Page 1

Section 7 operation

A SUPPLEMENT TO THE OPERATION MANUAL FOR THE

CINCINNATI CL-900 SERIES

LASER SYSTEM

For CINCINNATI Laser Control Software Version 8.3

CINCINNATI INCORPORATED

CINCINNATIR

EM-551 (N-04/11) COPYRIGHT 2011

C I N C I N N A T I, OHIO 4 5 2 1 1

CINCINNATI INCORPORATED

Page 2

Page 3

Section X : title contentS

Section 7: operation contentS

INTRODUCTION

HMI OVERVIEW

LASER SYSTEM DISPLAY WINDOW ...........................................................7-1

MENU BAR...............................................................................................7-2

TOOL BAR................................................................................................7-2

STATUS INDICATORS CONTROL BAR ..................................................7-3

PROCESS STATUS BAR .........................................................................7-3

APPLICATION WORKSPACE ..................................................................7-3

OPERATOR CONSOLE CONTROL BAR ................................................7-4

PROGRAM STATUS BAR ........................................................................7-4

MAIN STATUS BAR .................................................................................7-4

FILE TYPES ................................................................................................... 7-5

NC PROGRAM FILE ................................................................................7-5

PROCESS PARAMETER FILE ................................................................7-5

BATCH PROGRAM FILE .........................................................................7-6

CNC RUN WINDOW ...................................................................................... 7-7

CONTROL BARS

OPERATOR CONSOLE .................................................................................7-8

PROGRAM MODES .................................................................................7-8

LASER CONTROLS ...............................................................................7-10

OVERRIDE SETTINGS ..........................................................................7-10

OPERATING MODES ............................................................................ 7-11

OVERRIDE ADJUST ...................................................................................7-12

AUXILIARY FUNCTIONS .............................................................................7-13

MENU COMMANDS

FILE MENU ..................................................................................................7-14

NEW .......................................................................................................7-14

OPEN .....................................................................................................7-14

QUICK FILE OPEN ................................................................................7-16

OPEN LOADED PROGRAM ..................................................................7-16

OPEN CURRENT PROCESS ................................................................7-16

CLOSE ...................................................................................................7-17

SAVE ......................................................................................................7-17

SAVE AS .................................................................................................7-17

LOAD NC PROGRAM ............................................................................7-18

LOAD CURRENT PROGRAM ................................................................7-18

LOAD CURRENT BATCH ......................................................................7-19

PLOT NC PROGRAMS ..........................................................................7-19

RESTART LOADED PROGRAM ............................................................7-20

PRINT .....................................................................................................7-21

PRINT PREVIEW ...................................................................................7-22

PRINT SETUP ........................................................................................7-22

MRU FILE LIST ......................................................................................7-23

OPEN OPERATOR LOG ........................................................................7-23

EXIT ........................................................................................................7-23

EDIT MENU ..................................................................................................7-23

UNDO… .................................................................................................7-24

CUT ........................................................................................................7-24

COPY .....................................................................................................7-24

PASTE ....................................................................................................7-24

FIND .......................................................................................................7-24

REPLACE ...............................................................................................7-25

VIEW MENU .................................................................................................7-25

CONTROL BAR ......................................................................................7-25

LANGUAGE............................................................................................7-26

UNITS .....................................................................................................7-27

ALARMS AND MESSAGES WINDOW ..................................................7-27

EM-551 (N-04/11)

Page 4

AXES POSITIONS .................................................................................7-28

MODAL G CODES .................................................................................7-29

ALL POSITION INFORMATION .............................................................7-29

RUN WINDOW GRAPHICS ...................................................................7-30

WINDOW ZOOMING ..............................................................................7-30

MAINTENANCE MENU ................................................................................7-31

CONFIGURATION ..................................................................................7-31

DIAGNOSTICS .......................................................................................7-40

PALLET GATE CONTROL .....................................................................7-43

STATISTICS ...........................................................................................7-44

LASER MENU .............................................................................................. 7-45

LASER STATUS MONITOR ...................................................................7-45

AUTO SHUT-DOWN ..............................................................................7-46

LASER DIAGNOSTICS ..........................................................................7-47

VARIABLES MENU ......................................................................................7-48

LOCAL/GLOBAL VARIABLES ................................................................7-48

USER I/O VARIABLES ...........................................................................7-48

WORK OFFSETS ...................................................................................7-49

MACHINE OFFSETS .............................................................................7-49

UTILITIES MENU ......................................................................................... 7-49

STANDOFF CALIBRATION ....................................................................7-50

OPERATOR SETUP ...............................................................................7-50

LENS CENTERING ................................................................................7-53

SPEED GAS ...........................................................................................7-55

WINDOW MENU .......................................................................................... 7-55

CASCADE ..............................................................................................7-55

TILE ........................................................................................................7-55

ARRANGE ICONS .................................................................................7-55

WINDOW 1, 2 ... .....................................................................................7-55

HELP MENU .................................................................................................7-56

TOPICS ..................................................................................................7-56

MANUALS ..............................................................................................7-56

ABOUT CINCINNATI LASER SYSTEM .................................................7-56

CUTTING PROCESS PARAMETERS

INTRODUCTION ..........................................................................................7-57

PROCESS PARAMETER WINDOW ............................................................7-58

PIERCE PARAMETERS .........................................................................7-58

RAMPED PIERCE PARAMETERS ........................................................7-59

RAPID PIERCE PARAMETERS .............................................................7-60

CUT PARAMETERS ...............................................................................7-61

FOCUS PARAMETERS .........................................................................7-64

PROCESS PARAMETER NOTES .........................................................7-65

START-UP AND SHUT-DOWN

LASER SYSTEM START-UP ........................................................................7-65

CHILLER WARM-UP ....................................................................................7-67

SHUTTING DOWN THE LASER SYSTEM ..................................................7-68

CALIBRATION AND ADJUSTMENT PROCEDURES

NOZZLE STANDOFF CALIBRATION ...........................................................7-69

NONCONTACT STANDOFF SENSING ................................................ 7-69

LASER SHOT ...............................................................................................7-70

SETUP FOR A LASER SHOT ................................................................7-70

TAKING A LASER SHOT ........................................................................7-71

CENTERING THE FOCUSING LENS ..........................................................7-71

LENS CENTERING PROCEDURE ........................................................7-72

LENS FOCAL POINT LOCATION ................................................................7-75

FOCUS CALIBRATION - AUTO FOCUS HEAD ....................................7-76

ASSIST GAS PRESSURE ADJUSTMENT................................................... 7-77

RAPID PIERCE ADJUSTMENTS .................................................................7-77

EM-551 (N-04/11)

CUTTING PROCEDURES

FIRST RUN OF PARTS ................................................................................7-78

ERROR RECOVERY....................................................................................7-80

CUTTING HEAD BREAKAWAY .............................................................7-80

Page 5

RESTARTING A PROGRAM ..................................................................7-80

BATCH MODE PROGRAM EXECUTION ....................................................7-81

MACHINE SETUP CHECKING ....................................................................7-82

AUTO FOCUS CUTTING HEAD

FOCUS CONTROL SYSTEM CONFIGURATION ........................................7-84

AUTO FOCUS SETUP .................................................................................7-85

FOCUS CONTROL SYSTEM HOME OFFSETS ................................... 7-85

FOCUS SETUP FOR LENS CENTERING ............................................7-86

FOCUS-RELATED PROCESS PARAMETERS ...........................................7-87

AUTO FOCUS OPERATION ........................................................................7-87

HOMING THE FOCUS CONTROL SYSTEM .........................................7-87

WINDOWS ADMINISTRATION

MANAGER ACCOUNT .................................................................................7-89

LASER UTILITIES FOLDER ..................................................................7-89

SOFTWARE INSTALLATION AND UPGRADES ....................................7-90

SETUP ACCOUNT .......................................................................................7-90

SOFTWARE INSTALLATION AND UPGRADES ....................................7-91

EMERGENCY REPAIR DISK .................................................................7-91

NETWORK SETUP ................................................................................7-91

JOINING A DOMAIN...............................................................................7-91

DRIVE DESIGNATIONS ...............................................................................7-92

MAPPING NETWORK DRIVES .............................................................7-92

BACKING UP THE CONTROL .....................................................................7-92

MULTIPLE OPERATOR USER ACCOUNTS ............................................... 7-92

TOUCHSCREEN CALIBRATION .................................................................7-92

ALARMS AND MESSAGES

OPERATOR FYI MESSAGES ...................................................................... 7-93

SYSTEM ALARMS .......................................................................................7-95

PROGRAM ERRORS .................................................................................7-101

LASER ALARMS ........................................................................................7-104

TROUBLESHOOTING ...............................................................................7-104

LASER NC PROGRAMMING

STANDARD G CODES .............................................................................. 7-105

G00 RAPID TRAVERSE MOVE ...........................................................7-105

G01 LINEAR MOVE .............................................................................7-106

G02 AND G03 ARC MOVE...................................................................7-106

G04 DWELL .........................................................................................7-108

G09 EXACT STOP (ONE BLOCK) .......................................................7-109

G20 INCH MODE, G21 METRIC MODE ..............................................7-109

G31 POSITION CAPTURE MOVE .......................................................7-109

G40, G41, AND G42 KERF COMPENSATION ....................................7-109

G50 AND G51 COORDINATE SYSTEM SCALING ............................. 7-111

G52 LOCAL WORK COORDINATE SYSTEM ..................................... 7-112

G53 RAPID MOVE TO MACHINE COORDINATES............................. 7-112

G54…G59 WORK COORDINATE SYSTEM SELECTION ................. 7-113

G61 AND G64 EXACT STOP MODE ...................................................7-113

G65 SUB-PROGRAM CALL ................................................................ 7-113

G68 WORK COORDINATE ROTATION ............................................... 7-113

G90 AND G91 ABSOLUTE AND INCREMENTAL MODE .................... 7-114

G92 WORK COORDINATE SYSTEM SETTING ................................. 7-114

CUSTOM G CODES ..................................................................................7-115

G84 AND G85 START CUTTING SEQUENCE .................................... 7-115

G89 SET PROCESS PARAMETERS ................................................... 7-117

G102 SET ADDITIONAL PROCESS PARAMETERS ..........................7-119

G103 SET RAMPED PIERCE PARAMETERS .................................... 7-119

G120 AND G121 NON-STOP CUTTING ..............................................7-120

G123, G124, AND G125 VELOCITY BLENDING .................................7-122

M CODES ...................................................................................................7-123

M00 PROGRAM STOP ........................................................................7-123

M01 OPTIONAL STOP .........................................................................7-123

M02 END OF PROGRAM ....................................................................7-124

M30 END OF PROGRAM / REWIND ...................................................7-124

EM-551 (N-04/11)

Page 6

M35 BEAM OFF ...................................................................................7-124

M36 Z HOLD MODE.............................................................................7-124

M37 BEAM AND GAS OFF .................................................................7-124

M38 Z HOLD MODE (TIMED) ..............................................................7-124

M41 Z DOWN .......................................................................................7-125

M42 Z UP .............................................................................................7-125

M43 LOWER PALLET SPECIAL FUNCTION ......................................7-125

M44 DISABLE LOWER PALLET SPECIAL FUNCTION .....................7-126

M45 OPTIONAL STANDOFF MODE....................................................7-126

M47 PARTIAL Z UP .............................................................................7-127

M48 FEEDRATE OVERRIDE DISABLE ..............................................7-127

M49 FEEDRATE OVERRIDE ENABLE ................................................7-127

M50 SWITCH PALLETS .......................................................................7-127

M51 AUXILIARY OUTPUT (TIMED) .....................................................7-127

M67 OPTIONAL ASSIST GAS PRESSURE.........................................7-128

M90 BALL TRANSFER UP ...................................................................7-128

M91 BALL TRANSFER DOWN ............................................................7-128

M98 SUBPROGRAM CALL ..................................................................7-128

M99 END SUBPROGRAM ...................................................................7-129

M130 AND M131 Z-AXIS ANTIDIVE ....................................................7-129

M135 SPEED GAS BEAM OFF ...........................................................7-130

M151 AUXILIARY OUTPUT WITH CONFIRMATION ...........................7-130

CINCINNATI MACROS .............................................................................. 7-130

GRID MACROS ....................................................................................7-130

CUTTING MACROS ...................................................................................7-134

G73 HOLE MACRO..............................................................................7-134

G76 SLOT MACRO ..............................................................................7-134

G79 LINE MACRO ...............................................................................7-135

G83 OUTSIDE CIRCLE MACRO .........................................................7-136

G86 OUTSIDE RECTANGLE MACRO .................................................7-136

G88 BOLT CIRCLE MACRO ................................................................7-137

G104 SHAPE MACRO .........................................................................7-137

M2 LEAD-IN DESCRIPTION ................................................................7-139

G105 LEAD-IN MACRO .......................................................................7-140

PROGRAM STRUCTURE ..........................................................................7-141

PROGRAM NAME................................................................................7-141

PROGRAM BODY ................................................................................7-141

BEAM ON AND OFF COMMANDS ......................................................7-142

PROGRAM COMMENTS .....................................................................7-142

PROGRAM LINE NUMBERS ...............................................................7-142

BLOCK DELETE ..................................................................................7-142

END OF PROGRAM ............................................................................7-143

SUBPROGRAMS AND MACROS ........................................................7-143

LOCAL VARIABLES .............................................................................7-143

NESTED SUB-PROGRAM CALLS ......................................................7-145

PROGRAM VARIABLES ............................................................................7-145

LOCAL AND COMMON VARIABLES ...................................................7-145

SYSTEM VARIABLES ..........................................................................7-146

AUXILIARY FUNCTIONS ...........................................................................7-149

MATH FUNCTIONS ..............................................................................7-149

LOGIC FUNCTIONS ............................................................................7-150

AUXILIARY COMMANDS ....................................................................7-152

WORKPIECE EDGE DETECTION.......................................................7-154

NC CODE LIST ..........................................................................................7-162

M CODE LIST .......................................................................................7-162

G CODE LIST .......................................................................................7-163

EM-551 (N-04/11)

Page 7

EM-551 (N-04/11)

Page 8

EM-551 (N-04/11)

Page 9

CINCINNATI LASER SYSTEM SECTION 7

CINCINNATI CL-900 SERIES LASER SYSTEM - FIBER LASER

Supplement Manual, Section 7 - OPERATION, for CL-900 Models

This manual applies to all CL-900 Series Laser System - Fiber Lasers, including all frame sizes.

