Page 1

OPERATING MANUAL

for

CINCINNATI

ARROW E/DART 500/750 (ERM)

ARROW 500/750/1000/1250C (ERM)

ARROW 1250/1500/2000 (ERD)

VERTICAL MACHINING CENTERS

with

ACRAMA TIC 2100E CNC CONTROL

Release 3.0

PUBLICATION NO. 91203809--001

IMPORTANT

Carefully read the instructions and safety precautions given in this

manual. Do not attempt to operate this machine until you have thoroughly read and understood the material contained in this manual

and all other applicable manuals.

Atthetimeof writing,thebook wascompletelyup--to--date.However,

due to continual improvements in design, it is possible that descriptions contained herein mayvary toa slightextent fromthe systemdelivered toyou. This merelyimplies thatthesystem hasbeenimproved

to betterfulfill your requirements.Youare encouraged tocontact the

nearest Cincinnati Machine representative for clarification.

Patents Notice

Themachineandattachments andpartsthereof illustratedand describedin

this book are manufactured under and protected by issued and pending

British and Foreign Patents and copyright isreserved inany original design

feature thereof and in the contents of this book and every part thereof.

Cincinnati Machine U.K. Limited

P.O. Box 505, Kingsbury Road,

Birmingham, B24 0QU

1998 Cincinnati Machine, a Division of UNOVA Industrial Automation Systems, Inc.

Cincinnati Machine, CINCINNATI, DART, ARROW, SABRE, LANCER and HAWK are

trademarks ofCincinnati Machine, a division of UNOVA IndustrialAutomation Systems, Inc.

ACRAMATIC is a trademark of Vickers E.S.D., Inc.

Printed in England -- EDITION 3 -- January 1999

Page 2

WARNING 1

In order to clearly show

details of this machine,

some covers, shields,

guards, barriers, devices or

doors have either been

removed or shown in an

”open” position. All such

protective components

must be installed in position before operating this

machine.

FOREWORD

The purpose of this manual is to provide the necessary information to

enable suitably experienced personnel, to operate the CINCINNATI

MACHINE ARROW E/DART (ERM) and ARROW (ERD/ERM)

Vertical Machining Centers, when fitted with ACRAMATIC A2100

control.

Information contained inthis manual is not warrantedand is subject to

change without notice.

Themanual hasnotbeen preparedtoenable inexperiencedpersonnelto

operate the machine without further training.

Failure to follow this

instruction may result in

personal injury.

WARNING 2

CUTTING FLUIDS

When soluble coolants are

used, it is important to ensure that recommended

concentration levels are

maintained.

Failure to follow this

instructioncancausecorrosion of safety critical parts,

resulting in machine damage and/or serious personal

injury.

The owner/user is responsible for the training of inexperienced

personnel andfor providing thebackground necessary forexperienced

personnel to safely operate these machines.

The chapter on general safety precautions should be observed at all

times during machine operation and maintenance. Read this chapter

before readingthe remaining chapters inthis manual and operatingthe

machine.

Any questions pertaining to the operation of the machine should be

directed to:

Field Service Department Cincinnati Machine

Cincinnati Machine UK Limited, Marketing Company,

P.O. Box 505, Cincinnati,

Kingsbury Road, Ohio 45209--9988

Birmingham, B24 0QU USA.

England

Tel: 0121--351--3821 Main Tel: (513) 841--8100

Fax: 0121--313--1184 Service Tel: (513) 841 3000

Service Fax: (513) 841 8871

DANGER

HIGH VOLTAGE

Lethal voltages are present in the magnetics and electrical control cabinets when the MACHINE MAIN DISCONNECT is’ON’. Current andvoltage measurements should beattempted only byqualified electrical maintenance personnel.

Before working on any electrical circuits, turn the machine Main Disconnect Device ’OFF’ and lock It.

Capacitors inthe ServoDrives require upto 20minutes tocompletely discharge. Always verifythatdischarge

is complete using a known working and calibrated voltmeter before commencing work on these units.

Unless expressly statedin applicable CincinnatiMachine documentation orby the appropriate CincinnatiMa-

chine Field Service Representative, do NOT work with electrical power ’ON’. If such express statement of

advice exists, working with electrical power ’ON’ should be performed by a Cincinnati Machine Field Service

Representative. Thecustomerand subsequenttransfereesmust determinethat anyother personperforming

work with electrical power ’ON’ is trained and technically qualified.

Failure To Follow This Instruction May Result In Death Or Serious Personal Shock Injury.

-- 1

Page 3

Table of Contents

Chapter 1

Safety Precautions 1--1.........................

Important 1--1...........................................................

General Safety Instructions And Considerations 1--1............................

Personal Safety 1--1...................................................

Work Area Safety 1--2.................................................

Tool Safety 1--2......................................................

Lifting And Carrying Safety 1--2.........................................

Installation And Relocation Safety 1--3....................................

Setup And Operation Safety 1--3.........................................

Maintenance Safety 1--4...............................................

Materials Used With This Product 1--5....................................

LIFTING DEVICES 1--6..................................................

GENERAL 1--6......................................................

EYEBOLTS 1--6.....................................................

HOIST RINGS 1--8...................................................

SPREADER BARS AND LIFTING BEAMS 1--9...........................

CHAIN 1--9.........................................................

CABLE SLINGS 1--11.................................................

SYNTHETIC MATERIAL SLINGS 1--12..................................

P TYPE HOOKS 1--13.................................................

S HOOKS 1--13.......................................................

U TYPE HOOKS 1--15.................................................

GENERAL SAFETY LIFTING INFORMATION 1--16........................

Fluids Used With Machine Tools 1--17........................................

General Considerations 1--17.............................................

Lubricants 1--17.......................................................

Cutting Fluids 1--17....................................................

Sources Of Information -- USA 1--17......................................

Usage Information 1--18................................................

Cutting Fluids -- Preventative Maintenance 1--19................................

See Cautions 1 and 2 1--19...............................................

Water Quality 1--19....................................................

Too Soft 1--19.........................................................

Too Hard 1--19........................................................

Cleaning The Coolant Reservoir 1--19......................................

Lifespan 1--20.........................................................

Tramp Oil 1--20.......................................................

Filtering 1--20.........................................................

Rust Prevention 1--20...................................................

Printed Circuit Board Handling Instructions 1--21................................

General 1--21.........................................................

Recommended Handling Procedure 1--21...................................

Safety Features 1--22......................................................

Perimeter Guarding 1--22................................................

Operator Sliding Door(s) 1--22...........................................

Page 4

Table of Contents

Feed Hold Push Button 1--22.............................................

Emergency Stop Push Button 1--22........................................

Electrical Isolation Device 1--23..........................................

Air Supply Isolation Valve 1--23..........................................

Metric Lifting Points 1--23...............................................

Machine Related Safety And Usage Notes 1--23.................................

Axis Overtravel Condition 1--23..........................................

Through Spindle Coolant Option 1--23.....................................

Tooling Taper -- Spindle 1--23............................................

Inter--drilled Tooling 1--23...............................................

Drive Key Spindle Unit 1--23............................................

Safe Operation Of Multi--part Tooling 1--24.................................

Tool Drum Positioning 1--24.............................................

Tool Storage Drum 1--24................................................

Tool Storage Drum -- Pocket Wear 1--24....................................

Loading Tools into Spindle 1--24..........................................

Loading Tools into Storage Drum Pockets 1--24..............................

Levelling 1--24........................................................

Bolting to Foundation 1--24..............................................

Lithium Batteries 1--25.................................................

Chapter 2

System Information 2--1........................

Introduction 2--1.........................................................

Machine Information 2--2..................................................

Machine Location 2--3.................................................

EMC Directive Requirements 2--3........................................

NC Control 2--3......................................................

Axis Orientation 2--4..................................................

Guard Strength 2--5...................................................

Noise 2--5...........................................................

Work--piece/Work Holding Device Loading/Unloading 2--6....................

Fumes And Coolant Misting 2--6.........................................

Fire Hazard 2--6......................................................

Arrow E/Dart (ERM) Specification 2--7.......................................

Arrow (ERM) Specification 2--9............................................

Arrow (ERD) Specification 2--13.............................................

DART/ARROW (ERM)Table Dimensions 2--19..............................

ARROW (ERD)Table Dimensions 2--23....................................

Tool Holder And Retention Stud 2--24.........................................

JMTBA--BT Tool Holder And Retention S tud 2--25..............................

Motor Rating 2--26........................................................

6000rpm. Spindle

Arrow E/Dart Machine -- Standard Speed Range 2--27......................

6000rpm. Spindle

Arrow Machine -- Standard Speed Range 2--28...........................

8000rpm. Spindle Speed Range

Arrow Machine 2--29................................................

Page 5

Table of Contents

10,000rpm. Spindle Speed Range

Arrow Machine 2--30................................................

5000rpm. Spindle

Arrow Machine -- High Torque Speed Range 2--31........................

Chapter 3

Control Introduction 3--1........................

Operator Station 3--2.....................................................

Operator Station Assembly (OSA) Keypad 3--3.............................

Machine On 3--3......................................................

Machine Off 3--4.....................................................

Emergency Stop 3--4..................................................

Page And Position keys 3--4............................................

Numeric Keys 3--4....................................................

Escape, Help, Control, Alternate 3--5.....................................

The Control Screen 3--6...................................................

Display Areas 3--6....................................................

How Menu Buttons Function 3--7........................................

Production Menu Display 3--8...........................................

Current Menu Display 3--8.............................................

Status Bar 3--8.......................................................

General Mode Button Bar 3--8..............................................

Machine 3--9.........................................................

Edit 3--9............................................................

RAP (Resident Assistant Programmer) 3--13................................

SFP (Shop Floor Programming) 3--16......................................

Tools 3--16...........................................................

Multi--Setup 3--17.....................................................

More (Additional Mode Selections) 3--18...................................

Diagnostics 3--19......................................................

Service 3--20..........................................................

System Configuration 3--21.............................................

File Manager 3--22.....................................................

Mode Specific Button Bar 3--22..............................................

Back 3--22...........................................................

Display 3--22.........................................................

Home 3--22...........................................................

Touch Screen and Keyboards 3--23........................................

Plotter Display 3--24...................................................

Help Information 3--25..................................................

Machine Mode 3--26.......................................................

Display Groups buttons 3--26............................................

Menus 3--26..........................................................

Axis Displays 3--27.......................................................

Current 3--27.........................................................

To Go 3- -27..........................................................

4--View 3--27.........................................................

Page 6

Table of Contents

Limits 3--27..........................................................

Servo 3 --27...........................................................

Servo Setup 3--27......................................................

Program Debug 3--27...................................................

Offset Displays 3--28......................................................

Pallet Offsets Display 3--28..............................................

Multi Setup Offsets 3--28................................................

Fixture Offsets 3--28...................................................

Prog. Coord Offsets 3--28...............................................

Prog. Tool Offsets 3--28.................................................

Machine Offsets 3--28..................................................

Other Displays 3--29.......................................................

Program Display 3--29..................................................

Message 3--29.........................................................

System Registers 3--29..................................................

Variables Display 3--29.................................................

V iew Drawing Display 3--29.............................................

Plotter Display 3--29...................................................

Cycle Parameters 3--29.................................................

Program Parameters 3--29...............................................

Process Control Data Display 3--30........................................

Tables -- General 3--30..................................................

Coordinate Offsets 3--31....................................................

Coordinate Offset Types 3--31............................................

Words and Codes Associated with Offsets 3--32..............................

Entering Values to Offset Tables 3--32......................................

Pallet Offsets 3--33.....................................................

Basic Procedure for Setting Pallet Offsets 3--33..............................

Alternative Method for Setting Pallet Offsets 3--34...........................

