Page 1

OPERATING/PROGRAMMING SUPPLEMENT

for

CINCINNATI

HA WK TURNING CENTER

Model 150 / 200 / 250 (ERD)

with F ANUC SERIES 21i

CNC CONTROL

PUBLICATION NO. 91203597B001

IMPORTANT

Carefully read the instructions and safety precautions given in this

manual. Do not attempt to operate this machine until you have thoroughly read and understood the material contained in this manual

and all other applicable manuals.

Atthetime ofwriting,thebook wascompletely u p--to--date.However,

due to continual improvements in design, it is possible that descriptions contained herein may vary to a slight extent from the system delivered to you. This merely implies thatthe system hasbeen improved

to better fulfill your requirements.You areencouraged to contact the

nearest Cincinnati Machine representative for clarification.

Patents Notice

Themachine and attachments and partsthereof illustrated and describedin

this book are manufactured under and protected by issued and pending

British and Foreign Patents and copyright is reserved in any originaldesign

feature thereof and in the contents of this book and every part thereof.

IMPORTANT

Cincinnati Machine U.K. Limited

P.O. Box 505, Kingsbury Road,

Birmingham, B24 0QU

1998 Cincinnati Machine, a Division of UNOVA Industrial Automation Systems, Inc.

Cincinnati Machine, CINCINNATI, DART ,ARROW, SABRE, LANCER and HAWK are

trademarks of Cincinnati Machine, a division of UNOVAIndustrialAutomationSystems, Inc.

ACRAMATIC is a trademark of Vickers E.S.D., Inc.

Printed in England -- EDITION 1 -- June 1999

Page 2

WARNING 1

In order to clearly show

details of this machine,

some covers, shields,

guards, barriers, devices or

doors have either been

removed or shown in an

”open” position. All such

protective components

must be installed in position before operating this

machine.

Failure to follow this

instruction may result in

personal injury.

WARNING 2

FOREWORD

The purpose of this manual is to provide the necessary information to

enable suitably experienced personnel, to operate the CINCINNATI

HAWK 150/200/250 Turning Centers equipped with Fanuc 21i control

system.

Information contained in this manual is not warranted and is subject to

change without notice.

Themanualhasnotbeenpreparedtoenableinexperiencedpersonnelto

operate the machine without further training.

The owner/user is responsible for the training of inexperienced

personnel and for providing the background necessary for experienced

personnel to safely operate these m achines.

It is intended to cover t he control of the MTB (Machine ToolBuilders)

dependant functions as applicatble to the HAWK TURNING MACHINE with Fanuc control.

It does not include general part programming or control maintenance

information. These are covered in the appropriate GE FANUC

Operators and maintenance manuals, as supplied with the machine.

CUTTING FLUIDS

When soluble coolants are

used, it is important to ensure that recommended

The chapter on general safety precautions should be observed at all

times during m achine operation and maintenance. Read this chapter

before reading the remaining chapters in this manual and operating the

machine.

concentration levels are

maintained.

Failure to follow this

instructioncan cause corrosion of safety critical parts,

resulting in machine damage and/or serious personal

injury.

Anyquestionspertaining to the operationofthemachineshould be directedto:

Field Service Department Cincinnati Machine

Cincinnati Machine U.K. Ltd, Marketing Company,

P.O. Box 505, Cincinnati,

Kingsbury Road, Ohio 45209--9988,

Birmingham, B24 0QU USA.

England Main Tel: (513) 841--8100

Tel: 0121--351--3821 Service Tel: (513) 841 3000

Fax: 0121--313--1184 Service Fax: (513) 841 8871

DANGER

HIGH VOLTAGE

Lethal voltages are present in the magnetics and electrical control cabinets when the MACHINE MAIN DISCONNECT is ’ON’. Current and voltage measurements shouldbe attempted only by qualified electrical maintenance personnel.

Before working on any electrical circuits, turn the machine Main Disconnect Device ’OFF’ and lock It.

Capacitors in the ServoDrives requireupto 20 minutes tocompletely discharge. Alwaysverify thatdischarge

is complete using a known working and calibrated voltmeter before commencing work on these units.

Unless expresslystated inapplicable CincinnatiMachine documentation or by the appropriate Cincinnati Ma-

chine Field Service Representative, do NOT work with electrical power ’ON’. If such express statement of

advice exists, working with electrical power ’ON’ should be performed by a Cincinnati Machine Field Service

Representative. Thecustomer and subsequenttransferees must determinethat any other personperforming

work with electrical power ’ON’ is trained and technically qualified.

Failure To Follow This Instruction May Result In Death Or Serious Personal Shock Injury.

-- 1

Page 3

Table of Contents

Chapter 1

Safety Precautions 1--1.........................

Important 1--1...........................................................

General Safety Instructions And Considerations 1--2............................

Personal Safety 1--2...................................................

Work Area Safety 1--2.................................................

Tool Safety 1--3......................................................

Lifting And Carrying Safety 1--3.........................................

Installation And Relocation Safety 1--4....................................

Setup And Operation Safety 1--4.........................................

Maintenance Safety 1--5...............................................

Materials Used With This Product 1--6....................................

LIFTING DEVICES 1--7..................................................

GENERAL 1--7......................................................

EYEBOLTS 1--7.....................................................

HOIST RINGS 1--9...................................................

SPREADER BARS AND LIFTING BEAMS 1--10...........................

CHAIN 1--10.........................................................

CABLE SLINGS 1--12.................................................

SYNTHETIC MATERIAL SLINGS 1--13..................................

P TYPE HOOKS 1--14.................................................

S HOOKS 1--14.......................................................

U TYPE HOOKS 1--16.................................................

GENERAL SAFETY LIFTING INFORMATION 1--17........................

Fluids Used With Machine Tools 1--18........................................

General Considerations 1--18.............................................

Lubricants 1--18.......................................................

Cutting Fluids 1--18....................................................

Sources Of Information -- USA 1--18......................................

Usage Information 1--19................................................

Cutting Fluids -- Preventative Maintenance 1--20................................

See Cautions 1 and 2 1--20...............................................

Water Quality 1--20....................................................

Too Soft 1--20.........................................................

Too Hard 1--20........................................................

Cleaning The Coolant Reservoir 1--20......................................

Lifespan 1--21.........................................................

Tramp Oil 1--21.......................................................

Filtering 1-- 21.........................................................

Rust Prevention 1--21...................................................

Printed Circuit Board Handling Instructions 1--22................................

General 1--22.........................................................

Recommended Handling Procedure 1--22...................................

Safety Features 1--23......................................................

Perimeter Guarding 1--23................................................

Operator Sliding Door(s) 1--23...........................................

Page 4

Table of Contents

Feed Hold Push Button 1--24.............................................

Emergency Stop Push Button 1--24........................................

Electrical Isolation Device (Main Disconnect Switch) 1--24.....................

Air Supply Isolation Valve 1--24..........................................

Metric Lifting Points 1-- 24...............................................

Machine Related Safety And Usage Notes 1--25.................................

Axis Overtravel Condition 1--25..........................................

Safe Operation Of Lathe Chucks 1--25.....................................

Work Holding Devices 1--25.............................................

General Operation 1--26.................................................

Battery Replacement 1--27...............................................

Lithium Batteries 1--27.................................................

Chapter 2

System Information 2--1........................

Introduction 2--1.........................................................

Guard Strength 2--2...................................................

Noise 2--3...........................................................

Fumes And Coolant Misting 2--4.........................................

Fire Hazard 2--4......................................................

Machine Location -- See Caution 2--4.....................................

EMC Directive Requirements 2--4........................................

NC Control 2--5......................................................

Machine Information 2--5..................................................

Axis Orientation 2--6.....................................................

Hawk Specification 2--7...................................................

Machine And Range Drawings 2--9..........................................

Motor Rating 2--25........................................................

MACHINE ALIGNMENT AND PROGRAM POINTS 2--27......................

Machine Zero 2--27....................................................

Chapter 3

Functional Description of Controls 3--1..........

Introduction -- GE FANUC 21i--TA CNC System 3--1........................

OPERATOR PANEL -- PUSHBUTTON DESCRIPTIONS 3--2.................

AUTOMATIC OPERATION -- PROGRAMME SOURCE 3--3....................

MEMORY OPERATION -- (Push button with LED) (A1) 3--3.................

EDIT MODE -- (Push button with LED) (A2) 3--3...........................

MDI OPERATION -- (Push button with LED) (A3) 3--3......................

EXECUTION PUSHBUTTONS 3--3.........................................

CYCLE START (Push button with LED) (F1) 3--3...........................

CYCLE STOP (Push button with LED) (F2) 3--3............................

PROGRAMME STOP (Push button with LED) (F3) 3--4.....................

SPINDLE CONTROL BUTTONS 3--4.......................................

SPINDLE STOP (Push button with LED) (F5) 3--4..........................

SPINDLE CLOCKWISE (CW) (Push Button with LED) (F4) 3 --4..............

Page 5

Table of Contents

SPINDLE COUNTER CLOCKWISE (CCW) (Push button with LED) (F6) 3--4...

SPINDLE 100% (Push button with LED) (D5) 3--5..........................

SPINDLE SPEED INCREMENT (Push button with LED) (D6) 3--5............

SPINDLE SPEED DECREMENT (Push button with LED) (D4) 3--5............

OPERATION BUTTONS 3--5..............................................

ALIGN MACHINE -- (Push Button with LED) (A4) 3--5.....................

MPG MODE (HANDWHEEL) & INCREMENT SELECTION

PUSHBUTTONS 3--5..............................................

MPG MODE -- 0.001mm (Push Button with LED) (B4) 3--5...................

MPG MODE -- 0.010mm (Push Button with LED) (B5) 3--6...................

MPG MODE -- 0.100mm (Push Button with LED) (B6) 3--6...................

JOG MODE -- (Push Button with LED) (A5) 3--6...........................

OPERATION SELECT -- PUSHBUTTONS 3--6...............................

SINGLE B LOCK -- (Push Button with LED) (B1) 3--6.......................

BLOCK DELETE -- (Push Button with LED) (B2) 3--6.......................

OPTIONAL STOP -- (Push Button with LED) (B3) 3--6......................

DRY RUN -- (Push Button with LED) (C1) 3--6.............................

PROGRAMME TEST -- (Push Button with LED) (C2) 3--7...................

AXES INHIBIT -- (Push Button with LED) (C3) 3--7........................

AXIS/DIRECTION SELECTION PUSHBUTTONS 3--7........................

X+ AXIS (Push Button with LED) (B9) 3--7...............................

X-- AXIS (Push Button with LED) (D9) 3--7...............................

Z+ AXIS (Push Button with LED) (C10) 3--7...............................

Z-- AXIS (Push Button with LED) (C8) 3--7................................

RAPID TRAVERSE (Push Button with LED) (C9) 3--8......................

PARTS CATCHER DOWN (Push Button with LED) (A6) 3--8.................

PARTS CATCHER UP (Push Button with LED) (A7) 3--8....................

TURRET JOG + (INCREMENT) (Push Button with LED) (C4) 3-- 8............

TURRET JOG -- (DECREMENT) (Push Button with LED) (C5) 3-- 8............

CHUCK -- ID GRIP (Push Button with LED) (A8) 3--8.......................

CHUCK -- OD GRIP (Push Button with LED) (A9) 3--8......................

OFFSET MEASURE (Push Button with LED) (A10) 3--8.....................

TOOL SETTING ARM DOWN (Push Button with LED) (D2) 3--9.............

TOOL SETTING ARM UP (Push Button with LED) (D3) 3--9.................

PROGRAM RESTART (Push Button with LED) (D1) 3--9....................

AUX 1 -- Auxillary Push Button (Push Button with LED) (C6) 3-- 9.............

COOLANT BUTTONS 3--9................................................

COOLANT OFF (Push Button with LED) (F9) 3--9..........................

COOLANT ON (Push Button with LED) (F8) 3--9..........................

COOLANT AUTO (Push Button with LED) (F10) 3--9.......................

MISCELLANEOUS CONTROLS 3--10.......................................

MEMORY PROTECTION -- Keyswitch 3--10...............................

RS 232 SERIAL DATA PORT 3--10.......................................

FEED/RAPID/JOG OVERRIDE -- Selector Switch 3--10......................

EMERGENCY STOP (red mushroom pushbutton with latch) 3--10..............

MTB OPERATORS CONTROL PANEL 3--11..............................

Spindle Load Meter 3--11...............................................

Page 6

Table of Contents

0 to 100% Range (Continuous rating) 3--11.................................

110 to 150% Range -- Yellow Band (30 minutes 50% rating) 3--12...............

151 to 180% Range -- Red Band (1 minute overload capacity) 3--12..............

MASTER START -- Illuminated push button 3--12............................

CYCLE START 3--12..................................................

HANDWHEEL (MPG) 3--13.............................................

CHUCK UNCLAMP push button 3--13....................................

CHUCK CLAMP push button 3--13.......................................

TAILSTOCK QUILL ADVANCE/STEP ADVANCE push button 3--14...........

TAILSTOCK QUILL RETRACT push button 3--14...........................

Machine Pressure -- Tailstock Thrust -- Chuck Drawbar Force -- Chuck Brake (Dampener) Control . .

3--15

MAIN POWER DISCONNECT SWITCH 3--16.............................

Optional Operating Devices 3--17............................................

Swarf Conveyor 3--17..................................................

Wash Gun 3- -18.......................................................

GENERAL CHUCK SAFETY GUIDELINES 3--19..........................

CHUCKS 3--20...........................................................

CHUCKING SYSTEM TYPES 3--20......................................

CHUCK 3--20............................................................

CENTRIFUGAL FORCE AND SPEED LIMITATIONS 3--20..................

CHUCK LUBRICATION 3--20...........................................

