Page 1

Owner’s Manual

Keep with machine for reference

2674 N. Service Road, Jordan Station

Low Temp

3765 Champion Boulevard

free:800/858-4477

Model DL2000

3 Door Lift Models

Owner’s Manual

Revision 1.02A

Winston-Salem, NC 27105

336/661-1556 Fax: 336/661-1660 Toll-

Ontario, Canada LDR 1SO

905/562-4195 Fax: 905/562-4618

Toll-free:800/263-5798

Page 2

Title

Installation & Operation

Rev 1.02A

TABLE OF CONTENTS

SPECIFICATIONS .................................................................................................................................. 3

3 Door Lift Model ................................................................................................................................................. 3

GETTING STARTED .............................................................................................................................. 4

Introduction to 3Door Lift Model .......................................................................................................................... 4

Receiving and Installation ..................................................................................................................................... 4

1. Packaging .................................................................................................................................................. 4

2. Plumbing.................................................................................................................................................... 4

3. Electrical .................................................................................................................................................... 4

4. Chemical Feeder ........................................................................................................................................ 4

5. Scrap Trap Accumulator ............................................................................................................................ 5

6. Water Line ................................................................................................................................................. 6

7. Activating Machine ................................................................................................................................... 6

OPERATION ............................................................................................................................................ 7

Starting Instructions ............................................................................................................................................... 7

Operating Instructions ........................................................................................................................................... 8

1. Scraping a nd Pre-rinse ............................................................................................................................... 8

2. Sorting and R acking .................................................................................................................................. 8

3. Racking dishes ........................................................................................................................................... 8

4. Racking glasses ......................................................................................................................................... 9

5. Racking flatware ........................................................................................................................................ 9

6. Stacking & S torage .................................................................................................................................... 9

Cleaning and Maintenance .................................................................................................................................. 11

1. Cleaning the drain screen......................................................................................................................... 11

2. Cleaning the washer arms ........................................................................................................................ 11

3. Check Oper ations .................................................................................................................................... 11

4. Cleanup .................................................................................................................................................... 12

5. Empty the Scrap Tray .............................................................................................................................. 12

Quick servi ce guide ............................................................................................................................................. 13

Troubleshooting t he 3 Door LiftModel ............................................................................................................... 14

Will Not Start .......................................................................................................................................... 14

Out of Chemical....................................................................................................................................... 14

Dishes/Glasses are Not Clean .................................................................................................................. 14

Machine Will Not Hold Water ................................................................................................................ 14

Water Running o n the Floor .................................................................................................................... 14

Water Will Not Drain From the Machine ................................................................................................ 14

Water Coming Out of the Door ............................................................................................................... 14

Machine Will Not Shut Off ..................................................................................................................... 14

Machine Will Not Fill .............................................................................................................................. 14

ADDENDUM FOR MACHINES INSTALLED IN THE CITY OF CHICAGO ................................ 15

ELECTRICAL DIAGRAM .................................................................................................................... 16

Page 2

Page 3

Title

WATER CONSUMPTION

PER RACK

.93 GAL.

3.53 L

PER HOUR

37 GAL.

139 L

OPERATING CYCLE

WASH TIME-SEC

45

45

RINSE TIME-SEC

30

30

DWELL TIME-SEC

15

15

TOTAL CY C LE

90 Sec

90 Sec

OPERATING CAPACITY

RACKS PER HOUR

40

40

WASH TANK CAPACITY

1.7 GAL.

6.44 L

PUMP CAPACITY

35 GPM

132.5 LPM

WATER REQUIREMENTS

- Minimum

120°F

49°C

- Recommended

140°F

60°C

WATER INLET

½”

-

DRAIN CONNECTION

2”

-

CYCLE TEMPERATURES

WASH-°F (Minimum)

120°F

49°C

FRAME DIMENSIONS

DEPTH

25 ¾”

65.4 cm

WIDTH

25 ¾”

65.4 cm

TABLE HEIGHT

34”

86.0 cm

MAX CLEARANCE FOR DISHES

17”

43.0 cm

ELECTRICAL*

115 VAC

16 AMPS

WASH PUMP MOTOR 1 HP

13.4 AMPS

*Warning: Electrical and plumbing connections ne e d to be made by a qualified

Electrical, Plumbing and Safety codes.

SHIPPING WEI GHT

E (Approximate)

218#

98.7 kg

SPECIFICATIONS

3 Door Lift Model

Installation & Operation

Rev 1.02A

service person who will co mply with all available Federal, State and Loc al Health,

E-EXT (Approximate)

260#

Page 3

117.8 kg

Page 4

Title

Installation & Operation

Rev 1.02A

GETTING STARTED

Introduction to 3Door Lift Model

Dishwashers have been us ed w or l dwide for many years. This manual has been written to help you, the operator,

in your job. Your job is one of the “most important” in this restaurant. Why? Your product, the dishes and

glasses, is the first thing the customer notices when he sits down.. Clean, sparkling dishes and silverware will set

the mood for the customer when he observes the table setting.

Receiving and Installation

The dishwasher is shipped from the factory bubble packed on a pallet. The guidelines are listed in a step-by-step

procedure for your reference.

1. Packaging

Unwrap the machine and check for the following component parts:

Scrap accumulator complete with lid and scrap tray. This is normally an integral part of the

machine

Tube stiffeners. Tube stiffeners must be used to prevent the feed tubes from curling inside the

chemical pail and sucking air. These are pre-installed to the chemical pump and attached to the

back of the dishmachine. The ends of the chemical tubing have been flared so that the tubing will

not pull out of the stiffener. Red is for detergent, white for sanitizer, and blue for rinse aid.

