Page 1

CHATTANOOGA

®

GROUP INC.

Intelect

P.N. 78343 Rev. A

Legend Series

Service Manual

Page 2

I NEED TO KNOW . . .

Go to page

Warranty Information ..............................3

How the unit works..................................6

What might be wrong with my unit......25

What the error messages mean ...........26

Special Key Combinations....................27

CHATTANOOGA

GROUP INC.

How to calibrate the unit.......................38

How to open the unit ...............................9

How the boards interconnect ...............36

Where the connectors are.....................11

What the signals are..............................11

Part numbers..........................................46

How to get service help...........................3

How to close the unit...............................9

Technical Specifications.......................43

First look on this page to quickly find where to go in the manual

for more information !

Innovation starts here TM 2 Intelect® Legend Series Service Manual

Page 3

CHATTANOOGA

GROUP INC.

Intelect® Legend Two Year Limited Warranty

The Chattanooga Group Inc. (“Company”) warrants that the Intelect® Legend

Ultrasound or Stim (“Product”) excluding accessories is free of defects in material and

workmanship.

This warranty shall remain in effect for two (2) years from the date of the original

consumer purchase of this and extends to any owner of the product during the warranty

period. Accessories that are included as standard with the product (as listed in the user’s

manual) are warranted for 90 days. Ultrasound applicators 2cm

warranted for one (1) year. If this product fails to function during the two year warranty period

because of a defect in material or workmanship, the company or the selling dealer will replace

or repair this product without charge within a period of 30 days from the date on which the

defective product is returned to the company or dealer. The company or the dealer will ship

the replacement or the repaired product to the owner.

All repairs must be performed by a service center authorized by the Chattanooga

Group, Inc. Any modifications or repairs performed by unauthorized centers or groups will

void this warranty. To participate in warranty coverage, the product’s warranty registration

card (included with the product) must be filled out and returned to the Chattanooga Group,

Inc. by the original owner within 10 business days of purchase.

This warranty does not cover:

Replacement parts or labor furnished by anyone other than the Company, the dealer

or an approved Company service agent.

Defects or damage caused by labor furnished by someone other than Company, the

dealer or an approved Company service agent.

Any malfunction or failure in the product while it is in the possession of the owner

during the warranty period if the malfunction or failure is not caused by a defect in material or

workmanship or if the malfunction or failure is caused by unreasonable use, applications in

which the product was not intended or the failure to provide reasonable and necessary

maintenance.

The Company shall Not be Liable for Incidental or Consequential Damages.

To Obtain Service:

From Company or the selling dealer under this warranty, the owner must do or abide

by the following:

• A written claim must be made within the warranty period to Company or the

selling dealer.

• If the claim is made to the Company, the written claim should be sent to:

Chattanooga Group INC.

Australian Warehouse

Dingley Victoria 3172

Phone: (03) 9558 3825

Fax: (03) 9558 2491

• The product must be returned to Company or the selling dealer by the owner.

This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

The Company does not authorize any person or representative to create for it any

other obligation or liability in connection with the sale of the Product. Any representation or

agreement not contained in the warranty shall be void and of no effect.

2

, 5cm2 or 10cm2 are

Innovation starts here TM 3 Intelect® Legend Series Service Manual

Page 4

CHATTANOOGA

GROUP INC.

Start Here

About This Manual

This manual is intended to cover the Intelect® Legend Ultrasound and

Stim units and their accessories only.

The purpose of this service manual is to give a qualified technician

enough information to troubleshoot problems to the board level. Because of

the complexity and construction of these boards it is not recommended that

problems be traced to the component level. Some problems may be due to a

misunderstanding of how the machine operates. Thus it is important to read

the operators manual first to gain familiarity with how the machine operates

under normal circumstances.

Since this service manual is intended to assist in isolating the problem

to a circuit board, we will not cover the functions performed on each board in

detail.

This manual presents a brief theory of operation of each board and

accessory in the unit. It contains a troubleshooting guide for common

problems. This guide is not meant to cover every possible problem that a

service technician might encounter, but rather to give examples of what may

be seen. The manual also contains diagrams of the connector layout of each

board, a system diagram of how the unit is wired, and a list of signals carried

on each wire. Also included are calibration procedures for the unit, parts lists

and information on obtaining service.

Important !

The specifications and information put forth in this manual were in

effect at the time of publication. However, owing to Chattanooga Group’s

policy of continuous improvement, changes to these may be made at any time

without obligation on the part of Chattanooga Group, Inc.

Specifically, as there are improvements made to the circuit boards in

these units the connector

names may change. However, the location and

function of the connector will not likely change. Use reasonable judgment

and contact Chattanooga Group when in doubt.

Chattanooga Group, Inc., obviously cannot be responsible for work

performed on their units by individuals or other companies not approved or

authorized to perform service on Chattanooga Group equipment. Always try

to resolve any problems through your dealer or Chattanooga Group’s

customer service department FIRST.

Please read and understand the following precautions before

using or servicing a unit.

Innovation starts here TM 4 Intelect® Legend Series Service Manual

Page 5

CHATTANOOGA

GROUP INC.

PRECAUTIONARY INSTRUCTIONS

As with any electrical device, use extreme caution while working

inside the devices. Some of the circuits produce high voltages which

may be accessible while servicing the unit. Be especially mindful of jewelry

and tools that may accidentally come in contact with components inside the

unit.

Most of the electronic components incorporated in the unit are

electrostaticly sensitive. Always wear a static grounding strap and work

on a static dissipative surface.

CAUTION: Read, understand and practice the precautionary and

operating instructions contained in the unit’s manual and in this service

manual. Know the limitations and hazards associated with using any

ultrasound device. Observe the precautionary and operational decals placed

on the unit.

CAUTION: Do not operate the Intelect

to any unit other than Chattanooga Group, Inc., devices. Do not operate the

unit in an environment of short-wave diathermy use.

®

Legend Unit when connected

WARNING: Federal Law restricts this device to sale by, or on the order

of, a physician or licensed practitioner. This device should be used only under

the continued supervision of a physician or licensed practitioner.

CAUTION: The ultrasound generator should be routinely checked

before each use to determine that all controls function normally; especially

that the intensity control does properly adjust the intensity of the ultrasonic

power output in a stable manner. Also, determine that the treatment time

control does actually terminate ultrasonic power output when the timer

reaches zero.

CAUTION: Use of controls or adjustments or performance of

procedures other than those specified in the unit’s manual or in this service

manual may result in hazardous exposure to ultrasonic energy.

CAUTION: DO NOT use sharp objects such as a pencil point or ball

point pen to operate the buttons on the control panel as damage may result.

WARNING: Explosion hazard if used in the presence of flammable

anesthetics. The warning symbol for this hazard is prominently displayed on

the cabinet.

WARNING: For continued protection against fire hazard, replace fuses

only with ones of the same type and rating.

WARNING: Make certain that the unit is electrically grounded by

connecting only to a grounded electrical service receptacle conforming to the

applicable national and local electrical codes.

WARNING: This device should be kept out of the reach of children.

Innovation starts here TM 5 Intelect® Legend Series Service Manual

Page 6

CHATTANOOGA

GROUP INC.

Theory of Operation

Overview

To better understand the details in the following paragraphs, a quick

look at the operation of the entire system is helpful.

The unit is powered by a desktop switching power supply which

accepts 100-240VAC and delivers a regulated 12-16VDC. Each board within

the unit has its own local regulation as required by the particular board

functions.

The user interface consists of the membrane switch panel on the top of

the case and the LCD parameter screen for the Stim unit or LED displays for

the Ultrasound unit. Choices presented on the LCD screen are selected via

the membrane switches for the Stim unit while selections are made directly

from the membrane switches and reflected in the LED displays on the

Ultrasound unit. After a treatment is started on the Stim unit, the LCD screen

returns to a display showing the status of the outputs. The LED displays

constantly reflect the status of the Ultrasound unit. Alarms and feedback of

keypresses are provided by a beeper located inside the case.

Connection for the ultrasound applicator and for electrode lead wires

are made to panels on the side of the unit. The rear of the unit has the power

supply input connector, the fuse and the fan.

Accessories supplied with all Ultrasound units include at least one

applicator and ultrasound gel. Stim units have electrode leads and

electrodes.

The Control Boards

• The Ultrasound Control Board

The signals controlling the Ultrasound Generator Board are carried

through a 40 conductor cable from JP5 on the Control Board to J1 on the US

Generator Board. Refer to the signal list. The signals include address and

data lines, handshake lines and power supply controls.

