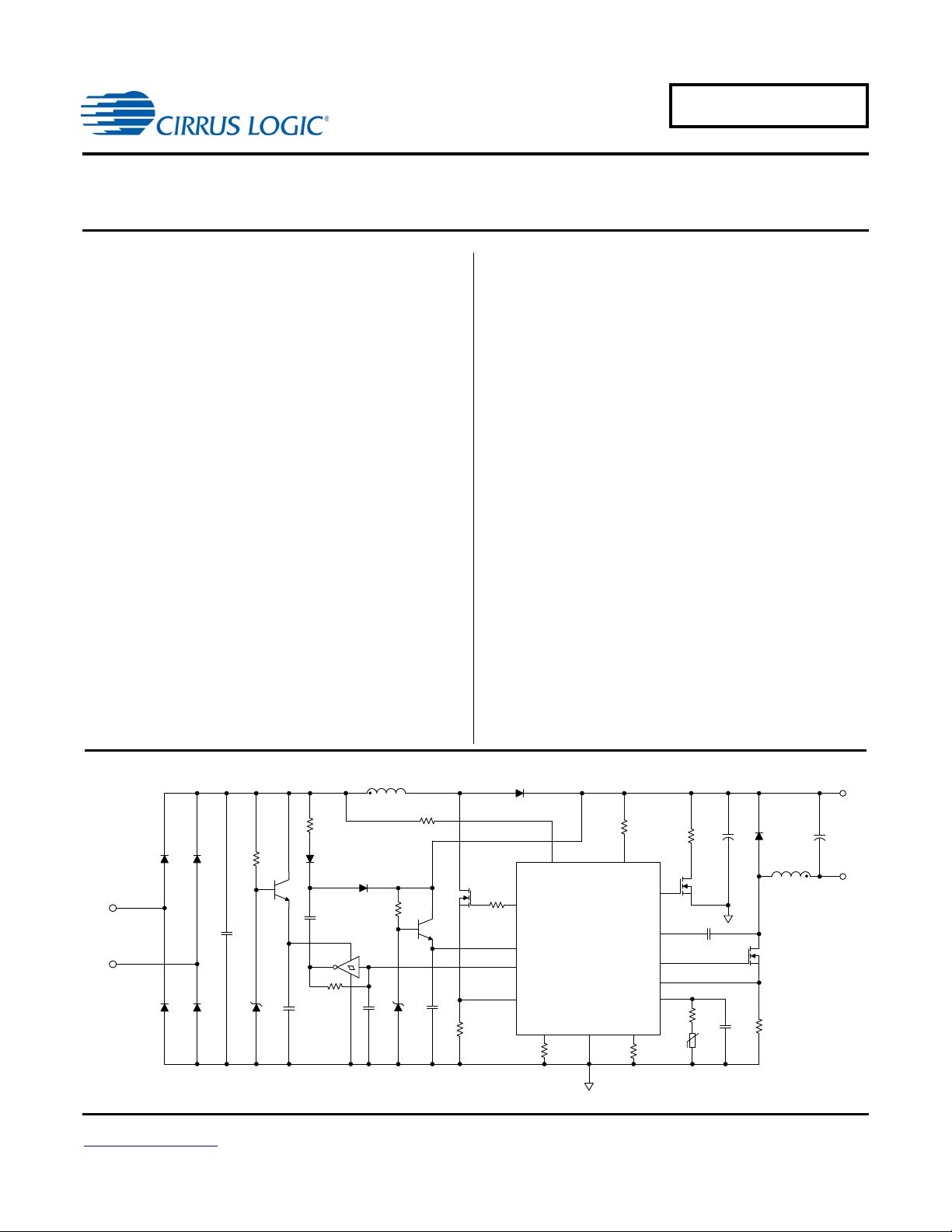

Page 1

Dimmable LED Driver IC

LED +

LED -

C

OUT

NTC

C

BST

D

BST

Q

BUCK

CS1680

VAC

BUCKGD

BSTOUT

9

CLAMP

BUCKZCD

BUCKSENSE

eOTP

12

2

13

R

CLAMP

R

S

C

NTC

R

BST

D1

12VAC/VDC

D2

V

rec t

V

BST

D

BUCK

Q

CLAMP

C5

VDD

GPIO

BST SENSE

BSTGD

C

rect

6

7

3

11

15

R

BUCK(Sense)

R

BST(Sense)

Q

BST

R4

Z2

D3

D4

GND

1

CTRL1

16

R

CTRL1

R1

C4

R

CTRL2

CTRL2

4

5

14

Q1

Z1

R5

C1 C3

R3

U1

D5

D6

R

rect

C2

Q2

L

BST

L

BUCK

R2

for Low-voltage Lighting

CS1680

Features

• Best-in-class Transformer Compatibility

- Magnetic Transformers

- Electronic Transformers

• Best-in-class Dimmer Compatibility

- Leading-edge (TRIAC) Dimmers

- Trailing-edge Dimmers

• High Efficiency

- Up to 80% for CS1680-00 Applications

- Up to 83% for CS1680-02 Applications

• Flicker-free Dimming

• 5% Minimum Dimming Level

• Cascade Boost-buck Topology with Constant-current

Output

- CS1680-00 Output Voltage 15V

- CS1680-02 Output Voltage 21V

• Fast Startup

• Tight LED Current Regulation: Better than ±10%

• >0.9 Power Factor on Magnetic Transformers

• Soft Start

• Protections:

- Output Open/Short

- Boost Overvoltage

- Overcurrent Detection

- External Overtemperature Using NTC

Overview

The CS1680 is a cascade boost-buck dimmable LED

driver for the 12V halogen lamp-replacement market.

The CS1680 uses a Cirrus Logic proprietary intelligent

digital control that provides exceptional single-lamp and

multi-lamp transformer compatibility for non-dimmer systems and dimmer systems paired with electronic and

magnetic low-voltage transformers.

The CS1680 integrates a continuous conduction mode

(CCM) boost converter that provides transformer compatibility and dimmer compatibility. An adaptive digital

algorithm controls the boost stage and dimmer compatibility operation mode to enable flicker-free operation

down to 5% output current with leading-edge and trailing-edge dimmers.

Applications

• MR16 Lamps

• All 12VAC/VDC Low-voltage Lighting Applications

Ordering Information

See page 15.

Cirrus Logic, Inc.

http://www.cirrus.com

Copyright Cirrus Logic, Inc. 2014

(All Rights Reserved)

