Page 1

Easy step-by-step

interactive 3D instructions

for this product can be found in

DOWNLOAD THE FREE APP

Availableon most iOS and AndroidDevices

AFTER YOUR ASSEMBLY WITH BILT,

DOWNLOAD THE myQ® APP

Installation Manual Inside

Page 2

Page 3

Installation Manual

Belt Drive Garage Door Opener

Models B2202 • B2212T • B2405 • B4505T

FOR RESIDENTIAL USE ONLY

PREǫPROGRAMMED REMOTE

CONTROL INCLUDED

To register your garage door opener to receive

updates and offers from Chamberlain, visit

chamberlain.registria.com or use the icon below:

1. Take a photo of the camera icon including

the points (

2. Send it in by texting the photo to 71403 (US).

).

www.chamberlain.com

• Please read this manual and the enclosed safety materials carefully!

• Fasten the manual near the garage door after installation.

• The door WILL NOT CLOSE unless the Protector System® is connected and properly aligned.

• Periodic checks of the garage door opener are required to ensure safe operation.

• The model number label is located on the left side panel of your garage door opener.

• This garage door opener is compatible with myQ® and Security+2.0® accessories.

• DO NOT install on a one-piece door if using devices or features providing unattended close. Unattended

devices and features are to be used ONLY with sectional doors.

Page 4

Contents

Preparation 5 Assembly 9 Installation 14

Install the Door Control 24

Install the Protector System® 27

Connect Power 31

Adjustments 33

Battery Backup 36

myQ® App Control 37

Connect WithYour Smartphone 37

Operation 38

Usingyour Garage Door Opener 38

Usingyour Door Control 39

Remote Controland Keyless Entry 41

HomeLink® 41

Erase the Memory 42

To Open the Door Manually 42

Maintenance 43

Troubleshooting 44

Warranty 46

Automatic Garage Door Opener Safety & Maintenance Guide 47

Repair Parts 49

Rail AssemblyParts 49

Installation Parts 49

Models B2202and B2212T 50

Models B2405and B4505T 51

Safety Symbol and Signal Word Review

This garage door opener has been designed and tested to offer safe service p rovided it is installed, operated,

maintained and tested in strict accordance with th e instructions and warnings contained in this manual.

Mechanical

Electrical

When you see thes e Safety Symb ols and Signal Words on the following pages, t hey will alert youto the

possibility of serious injury or death if youdo not comp ly with th e warnin gs th at accomp any them. The

hazard may come from someth ing mechanical or from electric shock. Read th e warnings carefully.

When you see this Signal Word on the following pages, it will alert you to the possibility of d amage to your

garage door and/or the garage door opener if you do not comply with the cautionary statements that

accompany it. Read t hem carefully.

WARNING: This product can expose you t o ch emicals including lead, which are known to the State of

California to cause cancer or birth defects or other reproductive harm. For more information go to

www.P65Warn ings.ca.gov

Unattended Operation

The Timer-to-Close (TTC) f eature, t he myQ® App, and myQ® Garage Door and Gate Monitor are examples of

unattended close and are to b e used ONLY with sectional doors. An y device or feature that allows the door to

close with out being in the line of sight of the door is considered unattend ed close. The Timer-to-Close (TTC)

feature, the myQ® App, and any other myQ® devices are to be used ONLYwith sectional doors.

The images throughout this manual are for reference only and your product may

look different.

4

Page 5

Torsion

Spring

Extension

Spring

Wi-Fi signal is weak.

The garage door opener will likely connect to your Wi-Fi

network. If not, try one of the options below.

No Wi-Fi signal. Try one of the following:

• Move your router closer to the garage door opener to

minimize interference from walls and other objects

• Buy a Wi-Fi range extender

Check Signal Strength. If you see:

Wi-Fi signal is strong. You’re all set!

Install your new garage door opener.

Preparation

Check the Door

To prevent possible SERIOUSINJURYor DEATH:

l ALWAYS call a trained door s yst ems technician if garage door bin ds, s ticks, or is out of b alance. An

unbalanced garage door m ay NOT reverse when required.

l NEVER try to loosen, move or adjust garage door, door spring s, cables, pulleys, brackets or their

hardware, ALLof which are under EXTREME tens ion.

l Disable ALLlocks and remove ALLropes connected to garage door BEFORE ins tallation and operating

garage door opener to avoid entanglement.

l DO NOT install on a one-piece door if using devices or features providing unatt ended close.

Unattended devices and features are to be used ONLY with sectional d oors.

To prevent damage t o garage door and opener:

l ALWAYS d isable locks BEFORE installing and operating the open er.

l ONLY operate garage door opener at 120V, 6 0H z to avoid malfunction and damage.

Before youb egin:

1. Disable locks and remove any ropes connected to t he garage door.

2. Lift the door halfway up. Release t he door. If balanced, it should stay in place, supp orted entirely b y its

springs .

3. Raise and lower the door to check for bindin g or sticking. If your door bin ds, s ticks, or is out of b alance,

call a trained door systems technician.

4. Check t he seal on the bottom of the door. Any gap between the floor and th e bottom of the door must

not exceed 1/4" (6 mm). Otherwise, t he safety reversal s ystem may not work properly.

5. The opener should be installed above the center of the d oor. If there is a torsion spring or cent er

bearing plate in the way of the header bracket, it m ay be in stalled within 4feet (1.2 m) to the left or

right of the door cent er. See page 15.

Before You Connect with Your Smartphone

Monitor and control your garage d oor from anywhere usin g the myQ® App. Youwill need a router with Wi-Fi®

and a s martphone or other mobile device. Make sure your mobile device is conn ected to your Wi-Fi® network.

Hold your mobile device in the place where your garage d oor opener will be installed and check the Wi-Fi®

sign al streng th.

Visit support.chamberlaingroup.com for more details.

See myQ® App Control page 37 to connect your g arage door opener to your Wi-Fi® network.

5

Page 6

3/16

7/16

1/2

5/32

5/16

9/16

1/4

7/16

Support Brackets

Hardware x2 (each)

Extension Brackets –Ê041A5281-1

Lag screws x4

Lag screws x12

Wood Blocks

Preparation

Tools Needed

Additional Items You May Need:

Survey your garage area to see if you will need any of the following items:

l (2) 2X4 Pieces of wood : May be used to fasten the h eader bracket to th e structural supports. Also

used to position the garage door opener d uring installation and for t esting the safet y reversing

sens ors.

l Support bracket and fastening hardware: Must be used if you have a finis hed ceiling in your garage.

l Extension brackets (Model 041A5281-1) or wood blocks: Depend ing upon garage construction,

extens ion brackets or wood b locks may b e needed to in stall the safety reversin g sens or.

l Fastening hardware: Altern ate floor mountin g of the safety reversing sensor will require hardware n ot

provided .

l Doo r reinfo rcement: Required if you have a lightweigh t steel, alumin um, fiberglass or glass panel door.

l Railextension kit: Required if your garage door is more than 7 feet (2.13 m) high.

6

Page 7

9 x2

14 x2

2

8 x1

7

7

18

12

8 x4

14 x1

14 x1

11

6

10

3

5

1

16

19

20

17

13

4

15

Preparation

Carton Inventory

Save the carton and packing material unt il the installation and adjustment is complete. Instructions for the

accessories will be attached to the accessory and are not in cluded in this manual. The images throughout th is

manual are for reference only and your product may look d iff erent.

1. H eader bracket

2. P ulley

3. Door b racket

4. Curved door arm

5. S traigh t door arm

(Packaged insid e front rail section)

6. Trolley

7. Emerg ency release rope and handle

8. Rail (1 front and 4 center sections)

9. H angin g brackets (2)

10. Garage door opener (motor unit)

11. Sprocket cover and s crews

12. “U” bracket

13. Belt

14. The Protector System

15. Battery Backup - Model B221 2T

16. Remote control

17. Wireless keypad - Models B2405 and B45 05T

18. Push Button Door Control - Models B22 02 and B2212T

19. White and red/white wire

20. Installation manual and all warning labels

See Hardware p age 8.

