Page 1

Auxiliary

Output

6 to 75 MHz

PLL Output

3.3 V

8 MHz to 75 MHz

Low-Jitter Timing

Reference

Output to Input

Clock Ratio

N

Timing Reference

PLL Output

PLL Lock Indicator

Fractional-N

Divider

Voltage Controlled

Oscillator

Internal

Loop Filter

Phase

Comparator

Delta-Sigma

Modulator

Hardware Configuration

Hardware Control

CS2200-OTP

Fractional-N Frequency Synthesizer

Features

Delta-Sigma Fractional-N Frequency Synthesis

– Generates a Low Jitter 6 - 75 MHz Clock

Relative to 8 - 75 MHz Reference Clock

Highly Accurate PLL Multiplication Factor

– Maximum Error Less Than 1 PPM

One-Time Programmability

– Configurable Hardware Control Pins

– Configurable Auxiliary Output

Flexible Sourcing of Reference Clock

– External Oscillator or Clock Source

– Supports Inexpensive Local Crystal

Minimal Board Space Required

– No External Analog Loop-filter

Components

General Description

The CS2200-OTP is an extremely versatile system

clocking device that utilizes a programmable phase lock

loop. The CS2200-OTP is based on an analog PLL architecture comprised of a Delta-Sigma Fractional-N

Frequency Synthesizer. This architecture allows for frequency synthesis and clock generation from a stable

reference clock. The CS2200-OTP has many configuration options which are set once prior to runtime. At

runtime there are three hardware configuration pins

available for mode and feature selection.

The CS2200-OTP is available in a 10-pin MSOP package in Commercial (-10°C to +70°C) and Automotive

(-40°C to +85°C) grades. Customer development kits

are also available for custom device prototyp ing, small

production programming, and device evaluation.

Please see “Ordering Information” on page 23 for complete details.

http://www.cirrus.com

Copyright Cirrus Logic, Inc. 2010

(All Rights Reserved)

MAY '10

DS842F2

Page 2

TABLE OF CONTENTS

1. PIN DESCRIPTION ................................................................................................................................. 4

2. TYPICAL CONNECTION DIAGRAM ..................................................................................................... 5

3. CHARACTERISTICS AND SPECIFICATIONS ...................................................................................... 6

RECOMMENDED OPERATING CONDITIONS .................................................................................... 6

ABSOLUTE MAXIMUM RATINGS ........................................................................................................ 6

DC ELECTRICAL CHARACTERISTICS . ... ... .... ... ... ... .... ... ... .................................................................. 6

AC ELECTRICAL CHARACTERISTICS ................................................................................................ 7

4. ARCHITECTURE OVERVIEW ............................................................................................................... 8

4.1 Delta-Sigma Fractional-N Frequency Synthesizer ........................................................................... 8

5. APPLICATIONS ..................................................................................................................................... 9

5.1 One Time Programmability .............................................................................................................. 9

5.2 Timing Reference Clock Input ..................... ..................................................................................... 9

5.2.1 Internal Timing Reference Clock Divider .. ... .... ... ... ... .... ... ... ..................................................... 9

5.2.2 Crystal Connections (XTI and XTO) ...................................................................................... 10

5.2.3 External Reference Clock (REF_CLK) .................................................................................. 10

5.3 Output to Input Frequency Ratio Configuration ............................................................................. 11

5.3.1 User Defined Ratio (RUD) ..................................................................................................... 11

5.3.2 Ratio Modifier (R-Mod) .......................................................................................................... 11

5.3.3 Effective Ratio (REFF) .......................................................................................................... 11

5.3.4 Ratio Configuration Summary ............................................................................................... 12

5.4 PLL Clock Output ........................................................................................................................... 13

5.5 Auxiliary Output ................. ... ... .... ... ... ....................................... ... ... ... .... ......................................... 14

5.6 Mode Pin Functionality ...................... ... ... ....................................... ... .... ... ... ... .... ... ... ...................... 14

5.6.1 M1 and M0 Mode Pin Functionality ....................................................................................... 14

5.6.2 M2 Mode Pin Functionality .................................................................................................... 15

5.6.2.1 M2 Configured as Output Disable .............................................................................. 15

5.6.2.2 M2 Configured as R-Mod Enable .............. ... .... ... ... ....................................... ... ... ... ... 15

5.6.2.3 M2 Configured as AuxOutSrc Override ..................................................................... 15

5.7 Clock Output Stability Considerations ......... ... ... ... .... ... ... ... .... ...................................... ... .... ... ......... 16

5.7.1 Output Switching ................................................................................................................... 16

5.7.2 PLL Unlock Conditions .......................................................................................................... 16

5.8 Required Power Up Sequencing for Programmed Devices .................. ......................................... 16

6. PARAMETER DESCRIPTIONS ........................................................................................................... 17

6.1 Modal Configuration Sets ..................... ... ....................................... ... .... ... ... ... .... ... ... ...................... 17

6.1.1 R-Mod Selection (RModSel[1:0]) ........................ ...... ....... ...... ....... ...... ....... ...... ...... ....... ...... ...17

6.1.2 Auxiliary Output Source Selection (AuxOutSrc[1:0]) .................... ......................................... 18

6.2 Ratio 0 - 3 .. ... ....................................... ... .... ...................................... .... ... ...................................... 18

6.3 Global Configuration Parameters ................................................................................................... 18

6.3.1 AUX PLL Lock Output Configuration (AuxLockCfg) .............................................................. 18

6.3.2 Reference Clock Input Divider (RefClkDiv[1:0]) .................................................................... 18

6.3.3 Enable PLL Clock Output on Unlock (ClkOutUnl) ................................................................. 19

6.3.4 M2 Pin Configuration (M2Config[2:0]) ................................................................................... 19

7. CALCULATING THE USER DEFINED RATIO .................................................................................... 20

7.1 12.20 Format ........................ ... ....................................... ... .... ... ... ... ................................................ 20

8. PROGRAMMING INFORMATION ....................................................................................................

9. PACKAGE DIMENSIONS .................................................................................................................... 22

THERMAL CHARACTERISTICS ......................................................................................................... 22

10. ORDERING INFORMATION ........... ... ... ... ... .... ... ....................................... ... ... ... .... ... ... ... ... .... ... ......... 23

11. REVISION HISTORY ................................ ... .... ... ....................................... ... ... ... .... ... ... ... ................... 23

CS2200-OTP

.... 21

LIST OF FIGURES

Figure 1. Typical Connection Diagram ........................................................................................................ 5

DS842F2 2

Page 3

Figure 2. Delta-Sigma Fractional-N Frequency Synthesizer .......................................................................8

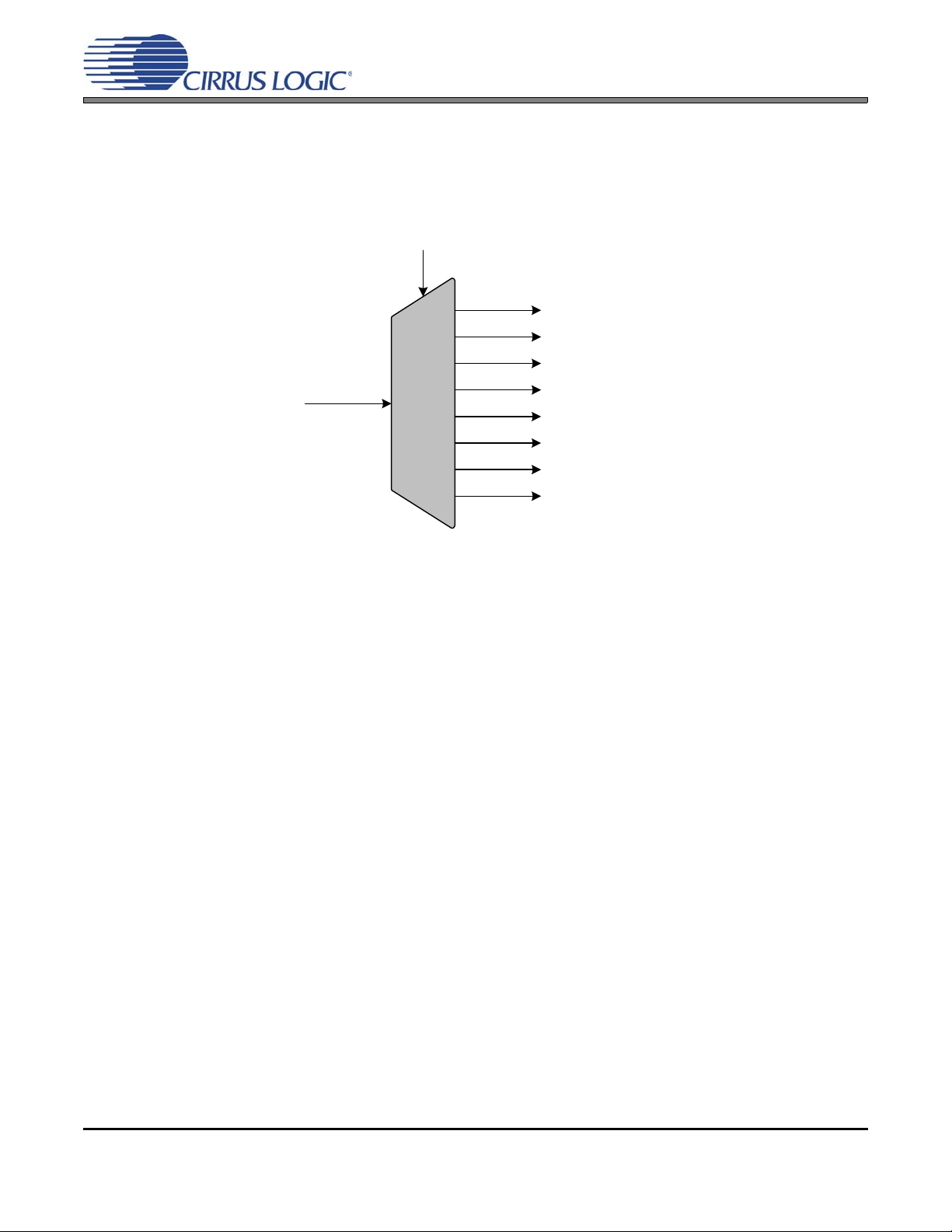

Figure 3. Internal Timing Reference Clock Divider ..................................................................................... 9

