Page 1

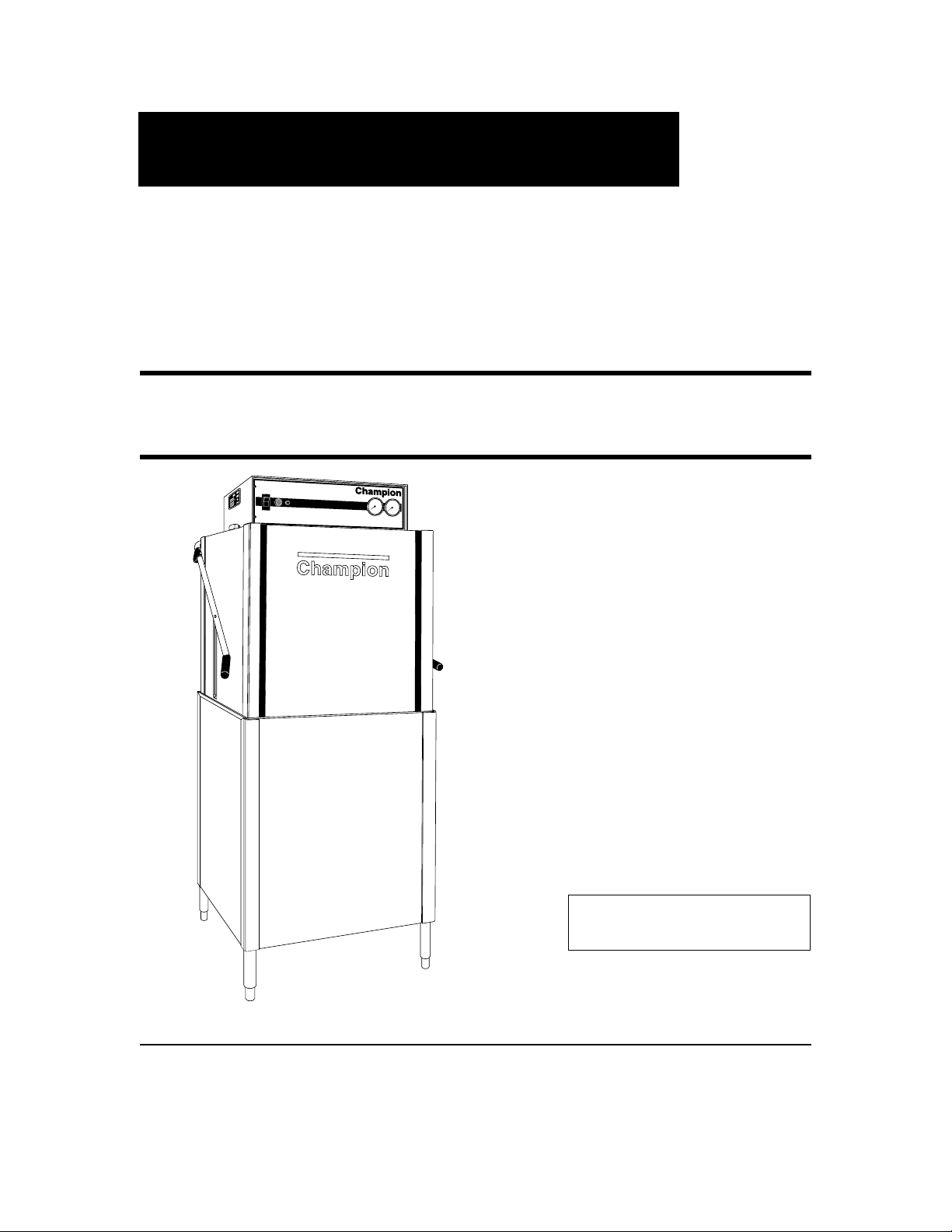

The Dishwashing Machine Specialists

Technical Manual

Door-Type

Dishwasher

Model

D-HB

High Temperature

with Built-in Booster

D-H1

High Temperature

D-LF

Low Temperature

April, 1996

P.O. Box 4149

Winston-Salem, North Carolina 27115-4149

336/661-1556 Fax: 336/661-1660

Email: champion@championindustries.com

Manual P/N 111807

Champion

Machine Serial No.

Champion Industries, Inc.

2674 N. Service Road

Jordan Station, Ontario, Canada L0R 1S0

905/562-4195 Fax: 905/562-4618

Page 2

Complete the information below so it will be available for quick reference.

Model Number

____________________________

Serial Number

_________________________

Voltage and Phase

_______________________________________________________________

Champion Parts Distributor

___________________________________

Phone

______________

______________________________________________________________________________

Champion Service Agency

____________________________________

Phone

______________

______________________________________________________________________________

Champion Industries Service: 1 (800) 858-4477 Champion Service Fax: 1 (336) 661-1660

In Canada:

Champion Service: 1 (800) 263-5798

Canada Service Fax: 1 (905) 562-4618

We strongly recommend that you fax your orders.

NOTE: When calling to order parts, be sure to have the model number, serial number, voltage,

and phase of your machine.

COPYRIGHT © 1996 by Champion Industries, Inc.

Machine Data Plate with

Model & Serial number

located on left side of

control cabinet.

Page 3

Revision History

Revision Revised Serial Number Comments

Date Pages Effectivity

4/16/96 — — Reissue manual with new replacement parts lists

9/16/96 11-12 — Revised straight-through to corner conversion

instructions

1

REVISIONS

Page 4

CONTENTS

Page

The Dishwashing Formula ............................................................................................................ 6

WARRANTY ................................................................................................................................ 7

INTRODUCTION......................................................................................................................... 8

GENERAL .................................................................................................................................... 9

Model Numbers ...................................................................................................................... 9

Standard Equipment................................................................................................................ 9

Options.................................................................................................................................... 9

Accessories ............................................................................................................................. 9

Electrical Power Requirements............................................................................................... 10

INSTALLATION........................................................................................................................... 11

Unpacking ............................................................................................................................... 11

Changing from Straight-through to Corner Operation ........................................................... 11

Electrical Connections ............................................................................................................ 12

Plumbing Connections............................................................................................................13

Water Connections .................................................................................................................. 13

Drain Connections .................................................................................................................. 14

Chemical Connections ............................................................................................................14

Model D-HB, D-H1 and D-LF......................................................................................... 15

Detergent................................................................................................................................. 15

Rinse Aid/Sanitizer ................................................................................................................. 16

INITIAL START-UP ..................................................................................................................... 18

Model D-HB, D-H1 and D-LF

OPERATION................................................................................................................................. 19

Model D-HB, D-H1 and D-LF

MAINTENANCE.......................................................................................................................... 20

Maintenance Schedule ............................................................................................................20

CLEANING...................................................................................................................... 20

Every 2 Hours or After Each Meal Period

Model D-HB, D-H1 and D-LF............................................................................ 20

Every 8 Hours or at the End of the Day

Model D-HB, D-H1 and D-LF............................................................................ 20

DELIMING ...................................................................................................................... 21

Deliming process

Model D-HB, D-H1 and D-LF............................................................................ 21

OPERATION CHECKS................................................................................................... 22

Daily...........................................................................................................................22

Weekly ....................................................................................................................... 22

2

CONTENTS

Page 5

CONTENTS

Page

TROUBLESHOOTING ................................................................................................................ 22

BASIC SERVICE .......................................................................................................................... 24

Electrical Service .................................................................................................................... 24

Fuses................................................................................................................................. 25

Motor Overloads............................................................................................................... 25

Timers............................................................................................................................... 26

Timed Fill/Low Water Tank Heat Protection................................................................... 27

Heater Element Wiring..................................................................................................... 28

Motor Connections........................................................................................................... 29

Mechanical Service................................................................................................................. 30

Pump Seal Replacement................................................................................................... 30

REPLACEMENT PARTS LIST.................................................................................................... 31

ELECTRICAL SCHEMATICS & DIAGRAMS .......................................................................... 67

LIST OF FIGURES

Figure 1 — Placement for Corner Operation.............................................................................. 11

Figure 2 — Changing the Track Assembly ................................................................................ 12

a — Straight-Through Configuration

b — Corner Configuration

Figure 3 — Drain Connection..................................................................................................... 14

Figure 4 — Chemical Connection Points ................................................................................... 15

Figure 5 — Detergent Probe Insertion Point .............................................................................. 15

Figure 6 — Rinse Aid Insertion Point ........................................................................................ 16

Figure 7 — Rinse Aid/Sanitizer Injection Points ....................................................................... 17

Figure 8 — Operator Controls .................................................................................................... 18

Figure 9 — Door Activated Drain Lever Assembly................................................................... 18

Figure 10 — Fuses ........................................................................................................................ 25

Figure 11 — Motor Overload ....................................................................................................... 25

Figure 12 — Cycle Timer ............................................................................................................. 26

Figure 13 — Cycle Timer Chart ................................................................................................... 26

Figure 14 — Fill Timer ................................................................................................................. 26

Figure 15 — Fill Timer Chart ....................................................................................................... 26

Figure 16 — Float Switch ............................................................................................................. 27

Figure 17 — Float Switch Troubleshooting Chart........................................................................ 27

Figure 18 — Pump Motor Wiring Diagrams ................................................................................ 29

Figure 19 — Pump Seal Replacement .......................................................................................... 30

Figure 20 — Doors, Panels and Gauges ....................................................................................... 32

Figure 21 — Door Handle Assembly and Springs ....................................................................... 34

Figure 22 — Door Linkage ........................................................................................................... 35

Figure 23 — Track Assembly, Float Switch and Drain Assembly............................................... 36

Figure 24 — Wash/Rinse Spray System Assembly (Beginning with S/N 11599 and above) ..... 38

3

CONTENTS

Page 6

LIST OF FIGURES (cont’d)

Figure 25 — Wash/Rinse Spray Arms (Beginning with S/N 77855 through S/N 11599) ........... 40

Figure 26 — Wash/Rinse Spray Arms (Prior to S/N 77854)........................................................ 42

