6-Channel Digital Amplifier Controller

Features

> 100 dB Dynamic Range - System Level

PWM PopGuard

CS44600

®

for Single-Ended Mode

< 0.03% THD+N @ 1 W - System Level

32 kHz to 192 kHz Sample Rates

Internal Oscillator Circuit Supports 24.576 MHz

to 54 MHz Crystals

Integrated Sample Rate Converter (SRC)

– Eliminates Clock Jitter Effects

– Input Sample Rate Independent Operation

Power Supply Rejection Realtime Feedback

Spread Spectrum Modulation - Reduces

Modulation Energy

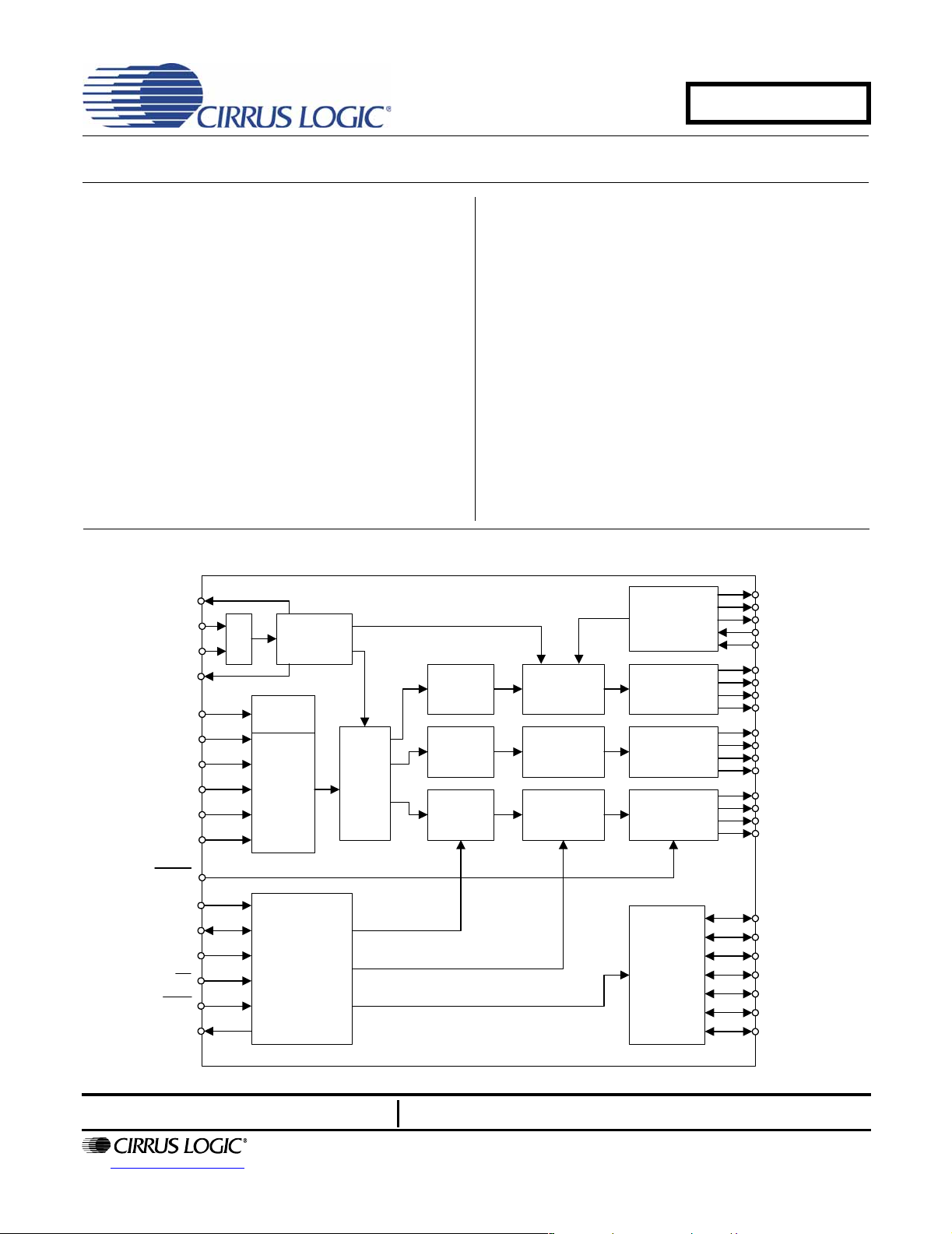

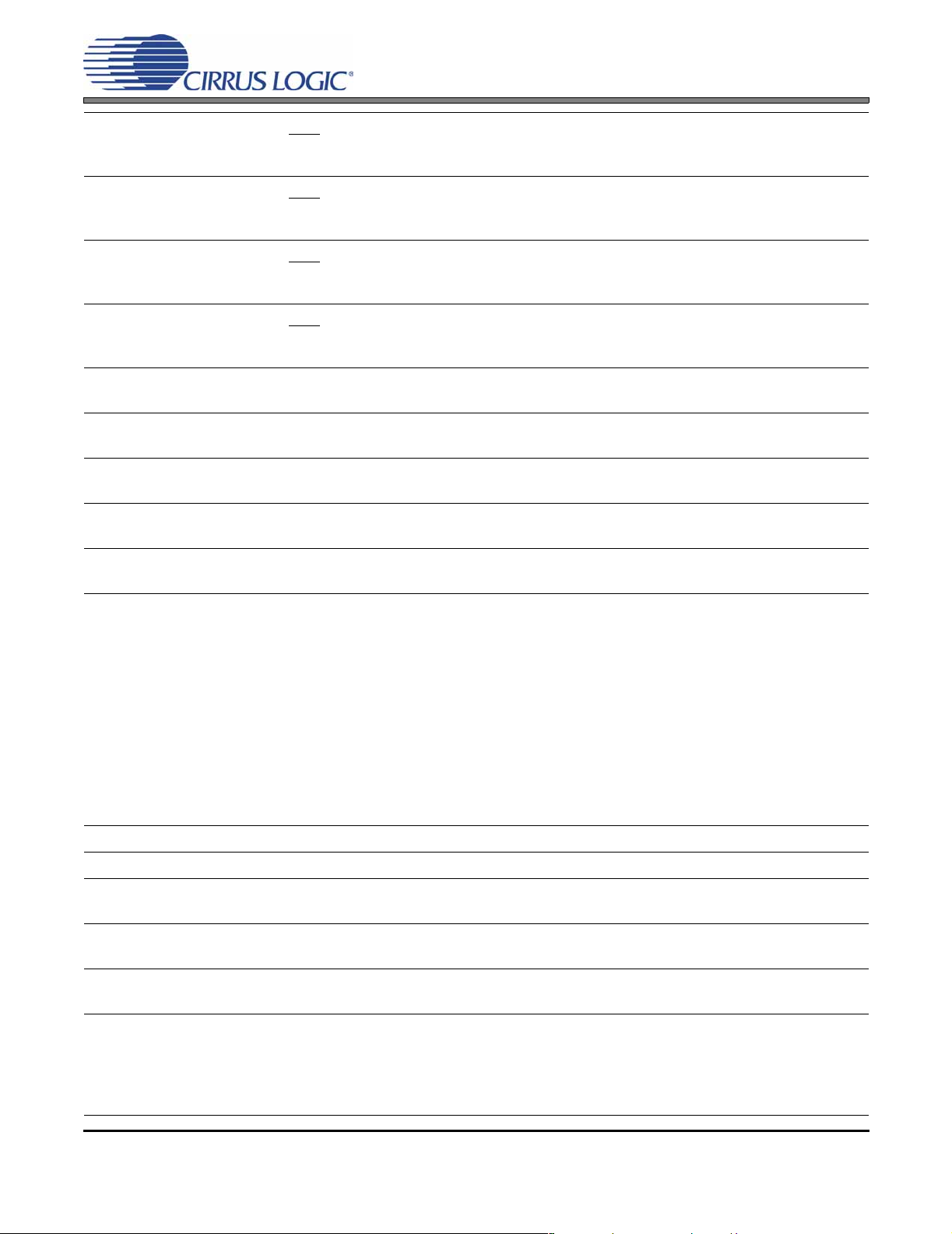

PS_SYNC

Control

Auto Fs

Detect

DAI

Serial

Port

PWM

Clock

Volume

/ Limiter

Volume

/ Limiter

SRC

Volume

/ Limiter

XTI

XTO

SYS_CLK

DAI_MCLK

DAI_SCLK

DAI_LRCK

DAI_SDIN1

DAI_SDIN2

DAI_SDIN3

XTAL

Eliminates AM Frequency Interference

Programmable Load Compensation Filters

Support for up to 40 kHz Audio Bandwidth

Digital Volume Control with Soft Ramp

– +24 to -127 dB in 0.25 dB Steps

Per Channel Programmable Peak Detect and

Limiter

SPI and I²C Host Control Interfaces

Separate 2.5 V to 5.0 V Serial Port and Host

Control Port Supplies

PSR_RESET

PSR_EN

PSR_MCLK

PSR_SYNC

PSR_DATA

PWMOUTA1+

PWMOUTA1PWMOUTB1+

PWMOUTB1-

PWMOUTA2+

PWMOUTA2PWMOUTB2+

PWMOUTB2-

PWMOUTA3+

PWMOUTA3PWMOUTB3+

PWMOUTB3-

Multibit

Σ∆

Modulator

Multibit

Σ∆

Modulator

Multibit

Σ∆

Modulator

Power

Supply

Rejection

PWM

Conversion

PWM

Conversion

PWM

Conversion

MUTE

SCL/CCLK

SDA/CDOUT

AD1/CDIN

AD0/CS

RST

INT

SPI/I2C Host

Control Port

Preliminary Product Information

http://www.cirrus.com

GPIO0

PWM

Backend

Control/

Status

This document contains information for a new product.

Cirrus Logic reserves the right to modify this product without notice.

Copyright © Cirrus Logic, Inc. 2005

(All Rights Reserved)

GPIO1

GPIO2

GPIO3

GPIO4

GPIO5

GPIO6

MAY '05

DS633PP1

CS44600

General Description

The CS44600 is a multi-channel digital-to-PWM Class D audio system controller including interpolation, sample rate

conversion, half- and full-bridge PWM driver outputs, and power supply rejection feedback in a 64-pin LQFP package.The architecture uses a direct-to-digital approach that maintains digital signal integrity to the final output filter,

minimizing analog interference effects which negatively affect system performance.

The CS44600 integrates on-chip digital volume control, peak detect with limiter, de-emphasis, and 7 GPIO’s, allowing easy interfacing to many commonly available power stages. The PWM amplifier can achieve greater than 90%

efficiency. This efficiency provides for smalle r device package, less heat sink requirements, and smaller power

supplies.

The CS44600 is ideal for audio systems requiring wide dynamic range, negligible distortion an d low noise, such as

A/V receivers, DVD receivers, digital speaker and automotive audio systems.

