Page 1

seruice

mnnuRL

HOD

PARTS

LIST

CATALOG

.—--X

h,

•;-

£^^01

®

[CINCINNATI:

No.

1

Tooimaster

MILLING

MACHINE

Identification

No.

6J-DK

Publication

No.

M-2109

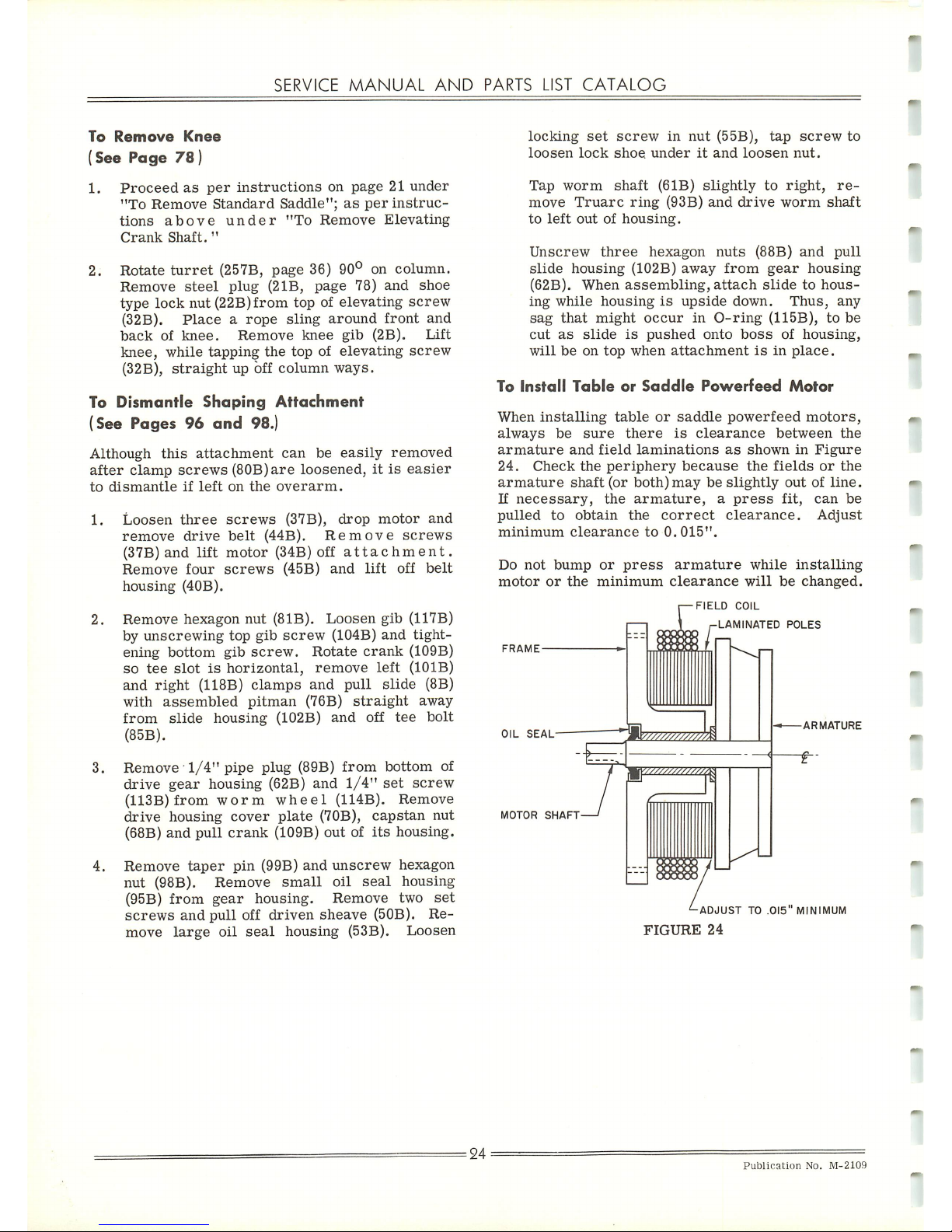

WHEN

ORDERING

REPAIR

PARTS

1.

Give

complete

Serial

Number

of

Machine.

2.

Give

Part

Number

and

Name.

3.

Give

Amount

Required.

UNLESS

THE

ABOVE

DATA

IS

INCLUDED

WE

CANNOT

FILL

YOURORDE

R

THE

CINCINNATI

MILLING

MACHINE

CO

CINCINNATI

9,

OHIO,

U.S

A.

Page 2

Page 3

SERVICE

MANUAL

AND

PARTS LIST

CATALOG

TABLE

OF

CONTENTS

This catalog to be used

only

for machines

whose

serial

number

begins

with

6J.

FUNCTIONAL

DIAGRAMS

DIMENSIONAL

DRAWING

CONVERSION CHART

(InchestoM/M)

LUBRICATION

DIAGRAM

AND

SPECIFICATIONS.

CMMCo.

RECOMMENDED

LUBRICANTS

......

INSTALLATION

INSTRUCTIONS

ADJUSTMENTS

To

Adjust

Gibs

Drive

Belts:

Styles

1-A,

1-B.

. . .

Drive

Belt:

Style

1-E

" "

Backlash

Eliminator

"

Quill

Powerfeed

Clutch:

Style

1-B

" "

Shaping

Attachment

Drive

Belt

. . .

" "

Shaping

Attachment

Gib

DISMANTLING

INSTRUCTIONS

To

Remove

V-Belt

Housing

Styles

1-A,

1-B

Style

1-D

Style

1-E

Splined

Spindle

Sleeve:

Styles

1-A,

1-B.

. . . . . , . .

Drive

Spindle

Assembly:

Style

1-A

:

Style

1-B

:

Styles

1-D,

1-E

Spindle

Housing

with

Spindle:

Styles

1-A,

1-B

. . . .

" :

Styles

1-D,

1-E

...

.

Spiral

Gear

Shaft:

Style

1-B

Transmission

Shaft:

Style

1-B

Speed

Change

Assembly:

Style

1-D

and

Dismantle

Powerfeed

Housing:

Styles

1-D,

1-E.

Overarm

and

Turret:

Styles

1-A,

1-B,

1-D,

1-E

. .

Overarm

(Heavy

Duty):

Style

1-C.

and

Dismantle

Overarm

Gear

Housing:

Style

1-C

. .

Page

4,

5

6

7

8,

9

10

11

12

12

12

12

12

12

12

13

13

13

13

13

14

15

15

16

16

16

17

17

18

18

18

Page 4

CINCINNATI

NO.

1

TOOLMASTER

MILLING

MACHINE

To

Remove

Single

Swivel

Housing

Spindle

and

Drive

—

Without

Hand

Feed:

Style

1-C

" "

Single

Swivel

Housing

Spindle

and

Drive

—

With

Hand

Feed:

Style

1-C

. .

" "

and

Dismantle

Double

Swivel

Housing:

Style

1-C

Table

" "

Table

Leadscrew

" "

Table

Powerfeed

Housing

To

Dismantle

Table

Powerfeed

Housing

To

Remove

Standard

Saddle

" "

Crossfeed

Screw

" "

and

Dismantle

Saddle

When

TableIsEquipped

With

Powerfeed

" " " "

Saddle

Powerfeed

Housing

Elevating

Crank

Shaft

" "

Elevating

Screw

and

Pedestal

Knee

To

Dismantle

Shaping

Attachment

To

Install

Table

or

Saddle

Powerfeed

Motor

KEY

NUMBER

INDEX

HOW

TO

ORDER

REPAIR

PARTS

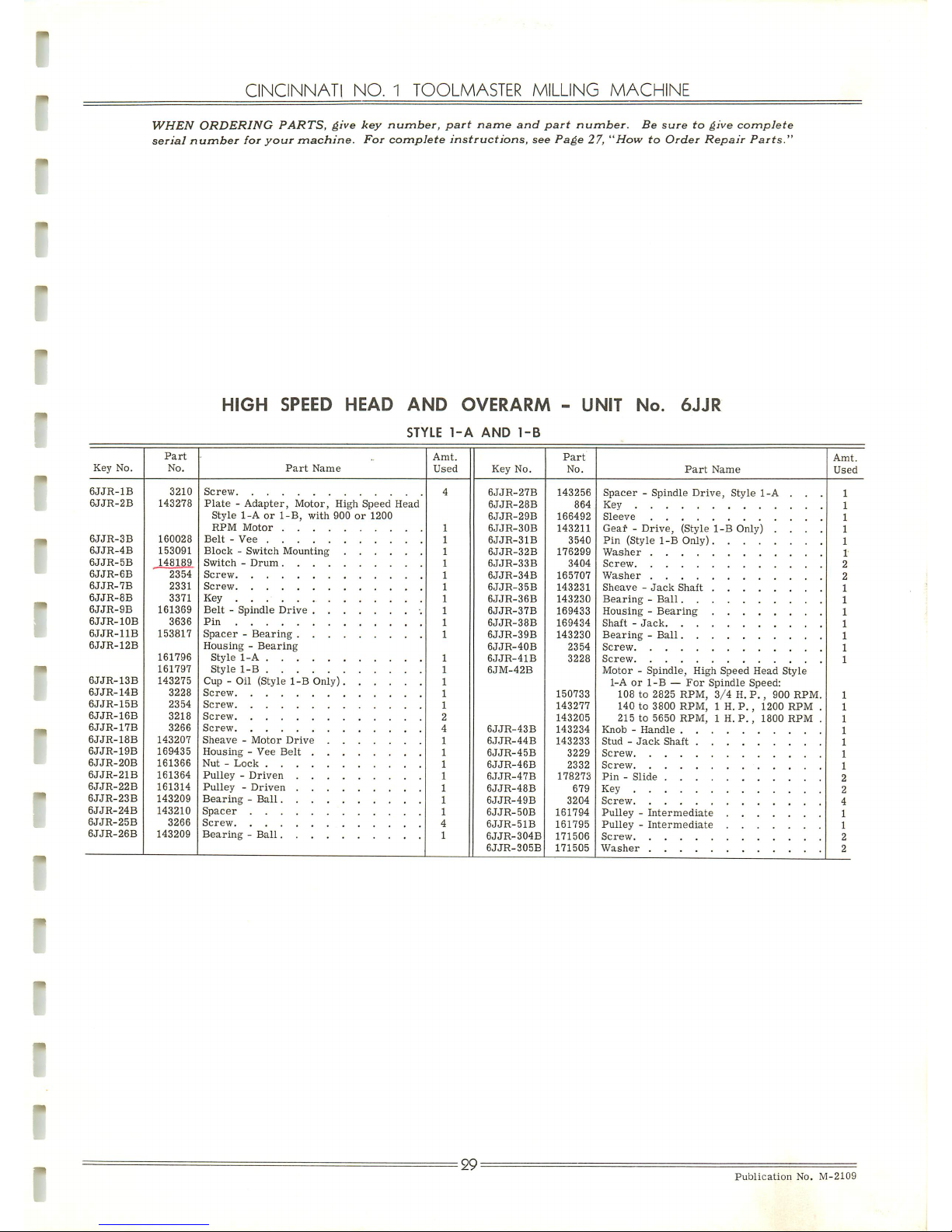

HIGH

SPEED

HEAD AND

OVERARM

(Unit

6JJR)....

HEAVY

DUTY

HEAD AND

OVERARM

(Unit

6JJS)

. . .

VARI-SPEED

HEAD AND OVERARM (Unit 6JKV). . . .

SADDLE-TABLE

(Unit

6JH)

KNEE (Unit 6JK)

COLUMN

(Unit

6JC)

COOLANT

PUMP

AND

PIPING

(Unit

6JP)

PRECISION MEASURING

EQUIPMENT

(Unit

6JJL).

. .

SHAPING

ATTACHMENT

(Unit

6JHF)

PLAIN,

SWIVEL AND UNIVERSAL VISES (Unit 6JKA)

INDEX

HEAD

AND

TAILSTOCK

(Unit

6JKA)

MACHINE

INSTRUCTION

PLATES

The

design

and

specifications

of

these

machines

are

subjecttochange

without

notice.

Page

18

19

19

19

20

20

21

21

22

22

22

23

23

24

24

24

25-26

27

29-41

43-53

55-67

69-77

79-89

91

91

93-95

97-99

101

103

105

Publication

No.

M-2109

Page 5

SERVICE

MANUAL

AND

PARTS

LIST

CATALOG

SPINDLE

DRIVE

MOTOR

TURRET

SWIVEL

LOCKING

NUTS

OVERARM

POSITIONING

PINION

SERIAL

NUMBER

PUSH

BUTTON

PANEL

TABLE

TRAVERSE

HANDWHEEL

KNEE

CLAMPS

SADDLE

CLAMP

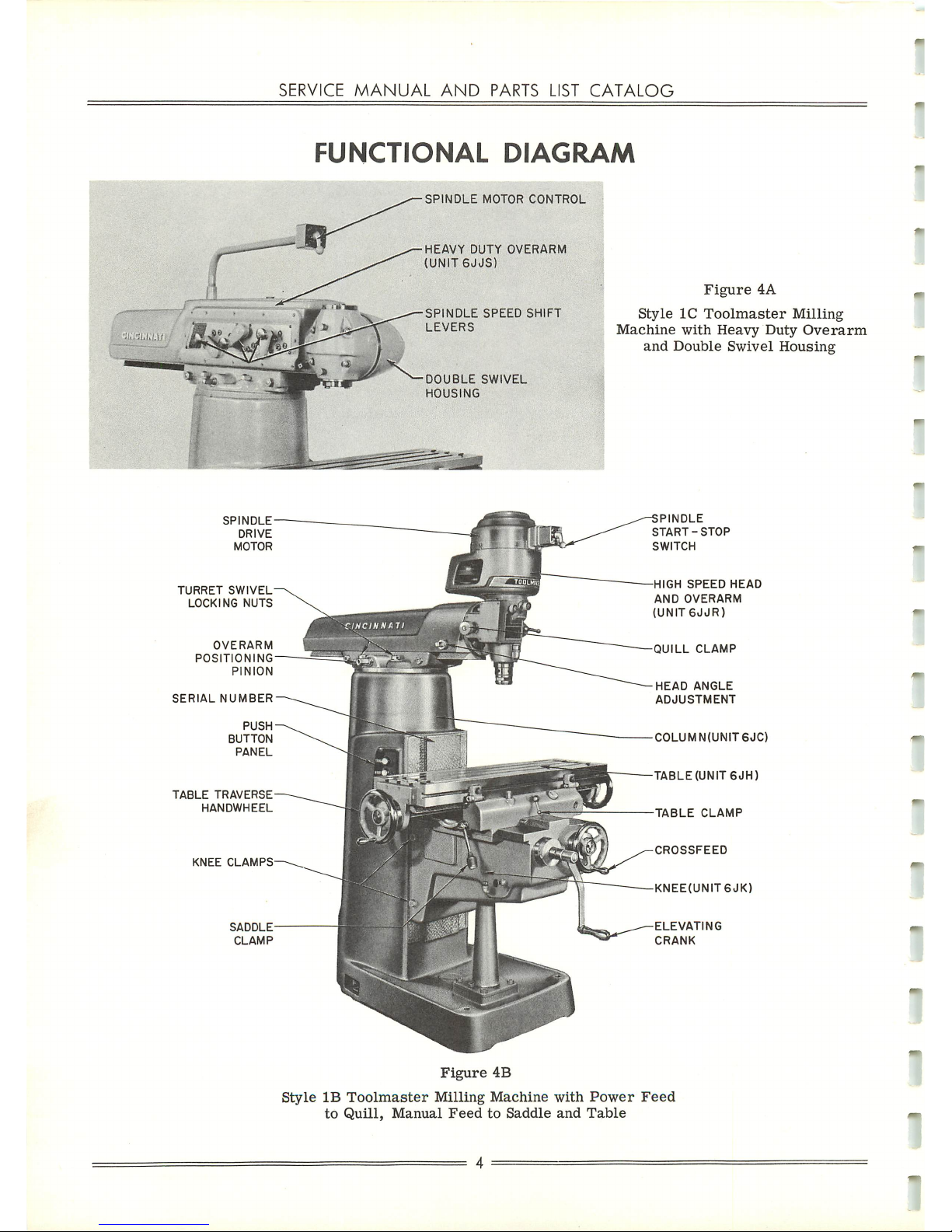

FUNCTIONAL

DIAGRAM

SPINDLE

MOTOR

CONTROL

HEAVY

DUTY

OVERARM

(UNIT6JJS)

