Page 1

VECTOR2 installation manual

LINEAR

SWING GATE

OPERATORS

Page 2

Company ProfileCompany Profile

CENTURION SYSTEMS (Pty) Ltd reserves the right to make changes to the products described in this manual without notice

and without obligation of CENTURION SYSTEMS (Pty) Ltd to notify any persons of any such revisions or changes.

Additionally, CENTURION SYSTEMS (Pty) Ltd makes no representations or warranties with respect to this manual.

No part of this document may be copied, stored in a retrieval system or transmitted in any form or by any means electronic,

mechanical, optical or photographic, without the express prior written consent of CENTURION SYSTEMS (Pty) Ltd

Sales and technical support

to over 50 countries

worldwide

100%

testing to

specifications

In-house

R & D

development

team

Manufacture to

international

quality standard

ISO 9001:2008

1986 1990 1995 1999

Competent

after-sales

technical support

Centurion Systems

today

Page 3

Contents

page 1

Page 2

page 2

page 3

Mechanical Setup

Electrical Setup

Commissioning and handover

IMPORTANT SAFETY INSTRUCTIONS

1. Declaration of conformity page 5

2. General description page 6

Lightning protection page 7

3. Icons used in this booklet page 7

4. Specifications page 8

Physical dimensions page 8

Technical specifications page 9

Control card page 10

Power supply page 10

Power supply, wall box and control card assembly page 10

Allowable gate mass page 10

5. Product identification page 12

6. Required tools & equipment page 14

7. Preparation of site page 15

General considerations for the installation page 15

Strength of the pillar page 16

Strength of the gate and gate bracket page 19

The Mechano Kit installation options page 20

8. Cabling requirements page 22

9. Operator installation page 23

Determine the gate bracket position page 24

Adjust origin clamp page 26

Inward swing gate Setup page 27

Outward swing gate Setup page 30

10. Determine gate swing angle page 33

11. Allowable wind loading page 34

12. Electrical Setup page 35

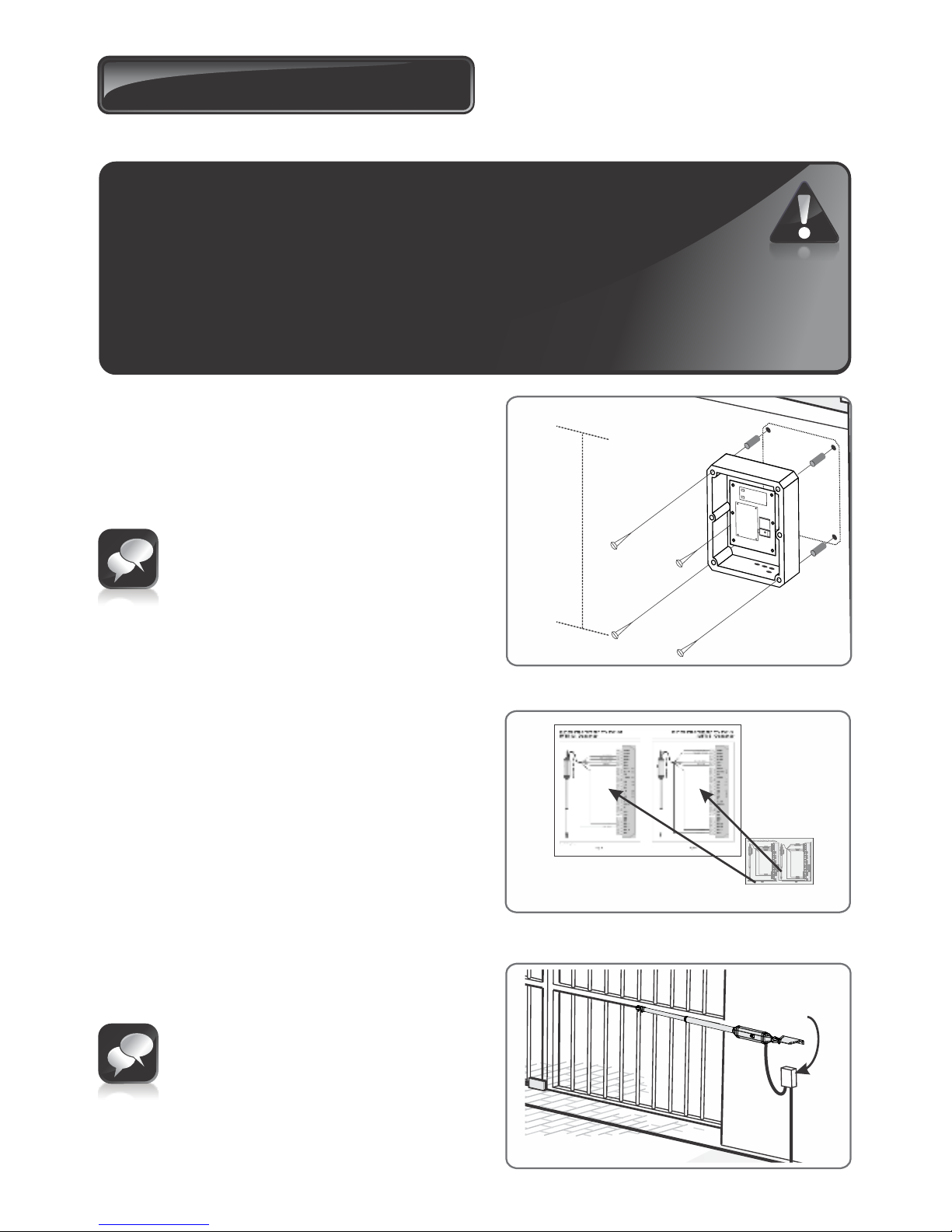

Secure control box to wall page 35

Connecting all wiring page 35

Setting the Limits page 36

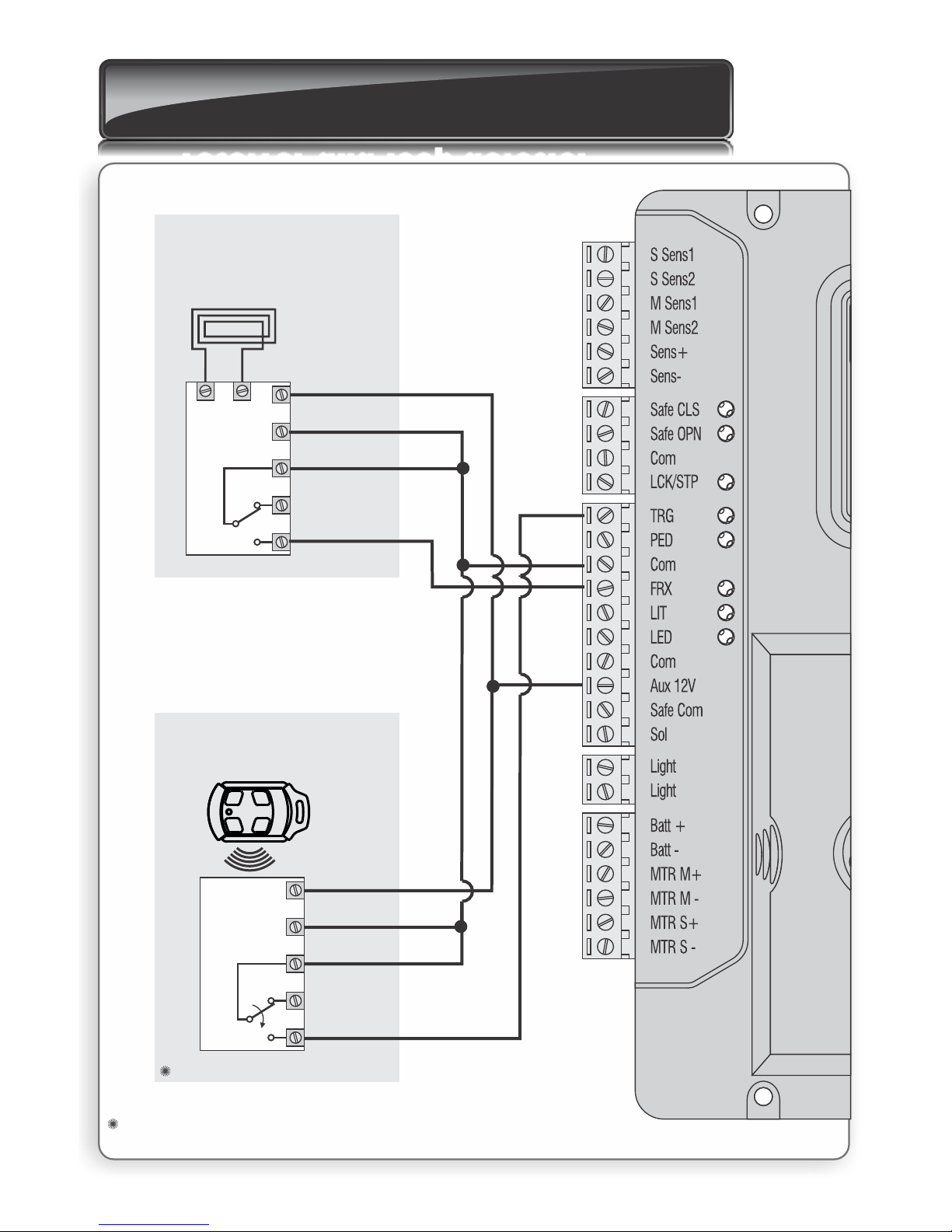

13. Wiring diagram for closing safety beam page 37

14. Wiring diagram for opening safety beam page 38

15. Wiring diagram for external radio receiver and loop detector page 39

