Page 1

Installation/Operation with Service Replacement Parts

Beginning with Serial No. R3448 and above

E-series Rack Conveyor Dishwasher

Model Machines

Single Tank

Model 44

Single Tank w/Prewash

Model 66 PW

Single Tank

44

66 PW

70 FFPW

80 HDPW

44 WS

66 WSPW

70 WSFFPW

80 WSHDPW

Single Dual-Rinse

44 DR

66 DRPW

70 DRFFPW

80 DRHDPW

44 DRWS

66 DRWSPW

70 DRWSFFPW

80 DRWSHDPW

54 DR

76 DRPW

80 DRFFPW

90 DRHDPW

Dual Tank Rack

64

86 PW

90 PPPW

100 HDPW

120 HDPW

Chemical Sanitizing

44 LT

66 LTPW

70 LTHDW

80 LTHDPW

www.championindustries.com

3765 Champion Boulevard

Winston-Salem, NC 27105

336/661-1556 Fax: 336/661-1660

Toll-free: 800.858.4477

Two Tank w/Prewash

Model 64

2674 N. Service Road, Jordan Station

Ontario, Canada L0R 1S0

905/562-4195 Fax: 905/562-4618

Toll-free: 800.263.5798

Dishwasher serial no.

Issue Date: 10.15.12

Manual P/N 114315 rev. H

For machines beginning with S/N R3448 and above

Printed in USA

Page 2

For future reference, record your dishwasher information in the box below.

Model Number__________________________ Serial Number_______________________

Voltage________________Hertz_____________ Phase__________________

Champion Service Agent __________________________________ Tel:______________________

Champion Parts Distributor _________________________________ Tel:______________________

National Service Department

In Canada: In the USA:

Toll-free: 800/ 263-5798 Toll-free: 800/ 858-4477

Tel: 905/ 562-4195 Tel: 336/ 661-1556

Fax: 905/ 562-4618 Fax: 336/ 661-1660

email: service@moyerdiebellimited.com email: service@championindustries.com

ATTENTION:

The dishwasher model number,

serial number, voltage, hertz and phase

are needed to identify your machine and to

answer questions.

Please have this information on-hand

if you call for service assistance.

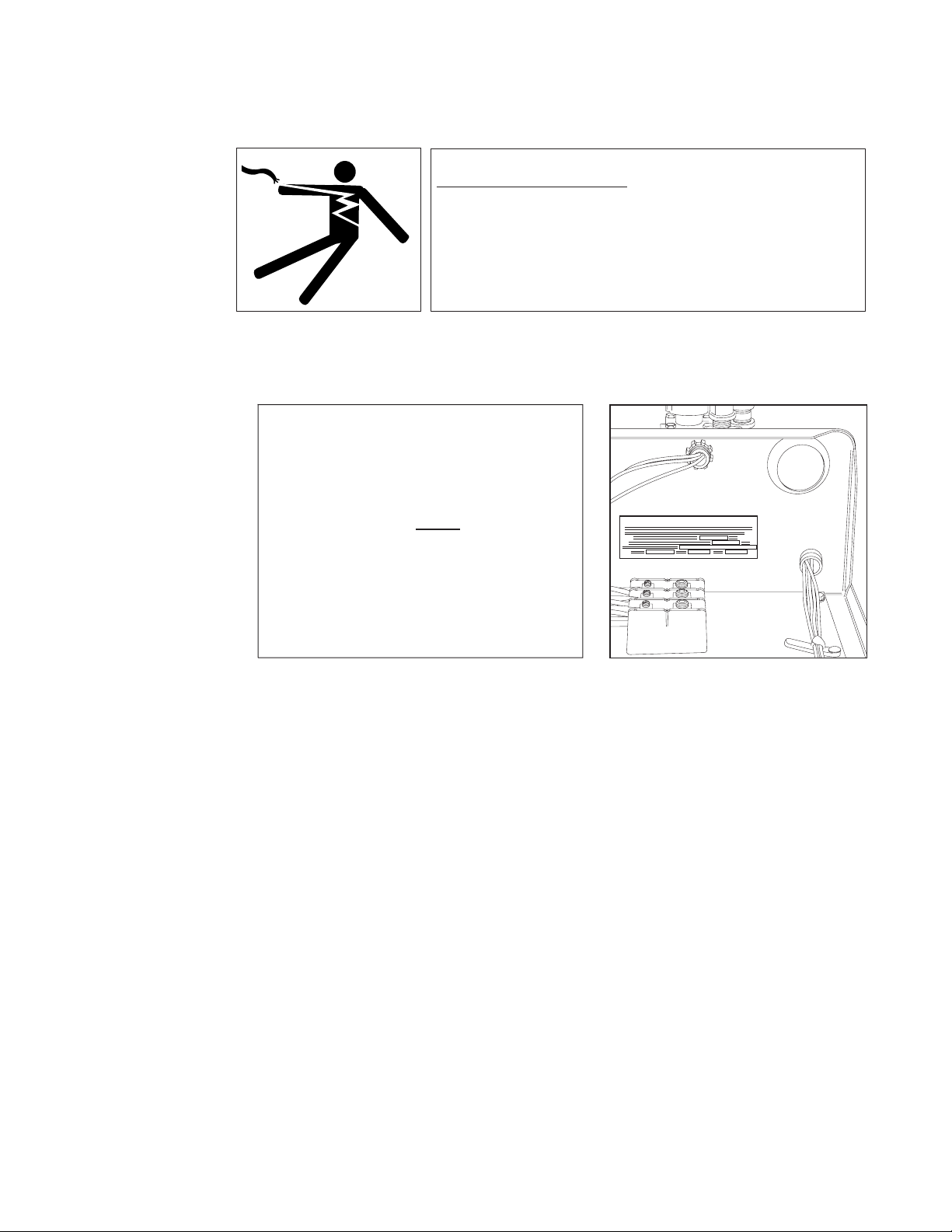

For all models:

The data plate mounts to

one side of the top-mounted

control cabinet.

The USGBC and the CaGBC Member Logos are trademarks owned by the U.S. Green Building Council and

The Canadian Green Building Council, respectively, and are used by permission. The logos signify only that Champion

Industries, Inc. is a USGBC member and a CaGBC member; USGBC and CaGBC do not review,

certify nor endorse the products or services offered by its members.

COPYRIGHT © 2012 All rights reserved Printed in the USA

Page 3

REGISTER YOUR PRODUCT ONLINE

Make sure you are connected to the internet then enter the address below.

In the U.S.A

http://www.championindustries.com/register

In Canada

http://www.championindustries.com/canada/register

Page 4

PRODUCT REGISTRATION

BY FAX

COMPLETE THIS FORM AND FAX TO:

(336) 661-1660 in the USA

1-(800) 204-0109 in Canada

PRODUCT REGISTRATION CARD

Model

Date of Installation:

Company Name:

Address:

Telephone #: ( ) ---

Serial #

(Street) Province Postal Code

Contact:

Installation Company:

Address:

Telephone #:

Contact:

FAILURE TO REGISTER YOUR PRODUCT MAY VOID YOUR WARRANTY

IMPORTANT IMPORTANT

Page 5

Revision History

Revision History

A revision might be a part number change, new instructions, or information that was not available

at print time. We reserve the right to make changes to this manual without notice and without incurring any liability by making the changes. Dishwasher owners may request a revised manual, at

no charge, by calling (800.858.4477) in the USA or (800.263.5798) in Canada.

Revision Revised Serial Number Description

Date Pages Effectivity

9.01.04 All RE3448 Released First Edition

9.01.04 20 RE3448 P/N 328473 replaced by 328977

9.01.04 20,23,25 RE3448 Added new door catches

9.01.04 23 RE3448 P/N 327891 replaced with 328974

12.16.04 43, 75,77 RE3448 Added 575 Volt Elements

2/16/05 91 RE3448 Added revised schematics

3/13/08 21,22 RE08024965 Addedbafetopreventdrafts

9/27/06 32-35 RE4320 Added rack rear guide to the track

7/17/08 80 RE08065126 Added timer to eliminate blower chatter

3/14/08 N/A RE0705549 Added Solid State Controls for special orders

8/18/09 98-99 J08102541 Added Digital Controls displays to cabinet

and digital display troubleshooting guide

6/12//09 N/A RE09045446 First Rack Model with digital display

10/13/09 All J08102541 Released Second Edition

1/22/10 92-97 J08102541 Added 575V/3PH Part Nos.

1/22/10 110-113 J08102541 Added 24" and 30" Sideloaders

3.17.10 80-83 J08102541 Added Fill Piping and CWT Piping

8.2.10 23 J08102541 Added 120 to set-point instructions

8.2.10 84 J08102541 Added Drain Basket Assy. P/N 107342

8.2.10 89 J08102541 Changed Item 2 P/N to 113984

8.2.10 106-107 J08102541 Revised Illustration and Parts List

8.26.10 107 J08102541 Corrected Item 36 P/N for 0507315 to 601707

11.16.10 55 J08102541 Corrected Item Numbers in Illustration

10.15.12 34-35 RE10095983 Updated 575V Drive Mtr. to 240V/60/1

39 J08102541 Chaned Item 2 from 328045 to 328046

52-53 J08102541 Corrected Item Numbers in Illustration

54-55 J08102541 Added E-84 Wash Manifold P/N's

91 J08102541 Removed Kit 900184 from List NLA

95 J08102541 Chenged Item 1 P/N 114505 for Digital Cabinet

121-150 -------------- Replaced All schems w/Current Digital revisions

i

Page 6

Limited Warranty

LIMITED WARRANTY

Champion Industries Inc. (herein referred to as Champion), 3765 Champion Blvd., Winston-Salem, North Carolina 27105,

and P.O. Box 301, 2674 N. Service Road, Jordan Station, Canada, L0R 1S0, warrants machines, and parts,

as set out below.

Warranty of Machines: Champion warrants all new machines of its manufacture bearing the name

"Champion" and installed within the United States and Canada to be free from defects in material and workman

ship for a period of one (1) year after the date of installation or fteen (15) months after the date of shipment by

Champion, whichever occurs rst. [See below for special provisions relating to glasswashers.] The warranty

registration card must be returned to Champion within ten (10) days after installation. If warranty card is not

returned to Champion within such period, the warranty will expire after one year from the date of shipment.

Champion will not assume any responsibility for extra costs for installation in any area where there are

jurisdictional problems with local trades or unions.

If a defect in workmanship or material is found to exist within the warranty period, Champion, at its election,

will either repair or replace the defective machine or accept return of the machine for full credit; provided;

however, as to glasswashers, Champion's obligation with respect to labor associated with any repairs shall end

(a) 120 days after shipment, or (b) 90 days after installation, whichever occurs rst. In the event that Champion

elects to repair, the labor and work to be performed in connection with the warranty shall be done during regular

working hours by a Champion authorized service technician. Defective parts become the property of Champion.

Use of replacement parts not authorized by Champion will relieve Champion of all further liability in connection

with its warranty. In no event will Champion's warranty obligation exceed Champion's charge for the machine.

The following are not covered by Champion's warranty:

a. Lighting of gas pilots or burners.

b. Cleaning of gas lines.

c. Replacement of fuses or resetting of overload breakers.

d. Adjustment of thermostats.

e. Adjustment of clutches.

f. Opening or closing of utility supply valves or switching of electrical supply current.

g. Cleaning of valves, strainers, screens, nozzles, or spray pipes.

h. Performance of regular maintenance and cleaning as outlined in operator’s guide.

i. Damages resulting from water conditions, accidents, alterations, improper use, abuse,

tampering, improper installation, or failure to follow maintenance and operation procedures.

j. Wear on Pulper cutter blocks, pulse vanes, and auger brush.

