Page 1

CS1810xx, CS4961xx, & CM-2

Digital Audio Networking Processor

CobraNet

Silicon Series

™

CS18100x, CS18101x, CS18102x, and CM-2

CS49610x, CS49611x, and CS49612x

Hardware User’s Manual

Version 2.3

Preliminary Product Information

http://www.cirrus.com

This document contains information for a new product.

Cirrus Logic reserves the right to modify this product without notice.

©Copyright 2005 Cirrus Logic, Inc. JUN ’05

DS651UM23

Page 2

CobraNet Hardware User’s Manual

Table of Contents

List of Figures.........................................................................................................................................4

1.0 .Introduction ..................................................................................................................................... 5

2.0 Features ...........................................................................................................................................6

2.1 CobraNet............................................................................................................................. 6

2.2 CobraNet Interface.............................................................................................................. 6

2.3 Host Interface...................................................................................................................... 7

2.4 Asynchronous Serial Interface ............................................................................................ 7

2.5 Synchronous Serial Audio Interface.................................................................................... 7

2.6 Audio Clock Interface .......................................................................................................... 7

2.7 Audio Routing and Processing............................................................................................ 7

3.0 Hardware..........................................................................................................................................8

4.0 Pinout and Signal Descriptions ........................................................................................................ 9

4.1 CS1810xx & CS4961xx Package Pinouts......................................................................... 10

4.1.1 CS1810xx/CS4961xx Pinout .............................................................................10

4.1.2 CM-2 Connector Pinout..................................................................................... 11

4.2 Signal Descriptions ...........................................................................................................12

4.2.1 Host Port Signals ..............................................................................................12

4.2.2 Asynchronous Serial Port (UART Bridge) Signals ............................................ 12

4.2.3 Synchronous Serial (Audio) Signals.................................................................. 13

4.2.4 Audio Clock Signals ..........................................................................................13

4.2.5 Miscellaneous Signals....................................................................................... 14

4.2.6 Power and Ground Signals ...............................................................................14

4.2.7 System Signals .................................................................................................15

4.3 Characteristics and Specifications .................................................................................... 16

4.3.1 Absolute Maximum Ratings ..............................................................................16

4.3.2 Recommended Operating Conditions ...............................................................16

4.3.3 Digital DC Characteristics .................................................................................16

4.3.4 Power Supply Characteristics ...........................................................................16

5.0 Synchronization..............................................................................................................................17

5.1 Synchronization Modes ..................................................................................................... 17

5.1.1 Internal Mode .................................................................................................... 18

5.1.2 External Word Clock Mode ...............................................................................18

5.1.3 External Master Clock Mode .............................................................................18

6.0 Digital Audio Interface ....................................................................................................................19

6.1 Digital Audio Interface Timing ........................................................................................... 20

6.1.1 Normal Mode Data Timing ................................................................................21

2

6.1.2 I

6.1.3 Standard Mode Data Timing .............................................................................22

7.0 Host Management Interface (HMI)................................................................................................. 23

7.1 Hardware...........................................................................................................................23

7.4 Protocol and Messages.....................................................................................................28

7.4.1 Messages .......................................................................................................... 28

7.4.1.1. Translate Address ................................................................................. 29

7.4.1.2. Interrupt Acknowledge........................................................................... 29

7.4.1.3. Goto Packet........................................................................................... 29

7.4.1.4. Goto Translation ....................................................................................29

7.4.1.5. Packet Received ...................................................................................30

7.4.1.6. Packet Transmit ....................................................................................30

7.4.1.7. Goto Counters ....................................................................................... 30

7.4.2 Status ................................................................................................................31

Table of Contents

S Mode Data Timing .......................................................................................21

2 ©Copyright 2005 Cirrus Logic, Inc. DS651UM23

Version 2.3

Page 3

CobraNet Hardware User’s Manual

Table of Contents

7.4.3 Data................................................................................................................... 32

7.4.3.1. Region length ........................................................................................ 32

7.4.3.2. Writable Region .....................................................................................32

7.4.3.3. Translation Complete ............................................................................ 32

7.4.3.4. Packet Transmission Complete............................................................. 32

7.4.3.5. Received Packet Available ....................................................................32

7.4.3.6. Message Togglebit ................................................................................ 32

8.0 HMI Reference Code ..................................................................................................................... 33

8.1 HMI Definitions.................................................................................................................. 33

8.2 HMI Access Code .............................................................................................................34

8.3 CM-1, CM-2 Auto-detection .............................................................................................. 36

9.0 Mechanical Drawings and Schematics ..........................................................................................37

9.1 CM-2 Mechanical Drawings .............................................................................................. 38

9.2 CM-2 Schematics.............................................................................................................. 44

9.3 CS1810xx/CS4961xx Package ......................................................................................... 51

9.4 Temperature Specifications ..............................................................................................52

10.0 Ordering Information ....................................................................................................................53

10.1 Device Part Numbers ...................................................................................................... 53

10.2 Device Part Numbering Scheme .....................................................................................53

DS651UM23 ©Copyright 2005 Cirrus Logic, Inc. 3

Version 2.3

Page 4

CobraNet Hardware User’s Manual

List of Figures

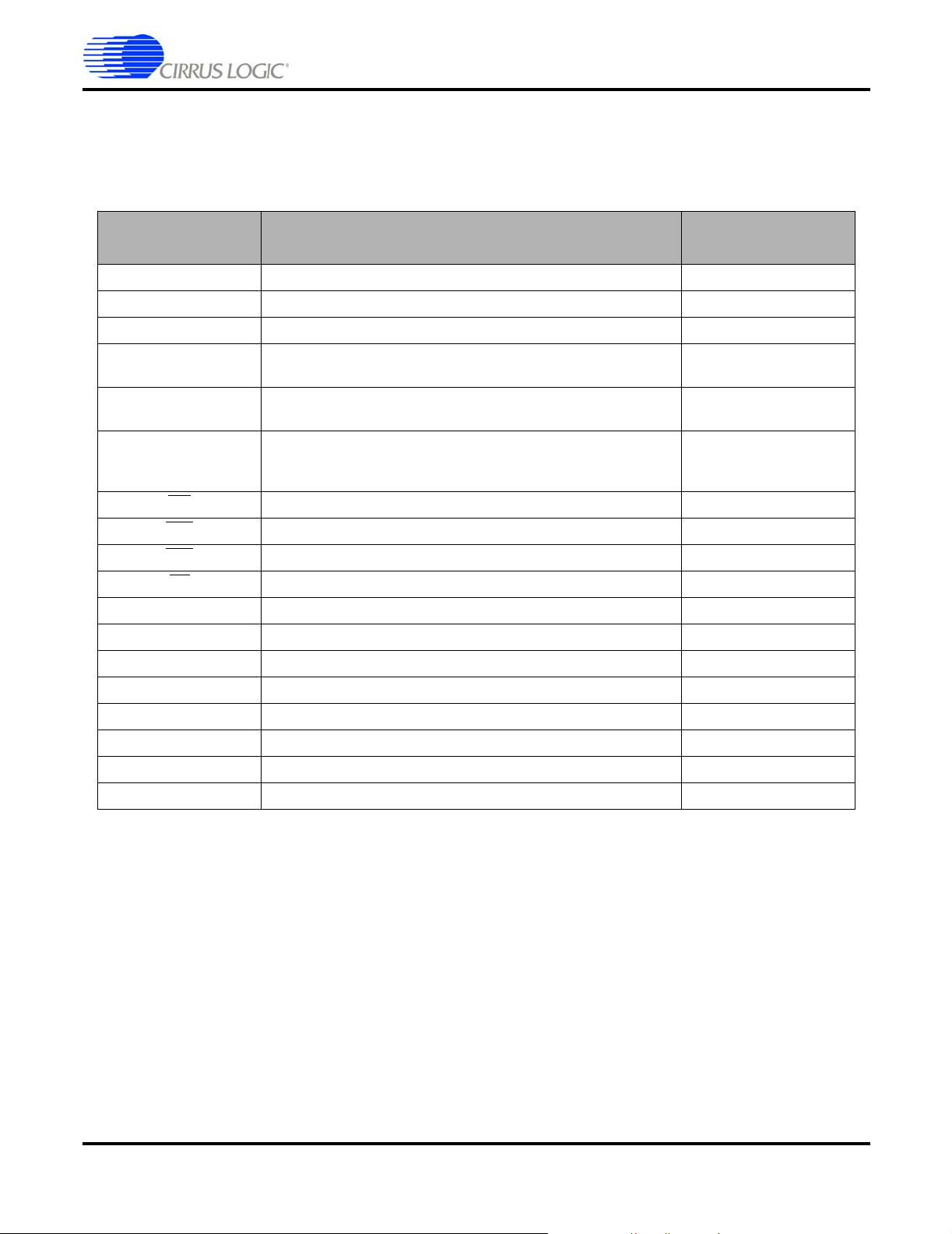

Figure 1. CobraNet Data Services .........................................................................................................5