16. Wiring diagram for other inputs page 40

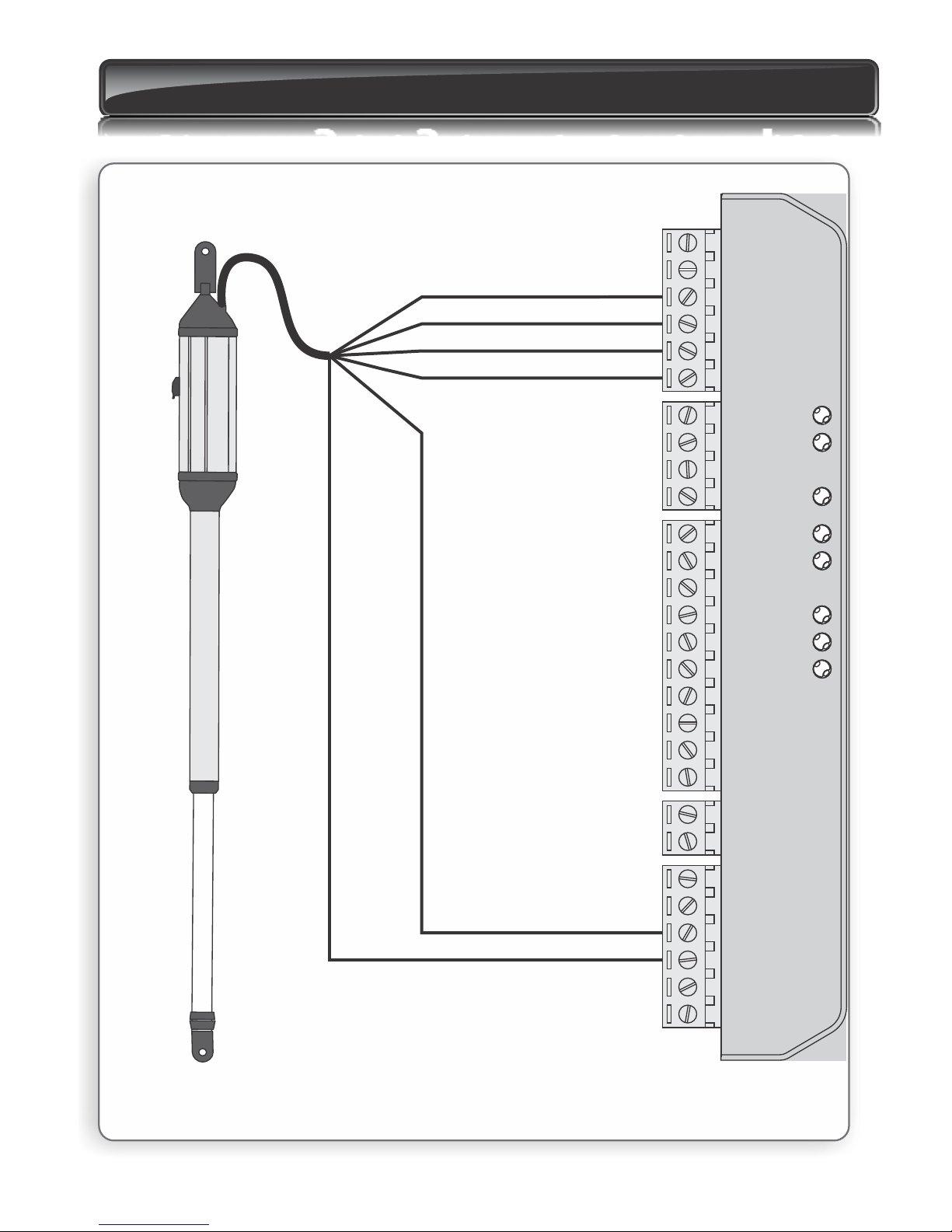

17. Wiring diagram for Master motor (MTRM) page 41

Page 4

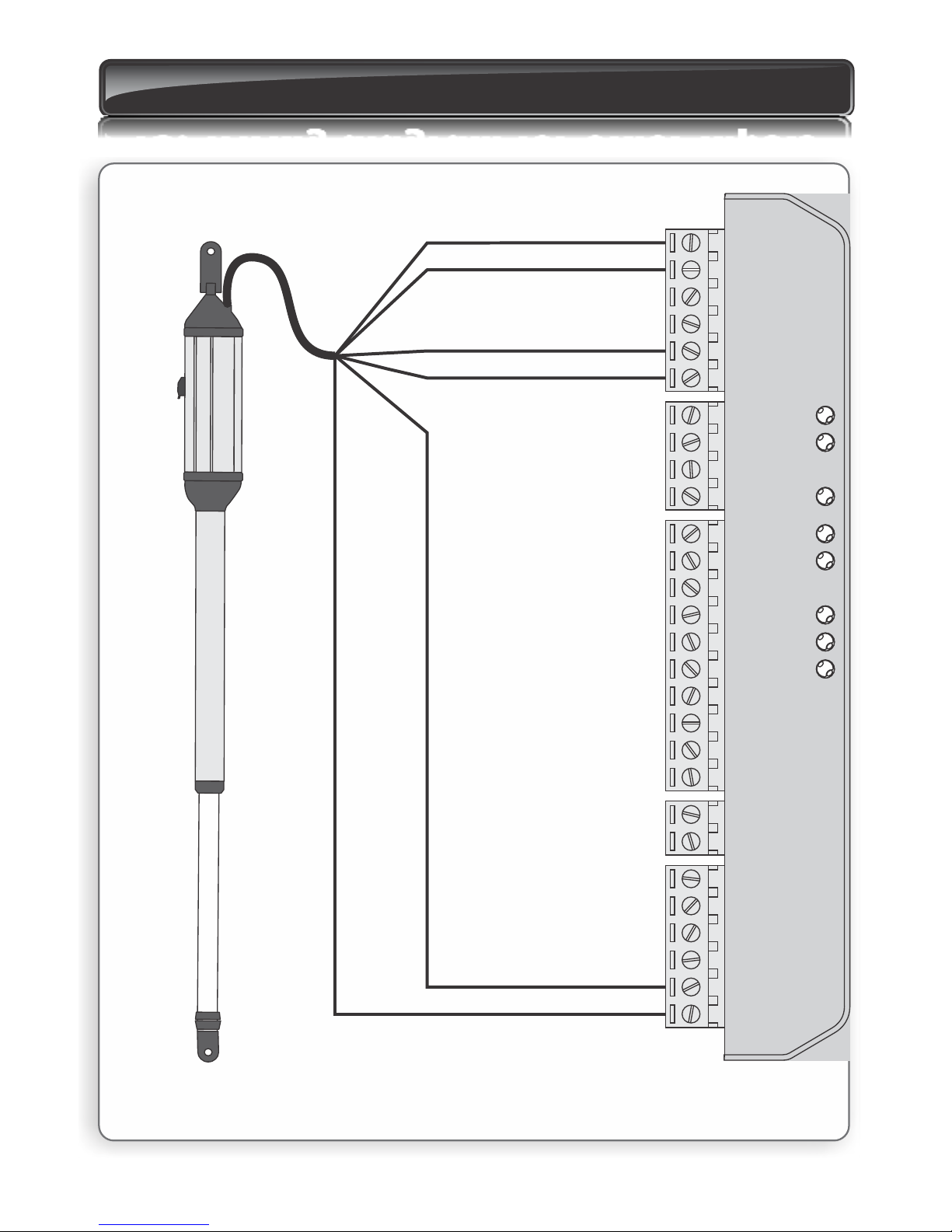

18. Wiring diagram for Slave motor (MTRS) page 42

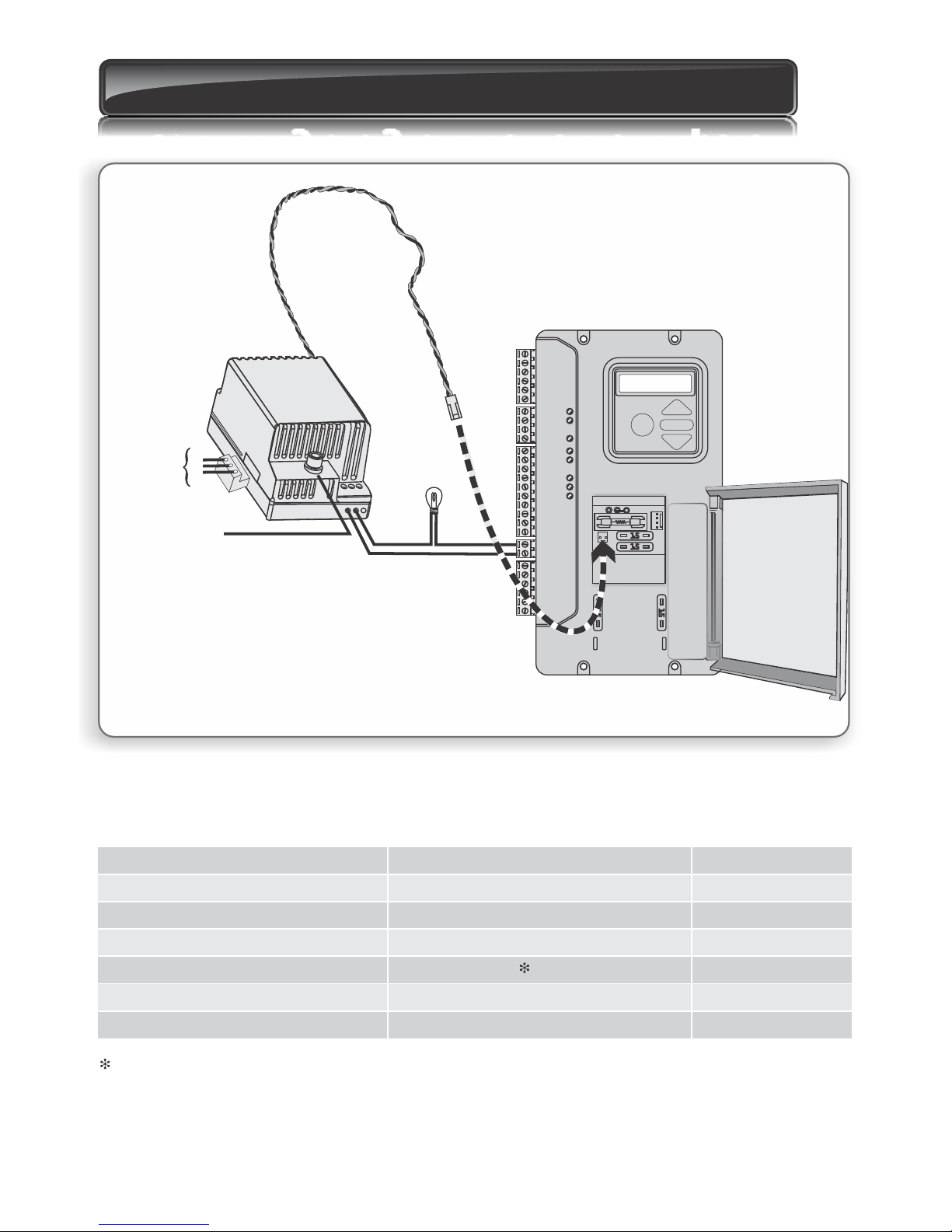

19. Charger and Pillar Light connections page 43

20. Setting up additional features page 44

21. Menu navigation map page 45

22. Controller features page 48

23. Factory defaults schedule page 58

24. Description of terminal functions page 64

25. Diagnostics page 67

Diagnostic LEDs page 67

Gate status LEDs page 67

LCD display page 68

Buzzer feedback page 69

26. Installation handover page 70

Page 5

Mount controller enclosure and

connect all wiring

Check cabling requirements

Mechanical setup

Gather required tools and equipment Page 14

Heed necessary site considerations Page 15

Page 22

Mount the wall bracket Page 24

Install motor and link to gate Page 25

Page 35

These quick steps are for the experienced installer who needs

a checklist to get a standard installation up and running in the

minimum of time.

Detailed installation features and functions are referred to

later in this manual.

