Champion 40KB, 40KPRB, PR36, FFPR26 60KB, 60KPRB Service Manual

...

Technical Manual

Two Tank

Rack Conveyor

with/without Prewash

With (FFPR26)

Basic With (PR22) With (PR36) 26" Front Feed

Model 22" Prewash 36" Prewash Prewash

40KB 40KPRB PR36/40KB FFPR26/40KB

60KB 60KPRB PR36/60KB FFPR26/60KB

64KB 64KPRB PR36/64KB FFPR26/64KB

Machine Serial No.

March, 2004

Manual P/N 112951 Rev. H

P.O. Box 4149 2674 N. Service Road

Winston-Salem, North Carolina 27115-4149 Jordan Station, Ontario, Canada L0R 1S0

336/661-1556 Fax: 336/661-1660 905/562-4195 Fax: 905/562-4618

www.championindustries.com

For machines beginning with

serial no. R1247 and above

Complete the information below so it will be available for quick reference.

Model Number Serial Number

Voltage and Phase

Champion Service Agency Phone

Champion Parts Source Phone

Champion Service:

Champion (USA) Champion (Canada)

Phone: 1 (336) 661-1556 Phone: 1 (905) 562-4195

1 (800) 858-4477 1 (800) 263-5798

Fax: 1 (336) 661-1660 Fax: 1 (905) 562-4618

We strongly recommend that you Fax your orders.

NOTE: When calling to order parts, be sure to have the model number, serial number,

voltage and phase of your machine.

COPYRIGHT © 2004 by Champion Industries, Inc.

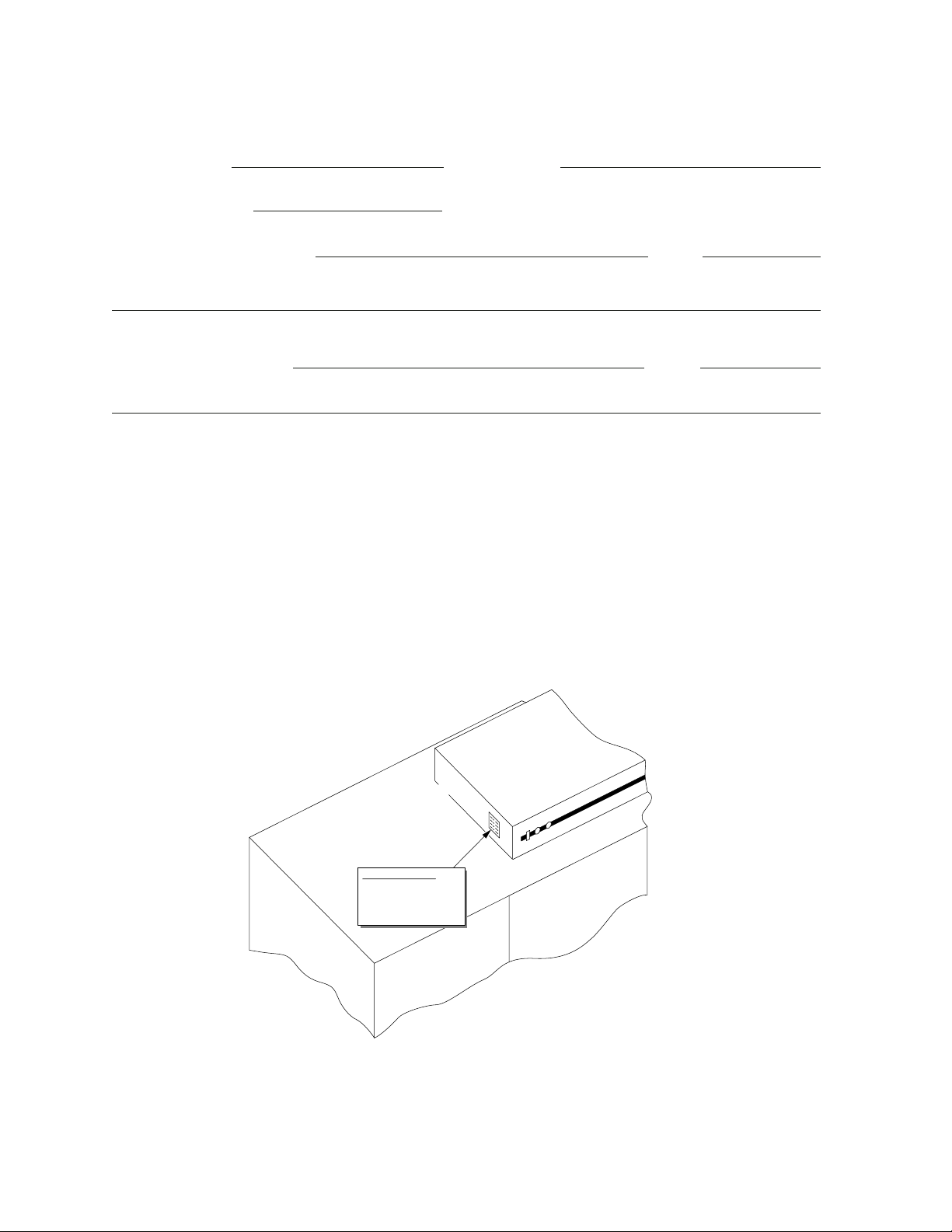

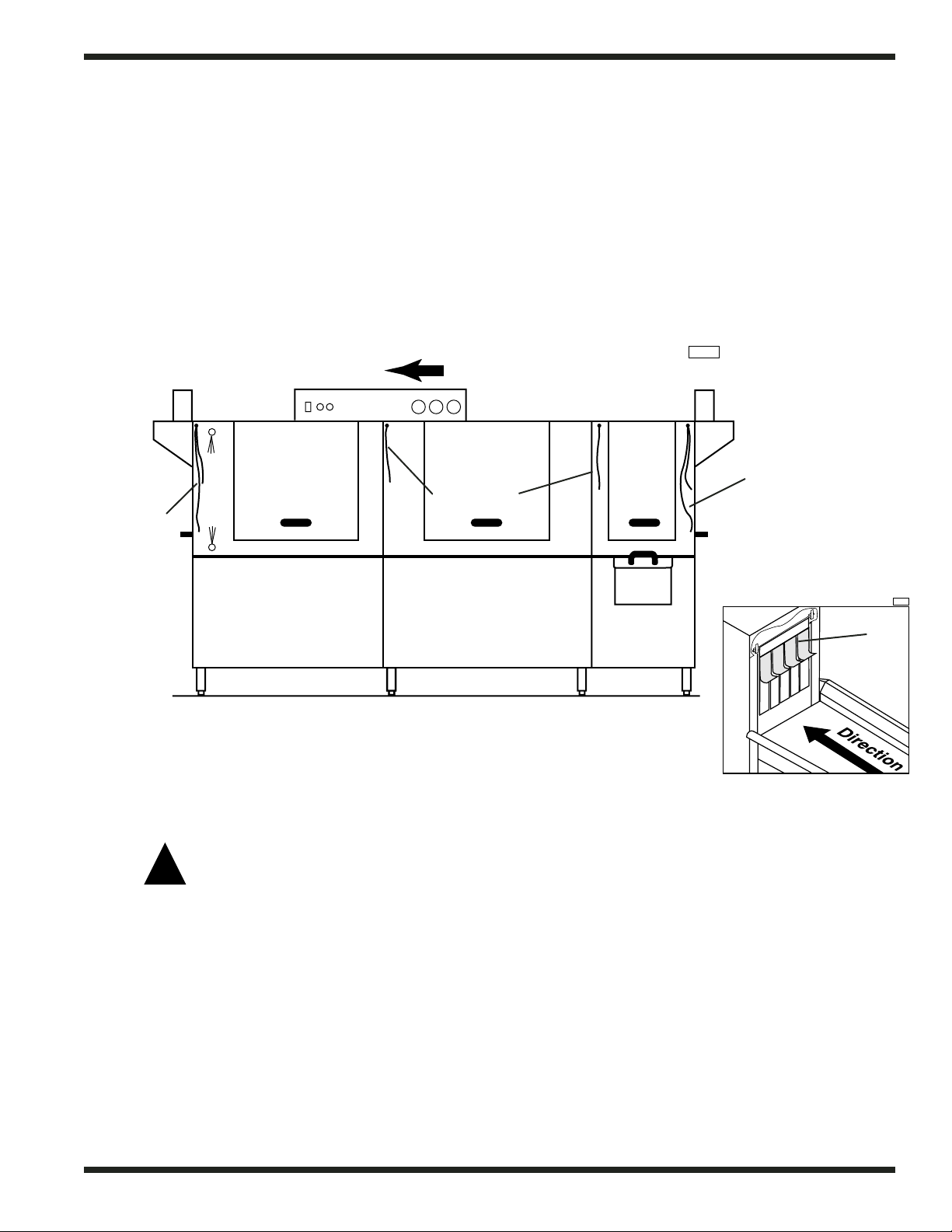

Machine Data Plate with

Model No., Serial No.,

Voltage and Phase is

located on the right or left

side of the Control Cabinet

Top of Machine

Control Cabinet

Left to Right

Model Shown

i

Revision History

Revision Revised Serial Number Comments

Date Pages Effectivity

3/10/99 All R-1247 First Issue of Manual and service replacement parts

1/26/00 35 ––– Added cradle assy P/N's

1/26/00 90 R1666 Changed motor contactor P/N 111642 to Motor

contactor P/N 108122

1/26/00 95 ––– Added dual float switch, P/N 11019 to parts list

5/23/00 39 R-1810 Changed pump assembly parts

10/1/00 95 ––– Corrected float switch, P/N 111019

10/10/00 35 ––– Added 40-60 KB cradle part numbers

11/01/00 54 R1529 Added new piping due to change in location of

pressure switch

11/01/00 58 All Inserted new drawing for all Serial numbers with no

booster or with Steam booster

4/3/01 89 ––– Revised machines for 12' thermometer – 109499

1/03/02 55,59 R2441 Change vacuum breaker 3/4" 1044129 to 113222

1/03/02 56,60,63,73,77 Change vacuum breaker 1/4" 107069 to 113218

1/03/02 56,59,63,73,77 R2441 Change Parker/Evans 1/4" solenoid valve 109885 to

GC solenoid valve 1/2" 113352 along with repair kit,

coils and piping changes

1/03/02 73,77 Added track stiffener 325667

5/20/02 56,60,63,73,77 Added 900836 Kit* Repair, 1/4" & 1/2" Vacuum

Breaker and 900837 Kit* Repair 3/4" Vacuum Breaker

2/5/03 39 Replaced impellers with new part numbers.

2/5/03 89 Replaced 108391 with 113622 thermometer.

2/5/03 91 Replaced Furnace (Siemens) overloads with

Telemecanique (Square D) overloads.

2/5/03 92, 115, 117 Replaced P/N 111826 with P/N 111827.

7/23/03 55, 56, 59, 60, 63, Revised plastic style vacuum breakers with

73, 74, 77, 78 bronze style.

7/23/03 89 Corrected part numbers for overlays.

3/11/04 43, 45, 67, 69 R3285 Replaced 111090 with 113721 reed switch.

71, 73

3/11/04 124 ––– Revised schematic 700935 revision H to revision I.