SPINDLE

SPEED

SHIFT

LEVERS

DOUBLE

SWIVEL

HOUSING

Figure

4A

Style

1C

Toolmaster

Milling

Machine

with

Heavy

Duty

Overarm

and

Double

Swivel

Housing

PINDLE

START-STOP

SWITCH

HIGH

SPEED

HEAD

AND

OVERARM

(UNIT6JJR)

QUILL

CLAMP

HEAD

ANGLE

ADJUSTMENT

COLUMN(UNIT6JC)

TABLE

(UNIT

6JH)

TABLE

CLAMP

CROSSFEED

KNEE(UNIT6JK)

ELEVATING

CRANK

Figure

4B

Style

IB

Toolmaster

Milling

Machine

with

Power

Feed

to

Quill,

Manual

FeedtoSaddle

and

Table

Page 6

CINCINNATI

NO.

1

TOOLMASTER

MILLING

MACHINE

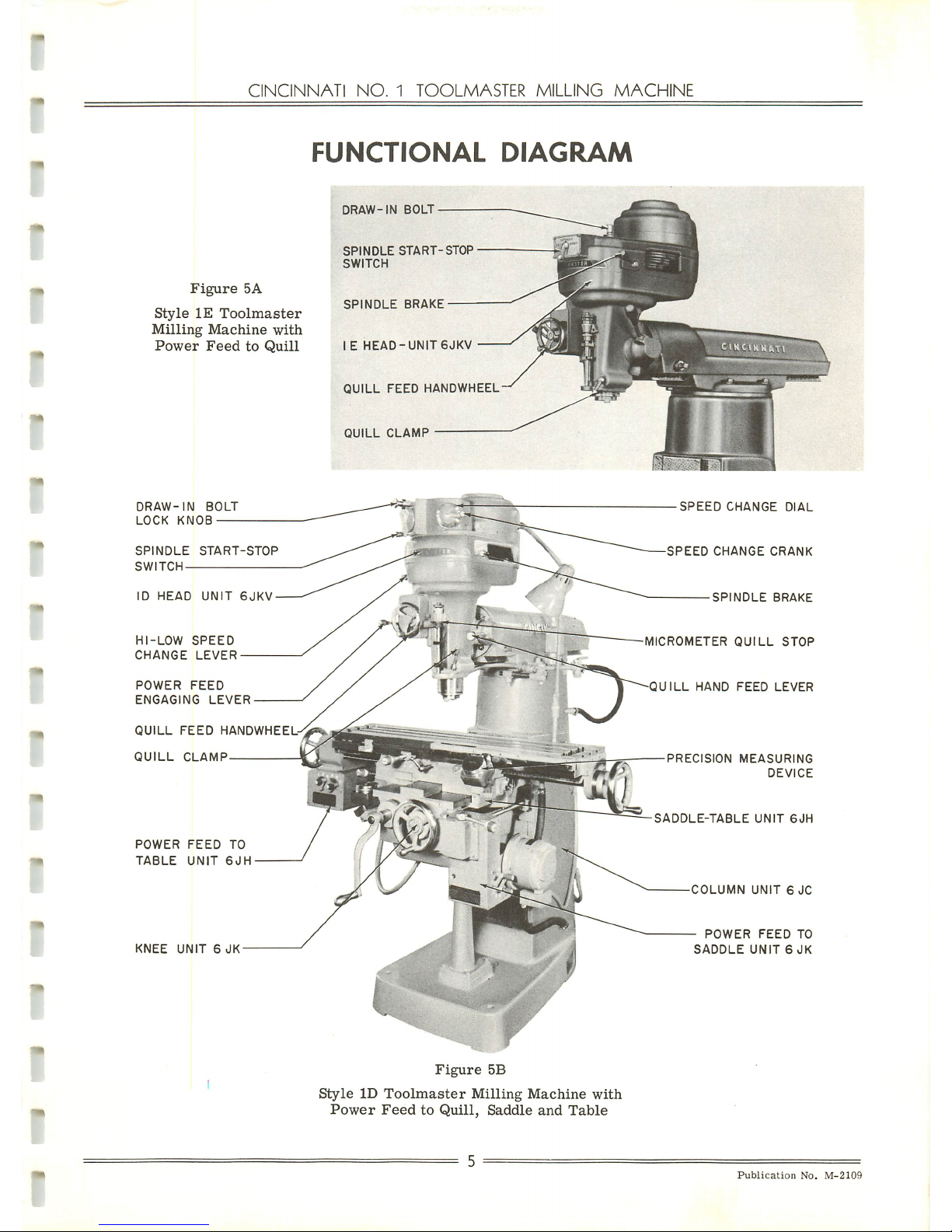

FUNCTIONAL

DIAGRAM

Figure

5A

Style

IE

Toolmaster

Milling

Machine

with

Power

Feed

to

Quill

DRAW-IN

BOLT

LOCK

KNOB

SPINDLE

START-STOP

SWITCH

ID

HEAD

UNIT

6JKV

HI-LOW

SPEED

CHANGE

LEVER

POWER

FEED

ENGAGING

LEVER

QUILL

FEED

HANDWHEEL-

QUILL

CLAMP

POWER

FEED

TO

TABLE

UNIT

6JH

KNEE

UNIT6JK

DRAW-IN

BOLT

SPINDLE

START-STOP

SWITCH

SPINDLE

BRAKE

IE

HEAD-UNIT

6JKV

QUILL

FEED

HANDWHEEL

QUILL

CLAMP

Figure

5B

Style

ID

Toolmaster

Milling

Machine

with

Power

FeedtoQuill,

Saddle

and

Table

Hi:

. \

SPEED

CHANGE

DIAL

SPEED

CHANGE

CRANK

SPINDLE

BRAKE

MICROMETER

QUILL

STOP

QUILL

HAND

FEED

LEVER

PRECISION

MEASURING

DEVICE

SADDLE-TABLE

UNIT

6JH

COLUMN

UNIT6JC

POWER

FEED

TO

SADDLE

UNIT

6JK

Publication

No.

M-2109

Page 7

SERVICE

MANUAL

AND

PARTS

LIST

CATALOG

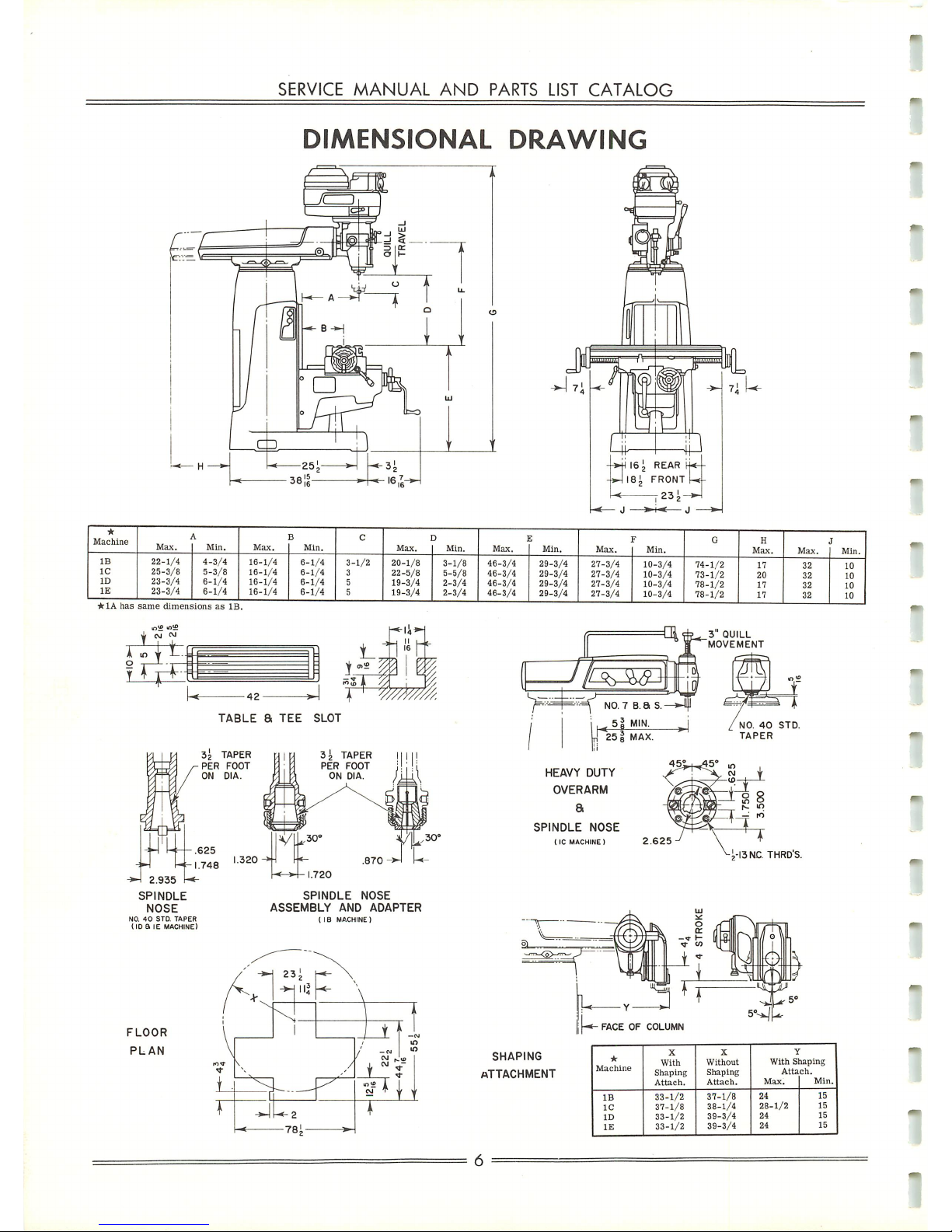

DIMENSIONAL

DRAWING

Machine

Max.

Min.

Max.

B

Min.

C

Max.

3

Min.

J

Max.

S

Min.

Max.

Min.

G

H

Max.

Max.IMin.

-

IB

1C

ID

IE

22-1/4

25-3/8

23-3/4

23-3/4

4-3/4

5-3/8

6-1/4

6-1/4

16-1/4

16-1/4

16-1/4

16-1/4

6-1/4

6-1/4

6-1/4

6-1/4

3-

3

5

5

1/2

20-1/8

22-5/8

19-3/4

19-3/4

3-1/8

5-5/8

2-3/4

2-3/4

46-3/4

46-3/4

46-3/4

46-3/4

29-3/4

29-3/4

29-3/4

29-3/4

27-3/4

27-3/4

27-3/4

27-3/4

10-3/4

10-3/4

10-3/4

10-3/4

74-1/2

73-1/2

78-1/2

78-1/2

17

20

17

17

32

32

32

32

10

10

10

10

*1Ahas

same

dimen.

ionsasIE

<•»

NO.40STD.

TAPER

(ID a IE

MACHINE)

FLOOR

PLAN

TABLE

a

TEE

SLOT

SPINDLE

NOSE

ASSEMBLY

AND

ADAPTER

( IB

MACHINE)

Ar

23^

-*-jll|

\

1

N

\

\

i

1 v

V 1

^

/

7

'i-

m

IO

ID

r

i_

^

1 -

i

— f i

r

^U-2

-*

78i

»~

1

Jx^J^i

^F^

NO.7b.as.

<5jMIN-

J

25 1 MAX.

HEAVY

DUTY

OVERARM

a

SPINDLE

NOSE

1IC

MACHINE)

2.625

SHAPING

ATTACHMENT

J.-13NC

THRD'S.

FACEOFCOLUMN

Machine

X

With

Shaping

Attach.

X

Without

Shaping

Attach.

With

S

Atta

Max.

Taping

ch.

Min.

IB

1C

ID

IE

33-1/2

37-1/8

33-1/2

33-1/2

37-1/8

38-1/4

39-3/4

39-3/4

24

28-1/2

24

24

15

15

15

15

Page 8

o

b

o

on

45.

O

b

3

3

ooo

45.

4=>

to

4i.

H-*

4=>

to

J>

CO

I—"

CO

Co

i-*

to

Co

i—'

NT

NT

h~i

to

NT

t—•

NT

H-»

i—•

i-.

•—.

m

co

•OJ

00

(n

1—i

to

i—*

*-*

en

to

to

-J

to

tn

-^t

CO

t—'

•—»

en

to

-OJ

•^J

OO

en

to

to

•-*

>—»

en

to

to

•^.l

i—'

cn

-J

OO

CO

M

en

to

H-»

-j

CO

cn

i—'

oo

1—1

I—i

\

\

~v

\

\ \ \

\

\ \ \ \ \

"V

-—

\

\

•"—,

*\

S

•^

•\

^^

\,

\.

\.

\^

\

\,

\

^

\

\^

\,

\

^

\,

*\

45.

Ol

to

fft

I—1

Ch

CO

(Ti

(TO

CT

co

Ol

H^

Ch

CO

Ch

NT

CT.

(o

Ch

1—i

CT,

CO

er

(XI

CT

CO

Ch

K-.

Ol

(o

o^

45.

CT,

co

Ch

1—'

CT

Co

CT

00

CT

OO

CT,

i—.

CT

OO

Ol

3

o

o-

<T>

-J

45.

to

45.

CT

4*

to

45.

45.

NT

4»

iDl

4i

NT

4^

4i

to

45.

CTi

45.

NT

45.

45.

to

45.

Ol

45.

NT

45.

45.

NT

45-

Ol

45.

to

45.

45.

NJ

45.

Ol

45.

NJ

45.

-0

~J

^1

Ch

Ch

or

Ch

Or

m

On

en

ejr

CJT

en

tn

cn

*.

45.

45.

45.

45.

45.