Page 1

Page 6

Electrical setup

Page 2

Commission system

Commissioning

and handover

Carry out professional handover to

client

Page 70

Page 70

Set limit switches and/or fit

mechanical endstops

Page 36

Page 7

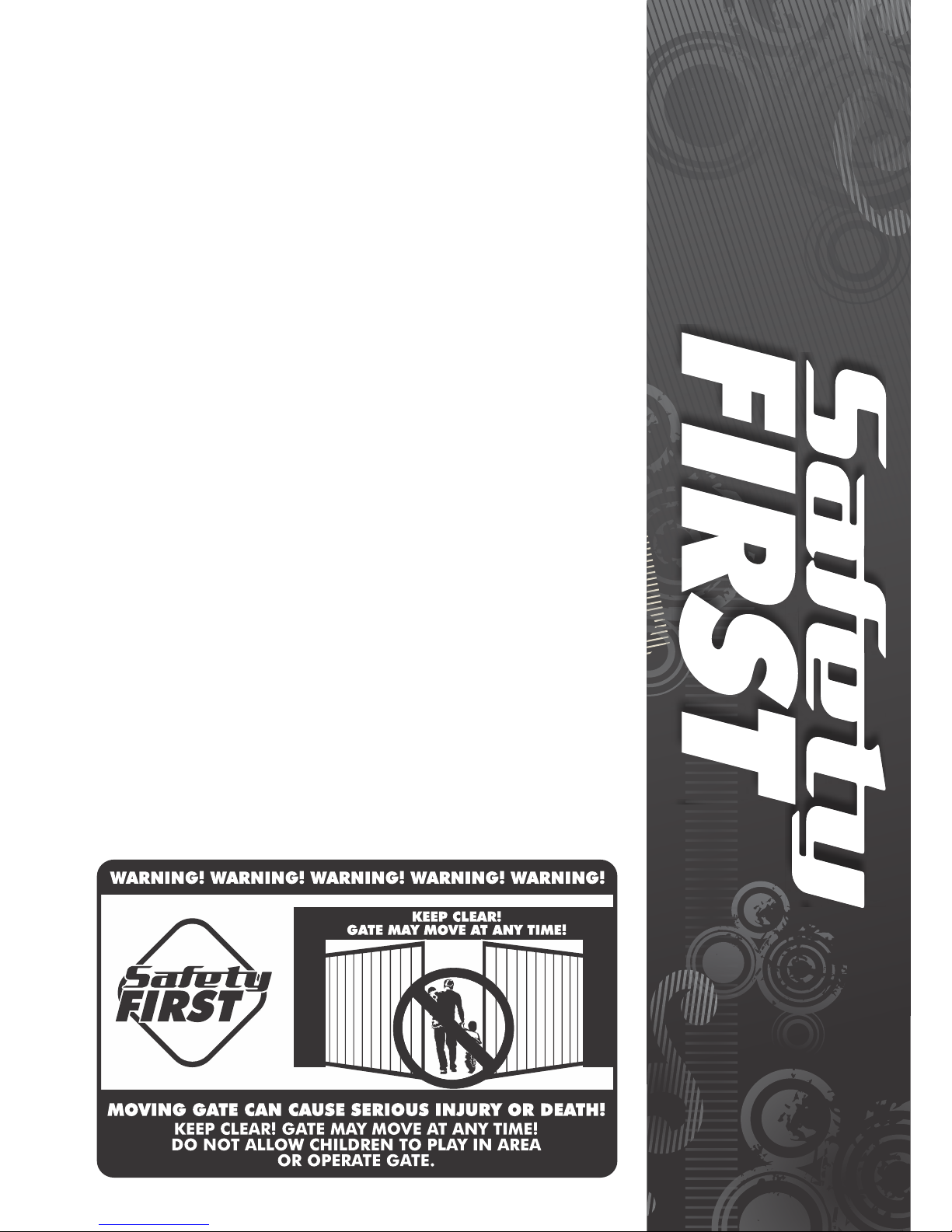

Warnings for the installer

CAREFULLY READ AND FOLLOW ALL INSTRUCTIONS

before beginning to install the product.

All installation, repair, and service work to this product

must be carried out by a suitably qualified person

This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning

use of the appliance by a person responsible for their safety

Do not activate your gate unless you can see it and can

determine that its area of travel is clear of people, pets, or

other obstructions

NO ONE MAY CROSS THE PATH OF A MOVING GATE.

Always keep people and objects away from the gate and its

area of travel

NEVER LET CHILDREN OPERATE OR PLAY WITH THE

GATE CONTROLS

Secure all easily accessed gate opener controls in order to

prevent unauthorised use of the gate

Do not in any way modify the components of the

automated system

Do not install the equipment in an explosive atmosphere:

the presence of flammable gasses or fumes is a serious

danger to safety

Before attempting any work on the system, cut electrical

power to the operator and disconnect the batteries

The mains power supply of the automated system must be

fitted with an all-pole switch with contact opening distance

of 3mm or greater. Use of a 5A thermal breaker with allpole circuit break is recommended

IMPORTANT

Safety Instructions

ATTENTION

To ensure the safety of people, it is important that you

read all the following instructions. Incorrect

installation or incorrect use of the product could cause

serious harm to people.

The installer, being either professional or DIY, is the

last person on the site who can ensure that the

operator is safely installed, and that the whole system

can be operated safely.

Page 3

Page 8

Make sure that an earth leakage circuit breaker with a

threshold of 30mA is fitted upstream of the system

Never short circuit the battery and do not try to recharge the

batteries with power supply units other than that supplied

with the product, or by Centurion Systems

Make sure that the earthing system is correctly constructed,

and that all metal parts of the system are suitably earthed

Safety devices must be fitted to the installation to guard

against mechanical movement risks such as crushing,

dragging and shearing

It is recommended that at least one warning indicator light be

fitted to every system

Always fit the warning signs visibly to the inside and outside of

the gate

The installer must explain and demonstrate the manual

operation of the gate in case of an emergency, and must hand

the User/Warnings guide over to the user

Explain these safety instructions to all persons authorised to

use this gate, and be sure that they understand the hazards

associated with automated gates

Do not leave packing materials (plastic, polystyrene, etc.)

within reach of children as such materials are potential

sources of danger

Dispose of all waste products like packaging materials, worn

out batteries, etc, according to local regulations

Always check the obstruction detection system, and safety

devices for correct operation

Centurion Systems does not accept any liability caused by

improper use of the product, or for use other than that for

which the automated system was intended

This product was designed and built strictly for the use

indicated in this documentation. Any other use, not expressly

indicated here, could compromise the service life/operation of

the product and/or be a source of danger

Everything not expressly specified in these instructions is not

permitted

Page 4

Page 9

Page 5

1. Declaration of conformity

Manufacturer:

Centurion Systems (Pty) Ltd

Unit 13 Production Park

Intersection Newmarket Road & Epsom Avenue

North Riding

Gauteng

South Africa

Declares that the product:

Product name: VECTOR2 Swing gate operator

Product options: All variants

Conforms with the following specifications:

Safety: SANS 60335-1:2007

IEC 60335-1:2006

Emissions: CISPR 22 CLASS B: Radiated emissions – 30MHz to 1000MHz

CISPR 22 CLASS B: Conducted emissions – 150 KHz to 30MHz

Immunity: IEC 61000-4-2 – Electrostatic discharge

IEC 61000-4-3 – Radiated immunity – 80MHz to 1000MHz

IEC 61000-4-4 – Electrical fast transients/burst

IEC 61000-4-5 – Surge immunity test

IEC 61000-4-6 – Conducted immunity – 150KHz to 80MHz

IEC 61000-4-8 – Power frequency magnetic field

IEC 61000-4-11– Voltage dips and interruption

Standard to which conformity is declared:

IEC 60335-1:2006 Safety

IEC 61000-6-3 Emissions

IEC 61000-6-1 Immunity

Signed at North Riding, South Africa on June 21, 2010

Ian Rozowsky

Research & Development Director.