Connector JP6 is for the membrane switches. JP1 is the power supply

connector and supplies power from the desktop power supply.

JP2 is the output power connector for the Ultrasound Generator Board.

JP4 supplies power to the fan and JP3 is for the beeper.

• The Stim Control Board

The signals controlling the Stim Board leave JP7 on the Control Board

and go through a 40 conductor cable to JP1 on the Stim Board. See the

Signal List for details. Signals include address and data lines, handshake

lines, and power supply control signals.

Connector JP4 is for the LCD screen. It is mounted directly behind the

board and against the front panel. JP9 carries power for the

electroluminescent backlighting.

Connector JP10 is for the membrane switches. JP1 is the power

supply connector and supplies power from the desktop power supply.

JP2 is the output power connector for the Stim Board.

Innovation starts here TM 6 Intelect® Legend Series Service Manual

Page 7

CHATTANOOGA

GROUP INC.

JP3 supplies power to the fan and JP6 is for the beeper.

The Stim Board

The Stim Board’s function is to generate various output waveforms

under the direction of the Control Board. Due to the variety of waveforms

commonly used in electrotherapy, there are different waveform generators on

the board, all controlled by a common Digital Signal Processor (DSP).

• The Sine Wave Generators

There are two of these on each Stim Board, one for channel 1 and the

other for channel 2. Each is identical except for their connections to the

output jacks. Under control of the DSP, Programmable Array Logic (PAL)

devices generate a driving signal which is fed to an amplifier. The output

amplitude of the amplifier is determined by a programmable power supply,

also controlled by the DSP. The resulting output is filtered and routed by

relays to the appropriate connector on the board.

These same generators are used to develop the VMS, or Biphasic

output, the Premod output, the Interferential output and the Russian output.

• The Hi-Volt Generator

The Hi-Volt output is only available from channel 2 of the unit. Under

control of the DSP, timing information is generated by a PAL. This is used to

control the charging and discharging of a transformer. The discharges are

routed through relays to obtain the proper polarity and connect them to the

proper output connector on the board.

JP2 on the Stim Board determines whether the board operates as

channels 1&2 or 3&4 on a CPS 400. This jumper

must be set for channels

1&2 for the unit to operate properly. See the board drawing in the Signal Lists

section for jumper configuration.

The Ultrasound Board

The Ultrasound Board uses a Phase Locked Loop (PLL) that is set by a

PAL based on control by the Control Board to generate a stable high

frequency signal. This signal is used to drive an amplifier whose output is

filtered and drives the transducer. The amplitude of the amplifier output is

determined by its programmable power supply. Other circuitry monitors the

temperature of the transducer as well as voltage and current of the drive to

the transducer.

The Ultrasound Board is controlled by signals from connector JP5 of

the Control Board that are carried through a 40 conductor cable to J1 on the

Ultrasound Board. The signals consist of address and data lines as well as

handshake lines. There are also signals for turning off the power supplies on

the Ultrasound Board when it is not generating output.

The power for the Ultrasound Board is through J2. Connector J3 is the

output of the Ultrasound Board which ultimately drives the transducer in the

applicator.

Innovation starts here TM 7 Intelect® Legend Series Service Manual

Page 8

CHATTANOOGA

GROUP INC.

The Ultrasound Applicator

The Ultrasound Applicator comes in several models, depending on the

surface area of the transducer and the shape of the face of the transducer.

The circuitry within all of them is the same.

Connection to the Applicator is through a triaxial cable. The center

conductor carries the drive to the transducer while the inner shield is the

return. The outer shield is used to monitor the transducer temperature using

a thermistor inside the Applicator.

A small circuit board inside the Applicator holds components for

transducer temperature sensing and the memory device. The memory device

stores the frequency and power information for the transducer. The memory

device communicates via the two shields of the cable.

The Membrane Switch Panel

The membrane switch panel connects to JP6 on the Ultrasound Control

Board and JP10 on the Stim Control Board. The switches are electrically

arranged such that one side of all the switches have a common return. The

other side of the switches are brought out individually to the connector. The

switch activations are buffered and latched on the Control Boards.

The LCD Parameter Screen

The LCD parameter screen mounts between the Control Board and the

top of the case. The interface between the LCD and the Stim Control Board’s

JP4 is a bi-directional 8-bit bus along with handshake signals. There is a

separate connection via JP9 for supplying power to the electroluminescent

backlight of the LCD. There is a module mounted on the Control Board which

generates the necessary voltage for this.

The LED Interface

The LED displays mount on the solder side of the Ultrasound Control

Board so as to show through the overlay on the case. They are soldered

directly to the board and therefore are not replaceable.

Innovation starts here TM 8 Intelect® Legend Series Service Manual

Page 9

CHATTANOOGA

GROUP INC.

General Service Procedures

Preventing damage to the case

The plastic case of the Intelect units is quite durable, as are the

membrane switch overlays. To remove the screws and open the case for

servicing it will be necessary to place the unit upside down. Be sure the work

surface is covered so that the unit isn’t scratched. Also be careful with tools

that may scratch the case or overlays.

Location of screws

There are 6 screws that hold the case together and all of them are

accessible from the bottom of the unit. These screws are distinguished from

others on the bottom in that they are all recessed into the plastic case.

Remove all 6 screws.

Opening the Case

Flip the unit back over and carefully lift the top of the case off the

bottom. The top of the case can be opened from the left and put on the right

side of the bottom without disconnecting the cables. If you do need to remove

any cables, NOTE THE ORIENTATION of these cables BEFORE unplugging

them because pin 1 is not marked on all the PC Boards. Mark the cable or

connector and the board before unplugging with a permanent marker, tape or

other means if you need to. You will also need to make note of which small 2wire connector is for the fan and which is for the beeper. If these become

swapped when assembling the unit, the beeper will sound continuously

whenever the power is on.

Special Tools

Almost any operation can be performed without any special tools. If

you need to replace the EPROMs or PALs on any of the boards, you

MUST

use a special tool to remove the parts. Attempting to remove these IC’s in

any other way can damage the socket and make the entire circuit board

unusable. The preferred tool is Burndy QILEXT-1, sold by Newark Electronics

as type 290N, P/N 95F3004.

Closing the case

Re-assemble the unit taking care to properly install any cables you may

have disconnected. When lowering the top down onto the bottom, be careful

not to capture any wires in the edge of the case. If you are having difficulty it

may be necessary to align one side of the case and then force the other side

to align. Also notice that the metal plates on either side must align with plastic

structures inside the case. After all this work look around the edge of the case

one last time to be sure everything looks OK. Now the back panel may have

fallen into the cabinet while aligning the top and bottom - don’t panic.

Carefully lift the rear edge of the top just enough to allow you to pull the panel

back into its slot in the top and bottom of the case.

Hold the unit together and flip it over (once again be sure the table is

covered so that the case isn’t scratched) and put the 6 screws back in place.

Don’t overtighten the screws, tighten them just until the edges of the case

seat together.

Innovation starts here TM 9 Intelect® Legend Series Service Manual

Page 10

Signal Lists

®

Intelect

Ultrasound Control Board

Below is a simple drawing showing the approximate locations of the

connectors and the position of pin 1 on each connector.

JP1

Legend US Control

PIN 1

JP2

CHATTANOOGA

GROUP INC.

PIN 1

PIN 1

PIN 1

JP3

JP5

JP4

PIN 1

PIN 1

JP6

Below are tables showing the signals for each connector on the Control

Board. The columns are arranged as pin number, signal description, type of

signal and any other notable information about the signal.