Control Software Versions

This document was last updated for compatibility with the following control software:

CNC/HMI software - 846540 Version 8.3

PLC software - 846539 Version 2

EM-551 (N-04/11)

Page 10

EM-551 (N-04/11)

Page 11

HMI OVERVIEW

The Human Machine Interface (HMI) is the means provided for interacting with the laser system control. The HMI tools

consist of the Operator Control Station front panel and side panel pushbutton controls, the LCD monitor/touchscreen, the

trackball pointing device, the keyboard, the remote station, and the Laser System CNC/HMI software. The pushbutton

controls and remote station functions are described in SECTION 6 - MACHINE CONTROLS of EM-550, CL-900

Fiber Laser Operation, Safety, and Maintenance manual.

This chapter presents an overview of the software user interface. The touchscreen, trackball, and keyboard can be used to

navigate around the user interface. The foundation of the software user interface is the Laser System Display window.

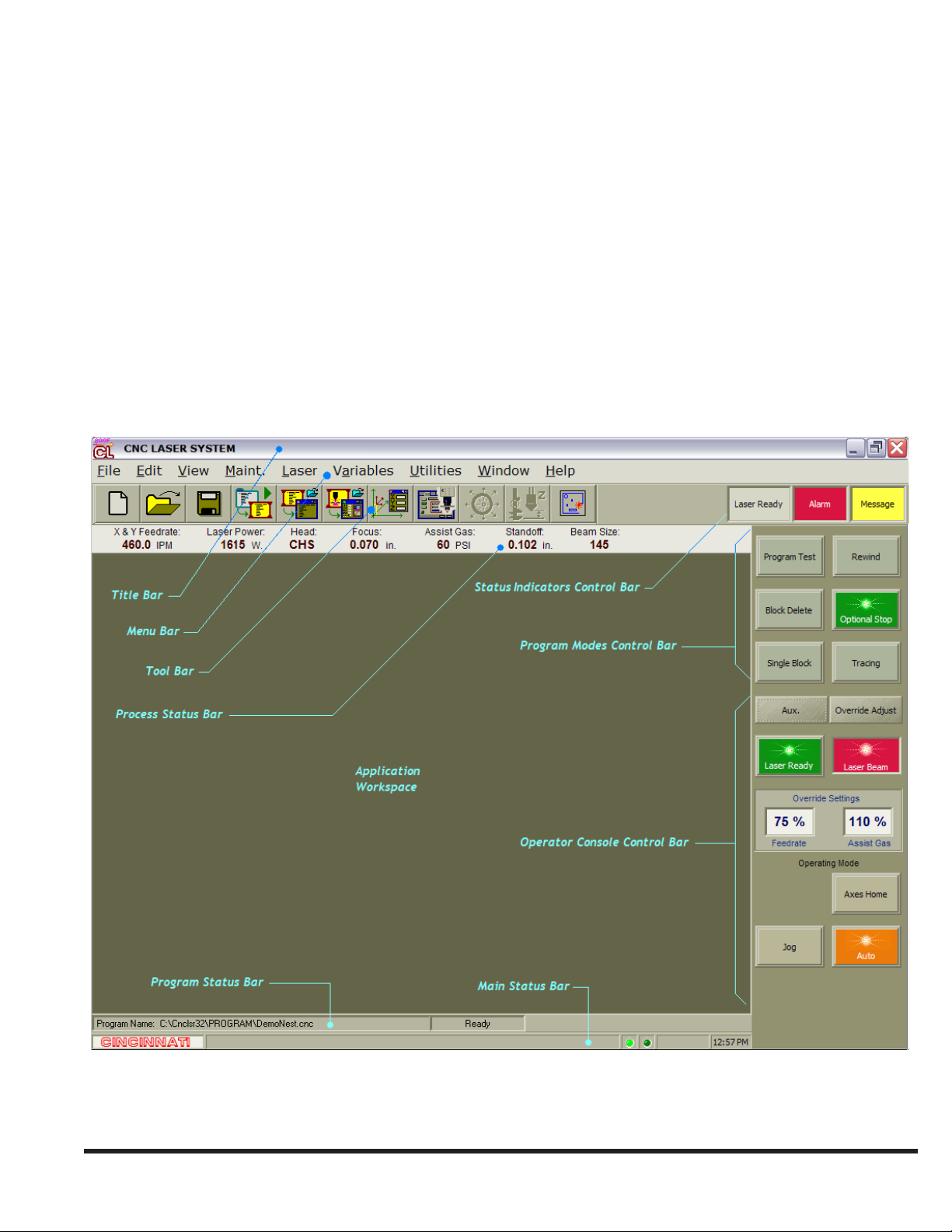

LASER SYSTEM DISPLAY WINDOW

The Laser System Display window occupies the entire display screen on the operator control station. The main components

of the Laser System Display window are the Title Bar, Menu Bar, Tool Bar, Status Indicators Control Bar, Application

Workspace, Operator Console Control Bar, and Main Status Bar. A Process Status Bar, Program Modes Control Bar, and

Program Status Bar may also be visible, depending on the current operating mode of the Laser System.

7-1

EM-551 (N-04/11)

Page 12

MENU BAR

The Menu Bar is the row of main menu titles across the top of the Laser System Display window. Selecting a menu title

opens a pop-up menu displaying a list of menu commands. See the MENU COMMANDS section for a description of each

command.

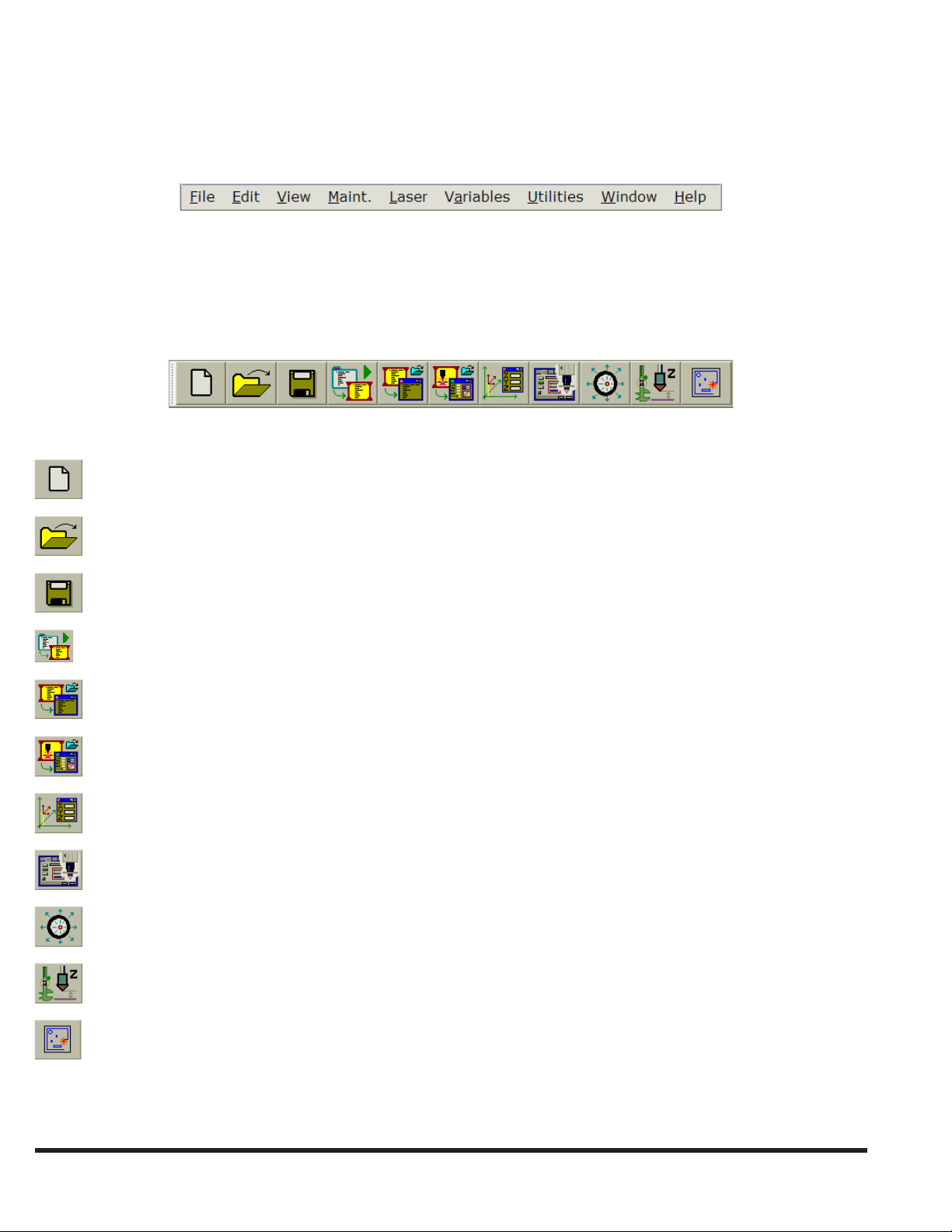

TOOL BAR

The Tool Bar, located below the Menu Bar, contains a row of buttons where each button corresponds to a menu command.

The Tool Bar provides convenient, single-touch access to some of the more commonly used menu commands. The Tool

Bar can be hidden or displayed by going to: View | Control Bars.

This list identies which menu command is associated with each Tool Bar button:

File | New

File | Open

File | Save

File | Load Current Program

File | Open Loaded Program

File | View Current Process

View | View Axes Positions

Utilities | Operator Setup

Utilities | Lens Centering Mode

Utilities | Standoff Calibration

Open the CINCINNATI Laser Programming and Nesting application, if installed.

EM-551 (N-04/11)

7-2

Page 13

STATUS INDICATORS CONTROL BAR

The Status Indicators Control Bar, which is normally positioned to the right of the Tool Bar, consists of separate indicators

for laser state: “alarm condition present” and “operator message ready”. The left-most indicator shows the current laser

operating state. Click or touch this indicator for a shortcut to open the Laser Status window. The “Alarm” indicator signies

the presence of system alarms or laser alarms when its color is red. A ashing red indicator means that one or more system

alarms are active. A solid red indicator means that only laser alarms are active. A yellow “Message” indicator signies

that one or more operator FYI messages are pending. Both the “Alarm” and “Message” indicators can be used as shortcut

buttons to open or close the Alarms and Messages window. The status indicators can be used as a shortcut to open or close

the Laser Status window.

PROCESS STATUS BAR

The Process Status Bar, which is located below the Tool Bar, displays critical process information such as feedrate, laser

power, beam focus position, assist gas pressure, and nozzle standoff. The Process Status Bar is only displayed when the

Laser System is in Auto mode. All displayed values are updated in real time. While the control is in Auto mode, the Process

Status Bar can be hidden or displayed by going to View | Control Bars | Process Status Bar.

APPLICATION WORKSPACE

The Application Workspace is the area (initially blank) which is below the Process Status Bar or Tool Bar and above the

Program Status Bar. NC program windows, Process Parameter windows, and all other user-activated windows and dialogs

will open in this area.

7-3

EM-551 (N-04/11)

Page 14

OPERATOR CONSOLE CONTROL BAR

The Operator Console Control Bar contains the user interface controls used by the machine operator to control and monitor

the basic operating mode of the Laser System. See OPERATOR CONSOLE in the CONTROL BARS section, for

information on this control bar.

PROGRAM STATUS BAR

The Program Status Bar, located just below the Application Workspace, displays the cutting program execution status. Like

the Program Modes Control Bar and the Process Status Bar, this status bar is visible only when the control is in Auto mode.

The Program Status Bar is divided into two elds, the left eld contains the le name of the currently loaded NC program.

This eld is empty when there is no NC program loaded into the control. The right eld indicates the current state of the

program execution subsystem. For example: “Program not loaded”, “Executing”, or “Program Stopped” may be displayed

here.

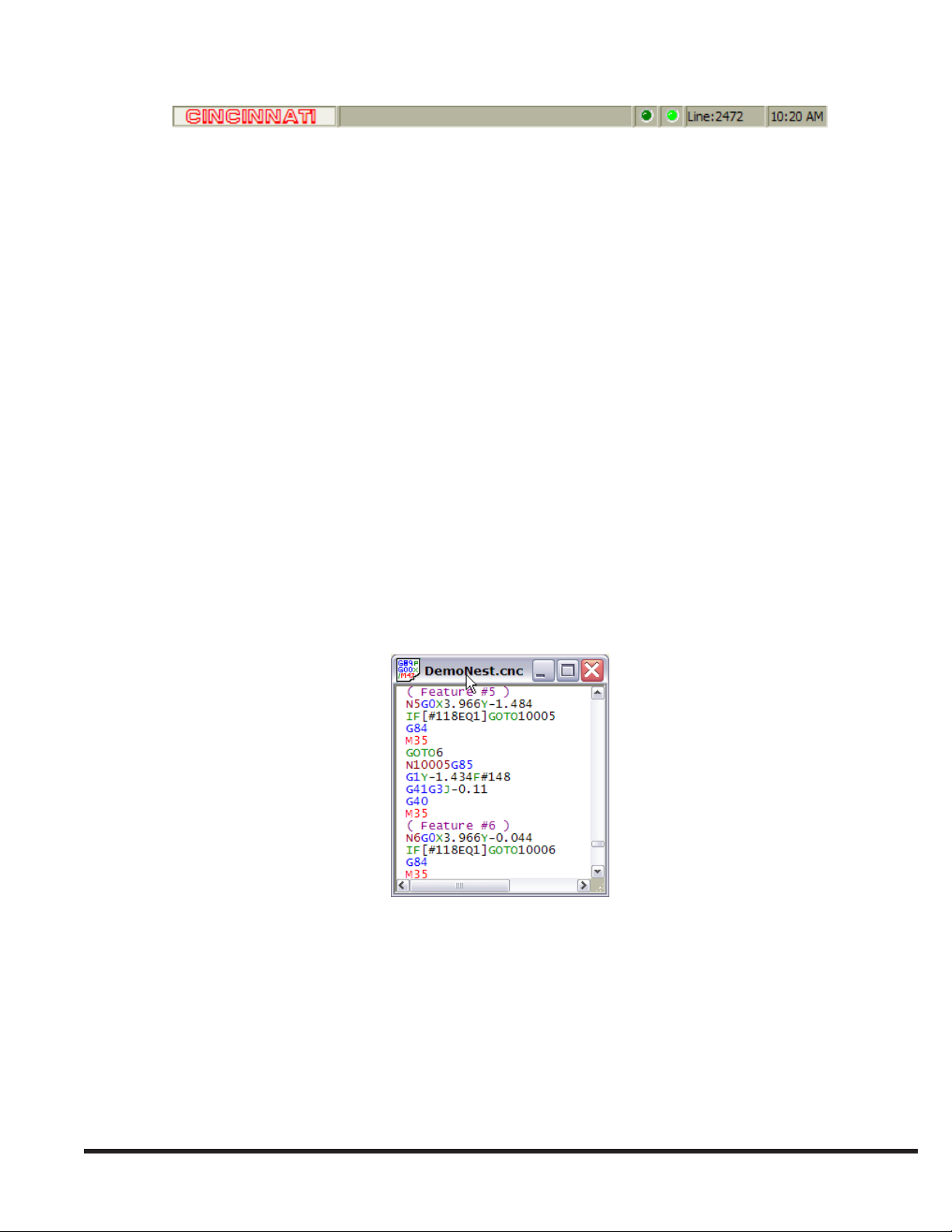

MAIN STATUS BAR

The Main Status Bar is displayed at the bottom of the Laser Status Monitor window, and is used to display operator help

messages and other general information. The Main Status Bar is divided into several sections. The section to the right of

the CINCINNATI logo displays a brief description of Menu Bar and Tool Bar button commands as these items are selected

with the trackball or keyboard.