Page 10

2. General description

Page 6

The VECTOR2 operator has been designed to safely and cost-effectively automate a wide

variety of swing gates, from single light-domestic swing gates to heavy industrial double

swing gates.

The fail-safe and fully redundant position and Collision Detection system has been

designed and tested to set the standard in safety of operation and to provide an

unparalleled level of reliability and durability in operation.

The gate Travel Limits are managed by a sealed double-redundant opto-electronic system

that has been designed not only to ensure ultra-reliable operation, but also to ensure

precise position and trajectory control. This enables very accurate and reliable collision

detection to ensure safe operation even under trying conditions.

The VECTOR2 control card has been designed to be easy and intuitive to use with helpful

instructions on the status of the operation during and after the installation. It also has a

built-in diagnostic procedure that can verify every aspect of the control card on site.

Some of the advanced features offered by the VECTOR2 controller are:

Fully automated single button Limit Setup for single and double swing gates

Full graphics LCD display provides an intuitive user interface with built-in diagnostics to

speed up and simplify the installation process

Separate safety inputs for sensitive edges or beams on both the closing and opening

directions of the gate

Advanced closed-loop speed control to maintain safe and reliable operation on inclined

gates under windy conditions

Fully configurable gate Run Profiles

Selectable and adjustable Autoclose with pushbutton override

Pedestrian (Partial) opening with automatic closure

Free-exit input

Positive Close Mode

Multiple Modes of Operation

Solenoid lock drive output up to 2A

Holiday Lockout

A status LED output to indicate the gate status remotely

Pillar Light control

Leaf delay selectable for either gate leaf

Onboard CENTURION receiver with selective adding and deleting of remotes

Page 11

Page 7

Lightning protection

The VECTOR2 electronic controller utilises the same proven surge protection philosophy

that is used in all CENTURION products. While this does not guarantee that the unit will

not be damaged in the event of a lightning strike or power surge, it greatly reduces the

likelihood of such damage occurring. The earth return for the surge protection is provided

via the mains power supply earth. In order to ensure that the surge protection is

effective, it is essential that the unit is properly earthed.

