Page 1

CS1630

D7

R13

NTC

Z2

BR1 BR1

AC

Mains

C7

L1

D2

BR1 BR 1

D5

C8

R11

L2

D6

C2

R4

R8

R14

R6

R7

Q4

Q2

Z1 C4

CS1630 /31

IAC

SOURCE

FBAUX

BSTOUT

GNDSGND

13

16

5

4

CLAMP

GD

FBSENSE

eOTP

15

10

12

11

1

2

BSTAUX

C3

R2

D1

Q3

R10

3

R

S

C

NTC

T1

R1

C1

R5

C6

D4

D3

C5

Q1

R9

R3

V

BST

V

rect

14

VDD

R12

D9

C9

C11

C12

D11

D8

R15 D10

Q5

R16

C10

Z3

IGND

LED2 +

LED 1+

LED 1-

LED2 -

D

GND

_QVCC

CS1631

2-Channel TRIAC Dimmable LED Driver IC

Features

• Best-in-class Dimmer Compatibility

- Leading-edge (TRIAC) Dimmers

- Trailing-edge Dimmers

- Digital Dimmers (with Integrated Power Supply)

• Correlated Color Temperature (CCT) Control System

• Up to 85% Efficiency

• Flicker-free Dimming

• Programmable Dimming Profile

- Constant CCT Dimming

- Black Body Line Dimming

• 0% Minimum Dimming Level

• Temperature Compensated LED Current

• End-of-line Programming Using Power Line Calibration

- Lower LED Binning Requirement

• Programmable Series or Parallel Two-Channel Output

- Interleaved Output Eliminates Additional Transformer

• Programmable Quasi-resonant Second Stage with

Constant-current Output

- Flyback, Buck, and Tapped Buck

• Register Lockout

• Fast Startup

• Tight LED Current Regulation: Better than ±5%

• Primary-side Regulation (PSR)

• >0.9 Power Factor

• IEC-61000-3-2 Compliant

• Soft Start

• Protections:

- Output Open/Short

- Current-sense Resistor Open/Short

- External Overtemperature Using NTC

Overview

The CS1630 and CS1631 are high-performance offline AC /DC

LED drivers for dimmable and high color rendering index (CRI)

LED replacement lamps and luminaires. They feature Cirrus

Logic’s proprietary digital dimmer compatibility control technology

and digital correlated color temperature (CCT) control system that

enables two-channel LED color mixing. The CS1630 is designed

for 120VAC line voltage applications, and the CS1631 is

optimized for 230VAC line voltage applications.

The CS1630/31 integrates a critical conduction mode boost

converter, providing power factor correction and superior dimmer

compatibility with a primary-side regulated quasi-resonant second

stage, which is configurable for isolated and non-isolated

topologies. The digital CCT control system provides the ability to

program dimming profiles, such as constant CCT dimming and

black body line dimming. The CS1630/31 optimizes LED color

mixing by temperature compensating LED current with an

external NTC. The IC controller is also equipped with power line

calibration for remote system calibration and end-of-line

programming. The CS1630/31 provides a register lockout feature

for security against potential access to proprietary registers.

Applications

• Dimmable Retrofit LED Lamps and LED Luminaries

• High CRI Lighting

• Offline LED Drivers

• Commercial Lighting

Ordering Information

See page 55.

Cirrus Logic, Inc.

http://www.cirrus.com

Copyright Cirrus Logic, Inc. 2013

(All Rights Reserved)

APR’13

DS954F3

Page 2

CS1630/31

TABLE OF CONTENTS

1.INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.PIN DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.CHARACTERISTICS AND SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2

3.2 I

C™ Port Switching Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.3 Power Line Calibration Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.4 Thermal Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.5 Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

4.TYPICAL PERFORMANCE PLOTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5.2 Startup Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5.3 Dimmer Switch Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5.3.1 Dimmer Learn Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.3.2 Dimmer Validate Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.3.3 No-dimmer Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.3.4 Leading-edge Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.3.5 Trailing-edge Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.4 Correlated Color Temperature Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

5.5 Dimming Signal Extraction and the Dim Mapping Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

5.6 Boost Stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

5.6.1 Maximum Peak Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.6.2 Output BSTOUT Sense & Input IAC Sense. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.6.3 Boost Auxiliary Winding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.6.4 Boost Overvoltage Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.7 Voltage Clamp Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

5.7.1 Clamp Overpower Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.8 Quasi-resonant Second Stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

5.8.1 Series & Parallel Two-Channel Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.8.2 Primary-side Current Control for Two-Channel Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.8.3 Auxiliary Winding Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.8.4 Control Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.8.5 Frequency Dithering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.8.6 Output Open Circuit Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.8.7 Overcurrent Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.8.8 Open Loop Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.9 Overtemperature Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

5.9.1 Internal Overtemperature Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.9.2 External Overtemperature Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.10 Power Line Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

5.10.1 Power Line Calibration Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.10.2 PLC Program Mode Characters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.10.3 Calibration Mode Operation Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.10.4 Register Lockout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2

5.11 I

C™ Communication Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

5.11.1 I

5.11.2 Control Port Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.11.3 Read Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.11.4 Write Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.11.5 Customer I

5.12 OTP Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.12.1 Programming the OTP Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2

C Control Port Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2

C Lockout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2 DS954F3

Page 3

CS1630/31

6.ONE-TIME PROGRAMMABLE (OTP) REGISTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.1 Registers Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

6.2 Configuration 0 (Config0) – Address 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

6.3 Lockout Key (LOCK0, LOCK1, LOCK2, LOCK3) – Address 1 - 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

6.4 Color Polynomial Coefficient (P30, P20, P10, P03, P02, P01, P21, P12, P11, P00) – Address 5 - 24 . . . . . . . . . . . .29

6.5 Color Polynomial Coefficient (Q3, Q2, Q1, Q0) – Address 25 - 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

6.6 Gate Drive Duration (GD_DUR) – Address 33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

6.7 Configuration 2 (Config2) – Address 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

6.8 Configuration 3 (Config3) – Address 35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

6.9 Configuration 4 (Config4) – Address 36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.10 Second Stage Dim (S2DIM) – Address 37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.11 Maximum TT (TTMAX) – Address 38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.12 Configuration 7 (Config7) – Address 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

6.13 Configuration 8 (Config8) – Address 40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

6.14 Channel 1 Output Current (CH1CUR) – Address 41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

6.15 Configuration 10 (Config10) – Address 42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

6.16 Channel 2 Output Current (CH2CUR) – Address 43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

6.17 Configuration 12 (Config12) – Address 44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

6.18 PU Coefficient (PID) – Address 45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

6.19 Maximum Switching Frequency (TTFREQ) – Address 46 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

6.20 Configuration 15 (Config15) – Address 47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

6.21 Configuration 16 (Config16) – Address 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

6.22 Configuration 17 (Config17) – Address 49 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

6.23 Configuration 18 (Config18) – Address 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

6.24 Peak Current (PEAK_CUR) – Address 51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

6.25 Configuration 38 (Config38) – Address 70 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

6.26 Configuration 44 (Config44) – Address 76 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

6.27 Configuration 45 (Config45) – Address 77 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

6.28 Configuration 46 (Config46) – Address 78 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

6.29 Configuration 47 (Config47) – Address 79 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

6.30 Configuration 48 (Config48) – Address 80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

6.31 Configuration 49 (Config49) – Address 81 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

6.32 Configuration 50 (Config50) – Address 82 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

6.33 Configuration 51 (Config51) – Address 83 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

6.34 Configuration 52 (Config52) – Address 84 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

6.35 Configuration 53 (Config53) – Address 85 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

6.36 Configuration 54 (Config54) – Address 86 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

6.37 Configuration 55 (Config55) – Address 87 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

6.38 PLC Dim (PLC_DIM) – Address 89 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

6.39 Configuration 58 (Config58) – Address 90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

6.40 Configuration 59 (Config59) – Address 91 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

6.41 Configuration 60 (Config60) – Address 92 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

6.42 Configuration 61 (Config61) – Address 93 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

6.43 Configuration 62 (Config62) – Address 94 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

6.44 CRC Tag (CRC_TAG) – Address 102 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

6.45 Channel 1 Color Calibration 3A (CH1_CAL3A) – Address 119 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

6.46 Channel 2 Color Calibration 3A (CH2_CAL3A) – Address 120 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

6.47 CRC Memory Tag 3A (CRC_MTAG3A) – Address 121 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

6.48 Channel 1 Color Calibration 3B (CH1_CAL3B) – Address 122 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

6.49 Channel 2 Color Calibration 3B (CH2_CAL3B) – Address 123 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

6.50 CRC Memory Tag 3B(CRC_MTAG3B) – Address 124 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

6.51 Channel 1 Color Calibration 3C (CH1_CAL3C) – Address 125 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

6.52 Channel 2 Color Calibration 3C (CH2_CAL3C) – Address 126 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

6.53 CRC Memory Tag 3C (CRC_MTAG3C) – Address 127 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

7.PACKAGE DRAWING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.ORDERING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

9.ENVIRONMENTAL, MANUFACTURING, & HANDLING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . 55

10.REVISION HISTORY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

DS954F3 3

Page 4

1. INTRODUCTION

V

Z

POR

+

-

Volt age

Regul ator

14

VDD

11

FBSENSE

+

-

15

FBAUX

+

-

13

GD

2

IAC

DAC

+

-

Peak

Contr ol

Fl yback Z CD

+

-

Output O pen

12

GND

OLP

+

-

16

BSTOUT

OCP

+

-

1

BSTAUX

Boost Z CD

3

CLAMP

V

ST(th )

V

STP(th )

V

OCP(th)

V

FBZC D(th)

V

OVP (th )

V

OLP(th)

V

FBZC D(th)

V

Pk_Max(th)

10

4

SGND

5

SOURCE

+

-

+

-

VDD

I

CONNECT

V

CONNECT(th)

V

SOURCE(th)