To the right of the command description is the laser control system “heartbeat” indicator. A properly functioning control

system is indicated by two alternately ashing green indicators. If either indicator stops ashing or turns red, power down

the system and restart it. If this does not return the indicators to their proper state, contact CINCINNATI INCORPORATED

Laser Service Department.

The next eld to the right is the NC Program le line number of the line where the cursor is currently located. This eld is

blank if an NC Program Edit window is not the currently active window.

EM-551 (N-04/11)

7-4

Page 15

In the far right section of the Main Status Bar, the current time is displayed.

FILE TYPES

The Laser System control software gets the information it needs to execute cutting applications from two types of data les:

NC Program les and Process Parameter les. A third type of le, the Batch Program le, may be used if desired, to create

a list of NC Program les to be executed in the specied order.

The File menu commands and Tool Bar buttons, described later, can be used to open these les for viewing/editing, and to

create new les. When opening an existing le or creating a new le, a window will appear in the Application Workspace,

displaying the le’s contents. The Title Bar of each le view window contains the name of its le.

When a le is modied, it must be saved using File | Save or Tool Bar Save command before any changes will take effect.

An asterisk “*” will appear next to the le name of any le that has been modied but not saved.

The following topics describe each of the three types of le and their view windows.

NC PROGRAM FILE

The NC Program le contains the NC codes that determine the part feature geometry and control the various machine

cutting functions. NC programs, which may be as simple as a single part or as complex as multiple sheets of nested parts,

are typically generated by nesting/post-processing software packages such as the CINCINNATI Laser Programming

and Nesting Software application. NC Program le names should end with “.cnc” (ex: “Filename.cnc”).

When an NC Program le is opened, its contents are displayed in a Program Edit window. Program Edit windows use

context coloring; distinct program components are displayed with different colors (G codes are blue, M codes are red,

etc).

PROCESS PARAMETER FILE

The Process Parameter le contains settings used to control the power and focusing attributes of the laser beam and the

cutting assist gas. Process Parameters are stored in multiple les, with a separate le for each distinct cutting process. All

CINCINNATI Laser Systems are shipped with a library of Process Parameter les containing the cutting parameter settings

recommended by CINCINNATI INCORPORATED. These les are stored in the “Cnclsr32/Material” folder on the laser

control’s computer hard disk drive. These les can be modied to specify other cutting processes by creating new Process

Parameter les with the preferred settings. Process Parameter le names should end with “.lib” (ex: “Filename.lib”).

G89 blocks in the NC Program le specify which Process Parameter le(s) will be used in each cutting application. See

CUSTOM G CODES in the LASER NC PROGRAMMING topic for more information on G89.

7-5

EM-551 (N-04/11)

Page 16

When a Process Parameter le is opened, the parameter settings are displayed in a Process Parameter window. See the

CUTTING PROCESS PARAMETERS topic for more information on process parameters.

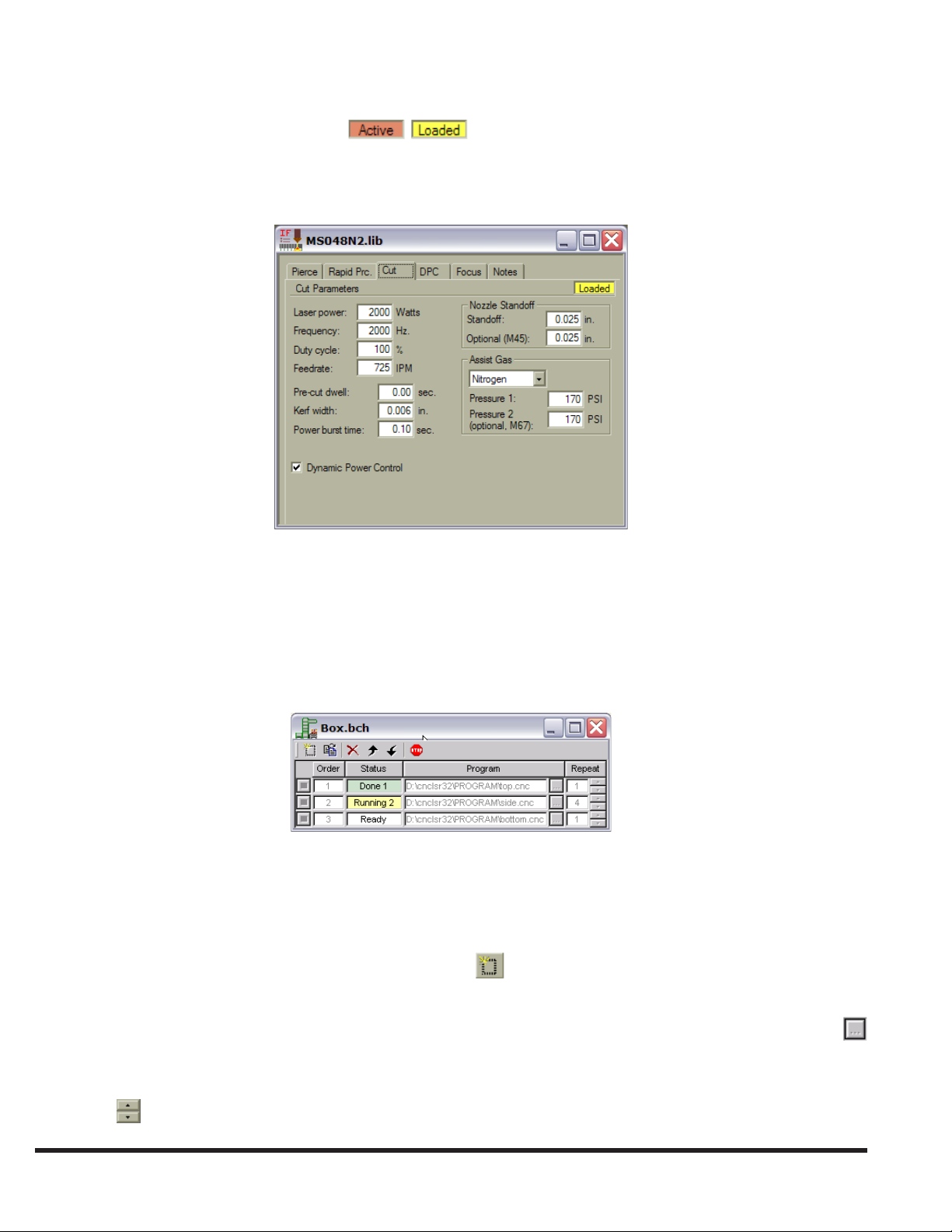

Note: An “Active” or “Loaded” indicator: may be displayed in the upper right corner of the Process

Parameter window. If a Process Parameter le that is loaded via a G89 block anywhere in the active NC program

is open in a window, a yellow “Loaded” indicator will be displayed. If this le represents the currently active

cutting process, then an orange “Active” indicator will be displayed.

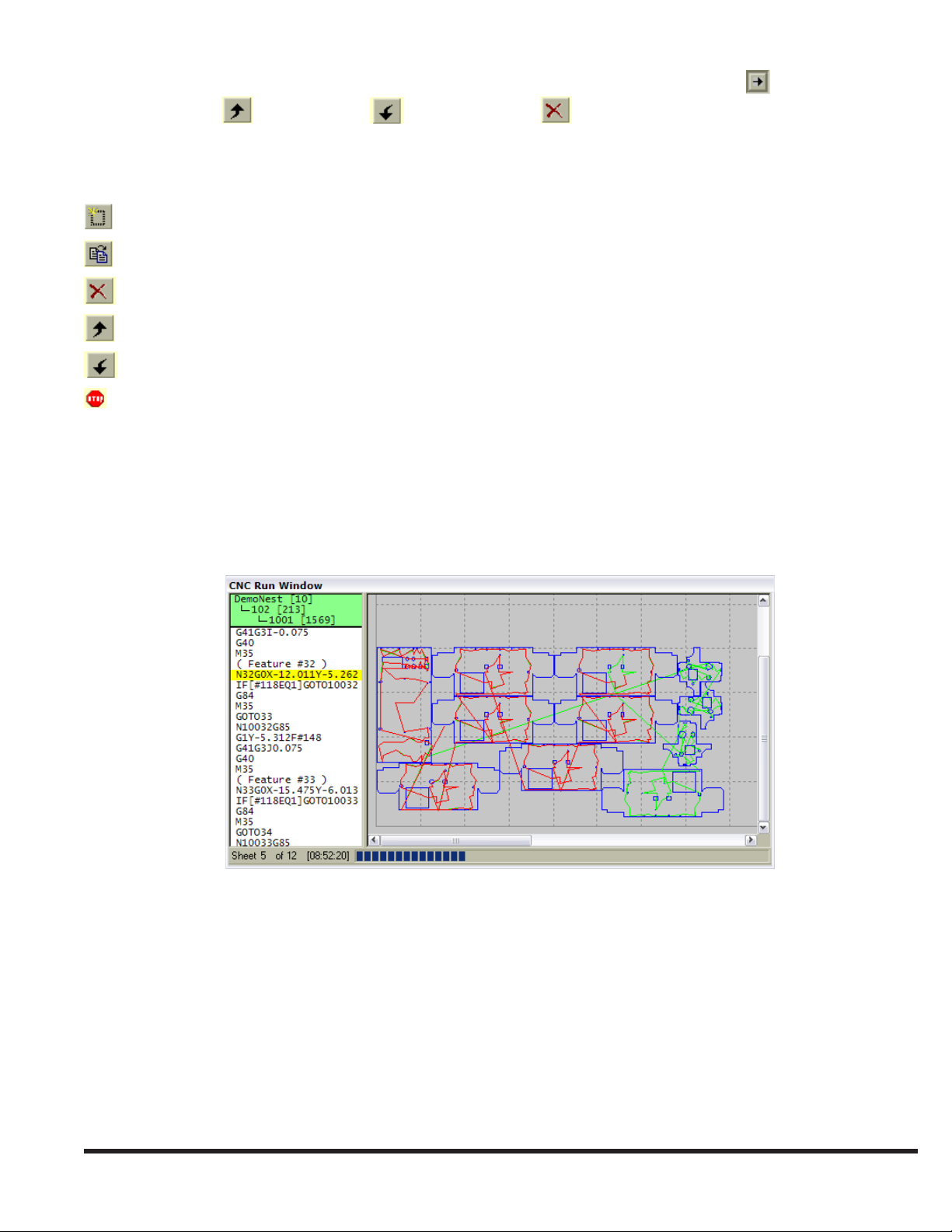

BATCH PROGRAM FILE

A Batch Program le is a list of NC Program les that will be loaded and executed in the order listed. It allows programs

to be grouped together in a logical manner and allows the control to keep track of which programs have been completed

and which program to load next. A Batch Program can contain up to one hundred program entries and each entry can be

repeated up to one hundred times. Batch Program le names should end with “.bch” (ex: “Filename.bch”).

When a Batch Program le is opened, the parameter settings are displayed in a Batch Program window:

Creating a Batch Program

To create a new Batch Program:

Select 1. File | New and then select “Batch” le type in the New Selection window. Click “OK” to close the New Selection

window.

In the new 2. Batch Program window, select the “New Entry” button until the window has enough rows for all NC

programs that will be added to the batch.

In each row, enter the NC Program le name in the 3. Program column by typing it directly or using the “Browse”

button to select it with the trackball.

Enter the number of times that each program will run in the 4. Repeat column by typing it directly or by using the arrow

buttons .

EM-551 (N-04/11)

7-6

Page 17

If it becomes necessary to move or delete an entire row, select the row using the “Row Select” 5. button and then press

the “Move Up” , “Move Down” , or “Delete Entry” button.

Editing a Batch Program

Batch Program editing functions are provided in the Batch Program window. The editing functions are:

Insert new row Inserts a new NC Program le entry after the selected entry or at the end of the list.

Copy a row Copies the selected row and inserts the copy into the list after the selected row.

Delete Entry Deletes the selected entry.

Move Up Moves the selected entry up one row in the list.

Move Down Moves the selected entry down one row in the list.

Stop the Batch Stops a running Batch Program.

