Page 1

Technical Manual

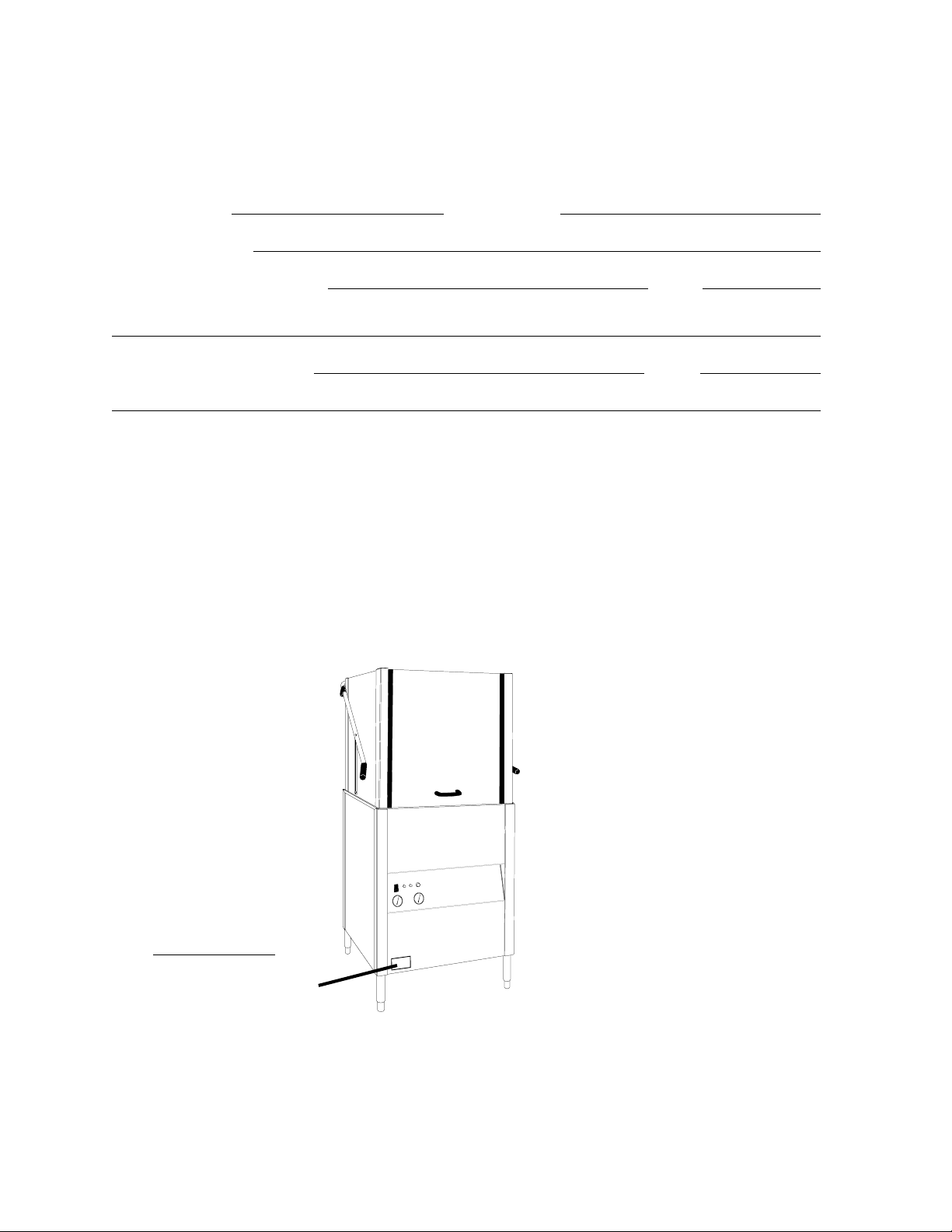

Door-Type

Extended Hood

Dishwasher

Model

D-HBT, D-HBTC

High Temperature

Extended Hood

with Built-in Booster

D-H1T, D-H1TC

High Temperature

Extended Hood

without Built-in Booster

July, 1998

P. O. Box 4149

Winston-Salem, North Carolina 27115-4149

336/661-1556 Fax: 336/661-1660

Machine Serial No.

Manual P/N 112724 Rev. A

2674 N. Service Road

Jordan Station, Ontario, Canada LOR 1SO

905/562-4195 Fax: 905/562-4618

Champion Industries, Inc.

Page 2

Complete the information below so it will be available for quick reference.

Model Number Serial Number

Voltage and Phase

Champion Parts Distributor Phone

(if applicable)

Champion Service Agency Phone

Champion Service:

Champion, US

Phone: 1(336) 661-1556

1(800) 858-4477

Fax: 1(336) 661-1660

Champion, Canada

Phone: 1(905) 562-4195

1(800) 263-5798

Fax: 1(905) 562-4618

Note: When calling to order parts, be sure to have the model number, serial number,

voltage and phase of your machine, along with your customer account number.

Machine Data Plate with

Model & Serial Number

located on the front panel.

Machine

COPYRIGHT ©1998 by Champion Industries, Inc.

Page 3

Revision History

Revision Revised Serial Number Comments

Date Pages Effectivity

2/12/98 All 91299 Issue of New Manual and

Service Parts List

4/23/98 52 – 53 91586 Redesigned overflow lift arm

P/N 112469 order P/N’s 112469-S

and 322218 for machines built prior

to S/N 91586

5/12/98 36 – 43 91612 Redesigned doors to include guide,

P/N 112772

7/2/98 68 – 69 —— Corrected Control Cabinet fuse

part numbers

REVISONS

1

Page 4

CONTENTS

LIMITED WARRANTY ............................................................................................................... 4

INTRODUCTION ......................................................................................................................... 5

INSTALLATION ........................................................................................................................... 8

INITIAL START-UP ..................................................................................................................... 16

OPERATION SUMMARY ........................................................................................................... 22

CLEANING ................................................................................................................................... 23

TROUBLESHOOTING ................................................................................................................ 25

BASIC SERVICE .......................................................................................................................... 27

REPLACEMENT PARTS ............................................................................................................. 33

ELECTRICAL SCHEMATIC ....................................................................................................... 73

CONTENTS

Model Number ....................................................................................................................6

Standard Equipment ........................................................................................................... 6

Options................................................................................................................................ 6

Electrical Power Requirements .......................................................................................... 7

Unpack the Dishwasher ...................................................................................................... 8

Electrical Connections ........................................................................................................ 10

Plumbing Connections ........................................................................................................ 12

Water Connections ......................................................................................................... 12

Drain Connections .......................................................................................................... 13

Chemical Connections.................................................................................................... 14

Cleaning Schedule .............................................................................................................. 23

Deliming Process ................................................................................................................24

LIST OF FIGURES

Figure 1 – Remove Front Panel .................................................................................................. 8

Figure 2 – Electrical Connection Location ................................................................................ 10

Figure 3 – Hinged Control Panel ................................................................................................ 11

Figure 4 – Main Terminal Block ................................................................................................ 11

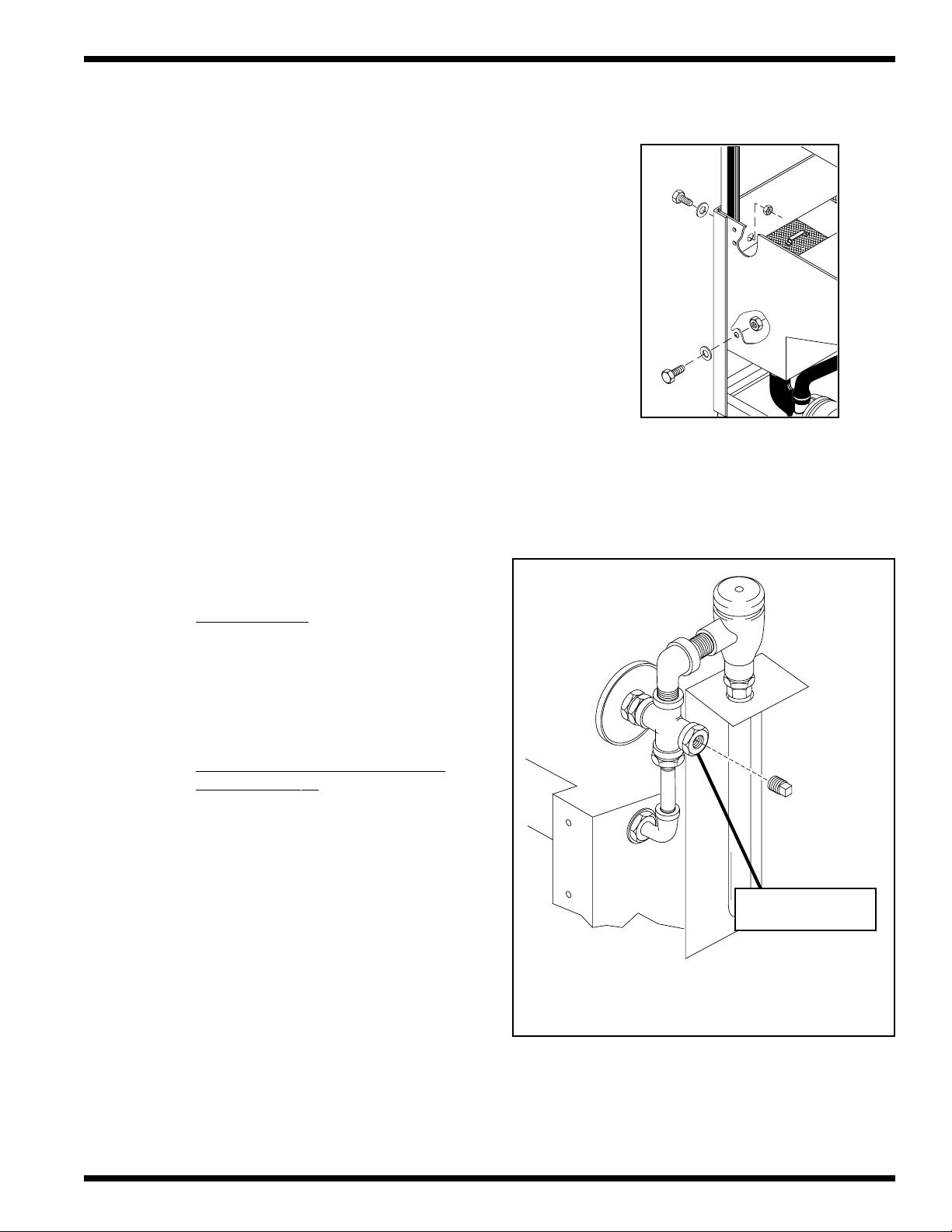

Figure 5 – Hot Water Connection (D-HBT Only)..................................................................... 12

Figure 6 – Hot Water Connection (D-H1T Only) ...................................................................... 12

Figure 7 – Drain Hose Connection ............................................................................................. 13

Figure 8 – Chemical Dispenser Signal Terminal Block ............................................................. 14

Figure 9 – Chemical Signal Connection Points ......................................................................... 14

Figure 10 – Detergent Probe Injection Points, 1/2" ..................................................................... 15

2

Page 5

CONTENTS

LIST OF FIGURES (cont.)

Figure 11 – Rinse Aid Injection Point (Top of Dishwasher) ........................................................ 15

Figure 12 – Fuses ......................................................................................................................... 28

Figure 13 – Motor Overload .........................................................................................................28

Figure 14 – Main Cycle Timer (45 second) ................................................................................. 29

Figure 15 – Fill Timer .................................................................................................................. 29

Figure 16 – Cycle Timers (2, 4, and 6 minute) ............................................................................ 29

Figure 17 – Heater Element Wiring ............................................................................................. 30

Figure 18 – Pump Motor Wiring Diagrams ................................................................................. 31

Figure 19 – Pump Seal Replacement ........................................................................................... 32

Figure 20 – Panels ........................................................................................................................ 34

Figure 21 – Doors, Guides and Stops (D-HBT, D-H1T) (Prior to S/N 91612)............................ 36

Figure 22 – Doors, Guides and Stops (Corner Model Only) (D-HBTC/D-H1TC)

(Prior to S/N 91612) ................................................................................................. 38

Figure 23 – Doors, Guides, & Stops (D-HBT, D-H1T)

(For machines beginning with S/N 91612 and above) ............................................. 40

Figure 24 – Doors, Guides & Stops (Corner Model Only) (D-HBTC/DH1TC)

(For machines beginning with S/N 91612 and above) ............................................. 42

Figure 25 – Door Handle, Spring Assembly and Safety Switch .................................................. 44

Figure 26 – Track Assembly ........................................................................................................ 46

Figure 27 – Wash/Rinse Spray Piping.......................................................................................... 48

Figure 28 – Wash/Rinse Spray Arms ........................................................................................... 50

Figure 29 – Drain Assembly and Scrap Screens .......................................................................... 52

Figure 30 – Wash Tank Heat and Thermostats ............................................................................. 54

Figure 31 – Electric Booster and Thermostats ............................................................................. 56

Figure 32 – Lower Fill Piping Assembly (D-HBT only) ............................................................. 58

Figure 33 – Upper Fill Piping Assembly (D-HBT/D-H1T) ......................................................... 60

Figure 34 – Lower Fill Piping Assembly (D-H1T only) .............................................................. 62

Figure 35 – Pump Assembly ........................................................................................................ 64

Figure 36 – Control Panel and Gauges ......................................................................................... 66

Figure 37 – Control Cabinet ......................................................................................................... 68

Figure 38 – Dishracks and PRV ................................................................................................... 70

Figure 39 – Electrical Schematic ................................................................................................. 73

3

Page 6

WARRANTY

LIMITED WARRANTY

Champion Industries, Inc., P.O. Box 4149, Winston-Salem, North Carolina 27115, and P.O. Box 301, 2674 North

Service Road , Jordan Station, Ontario, Canada L0R 1S0, warrants machines, and parts, as set out below.