Go to chamberlain.com for replacement or additional accessories:

3-button remote control m odel 953EV-P2

Wireless keypad model 940EV-P 2

(Packaged insid e the front rail s ection)

Safety reversing sen sors with 2 cond uctor white and white/black wire attached: sending sensor (1),

receiving sensor (1), and safety sens or brackets (2)

®

Multi-Function Control P anel - M odel B2405

Motion Detecting Control Panel - Model B4505

7

Page 8

ASSEMBLY INSTALLATION

Clevis Pin 5/16"x1-1/2"

Ring

Fastener (3)

Hex Bolt 5/16"-18x7/8" (4)

Self-Threading Screw

1/4"-14x5/8" (2)

Clevis Pin 5/16"x1" Clevis Pin 5/16"x1-1/4"

Hex Screw 10-24 (2)

Wing Nut (2)

Lag Screw 5/16"-9x1-5/8" (4)

Hex Screw #8x3/8" (3)

(packed with the

sprocket cover)

Bolt 1/4"-20x1-3/4"

Lock Nut

1/4"-20

Bolt

Nut 3/8"

Lock Washer 3/8"

Master Link

Threaded

Shaft with

Spring

Trolley Nut

Lock Washer

5/16"-18 (4)

Nut

5/16"-18 (4)

DOOR CONTROL

Insulated Staples

(Not Shown)

Screw 6ABx1" (2)

Screw

6ABx1-1/2" (2)

Drywall Anchors (2)

Models B2405 and B4505T

Models B2202 and B2212T

Drywall

Anchors (2)

Screw 6-32x1" (2)

Preparation

Hardware

8

Page 9

Assembly

Wear Pads

Front Rail Section

(TO DOOR)

“U” Bracket

(TO MOTOR UNIT)

Trolley

Rail Tab

On Top

Slide to stops

on top and sides

of “U” bracket

Screwdriver

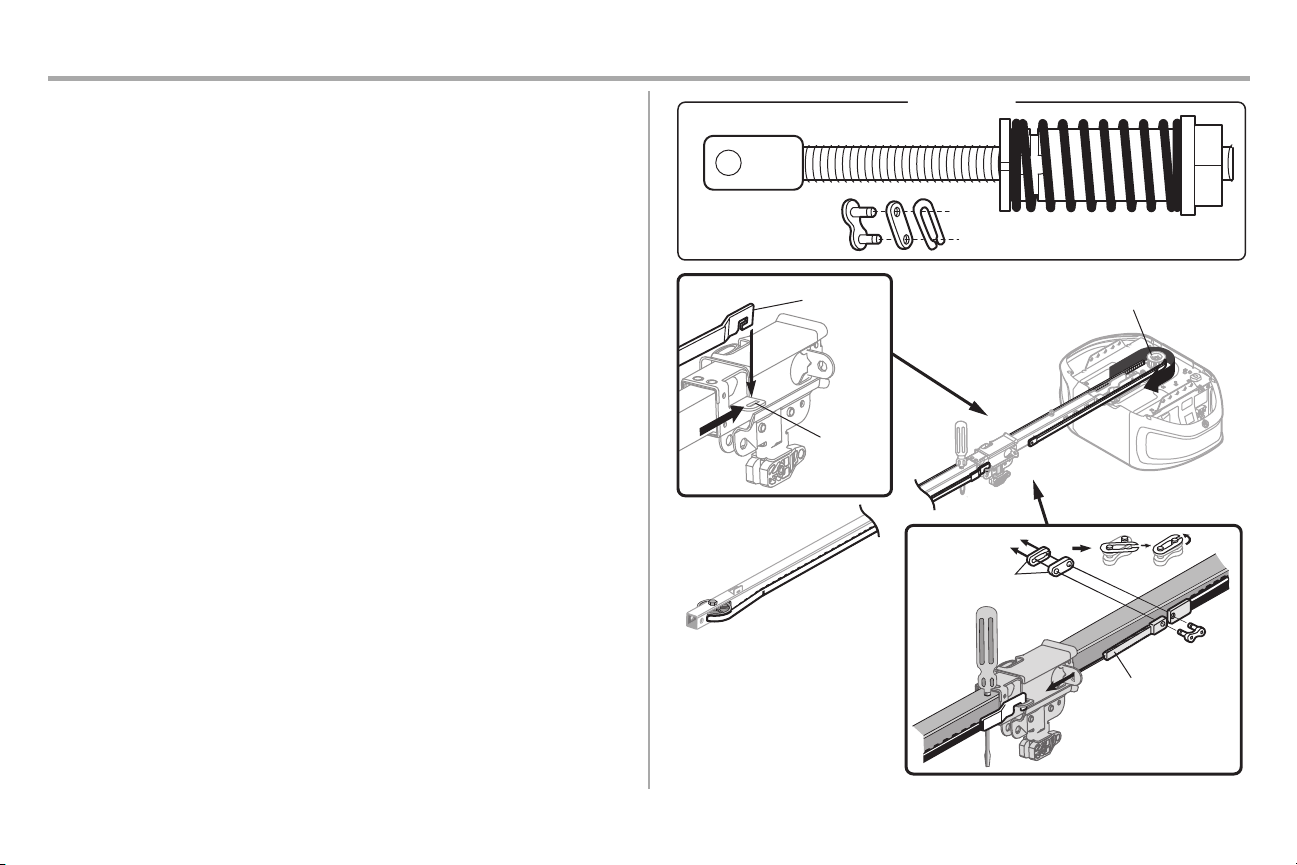

STEP 1 Assemble the Rail and Install the Trolley

To prevent INJURY from pinching, keep hands and fingers away f rom the joints while assemb ling th e rail.

To avoid installation difficulties, do not ru n the garage door o pener until instructed to do so.

The front rail h as a cut out “window” at the door end. The rail tab MUST be on top ofthe rail when assembled.

1. Rem ove t he straight door arm and hanging bracket packaged inside the front rail and set aside for

Installation S tep 5 and 9. NOTE: To preven t INJURY while unp acking the rail carefully remove the

straight d oor arm st ored within the rail section.

2. Alig n the rail s ections on a flat surface as sh own and slide the tapered ends into the larger ones. Tabs

along the side willlock int o p lace.

3. P lace the motor unit on packing material to protect the cover, and rest the back en d of the rail on top.

For conven ience, put asupport und er the front end of the rail.

4. As a temporary s top, insert a screwdriver into the hole in the s econd rail s ection from the motor unit,

as shown.

5. Check t o b e sure th ere are 4 plastic wear pads inside t he inner trolley. If they became loose during

shippin g, check allpacking material. Snap them back into p osition as shown.

6. S lide the trolley assemb ly toward the s crewdriver as shown.

7. S lide the rail onto th e “U” bracket, unt il it reaches all th e stops on the top and sides of the “U” b racket.

9

Page 10

Assembly

Bolt

1/4"-20x1-3/4"

Lock Nut

1/4"-20

HARDWARE

Bolts (Mounted in the

garage door opener)

Bolt

Lock Nut

Cover Protection

Bolt Hole

“U” Bracket

STEP 2 Fasten the Rail to the Motor Unit

To avoid SERIOUS d amage to garage d oor opener, use ONLYthose bolts/fasteners mounted in the top of

the opener.

1. Insert a 1/4"-20 x 1-3/4" bolt into the cover protection bolt h ole on the b ack en d of the rail as shown.

Tighten securely with a 1/4"-20 lock nut. DO NOT overtight en.

2. Rem ove t he bolts from the top of the m otor unit.

3. Use the carton to support the front end of the rail.

4. P lace the “U” bracket, flat side down onto the motor unit and align the bracket h oles with th e bolt

holes.

5. Fast en the “U” b racket with the previously rem oved bolts; DO NOT use any power t ools. The use of power

tools may permanen tly damage the garage door opener.

10

Page 11

Assembly

Rail

Idler Pulley

Grease Inside

Pulley

Bolt

Belt

Lock Washer

Nut

Bolt

Nut 3/8" Lock Washer 3/8"

HARDWARE

Trolley Connector

Rail Tab

STEP 3 Install the Idler Pulley

1. Lay the belt beside t he rail, as sh own. Grasp th e end with th e hooked trolley conn ector and pass

approximately 12" (30 cm) of belt through the wind ow. Keep the ribbed side toward the rail, and allow

it to hang until Assembly Step 4.

2. Rem ove t he tape from the idler pulley. The inside cen ter should be pre-greased. If d ry, regrease to

ensure proper operation.

3. P lace the idler pulley int o the window as shown.

4. Insert the id ler bolt f rom the top through the rail an d pulley. Tigh ten with a 3/8" lock washer and nut

5. Rotate t he pulley to be s ure it spins f reely.

6. Locate the rail tab. The rail tab is b etween the idler bolt and the trolley in the front rail s ection. Use a

underneath the rail unt il the lock washer is comp ress ed.

flathead screwdriver and lift the rail tab until t he tab is vertical (90º).

11

Page 12

Assembly

HARDWARE

Master Link

Figure 3

Threaded Shaft with Spring Trolley Nut

Threaded Shaft

Master Link

Sprocket

Figure 2

Figure 1

Trolley

Connector

Retaining

Slot

STEP 4 Install the Belt

1. P ull the belt around the id ler pulley and toward the trolley. The ribbed side must contact the pulley.

2. H ook the t rolley conn ector into the retaining slot on t he trolley as shown (Figure1).

3. With the trolley against th e screwdriver, dispen se the remaind er of the b elt along the rail

lengthtoward t he motor unit and around the sprocket (Figure2). The sprocket teeth must engage the

belt.

4. Check t o m ake s ure t he belt is not twist ed. Connect the trolley t hreaded shaft with the mast er link

(Figure3).

a. Push pins of master link bar through holes in en d of belt and trolley th readed shaft.

b. P ush mast er link cap over pins and past pin notches.

c. Slid e the closed end of the clip-on spring over one of the p ins. Push the open end of the clip-on

spring onto the other pin.