OCT’14

DS1055F1

Page 2

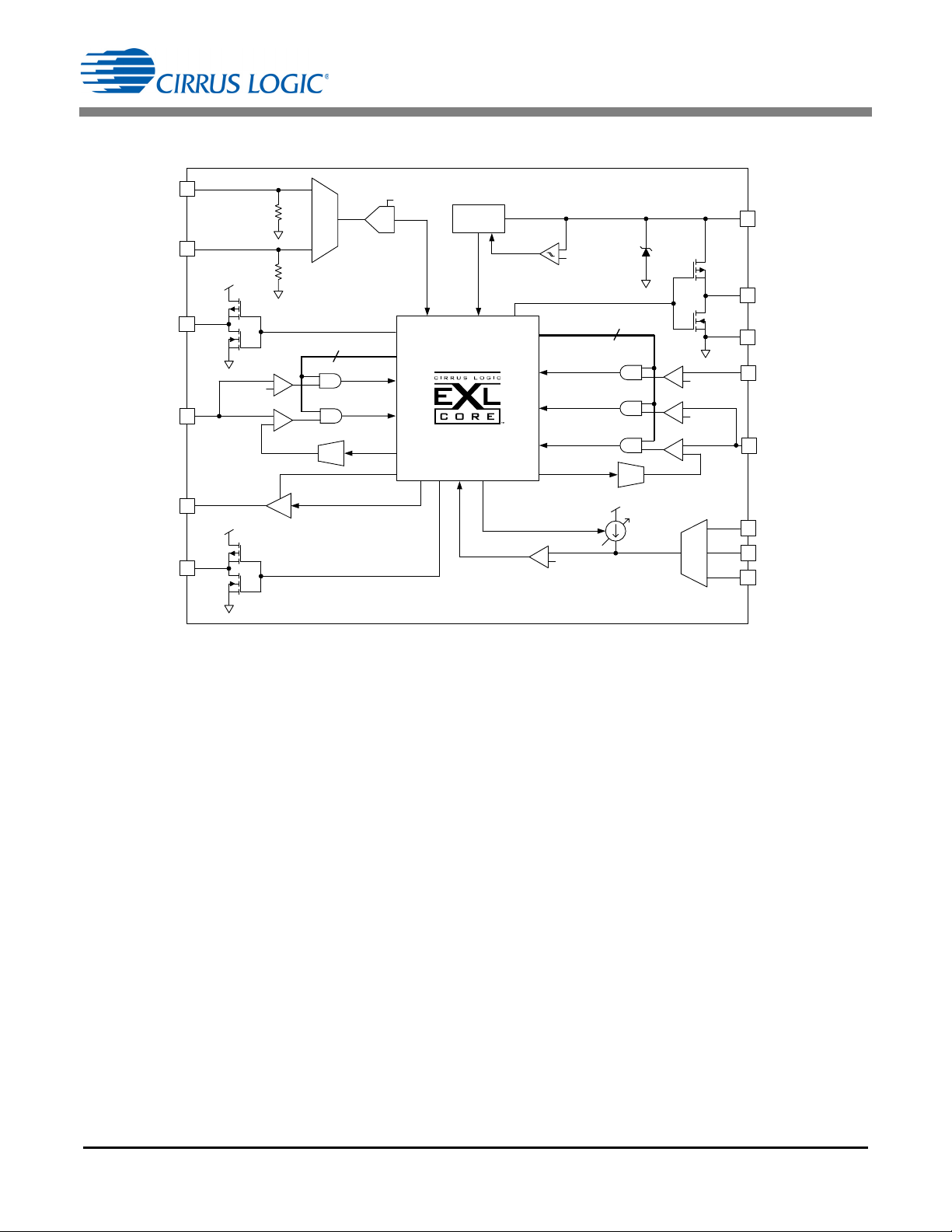

1. INTRODUCTION

V

Z

POR

+

-

Voltage

Regulator

6

VDD

13

BUCKSENSE

+

-

9

BUCKZCD

+

-

12

BUCKGD

VAC

DAC

+

-

ZCD

4

GND

15

BSTOUT

OCP

11

CLAMP

V

ST(th)

V

STP(th)

V

BUCKOCP(th)

V

BUCKZCD(th)

V

BUCKPK(th)

ADC

I

ref

5

BSTGD

VDD

7

GPIO

3

B

STSENSE

+

-

DAC

+

-

Boost

Peak Ctrl

BOCP

2

V

BSTOCP(th)

V

BSTPK(th)

+

-

I

CONNECT

V

CONNECT (th)

VDD

Buck

Peak Ctrl

MUX

CTRL2

1

14

eOTP

2

CTRL1

16

20k

20k

MUX

BST Blank

3

Buck Blank

VDD

Figure 1. CS1680 Block Diagram

CS1680

A typical schematic using the CS1680 for boost-buck

applications is shown on the previous page.

A startup circuit provides a low-impedance path to

improve electronic transformer compatibility. The GPIO

pin is used to disable the startup circuit when normal

operation is reached.

The CS1680 power supply is connected to an external

power supply network. A linear regulator at the output of

the boost converter provides steady-state operating

current to the IC. The rectified input voltage is sensed as

a current into pin VAC and is used to control the

adaptive transformer and dimmer compatibility

algorithm and extract the phase of the input voltage for

output dimming control.

During steady-state operation, the boost stage operates

in continuous conduction mode (CCM) to boost the

input voltage. This operation allows the boost stage to

2 DS1055F1

provide transformer and dimmer compatibility, reduces

bulk capacitor ripple current, and provides a regulated

input voltage to the buck stage.

The output voltage of the CCM boost is sensed by the

current into the boost output voltage sense pin

(BSTOUT). The buck stage is implemented with

peak-current mode control. Voltage across an external

user-selected resistor is sensed through pin

BUCKSENSE to control the peak current through the

buck stage inductor. Leading-edge blanking on pin

BUCKSENSE prevents false triggering.

When an external negative temperature coefficient

(NTC) thermistor is connected to the eOTP pin, the

CS1680 monitors the system temperature, allowing the

controller to reduce the output current of the system. If

the temperature reaches a designated high set point,

the IC is shutdown and stops switching.

