Page 1

BLANKETROL@

II

OPERATION MANUAL

The operator must read and understand the Operation Manual in its entirety prior to

operating the equipment.

Cincinnati Sub-Zero Products, inc., reserves the right to make equipment changes and

improvements which may not be reflected in this manual.

CAUTION

Federal law restricts this device to use only on the order of a physician.

DANGER

0

0

Notify the physician if the patient’s temperature is not responding properly

or does not reach the temperature prescribed in the prescribed time or if

there is a change in the prescribed temperature range. Failure to inform

the physician of the deviation may result in injury to the patient.

Do not use the Blanketrol II system in the presence of flammables.

Risk of explosion can result.

0

Power interruption will cause the Blanketrol II to revert to CHECK

SETPOINT

desired mode to resume operation.

resulting in no therapy to the patient. Follow instructions for

Failure to resume therapy could result in serious injury or death.

CAUTION

0

0

Use distilled/sterile water only.

Failure to use distilled/sterile water may

result in poor performance and damage to the Blanketrol II.

Do not use De-ionized Water. The majority of de-ionizers do not maintain

pH

a neutral

effect and the copper refrigeration line will begin to deteriorate and cause

a leak in the refrigeration system.

of 7. If the de-ionized water is acidic, it will cause a battery

0

0

0

Do not use alcohol. Alcohol may cause blanket deterioration.

Do not operate without water to avoid damage to internal components.

Do not overfill. Overfilling may result in overflow when the water in the

blanket drains back into the system when the system is turned off.

i

Page 2

WARNING

A physician’s order is required for setting blanket temperature and use of

equipment. At least every 20 minutes, or as directed by physician, check

patient’s temperature and skin condition of areas in contact with blanket;

also, check blanket water temperature. Pediatric, temperature-sensitive,

patients with vascular disease, and operating room patients should be

checked more frequently.

order to avoid serious injury or death.

The method of temperature control provided by all hyper-hypothermia

units presents the danger of heating or cooling body tissues, particularly

the skin, to a point where they are injured, i.e., burns or frostbite,

respectively. Depending on the extent and severity of a burn, very serious

and even fatal complications may arise.

Prevent excessive and/or prolonged tissue pressure and shearing forces,

especially over boney prominences, to prevent skin damage that may

result.

Do not place additional heat sources between the patient and blanket.

Skin damage may result.

Notify the physician promptly of any change in

The area between the patient and the blanket should be kept dry to avoid

injury to patient.

Use only YSI

400

series, or equivalent, probes on CSZ equipment. Failure

to do this will cause incorrect temperature readings.

BLANKETROL is a Registered Trademark of Cincinnati Sub-Zero Products, Inc.

@

Copyright 1982, Cincinnati Sub-Zero Products, Inc. All rights reserved.

3193B2ROM

ii

Page 3

SECTION 1. INTRODUCTION

TABLE OF CONTENTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Pace

No.

-

18

1-o.

l-l.

1-2.

l-3.

l-4.

1-4.1. External Features

l-4.2. External Features

1-4.3.

1-4.4.

l-5.

l-6.

1-6.1.

1-6.2. Cooling System

1-6.3.

General Safety Precautions

General Description of this Manual

General Description of the BLANKETROL II System

Clinical Applications

................................

Physical Description of the BLANKETROL II Unit

-

Front View

-

Right Side View

-

External Features

Rear View

Expanded Description of the BLANKETROL II Control Panel

Required Accessories

...............................

Functional Description of the BLANKETROL II System

Heating System

Circulating System

..................................

..................................

................................

l-6.4. Temperature Safety Control System

l-7. Specifications of the BLANKETROL II Unit

...........................

......................

...........

.............

.........................

......................

..........................

.....

.........

.....................

.................

SECTION 2 GENERAL PREPARATION OF THE BLANKETROL II SYSTEM . 19

2-l.

2-2.

2-3.

2-3.1.

2-3.2.

2-4.

2-5.

2-6.

Introduction

Unpacking the Shipment

First Time Set-up/System Test Routine

Inspecting and Arranging the Equipment

Completing a System Test Routine

Suggestions for Protecting the Reservoir from Bacteria and

for Decontamination Guidelines

Unit and Patient Related Precautions

Patient Preparation and Bedside Care

.....................................

............................

...................

..................

.....................

........................

.....................

.....................

.I3

.I4

.I4

-

32

.I9

.I9

.21

1

1

1

2

3

4

6

8

10

12

12

15

17

19

19

27

30

31

SECTION 3

3-l.

3-2.

3-3.

3-4.

3-5.

3-6.

3-7.

3-8.

OPERATING THE BLANKETROL II UNIT

Introduction

Arranging the System Components

Operating the BLANKETROL II Unit in Automatic Control Mode

Operating the BLANKETROL II Unit in Manual Control Mode

Operating the BLANKETROL II Unit in Manual Control Mode

with the Addition of the Patient Probe

Operating the BLANKETROL II Unit in Monitor Only Mode

Concluding Hyper-Hypothermia Treatment

Status Display Messages

.

. . . . . . . . . . . . .

33

-

48

.33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.33

. . . . . . . . . . . . . . . . . . . . .

.

35

. .

.

38

. . . .

.

40

. . . . . . . . . . . . . . . . . . .

.

41

. . . . .

.

43

. . . . . . . . . . . . . . . .

.44

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. .

III

Page 4

ILLUSTRATIONS

Paqe

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

No.

-

Figure l-l

BLANKETROL II Unit

Figure l-2 BLANKETROL II Unit

Figure l-3 BLANKETROL II Unit

Figure l-4 BLANKETROL II Unit

Figure l-5 Temperature Safety Limits

Front View

-

Right Side View

-

Rear View

-

Control Panel

............................

Figure 3-l BLANKETROL II System Equipment

.......................

...................

.......................

.....................

& Accessories

...........

5

7

9

11

16

48

iv

Page 5

INTRODUCTION

SECTION 1. INTRODUCTION

BLANJ5ZTFtOL

II,

HDDEL

22ZR

OPERATION

MANDAL

1-o.

To provide the patient maximum safety during the use of the BLANKETROL II

GENERAL SAFETY PRECAUTIONS

hyper-

hypothermia system, a thorough knowledge, understanding of the system, the correct

application and operating use of the system is required. Each person who is

responsible for the use or the direction of the use of the

nurses, technicians and operators must read and understand this

svstem, such as

operatinq

phvsicians,

manual all

precautions and warninss prior to use. It is recommended this manual be reviewed

at least semi-annually as a refresher to safe operation and application.

l-l.

GENERAL DESCRIPTION OF THIS MANUAL

This manual describes the operation, maintenance, and service of the CSZ

BLANKETROL II hyper-hypothermia system. Section One describes the physical and

functional characteristics of the BLANKETROL II System. Section Two describes how

to prepare the BLANKETROL II unit for general use. Section Three describes how to

operate the unit in the Manual Control Mode, Automatic Control Mode, and Monitor

Only Mode.

This manual is prepared for professional personnel who use the equipment for patient

care. It is designed to be stored with the BLANKETROL II unit and to be readily

available for reference when operating the BLANKETROL II System.

l-2.

GENERAL DESCRIPTION OF THE BLANKETROL II SYSTEM

The CSZ BLANKETROL II, Model 222R Hyper-Hypothermia System is used to either

lower or to raise a patient’s temperature and/or maintain a desired patient temperature

through conductive heat transfer.

The CSZ BLANKETROL II unit is composed of a

heater, a compressor, a circulating pump, and a microprocessor board. This unit

requires no field adiustments or calibrations in order to maintain the precise

measurement of temperature and temperature safetv limits.

1

Page 6

INTRODUCTION

B-L

II,

UIDEL

222R

OPERATION

l4ANUAL

l-2. GENERAL DESCRIPTION OF THE BLANKETROL II SYSTEM

(cont’d)

Water is heated or cooled and pumped from the unit to a blanket. The blanket* rests

under and/or on top of the patient and is designed so that the water circulates through

the blanket and returns back to the unit.

If cooled water is circulated through the blanket, the desired effect is to reduce the

patient’s temperature. If warmed water is circulated through the blanket, the desired

effect is to elevate the patient’s temperature.

The BLANKETROL II unit can be set so that it operates based on the temperature of

the circulating water (Manual Control) or it can be set so that it operates based on the

temperature of the patient (Automatic Control).

* The recommended blanket(s) for use is described in Section (I-5.)

1-3. CLINICAL APPLICATIONS

The BLANKETROL II unit is used primarily in hospital Intensive and Coronary Care

Units, in Operating,

Medical/Surgical floors. This hyper-hypothermia system can be used with adult and

pediatric patients to produce normothermia by lowering a patient’s elevated

temperature or raising a patient’s sub-normal temperature. It can also be utilized to

maintain normal body temperature (normothermia) during surgical procedures.

Surgically, this system can be used to produce moderate to profound hypothermia for

such procedures as amputations, cardiopulmonary by-pass surgery, vascular surgery,

and intracranial surgery. Medically, this system can be used to decrease the rate of

circulation, to reduce intracranial pressure, to control cerebral edema, and to reduce

oxygen requirements. This system is also used in the treatment of burns, shock,

cardiac arrest, and gastrointestinal hemorrhage.

Recovery and Emergency Rooms, in Burn Units, and on

Page 7

INTRODUCTION

BLANKETROL II,

mDEL

222R OPERATION MANUAL

l-4.

PHYSICAL DESCRIPTION OF THE BLANKETROL II UNIT

The BLANKETROL II unit is a compact unit with

Dimensions: 17 inches (43.2 cm.) Wide x

x 36 inches (90 cm.) High

Weight: 131 pounds (59.4 kg.)

Cabinet Construction: Powder coated steel

Bottom air discharge.

Storage compartment.

casters.

the following physical features:

17 inches (43.2 cm;) Deep

with plastic top. Dual reservoir.

Molded-in handle. Bumper guards.

Four 5 inch conductive, swivel type

3

Page 8

INTRODUCTION

I-4.1. EXTERNAL FEATURES

BLANKETROL II,

-

FRONT VIEW

HDDEL

222R

OPERATION MANUAL

The external features in Figure (l-l) of the BLANKETROL II unit are described as

follows:

A.

