Page 1

MULTIMETER CURRENT CLAMP

CPM

(Code: M80430)

INSTRUCTION MANUAL

( M98111201-03-10A )

CIRCUTOR S.A.

Page 2

--------- MULTIMETER CURRENT CLAMP

-

CPM

-------- PG No. 1

CPM ANALYZER INDEX page no.

SAFETY NOTES

Before using the equipment please read the user manual, paying special attention to

the SAFETY REQUIREMENTS section.

The symbol on the equipment means "CONSULT THE INSTRUCTION

MANUAL". It can also appear as a symbol of warning or caution in this manual.

WARNING and CAUTION statements can appear throughout this manual to avoid

hazard to persons or damage to equipment or other property.

1.- OVERVIEW

1.1.- Description

The CPM Current clamp provides functions for the measurement of voltage,

current, resistance, continuity sound alarm, diode test, as well as frequency

measurement.

Three push buttons allow for the selection of functions such as measurement

hold (HOLD), maximum value (MAX) and reset for current measurement DC (DCA

ZERO).

Page 3

--------- MULTIMETER CURRENT CLAMP

-

The analyzer is powered by a 9 V battery. Its design and its double insulation

makes the CPM a robust and secure instrument.

CPM

-------- PG No. 2

Page 4

--------- MULTIMETER CURRENT CLAMP

1.2.- Specifications

CPM

-------- PG No. 3

-

Display

3 ½ digit LCD display with a maximum

reading of 1999.

Display functions

Hold

MAX

Polarity

Measurement value hold.

Maximum measurement value hold.

Automatic, positive by default and indication

of negative polarity (-).

Overrange

Zero

Low battery indication

(OL) or (-OL) appears on the display.

Automatic

The“ “indicator appears when the battery

voltage is below the level of operation.

Reading rate

2.5 measurements a second, nominal.

Page 5

--------- MULTIMETER CURRENT CLAMP

-

CPM

-------- PG No. 4

Power Supply

Battery life

9 V, IEC 6F22 battery.

Typically 200 hours for a zinc-carbon

battery

Environmental conditions

Operating temperature

Storage temperature

0 °C to 40 °C (H.R. 0-70%)

20 °C to 60 °C, (H.R. 0-80%) with the

battery removed

Dimensions

Weight

Accessories

250 (W) x 100 (H) x 46 mm. (D.)

380 g, including the battery.

A pair of test probes

Transport case

Reference conditions

Referring to environmental conditions:

23 °C ± 5 °C, HR < 75%.

Page 6

--------- MULTIMETER CURRENT CLAMP

-

CPM

-------- PG No. 5

DC Voltage

Range

Accuracy

Input impedance

Overload protection

AC Voltage (50-500 Hz)

Ranges

Accuracy

Input impedance

Overload protection

Resistance

Ranges

Accuracy

Open circuit voltage

Overload protection

Frequency (Autoranging)

Ranges

Accuracy

Sensitivity

Overload protection

600 V

± (0.5% read. + 1 digit)

10 MΩ

600 V DC or AC rms

200 V, 600 V

± (1.2% read. + 4 digits)

10 MΩ

600 V DC or AC rms

2 kΩ, 200 kΩ

± (1.2% read. + 1 digit)

0.3 V DC

600 V DC or AC rms

2 kHz, 20 kHz

± 0.1% read. + 3 digits.

80 V rms minimum

600 V DC or AC rms

Page 7

--------- MULTIMETER CURRENT CLAMP

-

CPM

-------- PG No. 6

Continuity

Sound alarm

Overload protection

Diode test

Test current

Accuracy

Open circuit tension

Sound alarm

Overload protection

DC Current (Place the conductor in

the centre of the clamp).

Ranges

Resolution

Accuracy

Overload protection

AC Current (40 Hz to 500 Hz)

(Place the conductor in the centre of

the clamp.)

Ranges

Resolution

Accuracy

Overload protection

Less than 30Ω in the range of 2kΩ.