7

SCL

6

SDA

8

NC

9

SYNC

eOTP

15 k

ADC

MUX

15k

VDD

I

ref

t

FBZC D

I

CLAMP

t

BSTZCD

I

SOURCE

Blank 3

CS1630/31

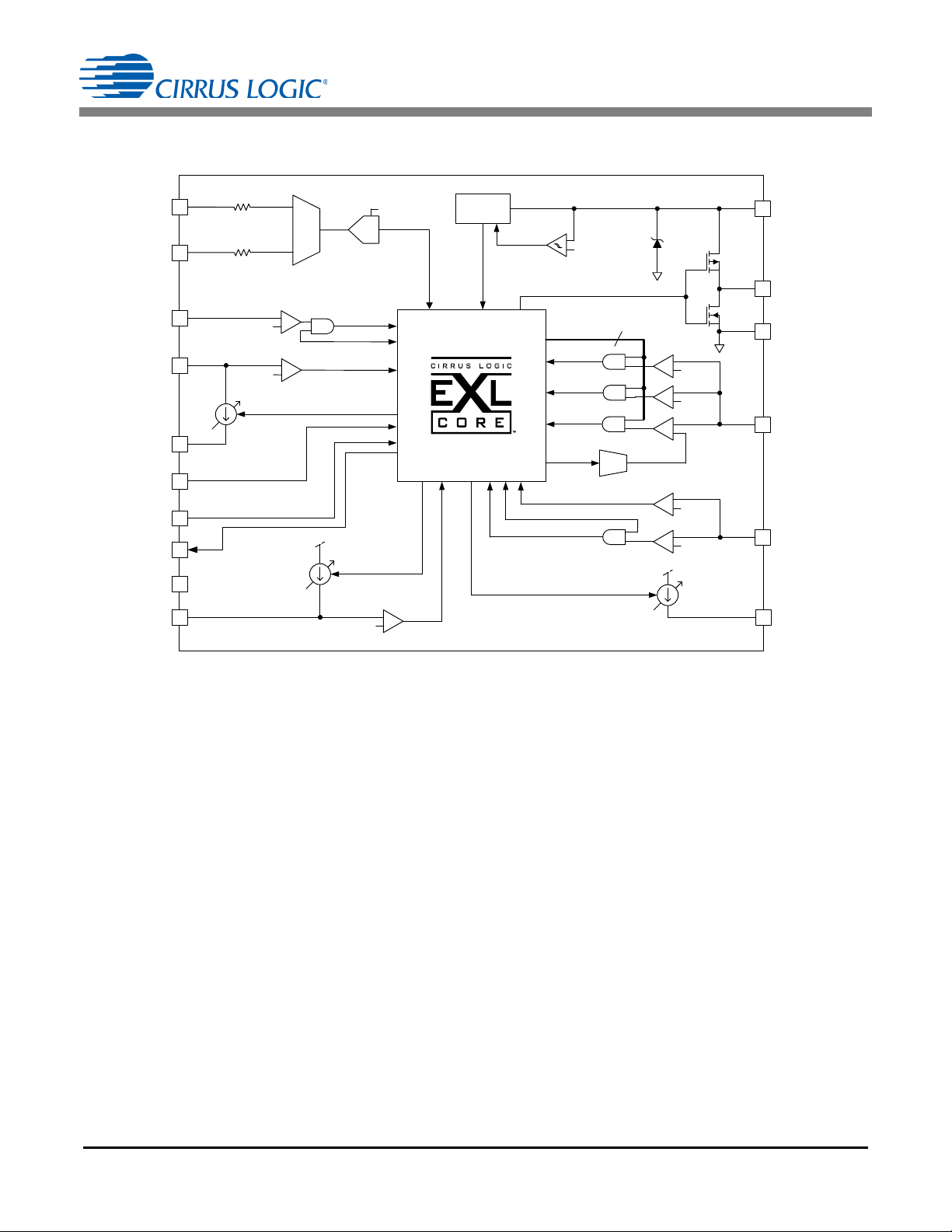

Figure 1. CS1630/31 Block Diagram

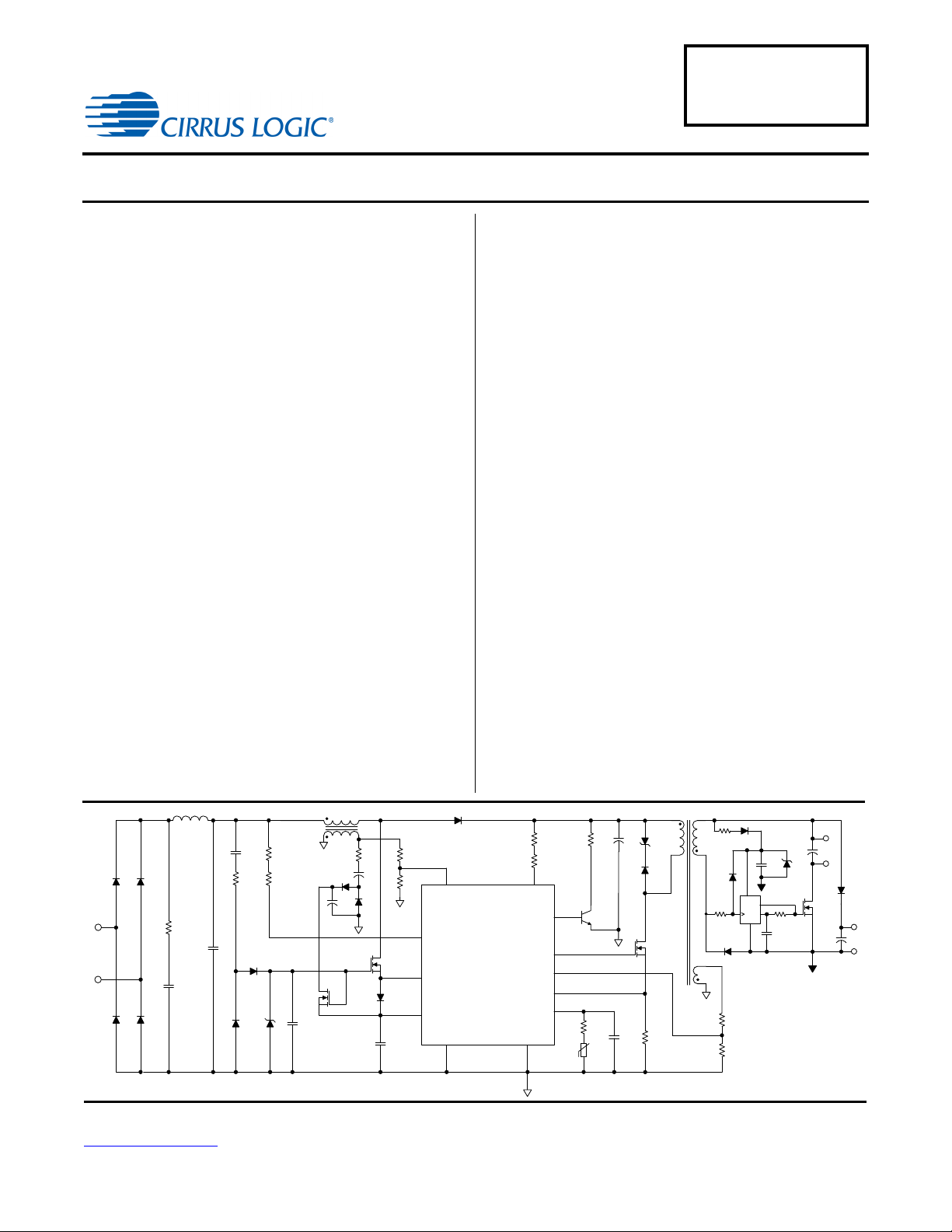

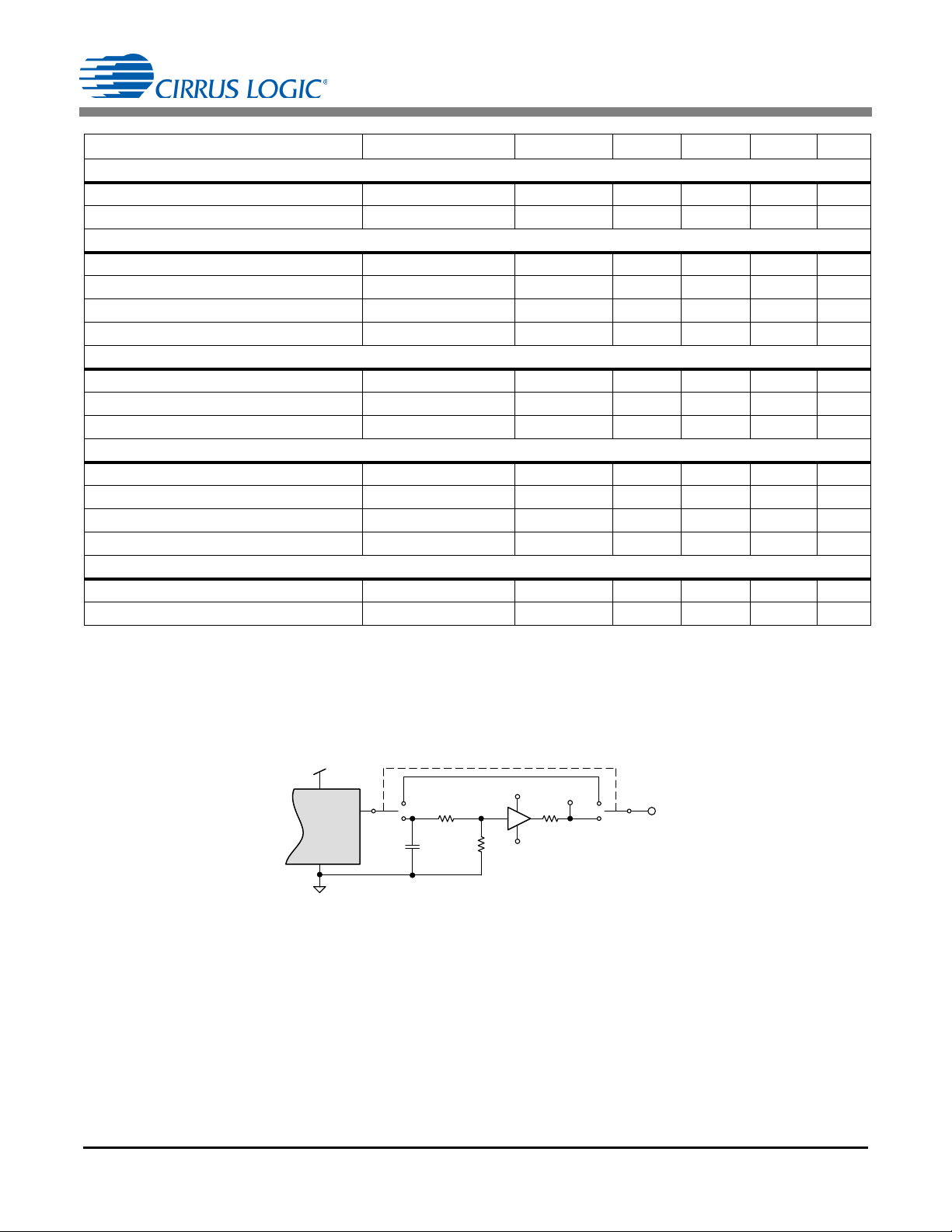

A typical schematic using the CS1630/31 IC is shown on the

front page.

Startup current is provided from a patent-pending, external

high-voltage source-follower network. In addition to providing

startup current, this unique topology is integral in providing

compatibility with digital dimmers by ensuring V

always available to the IC. During steady-state operation, an

auxiliary winding on the boost inductor back-biases the

DD

power is

source-follower circuit and provides steady-state operating

current to the IC to improve system efficiency.

The rectified input voltage is sensed as a current into pin IAC

and is used to control the adaptive dimmer compatibility

algorithm and extract the phase of the input voltage for output

dimming control. During steady-state operation, the external

high-voltage, source-follower circuit is source-switched in

critical conduction mode (CRM) to boost the input voltage.

This allows the boost stage to maintain good power factor,

provide dimmer compatibility, reduce bulk capacitor ripple

current, and provide a regulated input voltage to the second

stage.

The current into the boost output voltage sense pin BSTOUT

senses the output voltage of the CRM boost front-end.

4 DS954F3

The quasi-resonant second stage is implemented with peakcurrent mode primary-side control, which eliminates the need

for additional components to provide feedback from the

secondary and reduces system cost and complexity.

Voltage across an external user-selected resistor is sensed

through pin FBSENSE to control the peak current through the

second stage inductor. Leading-edge and trailing-edge

blanking on pin FBSENSE prevents false triggering.

Pin FBAUX is used to sense the second stage inductor

demagnetization to ensure quasi-resonant switching of the

output stage.

An internal current source is adjusted by a feedback loop to

regulate a constant reference voltage on pin eOTP for external

negative temperature coefficient (NTC) thermistor

measurements. An external NTC is connected to pin eOTP to

provide thermal protection of the system and LED temperature

compensation. The output current of the system is steadily

reduced when the system temperature exceeds a

programmable temperature set point. If the temperature

reaches a designated high set point, the IC is shutdown and

stops switching.

Page 5

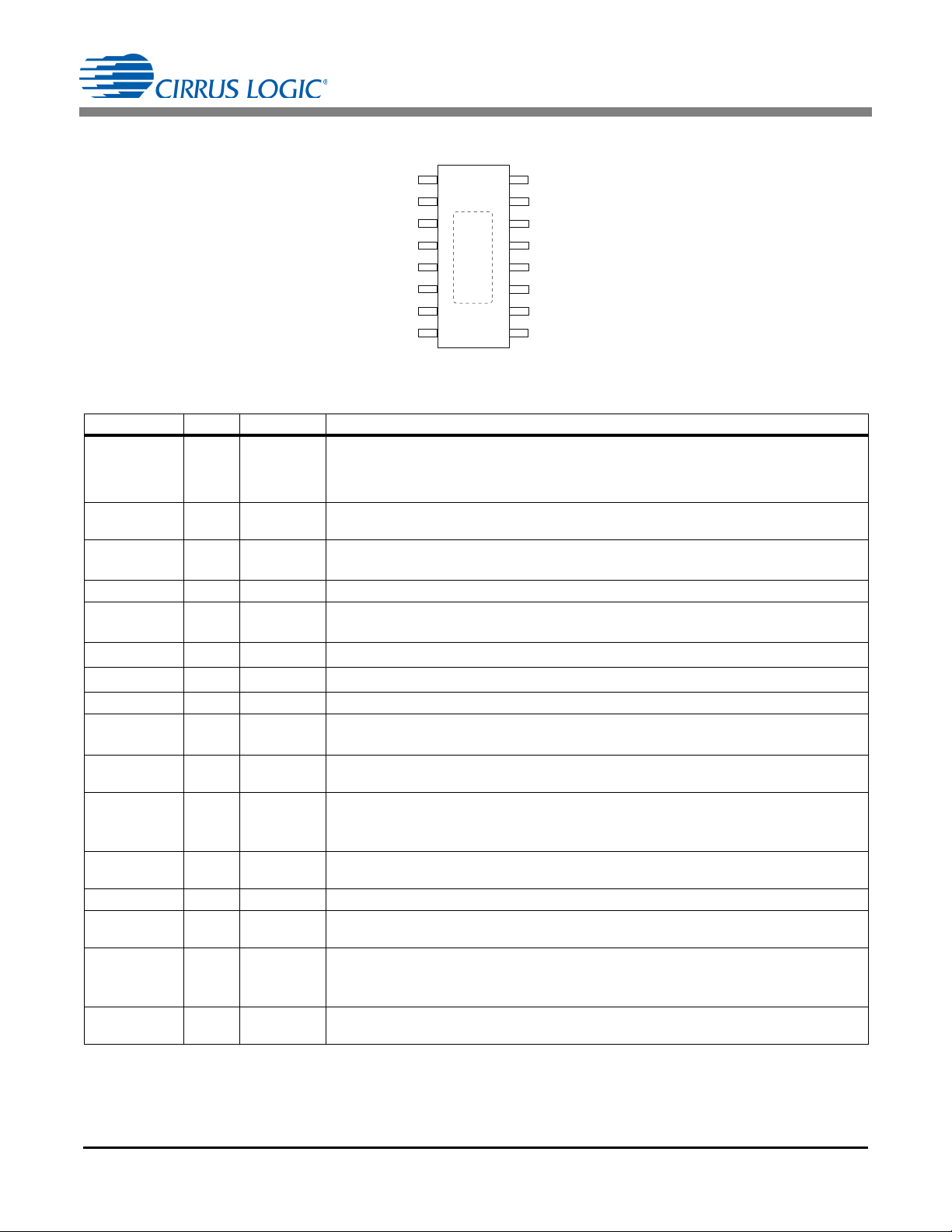

2. PIN DESCRIPTION

I2C Clock

Source Switch

Source Ground

Boost Zero-current Detect

Rectifier Voltage Sense

No Connection

SCL

SDAI

2

C Data

SOURCE

SGND

BSTAUX

eOTP

FBSENSE

GND

GD Gate Driver

VDD

IC Supply Voltage

FBAUX

Second Stage Zero-current Detect

BSTOUT

Boost Output Voltage Sense

IAC

CLAMP

V

oltage Clamp Current Source

16-lead SOIC

NC

SYNC

7

6

5

4

3

2

1

10

11

12

13

14

15

16

8

9

External Overtemperature Protection

Second Stage Current Sense

Ground

Second Stage Synchronization

Figure 2. CS1630/31

CS1630/31

Pin Name

BSTAUX

IAC

CLAMP

SGND

SOURCE

SDA

SCL

NC

SYNC

eOTP

FBSENSE

GND

GD

VDD

FBAUX

BSTOUT

DS954F3 5

Pin # I/O

1IN

2IN

3OUT

4PWR

5IN

6 I/O

7IN

8-

9OUT

10 IN

11 IN

12 PWR

13 OUT

14 PWR

15 IN

16 IN

Description

Boost Zero-current Detect — Boost Inductor demagnetization sensing input for

zero-current detection (ZCD) information. The pin is connected to the PFC boost

inductor auxiliary winding through an external resistor divider.