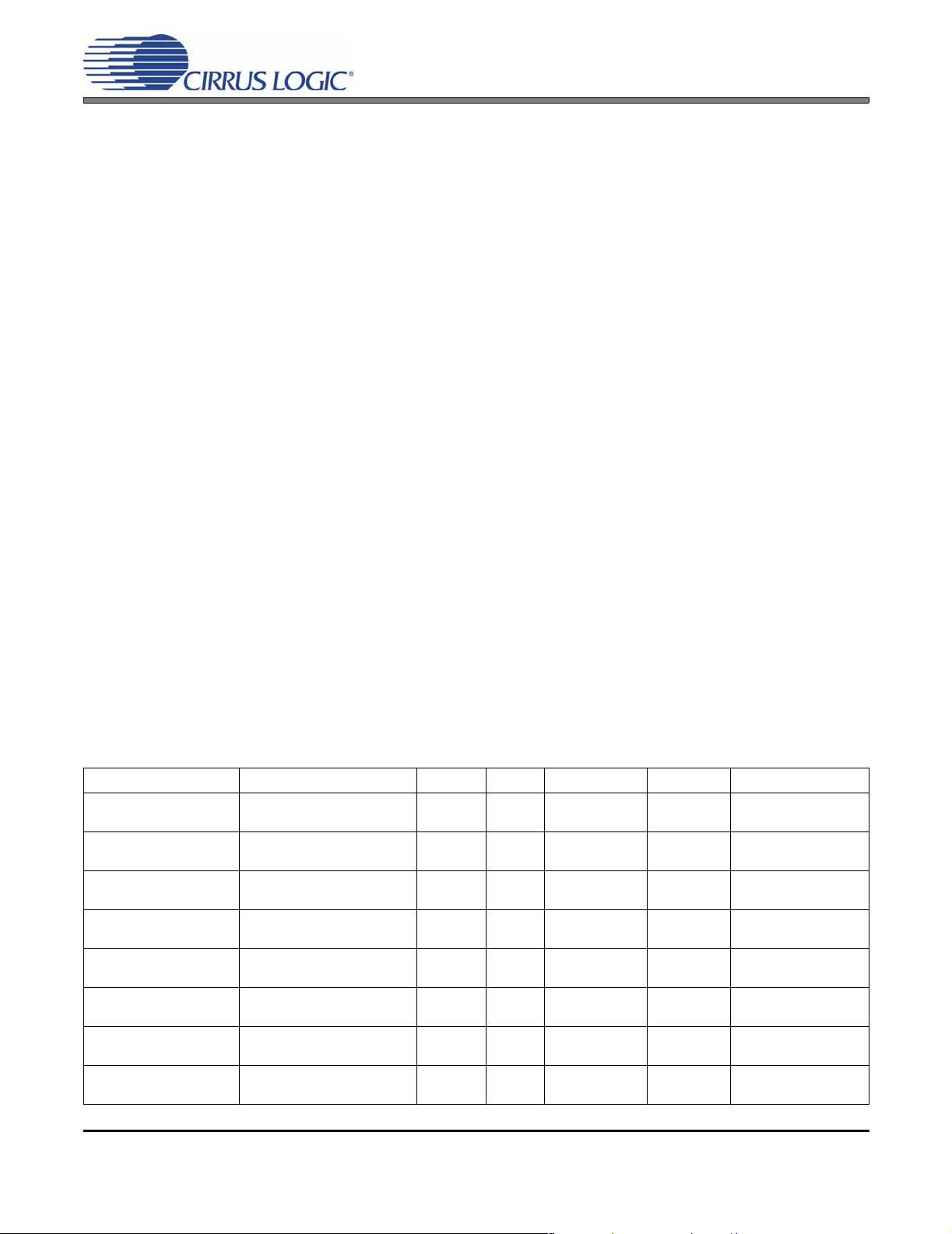

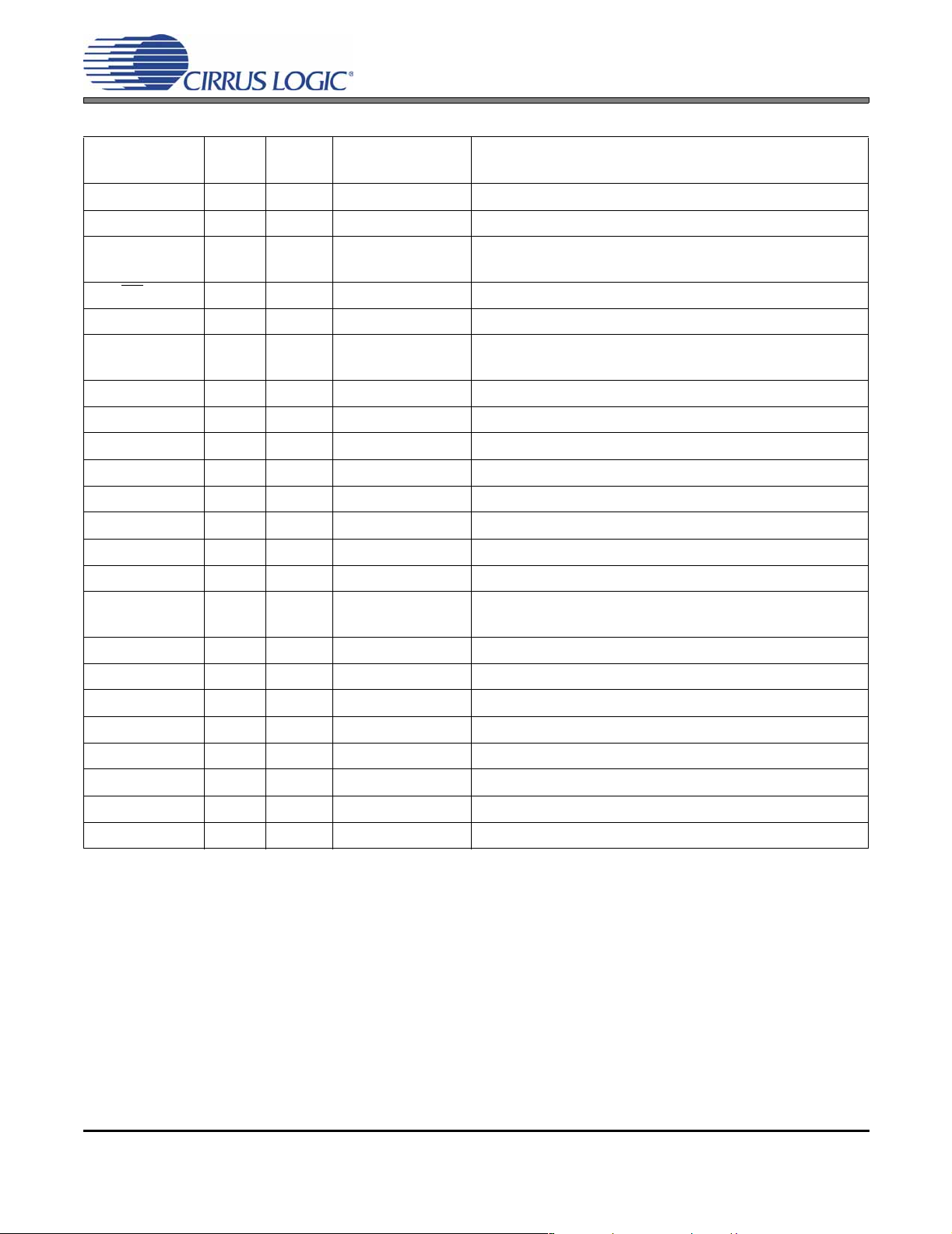

ORDERING INFORMATION

Product Description Package

6

CS44600

CS44600

CS44600

CS44600

CDB44800

CRD44800

CRD44800-ST-FB

CRD44600-PH-FB

-Channel Digital Amplifier

Controller

6

-Channel Digital Amplifier

Controller

6

-Channel Digital Amplifier

Controller

6

-Channel Digital Amplifier

Controller

CS44600/800 Evaluation

Board

8x50 W Half-Bridge

Reference Design Board

8x60 W Full-Bridge

Reference Design Board

2x100 W Full-Bridge

Reference Design Board

Pb-Free

LQFP YES -10° to +70°C Rail CS44600-CQZ

LQFP YES -10° to +70°C Tape and

LQFP YES -40° to +85°C Rail CS44600-DQZ

LQFP YES -40° to +85°C Tape and

- - - - CDB44800

- - - - CRD44800

- - - - CRD44800-ST-FB

- - - - CRD44600-PH-FB

Temp Rang e Container

Reel

Reel

Order#

CS44600-CQZR

CS44600-DQZR

2 DS633PP1

TABLE OF CONTENTS

1. CHARACTERISTICS AND SPECIFICATIONS ........................................................................ 8

SPECIFIED OPERATING CONDITIONS ...................................................................................... 8

ABSOLUTE MAXIMUM RATINGS ................................................................................................. 8

DC ELECTRICAL CHARACTERISTICS ................... ... ... .... ... ... ... .... ... ... ... ... .................................. 9

DIGITAL INTERFACE CHARACTERISTICS ................................................................................. 9

PWM OUTPUT PERFORMANCE CHARACTERISTICS ............................................................. 10

PWM FILTER CHARACTERISTICS ............................................................................................ 11

SWITCHING CHARACTERISTICS - XTI ..................................................................................... 11

SWITCHING CHARACTERISTICS - SYS_CLK .......................................................................... 12

SWITCHING CHARACTERISTICS - PWMOUTA1-B3 ................................................................ 12

SWITCHING CHARACTERISTICS - PS_SYNC .......................................................................... 12

SWITCHING CHARACTERISTICS - DAI INTERFACE ............................................................... 13

SWITCHING CHARACTERISTICS - CONTROL PORT - I²C FORMAT ...................................... 14

SWITCHING CHARACTERISTICS - CONTROL PORT - SPI FORMAT ..................................... 15

2. PIN DESCRIPTIONS .............................................................................................................. 16

2.1 I/O Pin Characteristics ..................................................................................................... 19

3. TYPICAL CONNECTION DIAGRAMS ................................................................................... 20

4. APPLICATIONS ..................................................................................................................... 22

4.1 Overview ... ... .... ... ... ... .... .......................................................................................... ......... 22

4.2 Feature Set Summary ..................................................................................................... 22

4.3 Clock Generation ................ ................................................. ... ......................................... 23

4.3.1 FsIn Domain Clocking ......................................................................................... 24

4.3.2 FsOut Domain Clocking ................................................ ... ... ................................ 24

4.4 FsIn Clock Domain Modules ................................... ................................ ......................... 26

4.4.1 Digital Audio Input Port .................... ... ... .... ... ................................................ ... ... 26

4.4.2 Auto Rate Detect .............. ... ... ............................................................................. 30

4.4.3 De-Emphasis ................................ ................................................ ... ................... 30

4.5 FsOut Clock Domain Modules ......................... ............................................................. ...31

4.5.1 Sample Rate Converter ............................. ... ... ... .... ... ......................................... 31

4.5.2 Load Compensation Filter .......................... .......................................... ............... 31

4.5.3 Digital Volume and Mute Control ............... ... ... ... .... ... ... ...................................... 31

4.5.4 Peak Detect / Limiter ........................................................................................... 32

4.5.5 PWM Engines ........................... .... ... ... ... ................................................. ... ... ... ... 32

4.5.6 Interpolation Filter .................. ... .... ... ................................................ .... ............... 33

4.5.7 Quantizer ............................... ... ................................................. ... ...................... 33

4.5.8 Modulator ...................................................... ... ................................................ ... 33

4.5.9 PWM Outputs ................... ... ... ... .... ... ... ................................................. ... ............ 33

4.5.10 Power Supply Rejection (PSR) Real-Time Feedback ....................................... 34

4.6 Control Port Description and Timing .......... ...................................................................... 35

4.6.1 SPI Mode ............................ ... ................................................. ... ......................... 35

4.6.2 I²C Mode ....................................................................... ...................................... 36

4.6.3 GPIOs ................................................................................................................. 37

4.6.4 Host Interrupt ................ ... ... ............................................. ... .... ... ... ... .... ............... 37

5. POWER SUPPLY, GROUNDING, AND PCB LAYOUT ......................................................... 38

5.1 Reset and Power-Up ....................................................................................................... 41

5.1.1 PWM PopGuard® Transient Control ................................................................... 41

5.1.2 Recommended Power-Up Sequence ................................................................. 41

5.1.3 Recommended PSR Calibration Sequence ....................................................... 42

5.1.4 Recommended Power-Down Sequence ............................................................. 43

6. REGISTER QUICK REFERENCE .......................................................................................... 44

7. REGISTER DESCRIPTION .................................................................................................... 48

7.1 Memory Address Pointer (MAP) ............................. ......................................................... 48

CS44600

DS633PP1 3

CS44600

7.1.1 Increment (INCR) ................................................................................................ 48

7.1.2 Memory Address Pointer (MAPx) ....................................................................... 48

7.2 CS44600 I.D. and Revision Register (address 01h) (Read Only) ................................... 48

7.2.1 Chip I.D. (Chip_IDx) ............................................................................................ 48

7.2.2 Chip Revision (Rev_IDx) ..................................................................................... 48

7.3 Clock Configuration and Power Control (address 02h) ................................................... 49

7.3.1 Enable SYS_CLK Output (EN_SYS_CLK) ......................................................... 49

7.3.2 SYS_CLK Clock Divider Settings (SYS_CLK_DIV[1:0]) ..................................... 49

7.3.3 PWM Master Clock Divider Settings (PWM_MCLK_DIV[1:0]) ......................... ... 49

7.3.4 Power Down XTAL (PDN_XTAL) ........................................................................ 49

7.3.5 Power Down Output Mode (PDN_OUTPUT_MODE) ......................................... 50

7.3.6 Power Down (PDN) ............................................................................................. 50

7.4 PWM Channel Power Down Control (address 03h) ........................................................ 50

7.4.1 Power Down PWM Channels (PDN_PWMB3:PDN_PWMA1) ............................ 50

7.5 Misc. Configuration (address 04h) ................................................................................... 51

7.5.1 Digital Interface Format (DIFX) ........................................................................... 51

7.5.2 AM Frequency Hopping (AM_FREQ_HOP) ........................................................ 51

7.5.3 Freeze Controls (FREEZE) ................................................................................. 51

7.5.4 De-Emphasis Control (DEM[1:0]) ....................................................................... 52

7.6 Ramp Configuration (address 05h) ................................................................................. 52

7.6.1 Ramp-Up/Down Setting (RAMP[1:0]) ................................................................ 52

7.6.2 Ramp Speed (RAMP_SPD[1:0]) ............................................. ... ... ... .... ... ... ... ... ... 52

7.7 Volume Control Configuration (address 06h) .................................................................. 53

7.7.1 Single Volume Control (SNGVOL) ...................................................................... 53

7.7.2 Soft Ramp and Zero Cross Control (SZC[1:0]) ................................................... 53

7.7.3 Enable 50% Duty Cycle for Mute Condition (MUTE_50/50) ............................... 53

7.7.4 Soft Ramp-Down on Interface Error (SRD_ERR) .............................................. 54

7.7.5 Soft Ramp-Up on Recovered Interface Error (SRU_ERR) ................................. 54

7.7.6 Auto-Mute (AMUTE) ........................................................................................... 54

7.8 Master Volume Control - Integer (address 07h) .............................................................. 55

7.8.1 Master Volume Control - Integer (MSTR_IVOL[7:0]) .......................................... 55

7.9 Master Volume Control - Fraction (address 08h) ............................. .... ... ......................... 55

7.9.1 Master Volume Control - Fraction (MSTR_FVOL[1:0]) ....................................... 55

7.10 Channel XX Volume Control - Integer (addresses 09h - 0Eh) ....................................... 57

7.10.1 Channel Volume Control - Integer (CHXx_IVOL[7:0]) ...................................... 57

7.11 Channel XX Volume Control1 - Fraction (address 11h) .............................................. 57

7.12 Channel XX Volume Control2 - Fraction (address 12h) ............................. .... ... ... ... ...... 57

7.12.1 Channel Volume Control - Fraction (CHXX_FVOL[1:0]) ................................... 57

7.13 Channel Mute (address 13h) ......................................................................................... 58

7.13.1 Independent Channel Mute (CHXX_MUTE) ..................................................... 58

7.14 Channel Invert (address 14h) ........................................................................................ 58

7.14.1 Invert Signal Polarity (CHXX_INV) ........................... ... ... ... .... ... ... ... .... ... ... ... ... ... 58

7.15 Peak Limiter Control Register (address 15h) ............................................................... 59

7.15.1 Peak Signal Limit All Channels (LIMIT_ALL) .................................................... 59

7.15.2 Peak Signal Limiter Enable (LIMIT_EN) ........................................................... 59

7.16 Limiter Attack Rate (address 16h) ................................................................................ 59

7.16.1 Attack Rate (ARATE[7:0]) ........................ ......................................................... 59

7.17 Limiter Release Rate (address 17h) ........................................................................... 60

7.17.1 Release Rate (RRATE[7:0]) .............................. .......... .......... ......... .......... ......... 60

7.18 Chnl XX Load Compensation Filter - Coarse Adjust (addresses 18h, 1Ah, 1Ch, 1Eh, 20h, 22h)

...................................................................................................................................... 60

7.18.1 Channel Compensation Filter - Coarse Adjust (CHXX_CORS[5:0]) ................. 60

7.19 Chnl XX Load Compensation Filter - Fine Adjust (addresses 19h, 1Bh, 1Dh, 1Fh, 21h, 23h)

...................................................................................................................................... 61

4 DS633PP1

CS44600

7.19.1 Channel Compensation Filter - Fine Adjust (CHXX_FINE[5:0]) ........................ 61

7.20 Interrupt Mode Control (address 28h) ........................................................................... 61

7.20.1 Interrupt Pin Control (INT1/INT0) ...................................................................... 61

7.20.2 Overflow Level/Edge Select (OVFL_L/E) .... ... ... .... ... ... ... ... .... ... ... ... ................... 62

7.21 Interrupt Mask (address 29h) ........................................................................................ 62

7.22 Interrupt Status (address 2Ah) (Read Only) ................................................................. 62

7.22.1 SRC Unlock Interrupt (SRC_UNLOCK) ............................................................ 62

7.22.2 SRC Lock Interrupt (SRC_LOCK) ..................................................................... 63

7.22.3 Ramp-Up Complete Interrupt (RMPUP_DONE) ............................................... 63

7.22.4 Ramp-Down Complete Interrupt (RMPDN_DONE) .... ... ... .... ... ... ... .... ... ... ......... 63

7.22.5 Mute Complete Interrupt (Mute_DONE) ........................................................... 63

7.22.6 Channel Over Flow Interrupt (OVFL_INT) ........................................................ 63

7.22.7 GPIO Interrupt Condition (GPIO_INT) ........ ... ... .... ... ... ... ... ................................ 63

7.23 Channel Over Flow Status (address 2Bh) (Read Only) ................................................. 64

7.23.1 ChXX_OVFL ..................................................................................................... 64

7.24 GPIO Pin In/Out (address 2Ch) ..................................................................................... 64

7.24.1 GPIO In/Out Selection (GPIOX_I/O) ........... ... ............................................. ... ... 64

7.25 GPIO Pin Polarity/Type (address 2Dh) .................................... ... ................................... 64

7.25.1 GPIO Polarity/Type Selection (GPIOX_P/T) .................. ................................... 64

7.26 GPIO Pin Level/Edge Trigger (address 2Eh) ................................................................. 65

7.26.1 GPIO Level/Edge Input Sensitive (GPIOX_L/E) ............................................... 65

7.27 GPIO Status Register (address 2Fh) ............................................................................. 65

7.27.1 GPIO Pin Status (GPIOX_STATUS) ................................................................. 65

7.28 GPIO Interrupt Mask Register (address 30h) ................................................................ 66

7.28.1 GPIO Pin Interrupt Mask (M_GPIOX) ............................................................... 66

7.29 PWM Configuration Register (address 31h) .............. ................................................... 66

7.29.1 Over Sample Rate Selection (OSRATE) .......................................................... 66

7.29.2 Channels A1 and B1 Output Configuration (A1/B1_OUT_CNFG) .................... 66

7.29.3 Channels A2 and B2 Output Configuration (A2/B2_OUT_CNFG) .................... 66

7.29.4 Channel A3 Output Configuration (A3_OUT_CNFG) ....................................... 67

7.29.5 Channel B3 Output Configuration (B3_OUT_CNFG) ....................................... 67

7.30 PWM Minimum Pulse Width Register (address 32h) .................................................... 67

7.30.1 Disable PWMOUTXX - Signal (DISABLE_PWMOUTXX-) .......................... ...... 67

7.30.2 Minimum PWM Output Pulse Settings (MIN_PULSE[4:0]) ...................... ......... 67

7.31 PWMOUT Delay Register (address 33h) ...................................................................... 68

7.31.1 Differential Signal Delay (DIFF_DLY[2:0]) ........................................................ 68

7.31.2 Channel Delay Settings (CHNL_DLY[4:0]) ...................................................... 68

7.32 PSR and Power Supply Configuration (address 34h) .................................................... 69

7.32.1 Power Supply Rejection Enable (PSR_EN) ...................... .... ... ......................... 69

7.32.2 Power Supply Rejection Reset (PSR_RESET) ................................................. 70

7.32.3 Power Supply Rejection Feedback Enable (FEEDBACK_EN) ......................... 70

7.32.4 Power Supply Sync Clock Divider Settings (PS_SYNC_DIV[2:0]) ................... 70

7.33 Decimator Shift/Scale (addresses 35h, 36h, 37h) ......................................................... 70

7.33.1 Decimator Shift (DEC_SHIFT[2:0]) ................................................................... 70

7.33.2 Decimator Scale (DEC_SCALE[18:0]) .............................................................. 71

7.34 Decimator Outd (addresses 3Bh, 3Ch, 3Dh) ................................................................. 71

7.34.1 Decimator Outd (DEC_OUTD[23:0]) ..................... ............ ............. ............. ...... 71

8. PARAMETER DEFINITIONS .................................................................................................. 72

9. REFERENCES ........................................................................................................................ 74

10. PACKAGE DIMENSIONS ........................................................................................... 75

11. THERMAL CHARACTERISTICS ......................................................................................... 76

12. REVISION HISTORY ............................................................................................................ 77