Examples of the defects not covered by warranty include, but are not limited to: (1) Damage to the exterior or

interior nish as a result of the above, (2) Use with utility service other than that designated on the rating plate,

(3) Improper connection to utility service, (4) Inadequate or excessive water pressure, (5) Corrosion from

chemicals dispensed in excess of recommended concentrations, (6) Failure of electrical components due to

connection of chemical dispensing equipment installed by others, (7) Leaks or damage resulting from such

leaks caused by the installer, including those at machine table connections or by connection of chemical

dispensing equipment installed by others, (8) Failure to comply with local building codes, (9) Damage

caused by labor dispute.

Warranty of Parts: Champion warrants all new machine parts produced or authorized by Champion to be free

from defects in material and workmanship for a period of 90 days from date of invoice. If any defect in

material and workmanship is found to exist within the warranty period Champion will replace the defective

part without charge.

DISCLAIMER OF WARRANTIES AND LIMITATIONS OF LIABILITY. CHAMPION'S WARRANTY IS ONLY TO THE EXTENT REFLECTED ABOVE. CHAMPION MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING,

BUT NOT LIMITED, TO ANY WARRANTY OF MERCHANTABILITY, OR FITNESS OF PURPOSE. CHAMPION SHALL

NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. THE REMEDIES SET OUT ABOVE ARE

THE EXCLUSIVE REMEDIES FOR ANY DEFECTS FOUND TO EXIST IN CHAMPION DISHWASHING MACHINES AND

CHAMPION PARTS, AND ALL OTHER REMEDIES ARE EXCLUDED, INCLUDING ANY LIABILITY FOR INCIDENTALS

OR CONSEQUENTIAL DAMAGES.

Champion does not authorize any other person, including persons who deal in Champion dishwashing machines

to change this warranty or create any other obligation in connection with Champion Dishwashing Machines.

ii

Page 7

Table of Contents

E-series Rack Conveyor Dishwashers

Revisions to this manual......................................................................................................................... i

Limited Warranty ................................................................................................................................... ii

Model Descriptions ................................................................................................................................. iv

Installation ................................................................................................1

Model Details .......................................................1

Receiving ............................................................2

Plumbing Connections.........................................2

Drain Connections ...............................................4

Ventilation ............................................................4

Electrical Connections .........................................5

Curtain Locations.................................................8

Hot Water Coil Tank Heat ....................................9

Door Safety Switches ..........................................11

Spray Arm and Scrap Screens ............................11

Operation .................................................................................................17

Operation .............................................................17

Cleaning and Maintenance ..................................18

Digital Display ......................................................20

Troubleshooting ...................................................26

Service Replacement Parts ....................................................................27

Electrical Schematics..............................................................................121

iii

Page 8

Model Descriptions

Model Descriptions

Electric high temperature single tank and multiple tank rack conveyor dishwashers

with built-in electric boosters in 40°F/22°C rise or optional 70°F/39°C rise.

Steam high temperature single tank and multiple tank rack conveyor dishwasher with

built-in steam booster in 40°F/22°C rise or an optional 70°F/39°C rise booster.

Hot water coil dishwashers utilizing recirculating hot water through a wash tank heater

coil to heat the wash water.

Electric low temperature chemical sanitizing single tank and multiple tank rack conveyor

dishwasher.

Dual Rinse machines utilizing an auxiliary rinse to save energy and improve washability.

The installation, and initial start-up of your dishwasher must be performed by qualied

electricians, plumbers, and authorized service technicians trained in commercial

dishwashers.

Defects and repairs caused by unauthorized installers will not be covered by the

dishwasher warranty.

iv

Page 9

Model Details

Model Details

Champion single tank and two tank rack conveyor dishwashers are fully automatic.

Standard equipment includes 1HP prewash, 2HP wash and 2HP power rinse pumps. The

conveyor drive is a 1/6 HP motor. All models are available in

right-to-left (R-L) or left-to-right (L-R) direction.

Model Numbers

Single Tank - Basic ................................................. 44, 54, 44 WS, 44 LT

Single Tank with 22" Prewash ................................. 66 PW, 76 PW, 66 WS, 66 LT PW

Single Tank with 36" Prewash ................................. 80 HDPW, 90 HDPW, 80WS HDPW

Single Tank with 26" Front Feed Prewash .............. 70 FFPW,80 FFPW, 70 WS FFPW

• The44DRand54DRbasicmodelsarehightemperature180°F/80°Chotfinalrinse

water sanitizing dishwashers. Prewash options are available in 22", 36", and

26"frontfeed.Built-instainlesssteelelectricboosterheatersin40°F/22°Cand

70°F/39°Criseareavailableandsteamboosterheatersin40°F/22°Cand70°F/39°C

rise. Dual-Rinse (DR) models feature a recirculating rinse that conserves energy.

• The44WSand44DRWSmodelsareWaterSaverhightemperature180°F/80°C

hot final rinse water sanitizing dishwashers. Prewash options are available in 22",

36",and26"frontfeed.Built-instainlesssteelelectricboosterheatersin40°F/22°C

and70°F/39°Criseareavailableandsteamboosterheatersin40°F/22°Cand70°F/39°C

rise. Dual-Rinse (DR) models feature a recirculating rinse that conserves energy.

• The44LTand66LTmodelsarelowtemperature140°F/60°Csodiumhypochlorite

(chlorine bleach) sanitizing final rinse to maintain a minimum concentration of

50 PPM on the wares. The concentration of sanitizer must be tested at regular

intervals using chlorine test papers.

Two Tank - Basic .......................................................64, 72, 84

Two Tank with 22" Prewash ......................................86 PW, 94 PW, 106 PW

Two Tank with 36" Prewash ......................................100 HDPW, 108 HDPW, 120 HDPW

Two Tank with 26" Front Feed Prewash ....................90 FFPW, 98 FFPW, 110 FFPW

•The64,and84basicmodelsarehightemperature180°F/80°Chotwaterfinalrinse

sanitizing models. Prewash options are available in 22", 36", and 26" front feed.

Built-instainlesssteelelectricboosterheatersin40°F/22°Cand70°F/39°Criseare

availableandsteamboosterheatersin40°F/22°Cand70°F/39°Crise.

•Allrackconveyordishwashermodelsarecoveredbya1-yearpartsandlaborlimited

warranty.

1

Page 10

Installation

Receiving

!!ATTENTION!!

Use caution when moving or lifting the dishwasher to prevent damaging the dishwasher or the installation

site. Check doorway and passageway clearance before moving the dishwasher. Remove dishwasher front

panels and check under the machine base for obstructions before moving.

1. Inspect the dishwasher for shipping damage

2. Check the dishwasher interior for curtains, panels and other supplies.

3. Lift the dishwasher off the shipping pallet and move the machine near its permanent location.

4. Leave a minimum of 6" between walls and the rear of the dishwasher.

5. Level the dishwasher side-to-side and front-to-back using a bubble level.

The dishwasher legs are adjusted by screwing them in or out.

6. Do not remove tags attached to the utility connections.

7. Remove the protective film from the dishwasher exterior.

8. Remove any foreign material from the dishwasher interior.

6"

6"

Wall Clearances

2

Page 11

Installation

Utilities

Hot Water Connections

NOTE:

Only qualified personnel should make dishwasher plumbing connections.

Connections must meet local plumbing and sanitary codes.

Improper installation is not covered be the dishwasher warranty.

Hot Water Requirements:

1. Connect a 3/4" NPT hot water supply line to the line strainer located at the top rear of the

dishwasher.

2. For a dishwasher without a booster heater, the hot water connection must supply a

minimumof180°F/82°Cmeasuredatthedishwasher.

3. Fora40°F/22°Criseboosterheater,thehotwaterconnectionmustsupplyaminimumof

140°F/60°Cmeasuredatthedishwasher.

4. Fora70°F/39°Criseboosterheater,thehotwaterconnectionmustsupplyaminimumof

110°F/43°Cmeasuredatthedishwasher.

5. For a single wash tank hot water coil heated dishwasher, the hot water connection must

supplyaminimumof185°F/85°Cmeasuredatthedishwasher.

6. For a two-tank hot water coil heated dishwasher, the hot water connection must supply a

minimumof195°F/91°Cmeasuredatthedishwasher.

7. For a low temperature chemical sanitizing dishwasher the hot water connection must

supplyaminimumof140°F/60°Cmeasuredatthedishwasher.

8. Install a pressure regulating valve (PRV) before the dishwasher supply connection to

maintain a flowing pressure of 20-25 PSI/137.8-172.4 kPa.

9. Install a service shut-off valve in the supply line, as close to the dishwasher as possible.

The size of the valve must be the same size or larger as the supply line.

Cold Water Connections

Cold Water Requirements:

1. Connect a 1/2" NPT cold water supply line for a dishwasher equipped with a prewash cold

water tempering option. Connection is located at the top of rear of the dishwasher load end.

2. Connect a 1/2" NPT cold water supply line for dishwashers required to have a drain water

temperature tempering option. Request a P/N 452891 for a drain tempering water kit.

3

Page 12

Installation

Drain Connections

1. The 1-1/2" drain line was removed and packed inside the dishwasher prior to shipping. Install the drain

line once the dishwasher has been placed in its final location.

2. Dual rinse (DR) models have a PVC drain line assembly packed inside the dishwasher also. Remove

this assembly and install it at the unload end of the dishwasher. The drain connection is made to the

main drain line with a hose-type connector.

3. Connect the 1-1/2" NPT drain line to above a drain sink or to a 1-1/2" or larger drain line connection.

4. Observe all local plumbing and sanitary codes when installing.

Steam Supply and Condensate Connections

1. The size of the steam supply line must be a 2" NPT line.

2. Check the steam pressure requirements prior to connecting the steam supply lines. Standard high

steam supply required is 15-30 PSI/103-201 kPa.

3. Low steam supply pressure is 7-14 PSI/48.2-96.5 kPa

4. Connect a steam supply line the same size or larger to the dishwasher at the steam supply strainer

located at the unload end of the dishwasher.

5. Condensate lines must be gravity drain with no back pressure. A condensate lift pump must be

installed if the condensate flow is above the finished floor.

Ventilation Connections

1. DO NOT VENT THE DISHWASHER INTO WALLS, CEILINGS OR ENCLOSED PLACES.

2. Vent stacks with adjustable dampers are supplied with the dishwasher to connect house vent.

3. Connect stainless steel water-tight duct inside the 4" x 16"/ 106mm x 407mm vent stacks supplied with

the dishwasher.