B.

C.

D.

E.

The control panel is composed of pressure sensitive touch switches and

four LED displays. An expanded description of the control panel is

presented in Section (1-4.4.).

The operatinq instructions are printed directly below the control panel.

This layout is designed to increase the operator’s efficient use of the

unit.

The power switch is a bevel rocker switch labeled ON at the top and OFF

at the bottom. The switch lights up green when ON. A circuit breaker

is built into the switch to protect against overload conditions.

storaqe drawer tilts out from the top

The

items such as probes, connector cables,

to provide storage space for

connecting hoses,

the drain

hose, and the Operator’s Manual.

The grille permits air to be drawn into

the unit and pass

over the

condenser. The air is then discharged through the bottom of the unit.

The grille should be kept from being blocked by being cleaned regularly

as described in Section (4-4.) of the Operation/Technical Manual.

F.

G.

H.

I.

The protective bumper quard surrounds the lower edge of the unit and

protects the unit as well as the walls.

Four conductive, swivel casters are specially designed to permit the unit

to move easily and to prevent it from tipping.

The Celsius/Fahrenheit selector switch, abbreviated C/F, is a rocker

switch that permits the operator to select the measurement scale,

Celsius or Fahrenheit, by which the unit functions. Celsius is in the

down position and Fahrenheit is in the up position.

The water fill opening is where the operator pours distilled/sterile water

to fill the reservoir.

Page 9

INTRODDCTION

BLMWZROL

II,-EL

222ROPEWTION

MANIJAL

FIGURE

l-1

BLANKETROL

Ii,

FRONT VIEW

5

Page 10

INTRODUCTION

1-4.2.

EXTERNAL FEATURES

BLANKETROL II.

-

RIGHT SIDE VIEW

I%lDEL

222R OPERATION

FlANUAL

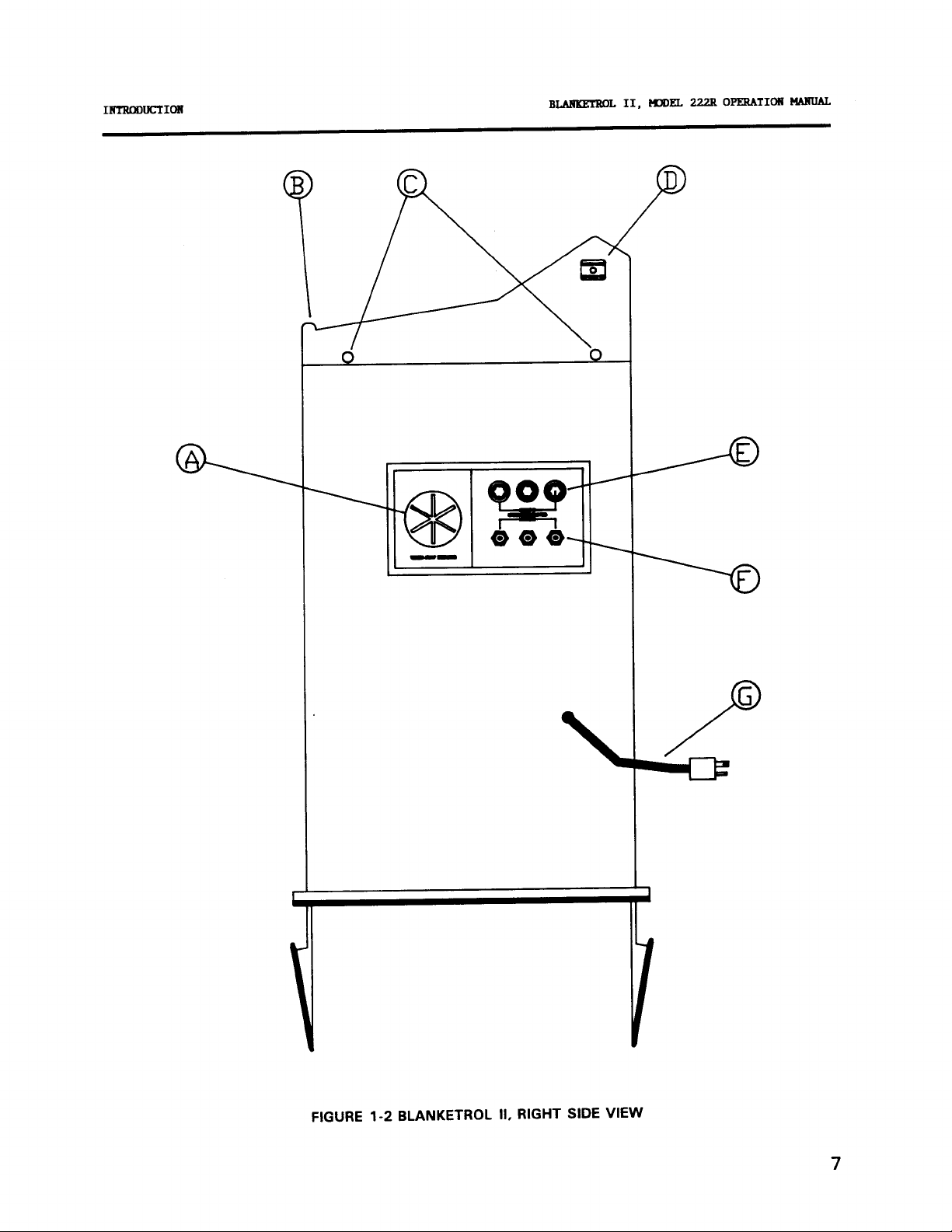

The external features in Figure (l-2) of the BLANKETROL II

follows:

A.

The water flow indicator is a paddle-wheel in the

water with a window to the outside. As water is

system, it must pass over the paddle-wheel causing it to spin (like a

pinwheel). The water flow indicator provides a visual display of the

general rate at which the water is circulating. For example, if the unit is

circulating water but the connecting hose is pinched, the circulation of

the water is restricted. The change in water flow decreases the speed

of the paddle-wheel.

When the problem of the pinched connecting hose is solved, an increase

in water flow can be seen by watching the water flow indicator increase

in speed. A total obstruction of the water path will cause the

wheel to stop completely.

B.

The molded-in handle permits the operator to grip the unit when moving

it.

C.

Two capped screws on the right and left side of the unit secure the top

to the base.

unit are described as

path of the circulating

circulated through the

paddle-

D.

E.

F.

G.

The patient probe

iack is where the Y.S.I. 400 series probe is connected

to the unit. Only one patient probe can be connected at a time.

Three female, quick-disconnect return

b

designed for water to flow

when the male coupling of the connecting

couplinns on the top row are

hose is attached.

The three male quick-disconnect outlet

designed for water to flow

out

couplinqs on the bottom row are

when the female coupling of the

connecting hose is attached.

The power cord with a hospital-grade 3-prong plug should

inserted into a properly grounded hospital grade receptacle for 1

VAC units and

220/240

VAC units.

Electrical Specifications are

described in Section (l-7.).

&

15/l

be

00

6

Page 11

1mUCT1ON

222ROPERATION

CIIDEL

BLMKETROL II,

MANUAL

FIGURE 1-2 BLANKETROL II, RIGHT SIDE VIEW

7

Page 12

t-¶lDEL

INTRODUCTION

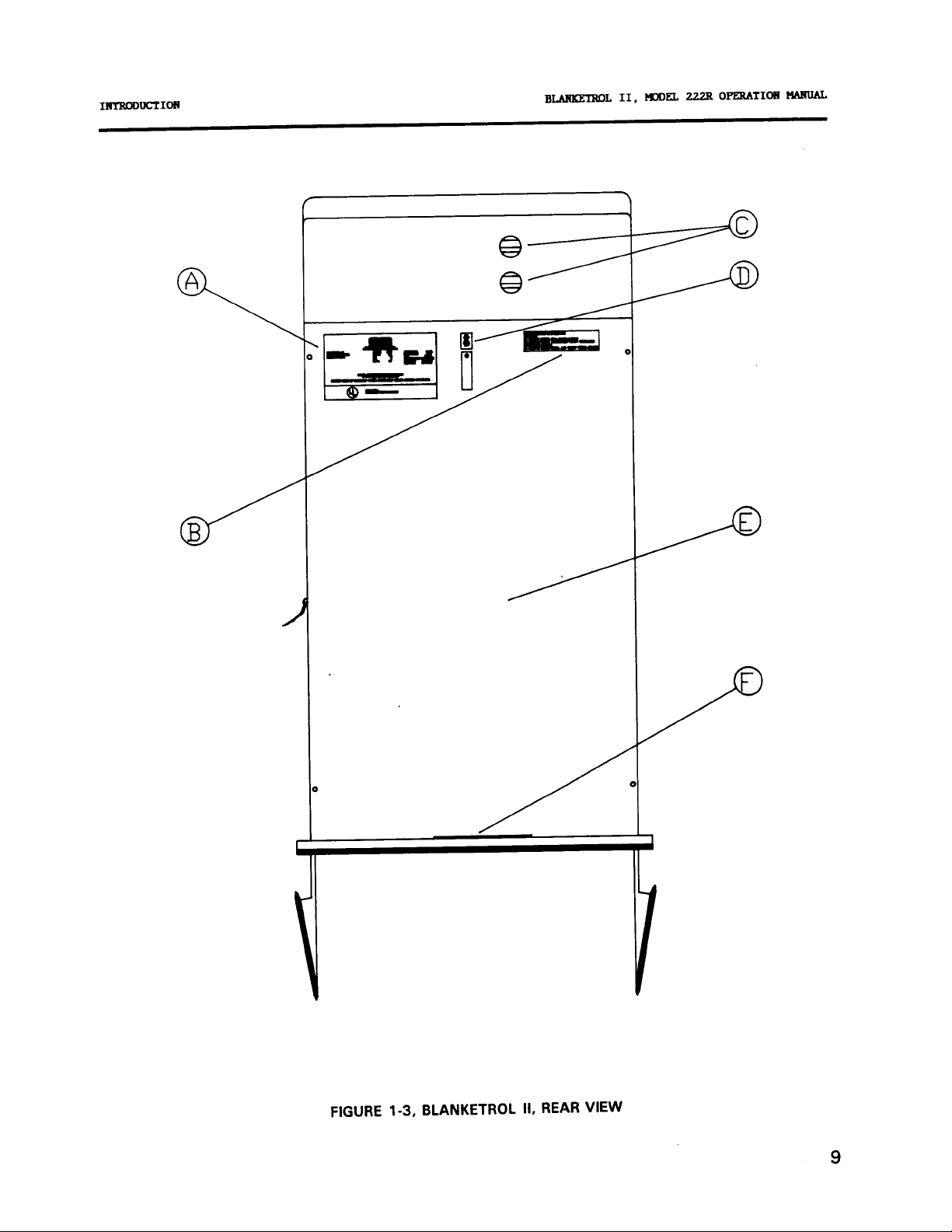

1-4.3. EXTERNAL FEATURES

BLANKETROL II,

-

REAR VIEW

222R OPERATION MANUAL

The external features in Figure (I-3) of the BLANKETROL II unit are described as

follows:

A.