REVISIONS

iii

CONTENTS

CONTENTS

Page

REVISION HISTORY ...................................................................................................................... i

WARRANTY .................................................................................................................................. vi

KEY COMPONENTS ...................................................................................................................... 1

INTRODUCTION .......................................................................................................................... 2

GENERAL........................................................................................................................................ 3

INSTALLATION ............................................................................................................................ 5

Unpacking .......................................................................................................................... 5

Electrical Connections ........................................................................................................ 5

Plumbing Connections ........................................................................................................ 6

Ventilation Connections ...................................................................................................... 6

Chemical Connections ........................................................................................................ 6

Curtain Locations ................................................................................................................ 7

Completing Installation ...................................................................................................... 7

OPERATION .................................................................................................................................... 8

MAINTENANCE ............................................................................................................................ 11

Maintenance Schedule ........................................................................................................ 11

Deliming .............................................................................................................................. 12

TROUBLESHOOTING .................................................................................................................. 13

ELECTRICAL SERVICE ................................................................................................................ 15

MECHANICAL SERVICE ..............................................................................................................23

TABLE LIMIT SWITCH INSTALLATION.................................................................................... 27

REPLACEMENT PARTS ................................................................................................................ 31

ELECTRICAL SCHEMATICS ...................................................................................................... 111

LIST OF FIGURES

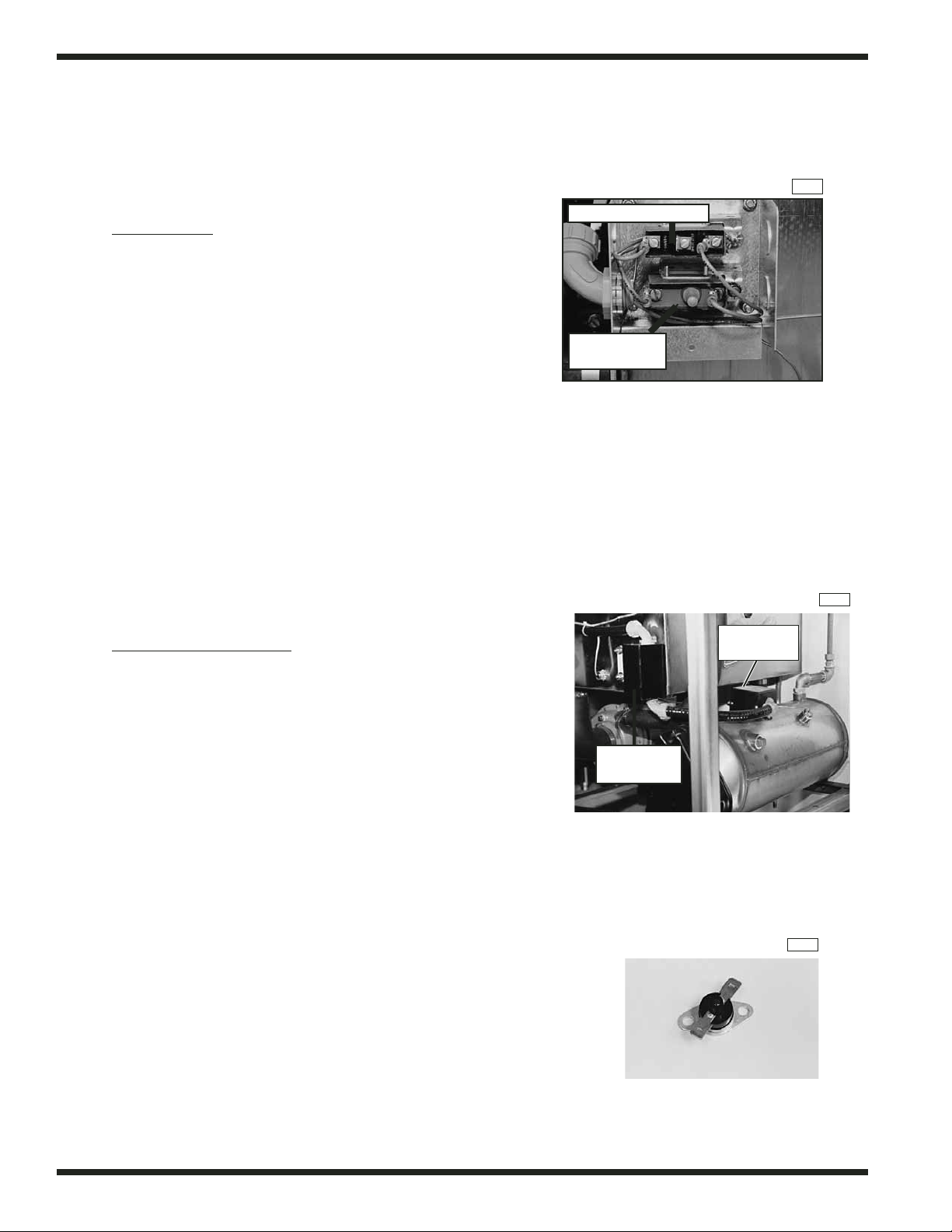

Figure 1 — Fuse Blocks .............................................................................................................. 15

Figure 2 — Motor Overload ...................................................................................................... 15

Figure 3 — Pump Timer ..............................................................................................................16

Figure 4 — Dual Float Switch .................................................................................................... 17

Figure 5 — Tank Heat Thermostats ............................................................................................ 18

Figure 6 — Booster Thermostat Locations (Electric) ................................................................ 18

Figure 7 — Booster High Limit Thermostat (Electric) .............................................................. 18

Figure 8 — Front View Typical 40°F/22°C rise Booster, One Tank 36 Kw shown .................. 22

Figure 9 — Front View Typical 70°F/39°C rise Booster, Two Tank 57 Kw shown .................... 22

Figure 10 — Idle Pump Switch Assembly .................................................................................... 24

iv

REVISIONS

LIST OF FIGURES (Cont.)

Figure 11 — Magnetic Switch and Magnet .................................................................................. 24

Figure 12 — Rinse-Saver Switch Mechanism .............................................................................. 24

Figure 13 — Crank Assembly........................................................................................................ 25

Figure 14 — Conveyor Drive Assembly ........................................................................................ 25

Figure 15 — View of Load End of Machine ................................................................................ 26

Figure 16 — Close-up View of Bearing Housing ........................................................................ 26

Figure 17 — Close-up View of Clutch Assembly.......................................................................... 26

Figure 18 — Conveyor Drive Assembly ........................................................................................ 32

Figure 19 — Track and Cradle Assembly .................................................................................... 34

Figure 20 — Track and Cradle Assembly-PR22, PR36 ................................................................ 36

Figure 21 — Motor and Pump Assembly (Wash, Power Rinse, Prewash) .................................... 38

Figure 22 — Idle Pump Mechanism ............................................................................................ 42

Figure 23 — Idle Pump Switch (FFPR26 Only) (All S/N’s) ........................................................ 44

Figure 24 — Wash System Assembly (Wash Tank and Power Rinse Tank) .................................. 46

Figure 25 — Wash System Assembly (PR22, FFPR26)................................................................ 48

Figure 26 — Wash System Assembly (PR36) .............................................................................. 50

Figure 27 — Outside Rinse Piping with Electric Booster ............................................................ 52

Figure 28 — Outside Rinse Piping with Electric Booster After R1529 ...................................... 54

Figure 29 — Fill and Outside Rinse Piping, w/No Booster and Steam w/Booster ...................... 58

Figure 30 — Cold Water Thermostat for Prewash Option .......................................................... 62

Figure 31 — Inside Rinse Piping .................................................................................................. 64

Figure 32 — Rinse Saver Mechanism (L-R) ................................................................................ 66

Figure 33 — Rinse Saver Mechanism (R-L) .............................................................................. 68

Figure 34 — Doors, Curtains, Miscellaneous................................................................................ 70

Figure 35 — Hood (PR22, PR36) ................................................................................................ 72

Figure 36 — Hood (FFPR26) ...................................................................................................... 76

Figure 37 — Tank (PR22).............................................................................................................. 80

Figure 38 — Tank (PR36) ............................................................................................................ 82

Figure 39 — Tank (FFPR26) ...................................................................................................... 84

Figure 40 — Drain Unit and Screens Wash/Power Rinse Tank .................................................... 86

Figure 41 — Control Cabinet ........................................................................................................88

Figure 42 — Control Panel ............................................................................................................ 90

Figure 43 — Tank Heat (Electric, R-L Shown) ............................................................................ 94

Figure 44 — Tank Heat (Steam Coils, R-L Shown) ...................................................................... 96

Figure 45 — Tank Heat (Steam Supply Piping) ............................................................................ 98

Figure 46 — Tank Heat (Condensate Piping)................................................................................ 100

Figure 47 — Tank Heat (Steam Injector, R-L Shown) .................................................................. 102

Figure 48 — Electric Booster (40°F/22°C Rise) .......................................................................... 104

Figure 49 — Electric Booster (70°F/39°C Rise) .......................................................................... 106

Figure 50 — K2 Steam Booster .................................................................................................... 108

v

CONTENTS

Figure 51 — Thrush Steam Booster (40°F/22°C - 70°F/39°C Rise) ............................................ 110

Figure 52 — Thrush Steam Booster (80°F/44°C Rise) ................................................................ 112

Figure 53 — Control Panel, Electric Booster (70°F/39°C Rise) .................................................. 114

Figure 54 — Control Panel, Electric Booster (40°F/22°C Rise) .................................................. 116

Figure 55 — Vent Hood Assembly ................................................................................................ 118

Figure 56 — Dish Racks ................................................................................................................ 120

ELECTRICAL SCHEMATICS

B700935/I — Wiring Diagram (64KB, 40KB, 60KB Steam/Electric)

B700936/G— Wiring Diagram (64KPRB, 40KPRB, 60KPRB Steam/Electric)

vi

REVISIONS

LIMITED WARRANTY

Champion Industries Inc. (herein referred to as Champion), P.O. Box 4149, Winston-Salem, North Carolina 27115, and P.O.

Box 301, 2674 N. Service Road, Jordan Station, Canada, L0R 1S0, warrants machines, and parts, as set out below.

Warranty of Machines: Champion warrants all new machines of its manufacture bearing the name “Champion”

and installed within the United States and Canada to be free from defects in material and workmanship for a period of

one (1) year after the date of installation or fifteen (15) months after the date of shipment by Champion, whichever

occurs first. [See below for special provisions relating to glasswashers.] The warranty registration card must be returned

to Champion within ten (10) days after installation. If warranty card is not returned to Champion within such period, the

warranty will expire after one year from the date of shipment.

Champion will not assume any responsibility for extra costs for installation in any area where there are

jurisdictional problems with local trades or unions.

