Page 1

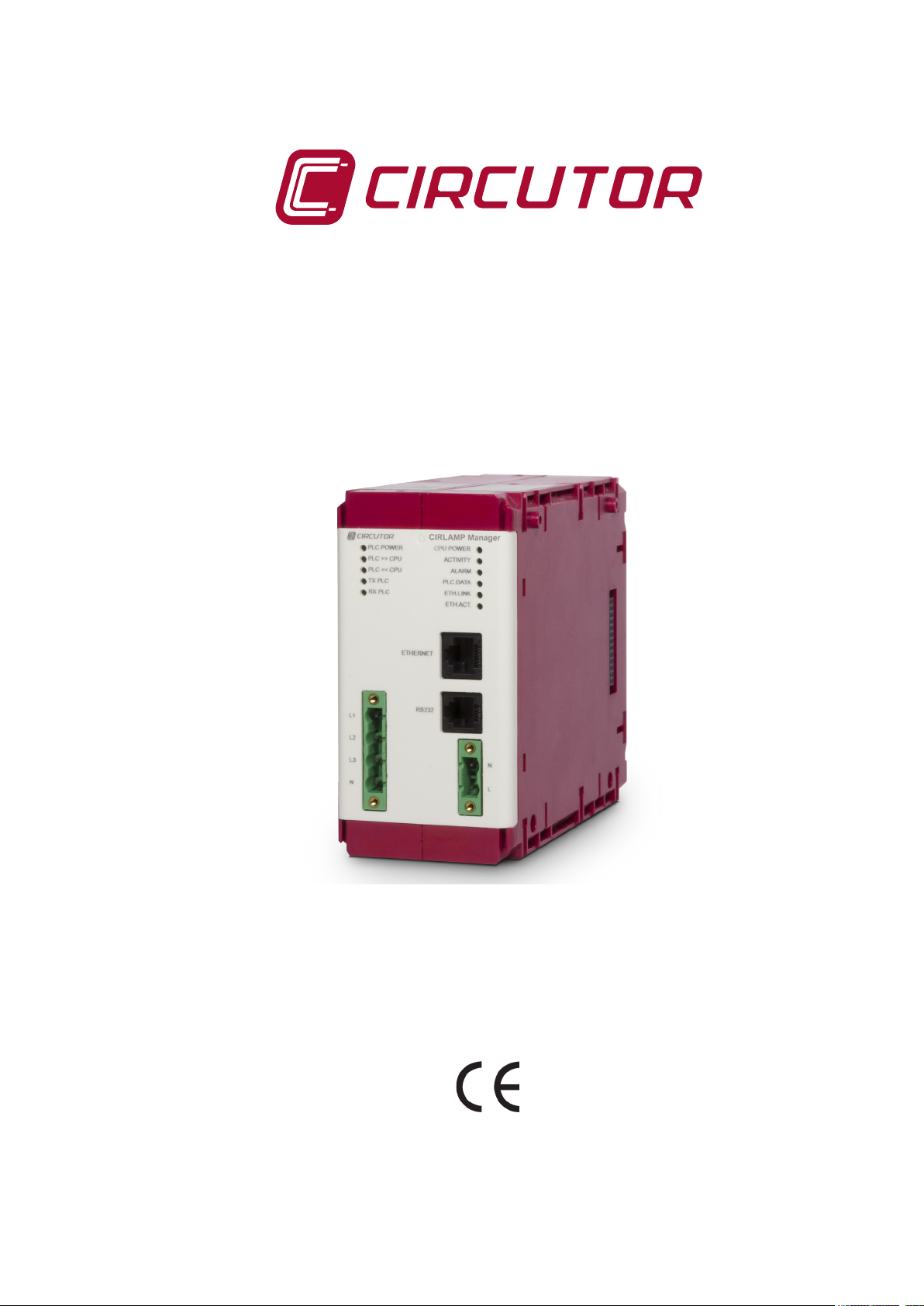

Management system for street lights

CirLAMP system

INSTRUCTION MANUAL

(M029B01-03-15B)

Page 2

CirLAMP system

2

Instruction Manual

Page 3

CirLAMP system

SAFETY PRECAUTIONS

Follow the warnings described in this manual with the symbols shown below.

DANGER

Warns of a risk, which could result in personal injury or material damage.

ATTENTION

Indicates that special attention should be paid to a speci c point.

If you must handle the unit for its installation, start-up or maintenance, the following

should be taken into consideration:

Incorrect handling or installation of the unit may result in injury to personnel as well as damage

to the unit. In particular, handling with voltages applied may result in electric shock, which may

cause death or serious injury to personnel. Defective installation or maintenance may also

lead to the risk of re.

Read the manual carefully prior to connecting the unit. Follow all installation and maintenance

instructions throughout the unit’s working life. Pay special attention to the installation standards of the National Electrical Code.

Refer to the instruction manual before using the unit

In this manual, if the instructions marked with this symbol are not respected or carried out correctly, it can

result in injury or damage to the unit and /or installations.

CIRCUTOR, SA reserves the right to modify features or the product manual without prior noti cation.

DISCLAIMER

CIRCUTOR, SA reserves the right to make modi cations to the device or the unit speci ca-

tions set out in this instruction manual without prior notice.

CIRCUTOR, SA on its web site, supplies its customers with the latest versions of the device

speci cations and the most updated manuals.

www.circutor.com

Instruction Manual

3

Page 4

CirLAMP system

CONTENTS

SAFETY PRECAUTIONS ���������������������������������������������������������������������������������������������������������������������������������������3

DISCLAIMER ����������������������������������������������������������������������������������������������������������������������������������������������������������3

CONTENTS ������������������������������������������������������������������������������������������������������������������������������������������������������������� 4

REVISION LOG �������������������������������������������������������������������������������������������������������������������������������������������������������6

1�- VERIFICATION UPON RECEPTION ����������������������������������������������������������������������������������������������������������������� 7

2�- PRODUCT DESCRIPTION �������������������������������������������������������������������������������������������������������������������������������� 7

3�- OPERATING PRINCIPLE ��������������������������������������������������������������������������������������������������������������������������������� 9

4�- CirLAMP Manager �����������������������������������������������������������������������������������������������������������������������������������������10

4�1�- INSTALLATION OF THE UNIT ����������������������������������������������������������������������������������������������������������������� 10

4�1�1� PRELIMINARY RECOMMENDATIONS �������������������������������������������������������������������������������������������10

4�1�2� INSTALLATION ��������������������������������������������������������������������������������������������������������������������������������10

4�1�3� UNIT TERMINALS ���������������������������������������������������������������������������������������������������������������������������� 12

4�2�- LEDs ��������������������������������������������������������������������������������������������������������������������������������������������������������� 14

4�3�- PLC ����������������������������������������������������������������������������������������������������������������������������������������������������������� 15

4�4�- ETHERNET ����������������������������������������������������������������������������������������������������������������������������������������������� 15

4�5�- DATABASES �������������������������������������������������������������������������������������������������������������������������������������������16

4�5�1� MEASUREMENTS DATABASE �������������������������������������������������������������������������������������������������������16

4�5�2� ALARM DATABASE �������������������������������������������������������������������������������������������������������������������������16

4�6�- WEB SERVER �����������������������������������������������������������������������������������������������������������������������������������������16

4�6�1� HOME SCREEN ��������������������������������������������������������������������������������������������������������������������������������16

4�6�2� MAIN SCREEN ��������������������������������������������������������������������������������������������������������������������������������� 18

4�6�3� NODES MENU: EQUIPMENTS TABLE �������������������������������������������������������������������������������������������21

4�6�4� NODES MENU: ORDERS ����������������������������������������������������������������������������������������������������������������29

4�6�5� NODES MENU: NODE MAP ������������������������������������������������������������������������������������������������������������53

4�6�6� NODES MENU: NODE UPDATE ������������������������������������������������������������������������������������������������������ 53

4�6�7� NODES MENU: INTRUDER LIST ����������������������������������������������������������������������������������������������������54

4�6�8� CirLAMP MANAGER MENU: REPORTS ����������������������������������������������������������������������������������������55

4�6�9� CirLAMP MANAGER MENU: INPUTS AND OUTPUTS ������������������������������������������������������������������56

4�6�10� CirLAMP MANAGER MENU: PARAMETERS ������������������������������������������������������������������������������� 57

4�6�11� CirLAMP MANAGER MENU: GEOLOCATION �����������������������������������������������������������������������������63

4�6�12� CirLAMP MANAGER MENU: TASKS �������������������������������������������������������������������������������������������� 64

4�6�13� CirLAMP MANAGER MENU: TASK STATUS �������������������������������������������������������������������������������71

4�6�14� CirLAMP MANAGER MENU: UPDATE �����������������������������������������������������������������������������������������72

4�6�15� CirLAMP MANAGER MENU: MODEM UPDATE ��������������������������������������������������������������������������72

4�6�16� CirLAMP MANAGER MENU: REBOOT ����������������������������������������������������������������������������������������72

5�- CIRLAMP NODE DN ���������������������������������������������������������������������������������������������������������������������������������������73

5�1�- INSTALLATION OF THE UNIT ����������������������������������������������������������������������������������������������������������������� 73

5�1�1� PRELIMINARY RECOMMENDATIONS��������������������������������������������������������������������������������������������73

5�1�2� INSTALLATION ��������������������������������������������������������������������������������������������������������������������������������73

5�1�3� UNIT TERMINALS ���������������������������������������������������������������������������������������������������������������������������� 74

5�1�4� CONNECTION DIAGRAM ���������������������������������������������������������������������������������������������������������������� 75

5�2�- CONNECTION WITH CirLAMP MANAGER ��������������������������������������������������������������������������������������������75

5�3�- OPERATION ���������������������������������������������������������������������������������������������������������������������������������������������75

5�3�1� WORK INTERVALS �������������������������������������������������������������������������������������������������������������������������� 75

5�3�2� ALARMS ������������������������������������������������������������������������������������������������������������������������������������������� 76

5�3�3� MEASUREMENT PARAMETERS ����������������������������������������������������������������������������������������������������77

6�- CIRLAMP NODE 1 ��� 10V �������������������������������������������������������������������������������������������������������������������������������78

6�1�- INSTALLATION OF THE UNIT ����������������������������������������������������������������������������������������������������������������� 78

6�1�1� PRELIMINARY RECOMMENDATIONS �������������������������������������������������������������������������������������������78

6�1�2� INSTALLATION ��������������������������������������������������������������������������������������������������������������������������������78

6�1�3� UNIT TERMINALS ���������������������������������������������������������������������������������������������������������������������������� 79

6�1�4� CONNECTION DIAGRAM ���������������������������������������������������������������������������������������������������������������� 80

6�2�- CONNECTION WITH CirLAMP MANAGER ��������������������������������������������������������������������������������������������80

6�3�- OPERATION ���������������������������������������������������������������������������������������������������������������������������������������������80

6�3�1� WORK INTERVALS �������������������������������������������������������������������������������������������������������������������������� 80

6�3�2� ALARMS ������������������������������������������������������������������������������������������������������������������������������������������� 81

6�3�3� MEASUREMENT PARAMETERS ����������������������������������������������������������������������������������������������������81

7�- CIRLAMP NODE DALI �����������������������������������������������������������������������������������������������������������������������������������82

7�1�- INSTALLATION OF THE UNIT ����������������������������������������������������������������������������������������������������������������� 82

4

Instruction Manual

Page 5

CirLAMP system

7�1�1� PRELIMINARY RECOMMENDATIONS �������������������������������������������������������������������������������������������82

7�1�2� INSTALLATION ��������������������������������������������������������������������������������������������������������������������������������82

7�1�3� UNIT TERMINALS ���������������������������������������������������������������������������������������������������������������������������� 83

7�1�4� CONNECTION DIAGRAM ���������������������������������������������������������������������������������������������������������������� 84

7�2�- CONNECTION WITH CirLAMP MANAGER ��������������������������������������������������������������������������������������������84

7�3�- OPERATION ���������������������������������������������������������������������������������������������������������������������������������������������84

7�3�1� WORK INTERVALS �������������������������������������������������������������������������������������������������������������������������� 84

7�3�2� ALARMS ������������������������������������������������������������������������������������������������������������������������������������������� 85

7�3�3� MEASUREMENT PARAMETERS ����������������������������������������������������������������������������������������������������85

8�- EXPANSION MODULE: M8I8O ����������������������������������������������������������������������������������������������������������������������� 86

8�1�- INSTALLATION OF THE UNIT ����������������������������������������������������������������������������������������������������������������� 86

8�1�1� PRELIMINARY RECOMMENDATIONS �������������������������������������������������������������������������������������������86

8�1�2� INSTALLATION ��������������������������������������������������������������������������������������������������������������������������������86

8�1�3� UNIT TERMINALS ���������������������������������������������������������������������������������������������������������������������������� 88

8�2�- OPERATION ���������������������������������������������������������������������������������������������������������������������������������������������89

8�2�1� LEDs ������������������������������������������������������������������������������������������������������������������������������������������������� 89

9�- TECHNICAL FEATURES ��������������������������������������������������������������������������������������������������������������������������������90

9�1�- CIRLAMP Manager ����������������������������������������������������������������������������������������������������������������������������������90

9�2�- CirLAMP Mode DN�����������������������������������������������������������������������������������������������������������������������������������92

9�3�- CirLAMP Node 1 ��� 10 V �������������������������������������������������������������������������������������������������������������������������� 94

9�4�- CirLAMP Node DALI �������������������������������������������������������������������������������������������������������������������������������� 96

9�5�- Expansion module: M8I8O ���������������������������������������������������������������������������������������������������������������������98

10�- MAINTENANCE AND TECHNICAL SERVICE ����������������������������������������������������������������������������������������������99

11�- GUARANTEE �������������������������������������������������������������������������������������������������������������������������������������������������99

12�- CE CERTIFICATE ���������������������������������������������������������������������������������������������������������������������������������������� 100

Instruction Manual

5

Page 6

REVISION LOG

Date Revision Description

09/14 M029B01-03-14A Initial Version

01/15 M029B01-03-15A Introduction of the CirLAMP Nodo DALI

07/15 M029B01-03-15B Changes in the following sections: 9.2. - 9.3. - 9.4.

CirLAMP system

Table 1: Revision log�

NB: The images of the units are solely for the purpose of illustration and may differ from the

original unit.

6

Instruction Manual

Page 7

CirLAMP system

1�- VERIFICATION UPON RECEPTION

Check the following points upon receiving the unit:

a) The unit meets the specications described in your order.

b) The unit has not suffered any damage during transport.

c) Perform an external visual inspection of the unit prior to switching it on.

d) Check that it has been delivered with the following:

CirLAMP Manager unit:

- An installation guide.

- Anchors for DIN rail.

- Six fastening pins.

- Two connectors.

CirLAMP Node unit:

- An installation guide.

M8I8O unit:

- An installation guide.

- Anchors for DIN rail.

- Six fastening pins.

- Two connectors.

If any problem is noticed upon reception, immediately contact the transport

company and/or CIRCUTOR's after-sales service.

2�- PRODUCT DESCRIPTION

The CirLAMP system enables smart management of street lights, increasing efciency by reducing energy consumption and creating tools to help the user with problem diagnosis and light

maintenance.

The system comprises:

CirLAMP manager + CirLAMP node

CirLAMP Manager is the system manager; it communicates with the CirLAMP Nodes installed

at each light point of the public lighting system via low voltage cables using the DCSK PLC (Power Line Communication) protocol.

Instruction Manual

7

Page 8

The unit features:

- A conguration web server, where the user can congure all the programming parameters for each light point.

- PLC (Power Line Communication) with the nodes on CENELEC Band B.

- A database for 1000 nodes, with capacity to store 1 million logs.

- An astronomical clock to switch each light point on and off (compatible with expansion

module M8I8O).

- 11 indicator LEDs.

CirLAMP Manager can be expanded with 1 expansion module:

M8I8O, expansion module with eight inputs and eight outputs.

CirLAMP system

The CirLAMP Nodes are regulating units that are installed at each light point.

They measure the main electrical parameters (voltage, current, active power, reactive power)

independently.

There are two CirLAMP Node models depending on the ballast:

CirLAMP Node DN, a regulating unit for lighting with electronic ballasts or bi-level

drivers.

CirLAMP Node 1 ��� 10V, a regulating unit for lighting with electronic ballasts or drivers

with a regulation range from 1 to 10V.

CirLAMP Node DALI, a regulating unit for lighting with electronic ballasts or drivers

with a DALI communications.

8

Instruction Manual

Page 9

CirLAMP system

The units include:

- PLC (Power Line Communication) with the CirLAMP Manager on CENELEC Band B.

- Systems to detect a burnt out lamp, an open capacitor and a ashing lamp, and to generate an alarm.

- (CirLAMP Node DN model) Relay output with ON/OFF control.

- (CirLAMP Node DN model) Relay output to control the bi-level ballasts.

- ( CirLAMP Node 1 ��� 10V model) 1 to 10V output to control ballasts with a regulation

range from 1 to 10V.

- (CirLAMP Node DALI model) DALI communications protocol to control ballasts .

3�- OPERATING PRINCIPLE

With the CirLAMP system it is possible to detect lighting anomalies, for example, burnt out

light bulbs, a blinking lamp, open capacitor, or control the useful life of each lamp, to ensure

correct maintenance of installations. When the CirLAMP system detects an incident, it sends

an email with detailed information.

