cincinnati CL-800 Maintenance Manual

OPERATION, SAFETY, AND MAINTENANCE MANUAL

CINCINNATIR

cl-800 SERIES lASER SYSTEM

(GE FANUC RESONATORS – 5x10, 6x12 Frame)

CINCINNATI INCORPORATED

CINCINNATIR

EM-534 (R-03/10) COPYRIGHT 2010

C I N C I N N A T I, OHIO 4 5 2 1 1

CINCINNATI INCORPORATED

cl-800 SERIES cONTENTS

INTRODUCTION

SECTION 1 IDENTIFICATION

SECTION 2 INSTALLATION

LIFTING AND MOVING ..................................................................................2-1

FOUNDATION ................................................................................................ 2-2

INSTALLATION OF MACHINE .......................................................................2-2

CHILLER ........................................................................................................2-2

LEVELING ......................................................................................................2-2

PRELIMINARY LEVELING .......................................................................2-3

FINAL LEVELING .....................................................................................2-3

ELECTRICAL CONNECTION ........................................................................ 2-5

SAFETY DEVICES ......................................................................................... 2-5

SECTION 3 SAFETY

SAFETY IS EVERYONE’S JOB .....................................................................3-1

INTRODUCTION TO LASER SAFETY ....................................................3-1

SAFETY STANDARDS AND PUBLICATIONS ...............................................3-2

LASER HAZARD CLASSIFICATION .............................................................3-3

CONTROL MEASURES ................................................................................. 3-3

EXPLANATION OF LASER RADIATION........................................................3-4

LASER TYPES .........................................................................................3-4

HAZARDS - CINCINNATI LASER SYSTEMS ................................................3-5

EYE HAZARDS ........................................................................................3-5

SKIN HAZARDS .......................................................................................3-5

NOMINAL HAZARD ZONES ..........................................................................3-6

BEAM EXPOSURE CATEGORIES ..........................................................3-6

ASSOCIATED HAZARDS .............................................................................. 3-7

ELECTRICAL ...........................................................................................3-7

FIRE .........................................................................................................3-8

FUME AND DUST ....................................................................................3-8

GAS STORAGE .............................................................................................3-9

COMPRESSED GAS CYLINDERS ..........................................................3-9

CRYOGENIC LIQUID .............................................................................3-10

TRAINING ....................................................................................................3-11

MACHINE HAZARDS AND WARNINGS ...................................................... 3-11

MOVING MACHINE MEMBERS ............................................................ 3-11

WARNING (AWARENESS) LIGHTS ......................................................3-12

SAFETY ENCLOSURE ..........................................................................3-12

OVERRIDING SAFETY ENCLOSURE DOORS FOR LASER SHOT .... 3-12

SAFETY SIGNS ...........................................................................................3-12

SAFETY GUIDELINES ................................................................................. 3-15

SAFETY MAINTENANCE CHECK ............................................................... 3-15

SECTION 4 SPECIFICATIONS

DIMENSIONS ................................................................................................. 4-1

SPECIFICATIONS ..........................................................................................4-1

PIPING CONNECTIONS ................................................................................ 4-2

EXTERNAL OPTICAL ELEMENTS ................................................................ 4-3

GAS REQUIREMENTS ..................................................................................4-3

AMBIENT TEMPERATURE ............................................................................4-6

CAPACITIES .................................................................................................. 4-6

PRINCIPLE OF OPERATION .........................................................................4-6

CONTOURING ACCURACY ..........................................................................4-7

EM-534 (R-03/10)

SECTION 5 SETUP AND USE

LOADING MATERIAL .....................................................................................5-1

GAUGING .......................................................................................................5-1

CUTTING Y-AXIS MATERIAL STOPS .....................................................5-1

X AND Y AXIS SQUARENESS ................................................................5-2

X-AXIS MATERIAL STOPS ......................................................................5-3

SECTION 6 MACHINE CONTROLS

OPERATOR CONTROL STATION .................................................................6-1

MACHINE OPERATOR PANELS ................................................................... 6-2

FRONT PANEL CONTROLS ....................................................................6-2

SIDE PANEL CONTROLS ........................................................................6-4

REMOTE STATION ........................................................................................ 6-5

LOAD FRAME EMERGENCY STOP ............................................................. 6-6

SECTION 7 OPERATION

FOR ADDITIONAL SETUP AND OPERATION INFORMATION FOR THIS

MACHINE, REFER TO EITHER THE ONLINE HELP INFORMATION IN

THE MACHINE SOFTWARE OR TO EM-544, “SECTION 7 OPERATION – A

SUPPLEMENT TO THE OPERATION MANUAL FOR THE CL-800 LASER

SYSTEM”, INCLUDED WITH THIS MANUAL.

SECTION 8 OPTIONS

FUME BLOWER ............................................................................................. 8-1

BALL TRANSFER LOAD STATION ................................................................8-1

LOWER PALLET SPECIAL FUNCTION (LPSF) ............................................8-1

MODULAR MATERIAL HANDLING SYSTEM (MMHS) .................................8-2

AIR ASSIST GAS FILTER AND DRYER ........................................................ 8-2

SECTION 9 MAINTENANCE AND ADJUSTMENTS

LUBRICATION REQUIREMENTS ..................................................................9-1

DRIVES LUBRICATION ...........................................................................9-1

Z-AXIS LUBRICATION .............................................................................9-1

FUME SYSTEM LUBRICATION ...............................................................9-2

MATERIAL CLAMP LUBRICATION ..........................................................9-2

BEAM DELIVERY SYSTEM ........................................................................... 9-2

MAGNETIC TRACK MAINTENANCE ............................................................ 9-2

PALLET DRIVE MAINTENANCE ...................................................................9-3

GEAR REDUCER.....................................................................................9-3

CHAIN DRIVE TENSION ADJUSTMENT ............................................... 9-3

SCRAP REMOVAL ...................................................................................9-3

PALLET GUIDE RAILS ...................................................................................9-3

ENCODER MAINTENANCE ..........................................................................9-3

ENCODER CLEANING ............................................................................9-4

OPTICS HANDLING & CLEANING ................................................................ 9-4

LENS INSTALLATION AND REMOVAL ...................................................9-5

LENS CLEANING .....................................................................................9-6

MIRROR COOLING .................................................................................9-6

MIRROR INSTALLATION AND REMOVAL ..............................................9-6

MIRROR CLEANING................................................................................9-7

AUTO FOCUS CUTTING HEAD ....................................................................9-7

MAINTENANCE .......................................................................................9-7

AUTO FOCUS TROUBLESHOOTING ..................................................... 9-8

BEAM BELLOWS ATTACHMENT ..................................................................9-9

BEAM DELIVERY ALIGNMENT ................................................................... 9-10

CARD SHOT ..........................................................................................9-11

COMPLETE SYSTEM ALIGNMENT ...................................................... 9-11

RESONATOR WARM-UP .......................................................................9-13

FIRST EXTERNAL MIRROR ALIGNMENT ............................................ 9-13

SECOND EXTERNAL MIRROR ALIGNMENT ....................................... 9-14

COLLIMATOR BEAM ALIGNMENT........................................................9-15

X-AXIS BEAM ALIGNMENT ...................................................................9-16

Y-AXIS BEAM ALIGNMENT ...................................................................9-17

Z-AXIS ALIGNMENT ..............................................................................9-18

FINAL ALIGNMENT CHECK ..................................................................9-19

EM-534 (R-03/10)

AIR DRYER ..................................................................................................9-19

DEFORMABLE OPTIC ACCUMULATOR CHARGING PROCEDURE ........ 9-20

PREVENTIVE MAINTENANCE ....................................................................9-21

DAILY MACHINE INSPECTION .............................................................9-21

WEEKLY MACHINE INSPECTION .......................................................9-22

SEMI-ANNUAL (1000 HOURS)

ANNUAL MACHINE INSPECTION ........................................................9-23

SECTION 10 SERVICE AND PARTS

ORDERING REPAIR PARTS ......................................................................10-1

RETURNING PARTS FOR CREDIT ............................................................. 10-1

SERVICE ...................................................................................................... 10-1

TECHNICAL TRAINING ...............................................................................10-1

CUSTOMER INFORMATION CENTER .......................................................10-1

MACHINE INSPECTION .....................9-22

EM-534 (R-03/10)

EM-534 (R-03/10)

INTRODUCTION

CINCINNATI CL-800 SERIES LASER SYSTEM

The Laser System produces two-dimensional contoured shapes from at material by moving a focused

laser beam along a programmed path. The beam from a stationary laser resonator is directed to a moving

lens by two mirrors mounted on a moving gantry. The workpiece remains stationary while a narrow strip

of material is removed along the path made by the lens. Material is removed by vaporization and melting

where the lens concentrates laser power into a small spot on the workpiece. Assist gas is also used to

control the cutting process.

The mirrors and lens are positioned by the gantry to produce the programmed workpiece geometry. A DSP

(Digital Signal Processor) motion controller commands servo drives to control the gantry motion. The

program is provided by the user and includes commands to specify feedrate, laser power, and assist gas.

The Laser System is equipped with an exhaust system, which draws air down from the cutting area to assist

in the removal of process by-products.

PART QUALITY

The following factors affect part quality:

Machine condition•

Operator ability•

Set-up and Programming•

Quality and type of material•

CINCINNATI machines are designed to be rugged and durable. However, improper adjustment or lack

of maintenance can reduce the quality of parts produced on the machine. The quality of a laser-cut edge

depends on the combination of a uniform laser beam of adequate power, properly focused on the workpiece

with an adequate supply of the correct assist gas, traveling at a speed compatible with the material removal

rate.

Uniform beam quality and power level are most inuenced by the alignment and cleanliness of the optical

elements (internal resonator mirrors, external beam delivery mirrors and the focusing lens).

Critical manual adjustments are: Lens focal point location and lens-to-nozzle centering. The Auto Focus

Cutting Head eliminates manual focal point adjustment.

Part quality depends on the program to command the correct combination of laser power, assist gas, and

feedrate for the material type and thickness being processed. Part accuracy depends on the program for

proper use of kerf width compensation and for selection of feedrate within radius contouring accuracy

limits.

Material quality can affect the repeatability of process parameters. Material with uniform composition,

uniform thickness, and a smooth, clean surface will minimize variations in part quality.

