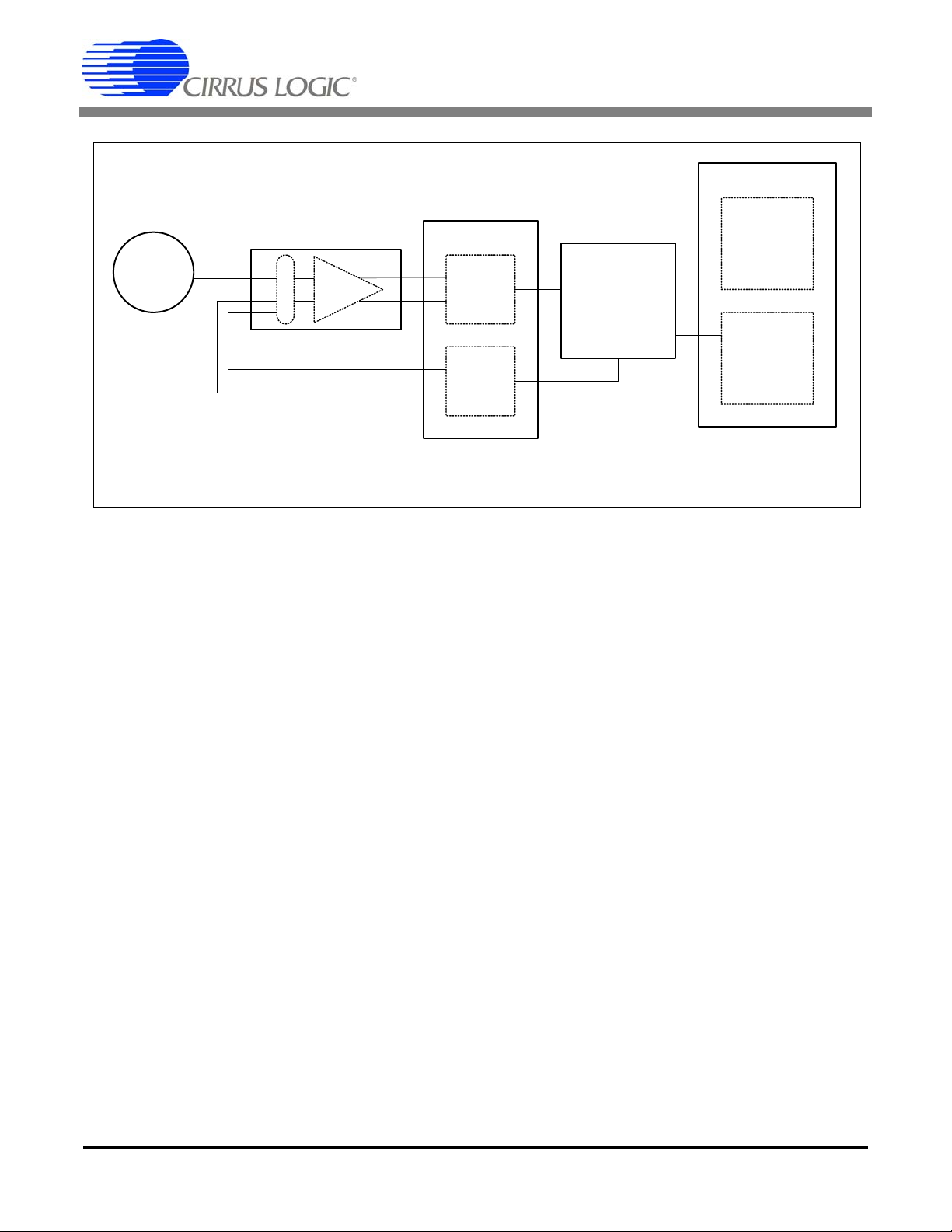

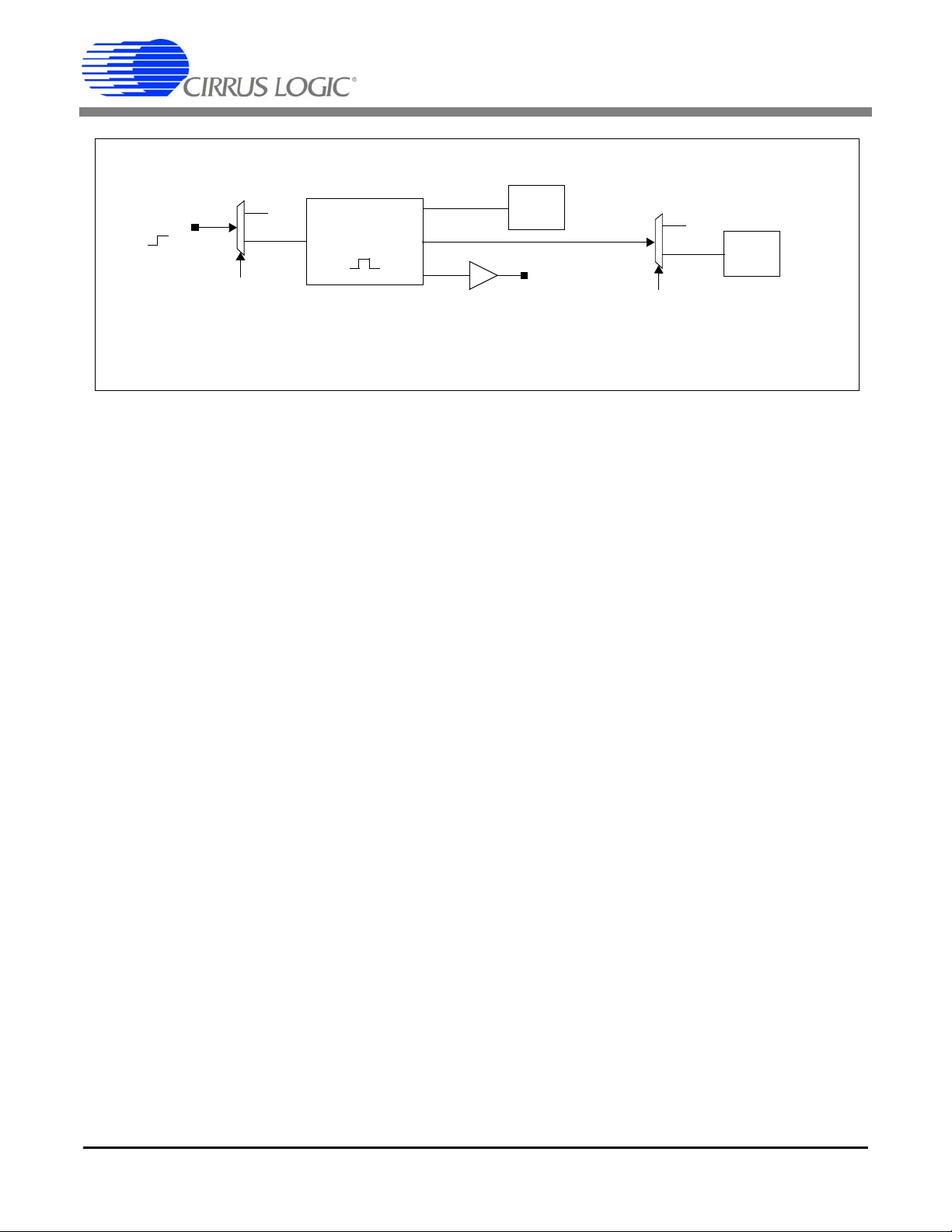

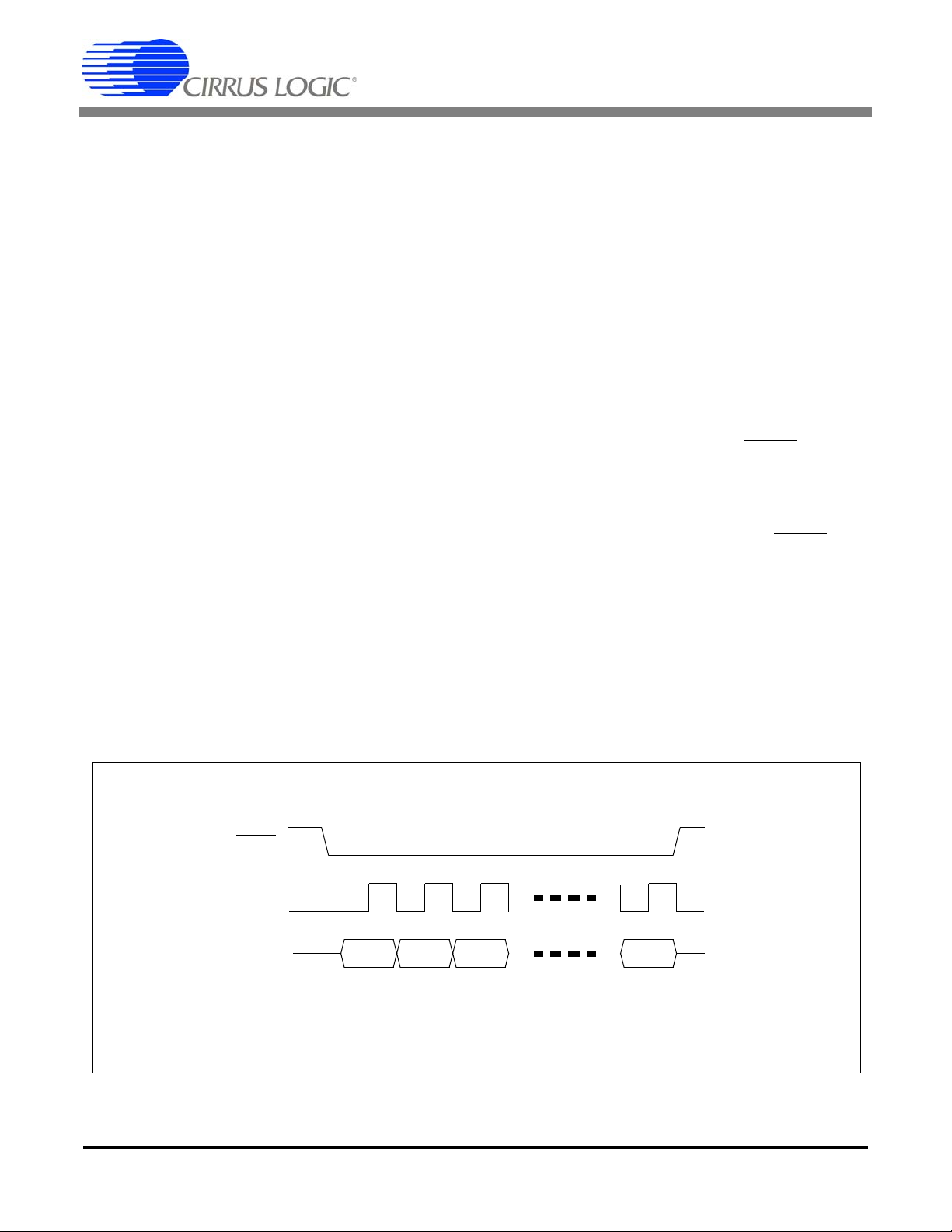

Figure 1. CS5378 Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

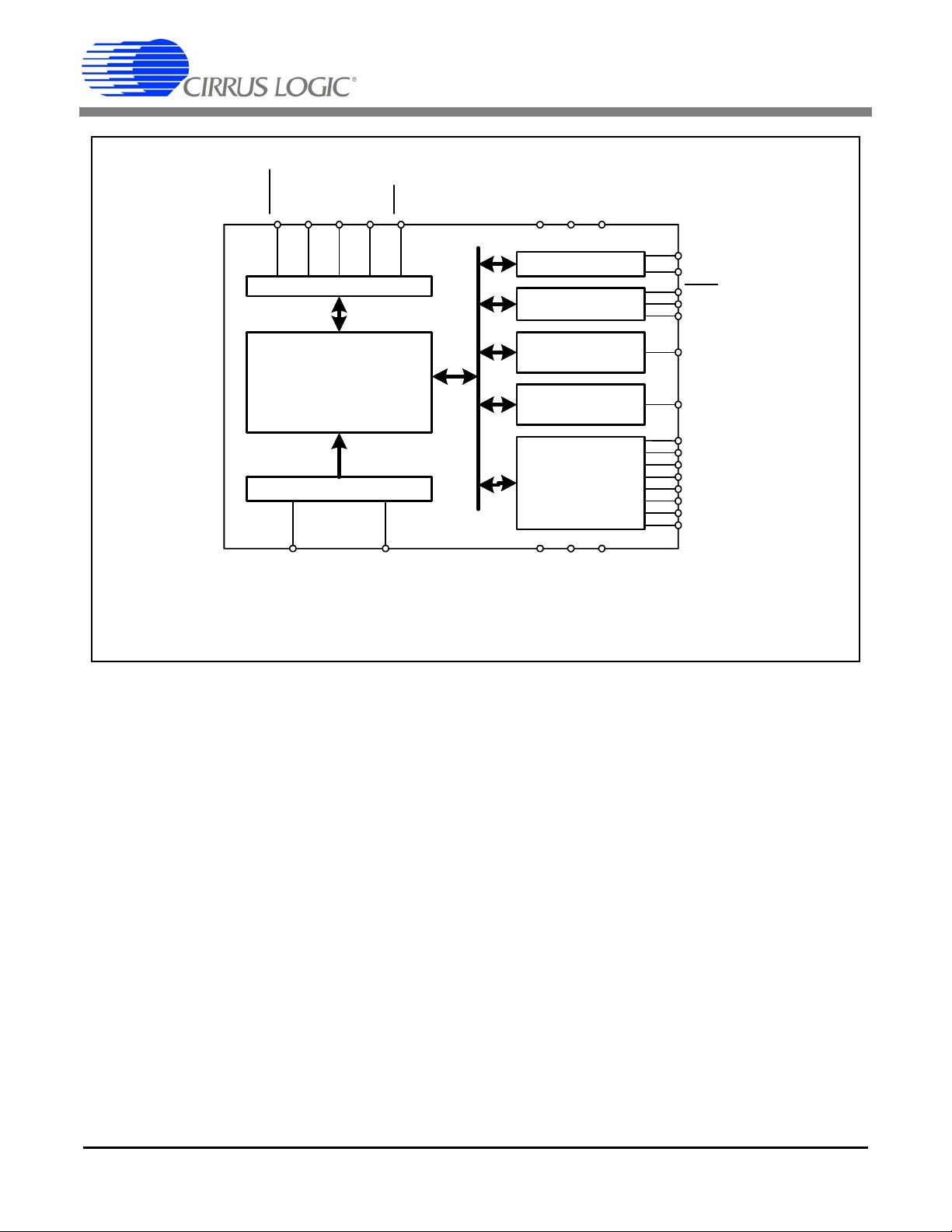

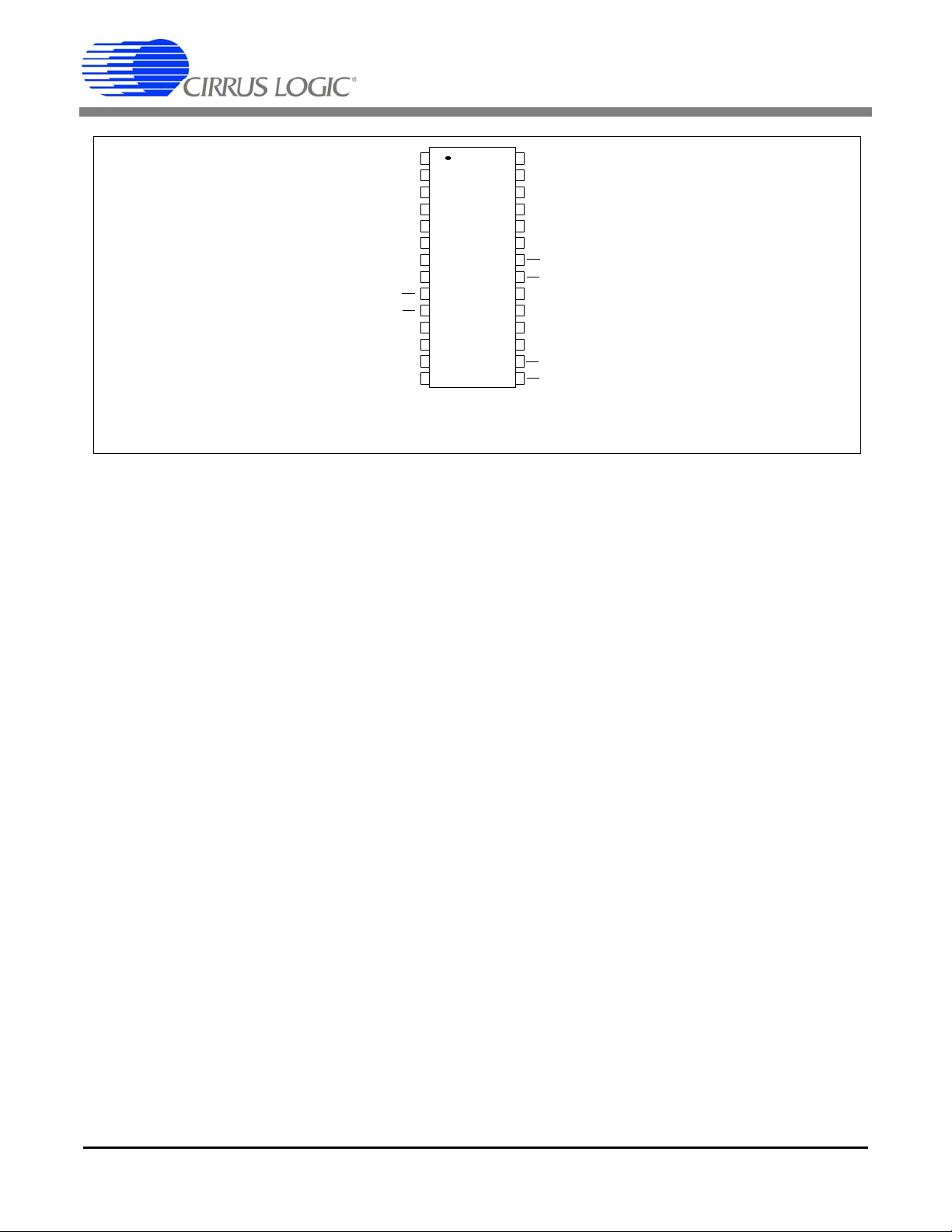

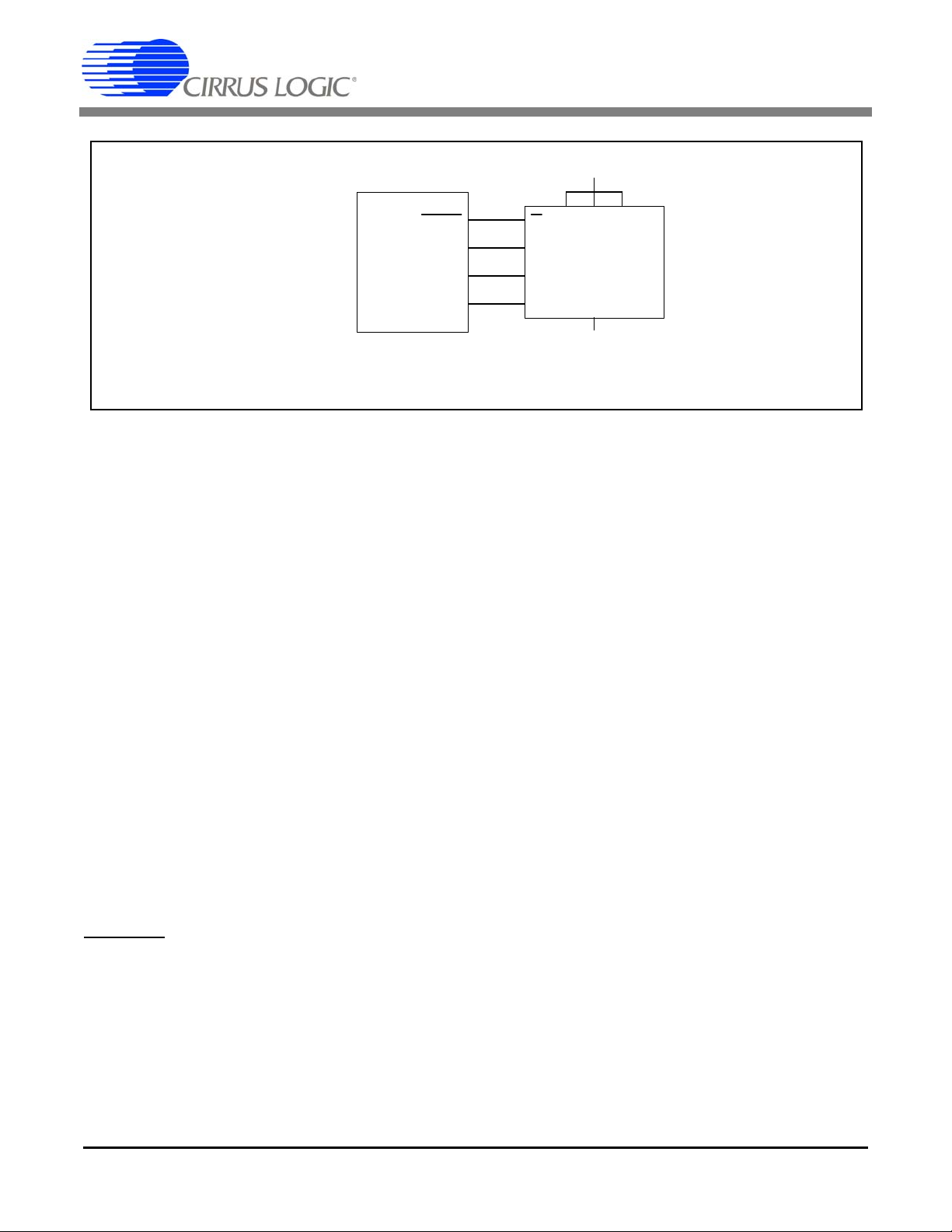

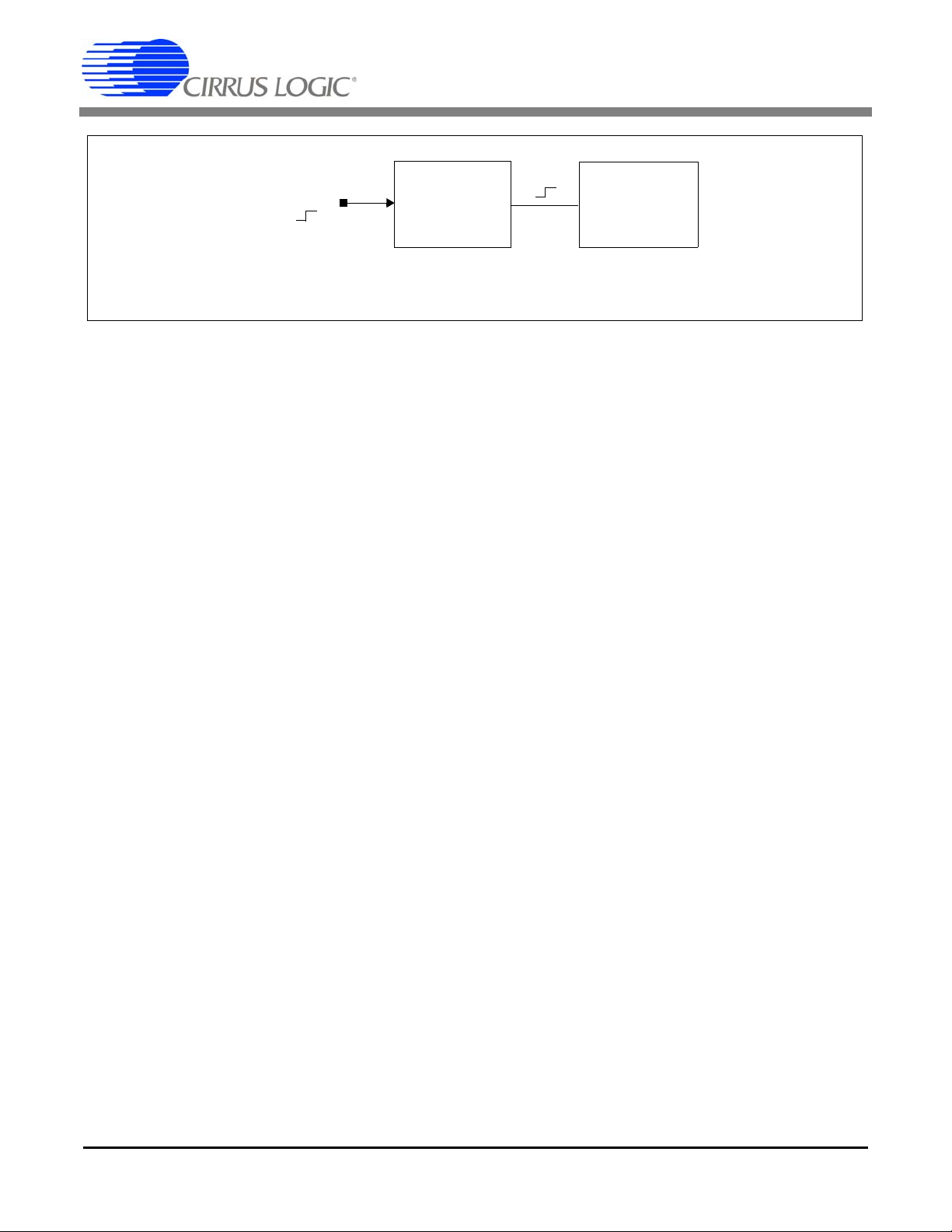

Figure 2. Digital Filtering Stages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

