Page 1

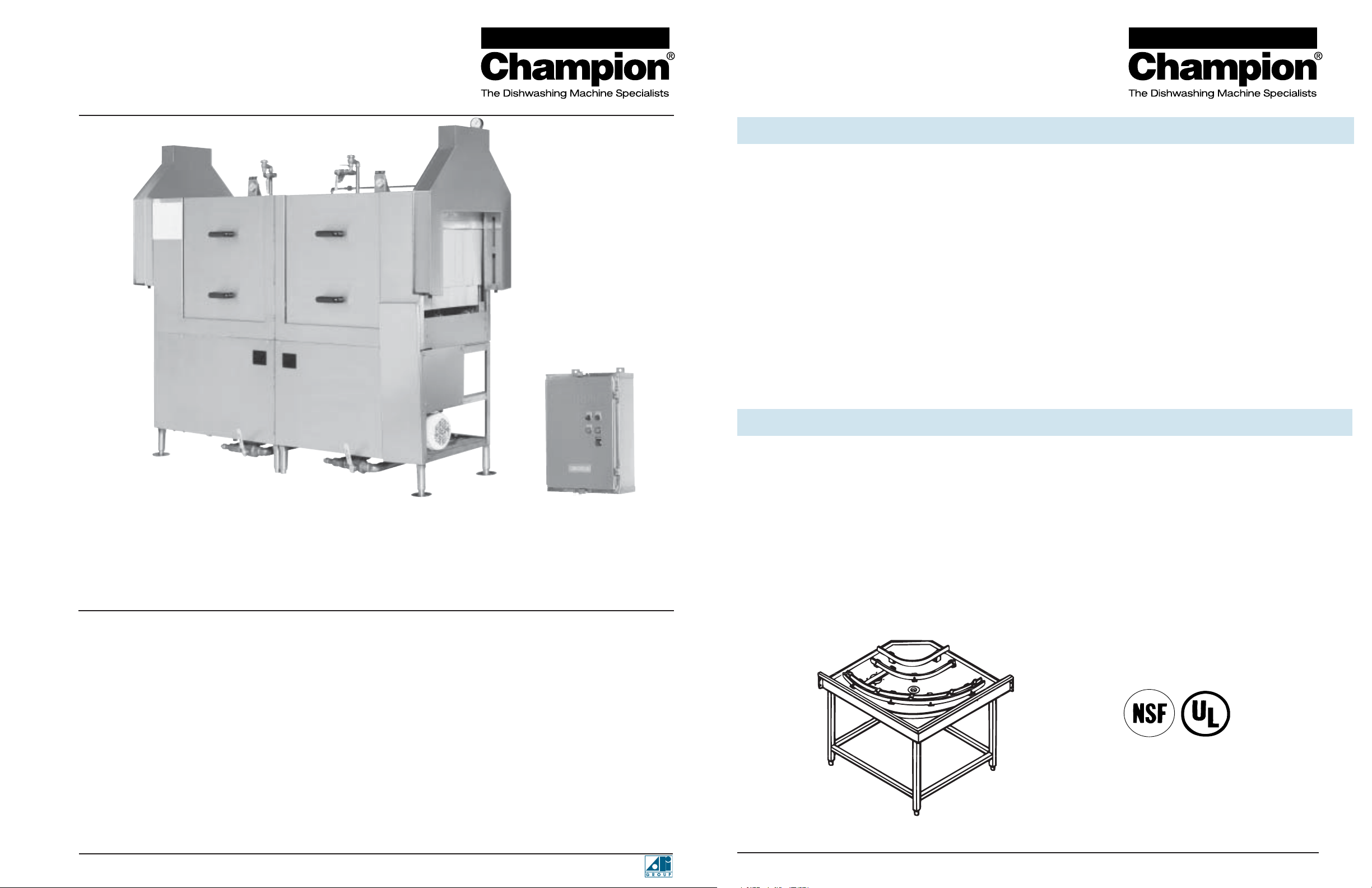

USN72

USN72

(250, 185, 135, 85, 60)