To control lighting maintenance, the CirLAMP Manager has:

PLC communication on CENELEC Band B with a DCSK system.

Light point management through access by location.

(CirLAMP NODE Location application)

Possibility of sending emails when a fault or incident is detected.

Management of tasks and conguration orders sent to the CirLAMP Nodes�

Regular reading of the status of alarms, voltage and powers.

Memory event log.

Ability to automatically download event les

Astronomical clock to switch each light point on and off.

(M8I8O Expansion module)

Alarm management and external event control with the input and output module.

(M8I8O Expansion module).

Instruction Manual

9

Page 10

CirLAMP system

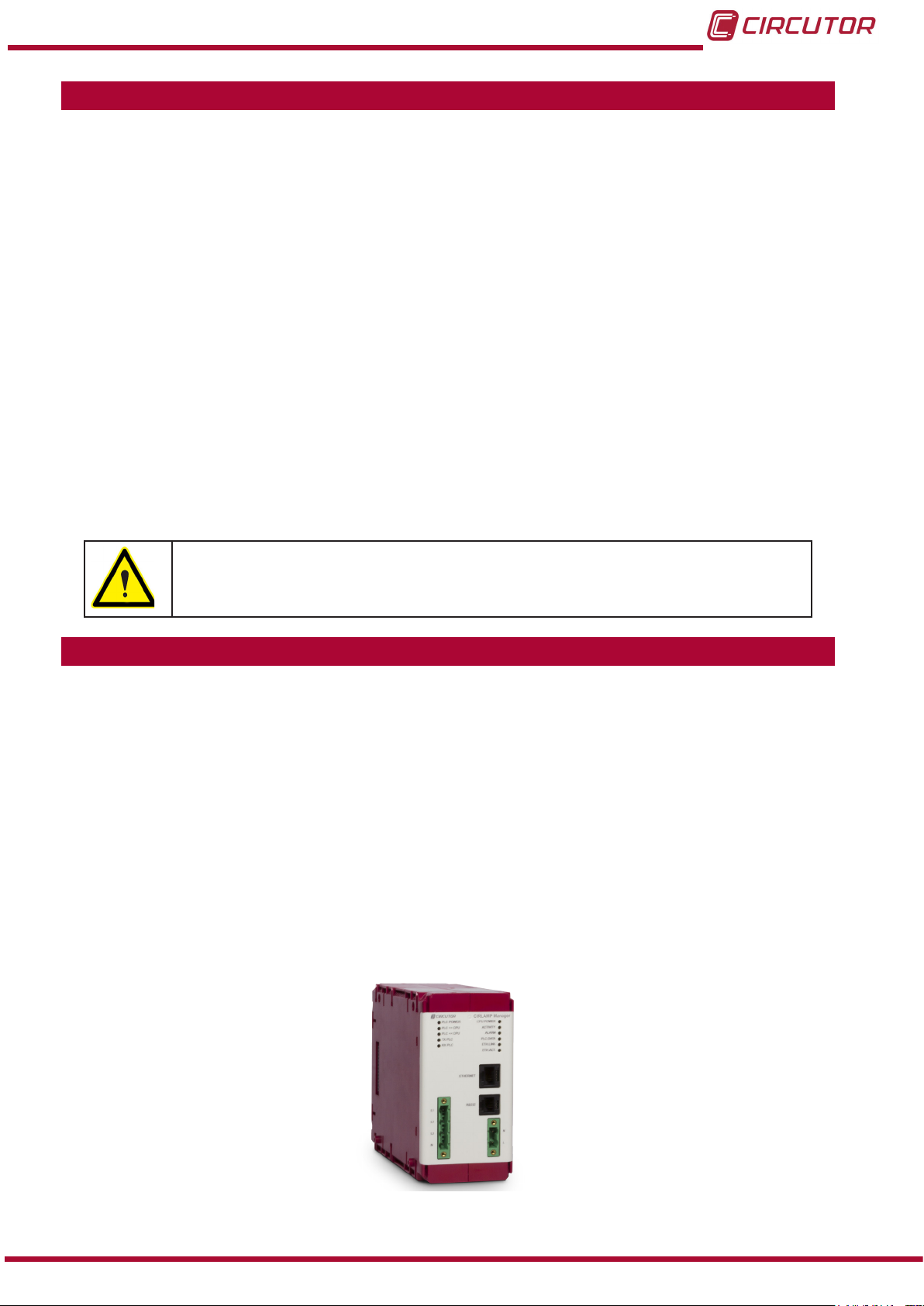

4�- CirLAMP Manager

4.1.- INSTALLATION OF THE UNIT

4�1�1� PRELIMINARY RECOMMENDATIONS

In order to use the unit safely, it is critical that individuals who handle it follow

the safety measures set out in the standards of the country where it is being

used, use the necessary personal protective equipment, and pay attention to

the various warnings indicated in this instruction manual.

The CirLAMP Manager unit must be installed by authorised and qualied staff.

The power supply plug must be disconnected before handling, altering the connections or

replacing the unit. It is dangerous to handle the unit while it is powered.

Also, it is critical to keep the cables in perfect condition in order to avoid accidents, personal

injury and damage to installations.

The manufacturer of the unit is not responsible for any damage resulting from failure by the

user or installer to observe the warnings and/or recommendations set out in this manual, nor

for damage resulting from the use of non-original products or accessories or those made by

other manufacturers.

If an anomaly or malfunction is detected in the unit, do not use it to perform any operation.

The unit must be disconnected from any power supply before carrying out any

maintenance or repairs, or handling any of the unit's connections.

Please contact the after-sales service if you suspect that there is an operational

fault in the unit.

4�1�2� INSTALLATION

The CirLAMP Manager unit must be installed on an electric panel or enclosure, attached to a

DIN rail (IEC 60715).

10

Two DIN rail brackets are supplied with the unit and must be installed on the unit before insta-

lling it on the electric panel.

To do so, follow these steps:

Instruction Manual

Page 11

CirLAMP system

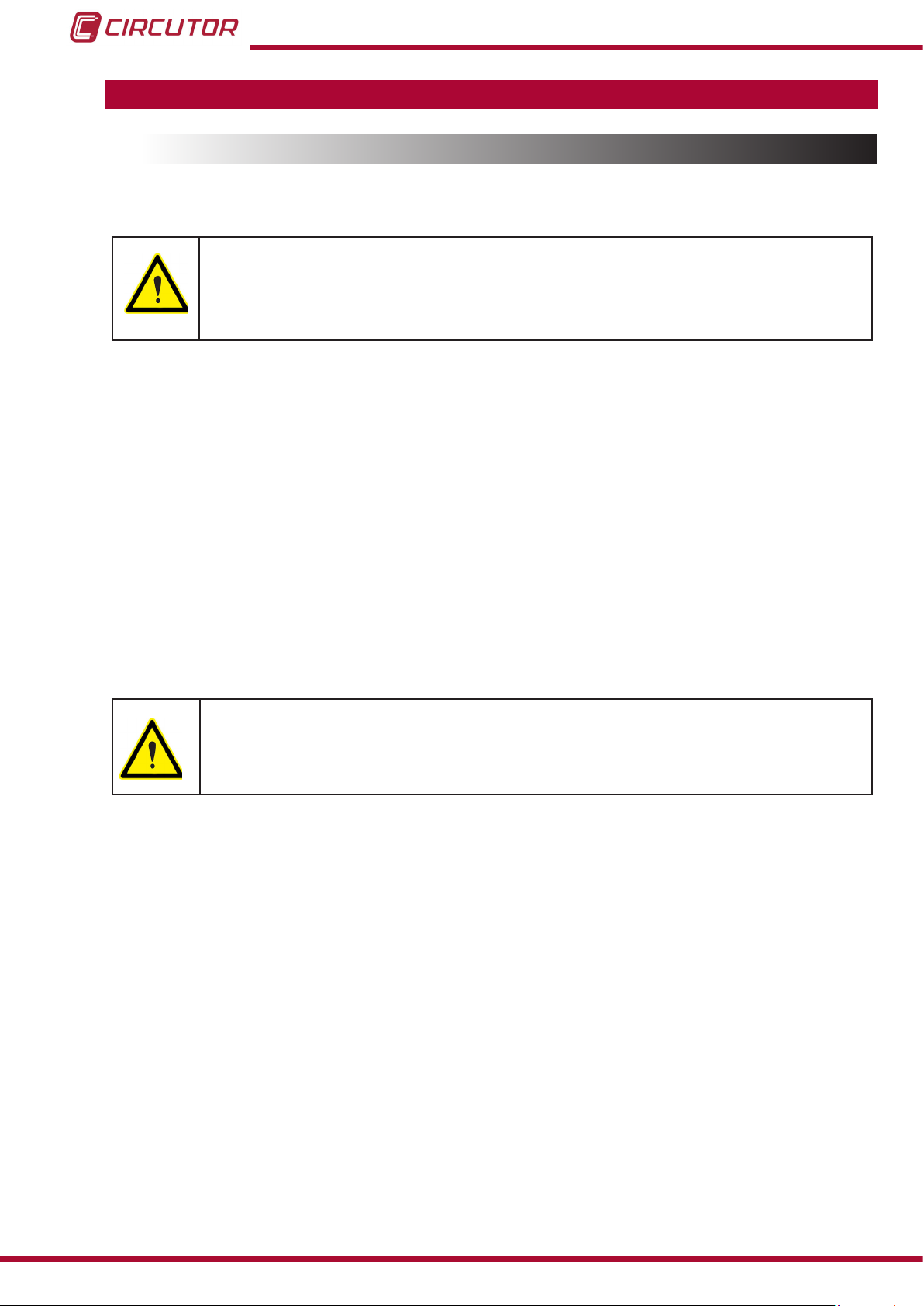

1�- Insert the rst bracket, as shown in Figure 1�

Figure 1: DIN rail brackets installation ( step 1)�

2�- Insert the second bracket in the rst bracket, Figure 2.

Figure 2: DIN rail brackets installation ( step 2)�

3�- Push the brackets into the rail until fully installed,Figure 3.

Figure 3: DIN rail brackets installation ( step 3)�

Terminals, opening covers or removing elements can expose parts that are

hazardous to the touch while the unit is powered. Do not use the unit until it is

fully installed.

The unit must be connected to a power circuit that is protected with gL fuses (IEC 269) or

M fuses, with a rating of 1 to 2 A. It must be tted with a circuit breaker or equivalent device

for disconnecting the unit from the power supply mains.

Instruction Manual

11

Page 12

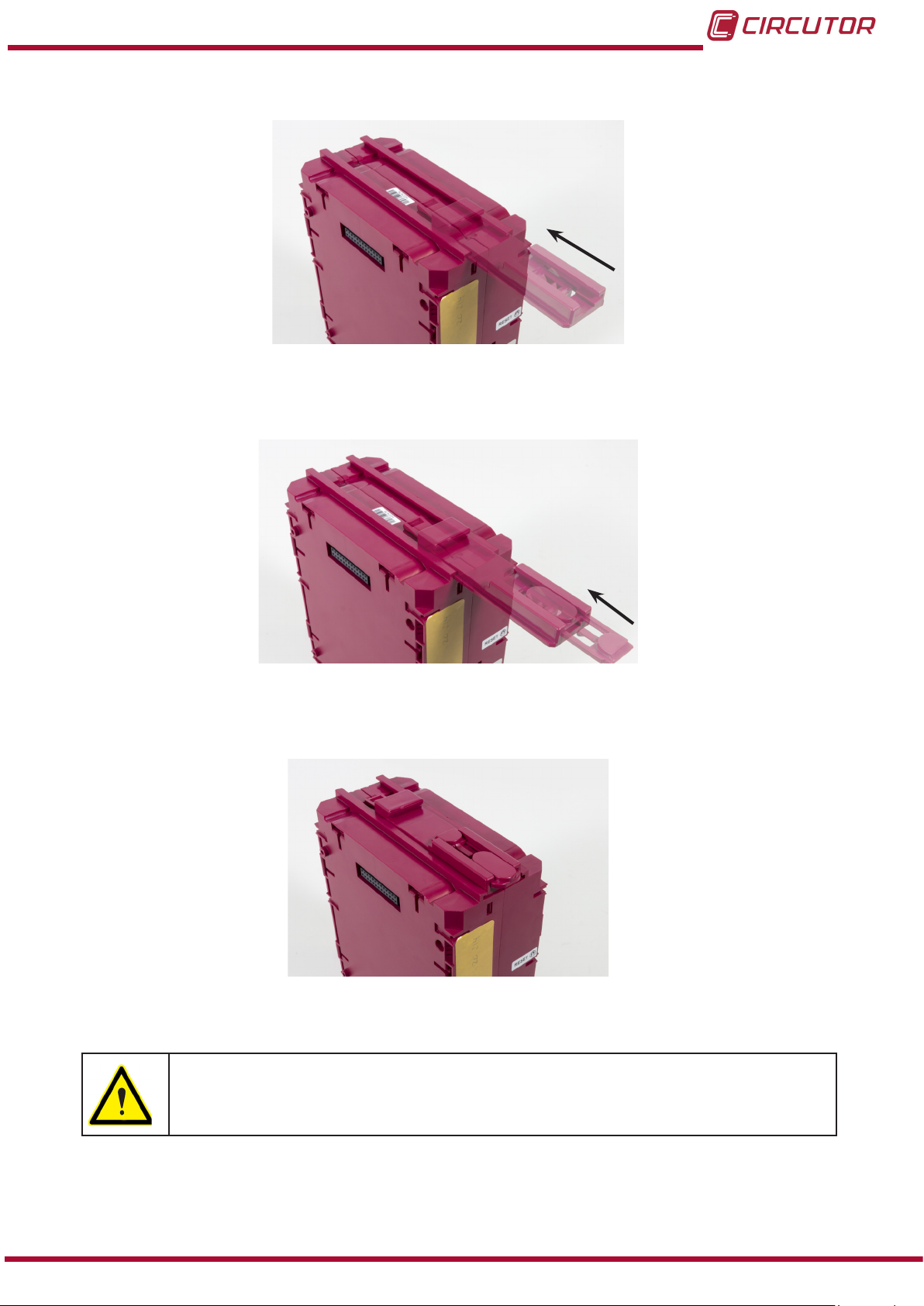

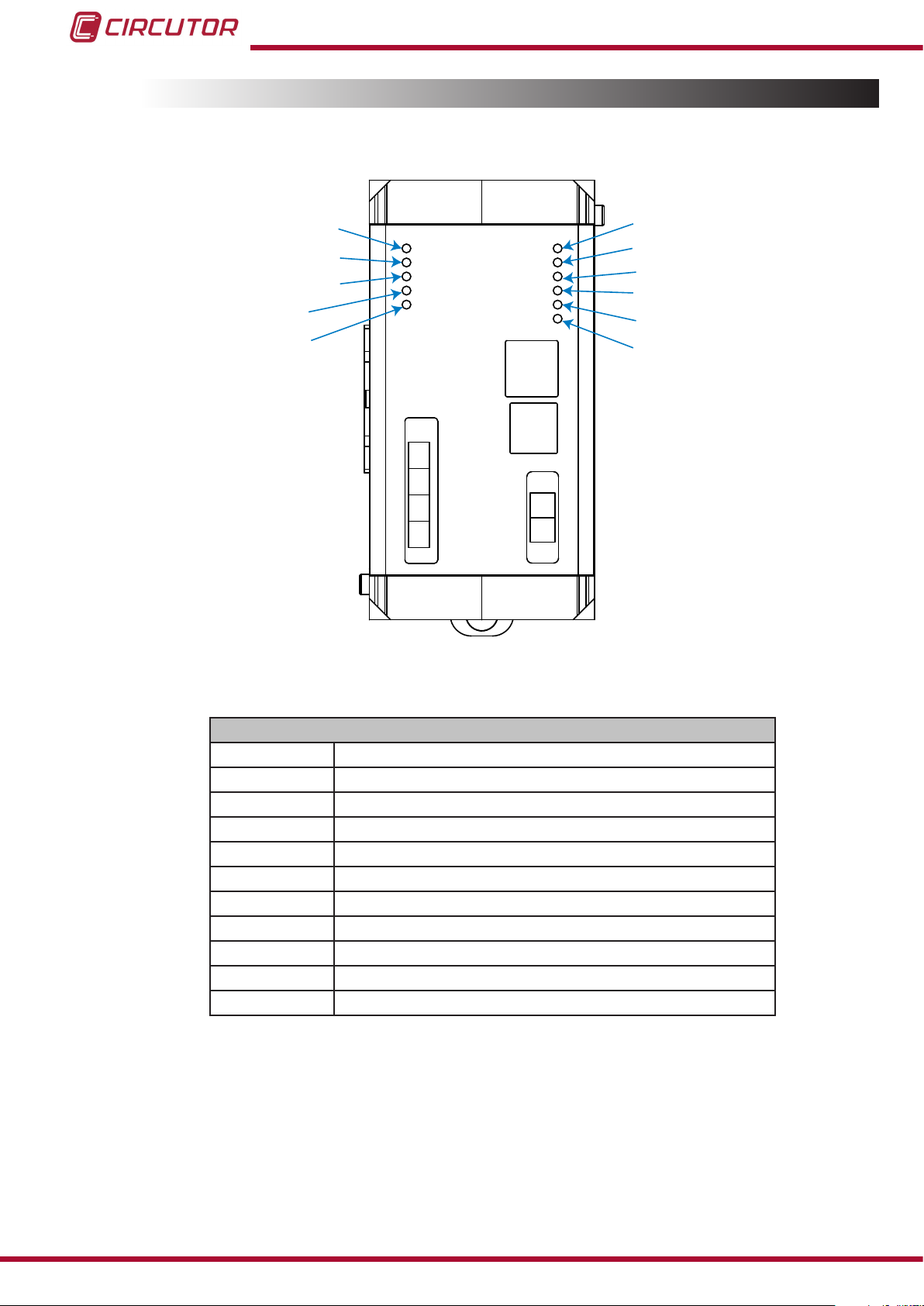

4�1�3� UNIT TERMINALS

1: L1, PLC connection L1 5: L, Auxiliary power supply

2: L2, PLC connection L2 6: N, Auxiliary power supply

3: L3, PLC connection L3 7: ETHERNET, Ethernet connection

4: N, PLC connection N

CirLAMP system

Table 2:List of CirLAMP Manager terminals�

Unit terminals

PLC POWER

PLC >> CPU

PLC << CPU

TX PLC

RX PLC

ETHERNET

CPU POWER

ACTIVITY

ALARM

PLC.DATA

ETH.LINK

ETH.ACT.