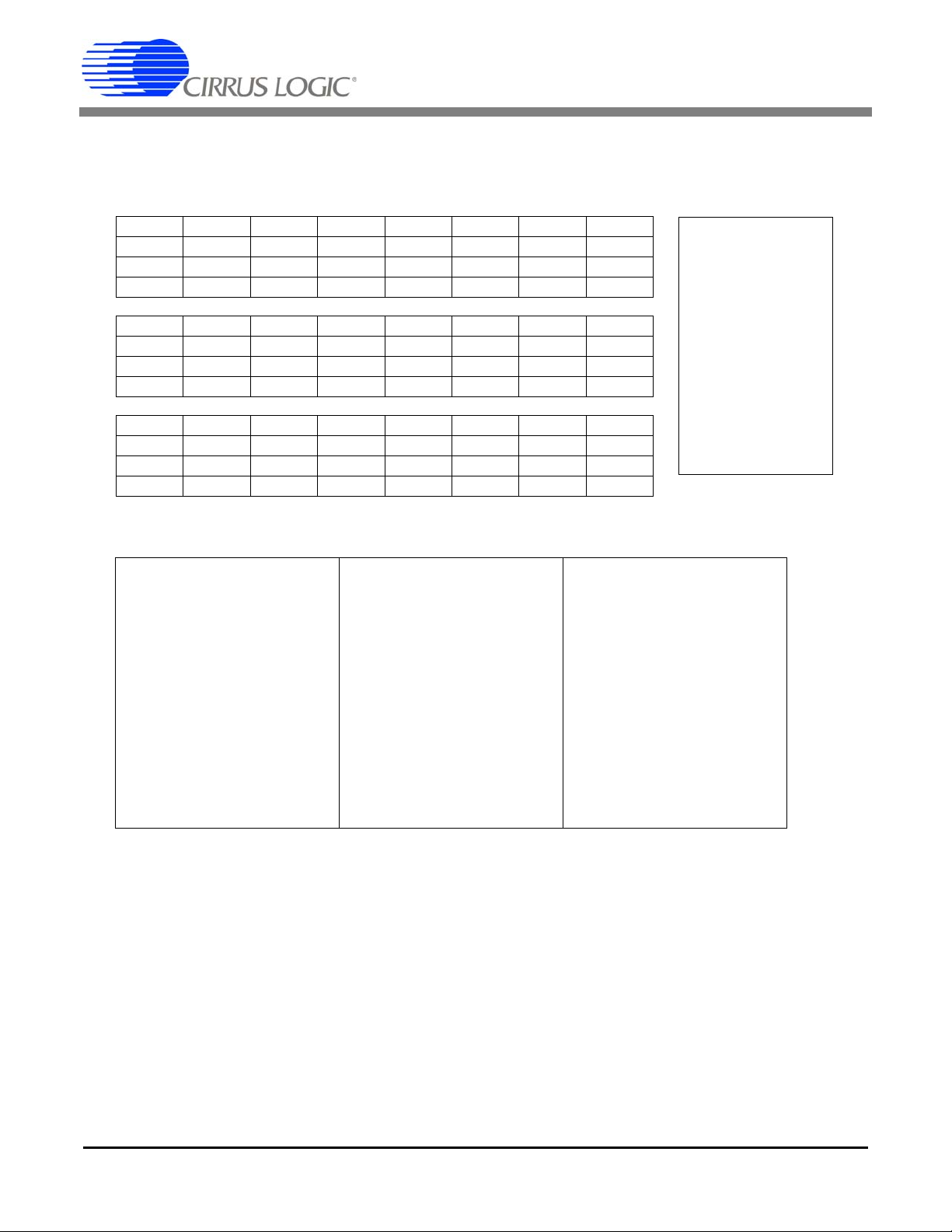

Figure 3. FIR and IIR Coefficient Set Selection Word . . . . . . . . . . . . . . . . . . . . . . . . . . 10

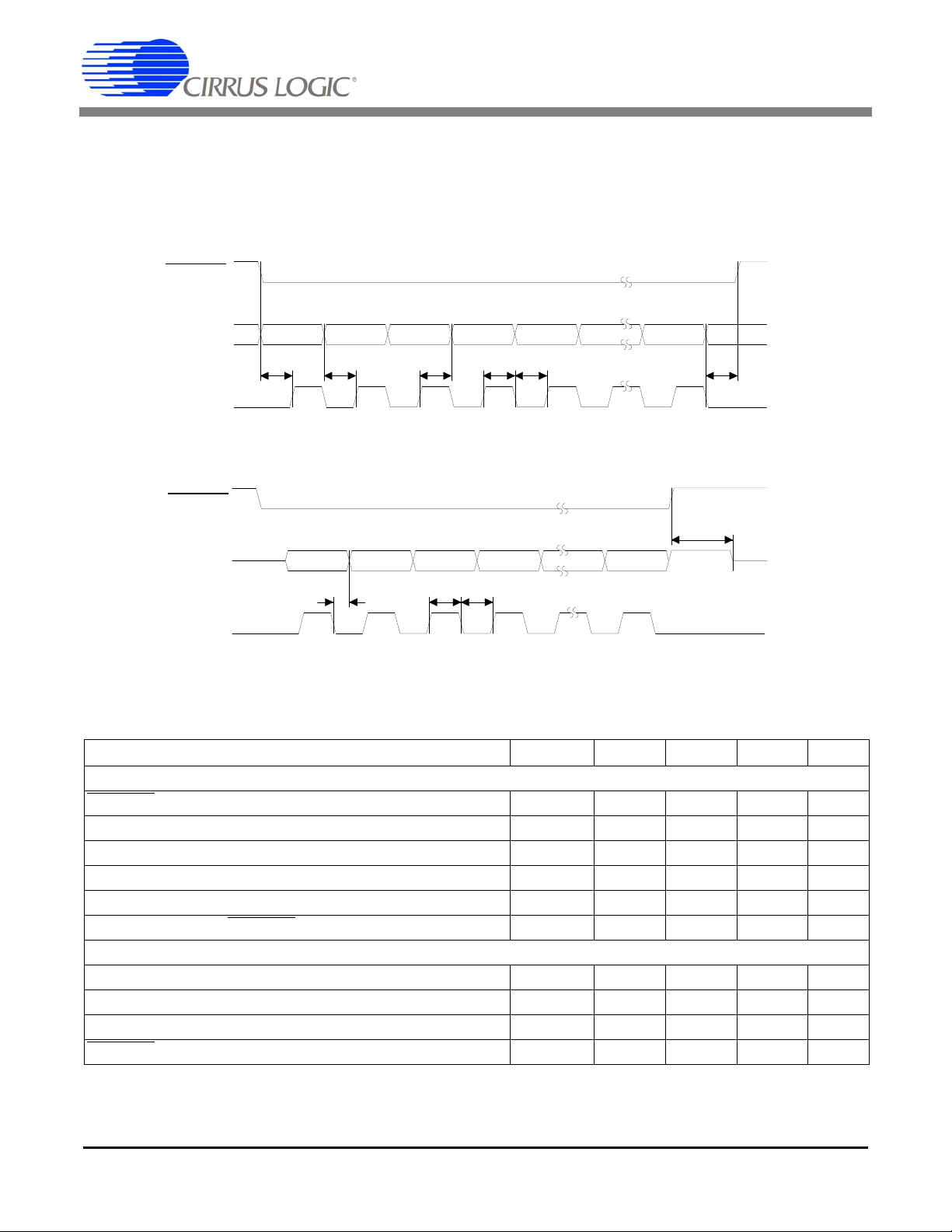

Figure 4. MOSI Write Timing in SPI Slave Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 5. MISO Read Timing in SPI Slave Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

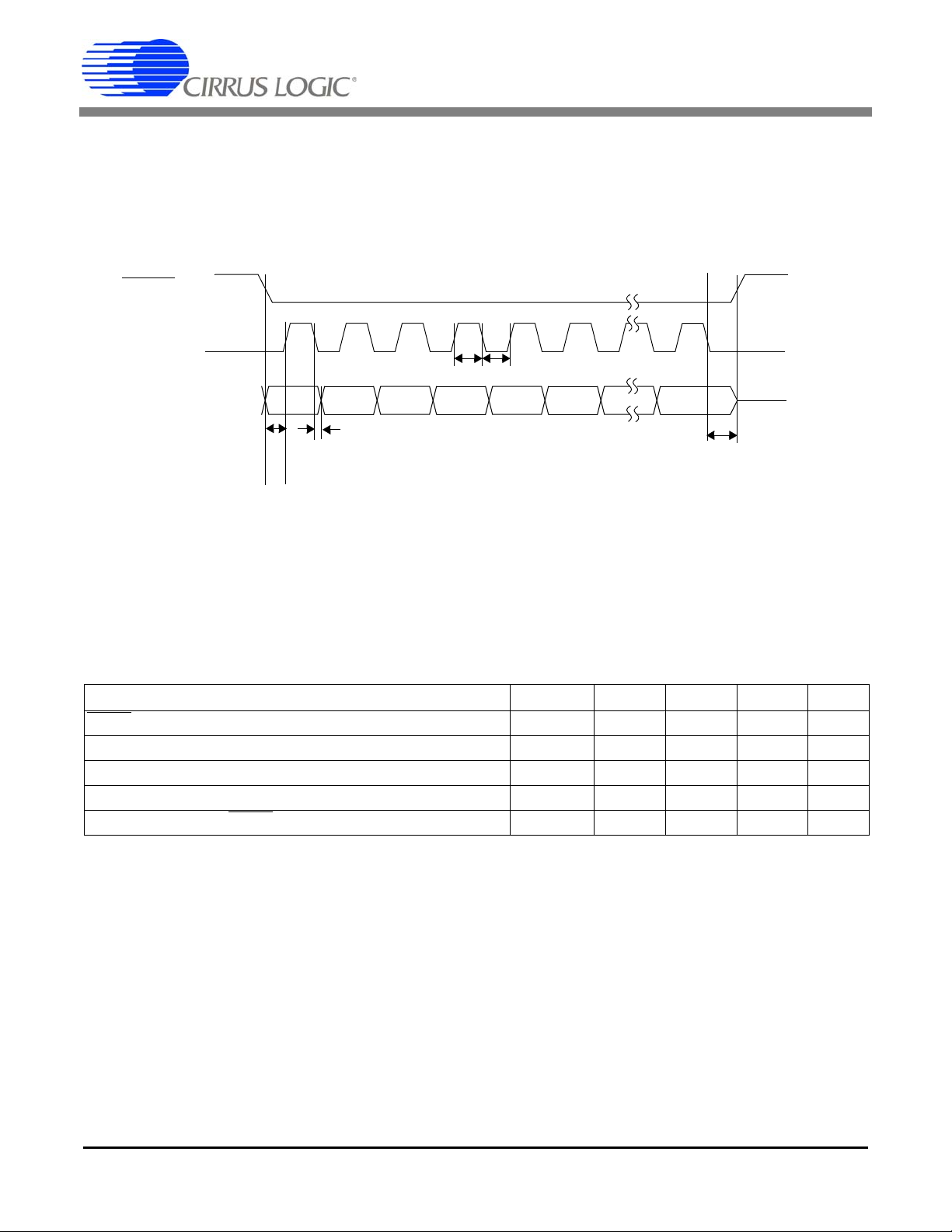

Figure 6. Serial Data Read Timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

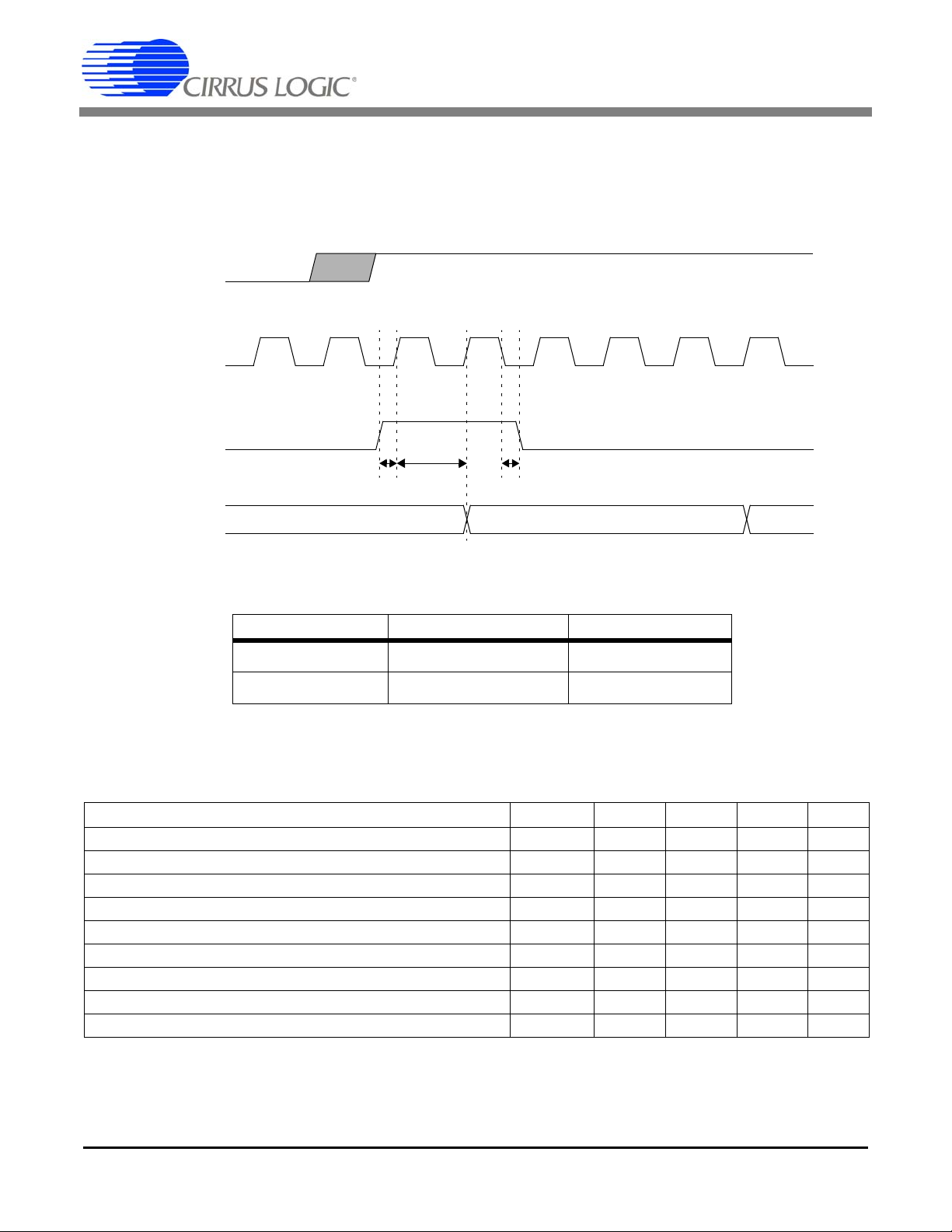

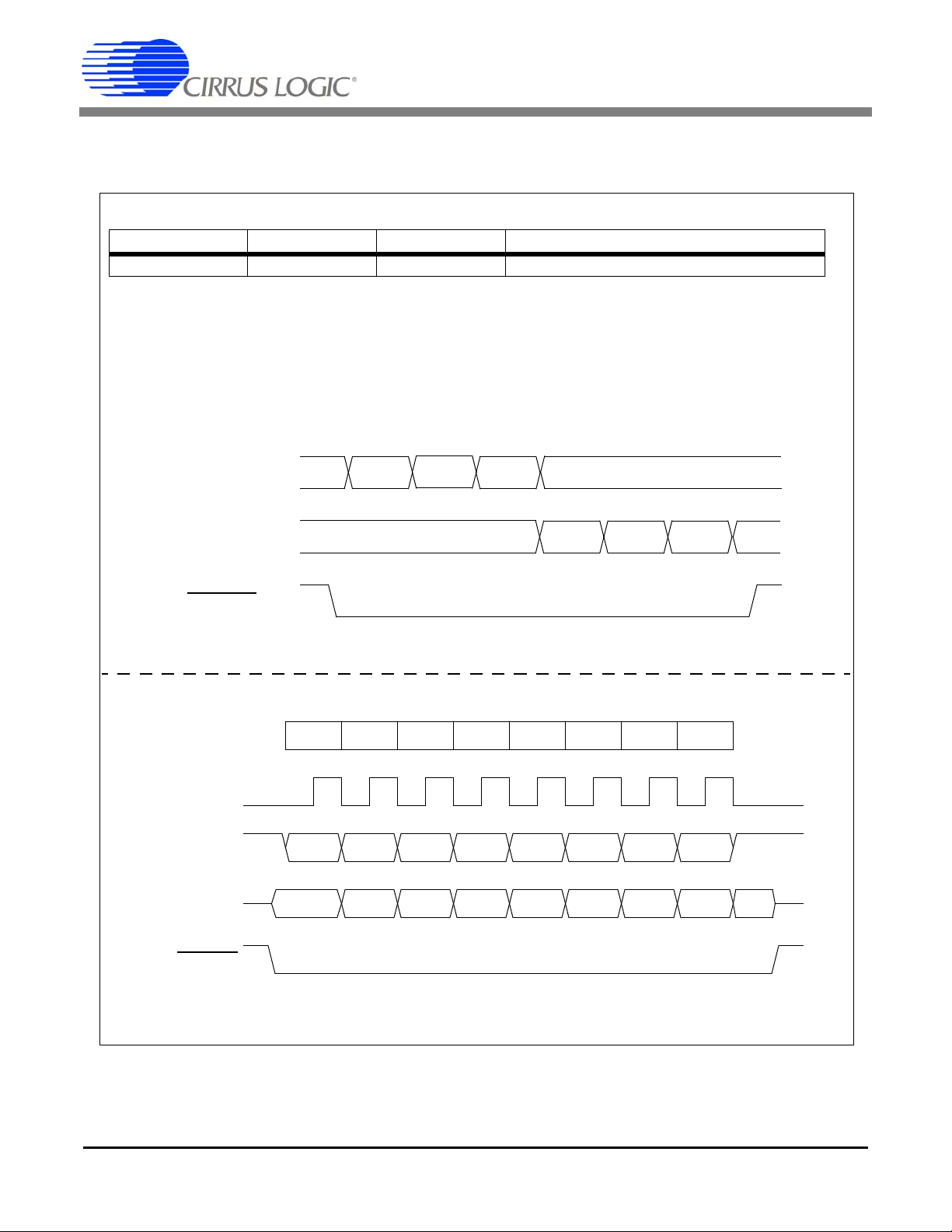

Figure 7. SYNC, MCLK, MSYNC, MDATA Interface Timing. . . . . . . . . . . . . . . . . . . . . 16

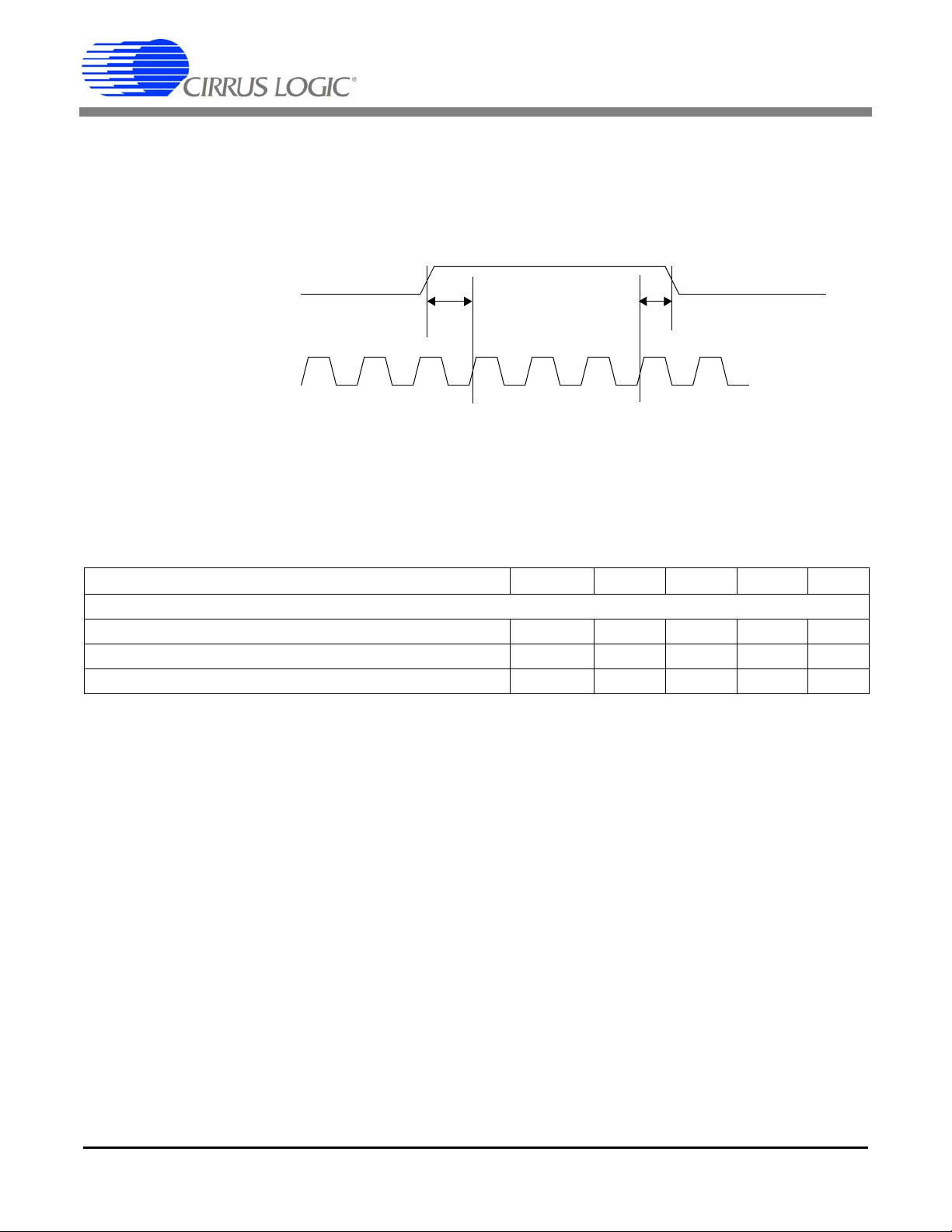

Figure 8. TBS Output Data Timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