OO

Oo

CO

00

oo

CtJ

NT NT

NT

NT

NT

NT

NT

I—.

>-.

H-

h-'

1—'

H-'

o O

o o O

O

Cn

00

t—1

O

00

-J

on

45.

to

O

to

^j

CTl

4^

CO

i—*

O

00

(T,

en

CO

NT

O

to

-J

en

45.

NJ

I-*

to

(X)

CTl

en

CO

1—*

o

(TO

-o

cn

-(5-

to

O

to

^J

CT

45.

OO I—*

0)

O 45.

00

00

-J

i—i

Ol

O

en

to

CO

00

NT

<-^

i—•

en

e->

45-

on

CO

--.1

HI

CTi

o

tn

tn

to

oo

NT

CT,

H-»

en

O

45.

OO

to

-o

>—'

CT

O

On

to

0O

oo

NJ

Ol

1—1

On

o

5

oo

>—*

On

to

CO

Ch

O 45.

oo

H-'

On

to

CO

Or

O

45.

00

i—'

on

to

CO

Ch

O

-p.

00

i—.

C/l

to

Oo

CT

o 45.

00

I-.

On

to

OO

Ol

O

45.

00

i—.

cn

to

co

Ol

lO

00

co

^J

^0

-0

Ch

Ch

on on

On

45.

4^

CO

CO CO

to to

h-'

I—.

h-*

o O

to

to

to

00

oo

-J

•<]

-0

CT

CT

On

On

cn

45.

45.

CO

oo

CO

to

to

H-»

I—.

i-i

o

o

§

O

rr

NT

00

45.

o

Ch

to

OO

45.

e-r

CT,

NT

00

4*

O

-OJ

CO

to

en

h-*

-o

CO

to

CJl

i—,

•~J

CO

to

cn

H-1

^j

to

to

cn

I—.

^J

CO

to

On

t—1 •^T OO

to

cn

I—.

^T

Co

on

(/i

tn

en

cn

Ol

Ch

-J

•o.

-4

00

00

fX)

to to

to

O a

o

O

>-•

h-1

1-^

NT

to

ro

OO

0o

co

45.

45.

45.

en

On

cn cn

cn

CT

CT,

•^l

^t

•-J

00

oo

00

CO

to

to

~"\

O

CO

Ol

to

to

cn

00

i—•

en

0O

>—•

45.

•^J

e-r

to

Or

o

(o

CT.

to

NT

cn

CXI

1—.

C/l

oo

t-»

45.

^j

O

00

or

O

OO CT,

liJ

to

cn

oo

i—'

on

00

)-.

45.

-^J

o

OO

Ol

§

o

1-*

to

4>

On

Ch

^J

to

O

i—1

NT

4>

On

e^

•-]

to

o

h-*

to

45.

on

O-i

~J

to

o

H-*

NT

45.

cn

CT,

-J

to

o

H-*

NJ

45.

en

CT,

^j

to

O

t—'

NJ

-(5.

on

Ol

^J

to

<Tl

CO

CT,

k~»

en

ro

en

en

NJ

tn

i—i

cn

NJ

45.

CO

t—»

I—1

en

to to

^-t

--J

cn

^)

CO

OO

h-.

On

to

oo

00

00

CO

to

to

KT

to

NT

to

NT

NT

NT

NT

\

\

^^

\

—.

\^

-\

\

^s

*\

*-s^

^

*\

~v.

*\

Co

to

)—I

O

to

Of)

-0

Ol

en

45.

CO

NT

H-1

o

to

OS

^J

Ch

en

4i

CO

to

1—.

o

to

to

~J

CT

On

4>

OO

NT

1-^

(T

CO

Ch

K-1

CT

CO

CT,

oo

CT

OJ

OT

1—1

CT

OO

Ol

3

o

n

45.

NT

45.

o^

45.

to

45- 45.

NJ

45.

CT

45.

NJ

45.

to

to

to

tn

to

to

00

00

oo

00

00

00

•~o

^J

•~o

on

CTl

en

(O

NJ

a

to

^4

en

45.

NJ

1—1

tiJ

00

Ol

45.

00

to

•~o

M

Ch

O

cn

to

0J

(X)

NJ

OT

H-1

On

45.

00

h-»

cn

to

Oo

Ch

O 45-

CO

1—»

cn

to

OO

Ol

00

oo

-OJ

-o

o

*0J

Ch

Ch

Ch

CT

en

en

en

en

4i

•£>

4i

45.

to

CO

CO

(O

NT

ro

NT

NT

1—'

i—•

h-'

^—'

CO

00

or

CO

>—•

00

Ch

to

©

oo

en

CO

e-T

r»

en

00

O

00

en

(O

o

^J

cn

to

o

•^1

en

NJ

O

^J

en

NT

NT

NJ

NT

ro

NJ

ro

NJ

NJ

ro

NJ

NJ

NJ

NJ

1—1

h-i

00

to

*o.

to

Ch

M

On

CD

on

to

4*

OO

CO

CO

to

~J

\—>

em

I—.

<-n

o

45.

to

45.

cx>

CO

•~J

to

-~J

h-i

or

o

e-n

cn

45.

45.

oo

CO

OO

ro

NT

i—*

M

•—'

O

CJ

to

to

§

to

00

45.

r->

Ch

to

OO

4*

o

or

to

oo

4^

e-T

CTl

NT

t>0

45.

o

CT,

to

oo

45.

O

CT

NT

00

45.

O

Ch

NT

00

45. O

(T,

NT

on

45.

©

CT

n;

oo

45.

o

CT

NJ

00

45.

o

o o O ©

O

o o

o

<o

<o

o O O O

O

o

o

o O

e-T

o O O

o

o o

o

o o

o o

O

o

O

o

>—•

1—'

H-

NJ

NJ

NJ

OO

oo

CO

45.

45.

45.

^\.

o

©

o

o

o

o

o o o O O

o

o

o

o

o o

O

o

O

a o

a O

o

o O

O o O

o

o

o

CO

Ch

tn

NJ

On

OO

1—»

cn

00

I—.

45.

^1

e_> OO

Ol

g

o

1—.

NJ

45.

en

O-i

^J

to

o

I—1

NJ

45.

cn

Ol

to

00

00

•-0)

-o;

-J

-0.

-0

-o

~0

-OJ

~J

-o

o>

Ch

Ch

Ch

rr,

Ch

CT,

Ch

Ch

CT

cn cn

cn

cn

en

en

en

en

tn

en

45.

45.

45>

45.

4^

45.

45.

45.

45.

45- CO

OO

CO

oo

OO

00

>—i

3

n

t—*

o

to

00

•"J

Ol

On

4»

00

to

*-*

o

to

oo

-J

Ch

On

45- OO

NT

I—.

O

to

oo

•^J

Ch

cn

45.

CO

NT

>—•

o

to

00

-J

CT

cn

45.

OO

NJ

OJ

to

oo

Ol

cn

45.

3-

n

to

o

to

o

to

O

to

to

tn

to

oo

00

00

GO

•~J

-Oj

•OJ

-o

ch

(T.

CT,

CT,

en en

on

45.

45.

45.

45.

CO

to

co

to

NT NT

NT

NT

h->

h-.

(—*

)-*

o

o o

O

to to

to

to

co

00

On

00

<->

00

en

CO

o

-oj

en

to

O

^1

en

to

O

~~4

en

NT

o

^l

45.

NT

to

^o

45.

NT

to

^J

45.

NT

to

-0

45.

l—i

to

fT

45.

h-»

to

CT,

4f

i—1

to

Ul

oo

^

00

Ol

%

-0

to

Ch

1—*

On

o

on

to

4»>

00

OO

oo

to

-Ol

t-*

Ch

H-»

ejr

o

45.

to

45.

OO

OO

~J

NT

-0

I—1

CT, O

cn

O 45-

CO

CO

00

OO

-^1

NJ

Ol

}—•

0)1

c_>

on

to

45.

to

CO

45.

O

Ch

ro

00

4=»

O

Ol

to

oo

45.

o

CTl

NT

oo

4±

o

Ch

NT

00

45. O

or

NT

00

a

o

Ch

NT

00

45.

<n

CT

NT

OO

45.

O

CT

NT

00

45.

o

er

ro

00

45.

o

Oi

%

o

o

o

o o o

o

o o o O

o O

O o

O

o

o

o

o

O o o o

o

o o O

CT

o

O

o

O o

o

O o O O

e_)

e_)

e_J

e_)

o

e_)

O o

OJ

O o

o

o

to

to

to

to

to

NT

to

to

to

NT

O

e-T

o

o

O

o

o

O

rr

o

to

to

to

to

tn

to

tn

tn

to

to

oa

OO

oo

OO

CO

00

oo

oo

•—i

3

n

to

co

-J

cr

On

4*

oo

to

M o

to

00

^J

e^

CJl

42.

CO

to

,—'

o

to

00

^1

er

eji

45.

Oo

NT

h-«

o

to

CO

-J

CT,

On

45.

00

NT

O

to

oo

^j

Ul

Ul

45.

CO

to

3"

n>

CO

oo

00 00

CO

CO

00

CO

CO

to

CO

to

to

NT

NT

NT

NT

NT

ro

NT

NT

NT

NT

IO

NT

NT

NT

NT

NT

NT

NT

NT

NT

NT

N.

NT

NJ

NT

NT

NT

ro

NJ

to

NT

NT

NT

NT

to

ro

to

to

to

NT

M

1—i

1—'

O

O

n

o

tn

tn

tn

tn

(XT

(X)

(X)

00

•^J

^-1

-0

~J

Ch

CT

er

Ch

en

en

en

en

45.

45.

45.

45.

(O

Oo

OO

OO

NJ

NJ

NJ

1-^

h-•

i—i

o

§

-o.

Cn

to

o

•OJ

45.

to

to

-oj

45.

NT

tn

•»)

4^

NT

to

•-4

4=>

>—'

to

IT,

45*

1—>

tn

en

45.

•-»

ten

CT

-P.

M

oo

Ch

CO

1—»

00

Ch

CO

K

on

Ol

OJ

O

00

on

OJ

e_J

00

Ol

\-*

On

o

On

to

45.

00

CO

oo

NT

•~j

i—»

Ch

H-*

on

O

J>

to

45.

(50

CO

-o

to

^j

H-»

eTi

o

cn

O

4>

to

CO

00

CO

•^1

NT

or

H^

or

c_J

to

45.

tu

Oo

OO

"^

Ol

to

00

45.

O

Ol

ro

00

45.

o

Ch

ro

oo

4*

o

Ch

NT

00

45.

O

Ch

NT

ca

-P^

c

en

NT

oo

45.

e-T

CT

NT

00

45.

e-r

CT

NT

00

45.

o

er

NT

00

45.

o

CT

NT

00

§

o

o O O o

o

o o O

o

o

o o o o

O

O o

O

O

o

O o o

o

o

o

o O O

O o

o O

O O

O

o

o

o

OJ

OJ

t_l

t_l

e-J

o

-J

-OJ

-J

-J

-J

»a

rn

Ch

Ch

Ch

(T.

Ch

Ch

Ch

Ch

CT.

cn

en

en

en en

cn

Ol

en

en

en

45.

45.

.J>

45.

45.

45.

45.

45.

45.

45.

CO

CO

CO

to

CjJ

OJ

OO

CjJ

OO CO

3

Cn

45.

Oo

to

H^

o

to

oo

^j

Ch

On

-f^

OO

to

1—'

o CO

00

-J

CTi

cn

45.

00

to

H-.

o

to

OO

-o

Ol

on

45.

U)

NT

!—•

c_>

to

oo

u,

45.

OJ

i—i

©

3"

CA

..!>

*>

J>

45.

45.

4*

45.

45. 45.

4*

4^

4^

4^

4i.

4i

45.

45.

45.

co

CO

(.jj

CO

oo

CO

CO

co

to

CO

co

OO

00

OO

CO

OO

OO

CO

OJ

CO

co

CO

CO

CO

00

CjJ

0O

oo

4>

45.

to

(O

00

CO

to

ro

NT

NT

t—'

i—1

t-*

t—'

O O O

O

to

tn to

to

00

(XI

oo

<X1

-.1

^l

•^i

^)

er

Ch Ch

CT

en

cn

cn

cn

45.

4^

45.

-15.

oo

0o

g

45.

to

Ol

45. I—1

to

oi

45.

1—«

to

CTl

J>

H-

(»

Ol

00

(-.

(TO

Ch

CO

•-'

00

en

CO

i—•

oo

en

CO

o

oo

en

CO

O

(XI

cn

OJ

o

NJ

o

CJl

NJ

o

On

to

45.

00 00

oo

to

~o

t—•

Ch

M

eji

o

4^

to

4*

00

OO

-J

NT

^J

V-«

CT,

o

On

o

45.

to

CO

oo

OO

~J

NT

CT

1—*

O-i

o

cn

to

4^

to

CjJ

oo

£

O

m

NT

00

45.

e->

Ch

NT

no

4±

O

ai

NT

00

4^.

O CT,

NT

00

45.

O

n\

NT

00

45. o

CT

NT

on

455.

(->

Ol

ro

00

45-

o

CT

to

oo

45.