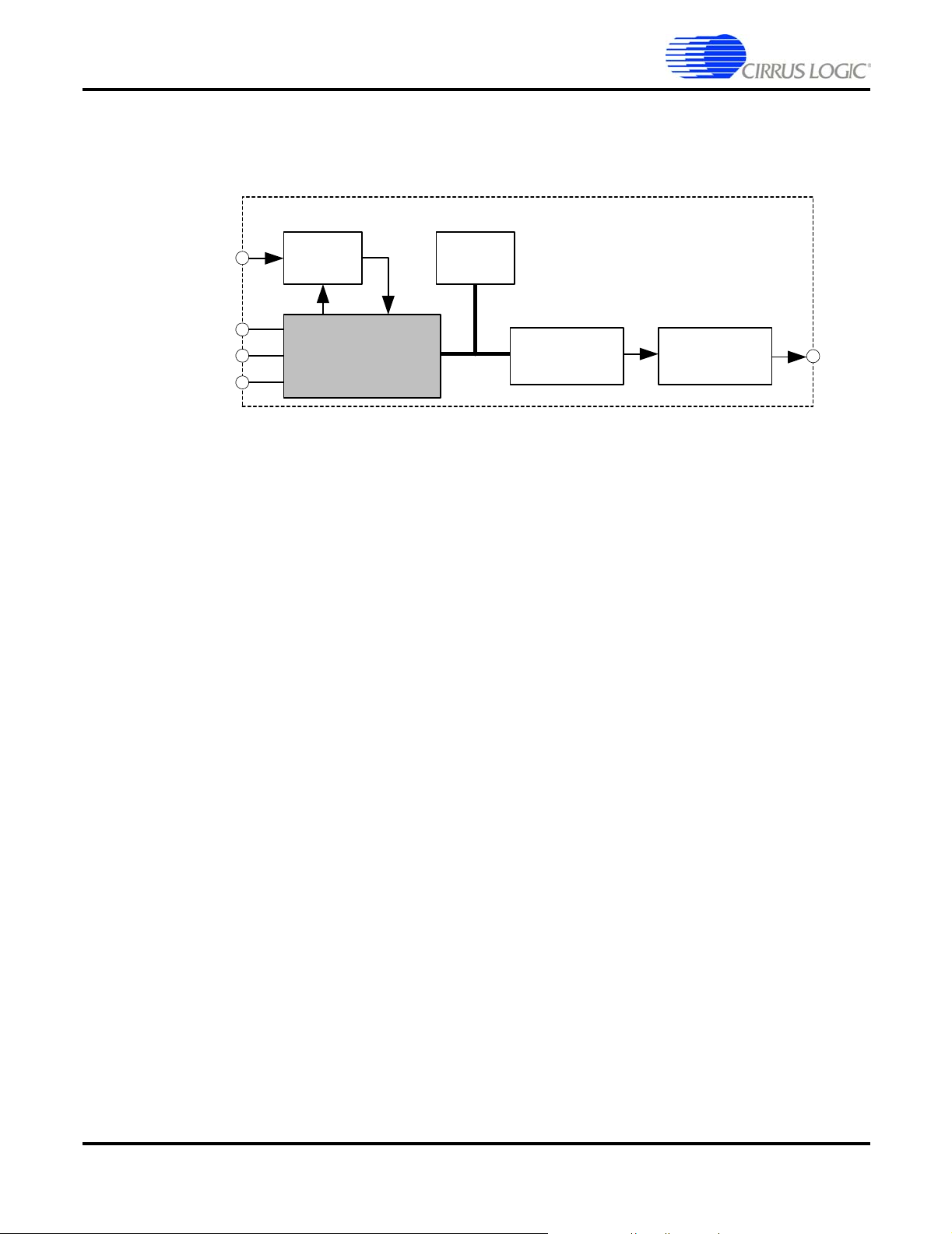

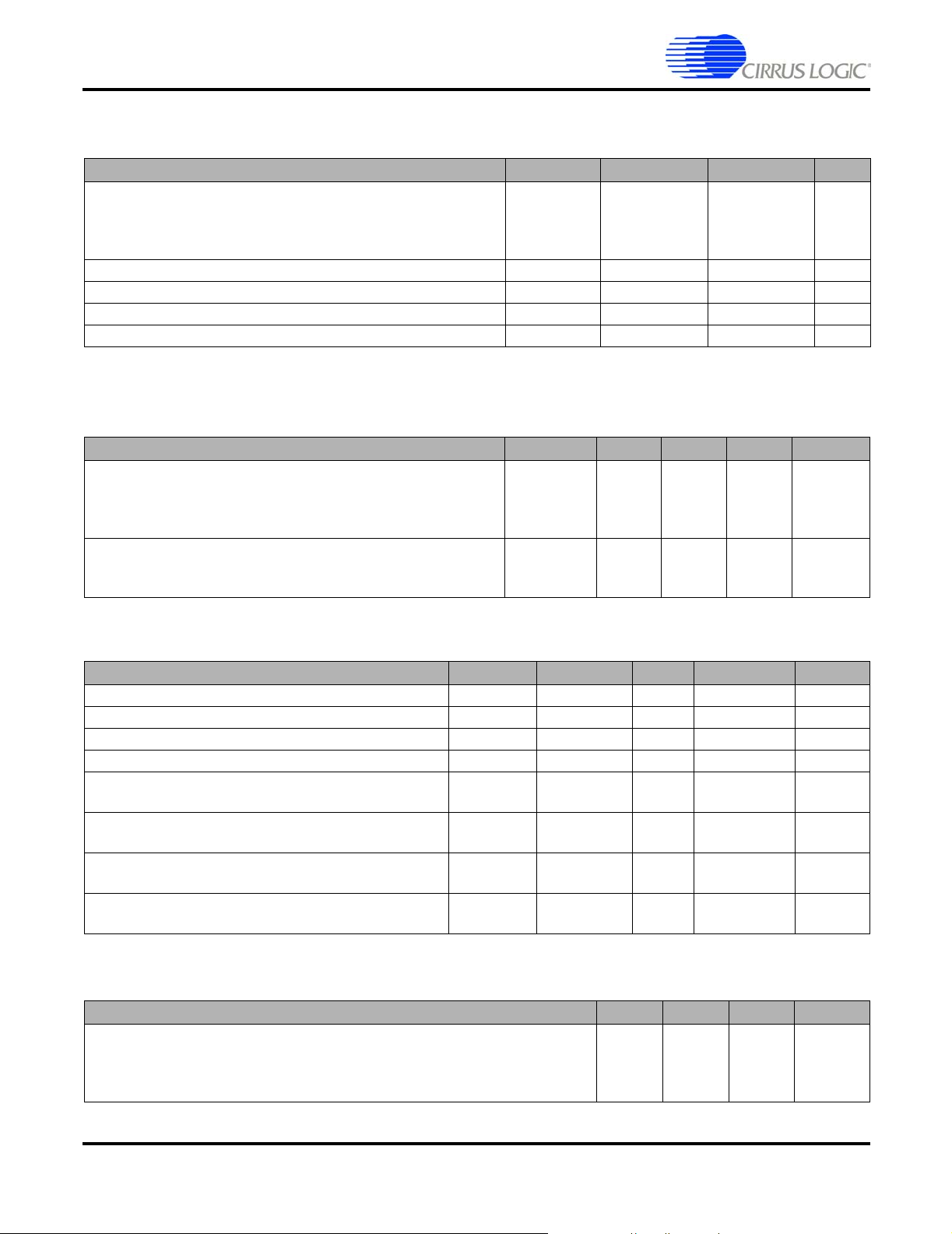

Figure 2. CobraNet Interface Hardware Block Diagram.........................................................................8

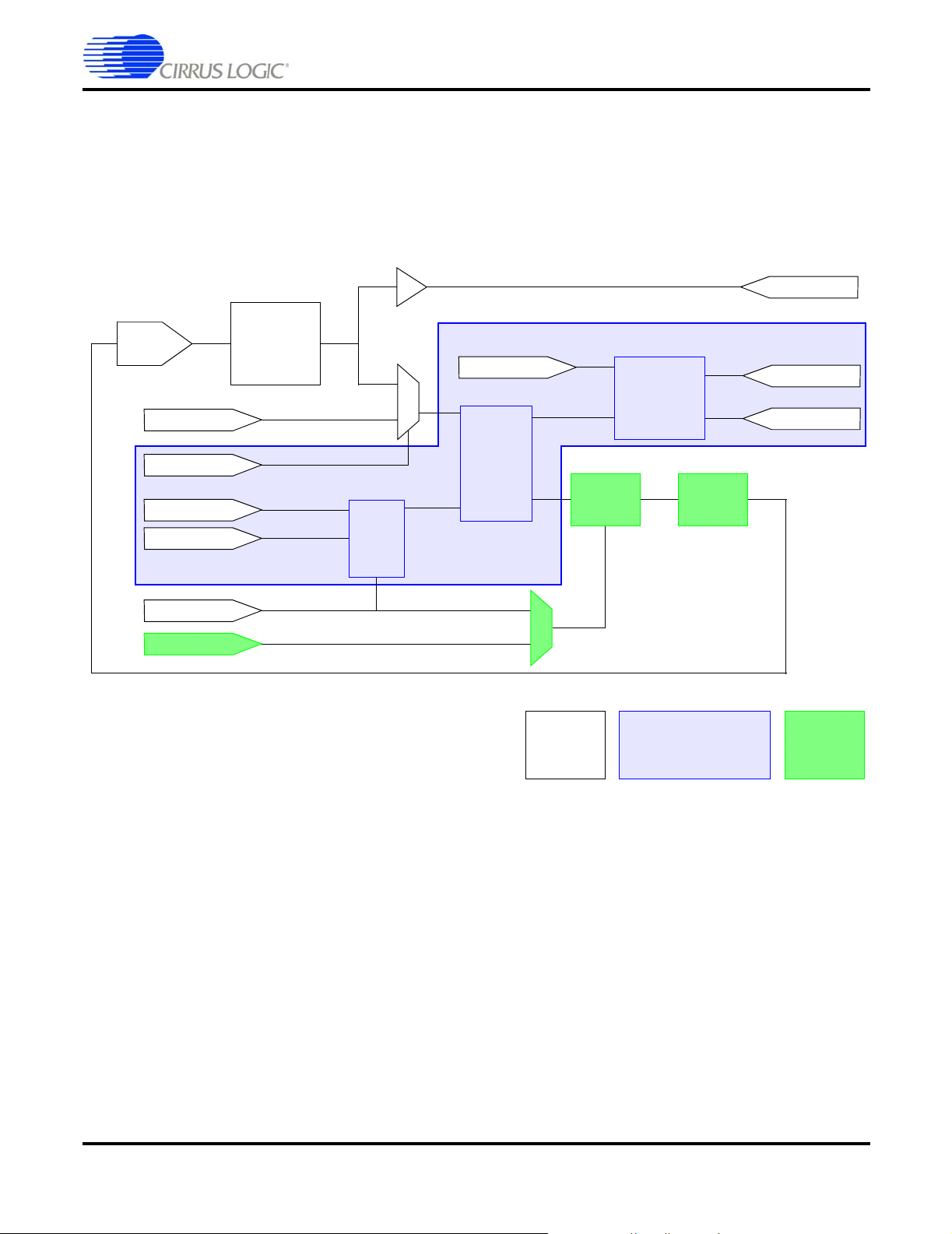

Figure 3. Audio Clock Sub-system ....................................................................................................... 17

Figure 4. Channel Structure for Synchronous Serial Audio at 64FS (One Sample Period) -

CS18100x/CS49610x & CS18101x/CS49611x............................................................ 19

Figure 5. Channel Structure for Synchronous Serial Audio at 128FS (One Sample Period) -

CS18102x/CS49612x ................................................................................................... 19

Figure 6. Timing Relationship between FS512_OUT, DAO1_SCLK and FS1..................................... 20

Figure 7. Serial Port Data Timing Overview......................................................................................... 20

Figure 8. Audio Data Timing Detail - Normal Mode, 64FS -

CS18100x/CS49610x, CS18101x/CS49611x .............................................................. 21

Figure 9. Audio Data Timing Detail - Normal Mode, 128FS -

CS18102x/CS49612x ................................................................................................... 21

Figure 10. Audio Data Timing Detail - I

CS18100x/CS49610x, CS18101x/CS49611x .............................................................. 21

Figure 11. Audio Data Timing Detail - I

CS18102x & CS49612x................................................................................................ 21

Figure 12. Audio Data Timing Detail - Standard Mode, 64FS -

CS18100x/CS49610x, CS18101x/CS49611x .............................................................. 22

Figure 13. Audio Data Timing Detail - Standard Mode, 128FS -

CS18102x/CS49612x ................................................................................................... 22

Figure 14. Host Port Read Cycle Timing - Motorola Mode ..................................................................25

Figure 15. Host Port Write Cycle Timing - Motorola Mode................................................................... 25

Figure 16. Parallal Control Port - Intel Mode Read Cycle ....................................................................27

Figure 17. Parallel Control Port - Intel Mode Write Cycle .................................................................... 27

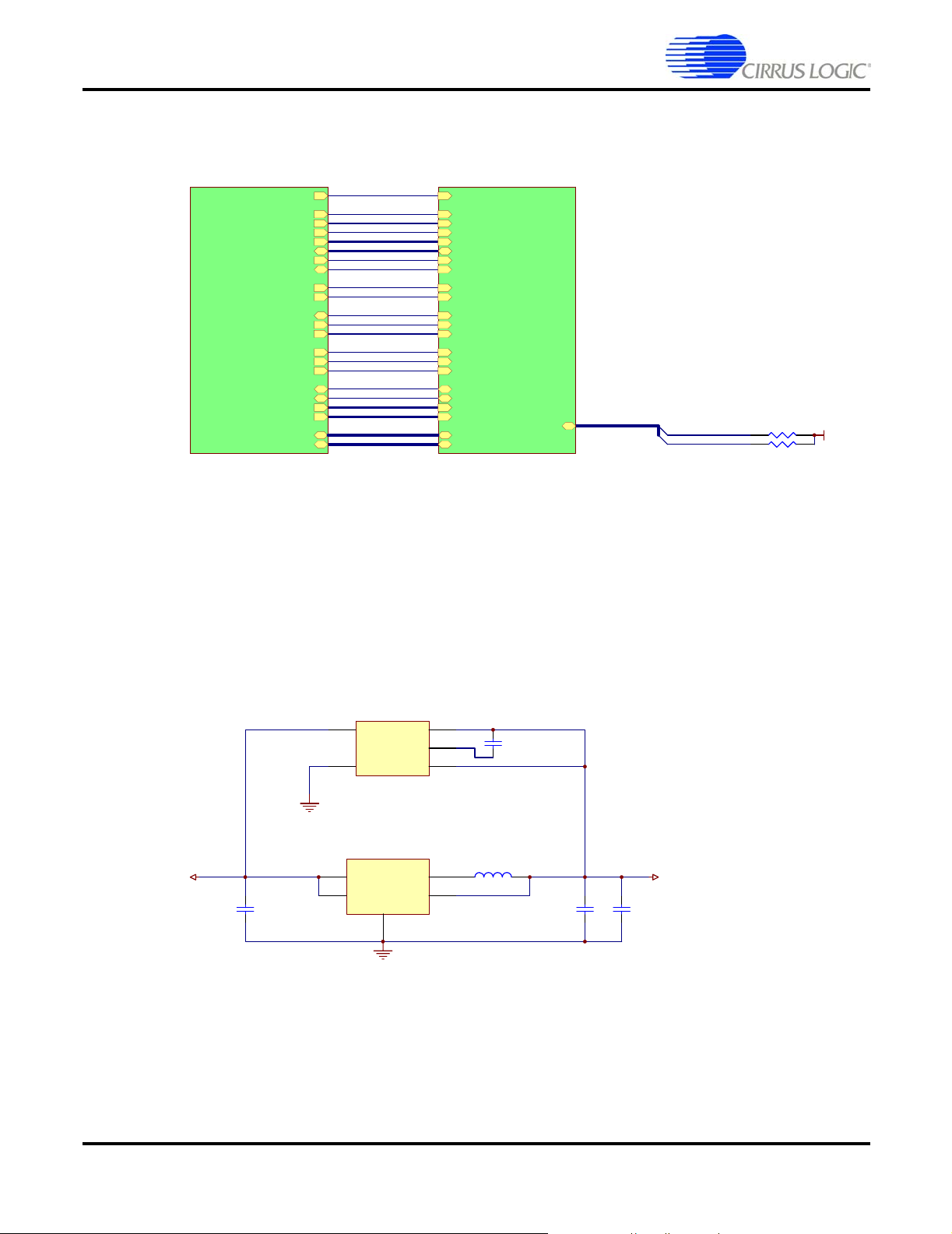

Figure 18. CM-2 Module Assembly Drawing, Top ...............................................................................38

Figure 19. CM-2 Module Assembly Drawing, Bottom ..........................................................................39

Figure 20. General PCB Dimensions ................................................................................................... 40

Figure 21. Example Configuration, Side View...................................................................................... 41

Figure 22. Faceplate Dimensions ........................................................................................................ 42

Figure 23. Connector Detail ................................................................................................................. 43

Figure 24. CM-2 RevF Schematic Page 1 of 7 ....................................................................................44

Figure 25. CM-2 RevF Schematic Page 2 of 7 ....................................................................................45

Figure 26. CM-2 RevF Schematic Page 3 of 7 ....................................................................................46

Figure 27. CM-2 RevF Schematic Page 4 of 7 ....................................................................................47

Figure 28. CM-2 RevF Schematic Page 5 of 7 ....................................................................................48

Figure 29. CM-2 RevF Schematic Page 6 of 7 ....................................................................................49

Figure 30. CM-2 RevF Schematic Page 7 of 7 ....................................................................................50

Figure 31. 144-Pin LQFP Package Drawing........................................................................................51

Figure 32. Device Part Numbering Explanation...................................................................................53

2

S Mode, 64FS -

2

S Mode, 128FS -

List of Figures

4 ©Copyright 2005 Cirrus Logic, Inc. DS651UM23

Version 2.3

Page 5

1.0 Introduction

This document is intended to help hardware designers integrate the CobraNetTM interface

into an audio system design. It covers the CS18100x, CS18101x, CS18102x, CS49610x,

CS49611x, and CS49612x members of the CobraNet

“x” is the ROM version (ROM ID). This document also describes the CM-2 module with

schematics, mechanical drawings, etc.

CobraNet is a combination of hardware (the CobraNet interface), network protocol, and

firmware. CobraNet operates on a switched Ethernet network and provides the following

additional communications services.