4. A minimum of 6 air changes per hour of kitchen is recommended

Ventilation Guidelines:

Dishwasher without a prewash tank option:

Load end- 200 CFM @ 1/4" SP/ 95 Liters/second

Unload end- 400 CFM @ 1/4" SP/ 189 Liters/second

Dishwasher with a Prewash tank option:

Load end- 150 CFM @ 1/4" SP/ 95 Liters/second

Unload end- 400 CFM @ 1/4" SP/ 189 Liters/second

Dishwashers with more than two tanks:

Load end- 200 CFM @ 1/4" SP/ 95 Liters/second

Unload end- 400 CFM @ 1/4" SP/ 189 Liters/second

4

Page 13

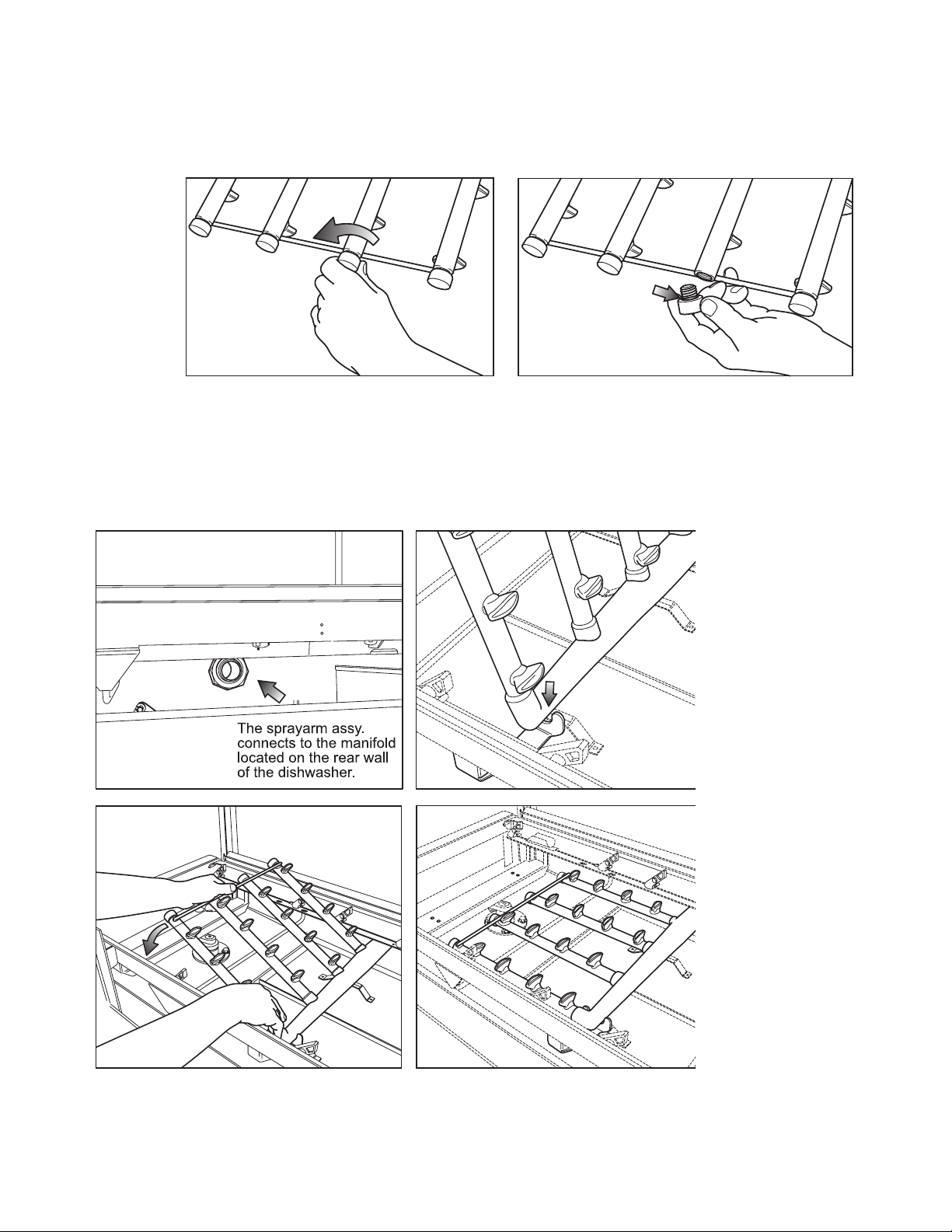

MACHINE ELECTRICAL CONNECTION

Installation

Electrical Connections

WARNING:

Electrocution or serious injury may result when working on an

energized circuit.

Disconnect power at the main breaker or service disconnect

switch before working on the circuit.

Lock-out and tag the breaker to indicate that work is being

performed on the circuit.

ATTENTION

A qualified electrician must connect the main incoming power to the dishwasher in accordance with all

local codes and regulations or in the absence of local codes in accordance with the National Electrical

Code.

!!ATTENTION!!

Electrical and grounding connections

must comply with the National Electrical Code

or in the absence of a National Code then

all Local Electrical Codes.

A qualified electrician MUST compare the

electrical power supply with the machine

electrical specifications stamped on the

MACHINE ELECTRICAL

CONNECTION PLATE

located inside the control cabinet before

connecting the main power to the dishwasher.

1. The Main incoming power to the dishwasher is made at the top of machine

in the control cabinet.

2. The electrician must connect the incoming power based on the information

that is stamped on the Machine Electrical Connection Plate.

3. Any change to the Machine Electrical Connection Plate must be approved

by the factory in advance.

4. The dishwasher main power terminal block is located inside the top-mounted

control cabinet.

5. A knock-out plug is provided at the rear of the control cabinet for electrical

service connections.

6. Built-in electric booster heaters have a separate main power connection

except Models 44 WS and 66WS.

7. Electric blower-dryers have a separate main power connection.

8. If the machine incoming voltage exceeds 208-240VAC then the Dual Rinse

(DR) models have a step-down transformer mounted on the frame of the

dishwasher to reduce the incoming voltage for the DR drain pump.

5

Page 14

Installation

Electrical Connections (continued)

Motor Rotation

1. Motor rotation was set at the factory.

2. The conveyor drive motor rotation is indicated by a red arrow located on the side of

the motor.

3. Check if all motors are running in the wrong direction.

4. Reverse the L1 and L2 wires on the output side of the dishwasher Main Terminal

Block (MTB) located inside the top-mounted control cabinet.

5. The photograph to the right shows the conveyor drive motor with its direction arrow.

6. A wash pump/motor assembly can be seen in the back.

WARNING:

Moving Conveyor Parts may cause INJURY OR DEATH.

Keep hands and clothing clear of the conveyor when the

conveyor is moving.

USE EXTREME CAUTION WHEN THE CONVEYOR

IS MOVING.

THREE PHASE

POWER CONNECTION

LINE IN

L1 L2 L3

GRD

Main Terminal Block Inside the Top-mounted Control

Cabinet.

6

Motor Direction Rotation Label on Motor Frame.

Page 15

1. Use a qualified detergent/chemical supplier

for detergent/chemical and dispensing

equipment needs.

2. Labeled detergent control circuit connection

terminals are provided in the control cabinet

for detergent and rinse agent/sanitizer

dispensing equipment (supplied by others).

3. The illustration on the right, shows the

terminal board for the machine.

4. The signal connection points include:

•Detergentsignal120VAC,1Amaxload.

•Rinseaid/Sanitizersignal120VAC,1Aload.

•VentFan120VAC,1Ampmaxampload

Installation

Chemical Connections

SIGNAL ONLY

VENT FAN

120V

COMMON

RINSE AID

120V

COMMON

DETERGENT

120V

5. A removable black plug is provided in the

load end side of the wash tank for installation

Detergent

Probe Location

of the detergent conductivity cell.

Vent Fan Signal Connection

1. A terminal block is provided inside the top-mounted control

cabinet to provide a 120VAC, 1 AMP Max Load signal.

NOTE:

The Vent Fan Signal Connection supplies 120VAC to a control

relay (supplied by others) when the dishwasher is ON and O

VAC when the dishwasher is OFF. Power to operate the vent

fan (supplied by others) must be supplied separately.

Machine Running & Table Limit Switch Signal Connections

SIGNAL ONLY

VENT FAN

120V

COMMON

RINSE AID

120V

1. Connections are provided for systems that

require that a signal to indicate the dishwasher

is running.

2. A signal connection is provided to indicate

that the dishwasher has stopped due to a

conveyor jam or when the clean dish table

is full of racks and additional racks cannot

exit the machine.

3. The table limit switch option is recommended

be installed on all dishwashers and can be

ordered from the factory P/N 407400.

SIGNAL ONLY

MACHINE

RUNNING

TABLE

LIMIT

SWITCH

7

Page 16

Installation

Curtain Locations

1. Refer to the illustrations below and hang the curtains as shown.

J-hooks are located in the corners of each section to accept the curtain rods.

• Standardlongcurtains 24”x20-1/4”

• Highhoodlongcurtains 24”x22-3/4”

• StandardshortcurtainsandDR 24”x13-1/4”

• Highhoodshortcurtains 24”x20-1/4”

• Finalrinsecurtain 24”x6-1/4”

2. Make sure the that the short flaps of the curtains face the load end of the dishwasher. The

longest curtains always go on each end of the dishwasher.

Single Tank Dishwasher Curtain Locations.

Final Rinse Curtain

Long CurtainDual RInse Curtain

DRFR

NOTE:

Misplacing a curtain or failing to

install a curtain will adversely affect

the proper operation of the machine.

Long Curtain

Dual Rinse Single Tank Dishwasher with Prewash Curtains.

8

Page 17

Installation

Hot Water Coil Tank Heat

Purging Air from the Dishwasher/Booster Heater System

CAUTION:

PERMANENT DAMAGE to the hot water recirculating pump can

occur if the air is not purged from the dishwasher/booster heater

system prior to placing the dishwasher into service.

Follow the instructions carefully to prevent damage to the

dishwasher hot water recirculating pump.

The air trapped in the Dishwasher Hot Water Recirculating Pump and Water Lines must be purged.

Refer to the illustration below and follow the procedure on the next page.

A

The air purge petcock is located behind the dishwasher

lower front panel at the booster end of the machine.

B

The dishwasher recirculating pump is located

near the base at the booster end of the machine.

9

Page 18

Installation

Hot Water Coil Tank Heat

Purging Air from the Dishwasher/Booster Heater System (continued)

Refer to the illustration on the previous page and follow the procedure below to purge the air from the

system. Plumbing and electrical service connections must be completed before purging the system.

To purge the air:

1. Make sure the dishwasher main power switch is OFF.

2. Make sure the main water supply valve located at the booster heater is OFF.

3. Open petcock (A) on the inlet side of the dishwasher hot water heater coil.

4. Remove the silver plug located in the center of the recirculating pump.

5. TurnthemainwatersupplyvalveON.Waterwillbegintolltheboosterheaterandthedishwasher

heater coil.

6. Waterandairwillbegintoowoutofthepurgepetcockandtherecirculatingpumpandeventually

only water will be observed.

7. Turn the booster heater power switch ON.

8. TurnthedishwasherpowerswitchON.Thedishwasherwashtankwillbegintollwithwater.

9. Continue to observe the petcock and the recirculating pump and make sure that there is a steady

streamofwaterisowingfrom(A)and(B).

10. Replace the silver plug (B) in the center of the recirculating pump then close the petcock (A).

11. Turn the dishwasher power switch OFF.

12. Purging is complete.

10

Page 19

Door Safety Switches

Dishwasher access doors are equipped with a door safety switch that automatically

stops the dishwasher pumps and conveyor drive if a door is raised while the dishwasher

is running. In addition, the dishwasher will not start if a door is left open.

1. If the dishwasher is running and a door is raised, then lighted GREEN START

pushbutton goes out and the pumps and conveyor drive stop.

2. Check the interior of the dishwasher for any dish racks still in the machine.

These dish racks must be washed again to ensure they are washed and sanitized

completely.

3. To restart the dishwasher, make sure all doors are closed, then push the GREEN

START pushbutton.