Figure 4. REF_CLK Frequency vs. a Fixed CLK_OUT ............................................................................. 10

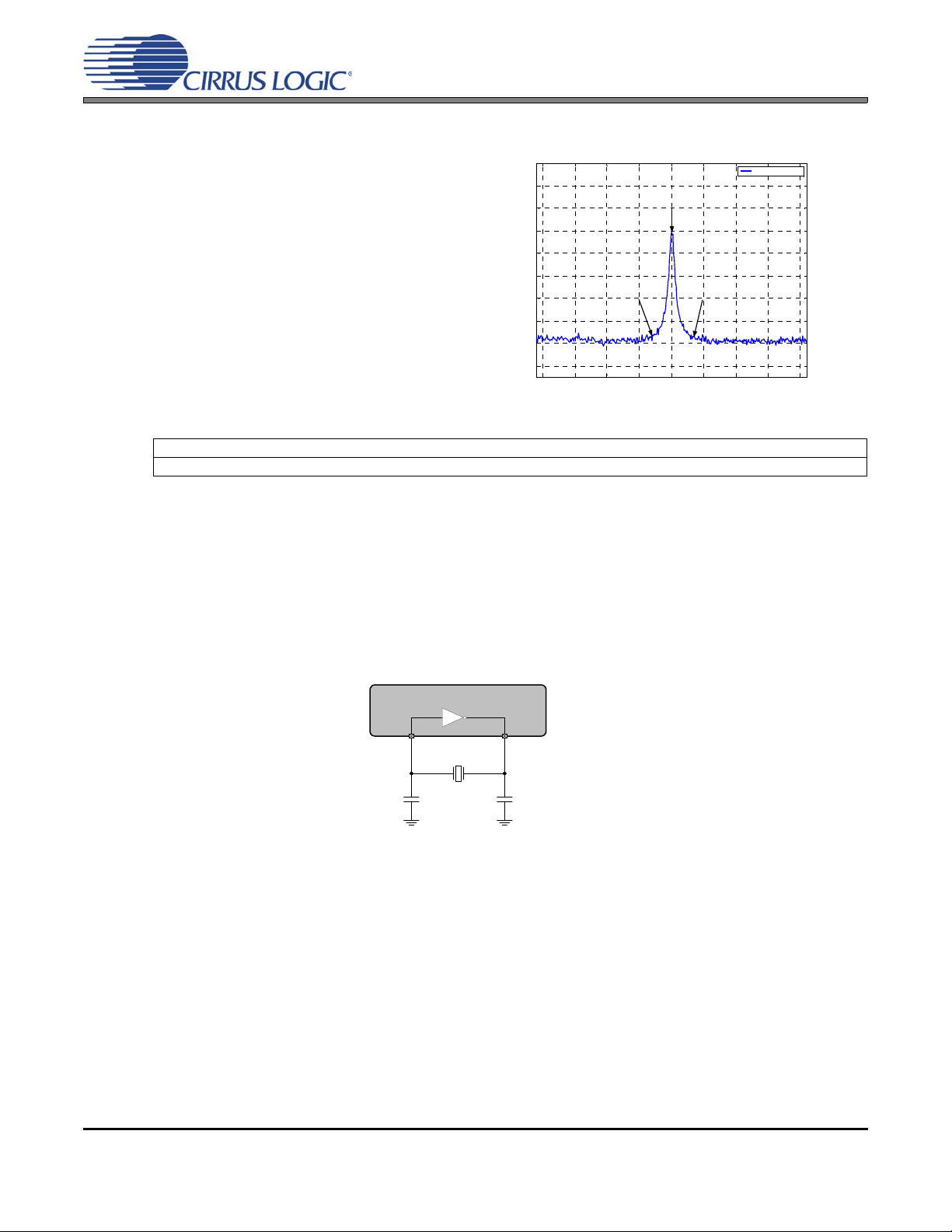

Figure 5. External Component Requirements for Crystal Circuit .............................................................. 10

Figure 6. Ratio Feature Summary ............................................................................................................. 12

Figure 7. PLL Clock Output Options ......................................................................................................... 13

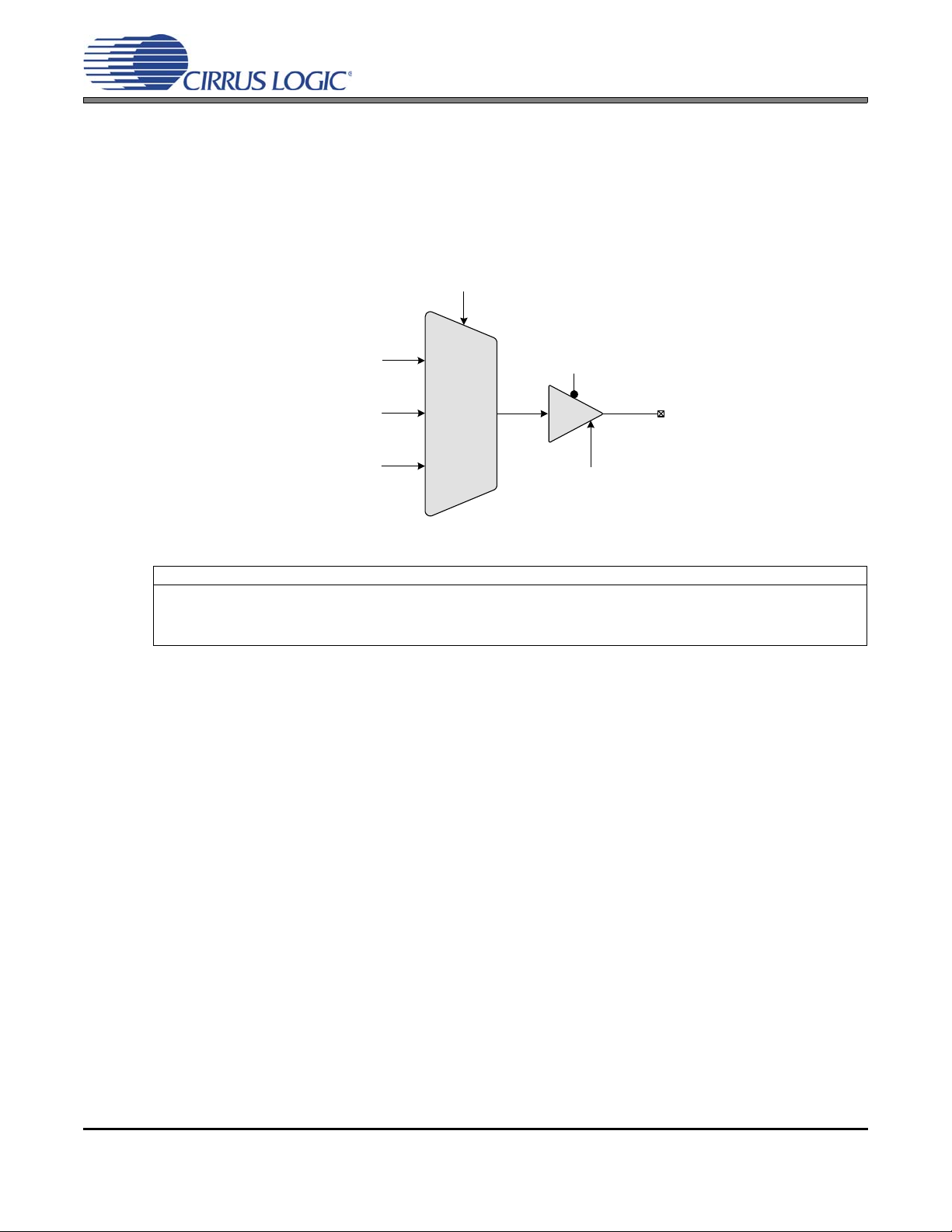

Figure 8. Auxiliary Output Selection .......................................................................................................... 14

Figure 9. M2 Mapping Options .................................................................................................................. 15

Figure 10. Parameter Configuration Sets .................................................................................................. 17

LIST OF TABLES

Table 1. Modal and Global Configuration ........................ .... ... ... ... .... ... ... ... ... .... ... ........................................ 9

Table 2. Ratio Modifier .............................................................................................................................. 11

Table 3. Example 12.20 R-Values ............................................................................................................ 20

CS2200-OTP

DS842F2 3

Page 4

1. PIN DESCRIPTION

1

2

3

4

5

6

7

8

9

10

XTO

CLK_OUT

GND

VD

XTI/REF_CLK

M2

M1

M0

AUX_OUT

TST_IN

Pin Name # Pin Description

VD 1 Digital Power (Input) - Positive power supply for the digital and analog sections.

GND 2 Ground (Input) - Ground reference.

CLK_OUT 3 PLL Clock Output (Output) - PLL clock output.

AUX_OUT 4

TST_IN

XTO

XTI/REF_CLK

M2 8 Mode Select (Input) - M2 is a configurable mode selection pin.

M1 9 Mode Select (Input) - M1 is a configurable mode selection pin.