B.

C.

D.

E.

F.

The maintenance label outlines the periodic checks for the BLANKETROL

II unit.

The specification label outlines the BLANKETROL II unit’s

electrical

requirements.

Two air vents provide air circulation for the microprocessor.

nvlon strap is used to secure and store the coiled power cord when

The

not in use.

The rear enclosure panel secured with four screws provides access to

the interior. The panel is removed to perform maintenance, repair, or

replacement of components.

The serial number label is permanently attached and located along the

bottom of the unit on top of the bumper guard.

8

Page 13

INTRODUCTION

BMNKF3WX

II.FXX.U%

22ZROPERATIONMANUAL

FIGURE 1-3, BLANKETROL II, REAR VIEW

9

Page 14

HDDEL

INTRODUCTION

BLANKETROL

II,

222R OPERATION MANUAL

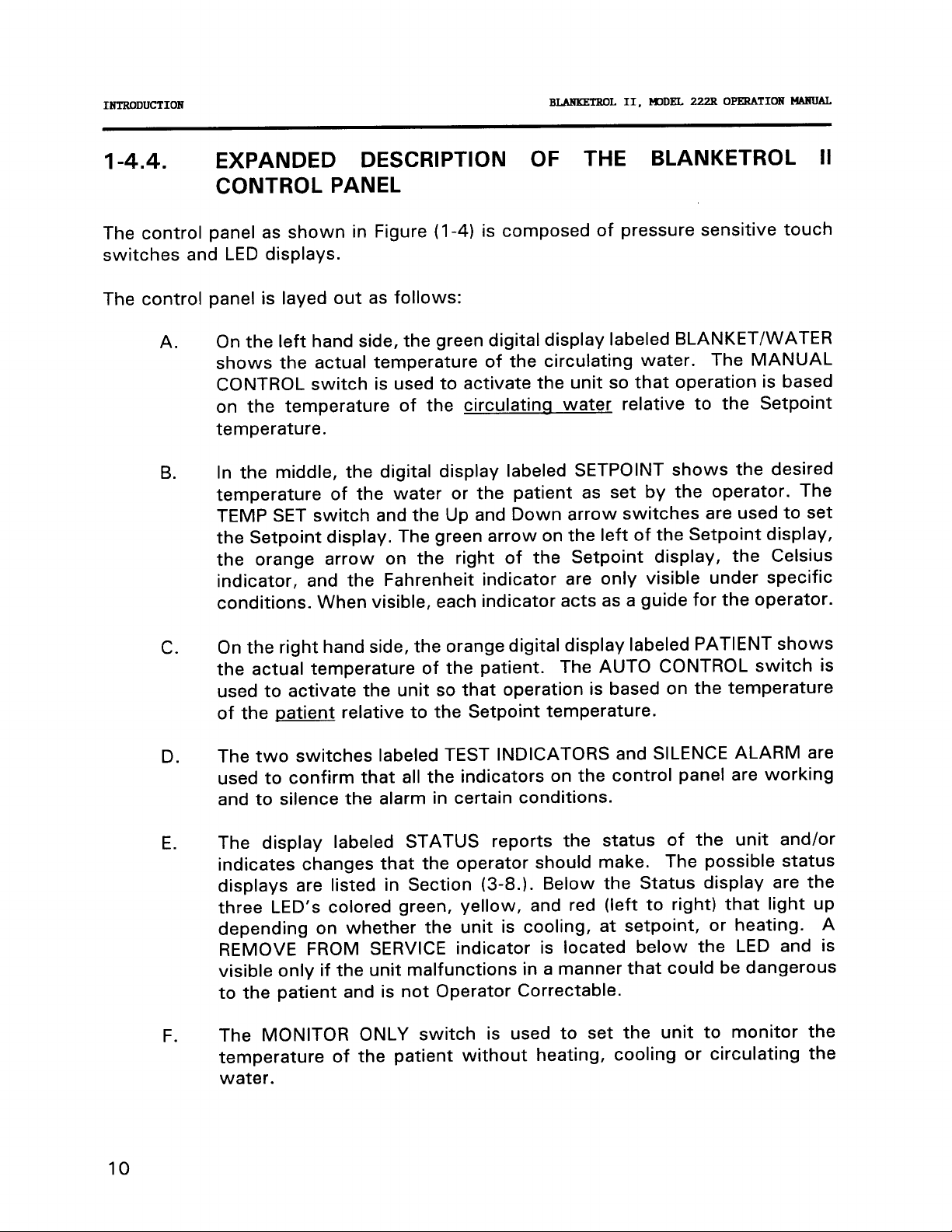

l-4.4. EXPANDED DESCRIPTION OF THE BLANKETROL II

CONTROL PANEL

The control panel as shown in Figure (I-4) is composed of pressure sensitive touch

switches and LED displays.

The control panel is

A.

On the left hand side, the green digital display labeled BLANKET/WATER

shows the actual temperature of the circulating water. The MANUAL

CONTROL switch is used to activate the unit so that operation is based

on the temperature of the circulating water relative to the

temperature.

B.

In the middle, the digital display labeled

temperature of the water or the patient as set by the operator. The

TEMP SET switch and the Up and Down arrow switches are used to set

Setpoint

the

the orange arrow on the right of the

indicator, and the Fahrenheit indicator are only visible under specific

conditions. When visible, each indicator acts as a guide for the operator.

C.

On the right hand side, the orange digital display labeled PATIENT shows

the actual temperature of the patient. The AUTO CONTROL switch is

used to activate the unit so that operation is based on the temperature

of the patient relative to the

layed out as follows:

SETPOINT shows the desired

display. The green arrow on the left of the

Setpoint

Setpoint

temperature.

Setpoint

Setpoint

display,

display, the Celsius

10

D.

E.

F.

The two switches labeled TEST INDICATORS and SILENCE ALARM are

used to confirm that all the indicators on the control panel are working

and to silence the alarm in certain conditions.

The display labeled STATUS reports the status of the unit and/or

indicates changes that the operator should make. The possible status

displays are listed in Section (3-8.). Below the Status display are the

three LED’s colored green, yellow, and red (left to right) that light up

depending on whether the unit is cooling, at setpoint, or heating. A

REMOVE FROM SERVICE indicator is located below the LED and is

visible only if the unit malfunctions in a manner that could be dangerous

to the patient and is not Operator Correctable.

The MONITOR ONLY switch is used to set the unit to monitor the

temperature of the patient without heating, cooling or circulating the

water.

Page 15

AUTO

CONTROL

MONrrcm

ONLY

Page 16

INTRODUCTION

BLANKETROL II,

MJDEL

222R OPERATION MANUAL

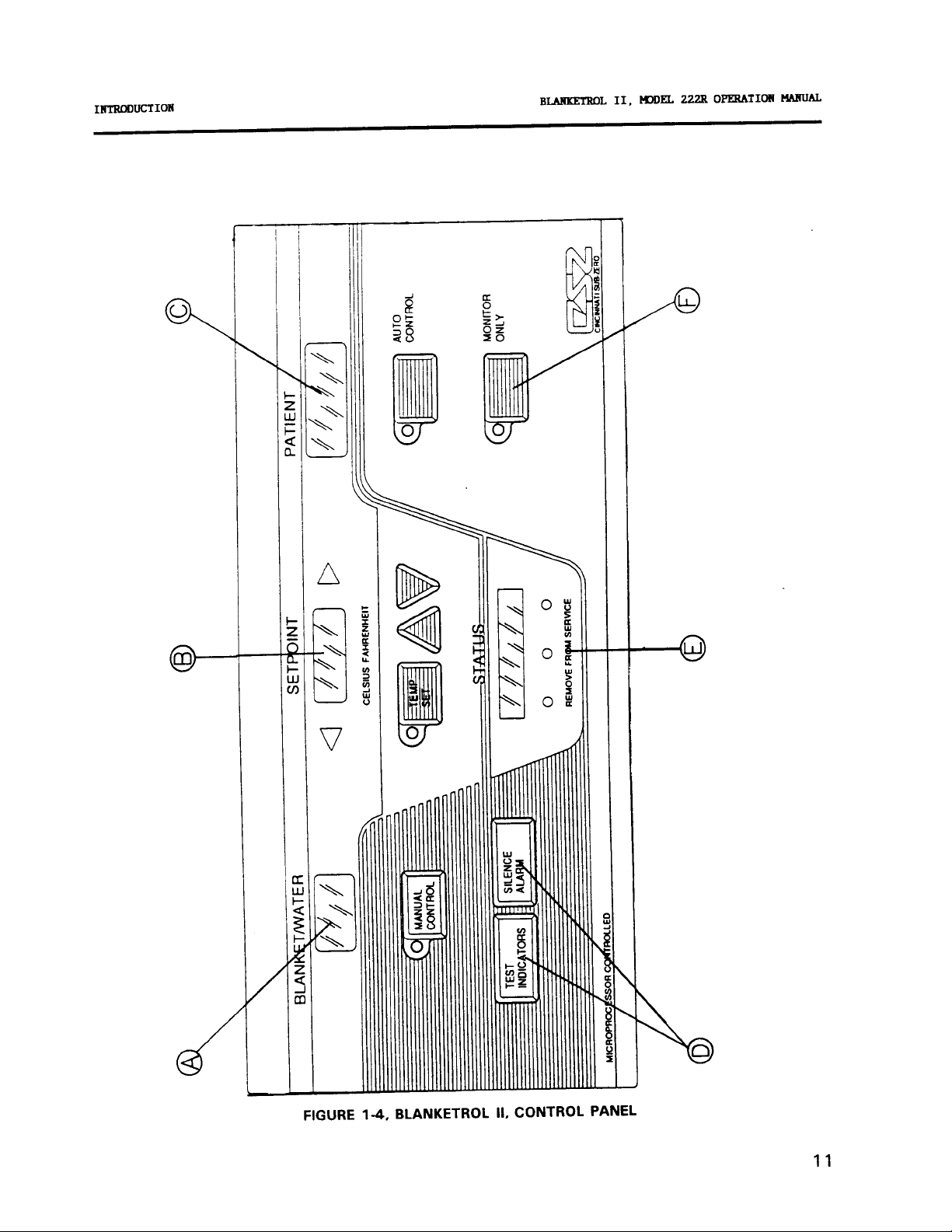

l-5.

