Page 1

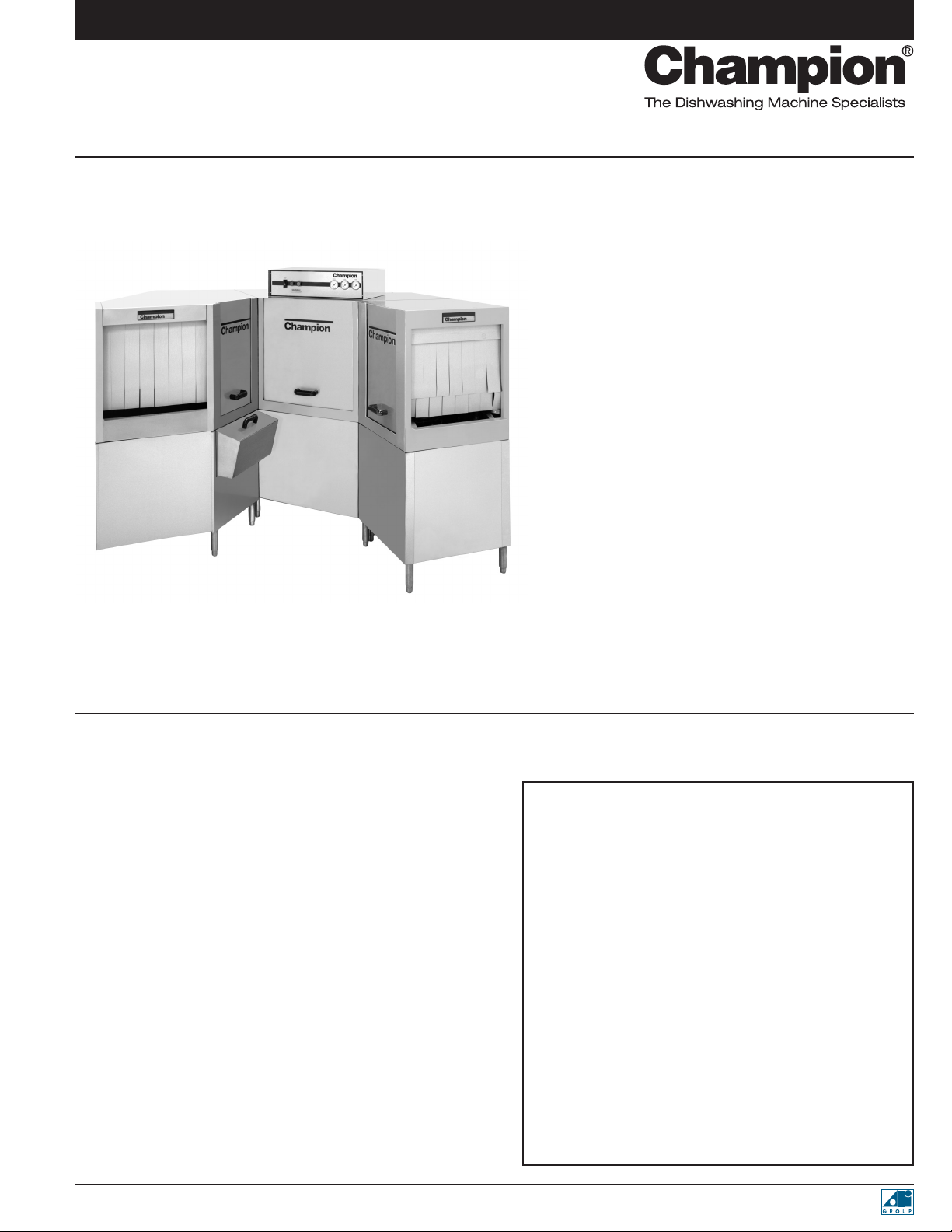

The Flexible Warewashing System!

Champion’s prewash, wash, and rinse drive

modular units will provide the design flexibility

to equip any size or shape dishroom with a high

production, fully-equipped rack conveyor

warewashing machine.

The 44 Modular Series is available in several corner

configurations to accommodate special needs.

Racks are moved automatically by means of a 90°

curved pawl bar and straight conveyor.

Three prewash units are available: 22" straight light

duty, 36" straight heavy duty, and 39" corner heavy

duty versions.

Wash units are available in either a single straight

through wash/drive, or a two-unit system with a corner

wash and final rinse drive.

(3M) 3/99

44 Modular Series

44KPRB Corner

Single Tank Rack Conveyor

Modular System

QUICK FACTS

Capacities

Racks per hr. (NSF rated) 158

Wash tank (gal.) 20

Conveyor speed (ft./min.) 5.6

Motor horsepower

Drive 1/4

Prewash 22", 36" & 37" 1

Wash 2

Water consumption

Gal. per hr. (max. use) 324

Gal. per rack 2.05

Temperature °F

Wash 160

Rinse 180

Heating

Tank heat, electric (Kw) 15

Tank heat, steam (lbs./hr.

required at 15 psi flow pressure) 75

Electric booster (Kw required for 40° rise) 38

Electric booster (Kw required for 70° rise) 63

Steam booster

(lbs./hr. required for 40° rise) 170

Steam booster

(lbs./hr. required for 70° rise) 280

Venting

Load end (minimum cfm) 150

Unload end (minimum cfm) 400

*Shown with optional load end panel

Standard Features

Automatic tank fill

Common utility connections

Control circuit, 120-volt

Convenient top-mounted controls

Conveyor drive 1/4-Hp motor

Door activated drain closure

Door safety switch

Enclosure panels (front and unload end)

Energy Sentinel (idle pump shut-off)

