Page 1

PROGRAMMING MANUAL

AN OPERATION SUPPLEMENT MANUAL FOR THE

CINCINNATI CL-707, CL-7A, AND CL-800

LASER SYSTEM WITH PC-BASED CONTROL

EM-423 (R-02/11) COPYRIGHT 2011

CINCINNATI INCORPORATED

Page 2

Page 3

PROGRAMMING CONTENTS

SECTION 1 STANDARD G-CODES

1.00 G00 RAPID TRAVERSE MOVE...........................................................1-1

1.01 G01 LINEAR MOVE.............................................................................1-1

FEEDRATE.......................................................................................... 1-2

1.02 G02 CLOCKWISE ARC .......................................................................1-2

1.03 G03 COUNTERCLOCKWISE ARC......................................................1-2

RECOMMENDED ARC FEEDRATE...................................................1-3

1.04 G04 DWELL......................................................................................... 1-3

1.09 G09 EXACT STOP (ONE BLOCK) ......................................................1-4

1.20 G20 INCH MODE.................................................................................1-4

1.21 G21 METRIC MODE............................................................................1-4

1.31 G31 POSITION CAPTURE MOVE....................................................... 1-4

1.40 G40 CANCEL KERF COMPENSATION.............................................. 1-4

1.41 G41 LEFT SIDE COMPENSATION..................................................... 1-4

1.42 G42 RIGHT SIDE COMPENSATION...................................................1-4

1.50 G50 CANCEL SCALING...................................................................... 1-5

1.51 G51 WORK COORDINATE SYSTEM SCALING.................................1-5

1.52 G52 LOCAL WORK COORDINATE SYSTEM ................................ 1-6

1.53 G53 RAPID MOVE TO MACHINE COORDINATES............................1-6

1.54 G54 THROUGH G59............................................................................1-6

1.61 G61 EXACT STOP MODE...................................................................1-7

1.64 G64 CANCEL EXACT STOP MODE ...................................................1-7

1.65 G65 SUB-PROGRAM CALL ................................................................1-7

1.68 G68 WORK COORDINATE SYSTEM ROTATION ........................1-7

1.69 G69 CANCEL ROTATION ...................................................................1-7

1.90 G90 ABSOLUTE MODE.......................................................................1-8

1.91 G91 INCREMENTAL MODE................................................................1-8

1.92 G92 WORK COORDINATE SYSTEM SETTING.................................1-8

SECTION 2 CUSTOM G-CODES

2.84 G84 PIERCE AND START CUT ..........................................................2-1

2.85 G85 START CUT WITHOUT PIERCE ................................................. 2-1

PIERCE OPTIONS (G84 T_)...............................................................2-1

AIRBLAST ...........................................................................................2-1

2.89 G89 PROCESS PARAMETERS..........................................................2-2

2.102 G102 ADDITIONAL PARAMETER SETTINGS ................................... 2-3

2.103 G103 RAMPED PIERCE SETTINGS................................................... 2-4

2.120 G120 DISABLE NON-STOP CUTTING ...............................................2-4

2.121 G121 ENABLE NON-STOP CUTTING ................................................2-4

SMART RAPIDS..................................................................................2-5

2.123 G123 PROGRAMMABLE BLEND........................................................ 2-6

2.124 G124 DEFAULT BLEND...................................................................... 2-6

2.125 G125 AUTO BLEND.............................................................................2-6

SECTION 3 M-CODES

3.00 M00 PROGRAM STOP........................................................................3-1

3.01 M01 OPTIONAL STOP ........................................................................3-1

3.02 M02 END OF PROGRAM.................................................................... 3-1

3.30 M30 END OF PROGRAM WITH REWIND ..........................................3-1

3.35 M35 BEAM OFF...................................................................................3-1

3.36 M36 SERVO HOLD FOR NONCONTACT Z-AXIS.............................. 3-1

3.37 M37 BEAM OFF, GAS OFF AND SHUTTER CLOSE .........................3-1

3.38 M38 TIMED NONCONTACT SERVO HOLD ....................................... 3-2

3.41 M41 COMMAND Z-AXIS DOWN TO CUT POSITION.........................3-2

3.42 M42 RETRACT Z-AXIS........................................................................3-2

3.43 M43 LOWER PALLET SPECIAL FUNCTION......................................3-2

3.44 M44 CANCEL LOWER PALLET SPECIAL FUNCTION ......................3-3

3.45 M45 APPLY OPTIONAL STANDOFF FOR CUTTING ........................ 3-3

3.47 M47 RAISE Z-AXIS, OPTIONALLY BY DISTANCE ............................3-3

EM-423 (R-02/11) iii

Page 4

3.48 M48 FEEDRATE OVERRIDE DISABLE...............................................3-3

3.49 M49 FEEDRATE OVERRIDE ENABLE................................................3-3

3.50 M50 SWITCH PALLETS.......................................................................3-3

3.51 M51 AUXILIARY TIMED OUTPUT.......................................................3-4

3.67 M67 APPLY OPTIONAL ASSIST GAS PRESSURE .......................3-4

3.98 M98 SUB-PROGRAM CALL WITH NO ARGUMENTS........................3-4

3.99 M99 END SUB-PROGRAM AND RETURN .........................................3-4

3.130 M130 Z-AXIS ANTI-DIVE DISABLE .....................................................3-4

3.131 M131 Z-AXIS ANTI-DIVE ENABLE ......................................................3-4

3.135 M135 DISCHARGE CURRENT OFF....................................................3-5

SECTION 4 CINCINNATI MACROS

4.65 GRID MACROS...................................................................................4-1

PART SUB GRID MACRO G65 P9800...............................................4-1

PART GRID MACRO: G65 P9900......................................................4-2

CUTTING MACROS.......................................................................................4-3

4.73 G73 HOLE MACRO ................................................................4-4

4.76 G76 SLOT MACRO.................................................................4-4

4.79 G79 LINE MACRO..................................................................4-4

4.83 G83 OUTSIDE CIRCLE MACRO............................................4-5

4.86 G86 OUTSIDE RECTANGLE MACRO...................................4-5

4.88 G88 BOLT CIRCLE MACRO...................................................4-5

4.104 G104 SHAPE MACRO...........................................................4-6

4.105 G105 LEAD-IN MACRO.........................................................4-8

SECTION 5 PROGRAM STRUCTURE

5.1 PROGRAM NAME.................................................................................5-1

5.2 PROGRAM BODY.................................................................................5-1

5.3 BEAM ON AND OFF COMMANDS.......................................................5-1

5.4 PROGRAM COMMENTS ......................................................................5-1

5.5 PROGRAM LINE NUMBERS ................................................................5-2

5.6 BLOCK DELETE....................................................................................5-2

5.7 END OF PROGRAM..............................................................................5-2

M02 ......................................................................................................5-2

M99 (P_)...............................................................................................5-2

M30 ......................................................................................................5-2

5.8 SUB-PROGRAMS AND MACROS........................................................5-2

SECTION 6 PROGRAM VARIABLES

6.1 LOCAL AND COMMON VARIABLES....................................................6-1

LOCAL VARIABLES: #1 - #99 ............................................................6-1

COMMON VARIABLES: #100 - #999 .................................................6-1

6.2 SYSTEM VARIABLES...........................................................................6-1

OFFSET DATA SYSTEM VARIABLES................................................6-1

CNC DATA SYSTEM VARIABLES......................................................6-2

MODAL DATA SYSTEM VARIABLES.................................................6-3

COORDINATE SYSTEM VARIABLES.................................................6-3

SECTION 7 AUXILIARY FUNCTIONS

7.1 MATH FUNCTIONS...............................................................................7-1

BRACES [ ]..........................................................................................7-1

7.2 LOGIC FUNCTIONS..............................................................................7-2

CONDITIONAL EXPRESSIONS..........................................................7-2

PROGRAM CONTROL COMMANDS..................................................7-2

7.3 AUXILIARY COMMANDS......................................................................7-3

DPRNT COMMAND (OPTION)...........................................................7-3

AUTOMATIC CORNER ROUNDING...................................................7-3

7.4 PROGRAMMING FOR MATERIAL HANDLING OPTION.....................7-4

7.5 WORKPIECE EDGE DETECTION........................................................7-5

CALIBRATION .....................................................................................7-5

OPERATION........................................................................................7-6

SPECIFICATIONS ...............................................................................7-7

7.6 OPTICAL PROBE................................................................................7-11

7.7 LASER OPTICAL PROBE...................................................................7-11

Page 5

SECTION 8 FILE TRANSFER & NETWORKING

8.1 FILE TRANSFER ..................................................................................8-1

NETWORK: .........................................................................................8-1

FLOPPY DISK: .................................................................................... 8-1

RS-232 INTERFACE: .......................................................................... 8-1

8.2 NETWORKING......................................................................................8-1

NETWORKING OPTIONS...................................................................8-2

SECTION 9 INDEX

INDEX ............................................................................................................9-1

EM-423 (R-02/11) v

Page 6

Page 7

SECTION 1 STANDARD G-CODES

the block in G90 mode, and incremental distances when

commanded in G91 mode. The command must specify

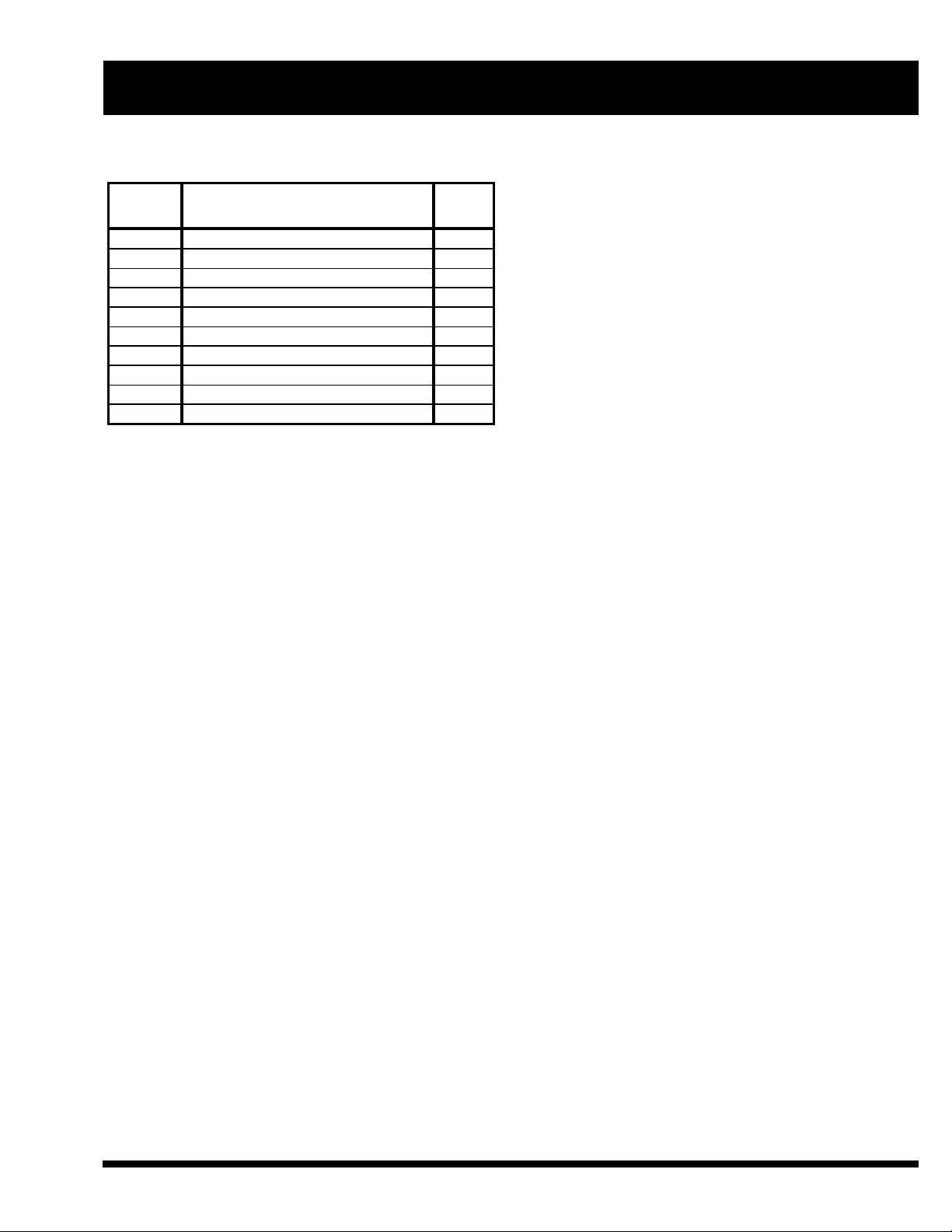

CODE DESCRIPTION SEC.

