cincinnati A2100 Operating Manual

OPERATING MANUAL

for CINCINNATI

ARROW E/DART 500/750 (ERM) ARROW 500/750/1000/1250C (ERM) ARROW 1250/1500/2000 (ERD) VERTICAL MACHINING CENTERS with

ACRAMATIC 2100E CNC CONTROL Release 3.0

PUBLICATION NO. 91203809-001

IMPORTANT

Carefully read the instructions and safety precautions given in this manual. Do not attempt to operate this machine until you have thoroughly read and understood the material contained in this manual and all other applicable manuals.

At the time of writing, the book was completely up--to--date. However, due to continual improvements in design, it is possible that descriptions contained herein may vary to a slight extent from the system delivered to you. This merely implies that the system has been improved to better fulfill your requirements. You are encouraged to contact the nearest Cincinnati Machine representative for clarification.

Patents Notice

The machine and attachments and parts thereof illustrated and described in this book are manufactured under and protected by issued and pending British and Foreign Patents and copyright is reserved in any original design feature thereof and in the contents of this book and every part thereof.

Cincinnati Machine U.K. Limited

P.O. Box 505, Kingsbury Road, Birmingham, B24 0QU

1998 Cincinnati Machine, a Division of UNOVA Industrial Automation Systems, Inc.

Cincinnati Machine, CINCINNATI, DART, ARROW, SABRE, LANCER and HAWK are trademarks of Cincinnati Machine, a division of UNOVA Industrial Automation Systems, Inc.

ACRAMATIC is a trademark of Vickers E.S.D., Inc.

Printed in England -- EDITION 3 -- January 1999

|

|

|

|

|

FOREWORD |

|

WARNING 1 |

|

|

||||

|

|

|

||||

In order to |

clearly |

show |

The purpose of this manual is to provide the necessary information to |

|||

enable suitably experienced personnel, to operate the CINCINNATI |

||||||

details |

of |

this |

machine, |

|||

MACHINE ARROW E/DART (ERM) and ARROW (ERD/ERM) |

||||||

some |

covers, |

shields, |

||||

Vertical Machining Centers, when fitted with ACRAMATIC A2100 |

||||||

guards, barriers, devices or |

||||||

doors |

have either |

been |

control. |

|||

removed or |

shown |

in an |

Information contained in this manual is not warranted and is subject to |

|||

”open” |

position. All |

such |

||||

change without notice. |

||||||

protective |

components |

|||||

must be installed in posi- |

The manual has not been prepared to enable inexperienced personnel to |

|||||

tion before |

operating this |

|||||

operate the machine without further training. |

||||||

machine. |

|

|

|

|||

Failure |

to |

follow |

this |

The owner/user is responsible for the training of inexperienced |

||

instruction |

may |

result in |

personnel and for providing the background necessary for experienced |

|||

personal injury. |

|

|

personnel to safely operate these machines. |

|||

|

|

|

|

|

||

|

|

|

|

|

|

|

The chapter on general safety precautions should be observed at all times during machine operation and maintenance. Read this chapter before reading the remaining chapters in this manual and operating the

machine.

WARNING 2

CUTTING FLUIDS |

|

Any questions pertaining to the operation of the machine should be |

||||

|

directed to: |

|

||||

When soluble coolants are |

|

|||||

Field Service Department |

Cincinnati Machine |

|||||

used, it is important to en- |

||||||

sure |

that |

recommended |

Cincinnati Machine UK Limited, |

Marketing Company, |

||

concentration levels |

are |

P.O. Box 505, |

Cincinnati, |

|||

maintained. |

|

|

Kingsbury Road, |

Ohio 45209-9988 |

||

Failure |

to |

follow |

this |

Birmingham, B24 0QU |

USA. |

|

England |

|

|||||

instruction can cause corro- |

|

|||||

sion of safety critical parts, |

Tel: 0121-351-3821 |

Main Tel: (513) 841-8100 |

||||

resulting in machine dam- |

Fax: 0121-313-1184 |

Service Tel: (513) 841 3000 |

||||

age and/or serious personal |

|

Service Fax: (513) 841 8871 |

||||

injury. |

|

|

|

|

|

|

DANGER

HIGH VOLTAGE

Lethal voltages are present in the magnetics and electrical control cabinets when the MACHINE MAIN DISCONNECT is ’ON’. Current and voltage measurements should be attempted only by qualified electrical maintenance personnel.