600 V DC or AC rms

1.0 mA ± 0.6 mA

± (6.0% read. + 3 digits)

3.0 V DC typically

< 30 mV

600 V DC or AC rms

200 A, 700 A

100 mA

± (1.5% read. + 5 digits)

700 A DC Max. during 1 minute.

200 A, 700 A

100 mA

±(1.5% read. + 5 digits) from 50 to 60

Hz

±(3.5% read. + 5 digits) from 40 to 500

Hz

Page 8

--------- MULTIMETER CURRENT CLAMP

-

700 A AC Max. during 1 minute.

CPM

-------- PG No. 7

Page 9

--------- MULTIMETER CURRENT CLAMP

-

CPM

-------- PG No. 8

2.- SAFETY REQUIREMENTS

2.1.- General

This equipment can be used in environments of Pollution Degree 2.

Overvoltage Category: See sections 2.2 and 2.3.

In order to ensure safety only the following specified types of the accessories

must be used:

Test probes:

Always keep the specified ranges in mind for both power supply and

measurement.

Obey the maximum environmental conditions specified for the apparatus at

all times.

Remember that voltages higher than 60 V DC or 30 V AC rms are potentially

dangerous.

The operator is only authorized to intervene for: Battery replacement

Specific instructions for these interventions are defined in the Maintenance

section.

Any other change made to the equipment must be done exclusively by

specialized personnel.

Strictly follow the cleaning recommendations that are described in the

Maintenance section.

