Cherry GH-703 Maintenance Manual

GH-703

MAINTENANCE MANUAL

Power Riveter

1224 East Warner Ave,

Santa Ana, CA 92705

Tel: 1-714-545-5511

Fax: 1-714-850-6093

www.cherryaerospace.com

Power Riveter

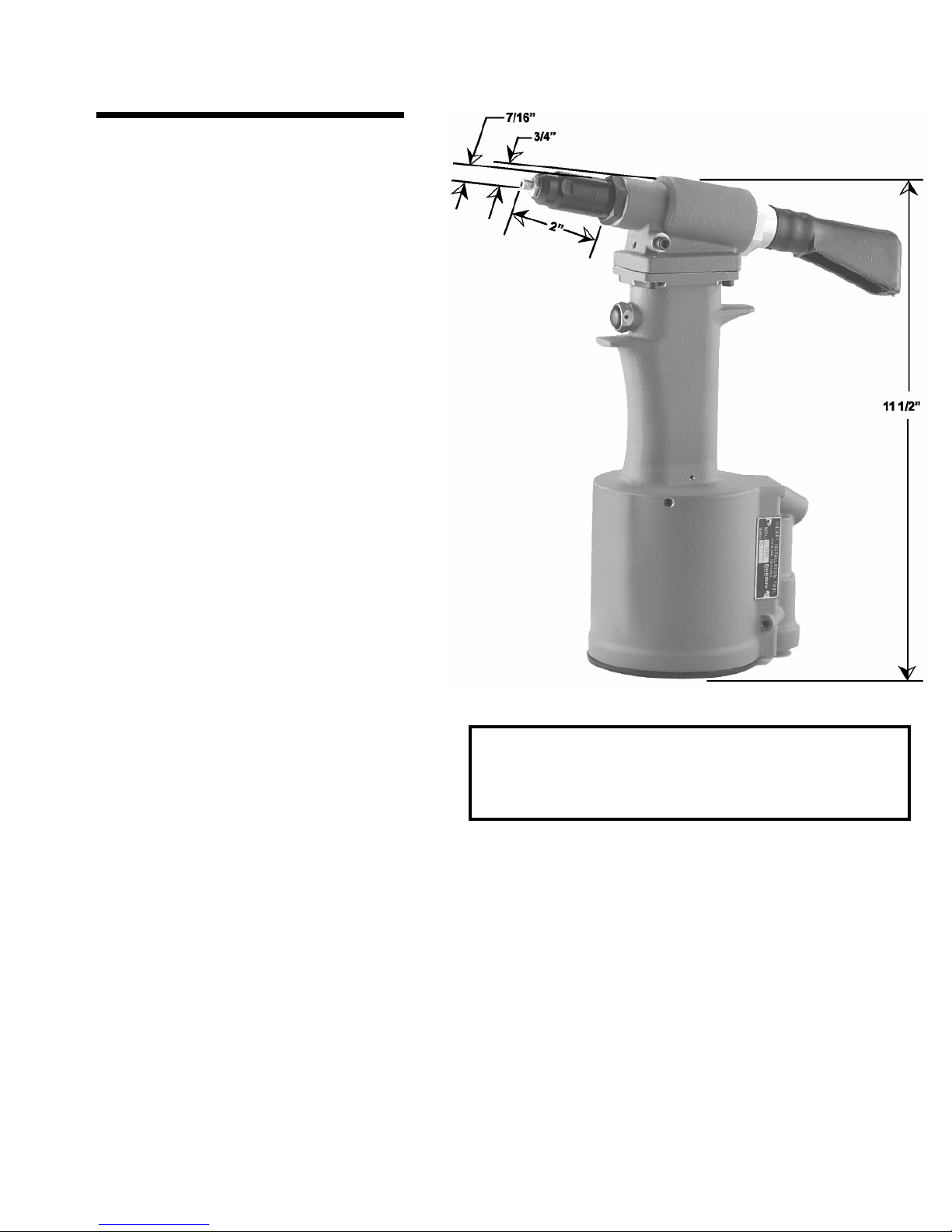

The Cherry® GH-703 is a pneumatichydraulic tool designed specif ically for the most

efficient installation of commercial fasteners. It

weighs only 5 pounds and can be operated in

any position with one hand. It has a full 3/4”

rivet setting stroke and a rated pull load of 2000

pounds.

The GH-703 riveter operat es on a wide range of

air pressure, with 90 to 120 psi providing the

maximum efficiency. At 90 lbs. air pressure, the

GH-703 has a decibel rating of 80dB(A) and

consumes 3 CFM at 20 cycles per minute.

A mandrel catcher bag may be attached to

eliminate costly cleanup.

G H-703

The GH-703 comes equipped with nosepiece 728A9-6 to set:

N Rivets - 3/16” diameter

Q Rivets - 3/16” diameter

Cherrymate

® Rivets - 1 /4” diameter

There is also a spare nosepiece, 728A9-4,

included for setting:

N Riv et s - 1 /8 ” dia m ete r

Q Riv et s - 1 /8 ” dia me te r

Cherrymate

® Rivets - 3/16” diameter

Warning: Approved eye protection

should be worn when operating, re-

pairing, or overhauling this tool.