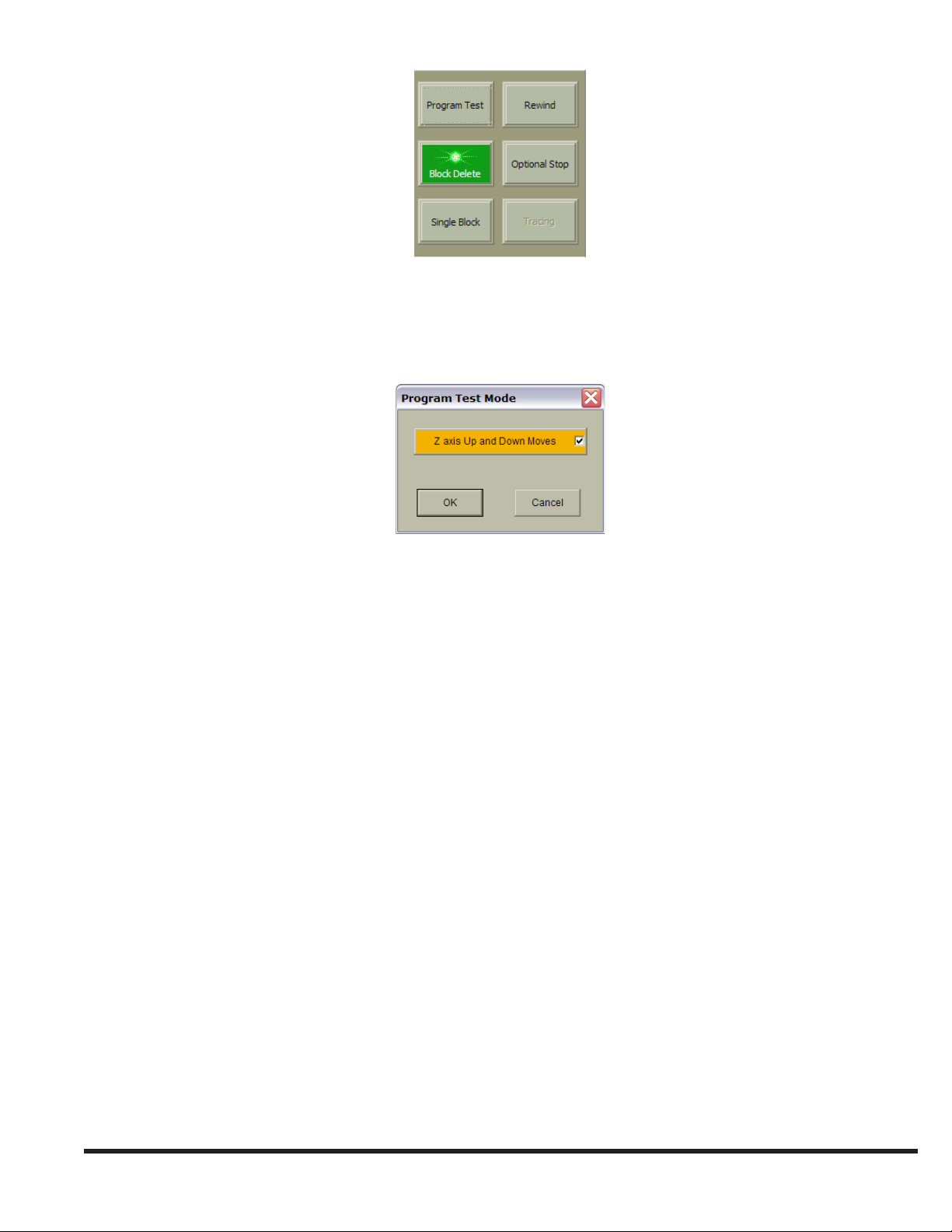

CNC RUN WINDOW

The CNC Run Window displays the execution status of the active cutting program, if a program is currently loaded. This

window cannot be manually opened or closed. The control software will automatically display the CNC Run Window

each time a part program is successfully loaded, and whenever the control enters Auto mode while a program is loaded.

Likewise, the CNC Run Window will automatically close whenever the control enters Jog mode or Axes Home mode.

The CNC Run Window has two sections and a status bar. The left section displays the NC program code with the active

block highlighted. To help locate the current position in an interrupted cutting program, the active subroutine name and

line number are displayed in a green box at the top of the NC code section. All currently active subroutines are displayed,

indented to the right to indicate the nesting depth for nested subroutines.

The right section is a graphical plot of the current sheet program. For each sheet, the status bar at the bottom of the window

displays the sheet number, the remaining runtime, and a bar graph showing the percentage of completed program blocks.

The plotting software interprets M50 as the start of another sheet.

Before the program starts each sheet, the plot shows all X-axis and Y-axis rapid moves in green. Contouring moves with the

laser beam on are shown in blue. Contouring moves with the laser beam off are shown in yellow. As the program runs, the

plot changes the color of all completed moves to red. To change the width of the plot section, select the divider between the

left and right sections and drag it to another location. To change the viewing area of the plot, use any of the various Zoom

7-7

EM-551 (N-04/11)

Page 18

features. See WINDOW ZOOMING in the VIEW MENU section.

If desired, the plot section and status bar can be hidden, resulting in a much smaller CNC Run Window. See RUN WINDOW

GRAPHICS in the VIEW MENU section.

CONTROL BARS

OPERATOR CONSOLE

The Operator Console Control Bar contains four different groups of user controls: Program Modes, Laser Resonator,

Override Settings, and Operating Mode. There are also two buttons that can be used to quickly open or close other control

bars.

Selecting the “Aux.” button will open the Auxiliary Functions Control Bar if it is not currently open, or close it if it is

currently open. Selecting the “Override Adjust” button will open the Override Adjust Control Bar if it is not currently open,

or close it if it is currently open.

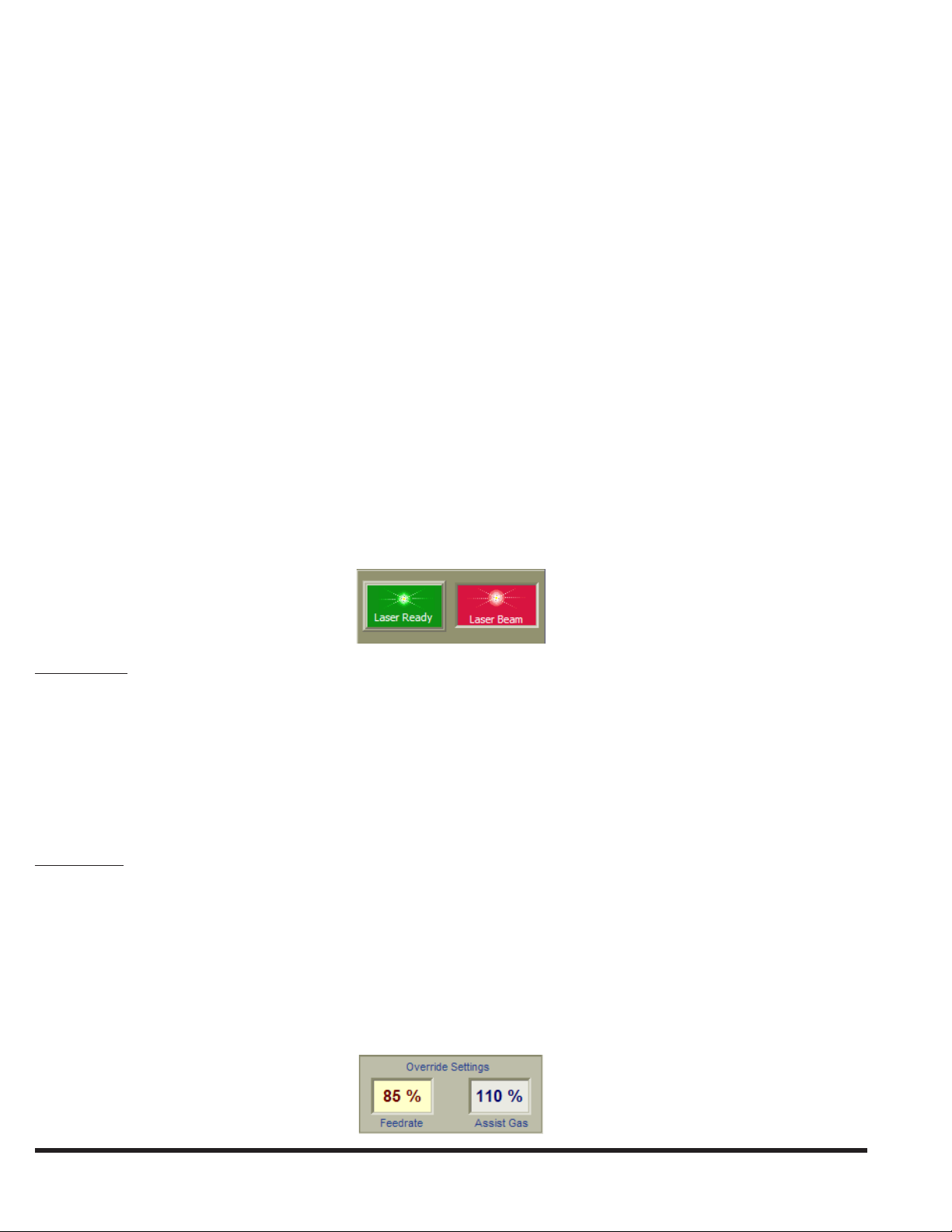

PROGRAM MODES

The top section of the Operator Console Control Bar contains controls that turn on or off the various program execution

modes that affect how the control software executes NC programs. Each control is both a button and indicator for the

corresponding mode. Like the button/indicators in the other control bars, these controls appear bright green (ON) when the

corresponding mode is active, and dull green or gray (OFF) when the mode is not active.

The Laser Control Software automatically displays the Program Modes Control Bar each time the CNC control enters Auto

mode. When the control enters Jog or Axes Home mode from Auto mode, this control bar will automatically close.

EM-551 (N-04/11)

7-8

Page 19

PROGRAM TEST MODE

Program Test Mode will run a part program without actually cutting material. Use the “Program Test” button to activate

Program Test Mode. In this mode, the laser beam and assist gas will not turn on during program execution. Selecting the

“Program Test” button when Program Test Mode is off will cause the ‘Program Test Mode’ dialog box to open.

The “Z-axis Up and Down Moves” button enables or disables Z-axis motion while Program Test Mode is active. If the

box is not checked, the cutting head will not move up or down, and the program will ignore the Pierce dwell. Select “OK”

to close the dialog and activate Program Test Mode; select “Cancel” to close the dialog without activating Program Test

Mode.

Keyboard Shortcut: F2

REWIND

The “Rewind” button sets the rst block of the active NC program as the next block to be executed when “CYCLE

START” is pressed. Use this function to restart the program from the beginning when program execution is interrupted. The

“Rewind” button is disabled while program execution is in progress. Note that this button does not stay in the green (ON)

state when selected, since it does not make a new mode active.

Keyboard Shortcut: F3

BLOCK DELETE MODE

While Block Delete mode is active, any block in the NC program that begins with the “ / ” (forward slash) character will

not be executed. The “Block Delete” button activates Block Delete mode. Block Delete mode can be enabled/disabled at

any time during program execution.

Keyboard Shortcut: F4

OPTIONAL STOP MODE

Optional Stop mode enables the use of M01 (or M1) in a program. Use the “Optional Stop” button to activate Optional

Stop program execution mode. When Optional Stop mode is active, the control changes to the Cycle Stop condition when

a program commands M01. Program execution resumes when “CYCLE START” is pressed. Optional Stop mode can be

enabled/disabled at any time during program execution.

Keyboard Shortcut: F5

7-9

EM-551 (N-04/11)

Page 20

SINGLE BLOCK MODE

In Single Block mode, only one NC Program block will be executed each time “CYCLE START” is pressed. The “Single

Block” button activates Single Block program execution mode.

Keyboard Shortcut: F6

TRACE MODE

The “Tracing” button activates program execution Trace mode. When Trace mode is active, the “TRACE FORWARD” and

“TRACE REVERSE” buttons on the machine operator front panel are enabled. Tracing is used to recover from program

interruptions; it allows the operator to step through the program in either the forward or reverse direction with the laser

beam off, as long as the “TRACE FORWARD” or “TRACE REVERSE” button is pressed. See ERROR RECOVERY in

the CUTTING PROCEDURES section.

Keyboard Shortcut: F7

Note: There is a limit to how far in reverse a program can be traced. As a program is running, a xed number of executed

program blocks are held in memory. This memory area, known as the “history buffer”, limits how far a program

can be traced in reverse. Large programs may contain more blocks than the history buffer can hold. Attempts to

trace backwards beyond the last block in the history buffer will cause the alarm “End of history buffer or beginning

of program reached. Reverse tracing is disabled.”

LASER CONTROLS

This part of the Operator Console Control Bar contains controls related to the laser.

Laser Ready: The “Laser Ready” button/indicator will appear bright green (ON) when the laser has nished its start up

sequence and is ready to turn the beam on, and dull green or gray (OFF) when the laser is not ready to turn the beam

on. If the “HIGH VOLTAGE” keyswitch on the Machine Operator Side Panel is in the LOCKED position, the indicator

will be appear off, displaying an image of a padlock.

Selecting this button when Laser Ready is off commands the control to connect power to the laser main power supply,

initiating the power-up sequence. During the power-up sequence, the indicator blinks on and off; when the power-up

sequence is complete, the indicator will remain on. Selecting this button when Laser Ready is on commands the control

to remove electrical power from the laser main power supply.

Laser Beam: This indicator displays the On/Off status of the laser beam. The “Laser Beam” indicator is red (ON) when

the laser is producing a beam. The laser produces a beam in response to requests for laser power. Laser power can be

requested by the cutting program or by the Lens Centering function. When the laser is not producing a beam, the

indicator color is dull red or gray (OFF).

OVERRIDE SETTINGS

In the center section of the Operator Console Control Bar, the current values of the Jog/Feedrate and Assist Gas Override

settings are displayed.

EM-551 (N-04/11)

7-10

Page 21

It is easy to change either override setting by selecting one of the override display boxes. This will cause the Override

Adjust Control Bar to open. Once selected, that display box will change to a red text/yellow background color to indicate

that the corresponding override is activated for adjustment in the Override Adjust Control Bar.