External scrap basket on prewash units

Interchangeable spray arms

Leakproof doors, internally fitted

Low-water tank heat protection

Prewash motor: 1-Hp, Wash pump motor: 2-Hp

Rinse saver device

Stainless steel construction, including base and feet

Tank heat, choice of electric, steam coil or

steam injector

Page 2

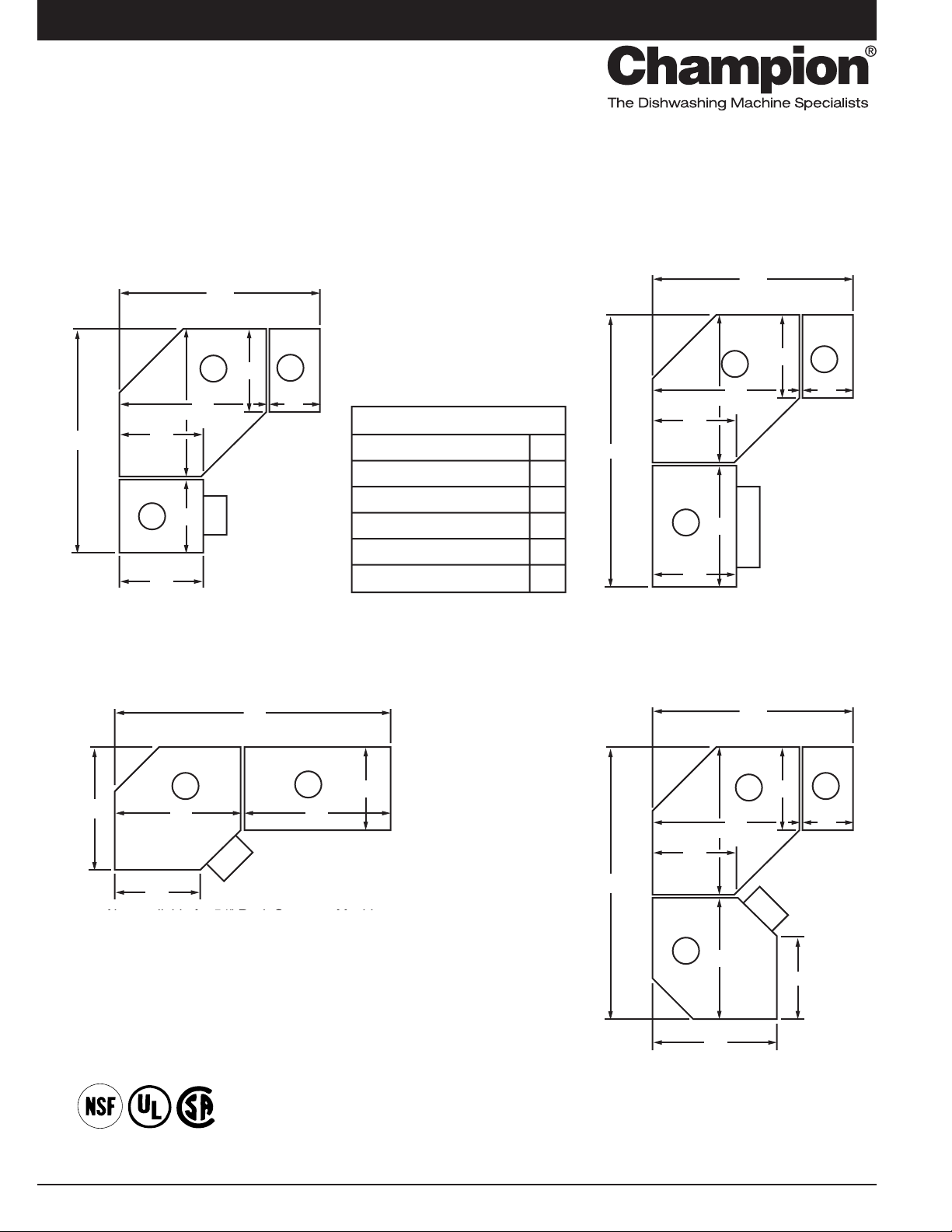

59"

66"

25"

25"

44"

44"

25"

15"

22"

A

90° Application

Modular Units

Prewash 22"

A

Prewash 36" B

Corner Prewash 39" C

Wash/Rinse Drive D

Corner Wash E

Final Rinse Drive F

E

F

59"

80"

25"

25"

44"

44"

25"

15"

36"

B

90° Application

E

F

59"

83"

25"

25"

39"

44"

44"

25"

15"

39"

C

180° Application

E

F

83"

39"

25"

39" 44"

25"

90° Application

Also available for 54" Rack Conveyor Machine

C

D

44 Modular Series

44KPRB Corner

Single Tank Rack Conveyor

Modular System

Champion Industries, Inc., P. O. Box 4149, Winston-Salem, NC 27115 • 336/661-1556 • Fax: 336/661-1979 • www.championindustries.com

Warning:

Plumbing and electrical connections

should be made by qualified workmen

who will observe all the applicable

plumbing, sanitary and safety codes

and the National Electrical Code.

Note:

Water Hammer Arrestor (meeting

ASSE-1010 standard or equivalent)

to be supplied (by others) in common

water supply line at service connection.

®

®

Typical Modular Configurations

Available in either right-to-left, or left-to-right operation

Due to an ongoing value analysis program at Champion, specifications contained in this catalog are subject to change without notice.

For electrical, drain, and booster

connections, consult the Factory.

For Options and Accessories,

see 44KB and 44KPRB Spec Sheet.

Also available for 54" Rack Conveyor Machine

90° Application

90° Application

90° Application

180° Application

Loading...

Loading...