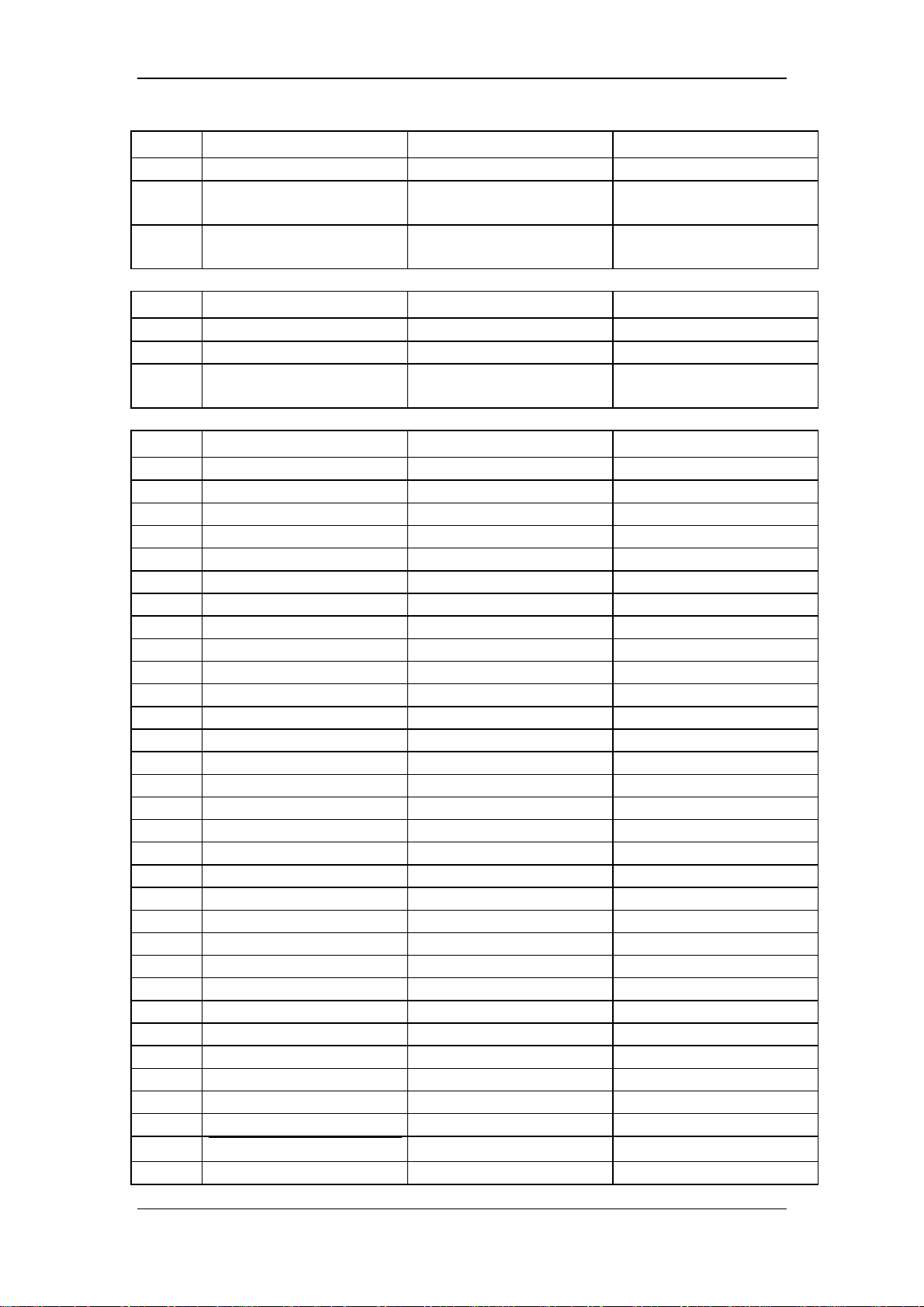

JP1 US Control Board

Pin # Signal Name Type

1 Battery In Power Unused

2 Battery In Power Unused

3 Power Supply In Power +8 to +18 VDC

4 Power Supply In Power +8 to +18 VDC

5 Ground

6 Ground

JP2 US Control Board

Pin # Signal Name Type

1 Power Out Power +8 to +18 VDC

2 Power Out Power +8 to +18 VDC

3 Ground

4 Ground

Innovation starts here TM 10 Intelect® Legend Series Service Manual

Page 11

CHATTANOOGA

GROUP INC.

JP3 US Control Board

Pin # Signal Name Type

1 Unregulated Power Power +8 to +18VDC,

Current Limited

2 Buzzer On Output Open Collector, Active

Low

JP4 US Control Board

Pin # Signal Name Type

1 Unregulated DC Power 8-18VDC

2 Fan On Output Open Collector, Active

Low

JP5 US Control Board

Pin # Signal Name Type

1 Ground

2 US Data Line 0 Bi-Directional Digital

3 Ground

4 US Data Line 1 Bi-Directional Digital

5 Ground

6 US Data Line 2 Bi-Directional Digital

7 Ground

8 US Data Line 3 Bi-Directional Digital

9 Ground

10 US Data Line 4 Bi-Directional Digital

11 Ground

12 US Data Line 5 Bi-Directional Digital

13 Ground

14 US Data Line 6 Bi-Directional Digital

15 Ground

16 US Data Line 7 Bi-Directional Digital

17 Ground

18 No Connection

19 Ground

20 US Address Line 0 Output Digital

21 Ground

22 US Address Line 1 Output Digital

23 Ground

24 No Connection

25 Ground

26 No Connection

27 Ground

28 No Connection

29 Ground

30

31 Ground

US Strobe

Output Digital Active Low

Innovation starts here TM 11 Intelect® Legend Series Service Manual

Page 12

CHATTANOOGA

GROUP INC.

