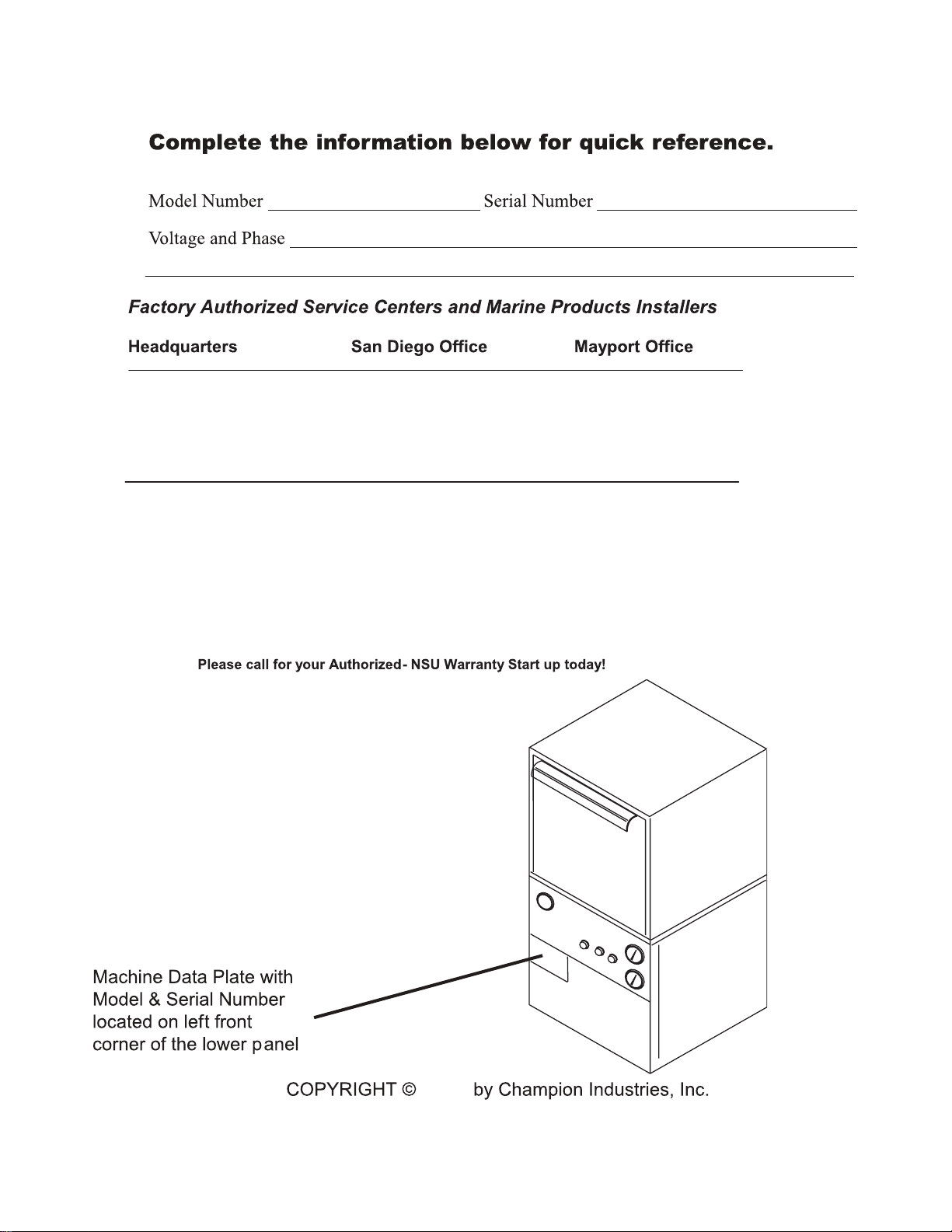

Page 1

I

Page 2

The Source

502 Rotary Street

Hampton, VA 23661

Tel: 1 (757) 825-1400

1 (800) 497-2144

Fax: 1 (757) 825-1202

Website: www.thesource2000.net Email:

Equipment Information HQ - Darlene Ehrenfried darlene.ehrenfried@thesource2000.com

Parts Information HQ - Lori Hicks lori.hicks@thesource2000.com

Service Information HQ - Jim Luther jim.luther@thesource2000.com

U.S. Navy POC - Judy Lowman, HQ judy.lowman@thesource2000.com

U.S. Navy POC - Nigel Pearce, San Diego, C nigel.pearce@thesource2000.com

U.S. Navy POC - Tony Cox, Mayport, FL tony.cox@thesource2000.com

U.S. Navy POC - Janet Searls, Norfolk, VA janet.searls@thesource2000.com

The Source (San Diego)

2101 Wilson Ave.

National City, CA 91950

Tel: 1 (619) 474-4143

Fax: 1 (619) 474-4160

The Source (Mayport)

1840 Mealy Street

Atlantic Beach, FL 32233

Tel: 1 (904) 241-4982

1 (888) 889-0291

Fax: 1 (904) 241-4039

2013

Page 3

TECHNICAL PUBLICATION SHEET

TECHNICAL PUBLICATION SHEET

i

Page 4

TECHNICAL MANUAL VALIDATION CERTIFICATE

TECHNICAL MANUAL VALIDATION CERTIFICA TE

ii

Page 5

APPROVAL AND PROCUREMENT RECORD

APPROVAL AND PROCUREMENT RECORD

iii

Page 6

TECHNICAL MANUAL DEFICIENCY/EVALUATION REPORT (TMDER)

TECHNICAL MANUAL

DEFICIENCY/EVALUA TION REPORT (TMDER)

(Form - NAVSEA 9086/10, REV. 6/85)

iv

Page 7

8/25/10 50-51 U2769 Revised illustration added note for

supersession of overflow tube and screen

Page 8

2/20/13 IFC, 45All Updated contact information

10/3/13 47 All Replaced Items 4-6, switches with Kits 900856, 900857

and 900858 respectively.

10/3/13 61 All Pump motor, seal and impleller no longer available

as separate parts, order Item 2 complete motor assembly.

Changed Item 4 to P/N 108629, Item 7 to P/N 115374

Page 9

vii

Page 10

SAFETY SUMMARY

SAFETY SUMMARY

Safety Symbols

• The following symbols appear throughout this manual alerting you to potential hazards. S tatements

associated with each symbol are printed in italics.

WARNING:

CAUTION:

!

Warning statements indicate any condition or practice that could result in

result in personal injury or possible loss of life.

Caution statements indicate any condition or practice which, if not strictly

observed or remedied, could result in damage to or destruction of the

dishwasher.

NOTE:

Note statements indicate any condition or practice which,

if observed, will help in the safe completion of a task.

General Safety Rules

• The following general safety rules must be observed in addition to the specific cautions and warnings

presented in this manual.

• Your Champion dishwasher may be an electric or steam heated machine using hot water

to clean and sanitize a variety of wares. Machine surfaces and wares become hot during and immediately following normal operations. Consult your supervisor and wear protective gear as directed to

avoid possible injury.

• Your dishwasher contains rotating spray arms.

Use caution when working around the dishwasher especially when loading or unloading wares.

• Operators must NOT bypass a safety interlock or control to operate the dishwasher.

• The service and maintenance instructions contained in this manual are intended for qualified service

personnel. These instructions assume that you are trained in basic electricity and mechanical theory.

If you are not a trained technician, then do not attempt to adjust or repair the dishwasher as serious

personal injury or damage to the dishwasher may result.

YLLL

Page 11

SAFETY SUMMARY

Warning and Caution Statement Listing

• The following listing gives the page number and text of all the warning and caution statements that appear

in this manual.

Warning Statements

Pg. 6- The installation of this unit must conform to local codes or, in the absence of local codes, to the National

Electrical Code and all National Codes governing plumbing, sanitation, safety and good trade practices.

Pg. 8- The installation of water supplies must conform to local codes or, in the absence of local code, all National

Codes governing plumbing, sanitation, safety and good trade practices.

Pg. 8- The installation of steam supplies must conform to local codes or, in the absence of local code, all National

Codes governing plumbing, sanitation, safety and good trade practices.

Pg. 10- The installation of drains must conform to local codes or, in the absence of local code, all National Codes

governing plumbing, sanitation, safety and good trade practices.

Pg. 10- The installation of ventilation must conform to local codes or, in the absence of local code, all National Codes

governing plumbing, sanitation, safety and good trade practices.

Pg. 11- The installation of electrical supplies and controls must conform to local codes or, in the absence of local

codes, the National Electrical Code and good trade practices.

Pg. 11- Dangerous voltages are present at the local electrical distribution system.

Dangerous voltages are present at the dishwasher when it is connected to the local electrical distribution

system.