Rectifier Voltage Sense — A current proportional to the rectified line voltage is fed

into this pin. The current is measured with an A/D converter.

Voltage Clamp Current Source — Connect to a voltage clamp circuit on the output

of the boost stage.

Source Ground — Common reference current return for the SOURCE pin.

Source Switch — Connected to the source of the boost stage external high-voltage

FET.

I2C™ Data — I2C data.

I2C™ Clock — I2C clock.

No Connection — Leave pin unconnected.

Second Stage Synchronization — A digital synchronization signal that indicates

which channel the controller is signaling for each gate switching period.

External Overtemperature Protection — Connect an external NTC thermistor to

this pin, allowing the internal A/D converter to sample the change to NTC resistance.

Second Stage Current Sense — The current flowing in the second stage FET is

sensed across a resistor. The resulting voltage is applied to this pin and digitized for

use by the second stage computational logic to determine the FET's duty cycle.

Ground — Common reference. Current return for both the input signal portion of the

IC and the gate driver.

Gate Driver — Gate drive for the second stage power FET.

IC Supply Voltage

— Connect a storage capacitor to this pin to serve as a reservoir for

operating current for the device, including the gate drive current to the power transistor.

Second Stage Zero-current Detect — Second stage inductor sensing input. The

pin is connected to the second stage inductor’s auxiliary winding through an external

resistor divider.

Boost Output Voltage Sense — A current proportional to the boost output is fed

into this pin. The current is measured with an A/D converter.

Page 6

CS1630/31

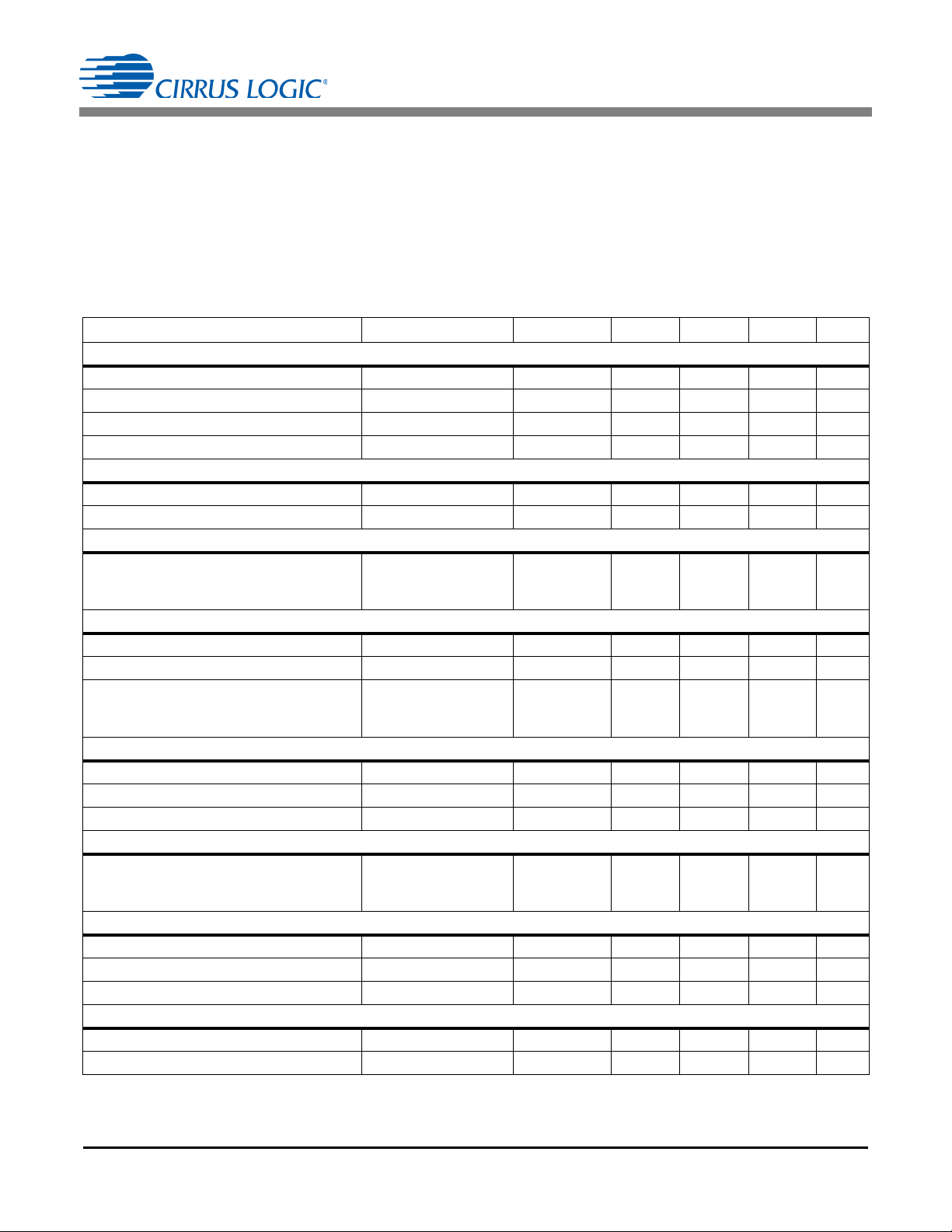

3. CHARACTERISTICS AND SPECIFICATIONS

3.1 Electrical Characteristics

Typical characteristics conditions:

=25ºC, VDD= 12V, GND = 0V

•T

A

• All voltages are measured with respect to GND.

• Unless otherwise specified, all currents are positive

when flowing into the IC.

Parameter Condition Symbol Min Typ Max Unit

VDD Supply Voltage

Operating Range After Turn-on V

Turn-on Threshold Voltage V

Turn-off Threshold Voltage (UVLO) V

Zener Voltage (Note 1) I

Increasing V

DD

Decreasing V

DD

=20mA V

DD

VDD Supply Current

Startup Supply Current V

Operating Supply Current (Note 5)

DD<VST(th)

CL= 0.25nF, Fsw60 kHz

Reference

Reference Current

V

CS1630

CS1631

= 200 V

BST

V

= 400 V

BST

Boost

Maximum Switching Frequency f

Clamp Current I

Dimmer Attach Peak Current

CS1630

CS1631

108 V

207 V

line

line

Boost Zero-current Detect

BSTZCD Threshold V

ZCD Sink Current (Note 2) I

BSTAUX Upper Voltage I

BSTZCD

Boost Protection

Clamp Turn-on

CS1630

CS1631

108 V

207 V

line

line

Second Stage Zero-current Detect

FBZCD Threshold V

ZCD Sink Current (Note 2) I

FBAUX Upper Voltage I

=1mA - VDD+0.6 - V

FBZCD

Second Stage Current Sense

Peak Control Threshold V

Delay to Output --100ns

Minimum/Maximum characteristics conditions:

= -40°C to +125°C, VDD= 11V to 17V, GND = 0 V

•T

J

DD

ST(th)

STP(th)

Z

I

ST

11 - 17 V

-8.5-V

-7.5-V

18.5 - 19.8 V

--200A

-5.8-mA

132

253

I

ref

BST(Max)

CLAMP

BSTZCD(th)

BSTZCD

-

-

--200kHz

--3.8-mA

-

-

-200-mV

-2 - - mA

133

133

590

508

-

-

-

-

A

A

mA

mA

=1mA - VDD+0.6 - V

132

253

FBZCD(th)

FBZCD

Pk_Max(th)

-

-

-200-mV

-2 - - mA

-1.4-V

146.7

141.7

-

-

A

A

6 DS954F3

Page 7

CS1630/31

GD OU T

GD

GND

VDD

Buffer

S

1

R

1

R

2

R

3

TP

+15V

-15V

S

2

V

DD

C

L

0.25 nF

Parameter Condition Symbol Min Typ Max Unit

Second Stage Pulse Width Modulator

Minimum Switching Frequency t

Maximum Switching Frequency t

FB(Min)

FB(Max)

Second Stage Gate Driver

Output Source Resistance

Output Sink Resistance

Rise Time (Note 5)

Fall Time (Note 5)

VDD=12V

VDD=12V

CL=0.25nF

CL=0.25nF

Second Stage Protection

Overcurrent Protection (OCP) V

Overvoltage Protection (OVP) V

Open Loop Protection (OLP) V

OCP(th)

OVP(th)

OLP(th)

External Overtemperature Protection (eOTP)

Pull-up Current Source – Maximum I

CONNECT

Conductance Accuracy (Note 3) - - ±5

Conductance Offset (Note 3) - ± 250 - nS

Current Source Voltage Threshold V

CONNECT(th)

Internal Overtemperature Protection (iOTP)

Thermal Shutdown Threshold (Note 4) T

Thermal Shutdown Hysteresis (Note 4) T

Notes: 1. The CS1630/31 has an internal shunt regulator that limits the voltage on the VDD pin. VZ, the shunt regulation voltage, is defined

in the VDD Supply Voltage section on page 6.

2. External circuitry should be designed to ensure that the ZCD current drawn from the internal clamp diode when it is forward biased

does not exceed specification.

3. Conductance is the inverse of resistance (1/) and is expressed in siemens (S). A decrease in conductance is equivalent to an

increase in resistance.

4. Specifications are guaranteed by design and are characterized and correlated using statistical process methods.

5. For test purposes, load capacitance (C

) is 0.25nF and is connected as shown in the following diagram.