32 US Board Enable Output Digital Active Low

33 Ground

34 US Read/Write Output Digital Active Low

35 Ground

36 No Connection

37 Ground

38 US Power Down 1 Output Digital

39 Ground

40 US Power Down 2 Output Digital

JP6 US Control Board

Pin # Signal Name Type

1 Ground

2 Switch 0 Input Digital Active Low

3 Switch 1 Input Digital Active Low

4 Switch 2 Input Digital Active Low

5 Switch 3 Input Digital Active Low

6 Switch 4 Input Digital Active Low

7 Switch 5 Input Digital Active Low

8 Switch 6 Input Digital Active Low

9 Switch 7 Input Digital Active Low

10 Switch 8 Input Digital Active Low

11 Switch 9 Input Digital Active Low

12 Switch 10 Input Digital Active Low

Innovation starts here TM 12 Intelect® Legend Series Service Manual

Page 13

Intelect

®

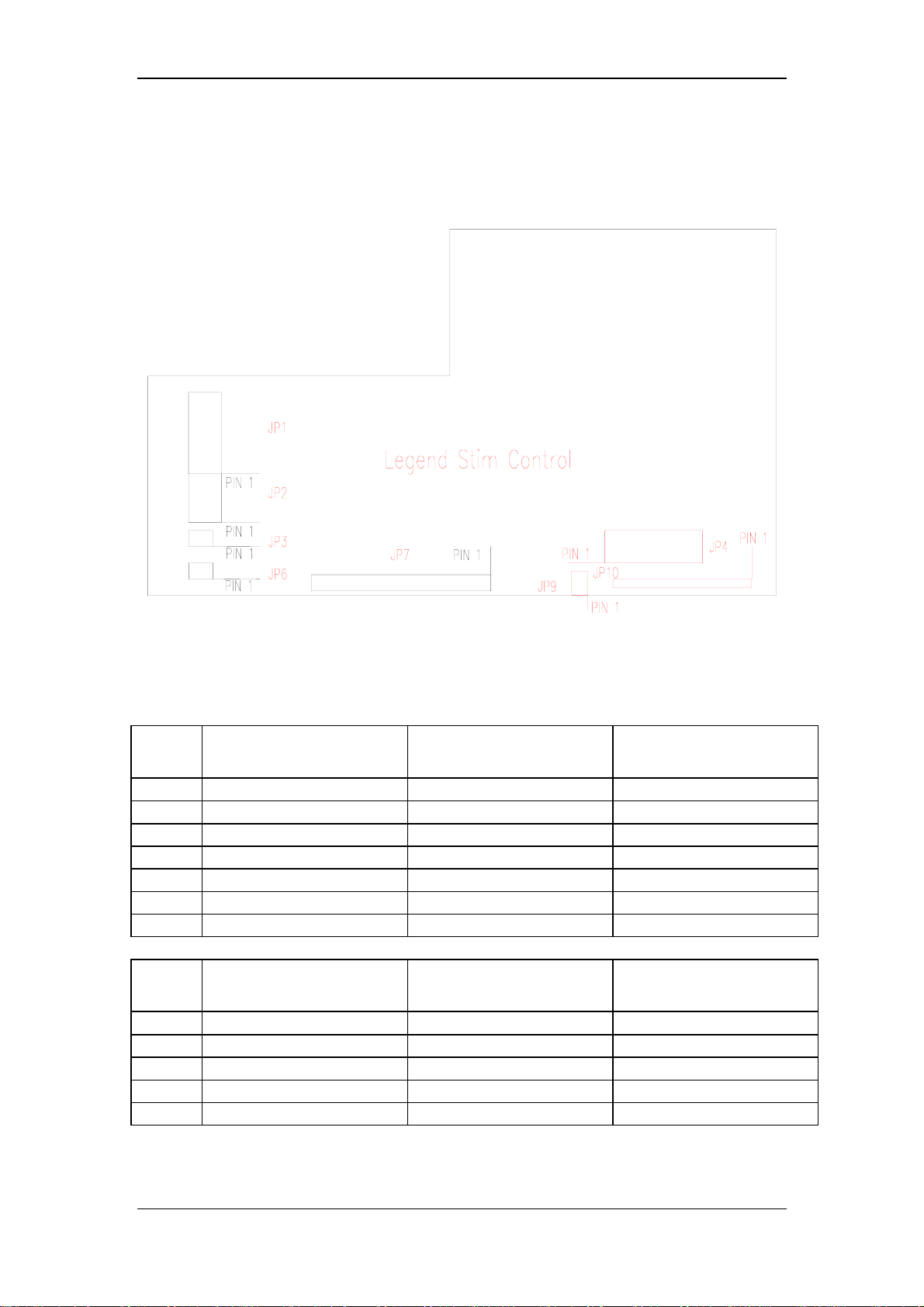

Legend Stim Control Board

Below is a simple drawing showing the approximate locations of the

connectors and the position of pin 1 on each connector.

CHATTANOOGA

GROUP INC.

Below are tables showing the signals for each connector on the Control

Board. The columns are arranged as pin number, signal description, type of

signal and any other notable information about the signal.

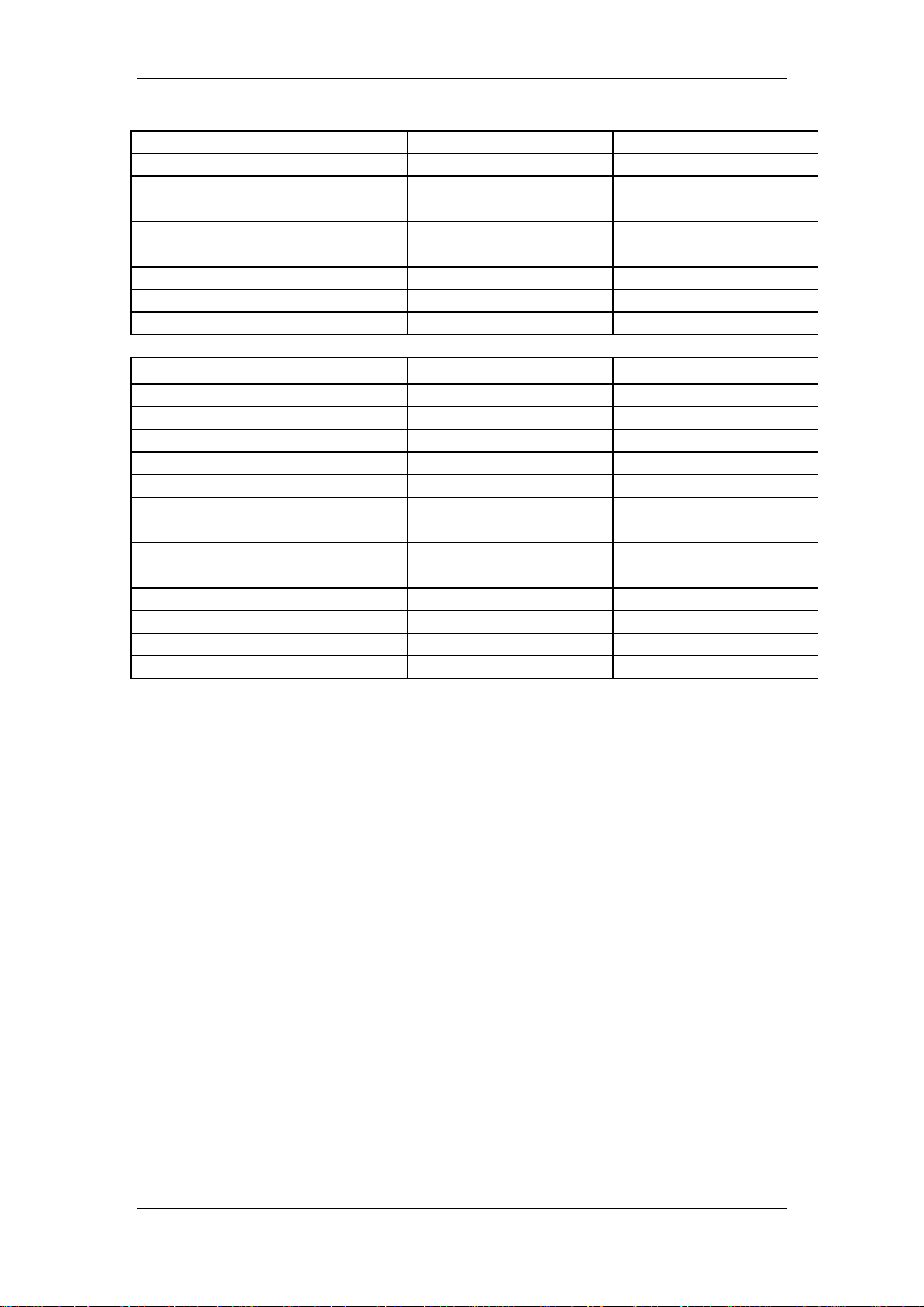

JP1 Stim Control

Board

Pin # Signal Name Type

1 Battery In Power Unused

2 Battery In Power Unused

3 Power Supply In Power +8 to +18 VDC

4 Power Supply In Power +8 to +18 VDC

5 Ground

6 Ground

JP2 Stim Control

Board

Pin # Signal Name Type

1 Power Out Power +8 to +18 VDC

2 Power Out Power +8 to +18 VDC

3 Ground

4 Ground

Innovation starts here TM 13 Intelect® Legend Series Service Manual

Page 14

CHATTANOOGA

GROUP INC.

JP3 Stim Control

Board

Pin # Signal Name Type

1 Unregulated Power Power +8 to +18VDC,

Current Limited

2 Buzzer On Output Open Collector, Active

Low

JP4 Stim Control

Board

Pin # Signal Name Type

1 Ground

2 Ground

3 VCC Power +5 Volts

4 LCD Bias Power -6 to -18 VDC, varies

with contrast

5 LCD Write Output Digital Active Low

6 LCD Read Output Digital Active Low

7 LCD Chip Enable Output Digital Active Low

8 LCD Command / Data

Select

9 No Connection

10 LCD Reset Output Digital Active Low

11 LCD Data Line 0 Bi-Directional Digital

12 LCD Data Line 1 Bi-Directional Digital

13 LCD Data Line 2 Bi-Directional Digital

14 LCD Data Line 3 Bi-Directional Digital

15 LCD Data Line 4 Bi-Directional Digital

16 LCD Data Line 5 Bi-Directional Digital

17 LCD Data Line 6 Bi-Directional Digital

18 LCD Data Line 7 Bi-Directional Digital

19 Ground

20 No Connection

JP6 Stim Control

Output Digital - Data is Active

Low

Board

Pin # Signal Name Type

1 Unregulated DC Power 8-18VDC

2 Fan On Output Open Collector, Active

Low

JP7 Stim Control

Board

Pin # Signal Name Type

1 Dual Port RAM Input Digital Active Low

Innovation starts here TM 14 Intelect® Legend Series Service Manual

Page 15

CHATTANOOGA

GROUP INC.