EM-534 (R-03/10)

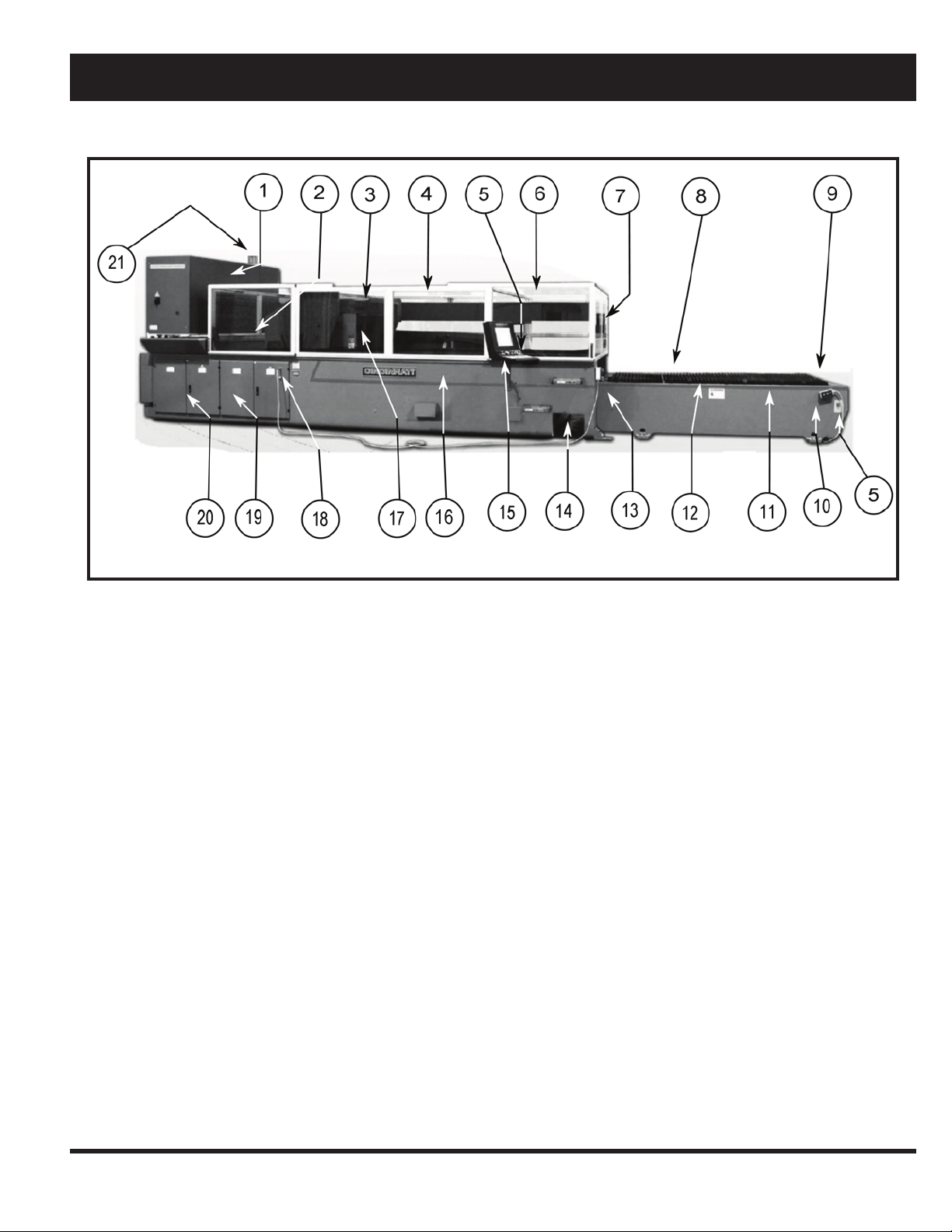

SEcTION 1 IDENTIFIcATION

CL-800 SERIES LASER SYSTEM

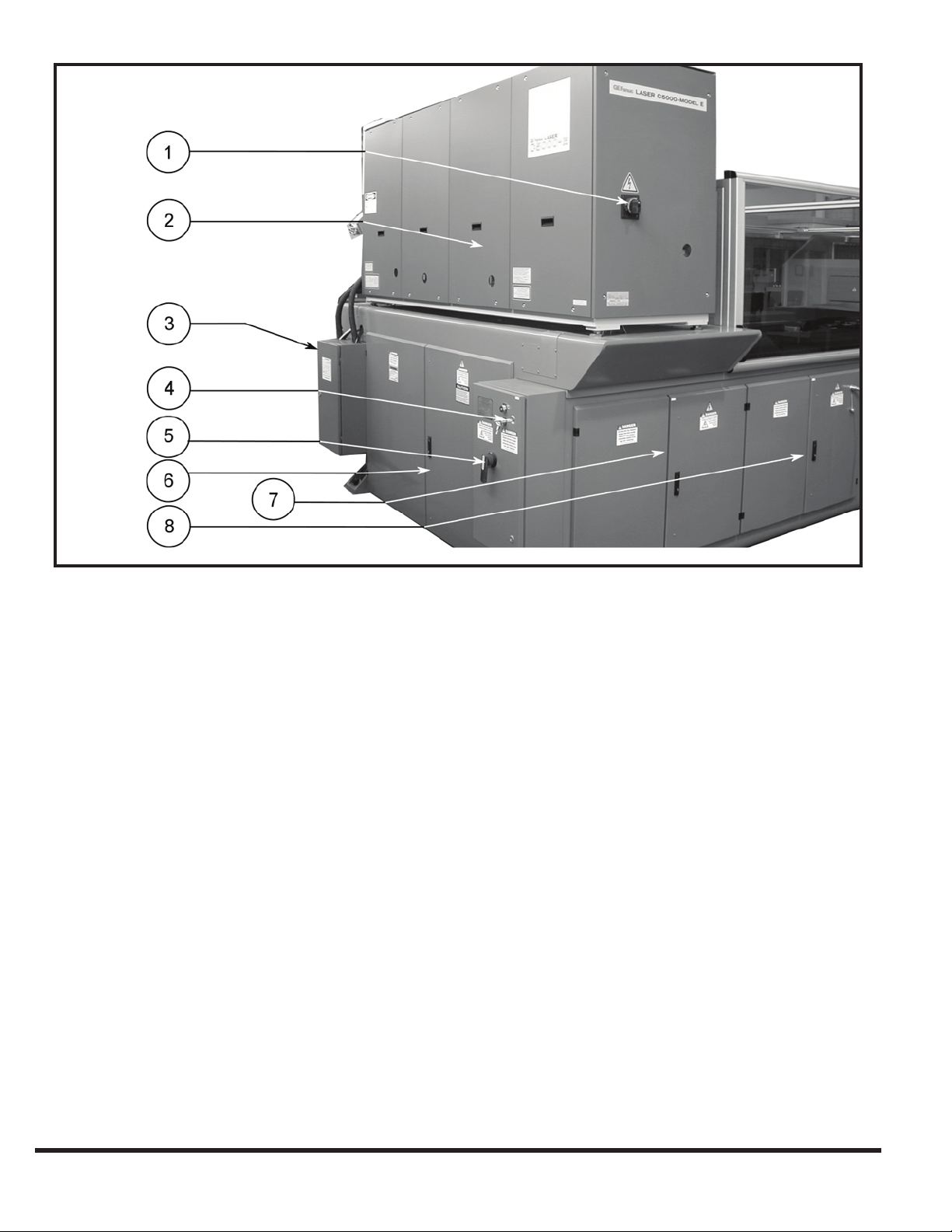

RESONATOR1.

RESONATOR SAFETY DOOR2.

X-BEAM DELIVERY MIRROR BOX3.

X-AXIS BEAM TUBE4.

E-STOPS5.

OPERATOR SAFETY DOOR6.

SAFETY ENCLOSURE7.

LOWER PALLET8.

LOAD FRAME9.

BALL TRANSFER REMOTE (OPT)10.

MATERIAL SUPPORTS11.

FIGURE 1-1 Front View

MATERIAL CLAMPS12.

REMOTE STATION13.

SCRAP BIN14.

OPERATOR CONTROL STATION15.

MAIN FRAME16.

Y-PLATE17.

REMOTE STATION CONNECTION18.

CONTROL ENCLOSURE19.

POWER ENCLOSURE20.

RESONATOR HIGH VOLTAGE LIGHT21.

1-1

EM-534 (R-03/10)

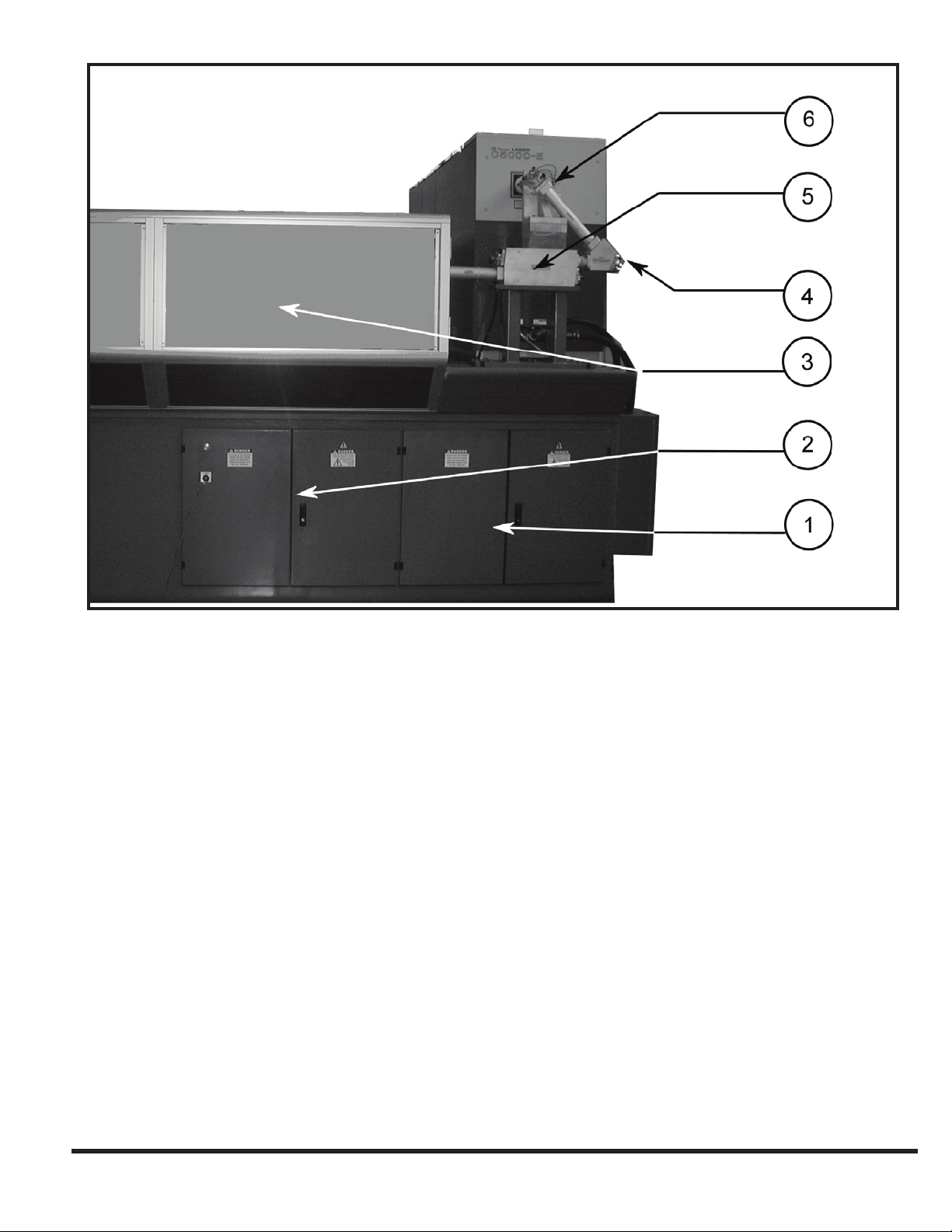

RESONATOR MAIN DISCONNECT1.

RESONATOR2.

GAS AND COOLANT CONNECTION3.

MAIN BREAKER INTERLOCK BYPASS KEY4.

FIGURE 1-2 Rear View

MAIN DISCONNECT5.

MAIN ENCLOSURE6.

POWER ENCLOSURE7.

CONTROL ENCLOSURE8.