Page 3

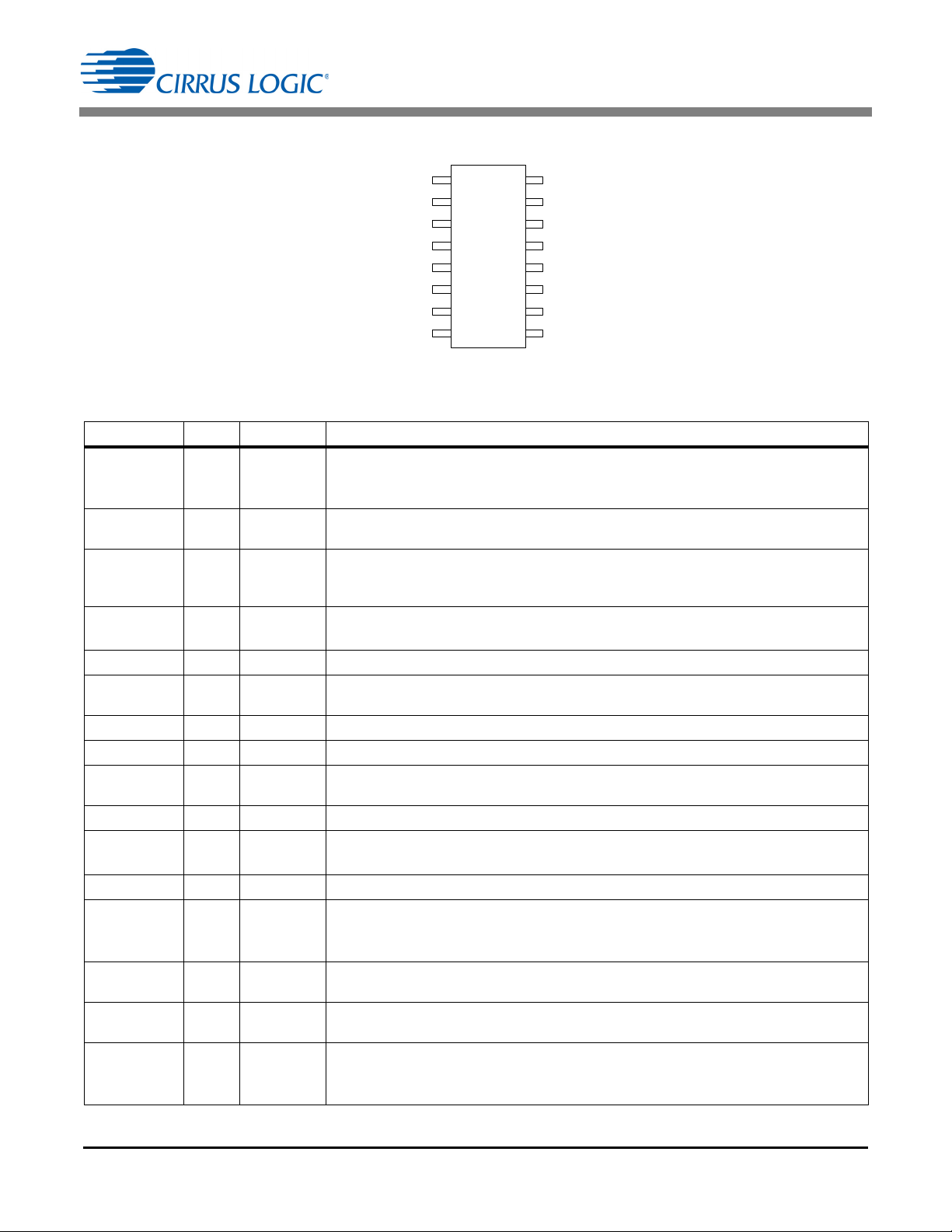

2. PIN DESCRIPTION

General Purpose Input/Output

Boost Gate Driver

Ground

Peak Current

E

xternal Overtemperature Protection

No Connect

GPIO

VDDIC Supply Voltage

BSTGD

GND

CTRL2

NC

CLAMP

BUCKGD

BUCKSENSE

VAC

BSTOUT

CTRL1

eOTP

BSTSENSEBoost Stage Current Sense

16-lead TSSOP

NC

BUCKZCD

7

6

5

4

3

2

1

10

11

12

13

14

15

16

8

9

No Connect

Voltage Clamp Current Source

Buck Gate Driver

Buck Stage Current Sense

Rectifier Voltage Sense

Boost Output Voltage Sense

Boost Stage Constant

Buck Stage Zero-current Detect

Figure 2. CS1680 Pin Assignments

CS1680

Pin Name

CTRL2

eOTP

BSTSENSE

GND

BSTGD

VDD

GPIO

NC

BUCKZCD

NC

CLAMP

BUCKGD

Pin # I/O

1IN

2IN

3IN

4PWR

5OUT

6PWR

7IN/OUT

8IN

9IN

10 IN

11 OUT

12 OUT

Description

Peak Current — Connect a resistor to this pin to set the comparator threshold to

reflect the desired boost peak current in Trailing Edge Electronic Transformer Mode (Mode 2).

External Overtemperature Protection — Connect an external NTC thermistor to

this pin, allowing the internal A/D converter to sample the change to NTC resistance.

Boost Stage Current Sense — The current flowing in the boost stage FET is

sensed across a resistor. The resulting voltage is applied to this pin and digitized for

use by the boost stage computational logic to determine the FET duty cycle.

Ground — Common reference. Current return for both the input signal portion of the

IC and the gate driver.

Boost Gate Driver — Gate drive for the boost stage power FET.

IC Supply Voltage —

operating current for the device, including the gate drive current to the power transistor

General Purpose Input/Output — Used to drive the FET gate for the startup circuit.

No Connect — Leave pin not connected.

Buck Stage Zero-current Detect — Buck stage inductor sensing input. The pin is

connected to the drain of the buck stage power FET with a capacitor.

No Connect — Leave pin not connected.

Voltage Clamp Current Source — Connect to a voltage clamp circuit on the output

of the boost stage.

Buck Gate Driver — Gate drive for the buck stage power FET.

Connect a storage capacitor to this pin to serve as a reservoir for

.

BUCKSENSE

VAC

BSTOUT

CTRL1

DS1055F1 3

13 IN

14 IN

15 IN

16 IN

Buck Stage Current Sense — The current flowing in the buck stage FET is sensed

across a resistor. The resulting voltage is applied to this pin and digitized for use by

the buck stage computational logic to determine the FET duty cycle.

Rectifier Voltage Sense — A current proportional to the rectified line voltage is fed

into this pin. The current is measured with an A/D converter.

Boost Output Voltage Sense — A current proportional to the boost output is fed

into this pin. The current is measured with an A/D converter.

Boost Stage Constant — Connect a resistor to this pin to set the constant ratio for

the boost stage current calculations in Leading Edge Electronic Transformer Mode

(Mode 3).