Multiple Setup Offsets 3--35.............................................

Basic Procedure for Setting Multiple Setup Offsets 3--35.......................

Alternative Method for Setting Multi--Setup Offsets 3--36......................

Fixture Offsets (H word) 3--37............................................

Basic Procedure for Setting Fixture Offsets 3--37.............................

NC Program Offsets (D word) 3--39.......................................

Combining Offsets 3--40................................................

Offset Table Field Descriptions 3--41......................................

Select Table Display Buttons 3 --41........................................

Pallet Offset Table Definitions 3--42.......................................

Multi--Setup Offset Table Definitions 3--43..................................

Fixture Offset Table Definitions 3--43......................................

NC Program Offset Table Definitions 3--43.................................

Tool Mode 3--44..........................................................

Active Tool Set 3--45...................................................

Tool File 3--45........................................................

Tool Loading and Unloading 3--45........................................

Tool Table Display Fields 3--46...........................................

Page 7

Table of Contents

Serial Number 3--46....................................................

Tool Handling 3--46....................................................

Tool Geometry 3--46...................................................

Tool Setup and Usage 3--46..............................................

Tool History 3--47.....................................................

Tool Sort By 3--47.....................................................

Single 3--47..........................................................

Tool Magazine 3--48...................................................

Inch/Metric Selection 3--48..............................................

Program Management 3--49.................................................

Directory Services (Registry, Import, Export) 3--49...........................

Machine Pendant 3--51.....................................................

Introduction 3--53......................................................

Main Electrical Cabinet 3--62................................................

Optional Operating Devices 3--63............................................

Wash Gun 3- -63..........................................................

Swarf Conveyor 3--63......................................................

Emergency S top -- (Red Push Button with Latch) 3--64........................

Swarf Conveyor Control -- Auto/Manual -- (Selector Switch) 3--64...............

Conveyor Direction -- (Selector Switch, spring centred) 3--64...................

Swarf Management System (Swarf Wash) 3--65..............................

Chapter 4

General Setup Guide 4--1.......................

Setup The Machine 4--1...................................................

Configure System 4--1....................................................

Align Machine 4--2.......................................................

Perform Operating Station Functions 4--2.....................................

Perform Operating Functions 4--2...........................................

Create Manual Data Input 4--2..............................................

Set / Load Tooling 4--3....................................................

Power Feed / Jog Axes 4--3................................................

Setup Part 4--3..........................................................

SetTramSurface 4--4.....................................................

Set Tool Lengths 4--4.....................................................

Find A Program 4--4......................................................

Load Part Program 4--4....................................................

Create Part Program 4--5..................................................

Edit Part Program 4--5....................................................

Position Set 4--5.........................................................

Create Multiple Setup 4--6.................................................

Copy Program 4--7.......................................................

Plot Program 4--7........................................................

Operating Checks 4--7....................................................

Run a Part Program 4--8...................................................

How Do I... 4--9.....................................

Master Controls 4--10......................................................

SwitchOnPower 4--10.................................................

Page 8

Table of Contents

Switch--Off Power 4--11.................................................

Use Emergency Stop Push Button 4--11....................................

Machine Alignment 4--12...................................................

Align the Machine 4--12................................................

Axes Alignment Procedure 4--12..........................................

Mechanism Alignment Procedure 4--13.....................................

Automatic Realignment 4--14............................................

Axes Functions 4--15......................................................

Jog the X or Y Axis 4--15...............................................

Jog the Z, A, or B Axis 4--15.............................................

Power Feed the X or Y Axis 4--16.........................................

Power Feed the Z, A or B Axis 4--16......................................

Move an Axis with the Handwheel 4--17....................................

Override An Overtravel Limit 4--17.......................................

Jog Mechanisms 4--18..................................................

Data Entry 4--19..........................................................

Keying In Data 4--19...................................................

Correcting Typing Mistakes 4--21.........................................

Select Text 4--21......................................................

Perform Operator Station Keypad Operations 4--22...........................

MDI Functions 4--25......................................................

Create A Manual Data Input (MDI) Program 4--25............................

Copy A MDI Program To Edit 4--25.......................................

Tool Functions 4--26.......................................................

Display Tool Table Fields 4--26...........................................

Display Tool Sort 4--27.................................................

Display Single Tool 4--28...............................................

Display Tool Magazine 4--29.............................................

Activate A Tool From Tool File 4--31......................................

Remove Tool From Magazine Display 4--32.................................

Find A Tool 4--35......................................................

Inch / Metric Tool Selection 4--36.........................................

Show Tool 4--36.......................................................

Create New Tool File Entry 4--38.........................................

Create New Tool File 4--39..............................................

Move New Tool File to Active Tool Set 4--40................................

Modify Data In Tool Data Table 4--41......................................

Load Authorized Tool Into Spindle 4--43...................................

Load Unauthorized Tool Into Spindle 4--44.................................

Unload Authorized Tool From Spindle 4--44................................

Unload Un--authorized Tool From Spindle 4--45..............................

Load/Unload Tool Storage Magazine 4--46..................................

SetTramSurface 4--47..................................................

Display Tool Tram Surface 4--49..........................................

Set Tool Length 4--50...................................................

Update Tool Data 4--52.................................................

Coordinate Reset 4--53..................................................

Page 9

Table of Contents

Set Position 4--54......................................................

G92 Position Set -- Z Axis 4--62..........................................

Establish The Home Set Position G28 P4 4--64..............................

Program Activation 4--65...................................................

Find A Program 4--65..................................................

Activate A Part Program 4--66............................................

Program Block Delete Feature 4--67..........................................

Select “Delete A Program Block” Function 4--67.............................

Deselect A “Deleted Program Block” Function 4--67..........................

Running the Active Part Program 4--69........................................

Operating Checks 4--69.................................................

Run a Part Program 4--69................................................

Workpiece Manager 4--70...................................................

Overview 4--70...........................................................

What Workpiece Manager Can Do 4--70....................................

What You Should Know 4--70............................................

How Pallet, Setup, and Fixture Offsets Interact 4--71.............................

To Start Workpiece Manager 4--72........................................

About The V iewer Menus 4--73...........................................

About the Status Bar 4--74...............................................

View Level Display Options 4--75.........................................

Fixture Offsets 4--77.......................................................

View Level Fixture 4--77................................................

Working Only with Fixtures 4--77.........................................

About Fixture Icons 4--78...............................................

About Fixture Buttons 4--78.............................................

Fixture Pattern 4--79....................................................

Using the Fixture Pattern F eature 4--79.....................................

Defining Fixture Machine Coordinates 4--80................................

Fixture Location with Edge Finder 4--80....................................

Fixture Location With Probe Cycles 4--81...................................

Deleting A Fixture 4--82................................................

Deleting a Fixture 4--82.................................................

Editing an Existing Fixture 4--83.........................................

Adding a Fixture 4 --85..................................................

Setups 4--87.............................................................

Overview 4--87........................................................

View Level Setup 4--87.................................................

Selecting Offset Types 4--88.............................................

Setup Definitions 4--88.................................................

About Setup Icons 4--89.................................................

About Setup List Icons 4--90.............................................

Incrementing The Setup List 4--90.........................................

About Setup Buttons 4--91...............................................

Setup Pattern 4--92.....................................................

Using the Setup Feature 4--92............................................

Apply One Program for All Setups 4 --93...................................

Page 10

Table of Contents

Defining Setup Machine Coordinates (One at a time) 4--94.....................

Setup Location with Edge Finder 4--94.....................................

Setup Location With Probe Cycles 4--96....................................

Activating a Setup for Program Execution 4--96..............................

Activating a Setup from the Setup Viewer 4--96..............................

Activating a Setup at the Pendant 4--96.....................................

Setting the Machining Sequence 4--97......................................

Basic Overview of Icons During Cycle Execution 4--97........................

Reorder Setup Machining Sequence 4--98...................................

Changing a Setup Status 4--98............................................

Activate Setup Options 4--99.............................................

Activate Setup Options 4--99.............................................

Editing Setups 4--100....................................................

Edit Existing Setup 4--100................................................

Add a Setup 4--102......................................................

Deleting a Setup 4 --104..................................................

Changing a Setup Program 4--105..........................................

Managing Multiple Machining Work Faces 4--106................................

Automatic Rotation of A or B axis 4--106....................................

How Can I Display Multiple Work Face 4--107...............................

Defining W ork Faces and Sides 4--108......................................

Selecting a Face 4--109..................................................

Apply Setup Pattern to all Faces 4--110......................................

Adding another Setup to a Work Face 4--111.................................

Rotating to a Work Face 4--112............................................

Pallet View 4--113.........................................................

Overview 4--113........................................................

Pallet Viewer 4 --113.....................................................

How Can I Limit Views 4--114............................................

About Pallet Icons 4--114.................................................

About Pallet List Icons 4--116.............................................

About Pallet Buttons 4--117...............................................

Adding Pallets 4--118....................................................

Locating Pallets 4--120...................................................

Changing Pallet Data and Location 4--121...................................

Swapping Pallet Data 0 Locations 4--121....................................

Swapping Pallet Data with Defined Locations 4--123...........................

Reorder Machine Pallet Sequence 4--124....................................

Selecting a Pallet to Run 4--125............................................

How Do I Disable Pallets 4--126...........................................

Pallet View Tips 4--126..................................................

Applying Probe Cycles 4--127................................................

Overview 4--127........................................................

Activating the P robe Menu 4--127..........................................

About the Probe Menu 4--129.............................................

About Probe Icons 4--129................................................

About Probe Buttons 4--130...............................................

Page 11

Table of Contents

Applying Probe Cycles 4--131.............................................

Selecting Probe Cycle Run Options 4--133...................................

Deleting a Probe Cycle 4--134.............................................

Modifying a Probe Cycle 4--135...........................................

Display all Probe Cycles 4--136............................................

Storing Probe Cycle Data 4--137...........................................

MULTIPLE SETUP FEATURE AND DESCRIPTION 4--138.......................

Introduction 4--138.........................................................

Defining the Multi Setup: Step 1 4--139.....................................

Defining the Multi Setup: Step 2a

(Plain Table/Pallet Table Applications) 4--140.............................

Defining the Multi Setup: Step 2b

(Rotary Axis Applications) 4--142......................................

Defining the Multi Setup: Step 3 4--144.....................................

Defining the Offsets 4--145...............................................

Run Defined Multi Setup 4--155...........................................

Chapter 5

Other Setup Information 5--1....................

How Do I... 5--1......................................................

Select Axes Display 5--2...............................................

Inhibit an Axis Using the Screen 5--3.....................................

Inhibit an Axis Using the Pendant 5--4....................................

Plotter 5--5.............................................................

Plotter Screen Setup 5--5...............................................

Plot A Program 5--7...................................................

Track Tool Movement With Plot 5--8.....................................

Program and File Management 5--9..........................................

Create Directory 5--9.....................................................

Transfer a Part Program into the Program Store Area of the Control 5--9.........

Copy (Backup) A Program To Diskette 5--11................................

Copy (Backup) Tool File or Active Tool

Data To Diskette 5 --12...............................................

Restore Active Tool Set from Diskette 5--14................................

Copy (Backup) Offset Tables To Diskette 5--15..............................

Copy (Backup) A Program from Program Store 5--17.........................

Copy Files 5--18..........................................................

Rename Files 5--19........................................................

Delete Files or Directory 5--20...............................................

Delete A Program 5--21.................................................

Execute a Part Program via Continuous Load 5--21..............................

Activate A Program From External Source 5--24.............................

Program Editor 5--26......................................................

Search For/Replace With 5--26...........................................

Edit Cut, Copy, And Paste 5--27..........................................