Warranty of Machines: Champion, warrants all new machines of its manufacture bearing the name “Champion”

and installed within the United States and Canada to be free from defects in material and workmanship for a period of

one (1) year after the date of installation or fifteen (15) months after the date of shipment by Champion, whichever

occurs first. [See below for special provisions relating to Model Series CG] The warranty registration card must be

returned to Champion within ten (10) days after installation. If warranty card is not returned to Champion within such

period, the warranty will expire after one year from the date of shipment.

Champion will not assume any responsibility for extra costs for installation in any area where there are

jurisdictional problems with local trades or unions.

If a defect in workmanship or material is found to exist within the warranty period, Champion at its election,

will either repair or replace the defective machine or accept return of the machine for full credit; provided, however, as

to Model Series CG, Champion’s obligation with respect to labor associated with any repairs shall end (a) 120 days

after shipment, or (b) 90 days after installation, whichever occurs first. In the event that Champion elects to repair, the

labor and work to be performed in connection with the warranty shall be done during regular working hours by a

Champion authorized service technician. Defective parts become the property of Champion. Use of replacement parts

not authorized by Champion will relieve Champion of all further liability in connection with its warranty. In no event

will Champion’s warranty obligation exceed Champion’s charge for the machine. The following are not covered by

Champion’s warranty:

a. Lighting of gas pilots or burners.

b. Cleaning of gas lines.

c. Replacement of fuses or resetting of overload breakers.

d. Adjustment of thermostats.

e. Adjustment of clutches.

f. Opening or closing of utility supply valves or switching of electrical supply current.

g. Cleaning of valves, strainers, screens, nozzles, or spray pipes.

h. Performance of regular maintenance and cleaning as outlined in operator’s guide.

i. Damages resulting from water conditions, accidents, alterations, improper use, abuse,

Examples of the defects not covered by warranty include, but are not limited to: (1) Damage to the exterior or

interior finish as a result of the above, (2) Use with utility service other than that designated on the rating plate,

(3) Improper connection to utility service, (4) Inadequate or excessive water pressure, (5) Corrosion from

chemicals dispensed in excess of recommended concentrations, (6) Failure of electrical components due to

connection of chemical dispensing equipment installed by others, (7) Leaks or damage resulting from such leaks

caused by the installer, including those at machine table connections or by connection of chemical dispensing

equipment installed by others, (8) Failure to comply with local building codes, (9) Damage caused by labor

dispute.

Warranty of Parts: Champion warrants all new machine parts produced or authorized by Champion to be free

from defects in material and workmanship for a period of 90 days from date of invoice. If any defect in

material and workmanship is found to exist within the warranty period Champion will replace the defective

part without charge.

tampering, improper installation, or failure to follow maintenance and operation procedures.

DISCLAIMER OF WARRANTIES AND LIMITATIONS OF LIABILITY. CHAMPION’S WARRANTY

IS ONLY TO THE EXTENT REFLECTED ABOVE. CHAMPION INDUSTRIES, INC. MAKES NO OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED, TO ANY WARRANTY OF

MERCHANTABILITY, OR FITNESS OF PURPOSE. CHAMPION SHALL NOT BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. THE REMEDIES SET OUT ABOVE ARE THE EXCLUSIVE

REMEDIES FOR ANY DEFECTS FOUND TO EXIST IN CHAMPION DISHWASHING MACHINES AND

CHAMPION PARTS, AND ALL OTHER REMEDIES ARE EXCLUDED, INCLUDING ANY LIABILITY FOR

INCIDENTALS OR CONSEQUENTIAL DAMAGES.

Champion does not authorize any other person, including persons who deal in Champion dishwashing machines, to

change this warranty or create any other obligation in connection with Champion Dishwashing Machines.

4

Page 7

INTRODUCTION

Welcome to Champion...

and thank you for allowing us to take care of

your dishwashing needs.

This manual covers the door-type dishwasher,

Model D-HBT, D-H1T, D-HBTC, D-H1TC.

Your machine was completely assembled,

inspected, and thoroughly tested at our factory

before it was shipped to your installation site.

This manual contains:

• Installation Instructions

• Operation and Cleaning Instructions

• Troubleshooting Guide

• Basic Service Information

• Replacement Parts Lists

• Electrical Schematics

INTRODUCTION

All information, illustrations and specifications

contained in this manual are based upon the

latest product information available at the time

of publication. Champion constantly improves

its products and reserves the right to make

changes at any time or to change specifications

or design without notice and without incurring

any obligation.

For your protection, factory authorized parts

should always be used for repairs.

Replacement parts may be ordered directly

from your Champion authorized service

agency. When ordering parts, please supply the

model number, serial number, voltage, and

phase of your machine, the part number, part

descriptions and quantity.

5

Page 8

GENERAL

Model Numbers

D-HBT, D-HBTC, D-H1T, D-H1TC

The D-HBT model is a high temperature

(180°F/82°C rinse) sanitizing model with

booster.

The D-H1T, D-H1TC models are high temperature (180°F/82°C rinse) sanitizing models.

Standard Equipment includes:

D-HBT, D-HBTC, D-H1T, DH1TC

• Automatic tank fill and start

• Adjustable cycle selector

• Built-in electric booster heater (D-HBT only)

• Field convertible to corner model

• Electric tank heat

• Low-water tank heat protection

• 2-hp drip-proof pump motor

• Door safety switch

• Door activated drain

Options

• Electric booster (70°F/39°C temperature

rise) heater for 110°F/43°C supply water

• Steam injector or steam coil tank heat

(steam booster 40°F/23°C-70°F/39°C rise)

• Common utility connections

• Two dish racks (peg and flat bottom)

• Detergent/chemical connection provisions

• Stainless steel front and side panels

• 1-1/2" O.D. gravity drain connection

• Water pressure reducing valve (mounted)

• Interchangeable upper and lower spray arms

Accessories

Additional dishracks:

Dish rack (peg) P/N 101285

Silverware rack (flat bottom) P/N 101273

3/4" Pressure reducing valve (PRV) P/N 112387

6

Page 9

GENERAL

Electrical Power Requirements: Electric Heat/Electric Booster

Model Voltage Booster Rise Machine Power Requirement

(D-HBT Only) Full Load Amps (125% Service Factor)

D-H1T 208/60/1 — 27.3 Amps 35 Amps

D-H1T 220/60/1 — 26.7 Amps 35 Amps

D-H1T 230/60/1 — 27.4 Amps 35 Amps

D-H1T 240/60/1 — 27.9 Amps 35 Amps

D-H1T 208/60/3 — 14.5 Amps 20 Amps

D-H1T 220/60/3 — 14.9 Amps 20 Amps

D-H1T 230/60/3 — 14.9 Amps 20 Amps

D-H1T 240/60/3 — 15.2 Amps 20 Amps

D-H1T 380/60/3 — 8.7 Amps 15 Amps

D-H1T 415/60/3 — 8.8 Amps 15 Amps

D-H1T 480/60/3 — 6.9 Amps 15 Amps

D-H1T 575/60/3 — 5.7 Amps 15 Amps

D-HBT 208/60/1 40°F/23°C 63.4 Amps 80 Amps

D-HBT 220/60/1 40°F/23°C 64.9 Amps 90 Amps

D-HBT 230/60/1 40°F/23°C 67.3 Amps 90 Amps

D-HBT 240/60/1 40°F/23°C 69.6 Amps 90 Amps

D-HBT 208/60/3 40°F/23°C 35.3 Amps 45 Amps

D-HBT 220/60/3 40°F/23°C 37 Amps 50 Amps

D-HBT 230/60/3 40°F/23°C 38 Amps 50 Amps

D-HBT 240/60/3 40°F/23°C 39.3 Amps 50 Amps

D-HBT 380/60/3 40°F/23°C 21.4 Amps 30 Amps

D-HBT 415/60/3 40°F/23°C 21.3 Amps 30 Amps

D-HBT 480/60/3 40°F/23°C 17.7 Amps 25 Amps

D-HBT 575/60/3 40°F/23°C 14.7 Amps 20 Amps

D-HBT 208/60/1 — — —

D-HBT 220/60/1 — — —

D-HBT 230/60/1 — — —

D-HBT 240/60/1 — — —

D-HBT 208/60/3 70°F/39°C 52 Amps 70 Amps

D-HBT 220/60/3 70°F/39°C 54.6 Amps 70 Amps

D-HBT 230/60/3 70°F/39°C 56.4 Amps 70 Amps

D-HBT 240/60/3 70°F/39°C 58.5 Amps 80 Amps

D-HBT 380/60/3 70°F/39°C 31.6 Amps 40 Amps

D-HBT 415/60/3 70°F/39°C 33.8 Amps 45 Amps

D-HBT 480/60/3 70°F/39°C 28.6 Amps 40 Amps

D-HBT 575/60/3 70°F/39°C 23.8 Amps 30 Amps

7

Page 10

INSTALLATION

INSTALLATION

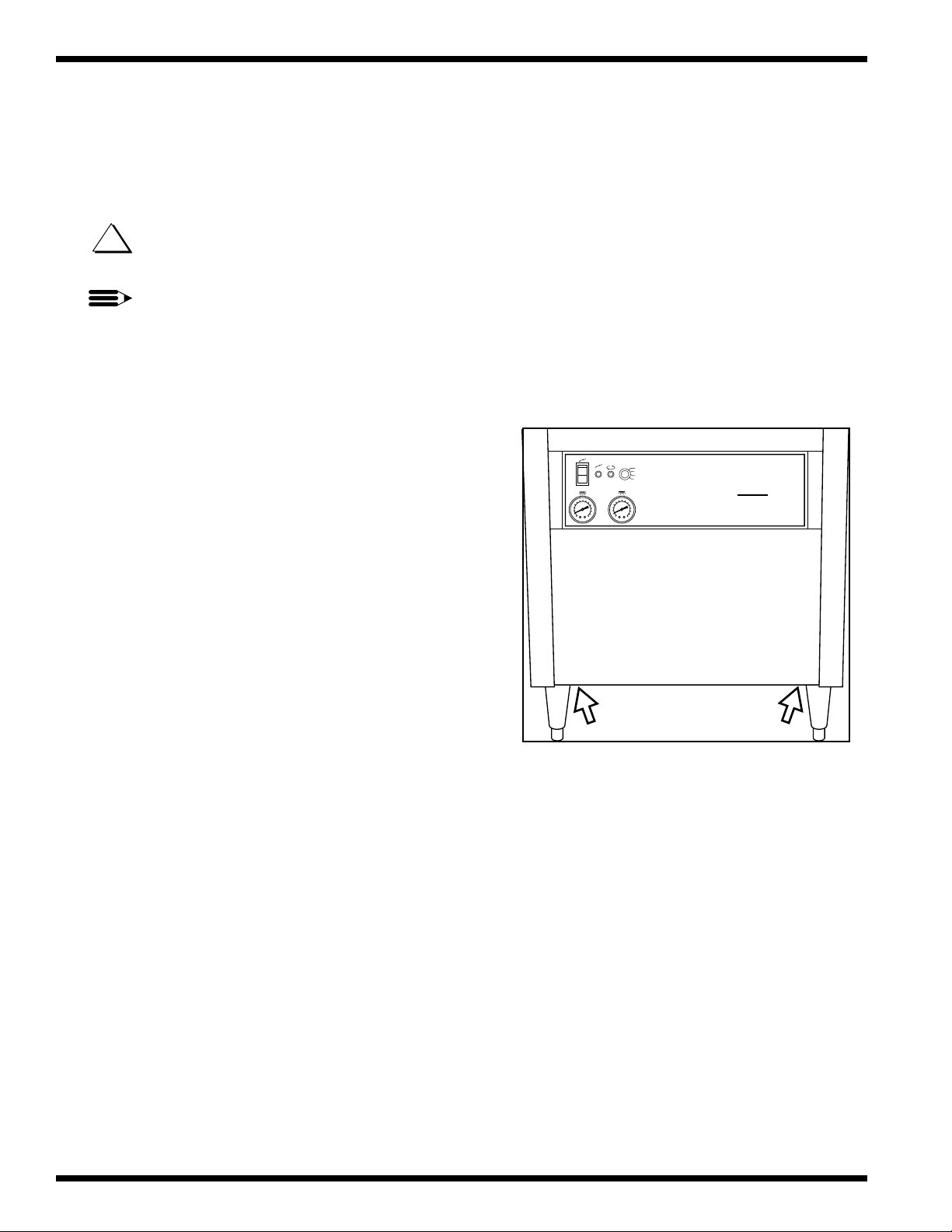

Unpack the dishwasher

CAUTION:

!

Care should be taken when lifting the

machine to prevent damage.

NOTE:

The installation of your machine must meet

all applicable health and safety codes.

1. Immediately after unpacking the machine,

inspect for any shipping damage. If damage is

found, save the packing material and contact

the carrier immediately.

2. Remove the dishwasher from the skid.

Move the machine to its permanent location.

POWER

CYCLE

RINSE PRESSURE

WASH

Champion

WARNING!

TURN OFF POWER BEFORE

SERVICING MACHINE

3. Level the machine (if required) by placing a

level on the top of the machine and adjusting

the feet. Level the machine front-to-back and

side-to-side.

4. Remove the dishracks from the interior of

the machine.