M0 10 Mode Select (Input) - M0 is a configurable mode selection pin.

Auxiliary Output (Output) - This pin outputs a buffered version of one of the input or output clocks,

or a status signal, depending on configuration.

5 Test Input (Input) - This pin is for factory test purposes and must be connected to GND for proper

operation.

Crystal Connections (XTI/XTO) / Timing Reference Clock Input (REF_CLK) (Input/Output) -

6

XTI/XTO are I/O pins for an external crystal which may be used to generate the low-jitter PLL input

7

clock. REF_CLK is an input for an externally generated low-jitter reference clock.

CS2200-OTP

4 DS842F2

Page 5

2. TYPICAL CONNECTION DIAGRAM

2

1

GND

M2

M1

XTI/REF_CLK

TST_IN

XTO

CLK_OUT

AUX_OUT

0.1 µF

VD

+3.3 V

M0

Low-Jitter

Timing Reference

System Microcontroller

1 µF

1

or

2

REF_CLK

XTO

XTI

XTO

or

40 pF

x

40 pF

Crystal

To circuitry which requires

a low-jitter clock

N.C.

To other circuitry or

Microcontroller

Figure 1. Typical Connection Diagram

CS2200-OTP

CS2200-OTP

DS842F2 5

Page 6

CS2200-OTP

3. CHARACTERISTICS AND SPECIFICATIONS

RECOMMENDED OPERATING CONDITIONS

GND = 0 V; all voltages with respect to ground. (Note ?)

Parameters Symbol Min Typ Max Units

DC Power Supply VD 3.1 3.3 3.5 V

Ambient Operating Temperature (Power Applied)

Commercial Grade

Automotive Grade

T

AC

T

AD

-10

-40

-

-

+70

+85

°C

°C

Notes: 1. Device functionality is not guaranteed or implied outside of these limits. Operation outside of these limits

may adversely affect device reliability.

ABSOLUTE MAXIMUM RATINGS

GND = 0 V; all voltages with respect to ground.

Parameters Symbol Min Max Units

DC Power Supply VD -0.3 6.0 V

Input Current I

Digital Input Voltage (Note 3)V

Ambient Operating Temperature (Power Applied) T

Storage Temperature T

IN

IN

A

stg

-±10mA

-0.3 VD + 0.4 V

-55 125 °C

-65 150 °C

WARNING:Operation at or beyond these limits may result in permanent damage to the device.

Notes: 2. The maximum over/under voltage is limited by the input current except on the power supply pin.

DC ELECTRICAL CHARACTERISTICS

Test Conditions (unless otherwise specified): VD = 3.1 V to 3.5 V; TA = -10°C to +70°C (Commercial Grade);

T

= -40°C to +85°C (Automotive Grade).

A

Parameters Symbol Min Typ Max Units

Power Supply Current - Unloaded (Note 4)I

Power Dissipation - Unloaded (Note 4)P

Input Leakage Current I

Input Capacitance I

High-Level Input Voltage V

Low-Level Input Voltage V

High-Level Output Voltage (I

Low-Level Output Voltage (I

= -1.2 mA) V

OH

= 1.2 mA) V

OH

D

D

IN

C

IH

IL

OH

OL

Notes: 3. To calculate the additional current consumption due to loading (per output pin), multiply clock output

frequency by load capacitance and power supply voltage.

For example,

f

CLK_OUT

(49.152 MHz) * CL (15 pF) * VD (3.3 V) = 2.4 mA of additional current due to

these loading conditions on CLK_OUT.

-1218mA

-4060mW

--±10µA

-8-pF

70% - - VD

--30%VD

80% - - VD

--20%VD

6 DS842F2

Page 7

CS2200-OTP

AC ELECTRICAL CHARACTERISTICS

Test Conditions (unless otherwise specified): VD = 3.1 V to 3.5 V; TA = -10°C to +70°C (Commercial Grade);

= -40°C to +85°C (Automotive Grade); CL=15pF.

T

A

Parameters Symbol Conditions Min Typ Max Units

Crystal Frequency

Fundamental Mode XTAL

Reference Clock Input Frequency f

Reference Clock Input Duty Cycle D

Internal System Clock Frequency f

PLL Clock Output Frequency f

PLL Clock Output Duty Cycle t

Clock Output Rise Time t

Clock Output Fall Time t

Period Jitter t

Base Band Jitter (100 Hz to 40 kHz) (Notes 10, 11) - 50 - ps rms

Wide Band JItter (100 Hz Corner) (Notes 10, 12) - 175 - ps rms

PLL Lock Time - REF_CLK t

Output Frequency Synthesis Resolution (Note 15)f

f

XTAL

REF_CLK

REF_CLK

SYS_CLK

CLK_OUT

OD

OR

OF

JIT

LR

err

RefClkDiv[1:0] = 10

RefClkDiv[1:0] = 01

RefClkDiv[1:0] = 00

RefClkDiv[1:0] = 10

RefClkDiv[1:0] = 01

RefClkDiv[1:0] = 00

Measured at VD/2 45 50 55 %

20% to 80% of VD - 1.7 3.0 ns

80% to 20% of VD - 1.7 3.0 ns

(Note 10) - 70 - ps rms

f

REF_CLK

= 8 to 75 MHz - 1 3 ms

8

16

32

8

16

32

45 - 55 %

814MHz

6-75MHz

0-±0.5ppm

-

-

-

-

-

-

14

28

50

14

28

56

MHz

MHz

MHz

MHz

MHz

MHz

Notes: 4.

f

CLK_OUT

= 24.576 MHz; Sample size = 10,000 points; AuxOutSrc[1:0] =11.

5. In accordance with AES-12id-2006 section 3.4.2. Measurements are Time Inte rval Error taken with 3rd

order 100 Hz to 40 kHz bandpass filter.

6. In accordance with AES-12id-2006 section 3.4.1. Measurements are Time Inte rval Error taken with 3rd

order 100 Hz Highpass filter.

7. The frequency accuracy of the PLL clock output is directly proportional to the frequency accuracy of the

reference clock.