5. Rem ove t he spring trolley nut f rom the threaded shaft .

6. Insert the t rolley threaded shaft th rough the hole in th e trolley.

12

Page 13

Assembly

Spring

Trolley Nut

Nut Ring Slot

Nut RingNut Ring

AFTER

1-1/4" (3.18 cm)

BEFORE

1" (2.5 cm)

Hex Screw #8x3/8"

(Packed with the sprocket cover)

HARDWARE

Hex Screw

Sprocket Cover

STEP 5 Tighten the Belt

1. By hand, thread the s pring trolley nut on the t hreaded shaft until it is finger tight against the trolley.

Do not use an y tools. Remove the screwdriver.

2. Insert a flathead screwdriver tip into one of the n ut ring slots and brace it firmly against th e trolley.

3. Tigh ten the spring trolley nut with an adjustable wrench or a 7/16" open end wrench about aquarter

turn until the spring releases and snaps the nut ring against th e trolley. This sets the spring to

optimum belt tension.

STEP 6 Install the Sprocket Cover

To avoid possible SERIOUS INJURYto f ing er from moving garage door opener:

l ALWAYS keep hand clear of sprocket while operating opener.

l Securely attach sprocket cover BEFORE operating.

1. P osition the sprocket cover over the sprocket as shown an d fasten to the mounting plate with #8x3/ 8"

hex screws provided.

You have now finished assembling you r garage door opener. Please read the fo llowing warnings before

proceeding to the installation section.

13

Page 14

Installation

IMPORTANT INSTALLATION INSTRUCTIONS

To reduce the risk of SEVERE INJURY or DEATH:

1. READ AND FOLLOW ALL INSTALLATION WARNINGS AND INSTRUCTIONS.

2. Install garage door opener ONLY on properly balanced and lubricated garage door. An improperly

balanced door m ay NOT reverse when required and could result in SEVERE INJURY or DEATH.

3. ALL repairs to cables, spring ass emb lies and other hardware MUST b e made by atrained door

systems technician BEFORE in stalling opener.

4. Disable ALL locks and remove ALLropes connected to garage door BEFORE installing opener to avoid

entanglement.

5. Wh ere possible, inst all t he door opener 7 feet (2.13 m) or more above the floor.

6. Mount the emergency release within reach, but at least 6 feet (1.83 m) above th e floor and avoiding

contact with vehicles to avoid accidental release.

7. NEVER conn ect garage door opener to power s ource until instructed to do so.

8. NEVER wear watches, rings or loose cloth ing while installing or servicing opener. They could be caught

in garage door or open er mechanisms.

9. Install wall-mount ed garage door control:

l within sight of the garage door.

l out of reach of small children at a minimum height of 5feet (1.5m) above floors, landing s, steps

or any other adjacent walking surface.

l away from ALL moving parts of the door.

10. Place en trapm ent warning label on wall next to garage door control in a promin ent location.

11. Place em ergency release/safety reverse test label in p lain view on inside of garage door.

12. Upon completion of installation, test safety reversal system. Door M UST reverse on contact with a 11/2" (3.8cm) high object (or a 2x4 laid f lat) on the floor.

13. DO NOT install on aone-piece door if using devices or features providing unatten ded close.

Unattended devices and features are to be used ONLY with sectional d oors.

14. SAVE THESE INSTRUCTIONS.

14

Page 15

Installation

Header Wall

Vertical Centerline of Garage Door

2x4

Structural

Supports

Level

(Optional)

Unfinished

Ceiling

2x4

OPTIONAL CEILING MOUNT

FOR HEADER BRACKET

Sectional door with curved track

Header Wall

Track

2" (5 cm)

Highest

Point of

Travel

Door

One-piece door with horizontal track

Header Wall

Track

2" (5 cm)

Highest

Point of

Travel

Door

One-piece door without track:

jamb hardware

Header Wall

8" (20 cm)

Highest

Point of

Travel

Door

Jamb

Hardware

One-piece door without track:

pivot hardware

Header Wall

8" (20 cm)

Highest

Point of

Travel

Door

Pivot

STEP 1 Determine the Header Bracket Location

To prevent possible SERIOUS INJURY or DEATH:

l Header bracket MUST be RIGIDLYfastened to structural s upport on header wall or ceiling, otherwise

garage door m ight NOT reverse when required. DO NOT in stall header bracket over drywall.

l Concrete anchors MUST be used if mounting header bracket or 2x4 into masonry.

l NEVER try to loosen, move or adjust garage door, sp rings, cables, pulleys, brackets, or their hardware,

ALL of which are under EXTREME tens ion.

l ALWAYS call a trained door s yst ems technician if garage door bin ds, s ticks, or is out of b alance. An

unbalanced garage door m igh t NOT revers e when required.

Installation p rocedures vary according to g arage door typ es. Follow th e instructions which apply to your d oor.

1. Close the door and mark the inside vertical centerline of the garage door.

2. Extend the line onto the header wall above th e door. You can fasten the header bracket within 4 feet

(1.22 m) of the left or right of the door center only if a torsion spring or cent er bearing plate is in the

way; or you can attach it to t he ceiling (see p age 16) when clearance is minimal. (It may be mounted on

the wall upsid e down if necessary, t o g ain approximately 1 /2" (1 cm). If you need to install the header

bracket on a2x4 (on wall or ceiling), use lag screws (not p rovided) to securely fasten the 2x4 to

structural supp orts as shown here and on page 16.

3. Open your door to the highest point of travel as shown. Draw an intersecting horizontal line on the

header wall 2" (5 cm) above th e high point:

l 2" (5 cm) above the high point for s ectional door and one-piece door with track.

l 8" (20 cm) above th e high point for one-piece door without track.

This height will provide travel clearance f or t he top edge of the door. NOT E: Ifthe total n umber of inches

exceeds the height available in your garage, use the maximum height possible, or refer to page 16 for ceiling

installation.

15

Page 16

Installation

Lag Screw 5/16"-9x1-5/8"

HARDWARE

UP

Wall Mounting

Holes

WALL INSTALLATION

CEILING INSTALLATION

Optional Mounting

Holes

Vertical

Centerline of

Garage Door

Header Wall

Header

Bracket

2x4

Structural

Support

Door

Spring

Garage Door

Highest Point

of Garage

Door Travel

Horizontal

Line

Lag

Screw

UP

Header Wall

Ceiling Mounting

Holes

Finished Ceiling

Vertical

Centerline of

Garage Door

Header

Bracket

6" (15 cm)

Maximum

Door Spring

Garage Door

Lag Screw

STEP 2 Install the Header Bracket

Youcan attach th e header bracket either to th e wall above the garage door, or to the ceiling . Followthe

inst ructions which will work bes t for your particular requirements . Do not install the header bracket over

drywall. If installing into masonry, use concrete anchors (not provided).

OPTION A - WALL INSTALLATION

1. Center the bracket on the vertical centerline with the bottom edge of the bracket on the horizontal line

as shown (with the arrowpointin g toward t he ceiling).

2. Mark t he vertical set of bracket holes. Drill 3/16" pilot holes and fasten th e bracket securely to a

structural supp ort with the hardware provided.

OPTION B - CEILING INSTALLATION

1. Extend the vertical centerline onto the ceiling as s hown.

2. Center the bracket on the vertical mark, no more than 6" (15 cm) from the wall. Make sure the arrowis

pointin g away from the wall.The bracket can be mounted flush agains t the ceiling when clearance is

minim al.

3. Mark t he side holes. Drill 3/16" pilot holes and fasten bracket securely to a st ructural s upport with the

hardware provided.

16

Page 17

Installation

HARDWARE

Clevis Pin

5/16"x1-1/2"

Ring Fastener

Clevis Pin

Ring Fastener

Connected Disconnected

One-piece door

without tracks

2x4 2x4

All other

door types

STEP 3 Attach the Rail to the Header Bracket

1. P osition the opener on the garage floor below the header bracket. Use packing material as aprotective

base.

NOTE: If t he door spring is in the way, youwill need help. Have someone hold the opener securely on a

temp orary support to allow th e rail to clear the sprin g.

2. P osition the rail b racket against the h eader bracket.

3. Alig n the bracket holes and join with a clevis pin as shown.

4. Insert a ring fastener to secure.

STEP 4 Position the Garage Door Opener

To prevent damage t o garage door, rest garage d oor opener rail on 2x4 placed on top section of door.

1. Rem ove t he packing material and lift the garage door opener onto a ladder.

2. Fully open th e door and place a 2x4 (laid f lat) und er the rail. For one-piece doors without tracks, lay the

2x4 on it's side.

NOTE: A 2x4 is id eal for setting the distance between the rail and the door. If th e ladder is not tall enough you

will need help at this point. If the door hits the trolley when it is raised, pull the t rolley release arm down to

disconn ect the inner and outer trolley. Slide the outer trolley t oward the garage door opener. The trolley can

remain disconn ected until instructed.

17

Page 18

Installation

Finished Ceiling

Lag Screw

1

2

3

Not

Provided

Not Provided

Not Provided

Hex Bolt

Nut

Lock

Washer

4 5

6

Lag Screw

Finished Ceiling

Structural Supports

Hidden

Supports

EXAMPLES

Unfinished Ceiling

HARDWARE

Hex Bolt

5/16"- 18x7/8"

Nut

5/16"-18

Lock Washer

5/16"-18

Lag Screw

5/16"-9x1-5/8"

STEP 5 Hang the Garage Door Opener

To avoid possible SERIOUS INJURYfrom a f alling garage door open er, fasten it SECURELY t o s tructural

supports of t he garage. Concrete anchors MUST be used if installing ANY brackets into masonry.