Copy Programs To Dual Display 5 --27.....................................

Copy A Program To Edit 5--29...........................................

Page 12

Table of Contents

Resequence A Program 5--29.............................................

Save Program Edits 5--30................................................

RAP Functions 5--32......................................................

Create A Rap Session 5--32..............................................

Edit A Rap Process 5--35................................................

Saving A Rap Session 5--36..............................................

Moving A Rap Session 5--37.............................................

Create An NC Program One Block At A Time With RAP 5--38..................

Create An NC Program With RAP 5--39....................................

Duplicating A RAP Process 5--40.........................................

Loading A Rap Process 5--40.............................................

Executing A RAP Process 5--41..........................................

Insert Axes Values in RAP 5--41..........................................

Using The Program Translator 5--42..........................................

Set--up Translator 5--42.................................................

Miscellaneous 5--48.......................................................

Calibrate The Display Screen 5--48........................................

Change Home Menu 5--48...............................................

NC Programming Execution (system configuration) 5--52......................

Activate Security Level 5--54.............................................

Connect a PC to the A2100E Control System 5--59...........................

Search Program For Cycle Execution 5--62..................................

Resume Cycle After Losing Synchronization 5--63...........................

Format A Diskette 5--63....................................................

Change Program Parameters 5--64.........................................

Change Cycle Parameters 5--67...........................................

Set Parts Counter 5--68.................................................

Probe Calibration 5--70.................................................

G72 Set Stylus and Tip Dimensions 5--70...................................

G72 Set Stylus and Tip Dimensions 5--72...................................

G74 Set Probe Length 5--72..............................................

Appendix A

Program Reference Data A--1................

Type I Block Word Addresses A--1...........................................

Type II Block Listing A--2.................................................

G Code Table Listing A--3.................................................

M Code Table Listing A--5.................................................

M Code Listing A--5......................................................

Drilling Cycle Parameter Table A--7..........................................

Tool Data Table A--8......................................................

System Table Names A--12..................................................

Parameter Variable Table Listing A--13........................................

Pallet Table A--14.........................................................

Multiple Setup Table A--14..................................................

Fixture Offsets Table (Used with H Word) A--15.................................

Tool Offsets Table (Used with O Word) A--15...................................

Page 13

Table of Contents

Programmable Offsets Table (Used with D Word) A--15...........................

Machine Offsets Table (Used with D WORD and G98,G98.1) A--15.................

Process Control Data Table A--15.............................................

Other System Variables A--16................................................

Arithmetic Functions A--19..................................................

Appendix B

System Configuration B--1...................

Overview B--1...........................................................

Security B-- 1............................................................

NC Programming Execution B--2............................................

Colon Block -- Colon Required B--2......................................

At Colon Block B--2...................................................

Reset Fixture Offsets B--2...............................................

Reset Programmable Offsets B--2.........................................

Reset Programmed Rotation B--2.........................................

Cutter Diameter Compensation (CDC) B--3....................................

Report CDC Error B--3.................................................

Constant Feedrate B--3.................................................

Glide On/Off B--3.....................................................

Report Alarms B--4....................................................

Report PRT Alarms B--4................................................

Report WTF Alarms B--4...............................................

Report COM Alarms B--4...............................................

Fixture Offset Axis of Rotation B--4......................................

Modes B-- 5.............................................................

Circular B--5............................................................

Endpoint Tolerance B--5................................................

Center Specification B--5...............................................

Linear B--5..............................................................

Collinear Angle B--5...................................................

M70 -- 79 User M Codes Execution (Option) B--6............................

Pulsed B--7..........................................................

Feedback0thru9 B--7.................................................

Page 14

Table of Contents

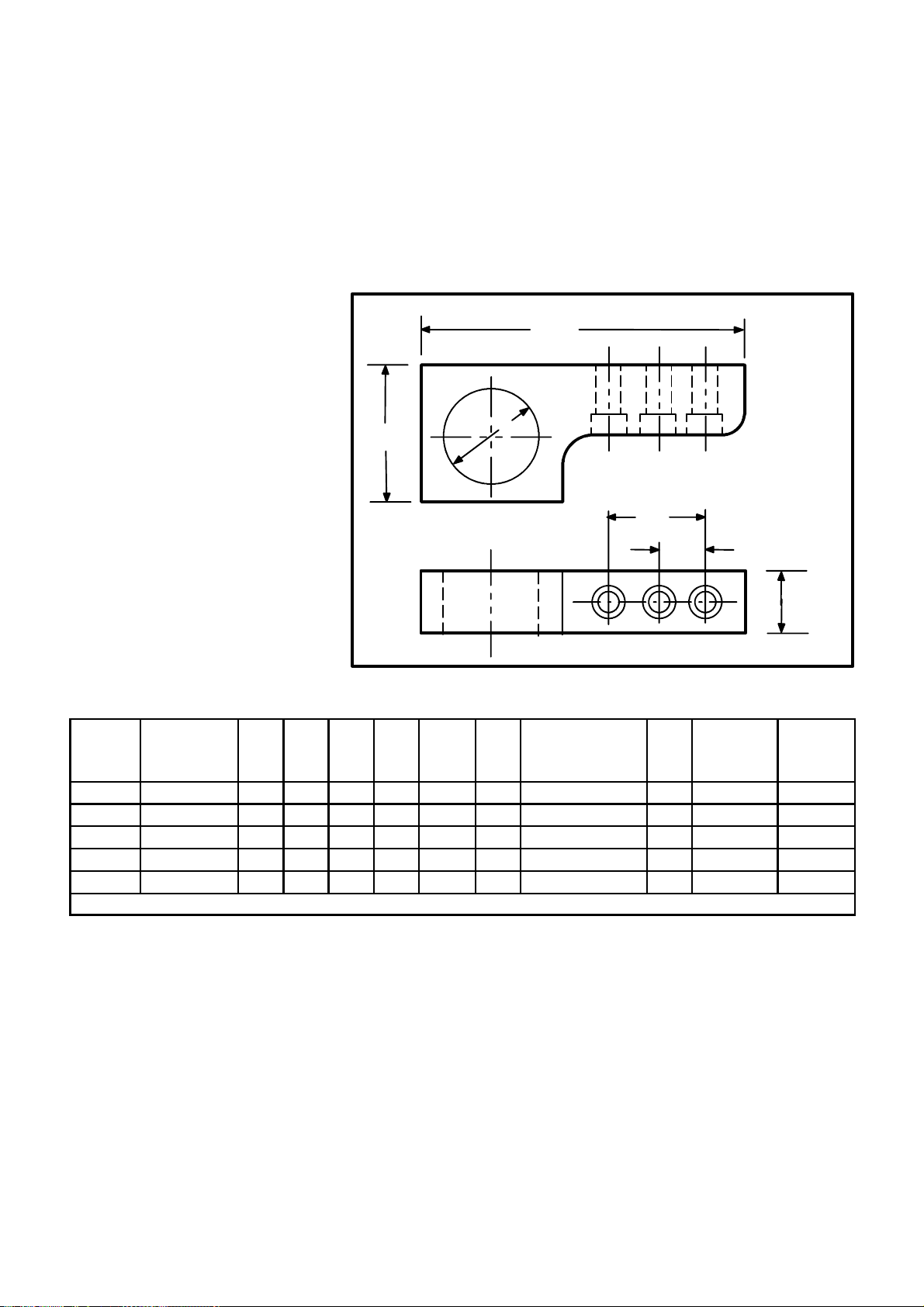

Fig. 1

Preferred Inch Lifting Eyebolts 1--6......................................

Fig. 2

Preferred Metric Lifting Eyebolts 1--7.....................................

Fig. 3

Eyebolt Loading 1--7..................................................

Fig. 4

Eyebolt I.D. Plates -- Inch and Metric 1--7..................................

Fig. 5

Instruction Plate -- Inch (Part Number 3375984) 1--7.........................

Fig. 6

Instruction Plate -- Metric (Part Number 3375983) 1--7.......................

Fig. 7

Hoist Ring 1--8.......................................................

Fig. 8

Hoist Ring Table 1--8..................................................

Fig. 9

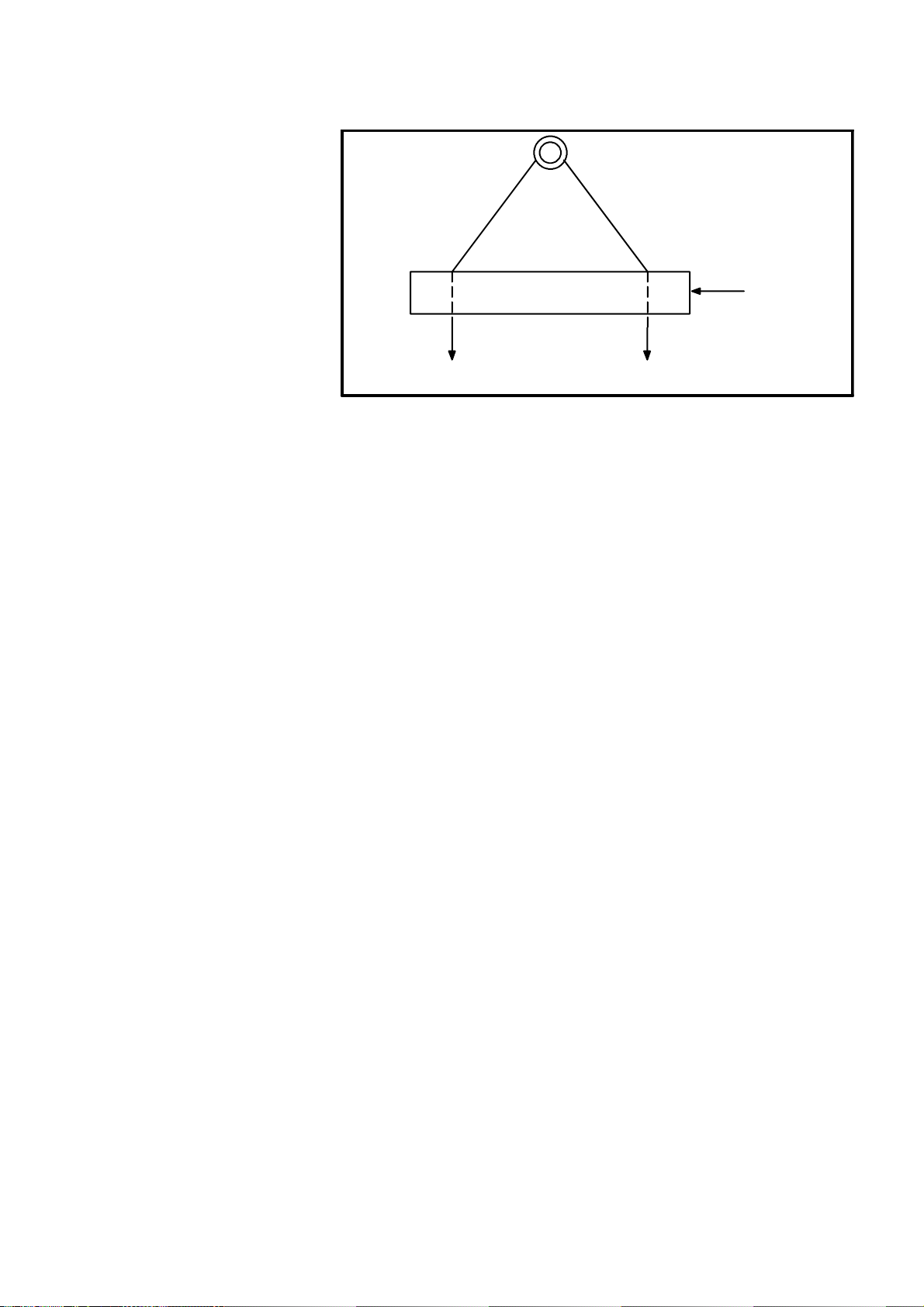

Spreader Bar -- Typical 1--9.............................................