DS633PP1 5

LIST OF FIGURES

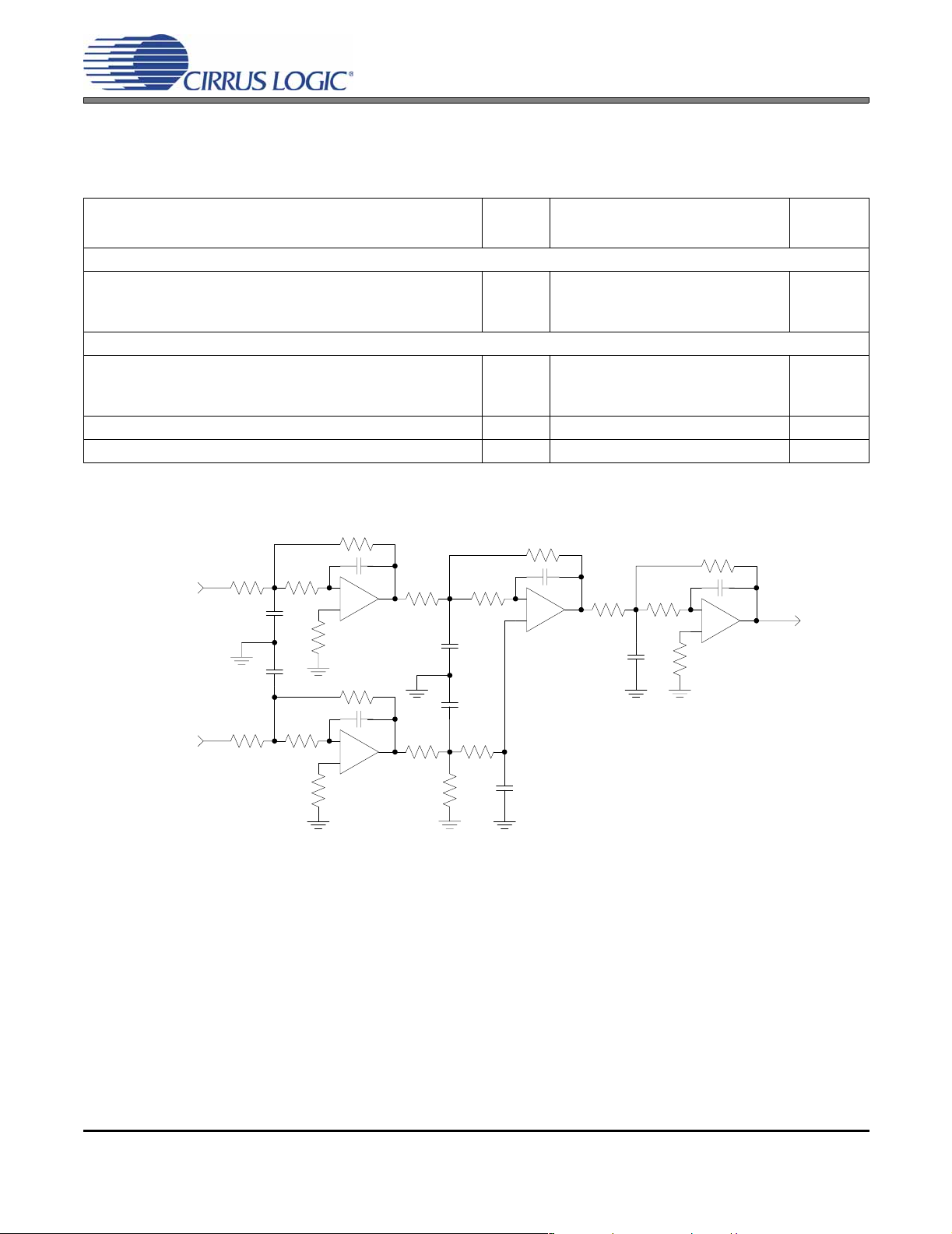

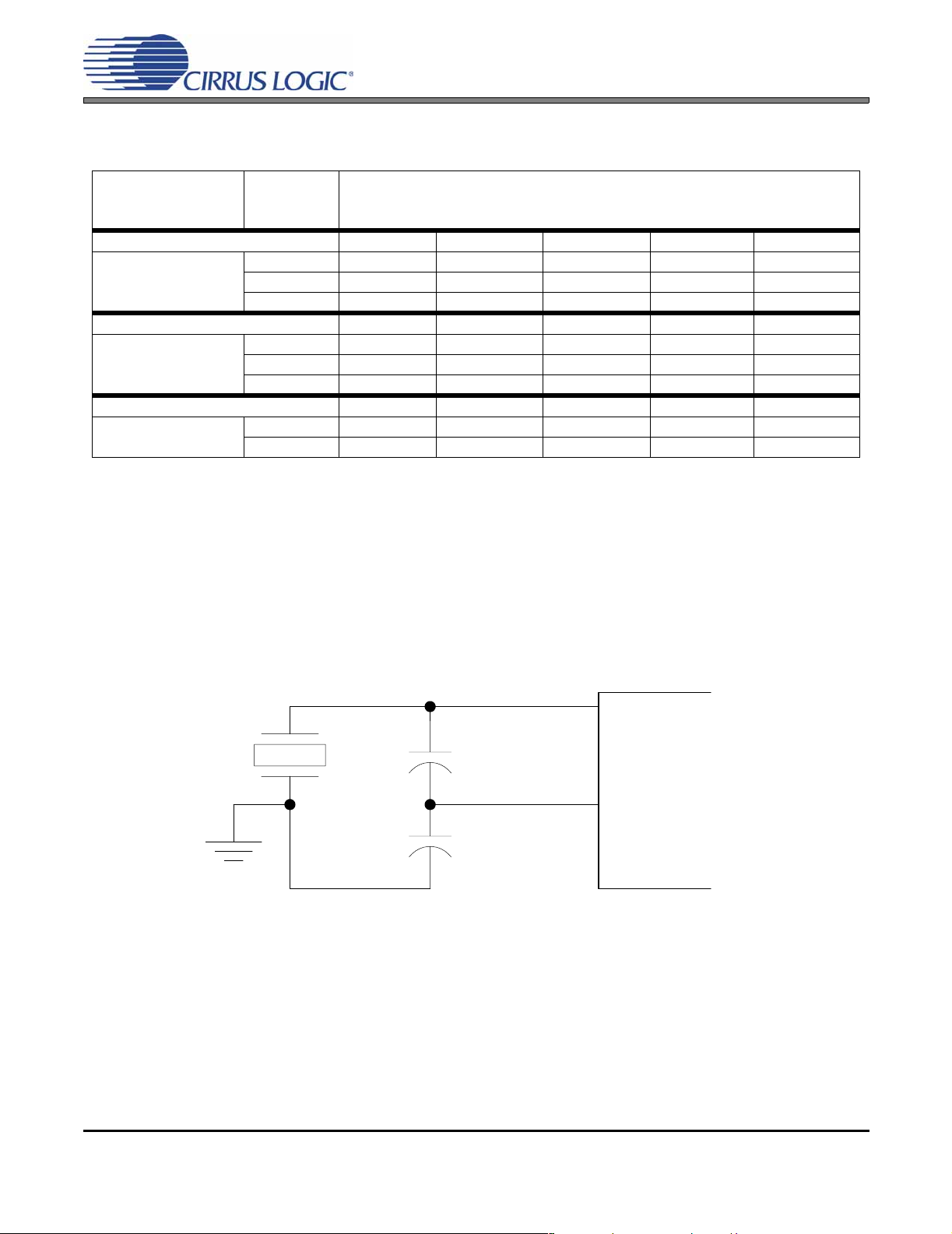

Figure 1. Performance Characteristics Evaluation Active Filter Circuit......................................... 10

Figure 2. XTI Timings.................................................................................................................... 11

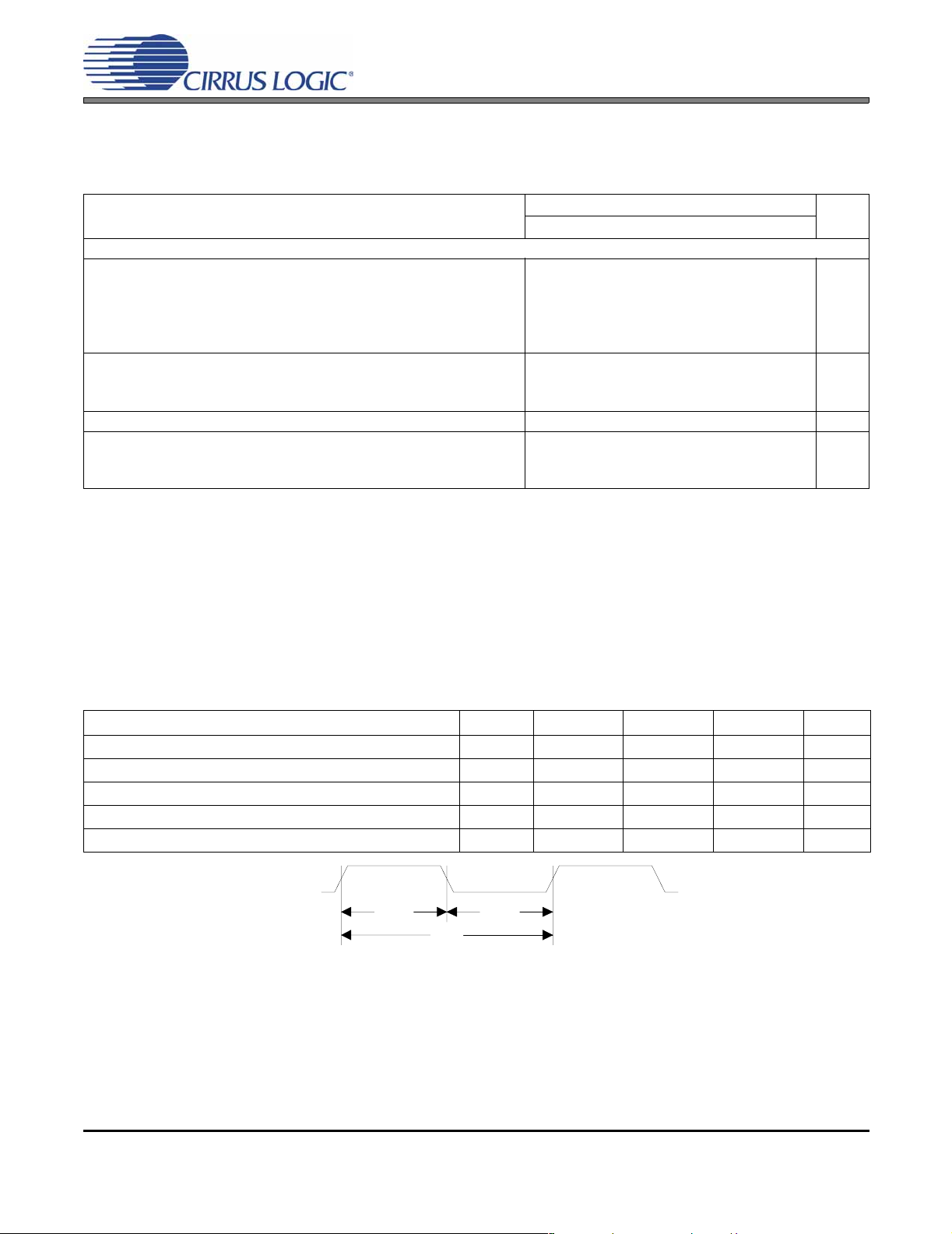

Figure 3. SYS_CLK Timings......................................................................................................... 12

Figure 4. PWMOUTxx Timings ............................... ... ... ... .... ... ... ... .... ... ... ... ... .... ............................ 12

Figure 5. PS_SYNC Timings............................ ... .... ... ... ... .... ... ... ... .... ... ... ...................................... 12

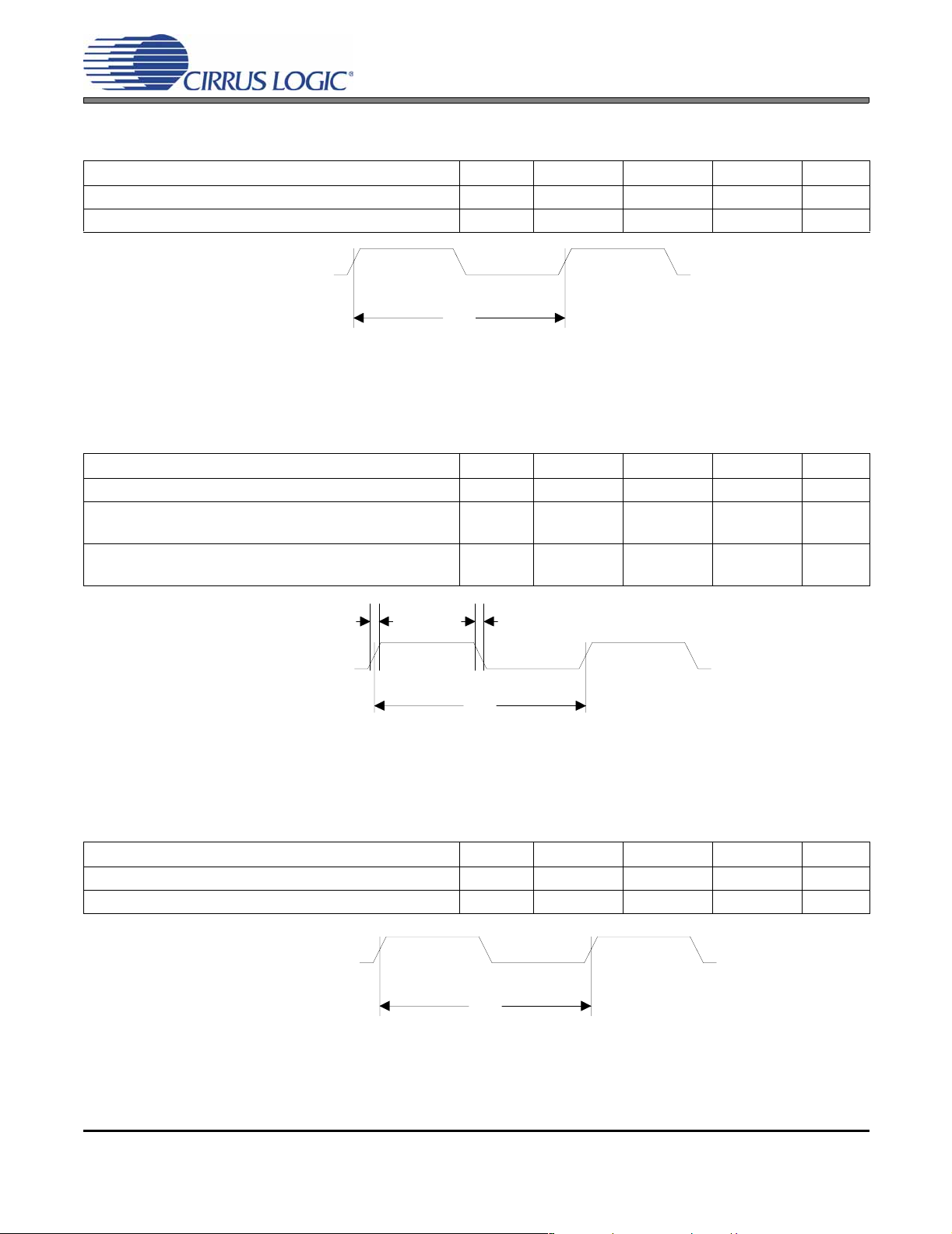

Figure 6. Serial Audio Interface Timing.........................................................................................13

Figure 7. Serial Audio Interface Timing - TDM Mode........................................ ... ... ... .... ... ... ... ... ... 13

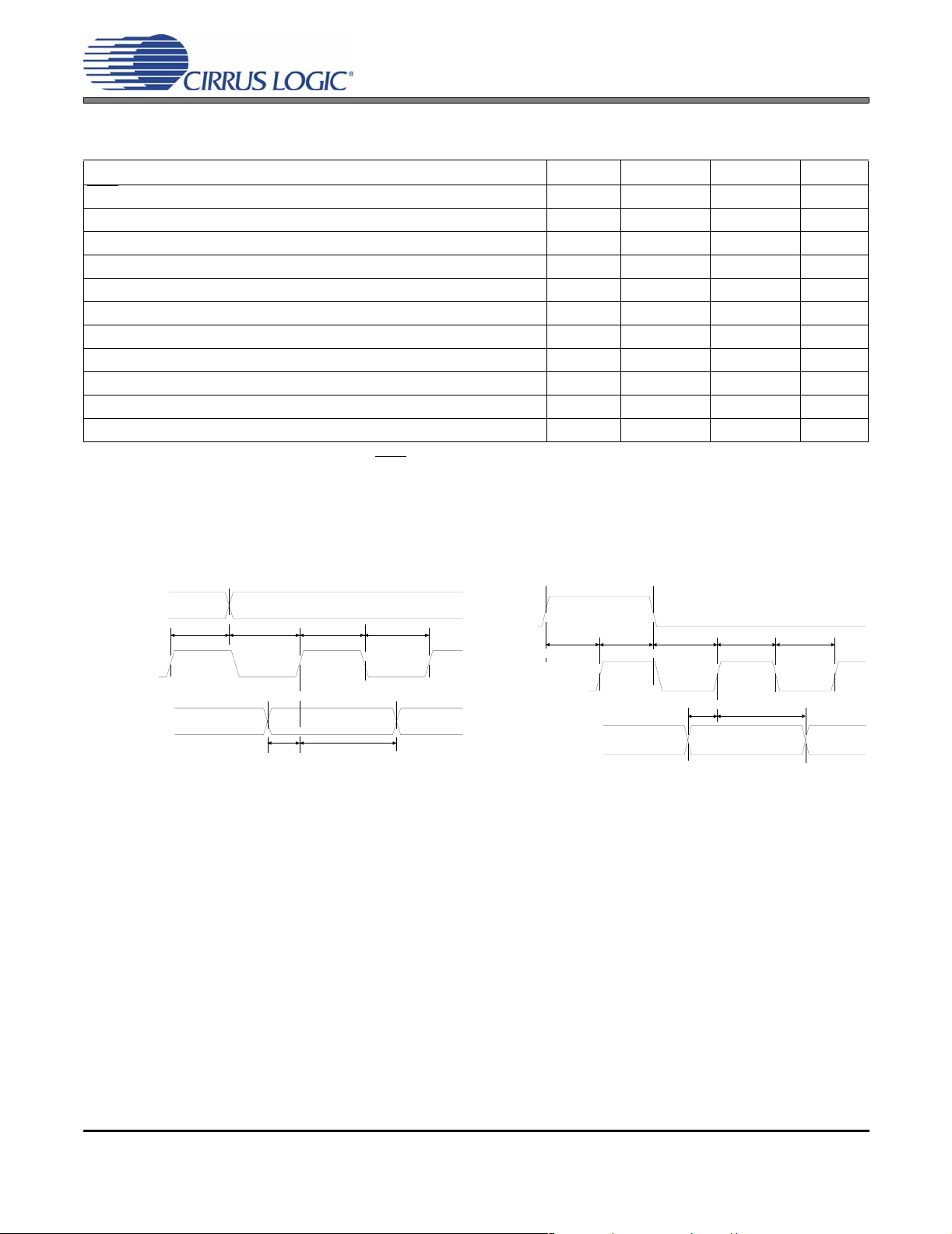

Figure 8. Control Port Timing - I²C Format.................................................................................... 14