TOP JAW RECOMMENDATIONS 3--21...................................

Chapter 4

Machine Start Up and Alignment Procedure 4--1..

Machine Start Up and Alignment Procedure 4--1............................

General 4--1.........................................................

Start Up and Shut Down Procedures 4--1..................................

Start Up 4--1.........................................................

Shut Down 4--1......................................................

Machine/Control Alignment Procedure 4--2................................

Turret Alignment 4--2..................................................

Drive Tool Machines only 4--2..........................................

Chapter 5

Software and Hardware Axis Overtravel 5--1......

Software Axis Overtravel 5--1...........................................

CANCELLING SOFTWARE RANGE CHECKING 5--1.....................

Hardware Axis Overtravel 5--1..........................................

Chapter 6

G codes 6--1...................................

G codes 6--1.........................................................

Chapter 7

M codes 7--1...................................

M codes 7--1.........................................................

Page 7

Table of Contents

M codes supported on Cincinnati Turning Centres 7--1.......................

Function Description of M Codes 7--2........................................

M00 PROGRAMME STOP (STOPS SPINDLE) 7--2.......................

M01 OPTIONAL PROGRAMME STOP (STOPS SPINDLE) 7--2.............

M02 END OF PROGRAMME 7--2......................................

M03 START SPINDLE CCW 7--3.......................................

M04 START SPINDLE CW 7--3........................................

M05 SPINDLE STOP 7--3.............................................

M08 FLOOD COOLANT START 7--3...................................

M09 COOLANT OFF 7--3.............................................

M13 STAR T SPINDLE COUNTER CLOCKWISE WITH COOLANT 7--3......

M14 STAR T SPINDLE CLOCKWISE WITH COOLANT 7--3................

M19 ORIENTED SPINDLE STOP 7--3...................................

M30 END OF PROGRAM AND REWIND 7--3............................

M34 PARTS CATCHER ADVANCE 7--4.................................

M35 PARTS CA TCHER RETRACT 7--4.................................

M44 RENISHAW TOOL SETTING ARM (TSA) UP 7--4....................

M45 RENISHAW TOOL SETTING ARM (TSA) DOWN 7--4.................

M46 FEEDRATE OVERRIDE DISABLE (100%) 7--4.......................

M47 FEEDRATE OVERRIDE ENABLE 7--4..............................

M48 SPINDLE SPEED OVERRIDE DISABLE (100%) 7--4..................

M49 SPINDLE SPEED OVERRIDE ENABLE 7--4.........................

M50 C--AXIS MODE OFF (Driven Tool Machines only) 7--5.................

M51 C--AXIS MODE ON (Driven Tool Machines only) 7--5..................

M52 C--AXIS BRAKE ON (In--Position Mode, Driven Tool FeatureDriven tool machines only)

7--5

M53 C--AXIS BRAKE ON-- (Interpolation Mode, Driven Tool Feature)Half pressure -- contour-

ing

(Driven tool machines only) 7--5......................................

M54 C--AXIS BRAKE OFF (Driven Tool Machines only) 7--6................

M61 BARFEED MACRO CALL 7-- 6....................................

M68 ADVANCE TAILSTOCK QUILL 7--6...............................

M69 RETRACT TAILSTOCK QUILL 7--6................................

M70 TO M73 CUSTOMER OUTPUTS (OPTIONAL) 7--6....................

M74 COLLET CHUCK MODE DISABLE 7--7.............................

M75 COLLET CHUCK MODE ENABLE 7--7.............................

M76 FORCE TURRET ROTATION CW 7-- 7..............................

M77 FORCE TURRET ROTATION CCW 7--7............................

M78 CHUCK OPEN 7--7..............................................

M79 CHUCK CLOSE 7--7.............................................

M80 BARFEED EJECT/RELOAD NEW BAR 7--7.........................

M86 BARFEED PRESSURE ON

(HYDRAFEED AND FEEDMASTER ONLY) 7--7.......................

M87 BARFEED PRESSURE OFF

(HYDRAFEED AND FEEDMASTER ONLY) 7--7.......................

M90 BARFEED MODE ON 7--7........................................

M91 BARFEED MODE OFF 7--7.......................................

M92 BARFEED ROTATION ON 7--8....................................

Page 8

Table of Contents

M93 BARFEED ROTATION OFF 7--8...................................

M94 INCREMENT PARTS COUNTER 7--8...............................

M98 SUBROUTINE CALL 7--8.........................................

M99 END OF SUBROUTINE 7--8.......................................

Chapter 8

Spindle Functions 8--1.........................

Spindle Functions 8--1....................................................

Driven Tool Machines 8--1.................................................

Spindle Jog 8--2.........................................................

Chapter 9

Tooling Functions 9--1..........................

Tool Turret 9--1......................................................

Turret Indexes 9--1....................................................

Driven Tool Machines 9--1.................................................

T Word 9--2.........................................................

Force Turret CW and CCW 9--2.........................................

Tool Life Management 9--2.............................................

Chapter 10

Driven Tools 10--1...............................

Introduction 10--1......................................................

C--Axis Mode Enable/Disable 10--1.......................................

C--Axis Initialisation 10--1...............................................

C--Axis Positioning Mode 10--1..........................................

Programming Considerations 10--2........................................

C--Axis Interpolation Mode 10--5.........................................

Programming Considerations 10--5........................................

Chapter 11

Toolsetter 11--1.................................

Introduction 11--1......................................................

TSA 11--1............................................................

HPA 11--2............................................................

Macro Probing Routines 11--2...............................................

Manual Tool Setting 11--2...............................................

Auto Tool Setting -- TSA only 11--3.......................................

Operator and Programming Notes 11--3....................................

Tool Setting Arm Activation -- TSA 11--3......................................

M44 TSA Up 11--3....................................................

M45 TSA Down 11--3.................................................

Tool Setting Arm Down Pushbutton 11--4..................................

Tool Setting Arm Up Pushbutton 11--4.....................................

HPA -- Manual Toolsetting Arm 11--4.........................................

Fitting Arm 11--4......................................................

Page 9

Table of Contents

Removing Arm 11--4...................................................

TSA/HPA Calibration 11--4..............................................

Stylus Alignment 11--5.....................................................

Stylus Alignment 11--5.................................................

Stylus Position 11--5...................................................

Control Options 11--5..................................................

Standard Calibration Data -- Base Number 522 11--5..........................

Adjusting the Software Back Off Distance 11--6..............................

Macro Parameters 11--6....................................................

Tool Nose Vector Hh 11--8...............................................

Calibration 11--9..........................................................

Manual Calibration -- Macro O9011 11--9......................................

Introduction 11--9......................................................

Description 11--9......................................................

Application 11--9......................................................

Format 11-- 9..........................................................

Macro Parameters 1 1--9.................................................

Outputs 11--10.........................................................

Manual Tool Setting -- Macro O9011 11--11.....................................

Description 11--11......................................................

Application 11--11......................................................

Format 11--11..........................................................

Macro Parameters 11--11.................................................

Outputs 11--11.........................................................

Set a Tool 11--11.......................................................

Broken Tool Check 11--12................................................

Auto Tool Setting -- Macro O9012 -- TSA Only 11--15.............................

Description 11--15......................................................

Application 11--15......................................................

Format 11-- 15..........................................................

Macro Parameters 11--15.................................................

Chapter 12

Parts Catcher 12--1..............................

Introduction 12--1......................................................

Operation 12--1........................................................

M34 Parts Catcher Advance 12--1........................................

M35 Parts Catcher Retract 12--1..........................................

Parts Catcher Advance Push Button 12--2...................................

Parts Catcher Retract Push Button 12--2....................................

Operator and Programming Notes 12--2....................................

Programming Example 12--2.............................................

Chapter 13

Barfeeder 13--1.................................

Introduction 13--1.........................................................

Page 10

Table of Contents

Bar Preparation 13--1...................................................

M--Codes 13--1........................................................

Standard Barfeed Sequence for Multifeed Unit:-- 13--2.........................

Standard Barfeed Sequence for Hydrafeed and Feedmaster 13--3.................

Barfeed Spindle Rotation Speed Bits -- Keep Relay K Bits 13--4....................

Chapter 14

Reserved Macro Routines 14--1..................

Used Macro V ariables 14--1..............................................

Chapter 15

Connection to Data Input/Output Devices 15--1....

Connection to Data Input and Output Devices 15--1..............................

Input/Output Device and Code Number 15--2................................

Chapter 16

Diagnostics 16--1...............................

PMC Input Address Reference List 16--2.......................................

PMC Output Address Reference List 16--3.....................................

FANUC Operators Panel Connection Signals 16--4...............................

FANUC Operator Station 16--5..............................................

Self--Diagnostic Function 16--5...........................................

Status Display LED 16--5...............................................

Test Mode 16--5.......................................................

FANUC Operator Station Key/LED -- Diagnostic Address Table 16--6...............

Alarm Messages 16--7.....................................................

Operator Messages 16--73...................................................

Page 11

Table of Contents

Fig. 1

Preferred Inch Lifting Eyebolts 1-- 7......................................

Fig. 2

Preferred Metric Lifting Eyebolts 1--8.....................................

Fig. 3

Eyebolt Loading 1--8..................................................

Fig. 4

Eyebolt I.D. Plates -- Inch and Metric 1--8..................................

Fig. 5

Instruction Plate -- Inch (Part Number 3375984) 1--8.........................

Fig. 6

Instruction Plate -- Metric (Part Number 3375983) 1--8.......................

Fig. 7

Hoist Ring 1--9.......................................................

Fig. 8

Hoist Ring Table 1--9..................................................

Fig. 9

Spreader Bar -- Typical 1--10.............................................

Fig. 10

Steel Alloy Chains 1--11................................................

Fig. 11

Wire Rope Slings 1--12.................................................

Fig. 12

Sling Load Angle Chart 1--13............................................

Fig. 13

“P” Type Lifting Hooks 1--14............................................

Fig. 14

“P” Type Lifting Hooks 1--14............................................

Fig. 15

“S” Hooks 1--15.......................................................

Fig. 16

“S” Hooks 1--15.......................................................

Fig. 17

“U” Type Lifting Hooks 1--16............................................

Fig. 18

“U” Lifting Hook Table 1--16............................................

Fig. 19

Safety Latch 1--17.....................................................

Fig. 20

Driven Head Tool Holder 1--26...........................................

Fig. 21

Hawk Turning Center 2--1..............................................

Fig. 22

Axis Orientation -- Hawk Turning Centre 2--6...............................

Fig. 23

Front View 2--9......................................................

Fig. 24

Left Side View 2--10...................................................

Fig. 25

Turning Capacity Chart -- Hawk 150 (VDI Tooling) 2--11......................

Fig. 26

Turning Capacity Chart -- Hawk 200 Machines (VDI Tooling) 2--12..............

1--26...................................................................

Page 12

Table of Contents

Fig. 27

Turning Capacity Chart -- Hawk 250 Machines (VDI Tooling) 2--13..............

Fig. 28

Data Sheets -- Hawk 150 (VDI Tooling) 2--14................................

Fig. 29

Stroke -- Hawk 200 Machines (VDI Tooling) 2--15............................

Fig. 30

Stroke -- Hawk 250 Machines (VDI Tooling) 2--16............................

Fig. 31

Optional Standard Tooling Package -- Hawk 150 (VDI Tooling) 2--17.............

Fig. 32

Optional Standard Tooling Package -- Hawk 200/250 Machines (VDI Tooling) 2--18.

Fig. 33

Work Holding Options -- Hawk 150 2--19...................................

Fig. 34

Work Holding Options -- Hawk 200 2--20...................................

Fig. 35

Work Holding Options -- Hawk 200 2--21...................................

Fig. 36

Work Holding Options -- Hawk 250 2--22...................................

Fig. 37

Work Holding Options -- Hawk 250 (Continued| 2--23.........................

Fig. 38

Bar Feed Options -- Hawk 150 machines 2--24...............................

Fig. 39

Hawk 150 -- Spindle Power Characteristics 2--25.............................

Fig. 40

Hawk 200 -- Spindle Power Characteristics 2--25.............................

Fig. 41

Hawk 250 -- Spindle Power Characteristics 2--26.............................

Fig. 42

Machine Alignment And Program Points 2--27...............................

Fig. 43

Control Station Layout for:

-- Hawk Turning centres with fanuc 21i TA 3--1.............................

Fig. 44

Operators Control Panel 3--2............................................

Fig. 45

MTB Operators Control Panel 3--11.......................................

Fig. 46

Spindle Load Meter 3--11...............................................

Fig. 47

Main Spindle Chuck & Tailstock Pressure 3--15..............................

Fig. 48

Chuck Brake Pressure (Option) 3--15......................................

Fig. 49

Swarf Conveyor Control Panel 3--17.......................................

Fig. 49

12 Position Turret -- showing Rotation Directions 9--1........................

Fig. 51

Driven Tool Setup -- Positioning Mode 10--2................................

Fig. 52

C--Axis Positioning 10--2................................................

Page 13

Table of Contents

Fig. 53

Canned Cycle -- Front Machining 10--3.....................................

Fig. 54

Canned Cycle -- Side Machining 10--4.....................................

Fig. 55

Driven Tool Setup -- Interpolation Mode 10--5...............................

Fig. 56

C--Axis Position Command 10--6.........................................

Fig. 57

Polar Co--ordinate Interpolation 10--7......................................

Fig. 58

Cylindrical Interpolation 10--8............................................

Fig. 58

Probe Configuration 11--1...............................................

Fig. 59

Probe Configuration 11--2...............................................

Fig. 60

Parts Catcher fitted to Operator Door 12--1..................................

Fig. 61

Operators Control Panel 16--6............................................

Page 14

Chapter 1 Safety Precautions

Important

WARNING

Read related safety precautions before operating

this machine. Failure to

follow safety instructions

may result in serious personal injury.

