Page 1

EASYBIRD AUTO-FEED

6 - PACKER

Part No. 40911 (40912 with Oscillating Base)

Instruction Manual

WARNING! THIS MACHINE CAN CAUSE SERIOUS INJURY OR DEATH.

THOROUGHLY READ INSTRUCTIONS BEFORE INSTALLING OR OPERATING TRAP.

Page 2

Table of Contents

Section Page

I. Introduction ......................................................................................... 1

II. Safety ................................................................................................. 2

III. Assembly ............................................................................................ 4

1. Contents ....................................................................................................... 4

2. Assembling Trailer ........................................................................ 6

3. Attaching Oscillating Base (If Equipped) ..................................................... 7

4. Mounting the Trap ........................................................................................ 7

5. Mounting the Throwing Arm Path Indicator .................................................. 8

6. Assembling the Magazine ............................................................................ 9

7. Mounting the Magazine Assembly ............................................................. 10

8. Installing the Mainspring ............................................................................. 11

9. Battery and release cord installation .......................................................... 12

IV. Trap Operation ................................................................................... 13

1. Adjusting the Target Retainer .................................................................... 13

2. Loading the Magazine and Firing the Trap ................................................. 15

V. Oscillating Base Operation ................................................................ 16

VI. Adjustments ....................................................................................... 17

1. Throwing arm limit switch .......................................................................... 17

2. Elevation Adjustment .................................................................................. 18

3. Distance Adjustment .................................................................................. 19

4. Oscillating Base Angle Adjustment ............................................................ 20

VII. Troubleshooting ................................................................................. 21

VIII. Maintenance ...................................................................................... 22

IX. Recommended Spare Parts & Ordering Info ............................................. 23

Warranty Certificate ....................................................................................................... 25

Contact Information ........................................................................................................ 26

Page 3

If you require parts or service assistance, please call the CHAMPION TRAPS AND TARGETS Customer Service Dept.

at (800) 379-1732

©2015 CHAMPION TRAPS AND TARGETS, Anoka, Minnesota 55303

1

I. Introduction

The Easybird Autofeed 6-Packer is a 12-volt battery powered trap designed for the

active sporting clays, trap, and skeet shooter looking for an automatic, lightweight, and

portable machine for practice/fun shooting.

Features of the EASYBIRD 6-PACKER trap include:

Lightweight and portable

Trailer with battery tray and 12” wheels

50 ft. release cord with handheld/foot pedal release. An individual can practice alone

with the EASYBIRD 6-PACKER trap.

Fast cycle time; the EASYBIRD 6-PACKER can keep 3 targets in the air at one time.

Target is delivered directly to the throwing arm – no target plate to adjust.

Maximum throwing distance approximately 75 yards.

On-Off-Safe Release switch safely and easily uncocks throwing arm.

Heavy duty clutch, frame, mainspring and cocking motor with gearbox.

Easy mainspring and elevation adjustments.

Arm Path Indicator Ring provides visual indication of throwing arm path for safety

All wiring out of sight, protected from the elements.

Throws standard 108 mm and 110mm clay targets.

Optional oscillating base adds these features

* Adds only 20 lbs to the 6-Packer

* 45 degrees oscillating angle provides a wide range of challenging targets.

* 34.28 degrees oscillating angle duplicates a 2 hole setting for ATA trap shooting.

* Connects to 6-Packer and uses the same 12V battery

* On/off switch mounted on rear panel of 6-Packer

* Lock down nut locks the base in a fixed position.

Page 4

If you require parts or service assistance, please call the CHAMPION TRAPS AND TARGETS Customer Service Dept.

at (800) 379-1732

©2015 CHAMPION TRAPS AND TARGETS, Anoka, Minnesota 55303

2

II. Safety

WARNING! THIS MACHINE CAN CAUSE SERIOUS INJURY OR DEATH.

THOROUGHLY READ INSTRUCTIONS BEFORE INSTALLING OR OPERATING TRAP.

DO NOT STAND IN FRONT OF THE TRAP WHEN IT IS IN THE COCKED POSITION.

SERIOUS INJURY OR DEATH CAN RESULT.

THIS TRAP IS CAPABLE OF THROWING TARGETS A DISTANCE OF 75 YARDS. USE

ONLY IN AREAS WHERE THERE IS NO RISK OF HITTING A PERSON WITH THE

TARGET.

CAUTION! The EASYBIRD 6-PACKER Trap must be bolted down to the trailer or to a flat,

solid surface to eliminate any movement of the trap while operating! Do not install in an

area that does not allow safe access to the trap during loading and use. Provide ample

clearance around trap. The ON/OFF/SAFE RELEASE switch for the EASYBIRD 6PACKER Trap is located on the rear of the trap to allow the trap to be uncocked before

approaching it. Provide for safe access to the switch that will not require anyone to walk

in front of the trap to load targets or perform work on it.

WARNING! IF THERE IS A TARGET ON THE THROWING ARM, SAFE RELEASING THE

THROWING ARM WILL THROW THE TARGET. DO NOT STAND IN FRONT OF THE TRAP

WHILE SAFE RELEASING THE THROWING ARM.

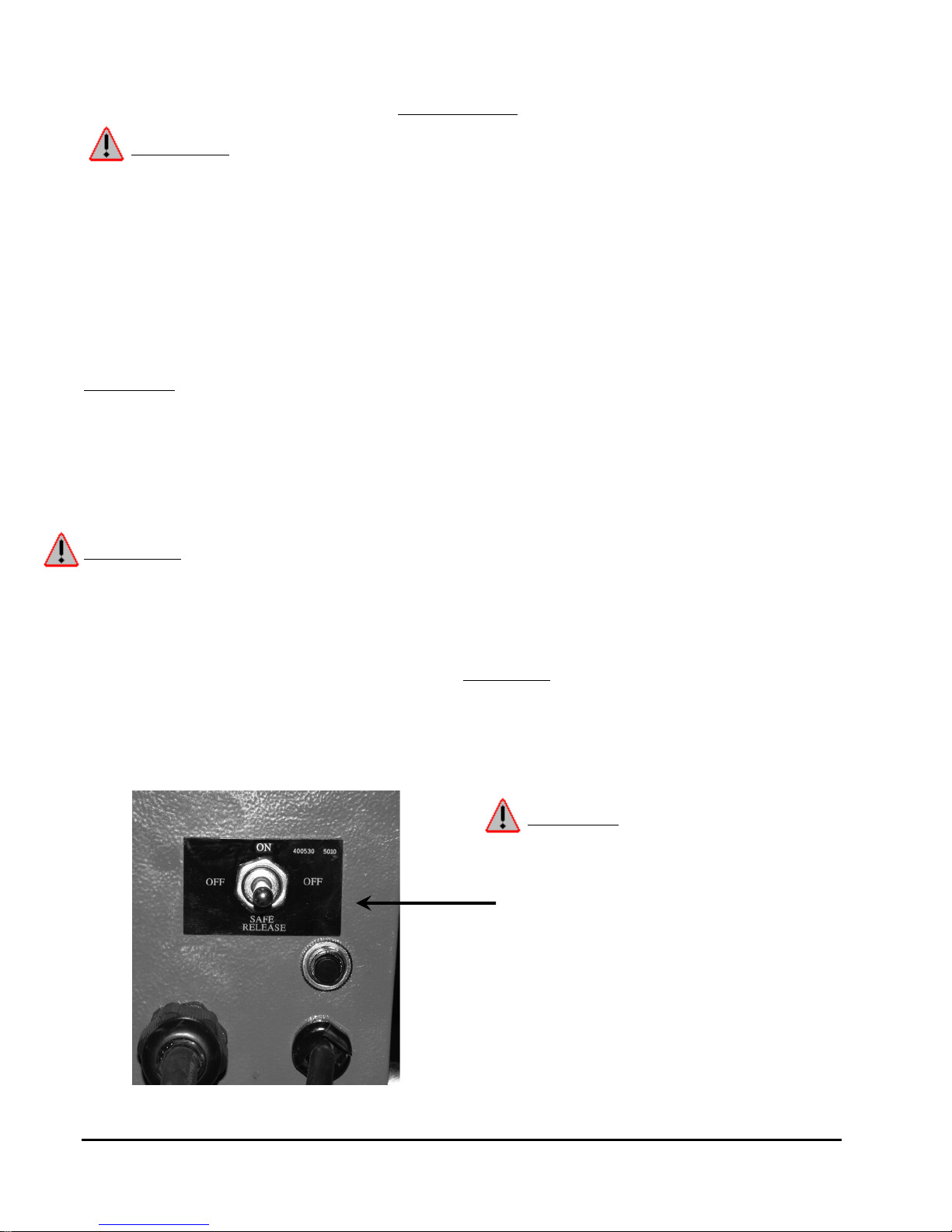

1. (FIGURES 1, 2 & 3) Before performing any work or maintenance on the EASYBIRD 6PACKER Trap, check to see if the trap throwing arm is in the “cocked” position (FIGURE