Fig. 10

Steel Alloy Chains 1--10................................................

Fig. 11

Wire Rope Slings 1--11.................................................

Fig. 12

Sling Load Angle Chart 1--12............................................

Fig. 13

“P” Type Lifting Hooks 1--13............................................

Fig. 14

“P” Type Lifting Hooks 1--13............................................

Fig. 15

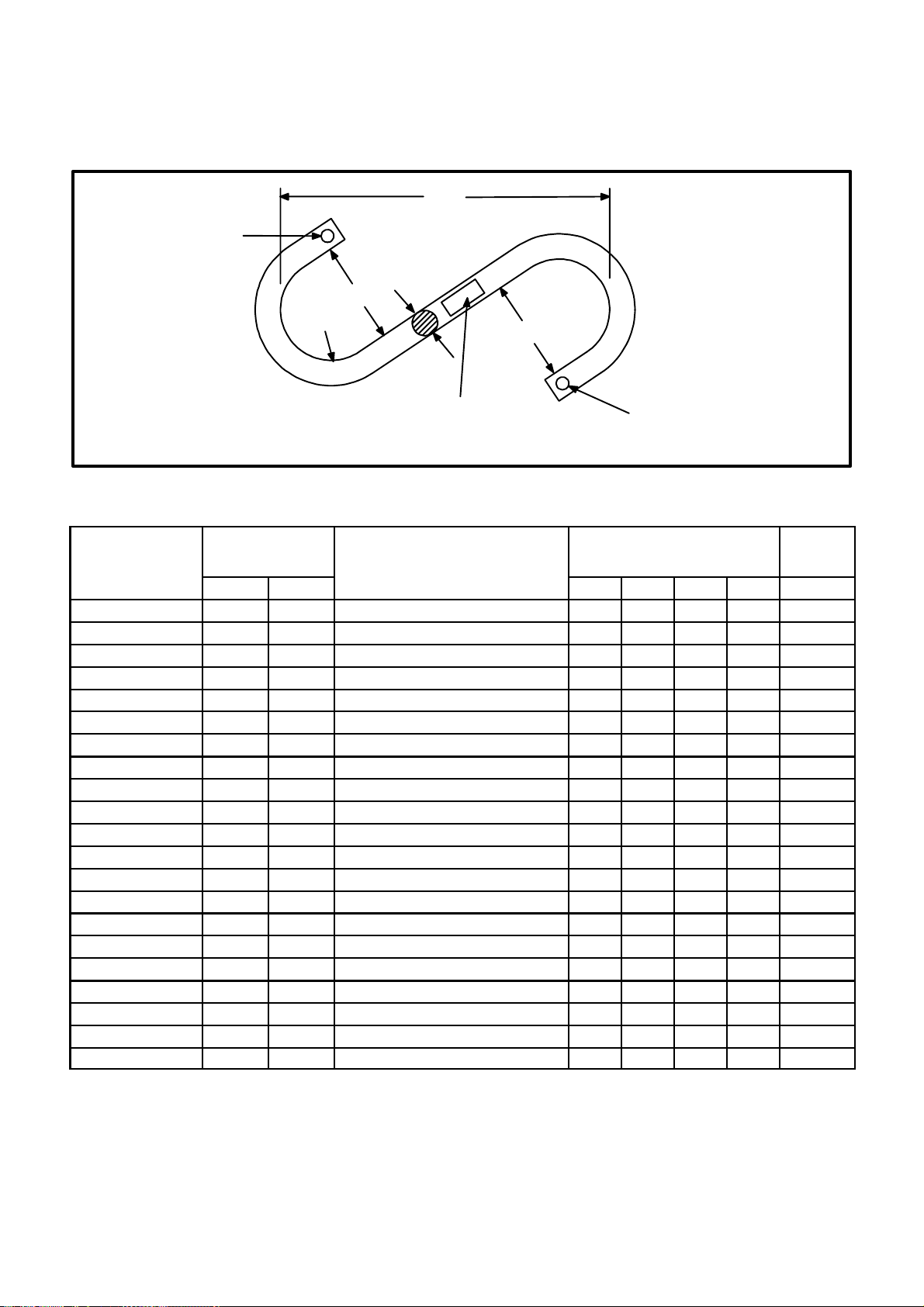

“S” Hooks 1--14.......................................................

Fig. 16

“S” Hooks 1--14.......................................................

Fig. 17

“U” Type Lifting Hooks 1--15............................................

Fig. 18

“U” Lifting Hook Table 1--15............................................

Fig. 19

Safety Latch 1--16.....................................................

Fig. 20

Arrow Vertical Machining Center 2--1.....................................

Fig. 21

Vertical Machining Center -- Axis Orientation 2 --4..........................

Fig. 22

Range Drawing for Arrow E / Dart / Arrow 500, 750 (ERM) Machines --

Front View 2--15......................................................

Fig. 23

Range Drawing for Arrow E / Dart / Arrow 500, 750 (ERM) Machines --

Right Hand Side View 2--16.............................................

Fig. 24

Range Drawing for Arrow (ERM) 1000, 1250C Machines -- Front View 2--17......

Fig. 25

Range Drawing for Arrow (ERM) 1000, 1250C Machines --

Right Hand Side View 2--18.............................................

Page 15

Table of Contents

Fig. 26

Table Dimensions 2--19.................................................

Fig. 27

Bolt and Tenon Sl ot Dimensions -- Typical 2--19.............................

Fig. 28

Range Drawing for Arrow (ERD) 1250, 1500, 2000 -- Plan View 2--20............

Fig. 29

Range Drawings for Arrow (ERD) 1250, 1500, 2000 -- Front View 2--21..........

Fig. 30

Range Drawing for Arrow (ERD) 1250, 1500, 2000 Machines --

Right Hand End View 2--22..............................................

Fig. 31

Table Dimensions 2--23.................................................

Fig. 32

Bolt and Tenon Sl ot Dimensions 2--23.....................................

Fig. 33

Tool Holder and Retention Stud 2--24......................................

Fig. 34

JMTBA_BT Tool Holder and Retention Stud 2--25...........................

Fig. 35

Spindle power characteristics (Arrow E/Dart Machine -- Standard Speed Range) 2--27

Fig. 36

Spindle power characteristics (Arrow Machine -- Standard Speed Range) 2--28.....

Fig. 37

Spindle power characteristics (8000 rpm Speed Range) 2--29...................

Fig. 38

Spindle power characteristics (10000 rpm Speed Range) 2--30..................

Fig. 39

Spindle power characteristics (High Torque Speed Range) 2--31.................

Fig. 40

Offsets 3--31..........................................................

Fig. 41

Pallet Offset Example 3--33..............................................

Fig. 42

Multiple Setup Offsets Example 3--35......................................

Fig. 43

Fixture Offset Example 3 --37.............................................

Fig. 44

NC Program Offsets Example 3--39.......................................

Fig. 45

Offset Combination Example 3--40........................................

Fig. 46

Swarf Conveyor Control Panel 3--63.......................................

Fig. 47

Orientation 4--43......................................................

Fig. 48

Orientation 4--44......................................................

Fig. 49

Orientation 4--47......................................................

Fig. 50

Offset Interaction 4--71.................................................

Fig. 51

Fixture Pattern Example 4--79............................................

Page 16

Table of Contents

Fig. 52

Setup Icon 4--89.......................................................

Fig. 53

Setup Pattern Example 4--92.............................................

Fig. 54

Setup Rotation 4--106...................................................

Fig. 55

Multi--Setup Example 4--138..............................................

Page 17

Chapter 1 Safety Precautions

Important

WARNING

Read related safety pre cautions before operating

this machine. Failure to

follow safety instructions

may result in serious personal injury.

WARNING

Inorder toclearlyshowdetailsofthis machine,some

covers, shields, guards,

barriers,devices, or doors

have either been removed

or shown in an ”open”

position. All such protective components must be

installedin positionbefore

operating this machine.

Failure to follow this

instruction may result in

serious personal injury.

Thesesafetyprecautions forthis CINCINNATImachinehave beenprepared

to assistthe operator, programmerand maintenancepersonnel inpracticing

good shop safety procedures.

Operator and maintenance personnel must read and understand these

precautions completely beforeoperating, setting up,running, or performing

maintenance on the machine.

Theseprecautions areto beused asaguide tosupplement safety precautions

and warnings in the following:

a. All other manuals pertaining to the machine.

b. Local, plant, and shop safety rules and codes.

c. National safety laws and regulations.

General Safety Instructions And Considerations

Personal Safety

Machineowners, operators,setup men,maintenance,and servicepersonnel

must be aware of the fact that constant day--to--day safety procedures are a

vital part of their job. Accident prevention must be one of the principal

objectives of the job regardless of what activity is involved.

Know and respect your machinery. Read and practice the prescribedsafety

and checkingprocedures. Make sure that everyonewho works for, with, or

near you fully understands and -- more importantly -- complies with the

following safety precautions and procedures when operating this machine.

Sudden movements, loud noises, horseplay, etc., must be avoided. These

distractions may result in unsafe conditions for those working near the

machinery.

Observe and follow safety instructions such as “NO SMOKING”, “High

Voltage”, “DANGER”, etc., in your working area.

Accidents can occur that result in serious personal injury to yourself or

othersdue toclothing andotherarticlesbecomingentangledin cutters,hand

wheels, levers, or moving machineelements. Thefollowing suggestions, if

followed, will help you to avoid such accidents: Neckties, scarfs, gloves

(except as worn for protection when handling sharp edged cutting tools or

rough, sharp or hot parts, see TOOL SAFETY) loose hanging clothing, and

jewelry such as watches, rings, or necklaces must not be worn around

moving machinery. Restrain long hair with a cap or net. Wear gloves only

when handling rough, sharp, or hot parts.

Use safety protective equipment. Wear clean approved eye or face

protection. Safety--toe shoes with slip--proof soles can help you avoid

injury. Keep your protective equipment in good condition.

Neveroperateor servicethisequipment ifaffectedbyalcohol,drugs orother

substances or conditions which decrease alertness or judgment.

Cincinnati Machine 91203809--001 Page 1--1

Page 18

WARNING

Failure to follow instructions on this page may result inserious personal injury.

Work Area Safety

Always keep your work area clean. Dirty work areas with such hazards as

oil, debris,or wateron the floormay cause someone to fall tothe floor,into

the machine, or onto other objects resulting in serious personal injury.

Make sureyour work area is free of hazardousobstructions and be awareof

protruding machine members.

Returntools andsimilarequipment totheirproper storage placeimmediately after use. Keep work benches neat, orderly, and clean.

Report unsafeworking conditions to your supervisor or safety department.

Items such as: worn or broken flooring, ladders, and handrails, unstable or

slippery platforms, or scaffolds must be reported and repaired before use.

Do not use skids, work pieces, stock, machines, tote pans, and boxes as

makeshift climbing aides.

T ool Safety

Sharp edged cutting tools must be handled with gloves or a shop cloth.

Inspect cutting tools before use and reject defective tools.

See WARNING 1.

Remove hand tooling such as wrenches, measuring equipment, hammers,

and other miscellaneous parts from the machine immediately after usage.

WARNING 1

CUTTING TOOLS

Use adequate hand

protection at all times

when handling sharp

edged cutting tools.

Failure to follow this

instruction may result in

serious personal injury.

Lifting And Carrying Safety

Contact supervision if you have any questions or are not sure about the

proper procedures for lifting and carrying.