Figure 9. Control Port Timing - SPI Format................................................................................... 15

Figure 10. CS44600 Pinout Diagram............................................................................................ 16

Figure 11. Typical Full-Bridge Connection Diagram ..................................................................... 20

Figure 12. Typical Half-Bridge Connection Diagram..................................................................... 21

Figure 13. CS44600 Data Flow Diagram (Single Channel Shown) .............................................. 23

Figure 14. Fundamental Mode Crystal Configuration ................................................................... 24

Figure 15. 3rd Overtone Crystal Configuration .......................................... ... .... ... ... ... .... ... ... ... ... ... 25

Figure 16. CS44600 Internal Clock Generation ............................................................................ 25

Figure 17. I²S Serial Audio Formats . ... .... ... ... ... ... .... ... ... ... .................................................... ... ... ... 27

Figure 18. Left-Justified Serial Audio Formats. ... .... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ......................... 27

Figure 19. Right-Justified Serial Audio Formats............................................................................ 28

Figure 20. One Line Mode #1 Serial Audio Format....................................................................... 28

Figure 21. One Line Mode #2 Serial Audio Format....................................................................... 29

Figure 22. TDM Mode Serial Audio Format ......................................... ... ... ... .... ... ... ... .... ... ... ... ... ... 29

Figure 23. De-Emphasis Curve..................................................................................................... 30

Figure 24. Control Port Timing in SPI Mode ..................................... ... ... ... ... .... ... ... ... .... ... ... ... ... ... 35

Figure 25. Control Port Timing, I²C Slave Mode Write.................................................................. 36

Figure 26. Control Port Timing, I²C Slave Mode Read.................................................................. 36

Figure 27. Recommended CS44600 Power Supply Decoupling Layout.... ... .... ... ... ...................... 38

Figure 28. Recommended CS44600 Crystal Circuit Layout ......................................................... 39

Figure 29. Recommended PSR Circuit Layout ............................................................................. 40

Figure 30. PSR Calibration Sequence .......................................................................................... 43

Figure 31. PWM Output Delay ...................................................................................................... 69

Figure 32. 64-Pin LQFP Package Drawing................................................................................... 75

CS44600

6 DS633PP1

LIST OF TABLES

Table 1. Common DAI_MCLK Frequencies.................................................................................. 24

Table 2. DAI Serial Audio Port Channel Allocations ..................................................................... 26

Table 3. Load Compensation Example Settings........................................................................... 31

Table 4. Typical PWM Switch Rate Settings................................................................................. 33

Table 5. Digital Audio Interface Formats....................................................................................... 51

Table 6. Master Integer Volume Settings...................................................................................... 55

Table 7. Master Fractional Volume Settings................................................................................. 56

Table 8. Channel Integer Volume Settings ................................................................................... 57

Table 9. Channel Fractional Volume Settings............................................................................... 58

Table 10. Limiter Attack Rate Settings..........................................................................................60

Table 11. Limiter Release Rate Settings....................................................................................... 60

Table 12. Channel Load Compensation Filter Coarse Adjust....................................................... 61

Table 13. Channel Load Compensation Filter Fine Adjust............................................................ 61

Table 14. PWM Minimum Pulse Width Settings...................... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ... ... ... 68

Table 15. Differential Signal Delay Settings.................................................................................. 68

Table 16. Channel Delay Settings.............................. ... ... .... ... ... ... .... ... ... ... ... .... ... ... ...................... 68

Table 17. Power Supply Sync Clock Divider Settings................................................................... 70

Table 18. Decimator Shift/Scale Coefficient Calculation Examples.............................................. 71

Table 19. Revision History.................. .... ... ... ... ... .... ... ... ... ................................................. ... ......... 77

CS44600

DS633PP1 7

CS44600

1. CHARACTERISTICS AND SPECIFICATIONS

(All Min/Max characteristics and specifications are guaranteed over the Specified Operating Conditions. Typical

performance characteristics and spe cif icat ion s ar e de riv e d from measurements taken at nominal supply voltages

and T

= 25°C.)

A

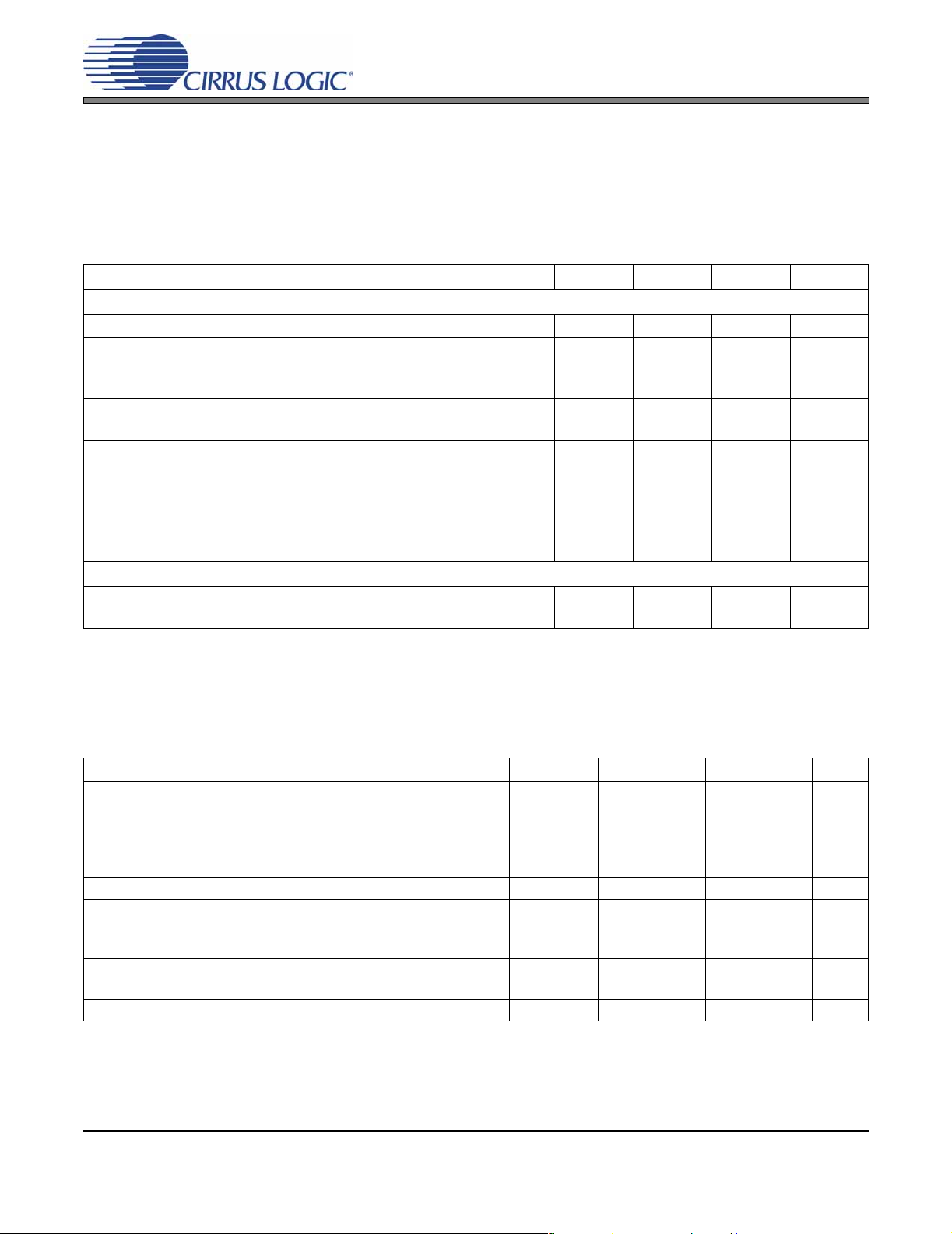

SPECIFIED OPERATING CONDITIONS

(GND = 0 V, all voltages with respect to ground)

Parameter Symbol Min Typ Max Units

DC Power Supply

Digital 2.5 V VD 2.37 2.5 2.63 V

XTAL (No t e 1) 2.5 V

3.3 V

5.0 V

PWM Interface 3.3 V

5.0 V

Serial Audio Interface2.5 V 3.3 V

5.0 V

Control Interface 2.5 V

3.3 V

5.0 V

Ambient Operating Temperature

Commercial -CQZ

Automotive -DQZ

VDX 2.37

3.14

4.75

VDP 3.14

4.75

VLS 2.37

3.14

4.75

VLC 2.37

3.14

4.75

T

A

-10

-40

2.5

3.3

5.0

3.3

5.0

2.5

3.3

5.0

2.5

3.3

5.0

-

-

2.63

3.47

5.25

3.47

5.25

2.63

3.47

5.25

2.63

3.47

5.25

+70

+85

V

V

V

V

V

V

V

V

V

V

V

°C

°C

Notes:

1. When using external crystal, VDX = 3.14 V(min). When using clock signal input, VDX = 2.37 V(min).

ABSOLUTE MAXIMUM RATINGS

(GND = 0 V; all voltages with respect to ground.)

Parameters Symbol Min Max Units

DC Power Supply Digital

XTAL

PWM Interface

Serial Audio Interface

Control Interface

Input Current (Note 2) I

Digital Input Voltage PWM Interface

(Note 3) Serial Audio Interface

Control Interface

Ambient Operating Temperature -CQ

(power applied) -DQ

Storag e Temperature T

WARNING:Operation at or beyond these limits may result in permanent damage to the device. Normal operation

is not guaranteed at these extremes.

2. Any pin except supplies. Transient currents of up to ±100 mA on the input pins will not cause SCR latch-up.

3. The maximum over/under voltage is limited by the input current.

VD

VDX

VDP

VLS

VLC

in

V

IND-PWM

V

IND-S

V

IND-C

T

stg

A

-0.3

-0.3

-0.3

-0.3

-0.3

-±10mA

-0.3

-0.3

-0.3

-20

-50

-65 +150 °C

3.5

6.0

6.0

6.0

6.0

VDP+0.4

VLS+0.4

VLC+0.4

+85

+95

V

V

V

V

V

V

V

V

°C

°C

8 DS633PP1

CS44600

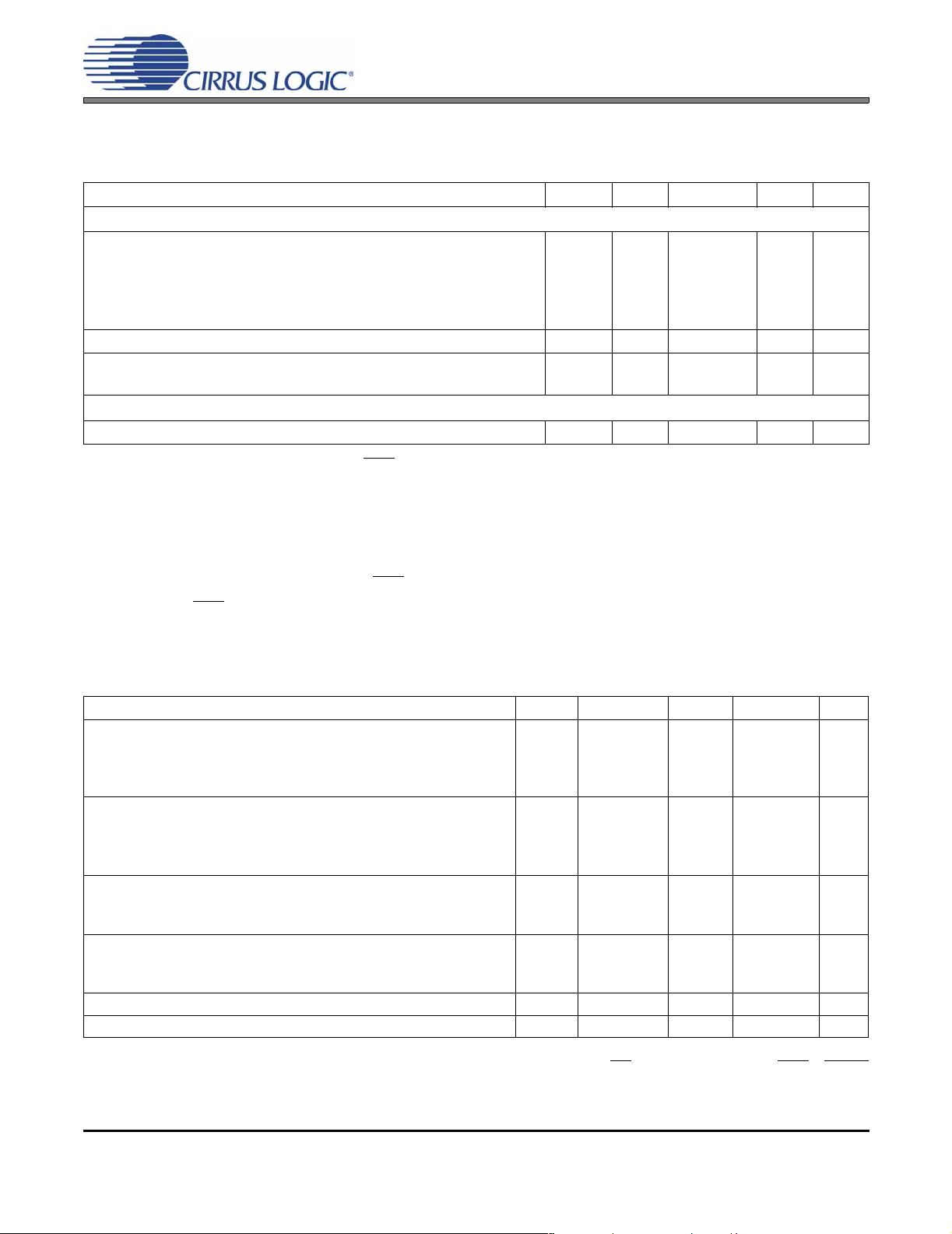

DC ELECTRICAL CHARACTERISTICS

(GND = 0 V, all voltages with respect to ground; DAI_MCLK = 12.288 MHz, XTAL = 24.576 MHz, PWM Switch

Rate = 384 kHz unless otherwise specified.)

Parameter Symbol Min Typ Max Units

Normal Operation (Note 4)

Power Supply Current (Note 5) VD = 2.5 V

VDX = 3.3 V

VDP = 3.3 V

VLS = 3.3 V

VLC = 3.3 V (Note 6)

I

I

I

I

I

D

DX

DP

LS

LC

-

-

-

-

-

150

2

1.2

150

250

-

-

-

-

Power Dissipation VD=2.5 V, VDX = VDP = VLS = VLC = 3.3 V - 387 500 mW

Power Supply Rejection Ratio (Note 7) (1 kHz)

(60 Hz)

PSRR -

15

-

40

-

Power-Down Mode (Note 8)

Power Supply Current All Supplies except VDX (Note 9) I

pd

-80-µA

mA

mA

mA

µA

µA

dB

dB

4. Normal operation is defined as RST

= HI with a 997 Hz, 0 dBFS input.

5. Current consumption increas es with increasing XTAL clock rates and PWM switch rates. Variance between DAI clock rates is negligible.

6. I

measured with no external loading on the SDA pin.