Page 4

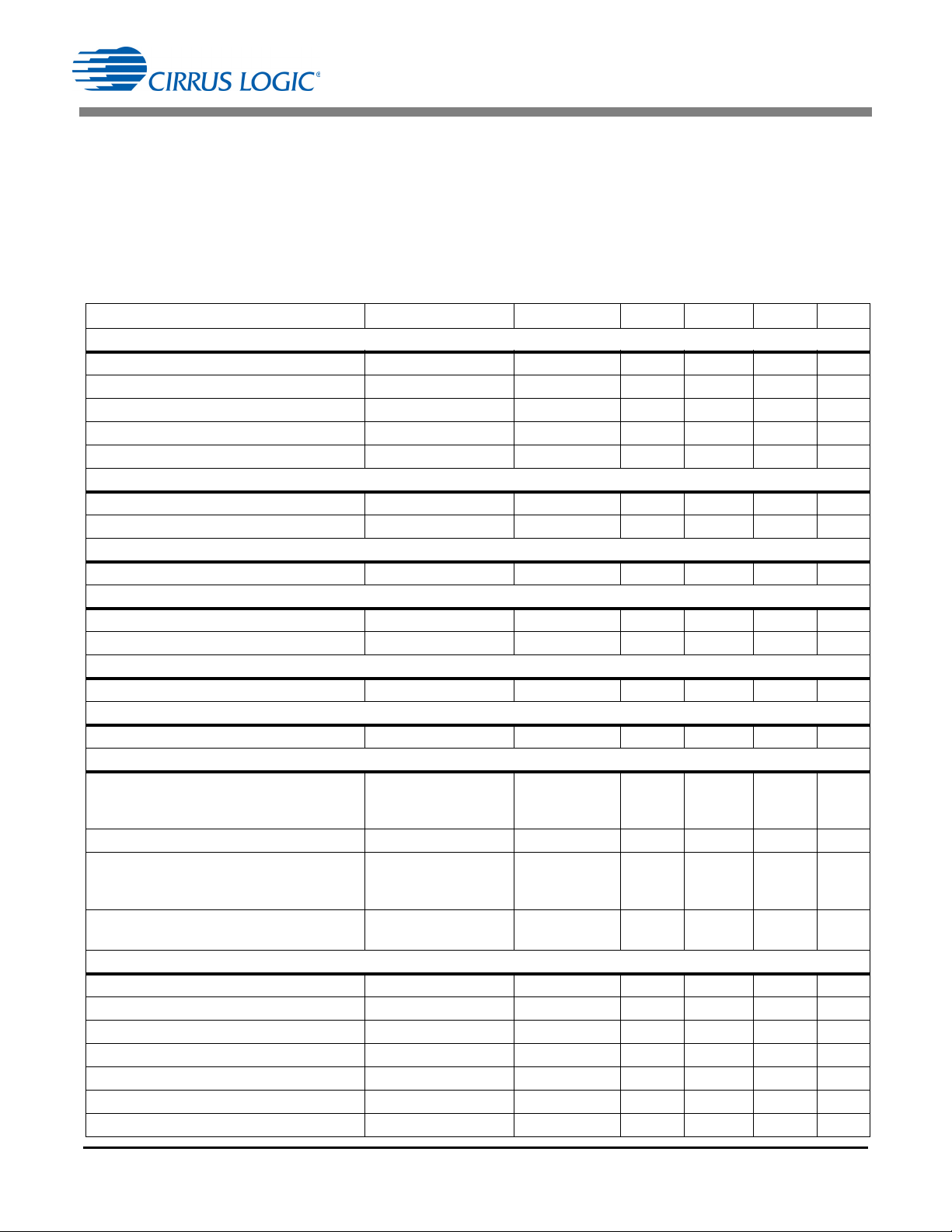

CS1680

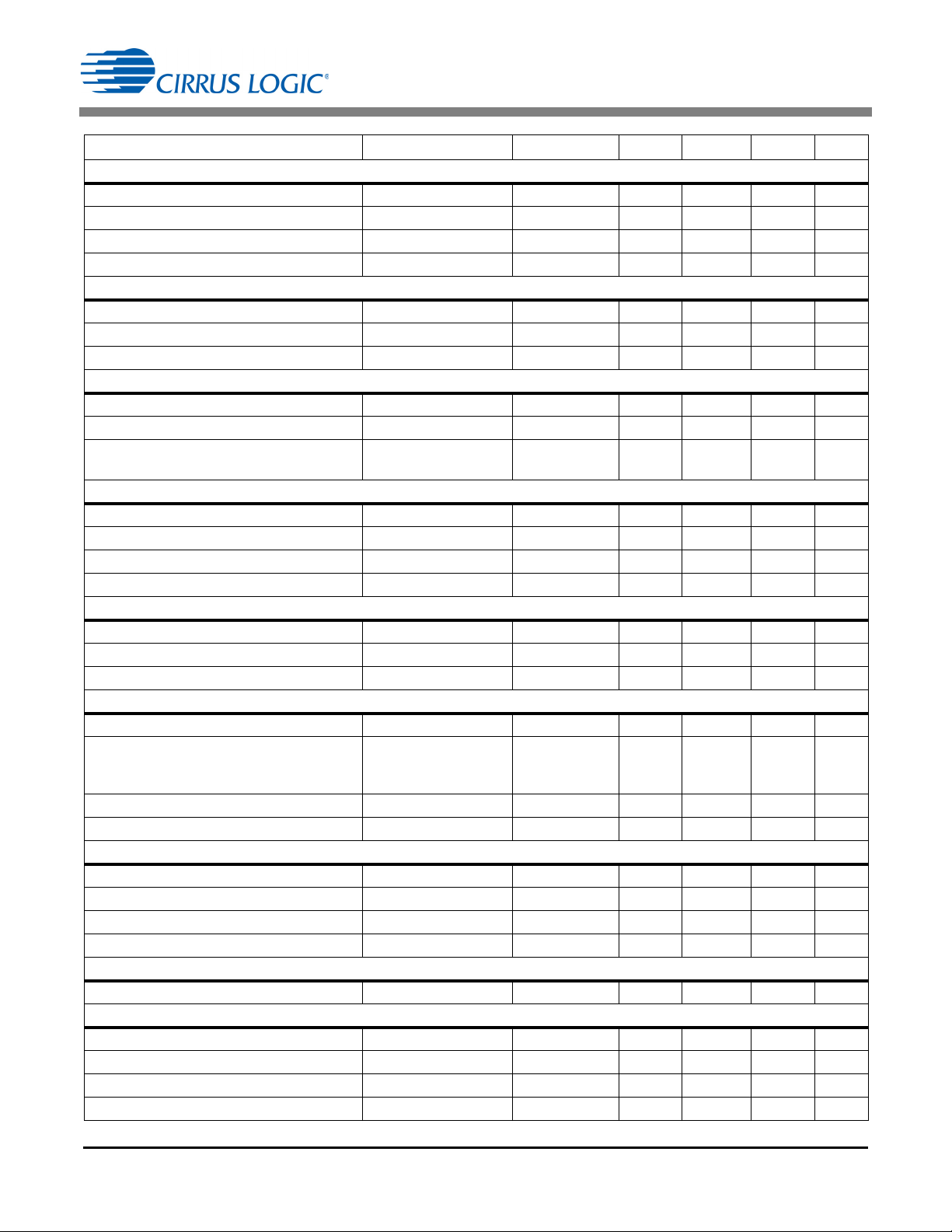

3. CHARACTERISTICS AND SPECIFICATIONS

3.1 Electrical Characteristics

Typical characteristics conditions:

=25°C, VDD= 12V, GND = 0 V

- T

A

- All voltages are measured with respect to GND.

- Unless otherwise specified, all currents are positive when

flowing into the IC.

Parameter Condition Symbol Min Typ Max Unit

VDD Supply Voltage

Operating Range

Turn-on Threshold Voltage

Turn-off Threshold Voltage (UVLO)

GPIO Low

Zener Voltage

(Note 1)

(Note 2)

After Turn-on

VDD Increasing

VDD Decreasing

V

>V

DD

I

=20mA

DD

VDD Supply Current

Startup Supply Current

Operating Supply Current

(Note 3)

VDD<V

C

= 0.25nF, fsw70 kHz

L

Reference

Reference Current I

Clamp Gate Drive

Output Source Resistance Z

Output Sink Resistance Z

Boost Output Mode1 Algorithm

Regulation Target

(Notes 1, 4) K

Boost Output Mode2 Mode Algorithm

Regulation Target

(Notes 1, 5) K

Boost Output Mode3 Algorithm

Regulation Range Low

(Notes 1, 6)

CS1680-00

CS1680-02

Regulation Range High

(Notes 1, 6) K

Accelerated Decrease On

CS1680-00

CS1680-02

Accelerated Increase On

(Notes 1, 7)

Accelerated Increase Off (Notes 1, 7)

Boost Pulse Width Modulator

Minimum On Time T1

Maximum On Time T1

Constant Off Time Mode1 T2

Minimum Off Time Mode2 & Mode3 T2

Maximum Off Time Mode2 & Mode 3 T2

Minimum Switching Frequency - 1.3 - kHz

Maximum Switching Frequency - 3.3 - MHz

Minimum/Maximum characteristics conditions:

- TJ= -40°C to +125 ° C, VDD= 11V to 17V, GND = 0 V

ST(th)

ST(th)

V

DD

V

ST(th)

V

STP(th)

K

GPIO(low)

V

I

ST

Z

11 - 17 V

-8.5-V

-7.5-V

-50.0-%

18.5 - 19.8 V

--1.0mA

-11-mA

ref

CLAMP(Source)

CLAMP(Sink)

Mode1(target)

Mode2(target)

K

Mode3(low)

-64-A

- 290 -

- 208 -

-73.3-%

-78.4-%

-

-

Mode3(high)

K

DEC(on)

-82.0-%

-

-

K

CLAMP(on)

K

CLAMP(off)

BST(min)

BST(max)

BST(fixed)

BST(min)

BST(max)

-

-

-0.1-s

- 800 - s

-0.5-s

-0.2-s

-0.9-s

60.0

65.9

52.2

60.4

87.8

85.1

-

-

-

-

-

-

%

%

%

%

%

%

4 DS1055F1

Page 5

CS1680

Parameter Condition Symbol Min Typ Max Unit

Boost Gate Driver

Output Source Resistance Z

Output Sink Resistance Z

Rise Time

Fall Time

CL=0.25nF

CL=0.25nF

BST(Source)

BST(Sink)

Boost Current Sense

Peak Control Threshold V

Leading-edge Blanking t

BSTPK(th)

BSTLEB

Delay to Output --100ns

Boost Protection

Overcurrent Protection (BOCP) V

Overvoltage Protection (BOP)

(Note 1) K

Clamp Turn-on

Clamp Turn-off

BSTOCP(th)

BOP

K

CLAMP(on)

K

CLAMP(off)

Buck Zero-Current Detect

BUCKZCD Threshold V

BUCKZCD Blanking t

ZCD Sink Current

BUCKAUX Upper Voltage

(Note 8) I

I

BUCKZCD

=1mA

BUCKZCD(th)

BUCKZCD

BUCKZCD

Buck Current Sense

Peak Control Threshold V

Leading-edge Blanking t

BUCKPK(th)

BUCKLEB

Delay to Output --100ns

Buck Pulse Width Modulator

Minimum On Time T1

BUCK(min)

Maximum On Time

CS1680-00

T1

BUCK(max)

CS1680-02

Minimum Switching Frequency - 625 - Hz

Maximum Switching Frequency - 200 - kHz

Buck Gate Driver

Output Source Resistance Z

Output Sink Resistance Z

Rise Time

Fall Time

CL=0.25nF

CL=0.25nF

BUCK(Source)

BUCK(Sink)

Buck Protection

Overcurrent Protection (OCP) V

BUCKOCP(th)

External Overtemperature Protection (eOTP), Boost Stage Constant, Peak Current

Maximum Pull-up Current Source I

Conductance Accuracy

Conductance Offset

(Note 9) --±5

(Note 9) - ±250 - nS

Current Source Voltage Threshold V

CONNECT

CONNECT(th)

- 19.9 -

- 10.5 -

-11-ns

-6-ns

-0.33- V

- 100 - ns

-1.05- V

- 93.75 -

-

-

87.8

85.1

-

-

- 200 - mV

- 250 - ns

-2 - - mA

-VDD+0.6 - V

-0.525- V

- 250 - ns

-0.55-s

-

-

12.8

25.6

-

-

s

s

- 12.7 -

-8.2-

-7.0-ns

-4.5-ns

-1.05- V

-80-A

-1.25- V

DS1055F1 5

Page 6

Parameter Condition Symbol Min Typ Max Unit

Internal Overtemperature Protection (iOTP)

Thermal Shutdown Threshold

Thermal Shutdown Hysteresis

Notes: 1. Threshold is characterized as a percentage of the full-scale boost output voltage, V

2. The CS1680 has an internal shunt regulator that limits the voltage on the VDD pin. VZ, the shunt regulation voltage, is defined in

the VDD Supply Voltage section on page 4.