2. Plumbing

The machine needs the following:

2” pipe for the drain outlet

½” pipe for the incoming water

A flex hose or quick disconnect union. The water inlet is at the top left corner of the dishwasher

3. Electrical

The machine is 110 volt. The master switch is at the top left side of the control box.

WARNING: Electrica l and plumbing connections need to be made by a qualified service person

who will comply with all available F e de r al, State, and local Health, Electr ic al, Plumbing Safety

Codes.

4. Chemical Feeder

The peristaltic pumps are assembled and included within the machine.

Page 4

Page 5

Title

Not supplied with

5. Scrap Trap Accumulator

The scrap trap accumulator is designed to perform two basic functions:

It allows a method to discharge all the heavy solids out of the machine with each wash and rinse

cycle.

It provides capacity to drain the contents of one cycle regardless of the ability of the existing drain

to accept the discharge rate.

There is a drain connection sleeve (2”) on the bottom of the scrap accumulator (See drain connection

instruction).

Standard dishwashers operate on 110 volts. Other voltage requirements are available on request. When

installing the single rack u nits, either model 3 Door Lift, it is recommended that a clean 20 amp circuit

be provided to the machine.

WARNING: Electrical and plumbing connections need to be made by a qualified service person who

will comply with all available Federal, State, and local Health, Electrical, Plumbing Safety Codes.

SCRAP TRAP ACCUMULATOR CONNECT ION:

Installation & Operation

Rev 1.02A

Machine

Page 5

Page 6

Title

Installation & Operation

Rev 1.02A

6. Water Line

The 3 Door Lift model should plumbed with ½” hot water line. The time necessary to deliver water to

the machine is controlled by the number four cam. This cam provides the serviceman with the

opportunity to fine-tune the machine to deliver the proper amount with each cycle. Refer to the service

manual for an in depth discussion of this procedure.

7. Activating Machine

The machine is equipped with a prime switch to activate the peristaltic pump at any time the master

switch is “ON”.

Following the completion of the installation, always fill the machine with water before the machine is

started.

Hold the fill button until the water level is approxima te ly ½” to ¾” below the overflow hole in the

PVC standpipe. This water level should be approximately even with the bottom edge splash guard

in sump area of machine.

Activate the prime switches for the three chemical pumps until the product is discharging into the

sump.

To start the machine, close the doors and the machine will cycle automatically.

The amount of product delivered by each cam is controlled by changing the opening in each cam. When

the micro switch rides down into the cam, the peristaltic pump motor begins to rotate. It will continue to

rotate until it rides up out of the groove. Therefore, to extend the amount of product delivered to the

machine, open the groove. To reduce the amount of product delivered to the machine, close the groove.

Cams are slip fit. A cam adjustment wrench is provided, but the cam can be adjusted with a small

screwdriver or the edge of a table knife.

Technical personnel are available during normal business hours should you, as an installer, have any

questions. We are available to serve you at 800-854-6417.

DISCLAIMER OF LIABILITY OF WARRANTY: COMPANY EXPRESSLY DISCLAIMS ANY AND ALL WARRANTIES, EXPRESS OR IMPLIED, RELATING TO THE INSTALLATION OF ANY AND ALL

EQUIPMENT THAT IS INSTALLED BY CHEMICAL DEALERS, CONTRACTED SERVICERS OR THIRD PARTY SERVICERS TO EQUIPMENT. IF THE INSTALLATION INSTRUCTI ONS ARE NOT

FOLLOWED EXACTLY (TO THE LETTER), OR, IF ANY PERSO N OR COMPANY CONDUCTING THE INSTALLATION OF THE EQUIPMENT, REVISE THE INSTALLATION PROCEDURES OR ALTER

THE INSTRUCTIONS IN ANY MANNER, THE WARRANTY BECOMES VOID. IF, DUE TO THE IMPROPER INSTALLATION OF EQUIPMENT, THIS EQUIPMENT CEASES T O OPERATE PROPERLY OR

AFFECTS OTHER PARTS OF THE DISHWASHING EQUIPMENT, IN THAT THE OTHER PARTS BECOME DEFECTIVE, THE WARRANTY BECOMES VOID. A WILL NOT BE LIABLE OR RESPONSIBLE

OR WARRANT EQUIPMENT, DUE TO IMPROPER INSTALLATION OF ANY MODEL DISHWASHER.

Page 6

Page 7

Title

Installation & Operation

Rev 1.02A

OPERATION

3 Door Lift dishwashers have been used worldwide for many years. This manual has been written to help you, the

operator, in your job.

The manual is divided into three sections. Sections A and B cover start-up and dish handling, and section C

covers troubleshooting.

Starting Instructions

Drain water if it is cold by lifting drain ball until all water is out of the machine.

Check drain screen and clean.

Replace it properly into the sump housing.

Check wash arm spray tips. If clogged, clean with toothpick and rinse at sink.

Check chemical lines to chemical containers

A. Red – detergent line

B. Blue – rinse agent line

C. Clear/White – sanitizer destainer line.

Press fill switch; fill until water is ½” lower than overflow on drain ball shaft or to the bottom of splash

shield.

Hold fill switch in until water level is proper and check temperature (should be approximately 140

degrees Fahrenheit; 60 degrees Celsius).

Insert tray of dishes into machine and close doors. Machine will automatically start when doors are

closed.

After the machine green cycle light turns off, raise doors, remove trays, and allow to dry before stacking.

If the doors are lifted during a wash cycle, the machine will automatically shut off.

3 Door Lift Model will complete the wash and rinse cycle and automatically feed the proper chemical

and turn itself off.