7

1

L1

2

3

4

L2

L3

N

N

L

6

5

12

Figure 4: CirLAMP Manager terminals�

Instruction Manual

Page 13

CirLAMP system

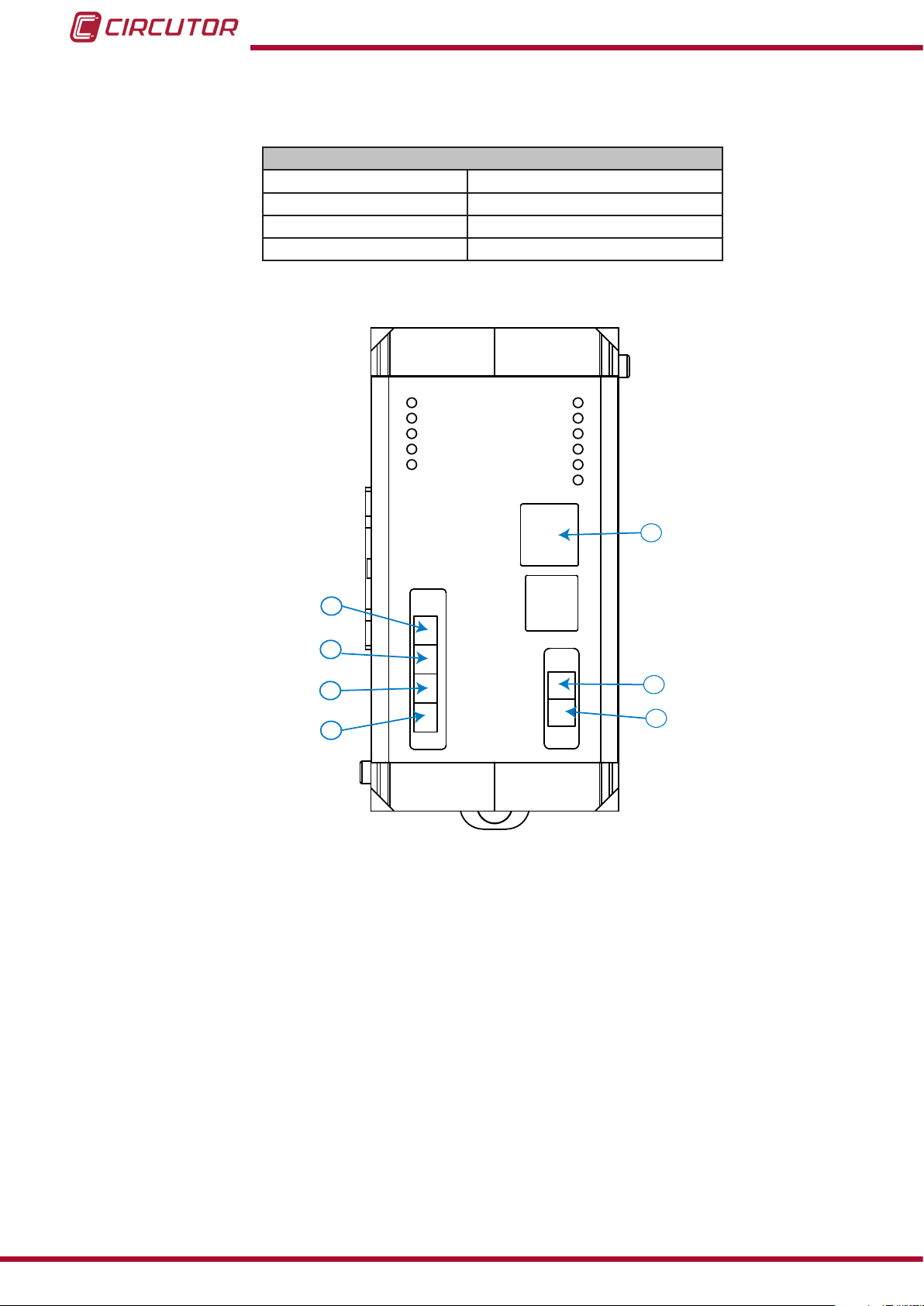

4�1�4� CONNECTION DIAGRAM

L1

L2

L3

N

PLC POWER

PLC >> CPU

PLC << CPU

TX PLC

RX PLC

CPU POWER

ACTIVITY

ALARM

PLC.DATA

ETH.LINK

ETH.ACT.

ETHERNET

N

L

L1

L2

L3

N

Figure 5: CirLAMP Manager connection diagram�

Instruction Manual

13

Page 14

4.2.- LEDs

CirLAMP Manager has 11 indicator LEDs.

CirLAMP system

PLC POWER

PLC >> CPU

PLC << CPU

TX PLC

RX PLC

PLC POWER

PLC >> CPU

PLC << CPU

TX PLC

RX PLC

CPU POWER

ACTIVITY

ALARM

PLC.DATA

ETH.LINK

ETH.ACT.

ETHERNET

L1

L2

L3

N

Figure 6: CirLAMP Manager LEDs�

N

L

CPU POWER

ACTIVITY

ALARM

PLC DATA

ETH.LINK

ETH.ACT.

Table 3:List of CirLAMP Manager LEDs�

LEDs

PLC POWER Part of the connected PLC.

PLC>>CPU Communication from the PLC to the CirLAMP Manager.

PLC<<CPU Communication from the CirLAMP Manager to the PLC.

TX PLC Sending frames.

RX PLC Receiving frames.

CPU POWER CirLAMP Manager connected.

ACTIVITY The unit is performing a task.

ALARM An alarm has been activated.

PLC DATA Receiving frames.

ETH�LINK The Ethernet port is connected.

ETH�ACT Ethernet port activity.

14

Instruction Manual

Page 15

Restaurant

23

bakery

Restaurant

23

bakery

Restaurant

23

bakery

Restaurant

23

bakery

Restaurant

23

bakery

Restaurant

23

bakery

Restaurant

23

bakery23bakery

Restaurant

23

bakery

CirLAMP system

4.3.- PLC

The CirLAMP Manager uses PLC technology to communicate with the nodes (CirLAMP

Nodes) through the electrical network.

PLC (Power Line Communications) transfers data via the electrical network using advanced

modulation technology.

The PLC frequency bands are dened by different committees: FCC for North America and

Canada, ARIB for Asia and Japan and CENELEC for Europe.

The CirLAMP Manager works on Band B, from 95kHz to 125kHz, dened by CENELEC.

(European Committee for Electrotechnical Standardization).

PC

CIRLAMP

Manager

Comunicaciones PLC

Figure 7:Connection of a CirLAMP system via PLC�

Bombilla

Balasto/Driver

CIRLAMP

Nodo

F N

Control

4.4.- ETHERNET

The unit has an Ethernet port (terminal 7 in Figure 4), which can exchange information bidirectionally through the web server and transfer les through FTP, using TCP/IP type communications.

Instruction Manual

15

Page 16

4.5.- DATABASES

CirLAMP Manager has two databases:

4�5�1� MEASUREMENTS DATABASE

The measurements database comprises the following features:

A database for 1000 light points, with capacity to store 1 million logs.

Hardware: non-volatile memory without battery.

Non-volatile memory write policy to save maximum write cycles on FLASH memory.

Delete policy for oldest information.

Automatic node registration.

Automatic node withdrawal.

4�5�2� ALARM DATABASE

CirLAMP system

The alarm database comprises the following features:

Database for each light point with capacity for 50,000 logs.

Hardware: non-volatile memory without battery.

Non-volatile memory write policy to save maximum write cycles on FLASH memory.

Delete policy for oldest information.

4.6.- WEB SERVER

CirLAMP Manager has a conguration web site where the user can fully congure the conguration parameters of each light point. Furthermore, the unit has an XML server, so that it can

be integrated into any global control and maintenance platform.

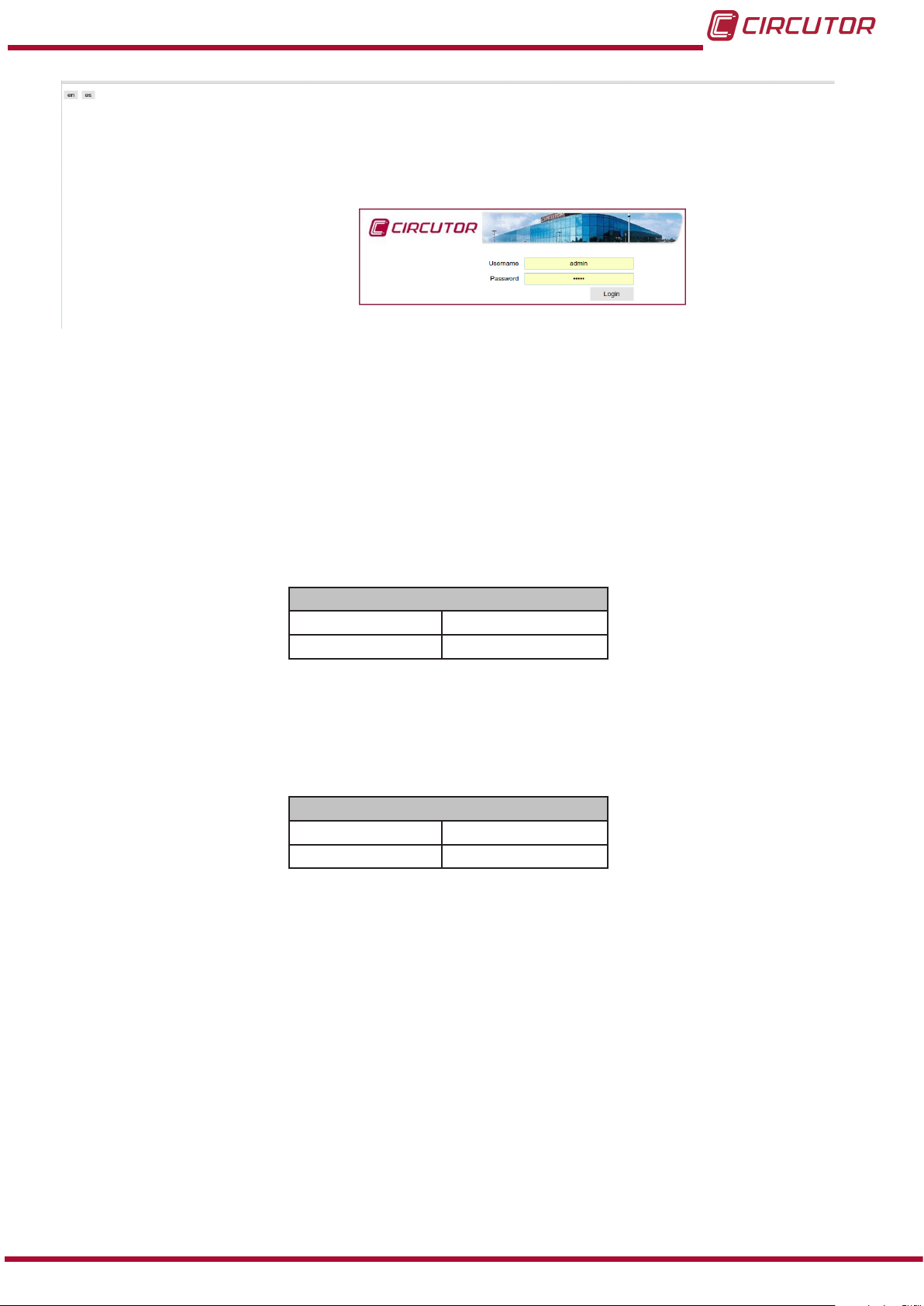

4�6�1� HOME SCREEN

CirLAMP Manager is accessed via an Ethernet connection.

The default IP address of the unit is: 192�168�42�30.

It can also be accessed from a local IP on the Ethernet port: 100�0�0�1�

16

The web site detects the browser language. If the browser’s language is Spanish, the web site

will be shown in Spanish. Otherwise, the language will be English.

You can also select the language using the buttons that appear on the upper left part of the web

site (Figure 8).

Instruction Manual

Page 17

CirLAMP system

Figure 8: Homepage�

You must enter the correct username and password to enter the CirLAMP Manager web site.

CirLAMP Manager has two types of users:

1�- User with write access, admin:

With this access the user can read and write the CirLAMP Manager parameters as well

as those of the CirLAMP nodes installed.

Table 4: Default username and password for a user with write access�

Default username and password

Username admin

Password admin

2�- User with read access, user:

With this access, the user can only access certain read elds in CirLAMP Manager�

Table 5: Default username and password for a user with read access�

Default username and password

Username user

Password user

Instruction Manual

17

Page 18

CirLAMP system

4�6�2� MAIN SCREEN

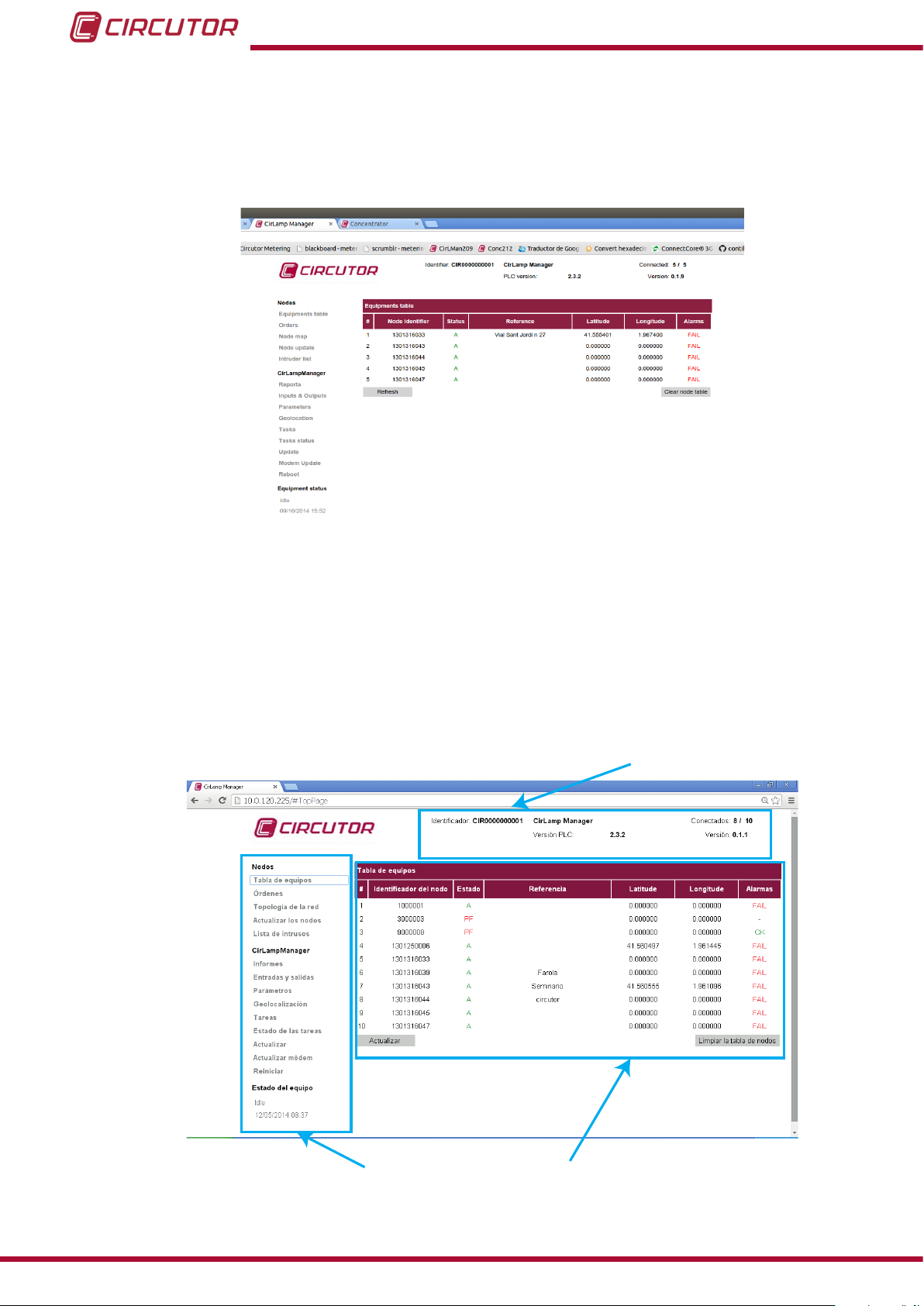

Figure 9 shows the web server's main screen, where you can access all the information relating

to the CirLAMP Manager and the CirLAMP Nodes installed.

