Page 1

21 - 130 AUTOMATIC TRANSMISSION - 48RE DR

AUTOMATIC TRANSMISSION - 48RE

TABLE OF CONTENTS

page page

AUTOMATIC TRANSMISSION - 48RE

DESCRIPTION ........................132

OPERATION ..........................134

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AUTOMATIC

TRANSMISSION .....................140

DIAGNOSIS AND TESTING - PRELIMINARY . 140

DIAGNOSIS AND TESTING - ROAD

TESTING ...........................140

DIAGNOSIS AND TESTING - HYDRAULIC

PRESSURE TEST ....................141

DIAGNOSIS AND TESTING - AIR TESTING

TRANSMISSION CLUTCH AND BAND

OPERATION ........................144

DIAGNOSIS AND TESTING - CONVERTER

HOUSING FLUID LEAK ................144

DIAGNOSIS AND TESTING - DIAGNOSIS

CHARTS ...........................145

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR .....................158

REMOVAL ............................158

DISASSEMBLY ........................160

CLEANING ...........................166

INSPECTION .........................166

ASSEMBLY ...........................166

INSTALLATION ........................174

SCHEMATICS AND DIAGRAMS

HYDRAULIC SCHEMATICS .............176

SPECIFICATIONS

TRANSMISSION .....................189

SPECIAL TOOLS

RE TRANSMISSION ..................191

ACCUMULATOR

DESCRIPTION ........................193

OPERATION ..........................193

INSPECTION .........................194

BANDS

DESCRIPTION ........................194

OPERATION ..........................194

ADJUSTMENTS

ADJUSTMENT - BANDS ...............195

BRAKE TRANSMISSION SHIFT INTERLOCK

SYSTEM

DESCRIPTION ........................196

OPERATION ..........................196

DIAGNOSIS AND TESTING - BRAKE

TRANSMISSION SHIFT INTERLOCK ......196

ADJUSTMENTS - BRAKE TRANSMISSION

SHIFT INTERLOCK ...................196

ELECTRONIC GOVERNOR

DESCRIPTION ........................197

OPERATION ..........................198

REMOVAL ............................199

INSTALLATION ........................200

EXTENSION HOUSING SEAL

REMOVAL ............................201

INSTALLATION ........................201

FLUID AND FILTER

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EFFECTS OF

INCORRECT FLUID LEVEL .............201

DIAGNOSIS AND TESTING - CAUSES OF

BURNT FLUID .......................201

DIAGNOSIS AND TESTING - FLUID

CONTAMINATION ....................202

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

CHECK ............................202

STANDARD PROCEDURE - FLUID AND

FILTER REPLACEMENT ...............203

STANDARD PROCEDURE - TRANSMISSION

FILL ...............................204

FRONT CLUTCH

DESCRIPTION ........................205

OPERATION ..........................205

DISASSEMBLY ........................205

INSPECTION .........................206

ASSEMBLY ...........................207

FRONT SERVO

DESCRIPTION ........................208

OPERATION ..........................208

DISASSEMBLY ........................209

CLEANING ...........................209

INSPECTION .........................209

ASSEMBLY ...........................209

GEARSHIFT CABLE

DIAGNOSIS AND TESTING - GEARSHIFT

CABLE .............................210

REMOVAL ............................210

INSTALLATION ........................211

ADJUSTMENTS

GEARSHIFT CABLE ..................212

OIL PUMP

DESCRIPTION ........................213

OPERATION ..........................213

DISASSEMBLY ........................214

CLEANING ...........................214

INSPECTION .........................214

ASSEMBLY ...........................214

Page 2

DR AUTOMATIC TRANSMISSION - 48RE 21 - 131

OUTPUT SHAFT FRONT BEARING

REMOVAL ............................216

INSTALLATION ........................216

OUTPUT SHAFT REAR BEARING

REMOVAL ............................216

INSTALLATION ........................217

OVERDRIVE CLUTCH

DESCRIPTION ........................217

OPERATION ..........................217

OVERDRIVE UNIT

REMOVAL ............................218

DISASSEMBLY ........................218

CLEANING ...........................225

INSPECTION .........................225

ASSEMBLY ...........................226

INSTALLATION ........................235

OVERRUNNING CLUTCH CAM/OVERDRIVE

PISTON RETAINER

DESCRIPTION ........................236

OPERATION ..........................236

DISASSEMBLY ........................236

CLEANING ...........................236

INSPECTION .........................237

ASSEMBLY ...........................237

PISTONS

DESCRIPTION ........................239

OPERATION ..........................239

PLANETARY GEARTRAIN/OUTPUT SHAFT

DESCRIPTION ........................241

OPERATION ..........................241

DISASSEMBLY ........................242

INSPECTION .........................243

ASSEMBLY ...........................244

REAR CLUTCH

DESCRIPTION ........................247

OPERATION ..........................248

DISASSEMBLY ........................248

CLEANING ...........................248

INSPECTION .........................248

ASSEMBLY ...........................249

REAR SERVO

DESCRIPTION ........................251

OPERATION ..........................251

DISASSEMBLY ........................251

CLEANING ...........................251

ASSEMBLY ...........................251

SHIFT MECHANISM

DESCRIPTION ........................252

OPERATION ..........................252

SOLENOID

DESCRIPTION ........................252

OPERATION ..........................252

SPEED SENSOR

DESCRIPTION ........................253

OPERATION ..........................253

THROTTLE VALVE CABLE

DESCRIPTION ........................253

ADJUSTMENTS - THROTTLE VALVE CABLE . 254

TORQUE CONVERTER

DESCRIPTION ........................255

OPERATION ..........................259

REMOVAL ............................260

INSTALLATION ........................260

TORQUE CONVERTER DRAINBACK VALVE

DESCRIPTION ........................261

OPERATION ..........................261

STANDARD PROCEDURE - TORQUE

CONVERTER DRAINBACK VALVE ........261

TOW/HAUL OVERDRIVE SWITCH

DESCRIPTION ........................261

OPERATION ..........................262

DIAGNOSIS AND TESTING - OVERDRIVE

ELECTRICAL CONTROLS ..............262

REMOVAL ............................262

INSTALLATION ........................262

TRANSMISSION RANGE SENSOR

DESCRIPTION ........................263

OPERATION ..........................263

DIAGNOSIS AND TESTING - TRANSMISSION

RANGE SENSOR (TRS) ................264

REMOVAL ............................265

INSTALLATION ........................266

TRANSMISSION TEMPERATURE SENSOR

DESCRIPTION ........................267

OPERATION ..........................267

VALVE BODY

DESCRIPTION ........................267

OPERATION ..........................272

REMOVAL ............................286

DISASSEMBLY ........................287

CLEANING ...........................298

INSPECTION .........................298

ASSEMBLY ...........................299

INSTALLATION ........................309

ADJUSTMENTS - VALVE BODY ...........310

Page 3

21 - 132 AUTOMATIC TRANSMISSION - 48RE DR

AUTOMATIC TRANSMISSION 48RE

DESCRIPTION

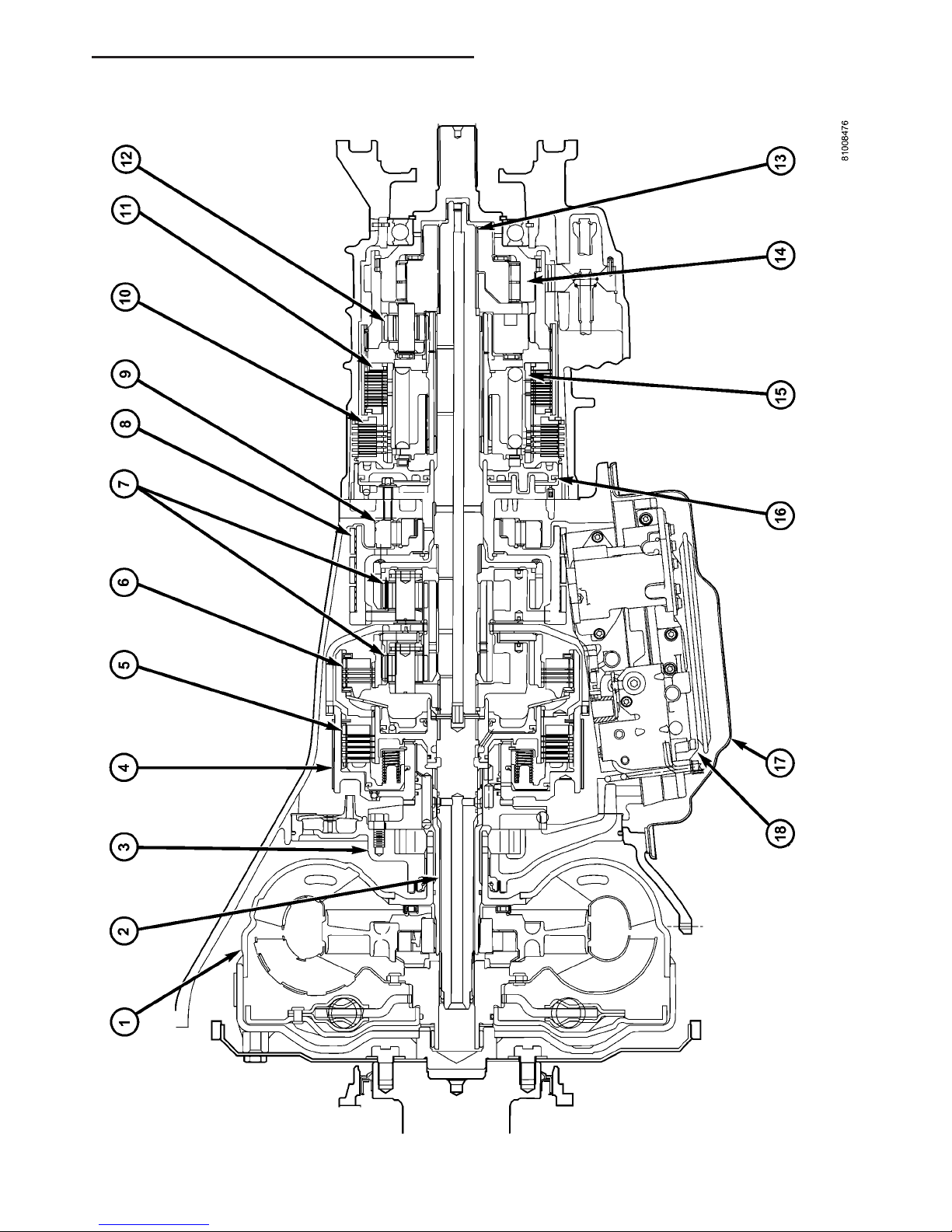

The 48RE (Fig. 1) is a four speed fully automatic

transmissions with an electronic governor. The 48RE

is equipped with a lock-up clutch in the torque converter. First through third gear ranges are provided

by the clutches, bands, overrunning clutch, and planetary gear sets in the transmission. Fourth gear

range is provided by the overdrive unit that contains

an overdrive clutch, direct clutch, planetary gear set,

and overrunning clutch.

The transmission contains a front, rear, and direct

clutch which function as the input driving components. It also contains the kickdown (front) and the

low/reverse (rear) bands which, along with the overrunning clutch and overdrive clutch, serve as the

holding components. The driving and holding components combine to select the necessary planetary gear

components, in the front, rear, or overdrive planetary

gear set, transfer the engine power from the input

shaft through to the output shaft.

The valve body is mounted to the lower side of the

transmission and contains the valves to control pressure regulation, fluid flow control, and clutch/band

application. The oil pump is mounted at the front of

the transmission and is driven by the torque converter hub. The pump supplies the oil pressure necessary for clutch/band actuation and transmission

lubrication.

Page 4

DR AUTOMATIC TRANSMISSION - 48RE 21 - 133

AUTOMATIC TRANSMISSION - 48RE (Continued)

Fig. 1 48RE Transmission

Page 5

21 - 134 AUTOMATIC TRANSMISSION - 48RE DR

AUTOMATIC TRANSMISSION - 48RE (Continued)

1 - TORQUE CONVERTER 10 - OVERDRIVE CLUTCH

2 - INPUT SHAFT 11 - DIRECT CLUTCH

3 - OIL PUMP 12 - PLANETARY GEAR

4 - FRONT BAND 13 - INTERMEDIATE SHAFT

5 - FRONT CLUTCH 14 - OVERDRIVE OVERRUNNING CLUTCH

6 - REAR CLUTCH 15 - DIRECT CLUTCH SPRING

7 - PLANETARIES 16 - OVERDRIVE PISTON RETAINER

8 - REAR BAND 17 - OIL PAN

9 - OVERRUNNING CLUTCH 18 - VALVE BODY

IDENTIFICATION

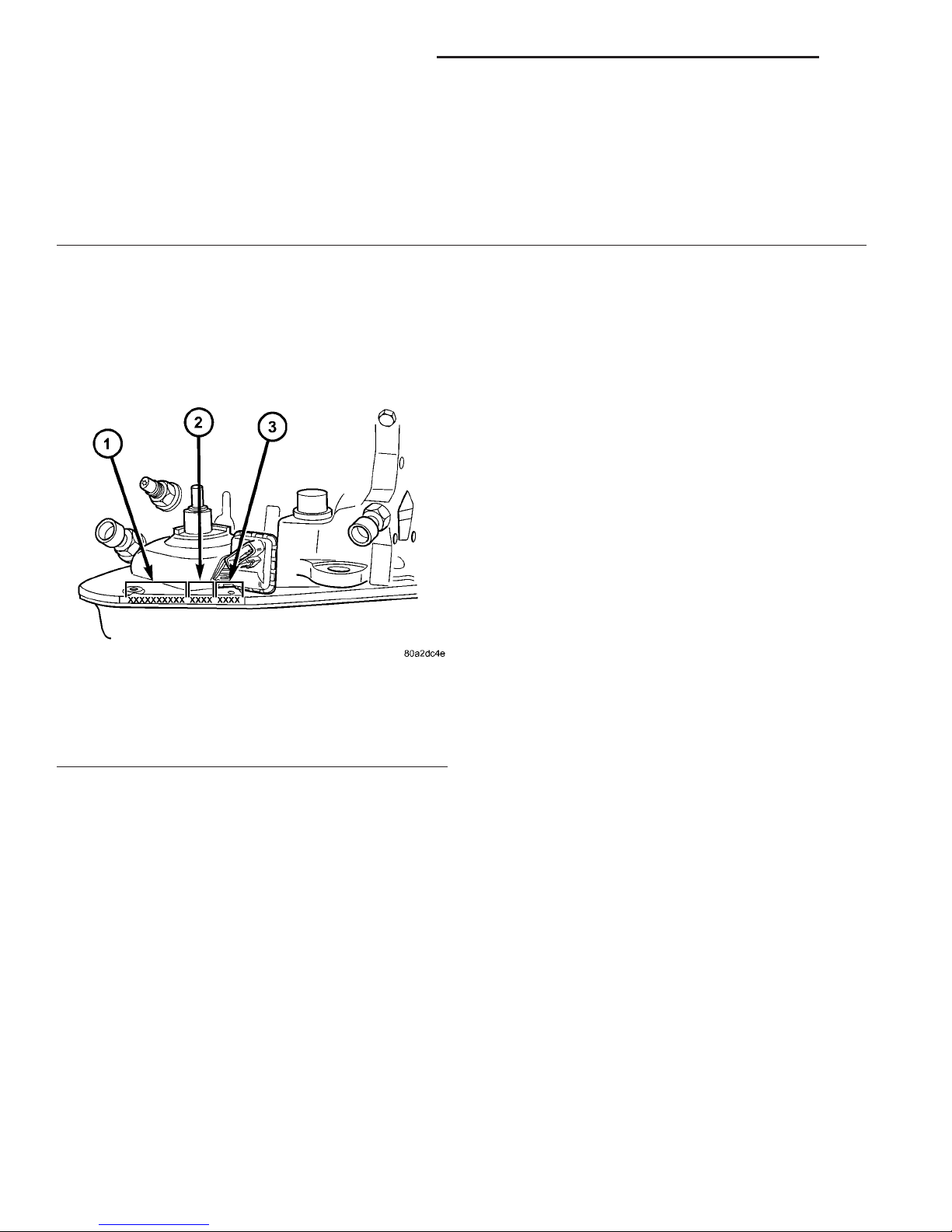

Transmission identification numbers are stamped

on the left side of the case just above the oil pan gasket surface (Fig. 2). Refer to this information when

ordering replacement parts.

Fig. 2 Transmission Part Number And Serial

Number Location

1 - PART NUMBER

2 - BUILD DATE

3 - SERIAL NUMBER

GEAR RATIOS

The 48RE gear ratios are:

1st .................................2.45:1

2nd ................................1.45:1

3rd ................................1.00:1

4th .................................0.69:1

Rev. ................................2.20:1

OPERATION

The application of each driving or holding component is controlled by the valve body based upon the

manual lever position, throttle pressure, and governor pressure. The governor pressure is a variable

pressure input to the valve body and is one of the

signals that a shift is necessary. First through fourth

gear are obtained by selectively applying and releasing the different clutches and bands. Engine power is

thereby routed to the various planetary gear assemblies which combine with the overrunning clutch

assemblies to generate the different gear ratios. The

torque converter clutch is hydraulically applied and

is released when fluid is vented from the hydraulic

circuit by the torque converter control (TCC) solenoid

on the valve body. The torque converter clutch is controlled by the Powertrain Control Module (PCM). The

torque converter clutch engages in fourth gear, and

in third gear under various conditions, such as when

the O/D switch is OFF, when the vehicle is cruising

on a level surface after the vehicle has warmed up.

The torque converter clutch can also be engaged in

the MANUAL SECOND gear position if high transmission temperatures are sensed by the PCM. The

torque converter clutch will disengage momentarily

when an increase in engine load is sensed by the

PCM, such as when the vehicle begins to go uphill or

the throttle pressure is increased. The torque converter clutch feature increases fuel economy and

reduces the transmission fluid temperature.

Since the overdrive clutch is applied in fourth gear

only and the direct clutch is applied in all ranges

except fourth gear, the transmission operation for

park, neutral, and first through third gear will be

described first. Once these powerflows are described,

the third to fourth shift sequence will be described.