High-Temperature Rack Conveyor

(250, 185, 135, 85, 60)

High-Temperature Rack Conveyor

Standard Features

Modular construction for easy installation

Deep tanks that contain water during 15° list

Heavy-duty dual chain drive with rear lugs

Exhaust vents extended to table level

Wash down duty motors

Low temperature shutdown with purge switch

Manual tank fill with water level sight glass

Conveyor jam limit switch

Low-water tank heat protection with 5 sec.

time delay

Easy service from front for piping and

components

One-piece door removal in only 3" clearance

Flanged feet for deck mounting

SST NEMA 12x style electrical box for remote mounting

Control circuit, 120-volt

Wash pump 2-hp motor

Rinse Pump 2-hp motor

Conveyor drive, 1/4-hp motor

Door safety switch within machine footprint

Manual drains plumbed to common connection

Interchangeable upper and lower spray arms

Leakproof doors, internally-fitted

Rinse saver device for water conservation

Stainless steel heavy-gauge construction

QUICK FACTS

Capacity (racks/hr.)

USN72 - 250 252

USN72 - 185 185

USN72 - 135 135

USN72 - 85 85

USN72 - 60 60

Water consumption (final rinse)

Gallons per hr. 285

Motor horsepower

Drive 1/4

Wash 2

Rinse 2

Temperatures

Wash 150°F

Rinse 160°F

Final Rinse 180°F

Special Product Design That Meets

US Navy Specifications.

Hatch Entry

Modular construction enables easy hatch entry for

installation.

Easy Door Removal

Easy to remove one piece doors that need only 3" clearance.

Easy to Clean

Large door openings and interchangeable upper and lower

spray arms with easily removable end caps.

Easy to Service

Most components are front accessible.

(1M) 4/03

Electric Heating

Wash Tank (kW) 20

Rinse Tank (kW) 30

Electric Booster 60°F rise (kW) 60

Steam Heating

Tank Heat (lbs/hr) 150

Steam Booster 60°F rise (lbs/hr) 255

High Performance

Ideal water pressure and volume for maximum

wash and rinse coverage.

High Quality

Durable, high quality construction designed for

long life and reduced maintenance in shipboard

conditions.

15° List Standard

Operates without water splashout or rack slippage

at 15° list.

Champion Options & Accessories

External electric booster heater 60°F rise.

External steam booster heater 70°F rise

90° motorized rack advance conveyor (specify load or unload)

Racks: dish or open racks (specify type)

Table limit switch, unmounted (recommended on all rack conveyor installations)

Tank heat (electric or steam coil)

Model MRA 90

90° Motorized Rack

Advance Curve

®

Champion Industries, Inc., P. O. Box 4149, Winston-Salem, NC 27115 • 336/661-1556 • Fax: 336/661-1979 • www.championindustries.com

®

Page 2

w"