Interrupt

2 Address Line 0 Output Digital

3 Ground

4 Address Line 1 Output Digital

5 Dual Port RAM Busy Input Digital Active Low

6 Address Line 2 Output Digital

7 Ground

8 Address Line 3 Output Digital

9 Dual Port RAM

Output Digital

Read/Write

10 Address Line 4 Output Digital

11 Ground

12 Address Line 5 Output Digital

13 Dual Port RAM Output

Output Digital Active Low

Enable

14 Address Line 6 Output Digital

15 Ground

16 Address Line 7 Output Digital

17 Dual Port RAM Chip

Output Digital Active Low

Enable Board 1

18 Address Line 8 Output Digital

19 Dual Port RAM Chip

Active Low

Enable Board 2

20 Address Line 9 Output Digital

21 Ground

22 Patient Disconnect Output Digital

23 Stim Channel 1

Output Digital

Power-Down

24 No Connection

25 Ground

26 Stim Data Line 0

27 MicroCurrent Probe

Input Digital

Switch

28 Stim Data Line 1 Bi-Directional Digital

29 Ground

30 Stim Data Line 2 Bi-Directional Digital

31 Ground

32 Stim Data Line 3 Bi-Directional Digital

33 Ground

34 Stim Data Line 4 Bi-Directional Digital

35 Stim Channel 2

Output Digital

Power-Down

36 Stim Data Line 5 Bi-Directional Digital

37 Ground

38 Stim Data Line 6 Bi-Directional

39 Stim Reset Output Digital Active Low

40 Stim Data Line 7 Bi-Directional Digital

Innovation starts here TM 15 Intelect® Legend Series Service Manual

Page 16

CHATTANOOGA

GROUP INC.

JP9 Stim Control

Board

Pin # Signal Name Type

1 Backlight Power Power Approx. 100VAC,

Approx. 400Hz

2 Ground

JP10 Stim Control

Board

Pin # Signal Name Type

1 Ground

2 Switch 0 Input Digital Active Low

3 Switch 1 Input Digital Active Low

4 Switch 2 Input Digital Active Low

5 Switch 3 Input Digital Active Low

6 Switch 4 Input Digital Active Low

7 Switch 5 Input Digital Active Low

8 Switch 6 Input Digital Active Low

9 Switch 7 Input Digital Active Low

10 Switch 8 Input Digital Active Low

11 Switch 9 Input Digital Active Low

12 Switch 10 Input Digital Active Low

13 Switch 11 Input Digital Active Low

14 Switch 12 Input Digital Active Low

15 Switch 13 Input Digital Active Low

16 Switch 14 Input Digital Active Low

17 Switch 15 Input Digital Active Low

Innovation starts here TM 16 Intelect® Legend Series Service Manual

Page 17

Ultrasound Generator Board

Below is a simple drawing showing the approximate locations of the

connectors and the position of pin 1 on each connector.

CHATTANOOGA

GROUP INC.

J1

PIN 1

PIN 1

J2

Ultrasound Generator Board

J3

Below are tables showing the signals for each connector on the Control

Board. The columns are arranged as pin number, signal description, type of

signal and any other notable information about the signal

J1 Ultrasound

Generator Board

Pin # Signal Name Type

1 Ground

2 US Data Line 0 Bi-Directional Digital

3 Ground

4 US Data Line 1 Bi-Directional Digital

5 Ground

6 US Data Line 2 Bi-Directional Digital

7 Ground

8 US Data Line 3 Bi-Directional Digital

9 Ground

10 US Data Line 4 Bi-Directional Digital

11 Ground

12 US Data Line 5 Bi-Directional Digital

13 Ground

14 US Data Line 6 Bi-Directional Digital

15 Ground

16 US Data Line 7 Bi-Directional Digital

17 Ground

18 No Connection

19 Ground

PIN 1

Innovation starts here TM 17 Intelect® Legend Series Service Manual

Page 18

CHATTANOOGA

GROUP INC.

20 US Address Line 0 Input Digital

21 Ground

22 US Address Line 1 Input Digital

23 Ground

24 No Connection

25 Ground

26 No Connection

27 Ground

28 No Connection

29 Ground

30

31 Ground

32 US Board Enable Input Digital Active Low

33 Ground

34 US Read/Write Input Digital Active Low

35 Ground

36 No Connection

37 Ground

38 US Control Circuitry

39 Ground

40 US Amplifier Power

US Strobe

Power Down

Down

J2 Ultrasound

Input Digital Active Low

Input Digital

Input Digital

Generator Board

Pin # Signal Name Type

1 DC Power Input Input 8-18 VDC

2 DC Power Input Input 8-18 VDC

3 Ground

4 Ground

J3 Ultrasound

Generator Board

Pin # Signal Name Type

1 US Generator Output Output 0-50V, 1-3 MHz Sine

Wave

2 Ground

3 Calibration Read/Write

OR

Ground

4 Ground

Bi-Directional 5V Digital During

Read

12V Digital During

Write

Innovation starts here TM 18 Intelect® Legend Series Service Manual

Page 19

Stim Board

Below is a simple drawing showing the approximate locations of the

connectors and the position of pin 1 on each connector.

Jumper for Ch. 1&2

Jumper for Ch. 3&4

Stim Board

CHATTANOOGA

GROUP INC.

JP1

JP2

PIN 1

PIN 1

PIN 1

J2

J3 J4 J5

PIN 1PIN 1PIN 1

PIN 1

J1

Below are tables showing the signals for each connector on the Control

Board. The columns are arranged as pin number, signal description, type of

signal and any other notable information about the signal. Note that the

jumper on JP2 MUST be positioned for channels 1&2 for the Stim unit to

operate.

JP1 Stim Board

Pin # Signal Name Type

1 Dual Port RAM

Interrupt

2 Address Line 0 Input Digital

3 Ground

4 Address Line 1 Input Digital

5 Dual Port RAM Busy Output Digital Active Low

6 Address Line 2 Input Digital

7 Ground

8 Address Line 3 Input Digital

9 Dual Port RAM

Read/Write

10 Address Line 4 Input Digital

11 Ground

12 Address Line 5 Input Digital

13 Dual Port RAM Output

Enable

14 Address Line 6 Input Digital

Output Digital Active Low

Input Digital

Input Digital Active Low

Innovation starts here TM 19 Intelect® Legend Series Service Manual

Page 20

CHATTANOOGA

GROUP INC.

15 Ground

16 Address Line 7 Input Digital

17 Dual Port RAM Chip

Enable Board 1

18 Address Line 8 Input Digital

19 Dual Port RAM Chip

Enable Board 2

20 Address Line 9 Input Digital

21 Ground

22 Patient Disconnect Input Digital

23 Stim Channel 1

Power-Down

24 No Connection

25 Ground

26 Stim Data Line 0

27 MicroCurrent Probe

Switch

28 Stim Data Line 1 Bi-Directional Digital

29 Ground

30 Stim Data Line 2 Bi-Directional Digital

31 Ground

32 Stim Data Line 3 Bi-Directional Digital

33 Ground

34 Stim Data Line 4 Bi-Directional Digital

35 Stim Channel 2

Power-Down

36 Stim Data Line 5 Bi-Directional Digital

37 Ground

38 Stim Data Line 6 Bi-Directional

39 Stim Reset Input Digital Active Low

40 Stim Data Line 7 Bi-Directional Digital

JP2 Stim Board Header for

Input Digital Active Low

Active Low

Input Digital

Output Digital

Input Digital

Jumper

Pin # Signal Name Type

1 Channel 3&4 Select Input Jumper Pin 2 to Here

if this board is for Ch.

3&4 in a 4-Ch. Unit

2 Dual Port RAM Chip

Enable

3 Channel 1&2 Select Input Jumper Pin 2 to Here

Input Digital Active Low

if this board is for Ch.

1&2 in ANY Unit

Innovation starts here TM 20 Intelect® Legend Series Service Manual

Page 21

CHATTANOOGA

GROUP INC.

J1 Stim Board

Pin # Signal Name Type

1 Power Input Input 8-18 VDC

2 Power Input Input 8-18 VDC

3 Ground

4 Ground

J2 Stim Board

Pin # Signal Name Type

1 Hi-Volt Probe Output Output Stim Output, 0-500V

Pulses

2 Hi-Volt Probe Pot Top Output Not Used

3 Hi-Volt Probe Pot

Wiper

4 Ground

Input Not Used

J3 Stim Board

Pin # Signal Name Type

1 Channel 2 Output Low Stim Output 0-100V Peak,

Depends on waveform

2 No Connection

3 Channel 2 Output Hi Stim Output 0-100V Peak,

Depends on waveform

J4 Stim Board

Pin # Signal Name Type

1 Channel 1 Output Low Stim Output 0-100V Peak,

Depends on waveform

2 No Connection

3 Channel 1 Output Hi Stim Output 0-100V Peak,

Depends on waveform

J5 Stim Board (Not Used on

Legend Series)

Pin # Signal Name Type

1 Microcurrent Probe

Output

2 Microcurrent Probe

LED Anode

3 Microcurrent Probe

Switch

4 Microcurrent Probe

Pot Top

5 Microcurrent Probe

Pot Wiper

6 Ground

Stim Output -60 to 60V Peak or DC

Not Used

Input Digital

Not Used

Not Used

Innovation starts here TM 21 Intelect® Legend Series Service Manual

Page 22

CHATTANOOGA

7 No Connection

8 Channel 1 Output Low Not Used

GROUP INC.