Page 7

Page 8

Title

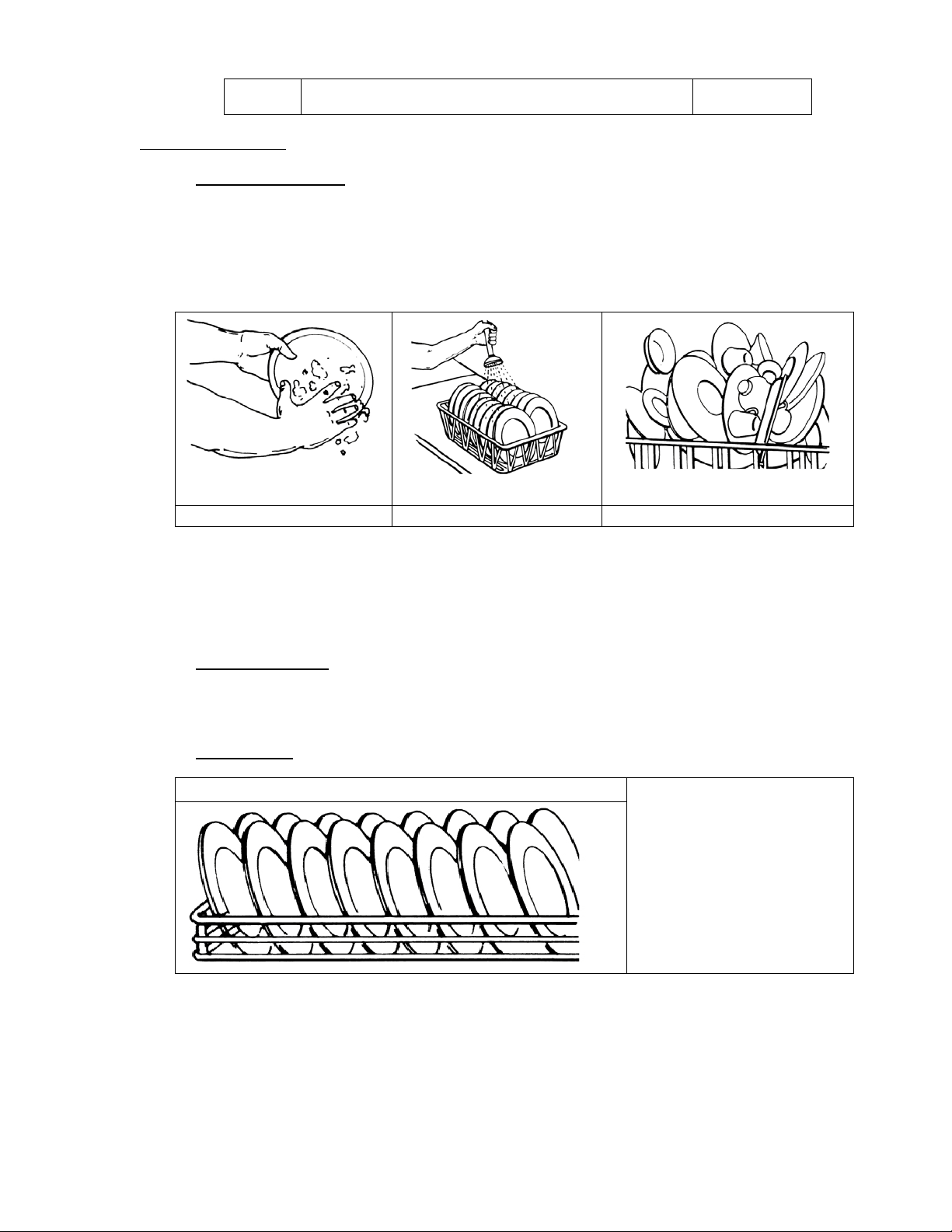

HAND SCRAPING

WET SCRAPING

DON’T PILE DISHES!!

PROPER RACKING

Operating Instru ctions

1. Scraping and Pre-rinse

Remove remaining food from utensils. Scrape by hand or by using a cleaning tool such as a sponge or

rubber spatula. For protection of the hands, wear gloves.

Use a pre-rinse hose for wet scraping to remove small particles of soil not removed by the hand scraping

operation. The purpose is to keep excessive garbage from going into the dishwashing machine.

For flatware, it is recommended that they be pre-soaked in a deep pan, generally a bus pan, using a

presoak detergent. This will prevent drying or adhering of soil on flatware and reduce tarnishing. A

presoak detergent is especially useful for the removal of protein soil such as egg, syrup, etc. Allot

approximately 30 minutes for presoaking if possible for better results.

2. Sorting and Racking

Properly placing the utensils in the rack is one of the most important jobs the operator must perform.

Sort out different utensils, separating dishes, bowls, cups, glassware and flatware.

3. Racking dishes

Installation & Operation

Rev 1.02A

Note in the illustration that the

plates are racked without

overlapping and that the sprays

from the top spray arm will strike

the food contact surfaces of the

dishes (face of the dishes)

Rack all the same sized plates together row by row. The dish rack will hold them just right for proper

washing. The entire surface of the soiled dish must be covered by the spray arm to provide sufficient

scrubbing action when the detergent solution is being sprayed on that dish.

Stacking dishes will not save time because the dishes will not be cleaned during the wash cycle and will

require sorting and rewashing.