O

CT,

NJ

00

45.

o

o o o o o o ©

O

o O

O

o O

O O

O O

O o o o

o

o

o

o

o

O

O

o

O

O

o o

o

O

o

O

C-J

t_j

OJ

0J

O

c_>

OJ

l_T

o

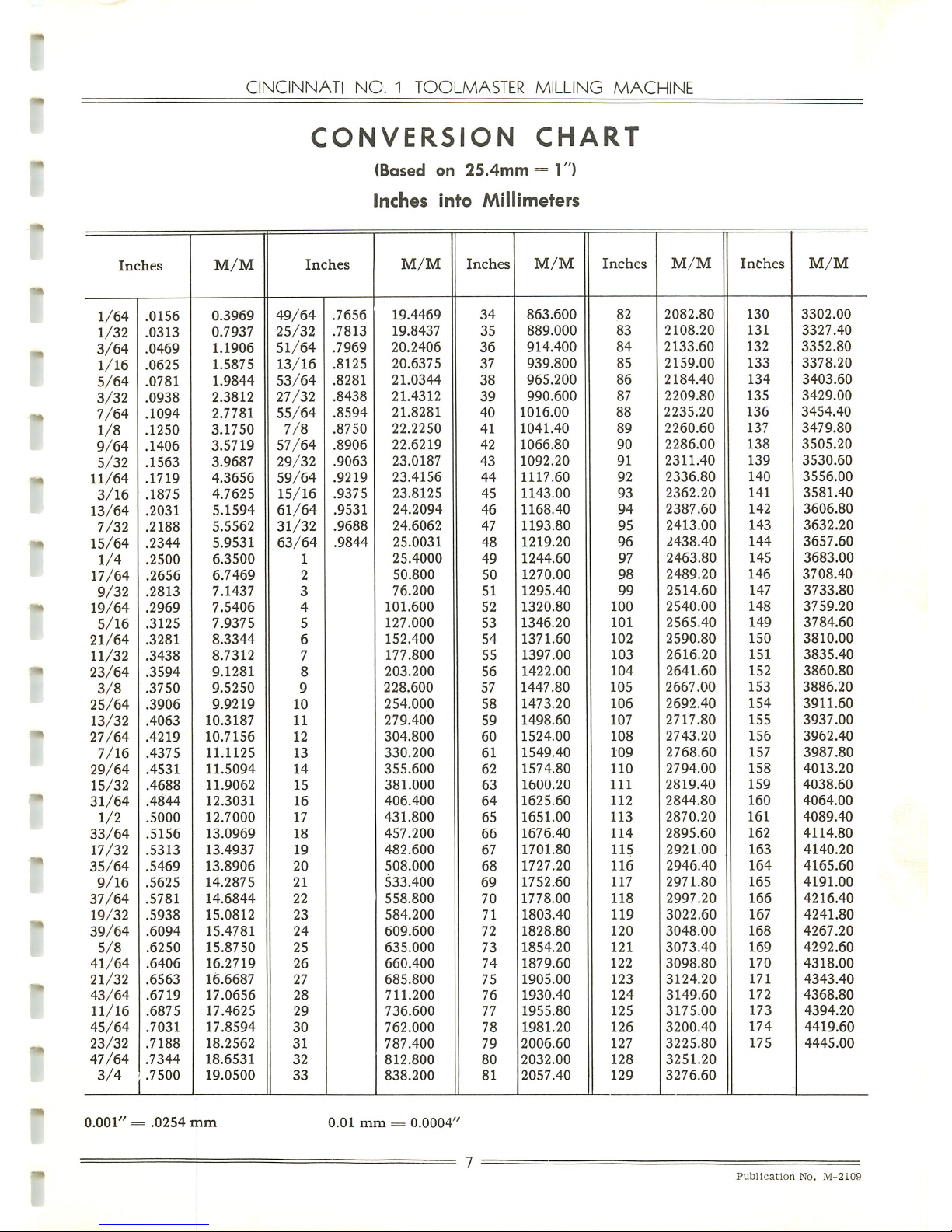

3

00

n a

• S^

u>

"-

— O

3 3

O

K>

= 3

|

II

O

to

n

>

7*

n

znz

z

>

O

O

O

>

o

>

o

Page 9

SERVICE

MANUAL

AND

PARTS

LIST

CATALOG

LUBRICATION

DIAGRAMS

OIL

LEVEL

GAGE

FOR

STATION

|6

IC

MACHINE

OIL

LEVEL

GAGE

FOR STATION

|4

SHAPING

ATTACHMENT

16

POWER

FEED

TO

TABLE

AND

SADDLE

OIL

LEVEL

GAGE

FOR

STATION

4

ONE

SHOT

PLUNGER

FOR

STATION

4

OIL

LEVEL

GAGE

FOR STATION

|5

Publication

No.

M-2109

Page 10

CINCINNATI

NO.

1

TOOLMASTER

MILLING

MACHINE

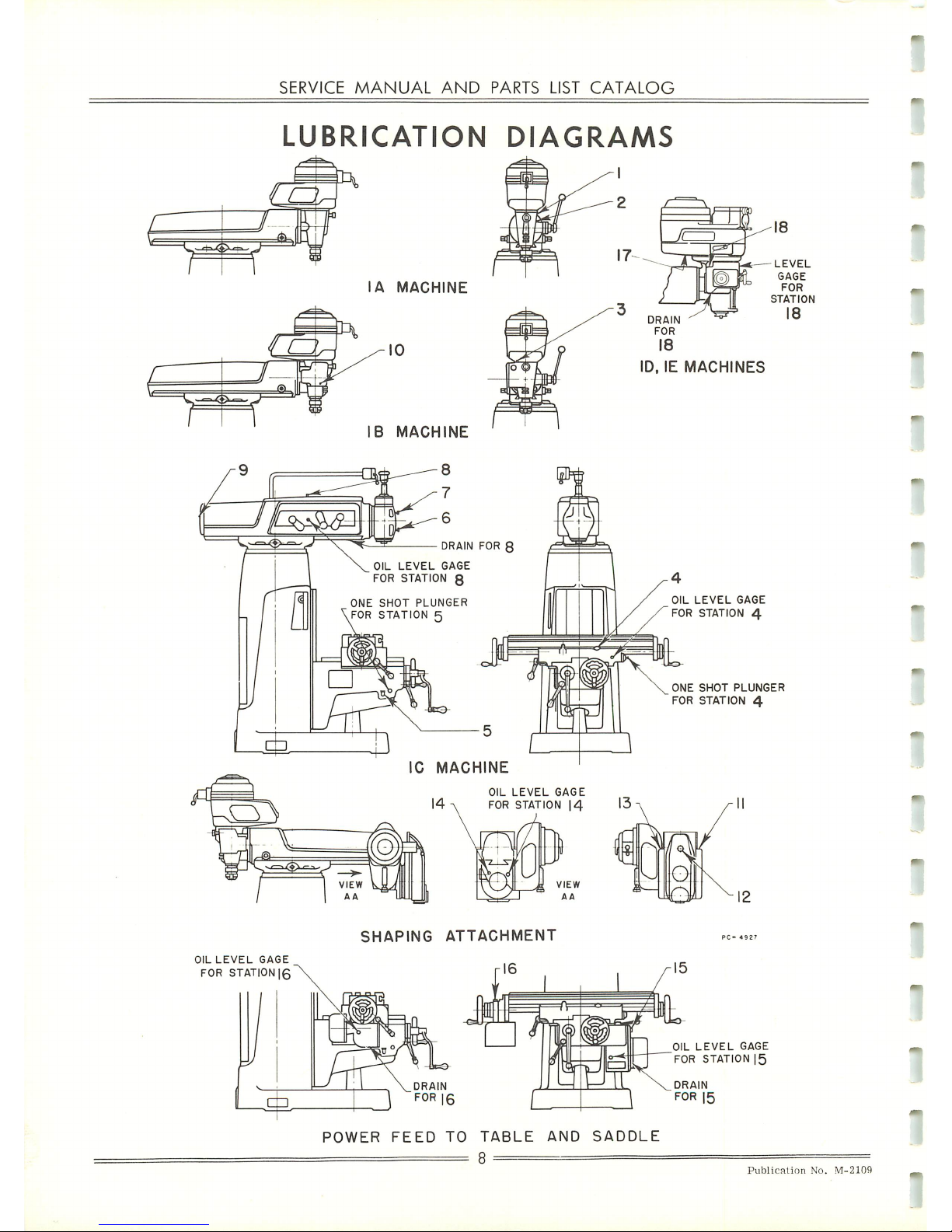

LUBRICATION

INSTRUCTIONS

and

SPECIFICATIONS

(See

diagrams

opposite

page)

Thoroughly

oil

all

moving

parts

as

they

are

installed,

then

lubricate

all

principal

points

as

listed

below

before

starting

motor.

Periodic

and

thorough

lubrication

with

correct

lubricant,

as

specified,

will

help

to

maintain

the

long

life

and

accuracy

built

into

each

machine.

The

intervals

listed

are

based

onanormal

eight

hour

day.

PURCHASE

LUBRICANTS

FROM

RELIABLE

DEALERS

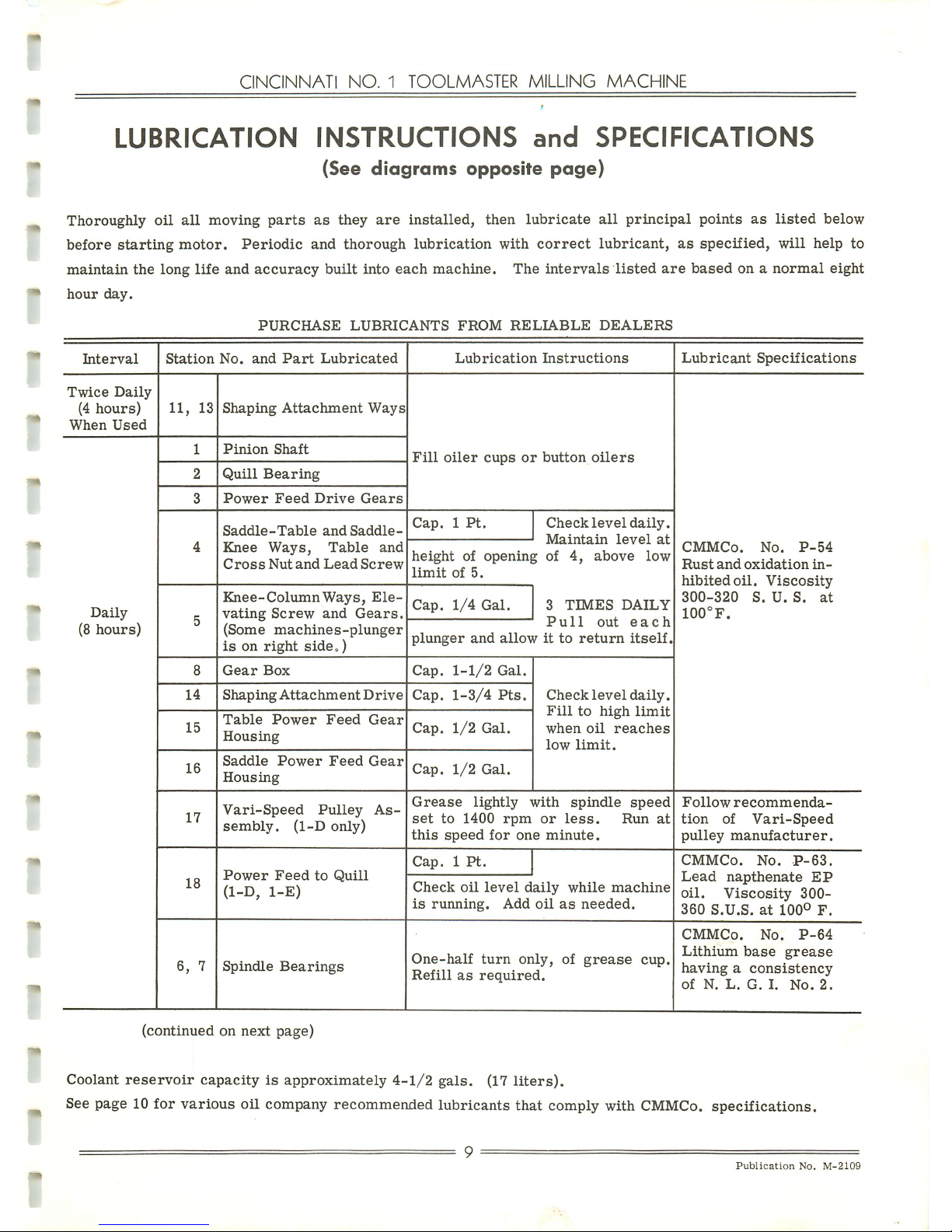

Interval

Twice

Daily

(4

hours)

When

Used

Daily

(8

hours)

Station

No.

and

Part

Lubricated

11,

13

14

15

16

17

18

6,

7

Shaping

Attachment

Ways

Pinion

Shaft

Quill

Bearing

Power

Feed

Drive

Gears

Saddle-Table

and

Saddle-

Knee

Ways,

Table

and

Cross

Nut

and

Lead

Screw

Knee-Column

Ways,

Ele

vating

Screw

and

Gears.

(Some

machines-plunger

isonright

side

„)

Gear

Box

Shaping

Attachment

Drive

Table

Power

Feed

Gear

Housing

Saddle

Power

Feed

Gear

Housing

Vari-Speed

Pulley

As

sembly.

(1-D

only)

Power

Feed

to

Quill

(1-D,

1-E)

Spindle

Bearings

Lubrication

Instructions

Fill

oiler

cupsorbutton

oilers

Cap.1Pt.

Check

level

daily.

Maintain

level

at

height

of

opening

of

4,

above

low

limit

of

5.

Cap.

1/4

Gal.

Cap.

1-1/2

Gal.

Cap.

1-3/4

Pts.

Cap.

1/2

Gal.

Cap.

1/2

Gal.

3

TIMES

DAILY

Pull

out

each

plunger

and

allowitto

return

itself.

Check

level

daily.

Fill

to

high

limit

when

oil

reaches

low

limit.

Grease

lightly

with

spindle

speed

set

to

1400

rpm

or

less.

Run

at

this

speed

for

one

minute.

Cap.1Pt.

Check

oil

level

daily

while

machine

is

running.

Add

oilasneeded.

One-half

turn

only,

of

grease

cup,

Refill

as

required.

Lubricant

Specifications

CMMCo.

No.

P-54

Rust

and

oxidation

in

hibited

oil.

Viscosity

300-320

S.U.S.

at

100°F.

Follow

recommenda

tion

of

Vari-Speed

pulley

manufacturer.

CMMCo.

No.

P-63.

Lead

napthenate

EP

oil.

Viscosity

300-

360

S.U.S.at100°

F.

CMMCo.

No.

P-64

Lithium

base

grease

havingaconsistency

of

N.

L.

G.

I.

No.

2.

(continued on next page)

Coolant

reservoir

capacityisapproximately

4-1/2

gals.

(17

liters).

See page 10

for

various

oil

company

recommended

lubricants

that

comply with CMMCo.

specifications.

9

Publication

No.

M-2109

Page 11

SERVICE

MANUAL

AND

PARTS LIST

CATALOG

LUBRICATION

INSTRUCTIONS

and

SPECIFICATIONS

(See

diagrams,

page

8)

Interval

Station

No.

and

Part

Lubricated

Lubrication

Instructions

Lubricant

Specifications

Weekly

12

Shaping

Attachment

Pit

man

Arm

Bearings

2 to 3

strokes

from

a

hand

gun.

(Approx.

1/2

oz.)

CMMCo.

No.

P-64.

(See

page

9.)

(48

hours)

10*

Quill—Power

Feed

(1A,

IB)

Cap.1Pt.

CMMCo.

No.

P-54.

(See

page

9.)

Periodically

9

Motor

Bearings

Lubricate

all

motors

only

according

to

motor

manufactur

er's

recommendations.

DO

NOT

OVERLUBRICATE.