G00 Rapid move to Work Coordinates 1.00

G01 Linear move to Work Coordinates 1.01

G02 Clockwise arc to Work Coordinates 1.02

G03 Counterclockwise arc to Work

Coordinates

G04 Dwell 1.04

G09 Exact Stop (one block) 1.09

G20 Inch Mode 1.20

G21 Metric Mode 1.21

G31 Position Capture Move 1.31

G40 Cancel Kerf Compensation 1.40

G41 Kerf Compensation Left 1.41

G42 Kerf Compensation Right 1.42

G50 Cancel Scaling 1.50

G51 Work Coordinate System Scaling 1.51

G52 Temporary Local Work Coordinate

System

G53 Rapid move to Machine Coordinates 1.53

G54

G59

G61 Modal Exact Stop 1.61

G64 Cancel Exact Stop Mode 1.64

G65 Sub-program call 1.65

G68 Work Coordinate System Rotation 1.68

G69 Cancel Rotation 1.69

G90 Absolute mode 1.90

G91 Incremental mode 1.91

G92 Set Work Coordinate Origin 1.92

Work Coordinate Offset selection 1.54

to

1.03

1.52

at least one axis.

The G00 command moves the axes at the rapid traverse

rate of the machine. G01, G02 and G03 move the axes at

the contouring feedrate (optionally specified in the block

with “F”). When the block does not command a feedrate,

the program uses the last defined contouring feedrate.

When the control applies the rapid traverse rate for a

G00 move, it does not change the contouring feedrate

used by the G01, G02, and G03 blocks.

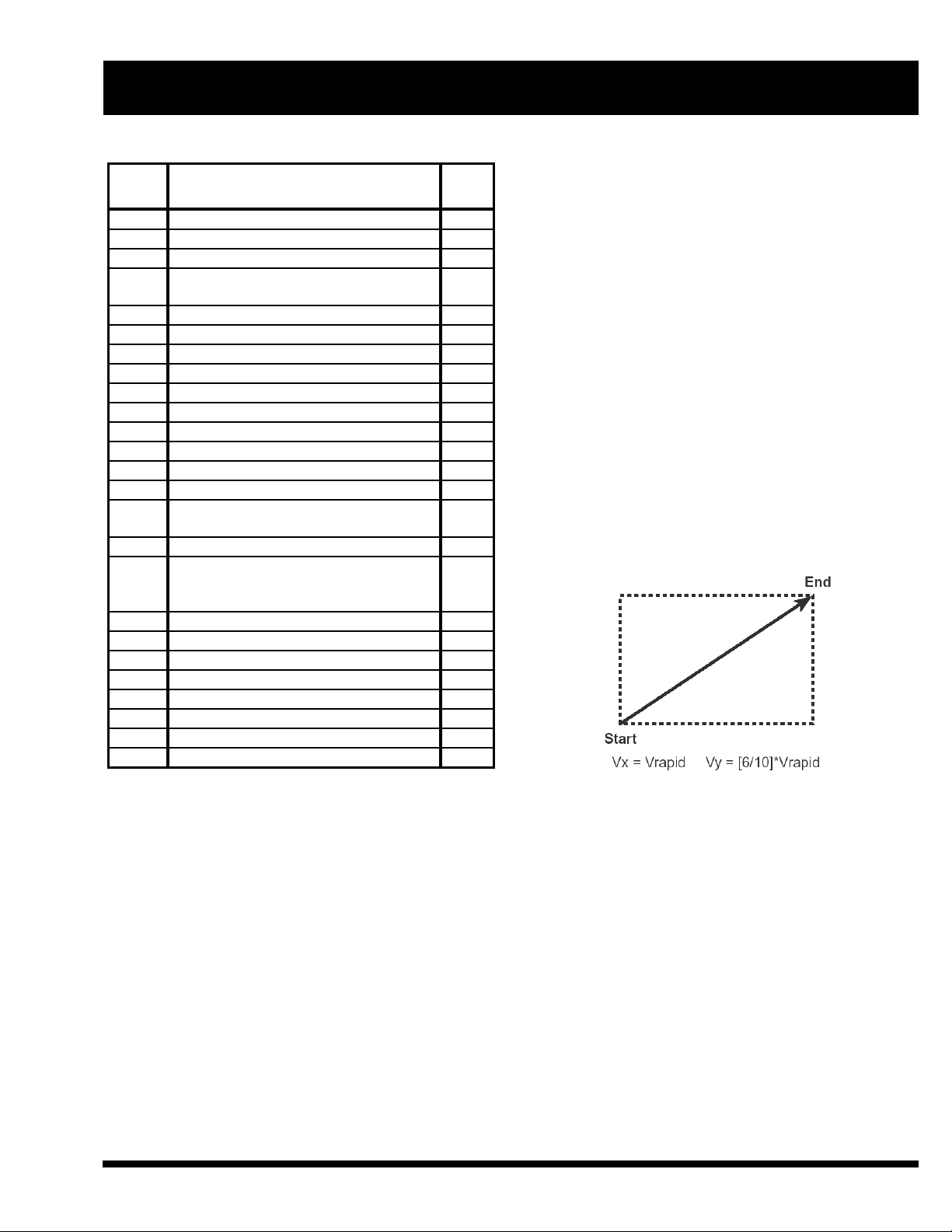

1.00 G00 RAPID TRAVERSE MOVE

The G00 command moves the cutting nozzle to a work

coordinate location (or incremental distance) using the

rapid traverse rate.

G00 X__ Y__

Example: (G91) G00 X10 Y6

When the command requires both axes to move, the axis

These four G-codes move the cutting nozzle to

commanded Work coordinates:

G00 Rapid Traverse move

G01 Linear move

G02 Clockwise Arc

G03 Counterclockwise Arc

These four G-codes form a modal group; the last G-code

moving the longer distance uses the rapid traverse rate of

the machine. The other axis moves at a lower velocity

proportional to the distance required, so both reach their

endpoints at the same time, approximating linear

interpolation.

If the command syntax is incorrect, a Message window

displays RAPID MOVE SYNTAX ERROR.

commanded in the group is active for all blocks until the

program commands another G-code in the group. The

default code when a program starts is G00. The leading

zero can be omitted; G0, G1, G2 and G3 are the same as

G00, G01, G02 and G03.

Each of these G-codes specifies the end of the move

with X and Y in the Work coordinate system. X and Y

1.01 G01 LINEAR MOVE

This command moves the cutting head to the work

coordinates (or incremental distance) defined by X and

Y, at a contouring feedrate optionally specified by F.

G01 X__ Y__ (F_)

are absolute coordinates when the program commands

EM-423 (R-02/11) 1-1

Page 8

Example: (G91) G01 X6 Y4 F250

When the command requires both axes to change

position, the machine moves each axis at a velocity

required to produce a combined feedrate equal to the

contouring feedrate. The move follows the linear path

between start and end points.

If the command syntax is incorrect, a Message window

displays LINEAR MOVE SYNTAX ERROR.

FEEDRATE

The program can specify contouring feedrate from a

parameter library. For example, the program can

command F#148 after a block calling G89 Pfilename.lib.

The user can also configure the control to assign feedrate

to a different variable than #148 (see “Common

Variables”, SECTION 6).

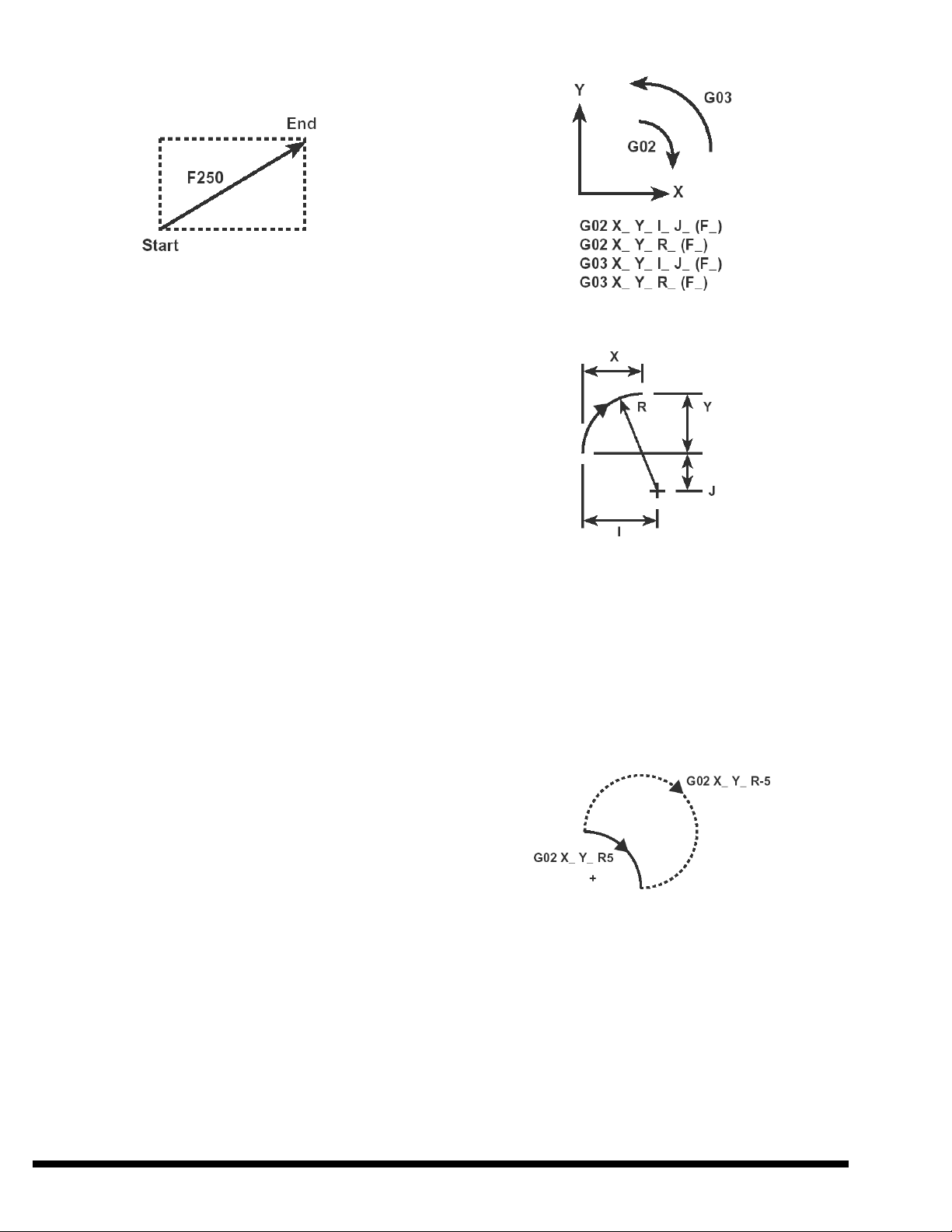

1.02 G02 CLOCKWISE ARC

1.03 G03 COUNTERCLOCKWISE

ARC

A program uses G02 or G03 to command a circular

contouring move ending at the work coordinates (or

incremental distances) specified by X and Y. The

command defines the shape of the arc either by

specifying incremental distances (with I and J) from the

starting position to the center, or by specifying the radius

(with R). The control software interprets “I” and “J” as

distances in the X and Y directions (respectively) from

the starting position to the center. When the command

specifies radius “R”, the control moves the nozzle along

a circular path with that radius.

The machine maintains the modal contouring feedrate

(F) along the circular path.

Example: (G91) G02 X5 Y4 I7 J-3

When the block uses “R” instead of “I and J”, there are

two possible arcs for a given direction (cw or ccw) and

end coordinates. To specify which arc to contour, the

block commands “R” with a positive or negative sign.

To specify an arc that is less than 180 degrees, the block

commands a positive “R” value. To specify an arc

greater than 180 degrees, the G02 or G03 block

commands “R” with a negative value.

Example:

When G02 or G03 specifies the same coordinates for the

start and end of the arc, the machine contours a complete

circle. For complete circles, the block must specify the

center with I and J. Programming software must specify

both coordinates accurately. If the ending coordinates for

a circular move are not exactly the same as the starting

coordinates, the path may be a very small arc instead of

a complete circle. To avoid this problem, programs can

omit X and Y from a G02 or G03 block to command a

complete circle; the control will automatically apply the

same starting and ending coordinates.

1-2 EM-423 (R-02/11)

Page 9

Example: (G91) G03 I3 J0

CL-707 Arc Feedrate Programming

(Original Drive Design)

Model K T0 Tmax

If the syntax is incorrect, the software will display the

CIRCULAR INTERPOLATION SYNTAX ERROR

message.