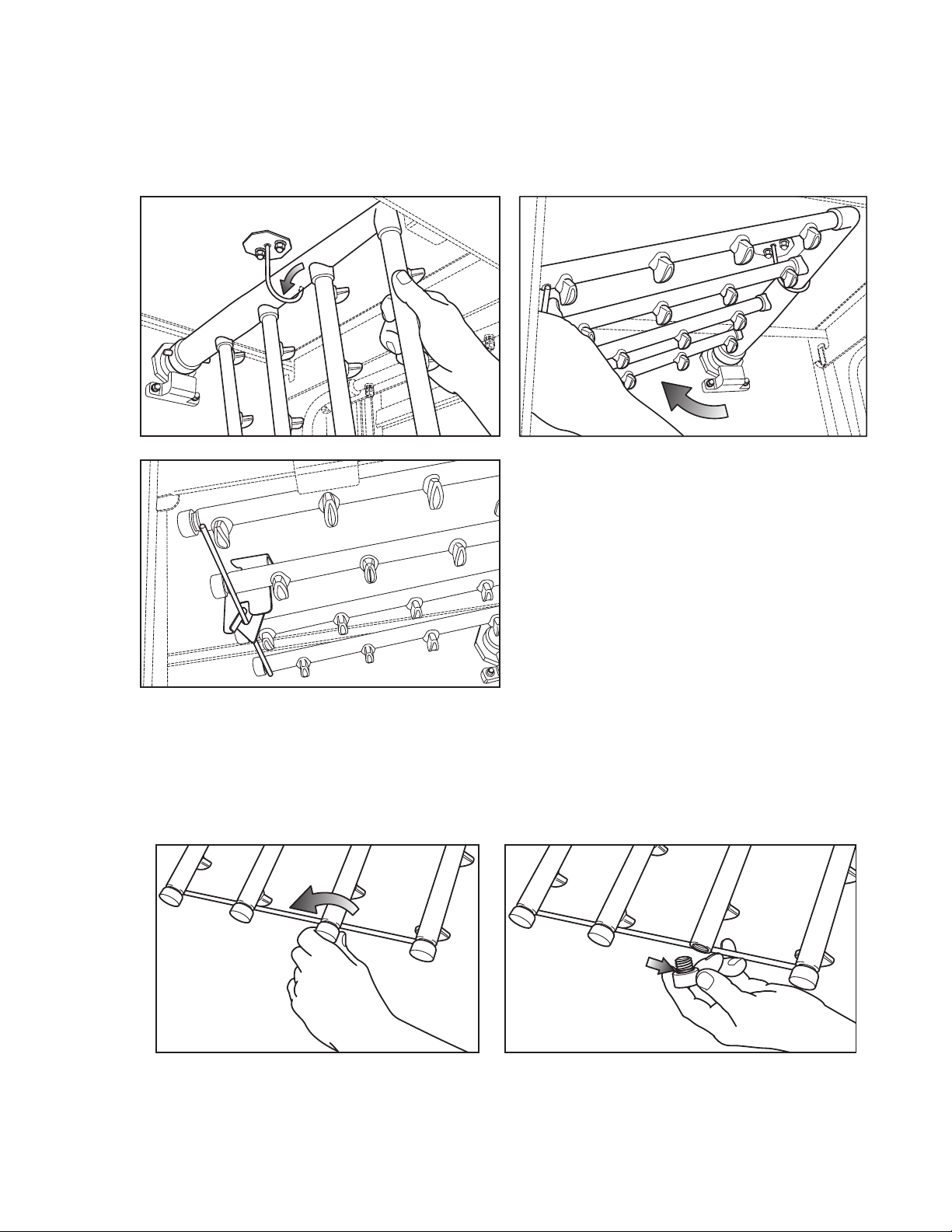

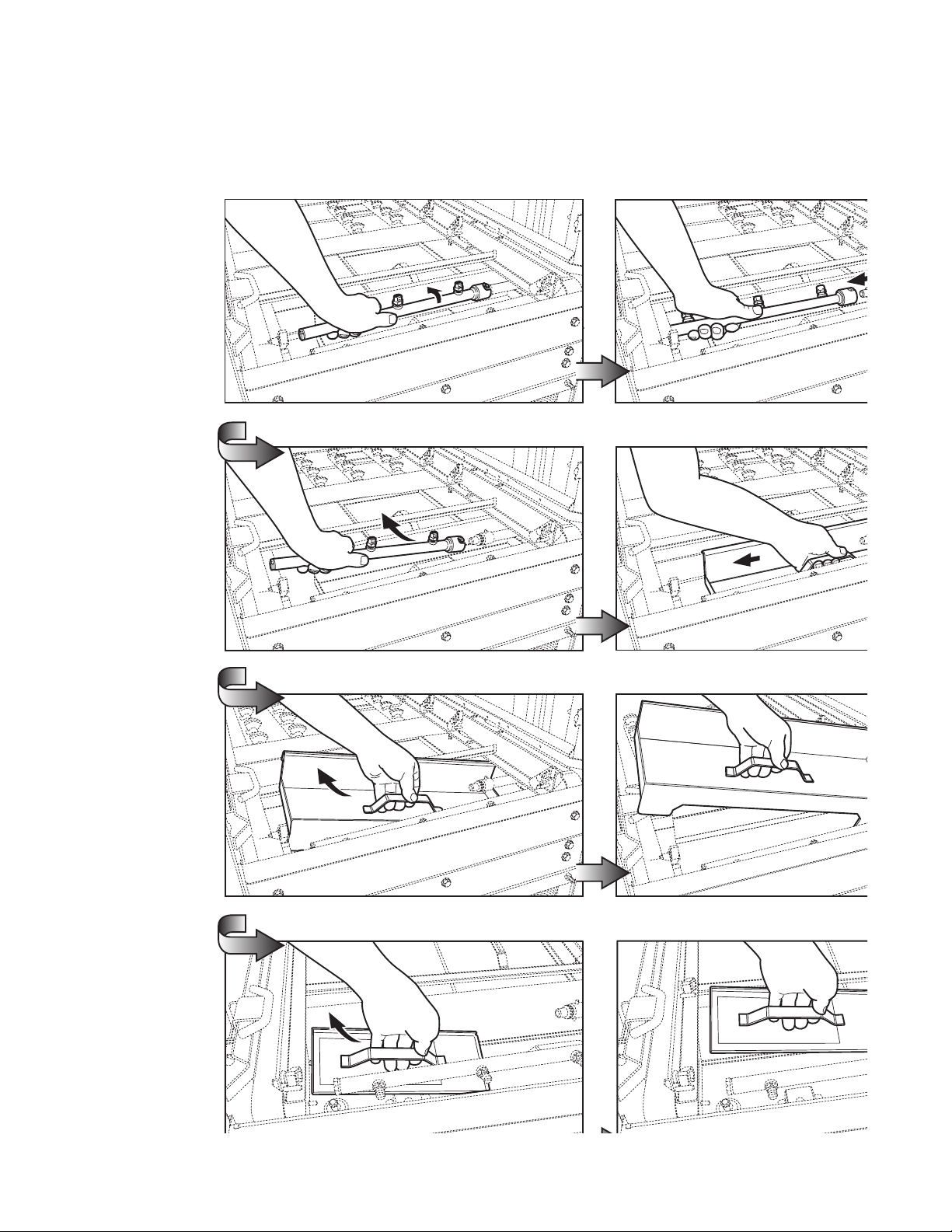

Spray arm and Scrap Screen Installation

The illustrations below and on the proceeding pages illustrate how to install and

remove the spray arm assemblies and scrap screens.

Installation

Removing the lower spray arm

assembly

11

Page 20

Installation

Removing the Spray arm End Plugs

Installing the Lower Spray arm Assembly

12

Page 21

Installation

Installing the Lower Spray arm Assembly

Removing the Spray arm End Plugs

13

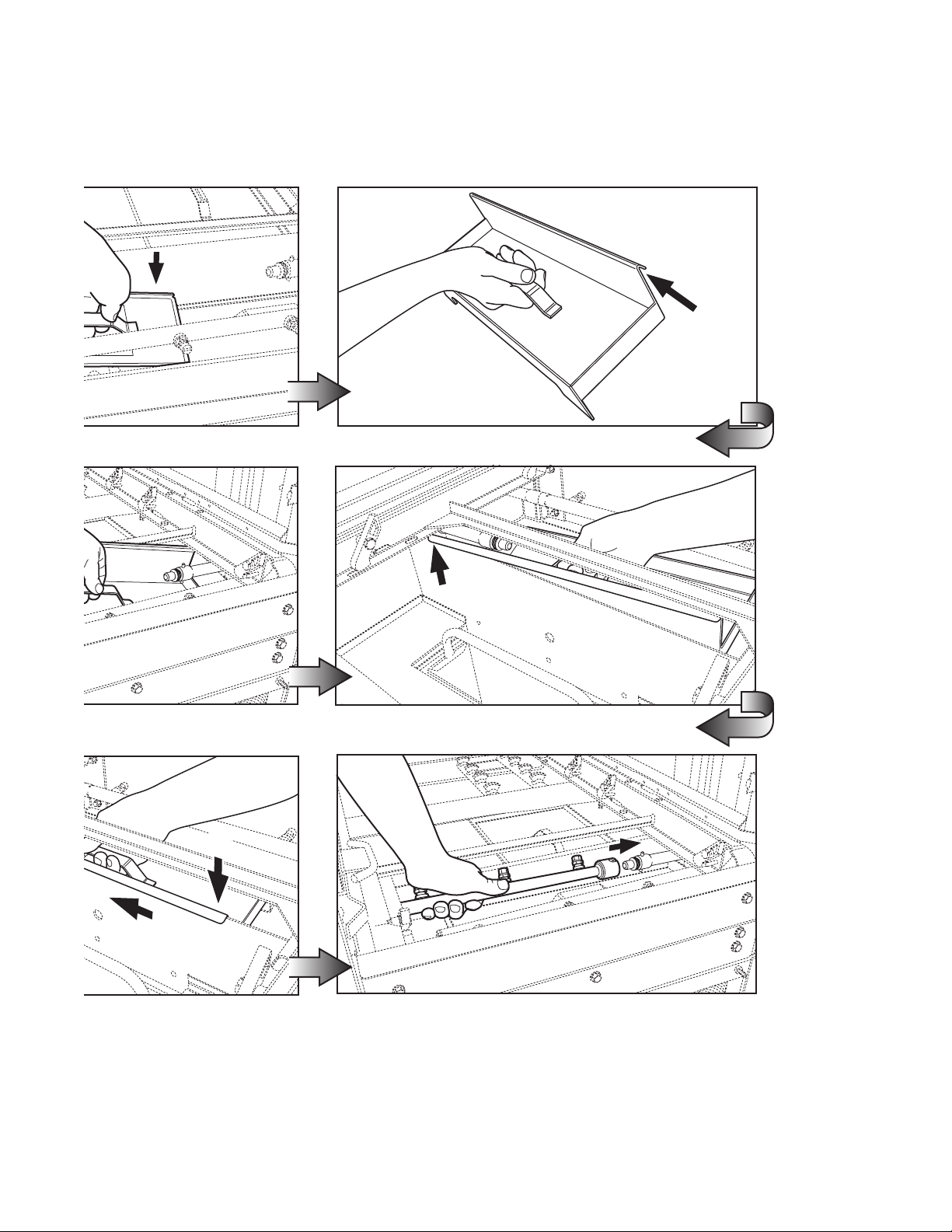

Page 22

Installation

Removing the Dual Rinse (DR) scrap screens

14

1

2

Page 23

Installation

Removing the Dual Rinse (DR) scrap screens (continued)

15

Page 24

Initial Start-Up

Check list

1. Remove white protective film from the dishwasher exterior.

2. Install lower panels to the dishwasher.

3. Remove any foreign material from inside of the machine.

4. Check dishwasher drain/overflows are closed and in securely seated.

5. Install scrap screens and baskets and spray arms.

6. Turn main utilities the dishwasher ON. (Power, water, steam if applicable).

7. Make sure doors are closed.

8. Turn dishwasher power switch ON.

9. Check tank water temperatures reach proper levels.

10. Check for leaks.

11. Drain the dishwasher and check that floor drains handle the water volume leaving

the dishwasher.

12. Push the Start button.

13. Open each dishwasher door to make sure the safety switch stops the conveyor.

14. Restart the dishwasher.

15. Insert an empty dish rack into the load end of the dishwasher.

The pumps and conveyor will run.

16. Allow the dish rack to travel to the unload end of the dishwasher. The final rinse

and the DR rinse (if equipped) will run.

17. Allow the rack to exit the dishwasher. The dishwasher pumps should run an

90-seconds and stop.