2). If it is, move the throwing arm to the uncocked position (FIGURE 3) by momentarily

pressing the ON/OFF/SAFE RELEASE switch (FIGURE 1) to the “safe release” position,

and after the arm releases to the uncocked position, release the ON/OFF/SAFE RELEASE

switch allowing it to return to the “OFF” position.

2. Finally, remove battery cables from battery.

WARNING! THE ON/OFF/SAFE RELEASE

(MAIN POWER) SWITCH ON THE TRAP

MUST BE IN THE ‘OFF‘ (CENTER)

POSITION AND THE BATTERY

DISCONNECTED FROM THE TRAP BEFORE

PERFORMING ANY REPAIR,

MAINTENANCE OR ASSEMBLY.

FIGURE 1

ON/OFF/SAFE RELEASE (Main Power) Switch

Page 5

If you require parts or service assistance, please call the CHAMPION TRAPS AND TARGETS Customer Service Dept.

at (800) 379-1732

©2015 CHAMPION TRAPS AND TARGETS, Anoka, Minnesota 55303

3

3. All personnel operating the trap should be thoroughly familiar with the operating instructions

and the safety issues relating to the trap.

4. Do not leave trap in the cocked position. Not only is this potentially dangerous, but it puts

undue stress on the mainspring.

5. Always load the trap magazine from the rear of the trap.

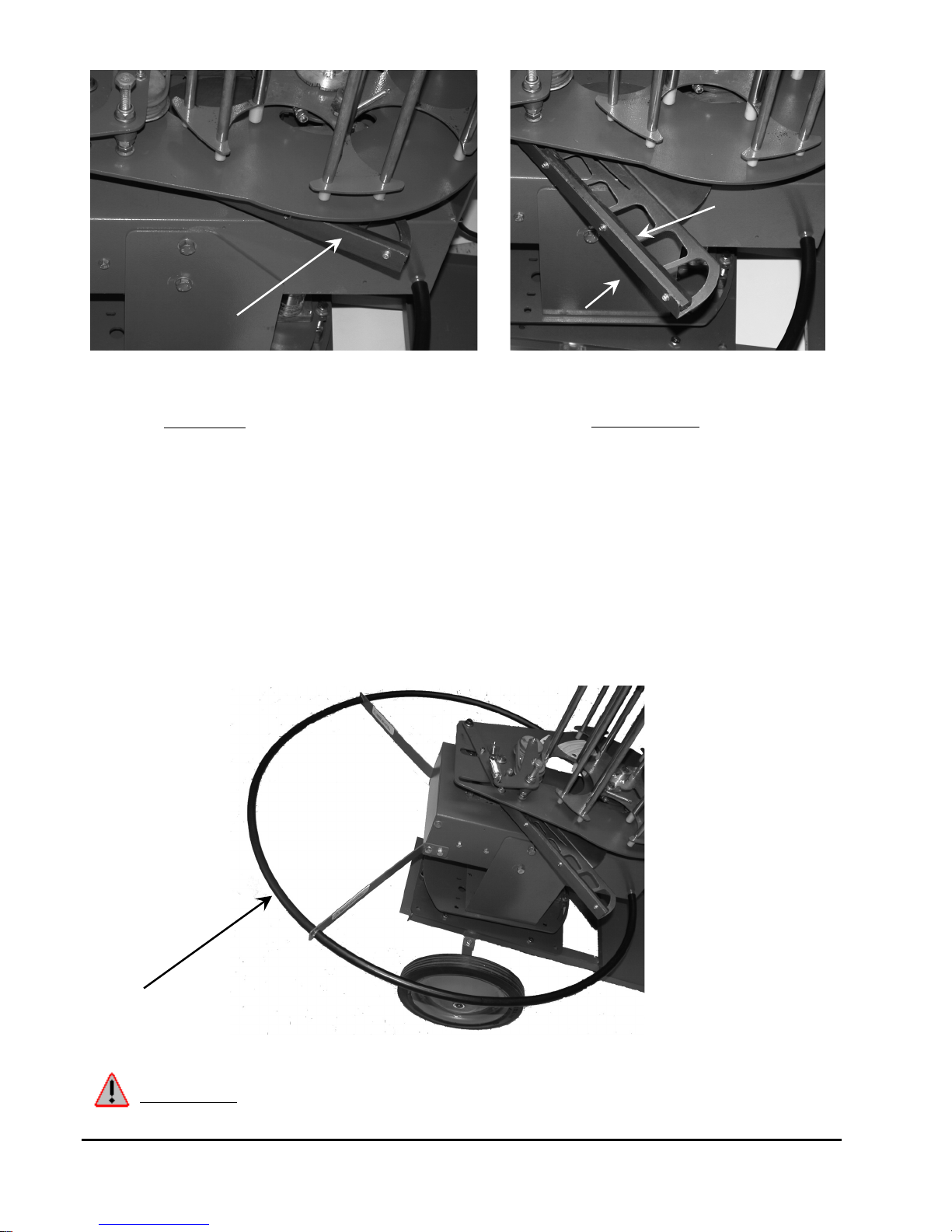

6. Keep hands and body outside the trap and throwing arm path indicator areas (FIGURE 4)

while the trap is operating. This ring shows the throwing arm’s path when throwing a target.

WARNING! FAILURE TO FOLLOW SAFETY RULES CAN RESULT IN SERIOUS

INJURY OR DEATH.

FIGURE 4

Throwing Arm Path Indicator

Throwing Arm

Path Indicator

FIGURE 3

Throwing Arm in

UNCOCKED Position

(arm position varies from 8 o’clock to 10

o’clock when viewed from rear of trap)

Throwing Arm

FIGURE 2

Throwing Arm in

COCKED Position

Throwing Arm

Flight Rail

Page 6

If you require parts or service assistance, please call the CHAMPION TRAPS AND TARGETS Customer Service Dept.