Hang ing th e garage d oor opener will vary depending on your garage. Beloware three example installations.

Your installation may be differen t. For ALL installations the g arage door opener MUST be conn ected to

structural supp orts. The instructions illust rate one of the examples below.

1. On finis hed ceilings , use th e lag s crews to attach a supp ort bracket (not p rovided) to the structural

supports before installing the garage door opener.

2. Make sure the garage door opener is aligned with the header bracket. Measure t he distance from each

side of the garage door opener to the support bracket.

3. Cut both pieces of the hangin g bracket to req uired length s.

4. At tach the end of each h angin g bracket to t he support bracket with appropriate h ardware (not

provided ).

5. At tach the garage door open er to th e hanging brackets with the hex bolts, lock washers, and nuts.

6. Rem ove t he 2x4 and manually close th e door. If the door hits the rail, raise the header bracket.

18

Page 19

Installation

or

or

or

STEP 6 Install the Light Bulbs

To prevent possible OVERHEATING of the en d panel or ligh t socket:

l Use ONLYA1 9 light bulbs .

l DO NOT use incand escent bulbs larger than 100W.

l DO NOT use compact fluorescent light bulbs larger than 26W (100W equivalent).

l DO NOT use halogen bulbs.

l DO NOT use short neck or specialty light bulbs.

LEDbulbs may cause rem ote control radio interference. Use ONLY LED bulbs recomm ended here:

chamb erlain.com/b ulb.

1. P ull light lens down.

2. Insert light bulb.

3. Close light lens .

STEP 7 Attach the Emergency Release Rope and Handle

To prevent possible SERIOUS INJURY or DEATH from a falling garage door:

l If possible, use emergen cy release handle to d isengage trolley ONLY when garage door is CLOSED.

Weak or broken springs or unbalanced door could result in an open door falling rapidly and/or

unexpected ly.

l NEVER use emergency release handle unless garage d oorway is clear of p ersons and obstructions.

l NEVER use handle to p ull d oor open or closed. If rope knot becomes untied, youcould fall.

1. Insert one end of the emergency release rope t hrough the h andle. Make sure th at “NOTICE” is right

side up. Secure with an overhand knot at least 1" (2.5 cm) from the end of the rope t o prevent slip ping.

2. Insert the oth er end of the emergency release rope through the hole in the trolley release arm. Mount

the emergency release within reach, but at least 6 feet (1.83m ) above floor, avoiding contact with

vehicles to prevent accidental release and secure with an overhand knot.

NOTE: If it is necessary to cut the emergency release rope, s eal the cut end with a match or lighter to prevent

unraveling. Ensure the emergency release rope and handle are above the top of all vehicles to avoid

entanglement.

19

Page 20

Installation

FIGURE 1

FIGURE 3 FIGURE 4

FIGURE 2

Vertical

Reinforcement

Vertical

Centerline

of Garage Door

UP

Door Bracket

Vertical Reinforcement

Vertical Reinforcement

Horizontal Reinforcement

Vertical Centerline

of Garage Door

Hardware

(not provided)

Door Bracket

UP

Vertical

Centerline

of Garage Door

UP

Vertical Centerline of

Garage Door

Hardware

(not provided)

UP

Inside Edge of Door or

Reinforcement Board

Self-Threading Screw

Self-Threading

Screw

HARDWARE

Self-Threading Screw

1/4"-14x5/8"

STEP 8 Install the Door Bracket

Fiberglass, alumin um or lightweight st eel g arage doors WILL REQUIRE reinforcement BEFORE installation

of door bracket. Contact the garage door manufacturer or installing dealer f or opener reinforcement

inst ructions or reinforcemen t kit. Failure t o rein force the top section as req uired accordin g to t he door

manufacturer m ay void the door warranty.

A horizontal and vertical reinforcement is needed for lightweight garage doors (fiberglass , aluminum, s teel,

doors with glass panel, etc.) (not provided). A horizontal rein forcemen t brace should be long enough to be

secured to two or t hree vertical supports. A vertical reinforcement brace s hould cover th e height of the top

panel. Contact the garage door manufacturer or installing dealer for opener reinforcement ins tructions or

reinforcement kit.

NOTE: Many door reinforcement kits provide for direct attachmen t ofthe clevis pin and door arm. In this case

you will not n eed the door bracket; p roceed to th e next step.

OPTION A - SECTIONAL DOORS

1. Center the door bracket on the previously marked vertical centerline used for t he header bracket

inst allation. Note correct UP placement, as stamp ed insid e bracket.

2. P osition the top edge of the bracket 2"-4" (5-10cm) belowthe top edge of t he door, OR directly below

any structural support across the top of the d oor.

3. Mark, d rill holes and install as follows, d epend ing on your door’s const ruction.

Metal or light weight doors using a vertical angle iron bracein the door panel support and the do or

bracket:

l Drill 3/16" fastening holes. Secure t he door bracket usin g the two 1/ 4"-14x5 /8" self-th reading screws.

(Figure1)

l Alternately, use two 5/1 6"-18x2" bolts, lock washers and nuts (not provided). (Figure2)

Metal,insulated or light weight factory reinforced doors:

l Drill 3/16" fastening holes. Secure t he door bracket usin g the self-threading screws. (Figure3)

Wood do ors:

l Use top and bottom or s ide to s ide door bracket holes. Drill 5/16" holes through the door and secure

bracket with 5/16"-18x2" carriage bolts, lock washers and nuts (not provided). (Figure4)

NOTE: The 1/4"-14x5/8" self-threading s crews are not intended for use on wood d oors.

20

Page 21

Installation

For a door with no exposed

framing, or for the optional

installation, use lag screws

5/16"x1-1/2" (not provided)

to fasten the door bracket.

Vertical

Centerline

of Garage

Door

Optional

Placement

of Door

Bracket

Door Bracket

Header Bracket

Header Wall

2x4 Support

(Finished Ceiling)

Door

Bracket

Top of Door

(Inside Garage)

Top Edge of

Door

Optional

Placement

Optional

Placement

Top Edge

of Door

Top of Door

(Inside Garage)

Door

Bracket

Hardware

(not provided)

Hardware

(not provided)

Metal Door Wood Door

Self-Threading Screw

STEP 8 Install the Door Bracket (continued)

OPTION B - ONE-PIECE DOORS

1. Center the door bracket on the top of t he door, in line with the header bracket as s hown.

2. Mark either the left and right, or the top and bottom holes.

Metal Doors:

l Drill 3/16" pilot holes and f asten th e bracket with the s elf-t hreadin g screws provided.

Wood Do ors:

l Drill 5/16" holes and use 5/16"-1 8x2" carriage bolts, lock washers and nuts (not provided) or 5/16"x1-

1/2" lag screws (not provided) depend ing on your installation n eeds.

NOTE: The door b racket may b e installed on t he top edge of the door if required for your installation. (Refer to

the dotted line optional placement drawing.)

21

Page 22

Installation

HARDWARE

Hex Bolt 5/16"-18x7/8"

Nut 5/16"-18

Lock Washer

5/16"-18

Clevis Pin 5/16"x1" Clevis Pin 5/16"x1-1/4"

Ring Fastener

Lock Washer

Nut

Hex Bolt

Clevis Pin

5/16"x1-1/4"

Cut If Needed

Ring Fastener

Clevis Pin

5/16"x1"

Straight

Door Arm

(Groove

facing out)

Curved

Door Arm

STEP 9 Connect the Door Arm to the Trolley

Installation will vary according to t he garage door type. Follow the in structions which apply to your door.

OPTION A - SECTIONAL DOORS

IMPORTANT: The groove on the straight door arm MUST f ace away from the curved door arm.

1. Close the door. Disconn ect the trolley b y pulling the emergency release handle.

2. At tach the straight door arm to the outer trolley usin g the clevis pin. Secure with th e ring fastener.

3. At tach the curved door arm to the door bracket using the clevis pin. Secure with the ring fast ener.

4. Bring arm sections together. Find two pairs of holes that line up and join sections . Select h oles as f ar

apart as possible to increase door arm rigidity and attach using the bolts, nuts, and lock washers.

5. P ull the emergency release handle toward the garage d oor opener until t he trolley release arm is

horizontal. The t rolley will re-engage automatically when th e garage door opener is activated.

NOTE: If t he holes in the curved d oor arm and th e straight door arm do not align, reverse the straight door

arm, select twoholes (as far apart as poss ible) and attach usin g bolts, nuts, and lock washers . Ifthe straight

door arm is hanging down too far, you m ay cut 6" (15 cm) from the solid end.