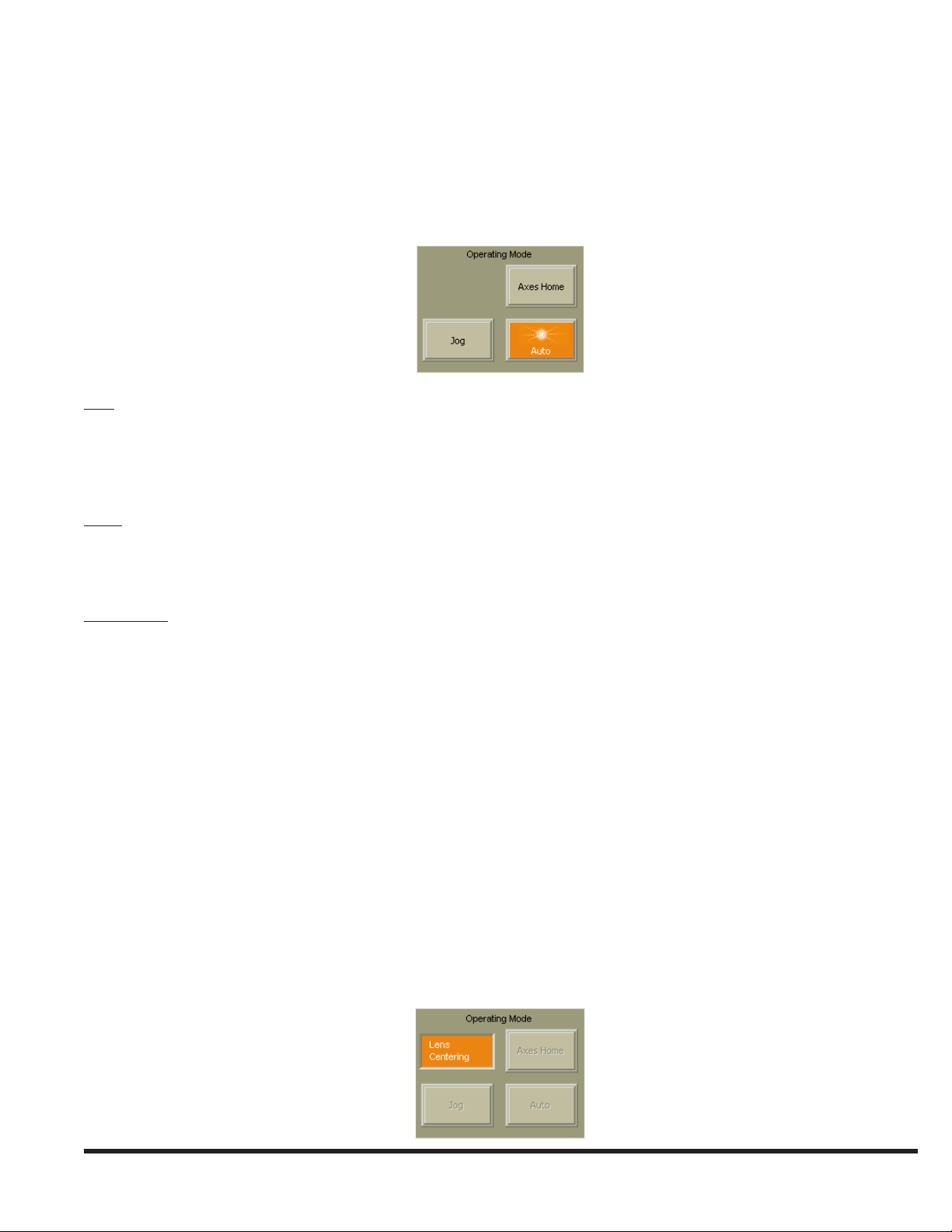

OPERATING MODES

The bottom section of the Operator Console Control Bar contains three button/indicator controls for the primary operating

mode, and an “Alternate Mode” indicator.

Jog: This button/indicator activates Jog mode. While the control is in Jog mode, the “Jog” indicator color is amber. In

Jog mode, the axis motion controls on the Operator Control Station front panel or the Remote Station can be used to

manually move (“jog”) each machine axis individually. Cutting program execution is disabled while Jog mode is active.

Most Maint. | Utilities functions, such as Lens Centering, are only enabled when the Laser System is in Jog mode. The

control will remain in Jog mode until another mode is selected.

Auto: This button/indicator activates Auto mode. The Laser System must be in Auto mode in order to run cutting programs.

While the control is in Auto mode, the “Auto” indicator color is amber, and most Maint. | Utilities functions, are

disabled. The NC Program les and Process Parameter Files while the control is executing a program in Auto mode. The

control will remain in Auto mode until another mode is selected.

Axes Home: This button/indicator activates Axes Home mode. When selected, the “Axes Home” button text changes to

“Homing” and the color changes to amber. To home the axes, the main drives must be on with no system alarms present.

The Axes Homing function begins when the operator presses the “CYCLE START” pushbutton. When all axes have

moved to their reference positions, all axis motion stops, the Axes Home function ends and the control automatically

changes to Jog mode.

Special Operating Mode

Special Operating Modes are alternate modes the Laser System is in while certain functions are active:

Lens Centering•

Standoff Calibration•

Note: The Laser System must be in Jog mode before a “Special Operating Mode” can be activated.

Special operating modes are typically modes in which the “CYCLE START” / “CYCLE STOP” buttons perform some

unique function other than starting the execution of a cutting program. For example, Standoff Calibration is a “Special

Operating Mode” since “CYCLE START” initiates the Noncontact Head standoff calibration sequence. When any of these

special operating modes are active, the amber-colored “Alternate Modes” indicator will be visible, and the three primary

operating mode buttons will be disabled.

7-11

EM-551 (N-04/11)

Page 22

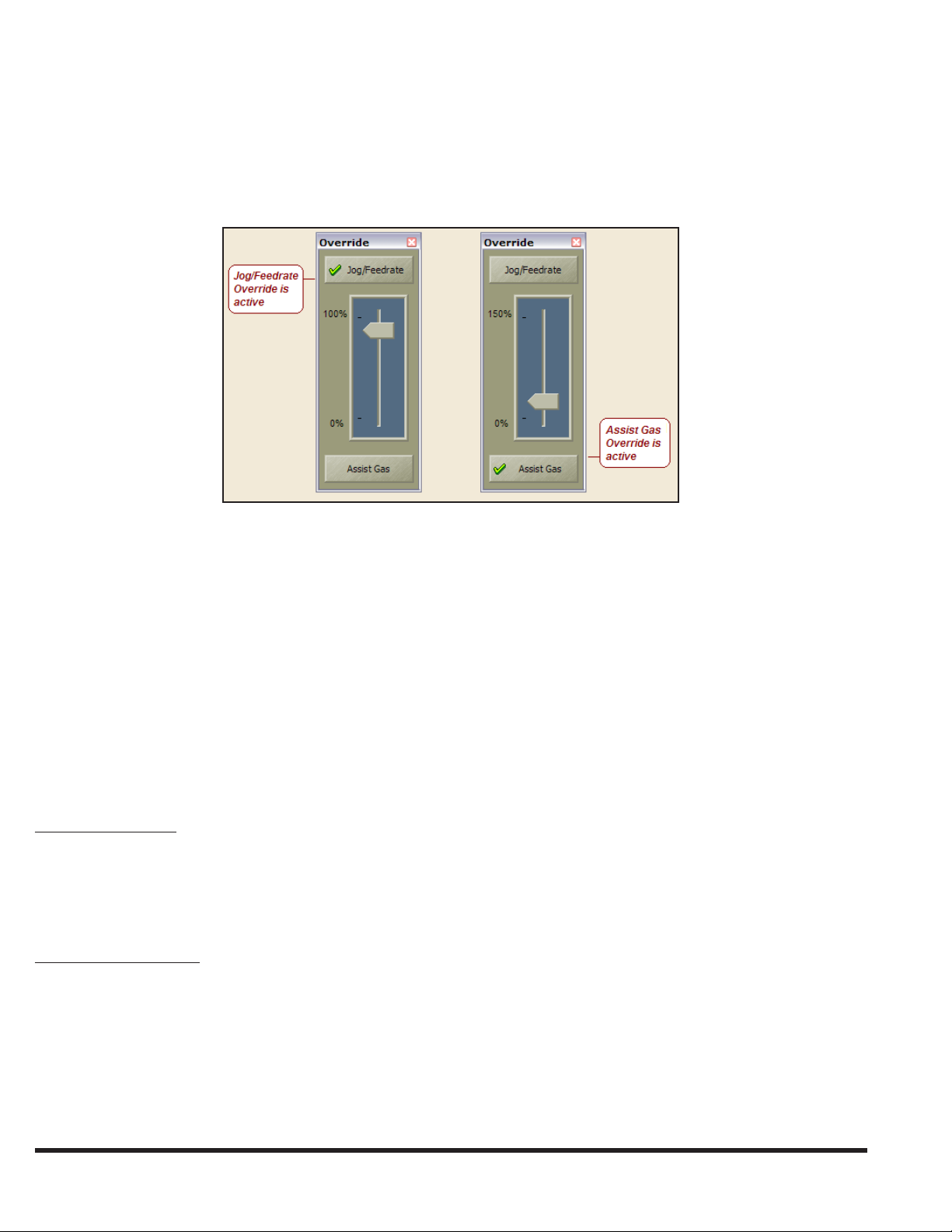

OVERRIDE ADJUST

The Override Adjust Control Bar contains a slider control that can be used to adjust the setting of either the Jog/Feedrate

Override or the Assist Gas Override function. Only one override setting, the active override, is adjusted at a time. The

active override is selected by selecting either the “Jog/Feedrate” or the “Assist Gas” button. The currently active override

is indicated by a green check mark on the corresponding button and a yellow background color for the “Override Settings”

indicator in the Operator Console Control Bar.

The Override Adjust Control Bar can be opened/closed in any of the following ways:

Select the “Override Adjust” button in the Operator Console Control Bar.•

▪ Select either “Override Settings” indicator in the Operator Console Control Bar; this will also make the corresponding

override active.

Go to: • View | Control Bars | Overrides

There are several ways to change the slider control setting in the Override Adjust Control Bar:

After selecting the slider control, the “Page Up” and “Page Down” keyboard keys will change the setting in 5% •

increments.

The “Up Arrow” and “Down Arrow” keyboard keys change the setting in 1% increments.•

Select the “Slider Control” indicator with the trackball pointing device and then drag it to any setting.•

Rotate the wheel on the trackball pointing device after selecting the slider control. •

Assist Gas Override: This setting modies the programmed assist gas pressure used for cutting. For example, if the program

species 200 PSI and the assist gas override is set to 75%, the actual cutting pressure will be: 75% of 200 PSI = 150 PSI.

This setting also affects the pressure achieved when assist gas is manually activated using one of the assist gas buttons

on the Auxiliary Functions Control Bar. The assist gas override setting is adjustable from 0% to 150%.

Note: The Assist Gas Override setting does not affect the assist gas pressure used when piercing.

Jog/Feedrate Override: When the NC cutting program commands the X-axis and/or Y-axis to a position with a G01,

G02, or G03 block, the actual feedrate will be the percentage of the commanded feedrate specied by the Jog/Feedrate

Override setting. For example, if Jog/Feedrate Override is set to 75% and the program species “F400”, the actual

feedrate will be 75% of 400 IPM = 300 IPM. The Jog/Feedrate Override setting is adjustable from 0% to 100%. The

Feedrate Override is disabled during rapid moves (G0) or when M48 is active.

Jog/Feedrate Override also changes the jogging speed of the X- and Y-axes when the “RAPID TRAVERSE” button

is not lit. The jogging speed at 100% is the “X/Y-axis Jog Speed” specied on the General page of the Maintenance/

Machine Conguration window (300 IPM or 7620 mm/min typical).

EM-551 (N-04/11)

7-12

Page 23

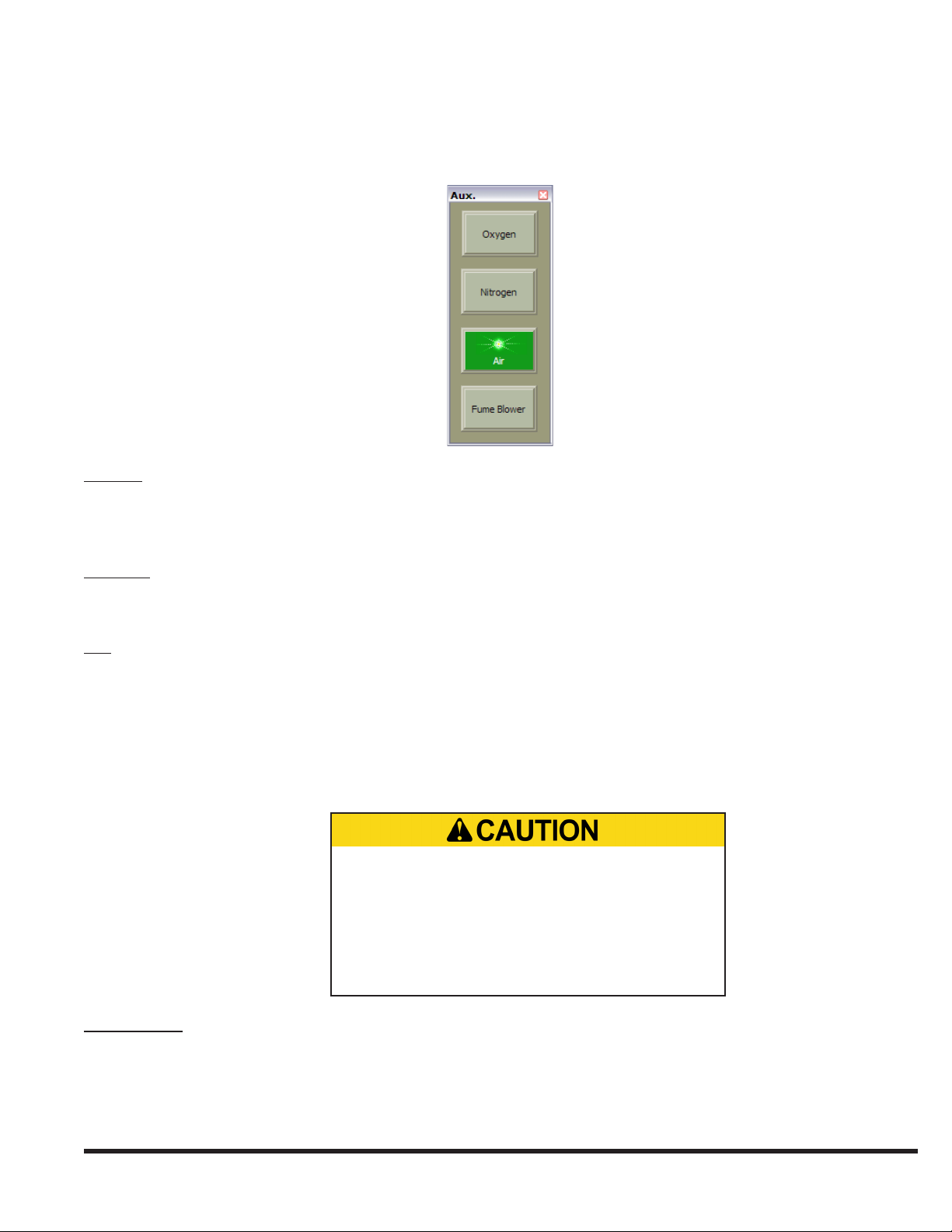

AUXILIARY FUNCTIONS

The Auxiliary Functions Control Bar contains buttons for manually activating assist gas ow and the fume blower system.

Open/close this control bar by selecting the “Aux.” button on the Operator Console Control Bar, or by selecting View |

Control Bars | Aux.

Oxygen: This control is both a manual activation button and indicator for oxygen assist gas. When executing a cutting

program, the control automatically commands assist gas ow through the nozzle. When oxygen assist gas is owing,

the “Oxygen” indicator color changes from dull green or gray (OFF) to bright green (ON). This button is used in Jog or

Auto mode to manually control the oxygen assist gas solenoid valve.