WARNING

Inordertoclearly showdetailsofthismachine,some

covers, shields, guards,

barriers,devices, ordoors

have either been removed

or shown in an ”open”

position. All such protective components must be

installedinpositionbefore

operating this machine.

Failure to follow this

instruction may result in

serious personal injury.

Thesesafety precautions for thisCINCINNATI machinehavebeenprepared

to assist the operator, programmer and maintenancepersonnelin practicing

good shop safety procedures.

Operator and maintenance personnel must read and understand these

precautions completely before operating, setting up, running, orperforming

maintenance on the machine.

Theseprecautions are to be used as aguidetosupplement safetyprecautions

and warnings in the following:

a. All other manuals pertaining to the machine.

b. Local, plant, and shop safety rules and codes.

c. National safety laws and regulations.

Cincinnati Machine 91203597B001 Page 1--1

Page 15

WARNING

Failure to follow instructions on this page may result in serious personal injury.

General Safety Instructions And Considerations

Personal Safety

Machineowners,operators,setupmen, maintenance, and servicepersonnel

must be aware of the fact that constant day--to--day safety procedures are a

vital part of their job. Accident prevention must be one of the principal

objectives of the job regardless of what activity is involved.

Know and respect your machinery. Read and practice the prescribed safety

and checking procedures. Make sure that everyone who works for, with, or

near you fully understands and -- more importantly -- complies with the

following safety precautions and procedures when operating this machine.

Sudden movements, loud noises, horseplay, etc., must be avoided. These

distractions may result in unsafe conditions for those working near the

machinery.

Observe and follow safety instructions such as “NO SMOKING”, “High

Voltage”, “DANGER”, etc., in your working area.

Accidents can occur that result in serious personal injury to yourself or

othersduetoclothingandother articlesbecomingentangled in cutters,hand

wheels, levers, or moving machineelements. The following suggestions, if

followed, will help you to avoid such accidents: Neckties, scarfs, gloves

(except as worn for protection when handling sharp edged cutting tools or

rough, sharp or hot parts, see TOOL SAFETY) loose hanging clothing, and

jewelry such as watches, rings, or necklaces must not be worn around

moving machinery. Restrain long hair with a cap or net. Wear gloves only

when handling rough, sharp, or hot parts.

Use safety protective equipment. Wear clean approved eye or face

protection. Safety--toe shoes with slip--proof soles can help you avoid

injury. Keep your protective equipment in good condition.

Neveroperateorservicethis equipmentifaffectedbyalcohol,drugsorother

substances or conditions which decrease alertness or judgment.

Work Area Safety

Always keep your work area clean. Dirty work areas with such hazards as

oil, debris, or water on the floor may cause someone to fall to the floor,into

the machine, or onto other objects resulting in serious personal injury.

Make sure your work area is free of hazardous obstructions and be aware of

protruding machine members.

Returntoolsandsimilarequipmenttotheirproperstorageplaceimmediately after use. Keep work benches neat, orderly, and clean.

Report unsafe working conditions to your supervisor or safety department.

Items such as: worn or broken flooring, ladders, and handrails, unstable or

slippery platforms, or scaffolds must be reported and repaired before use.

Do not use skids, work pieces, stock, machines, tote pans, and boxes as

makeshift climbing aides.

Page 1--2

Cincinnati Machine 91203597B001

Page 16

WARNING

Failure to follow instructions on this page may result in serious personal injury.

WARNING 1

CUTTING TOOLS

Use adequate hand

protection at all times

when handling sharp

edged cutting tools.

Failure to follow this

instruction may result in

serious personal injury.

T ool Safety

Sharp edged cutting tools must be handled with gloves or a shop cloth.

Inspect cutting tools before use and reject defective tools.

See WARNING 1.

Remove hand tooling such as wrenches, measuring equipment, hammers,

and other miscellaneous parts from the machine immediately after usage.

Lifting And Carrying Safety

Contact supervision if you have any questions or are not sure about the

proper procedures for lifting and carrying.

Before lifting or carrying an object, determine the weight and size by

referringto such things as tags, shipping data, labels, marked information,

or manuals.

Use power hoists or other mechanical lifting and carrying equipment for

heavy, bulky,orhardto handleobjects. Use hookup methods recommended

by your safety departmentand know the signals for safely directing a crane

operator.

Never place any part of your body under a suspended load or move a

suspended load over any part of another person’s body. Before lifting, be

certain that you have a safe spot for depositing the load. Never work on a

component while it is hanging from a crane or other lifting mechanism.

Ifindoubt as tothesizeortype ofliftingequipment,method, andprocedures

for lifting, contact CincinnatiMachine beforeproceeding to liftthe machine

or its components.

Always inspect slings, chains, hoists, and other lifting devices prior to use.

Do not use lifting devices found to be defective or questionable.

Neverexceedthe safety ratedcapacity of cranes, hoists,slings, eyebolts,and

other lifting equipment. F ollow, National and local, standards and

instructions applicable to any lifting equipment you use.

Before inserting an eyebolt, be certain that both the eyebolt and the hole

have the same size and type threads. To attain safe working loads, at least

90% of the threaded portion of a standard forged eyebolt must be engaged.

Cincinnati Machine 91203597B001 Page 1--3

Page 17

WARNING

Installation And Relocation Safety

Before lifting the machine, consult the machine m anual or Cincinnati

Machine for proper methods and procedures.

Failure to follow instructions on this page may result in serious personal injury.

An electrician must read and understand the electrical schematics prior to

connectingthe machine to the power source. After connecting the machine,

testallaspectsof the electrical system for proper functioning. Alwaysmake

sure the machine is grounded properly. Place all selector switches in their

OFF or neutral (disengaged) position. The doors of the main electrical

cabinet must be closed and the main disconnect switch must be in the OFF

position after the power source connection is complete.

Alwayslock the main disconnectdevice in the OFF position if the machine

is left unattended, unless machine is part of an unmanned manufacturing

system and in a production cycle.

When the machine is installed, be sure that the motors rotate in the proper

indicated direction.

Setup And Operation Safety

Readand understand all the safety instructions before setting up, operating,

or servicing this machine. Assign only qualified personnel, instructed in

safety and all machine functions, to operate or service this machine.

Operators and maintenancepersonnel must carefully read, understand, and

fully comply with all machine mounted warning and instruction plates. Do

notpaintover,alter,or defacethese platesorremovethemfromthemachine.

Replace all plates which become illegible. Replacement plates can be

purchased from Cincinnati Machine.

Safety guards, shields, barriers, covers, and protective devices must be

connected or in place before operating t he machine.

All safety features, disengagements, and interlocks must be in place and

functioningcorrectlypriorto operation of this equipment. Never bypass or

wire around any safety device.

When setting up or adjusting a workpiece or fixture, be certain it is a safe

distance away from the cutting tool. Always retract the workpiece a safe

distance from the cutting tool when loading and unloading.

The spindle must be stopped beforeadjusting the coolant dischargenozzle.

Neverbrakeor slow down moving machinerywith your hand or with some

makeshiftdevice.Neveruse machine power to remove a nut from anyshaft.

The spindle and slides must be stopped when measuring work pieces,

changing tools, or removing chips and grit. Remove chips and grit with a

chip rake or brush, not with your hands.

Page 1--4

Cincinnati Machine 91203597B001

Page 18

WARNING

Failure to follow instructions on this page may result in serious personal injury.

Keepall parts of your body offthe machinetable, table edge, outof the path

of moving units, trip dogs, trip plungers, and out of the “machining area”

during machining operations. Never lean on a machine or reach over or

throughamachine-- you canbecomeentangledintoolingandothermoving

elements or you may accidentally activate start buttons, feed controls, rapid

traverse controls, power work holding control, or similar devices.

During operation, be attentive to the machining process. Excessive

vibration, unusual sounds, etc., can indicate problems requiring your

immediate attention. Watch for conditions such as packed chips or grit

which can cause breakage of tooling or machine elements.

Shut off power to the machinewhenleaving the operating area or at the end

of your work period. Never leave the machine running unattended, unless

it has beendesignedto do so. TurnthemasterdisconnectdevicetotheOFF

position before cleaning the machineat the end of the working day or when

guards or covers are removed that expose hazardous areas.

Maintenance Safety

See DANGER notice.

Do not attempt to perform maintenanceon this machine until you read and

understand all the safety instructions.

Assign only qualified service or maintenance personnel trained by

Cincinnati Machine, to perform maintenance and repair work on this

machine. They should consult the service manual before attempting any

service or repair work and when in doubt contact Cincinnati Machine. Use

only Cincinnati Machine replacement parts; others may impairthe safety of

the machine. Before performing maintenance or service work, Warning or

Danger signs must be placed conspicuously about the machine. Before

detachingcounterweights ordriving mechanisms, verticalsliding members

must be blocked properly. See the Service Manual for proper dismantling

procedures.

Before removing or opening any electrical enclosure, cover,plate, or door,

be sure that the Main Disconnect Switch is in the OFF position. If any tool

is required to remove a guard, cover, bracket, or any basic part of this

machine, place the Main Disconnect Switch in the OFF position, lock it in

theOFF position. If possible, post a sign at the disconnect switch indicating

that maintenance is being performed.

Whenever maintenance is to be performed in an area away from the

disconnectandthedisconnectisnotlocked,tagall start button stations with

a “DO NOT START” tag. Adequate precautions, such as locks on circuit

breakers, warning notices, or other equally effective means must be taken

to prevent electrical equipment from being electrically activated when

maintenance work is being performed.

Before attempting to adjust, repair, or perform maintenance on electrical

circuits connected with yellow wires, first find the source of power, turn it

off, and lock it in the OFF position. Machine tool interlock control circuits

connected with yellow wires are powered from a source away from the

machine andcarry voltageeven when the machine’smaindisconnectdevice

is turned to the OFF position.

Whenremovingelectrical equipment, place numberorlabeledtags on those

wiresnot marked.Ifwiring, is replaced, besure it is of thesame type, length,

size, and has the same current carrying capacity.

Cincinnati Machine 91203597B001 Page 1--5

Page 19

WARNING

Failure to follow instructions on this page may result in serious personal injury.

Close and securely fasten all guards, shields, covers, plates, or doors before

power is reconnected.

An electrical technician must analyze the electrical system to determine the

possible use of power retaining devices such as capacitors. Such power

retaining devices must be disconnected, discharged, or made safe before

maintenance is performed.

Working space around electrical equipment must be clear of obstructions.

Provide adequate illumination to allow for proper operation and maintenance.

DANGER

HIGH VOLTAGE

Lethal voltages are presentin themagnetics and electrical

control cabinets whenthe MACHINE MAIN DISCONNECT is

’ON’. Current and voltage measurements should be attempted only by qualified electrical maintenance personnel.

Beforeworking on any electrical circuits, turn the machine

Main Disconnect Device ’OFF’ and lock It.

Capacitors in the Servo Drives require up to 20 minutes to

completely discharge. Always verify that discharge is

complete using a known working and calibrated v oltmeter

before commencing work on these units.

Unless expressly stated in applicable Cincinnati Machine

documentation or by the appropriate Cincinnati Machine

Field Service Representative, do NOT work with electrical

power ’ON’. If such express statement of advice exists,

working with electrical power ’ON’ should be performed by

a Cincinnati Machine Field Service Representative. The

customerandsubsequenttransfereesmustdeterminethat

any other person performing work with electrical power

’ON’ is trained and technically qualified.

F AILURETO FOLLOW THIS INSTRUCTION MAYRESULTIN

DEATH OR SERIOUS PERSONAL SHOCK INJURY.

Materials Used With This Product

Various materialsmaybe usedwiththisproduct.Beforeusing/mixing/diluting materials with this product, contact the manufacturer/authorized

supplier of the material to determine that the material is suitable for the

intended application andrequest a MaterialSafety DataSheet (MSDS) from

the material manufacturer.

Page 1--6

Cincinnati Machine 91203597B001

Page 20

NOTE

The information and tables

contained in this article relate to Cincinnati Machine

methods and standards.

Consult National, Local and

Plant Laws and Regulations

regarding lifting practices.

WARNING

Before inserting an eyebolt, check to be certain

that both the eyebolt and

the hole have the same

sizeandtypethreads. For

example: M12withM12or

.375 --16 with .375--16.

To attend safe working

loads, at least 90% of the

threaded portion of a

standard forged eyebolt

must be engaged.

Failure to follow this

instruction may result in

serious injury.

LIFTING DEVICES

GENERAL

The use of lifting devices is subject to certain hazards that cannot be met by

mechanical means but only by the exercise of intelligence, care, and

common sense. It is, therefore, essential to have competent and careful

operators, physically and mentally fit, thoroughly trained to the safe

operation of the equipment and the handling of the loads. Serious hazards

are overloading, dropping or slipping of the load caused by improper

hitching or slinging, standing or crawling under a load, swinging loads,

obstruction to the free passage of the load, using equipment for a purpose

or a manner for which it was not intended or designed..

EYEBOLTS

A straight lift is preferred when using eyebolts. An angular lift places

additional stresses on an eyebolt, above that of the load to be hoisted.

Ifthesituationnecessitates an angularlift,the safe workingload for angular

lifts shown in Fig. 1 and Fig. 2 should be used.

Whenmultiple eyeboltprovisionsaredesignedintoalift, it isrecommended

(in most applications) that a spreader bar be used. (See Fig. 9 which

illustrates a typical spreader bar arrangement.)

No greater stress should be allowed than that given under Safe Working

Load in Fig. 1 and Fig. 2.

To obtain greatest strength from an eyebolt, it must fit reasonably tight in

the hole with at least 90% of the threaded length engaged.

Eyebolts should never be welded or subjected to heat in excess of 900F

[480 C].