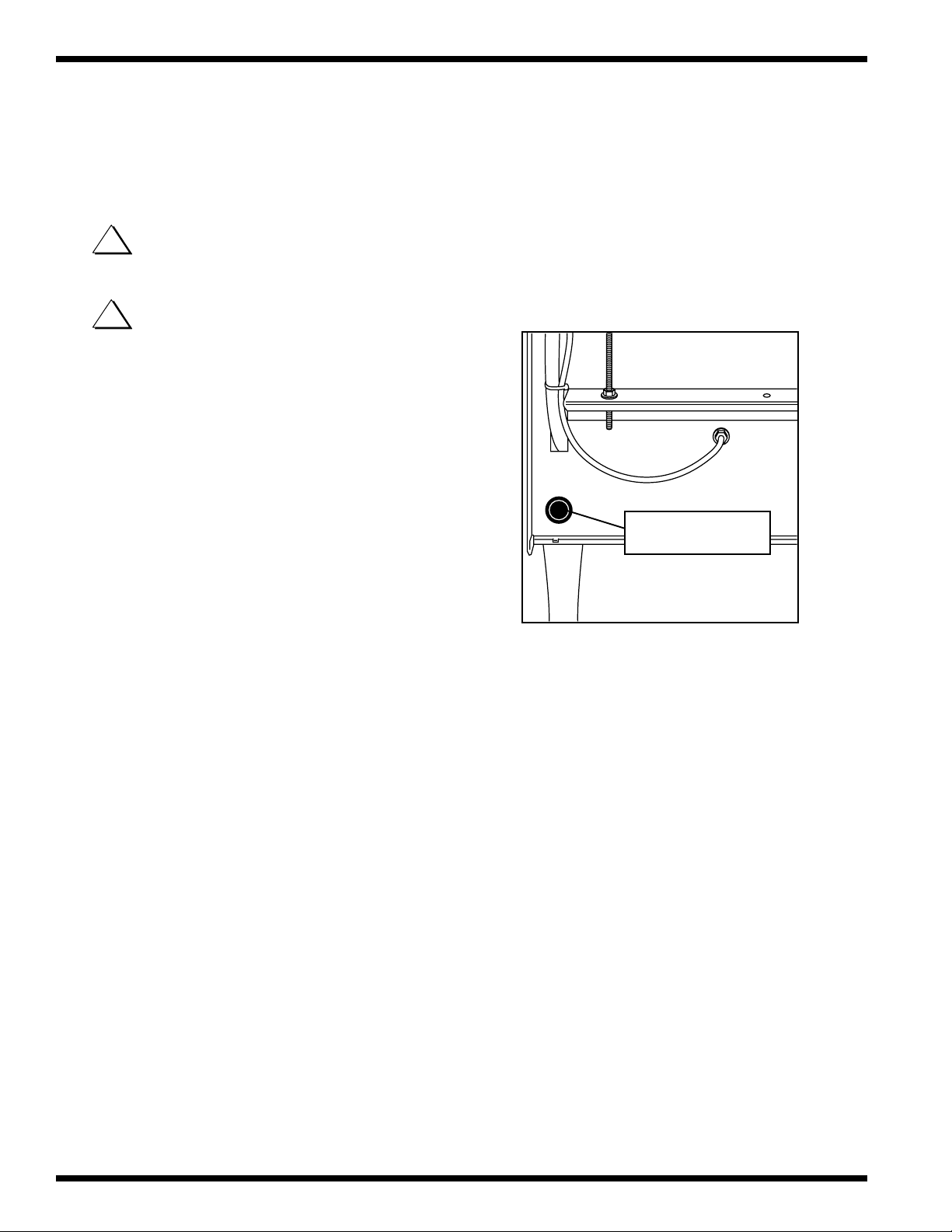

5. Refer to Fig. 1. Remove (2) screws that hold

the front panel. Remove the front panel in

preparation for service connections.

Figure 1

Remove Front Panel

8

Page 11

INSTALLATION

INSTALLATION (Cont.)

Electrical Connections

WARNING:

!

Electrical and grounding connections must

comply with all applicable Electrical Codes.

WARNING:

!

When working on the dishwasher, disconnect the electric service and place a tag at

the disconnect switch to indicate work is

being done on that circuit.

1. A qualified electrician must compare the

electrical power supply with the machine

electrical specifications before connecting

to the incoming service through a fused

disconnect switch.

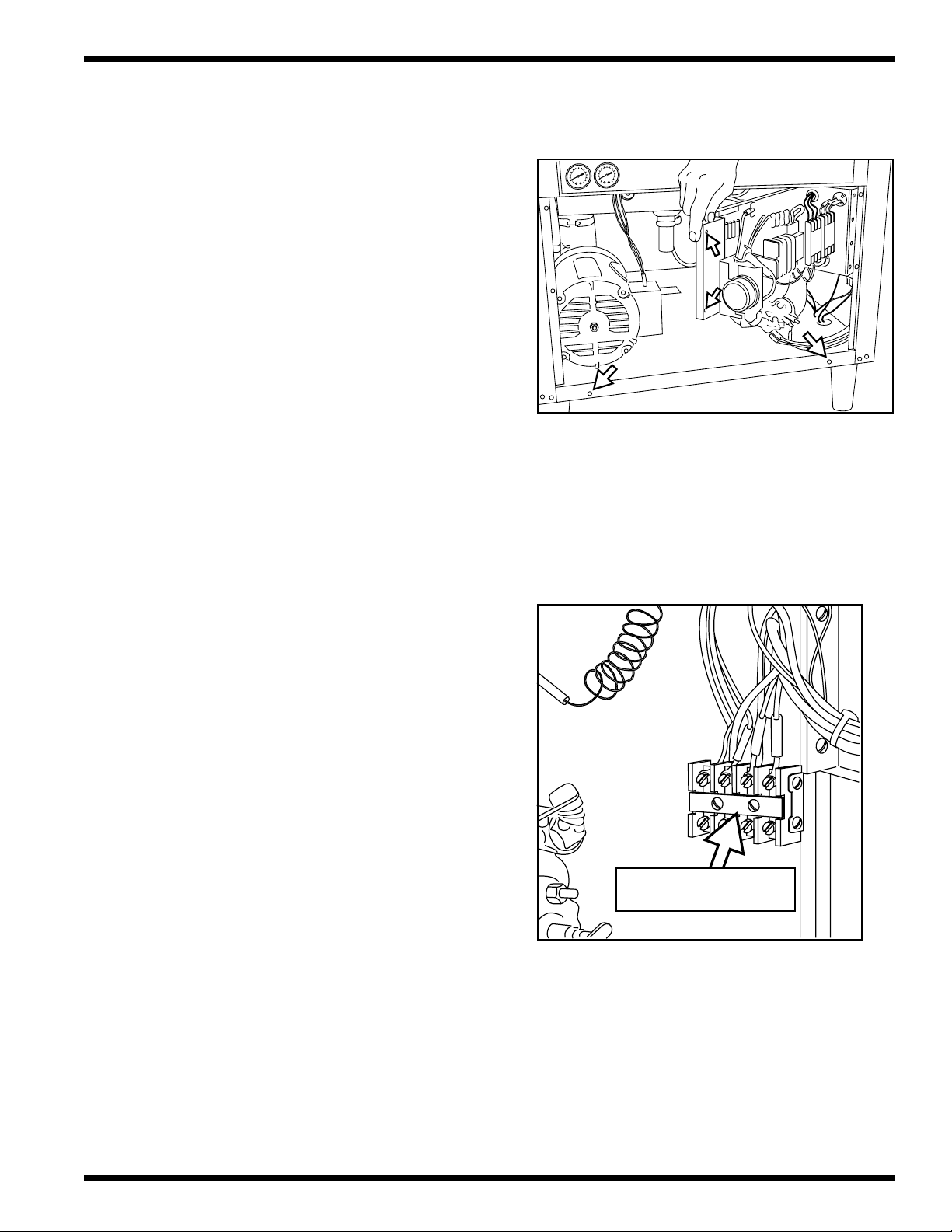

Refer to Fig. 2

2. A knock-out is provided at the lower right

rear corner (as viewed from the front) for

the electrical service connection. A fused

disconnect switch or circuit breaker

(supplied by others) is required to protect

the power supply circuit.

Electrical knock-out

lower rear corner

Figure 2

Electrical Connection Location

10

Page 12

Electrical Connections (Cont.)

Refer to Fig. 3

3. Remove (2) lower screws from the front

panel of the machine to expose the electrical controls. Remove (2) screws on the

control panel support. Swing the hinged

control panel forward.

INSTALLATION

Figure 3

Hinged Control Panel

Refer to Fig. 4

4. Three phase or single phase incoming

power wiring connections are made at the

bottom of the machine’s main terminal

block. The main terminal block is located

on the side of the front right post of the

dishwasher.

Electrical Power Connection

Figure 4

Main Terminal Block

11

Page 13

INSTALLATION

INSTALLATION (Cont.)

Plumbing Connections

NOTE:

Plumbing connections must comply with

all applicable sanitary and plumbing

codes.

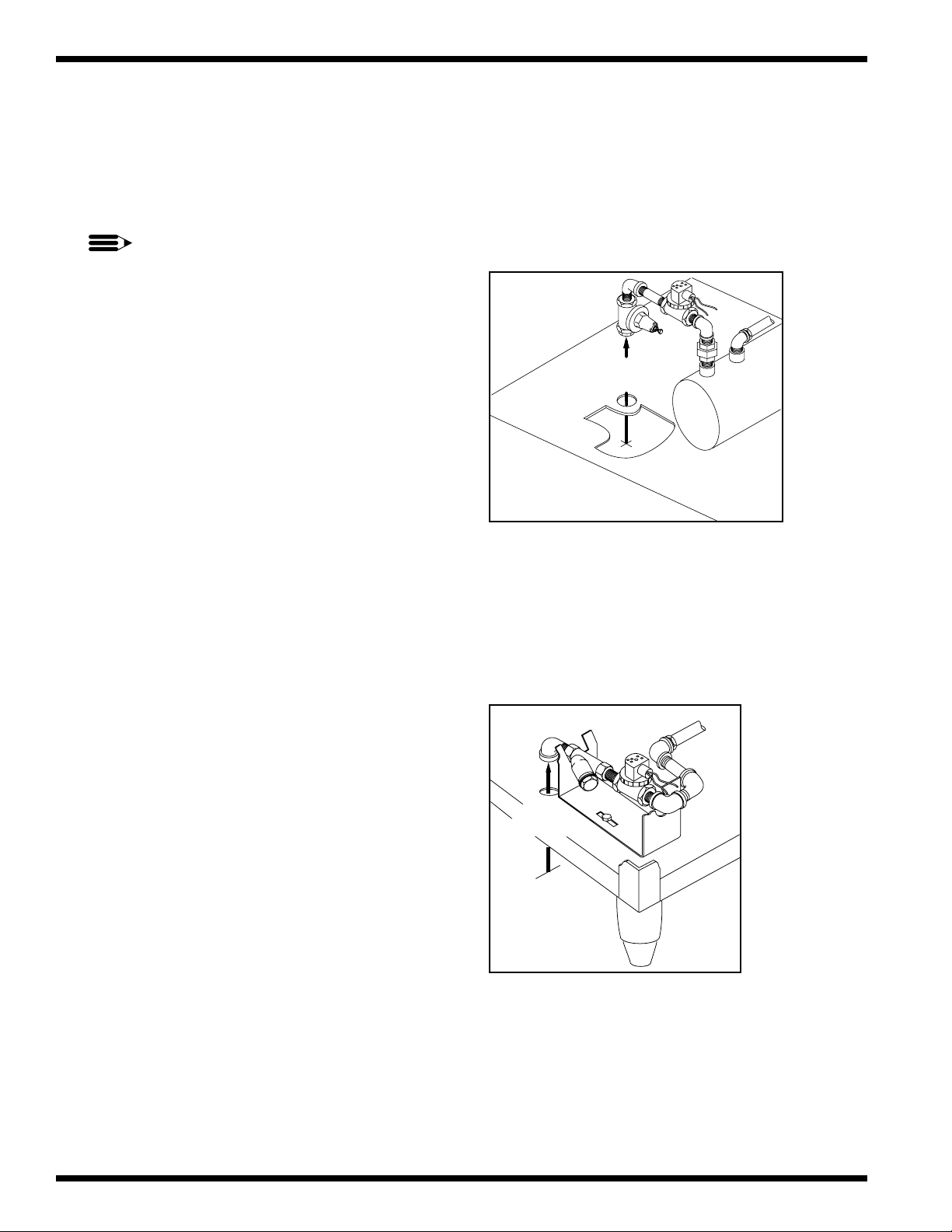

Water Connections

1. All D-HB/H1T series dishwashers require a

single, hot water supply.

The hot water connection to all D-HB/H1T

series dishwashers is 3/4" NPT.

The connection is made from

underneath the dishwasher.

The following minimum water

temperatures are recommended:

D-HBT with built-in 40° rise electric

booster (Minimum 140°F/60°C)

(Min./Max. flow pressure

20-22 PSI/138-151.8 kPa)

D-HBT with built-in 70° rise electric

booster (Minimum 110°F/43°C)

(Min./Max. flow pressure

20-22 PSI/138-151.8 kPa)

D-H1T without built-in booster

(Minimum 180°F/70°C)

(Min./Max. flow pressure

20-22 PSI/138-151.8 kPa)

Hot Water Connection

11"

[279mm]

R

O

FLO

11"

[279mm]

R

O

FLO

Figure 5

3/4" NPT

(D-HBT Only)

12

Refer to Figs. 5 and 6

Figure 6

Hot Water Connection

3/4" NPT

(D-H1T Only)

Page 14

Water Connections (Cont.)

2. A manual shut-off valve for steam and water

(supplied by others) should be installed in the

supply line to allow for servicing of the

machine. The shut-off valve should be the

same size or larger than the supply line.

3. Install a 3/4" pressure reducing valve (PRV)

in the water supply line if flow pressure

exceeds 20-22 PSI/138-151.8 kPa.

A PRV is standard equipment on Model

D-HBT. A PRV is not standard equipment on

Models D-H1T.