L

SD

SD(Hy)

-625-Hz

-200-kHz

-24-

-11-

--30ns

--20ns

-1.69-V

-1.25-V

-200-mV

-80-A

-1.25-V

-135-ºC

-14-ºC

DS954F3 7

Page 8

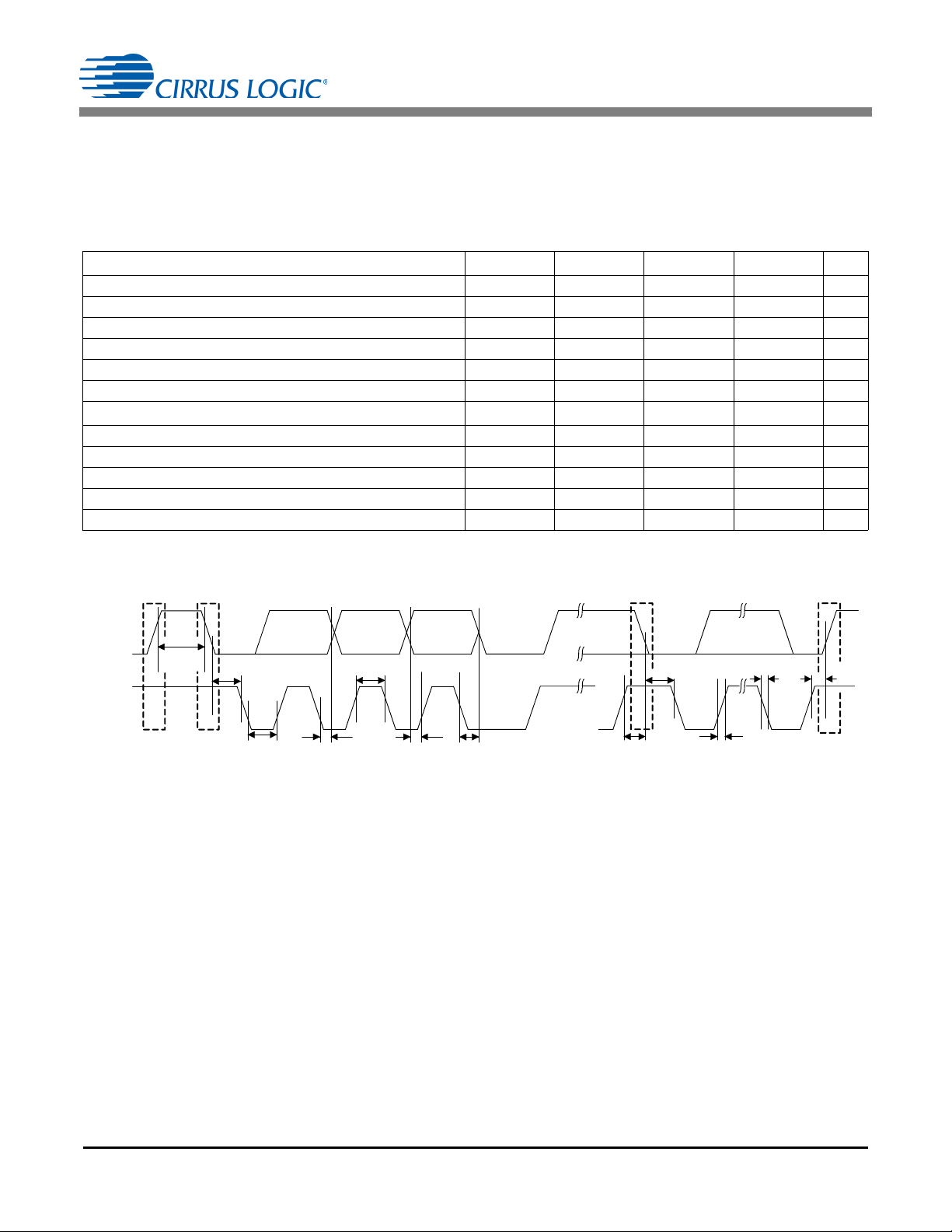

3.2 I2C™ Port Switching Characteristics

Stop

SDA

SCL

t

f

t

susp

Stop

t

r

t

hdst

t

sust

t

hddo

t

sud

t

high

t

hddi

t

low

t

hdst

t

buf

Start

Repeated

Start

Test conditions (unless otherwise specified):

• Inputs: Logic 0 = GND = 0 V, Logic 1 = 3.3 V.

• The CS1630 / 31 control port only supports I

• It is recommended that a 2.2 k pull-up resistor be placed from the SDA pin to V

Parameter Symbol Min Typ Max Unit

SCL Clock Frequency f

Bus Free Time Between Transmissions t

Start Condition Hold Time (prior to first clock pulse) t

Clock Low time t

Clock High Time t

Setup Time for Repeated Start Condition t

SDA Input Hold Time from SCL Falling

SDA Setup time to SCL Rising t

Setup Time for Stop Condition t

SDA Input Voltage Low V

SDA Input Voltage High V

SDA Output Voltage Low V

2

C slave functionality.

scl

buf

hdst

low

high

sust

t

hddi

sud

susp

il

ih

ol

CS1630/31

.

DD

--400kHz

1.3 - - µs

0.6 - - µs

1.3 - - µs

0.6 - - µs

0.6 - - µs

0-0.9µs

100 - - ns

0.6 - - µs

-1.5-V

-1.85-V

-0.25-V

8 DS954F3

Page 9

CS1630/31

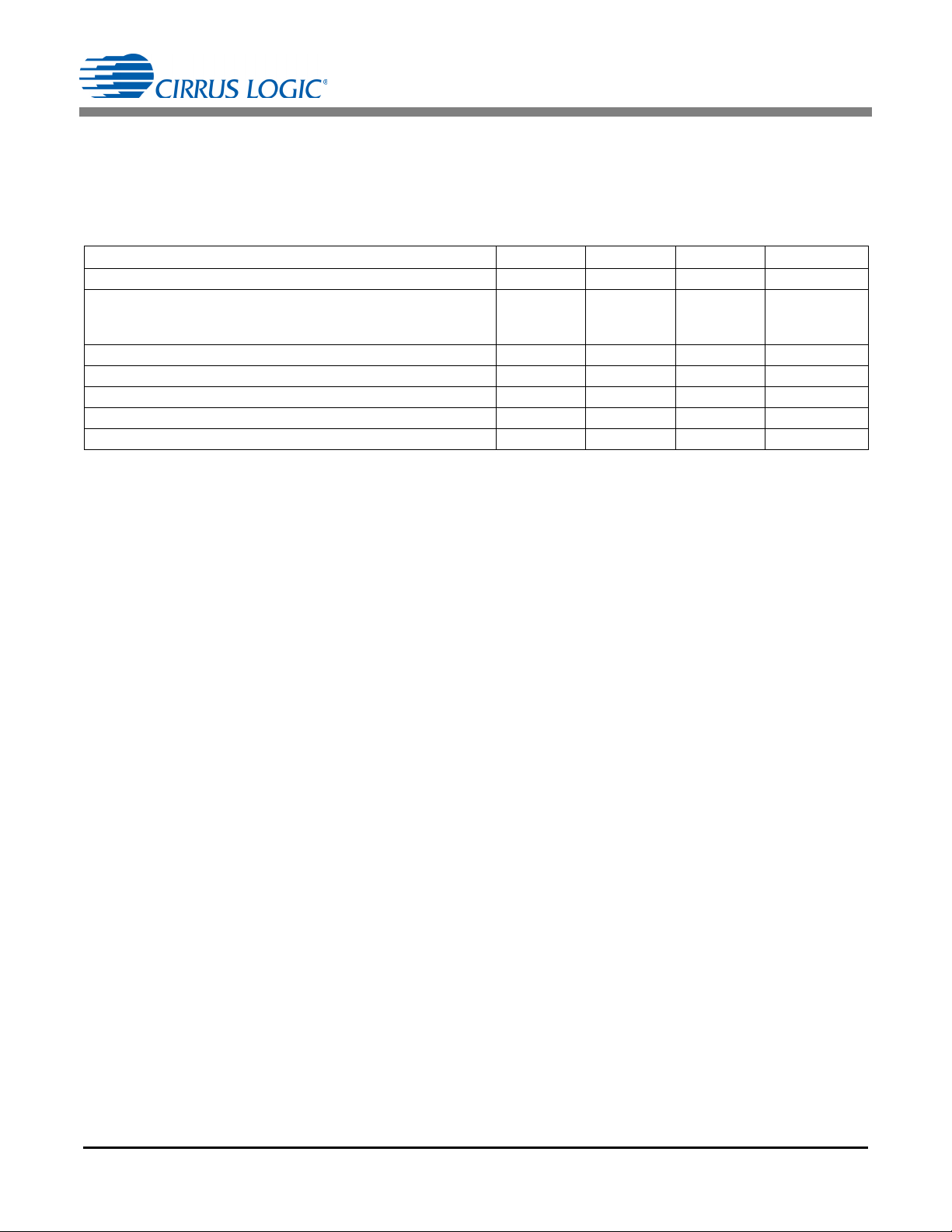

3.3 Power Line Calibration Characteristics

Typical characteristics conditions:

•TA=25ºC, VDD= 12V, GND = 0V

• All voltages are measured with respect to GND.

• Unless otherwise specified, all current is positive when

flowing into the IC.

Parameter (Note 6) Min Typ Max Units

Input Line Frequency (Note 7) 47 50/60 63 Hz

Input Voltage (Note 7)

CS1630

CS1631

Dual-bit 00 (“00”) 24 34 44 Degrees

Dual-bit 01 (“01”) 52 62 72 Degrees

Dual-bit 10 (“10”) 108 118 128 Degrees

Dual-bit 11 (“11”) 136 146 156 Degrees

Special Character (SC) 80 90 100 Degrees

Notes: 6. The CS1630/31 supports leading-edge phase-cut waveforms only for power line calibration.

7. Range is recommended for power line calibration operation only.

Minimum/Maximum characteristics conditions:

TJ=25ºC, VDD= 11V to 17V, GND = 0 V

114

218

120

230

126

242

V

V

DS954F3 9

Page 10

CS1630/31

3.4 Thermal Resistance

Symbol Parameter Value Unit

Junction-to-ambient Thermal Impedance 2 Layer PCB

JA

Junction-to-case Thermal Impedance 2 Layer PCB

JC

4 Layer PCB

4 Layer PCB

3.5 Absolute Maximum Ratings

Characteristics conditions:

All voltages are measured with respect to GND.

Pin Symbol Parameter Value Unit

14 V

1, 2, 5, 6, 7, 9,

10, 11, 15, 16

1, 2, 6, 7, 9, 10,

11,15,16

13 V

13 I

5I

SOURCE

3I

-P

-T

-T

All Pins ESD

DD

GD

GD

CLAMP

Stg

IC Supply Voltage 18.5 V

Analog Input Maximum Voltage -0.5 to (V

Analog Input Maximum Current 5 mA

Gate Drive Output Voltage -0.3 to (VDD+0.3) V

Gate Drive Output Current -1.0 / +0.5 A

Current into Pin 1.1 A

Clamp Output Current 5 mA

Total Power Dissipation 400 mW

D

Junction Temperature Operating Range (Note 8) -40 to +125 ºC

J

Storage Temperature Range -65 to +150 ºC

Electrostatic Discharge Capability Human Body Model

Charged Device Model

84

47

39

31

DD

2000

500

°C/W

°C/W

°C/W

°C/W

+0.5) V

V

V

Note: 8. Long-term operation at the maximum junction temperature will result in reduced product life. Derate internal power dissipation at

the rate of 50mW/ ºC for variation over temperature.

WARNING:

Operation at or beyond these limits may result in permanent damage to the device.

Normal operation is not guaranteed at these extremes.

10 DS954F3

Page 11

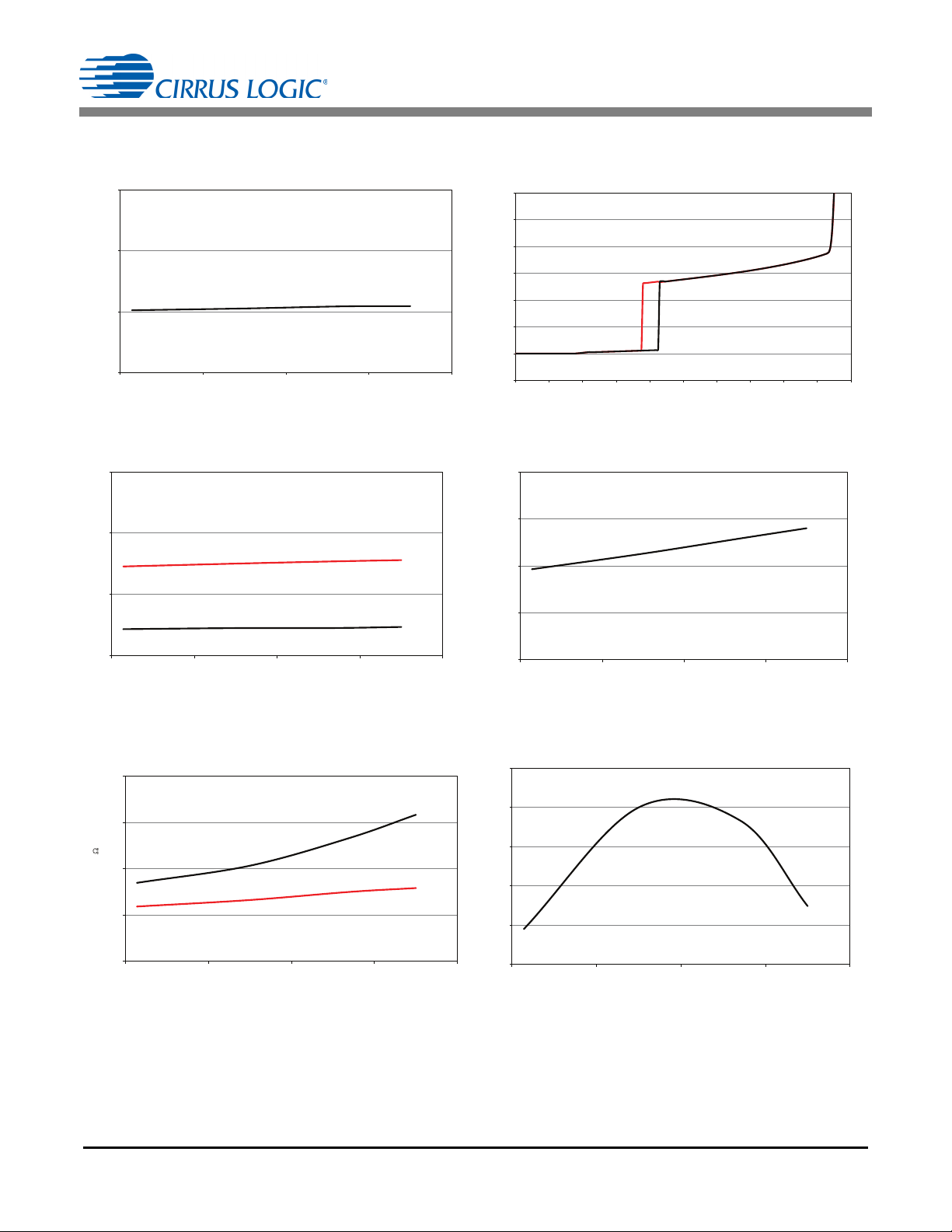

4. TYPICAL PERFORMANCE PLOTS

0

1

2

3

-50 0 50 100 150

UVLO Hysteresis

Temperature (°C)