Before working on any electrical circuits, turn the machine Main Disconnect Device ’OFF’ and lock It.

Capacitors in the Servo Drives require up to 20 minutes to completely discharge. Always verify that discharge is complete using a known working and calibrated voltmeter before commencing work on these units.

Unless expressly stated in applicable Cincinnati Machine documentation or by the appropriate Cincinnati Machine Field Service Representative, do NOT work with electrical power ’ON’. If such express statement of advice exists, working with electrical power ’ON’ should be performed by a Cincinnati Machine Field Service Representative. The customer and subsequent transferees must determine that any other person performing work with electrical power ’ON’ is trained and technically qualified.

Failure To Follow This Instruction May Result In Death Or Serious Personal Shock Injury.

-1

Table of Contents

Chapter 1 |

|

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . |

1-1 |

Important . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-1 |

General Safety Instructions And Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-1 |

Personal Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-1 |

Work Area Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-2 |

Tool Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-2 |

Lifting And Carrying Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-2 |

Installation And Relocation Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-3 |

Setup And Operation Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-3 |

Maintenance Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-4 |

Materials Used With This Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-5 |

LIFTING DEVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-6 |

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-6 |

EYEBOLTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-6 |

HOIST RINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-8 |

SPREADER BARS AND LIFTING BEAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-9 |

CHAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-9 |

CABLE SLINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-11 |

SYNTHETIC MATERIAL SLINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-12 |

P TYPE HOOKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-13 |

S HOOKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-13 |

U TYPE HOOKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-15 |

GENERAL SAFETY LIFTING INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . |

1-16 |

Fluids Used With Machine Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-17 |

General Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-17 |

Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-17 |

Cutting Fluids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-17 |

Sources Of Information - USA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-17 |

Usage Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-18 |

Cutting Fluids - Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-19 |

See Cautions 1 and 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-19 |

Water Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-19 |

Too Soft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-19 |

Too Hard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-19 |

Cleaning The Coolant Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-19 |

Lifespan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-20 |

Tramp Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-20 |

Filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-20 |

Rust Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-20 |

Printed Circuit Board Handling Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-21 |

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-21 |

Recommended Handling Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-21 |

Safety Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-22 |

Perimeter Guarding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-22 |

Operator Sliding Door(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-22 |

Table of Contents

Feed Hold Push Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-22 |

Emergency Stop Push Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-22 |

Electrical Isolation Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-23 |

Air Supply Isolation Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-23 |

Metric Lifting Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-23 |

Machine Related Safety And Usage Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-23 |

Axis Overtravel Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-23 |

Through Spindle Coolant Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-23 |

Tooling Taper - Spindle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-23 |

Inter-drilled Tooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-23 |

Drive Key Spindle Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-23 |

Safe Operation Of Multi-part Tooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-24 |

Tool Drum Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-24 |

Tool Storage Drum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-24 |

Tool Storage Drum - Pocket Wear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-24 |

Loading Tools into Spindle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-24 |

Loading Tools into Storage Drum Pockets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-24 |

Levelling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-24 |

Bolting to Foundation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-24 |

Lithium Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-25 |

Chapter 2 |

|

System Information . . . . . . . . . . . . . . . . . . . . . . . . |

2-1 |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-1 |

Machine Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-2 |

Machine Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-3 |

EMC Directive Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-3 |

NC Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-3 |

Axis Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-4 |

Guard Strength . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-5 |

Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-5 |

Work-piece/Work Holding Device Loading/Unloading . . . . . . . . . . . . . . . . . . . . |

2-6 |

Fumes And Coolant Misting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-6 |

Fire Hazard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-6 |

Arrow E/Dart (ERM) Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-7 |

Arrow (ERM) Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-9 |

Arrow (ERD) Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-13 |

DART/ARROW (ERM)Table Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-19 |

ARROW (ERD)Table Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-23 |

Tool Holder And Retention Stud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-24 |

JMTBA-BT Tool Holder And Retention Stud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-25 |

Motor Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-26 |

6000rpm. Spindle |

|

Arrow E/Dart Machine - Standard Speed Range . . . . . . . . . . . . . . . . . . . . . . |

2-27 |

6000rpm. Spindle |

|

Arrow Machine - Standard Speed Range . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-28 |

8000rpm. Spindle Speed Range |

|

Arrow Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-29 |

Table of Contents

10,000rpm. Spindle Speed Range |

|

Arrow Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-30 |

5000rpm. Spindle |

|

Arrow Machine - High Torque Speed Range . . . . . . . . . . . . . . . . . . . . . . . . |

