Page 1

valu-clean.com

P. O. Box 4982

Winston-Salem, NC 27115

336/661-1559 Fax: 336/661-1979

VC1000

Models Included:

Hood-Type

Dishwasher

2674 N. Service Road

Jordan Station, Ontario, Canada L0R 1S0

905/562-6630 Fax: 905/562-5422

Valu-Clean Manual

P/N 113566 Rev. A

October, 2003

Technical Manual

Page 2

Model and Serial number located

on the right side of the control cabinet.

Complete the information below so it will be available for quick reference.

Model Number Serial Number

Voltage and Phase

Valu-Clean Service Agency Phone

Valu-Clean Parts Source Phone

Valu-Clean (Canada) Valu-Clean (U.S.A.)

National Service Department National Service Department

Phone: 1 (905) 562-4195

Phone: 1 (336) 661-1559

1 (800) 263-5798

Fax: 1 (905) 562-4618 Fax: 1 (336) 661-1979

We strongly recommend that you Fax your orders.

NOTE: When calling to order parts, be sure to have the model number, serial number, voltage

of your machine.

COPYRIGHT © 2003 byValu-Clean

Page 3

i

REVISION HISTORY

Revision Revised Serial Number Comments

Date Pages Effectivity

8/01/02 — First issue of manual and replacement parts

10/13/03 iii — Added new figure number

10/13/03 16-17 — Added corner configuration instructions

Revision History

Page 4

REVISION HISTORY

Revision History (Cont)

ii

Page 5

iii

TABLE OF CONTENTS

CONTENTS

Page

REVISION HISTORY...................................................................................................................... i

SAFETY SYMBOLS ...................................................................................................................... v

GENERAL SPECIFICATIONS ...................................................................................................... 1

INSTALLATION .............................................................................................................................. 2

Electrical Connections ........................................................................................................ 2

Water Connections .............................................................................................................. 3

Drain Connections .............................................................................................................. 3

Ventilation............................................................................................................................ 3

Chemical Connections ........................................................................................................ 4

INITIAL START-UP ........................................................................................................................ 5

OPERATION .................................................................................................................................... 5

DAILY CLEANING........................................................................................................................ 6

MAINTENANCE ............................................................................................................................ 7

TROUBLESHOOTING .................................................................................................................... 8

REPLACEMENT PARTS ..............................................................................................................11

ELECTRICAL SCHEMATICS ...................................................................................................... 29

LIST OF FIGURES

Figure 1 — Door Assembly ........................................................................................ 12

Figure 2 — Wash/Rinse Assembly .............................................................................. 14

Figure 3 — Corner Conversion.................................................................................... 16

Figure 4 — Drain/Pump Assembly.............................................................................. 18

Figure 5 — Pump Assembly........................................................................................ 20

Figure 6 — Piping Assembly ...................................................................................... 22

Figure 7 — Control Panel............................................................................................ 24

Figure 8 — Control Cabinet ...................................................................................... 26

Page 6

THIS PAGE

INTENTIONALLY

LEFT BLANK

iv

Page 7

v

SAFETY SYMBOLS

Safety Symbols

• The following symbols appear throughout this manual alerting you to potential

hazards. Statements associated with each symbol are printed in italics.

NOTE:

Note statements indicate any condition or practice which,

if observed, will help in the safe completion of a task.

WARNING:

Warning statements indicate any condition or practice that

could result in personal injury or possible loss of life.

CAUTION:

Caution statements indicate any condition or practice which,

if not strictly observed or remedied, could result in damage

to or destruction of the equipment.

General Safety Rules

• The following general safety rules must be observed in addition to the specific cautions

and warnings presented in this manual.

• Operators should use caution when loading and unloading wares from the equipment.

• Operators must NOT bypass a safety interlock or control(s) to operate the dishwasher.

•The service and maintenance instructions contained in this manual are intended for

qualified service personnel. These instructions assume that you are trained in basic electricity

and mechanical theory. If you are not a trained technician, then do not attempt to adjust or

repair the equipment as serious personal injury or damage to the equipment may result.

!

Page 8

vi

THIS PAGE

INTENTIONALLY

LEFT BLANK

Page 9

1

GENERAL SPECIFICATIONS

About this manual

All information, illustrations and specifications contained in this manual are based upon the latest

product information available at the time of publication. Valu-Clean constantly improves its products

and reserves the right to make changes at any time or to change specifications or design without notice

and without incurring any obligation.

Organization of Manual

This manual is divided into seven parts:

• General Specifications

• Installation

• Daily Operation

• Cleaning and Maintenance

•Troubleshooting

•Replacement Parts, contains parts diagrams and parts list.