-2

0

2

4

6

8

10

12

0 2 4 6 8 10 12 14 16 18 20

I

DD

(mA)

VDD(V)

7

8

9

10

-50 0 50 10 0 150

VDD (V)

Temperature (

°C)

Turn On

Turn Off

18

18.5

19

19.5

20

-50 0 50 100 150

V

Z

(V)

Temperature (C°)

0

10

20

30

40

-50 0 50 100 150

Z

OUT

(:)

Temperature (ºC)

Source

Sink

-2

-1.5

-1

-0.5

0

0.5

-50 0 50 100 150

Drift (%)

Temperature (°C)

CS1630/31

Figure 3. UVLO Characteristics

Figure 5. Turn-on/off Threshold Voltage vs. Temperature

Figure 4. Supply Current vs. Voltage

Figure 6. Zener Voltage vs. Temperature

Figure 7. Gate Drive Resistance vs. Temperature

DS954F3 11

Figure 8. Reference Current (I

) Drift vs. Temperature

ref

Page 12

5. GENERAL DESCRIPTION

5.1 Overview

The CS1630 and CS1631 are high-performance offline AC /DC

LED drivers for dimmable and high color rendering index (CRI)

LED replacement lamps and luminaires. They feature Cirrus

Logic’s proprietary digital dimmer compatibility control

technology and digital correlated color temperature (CCT) control

system that enables two-channel LED color mixing. The CS1630

is designed for 120VAC line voltage applications, and the

CS1631 is optimized for 230VAC line voltage applications.

The CS1630/31 integrates a critical conduction mode (CRM)

boost converter, providing power factor correction and superior

dimmer compatibility with a primary-side regulated quasiresonant second stage, which is configurable for isolated and

non-isolated topologies. The digital CCT control system provides

the ability to program dimming profiles, such as constant CCT

dimming and black body line dimming. The CS1630/31

optimizes LED color mixing by temperature compensating LED

current with an external negative temperature coefficient

(NTC) thermistor. The IC controller is also equipped with power

line calibration for remote system calibration and end-of-line

programming. The CS1630/31 provides a register lockout

feature for security against potential access to proprietary

registers.

5.2 Startup Circuit

An external, high-voltage source-follower circuit is used to

deliver startup current to the IC. During steady-state operation,

an auxiliary winding on the boost inductor biases this circuit to

an off state to improve system efficiency, and all IC supply

current is generated from the auxiliary winding. The patent

pending technology of the external, high-voltage sourcefollower circuit enables system compatibility with digital

dimmers (dimmers containing an internal power supply) by

providing a continuous path for a dimmer’s power supply to

recharge during its off state. During steady-state operation,

high-voltage FET Q1 is source-switched by a variable internal

current source on the SOURCE pin to create the boost circuit.

A Schottky diode with a forward voltage less than 0.6V is

recommended for diode D5. Schottky diode D5 will limit inrush

current through the internal diode, preventing damage to the IC.

5.3 Dimmer Switch Detection

The CS1630/ 31 dimmer switch detection algorithm determines

if the solid-state lighting system is controlled by a regular switch,

a leading-edge dimmer, or a trailing-edge dimmer. Dimmer

switch detection is implemented using two modes: Dimmer

Learn Mode and Dimmer Validate Mode. These assist in

limiting the system power losses. Once the IC reaches UVLO

start threshold V

in Dimmer Learn Mode, allowing the dimmer switch detection

and begins operating, the CS1630/31 is

ST(th)

CS1630/31

circuit to set the operating state of the IC to one of three modes:

No-dimmer Mode, Leading-edge Mode, or Trailing-edge Mode.

5.3.1 Dimmer Learn Mode

In Dimmer Learn Mode, the dimmer detection circuit spends

approximately two line-cycles learning whether there is a

dimmer switch and, if present, whether it is a trailing-edge or

leading-edge dimmer. A modified version of the leading-edge

algorithm is used. The trailing-side slope of the input line

voltage is sensed to decide whether the dimmer switch is a

trailing-edge dimmer. The dimmer detection circuit transitions to

Dimmer Validate Mode once the circuit detects that a dimmer is

present.

5.3.2 Dimmer Validate Mode

During normal operation, CS1630/31 is in Dimmer Validate

Mode. This instructs the dimmer detection circuit to periodically

validate that the IC is executing the correct algorithm for the

attached dimmer. The dimmer detection algorithm periodically

verifies the IC operating state as a protection against incorrect

detection. As additional protection, the output of the dimmer

detection algorithm is low-pass filtered to prevent noise or

transient events from changing the IC’s operating mode. The IC

will return to Dimmer Learn Mode when it has determined that

the wrong algorithm is being executed.

5.3.3 No-dimmer Mode

Upon detection that the line is not phase cut with a dimmer, the

CS1630/ 31 operates in No-dimmer Mode, where it provides a

power factor that is in excess of 0.9. The CS1630/31

accomplishes this by boosting in CRM and DCM mode. The

peak current is modulated to provide link regulation. The

CS1630/ 31 alternates between two settings of peak current. To

regulate the boost output voltage, the CS1630/31 uses a peak

current set by register PEAK_CUR (see "Peak Current

(PEAK_CUR) – Address 51" on page 39). The time that this

current is used is determined by an internal compensation loop

to regulate the boost output voltage. The internal algorithm will

reduce the peak current of the boost stage to maintain output

voltage regulation and obtain the desired power factor.

5.3.4 Leading-edge Mode

In Leading-edge Mode, the CS1630/31 regulates boost output

voltage V

Figure 9. on page 13). The device executes a CCM boost

algorithm using dimmer attach current as the initial peak current

for the initial firing event of the dimmer. Upon gaining control of

the incoming current, the CS1630/ 31 transitions to a CRM

boost algorithm to regulate boost output voltage V

device periodically executes a probe event on the incoming

while maintaining the dimmer phase angle (see

BST

BST

. The

12 DS954F3

Page 13

CS1630/31

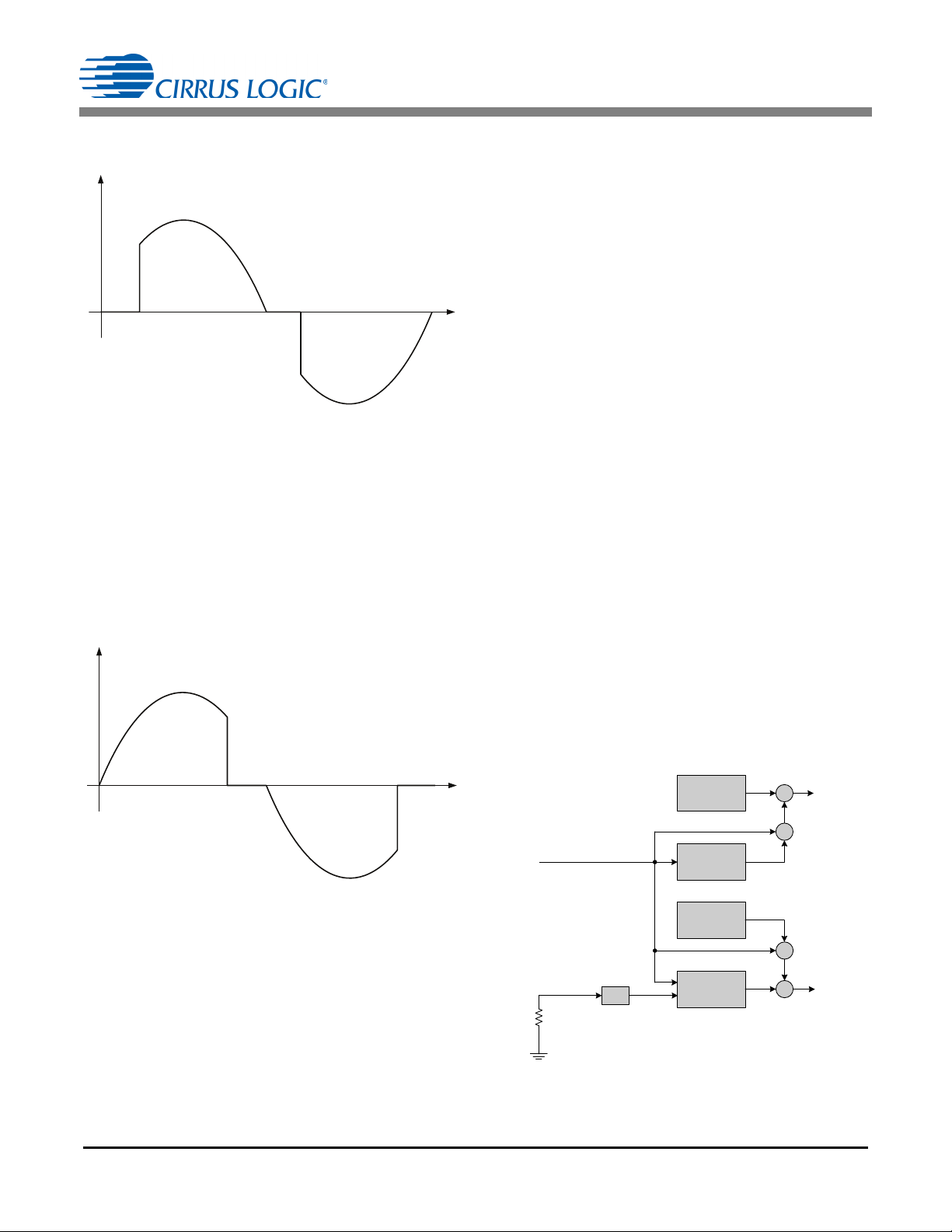

Figure 9. Leading-edge Mode Phase-cut Waveform

Figure 10. Trailing-edge Mode Phase-cut Waveform

Gain

White

dim

I

White

I

ref

White

I

ref

Color

X

X

ADC

NTC

I

Color

Gain

Color

X

X

Figure 11. Block Diagram of Color Control System

waveform. The information from the probe event is used to

maintain proper operation with the dimmer circuitry.

5.3.5 Trailing-edge Mode

In Trailing-edge Mode, the CS1630/31 determines its operation

based on the falling edge of the input voltage waveform (see

Figure 10). To provide proper dimmer operation, the

CS1630/ 31 executes the boost algorithm on the falling edge of

the input line voltage that maintains a charge in the dimmer

capacitor. To ensure maximum compatibility with dimmer

components, the device boosts during this falling edge event

using a peak current that must meet a minimum value.

Trailing-edge Mode, only the CRM boost algorithm is used.

Red and amber LEDs are necessary components in

color-mixing applications when providing warm white or other

CCTs. When mixing colors, red and amber LEDs are the most

temperature sensitive, so they cause a large variation in

temperature. The CS1630/31 is capable of providing LED

CCT and luminosity with temperature compensation using the

NTC thermistor to resolve the significant change in the

luminous output due to temperature variations.

Since LED lumens are mainly a function of temperature and

forward current, color temperature and luminosity can be

maintained by independently adjusting each string's output

current as the ambient temperature changes. This can be

done by mapping the NTC reading to a required value of the

current in each string using a digital mapping block.

In the CS1630/31, only one of the LED string currents is

compensated for due to temperature variations. The current in

the other string is kept constant over temperature, which may

result in the luminosity decreasing slightly as temperature

increases. In order for the ADC to resolve the entire range of

possible temperature variation in the LEDs, it is recommended

to select series resistor R

and NTC resistor R

S

appropriate Beta value, which retains the total resistance

(RS+R

) at all possible operating temperatures within the

NTC

tracking range of the ADC. The final temperature-to-digital

code mapping depends on these variables.

The CS1630/31 color control system also has the ability to

maintain a constant CCT or change CCT as the light dims.

In

OTP configurations allow the selection of the dimming profile.

A specific CCT profile can be programmed to the digital

mapping device. In this case, the mapping is two-dimensional:

one current versus temperature profile is generated for each

dim level. The CS1630/31 provides two-dimensional mapping

for the color LED’s current only, and one-dimensional

mapping (current versus dim level) for the other string. A

simplified block diagram of the color control system is shown

in Figure 11.

NTC

with the

5.4 Correlated Color Temperature Control

The CS1630/31 color control system can adjust and maintain

the correlated color temperature (CCT) for the LED colormixing application by connecting an external negative

temperature coefficient (NTC) thermistor to the eOTP pin. The

LED temperature variation can be accurately detected by the

internal eOTP feedback loops

Protection" on page 19).