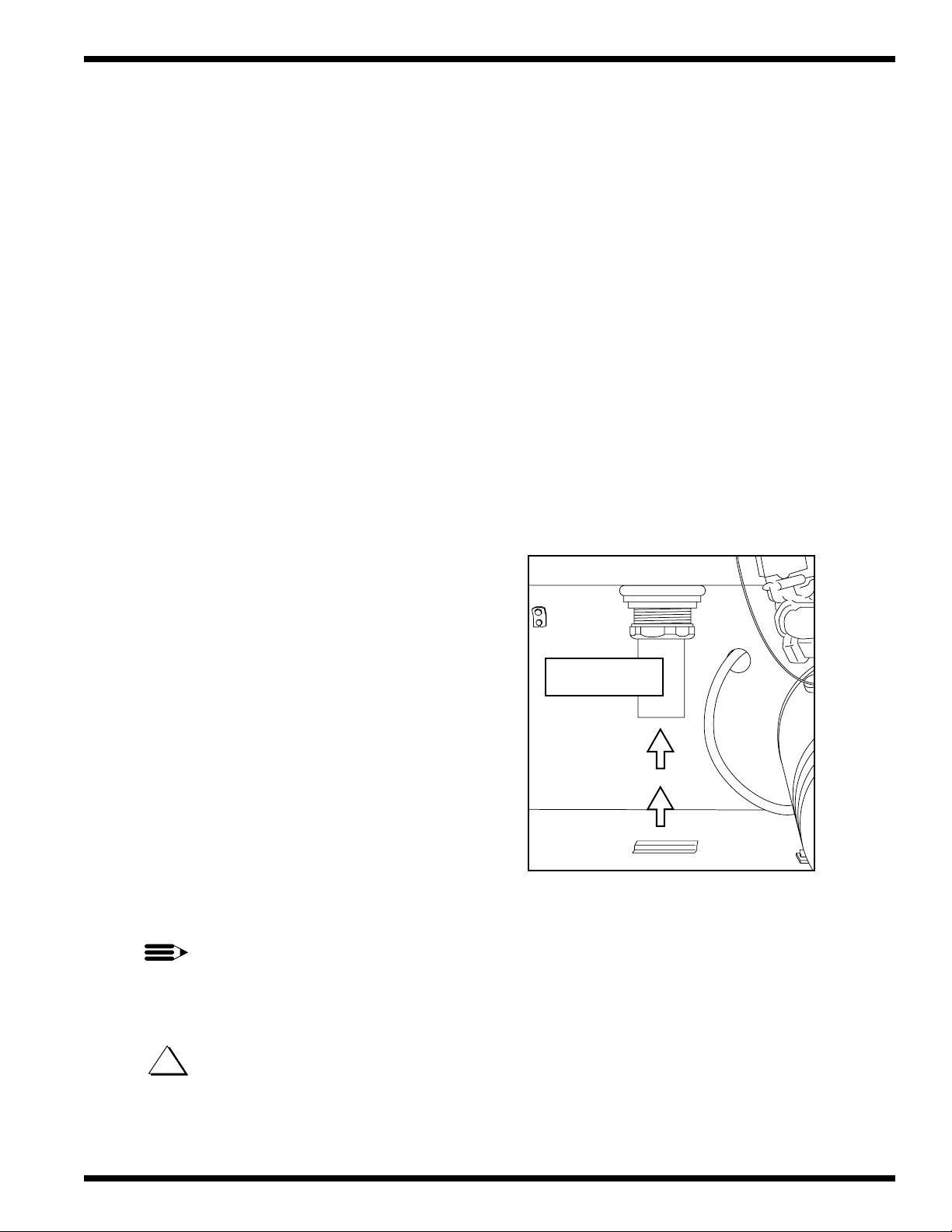

Drain Connections

INSTALLATION

Refer to Fig. 7

1. All models are GRAVITY DRAIN

machines equipped with a

1-1/2" O.D. hose connection point.

2. The maximum drain flow rate is

15 gallons/min-56.8 liters/min.

3. Drain height for all models must not

exceed 11" (280mm) above floor level.

4. The drain connection is made to the

dishwasher from underneath the machine

through an access hole in the machine

base.

Ventilation

NOTE:

Ventilation must comply with local sanitary

and plumbing codes.

11" [280mm]

Above floor level

Figure 7

Drain Hose Connection

1-1/2" O.D.

(Max flow rate = 15 gal/min-56.8 liters/min)

CAUTION:

!

Exhaust air should not be vented into a

wall, ceiling, or concealed space of a

building. Condensation can cause

damage.

13

Page 15

INSTALLATION

INSTALLATION (Cont.)

Chemical Connections

NOTE:

Consult a qualified chemical supplier

for your chemical needs.

Refer to Fig. 8

1. A chemical signal terminal block is

supplied for chemical dispensing

equipment.

2. The terminal block is located below

the control panel fuse block.

Refer to Fig. 9

3. The detergent signal is limited

to a maximum load of 1 Amp

Signal voltage is 115VAC.

4. The Rinse aid signal is limited

to a maximum load of 1 Amp.

Signal voltage is 115VAC.

COMMON

Figure 8

Chemical Dispenser

Signal

Terminal Block

Detergent Signal Connection Point

1 Amp Max Load/115VAC

Common Return

RINSE

DETERGENT

Rinse aid

Signal Connection Point

1 Amp Max load/115VAC

14

Figure 9

Chemical Signal

Connection Points

Page 16

Chemical Connections (Cont.)

Refer to Fig. 10

5. A 1/2" detergent probe injection point is

provided at the rear and left side of the

dishwasher.

6. Detergent may be added manually if

your dishwasher is not equipped with

dispensing equipment. Consult your

chemical supplier for recommended

amounts.

INSTALLATION

Figure 10

Detergent Probe

Injection Points, 1/2"

Refer to Fig. 11

7.

D-HBT, D-H1T

A 1/4" NPT rinse aid injection point is

provided in the final rinse manifold.

Use a liquid rinse aid.

The manifold is located on the top right

side of the dishwasher.

Models D-HBT and D-H1T do not

require sanitizer.

1/4" NPT Rinse aid

Injection Point

Figure 11

Rinse Aid Injection Point

(Top of Dishwasher)

15

Page 17

INITIAL START-UP

INITIAL START-UP

Complete the Installation

After plumbing and electrical connections are made, follow

the steps below to complete the installation of your dishwasher.

1. Remove the white protective covering from the

exterior of the machine.

2. Remove any foreign material from inside

the machine.

3. Make sure dishwasher power switch is off.

4. Turn main water supply on.

5. Turn main power on at the main power

service disconnect switch.

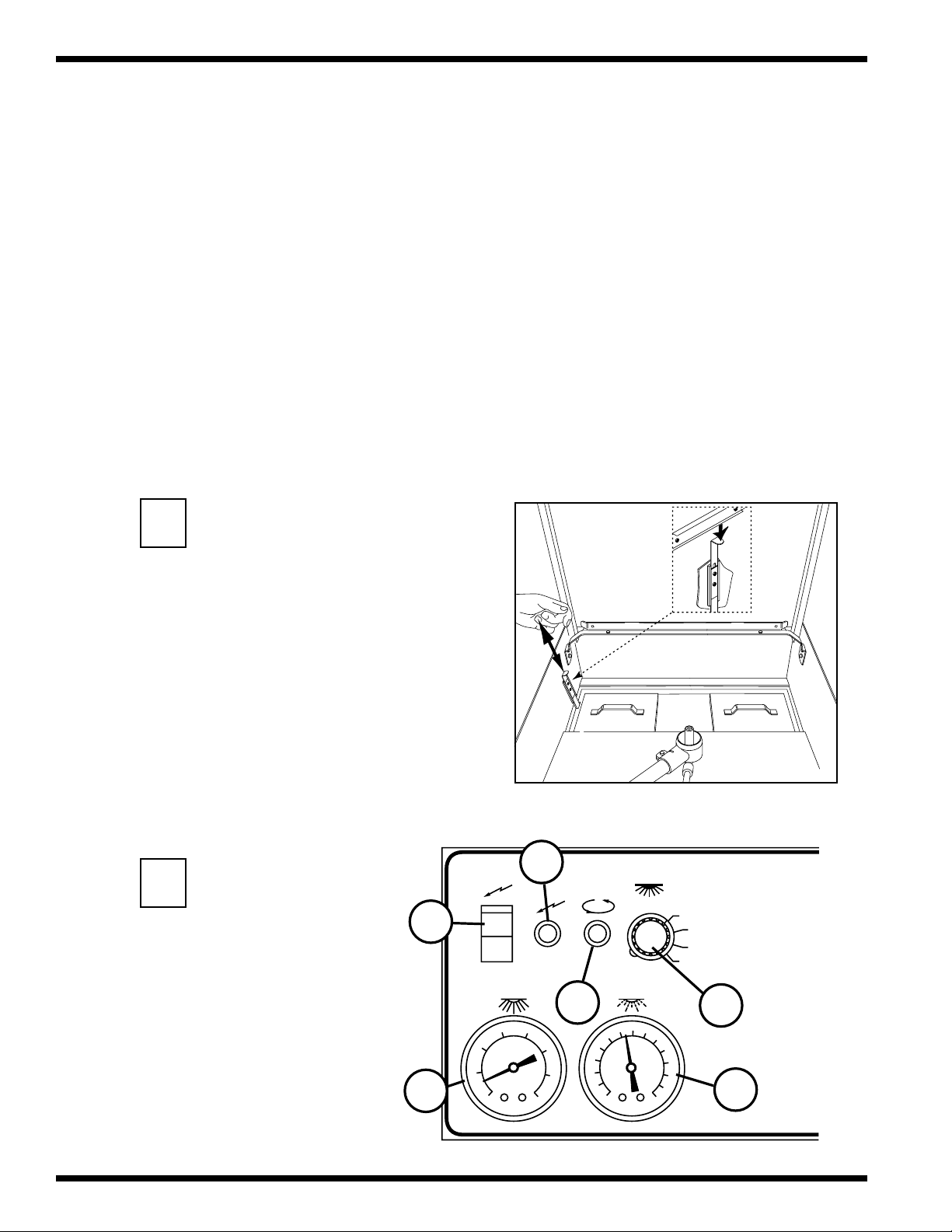

1

Install the Scrap Screens

and Drain-Overflow Assembly

Install scrap screens.

Make sure the door activated drain assembly

is in place. The drain is opened by manually

pulling up on the drain-overflow lever.

The drain closes when the doors are closed.

MAKE SURE DOORS

ARE FULLY CLOSED.

2

The controls are located

on the front of the dishwasher.

A- On/Off power switch

B- Power indicator Light

C- In cycle light

D- Wash cycle selector switch

E- Wash water

temperature gauge

F- Final rinse

pressure gauge

A

E

POWER

OFF

WASH

B

C

DOOR

WASH CYCLE

CYCLE

1 MIN

2 MIN

4 MIN

6 MIN

RINSE PRESSURE

D

F

16

Page 18

INITIAL START-UP (Cont.)

WASH

CYCLE

POWER

OFF

RINSE PRESSURE

WASH CYCLE

1 MIN

2 MIN

4 MIN

6 MIN

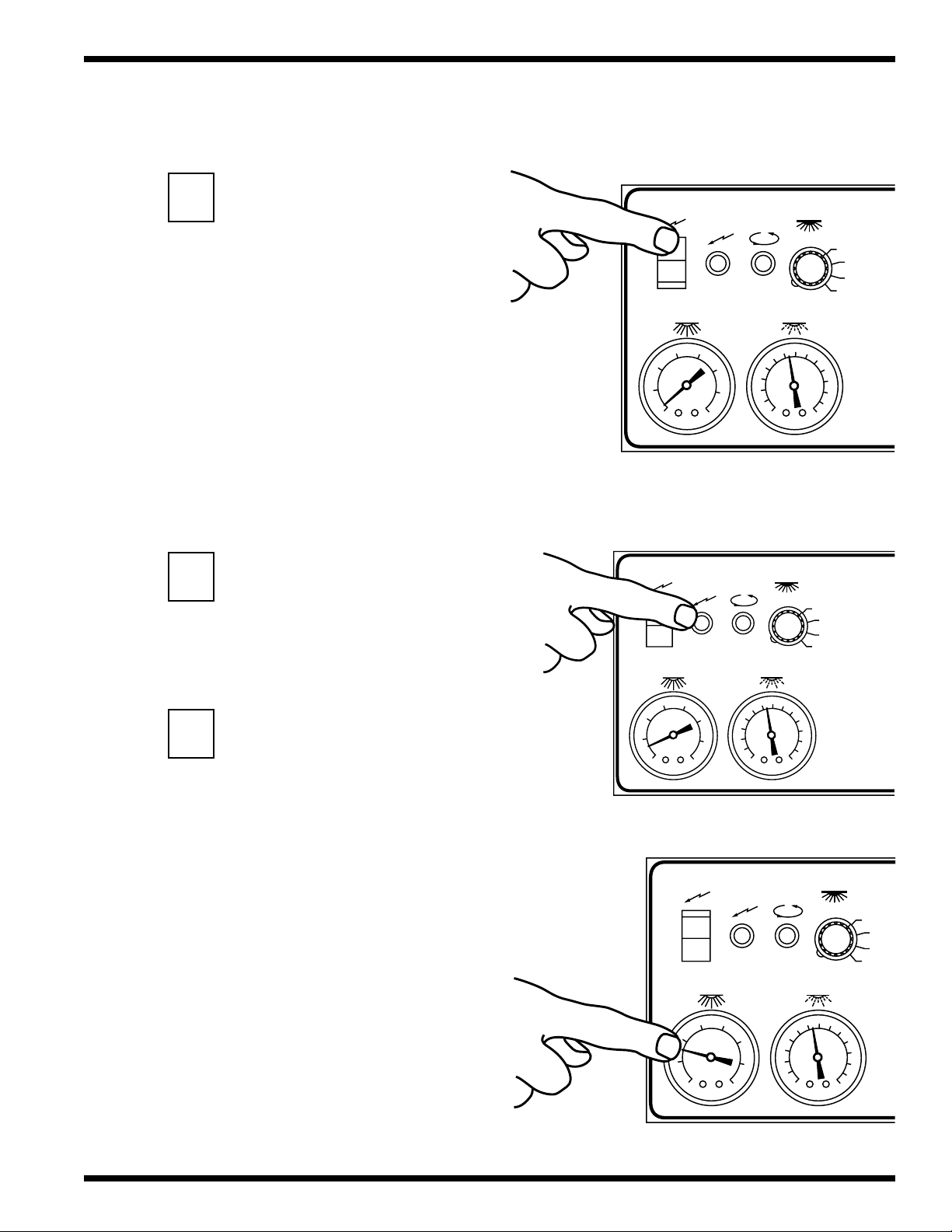

INITIAL START-UP

3

THE POWER SWITCH IS

ON DURING INITIAL FILL.