• Electrical Schematics

NOTE:

Unless noted otherwise, dimensions, capacities, temperatures, etc., given in this manual are

U.S. Customary Measures and the Metric Equivalent of the U.S. customary measures.

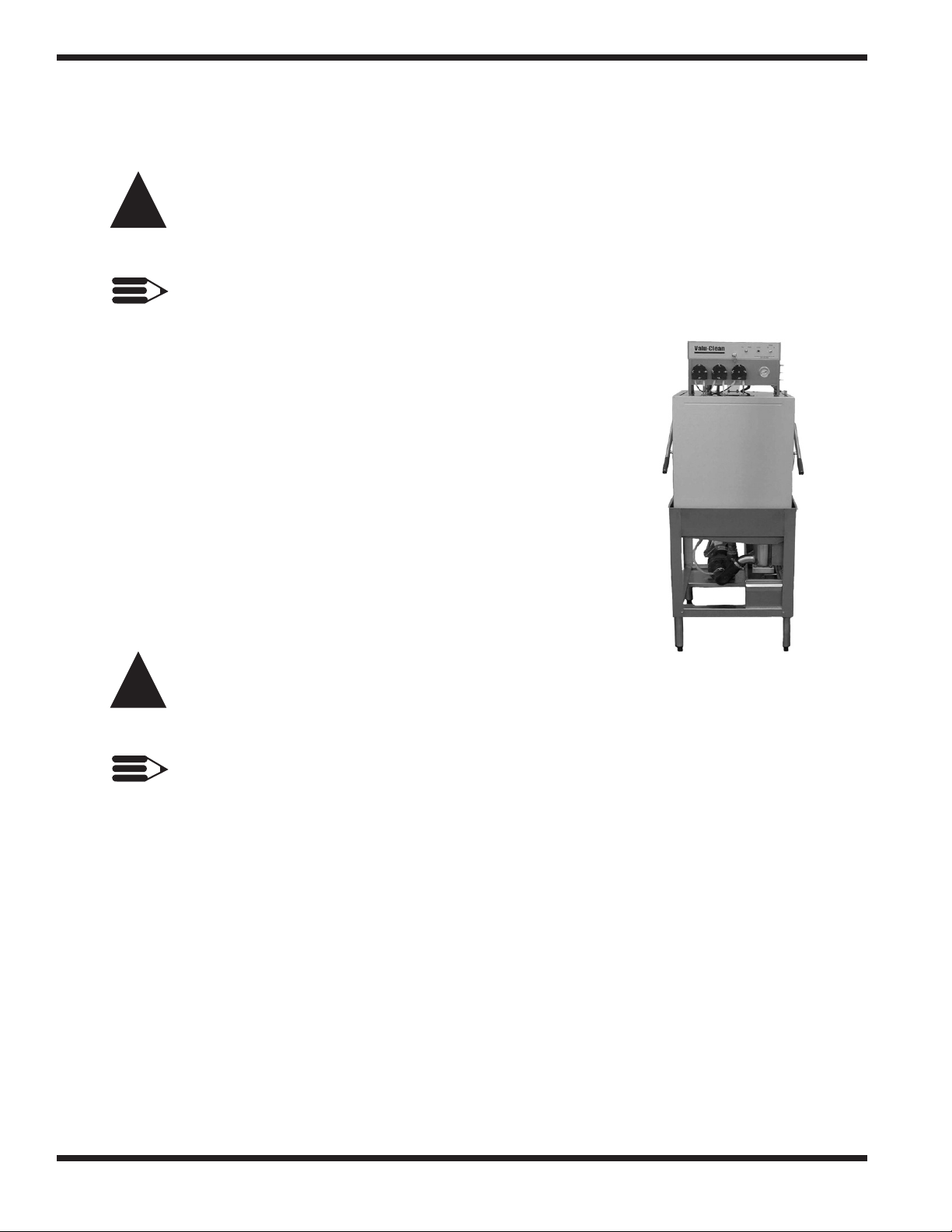

Model

The VC1000 model is a low temperature (140˚F/60˚C ) sanitizing model for use with a hypochlorite

(Chlorine) based sanitizer at a minimum concentration of 50PPM or to your local codes, in the final

rinse. The dishwasher includes three chemical dispenser pumps located in the control cabinet on the

top of the machine.

Standard Equipment

• Automatic Operation • Door safety switch

• Common utility connections • Field convertible to corner model

• Balanced door lift system • De-lime switch in control cabinet

• Interchangeable upper and lower • 1-hp drip-proof pump motor

spray arms

Page 10

Electrical Connections

WARNING:

Electrical grounding connections must comply with all applicable Electrical Codes.