Before lifting or carrying an object, determine the weight and size by

referringto such things as tags, shipping data, labels, marked information,

or manuals.

Use power hoists or other mechanical lifting and carrying equipment for

heavy,bulky,or hardto handleobjects. Usehookup methodsrecommended

by your safetydepartment and know thesignals for safelydirecting a crane

operator.

Never place any part of your body under a suspended load or move a

suspended load over any part of another person’s body. Before lifting, be

certain that you have a safe spot for depositing the load. Never work on a

component while it is hanging from a crane or other lifting mechanism.

Ifindoubt asto thesizeor typeof liftingequipment,method, andprocedures

for lifting, contact Cincinnati Machine beforeproceeding tolift the machine

or its components.

Always inspectslings, chains, hoists, and other lifting devices prior to use.

Do not use lifting devices found to be defective or questionable.

Page 1--2

Neverexceed thesafety ratedcapacityofcranes, hoists,slings, eyebolts,and

other lifting equipment. Follow, National and local, standards and

instructions applicable to any lifting equipment you use.

Before inserting an eyebolt, be certain that both the eyebolt and the hole

have the same size and type threads. To attain safe working loads, at least

90% of the threaded portion of a standardforged eyebolt must be engaged.

Cincinnati Machine 91203809--001

Page 19

WARNING

Installation And Relocation Safety

Before lifting the machine, consult the machine manual or Cincinnati

Machine for proper methods and procedures.

Failure to follow instructions on this page may result inserious personal injury.

An electrician must read and understand the electrical schematics prior to

connectingthe machineto the powersource. Afterconnecting themachine,

testall aspectsof theelectricalsystem forproper functioning.Always make

sure the machine is grounded properly. Place all selector switches in their

OFF or neutral (disengaged) position. The doors of the main electrical

cabinet must be closed andthe main disconnect switch must be in the OFF

position after the power source connection is complete.

Alwayslock the maindisconnect devicein the OFF position if the machine

is left unattended, unless machine is part of an unmanned manufacturing

system and in a production cycle.

When the machine is installed, be sure that the motors rotate in the proper

indicated direction.

Setup And Operation Safety

Readand understandall the safetyinstructions before settingup, operating,

or servicing this machine. Assign only qualified personnel, instructed in

safety and all machine functions, to operate or service this machine.

Operators and maintenance personnelmust carefullyread, understand, and

fully comply with all machine mounted warning and instruction plates. Do

notpaintover,alter,or defacetheseplatesorremovethemfrom themachine.

Replace all plates which become illegible. Replacement plates can be

purchased from Cincinnati Machine.

Safety guards, shields, barriers, covers, and protective devices must be

connected or in place before operating the machine.

All safety features, disengagements, and interlocks must be in place and

functioningcorrectly priorto operationof this equipment. Never bypassor

wire around any safety device.

When setting up or adjusting a workpiece or fixture, be certain it is a safe

distance away from the cutting tool. Always retract the workpiece a safe

distance from the cutting tool when loading and unloading.

The spindle must bestopped before adjustingthe coolant dischargenozzle.

Neverbrake or slowdown moving machinery withyour hand or withsome

makeshiftdevice.Never usemachinepowerto removea nut from anyshaft.

The spindle and slides must be stopped when measuring work pieces,

changing tools, or removing chips and grit. Remove chips and grit with a

chip rake or brush, not with your hands.

Keepall parts ofyour body offthe machinetable, tableedge, outof thepath

of moving units, trip dogs, trip plungers, and out of the “machining area”

during machining operations. Never lean on a machine or reach over or

througha machine-- you canbecomeentangled intooling and othermoving

elements or you may accidentally activate start buttons, feed controls, rapid

traverse controls, power work holding control, or similar devices.

During operation, be attentive to the machining process. Excessive

vibration, unusual sounds, etc., can indicate problems requiring your

Cincinnati Machine 91203809--001 Page 1--3

Page 20

WARNING

Failure to follow instructions on this page may result inserious personal injury.

immediate attention. Watch for conditions such as packed chips or grit

which can cause breakage of tooling or machine elements.

Shut offpower tothe machinewhen leaving the operatingarea orat the end

of your work period. Never leave the machine running unattended, unless

it hasbeen designedto do so. Turn themasterdisconnect deviceto theOFF

position beforecleaningthe machine atthe end of t he working day orwhen

guards or covers are removed that expose hazardous areas.

Maintenance Safety

See DANGER notice.

Do not attempt to perform maintenance on this machine until you readand

understand all the safety instructions.

Assign only qualified service or maintenance personnel trained by

Cincinnati Machine, to perform maintenance and repair work on this

machine. They should consult the service manual before attempting any

service or repair work and when in doubt contact Cincinnati Machine. Use

only Cincinnati Machine replacement parts; others may impair the safety of

the machine. Before performing maintenance or service work, W arning or

Danger signs must be placed conspicuously about the machine. Before

detachingcounterweightsor drivingmechanisms, vertical slidingmembers

must be blocked properly. See the Service Manual for proper dismantling

procedures.

Before removing or opening any electrical enclosure, cover, plate, or door,

be sure that the Main Disconnect Switch is in the OFF position. If any tool

is required to remove a guard, cover, bracket, or any basic part of this

machine, place the Main Disconnect Switch in the OFF position, lock it in

theOFF position.If possible, post a signat thedisconnect switchindicating

that maintenance is being performed.

Whenever maintenance is to be performed in an area away from the

disconnectandthe disconnectis notlocked,tag allstart buttonstations with

a “DO NOT START” tag. Adequate precautions, such as locks on circuit

breakers, warning notices, or other equally effective means must be taken

to prevent electrical equipment from being electrically activated when

maintenance work is being performed.

Before attempting to adjust, repair, or perform maintenance on electrical

circuits connected with yellow wires, first find the source of power, turn it

off, andlock it in the OFF position. Machine tool interlock control circuits

connected with yellow wires are powered from a source away from the

machine and carryvoltageeven whenthe machine’smain disconnect device

is turned to the OFF position.

Whenremovingelectricalequipment, placenumberorlabeledtags onthose

wiresnotmarked.If wiring, isreplaced, besureit is ofthesame type, length,

size, and has the same current carrying capacity.

Page 1--4

Close andsecurelyfasten all guards, shields, covers,plates, or doorsbefore

power is reconnected.

An electrical technician must analyzethe electrical system to determine the

possible use of power retaining devices such as capacitors. Such power

retaining devices must be disconnected, discharged, or made safe before

maintenance is performed.

Cincinnati Machine 91203809--001

Page 21

WARNING

Failure to follow instructions on this page may result inserious personal injury.

Working space around electrical equipment must be clear of obstructions.

Provide adequate illumination to allow for proper operation and maintenance.

DANGER

HIGH VOLTAGE

Lethal voltagesare present in themagnetics and electrical

control cabinets when theMACHINEMAINDISCONNECT is

’ON’. Current and voltage measurements should be attempted only by qualified electrical maintenance personnel.

Beforeworking on any electrical circuits,turn the machine

Main Disconnect Device ’OFF’ and lock It.

Capacitors in the Servo Drives require up to 20 minutes to

completely discharge. Always verify that discharge is

complete using a known working and calibrated voltmeter

before commencing work on these units.

Unless expressly stated in applicable Cincinnati Machine

documentation or by the appropriate Cincinnati Machine

Field Service Representative, do NOT work with electrical

power ’ON’. If such express statement of advice exists,

working with electrical power ’ON’ should be performed by

a Cincinnati Machine Field Service Representative. The

customerandsubsequenttransfereesmustdeterminethat

any other person performing work with electrical power

’ON’ is trained and technically qualified.

F AILURETO FOLLOW THIS INSTRUCTION MAYRESUL TIN

DEATH OR SERIOUS PERSONAL SHOCK INJURY.

Materials Used With This Product

Variousmaterialsmaybeused withthis product.Beforeusing/mixing/diluting materials with this product, contact the manufacturer/authorized

supplier of the material to determine that the material is suitable for the

intended applicationand requesta Material Safety DataSheet (MSDS) from

the material manufacturer.

Cincinnati Machine 91203809--001 Page 1--5

Page 22

NOTE

The information and tables

contained in this article relate to Cincinnati Machine

methods and standards.

Consult National, Local and

Plant Laws and Regulations

regarding lifting practices.

WARNING

Before inserting an eyebolt, check to be certain

that both the eyebolt and

the hole have the same

sizeandtypethreads. For

example: M12withM12or

.375 -- 16 with .375--16.

To attend safe working

loads, at least 90% of the

threaded portion of a

standard forged eyebolt

must be engaged.

Failure to follow this

instruction may result in

serious injury.

LIFTING DEVICES

GENERAL

The useof lifting devices is subject to certain hazards that cannot be met by

mechanical means but only by the exercise of intelligence, care, and

common sense. It is, therefore, essential to have competent and careful

operators, physically and mentally fit, thoroughly trained to the safe

operation of the equipment and the handling of the loads. Serious hazards

are overloading, dropping or slipping of the load caused by improper

hitching or slinging, standing or crawling under a load, swinging loads,

obstruction to the free passage of the load, using equipment for a purpose

or a manner for which it was not intended or designed..

EYEBOLTS

A straight lift is preferred when using eyebolts. An angular lift places

additional stresses on an eyebolt, above that of the load to be hoisted.

Ifthe situationnecessitatesan angularlift, thesafe workingload forangular

lifts shown in Fig. 1 and Fig. 2 should be used.

Whenmultiple eyeboltprovisions aredesignedinto alift, itisrecommended

(in most applications) that a spreader bar be used. (See Fig. 9 which

illustrates a typical spreader bar arrangement.)

No greater stress should be allowed than that given under Safe Working

Load in Fig. 1 and Fig. 2.

To obtain greatest strength from an eyebolt, it must fit reasonably tight in

the hole with at least 90% of the threaded length engaged.

Eyebolts should never be welded or subjected to heat in excess of 900F

[480 C].

Eyebolts should never bepainted orotherwise coatedwhen usedfor lifting,

as such coating will very likely cover up flaws.

Eyebolts should be routinely inspected for defects and if any defects are

found,theyshould bedestroyedby melting,crushing, orcuttingclearacross

the eye.