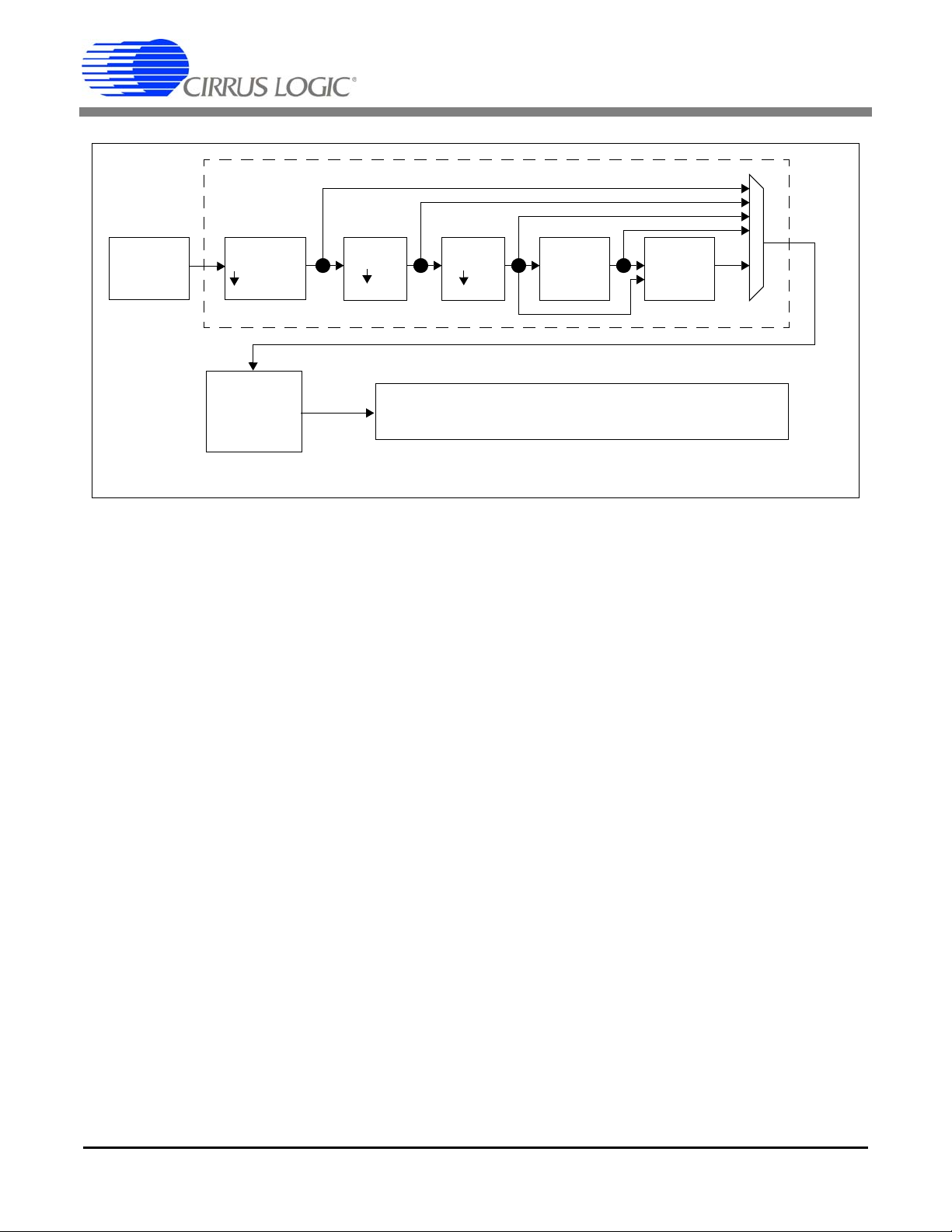

Figure 9. Single-Channel System Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

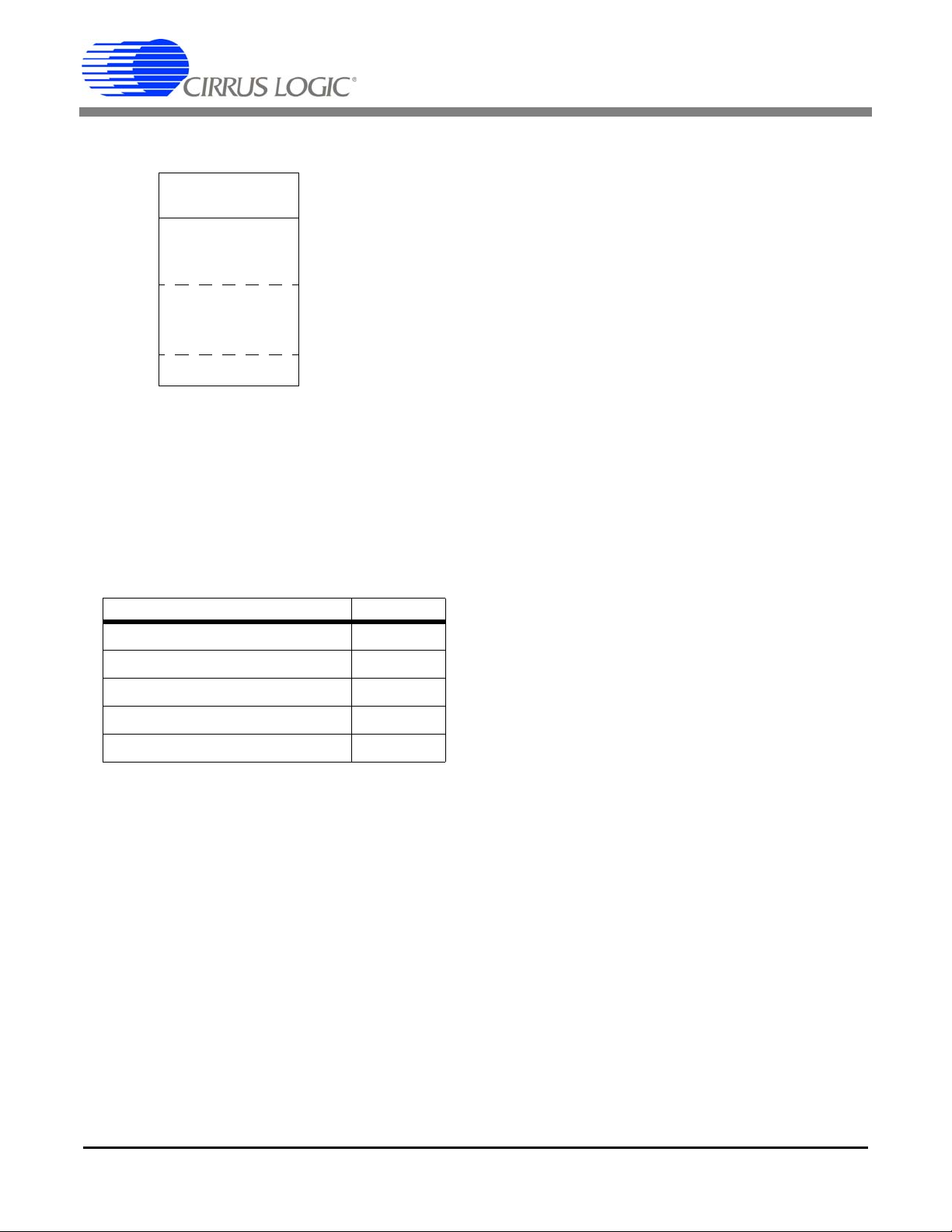

Figure 10. Power Supply Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

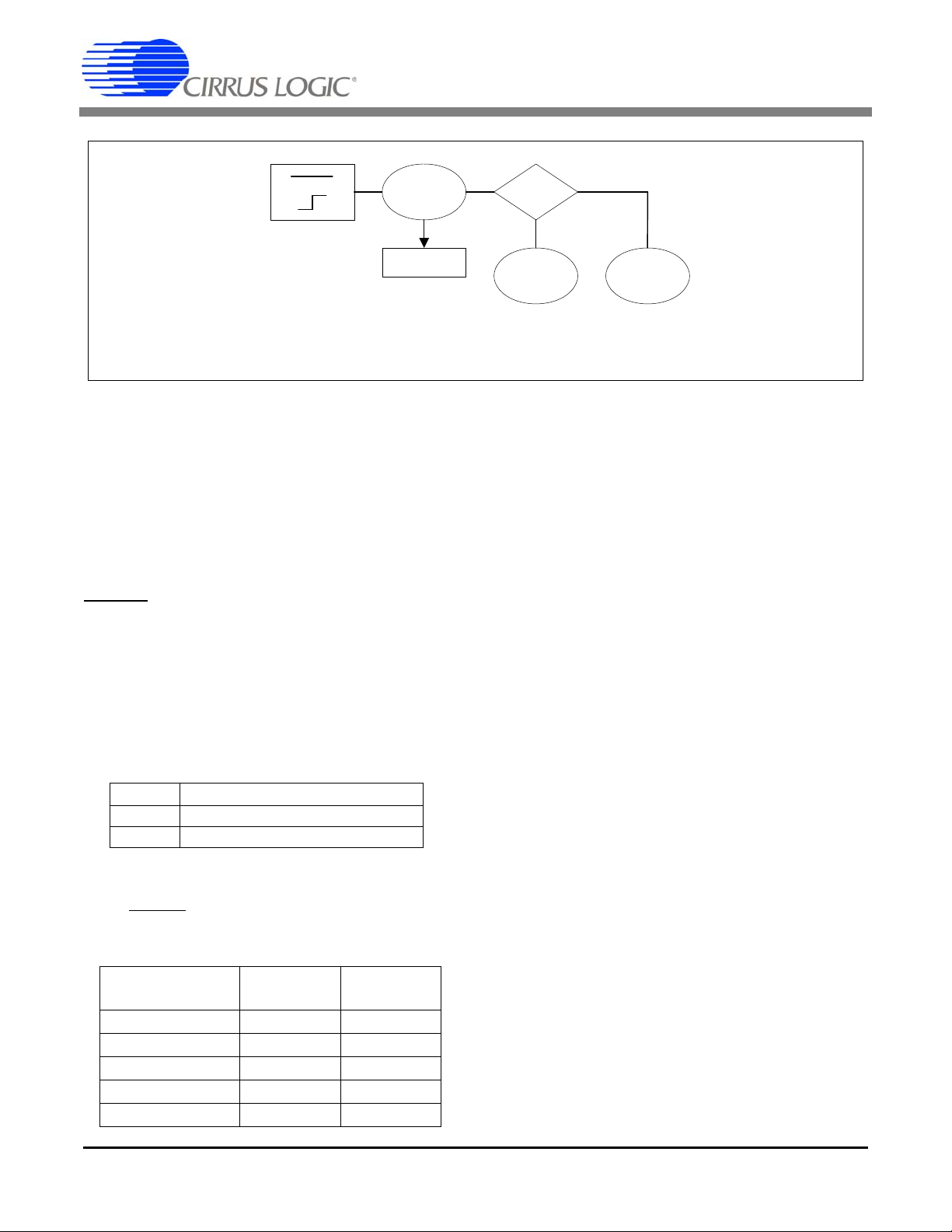

Figure 11. Reset Control Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 12. Clock Generation Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 13. Synchronization Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 14. EEPROM Configuration Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 15. EEPROM Serial Read Transactions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 16. 8 Kbyte EEPROM Memory Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 17. Serial Interface Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 18. Microcontroller Serial Transactions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 19. SPI Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

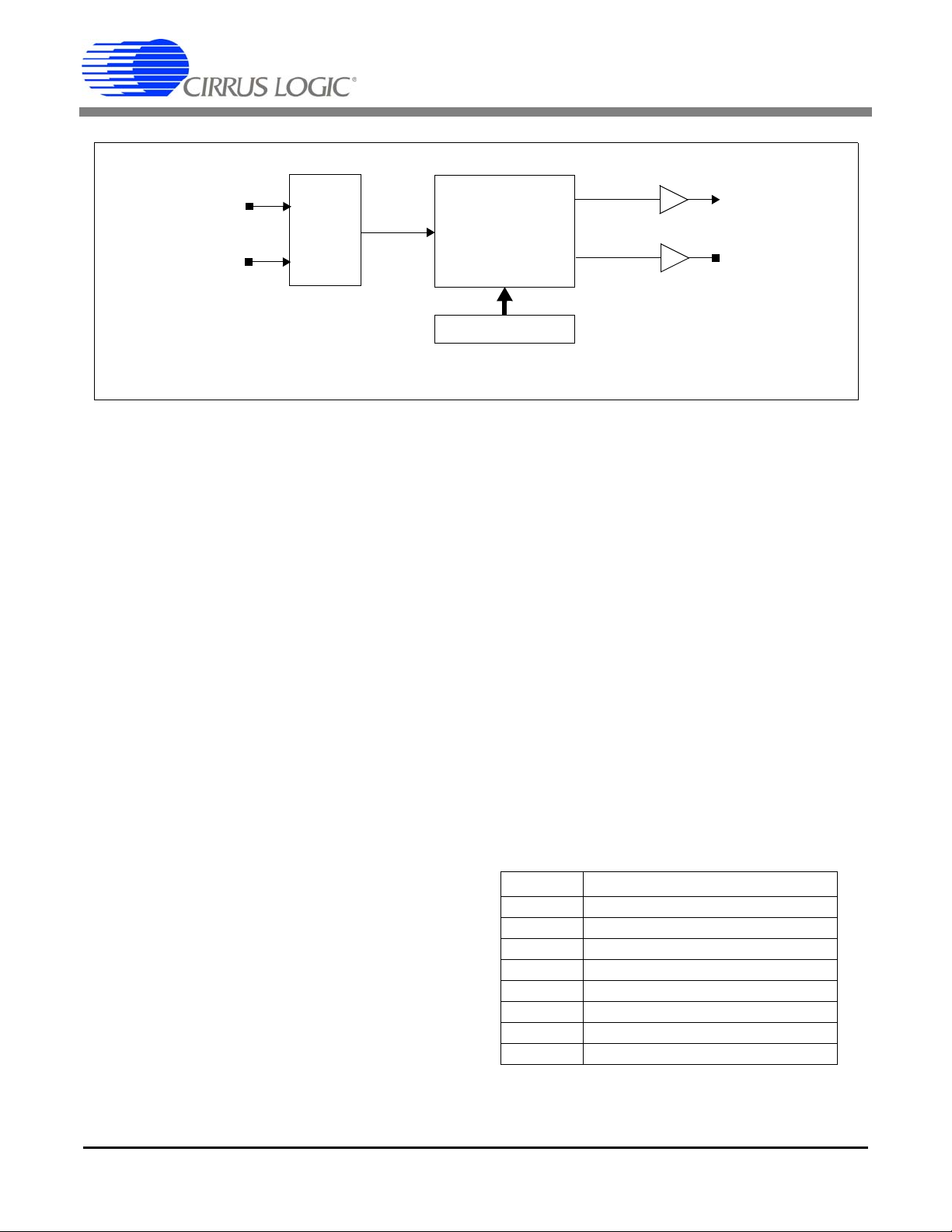

Figure 20. Modulator Data Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 21. Digital Filter Stages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 22. FIR and IIR Coefficient Set Selection Word . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 23. SINC Filter Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 24. SINC Filter Stages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 25. FIR Filter Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 26. FIR Filter Stages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 27. FIR1 Coefficients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 28. FIR2 Linear Phase Coefficients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

DS639F3 4

Page 5

Figure 29. FIR2 Minimum Phase Coefficients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 30. IIR Filter Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 31. IIR Filter Stages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 32. Gain and Offset Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 33. Serial Data Interface Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 34. 32-bit Serial Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 35. SD Port Transaction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 36. Test Bit Stream Generator Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 37. Time Break Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 38. GPIO Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 39. SPI Control Register SPICTRL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 40. SPI Command Register SPICMD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 41. SPI Data Register SPIDAT1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Figure 42. SPI Data Register SPIDAT2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 43. Hardware Configuration Register CONFIG. . . . . . . . . . . . . . . . . . . . . . . . . . 72

Figure 44. GPIO Configuration Register GPCFG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Figure 45. Filter Configuration Register FILTCFG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Figure 46. Gain Correction Register GAIN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Figure 47. Offset Correction Register OFFSET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Figure 48. Time Break Counter Register TIMEBRK . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Figure 49. Test Bit Stream Configuration Register TBSCFG. . . . . . . . . . . . . . . . . . . . . 78

Figure 50. Test Bit Stream Gain Register TBSGAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Figure 51. User Defined System Register SYSTEM1 . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Figure 52. Hardware Version ID Register VERSION . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Figure 53. Self Test Result Register SELFTEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Figure 54. CS5378 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

CS5378

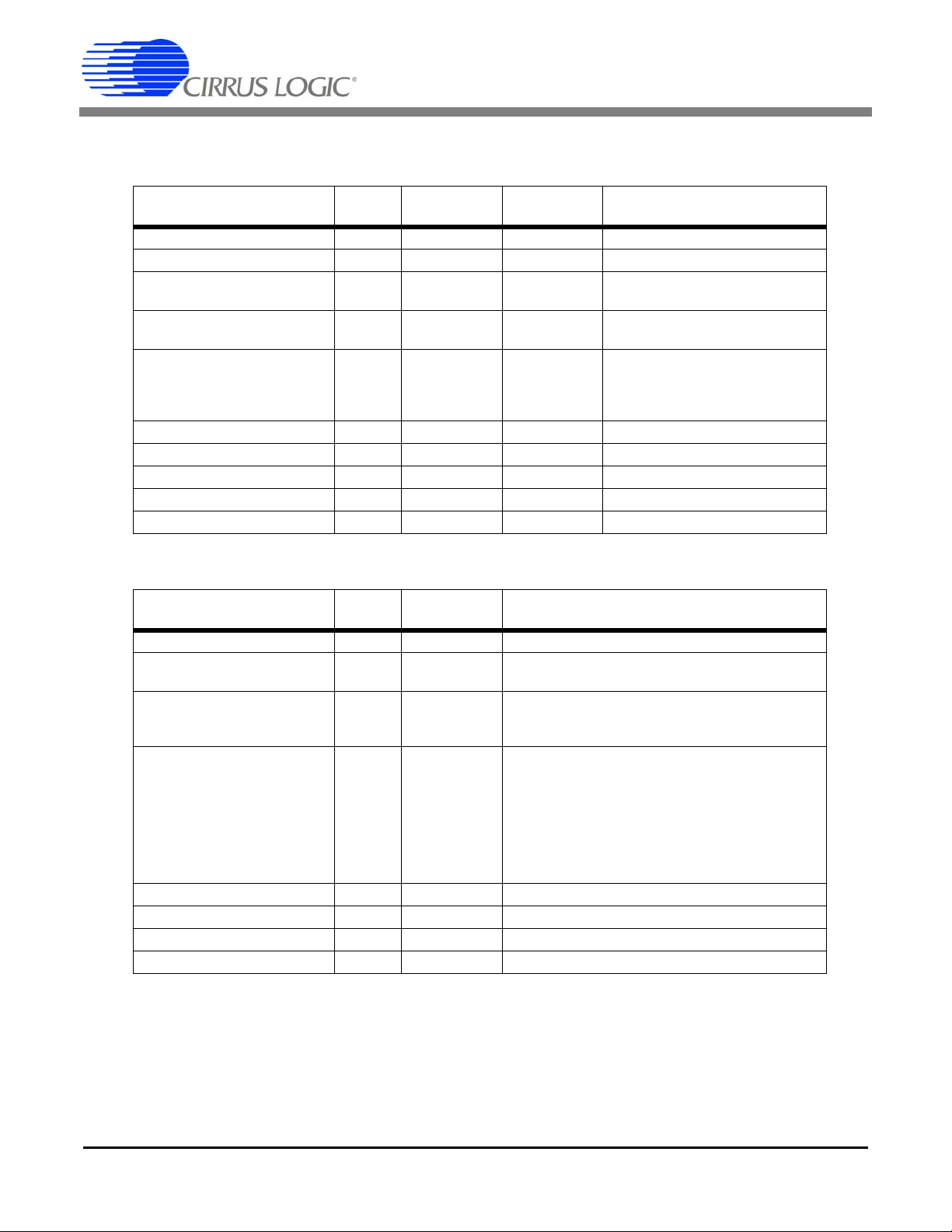

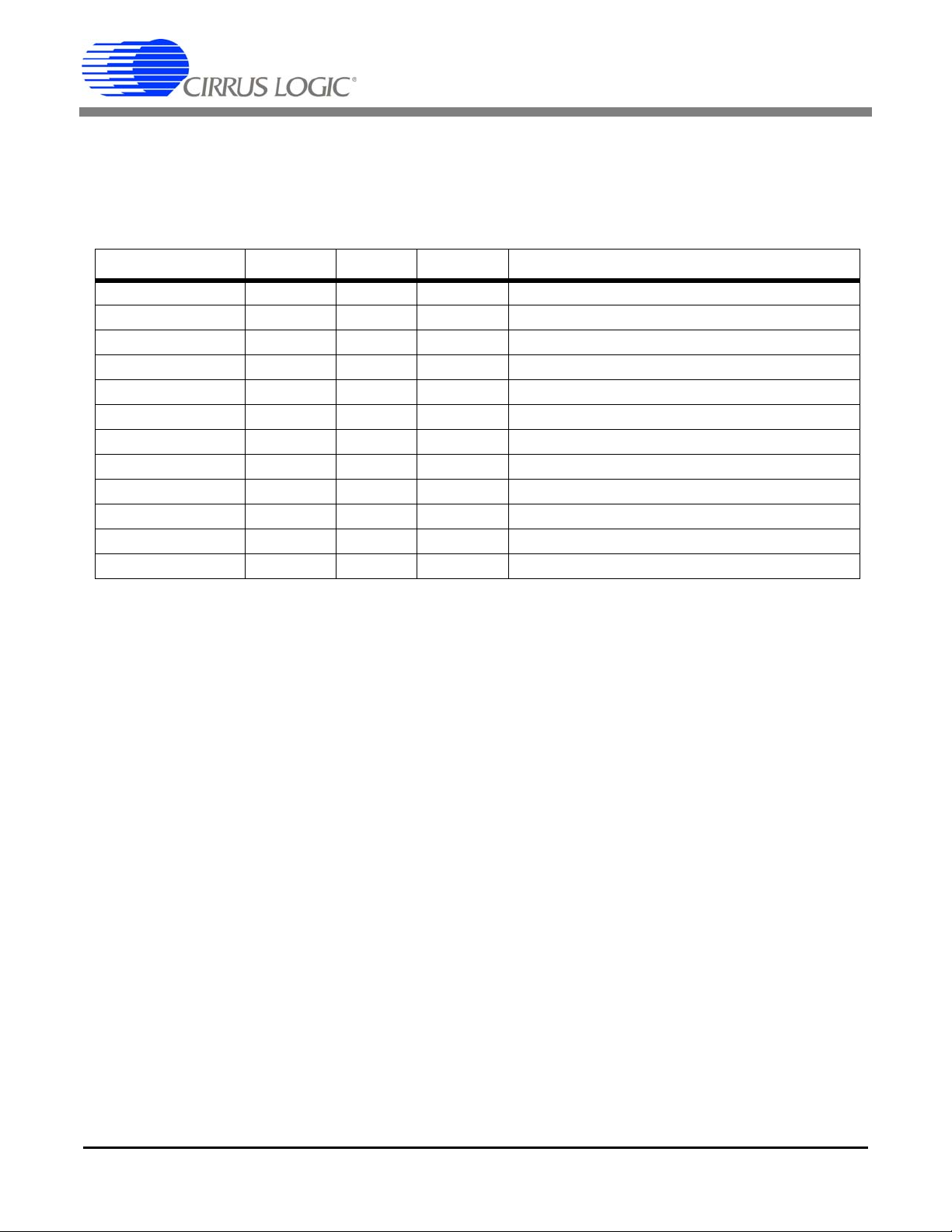

LIST OF TABLES

Table 1. Microcontroller and EEPROM Configuration Commands . . . . . . . . . . . . . . . . . 9

Table 2. TBS Configurations Using On-Chip Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 3. SPI and Digital Filter Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 4. PLL and BOOT Mode Reset Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 5. PLL Mode Selections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 6. Maximum EEPROM Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 7. EEPROM Boot Configuration Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 8. Example EEPROM File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 9. Microcontroller Boot Configuration Commands . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 10. Example Microcontroller Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 11. SINC Filter Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 12. SINC1 and SINC2 Filter Coefficients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 13. SINC3 Filter Coefficients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 14. FIR Filter Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 15. SINC + FIR Group Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 16. Minimum Phase Group Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 16. IIR Filter Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 17. IIR Filter Coefficients . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 18. TBS Configurations Using On-chip Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