WARNING:

When working on the diswasher, disconnect the electric service and place a tag at the

disconnect switch to indicate work is being done on that circuit.

1. A qualified electrician must compare the electrical power supply with the machine

electrical specifications before connecting to the incoming service through a fused

disconnect switch.

2. The electrical supply is single phase. The machine must be installed on 15A single phase

breaker.

3. A knock out is provided at the left rear corner of the control cabinet (as viewed from the

front) for electrical service connection or connection will be made from the plug

(depending on how the machine was ordered). A fused disconnect switch or circuit

breaker (supplied by others) is required to protect the power supply circuit.

4. Single phase incoming wire connections are made at the machine’s main terminal block.

The main terminal block is located in the control cabinet on the back wall and to the left

side of cabinet.

INSTALLATION

Unpack the dishwasher

CAUTION:

Care should be taken when lifting the machine to prevent damage.

NOTE:

The installation of your machine must meet all applicable health and safety codes.

1. Immediately after unpacking the machine, inspect for any shipping damage.

If damage is found, save the packing material and contact the carrier

immediately.

2. Remove the dishwasher from the skid. Move the machine to its

permanent location.

3. Machine must be placed on a sound self-draining floor.

4. Level the machine (if required) by placing a level on the top of the

machine and adjusting the feet. Level the machine from

front-back and side to side.

2

!

!

Page 11

3

INSTALLATION (CONT.)

Plumbing Connections

NOTE:

Plumbing connections must comply with all applicable sanitary and plumbing codes.

Water Connections

1. VC1000 dishwashers require a single, hot water supply.

2. The hot water connection to the dishwasher is at the 1/2" NPT Female “Y” strainer.

3. The connection is made from the top rear of the dishwasher.

4. The recommended minimum water temperature is 140˚F/60˚C.

5. A manual shut-off valve for water (supplied by others) should be installed in the supply

line to allow for servicing of the machine. The shut-off valve should be the same size or

larger than the supply line.

6. Install a pressure reducing valve (PRV) in the water supply line if flow pressure

exceeds 20-22 PSI/138-151.8kPa.

Drain Connections

1. The dishwasher is a gravity drain machine equipped with 1-1/2" O.D. hose connection point.

2. The maximum drain flow rate is 15 gallons/min-56.8 liters/min.

3. Drain height for the dishwasher must not exceed 11" (280mm) above the floor level.

4. The drain connection is made to the dishwasher by connecting to the tail piece located

on the bottom of the drain pan.

Ventilation

NOTE:

Ventilation must comply with local sanitary and plumbing codes.

CAUTION:

Exhaust air should not

be vented into a wall, ceiling, or concealed space of a building.

Condensation can cause damage.

!

Page 12

INSTALLATION (CONT.)

Chemical Pumps

NOTE:

Consult a qualified chemical supplier for your chemical needs.

1. Prime switches are located on the right hand side of the control cabinet.

Peristaltic Pump

To prime the peristaltic pump:

1. Insert pump inlet hose into the detergent container.

2. Close machine door and turn power switch to “ON” position.

3. Allow wash tank to fill up then press detergent pump prime switch to prime inlet

and outlet hose.

4. Stop priming when detergent reaches machine.

4

Page 13

5

INITIAL START-UP

Complete the installation

After the plumbing and electrical connections are made, follow the steps below to complete

the installation of your dishwasher.

1. Remove the protective covering from the exterior of the machine.

2. Remove any foreign material from the inside of the machine.

3. Make sure dishwasher power is off.

4. Turn the main water supply on.

5. Turn main power on at the main power service disconnect switch.

6. Install the pump suction filter.

7. Make sure that the overflow seats securely in the tank bottom.

8. Make sure doors are fully closed.

9. Turn power switch to the “ON” position.

10. Press and hold the fill switch until water overflows into the lower drain screen.

OPERATION

Operation and Use

1. Before washing make sure that:

• wall mounted on/off switch is switched on;

• water supply is open and water pressure is present;

• pump suction filter is installed in proper location;

• overflow tube is inserted in drain;

• rotating spray arms move freely;

• rinse, detergent and sanitizer containers are full;

2. Scrap and preflush all items to be washed. Load items into the rack.

Do not overload the rack. Wash only one layer of silverware in a rack.

3. Open the door and insert the rack into machine. Close door.

4. Machine starts automatically. CYCLE light glows green.

5. Remove rack when the CYCLE light goes out.

Page 14

DAILY CLEANING

Cleaning your machine is the best maintenace that you can provide. Components that are not

regularly flushed and cleaned do not perform well. The following schedules are the minimum

requirements necessary for the proper performance of your machine. Intervals should be

shortened whenever your machine is faced with abnormal conditions, hard water or mutliple

shifts. Before carrying out the cleaning operations, turn off the main disconnect switch for the

equipment.