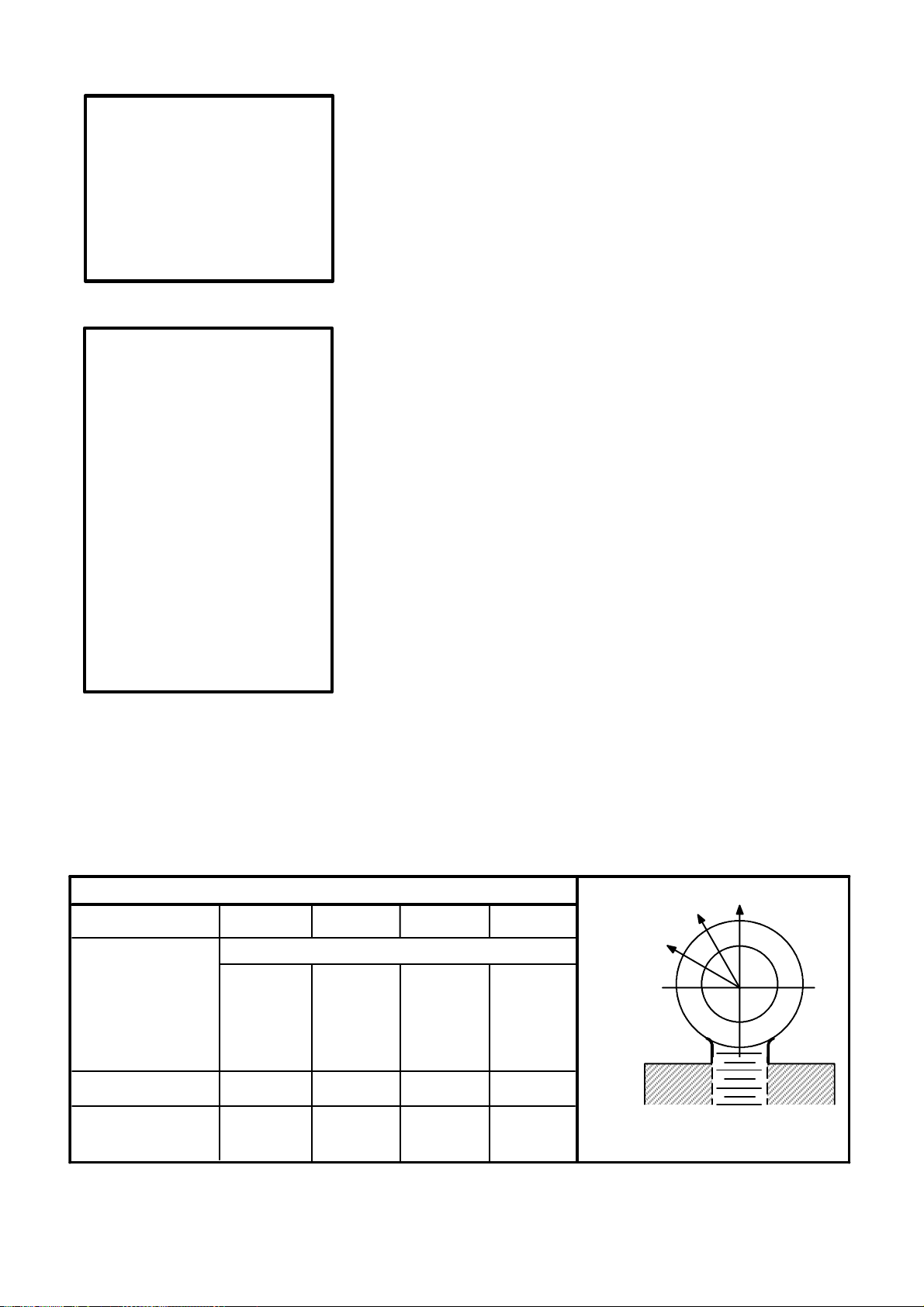

STRAIGHT SHANK INCH (ANSI/ASMEB18.15)

THREAD .375--16 .500--13 .625--11 1.000--8

SAFE WORKING LBS. [KG]

LOAD

90 DEGREES 1000 1840 2940 7880

[453] [834] [1333] [3573]

60 DEGREES 375 805 1340 3670

[170] [365] [607] [1664]

30 DEGREES 200 470 805 2390

[90] [213] [365] [1083]

PART NUMBER 3449 870 21312 19489

IDENTIFICATION

PLATE NUMBER 3338325 3338326 3338327 3338328

60

30

STRAIGHT SHANK INCH

90

Fig. 1

Preferred Inch Lifting Eyebolts

Page 1--6

Cincinnati Machine 91203809--001

Page 23

SHOULDER METRIC (ISO 3266--1984)

THREAD M12 M16 M20 M30

SPOTDIAMETER 32mm 37mm 42mm 67 mm

1.25 in. 1.50 in. 1.65 in. 2.63 in.

SAFE WORKING [KILOGRAMS] LBS.

LOAD

90 DEGREES [400] [630] [1000] [2500]

882 1389 2205 5512

45 DEGREES [100] [160] [250] [625]

220 352 551 1378

PART NUMBER 6014453--3 6014453--4 6014453--5 6014453--8

45

90

IDENTIFICATION

PLATE NUMBER 3338329 3338330 3338331 3338332

Fig. 2

Preferred Metric Lifting Eyebolts

5 MAX.

LOAD

NO

LOAD

30 MIN.

YES

YES

NO

Fig. 3

Eyebolt Loading

6.00

THIS MACHINE HAS BEEN

MANUFACTURED TO UTILIZE

”INCH” THREAD LIFTING

3.00

DEVICES. ANY EXCEPTION

TO THIS WILL BE LABELED

ADJACENT TO THE LIFT

POINT.

.12

.12

TYP.

NO 21 (.032) GAGE ALUMINUM.-- NO.AL 5052 ALLOY.ETCHED AREA S TO

BEBLACK BAKED ENAMEL. ETCHEDDEPTHTO BE .003 TO .005INCHES

------ OR ------ NO. 21 (.032)GAGE

ALUMINUM WITH METALPHOTOPROCESS.ALL LETTERINGTO BE HELVETICA MEDIUM.

.109 DIA.THRU

4PLACES

3375984

.08

.25

.12 R

Fig. 4

Eyebolt I.D. Plates -- Inch and Metric

3TYP.

NO 21 (.032) GAGE ALUMINUM.-- NO. AL 5052 ALLOY. ETCHED AREAS TO BE BLACK

BAKED ENAMEL. ETCHED DEPTH TO BE .003 to .005 INCHES ------ OR ------ NO. 21 (.032)

GAGE ALUMINUM

WITH METALPHOTO PROCESS. ALL LETTERING TO BE HELVETICAMEDIUM.

SURFACE GRAIN TO RUN PARALLEL TO LETTERING WITH SATINFINISH.

INCH

.375--16 UNC

THIS MACHINE HAS BEEN

MANUFACTURED TO UTILIZE

”METRIC” THREAD LIFTING

DEVICES. ANY EXCEPTION

75

TO THIS WILL BE LABELED

ADJACENT TO THE LIFT

POINT.

1.4

THRU--4

3TYP.

PLACES

3338325

SHOULDER METRIC

ISO METRIC

150

6.3

3375983

2

3R

3338329

M12

Fig. 5

Instruction Plate -- Inch (Part Number 3375984)

Cincinnati Machine 91203809--001 Page 1--7

Fig. 6

Instruction Plate -- Metric (Part Number 3375983)