18. Push the Stop button when the machine is running and the dishwasher should stop.

19. Push the dishwasher Power Switch OFF. The dishwasher should shut down.

16

Page 25

Operation

Operation

1. Check that the spray pipes, curtains, and scrap screens are in place and clean.

2. Check that the overflow drains are closed.

3. Check the chemical supplies. Turn on the detergent dispenser switches.

4. Turn on the exhaust vent system (if applicable), and make sure it is operating.

5. Close the door(s). Push the power switch ON, light will illuminate.

Machine will begin to fill via the fill valve and the final rinse piping.

6. When the tanks are full, wait until the wash tank has reached the proper temperature.

Check the wash tank temperature gauges located on the control cabinet. Minimum wash

temperatures are:

• 44LT,66LTPW-140°F/60°C

• 44,54,44WS-160°F/71°Cto175°F/79°C

• 66PW,76PW,66WSPW- 160-175°F/71-79°C

• 2-tank(Wash)150-165°FTO66°F/74°C

(PowerRinse)165-180°FTO74°F/82°C

• FinalRinseforallmodelsisaminimumof180-195°F/82-91°C.

• DualRinse(ifequipped)is165-180°F/74-82°CRinseforallmodels.

• Prewashforallmodelshasnotemperaturerating.

7. Push the Green start button. The pushbutton illuminates indicating the dishwasher

is ready for automatic operation.

8. Pre-scrap wares to remove large food particles and load wares into the dish racks.

DO NOT OVERLOAD RACKS.

9. Pegged racks are for plates and/or trays. Flat racks are for bowls and/or silverware.

Spread silverware evenly in a single layer in a flat rack or upright (loosely packed) in a

cutlery rack/cylinder.

10. Push a dish rack into the load-end of the dishwasher until it contacts the idle pump

switch lever, the conveyor and pumps will start.

11. The dishwasher will run for 90 seconds to wash, rinse and move the dish rack out

of the unload-end of the dishwasher.

12. Inserting another dish rack into the machine before the first rack exits will keep the

dishwasher running until the last dish rack exits the machine.

13. Check the final rinse pressure and temperature as the racks pass through the final

rinse. This final rinse pressure MUST be 20-22 psi [137.8-145 kPa] and the final rinse

temperatureMUSTbeaminimumof180-195°F/82-91°C.

14. The pumps and the conveyor drive will automatically stop after the last rack exits

the machine.

15. The machine may be stopped at any time during the cycle by pressing the red STOP

pushbutton. The green light or LED will go out.

16. Check the interior of the dishwasher for any dish racks still in the machine.

These dish racks must be washed again to ensure they are washed and sanitized

completely.

17. To restart, push the green START pushbutton and push another dish rack into the

dishwasher load-end until the pumps and conveyor start again.

18. Repeat steps 7-10 until all wares are washed.

17

Page 26

Cleaning

Cleaning

Cleaning your dishwasher is the best maintenance you can do.

The cleaning intervals below are the minimum requirements for most dishwashers.

You may need to clean your dishwasher more often when washing heavily soiled wares

or during long hours of continuous operation.

Daily or every 2 hours of operation

1. Turn power switch to OFF.

2. Pull drain lever(s) to drain water. Remove scrap screens and scrap baskets.

Clean inside of the tanks and flush with clean water.

Back flush the scrap screens until clean.

DO NOT STRIKE SCREENS OR BASKETS AGAINST SOLID OBJECTS

3. Remove the spray arm assemblies. Remove the end cap from each spray arm.

4. Flush the spray arms and nozzles to remove any debris.

5. Replace the end caps. Check the condition of the manifold O-ring.

6. Reinstall the spray arms.

7. Remove and clean the curtains. Allow them to dry at the end of the day.

8. Leave the doors open between operations, allowing the machine to dry.

9. Make sure that the final rinse nozzles are clear of mineral deposits.

10. Straighten a metal paper clip to clean the nozzles.

11. Check the temperature and pressure gauge readings during operation.

12. Inspect the machine for signs of water leaks.

13. Check the chemical supplies and refill as necessary..

18

Page 27

Cleaning

Cleaning (continued)

At the End of the Day

1. Perform Steps 1-10 on the previous page.

2. Removetheupperandlowerrinseandwashsprayarmsandendplugsandushwithfreshwater.

3. RemovetheDualRinse(DR)rinsearmassembliesandushwithfreshwater.

4. Cleanthenalrinsearmnozzlesusingasmallpaperclip.

5. Remove the curtains and clean with fresh water.

DO NOT USE STEEL WOOL TO CLEAN THE INTERIOR OF THE MACHINE.

Wipe the interior and exterior of the machine with a soft cloth and a mild detergent.

DO NOT HOSE THE EXTERIOR OF THE MACHINE WITH WATER.

6. Reassemble the dishwasher and leave the door open to allow overnight drying

7. Contact the chemical supplier for de-liming if required.

De-liming

Lime (scale) deposits are the result of minerals contained in the water feeding the dishwasher and appear

as a white haze on the surface of the dishwasher. Severe scaling can appear as a granular deposit.

These deposits are a result of the mineral content in the geographic area of the machine's location.

WARNING:

Death or injury can result from toxic fume when de-liming agents

come in contact with Chlorine Bleach, or other chemicals that contain

iodine, bromine, or fluorine.

USE EXTREME CAUTION WHEN HANDLING ANY DE-LIMING AGENT

CAUTION:

De-liming agents can cause chemical burns.

Wear rubber gloves, eye protection and any other protective

clothing as instructed by a qualified chemical supplier and follow

the instructions provided by the chemical supplier.

! A TTENTION !

Place a flat-bottom dish rack upside down on the idle pump start switch at the entrance end

of the dishwasher to keep the dishwasher running during the de-liming procedure.

19

Page 28

Maintenance

Maintenance

Weekly

1. Inspect all water lines for leaks and tighten at joints if required.

2. Clean any detergent residue from the exterior of the machine.

3. Check that the drain/overflow pipes seat tightly in their drains.

4. Clean any accumulated scale from the heating element.

5. Inspect the spray arms for any damage or missing parts.

6. Inspect the final rinse arms for missing parts.

7. Inspect the pawl bar and drive assembly for damage or missing parts.

8. Check that float switches move freely.

9. Check the idle pump actuator and the final rinse actuator for freedom of travel.

Monthly

1. Inspect interior of machine for lime deposits and clean.

2. Check o-rings on spray arm piping connections.

3. Check that the drain/overflow o-rings

4. Clean any accumulated scale from the heating element.

5. Inspect the spray arms o-rings and ensure all plugs are installed.

6. Inspect the final rinse arms for missing parts and are clean.

7. Inspect the pawl bar and drive assembly for damage or missing parts.

8. Check that float switches move freely.

9. Check the idle pump actuator and the final rinse actuator for freedom of travel.

10. Check the drive clutch and adjust as necessary.

11. Check the pump rotation and direction of rotation.

12. Check the operation of temperature gauges or displays.

13. Perform complete operation check.

Yearly

1. Contact authorized service agent to perform complete maintenance review of machine.

2. Correct any abnormal situations as recommended.

20

Page 29

This Page

Blank Page

Intentionally

Left Blank

21

Page 30

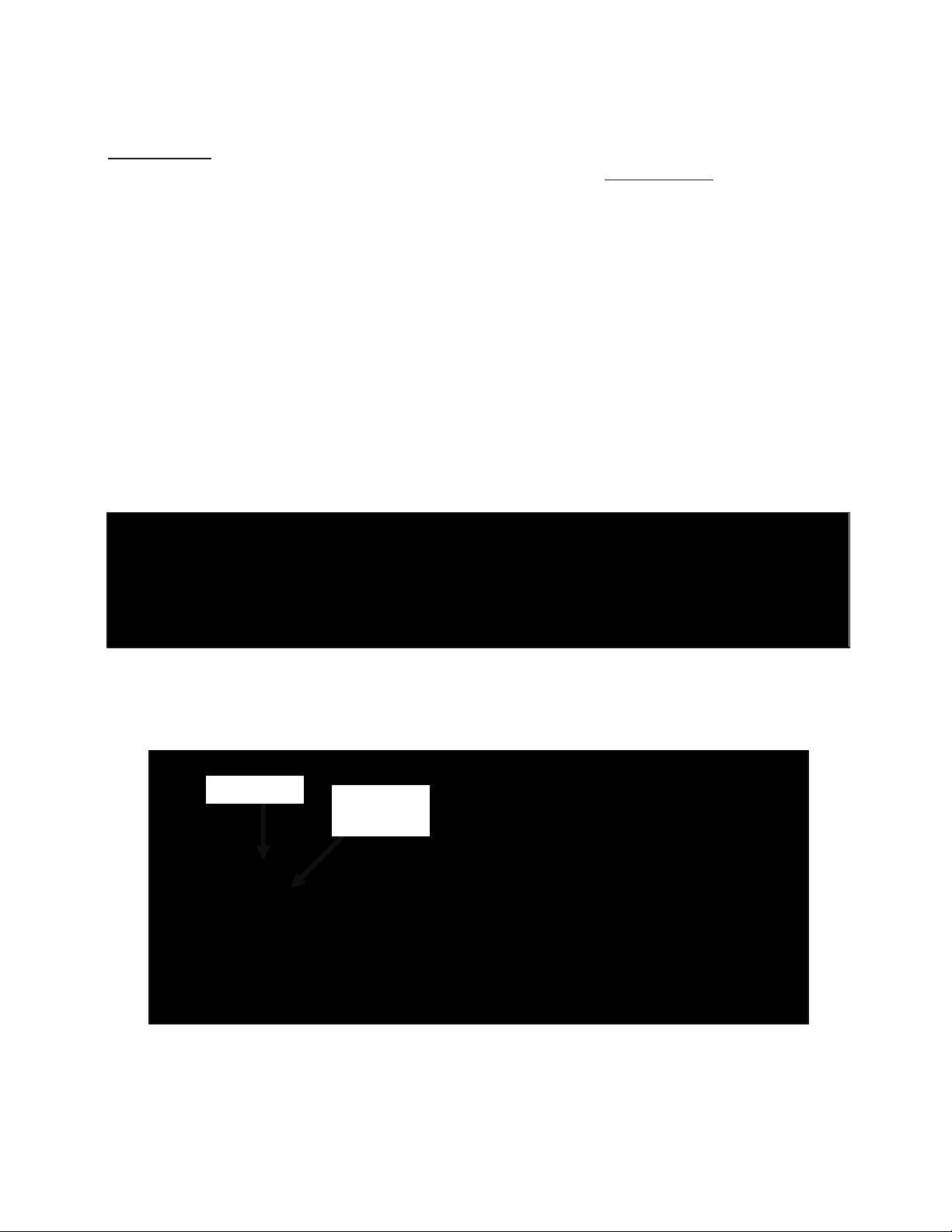

E-Rack Digital Temperature Display Meters

i

-

Digital Display

ATTENTION:

The Digital Temperature Displays only indicate temperature, they do not control

booster heaters. Electro-mechanical thermostats continue to control the tank and final rinse heat

circuits.

1. The analog temperature gauges have been replaced with digital temperature display meters.

2. The meters display temperatures for the prewash tank (if equipped), the wash tank,

power rinse tank (if equipped), the DR dual rinse tank (if equipped), and the final rinse.

3. A meter displays temperature in 2 ways:

a. The first display is a semi-circular LED bar that moves from left to right; as the temperature

increases in magnitude. The color of the bar changes from black, to orange, and to green.

b. The second display is a 3 digit LED that changes from OFF if the tank or final rinse heat is

disabled, to Blank and from a minimum temperature of 70

temperature set point of the meter.

(Refer to the "Display Meter Operation Checks" on the next page to change a Meter set-point.)

wash tank or final rinse

o

F to the maximum calibrated

Control cabinet showing digital temperature display meters on the right-hand side of the control cabinet.