Page 10

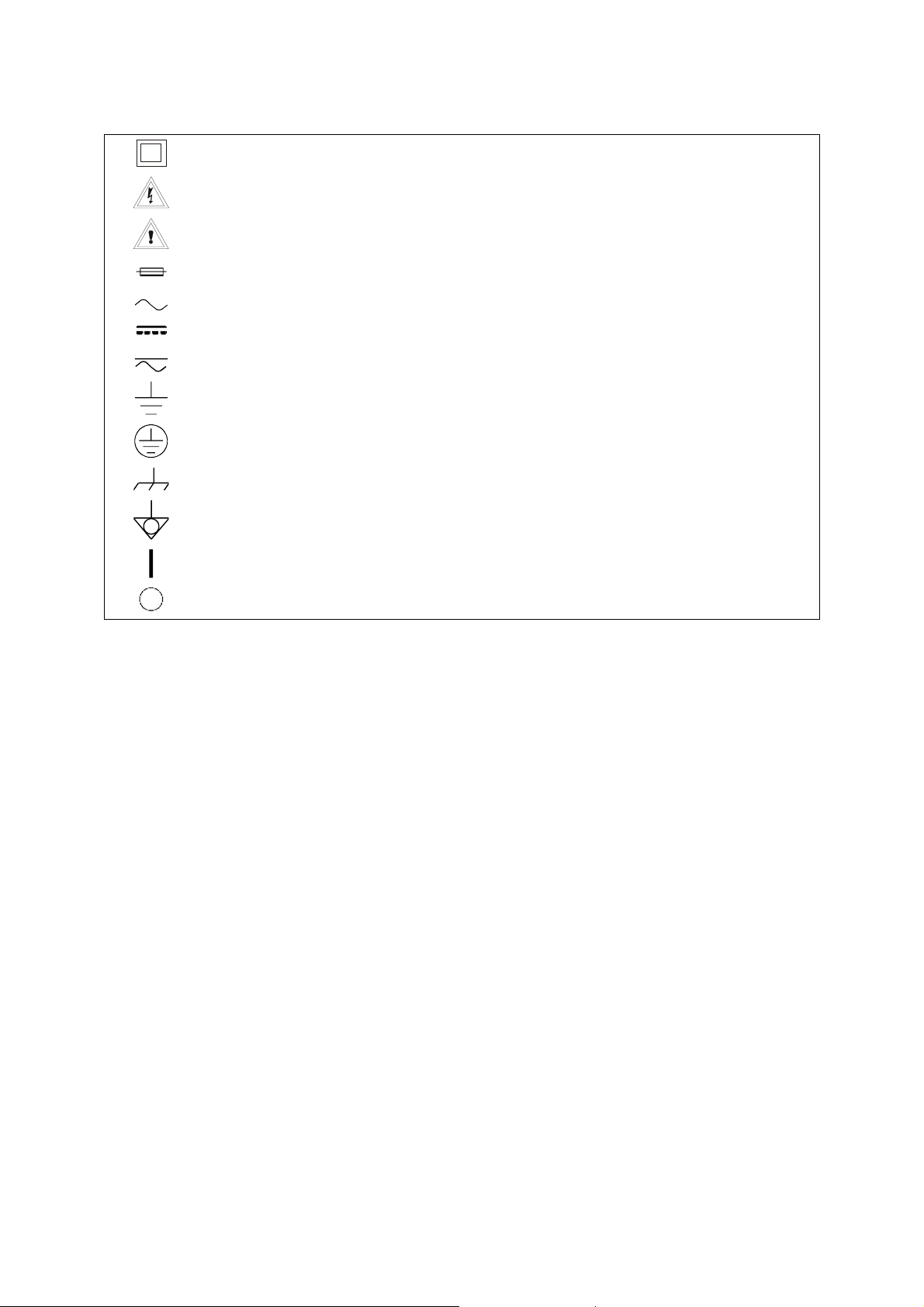

Symbols:

--------- MULTIMETER CURRENT CLAMP

-

CPM

-------- PG No. 9

The analyzer is protected by double or reinforced insulation.

Caution! Risk of electric shock.

Caution! See this manual before using the analyzer.

Fuse

Alternating current

Direct current

Alternate and direct

Earth terminal

Protection terminal

Shell terminal

Equipotentiality

Start

Stop

Page 11

--------- MULTIMETER CURRENT CLAMP

-

CPM

-------- PG No. 10

2.2.- Special precautions

This equipment can be used for Overvoltage Category II installations.

The clamp can be used exclusively for the measurement of current for

installations of up to 600 V with Overvoltage Category IV.

When using the test probes fingers must be kept behind the protection

outcrops.

Maintain the test probes in good condition.

Note the correspondence between the connection of the probes and

the measurement to be taken.

2.3.- Descriptive examples of overvoltage categories

Cat I Low voltage installations isolated from the mains.

Cat II Portable domestic installations.

Cat III Fixed domestic installations.

Cat IV Industrial installations.