If a defect in workmanship or material is found to exist within the warranty period, Champion, at its election, will either

repair or replace the defective machine or accept return of the machine for full credit; provided, however, as to glasswashers, Champion’s obligation with respect to labor associated with any repairs shall end (a) 120 days after shipment,

or (b) 90 days after installation, whichever occurs first. In the event that Champion elects to repair, the labor and work to

be performed in connection with the warranty shall be done during regular working hours by a Champion authorized

service technician. Defective parts become the property of Champion. Use of replacement parts not authorized by

Champion will relieve Champion of all further liability in connection with its warranty. In no event will Champion’s

warranty obligation exceed Champion’s charge for the machine. The following are not covered by Champion’s warranty:

a. Lighting of gas pilots or burners.

b. Cleaning of gas lines.

c. Replacement of fuses or resetting of overload breakers.

d. Adjustment of thermostats.

e. Adjustment of clutches.

f. Opening or closing of utility supply valves or switching of electrical supply current.

g. Cleaning of valves, strainers, screens, nozzles, or spray pipes.

h. Performance of regular maintenance and cleaning as outlined in operator’s guide.

i. Damages resulting from water conditions, accidents, alterations, improper use, abuse,

tampering, improper installation, or failure to follow maintenance and operation procedures.

j. Wear on Pulper cutter blocks, pulse vanes, and auger brush.

Examples of the defects not covered by warranty include, but are not limited to: (1) Damage to the exterior or interior

finish as a result of the above. (2) Use with utility service other than that designated on the rating plate. (3) Improper

connection to utility service. (4) Inadequate or excessive water pressure. (5) Corrosion from chemicals dispensed in

excess of recommended concentrations. (6) Failure of electrical components due to connection of chemical dispensing

equipment installed by others. (7) Leaks or damage resulting from such leaks caused by the installer, including those at

machine table connections or by connection of chemical dispensing equipment installed by others. (8) Failure to comply

with local building codes. (9) Damage caused by labor dispute.

Warranty of Parts: Champion warrants all new machine parts produced or authorized by Champion to be free

from defects in material and workmanship for a period of 90 days from date of invoice. If any defect in

material and workmanship is found to exist within the warranty period Champion will replace the defective

part without charge.

DISCLAIMER OF

WARRANTIES AND LIMITATIONS OF LIABILITY. CHAMPION’S WARRANTY

IS ONLY TO THE EXTENT REFLECTED ABOVE. CHAMPION MAKES NO OTHER WARRANTIES, EXPRESS

OR IMPLIED, INCLUDING, BUT NOT LIMITED, TO ANY WARRANTY OF MERCHANTABILITY, OR FITNESS

OF PURPOSE. CHAMPION SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

THE REMEDIES SET OUT ABOVE ARE THE EXCLUSIVE REMEDIES FOR ANY DEFECTS FOUND TO EXIST

IN CHAMPION DISHWASHING MACHINES AND CHAMPION PARTS, AND ALL OTHER REMEDIES ARE

EXCLUDED, INCLUDING ANY LIABILITY FOR INCIDENTALS OR CONSEQUENTIAL DAMAGES.

Champion does not authorize any other person, including persons who deal in Champion dishwashing machines to change

this warranty or create any other obligation in connection with Champion Dishwashing Machines.

1

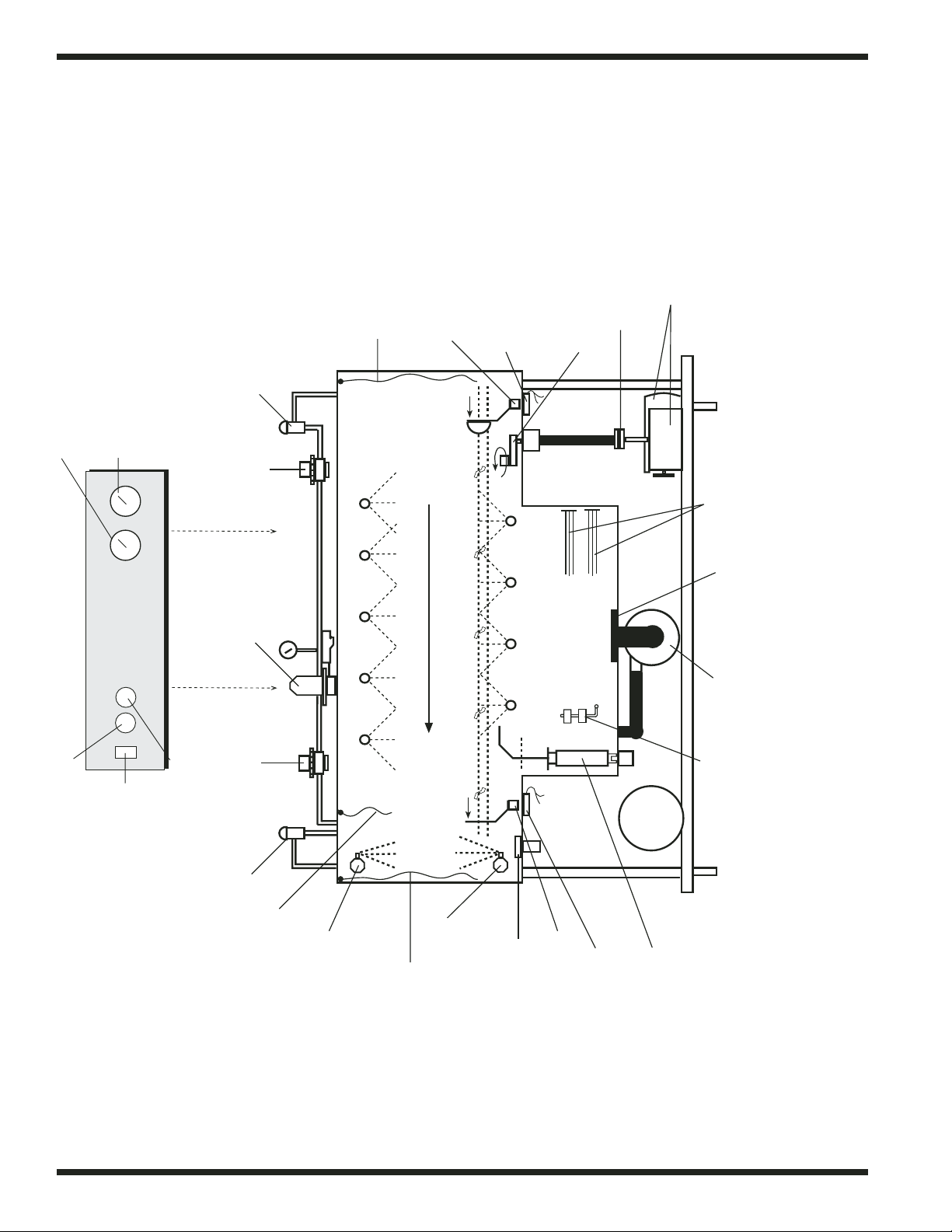

Vacuum

Breaker

Line Strainer

Power Rinse Tank

Heat Control

and High Limit

Thermostats

Power Rinse tank

Pump/Motor

Assembly

Dual Float Switch

Auto Fill/Low Water

Tank Heat Protection

Door-activated

Drain-overflow

Tube Assembly

Final Rinse-Saver

Mechanism

(Switch and Magnet)

Final Rinse

Booster Tank Assy

(Electric Only)

Power Rinse Tank

Heater Element

Final Rinse

Piping

Pushbutton Stop

Switch (Red)

Wash Spray

Arms

Pushbutton Start

Switch (Green)

Main Power Switch/

Circuit Breaker

Control

Transformer

Solenoid

Valve

Pressure Gauge

Pressure Reducing

Valve, PRV,

(Factory

installed on machines

with boosters)

Top Mounted Control Cabinet

Temperature

Gauges

Conveyor Crank

and Crosshead

Roller Assembly

Conveyor Drive Clutch

and Gear Reducer

Cradle Assembly

Idle Pump Mechanism

(Switch and Magnet)

Rack Conveyor Key Component Locations

(Right to Left Electrical Machine Shown)

KEY COMPONENTS

2

INTRODUCTION

INTRODUCTION

Welcome to Champion.

...and thank you for allowing us to take care of your dishwashing needs.

This manual covers several models. Model numbers are shown on the front cover.

Your machine has been completely assembled, inspected, and thoroughly tested at our factory

before it was shipped to your installation site.

This manual contains:

• Warranty information

• Operation and cleaning instructions

• Maintenance instructions

• Troubleshooting guide

• Basic service information

• Replacement parts lists

• Electrical schematics

Complete and return your warranty registration card within ten (10) days after the installation of

your machine.

All information, illustrations and specifications contained in this manual are based upon the latest product information available at the time of publication. Champion constantly improves its

products and reserves the right to make changes at any time or to change specifications or design

without notice and without incurring obligation.

For your protection, factory authorized parts should always be used for repairs.

Replacement parts may be ordered from your Champion authorized service agency. When

ordering parts, please supply the model number, serial number, voltage and phase of your

machine, the part number, part description, and quantity.

3

GENERAL

GENERAL

This manual covers the Champion two tank rack conveyor dishwashing machine. This machine is

fully automatic and is equipped with 2 H.P. wash/rinse pump motors and a 1/4 H.P. conveyor

drive motor. All models are available for right-to-left or left-to-right operation.

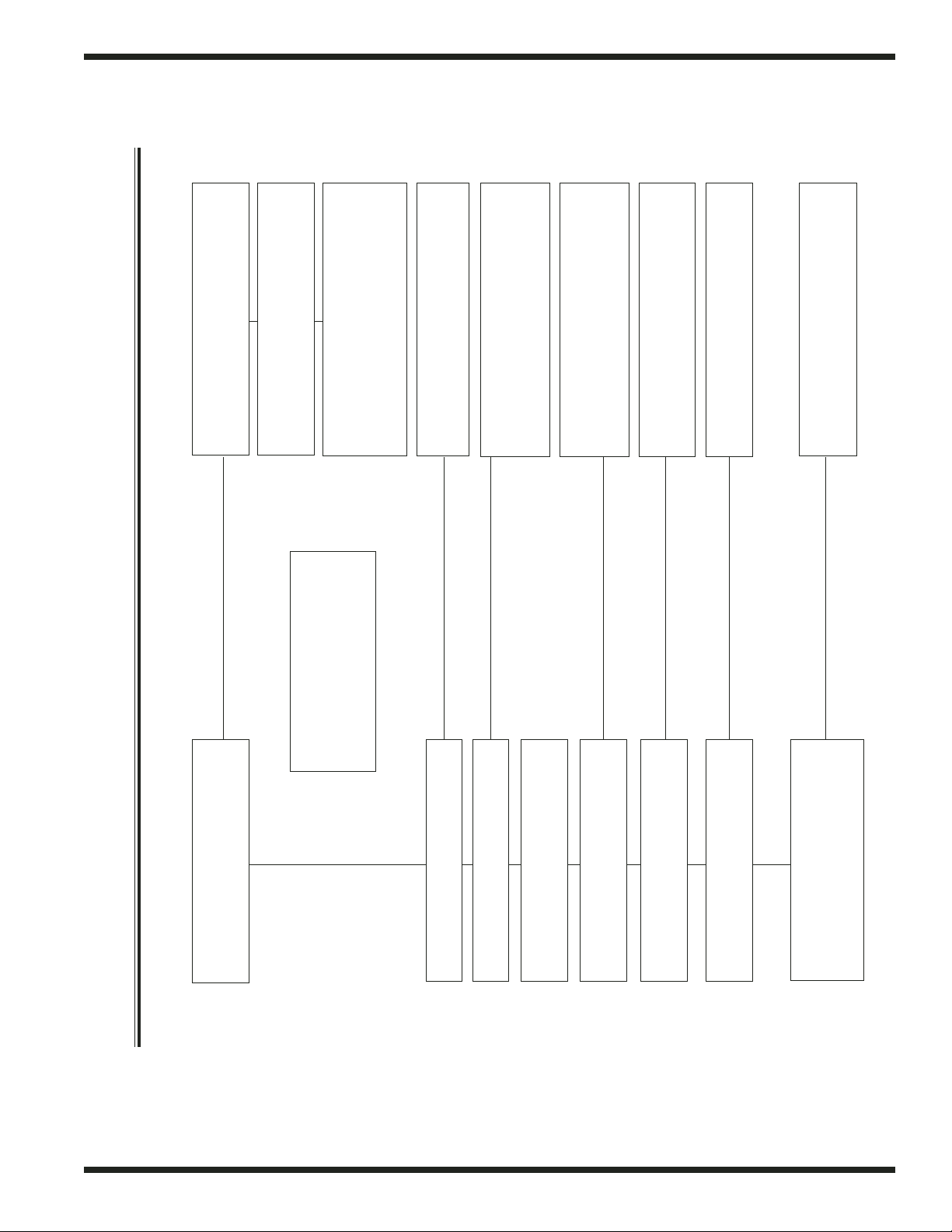

This series of dishwashers is modular in design. The following models and options are covered in

this manual:

Model Numbers

Two tank - Basic.................................................... 64KB, 40KB, 60KB

Two tank with 22" Prewash .................................. 64KPRB, 40KPRB, 60KPRB

Two tank with 36" Prewash .................................. PR36/64KB, PR36/40KB, PR36/60KB

Two tank with 26" Front Feed Prewash ................ FFPR26/64KB, FFPR26/40KB, FFPR26/60KB

• The 64KB basic model, along with its respective prewash option, is a high temperature

(180˚F/82°C final rinse) sanitizing model.

• The 40KB basic model, along with its respective prewash option, is a high temperature

(180˚F/82°C final rinse) sanitizing model.

• The 60KB basic model, along with its respective prewash option, is a high temperature

(180˚F/82°C final rinse) sanitizing model.

5

INSTALLATION

Unpacking

CAUTION:

Care should be taken when lifting the machine. The piping under the base can be damaged.

Remove the dishwasher front panels if lifting from the front with a forklift.

1. Immediately after unpacking your machine, inspect for any shipping damage. If damage is

found, save the packing material and contact the carrier upon receipt of the machine.

2. Remove the dishwasher from the skids. Adjust the feet if required, then move the machine to

its permanent location. The machine should not be installed within 6 inches [153mm] of any

wall or structure.

3. Level the machine by placing a level on the top of the machine and adjusting the feet. Level

front-to-back and side-to-side.

Electrical Connections

NOTE:

Electrical and grounding connections must comply with the National Electrical Code and/or

Local Electrical Codes.

WARNING:

When working on the dishwasher, disconnect the electric service and tag it to indicate work

is being done on that circuit.

1. The electrician should compare the electrical specifications on the machine electrical connection plate (located inside the control cabinet) to the electrical power supply before connecting to the incoming service at a fused disconnect switch.

2. Motor rotation was set at the factory. Ensure proper rotation of the conveyor drive shaft (red

arrow on shaft shows direction of rotation). Reversing the motor direction is done in the control cabinet by reversing the wires Ll and L2 on the disconnect switch side of the main electrical connection terminal block (Refer to the electrical diagrams in the back of this manual).

3. A knock-out plug is provided at the rear of the control cabinet for electrical service connections.

NOTE:

Electrical and grounding connections must comply with the National Electrical Code and/or

Local Electrical Codes.

NOTE:

Electric boosters require a separate electrical connection.

A fused disconnect switch or circuit breaker (supplied by user) is required to protect each

INSTALLATION

!

!

6

Chemical Connection

Terminal Board

INSTALLATION

Plumbing Connections

CAUTION:

Plumbing connections must comply with local sanitary and plumbing codes.

1. Connect the hot water supply at the final rinse piping connection located behind the control

cabinet at the top of the machine.

2. A “Y” line strainer is provided by Champion for machines without boosters.

A pressure reducing valve (PRV) is provided by Champion for machines with built-in boosters.

3. If the incoming hot water supply pressure exceeds 25 psi [173 kPa], a PRV must be installed

and set to 20-22 psi [138-151 kPa]. The PRV may be purchased from Champion or supplied

by others.

4. Install a manual shut-off valve in the steam and water supply lines to accommodate servicing

the machine. The valve should be the same size as or larger than the supply line.

5. Provide a suitable gravity drain to connect to a 1-5/8" OD drain tube.

Ventilation

1. Stainless steel watertight ducting should be installed INSIDE the 4" x 16" [102mm x 407mm]

vent stacks at the load and unload ends. A minimum of 6 air changes per hour of kitchen air

is recommended. The typical exhaust ventilation requirements for a rack machine using a

180˚F/82°C final rinse are:

• The load end requires 150 CFM @ 1/4" (SP), [71 Liters/sec] with prewash.

• The load end requires 200 CFM @ 1/4" (SP), [95 Liters/sec] without prewash.

• The unload end requires 400 CFM @ 1/4" (SP), [189 Liters/sec].

2. An adjustable damper is supplied with the vent stacks for adjusting the exhaust volume.

CAUTION:

Exhaust air should not be vented into a wall, ceiling, or concealed space of a building.

Condensation will cause damage.

Chemical Connections

1. Use a qualified detergent/chemical supplier.

2. Labeled control circuit connection terminals are provided

in the control cabinet for detergent and rinse agent/sanitizer

dispensing equipment (supplied by others).

3. Refer to the illustration below. The illustration shows the terminal board for current production machines.

Signal connection points include:

• Detergent signal 120VAC, 1 Amp Max amp load.

• Rinse aid/Sanitizer signal 120VAC, 1 Amp Max amp load.

4. A removable black plug is provided in the load end

side of the wash tank for installation of the

detergent conductivity cell.

!

!

SIGNAL ONLY

120V

120V

RINSE AID/

SANI

COMMON

DETERGENT

1R001

7

Long

curtain

Load End

Curtain Locations

(Machine with prewash shown)

Long curtain

Short

flaps

Short flaps on long curtains

face the load end of dishwasher

Curtain Locations

1. Refer to the illustrations below and hang the curtains as shown.

J-hooks are located in the corners of each section to accept the curtain rods.

• Standard long curtain 24" x 20-1/4" [610mm x 515mm]

• High hood long curtain 24" x 22-3/4" [610mm x 578mm]

• Standard short curtain 24" x 13-1/4" [610mm x 337mm]

• High hood short curtain 24" x 20-1/4" [610mm x 515mm]

2. Make sure the short flaps of the long curtains face the load end of the dishwasher.

The longest curtains always go on each end of the dishwasher.

INSTALLATION

Completing Installation

WARNING:

Do not insert racks into machine before tanks fill with water. Operating pumps dry will cause

pump seal damage and leakage that can result in a motor failure.

1. Remove any foreign material from inside the machine.

2. Check to insure that drains and overflow pipes are operational and sealed.

3. Position scrap screens on supports above the tanks.

4. After plumbing and electrical connections are completed, fill the tank and wait 10 minutes.

Check all plumbing connections for leaks.

5. Drain the tank and check the drain lines for leaks.

6. The formed down lip of the dishtable should be placed inside the machine. The dishtable

should be pitched toward the dishwasher for proper draining by adjusting its leveling feet.

The dishtable should be sealed to the dishwasher.

!

1R003

WASH

PRE

WASH

R-L Direction

Power Rinse

1R002a

8

Simplified Rack Conveyor Dishwasher

Right to Left Model

OPERATION PROCEDURE

OPERATION

Final Rinse Water

Wash Water

Temperature Gauge

Temperature Gauge

Vacuum

Breaker

Long Curtain

Idle Pump

Magnet

Idle Pump

Magnetic Switch

Conveyor Crank

Conveyor Drive

Motor and Gear

Clutch

Assembly

Reducer

Control Cabinet

Green Start Button

Lighted On-Off

Rocker Switch

Pressure

Regulating

Rinse Valve

Red Stop Button

Vacuum

Breaker

Fill Valve

Valve

Wash Arm Spray Pipes

Right to Left Model

Conveyor Direction

Wash Arm Spray Pipes

Booster

Electric Tank

Heaters

Pump

Strainer

Wash

Pump

Dual Float

Switch

Short Curtain

Rinse-Saver

Final Rinse

Drain-off

Adjustment

Magnet

Rinse-Saver

Magnetic Switch

Door Activated

Drain-overflow

Assembly

Long Curtain

Upper Final Rinse Pipe

Lower Final Rinse Pipe

9

OPERATION

Rack Conveyor Machine

Operation Procedure

Action Result

Turn Power Switch on

Press green start button

Insert soiled rack

Rack conveys thru machine

Rack activates final rinse

Rack exits the machine

Press stop push button

Drain machine for cleaning

after each meal period

or every 2 hours of use

Lighted On-Off Rocker Switch

on control cabinet will illuminate

Float switch activated

Tank(s) fill with water

When machine is full float

switch cuts off water

and calls for heat.

(Wait for proper temperature)

Conveyor drive motor

is activated

Wash pump starts

Continuous power on wire #13

and #2 120V Detergent signal

20 psi required flow pressure

Power to wire #70 and #2 120V

Rinse/Sanitize signal

Wash pumps shut down (timer)

Conveyor continues to run

Conveyor drive will stop

Check detergent and rinse aid

supply. Replenish if necessary

Doors are closed

Door activated drains

are closed

10

OPERATION

OPERATION

Follow the procedure below to operate your dishwasher properly.

1. Check that spray pipes, curtains, overflow drains, and scrap screens are in place and clean.

2. Turn on detergent dispenser switches and check detergent supply.

3. Turn on exhaust vent system (if applicable), and make sure it is operating.

4. Close door(s). Push the power switch to the ON position. Tanks will begin filling with water.

5. When tanks are full, check wash tank temperature gauge. Minimum wash temperatures are:

• 64KB, 40KB, 60KB Wash tank - 150°F/66°C

• 64KB, 40KB, 60KB Power rinse tank - 160°F/71°C

• Prewash tanks do not have tank heaters

6. Press the START button on the control cabinet. Only the conveyor will start. The pumps

WILL NOT OPERATE until the first rack enters the machine.

7. Scrap and pre-flush all items to be washed, and load the items into the rack.

DO NOT OVERLOAD RACKS.

Place dishes edgewise in a peg rack, cups and bowls upside down in a flat rack.

Spread silverware evenly in a single layer in a flat rack or

upright (loosely packed) in a cutlery rack.

8. Push the rack into the machine, and the pumps will start automatically.

9. Check the rinse pressure and temperature as the racks pass through the final rinse. This rinse

pressure MUST be 20-22 psi [138-151 kPa] and the final rinse temperature MUST be

180°F/82°C minimum.

10. The pumps will automatically stop shortly after the last rack leaves the machine.

The conveyor will continue to run.

11. The machine may be stopped any time during the cycle by pressing the STOP button on the

control cabinet. When restarted, items inside the machine will be fully washed and rinsed.

12. CLEAN scrap screens, scrap baskets (if applicable) and REPLACE tank water every 2 hours

of operation or after each meal period. Check chemical supply.