22

Page 23

Installation

HARDWARE

Hex Bolt 5/16"-18x7/8"

Nut 5/16"-18

Lock Washer

5/16" -18

Clevis Pin 5/16"x1" Clevis Pin 5/16"x1-1/4"

Ring Fastener

One-Piece Door without Track

One-Piece Door with Track

Ring Fastener

Ring Fastener

Ring Fastener

Nut

Nut

Ring Fastener

Lock Washer

Lock Washer

Clevis Pin 5/16"x1-1/4"

Clevis Pin

5/16"x1-1/4"

Hex Bolts

Hex Bolts

Clevis Pin

5/16"x1"

Clevis Pin

5/16"x1"

Straight Door Arm

(Groove facing out)

Curved Door Arm

STEP 9 Connect the Door Arm to the Trolley (continued)

OPTION B - ONE-PIECE DOORS

IMPORTANT: The groove on the straight door arm MUST f ace away from the curved door arm.

1. Close the door. Disconn ect the trolley b y pulling the emergency release handle.

2. Fast en the straight door arm and the curved door arm together to the long est poss ible length (with a 2

or 3 hole overlap) using the bolts, nuts, and lock washers .

3. At tach the straight door arm to the d oor bracket usin g the clevis pin. Secure with th e ring fasten er.

4. At tach the curved door arm to the trolley using the clevis pin. Secure with the ring fastener.

5. P ull the emergency release handle toward the garage d oor opener until t he trolley release arm is

horizontal.

23

Page 24

Installation

Screw 6ABx1-1/2" (2)

HARDWARE

Drywall Anchors (2)

1/4" (6 mm)

1

2 3

STEP 10 Install the Door Control

PUSH BUTTON DOOR CONTROL

To prevent possible SERIOUS INJURY or DEATH from electrocution:

l Be sure power is NOT connected BEFORE in stalling door control.

l Connect door cont rol O NLYto 12 VOLT low voltage wires.

To prevent possible SERIOUS INJURY or DEATH from a closing garage door:

l Install door control within sight of garage door, out of reach of s mall children at a minimum height of

5f eet (1.5m) above f loors, landing s, step s or any other adjacent walking surface, and away from ALL

moving parts of door.

l NEVER permit child ren to operate or play with door control push buttons or remote control

trans mitters.

l Activate door ONLYwhen it can be s een clearly, is properly adjust ed, and there are n o obs tructions to

door t ravel.

l ALWAYS keep garage d oor in sig ht until completely closed. NEVER p ermit anyone to cross path of

closing garage door.

INT RODUC TION

Install the door control within sight of the door at a minimum heigh t of 5 feet (1.5 m) above floors, land ings,

step s or any other adjacent walking surface, where small children cannot reach, and away f rom the moving

parts of the door.

NOTE: Your product may look different th an the illustrations.

1. S trip 1/4" (6 mm) of in sulation from one end of t he wire and sep arate the wires.

2. Conn ect one wire to each of the twos crews on the back of the d oor control. The wires can be conn ected

to either screw.

3. Mount the door control with th e hardware p rovided.

24

Page 25

Installation

Screw

6ABx1" (2)

Drywall

Anchors (2)

Screw

6-32x1" (2)

HARDWARE

7/16" (11 mm)

Wall

1

2 3

4-5 6

8

7

DRYWALL

GANG BOX

6ABx1"

6-32x1"

Drywall Anchor

DRYWALL GANG BOX

6ABx1"

6-32x1"

Drywall Anchor

MOTION DETEC TING AND MULTI-F UNCTION CONTROL PANEL

To prevent possible SERIOUS INJURY or DEATH from electrocution:

l Be sure power is NOT connected BEFORE in stalling door control.

l Connect door cont rol O NLYto 12 VOLT low voltage wires.

To prevent possible SERIOUS INJURY or DEATH from a closing garage door:

l Install door control within sight of garage door, out of reach of s mall children at a minimum height of

5f eet (1.5m) above f loors, landing s, step s or any other adjacent walking surface, and away from ALL

moving parts of door.

l NEVER permit child ren to operate or play with door control push buttons or remote control

trans mitters.

l Activate door ONLYwhen it can be s een clearly, is properly adjust ed, and there are n o obs tructions to

door t ravel.

l ALWAYS keep garage d oor in sig ht until completely closed. NEVER p ermit anyone to cross path of

closing garage door.

INT RODUC TION

Older Chamb erlain door controls and third party products are not compatible. Install door control within

sigh t of garage door, out of reach of small children at a minimum height of 5 f eet (1.5 m) above f loors,

landings, s teps or any other adjacent walking surface, and away from ALL moving parts of door. For gang box

inst allations it is n ot necessary to drill h oles or ins tall the drywall anch ors. Use the existing holes in t he gang

box.

NOTE: Your product may look different th an the illustrations.

1. S trip 7/16" (11 mm ) of insulation from one end of the wire and separate the wires.

2. Conn ect one wire to each of the twos crews on the back of the d oor control. The wires can be conn ected

to either screw. If your garage is pre-wired for the door control choose any two wires to connect, note

which wires are used so the correct wires are conn ected to the garage door opener in a later step.

3. Mark t he location of the bottom mounting hole and drill a 5/32 " hole.

4. Install the bottom screw, allowing 1/8" (3 mm) to protrude from the wall.

5. P osition the bottom hole of the door cont rol over the screw and slide down into place.

6. Lift the push bar up and mark the top h ole.

7. Rem ove t he door control f rom the wall and drill a 5/3 2" hole for the top screw.

8. P osition the bottom hole of the door cont rol over the screw and slide down into place. Attach the t op

screw.

25

Page 26

Installation

7/16" (11 mm)

2

3

1

HARDWARE

Insulated Staple (Not Shown)

Staple

RED

WHITE

STEP 11 Wire the Door Control to the Garage Door Opener

1. Run the whit e and red/white wire from the door control to the g arage door opener. At tach the wire to

the wall and ceiling with the staple (not applicable for gang box or pre-wired installations). Do not

pierce the wire with the staple as th is may cause a s hort or an open circuit.

2. S trip 7/16" (11 mm ) of insulation from the end of t he wire near the garage door open er.

3. Conn ect the wire to the red and white t ermin als on the garage door opener. If your garage is pre-wired

make sure you use the s ame wires that are conn ected to the door control. Toinsert or release wires from

the terminal, push in the tab with screwdriver tip.

STEP 12 Attach the Warning Labels

1. At tach the entrapment warning label on the wall near the door control with tacks or staples.

2. At tach the manual release/safety reverse test label in a visible location on the inside of the g arage

door.

26

Page 27

Installation

Safety Reversing SensorLight Beam Protection Area Safety Reversing Sensor

Wing Nut (2)

HARDWARE

Hex Screw 10-24 (2)

6" (15 cm) max.

Door track

1

2

3

Garage door

Wing nut

STEP 13 Install the Protector System

®

Be sure power is NOT connected to the garage door opener BEFORE installing the safety reversing sensor.

To prevent SERIOUS INJURY or DEATH from closing garage door:

l Correctly conn ect and align the safety reversing sensor. This required s afety device MUST NOT be

disabled.

l Install the safety reversing sens or so beam is NO HIGHER than 6" (15 cm) above garage f loor.

IMPORTANT : The safety reversing sensors MUST be connected and aligned correctly beforethe garage

door opener will move in the down direction.

The Protector S yst em® includes two saf ety reversing sensors which use a light beam to prevent the garage

door f rom closing. The sending sensor (amb er LED) t ransmits the beam to th e receiving sensor (green LED)

when both are p owered and align ed. If an obstruction breaks the light beam while the door is closing, t he

door will stop, and reverse to the full open position, and the garage door opener light s will flash 10 times.

When installing the safety reversing sensors, check:

l Sens ors are installed INSIDEt he garage.

l Sens or lenses are facing each oth er. IMPORTANT: Do not allowd irect sunlight to the receiving sen sor

(green LED).

l Sens or beam is NO HIGHER than 6" (15 cm) above the floor and the light beam is unobstructed.

The safety reversing sensors are des igned to clip onto the door track with the p rovided sensor brackets. If

the door t rack will not s upport the sensor bracket a wall ins tallation is recomm ended. The s ensor beam should

be NO HIGHER than 6" (15 cm) above th e floor.

DOOR TRACK INSTALLATION

1. S lide the curved arms of the sensor bracket around the ed ge of t he door track. Snap into place s o t hat

the sens or bracket is f lush against the track.

2. S lide the hex screw through the sensor.

3. At tach the sensor to th e bracket with the wing nut. Make sure the lens is not obstructed by the

bracket.

Repeat the steps with the other sensor on t he opposite door track. Both lenses must face each other.

27

Page 28

Installation

OR

1

Wing Nut

OPTIONAL

2 3

Door track

Inside

garage wall

6" (15 cm)

max.

Not provided

1

3

4

2

Inside

garage wall

Not

provided

Door track

6" (15 cm) max.

Wingnut

STEP 13 Install the Protector System (continued)

WALL OPTION

Make s ure the brackets on each side are clear of the door track an d have the same amount of clearance s o t he

sens ors will align correctly. If additional clearance is needed, use ext ension b rackets 041 A528 1-1 (not

provided ) or wood blocks.

1. At tach the sensor bracket against the wall with two lag screws (not provided).

2. S lide the hex screw through the sensor.

3. At tach the sensor to th e bracket with the wing nut. Make sure the lens is not obstructed by the

bracket.

Repeat the steps with the other sensor on t he opposite side of the garage door. Both lenses must face each

other.