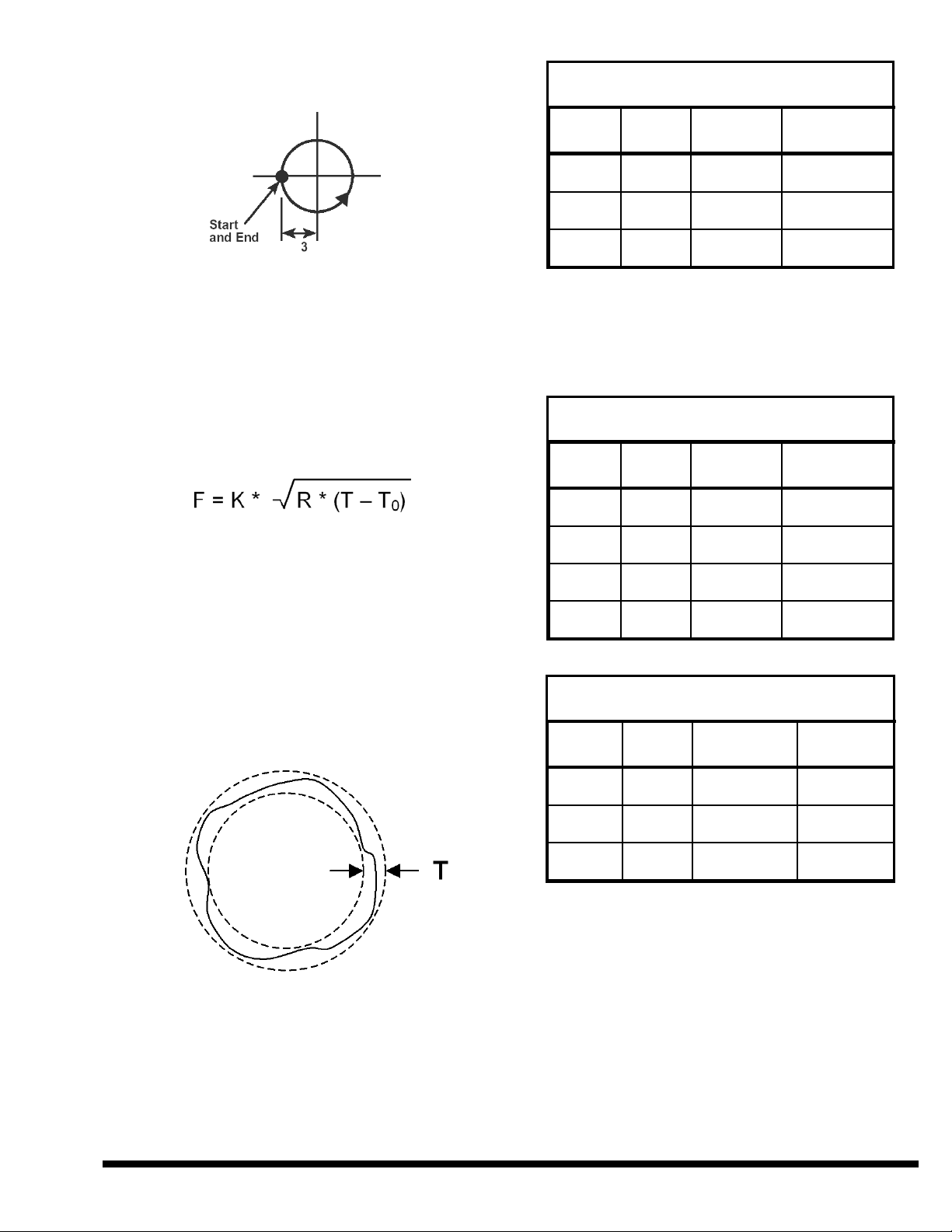

RECOMMENDED ARC FEEDRATE

Recommended maximum G02 or G03 feedrate depends

on machine design, arc radius, and allowable roundness

error. Use this equation to calculate the maximum

feedrate for each arc:

F = arc feedrate (IPM or mm/min.)

K = constant (1 / min.) See tables.

R = arc radius (inches or mm)

T = roundness tolerance (inches or mm)

T

= minimum radial error (inches or mm)

0

Roundness tolerance “T” is the radial distance between

two concentric circles that enclose the contoured shape.

To use this formula, the specified roundness tolerance

must be greater than “T

” and not more than “Tmax”.

0

4x8 18,000

5x10 18,000

6x12 18,000

.0002 in.

(.005 mm)

.0002 in.

(.005 mm)

.0002 in.

(.005 mm)

.006 in.

(.152 mm)

.006 in.

(.152 mm)

.005 in.

(.127 mm)

Arc feedrate programming parameters in the following

table apply to CL-707 laser systems with Serial

Numbers: 51226, 51242, 51296, 51466, 51509, 51553,

51572, 51631 and higher:

CL-707 Arc Feedrate Programming

(“Fast Pack” Drive Design)

Model K T0 Tmax

4x8 26,500

5x10 26,500

6x12 26,500

8x20 18,000

.0002 in.

(.005 mm)

.0002 in.

(.005 mm)

.0002 in.

(.005 mm)

.001 in.

(.025 mm)

.004 in.

(.102 mm)

.003 in.

(.076 mm)

.003 in.

(.076 mm)

.005 in.

(.127 mm)

CL-7A Arc Feedrate Programming

The maximum acceleration also determines the

maximum feedrate for contouring an arc. The following

tables include that requirement by specifying a

maximum roundness “Tmax” for each value of K. If the

roundness tolerance does not exceed Tmax, then the

calculated feedrate will not command the machine to

exceed the maximum acceleration.

EM-423 (R-02/11) 1-3

Model K T0 Tmax

4x8 6,000

5x10 6,000

6x12 6,000

.001 in.

(.025 mm)

.001 in.

(.025 mm)

.001 in.

(.025 mm)

.005 in.

(.127 mm)

.005 in.

(.127 mm)

.005 in.

(.127 mm)

To determine the feedrate for contouring an arc, compare

the calculated maximum feedrate to a minimum arc

feedrate (typically 30 IPM) and select the higher value.

Then compare the selected value to the material feedrate,

and use the lower value.

1.04 G04 DWELL

The G04 (or G4) command causes the CNC program to

dwell for the time specified by the P argument (in

milliseconds).

Page 10

Example (to dwell for one second):

G04 P1000

1.31 G31 POSITION CAPTURE

MOVE

This dwell time does not include the block processing

time of the CNC command.

If the software finds a syntax error, a message window

will display “DWELL SYNTAX ERROR”.

1.09 G09 EXACT STOP (ONE

BLOCK)

The program commands G09 (or G9) in the same block

as a G00, G01, G02 or G03 command. When the block

commands G09, the control does not proceed to the next

block until the axes reach zero feedrate. If the block does

not command G09, the control proceeds to the next

block when each axis position is within a specified

distance of the commanded position. The specified

distance is a system parameter.

Example: (G01 X_ Y_ ) G09

If the software finds a syntax error, a message window

will display “PROGRAMMING SYNTAX ERROR”.

1.20 G20 INCH MODE

1.21 G21 METRIC MODE

The G20 command puts the CNC in the inch units mode.

In G20 mode, the control interprets program coordinates

and feedrates in inch system units. (Positions are in

inches and feedrates are in inches per minute).

The G21 command puts the CNC in the metric units

mode. In G21 mode, the control interprets program

coordinates and feedrates in metric system units.

(Positions are in millimeters and feedrates are in

millimeters per minute).

When a program commands G31, the X and Y-axes

move to the specified coordinates in the Work

coordinate system. The G31 command uses the modal

contouring feedrate (F). While the axes are moving, the

control system monitors the Position Capture input. If

the control system receives the Position Capture input, it

records the X and Y-axis Machine coordinates at that

time and stores the values in system variables #5061 and

#5062.

G31 X_ Y_ (F_)

If the control detects more than one Position Capture

input during the move, it only saves the coordinates of

the first occurrence. If the control does not receive the

Position Capture input, it stores the coordinates at the

end of the move. The control always completes the move

to the coordinates specified in the G31 block (unless an

overtravel alarm stops motion).

Position Capture system variables:

#5061 = X axis Machine Coordinate

#5062 = Y axis Machine Coordinate

CINCINNATI macro programs use G31 to find

coordinates associated with optional measurement

functions (Workpiece Edge Detection or Optical Probe).

The machine control does not accept the G31 command

unless the machine configuration includes one of those

options.

1.40 G40 CANCEL KERF

COMPENSATION

1.41 G41 LEFT SIDE

COMPENSATION

The default mode is G20 when the CNC LASER

application starts. After the control runs a program, the

default mode is the same as the last program. To make

sure the control interprets a program correctly, the

program should begin by commanding G20 or G21 to

specify units.

G20 and G21 do not change the units mode of

CINCINNATI control windows. The windows display

values in inch or metric units as selected by the VIEW,

UNITS menu item.

1-4 EM-423 (R-02/11)

1.42 G42 RIGHT SIDE

COMPENSATION

G40 cancels G41 or G42. The cutting nozzle moves

from the compensated position to the commanded

coordinates during the G40 move.

Page 11

Example: G40

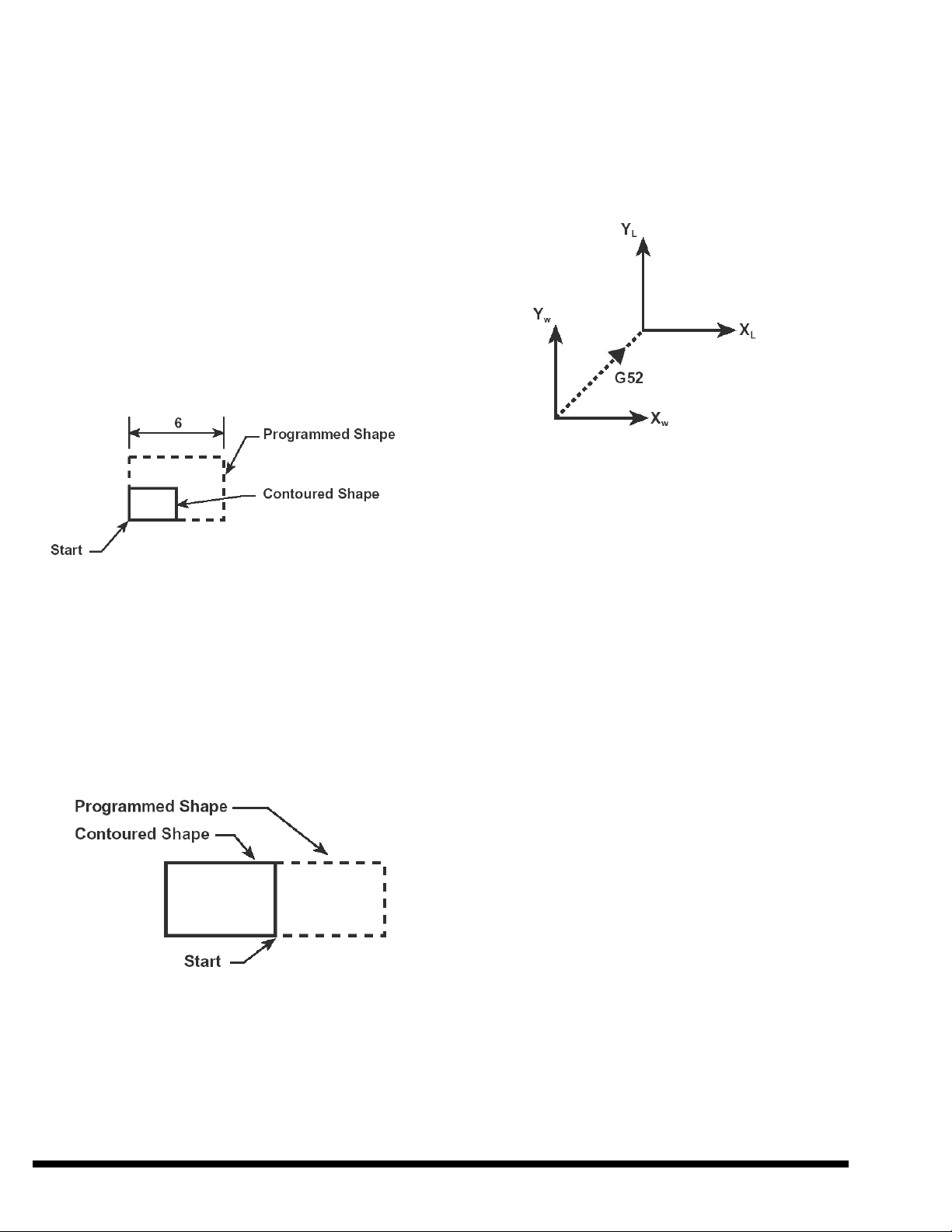

The CNC automatically commands the closest possible

position for the nozzle to contour the programmed shape

with the specified kerf size. If necessary, the control

inserts small moves so compensated paths intersect and

do not over-cut the shape.