at (800) 379-1732

©2015 CHAMPION TRAPS AND TARGETS, Anoka, Minnesota 55303

4

A

C

E-2

E-4

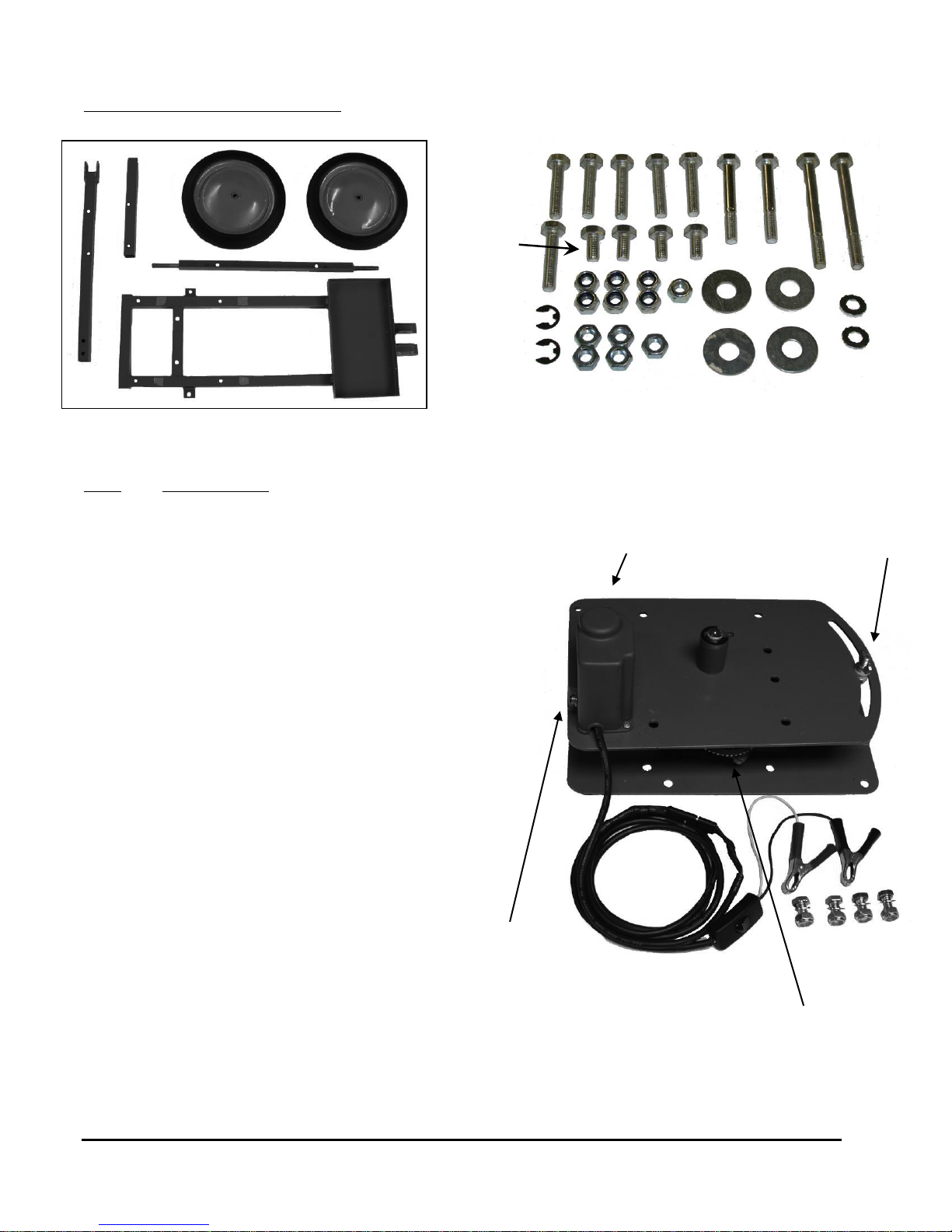

III. Assembly

1. Contents

1. Carefully inspect the carton and trap machine to be sure that damage hasn’t occurred

during shipping. Report any damage found immediately to the shipper.

2. Insure that all parts were included in shipping container and cartons. If any parts are

missing, call the CHAMPION TRAPS AND TARGETS Customer Service Department at

(800) 379-1732 to obtain replacement parts.

ITEM

DESCRIPTION

A.

6 Packer Trap (with magazine plates)

B.

Instruction Manual – 1ea

C.

Safety Ring Tube – 3 ea

D.

Trap Body Hardware Carton

D-1.

Front Tube Support – 2 ea

D-2.

Mainspring

D-3.

Mainspring Bolt

D-4.

Mainspring Bushing

D-5.

Flat Washer

D-6.

Tension Adjustment Flange Nut

D-7.

Tension Adjustment Lock Nut

E.

Magazine Hardware Carton

E-1.

Inner Magazine Rods – 6 ea

E-2.

Outer Magazine Rods – 12 ea

E-3.

Inner Magazine Stubs – 6 ea

E-4.

Outer Magazine Stubs – 12 ea

E-5.

Magazine Top Plate Screws – 18 ea

E-6.

Magazine Stub Screws – 18 ea

E-7.

Magazine Stub Screw Hex Wrench

D-1

E. Magazine Hardware Carton

D-2

D-3

D-4

D-5

D-6

D-7

E-1

E-3

E-5

E-6

E-7

E-7

D. Trap Body Hardware Carton

Page 7

If you require parts or service assistance, please call the CHAMPION TRAPS AND TARGETS Customer Service Dept.

at (800) 379-1732

©2015 CHAMPION TRAPS AND TARGETS, Anoka, Minnesota 55303

5

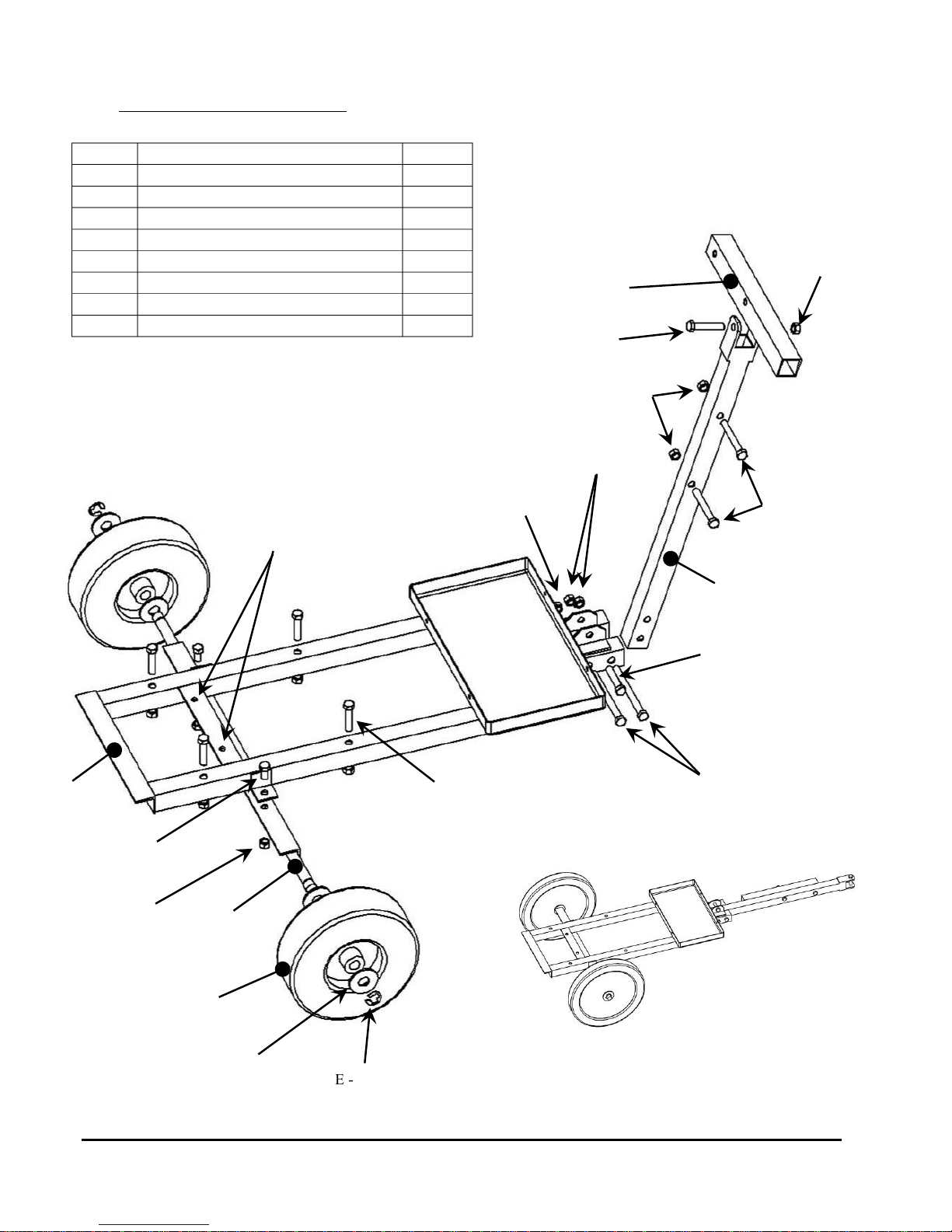

Contents (Continued)

ITEM

DESCRIPTION

F.