FLOOR OPTION

1. Measure t he position of both sensor brackets so they will be the same dist ance from the wall and

unobstructed.

2. At tach the bracket to the floor with concrete anch ors (not provided).

3. S lide the hex screw through the sensor.

4. At tach the sensor to th e bracket with the wing nut. Make sure the lens is not obstructed by the

bracket.

Repeat the steps with the other sensor on t he opposite side of the garage door. Both lenses must face each

other.

28

Page 29

Installation

Staple

1

2

3

HARDWARE

Insulated Staple (Not Shown)

7/16" (11 mm)

STEP 14 Wire the Safety Reversing Sensors

If your garage has pre-ins talled wiring for t he safety reversing sensors, see OPTION B - PRE-WIRED

INSTALLATION p age 30.

OPTION A - INSTALLATION WITH NO PRE-WIRING

1. Run the wire from both sens ors to t he garage door opener. At tach with staples, but DO NOT puncture

the wire.

2. S eparate the sens or wires and strip insulation from each end. Twist the two white wires together. Then

twist the two white/black wires togeth er.

3. Using a s crewdriver, push in the terminal tabs, and insert th e white wires into the white terminal.

Insert th e white/black wires into the grey terminal.

29

Page 30

Installation

Safety reversing sensor wires

White

White/Black

Yellow (for example)

Purple (for example)

Wire nuts (not provided)

Pre-installed wires

Safety reversing

sensor wires

1

3

4

7/16" (11 mm)

2

5

Purple

Yellow

Pre-installed

wires

Pre-installed wires

7/16" (11 mm)

Yellow

Purple

STEP 14 Wire the Safety Reversing Sensors (continued)

OPTION B - PRE-WIRED INSTALLAT ION

1. Cut the sens or wires, making sure there is enough wire to reach the p re-ins talled wires from the wall.

2. S eparate the sens or wires and strip insulation from each end. Choose two of the pre-installed wires

and strip insulation from each en d. Choose the same color pre-ins talled wires f or each sensor.

3. Conn ect the pre-ins talled wires to the sensor wires with wire n uts making sure the colors correspond

for each s ensor.

4. At th e garage door opener, strip the en d of the wires previously connected to the sensors. Twist the

like-colored wires together.

5. Using a s crewdriver, push in the terminal tabs, and insert th e wire color conn ected to the sensor's

white wire into the white t erminal. Ins ert the other wire color conn ected to the sensor's white/black wire

into the grey terminal.

30

Page 31

Installation

Ground Tab

Green Ground Screw

Ground Wire

White Wire

Black Wire

STEP 15 Connect Power

To prevent possible SERIOUS INJURY or DEATH from electrocution or f ire:

l Be sure power is NOT connected to the open er, and disconnect power to circuit BEFORE removing

cover t o establish permanent wiring connection.

l Garage d oor ins tallation and wiring MUST b e in comp liance with ALLlocal electrical and building

codes.

l NEVER use an extension cord, 2-wire adapt er, or change p lug in ANYway to make it fit outlet. Be sure

the opener is grounded.

To avoid installation difficulties, do not ru n the opener at this time.

To reduce the risk of electric shock, your garage door opener has a ground ing typ e plug with a third

grounding pin. This plug will only f it into a groundin g type outlet. If the plug d oesn’t fit into the outlet you

have, contact a qualified electrician to in stall the proper outlet.

THERE ARE TWO OPTIONS FOR CONNECTING POWER:

OPTION A - TYPIC AL WIR ING

1. P lug in t he garage door opener into a grounded outlet.

2. DO NOT run garage door open er at this time.

OPTION B - PERMANENT WIRING

If permanent wiring is required by your local code, refer to the fo llowing procedure. T o make a permanent

connection throug h the 7/8-inch hole in the top of the motor u nit (according to local code):

1. Rem ove t he motor unit cover screws and set the cover aside.

2. Rem ove t he attached 3-p rong cord.

3. Conn ect the black (line) wire to th e screw on the brass terminal; the white (neutral) wire to the screw on

the silver terminal; and the ground wire to the green ground screw. T he opener must be ground ed.

4. Rein stall the cover.

31

Page 32

Installation

Light Beam Protection Area

Receiving sensor - green LEDSending sensor - amber LED

Wing nut

RED

WHITE

GREY

3

2

1

STEP 16 Align the Safety Reversing Sensors

IMPORTANT : The safety reversing sensors MUST be connected and aligned correctly beforethe garage

door opener will move in the down direction.

When the g arage door opener has power, ch eck the safety reversing sensors. If the sensors are aligned and

wired correctly, both LEDs will glowsteadily.

To align the safety reversing sensors:

1. Loosen the wing nuts.

2. Ad just the sens ors up or down until both LEDs glow steady indicating alignmen t.

3. Tigh ten the wing nut to secure the sensor.

SAFETY SENSOR TR OUBLESHOOTIN G

If either of the sensor LEDs are off, th ere is no power to the sensor:

1. Check t hat you have power to th e garage door opener.

2. Check t he sens or wire is not s horted or broken.

3. Check t hat the s ensors are wired correctly; white wires to white terminal and white/black wires to grey

terminal.

If the green receiving senso r LED is blinking, the sensors are ob structed or misaligned:

1. Check f or obs tructions in the s ensor light beam.

2. Alig n the sens ors.

3. If th e receiving sensor (green LED) f aces direct sunligh t, switch the receiving sensor with th e sending

sens or and repeat STEP 12 Install the Protector System ® page 27 to ass ure p roper operation.

STEP 17 Ensure the Door Control is Wired Correctly

If the door control has been installed and wired correctly, t he command LED on the control p anel willblink or

the LEDbehin d the push butt on will blink if in stalled correctly.

32

Page 33

Adjustments

UP (Open)

DOWN (Close)

Correct

Incorrect

UP Button

Adjustment Button

DOWN Button

PROGRAMMING BUTTONS

Introduction

Without a properly installed safety reversal system , persons (particularly small children) could be

SERIOUSLY INJURED or KILLED by a closing garage door.

l Incorrect adjustmen t of g arage door travel lim its will interfere with proper operation of safety reversal

system.

l After ANYadjustments are made, the safety reversal s ystem MUST b e tested. Door MUST reverse on

contact with 1-1/2" (3.8 cm) h igh object (or 2x4 laid flat) on floor.

To prevent damage t o veh icles, be sure fully open door provides adequate clearance.

Your garage door opener is designed with electronic cont rols to make setup and adjustmen ts easy. The

adjustments allow you to program where t he door will stop in t he open (UP) and close (DOWN)position. The

electronic controls sense the amount of f orce required to open and close the door. The force is adjust ed

automatically when you program the travel.

ONE-PIECE DOORS ONLY

When sett ing th e UP travel for a one-piece door ensure that the door does n ot slant backwards when fully

open (UP). If the door is slanted backwards this willcause unn ecessary bucking and/or jerking when the door

is opening or closing.

PROGRAMMING BUTTONS

The programming buttons are located on the left side panel of the garage door open er and are used to

program th e travel. Wh ile p rogramming , the UP and DOWN buttons can be used to move t he door as needed.

33

Page 34

Adjustments

UP Button

Adjustment Button

DOWN Button

PROGRAMMING BUTTONS

1 2

3

4 5

6 7

STEP 1 Program the Travel

Without a properly installed safety reversal system , persons (particularly small children) could be

SERIOUSLY INJURED or KILLED by a closing garage door.

l Incorrect adjustmen t of g arage door travel lim its will interfere with proper operation of safety reversal

system.

l After ANYadjustments are made, the safety reversal s ystem MUST b e tested. Door MUST reverse on

contact with 1-1/2" (3.8 cm) h igh object (or 2x4 laid flat) on floor.

While programm ing, t he UP and DOWN buttons can be used to move t he door as needed.

1. P ress and hold t he Adjustm ent Button until the UP Button b egins to f lash and/ or a beep is heard.

2. P ress and hold t he UP Button until t he door is in the desired UP p osition.

3. Once the door is in the desired UP p osition press and release the Adjustment Button. The garage d oor

opener lights willflash twice and the DOWN Button will begin to flash. IMPORTANT NOTE: For one-

piece door installations refer to page 33.

4. P ress and hold t he DOWN butt on unt il the door is in the desired DOWN position.

5. Once the door is in the desired DOWN position press and release the Adjustment Button. The g arage

door open er lights will f lash twice and the UP Button will begin to f lash.

6. P ress and release the UP Button. When the door travels to the programm ed UP position, the DOWN

Button will begin to f lash.

7. P ress and release the DOWN Button. The door will travel to the programm ed DOWN posit ion.

Programming is comp lete.

* If the garage door opener light s are f lashing 5 times during the steps f or P rogram the Travel, the

programming has timed out. If the g arage door opener lig hts are flashing 10 times during the steps for

Program th e Travel, the safety reversing sens ors are m isalign ed or obstructed (refer to page 3 2). When the

sens ors are align ed and unobstructed, cycle th e door through a comp lete up and down cycle using the

remote control or the UP and DOWN buttons. P rogramm ing is complete. If youare unable t o operate the door

up and down, repeat the steps for Programming the Travel.