Make sure the doors are fully closed.

Push the On/Off power

switch to the UP position.

THE DISHWASHER FILLS

AUTOMATICALLY.

4

Note that the power indicator

light is illuminated.

POWER

OFF

WASH

CYCLE

RINSE PRESSURE

WASH CYCLE

1 MIN

2 MIN

4 MIN

6 MIN

5

Check Wash

Water Temperature

The wash tank heater and

the (booster tank heater, D-HBT only)

will begin to heat the water in

the dishwasher.

Wait approximately 10 minutes

for the wash tank water to

reach operating temperature.

The temperature should be a minimum

of 150°F/66°C for (D-HBT, D-H1T).

Prescrap the dishes. Load ware into

the dishrack. Open the doors, insert the

rack into the dishwasher.

POWER

OFF

WASH

WASH CYCLE

CYCLE

1 MIN

2 MIN

4 MIN

6 MIN

RINSE PRESSURE

17

Page 19

INITIAL START-UP

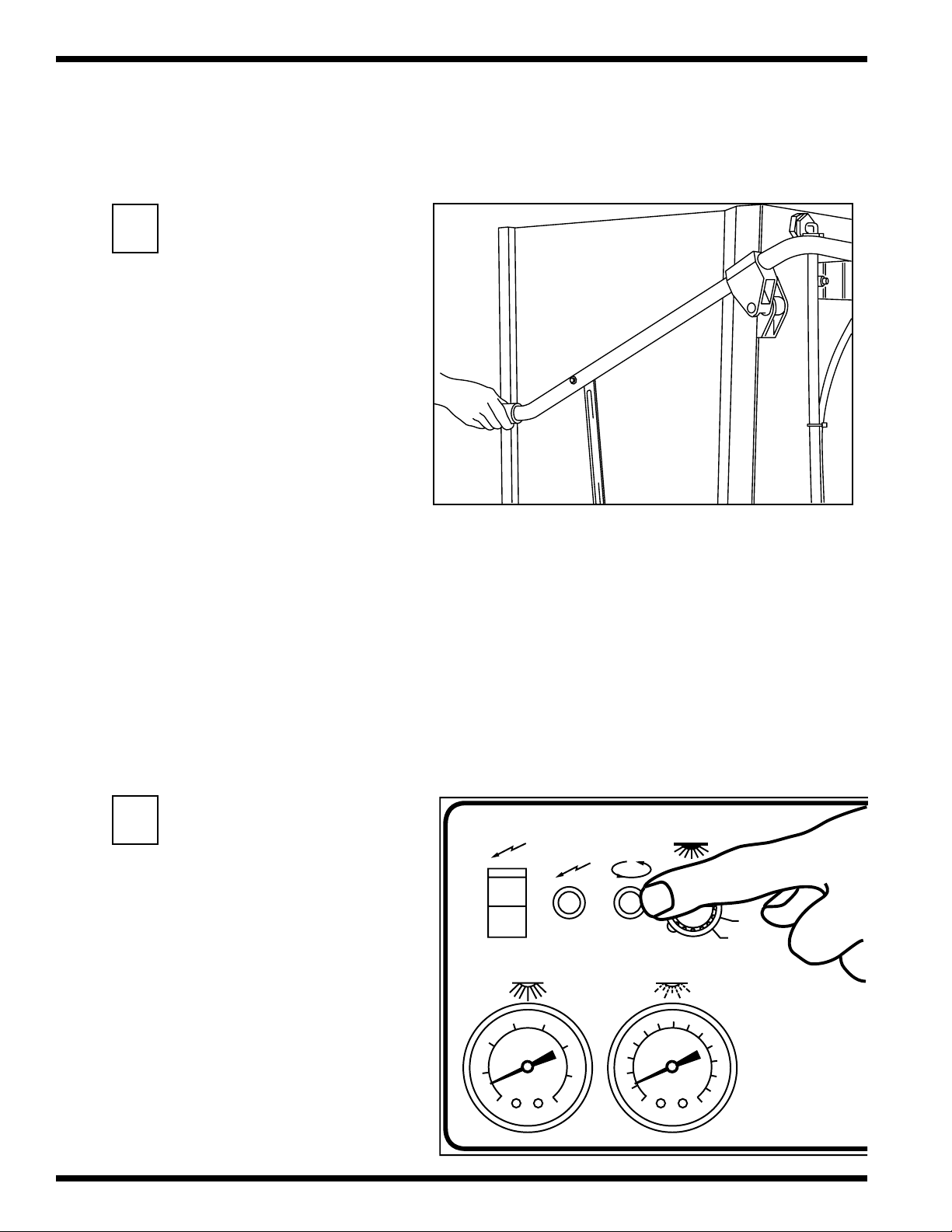

INITIAL START-UP (Cont.)

6

Fully close the dishwasher doors.

The dishwasher will begin the

automatic cycle.

Opening the doors anytime

during the cycle will stop the

dishwasher.

Closing the doors will resume

the automatic cycle where it

left off.

The cycle times are listed below:

1 Minute Wash Cycle Setting

Wash = 45 seconds

Dwell = 1 seconds

Final rinse = 14 seconds

4 Minute Wash Cycle Setting

Wash = 225 seconds (3 min 45 sec)

Dwell = 1 seconds

Final rinse = 14 seconds

7

Note that the in-cycle light

is lit during the automatic

dishwasher cycle.

2 Minute Wash Cycle Setting

Wash = 105 seconds (1 min 45 sec)

Dwell = 1 seconds

Final rinse = 14 seconds

6 Minute Wash Cycle Setting

Wash = 345 seconds (5 min 45 sec)

Dwell = 1 seconds

Final rinse = 14 seconds

POWER

OFF

WASH CYCLE

CYCLE

1 MIN

2 MIN

4 MIN

6 MIN

18

WASH

RINSE PRESSURE

Page 20

INITIAL START-UP (Cont.)

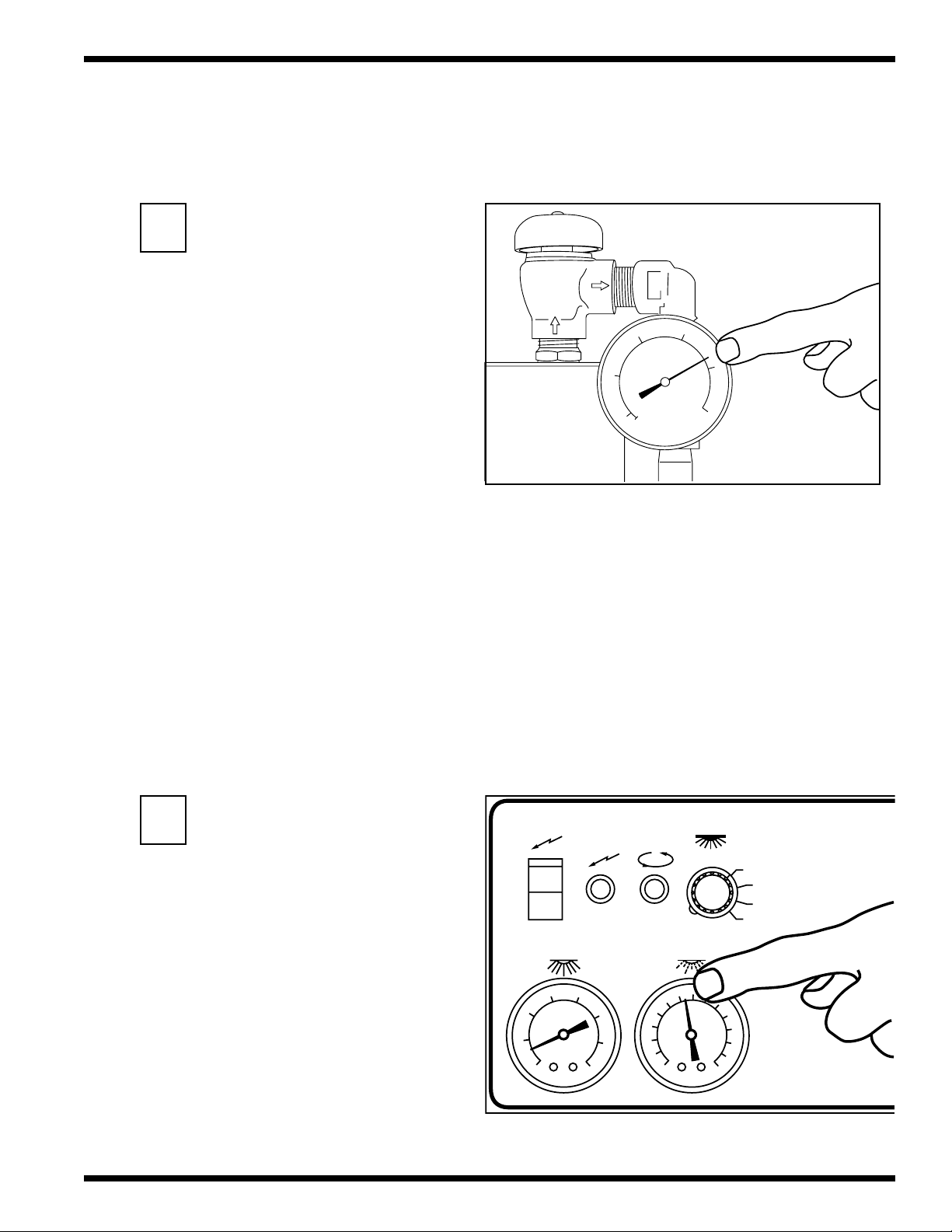

8

Check Final Rinse

Water Temperature

Check the final rinse water

temperature during the

final rinse cycle.

The final rinse water

temperature gauge is located

in the final rinse piping at

the top of the dishwasher.

INITIAL START-UP

100

50

0

150

200

250

The final rinse water temperature should be a minimum of

180°F/82°C for (D-HBT, D-H1T).

The optimum final rinse temperature

for (D-HBT, D-H1T) is

180-195°F/82-91°C.

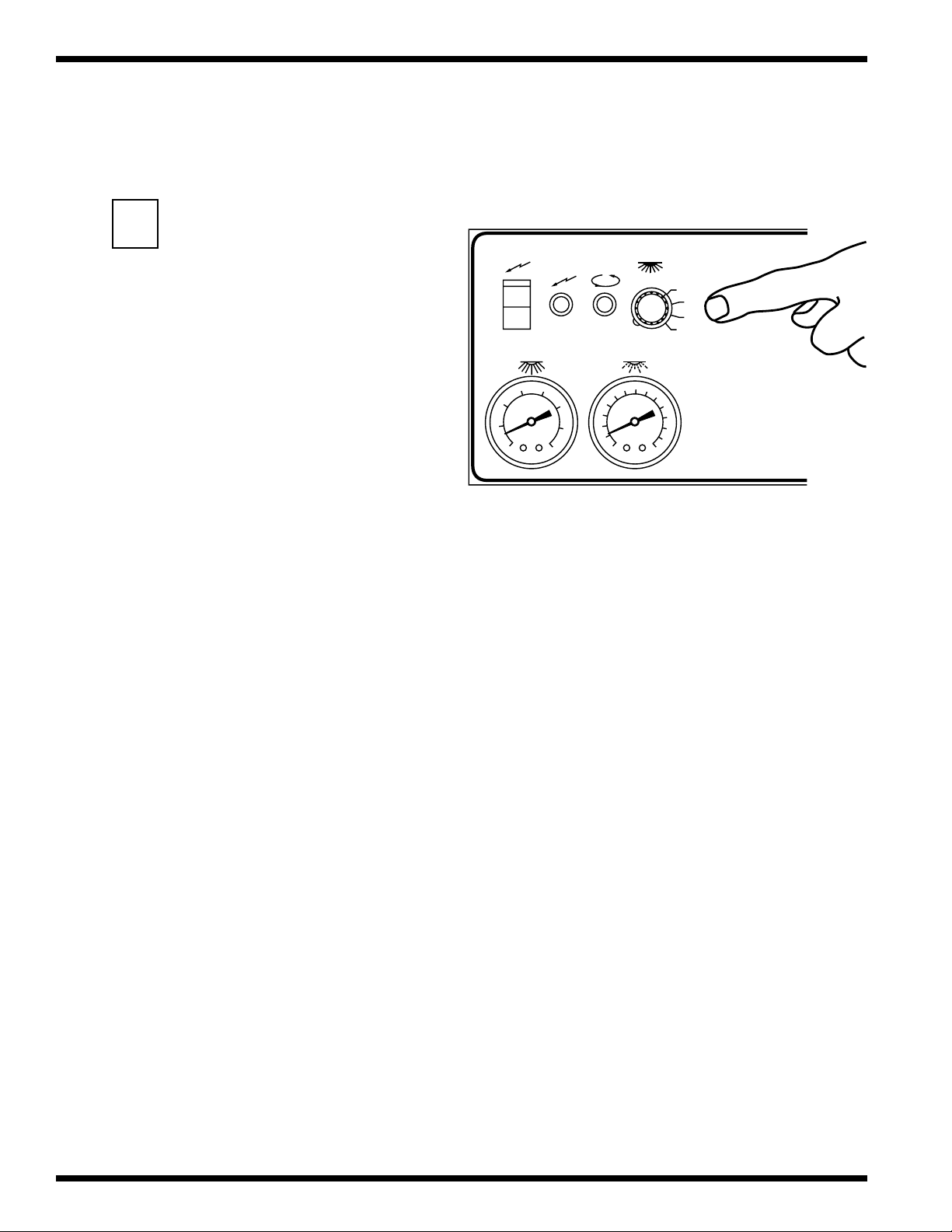

9

Check Final Rinse

Water Pressure

The final rinse water pressure gauge

should indicate a flowing pressure of

20-22 PSI/138-151.8 kPa during the

final rinse cycle for all models.