3. For test purposes, load capacitance C

4. Mode1 algorithm regulates value at the trough of the rectified waveform.

5. Mode2 algorithm regulates boost output voltage at the phase cut of each rectified waveform.

6. LED output current begins changing if boost output voltage is outside the Mode 3 algorithm regulation range.

7. Accelerated increase in LED output current begins at clamp on and continues until the boost output voltage falls to clamp off.

8. External circuitry should be designed to ensure that the ZCD current drawn from the internal clamp diode when it is forward biased

does not exceed specification.

9. The conductance is specified in Siemens (S or 1/). Each LSB of the internal ADC corresponds to 250 nS or one parallel 4 M

resistor. Full scale corresponds to 256 parallel 4M resistors or 15.625 k.

10. Specifications are guaranteed by design and are characterized and correlated using statistical process methods.

(Note 10) T

(Note 10) T

is connected to gate drive pins and is equal to 0.25nF.

L

SD

SD(Hy)

3.2 Thermal Resistance

Symbol Parameter TSSOP Unit

Junction-to-Ambient Thermal Impedance 2 Layer PCB

JA

Junction-to-Case Thermal Impedance 2 Layer PCB

JC

4 Layer PCB

4 Layer PCB

CS1680

- 135 - ºC

-14-ºC

BST(full)

138

103

44

28

°C/W

°C/W

°C/W

°C/W

3.3 Absolute Maximum Ratings

Characteristics conditions:

All voltages are measured with respect to GND.

Pin Symbol Parameter Value Unit

6V

DD

1, 2, 3, 8, 9,

10, 13, 14, 15, 16

1, 2, 3, 8, 9,

10, 13, 14, 15, 16

5, 11, 12 V

5, 11, 12 I

GD

GD

-P

-T

-T

Stg

All Pins ESD

Note: 11. Transient current of up to 170mA will not cause SCR latch-up

12. Long-term operation at the maximum junction temperature will result in reduced product life. Derate internal power dissipation at

the rate of 50 mW /°C for variation over temperature.

Operation at or beyond these limits may result in permanent damage to the device.

IC Supply Voltage 18.5 V

Analog Input Maximum Voltage -0.5 to (V

Analog Input Maximum Current

Gate Drive Output Voltage -0.3 to (VDD+0.3) V

Gate Drive Output Current -1.0 / +0.5 A

Total Power Dissipation 100 mW

D

Junction Temperature Operating Range (Note 12) -40 to +125 °C

J

Storage Temperature Range -65 to +150 °C

Electrostatic Discharge Capability Human Body Model

WARNING:

Normal operation is not guaranteed at these extremes.

(Note 11) 5mA

Charged Device Model

DD

2000

500

+0.5) V

V

V

6 DS1055F1

Page 7

4. TYPICAL PERFORMANCE PLOTS

0

1

2

3

-50 0 50 100 150

UVLO Hysteresis

Temperature (ºC)

-5

0

5

10

15

20

25

30

0 2 4 6 8 101214161820

IDD (mA)

VDD (V)

7

8

9

10

-50 0 50 100 150

VDD (V)

Temperature (ºC)

Turn Off

Turn On

18

18.5

19

19.5

20

-50 0 50 100 150

V

Z

(V)

Temperature (ºC)

0

5

10

15

20

25

30

-50 0 50 100 150

Resistance (:)

Temperature (oC)

BSTGD Source

BUCKGD Source

BSTGD Sink

BUCKGD Sink

-1.75

-1.25

-0.75

-0.25

0.25

-50 0 50 100 150

Drift (%)

Temperature (C)

CS1680

Figure 3. UVLO Characteristics

Figure 5. Turn On/ Off Threshold Voltage vs. Temperature

Figure 4. Supply Current vs. Voltage

Figure 6. Zener Voltage vs. Temperature

Figure 7. Gate Drive Resistance vs. Temperature

DS1055F1 7

Figure 8. Reference Current I

Drift vs. Temperature

ref

Page 8

5. GENERAL DESCRIPTION

CS1680

5.1 Overview

The CS1680 is a cascade boost-buck dimmable LED

driver for the 12V halogen lamp-replacement market.

The CS1680 uses a Cirrus Logic proprietary intelligent

digital control that provides exceptional single-lamp and

multi-lamp transformer compatibility for non-dimmer

systems and dimmer systems paired with electronic and

magnetic low-voltage transformers.

The CS1680 integrates a continuous conduction mode

(CCM) boost converter that provides transformer

compatibility and dimmer compatibility. An adaptive

digital algorithm controls the boost stage and dimmer

compatibility operation mode to enable flicker-free

operation down to 5% output current with leading-edge

and trailing-edge dimmers.

5.2 IC Startup and Power Supply

The startup circuit is constructed of a linear regulator

and charge pump, and is used to supply a power-on

voltage to the CS1680. The device provides a GPIO pin

that is used to disable the startup circuit once the boost

output voltage reaches 50% of full scale.

The linear regulator circuit uses transistor Q1 to provide

a supply voltage to a Schmitt-trigger inverter which

enables the charge pump circuit. The GPIO pin is

tri-stated while the controller is held in reset due to low

supply voltage. The charge pump increases the voltage

until the device starts converting. Once the supply

voltage V

exceeds threshold voltage V

DD

ST(th)

, the

controller polls the boost output voltage for 50% of full

scale before driving the GPIO pin low to disable the

startup circuit.

5.3 Boost Stage

The boost stage in the CS1680 is a low-side

asynchronous boost converter. Once the IC reaches its

UVLO start threshold voltage V

operating, the CS1680 executes a detection algorithm

to set the operating state of the IC (see Table 1 on

page 8). The boost stage utilizes a continuous current

mode (CCM) control algorithm.

5.3.1 Dimmer Compatibility

The CS1680 dimmer switch detection algorithm

determines if the solid-state lighting (SSL) system is

controlled: first, using a regular switch or a leading-edge

dimmer paired with a magnetic transformer, or a

12VAC/VDC source (Mode1); second, by a regular

switch or a trailing-edge dimmer paired with an electronic

and begins

ST(th)

transformer (Mode2); third, by a leading-edge dimmer

paired with an electronic transformer (Mode3).

Boost

Mode

Mode1

Mode2

Mode3

Source Line Switch Digital Control Loop

12 VAC/VDC Non-dimming

Magnetic

Transformer

Electronic

Transformer

Electronic

Transformer

Leading-edge

Dimmer

Non-dimming

Trailing-edge

Dimmer

Non-dimming

Leading-edge

Dimmer

Table 1. Operating State

Executes a boost peakcurrent algorithm with

PFC based control.

Executes a constant

boost peak-current

algorithm during the turnon time of the electronic

transformer.

Executes a constant

power control algorithm

where the boost inductor

current is controlled by

the instantaneous

rectified voltage signal.

Dimmer switch detection is implemented using a

process of elimination. The method of elimination

progresses through the detection algorithm to find the

best matching state of operation. In an attempt to find a

dimmer compatible mode, the detection algorithm starts

in Mode1, then tries Mode2, if Mode1 and Mode2 are

excluded the algorithm defaults to Mode3.