34

Page 35

Adjustments

1 2

1

2

Receiving sensor - green LED

STEP 2 Test the Safety Reversal System

Without a properly installed safety reversal system , persons (particularly small children) could be

SERIOUSLY INJURED or KILLED by a closing garage door.

l Safety reversal s yst em MUST be tested every month .

l After ANYadjustments are made, the safety reversal s ystem MUST b e tested. Door MUST reverse on

contact with 1-1/2" (3.8 cm) h igh object (or 2x4 laid flat) on the f loor.

1. With the door fully open, p lace a 1-1/ 2 inch (3.8 cm) board (or a 2x4 laid flat) on t he floor, cent ered

under the garage door.

2. P ress th e remote cont rol or wall-mount ed door control to close the door. The door should stop and

reverse when it makes contact with the board. The door returns to the previous open position. Opener

beeps and ligh ts flash 5 times.

3. If th e door reverses, remove the board. The tes t is complete.

If the door st ops but does not reverse:

1. Review the installation instructions provided to ensure allstep s were followed;

2. Ref er to Adjustmen t Step 1 and and set the d own limit closer to the garage floor. NOTE: On a sectional

door, m ake sure adjustment s do not force the door arm beyond a straight up and down position.

3. Rep eat the Safety Reversal test.

If the test continues to fail, call a trained door system s technician.

STEP 3 Test the Protector System®

Without a properly installed safety reversing sensor, persons (particularly s mall children) could be

SERIOUSLY INJURED or KILLED by a closing garage door.

1. Open the d oor. Place the garage door opener carton in th e path of t he door.

2. P ress th e remote cont rol p ush button t o close the door. The door will not move more th an 1"(2.5cm ),

the garage door opener lights will f lash 10 times, the green LEDon t he receiving sensor will blink.

The garage door opener will not close from a remote control if th e sensor light beam is misaligned or

obstructed. If the garage door opener closes the door when th e safety reversing sens or is obstructed (and the

sens ors are n o m ore than 6" [15cm] above the floor), call for a trained door systems techn ician.

35

Page 36

Battery Backup

Battery Status LED

Install the Battery

MODEL B2212T

To reduce the risk of FIRE or INJURY to persons:

l Disconnect ALL electric and battery power BEFORE performin g ANY service or mainten ance.

l Use ONLYChamberlain part # G4228 for rep lacement batt ery.

l DO NOT dispose of battery in fire. Battery may explode. Check with local codes for disposal

inst ructions.

ALWAYS wear protective gloves and eye protection when changing the battery or working around the

battery comp artment.

The 12V battery backup allows access in and out of your garage, even when the power is out. The battery does

not have to be fully charged to operate the garage door opener. When the garage door opener is operating on

battery power, it m ay run s lower and the following features are d isabled:

l Garage d oor opener lights

l myQ® Ap p control and monitoring

l Unattended close including Timer-to-Close

1. Unplug the garage door opener.

2. Open the lig ht lens on the right side panel of the g arage door opener. Use a Ph illips head screwdriver

to remove th e battery cover on the g arage door opener.

3. P artially insert the b attery into th e battery compartm ent with the terminals facing out.

4. Conn ect red (+) and black (-) wires f rom the garage door opener to the corresp ondin g termin als on the

battery.

5. Rep lace t he battery cover.

6. P lug in t he garage door opener.

7. Wait for the green Battery Status LED t o s tart flash ing bef ore p roceeding to test the b attery.

Test the Battery

Dependin g on the power level, th e battery may need to charge before performing the test. The g arage door

opener must be unplugged to test the battery.

1. Open and close the door using th e remote control or door control. While the motor is on, the battery

status LED will either glowsolid orange indicating opener is operating on battery power or will flash

indicating low battery power. NOTE: The garage door opener may run slower ifthe battery is not fully

charged.

2. P lug in t he garage door opener. Verify the battery status LEDis flashing green, indicating the battery

is charging.

Charge the Battery

The battery charges when the g arage door opener is plugged int o a 120V ac electrical outlet that has power

and requires 24 hours to fully charge. A fully charged battery supplies 12Vd c to the garage door opener for

one to two days of n ormal operation d uring an electrical power outage. Af ter the electrical p ower has been

restored, t he battery will recharge within 24 hours. The b attery will last app roximately 1 to 2 years with

normal usage. Instructions for replacement are p rovided with the battery. To obt ain maximum battery life and

prevent damage, disconn ect the battery when the garage door opener is unp lugged for an extended period

of time, such as a summer or winter home.

Battery Status

Green batterystatus LED: Allsystems are no rmal.

l A solid g reen LEDlight ind icates the battery is fully charg ed.

l A flashing green LEDindicates the battery is being charg ed.

Orange battery status LED: The garage do or opener has lost power and is in battery backup mo de.

l Solid orange LED while the motor is on, indicates the garage door opener is operating on battery power.

l A flashing orange LED while the motor is on, indicates the battery is low.

l The opener beeps every 2 s econds while operating on battery power.

Red b attery status LED: The battery needs to be replaced.

l A solid red LED in dicates th e battery will no longer hold acharge. Go to chamberlain.com t o p urchase a

replacement battery to allow your s yst em to operate during a power outage.

36

Page 37

myQ®App Control

An LED on the garage door

opener will indicate Wi-Fi®

status. See table below.

LED

Connect With Your Smartphone

YOU WILL NEED:

l Wi-Fi en abled smartph one, tablet or laptop

l Broadband Internet connection

l Wi-Fi s ign al in th e garage (2.4 GHz, 802.11b/g /n required), see page 5

l Pass word f or your home n etwork (router's main account, not guest network)

l myQ® s erial number located on the garage door opener

DOWNLOAD THE myQ® APP TO SET UP AN ACCOUNT AN D CONN ECT

Open and close your door, get alerts and set schedules from anywhere. Connected smart garage door

openers also receive software updates to en sure the opener has the latest operational f eatures.

The garage door opener must run through a complete cycle before it will activate Wi-Fi® programming.

1. Download the myQ® App.

2. S et up an account and conn ect.

If youalready have the myQ® App installed:

1. Check t hat your mobile d evice has the latest software.

2. Download the latest version of the myQ® App.

For more information on connecting your garage d oor opener, visit support.chamb erlaingroup.com.

NOTES:

myQ® Ap p control WILL NOT work ifthe garage d oor opener is operatin g on battery power.

To erase the Wi-Fi settings from t he opener, see page 42.

Goog le Play and the Google Pla y lo go are trade marks of Google LLC.

App Store and the Apple and App Store logos are trade ma rks of Apple Inc.

Wi-Fi Status

LED Definition

Blue Off - Wi-Fi® is n ot turned on.

Blinking - Garage door opener is in Wi-Fi® learn mode.

Solid - Mobile device conn ected to the garage door opener.

Blue and Green Blinking - Attemptin g to connect to router.

Green Blinking - Att empting to connect to the Internet server.

Solid - Wi-Fi® has been set up and garage door opener is connected to the Internet .

37

Page 38

Operation

IMPORTANT SAFETY INSTRUCTIONS

To reduce the risk of SEVERE INJURY or DEATH:

1. READ AND FOLLOW ALL WARNINGS ANDINSTRUCTIONS.

2. ALWAYS keep remote cont rols out of reach of children. NEVER permit children to operate or p lay with

garage door control p ush buttons or remote controls.

3. ONLYactivate garage door when it can b e seen clearly, it is properly adjusted, and there are no

obstructions to door travel.

4. ALWAYS keep garage door in sight and away f rom people and objects until completely closed . NO ONE

SHO ULD CROSS THE PATH OF THE MOVING DOOR.

5. NO ONE SH OULD GO UNDER A STOP PED, P ARTIALLYOPENEDDOOR.

6. If poss ible, use emergency release hand le to disengage trolley ONLY when garage door is CLOSED. Use

caution when using this release with th e door open. Weak or broken spring s or unb alanced door could

result in an open door falling rapidly and/or unexpectedly and increasin g the risk of SEVEREINJURY or

DEATH.

7. NEVER use emergency release hand le unless garage doorway is clear of persons and obst ructions.

8. NEVER use h andle to pull garage door open or closed. If rope knot becomes untied, youcould fall.

Using your Garage Door Opener

The garage door opener can b e activated through a wall-mounted door control, remote control, wireless keyless

entry or myQ® App.

When the d oor is closed and the garage door opener is activated the door will open. If the d oor makes contact

with an obs truction while opening, the door will stop, open er beeps and lights flash 5 times. When the door is

in any position other than closed and the garage door opener is activated, the door will close. If the garage

door m akes contact with an obstruction while closing, the door will reverse, opener beeps and lights flash 5

times . If the obstruction interrupts the sensor beam the garage door opener lights will blink 10 times.

However, you can close the door if you hold the button on the d oor control or keyless entry until the door is fully

closed.

The safety reversing sensors do not aff ect the opening cycle. The s afety reversin g sens or must be connected

and aligned correctly before the garage door opener will move in th e down direction.

9. Af ter ANY adjustm ents are made, the safety reversal syst em MUST be tested.

10. Safety reversal system MUST b e tested every month. Garage door MUST reverse on contact with 11/2"(3.8cm ) high object (or a 2x4 laid f lat) on the floor. Failure to adjust the garage door opener

properly increases the risk of SEVERE INJURYor DEATH.