LC

7. Valid with PSRR function enabled and the recommended external ADC (CS4461) and filtering.

8. Power down mode is defined as RST

9. When RST

pin = LOW, the internal oscillator is active to provide a valid clock for the SYS_CLK output.

pin = LOW with all clock and data lines held static.

DIGITAL INTERFACE CHARACTERISTICS

(GND = 0 V, all voltages with respect to ground)

Parameters (Note 10) Symbol Min Typ Max Units

High-Level Input Voltage XTAL

PWM Interface

Serial Audio Interface

Control Interface

Low-Level Input Voltage XTAL

PWM Interface

Serial Audio Interface

Control Interface

High-Level Output Voltage at I

= -2 mA PWM Interface

o

Serial Audio Interface

V

Control Interface

Low-Level Output Voltage at I

= 2 mA PWM Interface

o

Serial Audio Interface

Control Interface

Input Leakage Current I

0.7xVDX

V

IH

0.7xVDP

0.7xVLS

0.7xVLC

-

V

IL

-

-

-

VDP-1.0

OH

VLS-1.0

VLC-1.0

-

V

OL

-

-

in

--±10µA

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Input Capacitance - - 8 pF

10. Serial Port signals include: SYS_CLK, DAI_MCLK, DAI_SCLK, DAI_LRCK, DAI_SDIN1-3

Control Port signals include: SCL/CCLK, SDA/CDOUT, AD0/CS

, AD1/CDIN, INT, RST, MUTE

PWM signals include: PWMOUTA1-B3, PSR_MCLK, PSR_SYNC, PSR_DATA, PS_SYNC, GPIO[6:0]

-

-

-

-

0.2xVDX

0.2xVDP

0.2xVLS

0.2xVLC

-

-

-

0.45

0.45

0.45

V

V

V

V

V

V

V

V

V

V

V

V

V

V

DS633PP1 9

CS44600

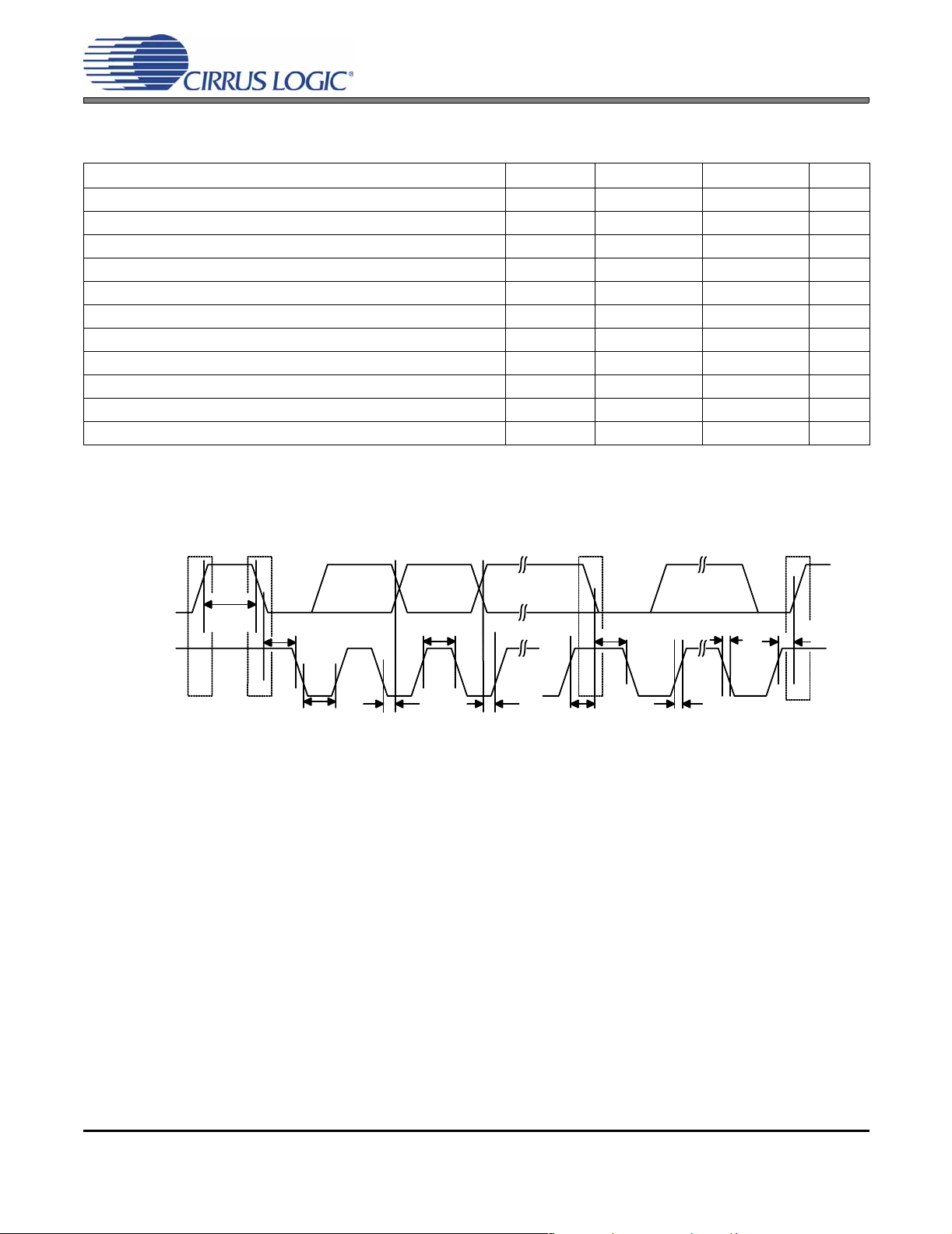

PWM OUTPUT PERFORMANCE CHARACTERISTICS

(Logic “0” = GND = 0 V; Logic “1” = VLS = VLC; VD = 2.5 V; DAI_MCLK = 12.288 MHz; XTAL= 24.576 MHz; PWM

Switch Rate = 384 kHz; Fs = 32 kHz to 192 kHz; Measurement bandwidth is 10 Hz to 20 kHz unless otherwise

specified; Performance measurements taken with a full-scale 997 Hz.)

Parameter Symbol Min Typ Max Unit

Dynamic Performance (Note 11)

24-Bits A-Weighted

unweighted

16-Bits unweighted

Total Harmonic Distortion + Noise (Note 11)

24-Bits 0 dB

THD+N -

-20 dB

-60 dB

Idle Channel Noise / Signal-to-Noise Ratio - 110 - dB

Interchannel Isolation (1 kHz) - 100 - dB

11. Performance characteristics measured using filter shown in Figure 1.

102

99

-

-

-

108

105

96

-90

-77

-45

-

-

-

-85

-

-

dB

dB

dB

dB

dB

dB

PWMOUTxx+

PWMOUTxx-

+

+

Figure 1. Performance Characteristics Evaluation Active Filter Circuit

+

+

Analog

Output

10 DS633PP1

CS44600

PWM FILTER CHARACTERISTICS

(Logic “0” = GND = 0 V; Logic “1” = VLS = VLC; VD = 2.5 V; DAI_MCLK = 12.288 MHz; XTAL = 24.576 MHz; PWM

Switch Rate = 384 kHz; Fs = 32 kHz to 192 kHz; Measurement bandwidth is 10 Hz to 20 kHz unless otherwise

specified.)

Parameter UnitMin Typ Max

Digital Filter Response (Note 12)

Passband

OSRATE = 0b to -0.01 dB corner

to -3 dB corner

OSRATE = 1b (Note 13) to -0.01 dB corner

to -3 dB corner

Frequency Response

OSRATE = 0b 10 Hz to 20 kHz

OSRATE = 1b (Note 13) 10 Hz to 40 kHz

Group Delay (Note 14) ms

De-emphasis Error Fs = 32 kHz

(Relative to 1 kHz) Fs = 44.1 kHz

Fs = 48 kHz

12. Filter response is not production tested but is characterized and guaranteed by design.

13. XTAL = 49.152 MHz; PWM Switch Rate = 768 kHz; Fs = 96 kHz to 192 kHz.

14. The equation for the group delay through the sample rate converter with OSRATE = 0b is (8.5 / Fsi) + (10

/ Fso) ± (4.5 / Fsi). The equation for the group delay through the sample rate converter with OSRATE = 1b

is (8.5 / Fsi) + (20 / Fso) ± (4.5 / Fsi).

0

0

0

0

-0.8

-1.2

-

-

-

-

-

-

-

-

-

-

-

-

1.6

24.0

3.3

44.5

+0.02

+0.02

±0.23

±0.14

±0.09

kHz

kHz

kHz

kHz

dB

dB

dB

dB

dB

SWITCHING CHARACTERISTICS - XTI

(VD = 2.5 V, VDP = VLC = VLS = 3.3 V, VDX = 2.5 V to 5.0 V; Inputs: Logic 0 = GND, Logic 1 = VDX)

Parameter Symbol Min Typ Max Unit

XTI period t

XTI high time t

XTI low time t

XTI Duty Cycle 45 50 55 %

External Crystal operating frequency 24.576 --- 54 MHz

clki

clkih

clkil

XTI

t

clkih

t

Figure 2. XTI Timings

clki

t

clkil

18.518 --- 40.69 ns

8.34 --- 22.38 ns

8.34 --- 22.38 ns

DS633PP1 11

CS44600

SWITCHING CHARACTERISTICS - SYS_CLK

(VD = 2.5 V, VDP = VLC = VDX = 3.3 V, VLS = 2.5 V to 5.0 V, Cload = 50 pF)

Parameter Symbol Min Typ Max Unit

SYS_CLK Period t

SYS_CLK Duty Cycle 45 50 55 %

sclki

18.518 --- --- ns

SYS_CLK

t

sclki

Figure 3. SYS_CLK Timings

SWITCHING CHARACTERISTICS - PWMOUTA1-B3

(VD = 2.5 V, VLS = VLC = VDX = 3.3 V, VDP = 3.3 V to 5.0 V unless otherwise specified, Cload = 10 pF)

Parameter Symbol Min Typ Max Unit

PWMOUTxx Period t

Rise Time of PWMOUTxx VDP = 5.0 V

VDP = 3.3 V

Fall Time of PWMOUTxx VDP = 5.0 V

VDP = 3.3 V

pwm

t

r

t

f

2.60 - 1.18 µs

-

-

-

-

1.6

2.1

1.1

1.4

-

-

-

-

ns

ns

ns

ns

t

r

t

f

PWMOUTxx

t

pwm

Figure 4. PWMOUTxx Timings

SWITCHING CHARACTERISTICS - PS_SYNC

(VD = 2.5 V, VLS = VLC = VDX = 3.3 V, VDP = 3.3 V to 5.0 V, Cload = 20 pF)

Parameter Symbol Min Typ Max Unit

PS_SYNC Period t

PS_SYNC Duty Cycle 45 50 55 %

psclki

PS_SYNC

t

psclki

Figure 5. PS_SYNC Timings

592.576 --- --- ns

12 DS633PP1

CS44600

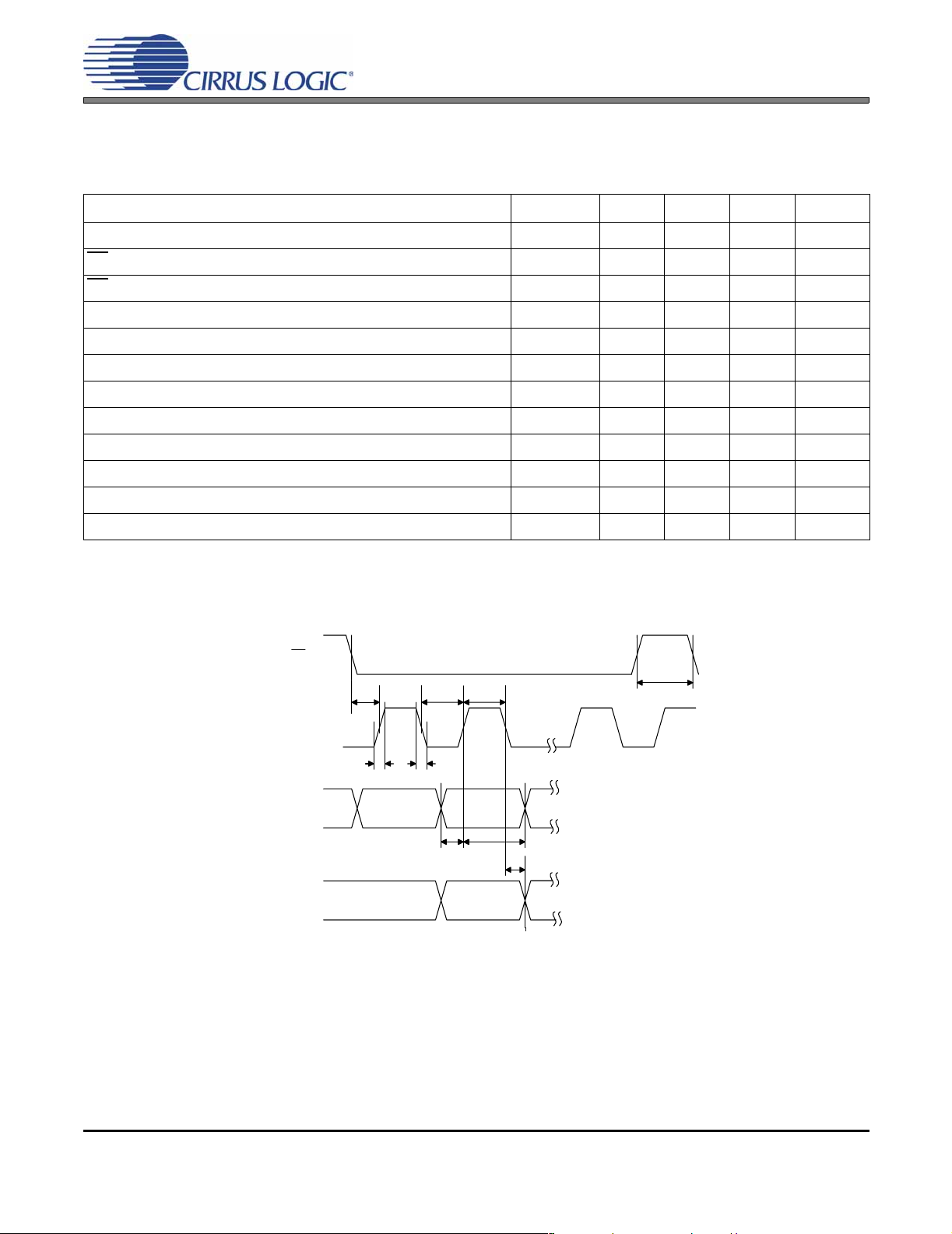

SWITCHING CHARACTERISTICS - DAI INTERFACE

(VD = 2.5 V, VDX = VDP = VLC = 3.3 V, VLS = 2.5 V to 5.0 V; Inputs: Logic 0 = GND, Logic 1 = VLS.)

Parameters Symbol Min Max Units

RST

pin Low Pulse Width (Note 15) 1-ms

DAI_MCLK Duty Cycle (Note 16) 40 60 %

DAI_SCLK Duty Cycle 45 55 %

DAI_LRCK Duty Cycle 45 55 %

DAI Sample Rate (Note 17) F

DAI_SDIN Setup Time Before DAI_SCLK Rising Edge t

DAI_SDIN Hold Time After DAI_SCLK Rising Edge t

DAI_SCLK High Time t

sckh

DAI_SCLK Low Time t

DAI_LRCK Setup Time Before DAI_SCLK Rising Edge t

DAI_SCLK Rising Edge Before DAI_LRCK Edge t

lrckd

s

ds

dh

sckl

lrcks

32 192 kHz

10 - ns

10 - ns

20 - ns

20 - ns

25 - ns

25 - ns

15. After powering up, the CS44600, RST

should be held low until after the power supplies and clocks are set-

tled.