CAUTION:

DO NOT allow racks to remain on unload dishtable. This could cause the conveyor to jam

and may damage machine. The installation of a table limit switch is highly recommended and

will reduce the risk of damage.

WARNING:

Do not leave water in tanks overnight.

!

!

11

MAINTENANCE

MAINTENANCE

The efficiency and life of your machine is increased by regularly scheduled preventive maintenance.

A well maintained machine gives better results and service. An investment of a few minutes of daily

maintenance will be worthwhile.

The best maintenance you can provide is to keep your machine clean. Components that are not

regularly cleaned and flushed will clog and become inoperative.

Intervals shown in the following schedules represent an average length of time between necessary

maintenance. Maintenance intervals should be shortened whenever your machine is faced with

abnormal working conditions, hard water, or multiple shift operations.

Maintenance Schedule

CLEANING

• Daily-Every 2 Hours of Operation

1. Turn power switch to OFF.

2. Remove all scrap screens, scrap baskets (if applicable), and pull drain lever(s) to drain

water. Clean inside of tanks and flush with clean water. Backflush scrap screens until clean.

Do not strike screens against solid objects.

3. Remove the spray pipes by a 1/4 turn, counterclockwise. Remove the end plug from each

spray pipe. Flush pipe and nozzles until clean. Do not strike spray pipes against solid

objects. Replace end plugs, verify that rubber seals are in place on manifolds. Reinstall

spray pipes using a 1/4 clockwise turn.

4. Remove and clean curtains. Hang them off the dishtable to dry.

5. Leave the doors open between operations to allow drying.

6. Verify that final rinse nozzles are clean and free of internal hard water deposits. Clean rinse

nozzle orifices with a small paper clip. Consult your chemical supplier for the proper use

and kind of deliming chemical.

7. Report any unusual conditions to your supervisor.

• As Required

1. Check temperature and pressure gauge readings.

2. Inspect machine and check pump motor for leaks around the shaft.

3. Check chemical supplies and refill as necessary.

• Weekly

1. Inspect all water lines for leaks and tighten at joints if required.

2. Clean all detergent residue from exterior of machine.

3. Check drain/overflow tube for leaks.

4. Clean accumulated scale from heating element.

5. Remove and closely inspect each spray arm for blockage.

12

MAINTENANCE

• Weekly (Cont.)

6. Straighten a paper clip and use it to clear each rinse nozzle.

7. Inspect pawl bars and drive assembly for wear and freedom of travel.

8. Check float switches in tank for freedom of travel.

9. Check idle pump and final rinse levers for freedom of travel.

DELIMING

Your dishwasher should be delimed regularly as required. This will depend on the mineral content of your water.

Inspect your machine interior for lime deposits. If deliming is required, a deliming agent should

be used for best results. Consult your chemical supplier for proper type and procedures.

DANGER:

Deliming solution, rinse agents, or other acids must not come in contact with household bleach (sodium hypochlorite) or any chemicals containing chlorine, iodine,

bromine, or fluorine. Mixing may cause hazardous gases to form. Consult your

chemical supplier.

!

13

TROUBLESHOOTING

In order to find the cause of a breakdown or abnormal operating condition in your dishwasher

please ensure that:

1. All switches are ON

2. Drain and overflow tube are in place and seated

3. Wash pipe and rinse nozzles are clean

4. Scrap screen(s) and scrap basket (if applicable) are properly positioned

5. Spray pipes are in their proper positions

6. Thermostat(s) are at their correct setting

7. Sanitizer, detergent, and rinse additive dispensers are adequately filled

8. Doors are fully closed.

If a problem still exists, use the following table for troubleshooting

CONDITION CAUSE SOLUTION

Machine will not start Door not closed.................................. Make sure doors are fully closed

Door safety switch faulty .................. Contact your service agency

Start switch faulty .............................. Contact your service agency

Main switch off.................................. Check disconnect

No rack inserted ................................ Place rack in unit

Overload protector tripped ................ Reset overload in control box

Low or no water Main water supply is turned off ........ Turn on house water supply

Drain/overflow tube is not

in place and seated ............................ Place and seat drain tube

Machine doors not fully closed ........ Close doors securely

Faulty fill valve.................................. Contact your service agency

Stuck or defective float...................... Check floats and clean

Clogged ‘Y’ strainer .......................... Clean or replace

Continuous water filling Stuck or defective float ...................... Check floats and clean

Fill valve will not close...................... Clean or replace

Drain tube not in place ...................... Look for drain tube in tank

Any motor not running Overload protector tripped ................ Reset overload in control box

Defective motor ................................ Contact your service agency

Wash tank water temperature Incoming water temperature

is low when in use at machine too low ............................ Raise temperature to: 140°F/60°C

Defective thermometer ...................... Check or replace

Defective thermostat .......................... Check for proper setting or replace

Defective heater element .................. Check or replace

Low steam pressure .......................... Check steam supply pressure

Defective steam trap .......................... Check or replace

Defective solenoid valve .................... Check or replace

TROUBLESHOOTING

14

CONDITION CAUSE SOLUTION

Insufficient pumped spray Clogged pump intake screen.............. Clean

pressure Clogged spray pipe ............................ Clean

Scrap screen full ................................ Must be kept clean and in place

Low water level in tank...................... Check drain and overflow tube

Pump motor rotation incorrect .......... Reverse connection between L1

and L2 in control cabinet (3 phase only)

Defective pump seal .......................... Contact service agent

Insufficient final rinse or no Faulty pressure reducing valve .......... Clean or replace

final rinse Improper setting on pressure

reducing valve.................................... Set flow pressure to 20-22 psi [138-151 kPa]

Clogged rinse nozzle and/or

pipe .................................................... Clean with paper clip/delime

Improper water line size .................... Have installer change to proper size

Clogged ‘Y’ strainer .......................... Clean or replace

Low final rinse temperature Low incoming water ........................ Check the booster (KB, KPRB models)

be sure the thermostat is set to maintain

180°F/82°C temperature.

Check valve to be sure it is clean

and operating.

Defective thermometer ...................... Check for proper setting or replace

Poor washing results Detergent dispenser not

operating properly.............................. Contact detergent supplier

Insufficient detergents ...................... Contact detergent supplier

Food Soil concentration too

high in wash tank .............................. Drain tank, clean and refill every 2 hours of

operation or after each meal period.

Wash water temperature

too low .............................................. See condition “Wash Tank

Water Temperature” above

Wash arm clogged.............................. Clean

Improperly scraped dishes ................ Check scraping procedures

Ware improperly

placed in rack .................................... Use proper racks. Do not overload racks

Improperly cleaned

equipment .......................................... Unclog wash sprays and rinse nozzles

to maintain proper pressure and flow

conditions. Overflows must be open.

Keep wash water as clean as possible.

Electric elements or steam

coils has soil/lime buildup ................ Clean and delime

TROUBLESHOOTING

15

Figure 1

Fuse Blocks

Figure 2

Motor Overload

ELECTRICAL SERVICE

ELECTRICAL SERVICE

Fuse Blocks—120VAC Control Voltage

Two fuse blocks, located in the center rear of the main control cabinet

protect the main control transformer. Each fuse block holds a fuse.

The fuses are marked 1FU and 2FU on the electrical schematic.

To Replace the fuse:

• Disconnect power to the machine at the main service switch.

• Flip the tab on the top of the fuse block to open the block.

• Remove the fuse and replace it.

• Close the fuse block and turn the main power on.

• If the fuse blows again, DO NOT INCREASE THE FUSE SIZE.

• DETERMINE THE CAUSE OF THE OVERLOAD.

Fig. 1 shows the fuse block opened and the fuse exposed.

Motor Overloads

Motor overloads are located to the left of the fuse blocks inside

the control cabinet. Each motor has one overload to protect it from

line voltage electrical overloads. In addition, an auxilary set of switch

contacts is built into the overload. The switch contacts disconnect

120VAC power to the motor contactor coils in the event of an overload

condition. Refer to Fig. 2.

Note the Switch Lever on the Overload.

• If the switch lever is off with the “0” showing

then the overload has tripped on an overload.

To Reset the Motor Overload:

• Flip the starter switch to the On position.

• Run the dishwasher and test the AMP

draw of the motor in question. If the motor

checks okay then there may be a wiring

problem or the overload may be defective.

To Replace a Motor Overload:

• Disconnect the wires to the overload.

• Release the mounting catch on the front

side of the overload, push forward and lift out.

• Snap the new overload into place and

reconnect the wires.

To adjust the overload setting:

The screwdriver in Fig. 2 is positioned

to adjust the motor overload AMP setting.

• Read the FLA motor amps that applies for the

machine voltage on the Motor Nameplate.

• Turn the setting to match nameplate FLA.

16

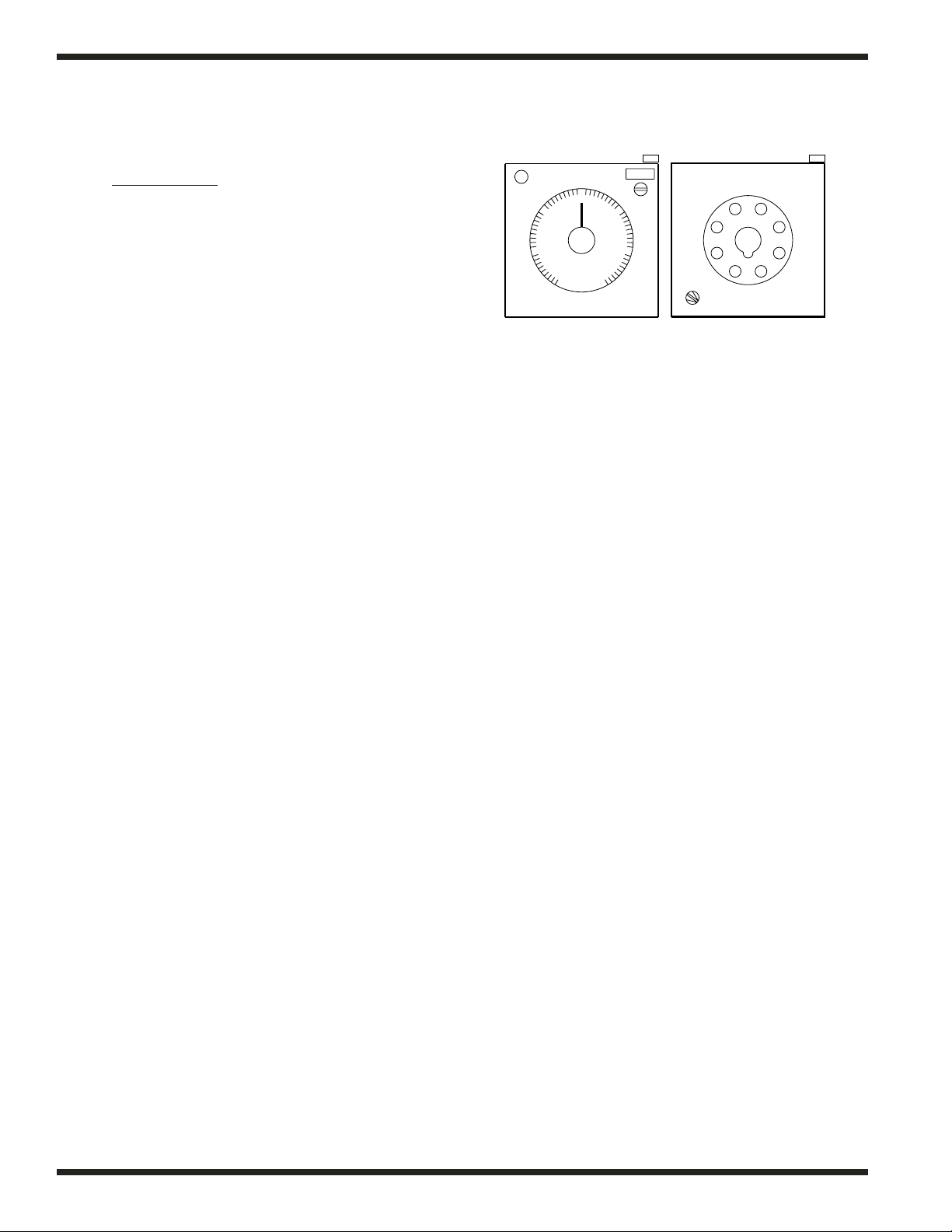

BackFront

Pump Timer

Refer to Fig. 3

The automatic timer located in the left center of the

control cabinet is set at the factory.