Figure 9: Main screen�

The screen is divided into three areas of information (Figure 10):

CirLAMP Manager information area.

Menu for accessing all web screens.

Central area.

CirLAMP manager

information area

18

Menu Central area

Figure 10: Areas on the main screen�

Instruction Manual

Page 19

CirLAMP system

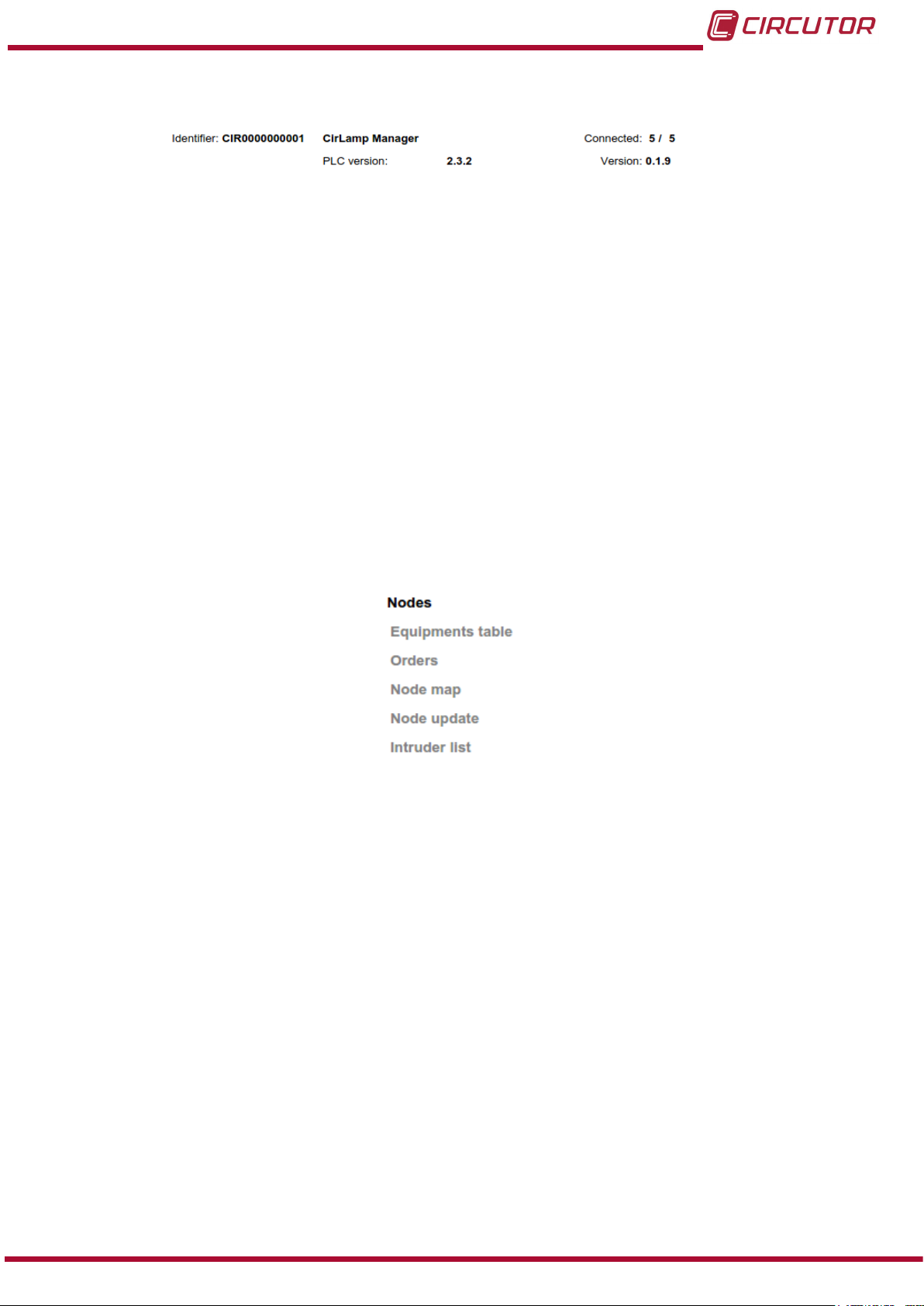

4�6�2�1 CirLAMP Manager information area�

Figure 11: CirLAMP Manager information area�

This area of the main screen shows all the information relating to CirLAMP Manager:

Identier: The unit identier is displayed (Example: CIR0000000001).

Name: Name given to the CirLAMP Manager. (Example:CirLamp Manager)

PLC version: PLC modem version.

Connected: Number of units connected/units detected.

Version: Firmware version of the CirLAMP Manager�

4�6�2�2 Menu

The CirLAMP Nodes and CirLAMP Manager screens can be accessed from the menu. The

unit status can also be viewed.

4�6�2�2�1� Menu: Nodes

Figure 12: Node selection menu�

The following screens can be accessed via the Nodes menu:

Equipments table: Accesses the table of nodes logged in the

CirLAMP Manager� (“4.6.3. NODES MENU: EQUIPMENTS TABLE”)

Orders: (“4�6�4� NODES MENU: ORDERS”)

Read access user: Cannot access the Orders screen.

Node map: Access the nodes map with the units connected at that instant.

(“4.6.5. NODES MENU: NODE MAP”)

Node update: Update nodes screen. (“4.6.6. NODES MENU: NODE UPDATE”)

Intruder list: Allows you to add the nodes that you do not wish to connect to CirLAMP

Manager to a list using the serial number of each node.

(“4.6.7. NODES MENU: INTRUDER LIST”)

Read access user: Cannot access the Intrusion list screen.

Instruction Manual

19

Page 20

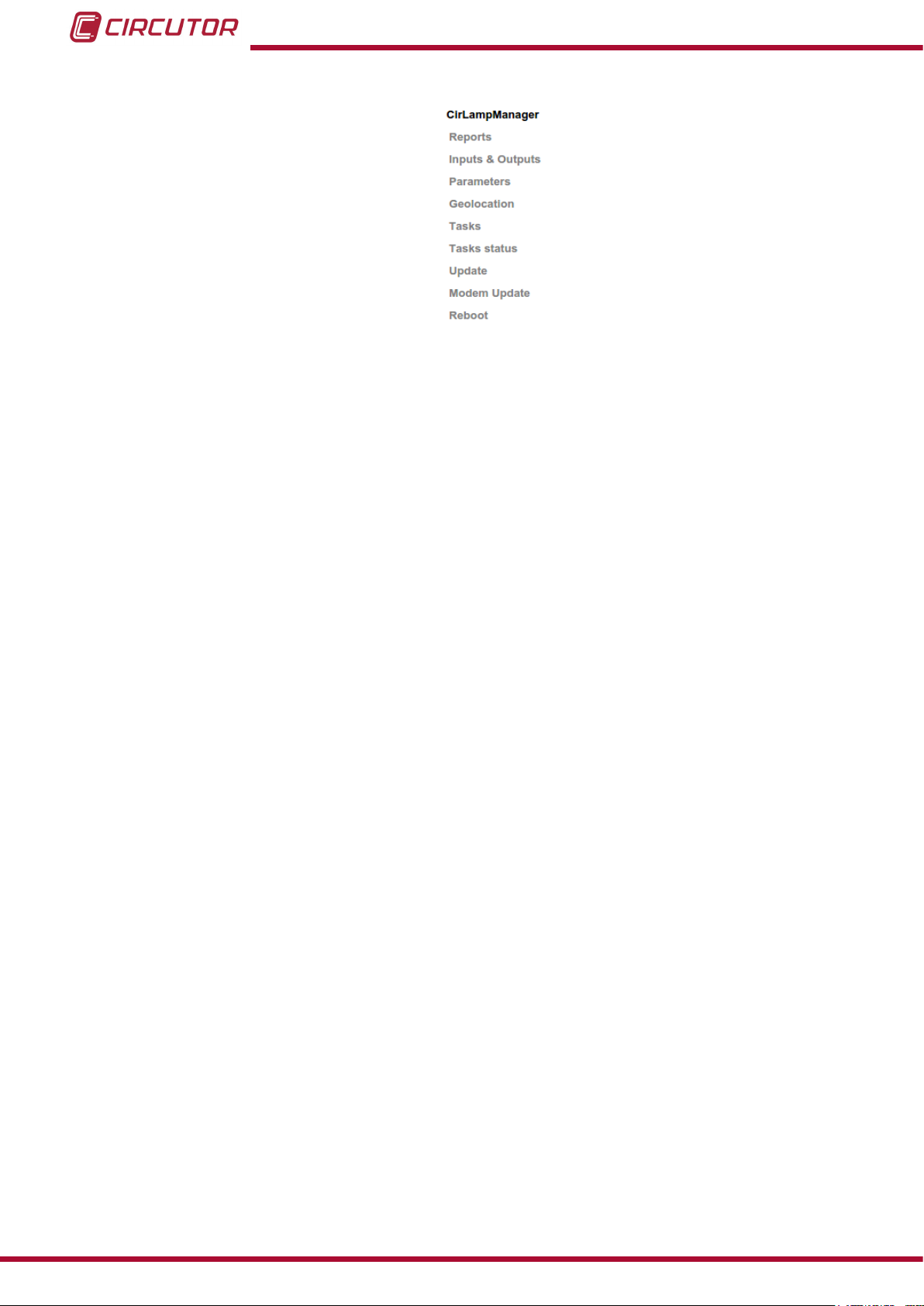

4�6�2�2�2� Menu: CIRLAMP Manager

Figure 13:CirLAMP Manager selection menu�

The following screens can be accessed from the CirLAMP Manager:

Reports: Accesses documents containing information on CirLAMP Manager�

(“4.6.8. CirLAMP MANAGER MENU: REPORTS”)

CirLAMP system

Inputs and outputs: (If the M8I8O expansion module is not connected, this option

does not appear ). Up to 8 inputs and outputs can be congured.

(“4.6.9. CirLAMP MANAGER MENU: INPUTS AND OUTPUTS”)

Read access user: This option does not appear in the selection menu.

Parameters: Provides access to the conguration of the CirLamp�

Manager (“4.6.10. CirLAMP MANAGER MENU: PARAMETERS”)

Read access user: This option does not appear in the selection menu.

Geolocation: Accesses the unit geolocation screen.

(“4.6.11. CirLAMP MANAGER MENU: GEOLOCATION”).

Read access user: This option does not appear in the selection menu.

Tasks: Accesses the unit tasks conguration screen.

( “4.6.12. CirLAMP MANAGER MENU: TASKS”)

Read access user: This option does not appear in the selection menu.

Task status: This button accesses the status screen for the

CirLAMP Manager tasks.

(“4.6.13. CirLAMP MANAGER MENU: TASK STATUS”)

Read access user: This option does not appear in the selection menu.

Update: Accesses the unit update screen.

(“4.6.14. CirLAMP MANAGER MENU: UPDATE”)

Read access user: This option does not appear in the selection menu.

20

Modem update: Accesses the screen for updating the unit's modem driver.

(“4.6.15. CirLAMP MANAGER MENU: MODEM UPDATE”)

Read access user: This option does not appear in the selection menu.

Reboot: Accesses the unit restart screen.

(“4.6.16. CirLAMP MANAGER MENU: REBOOT”)

Read access user: This option does not appear in the selection menu.

Instruction Manual

Page 21

CirLAMP system

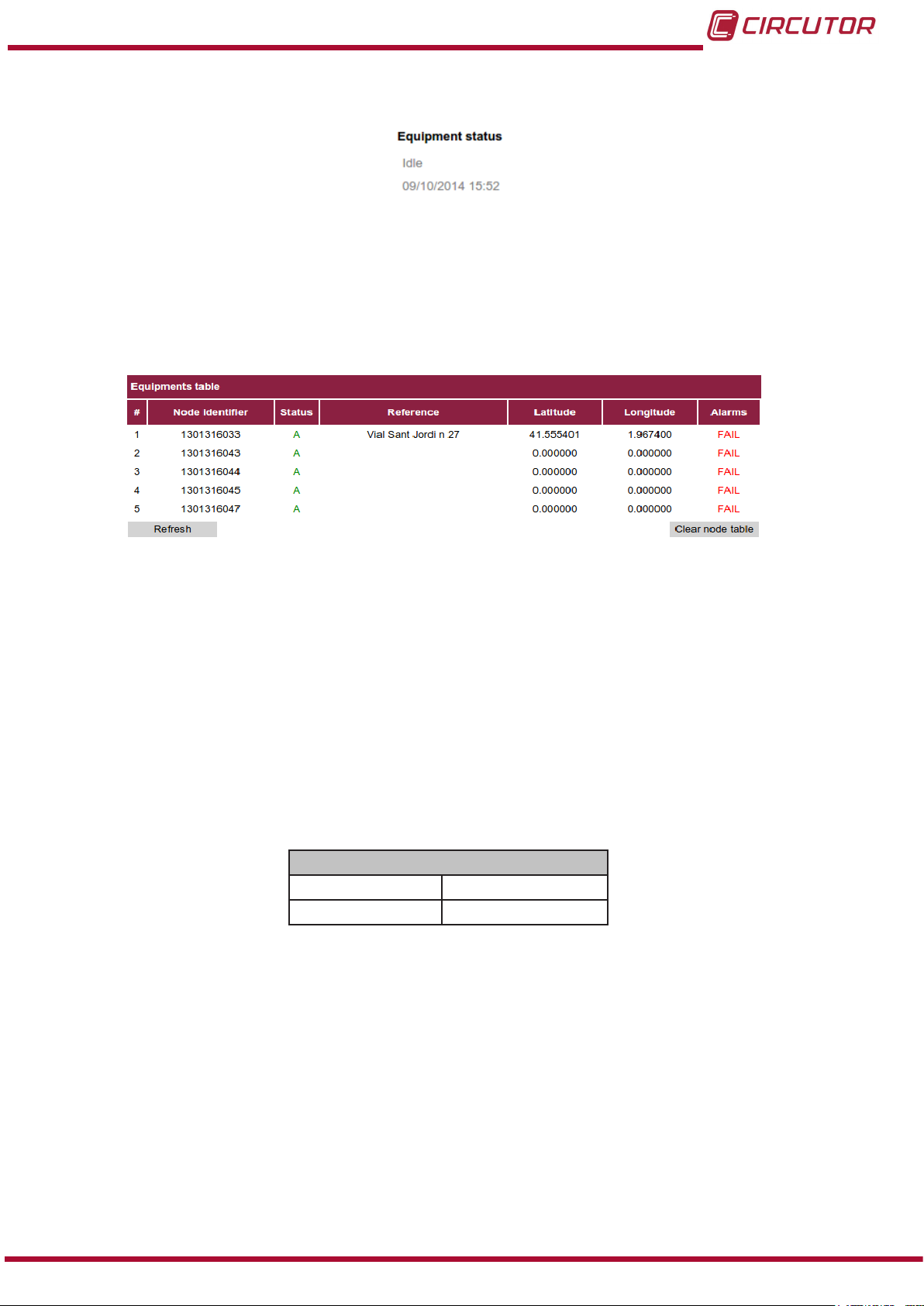

4�6�2�2�3� Equipment status

Figure 14:Unit status�

This section displays the CirLAMP Manager status or task in progress, as well as the current

time on the unit.

4�6�3� NODES MENU: EQUIPMENTS TABLE

Figure 15:Table of units�

This screen shows a table with all the CirLAMP Nodes logged in the CirLAMP Manager�

As seen in Figure 15, the table includes the following elds:

#: This column correlatively lists the units logged in the CirLAMP Manager�

Node identier: unit's serial number.

Status: current status of the unit. Two states are possible, see Table 6:

Table 6: Possible node states�

Status

A Active

PF Permanent fault

Reference: reference assigned to a node to help identify it.

Latitude: latitude assigned to the node.

Longitude: longitude assigned to the node.

Instruction Manual

21

Page 22

CirLAMP system

Alarms: current status of the node. Two states are possible, see Table 7:

Table 7: Alarms�

Status

OK No alarms

FAIL Node fault

NB: There is an application for iOS and Androids for positioning the nodes.(CirLAMP NODE

Location)

There are two buttons in the lower part of the table, with the following functions (Table 8):

Table 8: Buttons on the table of units�

Button Function

Update Updates the current content of the table of units.

Removes all nodes that are not active (Status: PF)

Clean the nodes table

from the CirLAMP Manager database.

If the nodes reconnect to the network at a later date,

they will automatically appear in the table of units.

To access all the information available relating to a node, click on the row for the selected unit.

