Page 1

CVM-NET

NET

Before performing any maintenance operations,

suspect an operational fault in the unit or in its

RESET

RESET

Modbus Address

Variable

Valid data window

03E8 Hi

Protocol

0 - Modbus

03E8 Lo

Peripheral number

00 to FF ( 0 to 255 dec)

03E9 Hi

Speed (Baud)

0- 1200, 1- 2400, 2- 4800,

3- 9600, 4- 19200

03E9 Low

Parity

0- No

03EA Hi

Length in bits

1- 8 bits

03EA Low

Stop bits

0- 1 bit

Modbus Address

Variable

Valid data window

0BB8,0BB9

Unit serial number

0 to FFFFFFFF (N)

0BBA Hi

Peripheral number

0 to FF (P)

0BBA Low

Port speed

0- 9600, 1-19200 (V)

Modbus Address

Variable

Valid data window

044C,044D

Primary voltage

0 to 000186A0 (100.000)

044E

Secondary voltage

0 to 03E7 (999)

044F

Primary current

0 to 2710 (10,000)

0450 Hi

Not used

00

0450 Low

Not used

00

0451 Hi

Harmonic calculation

00 – THD / 01- D

0451 Low

Not used

00

Modbus Address

Variable

Valid data window

04E2

PD calculation

0000 – No Pd

0024 – Three-phase current

04E3

Integration time

0 to 003C (0-60 minutes)

Digital output 1

Modbus Address

Variable

Valid data window

047E, 047F

MAX value or W·h imp

Hexadecimal value

0480, 0481

MIN value

Hexadecimal value

0482

Delay

0 to 270F (9,999

Decimal)

0483 Hi

Variable number

00 (See table of

variables)

0483 Low

Not used

00

Digital output 2

Modbus Address

Variable

Valid data window

04B0, 04B1

MAX value or W·h imp

Hexadecimal value

04B2, 04B3

MIN value

Hexadecimal value

04B4

Delay

0 to 270F (9,999

Decimal)

04B5 Hi

Variable number

00 (See table of

variables)

04B5 Low

Not used

00

CVM-

POWER ANALYZER

/ 5 A) .

n

www.circutor.com

, and, while holding

CVM-NET is an instrument that measures and

calculates the primary electric parameters in threephase industrial power grids (balanced or unbalanced).

It is measured in true RMS values, using three AC

voltage inputs, and three AC current inputs (through

current transformers I

The measured and calculated parameters are shown in

the table of variables.

You can find this manual in electronic format on th e website

protection system, remove the unit from service. The design of

the unit makes it easy to replace in the event of a fault.

of CIRCUTOR:

connection modifications, repairs, etc., you must

disconnect the unit from the power supply. If you

1.- KEYPAD

CVM-NET has a single button; it can be used to

functionally reset the unit or to restore default

communication parameters.

To functionally reset the unit, press the button

for at least one second, and the unit will reset its

system within 5 s.

To restore the default communication parameters

(19200/8N/1 see section 2.1.-), disconnect the auxiliary

power, then press the button

the button down, switch the unit back on. After 5 s, the

unit restores its factory settings.

2.- CONFIGURATION

As the unit has no keypad, the configuration settings

must be sent to the device via Modbus/RTU©

commands, or using the CIRCUTOR PowerStudio

Software, which can be downloaded for free from the

website:

www.circutor.com

2.1.- Configuration of configurati on s e t t ings

Two options are available for this:

2.1.1.- Using the peripheral number

By default, the unit has the following parameters:

3/19200/8/N/1. The following records are available for

changing the peripheral number or speed of

communications:

Example of a write command. Changing the peripheral

number. From 03 (3 decimal) to 0F (15 decimal), at 9600 bps.

TX: NP 10 03E8000306 000F 0300 0100 CRC

RX: NP 10 03E80003 CRC

After editing the registers with the new communications

parameters, must be reset the device with the next sentence,

entering in the peripheral number the original slave address (in

this case the number 03).

TX: NP 05 07D01100 CRC

RX: NP 05 07D01100 CRC

2.1.2.- Using the serial number (broadcast)

The serial number of the unit can be found on t he side

label of the device (e.g.:3104200679). This number

must be translated into hexadecimal l anguage so that

the sentence can be sent to the unit:

3104200679 (Decimal) B90657E7 (Hexadecimal)

The parameters to be set us ing the “broadcast” format

to the 00 peripheral are restricted, as they are only for

configuring the communication settings:

Example of a write command. Changing the peripheral number.

From 03 (3 decimal) to 0F (15 decimal), at 9600 bps.

TX: 00 10 0BB8000306 B90657E7 0F 00 CRC

RX: Time Out

2.2.- Transform a t ion ratio settings

The CVM-NET analyzer can perform indirect

measurements (using voltage and current t ransformers).