*Tilt

spindle housing 30° toward right to fill or check oil level. At 30° angle, the oil level should be even

with hole. To drain,

rotate

housing

70°—80°

to left. (1-A, 1-B)

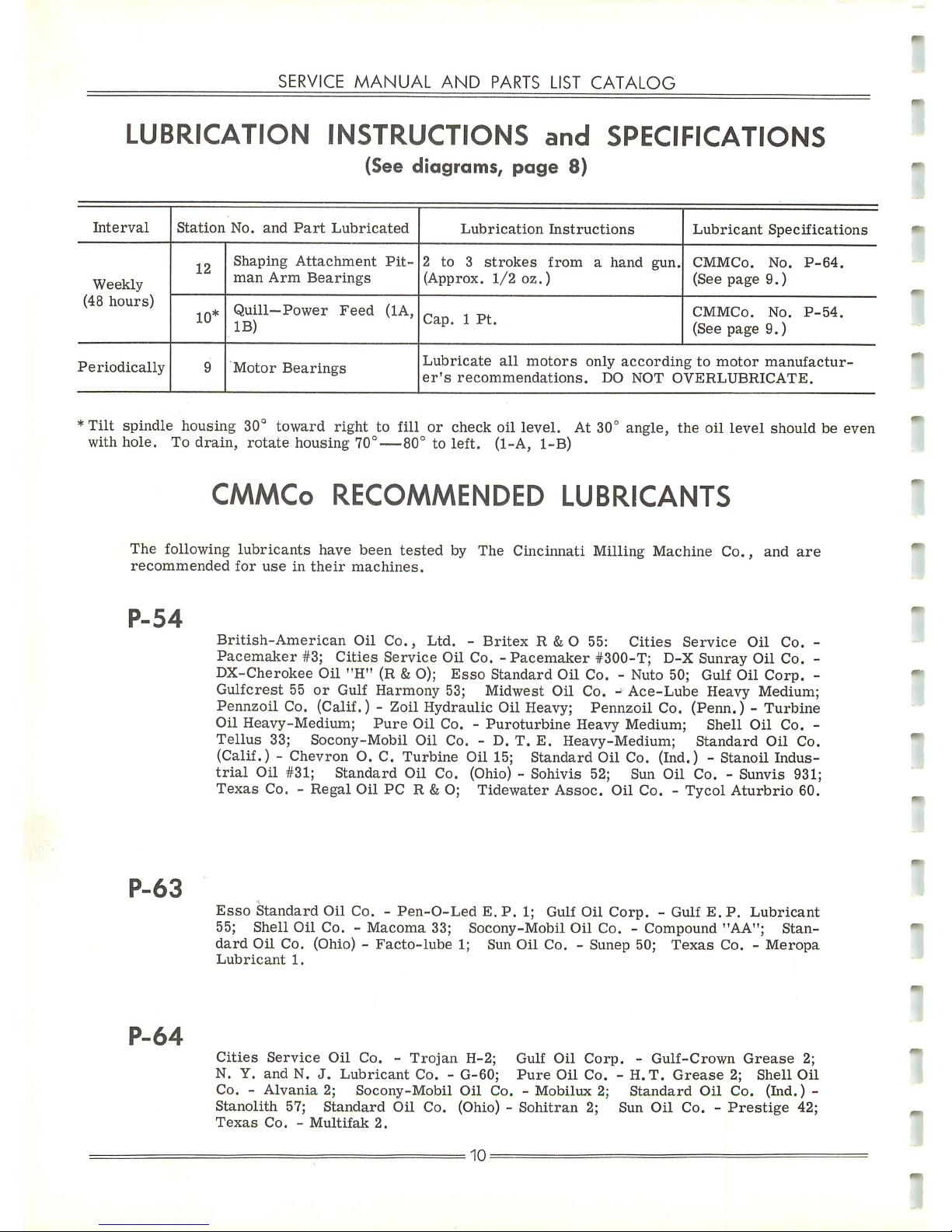

CMMCo

RECOMMENDED

LUBRICANTS

The

following

lubricants

have

been

tested

by The Cincinnati Milling Machine Co.

recommended

for

useintheir

machines.

and

are

P-54

P-63

P-64

British-American

Oil

Co.,

Ltd.-Britex

R & O 55:

Cities

Service

Oil

Co.

-

Pacemaker

#3;

Cities

Service

Oil Co.

-Pacemaker

#300-T; D-X Sunray Oil Co. -

DX-Cherokee Oil "H" (R &O);

Esso

Standard Oil Co. - Nuto 50; Gulf Oil Corp. -

Gulfcrest

55

or

Gulf Harmony 53; Midwest Oil Co. -

Ace-Lube

Heavy Medium;

Pennzoil Co. (Calif.) - Zoil Hydraulic Oil Heavy; Pennzoil Co. (Penn.) - Turbine

Oil

Heavy-Medium;

Pure

Oil

Co. -

Puroturbine

Heavy Medium;

Tellus

33;

Socony-Mobil

Oil

Co. - D.T.E.

Heavy-Medium;

(Calif.) - Chevron O. C. Turbine Oil 15; Standard Oil Co. (Ind

trial

Oil

#31;

Standard

Oil Co. (Ohio) - Sohivis 52; Sun

Oil

Shell

Oil

Co.

-

Standard

Oil

Co.

) -

Stanoil

Indus-

Co.-Sunvis

931;

Texas

Co. -

Regal

Oil

PC

R & O;

Tidewater

Assoc.

Oil

Co.-Tycol

Aturbrio

60.

Esso

Standard

Oil

Co.-Pen-O-Led

E.P.1; Gulf

Oil

Corp.

- Gulf E.P.Lubricant

55;

Shell

Oil

Co. -

Macoma

33;

Socony-Mobil

Oil

Co. -

Compound

"AA";

Stan

dard

Oil Co. (Ohio) -

Facto-lube

1; Sun Oil Co. - Sunep 50;

Texas

Co. -

Meropa

Lubricant

1.

Cities

Service

Oil

Co.-Trojan

H-2;

N. Y.

andN.J.

Lubricant

Co.-G-60;

Co.-Alvania

2;

Socony-Mobil

Oil

Co.-Mobilux

2

Stanolith

57;

Standard

Oil

Co. (Ohio) -

Sohitran

2;

Texas

Co.-Multifak

2.

10

=

Gulf

Oil

Corp.

-

Gulf-Crown

Grease

2;

Pure

Oil

Co.-H.T.

Grease

2;

Shell

Oil

Standard

Oil

Co.

(Ind.)

-

Sun

Oil

Co.-Prestige

42;

Page 12

CINCINNATI

NO.

1

TOOLMASTER

MILLING

MACHINE

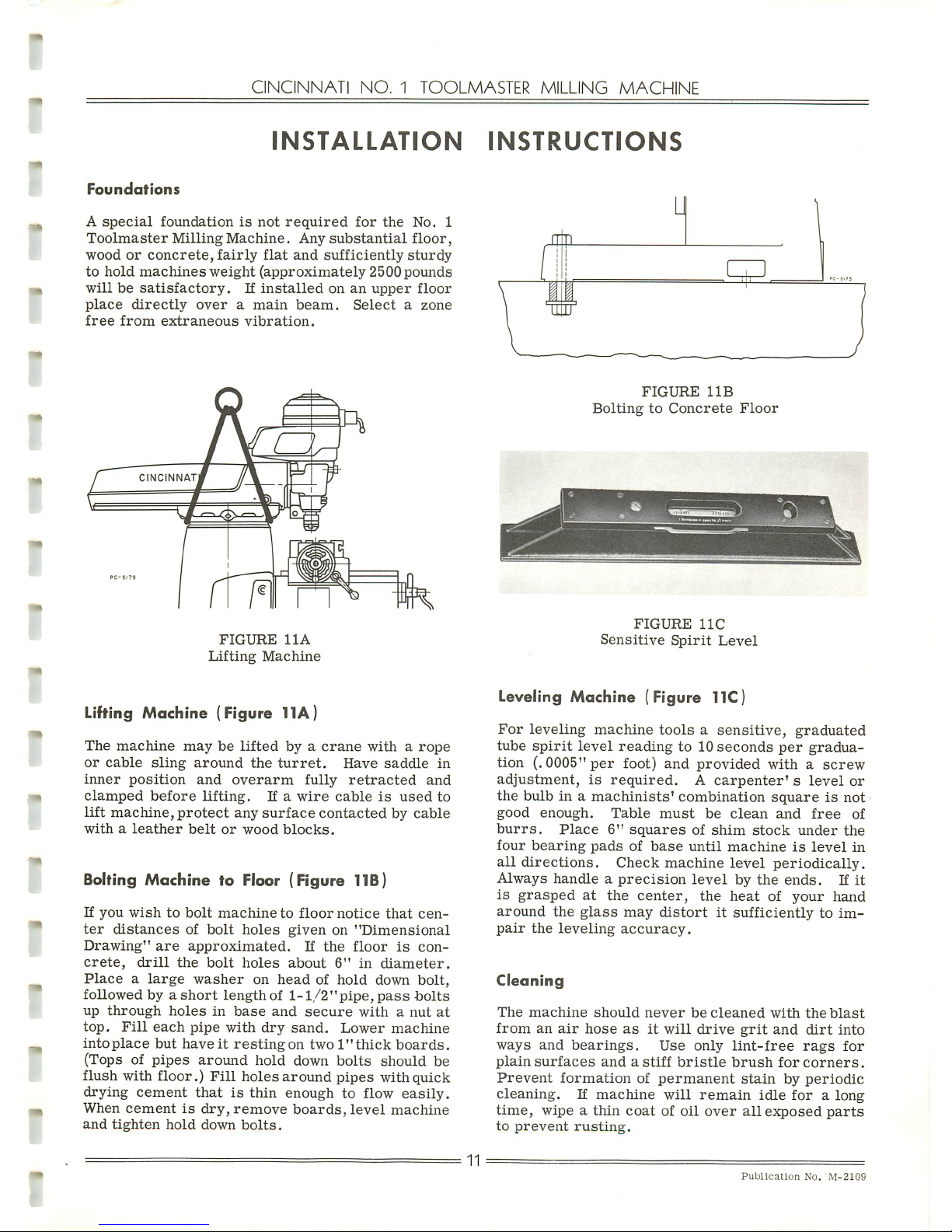

INSTALLATION

INSTRUCTIONS

Foundations

A

special

foundation

is

not

required

for

the

No.

1

Toolmaster

Milling

Machine.

Any

substantial

floor,

woodorconcrete,

fairly

flat

and

sufficiently

sturdy

to

hold

machines

weight

(approximately

2500

pounds

willbesatisfactory.

If

installed

onanupper

floor

place

directly

overamain

beam.

Select

a

zone

free

from

extraneous

vibration.

FIGURE

11A

Lifting

Machine

Lifting Machine (Figure 11A)

The

machine

maybelifted

byacrane

witharope

or

cable

sling

around

the

turret.

Have

saddle

in

inner

position

and

overarm

fully

retracted

and

clamped

before

lifting.

If a

wire

cable

is

used

to

lift

machine,

protect

any

surface

contacted

by

cable

withaleather

belt

or

wood

blocks.

Bolting

Machine

to Floor (Figure TIB)

If

you

wishtobolt

machinetofloor

notice

that

cen

ter

distances

of

bolt

holes

given

on

"Dimensional

Drawing"

are

approximated.

If

the

floor

is

con

crete,

drill

the

bolt

holes

about

6"

in

diameter.

Placealarge

washer

on

headofhold

down

bolt,

followedbya

short

lengthof1-1/2"pipe,

pass

bolts

up

through

holes

in

base

and

secure

withanut

at

top.

Fill

each

pipe

with

dry

sand.

Lower

machine

into

place

but

haveitresting

on

two

l"thick

boards.

(Topsofpipes

around

hold

down

bolts

should

be

flush

with

floor.)

Fill

holes

around

pipes

with

quick

drying

cement

thatisthin

enough

to flow

easily.

When

cementisdry,

remove

boards,

level

machine

and

tighten

hold

down

bolts.

11

FIGURE

11B

Bolting

to

Concrete

Floor

FIGURE

11C

Sensitive

Spirit

Level

Leveling Machine (Figure TIC)

For

leveling

machine

toolsasensitive,

graduated

tube

spirit

level

reading

to 10

seconds

per

gradua

tion

(.0005"

per

foot)

and

provided

withascrew

adjustment,

is

required.

A

carpenter'

s

level

or

the

bulbina

machinists'

combination

squareisnot

good

enough.

Table

must

be

clean

and

free

of

burrs.

Place

6"

squares

of

shim

stock

under

the

four

bearing

pads

of

base

until

machineislevel

in

all

directions.

Check

machine

level

periodically.

Always

handleaprecision

level

by

the

ends.

If

it

is

grasped

at

the

center,

the

heat

of

your

hand

around

the

glass

may

distort

it

sufficientlytoim

pair

the

leveling

accuracy.

Cleaning

The

machine

should

never

be

cleaned

with

the

blast

fromanair

hose

asitwill

drive

grit

and

dirt

into

ways

and

bearings.

Use

only

lint-free

rags

for

plain

surfaces

andastiff

bristle

brush

for

corners.

Prevent

formation

of

permanent

stain

by

periodic

cleaning.

If

machine

will

remain

idle

foralong

time,

wipeathin

coatofoil

over

all

exposed

parts

to

prevent

rusting.

Publication

No.

M-2109

Page 13

SERVICE

MANUAL

AND

PARTS

LIST

CATALOG

ADJUSTMENTS

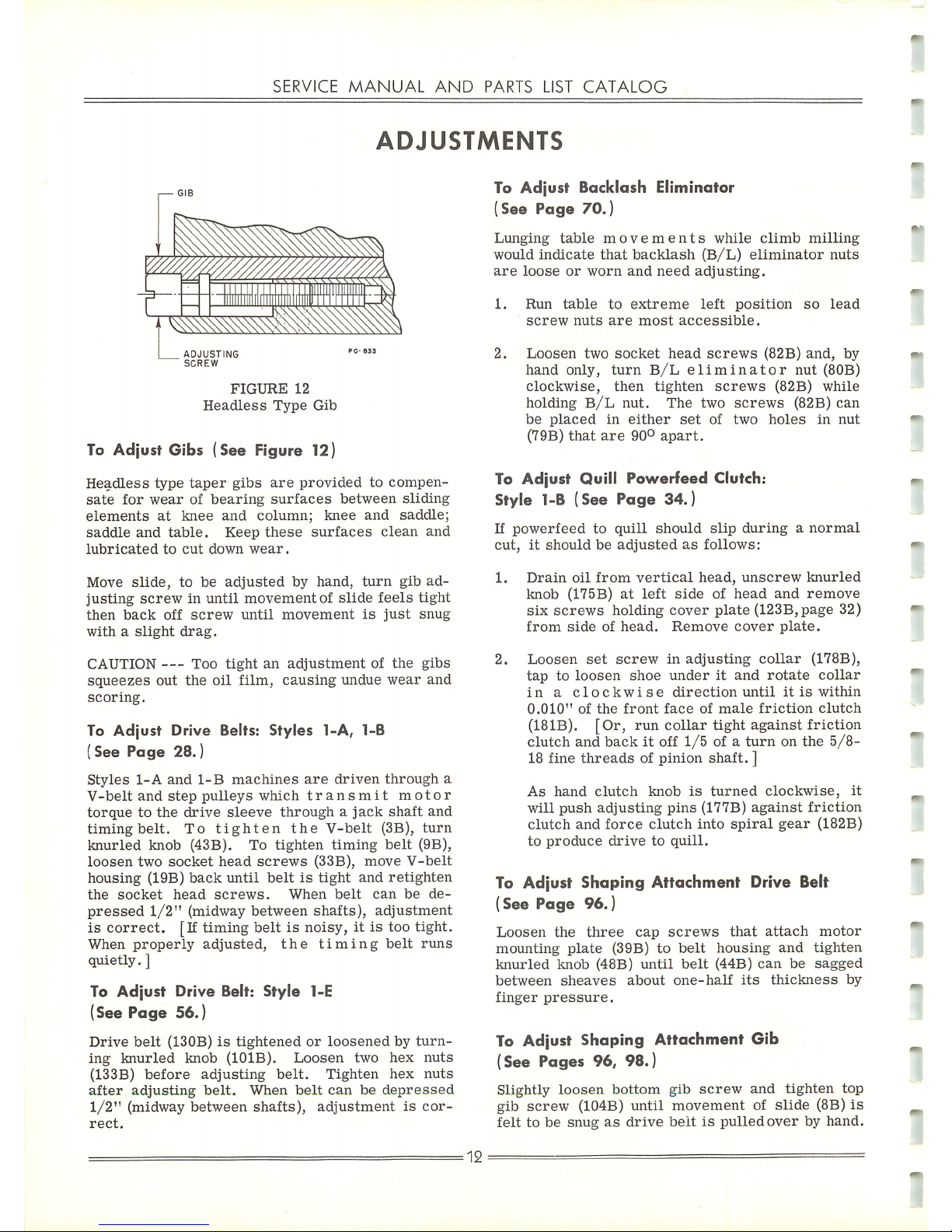

FIGURE

12

Headless

Type

Gib

To

Adjust

Gibs

(See

Figure 12)

Headless

type

taper

gibs

are

provided

to

compen

sate

for

wear

of

bearing

surfaces

between

sliding

elements

at

knee

and

column;

knee

and

saddle;

saddle

and

table.