16. See Table 1 on page 26 for suggested MCLK frequencies.

17. Max DAI sample rate is 96 kHz for One Line and TDM modes of operation.

DAI_LRCK

DAI_SCLK

DAI_SDINx

t

lrckd

t

lrcks

t

sckh

t

ds

t

dh

t

sckl

Figure 6. Serial Audio Interface Timing Figure 7. Serial Audio Interface Timing - TDM Mode

DAI_LRCK

(input)

DAI_SCLK

(input)

DAI_SDIN1

t

lrcks

t

lrckd

t

lrcks

t

sckh

t

ds

t

dh

MSB MSB-1

t

sckl

DS633PP1 13

CS44600

SWITCHING CHARACTERISTICS - CONTROL PORT - I²C FORMAT

(VD = 2.5 V, VDX = VDP = VLS = 3.3 V; VLC = 2.5 V to 5.0 V; Inputs: Logic 0 = GND, Logic 1 = VLC, CL=30pF)

Parameter Symbol Min Max Unit

SCL Clock Frequency f

Bus Free Time between Transmissions t

Start Condition Hold Time (prior to first clock pulse) t

Clock Low time t

Clock High Time t

Setup Time for Repeated Start Condition t

SDA Hold Time from SCL Falling (Note 18) t

SDA Setup time to SCL Rising t

Rise Time of SCL and SDA t

Fall Time SCL and SDA t

Setup Time for Stop Condition t

susp

scl

buf

hdst

low

high

sust

hdd

sud

r

f

- 100 kHz

4.7 - µs

4.0 - µs

4.7 - µs

4.0 - µs

4.7 - µs

10 - ns

250 - ns

-1000ns

-300ns

4.7 - µs

18. Data must be held for sufficient time to bridge the transition time, t

Repeated

Stop Start

Start

SDA

t

buf

t

hdst

t

high

SCL

t

low

t

hdd

Figure 8. Control Port Timing - I²C Format

t

sud

t

sust

, of SCL.

f

t

hdst

Stop

t

f

t

r

t

susp

14 DS633PP1

CS44600

SWITCHING CHARACTERISTICS - CONTROL PORT - SPI FORMAT

(VD = 2.5 V, VDP = VLS = 3.3 V; VLC = 2.5 V to 5.0 V; Inputs: Logic 0 = GND, Logic 1 = VLC, CL=30pF)

Parameter Symbol Min Typ Max Units

CCLK Clock Frequency f

CS

High Time between Transmissions t

CS

Falling to CCLK Edge t

CCLK Low Time t

CCLK High Time t

CDIN to CCLK Rising Setup Time t

CCLK Rising to DATA Hold Time (Note 19) t

CCLK Falling to CDOUT Stable t

Rise Time of CDOUT t

Fall Time of CDOUT t

Rise Time of CCLK and CDIN (Note 20) t

Fall Time of CCLK and CDIN (Note 20) t

sck

csh

css

scl

sch

dsu

dh

pd

r1

f1

r2

f2

19. Data must be held for sufficient time to bridge the transition time of CCLK.

20. For f

<1 MHz.

sck

CS

0-6.0MHz

1.0 - - µs

20 - - ns

66 - - ns

66 - - ns

40 - - ns

15 - - ns

- - 50 ns

- - 25 ns

- - 25 ns

- - 100 ns

- - 100 ns

CCLK

CDIN

CDOUT

t

t

sch

t

dsu

scl

t

f2

t

dh

t

pd

t

css

t

r2

Figure 9. Control Port Timing - SPI Format

t

csh

DS633PP1 15

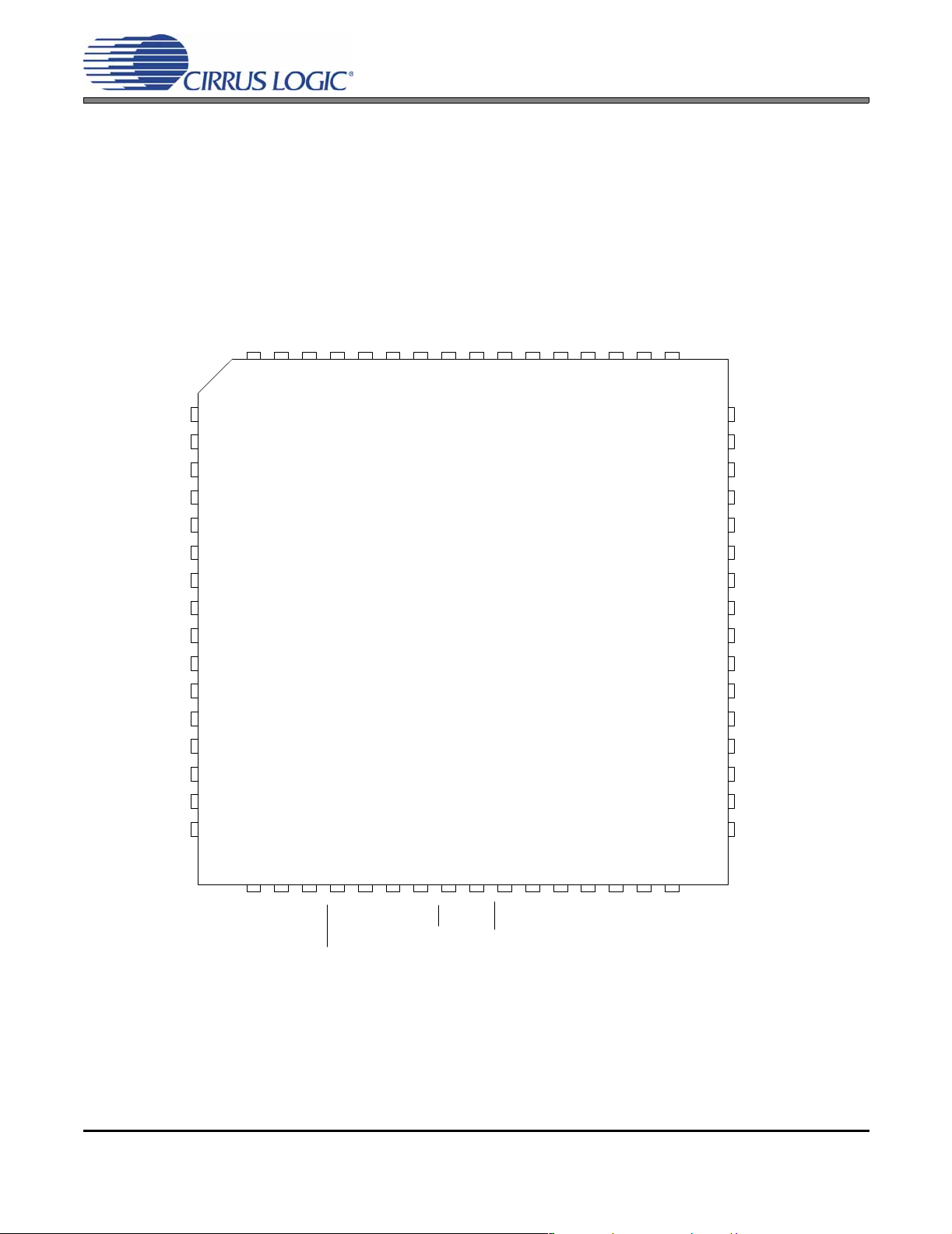

2. PIN DESCRIPTIONS

CS44600

GND

PSR_EN

PS_SYNC

GND

XTI

XTO

VDX

SYS_CLK

DAI_MCLK

DAI_SCLK

DAI_LRCK

DAI_SDIN1

DAI_SDIN2

DAI_SDIN3

PWMOUTA1+

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49

1

2

3

4

5

6

7

8

9

10

11

12

13

14

VDP

PWMOUTA1-

PWMOUTB1+

PWMOUTB1-

GND

PWMOUTA2+

CS44600

VDP

PWMOUTA2-

PWMOUTB2+

GND

PWMOUTB2-

PSR_SYNC

PSR_RESET

PSR_DATAL

PSR_MCLK

GND

48

PWMOUTA3+

47

PWMOUTA3-

46

VDP

45

PWMOUTB3+

44

PWMOUTB3-

43

GND

42

NC

41

NC

40

VDP

39

NC

38

NC

37

GND

36

GPIO0

35

NC

VLS

15

16

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

VLC

VD

GND

MUTE

SCL/CCLK

Figure 10. CS44600 Pinout Diagram

AD1/CDIN

SDA/CDOUT

INT

AD0/CS

RST

VD

GND

GPIO3

GPIO6

GPIO4

GPIO5

34

33

GPIO1

GPIO2

16 DS633PP1

Pin Name Pin # Pin Description

PS_SYNC 3

XTI 5

XTO 6 Crystal Oscillator Output (Output) - Crystal Oscillator output.

SYS_CLK 8

DAI_MCLK 9 Digital Audio Input Master Clock (Input) - Master audio clock.

Power Supply Synchronization Clock (Output) - The PWM synchronized clock to the

switch mode power supply.

Crystal Oscillator Input (Input) - Crystal Oscillator input or accepts an external clock

input signal that is used to drive the internal PWM core logic.

External System Clock (Output) - Clock output. This pin provides a divided down clock

derived from the XTI input.

CS44600

DAI_SCLK 10

DAI_LRCK 11

DAI_SDIN1

DAI_SDIN2

DAI_SDIN3

MUTE 20

SCL/CCLK 21

SDA/CDOUT 22

AD1/CDIN 23

AD0/CS

INT 25

RST 26

GPIO6 29

12

1314Digital Audio Input Serial Data (Input) - Input for two’s complement serial audio data.

24

Digital Audio Input Serial Clock (Input) - Serial clock for the Digital Audio Input Inter-

face. The clock frequency is a multiple of the Left/Right Clock running at Fs.

Digital Audio Input Left/Right Clock (Input) - Determines which channel, Left or Right,

is currently active on the serial audio data line. The rate is determined by the sampling frequency Fs.

Mute (Input) - The device will perform a hard mute on all channels. All internal registers

are not reset to their default settings.

Serial Control Port Clock (Input) - Serial clock for the serial control port. Requires an

external pull-up resistor to the logic interface voltage in I²C mode as shown in the Typical

Connection Diagram.

Serial Control Data (Input/Output) - SDA is a data I/O line in I²C mode and requires an

external pull-up resistor to the logic interface voltage, as shown in the Typical Connection

Diagram.; CDOUT is the output data line for the control port interface in SPI mode.

Address Bit 1 (I²C)/Serial Control Data (SPI) (Input) - AD1 is a chip address pin in I²C

mode.;CDIN is the input data line for the control port interface in SPI mode.

Address Bit 0 (I²C)/Control Port Chip Select (SPI) (Input) - AD0 is a chip address pin in

I²C mode; CS

Interrupt Request (Output) - CMOS or open-drain interrupt request output. This pin is

driven to the configured active state to indicate that the PWM Contro ller has status data

that should be read by the host.

Reset (Input) - The device enters a low power mode and all internal registers are reset to

their default settings when low.

General Purpose Input, Output (Input/Output) - This pin is configured as an input follow-

ing a RST

be individually controlled by the Host Controller.

is the chip select signal in SPI mode.

condition. It can be configured as a general purpose input or output which can

General Purpose Input, Output (Input/Output) - This pin is configured as an input follow-

GPIO5 30

GPIO4 31

DS633PP1 17

ing a RST

be individually controlled by the Host Controller.

General Purpose Input, Output (Input/Output) - This pin is configured as an input follow-

ing a RST

be individually controlled by the Host Controller.

condition. It can be configured as a general purpose input or output which can

condition. It can be configured as a general purpose input or output which can

GPIO3 32

GPIO2 33

GPIO1 34

GPIO0 35

PSR_MCLK 49

PSR_DATAL 50

CS44600

General Purpose Input, Output (Input/Output) - This pin is configured as an input follow-

ing a RST condition. It can be configured as a general purpose input or output which can

be individually controlled by the Host Controller.

General Purpose Input, Output (Input/Output) - This pin is configured as an input follow-

ing a RST

be individually controlled by the Host Controller.

General Purpose Input, Output (Input/Output) - This pin is configured as an input follow-

ing a RST

be individually controlled by the Host Controller.

General Purpose Input, Output (Input/Output) - This pin is configured as an input follow-

ing a RST

be individually controlled by the Host Controller.

Power Supply Rejection Master Clock (Output) - Master audio clock for externa l PSR

ADC (CS4461).

Power Supply Rejection Input Serial Data (Input) - Input for serial audio data from

external PSR ADC (CS4461).

condition. It can be configured as a general purpose input or output which can

condition. It can be configured as a general purpose input or output which can

condition. It can be configured as a general purpose input or output which can

PSR_SYNC 51

PSR_RESET 52

PSR_EN 2

PWMOUTA1+

PWMOUTA1PWMOUTB1+

PWMOUTB1PWMOUTA2+

PWMOUTA2PWMOUTB2+

PWMOUTB2PWMOUTA3+

PWMOUTA3PWMOUTB3+

PWMOUTB3-

VDX 7 Crystal Power (Input) - Positive power supply for the Crystal section.

VD 19, 27 Digital Power (Input) - Positive power supply for the digital section.

VLC 17

VLS 16

Power Supply Rejection Sync Clock (Input) - Synchronization signal for external PSR

ADC (CS4461).

Power Supply Rejection Reset (Output) - The reset pin for the external Power Supply

Rejection circuitry.

Power Supply Rejection Enable (Output) - The enable pin for the external Power Supply

Rejection circuitry.

64

63

61

60

58

57

PWM Output (Output) - PWM control signals for the Class D amplifier backend.

55

54

47

46

44

43

Host Interface Power (Input) - Determines the required signal level for the digital

input/output signals for the host interface.

Digital Audio Interface Power (Input) - Determines the required signal level for the digital

input signals for the digital audio interface.

VDP

GND

18 DS633PP1

39, 45,

56, 62

18, 28,

36, 42,

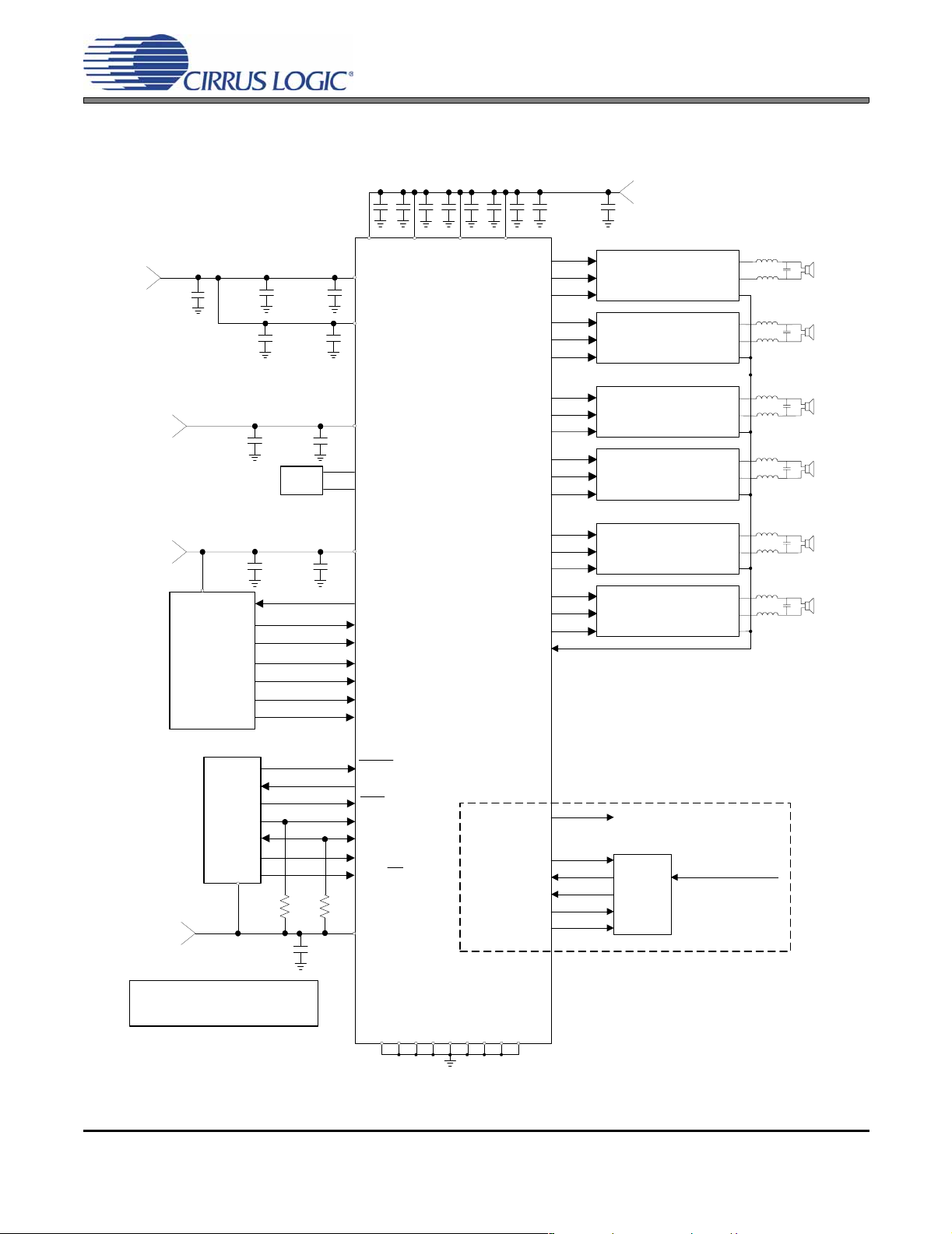

48, 53,

PWM Interface Power (Input) - Determines the required signal level for the digital

input/output signals for the PWM and GPIO interface.

1, 4,

Digital Ground (Input) - Ground reference for digital circuits.

59

CS44600

2.1 I/O Pin Characteristics

Power

Signal Name

RST VLC Input - 2.5 V and 3.3/5.0 V TTL Compatible.

SCL/CCLK VLC Input - 2.5 V and 3.3/5.0 V TTL Compatible, with Hysteresis.