DS842F2 7

Page 8

4. ARCHITECTURE OVERVIEW

Fractional-N

Divider

Timing Reference

Clock

PLL Output

Voltage Controlled

Oscillator

Internal

Loop Filter

Phase

Comparator

N

Delta-Sigma

Modulator

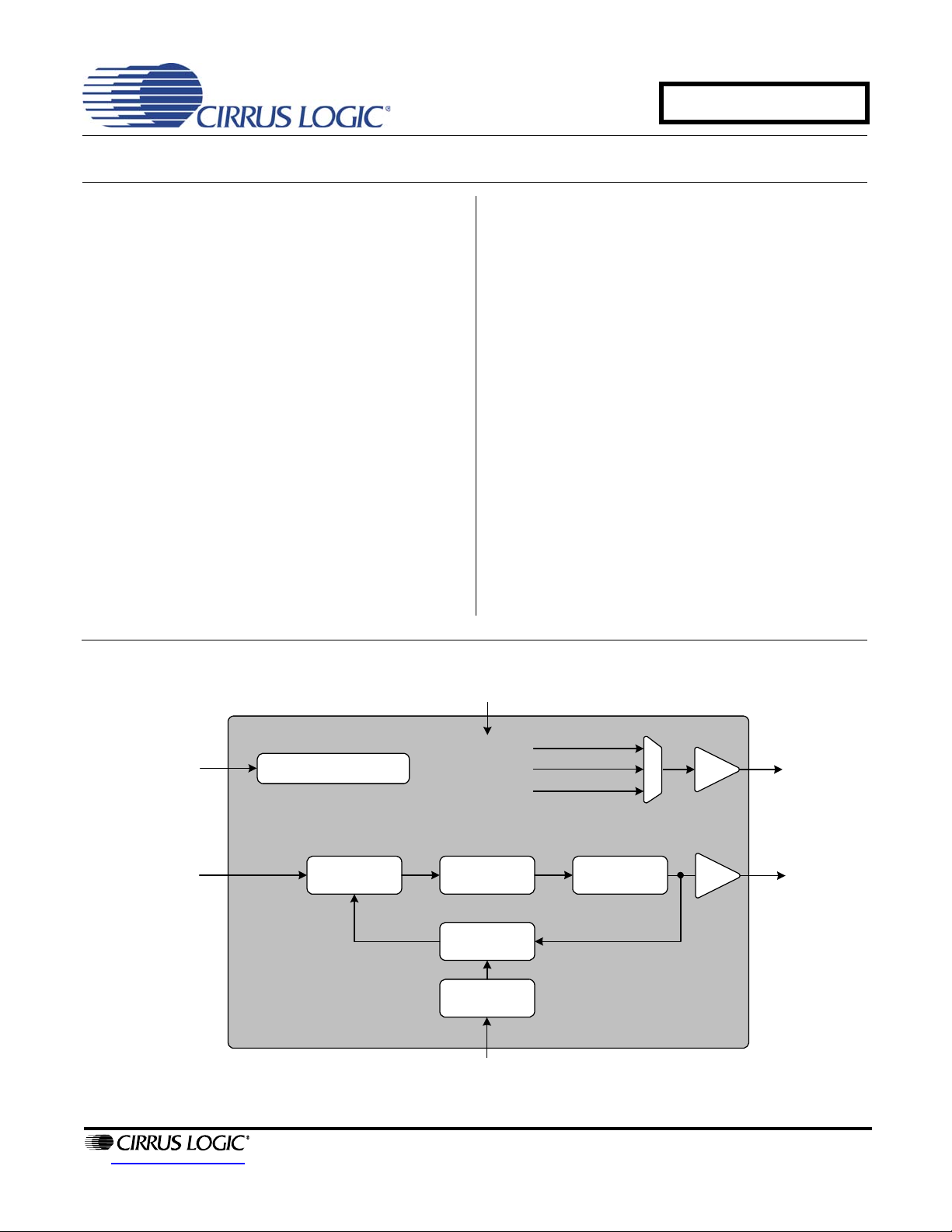

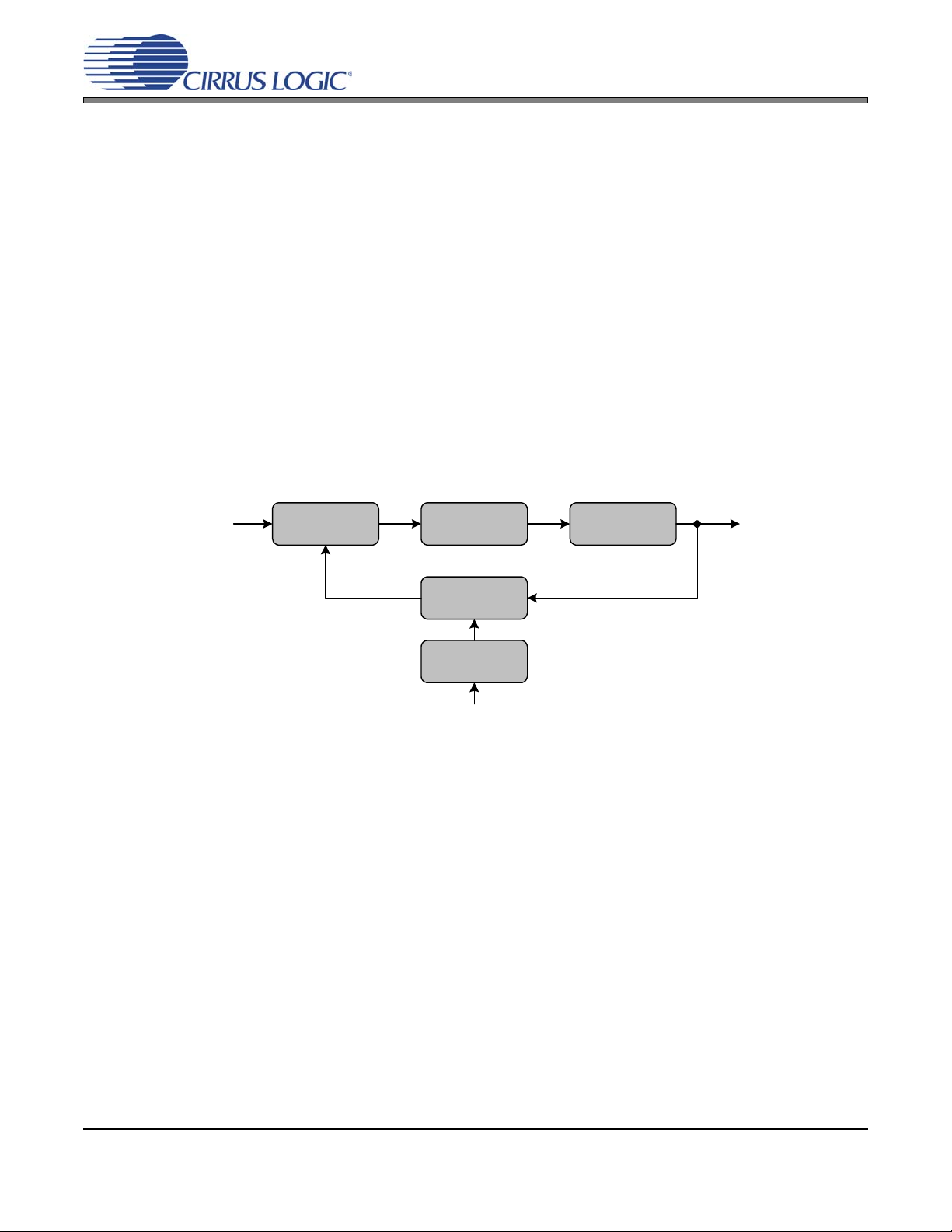

4.1 Delta-Sigma Fractional-N Frequency Synthesizer

The core of the CS2200 is a Delta-Sigma Fractional-N Frequency Synthesizer which has very high-resolution for Input/Output clock ratios, low phase noise, very wide range of output frequencies and the ability to

quickly tune to a new frequency. In very simplistic terms, the Fractional-N Freq uency Synthesizer multiplies

the Timing Reference Clock by the value of N to generate the PLL out put clock. The desired output to input

clock ratio is the value of N that is applied to the delta-sigma modulator (see Figure 2).

The analog PLL based frequency synthesizer uses a low-jitter timing reference clock as a time and phase

reference for the internal voltage controlled oscillator (VCO). The phase comparator compares the fractional-N divided clock with the original timing reference and generates a control signal. The control signal is filtered by the internal loop filter to generate the VCO’s control voltage which sets its output frequency. The

delta-sigma modulator modulates the loop integer divide ratio to get the desired fractional ratio betwee n the

reference clock and the VCO output (thus the duty cycle of the modulator sets the fractional value). This

allows the design to be optimized for very fast lock times for a wide rang e of outpu t freq uencies withou t the

need for external filter components. As with any Fractional-N Frequency Synthesizer the timing reference

clock should be stable and jitter-free.

CS2200-OTP

8 DS842F2

Figure 2. Delta-Sigma Fractional-N Frequency Synthesizer

Page 9

5. APPLICATIONS

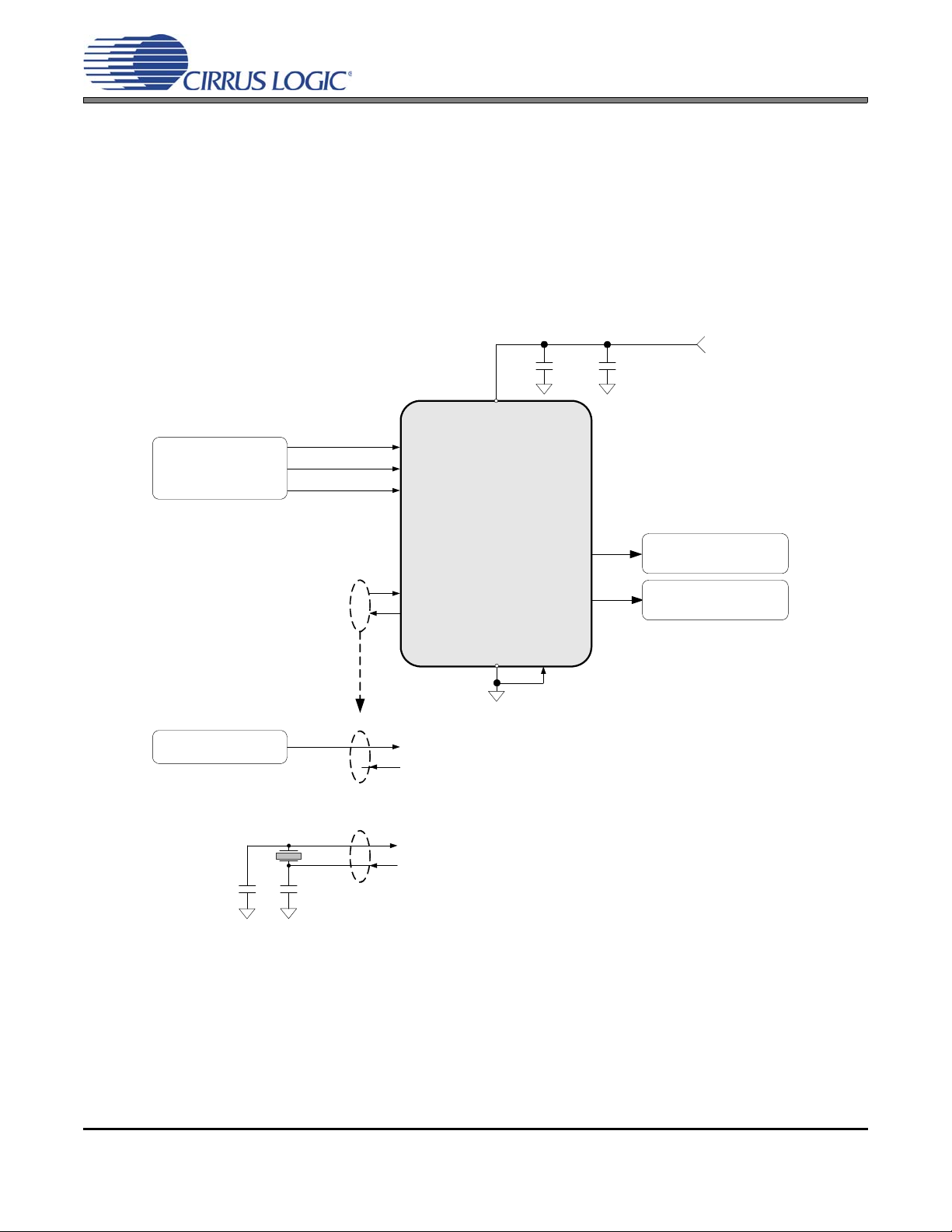

Figure 3. Internal Timing Reference Clock Divider

N

Internal Timing

Reference Clock

PLL Output

Fractional-N

Frequency

Synthesizer

Timing Reference

Clock Divider

÷1

÷2

÷4

XTI/REF_CLK

RefClkDiv[1:0]

8 MHz < SysClk < 14 MHz

8 MHz < RefClk <

Timing Reference Clock

50 MHz (XTI)

58 MHz (REF_CLK)

5.1 One Time Programmability

The one time programmable (OTP) circuitry in the CS2200-OTP allows for pre-configuration of the device

prior to use in a system. There are two types of parameter s that are used for device pre-configuration: modal

and global. The modal parameters are features which, when grouped tog ether, create a modal configuration

set (see Figure 10 on page 17). Up to four modal configuration sets can be permanently stored and then

dynamically selected using the M[1:0] mode select pins (see Table 1). The global parameters are the re-

maining configuration settings which do not change with the mode select pins. The modal and global parameters can be pre-set at the factory or user progr ammed using the customer deve lopment kit, CDK20 00;

Please see “Programming Information” on page 21 for more details.