Eyebolts should never be painted or otherwise coatedwhen used for lifting,

as such coating will very likely cover up flaws.

Eyebolts should be routinely inspected for defects and if any defects are

found,theyshouldbe destroyedbymelting,crushing,orcutting clearacross

the eye.

STRAIGHT SHANK INCH (ANSI/ASME B18.15)

THREAD .375-- 16 .500-- 13 .625--11 1.000--8

SAFE WORKING LBS. [KG]

LOAD

90 DEGREES 1000 1840 2940 7880

[453] [834] [1333] [3573]

60 DEGREES 375 805 1340 3670

[170] [365] [607] [1664]

30 DEGREES 200 470 805 2390

[90] [213] [365] [1083]

PART NUMBER 3449 870 21312 19489

IDENTIFICATION

PLATE NUMBER 3338325 3338326 3338327 3338328

60

30

STRAIGHT SHANK INCH

90

Fig. 1

Preferred Inch Lifting Eyebolts

Cincinnati Machine 91203597B001 Page 1--7

Page 21

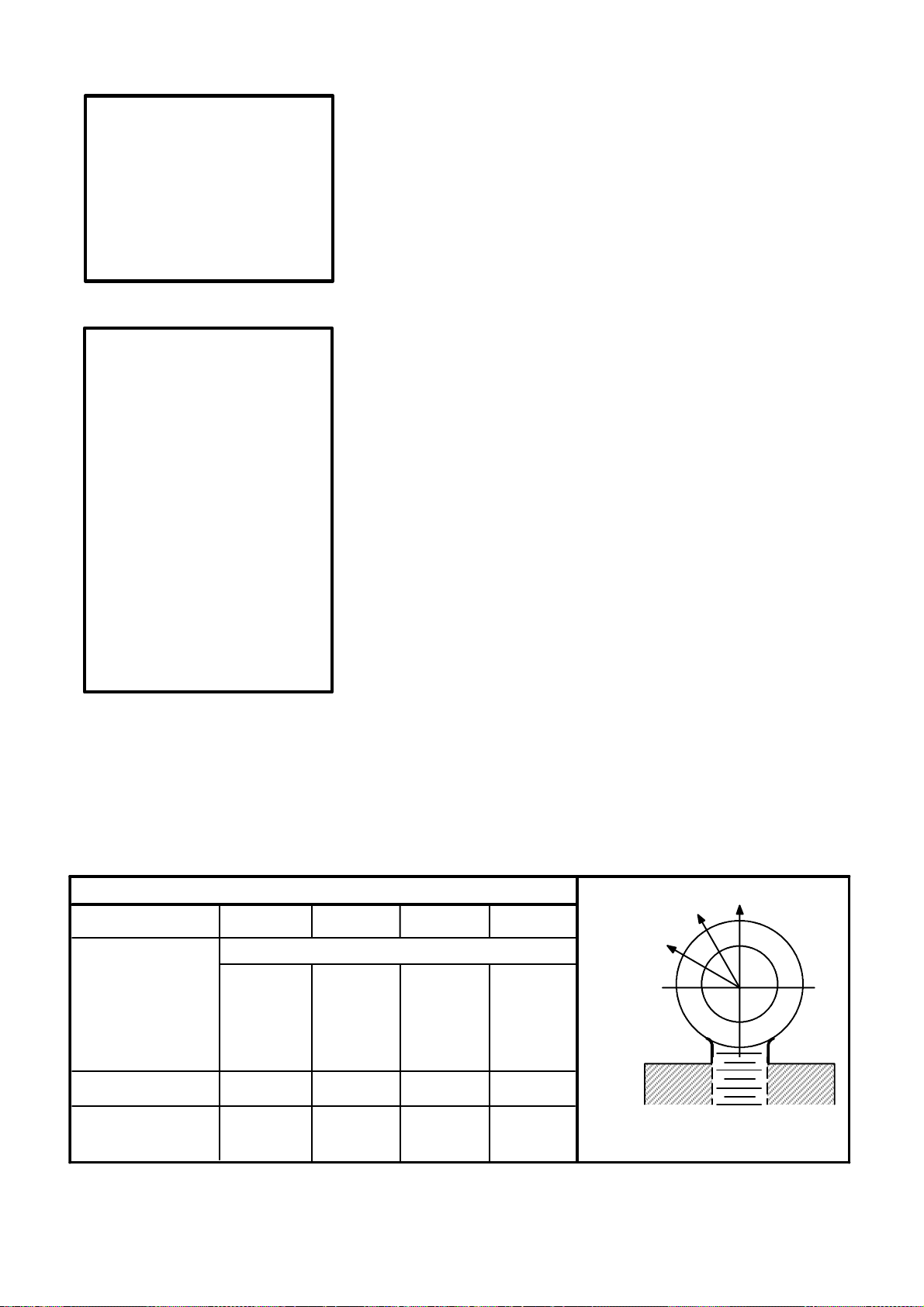

SHOULDER METRIC (ISO 3266--1984)

THREAD M12 M16 M20 M30

SPOTDIAMETER 32mm 37mm 42mm 67 mm

1.25 in. 1.50 in. 1.65 in. 2.63 in.

SAFE WORKING [KILOGRAMS] LBS.

LOAD

90 DEGREES [400] [630] [1000] [2500]

882 1389 2205 5512

45 DEGREES [100] [160] [250] [625]

220 352 551 1378

PART NUMBER 6014453--3 6014453--4 6014453--5 6014453--8

45

90

IDENTIFICATION

PLATE NUMBER 3338329 3338330 3338331 3338332

Fig. 2

Preferred Metric Lifting Eyebolts

5 MAX.

LOAD

NO

LOAD

30 MIN.

YES

YES

NO

Fig. 3

Eyebolt Loading

6.00

THIS MACHINE HAS BEEN

MANUFACTURED TO UTILIZE

”INCH” THREAD LIFTING

3.00

DEVICES. ANY EXCEPTION

TO THIS WILL BE LABELED

ADJACENT TO THE LIFT

POINT.

.12

.12

TYP.

NO 21 (.032) GAGEALUMINUM.-- NO. AL5052 ALLOY. ETCHEDAREAS TO

BEBLACK BAKEDENAMEL.ETCHEDDEPTHTO BE .003 TO .005 INCHES

------ OR ------ NO. 21 (.032) GAGE

ALUMINUM WITH METALPHOTOPROCESS.ALL LETTERING TO BEHELVETICA MEDIUM.

.109 DIA.THRU

4PLACES

3375984

.08

.25

.12 R

Fig. 4

Eyebolt I.D. Plates -- Inch and Metric

3TYP.

NO 21 (.032) GAGE ALUMINUM.-- NO. AL 5052 ALLOY. ETCHED AREAS TO BE BLACK

BAKED ENAMEL.ETCHED DEPTH TO BE .003 to .005 INCHES ------ OR ------ NO. 21 (.032)

GAGE ALUMINUM

WITH METALPHOTOPROCESS. ALLLETTERING TOBE HELVETICA MEDIUM.

SURFACE GRAIN TORUN PARALLEL TO LETTERING WITH SATINFINISH.

INCH

.375--16 UNC

THIS MACHINE HAS BEEN

MANUFACTURED TO UTILIZE

”METRIC” THREAD LIFTING

DEVICES. ANY EXCEPTION

75

TO THIS WILL BE LABELED

ADJACENT TO THE LIFT

POINT.

1.4

THRU--4

3TYP.

PLACES

3338325

SHOULDER METRIC

ISO METRIC

150

6.3

3375983

2

3R

3338329

M12

Fig. 5

Instruction Plate -- Inch (Part Number 3375984)

Page 1--8

Fig. 6

Instruction Plate -- Metric (Part Number 3375983)

Cincinnati Machine 91203597B001

Page 22

HOIST RINGS

A

PAR

T.N

O

PLATE

Hoist Rings are superior to eyebolts for angular lifting.

Be certain the thread projection is in accordance with the manufacturer’s

recommendation.

Do not recut any damaged threads on hoist rings.

To obtain the safe working load, torque to the recommended values shown

in the table below.

Fig. 7

Hoist Ring

CM HOIST

RING

PARTNO.

3346225 1 .375--16 12.0 16.3 1000 450 866 390 707 318 500 225 5013055 001

3346225 2 .500--13 28.0 38 2500 1130 2165 975 1767 795 1250 562 5013055 002

3346225 3 .625--11 60.0 81.3 4000 1810 3464 1559 2828 1273 2000 900 5013055 003

3346225 4 1.000--8 230.0 312 10000 4500 8660 3897 7071 3182 5000 2250 5013055 004

3346225 6 M12X1.75 27.0 36.6 2204 991 1908 859 1558 701 1102 496 5013055 006

3346225 7 M16X2 59.0 80 3857 1736 3340 1503 2726 1227 1928 868 5013055 007

3346225 8 M20X2.5 100.0 136 4736 2132 4103 1846 3349 1507 2369 1066 5013055 008

3346225 9 M30X3.5 229.0 310 9257 4166 8016 3607 6544 2945 4628 2083 5013055 009

CM HOIST

RING

PARTNO.

3346225 1 .375--16 12.0 16.3 1000 450 1000 450 1000 450 5013055 001

3346225 2 .500--13 28.0 38 2500 1130 2500 1130 2500 1130 5013055 002

3346225 3 .625--11 60.0 81.3 4000 1810 4000 1810 4000 1810 5013055 003

3346225 4 1.000--8 230.0 312 10000 4500 10000 4500 10000 4500 5013055 004

3346225 6 M12X1.75 27.0 36 2204 991 2204 991 2204 991 5013055 006

3346225 7 M16X2 59.0 80 3857 1736 3857 1736 3857 1736 5013055 007

3346225 8 M20X2.5 100.0 136 4736 2132 4736 2132 4736 2132 5013055 008

3346225 9 M30X3.5 229.0 310 9257 4166 9257 4166 9257 4166 5013055 009

Fig. 8

Hoist Ring Table

THREAD

SIZE

THREAD

SIZE

THREAD

TORQUE

Ft--Lb N--m Lb kg Lb kg Lb kg Lb kg

THREAD

TORQUE

Ft--Lb N--m Lb kg Lb kg Lb kg Ft--Lb N--m

Observe all other safety precautions normally practiced on eyebolts.

FF

90

_

WW

MAX. WT

EACH RING

FF

90

_

WW

MAX. WT

EACH RING

FF

60

_

WW

MAX. WT

EACH RING

FF

90

WW

MAX. WT

EACH RING

FF

45

_

WW

MAX. WT

EACH RING

FF

90

WW

MAX. WT

EACH RING

FF

30

_

WW

MAX. WT

EACH RING

NOTE F=FORCE W=WEIGHT

CM IDENT.

P

CM IDENT.

PART. NO.

.xxx--xx

PLATE

RT. NO.

.xxx--xx

.

Cincinnati Machine 91203597B001 Page 1--9

Page 23

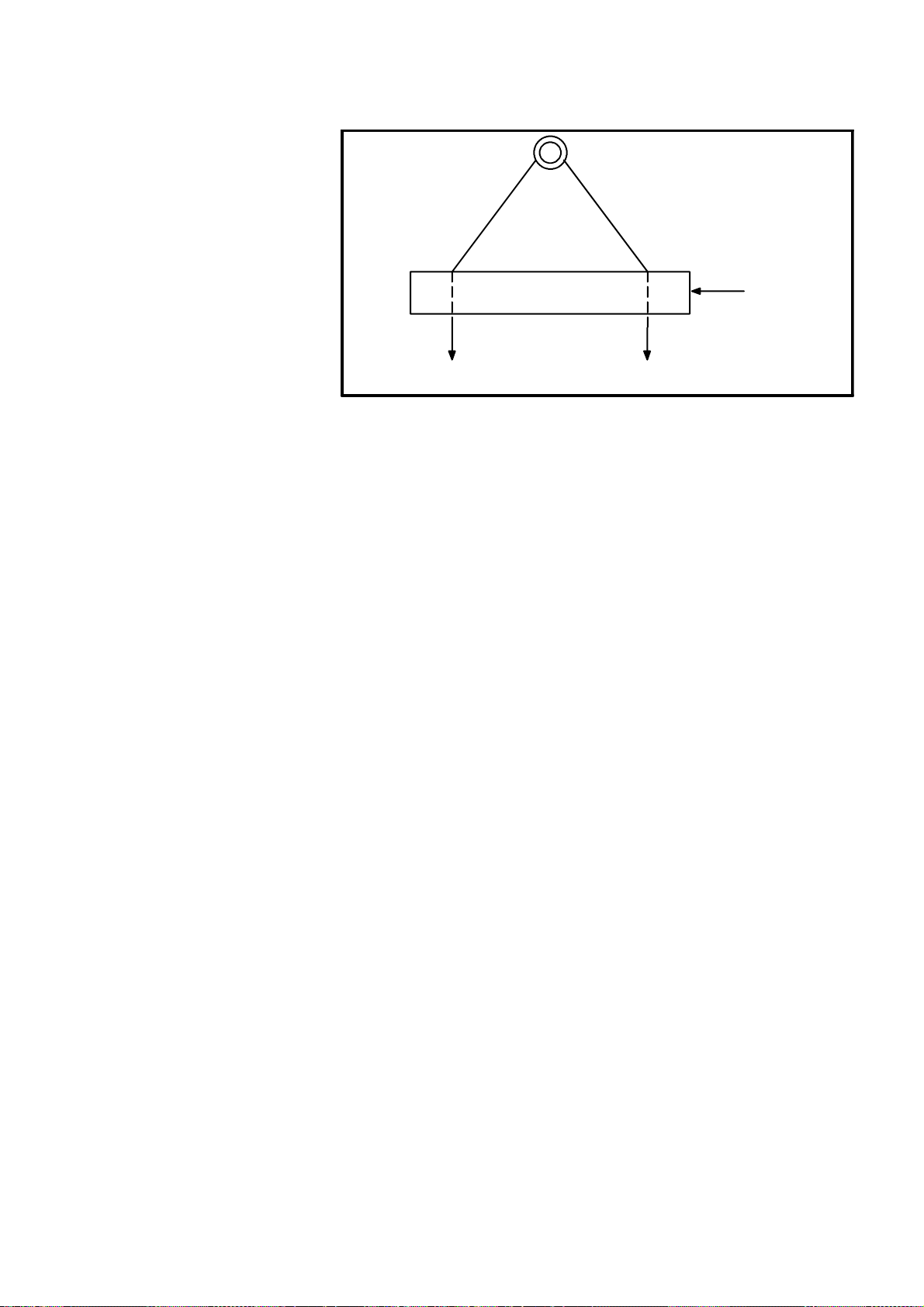

SPREADER BARS AND LIFTING BEAMS

p

y

p

SPREADER

TO LOAD TO LOAD

Fig. 9

S

reader Bar -- T

ical

Spreader bars are used when multiple eyebolts are designed into a lift.