Nitrogen: This control is both a manual activation button and indicator for nitrogen assist gas. When nitrogen assist gas is

owing, the “Nitrogen” indicator color changes from dull green or gray (OFF) to bright green (ON). This button is used

in Jog or Auto mode to manually control the nitrogen assist gas solenoid valve.

Air: This control is both a manual activation button and indicator for air assist gas. When air assist gas is owing, the “Air”

indicator color changes from dull green or gray (OFF) to bright green (ON). This button is used in Jog or Auto mode to

manually control the air assist gas solenoid valve.

Note: Only one assist gas can be active at a time. If nitrogen is owing when the oxygen button is selected, the nitrogen

gas solenoid will close and the oxygen gas solenoid will open, etc.

Verify correct installation of lens drawer and

nozzle tip before activating either assist gas

solenoid valve. Applying assist gas pressure

without proper installation of these parts can

force the lens drawer or nozzle tip out of position

or out of the cutting head. Unrestricted ow can

also damage assist gas supply components.

Fume Blower: This a manual activation button and indicator for the fume blower. Selecting this button toggles the fume

blower on or off when the program is not running. The fume blower turns on automatically when the machine is cutting.

When the program ends, the fume blower remains on for 60 seconds, plus the Blower OFF delay time specied on the

Auxiliary page of the Conguration window, and then turns off automatically. This button is used to provide additional

fume removal time. The “Fume Blower” indicator color is dull green or gray (OFF) when the fume blower is off and

bright green (ON) when the fume blower is running.

7-13

EM-551 (N-04/11)

Page 24

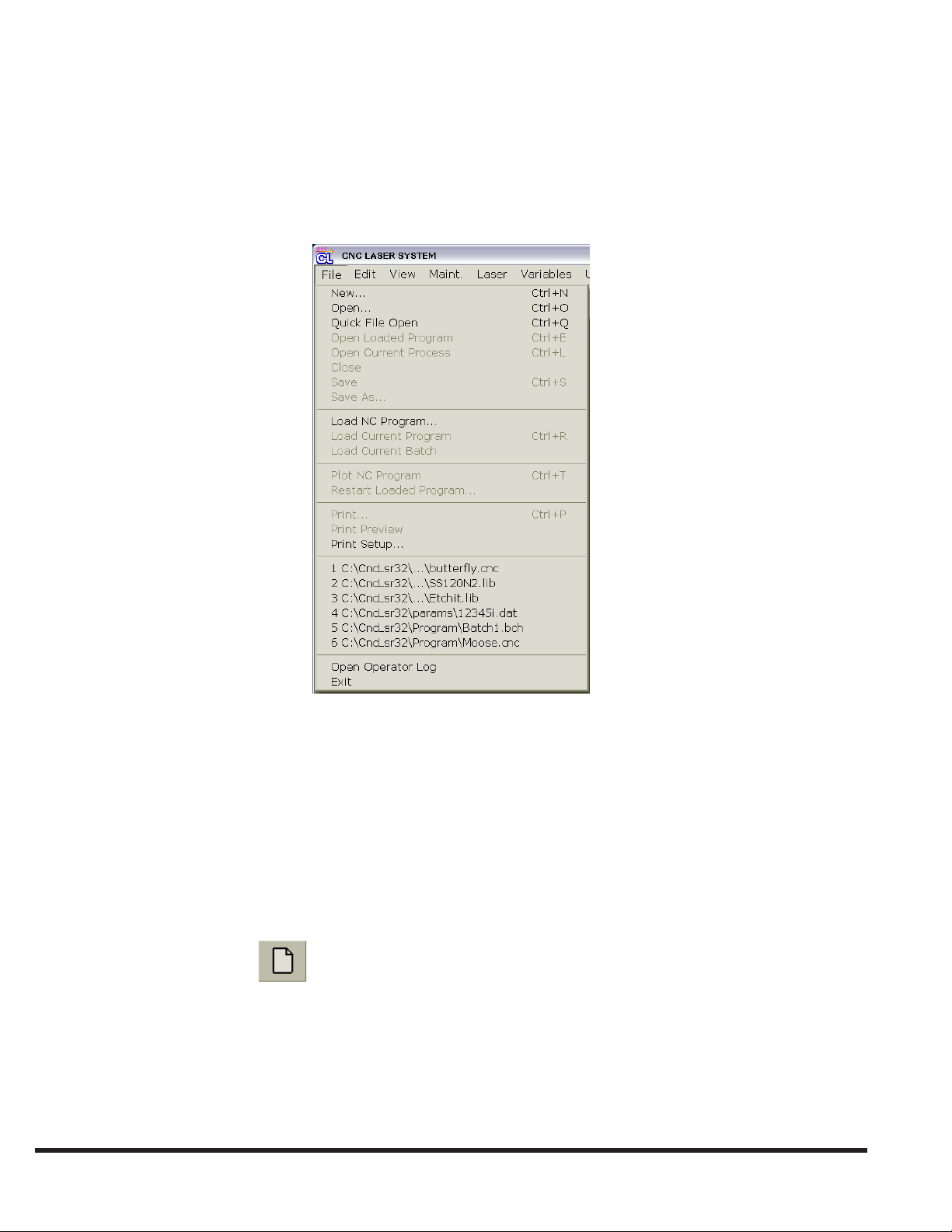

MENU COMMANDS

FILE MENU

In the File menu, various commands can be used to manage les and to activate le-related functions. Many of the File

menu commands, such as Open, Save, and Print, are standard commands used by most Microsoft Windows applications,

while others are for Laser System-specic functions: Open Current Process, Load Current Program, etc.

NEW

File | New creates a new le and opens a new window displaying the les contents. The Laser System software works

with three different types of data les (see FILE TYPES). Before a new le is generated, the ‘New File’ dialog box opens,

prompting the user to specify the type of le to create. The following types of le can be created::

NC Program File•

Process Parameter File•

Batch Program File•

Toolbar Shortcut:

Keyboard Shortcut: Ctrl + N or { Alt, F, N } sequence

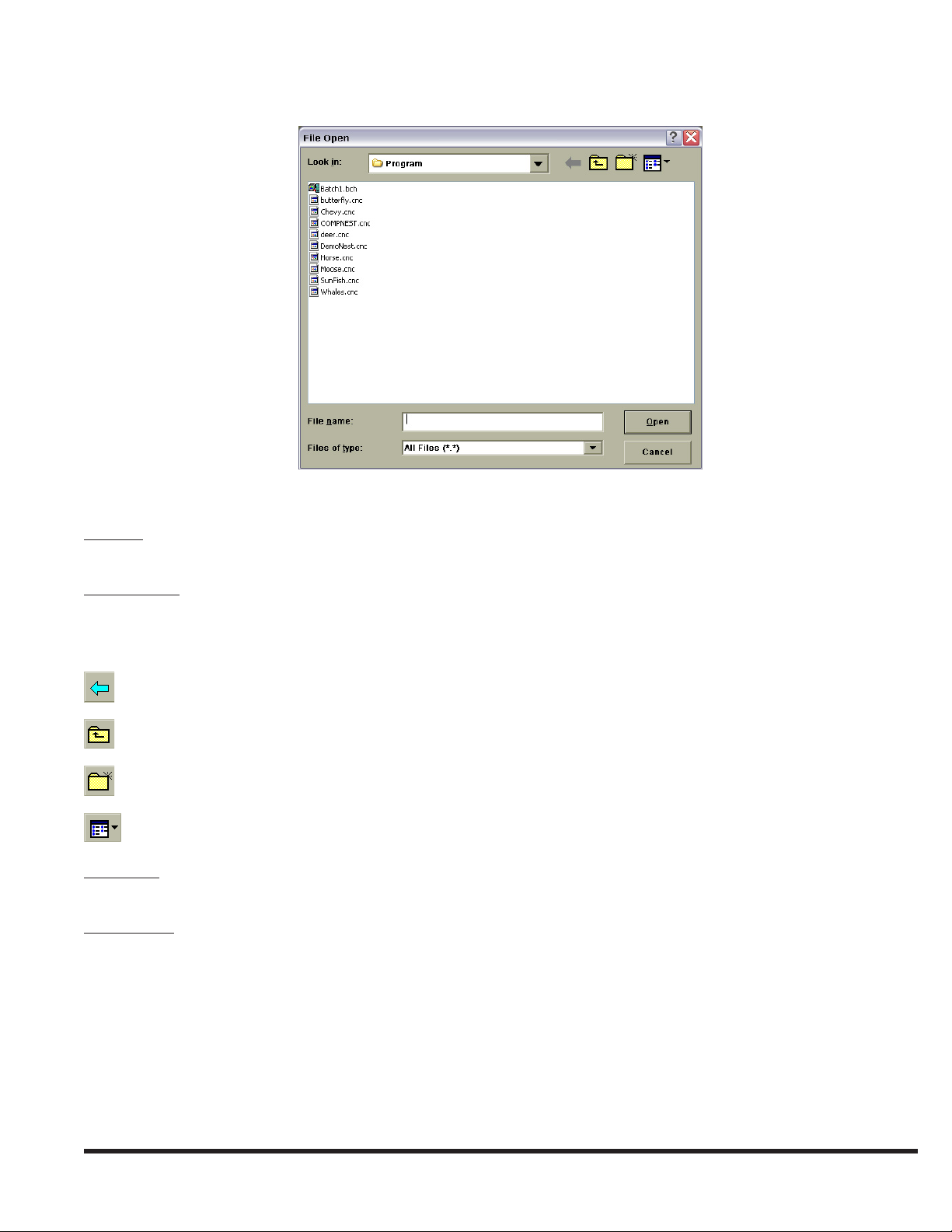

OPEN

File | Open opens an existing laser le in a new window. Multiple le windows of all types can be open at the same time.

This command causes the File Open window to appear. Use this window to select a le to open.

EM-551 (N-04/11)

7-14

Page 25

Note: Use the Most Recently Used (MRU) File List to quickly reopen a le that was recently closed. See the MRU FILE

LIST section for more information.

Use these controls in the File Open window to identify the le to be opened:

Look In: Displays the name of the folder whose contents are displayed in the browser box below. To see how the current

folder ts in the folder hierarchy, select the down arrow. To see what is inside a folder, select the folder.

File Browser: This is the large box below the “Look In” eld that lists the folders and les in the folder specied in the

“Look In” eld. Use the browser to graphically select a le or a different folder. Double-clicking a folder will cause its

contents to be displayed in the browser and its name to appear in the “Look In” eld. The buttons above the browser

window can be used to nd and select folders and les:

Navigate the browser to the previously selected folder.

Navigate the browser to the folder one level higher than the currently displayed folder.

Create a new folder.

Change the browser view mode.

File name: Type the name of the le to be opened here or use the browser window to graphically select the le to open.

Selecting a le in the browser window will cause its name to appear in the “File name” eld.

Files of type: Lists the types of les to display in the browser. The choices are:

All Files•

NC Program File (with • .cnc extension)

Process Parameter Files (with • .lib extension)

Batch Files (with • .bch extension)

Note: Only les with the extension listed in the “Files of Type” drop-down list are shown in the browser window.

7-15

EM-551 (N-04/11)

Page 26

Toolbar Shortcut:

Keyboard Shortcut: Ctrl + O or { Alt, F, O } sequence

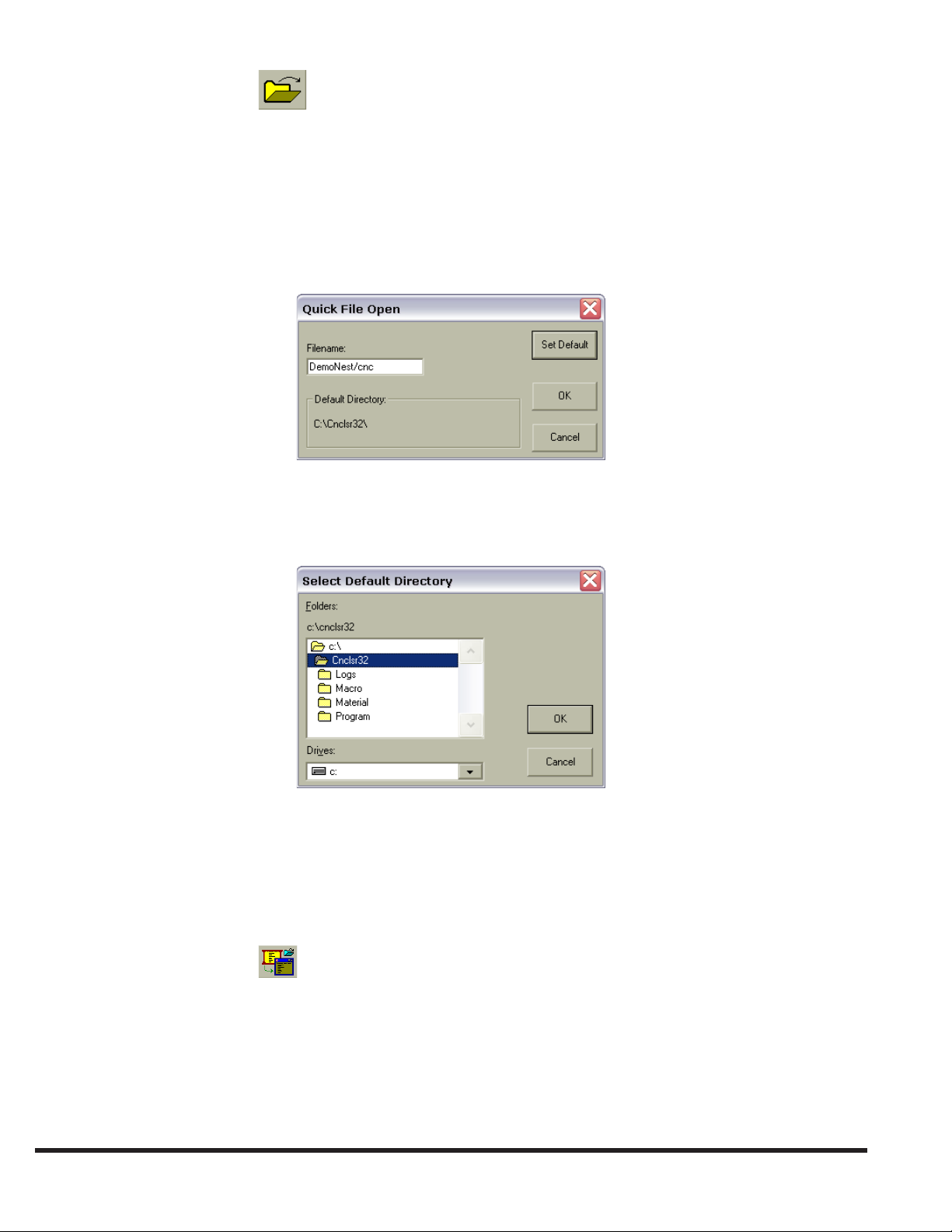

QUICK FILE OPEN

File | Quick File Open opens existing NC Program, Process Parameter, or Batch Program les. The Quick File Open

command will display the Quick File Open window. The name of the le to be opened is typed in the “Filename” eld. The

le must be located in the directory indicated in the ‘Default Directory’ box.