Figure 27 — Tank Heater Element and Thermostat..................................................................... 44

Figure 28 — Fill Piping Assembly ............................................................................................... 46

Figure 29 — Fill Piping Assembly ............................................................................................... 48

Figure 30 — Pump Assembly ....................................................................................................... 50

Figure 31 — Electric Booster Assembly and Thermostat ............................................................ 52

Figure 32 — Control Cabinet........................................................................................................ 54

Figure 33 — Dishracks ................................................................................................................. 56

Figure 34 — Steam Coil/Steam Injector Fill Piping .................................................................... 60

Figure 35 — Steam Coil and Booster Assembly .......................................................................... 62

Figure 36 — Steam Injector and Booster Assembly .................................................................... 64

Figure 37 — Electrical Schematic D-HB/D-H1, 3 Phase............................................................. 68

Figure 38 — Wiring Diagram D-HB, 3 Phase.............................................................................. 69

Figure 39 — Electrical Schematic D-HB/D-H1/D-LF, 1 Phase................................................... 70

Figure 40 — Wiring Diagram D-HB, 1 Phase.............................................................................. 71

Figure 41 — Wiring Diagram D-H1/D-LF, 3 Phase..................................................................... 72

4

CONTENTS

Page 7

5

COMPONENT DIAGRAM

D-HB

COMPONENT DIAGRAM

PRESSURE

GAUGE

FINAL RINSE

FILL VALVE

PRESSURE REDUCING

VALVE

(PG. 47)

(PG. 47)

(PG. 33)

VACUUM

BREAKER

GREEN START

SWITCH

(PG. 47)

(PG. 55)

FILL

TIMER

CYCLE

TIMER

(PG. 55)

(PG. 55)

MACHINE ELECTRICAL

CONNECTION

DATA PLATE (PG. 12)

LINE STRAINER

WATER

CONNECTION (PG. 47)

ELECTRICAL

CONNECTION

CHEMICAL

ELECTRICAL

CONNECTIONS (PG. 15)

DOOR SAFETY

MAGNETIC REED

SWITCH (PG. 33)

POWER

SWITCH

DOOR

SPRINGS

(PG. 55)

(PG. 35)

WASH

PUMP

(PG. 12)

(PG. 51)

FLOAT SWITCH

HEAT

PROTECTION (PG. 37)

TEMPERATURE

GAUGES

INTERCHANGEABLE

WASH/RINSE

SPRAY ARMS

DRAIN

ASSEMBLY

DRAIN

CONNECTION

(PG. 37)

(PG. 33)

(PG. 39)

BOOSTER

HIGH LIMIT

THERMOSTAT (PG. 53)

WASH TANK

HEATER

(PG. 37)

(PG. 45)

FINAL RINSE

BOOSTER HEATER

(D-HB ONLY) (PG. 53)

BOOSTER TANK HEAT

THERMOSTAT

WASH TANK HEAT

THERMOSTAT

(PG. 53)

(PG. 45)

Page 8

6

The Dishwasher Formula

Five Elements for Cleaning Dishes

A Perfect Score means Clean Ware for your customers . . .

Peak Dishwasher Performance for you.

Point Value

1. Time ..................................................................................

20

Wash and rinse times (set by NSF and Champion) allow everything to work.

2. Temperature ......................................................................

20

Heated water penetrates and loosens soil on dishes.

3. Mechanical Action ............................................................ 20

Pumps produce water pressure which flushes the soil off dishes.

4. Chemical Action ............................................................... 20

Detergent breaks down grease and loosens soil particles.

5. Procedure..........................................................................

20

Pre-scraping and rinsing removes large food particles from the dishes.

Proper washroom ventilation and humidity shortens dish drying time.

SCORE 100

Page 9

7

WARRANTY

LIMITED WARRANTY

Champion Industries Inc. (herein referred to as Champion), P.O. Box 4149, Winston-Salem, North Carolina 27115,

and P.O. Box 301, 2674 N. Service Road, Jordan Station, Canada, L0R 1S0, warrants machines, and parts, as set out

below.

Warranty of Machines: Champion warrants all new machines of its manufacture bearing the name “Champion”

and installed within the United States and Canada to be free from defects in material and workmanship for a

period of one (1) year after the date of installation or fifteen (15) months after the date of shipment by

Champion, whichever occurs first. [See below for special provisions relating to glasswashers.] The warranty

registration card must be returned to Champion within ten (10) days after installation. If warranty card is not

returned to Champion within such period, the warranty will expire after one year from the date of shipment.

Champion will not assume any responsibility for extra costs for installation in any area where there are

jurisdictional problems with local trades or unions.

If a defect in workmanship or material is found to exist within the warranty period, Champion, at its election,

will either repair or replace the defective machine or accept return of the machine for full credit; provided,

however, as to glasswashers, Champion’s obligation with respect to labor associated with any repairs shall end

(a) 120 days after shipment, or (b) 90 days after installation, whichever occurs first. In the event that Champion

elects to repair, the labor and work to be performed in connection with the warranty shall be done during regular

working hours by a Champion authorized service technician. Defective parts become the property of Champion.

Use of replacement parts not authorized by Champion will relieve Champion of all further liability in connection

with its warranty. In no event will Champion’s warranty obligation exceed Champion’s charge for the machine.

The following are not covered by Champion’s warranty:

a. Lighting of gas pilots or burners.

b. Cleaning of gas lines.

c. Replacement of fuses or resetting of overload breakers.

d. Adjustment of thermostats.

e. Adjustment of clutches.

f. Opening or closing of utility supply valves or switching of electrical supply current.

g. Cleaning of valves, strainers, screens, nozzles, or spray pipes.

h. Performance of regular maintenance and cleaning as outlined in operator’s guide.

i. Damages resulting from water conditions, accidents, alterations, improper use, abuse,

tampering, improper installation, or failure to follow maintenance and operation procedures.

j. Wear on Pulper cutter blocks, pulse vanes, and auger brush.

Examples of the defects not covered by warranty include, but are not limited to: (1) Damage to the exterior or

interior finish as a result of the above. (2) Use with utility service other than that designated on the rating plate.

(3) Improper connection to utility service. (4) Inadequate or excessive water pressure. (5) Corrosion from chemicals dispensed in excess of recommended concentrations. (6) Failure of electrical components due to connection

of chemical dispensing equipment installed by others. (7) Leaks or damage resulting from such leaks caused by

the installer, including those at machine table connections or by connection of chemical dispensing equipment

installed by others. (8) Failure to comply with local building codes. (9) Damage caused by labor dispute.

Warranty of Parts: Champion warrants all new machine parts produced or authorized by Champion to be free

from defects in material and workmanship for a period of 90 days from date of invoice. If any defect in

material and workmanship is found to exist within the warranty period Champion will replace the defective

part without charge.

DISCLAIMER OF WARRANTIES AND LIMITATIONS OF LIABILITY

. CHAMPION’S WARRANTY

IS ONLY TO THE EXTENT REFLECTED ABOVE. CHAMPION MAKES NO OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED, TO ANY WARRANTY OF

MERCHANTABILITY, OR FITNESS OF PURPOSE. CHAMPION SHALL NOT BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. THE REMEDIES SET OUT ABOVE ARE THE

EXCLUSIVE REMEDIES FOR ANY DEFECTS FOUND TO EXIST IN CHAMPION DISHWASHING

MACHINES AND CHAMPION PARTS, AND ALL OTHER REMEDIES ARE EXCLUDED, INCLUDING

ANY LIABILITY FOR INCIDENTALS OR CONSEQUENTIAL DAMAGES.

Champion does not authorize any other person, including persons who deal in Champion dishwashing machines to

Page 10

INTRODUCTION

Welcome to Champion . . .

and thank you for allowing us to take care of your dishwashing needs.

This manual covers the door-type series dishwasher models D-H1, D-HB, and D-LF.

Your machine was completely assembled, inspected, and thoroughly tested at our factory before

it was shipped to your installation site.

This manual contains:

• Warranty Information

• Operation and Cleaning Instructions

• Maintenance Instructions

• Troubleshooting Guide

• Basic Service Information

• Replacement Parts Lists

• Electrical Schematics

Complete and return your warranty registration card within ten (10) days after the installation of

your machine.

All information, illustrations and specifications contained in this manual are based upon the

latest product information available at the time of publication. Champion constantly improves

its products and reserves the right to make changes at any time or to change specifications or

design without notice and without incurring obligation.

For your protection, factory authorized parts should always be used for repairs.

Replacement parts may be ordered from your Champion authorized parts distributor or

from your Champion authorized service agency. When ordering parts, please supply the model

number, serial number, voltage and phase of your machine, the part number, part description and

quantity.

8

INTRODUCTION

Page 11

GENERAL

This manual covers the Champion door type dishwashing machine. These machines are fully

automatic and come equipped with a 1-HP pump motor.

The D-series dishwasher is available in the following models:

Model Numbers

D-H1, D-HB, D-LF

The D-H1 model is a high temperature (180°F/82°C rinse) sanitizing model without booster.

The D-HB model is a high temperature (180°F/82°C rinse) sanitizing model with booster.

The D-LF is a low temperature (Min. 120°F/49°C-140°F/60°C Optimum) sanitizing model for

use with a sodium hypochlorite (Chlorine) based sanitizer at a minimum concentration of

50PPM in the final rinse.