Page 8

Page 9

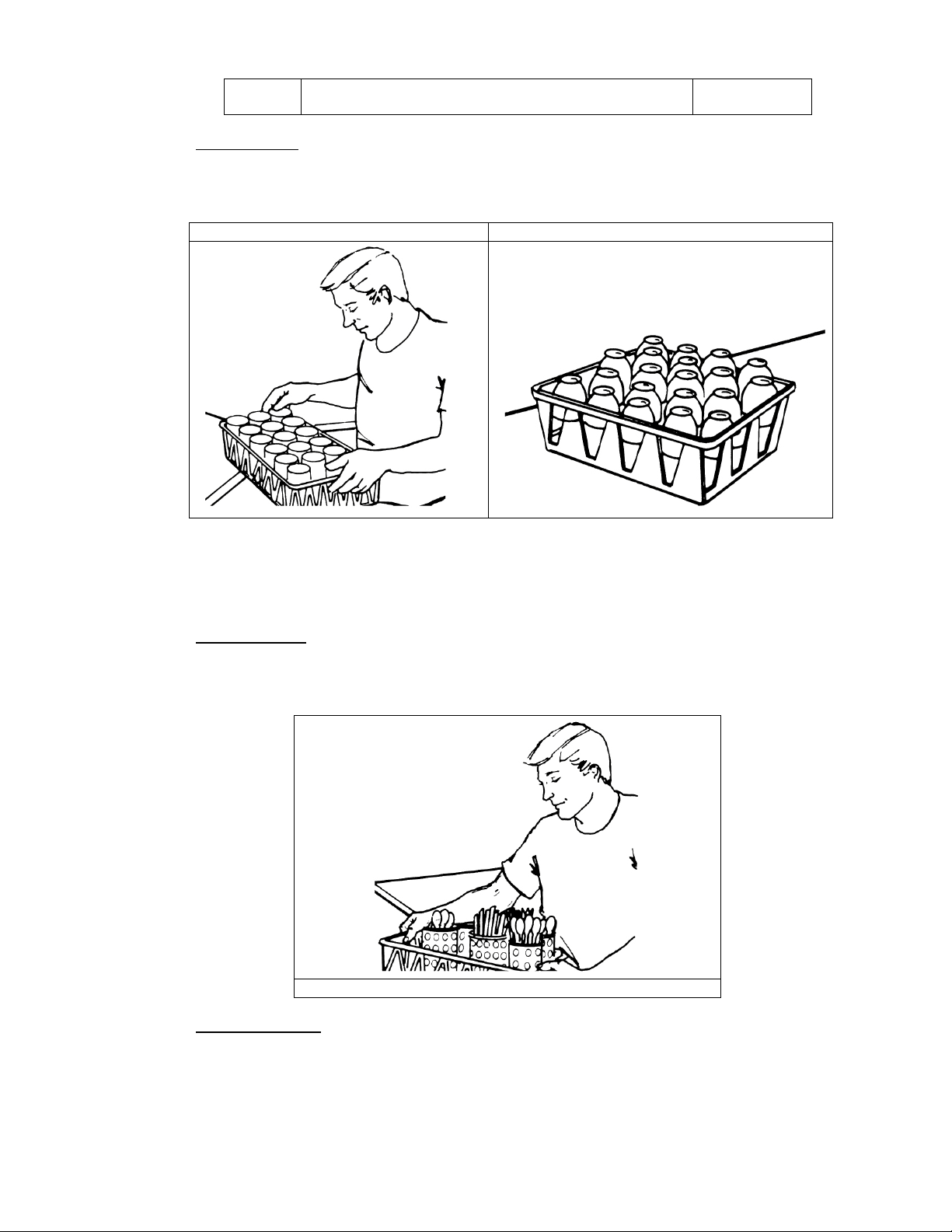

GLASS RACKING

CUP RACKING

WASH BASKET

4. Racking glasses

Glasses, cups, bowls and other deep dishes must be racked faced down. This is so as not to carry out

wash water and so the sprays can work on the internal surfaces. Rack glasses and cups in a properly

sized compartmentalized glass rack. Allow to air dry.

Glasses should be placed in the racks upside down in each compartment. The rinse additive is injected

into the rinse water to prevent spotting and speed the drying process. (Note: Company’s representative

can help you select the proper glass rack for your glasses.

5. Racking flatware

After presoaking, flatware is placed in a wash basket with handles down to prevent them from “nesting”

which provides maximum exposure to the wash process.

Title

Installation & Operation

Rev 1.02A

6. Stacking & Storage

Page 9

Page 10

Title

SORTING AND STORING FLATWARE

Stacking and storage of dishes being washed and sanitized is very important. A dish may be perfectly

washed but be completely contaminated from the handling after washing. Avoid storing dishes where

they may be soiled. Handling dishes with the hand on the food contact surfaces should be reduced to a

minimum (towel drying is an incorrect procedure). Do not stack plates and dishes higher than 12 inches.

Their combined weight can destroy the porcelain surface on the bottom plates.

Installation & Operation

Rev 1.02A

Page 10

Page 11

Title

REMOVE SCREEN

CLEAN SCREEN

REMOVE WASH ARM

CLEAN WASH ARM

RE-INSTALL WASH ARM

Installation & Operation

Rev 1.02A

Cleaning and Maintenanc e

Certain times of the day should be allotted to cleaning dishwashing machine. Follow the cleaning and inspection

procedures listed below:

1. Cleaning the drain screen

Remove the drain screen and thoroughly clean all foreign material from screen as shown in the illustration.

DO NOT BANG THE SCREEN ON THE TABLE TO JAR FOOD LOOSE. Use the faucet or the pre-rinse

hose. Re-install drain screen and ensure that it is in the proper position.

2. Cleaning the wa s her arms

Inspect the upper and lower spray arms to ensure they are not clogged with food scraps. Otherwise, full

and uniform spray pressures will not be delivered to the soiled dishes.