DS639F3 5

Page 6

CS5378

Serial Interface

Decimation and

Filtering Engine

Modulator D ata Interface

Test Bit Stream

Controller

Reset, Synchronization

TBSDATA

Time Break Controller

GPIO

General Purpose I/O

SCK

MOSI

VDDPAD

VDDPLL

VDDCORE

SYNC

MSYNC

TIMEB

GPIO5:PLL1

GPIO4:PLL0

GPIO3

GPIO2

GPIO1

GNDPAD

GNDCORE

GNDPLL

MDATA

MFLAG

GPIO0

GPIO6:PLL2

GPIO7:BOOT

DRDY

MISO

SS:EECS

RESET

CLK

MCLK

PLL, Clock Generation

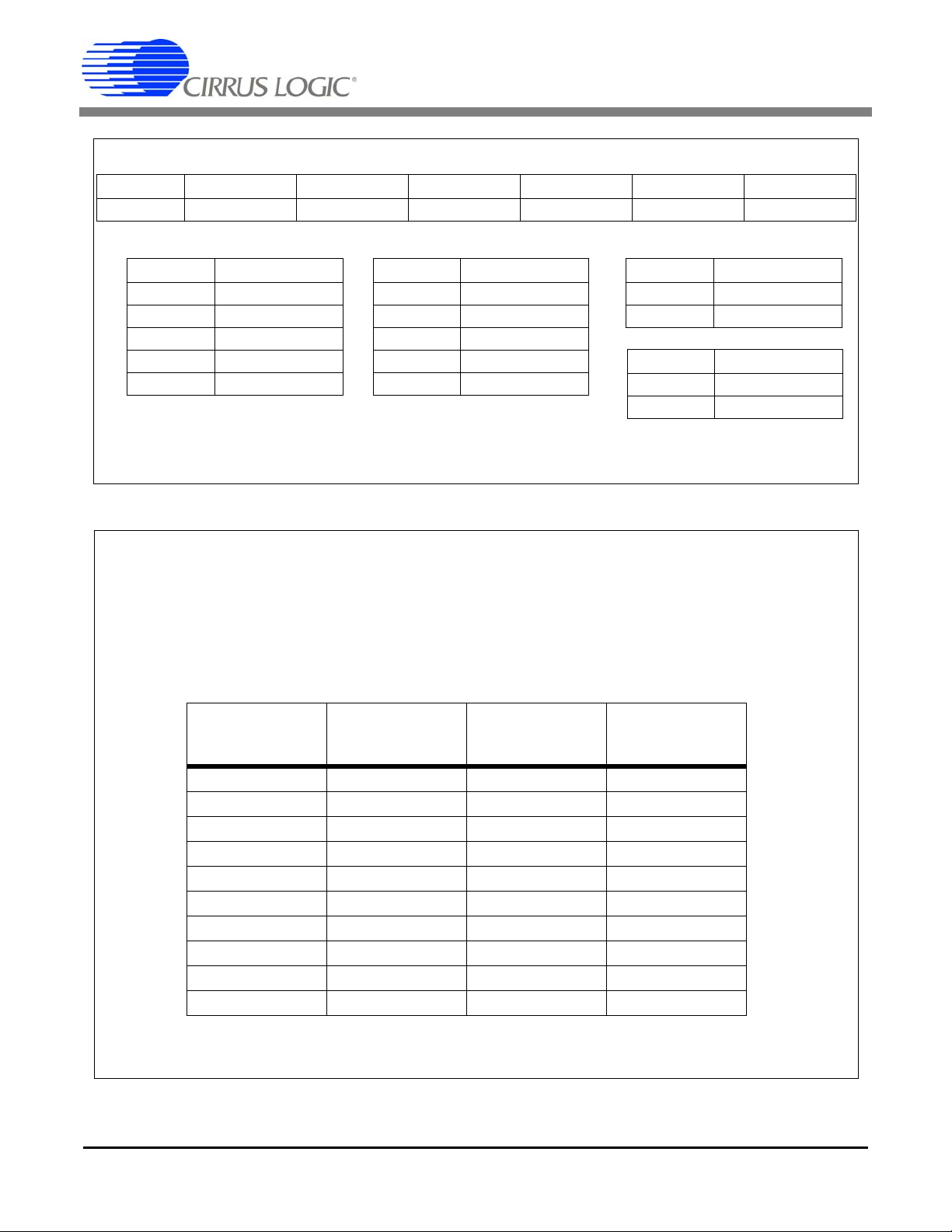

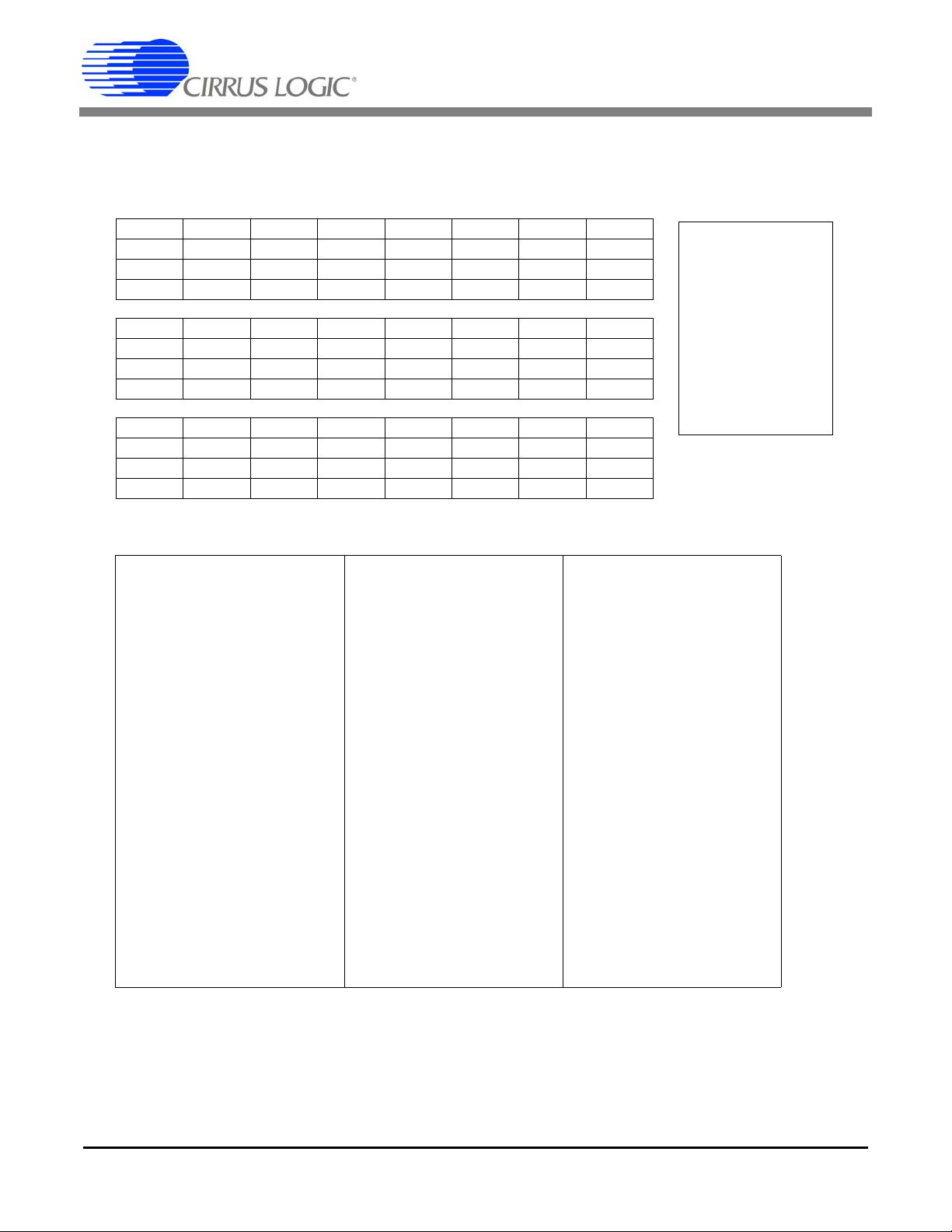

Figure 1. CS5378 Block Diagram

1. GENERAL DESCRIPTION

The CS5378 is a single channel digital filter with

integrated system peripherals. Figure 1 illustrates a

simplified block diagram of the CS5378.

1.1 Digital Filter Features

• Single channel decimation filter for CS5373A

ΔΣ modulator.

• Synchronous operation for simultaneous sampling in multi-sensor systems.

- Internal synchronization of digital filter

• Output word rates, including low bandwidth

rates.

- Standard output rates: 4000, 2000, 1000,

- Low bandwidth rates: 200, 125, 100, 50,

phase to an external SYNC signal.

500, 333, 250 SPS.

40, 25, 20, 10, 5, 1 SPS.

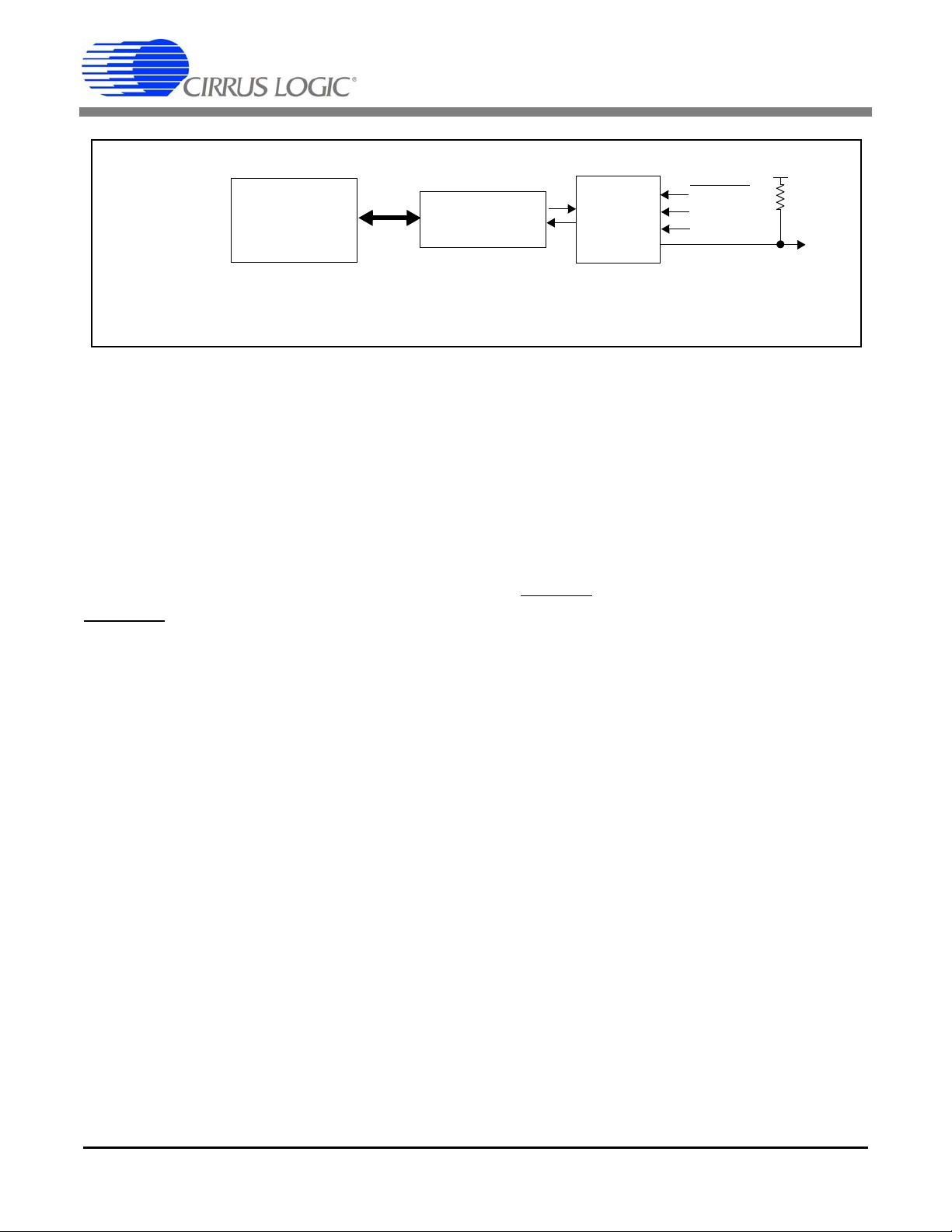

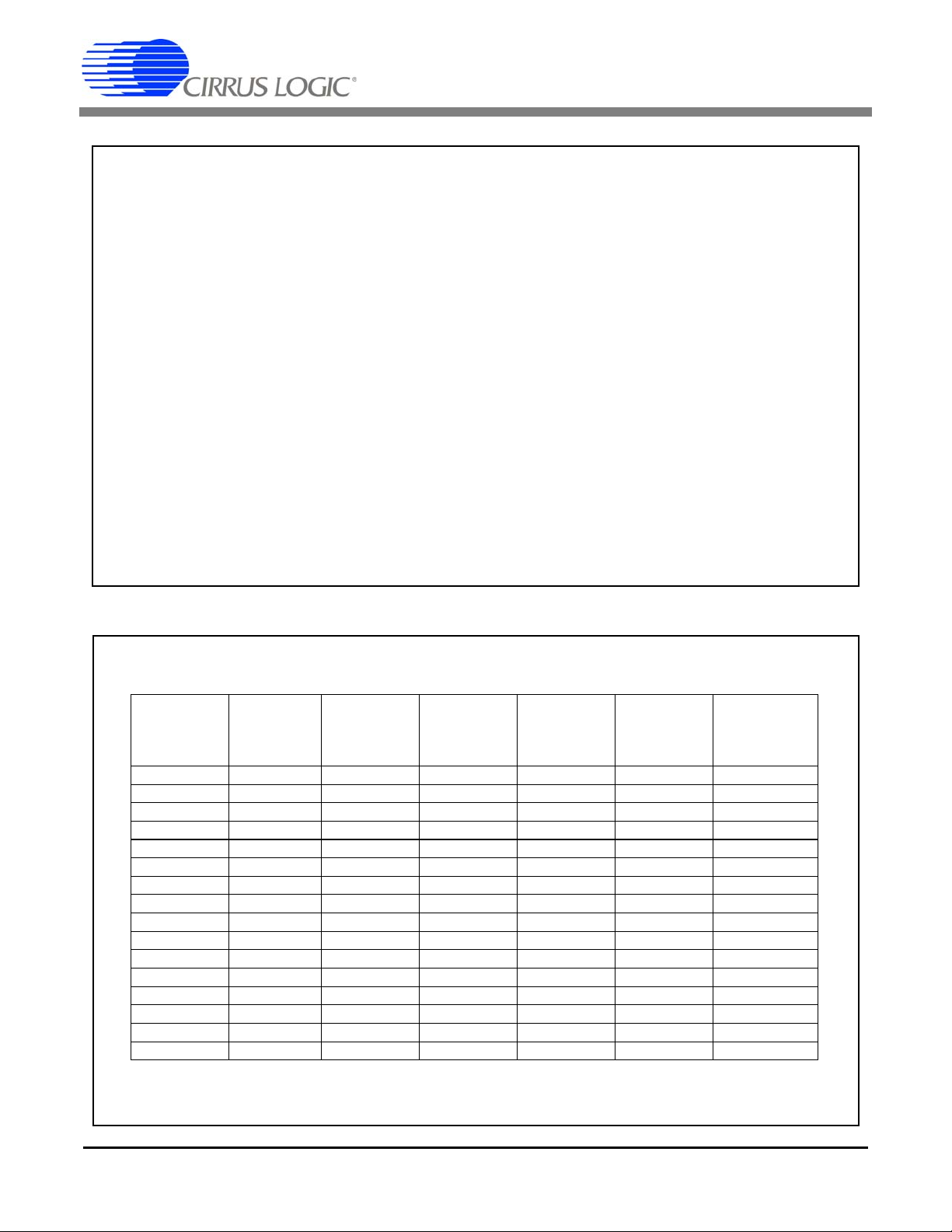

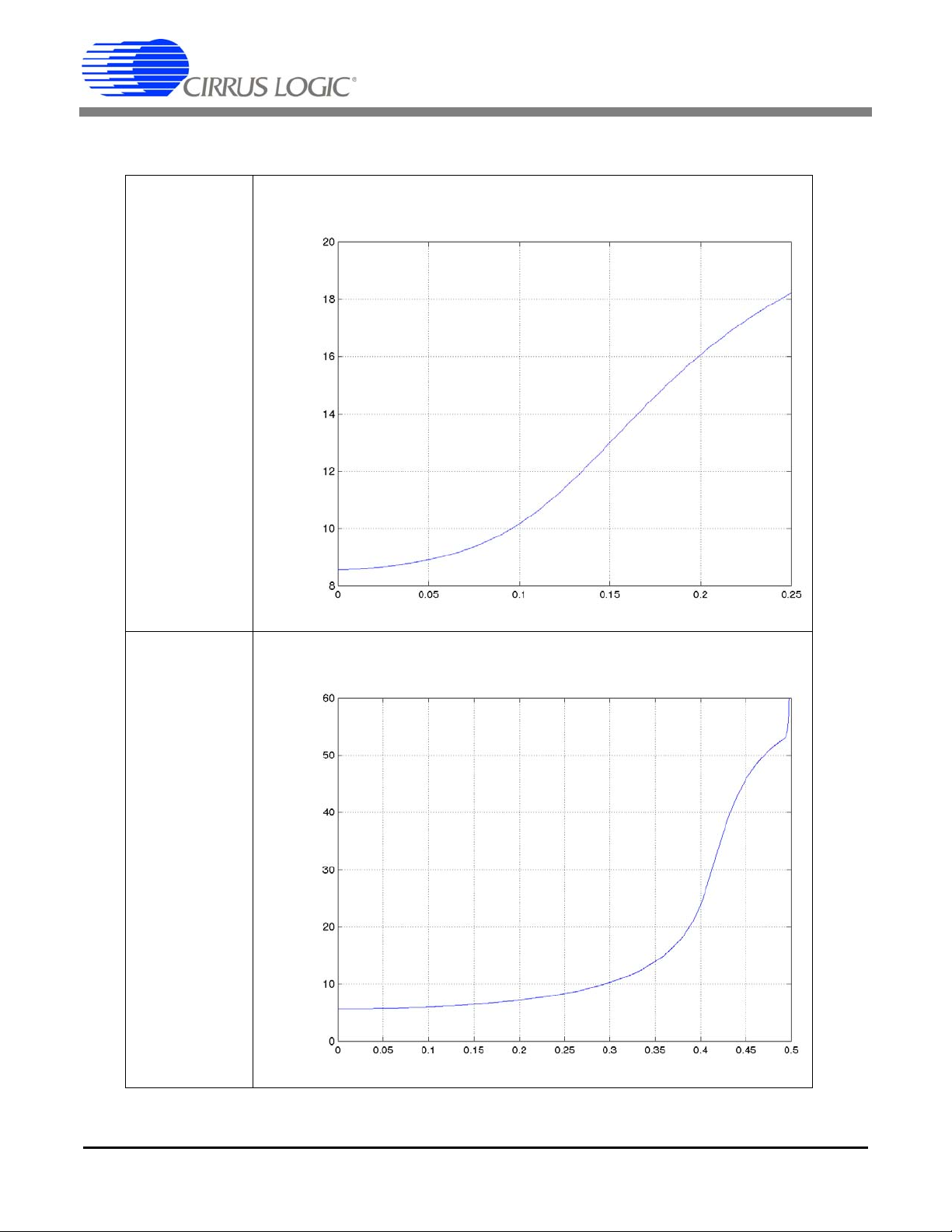

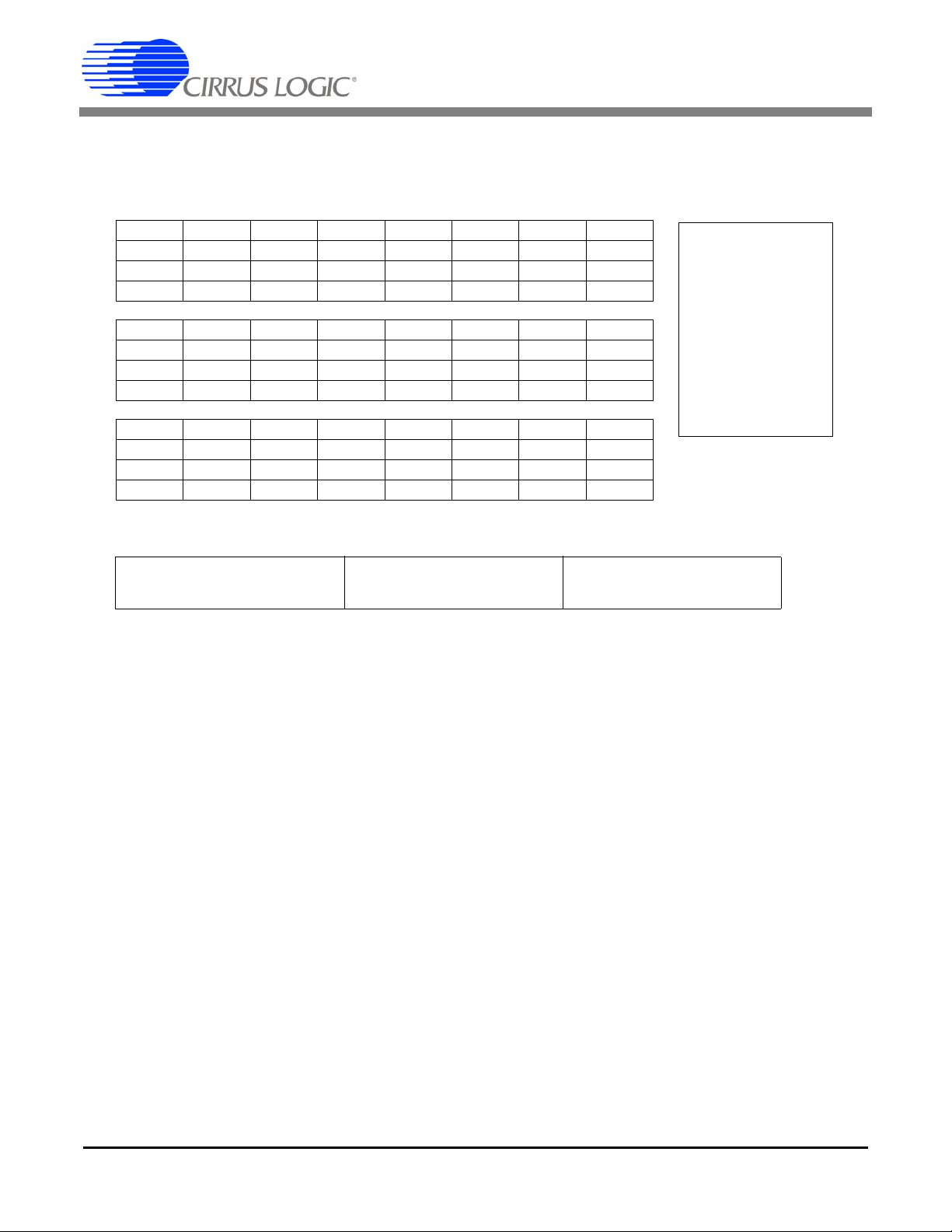

• Flexible digital filter configuration. (See Figure

2)

- Cascaded SINC, FIR, and IIR filters with

selectable output stage.

- Linear and minimum phase FIR low-pass

filter coefficients included.

- 3 Hz Butterworth IIR high-pass filter coefficients included.

- FIR and IIR coefficients programmable to

create a custom filter response.

• Digital gain correction to normalize sensor

gain.

• Digital offset correction and calibration.