Operation of the BLANKETROL II unit requires the use of the blanket(s) designed to

circulate warm or cool distilled/sterile water, a connecting hose with quick-disconnect

male and female couplings, and a YSI 400 series thermistor probe (if Automatic

Control Mode is to be utilized). BLANKETROL II System Equipment and accessories

are listed in Figure 3-l.

CSZ offers the widest selection of hyper-hypothermia blankets to serve your needs

providing both reusable and single-patient use blankets. The reusable blanket, the

lightweight

disconnect, error proof male and female couplings. A single-patient use blanket,

MAXI-THERM@, and a reusable connecting hose are also available. All CSZ blankets

offer significantly higher thermal transfer capability than any other brand of

hypothermia blankets.

CSZ also offers a disposable blanket cover, the DISPOSA-COVER’“, that guards

against stains, helps prevent cross-contamination, enhances patient comfort, provides

a moisture barrier, saves on nursing time, and offers greater economy because it

prolongs blanket life and reduces laundry costs.

REQUIRED ACCESSORIES

PLASTIPADB, comes with an integral nine foot extension hose with

quick-

hyper-

Only a Yellow Springs Instrument Company

STERI-PROBE’” single-patient use, should be used with the BLANKETROL II unit. If

a SINGLE-PATIENT probe is used, a REUSABLE CONNECTOR-CABLE is required in

order to connect the disposable probe to the unit. The type of probe may be a

rectal/esophageal or skin surface probe.

Operation of the BLANKETROL II unit requires the use of distilled/sterile water or a

distilled/sterile water-bacteriostatic agent preparation as described in Section (2-4.).

L

NOTE: DO NOT USE DE-IONIZED WATER.

(YSI) 400 Series probe, REUSABLE or

Draining the BLANKETROL II unit requires the use of a drain hose with a female

coupling. This hose is included in the packaging of the unit and can be retained in the

storage compartment of the unit.

l-6.

FUNCTIONAL

DESCRIPTION OF THE BLANKETROL II

SYSTEM

In the Manual Control Mode,

circulating water.

setpoint

temperature. The water circulates through the

The unit either heats or cools the water to reach the desired

the operator sets the desired temperature of the

blanket and either raises or

12

Page 17

INTRODUCTION

BLANKETROL II,

KlDEL

222R OPERATION MANUAL

l-6.

FUNCTIONAL DESCRIPTION OF THE BLANKETROL II

SYSTEM (cont’d)

lowers the temperature of the patient.

be closely monitored. There is no constant relationship between the temperature of

the circulating fluid and the temperature of the patient or the change in temperature

of the patient. In the Automatic Control Mode, the operator sets the desired

temperature of the patient. In addition, the operator must either attach to or insert

into the patient a YSI 400 Series probe.

BLANKETROL II unit. The probe is used to measure the actual temperature of the

patient and this measurement is then compared with the desired

by the unit’s microprocessor. If the actual patient temperature is lower than the

desired patient temperature, the BLANKETROL II unit heats the circulating water so

that the temperature of the patient is elevated to reach the desired Setpoint. At

Setpoint, the unit continues to circulate the water but the heater ceases to operate.

When the patient’s temperature falls outside the

heater/compressor resumes operation, heating/cooling the water until the patient’s

temperature is once again at Setpoint.

If the actual temperature is higher than the desired patient temperature, the

BLANKETROL II unit cools the circulating water so that the temperature of the patient

decreases to the desired

circulate the water, but the compressor stops. When the patient’s temperature falls

outside the

the water until the patient’s temperature is once again at Setpoint.

Setpoint

range, the compressor/heater resumes operation, cooling/heating

Setpoint

temperature.

In this case, the patient’s temperature must

The probe plug is then inserted into the

Setpoint

Setpoint

At Setpoint, the unit continues to

temperature

range, the

In addition, the BLANKETROL II unit can be set to operate in a Monitor Only Mode.

In this mode, the YSI 400 Series probe is attached to or inserted into the patient. The

probe plug is then inserted into the Blanketrol II unit. The operator then sets the

BLANKETROL II unit to monitor and display the patient’s actual temperature. In this

mode, the unit does not heat, cool, or circulate the water.

1-6.1.

The BLANKETROL II heating system consists of an immersion heater, water

temperature control, and three high temperature safety devices. Temperature ranges

are described in Section (l-6.4.).

The immersion heater is located in the circulating reservoir. The water circulating

the reservoir

is operational in the Manual Control or Automatic Control Modes whenever the control

system calls for an increase in the temperature of the circulating water. It is important

to note that the rate of change in the circulating water temperature is not directly pro-

portional to the rate of change in the temperature of the patient.

HEATING SYSTEM

flows around the immersion heater and is warmed. The heating system

in

13

Page 18

INTRODUCTION

BLANKEZTROL

II,

KlDEL

222R OPERATION MANUAL

1-6.2.

COOLING SYSTEM

The BLANKETROL II cooling system is composed of a compressor, a condenser, a

condenser fan, an evaporator coil, water temperature control, solenoid valve, hot gas

bypass valve, and three low temperature safety devices. Temperature ranges are

described in Section (1-6.4.).

The refrigerant of the cooling system flows through the evaporator coil located in the

circulating reservoir.

The water circulating in the reservoir flows over the evaporator

coil and is cooled.

The cooling system is operational in the Manual Control or Automatic Control Modes

whenever the control system calls for a decrease in the temperature of the circulating

water. It is important to note that the rate of change in the circulating water

temperature is not directly proportional to the rate of change in the temperature of the

patient.

CIRCULATING SYSTEM

The BLANKETROL II circulating water system is composed of a magnetically driven

circulating pump, a dual compartment reservoir, a water filter, quick-disconnect

fittings, connecting hose, and hyper-hypothermia blanket(s).

‘/2

The 2 gallon (7

liters) capacity dual compartment reservoir is composed of the circu-

lating reservoir situated under and connected to the replenishing reservoir. When the

operator fills the reservoir with distilled/sterile water

first and holds approximately

%

gallon (1.9 liters) of water. The remaining 1

*,

the circulating reservoir fills

%

gallons

(5.6 liters) are held in the replenishing reservoir. The water moves from the

replenishing reservoir to the circulating reservoir by gravity drain as needed.

The circulating water flows over and around the heating/cooling element located in

the circulating reservoir. The heated or cooled water then flows out of the reservoir

to the circulating pump, through the pump housing, through connecting hoses over

a water temperature sensor to the hyper-hypothermia blanket(s). The water circulates

through the blanket(s) and returns to the unit. The water then passes through the

water flow indicator, through the water filter and returns to the circulating reservoir

to be reheated or

retooled

and then recycled.

In addition, the circulating reservoir contains a low water level sensor which shuts

down the unit and sounds the alarm if the water level drops below a preset amount.

The unit becomes operational again after the water level is restored to normal.

*

Alternate water preparations are described in Section (2-4.)

NOTE: DO NOT USE DE-IONIZED WATER.

14

Page 19

INTRODUCTION

BLANKETROL II,

MODEL

222R

OE'ERATION

l-6.4. TEMPERATURE SAFETY CONTROL SYSTEM

The BLANKETROL II unit is designed to carefully measure and control the temperature

of the circulating water. The unit is engineered so that when the temperature of the

circulating water reaches the desired

setpoint

heating and cooling the water in order to maintain the

is designed not to exceed or fall below the desired temperature.

As a safety precaution, the BLANKETROL II unit has three high temperature safety

devices and three low temperature safety devices. Figure (I-5.) summarizes the high

and low temperature limits.

Each safety device continuously monitors the temperature of the circulating water and

almost any possible failure is protected by a back-up system.

precaution, if the water temperature sensor itself should fail, the unit shuts down and

indicates REMOVE FROM SERVICE. With this safety design, both the patient and the

unit are protected from injury or damage caused by extreme temperatures.

temperature, the unit operates between

setpoint

temperature. The unit

As an additional

MtlNUAL

At the same time, the operator must regularly monitor the patient whenever

hypothermia therapy is used.

hyper-

15

Page 20

INTRODUCTION

BLANKETROL

II, MODEL 222R OPERATION MANUAL

SAFETY CONTROLS FOR PROTECTION FROM HIGH TEMPERATURE

OF)

Circulating water reaches

shuts off heater.

f

42OC

.5OC

(107.6OF

+

microprocessor board

1

Circulating water reaches

44.6OC

1

+

(112OF

OC

+

2O)F, safety device shuts off

heater, status display flashes “HI TEMP” and the microprocessor board beeper is

sounded.

4OF), back-up safety device shuts

+

Circulating water reaches

46OC

+

2OC

(115OF

off the unit and indicates REMOVE FROM SERVICE, HI LIMIT.

SAFETY CONTROLS FOR PROTECTION FROM LOW TEMPERATURE

OF),

+

Circulating water reaches

+

4OC

(39.2OF

1

.5OC

off cooling system.

2”F),

f

Circulating water reaches

3OC

OC

1

+

(37OF

off cooling solenoid and indicates “LOW TEMP.”