Examples:

The control automatically cancels kerf compensation at

the end of any G00 or G53 move if the program

commands G00, G53, M02 or M30 in the next block.

If a program commands G40 in a block by itself, and

then commands a move without G41 or G42, the control

cancels compensation during that move.

A program commands kerf compensation with G41 or

G42. When a G01, G02 or G03 block commands G41 or

G42, the control begins that move with the nozzle offset

to one side of the programmed path. If a block

commands G41 or G42 without commanding a move,

the control ends the previous move with the cutting

nozzle offset to one side of the path.

Example: G41 and G42

1.50 G50 CANCEL SCALING

1.51 G51 WORK COORDINATE

SYSTEM SCALING

The CNC automatically offsets the cutting nozzle by half

the kerf width specified by last G89 command. (See

Section 2.89.)

G40, G41 and G42 form a modal group; the last G-code

commanded in the group is active for all blocks until the

program commands another code in the group. When

each program starts, the default code is G40.

EM-423 (R-02/11) 1-5

G51 X__ Y__ P__

G51 X__ Y__ I__ J__

The control interprets the work coordinate system at a

different scale or as a mirror image when the program

commands G51. The program can restore the normal

scale by commanding G50. When each program starts,

the default mode is G50. The Absolute Position window

and system variables indicate the actual position.

The G51 block defines the center of scaling with X and

Y, and the scale factor with “P”, “I” or “J”. To

command 1.0 scale (where the contoured shape is the

same as the programmed shape), the G51 block uses

P1000 (or I1000 or J1000). The G51 block can use I and

Page 12

J to command separate scale factors for the X and Y axes

(respectively). To contour a mirror image of the

programmed shape, the block commands I or J with a

negative value. The control does not scale the kerf

compensation offset distance when the program

commands scaling.

Example 1:

G91

G51 X0 Y0 P500

G01 X6

Y4

X-6

Y-4

G50

specified by X and Y in the G52 block. After the G52

block, the program makes contouring moves using the

new coordinate system. To restore the original work

coordinate system, the program commands “G52 X0

Y0”.

G52 X__ Y__

The G52 block does not move the cutting nozzle. The

Absolute Position window changes to indicate the nozzle

position in the temporary coordinate system.

Example 2:

G91

G51 X0 Y0 I-1000

G01 X6

Y4

X-6

Y-4

G50

To demonstrate how a program could use G52, consider

a program that uses a sub-program to contour the same

shape several times, and both the main program and subprogram use G90 (absolute) mode. The main program

would command a work coordinate system with G92 and

the sub-program would command a local coordinate

system with G52, then cancel it with G52 X0 Y0.

1.53 G53 RAPID MOVE TO MACHINE

COORDINATES

G53 X_ Y_

The G53 command moves the cutting nozzle at the rapid

traverse rate to a position specified by X and Y in the

machine coordinate system. G53 is only active in one

block and only in G90 absolute mode. No motion occurs

if the program commands G53 in G91 (incremental)

mode. The control does not change the machine

coordinate system when the program commands kerf

compensation, rotation, scaling, or mirror image, or if

the program changes the work coordinate system.

1.52 G52 LOCAL WORK

COORDINATE SYSTEM

The G52 command temporarily defines a new work

coordinate system while remembering the original. The

zero position of the new (or “local”) coordinate system

is at the coordinates in the original coordinate system

1-6 EM-423 (R-02/11)

1.54 G54 THROUGH G59

WORK COORDINATE SYSTEM SELECTION

A program can use G54 through G59 to command one of

six different pre-defined work coordinate systems. The

user can set the distance from Machine X0 Y0 to the

Work X0 Y0 position of each coordinate system with the

Page 13

“Position, Work Offset” window, or the program can

assign the distance with system variables #2501 through

#2506 (X) and #2601 through #2606 (Y).

G54 (OFFSET 1)

G55 (OFFSET 2)

G56 (OFFSET 3)

G57 (OFFSET 4)

G58 (OFFSET 5)

G59 (OFFSET 6)

program is in a separate file then the G65 block must

command “P” followed by the sub-program filename

including its extension (if any) and its path if different

from the calling program.

If the G65 command includes arguments, the command

must have a space between the last character of the

program name and the first argument. This is required

because program names can contain both numerals and

alphabetic characters.

A work coordinate system defined with G54 through

G59 does not need G92 to define its X0 Y0 position.

G54 through G59 override G92 by commanding a work

coordinate system with its X0 Y0 position preset on the

machine.

The G54 through G59 block does not move the cutting

nozzle. The absolute position window changes to

indicate the nozzle position in the new work coordinate

system.

If the block contains a syntax error, the control will

display the message “WORK COORDINATE SYNTAX

ERROR”.

1.61 G61 EXACT STOP MODE

1.64 G64 CANCEL EXACT STOP

MODE

G61 commands the CNC to use exact stop mode. In this

mode, the axes decelerate to a stop at the end of every

G00, G01, G02 or G03 block. The CNC remains in G61

mode until the program commands G64 or the program

ends.

The G64 command cancels exact stop mode. The default

mode when each program starts is G64. In G64 mode,

the control proceeds to the next block when each axis

position is within a specified distance of the commanded

position. The specified distance is a system parameter.

1.65 G65 SUB-PROGRAM CALL

(WITH OPTIONAL ARGUMENTS)

The G65 block specifies the sub-program name after

“P”, and may use other arguments to set local variables

in the subprogram.

Note: Revised CNC software (installed July 2001 or

later) does not require a space between the

program number and the first argument if a G65

command specifies P9800 or P9900.

For instructions on calling sub-programs with G65, see

SECTION 5. If the G65 block contains a syntax error,

the control displays the message “G65 SYNTAX

ERROR”.

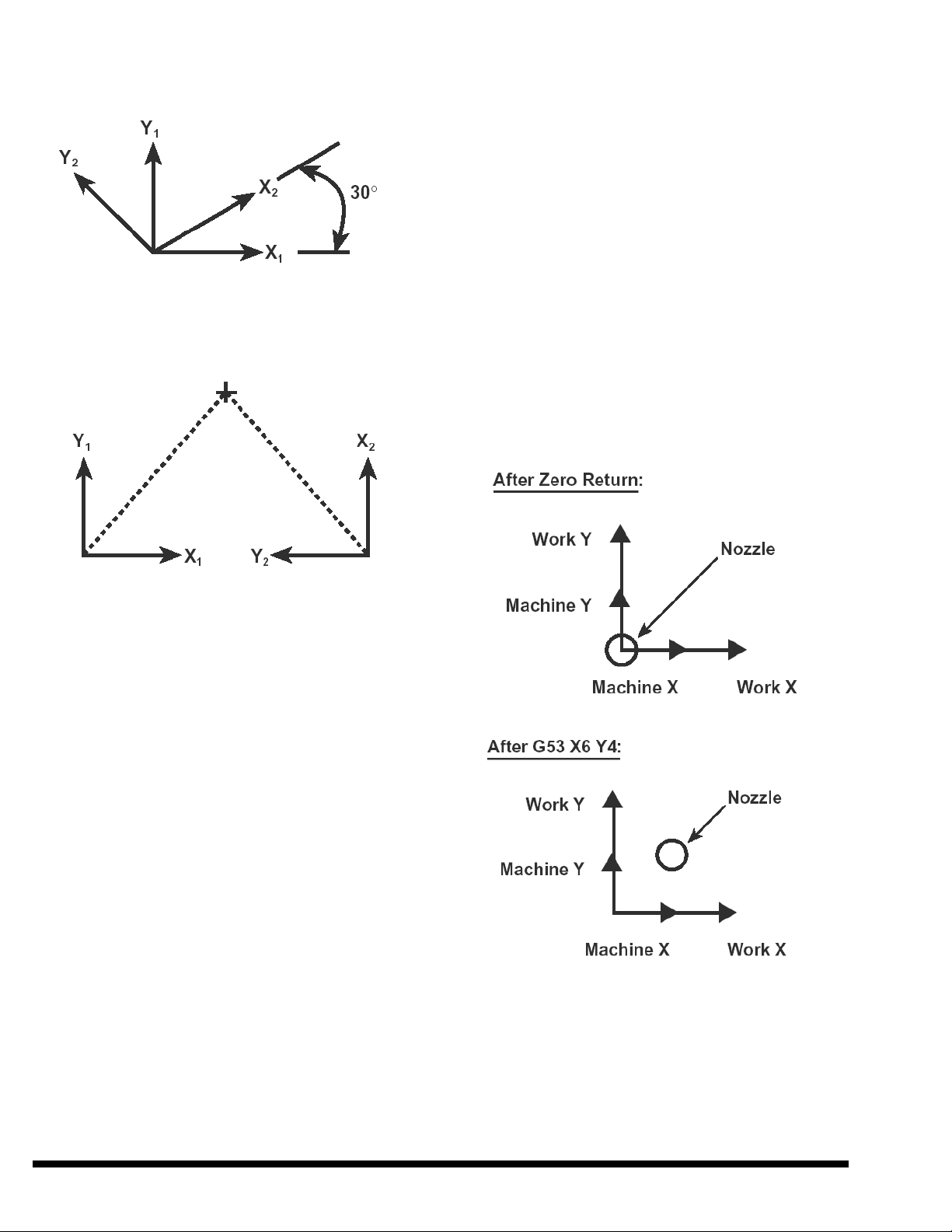

1.68 G68 WORK COORDINATE

SYSTEM ROTATION

1.69 G69 CANCEL ROTATION

A program can use the G68 command to rotate the work

coordinate system relative to the machine axes. The

command specifies the center of rotation with X and Y

work coordinates (or incremental distances). The

command specifies the amount of rotation with “R” in

degrees, with counterclockwise positive. In G90 mode,

R is the absolute angle of rotation. In G91 mode, R is the

incremental rotation angle that the control adds to any

previous rotation.

G68 X_ Y_ R_

The work coordinate system remains rotated until the

program commands G69 or the program is reset. G69

cancels all coordinate rotation. To cancel only the last

incremental rotation, command G68 in G91 mode with

the opposite amount for “R”.

The G68 or G69 block does not move the cutting nozzle.

The Absolute Position window and System Variables

indicate the nozzle position in the un-rotated work

coordinate system.

G65 P_ (A_ B_ C_ D_ etc. )

The G65 block must include “P” followed by the name

of the sub-program. If the sub-program is in the same

file as the CNC program, then the sub-program name

does not need an extension or path. However, if the sub-

EM-423 (R-02/11) 1-7

Page 14

Example 1: G68 X0 Y0 R30

X0 Y0 at Machine X0, Y0. The G92 command can

move the work coordinate system to any location.

G92 X_ Y_

X and Y define the new work coordinates corresponding

to the cutting nozzle position when the G92 block is

executed.

The G92 block does not move the cutting nozzle. The

Absolute Position window changes to indicate the nozzle

position in the new work coordinate system.

Example: G92 X0 Y0

Example 2: G68 X5 Y5 R90

1.90 G90 ABSOLUTE MODE

1.91 G91 INCREMENTAL MODE

In G90 absolute mode, the nozzle moves to the

coordinate location specified by the arguments in a G00,

G01, G02, G03 or G53 command. G90 mode is active

until the program commands G91 mode. When each

program starts, the default mode is G90.