Rail I/O Driver Receiver

SDA/CDOUT VLC

AD0/CS

AD1/CDIN VLC Input - 2.5 V and 3.3/5.0 V TTL Compatible, Internal pull-up.

INT VLC Output

MUTE VLC Input - 2.5 V and 3.3/5.0 V TTL Compatible.

DAI_SDINx VLS Input - 2.5 V and 3.3/5.0 V TTL Compatible.

DAI_SCLK VLS Input - 2.5 V and 3.3/5.0 V TTL Compatible.

DAI_LRCK VLS Input - 2.5 V and 3.3/5.0 V TTL Compatible.

DAI_MCLK VLS Input - 2.5 V and 3.3/5.0 V TTL Compatible.

SYS_CLK VLS Output 2.5-5.0 V, CMOS XTI VDX Input - 2.5 V and 3.3/5.0 V TTL Compatible, Internal pull-down.

XTO VDX Output - -

GPIOx VDP

PWMOUTAx+/- VDP Output 3.3/5.0 V, CMOS -

PWMOUTBx+/- VDP Output 3. 3/ 5.0 V, CMOS -

VLC Input - 2.5 V and 3.3/5.0 V TTL Compatible, Internal pull-up.

Input /

Output

Input /

Output

2.5-5.0 V,

CMOS/Open Drain

2.5-5.0 V,

CMOS/Open Drain

3.3/5.0 V,

CMOS/Open Drain

2.5 V and 3.3/5.0 V TTL Compatible, with Hysteresis.

-

3.3/5.0 V TTL Compatible.

PSR_MCLK VDP Output 3.3/5.0 V, CMOS PSR_SYNC VDP Input - 3.3/5.0 V TTL Compatible, Internal pull-up.

PSR_DATA VDP Input - 3.3/5.0 V TTL Compatible, Internal pull-up.

PSR_EN VDP Output 3.3/5.0 V, CM OS PSR_RESET VDP Output 3.3/5.0 V, CMOS PS_SYNC VDP Output 3.3/5.0 V, CM OS -

DS633PP1 19

3. TYPICAL CONNECTION DIAGRAMS

CS44600

+2.5 V

+3.3 V to

+5.0 V

+2.5 V to

+5.0 V

10 µF

+

0.1 µF

0.1 µF

0.1 µF

24.576 MHz

to 54 MHz

0.1 µF

Digital

Audio

Processor

0.01 µF

0.01 µF

0.01 µF

XTAL

0.01 µF

0.1 µF

0.01 µF

VD

VD

CS44600

VDX

XTI

XTO

VLS

SYS_CLK

DAI_MCLK

DAI_SCLK

DAI_LRCK

DAI_SDIN1

DAI_SDIN2

DAI_SDIN3

0.1 µF

0.01 µF

VDP

0.1 µF

0.01 µF

0.01 µF

PWMOUTA1+

PWMOUTA1-

GPIO1

PWMOUTB1+

PWMOUTB1-

GPIO2

PWMOUTA2+

PWMOUTA2-

GPIO3

PWMOUTB2+

PWMOUTB2-

GPIO4

PWMOUTA3+

PWMOUTA3-

GPIO5

PWMOUTB3+

PWMOUTB3-

GPIO6

GPIO0

0.1 µF

10 µF

+3.3 V to +5.0 V

PWM IN1

CONTROL

PWM IN2

CONTROL

PWM IN3

CONTROL

PWM IN4

CONTROL

PWM IN5

CONTROL

PWM IN6

CONTROL

OUT1

STATUS

OUT2

STATUS

OUT3

STATUS

OUT4

STATUS

OUT5

STATUS

OUT6

STATUS

Front Left

Front Right

Surr. Left

Surr. Right

Center

Subwoofer

MUTE

INT

Ω

2 k

RST

SCL/CCLK

SDA/CDOUT

AD1/CDIN

AD0/CS

VLC

GND

PS_SYNC

PSR_MCLK

PSR_SYNC

PSR_DATA

PSR_EN

PSR_RESET

Power Supply Sync Clock

Power Supply Rail

CS4461

ADC

Optional

Micro-

Controller

Ω

+2.5 V

to +5.0 V

Note: Resistors are required for

I²C control port operation

2 k

See

Note

0.1 µF

Figure 11. Typical Full-Bridge Connection Diagram

20 DS633PP1

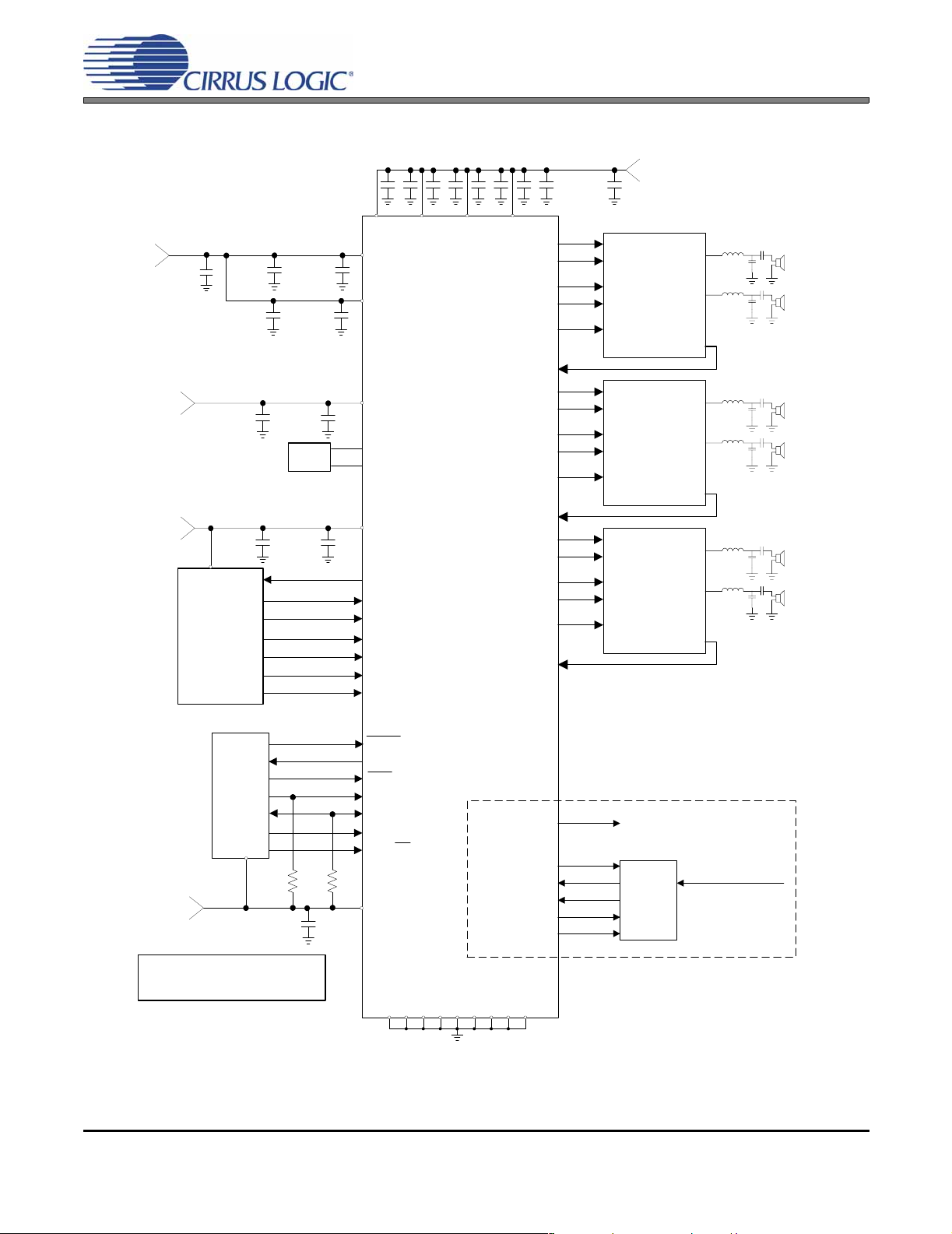

CS44600

+2.5 V

+3.3 V to

+5.0 V

+2.5 V to

+5.0 V

10 µF

+

0.1 µF

0.1 µF

0.1 µF

24.576 MHz

to 54 MHz

0.1 µF

Digital

Audio

Processor

0.01 µF

0.01 µF

0.01 µF

XTAL

0.01 µF

0.1 µF

0.01 µF

VD

VD

CS44600

VDX

XTI

XTO

VLS

SYS_CLK

DAI_MCLK

DAI_SCLK

DAI_LRCK

DAI_SDIN1

DAI_SDIN2

DAI_SDIN3

0.1 µF

0.01 µF

VDP

0.1 µF

0.01 µF

0.01 µF

PWMOUTA1+

PWMOUTA1PWMOUTB1+

PWMOUTB1-

GPIO3

GPIO0

PWMOUTA2+

PWMOUTA2-

PWMOUTB2+

PWMOUTB2-

GPIO4

GPIO1

PWMOUTA3+

PWMOUTA3-

PWMOUTB3+

PWMOUTB3-

GPIO5

GPIO2

0.1 µF

10 µF

+3.3 V to +5.0 V

PWM IN1

PWM IN2

CONTROL

PWM IN1

PWM IN2

CONTROL

PWM IN1

PWM IN2

CONTROL

OUT1

Front Left

OUT2

Front Right

STATUS

OUT1

Surr. Left

OUT2

Surr. Right

STATUS

OUT1

Center

OUT2

Subwoofer

STATUS

MUTE

INT

Ω

2 k

RST

SCL/CCLK

SDA/CDOUT

AD1/CDIN

AD0/CS

VLC

GND

PS_SYNC

PSR_MCLK

PSR_SYNC

PSR_DATA

PSR_EN

PSR_RESET

Power Supply Sync Clock

Power Supply Rail

CS4461

ADC

Optional

Micro-

Controller

Ω

+2.5 V

to +5.0 V

Note: Resistors are required for

I²C control port operation

2 k

See

Note

0.1 µF

Figure 12. Typical Half-Bridge Connection Diagram

DS633PP1 21

4. APPLICATIONS

4.1 Overview

The CS44600 is a multi-channel digital-to-PWM Class D audio system controller including interpolation,

sample rate conversion, half- and full-bridge PWM driver outputs, and power supply rejection feedb ack in a

64-pin LQFP package. The architecture uses a di rect-t o-digital ap proach that maintains digita l signal integrity to the final output filter, minimizing analog interference effects which negatively affect system performance.

The CS44600 integrates on-chip sample rate conversion, digital volume control, peak de tect with volume

limiter, de-emphasis, programmab le interrup t condit ions, and th e abilit y to chan ge the PW M switch ra te to

eliminate AM frequency interference. The CS44600 also has a programmable load compensation filter,

which allows the speaker load to vary while the output filter remains fixed, maintaining a flat frequency response. For single-ended half-bridge applications PWM Popguard

and realtime power supply feedback reduces noise coupling from the power supp ly. The PWM amplifier can

achieve greater than 90% efficiency. This efficiency provides for a smaller device package, less heat sink

requirements, and smaller power supplies.

The CS44600 is ideal for audio systems requiring wide dynamic range, negligible distortion, and low noise

such as A/V receivers, DVD receivers, digital speaker, and automotive audio systems.

4.2 Feature Set Summary

CS44600

®

reduces the transient pops an d clicks

Core Features

• 2.5 V digital core voltage, VD.

• VLC voltage pin for host interface logic levels between 2.5 V and 5.0 V.

• VLS voltage pin for digital audio interface logic levels between 2.5 V and 5.0 V.

• VDP voltage pin for PWM backend interface logic levels between 3.3 V and 5.0 V.

• VDX voltage pin for clock input signals between 2.5 V and 5.0 V.

Clocking

• Minimum of 128Fs DAI_MCLK for DAI serial interface.

• DAI interface uses automatic detection of LRCK/MCLK ratio to configure internal DAI/SRC clocks.

• All PWM Processing clocks generated internally via:

– An external crystal - 24.576 MHz to 54 MHz, or

– XTI input pin capable of supporting a clock signal at the VDX voltage level.

• Programmable divide of XTI by 1, 2, 4, 8 for SYS_CLK output.

• Programmable divide of XTI by 32, 64, 128, 256 for PS_SYNC (power supply synchronization signal).

Digital Audio Playback

• Supports 32 kHz, 44.1 kHz, 48 kHz, 88.2 kHz, 96 kHz, 176.4 kHz and 192 kHz sample frequencies.

• High performance sample rate converter.

• 16, 20 and 24 bit audio sample lengths.

• De-emphasis for 32 kHz, 44.1 kHz, 48 kHz.

22 DS633PP1

• Digital volume control with soft ramp.

• Individual channel volume gain, attenuation and mute capability; +24 to -127 dB in 0.25 dB steps.

• Master volume attenuation; +24 to -127 dB in 0.25 dB steps.

• Peak Detect and Volume Limiter with programmable attack and release rates.

• Signal-clipping interrupt indicator.

Additional Features

• Contains a two-stage digital output filter for speaker impedance compensation.

• Provide s 7 prog ram mabl e GPIO pins with interr upt ge neratio n for easily int erfa cing to a va riety of com-

monly available power state parts. Interrupts can be masked.

• Selectable over-sample rate for increased audio bandwidth.

• Power supply clock output, PS_SYNC, with programmable divider

CS44600

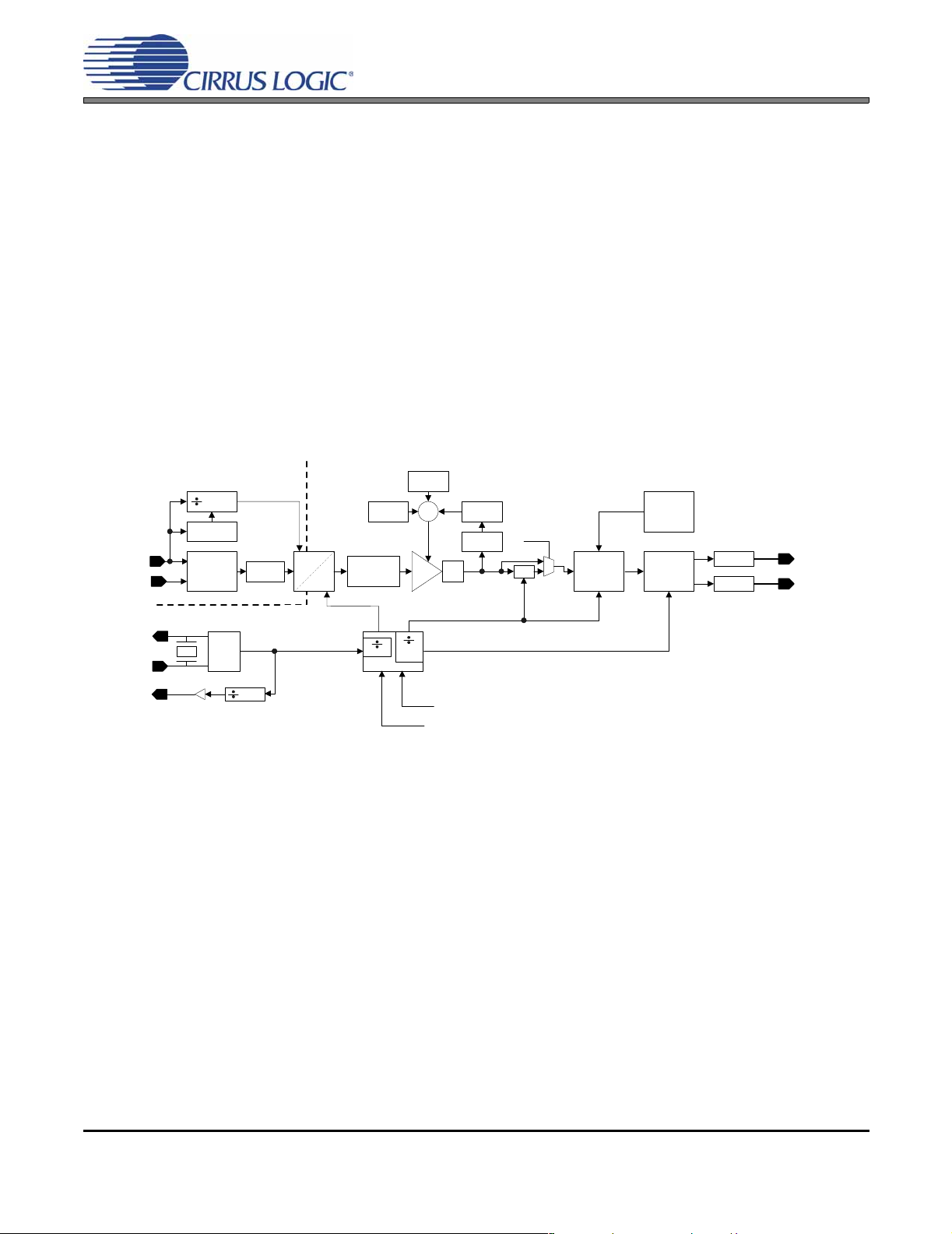

FsIn FsOut

1,2,4,8

De-

Emphasis

128Fs

DAI_MCLK

DAI_LRCK

DAI_SCLK

DAI_SDINx

XTO

XTI

SYS_CLK

1, 1.5, 2,

3, 4, 6, 8

Ratio Detect

Digital Audio

Input Port

XTAL /

CLKIN

Figure 13. CS44600 Data Flow Diagram (Single Channel Shown)

4.3 Clock Generation

The sources for internal clock generation for the PWM processing are as follows:

• FsIn Domain:

– DAI_MCLK, minimum 128Fs

SRC

SRC_MCLK (128Fs)

Channel

Volume

2-pole Load

Compensation

Filter

2.25

Clock Control

Master

Volume

VOL

1,1.5,

2,4

(AM_FREQ_HOP)

Σ

mute

MOD_MCLK

PWM_MCLK

Over Sample

(OSRATE)

AM Freq. Hop

LIMITER

PEAK

DETECT

Over Sample

(OSRATE)

x2

Multibit

Σ∆

Modulator

PSR

Feedback

PWM Engine

Delay

Delay

PWM_OUT+

PWM_OUT-

• FsOut Domain:

– XTI/XTO (Fundamental or 3

rd

overtone crystal), or

– Clock signal on XTI (VDX is used to set logic voltage level)

DS633PP1 23

4.3.1 FsIn Domain Clocking

Common DAI_MCLK frequencies and sample rates are shown in Table 1.