EM-534 (R-03/10)

1-2

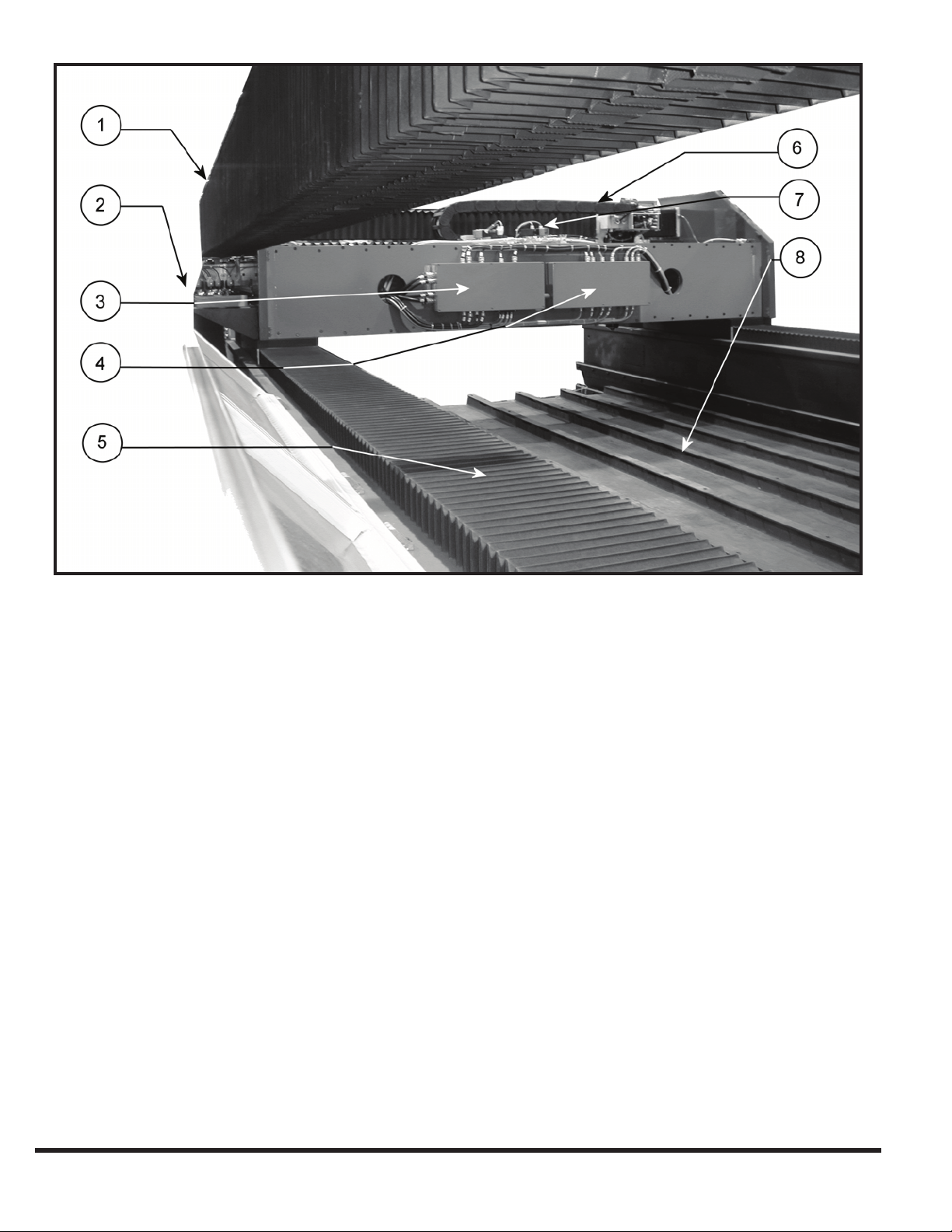

DRIVE ENCLOSURE1.

I/O ENCLOSURE2.

SAFETY ENCLOSURE3.

FIGURE 1-2a Rear View

SECOND EXTERNAL MIRROR (BEAM BENDER4.

COLLIMATOR5.

FIRST EXTERNAL6.

1-3

EM-534 (R-03/10)

X-AXIS BEAM BELLOWS1.

X-AXIS CABLE CARRIER2.

RIGHT GANTRY ENCLOSURE3.

LEFT GANTRY ENCLOSURE4.

FIGURE 1-2b Rear View

X-2 AXIS WAY COVER5.

Y-AXIS CABLE CARRIER6.

ASSIST GAS PROPORTIONAL VALVES7.

SCRAP TRAYS AND STRAP TRAY CAPS8.

EM-534 (R-03/10)

1-4

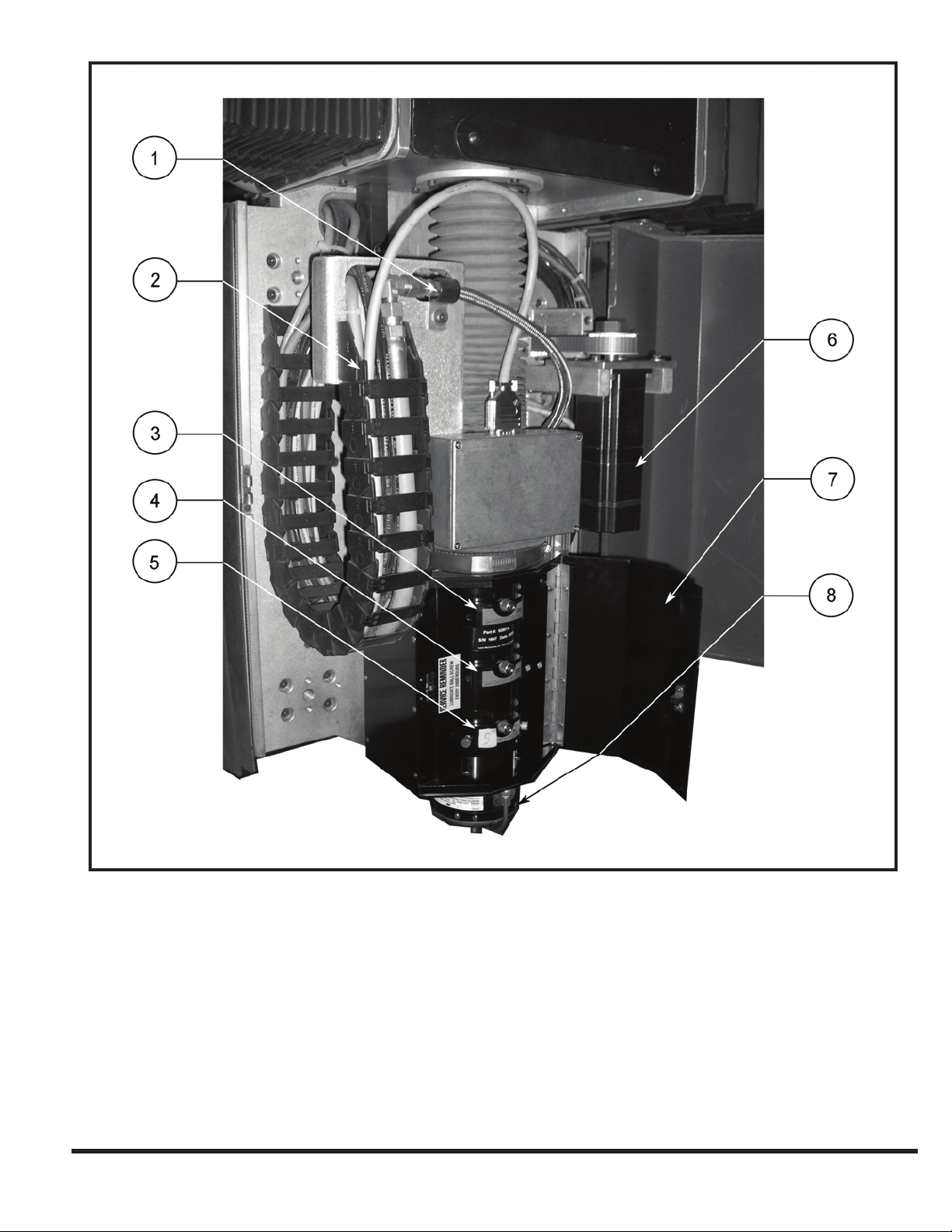

ASSIST GAS HOSE1.

Z AXIS CABLE CARRIER2.

10 INCH LENS DRAWER (EMPTY MANIFOLD SEAL)3.

7.5 INCH LENS DRAWER (EMPTY MANIFOLD SEAL)4.

FIGURE 1-3 Y-Plate and Auto Focus Head Assembly

5 INCH LENS DRAWER (INSTALLED)5.

Z-AXIS MOTOR6.

LENS DOOR7.

LOWER TIP ASSEMBLY8.

1-5

EM-534 (R-03/10)

EM-534 (R-03/10)

1-6

SEcTION 2 INSTAllATION

IMPORTANT: Before proceeding, contact CINCINNATI

Laser Service for pre-installation instructions.

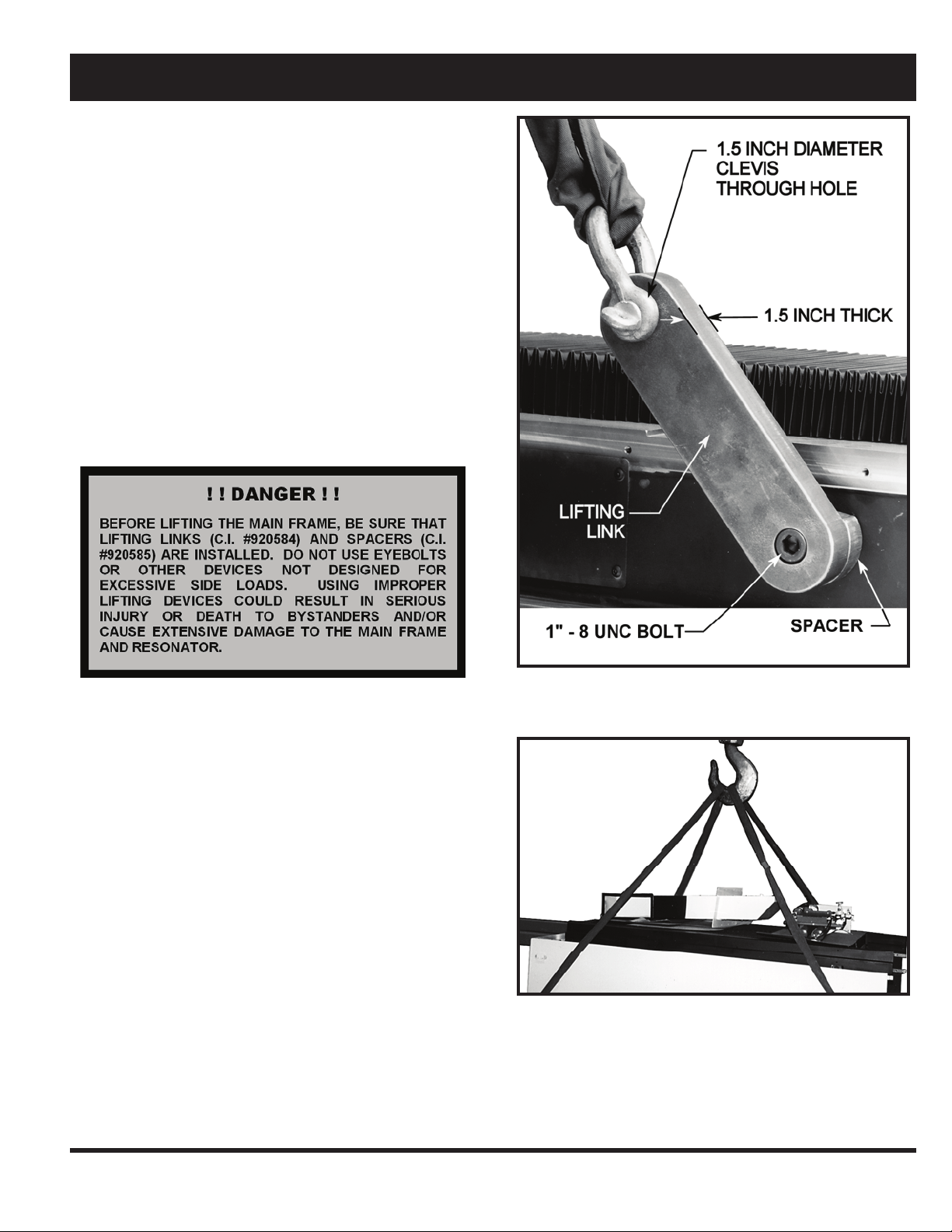

LIFTING AND MOVING

Machine weights are provided in SECTION 4.