Page 6

DR AUTOMATIC TRANSMISSION - 48RE 21 - 135

AUTOMATIC TRANSMISSION - 48RE (Continued)

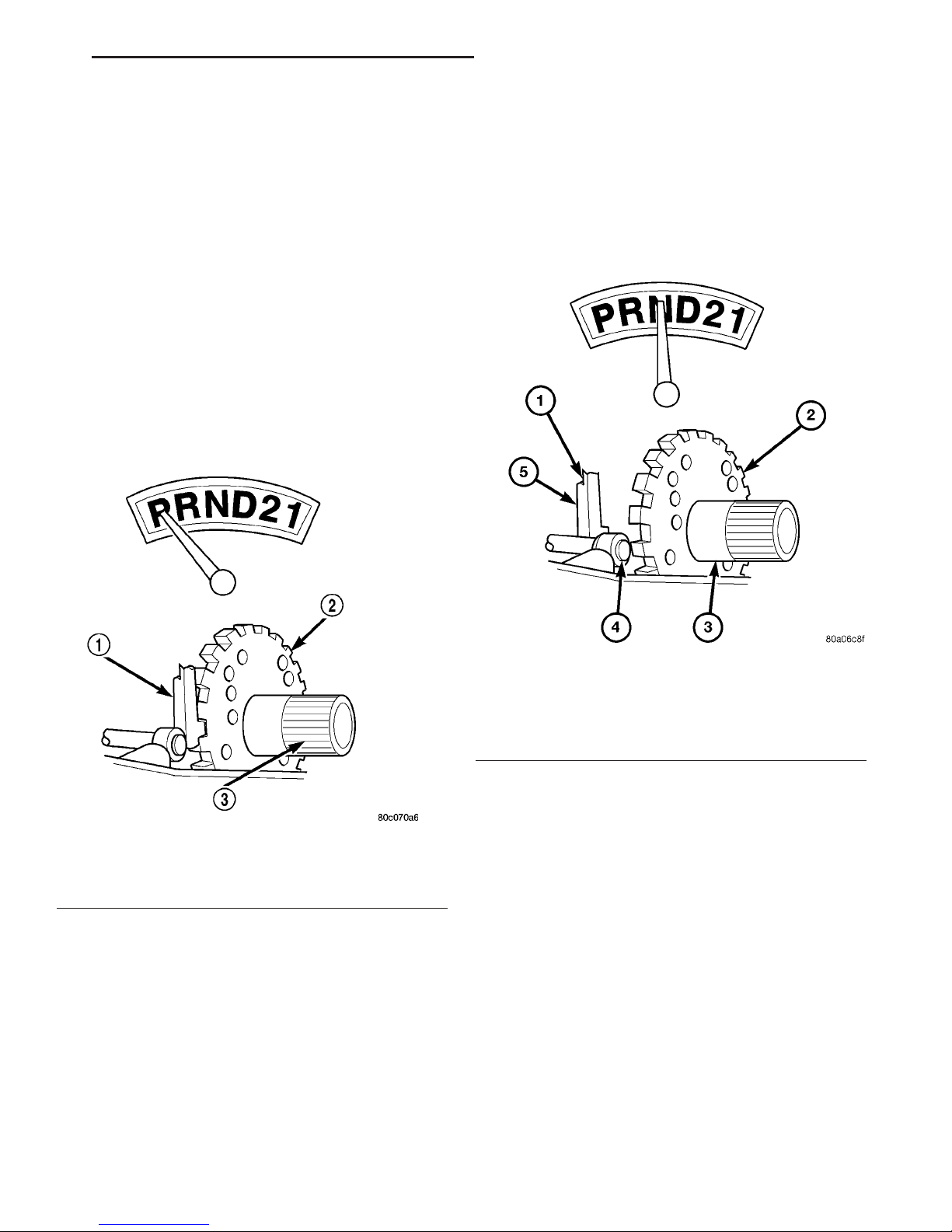

PARK POWERFLOW

As the engine is running and the crankshaft is

rotating, the flexplate and torque converter, which

are also bolted to it, are all rotating in a clockwise

direction as viewed from the front of the engine. The

notched hub of the torque converter is connected to

the oil pump’s internal gear, supplying the transmission with oil pressure. As the converter turns, it

turns the input shaft in a clockwise direction. As the

input shaft is rotating, the front clutch hub-rear

clutch retainer and all their associated parts are also

rotating, all being directly connected to the input

shaft. The power flow from the engine through the

front clutch hub and rear clutch retainer stops at the

rear clutch retainer. Therefore, no power flow to the

output shaft occurs because no clutches are applied.

The only mechanism in use at this time is the parking sprag (Fig. 3), which locks the parking gear on

the output shaft to the transmission case.

NEUTRAL POWERFLOW

With the gear selector in the NEUTRAL position

(Fig. 4), the power flow of the transmission is essentially the same as in the park position. The only

operational difference is that the parking sprag has

been disengaged, unlocking the output shaft from the

transmission case and allowing it to move freely.

Fig. 3 Park Powerflow

1 - PAWL ENGAGED FOR PARK

2 - PARK SPRAG

3 - OUTPUT SHAFT

Fig. 4 Neutral Powerflow

1 - PAWL DISENGAGED FOR NEUTRAL

2 - PARK SPRAG

3 - OUTPUT SHAFT

4 - CAM

5-PAWL

Page 7

21 - 136 AUTOMATIC TRANSMISSION - 48RE DR

AUTOMATIC TRANSMISSION - 48RE (Continued)

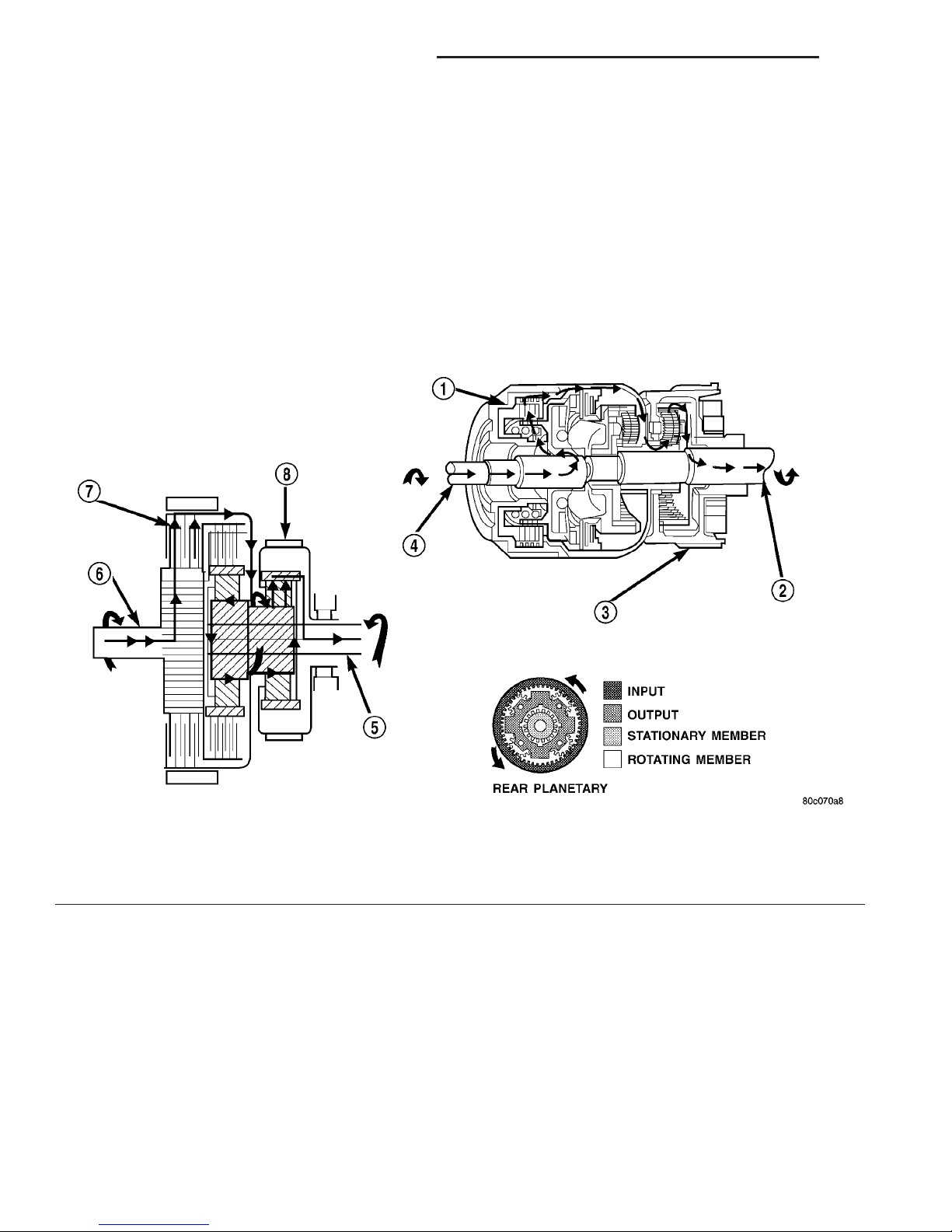

REVERSE POWERFLOW

When the gear selector is moved into the

REVERSE position (Fig. 5), the front clutch and the

rear band are applied. With the application of the

front clutch, engine torque is applied to the sun gear,

turning it in a clockwise direction. The clockwise

rotation of the sun gear causes the rear planet pinions to rotate against engine rotation in a counterclockwise direction. The rear band is holding the low

reverse drum, which is splined to the rear carrier.

Since the rear carrier is being held, the torque from

the planet pinions is transferred to the rear annulus

gear, which is splined to the output shaft. The output

shaft in turn rotates with the annulus gear in a

counterclockwise direction giving a reverse gear output. The entire transmission of torque is applied to

the rear planetary gearset only. Although there is

torque input to the front gearset through the sun

gear, no other member of the gearset is being held.

During the entire reverse stage of operation, the

front planetary gears are in an idling condition.

1 - FRONT CLUTCH ENGAGED 5 - OUTPUT SHAFT

2 - OUTPUT SHAFT 6 - INPUT SHAFT

3 - LOW/REVERSE BAND APPLIED 7 - FRONT CLUTCH ENGAGED

4 - INPUT SHAFT 8 - LOW/REVERSE BAND APPLIED

Fig. 5 Reverse Powerflow

Page 8

DR AUTOMATIC TRANSMISSION - 48RE 21 - 137

AUTOMATIC TRANSMISSION - 48RE (Continued)

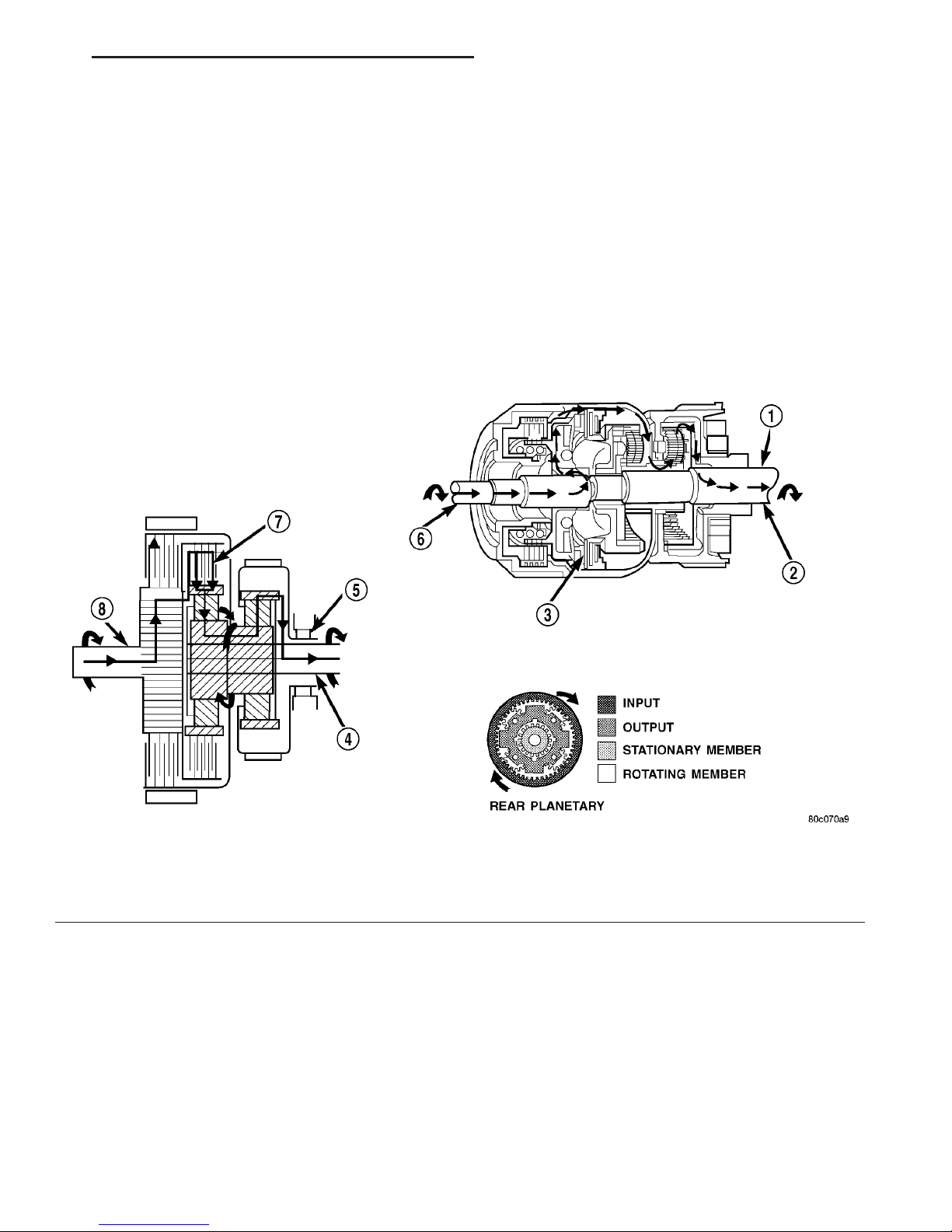

FIRST GEAR POWERFLOW

When the gearshift lever is moved into the DRIVE

position the transmission goes into first gear (Fig. 6).

As soon as the transmission is shifted from PARK or

NEUTRAL to DRIVE, the rear clutch applies, applying the rear clutch pack to the front annulus gear.

Engine torque is now applied to the front annulus

gear turning it in a clockwise direction. With the

front annulus gear turning in a clockwise direction, it

causes the front planets to turn in a clockwise direction. The rotation of the front planets cause the sun

to revolve in a counterclockwise direction. The sun

gear now transfers its counterclockwise rotation to

the rear planets which rotate back in a clockwise

direction. With the rear annulus gear stationary, the

rear planet rotation on the annulus gear causes the

rear planet carrier to revolve in a counterclockwise

direction. The rear planet carrier is splined into the

low-reverse drum, and the low reverse drum is

splined to the inner race of the over-running clutch.

With the over-running clutch locked, the planet carrier is held, and the resulting torque provided by the

planet pinions is transferred to the rear annulus

gear. The rear annulus gear is splined to the output

shaft and rotated along with it (clockwise) in an

underdrive gear reduction mode.

1 - OUTPUT SHAFT 5 - OVER-RUNNING CLUTCH HOLDING

2 - OVER-RUNNING CLUTCH HOLDING 6 - INPUT SHAFT

3 - REAR CLUTCH APPLIED 7 - REAR CLUTCH APPLIED

4 - OUTPUT SHAFT 8 - INPUT SHAFT

Fig. 6 First Gear Powerflow

Page 9

21 - 138 AUTOMATIC TRANSMISSION - 48RE DR

AUTOMATIC TRANSMISSION - 48RE (Continued)

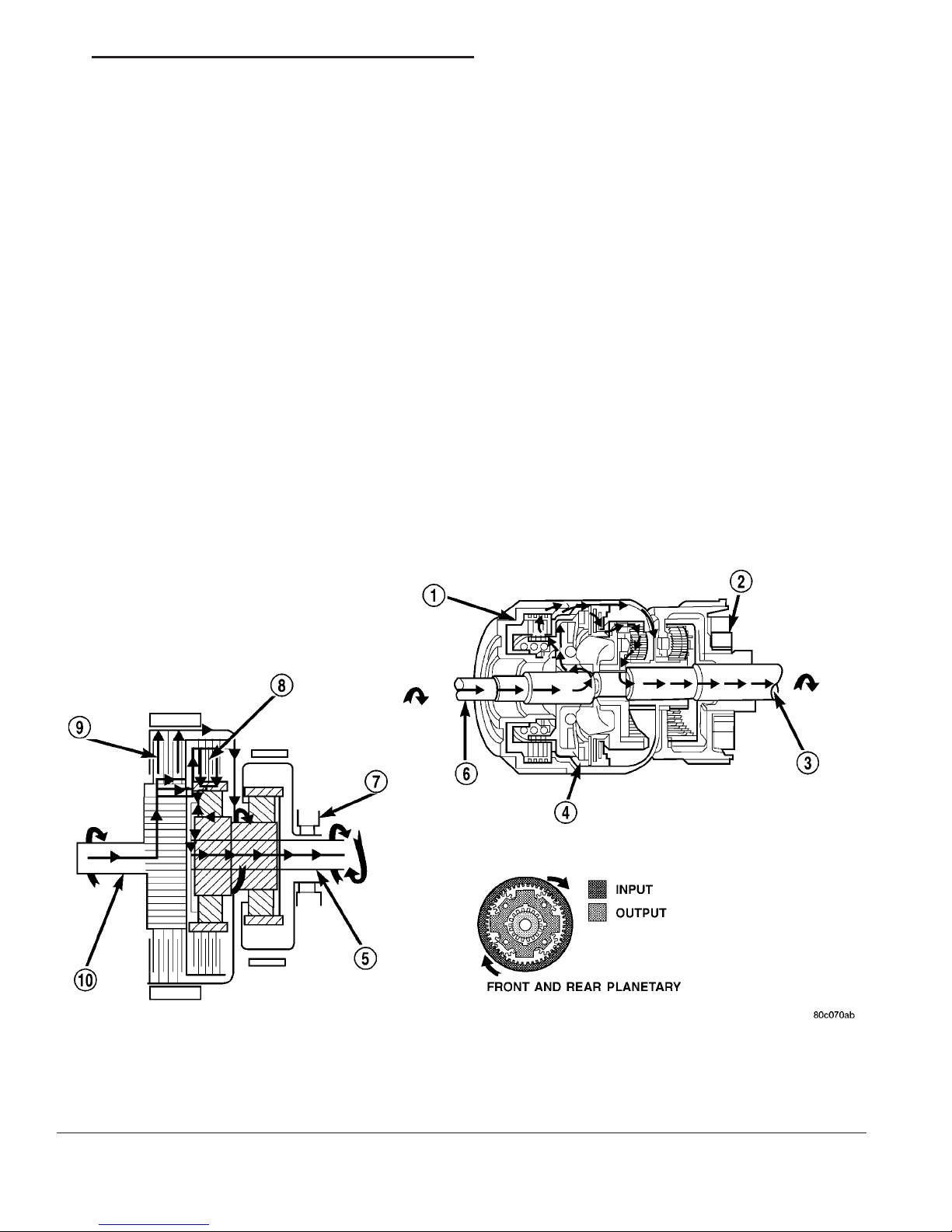

SECOND GEAR POWERFLOW

In DRIVE-SECOND (Fig. 7), the same elements

are applied as in MANUAL-SECOND. Therefore, the

power flow will be the same, and both gears will be

discussed as one in the same. In DRIVE-SECOND,

the transmission has proceeded from first gear to its

shift point, and is shifting from first gear to second.

The second gear shift is obtained by keeping the rear

clutch applied and applying the front (kickdown)

band. The front band holds the front clutch retainer

that is locked to the sun gear driving shell. With the

rear clutch still applied, the input is still on the front

annulus gear turning it clockwise at engine speed.

Now that the front band is holding the sun gear stationary, the annulus rotation causes the front planets

to rotate in a clockwise direction. The front carrier is

then also made to rotate in a clockwise direction but

at a reduced speed. This will transmit the torque to

the output shaft, which is directly connected to the

front planet carrier. The rear planetary annulus gear

will also be turning because it is directly splined to

the output shaft. All power flow has occurred in the

front planetary gear set during the drive-second

stage of operation, and now the over-running clutch,

in the rear of the transmission, is disengaged and

freewheeling on its hub.