3. Icons used in this manual

This icon indicates tips and other

information that could be useful

during the installation

This icon indicates warning, caution or attention! Please take special note of

critical aspects that MUST be adhered to in order to prevent injury

This icon denotes variations and

other aspects that should be

considered during installation

Page 12

4. Specifications

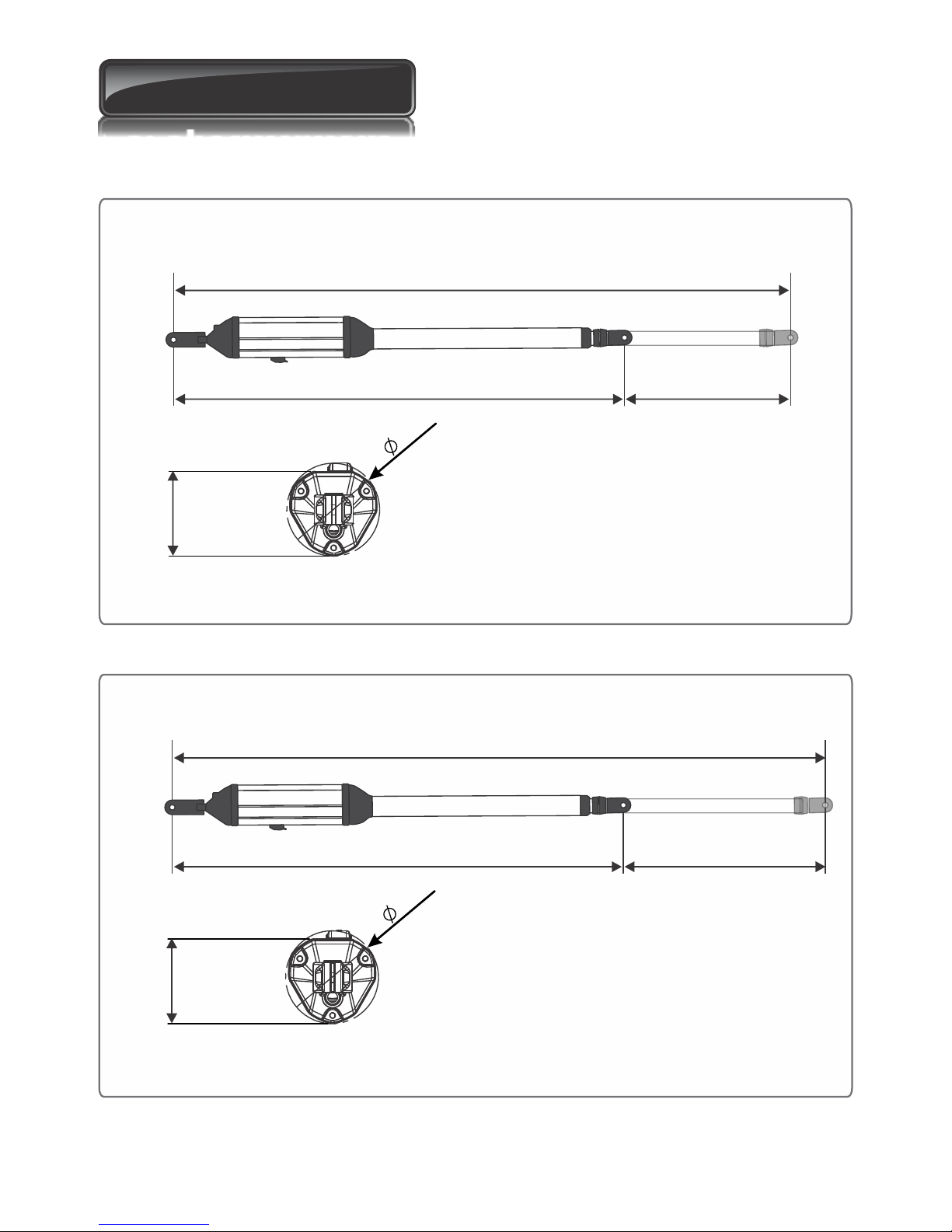

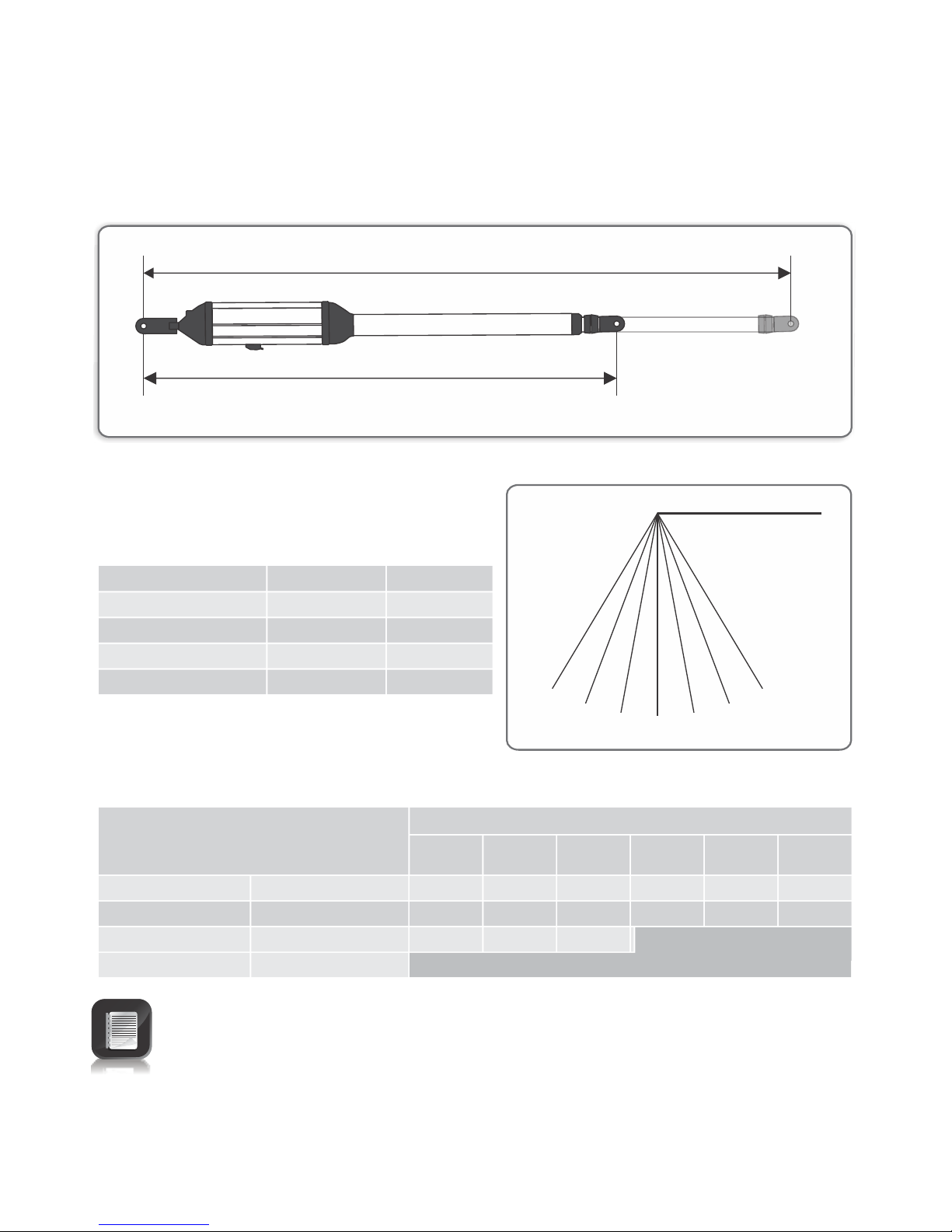

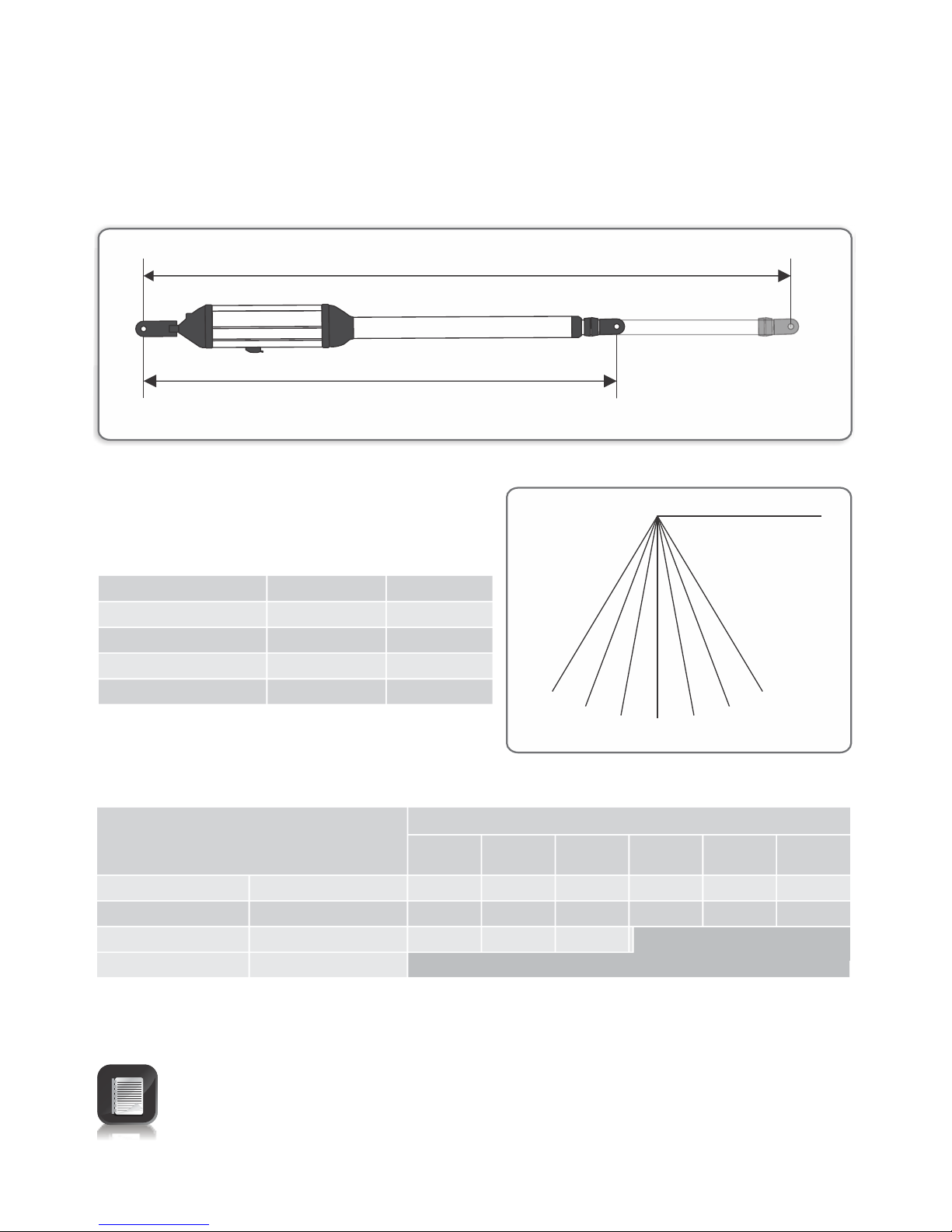