The “OK” button will open the le specied and close the Quick File Open window. The “Cancel” button will close the

Quick File Open window without opening a le. The “Set Default” button will open the Select Default Directory window

that will allow the user to select a new default directory. Once selected, this default directory will be saved and used until

a new selection is made.

Keyboard Shortcut: Ctrl + Q or { Alt, F, Q } sequence

OPEN LOADED PROGRAM

File | Open Loaded Program opens a window displaying the NC Program le currently loaded for execution. If no cutting

program is currently loaded, this command is disabled

Toolbar Shortcut:

Keyboard Shortcut: Ctrl + E

OPEN CURRENT PROCESS

File | Open Current Process opens a new window displaying the Process Parameter le currently being used for cutting.

If no cutting program is currently loaded for execution, this command is disabled.

EM-551 (N-04/11)

7-16

Page 27

Toolbar Shortcut:

Keyboard Shortcut : Ctrl + L

CLOSE

File | Close closes the active le. If the open le contains unsaved changes, the user will be prompted to save the changes

before closing the le. If a le is closed that has not been named, the Save As window will open rst, prompting the user

to name the le before closing it.

Note: If a le is closed without saving it, all changes made since the last time the le was saved will be lost.

Keyboard Shortcut: Ctrl + F4 or { Alt, F, C } sequence

“X” button on the window’s caption bar :

SAVE

File | Save saves any changes to the active le. The contents of the le will be written to its current location with its current

le name. When a new le is saved for the rst time, the Save As window will open rst, prompting the user to name the

le.

Toolbar Shortcut:

Keyboard Shortcut: Ctrl + S or { Alt, F, S } sequence

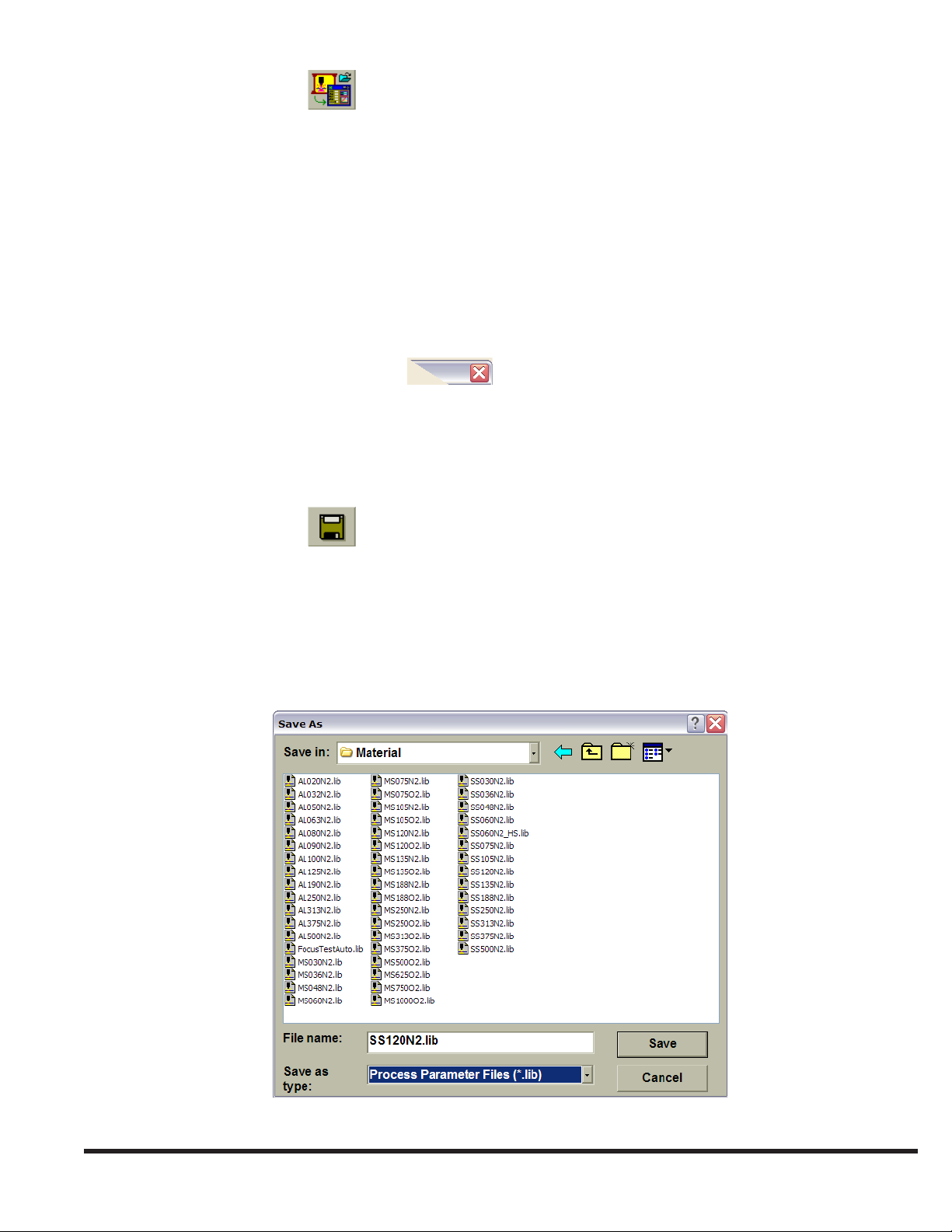

SAVE AS

File | Save As saves a new le with the specied name, or saves the contents of the active le to a different name and/or

location. This command causes the Save As window to open. Use this window to specify the le name and location.

Use these controls in the ‘Save As’ dialog box to specify the name of the le and its location:

7-17

EM-551 (N-04/11)

Page 28

Save in: Displays the name of the folder whose contents are displayed in the browser box below it. To see how the current

folder ts in the folder hierarchy, select the down arrow. To see what is inside a folder, select the folder.

File Browser: This is the large box below the “Save in” eld that lists the folders and les in the folder specied in the

“Save In” eld. Use the browser to graphically select a le or a different folder. Double-clicking a folder will cause its

contents to be displayed in the browser and its name to appear in the “Save in” eld. The buttons above the browser

window can be used to nd and select folders and les:

Navigate the browser to the previously selected folder.

Navigate the browser to the folder one level higher than the currently displayed folder.

Create a new folder.

Change the browser view mode.

File name: Enter the le name here or use the browser window to graphically select an existing le name. Selecting a le in

the browser window will cause its name to appear in the “File name” eld. If the le name entered here has no extension,

the extension listed in the “Save as type” drop-down list will be automatically added to the le name when it is saved.

Save as type: Species the type of le being saved. The list automatically includes the le type corresponding to the

document in the active window as the default type. For example, if the active window is a Process Parameter le, the

box will list “Process Parameter Files (*.lib)” as the le type.

Note: Only les with the extension listed in the “Files of Type” drop-down list are shown in the browser window.

Keyboard Shortcut: { Alt, F, A } sequence

LOAD NC PROGRAM

File | Load NC Program allows the user to specify an NC Program le to load into program execution memory. Each

program must be loaded into memory before it can be run. Once a program is loaded, it can be run multiple times without

being loaded again. Note that only one program can be loaded at a time. This command opens the Load NC Program

to Execute window, from which box to select a le to load. The Load NC Program to Execute window is similar to the

window used to open a le. See the OPEN topic in the FILE section for help with using this window.

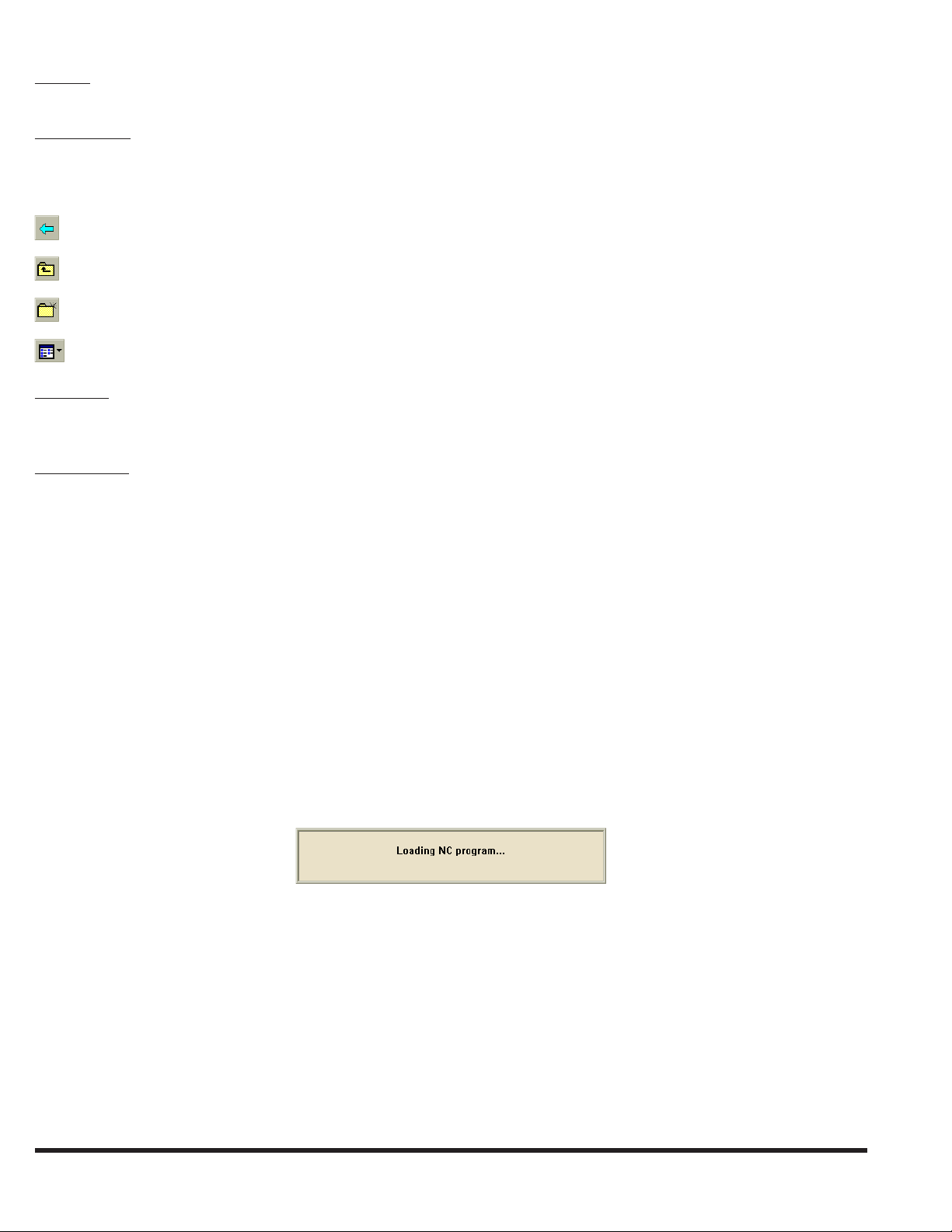

Some very large cutting programs may require several seconds to load. The following message window will be displayed

while the control is busy loading a program:

Note: The Laser System user interface is disabled until the control nishes loading the program.

Keyboard Shortcut: { Alt, F, L } sequence

LOAD CURRENT PROGRAM

File | Load Current Program loads the NC Program in the currently active Program Edit window into program execution

memory. This command is enabled only when an NC Program le is open in the currently active window. Each program

must be loaded into memory before it can be run. Once a program is loaded, it can be run multiple times without being

loaded again. Note that only one program can be loaded at a time.

Some very large cutting programs may require several seconds to load. The following message window will be displayed

EM-551 (N-04/11)

7-18

Page 29

while the control is busy loading a program:

Note: The Laser System user interface is disabled until the control nishes loading the program.

Toolbar Shortcut:

Keyboard Shortcut: Ctrl + R

LOAD CURRENT BATCH

File | Load Current Batch loads the currently open Batch Program le for execution. This command is enabled only

when a Batch Program le is open in the currently active window. See the BATCH PROGRAM FILE topic in the FILES

TYPES section for more about Batch Program les.

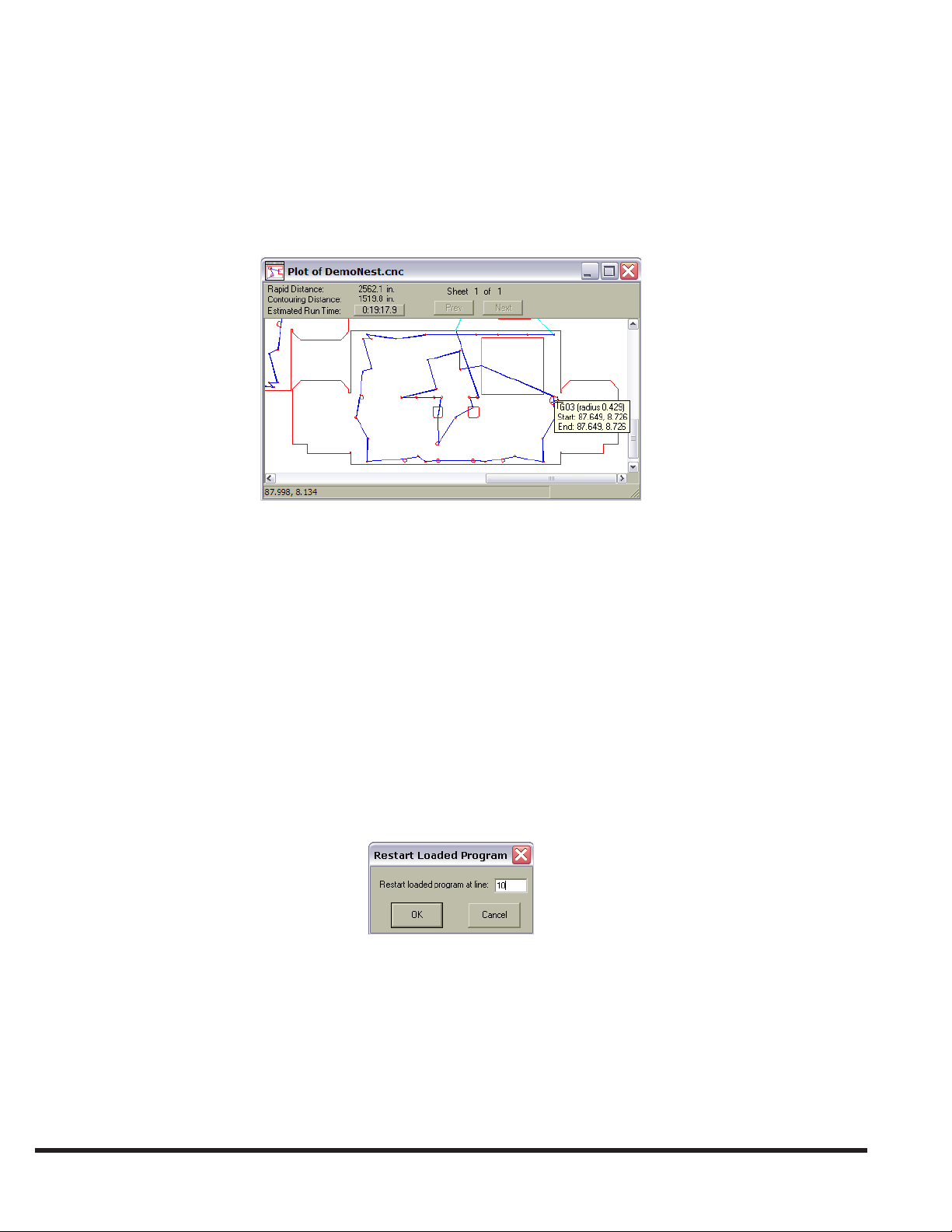

PLOT NC PROGRAMS

When the active window is an NC Program Edit window, the File | Plot NC Program command can be used to display a

graphical plot of the cutting program, one sheet at a time.