Standard Equipment includes:

D-H1, D-HB, D-LF

• Automatic tank fill • Common utility connections

• Built-in electric or steam booster heater • Two dish racks (peg and flat bottom)

(D-HB only) • Detergent/chemical connection provisions

• Door activated drain • Stainless steel front and side panels

• Field convertible to corner model • Top-mounted, splash-proof control console

• Electric tank heat • 60-second time cycle

• Balanced three door lift system • 1-1/2" O.D. gravity drain connection

• Low-water tank heat protection • Water pressure regulating valve

• 1-hp drip-proof pump motor (mounted) (D-HB only)

• Door safety switches • Interchangeable upper and lower spray arms

Options (D-HB only)

• Electric booster (70°F/39°C temperature rise)

heater for 110°F/43°C supply water

• Steam injector or steam coil tank heat

(steam booster 40°F/23°C – 70°F/39°C rise)

• Single source gas booster system

Accessories

Additional dishracks:

Dish rack (peg) P/N 101285

Silverware rack (flat bottom) P/N 101273

9

GENERAL

Page 12

Electrical Power Requirements

Model Voltage Booster Rise Machine Power Requirement

(D-HB Only) Full Load Amps (125% Service Factor)

D-H1/LF 115/60/1 — 48 Amps 60 Amps

D-H1/LF 208/60/1 — 23 Amps 29 Amps

D-H1/LF 220/60/1 — 23 Amps 29 Amps

D-H1/LF 230/60/1 — 23 Amps 29 Amps

D-H1/LF 240/60/1 — 24 Amps 30 Amps

D-H1/LF 208/60/3 — 12 Amps 15 Amps

D-H1/LF 220/60/3 — 13 Amps 16 Amps

D-H1/LF 230/60/3 — 13 Amps 16 Amps

D-H1/LF 240/60/3 — 13 Amps 16 Amps

D-H1/LF 380/60/3 — 7 Amps 9 Amps

D-H1/LF 415/60/3 — 8 Amps 10 Amps

D-H1/LF 480/60/3 — 6 Amps 8 Amps

D-H1/LF 575/60/3 — 5 Amps 6 Amps

D-HB 115/60/1 — — —

D-HB 208/60/1 40°F/23°C 59 Amps 74 Amps

D-HB 220/60/1 40°F/23°C 61 Amps 76 Amps

D-HB 230/60/1 40°F/23°C 63 Amps 79 Amps

D-HB 240/60/1 40°F/23°C 65 Amps 81 Amps

D-HB 208/60/3 40°F/23°C 33 Amps 41 Amps

D-HB 220/60/3 40°F/23°C 35 Amps 44 Amps

D-HB 230/60/3 40°F/23°C 36 Amps 45 Amps

D-HB 240/60/3 40°F/23°C 37 Amps 46 Amps

D-HB 380/60/3 40°F/23°C 20 Amps 25 Amps

D-HB 415/60/3 40°F/23°C 20 Amps 25 Amps

D-HB 480/60/3 40°F/23°C 17 Amps 21 Amps

D-HB 575/60/3 40°F/23°C 14 Amps 18 Amps

D-HB 115/60/1 — — —

D-HB 208/60/1 — — —

D-HB 220/60/1 — — —

D-HB 230/60/1 — — —

D-HB 240/60/1 — — —

D-HB 208/60/3 70°F/39°C 50 Amps 63 Amps

D-HB 220/60/3 70°F/39°C 52 Amps 65 Amps

D-HB 230/60/3 70°F/39°C 54 Amps 68 Amps

D-HB 240/60/3 70°F/39°C 56 Amps 70 Amps

D-HB 380/60/3 70°F/39°C 30 Amps 38 Amps

D-HB 415/60/3 70°F/39°C 33 Amps 41 Amps

D-HB 480/60/3 70°F/39°C 28 Amps 35 Amps

D-HB 575/60/3 70°F/39°C 23 Amps 29 Amps

10

GENERAL

Page 13

INSTALLATION

Unpacking

CAUTION:

Care should be taken when lifting the machine to prevent damage.

1. Immediately after unpacking the machine, inspect for any shipping damage.

If damage is found, save the packing material and contact the carrier immediately.

2. Remove the dishwasher from the skid. Adjust the feet if required, then move the

machine to its permanent location.

3. Level the machine (if required) by placing a level on the top of machine and adjusting

the feet. Level the machine front-to-back and side-to-side.

4. Remove the two dishracks from the interior of the machine.

NOTE:

The installation of your machine must meet local health codes.

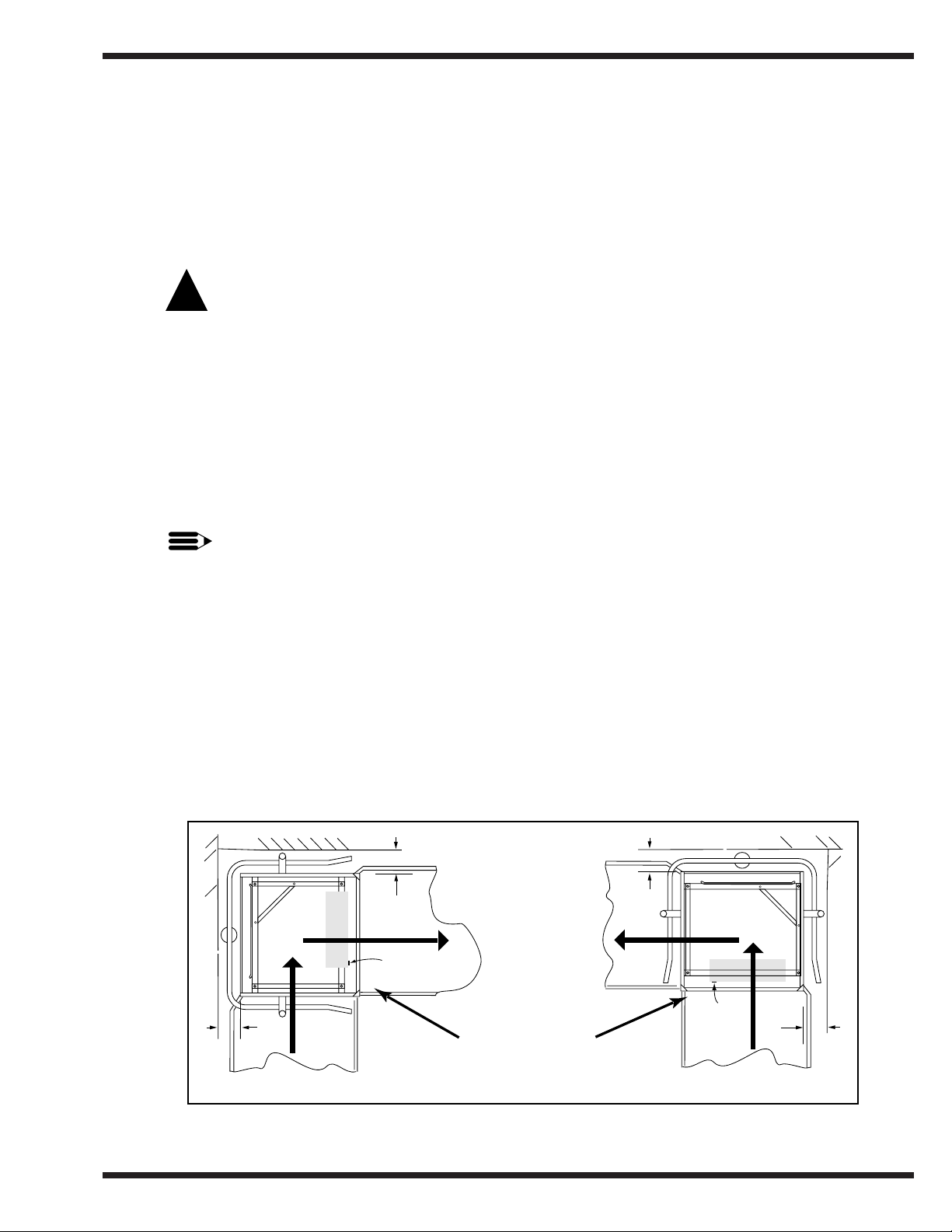

Changing from Straight-through to Corner Operation

Your door-type dishwasher is shipped from the factory in a straight-through configuration.

The following instructions explain how to convert your machine for corner operation.

Refer to Fig. 1 below.

1. Place the dishwasher so the operator controls are readily accessible.

2. Minimum clearance from any corner wall is 5-1/4" (133mm).

11

INSTALLATION

!

Figure 1

Placement for Corner Operation

Note:

Power switch is

readily accessible.

Do not place the dishwasher closer than 5-1/4" (133mm) to any wall.

5-1/4"[133mm] MIN.

5-1/4"[133mm] MIN.

W

A

LL

WALL

FRONT

POWER ON

SWITCH

5-1/4"[133mm] MIN.

5-1/4"[133mm] MIN.