1 - KICKDOWN BAND APPLIED 6 - INPUT SHAFT

2 - OUTPUT SHAFT 7 - REAR CLUTCH APPLIED

3 - REAR CLUTCH ENGAGED 8 - KICKDOWN BAND APPLIED

4 - OUTPUT SHAFT 9 - INPUT SHAFT

5 - OVER-RUNNING CLUTCH FREE-WHEELING

Fig. 7 Second Gear Powerflow

Page 10

DR AUTOMATIC TRANSMISSION - 48RE 21 - 139

AUTOMATIC TRANSMISSION - 48RE (Continued)

DIRECT DRIVE POWERFLOW

The vehicle has accelerated and reached the shift

point for the 2-3 upshift into direct drive (Fig. 8).

When the shift takes place, the front band is

released, and the front clutch is applied. The rear

clutch stays applied as it has been in all the forward

gears. With the front clutch now applied, engine

torque is now on the front clutch retainer, which is

locked to the sun gear driving shell. This means that

the sun gear is now turning in engine rotation (clockwise) and at engine speed. The rear clutch is still

applied so engine torque is also still on the front

annulus gear. If two members of the same planetary

set are driven, direct drive results. Therefore, when

two members are rotating at the same speed and in

the same direction, it is the same as being locked up.

The rear planetary set is also locked up, given the

sun gear is still the input, and the rear annulus gear

must turn with the output shaft. Both gears are

turning in the same direction and at the same speed.

The front and rear planet pinions do not turn at all

in direct drive. The only rotation is the input from

the engine to the connected parts, which are acting

as one common unit, to the output shaft.

FOURTH GEAR POWERFLOW

Fourth gear overdrive range is electronically controlled and hydraulically activated. Various sensor

inputs are supplied to the powertrain control module

to operate the overdrive solenoid on the valve body.

The solenoid contains a check ball that opens and

closes a vent port in the 3-4 shift valve feed passage.

The overdrive solenoid (and check ball) are not energized in first, second, third, or reverse gear. The vent

port remains open, diverting line pressure from the

2-3 shift valve away from the 3-4 shift valve. The

Tow/Haul control switch must be in the ON position

to transmit overdrive status to the PCM. A 3-4

upshift occurs only when the overdrive solenoid is

energized by the PCM. The PCM energizes the overdrive solenoid during the 3-4 upshift. This causes the

solenoid check ball to close the vent port allowing

line pressure from the 2-3 shift valve to act directly

on the 3-4 upshift valve. Line pressure on the 3-4

shift valve overcomes valve spring pressure moving

the valve to the upshift position. This action exposes

the feed passages to the 3-4 timing valve, 3-4 quick

fill valve, 3-4 accumulator, and ultimately to the

overdrive piston. Line pressure through the timing

1 - FRONT CLUTCH APPLIED 6 - INPUT SHAFT

2 - OVER-RUNNING CLUTCH FREE-WHEELING 7 - OVER-RUNNING CLUTCH FREE-WHEELING

3 - OUTPUT SHAFT 8 - REAR CLUTCH APPLIED

4 - REAR CLUTCH APPLIED 9 - FRONT CLUTCH APPLIED

5 - OUTPUT SHAFT 10 - INPUT SHAFT

Fig. 8 Direct Drive Powerflow

Page 11

21 - 140 AUTOMATIC TRANSMISSION - 48RE DR

AUTOMATIC TRANSMISSION - 48RE (Continued)

valve moves the overdrive piston into contact with

the overdrive clutch. The direct clutch is disengaged

before the overdrive clutch is engaged. The boost

valve provides increased fluid apply pressure to the

overdrive clutch during 3-4 upshifts, and when accelerating in fourth gear. The 3-4 accumulator cushions

overdrive clutch engagement to smooth 3-4 upshifts.

The accumulator is charged at the same time as

apply pressure acts against the overdrive piston.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AUTOMATIC

TRANSMISSION

Automatic transmission problems can be a result of

poor engine performance, incorrect fluid level, incorrect linkage or cable adjustment, band or hydraulic

control pressure adjustments, hydraulic system malfunctions or electrical/mechanical component malfunctions. Begin diagnosis by checking the easily

accessible items such as: fluid level and condition,

linkage adjustments and electrical connections. A

road test will determine if further diagnosis is necessary.

DIAGNOSIS AND TESTING - PRELIMINARY

Two basic procedures are required. One procedure

for vehicles that are drivable and an alternate procedure for disabled vehicles (will not back up or move

forward).

VEHICLE IS DRIVEABLE

(1) Check for transmission fault codes using DRBt

scan tool.

(2) Check fluid level and condition.

(3) Adjust throttle and gearshift linkage if complaint was based on delayed, erratic, or harsh shifts.

(4) Road test and note how transmission upshifts,

downshifts, and engages.

(5) Perform hydraulic pressure test if shift problems were noted during road test.

(6) Perform air-pressure test to check clutch-band

operation.

VEHICLE IS DISABLED

(1) Check fluid level and condition.

(2) Check for broken or disconnected gearshift or

throttle linkage.

(3) Check for cracked, leaking cooler lines, or loose

or missing pressure-port plugs.

(4) Raise and support vehicle on safety stands,

start engine, shift transmission into gear, and note

following:

(a) If propeller shaft turns but wheels do not,

problem is with differential or axle shafts.

(b) If propeller shaft does not turn and transmission is noisy, stop engine. Remove oil pan, and

check for debris. If pan is clear, remove transmission and check for damaged drive plate, converter,

oil pump, or input shaft.

(c) If propeller shaft does not turn and transmission is not noisy, perform hydraulic-pressure test to

determine if problem is hydraulic or mechanical.

DIAGNOSIS AND TESTING - ROAD TESTING

Before road testing, be sure the fluid level and con-

trol cable adjustments have been checked and

adjusted if necessary. Verify that diagnostic trouble

codes have been resolved.

Observe engine performance during the road test.

A poorly tuned engine will not allow accurate analysis of transmission operation.

Operate the transmission in all gear ranges. Check

for shift variations and engine flare which indicates

slippage. Note if shifts are harsh, spongy, delayed,

early, or if part throttle downshifts are sensitive.

Slippage indicated by engine flare, usually means

clutch, band or overrunning clutch problems. If the

condition is advanced, an overhaul will be necessary

to restore normal operation.

A slipping clutch or band can often be determined

by comparing which internal units are applied in the

various gear ranges. The Clutch and Band Application chart provides a basis for analyzing road test

results.

Page 12

DR AUTOMATIC TRANSMISSION - 48RE 21 - 141

AUTOMATIC TRANSMISSION - 48RE (Continued)

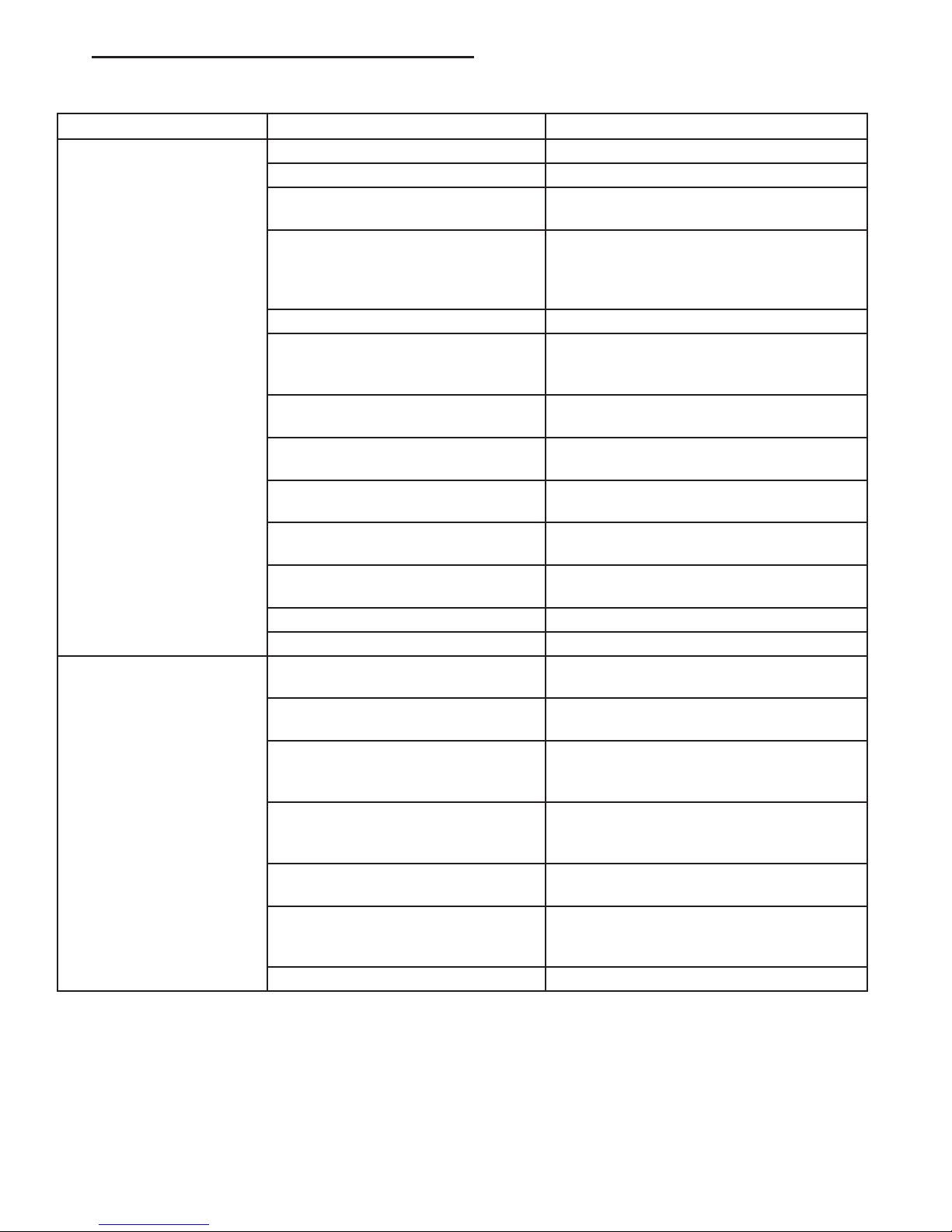

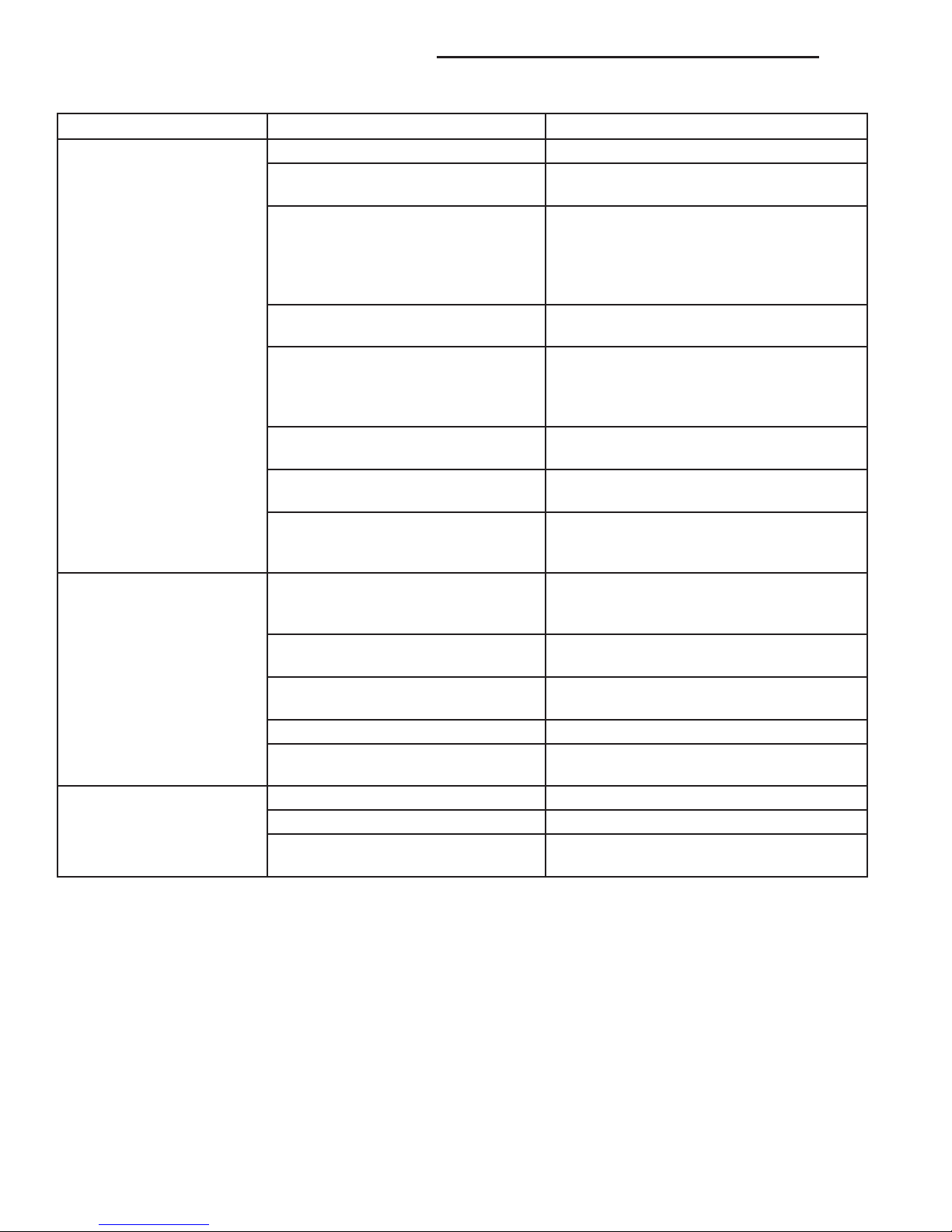

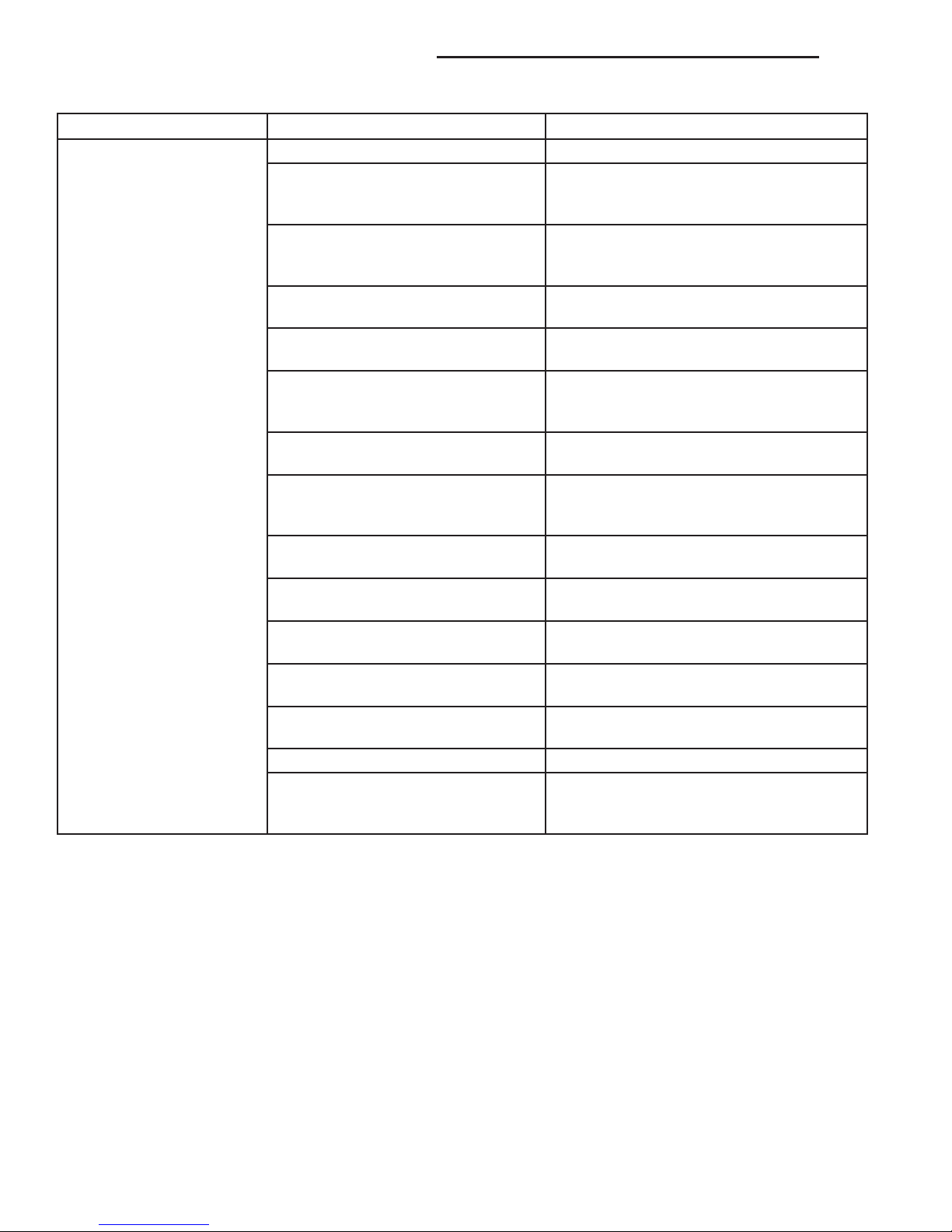

CLUTCH AND BAND APPLICATION CHART

SHIFT

LEVER

POSITION

Reverse X X X

Drive -

First

Drive -

Second

Drive -

Third

Drive Fourth

Manual

Second

Manual

First

Note that the rear clutch is applied in all forward

ranges (D, 2, 1). The transmission overrunning clutch

is applied in first gear (D, 2 and 1 ranges) only. The

rear band is applied in 1 and R range only.

Note that the overdrive clutch is applied only in

fourth gear and the overdrive direct clutch and overrunning clutch are applied in all ranges except fourth

gear.

For example: If slippage occurs in first gear in D

and 2 range but not in 1 range, the transmission

overrunning clutch is faulty. Similarly, if slippage

occurs in any two forward gears, the rear clutch is

slipping.

Applying the same method of analysis, note that

the front and rear clutches are applied simultaneously only in D range third and fourth gear. If the

transmission slips in third gear, either the front

clutch or the rear clutch is slipping.

If the transmission slips in fourth gear but not in

third gear, the overdrive clutch is slipping. By selecting another gear which does not use these clutches,

the slipping unit can be determined. For example, if

the transmission also slips in Reverse, the front

clutch is slipping. If the transmission does not slip in

Reverse, the rear clutch is slipping.

If slippage occurs during the 3-4 shift or only in

fourth gear, the overdrive clutch is slipping. Similarly, if the direct clutch were to fail, the transmission would lose both reverse gear and overrun

braking in 2 position (manual second gear).