Innovation starts here TM 22 Intelect® Legend Series Service Manual

Page 23

My Problem Is With . . .

Go to page

Error Messages......................................26

Special Key Combinations....................27

Power-On................................................28

No Output ...............................................29

Head Detection and ..............................30

Data Reading

CHATTANOOGA

GROUP INC.

Applicator Overheating.........................31

Head Warming........................................32

Display....................................................33

No Display, Garbled Display,

Black Display

Settings Return to Defaults after..........34

adjustments

None of the above ! ...................................35

Find the topic that best describes your problem and turn to

that section for troubleshooting help !

This troubleshooting guide will help you through a process of elimination. The key is to

gather as many clues as possible. Observe the behavior of as many aspects of the unit’s

operation as possible. If there is no clear path or conclusion, use the information you have

gathered as well as the theory of operation to guide you.

Innovation starts here TM 23 Intelect® Legend Series Service Manual

Page 24

CHATTANOOGA

GROUP INC.

Intelect Legend Stim Error Messages Explained

Below is a list of the messages displayed on the LCD screen when an

error is detected, as well as a brief explanation of the source of the message.

“Channels Needed for This Mode are Busy”

Either no channels are open to run a new signal, or the dedicated

channel for HiVolt is already being used.

“Over Current Fault on Channels X-X”

Where X is a channel number. Indicates that a severe overcurrent

was detected on the specified channel(s).

Intelect Legend US Error Messages Explained

Below is a list of the codes displayed on the LEDs when an error is

detected.

HHH

The applicator has reached a temperature that is too high, and the

US output has been stopped.

noHd

No ultrasound applicator detected.

E03

An attempt to set up an address on the onewire device failed.

E04

An attempt to read data from the ultrasound applicator failed.

E05

An attempt to program the ultrasound applicator failed. This only

occurs during calibration.

E06

The ultrasound applicator memory is full. This only occurs during

calibration.

E07

The memory device in the ultrasound applicator is not the proper

type.

E08

The ultrasound applicator is uncalibrated.

Innovation starts here TM 24 Intelect® Legend Series Service Manual

Page 25

Special Key Combinations

Intelect® Legend Stim

Here is a list of the key combinations available for adjusting LCD screen

contrast and saving presets.

Adjust the Contrast UP

Channel 1 & Intensity Up

Adjust the Contrast DOWN

Channel 1 & Intensity Down

Save Current Output Settings

Pause & Enter

Intelect® Legend US

Here is the key combination for saving presets.

CHATTANOOGA

GROUP INC.

Save Current Settings

Intensity Up & Display (Watts / W/cm

2

)

Innovation starts here TM 25 Intelect® Legend Series Service Manual

Page 26

CHATTANOOGA

GROUP INC.

Problems Powering Up The Unit

If there is an indicator on the power supply, does it turn off when you turn the

power switch on? (If there is no indicator use a voltmeter to monitor the power

supply output.)

Yes - Try another power supply. If the results are the same, open the

case of the unit and unplug the power connector to each board, one at a

time, until the unit comes on properly. That will be the bad board.

No - Does it remain on?

Yes - Is there any indication that power is getting to the unit, such

as the LCD or LEDs briefly flash or the beeper ticks?

Yes - Unplug everything but the power from the Control

Board and see if it comes on. If not, then it is bad. If it did,

the Stim board or US Generator Board is bad.

No - Check the fuse on the rear of the unit. Replace if

blown.

No - Check the AC power source and the power cord. It could also

be a bad power supply.

Innovation starts here TM 26 Intelect® Legend Series Service Manual

Page 27

CHATTANOOGA

GROUP INC.

No Ultrasound Output

First, check that the duty cycle or intensity is not so low that you can’t observe

water movement on the applicator head. If there is some movement, but not as

high as expected, use an ultrasound power meter to test the output. If it is low,

then follow the Applicator Calibration Procedure in this manual.

If there is absolutely no output, try another applicator. Any Chattanooga Group

applicator from an Intelect

®

Legend or CPS unit that has the same connector will

work.

Did swapping the applicator fix the problem?

Yes - The applicator is bad.

No - The generator board is probably bad. Also check the connector and

harness inside the unit.

If you do not have another applicator, you can check for output on the Ultrasound

Generator Board using an oscilloscope. Refer to the Ultrasound Generator Board

drawing and signal list in this manual. If there is output at the board connector,

the applicator is bad.

No Stim Output

Does the display change when a treatment is selected?

No - The Stim Board is probably bad. Also check the connector and

harness inside the unit.

Yes - First be sure the leads and electrodes are good. If possible test the

output with a resistor.

Next be sure the output type is available at the channel you are

monitoring. For example, HiVolt is only available from channel 2. See the

manual.

Also check the output harnesses and connectors or monitor the output at

the connector on the Stim Board.

If these checks do not reveal the source of the problem and there is no

output in one or more treatment modes, the Stim Board is faulty.

Innovation starts here TM 27 Intelect® Legend Series Service Manual

Page 28

CHATTANOOGA

GROUP INC.

Applicator Detection and Data Reading Problems

To help diagnose these problems, keep in mind how the unit operates.

The unit determines whether an applicator is connected based on the voltage

from the thermistor in the applicator. If the applicator is unplugged, the voltage

rises to 5V from its normal 2-3V. This is sensed and the unit will then try to get

the memory device in the applicator to acknowledge a reset signal. If this fails,

the message “noHd” is displayed. On the other hand, if the voltage drops low, it

is interpreted as the head overheating and “HHH” is displayed. This is also what

would happen if the applicator was shorted.

The voltage can be monitored WHILE THE ULTRASOUND GENERATOR

IS NOT RUNNING by measuring the voltage on the output pin of the connector

on the Ultrasound Generator Board. Refer to the board drawings and signal lists.

The calibration data is read both at start-up and when US is selected.

Errors E03, E04, E07 and E08 are due to problems in the communications at

these times. This can be caused by either the Applicator or the Ultrasound

Generator Board. The easiest way to determine which is bad is by trying another

Applicator. The unit will continue to give error messages if the Ultrasound

Generator Board is defective. If this is not possible, monitoring the output line

while the unit is trying to read the calibration data can help determine which

component is bad. Under normal conditions, a fast pulse train is seen as the

data is passed from the Applicator to the Generator Board with an amplitude of

5V. If the amplitude is 12V, the Ultrasound Generator Board is faulty. If the

pulse train is not observed, unplug the applicator and try pressing the Frequency

button while monitoring the output. If a single 5V pulse is observed, the

Applicator is bad. If no activity is seen then the Ultrasound Generator Board is

bad.

During calibration of the Applicator, an error message E06 means that

there is no more room in the memory device to store the calibration data. The

Applicator will have to be replaced. An E05 message could be due to either the

Applicator or the Ultrasound Generator Board. Use the information in the

previous paragraph to diagnose which it is.

Applicator Overheating

This is not normally due to any malfunction of the unit, but rather is related

to the coupling of the head to the patient. If good coupling (contact) to the skin is

not maintained during treatment the head can heat up. If the head gets too hot,

the unit will pause the treatment and display “HHH” in the display. The only part

that would be bad under these circumstances would be the Applicator.

For problems related to the Head Warming feature, refer to that section.

Innovation starts here TM 28 Intelect® Legend Series Service Manual

Page 29

CHATTANOOGA

GROUP INC.

Head Warming Problems

Usually an explanation of exactly how this feature works will help you

determine if the problem is due to the Applicator or the Ultrasound Generator

Board.

When Head Warming is selected, the ultrasound output is turned on at

half the maximum output for the head size, and the frequency is set to 3 MHz.

The head temperature is monitored and when it reaches a temperature slightly

above skin temperature the output is reduced to a level of about 10% of

maximum to maintain the temperature. If the temperature rises above the skin

temperature while at the 10% level, the output is turned off until the temperature

falls back down. On the other hand, if the temperature rises to the maximum

head temperature, the unit will display “HHH” and the output will be turned off to

protect the crystal in the Applicator. Bear these facts in mind: at any time Head

Warming is on the output can be off, at 10% or 50% of maximum and the unit is

functioning normally. Reaching “HHH” occasionally would not be abnormal but

could indicate that the Applicator is extremely inefficient. Recalibration (see the

Applicator Calibration Procedure) or replacement would be required to correct

this.