- Offset correction to remove measurement

DS639F3 6

Page 7

CS5378

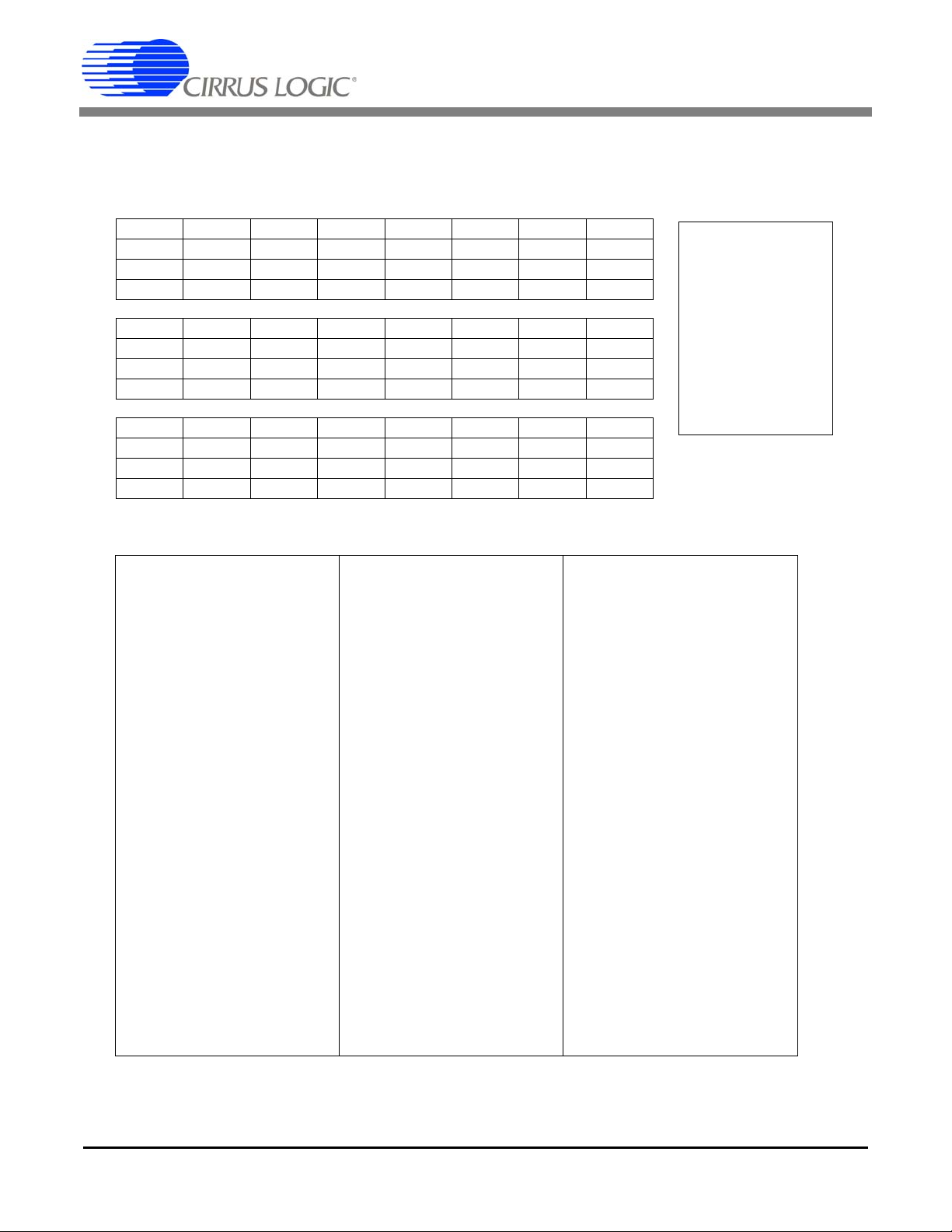

Figure 2. Digital Filtering Stages

Sinc Filter

2 - 64000

FIR1

4

FIR2

2

IIR1 IIR2

1

st

Order

2nd Order

Output to High Speed Serial Interface

DC Offset

Corrections

Output Word Rate from 4000 SPS ~ 1 SPS

Gain &

Modulator

512 kHz

Input

DC offset.

- Calibration engine for automatic calculation of offset correction factor.

• Time break controller to record system timing

information.

- Dedicated TB status bit in the output data

stream.

1.2 Integrated Peripheral Features

• Low jitter PLL to generate local clocks.

- 1.024 MHz, 2.048 MHz, 4.096 MHz standard clock or Manchester encoded input.

- Programmable output delay to match system group delay.

• 8 General Purpose I/O (GPIO) pins for local

hardware control.

• Synchronous operation for simultaneous sampling in multi-sensor systems.

- MCLK / MSYNC output signals to syn-

chronize external components.

• High speed serial data output.

- Asynchronous operation to 4 MHz for di-

rect connection to system telemetry.

- Internal 8-deep data FIFO for flexible out-

put timing.

- Selectable 24-bit data only or 32-bit sta-

tus+data output.

• Digital test bit stream signal generator suitable

for CS5373A ΔΣ test DAC.

- Sine wave output mode for testing total har-

monic distortion.

DS639F3 7

1.3 System Level Features

• Flexible configuration options.

- Configuration 'on-the-fly' via microcontroller or system telemetry.

- Fixed configuration via stand-alone boot

EEPROM.

• Low power consumption.

- 16 mW at 500 SPS OWR.

- 100 μW standby mode.

• Flexible power supply configurations.

- Separate digital logic core, telemetry I/O,

and PLL power supplies.

- Telemetry I/O and PLL interfaces operate

Page 8

CS5378

from 3.3 V or 5 V.

- Digital logic core operates from 2.5 V,

3.3 V or 5 V.

• Small 28-pin SSOP package.

- Total footprint 8 mm x 10 mm plus three

bypass capacitors.

1.4 Configuration Interface

• Configuration from microcontroller or standalone boot EEPROM.

- Microcontroller boot permits reconfigura-

tion during operation.

- EEPROM boot sets a fixed operational configuration.

• Configuration commands written through the

serial interface. (See Table 1)

- Standardized microcontroller interface us-

ing SPI™ registers. (See Table 3)

- Commands write digital filter registers and

FIR / IIR filter coefficients.

- Digital filter registers set hardware config-

uration options.

DS639F3 8

Page 9

Microcontroller Boot Configuration Commands

EEPROM Boot Configuration Commands

[DATA] indicates data word returned from digital filter.

(DATA) indicates multiple words of this type are to be written.

Name CMD

24-bit

DAT1

24-bit

DAT2

24-bit

Description

NOP 000000 - - No Operation

WRITE DF REGISTER 000001 REG DATA Write Digital Filter Register

READ DF REGISTER 000002 REG

[DATA]

-

-

Read Digital Filter Register

WRITE FIR COEFFICIENTS 000003 NUM FIR1

(FIR COEF)

NUM FIR2

(FIR COEF)

Write Custom FIR Coefficients

WRITE IIR COEFFICIENTS 000004 a11

b11

a22

b21

b10

a21

b20

b22

Write Custom IIR Coefficients

WRITE ROM COEFFICIENTS 000005 COEF SEL - Use On-Chip Coefficients

NOP 000006 - - No Operation

NOP 000007 - - No Operation

FILTER START 000008 - - Start Digital Filter Operation

FILTER STOP 000009 - - Stop Digital Filter Operation

Name CMD

8-bit

DATA

24-bit

Description

NOP 00 - No Operation

WRITE DF REGISTER 01 REG

DATA

Write Digital Filter Register

WRITE FIR COEFFICIENTS 02 NUM FIR1

NUM FIR2

(FIR COEF)