2-31 |

Chapter 3 |

|

Control Introduction . . . . . . . . . . . . . . . . . . . . . . . . |

3-1 |

Operator Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-2 |

Operator Station Assembly (OSA) Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-3 |

Machine On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-3 |

Machine Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-4 |

Emergency Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-4 |

Page And Position keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-4 |

Numeric Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-4 |

Escape, Help, Control, Alternate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-5 |

The Control Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-6 |

Display Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-6 |

How Menu Buttons Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-7 |

Production Menu Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-8 |

Current Menu Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-8 |

Status Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-8 |

General Mode Button Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-8 |

Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-9 |

Edit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-9 |

RAP (Resident Assistant Programmer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-13 |

SFP (Shop Floor Programming) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-16 |

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-16 |

Multi-Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-17 |

More (Additional Mode Selections) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-18 |

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-19 |

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-20 |

System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-21 |

File Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-22 |

Mode Specific Button Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-22 |

Back . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-22 |

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-22 |

Home . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-22 |

Touch Screen and Keyboards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-23 |

Plotter Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-24 |

Help Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-25 |

Machine Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-26 |

Display Groups buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-26 |

Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-26 |

Axis Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-27 |

Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-27 |

To Go . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-27 |

4-View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-27 |

Table of Contents

Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-27 |

Servo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-27 |

Servo Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-27 |

Program Debug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-27 |

Offset Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-28 |

Pallet Offsets Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-28 |

Multi Setup Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-28 |

Fixture Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-28 |

Prog. Coord Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-28 |

Prog. Tool Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-28 |

Machine Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-28 |

Other Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-29 |

Program Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-29 |

Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-29 |

System Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-29 |

Variables Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-29 |

View Drawing Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-29 |

Plotter Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-29 |

Cycle Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-29 |

Program Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-29 |

Process Control Data Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-30 |

Tables - General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-30 |

Coordinate Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-31 |

Coordinate Offset Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-31 |

Words and Codes Associated with Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-32 |

Entering Values to Offset Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-32 |

Pallet Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-33 |

Basic Procedure for Setting Pallet Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-33 |

Alternative Method for Setting Pallet Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-34 |

Multiple Setup Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-35 |

Basic Procedure for Setting Multiple Setup Offsets . . . . . . . . . . . . . . . . . . . . . . . |

3-35 |

Alternative Method for Setting Multi-Setup Offsets . . . . . . . . . . . . . . . . . . . . . . |

3-36 |

Fixture Offsets (H word) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-37 |

Basic Procedure for Setting Fixture Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-37 |

NC Program Offsets (D word) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-39 |

Combining Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-40 |

Offset Table Field Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-41 |

Select Table Display Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-41 |

Pallet Offset Table Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-42 |

Multi-Setup Offset Table Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-43 |

Fixture Offset Table Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-43 |

NC Program Offset Table Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-43 |

Tool Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-44 |

Active Tool Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-45 |

Tool File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-45 |

Tool Loading and Unloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-45 |

Tool Table Display Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-46 |

Table of Contents

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-46 |

Tool Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-46 |

Tool Geometry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-46 |

Tool Setup and Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-46 |

Tool History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-47 |

Tool Sort By . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-47 |

Single . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-47 |

Tool Magazine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-48 |

Inch/Metric Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-48 |

Program Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-49 |

Directory Services (Registry, Import, Export) . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-49 |

Machine Pendant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-51 |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-53 |

Main Electrical Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-62 |

Optional Operating Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-63 |

Wash Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-63 |

Swarf Conveyor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-63 |

Emergency Stop - (Red Push Button with Latch) . . . . . . . . . . . . . . . . . . . . . . . . |

3-64 |

Swarf Conveyor Control - Auto/Manual - (Selector Switch) . . . . . . . . . . . . . . . |

3-64 |

Conveyor Direction - (Selector Switch, spring centred) . . . . . . . . . . . . . . . . . . . |

3-64 |

Swarf Management System (Swarf Wash) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-65 |

Chapter 4 |

|

|

General Setup Guide . . . . . . . . . . . . . . . . . . . . . . . |

4-1 |

|

Setup The Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-1 |

|

Configure System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-1 |

|

Align Machine |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-2 |

Perform Operating Station Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-2 |

|

Perform Operating Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-2 |

|

Create Manual Data Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-2 |

|

Set / Load Tooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-3 |

|

Power Feed / Jog Axes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-3 |

|

Setup Part . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-3 |

Set Tram Surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-4 |

|

Set Tool Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-4 |

|

Find A Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-4 |

|

Load Part Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-4 |

|

Create Part Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-5 |

|

Edit Part Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-5 |

|

Position Set . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-5 |

Create Multiple Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-6 |

|

Copy Program . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-7 |

Plot Program . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-7 |

Operating Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-7 |

|

Run a Part Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-8 |

|

How Do I... |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-9 |

Master Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-10 |

Switch On Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-10 |

Table of Contents

Switch-Off Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-11 |

Use Emergency Stop Push Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-11 |