See “4.6.3.1. Node information menu”

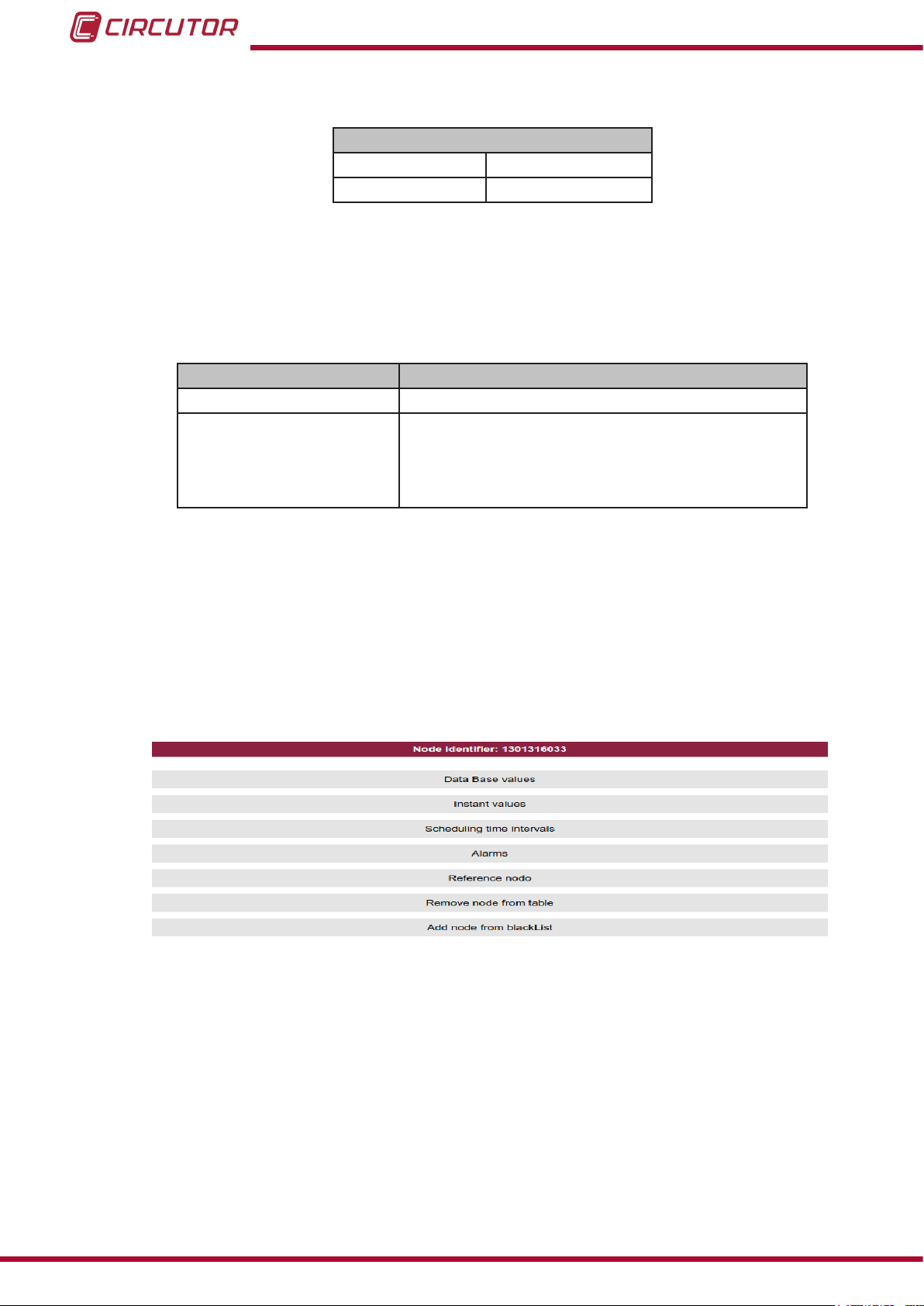

4�6�3�1� Node information menu

All the parameters of a CirLAMP Node can be viewed and congured from this screen.

The menu varies depending on the type of user used to enter the web site (Figure 16 and

Figure 17).

Figure 16:Node information menu (Write access user)�

22

Instruction Manual

Page 23

CirLAMP system

Figure 17:Node information menu (Read access user)�

4�6�3�1�1� Database values

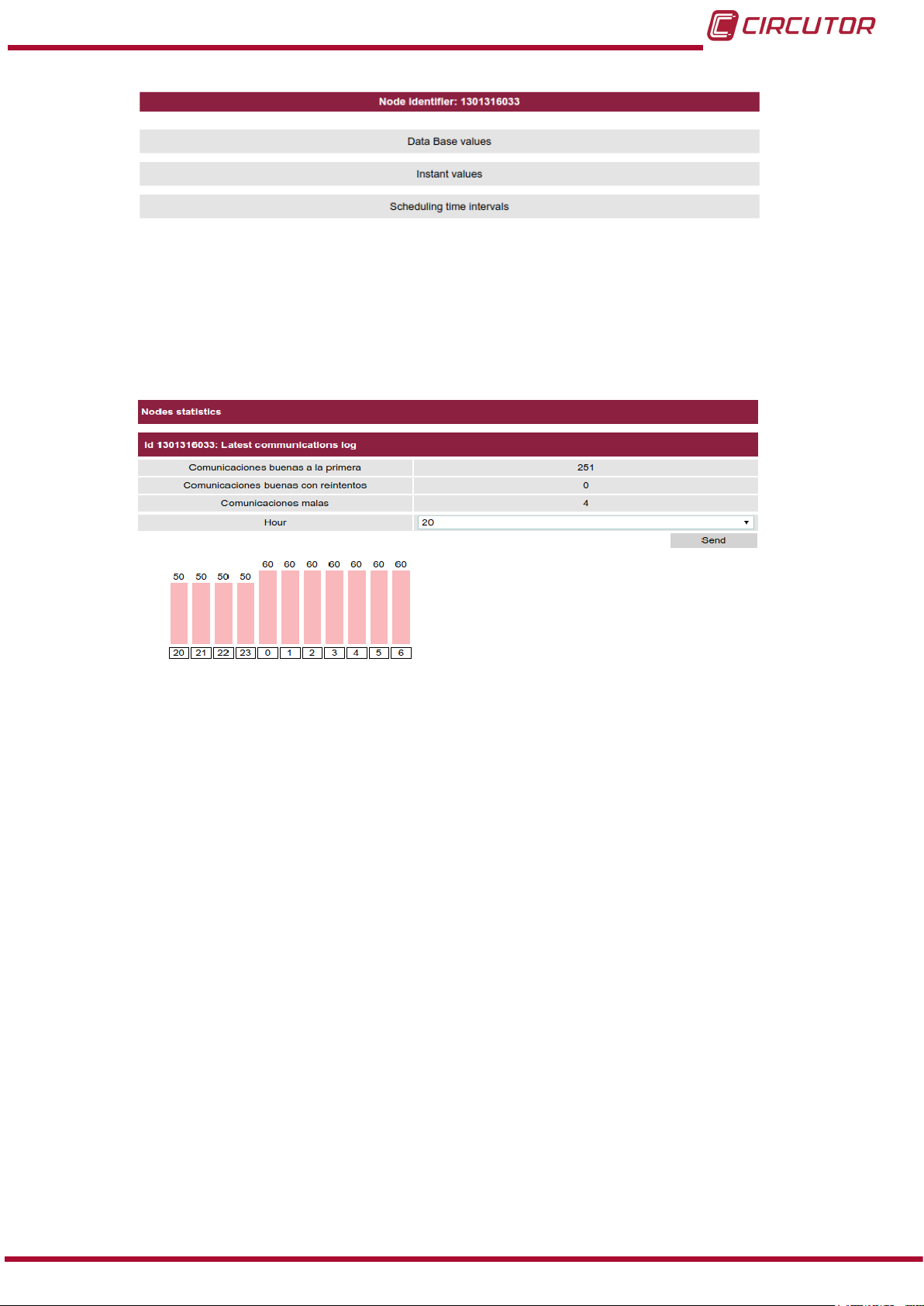

On this screen Figure 18 you can view the node data for the last 24 hours. You can select any

time on the graph and see instantaneous values for the unit at that time.

Figure 18:Database values screen�

Instruction Manual

23

Page 24

CirLAMP system

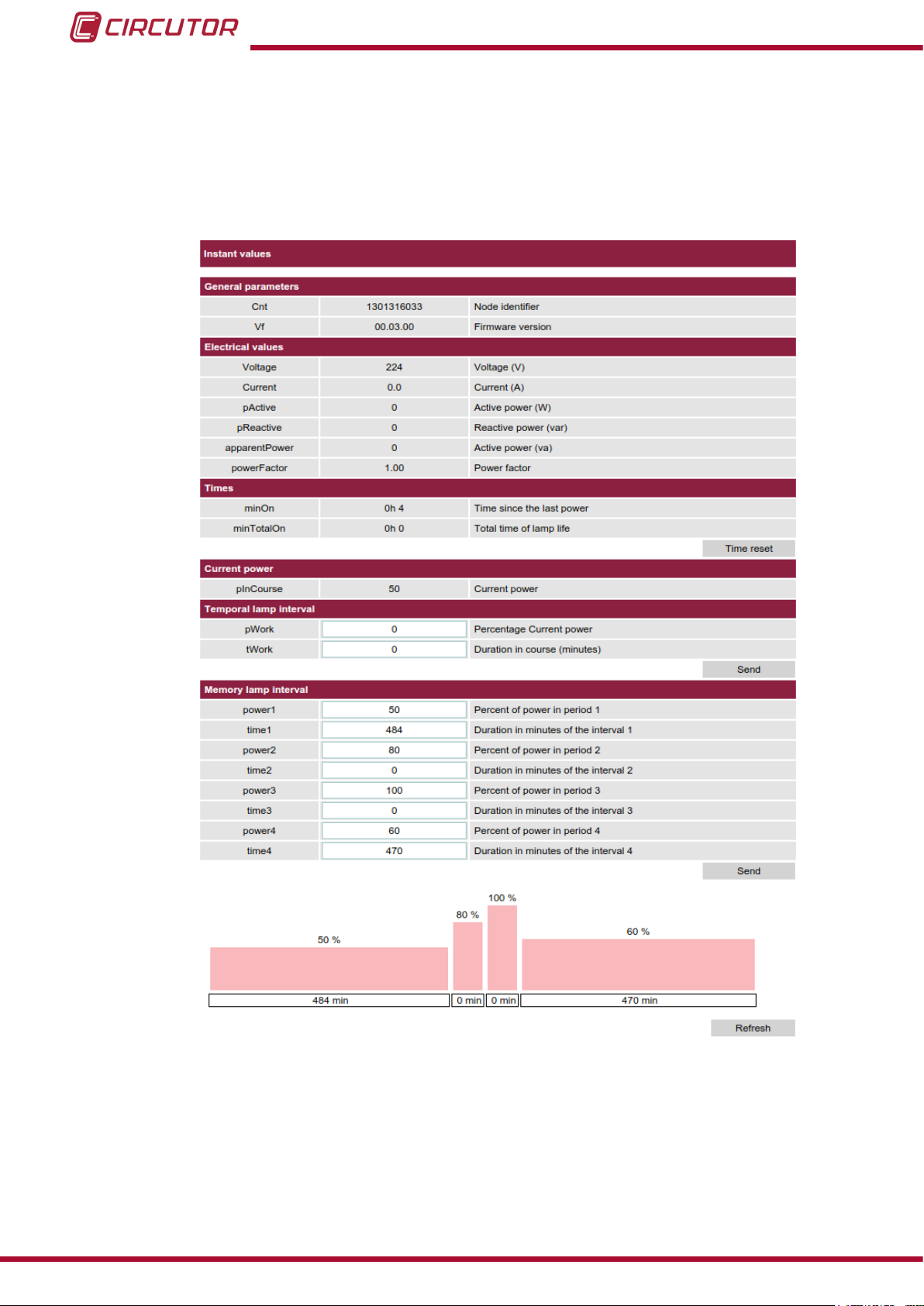

4�6�3�1�2� Instant values

On this screen, Figure 19, you can view the instantaneous consumption values and congure

the work time interval and memory work interval for each node.

NB: If the node is stopped the CirLAMP Manager cannot provide the data.

24

Figure 19:Instant values screen�

General parameters:

This section displays the identier and rmware version for the node selected.

Electric values:

This section displays the following electrical parameters:

Instruction Manual

Page 25

CirLAMP system

Table 9: Electrical parameters�

Parameter Units

Voltage: Voltage V

Current: Current A

pActive: Active power W

pReactive: Reactive power var

Times:

This section displays:

minOn: Time from the last switch on.

minTotalOn: The total useful life of the node.

Clicking on the Delete time button resets the two parameters.

Current power:

Is the power (in %) of the node at the moment when the instantaneous values are read.

Temporal lamp interval:

In this section you can congure:

pWork: Value of the power (in %) during the period determined by tWork�

tWork: Time interval in minutes for which we want the power value dened in pWork�

Click on the Send button to send the data to the unit.

NB: The parameters for the work time interval are not saved when the power supply is dis-

connected from the node.

Memory lamp interval:

In this section four different power intervals can be congured. The remaining time starts to

count down when the power supply is connected to the node.

power1: Power value in % during interval 1.

time1: Duration in minutes of interval 1.

power2: Power value in % during interval 2.

time2: Duration in minutes of interval 2.

power3: Power value in % during interval 3.

time3: Duration in minutes of interval 3.

power4: Power value in % during interval 4.

time4: Duration in minutes of interval 4.

Click on the Send button to send the data to the unit.

NB: The parameters for the memory work interval are not saved when the power supply is

disconnected from the node.

Read access user: The Delete time button is not enabled and the work time interval or the

work memory interval cannot be modied.

Instruction Manual

25

Page 26

CirLAMP system

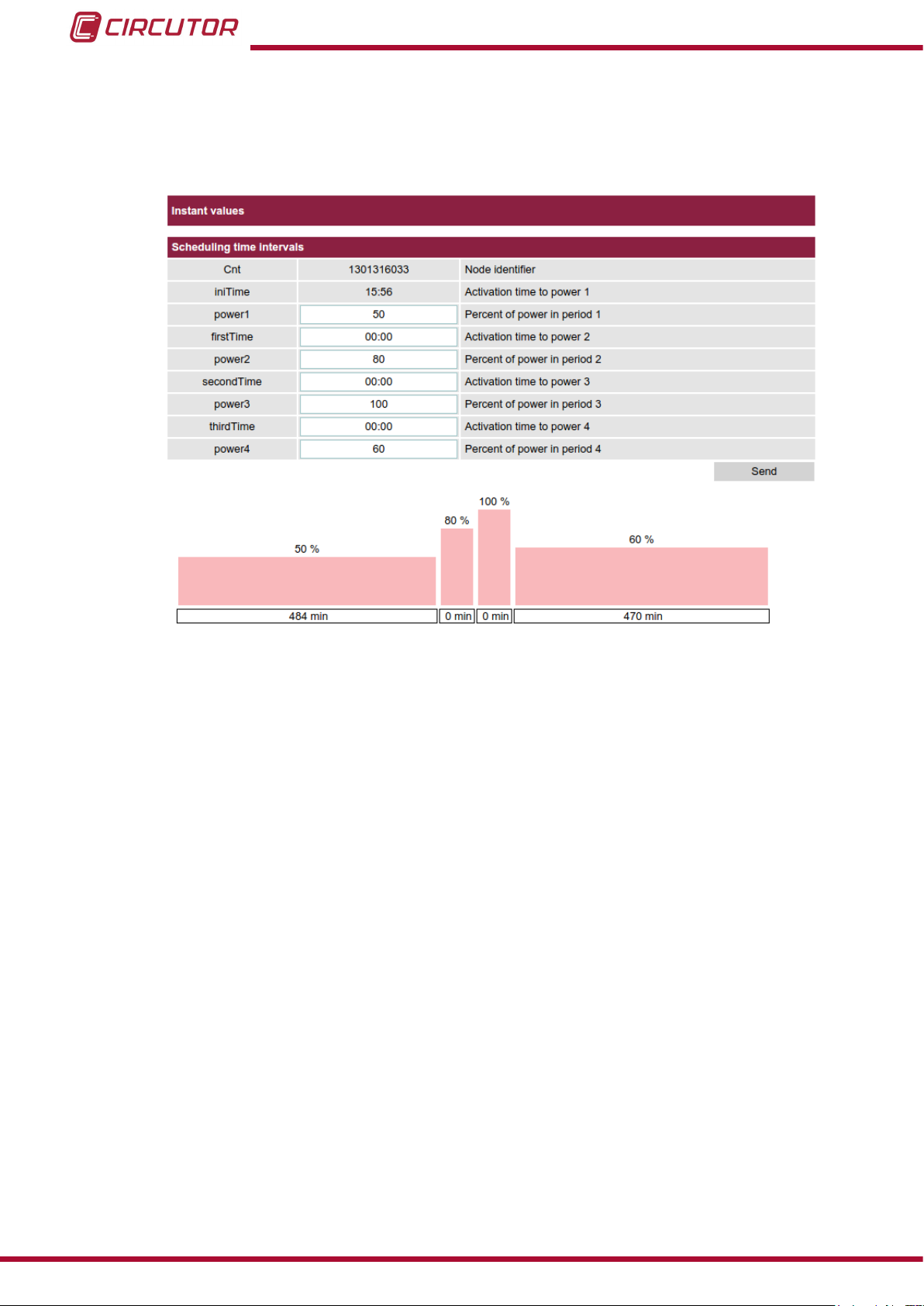

4�6�3�1�3� Scheduling time intervals in hours

If the CirLAMP Manager has the input and output module (M8I8O Expansion module) the

work intervals can be programmed automatically from Sunrise (Sunrise time).