Cleaning Schedule

Every 2 Hours or After Each Meal Period

1. Press the drain switch and hold to drain wash tank. When all the water has drained, release

the switch.

2. Turn dishwasher and wall switch OFF.

3. Flush the interior with fresh water.

4. Remove scrap wash pump inlet screen. Rinse throughly to make sure that it is clean. Do not

bang or beat it on the side of sink or other hard objects as this will eventually cause it to

break or bend thus causing it to not fit or work properly.

5. Reinstall the pump scrap screen.

6. Clean spray arm nozzles as needed.

7. Remove scrap screen from bottom of the drain pan. Rinse throughly to remove all debris.

8. Replace scrap screen at the bottom of the drain pan.

Frequently check and clean the nozzles. Blocked nozzles will prevent the machine from cleaning

properly. To clean the wash/rinse arms:

1. Undo the thumbscrew which hold the arms in place.

2. Turn and remove the end caps.

3. Flush arms with water, use a toothpick or paperclip (if necessary) to clear the nozzles.

4. Do not beat the arms on anything to clean nozzles.

5. Replace end caps.

6. Replace arms back into machine.

Every 8 Hours or at the End of the Day

1. Drain the machine and turn the power switch off..

2. Flush interior with fresh water.

3. Clean drain scrap screen and pump intake screen, as described above.

4. Clean spray arms and nozzles.

5. Throughly clean the exterior of the machine.

DO NOT HOSE DOWN WITH WATER.

6. Reassemble the machine.

7. Leave doors open to aid in drying the interior of machine.

CAUTION:

Do not leave water in wash tank overnight.

6

!

Page 15

7

MAINTENANCE

Before carrying out any maintenance operations, turn off the main disconnect switch for the

equipment.

Do not use corrosive products such as sodium hypochlorite (bleach), acids, steel wool or steel

brushes to clean the inside and the outside of machine.

The presence of calcium and magnesium salt in water can compromise machine performance.

Ask a qualified chemical person to remove the deposits periodically.

Stainless steel surfaces should be cleaned well in order to avoid some oxidation risks, or

chemical reactions.

Deliming

Your dishwasher should be delimed regularly depending on the mineral content of your water.

Inspect the machine interior for mineral deposits and use a deliming solution for the best

cleaning results.

NOTE:

Consult your chemical supplier for an appropriate deliming solution.

WARNING:

Deliming soultions or other acids must not come in contact with household bleach (sodium

hypochlorite) or any chemicals containing chlorine, iodine, bromine, or fluorine. Mixing will

cause hazardous gases to form.

Skin contact with deliming solutions can cause severe iritation and possible chemical burns.

Consult your chemical supplier for specific safety precautions.

Deliming Process

1. Remove all dishes from machine.

2. Remove chemical pick-up tubes from their containers.

3. Place each tube in a container of fresh water and prime the chemical lines for several

minutes to throughly flush chemical from the lines. Leave the pick-up tubes out of their

containers.

4. Drain machine by holding the drain toggle switch until empty. Fill machine with water only

by the fill toggle switch. Run 1 cycle to rinse the inside of the machine then drain by holding

the drain toggle switch. Refill the machine by holding the fill toggle switch.

5. Spray interior walls with deliming solution and let sit for 5 to 10 minutes depending on the

amount of build-up. Add deliming solution to wash tank. Do not let chemicals sit for longer

than 15 minutes.

6. Close door, run on the automatic cycle.

7. Repeat steps 3-5 if necessary.

8. Repeat Step 4.

9. Refill the machine and run an additional cycle at least two more times. Drain and refill the

machine after each cycle to throughly flush any deliming solution from the interior of the

machine.

10. Flip the power switch to OFF. Leave doors open to aid in drying overnight. Deliming process

is now complete.

!

Page 16

TROUBLESHOOTING

In order to find the cause of a breakdown or abnormal operating condition in your dishwasher

please ensure that:

1. All switches are ON

2. Drain overflow tube is in place and seated

3. Wash pipe and rinse nozzles are clean

4. Spray arms are in their proper positions

5. Pump inlet screen is properly positioned

6. Detergent, sanitizer and rinse additive dispensers are adequately filled

8. Doors are fully closed.

If a problem still exists, use the following table for troubleshooting

CONDITION CAUSE SOLUTION

Cycle will not start Door not closed.................................. Make sure doors are fully closed

Door safety switch faulty .................. Contact your service agency

Main switch off.................................. Check disconnect

Low or no water Main water supply is turned off ........ Turn on house water supply

Drain/overflow tube is not

in place and seated ............................ Clean, replace and seat drain tube

............................................................ as needed.