POWER

OFF

WASH

WASH CYCLE

CYCLE

1 MIN

2 MIN

4 MIN

6 MIN

RINSE PRESSURE

A pressure reducing valve (PRV) is

required if flow pressure exceeds

20-22 PSI/138-151.8 kPa.

19

Page 21

INITIAL START-UP

INITIAL START-UP (Cont.)

10

The Wash Cycle Selector

Switch

The wash cycle selector switch provides

the option of choosing four different

dishwasher cycle times.

To select a cycle time —

Make sure power is on and the dishwasher

has completed its last cycle.

Turn the selector knob to the desired

time as indicated on the control panel.

POWER

OFF

WASH

CYCLE

RINSE PRESSURE

WASH CYCLE

1 MIN

2 MIN

4 MIN

6 MIN

Close the doors.

The dishwasher will begin the cycle automatically.

If the timed fill is activated due to a loss of water, the

cycle will stop. When the dishwasher is full the automatic cycle will resume where it left off.

The maximum total wash cycle time is 6 minutes.

For example: You can not select 4 minutes then

turn the switch to 6 minutes during the automatic

2 minute cycle to extend the total cycle to 10 minutes.

The dishwasher cycle times are listed below:

1 Minute Wash Cycle Setting

Wash = 45 seconds

Dwell = 1 seconds

Final rinse = 14 seconds

4 Minute Wash Cycle Setting

Wash = 225 seconds (3 min 45 sec)

Dwell = 1 seconds

Final rinse = 14 seconds

2 Minute Wash Cycle Setting

Wash = 105 seconds (1 min 45 sec)

Dwell = 1 seconds

Final rinse = 14 seconds

6 Minute Wash Cycle Setting

Wash = 345 seconds (5 min 45 sec)

Dwell = 1 seconds

Final rinse = 14 seconds

20

Page 22

INITIAL START-UP

INITIAL START-UP (Cont.)

11

Complete the initial start-up

Check all the plumbing for leaks. Also, check the drain plumbing for leaks and be sure that the drain will

handle the drain water flow (15 gal/min-56.8 liters/min) from the dishwasher.

After the drain and the plumbing connections are checked, turn off the dishwasher power switch.

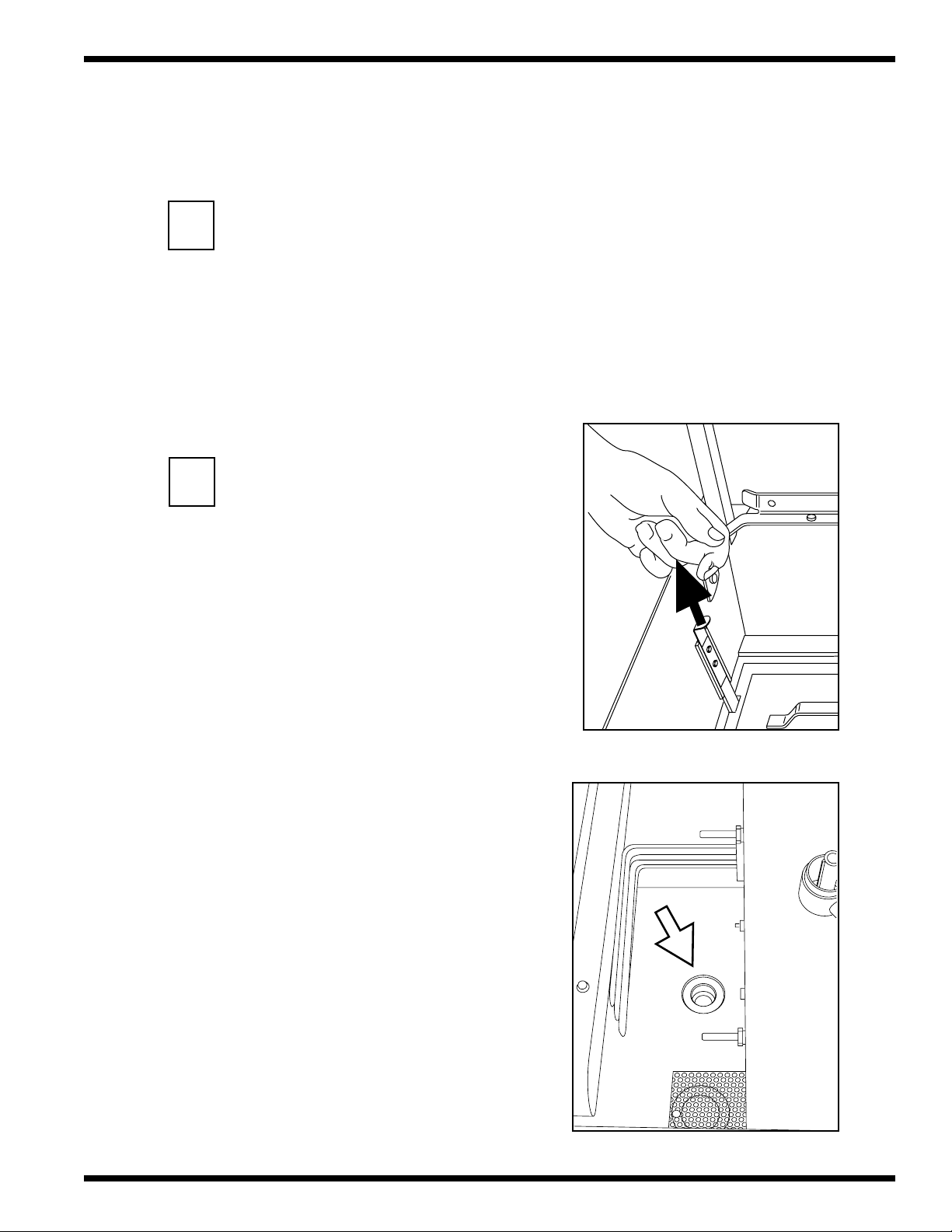

12

Drain the dishwasher

Make sure the dishwasher

power switch is turned off.

Open the doors.

Drain the dishwasher

by pulling the door activated drain lever up

The door activated drain lever is located on

the inside left rear corner of the dishwasher.

Remove the scrap screens and

check the drain located in

the bottom of the dishwasher

wash tank.

Make sure that the building drain handles the

water flow exiting the dishwasher.

Clean the interior of the wash

tank of any foreign material.

Leave the doors open to air

dry the interior of the

dishwasher.

The initial start-up is complete.

21

Page 23

OPERATION

OPERATION SUMMARY

Action Result

1. Push the On/Off power switch “UP” to

the ON position. Dishwasher fills

automatically.

2. Wait approximately 10 minutes for the

wash tank heater to heat the water. Then,

check the reading on the wash water

temperature gauge.

3. Prescrap and load the ware into the

dishrack.

4. Open the doors.

Insert a dishrack of soiled ware.

Fully close the doors.

Opening the doors anytime during the

automatic cycle stops the dishwasher.

Closing the doors will resume the cycle

where it left off.

5. Check the final rinse temperature gauge

reading during the 14 second final rinse

cycle.

1. The power indicator light illuminates. The

wash tank heater (D-HBT/H1T) and the

(booster tank heater, D-HBT) begin to heat.

2. The wash water temperature gauge should

indicate a minimum of 150°F/66°C for

D-HBT, D-H1T.

3. Ware should be placed edgewise in the peg

rack. Cups and bowls should be placed upside

down in the flat rack. Silverware should be

spread evenly in a single layer in the flat rack.

4. In cycle light illuminates as the dishwasher

begins a selected automatic cycle.

The total cycle times are listed below:

1 minute = 45 second wash

2 minute = 1 minute 45 second wash

4 minute = 3 minute 45 second wash

6 minute = 5 minute 45 second wash

5. The final rinse temperature gauge should

indicate a minimum of 180°F/82°C for D-HBT/

D-H1T. The optimum final rinse temperature

range is between 180-195°F/82-90°C.

22

6. Check the incoming water pressure

during the 14 second final rinse cycle.

7. The selected automatic cycle ends.

8. Open the doors. Remove the clean rack.

Insert another rack of soiled ware.

Fully close the doors.

9. Turn power OFF at the dishwasher.

Lift the drain lever up. Clean the scrap

screens. Clean the dishwasher after each

meal period or every two hours of

operation.

6. The water pressure gauge should indicate a

flowing pressure of 20-22 PSI/138-151.8 kPa.

A pressure reducing valve (PRV) is required if

flow pressure exceeds 20-22 PSI/138-151.8 kPa.

7. The in cycle light goes out.

8. The selected automatic cycle begins again.

9. Dishwasher wash tank drains completely.

Periodic cleaning reduces detergent

consumption and improves washing results.

Page 24

CLEANING

CLEANING

Cleaning your machine is the best maintenance that you can provide. Components that are not regularly

flushed and cleaned do not perform well.

The following schedules are the minimum requirements necessary for the proper performance of your

machine. Intervals should be shortened whenever your machine is faced with abnormal working conditions,

hard water, or multiple shift operations.

CLEANING SCHEDULE

Every 2 Hours or After Each Meal Period

1. Drain the dishwasher.

2. Flush interior with fresh water.

3. Clean scrap screens and pump intake screen.

4. Clean spray arm nozzles.

Every 8 Hours or at the End of the Day

1. Drain the machine.

2. Flush interior with fresh water.

3. Clean scrap screens and pump intake screen.

4. Clean spray arms.

5. Thoroughly clean the exterior

of machine.

DO NOT HOSE DOWN

WITH WATER.

6. Reassemble the machine.

7. Leave doors open to aid in drying.

CAUTION:

!

Do not leave water in wash

tank overnight.

23

Page 25

CLEANING

DELIMING

Your dishwasher should be delimed regularly depending on the mineral content of your water.

Inspect the machine interior for mineral deposits and use a deliming solution for the best cleaning

results.

NOTE:

Consult your chemical supplier for an appropriate deliming solution.

!

WARNING:

Deliming solutions or other acids must not come in contact with household bleach

(sodium hypochlorite) or any chemicals containing chlorine, iodine, bromine, or fluorine.

Mixing will cause hazardous gases to form.

Skin contact with deliming solutions can cause severe irritation and possible

chemical burns. Consult your chemical supplier for specific safety precautions.

DELIMING PROCESS

Model D-HBT and D-H1T

1. Remove all dishes from machine.

2. Remove any chemical pick-up tubes from their containers.

3. Place each tube in a container of fresh water and prime the chemical lines for several minutes

to thoroughly flush chemical from the lines. Leave pick-up tubes out of their containers.

4. Drain the machine and refill with fresh water.

5. Spray interior walls with deliming solution and let sit for 5 or 10 minutes depending on

amount of build-up. Add deliming solution to wash tank.

Do not let chemicals sit for longer than 15 minutes.

6. Close the doors to run an automatic cycle.

7. Repeat Steps 4-6 if necessary.

8. Lift the drain lever assembly and drain the machine.

9. Refill the machine and run a complete cycle two additional times. Drain and refill the machine after each cycle to thoroughly flush any deliming solution from the interior of the

machine.

24

10. Flip the power switch to OFF.

11. Drain machine.

12. Deliming is complete.

Page 26

TROUBLESHOOTING

Perform the seven checks listed below in the event that your dishwasher does not operate

as expected.

1. All switches are ON

2. Drain-overflow assembly is in place and seated

3. Wash and rinse nozzles are clean

4. Wash and rinse pipe assemblies are installed correctly

5. Scrap screens are properly positioned

6. Thermostat(s) are properly adjusted

7. Detergent and rinse additive dispensers are adequately filled

If a problem still exists, use the following table for troubleshooting

CONDITION CAUSE SOLUTION

Machine will not start Doors not closed ................................... Make sure doors are fully closed

Door safety switch faulty ...................... Contact your service agency

TROUBLESHOOTING

Main switch off ..................................... Check disconnect at main panel

Blown Fuse ........................................... Replace fuse

Machine washes Timer or door switch defective ............. Contact your service agency

constantly

Low or no water Main water supply is turned off ............ Turn on house water supply

Drain-overflow assembly is not ............ Place and seat drain-overflow

in place and seated

Machine doors not fully closed ............. Close doors securely

Faulty fill valve ..................................... Contact your service agency

Machine not filled initially ................... Push Power switch UP to fill

Clogged strainer in fill valve ................ Clean or replace

Continuous water filling Stuck or defective Fill Timer ................ Contact your service agency

Fill valve will not close ......................... Clean or replace

Drain-overflow not in place .................. Install drain-overflow assembly

Stuck or Defective float switch ............. Inspect or replace float switch

Wash motor not running Overload protector tripped .................... Reset overload in Control Box

Defective motor .................................... Contact your service agency

Wash tank water Incoming water temperature ................. Raise temperature to:

temperature is low at machine too low 110-140°F/43-60°C for D-HBT

when in use 180°F/82°C for D-H1T

Defective thermometer......................... Check or replace

Defective thermostat ............................. Check for proper setting

or replace

Defective heater element ...................... Check or replace

Defective solenoid valve ....................... Check or replace

Heater elements ..................................... Clean and delime

have soil/lime buildup

25

Page 27

TROUBLESHOOTING

TROUBLESHOOTING (Cont.)

CONDITION CAUSE SOLUTION

Insufficient pumped Clogged pump intake screen ................. Clean

spray pressure Clogged spray pipe ............................... Clean

Insufficient final rinse Faulty pressure reducing valve ............. Clean or replace

or no final rinse Improper setting on pressure ................. Set flow pressure at 20-22 PSI/

Scrap screen full.................................... Must be kept clean and in place

Low water level in tank ........................ Check drain-overflow assembly

Pump motor rotation incorrect .............. Reverse connection between L1

and L2 in Control Cabinet

Defective pump seal .............................. Contact Service Agent

reducing valve 138-151.8 kPa

Clogged rinse nozzle and/or ................. Clean

pipe

Improper water line size ....................... Have installer change to

proper size

Clogged strainer in fill valve ................ Clean or replace

Low final rinse Low incoming water Check the booster (D-HBT, D-H1T)

temperature temperature be sure the thermostat is set to

maintain180°F/82°C temperature.