If there is any question as to the spray arms being clear of food scraps, the spray arms should be

removed and cleaned. Note that water will blow from all jets if they are open. Use toothpick to open

clogged jets and flush to ensure that food scraps are out of the arm. If necessary, the stainless plug in the

end of the arm can be unscrewed and removed to clean the inside of the arm tube at the sink.

After the arm has been thoroughly cleaned, re-install back into the base.

3. Check Operations

Operate the machine for one cycle. Watch detergent, sanitizer and rinse additive “delivery tubes” at the

point where they inject chemical into the machine. Remember: red tube – detergent; blue tube-rinse; and

clear white tube-sanitizer. Check temperature at the end of the cycle for 120

Page 11

°

F minimum.

Page 12

Title

EMPTY SCRAP TRAY

4. Cleanup

Wipe down the machine and check the chemical level in the containers. Also inspect machine

for leaks or other items that might cause trouble during a rush period. You are now ready to wash

dishes.

Remember: The chemical containers should be saved for pickup by the serviceman during his regular

call. Do not throw them in the trash bin.

5. Empty the Scrap Tray

Remove scrap tray drawer and thoroughly rinse out. Clean tray after each meal, or once every hour if

very busy.

Installation & Operation

Rev 1.02A

Page 12

Page 13

Title

TECHNICAL ISSUE

CAUSE

SOLUTION

Debris inside water solenoid valve or

Clean and replace diaphragm/valve

Worn internal vac. Brkr parts

Replace or clean parts

Master on/off switch on machine turned

Reset or replace master switch

Installation & Operation

Rev 1.02A

Quick service guide

Starts with doors open Faulty #1 micro switch (start/stop) Replace micro switch

Faulty door switch Replace switch

Faulty #1 micro switch (start/stop) Replace micro switch

Continues cycle Faulty start/fill switch Replace switch

Faulty door switch Replace door switch

Wash motor will not shut off Delimer switch in wrong position Switch to

Faulty motor contactor Replace contactor

Faulty # 6 micro switch Replace micro switch

Sanitizer pump does not run Delimer switch in wrong position Switch to

Faulty sanitizer pump motor Replace sani motor

Debris inside water solenoid valve Clean and replace diaphragm

Water solenoid leaking High water pressure on supply line Decrease water pressure

Faulty water solenoid valve Replace valve

Leaking drain ball Replace drain ball

Does not fill or hold water in tank

Faulty #4 micro switch (Fill) Replace micro switch

NORMAL

NORMAL

position

position

Faulty valve

Vacuum breaker leaks Faulty check valve

Only runs when start/fill switch is

depressed

Will not start/ nothing works Wall breaker tripped Reset breaker

Runs, but none of the other functions

engage

Low incoming water pressure Increase water pressure

Faulty #1 micro switch (start/stop) Replace micro switch

Faulty Door switch Replace door switch

off, or faulty

Faulty #2 Micro switch (cycle reset) Replace micro switch

Faulty ice cube relay (yellow relay) Replace relay

Faulty motor contactor Replace contactor

Replace check valve

Page 13

Page 14

Title

Installation & Operation

Rev 1.02A

Troubleshooting the 3 Door LiftModel

Will Not Start

1. Check master switch on the control box to make sure that it is “ON”.

2. Check circuit breaker that services the dishwasher. Make sure it is “ON”.

3. After (ONLY after) checking steps 1 and 2, call the service technicians.

Out of Chemical

Check backup supply of chemicals. REMEMBER! Red product label to red tube, blue product label to blue

tube, and clear/white product label to clear/white tube. Note that sometimes ex tra product is left in storage

area at the direction of the restaurant manager. Before calling service technicians, check with the manager

for backup supplies.

Dishes/Glasses are No t Cl ean

1. Before you call service technician, check your temperature gauge on the machine. Check to insure water

°

temperature is at least 120

°

heater at 120

2. Check that your water softener contains salt and is operating properly. Your service agreement from

company calls for hot/soft water.

3. Check that dishes are racked properly. Check the screen and wash arm tips. If they are clear, call the

service technicians.

Machine Will Not Hold Water

Check the drain actuator for a knife, spoon, fork or foreign material then remove.

Water Running on the Floor

If water is overflowing, the scrap accumulator or the scrap drawer may need to be cleaned. If not, call your

plumber- the drain may be clogged.

Water Will Not Drain From the Machine

Check the drain solenoid. Call the service technician.

Water Coming Out of the Door

End plugs may be missing or lose. Check inside the scrap accumulator drawer. If the end pl ug came of f

during operation, it will be inside the scrap trap tray. Simply replace. If end plug is lost, call your service

technician.

Machine Will Not Shut Off

You can turn off the machine in an emergency by turning off the master switch located on the back of the

control box. After turning off the master switch, call service technician.

Machine Will Not Fill

Check gate valve on the top of the machine. Make sure “handle” has been opened. If it is, call your service

technician.

to 140° F. If temperature is okay, then…

F. The 3Door dishwasher must have hot water delivered from the primary

Page 14

Page 15

Title

Installation & Operation

Rev 1.02A

ADDENDUM FOR MACHINES INSTALLED IN THE CITY OF CHICAGO

All food dispensing establishments using chlorine or other approved chemical sanitizers shall at all times

maintain an adequate testing device.

Dishes and other eating and drinking utensils to be washed in a dishwashing machine shall be properly scraped

and pre-rinsed and shall be stacked in racks or trays so as to avoid overcrowding and so as to permit wash and

rinse waters to rinse waters to reach all surfaces of each utensil.

In machine washing, multi-use eating and drinking utensils shall be washed in water containing suitable

detergent at a temperature from 120 degrees F. to 140 degrees F. or other method approved by the Department of

Health.

The water in the wash tank shall be changed during operation as often as necessary to keep it reasonably clean.