Pg. 11- When working on the dishwasher, disconnect the electric service and place a red tag at the disconnect switch

to indicate work is being done on that circuit.

Pg. 12- The installation of electrical supplies and controls must conform to local codes or, in the absence of local

codes, the National Electrical Code and good trade practices.

Pg. 12- Dangerous voltages are present at the local electrical distribution system.

Dangerous voltages are present at the dishwasher when it is connected to the local electrical distribution

system.

Pg. 12- When working on the dishwasher, disconnect the electric service and place a red tag at the disconnect switch

to indicate work is being done on that circuit.

Pg. 19- Dangerous voltages are present at the local electrical distribution system.

Dangerous voltages are present at the dishwasher when it is connected to the local electrical distribution

system.

Pg. 19- When working on the dishwasher, disconnect the electric service and place a red tag at the disconnect switch

to indicate work is being done on that circuit.

Pg. 20- Perform the following checks before placing the machine into service for normal operation.

Pg. 20- Never bypass a safety device in order to operate the dishwasher for normal operation.

Pg. 22- Perform the following checks before placing the machine into service for normal operation.

L[

Page 12

SAFETY SUMMARY

SAFETY SUMMARY (Cont.)

Warning Statements (Cont.)

Pg. 22- Never bypass a safety device in order to operate the dishwasher for normal operation.

Pg. 23- Dishwasher surfaces, dishracks and wares become hot during and immediately after washing operations.

Wear protective gear per your supervisor's directions.

Pg. 24- Dishwasher surfaces, dishracks and wares become hot during and immediately after washing operations.

Wear protective gear per your supervisor's directions.

Pg. 27- Deliming solutions or other acids must not come in contact with household bleach (sodium hypochlorite) or

any chemicals containing chlorine, iodine, bromine, or fluorine.

Mixing will cause hazardous gases to form.

Skin contact with deliming solutions can cause severe irritation and possible chemical burns.

Pg. 27- Consult your chemical supplier for an appropriate deliming solution, protective gear and safety procedures.

Pg. 28- When working on the dishwasher, disconnect the electric service and place a red tag at the disconnect switch

to indicate work is being done on that circuit.

Pg. 29- When working on the dishwasher, disconnect the electric service and place a red tag at the disconnect switch

to indicate work is being done on that circuit..

Pg. 35- When working on the dishwasher, disconnect the electric service and place a red tag at the disconnect switch

to indicate work is being done on that circuit

Pg. 35- Use Extreme Caution when performing tests on energized circuits.

[

Page 13

SAFETY SUMMARY

SAFETY SUMMARY (Cont.)

Caution Statements

Pg. 5- Check piping mounted underneath dishwasher before lifting to avoid damaging the machine.

Pg. 6- Check piping mounted underneath dishwasher before lifting to avoid damaging the machine.

Pg. 18- Perform the following checks before placing the machine into service.

Pg. 26- Do not hose down the exterior of the machine with water.

Pg. 28- Only qualified service personnel should perform preventive maintenance on the dishwasher.

Pg. 29- Only qualified service personnel should perform preventive maintenance on the dishwasher.

Pg. 35- Only qualified service personnel should perform preventive maintenance on the dishwasher.

-

[L

Page 14

LIMITED WARRANTY

UNITED STATES NAVY LIMITED WARRANTY

Champion Industries Inc. (herein referred to as Champion), P.O. Box 4149, Winston-Salem, North Carolina 27115,

warrants machines, and parts, as set out below.

Warranty of Machines: Champion warrants all new machines of its manufacture bearing the name

"Champion" and installed within the United States to be free from defects in material and workman

ship for a period of one (1) year after the date of installation or fifteen (15) months after the date of shipment by

Champion, whichever occurs first. [See below for special provisions relating to glasswashers.] The warranty

registration card must be returned to Champion within ten (10) days after installation. If warranty card is not

returned to Champion within such period, the warranty will expire after one year from the date of shipment.

Champion will not assume any responsibility for extra costs for installation in any area where there are

jurisdictional problems with local trades or unions.

If a defect in workmanship or material is found to exist within the warranty period, Champion, at its election,

will either repair or replace the defective machine or accept return of the machine for full credit; provided, how

ever, as to glasswashers, Champion's obligation with respect to labor associated with any repairs shall end

(a) 120 days after shipment, or (b) 90 days after installation, whichever occurs first. In the event that Champion

elects to repair, the labor and work to be performed in connection with the warranty shall be done during regular

working hours by a Champion authorized service technician at a ship's homeport located within the continental

United States. Defective parts become the property of Champion. Use of replacement parts not authorized by

Champion will relieve Champion of all further liability in connection with its warranty. In no event will

Champion's warranty obligation exceed Champion's charge for the machine. The following are not covered by

Champion's warranty:

a. Lighting of gas pilots or burners.

b. Cleaning of gas lines.

c. Replacement of fuses or resetting of overload breakers.

d. Adjustment of thermostats.

e. Adjustment of clutches.

f. Opening or closing of utility supply valves or switching of electrical supply current.

g. Cleaning of valves, strainers, screens, nozzles, or spray pipes.

h. Performance of regular maintenance and cleaning as outlined in operator’s guide.

i. Damages resulting from water conditions, accidents, alterations, improper use, abuse,

tampering, improper installation, or failure to follow maintenance and operation procedures.

j. Wear on Pulper cutter blocks, pulse vanes, and auger brush.

Examples of the defects not covered by warranty include, but are not limited to: (1) Damage to the exterior or

interior finish as a result of the above, (2) Use with utility service other than that designated on the rating plate,

(3) Improper connection to utility service, (4) Inadequate or excessive water pressure, (5) Corrosion from

chemicals dispensed in excess of recommended concentrations, (6) Failure of electrical components due to

connection of chemical dispensing equipment installed by others, (7) Leaks or damage resulting from such

leaks caused by the installer, including those at machine table connections or by connection of chemical

dispensing equipment installed by others, (8) Failure to comply with local building codes, (9) Damage caused by

labor dispute.

Warranty of Parts: Champion warrants all new machine parts produced or authorized by Champion to be free

from defects in material and workmanship for a period of 90 days from date of invoice. If any defect in

material and workmanship is found to exist within the warranty period Champion will replace the defective

part without charge.

DISCLAIMER OF WARRANTIES AND LIMITATIONS OF LIABILITY. CHAMPION'S WARRANTY

IS ONLY TO THE EXTENT REFLECTED ABOVE. CHAMPION MAKES NO OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED, TO ANY WARRANTY OF

MERCHANTABILITY, OR FITNESS OF PURPOSE. CHAMPION SHALL NOT BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. THE REMEDIES SET OUT ABOVE ARE

THE EXCLUSIVE REMEDIES FOR ANY DEFECTS FOUND TO EXIST IN CHAMPION DISHWASHING

MACHINES AND CHAMPION PARTS, AND ALL OTHER REMEDIES ARE EXCLUDED,

INCLUDING ANY LIABILITY FOR INCIDENTALS OR CONSEQUENTIAL DAMAGES.

[LL

Champion does not authorize any other person, including persons who deal in Champion dishwashing

machines to change this warranty or create any other obligation in connection with Champion Dishwashing Machines.

Page 15

Electrical Power Requirements (Steam Heat)

Connections Between Dishwasher and Booster (Steam Only)

Steam and Condensate Connections (Steam Heat Only)

3.2.1 Control Cabinet

Page 16

Final Rinse (Steam) Thermostat Adjustment and Replacement

Fuses and Fuse Block Replacement

Page 17

Electric Tank Heat Assembly (Prior to S/N G3599)

Electric Tank Heat Assembly (After S/N G3600)

Electric Tank Heat Assembly (After S/N U2769)

Control Cabinet (Prior to S/N G3599)

No.180 Steam Booster and Steam Piping Assembly

Page 18

TABLE OF CONTENTS

This

Page

Intentionally

Left

Blank

xvi

Page 19

PART 1: GENERAL SPECIFICATIONS

PART 1: GENERAL SPECIFICATIONS

Welcome to Champion...

and thank you for allowing us to take care of your dishwashing needs.

1.1 About this Manual

All information, illustrations and specifications contained in this manual are based upon the

latest product information available at the time of publication. Champion constantly improves its products and reserves the right to make changes at any time or to change specifications or design without notice and without incurring any obligation.

Manual Organization

This manual is divided into eight parts:

→ Part 1, General Specifications, introduces this manual and the dishwasher in general.

→ Part 2, Installation, discusses the installation of the dishwasher and describes the

connection of utilities and services.

→ Part 3, Operation, discusses theory of operation, operator controls, initial start up and

shutdown procedures.

→ Part 4, Maintenance and Cleaning, discusses lubrication, preventive maintenance,

cleaning and deliming.