LED Bar

3 digit

LED

Close-up view of the display meters. Note the sem

and the numeric read-outs in the center.

22

circular indicator bars

Page 31

Digital Display

The set-point determines how the meter displays the yellow & green bar. For example, if the

set-point is 70, then the bar displays yellow from 0-70 then green from 70 and above.

23

Page 32

Calibration:

t

t

s

Digital Display

Calibration is an internal function of the display circuit board and does not calibrate temperature control

of the dishwasher components.

NOTE:

TheThermister Plug

from the display circuit board before calibration.

To calibrate the display board:

NOTE:

If the display shows "EEE", then the thermister plug is not disconnected. Disconnect

the thermister plug and repeat Steps 1-6 above.

and 1 wire from the Rinse Switch Connector must be disconnected

1. Turn dishwasher Power Switch OFF.

2. Disconnect the thermister plug and at least 1 wire from the rinse switch connector.

3. Turn Power Switch ON.

4. Press and hold the CHECK pushbutton while pressing and releasing the RESET button.

5. Release the CHECK pushbutton.

6. Display shows “CAL” flashing on METER 1 and METER 2.

7. Press and hold the TEST A pushbutton to calibrate Meter 1

(Test B for Meter 2).

8. The display calibrates and shows "160".

9. Release TEST A pushbutton. An "E" flashes in the center of METER 1.

10. Press the RESET pushbutton to exit the calibration mode.

11. Repeat Steps 2-8 to calibrate Meter 2.

12. Turn the dishwasher Power Switch OFF and reconnect the thermister plug and rinse switch

connector wire.

13. Turn Power Switch ON and return to normal operation.

1 2

Thermister was no

unplugged before

calibration

0

Display board is in the

calibration mode

Disconnect

thermister

plug

Temperature

display

Selector switch

o

F or oC

Rear Detail View of Digital Display Circuit Board

Disconnec

a rinse

switch wire

4

3

Meter calibrated

Calibration comp

when "E" flash

lete

e

24

Page 33

Display Codes and Definitions

The illustrations below show the codes that may appear in the temperature meter displays.

Digital Display

160 displayed and bar is blank

o

25

Page 34

Condition Cause Solution

Dishwasher will not run.

Low or no water.

Door not closed.

Main power OFF.

Dishwasher OFF.

Dish rack inserted wrong

Main water supply off.

PRV setting incorrect

Solenoid strainer clogged.

Solenoid valve defective.

Close door completely.

Check breaker on panel.

Turn dishwasher ON.

Check dish rack loading.

Open supply valve.

Adjust the PRV setting

Clean strainer.

Contact Service Agent.

Dishwasher stays in

wash cycle.

Conveyor jammed or table

limit switch has stopped

conveyor.

Contact Service Agent

Poor wash results.

Detergent not added to tank

Wares incorrectly loaded.

in dishrack.

Clogged screens .

Clogged spray arms.

Thermostat defective.

End plugs missing.

Water temperature low.

Check detergent suppy.

Reposition wares or

reduce amount of wares.

Clean screens..

Clean spray arms.

Contact Service Agent.

Check spray arms.

Check incoming water

temperature.

Dishwasher conveyor

will not run.

90-second timer defective

Check conveyor for jams

Remove racks from load

end of table.

Troubleshooting

Troubleshooting

Before calling for service check the following conditions.

1. Dishwasher main power and water supply is on.

2. Machine has been assembled correctly.

3. Conveyor is clear of any obstructions.

4. Drains are closed.

5. Screens and pump intake screens are clear.

6. Doors are closed and secure.

26

Page 35

Service Replacement Parts

Illustration ....................................................................................................................................Page

Prewash Doors and Panels ..........................................................................................................................28

Single Tank Doors and Panels .....................................................................................................................30

Two Tank Doors and Panels .........................................................................................................................32

Drive Motor Assembly................................................................................................................................... 34

Conveyor Drive Assembly ............................................................................................................................ 36

Prewash Track and Cradle Assembly ........................................................................................................... 38

Single Tank Track and Cradle Assembly ......................................................................................................40

Two Tank Track and Cradle Assembly ..........................................................................................................42

Prewash Screens .........................................................................................................................................44

Single Tank Scrap Screens ..........................................................................................................................46

Two Tank Scrap Screens ..............................................................................................................................48

Prewash Spray Arms .................................................................................................................................... 50

Single Tank Wash Spray Arms .....................................................................................................................52

Two Tank Wash and Rinse Spray Arms........................................................................................................54

Float Switches ..............................................................................................................................................56

Single Tank Electric Heat ..............................................................................................................................58

Two Tank Electric Heat .................................................................................................................................60

Two Tank Steam Heat with K2 Booster ........................................................................................................62

Single Tank Steam Heat ...............................................................................................................................64

Two Tank Steam Heat ..................................................................................................................................66

Thermostats..................................................................................................................................................68

E-series Thermostat and Junction Box .........................................................................................................70

Prewash Drain Overflow Assembly ..............................................................................................................72

Single and Two Tank Drain overflow Assembly ............................................................................................74

Final RInse Piping with Booster....................................................................................................................76

Fill Piping no Booster or Steam Booster.......................................................................................................78

Fill Piping with Booster .................................................................................................................................80

Cold Water Thermostat (CWT) Piping ..........................................................................................................82

Final Rinse Drain Assembly..........................................................................................................................84

Prewash Pump Suction and Discharge ........................................................................................................86

Wash and Rinse Pump Suction/Discharge ...................................................................................................88

Pump Motor Assembly.................................................................................................................................. 90

Electric Booster Assembly 40-60˚F Rise ...................................................................................................... 92

Electric Booster Assembly 70˚F Rise ........................................................................................................... 94

Standard Control Cabinet .............................................................................................................................96

Control Cabinet with Digital Display .............................................................................................................100

Extended Vent Cowls ...................................................................................................................................102

Standard Vent Cowls ....................................................................................................................................104

E44DR Dual Rinse Assembly .......................................................................................................................106

E44DR Recycle pump Assembly ..................................................................................................................108

Single Tank Hot Water Coil Heat ..................................................................................................................110

Double Tank Hot Water Coil Heat .................................................................................................................112

24" Sideloader ..............................................................................................................................................114

30" Sideloader ..............................................................................................................................................116

Dishracks ......................................................................................................................................................118

27

Page 36

Prewash Doors & Panels

12

25

24

6

9

22

23

10

7

8

8

12

26

16

18

11

17

5

4

3

12

12

2

19

21

20

12

15

11

13

14

1

(L-R Direction Shown)

28

Page 37

Prewash Panels & Doors

Item Part Description Qty.

No. No.

1 328977 Panel Assy. Front Perimeter 22" PW Prewash 1

- 328978 Panel Assy. Front Perimeter 36" PW Prewash 1

2 329351 Panel, 25" End Standard 1

3 328030 Table Flange Support 1

4 329926 Bafe,TableFlange

5 328006 Support, 22" PW Rear Screen 1

6 113828 Rod Curtain 5/16 x 24-5/8" 2

7 113720 Curtain 24 x 20-1/4"(load end) 2

8 113691 Guide, U-channel Door 2

9 113486 Screw 8-32 x 5/8" Flat Hd SST 12

10 327952 Door, E22 15" Prewash 1

- 327857 Door, E36 26" Prewash 1

11 108966 Door Handle 2

12 100073 Screw 1/4-20 x 1/2 Truss Head 2

13 328427 Cover, Refuse Basket 22" 1

- 328524 Cover, Refuse Basket 36" 1

14 328959 Basket, Refuse 22" 1

- 328967 Basket, Refuse 36" 1

15 100764 Screw, 6-32 x 1/2" Round Hd. SST 6

16 113937 Magnet, Door Safety 1

17 113719 Switch, Door Safety 1

18 329986 Bracket, E15" Door Water Diverter 1

- 329985 Bracket, E26" Door Water Diverter 1

19 108418 Plug, 1/2" 2

20 109034 Gasket 2

21 108417 Nut 2

22 331981 Bracket, Door Stop 1

23 328909 Dual Hook, Door 1

24 317345 Bracket, Door Catch 2

25 100141 Nut, Plain 1/4-20 SST 4

26 108954 Grip Nut, 6-32 w/nylon insert SST 6

29

Page 38

Single Tank Doors & Panels

20

19

21

9

22

11

27

25

29

5

6

9

8

3

23

24

26

28

7

10

11

11

4

2

18

17

16

30

(L-R Direction Shown)

15

14

2

12

13

1

Page 39

Single Tank Doors & Panels

Item Part Description Qty.

No. No.

1 328974 Panel Assy., 44 Front Perimeter 1

- 330981 Panel Assy., 54 Front Perimeter 1

2 329351 Panel, 25” End Standard 1

3 329985 Bracket, Water Diverter 1

4 329926 Bafe 1

5 327857 Door, E 26" 1

6 108966 Door Handle 1

7 113691 Guide, U-channel Door 2

8 113486 Screw, 8-32 x 5/8 Flat Head SST 12

9 108250 Rod, Curtain 5/16 x 24-5/8 2

--- 113828 Rod, Curtain, 5/16 x 21-1/2" 2

10 113720 Curtain 24 x 20-1/4 4 Ply 2

--- 109723 Curtain 24 x 6 -1/4 (RInse Curtain) 1

11 100007 Screw 1/4-20 x 1/2 Truss Head SST 6

12 100734 Bolt 1/4-20 x 1/2 SST 3

13 113943 Plug, 3/4" 2

14 108602 Gasket 2

15 113944 Nut 2

16 108418 Plug, 1/2" 4

17 109034 Gasket 4

18 108417 Nut 4

19 331981 Bracket, Door Stop 1

20 100141 Nut, Plain 1/4-20 SST 4

21 317345 Bracket, Door Catch 2

22 308133 Dual Hook, Door 1

23 113937 Magnet, Door 1

24 113719 Switch, Reed Aleph 1

25 108954 Grip Nut, 6-32 w/nylon insert SST 8

26 100764 Screw, 6-32 x 1/2" Round Hd. SST 8

27 109723 Curtain, Short Rinse, 24" x 6-1/4" 1

28 108043 Curtain, Medium, 24" x 13-1/4" Rinse 1

29 114012 Rod, Curtain, 5/16" x 23-5/8" 1

31

Page 40

Two Tank Doors & Panels

26

26

25

27

28

25

27

28

29

3

10

4

9

4

29

13

1

2

4

16

17

5

3

15

18

14

12

9

10

11

10

5

3

24

23

22

21

20

8

19

6

7

32

Page 41

Two Tank Doors & Panels

Item Part Description Qty.

No. No.

1 327857 Door, E26" 2

2 108966 Door Handle 2

3 100073 Screw 1/4-20 x 1/2 Truss Head 8

4 113691 Guide, U-channel Door 4

5 329351 Panel, 25” End standard 1

6 328975 Panel, 64 Front Perimeter 1

7 328976-01 Panel, 84 Front Perimeter Right Hand 1

8 328976 Panel, 84 Front Perimeter Left Hand 1

9 113720 Curtain 24 x 20-1/4” (Load/Unload) 2

10 108250 Rod, Curtain 5/16 x 24-5/8” 4

11 108043 Curtain 24 x 13-1/4” (between wash and rinse) 1

--- 114012 Rod, Curtain, 5/16" x 23-5/8" (use with Item No. 11) 1

--- 109723 Curtain 24 x 6-1/4” (Rinse/Final Rinse)(Not Shown) 1

12 328030 Table Flange 2

13 113486 Screw 8-32 x 5/8 Flat Head SST 12

14 329926 Bafe 1

15 331981 Bracket, Door Stop 1

16 100141 Nut, Plain 1/4-20 SST 4

17 317345 Bracket, Door Catch 2

18 308133 Dual Hook, Door 1

19 108418 Plug, 1/2" 4

20 109034 Gasket 4

21 108417 Nut 4

22 113943 Plug, 3/4" 4

23 108602 Gasket 4

24 113944 Nut 4

25 329985 Bracket, Water Diverter 2

26 108954 Grip Nut, 6-32 w/nylon insert SST 16

27 113937 Magnet, Door 2

28 113719 Switch, Door Safety 2

29 100764 Screw, 6-32 x 1/2" Round Hd. SST 16

33

Page 42

1

15

2

3

16

4

5

17

18

7

6

8

9

10

14

13

12

11

11

13

7

Drive Motor Assembly

34

Page 43

Drive Motor Assembly

Item Part Description Qty.