Mode1

In Mode1, the detectable inputs are a leading-edge

dimmer paired with a magnetic transformer, no dimmer

switch paired with a magnetic transformer, or a

12VDC/VAC source. Upon detection of a magnetic

transformer, the CS1680 operates in a PFC conduction

mode where the device provides a power factor that is

in excess of 0.9. The boost peak current I

BSTPK

is

modulated across the input voltage to follow a constant

resistance. The target resistance is modulated to

provide boost output regulation. The RMS input voltage

is used to determine the output LED current as a

fraction of full scale. If a DC input voltage is detected,

the controller will set the LED output at 100% of the

available RMS energy.

The boost output voltage V

is measured at the

BST

trough of the rectified voltage every half-line cycle and

compared against the regulation point, which is set by

resistor R

difference, the setting of LED output current I

(see Figure 11 on page 10). The voltage

BST

OUT

, and

the clamp activity are used in the control loop to scale

the boost inductor current allowing the boost output

8 DS1055F1

Page 9

CS1680

Regulation Range High

Regulation Range Low

Accelerated Decrease On

Accelerated Increase On

Accelerated Increase Off

V

BST

u

K

Mode 3(high)

V

BST

u

K

CLAMP(off)

V

BST

u

K

CLAMP(on)

V

BST

u

K

Mode 3(low)

V

BST

u

K

DEC(on)

t

v(t)

Voltage Threshold

Figure 9. Mode3 Output Regulation Algorithm

voltage to reach the regulation target set by

constant K

Mode1(target)

. If boost output voltage V

BST

below the target regulation point or the boost output

voltage is falling, the boost inductor current is increased.

If the boost output voltage is above the target regulation

point, the boost output voltage is rising, or the clamp has

been activated recently the boost current is decreased.

The LED output current is set using a third-order

polynomial of the rectified RMS voltage, computed over

a half-line cycle and filtered to avoid lamp flicker.

Mode2

In Mode 2, the CS1680 will detect if the input is a trailing

edge dimmer paired with an electronic transformer or no

dimmer switch paired with an electronic transformer. The

detection algorithm determines its operation based on

the falling edge of the input voltage waveform. To provide

proper dimmer operation, the CS1680 executes the

peak current inversely proportional to the boost output

voltage. The algorithm attempts to maintain a constant

is

power while limiting the boost peak current to prevent

saturating the boost inductor.

The Mode1 and Mode2 algorithms use properties of the

input waveform on a cycle-by-cycle basis to determine

the output current, and then adjusts the boost control

parameters to balance the input power with the

requested output power. Unlike the Mode1 and Mode2

algorithms, the Mode3 algorithm leaves the boost

parameters fixed and adjusts the output current to

balance input power and output power. As long as boost

output voltage V

remains between the voltage

BST

thresholds set by lower regulation range

constant K

constant K

Mode3(low)

Mode3(high)

and higher regulation range

, the LED output current I

remain constant (see Figure 9).

OUT

will

boost algorithm on the falling edge of the input line

voltage, which will maintain a charge in the dimmer

capacitor. To ensure maximum compatibility with dimmer

components, the device boosts during this falling edge

event using a peak current that must meet a minimum

value.

The boost output voltage V

is measured at the

BST

trailing edge of the rectified voltage every half-line cycle

and compared against the regulation point, which is set

by resistor R

(see Figure 11 on page 10). The

BST

voltage difference, the setting of LED output

current I

, and the clamp activity are used in the

OUT

control loop to modulate the boost turn-on time every

half-line cycle which allows the boost output voltage to

reach the regulation target set by constant

K

Mode2(target)

. If boost output voltage V

is below the

BST

target regulation point or the boost output voltage is

falling, the total turn-on time over a half-line cycle is

increased. If the boost output voltage is above the target

regulation point, the boost output voltage is rising, or the

clamp has been activated recently, the total turn-on time

over a half-line cycle is decreased. The Mode2

algorithm estimates the turn-on time of the transformer

by measuring the conduction angle of the rectified

voltage every half-line cycle. The LED output current is

set based on the output power requirements for a

particular conduction angle by the regulation loop.

Mode3

In Mode 3, the CS1680 will detect if the input is a leading

edge dimmer paired with an electronic transformer. The

CS1680 regulates boost output voltage V

maintaining the dimmer phase angle. The device

executes a CCM boost algorithm that keeps the boost

BST

while

If the boost output voltage V

regulation range high voltage threshold set by

constant K

Mode3(high)

(due to the phase angle of the

dimmer increasing which allows for the first stage to

produce additional power), LED output current I

gradually increased until the boost output voltage V

falls below the regulation range high threshold. The rate

of increase continues to add larger steps as long as

boost output voltage V

stays above the regulation

BST

high threshold. If the boost output voltage continues to

rise and reaches the clamp-on threshold set by

constant K

CLAMP(on)

, the clamp circuit will activate to

dissipate the excess power from the boost output. While

the clamp is on, the LED output current I

at an accelerated rate.

If the boost output voltage V

regulation range low voltage threshold set by

constant K

Mode3(low)

, LED output current I

gradually decreased. The rate of decrease continues to

subtract larger steps as long as the boost output voltage

stays below the regulation range low threshold. If the

rises above the

BST

increases

OUT

falls below the

BST

OUT

OUT

is

BST

is

DS1055F1 9

Page 10

CS1680

T1

BSTi

T2

BSTi

B

STGD

I

L

I

PKBST

IL = 0

Figure 10. Continuous Conduction Mode Operation

I

BSTPK max

V

BSTPK th

R

BST Sense

-------------------------------- -=

[Eq.1]

I

BSTPK OCP

V

BSTOCP th

R

BST Sense

---------------------------------=

[Eq.2]

D

BST

V

rec t

V

BST

R

rect

CS1680

I

BSTOUT

BSTOU T

VAC

ADC

I

ref

20 k

20 k

MUX

15

14

I

VAC

R

BST

L

BST

Figure 11. VAC and BSTOUT Input Pin Model

V

BST fullIrefRBST

20k+=

[Eq.3]

boost output voltage continues to fall and reaches the

lowest threshold set by constant K

DEC(on)

, the LED

output current is decreased at an accelerated rate.

If the LED output current I

boost output voltage V

BST

is at a maximum and

OUT

is still above the regulation

high threshold, the controller begins scaling down the

boost inductor current instead of increasing the LED

output current. If this happens, when the boost output

voltage falls below the regulation low threshold, the

boost input current is gradually increased back to

nominal before the LED output current begins to reduce

off from the maximum.

5.3.2 Boost Stage Control

The boost stage uses continuous conduction mode

operation for high compatibility with electronic

transformers. For current regulation, the controller

varies the peak current I

and transformer compatibility. When the dimmer is

paired with an electronic transformer, period T2

modulated to maintain a constant ripple current on the

boost inductor. When the dimmer is paired with a

magnetic transformer, the demagnetization period has

a constant T2

BST(fixed)

time.

as necessary for dimmer

BSTPK

BST

is

after one second. The boost overcurrent protection

current I

BSTPK(OCP)

is calculated using Equation 2:

Output BSTOUT Sense and Input VAC Sense

A current proportional to boost output voltage V

BST

is

supplied to the IC on pin BSTOUT and is used as a

control signal (see Figure 11). The ADC is used to

measure the magnitude of current I

resistor R

. The magnitude of current I

BST

BSTOUT

compared to an internal full scale reference current I

BSTOUT

through

is then

ref

of 64A.

Maximum Peak Current

The maximum boost inductor peak current I

is set using the current sense resistor R

pin BSTSENSE, which is sampled by a comparator

referenced to an internal DAC. Boost peak current

I

BSTPK(max)

is calculated using Equation 1:

Boost overcurrent protection (BOCP) is provided using

a higher threshold to detect the event of inductor

saturation. If the voltage on the BSTSENSE pin

exceeds a threshold voltage V

controller enters a BOCP fault. The IC output is

disabled, the gate drive output pins BSTGD and

BUCKGD turn off, and the controller attempts to restart

10 DS1055F1

BSTOCP(th)

BSTPK(max)

BST(Sense)

on

of 1.05V, the

Resistor R

determines boost output voltage V

sets the system full-scale voltage and

BST

regulation, boost

BST

overvoltage protection, and clamp behavior. Full-scale

voltage V

BST(full)

The CS1680-00 is designed for a resistor R

is calculated using Equation 3:

BST

equal to

604k, creating a full-scale voltage of 40V. The

CS1680-02 is designed for a resistor R

equal to

BST

560k, creating a full-scale voltage of 37V.