→ Part 5, discusses basic troubleshooting and service procedures.

→ Part 6, discusses replacement parts procurement and provides parts diagrams and

parts lists.

→ Part 7, contains the dishwasher electrical schematic.

→ Part 8, contains special inserts and late breaking information.

1.2 Model Numbers

USN-10

The USN-10 series is a undercounter high temperature (180°F/82°C rinse) sanitizing dishwasher. This model features electric or steam heat with booster.

The USN-10 is as front loading door model.

The USN-10 comes in the following model::

USN-10: 440V/60/3 Electric heat or Steam heat @ 15 PSI flow pressure

1

Page 20

Two electrical connections

Page 21

Page 22

Single Point Electrical Connection:

USN-10 440/60/3 70°F (E) 26 Amps 40 Amps

Two-Point Electrical Connection: Machine

USN-10 440/60/3 6 Amps 15 Amps

Two-Point Electrical Connection: Booster

USN-10 440/60/3 70°F (E) 20 Amps 25 Amps

Page 23

PART 2: INSTALLATION

PART 2: INSTALLA TION

In This Part—

• Unpacking the dishwasher

• Making Utility Connections

2.1 Unpack the Dishwasher

NOTE:

The installation of your dishwasher must meet all applicable health and safety codes

and conform to good trade practice.

Your USN-10 was completely assembled, inspected, and thoroughly tested at our factory

before shipment to your installation site.

• The dishwasher with booster are shipped on a single pallet.

• The booster is connected to the dishwasher.

Perform the following steps to unpack the dishwasher:

1. Remove protective wrap and hold downs from the pallet.

2. Inspect for any shipping damage. If damage is found, save the packing material

and contact the carrier immediately.

3. Check the interior of the dishwasher for the following items stowed inside:

- 1 set of flanged feet

- 1 set of dishracks

- Warranty information packet

CAUTION:

!

Check piping mounted underneath dishwasher before lifting to avoid damaging the

machine.

5

Page 24

PART 2: INSTALLATION

2.2 Permanent Placement

Perform the following steps to place the dishwasher in its permanent location.

1. Before moving the sections into position, inspect the location site to ensure the electrical,

plumbing, and ventilation services are provided in the correct locations. Compare the site

connections with the dishwasher to ensure they will match when the machine is set in its

permanent location.

!

2. Lift the dishwasher and replace the adjustable legs with flanged mounting feet provided.

3. Position dishwasher in its permanent location.

4. Level the dishwasher front to back and side to side by turning the adjustable feet.

5. Position the external booster heater at the unload end of the dishwasher.

6. Mount control cabinet to location nearest machine (if applicable).

7. Install deck plates and bolt dishwasher and booster to deck per standard procedures.

CAUTION:

Check piping mounted underneath dishwasher before lifting to avoid damaging the machine.

Make sure the load and unload openings align with the table system height.

Check alignment of common plumbing connections between booster and dishwasher.

2.3 Connections between the dishwasher and booster

(Steam Only)

WARNING:

The installation of this unit must conform to local codes or, in the absence of local codes,

to the National Electrical Code and all National Codes governing plumbing, sanitation,

safety and good trade practices.

Connect the plumbing and electrical connections between the dishwasher and booster heater.

1. Connect the 1/2" condensate union from the dishwasher to the booster.

2. Connect the 3/4" steam union from the dishwasher to the booster. .

3. Connect the 3/4" water line from the booster to the top of the dishwasher at the

vacuum breaker.

4. Pull the electrical conduit and harness from the junction box located on the lower

rear corner of the dishwasher to the booster junction box located on the lower left rear leg

of the booster stand.

5. Match the harness wire numbers to the booster junction box wiring.

6

Page 25

This

PART 2: INSTALLATION

Page

Intentionally

Left

Blank

7

Page 26

PART 2: INSTALLATION

2.4 Water Connections

Perform the following steps to connect the water supply

WARNING:

The installation of water supplies must conform to local codes or, in the absence of local

code, all National Codes governing plumbing, sanitation, safety and good trade practices.

1. Connect a 3/4" NPT hot water supply line (140°F minimum) to the water inlet valve located

at the booster.

2. Connect a 3/4" NPT hot water line (140°F minimum) to the water inlet valve located at the

rear of the dishwasher.

2.5 Steam and Condensate Connections (Steam heat only)

Perform the following steps to connect the steam supply and condensate return.

WARNING:

The installation of steam supplies must conform to local codes or, in the absence of local

code, all National Codes governing plumbing, sanitation, safety and good trade practices.

NOTE

A manual shut-off valve for steam (supplied by others) should be installed in the supply

lines to allow for servicing of the machine. The shut-off valve should be the same size or l

larger than the supply line.

1. Connect a steam supply line to the line strainer located at the booster.

2. Connect a steam condensate line to the tee fitting located at the booster.

Condensate must be gravity return to the boiler or to a pumping trap.

8

Page 27

This

PART 2: INSTALLATION

Page

Intentionally

Left

Blank

9

Page 28

1. The USN-10 undercounter dishwasher does not require a ventilation connection.

Page 29

2.8 Electrical Connections

Perform the following steps to connect the electrical supply.

WARNING:

The installation of electrical supplies and controls must conform to local codes or, in the

absence of local codes, the National Electrical Code and good trade practices.

WARNING:

Dangerous voltages are present at the local electrical distribution system.

Dangerous voltages are present at the dishwasher when it is connected to the

local electrical distribution system.

WARNING:

When working on the dishwasher, disconnect the electric service and place a tag at the

disconnect switch to indicate work is being done on that circuit.

PART 2: INSTALLATION

1. A qualified electrician must compare the electrical power supply with the machine electrical

specifications stamped on the MACHINE ELECTRICAL CONNECTION PLATE located

inside the control cabinet before connecting to the incoming service through a fused disconnect

switch.

2. Locate the dishwasher main electrical junction box for the machine.

The box is located either to the left or right of the dishwasher (depending on how the machine

was originally ordered from the factory).

3. Controls must be easily accessible to the operator.

4. Install the power supply wires from the local distribution panel to the control cabinet

at the incoming power terminal block.

5. Refer to Part 3.3, Start up procedure to test the installation.

11

Page 30

PART 2: INSTALLATION

2.9 Chemical Connections

Perform the following steps to connect the chemical dispensing equipment (supplied by others).

WARNING:

The installation of electrical supplies and controls must conform to local codes or, in the

absence of local codes, the National Electrical Code and good trade practices.

WARNING:

Dangerous voltages are present at the local electrical distribution system.

Dangerous voltages are present at the dishwasher when it is connected to the

local electrical distribution system.

WARNING:

When working on the dishwasher, disconnect the electric service and place a tag at the

disconnect switch to indicate work is being done on that circuit.

1. Chemical dispensing signal connection points are provided in the control cabinet.

2. The detergent signal is limited to a maximum load of 1 Amp. Signal voltage is 120VAC.

3. The Rinse aid signal is limited to a maximum load of 1 Amp. Signal voltage is 120VAC.

4. Sanitizer is not required for the USN-10 dishwasher.

5. The rinse aid injection point is located in the upper final rinse piping of the dishwasher.

6. The chemical equipment installer must cut a hole in the wash tank for a detergent

sensor and a detergent injection point.

12

Page 31

This

PART 2: INSTALLATION

Page

Intentionally

Left

Blank

13

Page 32

PART 3: OPERATION

PART 3: OPERA TION

In This Part—

• Theory of operation

• Description of operator controls

• Start up procedure

• Safety and operation checks

• Shutdown procedure

• Operation Summary

3.1 Theory of Operation

Dishwashing requires five components to be effective: time, temperature, mechanical

action, chemical action and proper procedure. Time allows everything to work. Temperature

produced by the heat system is required to heat water in order to penetrate and loosen food soils.

Mechanical action produced by the pump system creates water pressure to flush food soils from

wares. Chemical action in the form of detergents break down grease and dissolve food particles.

Proper procedures in the form of prescrapping, prerinsing, and proper loading maximize

dishwasher performance.

The USN-10 series dishwasher consists of a single wash tank. The tank is equipped with its

own spray system and a water holding tank. A recirculating pump draws water from the tank

and directs the water under pressure through the spray system and on to the dishes.

Wash water is heated in the tank by a steam coil or electric tank heater. The final rinse water for

sanitizing is heated in an external steam or electric booster heater.

The final stage of the washing operation occurs during the final rinse cycle. Upper and lower

final rinse spray pipes are located in the dishwasher. Final rinse water, heated to a minimum of

180°F, is forced by water line pressure from the final rinse booster heater. Water sprays from the

upper and lower final rinse piping on the wares to sanitize them. The wares are removed from the

dishwasher and operators stack the wares for the next meal period.