• Isochronous (Audio) Data Transport

• Sample Clock Distribution

• Control and Monitoring Data Transport

The CobraNet interface performs synchronous-to-isochronous and isochronous-tosynchronous conversions as well as the data formatting required for transporting real-time

digital audio over the network.

The CobraNet interface has provisions for carrying and utilizing control and monitoring

data such as Simple Network Management Protocol (SNMP) through the same network

connection as the audio. Standard data transport capabilities of Ethernet are shown here

as unregulated traffic. Since CobraNet is Ethernet based, in most cases, data

communications and CobraNet applications can coexist on the same physical network.

Figure 1 illustrates the different data services available through the CobraNet system.

CobraNet Hardware User’s Manual

Introduction

TM

Silicon Series of devices, where

Isochronous Data

Isochronous Data

(Audio)

(Audio)

Ethernet

Ethernet

Unregulated

Unregulated

Traffic

Tr af fi c

Control Data

Control Data

Clock

Clock

Figure 1. CobraNet Data Services

DS651UM23 ©Copyright 2005 Cirrus Logic, Inc. 5

Version 2.3

Page 6

CobraNet Hardware User’s Manual

Features

2.0 Features

2.1 CobraNet

• Real-time Digital Audio Distribution via Ethernet

• No Overall Limit on Network Channel Capacity

• Fully IEEE 802.3 Ethernet Standards Compliant

• Fiber optic and gigabit Ethernet variants are fully supported.

• Ethernet infrastructure can be used simultaneously for audio and data

communications.

• Free CobraCAD™ Audio Network Design Tool

• High-quality Audio Sample Clock Delivery Over Ethernet

• Bit-transparent 16-, 20-, and 24-bit Audio Transport

• Professional 48-kHz and 96-kHz sample rate

• Select Latency as Low as 1.33ms

• Flexible Many-to-many Network Audio Routing Capabilities

• Reduced-cost, Improved-performance, Convergent Audio Distribution

Infrastructure

2.2 CobraNet Interface

• 120 MIPS Customer-configurable Audio DSP

• Auto-negotiating 100Mbit Full-duplex Ethernet Connections

• Up to 32-channel Audio I/O Capability

• Implements CobraNet Protocol for real-time transport of audio over Ethernet.

• Local Management via 8-bit Parallel Host Port

• UDP/IP Network Stack with Dynamic IP Address Assignment via BOOTP or

RARP

• Remote Management via Simple Network Management Protocol (SNMP)

• Economical Three-chip Solution

• Available Module form factor allows for flexible integration into audio products.

• Non-volatile Storage of Configuration Parameters

• Safely Upgrade Firmware Over Ethernet Connection

• LED Indicators for Ethernet Link, Activity, Port Selection, and Conductor Status

• Watchdog Timer Output for System Integrity Assurance

• Comprehensive Power-on Self-test (POST)

• Error and Fault Reporting and Logging Mechanisms

6 ©Copyright 2005 Cirrus Logic, Inc. DS651UM23

Version 2.3

Page 7

2.3 Host Interface

• 8-bit Data, 4-bit Address

• Virtual 24-bit Addressing with 32-bit Data

• Polled, Interrupt, and DMA Modes of Operation

• Configure and Monitor CobraNet Interface

• Transmit or Receive Ethernet Packets at Near-100-Mbit Wire Speed

2.4 Asynchronous Serial Interface

• Full-duplex Capable

• 8-bit Data Format

• Supports all Standard Baud Rates

2.5 Synchronous Serial Audio Interface

• Up to Four Bi-directional Interfaces Supporting up to 32 Channels of Audio I/O

CobraNet Hardware User’s Manual

Features

• 64FS (3.072 MHz) Bit Rate for CS18100x/CS49610x and CS18101x/

CS49611x

• 128FS (6.144 MHz) Bit Rate for CS18102x/CS49612x

• Accommodates Many Synchronous Serial Formats Including I

• 32-bit Data Resolution on All Audio I/O

2.6 Audio Clock Interface

• 5 Host Audio-clocking Modes for Maximum Flexibility in Digital Audio Interface

Design

• Low-jitter Master Audio Clock Oscillator (24.576 MHz)

• Synchronize to Supplied Master and/or Sample Clock

• Sophisticated jitter attenuation assures network perturbations do not affect

audio performance.

2.7 Audio Routing and Processing

• Single-channel Granularity in Routing From Synchronous Serial Audio

Interface to CobraNet Network

• Two levels of inward audio routing affords flexibility in audio I/O interface design

in the host system.

2

S

• Local Audio Loopback and Output Duplication Capability

• Peak-read Audio Metering with Ballistics

DS651UM23 ©Copyright 2005 Cirrus Logic, Inc. 7

Version 2.3

Page 8

CobraNet Hardware User’s Manual

Hardware

3.0 Hardware

Figure 2 shows a high-level view of the CobraNet CM-2 interface hardware architecture.

Clock

Control

Audio

Serial

Host

Figure 2. CobraNet Interface Hardware Block Diagram

VCXO

CS1810xx/

CS4961xx

Clock

Flash

Memory

Ethernet

Controller

CobraNet CM-2

Module

Ethernet

Magnetics

Flash memory holds the CobraNet firmware and management interface variable settings.

The CS1810xx or CS4961xx network processor is the heart of the CobraNet interface. It

implements the network protocol stacks and performs the synchronous-to-isochronous

and isochronous-to-synchronous conversions. The network processor has a role in

sample clock regeneration and performs all interactions with the host system.

The sample clock is generated by a voltage-controlled crystal oscillator (VCXO)

controlled by the network processor. The VCXO frequency is carefully adjusted to achieve

lock with the network clock.

The Ethernet controller is a standard interface chip that implements the 100-Mbit Fast

Ethernet standard. As per Ethernet requirements the interface is transformer isolated.

8 ©Copyright 2005 Cirrus Logic, Inc. DS651UM23

Version 2.3

Page 9

4.0 Pinout and Signal Descriptions

This section details the chip pinout and signal interfaces for each module and is divided

as follows:

• "CS1810xx & CS4961xx Package Pinouts" on page 10

• "Host Port Signals" on page 12

• "Asynchronous Serial Port (UART Bridge) Signals" on page 12

• "Synchronous Serial (Audio) Signals" on page 13

• "Audio Clock Signals" on page 13

• "Miscellaneous Signals" on page 14

• "Power and Ground Signals" on page 14

• "System Signals" on page 15

CobraNet Hardware User’s Manual

Pinout and Signal Descriptions

DS651UM23 ©Copyright 2005 Cirrus Logic, Inc. 9

Version 2.3

Page 10

CobraNet Hardware User’s Manual

Pinout and Signal Descriptions

4.1 CS1810xx & CS4961xx Package Pinouts

4.1.1 CS1810xx/CS4961xx Pinout

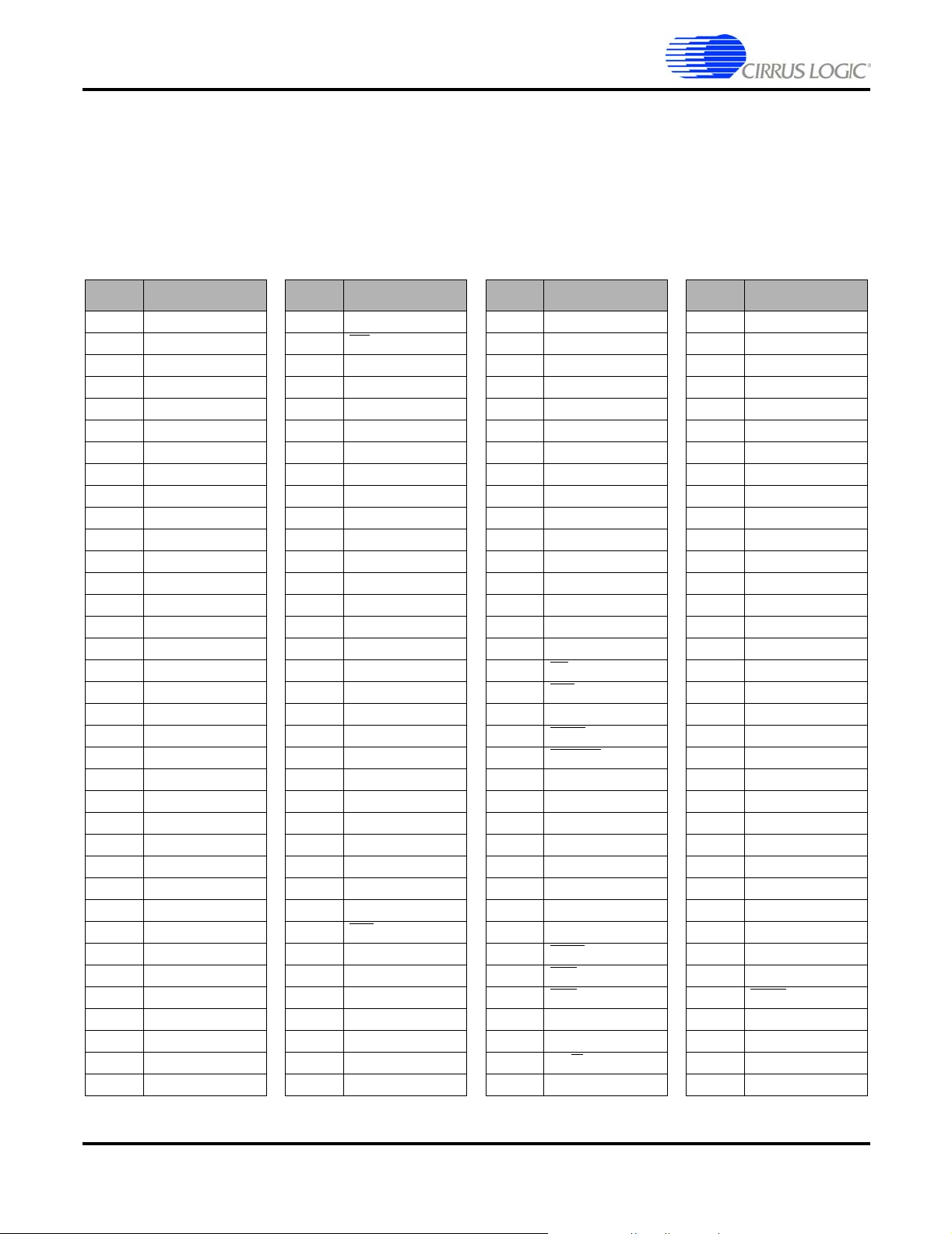

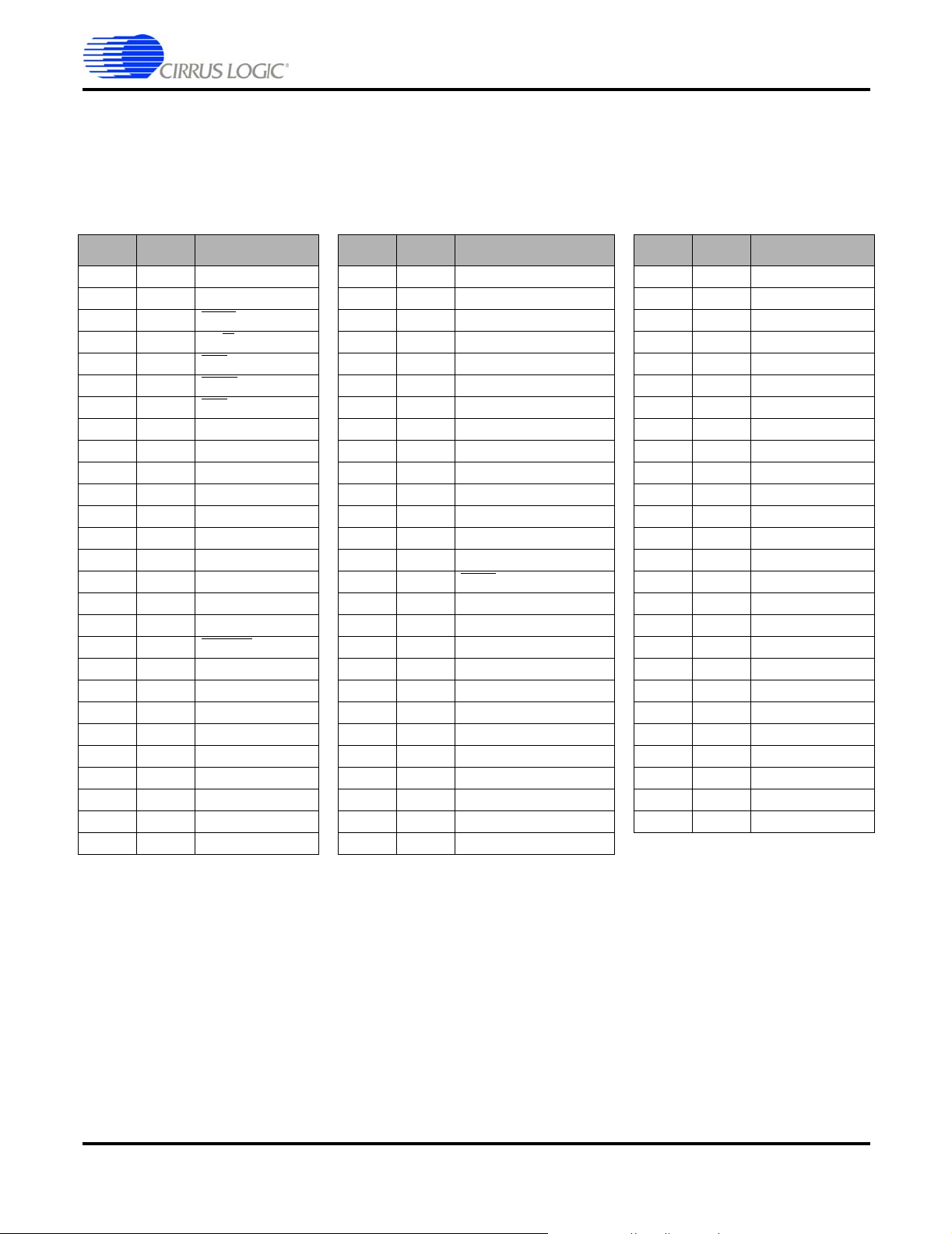

Ta b l e 1 lists the pinout for the 144-pin LQFP CS1810xx/CS4961xx device. The interfaces

for these signals are expanded in the following sections.