W

A

LL

WALL

FRONT

POWER ON

SWITCH

Page 14

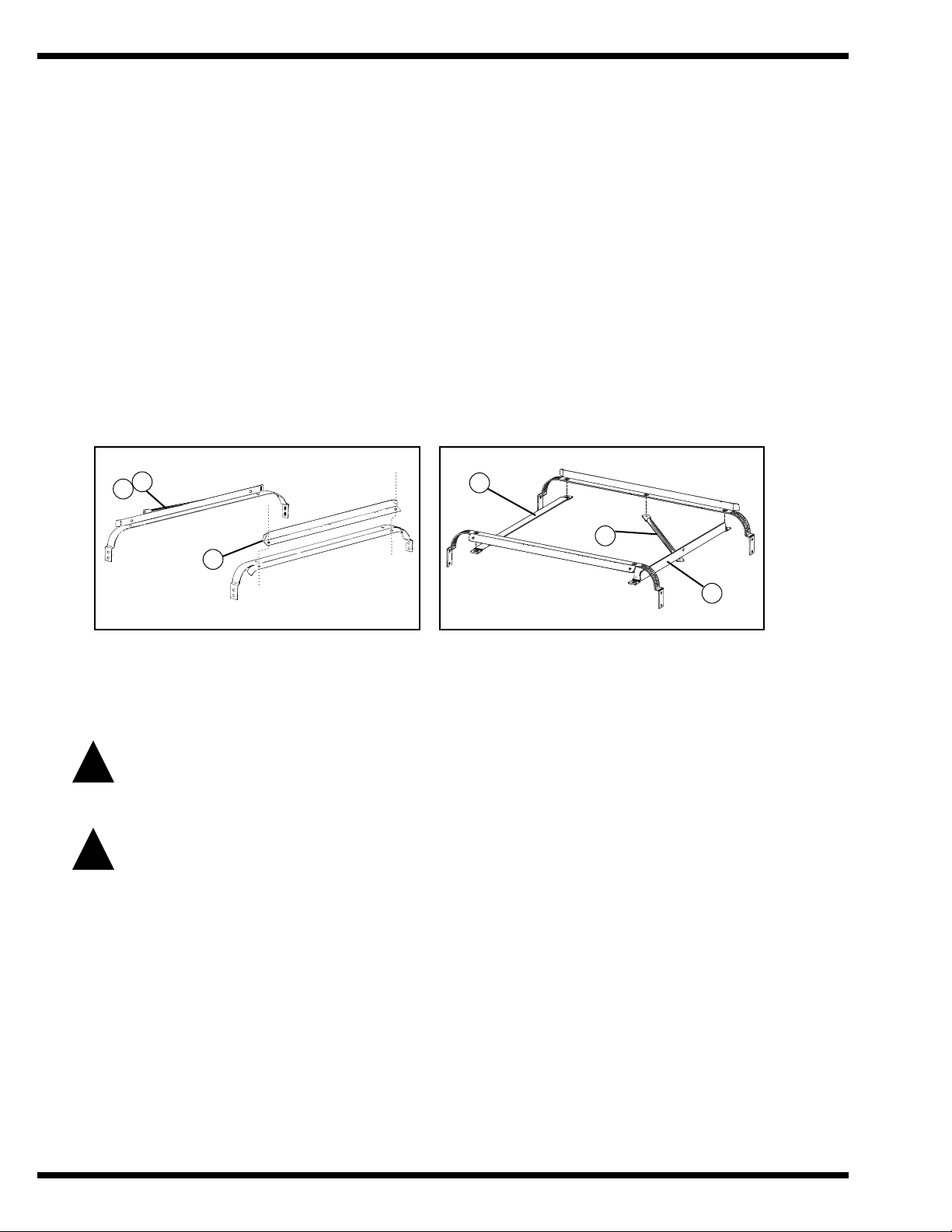

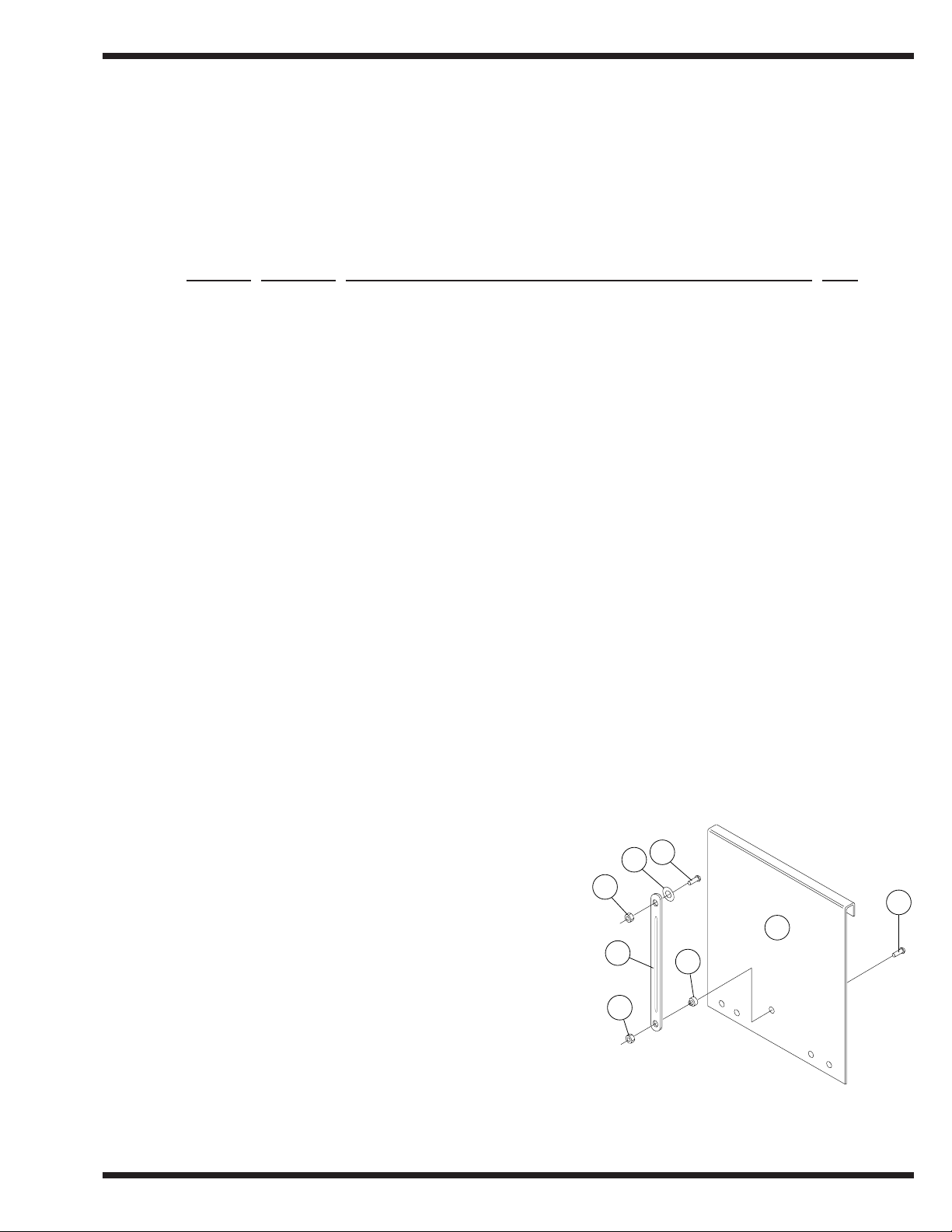

Changing from Straight-through to Corner Operation (cont’d)

Refer to Fig. 2 and perform the steps below.

1. Remove the front rack guide (A). Discard the square spacers.

2. Move front rack guide (A) to the left side of the rack tracks. (See Fig. 2b) Use existing

hardware.

3. Unbolt the track (B) and rack support rod (C).

4. Remove and save the two remaining fasteners from rear track.

5. Bolt (B) and (C) as shown in Fig. 2b.

Electrical Connections

WARNING:

Electrical and grounding connections must comply with the National Electrical Code

and/or Local Electrical Codes.

WARNING:

When working on the dishwasher, disconnect the electric service and place a tag at the

disconnect switch to indicate work is being done on that circuit.

1. A qualified electrician must compare the electrical power supply with the machine

electrical specifications stamped on the MACHINE ELECTRICAL CONNECTION

PLATE located inside the top mounted control cabinet before connecting to the incoming

service at a fused disconnect switch.

2. Motor rotation was set at the factory. Check the rotation of the motor shaft (CW when

viewed from rear of motor). For three phase machines, reversing the motor direction is

done in the control cabinet by reversing the wires L1 and L2 on the disconnect side of the

main electrical connection block. For single phase machines, motor rotation is changed at

the motor connection plate on the rear of the single phase motor.

12

INSTALLATION

!

!

Figure 2a

Straight-Through Configuration

Figure 2b

Corner Configuration

A

B

C

A

B

C

Figure 2

Changing the Track Assembly

Page 15

Electrical Connections (cont’d)

3. A knock-out is provided at the rear of the top mounted control cabinet for the electrical

service connection. A single source electrical connection has been provided. A fused

disconnect switch or circuit breaker (supplied by others) is required to protect each power

supply circuit.

Plumbing Connections

CAUTION:

Plumbing connections must comply with local sanitary and plumbing codes.

Water Connections

1. Connect the hot water supply to the “Y” strainer or pressure reducing valve (PRV) at the

final rinse piping (located behind the control cabinet at the top of the machine).

2. Minimum incoming water supply temperature requirements are listed below:

D-HB with built-in 40°F/23°C rise electric booster (Minimum 140°F/60°C)

(Min./Max. flow pressure 20-22 psi/138 Kpa)

D-HB with built-in 70°F/39°C rise electric booster (Minimum 110°F/43°C)

(Min./Max. flow pressure 20-22 psi/138 Kpa)

D-H1 without built-in booster (Minimum 180°F/70°C)

(Min./Max. flow pressure 20-22 psi/138 Kpa)

D-LF (Minimum 120°F/49°C - 140°F/60°C Optimum)

(Min./Max. flow pressure 20-22 psi/138 Kpa)

3. A manual shut-off valve for steam and water (supplied by others) should be installed in

supply line to allow for servicing of the machine. The shut-off valve should be the same

size or larger than the supply line.

4. A 3/4" Pressure Regulating Valve (PRV), should be installed on the incoming water supply

line if water flow pressure exceeds 20-22 psi/138 Kpa.

A PRV is standard equipment on Model D-HB.

A PRV is not standard equipment on Models D-H1 and D-LF.

The PRV may be obtained locally or direct from Champion.

13

INSTALLATION

!

Page 16

Drain Connections

Refer to Fig. 3 for the location of the machine drain.

1. Models D-HB, D-H1, and D-LF are GRAVITY DRAIN machines equipped

with a 1-1/2" hose connection point.

• Drain height for ALL MODELS must not exceed 15" above floor level.

WARNING:

Connection of the machine to a drain line higher than the machine drain height

will prevent the machine from draining properly.

Ventilation

NOTE:

Ventilation must comply with local sanitary and plumbing codes.

CAUTION:

Exhaust air should not be vented into a wall, ceiling, or concealed space of a building.

Condensation can cause damage.

14

INSTALLATION

!

Figure 3

D-HB, D-H1, D-LF

1-1/2" Drain Connection

Front Left Side of Machine

1-1/2" Drain Connection

!