For this reason, it has an input table for setting the

voltage and current transformation ratios. If the voltage

measurement is performed directly, the ratio is 1/1.

Example of programming voltage ratios; Direct voltage

measurement (230 ph-N), and current transformers with

primary ratio of 400 A.

Primary voltage 1(Dec) 00000001 (Hex)

Secondary voltage 1(Dec) 0001 (Hex)

Primary current 400 (Dec) 0190 (Hex)

Calculating harmonics 00 with regard to the Effective Value

TX: NP 10 044C00060C 000000010001019000000000 CRC

RX: NP 10 044C00060C CRC

Next, reset the unit (see section 2.1.1.-).

2.2.1.- Reading transformation ratios settings

As additional information, the user has a Modbus

command, for reading the transformation ratios setting in

th device:

TX: NP 04 044C0006 CRC

RX: NP 04 0C 00000001 0001 0190 00000000 CRC

2.3.- Maximum de m a nd s et t ings

The power analyzer can calculate the maximum value,

using the sliding window method. This calculat ion can be

associated to one of the three available variables, as

shown below.

variable

Example of maximum demand programming by three-phase

power, with a 15 minute period:

TX: NP 10 04E2000204 0010 000F CRC

RX: NP 10 04E20002 CRC

Next, reset the unit (see section 2.1.1.-).

0010 – Active power III

0022 – Apparent power III

2.3.1.- Reading maximum demand setting

As additional information, the user has a Modbus

command, for reading the maximum demand setting:

TX: NP 04 04E20002 CRC

RX: NP 04 04 0010 000F CRC

2.4.- Deleting m a x imum and minimum v a lues

The power analyzer records all the maximum and

minimum values for eac h parameter measured in the

Modbus/RTU variables table. A command is avai lable

for resetting these records:

TX: NP 05 0836 FF 00 CRC

RX: NP 05 0836 FF 00 CRC

2.5.- Deleting m a x imum demand

The maximum demand parameter, when calculated

using the sliding window, can be reset, allowing the

calculation to be restarted.

TX: NP 05 0838 FF 00 CRC

RX: NP 05 0838 FF 00 CRC

2.6.- Configuration and use of digital outputs

2.6.1.- Forcing digital outputs

The unit is fitted with two digital outputs, that can be

remotely managed in both their opening and closing

functions.

Forcing Digital Output number 1:

TX: NP 05 0000 XX 00 CRC

RX: NP 05 0000 XX 00 CRC

(Where XX FF Close / 00 Open)

Forcing Digital Output number 2:

TX: NP 05 0001 XX 00 CRC

RX: NP 05 0001 XX 00 CRC

(Where XX FF Close / 00 Open)

2.6.2.- Reading the digital output status

The user can request a reading of the digital output

status via Modbus/RTU using the following sentence:

TX: NP 01 0000 0008 CRC

RX: NP 01 01 XX CRC

Where XX 04 Both outputs open

05 Output 1 closed

06 Output 2 closed

07 Both outputs closed

2.6.3.- Digital output settings

Digital outputs, in addition to being remotely managed,

can be used as alarm elements, associated with an

electric variable by a maxim um or minimum value, or

fulfil the power pulse function associated with any

power consumption parameter (active or reactive). The

following input table is provided for programming them:

*When a power variable is selected, the analyzautomatically recognises the

power pulse function and applies the w·h value of the first record.

Example of alarm programming by maximum and minimum

value with voltage VL1. A maximum value of 240 V, a minimum

value of 200 V (the voltage value must be sent multiplied by 10

(as shown in the enclosed variables table), and delay of 10

s are programmed.

Maximum value 2400 (Decimal) → 00000960 (Hexadecimal)

Minimum value 2000 (Decimal) → 000007D0 (Hexadecimal)

Delay 10 (Decimal) → 000A (Hexadecimal)

Var number 01 (Decimal) → 01 (Hex)

Not used 00 (Decimal) → 00 (Hexadecimal)

TX: NP10047E00060C 00000960 000007D0 000A 0100 CRC

RX: 03 10 047E0006 CRC

Next, reset the unit (see section 2.1.1.-).

*When a power variable is selected, the analyzer automatically recognises

the power pulse function and applies the w·h value of the first record.

Example of alarm programming by maximum and minimum

value with voltage VL1. Maximum value: 240 V, minimum value:

200 V (Vx10), and a delay of 10 s.

Maximum value 2400 (Decimal) → 00000960 (Hexadecimal)

Minimum value 2000 (Decimal) → 000007D0 (Hexadecimal)

Delay 10 (Decimal) → 000A (Hexadecimal)

Var number 01 (Decimal) → 01 (Hex)

Not used 00 (Decimal) → 00 (Hexadecimal)

TX: NP1004B000060C 00000960 000007D0 000A 0100 CRC

RX: 03 10 04B00006 CRC

2.6.4.- Next, reset the unit (see 2.1.1.-).Reading digital

output settings

TX: NP 04 04 047X 0006 CRC

RX: NP 04 0C 00000960 000007D0 000A 01 00 CRC

(X: value of the inicial register for each digital output ).