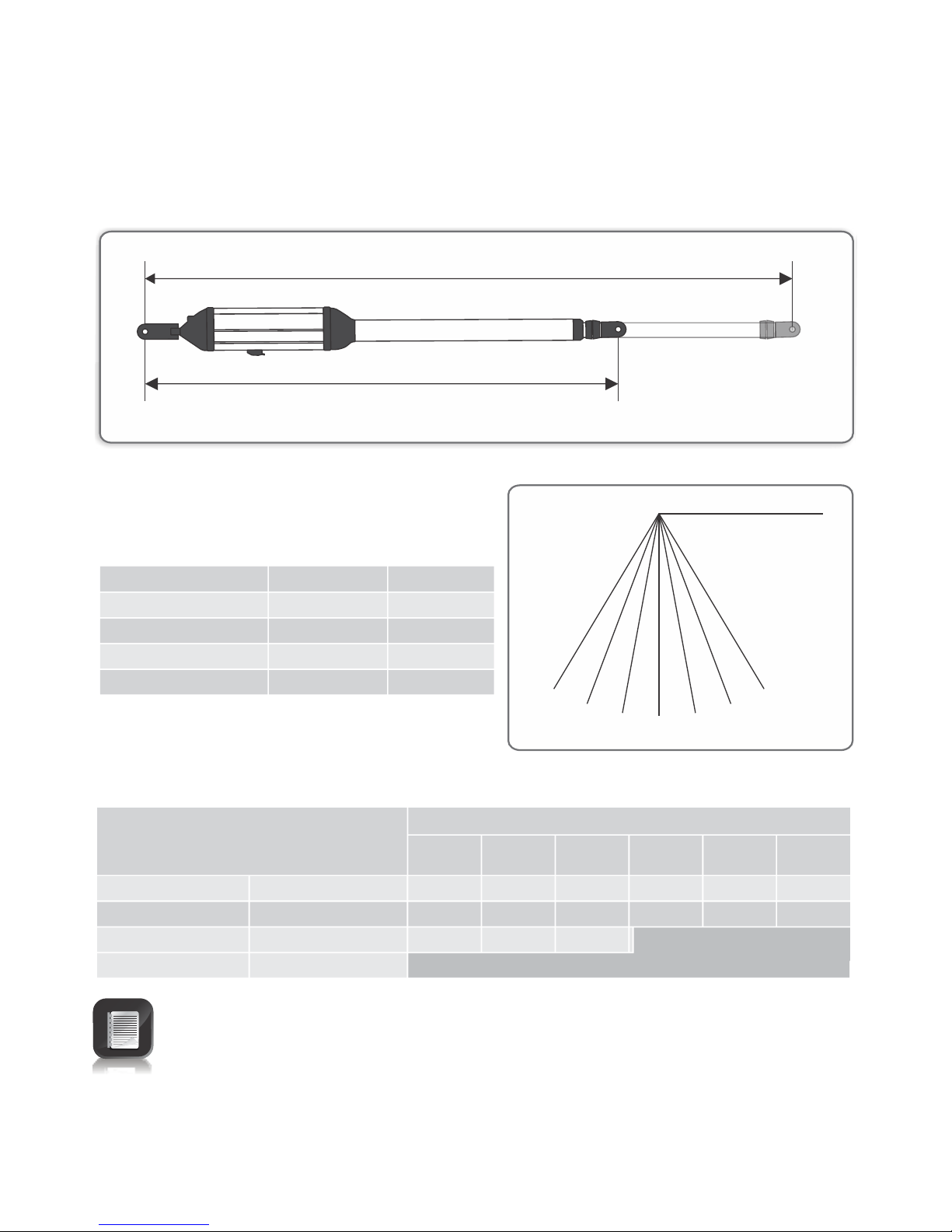

FIGURE 2. OVERALL DIMENSIONS

All dimensions shown in millimeters

FIGURE 1. OVERALL DIMENSIONS

Page 8

All dimensions shown in millimeters

Physical dimensions

1400mm Extended1400mm Extended1400mm Extended

1000mm Retracted1000mm Retracted1000mm Retracted 400mm Stroke400mm Stroke400mm Stroke

Model V400

100mm

95mm

Model V500

1600mm Extended1600mm Extended1600mm Extended

1100mm Retracted1100mm Retracted1100mm Retracted 500mm Stroke500mm Stroke500mm Stroke