A current proportional to the AC/DC input voltage is

supplied to the IC on pin VAC and is used by the boost

control algorithm. Dimmer detection and dim level

calculations are dependent on specific levels of the line

voltage. Resistor R

is required to be set equal to

rec

604k

For optimal performance, resistors R

rect

and R

BST

should use 1% or better resistors for best voltage

accuracy.

Boost Overvoltage Protection

The CS1680 supports boost overvoltage protection

(BOP) to protect bulk capacitor C

(see Figure 13 on

BST

Page 11

CS1680

V

BOP thVBST fullKBOP

=

[Eq.4]

CLAMP

R

CLAMP

V

BST

CS1680

11

C

BST

VDD

EXL

Core

Q

CLAMP

Figure 12. CLAMP Pin Model

V

CLAMP onVBST fullKCLAMP on

=

[Eq.5]

V

CLAMP offVBST fullKCLAMP off

=

[Eq.6]

GND

BUCKGD

BUC KSENSE

CS1680

R

BUCK( Sense)

Q

BUCK

LED +

LED -

V

BST

C

BST

D

BUCK

C

OUT

13

12

4

C4

BUCKZCD

9

L

BUCK

Figure 13. Buck Model

page 11). If the boost output voltage exceeds the

overvoltage protection threshold, a BOP fault signal is

generated. Boost overvoltage threshold V

BOP(th)

is

calculated using Equation 4:

For a nominal system design where resistor R

equals 604k and full-scale voltage V

40V, this sets threshold voltage V

BOP(th)

BST(full)

to 37.4V.

BST

equals

The control logic continuously averages this BOP fault

signal, and if at any point in time the average exceeds a

set event threshold, the boost stage is disabled.

5.3.3 Voltage Clamp Circuit

During transient events and interactions with electronic

transformers, it is possible for the boost stage to

generate more power than is consumed by the second

stage. A clamping circuit is added to the system to

dissipate the excess power. The CS1680 provides

active clamp circuitry on pin CLAMP, as shown in

Figure 12.

clamp circuit. If the cumulative turn-on time exceeds

200ms during the internally generated 2-second

window time, a COP event is actuated, disabling the

boost and buck stages. The clamp circuitry is turned off

during the fault event.

5.4 Buck Stage

The second stage is a current-regulated buck converter,

delivering the highest possible efficiency at a constant

current while minimizing line frequency ripple. A buck

stage is illustrated in Figure 13. Primary-side control is

used to simplify system design and reduce system cost

and complexity.

When operating with a dimmer, the dimming signal is

extracted in the time domain and is proportional to the

conduction angle of the dimmer. A control variable is

The clamp circuit is enabled when boost output

voltage V

voltage V

on until boost output voltage V

clamp turn-off threshold voltage V

voltage V

exceeds the clamp turn-on threshold

BST

CLAMP(on)

CLAMP(on)

. The clamp circuit will remain turned

is lowered below the

BST

CLAMP(off)

. Threshold

is calculated using Equation 5:

passed to the second stage to achieve 5% to 100%

output currents.

The buck stage control parameters assures the LED

current remains constant despite a ±10% line voltage

variation (line regulation), and the LED current remains

constant over a ± 20% variation in buck inductor

inductance.

Threshold voltage V

Equation 6:

CLAMP(off)

is calculated using

5.4.1 Buck Inductor Model

The BUCKSENSE input is used to sense the buck

inductor current. When the current reaches a certain

threshold, the gate drive turns off (output on pin

BUCKGD). The sensed current and internal calculation

are used to determine the switching period TT

Clamp Overpower Protection

The CS1680 clamp overpower protection (COP) control

logic continuously monitors the turn-on time of the

DS1055F1 11

The zero-current detect input on pin BUCKZCD is used

to determine the buck inductor zero-crossing

BUCK

.

Page 12

CS1680

I

BUCKPK max

V

BUCKPK th

R

BUCK Sense

------------------------------------ -=

[Eq.7]

I

BUCKPK OCP

V

BUCKOCP th

R

BUCK Sense

-------------------------------------=

[Eq.8]

CS1680

+

-

I

CONNECT

V

CONNECT

(th)

Comp_Out

eOTP

Control

eOTP

R

S

C

NTC

NTC

V

DD

2

(Optional)

Figure 14. eOTP Functional Diagram

period T2

time TT

BUCK

. The controller then uses the

BUCK

to determine gate turn-on time.

5.4.2 Current Sense Resistor Model

The digital algorithm ensures monotonic dimming from

5% to 100 % of the dimming range with a linear

relationship between the dimming signal and the LED

current. The buck stage is regulated by peak current

control with a 1% external sense resistor R

BUCK(Sense)

connected to the BUCKSENSE pin. Buck peak current

I

BUCKPK(max)

is calculated using Equation 7:

Overcurrent protection (OCP) is implemented by

monitoring the voltage across buck sense

resistor R

BUCK(Sense)

threshold voltage V

. If this voltage exceeds a

BUCKOCP(th)

of 1.05 V, a fault

condition occurs. The IC output is disabled, the gate

drive output pins BSTGD and BUCKGD turn off, and the

controller attempts to restart after one second. The buck

overcurrent protection current I

BUCKPK(OCP)

is

calculated using Equation 8:

5.4.3 Zero-current Detection

Zero-current switching is achieved by detecting the

buck inductor current zero-crossing using a capacitive

coupling network. The digital control algorithm rejects

line-frequency ripple created on the second-stage input

by the front-end boost stage, resulting in the highest

possible LED efficiency and long LED life.

5.5 Overtemperature Protection

The CS1680 incorporates both internal overtemperature

protection (iOTP) and the ability to connect an external

overtemperature sense circuit for IC protection. Typically, a negative temperature coefficient (NTC) thermistor is

used.

5.5.1 Internal Overtemperature Protection

Internal overtemperature protection (iOTP) is activated,

and switching is disabled when the die temperature of

the devices exceeds 135 °C. There is a hysteresis of

about 14°C before resuming normal operation.

5.5.2 External Overtemperature Protection

The external overtemperature protection (eOTP) pin is

used to implement overtemperature protection. A negative

temperature coefficient (NTC) thermistor resistive network

is connected to pin eOTP, usually in the form of a series

combination of a resistor R

and a thermistor R

S

NTC

(see

Figure 14). The CS1680 cyclically samples the resistance

connected to pin eOTP.

The total resistance on the eOTP pin gives an indication of

the temperature and is used in a digital feedback loop to

adjust current I

series resistor R

V

CONNECT(th)

of 1.25V. Current I

CONNECT

to maintain a constant reference voltage

S

into the NTC thermistor and

CONNECT

is generated

from a controlled current source with a full-scale current of

80A. When the loop is in equilibrium, the voltage on pin

eOTP fluctuates around voltage V

resistance ADC is used to generate I

CONNECT

CONNECT(th)

. A

. The ADC

output is filtered to suppress noise and compared against

a reference that corresponds to 125°C. A second low-pass

filter with a time constant of two seconds filters the ADC

output and is used to scale down the internal dim level of

the system (and hence LED current I

LED

) if the

temperature exceeds 95 °C. The large time constant for

this filter ensures that the dim scaling does not happen

spontaneously and is not noticeable (suppress spurious

glitches). The eOTP tracking circuit is designed to function

accurately with external capacitance up to 470pF.

The tracking range of this resistance ADC is approximately

15.5k to 4 M. The series resistor R

is used to adjust

S

the resistance of the NTC thermistor to fall within the ADC

tracking range, allowing the entire dynamic range of the

ADC to be well used. The CS1680 recognizes a resistance

(R

S+RNTC

) equal to 20.3k which corresponds to a

temperature of 95°C, as the beginning of an

overtemperature dimming event and starts reducing the

power dissipation. The output current is scaled until the

series resistance (R

S+RNTC

) value reaches 16.6k

(125°C). Beyond this temperature, the IC enters a fault

state and shuts down. This fault state is a latched

protection state, and the fault state is not cleared until the

power to the IC is recycled.