The main frame is lifted using four standard lifting clevises

attached to four lifting links (C.I. #920584) with spacers (C.I.

#920585). The four lifting links (supplied by CINCINNATI)

are attached to the inside of the main frame with 1”-8 UNC

SHCS bolts. See Figure 2-1.

When lifting with chains, cables or straps, use the maximum

length possible to reduce the side loading generated at the

lift points. Use spreader bars or intermediate lifting beam if

ceiling height will not allow a high pick.

IMPORTANT: Extreme care must be taken not to subject

the machine to shock loads. The machine must be

lifted and set down gently. Do not allow any weight

to rest on resonator enclosure. Set the machine on its

feet without letting the enclosure “touch down” rst.

The load frame can be lifted using straps with S-hooks at

each of the four outer corners. The S-hooks are hooked in

the access holes located at the bottom of the load frame.

Adequate padding must be used at all points to protect the

machine’s nish. The straps can be gathered and lifted with

a hook attachment. See Figure 2-2

FIGURE 2-1 Lifting Main Frame

FIGURE 2-2 Lifting Load Frame

2-1

EM-534 (R-03/10)

FOUNDATION

A Certied Foundation Plan drawing is provided when the

machine is ordered. This drawing provides the user with

detailed information required to locate the equipment and

the eight machine anchors. The customer should prepare

the eight anchor locations prior to arrival of the equipment.

The eight pads must be pre-leveled to lie in the same plane

within .50 inches (12.7 mm), and the anchor holes should

be drilled as specied on the Foundation Plan drawing.

CINCINNATI INCORPORATED provides anchors, studs,

nuts, and shims for nal leveling.

If the machine is to be installed near shock inducing

equipment such as punch presses, turret punches, etc.,

contact CINCINNATI INCORPORATED.

INSTALLATION OF MACHINE

Remove neoprene shipping feet before setting machine on

the anchor studs.

After setting the machine on the anchor studs, place washers

and nuts on studs, but do not tighten. Installation consists of

the following steps:

Remove lifting clevises and spacers. 1.

Connect the customer-furnished fume exhaust system 4.

to the fume duct exit port.

Complete preliminary leveling procedure described 5.

below.

Install safety mats, using instructions provided with the 6.

machine.

CINCINNATI Service will install the operator control 7.

station and complete nal electrical connections to the

control.

Install gas lines, wiring, and hoses as described in the 8.

pre-installation manual.

CHILLER

The water chiller is a free-standing unit requiring only oor

support. Cooling lines are connected to the main frame

at a central location on the beam delivery side. Hoses are

furnished to connect the chiller when located as shown on

foundation plan. Consult CINCINNATI INCORPORATED

if an alternative chiller location is required. See SECTION

4 for chiller uid specications.

Remove all steel banding and protective wrappings.2.

Install fume fan (optional) and fume duct connecting 3.

to fume plenum with ange and fasteners provided.

Seal connection with a bead of RTV silicone. Make the

electrical connection to the fan drive motor with wiring

provided.

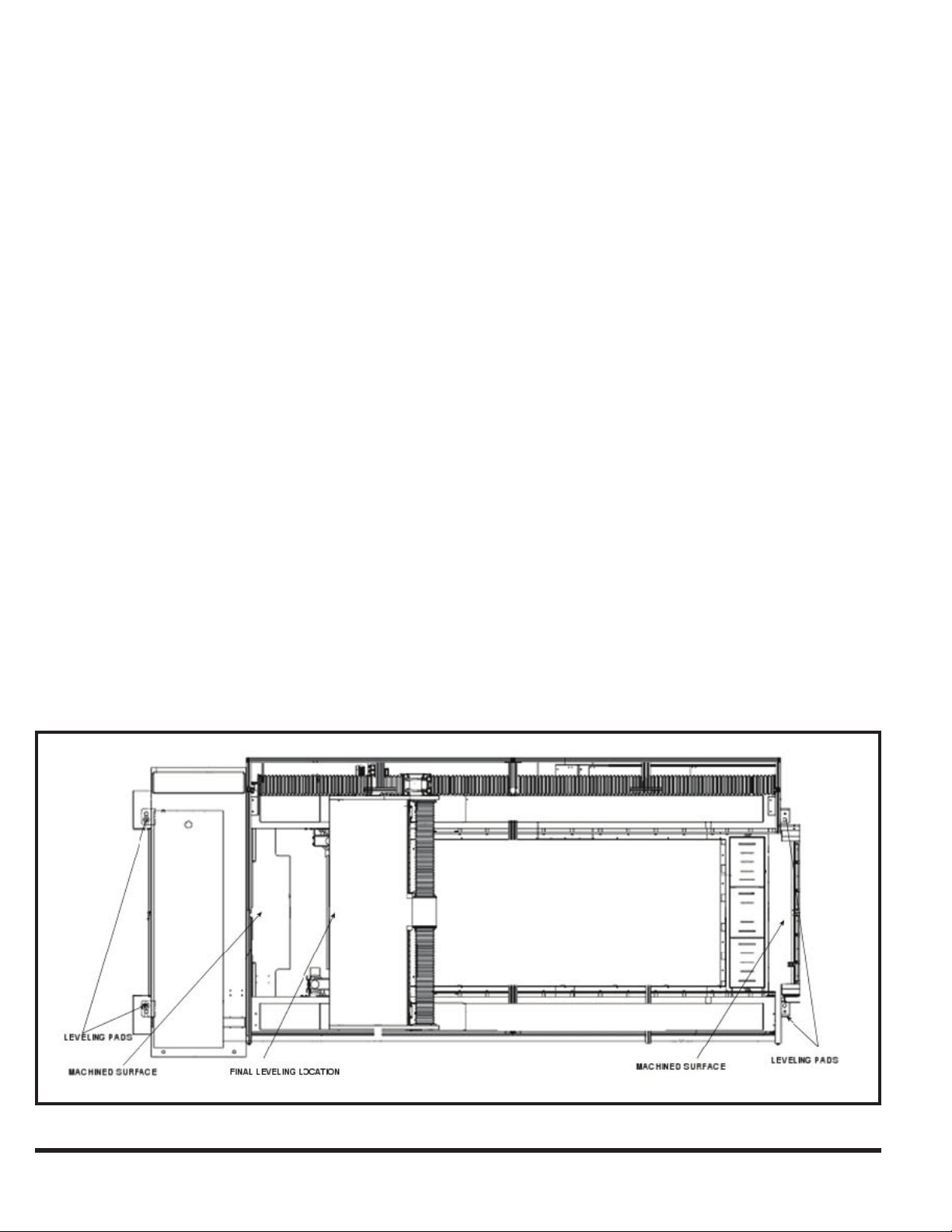

LEVELING

Main frame leveling adjustments are made using jackscrews

provided at the mounting pads. Figure 2-3 shows the

mounting pads. The machine foot mounting pads are

located on the outside surface of the main frame in the four

corners.

EM-534 (R-03/10)

FIGURE 2-3 Main Frame Leveling Adjustments

2-2

Slotted shims are inserted between the machine foot and

steel spacer block as shown on the Foundation Plan drawing.

After shims are inserted, jackscrews are to be backed off or

removed. The procedure for leveling is described in the next

sections.

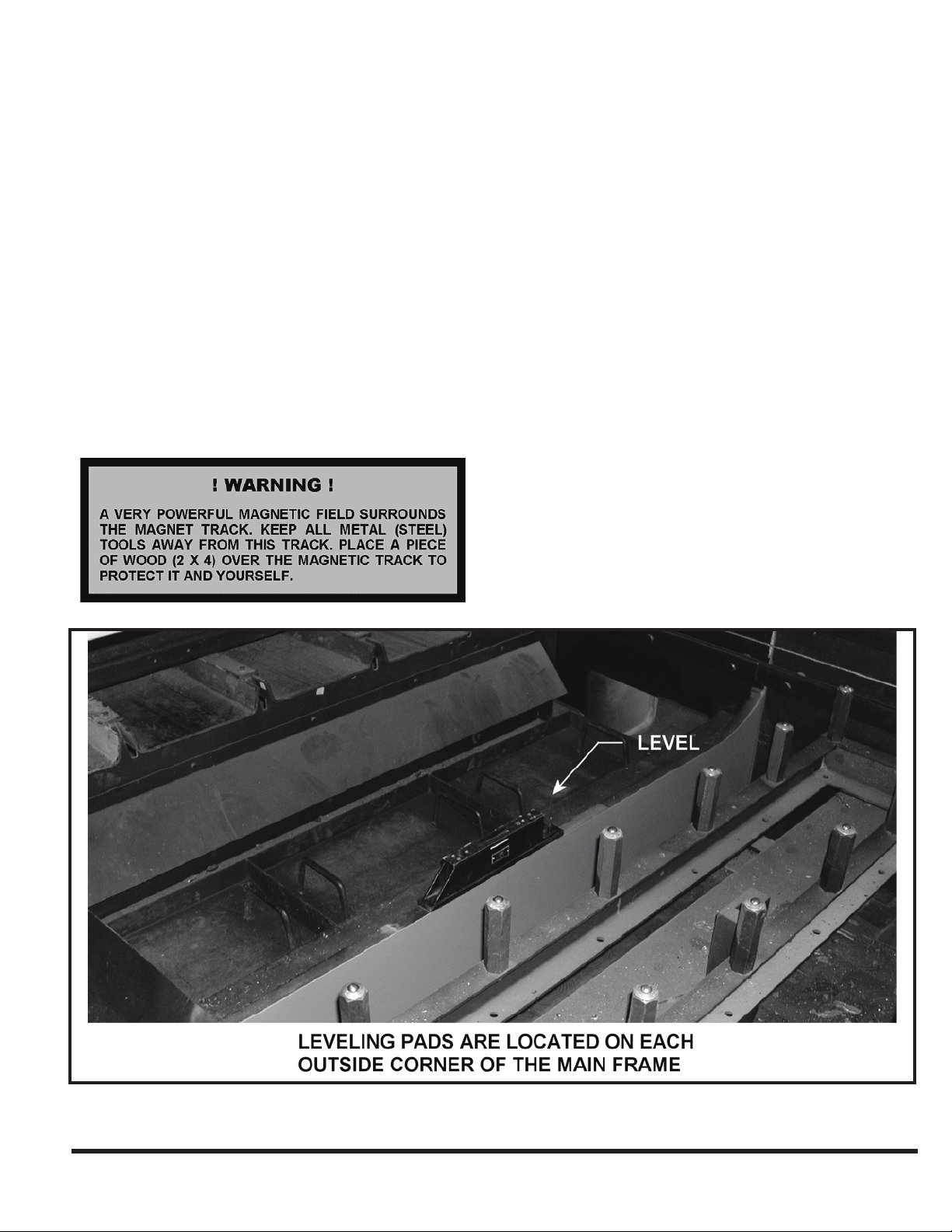

PRELIMINARY LEVELING

To check cross-leveling, place a precision level 1.

on machined pads on each end of main frame. For

preliminary leveling, a level with .004”/ft. precision is

sufcient (0.33 mm per meter). See Figures 2-3 and 2-4.