M98229901-03-14A

Page 2

CVM-NET

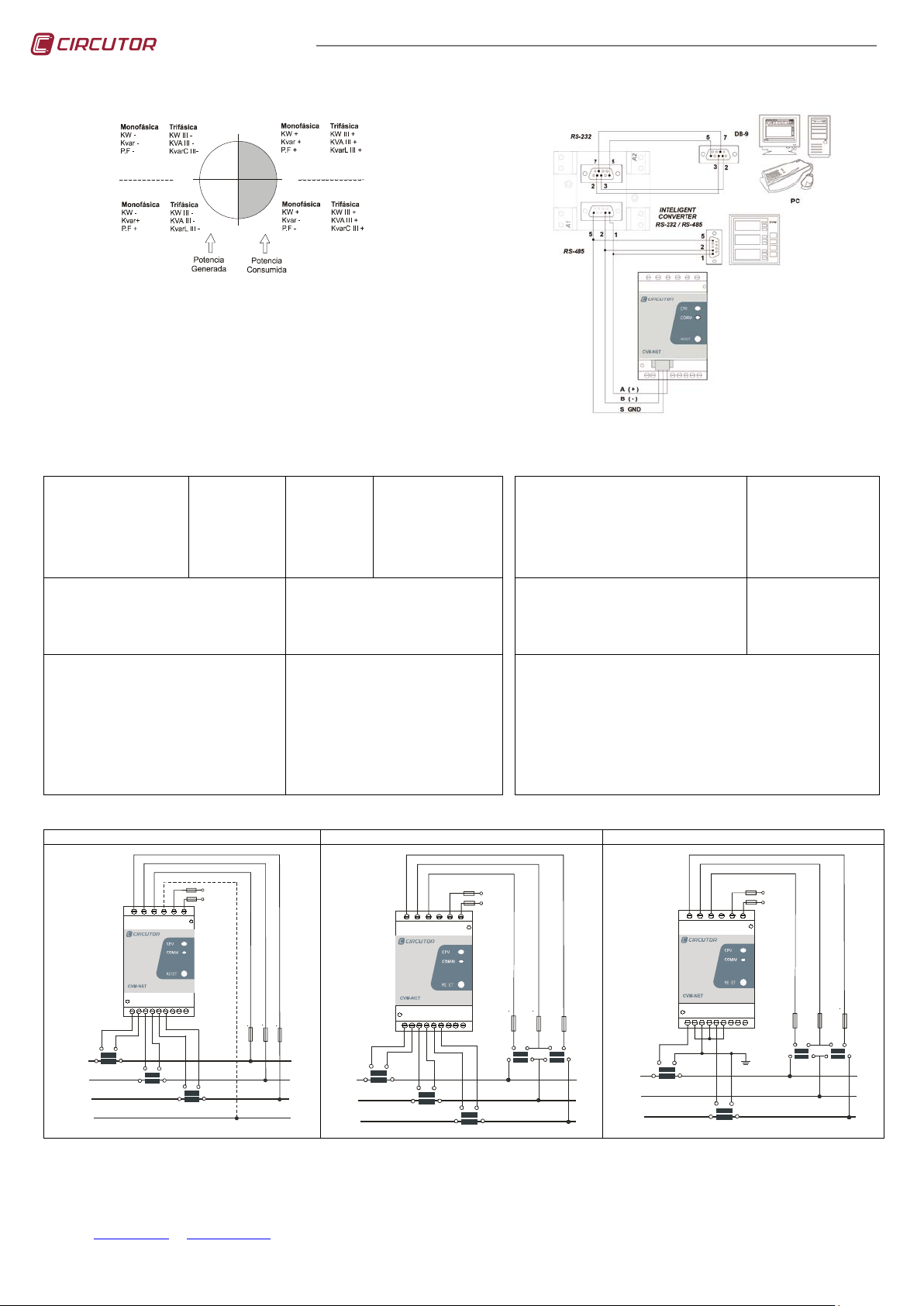

0º

90º

180º

-90º

Capacitivo

Capacitivo

Inductivo

Inductivo

Power circuit:

AC version

DC version

Plus version: C. & DC

Metering circuit:

Mechanical characteristics:

- Weight:

0.210 kg

Features of the output transistors

- Pulse duration:

100 ms

Precisions Class:

Maximum altitude operating:

2000 meters

Safety:

EN 61000-4-4, EN 61000-4-5, EN 55011, CE

4 wires / 3 wires ( low voltage )

3 wires (2 voltage and 3 current transformers)