The USN-10 is equipped with several safety features. A door safety switch prevents the unit

from running if a door is open. A float switch located in the tank maintains the water level in the

unit if the water level falls below a preset level. A high limit thermostat is mounted inside of the

tank to protect from overheating.

14

Page 33

PART 3: OPERATION

3.2 Description of Operator Controls and Indicators

3.2.1 Control Cabinet

CONTROL TYPE FUNCTION

1

On/OFF Switch Selector Controls power to the

dishwasher.

Connects power to

tank and booster

heat circuits, pump

contactors.

2

Power ON light Red pilot Signals control power

connected to unit if

ON/OFF selector ON.

3

Start switch Green Initial Auto Fill.

Pushbutton Starts Pump.

4

Wash /Rinse Selector Manual operation

Switch of wash and rinse

Table 3.1

Controls and Indicators

Control Cabinet

15

Page 34

PART 3: OPERATION

3.2 Description of Operator Controls and Indicators (Cont.)

3.2.2 Dishwasher

WATER LEVEL

Champion

CHAMPION INDUSTRIES, WINSTON-SALEM, NC

OFF

RINSE WASHOFF ON START

MANUALPOWER

WARNING!

TURN POWER OFF BEFORE

SERVICING MACHINE

WASH TEMPERATURE

CYCLE

RINSE TEMPERATURE

16

Figure 3.2

Controls and Indicators

Dishwasher

Page 35

PART 3: OPERATION

CONTROL TYPE FUNCTION

1

Inlet water Ball valve Connects incoming water supply

valve for the booster

2

Inlet water Ball valve Connects incoming water supply for

supply valve the tank fills.

Inlet water Ball valve Controls manual fill to wash tank

3

supply valves

4

Water level Sight glass Indicates water level in wash

gauges Water line visible in

center of glass indicates correct

water level in tank.

5

Tank water Scaled Indicates water temperature in

temperature thermometer wash and rinse.

gauges dial Wash = 150°F minimum

Rinse = 180°F minimum

6

Final rinse 0-60 PSI Indicates final rinse water pressure

gauge during the final rinse.

20-22 PSIG minimum flow pressure

7

Final rinse Scaled Indicates final rinse temperature

gauge thermometer during the final rinse

dial 180-195°F optimum range

Table 3.2

Controls and Indicators

Dishwasher

17

Page 36

PART 3: OPERATION

3.3 Start Up Procedure

Perform the following steps to start up the dishwasher for first time operation.

!

1. Check the exterior of the machine for any foreign material and remove.

2. Open the door.

3. Check the interior of the machine and remove any foreign material.

Perform the following checks before placing the machine into service.

NOTE:

To install the upper and lower spray arms:

Insert the arm into its manifold and install the retaining screw.

4. Make sure the upper and lower spray arms are secure in the manifold.

5. Remove the scrap screens and make sure the overflow tube is down

and the pump intake screen is in place.

6. Replace the scrap screen.

7. Close the door.

9. Check the chemical injection system, (supplied by others), and fill as required.

10. Open the water supply valves. Check for leaks and take corrective action as required.

11. Open the steam supply valves (if applicable). Check for leaks and take corrective action if

required.

12. Monitor the water level gauge. Tank is full when the water line reaches the center of the

gauge.

13. Check the dishwasher for leaks.

14. Turn the main power on at the breaker panel or fused disconnect switch

for the dishwasher.

15. Turn the main power on at the breaker panel or fused disconnect switch

for the electric booster heater (if applicable).

16. Turn the power selector switch on the front of the control cabinet to the “ON” position.

The red power on light will illuminate.

CAUTION:

18

NOTE:

Allow sufficient time for the tanks to reach proper temperatures.

Wash tank temperature = 150°F. minimum

17. Monitor the tank thermometers located on the lower front panel of the dishwasher

for the proper temperature reading.

18. Press the GREEN start button on the front of the control cabinet.

Pump will start and machine will fill.

Page 37

PART 3: OPERATION

19. Check the direction of rotation of the pump motor.

Proper rotation is CW when viewing the motor from the rear.

WARNING:

Dangerous voltages are present at the local electrical distribution system.

Dangerous voltages are present at the dishwasher when it is connected to the

local electrical distribution system.

WARNING:

When working on the dishwasher, disconnect the electric service and place a tag at the

disconnect switch to indicate work is being done on that circuit.

20. If rotation direction is incorrect, reverse wires L1 and L2 on the disconnect switch side of

the main electrical connection terminal block located inside the remote control cabinet.

21. Proceed to Part 3.4, Safety and Operation Checks, on next page

19

Page 38

PART 3: OPERATION

3.4 Safety and Operation Checks

Refer to Part 3.3, Start up Procedure, on the previous page before performing the

steps listed below.

Perform the following steps to check the dishwasher safety devices and to

operate the dishwasher for first time.

Safety Checks

WARNING:

Perform the following checks before placing the machine into service

for normal operation.

WARNING:

Never bypass a safety device in order to operate the dishwasher for normal operation.

Only qualified service technicians are authorized to bypass a safety device for the

purpose of troubleshooting and repair.

NOTE:

Refer to the corresponding repair or adjustment procedure in Part 5, Basic Service,

if a safety device fails to function in the manner prescribed below.

Dishwasher Condition

The dishwasher is full of water, steam or electric heat energized, and dishwasher power is on.

Temperature gauges indicate proper temperatures.

Door Safety Switch Check

1. Slowly open the door approximately 1 inch.

Dishwasher pump stops.

2. Close wash tank door. Press green start button.

Pump runs and the machine will fill.

20

Page 39

PART 3: OPERATION

This

Page

Intentionally

Left

Blank

21

Page 40

PART 3: OPERATION

3.4 Safety and Operation Checks (Cont.)

Perform the following steps to check the dishwasher safety devices and to operate

the dishwasher for first time.

Safety Checks (Cont.)

WARNING:

Perform the following checks before placing the machine into service

for normal operation.

WARNING:

Never bypass a safety device in order to operate the dishwasher for normal operation.

Only qualified service technicians are authorized to bypass a safety device for the

purpose of troubleshooting and repair.

NOTE:

Refer to the corresponding repair or adjustment procedure in Part 5, Basic Service,

if a safety device fails to function in the manner prescribed below.

Dishwasher Condition

The dishwasher is full of water, steam or electric heat energized, and dishwasher power is on.

Temperature gauges indicate proper temperatures. The pump is running.

Booster Low Temperature Check

1. Insert rack into the machine to operate the final rinse.

2. Monitor the final rinse temperature gauge located on the top of the dishwasher

in the upper final rinse piping. Minimum temperature required is 180°F.

3. Check the steam or electric power supply if temperature drops below 180°F.

22

Page 41

PART 3: OPERATION

Operation Checks

Refer to Part 3.3, Start up Procedure, on pages 20-21 before performing the

steps listed below.

Perform the following steps to check the dishwasher operation for first time.

Operation Checks

Dishwasher Condition

The dishwasher is full of water, steam or electric heat energized, and dishwasher power is on.

Temperature gauges indicate proper temperatures. The pump is running.

1. Prescrap and prerinse wares to remove large food particles.

Hard Baked-on soils may require soaking or scrubbing.

2. Load a dishrack with soiled wares.

Place dishes edgewise in a peg rack.

Place cups and bowls upside down in a flat bottom rack.

Spread silverware evenly in a single layer in a flat bottom rack.

3. Do not overload dishracks.

4. Open the door and slide the rack into the dishwasher.

Close and latch the door.

5. Monitor the wash temperature gauges.

Wash tank temperature must maintain 150°F. minimum.

6. Monitor the final rinse temperature gauge as the dishrack begins the final

rinse cycle. Minimum temperature required is 180-195 °F.

7. Monitor the final rinse pressure during the final rinse. Minimum final rinse

FLOWING pressure must be 20-22 psig. The pressure gauge may indicate a higher

rinse pressure after the final rinse water stops flowing. This is a normal condition.

WARNING:

Dishwasher surfaces, dishracks and wares become hot during and immediately

after washing operations. Wear protective gear per your supervisor's directions.

8. Adjust chemical dispensing equipment (supplied by others) as required.

23

Page 42

PART 3: OPERATION

3.5 Shutdown Procedure

Perform the following steps to shutdown the dishwasher after operation.

WARNING:

Dishwasher surfaces, dishracks and wares become hot during and immediately

after washing operations. Wear protective gear per your supervisor's directions.

1. Turn the power selector switch on the remote control cabinet to OFF.

The red power light goes out.

2. Turn the power off to the dishwasher at the main service disconnect switch or breaker.

3. Turn the power off to the electric booster (if applicable) at the main service disconnect

switch or breaker.