Circulating water reaches 1

+

OC

+

1 (34OF .5OC

off the unit and indicates REMOVE FROM SERVICE, LOW LIMIT.

microprocessor board shuts

microprocessor board shuts

OF),

back-up safety device shuts

16

FIGURE

(I

-5) TEMPERATURE SAFETY LIMITS

Page 21

INTRODUCTION

BLANKETROL II,

KlDEL

222R OPERATION MANUAL

1-7.

SPECIFICATIONS OF THE BLANKETROL II UNIT

BLANKETROL

PHYSICAL

Dimensions:

Weight:

17”D

(43.18cm.W

cm.D x

134 Ibs.

91.44cm.H)

(60.3kg.)

36”H

x 17”W x

x 43.18

Cabinet Construction:

Epoxy-coated steel with plastic

top. Dual reservoir. Bottom air

discharge.

Molded-in handle.

Bumper guard. Storage

compartment. Four 5”

360°

conductive,

swivel-type

casters.

CONTROL SYSTEM

Microprocessor controlled,

OF

“ON-OFF” switch,

OC

or

Switch,

Digital LED Read Outs, 6 Alarm

Indications, 4 Mode Indications.

Controller Range:

42OC

to

Water Temp.:

Patient Temp.:

4OC

(39.2OF

to

to

4o”c3o”c

104OF)(86OF to

Display Accuracy:

f

Water Temp.

Patient Temp.

+

.25OC

(k

Display Range:

5o”c

-

Water Temp.

Patient Temp.

Display Type:

o”c

122OF)

-

(32OF

43.5OC

-

IOOC

-

50°F

Digital/Color-Coded

1

IOOF

Temp.Settings:

(.2OF)

OC

.1

Water Temp.

:

Patient Temp.:

Patient Probe Jacks:

Probe Type:

(.2OF)

OC

.I

One

YSI Series 400

Lighted

107.6OF)

l°F)(+

.5OC

.5OF)

II

MODEL 222R FEATURES

THERMAL SYSTEM

Compressor:

Heater:

NOTE: Water cooling rate is approx-

imately

heating rate is approximately 3

per minute.

4OC

CIRCULATING SYSTEM

Dual Reservoirs, 2 gallon (7% liters)

total capacity. Error proof,

disconnect couplings. All circulating

components are non-corrosive.

ELECTRICAL SYSTEM

Electrical Characteristics:

(Std.)

(Opt.)

Power Cord:

Leakage Current: Under 100

Circuit Breaker:

SAFETY SYSTEM

Maximum High Control Setting:

42OC

Primary High:

Secondary High Independent Backup:

2OC

46OC

+

Maximum Low Control Setting:

4OC

Primary Low:

1°C

_+

3OC

Secondary Low Independent Backup:

.5OC

+

1°C

l/3

HP (Copeland)

800 Watts

(8°F)

per minute and the

115V,60Hz.,

220V,50Hz.,

16/3

SJT,

Hospital grade plug

In Power Switch

(107.6OF)

l°C

f

44.6OC

(112OF

(115OF

(39.2OF)

(37OF

(34OF

(6O

OC

quick-

9.6 Amps

5 Amps

pa

2OF)

f

+

4OF)

2O)F

f

l°F)

f

F)

17

Page 22

INTRODUCTION

BIANKETROL

II,

mDEL

222R OPERATION MANUAL

l-7.

SPECIFICATIONS OF THE BLANKETROL II UNIT

BLANKETROL II MODEL 222R FEATURES

Defective or Dislodged Probe Alarm:

&

Audible

Primary

&

Secondary High and

Visual

Secondary Low Limit Failure Alarm:

&

Audible

Low Water Alarm:

Visual

Audible

&

Visual

Defective Water Temp Sensor:

Audible & Visual

Water Flow Indicator: Visual

Optional:

Low Flow Alarm Kit

Audible & Visual

(cont’d)

2 yr.

years

WARRANTY

parts (compressor-additional 3

pro-rated)

18

Page 23

GENEFML

PREPARATION OF THE

BIANKETW

SYSTm

L

II

B-L

II, MODEL

222ROPERATIONMNUAL

SECTION 2.

GENERAL PREPARATION OF THE BLANKETROL II

SYSTEM

2-l.

This section describes the procedures to prepare the BLANKETROL II unit for general

use. This entails unpacking the shipment, arranging all the equipment the first time,

and completing a test routine.

water-bacteriocidal agent preparations, standard safety precautions, and patient

preparation/bedside care when using the hyper-hypothermia blanket(s).

2-2.

Inside the packing carton, the BLANKETROL II unit is covered with a plastic wrap and

is cushioned with foam padding on the top. Corrugated cardboard protectors on the

top, bottom, and four corners. A large envelope with the manuals, warranty card, and

the drain hose is enclosed in the storage compartment of the unit. BE SURE TO

COMPLETE AND RETURN THE WARRANTY CARD.

INTRODUCTION

This section also outlines the optional distilled/sterile

UNPACKING THE SHIPMENT

During the unpacking process, look carefully for signs of shipping damage. If any

damage is found, notify the transportation company immediately and file a claim. The

transportation company is responsible for the shipment after it leaves the factory. If

problems other than shipping damage are found, notify your Cincinnati Sub-Zero

representative or the Cincinnati Sub-Zero office at l-800-989-7373.

2-3. FIRST TIME SET-UP/SYSTEM TEST ROUTINE

This section describes the tasks necessary to inspect and arrange the equipment for

the first time after unpacking and describes a System Test Routine to check out the

control panel.

The System Test Routine can also be used to teach operators unfamiliar with the

equipment how to use the unit.

The following tasks should be completed prior to assigning the unit for floor use:

2-3.1.

a.

INSPECTING AND ARRANGING THE EQUIPMENT

Place the BLANKETROL II unit in an uncluttered work space that is

accessible to the correct power source. Position the unit so that the

control panel faces the operator.

19

Page 24

BLANKFaTROL

TEE

GENERAL PREPARATION OF

II

SYSTEM

BLANKETROL II,

MlDEL

222R OPERATION

MAAUAL

2-3.1.

b.

C.

d.

e.

INSPECTING AND ARRANGING THE EQUIPMENT (cont’d)

If the unit was shipped on its side, permit the unit to rest in an upright

position for approximately one hour before operating.

Review Section (I-4.) to identify the features of the BLANKETROL II

unit.

Collect and arrange the following equipment and supplies:

1.

2. Connecting hose with quick-disconnect fittings if using disposable

3. Distilled/sterile water

Visually inspect the BLANKETROL II unit to determine that there are no

missing parts, unusual dents or punctures.

Hyper-hypothermia blanket(s) described in Section (l-5.)

blanket(s)

a

the distilled/sterile water-bacteriocidal

preparation described in Section (2-4.). DO NOT USE ALCOHOL

or DE-IONIZED WATER. The reservoir holds approximately 2

(7%

gallons

unit requires approximately

liters). Each empty blanket that is connected to the

%

gallon (1.9 liters) of water.

f.

h.

Examine the power cord for cuts or exposed wires and the power plug

(3-prong

for

115/l

00 VAC units, appropriate plug for

220/240

VAC

units) for bent or missing prongs.

Lift the lid of the water fill opening and gradually pour approximately 2

gallons (7

%

liters) of distilled/sterile water

a

the distilled/sterile

water-

bacteriostatic agent preparation into the reservoir. Stop pouring when

the water reaches the strainer visible at the bottom of the water fill

opening.

Connect the blanket(s) to the BLANKETROL II unit by attaching the

quick-disconnect female coupling of the connecting hose to a male outlet

coupling (on the bottom row) of the unit.

Attach the male

quick-

disconnect coupling of the connecting hose to a female return coupling

(on the top row) of the unit.

Each blanket must be connected to one

outlet and one return.

20

Page 25

GENERAL PREPARATION OF THE

LtunsmOL II

B

SYSTm

BLANKETROL

II,KlDEL222ROPEMTIONMANlJAL

2-3.1.

INSPECTING AND ARRANGING THE EQUIPMENT

(cont’d)

To attach the couplings:

Grasp the female coupling of the connecting hose

1.

Slide the collar back towards the hose

2.

Push the female coupling over a male coupling of the unit

3.

Allow the collar to SNAP into place and return to its original

4.

position

Gently pull on the connecting hose to assure a positive connection

5.

Next, push back the collar of a female return hose on the unit

6.

with one hand

With the other hand, insert the male coupling of the connecting

7.

hose

Release the collar of the female return coupling

8.

Push the male coupling until it SNAPS into position

9.

10.

i.

Check that the blanket is laying flat and that the connecting hose to the

Gently pull the connecting hose to assure a positive connection

unit is not twisted or pinched.

j.

Check that the power switch of the unit is OFF.

k.

Insert the 3-prong plug for 1

for

220/240

VAC units) into a properly grounded hospital grade

15/l

00 VAC units (appropriate ground plug

receptacle.

WARNING: DO NOT BY-PASS THE GROUND PLUG. ELECTRICAL HAZARDS

MAY RESULT.

2-3.2. COMPLETING A SYSTEM TEST ROUTINE

After arranging the equipment as described in Section

(2-3.1.),

Test Routine which describes what switches to press and the changes to observe.

a.

Make sure that the power switch is in the “ON” position.

1.

2.

3.

The switch lights up green.

The microprocessor board goes through self-test.

The status display in the center of the control panel flashes CK

SETPT.

4. The Celsius

or Fahrenheit indicator lights up.

complete this System

21

Page 26

H3DEL

GENERAL

PREPARATION OF TEE B

II

SYSTm B-L II, LANZTROL

222R OPERATION MANUAL

2-3.2. COMPLETING A SYSTEM TEST ROUTINE (cont’d)

If any of the above are not observed, consult the Troubleshooting Guide in Section

(6.) of the Operation/Technical Manual. If they are observed, continue with the test

routine.

b.

Press and hold the TEST INDICATOR switch.

1.

The yellow and green arrow, the LED’s in the corner of the

switches, the Celsius/Fahrenheit indicator, and the Remove From

Service indicator flash on and then off.

2. Then, all the displays flash.

The operator should note that all the displays and indicators do light up. If they do not

light up, consult the Troubleshooting Guide in Section (6.) of the Operation/Technical

Manual. If they do light up, continue with the test routine. The Status display

continues to flash CK SETPT.