An effective concentration of detergent in the wash water shall be maintained at all times.

Bactericidal treatment shall consist of exposure of all surfaces of dishes and utensils being washed to a rinse of

clean water, at a temperature of not less than 180 degrees F. or other method approved by the Department of

Health.

All dishwashing machines shall maintain a flow pressure not less than 15 or more than 25 pounds per square inch

on the fresh water line at the machine and not less than 10 pounds per square inch at the rinse nozzles. A suitable

gauge cock shall be provided immediately upstream from the final rinse sprays to permit checking the flow of the

±

final rinse water. An easily readable thermometer accurate to

and rinse water lines of the dishwashing machine which will indicate the temperature of the water solution

therein.

Dishwashing machines shall be thoroughly cleaned at least once each day. The pumps and the wash and rinse

sprays or jets shall be so designed that a forceful stream of water will reach all surfaces of the utensils when they

are properly racked. These parts shall be thoroughly cleaned at least once each day. The pumps and the wash and

rinse sprays or jet shall be so designed that a forceful stream of water will reach all surfaces of the utensils when

they are properly racked. These parts shall be readily accessible for inspection and cleaning.

After bactericidal treatment, utensils and containers shall be stored at a sufficient height above the floor in a

clean, dry place protected from flies, splash, dust, overhead leakage and condensation, and other contamination

until used for serving.

Drain racks, trays and shelves shall be made of non-corrodible material and shall be kept clean.

In handling containers and utensils the surface thereof which come in contact with food or drink shall not be

touched by hands, except during the process of washing.

Tables for clean and dirty dishes and food shall be so arranged that the dirty dishes will be as far removed from

the food and clean dishes as may be possible.

All single-service articles and utensils shall be purchased in sanitary cartons and stored therein in a clean, dry

place until used, and after removal from the cartons, these articles shall be handled in such a manner to prevent

contamination.

Please note the following procedures must be followed for City of Chicago Approval:

1. All low energy models must have low-level sani alar m s , b o th visual and a ud i o.

2. All mode ls m us t have a City of Chicago appro v a l data label affixed to the m ac hine.

3. Chlorine sanitizer must be a minimum of 100 PPM.

2 degrees F. shall be provided on both the wash

Page 15

Page 16

Title

ELECTRICAL DIAGRAM

Installation & Operation

Rev 1.02A

Page 16

Page 17

2674 N. Service Road, Jordan Station

Low Temp

Revision 1.03A

3765 Champion Boulevard

free:800/858-4477

Model DL2000

3 Door Lift Models

Parts Manual

Winston-Salem, NC 27105

336/661-1556 Fax: 336/661-1660 Toll-

Ontario, Canada LDR 1S 0

905/562-4195 Fax: 905/562-4618

Toll-free:800/263-5798

Page 18

Title

Parts Manual

Rev 1.03A

TABLE OF CONTENTS

PARTS MANUAL .................................................................................................................................... 3

Initial Parts Kit (Part # 01100.85).......................................................................................................................... 3

Exploded View Drawi ngs ...................................................................................................................................... 4

Cabinet Assembl y .............................................................................................................................................. 4

Control Box ....................................................................................................................................................... 5

Plumbing System ............................................................................................................................................... 6

Pump Assembly ................................................................................................................................................. 7

Spray System Asse mbly .................................................................................................................................... 8

Drain System Assembl y .................................................................................................................................... 9

Door Actuator Assembly ................................................................................................................................. 10

Peristaltic Pump Assembly .............................................................................................................................. 11

Page 2

Page 19

Title

PART NO.

D E S C R I P T I O N

QTY

00100.00

Drain Ball Solenoid 120V

1

00115.08

Drain Sump Screen (A/C)

1

00120.02

Thermometer (Bi Metal)

1

00121.25

Drain Ball

1

00200.10

Pump Assy. 110/220V 60Hz (Open)

1

00206.30

Pump Seal Kit

1

00307.30

Spray Ar m Assy. ES Long w/bearing &plug

1

00404.82

Motor Contactor 115V/60HZ

1

00411.00

Micro Switch

1

00415.00

Peristaltic Pump Assy. 120V/60hz

1

00418.00

Peristaltic Pump Cover

1

00425.51

Chemical T ubing Blue

50

00425.53

Chemical T ubing Red

50

00425.54

Chemical Tubing White

50

00433.10

Master Switch (20 Amp)

1

00435.10

Squeeze Tube Orange 8"

1

00500.00

Timer Motor 90 Sec 110V/60Hz

1

00562.00

Roller Door Switch

1

00602.00

Door Spring

1

00631.00

Ice Cube Relay 120V

1

00955.00

5/16-18 X 5/8 Thumbscrew

1

01550.00

Solenoid Stop

1

03470.01

Toggle Switch(Moment) .25 Flat Term

1

PARTS MANUAL

Initial Parts Kit (Part # 01100.85)

Parts Manual

Rev 1.03A

Page 3

Page 20

Title

01 3 01506.45

Door Standard (Blanks)

12

31

00912.00

1/4-20 Nylon Lock Nut

02 2 01516.50

3-Door Bracket outside Style

13 4 00906.00

1/4-20 X 1/2 Hexhead Bolt

03 1 01505.16

Corner Tray Track Bolt On Rail

14 9 00924.00

1/4 SS Washer

03a 1 01505.10

Tray Track

15 4 01310.20

Bullet Foot Plastic

04 1 01502.70

Pan - Bolt On No Legs

16 1 01577.10

Molded Scrap Trap Body - New

05 1 01510.40

Wrapper

17 1 01577.21

S/S Scrap Trap Drawer

06 6 01554.30

EZ Glide Door Guide SS 21 1/8"