12 DS1055F1

Page 13

When exiting reset, the chip enters startup and the ADC

Temperature (°C)

Current (I

LED

, Nom. )

125

95

50%

100%

0

25

Figure 15. LED Current vs. eOTP Temperature

quickly (<15 ms) tracks the external temperature to check

if it is below 120°C reference code before the controller is

powered up. If this check fails, the chip will wait until this

condition becomes true before initializing the rest of the

system; that is, until the resistance (R

S+RNTC

) rises above

17.02k.

For example, a 14 k (±1% tolerance) series resistor is

required to allow measurements of up to 130°C to be

within the eOTP tracking range when a 100k NTC with a

Beta of 4275. If the temperature exceeds 95°C,

thermistor R

resistor R

is approximately 6.3k and series

NTC

is 14k, so the eOTP pin has a total resistance

S

of 20.3k. The eOTP pin initiates protective dimming

action by reducing the power dissipation. At 125°C, the

thermistor R

has 2.6k plus a series resistor RS equal

NTC

to 14k present a resistance of 16.6k at the eOTP pin

reaching the point where a thermal shutdown fault

CS1680

intervenes. The CS1680 fault state is not cleared until the

power to the IC is recycled (see Figure 15).

If the external overtemperature protection feature is not

required, connect the eOTP pin to GND using a

50k-to-500k resistor to disable the eOTP feature.

DS1055F1 13

Page 14

6. PACKAGE DRAWING

16L TSSOP (170 MIL BODY) PACKAGE DRAWING

CS1680

Dimension MIN NOM MAX MIN NOM MAX

A -- -- 1.1 -- -- 0.043

A1 0.05 -- 0.15 0.002 -- 0.006

A2 0.85 -- 0.95 0.033 -- 0.037

b 0.19 -- 0.27 0.007 -- 0.011

b1 0.19 -- 0.25 0.007 -- 0.010

c 0.13 -- 0.18 0.005 -- 0.007

c1 0.09 -- 0.14 0.004 -- 0.006

D 4.9 5 5.1 0.193 0.197 0.201

E1 4.3 4.4 4.5 0.169 0.173 0.177

E 6.3 6.4 6.5 0.248 0.252 0.256

e 0.65BSC 0.026BSC

L 0.5 0.6 0.7 .020 0.024 0.028

L1 1REF 0.039REF

Θ10°--8°0°--8°

Θ2 12°TYP 12° TYP

Θ3 12°TYP 12° TYP

R1 0.09 -- -- 0.004 -- --

mm inch

14 DS1055F1

Page 15

Dimension MIN NOM MAX MIN NOM MAX

R2 0.09 -- -- 0.004 -- --

S 0.2 -- -- 0.008 - --

aaa 0.2 0.008

bbb 0.1 0.004

ccc 0.1 0.004

ddd 0.05 0.002

Notes:

1. Controlling dimensions are in millimeters.

2. Dimensions and tolerances per ASME Y14.5 M.

3. This drawing conforms to JEDEC outline MS-012, variation AC for standard 16L TSSOP narrow body.

4. Recommended reflow profile is per JEDEC/IPC J-STD-020.

7. ORDERING INFORMATION

CS1680

mm inch

Ordering Number AC Line Voltage Temperature Package Description

CS1680-FZZ Bulk

12VAC/VDC -40 °C to +125 °C

CS1680-FZZR Tape & Reel 3.09.1

CS168002-FZZ Bulk

12VAC/VDC -40 °C to +125 °C

CS168002-FZZR Tape & Reel 3.07.2

16-lead TSSOP,

Lead (Pb) Free

16-lead TSSOP,

Lead (Pb) Free

Configuration

Version

3.09.1

3.07.2

8. ENVIRONMENTAL, MANUFACTURING, & HANDLING INFORMATION

Part Number Peak Reflow Temp MSL Rating

CS1680-FZZ 260 °C 3 7 Days

CS168002-FZZ 260 °C 3 7 Days

a. MSL (Moisture Sensitivity Level) as specified by IPC/JEDEC J-STD-020.

b. Stored at 30°C, 60% relative humidity.

a

Max Floor Life

b

DS1055F1 15

Page 16

REVISION HISTORY

Contacting Cirrus Logic Support

For all product questions and inquiries contact a Cirrus Logic Sales Representative.

To find one nearest you go to http://www.cirrus.com

IMPORTANT NOTICE

Cirrus Logic, Inc. and its subsidiaries (“Cirrus”) believe that the information contained in this document is accurate and reliable. However, the information is subject

to change without notice and is provided “AS IS” without warranty of any kind (express or implied). Customers are advised to obtain the latest version of relevant

information to verify, before placing orders, that information being relied on is current and complete. All products are sold subject to the terms and conditions of sale

supplied at the time of order acknowledgment, including those pertaining to warranty, indemnification, and limitation of liability. No responsibility is assumed by Cirrus

for the use of this information, including use of this information as the basis for manufacture or sale of any items, or for infringement of patents or other rights of third

parties. This document is the property of Cirrus and by furnishing this information, Cirrus grants no license, express or implied under any patents, mask work rights,

copyrights, trademarks, trade secrets or other intellectual property rights. Cirrus owns the copyrights associated with the information contained herein and gives consent for copies to be made of the information only for use within your organization with respect to Cirrus integrated circuits or other products of Cirrus. This consent

does not extend to other copying such as copying for general distribution, advertising or promotional purposes, or for creating any work for resale.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL APPLICATIONS”). CIRRUS PRODUCTS ARE NOT DESIGNED, AUTHORIZED OR WARRANTED FOR USE

IN PRODUCTS SURGICALLY IMPLANTED INTO THE BODY, AUTOMOTIVE SAFETY OR SECURITY DEVICES, LIFE SUPPORT PRODUCTS OR OTHER CRITICAL APPLICATIONS. INCLUSION OF CIRRUS PRODUCTS IN SUCH APPLICATIONS IS UNDERSTOOD TO BE FULLY AT THE CUSTOMER'S RISK AND CIRRUS DISCLAIMS AND MAKES NO WARRANTY, EXPRESS, STATUTORY OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR PARTICULAR PURPOSE, WITH REGARD TO ANY CIRRUS PRODUCT THAT IS USED IN SUCH A MANNER. IF THE CUSTOMER OR CUSTOMER'S CUSTOMER USES OR PERMITS THE USE OF CIRRUS PRODUCTS IN CRITICAL APPLICATIONS, CUSTOMER AGREES, BY SUCH USE, TO FULLY

INDEMNIFY CIRRUS, ITS OFFICERS, DIRECTORS, EMPLOYEES, DISTRIBUTORS AND OTHER AGENTS FROM ANY AND ALL LIABILITY, INCLUDING ATTORNEYS' FEES AND COSTS, THAT MAY RESULT FROM OR ARISE IN CONNECTION WITH THESE USES.

Use of the formulas, equations, calculations, graphs, and/or other design guide information is at your sole discretion and does not guarantee any specific results or

performance. The formulas, equations, graphs, and/or other design guide information are provided as a reference guide only and are intended to assist but not to be

solely relied upon for design work, design calculations, or other purposes. Cirrus Logic makes no representations or warranties concerning the formulas, equations,

graphs, and/or other design guide information.

Cirrus Logic, Cirrus, the Cirrus Logic logo designs, EXL Core, and the EXL Core logo design are trademarks of Cirrus Logic, Inc. All other brand and product names

in this document may be trademarks or service marks of their respective owners.

Revision Date Changes

PP1 JAN 2014 Content updates for revision B silicon

PP2 FEB 2014 Content update for configuration version 3.07.2

F1 OCT 2014 Final release

CS1680

16 DS1055F1

Loading...

Loading...