No. No.

1 0509199 Drive Motor Switch 1

2 327918 Bracket, Motor Switch Mounting 1

3 See Sheave and V-Belt Chart Below

4 327916 Plate, Drive Motor Mounting 1

5 327920 Plate, 44 Motor Assy Mounting 1

5 327917 Plate, 64 Motor Assy Mounting 1

6 327919 Bracket, Motor Spring Mounting 1

7 106482 Washer Lock 1/4 Split SST 4

8 102376 Washer, Flat 5/16 x 3/4 x .06 SST 2

9 113702 Spring 0.6OD x 0.095 Wire x 1.5 Lg 1

10 113704 Screw, 5/16 x 3-1/2 Hex Head SST 1

11 113700 Bushing 3/8 x 3/4 x 1/16 Thrust Bronze 3

12 113703 Bushing, 3/4 x 7/8 x 3/8 x 1-1/8 Flg 1

13 113701 Bushing 1/4 x 3/8 x 1/2 x 1/16 Flg Bronze 1

14 113732 Motor, Gear 1/6HP 3PH, MV 1

--- 113679 Motor, Gear 1/6HP 1PH, MV 1

Used on 1 and 3 PH machines prior to S/N RE4397

--- 114598 Motor, Gear 1/6HP 3 PH, 575V (Prior to S/N RE10095983) 1

--- 113679 Motor, Gear 1/6HP 240V/60/1 (Use for 575V Only with

P/N 112246, Transformer--Contact Factory for Kit P/N 900945

Beginning with S/N RE10095983 and above 1

15 100734 Bolt 1/4-20 x 1/2 Hex Head SST 2

16 100736 Bolt 1/4-20 x 3/4 Hex Head 3

17 100734 Bolt 1/4-20 x 1/2 Hex Head SST 2

18 109009 Grip Nut, 5/16-18 w/nylon insert 1

Sheave and V-belt Chart

Model Motor Sheave Part No. Drive Sheave Part No. V-Belt Drive Part No.

E44 103166: AK39 5/8 Bore 113892: AK59 5/8 Bore 100794: 4L 310

E44DR 103166: AK39 5/8 Bore 113892: AK59 5/8 Bore 100794: 4L 310

E44WS 113688: AK34 5/8 Bore 113995: AK89H 5/8 Bore 114002: 4L 380

E44DRWS 113688: AK34 5/8 Bore 114003: AK74 5/8 Bore 100799: 4L 350

E54DR 113896: AK54 5/8 Bore 113892: AK59 5/8 Bore 100797: 4L 340

E64 113689: AK46 5/8 Bore 113896: AK54 5/8 Bore 100797: 4L 340

E84 103170: AK49 5/8 Bore 108897:AK44 5/8 Bore 100794: 4L 310

35

Page 44

14

15

21

22

24

23

25

24

20

19

19

21

20

17

1

26

3

4

5

7

6

8

9

10

11

12

13

18

2

16

Tank Bottom

Conveyor Drive Assembly

36

Page 45

Conveyor Drive Assembly

Item Part Description Qty.

No. No.

1 202381 Roller Crosshead 1

2 100868 Roller Stud Crosshead 1

3 107089 Nut Jam 1/2-13 1

4 206300 Crank, Rack Arm 1

5 206301 Shaft 5/8" O.D. x 9" LG. 1

6 113861 Housing, Bearing/Seal 1

7 102244 Seal 5/8” 1

8 206303 Gasket/Bearing Seal 1

9 100382 Bearing Jaf #EK104-10 1

10 100007 Screw, 10-32 x 3/8 Truss Head 1

11 104925 Washer 1/4 x 1 x 16 Gauge 1

12 103180 Wiper Ring 1

13 104916 Key 3/16 x 3/16 x 3/4 SST 1

14 See Sheave and V-belt Chart on page 35. 1

15 See Sheave and V-belt Chart on page 35.

16 327924 Bracket, 44 Drive Bearing Mounting 1

17 113860 Bearing, Sealed 5/8 Bore 1

18 104923 Screw 1/4-20 x 3/8 Round Head 4

19 100739 Bolt 5/16-18 x 3/4 Hex Head SST 8

20 106013 Washer Lock 5/16 Split 8

21 102376 Washer,at5/16" 8

22 100154 Nut Plain 5/16-18 SST 8

23 100746 Bolt 3/8-16 x 1-1/4" Hex Head 2

24 104618 Washer 3/8 x 7/8 x 1/16 SST 2

25 109010 Grip Nut, 3/8" w/nylon insert 2

26 100769 Screw, Set 3/8-16" x 3/4" Dog Point 1

37

Page 46

Prewash Track & Cradle Assembly

12

10

11

19

13

14

14

8

7

19

20

9

6

2

4

3

15

23

17

18

16

18

22

20

19

23

17

18

Tank

17

5

1

21

38

Page 47

Prewash Track & Cradle Assembly

Item Part Description Qty.

No. No.

1 113719 Switch, Door Safety 1

2 328046 Bracket, E PW IdlePump 1

3 113937 Magnet, SS 1

4 100764 Screw, 6-32 x 1/2 Round Head SST 2

5 108954 Nut, Grip 6-32 Hex Head W/Nylon Insert 2

6 106482 Washer Lock 1/4 Split 2

7 327833 Pin Idle Switch lever 1

8 100736 Screw, 1/4-20 x 3/4" Hex Head 2

9 328041 Track, 22” PW Rear 1

10 328043 Cradle, 22” PW 1

11 204513 Pawl, Cradle 4

12 206345 Spacer, Rack Cradle Pawl 4

13 113692 Bolt, Shoulder, 3/8 x 3/4 x 5/16-18 x 3/8" SST 4

14 333155 Cradle, Drive Rod Single Tank, 22" PW 2

14 333155 Cradle Drive RodTwo Tank 22" PW or Single Tank E 36" PW 2

15 206343 Bearing, E Cradle Support 4

16 327955 Track, 22” PW Front 1

17 100735 Bolt 1/4-20 x 5/8" Hex Head SST 8

18 112318 Washer, Flat 1/4-20 8

19 100142 Nut, Grip 5/16-18 6

20 331988 Bracket, Lower Washarm Support 2

21 100734 Bolt, Hex. Hd. 1/4-20 x 1/2" 6

22 206920 Rod, Lower Washarm Support, Threaded 1

23 100141 Nut, Grip 1/4-20 8

24 106482 Washer Lock 1/4-20 Split 2

---- 414334 Cradle Assembly, Complete, PW22"

---- 414438 Cradle Assembly Complete, PW36"

---- 900897 Kit, Idle Pump Assy.

39

Page 48

SingleTank Track & Cradle Assembly

15

23

18

14

10

15

17

24

16

13

23

22

12

11

25

17

2

9

1

21

19

6

7

8

4

5

1

(For WS and LT Models Only)

(For DR, DRWS Models Only)

20

40

Page 49

Single Tank Track & Cradle Assembly

Item Part Description Qty.

No. No.

1 113719 Switch, Reed Aleph 1

2 414344 Switch, Idle Assembly (Includes Items 3-8)(Prior to 8/30/08) 1

3 113937 Magnet, SS 1

4 100764 Screw, 6-32 x 1/2 Round Head SST 2

5 108954 Nut, Grip 6-32 Hex Head W/Nylon Insert 2

6 106482 Washer Lock 1/4 Split 2

7 327833 Pin Idle Pump Switch 1

8 100736 Screw, 1/4-20 x 3/4 Hex Head 2

9 414370 Track, E44 Front 1

10 414307 Cradle, E44 1

11 113692 Screw, 3/8 x .875 x 5/15-18 8

12 206345 Bushing, Rack Cradle Pawl 8

13 204513 Pawl, NG Cradle 8

14 414357 Track, E44 Rear 1

15 206343 Bearing, Rack Cradle Slide 4

16 100412 Nut, Grip 5/16-18 1

17 100141 Nut, Grip 1/4-20 4

18 100736 Bolt 1/4-20 x 3/4 Hex Head SST 2

--- 106482 Washer Lock 1/4-20 Split 2

19 329295 Switch, Idle Weldment (After 6-30/08) (For DR, DRWS Models) 1

20 329783 Switch, Idle Assy. Weldment (After 6-30/08) (For WS, LT Models) 1

21 100734 Bolt, Hex. Hd. 1/4-20 x 1/2" 6

22 100142 Nut, Grip 5/16-18 2

23 331988 Bracket Lower Washarm Support 2

24 206920 Rod, Support 1

25 100735 Bolt 1/4-20 x 5/8" Hex Hd., SST 8

--- 414377 Cradle, E-44 Complete (Includes Items 10-13 and 16) 1

--- 329486 Track, 26" Front Feed Assy.

--- 900897 Kit. Idle Pump Assy.

41

Page 50

Two Tank Track & Cradle Assembly

13

18

21

19

16

16

21

10

15

17

22

18

20

18

21

12

11

14

10

17

21

18

20

9

23

42

5

4

3

6

2

2

7

8

1

Page 51

Two Tank Track & Cradle Assembly

Item Part Description Qty.

No. No.

1 1 13719 Switch, Reed Aleph 1

2 414344 Switch, Idle Assembly (Includes Items 3-8) 1

3 113937 Magnet, SS 1

4 100764 Screw, 6-32 x 1/2 Round Head SST 2

5 108954 Nut, Grip 6-32 Hex Head W/Nylon Insert 2

6 106482 Washer Lock 1/4 Split 2

7 327833 Pin Idle Pump Switch 1

8 100736 Screw, 1/4-20 x 3/4 Hex Head 2

9 414370 Track, 64 Front LR 328981 RL 1

10 415667 Cradle, 64 Assembly Front L-R 328981 RL 1

11 113692 Bolt Shoulder, 3/8 X 3/4 X 5-16 X 18 SST 12

12 206345 Bushing, Rack Cradle Pawl 12

13 204513 Pawl, NG Cradle 12

14 414308 Cradle, 64 1

15 414358 Track, 64 Rear 1

16 206343 Bearing, Rack Cradle Slide 8

17 100141 Nut, Grip 1/4-20 4

18 100142 Nut, Grip 5/16-18 3

19 100736 Bolt 1/4-20 x 3/4 Hex Head SST 2

--- 106482 Washer Lock 1/4-20 Split 2

20 100734 Bolt, Hex. Hd. 1/4-20 x 1/2" 8

21 331988 Bracket, Lower Washarm Support 4

22 206920 Rod, Lower Washarm Support 2

23 100735 Bolt 1/4-20 x 5/8" Hex Hd., SST 8

--- 414378 Cradle Assy. Complete E-64

---- 415839 Cradle Assy. Complete E84

43

Page 52

2

1

Prewash Screens

44

Page 53

Prewash Screens

Item Part Description Qty.

No. No.

1 328958 Screen Assy 1

2 328959 Refuse Basket 1

45

Page 54

2

1

3

5

4

Tank

Tank

4

Single Tank Scrap Screens

46

Page 55

Single Tank Scrap Screens

Item Part Description Qty.