Page 24

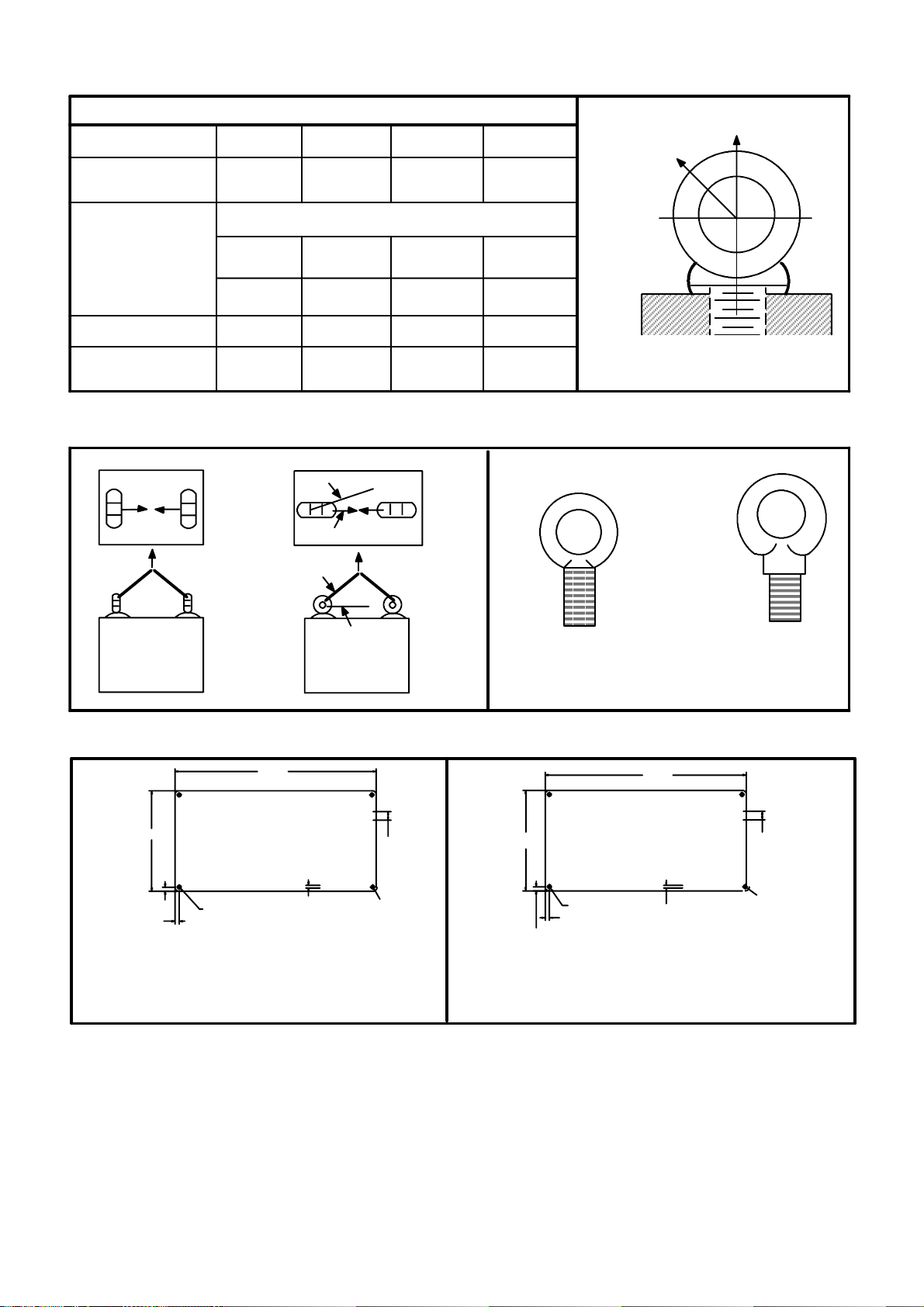

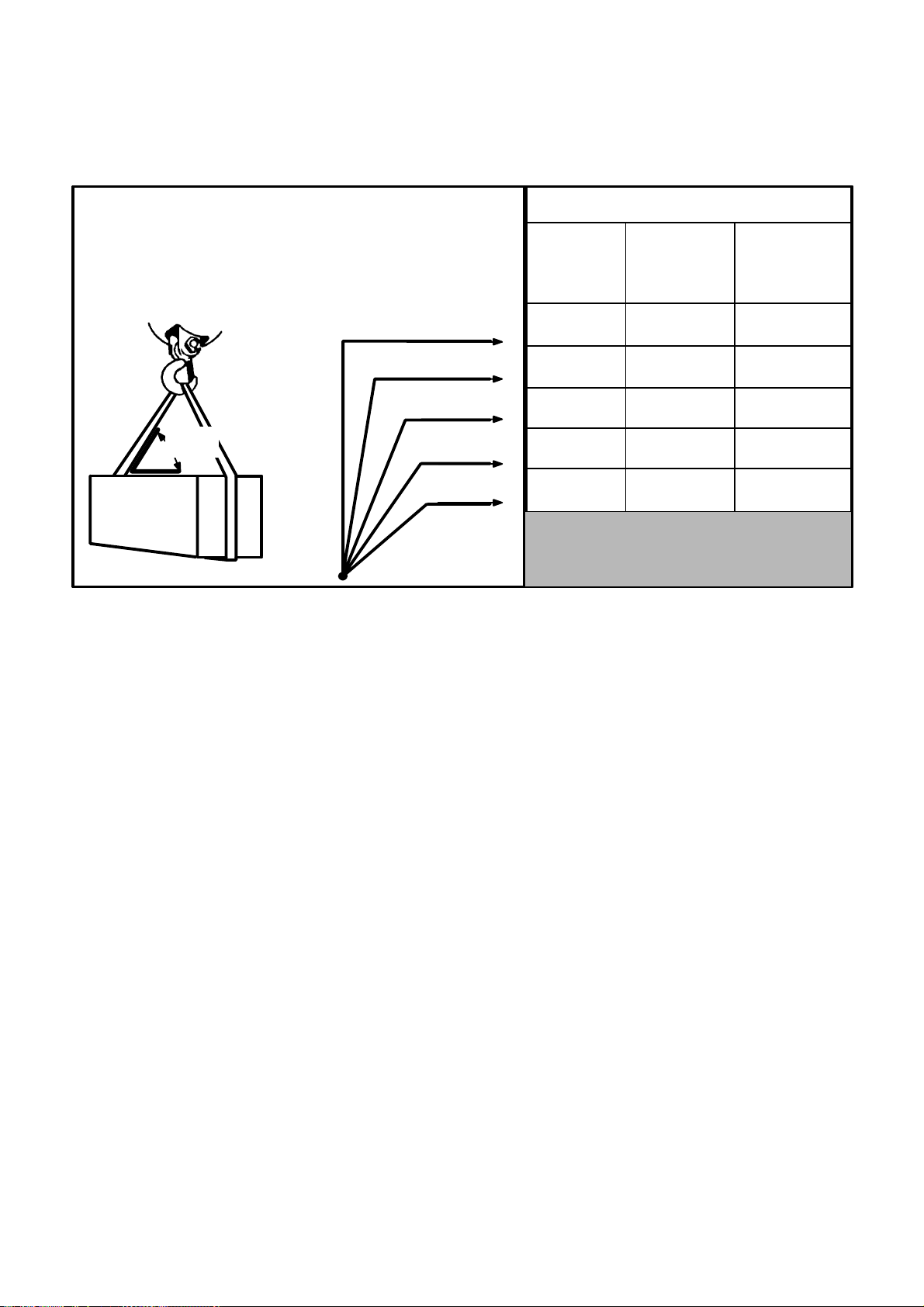

HOIST RINGS

A

PAR

T.N

O

PLATE

Hoist Rings are superior to eyebolts for angular lifting.

Be certain the thread projection is in accordance with the manufacturer’s

recommendation.

Do not recut any damaged threads on hoist rings.

To obtain the safe working load, torque to the recommended values shown

in the table below.

Fig. 7

Hoist Ring

CM HOIST

RING

PARTNO.

3346225 1 .375--16 12.0 16.3 1000 450 866 390 707 318 500 225 5013055 001

3346225 2 .500--13 28.0 38 2500 1130 2165 975 1767 795 1250 562 5013055 002

3346225 3 .625--11 60.0 81.3 4000 1810 3464 1559 2828 1273 2000 900 5013055 003

3346225 4 1.000--8 230.0 312 10000 4500 8660 3897 7071 3182 5000 2250 5013055 004

3346225 6 M12X1.75 27.0 36.6 2204 991 1908 859 1558 701 1102 496 5013055 006

3346225 7 M16X2 59.0 80 3857 1736 3340 1503 2726 1227 1928 868 5013055 007

3346225 8 M20X2.5 100.0 136 4736 2132 4103 1846 3349 1507 2369 1066 5013055 008

3346225 9 M30X3.5 229.0 310 9257 4166 8016 3607 6544 2945 4628 2083 5013055 009

CM HOIST

RING

PARTNO.

3346225 1 .375--16 12.0 16.3 1000 450 1000 450 1000 450 5013055 001

3346225 2 .500--13 28.0 38 2500 1130 2500 1130 2500 1130 5013055 002

3346225 3 .625--11 60.0 81.3 4000 1810 4000 1810 4000 1810 5013055 003

3346225 4 1.000--8 230.0 312 10000 4500 10000 4500 10000 4500 5013055 004

3346225 6 M12X1.75 27.0 36 2204 991 2204 991 2204 991 5013055 006

3346225 7 M16X2 59.0 80 3857 1736 3857 1736 3857 1736 5013055 007

3346225 8 M20X2.5 100.0 136 4736 2132 4736 2132 4736 2132 5013055 008

3346225 9 M30X3.5 229.0 310 9257 4166 9257 4166 9257 4166 5013055 009

Fig. 8

Hoist Ring Table

THREAD

SIZE

THREAD

SIZE

THREAD

TORQUE

Ft--Lb N--m Lb kg Lb kg Lb kg Lb kg

THREAD

TORQUE

Ft--Lb N--m Lb kg Lb kg Lb kg Ft--Lb N--m

Observe all other safety precautions normally practiced on eyebolts.

FF

90

_

WW

MAX. WT

EACH RING

FF

90

_

WW

MAX. WT

EACH RING

FF

60

_

WW

MAX. WT

EACH RING

FF

90

WW

MAX. WT

EACH RING

FF

45

_

WW

MAX. WT

EACH RING

FF

90

WW

MAX. WT

EACH RING

FF

30

_

WW

MAX. WT

EACH RING

NOTE F=FORCE W=WEIGHT

CM IDENT.

P

CM IDENT.

PART. NO.

.xxx--xx

PLATE

RT. NO.

.xxx--xx

.

Page 1--8

Cincinnati Machine 91203809--001

Page 25

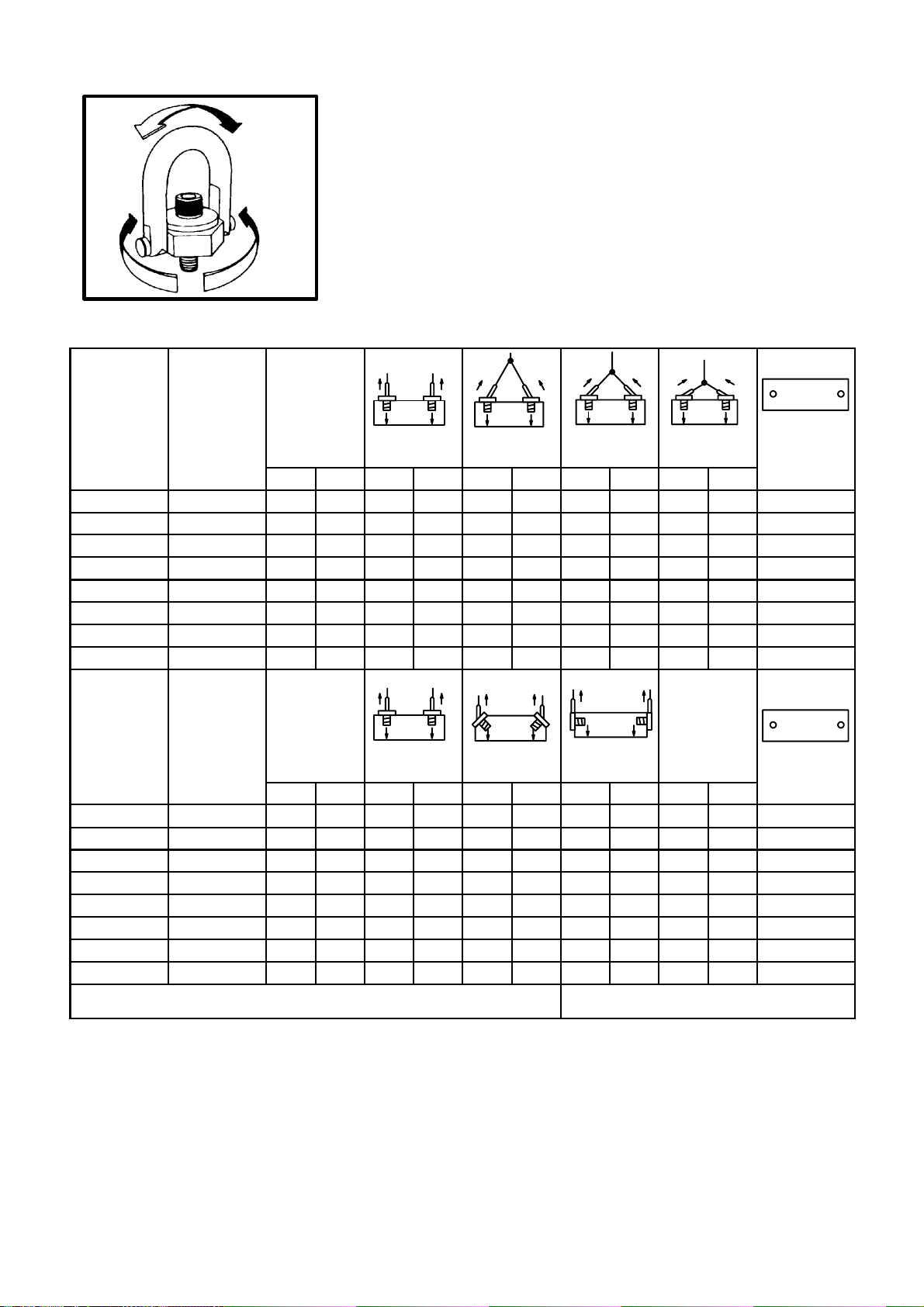

SPREADER BARS AND LIFTING BEAMS

p

y

p

SPREADER

TO LOAD TO LOAD

Fig. 9

S

reader Bar -- T

ical

Spreader bars are used when multiple eyebolts are designed into a lift.

Always observe the following safety precautions when using a spreader bar

or lifting beam

Do not exceed the safe working load.

Use the spreader or beam to handle parts or components only for which it

was designed.

Inspect it before each use.

Do not alter or weld anything to bar or beam.

Store properly to avoid damage.

CHAIN

Selectachain withthe suitablecharacteristics andcapacityforthe load.See

above. Always observe the following safety precautions.

Do not shorten chains with knots, bolts, or any non--approved method.

Never use damaged chain.

Hitch chain securely to the load.

Pad sharpcorners with material of sufficient strengthto withstand loadand

protect chain.