If the head never warms up, check for output at 3 MHz by selecting 3.3MHz,

Continuous and pressing Start. Is there output at 3 MHz?

Yes - Something is malfunctioning on the Ultrasound Generator Board.

No - Remember that Head Warming uses the 3 MHz output. The

Applicator may need to be recalibrated for 3 MHz operation (see the

Applicator Calibration Procedure) or be replaced.

Display Related Problems

Stim unit LCD

Is the LCD screen completely black?

Yes - Adjust the contrast. Is the problem corrected?

No - The LCD screen should be replaced.

No - Is the LCD screen garbled ? (lines, odd text, etc.)

Yes - Is the problem consistent? (If there is a line across the

screen, is it always in the same place?)

Yes - The problem is most likely the LCD display.

No - The problem is usually the Control Board.

No - Is the LCD screen completely blank?

Innovation starts here TM 29 Intelect® Legend Series Service Manual

Page 30

Yes - Are there other signs that the unit is functioning such

as the fan runs when a treatment is selected and the

intensity increased? If not, check the items in the Power-On

section. Otherwise, try adjusting the contrast. If that doesn’t

correct the problem, it could be in either the LCD or the

Control Board. Check the signals on JP4 (refer to the signal

list) to help determine which it might be.

No - See the section titled “My Problem Isn’t Described

Here” for some additional troubleshooting tips. Your

problem will be either a defective Control Board or LCD

screen, or possibly the connection between them.

Ultrasound unit LEDs

Are any LEDs working?

Yes - The Control Board is faulty.

CHATTANOOGA

GROUP INC.

No - Are there other signs that the unit is functioning such as the fan runs

when Start is pressed and the intensity increased? If not, check the items

in the Power-On section. If those checks reveal that there is power to the

Control Board, then it is faulty.

Settings Return to Defaults After Adjustments

This is usually caused by a faulty Membrane Switch. If a switch sticks, the

function it performs can cause changes in the parameters selected and other odd

behavior.

Occasionally this can be due to a defective Control Board as well.

Innovation starts here TM 30 Intelect® Legend Series Service Manual

Page 31

CHATTANOOGA

GROUP INC.

My Problem Isn’t Described Here !

While we have tried to make this manual as complete as possible and

include as much troubleshooting help as we can, there will still be some problems

which haven’t been foreseen or are so rare as to not be included.

Some tips:

•Always begin by reading the Theory of Operation and review the Signal

Lists. By understanding what the unit is supposed to be doing and how the

circuit boards communicate, you can usually probe some of the signals and/or

swap some boards and determine the source of the problem.

•Observe the unit’s operation and find as many details of the problem as

possible, such as the mode it occurs in, settings, etc.

•Is the problem repeatable or intermittent?

•Consider parts that may wear as more likely to fail.

•Examine the circuit boards carefully for signs of failed components such

as oily residue underneath an electrolytic capacitor, charred or broken

components.

•Replace the complete circuit board, do not attempt to repair it.

Innovation starts here TM 31 Intelect® Legend Series Service Manual

Page 32

These pages have the wiring diagrams for the Intelect® Legend Ultrasound

and Intelect

®

Legend Stim units. Refer to them for connection information and

part numbers.

CHATTANOOGA

GROUP INC.

Wiring Diagrams

®

Intelect

Innovation starts here TM 32 Intelect® Legend Series Service Manual

Legend Ultrasound

Page 33

CHATTANOOGA

GROUP INC.

®

Intelect

Innovation starts here TM 33 Intelect® Legend Series Service Manual

Legend Stim

Page 34

CHATTANOOGA

GROUP INC.

Calibration Procedures

These calibration procedures apply to calibration of the Intelect® Legend

Ultrasound and Intelect

®

Legend Stim units. Following it is a calibration

procedure for the ultrasound applicators.

Intelect® Legend Stim

Calibration Procedure

Equipment Required:

Oscilloscope

Scope Probe (X10)

(2) 510-ohm Loads

A. Unit Startup and Fan Testing

1. Plug the 510-ohm loads into the output jacks. With the unit properly

plugged into its power supply, turn the unit on. The unit should beep once,

time and output screen should display and the fan should be blowing

inward. Check for excessive fan noise.

B. Stimulator Test

1. IFC: Connect scope probe across load on Channel 1. Press IFC and

heading of menu should display: Ch1-2: IFC. Press Up Intensity arrow to

increase Output to 50ma and press Start. Screen should change to opening

display listing: Channel 1 IFC at top and timer display in large letters

counting down from 15:00 and Output at 50ma. Below the output is: Ch2

IFC. Verify waveform is similar to that shown below with oscilloscope.

Move the oscilloscope probe to the Channel 2 load and verify that the

waveform is similar to that shown below using the oscilloscope. Press

Pause and observe the output. Main display will show a P beside the

output and output will drop to 0.0ma . Press Pause to restart and Stop to

reset.

IFC waveform; ‘scope set to 20V/div & .2mSec/div

Innovation starts here TM 34 Intelect® Legend Series Service Manual

Page 35

CHATTANOOGA

2. Premod: With the oscilloscope probe on channel 2, press Channel 2

button. Press Premod and observe: Channel 2 Premod. Adjust output

with Intensity arrow to 50ma and press Start. Main screen should display

Channel 2 Premod with timer counting down from 15:00 and 50ma as

output with Ch1 - Avail below. Verify waveform is similar to that below

using the oscilloscope. Press Stop to reset.

GROUP INC.

Premod Waveform; ‘scope set to 10V/div, 1mSec/div

3. HiVolt: Press HiVolt and Main Menu should display at top: Ch2: High

Volt. Time should be set to 20:00 and Int should now read 0v. Press Enter

to select Probe. Output must display 0v. Press Enter again to select Pads.

Increase Output with the Intensity up button to 500. Press Start and verify

that the output waveform is similar to that shown below. Press Enter and

use Main Menu down button to move to Polarity. Toggle polarity from

positive to negative and observe that the waveform changes as shown

below. Press Stop upon successful completion.

Positive

Negative

Hi-Volt Waveforms; ‘scope set to 50V/div, 20uSec/div

4. Russian: Press Channel 1 button. Press Russian & observe: Channel 1

Russian . At Mode, press Enter and select CoContract and press Enter

again. Main Menu heading must say: Ch1-2: Russian. Move down to

Cycle Time with the arrow keys and press Enter. Select Continuous and

press Enter again. Increase Intensity with the arrow key to maximum

100ma and press Start. Verify on Main screen that both Channels reach

100 by pressing the Channel 1 and 2 button. Verify that the output

Innovation starts here TM 35 Intelect® Legend Series Service Manual

Page 36

waveform on both channels is similar to that shown below using the

oscilloscope.

CHATTANOOGA

GROUP INC.

Russian Waveform; ‘scope set to 50V/div, 5mSec/div

Press pause to pause the operation and then press the Up and Down Time

buttons to confirm that the time changes. Set the treatment time to 1 minute

and push Start. Upon completion, you should hear 2 beeps, a pause, and

then 2 more beeps to indicate end of treatment. The output must be at zero

at this time.

C. Screen Intensity Adjustment

1. Hold Channel 1 and Intensity up or down button to adjust the screen for

proper display.

Remove power; Test is complete!

Intelect® Legend US

Calibration Procedure

Note: All caps indicate a front panel button.

1. Plug the applicator and appropriate power supply into the unit. Plug the

power supply into an appropriate outlet and turn the unit on. It should beep

and the LEDs should illuminate, then fill with default time, duty cycle, and

frequency.

2. Unplug the applicator. The message ‘noHd’ should appear in the treatment

time display. Plug the applicator back in, press a key and observe that the

message disappears.

3. Press HEAD WARM. The fan should start and output will be displayed on the

LEDs. Pressing it a second time will stop the fan and the output will return to

0.0.

4. Press the FREQUENCY button and verify that 1 MHz and 3 MHz LEDs are

illuminated. Leave 1 MHz selected.

Innovation starts here TM 36 Intelect® Legend Series Service Manual

Page 37

CHATTANOOGA

GROUP INC.