Page 12

--------- MULTIMETER CURRENT CLAMP

-

3.- INSTRUCTIONS FOR USE

3.1.- Description of controls and elements

B

CPM

A

-------- PG No. 11

Page 13

--------- MULTIMETER CURRENT CLAMP

-

CPM

-------- PG No. 12

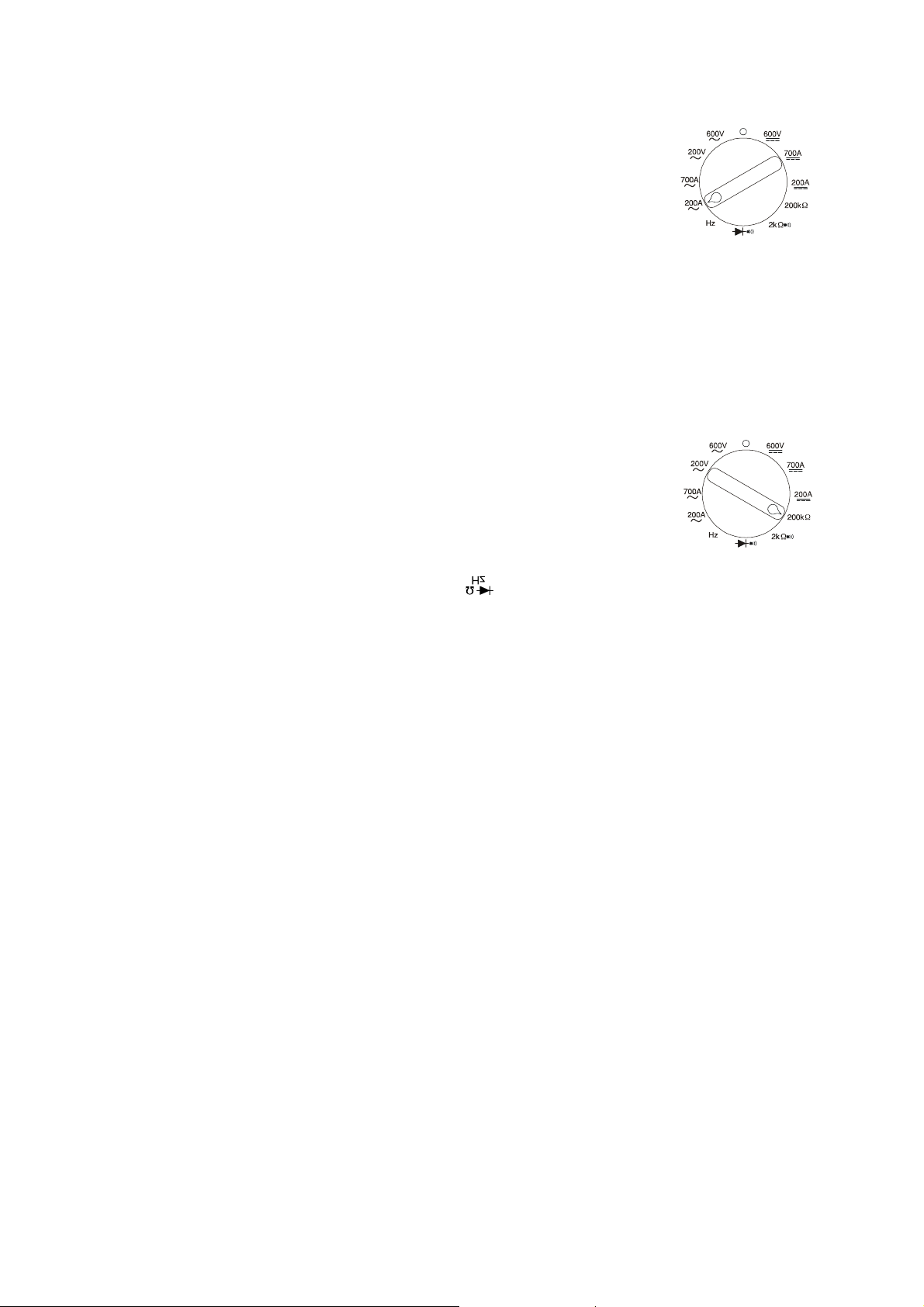

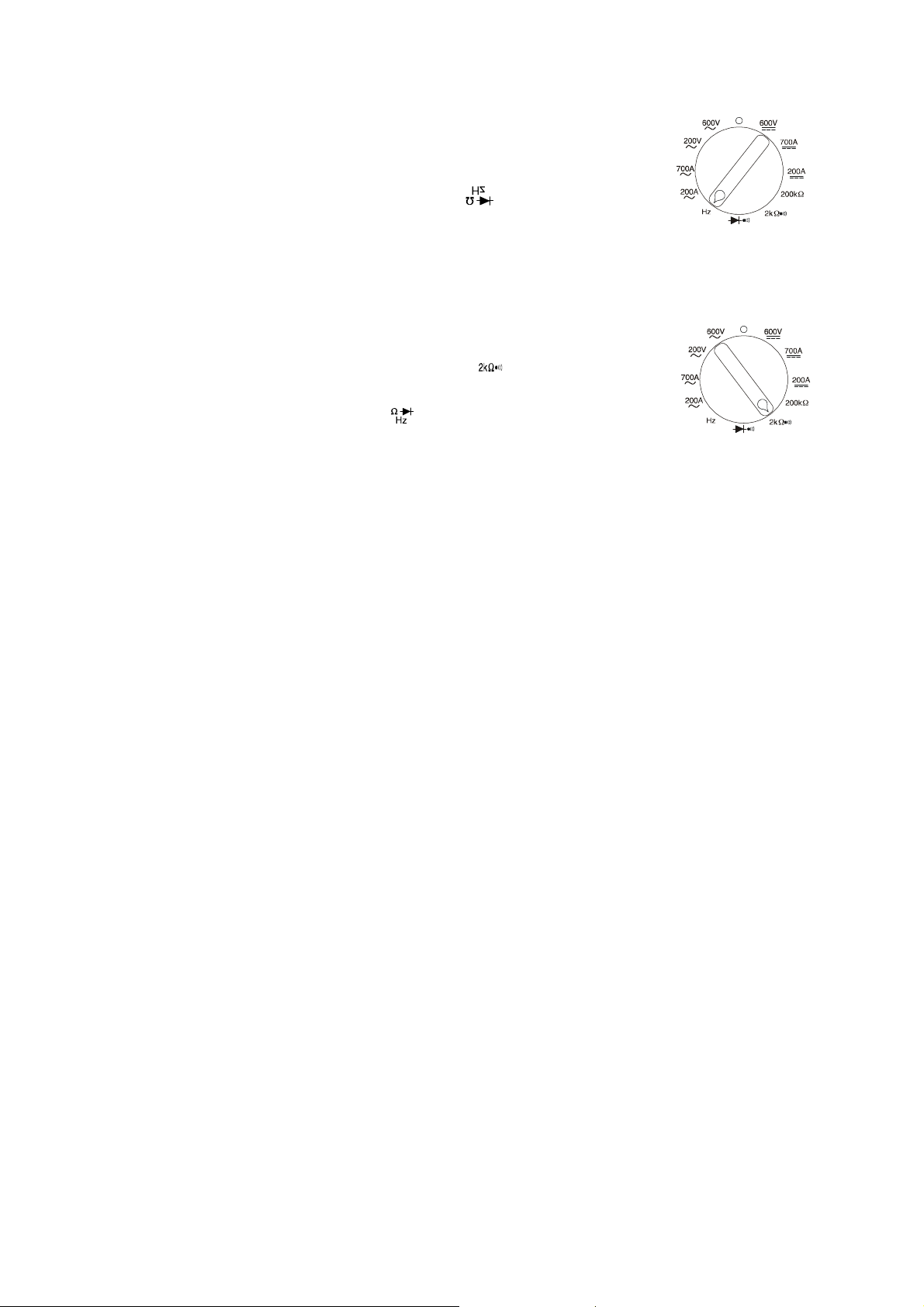

[1] Rotary function switch

Analyzer off

DC voltage measurement, range 600 V

DC current measurement, range 700 A

DC current measurement, range 200 A

Resistance measurement, range 200 kΩ

Continuity test and resistance measurement, range 2 kΩ

Diode test

Hz Frequency measurement

AC current measurement, range 200 A

AC current measurement, range 700 A

AC voltage measurement, range 200 V

AC voltage measurement, range 600 V

[2] DCA ZERO

In DC current measurement mode, press this key to select/deselect the

relative measurement mode, the ZERO indicator will appear on the display

and the measurement will change to zero, while the reading is stored as a

reference value.

Page 14

--------- MULTIMETER CURRENT CLAMP

-

CPM

-------- PG No. 13

[3] V input terminal for AC/DC voltage measurement

[4] COM common input terminal for test probes for all measurements.

[5] Input terminal for resistance measurements, frequency and diode

tests.

[6] DISPLAY

Display of measured values and operating mode

[7] MAX maximum value hold key

This key selects/deselects the MAX measuring mode. In this measuring mode

the absolute maximum value is held. When this function is activated "MAX"

appears on the upper part of the display. This function does not operate in

frequencymeter mode.

[8] Measurement hold key.

This key allows to select/deselect the "HOLD" function (measurement hold).

When this function is activated a "H" appears on the upper line of the display.

The HOLD function is deactivated on function or range change.

Page 15

--------- MULTIMETER CURRENT CLAMP

-

CPM

-------- PG No. 14

3.2.- Use

ATTENTION

When the value to be measured is unknown always place the rotary switch to the

highest range and reduce it progressively in function of the value in question.

3.2.1.- Voltage measurement

1. Connect the red test probe to the "V" terminal [3] and the

black test probe to "COM" terminal [4].

2. Set the rotary switch [1] to the appropriate "V" position

(AC or DC and suitable range). If the size of the voltage

to be measured is unknown, set the switch to the highest range and then

start reducing it until the highest accuracy is obtained.

3. Connect the test probes to the points to be measured and read the display.

For DC voltages, the "-" sign indicates a negative polarity.