Faulty fill valve .................................. Contact your chemcial supplier.

Continuous water filling Fill valve will not close .................... Clean or replace

Any motor not running Defective contactor ............................ Contact your chemical supplier

Defective motor ................................ Contact your chemical supplier

Wash tank water temperature Incoming water temperature

is low when in use at machine too low ............................ Raise temperature to 140˚F/60˚C

Defective thermometer ...................... Check or replace

Defective solenoid valve .................... Check or replace

Arms not rotating Rinse nozzles not clean...................... Clean

Bearings worn .................................... Replace

Water supply pressure low ................ Check incoming water pressure

Insufficient pumped spray Clogged pump intake screen.............. Clean

pressure Clogged spray pipe ............................ Clean

Low water level in tank .................... Check drain and overflow tube, timer may

............................................................ need adjustment, contact chemical supplier

Defective pump seal .......................... Contact service agent

Insufficient rinse or no Faulty pressure reducing valve .......... Clean or replace

rinse Improper setting on pressure

reducing valve.................................... Set flow pressure to 20-22 psi [138-151 kPa]

Clogged rinse nozzle and/or pipe ...... Clean with paper clip/delime

Improper water line size .................... Have installer change to proper size 1/2" NPT

8

Page 17

9

TROUBLESHOOTING (CONT)

CONDITION CAUSE SOLUTION

Low final rinse temperature Low incoming water .......................... Check valve to be sure it is clean and operating.

Defective thermometer ...................... Check for proper setting or replace

Machine leaking Leaking at chemical hose .................. Replace hoses

Pump seal leaking .............................. Replace seal

Leaking at pump hose........................ Contact your chemical supplier

Leaking at doors ................................ Check to make sure that doors are fully closed

Water splashing out door Nozzles/End caps missing ................ Replace caps

Wash nozzles blocked ........................ Clean

Arms not rotating .............................. Replace bearings

Door handle twisted (pass through) .. Adjust or replace handle

Poor washing results Detergent dispenser not

operating properly.............................. Contact detergent supplier

Insufficient detergents........................ Contact detergent supplier

Food Soil concentration too

high in wash tank .............................. Prescrap dishes throughly

Wash water temperature

too low .............................................. See condition “Wash Tank

Water Temperature” above

Wash arm clogged.............................. Clean

Improperly scraped dishes ................ Check scraping procedures

Ware improperly

placed in rack .................................... Use proper racks. Do not overload racks

Improperly cleaned

equipment .......................................... Unclog wash sprays and rinse nozzles

to maintain proper pressure and flow

conditions. Overflows must be open.

Keep wash water as clean as possible.