18 1 01577.30

Molded Scrap Trap Lid - SS

07 1 00124.65

Drain Ball Seat

19 1 01577.50

Molded Scrap Trap-Mount Bracket

08 1 00125.10

Drain Sump Gasket

20 6 00636.10

EZ Glide Door Guide Sq 21 7/8”

09 1 00101.20

Solenoid Bracket C LH

21 2 17552.00

Door Stop

10 1 00101.10

Solenoid Bracket C RH

22 1 01502.75

E Stand - Bolt On No Legs

11 1 01558.20

Chem. Support Bracket

23 4 01145.00

Leg Assy. w\Adjustable Socket

11a 3 00427.00

Snap Bushing 375-4

24 1 01570.24

Pan Support Bracket - C long

Exploded View Drawings

Cabinet Assembly

Parts Manual

Rev 1.03A

Item Qty Part No Description

Item Qty Part No Description

Page 4

Page 21

1 1 01503.09

Control Box Body

16 4 00906.00

1/4-20 X 1/2 Hexhead Bolt

2 1 01504.09

Control Box Lid

17 4 00924.00

1/4 SS Washer

4* 1 00407.80

Timer 90 Sec 8 Cam 120/60Hz

19

12

00911.00

8-32 X 1/2 Panh ead Screw

5 1 00475.00

Toggle Sw dpdt 5 amp/Delimer

20 3 00418.00

Peristaltic Pump C over

6 1 00631.00

Ice Cube Relay 120V

21 3 00419.00

Peristaltic Pump Rotor Assy

7 1 00404.82

Motor Contactor 115V/60HZ

22 6 00919.00

10-32 X 1 1/2 Panhead Bolt

8 1 00454.10

3 Pole Socket Terminal Bloc k

23 3 00417.00

Peristaltic Pump Block

9 2 03470.00

Toggle Sw Momentary ScTerm

24 3 00416.00

Peristaltic Pump Motor 120/60

11 5 00470.10

Toggle Switch Rubber Boot

26 4 00917.00

8-32 PM Nut

12 4 00911.50

8-32 X 3/8 Pan Head Screw

27 1 03470.01

Toggle Sw Moment 25 Flat Term

14 1 03408.50

Counter (Panel Mount) 120/60

29 1 00450.00

Key Only

15 2 00907.00

6-32 X 1/2 SS Panhead Screw

30 1 00500.00

Timer Motor 90 Sec 115V/60Hz

Control Box

Title

Parts Manual

Rev 1.03A

Item Qty Part No Description

3 1 00449.00 Lock And Key 18 4 00912.00 1/4-20 Nylon Lock Nut

10 1 00471.10 Toggle switch DPST 20AMP 25 3 00918.00 10-32 X 1 1/2 Filister Bolt

13 1 00406.00 Control Box Ligh t .5" Dia Red 28 1 00414.86 Wiring Harness

*00411.00 –Microswitch only.

Item Qty Part No Description

Page 5

Page 22

Title

01 1 03603.10

½” Water Sol Valve 120v/60hz

12 2 00745.00

½” 90 Deg Street Elbow

1

00747.10

Nipple Brass ½” x5

03 1 03603.20

½ “Water Soleno id Bonnet

14

1

41062.10

½” Ball Valve Stra iner Only

06 1 00707.00

1/2" Water Solenoid Repair Kit JE

17 4 00914.10

1/4-20 X 5/8 Hexhead Bolt

07

18 8 00924.00

1/4 SS Washer

1

03624.00

Vacuum Breaker Assembly, Watts**

1

00739.50

Vacuum Breaker Cap, SS (fits ½/ ¾)

10

21 4 00912.00

¼-20 Nylon Lock Nut

Plumbing System

Parts Manual

Rev 1.03A

Item Qty Part No Description

02 1 00786.00 Water Sol Plunger G JE ¾ & ½

04 1 00738.10 Solenoid Coil JE 120V (¾ & ½)

05 1 00706.10 ¾” Solenoid JE Spring Only

08

09

11

2 00421.51 6-32 x 1/4" Pan Head Screw

1 03624.25 ½” Vacuum Breaker Bonnet, Brass

1 03623.00 ½” Vacuum Breaker Repair Kit

Item Qty Part No Description

13

1 00742.00 ½”x1-1/2” Brass Nipple

15

1 41062.00 ½” St r ainer Ball Valve

16

19 2 00721.00 ½” Jamb Nut

20 1 13302.17 Flange Sq (3/ 4 Dia.)

22 1 04306.00 Square Manifold Gasket

Page 6

Page 23

01 1 00206.30

Pump Seal Kit

10 2 03101.00

Hose Clamp # 16 1"

02 1 00201.00

Pump Motor 1Hp 115/208-230V

11 2 00238.00

3/8 Male Plug

03 1 03222.10

Impeller (Universal) Open

12 1 00906.00

1/4-20 X 1/2 Hexhead Bolt

04 1 03224.00

Pump Base

13 1 00912.00

1/4-20 Nylon Lock Nut

05 1 03226.00

Pump O Ring Gasket

14 4 00921.00

3/8-16 X 3/4 SS Hexhead Bolt

06 1 04206.00

Pump Cover

15 1 00924.00

1/4 SS Washer

07 1 50302.40

1 ¼ MIP X 1" Barb Fitting

16 1 00200.10

Pump Assy. 110/ 220V 60Hz

08 1 50302.06

1" MPT X 1" Barb PVC Sch 80

17 2 03108.67

Transfer Hose 1" Reinforced 2"