C.

Press the TEMP SET switch.

1.

2.

3.

4.

The microprocessor board beeps.

The LED in the corner of the switch lights up.

The Status display shows SET TEMP.

The

Setpoint

display shows

a

37OC

98.6OF

(depending upon the

position of the Celsius/Fahrenheit indicator switch). Each

time the operator presses the TEMP SET switch after just having

plugged in the

unit, the

Setpoint

display shows

98.6OF.

a

37OC

22

d.

e.

Change the position

front of the unit).

The

1.

2.

Setpoint

98.6OF

to

The Celsius/Fahrenheit indicator changes from Celsius to

Fahrenheit (or from Fahrenheit to Celsius).

Press

1.

2.

3.

4.

5.

6.

the MONITOR ONLY switch.

The microprocessor board beeps.

The LED in the corner of the switch lights up.

Celsius/Fahrenheit indicator is lit.

The Status display shows MONITOR.

Setpoint

The

For

this

test routine, the Patient display is blank because the

probe is not inserted in the probe jack.

of the Celsius/Fahrenheit Selector switch (on the

display changes from

98.6OF

37OC).

display is blank.

(or from37OC to

Page 27

GENERAL PREPARATION OF TEE BLANKETROL II

SYSTEM

BLANKETROL II,

HDDEL

222R

OPERATION MANUAL

2-3.2.

NOTE:

COMPLETING A SYSTEM TEST ROUTINE (cont’d)

f. Press the TEMP SET switch.

The microprocessor board beeps.

The LED in the corner of the switch lights up.

The Celsius/Fahrenheit indicator is lit.

The

Setpoint

display shows

The Status display shows SET TEMP.

IN ORDER TO CHANGE FROM ONE MODE TO ANOTHER, THE

TEMP

CAN BE SET. For example; to change from Monitor Only Mode to

Manual Control Mode, the Temp Set switch must be pressed first

before the Manual Control Mode switch can be pressed.

1.

2.

3.

4.

5.

6.

7.

8.

9.

SET SWITCH MUST BE PRESSED BEFORE THE NEXT MODE

The microprocessor board beeps.

The LED in the corner of the switch lights up.

The Celsius/Fahrenheit indicator is lit.

Setpoint

The

The

Blanket/Water display shows the temperature of the water in

display shows a temperature reading.

the reservoir.

The green arrow (left of the

The Status display shows COOLING, AT SETPT

depending upon the relationship of the water in the reservoir to

the Setpoint.

A LED corresponding to the Status display lights up green for

COOLING, yellow for AT SETPT, or red for HEATING.

The pump is activated; there is a soft hum.

The heater or compressor may be activated.

The Water Flow indicator on the right side panel begins to move.

The water moves from the unit through the blanket and returns to

the unit.

9.

1.

2.

3.

4.

5.

Press the MANUAL CONTROL switch.

10.

11.

37OC or

Setpoint

98.6OF.

display) lights up.

a

HEATING,

If in the process of filling the blankets the water is no longer visible in the bottom of

the water fill opening, more distilled/sterile water should be added.

23

Page 28

BLANKETFUlL

II GENERAL PREPARATION OF TEE

SYSm

BLANKETROL II,

HDDEL

222R OPERATION MANUAL

2-3.2.

COMPLETING A SYSTEM TEST ROUTINE (cont’d)

If at any time the water falls below a preset limit, the Low Water sensor is activated

and the Status display flashes LO WATER and the alarm sounds. The unit shuts down

and the operator cannot proceed until this is corrected as described in Section (3-8.).

h.

Check the blanket for leaks. If a leak is found, the blanket cannot be

used. The repair of reusable blankets is described in

Set

(4-6) of the

Operation/Technical Manual.

i.

Check the couplings at the unit and at the blanket for positive

connection.

j.

Press the TEMP SET switch

1.

The microprocessor board beeps.

2. The LED in the corner of the switch lights up.

3. The

green arrow left of the

Setpoint

display goes out.

4. The Blanket/Water display goes blank.

5. The Celsius/Fahrenheit indicator is lit.

6. The

7. The

Status display shows SET TEMP.

pump shuts down, the heating/cooling stops.

I.

k.

When the TEMP SET switch is pressed, the operating mode (e.g. Manual

a

Control Mode, Automatic Control Mode

Monitor Only Mode) is

cancelled. The operator is once again at the beginning of the mode

selection procedure.

Press the Up arrow next to the TEMP SET switch.

1.

The microprocessor board beeps each time it

2. The

Setpoint

display changes; the numbers move up the scale.

is pressed.

The longer the switch is pressed the faster the digits change.

When the switch is released and repressed, the digits once again

change slowly and then increase in speed. The highest setting is

or

107.6OF.

42OC

Press the Down arrow next to the TEMP SET switch.

1.

2. The

The microprocessor board beeps each time it is pressed.

Setpoint

display changes; the numbers move down the scale.

The longer the switch is pressed the faster the digits change.

When the switch is released and repressed, the digits once again

change slowly and then increase in speed. The lowest setting is

4OC or

39.2OF.

24

Page 29

2228

TH!?a

BGENERAL PREPARATION OF

LtimxmOL

IISYSTm

B-L

II,

UJDEL

OPERATION

2-3.2. COMPLETING A SYSTEM TEST ROUTINE (cont’d)

klANUAL

m.

n.

0.

Press the Up arrow or Down arrow so that the

-

a number between

display to show

30°C

32.3OC

or

40°C

-

9OoF.

(86OF

104°F). For example, set the

SETPOINT display shows

Insert a YSI 400 series probe jack on the side of the unit.

Press the AUTO CONTROL switch.

1.

2.

3.

Setpoint

The

The alarm sounds.

The Status display flashes CK PROBE.

display goes blank.

The alarm sounds because the patient probe, as held by the operator in the open air,

30°C

for this test routine, detects a reading below

(86°F). The unit will not operate

in the Auto Control Mode unless the probe is properly placed on a patient and reading

above

30°C

Pm

(86°F).

Press the SILENCE ALARM switch.

1.

2.

The alarm stops.

The Status display continues to flash CK PROBE.

The Operator has 5 minutes to correct the problem. In an actual

situation, the operator would check the probe and then continue

operation.

Press

1.

2.

3.

4.

r.

Press

shows a number less than

the TEMP SET switch.

The microprocessor board beeps.

The LED in the corner of the switch lights up.

The

Setpoint

display shows a temperature reading.

The Status display shows SET TEMP.

the Up arrow or the Down arrow so that the

30°C

For example, set the display to show 41

S. Press the AUTO CONTROL switch.

2.

1.

Setpoint

The

The Status display flashes CK SETPT.

display goes blank.

Setpoint

or

106°F.

OC

40°C

display

(104OF).

(86OF) or greater than

25

Page 30

BIANKETROL

II GENERAL PREPARATION OF TEE

SYSTM

BLANKETROL II,

HODEL

222R OPERATION MANUAL

2-3.2.

COMPLETING A SYSTEM TEST ROUTINE (cont’d)

The display flashes because the

Setpoint

Automatic Control Mode temperature range of

104°F).

Setpoint

t.

Press the TEMP SET switch

1.

2.

3.

The unit will not operate in Automatic Control Mode unless the

display shows a number within the range.

The microprocessor board beeps.

The LED in the corner of the switch lights up.

The

Setpoint

display shows a temperature reading.

4. The Status display shows SET TEMP.

U.

Press the MANUAL CONTROL switch.

The microprocessor board beeps.

1.

The LED in the corner of the switch lights up.

2.

The green arrow left of the

3.

4.

The Celsius/Fahrenheit indicator is lit.

The Blanket/Water display shows the temperature of the water in

5.

Setpoint

the reservoir.

The Patient display shows the temperature reading of the probe,

6.

as it is held by the operator, if the probe reading is in the range of

-

-43.5OC

7.

The

Setpoint

8.

The Status display shows COOLING, AT SETPT, or HEATING

(50°F

IOOC

display shows a temperature reading.

110°F).

depending upon the relationship of the water in the reservoir to

the Setpoint.

A LED corresponding to the Status display lights up: green for

9.

COOLING, yellow for AT SETPT, or red for HEATING.

IO.

. 11.

12.

The pump is activated; there is a soft hum.

The heater or compressor may be activated.

The water flow indicator on the right side panel begins to move.

temperature is outside the

30°C-40°C

(86OF-

display lights up.

This step is included to show that the patient display lights up when the probe is

inserted and the unit is in the Manual Control Mode as well as when the unit operates

in the Automatic Control Mode.

V.

To complete this test routine, turn the power switch OFF.

The control panel goes blank.

1.

The green light of the power switch goes out.

2.

26

Page 31

GENF3AL

PREPARATION OF

BLANKETROL II

SYSTENTHE

B-L

II,

kl3DEL

222R OPERATION

2-3.2. COMPLETING A SYSTEM TEST ROUTINE (cont’d)

If the power switch is set ON again without having unplugged the unit

and the Temp Set switch is pressed, the

temperature that was on the display prior to the operator turning the unit

off.

W. Remove the probe from the probe jack, loosely coil it and place it in the

storage drawer in front of the unit.

In an actual situation, the probe is

cleaned as described in Section (4-7.) of the Operation/Technical Manual

before it is stored.

Setpoint

display shows the

MNUAL

X.

Disconnect the power cord from the power source, loosely coil it and

attach it to the back panel using the nylon strap.

-

Y*

For reusable

PLASTIPAD

-

blankets, disconnect the connecting hose

from the unit. Loosely coil the hose lengthwise in the center of the

l/3

blanket. Fold the blanket lengthwise into the center,

side and

l/3

from the right side.

The water can remain in the blanket

from the left

and in the unit between periods of use.

For single-use MAXI-THERM blankets, follow the instructions packaged

with the blanket. The water should be changed monthly

as described in

Section (4-2.) of the Operation/Technical Manual.

The BLANKETROL II System; unit, connecting hose, blanket(s), and

probe are now

ready for patient use.

2-4.

SUGGESTIONS FOR PROTECTING THE RESERVOIR FROM

BACTERIA AND FOR DECONTAMINATION GUIDELINES

If distilled/sterile water is used and changed monthly, there should be no problem with

bacteria forming in the reservoir or blanket(s). If hospital procedures require the use

of a bacteriostatic or bactericidal agent, we suggest Hospital-Approved

Agents which are non-acidic and non-foaming.