Parameter Type M[1:0] pins = 00 M[1:0] pins = 01 M[1:0] pins = 10 M[1:0] pins = 11

Modal Configuration Set 0

Ratio 0

Global Configuration settings set once for all modes.

Table 1. Modal and Global Configuration

5.2 Timing Reference Clock Input

Configuration Set 1

Ratio 1

Configuration Set 2

Ratio 2

CS2200-OTP

Configuration Set 3

Ratio 3

The low jitter timing reference clock (RefClk) can be provided by either an external reference clock or an

external crystal in conjunction with the internal oscillator. In order to maintain a stable and low-jitter PLL output the timing reference clock must also be stable and low-jitter; the quality of the timing reference clock

directly affects the performance of the PLL and hence the quality of the PLL output.

5.2.1 Internal Timing Reference Clock Divider

The Internal Timing Reference Clock (SysClk) is limited to a lower maximum frequency than that allowed

on the XTI/REF_CLK pin. The CS2200-OTP supports the wider external frequency range by offering an

internal divider for RefClk. The RefClkDiv[1:0] global parameter should be configured such that SysClk,

the divided RefClk, then falls within the valid range as indicated in “AC Electrical Characteristics” on

page 7.

It should be noted that the maximum allowable input frequency of the XTI/REF_CLK pin is dependent

upon its configuration as either a crystal connection or external clock input. See the “AC Electrical Char-

acteristics” on page 7 for more details.

For the lowest possible output jitter, attention should be paid to th e absolute frequency of the Timing Reference Clock relative to the PLL Output frequency ( CLK_OUT ). To minimize outp ut jitter, the Timing Reference Clock frequency should be chosen such that f

where N is an integer. Figure 4 shows the effect of varying the RefClk frequency around f

is at least +/-15 kHz from f

RefClk

CLK_OUT

CLK_OUT

*N/32

*N/32.

It should be noted that there will be a jitter null at the zero point when N = 32 (not shown in Figure 4). An

DS842F2 9

Page 10

CS2200-OTP

-80 -60 -40 -20 0 20 40 60 80

20

40

60

80

100

120

140

160

180

Normalized REF__CLK Frequency (kHz)

Typical Base Band Jitter (psec)

CLK__OUT Jitt er

-15 kHz +15 kHz

CLK__OUT

f

*32/N

Figure 4. REF_CLK Frequency vs. a Fixed CLK_OUT

fLf

RefClkfH

≤≤

fLf

CLK_OUT

31

32

----- -

15kHz+×=

12.288MHz 0.96875 15kHz+×=

11.919MHz=

fHf

CLK_OUT

32

32

----- -

15kHz–×=

12.288MHz 115kHz+×=

12.273MHz=

XTI XTO

40 pF 40 pF

Figure 5. External Component Requirements for Crystal Circuit

example of how to determine the range of RefClk frequencies around 12 MHz to be used in order to

achieve the lowest jitter PLL output at a frequency of 12.288 MHz is as follows:

where:

and

Referenced Control Parameter Definition

RefClkDiv[1:0].......................“Reference Clock Input Divider (RefClkDiv[1:0])” on page 18

5.2.2 Crystal Connections (XTI and XTO)

An external crystal may be used to generate RefClk. To accomplish this, a 20 pF fundamental mode parallel resonant crystal must be connected between the XTI and XTO pins as shown in Figure 5. As shown,

nothing other than the crystal and its load capacitors should be connected to XTI and XTO. Please refer

to the “AC Electrical Characteristics” on page 7 for the allowed crystal frequency range.

5.2.3 External Reference Clock (REF_CLK)

For operation with an externally generated REF_CLK signal, XTI/REF_CLK should be connected to the

reference clock source and XTO should be left unconnected or terminated through a 47 kΩ resistor to

GND.

10 DS842F2

Page 11

5.3 Output to Input Frequency Ratio Configuration

5.3.1 User Defined Ratio (RUD)

The User Defined Ratio, RUD, is a 32-bit un-signed fixed-point number which determines the basis for the

desired input to output clock ratio. Up to four different ratios, Ratio

time programmable memory. Selection between the four ratios is achieved by the M[1:0] mode select

pins. The 32-bit R

is represented in a 12.20 format where the 12 MSBs represent the integer binary

UD

portion while the remaining 20 LSBs represent the fractional binary portion. The maximum multiplication

factor is approximately 4096 with a resolution of 0.954 PPM in this configuration. See “Calculating the

User Defined Ratio” on page 20 for more information.

The status of internal dividers, such as the internal timing reference clock divider, are automatically taken

into account. Therefore R

Referenced Control Parameter Definition

Ratio 0-3................................“Ratio 0 - 3” on page 18

M[1:0]....................................“M1 and M0 Mode Pin Functionality” on page 14

is simply the desired ratio of the output to input clock frequencies.

UD

5.3.2 Ratio Modifier (R-Mod)

CS2200-OTP

, can be stored in the CS2200’s one

0-3

The Ratio Modifier is used to internally multiply/divide the currently ad dressed RUD (Ratio

register space remain unchanged). The available options for R-Mod are summarized in Table 2 on

page 11. R-Mod is enabled via the M2 pin in conjunction with the appropriate setting of the M2Config[2:0]

global parameter (see Section 5.6.2 on page 15).

Referenced Control Parameter Definition

Ratio 0-3................................“Ratio 0 - 3” on page 18

RModSel[1:0] ........................“R-Mod Selection (RModSel[1:0])” section on page 17

M2Config[2:0]........................“M2 Pin Configuration (M2Config[2:0])” on page 19

5.3.3 Effective Ratio (R

The Effective Ratio (R

previously described. R

R

= RUD • R-Mod

EFF

stored in the

0-3

RModSel[1:0] R Modifier

00 0.5

01 0.25

10 0.125

11 0.0625

Table 2. Ratio Modifier

)

EFF

) is an internal calculation comprised of RUD and the appropriate modifiers, as

EFF

is calculated as follows:

EFF

To simplify operation the device handles some of the ratio calculation functions automatically (such as

when the internal timing reference clock divider is set). For this reason, the Effective Ratio does not need

to be altered to account for internal dividers.

Ratio modifiers which would produce an overflow or truncation of R

the maximum and minimum allowable values for R

are dictated by the frequency limits for both the

EFF

should not be used. In all cases,

EFF

input and output clocks as shown in the “AC Electrical Characteristics” on page 7.

DS842F2 11

Page 12

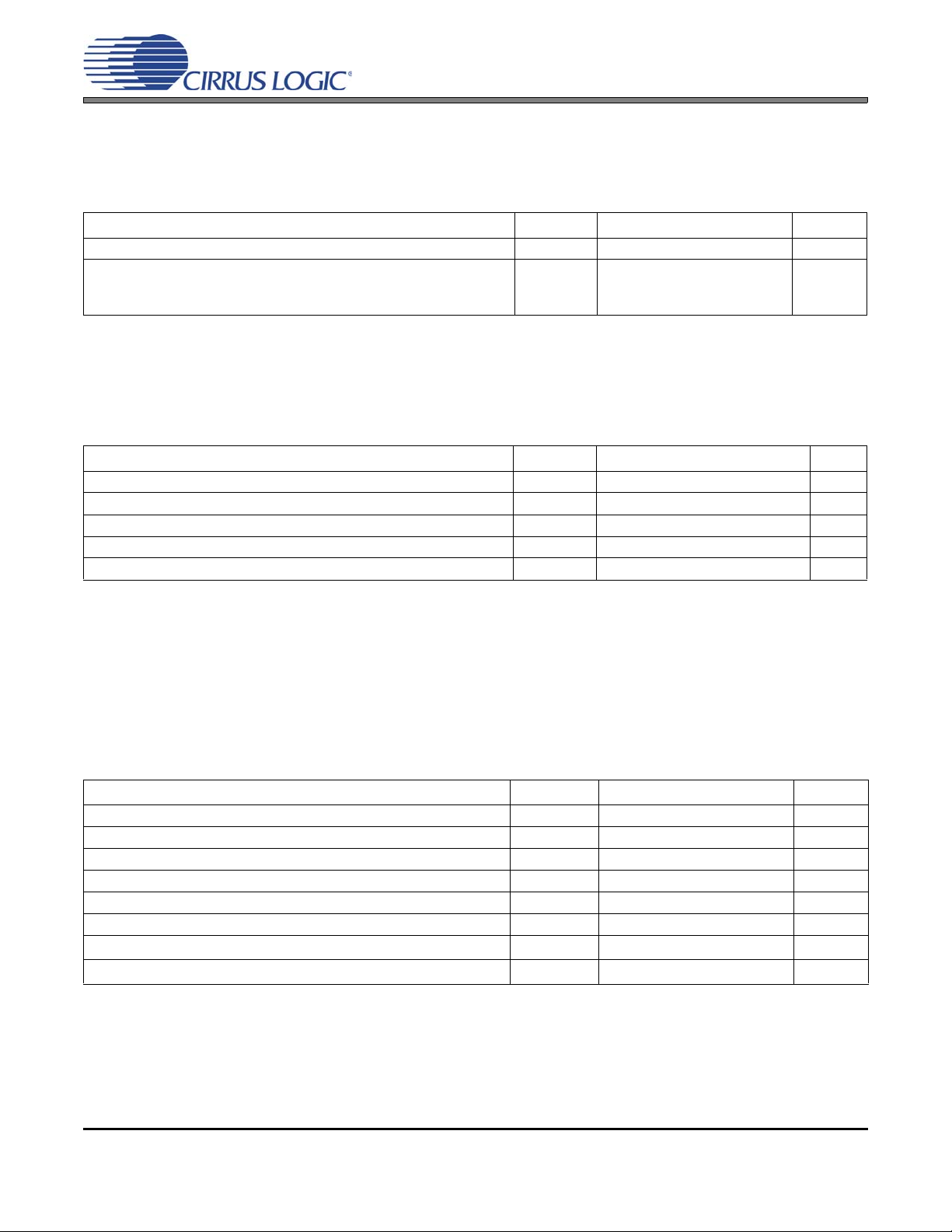

Selection of the user defined ratio from the four stored ratios is made by using the M[1:0] pins.