Always observe the following safety precautions when using a spreader bar

or lifting beam

Do not exceed the safe working load.

Use the spreader or beam to handle parts or components only for which it

was designed.

Inspect it before each use.

Do not alter or weld anything to bar or beam.

Store properly to avoid damage.

CHAIN

Selectachainwiththesuitablecharacteristics and capacityforthe load. See

above. Always observe the following safety precautions.

Do not shorten chains with knots, bolts, or any non--approved method.

Never use damaged chain.

Hitch chain securely to the load.

Pad sharp cornerswith materialof sufficientstrength to withstand load and

protect chain.

Page 1--10

Cincinnati Machine 91203597B001

Page 24

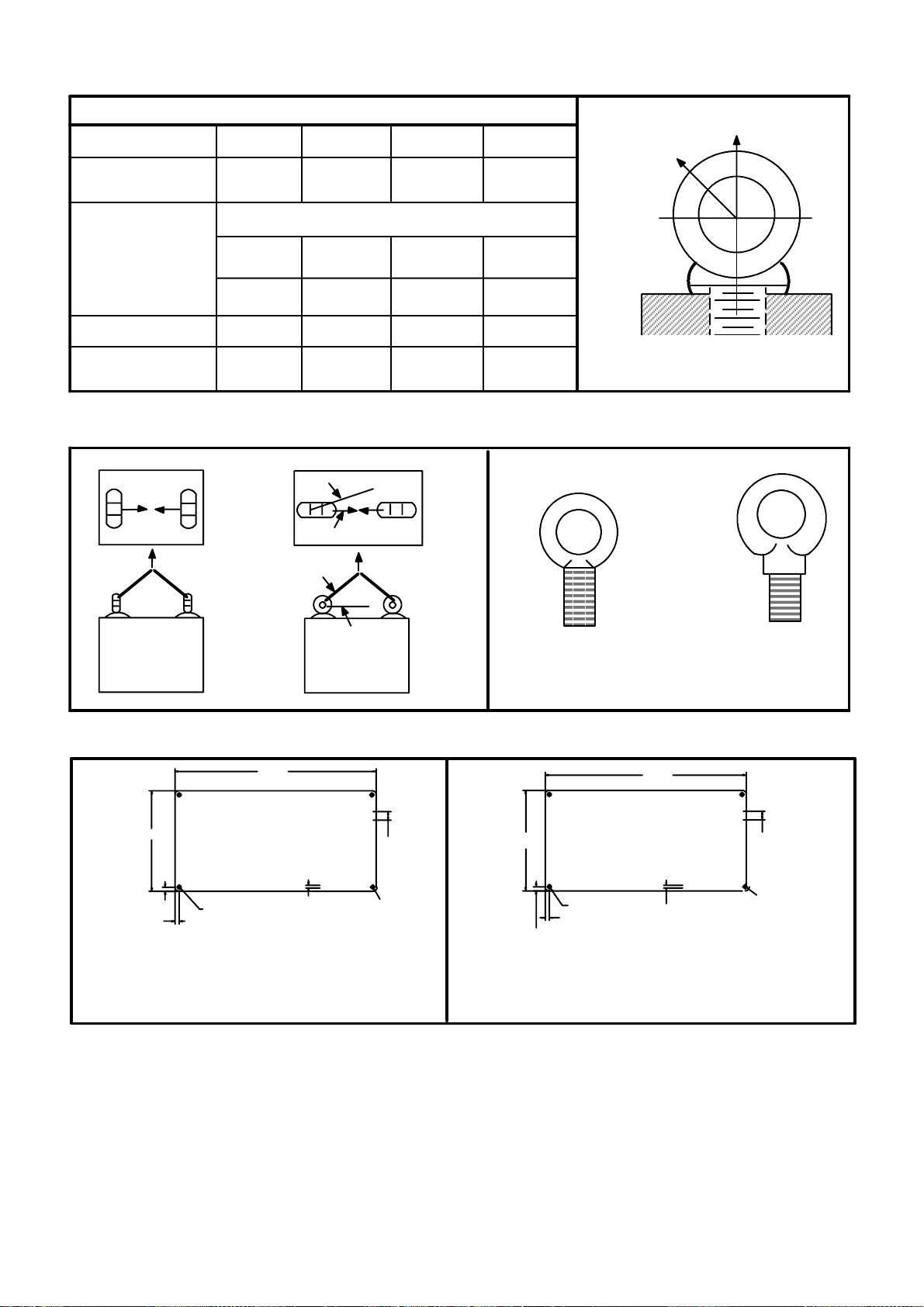

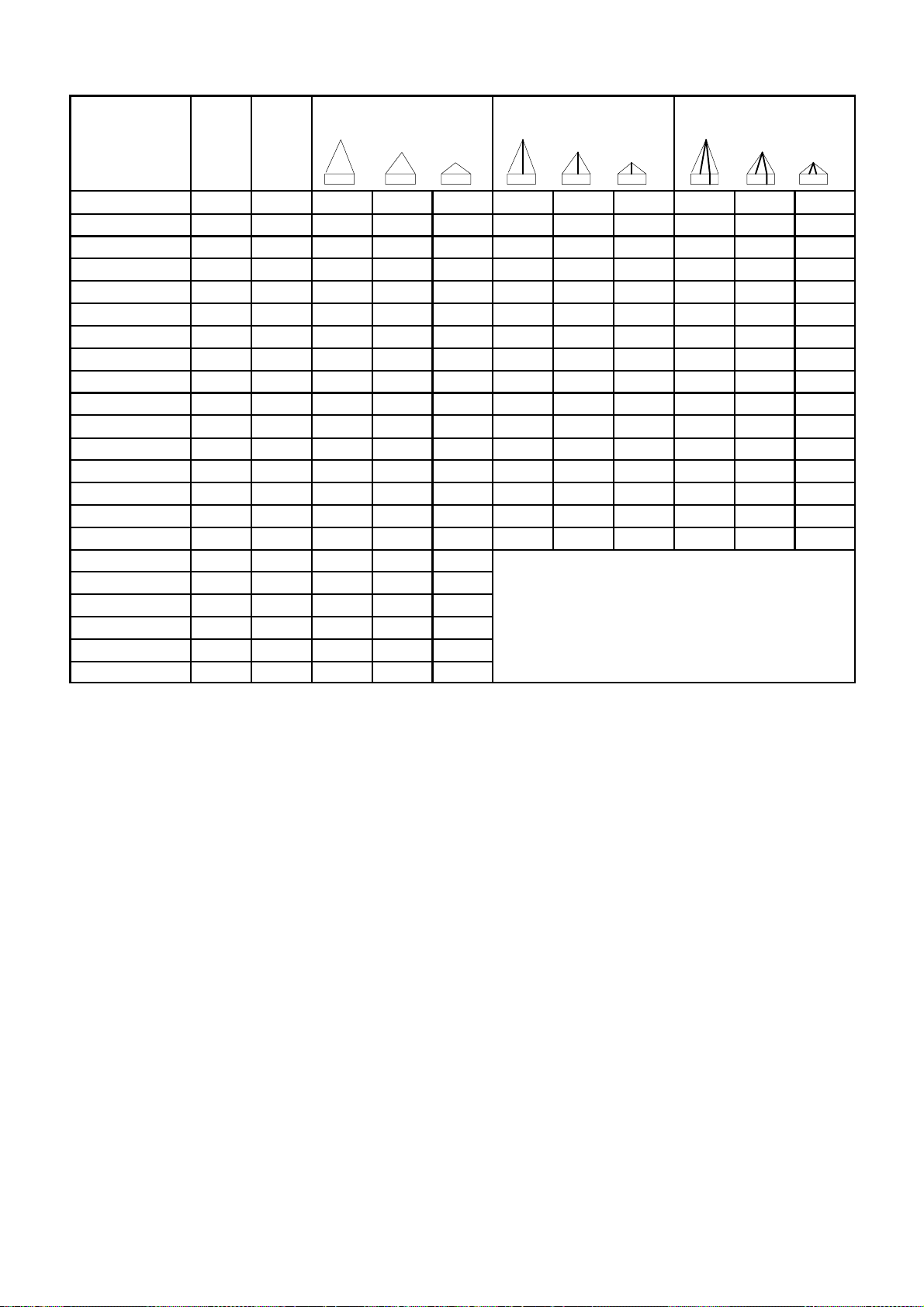

DOUBLE SLING CHAINS

SIZE OF

CHAIN

9/32 in. lbs. 3 250 5 625 4 600 3 250 8 400 6 900 4 875 8400 6900 4 875

.7.2 mm kg. 1 475 2 550 2 085 1 475 3 810 3 130 2 210 3 810 3 130 2 210

3/8 in. lbs. 6 600 11 400 9 300 6 600 17 100 13 950 9 900 17 100 13 950 9 900

9.5 mm kg. 2 995 5 170 4 220 2 995 7 750 6 330 4 490 7750 6 330 4 490

1/2 in. lbs. 11 250 19 700 15 900 11 250 29 250 23 850 16 875 29 250 23 850 16 875

712.7 mm kg. 5 100 8 845 7 210 5 100 13 270 10 820 7650 13 270 10 820 7650

5/8 in. lbs. 16 500 28 600 23 300 16 500 42 900 34 950 24 750 42 900 34 950 24 750

15.9 mm kg. 7 480 12 970 10 570 7 480 19 460 15 850 11 230 19 460 15 850 11 230

3/4 in. lbs. 23 000 39 800 32 500 23 000 59 700 48 750 34 500 59 700 48 700 34 500

19.1 mm kg. 10 430 18 050 14 740 10 430 27 080 22 110 15 650 27 080 22 110 15 650

7/8 in. lbs. 28 750 49 800 40 700 28 750 74 700 61 050 43 125 74 700 61 050 43 125

22.6 mm kg. 13 040 22 590 18 460 13 040 33 880 27 690 19 560 33 880 27 690 19 560

1in. lbs. 38 750 67 100 54 800 38 750 100 650 82 200 58 125 100 660 82 200 58 125

25.4 mm kg. 17 580 30 440 24 860 17 580 45 650 37 290 26 260 45 650 37 290 26 260

1 1/4 in. lbs. 57 500 99 600 81 300 57 500 149 400 121 950 86 250 149 400 121 950 86 250

31.8 mm kg. 26 080 45 180 36 880 26 080 67 770 55 320 39 120 67 770 55 320 39 120

1 1/2 in. lbs. 80 000 138 500 113 000 80 000

38.1 mm kg. 36 290 62 820 51 260 36 290

1 3/4 in. lbs. 100 000 73 200 41 000 100 000

44.5 mm kg. 45 360 78 560 63 960 45 360

2in. lbs. 130 000 225 000 183 000 130 000

50.8 mm kg. 26 750 102 060 83 000 26 750

SINGLE

CHAIN

90

TYPE D

60 45 30

TRIPLE SLING CHAINS

TYPE T

60 45 30

QUAD SLING CHAINS

TYPE Q

60 45 30

Fig. 10

Steel Alloy Chains

Keep hands and fingers from between the chain and load.

Avoidshockloading-- particularlywhenworkingat temperaturesbelow40

F[4 C].

Never pull chain from under load when load is resting on chain.

Correct kinks and twisting in chain before lifting.

Lift from center of hooks. Avoid lifting from the point.

Assurethatloadisfreeto move beforelifting.Keepclearof all obstructions.

When using a basket hitch, balance load and assure that chain legs contain

or support load from the sides above the center of gravity.

Storechainsin an area where they will notbe subject to mechanicaldamage

or corrosive action.