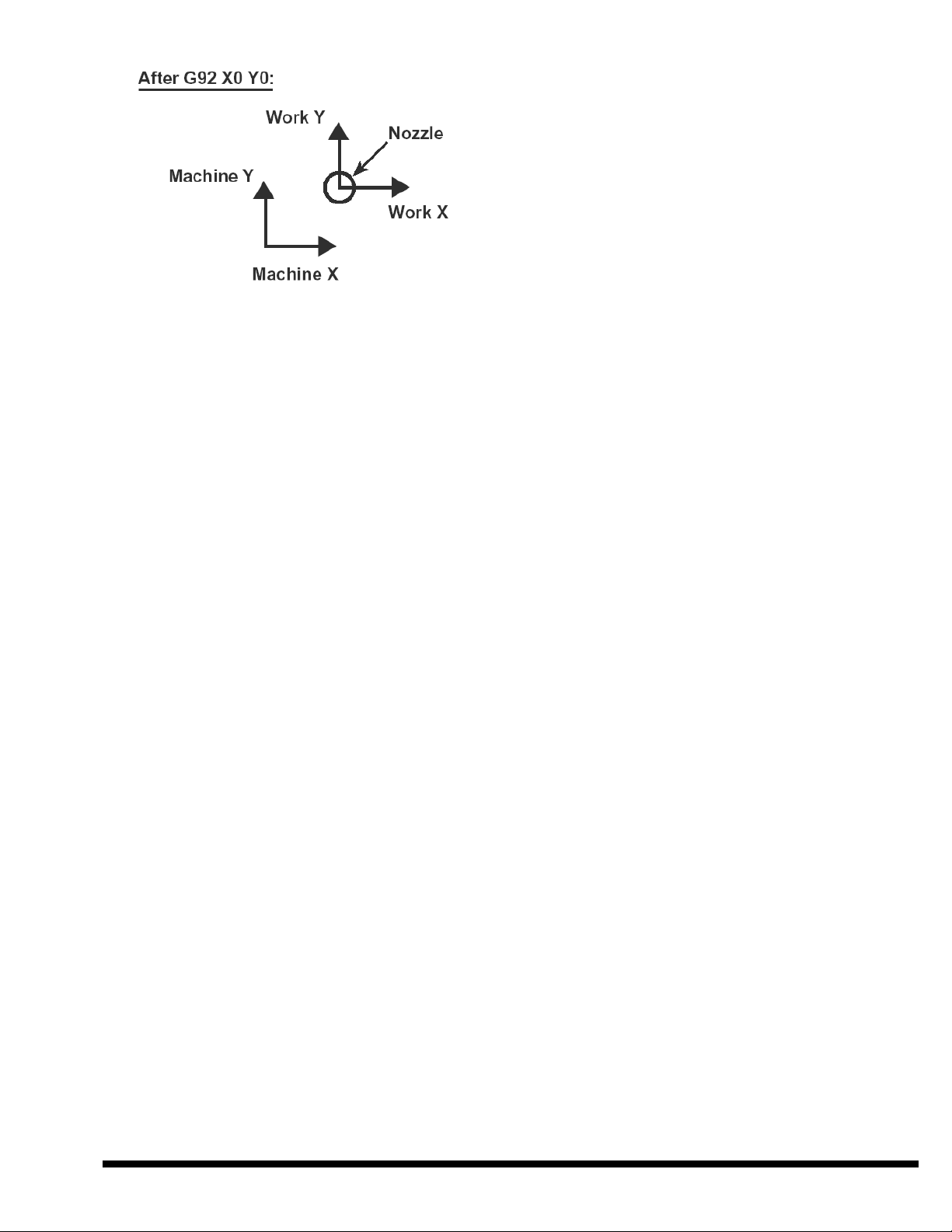

The G92 X0 Y0 command moves the work coordinate

system X0 Y0 location to the current position of the

cutting nozzle. Programmers often use this command to

begin a sub-program written in G90 mode.

G92 Example:

In G90 mode, X and Y coordinate values are modal. In

other words, if a block does not specify X or Y, the

control uses the last commanded value for X or Y.

In G91 incremental mode, the cutting nozzle moves a

distance from its starting location specified by X and Y

in a G00, G01, G02 or G03 command. G91 mode is

active until the program commands G90 or the program

ends. The control ignores a G53 command while

operating in G91 mode.

1.92 G92 WORK COORDINATE

SYSTEM SETTING

This command sets the work coordinate system location.

When the machine completes the Axes Home operation,

the control establishes the work coordinate system with

1-8 EM-423 (R-02/11)

Page 15

EM-423 (R-02/11) 1-9

Page 16

1-10 EM-423 (R-02/11)

Page 17

SECTION 2 CUSTOM G-CODES

The CINCINNATI control has built-in functions

programmed with custom G-Codes.

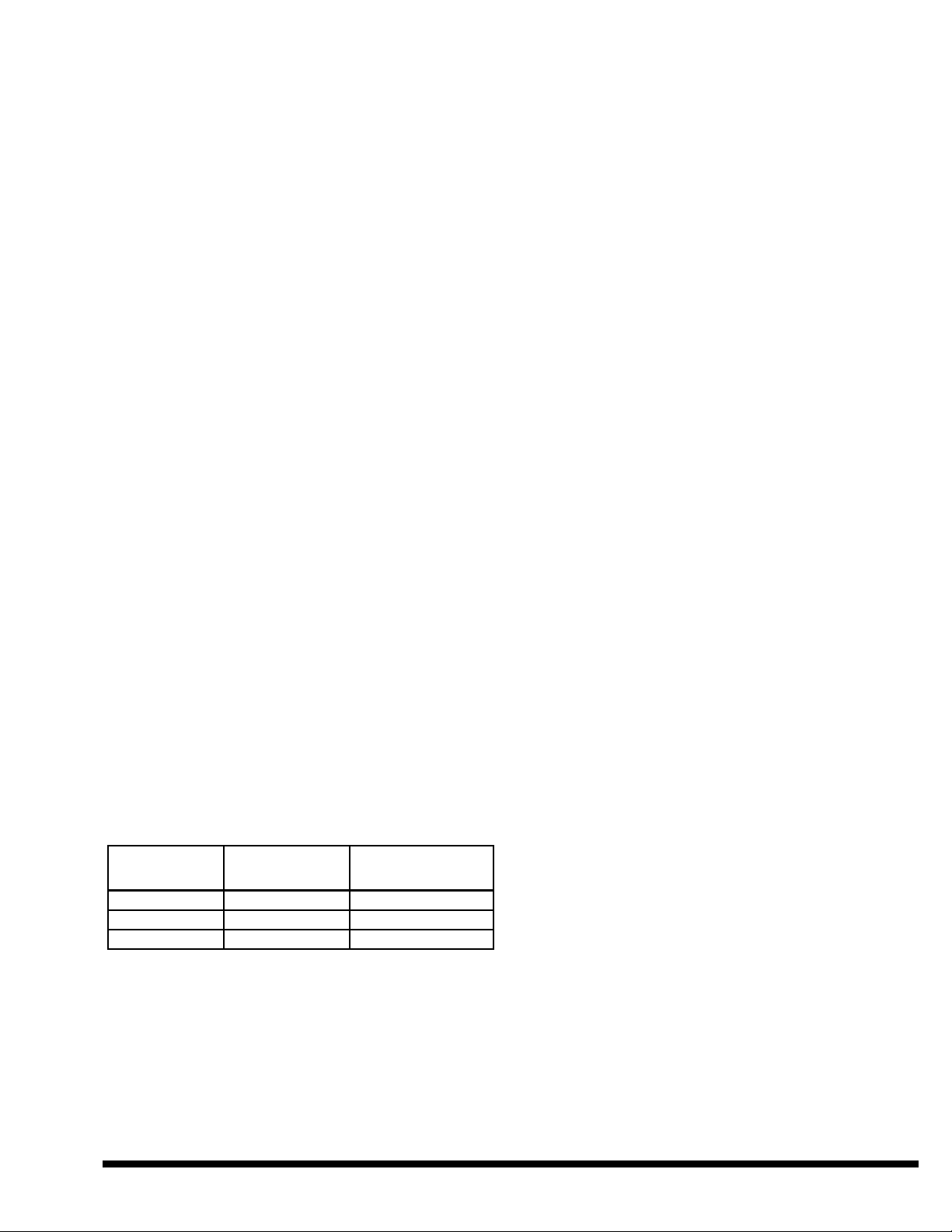

CODE DESCRIPTION SEC.

G84 Pierce and Start Cut 2.84

G85 Start Cut without Pierce 2.85

G89 Process Parameters 2.89

G102 Additional Parameters 2.102

G103 Ramped Pierce Parameters 2.103

G120 Disable Non-Stop Cutting 2.120

G121 Enable Non-Stop Cutting 2.121

G123 Programmable Blend 2.123

G124 Default Blend 2.124

G125 Auto Blend 2.125

2.84 G84 PIERCE AND START CUT

2.85 G85 START CUT WITHOUT

PIERCE

A program uses G84 or G85 to begin user-programmed

cutting sequences. G84 and G85 command the Z-axis to

move the nozzle down to the standoff position (if not

already there), and then command the pierce and/or cut

parameters. When the control finishes the G84 or G85

command, it returns to the program with the laser beam

on, assist gas on, and shutter open, ready to proceed with

contouring commands (G01, G02, G03). G84 and G85

also turn coolant on if the process parameters specify

coolant.

A program uses G85 to begin a cut sequence when the

application does not require the pierce cycle of G84.

G85 duplicates all other functions of G84, including

precut dwell and power burst time (see G102

description). After a program commands processing

parameters with G89, any cut sequence can start with

G84 or G85. Examples of G85 applications are: starting

a cut inside an opening, off the edge of the sheet, or in a

kerf.

AUTO RESTART

Tracing Function Forward or Reverse button to move in

the forward or reverse direction to another program

block. De-select Tracing mode and then press Cycle

Start to resume the cut. If an alarm condition interrupts

a program and the operator presses Cycle Start without

selecting Tracing mode, the cutting nozzle moves to the

start of the interrupted block and resumes cutting.

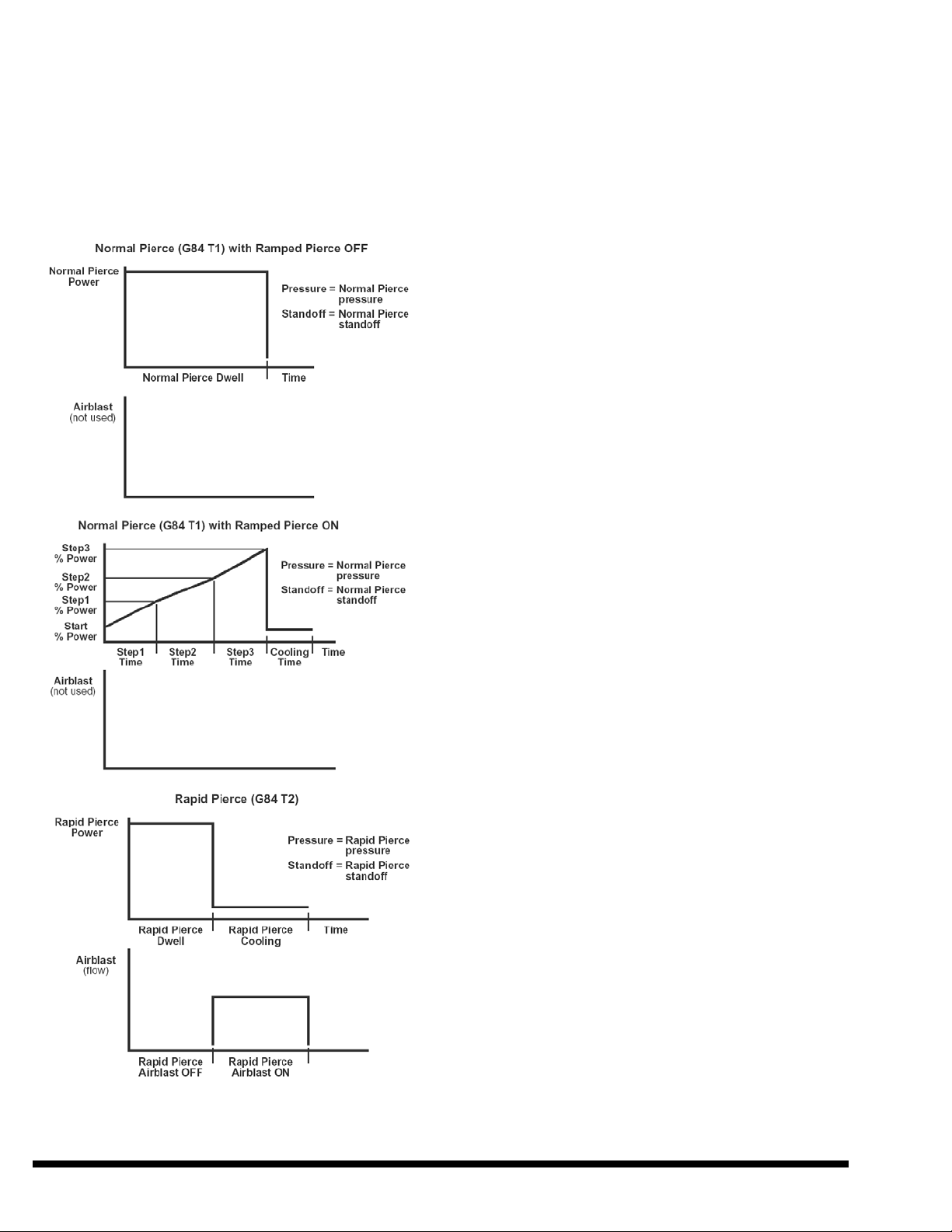

PIERCE OPTIONS (G84 T_)

Each process parameter library file has one set of cutting

parameters and three pierce options. The G84 “T”

argument selects the pierce option for each cutting path.