Pump Assem bly

Title

Parts Manual

Rev 1.03A

Item Qty Part No Description

09 1 00246.40 Motor Sucti on Tube

Item Qty Part No Description

Page 7

Page 24

Title

01 4 00914.00

1/4-20 X 3/4 Hexhead Bolt

09 1 04306.00

Square Manifold Gasket

02 9 00924.00

1/4 SS Washer

10 1 03108.10

Transfer Hose 10"

03 4 00912.00

1/4-20 Nylon Lock Nut

11 2 03101.00

Hose Clamp # 16 1"

04 1 00966.10

10-32 X 1/4 Hexhead SS Bolt

12 1 00905.82

1/4-20 X 3/8 Truss Head Bolt

05 2 00342.00

Spray Arm Bearing

13 1 00357.10

Lower Spray Base EAH

06 2 00310.00

Spray Arm

14 4 00955.00

5/16 -18x 5/8 T h u mbscrew

07 4 00308.50

Spray Arm End Plug SS

15 1 50302.06

1" MPT X 1" Barb PVC Sch 80

08 1 00305.03

Spray Manifold

16 1 00302.84

Spray Base O ring

Spray System Assembly

Parts Manual

Rev 1.03A

Item Qty Part No Description

Item Qty Part No Description

Page 8

Page 25

Title

01 1 00900.10

Cotter pin 1/8" X 1"

16 1 00120.02

Thermometer ( Bi Metal)

02 2 00927.00

8-32 Nylon Lock Nut

17 4 00914.00

1/4-20 X 3/4 Hexhead Bolt

03 1 00110.07

Drain Ball Chain-12 Link

18 4 00915.00

1/4-20 SS Nut

04 1 00902.00

8-32 X 1 1/4 Panhead Bolt

19 1 01507.50

Solenoid Cover TM A/B/C

05 6 00922.00

1/4 Lock Star Washer

20 1 00122.00

Drain Solenoid Spring Assy.

06 1 00121.25

Drain Ball Assy

21 1 01551.00

Solenoid Link

08 1 03812.00

8-32 X 5/8 Panhead Screw

23 1 00100.00

Drain Ball Solenoid 120V

09 1 01313.20

2" Spg X Fip Adapter

24 1 01550.00

Solenoid Stop

11 1 41019.11

1/2 ID X 11/16 OD Hose 9"L

26 1 00102.00

Solenoid Base

12 1 00105.20

Drain Solenoid Linkage Washer

27 9 00906.00

1/4-20 X 1/2 Hexhead Bolt

13 1 05030.22

Tubing 2" X 3 3/4"

28 2 00103.00

Solenoid Bar

14 1 05030.24

Tubing 2" X 13 ¾"

29 2 00106.00

Slot Washer Large-SS

15 2 00936.00

312-250 Shorty Bushing

Drain System Assembly

Parts Manual

Rev 1.03A

Item Qty Part No Description

Item Qty Part No Description

07 1 00115.08 Drain Sump Screen 22 1 00105.00 Solenoid Spring

10 3 01312.20 2" Vent ELL Hub X Hub 25 1 00464.07 3/8 SS Tubing(TM A/B Sol Wire)

Page 9

Page 26

Title

01 1 00613.09

Door Handle EAH

13 8 00912.00

1/4-20 Nylon Lock Nut

02 1 01556.50

RH Door Handle Support Brckt

14 4 00610.00

Door Handle S pacer Small

03 1 00603.07

Door Spring Extension Rod AB

15 4 00611.00

Door Handle S pacer (Lg)

00602.20

Door Spring –Heavy Duty

17 1 01555.50

LH Door Handle Support Brckt

05 2 01506.30

Door A B C M CMA-44

18 2 00903.00

1/4-20 X 1 3/4 SS Hexhead Bolt

06 2 01553.00

Door Handle Link

19 2 00607.04

Door Handle Cap 1"

07 1 00606.00

Eye Bolt 5/16-18 X 8 1/2

20 2 01552.00

Door Stop

08 1 00913.00

5/16-18 SS Nut

21 1 00563.40

Door Switch Bracket (8-08)

09 1 00926.00

5/16 SS Washer

22 1 00563.42

Door Switch Actuator (8-08)

10 1 00900.00

Cotter Pin

23 1 00562.00

Roller Door Switch

11 4 00906.00

1/4-20 X 1/2 Hexhead Bolt

24 1 00562.60

Connector Door Roller S witch

12 6 00924.00

1/4 SS Washer

25 1 00546.00

18 AWG Switch Cord

Door Actuator Assembly

Parts Manual

Rev 1.03A

Item Qty Part No Description

04 1

Item Qty Part No Description

00602.00 Door Spring 16 2 00910.00 1/4-20 X1 1/2 SS Hexhead Bolt

Page 10

Page 27

Title

01 1 00416.00

Peristaltic Pump Motor 120v/60hz

08 1 00435.10

Squeeze Tube 8" Orange

02 1 00417.10

Peristaltic Pump Block

09 1 00419.00

Peristaltic Pump Rotor Assy.

03 2 00919.00

10-32 X 1 1/2 Panhead Bolt

10 2 00448.00

Male Barrel connector 14-16 gauge

04 1 00918.00

10-32 X 1 1/2 Filister Bolt

11 1 00425.51

Chemical Tubing Blue

05 1 00418.00

Peristaltic Pump Cover

11 1 00425.53

Chemical Tubing Red

06 1 03415.40

Liquid Tight Fitting 1/4"

11 1 00425.54

Chemical Tubing White

07 4 00911.00

8-32 X 1/2 Panhead Screw

12 1 00443.00

Tube Stiff ener

Peristaltic Pump Assembly

Parts Manual

Rev 1.03A

Item Qty Part No Description

Item Qty Part No Description

Page 11

Loading...

Loading...