Cincinnati Machine 91203597B001 Page 1--11

Page 25

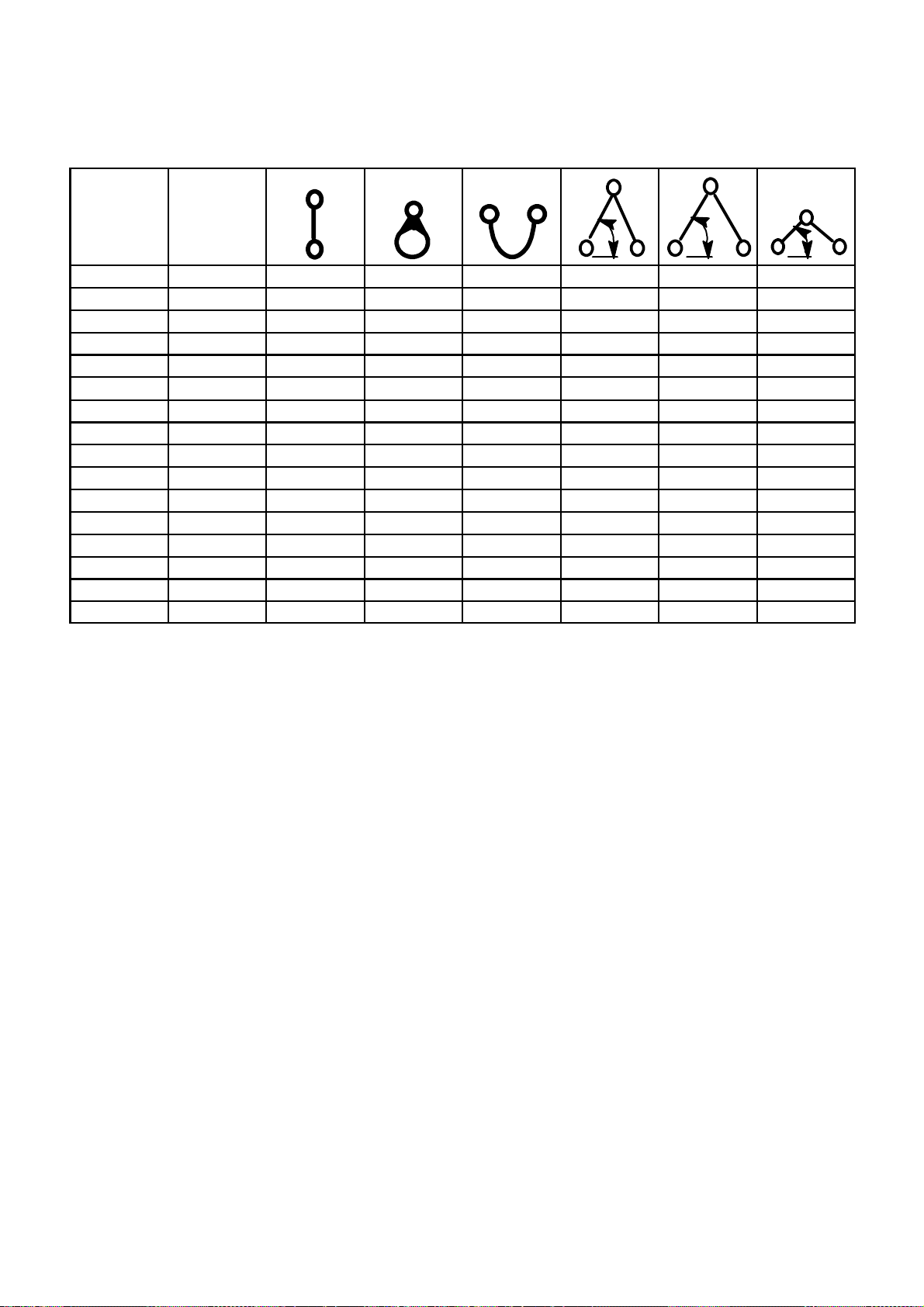

CABLE SLINGS

Select the appropriate size wire rope and hitch. See Table below.

CABLE

SIZE

1/4 in. lbs. 980 740 1400 1700 1400 980

6.4 mm kg. 445 335 635 770 635 445

1/2 in. lbs. 3600 2800 5200 6400 5200 3600

712.7 mm kg. 1630 1270 2360 2900 2360 1630

3/4 in. lbs. 7800 5800 11100 13600 11100 7800

19.1 mm kg. 3450 2630 5035 6170 5035 3450

1in. lbs. 13400 1000 18800 22000 18800 13400

25.4 mm kg. 6080 4540 8530 9980 8530 6080

1 1/4 in. lbs. 19600 14800 28000 34000 28000 19600

31.8 mm kg. 8890 6710 12700 15420 12700 6710

1 1/2 in. lbs. 28000 20000 40000 48000 40000 28000

38.1 mm kg. 12700 9070 18140 21770 18140 12700

1 3/4 in. lbs. 38000 28000 54000 66000 54000 38000

44.5 mm kg. 17240 12700 24490 29940 24490 17240

2in. lbs. 50000 36000 70000 86000 70000 50000

50.8 mm kg. 22680 16330 31750 39000 31750 22680

Fig. 11

Wire Rope Slings

ESTIMATED

RATINGCA-

PACITY

(For Exact

Rating Check

Sling Tag)

VERTICAL

CHOKER

HITCH

BASKET

HITCH

60 45

30

Guide loads with a tag line when practical.

When using multiple leg sling, select longest one possible.

Examine for damaged or worn area.

Attach securely to load.

Pad sharp corners to protect wire rope.

Center load in the base (bowl) of the hook to prevent hook point loading.

Do not kink, twist, or loop legs.

Keep hands and fingers from between wire rope and load.

Stand clear of attached load.

Start lift slowly to avoid shock injury.

Do not pull wire rope from under a load when the load is resting on it.

Do not shorten sling by knotting, by wire ropeclips, or by any other means.

Do not inspect wire rope by passing barehands over the body.Brokenwire,

if present, may puncture the hands.

Keep wire rope well--lubricated to prevent corrosion.

Page 1--12

Use gloves at all times when handling.

Cincinnati Machine 91203597B001

Page 26

SYNTHETIC MATERIAL SLINGS

Select the sling with the suitable characteristics and capability for the load

and environment. See Fig. 12.

AS THE SLING TO LOAD ANGLE

DECREASES, SO DOES THE RATED CAPACITY OF A SLING.

SLING--TO--LOAD ANGLE IS ALWAYS

THE ANGLE BETWEEN THE SLING LEG AND

THE HORIZONTALSURFACE.

SLING

TO

LOAD

ANGLE

Fig. 12

Sling Load Angle Chart

USE THIS CHART

FOR ALL TYPE

SLINGS; ROPE,

CHAIN, OR NYLON.

90

75

60

45

30

RATEDSLING CAPACITY--ONE LEG

SLING

LIFTING

EFFICIENCY

100.0 %

96.6 %

86.6 %

70.7 %

50.0 %

If Sling Ca-

pacity

at 90

is...

(LB. [KG])

1000

[454

]

1000

[454

]

1000

[454

]

1000

[454

]

1000

[454

]

Then Actual

Sling Capacity

is ...

(LB. [KG])

1000

[454

]

968

[439

]

866

[390

]

707

[320

]

500

[225

]

When using a choker hitch, the sling shall be long enough to assure that the

choking action is on the webbing.

Slings used in a basket hitch shall have the load balanced.

Do not drag slings over the floor or any abrasive surface.

Do not twist or tie knots in slings.

Never pull sling from load when the load is resting on it.

Protect sling from sharp corners and abrasive surfaces.

Do not drop slings.

Store slings in an area where they will not be subject to mechanical or

chemical damage.

Do not use where acid conditions exist.

Do not use polyester and polypropylene slings where caustic conditions

exist.

Do not use polyester and nylon slings at temperatures in excess of 180

F nor polypropylene slings at temperatures in excess of 200 F.

Do not use aluminum fittings where caustic conditions exist.

Cincinnati Machine 91203597B001 Page 1--13

Page 27

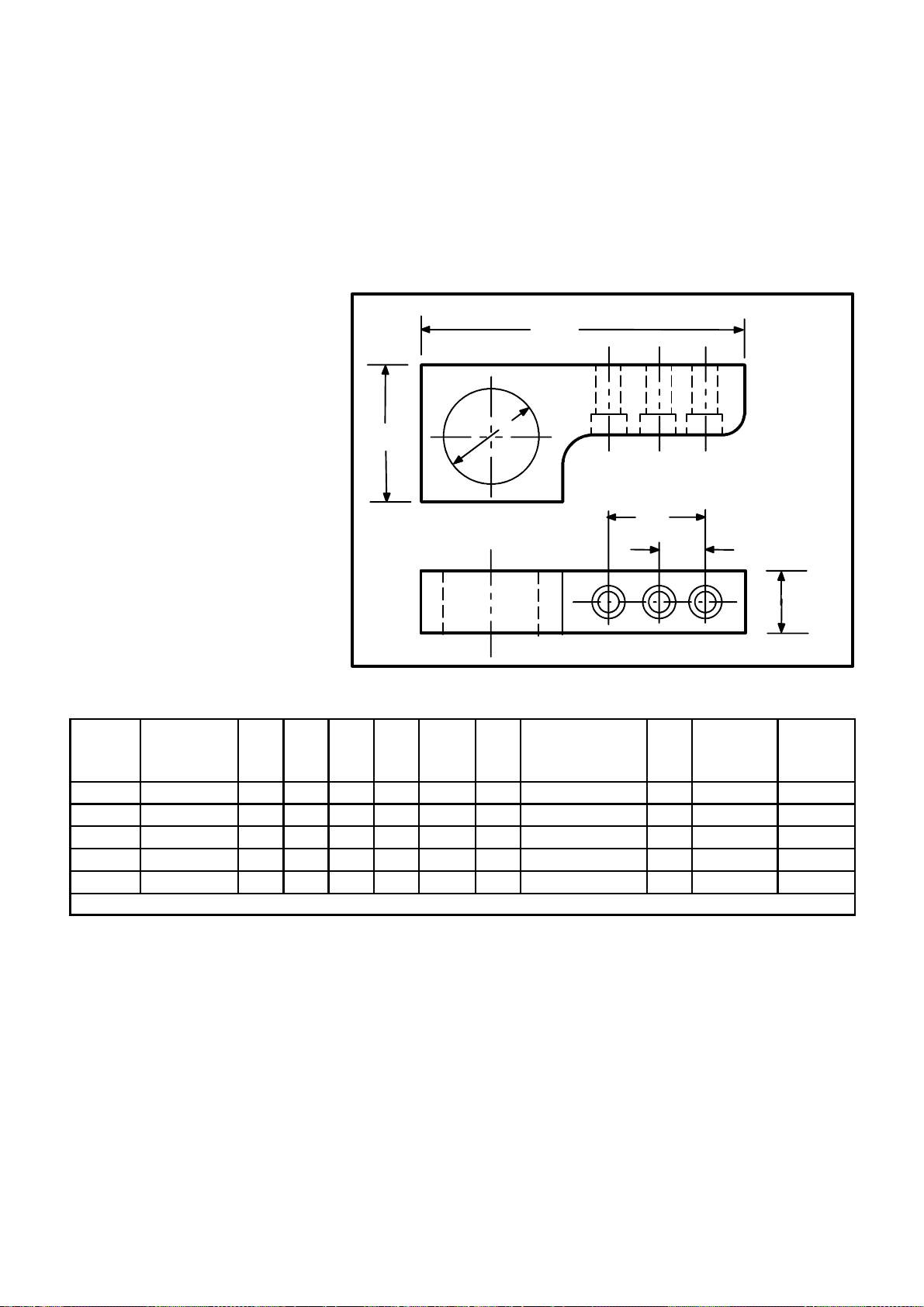

P TYPE HOOKS

N

O

P type hooks are a proprietary design and should be considered for heavy

(machine and unit) lifts.

Fig. 14 gives dimensional data, safe working loads andscrewtorquevalues

for P type hooks.

The use of these hooks must be shown on the assembly drawing, listed in

the Bill of Material and shown in the lifting section of the ServiceManual.

B

D

C

F

E

Fig. 13

“P” Type Lifting Hooks

PART

NO.

.

402517 1800 [818] 2.00 9.75 4.50 3.00 2.50 -- -- -- 2415 2 160 217

296513 2500 [1136] 1.75 10.63 4.00 2.50 4.00 -- -- -- 2415 2 160 217

296514 3500 [1590] 2.00 12.25 4.50 3.00 2.50 5.00 2415 3 160 217

402335 5000 [2273] 2.25 12.25 4.50 3.00 5.00 -- -- -- 180139 2 370 502

296515 8000 [3636] 2.25 15.75 4.50 3.00 4.00 7.88 180139 3 370 502

Fig. 14

“P” Type Lifting Hooks

LIFTING SCREW SCREW

CAPACITY

LBS. [KG]

A B C D E F SCREW NO. QTY.