Trailer Frame

G.

Trailer Axle

H.

Trailer Wheel – 2ea

I.

Trailer Draw Bar

J.

Trailer Cross Bar

K.

Trailer Hardware Bag

K-1.

10mm x 110mm Hex Head Bolt – 2 ea

K-2.

10mm x 75mm Hex Head Bolt – 2 ea

K-3.

10mm x 50mm Hex Head Bolt – 6 ea

K-4.

10mm x 20mm Hex Head Bolt – 4 ea

K-5.

10mm Hex Nut – 5 ea

K-6.

10mm Lock Nut – 7 ea

K-7.

10mm Washer - 2 ea

K-8.

Large Washer - 4 ea

K-9.

E- Clip -2 ea

L.

Oscillating Base (If Equipped)

L-1.

Oscillating Base Unit

L-2.

Mounting Bolts, Washers and Lock Nuts – 4 ea

L-3.

Gear Motor

L-4.

Circuit Breaker

L-5.

Drive Belt

L-6.

Power Cable Assy

G

H

F I K-2 J K-4

K-9

K-3

K-1

L-1

L-6 Power Cable Assy

L-2

Mounting

K-6

K-5

K. Trailer Hardware Bag

Lock Down Nut

K-7

L. Oscillating Base

L-3 Gear Motor

K-8

L-5 Drive Belt

L-4 Circuit Breaker

Page 8

If you require parts or service assistance, please call the CHAMPION TRAPS AND TARGETS Customer Service Dept.

at (800) 379-1732

©2015 CHAMPION TRAPS AND TARGETS, Anoka, Minnesota 55303

6

2. Assembling Trailer

For pulling behind an ATV or garden tractor:

Remove cross bar and bolt to side of draw bar.

Bolt draw bar in horizontal position as shown.

Draw Bar

10mm x 75mm

Hex Head Bolts

Wheel (2)

Battery

Tray

Axle

Frame

Cross Bar

10mm Lock

Nuts (2)

10mm Hex Nuts

10mm Hex

Nut

10mm x 50mm

Hex Head Bolt

10mm x 50mm

Hex Head Bolt

10mm x 100mm

Hex Head Bolts

10mm x 20mm

Hex Head Bolts (2)

10mm Hex Nuts

10mm Lock Nut

E - Clip (2)

Use these 4 holes to mount 6-Packer (with

oscillating base) to frame with 10mm x

50mm Hex Head Bolts, and Lock Nuts

Large

Washer (4)

Qty.

K-1.

10mm x 110mm Hex Head Bolt

2

K-2.

10mm x 75mm Hex Head Bolt

2

K-3.

10mm x 50mm Hex Head Bolt

6

K-4.

10mm x 20mm Hex Head Bolt

4

K-5.

10mm Hex Nut

5

K-6.

10mm Lock Nut

7

K-7.

10mm Washer

2

K-8.

Large Washer

4

K-9.

E-Clip

2

Use these 2 holes to mount 6-Packer

(without oscillating base) to frame

with 10mm x 20mm Hex Head Bolts,

Washers, and Lock Nuts

Page 9

If you require parts or service assistance, please call the CHAMPION TRAPS AND TARGETS Customer Service Dept.

at (800) 379-1732

©2015 CHAMPION TRAPS AND TARGETS, Anoka, Minnesota 55303

7

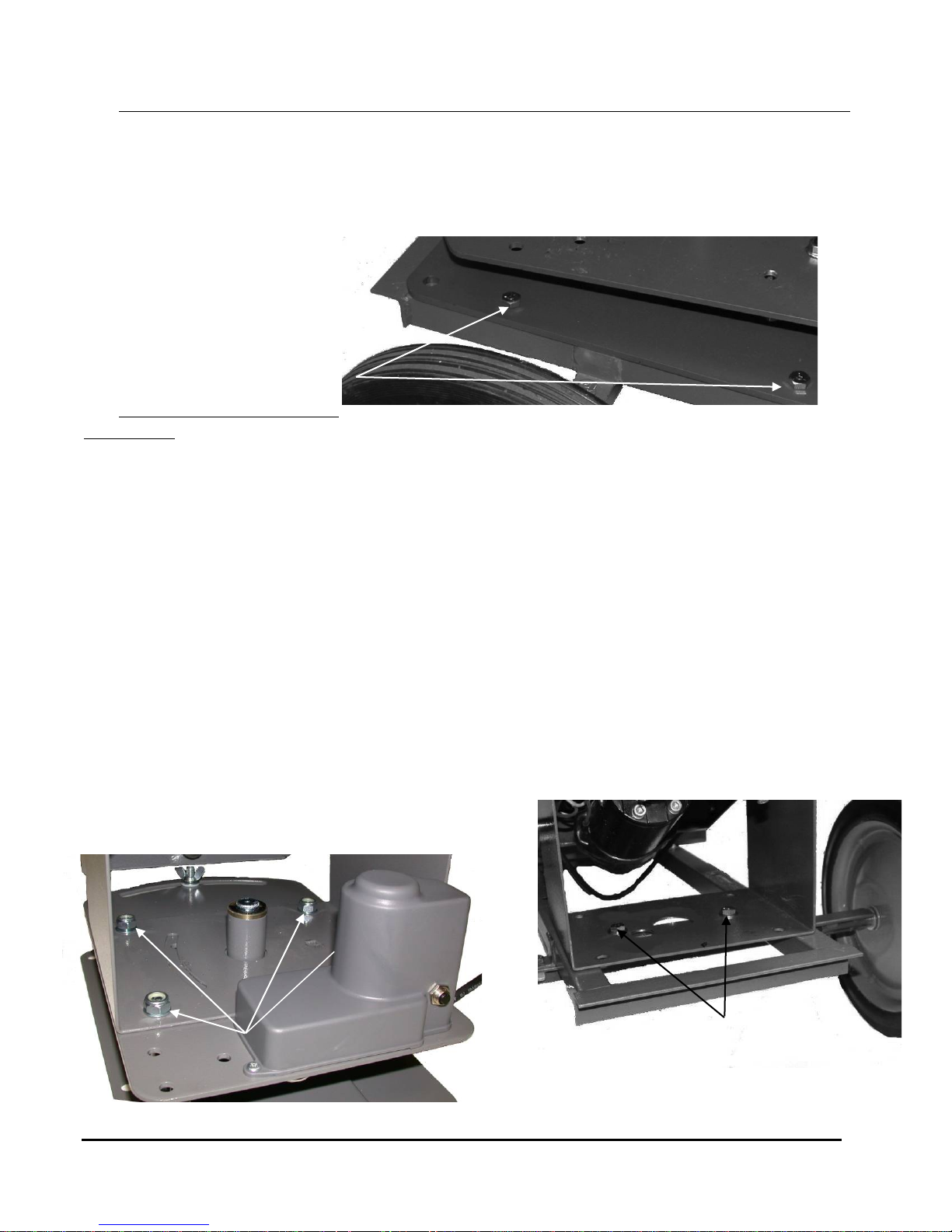

3. Attaching Oscillating Base (If purchased with 6-Packer Trap)

1. The EasyBird Oscillating Base has (4) pre-drilled holes that align with the four mounting

holes on the frame of the 6-Packer trailer. Use (4) of the 10mm x 50mm hex head bolts and

(4) of the 10mm lock nuts supplied with the trailer to securely fasten the oscillating base to

the trailer frame as shown. The gear motor on the top of the oscillating base is to the

front, the lock down nut and bolt is to the rear.