Machine Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-12 |

Align the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-12 |

Axes Alignment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-12 |

Mechanism Alignment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-13 |

Automatic Realignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-14 |

Axes Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-15 |

Jog the X or Y Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-15 |

Jog the Z, A, or B Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-15 |

Power Feed the X or Y Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-16 |

Power Feed the Z, A or B Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-16 |

Move an Axis with the Handwheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-17 |

Override An Overtravel Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-17 |

Jog Mechanisms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-18 |

Data Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-19 |

Keying In Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-19 |

Correcting Typing Mistakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-21 |

Select Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-21 |

Perform Operator Station Keypad Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-22 |

MDI Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-25 |

Create A Manual Data Input (MDI) Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-25 |

Copy A MDI Program To Edit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-25 |

Tool Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-26 |

Display Tool Table Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-26 |

Display Tool Sort . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-27 |

Display Single Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-28 |

Display Tool Magazine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-29 |

Activate A Tool From Tool File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-31 |

Remove Tool From Magazine Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-32 |

Find A Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-35 |

Inch / Metric Tool Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-36 |

Show Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-36 |

Create New Tool File Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-38 |

Create New Tool File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-39 |

Move New Tool File to Active Tool Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-40 |

Modify Data In Tool Data Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-41 |

Load Authorized Tool Into Spindle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-43 |

Load Unauthorized Tool Into Spindle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-44 |

Unload Authorized Tool From Spindle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-44 |

Unload Un-authorized Tool From Spindle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-45 |

Load/Unload Tool Storage Magazine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-46 |

Set Tram Surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-47 |

Display Tool Tram Surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-49 |

Set Tool Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-50 |

Update Tool Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-52 |

Coordinate Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-53 |

Table of Contents

Set Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-54 |

G92 Position Set - Z Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-62 |

Establish The Home Set Position G28 P4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-64 |

Program Activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-65 |

Find A Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-65 |

Activate A Part Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-66 |

Program Block Delete Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-67 |

Select “Delete A Program Block” Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-67 |

Deselect A “Deleted Program Block” Function . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-67 |

Running the Active Part Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-69 |

Operating Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-69 |

Run a Part Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-69 |

Workpiece Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-70 |

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-70 |

What Workpiece Manager Can Do . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-70 |

What You Should Know . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-70 |

How Pallet, Setup, and Fixture Offsets Interact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-71 |

To Start Workpiece Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-72 |

About The Viewer Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-73 |

About the Status Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-74 |

View Level Display Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-75 |

Fixture Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-77 |

View Level Fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-77 |

Working Only with Fixtures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-77 |

About Fixture Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-78 |

About Fixture Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-78 |

Fixture Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-79 |

Using the Fixture Pattern Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-79 |

Defining Fixture Machine Coordinates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-80 |

Fixture Location with Edge Finder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-80 |

Fixture Location With Probe Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-81 |

Deleting A Fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-82 |

Deleting a Fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-82 |

Editing an Existing Fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-83 |

Adding a Fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-85 |

Setups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-87 |

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-87 |

View Level Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-87 |

Selecting Offset Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-88 |

Setup Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-88 |

About Setup Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-89 |

About Setup List Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-90 |

Incrementing The Setup List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-90 |

About Setup Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-91 |

Setup Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-92 |

Using the Setup Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-92 |

Apply One Program for All Setups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-93 |

Table of Contents

Defining Setup Machine Coordinates (One at a time) . . . . . . . . . . . . . . . . . . . . . |

4-94 |

Setup Location with Edge Finder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-94 |

Setup Location With Probe Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-96 |

Activating a Setup for Program Execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-96 |

Activating a Setup from the Setup Viewer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-96 |

Activating a Setup at the Pendant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-96 |

Setting the Machining Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-97 |

Basic Overview of Icons During Cycle Execution . . . . . . . . . . . . . . . . . . . . . . . . |

4-97 |

Reorder Setup Machining Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-98 |

Changing a Setup Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-98 |

Activate Setup Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-99 |

Activate Setup Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-99 |

Editing Setups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-100 |

Edit Existing Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-100 |

Add a Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-102 |

Deleting a Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-104 |

Changing a Setup Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-105 |

Managing Multiple Machining Work Faces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-106 |