Table 1. CS1810xx/CS4961xx Pin Assignments

Pin # Pin Name Pin # Pin Name Pin # Pin Name Pin # Pin Name

1 VCXO_CTRL 37 DATA1 73 VDDIO 109 HADDR1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33 VDDIO 69 GND 105 HADDR3 141 NC

34

35

36

MCLK_SEL 38 WE 74 ADDR10 110 HADDR0

DBDA 39 DATA0 75 ADDR14 111 HDATA7

DBCK 40 DATA15 76 GND 112 HDATA6

NC 41 DATA14 77 ADDR13 113 VDDIO

NC 42 DATA13 78 NC 114 HDATA5

NC 43 DATA12 79 NC 115 HDATA4

DAO_MCLK 44 VDDIO 80 NC 116 GND

TEST 45 DATA11 81 NC 117 HDATA3

VDDD 46 DATA10 82 ADDR15 118 HDATA2

HS3 47 GND 83 VDDD 119 VDDD

NC 48 DATA9 84 ADDR16 120 HDATA1

GND 49 DATA8 85 ADDR17 121 HDATA0

DAO2_LRCLK 50 NC 86 GND 122 GND

DAO1_DATA3 51 NC 87 ADDR18 123 XTAL_OUT

DAO1_DATA2/HS2 52 NC 88 ADDR19 124 XTO

DAO1_DATA1/HS1 53 NC 89 OE 125 XTI

VDDIO 54 VDDD 90 CS1 126 GND_a

DAO1_DATA0/HS0 55 ADDR12 91 VDDIO 127 FILT2

DAO1_SCLK 56 ADDR11 92 MUTE 128 FILT1

GND 57 GND 93 HRESET 129 VDDA

DAO1_LRCLK 58 ADDR9 94 GND 130 VDDD

UART_TX_OE 59 ADDR8 95 WATCHDOG 131 DAI1_DATA3

VDDD 60 VDDIO 96 IOWAIT 132 DAI1_DATA2

UART_TXD 61 ADDR7 97 REFCLK_IN 133 GND

UART_RXD 62 ADDR6 98 VDDD 134 DAI1_DATA1

GND 63 GND 99 GPIO0 135 DAI1_DATA0

NC 64 ADDR5 100 GPIO1 136 VDDIO

DATA7 65 CS2 101 GND 137 DAI1_SCLK

DATA6 66 VDDD 102 HACK 138 DAI1_LRCLK

DATA5 67 ADDR4 103 HDS 139 GND

DATA4 68 ADDR3 104 HEN 140 HREQ

DATA3 70 ADDR2 106 HADDR2 142 NC

DATA2 71 ADDR1 107 HR/W 143 IRQ1

GND 72 ADDR0 108 GPIO2 144 IRQ2

10 ©Copyright 2005 Cirrus Logic, Inc. DS651UM23

Version 2.3

Page 11

CobraNet Hardware User’s Manual

Pinout and Signal Descriptions

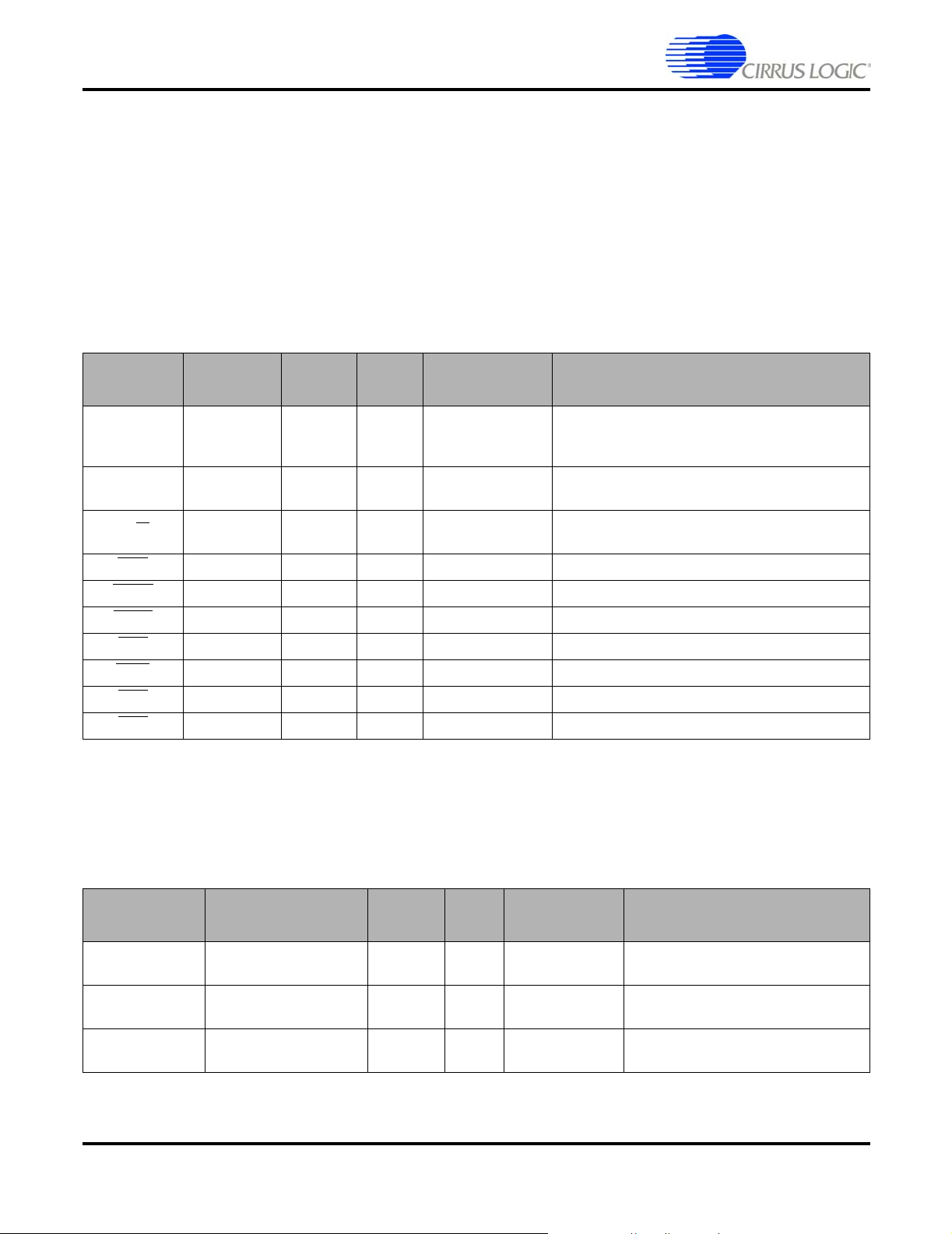

4.1.2 CM-2 Connector Pinout

Ta b l e 1 lists the pinout for the four pinout connectors on the CM-2 board (J1-J4). The

interfaces for these signals are expanded following the table.

Table 2. CM-2 Pin Assignments

Conn. Pin # Pin Name Conn. Pin # Pin Name Conn. Pin # Pin Name

J1/J2 A1 UART_RXD J1/J2 B8 GND J3/J4 A15 DAI1_DATA3

J1/J2 A2 UART_TX_OE J1/J2 B9 VCC_+3.3V J3/J4 A16 RSVD3

J1/J2 A3 HACK

J1/J2 A4 HR/W

J1/J2 A5 HDS

J1/J2 A6 HREQ

J1/J2 A7 HEN

J1/J2 A8 HADDR0 J1/J2 B15 VCC_+3.3V J3/J4 B2 VCC_+3.3V

J1/J2 A9 HADDR1 J1/J2 B16 GND J3/J4 B3 GND

J1/J2 A10 HADDR2 J1/J2 B17 VCC_+3.3V J3/J4 B4 VCC_+3.3V

J1/J2 A11 HDATA0 J1/J2 B18 RSVD1 J3/J4 B5 GND

J1/J2 A12 HDATA1 J1/J2 B19 GND J3/J4 B6 VCC_+3.3V

J1/J2 A13 HDATA2 J1/J2 B20 VCC_+3.3V J3/J4 B7 GND

J1/J2 A14 HDATA3 J3/J4 A1 RSVD2 J3/J4 B8 VCC_+3.3V

J1/J2 A15 HDATA4 J3/J4 A2 MUTE

J1/J2 A16 HDATA5 J3/J4 A3 FS1 J3/J4 B10 VCC_+3.3V

J1/J2 A17 HDATA6 J3/J4 A4 MCLK_OUT J3/J4 B11 GND

J1/J2 A18 HRESET

J1/J2 A19 HDATA7 J3/J4 A6 REFCLK_IN J3/J4 B13 GND

J1/J2 A20 HADDR3 J3/J4 A7 DAO1_SCLK/DAI1_SCLK J3/J4 B14 VCC_+3.3V

J1/J2 B1 UART_TXD J3/J4 A8 DAO1_DATA0 J3/J4 B15 GND

J1/J2 B2 GND J3/J4 A9 DAO1_DATA1 J3/J4 B16 GND

J1/J2 B3 VCC_+3.3V J3/J4 A10 DAO1_DATA2 J3/J4 B17 VCC_+5V

J1/J2 B4 GND J3/J4 A11 DAO1_DATA3 J3/J4 B18 VCC_+5V

J1/J2 B5 VCC_+3.3V J3/J4 A12 DAI1_DATA0 J3/J4 B19 AUX_POWER3

J1/J2 B6 GND J3/J4 A13 DAI1_DATA1 J3/J4 B20 AUX_POWER1

J1/J2 B7 VCC_+3.3V J3/J4 A14 DAI1_DATA2

J1/J2 B10 GND J3/J4 A17 WATCHDOG

J1/J2 B11 VCC_+3.3V J3/J4 A18 RSVD4

J1/J2 B12 GND J3/J4 A19 AUX_POWER2

J1/J2 B13 VCC_+3.3V J3/J4 A20 AUX_POWER0

J1/J2 B14 GND J3/J4 B1 GND

J3/J4 B9 GND

J3/J4 A5 MCLK_IN J3/J4 B12 VCC_+3.3V

DS651UM23 ©Copyright 2005 Cirrus Logic, Inc. 11

Version 2.3

Page 12

CobraNet Hardware User’s Manual

Pinout and Signal Descriptions

4.2 Signal Descriptions

4.2.1 Host Port Signals

The host port is used to manage and monitor the CobraNet interface. Electrical operation

and protocol is detailed in the "Host Management Interface (HMI)" on page 23 of this

Manual.

The host port can operate in two modes in order to accomodate Motorola

interfaces. The default mode is Motorola. Intel mode is set via a firmware modification.

Table 2-1: Host Port Signals

Signal Description Direction

HDATA[7:0] Host Data In/Out

HADDR[3:0] Host Address In

HRW

HRD Host Read In J1:A4 107 Host Read (Intel mode).

Host Request Out J1:A6 140 Host port data request.

HREQ

Host Alert Out J1:A3 102 Host port interrupt request.

HACK

HDS

Host Strobe In J1:A5 103 Host port strobe (Motorola mode).

HWR

Host Enable In J1:A7 104 Host Port Enable.

HEN

Host

Direction

Host Write In J1:A5 103 Host Write (Intel mode).

In J1:A4 107 Host port transfer direction (Motorola mode).

CM-2

Pin #

J1:A19,

A[17:11]

J1:A20,

A[10:8]

CS1810xx/

CS4961xx Pin #

111, 112, 114,

115, 117, 118,

102, 121

105, 106, 109,110 Host port address.

Host port data.

Notes

®

or Intel® style

HCS

Select In J1:A7 104 Select (Intel mode).

4.2.2 Asynchronous Serial Port (UART Bridge) Signals

Level-shifting drive circuits are typically required between these signals and any external

connections.

Signal Description Direction

UART_RXD

UART_TXD

UART_TX_OE Transmit Drive Enable Out J1:A2 23

12 ©Copyright 2005 Cirrus Logic, Inc. DS651UM23

Asynchronous Serial

Receive Data

Asynchronous Serial

Transmit Data

In J1:A1 26 Pull-up to VCC if unused.

Out J1:B1 25

CM-2

Pin #

CS1810xx/

CS4961xx Pin #

Notes

Enable transmit (active high) drive for

two wire multi-drop interface.

Version 2.3

Page 13

4.2.3 Synchronous Serial (Audio) Signals

The synchronous serial interfaces are used to bring digital audio into and out of the

system. Typically the synchronous serial is wired to ADCs and/or DACs. Detailed timing

and format is described in "Digital Audio Interface" on page 19.

CobraNet Hardware User’s Manual

Pinout and Signal Descriptions

Signal Description Direction

DAO1_SCLK Audio Bit Clock Out J3:A7 20

DAO1_DATA[3:0]

DAI1_DATA[3:0] Audio Input Data In

DAI1_SCLK Audio Bit Clock In J4:A7 137

Audio Output

Data

Out

CM-2

Pin #

J3:A18,

B18

J3:

A[15:12]

CS1810xx/

CS4961xx Pin #

15-17, 19

131, 132, 134, 135

4.2.4 Audio Clock Signals

See "Synchronization" on page 17 for an overview of synchronization modes and issues.

Notes

Synchronous serial bit clock.

64 FS for CS18100x & CS49610x (2x1 channel)

64 FS for CS18101x & CS49611x (2x4

channels)

128 FS for CS18102x & CS49612x (4x4

channels)

Typically tied to DAI1_SCLK.