4. Close the steam supply valve (steam heated dishwashers).

5. Remove the upper and lower spray arms.

6. Inspect spray arm.

7. Flush arms with water.

8. Set spray arms aside.

9. Flush interior of machine to remove debris on upper hood surfaces.

10. Remove scrap screen from dishwasher interior.

11. Flush both sides of screen in remote sink to remove accumulated debris.

12. Flush interior of lower tank with fresh water to remove debris.

13. Clean drain screen.

14. Wipe interior of dishwasher including tank bottom.

15. Remove and clean pump intake screen. Replace immediately after cleaning.

16. Remove overflow tube and flush water down drain.

17. Clean float switch assembly and check for free movement.

18. Flush steam coil or electric heater.

Use a nonferrous scrub pad to remove scale from electric heaters if necessary.

19. Replace overflow tube.

20. Replace scrap screen.

21. Replace spray arm assemblies.

22. Leave door open to aid air drying of dishwasher interior.

23. Turn power off to exhaust vents (if applicable).

24

Page 43

PART 3: OPERATION

3.6 Operation Summary

The following summarizes the steps for the normal operation of your

dishwasher.

1. Check that spray arms, scrap screen, and door are in place.

2. Check detergent and rinse aid reservoirs are replenished.

(Dispensing equipment and chemicals supplied by others.)

3. Check that drain is closed.

4. Turn power on to the dishwasher at the main service disconnect switch.

5. Monitor water level gauge.

6. Turn power selector switch at control cabinet to ON.

7. Push Green start button on control cabinet for inital auto fill.

8. Wait for tank water temperatures to reach operating temperature.

Wash tank temperature = 150°F. minimum.

9. Scrap and prerinse wares. Place in dishracks. Do not overload racks.

10. Press Green start button on control cabinet to start wash cycle. Pump runs.

11. Open door and slide dishrack into dishwasher.

12. Check the final rinse temperature and the final rinse pressure during the final rinse

(180°-195°F @ 20-22 psig flow pressure).

NOTE:

The dishwasher may be stopped by turning the power selector switch on

the control cabinet to the OFF position. Press the GREEN start button and

all wares inside the dishwasher will be fully washed and rinsed.

13. Refer to Part 4.2, Cleaning Schedule for daily cleaning instructions.

14. Perform the shutdown procedure described on the preceding page.

25

Page 44

PART 4: CLEANING AND MAINTENANCE

PART 4: CLEANING AND MAINTENANCE

In This Part—

• Introduction

• Daily cleaning schedules

• Deliming schedules

• Preventive maintenance schedules

• Lubrication schedules

4.1 Introduction

Cleaning your machine is the best maintenance that you can provide. Components that are not

regularly flushed and cleaned do not perform well.

The following schedules are the minimum requirements necessary for the proper performance

of your machine. Intervals should be shortened whenever your machine is faced with abnormal

working conditions, hard water, or multiple shift operations.

4.2 Daily Cleaning Schedules

Every 2 Hours or After Each Meal Period

1. Drain the dishwasher.

2. Flush interior with fresh water.

3. Clean scrap screen and pump intake screen.

4. Clean spray arm nozzles.

Every 8 Hours or at the End of the Day

1. Drain the machine.

2. Flush interior with fresh water.

3. Clean scrap screen and pump intake screen.

4. Clean spray arms.

5. Clean the final rinse nozzle openings with a paper clip.

CAUTION:

!

6. Thoroughly clean the exterior of machine with mild soap solution.

7. Reassemble the machine.

8. Leave doors open to aid in drying.

Do not hose down the exterior of the machine with water.

26

Page 45

PART 4: CLEANING AND MAINTENANCE

4.3 Deliming Schedules

Your dishwasher should be delimed regularly depending on the mineral content of your water. Inspect the

machine interior for mineral deposits and use a deliming solution for the best cleaning results.

WARNING:

Deliming solutions or other acids must not come in contact with household bleach

(sodium hypochlorite) or any chemicals containing chlorine, iodine, bromine, or fluorine.

Mixing will cause hazardous gases to form.

Skin contact with deliming solutions can cause severe irritation and possible chemical burns.

WARNING:

Consult your chemical supplier for an appropriate deliming solution,

protective gear and safety procedures.

27

Page 46

PART 4: CLEANING AND MAINTENANCE

4.4 Preventive Maintenance Schedules

Weekly Maintenance Requirements

Perform the following procedures every week.

!

1. Inspect for leaks including all piping, tank seams, and supply connections.

2. Inspect the front door for proper fit and ease of operation.

3. Check the operation of door safety switch.

CAUTION:

Only qualified service personnel should perform preventive maintenance

on the dishwasher

Tighten or repair as required.

Refer to Part 3.4, Safety and Operation Checks on page 22.

WARNING:

When working on the dishwasher, disconnect the electric service and place a tag at the

disconnect switch to indicate work is being done on that circuit.

4. Turn the power selector switch to OFF at the control cabinet.

5. Drain the dishwasher if required and inspect the float switches and probes in the

bottom of the tank. Float switch should move freely. Clean if necessary.

6. Check the spray arms and internal structures for wear or damage.

7. Reassemble the dishwasher.

8. Turn the power selector switch to ON at the control cabinet.

9. Check the operation of the start and stop switches on the control cabinet.

10. Check that the red power indicator works correctly.

11. Return the dishwasher to normal operation.

28

Page 47

PART 4: CLEANING AND MAINTENANCE

Quarterly Maintenance Requirements

Perform the following procedures every four months.

!

CAUTION:

Only qualified service personnel should perform preventive maintenance

on the dishwasher.

1. Perform all the procedures described in the weekly maintenance requirements.

2. Refer to Part 3.4, Safety and Operation Checks, and perform all the checks

described in this part.

3. Close all water and steam supplies. Run the dishwasher for 2 minutes to relieve

water and steam pressure in the lines.

4. Disassemble the water and steam inlet line strainers and clean as necessary.

WARNING:

When working on the dishwasher, disconnect the electric service and place a tag at the

disconnect switch to indicate work is being done on that circuit.

5. Disconnect the power to the dishwasher at the main service disconnect switch.

Tag the circuit to indicate work is being performed on that circuit.

6. Open the control cabinet enclosure(s) and check the tightness of all electrical

wiring connections.

7. Inspect all wiring for signs of heat damage and replace if necessary.

8. Manually operate the contactors and overloads checking for free movement.

9. Close the control cabinet enclosures.

10. Inspect and tighten all mounting hardware. Replace missing or damaged fasteners with

stainless steel replacements.

11. Return the dishwasher to normal operation.

Annual Maintenance Requirements

The steam booster (if equipped) requires annual cleaning.

Refer to Part 5.3.12, Steam Booster Service, for instructions on steam booster maintenance.

29

Page 48

4.5 Lubrication Schedules

1. The USN-10 undercounter dishwasher does not require lubrication.

Page 49

PART 4: CLEANING AND MAINTENANCE

This

Page

Intentionally

Left

Blank

31

Page 50

PART 5: BASIC SERVICE

PART 5: BASIC SERVICE

In This Part—

• Introduction

• General troubleshooting

• Component adjustment, repair, and replacement

5.1 Introduction

Part 5, Basic Service covers component adjustment, repair and replacement for the major

components of your dishwasher. Use the Troubleshooting Guide to identify the operating

condition of your machine and follow the suggested solution. Some solutions refer to a

Repair Procedure 5.3.xx; these solutions should be attempted only by qualified service

personnel. Basic Service does not cover all possible repair procedures. If you require

additional service support, you may call your local service company at:

See Inside Front Cover for Service Company information

Please have the Model and Serial Number of the machine ready when you call.

Schematics

Champion places an electrical schematic in the control cabinet of every machine before it is

shipped. Schematics are included at the back of this manual as well. Be aware that these schematics include options that may not apply to your machine. Options are enclosed in dashed lines with

the words (IF USED) next to them on the schematic. Disregard any options that appear on the

schematics which are not a part of your machine.

Electrical Circuit Tests

Use a clip-on AC current tester to check the motors and electric heaters.

Use a VOM to test line voltages and the 120VAC control circuit.

NOTE:

DO NOT USE CHASSIS GROUND WHEN PERFORMING VOLTAGE CHECKS.

Doing so will result in false and inaccurate readings.

PERFORM VOLTAGE CHECKS BY READING FROM THE HOT SIDE OF THE

LINE AND NEUTRAL (any #2 or white wire).

Tools

Most repairs can be made with: Standard set of hand tools, Volt/Ohm Meter (VOM), and

Clip-on AC current tester. Special tools necessary to perform a repair are noted in the specific

repair procedure.