Solenoid valve defective........................ Check valve to be sure it is clean

and operating

Defective thermometer ......................... Check for proper setting or

replace

Poor washing results Detergent dispenser ............................... Contact detergent supplier

not operating properly

Insufficient detergents........................... Contact detergent supplier

Wash water temperature ....................... See condition “Wash Tank

too low Water Temperature” above

Wash arm clogged ................................ Clean

Improperly scraped dishes .................... Check scraping procedures

Ware being improperly ......................... Use proper racks. Do not

placed in rack overload racks

Improperly cleaned ............................... Unclog wash sprays and rinse

equipment nozzles to maintain proper

pressure and flow conditions.

Overflows must be open. Keep

wash water as clean as possible.

Heater elements ..................................... Clean and delime

have soil/lime buildup

26

Page 28

BASIC SERVICE

BASIC SERVICE

This Basic Service section does not cover all possible repair procedures. If you require additional

service support, you may call your local service company or:

Champion National Service

USA: 1-800-858-4477

Canada: 1-800-263-5798

Please have the Model and Serial Number of the machine ready when you call.

ELECTRICAL SERVICE

NOTE:

DO NOT USE CHASSIS GROUND WHEN PERFORMING VOLTAGE CHECKS.

Doing so will result in false and inaccurate readings.

PERFORM VOLTAGE CHECKS BY READING FROM THE HOT SIDE OF THE

LINE AND NEUTRAL (any #2 or white wire).

WARNING:

!

USE EXTREME CAUTION when performing tests on energized circuits.

WARNING:

!

When repairing a circuit, disconnect the power at the main service disconnect switch and

place a tag at the disconnect switch to indicate that work is being performed on the circuit.

Troubleshooting

Schematics

Champion places an electrical schematic in the control cabinet of every machine before it is

shipped. Schematics are included at the back of this manual as well. Be aware that these schematics include options that may not apply to your machine. Options are enclosed in dashed lines with

the words (IF USED) next to them on the schematic. Disregard any options that appear on the

schematics which are not a part of your machine.

Tools

All electrical repairs can be made with: Standard set of hand tools

Volt/Ohm Meter (VOM)

Clip-on AC current tester

Circuit Tests

Use a clip-on AC current tester to check the motors and electric heaters.

Use a VOM to test line voltages and the 115VAC control circuit.

27

Page 29

BASIC SERVICE

ELECTRICAL SERVICE (Cont.)

Fuses —

Refer to Fig. 12.

There are two fuse blocks. A 3 pole block

(A) is located in the main control cabinet.

The (A) fuses protect the wash tank heater

circuit. Booster heater circuits

(D-HBT only) are not fused. A 2 pole

fuse block is located on the machine base

to protect the control circuit.

To Replace a fuse:

Turn the dishwasher main power switch

off. Disconnect power to the machine at

the main service disconnect switch.

Replace the fuse. If the fuse blows again,

DO NOT INCREASE THE FUSE SIZE.

DETERMINE THE CAUSE OF THE OVERLOAD.

Motor Overloads

The wash pump motor has an overload to protect it from line

voltage electrical overloads. The overload disconnects

120VAC power to the motor contactor coil.

Refer to Fig. 13.

—

A

Figure 12

Wash tank heater fuses

Control Cabinet

Switch Lever

Note the Switch Lever on the Overload.

If the switch lever is off with the “0” showing

then the overload has tripped.

To Reset the Motor Overload:

Flip the overload switch to the On position.

A “1” should be visible on the switch lever.

To Replace a Motor Overload:

Disconnect the wires to the overload.

Release the mounting catch on the front

side of the overload. Push forward and lift out.

Snap the new overload into place and reconnect

the wires.

To adjust the overload setting:

The screwdriver in Fig. 13 is positioned

to adjust the motor overload AMP setting.

Read the full load amps (FLA) motor amps on the motor

nameplate. Turn the setting to match the name plate.

Figure 13

Motor Overload

28

Page 30

0

1

2

3

UP

4

5

6

Omron

H2C

6 M

ELECTRICAL SERVICE (Cont.)

Electromechanical Timers

D-HBT, D-H1T, models have two non-adjustable

timers. They are the 45 second main cycle timer

and the fill timer. The timers are mounted on the

swing-out control cabinet. Remove the lower

front panel to access the timers.

There are three adjustable timers located on the lower

right rear corner of the wash tank. These timers

control the 2, 4, and 6 minute wash cycle operations.

Remove the lower front and left side panel to access

the timers.

BASIC SERVICE

Main Cycle Timer

—

Refer to Fig. 14.

The main cycle timer controls the non-adjustable

45-second wash time. It also resets and connects

to the adjustable 2, 4, and 6 minute timers through

the wash cycle selector switch. The main cycle timer

also controls the 1 second dwell and the 14 second

final rinse portion of the total wash cycle time.

Fill Timer

—

Refer to Fig. 15.

The fill timer controls the dishwasher’s

fill operation. The timer consists of a timer motor,

one micro-switch, and one non-adjustable plastic

cam. The fill timer operates during initial fill.

The fill timer also operates if main power is turned

off and then turned back on even if the dishwasher

is full of water.

Adjustable Wash Cycle Timers

—

Refer to Fig. 16 and detail views to the right.

The adjustable cycle timers are preset for 2, 4, and

6 minutes at the factory. All the adjustable timers

are powered at the same time and run concurrently.

Each timer has an indicator lite (A) on the front.

The lite is “ON” when the timer is counting down.

Replacement timers are not preset. The installer

must set the time range (B) to “6M” for six minutes.

The timer dial (C) should be turned to match the

original timer setting. The Hertz selector (D) must

be set to match the supplied HZ, 50Hz or 60Hz.

The adjustable timers are interchangeable.

Figure 14

Main Cycle Timer

(45 second)

Figure 15

Fill Timer

A

B

C

Timer (Front)

5

4

6T4T2T

Figure 16

Cycle Timers (2, 4, and 6 minute)

3

2

50

60

6

7

1

8

D

Timer (Back)

29

Page 31

BASIC SERVICE

1L1

1L2

1L3

1L1

1L2

1L3

ELECTRICAL SERVICE (Cont.)

Heater Element Wiring – Booster Tank and Wash Tank Heater Elements

Refer to the illustrations and follow the steps below to properly install terminal jumpers and to

make line power connections to a replacement element.

Step 1. Hold the element assembly with the calrod coils facing toward you.

Step 2. Match your element coil to Configuration A, B, C, or D.

Step 3. Rotate your element coils to match the correct configuration.

Step 4. Turn the element over and match your element to the correct terminal configuration.

Step 5. Install terminal jumpers according to the illustration for your voltage requirement.

Step 6. Install the element and make your line connections 1L1, 1L2, or 1L3 per the illustration.

Configuration A

Booster tank element

View of calrod coils

Configuration B

Booster tank element

View of calrod coils

Configuration C

Booster tank element

View of calrod coils

Terminal Connections View of element

1L3

1L1

1L2

1L3

1L1

1L2

1L1

1L2

208V/1 Phase 208-240V/3 Phase 480V/3 Phase 208-240V/3 Phase

Delta Connection 575V/3 Phase Wye Connection for

Delta Connection 380-415V/3 Phase

Terminal Connections View of element

1L1

1L2

208V/1 Phase 208-240V/3 Phase 480V/3 Phase 208-240V/3 Phase

1L1

1L2

1L3

1L1

1L2

1L3

1L3

1L1

1L2

Delta Connection 575V/3 Phase Wye Connection for

Delta Connection 380-415V/3 Phase

Terminal Connections View of element

1L1

1L2

1L1

1L3

1L2

1L1

1L3

1L2

1L1

1L2

1L3

208V/1 Phase 208-240V/3 Phase 480V/3 Phase 208-240V/3 Phase

Delta Connection 575V/3 Phase Wye Connection for

Delta Connection 380-415V/3 Phase

Configuration D

Terminal Connections View of element

Wash tank element

View of calrod coils

1L1

1L2

1L1

1L3

1L2

208V/1 Phase 208-240V/3 Phase 480V/3 Phase 208-240V/3 Phase

Delta Connection 575V/3 Phase Wye Connection for

Delta Connection 380-415V/3 Phase

1L1

1L2

1L3

Figure 17

30

Heater Element Wiring

Page 32

BASIC SERVICE

654

987

321

LINE

ELECTRICAL SERVICE (Cont.)

Motor Connections —

1. Models D-HBT and D-H1T are available in either single phase or 3 phase voltages.

2. Motor rotation was set at the factory. For three phase machines, reversing the motor direction

is done in the control cabinet by reversing the wires L1 and L2 on the disconnect side of the

main electrical connection block. For single phase machines, motor rotation is changed at the

motor connection plate on the rear of the single phase motor (if necessary).

Refer to Fig. 18 for the proper wiring of the pump motor for single and three phase voltages.

Single Phase - Low Voltage

L1

3

4

L2

208-240V

Three Phase - Low Voltage

654

987

LINE

J

8

LINE

2

Figure 18

Pump Motor Wiring Diagrams

Three Phase - High Voltage

480V

Single Phase - High Voltage

LINE

J

2

LINE

3

L2

L1

4

8

575V Only

Three Phase

321

LINE

321

LINE

31

Page 33

BASIC SERVICE

MECHANICAL SERVICE

Pump Seal Replacement

1. Disconnect the power to the machine at the main breaker panel or fuse box.

2. Drain the machine.

3. Remove the front and side panels.

4. Remove drain plug on the pump volute and drain the pump.

5. Remove the pump hoses.

6. Disconnect the wires to the motor at the motor junction box.

7. Unbolt motor from machine base and remove the pump/motor assembly.

8. Remove bolts on volute and carefully remove from the pump flange.

9. Remove the impeller retaining bolt and nut from center of impeller.

10. Lock the motor shaft with a wrench or pliers. The back of motor shaft is square.

11. Turn the impeller counter-clockwise to remove from shaft (right hand threads).

12. Remove the old seal and discard.

13. Check seal seat in the pump flange and clean thoroughly.

14. Press rubber seal/ceramic portion of seal assembly into the pump flange. Use a water

soluble lubricant. Be careful to keep the ceramic clean.

15. Install the rotating part of the seal on the shaft with the graphite surface toward the ceramic.

Use a water soluble lubricant on the rubber seal part only (not the graphite).

16. Reinstall impeller, and new flange gasket. Reinstall bolts. Reinstall drain plug.

17. Reinstall the pump/motor assembly and reconnect the pump hoses.

18. Fill the dishwasher with water.

19. Check motor rotation by bump starting motor.

Correct motor shaft rotation is clockwise when viewing motor from the rear.

20. Test run and check for leaks.

Water

Slinger

Backing Plate

Pump Flange

Backing Plate

Mtg. Nut

Impeller

Washer

Seal Assy.

Figure 19

Pump Seal Replacement

Nut

Gaskets

Bolt

(B)

Bolt

(A)

Volute

Plug

32

Page 34

REPLACEMENT PARTS

7

12

10

10

11

11

10

6

1

5

9

6

8

2

3

4

9

9

7

8

34

Figure 20 - D-HBT/D-H1T

Panels

Page 35

REPLACEMENT PARTS

D-HBT

PANELS

Fig. 20 Part

Item No. No. Part Description Qty.

1 321929 RH PANEL NO CUT OUT ................................................................ 1

2 321933 PANEL, INSTRUMENT ................................................................... 1

3 112388 DECAL, CONTROL PANEL ............................................................ 1

4 322074 PANEL, FRONT LOWER ................................................................. 1

5 321941 LH PANEL W/CUTOUT ................................................................... 1

6 108418 PLUG PLASTIC ................................................................................ 2

7 109034 WASHER 13/16 X 1-13/16 FIBER.................................................... 2

8 108417 NUT, PLASTIC.................................................................................. 2

9 100779 SCREW, 1/4-20 X 5/8 TRUSS HEAD .............................................. 6

10 0504822 SCREW, 8-32 X 1/2 PAN HEAD ...................................................... 4

11 100763 SCREW, 10-32 X 1-1/4 ROUND HEAD .......................................... 2

12 112587 FOOT, CAST GREY.......................................................................... 4

35

Page 36

REPLACEMENT PARTS

5

6

1

2

3

4

8

10

20

19

9

7

17

25

26

24

11

13

12

15

14

18

16

36

22

21

23

21

22

Figure 21 - DHB-T/DH1-T

Doors, Guides, & Stops

(Prior to S/N 91612 )

Page 37

REPLACEMENT PARTS

DHB-T/DH1-T

DOORS, GUIDES, & STOPS

(Prior to S/N 91612)

Fig. 21 Part

Item No. No. Part Description Qty.