Output synchronous serial audio data

DAO1_DATA[3:1] not used for CS18100x &

CS49610x.

Input synchronous serial audio data

DAI1_DATA[3:1] not used for CS18100x &

CS49610x.

Should be tied to DAO1_SCLK.

Synchronous serial bit clock.

Signal Description Direction

DAI1_LRCLK

DAO1_LRCLK

(FS1)

DAO2_LRCLK

(FS1)

REFCLK_IN Reference clock In J3:A6 97

MCLK_IN

MCLK_OUT

Sample clock

input

Sample clock

output

Sample clock

output

Master audio

clock input

Master audio

clock output

In 138 Should be tied to DAO1_LRCLK for all devices.

Out J3:A3 22

Out J3:A3 14 FS1 (word clock) for CS18102x & CS49612x.

In J3:A5 8*

Out J3:A4 8* Low jitter 24.576 MHz master audio clock.

CM-2

Pin #

CS1810xx/

CS4961xx Pin #

*An external multiplexor controlled by this pin is required for full MCLK_IN and MCLK out

implementation.

Notes

FS1 (word clock) for CS18100x/CS49610x and

CS18101x/CS49611x.

Clock input for synchronizing network to an

external clock source, for redundancy control

and synchronization of FS divider chain to

external source. See "Synchronization" on

page 17 for more detail.

For systems featuring multiple CobraNet

interfaces operating off a common master

clock. See "Synchronization" on page 17 for

more detail.

DS651UM23 ©Copyright 2005 Cirrus Logic, Inc. 13

Version 2.3

Page 14

CobraNet Hardware User’s Manual

Pinout and Signal Descriptions

4.2.5 Miscellaneous Signals

Signal Description Direction

HRESET Reset In J1:A18 93

WATCHDOG Watch Dog Out J3:A17 95

MUTE

NC No Connect - -

Interface

Ready

Out J3:A2 92

CM-2

Pin #

CS1810xx/

CS4961xx Pin #

28, 50-53, 78-

81, 141, 142

4.2.6 Power and Ground Signals

Signal Description CM-2 Pin #

J1:B20, B17, B15,

B13, B11, B9, B7,

VCC_+3V

System Digital +3.3 v

B5, B3

J3:B14, B12, B10,

B8, B6, B4, B2

System reset (active low).

10 ns max rise time. 1 ms min assertion time.

Toggles at 750 Hz nominal rate to indicate proper

operation. Period duration in excess of 200 ms

indicates hardware or software failure has occurred

and the interface should be reset. Note that

improper operation can also be indicated by short

pulses (<100 ns).

Asserts (active low) during initialization and when a

fault is detected or connection to the network is lost.

CS1810xx/CS4961xx

Pin #

N/A

Notes

Specification

± 0.3v, 500 mA Typ., 750 mA Max.

3.3

_+5V

VCC

VDDD N/A

VDDIO N/A

VDDA N/A 129 Filtered +1.8 V @ 10mA Typ.

AUX_POWER

[3-0]

GND Digital Ground

14 ©Copyright 2005 Cirrus Logic, Inc. DS651UM23

J3;B[18:17] N/A Backwards Compatibility

J3:B[20:19],

A[20:19]

J1:B19, B16, B14,

B12, B10, B8, B6,

B4, B2

J3:B16, B15, B13,

B11, B9, B7, B5,

B3, B1

10, 24, 54, 66, 83,

98, 119, 130

18, 33, 44, 60, 73,

91, 113, 136

N/A

13, 21, 27, 36, 47,

57, 63, 69, 76, 86,

94, 101, 116, 122,

126, 133, 139

+1.8 V @ 500mA Typ. for Core Logic

+3.3 V @ 120mA Typ. for I/O Logic

Version 2.3

Page 15

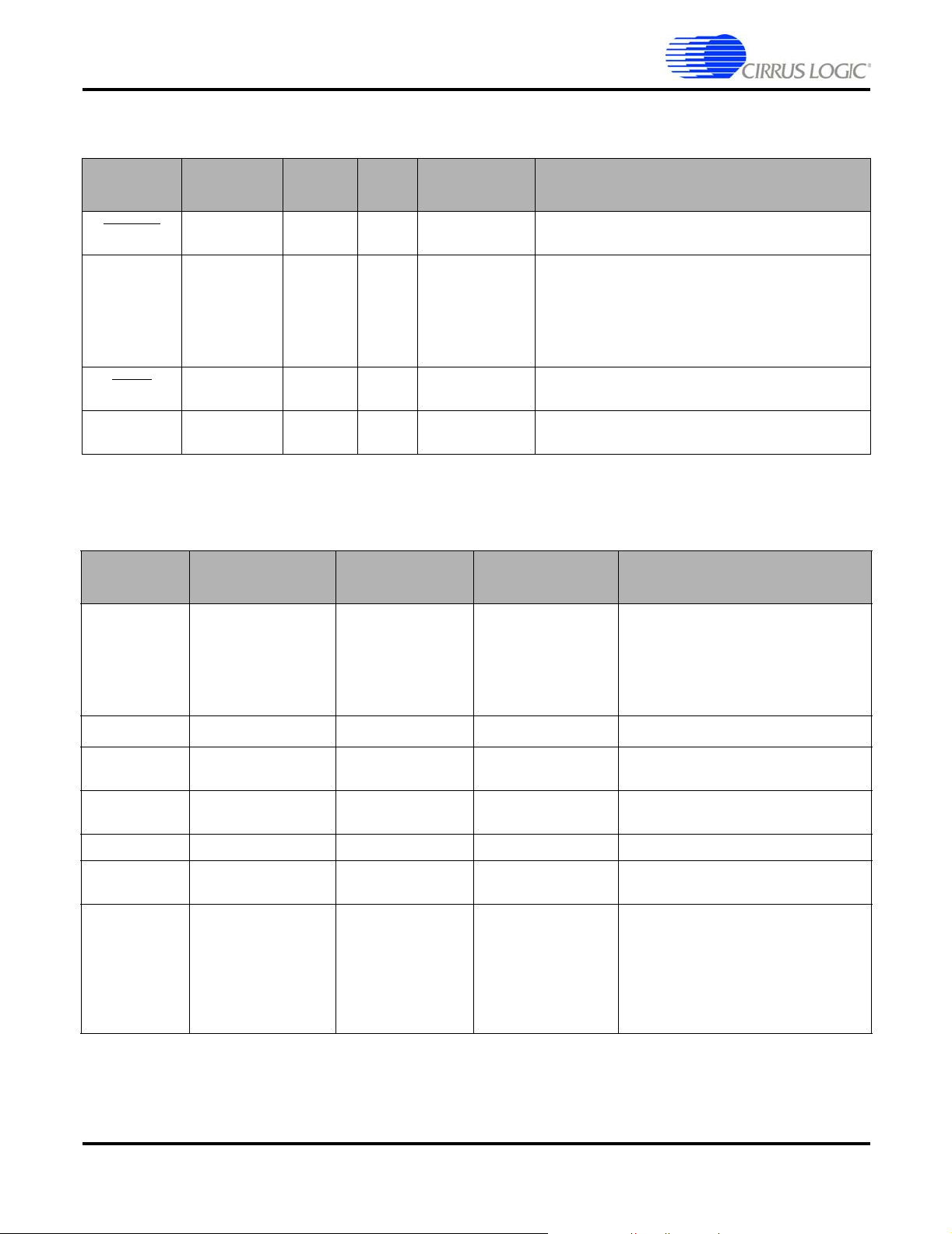

4.2.7 System Signals

Use these CS1810xx/CS4961xx signals stricktly in the manner described in CM-2

Schematics (Section 9.2 on page 44). Each signal is briefly described below.

CobraNet Hardware User’s Manual

Pinout and Signal Descriptions

Signal Description

VCXO_CTRL A Delta-sigma DAC Output for Controlling the On-board VCXO 1

MCLK_SEL Control Signal for Selecting MCLK Sources 2

DBDA, DBCK I2C Debugger Interface 3, 4

TEST

DATA[15:0] Data Bus for Flash & Ethernet Controller(s)

ADDR[19:0] Address Bus for Flash & Ethernet Controller(s)

WE

CS1

CS2

OE

IOWAIT Wait State Signal from Ethernet Controller(s) 96

GPIO[2:0] General-purpose I/O Signals 99, 100, 108

XTI Reference Clock Input / Crystal Oscillator Input 125

XTO Crystal Oscillator Output 124

Used for testing during manufacturing. Keep grounded for normal

operation.

Write Enable for Flash and Ethernet Controller(s) 38

Chip Select for Flash Memory Device 90

Chip Select for Ethernet Controller(s) 65

Output Enable 89

CS1810xx/CS4961xx

Pin #

9

29-32, 34, 35, 37, 39-43,

45, 46, 48, 49

55, 56, 58, 59, 61, 62, 64,

67, 68, 70-72, 74, 75, 77,

82, 84, 85, 87, 88

XTAL_OUT A Buffered Version of XTI 123

FILT2, FILT1 PLL Loop Filter 127, 128

DAO_MCLK MCLK Input 8

HS[3:0] CS1810xx/CS4961xx Boot Mode Selection 11, 16, 17, 19

DS651UM23 ©Copyright 2005 Cirrus Logic, Inc. 15

Version 2.3

Page 16

CobraNet Hardware User’s Manual

Pinout and Signal Descriptions

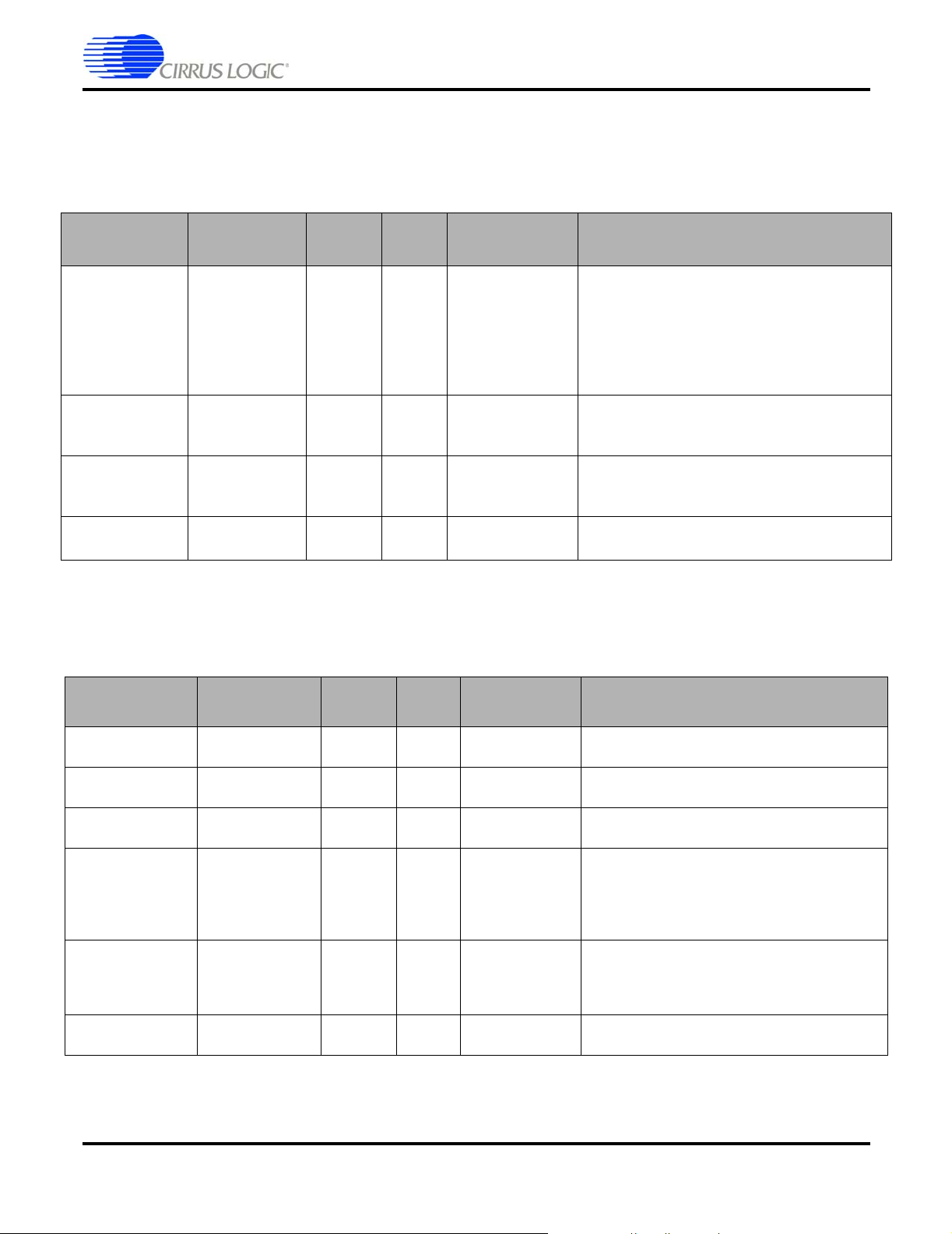

4.3 Characteristics and Specifications

4.3.1 Absolute Maximum Ratings

Parameter Symbol Min Max Unit

DC power supplies: Core supply

PLL supply

I/O supply

VDD

VDDA

VDDIO

|VDDA – VDD|

Input current, any pin except supplies I

Input voltage on FILT1, FILT2 V

Input voltage on I/O pins V

Storage temperature T

in

filt

inio

stg

–0.3

–0.3

–0.3

-

-+/- 10mA

-5.0V

–65 150 °C

2.0

2.0

5.0

0.3

2.0 V

Caution: Operation at or beyond these limits may result in permanent damage to the device. Normal operation is

not guaranteed at these extremes.