Normal Pierce G84 or G84 T1:

G84 T1 is the same command as G84. The program

commands normal pierce parameters with a G89 library

file, or explicitly with G89, G102 and G103 macro calls.

Rapid Pierce G84 T2:

The program commands G84 T2 to use rapid pierce.

Rapid pierce has separate laser power, gas pressure,

dwell time and standoff parameters. Laser pulse mode is

always 5000 Hz and 100% duty cycle. G84 T2 uses the

same assist gas (#1 or #2) and part coolant status as

normal pierce.

Rapid pierce uses a single power level during the pierce,

so ramped pierce is always OFF. Rapid pierce also has a

cooling time parameter independent from G84 T1 and

airblast time parameters.

G89 loads rapid pierce parameters from a library file.

The NC program cannot set rapid pierce parameters

explicitly with G89, G102 or G103. When the program

commands normal pierce parameters explicitly, the

default T2 parameters are the same as T1.

G84 T3:

G84 T3 operates the same as G85 (no pierce).

Note: All G84 pierce options (T1, T2 or T3) command

pre-cut dwell before returning to the program.

For a description of pre-cut dwell, see G102 in

this section.

When a laser system has the CINCINNATI control, the

CNC program does not require special codes or

commands to activate Auto Restart. When an alarm

condition interrupts a program, the operator can restart

the program at any block. After correcting the condition

that caused the interruption, the operator can select

Tracing mode, press Cycle Start, then hold down the

EM-423 (R-02/11) 2-1

AIRBLAST

The rapid pierce process uses a separate blast of

compressed air to help clear molten material from the

pierce area. Two airblast parameters (“OFF time” and

“ON time”) control the opening of the airblast solenoid

valve.

Page 18

The OFF time is a delay that starts when the pierce

begins. The air valve is closed during the OFF time.

When the delay ends, the air solenoid valve opens. The

valve then stays open for the ON time. To edit the

airblast times, open the Process Library Window.

The following figures show the function of G84 T1 and

T2 parameters:

2.89 G89 PROCESS PARAMETERS

The program sets processing parameters by commanding

G89. When G89 loads processing parameters with a

library file, the operator can edit the parameters while

the program is running; however, changes will NOT take

effect until the next G84 (or G85). To change

parameters, open the library file, edit the parameter(s)

then save the library file.

The CINCINNATI control will also accept G89, G102

and G103 commands programmed with explicit

parameters.

G89 WITH LIBRARY FILE

G89 Pfilename.lib

The G89 command uses address “P” to specify a library

file. The operator can edit library files in the Process

Parameter window. The default path is:

D:\CNCLSR32\MATERIAL\

The filename must include the “.lib” extension.

If the library file is not in the MATERIAL folder, the

G89 command must include the path. The user can

create other library directories, in either the MATERIAL

folder or elsewhere on the disk.

CINCINNATI INCORPORATED provides a set of

read-only library files in this folder:

“D:\CNCLSR32\MATERIAL\ARCHIVE\”

The MATERIAL directory includes copies of the same

library files, which the user can edit.

Library filenames provided by CINCINNATI

INCORPORATED begin with an abbreviation for

material:

AL . . . Aluminum

MS . . . Mild Steel

SS . . . Stainless Steel

After the material abbreviation, the library filename has

a three-digit number representing the material thickness

in mils.

Example: (For 10 gauge mild steel 0.135”): MS135

The filename may include other characters after the

thickness number, to indicate a resonator type or

processing application.

After the thickness number, the filename may have a

chemical abbreviation for the cutting assist gas:

2-2 EM-423 (R-02/11)

Page 19

O2 . . . Oxygen

N2 . . . Nitrogen

For applications using coolant, the library filename ends

with the word “wet”.

Examples: (10 gauge mild steel, oxygen cut)

Without coolant: MS135O2.lib

With coolant: MS135O2wet.lib

When pulsed laser output is used, frequency and

duty cycle are specified with a 4-digit code in which

the first two digits specify frequency (Hz/100) and

the last two digits specify duty cycle (%).

For DC (diffusion-cooled) resonator, maximum

frequency is 5000 Hz and minimum duty cycle is the

value necessary for a pulse ON time of 26

microseconds at the commanded frequency.

G89 CALL WITH ARGUMENTS:

G89 T_ A_ I_ M_ S_ C_ D_ Q_ B_ E_ H_ R_ J_

K_ U_ V_

T = Cut power level, watts.

A = Cut gas code. See Note 1.

I = Cut gas pressure. See Note 2.

M = Cut laser mode, see Note 3.

S = Cut pulse code, see Note 4.

C = Cut coolant code. See Note 5.

D = Pierce time, seconds.

Q = Pierce power level, watts.

B = Pierce gas code. See Note 1.

E = Pierce gas pressure. See Note 2.

H = Pierce laser mode, see Note 3.

R = Pierce pulse code, see Note 4.

J = Pierce coolant code. See Note 5.

K = Kerf width, see Note 2.

U = Maximum feedrate for Dynamic Power, see Note 2.

V = Minimum percent for Dynamic Power (% at zero

feedrate)

Notes:

1. Assist gas codes (A & B):

11 = Gas Port #1 (usually O2)

12 = Gas Port #2 (usually N2)

2. G89 interprets pressures, kerf width, and dynamic

power feedrate in the active units:

Parameter G20 unit G21 unit

I & E PSI kPa

K inches mm

U IPM mm/min

5. Coolant codes (C & J):

8 = coolant ON

9 = coolant OFF

When CINCINNATI laser systems with Fanuc control

have the Macro Executor option, programs written for

those laser systems can specify process parameters with

G89 X_, where X is followed by a library code number

from 1 to 100. The CINCINNATI control will accept a

program with the “G89 X” command (instead of G89 P),

if the Material folder has a library file with the same

name as the number following “X”. For example, the

CINCINNATI control will accept a program

commanding “G89 X32” if the Material folder has a

library file named “32.lib”.

When a program commands G89, G102 or G103 with

explicit parameters, the CINCINNATI control checks

the parameters for out-of-range values. If the control

finds any, it displays an error message in a pop-up

window indicating which parameter has the error. The

window identifies parameters by the name used in the

Process Parameter Library window, not by the G89,

G102 or G103 argument. For example, “Pierce Gas

Pressure out-of-range” instead of “G89 E out-of-range”.

2.102 G102 ADDITIONAL

PARAMETER SETTINGS

The Parameter Library window includes settings for

dynamic gas pressure, noncontact standoff, optional

pressure, precut dwell and power burst time. In addition

to commanding these parameters in a library file with

G89, the program can also command these parameters

explicitly with G102.

G102 A_ B_ S_ Z_ D_ I_ T_ Q_ R_ U_ V_

3. Laser mode (M & H):

61 = Continuous Wave

62 = Gated Pulse

66 = Dynamic Power

4. Pulse codes (S and R):

EM-423 (R-02/11) 2-3

A = Dynamic gas pressure near field setting

B = Dynamic gas pressure far field setting

S = Pierce standoff

Z = Cut standoff

D = Precut dwell, seconds

I = Optional pressure

T = Power burst time, seconds

Q = Pierce Focus, Near Field

Page 20

R = Pierce Focus, Far Field

U = Cut Focus, Near Field

V = Cut Focus, Far Field

G102 interprets pressure, standoff and focus settings in

the active units:

Parameters G20 unit G21 unit

A, B & I PSI kPa

S & Z inches mm

Q, R, U & V inches mm

A & B: When a program commands dynamic gas

pressure, the control regulates cutting assist gas

pressure between the Near (A) and Far (B) field

settings based on the machine position of the nozzle.

Near field is where the laser beam length is shortest.

S & Z: The program uses these settings to command

pierce and cut nozzle standoff distance for the

noncontact head.

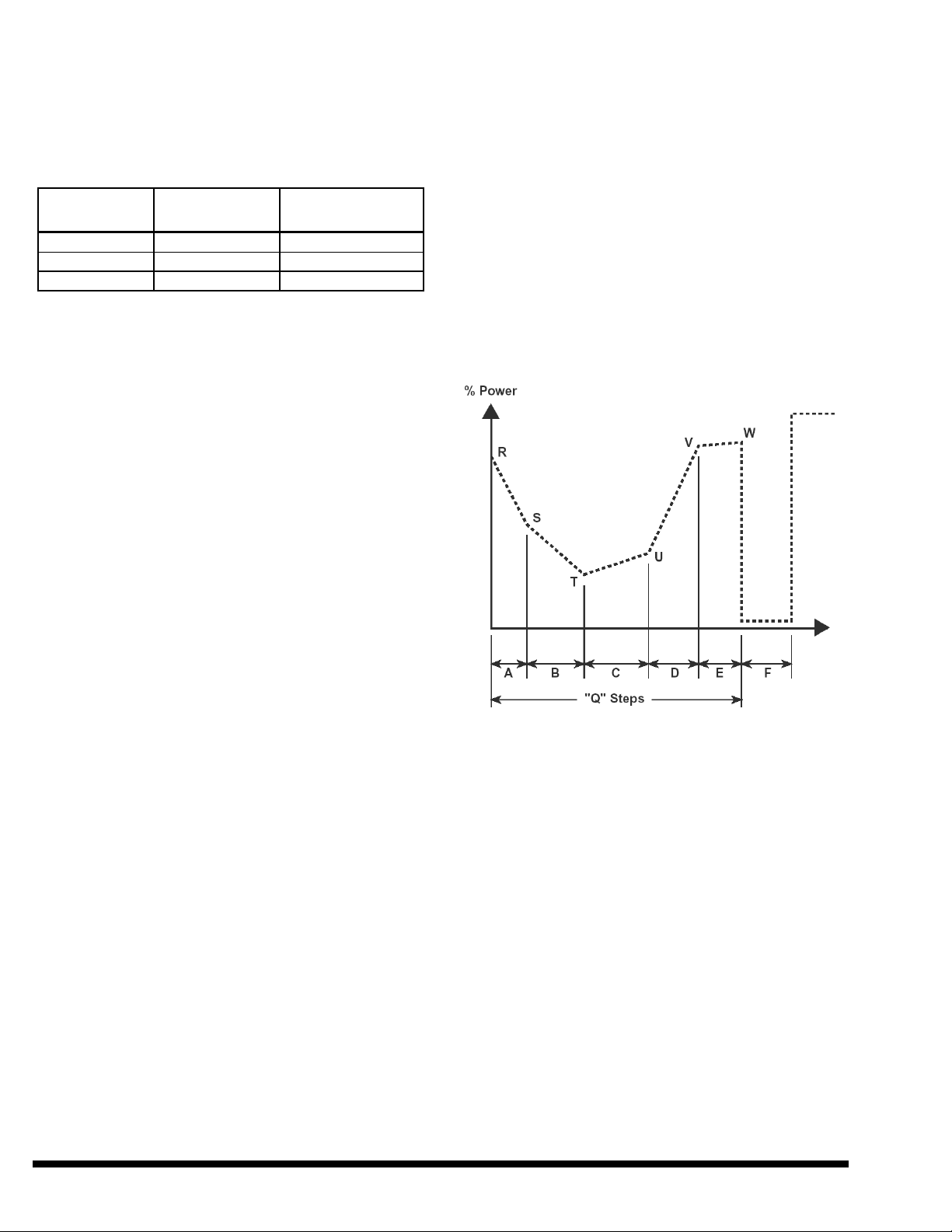

G103 A_ B_ C_ D_ E_ F_ Q_ R_ S_ T_ U_ V_ W_

A = Ramp 1 duration, seconds

B = Ramp 2 duration, seconds

C = Ramp 3 duration, seconds

D = Ramp 4 duration, seconds

E = Ramp 5 duration, seconds

F = Tip cooling time, seconds

Q = Number of ramp steps (1 to 5)

R = Percent power at start of first ramp

S = Percent power at start of second ramp

T = Percent power at start of third ramp

U = Percent power at start of fourth ramp

V = Percent power at start of fifth ramp

W = Percent power at end of fifth ramp

D: Before returning to the program, G84 and G85

command the cutting parameters and then command

the pre-cut dwell.

I: The assist gas pressure controller uses the optional

pressure setting when a program commands M67.

T: When the laser system starts a contouring move using

dynamic power, the control maintains dynamic power

at 100% for the time specified for Power Burst. After

the Power Burst time, the control regulates dynamic

power according to the actual feedrate.

Q, R, U and V: When CL-707 lasers or CL-7A lasers

with CINCINNATI control have the Auto Focus

Cutting Head option, the G102 command has

additional arguments to specify focus settings. The

settings specify focus position relative to the nozzle

tip. The Auto Focus drive uses the Near field settings

when the cutting head is closest to the laser source,

and changes focus between the Near and Far settings

as X and Y-axis motion changes the optical path

length. Q and R specify the Near and Far field pierce

focus settings. U and V specify the Near and Far

field cut focus settings.