32

Page 51

PART 5: BASIC SERVICE

5.2 General Troubleshooting

In the event that your dishwasher does not perform as expected, refer to the troubleshooting guide

below. Perform the action suggested in the solution column. Contact a qualified service

technician if the solution refers to a Repair Procedure in Part 5.3.

Many conditions may be resolved by performing the seven basic checks listed below:

1. All switches are ON

2. Drain valves closed

3. Wash and rinse nozzles are clean

4. Wash and rinse pipe assemblies are installed correctly

5. Scrap screen is properly positioned

6. Thermostat(s) are properly adjusted

7. Detergent and rinse additive dispensers are adequately filled

CONDITION CAUSE SOLUTION

Machine will not start Door not closed .................................... Make sure door is fully closed

Main switch off .................................... Check disconnect at main panel

Check machine power switch

Door safety switch faulty ..................... Refer to Repair Procedure 5.3.15

Water level low in tank(s) .................. Check float switch and fill tanks

Defective float switch .......................... Refer to Repair Procedure 5.3.5

Motor overload tripped ........................ Refer to Repair Procedure 5.3.17

Blown fuse or circuit breaker .............. Refer to Repair Procedure 5.3.16

Low or no water Main water supply is turned off .......... Turn on main water supply

Machine not filled initially .................. Close drains/Open manual fill valves

Tank overflow removed ....................... Reinstall overflow tube

Clogged line strainer ............................ Clean strainer screen/replace strainer

Faulty manual fill valve ....................... Replace manual fill valve

Pump motor not running Motor overload tripped ........................ Refer to Repair Procedure 5.3.17

Defective motor .................................... Refer to Repair Procedure 5.3.14

Tank(s) water Incoming water temperature ................ Raise temperature to:

temperature is low at machine too low 140°F/43-60°C

when in use Defective thermometer ....................... Refer to Repair Procedure 5.3.7

Defective thermostat ............................ Refer to Repair Procedure 5.3.8

Steam supply shut off .......................... Turn on steam supply

Low steam pressure .............................. Correct steam pressure is 15-30 PSI

Defective steam solenoid valve ........... Refer to Repair Procedure 5.3.4

Defective steam trap ............................ Refer to Repair Procedure 5.3.12

33

Page 52

PART 5: BASIC SERVICE

5.2 General Troubleshooting (Cont.)

CONDITION CAUSE SOLUTION

Insufficient pumped Clogged pump intake screen ................ Clean pump intake screen

spray pressure Clogged spray pipe ............................... Clean spray pipe

Insufficient final rinse Faulty pressure reducing valve ............ Refer to Repair Procedure 5.3.1

or no final rinse Improper setting on pressure ............... Correct pressure setting is 20-22 PSI

Scrap screen full of debris ................... Must be kept clean and in place

Low water level in tank ....................... Check drain valve(s)

Pump motor rotation incorrect Refer to Part 3.3, Start-up Procedure,

Steps 19-20, page 19

reducing valve

Clogged rinse nozzle and/or pipe ........ Clean pipe/nozzles

Clogged line strainer ............................ Clean screen or replace line strainer

Defective solenoid valve ...................... Refer to Repair Procedure 5.3.4

Low final rinse Low incoming water ............................ Increase incoming water temperature

110°F minimum for 70°rise booster

140°F minimum for 40°rise booster

Booster steam supply shut off ............. Turn on steam supply

Booster water supply shut off .............. Turn on water supply

Rinse nozzle missing Replace missing part

Defective final rinse thermostat .......... Refer to Repair Procedure 5.3.10

Defective thermometer ........................ Refer to Repair Procedure 5.3.7

Low steam pressure .............................. Correct steam pressure is 15-30 PSI

Defective steam solenoid valve ........... Refer to Repair Procedure 5.3.4

Defective steam trap ............................ Refer to Repair Procedure 5.3.12

Poor washing results Detergent dispenser .............................. Contact detergent supplier

not operating properly

Insufficient detergents ......................... Contact detergent supplier

Wash water temperature ...................... See condition “Wash Tank

too low Water Temperature is low”

Wash arm clogged ................................ Clean

Improperly scraped dishes ................... Check scraping procedures

Ware improperly placed in rack .......... Use proper racks. Do not

overload racks

Overflow clogged ................................. Check overflow tube

debris not skimmed from tank(s) ........

Wash water not drained at specified ... Drain tank every two hours

intervals or after each meal period.

34

Page 53

PART 5: BASIC SERVICE

5.3 Component Repair and Replacement

Part 5.3 contains instructions for the adjustment, repair, and replacement of components which may

require service due to normal wear and tear. The following procedures should only be performed by

qualified service personnel.

THE FOLLOWING CAUTION AND WARNINGS MUST BE FOLLOWED AT ALL TIMES

CAUTION:

!

Only qualified service personnel should perform adjustments and repairs to the dishwasher.

WARNING:

When repairing a circuit, disconnect the power at the main service disconnect switch and

place a tag at the disconnect switch to indicate that work is being performed on the circuit.

WARNING:

Use Extreme Caution when performing tests on energized circuits.

5.3.1 Pressure Reducing V alve, (PR V), Adjustment

The PRV is located on the 3/4" incoming water supply before the final rinse booster assembly. To adjust

the pressure setting on the PRV, loosen the locknut on the adjusting screw in the top of the PRV. Turn the

adjusting screw clockwise to increase the pressure setting. Turn the screw counterclockwise to decrease

the pressure setting. The USN-10 dishwasher requires a flowing pressure of 20-22 PSI during the final

rinse. With the dishwasher in normal operation, place a dishrack in the machine. While final rinse water

is flowing, monitor the final rinse pressure gauge located at the top of

final rinse piping assembly. Adjust the PRV screw to achieve a flowing

pressure of 20-22 PSI.

The PRV does not contain any service replacement parts. If adjustment

will not provide the proper flowing pressure, then replace the PRV. To

replace the PRV: Turn main water supply to the dishwasher off. Place a

rack in the dishwasher to activate the final rinse. This will bleed any

water pressure out of the line. Remove the PRV from the piping system

Reinstall using pipe sealing compound. Turn the water supply on, test

for leaks, and perform the adjustment described above.

35

Page 54

PART 5: BASIC SERVICE

5.3 Component Repair and Replacement (Cont.)

5.3.2 Water Line Strainers

There are two of water line strainers on the USN-10 dishwasher. The first strainer is located on

the 3/4" main water line to the booster. The second is located on the incoming

water line for the tank fill. The line strainer screen may become clogged with

debris. To clean the strainer screen: Turn off the main water supply valves.

Open the tank fill manual valves to bleed off pressure. Run a dishrack through

the machine to operate the final rinse and bleed off water pressure at the booster.

Turn power off at the dishwasher control cabinet. Remove the locknut at the

end of each strainer "Y". Remove the strainer screen and flush clean with water.

Reinstall in reverse order. Turn on water supplies and check for leaks.

5.3.3 Vacuum Breaker Repair

Vacuum Breakers are located at the top of the USN-10 in the 1/2" final rinse water line and each

of the 1/2" tank fill lines. They prevent the siphoning of dish-machine water back into the

potable water supply. Each vacuum breaker contains a moveable float. To replace the float:

Turn off the main water supplies. Turn off the power at the dishwasher control switch. Unscrew

the top of the vacuum breaker. Remove the float. Inspect the interior of the vacuum breaker.

Remove any mineral deposits and inspect the float seating surfaces for pitting. (If badly pitted,

replace the entire vacuum breaker assembly). Install a new float repair kit and reassemble in

reverse order. Turn on power and water supplies. Operate the dishwasher and check for leaks.

5.3.4 Water Solenoid Valve Repair

A 1/2" water solenoid is located in the final rinse water line at theoutlet of the

final rinse booster. The valve is controlled by the operation of the final rinse

switch assembly which connects 120VAC to the valve coil during a final rinse

operation. If the valve fails to operate, first check that 120VAC is supplied to

the valve coil. If voltage is not present, then refer to the electrical schematic

and troubleshoot the circuit. If voltage is present then the valve may require a

rebuild kit or replacement coil. Turn off power at the dishwasher power switch

and main disconnect. Turn off main incoming water supply and bleed off any

water pressure in the line. Check the coil for continuity with a VOM set at the

highest resistance range. If the coil checks good then disassemble the valve by

unscrewing the threaded bonnet with a strap or spanner wrench. Remove and

inspect the valve piston and diaphragm. Inspect the valve seat for mineral deposits and pitting.

(Replace the complete valve assembly if pitting is severe). Reassemble the valve in reverse order.

Turn on power and water supplies and check for leaks.

36

Page 55

PART 5: BASIC SERVICE

5.3.5 Float Switch Replacement

Refer to Fig. 6.4, Fig. 6.5, and Fig. 6.6, Part 6, Replacement Parts, for a detailed drawing of the float

switch assembly. The tank contains a float switch assembly which monitors the water level in the tank.