4. Mounting the Trap

CAUTION! The EASYBIRD 6-PACKER Trap must be bolted down to the trailer or to a flat,

solid surface to eliminate any movement of the trap while operating ! Do not install in an

area that does not allow safe access to the trap during loading and use. Provide ample

clearance around trap. The ON/OFF/SAFE RELEASE switch for the EASYBIRD 6PACKER Trap is located on the rear of the trap to allow the trap to be uncocked before

approaching it. Provide for safe access to the switch that will not require anyone to walk

in front of the trap to load targets or perform work on it.

Front of Trailer

Mounting Bolts

If mounting the 6-Packer to the oscillating base,

Use the 10mm x 20mm hex head bolts (4), 10mm

washers (4) and 10mm lock nuts (4) provided with

the oscillating base to securely fasten the 6-Packer

trap to the oscillating base. Bolts should be inserted

from underneath with the washers and nuts on top

as shown. The mounting bolt that is directly over the

shock absorber can be installed after the oscillating

base is connected and the oscillating base can be

moved slightly using the jog switch.

Mounting Bolts

Mounting Bolts

If mounting the 6-Packer to the trailer,

Use the 10mm x 20mm hex head bolts

(2) washers (2) and 10mm lock nuts (2)

provided with the trailer to securely

fasten the 6-Packer trap to the trailer as

shown. The curved slot and square hole

in the 6-Packer mounting bracket line up

with the 2 holes in the trailer cross bar.

Page 10

If you require parts or service assistance, please call the CHAMPION TRAPS AND TARGETS Customer Service Dept.

at (800) 379-1732

©2015 CHAMPION TRAPS AND TARGETS, Anoka, Minnesota 55303

8

5. Mounting the Throwing Arm Path Indicator

1. Attach the two (2) Front Tube Supports (D-1) to front sides of trap body

using the four (4) existing bolts in the lower front body (two on each side). Make

sure that warning labels are upright. Tighten all four (4) bolts on Front Tube

Supports securely.

2. Slide three (3) pieces of Arm Path Indicator Tubing (C) over ends of

Front Tube Supports and Rear Tube Support Studs at rear of trap body. This

ring indicates the approximate path of the Throwing Arm.

WARNING! FAILURE TO KEEP HANDS AND BODY OUTSIDE THE THROWING ARM

PATH INDICATOR AREA CAN RESULT IN SERIOUS INJURY OR DEATH FROM

BEING STRUCK BY THE THROWING ARM DURING USE.

CAUTION! Do not lift trap by throwing arm path indicator, or front tube

supports, these were not designed to be a lifting point.

Front Tube

Supports

Rear Tube

Support Stud

Arm Path Indicator

Tubing

Page 11

If you require parts or service assistance, please call the CHAMPION TRAPS AND TARGETS Customer Service Dept.

at (800) 379-1732

©2015 CHAMPION TRAPS AND TARGETS, Anoka, Minnesota 55303

9

6. Assembling the Magazine

The magazine ships unassembled. The top and bottom magazine plates are shipped attached

to the Trap body (FIGURE 5). The magazine rods, stubs and screws are shipped in the

hardware carton inside the shipping box.

To Assemble the Magazine:

1. Remove the magazine index gear by first removing the retaining plate and the key

(FIGURE 9) using the E-7 hex wrench

2. Lift the top and bottom magazine plates off the trap body.

3. Separate the top and bottom magazine plates by removing the cardboard, protective

wrapping, and the wire ties that secure them to each other (FIGURE 5).

4. The magazine is assembled following the picture shown in figure 6.

NOTE: When installing the eighteen (18) socket head cap screws that secure the inner and

outer magazine stubs on the bottom of the magazine assembly, gently tighten the screws until

they stop and turn them an additional 1/4 turn. DO NOT OVERTIGHTEN!

Figure 5 – Magazine Plates Figure 6 – Assembling the Magazine

ITEM

DESCRIPTION

E-1.

Inner Magazine Rods – 6 ea

E-2.

Outer Magazine Rods – 12 ea

E-3.

Inner Magazine Stubs – 6 ea

E-4.

Outer Magazine Stubs – 12 ea

E-5.

Magazine Top Plate Screws – 18 ea

E-6.

Magazine Stub Screws – 18 ea

E-9.

Magazine Top Plate

E-10.

Magazine Bottom Plate

Wire Ties

E-1

E-2

E-3

E-4

E-5

E-6

E-9

E-10

Figure 7 –

Assembled

Magazine

Page 12

If you require parts or service assistance, please call the CHAMPION TRAPS AND TARGETS Customer Service Dept.

at (800) 379-1732

©2015 CHAMPION TRAPS AND TARGETS, Anoka, Minnesota 55303

10

7. Mounting the Magazine Assembly

To mount the magazine assembly:

1. Slide the magazine over the magazine shaft and align the gap in the brake disk clamp on

the bottom of the magazine so that it falls over the locating cap screw head on the

magazine plate. (FIGURE 8) NOTE: Brake disk is shown separated from bottom of

magazine for clarity.

2. Rotate the magazine index pawl clockwise, and while holding index pawl in place, place the

magazine ratchet gear on the shaft and align the keyway in the shaft collar with the keyway

in the magazine shaft (FIGURE 9). Insert the key and attach the retaining plate with the

socket head cap screw as shown.

Figure 8 – Brake Disk Locating Screw and Brake Disk Orientation

Note: Brake Disk is shown removed from bottom of Magazine for clarification

Figure 9 – Magazine Orientation

Retaining

Plate

Locating

Screw Head

Brake Disk

Orientation

Key

Magazine

Ratchet Gear

Magazine Index

Pawl

Page 13

If you require parts or service assistance, please call the CHAMPION TRAPS AND TARGETS Customer Service Dept.

at (800) 379-1732

©2015 CHAMPION TRAPS AND TARGETS, Anoka, Minnesota 55303

11

Mainspring Bolt (D-3)

Mainspring

Bushing (D-4)

8. Installing the Mainspring

1. Remove the plastic tie holding the arm in place and rotate the arm counter clockwise 180°

so it is facing forward of the trap in the 12 o’clock position. Remove Mainspring (D-2) and

all remaining hardware from shipping cartons and bags.

2. Mainspring Hex Bolt (D-3) should be assembled into Mainspring (D-2) through largest

opening with the threaded end of mainspring bolt showing.

3. Place Mainspring and Bolt inside body of trap and push threaded end of Mainspring Bolt

through hole in rear of body.

4. Attach the hook end of the mainspring through the crankshaft eyebolt located inside of trap

body. First remove the wire tie holding the eyebolt in position and rotate the eyebolt so it is

pointing toward rear of trap.

5. Slide Mainspring Bushing (D-4) over Mainspring Hex Bolt so small end fits into trap body

6. Attach Flat Washer (D-5) and Tension Adjustment Flange Nut (D-6)

7. With the throwing arm still facing forward of the trap, tighten the Tension Adjustment Flange

Nut until all the slack is taken up in the spring and bolt. This is the minimum spring tension

point and operating the trap at any less tension will cause “spring slap” that can damage

the machine. Add the Tension Adjustment Lock Nut (D-7) and tighten against 1st nut.

8. The throwing arm is now in the uncocked position and is under minimum tension.

Tension Adjustment

Flange Nut (D-6)

Rear of Trap

Flat Washer (D-5)

Tension Adjustment

Lock Nut (D-7)

Crankshaft Eyebolt

Page 14

If you require parts or service assistance, please call the CHAMPION TRAPS AND TARGETS Customer Service Dept.

at (800) 379-1732

©2015 CHAMPION TRAPS AND TARGETS, Anoka, Minnesota 55303

12

9. Battery and Release Cord Installation

WARNING! MAKE SURE THE OSCILLATING BASE “ON-OFF-JOG” SWITCH ON THE

BACK OF THE 6-PACKER IS SET TO THE “OFF” POSITION AND THE TRAP “ONOFF-SAFE RELEASE” SWITCH ON THE BACK OF THE 6-PACKER IS SET TO THE

“OFF” POSITION BEFORE CONNECTING THE OSCILLATING BASE POWER CORD.