DS954F3 13

(see "External Overtemperature

Page 14

CS1630/31

where,

T = the measured normalized temperature and is 0 T 1.0

D = the normalized dim value and is 0

D1.0

GAIN

DTR

= gain of the channel based on the temperature measurement and the dim value:

where,

D = the normalized dim value and is 0

D1.0

GAIN

DR

= gain of the channel based on the dim value

GAIN

DTR

P30 T3 P20 T2 P10++T P03 D3 P02++D2 P01 D P21 T2D++= P12 T D2 P11 T D P00+++

[Eq.1]

GAIN

DR

Q3= D3 Q2 D2 Q1 D Q0+++

[Eq.2]

P

IN max

I

PKVRMS typ

2

------------------------------------------------

=

[Eq.3]

The reference currents are the required values at ambient

temperature TA= 25ºC and dim = 100%. They are multiplied

by the appropriate gains, and these values are passed to the

final power stage. The CS1630 / 31 uses polynomial

approximations in one and two dimensions to generate the

color gains. These polynomials can be up to third-order.

GAIN

compensation profile and dimming profile of the temperaturesensitive LEDs (see Equation 1). Profiles are programmed

through the Color Polynomial Coefficient registers (see "Color

Polynomial Coefficient (P30, P20, P10, P03, P02, P01, P21,

P12, P11, P00) – Address 5 - 24" on page 29).

GAIN

white LEDs (see Equation 2). The profile is programmed

through the Color Polynomial Coefficient registers (see "Color

Polynomial Coefficient (Q3, Q2, Q1, Q0) – Address 25 - 32" on

page 30).

Cirrus Logic, Inc. and its affiliates and subsidiaries generally

make no representations or warranties that the combination of

Cirrus Logic’s products with light-emitting diodes (“LEDs”),

converter materials, and/or other components will not infringe

any third-party patents, including any patents related to color

mixing in LED lighting applications, such as, for example, U.S.

Patent No. 7,213,940 and related patents of Cree, Inc. For

more information, please see Cirrus Logic’s Terms and

Conditions of Sale, or contact a Cirrus Logic sales

representative.

approximations create a custom temperature

DTR

approximation allows custom dimming profile of the

DR

5.5 Dimming Signal Extraction and the

5.6 Boost Stage

The high-voltage FET in the source-follower startup circuit is

source-switched by a variable current source on the SOURCE

pin to operate a boost circuit. Peak FET switching current is

set by the PEAK_CUR register (see "Peak Current

(PEAK_CUR) – Address 51" on page 39).

In No-dimmer Mode, the boost stage begins operating when

the start threshold is reached during each rectified half line-cycle and is disabled at the nominal boost output voltage. The

peak FET switching current determines the percentage of the

rectified input voltage conduction angle over which the boost

stage will operate. The control algorithm adjusts the peak FET

switching current to maximize the operating time of the boost

stage, thus improving the input power factor.

When operating in Leading-edge Mode, the boost stage

ensures the hold current requirement of the dimmer is met

from the initiation of each half-line dimmer conduction cycle

until the peak of the rectified input voltage. Trailing-edge Mode

boost stage ensures that the trailing-edge is exposed at the

correct time with the correct current.

5.6.1 Maximum Peak Current

The maximum boost inductor peak current is configured by

adjusting the peak switching current with peak current

code I

(PEAK_CUR) – Address 51" on page 39) is used to store peak

current code I

to peak current code I

. The PEAK_CUR register (see "Peak Current

PK(code)

. Maximum power output is proportional

PK(code)

, as shown in Equation 3:

PK(code)

Dim Mapping Algorithm

When operating with a dimmer, the dimming signal is

extracted in the time domain and is proportional to the

conduction angle of the dimmer. A control variable is passed

to the quasi-resonant second stage to achieve output currents

from 0% to 100%.

where,

= the correction term at 0.55

V

RMS(typ)

I

PK

= nominal operating input RMS voltage

= peak current code I

PK(code)

4.1mA

14 DS954F3

Page 15

CS1630/31

V

BST

CS1630 /31

15 k

ADC

R

BST

I

BSTOUT

I

ref

16

BSTOU T

R8

R9

Figure 12. BSTOUT Input Pin Model

R

BST

V

BST

I

ref

--------------

400V

133A

------------------

3M==

[Eq.4]

R3

R

IA C

I

AC

IAC

V

rect

CS1630 /31

15 k

ADC

R4

2

I

ref

12

Figure 13. IAC Input Pin Model

R

IAC

R

BST

=

[Eq.5]

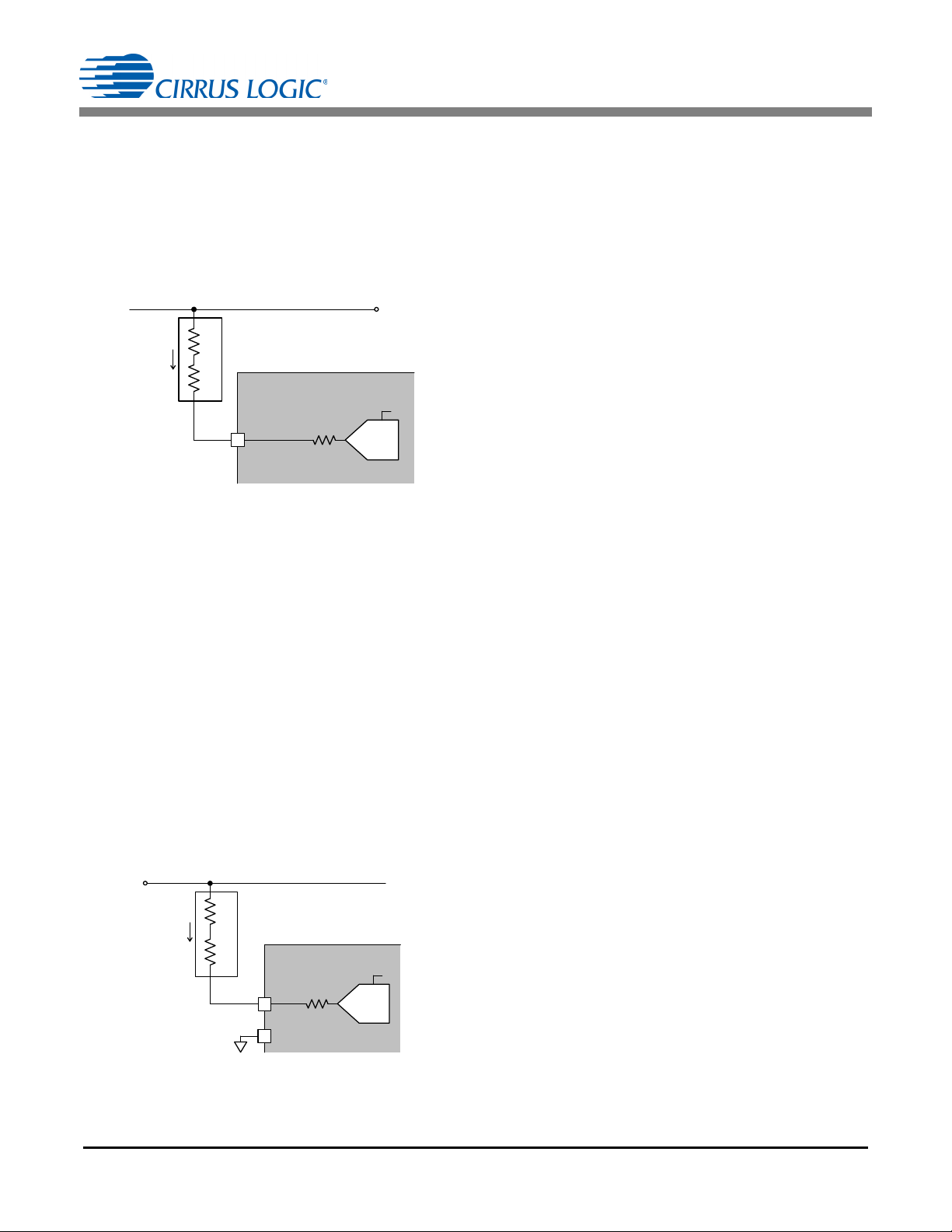

5.6.2 Output BSTOUT Sense & Input IAC Sense

A current proportional to boost output voltage V

to the IC on pin BSTOUT and is used as a feedback control

signal (see Figure 12). The ADC is used to measure the

magnitude of current I

magnitude of current I

reference current I

Resistor R

BST

of 133A.

ref

sets the feedback current at the nominal boost

BSTOUT

through resistor R

BSTOUT

is then compared to an internal

output voltage. For 230VAC line voltage applications,

resistor R

is calculated as shown in Equation 4:

BST

where,

V

= nominal boost output voltage

BST

I

= internal reference current

ref

For 120VAC line voltage applications (CS1630), nominal

boost output voltage V

is 200V, and resistor R

BST

1.5M. By using digital loop compensation, the voltage

feedback signal does not require an external compensation

network.

A current proportional to the AC input voltage is supplied to the

IC on pin IAC and is used by the boost control algorithm (see

Figure 13).

is supplied

BST

BST

. The

BST

is

Resistor R

For optimal performance, resistors R

1% tolerance or better resistors for best V

sets current IAC and is derived from Equation 5:

IAC

IAC

and R

should use

BST

BST

voltage

accuracy.

5.6.3 Boost Auxiliary Winding

The boost auxiliary winding is used for zero-current detection

(ZCD). The voltage on the auxiliary winding is sensed through

the BSTAUX pin of the IC. It is also used to deliver startup

current during startup time (see "Startup Circuit" on page 12).

5.6.4 Boost Overvoltage Protection

The CS1630/31 supports boost overvoltage protection (BOP)

to protect the bulk capacitor C8 (see Figure 14. on page 16).

If the boost output voltage exceeds the overvoltage protection

thresholds programmed in the OTP registers a BOP fault

signal is generated. The voltage level, V

within 227V to 257V for a CS1630 and 432V to 462V for a

CS1631 (see "Configuration 53 (Config53) – Address 85" on

page 45). The control logic continuously averages the BOP

fault signal using a leaky integrator. When the output of the

leaky integrator exceeds a certain threshold, which can be set

using bits BOP_INTEG[3:0] in register Config53 (see

"Configuration 53 (Config53) – Address 85" on page 45), a

boost overvoltage fault is declared and the system stops

boosting. More information on the leaky integrator size and

sample rate is provided in section 6.23 "Configuration 18

(Config18) – Address 50" on page 38.

During a boost overvoltage protection event, the second stage

is kept enabled only if the MAX_CUR bit in register Config45

(see "Configuration 45 (Config45) – Address 77" on page 40)

is set to ‘1’ (enabled), and its dim input is railed to full scale.

This allows the second stage to quickly dissipate the stored

energy on the bulk capacitor C8, bringing down the boost

output voltage to a safe value. A visible flash on the LED might

appear, indicating that an overvoltage event has occurred.

When the boost output voltage drops to 195V (for a 120V

application), or 392V (for a 230V application), the boost stage

is enabled if bit BOP_RSTART in register Config54 (see

"Configuration 54 (Config54) – Address 86" on page 46) is set

to ‘1’, and the system returns to normal operation. If bit

BOP_RSTART is set to ‘0’, a boost overvoltage fault is latched

and the system stays in the fault mode until the input power is

recycled.

BOP(th)

, can be set

DS954F3 15

5.7 Voltage Clamp Circuit

To keep dimmers conducting and prevent them from misfiring,

a minimum power needs to be delivered from the dimmer to

the load. This power is nominally around 2W for 230 V and

120V TRIAC dimmers. At low dim angles (

power cannot be converted into light by the second stage due

to the dim mapping at light loads. The boost output

voltage V

can rise above the safe operating voltage of the

BST

primary-side bulk capacitor C8.