Keep

these

surfaces

clean

and

lubricated

to

cut

down

wear.

Move

slide,

to

be

adjusted

by

hand,

turn

gib

ad

justing

screwinuntil

movementofslide

feels

tight

then

back

off

screw

until

movement

is

just

snug

withaslight

drag.

CAUTION

—

Too

tight

an

adjustment

of

the

gibs

squeezes

out

the

oil

film,

causing

undue

wear

and

scoring.

To

Adjust

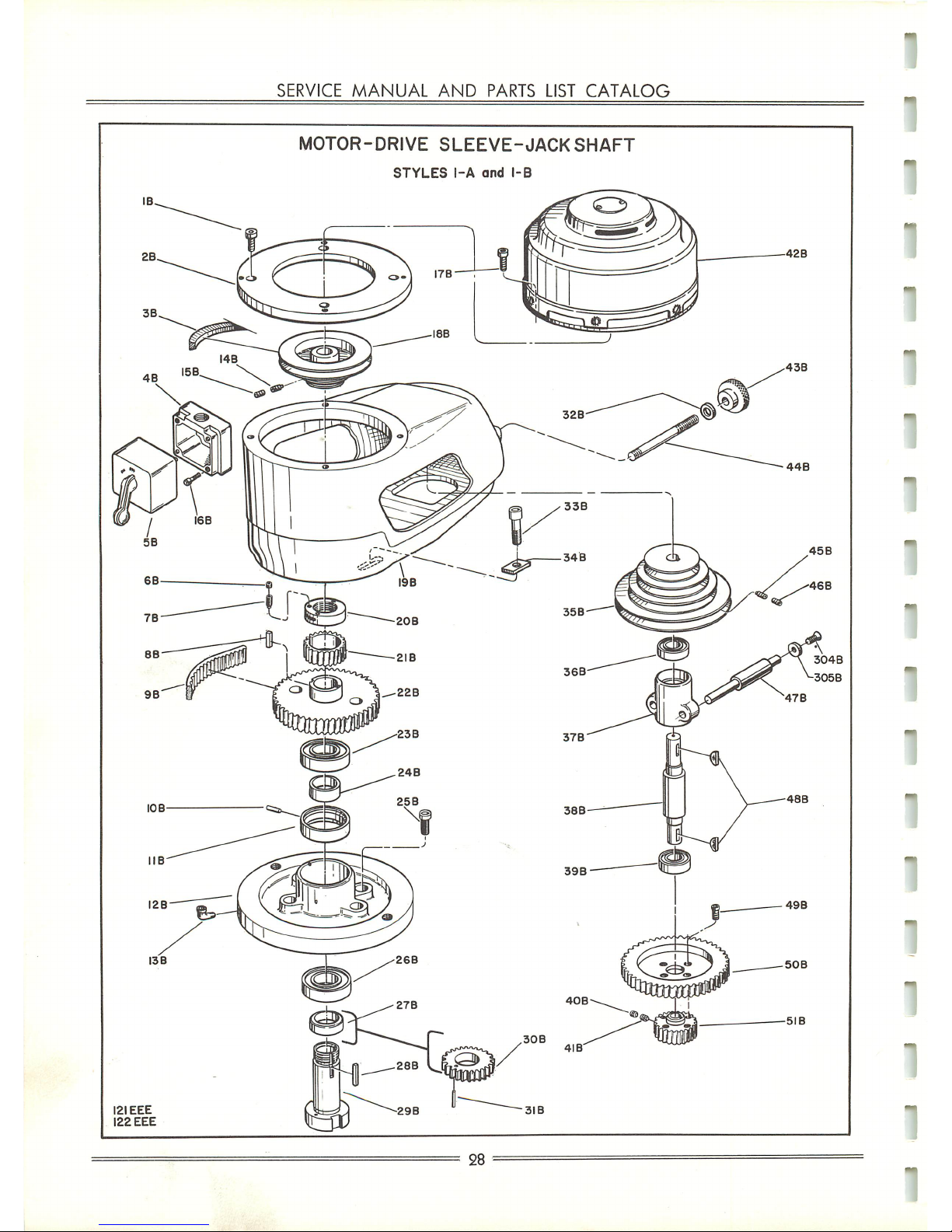

Drive Belts: Styles 1-A, 1-B

(See

Page

28.)

Styles

1-A

and

1-B

machines

are

driven

through

a

V-belt

and

step

pulleys

which

transmit

motor

torquetothe

drive

sleeve

throughajack

shaft

and

timing

belt.

To

tighten

the

V-belt

(3B),

turn

knurled

knob (43B). To

tighten

timing

belt

(9B),

loosen

two

socket

head

screws

(33B),

move

V-belt

housing

(19B)

back

until

beltistight

and

retighten

the

socket

head

screws.

When

belt

can

be

de

pressed

1/2"

(midway

between

shafts),

adjustment

is

correct.

[If

timing

beltisnoisy,itis too tight.

When

properly

adjusted,

the

timing

belt

runs

quietly.]

To

Adjust

Drive Belt:

Style

1-E

(See Page 56.)

Drive

belt

(130B)istightened

or

loosened

by

turn

ing

knurled

knob

(101B).

Loosen

two

hex

nuts

(133B)

before

adjusting

belt.

Tighten

hex

nuts

after

adjusting

belt.

When

belt

can

be

depressed

1/2"

(midway

between

shafts),

adjustment

is

cor

rect.

To

Adjust

Backlash Eliminator

(See Page 70.)

Lunging

table

movements

while

climb

milling

would

indicate

that

backlash

(B/L)

eliminator

nuts

are

loose

or

worn

and

need

adjusting.

1.

Run

table

to

extreme

left

position

so

lead

screw

nuts

are

most

accessible.

2.

Loosen

two

socket

head

screws

(82B)

and,

by

hand

only,

turn

B/L

eliminator

nut

(80B)

clockwise,

then

tighten

screws

(82B)

while

holding

B/L

nut.

The

two

screws

(82B)

can

be

placed

in

either

set

of

two

holes

in

nut

(79B)

that

are

90°

apart.

To

Adjust

Quill

Powerfeed

Clutch:

Style 1-B (See Page 34.)

If

powerfeed

to

quill

should

slip

duringanormal

cut,itshouldbeadjusted

as

follows:

1.

Drain

oil

from

vertical

head,

unscrew

knurled

knob

(175B)atleft

side

of

head

and

remove

six

screws

holding

cover

plate

(123B,page

32)

from

side

of

head.

Remove

cover

plate.

2.

Loosen

set

screw

in

adjusting

collar

(178B),

taptoloosen

shoe

underitand

rotate

collar

in

a

clockwise

direction

until

itiswithin

0.010"

of

the

front

face

of

male

friction

clutch

(181B).

[Or,

run

collar

tight

against

friction

clutch

and

backitoff

1/5

of a

turnonthe

5/8-

18 fine

threads

of pinion

shaft.

]

As

hand

clutch

knob

is

turned

clockwise,

it

will

push

adjusting

pins

(177B)

against

friction

clutch

and

force

clutch

into

spiral

gear

(182B)

to

produce

drivetoquill.

To Adjust Shaping

Attachment

Drive Belt

(See Page

96.)

Loosen

the

three

cap

screws

that

attach

motor

mounting

plate

(39B)tobelt

housing

and

tighten

knurled

knob

(48B)

until

belt

(44B)

can

be

sagged

between

sheaves

about

one-half

its

thickness

by

finger

pressure.

To Adjust Shaping Attachment Gib

(See Pages 96, 98.)

Slightly

loosen

bottom

gib

screw

and

tighten

top

gib

screw

(104B) until movement of slide (8B)

is

felttobe

snugasdrive

beltispulled

overbyhand.

=

12

Page 14

CINCINNATI

NO.1TOOLMASTER

MILLING

MACHINE

DISMANTLING

PROCEDURE

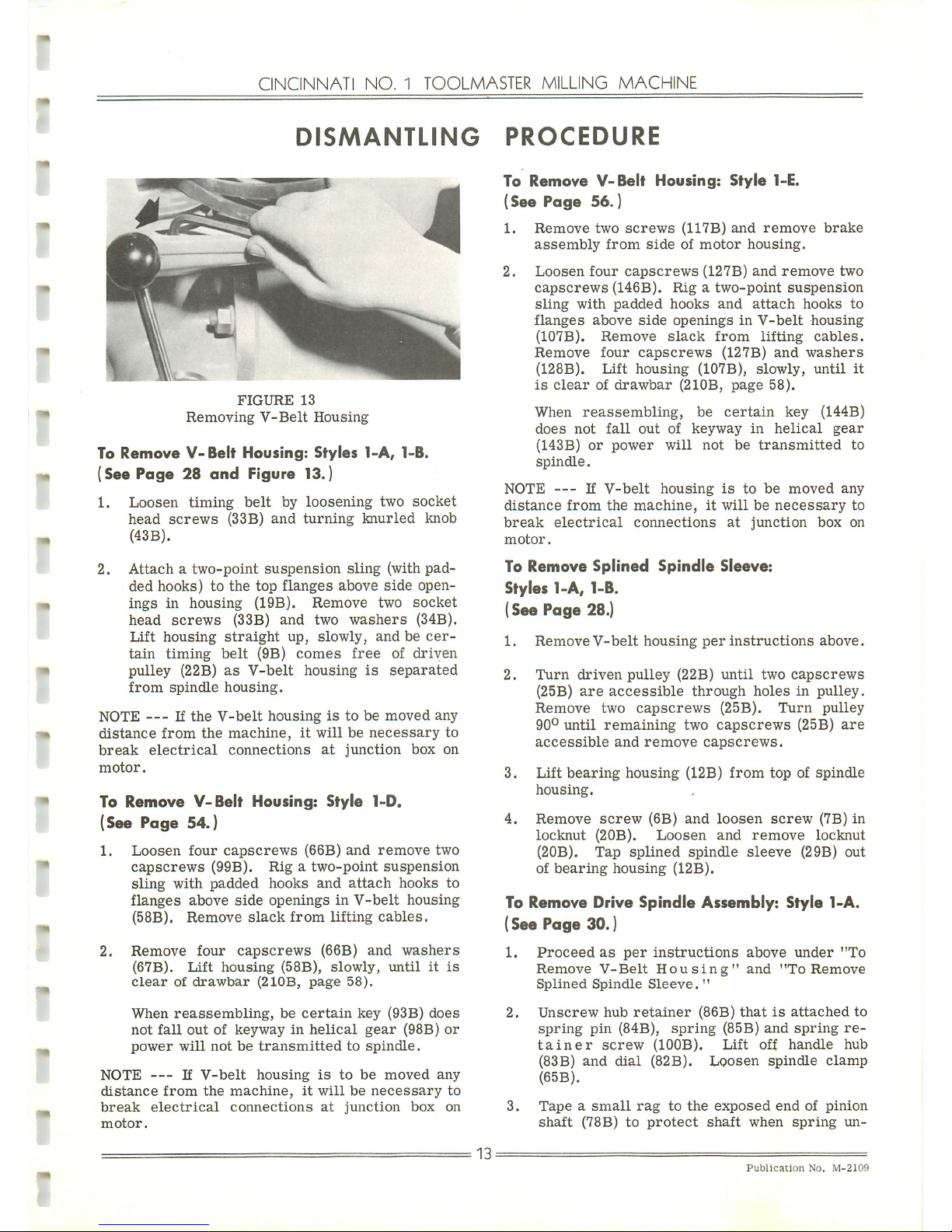

FIGURE

13

Removing

V-Belt

Housing

To

Remove

V-Belt

Housing:

Styles

1-A,

1-B.

(See

Page 28

and

Figure 13.)

1.

Loosen

timing

belt

by

loosening

two

socket

head

screws

(33B)

and

turning

knurled

knob

(43B).

2. Attach a

two-point

suspension

sling (with pad

ded

hooks)tothe

top

flanges

above

side

open

ings

in

housing

(19B).

Remove

two

socket

head

screws

(33B)

and

two

washers

(34B).

Lift

housing

straight

up,

slowly,

andbecer

tain

timing

belt

(9B)

comes

free

of

driven

pulley

(22B)

as

V-belt

housing

is

separated

from

spindle

housing.

NOTE

— If

the

V-belt

housingistobemoved

any

distance

from

the

machine,itwillbenecessary

to

break

electrical

connections

at

junction

box

on

motor.

To

Remove

V-Belt

Housing:

Style

1-D.

(See Page 54.)

1.

Loosen

four

capscrews

(66B)

and

remove

two

capscrews

(99B).

Rigatwo-point

suspension

sling

with

padded

hooks

and

attach

hooks

to

flanges

above

side

openingsinV-belt

housing

(58B).

Remove

slack

from

lifting

cables.

2.

Remove

four

capscrews

(66B)

and

washers

(67B).

Lift

housing

(58B),

slowly,

untilitis

clear

of

drawbar

(210B,

page

58).

When

reassembling,

be

certain

key

(93B)

does

not

fall

outofkeywayinhelical

gear

(98B)

or

power

will

notbetransmitted

to

spindle.

NOTE

— If

V-belt

housing

is

to

be

moved

any

distance

from

the

machine,

it

willbenecessary

to

break

electrical

connections

at

junction

box

on

motor.

13:

To

Remove

V-Belt

Housing:

Style

1-E.

(See

Page

56.)

1.

Remove

two

screws

(117B)

and

remove

brake

assembly

from

sideofmotor

housing.

2.

Loosen

four

capscrews

(127B)

and

remove

two

capscrews

(146B).

Rigatwo-point

suspension

sling

with

padded

hooks

and

attach

hooks

to

flanges

above

side

openings

in

V-belt

housing

(107B).

Remove

slack

from

lifting

cables.