1. Unplug the power switch / battery clips cord from the oscillating base power cord, if they

are included, and save this cord for future use.

2. Plug the oscillating base power cord directly into the matching connector on the bottom rear

of the 6-Packer trap.

WARNING! MAKE SURE THAT THE “ON-OFF-SAFE RELEASE” SWITCH IS SET TO

THE “OFF” POSITION BEFORE CONNECTING POWER TO THE TRAP.

3. Connect the red battery lead to the positive (+) terminal and the black battery lead to the

negative (-) terminal of an adequately charged deep cycle 12V battery.

Remote Release

Cord

Oscillating Base

Power Cord

Page 15

If you require parts or service assistance, please call the CHAMPION TRAPS AND TARGETS Customer Service Dept.

at (800) 379-1732

©2015 CHAMPION TRAPS AND TARGETS, Anoka, Minnesota 55303

13

IV. Trap Operation

1. Adjusting the Target Retainer

WARNING! BEFORE MAKING ANY ADJUSTMENTS, MAKE SURE THE THROWING ARM

IS IN THE UNCOCKED POSITION, THE ON/OFF/SAFE RELEASE SWITCH IS IN THE

“OFF” POSITION, AND THE BATTERY IS REMOVED FROM THE TRAP.

For best results, the Target Retainer System splitter height needs to be adjusted for the brand

of target being used. Adjustment is as follows:

Step 1: Load 8 to 10 targets (108mm standard or 110mm international) into one of the

magazine columns.

Step 2: Rotate the magazine clockwise until the column of targets just makes contact with the

target splitter on the leading target retainer roller.

Note: Both rollers are fixed at the same height with respect to each other.

Step 3: The target splitter should be adjusted so that the knife edge of the target splitter is the

same height as the small gap between the first (bottom) and second target in the

column.

Step 4: To raise the height of the target splitters (along with the retainer rollers), loosen the

upper adjusting nylon lock nut on the retainer system and turn the lower nylon lock

nut counter-clockwise until the target splitter is aligned with the gap between the

bottom and second target. After adjusting, tighten the upper adjusting nylon lock nut

to lock the retainer in position.

Step 5: To lower the height of the target splitters (along with the retainer rollers), loosen the

upper adjusting nylon lock nut on the retainer system and turn the lower nylon lock

nut clockwise until the splitter is aligned with the gap between the bottom and second

target. After adjusting, tighten the upper adjusting nylon lock nut to lock the retainer

in position.

Step 6: Test the adjustment by loading the magazine and throwing several targets as

described in the following section to insure the splitters are at the appropriate height.

FIGURE 10 – Target Splitter Location

FIGURE 11 – Upper and Lower Retainer

Target Splitter

Retainer

Adjustment Nuts

O-Rings

Page 16

If you require parts or service assistance, please call the CHAMPION TRAPS AND TARGETS Customer Service Dept.

at (800) 379-1732

©2015 CHAMPION TRAPS AND TARGETS, Anoka, Minnesota 55303

14

Step 7: FOR 110mm TARGETS ONLY - Turn stop pin lock nuts down towards top plate until

the flat side of the top lock nut is resting against the target splitter arm. This will decrease the

movement of the target splitter arm for the 110mm targets, and ensure that the last target in

each magazine column feeds correctly.

Target Splitter Arm

Stop Pin Lock Nuts

Stop Pin Lock Nut Setting for

110mm International Targets

Only

TOP VIEW

FRONT VIEW

Page 17

If you require parts or service assistance, please call the CHAMPION TRAPS AND TARGETS Customer Service Dept.

at (800) 379-1732

©2015 CHAMPION TRAPS AND TARGETS, Anoka, Minnesota 55303

15

2. Loading the Magazine and Firing the Trap

WARNING! DO NOT STAND IN FRONT OF TRAP OR IN THE PATH OF THE

THROWING ARM SERIOUS INJURY OR DEATH MAY RESULT!

1. The throwing arm path indicator must be mounted properly before using trap.

2. Make sure that the trap is located to allow ample clearance around machine to allow for the

oscillating movement and to provide safe access to the rear of the trap during operation. It

must be located so that the user has safe access to the rear to operate the On/Off/Safe

Release switch and reload the trap without having to move in front of the trap at any time.

3. Make sure that the ON/OFF/SAFE RELEASE switch is in the “OFF” ( center ) position

(FIGURE 12) and the throwing arm is in the uncocked position (see page 2 and 3).

4. While standing at the rear of the trap, rotate the magazine assembly clockwise by hand

until an empty column is over the large drop hole in the top plate of the trap.

5. Load the magazine column to the left of this column with up to 25 targets (108mm standard

or 110mm international)

6. Rotate the magazine assembly clockwise until the column that was just loaded is halfway

over the large drop hole.

7. Load each of the remaining magazine columns with up to 25 targets Ensure that there is an

adequately charged 12VDC battery connected to the trap and that the remote release cord

is safely away from the trap.

8. Turn the ON/OFF/SAFE RELEASE switch to the “ON” position.

9. At this time the trap should cock the throwing arm.

10. Pressing the foot switch on the remote release will release the throwing arm, re-cock the

throwing arm and deliver a target to the throwing arm.

11. If a target does not drop while the throwing arm is re-cocking, or the arm

continuously fires, the limit switch needs adjustment (see page 16)

THE THROWING ARM WILL THROW THE TARGET. DO NOT STAND IN FRONT OF

THE TRAP.

12. When reloading the trap, first move the ON/OFF/SAFE RELEASE switch on the

EASYBIRD 6-PACKER Trap to the “Safe Release” position momentarily to uncock the

throwing arm and allow it to return to the ‘OFF’ position to turn power to the EASYBIRD 6PACKER Trap off. The trap magazine columns can then be safely reloaded with targets

from the rear of the trap.

FIGURE 12

6 Packer

ON/OFF/SAFE RELEASE

Switch

Page 18

If you require parts or service assistance, please call the CHAMPION TRAPS AND TARGETS Customer Service Dept.

at (800) 379-1732

©2015 CHAMPION TRAPS AND TARGETS, Anoka, Minnesota 55303

16

V. Oscillating Base Operation

WARNING! DO NOT STAND IN FRONT OF TRAP OR IN THE PATH OF THE THROWING

ARM! SERIOUS INJURY OR DEATH MAY RESULT!

1. Make sure that the ON/OFF/SAFE RELEASE switch (FIGURE 12) and the ON/OFF/JOG switch for

the Oscillating Base (FIGURE 13) on the EasyBird Auto-Feed 6-Packer are both in the “OFF”

position.

2. Ensure that there is an adequately charged 12VDC battery connected to the EasyBird Auto-Feed 6Packer and that the remote release cord is safely away from the trap.

3. Make sure that the lock down nut that locks the oscillating base in a fixed position is loose

(See Page 5.), allowing free movement of the base while under electrical power.

4. The EasyBird Auto-Feed 6-Packer can now be switched ON and used to throw targets.

5. Turn the ON/OFF/JOG switch for the Oscillating Base to the “ON” position to start the trap

oscillating.

6. To rotate the trap to a specific position, hold the ON/OFFJOG switch for the Oscillating Base to the

“JOG” position and release the switch when the trap rotates to the position desired.

WARNING! IF THERE IS A TARGET ON THE THROWING ARM, SAFE RELEASING

THE THROWING ARM WILL THROW THE TARGET. DO NOT STAND IN FRONT OF

THE TRAP.

7. When reloading the trap, first turn the ON/OFF switch for the Oscillating Base to the “OFF” position.

Move the ON/OFF/SAFE RELEASE switch on the 6-Packer Trap to the “SAFE RELEASE” position

momentarily to uncock the throwing arm and allow it to return to the ‘OFF’ position to turn power to

the Trap off. The trap magazine can then be safely reloaded with targets from the rear of the trap.