Figure 20:Screen for scheduling time intervals in hours�

The parameters are:

Cnt: Node identier.

inTime: Interval 1 activation time. This parameter cannot be modied; it coincides

with the Sunrise value (Sunrise time).

power1: Power value in % during interval 1.

rstTime: Interval 2 activation time.

power2: Power value in % during interval 2.

secondTime: Interval 3 activation time.

power3: Power value in % during interval 3.

thirdTime: Interval 4 activation time.

power4: Power value in % during interval 4. Interval 4 will last until the node has

no power supply.

Click on the Send button to send the data to the unit.

Read access user: The programming of intervals in hours cannot be modied.

26

Instruction Manual

Page 27

CirLAMP system

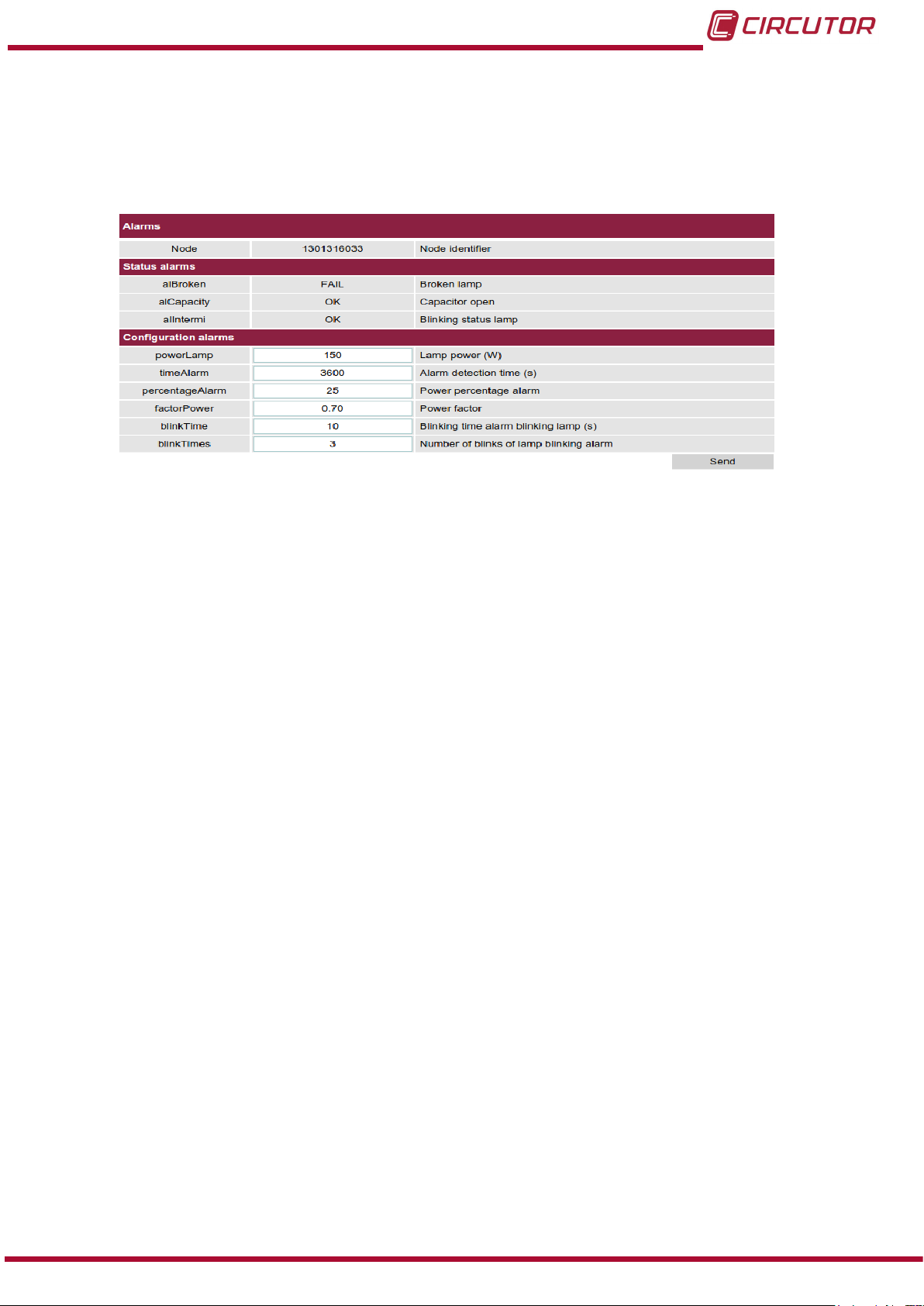

4�6�3�1�4� Alarms

Read access user: Cannot access the Alarms screen.

On this screen, Figure 21, you can view and congure the node alarms.

Figure 21:Alarm screen�

Status alarms:

Each CirLAMP node has the following alarms:

Detection of burnt out lamp (alBroken)

Each CirLAMP node detects the anomalous operation of each light. If the lamp is burnt

out the node detects this and generates an alarm.

Open capacitor detection and alert (alCapacity)

A malfunction or anomalous operation may be due to a deteriorated PFC capacitor. This

causes high consumption of inductive reactive power, which is detected after it has remained active for 1 hour.

Blinking lamp detection and alert (alIntermi)

Depending on the type of lamp, once it has reached the end of its useful life, it does not

switch off but starts to switch on intermittently, the CirLAMP detects this anomalous

situation and activates the alIntermi alarm if the lamp switches off more than a program-

mable number of times over a period of 2 hours.

Value 1 in the alarm status column indicates that the alarm is activated.

Conguration alarms:

The conguration parameters for the alarm are:

powerLamp, lamp power in W.

timeAlarm, alarm detection time.

percentageAlarm, value of the percentage of power under which the alarm will be

activated.

factorPower, node power factor value.

blinkTime, bulb blinking time to activate the alIntermi alarm.

blinkTimes, number of bulb blinks to activate the alIntermi alarm.

Instruction Manual

27

Page 28

CirLAMP system

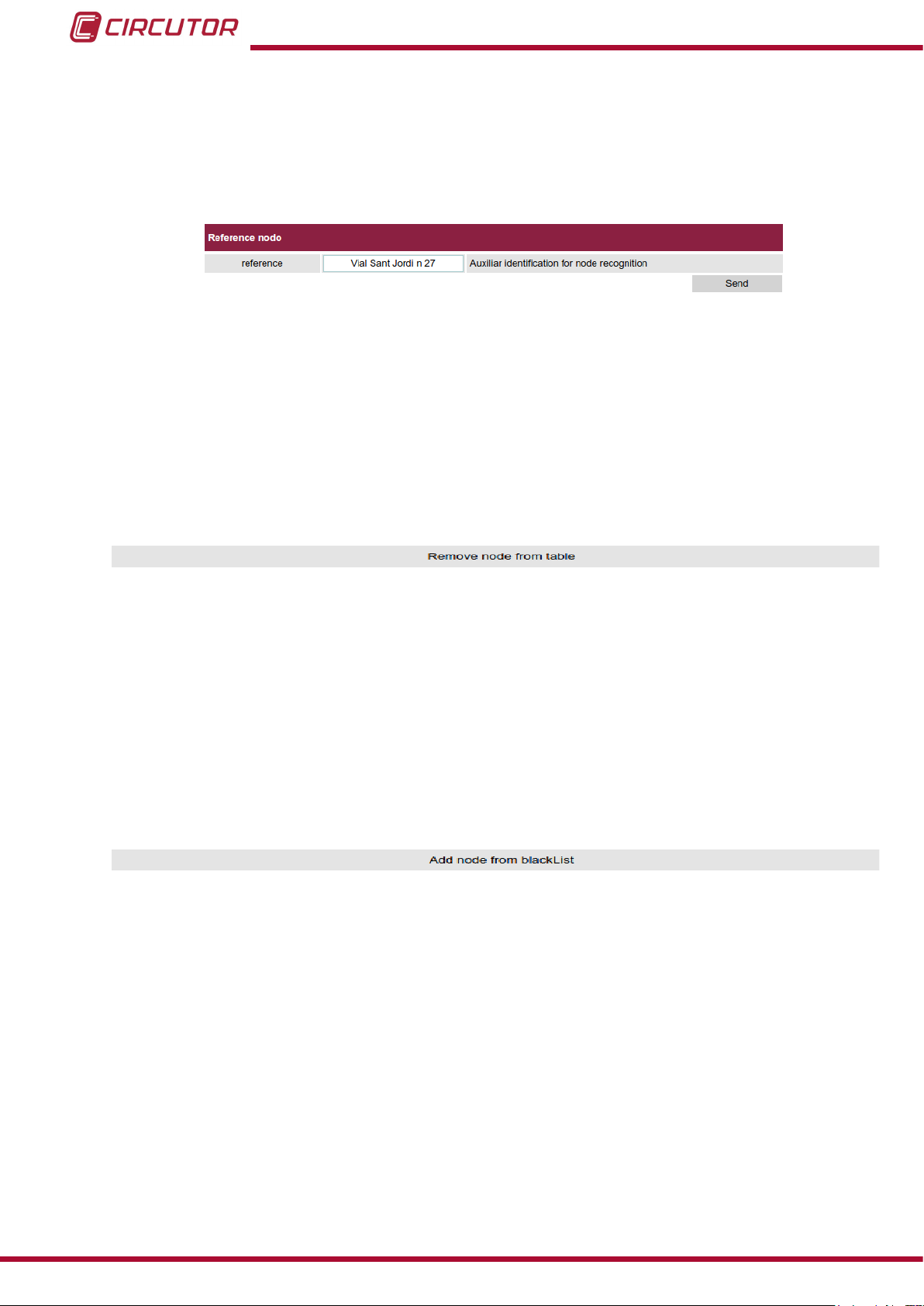

4�6�3�1�5� Reference node

Read access user: Cannot access the Reference node screen.

On this screen, Figure 22, you can view and modify the node reference, i.e, the identifying text

to differentiate it from the other nodes in the installation.

Figure 22:Reference node

4�6�3�1�6� Remove node from the table

Read access user: Cannot access the Remove node from the table screen.

Clicking on this button deletes the node from the table of units and the database.

If the node reconnects to the network at a later date, it will automatically appear in the table of

units.

Figure 23:Remove node from the table�

4�6�3�1�7� Add node from blackList

Read access user: Cannot access the Add node from blackList screen.

Clicking on this button deletes the node from the table of units and database and adds it to the

intrusion list.

Units which are included in the intrusion list will not be registered in the nodes table again until

they are deleted from the intrusion list.

Figure 24:Add node from blackList�

28

Instruction Manual

Page 29

CirLAMP system

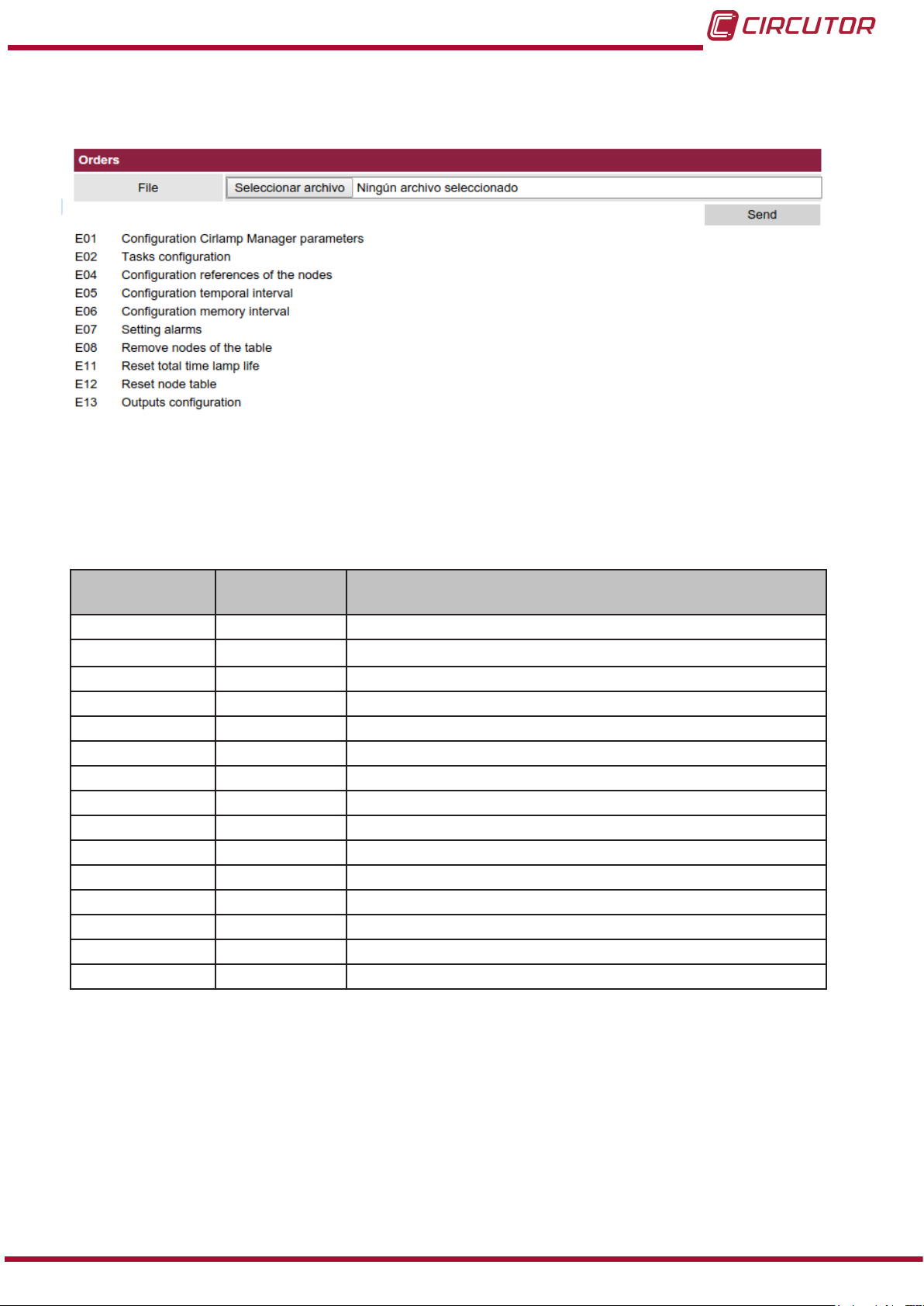

4�6�4� NODES MENU: ORDERS

On this screen, Figure 25, you can select the orders le that you want to send to the unit.

Figure 25:Orders screen�

The orders les are in .xml format.

The orders les that can be created in CirLAMP Manager are detailed in Table 10.

Table 10: Orders available for CirLAMP Manager�

Code

Write le

E01 L01 Conguration of parameters

E02

E03 - Update rmware.

E04 L04 Nodes references.

E05 L05 Work time interval.

E06 L06 Memory interval.

E07 L07 Alarm adjustment.

E08 L08 Delete nodes from list.

E09 - Manage the nodes black list.

E11 L11 Set the total useful life for node lamps to 0.

E12 L12 Delete all nodes from the network.

E13 L13 Manage the inputs/outputs module.

- L14 List of spontaneous events.

E17 L17 Memory time interval, via time conguration.

C06 - Modication of date in CirLAMP Manager.

Code

Read le

L02

Description

Conguration of tasks.