Page 17

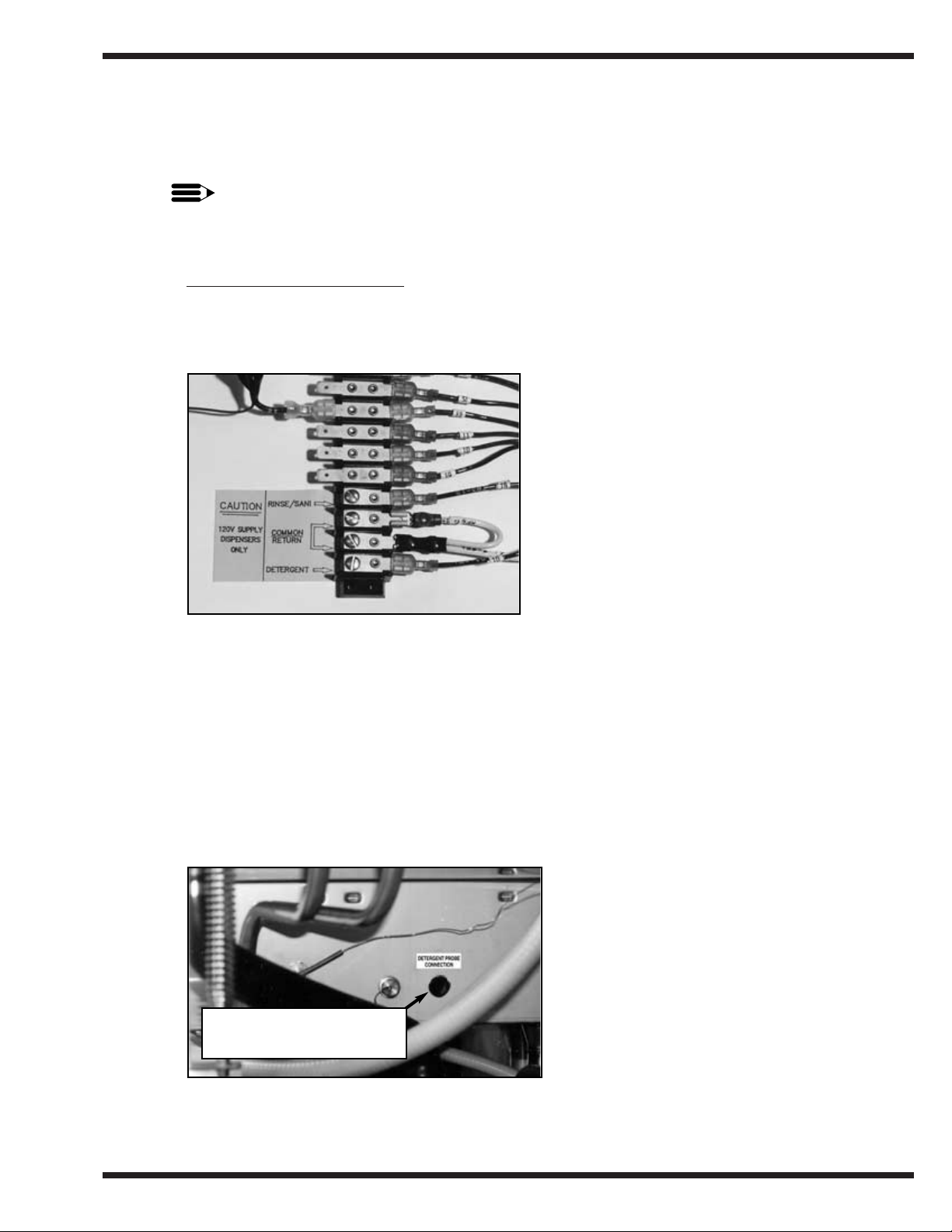

Chemical Connections

NOTE:

Consult a qualified chemical supplier for your chemical needs.

Models D-HB, D-H1 and D-LF

1. Refer to Fig. 4

Labeled chemical signal connection points are provided inside the

control cabinet for chemical dispensing equipment (supplied by others).

Detergent

1. Refer to Fig. 5

A removable black plug, located on the rear of the wash tank is provided as a detergent

probe insertion point.

15

INSTALLATION

Figure 4

D-HB, D-H1, D-LF

Chemical Connection Points

Left Side Interior of Control Cabinet

Signal connection points include:

• Detergent signal 120VAC

between Wire #10 and Wire #2

(1 AMP MAX AMP LOAD)

• Rinse Aid/Sanitizer signal 120VAC

between Wire #15 and Wire #2

(1 AMP MAX AMP LOAD)

1/2" Black Removable Plug

Detergent Probe Insertion Point

Figure 5

D-HB, D-H1, D-LF

Detergent Probe Insertion Point

Wash Tank (Rear)

Page 18

Chemical Connections (cont’d)

Detergent (cont’d)

2. Detergent may be added manually if dishwasher is not equipped with dispensing

equipment. Consult your chemical supplier for recommended amounts.

Rinse Aid/Sanitizer

Model D-HB and D-H1

Refer to Fig. 6

1. A rinse aid injection point is provided via a 1/8" NPT plug located in the final rinse piping.

The plug is located in a Tee fitting on the outlet side of the vacuum breaker. The vacuum

breaker is located behind the control cabinet at the top of the machine.

2. Use a liquid rinse aid.

NOTE:

Models D-HB and D-H1 do not require sanitizer.

16

INSTALLATION

Figure 6

Rinse aid Insertion Point

D-HB, D-H1 Only

1/8" NPT plug

Rinse aid Injection Point

Page 19

Chemical Connections (cont’d)

Rinse Aid/Sanitizer (cont’d)

Model D-LF

Refer to Fig. 7

1. A Rinse aid injection point is provided via a 1/8" NPT plug located in the final rinse

piping. The plug is located in a Tee fitting on the outlet side of the vacuum breaker. The

vacuum breaker is located behind the control cabinet at the top of the machine.

2. Use a liquid rinse aid.

3. A Sanitizer injection point is provided via a 1/4" NPT plug located in the final rinse piping.

The plug is located in a Tee fitting on the outlet side of the vacuum breaker. The vacuum

breaker is located behind the control cabinet at the top of the machine.

4. Use a sodium hypochlorite (Chlorine) based sanitizer at a minimum concentration of

50PPM in the final rinse.

Use chlorine test papers to verify and monitor the 50PPM chlorine level.

WARNING:

Never premix rinse aid with the sanitizing agent. Mixing may cause hazardous gases to form.

CAUTION:

Some metal, including silver, aluminum, and pewter are attacked by sodium hypochlorite

(chlorine sanitizer). Avoid cleaning these metals in a D-LF dishwasher.

17

INSTALLATION

Figure 7

D-LF

Rinse Aid/Sanitizer Injection Points

1/4" NPT plug

Sanitizer injection point

1/8" NPT plug

Rinse aid injection point

!

!

Page 20

INITIAL START-UP

After plumbing and electrical connections are completed, follow the steps below to place your

machine in service.

Model D-HB, D-H1 and D-LF

Refer to Figs. 8 and 9 below.

1. Remove any foreign material from inside the machine. Make sure scrap screens are

in place.

2. Make sure drain lever assembly is closed.

3. Close the Door.

4. Turn the water and main power sources to the dishwasher ON.

5. Flip the Power switch to the ON position. The “power on” light will illuminate and the

machine will automatically fill with water.

6. Check the machine for leaks.

7. Push the Green Start Button to check automatic cycle.

8. Check pump motor rotation. Rotation is CW when viewed from rear of motor.

9. If machine checks okay, lift the drain lever assembly to drain machine.

10. Flip the power switch to OFF.

18

INITIAL START-UP

Figure 8

Operator Controls

Top Mounted Control Cabinet

Figure 9

Door Activated

Drain Lever Assembly

Main power switch

circuit breaker

Green pushbutton

start switch

Green in cycle lite

Pressure gauge

Drain lever assembly

Temperature Gauges

Page 21

OPERATION

Model D-HB, D-H1 and D-LF

1. Close the door and flip power switch ON Power light illuminates. Tank fills

automatically and tank heat comes on.

2. Monitor wash tank temperature gauge Wait for temperature reading to reach

Min. 150°F/66°C (D-HB, D-H1 Only)

Temperature reading must be

Min. 120°F-140°F/49°C-60°C Optimum

(For D-LF Only)

3. Prescrap and load ware into rack Place dishes edgewise in peg rack, cups

and bowls upside down in flat rack, and

silverware spread evenly in single layer in

flat rack.

4. Open door, insert rack

5. Close door, Push Green start button Green cycle light will illuminate. Automatic

cycle begins.

Machine washes for 45 sec., then pauses for

1 sec.

6. During Final Rinse monitor pressure Machine final rinses for 14 sec. Pressure

gauge and final rinse temperature gauge reading must read between 20-22 PSI.

gauge Temperature gauge must read

180-195°F/82-91°C (D-HB, D-H1 Only)

Min. 120°-140°F/49°C-60°C Optimum

(D-LF Only)

7. 60-second cycle complete Green cycle light goes out.

8. Open door, remove clean rack Insert another rack of soiled ware.

9. After each meal period or every two Lift drain lever assembly to drain

hours operation machine. Flush interior and clean scrap

screens and pump intake strainer. Check

spray arms and clean if necessary.

NOTE:

Opening the door at any time during the cycle will stop the machine.

Closing the door and pushing the Green start button will resume the cycle where it left off.

19

OPERATION

Page 22

MAINTENANCE

Cleaning your machine is the best maintenance that you can provide. Components that are not

regularly flushed and cleaned do not perform well.

The Maintenance intervals shown in the following schedules are the minimum requirements

necessary for the proper performance of your machine. Maintenance intervals should be

shortened whenever your machine is faced with abnormal working conditions, hard water, or

multiple shift operations.