Write Custom FIR Coefficients

WRITE IIR COEFFICIENTS 03 a11

b10

b11

a21

a22

b20

b21

b22

Write Custom IIR Coefficients

WRITE ROM COEFFICIENTS 04 COEF SEL Use On-Chip Coefficients

NOP 05 - No Operation

NOP 06 - No Operation

FILTER START 07 - Start Digital Filter Operation

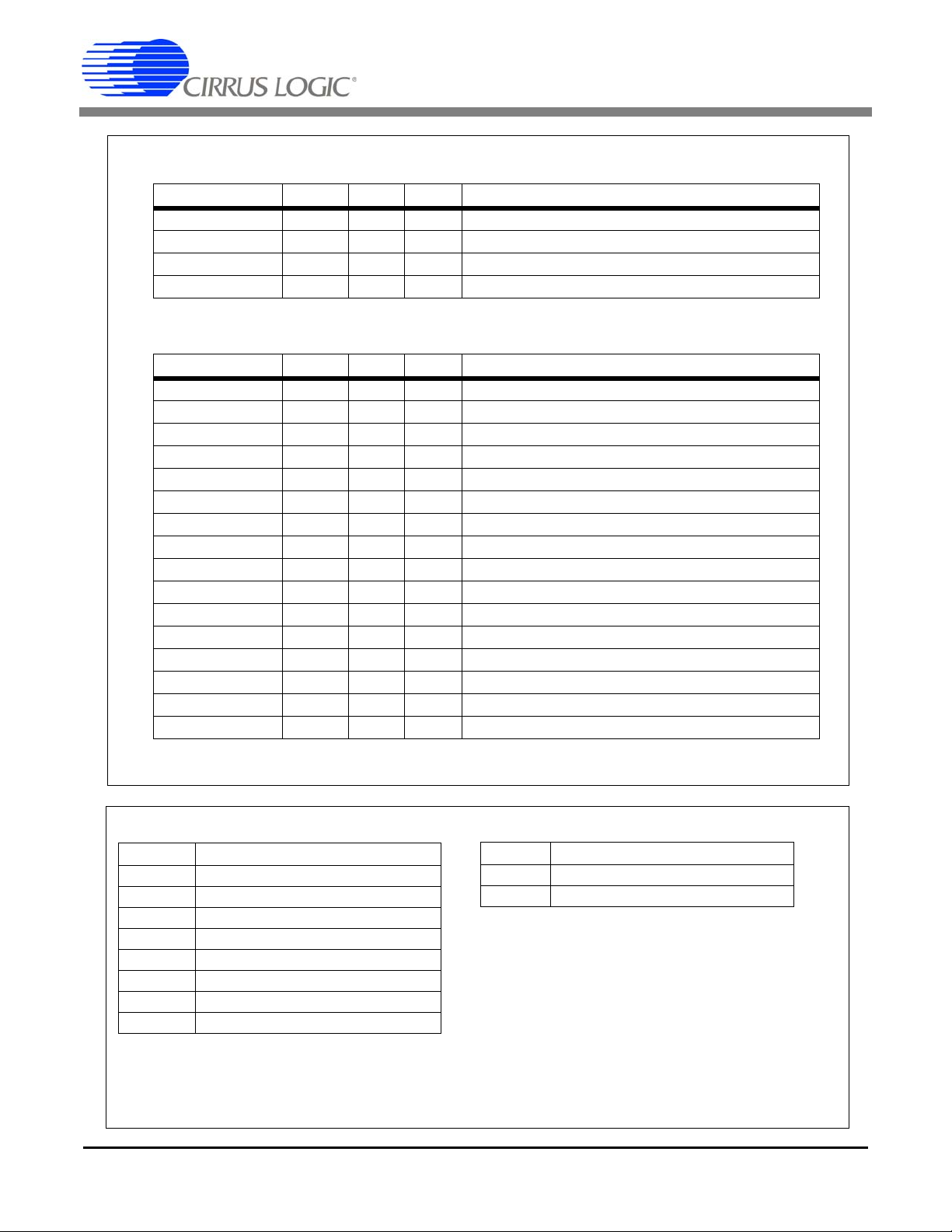

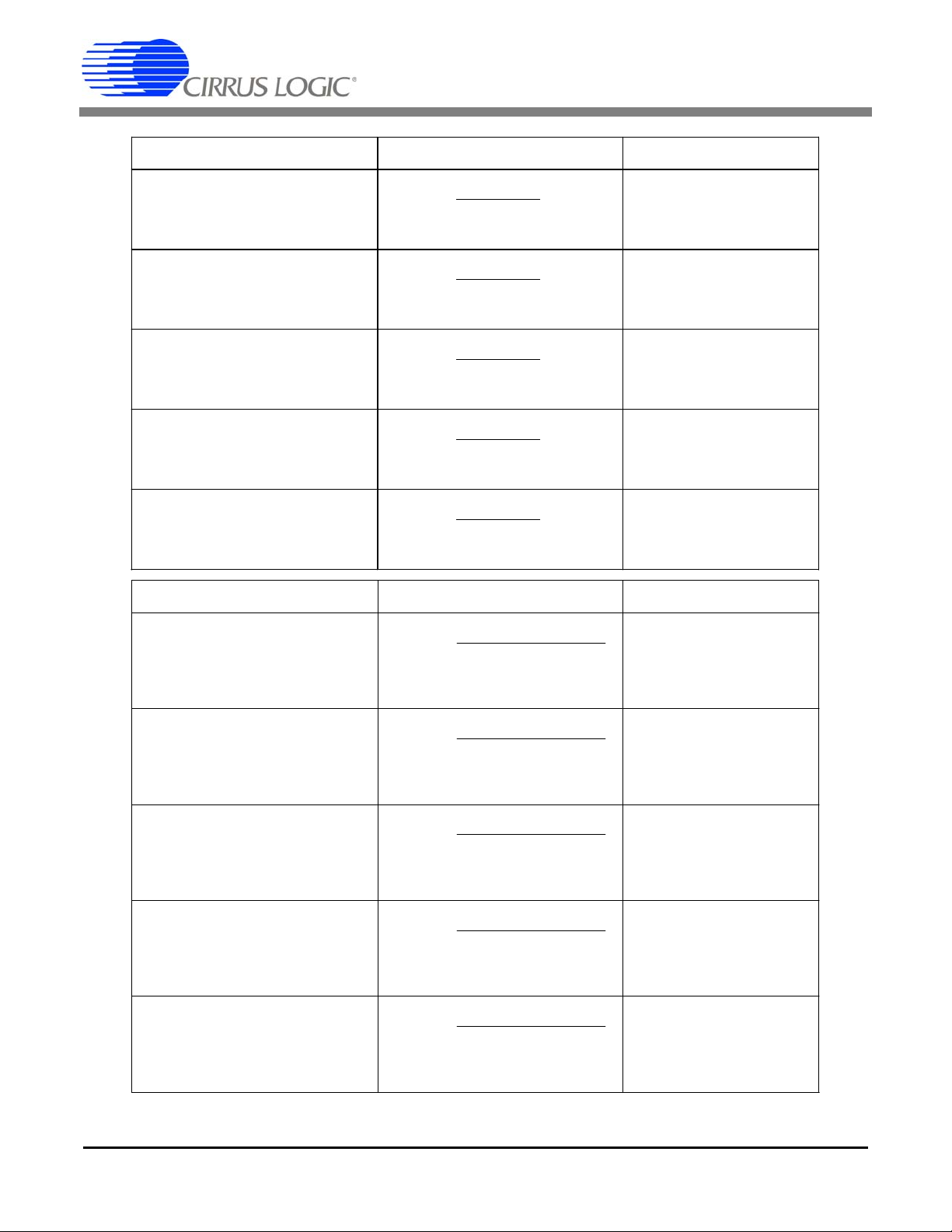

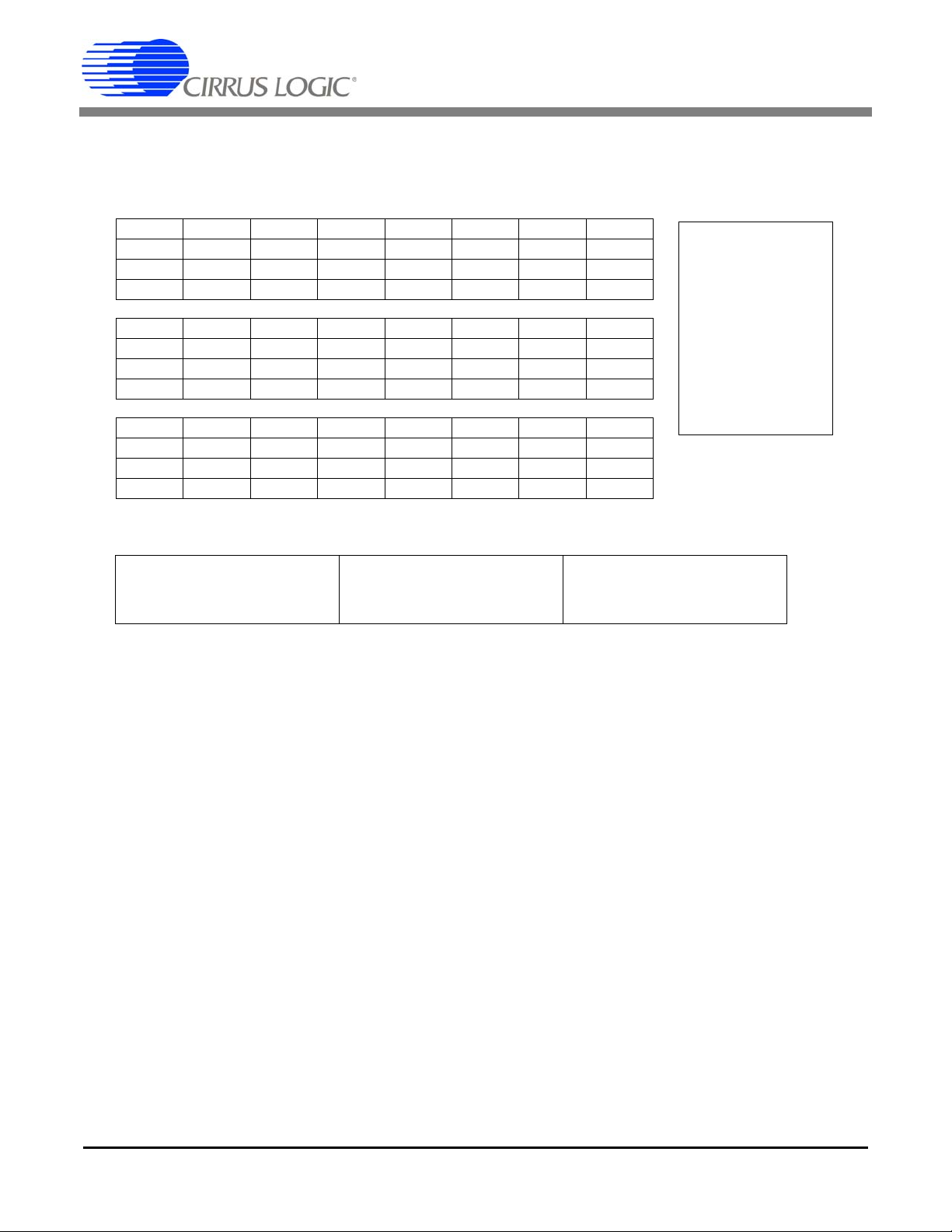

Table 1. Microcontroller and EEPROM Configuration Commands

CS5378

DS639F3 9

Page 10

CS5378

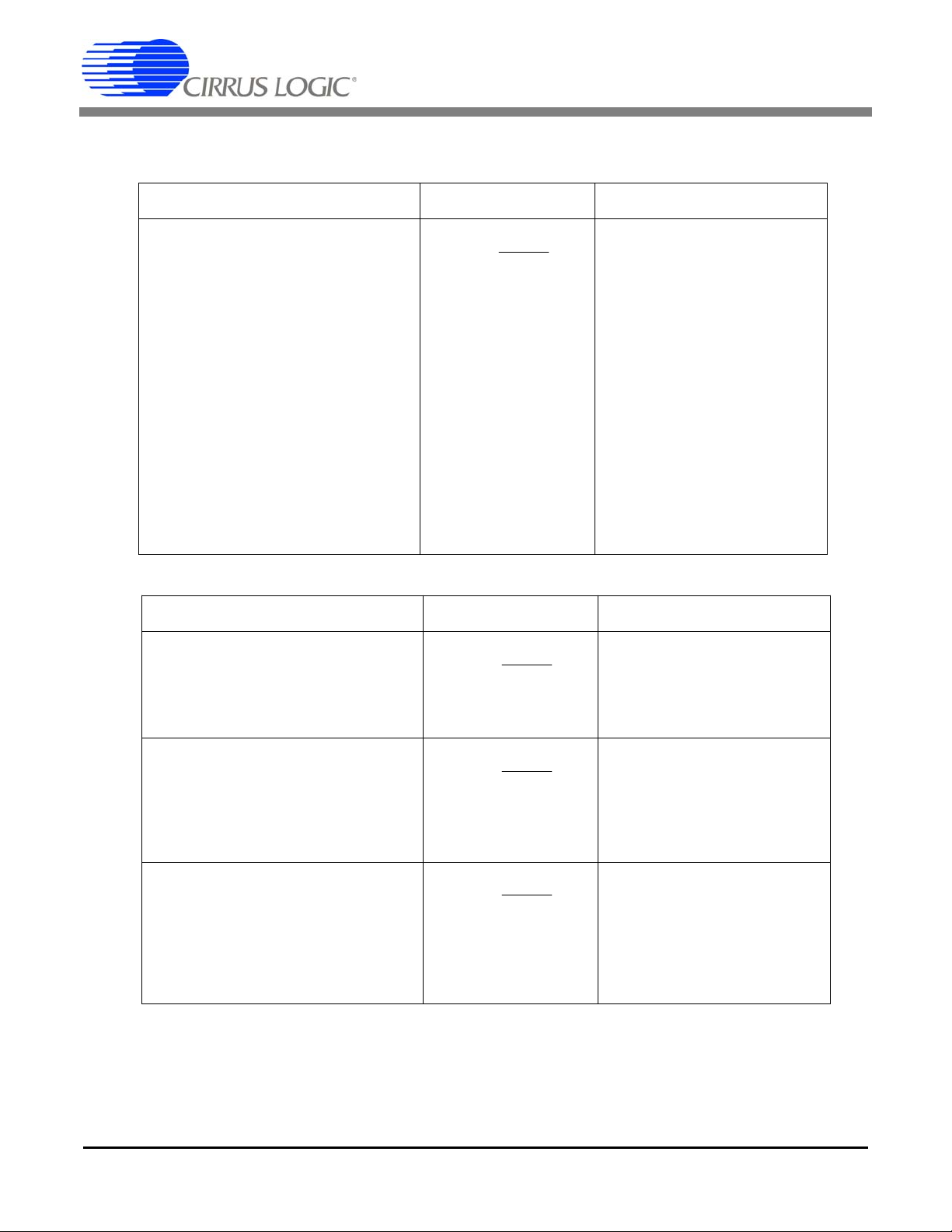

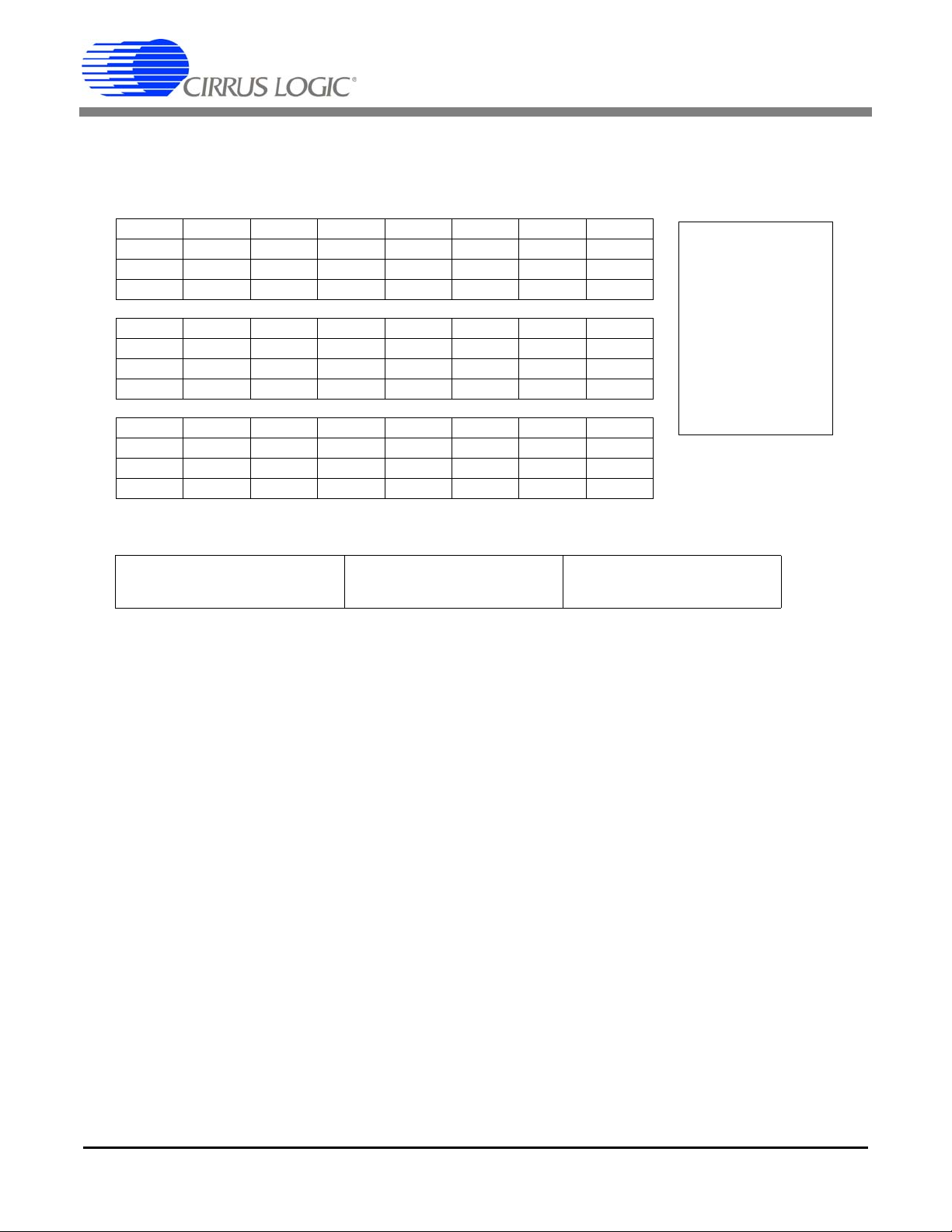

Bits 23:20 19:16 15:12 11:8 7:4 3:0

Selection 0000 0000 IIR2 IIR1 FIR2 FIR1

Figure 3. FIR and IIR Coefficient Set Selection Word

Bits 15:12 IIR2 Coefficients

0000 3 Hz @ 2000 SPS

0001 3 Hz @ 1000 SPS

0010 3 Hz @ 500 SPS

0011 3 Hz @ 333 SPS

0100 3 Hz @ 250 SPS

Bits 11:8 IIR1 Coefficients

0000 3 Hz @ 2000 SPS

0001 3 Hz @ 1000 SPS

0010 3 Hz @ 500 SPS

0011 3 Hz @ 333 SPS

0100 3 Hz @ 250 SPS

Bits 7:4 FIR2 Coefficients

0000 Linear Phase

0001 Minimum Phase

Bits 3:0 FIR1 Coefficients

0000 Linear Phase

0001 Minimum Phase

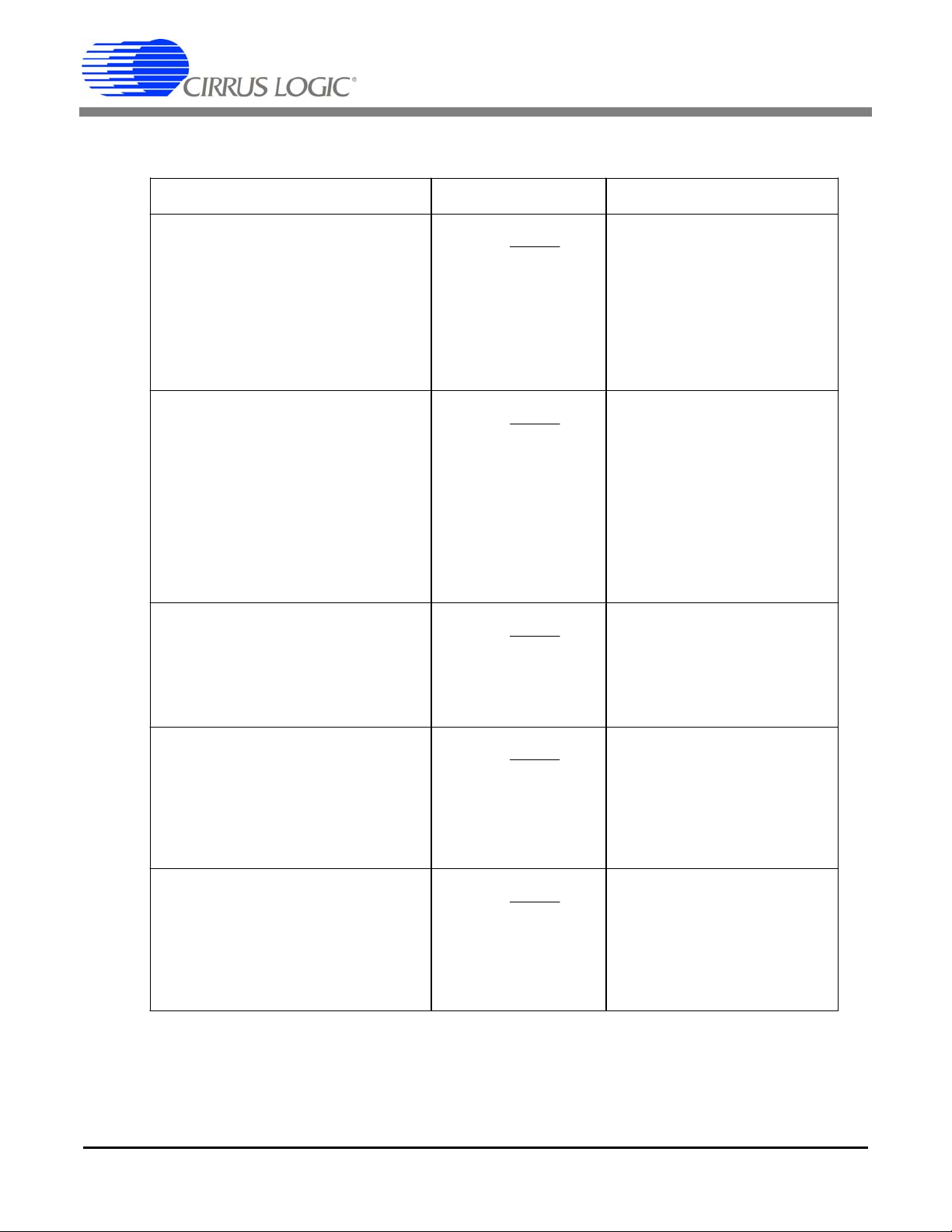

Test Bit Stream Characteristic Equation:

(Signal Freq) * (# TBS Data) * (Interpolation + 1) = Output Rate

Example: (31.25 Hz) * (1024) * (0x07 + 1) = 256 kHz

Signal

Frequency

(TBSDATA)

Output

Rate

(TBSCLK)

Output Rate

Selection

(RATE)

Interpolation

Selection

(INTP)

10.00 Hz 256 kHz 0x4 0x18

10.00 Hz 512 kHz 0x5 0x31

25.00 Hz 256 kHz 0x4 0x09

25.00 Hz 512 kHz 0x5 0x13

31.25 Hz 256 kHz 0x4 0x07

31.25 Hz 512 kHz 0x5 0x0F

50.00 Hz 256 kHz 0x4 0x04

50.00 Hz 512 kHz 0x5 0x09

125.00 Hz 256 kHz 0x4 0x01

125.00 Hz 512 kHz 0x5 0x03

Table 2. TBS Configurations Using On-Chip Data

DS639F3 10

Page 11

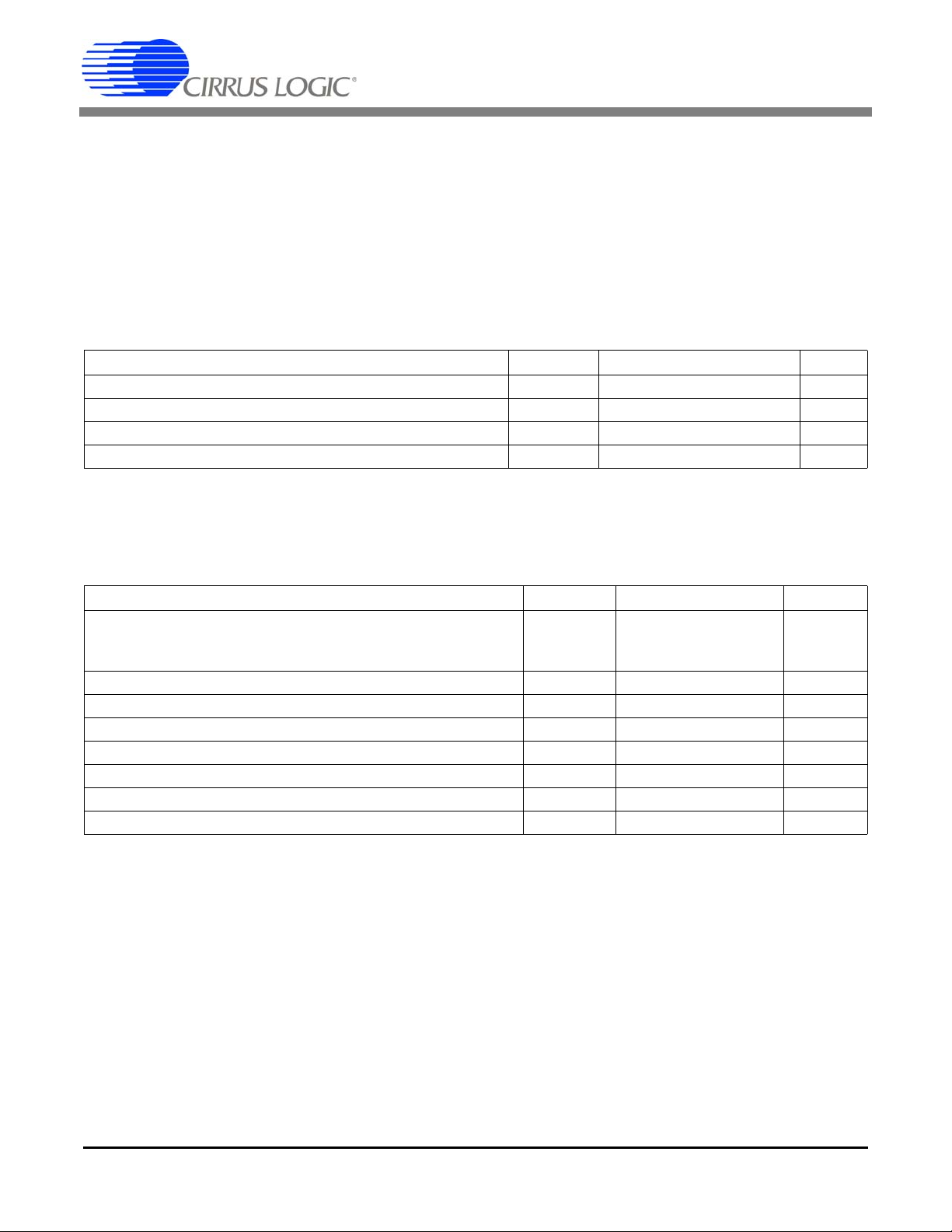

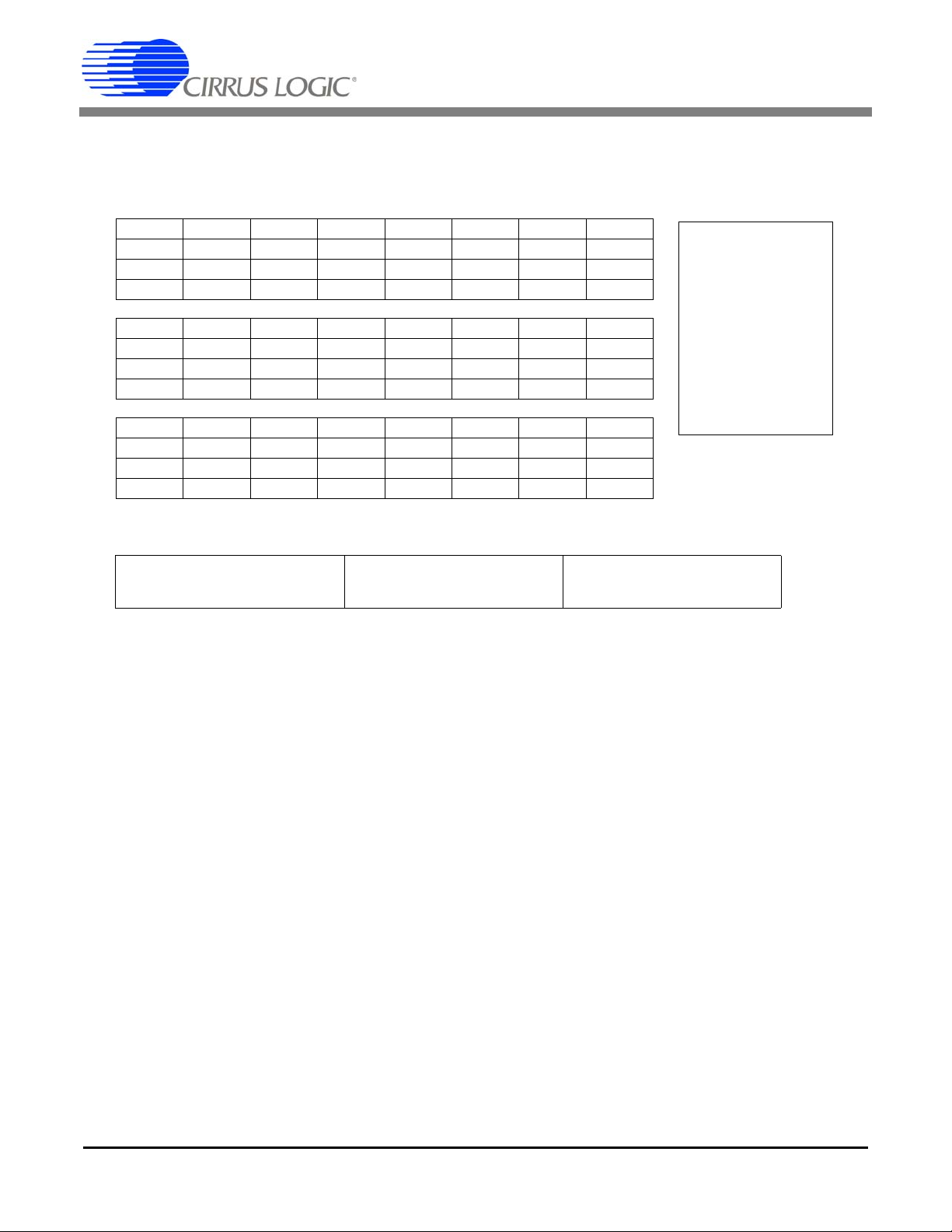

CS5378

SPI Registers

Digital Filter Registers

Name Addr. Type # Bits Description

SPICTRL 00 - 02 R/W 8, 8, 8 SPI Control

SPICMD 03 - 05 R/W 8, 8, 8 SPI Command

SPIDAT1 06 - 08 R/W 8, 8, 8 SPI Data 1

SPIDAT2 09 - 0B R/W 8, 8, 8 SPI Data 2

Name Addr. Type # Bits Description

CONFIG 00 R/W 24 Hardware Configuration

RESERVED 01-0D R/W 24 Reserved

GPCFG 0E R/W 24 GPIO[7:0] Direction, Pull-up Enable, and Data

RESERVED 0F-1F R/W 24 Reserved

FILTCFG 20 R/W 24 Digital Filter Configuration

GAIN 21 R/W 24 Gain Correction

RESERVED 22-24 R/W 24 Reserved

OFFSET 25 R/W 24 Offset Correction

RESERVED 26-28 R/W 24 Reserved

TIMEBRK 29 R/W 24 Time Break Delay

TBSCFG 2A R/W 24 Test Bit Stream Configuration

TBSGAIN 2B R/W 24 Test Bit Stream Gain

SYSTEM1 2C R/W 24 User Defined System Register 1

SYSTEM2 2D R/W 24 User Defined System Register 2

VERSION 2E R/W 24 Hardware Version ID

SELFTEST 2F R/W 24 Self-Test Result Code

Table 3. SPI and Digital Filter Registers

Table 4. PLL and BOOT Mode Reset Configurations

PLL[2:0] Mode Selection on Reset

111 32.768 MHz clock input (PLL bypass).

110 1.024 MHz clock input.

101 2.048 MHz clock input.

100 4.096 MHz clock input.

011 32.768 MHz clock input (PLL bypass).

010 1.024 MHz Manchester input.

001 2.048 MHz Manchester input.

000 4.096 MHz Manchester input.

Configuration Note:

States of the PLL[2:0] and BOOT pins are

latched immediately after reset to select modes.

These pins have a weak (~100 kΩ) pull-up resistor enabled by default. An external 10 kΩ

pull-down is required to set a low condition.

BOOT Mode Selection on Reset

1 EEPROM boot

0 Microcontroller boot

DS639F3 11

Page 12

CS5378

2. CHARACTERISTICS AND SPECIFICATIONS

• Min / Max characteristics and specifications are guaranteed over the Specified Operating Conditions.

• Typical performance characteristics and specifications are derived from measurements taken at nominal supply voltages and TA = 25°C.

• GND, GND1, GND2 = 0 V, all voltages with respect to 0 V.

SPECIFIED OPERATING CONDITIONS

Parameter Symbol Min Nom Max Unit

Logic Core Power Supply VDDCORE 2.375 2.5 5.25 V

PLL Power Supply VDDPLL 3.135 3.3 5.25 V

I/O Power Supply VDDPAD 3.135 3.3 5.25 V

Ambient Operating Temperature Industrial (-IQ) T

A

-40 - 85 °C

ABSOLUTE MAXIMUM RATINGS

Parameter Symbol Min Max Units

DC Power Supplies Logic Core

Input Current, Any Pin Except Supplies (Note 1) I

Input Current, Power Supplies (Note 1) I

Output Current (Note 1) I

Power Dissipation P

Digital Input Voltages V

Ambient Operating Temperature (Power Applied) T

Storage Temperature Range T

1. Transient currents up to 100 mA will not cause SCR latch-up.

PLL

I/O

VDDCORE

VDDPLL

VDDPAD

IN

IN

OUT

DN

IND

A

STG

-0.3

-0.3

-0.3

-±10mA

-±50mA

-±25mA

-500mW

-0.3 VDD+0.3 V

-40 85 °C

-65 150 °C

6.0

6.0

6.0

V

V

V

DS639F3 12

Page 13

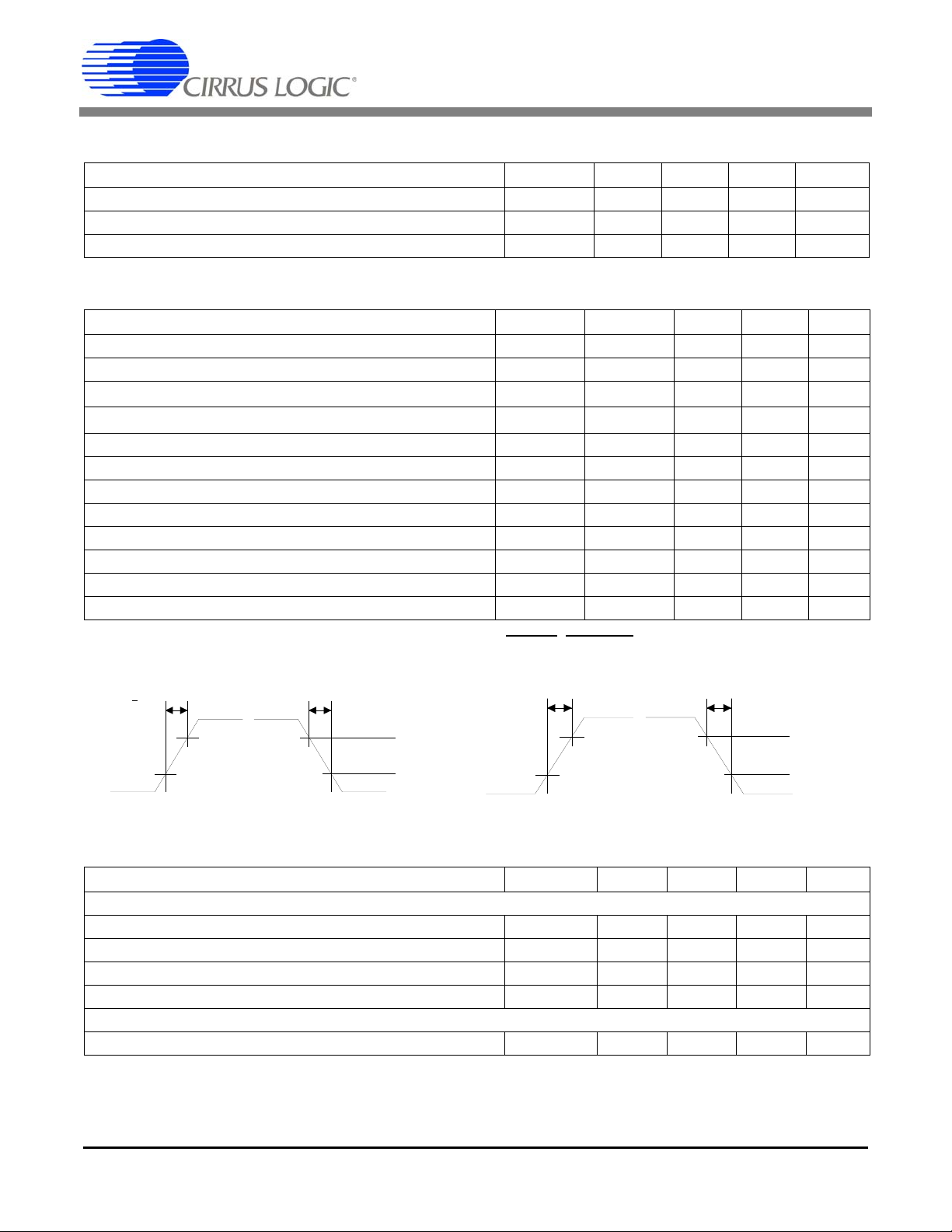

THERMAL CHARACTERISTICS

2.6 V

0.7 V

t

fallin

t

risein

4.6 V

0.4 V

t

riseout

t

fallout

0.90 * VDD

0.10 * VDD

0.90 * VDD

0.10 * VDD

Parameter Symbol Min Typ Max Unit

Allowable Junction Temperature T

Junction to Ambient Thermal Impedance (4-Layer PCB) Θ

Ambient Operating Temperature (Power Applied) T

DIGITAL CHARACTERISTICS

Parameter Symbol Min Typ Max Unit

High-Level Input Drive Voltage V

Low-Level Input Drive Voltage V

High-Level Output Drive Voltage I

Low-Level Output Drive Voltage I

Rise Times, Digital Inputs t

Fall Times, Digital Inputs t

Rise Times, Digital Outputs t

Fall Times, Digital Outputs t

Input Leakage Current (Note 2) I

3-State Leakage Current I

Digital Input Capacitance C

Digital Output Pin Capacitance C

= -40 µA V

out

= +40 µA V

out

RISE

FALL

RISE

FALL

OUT

IH

OH

OL

IN

OZ

IL

IN

JA

A

J

--135°C

-50 °C / W

-40 - +85 °C

0.6 * VDD - VDD V

0.0 - 0.8 V

VDD - 0.3 - VDD V

0.0 - 0.3 V

--100ns

--100ns

--100ns

--100ns

-± 1± 10µA

--± 10µA

-9-pF

-9-pF

CS5378

Notes: 2. Maximum leakage for pins with pull-up resistors (RESET, SS:EECS, GPIO, MOSI, SCK) is ±250 μA.