No. No.

1 414328 Screen, E-44 L-R Front 1

2 414329 Screen, E-44 L-R Rear 1

3 414300 Basket, Rack 1

4 331922 Support, Screen 2

5 328653 Screen, Outboard, (E54DR) 1

47

Page 56

Two Tank Scrap Screens

3

2

3

2

4

1

5

1

4

5

5

5

48

Page 57

Two Tank Scrap Screens

Item Part Description Qty.

No. No.

1 414328 Screen, E-44 L-R Front 1

2 414329 Screen, E-44 L-R Rear 1

3 414300 Basket, Rack 1

4 331922 Support, Screen 4

5 328653 Screen, Outboard, (E-84 Only) 1

49

Page 58

Prewash Spray Arms

17

16

15

6

Rear Wall

5

of Hood

18

3

8

14

4

13

2

12

11

10

9

12

7

3

5

12

9

4

2

1

19

50

Page 59

Prewash Spray Arms

Item Part Description Qty.

No. No.

1 414569 Wash Manifold Assembly 6” Lower 1

2 113723 O-Ring,1.75 ID 1

3 113738 Block, Washarm Retaining 4

4 113540 Locknut 2NPT SST 2

5 113741 Gasket, Flat EDPM 2-3/8 ID 2

6 328028 Standpipe, 22” PW 1

7 414568 Wash Manifold Assy 6” Upper 1

8 328998 Bracket, Upper Safety 1

9 113555 Plug, Wash Arm E-Series (Qty per arm) 4

10 113716 O-ring 4

11 328634 Support, Upper Wash 1

12 106014 Nut, Acorn 1/4-20 SST 8

13 106482 Washer, Lock 1/4" Split SST 8

14 106026 Washer, Flat 1/4" SST 8

15 329000-1 Bracket 1

16 106141 Grip Nut, 1/4" SST 2

17 100735 Bolt, Hex Hd. 1/4-20 SST 2

18 329001 Support, Upper Wash 1

19 328253 Bracket Support 1

51

Page 60

Single Tank Wash Spray Arms

14

13

10

6

Rear Wall

of Hood

18

2

11

5

4

12

17

16

15

7

3

16

52

2

16

9

8

5

3

1

4

9

8

Page 61

Single Tank Wash Spray Arms

Item Part Description Qty.

No. No.

1 414567 Wash Manifold Assembly 10” 15° Lower (L-R) 1

--- 414566 Wash Manifold Assembly 10” 15° Lower (R-L) 1

2 113741 Gasket, Flat EDPM 2-3/8 ID 2

3 113738 Block, Washarm Retaining 2

4 113723 O-ring 2

5 113540 Locknut 2NPT SST 2

6 327993 Standpipe, R-L 44 1

--- 414317 Standpipe, L-R 44 1

7 414289 Wash Manifold Assy 14” Straight Upper (L-R) 1

--- 414288 Wash Manifold Assy 14” Straight Upper (R-L) 1

8 113555 Plug, Wash Arm E-Series (Qty per arm) 4

9 113716 O-ring 4

10 329001 Bracket, Upper Wash arm support 1

11 328998 Bracket, Upper Safety Catch 1

12 106026 Washer, Flat 1/4" SST 4

13 100141 Grip Nut, 1/4-20 SST 10

14 100736 Bolt, Hex Hd. 1/4-20 x 3/4" SST 10

15 328034 Support, Upper Wash 1

16 106014 Nut, Acorn 1/4" SST 8

17 106482 Washer, Lock 1/4" Split SST 4

18 329000-1 Latch, E Upper Washarm Weldment (L-R Operation) 1

--- 329000-2 Latch, E Upper Washarm Weldment (R-L Operation) 1

53

Page 62

Two Tank Wash & Rinse Spray Arms

19

14

12

11

18

8

17

1

16

15

14

12

2

11

13

4

7

Rear Wall

of Hood

11

11

4

9

5

10

1

Rear Wall

of Hood

2

1

3

4

3

11

3

2

3

54

1

11

2

9

4

10

5

9

6

10

9

6

10

Page 63

Two Tank Wash & Rinse Spray Arms

Item Part Description Qty.

No. No.

1 113741 Gasket, Flat EDPM 2-3/8 ID 4

2 113540 Locknut 2NPT SST 4

3 113738 Block, Washarm Retaining 2

4 113723 O-ring,1.75 ID 2

5 414289 Wash Manifold Assembly 14” Straight Upper (L-R) 2

--- 414288 Wash Manifold Assembly 14” Straight Upper (R-L) 2

--- 414565 Wash Manifold Assy. E84 (L-R) 2

--- 414564 Wash Manifold Assy. E84 (R-L) 2

6 414291 Wash Manifold Assembly 10” 15° Lower (L-R) 2

--- 414290 Wash Manifold Assembly 10” 15° Lower (R-L) 2

--- 414564 Wash Manifold Assy. E84 (L-R) 2

--- 414565 Wash Manifold Assy. E84 (R-L) 2

7 414318 Standpipe 64 L-R Wash 1

--- 328443 Standpipe 64 R-L Wash 1

8 414319 Standpipe 64 L-R Rinse 1

--- 328445 Standpipe 64 R-L Rinse 1

9 113555 Plug, Wash Arm E-Series (Qty per arm) 4

10 113716 O-ring 4

11 106014 Nut, Acorn 1/4" SST 10

12 106482 Washer, 1/4" Split SST 8

13 328034 Support, Upper Washarm 2

14 106026 Washer, Flat 1/4" SST 8

15 100141 Grip Nut, 1/4" SST 4

16 328998 Bracket, Upper Safety 2

17 329000-1 Latch, E Upper Washarm Weldment (L-R Operation) 2

--- 329000-2 Latch, E Upper Washarm Weldment (R-L Operation) 2

18 329001 Bracket, Upper Washarm Support 2

19 100736 Bolt, Hex Hd. 1/4-20 x 3/4" SST 4

55

Page 64

Float Switches

Two Tank

Prewash

Single Tank

4

3

2

1

56

Page 65

Float Switches

Item Part Description Qty.

No. No.

1 104584 Nut, Plain 1/2-13

1

2 107589 Washer, Flat 1/2” 1

3 111151 C-Clip A/R

4 110854 Float Switch, Dual Prewash 1

-- 113291 Float Switch, Dual Wash/Rinse E-44 1

-- 113291 Float Switch, Dual Wash/Rinse E-64 2

-- 110750 Gasket, Float Switch (Not Shown) A/R

57

Page 66

Single Tank Electric Heat

1

2

3

4

3

5

6

58

Page 67

Single Tank Electric Heat

Item Part Description Qty.

No. No.

1 113516 Heater 15/18KW 208V,380V 1

113517 Heater 15/16.3KW 230/240V, 400/415V 1

113518 Heater 15/16.3KW 460/480V 1

113519 Heater 15KW 575V 1

2 100153 Bolt, 3/18-16 x 1 Hex Head 4

3 104618 Washer 3/8 x 7/8 x 1/16 SST 8

4 108345 Gasket 3 x 3 x 1/8” 2” Hole 1

5 106407 Washer Lock 3/8 Split 4

6 100140 Nut Plain 3/8-16 4

59

Page 68

Two Tank Electric Heat

3

1

A

Tank

2

Rinse

60

2

Wash

Page 69

Two Tank Electric Heat

Item Part Description Qty.

No. No.

1 113516 Heater 15/18KW 200/220V (Wash) 1

113517 Heater 15/16.3KW 230/240V(Wash) 1

113518 Heater 15/16.3KW 460/480V (Wash) 1

113519 Heater 15KW 575V (Wash) 1

2 108345 Gasket 3 x 3 x 1/8” 2” Hole 1

3 113804 Heater 10/12.1 KW 200/220V (Rinse) 1

118842 Heater 10/11KW 230/240V (Rinse) 1

113883 Heater 10/11KW 460/480V (Rinse) 1

113884 Heater 10/11KW 575V (Rinse) 1

A Element Fasteners (Qty Per Element)

100153 Bolt, 3/18-16 x 1 Hex Head 4

104618 Washer 3/8 x 7/8 x 1/16 SST 8

106407 Washer Lock 3/8 Split 4

100140 Nut Plain 3/8-16 4

61

Page 70

Two Tank Steam Heat with K2 Steam Booster

8

2

2

9

11

10

1

6

8

5

7

3

2

4

1

5

62

Page 71

Two Tank Steam Heat with K2 Steam Booster

Item Part Description Qty.

No. No.

1 109069 Thermostat, Control 1

2 109887 Valve, 3/4" Solenoid 120VAC 3

--- 109903 Kit, Repair Solenoid Valve A/R

--- 108516 Coil, Replacement 120VAC A/R

3 105782 Union 1/2 NPT BI 4

4 104649 Relief, Valve 1

5 111380 Trap, Steam I/2" 3

6 100123 Cock, Gauge 1/4" 1

7 100263 Strainer, Line 1-1/4" BI 1

8 108345 Gasket 2

9 110189 Booster, K2 Spirec 1

10 327907 Coil, Steam R-L 1

11 327908 Coil, Steam L-R 1

63

Page 72

Single Tank Steam Heat

1

2

3

4

5

6

8

64

7

Tank

Page 73

Single Tank Steam Heat

Item Part Description Qty.

No. No.

1 327908 Coil, Steam RH (Shown) 1

1 327907 Coil, Steam LH 1

2 102554 Union 3/4 SST 1

3 100548 Locknut, 3/4NPT SST 1

4 113918 Nipple, Rtoe 3/4 x 1-3/4 1

5 100740 Bolt 5/16-18 x 1 Hex Head 4

6 102376 Washer 5/16 X 3/4 x 1/16 8

7 108345 Gasket 3 x 3 1/8” 2IN Hole 1

8 106013 Washer Lock 5/16 Split 4

9 100154 Nut Plain 5/16-18 4

65

Page 74

1

3

4

5

6

2

3

7

Tank

Tank

8

9

10

Two Tank Steam Heat

66

Page 75

Two Tank Steam Heat

Item Part Description Qty.

No. No.

1 327907 Coil, Steam LH 1

2 100740 Bolt 5/16-18 x 1 Hex Head 8

3 102376 Washer 5/16 X 3/4 x 1/16 16

4 108345 Gasket 3 x 3 1/8” 2IN Hole 2

5 106013 Washer Lock 5/16 Split 8

6 100154 Nut Plain 5/16-18 8

7 327908 Coil, Steam RH 1

8 102554 Union 3/4 SST 2

9 100548 Locknut, 3/4NPT SST 2

10 113918 Nipple, Rtoe 3/4 x 1-3/4 2

67

Page 76

Thermostats

Two Tank

Single Tank

2

4

5

Front of Tank Wall

3

2

1

1*

1

68

Page 77

Thermostats

Item Part Description Qty.

No. No.

1 109069 Thermostat w/capillary - Single Tank 1

-- 109069 Thermostat w/capillary -Two Tank 2

1* 109069 Thermostat w/capillary -DR Models Only

2 110561 Thermostat, Fixed Hi Limit - Single Tank 1

-- 110561 Thermostat, Fixed Hi Limit -Two Tank 2

3 201041 Washer 7/8 ID x 1/8 Thk - Single Tank 2

-- 201041 Washer 7/8 ID x 1/8 Thk - Two Tank 4

4 109034 Gasket. Plug - Single Tank 2

-- 109034 Gasket. Plug - Two Tank 4

5 100547 Locknut 1-1/2 NPT SST - Single Tank 2

100547 Locknut 1-1/2 NPT SST - Two Tank 4

69

Page 78

E-Series Thermostat and Junction Box

Thermistor Connection Block

1

2

1

Inter-wiring Connection Block

1

8

3

5

3

6

4

2

12

11

10

9