MANY OTHER STYLES AND SIZES OF COMMERCIAL RIVETS CAN BE SET WITH THIS

TOOL. REFER TO THE NOSEPIECE SELECTION CHART ON PAGE 8 FOR APPLICABLE

PART NUMBERS.

1

How the GH-703 Operates

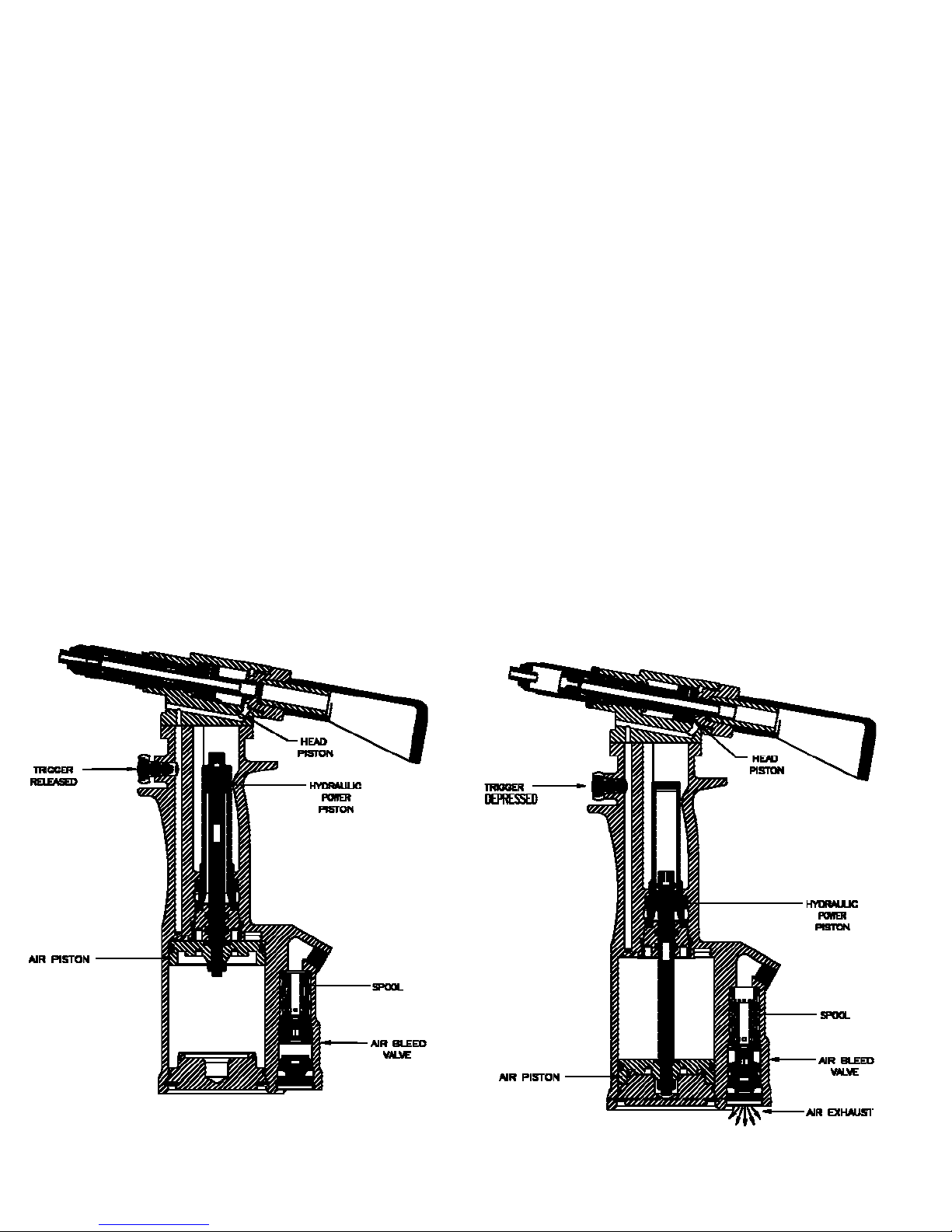

When the tool is pressurized by hooking up to an

air line, the valve spool is forced upward. This

movement aligns the port in the spool with the lower

port within the handle, allowin g air pressure to enter

the bottom port of the power air cylinder. This forces

the air piston upward.

When the trigger is depressed, air bleeds out from

behind the trigger, lowering air pressure against the

bottom of the s pool. Air pres sure is no w greater on

top of the spool, forcing it down. This action shuts

off the air path to the bottom of the power air cylinder,

and simultaneously opens the upper port, allowing

pressure to enter directly into the top of the air

cylinder. This forces the air piston downward.

The air piston is connected to the hydraulic power

piston with a common connecting rod. When the

air piston is activated by changes in the air valve,

it in turn activates the hydraulic power piston. Air

pressure also travels up through a port in the handle

to enter the rear of the head cylinder. This air

pressure forces the return of the head piston to its

full forward position.

The center area of the ha ndle (that part held by the

hand during riveting) contains the hydraulic system.

The hydraulic power piston has its own cylinder

containing the fluid which is pressurized by the

downward travel of the piston. This forc es the fluid

up through the handle into the front of the head

cylinder, thereby exerting the force needed to push

the head piston back in a full 3/4” rivet setting stroke.

This same fluid then returns to the power cylinder

by the forward action of the head piston under air

pressure.

SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

2

Loading...

Loading...