Automatic Rotation of A or B axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-106 |

How Can I Display Multiple Work Face . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-107 |

Defining Work Faces and Sides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-108 |

Selecting a Face . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-109 |

Apply Setup Pattern to all Faces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-110 |

Adding another Setup to a Work Face . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-111 |

Rotating to a Work Face . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-112 |

Pallet View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-113 |

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-113 |

Pallet Viewer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-113 |

How Can I Limit Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-114 |

About Pallet Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-114 |

About Pallet List Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-116 |

About Pallet Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-117 |

Adding Pallets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-118 |

Locating Pallets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-120 |

Changing Pallet Data and Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-121 |

Swapping Pallet Data 0 Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-121 |

Swapping Pallet Data with Defined Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-123 |

Reorder Machine Pallet Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-124 |

Selecting a Pallet to Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-125 |

How Do I Disable Pallets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-126 |

Pallet View Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-126 |

Applying Probe Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-127 |

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-127 |

Activating the Probe Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-127 |

About the Probe Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-129 |

About Probe Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-129 |

About Probe Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-130 |

Table of Contents

Applying Probe Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-131 |

Selecting Probe Cycle Run Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-133 |

Deleting a Probe Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-134 |

Modifying a Probe Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-135 |

Display all Probe Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-136 |

Storing Probe Cycle Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-137 |

MULTIPLE SETUP FEATURE AND DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . |

4-138 |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-138 |

Defining the Multi Setup: Step 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-139 |

Defining the Multi Setup: Step 2a |

|

(Plain Table/Pallet Table Applications) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-140 |

Defining the Multi Setup: Step 2b |

|

(Rotary Axis Applications) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-142 |

Defining the Multi Setup: Step 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-144 |

Defining the Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-145 |

Run Defined Multi Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-155 |

Chapter 5 |

|

Other Setup Information . . . . . . . . . . . . . . . . . . . . |

5-1 |

How Do I... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-1 |

Select Axes Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-2 |

Inhibit an Axis Using the Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-3 |

Inhibit an Axis Using the Pendant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-4 |

Plotter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-5 |

Plotter Screen Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-5 |

Plot A Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-7 |

Track Tool Movement With Plot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-8 |

Program and File Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-9 |

Create Directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-9 |

Transfer a Part Program into the Program Store Area of the Control . . . . . . . . . |

5-9 |

Copy (Backup) A Program To Diskette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-11 |

Copy (Backup) Tool File or Active Tool |

|

Data To Diskette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-12 |

Restore Active Tool Set from Diskette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-14 |

Copy (Backup) Offset Tables To Diskette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-15 |

Copy (Backup) A Program from Program Store . . . . . . . . . . . . . . . . . . . . . . . . . |

5-17 |

Copy Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-18 |

Rename Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-19 |

Delete Files or Directory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-20 |

Delete A Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-21 |

Execute a Part Program via Continuous Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-21 |

Activate A Program From External Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-24 |

Program Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-26 |

Search For/Replace With . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-26 |

Edit Cut, Copy, And Paste . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-27 |

Copy Programs To Dual Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-27 |

Copy A Program To Edit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-29 |

Table of Contents

Resequence A Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-29 |

Save Program Edits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-30 |

RAP Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-32 |

Create A Rap Session . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-32 |

Edit A Rap Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-35 |

Saving A Rap Session . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-36 |

Moving A Rap Session . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-37 |

Create An NC Program One Block At A Time With RAP . . . . . . . . . . . . . . . . . . |

5-38 |

Create An NC Program With RAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-39 |

Duplicating A RAP Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-40 |

Loading A Rap Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-40 |

Executing A RAP Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-41 |

Insert Axes Values in RAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-41 |

Using The Program Translator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-42 |

Set-up Translator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-42 |

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-48 |

Calibrate The Display Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-48 |

Change Home Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-48 |

NC Programming Execution (system configuration) . . . . . . . . . . . . . . . . . . . . . . |

5-52 |

Activate Security Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-54 |

Connect a PC to the A2100E Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-59 |

Search Program For Cycle Execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-62 |

Resume Cycle After Losing Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-63 |

Format A Diskette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-63 |

Change Program Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-64 |

Change Cycle Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-67 |

Set Parts Counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-68 |

Probe Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-70 |

G72 Set Stylus and Tip Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-70 |

G72 Set Stylus and Tip Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-72 |

G74 Set Probe Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-72 |

Appendix A |

|

Program Reference Data . . . . . . . . . . . . . . . . |

A--1 |

Type I Block Word Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-1 |

Type II Block Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-2 |

G Code Table Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-3 |

M Code Table Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-5 |

M Code Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-5 |

Drilling Cycle Parameter Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-7 |