The Pump Timer controls the amount of time that

the pumps will run before the last rack enters the

load end of the dishwasher tunnel.

The Pump Timer is an OFF DELAY timer.

Each timer is marked

with a tag noting

the time set by the factory.

The timer has the following user defined settings:

1. Adjustable timer range

2. Timer knob setting

3. Indicator light (ON when timer is counting)

4. 50 Hz or 60 Hz setting on the back of the timer

To Replace a Timer:

• Disconnect power to the machine at the main service switch.

• Remove the defective timer and install the replacement.

• Adjust the new timer setting to match the setting

of the original timer.

Operation Sequence:

• A dishrack entering the machine contacts the idle pump switch lever.

• Normally closed contacts of the idle pump switch open, de-energizing control relay 1CR.

• Normally closed contacts (1, 9) of 1CR close and apply 120VAC to reset coil of pump timer.

• Pump timer resets.

• The dishrack moves off the idle pump switch lever. The switch contacts close.

• 1CR energizes and contacts (1, 9) open removing 120VAC from the pump timer reset coil.

• The pump timer begins to time down for its preset time setting.

• The timer is reset each time the idle pump switch is activated. If the timer is reset only once it

will time out and shut the pumps off after the rack has exited the dishwasher.

To Check the Pump Timer Setting:

• Turn the power on.

• Place a rack on the conveyor.

• Press the Green start button. The conveyor drive will start.

• When the rack enters the load end the pumps will start.

• Wait for the rack to exit the tunnel at the unload end.

• When the pumps stop, push the red stop button.

• Measure the distance between the exit end of the tunnel and the rack.

• The rack should be about 1 foot past the end of the tunnel.

• If the distance is less than 1 foot, increase the pump timer setting. Continue to increase the

timer setting a few seconds at a time until the proper distance is reached.

• If the measured distance is greater than 1 foot, decrease the pump timer setting. Continue to

decrease the timer setting a few seconds at a time until the proper distance is reached.

ELECTRICAL SERVICE

0

1

2

3

UP

4

5

6

Omron

H2C

6M

1R006

50

60

1

2

3

4

5

6

7

8

1R007

Figure 3

Pump Timer

17

Figure 4

Dual Float

Switch

ELECTRICAL SERVICE (Cont.)

Automatic Fill/Low Water Heat Protection

Dual Float Switches –

Refer to F

ig. 4

Each tank contains a dual float. The device consists of

an angled stem containing two reed switches.

Two stainless steel ball floats slide over the

stem and are free to move up and down.

The floats contain magnets. When the float moves on the

stem, it opens and closes its associated reed switch inside the

stem. The reed switches control relays. The relays control the

automatic fill and heat for different parts of the machine.

Float switches and their relays operate on 24VAC.

Circuit Explanation –

The following is a general explanation of the float switch circuit.

Refer to the electrical schematic on your machine for a detailed

description of the individual floats, relays, and wiring.

Bottom Float and Reed Switch:

• The bottom float controls the heat.

• When the bottom float is down, the bottom reed switch contacts are open.

• When the bottom float is up, the bottom reed switch contacts close.

Top Float and Reed Switch:

• The top float controls a fill valve.

• When the top float is down, the top reed switch contacts are open.

• When the top float is up, the top reed switch contacts are closed.

Initial Fill –

• When the tank is completely empty, both floats are down and their reed switch contacts are open.

• The control relay for the float switch is de-energized.

• The fill valve for the tank is energized and the tank begins to fill with water.

• As the water level in the tank rises, the bottom float begins to move up.

• When the bottom float is completely up, its NO reed switch contacts close.

• This prepares the heat circuit, but the heat Does Not energize at this time.

• The tank continues to fill until the top float is completely up.

• The top float’s NO reed switch contacts close. Its control relay energizes.

• The fill valve de-energizes.

• The heat circuit energizes through the float switch and the contacts of the control relay.

During Normal Operation –

• If the water level in a tank falls below the level of the top float, the top float moves down and

its reed switch contacts open.

• When the water level falls below the level of the bottom float, the bottom float moves down

and its reed switch opens.

• The control relay de-energizes. The f ill valve energizes and refills the tank.

• The heat circuit will de-energize until the water level in the tank raises the top float again.

• The bottom float keeps the heat circuit ready as long as the water level is above the level of

the bottom float.

ELECTRICAL SERVICE

18

1R010

1R009

Figure 5

Tank Heat Thermostats

Figure 6

Booster Thermostat Locations

Figure 7

Booster – High Limit Thermostat

ELECTRICAL SERVICE

ELECTRICAL SERVICE (Cont.)

Thermostat Locations and Adjustments

Refer to Fig. 5

Electric tank heat is controlled by two thermostats.

1. The control thermostat which regulates the temperature.

2. The high limit thermostat which protects from overheating.

Location:

Both thermostats are located on front of tank, inside a black

enclosure box behind the front access panel.

Adjustment:

The Control Thermostat has an adjustment screw on one side.

• The thermostat is wired Normally Closed.

• Turn the adjustment screw clockwise to increase

the temperature in the tank and counterclockwise

to decrease the temperature in the tank.

The High Limit Thermostat is not adjustable.

It contains a red reset button in its center.

• The red button pops out if the temperature

in the tank exceeds 210°F/99°C.

• Press the red button in to reset the high limit.

Determine the cause of the high temperature condition.

Refer to F

ig. 6 and Fig. 7.

Electric Booster Heat is controlled by two thermostats.

1. The control thermostat which regulates the temperature.

2. The high limit thermostat which protects from overheating.

3. Each tank has a control and a high limit thermostat.

Location:

The control thermostat is enclosed in a black box mounted

on the front of the wash tank behind the front access panel.

The high limit thermostat is enclosed in a box mounted

on top of the booster tank.

Adjustment:

The control thermostat has an adjustment screw on one side.

• The thermostat is wired Normally Closed.

• Turn the adjustment screw clockwise to increase the booster tank temperature

and counterclockwise to decrease the booster tank temperature.

The high limit thermostat is a bimetal snap design. It is not adjustable.

• A button with a red dot in the center pops out when

the temperature exceeds 210°F/99°C.

• Press the red reset button in to reset the high limit.

Determine the cause of the high temperature condition.

Control Thermostat

High limit

Thermostat

High Limit

Thermostat

Control

Thermostat

1R011

19

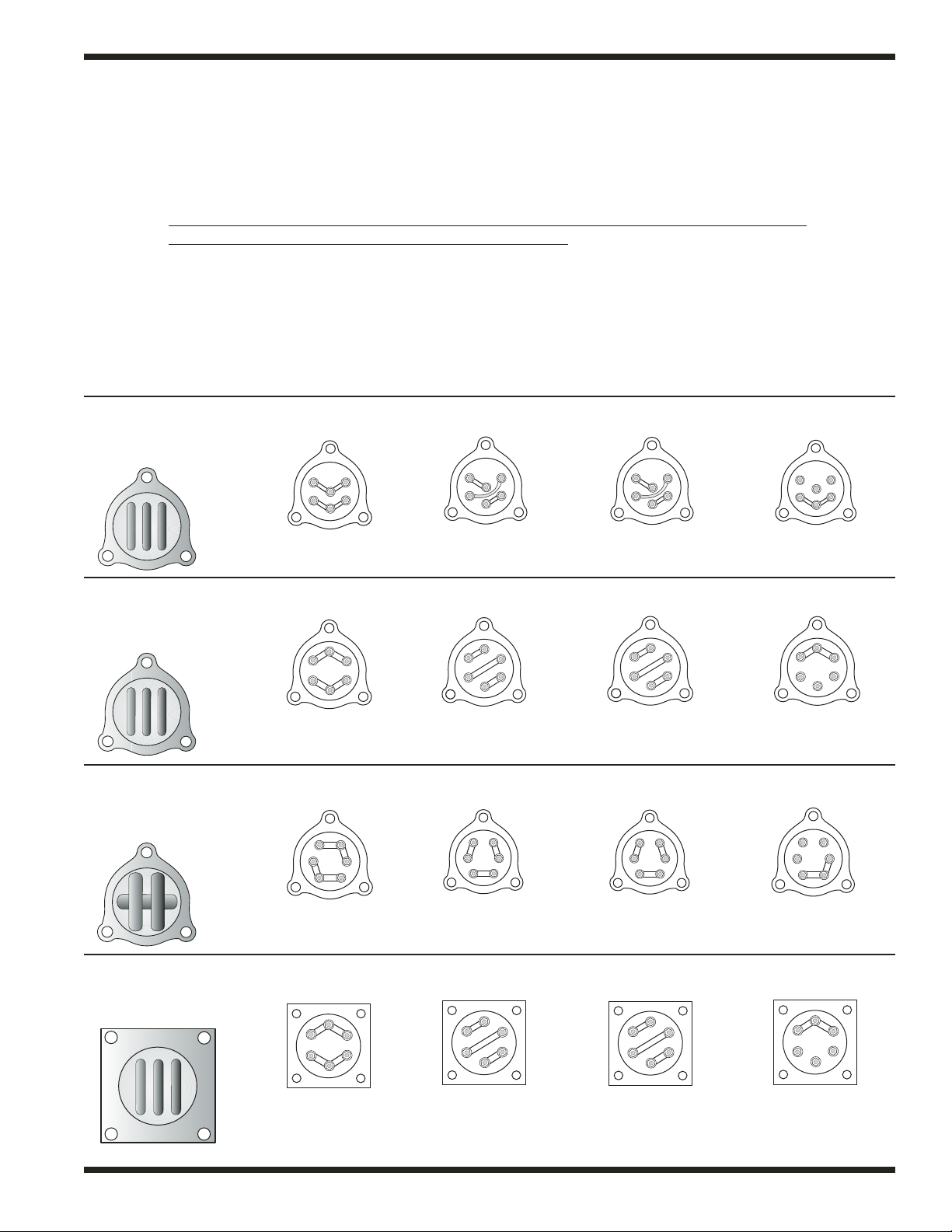

480V/3 Phase

575V/3 Phase

Delta Connection

480V/3 Phase

575V/3 Phase

Delta Connection

480V/3 Phase

575V/3 Phase

Delta Connection

480V/3 Phase

575V/3 Phase

Delta Connection

208-240V/3 Phase

Wye Connection for

380-415V/3 Phase

208-240V/3 Phase

Wye Connection for

380-415V/3 Phase

208-240V/3 Phase

Wye Connection for

380-415V/3 Phase

208-240V/3 Phase

Wye Connection for

380-415V/3 Phase

208-240V/3 Phase

Delta Connection

208-240V/3 Phase

Delta Connection

208-240V/3 Phase

Delta Connection

208-240V/3 Phase

Delta Connection

208V/1 Phase

208V/1 Phase

208V/1 Phase

208V/1 Phase

Configuration C

Booster tank element

View of calrod coils

Terminal Connections view of element

Terminal Connections view of element

Configuration D

Wash tank element

View of calrod coils

Configuration B

Booster tank element

View of calrod coils

Configuration A

Booster tank element

View of calrod coils

Terminal Connections view of element

Terminal Connections view of element

ELECTRICAL SERVICE (Cont.)