Page 18

10

THIS PAGE

INTENTIONALLY

LEFT BLANK

Page 19

11

REPLACEMENT PARTS

REPLACEMENT

PARTS

Page 20

12

Figure 1-

Door Assembly

REPLACEMENT PARTS

V

a

l

u

-

C

l

ea

n

2

1

4

3

5

6

7

10

13

14

10

13

17

18

15

16

19

20

21

22

24

26

23

27

28

29

28

27

27

28

30

25

24

11

8

9

12

Page 21

13

REPLACEMENT PARTS

DOOR ASSEMBLY

Fig. 1 Part

Item No. No. Part Description Qty

1 0510458 DOOR HANDLE, VC1000...................................................................... 1

2 0510456 DOOR HANDLE BUSHING .................................................................. 4

3 0510459 SPRING, DOOR VC1000 ........................................................................ 1

4 0510460 GRIP, DOOR HANDLE .......................................................................... 2

5 107965 NUT, GRIP 8-32 W/NYLON INSERT.................................................... 2

6 111439 MAGNET, PERMANENT ...................................................................... 1

7 W333052 DOOR, VC1000 WELD ASSY................................................................ 1

8 0710488 DOOR STOP WELDMENT .................................................................... 2

9 107893 SHOCK ABSORBER (NOT SHOWN) .................................................. 2

10 0509274 NUT, ACORN 5/16-18 SST .................................................................... 4

11 0510456 BUSHING, DOOR HANDLE.................................................................. 4

12 0310490 WASHER, 0.313 X 1.00 16 GAUGE SST .............................................. 2

13 102376 WASHER, FLAT 5/16 X 3/4 X 1/16........................................................ 4

14 W1554 LINKAGE, DOOR HANDLE.................................................................. 2

15 0501539 NUT, HEX 1/4-20 SST ............................................................................ 4

16 0501501 LOCK WASHER 1/4" .............................................................................. 4

17 0510492 J BOLT, 5/16-18 UNC X 5" .................................................................... 2

18 100154 NUT, PLAIN 5/16-18 .............................................................................. 4

19 W333257 SUPPORT, REAR HOSE/CABLE .......................................................... 1

20 104883 SCREW, 6-32 X 3/8 ROUND HEAD...................................................... 2

21 111090 HAMLIN REED SWITCH ...................................................................... 1

22 108954 NUT, GRIP 6-32 W/NYLON INSERT.................................................... 2

23 W1539 WEARSTRIP, DOOR VC1000 ................................................................ 2

24 0509439 SCREW, 10-32 X 1/4 HEX HEAD.......................................................... 8

25 0510457 CLIP ON WEARSTRIP .......................................................................... 2

26 0508665 SCREW, 10-32 X 5/8 HEX WASHER HEAD ........................................ 2

27 0501478 WASHER 17/64 ID X 9/16 OD 18GA .................................................... 8

28 107967 NUT, GRIP 1/4-20 W/NYLON INSERT ................................................ 2

29 0501419 BOLT, 1/4-20 X 1/2 HEX HEAD ............................................................ 4

30 W1542 BRACKET, PILLAR RH SUPPORT ...................................................... 1

W15425 BRACKET, PILLAR LH SUPPORT ...................................................... 1

31 W1560 REMOVABLE TRACK GUIDE CORNER CONVERSION(NOT SHOWN) A/R

32 W1557 TRACK WELDED ASSEMBLY (NOT SHOWN).................................. A/R

Page 22

14

Figure 2-

wash/rinse assembly

REPLACEMENT PARTS

4

1

15

3

2

18

15

6

7

8

3

13

14

2

12

9

11

10

17

16

Page 23

15

REPLACEMENT PARTS

WASH/RINSE ASSMEBLY

Fig. 2 Part

Item No. No. Part Description Qty

1W333242 WASH TUBE, 25MM SS VC1000 .......................................................... 1

2 0510420 SPRAYARM COMPLETE ...................................................................... 2

3 0510495 SCREW, THUMB 5/16-18 ...................................................................... 4

4 0510484 UPPER WASHARM HUB ...................................................................... 1

5 0510483 LOWER WASHARM HUB .................................................................... 1

6 100735 BOLT 1/4-20 X 5/8 HEX HEAD ............................................................ 4

7 0501478 WASHER 17/64 ID X 9/16 OD 18GA .................................................... 4

8 107440 THERMOMETER 8’ FLANGE .............................................................. 1

9 0510512 POLY NUT, 1/4 NPT .............................................................................. 3

10 0509989 ELBOW 1/4 TUBE X W1/4 MPT COMP POLY .................................... 3

11 201029 LOCKNUT 1/2" NP ................................................................................ 1

12 107967 NUT, GRIP 1/4-20 W/NYLON INSERT ................................................ 4

13 0510489 GASKET, LOWER HUB ........................................................................ 1

14 0300823 WASHER 9/32ID X 1"OD ...................................................................... 4

15 0501395 SCREW SOCKET 1/4-20 X 5/16 ............................................................ 2

16 113098 FOOT INSERT ........................................................................................ 4

17 B501381 RING, POSI GRIP LOCKING ................................................................ 4

18 0510534 WASH ARM END CAP .......................................................................... 4

19 0510536 WASH ARM BEARING REBUILD KIT (NOT SHOWN) .................... A/R

20 0510535 BEARING ASSEMBLY WASH ARM (NOT SHOWN) ........................ A/R

Page 24

16

Figure 3 -

Corner Track Conversion

REPLACEMENT PARTS

1

A

Page 25

17

REPLACEMENT PARTS

CORNER TRACKS CONVERSION

Fig. 2 Part

Item No. No. Part Description Qty

1 W1557 Rack Slide VC1000, Assy ........................................................................ 1

CORNER CONVERSION INSTRUCTIONS

Remove existing screws from front rack slide guide (a) and move to either side. Install with exisiting

screws. Corner conversion is now complete.