If the program has no syntax errors, this command will open a new Program Plot window showing the programmed tool

path. The plot represents where the cutting head would move if the operator ran the program. If the program has a syntax

error, selecting “Plot NC Program” will only display the error message, and the cursor in the Program Edit window will be

positioned on the line containing the error.

The Program Plot window uses different colors to display two types of rapid traverse moves (light blue for Z-axis up and

dark blue for Z-axis down), and two types of contouring moves (red for laser on and green for laser off). When the program

uses more than one sheet, the “Next” and “Prev” buttons change the plot window to display another sheet. The plotting

software interprets M50 in the program as the beginning of another sheet.

The top section of the Program Plot window displays the total Rapid Distance, Contouring Distance, and Estimated Run

Time for each sheet. The estimated run time does not include time to exchange pallets (M50) or the effect of the Feedrate

Override setting. The plotting function assumes that the pallets are in position and the machine is ready to run.

7-19

EM-551 (N-04/11)

Page 30

At the bottom of the Program Plot window, a status bar displays the overall X-axis and Y-axis dimensions of the cutting

program.

To change the plot window magnication, use the Zoom functions (see WINDOW ZOOMING in the VIEW MENU

section).

The Program Plot window can also display information about individual lines and arcs in a program. When the cursor is

positioned on a line or arc, a small pop-up window displays the command type (G00, G01, G02, or G03) with the X and Y

machine coordinates of the start and end. The pop-up window also displays the radius for a G02 or G03 arc.

Keyboard Shortcut: Ctrl + T

RESTART LOADED PROGRAM

File | Restart Loaded Program activates the Program Restart function, which allows a program to be restarted at a

specied line number. This function is intended for use when long programs are terminated before completion and the

normal program recovery method cannot be used. Program Restart is particularly useful with the Automatic Laser Shutdown function (see Auto SHUT-DOWN, in the LASER MENU section), which will display the last absolute line number

executed when a program has not run to completion.

Note: Restart Loaded Program will be enabled only if a program is loaded, the machine is in Auto mode, and is not

currently running a program. At all other times, this menu command will appear grayed, indicating the Program

Restart function is disabled.

When this command is selected, the Restart Loaded Program window will be displayed, prompting the user for an absolute

line number to restart the program at.

Note: Absolute line numbers identify the sequential position of a row or block of code in a program le. This number is

always relative to the rst line in the program, and is not necessarily the same as the optional program line number,

“Nxxxxx”.

The absolute line number of a part program is displayed in the Main Status Bar when the program le is open in a Program

Edit window, and that window is the active window. To determine the absolute line number corresponding to a given block

in a program le, open the le, move the cursor to the desired block and observe the line number in the status bar.

Note: If any window other than a Program Edit window is the active window, the line number will not be displayed in

EM-551 (N-04/11)

7-20

Page 31

the Main Status Bar.

Selecting “Cancel” will close the dialog and abort the restart operation. Selecting “OK” will cause the control to search

through the program from the beginning until it nds the desired line number. A message window will be displayed, stating:

“Please wait while restart line number is found”. This may take a few seconds to nish. If the line number is not reached

before an M30, M02, or M99 in a main program, an error will be displayed stating “Restart End” and the program will be

rewound.

After the line number is reached, the CNC Run Window will be updated to show the next line to be executed. Press “CYCLE

START” and the Z-axis will move to the full up position, then the X- and Y-axes will move from the current position to

the beginning of the current block at 500 IPM. Normal program execution will resume from there. If the program would

normally have been cutting at this point, the Z-axis will move down and cutting will resume, otherwise the head will remain

up until the program commands it down to start cutting.

The following restrictions apply to the Program Restart function:

The • Program Restart function works best with “straight line” programs, for example, programs that do not contain

subroutine calls, macro calls, or “while” loops.

A program cannot be restarted inside a macro.•

A program can be restarted inside a subroutine as long as that subroutine is located in the same le as the main program. •

Note, however, if this is done, the program will restart at the rst instance the subroutine is called.

If a program is restarted inside a “while” loop, the program will restart at the rst iteration through the loop.•

If the work coordinate system of a program depends on the starting position of the cutting head (for example, a program •

beginning with G92 X0 Y0), then the program will not restart at the correct work coordinates unless the cutting head

has not moved since the program was terminated.

Keyboard Shortcut: { Alt, F, E } sequence

File | Print uses the specied printer to print the document displayed in the active window. This command opens the Print

window containing the following controls:

Note: The File | Print command is enabled only when the currently active window contains a document type that supports

printing, such as program and Process Parameter documents.

Use these controls in the Print window to specify how the le is to be printed:

Name: This box displays a list of printers connected to the computer.

7-21

EM-551 (N-04/11)

Page 32

Properties: Select this button to set up options for the selected printer. The options available depend on the features of the

printer specied in the “Name” eld.

Print to le: Check this box to print the document to a le instead of routing it directly to a printer. It will prompt the user

to specify the le name and location.

Print range: This section species what portion of the document to print: the entire document, specic pages, or the

selection highlighted.

Number of copies: This box species how many copies of the document to print.

Collate: When printing more than one copy, this selection species whether the copies will be collated.

Keyboard Shortcut: Ctrl + P or { Alt, F, P } sequence

PRINT PREVIEW

Use File | Print Preview to display the document in the active window, as it will appear when printed.

Note: This command is enabled only when the currently active window contains a document type that supports printing,

such as NC Program and Process Parameter documents.

The Print Preview command opens a Print Preview window in which one or two pages of the active document are

displayed in their printed format. A toolbar at the top of the Print Preview window contains buttons for changing the page

and scaling of the preview:

Print: Open the ‘Print’ dialog box to start a print job.

Next Page: Preview the next printed page.

Prev. Page: Preview the previous printed page.

One Page/Two Page: Toggle between previewing one or two pages at a time.

Zoom In: Take a closer look at the printed page.

Zoom Out: Take a larger look at the printed page.

Close: Return from Print Preview to the editing window.

Keyboard Shortcut: { Alt, F, V } sequence

PRINT SETUP

This File | Print Setup command species where and how to print a document. The Print Setup command opens the Print

Setup window. Use the controls in this dialog box to select a printer and printing options.

EM-551 (N-04/11)

7-22

Page 33

Name: This eld displays a list of printers connected to the computer.

7-23

EM-551 (N-04/11)

Page 34

Properties: Select this button to set up options for the selected printer. The options available depend on the features of the

printer specied in the “Name” eld.

Paper Size: Species the size of paper on which to print the document.

Paper Source: Species where the paper is located in the printer. Different printer models support different paper sources;

such as the upper tray, envelope feed and manual feed.

Orientation: Species whether the document should be printed with its top along the short edge of the paper (portrait) or

along the long edge of the paper (landscape).

Network: Select this button to connect to a network shared printer.

Keyboard Shortcut: { Alt, F, R } sequence

MRU FILE LIST

When closing a Process Parameter le, NC Program le or Batch Program le, that le name is added to the Most Recently

Used (MRU) File List. This list, which is displayed near the bottom of the File menu, can contain up to six le names. To

quickly reopen a le that was recently closed, simply select the corresponding item from the MRU File List.

Keyboard Shortcut: { Alt, F, 1 } , { Alt, F, 2 } , { Alt, F, 3 } or { Alt, F, 4 } sequence

OPEN OPERATOR LOG

The Operator Log File is a text le that the user can use as a simple note pad. It can be quickly opened by using the File

| Open Operator Log command.

EXIT

File | Exit will terminate the CNC/HMI program. Before exiting, always make sure the servo drives are off, laser power

supply is off and any open le changes have been saved. The Exit command is disabled while cutting program execution

is in progress.

Keyboard Shortcut: Alt + F4 or { Alt, F, X } sequence

“X” button on Laser Display window Title Bar:

Double-click icon on Laser Display window Title Bar:

EDIT MENU

Use the Edit menu commands for common text editing functions. These commands are only enabled when an NC Program

window is the currently active window.

EM-551 (N-04/11)

7-24

Page 35

UNDO…

Edit | Undo… will reverse the last editing action, if possible. The name of the command changes depending on the last

action (for example, “Undo Typing”, “Undo Cut”, etc.).

Keyboard Shortcut: Ctrl + Z or Alt + Backspace or { Alt, E, U } sequence

CUT

Edit | Cut will remove the currently selected text from the le and put it on the clipboard. Text in the clipboard can be

pasted to another location. This command is unavailable if no text is currently selected. Cutting text to the clipboard

replaces anything that may have been previously stored on the clipboard.

Keyboard Shortcut: Ctrl + X or { Alt, E, T } sequence

COPY

Edit | Copy will place a copy of the selected text on the clipboard without removing the selection from the active le.

This command is unavailable if no data is currently selected. Copying text to the clipboard replaces any previous clipboard

contents.

Keyboard Shortcut: Ctrl + C or { Alt, E, C } sequence

PASTE

Edit | Paste inserts a copy of the clipboard contents at the insertion point in the active le window. This command is

unavailable if the clipboard is empty.

Keyboard Shortcut: Ctrl + V or { Alt, E, P } sequence

FIND

Edit | Find opens the Find window, allowing the user to specify text to search for in the active le. The Find window

contains check boxes to specify matching the case of the searched letters (uppercase or lowercase), and whole words only.

Use the direction buttons to specify searching “Down” (towards end of le) or “Up” (towards beginning of le). After

entering text to search for in the “Find what” eld, click “Find Next” to nd the rst occurrence of the specied text.

7-25

EM-551 (N-04/11)

Page 36

Note: After “Find Next” has been selected, the Find window will close. The F3 key on the keyboard can now be used as

a “Find Next” shortcut, nding additional instances of the specied text.

Keyboard Shortcut: Ctrl + F or { Alt, E, F } sequence

REPLACE

Edit | Replace will open the Replace window, which functions similar to the Find window, except that when specied

text is found, it can be replaced with another text string specied in the “Replace with” eld. Use the “Replace” button to

replace only the text selection that is currently highlighted. Use “Replace All” to replace all occurrences of the specied

text in the entire le at once.

Keyboard Shortcut: { Alt, E, R } sequence

VIEW MENU

The View menu allows the user to change how the user interface is displayed and congured, and open various status

display windows.

CONTROL BAR

View | Control Bars displays a y-out menu with selections that display or hide the various control bars. A control bar is a

group of user interface buttons and/or indicators that can be displayed or hidden with one command. A check mark appears

next to the menu item for each control bar that is currently displayed.

EM-551 (N-04/11)

7-26

Page 37

Note: At times, changes to the state of a control bar will not be permitted, in which case that menu item will be disabled.

For example, the Process Status Control Bar cannot be displayed when the control is in Jog mode.

Standard Toolbar: The Standard Toolbar contains buttons for common commands, such as “File Open” and “Load Current

Program”. See TOOL BAR in the HMI OVERVIEW section for more details.

Status Bar: The main status bar is at the bottom of the application window. It contains operator help messages, the program

line number, and the time. See MAIN STATUS BAR in the HMI OVERVIEW section for more details.

Process Status Bar: The Process Status Bar displays actual cutting parameters. See PROCESS STATUS BAR in the HMI

OVERVIEW section for more details.

Operator Console: This control bar contains controls for operating mode, override settings, and laser control. See

OPERATOR CONSOLE in the CONTROL BARS section for more details.

Overrides: This submenu item displays or hides the Override Adjust Control Bar, used to change the Assist Gas pressure or

Feedrate override setting. See OVERRIDE ADJUST in the CONTROL BARS section for more details.

Aux.: This submenu item displays or hides the Auxiliary Functions Control Bar, which contains “Assist Gas” and “Fume

Blower” buttons/indicators. See AUXILIARY FUNCTIONS in the CONTROL BARS section for more details.

Fault Indicators: The three “Fault” indicators are displayed as one control bar. If the control bar is moved and then closed,

this command will open the control bar at the default screen location (on the right side of the tool bar). See STATUS

INDICATORS TOOL BAR in the HMI OVERVIEW section for more details.

Apply Default Locations: This submenu command displays all control bars at their default screen locations. Use this

command to restore any control bars that were moved or closed.

Keyboard Shortcut: { Alt, V, B, D } sequence

LANGUAGE

View | Language opens a y-out menu showing the available user interface languages. Use this command to change the

language used for all user interface text display by the Laser System CNC/HMI application. A check mark will appear next

to the currently active language. Before selecting a new language, save/close any open les. The CNC/HMI application

will automatically close after the new language is selected. When the CNC/HMI application is restarted, the new user

interface language will be active.

7-27

EM-551 (N-04/11)

Page 38

Keyboard Shortcut: { Alt, V, L } sequence

UNITS

View | Units opens a y-out menu to congure the user interface for displaying English or Metric units.