Maintenance Schedule

CLEANING

• Every 2 Hours or After Each Meal Period

Model D-HB, D-H1, and D-LF

1. Flip the power switch OFF.

2. Lift drain lever, drain the machine.

3. Flush tank interior with fresh water.

4. Remove and clean the scrap screens. Clean the pump intake screen.

5. Inspect the spray arm nozzles and rinse nozzles. Clean if necessary.

6. Close door, flip power switch ON to refill machine.

• Every 8 Hours or at the End of the Day

Model D-HB, D-H1, and D-LF

1. Flip the power switch OFF.

2. Lift drain lever, drain the machine.

3. Flush tank interior with fresh water.

4. Remove and clean the scrap screens. Clean the pump intake screen.

5. Remove the spray arms.

6. Clean and inspect the spray arm bearings.

7. Flush the wash arm and rinse arm assemblies and nozzles.

8. Back flush the scrap screens and pump intake strainer.

9. Thoroughly clean the exterior of the machine. DO NOT HOSE DOWN WITH WATER.

10. Reassemble the machine. Leave the door open to aid overnight drying.

CAUTION:

DO NOT LEAVE WATER IN WASH TANK OVERNIGHT

20

MAINTENANCE

!

Page 23

DELIMING

Your dishwasher should be delimed regularly depending on the mineral content of your water.

Inspect the machine interior for mineral deposits and use a deliming solution for the best

cleaning results.

NOTE:

Consult your chemical supplier for an appropriate deliming solution.

WARNING:

Deliming solutions or other acids must not come in contact with household bleach

(sodium hypochlorite) or any chemicals containing chlorine, iodine, bromine, or fluorine.

Mixing will cause hazardous gases to form.

Skin contact with deliming solutions can cause severe irritation and possible chemical

burns. Consult your chemical supplier for specific safety precautions.

DELIMING PROCESS

Model D-HB, D-H1, and D-LF

1. Remove all dishes from machine.

2. Remove any chemical pick-up tubes from their containers.

3. Place each tube in a container of fresh water and prime the chemical lines for several

minutes to thoroughly flush chemical from the lines. Leave pick-up tubes out of their

containers.

4. Drain the machine and refill with fresh water.

5. Spray interior walls with delimimg solution and let sit for 5 or 10 minutes depending on

amount of build-up. Add deliming solution to wash tank. Do not let chemicals sit for longer

than 15 minutes.

6. Push the Green start button and run an automatic cycle.

7. Repeat Steps 3-4 if necessary.

8. Lift the drain lever assembly and drain the machine.

9. Refill the machine and run a complete cycle two additional times. Drain and refill the

machine after each cycle to thoroughly flush any deliming solution from the interior of

the machine.

10. Flip the power switch to OFF.

11. Drain machine.

12. Deliming is complete.

21

MAINTENANCE

!

Page 24

OPERATION CHECKS

• Daily

1. Check temperature gauges for proper readings.

2. Check pressure gauge for proper reading (D-H1, D-HB ONLY).

3. Check for leaks.

4. Check chemical supplies and refill as necessary.

• Weekly

1. Inspect all water lines for leaks.

2. Clean all detergent residue from the exterior of the machine.

3. Check the drains for leaks.

4. Clean accumulated mineral deposits from the tank heating elements

5. Check that float switch moves freely.

TROUBLESHOOTING

Before determining any specific cause of a breakdown or abnormal operation on your

dishwasher, check that:

Checklist

1. Main power and water supply are turned on to the machine

2. All switches are ON

3. Drain and overflow tube are in place and seated

4. Wash pipe and rinse nozzles are clean

5. Scrap screen(s) are properly positioned

6. Spray pipes are in their proper positions

7. Doors are fully closed

8. Thermostat(s) are at their correct setting

9. Sanitizer, detergent, and rinse additive dispensers are adequately filled.

If a problem still exists, use the following for troubleshooting.

CONDITION CAUSE SOLUTION

Machine will not start Door not closed ...................................Make sure doors are fully closed

Door safety switch faulty ....................Contact your service agency

Start switch faulty ...............................Contact your service agency

Main switch OFF ................................Check disconnect

Overload protector tripped ..................Reset overload in Control Box

Low or no water Main water supply is turned off..........Turn on house water supply

Drain/overflow tube is not

in place and seated ..........................Place and seat drain tube

Defective drain/overflow O’ring.........Replace O’ring

Machine doors not fully closed...........Close doors securely

Faulty fill valve ...................................Contact your service agency

Defective fill timer ..............................Replace fill timer

Stuck or defective float .......................Check floats and clean

Clogged “Y” strainer...........................Clean or replace

Continuous water filling Stuck or defective float .......................Check floats and clean

Defective drain/overflow O’ring.........Replace O’ring

Fill valve will not close.......................Clean or replace

Defective fill timer ..............................Replace fill timer

Drain tube not in place........................Look for drain tube in tank

22

MAINTENANCE

Page 25

CONDITION CAUSE SOLUTION

Any motor not running Overload protector tripped ..................Reset overload in Control Box

Defective motor...................................Contact your service agency

Wash tank water temperature Incoming water temperature

is low when in use at machine too low ..........................Raise temperature to:

140°F/60°C for D-HB and D-LF,

180°F/82°C for D-H1

Defective thermometer........................Check or replace

Defective thermostat ...........................Check for proper setting or replace

Lime scale buildup

on heating elements.........................Delime element

Defective heater element.....................Check or replace

Low steam pressure.............................Check steam supply pressure (15-30 psi)

Defective steam trap............................Check or replace

Defective solenoid valve.....................Check or replace

Insufficient pumped spray Clogged pump intake screen ...............Clean

pressure Clogged spray pipe..............................Clean

Scrap screen full..................................Must be kept clean and in place

Low water level in tank ......................Check drain and overflow tube

Pump motor rotation incorrect ............Reverse connection between L1 and L2

in Control Cabinet (3PH machines only)

Defective pump seal............................Contact Service Agent

Insufficient final rinse or no Faulty pressure reducing valve ...........Clean or replace

final rinse Improper setting on pressure

reducing valve .................................Set psi flow pressure at 20-22 psi/138 Kpa

Clogged rinse nozzle and/or pipe........Clean

Improper water line size......................Have installer change to proper size (3/4" min.)

Clogged “Y” strainer...........................Clean or replace

Low final rinse temperature Low incoming water temperature .......Check house supply water temperature

Improper setting of booster

thermostat........................................Be sure booster thermostat is set to maintain

180°F/82°C temperature

Defective booster thermostat ..............Replace thermostat

Defective thermometer........................Check for proper setting or replace

Poor washing results Detergent dispenser not

operating properly ...........................Contact detergent supplier

Insufficient detergents.........................Contact detergent supplier

Wash water temperature

too low.............................................See condition “Wash Tank Water Temperature”

above

Wash arm clogged...............................Clean

Improperly scraped dishes ..................Check scraping procedures

Ware being improperly placed

in rack..............................................Use proper racks. Do not overload racks

Improperly cleaned equipment............Unclog wash sprays and rinse nozzles to

maintain proper pressure and flow conditions.

Overflows must be open. Keep wash water

as clean as possible.

Electric Elements or steam

coils has soil/lime buildup ..............Clean and/or delime

Poor drying results Insufficient rinse-aid ...........................Contact chemical supplier

Low final rinse temp ...........................See condition “Low final rinse temperature.”

23

TROUBLESHOOTING

Page 26

24

BASIC SERVICE

BASIC SERVICE

This Basic Service section does not cover all possible repair procedures. If you require additional

service support, you may call your local service company or:

Champion National Service

1-800-858-4477

In Canada

1-800-263-5798

Please have the Model and Serial Number of the machine ready when you call.

ELECTRICAL SERVICE

NOTE:

DO NOT USE CHASSIS GROUND WHEN PERFORMING VOLTAGE CHECKS.

Doing so will result in false and inaccurate readings.

PERFORM VOLTAGE CHECKS BY READING FROM THE HOT SIDE OF THE

LINE AND NEUTRAL (any #2 or white wire).

WARNING:

USE EXTREME CAUTION when performing tests on energized circuits.

WARNING:

When repairing a circuit, disconnect the power at the main service disconnect switch and

place a tag at the disconnect switch to indicate that work is being performed on the circuit.

Troubleshooting

Schematics

Champion places an electrical schematic in the control cabinet of every machine before it is

shipped. Schematics are included at the back of this manual as well. Be aware that these

schematics include options that may not apply to your machine. Options are enclosed in dashed

lines with the words (IF USED) next to them on the schematic. Disregard any options that

appear on the schematics which are not a part of your machine.

Tools

All electrical repairs can be made with: Standard set of hand tools

Volt/Ohm Meter (VOM)

Clip-on AC current tester

Circuit Tests

Use a clip-on AC current tester to check the motors and electric heaters.

Use a VOM to test line voltages and the 120VAC and the 24VAC control circuits.

!

!

Page 27

25

BASIC SERVICE

ELECTRICAL SERVICE (cont’d)

Fuses

—

Refer to Fig. 10.

There are two fuse blocks, located in the center of

the main control cabinet. The (A) fuses protect the

main control transformer. The (B) fuses protect the

wash tank heater circuit.

Fuses are marked FU on the electrical schematic.

Booster heater circuits (D-HB only) are not fused.

To Replace a fuse:

Turn the dishwasher main power switch off.

Disconnect power to the machine at the main service disconnect switch.

Replace the fuse. If the fuse blows again,

DO NOT INCREASE THE FUSE SIZE.

DETERMINE THE CAUSE OF THE OVERLOAD.

Motor Overloads —

The wash pump motor has an overload to protect it from line voltage electrical overloads. The

overload disconnects 120VAC power to the motor contactor coil.

Refer to Fig. 11.

Note the Switch Lever on the Overload.

If the switch lever is off with the “0” showing

then the overload has tripped.

To Reset the Motor Overload:

Flip the overload switch to the On position.

A “1” should be visible on the switch lever.

To Replace a Motor Overload:

Disconnect the wires to the overload.

Release the mounting catch on the front

side of the overload. Push forward and lift out.

Snap the new overload into place and reconnect

the wires.

To adjust the overload setting:

The screwdriver in Fig. 11 is positioned

to adjust the motor overload AMP setting.