Remove

four

capscrews

(127B)

and

washers

(128B).

Lift

housing

(107B),

slowly,

until

it

is

clearofdrawbar

(210B,

page

58).

When

reassembling,

be

certain

key

(144B)

does

not

fall

out

of

keyway

in

helical

gear

(143B)orpower

will

not

be

transmitted

to

spindle.

NOTE

— If

V-belt

housing

is

to

be

moved

any

distance

from

the

machine,

it

willbenecessary

to

break

electrical

connections

at

junction

box

on

motor.

To

Remove

Splined Spindle

Sleeve:

Styles 1-A, 1-B.

(See Page 28.)

1.

Remove

V-belt

housing

per

instructions

above.

2.

Turn

driven

pulley

(22B)

until

two

capscrews

(25B)

are

accessible

through

holesinpulley.

Remove

two

capscrews

(25B).

Turn

pulley

90°

until

remaining

two

capscrews

(25B)

are

accessible

and

remove

capscrews.

3.

Lift

bearing

housing

(12B)

from

topofspindle

housing.

4.

Remove

screw

(6B)

and

loosen

screw

(7B)

in

locknut

(20B).

Loosen

and

remove

locknut

(20B).

Tap

splined

spindle

sleeve

(29B)

out

of

bearing

housing

(12B).

To

Remove

Drive

Spindle

Assembly:

Style

1-A.

(See Page 30.)

1.

Proceed

as

per

instructions

above

under

"To

Remove

V-Belt

Housing"

and

"To

Remove

Splined

Spindle

Sleeve.

"

2.

Unscrew

hub

retainer

(86B)

thatisattached

to

spring

pin

(84B),

spring

(85B)

and

spring

re

tain

er

screw

(100B).

Lift

off

handle

hub

(83B)

and

dial

(82B).

Loosen

spindle

clamp

(65B).

3.

Tapeasmall

rag

to

the

exposed

endofpinion

shaft

(78B)toprotect

shaft

when

spring

un-

Publication

No.

M-2109

Page 15

SERVICE

MANUAL

AND

PARTS LIST

CATALOG

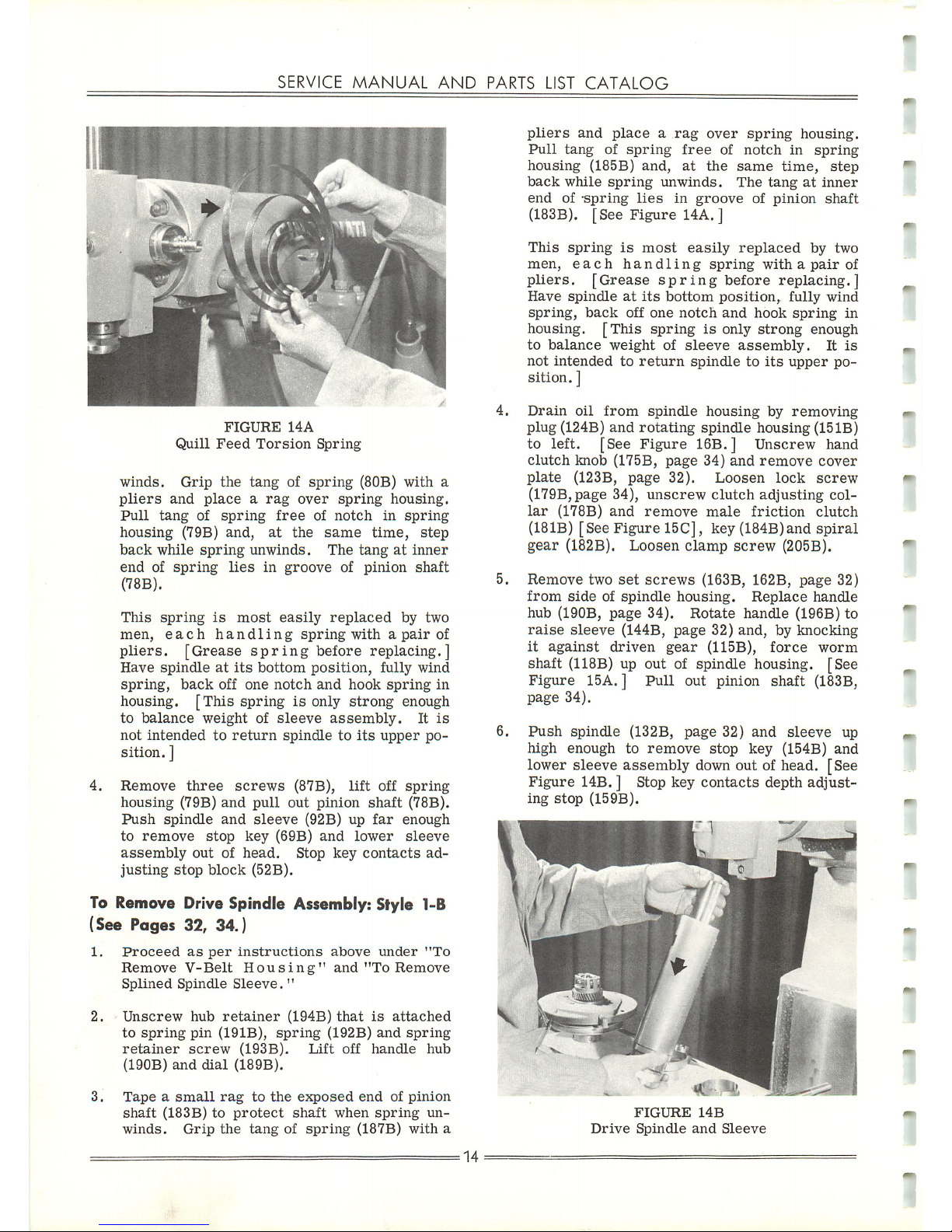

FIGURE

14A

Quill

Feed

Torsion

Spring

winds.

Grip

the

tangofspring

(80B) with a

pliers

and

placearag

over

spring

housing.

Pull

tang

of

spring

free

of

notch

in

spring

housing

(79B)

and,

at

the

same

time,

step

back

while

spring

unwinds.

The

tangatinner

endofspring

lies

in

groove

of

pinion

shaft

(78B).

This

spring

is

most

easily

replaced

by

two

men,

each

handling

spring

withapair

of

pliers.

[Grease

spring

before replacing.]

Have

spindleatits

bottom

position,

fully

wind

spring,

back

off

one

notch

and

hook

spring

in

housing.

[This

springisonly

strong

enough

to

balance

weight

of

sleeve

assembly.

It

is

not

intendedtoreturn

spindletoits

upper

po

sition. ]

4.

Remove

three

screws

(87B),

lift

off

spring

housing

(79B)

and

pull

out

pinion

shaft

(78B).

Push

spindle

and

sleeve

(92B) up

far

enough

to

remove

stop

key

(69B)

and

lower

sleeve

assembly

out

of

head.

Stop

key

contacts

ad

justing

stop

block

(52B).

To

Remove

Drive Spindle

Assembly:

Style 1-B

(See Pages 32, 34.)

1.

Proceed

as

per

instructions

above

under

"To

Remove

V-Belt

Housing"

and

"To

Remove

Splined

Spindle

Sleeve."

2.

Unscrew

hub

retainer

(194B)

that

is

attached

to

spring

pin

(191B),

spring

(192B)

and

spring

retainer

screw

(193B).

Lift

off

handle

hub

(190B)

and

dial

(189B).

3.

Tapeasmall

rag

to

the

exposed

endofpinion

shaft

(183B)toprotect

shaft

when

spring

un

winds.

Grip

the

tangofspring

(187B)

with

a

=

14

pliers

and

placearag

over

spring

housing.

Pull

tang

of

spring

free

of

notch

in

spring

housing

(185B)

and,

at

the

same

time,

step

back

while

spring

unwinds.

The

tangatinner

endof-spring

lies

in

groove

of

pinion

shaft

(183B). [See

Figure

14A. ]

This

spring

is

most

easily

replaced

by

two

men,

each

handling

spring

withapair

of

pliers.

[Grease

spring

before

replacing.]

Have

spindleatits

bottom

position,

fully

wind

spring,

back

off

one

notch

and

hook

spring

in

housing.

[This

springisonly

strong

enough

to

balance

weight

of

sleeve

assembly.

It

is

not

intended

to

return

spindletoits

upper

po

sition.

]

Drain

oil

from

spindle

housing

by

removing

plug (124B)

and

rotating

spindle

housing (15

IB)

to left. [See

Figure

16B.] Unscrew hand

clutch

knob (175B,

page

34)

and

remove

cover

plate

(123B,

page

32).

Loosen

lock

screw

(179B,page 34),

unscrew

clutch

adjusting

col

lar

(178B)

and

remove

male

friction

clutch

(181B)

[See Figure 15C], key (184B)and

spiral

gear

(182B). Loosen

clamp

screw

(205B).

Remove

two

set

screws

(163B, 162B,

page

32)

from

sideofspindle

housing.

Replace

handle

hub (190B, page 34).

Rotate

handle (196B) to

raise

sleeve

(144B, page 32) and, by knocking

it

against

driven

gear

(115B),

force

worm

shaft

(118B)

up out of spindle housing. [See

Figure 15A. ] Pull out pinion shaft (183B,

page

34).

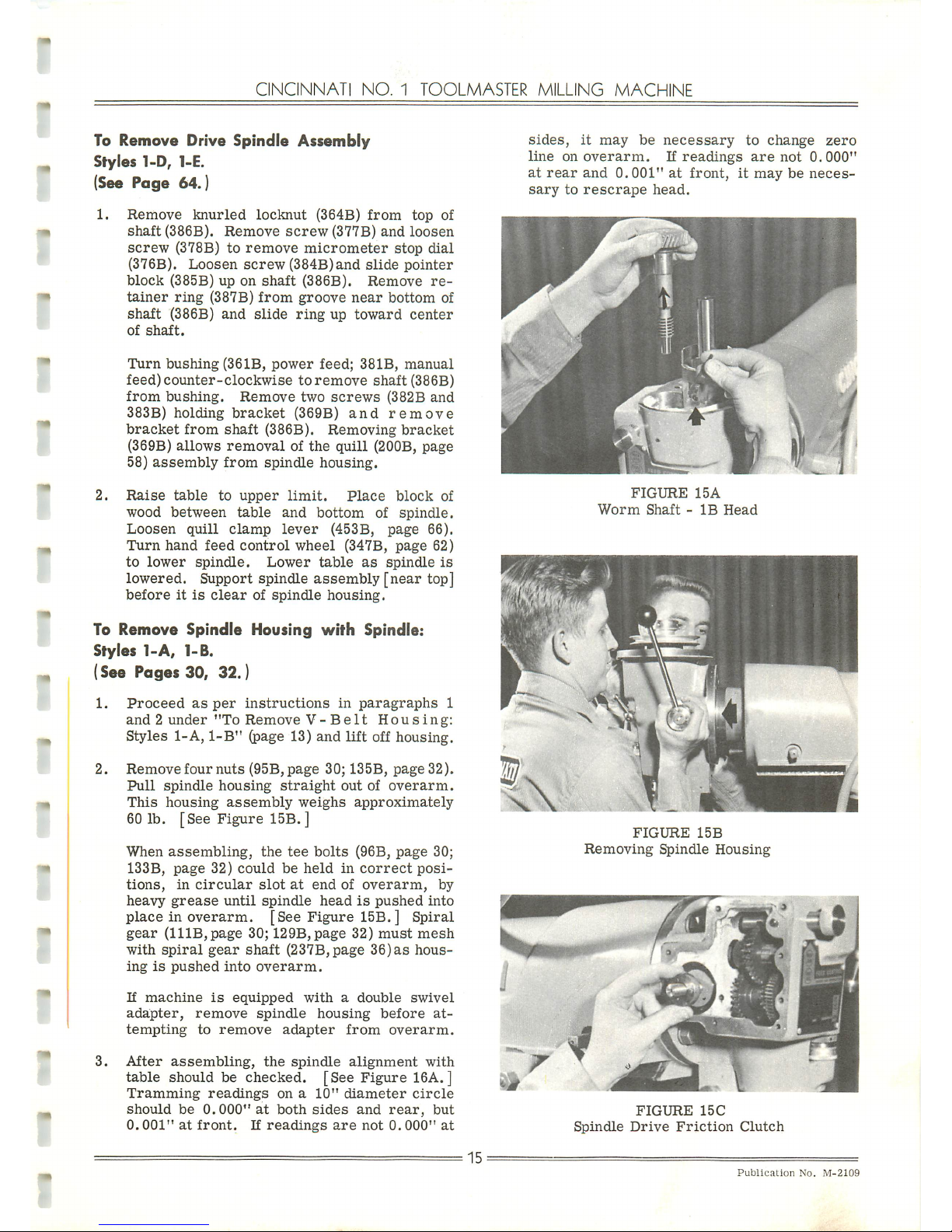

Push

spindle (132B,

page

32)

and

sleeve

up

high

enough

to

remove

stop

key

(154B)

and

lower sleeve

assembly

down out of head. [See

Figure

14B. ] Stop key contacts depth adjust

ing

stop

(159B).

FIGURE

14B

Drive

Spindle

and

Sleeve

Page 16

CINCINNATI

NO.

1

TOOLMASTER

MILLING

MACHINE

To

Remove

Drive

Spindle

Assembly

Styles

1-D, 1-E.

(See Page 64.)

1.

Remove

knurled

locknut

(364B)

from

top of

shaft

(386B).

Remove

screw

(377B)

and

loosen

screw

(378B) to

remove

micrometer

stop

dial

(376B).

Loosen

screw

(384B)and

slide

pointer

block

(385B) up on

shaft

(386B).

Remove

re

tainer

ring

(387B)

from

groove

near

bottom

of

shaft

(386B)

and

slide

ring

up

toward

center

of

shaft.

Turn

bushing

(361B,

power

feed;

381B,

manual

feed)counter-clockwise

toremove

shaft

(386B)

from

bushing.

Remove

two

screws

(382B

and

383B)

holding

bracket

(369B)

and

remove

bracket

from

shaft

(386B).

Removing

bracket

(369B)

allows

removal

of the quill (200B, page

58)

assembly

from

spindle

housing.

2.

Raise

table

to

upper

limit.

Place

block

of

wood

between

table

and

bottom

of

spindle.

Loosen

quill

clamp

lever

(453B,

page

66).

Turn

hand

feed

control

wheel

(347B,

page

62)

to

lower

spindle.

Lower

table

as

spindle

is

lowered. Support spindle

assembly

[near

top]

beforeitis

clear

of

spindle

housing.

To

Remove

Spindle

Housing

with

Spindle:

Styles

1-A,

1-B.

(See Pages 30,

32.)

1.

Proceed

as

per

instructions

in

paragraphs

1

and2under

"To

Remove

V-Belt

Housing:

Styles 1-A,

1-B"

(page 13) and

lift

off housing.

2.

Remove

four

nuts

(95B,page

30; 135B,

page

32).

Pull

spindle

housing

straight

outofoverarm.

This

housing

assembly

weighs

approximately

60 lb. [See Figure 15B.]