11. ALWAYS KEEP GARAGEDOOR PROPERLY BALANCED (see page 5). An improperly balanced door may

NOT revers e when required and could result in S EVERE INJURY or DEATH.

12. ALL repairs to cables, spring ass emblies and other hardware, ALL of which are under EXTREME

tens ion, MUST be m ade by a trained door system s techn ician.

13. ALWAYS disconnect electric and battery power to garage door opener BEFORE making ANY repairs or

removing covers.

14. This operator system is equipped with an unattended operation feature. The door could move

unexpected ly. NO ONE SH OULD CRO SS THE PATH OF THE MOVING DOOR.

15. DO NOT install on aone-piece door if using devices or features providing unatten ded close.

Unattended devices and features are to be used ONLY with sectional d oors.

16. SAVE THESE INSTRUCTIONS.

The garage door opener lights will t urn on when th e opener is in itially plugged in, the opener is activated,

power is restored after interruption, or when safety reversing sensor light beam is obstructed. The garage

door open er lights automatically turn off after a set leng th of time. Toadjust the light set ting s, see Using your

Door Cont rol.

For energy efficiency the garage d oor opener will enter sleep mode when the door is fully closed. The sleep

mode shuts th e garage door opener down until activated. While in s leep mode the opener lights and th e

safety sensor LEDs will turn off. The garage d oor opener will not g o into the sleep mode unt il it has completed

5 cycles upon power up.

38

Page 39

Operation

Command

LED

Push Bar

Motion Sensor

Switch

LIGHT Button

Motion Sensor

LEARN Button

LOCK Button

Using your Door Control

MOTION DETEC TING CONTROL PANEL

SYNCHRONI ZE THE DOOR CONT ROL: To s ynch ronize the door control t o the garage door opener, press the

push bar until the garage door opener activates (it may take up to 3 presses). Test th e door control b y

pressing the push bar; each p ress of the push bar will activate the garage door opener.

PUSH BAR: Press the p ush bar to open or close th e door.

LEARN BUTTON: Use to program compatible remote cont rols, wireless keyless ent ries and myQ®devices to

the garage door opener.

MOTION SENSOR: Turns the garage door opener lights on when motion is detected . Lights stay on for 4-1/2

minutes (factory s etting), then turn off. Set the motion sens or s witch ON or OFF t o cont rol t his feature.

LOCK: Prevents remote controls from working, while still allowing activation from the door cont rol and keyless

entry. (Factory setting is OFF.)

Turn O N: Press and hold the LOCK b utton for 2 s econds . The command LED will flash as long as the lock

feature is on.

Turn O FF: P ress and hold t he LOCK button for 2 second s. The command LED will stop flashin g and normal

operation will resume.

LIGHT BUT TON: Turns th e garage d oor opener lights on or off when pressed. Lights stay on for 4-1/2

minutes (factory s etting). The LIGHT button willnot control t he lights when the door is in motion.

To change the amount of time the light s stay on:

Press and hold the LOCK b utton (approximately 1 0 seconds ) until t he garage door opener lights flash. The

time interval is ind icated by the number of times th e garage door opener lights flash:

l 1 flash is 1-1/ 2 minutes

l 2 flashes is 2-1 /2 minutes

l 3 flashes is 3-1 /2 minutes

l 4 flashes is 4-1 /2 minutes

To cycle through the time intervals repeat the step above. If th e push bar LED is contin uously blinking, the

LOCK feature n eeds to be turned off.

To turn the lig ht feature ON (Factory default is On):

1. Close the garage door.

2. S tart with the garage door opener lights "ON".

3. P ress and hold t he LIGHT button (approximately 10 seconds) until the garage door opener light s turn

off, then on again.

To turn the lig ht feature OFF:

1. Close the garage door.

2. S tart with the garage door opener lights "OFF".

3. P ress and hold t he LIGHT button (approximately 10 seconds) until the garage door opener light s turn

off, then on again.

39

Page 40

Operation

Command LED

LIGHT Button

LEARN Button

LOCK Button

Push Bar

Push Button

LIGHT Button

MULTI-F UNC TION CONTROL PANEL

SYNCHRONI ZE THE DOOR CONT ROL: To s ynch ronize the door control

to the garage d oor opener, press the push bar until the garage door

opener activates (it may t ake up to 3 presses). Test the door control b y

pressing the push bar; each p ress of the push bar will activate the

garage door opener.

PUSH BAR: Press the p ush bar to open or close th e door.

LEARN BUTTON: Use to program compatible remote cont rols, wireless

keyless entries and myQ®devices to the garage door opener.

LOCK: Prevents remote controls from working, while still allowing

activation from the door control and keyless entry. (Factory setting is

OFF.)

Turn O N:

Press and hold the LOCK b utton for 2 s econds. The comm and LED will

flash as long as the lock feature is on.

Turn O FF:

Press and hold the LOCK b utton for 2 s econds. The comm and LED will

stop flashing and normal operation will resume.

LIGHT BUT TON: Turns th e garage d oor opener lights on or off when

pressed. Lights stay on for 4-1/2 min utes (factory setting). The LIGHT

button will not cont rol t he lights when the door is in motion.

To change the amount of time the light s stay on:

Press and hold the LOCK b utton (approximately 1 0 seconds ) until t he

garage door opener lights flash. The t ime interval is indicated by the

number of times th e garage door opener lights flash:

l 1 flash is 1-1/ 2 minutes

l 2 flashes is 2-1 /2 minutes

l 3 flashes is 3-1 /2 minutes

l 4 flashes is 4-1 /2 minutes

To cycle through the time intervals repeat the step above. If th e push

bar LEDis continuously blinking, the LOCK feature n eeds to be t urned

off.

To turn the Light feature on or off (Factory default is On):

Turn O FF:

1. Close the garage door.

2. S tart with the garage door opener lights "OFF".

3. P ress and hold t he LIGHT button (approximately 10 seconds)

until the garage door opener lights turn off, then on again.

Turn O N:

1. Close the garage door.

2. S tart with the garage door opener lights "ON".

3. P ress and hold t he LIGHT button (approximately 10 seconds)

until the garage door opener lights turn off, then on again.

PUSH BUTTON DOOR CONTROL

SYNCHRONI ZE THE DOOR CONT ROL: To s ynch ronize the door control

to the garage d oor opener, press the push butt on until t he garage door

opener activates (it may t ake up to 3 presses).

PUSH BUTTON: P ress th e button to open or close the door.

LIGHT /LEARN BU TTON: Press th e LIGHT button to turn th e garage

door open er lights on or off . When the lights are turned on they will

stay on unt il the LIGHT button is p ress ed again, or until the garage door

opener is activated. Once the garage door opener is activated the light s

will turn off after the s pecified period of time (the factory setting is 41/2 min utes). The LIGHT button will not control the lights when the d oor

is in motion.

40

Page 41

Operation

PIN

OR

OR

? ? ? ?

Push

Button

LIGHT

Button

“click”

“click”

PIN

OR

1-2

3

LEARN LED

LEARN

Button

Remote Control and Keyless Entry

PRE-PROGRAMMED REMOTE CONTROL INCLUDED, NO NEED TO PROGRAM THE

REMOTE.

To add or reprogram a rem ote control, follow t he instructions below. Older Chamberlain remote controls are

NOT compatible.

PROGRAM USING T HE MOTION DETECTING OR MULTI-FUNCTION CONTROL PANEL

1. P ress th e LEARN b utton on the door control t o enter programming mode. The comm and LED will f lash

once.

2. P ress th e LEARN b utton again, the command LED will f lash once again.

3. Remote control: Press th e button on the remote control that you wish to operate your garage door.

Keyless entry: Enter a 4-digit personal id entif ication number (PIN) of your choice on the keyless entry

keypad. Then press th e ENTER button.

PROGRAM USING T HE PUSH BUTTON DOOR CONTROL

1. P ress and hold t he light butt on and the push button until the push button LED begins to blink.

2. Remote control: Press th e button on the remote control that you wish to operate your garage door.

Keyless entry: Enter a 4-digit personal id entif ication number (PIN) of your choice on the keyless entry

keypad. Then press th e ENTER button.

PROGRAM USING T HE GARAGE DOOR OPENER LEARN BUTTON

1. Locate the LEARN Button.

2. P ress and immediately release the LEARN button. The LEARN LED will glows teady for 30 seconds.

Within 30 seconds...

3. Remote Con trol: Press and hold the b utton on the remote control that you wish to use.

Keyless Entry: Enter a 4-digit personal id entif ication number (PIN) of your choice on the keyless entry

keypad. Then press and hold t he ENTER b utton.

Release the button when the garage d oor opener lights blink or two clicks are heard.

HomeLink®

If your vehicle is equipped with HomeLink®, a Compatib ility Bridge™ (not included) may b e necessary for

certain vehicles. Visit bridge.chamberlain.com t o f ind out if a Bridge is needed.

The garage door opener lights will f lash (or t wo clicks will be heard) when the code has been programmed.

Repeat the steps for programming addit ional remote controls or keyless entry devices. If programming is