4.3.2 Recommended Operating Conditions

Parameter Symbol Min Typ Max Unit

DC power supplies: Core supply

PLL supply

I/O supply

|VDDA – VDD|

Ambient operating temperature

- CQ

- DQ

VDD

VDDA

VDDIO

T

A

1.71

1.71

3.13

0

- 40

1.8

1.8

3.3

-

1.89

1.89

3.46

0.3

+ 70

+ 85

V

V

V

V

V

V

V

V

°C

4.3.3 Digital DC Characteristics

(measurements performed under static conditions.)

Parameter Symbol Min Typ Max Unit

High-level input voltage V

Low-level input voltage, except XTI V

Low-level input voltage, XTI V

Input Hysteresis V

High-level output voltage at

I

= –8.0 mAO = –16.0 mA

O

Low-level output voltage at

I

= 8.0 mAO = –16.0 mA

O

V

V

Input leakage current (all pins without internal pull-

IH

IL

ILXTI

hys

OH

OL

I

IN

2.0 - - V

VDDIO * 0.9 - - V

up resistors except XTI)

Input leakage current (pins with internal pull-up

I

IN-PU

resistors, XTI)

4.3.4 Power Supply Characteristics

(measurements performed under operating conditions))

Parameter Min Typ Max Unit

Power supply current:

Core and I/O operating: VDD (Note 1)

PLL operating: VDDA

With external memory and most ports operating: VDDIO

--0.8V

--0.6V

0.3 V

--VDDIO * 0.1V

--5µA

--50µA

-

-

-

500

10

120

-

-

-

mA

mA

mA

NOTES:1. Dependent on application firmware and DSP clock speed.

16 ©Copyright 2005 Cirrus Logic, Inc. DS651UM23

Version 2.3

Page 17

5.0 Synchronization

Figure 3 shows clock related circuits for the CS1810xx/CS4961xx and board design

(CM-2). This circuitry allows the synchronization modes documented below to be

achieved. Modes are distinguished by different settings of the multiplexors and software

elements.

CobraNet Hardware User’s Manual

Synchronization

MCLK_OUT

DAC

MCLK_IN

MCLK_SEL

RefClkEnable

RefClkPolarity

REFCLK_IN

BeatReceived

VCXO

24.576 MHz

Edge

Detect

AClkConfig

Sample

Phase

Counter

Legend:

Detector

External

Hardware

Component

(CM2)

Audio

Clock

Generator

Phase

Hardware

Component

(CS1810xx, CS4961xx)

CS1810xx/CS4961xx

FS1

SLCK

Loop

Filter

Internal

Software

Component

Figure 3. Audio Clock Sub-system

5.1 Synchronization Modes

Clock synchronization mode for conductor and performer roles is independently

selectable via management interface variables syncConductorClock and

syncPerformerClock. The role (conductor or performer) is determined by the network

environment including the conductor priority setting of the device and the other devices on

the network. It is possible to ensure you will never assume the conductor role by selecting

a conductor priority of zero. However, it is not reasonable to assume that by setting a high

conductor priority, you will always assume the conductor role. For more information, refer

to CobraNet Programmer’s Reference Manual.

DS651UM23 ©Copyright 2005 Cirrus Logic, Inc. 17

Version 2.3

Page 18

CobraNet Hardware User’s Manual

Synchronization

The following synchronization modes are further described below:

• "Internal Mode" on page 18

• "External Word Clock Mode" on page 18

• "External Master Clock Mode" on page 18

5.1.1 Internal Mode

All CobraNet clocks are derived from the onboard VCXO. The master clock generated by

the VCXO is available to external circuits via the master clock output.

Conductor—The VCXO is “parked” according to the syncClockTrim setting.

Performer—The VCXO is “steered” to match the clock transmitted by the Conductor.

5.1.2 External Word Clock Mode

All CobraNet clocks are derived from the onboard VCXO. The VCXO is steered from an

external clock supplied to the reference clock input. The clock supplied can be any

integral division of the sample clock in the range of 750Hz to 48kHz.

External synchronization lock range: ±5 µs. This specification indicates drift or wander

between the supplied clock and the generated network clock at the conductor. Absolute

phase difference between the supplied reference clock and generated sample clock is

dependant on network topology.

Conductor—This mode gives a means for synchronizing an entire CobraNet network to

an external clock.

Performer—The interface disregards the fine timing information delivered over the

network from the conductor. Coarse timing information from the conductor is still used;

fine timing information is instead supplied by the reference clock. The external clock

source must be synchronous with the network conductor. This mode is useful in

installations where a house sync source is readily available.

5.1.3 External Master Clock Mode

The VCXO is disabled and MCLK_IN is used as the master clock for the node. This is a

“hard” synchronization mode. The supplied clock is used directly by the CobraNet

interface for all timing. This mode is primarily useful for devices with multiple CobraNet

interfaces sharing a common master audio clock. The supplied clock must be

24.576 MHz. The supplied clock must have a ±37 ppm precision.

Conductor—The entire network is synchronized to the supplied master clock.

Performer—The node will initially lock to the network clock and will “jam sync” via the

supplied master clock. The external clock source must be synchronous with the network

conductor.

18 ©Copyright 2005 Cirrus Logic, Inc. DS651UM23

Version 2.3

Page 19

6.0 Digital Audio Interface

p

The CS18101x/CS49611x, CS18102x/CS49612x, and CM-2 support four bi-directional

synchronous serial interfaces. The CS18100x & CS49610x support one bi-directional

synchronous serial interface. All interfaces operate in master mode with DAO1_SCLK as

the bit clock and FS1 as the frame clock. A sample period worth of synchronous serial

data includes two (or four) audio channels. CobraNet supports two synchronous serial bit

rates: 48 Khz and 96 KHz. However, 96 kHz sample rate is not available when using

CS18102x/CS49612x with 16X16 channels. Bit rate is selected by the modeRateControl

variable. All synchronous serial interfaces operate from a common clock at the same bit

rate.

CobraNet Hardware User’s Manual

Digital Audio Interface

DAO1_D A TA0 / D A I1_D A T A0

DAO1_D A TA1 / D A I1_D A T A1

DAO1_D A TA2 / D A I1_D A T A2

DAO1_D A TA3 / D A I1_D A T A3

* Not

Figure 4. Channel Structure for Synchronous Serial Audio at 64FS (One Sample Period) - CS18100x/CS49610x &

resent in CS18100x or CS49610x.

DAO1_DATA0 / DAI1_DATA0

DAO1_DATA1 / DAI1_DATA1

FS1

FS1

1 2

3 4

5 6

7 8

CS18101x/CS49611x

1 2

5 6

3 4

7 8

DAO1_DATA2 / DAI1_DATA2

DAO1_DATA3 / DAI1_DATA3

Figure 5. Channel Structure for Synchronous Serial Audio at 128FS (One Sample Period) - CS18102x/CS49612x

9 10

13 14

11 12

15 16

Default channel ordering is shown above. Note that the first channel always begins after

the rising or falling edge of FS1 (depending on the mode).

DAI1_SCLK period depends on the sample rate selected. Up to 32 significant bits are

received and buffered by the DSP for synchronous inputs. Up to 32 significant bits are

transmitted by the DSP for synchronous outputs. Bit 31 is always the most significant

(sign) bit. A 16-bit audio source must drive to bit periods 31-16 with audio data and bits

15-0 should be actively driven with either a dither signal or zeros. Cirrus Logic

recommends driving unused LS bits to zero.

DS651UM23 ©Copyright 2005 Cirrus Logic, Inc. 19

Version 2.3

Page 20

CobraNet Hardware User’s Manual

Digital Audio Interface

Although data is always transmitted and received with a 32-bit resolution by the

synchronous serial ports, the resolution of the data transferred to/from the Ethernet may

be less. Incoming audio data is truncated to the selected resolution. Unused least

significant bits on outgoing data is zero filled.

6.1 Digital Audio Interface Timing

MCLK_OUT

DAO1_SCLK

FS1

0 –5ns

0 –10ns

Figure 6. Timing Relationship between FS512_OUT, DAO1_SCLK and FS1

An DAO1_SCLK edge follows an MCLK_OUT edge by 0.0 to 5.0ns. An FS1 edge follows

a MCLK_OUT edge by 0.0 to 10.0ns.

Note: The DAO1_SCLK and FS1 might be synchronized with the either the falling edge or

the rising edge of MCLK_OUT. Which edge is impossible to predict since it depends

on power up timing.

≥5ns ≥0ns

DAO1_SCLK

DAI1_DATAx

DAO1_DATAx

0 –12ns

Figure 7. Serial Port Data Timing Overview

Setup times for DAI1_DATAx and FS1 are 5.0 ns with a hold time of 0.0 ns with respect to

the DAI1_SCLK edge. Clock to output times for DAO1_DATAx is 0.0 to 12.0 ns from the

edge of DAO1_SCLK.

20 ©Copyright 2005 Cirrus Logic, Inc. DS651UM23

Version 2.3

Page 21

6.1.1 Normal Mode Data Timing

3

3

3

3

DAI1_SCLK

FS1

CobraNet Hardware User’s Manual

Digital Audio Interface

DAI1_DATAx

DAO1_DATAx

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 231 0 Unused

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 231 0 Unused

Figure 8. Audio Data Timing Detail - Normal Mode, 64FS - CS18100x/CS49610x, CS18101x/CS49611x

DAI1_SCLK

FS1

DAI1_DATAx

DAO1_DATAx

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 231 0 Unused 22 21 20 1918 17 16 15 14 13 12 1110 9 8 7 6 5 4 3 2 2

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 231 0 Unused 22 21 20 19 1817 16 15 14 1312 11 10 9 8 7 6 5 4 3 2 2

Figure 9. Audio Data Timing Detail - Normal Mode, 128FS - CS18102x/CS49612x

Each audio channel is comprised of 32 bits of data, regardless of audio sample size. The

figure above shows 24-bit audio data.

The MSB is left justified and is aligned with FS1. Data is sampled on the rising edge of

DAI_SCLK and data changes on the falling edge.

6.1.2 I2S Mode Data Timing

1 0 Unused

1 0 Unused

DAI1_SCLK

FS1

DAI1_DATAx

DAO1_DATAx

DAI1_SCLK

FS1

DAI1_DATAx

DAO1_DATAx

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 231 0 Unused

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 231 0 Unused

Figure 10. Audio Data Timing Detail - I2S Mode, 64FS - CS18100x/CS49610x, CS18101x/CS49611x

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 231 0 Unused 22 21 20 19 18 17 1615 14 13 12 1110 9 8 7 6 5 4 3 2 2

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 231 0 Unused 22 21 20 1918 17 16 15 14 1312 11 10 9 8 7 6 5 4 3 2 2

2

Figure 11. Audio Data Timing Detail - I

S Mode, 128FS - CS18102x & CS49612x

1 0 Unused

1 0 Unused

Each audio channel is comprised of 32 bits of data, regardless of audio sample size. The

figure above shows 24-bit audio data.

The MSB is left justified and arrives one bit period following FS1. Data is sampled on the

rising edge of DAI_SCLK and data changes on the falling edge.

DS651UM23 ©Copyright 2005 Cirrus Logic, Inc. 21

Version 2.3

Page 22

CobraNet Hardware User’s Manual

3

3

Digital Audio Interface

6.1.3 Standard Mode Data Timing

DAI1_SCLK

FS1

DAI1_DATAx

DAO1_DATAx

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 231 0 Unused

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 231 0 Unused

Figure 12. Audio Data Timing Detail - Standard Mode, 64FS - CS18100x/CS49610x, CS18101x/CS49611x

DAI1_SCLK

FS1

DAI1_DATAx

DAO1_DATAx

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 231 0 Unused 22 21 20 1918 17 16 15 14 13 12 1110 9 8 7 6 5 4 3 2 2

23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 231 0 Unused 22 21 20 19 1817 16 15 14 1312 11 10 9 8 7 6 5 4 3 2 2

Figure 13. Audio Data Timing Detail - Standard Mode, 128FS - CS18102x/CS49612x

Each audio channel is comprised of 32 bits of data, regardless of audio sample size. The

figure above shows 24-bit audio data.

The MSB is left justified and is aligned with FS1. Data is sampled on the rising edge of

DAI_SCLK and data changes on the falling edge.

1 0 Unused

1 0 Unused

22 ©Copyright 2005 Cirrus Logic, Inc. DS651UM23

Version 2.3

Page 23

7.0 Host Management Interface (HMI)

7.1 Hardware

The host port is 8 bits wide with 4 bits of addressing. Ten of the 16 addressable registers

are implemented. The upper two registers can be used to configure and retrieve the

status on the host port hardware. However, only the first 8 are essential for normal HMI

communications. It is therefore feasible, in most applications, to utilize only the first 3

address bits and tie the most significant bit (A3) low.

CobraNet Hardware User’s Manual

Host Management Interface (HMI)

Host port hardware supports Intel

®

(little-endian), Motorola®, and Motorola multiplexed

bus (big-endian) protocols. Standard CobraNet firmware configures the port in the

Motorola, big-endian mode.

The host port memory map is shown in Tabl e 3 . Refer also to "HMI Definitions" on

page 33 and "HMI Access Code" on page 34.

Host Address Register

0 Message A (MS)

1 Message B

2 Message C

3 Message D (LS)

4 Data A (MS)

5 Data B

6 Data C

7 Data D (LS)

8 Control

9 Status

Table 3. Host port memory map

The message and data registers provide separate bi-directional data conduits between

the host processor and the CS1810xx/CS4961xx. A 32-bit word of data is transferred to

the CS1810xx/CS4961xx when the host writes the D message or data register after

presumably previously writing the A, B, and C registers with valid data. Data is transferred

from the CS1810xx/CS4961xx following a read of the D message or data register. Again,

presumably the A, B, and C registers are read previously.

Two additional hardware signals are associated with the host port: HACK

and HREQ.

Both are outputs to the host.