3 wires (2 voltage and 2 current transformers)

S2

P2

S1

P1

L1

L2

L3

N

S2

P2

S1

P1

S2

P2

S1

P1

N

V

L1

V

L2

V

L3

min

max Pd

max

clear

COMM

CPU

CVM-MINI

reset reset energy

1 2 3 4 5 6 7 8 9

10 11 12 13 14 15

Alimentación

Power Supply

S2

P2

S1

P1

L1

L2

L3

S2

P2

S1

P1

S2

P2

S1

P1

1 2 3 4 5 6 7 8 9

10 11 12 13 14 15

b

B

aAbBa

A

V

L1

V

L2

V

L3

Alimentación

Power Supply

L1

L2

L3

1 2 3 4 5 6 7 8 9

10 11 12 13 14 15

b

B

a

A

b

B

a

A

V

L1

V

L2

V

L3

S2

P2

S1

P1

S2

P2

S1

P1

Alimentación

Power Supply

FOUR CVM -NE T Q UADRANTS

2.7.- CVM-NET COMMUNICATIONS

One or several CVM-NET analyzers can be connected to a computer or PLC. This system

makes it possible to centralise the data in a single record point, in addition to the normal

operation of each of them (PowerStudio® System). The CVM-NET has an RS-485 serial

communication output. If more than one analyzer is connected to a serial communication bus

(RS-485), each analyzer must be assigned a peripheral number or address (from 01 to 255),

with a maximum of 32 units per communication bus, so that the central computer sends the

queries from the various records measured or calculated to these addresses.

The CVM-NET power analyzer communicates using the MODBUS RTU© protocol (Pulling

Question / Answer).

3.- TECHNICAL SPECIFICATIONS

- Single-phase:

- Voltage tolerance:

- Frequency:

- Maximum consumption:

- Working temperature:

- Humidity (non-condensing):

- Case material:

- Protection titted unit (frontal):

- Protection non-fitted unit (sides and rear cover):

- Dimensions (mm):

- Voltage:

- Current:

- Power / Energy:

Measurement sensors: Current / Voltage

Power factor:

Full-scale measurement margin: ITF / Shunt

Temperature sensor: Precision / Working window

- Temperature measurement: with forced ventilation

- Temperature measurement: without forced ventilation

4.- CONNECTIONS

230 V AC

-15% / +10%

50 - 60 Hz

3.0 V·A

-10 …..+ 50 ºC

5 ….. 95%

20…120V DC

1,2…2 W

-10 …..+ 50 ºC

5 ….. 95%

85..265V AC /95..300V DC

50 - 60 Hz (AC mode.)

3.0 V·A/ 3W

-10 …..+ 50 ºC

5 ….. 95%

V0 self-extinguishing plastic

IP 51

IP 31

85 x 52 x 70 mm (3 modules)

0.5% ± 1 digit

0.5% ± 1 digit

1% ± 1 digit

External transformers / direct voltage

0.5 to 1

0.2 ..... 120% / 2 ..... 120%

± 2 ºC / -10 ….. +50 ºC

+ 14.0 ºC

+ 3.5 ºC

- Nominal voltage: phase-neutral / between phases

- Frequency:

- Nominal current:

- Permanent overload:

- Voltage consumption of the circuit:

- Current consumption of the circuit: ITF / Shunt

- Type: Opto-isolated transistor (commutator open).

- Maximum switching voltage:

- Maximum switching current:

- Maximum frequency:

300 V AC / 520 V AC

45 ~ 65 Hz

I

/ 5 A

n

1.2 I

n

0.7 V·A

0.9 V·A / 0.75 V·A

NPN

24 V DC

50 mA

5 pulse / s

Category III - 300 V AC / 520 V AC E N-61010 Class II double-insulated electric shock

protection.

The system should be c onnec ted t o a power supply circuit pr otec t ed by fuses gl or M type,

with current ratings between 0.5 and 1 A. It shoul d be prov ided with a MCCB or equiv al ent

device to switch off the system from the power supply circuit. The power supply and

voltage measuring circuit is connected with cable minimum cross section of 1 mm2

Standards:

IEC 664, VDE 0110, UL 94, IEC 801, IEC 348, IEC 571-1, EN 61000-6-3,

EN 61000-6-1, EN 61010-1, EN 61000-4-11, EN 61000-4-2, EN 61000-4-3,

5.- TECHNICAL SERVICE

In the event of any equipment failure or any operational queries please contact the technical service of CIRCUTOR S.A.

CIRCUTOR S.A. - After sales service

Vial Sant Jordi, s/n

08232 -Viladecavalls (Barcelona)

tel - (+34) 93 745 29 00 & fax - (+34) 93 745 29 14

E-mail :

sat@circutor.es www.circutor.com

M98229901-03-14A

Loading...

Loading...