Lift machine with jackscrews and shim under mounting

feet (shims are provided).

Longitudinal level is checked on the top of the X-Axis 2.

guide way. Adjust as described above. (See Figure

2-5.) Longitudinal leveling does not require a precision

level.

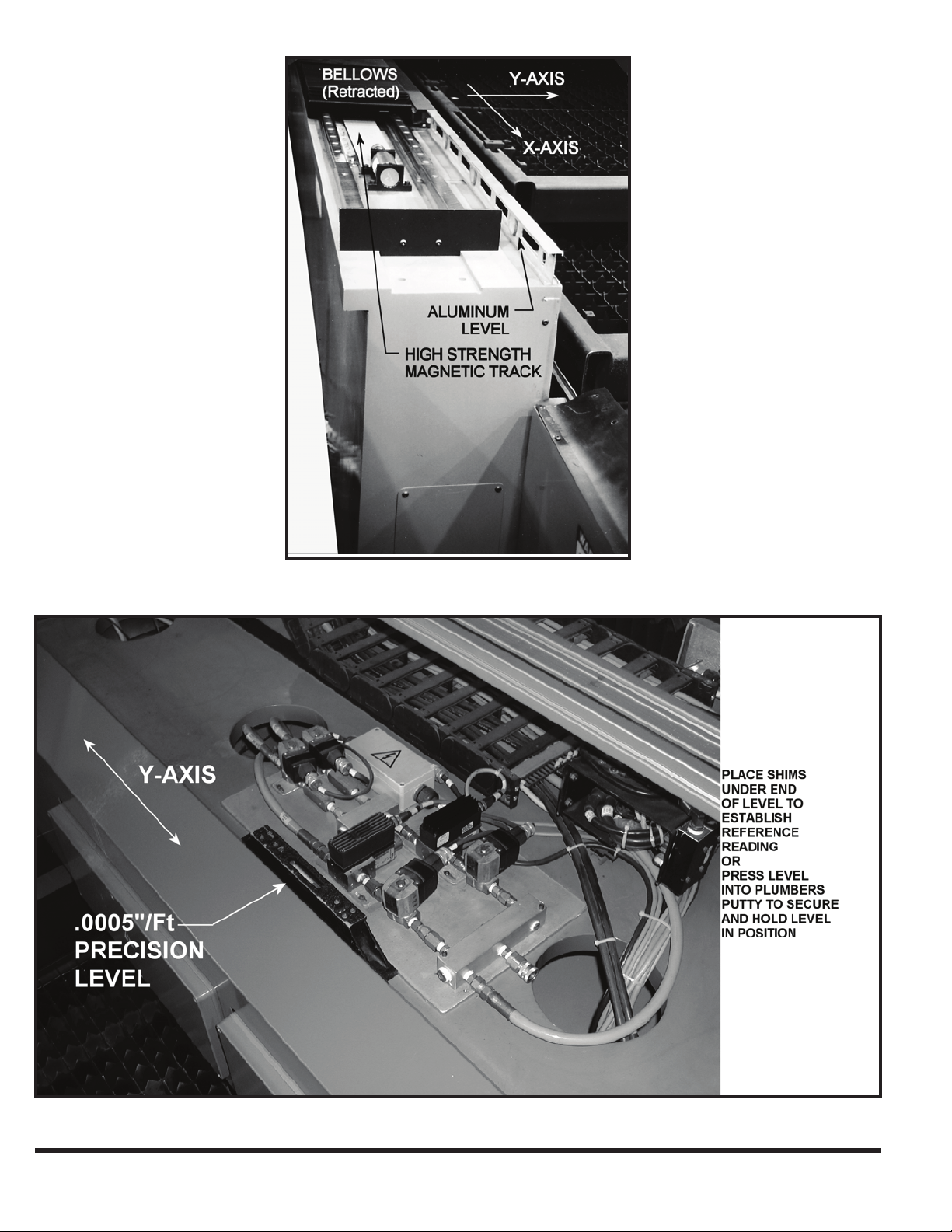

FINAL LEVELING

Final leveling should be done with a CINCINNATI

INCORPORATED Service Representative present.

The purpose of nal leveling is to ensure that the gantry does

not rotate about the X-axis as the gantry moves from end-toend. Excessive rotation will cause laser beam misalignment

during operation.

Use a 15” (380 mm) precision spirit level with a 1.

sensitivity of .0005”/ft. (0.04 mm per meter).

Place the level on the top of the gantry and position 2.

the gantry at X = 0. See Figure 2-6. The gantry may be

moved by manually pushing it when drives are off, or

by using JOG mode when drives on.

The top of the gantry is not machined. Therefore, it 3.

will be necessary to shim one or both ends of the level

to establish a reference reading and make the level

sit solidly in place. Paper shims can be used for this

purpose.

FIGURE 2-4 Cross leveling (Preliminary)

2-3

EM-534 (R-03/10)

FIGURE 2-5 Longitudinal leveling

EM-534 (R-03/10)

FIGURE 2-6 Final leveling with precision level

2-4

Observe the position of the bubble while moving the 4.

gantry from X = 0 to X = Maximum travel. The maximum

acceptable deviation is one division of the level (.0005”/

ft. or 0.04 mm per meter) as the gantry moves from

end-to-end. This ensures that the frame is not in a twist.

Adjust as described above, using jackscrews to add or

remove shims under mounting feet.

When Step 4 is complete, lightly tighten anchor nuts and 5.

recheck level as specied in Step 4. Verify that jacking

screws are backed off and not supporting the machine.

The standard electrical input is 460 volt, 3 phase and

50/60 hertz. The machine must be properly grounded in

accordance with the National Electric Code NFPA 70, 2002

edition, article 250, sections 50 through 70. CINCINNATI

INCORPORATED recommends using an individual

electrode per article 250.52 (5) to avoid interference from

other equipment. Place ground electrode as indicated

on foundation plan drawing. Do not start the machine

until the SAFETY section of this manual has been read

thoroughly and a CINCINNATI INCORPORATED Service

Representative is present.

Tighten the anchor nuts.6.

Repeat Step 4 as a nal level check.7.

ELECTRICAL CONNECTION

Each Laser System customer is supplied a complete set of

Foundation Plan drawings prior to machine shipment. The

electrical load requirements and connection points are called

out on these drawings. Be certain that a suitably sized wire

is brought to the main disconnect and the proper voltage is

supplied.

The machine controls have been designed to operate

satisfactorily with good quality incoming electrical power.

It is important that the electrical power be free of excessive

noise and power uctuations. Refer to the pre-installation

instructions for details of input power requirements.

SAFETY DEVICES

DO NOT START MACHINE UNTIL YOU HAVE

THOROUGHLY READ THE SAFETY SECTION

OF THIS MANUAL AND A CINCINNATI

INCORPORATED SERVICE REPRESENTATIVE IS

PRESENT.

2-5

EM-534 (R-03/10)

EM-534 (R-03/10)

2-6

SEcTION 3 SAFETY

SAFETY IS EVERYONE’S JOB

The CINCINNATI Laser System manufactured by

CINCINNATI INCORPORATED has been designed to

meet the highest order of reliability and ease of operator use.

This system has been certied under Federal Regulations

21 CFR, subpart J, as a Class 4 Laser product as required

by the Federal Radiation Control for Health and Safety

Act of 1968. This certication is on le with the Food and

Drug Administration “Center for Devices and Radiological

Health” (CDRH) Division, Ofce of Compliance, 2098

Gaither Road, Rockville, Maryland 20850.

CINCINNATI INCORPORATED recommends the

customer read and understand the requirements of the

American National Standard ANSI B11.21 entitled “Safety

Requirements for Design, Construction, Care and Use of

Machine Tools Using Lasers for Processing Materials” and

ANSI Z136.1 entitled “American National Standard for

Safe Use of Lasers”. They are available from the American

National Standards Institute, 25 West 43rd Street, New

York, New York 10036.

For additional safety information, we recommend you:

Obtain applicable safety data from:1.

National Safety Council, 1121 Spring Lake Drive, a.

Itasca, Illinois 60143-3201

The Laser Institute of America, Suite 128, 13501 b.

Ingenuity Drive, Orlando, Florida 32826.

Determine your responsibilities under your state and 2.

local safety codes.

Request assistance from the loss prevention department 3.

of your workmen’s compensation carrier.

Personnel responsible for your Laser System operator

training program, maintenance, and manufacturing

operations must read and understand this Operation, Safety

and Maintenance manual. No one should set up, operate or

maintain this Laser System until they thoroughly understand

it and know how to do their job safely. Read this manual in

its entirety.

INTRODUCTION TO LASER SAFETY

The laser beam is a strong, highly directional beam of

energy that, if directed, reected or focused upon an object,

will be partially absorbed. This absorbed energy can raise

the temperature of the object enough to cause material

changes at the point where the laser beam hits the object.

This process can also produce adverse biological effects in

human tissue.

A BRIEF DISCUSSION ON RADIATION

Radiation is energy radiated or given off in the form of

waves or particles. It is a general term used to describe

energy emitted from a wide range of sources. Some

sources are man-made such as radio waves and some are

made naturally such as the rays coming from the sun. To

keep track of all the various kinds of radiation, scientists

developed a system to separate radiation by the length of

the wave (or frequency) being sent out by the source. This

is called the “electromagnetic spectrum”. This spectrum

covers the entire range of energy wavelengths from the

very short gamma rays to the much longer wavelength of

commercial electricity sent out from your electric company

(i.e. 60 cycle current).

All forms of electromagnetic radiation travel at the speed of

light, but at differing frequencies. The longer the wavelength

is, the lower the frequency. The energy transmitted by

radiation is also related to its frequency. Higher frequency

radiation can transmit greater energy.

Some radiation interferes with the internal energy that

holds atoms together as molecules. If the energy of a ray

of radiation is great enough, it will attract electrons away

from an atom or add additional electrons to it. This is

called “ionizing” radiation. X-rays are an example of this

type of radiation. CINCINNATI Laser Systems do not use

“ionizing” radiation.

Radiation that lacks the energy to deform atoms is called

“non-ionizing” radiation. This is the type used in a

CINCINNATI LASER SYSTEM. The source used to

generate the laser beam is carbon dioxide gas (CO

laser beam is emitted in a continuous wave (CW) at a xed

wavelength of 10.6 micrometers. This wavelength is in the

far-infrared region of the electromagnetic spectrum. The

beam is invisible and has high heat energy.

Non-ionizing radiation can cause harm. This is a result of

the energy being absorbed and raising the temperature of

the part of the body being hit. Over time, the heat energy

being absorbed will reach a harmful level. This injury is

similar to the burn you can get from a bonre by standing

too close for too long or the burn you can get from being out

too long in the sun.

If the body part exposed to “non-ionizing” radiation is the

hardened, dead-cell tissue of the outer skin, minor harm will

be done. A reddening of the tissue and mild soreness might

be the only result. However, if that same radiation energy

gets inside the body to less well-protected tissue, the tissue

may not only be heated, but may become permanently

damaged as well.

). The

2

3-1

EM-534 (R-03/10)

For example, the eyes are very susceptible to radiation. The

cells of the cornea and retina are not protected by a layer of

dead skin and thus can be damaged much easier than your

skin. The eye should always be protected from radiated

energy. Eye hazards and eye protection are covered in more

detail later in this section.