Effective Ratio R

EFF

Ratio Format

SysClk

PLL Output

Frequency

Synthesizer

Ratio 0

Ratio 1

Ratio 2

Ratio 3

12.20

M[1:0] pins

RModSel[1:0]

4

Ratio

Modifier

R Correction

RefClkDiv[1:0]

Timing Reference Clock

(XTI/REF_CLK)

Divide

RefClkDiv[1:0]

Static Ratio, ‘N’

User Defined Ratio R

UD

M2 pin

Referenced Control Parameter Definition

M[1:0] pins.............................“M1 and M0 Mode Pin Functionality” on page 14

5.3.4 Ratio Configuration Summary

CS2200-OTP

The RUD is the user defined ratio for which up to four different values (Ratio

) can be stored in the one

0-3

time programmable memory. The M[1:0] pins then select the user defined ratio to be used as well as the

modal configuration set. R-Mod is applied accordingly. The user defined ratio and ratio modifier make up

the effective ratio R

, the final calculation used to determine the output to input clock ratio. The effective

EFF

ratio is then corrected for the internal dividers. The conceptual diagram in Figure 6 summarizes the fea-

tures involved in the calculation of the ratio va lues us ed to ge nerate the fractiona l-N value which con trols

the Frequency Synthesizer. The subscript ‘4’ indicates the modal parameters.

Figure 6. Ratio Feature Summary

Referenced Control Parameter Definition

Ratio 0-3................................“Ratio 0 - 3” on page 18

M[1:0] pins.............................“M1 and M0 Mode Pin Functionality” on page 14

RModSel[1:0] ........................“R-Mod Selection (RModSel[1:0])” section on page 17

RefClkDiv[1:0].......................“Reference Clock Input Divider (RefClkDiv[1:0])” on page 18

12 DS842F2

Page 13

5.4 PLL Clock Output

PLL Locked/Unlocked

PLL Output

2:1 Mux

M2 pin with

M2Config[1:0] = 000, 010

2:1 Mux

ClkOutUnl

0

PLL Clock Output Pin

(CLK_OUT)

0

1

0

1

PLL Clock Output

PLLClkOut

The PLL clock output pin (CLK_OUT) provides a buffered version of the outp ut of the frequency synthesizer.

The driver can be set to high-impedance with the M2 p in when the M2Config[1:0] global parameter is set to

either 000 or 010. The output from the PLL automatically drives a static low condition while the PLL is unlocked (when the clock may be unreliable ). This feature can be disabled by setting the ClkOutUnl global

parameter, however the state CLK_OUT may then be unreliable during an unlock condition.

Referenced Control Parameter Definition

ClkOutUnl..............................“Enable PLL Clock Output on Unlock (ClkOutUnl)” on page 19

ClkOutDis..............................“M2 Configured as Output Disable” on page 15

M2Config[2:0]........................“M2 Pin Configuration (M2Config[2:0])” on page 19

CS2200-OTP

Figure 7. PLL Clock Output Options

DS842F2 13

Page 14

5.5 Auxiliary Output

3:1 Mux

Auxiliary Output Pin

(AUX_OUT)

AuxOutDis

AuxOutSrc[1:0]

AuxLockCfg

Timing Reference Clock

(RefClk)

PLL Clock Output

(PLLClkOut)

PLL Lock/Unlock Indicat i on

(Lock)

The auxiliary output pin (AUX_OUT) can be mapped, as shown in Figure 8, to one of three signals: reference clock (RefClk), additional PLL clock output (CLK_OUT) , or a PLL lock indicator (Lock). The mux is controlled via the AuxOutSrc[1:0] modal parameter. If AUX_OUT is set to Lock, the AuxLockCfg global

parameter is then used to control the output driver type and polarity of the LOCK signal (see section 6.3.1

on page 18). If AUX_OUT is set to CLK_OUT, the phase of the PLL Clock Output signal on AUX_OUT may

differ from the CLK_OUT pin. The driver for the pin can be set to high-impedance using the M2 pin when

the M2Config[1:0] global parameter is set to either 001 or 010.

CS2200-OTP

Figure 8. Auxiliary Output Selection

Referenced Control Parameter Definition

AuxOutSrc[1:0]......................“Auxiliary Output Source Selection (AuxOutSrc[1:0])” on page 18

AuxOutDis.............................“M2 Configured as Output Disable” on page 15

AuxLockCfg...........................“AUX PLL Lock Output Configuration (AuxLockCfg)” section on page 18

M2Config[2:0]........................“M2 Pin Configuration (M2Config[2:0])” on page 19

5.6 Mode Pin Functionality

5.6.1 M1 and M0 Mode Pin Functionality

M[1:0] determine the functional mode of the device and select both the default User Defined Ratio and

the set of modal parameters. The modal parameters are RModSel[1:0] and AuxOutSrc[1:0]. By modifying

one or more of the modal parameters between the 4 sets, different functional configurations can be

achieved. However, global parameters are fixed and the same value will be applied to each functional

configuration. Figure 10 on page 17 provides a summary of all parameters used by the device.

14 DS842F2

Page 15

5.6.2 M2 Mode Pin Functionality

M2 pin

Disable CLK_OUT and AUX_OUT pins

Disable AUX_OUT pin

Disable CLK_OUT pin

RModSel[1:0] Modal Parameter Enable

Force AuxOutSel[1:0] = 10 (PLL Clock Out)

Reserved

Reserved

M2Config[2:0] global parameter

000

001

010

011

100

101

110

111

Reserved

M2 usage is mapped to one of the optional special functions via the M2Config[2:0] g lobal parameter . Depending on what M2 is mapped to, it will either act as an output enable/disable pin or override certain modal parameters. Figure 9 summarizes the available options and the following sections will describe each

option in more detail.

CS2200-OTP

Figure 9. M2 Mapping Options

5.6.2.1 M2 Configured as Outpu t Disable

If M2Config[2:0] is set to either ‘000’, ‘001’, or ‘010’, M2 becomes an output disable pin for one or

both output pins. If M2 is driven ‘low’, the corresponding output(s) will be enabled, if M2 is driven

‘high’, the corresponding output(s) will be disabled.

5.6.2.2 M2 Configured as R-Mod Enable

If M2Config[2:0] is set to ‘011’, M2 becomes the R-Mod enable pin. It should be noted that M2 is

the only way to enable R-Mod. Even though the RModSel[1:0] modal parameter can be set arbi-

trarily for each configuration set, it will not take effect unless enabled via M2. If M2 is driven ‘low’,

R-Mod will be disabled, if M2 is driven ‘high’ R-Mod will be enabled.

5.6.2.3 M2 Configured as AuxOutSrc Override

If M2Config[2:0] is set to ‘111’, M2 when driven ‘high’ will override the AuxOutSrc[1:0] modal parameter and force the AUX_OUT source to PLL Clock Output . Wh en M2 is driven ‘low’, AUX_OUT

will function according to AuxOutSrc[1:0].

DS842F2 15

Page 16

5.7 Clock Output Stability Considerations

5.7.1 Output Switching

The CS2200-OTP is designed such that re-configuration of the clock routing functions do not result in a

partial clock period on any of the active outputs (CLK_OUT and/or AUX_OUT). In particular, enabling or

disabling an output, changing the auxiliary output source between REF_CLK and CLK_OUT, and the automatic disabling of the output(s) during unlock will not cause a runt or partial clock period.

The following exceptions/limitations exist:

• Enabling/disabling AUX_OUT when AuxOutSrc[1:0] = 11 (unlock indicator).

• Switching AuxOutSrc[1:0] to or from 11 (unlock indicator)

(Transitions between AuxOutSrc[1:0] = [00,10] will not produce a glitch).

When any of these exceptions occur, a partial clock period on the output may result.

5.7.2 PLL Unlock Conditions

Certain changes to the clock inputs and mode pins can cause the PLL to lose lock which will affect the

presence of a clock signal on CLK_OUT. The following outlin es which conditions ca use the PLL to go unlocked:

CS2200-OTP

• Any change in the state of the M1 and M0 pins will cause the PLL to temporarily lose lock as the new

setting takes affect .

• Changes made to the state of the M2 when the M2Config[2:0] global parameter is set to 011, 100, 101,

or 110 can cause the PLL to temporarily lose lock as the new setting takes affect.

• Any discontinuities on the Timing Reference Clock, REF_CLK.

5.8 Required Power Up Sequencing for Programmed Devices

• Apply power. All input pins, except XTI/REF_CLK, should be held in a static logic hi or lo state until the

DC Power Supply specification in the “Recommended Operating Conditions” table on page 6 are met.