INCH INCH INCH INCH INCH INCH

WHEN DESIGNING METRIC SIZES SEE THE CURRENT LIFTING MANUAL

TORQUE TORQUE

LB./FT. N--m

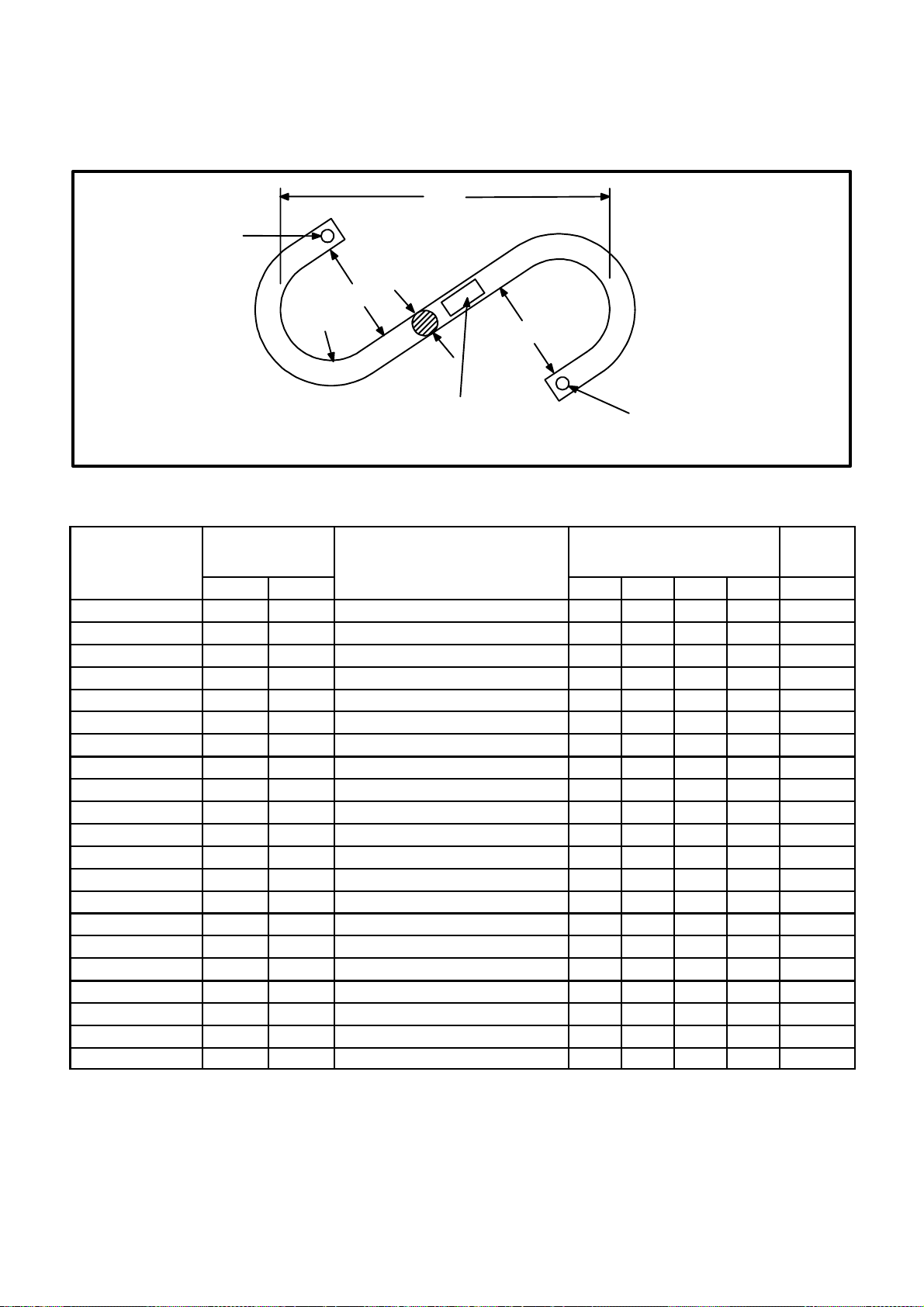

S HOOKS

A

The use of S hooks in conjunction with some of the other lifting devices

dictates additional safety rules which must always be practiced.

Never use more than one S hook in a single chain link or hook.

Inspect the S hook before each use and if damaged destroy by cutting into

two pieces.

Neverexceed the safe workingload which should be stamped on each hook.

Do not paint, weld, or expose an S hook to high heat.

Page 1--14

Cincinnati Machine 91203597B001

Page 28

STAMPTO

INDICATE ALLOY

Do not use when either or both S hooks are opened more than 15% of the

normal throat opening or twisted more than 10 from the plane of the

unbent hook.

B

A

C

R(REF.)

STAMPWORKING LOAD LIMIT WITHLOW STRESS

CHARACTERS PER NUCLEAR AMERICAN

SOCIETY OF MECHANICAL ENGINEERS CODE

SECTION III,DIV. 1, PARAGRAPH NA--3766.6 (2)

C

STAMP MFGR. NAME OR TRADEMARK FOR

IDENTIFICATION

Fig. 15

“S” Hooks

PARTNO.

MAX. WORKING

LOAD

LBS. KG

MANUFACTURER AND

CODE NUMBER

ALL DIMENSIONS IN

INCHES

(See Fig 16.)

S--HOOK

WEIGHT

A B C R LBS.

3590535--5 650 294 CM Chain 562250 0.500 7.50 2.00 1.00 0.80

Amer. Chain & Cable 5933--00800 0.500 5.50 1.50 0.75 0.63

3590535--7 1 015 460 CM Chain 562262 0.625 9.00 2.50 1.25 1.60

Amer. Chain & Cable 5933--01000 0.625 7.00 1.88 0.94 1.30

3590535--8 1 465 664 CM Chain 562275 0.750 10.50 3.00 1.50 2.60

Amer. Chain & Cable 5933--01200 0.750 8.25 2.25 1.12 2.10

3590535--9 1 990 902 CM Chain 562287 0.875 12.00 3.50 1.75 4.20

Amer. Chain & Cable 5933--01400 0.875 9.62 2.62 1.31 3.40

3590535--10 2 600 1179 CM Chain 562300 1.000 13.00 4.00 2.00 6.00

Amer. Chain & Cable 5933--01600 1.000 11.00 3.00 1.50 5.10

3590535--12 3 290 1492 CM Chain 562310--B 1.125 15.00 4.50 2.25 8.70

Amer. Chain & Cable 5933--01800 1.125 12.12 3.38 1.69 7.00

3590535--14 4 065 1843 CM Chain 562325--B 1.250 16.00 5.00 2.50 11.70

Amer. Chain & Cable 5933--02000 1.250 13.75 3.75 1.88 10.00

3590535--15 4 915 2229 CM Chain 562337--B 1.375 17.00 5.50 2.75 15.40

Amer. Chain & Cable 5933--02200 1.375 14.88 4.12 2.06 13.00

3590535--16 5 850 2653 CM Chain 562350--B 1.500 18.00 6.00 3.00 19.50

Amer. Chain & Cable 5933--02400 1.500 16.50 4.50 2.25 17.50

3590535--18 9 500 4309 Amer. Chain & Cable 5933--02800 1.750 19.25 5.25 2.62 28.00

3590535--20 12 500 5669 Amer. Chain & Cable 5933--03200 2.000 22.00 6.00 6.00 41.00

3590535--25 19 000 8618 Amer. Chain & Cable 5933--04000 2.500 27.50 7.50 9.75 79.00

Fig. 16

“S” Hooks

Cincinnati Machine 91203597B001 Page 1--15

Page 29

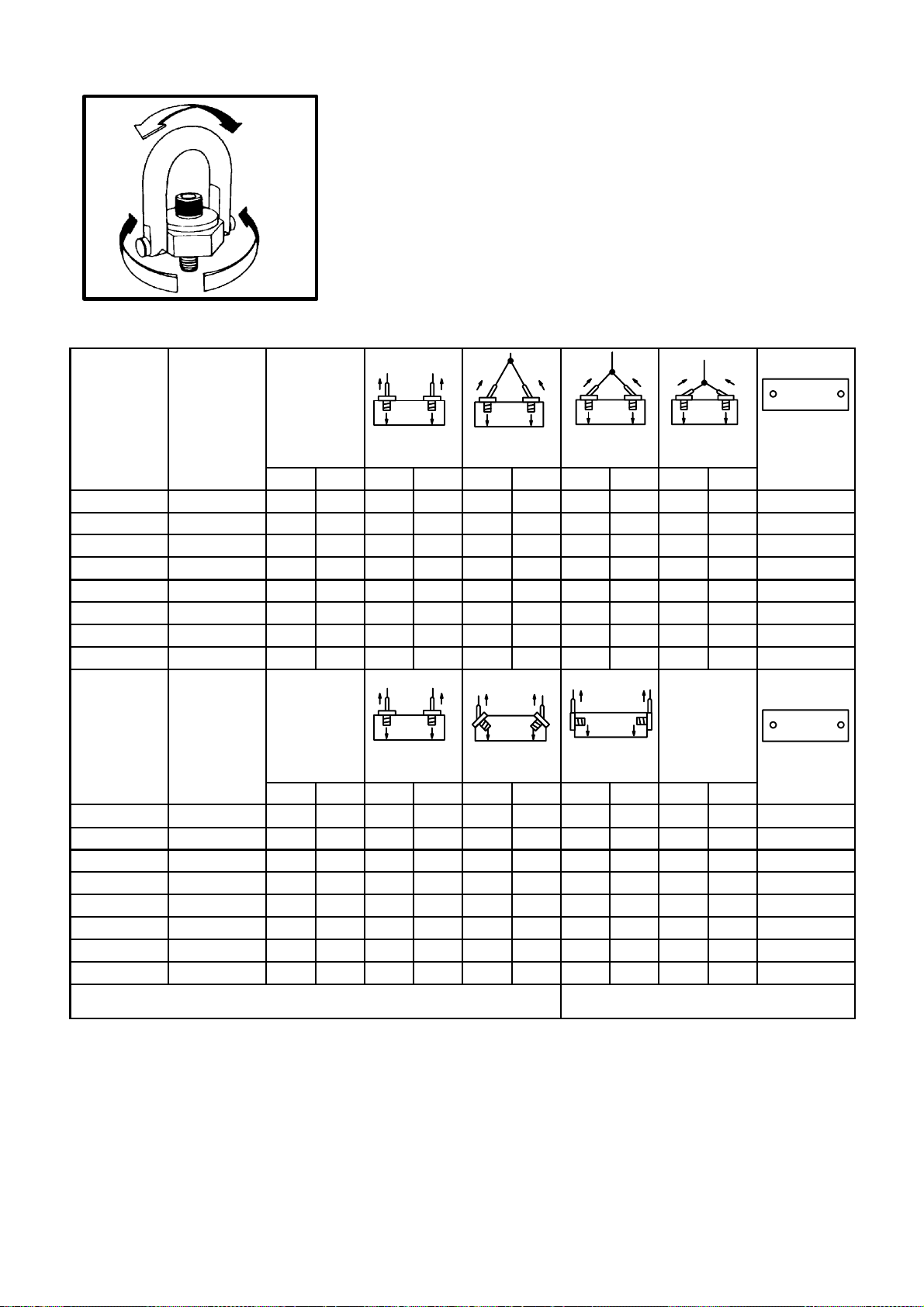

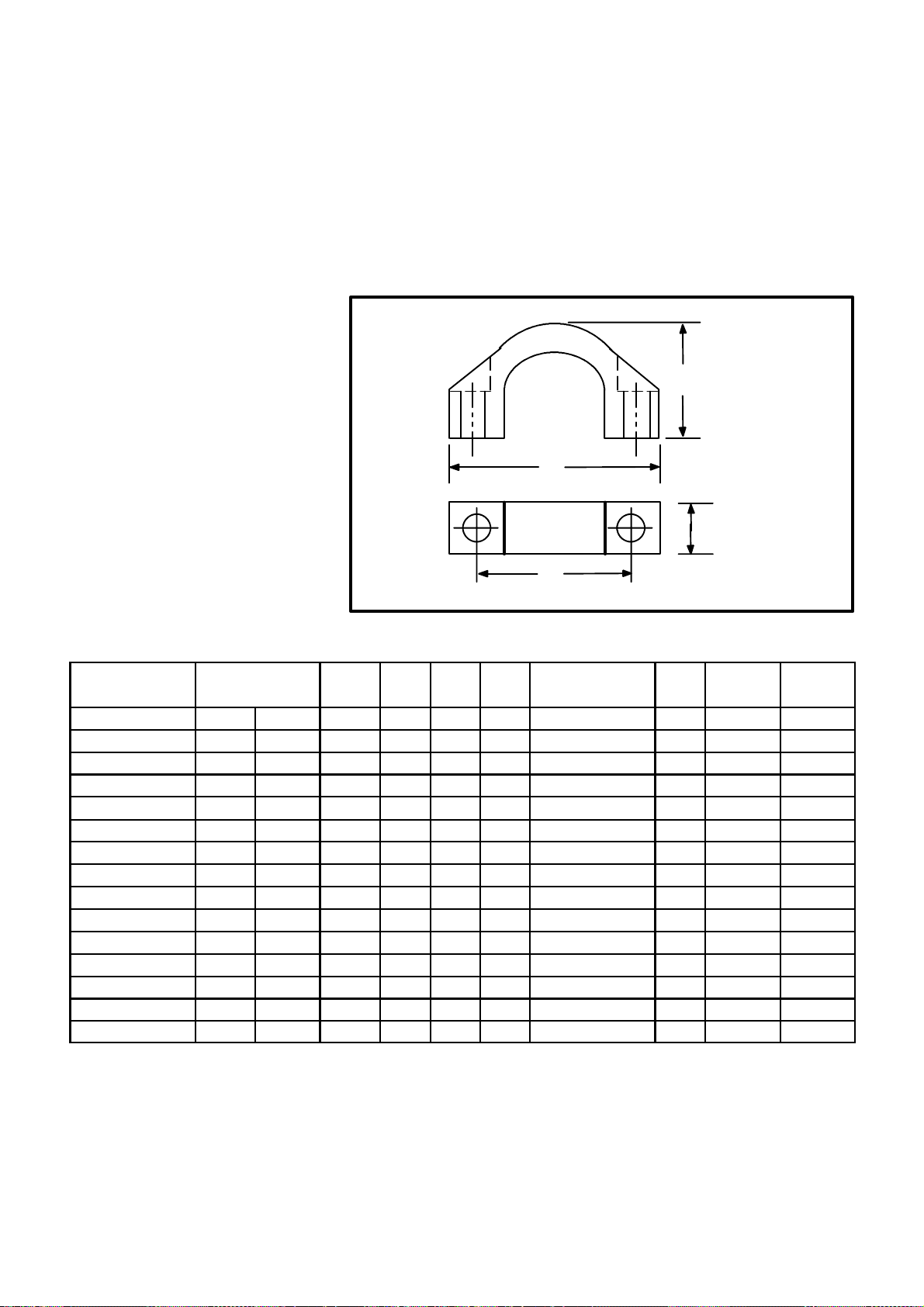

U TYPE HOOKS

U type hooks are a proprietary design and should be considered for heavy

(machine and unit) lifts.

Fig. 17 and Fig. 18 give dimensional data, safe working loads and screw

torque values for U type hooks.

The use of these hooks must be shown on the assembly drawing, listed in

the Bill of Material and shown in the lifting section of the ServiceManual.

C

B

D

A

Fig. 17

“U” Type Lifting Hooks

LIFTING SCREW SCREW

PARTNO.