Tool Data Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-8 |

System Table Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-12 |

Parameter Variable Table Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-13 |

Pallet Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-14 |

Multiple Setup Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-14 |

Fixture Offsets Table (Used with H Word) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-15 |

Tool Offsets Table (Used with O Word) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-15 |

Table of Contents

Programmable Offsets Table (Used with D Word) . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-15 |

Machine Offsets Table (Used with D WORD and G98,G98.1) . . . . . . . . . . . . . . . . . |

A-15 |

Process Control Data Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-15 |

Other System Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-16 |

Arithmetic Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-19 |

Appendix B |

|

System Configuration . . . . . . . . . . . . . . . . . . . |

B--1 |

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-1 |

Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-1 |

NC Programming Execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-2 |

Colon Block - Colon Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-2 |

At Colon Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-2 |

Reset Fixture Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-2 |

Reset Programmable Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-2 |

Reset Programmed Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-2 |

Cutter Diameter Compensation (CDC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-3 |

Report CDC Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-3 |

Constant Feedrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-3 |

Glide On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-3 |

Report Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-4 |

Report PRT Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-4 |

Report WTF Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-4 |

Report COM Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-4 |

Fixture Offset Axis of Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-4 |

Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-5 |

Circular . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-5 |

Endpoint Tolerance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-5 |

Center Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-5 |

Linear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-5 |

Collinear Angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-5 |

M70 - 79 User M Codes Execution (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-6 |

Pulsed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-7 |

Feedback 0 thru 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-7 |

Table of Contents

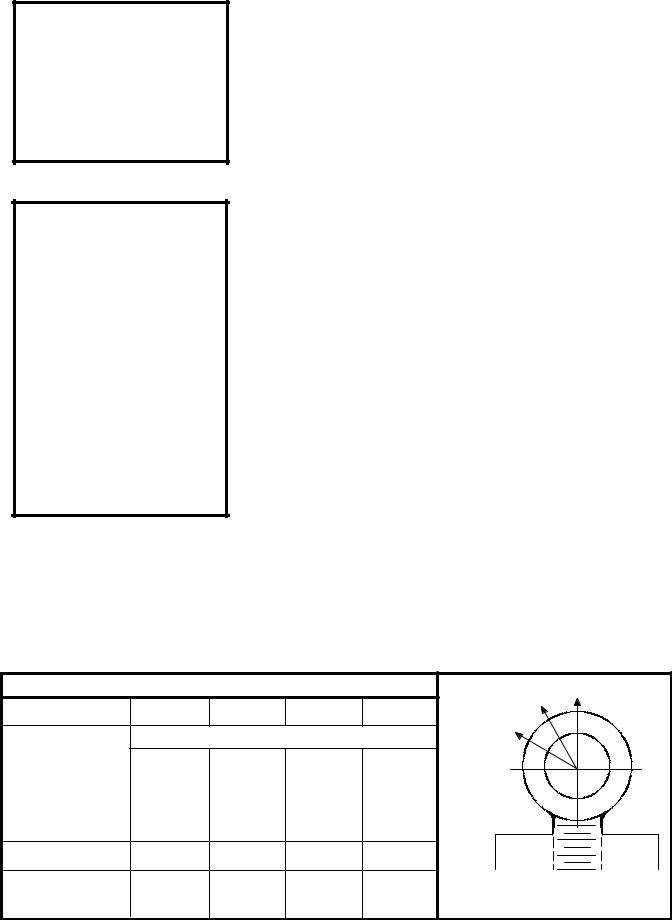

Fig. 1 |

|

Preferred Inch Lifting Eyebolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-6 |

Fig. 2 |

|

Preferred Metric Lifting Eyebolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-7 |

Fig. 3 |

|

Eyebolt Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-7 |

Fig. 4 |

|

Eyebolt I.D. Plates - Inch and Metric . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-7 |

Fig. 5 |

|

Instruction Plate - Inch (Part Number 3375984) . . . . . . . . . . . . . . . . . . . . . . . . . |

1-7 |

Fig. 6 |

|

Instruction Plate - Metric (Part Number 3375983) . . . . . . . . . . . . . . . . . . . . . . . |