Mode

(sample-rate range)

DAI_MCLK/LRCK Ratio −> 256x 384x 512x 768x 1024x

Single Speed

(4 to 50 kHz)

DAI_MCLK/LRCK Ratio −> 128x 192x 256x 384x 512x

Double Speed

(50 to 100 kHz)

DAI_MCLK/LRCK Ratio −> 64x 96x 128x 192x 256x

Quad Speed

(100 to 200 kHz)

Sample

Rate

(kHz)

32 8.1920 12.2880 16.3840 24.5760 32.7680

44.1 11.2896 16.9344 22.5792 33.8688 45.1584

48 12.2880 18.4320 24.5760 36.8640 49.1520

64 8.1920 12.2880 16.3840 24.5760 32.7680

88.2 11.2896 16.9344 22.5792 33.8688 45.1584

96 12.2880 18.4320 24.5760 36.8640 49.1520

176.4 n/a n/a 22.5792 33.8688 45.1584

192 n/a n/a 24.5760 36.8640 49.1520

Table 1. Common DAI_MCLK Frequencies

DAI_MCLK (MHz)

4.3.2 FsOut Domain Clocking

CS44600

To ensure the highest quality conversion of PWM signals, the CS44600 is capable of operating from a

fundamental mode or 3

to 54 MHz. If XTI is being directly driven by a clock signal, XTO can be left floating or tied to ground

through a pull-down resistor and the internal oscillator should be powered down using the PDN_XTAL bit

in register 02h.

rd

overtone crystal, or a clock signal attached to XTI, at a frequency of 24.576 MHz

XTI

Y1

C1

XTO

C2

Figure 14. Fundamental Mode Crystal Configuration

24 DS633PP1

CS44600

Y1

XTI

C1

XTO

L1

C3

Figure 15. 3rd Overtone Crystal Configuration

Appropriate clock dividers for each functional block and a programmable divider to support an output for

switched-mode power supply synchronization are provided. The clock generation for the CS44600 is

shown in the Figure 16.

XTO

XTI

System Clock

Divider

PWM Master

Clock Divider

C2

PWM_MCLK

PWM Modulator

Clock Divider

MOD_MCLKSYS_CLK

PS_SYNC

Power Supply

Sync. Divider

Figure 16. CS44600 Internal Clock Generation

Sample Rate Converter

Clock Divider

SRC_MCLK

DS633PP1 25

4.4 FsIn Clock Domain Modules

4.4.1 Digital Audio Input Port

The CS44600 interfaces to an external Digita l Audio Processor via the Digital Audio Input serial port, the

DAI serial port. The DAI port has 3 stereo data inputs with support for I²S, left-justified and right-justified

formats. The DAI port operates in slave operation only, where DAI_LRCK, DAI_SCLK and DAI_MCLK are

always inputs. The signal DAI_LR CK must be equal to the sample rate, Fs and must be synchronously

derived from the supplied master c lock, DAI_MCLK. The serial bit clock, DAI_SCLK, is used to sample

the data bits and must be synchronously derived from the master clock.

DAI_SDIN1, DAI_SDIN2, and DAI_SDIN3 are the serial data input pins supplying the associated internal

PWM channel modulators. The serial data interface format selection (left-justified, right-justified, I²S, one

line mode, or TDM) for the DAI serial port data input pins is conf igured using the appropriate bits in the

register “Misc. Configuration (address 04h)” on pag e 52. The serial audio data is presented in 2's complement binary form with the MSB first in all formats.

When operated in One Line Data Mode, 6 channels of PWM data are input on DAI_SDIN1. In TDM mode,

all 6 channels are multiplexed onto the DAI_SDIN1 data line. Table 2 outlines the serial port channel allocations.

Serial Data Input s Data mode Channel Assignments

DAI_SDIN1 Normal (I²S,LJ,RJ)

One Line #1 or #2

TDM

DAI_SDIN2 Normal (I²S,LJ,RJ)

One Line #1 or #2

TDM

DAI_SDIN3 Normal (I²S,LJ,RJ)

One Line #1 or #2

TDM

Table 2. DAI Serial Audio Port Channel Allocations

The DAI digital audio serial ports support 6 formats with varying bit depths from 16 to 24 as shown in Fig-

ure 17, Figure 18, Figure 19, Figure 20, Figure 21 and Figure 22. These formats are selected using the

configuration bits in the “Misc. Configuration (address 04h)” on page 52.

PWMOUTA1(left channel)/PWMOUTB1(right channel)

PWMOUTA1/A2/A3/B1/B2/B3

PWMOUTA1/A2/A3/B1/B2/B3

PWMOUTA2(left channel)/PWMOUTB2(right channel)

not used

not used

PWMOUTA3(left channel)/PWMOUTB3(right channel)

not used

not used

CS44600

26 DS633PP1

CS44600

4.4.1.1 I²S Data Format

For I²S, data is received most si gnificant bit first, one DAI_SCLK delay after the transition of DAI_LRCK,

and is valid on the rising edge of DAI_SCLK. For the I² S format, the left chann el data is presented when

DAI_LRCK is low; the right channel data is presented when DAI_LRCK is high.

DAI_LRCK

DAI_SCLK

DAI_ S DINx

MSB

-2 -3 -4 -5

-1

Left Channel

+3 +2 +1+5 +4

I²S Mode, Data Valid on Rising Edge of DAI_SCLK

Bits/Sample SCLK Rates

16 32, 48, 64, 128, 256 Fs

18 to 24 48, 64, 128, 256 Fs

4.4.1.2 Left-Justified Data Format

For left-justified format, data is received most significant bit first on the first DAI_SCLK after a DAI_LRCK

transition and is valid on the rising edge of DAI_SCLK. For the left-justified format, the left channel data

is presented when DAI_LRCK is high and the right channel data is presented when DAI_LRCK is low.

DAI_LRCK

DAI_SCLK

Left Channel

Right C hannel

LSB LSB

MSB

-1

-2 -3 -4

Figure 17. I²S Serial Audio Formats

Right Channel

+3 +2 +1+5 +4

DAI_S D INx

MSB LSB MSB LSB

-1 -2 -3 -4 -5

+3 +2 +1+5 +4

-1

-2 -3 -4

+3 +2 +1+5 +4

Left-Justified Mode, Data Valid on Rising Edge of DAI_SCLK

Bits/Sample SCLK Rate(s)

16 32, 48, 64, 128, 256 Fs

18 to 24 48, 64, 128, 256 Fs

Figure 18. Left-Justified Serial Audio Formats

DS633PP1 27

CS44600

4.4.1.3 Right-Justified Data Format

In the right-justified format, data is received most significant bit first and with the least significant bit presented on the last DAI_SCLK before the DAI_LRCK transition and is valid on the rising edge of

DAI_SCLK. For the right-justified format, the left channel data is presented when DAI_LRCK is high and

the right channel data is presented when DAI_LRCK is low. Either 16 bits per sample or 24 bits per sample are supported.

DAI_LRCK

DAI_SCLK

DAI_ S DINx

Left Channel

15 14 13 12 11 10

6543210987

15 14 13 12 11 10

Right Channel

6543210987

Right-Justified Mode, Data Valid on Rising Edge of DAI_SCLK

Bits/Sample SCLK Rate(s)

16 32, 48, 64, 128, 256 Fs

24 48, 64, 128, 256 Fs

Figure 19. Right-Justified Serial Audio Formats

4.4.1.4 One Line Mode #1

In One Line mode #1 format, data is received most significant bit first on the first DAI_SCLK after a

DAI_LRCK transition and is valid on the rising edge of DAI_SCLK. DAI_SCL K must oper ate at a 128F s

rate. DAI_LRCK identifies the start of a new frame and is eq ual to th e sa mple p eri od. DAI_L RCK is sa mpled as valid on the same clock edge as the most significant bit of the first data sample an d must be h eld

high for 64 DAI_SCLK periods. Each time slot is 20 bits wide, with the valid data sample left-justified within

the time slot. Valid data lengths are 16, 18, or 20 bits. Valid samples rates for this mode are 32 kHz to

96 kHz.

64 clks 64 clks

DAI_LRCK

DAI_SCLK

DAI_SDIN1

Left Channels

LSBMSB

PWMOUTA1 PWMOUTB1PWMOUTA2 PWMOUTB2PWMOUTA3

20 clks

LSBMSB LSBMSB LSBMSB LSBMSB LSBMSB MSB

20 clks 20 clks 20 clks 20 clks 20 clks

Right Channels

PWMOUTB3

Figure 20. One Line Mode #1 Serial Audio Format

28 DS633PP1

4.4.1.5 One Line Mode #2

In One Line mode #2 format, data is received most significant bit first on the first DAI_SCLK after a

DAI_LRCK transition and is valid on the rising edge of DAI_SCLK. DAI_SCLK must operate at a 256 Fs

rate. DAI_LRCK identifies the start of a new frame and is equal to the sample period. DAI_LRCK is sampled as valid on the same clock edge as the most significant bit of the first data sample and must be held

high for 128 DAI_SCLK periods. Each time slot is 24 bits wide, with the valid data sample left-justified within the time slot. Valid data lengths are 16, 18, 20, or 24 bits. Valid samples rates for this mode are 32 kHz

to 96 kHz.

128 clks 128 clks

DAI_LRCK

DAI_SCLK

Left Channels

Right Channels

CS44600

DAI_SDIN1

DAI_LRCK

DAI_SCLK

DAI_SDIN1

LSBMSB LSBMSB LSBMSB LSBMSB LSBMSB LSBMSB MSB

PWMOUTA1 PWMOUTB1PWMOUTA2 PWMOUTB2PWMOUTA3

24 clks 24 clks 24 clks 24 clks 24 clks 24 clks

PWMOUTB3

Figure 21. One Line Mode #2 Serial Audio Format

4.4.1.6 TDM Mode

In TDM mode format, data is received most significant bit first on the first DAI_SCLK after a DAI_LRCK

transition and is valid on the rising edge of DAI_SCLK. DAI_SCLK must operate at a 256 Fs rate.

DAI_LRCK identifies the start of a new frame and is equal to the sample period. DAI_LRCK is sampled

as valid on the proceeding clock edge as the most significant bit of the first data sample and must be he ld

valid for at least 1 DAI_SCLK period. Each time slot is 32 bits wide, with the valid data sample left-justified

within the time slot. Valid data lengths are 16, 18, 20, 24 or 32 bits. Valid samples rates for this mode are

32 kHz to 96 kHz.

256 clks

LSBMSB LSBMSB LSBMSB LSBMSB LSBMSB

PWMOUTA1 PWMOUTA2 PWMOUTB1PWMOUTA3

32 clks 32 clks 32 clks 32 clks 32 clks 32 clks

PWMOUTB2

LSBMSB

PWMOUTB3

32 clks 32 clks

Figure 22. TDM Mode Serial Audio Format

DS633PP1 29

4.4.2 Auto Rate Detect

The CS44600 will automatically determine the incoming sample rate, DAI_LRCK, to master clock,

DAI_MCLK, ratio and configure the appropriate internal cloc k divi der suc h that the sampl e ra te co nver tor

receives the required clock rate. A min imum DAI_MCLK rate of 128F s is required for proper ope ration.

The supported DAI_MCLK to DAI_LRCK ratios are shown in Table 1 on page 26.

4.4.3 De-Emphasis

The CS44600 includes on-chip digital de-emphasis filters. The de-em phasis feature is included to accommodate older audio recordings that utilize pre-emphasis equalization as a means of noise reduction.

Figure 23 shows the de-emphasis curve. The frequency response of the de-emphasis curve will scale pro-

portionally with changes in sample rate, Fs. The required de-emphasis filter for 32 kHz, 44.1 kHz, or

48 kHz is selected via the de-emphasis control bits in “Misc. Configuration (address 04h)” on page 52.

CS44600

Gain

dB

T1=50 µs

0dB

T2 = 15 µs

-10dB

F1 F2

3.183 kHz 10.61 kHz

Figure 23. De-Emphasis Curve

Frequency

30 DS633PP1

4.5 FsOut Clock Domain Modules

4.5.1 Sample Rate Converter

One of the characteristics of a PWM amplifier is that the frequ ency content of out-of-band noise genera ted

by the modulator is dependent on the PWM switching frequency. The power stage external LC an d snubber filter component values are based on this switching frequency. To accommodate input sample rates

ranging from 32 kHz to 192 kHz the CS44600 utilizes a Sample Rate Converter (SRC) and several clocking modes that keep the PWM switching frequency fixed.

The SRC supports a range of sample rate conversion to upsample rates from 32 kHz to 192 kHz to a fixed

FsOut sample rate. This is typically 384 kHz for most audio applications. The SRC also allows the PWM

modulator output to be independent of the input clock jitter since the output of the SRC is clocked from a

very stable crystal or oscillator. This results in very low jitter PWM output and higher dynamic range.

4.5.2 Load Compensation Filter

To accommodate varying speaker impedances, the CS44600 incorporates a 2-pole load compensation

filter to adjust the effective frequency response of the on-card L/C de-modulation filter. The frequency response of the 2-pole inductor/capacitor filter used on the board to filter out the high-frequency PWM

switching clock is highly dependant on the resistive load (speaker) attached.

If the L/C filter implemented was designed for a low impedance load (4 Ω speaker), but an 8 Ω speaker

was attached, the frequency response would have a large peaking near the resonant frequency of the

L/C. The peaking usually starts at around 15 kHz, with about a +4 dB of gain at around 20 kHz. This phenomenon will cause the system to not meet the frequency response requirements as specified by Dolby

Labs.

CS44600

By using the programmable 2-pole load compensation filter, the overall frequency respo nse of the system

can be modified to cut the amount of peaking. The 2 poles of the filter are indep endently configurable and

are concatenated to form the overall filter response. The first filter is defined as a coarse setting. This filter

should be programmed to provide most of the attenuation of the peaking. The second filte r, defined as the

fine adjust, is used to achieve incremental improvements to the overall frequency response. Table 3

shows example register settings based on an output filter that has been designed for a 4 Ω load impedance. See “Channel Compensation Filter - Coarse Adjust (CHXX_CORS[5:0])” on page 62 and “Channel

Compensation Filter - Fine Adjust (CHXX_FINE[5:0])” on page 63.

Load Impedance Coarse Filter Setting Fine Filter Setting

6 Ω -1.2 dB 0 dB

8 Ω -1.8 dB 0 dB

16 Ω -3.4 dB 0 dB

T able 3. Load Compensation Example Settings

4.5.3 Digital Volume and Mute Control

The CS44600 provides two levels of volume control. A Master Volume Control Register is used to set the

volume level across all PWM channels. The register value, which selects a volume range of +24 dB to 127 dB in 0.25 dB steps, is used to control the overall volume setting of all the amplifier channels. Volume

control changes are programmable to ramp in increme nts of 0.125 dB at a variable rate controlled by the

SZC[1:0] bits in “Volume Control Configuration (address 06h)” on page 55.

Each PWM channel’s output level is controlled via a Channel Volume Control register operating over the

range of +24 dB to -127 dB attenuation with 0.25 dB resolution. See “Channel XX Volume Control - Inte-

DS633PP1 31

ger (addresses 09h - 10h)” on page 58. Volume control changes are programmable to ramp in increments

of 0.125 dB at a variable rate controlled by the SZC[1:0] bits.

Each PWM channel output can be independentl y muted via mute control bits in the register “Channel Mute

(address 13h)” on page 60.

When enabled, each CHXX_MUTE bit attenuates the corresponding PWM channel to its maximum va lue