Instruction Manual

29

Page 30

CirLAMP system

4.6.4.1. E01-L01, Conguration of parameters

Format of le E01 (Figure 26):

<Order IdReq=”E01” IdPet=”(UInt32)” Version=”3�1”>

<CirLamp Id=”CIR4600000001”>

<E01 netId=”Val” name=”CirLamp Manager” DCPwdAdm=”Val” DCPwdRead=”Val” ipCom=”Val” PortWS=”(integer)” ipMask=”Val” ipGtw=”(string)” ipDhcp=”Y/N” ipLoc=”Val” ipMaskLoc=”Val” Pse=”(val)” Priority=”Val” IPNTP=”(val)” IPftp=”(val)” FTPUser=”Val” FTPPwd=”Val” RetryFtp=”(integer)” TimeSendReq=”(integer)”

TimeDisconMeter=”Val” TimeRetryInterval=”(integer)” ReportFormat=”Y/N” ValuesCheckDelay=”(seconds)” MaxOrderOutdate=”(integer)” TimeDelayRestart=”(integer)”

NTPMaxDeviation=”(integer)” AccInacTimeout=”(integer)” AccSimulMax=”(integer)”

PrimaryDns=”(val)” SecondaryDns=”(val)” PathReports=”(string)” TimeZone=”(integer)” mailHost=”MAILHOST” mailUser=”(string)” mailPassword=”(string)” mainMail=”(string)” destinationMail=”(string)” hourIni=”(val)” hourEnd=”(val)” activeFilterTime=”(val)” latitude=”(val)” longitude=”(val)” viewNodes=”Y”>

</E01>

</CirLamp>

</Order>

Figure 26: File E01�

Format of le L01 (Figure 27):

<Report IdRpt=” L01” IdPet=”0” Version=”3�1”>

<CirLamp Id=”CIR4600000001”>

<L01 Fh=”20120914093550S” netId=”1” name=”CirLamp Manager” Mod=”CirLampManager” Af=”2012” Vf=”0�0�1” VfComm=”2220” ipCom=”10�0�120�212”

PortWS=”8080” ipMask=”255�255�255�0” ipGtw=”10�0�120�254” ipDhcp=”N” ipLoc=”100�0�0�1” ipMaskLoc=”255�255�255�0” Pse=”38400” Priority=”Y” IPNTP=”0�

pool�ntp�org” IPftp=”” FTPUser=”DCUPLOAD” FTPPwd=”DCUPLOAD” RetryFtp=”2”

TimeBetwFtp=”10” TimeSendReq=”3600” TimeDisconMeter=”300” RetryDisconMeter=”3” TimeRetryInterval=”15” ReportFormat=”Y” ValuesCheckDelay=”5” MaxOrderOutdate=”300” TimeDelayRestart=”60” NTPMaxDeviation=”30” AccInacTimeout=”20”

AccSimulMax=”10” PrimaryDns=”8�8�8�8” SecondaryDns=”8�8�4�4” PathReports=”/upload” TimeZone=”0” mailHost=”MAILHOST” mailUser=”MAILUSER” mailPassword=”MAILPASSWORD” mainMail=”mainmail@mail�es” destinationMail=“destination@mail�

es” hourIni=”0” hourEnd=”0” activeFilterTime=”N” latitude=”149620�000000” longitude=”7229�000000” viewNodes=”Y”>

</L01>

</CirLamp>

</Report>

Figure 27: File L01�

Where:

30

Root element: <Report/Order>

<Report/Order> is the root element of the le. Its attributes indicate the data necessary to

process the le:

Instruction Manual

Page 31

CirLAMP system

Table 11:File E01-L01, <Report/Order> element

Attribute Description

IdRpt/IdReq Report/order identier.

IdPet Single identier for the order.

Version Version identier.

Container element: <CirLamp>

< CirLamp> is the container element for the report order:

Table 12:File E01-L01, <CirLamp> element

Attribute Description

Id CirLamp Manager identier.

Container element: < L01/E01>

< L01/E01> is the container element for all CirLAMP Manager parameters:

Table 13:File E01-L01, <Report/Order> element

Attribute Description

name Name assigned to the CirLAMP Manager�

Fh Date (Y/M/D H:M:S). (read parameter)

netId Network identier.

Mod Unit model. (read parameter)

AF Year of manufacture. (read parameter)

DCPwdAdm Administrator user password.

DCPwdRead Read user password.

Vf Firmware version. (read parameter)

VfComm PLC version. (read parameter)

ipCom CirLamp Manager IP.

PortWS Communications port used when communicating through the Web

Server (Example: 8080).

ipMask Subnet mask IP. (Used if the DHCP is disabled)

ipGtw Gateway IP. (Used if the DHCP is disabled)

ipDhcp Indicates whether the DHCP is enabled (Y) or disabled (N).

ipLoc Additional internal IP to the one previously named.

ipMaskLoc Local subnet mask.

Pse Serial port speed. (Read parameter)

Priority Priority is enabled (Y) or disabled (N).

IPNTP IP address for synchronisation with the NTP server.

IPftp

IP address of the FTP server where you can download and upload

reports.

FTPUser Username for accessing the FTP.

FTPPwd Password for accessing the FTP.

RetryFyp Number of retries to access the FTP servers.

TimeBetwFtp Time between retries when accessing the FTP server.

Instruction Manual

31

Page 32

CirLAMP system

Attribute Description

Maximum time for sending a report. If the report read time is higher

TimeSendReq

TimeDisconMeter

RetryDisconMeter

TimeRetryInterval Time between reattempts to communicate with the units.

ReportFormat Indicates the format of the reports: compressed (1), normal (0).

ValuesCheckDelay Number of seconds delay to execute an order.

MaxOrderOutdate

TimeDelayRestart

NTPMaxDeviation

AccInacTimeout Period of inactivity before the WEB session ends. (minutes)

AccSimulMax Maximum number of simultaneous users on the WEB.

PrimaryDns Primary DNS IP address.

SecondaryDns Secondary DNS IP address.

PathReports Directory for uploading the le to the FTP.

TimeZone

mailHost Mail server.

mailUser Mail user.

mailPassword Mail password.

mainMail Address from which mail is sent.

destinationMail Address to which mail is sent.

hourIni Start time for communication with the tasks.

hourEnd End time for communication with the tasks.

activeFilterTime

latitude CirLAMP Manager latitude.

longitude CirLAMP Manager longitude.

viewNodes

than indicated, a report containing the information collected to date

will be sent and it will continue to read the information until it is complete. (seconds)

If the time of the last communication exceeds the time indicated by

this variable, the unit will change from active to inactive. (seconds)

Number of retries to communicate with the nodes connected to the

CirLAMP Manager network.

Maximum time to initiate an order, i.e., if an order is programmed

with an initiate execution time higher than this value, the order will

be aborted. (seconds)

Wait time before continuing with tasks after starting the unit. (seconds)

The unit will generate an event when the deviation in seconds, between the NTP and the unit, is greater than that indicated.

Time zone:

0 : Barcelona, 1: London, 2: Athens, 3: Argentina, 4: Brazil

5 : Colombia, 6: Central America.

The lter for the tasks communication time is enabled (Y) or disabled (N).

Indicates whether you want to view the CirLAMP Nodes on the

map or not.

32

Instruction Manual

Page 33

CirLAMP system

4.6.4.2. E02-L02, Conguration of tasks

Format of le E02 (Figure 28):

<Order IdRpt=”E02” IdPet=”0” Version=”3�1”>

<CirLamp Id=”CIR4600000001”>

<E02>

<TP TpTar=”1” TpHi=”20120915011000S” TpPer=”00000001000000” TpCompl=”Y” TpPrio=”2”>

<TpPro TpReq=”L01” TpSend=”Y” TpStore=”Y”>

<TpAttr/>

</TpPro>

</TP>

</E02>

</CirLamp>

</Order>

Figure 28: File E02�

Format of le L02 (Figure 29):

<Report IdRpt=”L02” IdPet=”0” Version=”3�1”>

<CirLamp Id=”CIR4600000001”>

<L02>

<TP TpTar=”1” TpHi=”20120915011000S” TpPer=”00000001000000” TpCompl=”Y” TpPrio=”2”>

<TpPro TpReq=”L01” TpSend=”Y” TpStore=”Y”>

<TpAttr/>

</TpPro>

</TP>

</L02>

</CirLamp>

</Report>

Figure 29: File L02�

Where:

Root element: <Report/Order>

<Report/Order> is the root element of the le. Its attributes indicate the data necessary to

process the le:

Table 14:File E02-L02, element <Report/Order>

Attribute Description

IdRpt/IdReq Report/order identier.

IdPet Single identier for the order.

Version Version identier.

Container element: <CirLamp>

< CirLamp> is the container element for the report order:

Table 15:File E02-L02, element <CirLamp>

Attribute Description

Id CirLamp Manager identier.

Instruction Manual

33

Page 34

CirLAMP system

Container element: < L02/E02>

< L02/E02> is the container element for information relating to the conguration of the tasks.

Container element: < TP>

< TP> is the container element for information relating to a task:

Table 16:File E02-L02, element <TP>

Attribute Description

TpTar Task identication number.

Task start time. Format: YYYYMMDDHHmmssX

TpHi

TpPer Frequency, time between queries. Format: YYYYMMDDHHmmss.

TpPrio

A : year, M: month, D: day, H: hour, m: minute, s: second

X: summer (S) or winter (W).

Task priority.

1 : Maximum priority. 2: Normal priority. 3: Low priority.

Container element: < TPPro>

< TPPro> is the container element for information relating to a report:

Table 17:File E02-L02, element <TPPro>

Attribute Description

TpReq Report created in this task.

TpSend

TpStore Frequency, time between queries. Format: YYYYMMDDHHmmss.

Indicates whether the report obtained is sent to the FTP server or not.

Y: The le is sent. N: The le is not sent.

4.6.4.3. E03, Update rmware

Format of le E03 (Figure 30):

<Order IdReq=”E03” IdPet=”(UInt32)” Version=”3�1”>

<CirLamp Id=”CIR4600000001”>

<E03 ActDate=”20100101001500000W” Firmware=”(String)”/>

</CirLamp>

</Order>

Figure 30: File E03�

Where:

34

Root element: <Order>

Order> is the root element of the le. Its attributes indicate the data necessary to process the

le:

Table 18:File E03, element <Order>

Attribute Description

IdRpt/IdReq Report/order identier.

IdPet Single identier for the order.

Version Version identier.

Instruction Manual

Page 35

CirLAMP system

Container element: <CirLamp>

< CirLamp> is the container element for the report order:

Table 19:File E03, element <CirLamp>

Attribute Description

Id CirLamp Manager identier.

Container element: < E03>

< E03> is the container element for information relating to the updating of the unit:

Table 20:File E03, element <E03>

Attribute Description

ActDate Activation date for the update rmware order.

Firmware File download path required to update the CirLAMP Manager�

4�6�4�4� E04-L04, Nodes reference

Format of le E04 (Figure 31):

<Order IdReq=”E04” IdPet=”1” Version=”3�1”>

<CirLamp Id=”CIR0000001”>

<E04>

<Node nodeId=”1000001” Reference=”Street X n1” latitude=”37�6737” longitude=”-4�93”/>

</E04>

</CirLamp>

</Order>

Figure 31: File E04�

Format of le L04 (Figure 32):

<Report IdRpt=”L04” IdPet=”1” Version=”3�1”>

<CirLamp Id=”CIR0000000001”>

<L04 Fh=”20121113121605W”>

<Node nodeId=”9000009” Reference=”Vial Sant Jordi n 48” latitude=”37�6737” longitude=”-4�93”/>

</L04>

</CirLamp>

</Report>

Figure 32: File L04�

Where:

Root element: <Report/Order>

<Report/Order> is the root element of the le. Its attributes indicate the data necessary to

process the le:

Instruction Manual

35

Page 36

CirLAMP system

Table 21:File E04-L04, element <Report/Order>

Attribute Description

IdRpt/IdReq Report/order identier.

IdPet Single identier for the order.

Version Version identier.

Container element: <CirLamp>

< CirLamp> is the container element for the report order:

Table 22:File E04-L04, element <CirLamp>

Attribute Description

Id CirLamp Manager identier.

Container element: < L04/E04>

< L04/E04> is the container element for information relating to the reference for the network

nodes.

Container element: < Node>

< Node> is the container element for information relating to a node:

Table 23:File E04-L04, element <Node>

Attribute Description

nodeId Node identier.

Reference Node reference for better physical localisation of the node.

latitude CirLAMP Node latitude.

longitude CirLAMP Node longitude.

4�6�4�5� E05-L05, Work time interval

Format of le E05 (Figure 33):

<Order IdReq=”E05” IdPet=”2” Version=”3�1”>

<CirLamp Id=”CIR0000001”>

<E05 ActDate=”20121114165000000W”>

<Node nodeId=”9000009”>

<Interval time=”60” power=”59”/>

</Node>

</E05>

</CirLamp>

</Order>

Figure 33: File E05�

36

Instruction Manual

Page 37

CirLAMP system

Format of le L05 (Figure 34):

<Report IdRpt=”L05” IdPet=”148” Version=”3�1”>

<CirLamp Id=”CIR0000000001”>

<L05 Fh=”20140310154742W”>

<Node Id=”1301250033” Fh=”20140310154733W” time=”0” power=”0”>

<Node Id=”1301316033” Fh=”20140310154734W” time=”0” power=”0”>

<Node Id=”1301316039” Fh=”20140310154735W” time=”0” power=”0”>

<Node Id=”1301316043” Fh=”20140310154737W” time=”0” power=”0”>

</L05>

</CirLamp>

</Report>

Figure 34: File L05�

Where:

Root element: <Report/Order>

<Report/Order> is the root element of the le. Its attributes indicate the data necessary to

process the le:

Table 24:File E05-L05, element <Report/Order>

Attribute Description

IdRpt/IdReq Report/order identier.

IdPet Single identier for the order.

Version Version identier.

Container element: <CirLamp>

< CirLamp> is the container element for the report order:

Table 25:File E05-L05, element <CirLamp>

Attribute Description

Id CirLamp Manager identier.

Container element: < L05/E05>

< L05/E05> is the container element for information relating to the work time interval:

Table 26:File E05-L05, element <L05/E05>

Attribute Description

ActDate Order activation date.

Container element: < Node>

< Node> is the container element for information relating to a node:

Table 27:File E05-L05, element <Node>

Attribute Description

nodeId Node identier.

Container element: < Interval>

< Interval> is the container element for information relating to the work time interval:

Instruction Manual

37

Page 38

CirLAMP system

Table 28:File E05-L05, element <Interval>

Attribute Description

time Duration in minutes for the work time interval.

power % of power in the work time interval.

4�6�4�6� E06-L06, Memory work interval

Format of le E06 (Figure 35):

<Order IdReq=”E06” IdPet=”5” Version=”3�1”>

<CirLamp Id=”CIR0000001”>

<E06 ActDate=”20121114165000000W”>

<Node nodeId=”9000009”>

<Interval time1=”10” power1=”57” time2=”10” power2=”79”

time3=”50” power3=”80” time4=”50” power4=”99”/>

</Node>

</E06>

</CirLamp>

</Order>

Figure 35: File E06�

Format of le L06 (Figure 36):

<Report IdRpt=”L06” IdPet=”148” Version=”3�1”>

<CirLamp Id=”CIR0000000001”>

<L06 Fh=”20140310155200W”>

<Node Id=”1301250033” Fh=”20140310155150W” time1=”552” power1=”100” time2=”330” power2=”70” time3=”310” power3=”50” time4=”98” power4=”100”/>

<Node Id=”1301316033” Fh=”20140310155152W” time1=”552” power1=”100” time2=”330” power2=”70” time3=”310” power3=”50” time4=”98” power4=”100”/>

</L06>

</CirLamp>

</Report>

Figure 36: File L06�

Where:

Root element: <Report/Order>

<Report/Order> is the root element of the le. Its attributes indicate the data necessary to

process the le:

Table 29:File E06-L06, element <Report/Order>

Attribute Description

IdRpt/IdReq Report/order identier.

IdPet Single identier for the order.

Version Version identier.

38

Instruction Manual

Page 39

CirLAMP system

Container element: <CirLamp>

< CirLamp> is the container element for the report order:

Table 30:File E06-L06, element <CirLamp>

Attribute Description

Id CirLamp Manager identier.

Container element: < L06/E06>

< L06/E06> is the container element for information relating to the memory work interval:

Table 31:File E06-L06, element <L06/E06>

Attribute Description

ActDate Order activation date.

Container element: < Node>

< Node> is the container element for information relating to a node:

Table 32:File E06-L06, element <Node>

Attribute Description

nodeId Node identier.

Container element: < Interval>

< Interval> is the container element for information relating to the memory work interval:

Table 33:File E06-L06, element <Interval>

Attribute Description

time1 Duration in minutes of memory work interval number one.

power1

time2

power2

time3

power3

time4

power4

% of power in the memory work interval number one.

Duration in minutes of memory work interval number two.

% of power in memory work interval number two.

Duration in minutes of memory work interval number three.

% of power in memory work interval number three.

Duration in minutes of memory work interval number four.

% of power in memory work interval number four.

Instruction Manual

39

Page 40

CirLAMP system

4�6�4�7� E07-L07, Alarm adjustment

Format of le E07 (Figure 37):

<Order IdReq=”E07” IdPet=”2” Version=”3�1”>

<CirLamp Id=”CIR0000001”>

<E07 ActDate=”20121114165000000W”>

<Node nodeId=”7000007”>

<Alarms blinkActive=”31” blinkTime=”301” blinkTimes=”3” blinkTotalTime=”7201” brokenActive=”31” brokenTime=”3601” capacitorReactive=”51” capacitorTime=”3601” powerLamp=”151” timeAlarm=”3663” percentageAlarm=”33” factorPower=”0�93”/>

</Node>

</E07>

</CirLamp>

</Order>

Figure 37: File E07�

Format of le L07 (Figure 38):

<Report IdRpt=”L07” IdPet=”148” Version=”3�1”>

<CirLamp Id=”CIR0000000001”>

<L07 Fh=”20140310155534W”>

<Node Id=”1301250033” Fh=”20140310155518W” powerLamp=”151”

timeAlarm=”3661” percentageAlarm=”31” factorPower=”0�93” brokenTime=”0” blinkTimes=”3”/>

</L07>

</CirLamp>

</Report>

Figure 38: File L07�

Where:

Root element: <Report/Order>

<Report/Order> is the root element of the le. Its attributes indicate the data necessary to

process the le:

Table 34:File E07-L07, element <Report/Order>

Attribute Description

IdRpt/IdReq Report/order identier.

IdPet Single identier for the order.

Version Version identier.

40

Container element: <CirLamp>

< CirLamp> is the container element for the report order:

Table 35:File E07-L07, element <CirLamp>

Attribute Description

Id CirLamp Manager identier.