1-7 |

Fig. 7 |

|

Hoist Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-8 |

Fig. 8 |

|

Hoist Ring Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-8 |

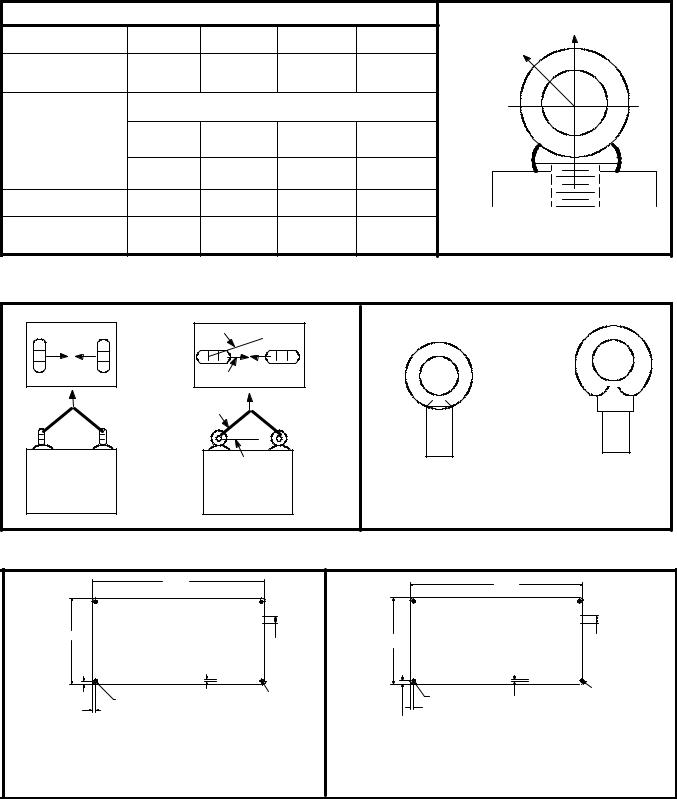

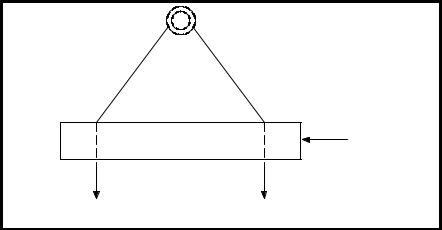

Fig. 9 |

|

Spreader Bar - Typical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-9 |

Fig. 10 |

|

Steel Alloy Chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-10 |

Fig. 11 |

|

Wire Rope Slings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-11 |

Fig. 12 |

|

Sling Load Angle Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-12 |

Fig. 13 |

|

“P” Type Lifting Hooks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-13 |

Fig. 14 |

|

“P” Type Lifting Hooks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-13 |

Fig. 15 |

|

“S” Hooks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-14 |

Fig. 16 |

|

“S” Hooks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-14 |

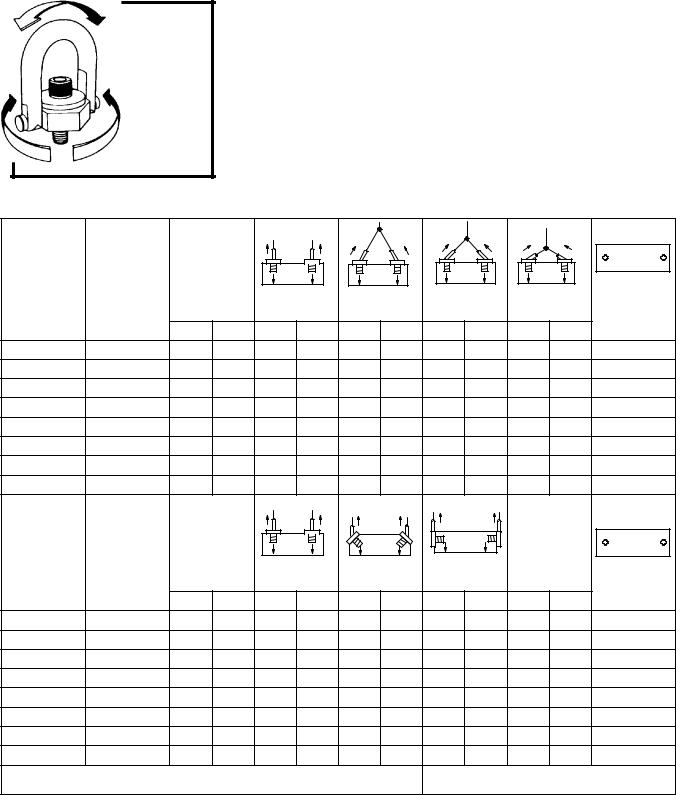

Fig. 17 |

|

“U” Type Lifting Hooks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-15 |

Fig. 18 |

|

“U” Lifting Hook Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-15 |

Fig. 19 |

|

Safety Latch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-16 |

Fig. 20 |

|

Arrow Vertical Machining Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-1 |