Cincinnati Machine 91203809--001 Page 1--9

Page 26

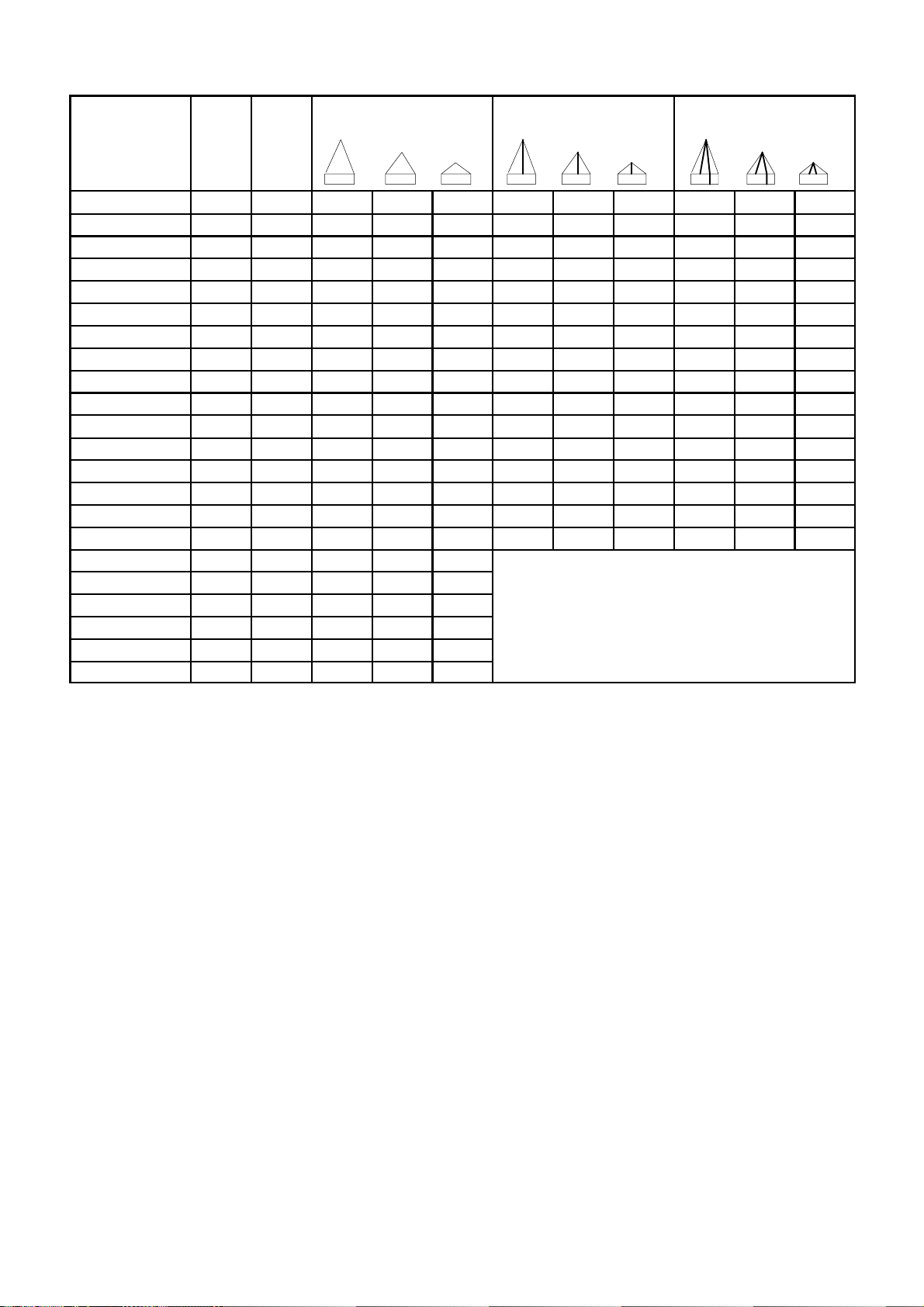

DOUBLE SLING CHAINS

SIZE OF

CHAIN

9/32 in. lbs. 3 250 5 625 4 600 3 250 8 400 6 900 4 875 8400 6900 4 875

.7.2 mm kg. 1 475 2 550 2 085 1 475 3 810 3 130 2 210 3 810 3 130 2 210

3/8 in. lbs. 6 600 11 400 9 300 6 600 17 100 13 950 9 900 17 100 13 950 9 900

9.5 mm kg. 2 995 5 170 4 220 2 995 7 750 6 330 4 490 7750 6 330 4 490

1/2 in. lbs . 11 250 19 700 15 900 11 250 29 250 23 850 16 875 29 250 23 850 16 875

712.7 mm kg. 5 100 8 845 7 210 5 100 13 270 10 820 7650 13 270 10 820 7650

5/8 in. lbs . 16 500 28 600 23 300 16 500 42 900 34 950 24 750 42 900 34 950 24 750

15.9 mm kg. 7 480 12 970 10 570 7 480 19 460 15 850 11 230 19 460 15 850 11 230

3/4 in. lbs . 23 000 39 800 32 500 23 000 59 700 48 750 34 500 59 700 48 700 34 500

19.1 mm kg. 10 430 18 050 14 740 10 430 27 080 22 110 15 650 27 080 22 110 15 650

7/8 in. lbs . 28 750 49 800 40 700 28 750 74 700 61 050 43 125 74 700 61 050 43 125

22.6 mm kg. 13 040 22 590 18 460 13 040 33 880 27 690 19 560 33 880 27 690 19 560

1in. lbs . 38 750 67 100 54 800 38 750 100 650 82 200 58 125 100 660 82 200 58 125

25.4 mm kg. 17 580 30 440 24 860 17 580 45 650 37 290 26 260 45 650 37 290 26 260

1 1/4 in. lbs. 57 500 99 600 81 300 57 500 149 400 121 950 86 250 149 400 121 950 86 250

31.8 mm kg. 26 080 45 180 36 880 26 080 67 770 55 320 39 120 67 770 55 320 39 120

1 1/2 in. lbs. 80 000 138 500 113 000 80 000

38.1 mm kg. 36 290 62 820 51 260 36 290

1 3/4 in. lbs. 100 000 73 200 41 000 100 000

44.5 mm kg. 45 360 78 560 63 960 45 360

2in. lbs . 130 000 225 000 183 000 130 000

50.8 mm kg. 26 750 102 060 83 000 26 750

SINGLE

CHAIN

90

TYPE D

60 45 30

TRIPLE SLING CHAINS

TYPE T

60 45 30

QUAD SLING CHAINS

TYPE Q

60 45 30

Fig. 10

Steel Alloy Chains

Keep hands and fingers from between the chain and load.

Avoidshock l oading --particularlywhenworkingattemperaturesbelow40

F[4 C].

Never pull chain from under load when load is resting on chain.

Correct kinks and twisting in chain before lifting.

Lift from center of hooks. Avoid lifting from the point.

Assurethat loadis freeto movebeforelifting. Keepclearof allobstructions.

When using a basket hitch, balance load and assure that chain legs contain

or support load from the sides above the center of gravity.

Storechains inan areawherethey will not be subjectto mechanical damage

or corrosive action.

Page 1--10

Cincinnati Machine 91203809--001

Page 27

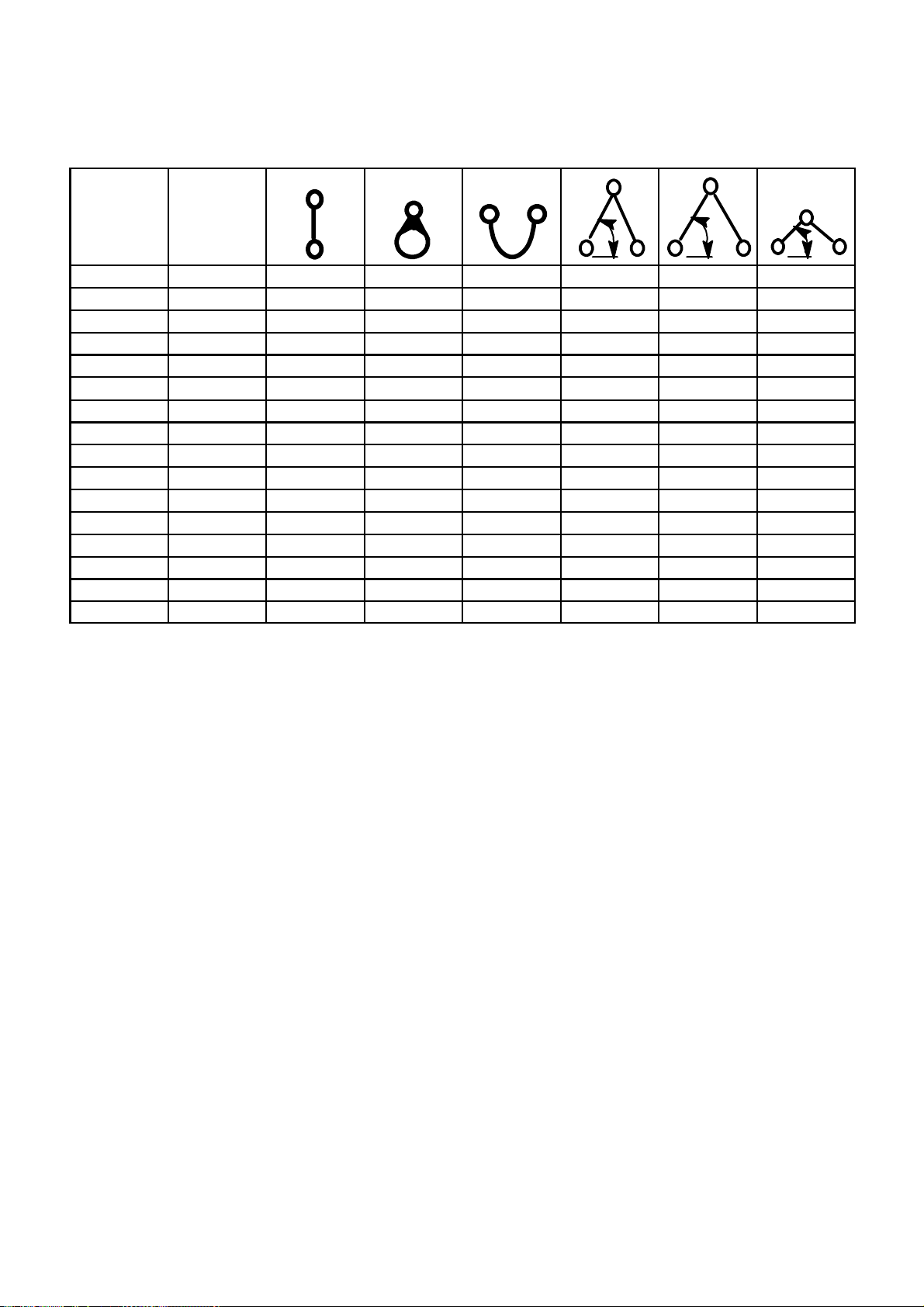

CABLE SLINGS

Select the appropriate size wire rope and hitch. See Table below

CABLE

SIZE

1/4 in. lbs. 980 740 1400 1700 1400 980

6.4 mm kg. 445 335 635 770 635 445

1/2 in. lbs. 3600 2800 5200 6400 5200 3600

712.7 mm kg. 1630 1270 2360 2900 2360 1630

3/4 in. lbs. 7800 5800 11100 13600 11100 7800

19.1 mm kg. 3450 2630 5035 6170 5035 3450

1in. lbs. 13400 1000 18800 22000 18800 13400

25.4 mm kg. 6080 4540 8530 9980 8530 6080

1 1/4 in. lbs. 19600 14800 28000 34000 28000 19600

31.8 mm kg. 8890 6710 12700 15420 12700 6710

1 1/2 in. lbs. 28000 20000 40000 48000 40000 28000

38.1 mm kg. 12700 9070 18140 21770 18140 12700

1 3/4 in. lbs. 38000 28000 54000 66000 54000 38000

44.5 mm kg. 17240 12700 24490 29940 24490 17240

2in. lbs. 50000 36000 70000 86000 70000 50000

50.8 mm kg. 22680 16330 31750 39000 31750 22680

Fig. 11

Wire Rope Slings

ESTIMATED

RATINGCA-

PACITY

(For Exact

Rating Check

Sling Tag)

VERTICAL

CHOKER

HITCH

BASKET

HITCH

60 45

30

Guide loads with a tag line when practical.

When using multiple leg sling, select longest one possible.

Examine for damaged or worn area.

Attach securely to load.

Pad sharp corners to protect wire rope.

Center load in the base (bowl) of the hook to prevent hook point loading.

Do not kink, twist, or loop legs.

Keep hands and fingers from between wire rope and load.

Stand clear of attached load.

Start lift slowly to avoid shock injury.

Do not pull wire rope from under a load when the load is resting on it.

Do notshorten sling byknotting, by wirerope clips, orby any othermeans.

Do notinspect wire rope by passingbare hands overthe body. Brokenwire,

if present, may puncture the hands.

Keep wire rope well--lubricated to prevent corrosion.

Use gloves at all times when handling.

Cincinnati Machine 91203809--001 Page 1--11

Page 28

SYNTHETIC MATERIAL SLINGS

Select the sling with the suitable characteristics and capability for the load

and environment. See Fig. 12

AS THE SLING TO LOAD ANGLE

DECREASES, SO DOES THE RATED CAPACITY OF A SLING.

SLING--TO--LOAD ANGLE IS ALWAYS

THE ANGLE BETWEEN THE SLING LEG AND