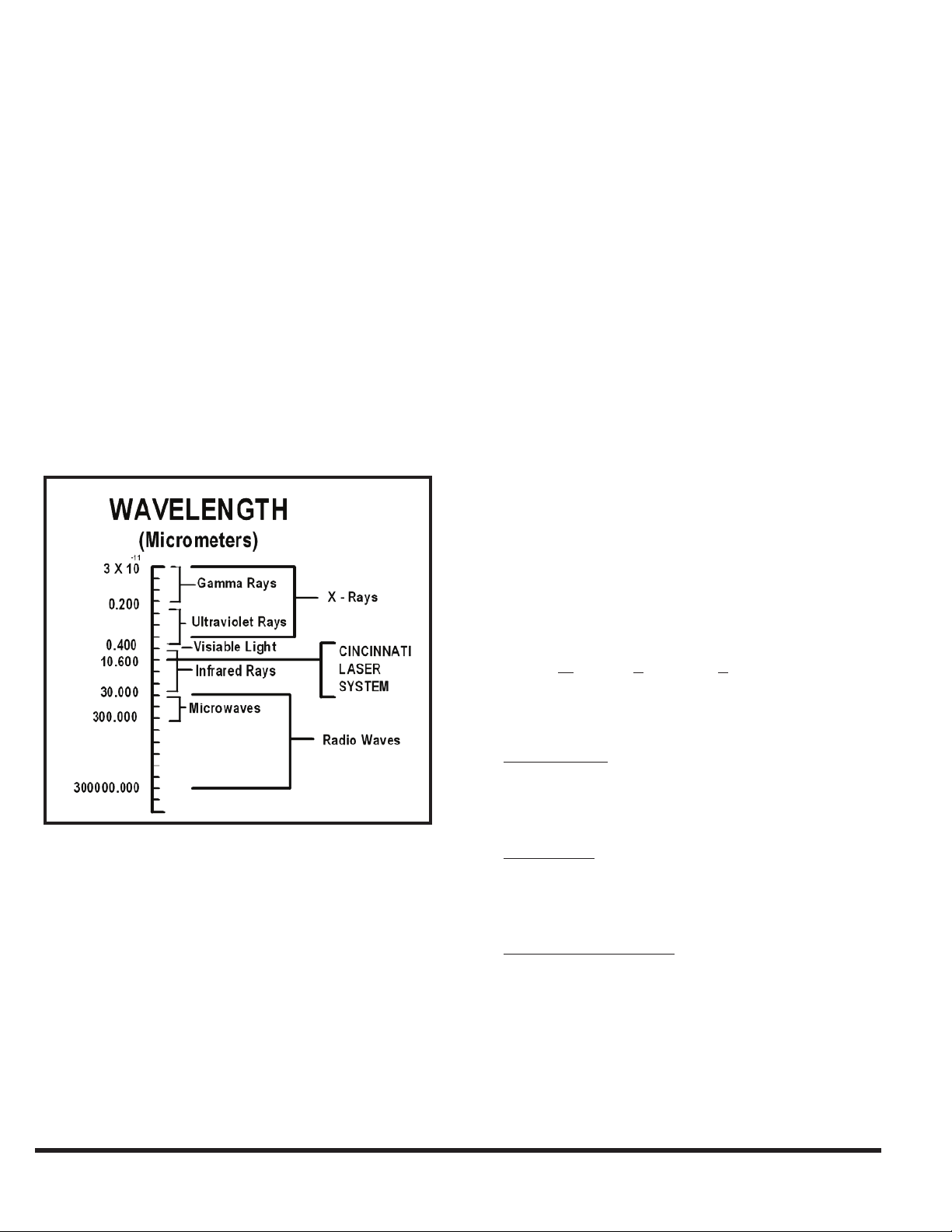

Figure 3-1 is a chart of the electromagnetic spectrum.

The CINCINNATI (CO

) LASER SYSTEM operates at a

2

wavelength of 10.6 micrometers. As you can see from the

chart, this wavelength is in the infrared range. Breaking the

infrared range down further, the radiation generated from

a carbon dioxide gas laser is considered to be in the farinfrared range.

This brief introduction has been prepared to alleviate any

unwarranted worries regarding laser radiation safety. A more

detailed discussion can be obtained in OSHA Publication

8-1.7 entitled “Guidelines for Laser Safety and Hazard

Assessment”.

International Electrotechnical Commission (IEC) has been

developing laser safety standards.

In 1968, the U.S. Government passed a law regulating

products used in the United States that radiate energy.

The law is the “Radiation Control for Health and Safety

Act of 1968”. This law sets standards of performance for

electrical products that emit radiation. These are called

U. S. Federal Laser Product Performance Standards or

FLPPS. Manufacturers use FLPPS to ensure the design and

manufacture of their product properly controls radiation

hazards before the product is released to their customers.

Examples of some of the products covered under this law

are x-ray machines, microwave ovens, hair dryers and all

types of lasers.

The Federal Standards covering Lasers and Laser Products

(i.e. devices or machines containing a laser) are covered

in the Federal Register at 21 CFR Part 1040. In these

standards, the level of radiation accessible to persons is

used to group lasers into one of four classes. The classes

are Class 1, Class 2, Class 3, and Class 4. These classes or

risk categories establish the hazard controls required in the

product’s design before a manufacturer can turn a product

over to a user.

FIGURE 3-1 Electromagnetic Spectrum

SAFETY STANDARDS AND PUBLICATIONS

There are a wide variety of laser safety standards and

publications. These include regulations of the Federal

Government, and of several state and local governments.

Additionally there are non-regulatory standards, such as the

ones of the American National Standards Institute (ANSI)

and of the American Conference of Governmental Industrial

Hygienists (ACGIH). Internationally, the World Health

Organization (WHO) has laser safety guidelines, and the

Research studies, along with an understanding of the hazards

of sunlight and conventional, man-made light sources have

permitted scientists to establish safe exposure limits for

nearly all types of laser radiation. Laser safety specialists call

these limits Maximum Permissible Exposures (MPE’s).

Of the standards and publications that apply to users of

CINCINNATI Laser Systems, three will be most helpful:

ANSI B11.211. “American National Standard for

Machines Using Lasers”. The contents of this standard

came from the users and manufacturers of the machines

that use laser generated beams to process material.

ANSI Z136.12. “American National Standard for Safe Use

of Lasers”. This standard, which is technical in content,

was developed by the research and health community to

cover all types of lasers and laser applications.

OSHA Publication 8-1.73. “Guidelines for Laser Safety

and Hazard Assessment”. This was developed for

OSHA eld personnel to help in their job of enforcing

workplace safety standards.

EM-534 (R-03/10)

3-2

LASER HAZARD CLASSIFICATION

As previously indicated, laser products are placed into one

of four classes. These are:

Class 1 A Class 1 laser is considered safe based upon

current medical knowledge. This class includes all lasers

or laser systems which cannot emit levels of optical

radiation above the exposure limits for the eye under any

exposure conditions inherent in the design of the laser

product.

Class 2 A Class 2 laser or laser system must emit a visible

laser beam, whose natural brightness will limit exposure

by making the eye turn away. Momentary viewing is not

considered hazardous since the average radiant power

limit on this type of device must not exceed 1 milliwatt

(mW).

Class 3 A Class 3 laser or laser system can emit any

wavelength, visible or non-visible. The Class 3 laser

is divided into two subclasses, Class 3a and Class 3b.

These lasers and laser systems are not considered a re

hazard or a serious skin hazard. Any CW (continuous

wave) laser that is not a Class 1 or Class 2 is a Class 3

device if its output power is 0.5 watts or less. Since the

output beam of such a laser is denitely hazardous when

the beam is allowed to directly enter the eye, control

measures for the Class 3 lasers and laser systems center

on eliminating this possibility.

Class 4 A Class 4 laser or laser system is any that exceeds

the output limits (Accessible Emission Limits, AEL’s) of

a Class 3 device. As would be expected, these lasers may

be a re and skin hazard or a diffuse reection hazard or

both. Very stringent control measures are required for a

Class 4 laser or laser system.

Because of the power needed to cut metal, all lasers used to cut

metal are Class 4 lasers. Some Class 4 lasers are embedded

in enclosures or rooms and called Class 1 laser products or

Class 1 laser systems. However, control measures must still

be established to insure that the enclosure is maintained and

that proper operating procedures are followed.

CONTROL MEASURES

The CINCINNATI Laser System has been designed

and manufactured using the highest engineering control

measures practical. However, even these high standards

have limitations. Laser safety requirements call for

administrative and procedural controls to be incorporated

in the use of lasers in order to minimize or eliminate the

potential of personal injury during laser operation.

Laser safety experts have determined the best way to control

hazards presented by laser products is to establish a clear

plan of hazard control with specic responsibilities spelled

out for all workers involved. The plan has four (4) worker

categories. The Laser Safety Ofcer (LSO) is one category

and the other categories are for personnel working in laser

operations, plant maintenance and laser service.

LASER SAFETY OFFICER

When an organization uses powerful laser products such as

those strong enough to cut metal, it is recommended that

someone in the organization be designated the Laser Safety

Ofce (LSO). This is especially true when dealing with

Class 4 lasers whether they are embedded in a full enclosure

and called Class 1 systems or not.

The LSO should be an employee who is part of the

management organization. The LSO must be given the

responsibility and authority to monitor and enforce the

procedures established for controlling laser hazards. Unless

a great number of laser products are involved, this will not

be a fulltime job but daily auditing of work procedures is

often a good idea. The LSO is responsible for seeing that

written standard operating procedures (SOP) for the laser

system are available. The information needed to establish

these SOP’s will come from the material provided by the

laser system manufacturer, auxiliary equipment providers,

and company safety rules. Each operator, maintenance

person, or laser service person should have access to these

SOP’s and fully understand their content.

OPERATING PERSONNEL

These people are responsible for the productive use of

the laser cutting system over the full range of its intended

function. These persons should be thoroughly familiar with

all operating controls, adjustments, and hazards associated

with their function.

MAINTENANCE PERSONNEL

Laser safety procedures classify Maintenance level tasks

as those done on machinery when the laser beam hazards

are not present. Therefore, maintenance personnel are

responsible for procedures that are completed in and around

a laser system with the laser power off. Maintenance

personnel should be thoroughly trained in the performance

of those procedures.

3-3

EM-534 (R-03/10)

SERVICE PERSONNEL

Service personnel do the work required to maintain the

laser system while the laser beam is active. They must have

the complete knowledge of laser hazards and the controls

provided by the system manufacturer for their protection

from those hazards. They are responsible for doing the

procedures and adjustments described in the manufacturer’s

service manual such as Mode Burns, Tape Shots and Mirror

Alignments. During these tasks, the laser beam needs to

be available and therefore exposure to the hazards of the

beam is possible. To get to the mirrors and beam locations,

the service level worker often must override or defeat the

protection provided. The duty of a service person requires

a higher level of training and education than that of the

maintenance function.

SAFETY PROGRAM

A strong commitment from management must exist in

order for an effective safety program to be established with

personnel involved in the use of the CINCINNATI Laser

System. Additional information concerning this topic can

be located in the American National Standard B11.21 &

Z136.1. Refer to Appendix D of the ANSI Z136.1 standard

for a guide for organizing and implementing a laser safety

and training program.

process that takes place in a laser. Stimulated emission

occurs when the energy released from one atom interacts

with another atom that is still excited. The interaction

stimulates the excited atom into releasing its own energy

as light. Most of the light produced by stimulated emission

has the same frequency and same phase as the stimulating

light. It also travels in the same direction, and so it combines

with and amplies the triggering light. Such light is called

coherent radiation.