90°), this excess

Page 16

CS1630/31

CLAMP

Q3

R10

I

CLAMP

V

BST

S1

CS1630 /31

V

BE

VDD

3

C8

Figure 14. CLAMP Pin Model

D7

R13

Z2

R11

R14

Q4

CS1630/31

FBAUX

GND

13

GD

FBSENSE

15

12

11

T1

V

BST

R12

D9

C9

C11

C12

D11

D8

R15 D10

Q5

R16

C10

Z3

IGND

LED2 +

LED 1+

LED 1-

LED2 -

D

GND

_QVCC

Figure 15. Flyback Parallel Output Model

R13

R11

R14

Q4

L3

D8

CS1630 /31

FBAUX

GND

13

GD

FBSENSE

15

12

11

V

BST

R12

D9

C9

C11

C12

D11

R15 D10

Q5

R16

C10

Z3

IGND

LED 2+

LED1 +

LED 1-

LED 2-

D

GND

_QVCC

Figure 16. Buck Parallel Output Model

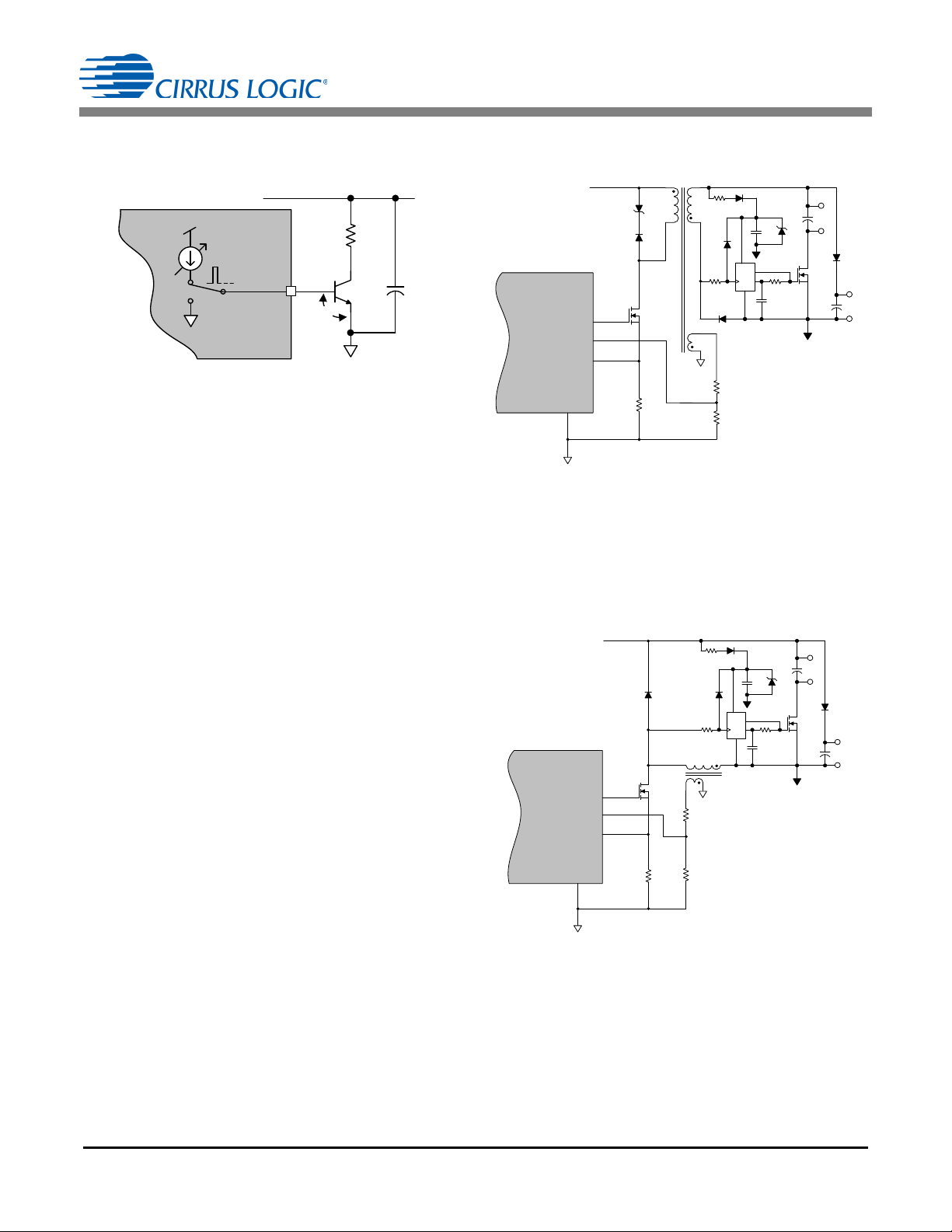

The CS1630/31 provides active clamp circuitry on the CLAMP

pin, as shown in Figure 14.

A PWM control loop ensures that the boost output

voltage V

does not exceed 227V for 120VAC applications

BST

or 424V for 230VAC applications. This control turns on the

BJT of the voltage clamp circuit, allowing the clamp circuit to

sink current through the load resistor, preventing boost output

voltage V

from exceeding the maximum safe voltage.

BST

5.7.1 Clamp Overpower Protection

The CS1630/31 clamp overpower protection (COP) control

logic continuously monitors the turn-on time of the clamp

circuit. If the cumulative turn-on time exceeds 84.48ms during

the internally generated 1 second window time, a COP event

is actuated, disabling the boost and second stages. The clamp

circuitry is turned off during the fault event.

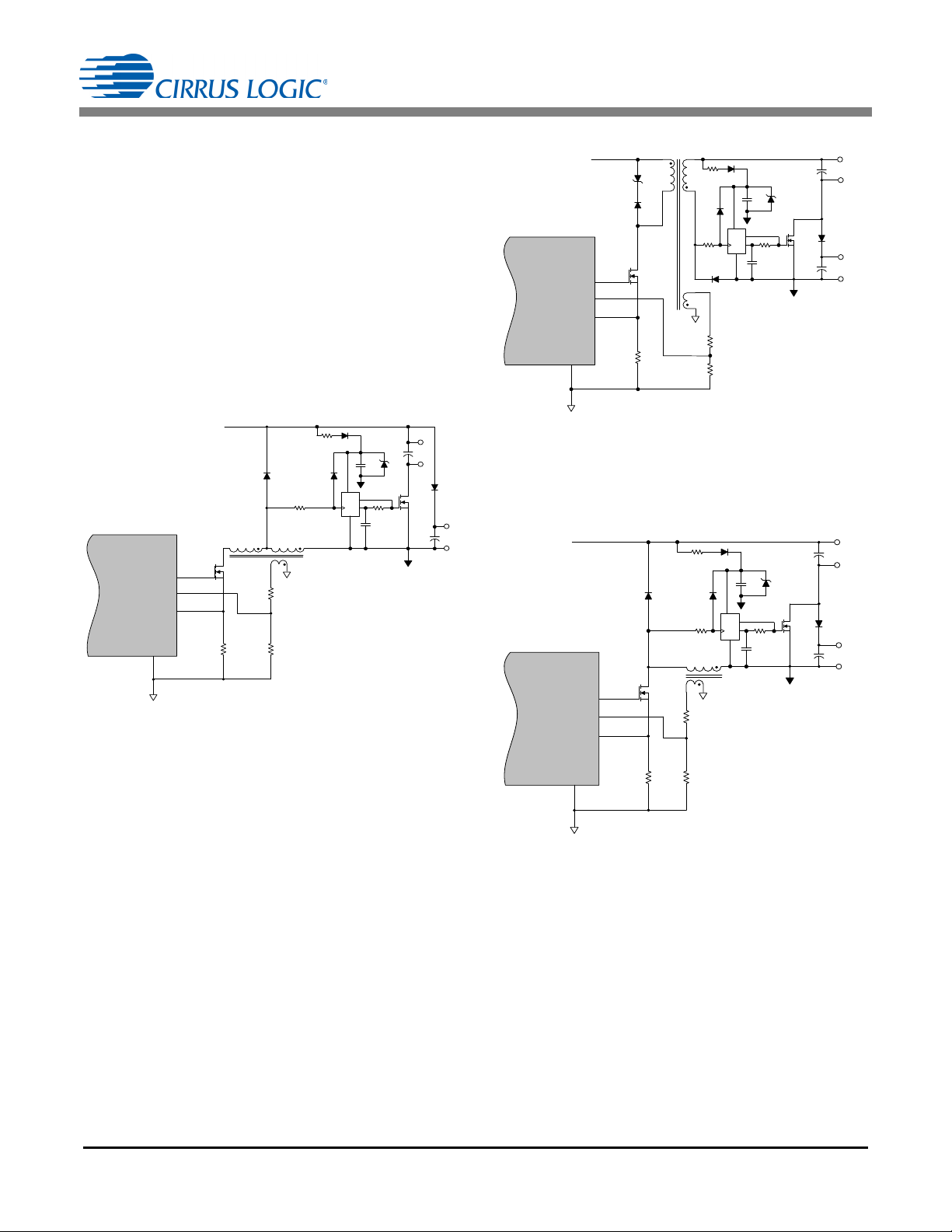

Figure 15 illustrates a quasi-resonant flyback stage

configured for two-channel parallel output.

The flyback stage is controlled by measuring current in the

transformer primary and voltage on the auxiliary winding.

Quasi-resonant operation is achieved by detecting

transformer flyback using an auxiliary winding.

A quasi-resonant buck stage configured for two-channel

parallel output is illustrated in Figure 16.

5.8 Quasi-resonant Second Stage

The second stage is a quasi-resonant current-regulated DCDC converter capable of flyback, buck, or tapped buck

operation. The second stage output configuration is set by bit

S2CONFIG in register Config12 (see "Configuration 12

(Config12) – Address 44" on page 36) and bits BUCK[3:0] in

register Config10 (see "Configuration 10 (Config10) – Address

42" on page 35). To deliver the highest possible efficiency, the

second stage can operate in quasi-resonant mode and

provides constant output current with minimum line-frequency

ripple. Primary-side control is used to simplify system design

and reduce system cost and complexity.

The digital algorithm ensures monotonic dimming from 0 % to

100% of the dimming range with a linear relationship between

the dimming signal and the LED current.

16 DS954F3

Page 17

The buck stage is controlled by measuring current in the buck

R13

R11 R14

Q4

L3

CS1630 /31

FBAUX

GND

13

GD

FBSEN SE

15

12

11

D8

V

BST

R12

D9

C9

C11

C12

D11

R15 D10

Q5

R16

C10

Z3

IGND

LED2 +

LED1 +

LED1 -

LED 2-

D

GND

_QVCC

Figure 17. Tapped Buck Parallel Output Model

D7

R13

Z2

R11

R14

Q4

CS1630 /31

FBAUX

GND

13

GD

FBSENSE

15

12

11

T1

V

BST

R12

D9

C9

D8

R15 D10

R16

C10

Z3

D

GND

_QVCC

Q5

IGND

C12

LED 2+

LED2 -

C11

LED 1+

LED 1-

D11

Figure 18. Flyback Series Output Model

R13

R11 R14

Q4

L3

CS1630 /31

FBAUX

GND

13

GD

FBSENSE

15

12

11

V

BST

R12

D9

C9

R15 D10

R16

C10

Z3

D

GND

_QVCC

Q5

IGND

D11

D8

C12

LED1 +

LED1 -

C11

LED2 +

LED 2-

Figure 19. Buck Series Output Model

inductor and voltage on the auxiliary winding. Quasi-resonant

operation is achieved by detecting buck inductor

demagnetization using an auxiliary winding. The digital control

algorithm rejects line-frequency ripple created on the second

stage input by the front-end boost stage, resulting in the

highest possible LED efficiency and long LED life.

The tapped buck stage operates similar to a buck stage. The

tapped buck topology provides minimum turn-on time and

improves conversion efficiency when large input-to-output

voltage ratio is present. The tapped buck inductor behaves as

a transformer for voltage conversion and is controlled by

measuring current in the tapped inductor and voltage on the

auxiliary winding. Quasi-resonant operation is achieved by

detecting tapped inductor demagnetization using an auxiliary

winding.

CS1630/31

Similarly, a series connection in a flyback stage and buck

stage use an NMOS switch and a PMOS switch, respectively,

as shown in Figures 18 and 19.

5.8.1 Series & Parallel Two-Channel Output

The CS1630/31 is designed to be programmed to support

series or parallel two-channel output configurations using one

set of power magnetics. Series or parallel configuration is set

by bit STRING and bit LED_ARG in the Config3 register (see

"Configuration 3 (Config3) – Address 35" on page 32). A

parallel connection for a flyback stage and buck stage are

connected differently: an NMOS switch is used in flyback

configuration, and a PMOS switch is used in buck / tapped

buck configuration (see Figures 15, 16, and 17).

DS954F3 17

Page 18

CS1630/31

R13

R11

R14

Q4

L3

CS1630 /31

FBAUX

GND

13

GD

FBSEN SE

15

12

11

V

BST

R12

D9

C9

R15

D10

R16

C10

Z3

D

GND

_QVCC

Q5

IGND

C12

LED1 +

LED 1-

C11

LED 2+

LED 2-

D11

D8

Figure 20. Tapped Buck Series Output Model

CH1CUR

5112R

SenseICH1

NV

Sense

----------------------------------------------------------

= [Eq. 6]

CH2CUR

5112R

SenseICH2

NV

Sense

----------------------------------------------------------

= [Eq. 7]

Figure 20 illustrates the tapped buck stage configured for

series output mode.

To maintain constant output current with minimum linefrequency ripple, the following are required:

• For parallel configurations, a minimum voltage potential

difference between two strings

• For series configurations, a minimum current amplitude

difference between two strings

5.8.2 Primary-side Current Control for Two-Channel Output

The CS1630/31 regulates two-channel output current

independently using primary-side control, which eliminates

the need for opto-coupler feedback. The control loop operates

in peak current control mode, with the peak current set cycleby-cycle by the two independent current regulation loops.

Demagnetization time of the second stage inductor is sensed

by the FBAUX pin using an auxiliary winding on the second

stage inductor. The FBAUX pin supplies an input to the digital

control loop.