Read the full load amps (FLA) motor amps on the motor

nameplate. Adjust the overload dial to 125% of the nameplate

FLA or the maximum setting.

ELECTRICAL SERVICE (cont’d)

Timers

Figure 11

Motor Overload

Figure 10

Fuses

(Three phase shown)

A

B

Switch Lever

Page 28

D-HB, D-H1, and D-LF models have two timers

located in the top mounted main control cabinet.

These timers are not adjustable.

The timer chart is shown in Fig. 13.

Cycle Timer —

Refer to Fig. 12.

The cycle timer controls the dishwasher’s 60-second

operation. The timer consists of a timer motor, four

micro-switches, and four non-adjustable metal cams.

Cam A controls power to the timer motor

Cam B controls power to the wash motor.

Cam C controls power to the final rinse valve.

Cam D controls the dishwasher instant start.

Fill Timer —

Refer to Fig. 14.

The fill timer controls the dishwasher’s 90-second fill operation.

The timer consists of a timer motor, one micro-switch, and one

non-adjustable plastic cam. The fill timer operates during initial fill

and any time the low water tank heat protection circuit calls for

make-up water. Refer to Timed Fill/Low Water Tank Heat Protection

on the next page for an explanation of the fill timer operation.

ELECTRICAL SERVICE (cont’d)

Timed Fill/Low Water Tank Heat Protection —

26

BASIC SERVICE

Figure 14

Fill Timer

Figure 12

Cycle Timer

Figure 13

Cycle Timer Chart

A

B

C

D

Figure 15

Fill Timer Chart

10

52015 253530 40 50

TIMER CYCLE 60-SEC.

8

WASH 45-SEC.

DWELL 1-SEC.

RINSE 14-SEC.

8 53

INSTANT START 45-SEC.

CAM

TIMER

CAM

WASH

CAM

RINSE

CAM

INSTANT

START

A

B

C

D

SECOND

NOTRA

NC

NO

TRB

NC

NOTRC

NC

NO

TRD

NC

0

1

45

45

47

55 60

2

NCN

COM.

TIMER

SWITCH

DETAIL

3

O

1

FILL TIME 90-SEC.

FILL TIMER

Page 29

Models D-HB, D-H1, and D-LF use a float switch and fill timer to control

tank fill and tank heat.

For Model D-HB only, the built-in booster heat circuit is also controlled

by the float switch.

Operation:

1. When dishwasher main power switch is turned on, fill timer runs for

a minimum of 90 seconds to fill the tank.

2. The float switch ball rises; its normally open contacts close. The fill

circuit times out; the fill solenoid de-energizes, and the tank heat and

booster heat energize.

3. If water level drops below the float level, the float switch ball moves

down; heat de-energizes. The fill solenoid energizes and the fill timer

runs for a minimum of 90 seconds to refill the tank.

4. If the tank is not full of water at the end of the 90-second fill timer

cycle, then the fill timer will cycle again. When the float switch is

satisfied, the fill timer stops after completing its 90-sec. cycle.

5. Refer to the float switch troubleshooting chart below (Fig.17) for a

quick guide to evaluating float switch problems.

27

BASIC SERVICE

Figure 16

Float Switch

Figure 17

Float Switch

Troubleshooting Cahrt

System

Checks

YES

YES

YES

NO

NO

NO

Wash

Tank Fills Constantly

Is Tank Full

of Water?

Is the Float

Ball Up?

Close

Drain

Clean

Float

Assy

Is Heat ON

when called

for?

Replace

Float

Check

Solenoid

Valve

Page 30

28

BASIC SERVICE

ELECTRICAL SERVICE (cont’d)

Heater Element Wiring – Booster Tank and Wash Tank Heater Elements

Refer to the illustrations and follow the steps below to properly install terminal jumpers and to

make line power connections to a replacement element.

Step 1. Hold the element assembly with the calrod coils facing toward you.

Step 2. Match your element coil to Configuration A, B, C, or D.

Step 3. Rotate your element coils to match the correct configuration.

Step 4. Turn the element over and match your element to the correct terminal configuration.

Step 5. Install terminal jumpers according to the illustration for your voltage requirement.

Step 6. Install the element and make your line connections 1L1, 1L2, or 1L3 per the illustration.

Configuration A

Booster tank element

View of calrod coils

Terminal Connections view of element

Configuration B

Booster tank element

View of calrod coils

Terminal Connections view of element

Configuration C

Booster tank element

View of calrod coils

Terminal Connections view of element

Configuration D

Wash tank element

View of calrod coils

Terminal Connections view of element

208V/1 Phase 208-240V/3 Phase

Delta Connection

480V/3 Phase

575V/3 Phase

Delta Connection

208-240V/3 Phase

Wye Connection for

380-415V/3 Phase

208V/1 Phase 208-240V/3 Phase

Delta Connection

480V/3 Phase

575V/3 Phase

Delta Connection

208-240V/3 Phase

Wye Connection for

380-415V/3 Phase

208V/1 Phase 208-240V/3 Phase

Delta Connection

480V/3 Phase

575V/3 Phase

Delta Connection

208-240V/3 Phase

Wye Connection for

380-415V/3 Phase

208V/1 Phase 208-240V/3 Phase

Delta Connection

480V/3 Phase

575V/3 Phase

Delta Connection

208-240V/3 Phase

Wye Connection for

380-415V/3 Phase

1L1

1L2

1L1

1L2

1L3

1L1

1L2

1L3

1L1

1L2

1L3

1L1

1L2

1L1

1L2

1L3

1L1

1L2

1L3

1L1

1L2

1L3

1L1

1L2

1L1

1L2

1L3

1L1

1L2

1L3

1L1

1L2

1L3

1L2

1L1

1L1

1L2

1L3

1L1

1L2

1L3

1L1

1L2

1L3

Page 31

ELECTRICAL SERVICE (cont’d)

Motor Connections —

1. Models D-HB, D-H1, and D-LF are available in either single phase or 3 phase voltages.

2. Motor rotation was set at the factory. For three phase machines, reversing the motor

direction is done in the control cabinet by reversing the wires L1 and L2 on the disconnect

side of the main electrical connection block. For single phase machines, motor rotation is

changed at the motor connection plate on the rear of the single phase motor (If necessary).

Refer to Fig. 18 for the proper wiring of the pump motor for single and three phase voltages.

29

BASIC SERVICE

Three Phase - High Voltage

Figure 18

Pump Motor Wiring Diagrams

Single Phase - Low Voltage

Single Phase - High Voltage

Three Phase - Low Voltage

575V Only

Three Phase

208-240V

208-240V

480V

115V

J

8

2

LINE

L1

3

4

L2

654

987

LINE

654

987

L1

3

4

L2

8

LINE

J

2

LINE

321

LINE

321

LINE

321

LINE

Page 32

MECHANICAL SERVICE

Pump Seal Replacement

1. Disconnect the power to the machine at the main breaker panel or fuse box.

2. Drain the machine.

3. Remove the front and side panels.

4. Remove drain plug on the pump volute and drain the pump.

5. Remove the pump hoses.

6. Disconnect the wires to the motor at the motor junction box.

7. Unbolt motor from machine base and remove the pump/motor assembly.

8. Remove bolts on volute and carefully remove from the pump flange.

9. Lock the motor shaft with a wrench or pliers. The back of motor shaft is square.

10. Turn the impeller counter-clockwise to remove from shaft (right hand threads).

11. Remove any shims or spacers and save for reassembly.

12. Remove the old seal and discard.

13. Check seal seat in the pump flange and clean thoroughly.

14. Press rubber seal/ceramic portion of seal assembly into the pump flange. Use a water

soluble lubricant. Be careful to keep the ceramic clean.

15. Install the rotating part of the seal on the shaft with the graphite surface toward the

ceramic. Use a water soluble lubricant on the rubber seal part only (not the graphite).

16. Reinstall spacers, impeller, and new flange gasket. Reinstall bolts.

17. Reinstall the pump/motor assembly and reconnect the pump hoses.

18. Fill the dishwasher with water.

19. Check motor rotation by bump starting motor.

Correct motor shaft rotation is clockwise when viewing motor from the rear.

20. Test run and check for leaks.

Figure 19

Pump Seal Replacement

30

BASIC SERVICE

Pump Flange

Seal Assy.

Impeller

Gaskets

Volute

Plug

Bolt

(A)

Nut

Backing Plate

Mtg. Nut

Backing Plate

Washer

Bolt

(B)

Water

Slinger

1.4 HP Motor

Page 33

31

REPLACEMENT PARTS

REPLACEMENT

PARTS

Page 34

32

REPLACEMENT PARTS

Figure 20 – D-HB/D-H1/D-LF

Doors, Panels and Gauges

1

4

2

26

20

19

6

5

7

17

18

9

8

7

16

15

14

4

21

21

22

23

24

25

5

28

5

27

5

6

5

4

3

1

2

10

7

8

9

10

11

13

12

34

35

31

32

29

30

33

20

36

Page 35

33

REPLACEMENT PARTS

D-HB/D-H1/D-LF

DOORS, PANELS AND GAUGES

Fig. 20 Part

Item No. No. Part Description Qty.

1 107398-1 Block, door lift. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 107398-2 Roller, door lift block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3 0307326 Door, right side (Beginning with S/N 10400 through S/N 13809). 1

3 0709405 Door, right side (Beginning with S/N 13809 and above). . . . . . . . 1

4 0501412 Screw (10-32 x 3/8 Truss hd) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 0503722 Nut, hex (10-32 SST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6 0308704 Guard, splash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

7 110383 Screw (M8 x 12MM Pan hd) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

8 304811 Plate, reinforcing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

9 109395 Gasket, reinforcing plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

10 108053 Plug, cornerpost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

11 107367 Chain, bead #10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 ft.