Bacteriocidal

NOTE:

DO NOT USE DE-IONIZED WATER. THE MAJORITY OF

DE-IONIZERS DO NOT MAINTAIN A NEUTRAL PH OF 7. IF THE

DE-IONIZED WATER IS ACIDIC, IT WILL CAUSE A BATTERY

EFFECT AND THE COPPER REFRIGERATION LINE WILL BEGIN TO

DETERIORATE AND CAUSE A LEAK IN THE REFRIGERATION

SYSTEM.

27

Page 32

PREPARATION

SYSTm

OF TBE GENERAL

B-

L II

BLMKEXROL II,

MDDEL

222R OPERATION MANUAL

2-4.

SUGGESTIONS FOR PROTECTING THE RESERVOIR

FROM BACTERIA AND FOR DECONTAMINATION

GUIDELINES

SUGGESTED DECONTAMINATION GUIDELINES FOR CINCINNATI SUB-ZERO

EQUIPMENT

(Developed in conjunction with the risk management department

at the Shriners Burn Institute in Cincinnati, Ohio)

Decontamination in the Healthcare environment is of the utmost concern with today’s

array of potential infectious diseases. Cincinnati Sub-Zero has always been aware of

these concerns in conjunction with the water reservoirs and circulatory systems of

a

CSZ equipment.

For this reason,

schedule for flushing and cleaning the water system in an effort to inhibit the growth

of bacteria and fungi.

The following decontamination procedure was developed to effectively rid the water

system of all bacteria and not damage any of the internal components of the

M

equipment.

Steps should be followed as closely as possible. This decontamination

procedure should be conducted every three (3) months.

CSZ equipment have a suggested monthly

The Procedure:

a.

b.

CAUTION:

Drain the water from the reservoir as described in Section (4-2.

Flush the unit three (3) times per the following procedure.

1.

Add one (1) ounce (30 cc) of household bleach

hypochlorite) to the empty water reservoir.

IT IS STRONGLY SUGGESTED THAT APPROPRIATE EYE

PROTECTION AND GLOVES BE WORN WHEN HANDLING AND

USING BLEACH. WEARING AN APRON IS ALSO SUGGESTED TO

PROTECT CLOTHING.

2.

3. Turn the unit on and circulate per the chart below.

Fill the reservoir with warm tap water.

1).

sodium

(

28

Page 33

GENIXAL

PREPARATION OF THE

BLANKETROL

II

SYSTM

BLANKETROL II,

HDDEL

222R

OPEMTION

t4ANUAL

2-4.

C.

d.

e.

f.

SUGGESTIONS FOR PROTECTING THE RESERVOIR

FROM BACTERIA AND FOR DECONTAMINATION

GUIDELINES

UNIT

Blanketrol II

4.

Rinse the unit three (3) times as described in (b) except to omit the

household bleach (sodium hypochlorite).

After the third rinse, drain the unit and add 32 ounces

distilled water to the water reservoir and circulate.

Check the water with “Fat-Chek” Ph strips or other appropriate test

method for detecting bleach. If bleach is detected, repeat steps

Once

Propylene Glycol to the water reservoir per the following chart:

Drain the unit after each flush.

no

bleach is detected, add the appropriate amount of U.S.P. Grade

(cont’d)

MODE

Manual

TEMPERATURE DURATION

lOOoF

5 Min.

(1

liter) of sterile

(c,d,e).

9.

h.

i.

UNIT

Blanketrol II

U.S.P. GRADE PROPYLENE GLYCOL PER UNIT

16 oz. (500 cc)

Continue to fill the water reservoir with sterile distilled water.

Document the maintenance of the unit.

The unit is now ready to be placed back in service.

29

Page 34

GENERAL PREPARATION OF TBE B

LMKETROL II

SYSTR4

BLANKETRDL

II,

KlDEL

222R OPERATION MANUAL

2-5.

UNIT AND PATIENT RELATED PRECAUTIONS

This unit requires both water and electricity to operate.

WARNING: ANYTIME WATER IS FOUND LEAKING INTO OR AROUND THE

UNIT, THE CONNECTING HOSE, AND/OR BLANKET, TURN THE

UNIT OFF, DISCONNECT THE POWER CORD FROM ITS POWER

SOURCE, AND CORRECT THE PROBLEM BEFORE PROCEEDING.

CAUTION: EXERCISE EXTREME CAUTION IF THE UNIT IS USED FOR

PATIENTS WHO ARE ELECTRICALLY SUSCEPTIBLE (PROBE,

CATHETER, OR ELECTRODES DIRECTLY CONNECTED TO THE

HEART).

1.

Test for leakage current prior to general floor use. See Section (5-18.) of

the Operation/Technical Manual.

2.

Anytime a repair is made, make sure that the power cord is disconnected

from the power source before disassembly.

The repair and servicing of the BLANKETROL II unit as described

3.

in Section (5.). requires no special tools.

However, only persons with the

proper skills and knowledge should undertake any repairs, servicing or

maintenance of the unit.

The high and low temperature safety devices protect the patient and the unit

4.

from injury or damage that can be caused by temperature extremes. At the

same time, a patient should be monitored closely when hyper-hypothermia

treatment is used.

Anytime the unit sounds an alarm, the operator should immediately check

5.

the Status display and act accordingly, e.g., add water, remove from

service, check the probe.

The BLANKETROL II unit is equipped with a circuit breaker in the ON/OFF

6.

power switch to protect against current overload.

30

Page 35

GEXERAL

PREPARATION OF TEE B

MNKETROL II

srsm

BLANKETROL II,

HlDEL

222R OPERATION

M4NUAL

2-6.

PATIENT PREPARATION AND BEDSIDE CARE

Effective use of the BLANKETROL II system must include proper patient care prior to

and while using the hyper-hypothermia blanket(s). Standard nursing procedures,

before using the blanket(s), include the following tasks:

CAUTION: THE DESIRED

SETPOINT

TEMPERATURE SHOULD BE SET ONLY AS

PRESCRIBED AND UNDER THE ORDER OF A PHYSICIAN.

a.

b.

C.

d.

e.

A base line recording should be made of vital signs, level of consciousness

and responsiveness.

Lanolin or a lanolin/cold-cream mixture may be applied to the patient’s

exposed skin.

Protective wraps may be used to cover patient’s hands and feet.

As ordered, a retention urinary catheter may be inserted to evaluate renal

function and renal output.

As ordered, an intravenous infusion may be started.

f.

As ordered,

drv

A

sheet or DISPOSA-COVER should be placed between the

preinduction medications may be administered.

hypothermia blanket and the patient.

Standard nursing procedures while using a hyper-hypothermia blanket include the

following tasks:

a.

Patient’s vital signs should be recorded and evaluated frequently. Operating

room, temperature sensitive and pediatric patients may deviate from normal

responses to external applications of heat and cold.

Patient core

temperature and the condition of the skin in contact with the blanket and

blanket water temperature should be checked every twenty minutes.

Operating room, temperature sensitive and pediatric patients should be

checked more frequently. Notify the physician if the patient’s core

temperature does not reach the prescribed temperature in the time

prescribed or deviates from the prescribed temperature range.

hyper-

31

Page 36

222R

THE

BLANKETROL II GENERAL PREPARATION OF

SYSTM

BLANKEZTROL

II,

HJDEL

OPERATION MANUAL

2-6. PATIENT PREPARATION AND BEDSIDE CARE (cont’d)

b.

C.

d.

e.

f.

9.

The position and the placement of the probe should be inspected regularly.

Also, the BLANKETROL II unit activates an alarm when the patient probe

110°F).

-

registers outside the range of

30°C

43.5OC

-

(86OF

Level of consciousness, strength of extremities, changes in cardiac rate,

changes in cardiac rhythms, pupil size, and response should be observed and

recorded.

Changes in skin color, edema, inflammation, or indications of pressure,

especially over bony prominences, should be noted and treated as ordered.

Prevent prolonged tissue pressure and shearing forces over bony

prominences.

The patient should be turned and properly positioned frequentlv.

As ordered, medications to prevent shivering may be administered.

The patient’s nasal passages, air-way and oral cavity should be kept free of

secretions and/or mucus build-up.

WARNING: THE PATIENT SHOULD BE CONSTANTLY ATTENDED. THE MISUSE

OF HYPER-HYPOTHERMIA EQUIPMENT PRESENTS THE POTENTIAL

FOR PATIENT INJURY.

CAUTION:

THE APPLICATION OF HEATING OR COOLING MAY EFFECT THE

TOXICITY OF SOLUTION. PREP SOLUTIONS HAVE BEEN

REPORTED TO INJURE THE SKIN WHEN ALLOWED TO REMAIN

BETWEEN PATIENT AND A WATER-CIRCULATING HEATING

BLANKET DURING PROLONGED PROCEDURES. -- KEEP THE AREA

BETWEEN THE PATIENT AND THE BLANKET

DRY.

32

Page 37

OPERATING TEE

B-TROL

II UNIT

BLANKETROL II.

KIDEL

222R OPERATION

FM.NUAL

SECTION 3

OPERATING THE BLANKETROL II SYSTEM

3-l. INTRODUCTION

This section describes how to operate the BLANKETROL II unit in order to control

your patient’s temperature. First, collect the equipment and prepare the patient.

Second, decide which mode of operation to use. Third, set the appropriate controls;

Automatic Control Mode, Manual Control Mode, or Monitor Only Mode.

3-2.

a.

ARRANGING THE SYSTEM COMPONENTS

Collect all supplies and equipment.

1.

2.

3.

4. Connecting hose, if using MAXI-THERM disposable blanket(s)

5.

6. Connector cable (if using disposable probes)

7. Distilled/sterile water

BLANKETROL II unit

Hyper-hypothermia blanket(s)

Dry sheet, bath blanket or DISPOSA-COVER

YSI 400 series probe

b.

C.

d.

e.

f.

g.

Place the BLANKETROL II unit in the patient area, accessible to the

correct power source.

Review Section (l-4.) that outlines the features of the unit and control

panel.