POWER CONSUMPTION

Parameter Symbol Min Typ Max Unit

Operational Power Consumption

1.024 MHz Digital Filter Clock PWR

2.048 MHz Digital Filter Clock PWR

4.096 MHz Digital Filter Clock PWR

8.192 MHz Digital Filter Clock PWR

Standby Power Consumption

32 kHz Digital Filter Clock, Filter Stopped PWR

1

2

4

8

S

-12-mW

-14-mW

-16-mW

-24-mW

- 100 - µW

DS639F3 13

Page 14

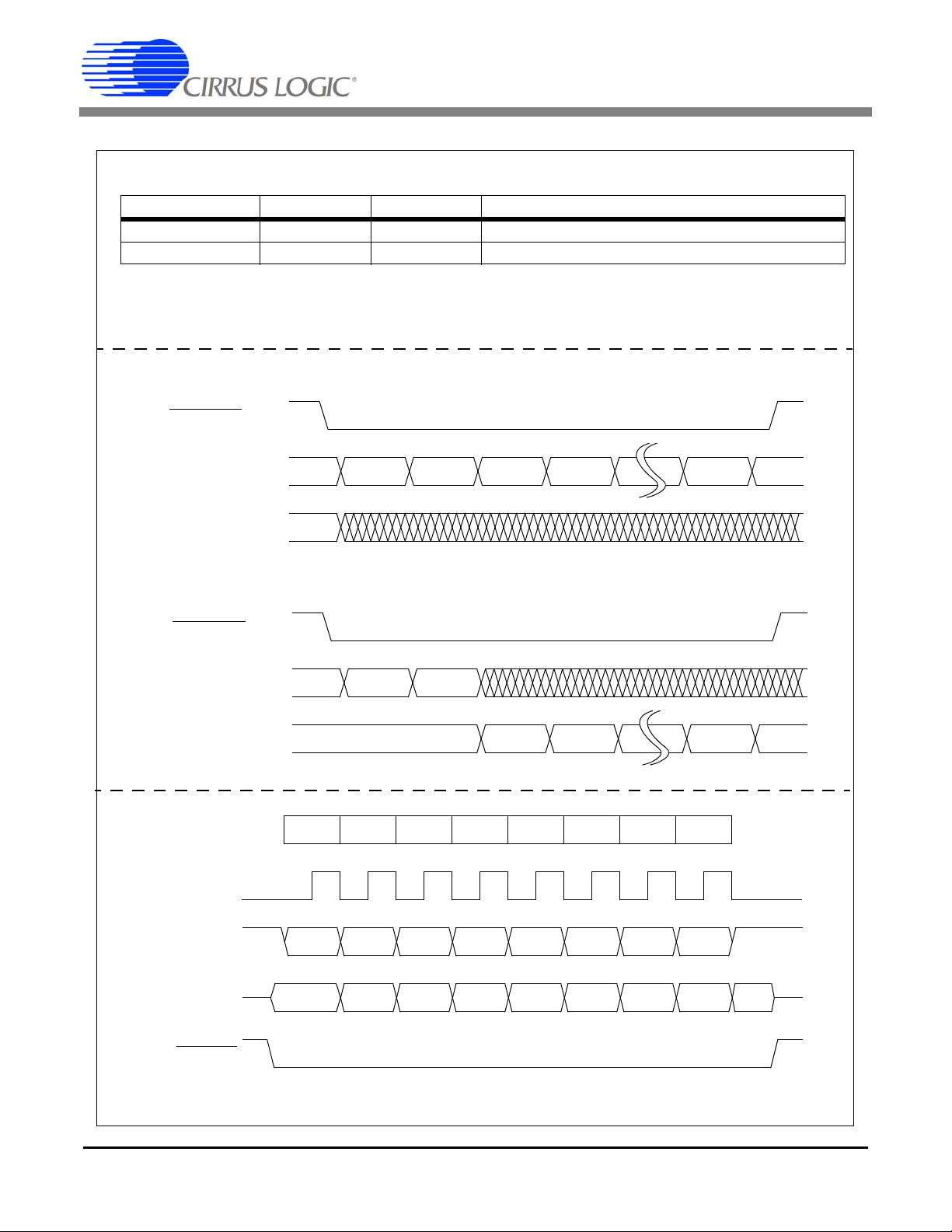

SWITCHING CHARACTERISTICS

Figure 4. MOSI Write Timing in SPI Slave Mode

SSI

MOSI

SCLK

MSB MSB - 1

LSB

t

6

t

5

t

4

t

3

t

2

t

1

SCK

SS:EECS

Figure 5. MISO Read Timing in SPI Slave Mode

MISO

SCLK

MSB MSB - 1 LSB

t

10

t

9

t

8

t

7

SSI

SS:EECS

SCK

Serial Configuration Interface Timing (External Master)

CS5378

Parameter Symbol Min Typ Max Unit

MOSI Write Timing

SS:EECS

Data Set-up Time Prior to SCK Rising t

Data Hold Time After SCK Rising t

SCK High Time t

SCK Low Time t

SCK Falling Prior to SS:EECS

Enable to Valid Latch Clock t

Disable t

1

2

3

4

5

6

60 - - ns

60 - - ns

120 - - ns

120 - - ns

120 - - ns

60 - - ns

MISO Read Timing

SCK Falling to New Data Bit t

SCK High Time t

SCK Low Time t

SS:EECS

DS639F3 14

Rising to MISO Hi-Z t

7

8

9

10

- - 60 ns

120 - - ns

120 - - ns

--150ns

Page 15

SWITCHING CHARACTERISTICS

Figure 6. Serial Data Read Timing

MISO

SCK

t

3

DRDY

t

4

t

2

t

1

t

5

Serial Data Interface Timing

CS5378

Parameter Symbol Min Typ Max Unit

DRDY

Falling Edge to SCK Rising t

SCK Falling to New Data Bit t

SCK High Time t

SCK Low Time t

Final SCK Falling to DRDY

Rising t

1

2

3

4

5

60 - - ns

--120ns

120 - - ns

120 - - ns

60 - - ns

DS639F3 15

Page 16

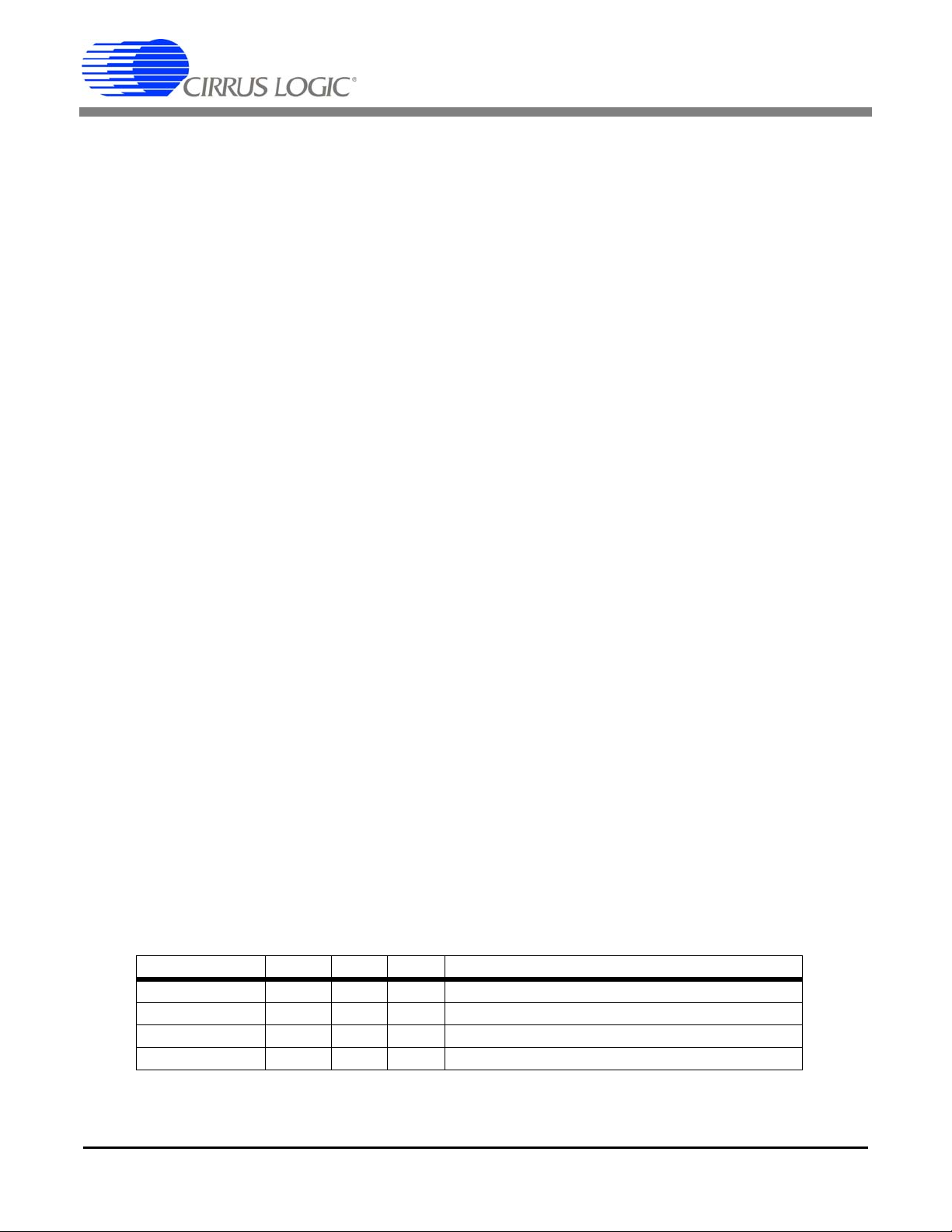

SWITCHING CHARACTERISTICS

MSYNC

MCLK

MDATA

Figure 7. SYNC, MCLK, MSYNC, MDATA Interface Timing

t

msd

t

msd

t

msh

Data1 Data2

SYNC

f

MCLK

2.048 MHz 1.024 MHz

t

msd

= T

MCLK

/ 4 t

msd

= 122 ns t

msd

= 244 ns

t

msh

= T

MCLK

t

msh

= 488 ns t

msh

= 976 ns

Note: SYNC input latched on MCLK rising edge. MSYNC output triggered by MCLK falling edge.

CLK, SYNC, MCLK, MSYNC, and MDATA

CS5378

Master Clock Frequency (Note 3) CLK 32 32.768 33 MHz

Master Clock Duty Cycle DTY 40 - 60 %

Master Clock Rise Time t

Master Clock Fall Time t

Master Clock Jitter JTR - - 300 ps

Synchronization after SYNC rising (Note 4) SYNC -2 - 2 μs

MSYNC Setup Time to MCLK rising t

MCLK rising to Valid MDATA t

MSYNC falling to MCLK rising t

Notes: 3. PLL bypass mode. The PLL generates a 32.768 MHz master clock when enabled.

4. Sampling synchronization between multiple CS5378 devices receiving identical SYNC signals.

DS639F3 16

Parameter Symbol Min Typ Max Unit

- - 20 ns

- - 20 ns

20 - - ns

- - 75 ns

20 - - ns

RISE

FALL

mss

mdv

msf

Page 17

SWITCHING CHARACTERISTICS

Figure 8. TBS Output Data Timing

TBSDATA

MCLK

t

2

t

1

Note: Example timing shown for a 256 kHz output rate and no programmable delays.

Test Bit Stream (TBS)

CS5378

Parameter Symbol Min Typ Max Unit

TBS Data Output Timing

TBS Data Bit Rate - 256 - kbps

TBS Data Rising to MCLK Rising Setup Time t

MCLK Rising to TBS Data Falling Hold Time (Note 5) t

5. TBSDATA can be delayed from 0 to 63 full bit periods. The timing diagram shows no TBSDATA delay.

1

2

60 - - ns

60 - - ns

DS639F3 17

Page 18

CS5378

ΔΣ

Modulator

Test

DAC

Digital Filter

AMP

Differential

Sensor

M

U

X

μController

or

Configuration

EEPROM

System

Telemetry

CS3301A

CS3302A

CS5378

CS5373A

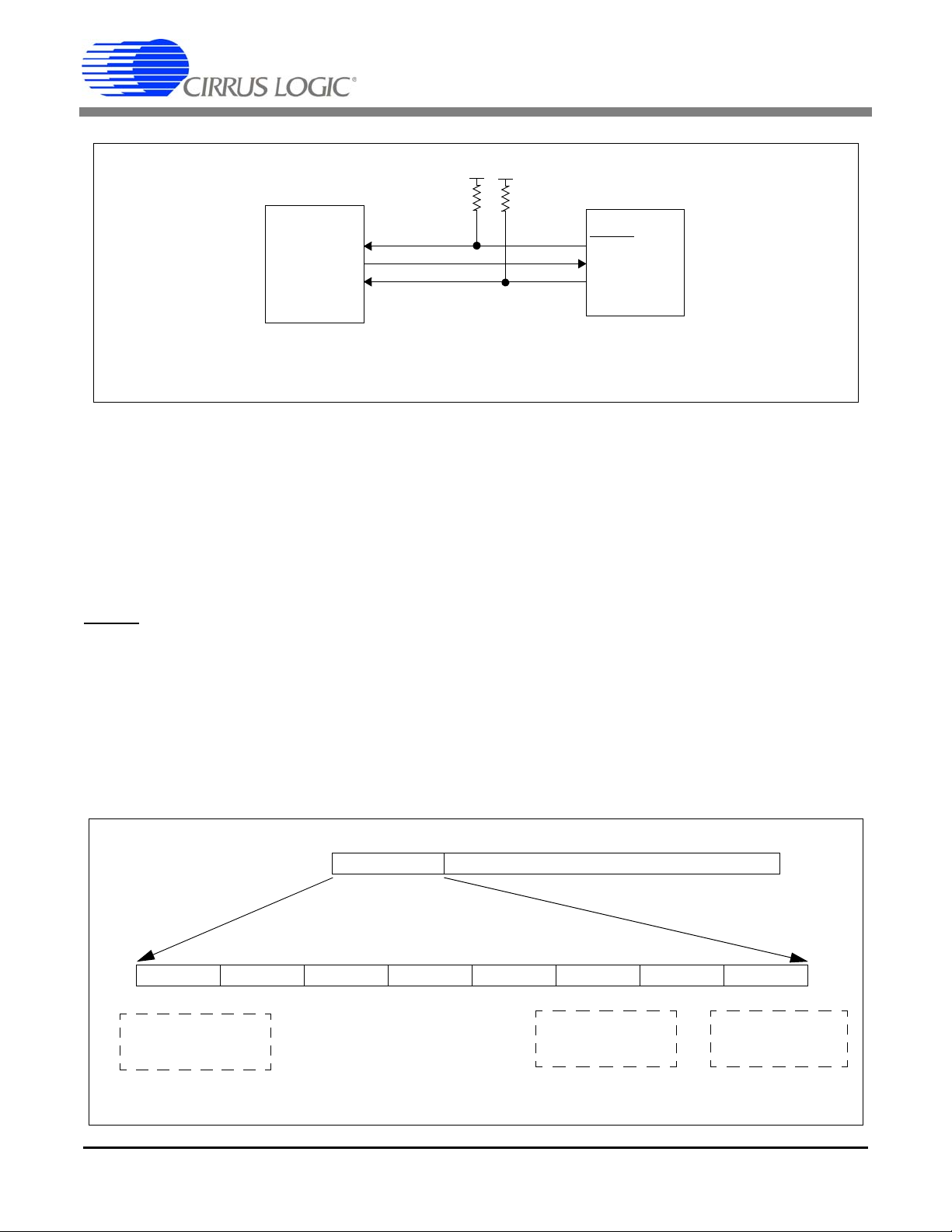

Figure 9. Single-Channel System Block Diagram

3. SYSTEM DESIGN WITH CS5378

Figure 9 illustrates a simplified block diagram of

the CS5378 in a single channel measurement system.

A differential sensor is connected through the

CS3301A/02A differential amplifiers to the

CS5373A ΔΣ modulator, where analog to digital

conversion occurs. The modulator’s 1-bit output

connects to the CS5378 MDATA input, where the

oversampled ΔΣ data is decimated and filtered to

24-bit output samples at a programmed output rate.

These output samples are buffered into an 8-deep

data FIFO and then passed to the system telemetry.

System self tests are performed by connecting the

CS5378 test bit stream (TBS) generator to the

CS5373A test DAC. Analog tests drive differential

signals from the CS5373A test DAC into the multiplexed inputs of the CS3301A/02A amplifiers or

directly to the differential sensor. Digital loopback

tests internally connect the TBS digital output directly to the CS5378 modulator input.

3.1 Power Supplies

The system shown in Figure 9 typically operates

from a ±2.5 V analog power supply and a 3.3 V

digital power supply. The CS5378 logic core can

be powered from 2.5 V to minimize power consumption, if required.

3.2 Reset Control

System reset is required only for the CS5378 device, and is a standard active low signal that can be

generated by a power supply monitor or microcontroller. Other system devices default to a powerdown state when the CS5378 is reset.

3.3 PLL and Clock Generation

A PLL is included on the CS5378 to generate an internal 32.768 MHz master clock from a

1.024 MHz, 2.048 MHz, or 4.096 MHz standard

clock or Manchester encoded input. Clock inputs

for other system devices are driven by clock outputs from the CS5378.

DS639F3 18

Page 19

CS5378

3.4 Synchronization

Digital filter phase and analog sample timing of the

ΔΣ modulator connected to the CS5378 are synchronized by a rising edge on the SYNC pin. If a

synchronization signal is received identically by all

CS5378 devices in a measurement network, synchronous sampling across the network is guaranteed.

3.5 System Configuration

Through the serial configuration interface, filter

coefficients and digital filter register settings can

either be programmed by a microcontroller or automatically loaded from an external EEPROM after

reset. System configuration is only required for the

CS5378 device, as other devices are configured via

the CS5378 General Purpose I/O pins.

Two registers in the digital filter, SYSTEM1 and

SYSTEM2 (0x2C, 0x2D), are provided for user defined system information. These are general purpose registers that will hold any 24-bit data values

written to them.

3.6 Digital Filter Operation

3.7 Data Collection

Data is collected from the CS5378 through the serial data interface. When data is available, serial

transactions are automatically initiated to transfer

24-bit data or 32-bit status+data from the output

FIFO to the system telemetry. The output FIFO has

eight data locations to permit latency in data collection.

3.8 Integrated peripherals

Test Bit Stream (TBS)

A digital signal generator built into the CS5378

produces a 1-bit ΔΣ sine wave. This digital test bit

stream is connected to the CS5373A test DAC to

create high quality analog test signals or internally

looped back to the CS5378 MDATA input to test

the digital filter and data collection circuitry.

Time Break

Timing information is recorded during data collection by strobing the TIMEB pin. A dedicated flag

in the sample status bits, TB, is set high to indicate

during which measurement the timing event occurred.

After analog to digital conversion occurs in the

modulator, the oversampled 1-bit ΔΣ data is read

into the CS5378 through the MDATA pin. The digital filter then processes data through the enabled

filter stages, decimating it to 24-bit words at a programmed output word rate. The final 24-bit samples are concatenated with 8-bit status words and

placed into an output FIFO.

DS639F3 19

General Purpose I/O (GPIO)

Eight general purpose pins are available on the

CS5378 for system control. Each pin can be set as

input or output, high or low, with an internal pullup enabled or disabled. The CS3301A/02A and

CS5373A devices in Figure 9 are configured by

simple pin settings controlled through the CS5378

GPIO pins.

Page 20

4. POWER SUPPLIES

1

2

3

4

5

6

7

821

22

23

24

25

26

27

28

9

10

11

12 17

18

19

20

13

14 15

16

VDDPAD

GNDPAD

GNDCORE

VDDCORE

Figure 10. Power Supply Block Diagram

GNDPLL

VDDPLL

CS5378

The CS5378 has three sets of power supply inputs.

One set supplies power to the I/O pins of the device

(VDDPAD), another supplies power to the logic

core (VDDCORE) and the third supplies power to

the PLL (VDDPLL). The I/O pin power supplies

determine the maximum input and output voltages

when interfacing to peripherals, the logic core power supply largely determines the power consumption of the CS5378 and the PLL power supply

powers the internal PLL circuitry.

4.1 Pin Descriptions

VDDPAD, GNDPAD - Pins 9, 10

Sets the interface voltage to a microcontroller, system telemetry, modulator, and test DAC. VDDPAD can be driven with voltages from 3.3 V to

5V.

VDDPLL, GNDPLL - Pins 15, 16

Sets the operational voltage of the internal CS5378

PLL circuitry. Can be driven with voltages from

3.3 V to 5 V.

DS639F3 20

VDDCORE, GNDCORE - Pins 21, 22

Sets the operational voltage of the CS5378 logic

core. VDDCORE can be driven with voltages from

2.5 V to 5 V. A 2.5 V supply will minimize total

power consumption.

4.2 Bypass Capacitors

Each power supply pin should be bypassed with

parallel 1 μF and 0.01 μF caps, or by a single

0.1 μF cap, placed as close as possible to the

CS5378. Bypass capacitors should be ceramic

(X7R, C0G), tantalum, or other good quality dielectric type.

4.3 Power Consumption

Power consumption of the CS5378 depends primarily on the power supply voltage of the logic

core (VDDCORE) and the programmed digital filter clock rate. Digital filter clock rates are selected

based on the required output word rate as explained

in “Digital Filter Initialization” on page 38.

Page 21

5. RESET CONTROL

RESET

Self-Tests

SELFTEST

Register

BOOT

Pin

EEPROM

Boot

μController

Boot

1

0

Figure 11. Reset Control Block Diagram

BOOT Reset Mode

1 EEPROM boot

0 Microcontroller boot

Self-Test

Type

Pass

Code

Fail

Code

Program ROM 0x00000A 0x00000F

Data ROM 0x0000A0 0x0000F0

Program RAM 0x000A00 0x000F00

Data RAM 0x00A000 0x00F000

Execution Unit 0x0A0000 0x0F0000

CS5378

The CS5378 reset signal is active low. When released, a series of self-tests are performed and the

device either actively boots from an external EEPROM or enters an idle state waiting for microcontroller configuration.

5.1 Pin Descriptions

RESET

Reset input, active low.

- Pin 18

GPIO7:BOOT - Pin 28

Boot mode select, latched immediately following

reset. Weak (~100 kΩ) internal pull-up defaults

high, external 10 kΩ pull-down required to set low.

combined into the SELFTEST register (0x2F),

with 0x0AAAAA indicating all passed. Self-tests

require 60 ms to complete.

5.3 Boot Configurations

The logic state of the BOOT pin after reset determines if the CS5378 actively reads configuration

information from EEPROM or enters an idle state

waiting for a microcontroller to write configuration

commands.

EEPROM Boot

When the BOOT pin is high after reset, the CS5378

actively reads data from an external serial EEPROM and then begins operation in the specified

configuration. Configuration commands and data

are encoded in the EEPROM as specified in the

‘Configuration By EEPROM’ section of this data

sheet, starting on page 25.

5.2 Reset Self-Tests

After RESET is released but before booting, a series of digital filter self-tests are run. Results are

DS639F3 21

Microcontroller Boot

When the BOOT pin is low after reset, the CS5378

enters an idle state waiting for a microcontroller to

write configuration commands and initialize filter

operation. Configuration commands and data are

written as specified in the ‘Configuration By Microcontroller’ section of this data sheet, starting on

page 30.

Page 22

6. PLL AND CLOCK GENERATION

PLL

CLK

DSPCFG Register

MCLK

Internal

Clocks

Figure 12. Clock Generation Block Diagram

Clock Divider

Generator

and MCLK

Output

PLL[2:0]

32.768

MHz

PLL[2:0] PLL Mode

111 32.768 MHz clock input (PLL bypass).

110 1.024 MHz clock input.

101 2.048 MHz clock input.

100 4.096 MHz clock input.

011 32.768 MHz clock input (PLL bypass).

010 1.024 MHz Manchester input.

001 2.048 MHz Manchester input.

000 4.096 MHz Manchester input.

Table 5. PLL Mode Selections

CS5378

The CS5378 requires a 32.768 MHz master clock,

which can be supplied directly or from an internal

phase locked loop. This master clock is used to

generate an internal digital filter clock and an external modulator clock.

The internal PLL will lock to standard clock or

Manchester encoded input signals. The input type

and input frequency are selected by the reset state

of the PLL mode select pins.

6.1 Pin Descriptions

CLK - Pin 17

Clock or PLL input, standard clock or Manchester.

GPIO[4:6]:PLL[0:2] - Pins 5, 6, 7

PLL mode select, latched immediately after reset.

Weak (~100 kΩ) internal pull-ups default high, external 10 kΩ pull-downs required to set low.

A weak internal pull-up resistor (~100 kΩ) will

hold the PLL mode select pins high by default. To

force the pin low on reset, an external 10 kΩ pulldown resistor should be connected. Once the pin

state is latched following reset, the GPIO[4:6] pins

function without affecting PLL operation.