Instruction Manual

Page 41

CirLAMP system

Container element: < L07/E07>

< L07/E07> is the container element for information relating to alarm adjustment:

Table 36:File E07-L07, element <L07/E07>

Attribute Description

ActDate Order activation date.

Container element: < Node>

< Node> is the container element for information relating to a node:

Table 37:File E07-L07, element <Node>

Attribute Description

nodeId Node identier.

Container element: < Alarms>

<Alarms> is the container element for information relating to the adjustment of a node's

alarms:

Table 38:File E07-L07, element <Interval>

Attribute Description

blinkActive Threshold of active power for the intermittent bulb alarm.

blinkTime

blinkTimes

blinkTotalTime

brokenActive

brokenTime

capacitorReactive

capacitorTime

powerLamp

timeAlarm

percentageAlarm

factorPower

Blinking time for the intermittent bulb alarm (seconds).

Number of blinks for the intermittent bulb alarm.

Total blinking time for the intermittent bulb alarm (seconds).

Threshold of active power for the burnt out lamp alarm.

Alarm time for the burnt out lamp (seconds).

Threshold of reactive power for the broken capacitor alarm.

Broken capacitor alarm time (seconds).

Lamp power

Alarm detection time (seconds).

Minimum percentage to detect the alarm.

Minimum power factor to detect the alarm.

4�6�4�8� E08-L08, Delete nodes from the network

Format of le E08 (Figure 39):

<Order IdReq=”E08” IdPet=”2” Version=”3�0”>

<CirLamp Id=”CIR0000001”>

<E08 ActDate=”20121114165000000W”>

<Node nodeId=”2000002”/>

</E08>

</CirLamp>

</Order>

Figure 39: File E08�

Instruction Manual

41

Page 42

CirLAMP system

Format of le L08 (Figure 40):

<Report IdRpt=”L08” IdPet=”0” Version=”3�1”>

<CirLamp Id=”CIR0000000001”>

<Node Id=”6000006” remove=”OK”/>

</CirLamp>

</Report>

Figure 40: File L08�

Where:

Root element: <Report/Order>

<Report/Order> is the root element of the le. Its attributes indicate the data necessary to pro-

cess the le:

Table 39:File E08-L08, element <Report/Order>

Attribute Description

IdRpt/IdReq Report/order identier.

IdPet Single identier for the order.

Version Version identier.

Container element: <CirLamp>

< CirLamp> is the container element for the report order:

Table 40:File E08-L08, element <CirLamp>

Attribute Description

Id CirLamp Manager identier.

Container element: < L08/E08>

< L08/E08> is the container element for information relating to the deletion of nodes from the

network:

Table 41:File E08-L08, element <L08/E08>

Attribute Description

ActDate Order activation date.

Container element: < Node>

< Node> is the container element for information relating to a node:

Table 42:File E08-L08, element <Node>

Attribute Description

nodeId Node identier.

42

Instruction Manual

Page 43

CirLAMP system

4�6�4�9� E09, Manage the nodes black list

Format of le E09 (Figure 41):

<Order IdReq=”E09” IdPet=”2” Version=”3�0”>

<CirLamp Id=”CIR0000001”>

<E09 ActDate=”20121114165000000W”>

<Node nodeId=”1000000”/>

</E09>

</CirLamp>

</Order>

Figure 41: File E09�

Where:

Root element: <Report/Order>

<Report/Order> is the root element of the le. Its attributes indicate the data necessary to pro-

cess the le:

Table 43:File E09, element <Report/Order>

Attribute Description

IdRpt/IdReq Report/order identier.

IdPet Single identier for the order.

Version Version identier.

Container element: <CirLamp>

< CirLamp> is the container element for the report order:

Table 44:File E09, element <CirLamp>

Attribute Description

Id CirLamp Manager identier.

Container element: < E09>

< /E09> is the container element for information relating to the modication of the network

nodes black list.

Table 45:File E09, element <E09>

Attribute Description

ActDate Order activation date.

Container element: < Node>

< Node> is the container element for information relating to a node:

Table 46:File E09, element <Node>

Attribute Description

nodeId Node identier.

Instruction Manual

43

Page 44

CirLAMP system

4�6�4�10� E11-L11, Set the total useful time for node lamps to 0�

Format of le E11 for resetting the total useful life of the lamps (Figure 42):

<Order IdReq=”E11” IdPet=”2” Version=”3�0”>

<CirLamp Id=”CIR0000001”>

<E11 ActDate=”20121114165000000W”>

<Node nodeId=”1301250033”/>

</E11>

</CirLamp>

</Order>

Figure 42: File E11�

Format of le L11 conrming that the total useful life of the lamps has been reset (Figure 43):

<Report IdRpt=”L11” IdPet=”0” Version=”3�1”>

<CirLamp Id=”CIR0000000001”>

<Node Id=”6000006” resetTime=”OK”/>

</CirLamp>

</Report>

Figure 43: File L11�

Where:

Root element: <Report/Order>

<Report/Order> is the root element of the le. Its attributes indicate the data necessary to

process the le:

Table 47:File E11-L11, element <Report/Order>

Attribute Description

IdRpt/IdReq Report/order identier.

IdPet Single identier for the order.

Version Version identier.

Container element: <CirLamp>

< CirLamp> is the container element for the report order:

Table 48:File E11-L11, element <CirLamp>

Attribute Description

Id CirLamp Manager identier.

Container element: < E11/L11>

< E11> is the container element for information relating to setting the total useful life of the node

lamps to 0:

44

Table 49:File E11-L11, element <E11>

Attribute Description

ActDate Order activation date.

Instruction Manual

Page 45

CirLAMP system

Container element: < Node>

< Node> is the container element for information relating to a node:

Table 50:File E09, element <Node>

Attribute Description

nodeId Node identier.

4�6�4�11� E12-L12, Delete all nodes from the network�

Format of le E12 for deleting all nodes from the network (Figure 44):

<Order IdReq=”E12” IdPet=”2” Version=”3�0”>

<CirLamp Id=”CIR0000001”>

<E12 ActDate=”20121114165000000W”>

</E12>

</CirLamp>

</Order>

Figure 44: File E12�

Format of conrmation le L12 (Figure 45):

<Report IdRpt=”L12” IdPet=”0” Version=”3�1”>

<CirLampManager Id=”CIR0000000001” DeletedCorrectly=”OK”/>

</Report>

Figure 45: File L12�

Where:

Root element: <Report/Order>

<Report/Order> is the root element of the le. Its attributes indicate the data necessary to pro-

cess the le:

Table 51:File E12-L12, element <Report/Order>

Attribute Description

IdRpt/IdReq Report/order identier.

IdPet Single identier for the order.

Version Version identier.

Container element: <CirLamp>

< CirLamp> is the container element for the report order:

Table 52:File E12-L12, element <CirLamp>

Attribute Description

Id CirLamp Manager identier.

Container element: < E12/L12>

< E12> is the container element for information relating to the deletion of all nodes from the

network:

Instruction Manual

45

Page 46

CirLAMP system

Table 53:File E12-L12, element <E12>

Attribute Description

ActDate Order activation date.

4�6�4�12� E13-L13, Management of the Inputs/Outputs module

(M8I8O Expansion module).

Format of conguration le E13 (Figure 46):

<Order IdReq=”E13” IdPet=”2” Version=”3�0”>

<CirLamp Id=”CIR0000001”>

<E13 ActDate=”20121114165000000W” offsetSunRise=”10” offsetSunSet=”-20”>

<Input Dir=”1” SponEnable=”N”/>

<Input Dir=”2” SponEnable=”Y”/>

<Input Dir=”3” SponEnable=”N”/>

<Input Dir=”4” SponEnable=”Y”/>

<Input Dir=”5” SponEnable=”N”/>

<Input Dir=”6” SponEnable=”Y”/>

<Input Dir=”7” SponEnable=”N”/>

<Input Dir=”8” SponEnable=”Y”/>

<Output Dir=”1” Ocaso=”N” Orto=”N” In1=”Y” In2=”N” In3=”Y” In4=”N”

In5=”N” In6=”N” In7=”N” In8=”N” On=”N” Off=”N” SincNode=”Y”/>

<Output Dir=”2” Ocaso=”N” Orto=”N” In1=”N” In2=”N” In3=”N” In4=”N”

In5=”N” In6=”N” In7=”N” In8=”N” On=”N” Off=”Y” SincNode=”N”/>

<Output Dir=”3” Ocaso=”N” Orto=”N” In1=”N” In2=”N” In3=”N” In4=”N”

In5=”N” In6=”N” In7=”N” In8=”N” On=”Y” Off=”N” SincNode=”N”/>

<Output Dir=”4” Ocaso=”N” Orto=”N” In1=”N” In2=”N” In3=”N” In4=”N”

In5=”N” In6=”N” In7=”N” In8=”Y” On=”N” Off=”N” SincNode=”N”/>

<Output Dir=”5” Ocaso=”N” Orto=”N” In1=”N” In2=”N” In3=”N” In4=”N”

In5=”N” In6=”N” In7=”Y” In8=”N” On=”N” Off=”N” SincNode=”N”/>

<Output Dir=”6” Ocaso=”N” Orto=”N” In1=”N” In2=”N” In3=”N” In4=”N”

In5=”N” In6=”Y” In7=”N” In8=”N” On=”N” Off=”N” SincNode=”N”/>

<Output Dir=”7” Ocaso=”N” Orto=”N” In1=”N” In2=”N” In3=”N” In4=”N”

In5=”Y” In6=”N” In7=”N” In8=”N” On=”N” Off=”N” SincNode=”N”/>

<Output Dir=”8” Ocaso=”N” Orto=”N” In1=”N” In2=”N” In3=”N” In4=”Y”

In5=”N” In6=”N” In7=”N” In8=”N” On=”N” Off=”N” SincNode=”N”/>

</E13>

</CirLamp>

</Order>

Figure 46: File E13�

46

Instruction Manual

Page 47

CirLAMP system

Format of le L13 for reading the status of the Inputs/Outputs (Figure 47):

<Report IdRpt=”L13” IdPet=”147” Version=”3�1”>

<CirLamp Id=”CIR0000000001”>

<L13 Fh=”20140227121325W” offsetSunRise=”10” offsetSunSet=”-20”>

<Input Dir=”1” Value=”0” SponEnable=”N”/>

<Input Dir=”2” Value=”0” SponEnable=”N”/>

<Input Dir=”3” Value=”0” SponEnable=”N”/>

<Input Dir=”4” Value=”0” SponEnable=”N”/>

<Input Dir=”5” Value=”0” SponEnable=”N”/>

<Input Dir=”6” Value=”0” SponEnable=”N”/>

<Input Dir=”7” Value=”0” SponEnable=”N”/>

<Input Dir=”8” Value=”0” SponEnable=”N”/>

<Output Dir=”1” Ocaso”0” Orto”0” In1”1” In2”0” In3”1” In4”0” In5”0”

In6”0” In7”0” In8”0” On”0” Off”0” SincNode”0” Value=”0”/>

<Output Dir=”2” Ocaso”0” Orto”0” In1”0” In2”0” In3”0” In4”0” In5”1”

In6”0” In7”0” In8”0” On”0” Off”1” SincNode”0” Value=”0”/>

<Output Dir=”3” Ocaso”0” Orto”0” In1”0” In2”0” In3”0” In4”1” In5”0”

In6”0” In7”0” In8”0” On”1” Off”0” SincNode”0” Value=”1”/>

<Output Dir=”4” Ocaso”0” Orto”0” In1”0” In2”0” In3”0” In4”0” In5”0”

In6”0” In7”1” In8”0” On”0” Off”0” SincNode”0” Value=”0”/>

<Output Dir=”5” Ocaso”0” Orto”0” In1”0” In2”0” In3”0” In4”0” In5”0”

In6”0” In7”1” In8”0” On”0” Off”0” SincNode”0” Value=”0”/>

<Output Dir=”6” Ocaso”0” Orto”0” In1”0” In2”0” In3”0” In4”0” In5”0”

In6”0” In7”0” In8”1” On”0” Off”0” SincNode”0” Value=”0”/>

<Output Dir=”7” Ocaso”0” Orto”0” In1”0” In2”0” In3”0” In4”0” In5”0”

In6”0” In7”0” In8”0” On”0” Off”0” SincNode”0” Value=”0”/>

<Output Dir=”8” Ocaso”1” Orto”0” In1”1” In2”0” In3”0” In4”0” In5”1”

In6”0” In7”0” In8”0” On”0” Off”0” SincNode”1” Value=”0”/>

</L13>

</CirLamp>

</Report>

Figure 47: File L13�

Where:

Root element: <Report/Order>

<Report/Order> is the root element of the le. Its attributes indicate the data necessary to

process the le:

Table 54:File E13-L13, element <Report/Order>

Attribute Description

IdRpt/IdReq Report/order identier.

IdPet Single identier for the order.

Version Version identier.

Container element: <CirLamp>

< CirLamp> is the container element for the report order:

Table 55:File E13-L13, element <CirLamp>

Attribute Description

Id CirLamp Manager identier.

Instruction Manual

47

Page 48

CirLAMP system

Container element: < E13/L13>

< E13/L13> is the container element for information relating to the conguration of the unit's

inputs/outputs:

Table 56:File E13-L13, element <E13/L13>

Attribute Description

ActDate Order activation date.(E13)

Fh Report date. (read L13)

OffsetSunRise Length of deviation in minutes before activating

the output congured for sunrise.

OffsetSunSet Length of deviation in minutes before activating

the output congured for sunset.

Container element: < Input>

< Input> is the container element for information relating to the conguration of an input for the

unit:

Table 57:File E13-L13, element <Input>

Attribute Description

Dir Input direction.

Value Indicates whether the input is active (1: active, 0: inactive) (only in le

L13).

SponEnable Activates or deactivates the spontaneous event in the inputs.

Container element: < Output>

< Output> is the container element for information relating to the conguration of an output for

the unit:

Table 58:File E13-L13, element <Output>

Attribute Description

Dir Output direction

Sunset

Sunrise

In1

In2

In3

In4

In5

In6

In7

In8

Enables or disables the activation of the output during sunset.

(1: enabled, 0: disabled)

Enables or disables the activation of the output during sunrise.

(1: enabled, 0: disabled)

Enables or disables the activation of the output via input 1. (1: enabled, 0: disabled)

Enables or disables the activation of the output via input 2. (1: enabled, 0: disabled)

Enables or disables the activation of the output via input 3. (1: enabled, 0: disabled)

Enables or disables the activation of the output via input 4. (1: enabled, 0: disabled)

Enables or disables the activation of the output via input 5. (1: enabled, 0: disabled)

Enables or disables the activation of the output via input 6. (1: enabled, 0: disabled)

Enables or disables the activation of the output via input 7. (1: enabled, 0: disabled)

Enables or disables the activation of the output via input 8. (1: enabled, 0: disabled)

48

Instruction Manual

Page 49

CirLAMP system

Attribute Description

Value

SincNode

Indicates whether the input is active or not (1: active, 0: inactive)

(only in le L13).

Activates or deactivates synchronisation with the nodes when the

output is activated.

4�6�4�13� L14, List of spontaneous events

Format of conguration le L14 (Figure 48):

<Report IdRpt=”L14” IdPet=”0” Version=”3�1”>

<CirLamp Id=”CIR0000000001”>

<L14 Fh=”20130311150733W” Et=”10” C=”1”>

<D1>ED1</D1>

<D2>1</D2>

</L14>

</CirLamp>

</Report>

Figure 48: File L14�

Where:

Root element: <Report/Order>

<Report/Order> is the root element of the le. Its attributes indicate the data necessary to pro-

cess the le:

Table 59:File L14, element <Report/Order>

Attribute Description

IdRpt/IdReq Report/order identier.

IdPet Single identier for the order.

Version Version identier.

Container element: <CirLamp>

< CirLamp> is the container element for the report order:

Table 60:File L14, element <CirLamp>

Attribute Description

Id CirLamp Manager identier.

Container element: < L14>

< L14> is the container element for information relating to events in the CirLAMP Manager:

Table 61:File L14, element <L14>

Attribute Description

Fh Date.

Et Event group.

C Event code.

Instruction Manual

49

Page 50

CirLAMP system

Container element: <D1>

< D1> is the container element for information relating to the event:

It contains data relating to the event, if necessary.

Container element: <D2>

< D3> is the container element for information relating to the event:

It contains data relating to the event, if necessary.

4�6�4�14� L17-E17, Memory work interval, via time conguration.

Format of conguration le E17 (Figure 49):

<Order IdReq=”E17” IdPet=”111” Version=”3�0”>

<CirLamp Id=”CIR0000001”>

<E17>

<Node nodeId=”ALLNODES”>

<Interval power1=”60” hour2=”19” min2=”00” power2=”10”

hour3=”00” min3=”30” power3=”80” hour4=”05” min4=”40” power4=”100”/>

</Node>

</E17>

</CirLamp>

</Order>

Figure 49: File E17�

Format of conguration le L17 (Figure 50):

<Report IdRpt=”L17” IdPet=”148” Version=”3�1”>

<CirLamp Id=”CIR0000000001”>

<L17 Fh=”20140310160019W”>

<Node Id=”1301250033” hour1=”9” min1=”48” power1=”100” hour2=”19”

min2=”0” power2=”70” hour3=”0” min3=”30” power3=”50” hour4=”5” min4=”40” power4=”100”/>