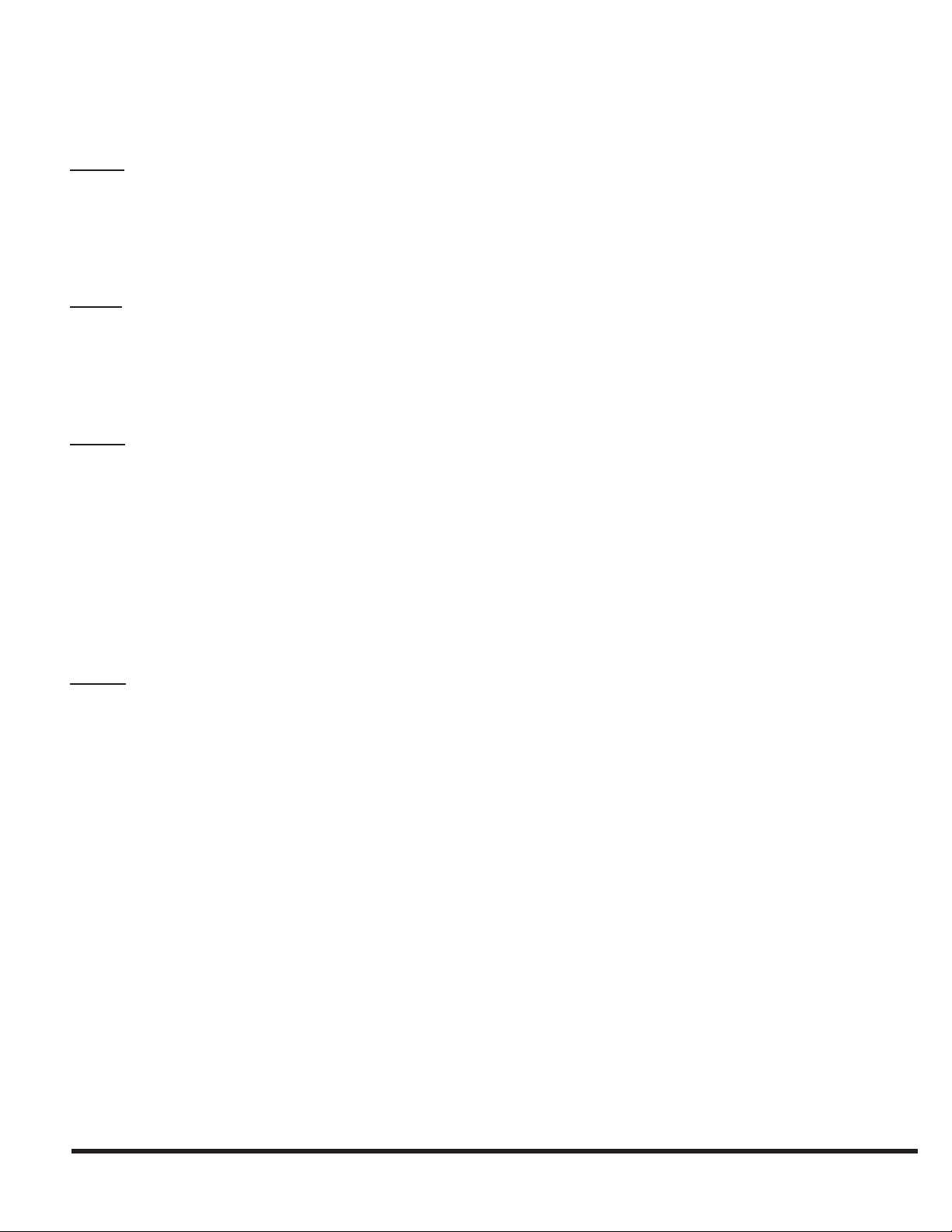

LASER TYPES

There are four major types of lasers. The difference between

them is the material used inside the laser that will emit the

energy after being excited. These four types are solid-state

lasers, gas lasers, dye lasers, and semi-conductor lasers.

CINCINNATI Laser Systems use gas type lasers to generate

the cutting beam and gas and semi-conductor lasers to

generate the positioning beam when that feature is supplied.

In all cases (i.e. for cutting or positioning), the actual lasergenerating unit is located at one end of the CINCINNATI

Laser System and the beam is directed to the cutting head

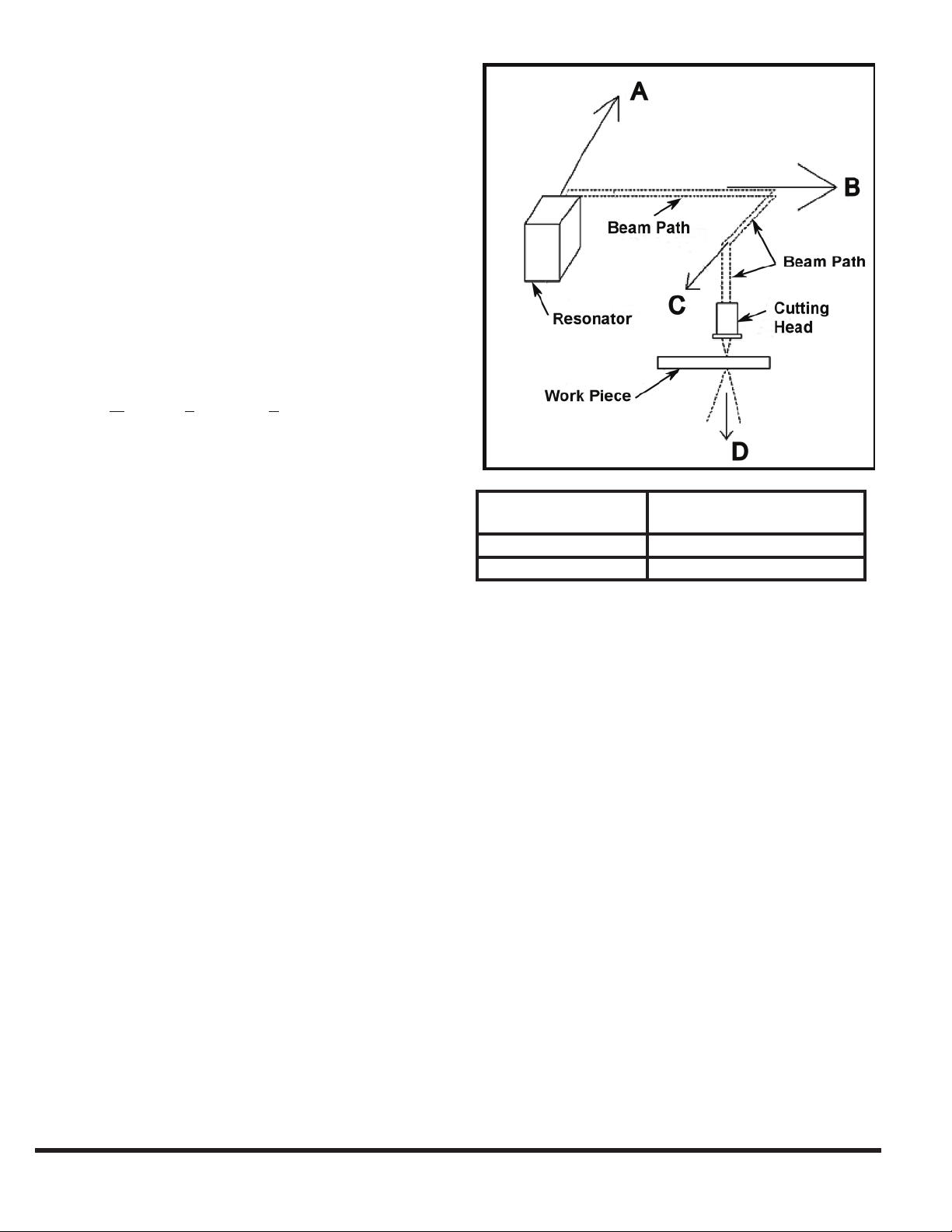

through an enclosed beam tube. See Figure 3-2.

EXPLANATION OF LASER RADIATION

Light is a form of energy that is released from individual

atoms or molecules in a substance. To understand how a

laser works, it is necessary to know something about the

nature of atoms and how they interact with light and other

forms of energy.

Every atom is a storehouse of energy. The amount of energy

in an atom depends in part on the motion of the electrons

that orbit the atom’s nucleus. When an atom absorbs energy,

the energy levels of the electrons increase and the atom is

said to be excited. The atoms of a substance become excited

when they absorb heat, light, or other forms of energy that

pass through the substance. An excited atom can return to

its normal energy level by releasing its excess energy in the

form of light. When this release of light occurs randomly, it

is called spontaneous emission.

In spontaneous emission, excited atoms release light

irregularly. As a result, the light has different frequencies,

different phases, and travels in different directions. Light

released in this way is called incoherent light. Such light is

produced by the sun and by ordinary electric light bulbs.

FIGURE 3-2 Beam Path

The enclosure at one end of the CINCINNATI Laser System

is the laser resonator where the laser beam is created. An

electronically actuated shutter system is used to allow the

beam to exit the resonator and enter the beam tube. At this

point, the beam is approximately 1.0” (25 mm) in diameter.

The beam is then directed to the laser cutting head by a

series of special mirrors. After the beam enters the cutting

head, the lens will focus it down to a point as the beam

travels out of the nozzle and onto the work piece.

Excited atoms also may release light systematically. This

kind of release, called stimulated emission, is the main

EM-534 (R-03/10)