If the transmission will not shift to fourth gear, the

control switch, overdrive solenoid or related wiring

may also be the problem cause.

FRONT

CLUTCH

TRANSMISSION CLUTCHES AND BANDS OVERDRIVE CLUTCHES

FRONT

BAND

XX XX

XX XX

XX X

XX XX

REAR

CLUTCH

XXXX

XXX XX

REAR

BAND

a slipping unit and check operation. Proper use of

the Clutch and Band Application Chart is the key.

slipping unit, the actual cause of a malfunction usually cannot be determined until hydraulic and air

pressure tests are performed. Practically any condition can be caused by leaking hydraulic circuits or

sticking valves.

in D range first gear, do not disassemble the transmission. Perform the hydraulic and air pressure tests

to help determine the probable cause.

OVER-

RUNNING

CLUTCH

This process of elimination can be used to identify

Although road test analysis will help determine the

Unless a malfunction is obvious, such as no drive

OVERDRIVE

CLUTCH

DIAGNOSIS AND TESTING - HYDRAULIC

PRESSURE TEST

Hydraulic test pressures range from a low of one

psi (6.895 kPa) governor pressure, to 300 psi (2068

kPa) at the rear servo pressure port in reverse.

An accurate tachometer and pressure test gauges

are required. Test Gauge C-3292 has a 100 psi range

and is used at the accumulator, governor, and front

servo ports. Test Gauge C-3293-SP has a 300 psi

range and is used at the rear servo and overdrive

ports where pressures exceed 100 psi.

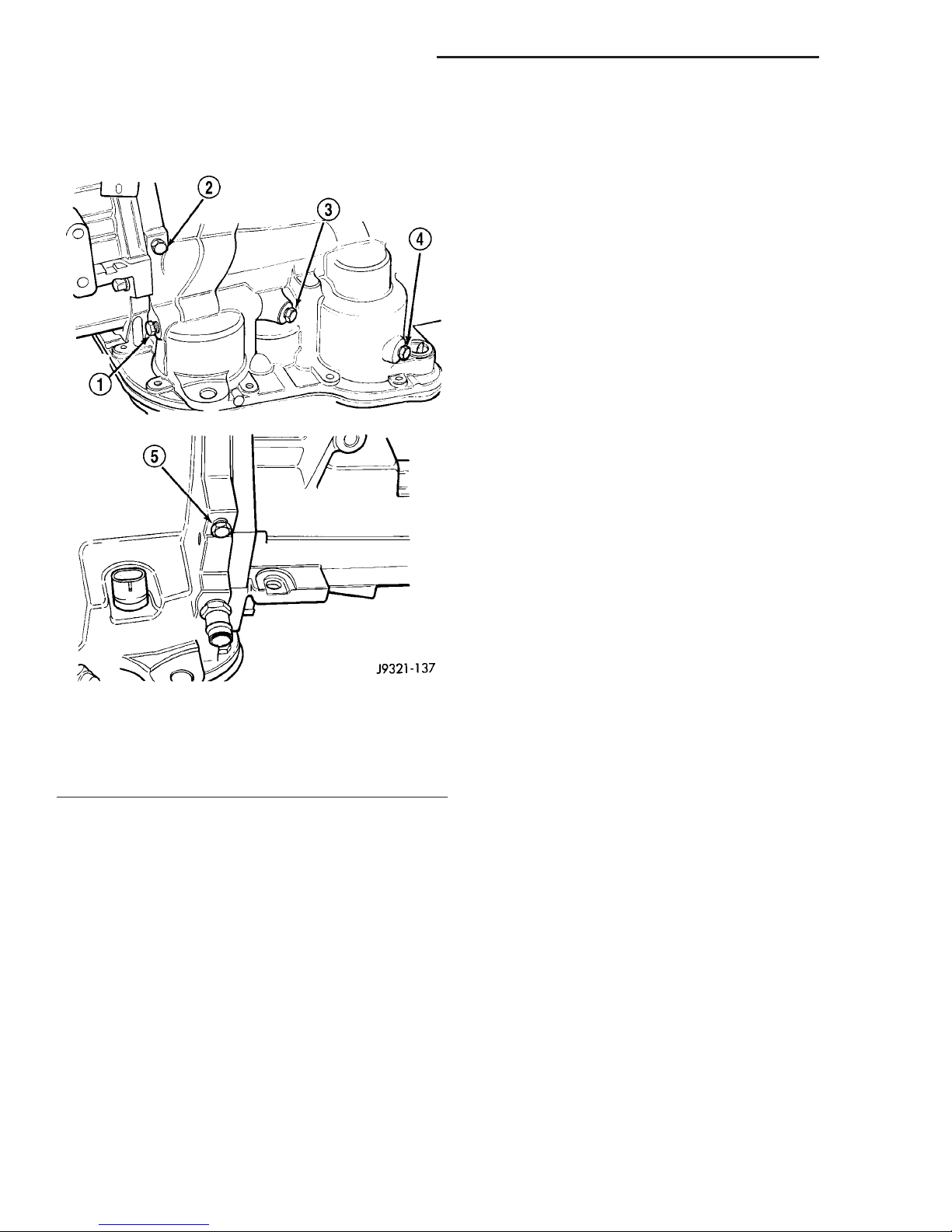

Pressure Test Port Locations

Test ports are located at both sides of the transmission case (Fig. 9).

Line pressure is checked at the accumulator port

on the right side of the case. The front servo pressure

port is at the right side of the case just behind the

filler tube opening.

DIRECT

CLUTCH

OVER-

RUNNING

CLUTCH

Page 13

21 - 142 AUTOMATIC TRANSMISSION - 48RE DR

AUTOMATIC TRANSMISSION - 48RE (Continued)

The rear servo and governor pressure ports are at

the right rear of the transmission case. The overdrive

clutch pressure port is at the left rear of the case.

Fig. 9 Pressure Test Port Locations

1 - REAR SERVO TEST PORT

2 - GOVERNOR TEST PORT

3 - ACCUMULATOR TEST PORT

4 - FRONT SERVO TEST PORT

5 - OVERDRIVE CLUTCH TEST PORT

Test One - Transmission In Manual Low

This test checks pump output, pressure regulation,

and condition of the rear clutch and servo circuit.

Both test gauges are required for this test.

(1) Connect tachometer to engine. Position tachometer so it can be observed from driver seat if helper

will be operating engine. Raise vehicle on hoist that

will allow rear wheels to rotate freely.

(2) Connect 100 psi Gauge C-3292 to accumulator

port. Then connect 300 psi Gauge C-3293-SP to rear

servo port.

(3) Disconnect throttle and gearshift cables from

levers on transmission valve body manual shaft.

(4) Have helper start and run engine at 1000 rpm.

(5) Move transmission shift lever fully forward

into 1 range.

(6) Gradually move transmission throttle lever

from full forward to full rearward position and note

pressures on both gauges:

• Line pressure at accumulator port should be

54-60 psi (372-414 kPa) with throttle lever forward

and gradually increase to 90-96 psi (621-662 kPa) as

throttle lever is moved rearward.

• Rear servo pressure should be same as line pressure within 3 psi (20.68 kPa).

Test Two - Transmission In 2 Range

This test checks pump output, line pressure and

pressure regulation. Use 100 psi Test Gauge C-3292

for this test.

(1) Leave vehicle in place on hoist and leave Test

Gauge C-3292 connected to accumulator port.

(2) Have helper start and run engine at 1000 rpm.

(3) Move transmission shift lever one detent rearward from full forward position. This is 2 range.

(4) Move transmission throttle lever from full forward to full rearward position and read pressure on

gauge.

(5) Line pressure should be 54-60 psi (372-414

kPa) with throttle lever forward and gradually

increase to 90-96 psi (621-662 kPa) as lever is moved

rearward.

Test Three - Transmission In D Range Third Gear

This test checks pressure regulation and condition

of the clutch circuits. Both test gauges are required

for this test.

(1) Turn OD switch off.

(2) Leave vehicle on hoist and leave Gauge C-3292

in place at accumulator port.

(3) Move Gauge C-3293-SP over to front servo port

for this test.

(4) Have helper start and run engine at 1600 rpm

for this test.

(5) Move transmission shift lever two detents rearward from full forward position. This is D range.

(6) Read pressures on both gauges as transmission

throttle lever is gradually moved from full forward to

full rearward position:

• Line pressure at accumulator in D range third

gear, should be 54-60 psi (372-414 kPa) with throttle

lever forward and increase as lever is moved rearward.

• Front servo pressure in D range third gear,

should be within 3 psi (21 kPa) of line pressure up to

kickdown point.

Test Four - Transmission In Reverse

This test checks pump output, pressure regulation

and the front clutch and rear servo circuits. Use 300

psi Test Gauge C-3293-SP for this test.

(1) Leave vehicle on hoist and leave gauge C-3292

in place at accumulator port.

(2) Move 300 psi Gauge C-3293-SP back to rear

servo port.

Page 14

DR AUTOMATIC TRANSMISSION - 48RE 21 - 143

AUTOMATIC TRANSMISSION - 48RE (Continued)

(3) Have helper start and run engine at 1600 rpm

for test.

Move transmission shift lever four detents rear-

(4)

ward from full forward position. This is Reverse range.

(5) Move transmission throttle lever fully forward

then fully rearward and note reading at Gauge

C-3293-SP.

(6) Pressure should be 145 - 175 psi (1000-1207

kPa) with throttle lever forward and increase to 230 280 psi (1586-1931 kPa) as lever is gradually moved

rearward.

Test Five - Governor Pressure

This test checks governor operation by measuring

governor pressure response to changes in vehicle

speed. It is usually not necessary to check governor

operation unless shift speeds are incorrect or if the

transmission will not downshift. The test should be

performed on the road or on a hoist that will allow

the rear wheels to rotate freely.

(1) Move 100 psi Test Gauge C-3292 to governor

pressure port.

(2) Move transmission shift lever two detents rearward from full forward position. This is D range.

(3) Have helper start and run engine at curb idle

speed. Then firmly apply service brakes so wheels

will not rotate.

(4) Note governor pressure:

Governor pressure should be no more than 20.6

•

kPa (3 psi) at curb idle speed and wheels not rotating.

• If pressure exceeds 20.6 kPa (3 psi), a fault

exists in governor pressure control system.

(5) Release brakes, slowly increase engine speed,

and observe speedometer and pressure test gauge (do

not exceed 30 mph on speedometer). Governor pressure should increase in proportion to vehicle speed.

Or approximately 6.89 kPa (1 psi) for every 1 mph.

(6) Governor pressure rise should be smooth and

drop back to no more than 20.6 kPa (3 psi), after

engine returns to curb idle and brakes are applied to

prevent wheels from rotating.

Compare results of pressure test with analysis

(7)

chart.

Test Six - Transmission In Overdrive Fourth Gear

This test checks line pressure at the overdrive

clutch in fourth gear range. Use 300 psi Test Gauge

C-3293-SP for this test. The test should be performed

on the road or on a chassis dyno.

Remove tachometer; it is not needed for this test.

(1)

(2) Move 300 psi Gauge to overdrive clutch pressure test port. Then remove other gauge and reinstall

test port plug.

(3) Lower vehicle.

(4) Turn OD switch on.

(5) Secure test gauge so it can be viewed from

drivers seat.

(6) Start engine and shift into D range.

(7) Increase vehicle speed gradually until 3-4 shift

occurs and note gauge pressure.

(8) Pressure should be 524-565 kPa (76-82 psi)

with closed throttle and increase to 690-896 kPa

(100-130 psi) at 1/2 to 3/4 throttle. Note that pressure can increase to around 965 kPa (140 psi) at full

throttle.

(9) Return to shop or move vehicle off chassis

dyno.