Page 26

18

Figure 4-

Drain/Pump Assembly

REPLACEMENT PARTS

14

A

17

13

12

10

11

12

15

16

4

6

7

8

5

23

9

3

24

25

21

22

20

2

1

19

18

B

A

Page 27

19

REPLACEMENT PARTS

DRAIN/PUMP ASSMEBLY

Fig. 4 Part

Item No. No. Part Description Qty

1 0501412 SCREW, 10-32 X 3/8 TRUSS HEAD...................................................... 1

2 0310479 COVER, SOLENOID .............................................................................. 1

3 0510417 SCREEN, PUMP INLET ........................................................................ 1

4 107965 NUT, GRIP 8-32 W/NYLON INSERT.................................................... 1

5 0310491 DRAIN STOPPER LIFT BRACKET ...................................................... 1

6 0710496 ASSY, DRAIN BALL/OVERFLOW ...................................................... 1

-- 0510497 DRAIN BALL OVERFLOW TUBE........................................................ A/R

7 0508667 SCREW, RH 8-32 X 7/8 SS .................................................................... 1

8 104165 CLAMP, HOSE M40................................................................................ 2

9

10 0710474 PUMP INLET HOSE NIPPLE ................................................................ 1

11 0510421 PUMP DISCHARGE FITTING .............................................................. 1

12 0502571 HOSE CLAMP DISCHARGE ................................................................ 2

13 0509235 HOSE, 1.25 ID X 1.625 OD BRAIDED PVC........................................ 6ft

14 0502665 TUBING, 1/2" X 3/4" INNER BRAID.................................................... 5ft

15 100739 BOLT 5/16-18 X 3/4 HEX HEAD .......................................................... 4

16 100826 WASHER, FLAT 5/16ID.......................................................................... 8

17 0503679 CLAMP, SS GEAR TYPE 7/16 .............................................................. 1

18 W333009 FILTER BASKET/DRAIN SCREEN ...................................................... 1

19 W333002 DRAIN PAN WELD ................................................................................ 1

20 0510400 SOLENOID 120V 60HZ.......................................................................... 1

21 0510493 BOLT, CARRIAGE 10-24 X 1/2 (FOR DRAIN SOLENOID) .............. 4

22 0510494 LOCKNUT, 10-24 W/NYLON INSERT ................................................ 4

23 0501423 SCREW, RH 10-32 X 1-1/4 .................................................................... 4

24 0310477 SOLENOID LIFT STOP (GUIDE SOLENOID, SMALL) .................... 1

25 0310478 GUIDE, SOLENOID LIFT (LONG) ...................................................... 1

26 0501406 SCREW, SLOT RH 8-32 X 1/2(NOT SHOWN) .................................... 1

27 107965 NUT, GRIP 8-32 W/NYLON INSERT.................................................... 4

A 100739 BOLT 5/16-18 X 3/4 HEX HEAD .......................................................... 4

100826 WASHER, FLAT 5/16ID .......................................................................... 8

109009 NUT, GRIP 5/16 W/NYLON INSERT .................................................... 4

B 107967 NUT, GRIP 1/4-20 W/NYLON INSERT ................................................ 4

9 109578 HOSE, DISCHARGE .............................................................................. 1

10 0510421 PUMP DICHARGE FITTING ................................................................ 1

11 108528 HOSE BARB 1/2 X 1/2

12

13 0509235 HOSE, 1.25ID X .620 OD BRAIDED .................................................... A/R

14

15

16

17

18

19 W333009 FILTER BASKET/DRAIN SCREEN ...................................................... 1

Page 28

20

Figure 5-

Pump Assembly

REPLACEMENT PARTS

1

2

3

4

6

7

8

9

5

Page 29

21

REPLACEMENT PARTS

PUMP ASSMEBLY

Fig. 5 Part

Item No. No. Part Description Qty

1 0510525 PUMP, MOTOR VC1000 ........................................................................ 1

2 0510526 FLINGER, WASHER .............................................................................. 1

3 0510527 ADAPTER IRON .................................................................................... 1

4 0510529 SEAL 5/8 BN-CM.................................................................................... 1

5 0510528 CASE GASKET ...................................................................................... 1

6 0510530 IMPELLER BRONZE 3-7/8 .................................................................... 1

7 0510531 WASHER “P” IMPELLER ...................................................................... 1

8 0510532 IMPELLER NUT .................................................................................... 1

9 0501533 VOLUTE .................................................................................................. 1

Page 30

22

Figure 6-

Piping Assembly

REPLACEMENT PARTS

V

a

l

u

-

C

l

ea

n

1

2

3

4

5

6

7

8

9

10

11

5

12

14

13

5

15

Page 31

23

REPLACEMENT PARTS

PIPING ASSEMBLY

Fig. 6 Part

Item No. No. Part Description Qty

1 0502665 TUBING 1/2 X 3/4 INNER BRAID........................................................ A/R

2 0503679 CLAMP, GEAR SST TYPE 7/16............................................................ 1