When the water level drops below a preset level the ball on the float switch stem drops and opens a reed

switch . The control relay associated with the float switch changes state. A set of normally closed

contacts open interrupting power to the 120VAC control circuit and the dishwasher stops. If you suspect

a defective float switch: Turn power off at the dishwasher control cabinet. Drain the tank and inspect the

float.

Make sure the float is clean and moves freely. Identify the float switch wires in the junction box located

on the lower corner of the dishwasher front. Disconnect the float switch and connect its associated

control wires together. Turn power on and restart the dishwasher. If the dishwasher operates normally,

then replace the float. To remove the float assembly: Remove the float switch cover. Remove the

5/16-18 nut on the outside of the tank. The mounting hole is keyed so the float switch will not turn.

Remove the float switch assembly from the inside of the tank. Install a replacement in reverse order.

Reconnect the float switch wires in the junction box. Turn power on, refill the tank, and test the

dishwasher for normal operation.

5.3.6 Drain and Overflow Assembly

Refer to Fig. 6.3, Part 6, Replacement Parts, for a detailed drawing of the drain and overflow assembly.

Note items 1-4. These parts make up the overflow assembly. The assembly consists of an overflow tube

with drain box topped by a hinged cover. The cover tilts up to allow inspection and cleaning. Lift up the

hinged cover and inspect the overflow tube if an obstruction is suspected. Item 10 shows the drain

screen. This screen should be inspected daily and cleaned. Item 12 illustrates the drain assembly. It

consists of soldered copper pipe and if defective must be replaced as a unit. Note the cleanout plug to the

left of the drain valve. This plug can be removed to clean possible obstructions from the drain assembly.

Item 13 shows the 1-1/2" cleanout plug in the drain trunk line. Remove the plug to inspect and clean the

main dishwasher drain line.

5.3.7 Thermometer Replacement

Refer to Fig. 6.4, Fig 6.5, and Fig. 6.6, Part 6, Replacement Parts, for a detailed drawing of the ther mometer assemblies. The thermometers are mounted to brackets on the front of the dishwasher. Thermometer capillary tubes run from the bottom of the dishwasher to the right and left ends of the tanks.

The thermometer bulbs are retained inside the tanks by a 1/2" locknut. The final rinse thermometer bulb

mounts directly into the upper final rinse piping at the top of the dishwasher. Tank and final rinse thermometers are factory sealed indicating devices which are accurate within ±3° of the intended range of

use. The thermometers cannot be calibrated and must be replaced if defective. To replace a thermometer:

Drain the machine and turn off all power. Have a helper hold the thermometer bulb from the outside of

the machine. Remove the 1/2" locknut from the inside of the tank and pull the thermometer sensor bulb

out of the tank. Remove the nuts and retainer from the thermometer bracket. Pull the thermometer out

the front of the bracket. Replace the thermometer and reassemble in reverse order. Be sure to apply

plumber's putty, (Champion P/N 104889), to seal the thermometer bulb fitting in the tank. Return the

dishwasher to normal operation and check the

temperature reading.

37

Page 56

PART 5: BASIC SERVICE

5.3 Component Repair and Replacement (Cont.)

5.3.8 Tank Heat Thermostat Adjustment and Replacement

Refer to Fig. 6.4, Fig. 6.5 and Fig. 6.6 , Part 6, Replacement Parts, for a detailed drawing of the

thermostat assembly. The tank has a control thermostat mounted on its front in a stainless steel

enclosure. The thermostat capillary tube runs to the side of the tank. The thermostat sensor bulb

enters the tank and is secured inside the tank with a 1/2" locknut. The thermostat is adjusted by

turning a small adjustment screw mounted on the side of the device. The thermostat has an

operating range of 110-200°F. Place the machine in normal operation and monitor the thermometer. Wash tank temperature should maintain a minimum of 150°F. Final rinse booster tank

temperature should maintain a minimum of 180°F.

Final Rinse Booster Tank Temperature = 180°F minimum

To adjust a thermostat: Turn the adjusting screw incrementally 1/8 to 1/4 of a turn clockwise.

Monitor the temperature thermometer after each adjustment until the desired temperature setting

is maintained during normal dishwasher operation.

To replace a thermostat: Drain the tanks and turn off all power to the dishwasher.

Have a helper hold the thermostat sensor bulb from the outside of the machine and remove

the 1/2" locknut from the interior of the tank. Pull the bulb and capillary back to the thermostat

junction box. Note the wire locations and disconnect the thermostat. Remove two retaining nuts

and remove the thermostat assembly. Install a new thermostat in reverse order. Be sure to apply

plumber's putty, (Champion P/N 104889), to seal the thermostat bulb fitting in the tank. Return

the dishwasher to normal operating condition and adjust the thermostat as described above.

Wash Tank Temperature = 150°F minimum

5.3.9 Tank Heat High Limit Adjustment and Replacement

Refer to Fig 6.4, Fig. 6.5 and Fig. 6.6, Part 6, Replacement Parts, for the detailed drawing of the

thermostat and high limit assembly. The tank has two types of thermostats. The tank heat thermostat (as described in 5.3.8) and a tank high limit thermostat. The high limit thermostat protects

the tank from overheating. The high limit thermostat is located below the tank thermostat and

above the element. The high limit is not adjustable. It contains a red pushbutton located in the

center. The red button pops out if the temperature exceeds 210°F/99°C. Press the red button to

reset the high limit. Determine the cause of the high temperature condition.

To replace the highlimit: Drain the tanks and turn off all power to the dishwasher. Have a

helper hold the high limit bulb from the inside of the machine and remove the locknut from the

interior of the tank. Pull the bulb back to the junction box. Note the wire location s and disconnect the high limit. Install the new high limit in the reverse order, making sure that you apply a

plumber's putty (Champion P/N 104889), to seal the high limit fitting in the tank. Return the

dishwasher to normal operating condition.

5.310 Final Rinse (Steam) Thermostat Adjustment and Replacement

Refer to Fig. 6.16, Part 6, Replacement Parts, for a detailed drawing of the steam booster

assembly. Note Item 1. This shows the location of the final rinse control thermostat. The

thermostat has a range of 105-195°F. However, the operating range for final rinse application is

180-195°F. The thermostat wiring to the normally closed and common contacts. The normally

closed contacts open when the thermostat is satisfied.

The final rinse thermostat controls operation of the steam booster solenoid. It senses the outlet

temperature of the final rinse water leaving the booster and energizes or denergizes the steam

solenoid as needed to maintain the final rinse temperature within 180-195°F.

38

Page 57

PART 5: BASIC SERVICE

5.3 Component Repair and Replacement (Cont.)

5.3.10 Final Rinse (Steam) Thermostat Adjustment and Replacement (cont)

NOTE:

The final rinse control thermostat serves two functions-first as the final rinse control thermostat and second as the final rinse low temperature cutoff thermostat. When you adjust the

final rinse control thermostat, you are also adjusting the final rinse low temperature cutoff

thermostat.

To replace the final rinse/ cutoff thermostat: Turn off the water and steam supplies to the booster.

Place a rack in the dishwasher to operate the final rinse and bleed off any water pressure from the line.

Turn power off to the dishwasher at the dishwasher control. Remove the protective cap from the thermostat body. Note the location of the wires and disconnect. Disconnect the conduit. Remove the thermostat

from the booster piping. Install the replacement as shown in the diagram below. Follow instructions as

listed on Part 8: Service Bulletins on Page 91. Return the dishwasher to normal operation and perform

the adjustment procedures described on the previous page.

12 Inches

5.3.11 Steam Solenoid Valve Repair

The USN-10 dishwasher uses a 3/4" steam solenoid valve on

the tank steam supply line. The 3/4" steam valves are identical in

appearance to the 3/4" water valves, (See 5.3.4). The steam

booster uses a 3/4" steam solenoid valve on the inlet of the booster

steam supply line, (See picture to the right)

12 inches

39

Page 58

PART 5: BASIC SERVICE

5.3 Component Repair and Replacement (Cont.)

5.3.11 Steam Solenoid Valve Repair (Cont.)

The 3/4" valves are controlled by a tank heat thermostat, (See 5.3.8), which connects 120VAC

to the valve coil during a call for heat. If the valve fails to operate, first check that 120VAC is

supplied to the valve coil. If voltage is not present, then refer to the electrical schematic and

troubleshoot the circuit. If voltage is present then the valve may require a rebuild kit or replacement coil. Turn off power at the dishwasher power switch and main disconnect. Turn

off main incoming steam supply and bleed off any steam pressure in the line. Check the coil for

continuity with a VOM set at the highest resistance range. If the coil checks good then disassemble the valve by unscrewing the threaded bonnet with a strap or spanner wrench. Remove

and inspect the valve piston and diaphragm. Inspect the valve seat for mineral deposits and

pitting. (Replace the complete valve assembly if pitting is severe). Reassemble the valve in

reverse order. Turn on steam and power supplies and check for leaks.