8. To lock the base in a fixed position: Make sure the throwing arm on the 6-Packer Trap is in the

uncocked position and that the ON/OFF/SAFE RELEASE switch on the 6-Packer Trap is in the

“OFF” position. Hold the ON/OFF/JOG switch for the Oscillating Base to the “JOG” position and

release the switch when the trap rotates to the position desired. Finally, tighten the lock down nut

at the front of the oscillating base (See Page 5.) to lock the base in the position and prevent drifting

when firing the trap.

CAUTION! Be sure to loosen the lock down nut that locks the base in a fixed position

(See Page 5.) prior to turning the switch on the base to the “ON” position. Failure to

do so will cause belt damage or the circuit breaker to trip.

FIGURE 13

Oscillating Base

ON/OFF/JOG

Switch

Page 19

If you require parts or service assistance, please call the CHAMPION TRAPS AND TARGETS Customer Service Dept.

at (800) 379-1732

©2015 CHAMPION TRAPS AND TARGETS, Anoka, Minnesota 55303

17

VI. Adjustments

1. Throwing Arm Limit Switch

WARNING! BEFORE MAKING ANY ADJUSTMENTS, MAKE SURE THE

THROWING ARM IS IN THE UNCOCKED POSITION, THE ON/OFF/SAFE

RELEASE SWITCH IS IN THE “OFF” POSITION, AND THE BATTERY IS

DISCONNECTED FROM THE TRAP.

1. The limit switch controls the stop position of the throwing arm during the traps

cocking cycle. The switch position is set from the factory and only needs

adjustment if a target does not drop while the arm is cocking, or if the

trap continuously fires. It is important that the switch be properly adjusted to

provide safe and efficient use. The limit switch is located under the trap near

the front. Adjustments to the limit switch are made by loosening the two

mounting screws and moving the switch slightly. Move the switch towards the

center of the trap for the arm to stop further away from the edge of the main

body. Move the switch towards the end of the trap for the arm to stop closer

to the edge of the main body. Be sure to re-tighten the mounting screws after

adjusting the switch.

2. Adjust arm so that a target drops onto the throwing arm as the arm is cocking.

The tip of the arm should stop about 1” - 2” from the edge of the main body of the

trap. CAUTION! Adjusting the arm to stop at a point too far away from the spring’s over-

center point can result in a delayed release or improper loading and targets breaking.

WARNING! ADJUSTING THE ARM TO STOP AT A POINT TOO CLOSE

TO THE SPRING’S OVER-CENTER POINT CAN RESULT IN THE ARM

CONTINUOUSLY FIRING AND CAUSING POTENTIAL INJURY FROM

BEING STRUCK BY THE ARM.

If target has not dropped onto the

throwing arm:

Move switch this direction (towards

the end of the machine) to stop arm

closer to edge of top plate

If arm continuously fires:

Move switch this direction

(towards the center of the

machine) to stop arm further

from edge of top plate

Tip of Arm 1” - 2” From

Edge of Main Body

Switch Mounting Screws

Page 20

If you require parts or service assistance, please call the CHAMPION TRAPS AND TARGETS Customer Service Dept.

at (800) 379-1732

©2015 CHAMPION TRAPS AND TARGETS, Anoka, Minnesota 55303

18

2. Elevation Adjustment

WARNING! BEFORE MAKING ANY ADJUSTMENTS, MAKE SURE THE

THROWING ARM IS IN THE UNCOCKED POSITION, THE ON/OFF/SAFE

RELEASE SWITCH IS IN THE “OFF” POSITION, AND THE BATTERY IS

DISCONNECTED FROM THE TRAP.

1. To adjust the elevation, slightly loosen the four nuts--two on each side of the

trap.

2. Change the elevation by grasping the trap main body and pivoting the trap to

the desired position. Leave clearance between the rear edge of the trap body

and the lock down nut if using the oscillating base.

3. Re-tighten the four nuts to secure the trap in the new position.

Elevation

Adjustment

Clearance Between

Trap Body and Lock

Down Nut

Page 21

If you require parts or service assistance, please call the CHAMPION TRAPS AND TARGETS Customer Service Dept.

at (800) 379-1732

©2015 CHAMPION TRAPS AND TARGETS, Anoka, Minnesota 55303

19

3. Distance Adjustment

WARNING! BEFORE MAKING ANY ADJUSTMENTS, MAKE SURE THE

THROWING ARM IS IN THE UNCOCKED POSITION, THE ON/OFF/SAFE

RELEASE SWITCH IS IN THE “OFF” POSITION, AND THE BATTERY IS

DISCONNECTED FROM THE TRAP.

THIS TRAP IS CAPABLE OF THROWING TARGETS A MAXIMUM DISTANCE

OF 75 YARDS. USE ONLY IN AREAS WHERE THERE IS NO RISK OF

CAUSING DAMAGE, OR HITTING A PERSON WITH A TARGET.

The trap has an adjustable throwing range of approximately 55 to 75 yards. Adjustments to

throwing distance are made by adjusting the mainspring tension.

1. Loosen the Tension Adjustment Lock Nut. Turn the Tension Adjustment Flange Nut

clockwise to increase spring tension and target distance, or counter-clockwise to decrease

spring tension and target distance.

2. Maximum spring tension is set when mainspring bushing contacts the step on the

mainspring bolt. At this point the Tension Adjustment Flange Nut cannot be turned

clockwise any farther. It is recommended spring tension be adjusted in five-turn increments

and the results observed before adjusting further .

3. Make sure the spring tension is not reduced to the point that there is slack in the spring

when the arm is in the twelve o’clock position (straight out in front). Take up any slack in

the spring when the arm is in this position. This is the minimum tension point to ensure that

damaging spring slap does not occur.

4. After adjusting the spring to the desired tension, tighten the Tension Adjustment Lock Nut

against the Tension Adjustment Flange Nut to lock the setting in place.

Tension Adjustment

Flange Nut

Tension Adjustment

Lock Nut

Page 22

If you require parts or service assistance, please call the CHAMPION TRAPS AND TARGETS Customer Service Dept.

at (800) 379-1732

©2015 CHAMPION TRAPS AND TARGETS, Anoka, Minnesota 55303

20

4. Oscillating Base Angle Adjustment

1. The Oscillating Base comes factory set to oscillate at 45 degrees total angle. The

oscillating angle can be adjusted to 34 degrees of total angle (2 hole ATA equivalent) by

moving the linkage bar to the optional 34 degree oscillation hole.

2. To help in moving linkage, remove drive belt by slipping it down and off the large pulley.

3. Loosen lock nut by turning counter clockwise until it touches bottom of linkage bar.

4. Loosen top flange nut by turning counterclockwise until it touches bottom of lock nut.

5. Turn linkage bar bolt counter clockwise with a pliers or short arm hex wrench until linkage

bar bolt clears bottom plate of oscillating base.

6. Slide linkage bar bolt to the optional 34 degree hole.

7. Turn linkage bar bolt clockwise into bottom plate tapped hole until flange nut touches

bottom plate, then turn linkage bolt counter clockwise 1 turn.

8. Tighten top flange nut by turning clockwise until tight against bottom plate (hold linkage bar

bolt to prevent from turning).

9. Tighten lock nut by turning clockwise until tight against flange nut.

10. Attach drive belt by sliding it up and onto large pulley.

34 Degree

Hole

45 Degree Hole

Factory Setting

Flange Nut

Linkage Bar

Bolt

Bottom Plate

Lock Nut

Drive Belt

Linkage Bar

Page 23

If you require parts or service assistance, please call the CHAMPION TRAPS AND TARGETS Customer Service Dept.

at (800) 379-1732

©2015 CHAMPION TRAPS AND TARGETS, Anoka, Minnesota 55303

21

VII. Troubleshooting

6 Packer Trap

I. THE MOTOR WILL NOT START

1. The “ON-OFF-SAFE RELEASE” switch on the trap is in the “OFF” position.

2. The circuit breaker is tripped on the rear of the machine - determine cause before

resetting.