HACK

may be wired to an interrupt request input on the host. HACK can be made to

assert (logic 0) on specific events as specified by the hackEnable MI variable. HACK

is

deasserted (logic 1) by issuance of the Acknowledge Interrupt message (see “Messages”

below).

DS651UM23 ©Copyright 2005 Cirrus Logic, Inc. 23

Version 2.3

Page 24

CobraNet Hardware User’s Manual

Host Management Interface (HMI)

HREQ may be wired to a host interrupt or DMA request input. HREQ is used to signal the

host that data is available (read case, logic 0) or space is available in the host port data

channel (write case, logic 1).

The read and write case are distinguished by the HMI based on the preceding message.

Identify, Goto Translation (read), Goto Packet (read) and Goto Counters cause HREQ

represent read status. Goto Translation (write) and Goto Packet (write) switch HREQ

write mode. All other commands have no effect on HREQ

to

to

operation.

In general, the host can read from the CS1810xx/CS4961xx when HREQ

write data to CS1810xx/CS4961xx when HREQ

7.2 Host Port Timing - Motorola® Mode

(CL = 20 pF)

Parameter Symbol Min Max Unit

Address setup before HEN

Address hold time after HEN

Delay between HDS

Data valid after HEN

HEN

and HDS low for read t

Data hold time after HEN

Data high-Z after HEN

HEN

or HDS high to HEN and HDS low for next read t

HEN

or HDS high to HEN and HDS low for next write t

HR/W

rising to HREQ falling

Delay between HDS

Data setup before HEN

HEN

and HDS low for write t

HRW

setup before HEN and HDS low t

HRW

hold time after HEN or HDS high t

Data hold after HEN

HEN

or HDS high to HEN and HDS low with HRW high for

next read

and HDS low t

and HDS low t

Read

then HEN low or HEN then HDS low t

and HDS low with HRW high t

or HDS high after read t

or HDS high after read t

Write

then HEN low or HEN then HDS low t

or HDS high t

or HDS high t

mas

mah

mcdr

mdd

mrpw

mdhr

mdis

mrd

mrdtw

t

mrwirqh

mcdw

mdsu

mwpw

mrwsu

mrwhld

mdhw

t

mwtrd

is low and can

is high.

5-ns

5-ns

0-ns

-19ns

24 - ns

8-ns

-18ns

30 - ns

30 - ns

-12ns

0-ns

8-ns

24 - ns

24 - ns

8-ns

8-ns

30 - ns

or HDS high to HEN and HDS low for next write t

HEN

HRW

rising to HREQ falling

mwd

t

mrwbsyl

30 - ns

-12ns

NOTES:1. The system designer should be aware that the actual maximum speed of the communication port may

be limited by the firmware application. Hardware handshaking on the HREQ

pin/bit should be observed

to prevent overflowing the input data buffer.

24 ©Copyright 2005 Cirrus Logic, Inc. DS651UM23

Version 2.3

Page 25

HADDR[3:0]

HDATA[7:0]

HEN

HRW

HDS

HREQ

t

mas

t

mah

LSP

t

mdhr

t

t

mrwsu

t

mcdr

mdd

t

mrpw

t

mrd

t

mdis

Figure 14. Host Port Read Cycle Timing - Motorola Mode

CobraNet Hardware User’s Manual

Host Management Interface (HMI)

MSP

t

mrwhld

t

mrdtw

t

mrwirqh

HADDR[3:0]

HDATA[7:0]

HEN

HRW

HDS

HREQ

t

mas

t

mah

LSP MSP

t

mdsu

t

mcdw

t

mrwsu

t

mdhw

t

mwpw

t

mwd

t

mrwirql

Figure 15. Host Port Write Cycle Timing - Motorola Mode

t

mrwhld

t

mwtrd

DS651UM23 ©Copyright 2005 Cirrus Logic, Inc. 25

Version 2.3

Page 26

CobraNet Hardware User’s Manual

Host Management Interface (HMI)

7.3 Host Port Timing - Intel® Mode

(CL = 20 pF)

Parameter Symbol Min Max Unit

Address setup before HCS

low

Address hold time after HCS

high

and HRD low or HCS and HWR

and HRD low or HCS and HWR

Read

t

ias

t

iah

5-ns

5-ns

Delay between HRD

Data valid after HCS

HCS

and HRD low for read t

Data hold time after HCS

Data high-Z after HCS

HCS

or HRD high to HCS and HRD low for next read t

HCS

or HRD high to HCS and HWR low for next write t

HRD

rising to HREQ rising

then HCS low or HCS then HRD low t

and HRD low t

or HRD high t

or HRD high t

icdr

idd

irpw

idhr

idis

ird

irdtw

t

irdirqhl

0-ns

-18ns

24 - ns

8-ns

-18ns

30 - ns

30 - ns

-12ns

Write

Delay between HWR

Data setup before HCS

HCS

and HWR low for write t

Data hold after HCS

HCS

or HWR high to HCS and HRD low for next read t

HCS

or HWR high to HCS and HWR low for next write t

HWR

rising to HREQ falling

then HCS low or HCS then HWR low t

or HWR high t

or HWR high t

icdw

idsu

iwpw

idhw

iwtrd

iwd

t

iwrbsyl

0-ns

8-ns

24 - ns

8-ns

30 - ns

30 - ns

-12ns

NOTES:1. The system designer should be aware that the actual maximum speed of the communication port may

be limited by the firmware application. Hardware handshaking on the HREQ

pin/bit should be observed

to prevent overflowing the input data buffer.

26 ©Copyright 2005 Cirrus Logic, Inc. DS651UM23

Version 2.3

Page 27

HADDR[3:0]

HDATA[7:0]

HCS

HWR

HRD

HREQ

t

iah

t

ias

t

icdr

LSP

t

idd

t

irpw

idhr

t

idis

t

ird

t

Figure 16. Parallal Control Port - Intel Mode Read Cycle

CobraNet Hardware User’s Manual

Host Management Interface (HMI)

MSP

t

irdtw

t

irdirq h

HADDR[3:0]

HDATA[7:0]

HCS

HRD

HWR

HREQ

t

iah

t

ias

t

icdw

LSP MSP

t

idhw

t

idsu

t

iwpw

t

iw d

Figure 17. Parallel Control Port - Intel Mode Write Cycle

t

iwrbs yl

t

iwtr d

DS651UM23 ©Copyright 2005 Cirrus Logic, Inc. 27

Version 2.3

Page 28

CobraNet Hardware User’s Manual

Host Management Interface (HMI)

7.4 Protocol and Messages

The message conduit is used to issue commands to the CS1810xx/CS4961xx and

retrieve HMI status. The data conduit is used to transfer data dependent on the HMI state

as determined by commands issued by the host via the message conduit.

7.4.1 Messages

Messages are used to efficiently invoke action in the CS1810xx/CS4961xx. To send a

message, the host optionally writes to the A, B, and C registers. Writing to the D register

transmits the message to the CS1810xx/CS4961xx. A listing of all HMI messages is

shown in Ta bl e 4 . Refer also to "HMI Definitions" on page 33 and "HMI Access Code" on

page 34.

Message

Translate Address n/c Address (MS) Address Address (LS) 0xB3

Acknowledge Interrupt n/c n/c n/c n/c 0xB4

Identify read n/c n/c 7 0xB5

Goto Packet Transmit

Buffer

Goto Translation write n/c n/c 5 0xB5

Acknowledge Packet

Receipt

Transmit Packet n/c n/c n/c 3 0xB5

Goto Counters read n/c n/c 2 0xB5

Goto Packet Receive

Buffer

Goto Translation read n/c n/c 0 0xB5

DRQ Handshake

Mode

write n/c n/c 6 0xB5

n/c n/c n/c 4 0xB5

read n/c n/c 1 0xB5

Table 4. HMI messages

A B C D

28 ©Copyright 2005 Cirrus Logic, Inc. DS651UM23

Version 2.3

Page 29

CobraNet Hardware User’s Manual

Host Management Interface (HMI)

7.4.1.1. Translate Address

Translate Address does not actually update the address pointers but initiates the

processing required to eventually move them. The host can accomplish other tasks,

including HMI Reads and Writes while the address translation is being processed. A

logical description of Translate Address is given below. A contextual use of the Translate

Address operation is shown in the reference implementations. Refer also to "HMI

Definitions" on page 33 and "HMI Access Code" on page 34.

void TranslateAddress(

long address )

{

int msgack = MSG_D;

MSG_A = ( address & 0xff0000 ) >> 16;

MSG_B = ( address & 0xff00 ) >> 8;

MSG_C = address & 0xff;

MSG_D = CVR_TRANSLATE_ADDRESS;

while( !( ( msgack ^ MSG_D ) & ( 1 << MSG_TOGGLE_BO ) ) );

}

7.4.1.2. Interrupt Acknowledge

Causes HACK to be de-asserted.

void InterruptAck( void )

{

int msgack = MSG_D;

MSG_D = CVR_INTERRUPT_ACK;

while( !( ( msgack ^ MSG_D ) & ( 1 << MSG_TOGGLE_BO ) ) );

}

7.4.1.3. Goto Packet

Moves HMI pointers to bridgeRxPktBuffer (write = 0) or bridgeTxPktBuffer (write = 1).

void GotoPacket(

bool write )

{

int msgack = MSG_D;

MSG_C = write ? MOP_GOTO_PACKET_TRANSMIT : MOP_GOTO_PACKET_RECEIVE;

MSG_D = CVR_MULTIPLEX_OP;

while( !( ( msgack ^ MSG_D ) & ( 1 << MSG_TOGGLE_BO ) ) );

}

7.4.1.4. Goto Translation

Moves HMI data pointers to the results of the most recently completed translate address

operation. The write parameter dictates the operation of the HREQ

signal and only needs

to be supplied for applications using hardware data handshaking via this signal.

void GotoTranslation(

bool write = 0 )

{

int msgack = MSG_D;

MSG_C = write ? MOP_GOTO_TRANSLATION_WRITE : MOP_GOTO_TRANSLATION_READ;

MSG_D = CVR_MULTIPLEX_OP;

while( !( ( msgack ^ MSG_D ) & ( 1 << MSG_TOGGLE_BO ) ) );

}

DS651UM23 ©Copyright 2005 Cirrus Logic, Inc. 29

Version 2.3

Page 30

CobraNet Hardware User’s Manual

Host Management Interface (HMI)

7.4.1.5. Packet Received

Sets bridgeRxPkt = bridgeRxReady thus acknowledging receipt of the packet in

bridgeRxPktBuffer.

void PacketReceive( void )

{

int msgack = MSG_D;

MSG_C = MOP_PACKET_RECEIVE;

MSG_D = CVR_MULTIPLEX_OP;

while( !( ( msgack ^ MSG_D ) & ( 1 << MSG_TOGGLE_BO ) ) );

}

7.4.1.6. Packet Transmit

Sets bridgeTxPkt = bridgeTxPktDone+1 thus initiating transmission of the contents of

bridgeTxPktBuffer. Presumably bridgeTxPktBuffer has been previously written with valid

packet data.

void PacketTransmit( void )

{

int msgack = MSG_D;

MSG_C = MOP_PACKET_TRANSMIT;

MSG_D = CVR_MULTIPLEX_OP;

while( !( ( msgack ^ MSG_D ) & ( 1 << MSG_TOGGLE_BO ) ) );

}

7.4.1.7. Goto Counters

Moves HMI data pointers to interrupt status variables (beginning at hackStatus).

void GotoCounters( void )

{

int msgack = MSG_D;

MSG_C = MOP_GOTO_COUNTERS;

MSG_D = CVR_MULTIPLEX_OP;

while( !( ( msgack ^ MSG_D ) & ( 1 << MSG_TOGGLE_BO ) ) );

}

30 ©Copyright 2005 Cirrus Logic, Inc. DS651UM23

Version 2.3

Page 31

7.4.2 Status

CobraNet Hardware User’s Manual

Host Management Interface (HMI)

HMI status can always be retrieved by reading the message conduit. Status is updated in

a pipelined manner whenever the Message D register is read. Reading the message

conduit gives the current status as of the last time the conduit was read. Bitfields in the

HMI Status Register are outlined in Tabl e 5 below. Refer also to "HMI Definitions" on

page 33 and "HMI Access Code" on page 34.

Status Bit(s)

Reserved [31:24]

Region Length [23:8]

Reserved [7:5]

Writable Region 4

Translation Complete 3

Packet Transmission Complete 2

Received Packet Available 1

Message Togglebit 0

Table 5. HMI status bits

DS651UM23 ©Copyright 2005 Cirrus Logic, Inc. 31

Version 2.3

Page 32

CobraNet Hardware User’s Manual

Host Management Interface (HMI)

7.4.3 Data

Before accessing data, address setup must be performed. Address setup consists of

issuing a Translate Address request, waiting for the request to complete, then issuing a

Goto Translation.

Pipelining requires that a “garbage read” be performed following an address change. The

second word read contains the data for the address requested. No similar pipelining issue

exists with respect to write operations.

7.4.3.1. Region length

Distance from the original pointer position (as per Translate Address) to the end of the

instantiated region. A value of 0 indicates an invalid pointer.

7.4.3.2. Writable Region

When set, this bit indicates the address pointer is positioned within a writable region. MI

variables may be modified in a writable region by writing data to the data conduit.

7.4.3.3. Translation Complete

When set, this bit indicates that the address translator is available (translation results are

available and a new translation request may be submitted). This bit is cleared when a

Translate Address message is issued and is set when the translation completes.

7.4.3.4. Packet Transmission Complete

This bit is cleared when transmission is initiated by issuance of the Transmit Packet

message. The bit is set when the packet has been transmitted and the transmit buffer is

ready to accept a new packet.