• Apply input clock.

• For CDK programmed devices, toggle the state of the M0, M1, or both pins at least 3 times to initialize

the device. This must be done after the power supply is stable and before normal operation is expected.

Note:This operation is not required for factory programmed devices.

• After the specified PLL lock time on page 7 has passed, the device will output the desired clock as configured by the M0-M2 pins.

16 DS842F2

Page 17

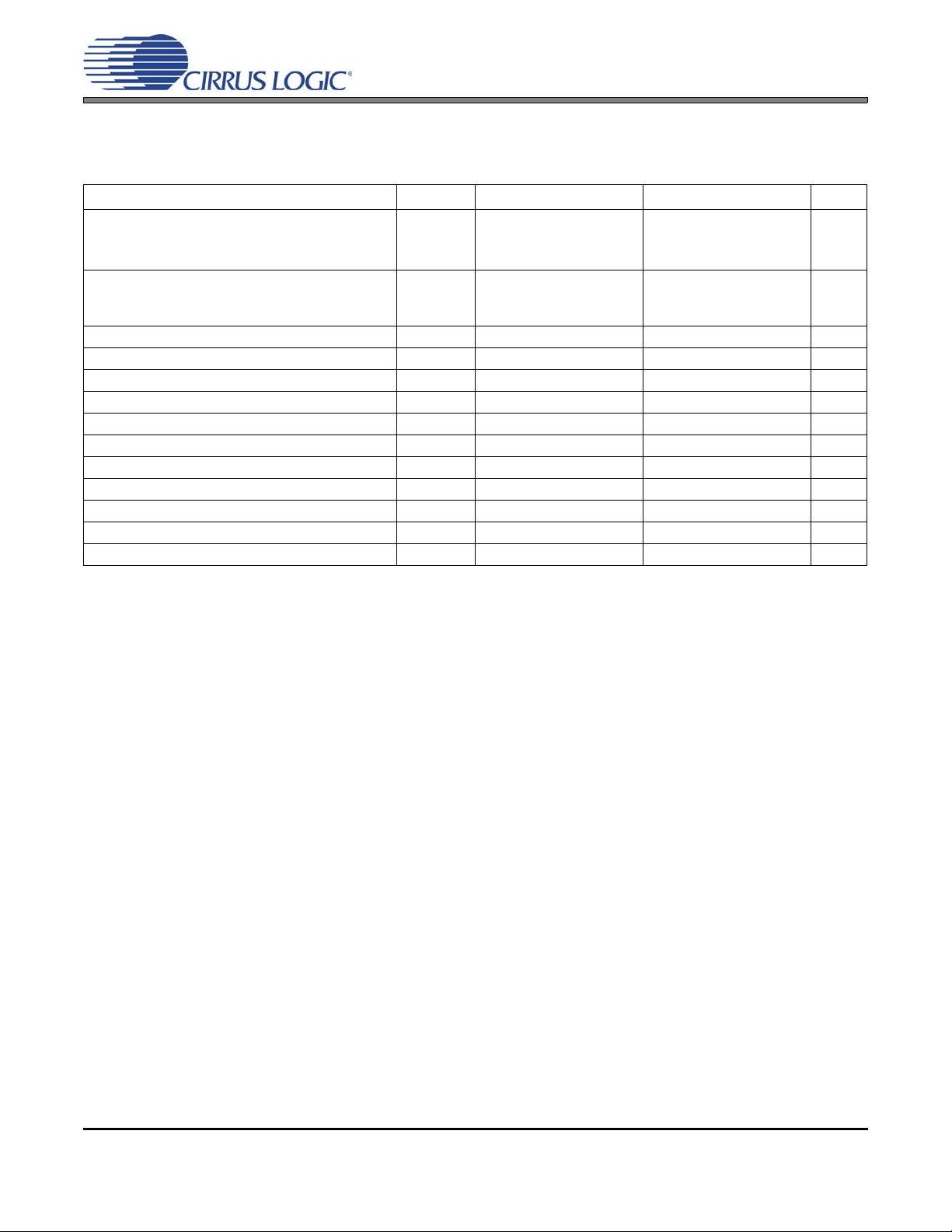

CS2200-OTP

M[1:0] pins

Modal Configuration Set #0

RModSel[1:0] AuxOutSrc[1:0]

Modal Configuration Set #1

Ratio 1 RModSel[1:0] AuxOutSrc[1:0]

Modal Configuration Set #2

Ratio 2 RModSel[1:0] AuxOutSrc[1:0]

Modal Configuration Set #3

Ratio 3 RModSel[1:0] AuxOutSrc[1:0]

00

01

10

11

Global Configuration Set

RefClkDiv[1:0] ClkOutUnlAuxLockCfg M2Config[2:0]

Ratio 0

Digital/PLL Core

6. PARAMETER DESCRIPTIONS

As mentioned in Section 5.1 on page 9, there are two different kinds of parameter configuration sets, Modal and

Global. These configuration sets, shown in Figure 10, can be programmed in the field using the CDK2000 or preprogrammed at the factory. Please see “Programming Information” on page 21 for more details.

6.1 Modal Configuration Sets

6.1.1 R-Mod Selection (RModSel[1:0])

Figure 10. Parameter Configuration Sets

There are four instances of each of these configuration parameters. Sele ction between the four stored sets

is made using the M[1:0] pins.

Selects the R-Mod value, which is used as a factor in determining the PLL’s Fractional N.

RModSel[1:0] R-Mod Selection

00 Right-shift R-value by 1 (÷ 2).

01 Right-shift R-value by 2 (÷ 4).

10 Right-shift R-value by 3 (÷ 8).

11 Right-shift R-value by 4 (÷ 16).

Application: “Ratio Modifier (R-Mod)” on page 11

Note: This parameter does not take affect unless M2 pin is high and the M2Config[2:0] global param-

eter is set to ‘011’.

DS842F2 17

Page 18

6.1.2 Auxiliary Output Source Selection (AuxOutSrc[1:0])

Selects the source of the AUX_OUT signal.

AuxOutSrc[1:0] Auxiliary Output Source

00 RefClk.

01 Reserved.

10 CLK_OUT.

11 PLL Lock Status Indicator.

Application: “Auxiliary Output” on page 14

Note: When set to 11, the AuxLockCfg global parameter sets the polarity and driver type (“AUX PLL

Lock Output Configuration (AuxLockCfg)” on page 18).

6.2 Ratio 0 - 3

The four 32-bit User Defined Ratios are stored in the CS220 0’s one time programmable memo ry. See “Out-

put to Input Frequency Ratio Configuration” on page 11 and “Calculating the User Defined Ratio” on

page 20 for more details.

6.3 Global Configuration Parameters

6.3.1 AUX PLL Lock Output Configuration (AuxLockCfg)

CS2200-OTP

When the AUX_OUT pin is configured as a lock indicator (AuxOutSrc[1:0] modal parameter = ‘11’), this

global parameter configures the AUX_OUT driver to either push-pull or op en drain. It also determines the

polarity of the lock signal. If AUX_OUT is configured as a clock output, the state of this parameter is disregarded.

AuxLockCfg AUX_OUT Driver Configuration

0 Push-Pull, Active High (output ‘high’ for unlocked condition, ‘low’ for locked condition).

1 Open Drain, Active Low (output ‘low’ for unlocked condition, high-Z for locked condition).

Application: “Auxiliary Output” on page 14

Note: AUX_OUT is an unlock indicator, signalling an error condition when the PLL is u nlocked. There-

fore, the pin polarity is defined relative to the unlock condition.

6.3.2 Reference Clock Input Divider (RefClkDiv[1:0])

Selects the input divider for the timing reference clock.

RefClkDiv[1:0] Reference Clock Input Divider REF_CLK Frequency Range

00 ÷ 4. 32 MHz to 56 MHz (50 MHz with XTI)

01 ÷ 2. 16 MHz to 28 MHz

10 ÷ 1. 8 MHz to 14 MHz

11 Reserved.

Application: “Internal Timing Reference Clock Divider” on page 9

18 DS842F2

Page 19

6.3.3 Enable PLL Clock Output on Unlock (ClkOutUnl)

Defines the state of the PLL output during the PLL unlock condition.

ClkOutUnl Clock Output Enable Status

0 Clock outputs are driven ‘low’ when PLL is unlocked.

1 Clock outputs are always enabled (results in unpredictable output when PLL is unlocked).

Application: “PLL Clock Output” on page 13

6.3.4 M2 Pin Configuration (M2Config[2:0])

Controls which special function is mapped to the M2 pin.

M2Config[2:0] M2 pin function

000 Disable CLK_OUT pin.

001 Disable AUX_OUT pin.

010 Disable CLK_OUT and AUX_OUT.

011 RModSel[1:0] Modal Parameter Enable.

100 Reserved.

101 Reserved.

110 Reserved.

111 Force AuxOutSrc[1:0] = 10 (PLL Clock Out).

Application: “M2 Mode Pin Functionality” on page 15

CS2200-OTP

DS842F2 19

Page 20

CS2200-OTP

7. CALCULATING THE USER DEFINED RATIO

Note: The software for use with the evaluation kit has built in tools to aid in calculating and converting the User

Defined Ratio. This section is for those who would like to know more about how the User Defined Ratio is

calculated and stored.

Most calculators do not interpret the fixed point binary representation which the CS2200-OTP uses to define the

output to input clock ratio (see Section 5.3.1 on page 11); However, with a simple conversion we can use these tools

to generate a binary or hex value for Ratio

ming Information” on page 21 for more details on programming.