1 100141 NUT, GRIP 1/4-20 SST ................................................................... 2

2 317345 BRACKET, DOOR CATCH ............................................................ 1

3 317344 HOOK, DOOR CATCH ................................................................... 1

4 108053 PLUG, CORNER POST .................................................................. 2

5 107970 SCREW, 8/32 X 1 FILLISTER HEAD ........................................... 48

6 112704 DOOR GUIDE, SIDE DOOR LEFT ............................................... 2

7 112705 DOOR GUIDE, SIDE DOOR RIGHT ............................................ 2

8 112703 DOOR GUIDE, FRONT DOOR RIGHT ........................................ 1

9 112702 DOOR GUIDE, FRONT DOOR LEFT ........................................... 1

10 100073 SCREW, 1/4-20 X 1/2 TRUSS HEAD ............................................ 1

11 111090 SWITCH, MAGNETIC ................................................................... 1

12 108954 NUT, GRIP 6-32 .............................................................................. 2

13 322790 DOOR, FRONT ............................................................................... 1

14 108966 HANDLE, DOOR ............................................................................ 1

15 100073 SCREW, 1/4-20 X 1/2 TRUSS HEAD ............................................ 2

16 106382 SCREW, 6-32 X 3/8 TRUSS HEAD ............................................... 2

17 108954 NUT, GRIP 6-32 .............................................................................. 2

18 111026 MAGNET ......................................................................................... 1

19 ——— SIDE DOOR, UPPER (Replaced by Kit 900793, see below) ......... 2

20 322788 SIDE DOOR, LOWER .................................................................... 2

21 100097 SCREW, 10-32 X 1/2 TRUSS HEAD ............................................. 8

22 107966 NUT, GRIP 10-32 ............................................................................ 2

23 322077 SPLASH GUARD ............................................................................ 2

24 323066 DOOR STOP .................................................................................... 2

25 107893 SHOCK ABSORBER ...................................................................... 8

26 100740 BOLT, 5/16-18 X 1 HEX HEAD ..................................................... 2

— 900793 KIT, SIDE DOOR ............................................................................ 1

(Refer to Figure 23, page 40)

(Kit includes:

Qty. 1, Item 19, Qty. 2, Item 25, Qty. 1, Items 27-28, Qty. 4, Item 29)

37

Page 38

REPLACEMENT PARTS

2

3

1

4

3

4

5

13

12

6

11

5

7

38

8

9

8

9

10

14

8

9

8

9

Figure 22 - DHB-TC/DH1-TC

Doors, Guides, & Stops (Corner Model Only)

(Prior to S/N 91612 )

Page 39

REPLACEMENT PARTS

DHB-TC/DH1-TC

DOORS, GUIDES, & STOPS (Corner Model Only)

(Prior to S/N 91612)

Fig. 22 Part

Item No. No. Part Description Qty.

1 108053 PLUG, CORNERPOST ................................................................... 2

2 107970 SCREW, 8-32 X 1 FILISTER HEAD.............................................. 32

3 112704 GUIDE, DOOR LEFT ..................................................................... 2

4 112705 GUIDE, DOOR RIGHT ................................................................... 2

5 ——— DOOR, UPPER (Replaced by Kit 900793, see below) ................... 2

6 322788 DOOR, LOWER SIDE .................................................................... 1

7 323221-S DOOR LOWER FRONT ................................................................. 1

8 100097 SCREW 10-32 X 1/2 TRUSS HEAD .............................................. 8

9 107966 NUT, GRIP 10-32 ............................................................................ 8

10 322077 GUARD, SPLASH ........................................................................... 1

11 323006 STOP, DOOR ................................................................................... 1

12 100740 BOLT, 5/16-18 X 1 HEX HEAD ..................................................... 1

13 107893 SHOCK ABSORBER ...................................................................... 4

14 323224 BRACKET, CORNER MACHINE DOOR LIFT ........................... 1

— 900793 KIT, SIDE DOOR ............................................................................ 1

Refer to Figure 24, page 42)

(Kit Includes:

Qty. 1, Item 5, Qty. 2, Item 13, Qty. 1 Items 15-16, Qty. 4, Item 17)

39

Page 40

REPLACEMENT PARTS

1

2

3

4

5

7

8

10

9

27

28

25

20

19

16

25

24

26

29

7

17

11

13

12

15

14

18

16

40

22

21

22

23

21

Figure 23 - DHB-T/DH1-T

Doors, Guides, & Stops

(For machines beginning with S/N 91612 and above)

Page 41

REPLACEMENT PARTS

DHB-T/DH1-T

DOORS, GUIDES, & STOPS

(For machines beginning with S/N 91612 and above)

Fig. 23 Part

Item No. No. Part Description Qty.

1 100141 NUT, GRIP 1/4-20 SST ................................................................... 2

2 317345 BRACKET, DOOR CATCH ............................................................ 1

3 317344 HOOK, DOOR CATCH ................................................................... 1

4 108053 PLUG, CORNER POST .................................................................. 2

5 107970 SCREW, 8/32 X 1 FILLISTER HEAD ........................................... 48

6 112704 DOOR GUIDE, SIDE DOOR LEFT ............................................... 2

7 112705 DOOR GUIDE, SIDE DOOR RIGHT ............................................ 2

8 112703 DOOR GUIDE, FRONT DOOR RIGHT ........................................ 1

9 112702 DOOR GUIDE, FRONT DOOR LEFT ........................................... 1

10 100073 SCREW, 1/4-20 X 1/2 TRUSS HEAD ............................................ 1

11 111090 SWITCH, MAGNETIC ................................................................... 1

12 108954 NUT, GRIP 6-32 .............................................................................. 2

13 322790 DOOR, FRONT ............................................................................... 1

14 108966 HANDLE, DOOR ............................................................................ 1

15 100073 SCREW, 1/4-20 X 1/2 TRUSS HEAD ............................................ 2

16 106382 SCREW, 6-32 X 3/8 TRUSS HEAD ............................................... 2

17 108954 NUT, GRIP 6-32 .............................................................................. 2

18 111026 MAGNET ......................................................................................... 1

19 322789 SIDE DOOR, UPPER ...................................................................... 2

20 322788 SIDE DOOR, LOWER .................................................................... 2

21 100097 SCREW, 10-32 X 1/2 TRUSS HEAD ............................................. 8

22 107966 NUT, GRIP 10-32 ............................................................................ 2

23 322077 SPLASH GUARD ............................................................................ 2

24 323066 DOOR STOP .................................................................................... 2

25 107893 SHOCK ABSORBER ...................................................................... 8

26 100740 BOLT, 5/16-18 X 1 HEX HEAD ..................................................... 2

27 323305 ANGLE, DOOR STOP .................................................................... 2

28 112772 STOP, DELRIN SPLASH BAFFLE ................................................ 2

29 100097 SCREW, 10-32 X 1/2 TRUSS HEAD ............................................. 8

41

Page 42

REPLACEMENT PARTS

2

3

1

4

3

4

5

5

17

16

13

6

8

9

16

15

15

13

12

7

11

10

14

12

8

9

42

8

9

8

9

Figure 24 - DHB-TC/DH1-TC

Doors, Guides, & Stops (Corner Model Only)

(For machines beginning with S/N 91612 and above)

Page 43

REPLACEMENT PARTS

DHB-TC/DH1-TC

DOORS, GUIDES, & STOPS (Corner Model Only)

(For machines beginning with S/N 91612 and above)

Fig. 24 Part

Item No. No. Part Description Qty.

1 108053 PLUG, CORNERPOST ................................................................... 2

2 107970 SCREW, 8-32 X 1 FILISTER HEAD.............................................. 32

3 112704 GUIDE, DOOR LEFT ..................................................................... 2

4 112705 GUIDE, DOOR RIGHT ................................................................... 2

5 322789 DOOR, UPPER (Replaced by Kit 900793, see below) ................... 2

6 322788 DOOR, LOWER SIDE .................................................................... 1

7 323221-S DOOR, LOWER FRONT ................................................................ 1

8 100097 SCREW 10-32 X 1/2 TRUSS HEAD .............................................. 8

9 107966 NUT, GRIP 10-32 ............................................................................ 8

10 322077 GUARD, SPLASH ........................................................................... 1

11 323006 STOP, DOOR ................................................................................... 1

12 100740 BOLT, 5/16-18 X 1 HEX HEAD ..................................................... 1

13 107893 SHOCK ABSORBER ...................................................................... 6

14 323224 BRACKET, CORNER MACHINE DOOR LIFT ........................... 1

15 323305 ANGLE, DOOR STOP .................................................................... 2

16 112772 STOP, DELRIN SPLASH BAFFLE ................................................ 2

17 100097 SCREW, 10-32 X 1/2 TRUSS HEAD ............................................. 8

43

Page 44

REPLACEMENT PARTS

28 30

29

2

1

30

3

5

2

3

6

4

1

9

7

24

24

5

6

26

27

9

10

11

26

11

10

24

25

8

12

13

14

26

27

7

11

8

10

26

11

24

25

20

21

20

18

23

22

19

12

15

13

14

16

17

18

Figure 25 - D-HBT/D-H1T

Door Handle, Spring Assembly, and Safety Switch

10

44

Page 45

REPLACEMENT PARTS

D-HBT/D-H1T

DOOR HANDLE , SPRING ASSEMBLY, AND SAFETY SWITCH

Fig. 25 Part

Item No. No. Part Description Qty.

1 0509168 BOLT 5/16-18 X 11 HEX HEAD ...................................................... 2

2 108066 SPRING, EXTENSION ..................................................................... 2

3 107397 BLOCK, SPRING HOOK ................................................................. 2

4 0509166 DOOR HANDLE ............................................................................... 1

5 107437 BOLT M6 X 45MM HEX HEAD ...................................................... 4

6 107396 BLOCK, UPPER PIVOT ................................................................... 2

7 107393 PIN, PIVOT ........................................................................................ 2

8 107962 HANDLE, GRIP ................................................................................ 2

9 107395 BLOCK, LOWER PIVOT ................................................................. 2

10 107420 NUT, PLAIN M6................................................................................ 8

11 107436 SCREW M6 X 16MM FILISTER ..................................................... 6

12 107399 SUPPORT, PIVOT BLOCK............................................................... 2

13 108368 GASKET, BACKING ........................................................................ 2

14 304811 PLATE, BACKING............................................................................ 2

15 100740 BOLT 5/16-18 X 1 HEX HEAD ........................................................ 2

16 107966 NUT, GRIP 10-32 W/NYLON INSERT ............................................ 8

17 322077 GUARD, SPLASH ............................................................................. 2

18 100097 SCREW 10-32 X 1/2 TRUSS HEAD ................................................ 8

19 0509264 BUSHING, SIDE DOOR ................................................................... 2

20 0509274 NUT, ACORN 5/16-18 SST ............................................................... 2

21 0309167 LIFT BAR, DOOR ............................................................................. 2

22 102376 WASHER, FLAT ................................................................................ 2

23 104002 BOLT 5/16-18 X 1-1/2 ....................................................................... 2

24 100154 NUT, PLAIN 5/16-18......................................................................... 4

25 106013 WASHER, LOCK 5/16 SPLIT ........................................................... 2

26 102376 WASHER 5/16 X 3/4 X 1/16 ............................................................. 4

27 321927 SPRING ANCHOR BRACKET ........................................................ 1

28 0509199 SWITCH, DOOR SAFETY ............................................................... 1

29 0309451 BRACKET, SWITCH ........................................................................ 1

30 107967 NUT, GRIP (1/4-20 W/NYLON INSERT) ........................................ 2

45

Page 46

REPLACEMENT PARTS

6

2

6

8

6

1

6

7

8

9

10

7

4

6

11

7

9

10

5

11

7

6

7

3

7

9

10

8

8

9

10

46

Figure 26 - D-HBT/D-H1T

Track Assembly

(Corner configuration shown)

Page 47

REPLACEMENT PARTS

D-HBT/D-H1T

TRACK ASSEMBLY

Fig. 26 Part

Item No. No. Part Description Qty.

1 0309469 GUIDE, RIGHT HAND ..................................................................... 1

2 0309472 TRACK, REAR.................................................................................. 1

3 0309468 GUIDE, LEFT HAND ....................................................................... 1

4 0309470 SUPPORT, RACK .............................................................................. 1

5 0309471 TRACK, FRONT ............................................................................... 1

6 106727 SCREW (10-32 X 5/8 FLAT HD) ...................................................... 6

7 107966 NUT, GRIP (10-32 W/NYLON INSERT) ......................................... 6

8 100779 BOLT (1/4 -20 X 5/8 TRUSS HD)..................................................... 8

9 106482 WASHER, LOCK .............................................................................. 8

10 100003 NUT (1/4-20 HEX HD) ...................................................................... 8

11 0309473 SPACER ............................................................................................. 2

47

Page 48

REPLACEMENT PARTS

6

10

1

2

3

4

5

4

14

13

11

12

12

8

7

11

2

8

9

48

FRONT

12

LEFT SIDE

Figure 27 - D-HBT/D-H1T

Wash/Rinse Spray Piping

Page 49

REPLACEMENT PARTS

D-HBT/D-H1T

WASH/RINSE SPRAY PIPING

Fig. 27 Part

Item No. No. Part Description Qty.

1 112688 RINSE TUBE ..................................................................................... 1

2 0509181 FITTING, STRAIGHT COMPRESSION.......................................... 2

3 0509150 CONNECTOR, TOP RINSE.............................................................. 1

4 0509180 FITTING, STRAIGHT COMPRESSION.......................................... 2

5 0309445 RINSE TUBE, TOP ........................................................................... 1

6 0509179 FITTING, BULKHEAD 1/2"NPT ..................................................... 1

7 0507445 SPINDLE, WASH ARM .................................................................... 2

8 109864 SUPPORT, WASH ARM .................................................................... 2

9 0509178 CONNECTOR, BOTTOM RINSE .................................................... 1

10 112684 STANDPIPE, WASH ......................................................................... 1

11 100736 BOLT 1/4-20 X 3/4 HEX HEAD ....................................................... 2

12 107967 NUT, GRIP 1/4-20 ............................................................................. 1

13 106482 WASHER, SPLIT LOCK SST ........................................................... 2

14 0309350 WASHER ........................................................................................... 1

49

Page 50

REPLACEMENT PARTS

2

1

3

2

4

5

3

6

7

50

8

Figure 28 - D-HBT/D-H1T

Wash/Rinse Spray Arms

Page 51

REPLACEMENT PARTS

D-HBT/D-H1T

WASH/RINSE SPRAY ARMS

Fig. 28 Part

Item No. No. Part Description Qty.

1 0507443 SPINDLE, RINSE ARM .................................................................... 2

2 0508376 NOZZLE, RINSE ARM (D-HBT/ D-H1T ONLY) ............................ 12

3 112164 BEARING, RINSE ARM ................................................................... 4

4 0707453 RINSE ARM ASSY. (INCLUDES 2 & 3) ......................................... 2

5 0507444 NUT, RINSE ARM ............................................................................ 2

6 109835 SCREW (#8 X 1/2 PAN HD) ............................................................. 4

7