Heater Element Wiring – Booster Tank and Wash Tank Heater Elements

Refer to the illustrations and follo

w the steps below to properly install terminal jumpers and

to make line po

wer connections to a replacement element.

Step 1. Hold the element assembly with the calrod coils facing toward you.

Step 2. Match your element coil to Configuration A, B, C, or D.

Step 3. Rotate your element coils to match the correct configuration.

Step 4. Flip the element over and match your element to the correct terminal configuration.

Step 5. Install terminal jumpers according to the illustration for your voltage requirement.

Step 6. Install the element and make your line connections 1L1, 1L2, or 1L3 per the illustration.

ELECTRICAL SERVICE

1L1

1L2

1L3

1L1

1L2

1L3

1L1

1L2

1L3

1L1

1L2

1L3

1L2

1L1

1L1

1L2

1L1

1L2

1L1

1L2

1L1

1L2

1L3

1L1

1L2

1L3

1L1

1L2

1L3

3

1L1

1L2

1L3

1L1

1L2

1L3

1L1

1L2

1L3

3

1L

1L

20

Low voltage

208-230V/1PH

Only

Motors

Motor Specifications

Voltage: Standard motors are multi-voltage

Low voltage: 208-230VAC

High voltage: 460VAC or 575VAC only

Phase: Motors may be single or three phase

Wiring Connections:

Refer to the diagrams below for 3 phase motor lead wiring.

Low voltage High Voltage 575V/3PH

208-230V/3PH 460V/3PH Only

Refer to the diagram at right

for single phase motor lead wiring.

Troubleshooting:

Motor will not run:

1. Check incoming power to control cabinet.

2. Check for tripped manual motor starter (overload) in control cabinet.

(Refer to Motor Overload service section for the proper setting)

3. Check power at motor contactor.

Motor runs hot and trips motor starter overload:

1. Check for proper voltage between L1-L2, or (L1-L2, L2-L3, L1-L3 for 3 phase).

2. Check FLA on motor leads L1, L2, (also L3 for 3 phase) using amp tester.

(Motor full load amp (FLA) ratings are stamped on motor nameplate).

Motor Replacement:

1. Disconnect the power to the machine.

2. Disconnect the wires at the motor junction box.

3. Make note of the motor connections in order to phase the replacement correctly.

4. Install the new motor and check for proper rotation.

5. Proper shaft rotation is clockwise looking at the rear of the motor.

6. Motor rotation can be reversed by switching L1 and L2 on 3 phase motors. Single phase

motor rotation cannot be reversed

7. Replacement motors are available as complete assemblies.

8. Champion cannot provide replacement bearings, stators, or rotors for motor repair parts.

ELECTRICAL SERVICE

321

LINE

654

987

321

654

987

321

LINE

2

8

J

LINE

LINE

L1

L2

4

3

21

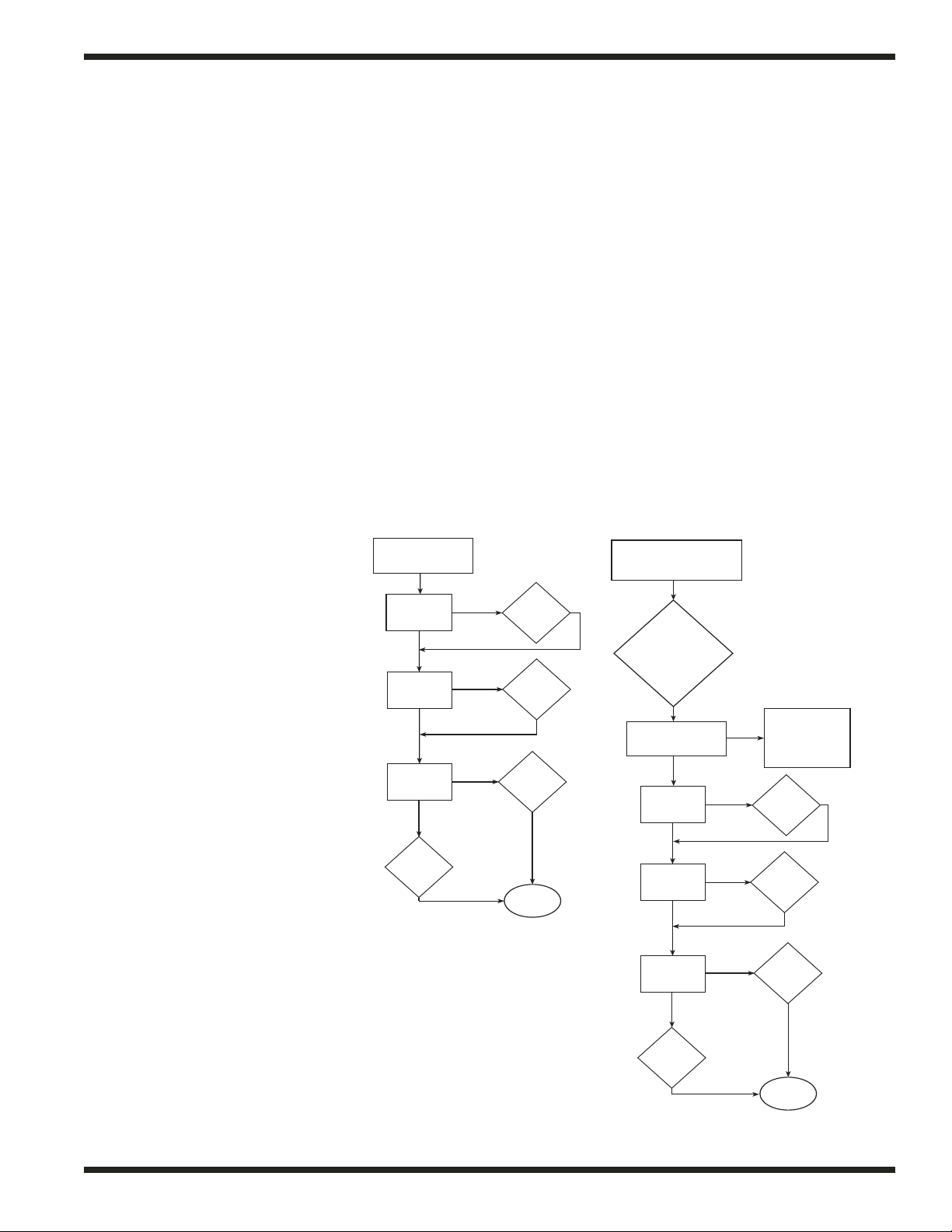

Dual Float Switches –

Troubleshooting:

The dual float controls fill and heat circuits.

Identifying a Dual Float Problem:

The most common trouble conditions associated with a dual float failure are:

1. The tank fills constantly.

2. The tank heat will not come on.

Inspect the Dual Float:

1. Be sure that the dual float assembly is clean and free of scale build-up.

2. Be sure that the stainless steel balls on the float assembly move up and down freely.

In addition to checking the float operation, perform the following—

System Checks:

1. All drain valves are fully closed.

2. Incoming water supply Flow Pressure is 20-22 psi [138-151 kPa].

3. Fuses in control cabinet are good (Electric Heat Only).

4. Tank Heat thermostats and/or High limit thermostats operate correctly.

5. Booster Heat thermostats and/or High limit thermostats operate correctly.

ELECTRICAL SERVICE

Dual Float Troubleshooting Diagrams:

YES

Water Shuts OFF

Machine is in

Final Rinse Mode

Not a Dual Float

Problem

System

Checks

System

Checks

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

Wash or Prewash

Tank Fills Constantly

Is Tank Full

of Water?

Are the Float

Balls Up?

Close

Drain

Valve

Clean

Float

Assy

Is Heat ON

when called

for?

Replace

Dual

Float

Check

Solenoid

Valve

Are the Float

Balls Up?

Check

Solenoid

Valve

Is Heat ON

when called

for?

Replace

Dual

Float

Clean

Float

Assy

Close

Drain

Valve

Is Tank Full

of Water?

Check to ensure

that

Rinse-Saver Lever

is not

Operated

Water Runs Constantly

Through Final Rinse Piping

22

Canister No.1

L-R Direction

Water

Supply

In

Canister No.1

Canister No.2

ELECTRICAL SERVICE

Figure 8

Front View

Typical 40°F/22°C Rise Booster

One Tank – Total 36Kw Shown

Figure 9

Front View

Typical 70°F/39°C Rise Booster

Two-Tank – Total 57Kw Shown

12Kw

9Kw

9Kw

9Kw9Kw

9Kw

12Kw

12Kw

Dishwasher

Unload

End

12Kw

Electric Booster Heater — Element Installation

Refer to Fig. 8 and Fig. 9

Champion built-in boosters are constructed of

stainless steel and have locations for three electric

booster heater elements.

1. The two booster configurations for rack

conveyor models are:

Single tank - 40°F/22°C rise booster

Two tank - 70°F/39°C rise booster

The total Kw rating of the booster assembly is

determined by the model number of the machine

and the minimum temperature of the incoming

water supply.

2. The highest rated Kw element

should always be installed in the

bottom right corner location of

booster canister No. 1.