When

assembling,

the

tee

bolts

(96B,

page

30;

133B,

page

32)

couldbeheldincorrect

posi

tions,

in

circular

slot

at

endofoverarm,

by

heavy

grease

until

spindle

headispushed

into

place in

overarm.

[See

Figure

15B.] Spiral

gear

(11

IB,

page

30;

129B,page

32)

must

mesh

with

spiral

gear

shaft

(237B,page

36)ashous

ingispushed

into

overarm.

If

machine

is

equipped

withadouble

swivel

adapter,

remove

spindle

housing

before

at

tempting

to

remove

adapter

from

overarm.

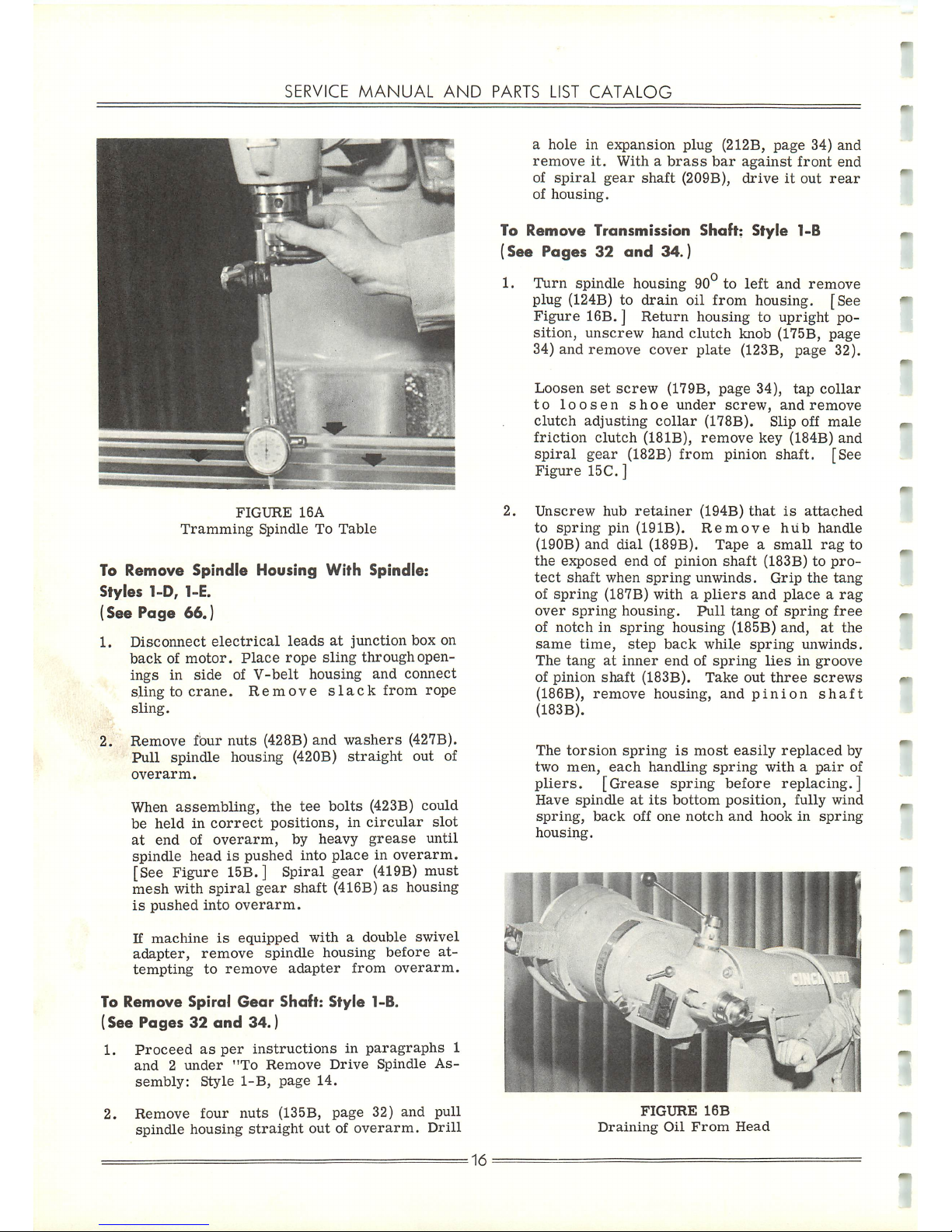

3.

After

assembling,

the

spindle

alignment

with

table

should be

checked.

[See

Figure

16A. ]

Tramming

readings

ona10"

diameter

circle

should

be

0.000"

at

both

sides

and

rear,

but

0.001"

at

front.

If

readings

are

not

0.000"

at

15

sides,

it

may

be

necessary

to

change

zero

line

on

overarm.

If

readings

are

not

0.000"

at

rear

and

0.001"

at

front,itmaybeneces

sarytorescrape

head.

FIGURE

15A

Worm

Shaft-IB

Head

FIGURE

15B

Removing

Spindle

Housing

FIGURE

15C

Spindle

Drive

Friction

Clutch

Publication

No.

M-2109

Page 17

SERVICE

MANUAL

AND

PARTS

LIST

CATALOG

FIGURE

16A

Tramming

Spindle

To

Table

To

Remove

Spindle

Housing

With

Spindle:

Styles

1-D, 1-E.

(See Page 66.)

1,

Disconnect

electrical

leadsatjunction

box

on

backofmotor.

Place

rope

sling

through

open

ings

in

sideofV-belt

housing

and

connect

slingtocrane.

Remove

slack

from

rope

sling.

2. Remove four

nuts

(428B)

and

washers

(427B).

Pull

spindle

housing

(420B)

straight

out

of

overarm.

When

assembling,

the

tee

bolts

(423B) could

be

heldincorrect

positions,

in

circular

slot

at

end

of

overarm,

by

heavy

grease

until

spindle

headispushed

into

placeinoverarm.

[See Figure 15B.] Spiral gear

(419B)

must

mesh

with

spiral

gear

shaft

(416B)ashousing

is

pushed

into

overarm.

If

machine

is

equipped

withadouble

swivel

adapter,

remove

spindle

housing

before

at

tempting

to

remove

adapter

from

overarm.

To

Remove

Spiral

Gear

Shaft:

Style

1-B.

(See

Pages32and

34.)

1.

Proceed

as

per

instructions

in

paragraphs

1

and2under

"To

Remove

Drive

Spindle

As

sembly:

Style

1-B,

page

14.

2.

Remove

four

nuts

(135B,

page

32)

and

pull

spindle housing

straight

out of

overarm.

Drill

=

16

a

holeinexpansion

plug

(212B,

page

34)

and

remove

it.

Withabrass

bar

against

front

end

of

spiral

gear

shaft

(209B),

driveitout

rear

of

housing.

To

Remove

Transmission

Shaft:

Style

1-B

(See Pages 32

and

34.)

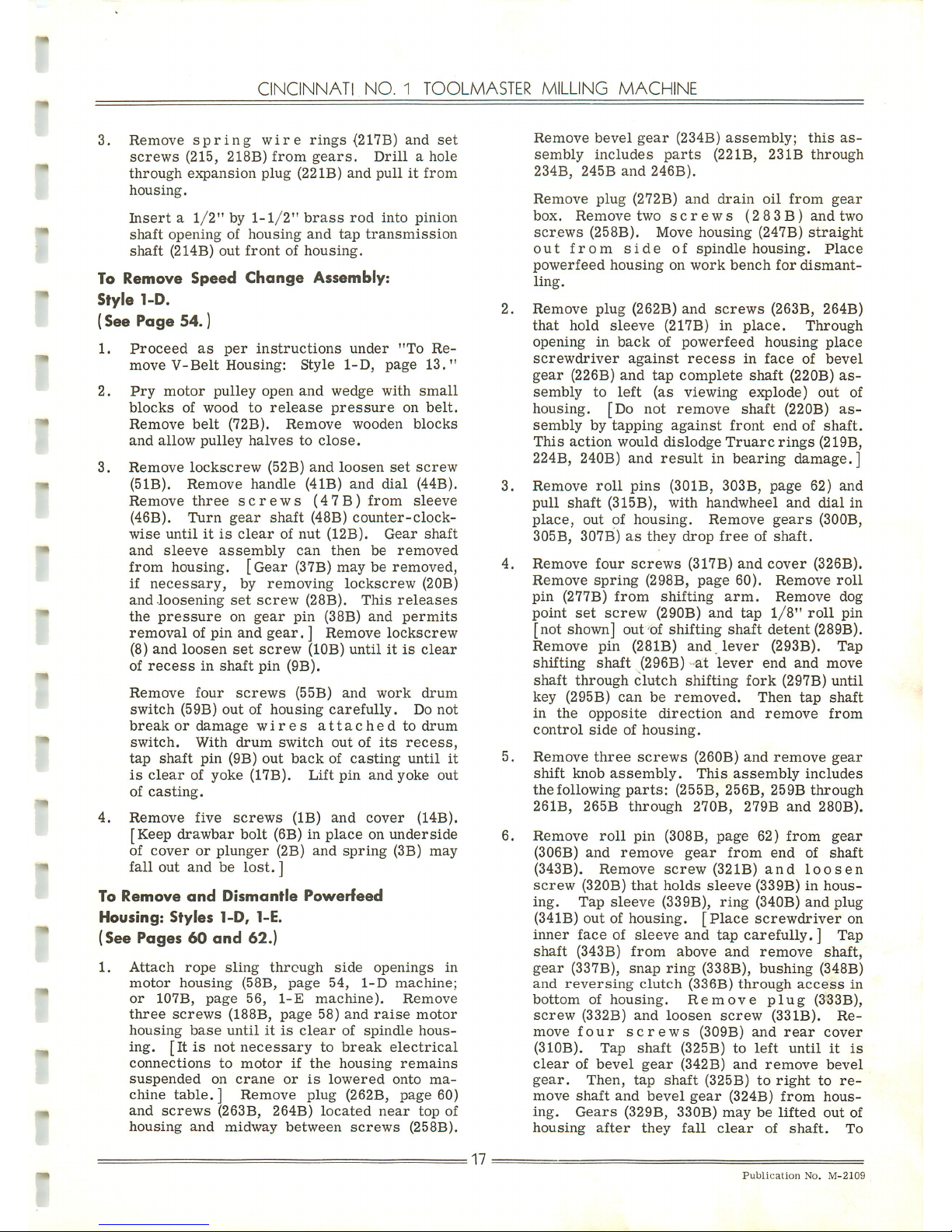

1.

Turn

spindle

housing

90°

to left and

remove

plug

(124B)

to drain oil from housing. [See

Figure

16B. ] Return housing to upright po

sition,

unscrew

hand

clutch

knob

(175B,

page

34) and

remove

cover

plate

(123B, page 32).

Loosen

set

screw

(179B,

page

34),

tap

collar

to

loosen

shoe

under

screw,

and

remove

clutch

adjusting

collar

(178B). Slip off

male

friction

clutch

(18IB),

remove

key

(184B)

and

spiral

gear

(182B)

from

pinion shaft. [See

Figure

15C.]

2.

Unscrew

hub

retainer

(194B)

that

is

attached

to

spring

pin

(191B).

Remove

hub

handle

(190B)

and

dial

(189B).

Tapeasmall

rag

to

the

exposed

endofpinion

shaft

(183B)topro

tect

shaft

when

spring

unwinds.

Grip

the

tang

of

spring

(187B)

withapliers

and

placearag

over

spring

housing.

Pull

tangofspring

free

of

notchinspring

housing

(185B)

and,

at

the

same

time,

step

back

while

spring

unwinds.

The

tangatinner

endofspring

liesingroove

of

pinion

shaft

(183B).

Take

out

three

screws

(186B),

remove

housing,

and

pinion

shaft

(183B).

The

torsion

spring

is

most

easily

replaced

by

two

men,

each

handling

spring

withapair

of

pliers.

[Grease

spring

before

replacing.]

Have

spindle

at

its

bottom

position,

fully

wind

spring,

back

off

one

notch

and

hookinspring

housing.

r~*mi

FIGURE

16B

Draining

Oil

From

Head

Page 18

CINCINNATI

NO.

1

TOOLMASTER

MILLING

MACHINE

3.

Remove

spring

wire

rings

(217B)

and

set

screws

(215,

218B)

from

gears.

Drillahole

through

expansion

plug

(22IB)

and

pullitfrom

housing.

Inserta1/2"by1-1/2"

brass

rod

into

pinion

shaft

opening

of

housing

and

tap

transmission

shaft

(214B)

out

frontofhousing.

To

Remove

Speed

Change

Assembly:

Style

1-D.

(See Page 54.)

1.

Proceed

as

per

instructions

under

"To

Re

move

V-Belt

Housing:

Style

1-D,

page

13."

2.

Pry

motor

pulley

open

and

wedge

with

small

blocks

of

wood

to

release

pressure

on

belt.

Remove

belt

(72B).

Remove

wooden

blocks

and

allow

pulley

halves

to

close.

3.

Remove

lockscrew

(52B)

and

loosen

set

screw

(51B).

Remove

handle

(41B)

and

dial

(44B).

Remove

three

screws

(47B)

from

sleeve

(46B).

Turn

gear

shaft

(48B)

counter-clock

wise

untilitis

clear

of

nut

(12B).

Gear

shaft

and

sleeve

assembly

can

then

be

removed

from housing.

[Gear

(37B)

may be removed,

if

necessary,

by

removing

lockscrew

(20B)

and

loosening

set

screw

(28B).

This

releases

the

pressure

on

gear

pin

(38B)

and

permits

removal of pin and

gear.

] Remove lockscrew

(8)

and

loosen

set

screw

(10B)

untilitis

clear

of

recess

in

shaft

pin

(9B).

Remove

four

screws

(55B)

and

work

drum

switch

(59B)

outofhousing

carefully.

Do

not

break

or

damage

wires

attached

to

drum

switch.

With

drum

switch

outofits

recess,

tap

shaft

pin

(9B)

out

backofcasting

until

it

is

clear

of

yoke

(17B).

Lift

pin

and

yoke

out

of

casting.

4.

Remove

five

screws

(IB)

and

cover

(14B).

[Keep drawbar bolt (6B) in place on underside

of

coverorplunger

(2B)

and

spring

(3B)

may

fall out and be

lost.

]

To

Remove

and

Dismantle

Powerfeed

Housing:

Styles

1-D, 1-E.

(See Pages 60

and

62.)

1.

Attach

rope

sling

through

side

openings

in

motor

housing

(58B,

page

54,

1-D

machine;

or

107B,

page

56,

1-E

machine).

Remove

three

screws

(188B,

page

58)

and

raise

motor

housing

base

untilitis

clear

of

spindle

hous

ing.

[Itisnot

necessary

to

break

electrical

connections

to

motor

if

the

housing

remains

suspended

on

crane

or

is

lowered

onto

ma

chine

table.]

Remove plug (262B, page 60)

and

screws

(263B,

264B)

located

near

top

of

housing

and

midway

between

screws

(258B).

.17

Remove

bevel

gear

(234B)

assembly;

this

as