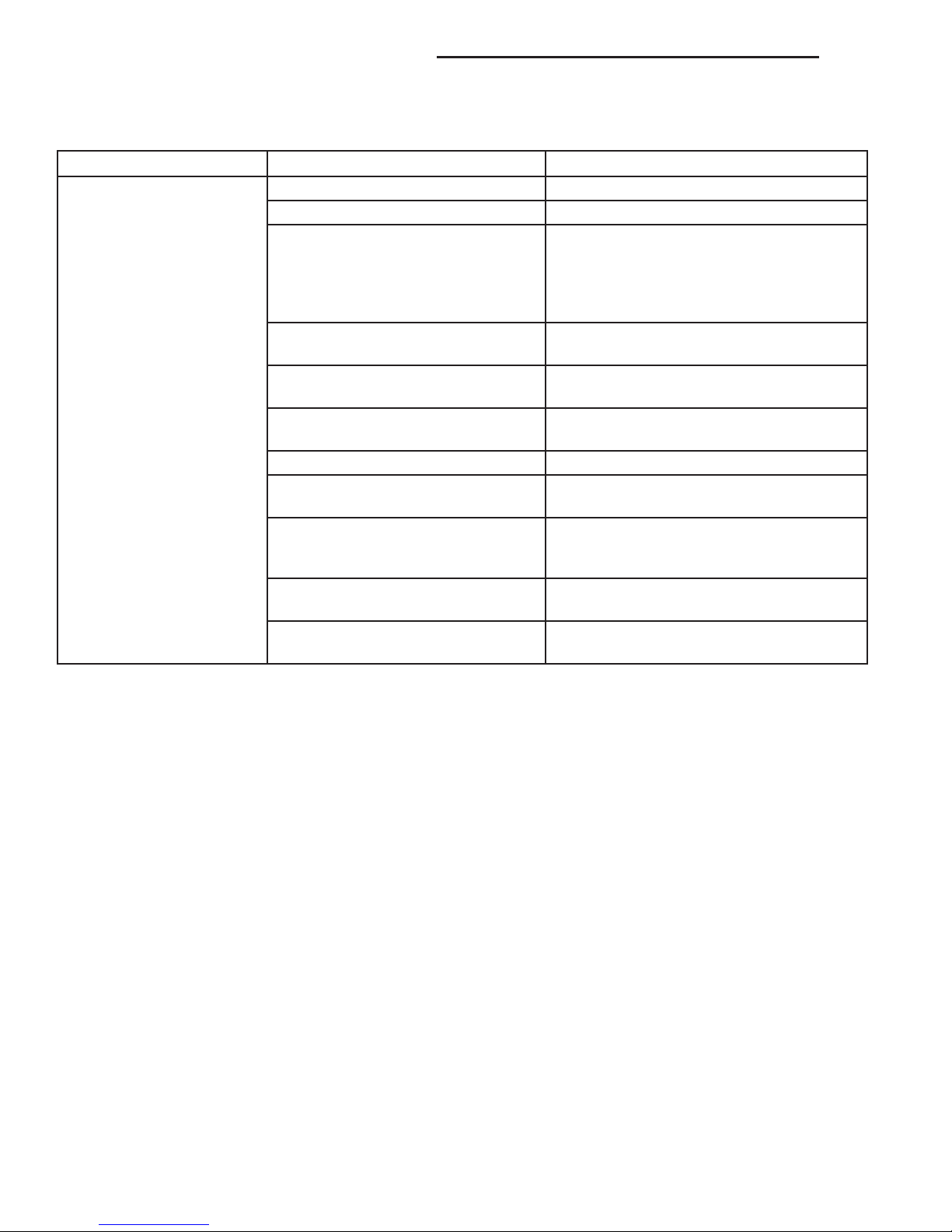

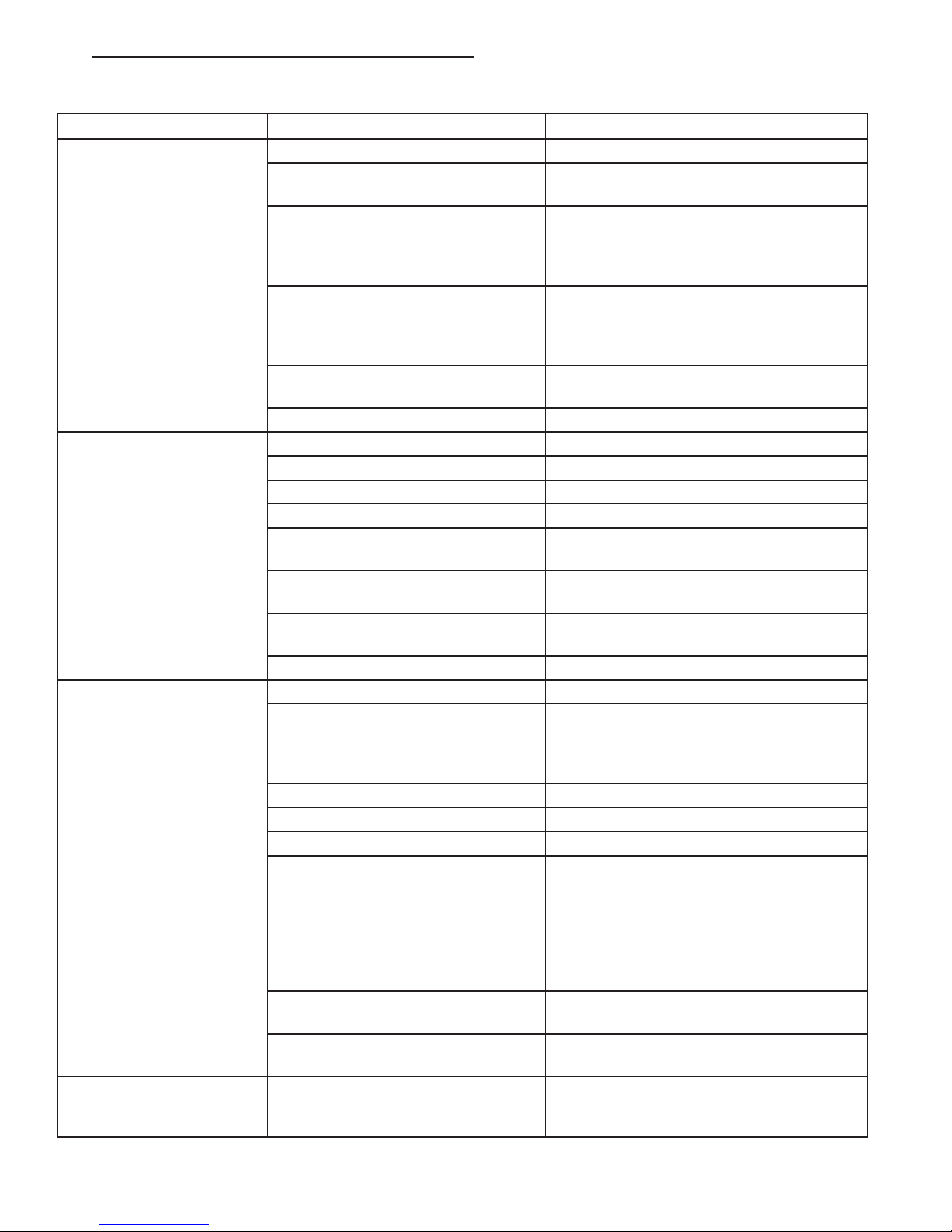

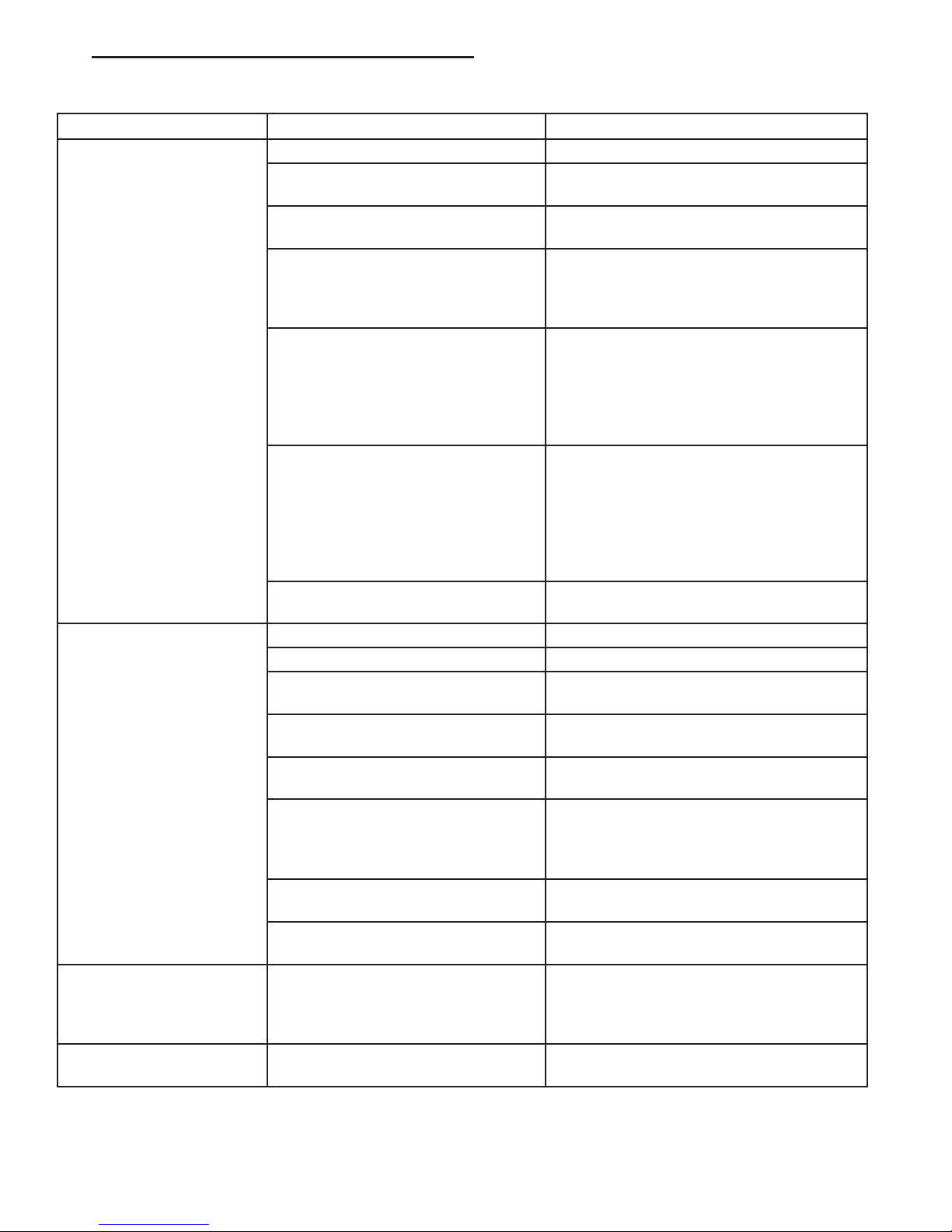

PRESSURE TEST ANALYSIS CHART

TEST CONDITION INDICATION

Line pressure OK during

any one test

Line pressure OK in R

but low in D, 2, 1

Pressure low in D Fourth

Gear Range

Pressure OK in 1, 2 but

low in D3 and R

Pressure OK in 2 but low

in R and 1

Front servo pressure in 2 Leakage in servo; broken

Pressure low in all

positions

Governor pressure too

high at idle speed

Governor pressure low at

all mph figures

Lubrication pressure low

at all throttle positions

Line pressure high Output shaft plugged,

Line pressure low Sticky regulator valve,

Pump and regulator

valve OK

Leakage in rear clutch

area (seal rings, clutch

seals)

Overdrive clutch piston

seal, or check ball

problem

Leakage in front clutch

area

Leakage in rear servo

servo ring or cracked

servo piston

Clogged filter, stuck

regulator valve, worn or

faulty pump, low oil level

Governor pressure

solenoid valve system

fault. Refer to diagnostic

book.

Faulty governor pressure

solenoid, transmission

control module, or

governor pressure

sensor

Clogged fluid cooler or

lines, seal rings leaking,

worn pump bushings,

pump, clutch retainer, or

clogged filter.

sticky regulator valve

clogged filter, worn pump

Page 15

21 - 144 AUTOMATIC TRANSMISSION - 48RE DR

AUTOMATIC TRANSMISSION - 48RE (Continued)

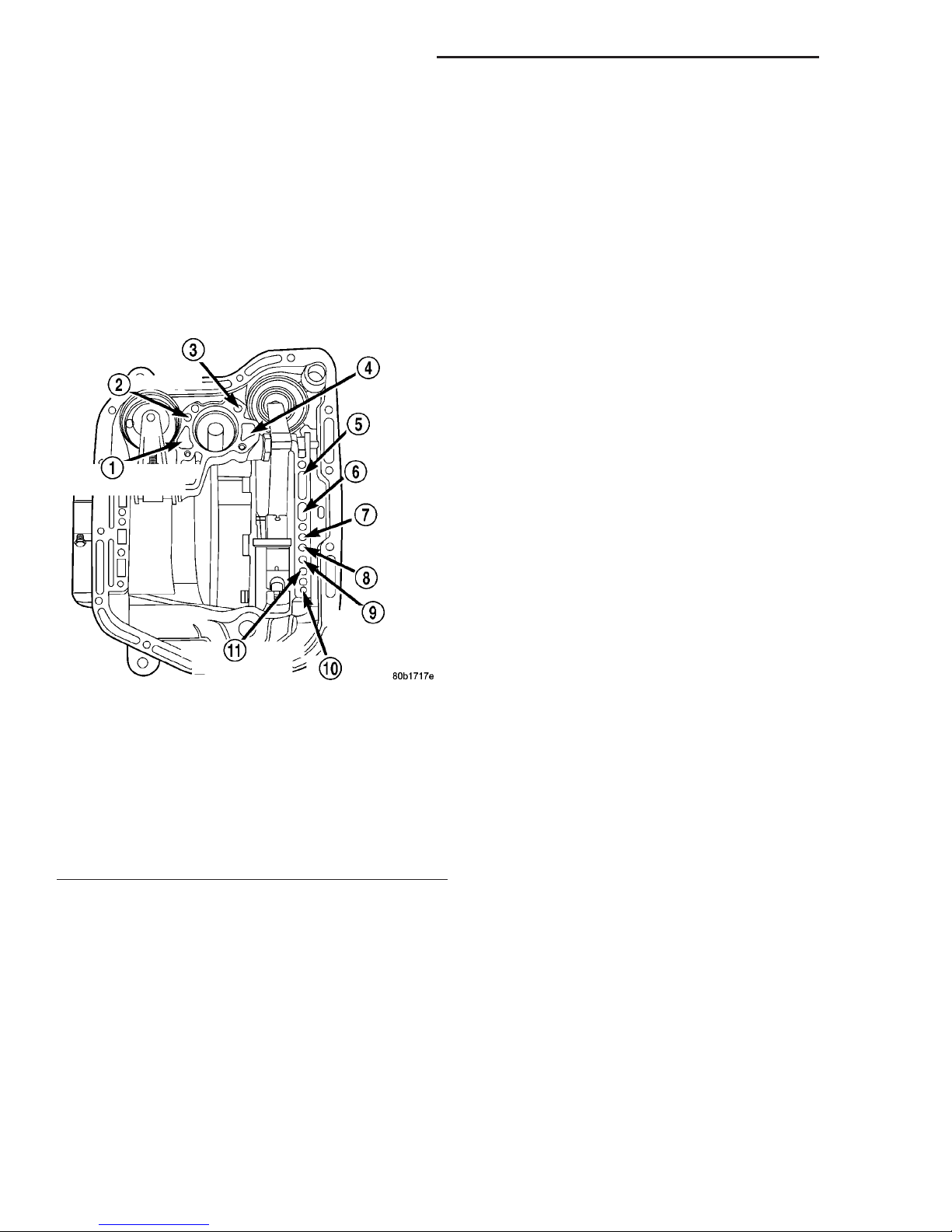

DIAGNOSIS AND TESTING - AIR TESTING

TRANSMISSION CLUTCH AND BAND

OPERATION

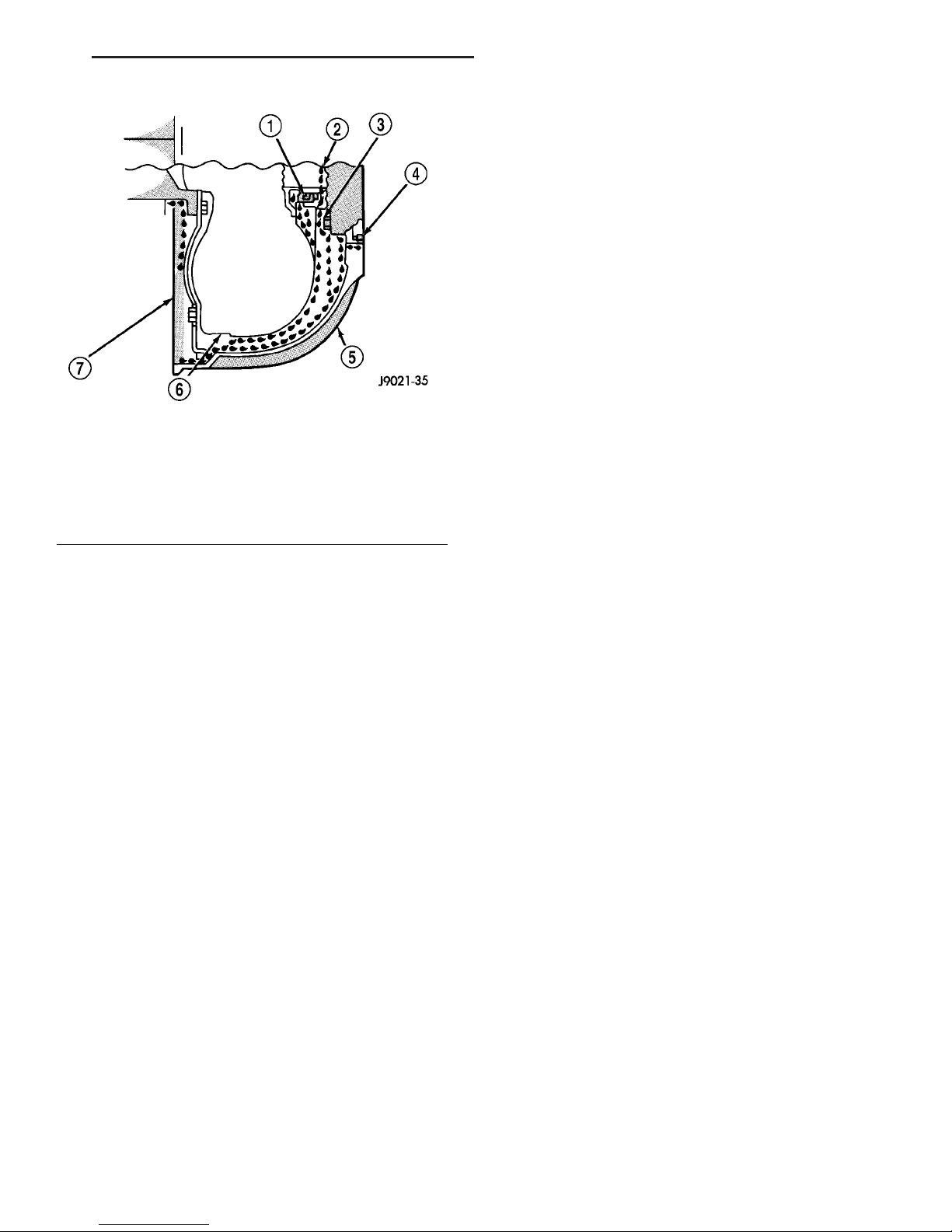

Air-pressure testing can be used to check transmission front/rear clutch and band operation. The test

can be conducted with the transmission either in the

vehicle or on the work bench, as a final check, after

overhaul.

Air-pressure testing requires that the oil pan and

valve body be removed from the transmission. The

servo and clutch apply passages are shown (Fig. 10).

Fig. 10 Air Pressure Test Passages

1 - LINE PRESSURE TO ACCUMULATOR

2 - REAR SERVO APPLY

3 - FRONT SERVO APPLY

4 - FRONT SERVO RELEASE

5 - PUMP SUCTION

6 - PUMP PRESSURE

7 - FRONT CLUTCH APPLY

8 - REAR CLUTCH APPLY

9 - TO TORQUE CONVERTOR

10 - TO COOLER

11 - FROM TORQUE CONVERTER

Front Clutch Air Test

Place one or two fingers on the clutch housing and

apply air pressure through front clutch apply passage. Piston movement can be felt and a soft thump

heard as the clutch applies.

Rear Clutch Air Test

Place one or two fingers on the clutch housing and

apply air pressure through rear clutch apply passage.

Piston movement can be felt and a soft thump heard

as the clutch applies.

Front Servo Air Test

Apply air pressure to the front servo apply passage. The servo rod should extend and cause the

band to tighten around the drum. Spring pressure

should release the servo when air pressure is

removed.

Rear Servo Air Test

Apply air pressure to the rear servo apply passage.

The servo rod should extend and cause the band to

tighten around the drum. Spring pressure should

release the servo when air pressure is removed.

DIAGNOSIS AND TESTING - CONVERTER

HOUSING FLUID LEAK

When diagnosing converter housing fluid leaks,

two items must be established before repair.

(1) Verify that a leak condition actually exists.

(2) Determined the true source of the leak.

Some suspected converter housing fluid leaks may

not be leaks at all. They may only be the result of

residual fluid in the converter housing, or excess

fluid spilled during factory fill or fill after repair.

Converter housing leaks have several potential

sources. Through careful observation, a leak source

can be identified before removing the transmission

for repair. Pump seal leaks tend to move along the

drive hub and onto the rear of the converter. Pump

body leaks follow the same path as a seal leak (Fig.

11). Pump vent or pump attaching bolt leaks are generally deposited on the inside of the converter housing and not on the converter itself (Fig. 11). Pump

o-ring or gasket leaks usually travel down the inside

of the converter housing. Front band lever pin plug

leaks are generally deposited on the housing and not

on the converter.

Page 16

DR AUTOMATIC TRANSMISSION - 48RE 21 - 145

AUTOMATIC TRANSMISSION - 48RE (Continued)

(4) Inspect pump bushing and converter hub. If

bushing is scored, replace it. If converter hub is

scored, either polish it with crocus cloth or replace

converter.

(5) Install new pump seal, O-ring, and gasket.

Replace oil pump if cracked, porous or damaged in

any way. Be sure to loosen the front band before

installing the oil pump, damage to the oil pump seal

may occur if the band is still tightened to the front

clutch retainer.

(6) Loosen kickdown lever pin access plug three

turns. Apply Loctite™ 592, or Permatext No.2to

plug threads and tighten plug to 17 N·m (150 in. lbs.)

torque.

(7) Adjust front band.

(8) Lubricate pump seal and converter hub with

Fig. 11 Converter Housing Leak Paths

1 - PUMP SEAL

2 - PUMP VENT

3 - PUMP BOLT

4 - PUMP GASKET

5 - CONVERTER HOUSING

6 - CONVERTER

7 - REAR MAIN SEAL LEAK

transmission fluid or petroleum jelly and install converter.

(9) Install transmission and converter housing

dust shield.

(10) Lower vehicle.

DIAGNOSIS AND TESTING - DIAGNOSIS

CHARTS

TORQUE CONVERTER LEAK POINTS

Possible sources of converter leaks are:

• Leaks at the weld joint around the outside diam-

eter weld.

• Leaks at the converter hub weld.

CONVERTER HOUSING AREA LEAK CORRECTION

(1) Remove converter.

(2) Tighten front band adjusting screw until band

is tight around front clutch retainer. This prevents

front/rear clutches from coming out when oil pump is

removed.

(3) Remove oil pump and remove pump seal.

Inspect pump housing drainback and vent holes for

obstructions. Clear holes with solvent and wire.

The diagnosis charts provide additional reference

when diagnosing a transmission fault. The charts

provide general information on a variety of transmission, overdrive unit and converter clutch fault conditions.

The hydraulic flow charts in the Schematics and

Diagrams section of this group, outline fluid flow and

hydraulic circuitry. Circuit operation is provided for

PARK, NEUTRAL, FIRST, SECOND, THIRD,

FOURTH, MANUAL FIRST, MANUAL SECOND,

and REVERSE gear ranges. Normal working pressures are also supplied for each of the gear ranges.