The power conversion for two-channel output is carried out by

interleaving the PWM. The two-channel control system

consists of two components:

• A toggle device (phase synchronizer circuit) on the

secondary side that alternatively activates each output

channel for each switching event

• A digital sequencer on the primary side determines which

output channel is active for any given switching event

As the output is toggled between each channel, a sequencer

on the primary side identifies the current control phase and

regulates the current in each output channel. To ensure

proper operation for a parallel configuration, the two output

channels should target a voltage differential that is greater

than 20%. For a series configuration, the two output channels

should target a current differential that is greater than 20%.

18 DS954F3

5.8.3 Auxiliary Winding Configuration

The second-stage inductor auxiliary winding is used for zerocurrent detection (ZCD) and overvoltage protection (OVP). The

auxiliary winding is sensed through the FBAUX pin of the IC.

5.8.4 Control Parameters

The second-stage control parameters are set to assure:

• Line Regulation — The LED current remains constant

despite a ±10% AC line voltage variation.

• Effect of Variation in Transformer Magnetizing

Inductance — The LED current remains constant over

a ±20% variation in magnetizing inductance.

The FBSENSE input is used to sense the current in the

second stage inductor. When this current reaches a certain

threshold, the gate drive turns off (output on pin GD).

Two OTP values are required to set the second-stage output

currents, CH1CUR for channel 1 and CH2CUR for channel 2

(see "Channel 1 Output Current (CH1CUR) – Address 41" on

page 35 and "Channel 2 Output Current (CH2CUR) – Address

43" on page 35). Equations 6 and 7 are used to calculate the

values to be programmed into registers CH1CUR and

CH2CUR.

where,

= resistance of current sense resistor

R

Sense

V

= full scale voltage across sense resistor (~1.4V)

Sense

I

= target current in channel 1 LED string

CH1

I

= target current in channel 2 LED string

CH2

Sense resistor R

is determined by the input voltage,

Sense

switching frequency, auxiliary transformer turns ratio, target

output current and output voltage for each channel.

The zero-current detect input on pin FBAUX is used to

determine the demagnetization cycle period T2 . The controller

then uses these inputs to control the gate drive output pin GD.

5.8.5 Frequency Dithering

The peak amplitude of switching harmonics can be reduced by

spreading the energy into wider spectrums. The frequency

dithering level can be managed using bits DITLEVEL[1:0] in

register Config61 (see "Configuration 61 (Config61) – Address

93" on page 49). Additionally, the CS1630/31 has an option to

enable dithering only in No-dimmer Mode by setting bit

DITNODIM to ‘1’. If output currents differ, the CS1630/31 also

has an option to allow for less dither on one of the two

channels by selecting the channel using bit DITCHAN. The

channel selected for less dither attenuates the dither level by

the percentage configured by bits DITATT[1:0].

Page 19

CS1630/31

5.8.6 Output Open Circuit Protection

Output open circuit protection and output overvoltage

protection (OVP) are implemented by monitoring the output

voltage through the second-stage inductor auxiliary winding.

Overvoltage protection is enabled by setting bit OVP to ‘0’ in

register Config47 (see "Configuration 47 (Config47) – Address

79" on page 41). If the voltage on the FBAUX pin exceeds a

threshold (V

gate drive is turned off and outside of the blanking window

configured by bit OVP_TYPE and bits OVP_BLANK[2:0] in

register Config50 (see "Configuration 50 (Config50) – Address

82" on page 43), then the OVP event accumulator is

incremented by 1 before the start of the next switching cycle.

If the OVP comparator threshold is not exceeded during the

switching cycle, the event accumulator is decremented by 1. If

the event accumulator count exceeds or equals the count set

by bits OVP_CNT[2:0] in register Config50 then an OVP fault

is declared and enters a fault state.

The fault state is latched if bit OVP_LAT in register Config50

is set high. The OVP fault state is not cleared until the power

to the IC is recycled. Otherwise, if bit OVP_LAT is set low, the

system is restarted after a specified amount of time configured

by using the bit FAULT_SLOW and bits RESTART[5:0] in

register Config51 (see "Configuration 51 (Config51) – Address

83" on page 43). The fault behavior during the fault state

initiated by this protection depends on the setting for bit

FAULT_SHDN in register Config51.

) of 1.25V during the time the second stage

OVP(th)

5.8.7 Overcurrent Protection

Overcurrent protection (OCP) is implemented by monitoring

the voltage across the second-stage sense resistor.

Overcurrent protection is enabled by setting bit OCP to ‘0’ in

register Config47 (see "Configuration 47 (Config47) – Address

79" on page 41). If this voltage exceeds a threshold (V

of 1.69V during the time the second stage gate drive is turned

on’ and outside of the blanking window configured by bits

OCP_BLANK[2:0] in register Config48 (see "Configuration 48

(Config48) – Address 80" on page 42), then the OCP event

accumulator is incremented by 1 after the gate drive turns off.

If the OCP comparator threshold is not exceeded during this

time, the event accumulator is decremented by 1. If the event

accumulator count exceeds or equals the count set by bits

OCP_CNT[2:0] in register Config49 (see "Configuration 49

(Config49) – Address 81" on page 42) then an OCP fault is

declared and enters a fault state.

The fault state is latched if bit OCP_LAT in register Config49

is set high. The OCP fault state is not cleared until the power

to the IC is recycled. Otherwise, if bit OCP_LAT is set low, the

system is restarted after a specified amount of time configured

by using the bit FAULT_SLOW and bits RESTART[5:0] in

register Config51 (see "Configuration 51 (Config51) – Address

83" on page 43). The fault behavior during the fault state

initiated by this protection depends on the setting for bit

FAULT_SHDN in register Config51.

OCP(th)

5.8.8 Open Loop Protection

Open loop protection (OLP) and sense resistor short

protection are implemented by monitoring the voltage across

the sense resistor. Open loop protection is enabled by setting

bit OLP to ‘0’ in register Config47 (see "Configuration 47

(Config47) – Address 79" on page 41). If the voltage on pin

FBSENSE does not reach the protection threshold

voltage V

the second stage gate drive is turned on and the blanking

window configured by bits OLP_BLANK[2:0] in register

Config48 (see "Configuration 48 (Config48) – Address 80" on

page 42) has elapsed, then the OLP event accumulator is

incremented by 1. If the OLP comparator threshold is

exceeded during this time, the event accumulator is

decremented by 1. If the event accumulator count exceeds or

equals the count set by bits OLP_CNT[2:0] in register

Config49 (see "Configuration 49 (Config49) – Address 81" on

page 42) then an OLP fault is declared and enters a fault

state.

The fault state is latched if bit OCP_LAT in register Config49

is set high. The OLP fault state is not cleared until the power

to the IC is recycled. Otherwise, if bit OLP_LAT is set low, the

system is restarted after a specified amount of time configured

by using the bit FAULT_SLOW and bits RESTART[5:0] in

register Config51 (see "Configuration 51 (Config51) – Address

83" on page 43). The fault behavior during the fault state

initiated by this protection depends on the setting for bit

FAULT_SHDN in register Config51.

of 200mV during a 250ns scan period after

OLP(th)

5.9 Overtemperature Protection

The CS1630/31 incorporates an internal overtemperature

protection (iOTP) circuit for IC protection and the circuitry

required to connect an external overtemperature protection

)

(eOTP) device. Typically, a negative temperature coefficient

(NTC) thermistor is used.

5.9.1 Internal Overtemperature Protection

Internal overtemperature protection (iOTP) is activated and

power switching devices are disabled when the die

temperature of the CS1630/31 exceeds 135 °C. A hysteresis

of about 7°C occurs before resuming normal operation.

5.9.2 External Overtemperature Protection

The external overtemperature protection (eOTP) pin is used to

implement overtemperature protection using an external NTC

thermistor R

converted to an 8-bit digital ‘CODE’ (which gives an indication

of the temperature) using a digital feedback loop that adjusts

the current I

resistor R

(V

CONNECT(th)

. The total resistance on the eOTP pin is

NTC

CONNECT

to maintain a constant reference voltage of 1.25V

S

into the NTC thermistor R

).

NTC

and series

DS954F3 19

Page 20

CS1630/31

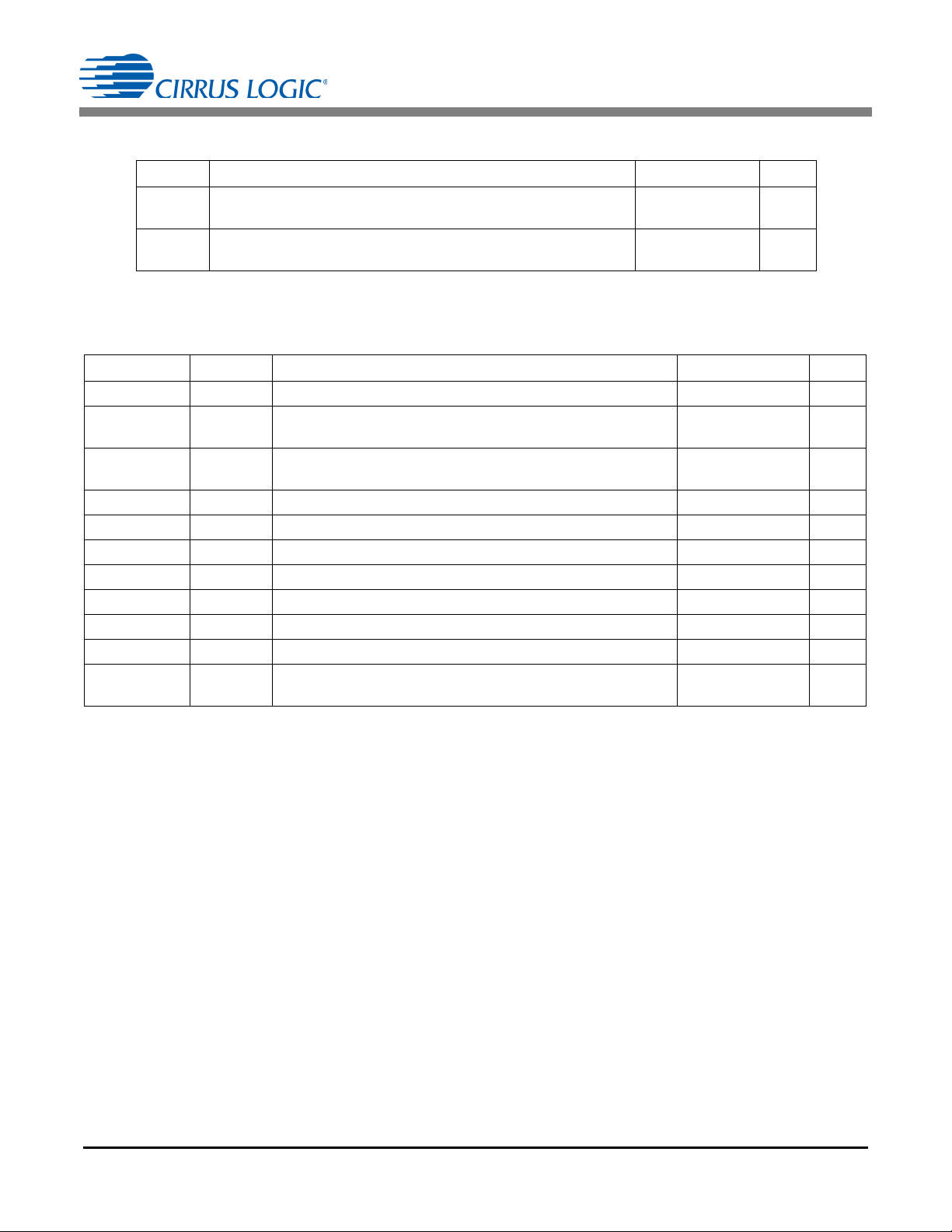

CS1630/31

+

-

I

CONNECT

V

CONNECT (th)

Comp_Out

eOTP

Control

eOTP

R

S

C

NTC

NTC

V

DD

10

Figure 21. eOTP Functional Diagram

I

CONNECT

V

CONNECT th

R

-------------------------------------

=

[Eq.8]

CODE

I

CONNECT

2

N

---------------------------

V

CONNECT th

R

NTCRS

+

-------------------------------------

=

[Eq.9]

CODE

2NV

CONNECT th

I

CONNECTRNTCRS

+

-----------------------------------------------------------------

=

[Eq.10]

4M

R

NTCRS

+

---------------------------------

=

256 1.25 V

80AR

NTCRS

+

----------------------------------------------------------

=

Figure 21 illustrates the functional block diagram when

connecting an optional external NTC temperature sensor to

the eOTP circuit.

Current I

CONNECT

is generated from an 8-bit controlled current

source with a full-scale current of 80A. See Equation 8:

When the loop is in equilibrium, the voltage on the eOTP pin

fluctuates around threshold voltage V

digital ‘CODE’ output by the ADC is used to generate

current I

current I

CONNECT

CONNECT

. In normal operating mode,

is updated once every seventh half

line-cycle by a single ± LSB step. See Equation 9:

Use Equation 9 to solve for the 8-bit digital CODE output.

See Equation 10:

The tracking range of this ADC is approximately 15.5 k to

4M. The series resistor R

of the NTC thermistor R