Page 16

--------- MULTIMETER CURRENT CLAMP

-

CPM

-------- PG No. 15

3.2.2.- Current measurement

1. Set the rotary switch [1] to the desired higher range 700 A

(AC or DC). In DC current measurement mode use the

DCA ZERO button [2] to delete the offset due to the

residual magnetism of the clamp.

2. Press the trigger to open the clamp and encompass one conductor only.

Read the current value directly from the display [6]. It is recommended to

place the conductor in the centre of the clamp for maximum accuracy.

3. When the reading is less than 200 counts, set the switch [1] to the

measurement range below the current position. For maximum accuracy,

select the lowest range margin in which the measurement can be taken (i.e.

the overrange indicator does not appear).

3.2.3.- Resistance measurement

1. Set the rotary switch [1] to the desired resistance

measurement range.

2. Disconnect the power supply to the circuit being

measured.

3. Connect the red test probe to the terminal [5] and the black test probe

to the COM terminal [4].

4. Connect the load using the test probes. On the display [6] the value of the

tested resistance will appear in ohms.

Page 17

--------- MULTIMETER CURRENT CLAMP

-

CPM

-------- PG No. 16

3.2.4.- Frequency measurement

1. Set the rotary switch [1] to the Hz position.

2. Connect the red test probe to the terminal [5] and the

black test probe to the COM terminal [4].

3. Connect the test probes in parallel with the points to be measured and read

the frequency value on the display [6].

3.2.5.- Continuity sound alarm

1. Set the rotary switch [1] to position“ “ .

2. Connect the black test probe to the COM terminal [4] and

the red test probe to the terminal [5].

3. Connect the test probes to the points to be verified.

4. If the resistance value is less than 30 Ω the built in alarm will sound.

Page 18

--------- MULTIMETER CURRENT CLAMP

-

CPM

-------- PG No. 17

3.2.6.- Diode test

1. Connect the black test probe to the COM terminal [4]

and the red test probe to the terminal [5].

2. Set the rotary switch [1] to the position “ “ .

3. Disconnect the power supply to the circuit being tested.

4. Connect the black test probe to the negative (-) side of the diode and the

red test probe to the positive (+) side. Normally the direct voltage of a good

silicon diode is of 0.6 V.

5. On inverting the test probes, if the diode is good “OL” will appear on the

display [1] and if it is faulty, 000 or another value will appear.

6. If the diode is open, the “OL” indicator will appear for each direction.

7. If the diode of a circuit is measured and a low measurement is obtained for

each measurement direction, then the junction must be in parallel and with

a resistance of less than 1 kΩ. In this case the diode must be disconnected

from the circuit in order to perform an exact measurement.

Page 19

--------- MULTIMETER CURRENT CLAMP

-

CPM

-------- PG No. 18

4.- MAINTENANCE

Attention : Disconnect the test probes before changing the battery or performing

any maintenance service.

4.1.- Battery replacement

When the symbol “ ” appears on the lower left corner of the LCD indicator,

the batteries must be replaced:

1. Loosen the screws with a suitable screwdriver and remove the back cover.

2. Replace the battery with an IEC 6F22 9 V.

3. Close the back cover.

4.2.- Cleaning and storage

Caution : To clean the case, make sure that the equipment is disconnected.

Page 20

--------- MULTIMETER CURRENT CLAMP

-

CPM

-------- PG No. 19

Caution : Do not use aromatic hydrocarbons or chlorinated solvents for

cleaning. These products can attack the materials used to make

the case.

Clean the case periodically with a soft cloth moistened with water and

detergent. Do not use abrasives or solvents. Dry thoroughly before reusing the

equipment.

4.3.- TECHNICAL SERVICE

In the case of any query regarding the operation or fault of the equipment

contact the CIRCUTOR S.A technical service.

CIRCUTOR S.A. - Post-sales service

Vial Sant Jordi, s/n

08232 – Viladecavalls

Tel. 902449459 (Spain)

Tel. – (+34) 93 745 29 00 (rest of the world)

Fax – (+34)93 745 29 14

E-mail: sat@circutor.es

Loading...

Loading...