2.103 G103 RAMPED PIERCE

SETTINGS

To set parameters for ramped pierce power, the CNC

program can either command G89 with a library file, or

command G103 with explicit settings.

G103 Ramped Pierce Arguments

2.120 G120 DISABLE NON-STOP

CUTTING

2.121 G121 ENABLE NON-STOP

CUTTING

When a program commands Non-Stop Cutting (G121),

the CNC replaces short G00 moves between cut

sequences with “Smart Rapid” moves. A Smart Rapid

move commands the laser beam off and on without

stopping the axes. (See Smart Rapids description below.)

During a Smart Rapid move, the control maintains assist

gas flow, even when the laser beam is off.

Notes: A program can only command Non-Stop cutting

mode when the process parameters specify no

pierce time and no precut dwell.

2-4 EM-423 (R-02/11)

Page 21

If the operator edits and saves process

parameters while running a program in Non-

program should not command G00. The control will not

replace G01 G02 or G03 moves with Smart Rapids.

Stop mode, the CNC ignores the changes until

the program ends.

Notes: In this description, G85 can replace G84.

The G120 command cancels Non-Stop cutting mode.

When each program starts, the default mode is G120.

SMART RAPIDS

Programming software normally commands a single

G00 linear rapid move between the end of one cut

sequence and the beginning of the next. The G00 move

commands the shortest distance between the two points

(to minimize the time between cuts). However, in the

default mode (G120), the nozzle must stop before and

after the G00 move (to turn the beam off and on). In

Non-Stop cutting mode (G121), the nozzle does not stop

to turn the beam off or on.

When the operator loads a program, the control

translates the program into commands for the CNC to

execute. If the program specifies G121 mode, the control

translates G00 moves into “Smart Rapid” moves. The

control replaces the G00 move and the contouring moves

before and after it with commands that maintain the

original beam-on path without stopping the axes.

The CINCINNATI software performs these tasks to

create a Smart Rapid:

When the move before M35 or after G84 is an

arc, the control inserts a Smart Rapid G01 move

tangent to the arc at the intersection point.

BEAM ON / OFF TIMING

The laser system can turn the beam on and off at a

desired time within 3 to 5 milliseconds. This means that

the cut actually starts or stops within a distance

representing 3 to 5 milliseconds of travel on either side

of the desired point.

Example:

At 300 inches/min., the length of the tolerance band

could be (300 in./min.) / (60 sec./min.) * .005 sec. = ±

.025 inches (0.63 mm)

The size of the tolerance band depends on the control

design. In the original control design, the tolerance is ±

5 milliseconds. For laser systems with the “Fast Pack”

control design, the tolerance is ± 3 milliseconds.

CUT EXTENSION

The CNC determines the G121 extension time to control

how the laser system cuts shapes in G121 mode.

1. Command M35.

2. Command a G01 move after M35 at the same

feedrate and direction as the move before M35.

3. Command a G01 move at high feedrate between the

G01 moves inserted in Steps 2 and 4.

4. Command a G01 move before G84 at the same

feedrate and direction as the move after G84.

5. Command G84.

6. Lengthen the move after G84.

Although the CNC uses a “linear” G01 connecting move

(instead of G00), the high G01 feedrate produces a

curved path as the axes blend with the other G01 moves.

The result is a smooth non-stop transition between cuts.

If the original program has anything other than a single

G00 move between cuts (between M35 and G84), the

control does not create a Smart Rapid.

During a Smart Rapid move, the nozzle may deviate

from the original programmed path while the beam is

off. If the nozzle must follow the original path, then the

Consider a round hole with a radial lead-in. In

conventional cutting, the programmer might end the

lead-in with exact stop (G09). However, a lead-in

programmed for Non-Stop mode may not command

exact stop, and the end of the lead-in would blend into

the start of the circular move. Also, beam On/Off

positions are not as precise when using Smart Rapids (as

described above). Thus, the slug from a 360-degree

circular hole may not drop because the beam would not

cut the entire perimeter of the hole (see figure below).

Extending the circular move assures that the beam will

cut the entire shape.

EM-423 (R-02/11) 2-5

Page 22

It is important to place the lead-in so the extension of its

last entity will meet or overlap the beginning of the first

contoured entity. If the program commands a lead-in at a

corner, the extension of the last entity will cut past the

desired perimeter of the feature, as shown in the

following diagram.

EFFICIENCY

As described above, the path of a Smart Rapid is not a

straight line. The ends are smoothed, the way a baseball

player rounds the base paths on an extra base hit.

Program efficiency is greatest when the path length is

shorter. Path length between two features depends on

cutting direction and placement of lead-ins, as shown in

the following diagram.

2.123 G123 PROGRAMMABLE

BLEND

2.124 G124 DEFAULT BLEND

2.125 G125 AUTO BLEND

The process of ending one contouring move and

beginning the next move usually requires changing the

velocity of one or both axes. In this manual, this process

is called a “blend”.

The objective of a blend is to change the axis from

executing the preceding move at its constant velocity to

executing the next move at a different constant velocity.

To accomplish this transition, acceleration also changes

during the blend. When velocity is constant, acceleration

is zero. Therefore, during a blend (between linear moves,

for example), acceleration begins at zero, increases or

decreases to produce the velocity change, then returns to

zero to complete the blend.

The CINCINNATI control executes a blend using two

parameters: the overall time to complete the velocity

change and the portion of that time which is used to

change the acceleration. Just as a motion system has a

maximum velocity and a maximum acceleration, it is

also limited by how quickly it can change acceleration.

The cases shown in the figure have two programming

differences: the cutting direction of the left hole, and the

location of the lead-in on the right hole. Note the “Uturns” required in the top path.

When selecting lead-in locations, the desire to minimize

Smart Rapid path length may conflict with the desire to

maximize “head down” operation (by avoiding tipped

slugs). The conflicting requirements often require some

compromise.

Short blend times improve contouring accuracy and

increase productivity by using high acceleration, but can

produce servo following errors if the machine attempts

to exceed its acceleration capability. Long blend times

avoid servo following errors but sacrifice contouring

accuracy. Since blend time settings can affect processing

results, users can program blend times with three

different commands:

G123 specifies fixed time values for all blends:

G123 A_ S_

A = Total blend time, in milliseconds

S = Time for acceleration change, in milliseconds

The minimum value of “A” is S * 2.

2-6 EM-423 (R-02/11)

Page 23

G124 commands the control to use a set of default times

for all blends. The default time values are set by

CINCINNATI INCORPORATED.

G125 Auto Blend enables the control to determine the

minimum X and Y blend times independently for each

move.

When each program starts, the default mode is G125.

Different parts of a program can use different blend

control modes. A program can change from G123, G124

or G125 to either of the other modes.

If either G123 or G124 setting is less than a minimum

time, the control uses the minimum time without

displaying an error message. The control determines the

minimum blend time for each move using parameters set

by CINCINNATI INCORPORATED.

EM-423 (R-02/11) 2-7

Page 24

2-8 EM-423 (R-02/11)

Page 25

SECTION 3 M-CODES

Most M-codes command machine functions not directly

related to CNC operation. If an M-code block does not

have the proper syntax, program execution stops and a

message window displays the message “INVALID MCODE”.

has selected the Optional Stop button on the CNC

control window. The program resumes when the

operator presses CYCLE START.

3.02 M02 END OF PROGRAM

CODE DESCRIPTION SEC.

M00 Cycle Stop 3.00

M01 Optional Stop 3.01

M02 Program End (No Rewind) 3.02

M30 Program End (and Rewind) 3.30

M35 Beam Off 3.35

M36 Noncontact Z-Axis Servo Hold 3.36

M37 Beam Off, Gas Off, Shutter Close 3.37

M38 Timed Z-Axis Servo Hold 3.38

M41 Lower Z –Axis 3.41

M42 Retract (Raise) Z Axis 3.42

M43 Enable Lower Pallet Special

Function

M44 Disable Lower Pallet Special

Function

M45 Apply Optional Standoff 3.45

M47 Raise Z-Axis, optionally by

distance

M48 Disable Feedrate Override 3.48

M49 Enable Feedrate Override 3.49

M50 Switch Pallets 3.50

M51 Enable Timed Auxiliary Output 3.51

M67 Apply Optional Gas Pressure 3.67

M98 Call Sub-program 3.98

M99 Return from Sub-program 3.99

M130 Disable Anti-dive 3.130

M131 Enable Anti-dive 3.131

M135 Beam Off with Gas On 3.135

3.43

3.44

3.47

3.00 M00 PROGRAM STOP

When the CNC executes a program block commanding

M00 (or M0), the program stops until the operator

presses CYCLE START. If the laser beam and assist gas

were on, the M00 command turns them off. M00 places

the CNC in a Cycle Stop condition. Modal information

does not change.

3.01 M01 OPTIONAL STOP

The M01 (or M1) command has the same function as the

M00 command, except M01 is only active if the operator

A CNC program can use M02 (or M2) as the last block.

This function disables all processing functions, resets all

previously requested M-codes and prevents further

execution. The program does not rewind automatically.

When the operator loads a program into the CNC, the

control ignores any codes following M02.

3.30 M30 END OF PROGRAM WITH

REWIND

Most CNC main programs use M30 as the last block.

This function disables all processing functions, resets the

CNC, cancels all previously requested M-codes,

prevents further execution and rewinds the program.

3.35 M35 BEAM OFF

M35 turns the laser beam OFF at the end of a cut

sequence. Laser discharge current stops. Assist gas flow

also stops, unless the SPEED GAS option in the

Variables menu is selected (see M135). Discharge

current remains OFF until the next G84 or G85.

3.36 M36 SERVO HOLD FOR

NONCONTACT Z-AXIS

The M36 command places the Z-axis control for the

Non-contact head in a servo hold condition when the

nozzle is in the cutting position and the laser beam is

ON. The noncontact head does not follow the material

after the program commands M36. To clear M36, the

program commands M35, M37, M42, M47 or M30, or

the operator presses RESET.

3.37 M37 BEAM OFF, GAS OFF AND

SHUTTER CLOSE

M37 turns off the laser beam and assist gas and

commands the shutter to close. M37 also resets any

previously requested M-codes.

To avoid unnecessary cycling of the gas valves and

shutter, most programs use M35 instead of M37. The

EM-423 (R-02/11) 3-1

Page 26

control accepts M37 to support programs written for

laser systems without M35.

3.38 M38 TIMED NONCONTACT

SERVO HOLD

M38 places the Z-axis control for the Noncontact head

in a servo hold condition for a period of time after the

control establishes the cutting position. The M38 block

specifies the time with the P argument (in milliseconds).

Example:

M38 P2000

(This example commands the Z-axis to maintain a

fixed position for 2 seconds after reaching the nozzle

standoff position.)

To start the M38 time, the Z-axis must be in the cutting

position with the beam on, and the X or Y axis must be

moving. The Z-axis maintains position until the time has

elapsed. After the specified time, the Z-axis goes into

tracking mode.

The program can command M38 before or after G84. To

cancel M38, the program commands M36, M42, M47 or

M30, or the operator presses RESET.

3.41 M41 COMMAND Z-AXIS DOWN

TO CUT POSITION

systems equipped with the Lower Pallet Special

Function option, users can extend the allowable beam-on

range to 7.0 inches (178mm) on the lower pallet by

commanding M43.

The M43 operating mode allows the machine to process

square or rectangular tubing or other formed parts on the

lower pallet. Operation above 1.5 inches (38mm) is not

possible on the upper pallet because the Z-axis reaches

its upper limit.

M43 changes these control functions:

1. The Z-axis travels down from the top position at a

lower speed to find the material surface.

2. The pallets cannot be moved with M50 or with

pallet JOG buttons.

3. The Y-axis cannot exceed the machine coordinate

specified on the CONFIGURATION window for

this option.

M43 disables pallet motion because material over 1 inch

(25mm) high will not clear the upper pallet. Since the

pallets cannot move and the X-axis beam delivery blocks

access to the pallet from one side of the main frame, the

operator must load and unload the pallet from the other

side of the main frame (the operator side). To keep

material within reach of the operator side, the control

does not allow the Y-axis to exceed the machine position

set on the CONFIGURATION screen.

M41 commands the Z-axis to move the cutting nozzle

down to the commanded standoff position. Programs

normally do not use M41 because G84 and G85 include

that function. M41 allows a program to command the

cutting nozzle down to the material without starting a

cut.

If the cutting head does not find material, the Z-axis

travels down until it reaches a minimum position or

exceeds a time limit, causing motion to stop.