12 107368 Chain, end coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

13 0501412 Screw (10-32 x 3/8 Truss hd) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

14 0508752 Screw (4-40 x 5/8 Round hd) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

15 0501419 Bolt (1/4 x 20 x 1/2 Hex hd) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

16 0508144 Screw (8-32 x 3/4 Round hd) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

17 108347 Guide, door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

18 108410 Gasket, door guide (26") . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

19 108954 Nut, grip (6-32 w/nylon insert). . . . . . . . . . . . . . . . . . . . . . . . . . . 2

20 111026 Magnet, door safety switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

(Beginning with S/N 12340M and above)

20 109935 Magnet, door safety (Prior to S/N 12340M) . . . . . . . . . . . . . . . . . 1

21 100779 Screw (1/4-20 x 5/8 Truss hd) . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

22 0307333 Bracket, booster support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

23 0501539 Nut (1/4-20 SST Hex hd) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

24 309070 Panel, perimeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

25 0707352 Door, front (Beginning with S/N 12340 through S/N 13808) . . . . 1

25 0709402 Door, front (Beginning with S/N 13809 and above) . . . . . . . . . . . 1

26 0707351 Door, left side (Beginning with S/N 10400 through S/N 12339). . 1

26 0708896 Door, left side (Beginning with S/N 12340 through S/N 13808). . 1

26 0709404 Door, left side (Beginning with S/N 13809 and above). . . . . . . . . 1

27 0307327 Bracket, door lift (Prior to S/N 13809) . . . . . . . . . . . . . . . . . . . . . 1

27 0309277 Bracket, door lift (Beginning with S/N 13809 and above) . . . . . . 1

28 0307328 Stop, door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

29 107440 Thermometer, 8 ft (Wash) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

30 107444 Overlay, wash thermometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

30 107442 Overlay, wash thermometer (Model D-LF only). . . . . . . . . . . . . . 1

31 108391 Thermometer, 4 ft (Final rinse) . . . . . . . . . . . . . . . . . . . . . . . . . . 1

32 107445 Overlay, final rinse thermometer . . . . . . . . . . . . . . . . . . . . . . . . . 1

32 107443 Overlay, final rinse (Model D-LF only) . . . . . . . . . . . . . . . . . . . . 1

33 305404 Cover, control cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

34 100135 Gauge, pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

35 109765 Overlay, pressure gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

36 111090 Switch, magnetic door safety

(Beginning with S/N 12340M and above) . . . . . . . . . . . . . . . . . . 1

36 109934 Switch, magnetic (Prior to S/N 12340M) . . . . . . . . . . . . . . . . . . . 1

Page 36

34

REPLACEMENT PARTS

Fig. 21 – D-HB/D-H1/D-LF

Door Handle Assembly and Springs

See

Detail

C

See

Detail

B

See

Detail

A

7

8

8

2

2

4

5

3

4

5

6

9

10

11

12

11

12

13

14

15

16

17

18

19

20

24

21 24

25

23

22

C

B

A

1

1

NOTE:

Door lift block parts (Items 14-19) are used

on machines built prior to S/N 13809

Refer to Fig. 22, bottom of page 35,

Door lift linkage parts (Items 26-33)

are used on machines beginning with

S/N 13809 and above.

Page 37

35

REPLACEMENT PARTS

D-HB/D-H1/D-LF

DOOR HANDLE ASSEMBLY AND SPRINGS

Fig. 21 Part

Item No. No. Part Description Qty.

1 107397 Block, spring hook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 108066 Spring, extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3 107969 Bolt, extension spring (5/16-18 x 4 Hex hd) . . . . . . . . . . . . . . . . . . 2

4 100154 Nut, plain (5/16-18) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5 102376 Washer (5/16 x 3/4 x 1/16). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6 106013 Washer, lock (5/16 split). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

7 108363 Lever, door (Prior to S/N 13809) . . . . . . . . . . . . . . . . . . . . . . . . . . 1

7 0509166 Lever, door (Beginning with S/N 13809 and above) . . . . . . . . . . . . 1

8 107962 Handle, grip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

9 304811 Plate, backing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

10 108368 Gasket, backing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

11 107436 Screw (M6 x 16mm Filister) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

12 107420 Nut, plain (M6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

13 107399 Support, pivot block (Top and side view shown) . . . . . . . . . . . . . . 2

14 107398-1 Lift, block door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

15 107398-2 Roller, door lift block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

16 307645 Plate, door reinforcing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

17 109395 Gasket, reinforcing plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

18 110383 Screw (M8 x 12mm Pan hd) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

19 108022 Washer (8mm Plastic) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

20 107437 Bolt (M6 x 45mm Hex hd) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

21 107396 Block, upper pivot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

22 107395 Block, lower pivot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

23 107436 Screw (M6 x 16mm Filister) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

24 107420 Nut, plain (M6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

25 107393 Pin, pivot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

26 104002 Bolt (5/16-18 x 1-1/2). . . . . . 2

27 100826 Washer, flat . . . . . . . . . . . . . 2

28 0509274 Nut, acorn (5/16-18 SST) . . . 4

29 0309167 Lift bar, door . . . . . . . . . . . . 2

30 0509264 Bushing, side door . . . . . . . . 2

31 See pages 32-33 for doors

32 100740 Bolt (5/16-18 x 1 Hex hd). . . 2

31

32

26

30

29

28

28

27

Fig. 22 – D-HB/D-H1/D-LF

Door Linkage

For machines beginning with S/N 13809

and above

Page 38

36

REPLACEMENT PARTS

Fig. 23 – D-HB/D-H1/D-LF

Track Assembly, Float Switch, and Drain Assembly

6

2

6

8

9

1

6

8

9

11

10

7

12

5

12

7

11

10

8

9

7

7

7

10

9

4

6

6

6

7

11

10

9

8

3

21

17

20

19

18

23

25

24

22

16

14

13

15

26

27

28

Page 39

37

REPLACEMENT PARTS

D-HB/D-H1/D-LF

TRACK ASSEMBLY, FLOAT SWITCH AND DRAIN ASSEMBLY

Fig. 23 Part

Item No. No. Part Description Qty.

1 0309469 Guide, right hand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 0309472 Track, rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3 0309468 Guide, left hand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

4 0309470 Support, rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

5 0309471 Track, front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

6 106727 Screw (10-32 x 5/8 Flat Hd) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

7 107966 Nut, grip (10-32 w/nylon insert) . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

8 100779 Bolt (1/4 -20 x 5/8 Truss Hd) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

9 0501481 Washer, sealing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

10 0501501 Washer, lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

11 0501539 Nut (1/4-20 Hex Hd) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

12 0309473 Spacer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

13 0507709 Washer, flat (#10 SST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

14 107966 Nut, grip (10-32 w/nylon insert) . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

15 308005 Strainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

16 305164 Scrap, screen (10 3/8). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

17 0307310 Drain, lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

18 100154 Nut (Plain 5/16-18) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

19 0507312 Bolt (5/16-18 x 1 3/4 Hex hd SST). . . . . . . . . . . . . . . . . . . . . . . . . 1

20 107967 Nut, grip (1/4-20 w/nylon insert) . . . . . . . . . . . . . . . . . . . . . . . . . . 1

21 0708493 Drain pipe assy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

22 0307309 Standpipe, lift rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

23 0307355 Drain, cover plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

24 111532 O-ring, drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

25 0308514 Screen, filler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

26 111092 Float switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

27 104584 Nut (Plain 1/2-13 Hex hd. SST) . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

28 111151 C-clip. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Page 40

38

REPLACEMENT PARTS

Fig. 24 – D-HB/D-H1/D-LF

Wash/Rinse Spray System Assembly

4

6

5

7

1

3

2

7

6

5

4

8

13

14

11

12

10

9

18

17

15

16

19

20

21

22

For S/N 11599 and above

Page 41

39

REPLACEMENT PARTS

D-HB/D-H1/D-LF

WASH/RINSE SPRAY SYSTEM ASSEMBLY

(Items 1-14 apply to machines beginning with S/N 10702M and above)

Fig. 24 Part

Item No. No. Part Description Qty.

1 309441 Support, standpipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 0501539 Nut (1/4-20 Hex hd SST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3 0501501 Washer, split lock (SST). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

4 109864 Support, wash arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

5 107967 Nut, grip (1/4-20) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

6 100736 Bolt (1/4-20 x 3/4 Hex hd) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

7 0507445 Spindle, wash arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

8 109783 Standpipe, rinse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

9 109781 Standpipe, wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

10 108620 Gasket, rinse pipe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

11 109854 Gasket, standpipe wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

12 100740 Bolt (5/16-18 x 1 Hex hd) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

13 102376 Washer, flat (5/16 x 3/4 x .050 SST) . . . . . . . . . . . . . . . . . . . . . . . 8

14 100154 Nut, plain (5/16-18 SST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

(Items 15-16 apply to machines beginning with S/N 11599 and above)

15 0507443 Spindle, rinse arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

16 0507444 Nut, rinse arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

17 0707453 Rinse arm assy. (Includes 18 & 19) . . . . . . . . . . . . . . . . . . . . . . . . 2

17 0708899 Rinse arm assy. (Model D-LF only) . . . . . . . . . . . . . . . . . . . . . . . . 1

18 0508376 Nozzle, rinse arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

18 0507451 Nozzle, rinse arm (SST) (Model D-LF only) . . . . . . . . . . . . . . . . . 1

19 112164 Bearing, rinse arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

20 0707452-S Wash arm assy. (Includes 21 & 22) . . . . . . . . . . . . . . . . . . . . . . . . 2

21 0507446 Bearing, wash arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

22 0501563 Screw (#8 XC 1/2 Pan hd) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

— 0707450 Rinse arm (Does not include items 18-19) . . . . . . . . . . . . . . . . . . .

— 0707456 Wash arm (Does not include item 21). . . . . . . . . . . . . . . . . . . . . . .

Page 42

40

REPLACEMENT PARTS

Fig. 25 – D-HB/D-H1/D-LF

Wash/Rinse Spray Arms

(For machines beginning with S/N 77855 through S/N 11599)

1

2

4

5

4

2

7

8

9

11

10