303427 1 500 [680} 2.75 4.00 2.25 1.25 3248 2 45 61

303429 3 500 [1587] 3.25 4.50 2.50 1.50 2400 2 90 122

301269 6 000 [2720] 4.00 6.00 3.75 2.00 2415 2 160 217

301270 8 000 [3600} 5.00 6.50 3.88 2.25 180139 2 570 502

301271 12 000 [5442] 6.00 8.00 4.50 2.50 308196---3 2 735 997

301272 16 000 [7256] 7.00 9.50 5.30 3.00 308197---4 2 1290 1749

311105 25 000 [11 337] 7.00 14.25 6.00 3.50 308197---4 2 1290 1749

990819 1 500 [680] 75 107 60 32.0 1234074 2 41 30

3988405 3 000 [1360] 90 120 65 38.0 1234100 2 108 80

3990821 6 000 [2720] 105 155 95 50.0 1400264 2 230 170

5024235 8 000 [3600] 130 180 103 57.2 1400400 2 407 300

5025776 14 000 [6500] 170 250 133 76.2 6010088--3 2 1356 1000

5026032 22 500 [10 200] 300/180 380 159 88.9 6010088--3 4 1356 1000

CAPACITY

LB. [KG] in in in in SCREW NO. QTY. LB./FT. N--m

LB. [KG] mm mm mm mm SCREW NO. QTY. N--m LB./FT.

A B C D

TORQUE TORQUE

Fig. 18

“U” Lifting Hook Table

Page 1--16

Cincinnati Machine 91203597B001

Page 30

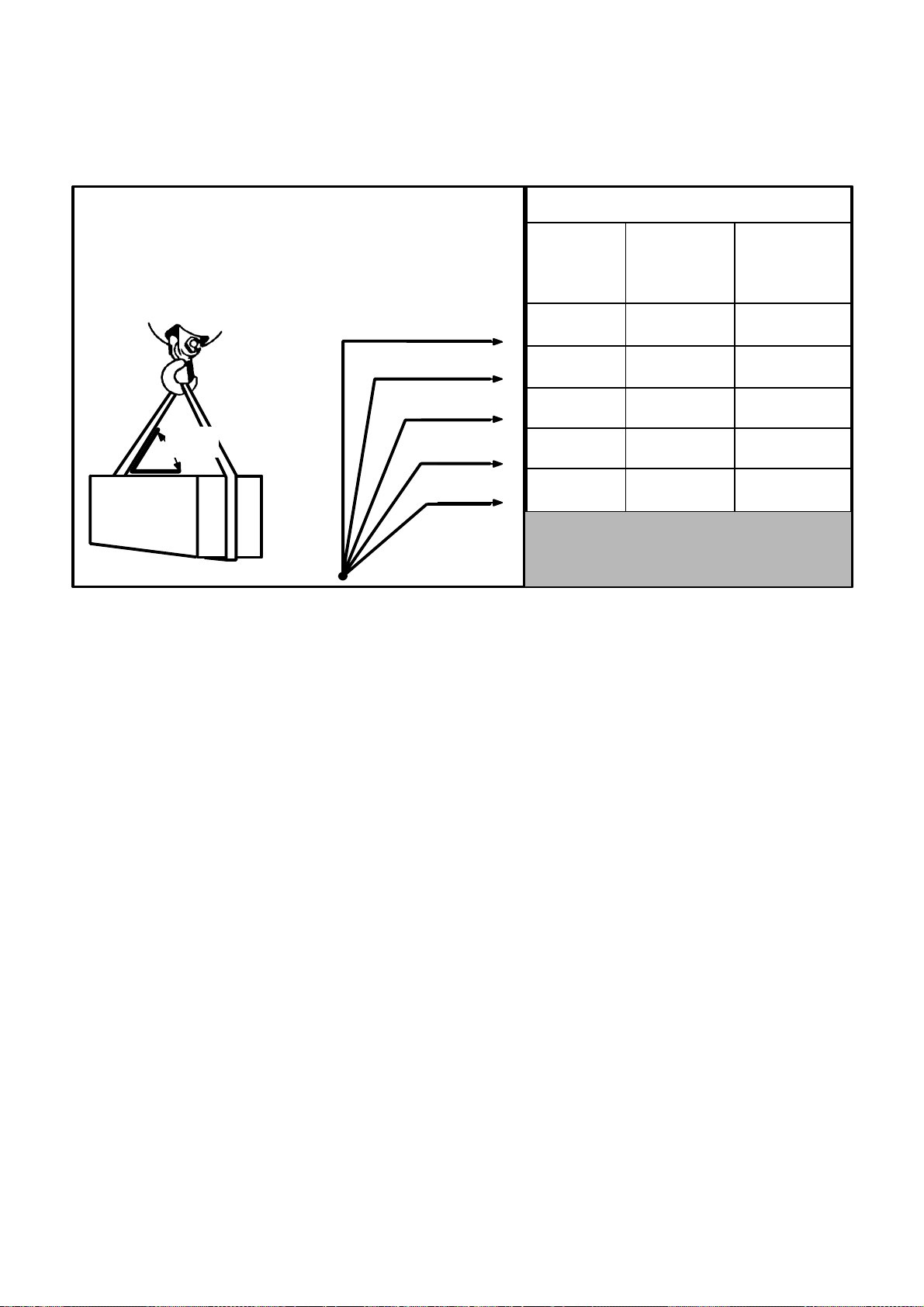

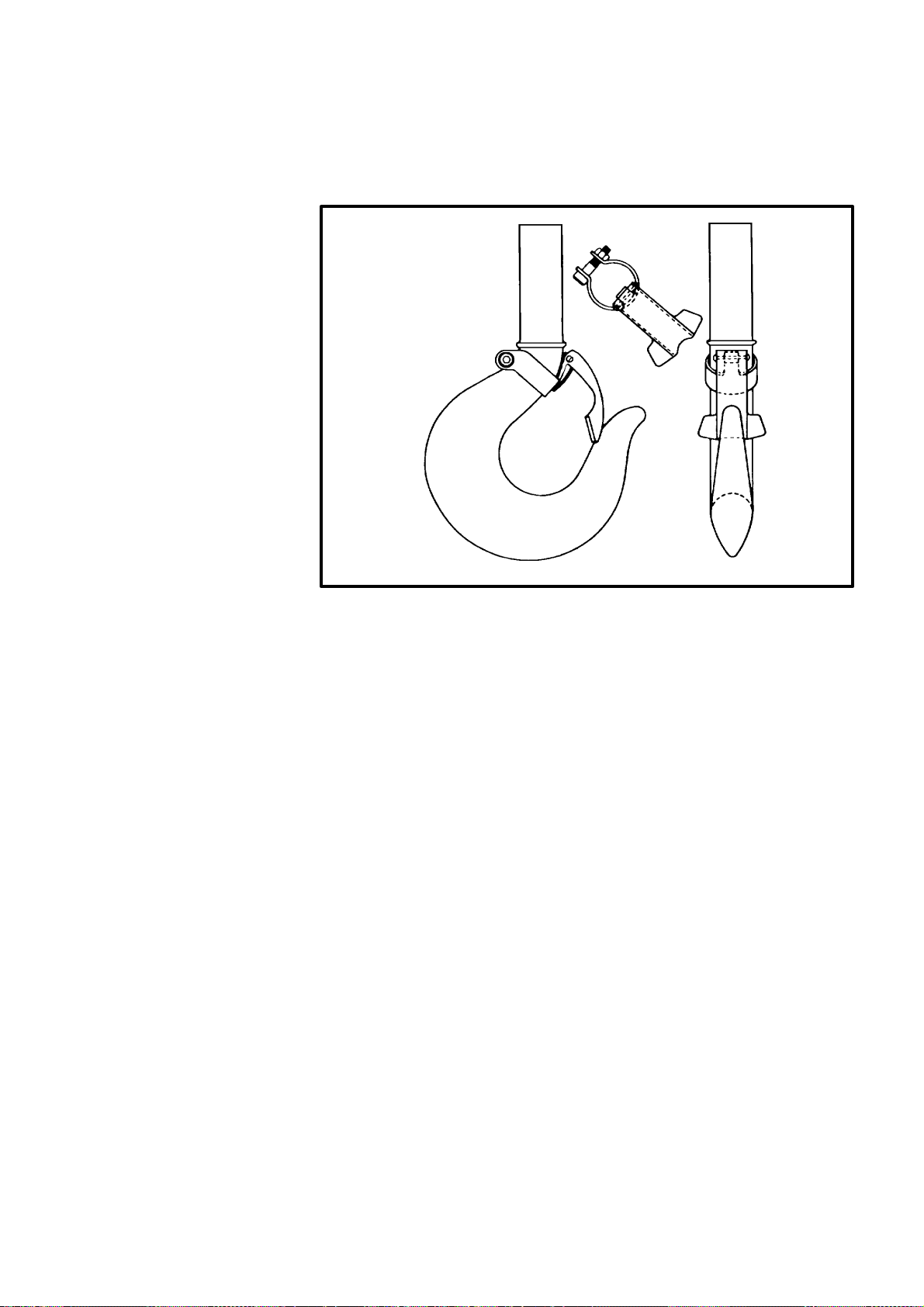

GENERAL SAFETY LIFTING INFORMATION

Allhooks or cranes or any othertype lifting device should be equippedwith

a safety latch (see Fig. 19) similar to the one manufactured by the

Harrington Co., Plymouth Meeting, Pennsylvania.

Fig. 19

Safety Latch

Illustrations or descriptions of any special lifting devices or techniques

required for servicing components of a specific machine are found in the

section dealing with the particular component.

Always contact the nearest Cincinnati Machine representative if there are

any questions regarding the lifting of any machine components.

Cincinnati Machine 91203597B001 Page 1--17

Page 31

WARNING

CUTTING FLUIDS

When soluble coolants

areused, it is important to

ensure that recommended concentration

levels are maintained.

Fluids Used With Machine Tools

General Considerations

Various fluid products, such as cutting fluids, lubricants, etc., are used with

this machine tool. The correct type and quantity is identified by instruction

platesonthemachineand/or writteninstructions inthesuppliedmanual(s).

Before using fluids or related products not specifically approved or

recommended with this machine tool, the owner/user should contact the

authorized supplier, closest Cincinnati Machine regional field office for

assistance in determining if the product is suitable for the particular

application.

Lubricants

Only those lubricants (oils and greases) tested and approved by Cincinnati

Machine, should be used in Cincinnati machine tools. For information

concerning latest lubricants manual, contact Cincinnati Machine service

department.

Cutting Fluids

Before filling the machine, ensure that the product is suitable for the

application. Frequently, check for storage, tank unit or hose leaks.

Watermixedfluids thatcontainemulsifiersmustbeprotectedfromfreezing.

Cutting fluid products should be tailored to each machine tool application

and workpiece requirement for maximum efficiency. See WARNING.

Failure to follow this Instruction can cause corrosion of safety critical

parts, resulting in machine damage and/or personal injury.

For assistance in determining the correct cutting fluid, contact nearest

Cincinnati Machine Service Department.

Sources Of Information -- USA

Beforeusinganyfluidproductwiththismachinetool,theowner/usershould

request a Technical Data Product Safety Sheet (for example: OSHA Form

20 or a similar technical data information sheet) f rom the product

manufacturer. This data should include the following:

Fire and Explosion Hazard Chemical and Trade Name

Data Acute Toxicity Properties

Spill or Leak Procedures Hazardous Ingredients

Special Protective Information Physical Data

Special Precautions Recommended Dilutions

Page 1--18

Cincinnati Machine 91203597B001

Page 32

Listed below are some other sources which can be contacted to obtain

additional up--to--date information concerning the safe use, handling,

storage and disposal of products, materials, chemicals or substances.

Occupational Safety and Health Resource Conservation and

Act (OSHA) Public Law Recovery Act (RCRA) Public Law

Department of Transportation National Institute for

(DOT) Hazard Classification— Occupational Safety and

The Transportation Safety Act Health (NIOSH)

Product Safety Data Sheet Cincinnati Machine

Toxic Substances Control Act P.O. Box 9013

(TSCA) Public Law Cincinnati, Ohio 45209

Federal Insecticide, Fungicide and American National Standards

Rodenticide Act (FIFRA) Public Institute, Inc. (ANSI)

Law

American Conference of

Environmental Protection Agency Governmental Industrial

Hygienists,

Threshold Limit

Federal Hazardous Substances Act Values

Clean Water Act

After receiving the data, analyze and perform the necessary procedures to

assure the safe handling, storage, use and disposal of the product.

Emergency/FirstAidproceduresand training should be readilyavailableto

personnelhandlingor usingproductswhichmaybehazardous(flammable),

harmful (toxic) and/or reactive (unstable)

The owner/user should become familiar with and keep informed on all

regulated materials or substances. Copies of the latest regulated material

may be obtained from agencies, such as NIOSH, Registry of Toxic Effects

for Chemical Substances, U.S. Department of Health Education and

Welfare, Public Health Service, Center for Disease Control, and the

National Institute for Occupational Safety and Health.

Usage Information

Products must not be mixed with other products unless permission and/or

instructionshavebeengrantedbythemanufacturer(s).Productconcentrates

must be mixed and diluted exactly as instructed by the manufacturer for a

particular approved application.

All product CAUTION, WARNING and DANGER labels, tags and printed

instructions accompanying the products must be read and followed This

instruction shall remain with the product at all times. Additional product

instruction labels, signs, etc., should be acquired and displayed with

concentrates that are purchased in bulk and then dispensed in small or

diluted quantities

Cincinnati Machine 91203597B001 Page 1--19

Page 33

Cutting Fluids -- Preventative Maintenance

SeeCautions1and2

CAUTION 1

COOLANTS