BALDOR

3Ø MV

2HP

BALDOR

2HP

3Ø MV

BALDOR

3Ø MV

2HP

BALDOR

2HP

3Ø MV

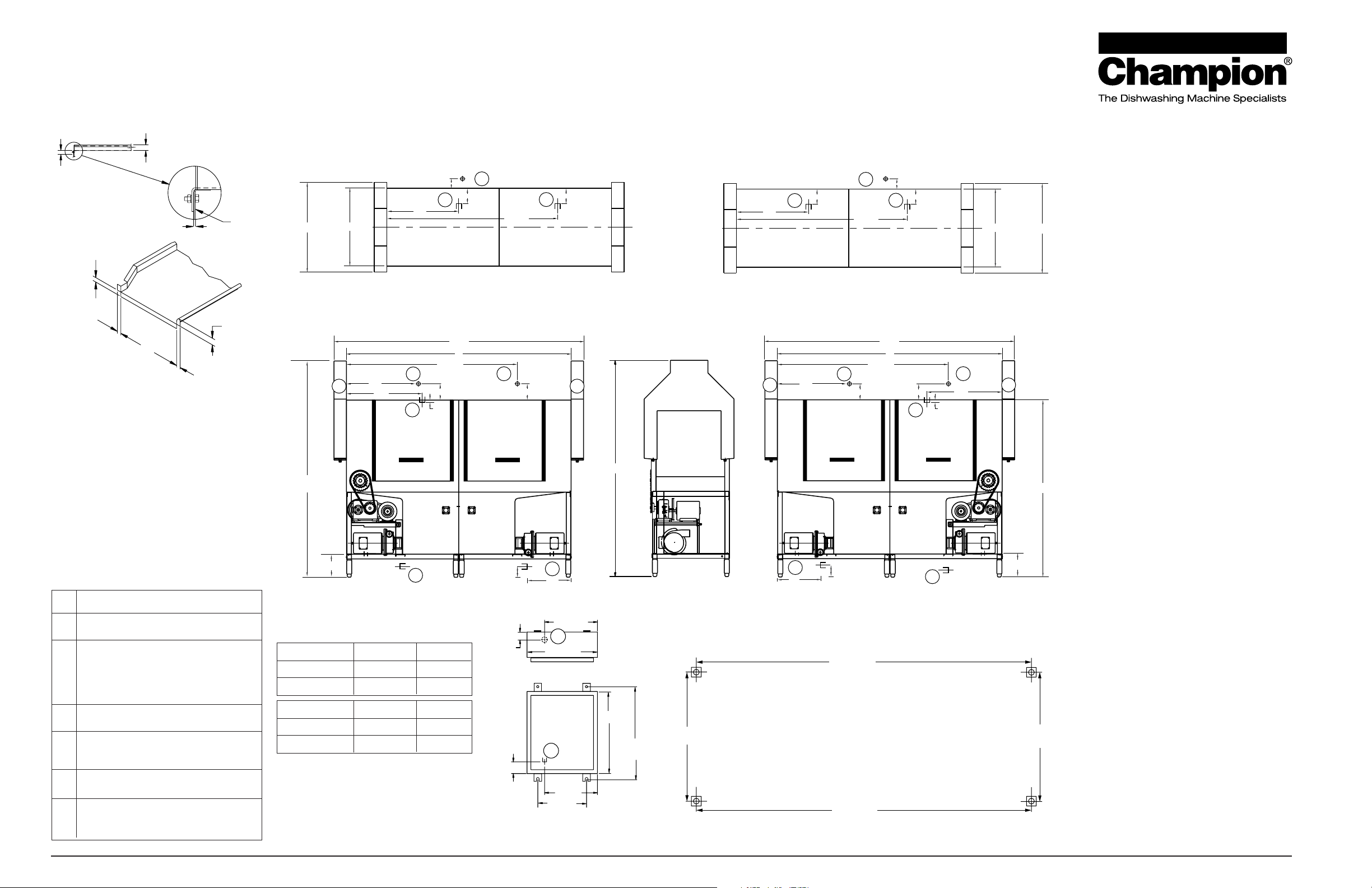

USN72

(250, 185, 135, 85, 60)

High-Temperature Rack Conveyor

Right-to-left operation

1-1/2"

3

22"

2'-1"

2

9-1/2" 9-1/2"

1-1/2"

Side View

1-1/2"

2-1/4" Min.

1/8"

Suggested Tab le

Attachment

Machine

2'-4 3/4"

Plan View

1-3/8"

21-7/8"

Suggested Tab le

Construction

Warning:

Plumbing and electrical connections

should be made by qualified workmen

who will observe all the applicable

plumbing, sanitary, safety and the

National Electrical Codes.

Plumbing Notes:

Because of the variation in house-supplied

water pressure, water pressure regulating

valve (PRV) may be needed (water PRV is

standard on machines with booster). The PRV

can either be purchased from Champion or

obtained locally.

Venting Notes:

Fabricated duct size: 11.88" x 3.88"

(Inside dimensions)

Utilities

1-3/8"

2-1/4" Min.