6.3 Synchronous Clocking

To guarantee synchronous measurements throughout a sensor network, a system clock should be distributed to arrive at all nodes in phase. The

distributed system clock can either be the full

32.768 MHz master clock, or the CS5378 PLL can

create a synchronous 32.768 MHz clock from a

slower clock. To ensure the generated clock remains synchronous with the network, the CS5378

PLL uses a phase/frequency detector architecture.

6.2 PLL Mode Select

The CS5378 PLL operational mode and frequency

are selected immediately after reset based on the

state of the PLL[0:2] pins. On the rising edge of the

reset signal, the digital high or low state of the

PLL[0:2] pins is latched and used to program the

clock input type and frequency.

DS639F3 22

Page 23

CS5378

6.4 Master Clock Jitter and Skew

Care must be taken to minimize jitter and skew on

the distributed system clock as both parameters affect measurement performance.

Jitter on the input clock causes jitter in the generated modulator clock, resulting in sample timing errors and increased noise.

Skew between input clocks from node to node creates a sample timing offset, resulting in systematic

measurement errors in a reconstructed signal.

DS639F3 23

Page 24

7. SYNCHRONIZATION

Figure 13. Synchronization Block Diagram

SYNC

MSYNC

Digital

Filter

Generator

MSYNC

0

1

MSEN

0

1

TSYNC

Test Bit

Stream

Output

CS5378

The CS5378 has a dedicated SYNC input that

aligns the internal digital filter phase and generates

an external signal for synchronizing modulator analog sampling. By providing simultaneous rising

edges to the SYNC pins of multiple CS5378 devices, synchronous sampling across a network can be

guaranteed.

7.1 Pin Description

SYNC - Pin 19

Synchronization input, rising edge triggered.

7.2 MSYNC Generation

The SYNC signal rising edge is used to generate a

retimed synchronization signal, MSYNC. The

MSYNC signal reinitializes internal digital filter

phase and is driven onto the MSYNC output pin to

phase align modulator analog sampling.

The MSEN bit in the digital filter CONFIG register

(0x00) enables MSYNC generation. See “Modulator Interface” on page 36 for more information

about MSYNC.

7.3 Digital Filter Synchronization

The internal MSYNC signal resets the digital filter

state machine to establish a known digital filter

phase. Filter convolutions restart, and the next output word is available one full sample period later.

Repetitive synchronization is supported when

SYNC events occur at exactly the selected output

rate. In this case, re-synchronization will occur at

the start of a convolution cycle when the digital filter state machine is already reset.

7.4 Modulator Synchronization

The external MSYNC signal phase aligns modulator analog sampling when connected to the

CS5373A MSYNC input. This ensures synchronous analog sampling relative to MCLK.

Repetitive synchronization of the modulators is

supported when SYNC events occur at exactly the

selected output rate. In this case, re-synchronization always occurs at the start of analog sampling.

7.5 Test Bit Stream Synchronization

When the test bit stream generator is enabled, an

MSYNC signal can reset the internal data pointer.

This restarts the test bit stream from the first data

point to establish a known output signal phase.

The TSYNC bit in the digital filter TBSCFG register (0x2A) enables synchronization of the test bit

stream by MSYNC. When TSYNC is disabled, the

test bit stream phase is not affected by MSYNC.

DS639F3 24

Page 25

8. CONFIGURATION BY EEPROM

SS:EECS

SCK

MISO

MOSI

CS5378 AT25640

CS

SCK

SI

SO

27

24

25

26

1

6

2

5

VD

GND

WP VCC HOLD

387

4

Figure 14. EEPROM Configuration Block Diagram

CS5378

After reset, the CS5378 reads the state of the

GPIO7:BOOT pin to determine a source for configuration commands. If BOOT is high, the

CS5378 initiates serial transactions to read configuration information from an external EEPROM.

8.1 Pin Descriptions

Pins required for EEPROM boot are listed here,

other serial pins are inactive.

SCK - Pin 24

Serial clock output, nominally 1.024 MHz.

MISO - Pin 25

Serial data input pin. Valid on rising edge of SCK,

transition on falling edge.

MOSI - Pin 26

Serial data output pin. Valid on rising edge of

SCK, transition on falling edge.

SS:EECS - Pin 27

EEPROM chip select output, active low.

8.2 EEPROM Hardware Interface

When booting from EEPROM the CS5378 actively

performs serial transactions, as shown in Figure 15,

DS639F3 25

to read configuration commands and data. 8-bit

SPI opcodes and 16-bit addresses are combined to

read back 8-bit configuration commands and 24-bit

configuration data.

System design should include a connection to the

configuration EEPROM for in-circuit reprogramming. The CS5378 serial pins tri-state when inactive to support external connections to the serial

bus.

8.3 EEPROM Organization

The boot EEPROM holds the 8-bit commands and

24-bit data required to initialize the CS5378 into an

operational state. Configuration information starts

at memory location 0x10, with addresses 0x00 to

0x0F free for use as manufacturing header information.

The first serial transaction reads a 1-byte command

from memory location 0x10 and then, depending

on the command type, reads multiple 3-byte data

words to complete the command. Command and

data reads continue until the ‘Filter Start’ command

is recognized.

Page 26

SCK

MOSI

SS:EECS

MSB LSB

MISO

X

612345

MSB LSB612345

18276543

Cycle

MOSI

MISO

0x03 ADDR

DATA1 DATA3DATA2

SS:EECS

READ

1 BYTE / 3 BYTE

ADDR

CMD

ADDR

DATA

2 BYTE

Figure 15. EEPROM Serial Read Transactions

Serial Read from EEPROM

Instruction Opcode Address Definition

Read 0x03 ADDR[15:0] Read data beginning at the address given in ADDR.

CS5378

DS639F3 26

Page 27

CS5378

Figure 16. 8 Kbyte EEPROM Memory Organization

0000h

1FFFh

EEPROM

Manufacturing

Information

EEPROM

Command and

Data Values

Mfg Header

8-bit Command

0010h

N x 24-bit Data

8-bit Command

N x 24-bit Data

. . .

Table 6. Maximum EEPROM Configuration

Memory Requirement Bytes

Digital Filter Registers (12) 84

FIR Coefficients (255+255) 1537

IIR Coefficients (3+5) 25

‘Filter Start’ Command 1

Total Bytes 1647

Write DF Register - 0x01

This EEPROM command writes a data value to the

specified digital filter register. Digital filter registers control hardware peripherals and filtering

functions. See “Digital Filter Registers” on page 71

for the bit definitions of the digital filter registers.

Sample Command:

Write digital filter register 0x00 with data value

0x060431. Then write 0x20 with data 0x000240.

01 00 00 00 06 04 31

01 00 00 20 00 02 40

Write FIR Coefficients - 0x02

The maximum number of bytes that will be written

for a single configuration is less than 2 KByte

(16 Kbit), including command overhead:

Supported serial configuration EEPROMs are

SPI mode 0 (0,0) compatible, 16-bit addresses, 8bit data, larger than 2 KByte (16 KBit). ATMEL

AT25640, AT25128, or similar serial EEPROMs

are recommended.

8.4 EEPROM Configuration Commands

A summary of available EEPROM commands is

shown in Table 7.

This EEPROM command writes custom coefficients for the FIR1 and FIR2 filters. The first two

data words set the number of FIR1 and FIR2 coefficients to be written. The remaining data words are

the concatenated FIR1 and FIR2 coefficients.

A maximum of 255 coefficients can be written for

each FIR filter, though the available digital filter

computation cycles will limit their practical size.

See “FIR Filter” on page 44 for more information

about FIR filter coefficients.

Sample Command:

Write FIR1 coefficients 0x00022E, 0x000771 then

FIR2 coefficients 0xFFFFB9, 0xFFFE8D.

02 00 00 02 00 00 02

00 02 2E 00 07 71 FF FF B9 FF FE 8D

Write IIR Coefficients - 0x03

This EEPROM command writes custom coefficients for the two stage IIR filter. The IIR architecture and number of coefficients is fixed, so eight

data words containing coefficient values always

immediately follow the command byte. The IIR coefficient write order is: a11, b10, b11, a21, a22,

b20, b21, and b22. See “IIR Filter” on page 52 for

more information about IIR filter coefficients.

DS639F3 27

Page 28

CS5378

Table 7. EEPROM Boot Configuration Commands

(DATA) indicates multiple words of this type are to be written.

Name CMD

8-bit

DATA

24-bit

Description

NOP 00 - No Operation

WRITE DF REGISTER 01 REG

DATA

Write Digital Filter Register

WRITE FIR COEFFICIENTS 02 NUM FIR1

NUM FIR2

(FIR COEF)

Write Custom FIR Coefficients

WRITE IIR COEFFICIENTS 03 a11

b10

b11

a21

a22

b20

b21

b22

Write Custom IIR Coefficients

WRITE ROM COEFFICIENTS 04 COEF SEL Use On-Chip Coefficients

NOP 05 - No Operation

NOP 06 - No Operation

FILTER START 07 - Start Digital Filter Operation

Sample Command:

Write IIR1 coefficients 0x84BC9D, 0x7DA1B1,

0x825E4F, and IIR2 coefficients 0x83694F,

0x3CAD5F, 0x3E5104, 0x835DF8, 0x3E5104.

03

84 BC 9D 7D A1 B1 82 5E 4F 83 69 4F

3C AD 5F 3E 51 04 83 5D F8 3E 51 04

Write ROM Coefficients - 0x04

This EEPROM command selects the on-chip coefficients for the FIR1, FIR2, IIR 1st order, and IIR

2nd order filters for use by the digital filter. One

data word is required to select which internal coefficient sets to use. See “Filter Coefficient Selection” on page 38 for information about selecting

on-chip FIR and IIR coefficient sets.

Sample Command:

Select IIR1 and IIR2 3 Hz @ 500 SPS low-cut coefficients, with FIR1 and FIR2 linear phase highcut coefficients. Data word 0x002200.

04 00 22 00

Filter Start - 0x07

This EEPROM command initializes and starts the

digital filter. Measurement data becomes available

one full sample period after this command is issued. No data words are required for this EEPROM command.

Sample Command:

07

DS639F3 28

Page 29

8.5 Example EEPROM Configuration

Table 8. Example EEPROM File

Addr Data Description

00 00 Mfg header

01 00

02 00

03 00

04 00

05 00

06 00

07 00

08 00

09 00

0A 00

0B 00

0C 00

0D 00

0E 00

0F 00

10 04 Write ROM Coefficients

11 00

12 22

13 00

14 01 Write CONFIG Register

15 00

16 00

17 00

18 06

19 04

1A 31

1B 01 Write FILTCFG Register

1C 00

1D 00

1E 20

1F 00

Addr Data Description

21 02

22 40

23 01 Write TBSCFG Register

24 00

25 00

26 2A

27 07

28 40

29 40

2A 01 Write TBSGAIN Register

2B 00

2C 00

2D 2B

2E 04

2F B0

30 00

31 07 Filter Start

Table 8 shows an example EEPROM file for a minimal CS5378 configuration.

CS5378

DS639F3 29

Page 30

9. CONFIGURATION BY MICROCONTROLLER

SCK

MISO

MOSI

Pin Logic

SPI™

Figure 17. Serial Interface Block Diagram

Command

SS:EECS

Registers

Digital Filter

Interpreter

Serial

CS5378

After reset, the CS5378 reads the state of the

GPIO7:BOOT pin to determine a source for configuration commands. If BOOT is low, the CS5378

receives configuration commands from a microcontroller.

9.1 Pin Descriptions

Pins required for microcontroller boot are listed

here, other serial pins are inactive.

SS:EECS - Pin 27

Slave select input pin, active low. Serial chip select

input from a microcontroller.

MOSI - Pin 26

Serial data input pin. Valid on rising edge of SCK,

transition on falling edge.

MISO - Pin 25

Serial data output pin. Valid on rising edge of

SCK, transition on falling edge. Open drain output

requiring a 10 kΩ pull-up resistor.

9.2 Microcontroller Hardware Interface

When booting from a microcontroller the CS5378

receives configuration commands and configuration data through serial transactions, as shown in

Figure 18. 8-bit SPI opcodes and 8-bit addresses

are combined to read and write 24-bit configuration

commands and data.

Microcontroller serial transactions require toggling

the SS:EECS pin as the CS5378 chip select and

writing a serial clock to the SCK input. Serial data

is input to the CS5378 on the MOSI pin, and output

on the MISO pin.

9.3 Microcontroller Serial Transactions

Microcontroller configuration commands are written to the digital filter through SPI registers. A 24bit command and two 24-bit data words can be

written to the SPI registers in any single serial

transaction. Some commands require additional

data words through additional serial transactions to

complete.

SCK - Pin 24

Serial clock input pin. Serial clock input from microcontroller, maximum 4.096 MHz.

9.3.1 SPI opcodes

A microcontroller communicates with the CS5378

serial port using standard 8-bit SPI opcodes and an

8-bit address. The standard SPI ‘Read’ and ‘Write’

opcodes are listed in Figure 18.

DS639F3 30

Page 31

SCK

MOSI

Figure 18. Microcontroller Serial Transactions

SS:EECS

MSB LSB

MISO

X

612345

MSB LSB612345

18276543

Cycle

MISO 0x02 ADDR Data1

MOSI

MISO

MOSI

Microcontroller Write to SPI Registers

Microcontroller Read from SPI Registers

DataNData2

SS:EECS

SS:EECS

0x03 ADDR

Data1 DataNData2

Instruction Opcode Address Definition

Write 0x02 ADDR[7:0] Write SPI registers beginning at the address in ADDR.

Read 0x03 ADDR[7:0] Read SPI registers beginning at the address in ADDR.

CS5378

DS639F3 31

Page 32

CS5378

Name Addr. Type # Bits Description

SPICTRL 00 - 02 R/W 8, 8, 8 SPI Control

SPICMD 03 - 05 R/W 8, 8, 8 SPI Command

SPIDAT1 06 - 08 R/W 8, 8, 8 SPI Data 1

SPIDAT2 09 - 0B R/W 8, 8, 8 SPI Data 2

Figure 19. SPI Registers

9.3.2 SPI registers

The SPI registers are shown in Figure 19 and are

24-bit registers mapped into an 8-bit register space

as high, mid, and low bytes. See “SPI Registers” on

page 66 for the bit definitions of the SPI registers.

9.3.3 Serial transactions

A serial transaction to the SPI registers starts with

an SPI opcode, followed by an address, and then

some number of data bytes written or read starting

at that address.

Typical serial write transactions require sending

groups of 5, 8, or 11 total bytes to the SPICMD or

SPIDAT1 registers:

5-byte write to SPICMD

02 03 12 34 56

5-byte write to SPIDAT1

02 06 12 34 56

MOSI: 03 01 00

MISO: xx xx 12

5-byte read of SPIDAT1

MOSI: 03 06 00 00 00

MISO: xx xx 12 34 56

9.3.4 Multiple serial transactions

Some configuration commands require multiple serial transactions to complete. There must be a

small delay between transactions for the CS5378 to

process the incoming data. Two methods can be

used to ensure the CS5378 is ready to receive the

next configuration command.

1) Delay a fixed 1 ms period to guarantee enough

time for the command to be completed.

2) Verify the status of the E2DREQ bit by reading

the SPICTRL register. When low, the CS5378 is

ready for the next command.

8-byte write to SPICMD, SPIDAT1

02 03 12 34 56 AB CD EF

8-byte write to SPIDAT1, SPIDAT2

02 06 12 34 56 AB CD EF

11-byte write to SPICMD, SPIDAT1, SPIDAT2

02 03 12 34 56 AB CD EF 65 43 21

Typical serial read transactions require groups of 3

or 5 bytes, split between writing into MOSI and

reading from MISO.

3-byte read of mid-byte of SPICTRL

9.3.5 Polling E2DREQ

One transaction type that can always be performed

no matter the delay from the previous configuration

command is reading E2DREQ in the mid-byte of

the SPICTRL register. A 3-byte read transaction.

MOSI: 03 01 00

MISO: xx xx 01 <- E2DREQ bit high

MISO: xx xx 00 <- E2DREQ bit low

The E2DREQ bit reads high while a serial transac-

tion is being processed. When low, the digital filter

is ready to receive a new serial transaction.

DS639F3 32

Page 33

CS5378

[DATA] indicates data word returned from digital filter.

(DATA) indicates multiple words of this type are to be written.

Name CMD

24-bit

DAT1

24-bit

DAT2

24-bit

Description

NOP 000000 - - No Operation

WRITE DF REGISTER 000001 REG DATA Write Digital Filter Register

READ DF REGISTER 000002 REG

[DATA]

-

-

Read Digital Filter Register

WRITE FIR COEFFICIENTS 000003 NUM FIR1

(FIR COEF)

NUM FIR2

(FIR COEF)

Write Custom FIR Coefficients

WRITE IIR COEFFICIENTS 000004 a11

b11

a22

b21

b10

a21

b20

b22

Write Custom IIR Coefficients

WRITE ROM COEFFICIENTS 000005 COEF SEL - Use On-Chip Coefficients

NOP 000006 - - No Operation

NOP 000007 - - No Operation

FILTER START 000008 - - Start Digital Filter Operation

FILTER STOP 000009 - - Stop Digital Filter Operation

Table 9. Microcontroller Boot Configuration Commands

9.4 Microcontroller Configuration Commands

A summary of available microcontroller configuration commands is listed in Table 9.

Write DF Register - 0x01

This configuration command writes a specified

digital filter register. Digital filter registers control

hardware peripherals and filtering functions. See

“Digital Filter Registers” on page 71 for the bit definitions of the digital filter registers.

Sample Command:

Write digital filter register 0x00 with data value

0x060431. Then write 0x20 with data 0x000240.

02 03 00 00 01 00 00 00 06 04 31

Delay 1 ms or poll E2DREQ

02 03 00 00 01 00 00 20 00 02 40

Delay 1 ms or poll E2DREQ

Read DF Register - 0x02

This command reads a specified digital filter register. The register value is requested in the first serial

transaction, with the register value copied to

SPIDAT1 and read in a subsequent serial transaction.

Sample Command:

Read digital filter registers 0x00 and 0x20.

02 03 00 00 02 00 00 00

Delay 1 ms or poll E2DREQ

MOSI: 03 06 00 00 00

MISO: xx xx 06 04 31

02 03 00 00 02 00 00 20

Delay 1 ms or poll E2DREQ

MOSI: 03 06 00 00 00

MISO: xx xx 00 02 40

DS639F3 33

Page 34

CS5378

Write FIR Coefficients - 0x03

This command writes custom coefficients for the

FIR1 and FIR2 filters. The first two data words set

the number of FIR1 and FIR2 coefficients to be

written. The remaining data words are the concatenated FIR1 and FIR2 coefficients.

A maximum of 255 coefficients can be written for

each FIR filter, though the available digital filter

computation cycles will limit their practical size.

See “FIR Filter” on page 44 for more information

about FIR filter coefficients.

Sample Command:

Write FIR1 coefficients 0x00022E, 0x000771 then

FIR2 coefficients 0xFFFFB9, 0xFFFE8D.

02 03 00 00 03 00 00 02 00 00 02

Delay 1 ms or poll E2DREQ

02 06 00 02 2E 00 07 71

Delay 1 ms or poll E2DREQ

02 06 FF FF B9 FF FE 8D

Delay 1 ms or poll E2DREQ

Write IIR Coefficients - 0x04

This command writes custom coefficients for the

two stage IIR filter. The IIR architecture and number of coefficients is fixed, so eight coefficient values immediately follow this command. The IIR

coefficient write order is: a11, b10, b11, a21, a22,

b20, b21, and b22. See “IIR Filter” on page 52 for

more information about IIR filter coefficients.

Sample Command:

Write IIR1 coefficients 0x84BC9D, 0x7DA1B1,

0x825E4F, and IIR2 coefficients 0x83694F,

0x3CAD5F, 0x3E5104, 0x835DF8, 0x3E5104.

02 06 3C AD 5F 3E 51 04

Delay 1 ms or poll E2DREQ

02 06 83 5D F8 3E 51 04

Delay 1 ms or poll E2DREQ

Write ROM Coefficients - 0x05

This configuration command selects the on-chip

coefficients for FIR1, FIR2, IIR 1st order, and IIR

2nd order filters for use by the digital filter. One

data word is required to select which internal coefficient sets to use. See “Filter Coefficient Selection” on page 38 for information about selecting

on-chip FIR and IIR coefficient sets.

Sample Command:

Select IIR1 and IIR2 3 Hz @ 500 SPS low-cut coefficients, with FIR1 and FIR2 linear phase highcut coefficients. Data word 0x002200.

02 03 00 00 05 00 22 00

Delay 1 ms or poll E2DREQ

Filter Start - 0x08

This command initializes and starts the digital filter. Measurement data becomes available one full

sample period after this command is issued. No

data words are required for this command.

Sample Command:

02 03 00 00 08

Delay 1 ms or poll E2DREQ

Filter Stop - 0x09

This command disables the digital filter. Measurement data output stops immediately after this command is issued. No data words are required for this

command.

02 03 00 00 04 84 BC 9D 7D A1 B1

Delay 1 ms or poll E2DREQ

02 06 82 5E 4F 83 69 4F

Delay 1 ms or poll E2DREQ

DS639F3 34

Sample Command:

02 03 00 00 09

Delay 1 ms or poll E2DREQ

Page 35

9.5 Example Microcontroller Configuration

Table 10. Example Microcontroller Configuration

Transaction SPI Data Description

01 02 03 00 00 05 00 22 00 Write ROM coefficients

02 Delay 1ms or poll E2DREQ

03 02 03 00 00 01 00 00 00 06 04 31 Write CONFIG Register

04 Delay 1ms or poll E2DREQ

05 02 03 00 00 01 00 00 20 00 02 40 Write FILTCFG Register

06 Delay 1ms or poll E2DREQ

07 02 03 00 00 01 00 00 2A 07 40 40 Write TBSCFG Register

08 Delay 1ms or poll E2DREQ

09 02 03 00 00 01 00 00 2B 04 B0 00 Write TBSGAIN Register

10 Delay 1ms or poll E2DREQ

11 02 03 00 00 08 Filter Start

Table 10 shows an example microcontroller transactions for a minimal CS5378 configuration.

CS5378

DS639F3 35

Page 36

CS5378

Figure 20. Modulator Data Interface

FIR

IIR

Filters

Filter

Output to High Speed Serial Interface

DC Offset

Correction

Output Rate 4000 SPS ~ 1 SPS

& Gain

MDATA

MFLAG

MDI Input

512 kHz

MCLK /

Generate

MSYNC

CLK

SYNC

MSYNC

SINC

Filter

MCLK

10.MODULATOR INTERFACE

The CS5378 performs digital filtering for a ΔΣ type

modulator. Signals from the ΔΣ modulators are

connected through the modulator data interface

(MDI).

10.1 Pin Descriptions

MCLK - Pin 11

Modulator clock output. Nominally 2.048 MHz or

1.024 MHz.

MSYNC - Pin 12

Modulator synchronization signal output. Generated from the SYNC input.

MDATA - Pin 13

Modulator data input, nominally 512 kbit/s.

MFLAG - Pin 14

10.2 Modulator Clock Generation

The MCLK output is a low-jitter, low-skew modulator clock generated from the 32.768 MHz master

clock.

MCLK typically operates at 2.048 MHz unless analog low-power modes require a 1.024 MHz modulator clock.

The MCLK rate is selected and the MCLK output

is enabled by bits in the digital filter CONFIG register (0x00). By default MCLK is disabled and

driven low.

10.3 Modulator Synchronization

The MSYNC output signal follows an input to the

SYNC pin. MSYNC phase aligns the modulator

sampling instant to guarantee synchronous analog

sampling across a measurement network.

Modulator flag input. Driven high when the modulator is unstable due to an analog over-range condition.

DS639F3 36

MSYNC is enabled by a bit in the CONFIG register

(0x00). By default SYNC inputs do not cause an

MSYNC output.

Page 37

CS5378

10.4 Modulator Data Input

The MDATA input expects 1-bit ΔΣ data at a

512 kHz or 256 kHz rate. The input rate is selected

by a bit in the CONFIG register (0x00). By default,

MDATA is expected at 512 kHz.