1R013

Highest Rated Kw Element

installed in bottom right corner

of Canister No.1

1R012

23

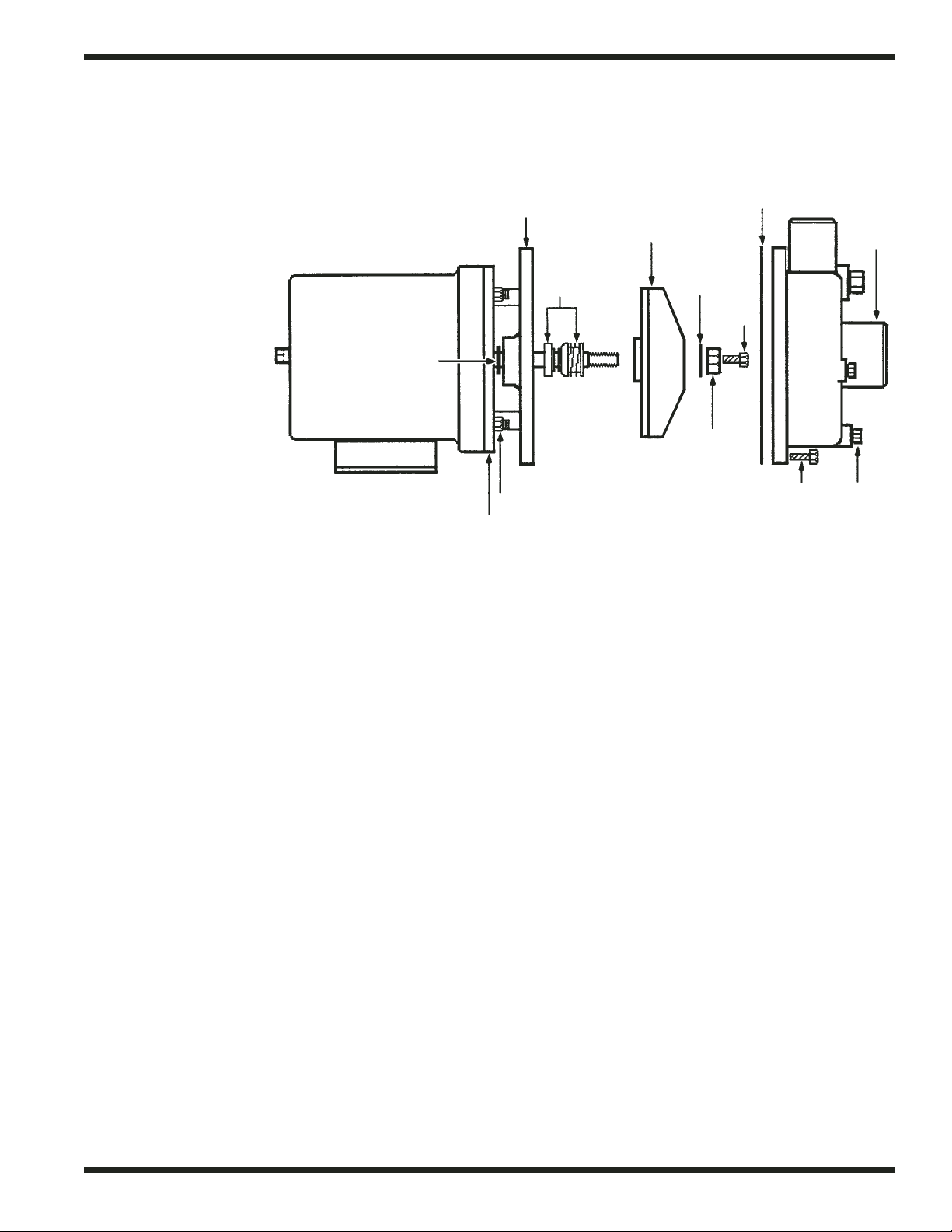

MECHANICAL SERVICE

Plug

Volute

Bolt

(A)

Backing Plate

Backing Plate

Mounting Nut

Seal Assy

Pump Flange

Impeller

Washer

Bolt

(B)

Gasket

Nut

MECHANICAL SERVICE

Pump Seal Replacement:

WARNING:

Disconnect all

power to the

machine at the

main power

source and

place a tag at

the disconnect

switch to show

that work is

being done

on the circuit.

1. Disconnect the power to the machine.

2. Drain the machine. Remove the plug from the lowest point on the pump volute and drain the

pump.

3. Remove the pump hoses.

4. Disconnect the wires to the motor at the motor junction box.

5. Unbolt the motor from the base of the machine and remove the motor and pump.

6. Remove all the bolts (A) on the volute and carefully remove the volute from the pump flange.

7. Lock the motor shaft holding the square end of the rear shaft with a wrench or vise grips.

8. Remove the impeller retaining bolt (B). Remove the large retaining nut and washer.

9. Remove the impeller using a strap wrench. Turn it counterclockwise. Do not strike the

impeller with a hammer to loosen or remove it.

10. Check the impeller counterbore for shim washers. Be sure to reinstall. Not all impellers

have shims.

11. Remove the old seal and discard. Check the seal seat in the pump flange and clean thoroughly.

12. Clean the seating surface on the motor shaft with #600 emery paper or crocus cloth.

13. Check the water slinger and replace if worn or missing. Remove the (4) backing plate mtg.

nuts to gain access to the slinger.

14. Press the rubber seal and ceramic into the pump flange. Use a water soluble lubricant. Keep

the ceramic clean.

15. Install the rotating part of the seal on the shaft with the graphite surface toward the ceramic.

Use a water soluble lubricant.

16. Reinstall the impeller, washer, lock-nut, and bolt. Install a new flange gasket. Bolt the volute

to the flange.

17. Reinstall the pump and motor assembly on the base of the machine and reconnect the pump

hoses.

18. Reconnect the power and fill the tank with water. Check for leaks.

19. Bump start the pump to check the motor for correct rotation.

20. Proper shaft rotation is clockwise looking at the rear of the motor.

Water

Slinger

24

1R016

1R014

MECHANICAL SERVICE

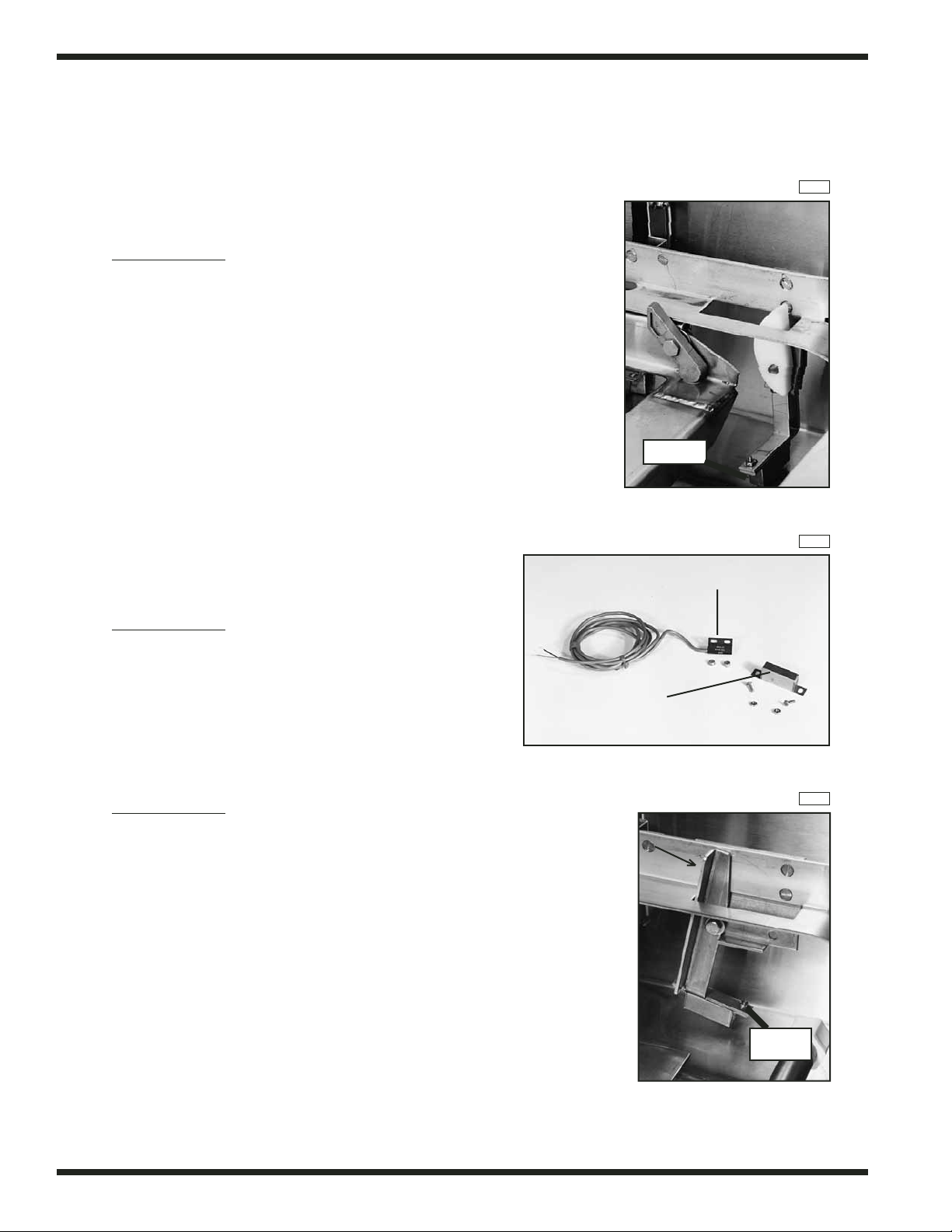

Figure 12

Rinse-Saver Switch Mechanism

Figure 11

Magnetic Switch and Magnet

Figure 10

Idle Pump Switch Assembly

Magnetic Switch

Magnet

MECHANICAL SERVICE (Cont.)

Idle Pump and Rinse-Saver Switch Assemblies

Idle Pump Switch Assembly –

Refer to F

ig. 10. The idle pump switch, also called the rack switch is

located on the load end of the conveyor track. It is made up of a lever

mechanism, a magnet, and a magnetic reed switch. The magnetic switch

contacts are closed when the idle pump lever is at rest as pictured in figure 10. When a rack is placed into the machine, it contacts the idle pump

lever. The magnet swings away from the magnetic switch. The closed

contacts of the switch open and power is removed from control relay

1CR. The normally closed contacts, (1, 9) of 1CR, close and apply

120VAC to the PUMP TIMER RESET COIL. The timer resets and the

wash pump(s) start. When the rack moves past the idle pump lever, the

magnet returns to its resting state. The magnetic switch contacts close.

Power is re-applied to 1CR and the 120VAC is removed from the pump

timer reset coil. The timer begins to count down. The idle pump switch

will reset the timer each time a rack contacts the lever. If only one rack

operates the idle pump switch then the timer will time out after its preset

time and the pumps will stop.

Magnetic Switch and Magnet –

Refer to F

ig. 11. The magnetic switches are located

on the underside of the tank hood. Studs are welded on

the hood and the switches are nutted securely in place.

The magnets are mounted on the ends of the idle pump

and rinse-saver levers by screws and nuts. The magnets

are enclosed in stainless steel housings.

Rinse-Saver Switch Assembly –

Refer to F

ig. 12. The rinse-saver switch assembly, also called the final

rinse switch, is located on the unload end of the conveyor track. It is

made up of a lever assembly, magnetic switch, and magnet. The contacts

of the magnetic switch are closed when the magnet is in the rest position

as pictured in figure 12. The operation of the final rinse is controlled by

the rinse-saver switch. When a rack contacts the lever of the switch

assembly, the magnet moves away from the magnetic switch. The

contacts of the switch open and power is removed from control relay

2CR. The normally closed contacts (12, 4) of 2CR close. 120VAC power

is applied to the final rinse water solenoid valve. 180°F/82°C final rinse

water is supplied to sanitize the dishes. Power will continue to be applied

to the solenoid valve as long as a rack operates the rinse-saver assembly.

When the rack moves past the lever, the magnet returns to its rest

position. The magnetic switch closes and the final rinse turns off.

Magnet

1R015

Magnet

Loading...

Loading...