Page 17

21 - 146 AUTOMATIC TRANSMISSION - 48RE DR

AUTOMATIC TRANSMISSION - 48RE (Continued)

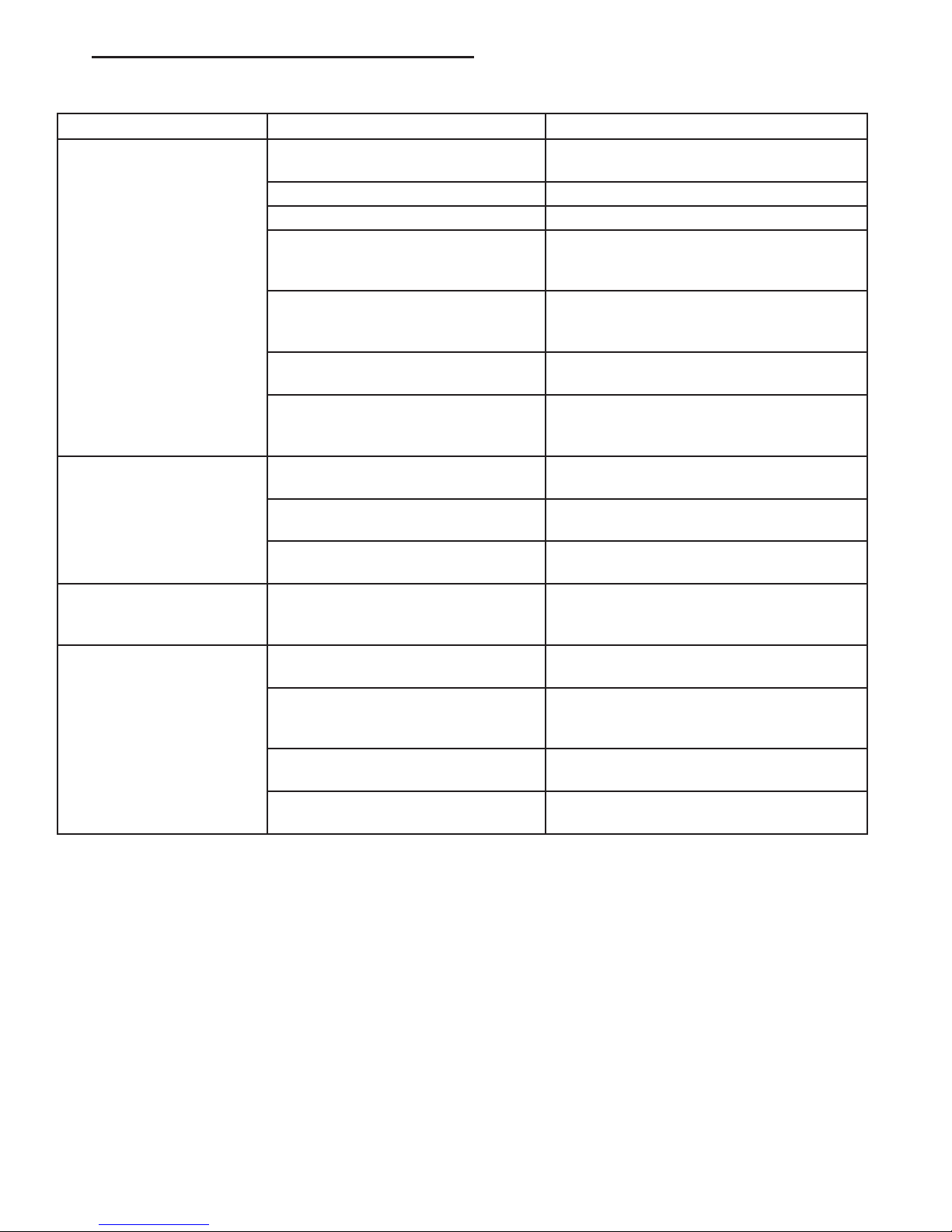

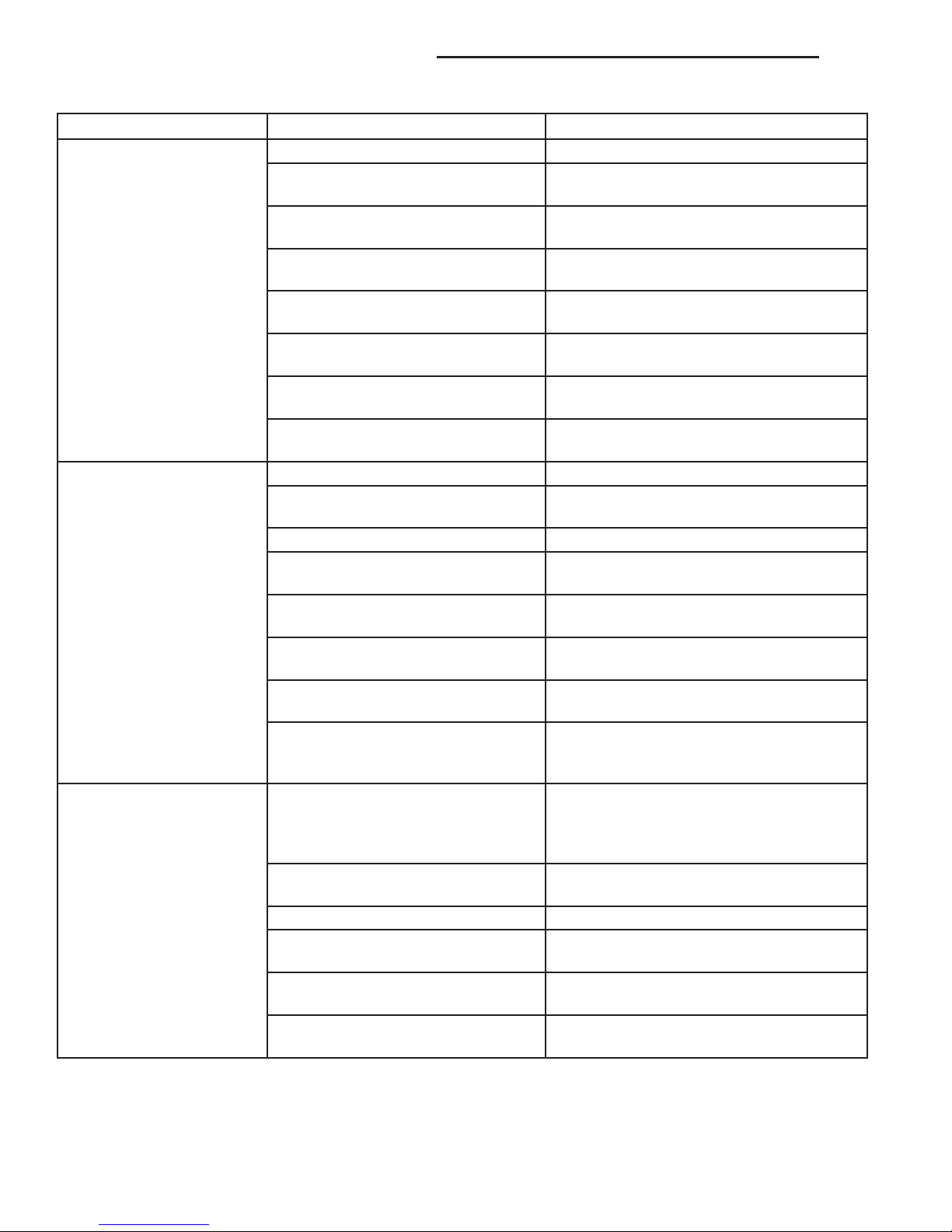

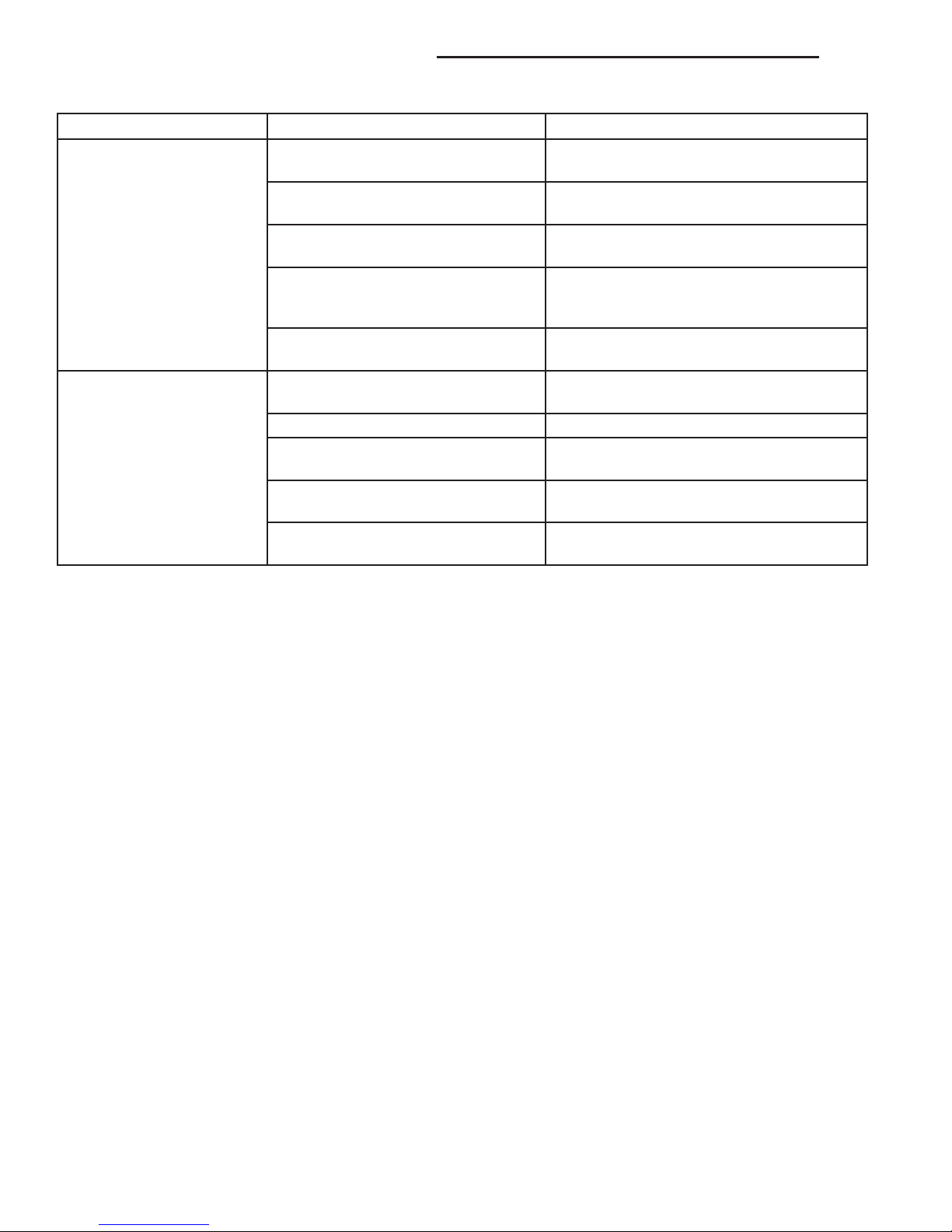

DIAGNOSIS CHARTS

CONDITION POSSIBLE CAUSES CORRECTION

HARSH ENGAGEMENT

(FROM NEUTRAL TO

DRIVE OR REVERSE)

1. Fluid Level Low. 1. Add Fluid

2. Throttle Linkage Mis-adjusted. 2. Adjust linkage - setting may be too long.

3. Mount and Driveline Bolts Loose. 3. Check engine mount, transmission

mount, propeller shaft, rear spring to body

bolts, rear control arms, crossmember and

axle bolt torque. Tighten loose bolts and

replace missing bolts.

4. U-Joint Worn/Broken. 4. Remove propeller shaft and replace

U-Joint.

5. Axle Backlash Incorrect. 5. Check per Service Manual. Correct as

needed.

6. Hydraulic Pressure Incorrect. 6. Check pressure. Remove, overhaul or

adjust valve body as needed.

7. Band Mis-adjusted. 7. Adjust rear band.

8. Valve Body Check Balls Missing. 8. Inspect valve body for proper check ball

installation.

9. Axle Pinion Flange Loose. 9. Replace nut and check pinion threads

before installing new nut. Replace pinion

gear if threads are damaged.

10. Clutch, band or planetary

component damaged.

11. Converter Clutch Faulty. 11. Replace converter and flush cooler and

10. Remove, disassemble and repair

transmission as necessary.

line before installing new converter.

Page 18

DR AUTOMATIC TRANSMISSION - 48RE 21 - 147

AUTOMATIC TRANSMISSION - 48RE (Continued)

CONDITION POSSIBLE CAUSES CORRECTION

DELAYED ENGAGEMENT

(FROM NEUTRAL TO

DRIVE OR REVERSE)

NO DRIVE RANGE

(REVERSE OK)

1. Fluid Level Low. 1. Correct level and check for leaks.

2. Filter Clogged. 2. Change filter.

3. Gearshift Linkage Mis-adjusted. 3. Adjust linkage and repair linkage if worn

or damaged.

4. Torque Converter Drain Back (Oil

drains from torque converter into

transmission sump).

5. Rear Band Mis-adjusted. 5. Adjust band.

6. Valve Body Filter Plugged. 6. Replace fluid and filter. If oil pan and old

7. Oil Pump Gears Worn/Damaged. 7. Remove transmission and replace oil

8. Governor Circuit and Solenoid

Valve Electrical Fault.

9. Hydraulic Pressure Incorrect. 9. Perform pressure test, remove

10. Reaction Shaft Seal Rings

Worn/Broken.

11. Rear Clutch/Input Shaft, Rear

Clutch Seal Rings Damaged.

12. Regulator Valve Stuck. 12. Clean.

13. Cooler Plugged. 13. Transfer case failure can plug cooler.

1. Fluid Level Low. 1. Add fluid and check for leaks if drive is

2. Gearshift Linkage/Cable

Loose/Misadjusted.

3. Rear Clutch Burnt. 3. Remove and disassemble transmission

4. Valve Body Malfunction. 4. Remove and disassemble valve body.

5. Transmission Overrunning Clutch

Broken.

6. Input Shaft Seal Rings Worn/

Damaged.

7. Front Planetary Failed Broken. 7. Remove and repair.

4. If vehicle moves normally after 5

seconds after shifting into gear, no repair is

necessary. If longer, inspect pump bushing

for wear. Replace pump house.

fluid were full of clutch disc material and/or

metal particles, overhaul will be necessary.

pump.

8. Test with DRBT scan tool and repair as

required.

transmission and repair as needed.

10. Remove transmission, remove oil pump

and replace seal rings.

11. Remove and disassemble transmission

and repair as necessary.

restored.

2. Repair or replace linkage components.

and rear clutch and seals. Repair/replace

worn or damaged parts as needed.

Replace assembly if any valves or bores

are damaged.

5. Remove and disassemble transmission.

Replace overrunning clutch.

6. Remove and disassemble transmission.

Replace seal rings and any other worn or

damaged parts.

Page 19

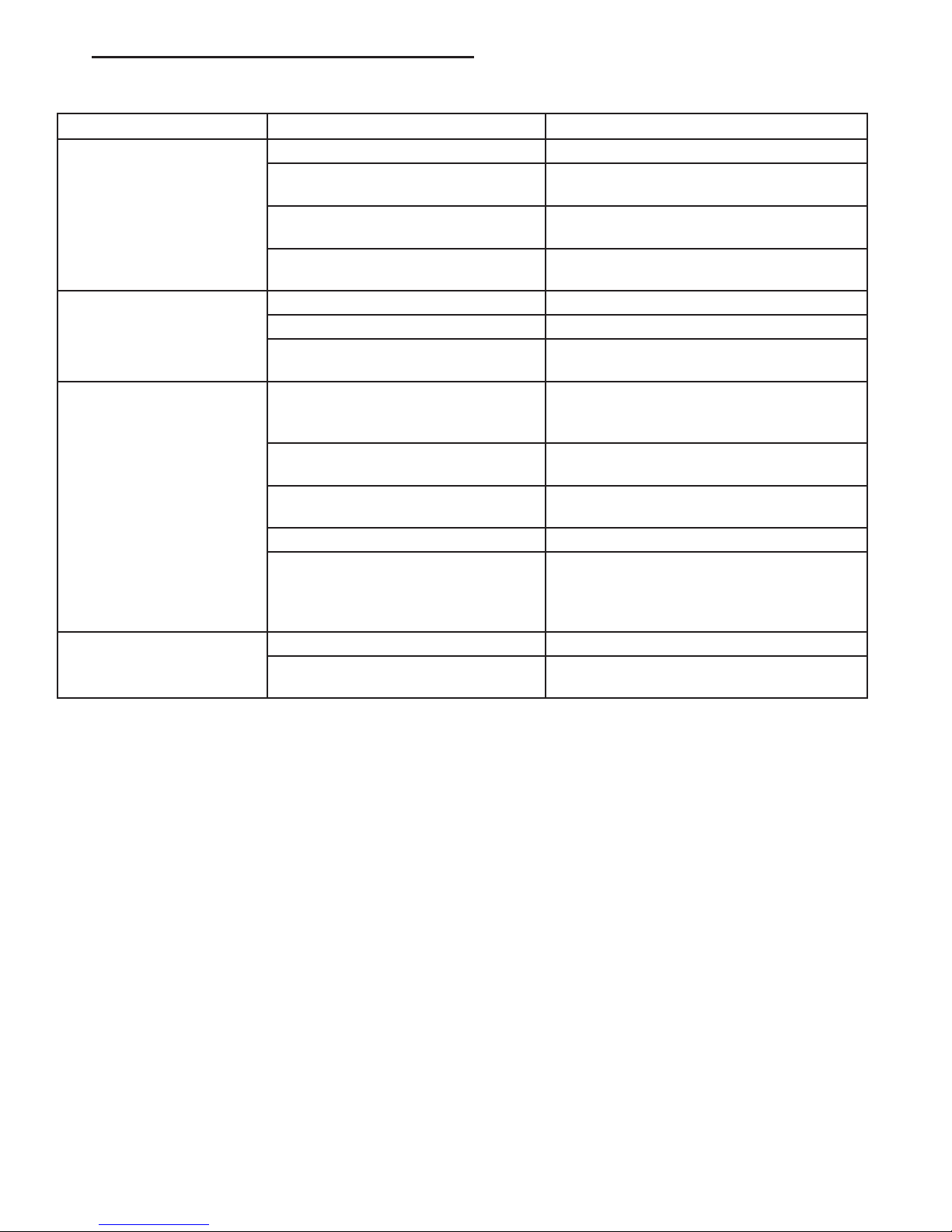

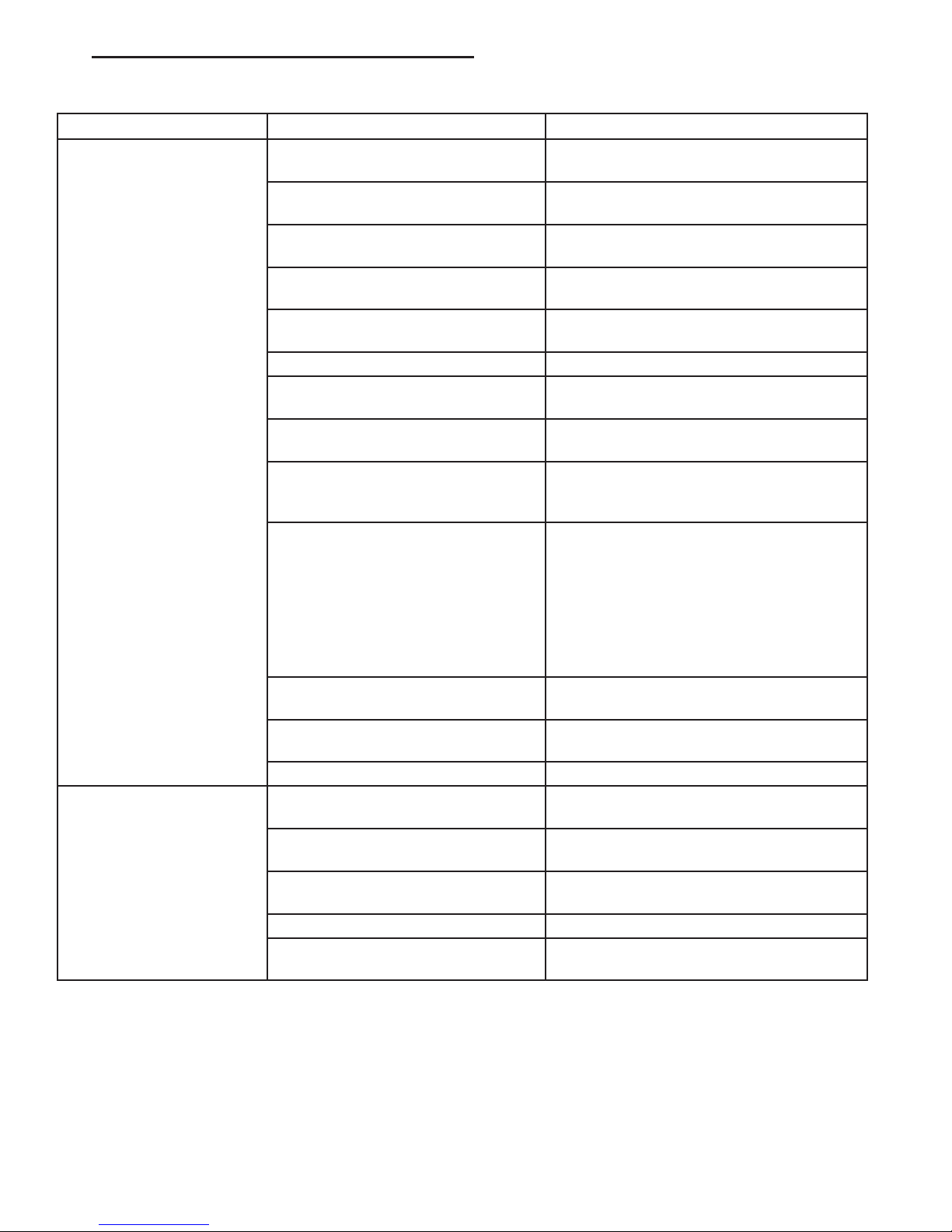

21 - 148 AUTOMATIC TRANSMISSION - 48RE DR

AUTOMATIC TRANSMISSION - 48RE (Continued)

CONDITION POSSIBLE CAUSES CORRECTION

NO DRIVE OR REVERSE

(VEHICLE WILL NOT

MOVE)

SHIFTS DELAYED OR

ERRATIC (SHIFTS ALSO

HARSH AT TIMES)

1. Fluid Level Low. 1. Add fluid and check for leaks if drive is

restored.