Fig. 21 |

|

Vertical Machining Center - Axis Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-4 |

Fig. 22 |

|

Range Drawing for Arrow E / Dart / Arrow 500, 750 (ERM) Machines - |

|

Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-15 |

Fig. 23 |

|

Range Drawing for Arrow E / Dart / Arrow 500, 750 (ERM) Machines - |

|

Right Hand Side View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-16 |

Fig. 24 |

|

Range Drawing for Arrow (ERM) 1000, 1250C Machines - Front View . . . . . . |

2-17 |

Fig. 25 |

|

Range Drawing for Arrow (ERM) 1000, 1250C Machines - |

|

Right Hand Side View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-18 |

Table of Contents

Fig. 26 |

|

Table Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-19 |

Fig. 27 |

|

Bolt and Tenon Slot Dimensions - Typical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-19 |

Fig. 28 |

|

Range Drawing for Arrow (ERD) 1250, 1500, 2000 - Plan View . . . . . . . . . . . . |

2-20 |

Fig. 29 |

|

Range Drawings for Arrow (ERD) 1250, 1500, 2000 - Front View . . . . . . . . . . |

2-21 |

Fig. 30 |

|

Range Drawing for Arrow (ERD) 1250, 1500, 2000 Machines - |

|

Right Hand End View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-22 |

Fig. 31 |

|

Table Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-23 |

Fig. 32 |

|

Bolt and Tenon Slot Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-23 |

Fig. 33 |

|

Tool Holder and Retention Stud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-24 |

Fig. 34 |

|

JMTBA_BT Tool Holder and Retention Stud . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-25 |

Fig. 35 |

|

Spindle power characteristics (Arrow E/Dart Machine - Standard Speed Range) |

2-27 |

Fig. 36 |

|

Spindle power characteristics (Arrow Machine - Standard Speed Range) . . . . . |

2-28 |

Fig. 37 |

|

Spindle power characteristics (8000 rpm Speed Range) . . . . . . . . . . . . . . . . . . . |

2-29 |

Fig. 38 |

|

Spindle power characteristics (10000 rpm Speed Range) . . . . . . . . . . . . . . . . . . |

2-30 |

Fig. 39 |

|

Spindle power characteristics (High Torque Speed Range) . . . . . . . . . . . . . . . . . |

2-31 |

Fig. 40 |

|

Offsets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-31 |

Fig. 41 |

|

Pallet Offset Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-33 |

Fig. 42 |

|

Multiple Setup Offsets Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-35 |

Fig. 43 |

|

Fixture Offset Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-37 |

Fig. 44 |

|

NC Program Offsets Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-39 |

Fig. 45 |

|

Offset Combination Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-40 |

Fig. 46 |

|

Swarf Conveyor Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-63 |

Fig. 47 |

|

Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-43 |

Fig. 48 |

|

Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-44 |

Fig. 49 |

|

Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-47 |

Fig. 50 |

|

Offset Interaction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-71 |

Fig. 51 |

|

Fixture Pattern Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-79 |

Table of Contents

Fig. 52 |

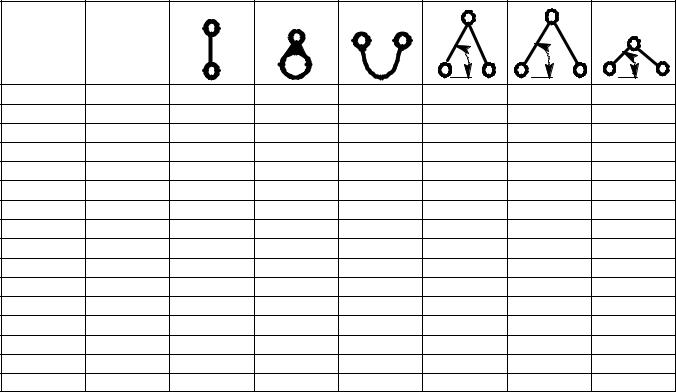

|