3-4

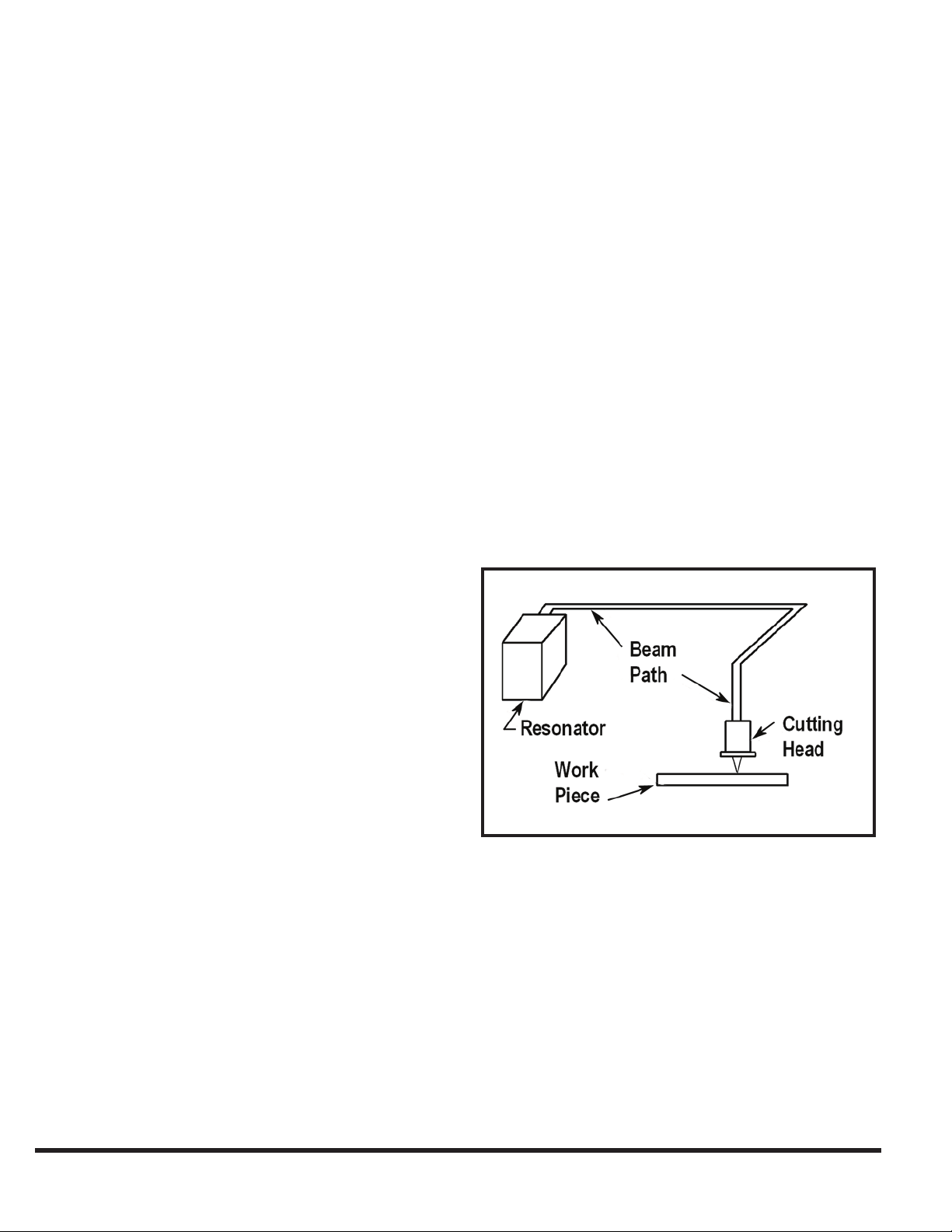

In order to cut (vaporize) steel you need to generate a power

density of over 2 million watts per square centimeter. To

help visualize this concentration of power, Table 3-1

compares power densities of various conditions.

Condition Power Density

Sunlight on the earth’s surface 0.10 w/cm

100 watt light bulb surface 1.0 w/cm

Soldering Iron Tip 100 w/cm

4000-watt laser beam, 1.00”

(25.4 mm) diameter.

4000-watt laser beam, 0.010”

(0.254 mm) focus spot diameter.

Steel Threshold 2 million w/cm

TABLE 3-1 Power Density Comparisons

800 w/cm

8 million w/cm

2

2

2

2

2

2

Gas lasers have several power sources, including chemical

reactions, electric current, electron beams, ultraviolet rays

and radio frequency excitation. Most gas lasers produce a

continuous beam of light. Gas lasers can produce beams

of higher average power than solid lasers because the gas

cools the laser as it ows through the tube. Light from a

gas laser has a narrower frequency range than light from a

solid laser.

The CINCINNATI Laser System can be provided with a

second laser used for positioning. The positioning laser is a

diode laser with very low power. It is located in the resonator

cabinet and produces a visible red beam when turned on.

Due to the visible nature of this beam and its power level,

the positioning laser is designated as a Class 2 or Class

3a laser product depending on the type of laser furnished.

Since Class 2 and Class 3a laser beams are considered a

chronic viewing hazard, the laser system includes signs

warning personnel not to stare into the red beam.

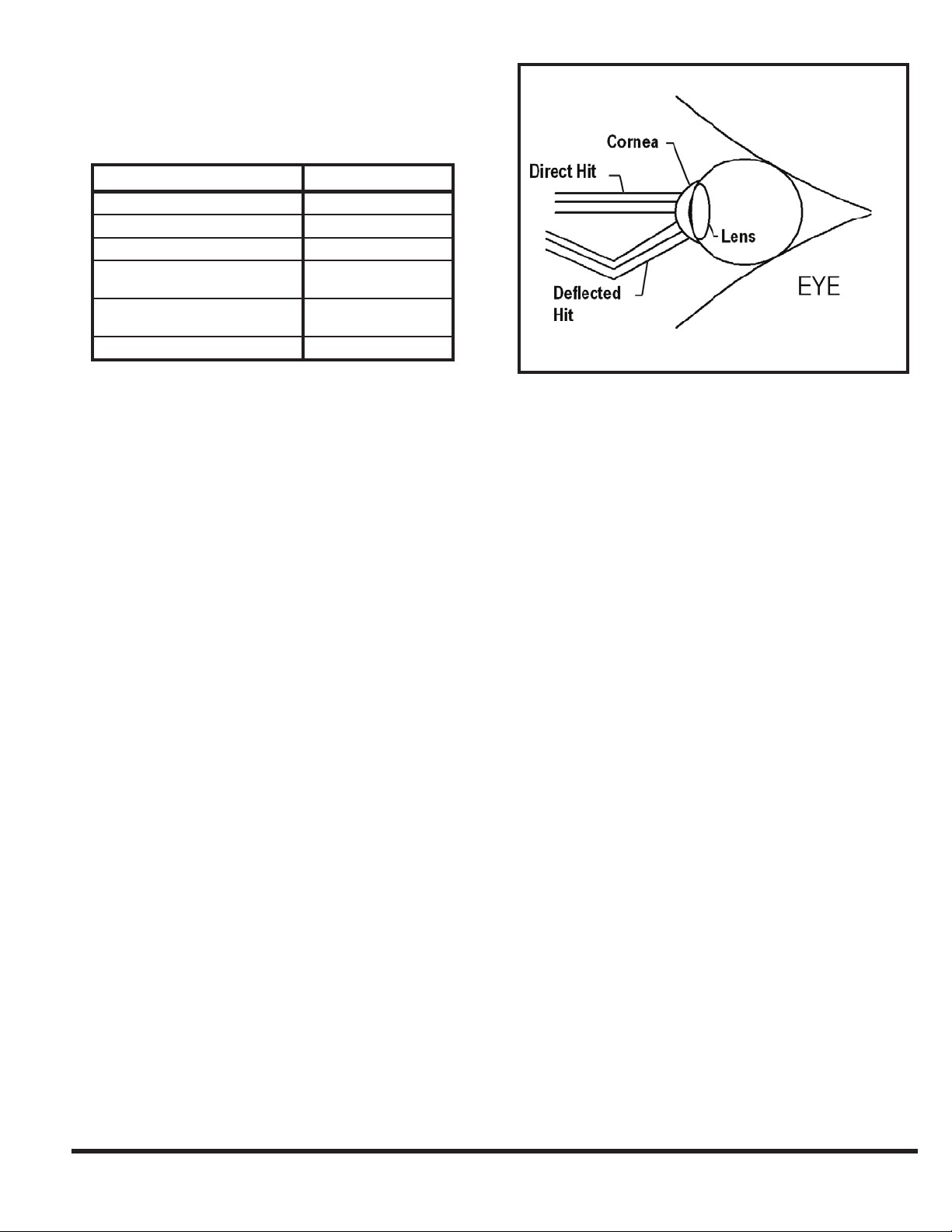

FIGURE 3-3 The Eye

The type and style of eye protection to use should be

worked out with the supplier of your shop eye protection. In

general, the normal polycarbonate safety glasses with side

shields used in metal working shops and meeting the ANSI

Z87 Standard will provide all the protection necessary from

reected beams for operating and maintenance personnel.

Their work should not expose them to the possibility of

direct beam exposure. The procedures established for

service personnel are designed to protect them from direct

beam exposure. However, it is recommended that their

safety glasses have a protective optical density of 4.

Staring at the cutting plume is not necessary or advisable.

The light energy being sent out by the cutting process is

a mixture of many wavelengths. Besides the reection of

the laser beam there is the scattered radiation of the cutting

process. The plume emits visible light and ultraviolet

light.

HAZARDS - CINCINNATI LASER SYSTEMS

EYE HAZARDS

The beam of a CINCINNATI Laser System is a potential eye

hazard. If the beam directly or indirectly hits the eye, there

is a potential for injury to several different areas, depending

upon which eye part absorbs the most radiant energy.

Laser radiation in the far-infrared region will be absorbed in

the front surface of the eye. Thus, if the eye is not protected,

it may receive damage to the cornea and lens from direct

or reected laser beam exposure. Therefore, all operation,

maintenance and service personnel working at the

CINCINNATI Laser System must wear eye protection.

It is the users responsibility to establish and enforce an eye

protection program.

SKIN HAZARDS

Laser radiation striking the skin is reected, absorbed

and transmitted; the percentage of each depends upon the

characteristics of the skin at the wavelengths of concern.

Effects on the skin from absorbed radiation may vary from

mild redness to blistering and/or charring, depending upon

the total energy absorbed and the rate at which it is absorbed.

Unnecessary exposure of the skin to laser radiation should

be avoided regardless of the level of radiant energy.

3-5

EM-534 (R-03/10)

The CINCINNATI Laser System has been tested and found

to have no detectable x-ray emissions and related hazards.

In general, the hazards presented by the CINCINNATI

Laser System will be severe burns, lacerations and possible

amputation if members of the body are exposed to the direct

beam or reected beams of high energy. The design of the

Laser System provides engineered protection from these

hazards for personnel while properly using this equipment.

This basic design should not be altered or modied in any

manner.

NOMINAL HAZARD ZONES

Safety standards dene a laser’s Nominal Hazard Zone

(NHZ) as “the space within which the level of the direct

reected or scattered radiation during operation exceeds the

applicable Maximum Permissible Exposure (MPE)”. When

considering a CINCINNATI Laser System, the radiation

hazard is the laser beam which is strong enough to cause

severe burns to the surface of the eye or skin if a worker is

directly in its path or hit by the beam as it is reected off

machine or piece part surfaces. The nominal hazard zone

is the space in all directions away from the beam where

the heat from the beam is strong enough to cause injury.

The NHZ can be calculated using the formulas and charts

contained in the ANSI Z136.1 Safety Standard and used in

this manual.

During piece part cutting, the beam is fully contained within

the beam tube and exits only at the cutting head. Figure 3-4

shows the usual path of the laser beam. On some models,

this path is slightly changed due to different positions of

the laser resonator or additional features enclosed within

the path. At the cutting head, the lens focuses the beam

downward to a spot as the beam exits to process material.

BEAM EXPOSURE CATEGORIES

There are three categories of potential laser beam exposures

on any laser cutting system:

Intra-beam Exposure•

Specular Reection Beam Exposure •

Diffuse Reection Beam Exposure •

DIRECTION HAZARD DISTANCE

A, B or C 2439.1 Ft. (743.4 m)

D 56.1 Ft. (17.1 m)

FIGURE 3-4 Uncontained beam hazard distance

The CINCINNATI Laser System’s design deals with beam

exposure categories in various ways:

Intra-beam (Direct) Exposure occurs when an object is •

in the beam’s path. See directions A, B, C & D in Figure

3-4.

The fully enclosed beam tube guards this potential

exposure, by appropriate interlocks and warning labels

on service access panels. After the beam leaves the lens,

the Laser System’s two-axis motion system provides

for a xed downward beam direction. Automatic beam

shutoff occurs through redundant mechanisms if the

cutting head is knocked off or rises more than 1-1/2”

(38 mm) above the top of the cutting pallet.

Specular Reection occurs when the beam reects off a •

mirror-like object.

EM-534 (R-03/10)

This mirror-like reection of the focused beam off a

work piece is directed upward into the cutting head and

gantry due to the xed downward beam direction and

the horizontal work piece orientation.

Diffuse Reection occurs when the beam reects off •

the work piece during cutting or when the unfocused

beam hits an object.

3-6

Loading...

Loading...