2. Gearshift Linkage/Cable

Loose/Misadjusted.

3. U-Joint/Axle/Transfer Case

Broken.

4. Filter Plugged. 4. Remove and disassemble transmission.

5. Oil Pump Damaged. 5. Perform pressure test to confirm low

6. Valve Body Malfunctioned. 6. Check and inspect valve body. Replace

7. Transmission Internal Component

Damaged.

8. Park Sprag not Releasing - Check

Stall Speed, Worn/Damaged/Stuck.

9. Torque Converter Damage. 9. Inspect and replace as required.

1. Fluid Level Low/High. 1. Correct fluid level and check for leaks if

2. Fluid Filter Clogged. 2. Replace filter. If filter and fluid contained

3. Throttle Linkage Mis-adjusted. 3. Adjust linkage as described in service

4. Throttle Linkage Binding. 4. Check cable for binding. Check for return

5. Gearshift Linkage/Cable

Mis-adjusted.

6. Clutch or Servo Failure. 6. Remove valve body and air test clutch,

7. Governor Circuit Electrical Fault. 7. Test using DRBT scan tool and repair as

8. Front Band Mis-adjusted. 8. Adjust band.

9. Pump Suction Passage Leak. 9. Check for excessive foam on dipstick

2. Inspect, adjust and reassemble linkage

as needed. Replace worn/damaged parts.

3. Perform preliminary inspection procedure

for vehicle that will not move. Refer to

procedure in diagnosis section.

Repair or replace failed components as

needed. Replace filter. If filter and fluid

contained clutch material or metal particles,

an overhaul may be necessary. Perform

lube flow test. Flush oil. Replace cooler as

necessary.

pressure. Replace pump body assembly if

necessary.

valve body (as assembly) if any valve or

bore is damaged. Clean and reassemble

correctly if all parts are in good condition.

7. Remove and disassemble transmission.

Repair or replace failed components as

needed.

8. Remove, disassemble, repair.

low.

clutch material or metal particles, an

overhaul may be necessary. Perform lube

flow test.

section.

to closed throttle at transmission.

5. Adjust linkage/cable as described in

service section.

and band servo operation. Disassemble

and repair transmission as needed.

required.

after normal driving. Check for loose pump

bolts, defective gasket. Replace pump

assembly if needed.

Page 20

DR AUTOMATIC TRANSMISSION - 48RE 21 - 149

AUTOMATIC TRANSMISSION - 48RE (Continued)

CONDITION POSSIBLE CAUSES CORRECTION

NO REVERSE (D RANGES

OK)

HAS FIRST/REVERSE

ONLY (NO 1-2 OR 2-3

UPSHIFT)

MOVES IN 2ND OR 3RD

GEAR, ABRUPTLY

DOWNSHIFTS TO LOW

NO LOW GEAR (MOVES

IN 2ND OR 3RD GEAR

ONLY)

1. Gearshift Linkage/Cable

Mis-adjusted/Damaged.

2. Park Sprag Sticking. 2. Replace overdrive annulus gear.

3. Rear Band Mis-adjusted/Worn. 3. Adjust band; replace.

4. Valve Body Malfunction. 4. Remove and service valve body. Replace

5. Rear Servo Malfunction. 5. Remove and disassemble transmission.

6. Direct Clutch in Overdrive Worn. 6. Disassemble overdrive. Replace worn or

7. Front Clutch Burnt. 7. Remove and disassemble transmission.

1. Governor Circuit Electrical Fault. 1. Test using DRBT scan tool and repair as

2. Valve Body Malfunction. 2. Repair stuck 1-2 shift valve or governor

3. Front Servo/Kickdown Band

Damaged/Burned.

1. Valve Body Malfunction. 1. Remove, clean and inspect. Look for

1. Governor Circuit Electrical Fault. 1. Test with DRBT scan tool and repair as

2. Valve Body Malfunction. 2. Remove, clean and inspect. Look for

3. Front Servo Piston Cocked in

Bore.

4. Front Band Linkage Malfunction 4. Inspect linkage and look for bind in

1. Repair or replace linkage parts as

needed.

valve body if any valves or valve bores are

worn or damaged.

Replace worn/damaged servo parts as

necessary.

damaged parts.

Replace worn, damaged clutch parts as

required.

required.

plug.

3. Repair/replace.

stuck 1-2 valve or governor plug.

required.

sticking 1-2 shift valve, 2-3 shift valve,

governor plug or broken springs.

3. Inspect servo and repair as required.

linkage.

Page 21

21 - 150 AUTOMATIC TRANSMISSION - 48RE DR

AUTOMATIC TRANSMISSION - 48RE (Continued)

CONDITION POSSIBLE CAUSES CORRECTION

NO KICKDOWN OR

NORMAL DOWNSHIFT

STUCK IN LOW GEAR

(WILL NOT UPSHIFT)

CREEPS IN NEUTRAL 1. Gearshift Linkage Mis-adjusted. 1. Adjust linkage.

1. Throttle Linkage Mis-adjusted. 1. Adjust linkage.

2. Accelerator Pedal Travel

Restricted.

3. Valve Body Hydraulic Pressures

Too High or Too Low Due to Valve

Body Malfunction or Incorrect

Hydraulic Control Pressure

Adjustments.

4. Governor Circuit Electrical Fault. 4. Test with DRBT scan tool and repair as

5. Valve Body Malfunction. 5. Perform hydraulic pressure tests to

6. TPS Malfunction. 6. Replace sensor, check with DRBT scan

7. PCM Malfunction. 7. Check with DRBT scan tool and replace

8. Valve Body Malfunction. 8. Repair sticking 1-2, 2-3 shift valves,

1. Throttle Linkage Mis-adjusted/

Stuck.

2. Gearshift Linkage Mis-adjusted. 2. Adjust linkage and repair linkage if worn

3. Governor Component Electrical

Fault.

4. Front Band Out of Adjustment. 4. Adjust Band.

5. Clutch or Servo Malfunction. 5. Air pressure check operation of clutches

2. Rear Clutch Dragging/Warped. 2. Disassemble and repair.

3. Valve Body Malfunction. 3. Perform hydraulic pressure test to

2. Verify floor mat is not under pedal, repair

worn accelerator cable or bent brackets.

3. Perform hydraulic pressure tests to

determine cause and repair as required.

Correct valve body pressure adjustments as

required.

required.

determine cause and repair as required.

Correct valve body pressure adjustments as

required.

tool.

if required.

governor plugs, 3-4 solenoid, 3-4 shift

valve, 3-4 timing valve.

1. Adjust linkage and repair linkage if worn

or damaged. Check for binding cable or

missing return spring.

or damaged.

3. Check operating pressures and test with

DRBT scan tool, repair faulty component.

and bands. Repair faulty component.

determine cause and repair as required.

Page 22

DR AUTOMATIC TRANSMISSION - 48RE 21 - 151

AUTOMATIC TRANSMISSION - 48RE (Continued)

CONDITION POSSIBLE CAUSES CORRECTION

BUZZING NOISE 1. Fluid Level Low 1. Add fluid and check for leaks.

2. Shift Cable Mis-assembled. 2. Route cable away from engine and bell

housing.

3. Valve Body Mis-assembled. 3. Remove, disassemble, inspect valve

body. Reassemble correctly if necessary.

Replace assembly if valves or springs are

damaged. Check for loose bolts or screws.

4. Pump Passages Leaking. 4. Check pump for porous casting, scores

on mating surfaces and excess rotor

clearance. Repair as required. Loose pump

bolts.

5. Cooling System Cooler Plugged. 5. Flow check cooler circuit. Repair as

needed.

6. Overrunning Clutch Damaged. 6. Replace clutch.

SLIPS IN REVERSE ONLY 1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Gearshift Linkage Mis-adjusted. 2. Adjust linkage.

3. Rear Band Mis-adjusted. 3. Adjust band.

4. Rear Band Worn. 4. Replace as required.

5. Overdrive Direct Clutch Worn. 5. Disassemble overdrive. Repair as

needed.

6. Hydraulic Pressure Too Low. 6. Perform hydraulic pressure tests to

determine cause.

7. Rear Servo Leaking. 7. Air pressure check clutch-servo operation

and repair as required.

8. Band Linkage Binding. 8. Inspect and repair as required.

SLIPS IN FORWARD

DRIVE RANGES

SLIPS IN LOW GEAR 9D9

ONLY, BUT NOT IN

MANUAL 1 POSITION

1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Fluid Foaming. 2. Check for high oil level, bad pump

gasket or seals, dirt between pump halves

and loose pump bolts. Replace pump if

necessary.

3. Throttle Linkage Mis-adjusted. 3. Adjust linkage.

4. Gearshift Linkage Mis-adjusted. 4. Adjust linkage.

5. Rear Clutch Worn. 5. Inspect and replace as needed.

6. Low Hydraulic Pressure Due to

Worn Pump, Incorrect Control

Pressure Adjustments, Valve Body

Warpage or Malfunction, Sticking,

Leaking Seal Rings, Clutch Seals

Leaking, Servo Leaks, Clogged Filter

or Cooler Lines.

7. Rear Clutch Malfunction, Leaking

Seals or Worn Plates.

8. Overrunning Clutch Worn, Not

Holding (Slips in 1 Only).

Overrunning Clutch Faulty. Replace overrunning clutch.

6. Perform hydraulic and air pressure tests

to determine cause.

7. Air pressure check clutch-servo operation

and repair as required.

8. Replace Clutch.

Page 23

21 - 152 AUTOMATIC TRANSMISSION - 48RE DR

AUTOMATIC TRANSMISSION - 48RE (Continued)

CONDITION POSSIBLE CAUSES CORRECTION

GROWLING, GRATING OR

SCRAPING NOISES

DRAGS OR LOCKS UP 1. Fluid Level Low. 1. Check and adjust level.

NO 4-3 DOWNSHIFT 1. Circuit Wiring and/or Connectors

1. Drive Plate Broken. 1. Replace.

2. Torque Converter Bolts Hitting

Dust Shield.

3. Planetary Gear Set Broken/

Seized.

4. Overrunning Clutch Worn/Broken. 4. Inspect and check for debris in oil pan.

5. Oil Pump Components Scored/

Binding.

6. Output Shaft Bearing or Bushing

Damaged.

7. Clutch Operation Faulty. 7. Perform air pressure check and repair as

8. Front and Rear Bands Mis-

adjusted.

2. Clutch Dragging/Failed 2. Air pressure check clutch operation and

3. Front or Rear Band Mis-adjusted. 3. Adjust bands.

4. Case Leaks Internally. 4. Check for leakage between passages in

5. Servo Band or Linkage

Malfunction.

6. Overrunning Clutch Worn. 6. Remove and inspect clutch. Repair as

7. Planetary Gears Broken. 7. Remove, inspect and repair as required

8. Converter Clutch Dragging. 8. Check for plugged cooler. Perform flow

Shorted.

2. PCM Malfunction. 2. Check PCM operation with DRBT scan

3. TPS Malfunction 3. Check TPS with DRBT scan tool at PCM.

4. Lockup Solenoid Not Venting. 4. Remove valve body and replace solenoid

5. Overdrive Solenoid Not Venting. 5. Remove valve body and replace solenoid

6. Valve Body Valve Sticking. 6. Repair stuck 3-4 shift valve or lockup

2. Dust shield bent. Replace or repair.

3. Check for debris in oil pan and repair as

required.

Repair as required.

5. Remove, inspect and repair as required.

6. Remove, inspect and repair as required.

required.

8. Adjust bands.

repair as required.

case.

5. Air pressure check servo operation and

repair as required.

required.

(look for debris in oil pan).

check. Inspect pump for excessive side

clearance. Replace pump as required.

1. Test wiring and connectors with test lamp

and volt/ohmmeter. Repair wiring as

necessary. Replace connectors and/or

harnesses as required.

tool. Replace PCM only if faulty.

assembly if plugged or shorted.

if plugged or shorted.

timing valve.

Page 24

DR AUTOMATIC TRANSMISSION - 48RE 21 - 153

AUTOMATIC TRANSMISSION - 48RE (Continued)

CONDITION POSSIBLE CAUSES CORRECTION

NO 4-3 DOWNSHIFT

WHEN CONTROL SWITCH

IS TURNED OFF

CLUNK NOISE FROM

DRIVELINE ON CLOSED

THROTTLE 4-3

DOWNSHIFT

3-4 UPSHIFT OCCURS

IMMEDIATELY AFTER 2-3

SHIFT

WHINE/NOISE RELATED

TO ENGINE SPEED

1. Control Switch Open/Shorted. 1. Test and replace switch if faulty.

2. Overdrive Solenoid Connector

Shorted.

3. PCM Malfunction. 3. Test with DRBT scan tool. Replace PCM

4. Valve Body Stuck Valves. 4. Repair stuck 3-4, lockup or lockup timing

1. Transmission Fluid Low. 1. Add Fluid.

2. Throttle Cable Mis-adjusted. 2. Adjust cable.

3. Overdrive Clutch Select Spacer

Wrong Spacer.

1. Overdrive Solenoid Connector or

Wiring Shorted.

2. TPS Malfunction. 2. Test TPS and replace as necessary.

3. PCM Malfunction. 3. Test PCM with DRBT scan tool and

4. Overdrive Solenoid Malfunction. 4. Replace solenoid.

5. Valve Body Malfunction. 5. Remove, disassemble, clean and inspect

1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Shift Cable Incorrect Routing. 2. Check shift cable for correct routing.

2. Test solenoids and replace if seized or

shorted.

if faulty.

valve.

3. Replace overdrive piston thrust plate

spacer.

1. Test connector and wiring for loose

connections, shorts or ground and repair as

needed.

Check with DRBT scan tool.

replace controller if faulty.

valve body components. Make sure all

valves and plugs slide freely in bores.

Polish valves with crocus cloth if needed.

Should not touch engine or bell housing.

Page 25

21 - 154 AUTOMATIC TRANSMISSION - 48RE DR

AUTOMATIC TRANSMISSION - 48RE (Continued)

CONDITION POSSIBLE CAUSES CORRECTION

NO 3-4 UPSHIFT 1. O/D Switch In OFF Position. 1. Turn control switch to ON position.

2. Overdrive Circuit Fuse Blown. 2. Replace fuse. Determine why fuse failed

and repair as necessary (i.e., shorts or

grounds in circuit).

3. O/D Switch Wire Shorted/Open

Cut.

4. Distance or Coolant Sensor

Malfunction.

5. TPS Malfunction. 5. Check with DRBT scan tool and replace

6. Neutral Sense to PCM Wire

Shorted/Cut.

7. PCM Malfunction. 7. Check with DRBT scan tool and replace

8. Overdrive Solenoid Shorted/Open. 8. Replace solenoid if shorted or open and

9. Solenoid Feed Orifice in Valve

Body Blocked.

10. Overdrive Clutch Failed. 10. Disassemble overdrive and repair as

11. Hydraulic Pressure Low. 11. Pressure test transmission to determine

12. Valve Body Valve Stuck. 12. Repair stuck 3-4 shift valve, 3-4 timing

13. O/D Piston Incorrect Spacer. 13. Remove unit, check end play and install

14. Overdrive Piston Seal Failure. 14. Replace both seals.

15. O/D Check Valve/Orifice Failed. 15. Check for free movement and secure

3. Check wires/connections with 12V test

lamp and voltmeter. Repair damaged or

loose wire/connection as necessary.

4. Check with DRBT scan tool and repair or

replace as necessary.

if necessary.

6. Test switch/sensor as described in

service section and replace if necessary.

Engine no start.

if necessary.

repair loose or damaged wires (DRBT scan

tool).

9. Remove, disassemble, and clean valve

body thoroughly. Check feed orifice.

needed.

cause.

valve.

correct spacer.

assembly (in piston retainer). Check ball

bleed orifice.

Page 26

DR AUTOMATIC TRANSMISSION - 48RE 21 - 155

AUTOMATIC TRANSMISSION - 48RE (Continued)

CONDITION POSSIBLE CAUSES CORRECTION

SLIPS IN OVERDRIVE

FOURTH GEAR

DELAYED 3-4 UPSHIFT

(SLOW TO ENGAGE)

TORQUE CONVERTER

LOCKS UP IN SECOND

AND/OR THIRD GEAR

HARSH 1-2, 2-3, 3-4 OR

3-2 SHIFTS

1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Overdrive Clutch Pack Worn. 2. Remove overdrive unit and rebuild clutch

pack.

3. Overdrive Piston Retainer Bleed

Orifice Blown Out.

4. Overdrive Piston or Seal

Malfunction.

5. 3-4 Shift Valve, Timing Valve or

Accumulator Malfunction.

6. Overdrive Unit Thrust Bearing

Failure.

7. O/D Check Valve/Bleed Orifice

Failure.

1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Throttle Valve Cable Mis-adjusted. 2. Adjust throttle valve cable.

3. Overdrive Clutch Pack Worn/

Burnt.

4. TPS Faulty. 4. Test with DRBT scan tool and replace as

5. Overdrive Clutch Bleed Orifice

Plugged.

6. Overdrive Solenoid or Wiring

Shorted/Open.

7. Overdrive Excess Clearance. 7. Remove unit. Measure end play and

8. O/D Check Valve Missing or

Stuck.

Lockup Solenoid, Relay or Wiring

Shorted/Open.

Lockup Solenoid Malfunction. Remove valve body and replace solenoid

3. Disassemble transmission, remove

retainer and replace orifice.

4. Remove overdrive unit. Replace seals if

worn. Replace piston if damaged. If piston

retainer is damaged, remove and

disassemble the transmission.

5. Remove and overhaul valve body.

Replace accumulator seals. Make sure all

valves operate freely in bores and do not

bind or stick. Make sure valve body screws

are correctly tightened and separator plates

are properly positioned.