4' - 8 3/4"

7 3/8"

22"

23"

3

2

24"

Door

(Liftout)

4B

Front View

6'-8"

6'

46-1/4"

5-1/4"

3/4"

(Liftout)

1 Electrical

Remote mounted cabinet (See Amp chart)

2 Hot Water (final rinse)

3/4" NPT 180°F hot water connection.

Flow pressure 20-22 psi without booster

3 Tank Fill

1/2" NPT

4A Drain

1-1/2" NPT machine connection.

Maximum flow 15 gpm.

4B Drain Cleanout

1-1/2" NPT machine connection

Machine Rated Amps Min/Max

Electric 72 100/100

Steam 60°F rise 8 10/10

Booster Rated Amps Min/Max

Electric 60°F rise 79 100/100

Steam 60°F rise — —

Volume crated: 250 cu. ft.

Shipping weight crated: 1000 lbs.

5 Vents

Load end: 500 CFM @ 1/4" S.P.

Champion Industries, Inc., P. O. Box 4149, Winston-Salem, NC 27115 • 336/661-1556 • Fax: 336/661-1979 • Email: champion@championindustries.com

B Unload end: 500 CFM @ 1/4" S.P.

A

Details, Dimensions & Connections

3

46-1/4"

3

5-1/4"

24"

Door

4-1/2"

2"

Plan View

3"

55

4A

14"

13-1/2"

1

18-5/32"

Remote

Control

Cabinet

1

13-1/2"

12-5/32"

C-C

Front View

5'-9 1/4"

21-5/32"

22-27/32"

C-C

End View

22"

DETAILED SPECIFICATIONS

Left-to-right operation

2

9-1/2" 9-1/2"

3

22"

46-1/4"

Plan View

22"

4A

14"

Note:

Machine legs are angle stainless steel

welded to a flat deck plate with 1/2" bolt holes

located to deck plan shown.

3

5-1/4"

24"

Door

(Liftout)

4-1/2"

67-3/4"

67-3/4"

1-1/2"

3

6'-8"

6'

46-1/4"

5-1/4"

Front View

2

24"

Door

(Liftout)

4B

3/4"

23"

2'-1"

2'-4 3/4"

3

55

4'-8 3/4"

7 3/8"

Design and Construction

USN72 is a fully-automatic dishwashing

machine constructed entirely of heavy-gauge

stainless steel. The stainless steel angle frame

provides a rigid, heavy-duty support for internal

components, tank and hood, enhancing the

reliability and extending the service life of the

machine.The tank and hood are of water-tight,

single-unit construction. The leak-proof

internally-mounted front door permits easy

access to the tank for cleaning. Perforated

stainless steel refuse screens and pump intake

strainer are easy to remove and clean.

Pump and Motor

The wash pump and rinse pump provide highpressure recirculating spray. The 2-hp pump

motor is wired through a magnetic contactor

and has thermal overload protection. Pump and

motor are mounted directly to the frame.

Spray System

Upper and lower wash spray arms distribute

high pressure “water knife” cleaning action

across every surface of the wares. 180°F

sanitizing spray is delivered through upper and

lower final rinse spray arms.

Rinse Saver

The standard rinse saver is comprised of a

magnetic switch which activates the final rinse

only when wares are present in the final rinse

area.

Tank Heating and Filling System

The machine has a manual fill and sight glass for

each tank. Proper tank temperature is maintained by thermostatically controlled electric

tank heat, or steam heat with positive low-water

protection.

Fully-automatic Operation

The “start” button starts the conveyor and

establishes control voltage to the pump motor,

rinse saver.

Rack Conveyor

The rack conveyor is stainless steel chain and

has rear lugs to prevent rack slippage. It is

driven by a 1/4-hp motor and uses 20" x 20"

racks.

Due to an ongoing value analysis program at

Champion, specifications contained in this catalog

are subject to change without notice.

Loading...

Loading...