5. Press DUTY CYCLE until Continuous is illuminated, noting that each LED is

functioning. Use the INTENSITY up button to set the output to 2.0W/cm

2

.

The fan should begin running. Press START. By applying a small amount of

water to the transducer, verify that there is ultrasound output.

6. Observe that the treatment time counts down on the LEDs. Press PAUSE.

The output should stop, the fan should stop and the treatment timer should

stop counting down. Press START and the output should resume. Press

STOP and verify that the output stops, the treatment timer is reset back to the

default, the output display is reset back to 0.0 and the fan stops.

7. Use the TIME up button to verify that the treatment time will not go above 15

minutes. Use the DOWN button to set the time back to 1 minute. Select 10%

Duty Cycle using the DUTY CYCLE button, increase the intensity to maximum

and press START. While the unit is running, press the DISPLAY button and

verify that the displayed power changes from 2.0 W/cm

2

to 10.0 Watts

(assuming a 5cm applicator is attached). Allow the unit to run until treatment

time runs out. Two beeps should be heard followed by another two beeps

and then the display will clear back to the default.

8. Testing complete.

Intelect® Legend Applicator

Calibration Procedure

1. Put unit into calibration mode. Turn the unit ON while holding down the Intensity UP

button. It is not necessary to hold the button down after the initial beep sound.

2. The Min/Sec display should read CAL0 indicating that the machine is in calibration

mode and at the first calibration step.

3. Place the applicator into the Ultrasound power meter.

4. Select the calibration frequency using the FREQUENCY button (1MHz or 3MHz).

5. Set the Head Size using the DUTY CYCLE button.

10% = 1cm applicator

20% = 2cm applicator

50% = 5cm applicator

Continuous = 10cm applicator

6. Once Applicator size and Frequency are chosen, push the START button. This will

begin the scan and calibration. The zero in CAL0 will flash while the scan is in progress.

Do not disturb the machine while it is scanning.

7. When the scan is complete the display will change to CAL1.

8. Re-zero the Ultrasound power meter.

9. Using the Intensity UP button, increase the output until the power meter reads 4

(four) watts.

Innovation starts here TM 37 Intelect® Legend Series Service Manual

Page 38

CHATTANOOGA

GROUP INC.

10. Push the START button. The unit will hold the settings in memory. The display will

change to CAL2.

11. If you are satisfied with the calibration, push START.

12. The unit will beep to indicate that the new calibration values have been stored in the

applicator.

13. The display will change to CAL0 and is now ready for the next calibration.

14. After both frequencies have been calibrated and before removing the applicator

head from the power meter, check the accuracy of the power calibration. Cycle the

power to the unit off and then back on. Select continuous duty cycle and increase the

output to the settings listed. Verify that the power indicated on the UPM-DT-10 power

meter is within the indicated range. Check power at both 1 MHz and 3.3 Mhz.

Head size Power level Output range

2

2 cm

4 watts 3.44-4.56

2

5 cm

10 watts 8.6-11.4

2

10 cm

10 watts 8.6-11.4

15 watts 12.9-17.1

20 watts 17.2-22.8

2 watts 1.72-2.28

5 watts 4.3-5.7

5 watts 4.3-5.7

15. Calibration complete. If you are not satisfied with the calibration and wish to start

over, turn the machine OFF and begin at step one listed above.

.

Innovation starts here TM 38 Intelect® Legend Series Service Manual

Page 39

Technical Specifications

Listed here are the specifications for the Intelect® Legend Ultrasound.

Dimensions: 8.25” x 11” x 2.5”

Weight: 2 lb.

Applicators: 2, 5, & 10 cm²

Power: 90V-264V, 47-63Hz

2 cm² Applicator

Frequency (Mhz): 1.0 MHz, 3.3 MHz (all +/- 5%)

Power (watts): 0.2 watt to 4 watts

ERA (cm²): 1.8 cm²

Effective Radiating Area: 1.8 cm² +/-0.4 cm²

Maximum beam

non-uniformity ratio: 6.0:1

Beam type: Collimating

5 cm² Applicator

Frequency (Mhz): 1.0 MHz, 3.3 MHz (all +/- 5%)

Power (watts): 0.4 watt to 10 watts

ERA (cm²): 4.0 cm²

Effective Radiating Area: 4.0 cm² +/-1.0 cm²

Maximum beam

non-uniformity ratio: 6.0:1

Beam type: Collimating

10 cm² Applicator

Frequency (Mhz): 1.0 MHz, 3.3 MHz (all +/- 5%)

Power (watts): 1 MHz: .1 watt to 20 watts, 3.3 MHz: 1-10 watts

ERA (cm²): 8.5 cm²

Effective Radiating Area: 8.5 cm² +/-1.5 cm²

Maximum beam

non-uniformity ratio: 6.0:1

Beam type: Collimating

Duty Cycle

Pulsed: 10%, 20%, 50%

Continuous: 100%

Pulse Duration:

5 msec +20% (50% duty cycle, pulsed mode)

2 msec +20% (20% duty cycle, pulsed mode)

CHATTANOOGA

GROUP INC.

Innovation starts here TM 39 Intelect® Legend Series Service Manual

Page 40

Ultrasonic Power:

10 cm² crystal at 1.0 MHz: Variable from 1 watt to 20 watts

10 cm² crystal at 3.3 MHz: Variable from 1 watt to 10 watts

5 cm² crystal: Variable from 0.4 watt to 10 watts

2 cm² crystal: Variable from 0.2 watt to 4 watts

CHATTANOOGA

GROUP INC.

Innovation starts here TM 40 Intelect® Legend Series Service Manual

Page 41

CHATTANOOGA

GROUP INC.

Listed here are the specifications for the Intelect

®

Legend Stim.

Interferential

Output Channels: 1 & 2

Amplitude: 0-50 mA RMS into a 500 ohm load

Current Limit: 50 mA RMS

Voltage (max.): 200 Volts Peak to Peak

Carrier Frequency: 5000 Hz

Beat Frequencies: 0-200 Hz

Premod

Channels: 1 & 2

Amplitude: 0-50 mA RMS into a 500 ohm load

Current Limit: 50 mA RMS

Voltage (max.): 200 Volts Peak to Peak

Carrier Frequency: 2000-5000 Hz

Beat Frequency: 0-200 Hz

Russian

Channels: 1 & 2

Amplitude: 0 to 100 mA RMS into a 500 ohm Load

(During On-Time of Burst)

Current Limit: 50 mA Average

Voltage (max.): 200 Volts Peak to Peak

Carrier Frequency: 2500 Hz

Burst Frequency: 20-100 Hz

Duty Cycle: 10% to 50%

HiVolt

Description: The output is a fast-rising dual pulse with approximately 75

microseconds spacing between pulses.

Pulse duration: First peak is 5 microseconds at one-half pulse height and

second peak is 8 microseconds at one-half pulse height. These

measurements are with a load impedance of 1,000 ohms. Pulse duration

varies according to body impedance (load resistance).

Channel: 2 Only

Voltage Current: 0-500 Volts

Output Current: 0-2500 milliamps peak

Frequency: 1-120 pulses per second

Innovation starts here TM 41 Intelect® Legend Series Service Manual

Page 42

CHATTANOOGA

GROUP INC.

Parts List

The following is a list of replaceable parts for the Intelect® Legend

Ultrasound and Intelect

®

Legend Stim units with their Chattanooga Group part

numbers.

78211 Intelect Ultrasound Control Board Assembly

78811 Intelect Stim Control Board Assembly

77001 Ultrasound Generator Board Assembly

78321 Stim Generator Board Assembly

78234 2cm Applicator Assembly

78233 5cm Applicator Assembly

78232 10cm Applicator Assembly

78105 40 Conductor Cable Assembly, Control Bd to US Generator Bd

71741 3- Ampere Slo-Blo Fuse

72315 4- Ampere Slo-Blo Fuse

77007 LCD Screen

78108 Fan for CPS Ultrasound or Stim

78215 Intelect Ultrasound Membrane Switch

78217 Intelect Stim Membrane Switch

78121 120VAC Power Cord

78082 Intelect Ultrasound or Stim Power Supply

78113 UL-544 Power Supply

78107 Buzzer for Intelect Stim or Ultrasound

78023 Power Switch

78109 Ultrasound Output Harness

78092 Stim Output Harness

78097 Stim HiVolt Output Harness

Innovation starts here TM 42 Intelect® Legend Series Service Manual

Loading...

Loading...