7.4.3.5. Received Packet Available

This bit is set when a packet is received into the packet bridge. It is cleared when the

packet data is read and receipt is acknowledged by issuance of an Acknowledge Packet

Receipt message. Note that Received Packet Available only goes low when there are no

longer any pending received packets for the packet bridge. The packet bridge has the

capacity to queue multiple packets in the receive direction.

7.4.3.6. Message Togglebit

This bit toggles on completion of processing of each message. A safe means for the host

to acknowledge processing of messages is as follows:

void WaitToggle( void )

{

int msgack = MSG_D; /* clean pipeline */

msgack = MSG_D; /* record current state of togglebit */

MSG_D = YOUR_COMMAND_HERE; /* issue command */

/* wait for togglebit to flip */

while( !( ( msgack ^ MSG_D ) & ( 1 << MSG_TOGGLE_BO ) ) );

}

32 ©Copyright 2005 Cirrus Logic, Inc. DS651UM23

Version 2.3

Page 33

8.0 HMI Reference Code

The following C code provides examples in using HMI messages, HMI status, and the

HMI memory map.

8.1 HMI Definitions

/*========================================================================

** hmi.h

** CobraNet Host Management Interface example code

** Definitions

**------------------------------------------------------------------------

** $Header$

** Copyright (c) 2004, Peak Audio, a division of Cirrus Logic, Inc.

**========================================================================*/

#define MSG_A 0

#define MSG_B 1

#define MSG_C 2

#define MSG_D 3

#define DATA_A 4

#define DATA_B 5

#define DATA_C 6

#define DATA_D 7

#define CONTROL 8

#define STATUS 9

CobraNet Hardware User’s Manual

HMI Reference Code

#define CVR_SET_ADDRESS 0xb2 /* Not availbale on CS1810xx/CS4961xx/CM-2. */

/*CM-1 and Reference Design only. */

#define CVR_TRANSLATE_ADDRESS 0xb3

#define CVR_INTERRUPT_ACK 0xb4

#define CVR_MULTIPLEX_OP 0xb5

#define MOP_GOTO_TRANSLATION_READ 0

#define MOP_GOTO_TRANSLATION_WRITE 5

#define MOP_GOTO_PACKET_RECEIVE 1

#define MOP_GOTO_PACKET_TRANSMIT 6

#define MOP_GOTO_COUNTERS 2

#define MOP_PACKET_TRANSMIT 3

#define MOP_PACKET_RECEIPT 4

#define MOP_IDENTIFY 7

#define MSG_TOGGLE_BO 0

#define MSG_RXPACKET_BO 1

#define MSG_TXPACKET_BO 2

#define MSG_TRANSLATION_BO 3

#define MSG_WRITABLE_BO 4

#define MSG_LENGTH_BO 8

DS651UM23 ©Copyright 2005 Cirrus Logic, Inc. 33

Version 2.3

Page 34

CobraNet Hardware User’s Manual

HMI Reference Code

8.2 HMI Access Code

/*========================================================================

** hmi.c

** CobraNet Host Management Interface example code

** Simple edition

**------------------------------------------------------------------------

** $Header$

** Copyright (c) 2004, Peak Audio, a division of Cirrus Logic, Inc.

**========================================================================*/

#include "hmi.h"

/* variables model HMI state */

long PeekLimit;

long PeekPointer = -1;

long PokeLimit;

long PokePointer = -1;

/* access host port hardware */

#define HMI_BASE 0

unsigned char ReadRegister(

int hmiregister )

{

return *(unsigned char volatile *const) ( hmiregister + HMI_BASE );

}

void WriteRegister(

int hmiregister,

unsigned char value )

{

*(unsigned char volatile *const) ( hmiregister + HMI_BASE ) = value;

}

void SendMessage(

unsigned char message )

{

int msgack = ReadRegister( MSG_D );

/* issue (last byte of) message */

WriteRegister( MSG_D, message );

/* wait for acceptance of message */

while( !( ( msgack ^ ReadRegister( MSG_D ) ) & ( 1 << MSG_TOGGLE_BO ) ) );

}

void SetAddress(

long address )

{

/* translate address */

WriteRegister( MSG_A, ( address & 0xff0000 ) >> 16 );

WriteRegister( MSG_B, ( address & 0xff00 ) >> 8 );

WriteRegister( MSG_C, address & 0xff );

SendMessage( CVR_TRANSLATE_ADDRESS );

/* wait for completion of translate address */

34 ©Copyright 2005 Cirrus Logic, Inc. DS651UM23

Version 2.3

Page 35

CobraNet Hardware User’s Manual

while( !( ReadRegister( MSG_D ) & ( 1 << MSG_TRANSLATION_BO ) ) );

/* goto translation */

WriteRegister( MSG_C, MOP_GOTO_TRANSLATION_READ );

SendMessage( CVR_MULTIPLEX_OP );

/* "garbage" read clears data pipeline */

ReadRegister( DATA_D );

/* maintain local pointers */

PeekPointer = PokePointer = address;

PeekLimit = PokeLimit = PeekPointer +

ReadRegister( MSG_C ) + ( ReadRegister( MSG_B ) << 8 );

/* read-only region addressed */

if( !( ReadRegister( MSG_A ) & ( 1 << MSG_WRITABLE_BO ) ) ) {

PokeLimit = PokePointer;

}

}

unsigned long Peek(

long address )

{

if( address != PeekPointer ) {

SetAddress( address );

}

if( PeekPointer >= PeekLimit ) {

throw "Peek addressing error!";

}

unsigned long value = ReadRegister( DATA_A ) << 24;

value += ReadRegister( DATA_B ) << 16;

value += ReadRegister( DATA_C ) << 8;

value += ReadRegister( DATA_D );

PeekPointer++; /* maintain local pointer */

return value;

}

HMI Reference Code

void Poke(

long address,

unsigned long value )

{

if( address != PokePointer ) {

SetAddress( address );

}

if( PokePointer >= PokeLimit ) {

throw "Poke addressing error or read-only!";

}

WriteRegister( DATA_A, (unsigned char) ( ( value >> 24 ) & 0xff ) );

WriteRegister( DATA_B, (unsigned char) ( ( value >> 16 ) & 0xff ) );

WriteRegister( DATA_C, (unsigned char) ( ( value >> 8 ) & 0xff ) );

WriteRegister( DATA_D, (unsigned char) ( value & 0xff ) );

/* maintain local pointers */

PokePointer++;

PeekPointer = -1; /* force SetAddress()next Peek() to freshen data */

}

DS651UM23 ©Copyright 2005 Cirrus Logic, Inc. 35

Version 2.3

Page 36

CobraNet Hardware User’s Manual

HMI Reference Code

8.3 CM-1, CM-2 Auto-detection

The following function is useful for systems that support both the CM-1 and CM-2 or

where a CobraNet interface is an optional add-in.

Detect() returns 0 if no CobraNet interface module is detected, 1 for CM-1 and 2 for CM-2.

int Detect( void ) {

/* check for presence of CM-1 */

MSG_B = 0x55; /* write to CM-1 CVR register */

DATA_A = 0xaa; /* write to unused CM-1 register to flip data bus */

if( MSG_B == 0x55 ) { /* read back CVR */

/* redo same detection with different data */

MSG_B = 0x3c;

DATA_A = 0xc3;

if( MSG_B == 0x3c ) {

return 1; /* CM-1 detected */

}

}

/* check for presence of CM-2 */

/* issue identify command */

MSG_C = MOP_IDENTIFY;

MSG_D = CVR_MULTIPLEX_OP;

int msgack = MSG_D; /* clean pipeline */

msgack = MSG_D;

/* wait for togglebit to flip in response to command */

int tm0 = gettimeofday();

while( !( ( MSG_D ^ toggle ) & ( 1 << MSG_TOGGLE_BO ) ) ) {

int tm1 = gettimeofday();

if( ( tm1 - tm0 ) > time_out ) {

return 0; /* command timed out, no CobraNet interface present */

}

}

int garbage = MSG_D; /* clean pipeline */

/* verify identify results */

if( DATA_A == 'C' ) if( DATA_B == 'S' )

if( DATA_C == ( 18101 >> 8 ) ) if( DATA_D == ( 18101&0xff ) {

return 2; /* CM-2 detected */

}

return 0; /* no interface or non-supported interface */

}

36 ©Copyright 2005 Cirrus Logic, Inc. DS651UM23

Version 2.3

Page 37

9.0 Mechanical Drawings and Schematics

The section contains detailed drawings of the CM-2 board and CS1810xx/CS4961xx

device package design. The mechanical drawings are arranged as follows:

• "CM-2 Module Assembly Drawing, Top" on page 38

• "General PCB Dimensions" on page 40

• "Example Configuration, Side View" on page 41

• "Faceplate Dimensions" on page 42

• "Connector Detail" on page 43

• "CM-2 RevF Schematic Page 1 of 7" on page 44

• "CM-2 RevF Schematic Page 2 of 7" on page 45

• "CM-2 RevF Schematic Page 3 of 7" on page 46

• "CM-2 RevF Schematic Page 4 of 7" on page 47

• "CM-2 RevF Schematic Page 5 of 7" on page 48

• "CM-2 RevF Schematic Page 6 of 7" on page 49

CobraNet Hardware User’s Manual

Mechanical Drawings and Schematics

• "CM-2 RevF Schematic Page 7 of 7" on page 50

• "144-Pin LQFP Package Drawing" on page 51

DS651UM23 ©Copyright 2005 Cirrus Logic, Inc. 37

Version 2.3

Page 38

CobraNet Hardware User’s Manual

Mechanical Drawings and Schematics

9.1 CM-2 Mechanical Drawings

NOT TO SCALE

Figure 18. CM-2 Module Assembly Drawing, Top

38 ©Copyright 2005 Cirrus Logic, Inc. DS651UM23

Version 2.3

Page 39

CobraNet Hardware User’s Manual

Mechanical Drawings and Schematics

NOT TO SCALE

Figure 19. CM-2 Module Assembly Drawing, Bottom

DS651UM23 ©Copyright 2005 Cirrus Logic, Inc. 39

Version 2.3

Page 40

CobraNet Hardware User’s Manual

Mechanical Drawings and Schematics

3.500

0.175

2x Mounting holes for PCB standoffs

4x 0.16 Hole, 0.3 pads

B20

A20

B1B1

A1A1

Component Side = J3

Bottom Side = J4

Viewed from component side up.

B20

A20

0.175

Component Side = J1

Bottom Side = J2

3.500

2.86

0.3

General PCB dimensions

NOT TO SCALE

2x Mounting holes for front faceplate.

Figure 20. General PCB Dimensions

40 ©Copyright 2005 Cirrus Logic, Inc. DS651UM23

Version 2.3

Page 41

CobraNet Hardware User’s Manual

Mechanical Drawings and Schematics

0.340

This distance accounts for the thickness of the faceplate

NOT TO SCALE

Figure 21. Example Configuration, Side View

DS651UM23 ©Copyright 2005 Cirrus Logic, Inc. 41

Version 2.3

Page 42

CobraNet Hardware User’s Manual

Mechanical Drawings and Schematics

0.862

4-40 PEM's, x2

0.680

0.300

1.000

0.810

0.800

0.700

1.000 max, 0.9 typ.

0.490

0.340

0.175

ote: Mechanical dimensions for the CM-2 and CM-1 Rev F are identical.

There are differences with earlier versions of the CM-1, however. For

3.500

0.550

Faceplate material is 20 guage, 0.037" thick

1.343

Chrome plating on faceplate

1.333

Faceplate Dimensions

reference, earlier versions of the CM-1 dimensions are shown in RED.

0.175

0.125 dia, 2x

0.431

0.421

0.300

2x, Hole Diameter 0.160

NOT TO SCALE

0.500

Figure 22. Faceplate Dimensions

42 ©Copyright 2005 Cirrus Logic, Inc. DS651UM23

Version 2.3

Page 43

CobraNet Hardware User’s Manual

Mechanical Drawings and Schematics

Component

Side Up

8x 0.047 Alignment holes

J3

J1

0.157 1.576 1.925 3.343

0.208

0.039

Connector Detail

Figure 23. Connector Detail

DS651UM23 ©Copyright 2005 Cirrus Logic, Inc. 43

Version 2.3

NOT TO SCALE

Page 44

CobraNet Hardware User’s Manual

Mechanical Drawings and Schematics

9.2 CM-2 Schematics

connector

connector.sch

HRESET#

HEN#

HRW

HDS#

HADDR[0..3]

HDATA[0..7]

HREQ#

HACK#

WATCHDOG

MUTE#

UART_TX_OE

UART_TXD

UART_RXD

MCLK_OUT

MCLK_IN

REFCLK_IN

SSI_CLK

SSI_DIN[0..3]

SSI_DOUT[0..3]

RSVD[1..5]

AUX_POWER[0..3]

FS1

HRESET#

HEN#

HRW

HDS#

HADDR[0..3]

HDATA[0..7]

HREQ#

HACK#

WATCHDOG

MUTE#

UART_TX_OE

UART_TXD

UART_RXD

MCLK_OUT

MCLK_IN

REFCLK_IN

FS1

SSI_CLK

SSI_DIN[0..3]

SSI_DOUT[0..3]

RSVD[1..5]

AUX_POWER[0..3]

core

core.sch

HRESET#

HEN#

HRW

HDS#

HADDR[0..3]

HDATA[0..7]

HREQ#

HACK#

WATCHDOG

MUTE#

UART_TX_OE

UART_TXD

UART_RXD

MCLK_OUT

MCLK_IN

REFCLK_IN

FS1

SSI_CLK

SSI_DIN[0..3]

SSI_DOUT[0..3]

RSVD[1..5]

AUX_POWER[3..0]

GPIO[0..1]

GPIO[0..1]

GPIO[0..1] is not used elsewhere.

These pulldowns ar e used for test points and

to keep these signa ls at valid levels.

GPIO1

R1GP IO0

R2

10K Ohm

GND

VCC_+3.3