7.1 12.20 Format

to be stored in one time programmable memory. Please see “Program-

0-3

To calculate the User Defined Ratio (RUD) to store in the register(s), divide the desir ed output clock frequency by the given input clock (RefClk). Then multiply the desired ratio by the scaling factor of 2

scaled decimal representation; then use the decimal to binary/hex conversion function on a calculator and

write to the register. A few examples have been provided in Table 3.

Scaled Decimal

Desired Output to Input Clock Ratio

(output clock/input clock)

12.288 MHz/10 MHz=1.2288

11.2896 MHz/44.1 kHz=256

Table 3. Example 12.20 R-Values

Representation =

(output clock/input clock)

1288490 00 13 A9 2A

268435456 10 00 00 00

• 2

Hex Representation of

20

Binary R

20

to get the

UD

20 DS842F2

Page 21

CS2200-OTP

8. PROGRAMMING INFORMATION

Field programming of the CS2200-OTP is achieved using the hardware and software tools included with the

CDK2000. The software tools can be downloaded from www.cirrus.com for evaluation pr ior to or dering a CDK. Th e

CDK2000 is designed with built-in features to ease the process of programming small quantities of de vice s for p rototype and small production builds. In addition to its fi eld programming capabilities, the CDK2000 can also be used

for the complete evaluation of programmed CS2200-OTP devices.

The CS2200-OTP can also be factory programmed for large quantity orders. When ordering factory programmed

devices, the CDK should first be used to program and evaluate the desired config uration . When ev aluatio n is complete, the CS2000 Configuration Wizard is used to generate a file containing all device configuration information;

this file is conveyed to Cirrus Logic as a comp lete specification for the factory programming configuration. Please

contact your local Cirrus Logic sales representative for more information regarding factory programmed parts.

See the CDK2000 datasheet, available at www.cirrus.com, for detailed information on the use of the CDK2000 programming and evaluation tools.

Below is a form which represents the information required for prog ramming a device (noted in gray). The “Parameter

Descriptions” section beginning on page 17 describes the functions of each parameter. This form may be used ei-

ther for personal notation for device configuration or it can be filled out and given to a Cirrus representative in conjunction with the programming file from the CDK2000 as an additional check. The User Defined Ratio may be filled

out in decimal or it may be entered as hex as outlined in “Calculating the User Defined Ratio” on page 20. For all

other parameters mark a ‘0’ or ‘1’ below the parameter name.

OTP Modal and Global Configuration Parameters Form

Modal Configuration Set #0

Ratio 0 (dec)

Ratio 0 (hex) __ __ : __ __ : __ __ : __ __

RModSel1 RModSel0 AuxOutSrc1 AuxOutSrc0

Modal Configuration Set #1

Ratio 1 (dec)

Ratio 1 (hex) __ __ : __ __ : __ __ : __ __

RModSel1 RModSel0 AuxOutSrc1 AuxOutSrc0

Modal Configuration Set #2

Ratio 2 (dec)

Ratio 2 (hex) __ __ : __ __ : __ __ : __ __

RModSel1 RModSel0 AuxOutSrc1 AuxOutSrc0

Modal Configuration Set #3

Ratio 3 (dec)

Ratio 3 (hex) __ __ : __ __ : __ __ : __ __

RModSel1 RModSel0 AuxOutSrc1 AuxOutSrc0

Global Configuration Set

AuxLockCfg RefClkDiv1 RefClkDiv0 ClkOutUnl M2Cfg2 M2Cfg1 M2Cfg0

DS842F2 21

Page 22

CS2200-OTP

10L MSOP (3 mm BODY) PACKAGE DRAWING (Note 1)

E

N

1

23

e

b

A1

A2

A

D

SEATING

PLANE

E1

1

L

SIDE VIEW

END VIEW

TOP VIEW

∝

L1

c

9. PACKAGE DIMENSIONS

INCHES MILLIMETERS NOTE

DIM MIN NOM MAX MIN NOM MAX

A -- -- 0.0433 -- -- 1.10

A1 0 -- 0.0059 0 -- 0.15

A2 0.0295 -- 0.0374 0.75 -- 0.95

b 0.0059 -- 0.0118 0.15 -- 0.30 4, 5

c 0.0031 -- 0.0091 0.08 -- 0.23

D -- 0.1181 BSC -- -- 3.00 BSC -- 2

E -- 0.1929 BSC -- -- 4.90 BSC --

E1 -- 0.1181 BSC -- -- 3.00 BSC -- 3

e -- 0.0197 BSC -- -- 0.50 BSC -L 0.0157 0.0236 0.0315 0.40 0.60 0.80

L1 -- 0.0374 REF -- -- 0.95 REF --

Notes: 1. Reference document: JEDEC MO-187

2. D does not include mold flash or protrusions which is 0.15 mm max. per side.

3. E1 does not include inter-lead flash or protrusions which is 0.15 mm max per side.

4. Dimension b does not include a total allowable dambar protrusion of 0.08 mm max.

5. Exceptions to JEDEC dimension.

THERMAL CHARACTERISTICS

Parameter Symbol Min Typ Max Units

Junction to Ambient Thermal Impedance JEDEC 2-Layer

22 DS842F2

JEDEC 4-Layer

θ

JA

θ

JA

-

-

170

100

-

-

°C/W

°C/W

Page 23

CS2200-OTP

10.ORDERING INFORMATION

The CS2200-OTP is ordered as an un-prog rammed device. The CS220 0-OTP can also be factor y programm ed for

large quantity orders. Please see “Programming Information” on page 21 for more details.

Product Description Package

CS2200-OTP Clockin g Device 10L-MSOP Yes

CS2200-OTP Clockin g Device 10L-MSOP Yes -10° to +70°C

CS2200-OTP Clockin g Device 10L-MSOP Yes

CS2200-OTP Clockin g Device 10L-MSOP Yes -40° to +85°C

CDK2000 Evaluation Platform - Yes - - - CDK2000-CLK

Pb-Free Grade

Commercial

Automotive

Temp Range Container

-10° to +70°C Rail CS2200P-CZZ

Tape and

Reel

-40° to +85°C Rail CS2200P-DZZ

Tape and

Reel

Order#

CS2200P-CZZR

CS2200P-DZZR

11.REVISION HISTORY

Release Changes

F1 Updated Pe riod Jitter specification in “AC Electrical Characteristics” on page 7.

Updated Crystal and Ref Clock Frequency specifications in “AC Electrical Characteristics” on page 7.

Added Mode pin toggle requirement to startup for CDK programmed devices to “Required Power Up

Sequencing for Programmed Devices” on page 16.

F2 Updated to add Automotive Grade temperature ranges and ordering options.

DS842F2 23

Page 24

CS2200-OTP

Contacting Cirrus Logic Support

For all product questions and inquiries, contact a Cirrus Logic Sales Representative.

To find one nearest you, go to www.cirrus.com

.

IMPORTANT NOTICE

Cirrus Logic, Inc. and its subsidiaries (“Cirrus”) believe that the information contained in this document is accurate and reliable. However, the information is subject

to change without noti ce and is provided “AS IS” wi thout war ranty of any kind (express or impli ed). Cust omers ar e advised t o obtain the latest version of relevant

information to verify, before placing orders, that information being relied on is current and complete. All products are sold subject to the terms and conditions of sale

supplied at the time of order acknowled gment, including tho se pertaining to warra nty, indemnification, an d limitation of liability. No responsibility is assumed by Cirrus

for the use of this information, including use of this information as the basis for manufacture or sale of any items, or for infringement of patents or other rights of third

parties. This document is the property of Cirrus and by furnishing this information, Cirrus grants no lice n s e, e x press or implied under any patents, mask work rights,

copyrights, trademarks, trade secrets or other intellectual property rights. Cirrus owns the copyrights associated with the information contained herein and gives consent for copies to be made of the information only for use within your organization with respect to Cirrus integrated circuits or other products of Cirrus. This consent

does not extend to other copying such as copying for general distribution, advertising or promotional purposes, or for creating any work for resale.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL APPLICATIONS”). CIRRUS PRODUCTS ARE NOT DESIGNED, AUTHORIZED OR WARRANTED FOR USE

IN PRODUCTS SURGICALLY IMPLANTED INTO THE BODY, AUTOMOTIVE SAFETY OR SECURITY DEVICES, LIFE SUPPORT PRODUCTS OR OTHER CRITICAL APPLICATIONS. INCLUSION OF CIRRUS PRODUCTS IN SUCH APPLICATIONS IS UNDERSTOOD TO BE FULLY AT THE CUSTOMER’S RISK AND CIRRUS DISCLAIMS AND MAKES NO WARRANTY, EXPRESS, STATUTORY OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR PARTICULAR PURPOSE, WITH REGARD TO ANY CIRRUS PRODUCT THAT IS USED IN SUCH A MANNER. IF THE CUSTOMER OR CUSTOMER’S CUSTOMER USES OR PERMITS THE USE OF CIRRUS PRODUCTS IN CRITICAL APPLICATIONS, CUSTOMER AGREES, BY SUCH USE, TO FULLY

INDEMNIFY CIRRUS, ITS OFFICERS, DI RECTORS, EMPL OYEES, DIST RIBUT ORS AND OTHER AGENTS FROM ANY AND ALL LIABILITY, INCLUDING ATTORNEYS’ FEES AND COSTS, THAT MAY RESULT FROM OR ARISE IN CONNECTION WITH THESE USES .

Cirrus Logic, Cirrus, and the Cirrus Logic logo designs are trade marks of Cirrus Logic, Inc. All other brand and product names in this document may be trademarks

or service marks of their respective owners.

24 DS842F2

Loading...

Loading...