The 3/4" valve is controlled by the final rinse control thermostat, (See 5.3.10), which connects

120VAC to the valve coil during a call for heat. If the valve fails to operate, first check that

120VAC is supplied to the valve coil. If voltage is not present, then refer to the electrical schematic and troubleshoot the circuit. If voltage is present then the valve may require a rebuild kit or

replacement coil. Turn off power at the dishwasher power switch and main disconnect. Turn off

main incoming steam supply and bleed off any steam pressure in the line. Check the coil for

continuity with a VOM set at the highest resistance range. If the coil checks good then disassemble the valve by removing the four bolts in the valve bonnet. Remove and inspect the valve

piston and diaphragm. Inspect the valve seat for mineral deposits and pitting. (Replace the

complete valve assembly if pitting is severe). Reassemble the valve in reverse order. Turn on

steam and power supplies and check for leaks.

5.3.12 Steam Trap Repair and Replacement

1/2" NPT thermodynamic steam traps are installed in the condensate lines

for the steam booster and tank heat steam coils. All condensate lines for

the USN-10 must be gravity drain with no back pressure in order for the

steam trap to function correctly.

To test the operation of a steam trap: Turn off the steam and water

supplies. Turn off the power at the dishwasher control cabinet. Bleed any steam pressure from

the lines. Disconnect the condensate return line downstream from the steam trap. Return the

dishwasher to normal operation and observe the discharge coming from the steam trap. If you do

not observe small amounts of water periodically discharged then the stream trap is most likely

defective.

To clean a steam trap: Turn off the steam and water supplies. Turn off the power at the dishwasher control cabinet. Bleed any steam pressure from the lines. Remove the large hex cap in

the center of the steam trap. Remove the disc and inspect the steam trap orifice below.

Clean the orifice with a paper clip or other smooth tool. Reassemble the trap in reverse order.

To replace a steam trap: Turn off the steam and water supplies. Turn off the power at the

dishwasher control cabinet. Bleed any steam pressure from the lines. Break the union in the

condensate line before the steam trap. Remove the trap. Install a replacement trap in reverse

order making sure to apply pipe sealant to threads. Return the dishwasher to normal operation

and test the trap as described above.

40

Page 59

PART 5: BASIC SERVICE

Flow header gasket

P/N 112356

Return header gasket

P/N 112357

Steam Booster

5.3 Component Repair and Replacement (Cont.)

5.3.13 Steam Booster Service

Refer to Fig. 6.16, Part 6, Replacement Parts, for a detailed drawing of the steam booster

assembly. The steam booster consists of three pieces as shown on the next page: the shell

casting into which the straight seamless copper tubes are fitted, the rear header, and the flow

header with two tappings for tank connections. Headers are bolted to the shell casting and sealed

against leaks by heavy gaskets. Where soft water or low percentage of mineral deposits is used,

it should only be necessary to clean the heater tubes annually. No acids are needed to clean the

heater tubes.

NOTE:

A single spiral, fine wire brush, 3/4" external diameter, (Champion P/N 112806),

or comparable is recommended for cleaning the booster heater tubes.

Annual Heater Tube Cleaning

Parts Required:

P/N 112357, Gasket (Return header)

P/N 112356, Gasket (Flow header)

Special Tools Required:

Torque wrench (30 ft/lbs needed)

To clean the heater tubes: Turn off all power,

steam, and water supplies to the booster and

dishwasher.

Refer to Fig. 6.16, Part 6, Replacement Parts.

Note (Item 1), thermostats.

Remove the thermostat covers, mark and disconnect the wires. Remove the conduit and fittings.

Mark the location of each thermostat before removal, then unscrew each thermostat from its

piping. Break the unions, (Item 12) and remove the piping assemblies from the booster header.

Remove the eight (8) bolts from each header. Remove the flow and return headers. Inspect the

exposed copper tubes and clean as necessary using the cleaning brush

(Champion P/N 112806). Clean the headers as required.

Install new header gaskets and reassemble in reverse order.

To torque the header bolts:

Refer to the torque sequence diagram to the right.

Torque each bolt in three steps:

1) handtight

2) 20 ft/lb

3) 30 ft/lb

Retorque each bolt to 30 ft/lb after 24 hours.

Bolts = 3/8-16

SA-449

Type 1

8

8 BOLTS

4

1

5

3

7

6

2

41

Page 60

PART 5: BASIC SERVICE

5.3 Component Repair and Replacement (Cont.)

5.3.14 Pump Seal Replacement

Refer to Fig. 6.8, Replacement Parts, for a detailed drawing of the pump/motor assembly.

Perform the steps listed below to replace a pump seal.

1. Disconnect the power to the machine at the main breaker panel or fuse box.

2. Drain the machine.

3. Remove the front and side panels (if applicable).

4. Remove drain plug on the pump volute and drain the pump.

5. Remove the pump hoses.

6. Disconnect the wires to the motor at the motor junction box.

7. Unbolt motor from machine base and remove the pump/motor assembly.

8. Remove bolts on volute and carefully remove from the pump flange.

9. Remove the impeller retaining bolt and nut from center of impeller.

10. Lock the motor shaft with a wrench or pliers. The back of motor shaft is square.

11. Turn the impeller counterclockwise to remove from shaft (right hand threads).

12. Remove the old seal and discard.

13. Check seal seat in the pump flange and clean thoroughly.

14. Press rubber seal/ceramic portion of seal assembly into the pump flange. Use a water

soluble lubricant. Be careful to keep the ceramic clean.

15. Install the rotating part of the seal on the shaft with the graphite surface toward the ceramic.

Use a water soluble lubricant on the rubber seal part only (not the graphite).

16. Reinstall impeller, and new flange gaskets. Reinstall bolts. Reinstall drain plug.

17. Reinstall the pump/motor assembly and reconnect the pump hoses.

18. Fill the dishwasher with water.

19. Check motor rotation by bump starting motor.

Correct motor shaft rotation is clockwise when viewing motor from the rear.

20. Test run and check for leaks.

5.3.15 Door Safety Switch

Refer to Fig. 6.1 Replacement parts item numbers 9 and 10. The door safety switch assembly

consists of a magnet on the inside wall of the tank and a magnetic reed switch mounted to the

bottom of the tank. Studs are welded on the bottom of the tank and nuts hold the switch in place.

The magnet is mounted to a bracket that pivots causing a break in the connection with the switch

when the door is opened or closed. The magnet is enclosed by a stainless steel housing. The door

safety switch prevents the machine from operating when the door is opened during operation.

To check the door safety switch: Disconnect the power to the machine at the main breaker

panel or fuse box. Inspect the inside of the machine to make sure that the magnet and bracket is

in place and secure. Remove the screws on the front panel of the machine. Swing the panel open

and look for the switch located to the right side of the panel underneath the edge of the tank.

Remove the door switch cover and disconnect the reed switch leads. Make sure that the door is

fully closed. Connect the door switch harness wires together. Turn the power on and check to see

if the machine runs normally. If machine operates, turn off power and replace the door safety

switch. Do not leave the door switch bypassed for any other reason than to test.

To replace the door safety switch: Disconnect the power to the machine at the main breaker

panel or fuse box. . Note the orientation of the reed switch. Mark the wires and disconnect.

Remove the (2) retaining nuts holding the switch. Install the new switch and reassemble in the

reverse order. Restore power to the machine and check for proper operation.

42

Page 61

PART 5: BASIC SERVICE

5.3 Component Repair and Replacement (Cont)

5.3.16 Fuses and Fuse Block Replacement

Fuse Blocks—120VAC Control Voltage

The two fuse blocks, located on the center row and to the left side

of the control cabinet protect the main control transformer. Each

fuse block holds a fuse. The fuses are marked 1FU and 2FU on

the electrical schematic.

To Replace the fuse:

• Disconnect power to the machine at the main service switch.

• Remove the fuse and replace it.

• Close the fuse block and turn the main power on.

• If the fuse blows again, DO NOT INCREASE THE FUSE SIZE.

• DETERMINE THE CAUSE OF THE OVERLOAD.

5.3.17 Motor Overload Adjustment and Replacement

Motor overloads are located to the left of the fuse blocks inside the control cabinet. Each motor

has one overload to protect it from line voltage electrical overloads. In addition, an auxiliary set

of switch contacts is built into the overload. The switch contacts disconnect 120VAC power to the

motor contactor coils in the event of an overload condition. Refer to Fig. X. If the switch lever is