3. Battery is inadequately charged - recharge battery.

4. Electrical connections are loose or damaged.

5. The motor is burned out.

6. The throwing arm is blocked from rotating. Remove mainspring and check to see if

arm rotates freely.

II. THE MOTOR STARTS, BUT DOES NOT COCK THROWING ARM

1. Battery is inadequately charged - recharge battery.

2. Gearbox or coupling is broken.

IV. THE TRAP COCKS, BUT DOES NOT FIRE

1. The “ON-OFF-SAFE RELEASE” switch is in the “OFF” position.

2. Electrical connections are loose or damaged.

3. The remote fire button or wireless release system is damaged.

V. THE THROWING ARM DOES NOT STOP AND CONTINUES FIRING

1. The throwing arm limit switch is damaged or out of adjustment.

2. Remote release system fire button stuck in the “on” position.

3. Remote release system cord wires are shorted together.

VI. EXCESSIVE TRAP NOISE OR VIBRATION

1. Check all bolts to make sure they are tight.

2. The mainspring is loose causing “spring slap”. Check to make sure there is not any

slack in the spring when throwing arm is in 12 o’clock position.

Oscillating Base

I. THE MOTOR DOES NOT RUN

1. The “ON-OFF” switch on the Oscillating Base is in the “OFF” position.

2. The circuit breaker is tripped - determine cause before resetting.

3. Battery is inadequately charged - recharge battery.

4. Electrical connections are loose or damaged.

5. The motor is burned out.

6. The base is blocked from rotating, or the lock down nut is tight.

II. THE MOTOR RUNS, BUT THE BASE DOES NOT OSCILLATE

1. The drive linkage bar is disconnected or the linkage bar mounting bolt is broken –

check and replace as necessary.

2. Drive belt is broken, loose, or the gear motor mounting bolts are loose – replace belt

or tighten belt and gear motor mounting bolts.

Page 24

If you require parts or service assistance, please call the CHAMPION TRAPS AND TARGETS Customer Service Dept.

at (800) 379-1732

©2015 CHAMPION TRAPS AND TARGETS, Anoka, Minnesota 55303

22

VIII. Maintenance

WARNING: BEFORE PERFORMING ANY MAINTENANCE ON THE EASYBIRD 6 PACKER TRAP MAKE SURE THAT THE THROWING ARM IS IN THE UNCOCKED

POSITION (SEE FIGURE 3), THE ON/OFF/SAFE RELEASE SWITCH ON THE EASYBIRD

6-PACKER TRAP (SEE FIGURE 1) IS IN THE “OFF” POSITION AND THE BATTERY HAS

BEEN DISCONNECTED FROM THE EASYBIRD 6-PACKER TRAP.

Preventive Maintenance Action

Frequency

Remove dust, dirt, and target debris with soft brush

Before every use

Check mounting bolts to insure they remain tight

Every month or 8,000 cycles

Lubricate moving parts with a good quality Teflon

Every month or 8,000 cycles

based lubricating oil such as OUTERS Tri-Lube

Replace "O" Rings

Every three months or 25,000 cycles

Replace Flight Rail

Every three months or 25,000 cycles

Disconnect Battery

After Every use

Check condition of oscillating base drive belt

Every month or 8,000 cycles

Page 25

If you require parts or service assistance, please call the CHAMPION TRAPS AND TARGETS Customer Service Dept.

at (800) 379-1732

©2015 CHAMPION TRAPS AND TARGETS, Anoka, Minnesota 55303

23

IX. Recommended Spare Parts

QTY

PART NO.

DESCRIPTION

LOCATION

1

45305

Mainspring

Page 4, D-2

1

40226

Flight Rail

Page 3, Figure 3

1

45293

#336 O-Ring (set of 2)

Page 13, Figure 10

1

45311

Oscillating Base Drive Belt

Page 5, L-5

ORDERING PARTS

Parts can be ordered through the Champion Traps and Targets Customer Service Dept.

at (800) 379-1732.

Prices are subject to change without notification. Minimum order value of $10.00

Page 26

If you require parts or service assistance, please call the CHAMPION TRAPS AND TARGETS Customer Service Dept.

at (800) 379-1732

©2015 CHAMPION TRAPS AND TARGETS, Anoka, Minnesota 55303

24

Page 27

If you require parts or service assistance, please call the CHAMPION TRAPS AND TARGETS Customer Service Dept.

at (800) 379-1732

©2015 CHAMPION TRAPS AND TARGETS, Anoka, Minnesota 55303

25

Warranty Certificate

(Please fill out completely & return with a copy of the receipt)

Owner’s Name: _______________________________________________________

Owner’s Signature:_____________________________________________________

Address: ___________________________________Ph #: ___________________

City: _______________________________ State: _______ Zip: ______________

Date of Purchase: ________________

Business Where Easybird 6-Packer Was Purchased:_____________________

WARRANTY CERTIFICATE

Congratulations on the purchase of your new CHAMPION EASYBIRD 6-PACKER trap machine. Your new

EASYBIRD 6-PACKER is warranted to be free from defects in material or workmanship for a period of one (1)

year from the date of purchase. This warranty is extended only to the original consumer purchaser. Should you

believe that your CHAMPION EASYBIRD 6-PACKER is defective in material or workmanship, you should

contact the CHAMPION TRAPS AND TARGETS Customer Service Department via phone at 800-379-1732.

In the event a warranty repair is required, all parts will be provided at no charge. THIS WARRANTY DOES

NOT COVER DEFECTS OR DAMAGE RESULTING FROM: CARELESSNESS, MISUSE, IMPROPER

INSTALLATION, MODIFICATION, OR NORMAL WEAR AND TEAR.

IN ORDER FOR THIS WARRANTY TO BE IN EFFECT, YOU MUST FILL OUT THIS WARRANTY

CERTIFICATE AND RETURN IT TO CHAMPION TRAPS AND TARGETS WITHIN 30 DAYS OF PURCHASE.

THE WARRANTY CERTIFICATE MUST BE FILLED OUT COMPLETELY AND SIGNED BY THE OWNER IN

ORDER TO BE VALID. WARRANTY SERVICES CANNOT BE PROVIDED WITHOUT MEETING THE ABOVE

REQUIREMENT. Retain a copy of this warranty certificate for future reference. THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED TO THE DURATION OF

THIS LIMITED WARRANTY.

CHAMPION TRAPS AND TARGETS IS NOT LIABLE FOR DAMAGES IN EXCESS OF THE PURCHASE

PRICE OF THE PRODUCT AND UNDER NO CIRCUMSTANCES SHALL CHAMPION TRAPS AND TARGETS BE

LIABLE FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES. HOWEVER, SOME STATES DO NOT ALLOW

LIMITATIONS ON INCIDENTAL, OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR

EXCLUSION MAY NOT APPLY TO YOU.

The above warranty provides the sole and exclusive warranty available to the customer in the event of a defect in

material or workmanship in the CHAMPION EASYBIRD 6-PACKER. This warranty gives you specific legal rights, and

you may also have other rights which vary from State to State.

CHAMPION TRAPS AND TARGETS

1 VISTA WAY

ANOKA, MN 55303

1-800-379-1732

www.championtarget.com

Page 28

If you require parts or service assistance, please call the CHAMPION TRAPS AND TARGETS Customer Service Dept.

at (800) 379-1732

©2015 CHAMPION TRAPS AND TARGETS, Anoka, Minnesota 55303

26

CONTACT INFORMATION

Champion Traps and Targets

1 Vista Way

Anoka, MN 55303

Toll Free: (800) 635-7656

Internet: www.championtarget.com

Email: tech.expert@vistaoutdoor.com

MADE IN CHINA

PRINTED IN CHINA 02/17/16

Loading...

Loading...