3.42 M42 RETRACT Z-AXIS

M42 commands the Z-axis to the full up position. The

shutter is commanded to close. Programs use M42 to

command the Z-axis to the required position for pallet

motion.

3.43 M43 LOWER PALLET SPECIAL

FUNCTION

In normal operation, the control only allows the beam on

when the cutting nozzle is within 1.5 inches (38mm) of

the material support height on either pallet. On laser

Recommended procedure to use M43:

1. Move the upper pallet OUT and the lower pallet

IN.

2. Jog the nozzle to Machine Y0.

3. Load and execute a program with only M43 and

M30. (CINCINNATI provides such a program

named “M43.cnc”.)

4. Verify M43 mode is active (FYI Message).

5. Load material on the lower pallet.

6. Load the CNC program for the loaded material.

Programs using M43 mode can begin with M43, but to

avoid accidental damage, do not load material over 1

inch (25mm) high until M43 mode is already active. The

control will execute the M43 command with Program

Test on or off.

3-2 EM-423 (R-02/11)

Page 27

When a laser system has this option, the CNC is in M43

mode each time the operator turns on the machine

control. M43 mode is NOT cancelled by M30, RESET

or turning off the control. The only way to cancel M43

mode is to run a program commanding M44.

3.44 M44 CANCEL LOWER PALLET

SPECIAL FUNCTION

3.47 M47 RAISE Z-AXIS,

OPTIONALLY BY DISTANCE

M47 commands the Z-axis to raise a fixed distance, or a

programmed distance if the command specifies a value

with “P”. The Z-axis Maintenance Configuration

window displays the fixed M47 distance as “Default

Partial Z-Up Distance (M47)”.

The M47 command can specify a programmed distance

with “P”. The distance units are thousandths of an inch

for G20 mode and thousandths of a millimeter in G21

mode. Maximum command is M47 P3000 for 3 inches

or M47 P76200 for 76.2 mm.

Programs raise the Z-axis with M47 to avoid interference with clamps or tipped parts during a non-cutting

move.

M44 cancels the Lower Pallet Special Function mode

commanded with M43. The M44 command restores

normal Z-axis speed, pallet motion and Y-axis range.

The control will execute the M44 command with

Program Test on or off.

To cancel M43 mode:

1. Remove any material or fixture over 1 inch (25

mm) high.

2. Load and execute any program beginning with

M44.

3.45 M45 APPLY OPTIONAL

STANDOFF FOR CUTTING

When the CNC program commands M45 after starting a

cut sequence, the non-contact head standoff changes to

the “Optional Standoff” distance specified in the active

parameter library file. The M45 command does not

change pierce standoff.

3.48 M48 FEEDRATE OVERRIDE

DISABLE

M48 disables the feedrate override dial on the operator

control station and sets the feedrate to 100% of the value

specified in the program. M48 is canceled by M49, M30

or RESET.

3.49 M49 FEEDRATE OVERRIDE

ENABLE

M49 restores the function of the feedrate override dial on

the operator control station. When a program starts, the

default mode is M49.

3.50 M50 SWITCH PALLETS

M50 commands the upper and lower pallets to switch

positions. The pallets will switch positions only if the

Pallet Not Ready pushbutton/indicator is not illuminated.

If necessary, the M50 command will also retract the

cutting nozzle (like M42).

The control illuminates the PALLET NOT READY

pushbutton when a program starts. The illuminated

button indicates the pallets are “Not Ready” to switch

positions. The operator can press the button to toggle the

status ON or OFF before the program reaches the M50

block. If the button is not illuminated when the program

executes the M50 block, the pallets will reverse

positions.

EM-423 (R-02/11) 3-3

If the PALLET NOT READY button is illuminated

when the program reaches the M50 block, the program

will stop. To resume the program, the operator can then

press the PALLET NOT READY button and the pallets

will reverse positions.

Page 28

3.51 M51 AUXILIARY TIMED

OUTPUT

M51 commands a set of isolated relay contacts to close

for the time specified by the P argument. Data Range is

0 to 10000 milliseconds. The default time is zero.

(This example calls a sub-program named “1200”

three times.)

When a program calls a sub-program with M98, the two

programs share the same set of local variables (See

SECTION 5).

Example:

M51 P1000

(This example commands the auxiliary contacts to

close for one second.)

3.67 M67 APPLY OPTIONAL ASSIST

GAS PRESSURE

M67 changes the cutting assist gas pressure command to

the Optional Pressure setting in the parameter library file

or specified by G102 I_. The pressure command is valid

until replaced by the next G84 or G85.

3.98 M98 SUB-PROGRAM CALL

WITH NO ARGUMENTS

The M98 command transfers control from the calling

program to a sub-program. The M98 block specifies the

sub-program name after “P”. If the sub-program is in the

same file as the calling program, only the program name

is required. If the sub-program is in a separate file, “P” is

followed by the filename including its extension (if any)

and its path if different from the calling program.

3.99 M99 END SUB-PROGRAM AND

RETURN

The M99 command returns control to the program that

called the sub-program. The block following the subprogram call is executed next. Sub-programs called with

M98 or G65 can end with M99.

If a main program commands M99, the control restarts

the main program from the beginning.

If the M99 command includes the optional “P”

argument, the sub-program returns to the calling

program at the sequence number specified after “P”. If

the M99 “P” command is in the main program, the

control returns to the line number specified by “P” in the

same program (same as GOTO).

Example:

M99 P500

(If commanded in a sub-program, this example

returns to the calling program at line N500. If

commanded in a main program, this example returns

to line N500 in the main program.)

Example:

The program can call the sub-program more than once

by specifying the number of times with “L”.

Example:

M98 P1200 L3

3.130 M130 Z-AXIS ANTI-DIVE

DISABLE

3.131 M131 Z-AXIS ANTI-DIVE

ENABLE

M130 and M131 disable and enable the Z-axis anti-dive

function.

M131 enables the anti-dive function. The cutting head

follows limited variation in the material surface but

maintains Z-axis position when it does not detect

material. M131 is the default mode. All programs start in

M131 mode, with anti-dive enabled.

M130 disables the anti-dive function. If M130 is active,

the Z-axis does not use anti-dive mode. The Z-axis

lowers the cutting head until it detects material or an

overtravel alarm occurs.

3-4 EM-423 (R-02/11)

Page 29

When a program commands M130, the control disables

anti-dive until one of the following occurs:

1. The program commands M131.

2. The program commands M30.

3. The operator rewinds the program.

4. The operator loads a new program.

While M130 is active, the control displays the FYI

message: “Z-axis anti-dive is disabled.”

Programs use M130 for applications with significant

material vibration. M130 allows the head to follow

moderately warped material or thin gauge material that

flutters due to interaction with assist gas pressure.

3.135 M135 DISCHARGE CURRENT

OFF

M135 is similar to M35 except M135 leaves the assist

gas ON. Discharge current remains OFF until the next

G84 or G85. M35 acts like M135 when the SPEED GAS

option in the Variables menu is selected. M135 leaves

the gas ON independent of the SPEED GAS selection.

EM-423 (R-02/11) 3-5

Page 30

3-6 EM-423 (R-02/11)

Page 31

SECTION 4 CINCINNATI MACROS

CINCINNATI macro programs simplify programming

for common applications. The macros are in two groups:

grid macros and cutting macros. Grid macros call a

user’s sub-program in a rectangular pattern of rows and

columns. Cutting macros cut common shapes based on

specified dimensions.

4.65 GRID MACROS

Programs use CINCINNATI grid macros to repeat a subprogram in a pattern of rows and columns. The subprogram can repeat a feature within a part, or repeat a

part on a sheet.

PART SUB GRID MACRO G65 P9800

Programs can use the P9800 grid macro to repeat a part

feature in a rectangular grid pattern. A typical

application is a part with an array of holes or slots. The

user must provide a separate sub-program to cut one

feature. The part program calls the grid macro once, and

the grid macro calls the sub-program several times to cut

the features.

G65 P9800 A_ B_ I_ J_ X_ Y_ S_ (R_ K_)

B = Number of sub-program calls in local Y

direction (rows).

I ,J = Local X and Y distances between sub-program

calls.

X, Y = Local X and Y coordinates where the grid macro

calls the sub-program farthest from local X0,

Y0.

S = Sub-program name.

Since the macro call provides the sub-program

name as a macro argument, the name must be an

integer number with no extension or leading

zeroes.

Note: Revised software (installed July 2001 or

later) will ignore leading zeroes in the

sub-program name if necessary to find

the specified sub-program number.

The sub-program can be in the same file as the

calling program or a separate file in the same

directory. If the sub-program is a separate file

and the filename has an extension, the grid

macro will not find the sub-program. To rename

the file without an extension, use Windows

Explorer.

(In this figure, the grid macro calls the subprogram at the center of each hole.)

A = Number of sub-program calls in local X

direction (columns).

Note: The macro call should include a space

between “9800” and “A” in order to

separate “A” from the macro program

name. However, revised CNC software

(installed July 2001 or later) does not

require a space between the program

number and the first argument if a G65

command specifies P9800 or P9900.

R = Rotation angle for the sub-program relative to

the part coordinate system, in degrees. Default

angle is zero with counterclockwise positive.

K = Quantity of sub-program calls for the grid macro

to skip. Default is zero.

When restarting an interrupted program, the

operator can use the “K” argument to make the

macro skip some of the sub-program calls. The

macro skips the number of calls specified by

“K” and begins with the sub-program call at the

next position.

G65 P9800 DESCRIPTION

The 9800 grid macro moves the cutting head in rapid

traverse to the locations defined by A, B, I, J, X and Y,

and calls the sub-program from each location. When the

macro call specifies “R”, the macro commands

coordinate rotation before calling the sub-program. If the

sub-program is written is G91 mode, it must end at its

starting point.

EM-423 (R-02/11) 4-1

Page 32

The 9800 grid macro does not raise or lower the cutting

head. The macro maintains the Z-axis position at the end

of the sub-program for the move between sub-program

calls.

The grid macro calls the first sub-program from work

coordinates X, Y when K is zero. To complete the first

row, the macro proceeds in the local -X direction. The

second row begins under the first part at a lower Y

coordinate, and repeats in the local -X direction. This

procedure continues until the macro completes all rows.

EXAMPLE PROGRAM USING P9800

This example part has six holes 1.5 inch diameter, on 2

inch centers in 3 columns and 2 rows in the center of an

8 x 6 rectangle.

(In this figure, the grid macro calls the subprogram from the lower left corner of each part.)

A = Number of parts in Machine X direction

(columns).

Note: The macro call should include a space

between “9900” and “A” in order to

separate “A” from the macro program

name. Revised software (installed July

2001 or later) does not require a space

between the program number and the

first argument if a G65 command

specifies P9800 or P9900.

O2000 (PART PROGRAM WITH 9800)

G20 G90 F100

G89 PMS135.LIB

G92 X0 Y0

G65 P9800 A3 B2 I2 J2 X6 Y4 S2001 R0 K0

G86 X4 Y3 I8 J6

M30

O2001 (HOLE SUB-PROGRAM)

G91

G73 X0 Y0 D1.5

G90

M99

PART GRID MACRO: G65 P9900

Programs use the 9900 grid macro to repeat a part in a

rectangular grid pattern on the sheet. The program calls

the grid macro once and the grid macro repeatedly calls

a sub-program for one part.

G65 P9900 A_ B_ I_ J_ X_ Y_ S_ (R_ K_ Z_)

B = Number of parts in Machine Y direction (rows).

I, J = Distances between part calls in Machine X and

Y directions.

X, Y = Machine coordinates where the grid macro calls

the part farthest from machine X0, Y0.

S = Part program name.

Since the macro call provides the part subprogram name as a macro argument, the name

must be an integer number with no extension or

leading zeroes.

Note: Revised software (installed July 2001 or

later) will ignore leading zeroes in the

sub-program name if necessary to find

the specified sub-program number.

The sub-program can be in the same file as the

calling program or a separate file in the same

directory. If the sub-program is a separate file

and the filename has an extension, the grid

macro will not find the sub-program. To rename

the file without an extension, use Windows

Explorer.

R = Rotation angle for the part program (relative to

the machine coordinate system), in degrees.

4-2 EM-423 (R-02/11)

Page 33

Default angle is zero with counterclockwise

positive.

K = Quantity of parts to be skipped before the first is

cut. Default is zero.

When restarting an interrupted program, the

operator can use the “K” argument to make the

macro skip some of the sub-program calls. The

macro skips the number of calls specified by

“K” and begins with the sub-program call at the

next position.

Z = Z-axis flag. Default is “Z1” (to raise head

between parts).

When the macro call does not specify “Z”, or

specifies “Z” with zero or a positive number, the

grid macro commands M47 to raise the cutting

head before moving into position to call the subprogram for each part.