Check the level of distilled/sterile water in the reservoir. To do so, lift

the cover of the water fill opening and the water should be visible,

touching the strainer.

If needed, carefully add distilled/sterile water. In

addition, if the water falls below a preset level, the alarm sounds and the

Status display flashes LO WATER. The operator cannot proceed until

this is corrected as described in Section (3-8.).

Check that the power switch is in the OFF position.

Inspect the power plug

plug for

220/240

VAC units) for bent or missing prongs.

Insert the 3-prong plug for

220/240

VAC units) into a properly grounded hospital grade receptacle.

(3-prong for

115/l

115/l

00 VAC units, appropriate

00 VAC (appropriate ground plug for

33

Page 38

OPFXATING

TEE BLANKETROL II

UNIT

BIANKETROL

II,

tWDEL

2228

OPERATION MANUAL

3-2.

ARRANGING THE SYSTEM COMPONENTS (cont’d)

WARNING: DO NOT BY-PASS THE GROUND PLUG; ELECTRICAL HAZARDS

MAY RESULT.

h.

i.

j.

k.

I.

m.

Lay the hyper-hypothermia blanket flat with the hose arranged without

kinks towards the unit.

If the blanket is already filled, check that there are no leaks.

Cover the blanket with a dry sheet, bath blanket or DISPOSA-COVER.

Connect the blanket to the BLANKETROL II unit as described

in Section

(2-3.1.),

Step (h).

If a MAXI-THERM single-patient use hyper-hypothermia blanket is used,

connect the color coded couplings of the connecting hose to the blanket

as described in the instructions packaged with each blanket.

Check that the blanket is flat and the connecting hose is not twisted or

pinched.

n.

0.

P-

The hyper-hypothermia blanket may be

positioning the patient.

To do so, operate the unit in Manual Control

precooled or prewarmed before

Mode for a few minutes.

Place the patient on the hyper-hypothermia blanket.

If the patient’s temperature is to be monitored as required in Automatic

Control Mode or Monitor Only Mode, insert into or attach to the patient

a YSI 400 Series probe.

1.

A rectal probe is inserted into the rectum and secured with tape

to the leg of the patient.

2.

The diaphragm of a skin probe is taped to the patient, usually

under the patient’s arm or on the chest.

3.

The esophageal probe is inserted into the patient. It is often

preferred that the patient is comatose or under anesthesia.

The probe should be inspected periodically to insure that it is not

dislodged or impacted. The BLANKETROL II unit sounds an alarm

30°C

when the reading from the probe falls below

(86°F). It is

34

Page 39

OPERATING TEE BLANKETROL II

UNIT

B-L II,

HDDEL

222R OPERATION MANUAL

3-2

ARRANGING THE SYSTEM COMPONENTS

(cont’d)

important that the probe be inserted into or attached to the

patient at least one minute before pressing a Control Mode

switch. This will prevent the accidental triggering of the CK

PROBE Status message.

q.

If a hyper-hypothermia blanket is to be used on top of the patient, cover

it with a DISPOSA-COVER or place a sheet between the patient and the

thermal blanket.

r.

Connect the blanket on top of the patient to the BLANKETROL II unit

following the procedure described in Section (2-3.1.) Step (h).

S. If a hyper-hypothermia blanket is not used on top of the paitent, cover

the patient with a top sheet and/or blanket. Patient preparation and

bedside care are further described in Section (2-6.).

t.

Choose which operating mode to use: Operating in Automatic Control

Mode is described in Section (3-3.). Operating in Manual Control Mode

is described in Section (3-4.). Operating in Monitor Only Mode is

described in Section (3-6.).

3-3. OPERATING THE BLANKETROL II UNIT IN AUTOMATIC

CONTROL MODE

The BLANKETROL II unit can be set so that it operates based upon the actual

temperature of the patient relative to the

desired patient temperature in Celsius or Fahrenheit, insert into or attach to the patient

a probe and press the AUTO CONTROL switch. The BLANKETROL II unit activates

to heat or cool the water, to circulate the water, and to control and monitor the

change in the patient’s temperature.

After arranging the equipment as described in Section

a.

b.

C.

Check the placement of the YSI 400 series probe in or on the patient.

Insert the probe plug into the probe jack on the right side of the unit.

Press the power switch ON

1.

2.

3.

4.

The switch lights up green.

The microprocessor board goes through self test.

The Status display flashes CK SETPT.

The Celsius or Fahrenheit indicator lights up.

SETPOINT temperature. To do so, set the

(3-2.),

proceed as follows:

35

Page 40

OPERATING

TFIE

BLANKETROL II UNIT

BLANKETROL II,

MJDEL

222R OPERATION MANUAL

3-3.

d.

e.

f.

9.

OPERATING THE BLANKETROL II UNIT IN AUTOMATIC

CONTROL MODE (cont’d)

Consult the physician’s orders to determine the desired patient

temperature. As a safety precaution, the

-

set between

30°C

-

40°C

(86OF

Control Mode.

Set the Celsius/Fahrenheit Selector switch (on the front panel) so that

a

the required indicator (Celsius

Fahrenheit) is showing on the control

panel.

Press the TEMP SET switch

The microprocessor board beeps.

1.

The LED in the corner of the switch lights up.

2.

SETPOINT display shows a temperature reading.

The

3.

The Status display shows SET TEMP.

4.

m

Press the Up arrow

Down arrow to change the

the desired patient temperature. The display can only be set between

104OF).

-

3o”c

-4OOC

(86OF

SETPOINT display can only be

104OF) to operate in Automatic

SETPOINT

display to

h.

1.

2. The

Press

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

The microprocessor board beeps.

SETPOINT display changes.

the AUTO CONTROL switch.

The microprocessor board beeps.

The LED in the corner of the switch lights up.

The yellow arrow to the right of the

SETPOINT display lights up.

The Patient display shows the patient’s actual temperature.

The Blanket/Water display shows the actual temperature of the

circulating water.

The Status display shows COOLING, AT SETPT, or HEATING

depending upon the relationship of the patient’s temperature to

SETPOINT display.

the

A LED corresponding to the Status display lights up: green for

COOLING, yellow for AT SETPT, or red for HEATING.

The pump is activated. There is a soft hum. The heater or

compressor may also be activated.

The Water Flow indicator on the right side panel begins to move.

The water moves from the unit to the blanket and returns to the

unit.

36

Page 41

OPERATING

THE

BLANKETROL II UNIT

BLANKETROL II,

NlDEL

222R OPERATION

t-WNUAL

3-3.

i.

j.

k.

The BLANKETROL II Unit is now operating in Automatic Control Mode. You should

continue to monitor the unit

described in Section (2-6.).

If at any time the Status display shows a message other than the messages described

in Automatic Control Mode procedures, make the changes indicated by the display

and/or consult the list of display messages in Section (3-8.). At any time the unit

sounds an alarm and the Status display flashes a message, make the changes

indicated.

OPERATING THE BLANKETROL II UNIT IN AUTOMATIC

CONTROL MODE

Check the Water Flow indicator to confirm that the water is circulating.

Feel the hyper-hypothermia blanket to confirm that the blanket is

heating/cooling.

To make any changes in the control settings, press the TEMP SET

switch and begin again.

and

(cont’d)

the patient. (Review the suggestions for patient care

To turn off the unit or discontinue hyper-hypothermia treatment, proceed as

described in Section (3-7.).

NOTE:

IN ORDER TO CHANGE FROM AUTOMATIC CONTROL MODE TO

MANUAL CONTROL MODE, FIRST PRESS THE TEMP SET SWITCH

AND THEN PROCEED TO MANUAL CONTROL MODE.

In order to change from Automatic Control Mode to Monitor Only Mode, simply press

the Monitor Only switch.

WARNING: IF AT ALL POSSIBLE, REMOVE THE PROBE FROM PATIENT

CONTACT BEFORE ACTIVATING AN

ELECTROSURGICAL

UNIT.

THE RF INTERFERENCE MAY CAUSE THE PATIENT TEMPERATURE

TO JUMP UP AND DOWN AND CYCLE THE MACHINE FROM

COOLING TO HEATING OR VICE VERSA.

37

Page 42

BLAAICETROL

TEE

OPERATING

II UNIT

BLANKETROL II,

W3DEL

2228

OPERATION MANUAL

3-4.

OPERATING THE BLANKETROL II UNIT IN MANUAL

CONTROL MODE

The BLANKETROL II unit can be set so that it operates based upon the actual

temperature of the circulating water relative to the

set the desired water temperature, in Celsius or Fahrenheit, and depress the MANUAL

CONTROL Switch. The BLANKETROL II unit activates to heat or cool the water and

to circulate the water.

The operator must continue to monitor the patient’s

temperature.

Given the many variables such as patient size, weight, or condition, there is no direct

relationship between the temperature of the circulating water and the patient’s

temperature. Both water temperature and the patient temperature should be closely

monitored.

After arranging the equipment as described in Section

a.

Press the power switch ON.

1.

2.

3.

4.

The switch lights up green.

The microprocessor board goes through self-test.

The Status display flashes CK SETPT.

a

The Celsius

Fahrenheit indictor lights up.

SETPOINT temperature. To do so,

(3-2.),

proceed as follows:

b.

C.

d.

e.

Consult the physician’s orders to determine the desired patient

temperature and the desired water temperature setting.

Set the Celsius/Fahrenheit Selector switch (on the front panel) so the

required indicator (Celsius or Fahrenheit) is showing on the control panel.

Press the TEMP SET switch.

microprocessor board beeps.

I.

2.

3.

4.

Press the Up arrow

The

LED in the corner of the switch lights up.

The

SETPOINT display shows a temperature reading.

The

Status display shows SET TEMP.

The

or Down arrow to change the

SETPOINT

display to

the desired Blanket/Water temperature. As a safety precaution, the

42OC

-

Blanket/Water temperature can only be set between

107.6OF).

-

(39.2OF

4OC

38

Page 43

OPERATING THE

BLAN'KElTROL

II UNIT

B-L II,

M3DEL

222R OPERATION

I-WNUAL

3-4.

OPERATING THE BLANKETROL II UNIT IN MANUAL

CONTROL MODE (cont’d)

1.

2. The

f.