3 108528 HOSE BARB 1/2 X 1/2 90˚ .................................................................... 1

4 0510416 CHECK VALVE 1/2" .............................................................................. 1

5 100209 NIPPLE, 1/2" CLOSE BRASS .............................................................. 3

6 113220 VACUUM BREAKER BRASS 1/2"........................................................ 1

7 113221 REPAIR KIT 1/2" VACUUM BREAKER .............................................. 1

8 0509938 ELBOW, 1/2" FORGED 90˚ .................................................................... 1

9 109886 VALVE, 1/2" ............................................................................................ 1

10 108516 COIL,VALVE .......................................................................................... 1

11 109902 REPAIR KIT, VALVE 1/2" ...................................................................... 1

12 104421 LINE STRAINER 1/2" ............................................................................ 1

13 0501539 NUT, PLAIN 1/4-20 ................................................................................ 2

14 0501501 LOCKWASHER 1/4 ................................................................................ 2

15 0310422 BRACKET, PLUMBING VC1000 .......................................................... 1

Page 32

24

Figure 7-

Control Panel

REPLACEMENT PARTS

V

a

l

u

-

C

l

ea

n

2

3

4

5

1

A

B

C

Page 33

25

REPLACEMENT PARTS

CONTROL PANEL

Fig. 7 Part

Item No. No. Part Description Qty

1 107440 THERMOMETER, FLANGE 8FT .......................................................... 1

2 0501398 TOGGLE SWITCH ON-OFF .................................................................. 1

3 0508551 LAMP , GREEN NEON 125VAC............................................................ 1

4 0510399 TOGGLE SWITCH MOMENTARY VC1000 ........................................ 1

5 B500394R LOCK, CABINET REWORKED ............................................................ 1

CHEMICAL PUMPS

A RINSE AID PUMP

109829 PUMP, PERISTALLIC ............................................................................ 1

108194 TUBE 3/16ID X 3/8OD (INCLUDED IN 109829, NOT SHOWN) ...... 1

0501518 TIE, NYLON ............................................................................................ 2

0502666 TUBING, 1/8ID X 1/4OD PVC BEVERAGE ........................................ A/R

0306363 TUBE, STIFFNER 3/8 ID X 11-7/8 LONG (NOT SHOWN) ................ 1

0501869 STRAINER (CHEMICAL BOTTLE)(NOT SHOWN) .......................... 1

0505483 LABEL RINSE AID ................................................................................ 1

B SANTIZING PUMP

109829 PUMP, PERISTALLIC ............................................................................ 1

108194 TUBE 3/16ID X 3/8OD (INCLUDED IN 109829, NOT SHOWN) ...... 1

0501518 TIE, NYLON ............................................................................................ 2

0502666 TUBING, 1/8ID X 1/4OD PVC BEVERAGE ........................................ A/R

0306363 TUBE, STIFFNER 3/8 ID X 11-7/8 LONG (NOT SHOWN) ................ 1

0501869 STRAINER (CHEMICAL BOTTLE)(NOT SHOWN) .......................... 1

0503694 LABEL SANITIZER................................................................................ 1

C DETERGENT PUMP

109829 PUMP, PERISTALLIC ............................................................................ 1

108194 TUBE 3/16ID X 3/8OD (INCLUDED IN 109829, NOT SHOWN) ...... 1

0501518 TIE, NYLON ............................................................................................ 2

0502666 TUBING, 1/8ID X 1/4OD PVC BEVERAGE ........................................ A/R

0306363 TUBE, STIFFNER 3/8 ID X 11-7/8 LONG (NOT SHOWN) ................ 1

0501869 STRAINER (CHEMICAL BOTTLE)(NOT SHOWN) .......................... 1

0503695 LABEL DETERGENT ............................................................................ 1

Page 34

26

Figure 8-

Control Cabinet

REPLACEMENT PARTS

7

1

10

6

5

2

9

4

8

3

Page 35

27

REPLACEMENT PARTS

CONTROL CABINET

Fig. 8 Part

Item No. No. Part Description Qty

1 0510397 TIMER ASSEMBLY ................................................................................ 1

2 111068 RELAY 120VAC 2PDT............................................................................ 1

3 111036 SOCKET, RELAY .................................................................................... 1

4 0501373 TOGGLE SWITCH.................................................................................. 1

5 0509296 COUNTER, 120VAC NON-RESET ........................................................ 1

6 107369 CONTACTOR, 2POLE 120V .................................................................. 1

7 0503757 MOTOR, PUMP DRIVE .......................................................................... 1

8 108299 MOTOR REDUCER 35RPM .................................................................. 2

9 107440 THERMOMETER, FLANGE 8FT ........................................................ 1

10 0510399 TOGGLE SWITCCH .............................................................................. 3

Page 36

28

THIS PAGE

INTENTIONALLY

LEFT BLANK

Page 37

29

ELECTRICAL

SCHEMATICS

Loading...

Loading...