6. Disassemble overdrive unit and replace

thrust bearing (NO. 1 thrust bearing is

between overdrive piston and clutch hub;

NO. 2 thrust bearing is between the

planetary gear and the direct clutch spring

plate; NO. 3 thrust bearing is between

overrunning clutch hub and output shaft).

7. Check for function/secure orifice insert in

O/D piston retainer.

3. Remove unit and rebuild clutch pack.

necessary

5. Disassemble transmission and replace

orifice.

6. Test solenoid and check wiring for

loose/corroded connections or shorts/

grounds. Replace solenoid if faulty and

repair wiring if necessary.

select proper spacer.

8. Check for presence of check valve.

Repair or replace as required.

Test solenoid, relay and wiring for

continuity, shorts or grounds. Replace

solenoid and relay if faulty. Repair wiring

and connectors as necessary.

assembly.

Page 27

21 - 156 AUTOMATIC TRANSMISSION - 48RE DR

AUTOMATIC TRANSMISSION - 48RE (Continued)

CONDITION POSSIBLE CAUSES CORRECTION

NO START IN PARK OR

NEUTRAL

NO REVERSE (OR SLIPS

IN REVERSE)

1. Gearshift Linkage/Cable

Mis-adjusted.

2. Neutral Sense Wire Open/Cut. 2. Check continuity with test lamp. Repair

3. Park/Neutral Switch, or

Transmission Range Sensor Faulty.

4. Park/Neutral Switch, or

Transmission Range Sensor

Connection Faulty.

5. Valve Body Manual Lever

Assembly Bent/Worn/Broken.

1. Direct Clutch Pack (front clutch)

Worn.

2. Rear Band Mis-adjusted. 2. Adjust band.

3. Front Clutch Malfunctioned/

Burned.

4. Overdrive Thrust Bearing Failure. 4. Disassemble geartrain and replace

5. Direct Clutch Spring Collapsed/

Broken.

1. Adjust linkage/cable.

as required.

3. Refer to service section for test and

replacement procedure.

4. Connectors spread open. Repair.

5. Inspect lever assembly and replace if

damaged.

1. Disassemble unit and rebuild clutch

pack.

3. Air-pressure test clutch operation.

Remove and rebuild if necessary.

bearings.

5. Remove and disassemble unit. Check

clutch position and replace spring.

Page 28

DR AUTOMATIC TRANSMISSION - 48RE 21 - 157

AUTOMATIC TRANSMISSION - 48RE (Continued)

CONDITION POSSIBLE CAUSES CORRECTION

OIL LEAKS. 1. Fluid Lines and Fittings Loose/

Leaks/Damaged.

2. Fill Tube (where tube enters case)

Leaks/Damaged.

3. Pressure Port Plug Loose

Loose/Damaged.

4. Pan Gasket Leaks. 4. Tighten pan screws (150 in. lbs.). If leaks

5. Valve Body Manual Lever Shaft

Seal Leaks/Worn.

6. Rear Bearing Access Plate Leaks. 6. Replace gasket. Tighten screws.

7. Gasket Damaged or Bolts are

Loose.

8. Adapter/Extension Gasket

Damaged Leaks/Damaged.

9. Park/Neutral Switch, or

Transmission Range Sensor

Leaks/Damaged.

10. Converter Housing Area Leaks. 10. Check for leaks at seal caused by worn

11. Pump Seal Leaks/Worn/

Damaged.

12. Torque Converter Weld

Leak/Cracked Hub.

13. Case Porosity Leaks. 13. Replace case.

NOISY OPERATION IN

FOURTH GEAR ONLY

1. Overdrive Clutch Discs, Plates or

Snap Rings Damaged.

2. Overdrive Piston or Planetary

Thrust Bearing Damaged.

3. Output Shaft Bearings Scored/

Damaged.

4. Planetary Gears Worn/Chipped. 4. Remove and overhaul overdrive unit.

5. Overdrive Unit Overrunning Clutch

Rollers Worn/Scored.

1. Tighten fittings. If leaks persist, replace

fittings and lines if necessary.

2. Replace tube seal. Inspect tube for

cracks in fill tube.

3. Tighten to correct torque. Replace plug

or reseal if leak persists.

persist, replace gasket.

5. Replace shaft seal.

7. Replace bolts or gasket or tighten both.

8. Replace gasket.

9. Replace switch and gasket.

seal or burr on converter hub (cutting seal),

worn bushing, missing oil return, oil in front

pump housing or hole plugged. Check for

leaks past O-ring seal on pump or past

pump-to-case bolts; pump housing porous,

oil coming out vent due to overfill or leak

past front band shaft access plug.

11. Replace seal.

12. Replace converter.

1. Remove unit and rebuild clutch pack.

2. Remove and disassemble unit. Replace

either thrust bearing if damaged.

3. Remove and disassemble unit. Replace

either bearing if damaged.

5. Remove and overhaul overdrive unit.

Page 29

21 - 158 AUTOMATIC TRANSMISSION - 48RE DR

AUTOMATIC TRANSMISSION - 48RE (Continued)

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR

Damaged or worn threads in the aluminum transmission case and valve body can be repaired by the

use of Heli-Coils™, or equivalent. This repair consists of drilling out the worn-out damaged threads.

Then tap the hole with a special Heli-Coil™ tap, or

equivalent, and installing a Heli-Coil™ insert, or

equivalent, into the hole. This brings the hole back to

its original thread size.

Heli-Coil™, or equivalent, tools and inserts are

readily available from most automotive parts suppliers.

REMOVAL

NOTE: The overdrive unit can be removed and serviced separately. It is not necessary to remove the

entire transmission assembly to perform overdrive

unit repairs.

(1) Disconnect battery negative cable.

(2) Raise vehicle.

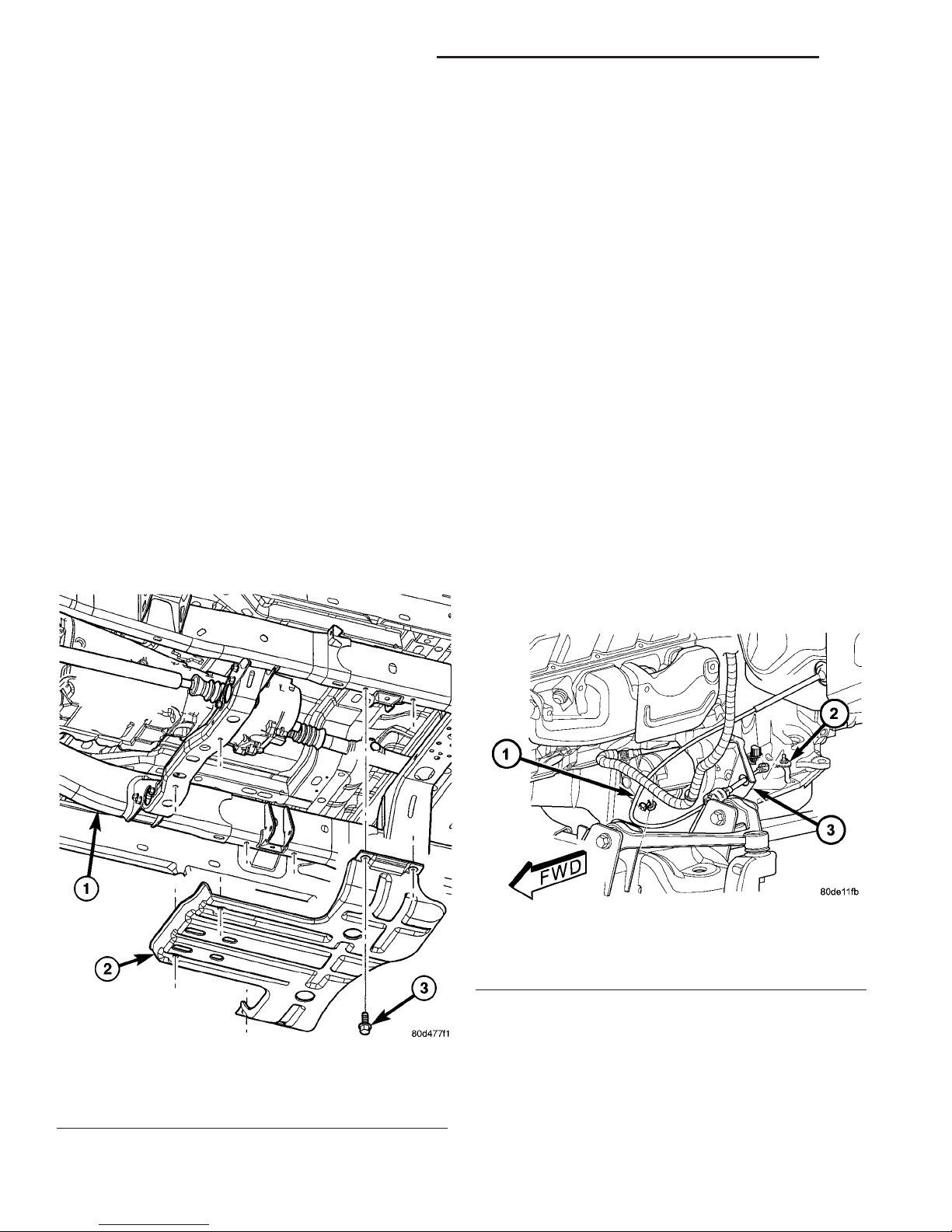

(3) Remove the transfer case skid plate (Fig. 12), if

equipped.

(4) Disconnect and lower or remove necessary

exhaust components.

(5) Remove engine-to-transmission struts.

(6) Remove starter motor. (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

(7) Disconnect and remove the crankshaft position

sensor. (Refer to 14 - FUEL SYSTEM/FUEL INJECTION/CRANKSHAFT POSITION SENSOR REMOVAL) Retain the sensor attaching bolts.

(8) If transmission is being removed for overhaul,

remove transmission oil pan, drain fluid and reinstall

pan.

(9) Remove torque converter access cover.

(10) Rotate crankshaft in clockwise direction until

converter bolts are accessible. Then remove bolts one

at a time. Rotate crankshaft with socket wrench on

dampener bolt.

(11) Mark propeller shaft and axle yokes for

assembly alignment. Then disconnect and remove

propeller shaft. On4x4models, remove both propeller shafts. (Refer to 3 - DIFFERENTIAL & DRIVELINE/PROPELLER SHAFT/PROPELLER SHAFT REMOVAL)

(12) Disconnect wires from the transmission range

sensor and transmission solenoid connector.

(13) Disconnect gearshift cable (Fig. 13) from the

transmission.

Fig. 12 Transfer Case Skid Plate

1 - FRAME RAIL

2 - SKID PLATE

3 - BOLTS (6)

Fig. 13 Gearshift Cable At Transmission

1 - GEARSHIFT CABLE

2 - TRANSMISSION MANUAL LEVER

3 - CABLE SUPPORT BRACKET

Page 30

DR AUTOMATIC TRANSMISSION - 48RE 21 - 159

AUTOMATIC TRANSMISSION - 48RE (Continued)

(14) Disconnect throttle valve cable from transmis-

sion bracket and throttle valve lever.

(15) On 4X4 models, disconnect shift rod from

transfer case shift lever.

(16) Support rear of engine with safety stand or

jack.

(17) Raise transmission slightly with service jack

to relieve load on crossmember and supports.

(18) Remove bolts securing rear support and cushion (Fig. 14) and (Fig. 15) to transmission and crossmember and remove rear support.

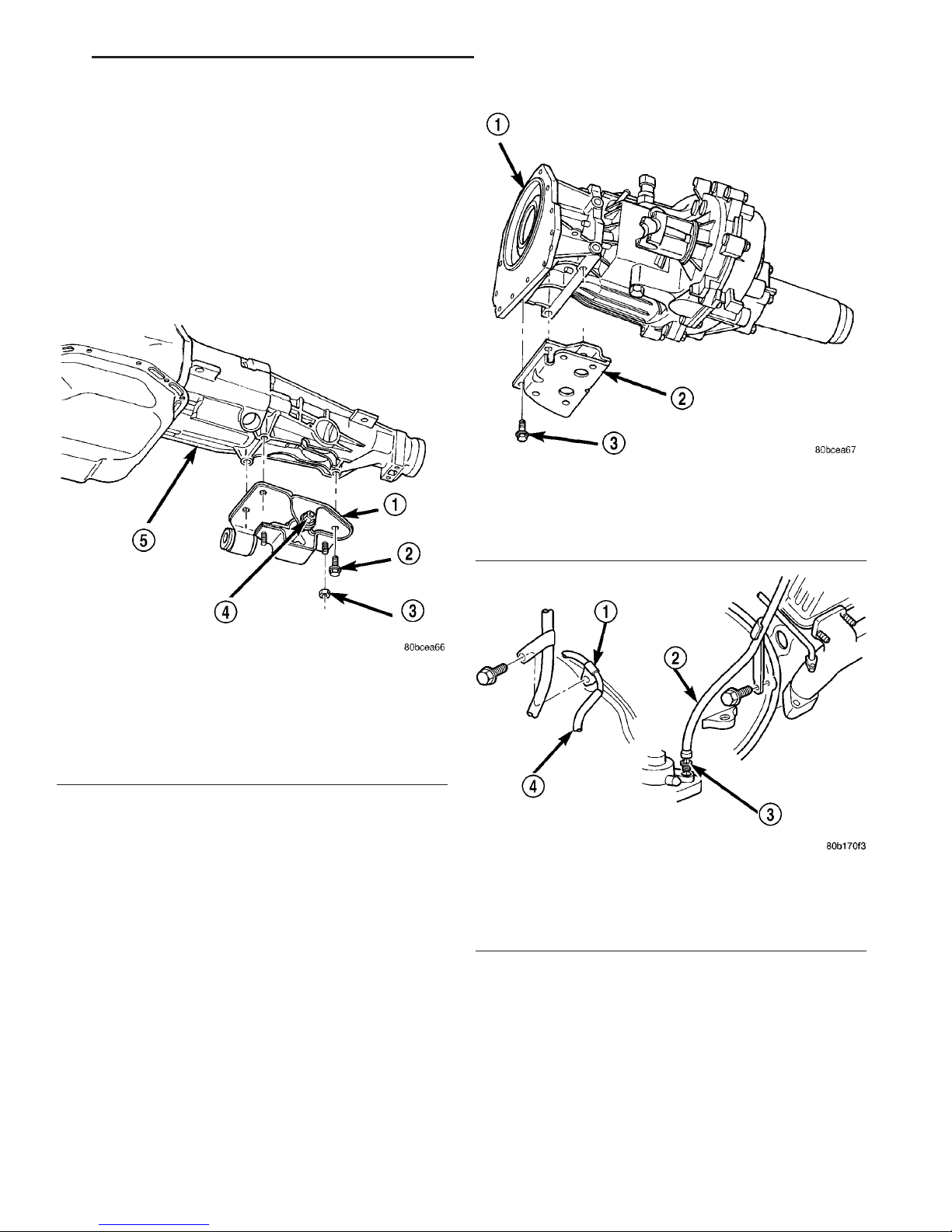

Fig. 15 Engine Rear Mount - 4X4 Automatic

Transmission

1 - TRANSMISSION

2 - ENGINE REAR MOUNT

3 - BOLT

Fig. 14 Engine Rear Mount - 4X2 Automatic

Transmission

1 - ENGINE REAR MOUNT

2 - BOLT

3 - NUT

4 - THROUGH BOLT NUT

5 - TRANSMISSION

(19) Remove bolts attaching crossmember to frame

and remove crossmember.

(20) On 4X4 models, remove transfer case with

transmission jack or aid of helper.

(21) Disconnect fluid cooler lines at transmission.

(22) Remove fill tube bracket bolts and pull tube

out of transmission. Retain fill tube seal. On 4X4

models, it will also be necessary to remove bolt

attaching transfer case vent tube to converter housing (Fig. 16).

(23) Remove all converter housing bolts.

(24) Carefully work transmission and torque converter assembly rearward off engine block dowels.

(25) Lower transmission and remove assembly

from under the vehicle.

(26) To remove torque converter, remove C-clamp

from edge of bell housing and carefully slide torque

converter out of the transmission.

Fig. 16 Fill Tube Attachment

1 - TRANSFER CASE VENT TUBE

2 - FILL TUBE (V8)

3 - TUBE SEAL

4 - FILL TUBE (V6)

Page 31

21 - 160 AUTOMATIC TRANSMISSION - 48RE DR

AUTOMATIC TRANSMISSION - 48RE (Continued)

DISASSEMBLY

(1) Clean exterior of transmission with suitable

solvent or pressure washer.

(2) Place transmission in vertical position.

(3) Measure the input shaft end play as follows

(Fig. 17).

(a) Attach Adapter 8266-5 to Handle 8266-8.

(b) Attach dial indicator C-3339 to Handle

8266-8.

(c) Install the assembled tool onto the input

shaft of the transmission and tighten the retaining

screw on Adapter 8266-5 to secure it to the input

shaft.

(d) Position the dial indicator plunger against a

flat spot on the oil pump and zero the dial indicator.

(e) Move input shaft in and out and record reading. Record the maximum travel for assembly reference

(7) Remove filter from valve body (Fig. 18). Keep

filter screws separate from other valve body screws.

Filter screws are longer and should be kept with filter.

Fig. 18 Oil Filter Removal

1 - OIL FILTER

2 - VALVE BODY

3 - FILTER SCREWS (2)

Fig. 17 Checking Input Shaft End Play

1 - TOOL 8266-8

2 - TOOL 8266-5

3 - TOOL C-3339

(4) Remove the overdrive unit from the main

transmission case. If overdrive unit is not to be serviced, install Alignment Shaft 6227-2 into the overdrive unit to prevent misalignment of the overdrive

clutches during service of main transmission components.

(5) Remove throttle and shift levers from valve

body manual shaft and throttle lever shaft.

(6) Remove transmission oil pan and gasket.

(8) Remove the transmission range sensor.

(9) Remove hex head bolts attaching valve body to

transmission case (Fig. 19). A total of 10 bolts are

used. Note different bolt lengths for assembly reference.

Fig. 19 Valve Body Bolt Locations

1 - VALVE BODY BOLTS

2 - VALVE BODY BOLTS

Page 32

DR AUTOMATIC TRANSMISSION - 48RE 21 - 161

AUTOMATIC TRANSMISSION - 48RE (Continued)

(10) Remove valve body assembly. Push valve body

harness connector out of case. Then work park rod

and valve body out of case (Fig. 20).

Fig. 22 Front Band Lever Pin Access Plug

1 - FRONT BAND REACTION PIN ACCESS PLUG

2 - 1/4 DRIVE EXTENSION AND RATCHET

(14) Remove oil pump and reaction shaft support

assembly as follows:

(a) Tighten front band adjusting screw until

band is tight around front clutch retainer (Fig. 23).

Fig. 20 Valve Body Removal

1 - GOVERNOR PRESSURE SENSOR

2 - VALVE BODY

3 - PARK ROD

4 - ACCUMULATOR PISTON

5 - GOVERNOR PRESSURE SOLENOID

This will prevent retainer from coming out with

pump and possibly damaging clutch or pump components.

(11) Remove accumulator outer spring, piston and

inner spring (Fig. 21). Note position of piston and

springs for assembly reference. Remove and discard

piston seals if worn or cut.