100mm

95mm

Page 13

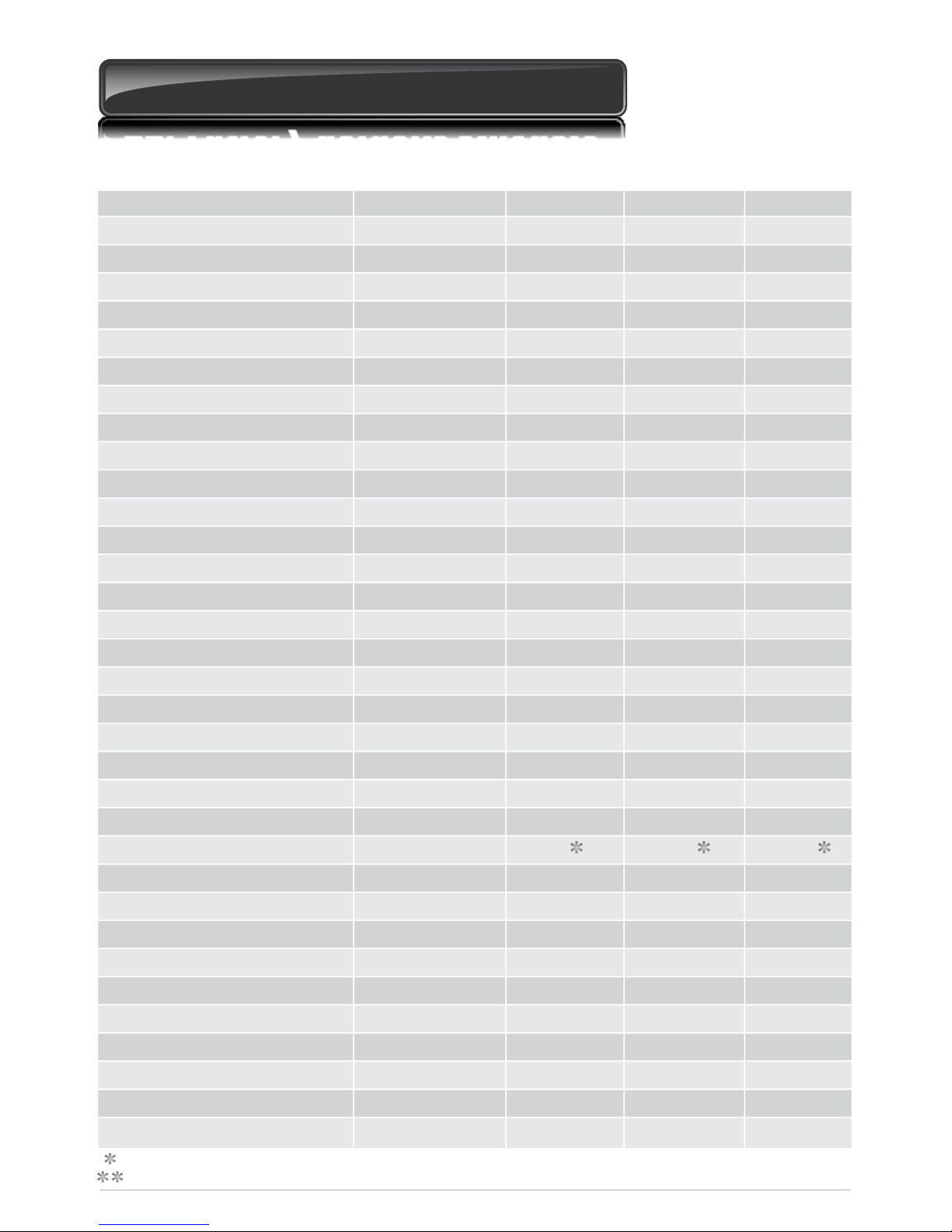

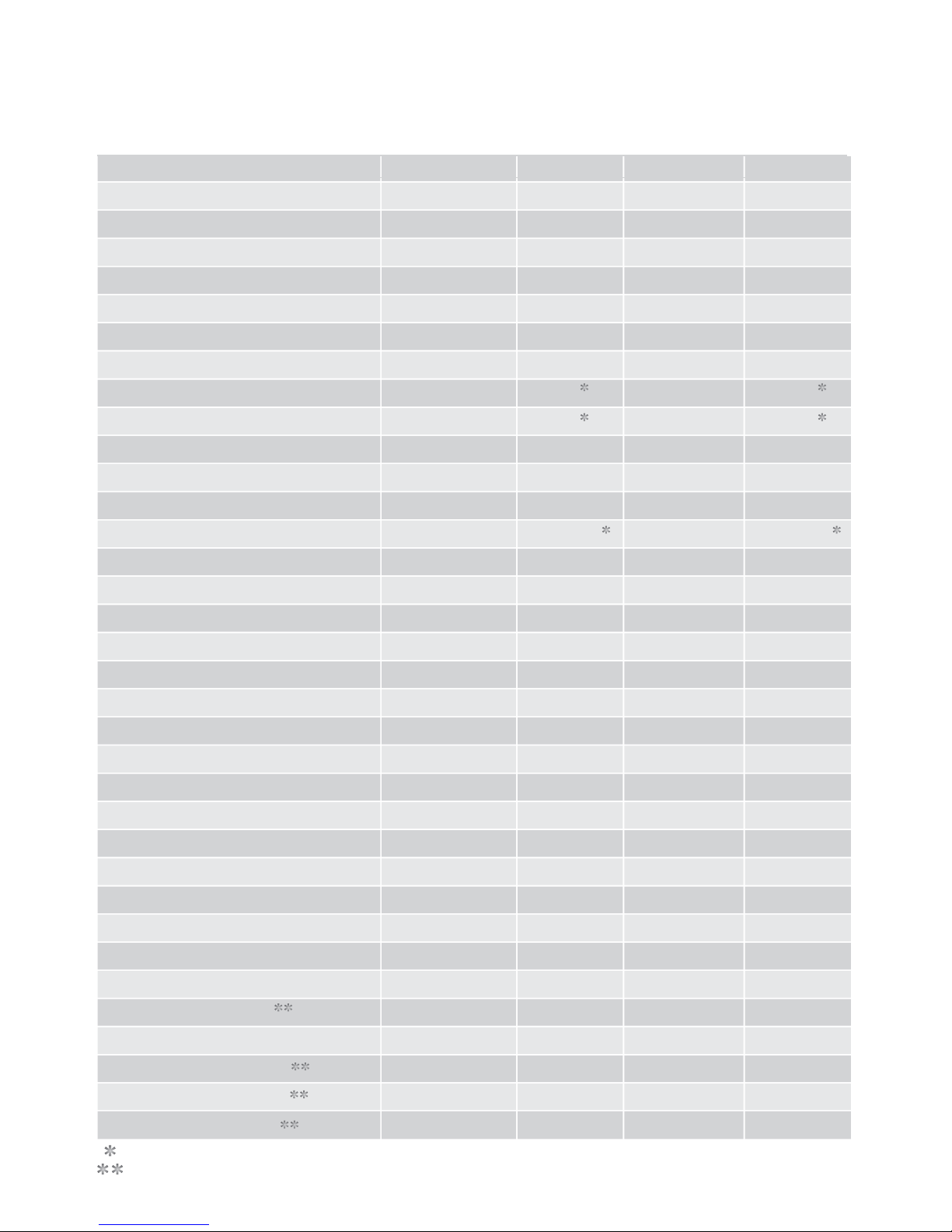

Page 9

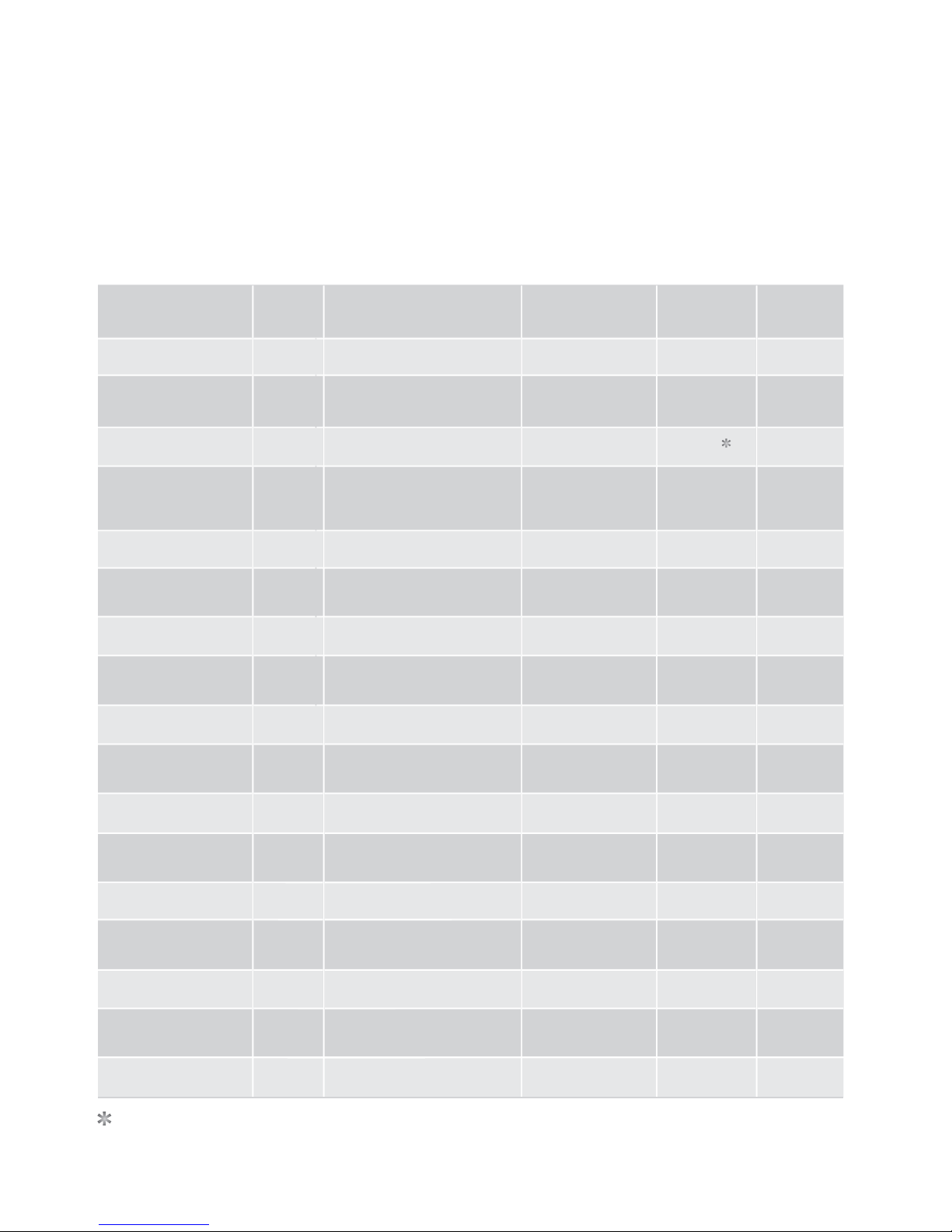

Can operate off a solar supply, consult Centurion Systems for assistance

Can increase battery capacity for longer standby times

Based on 25°C ambient temperature and unit not in direct sunlight

Based on an operator push force of less than 50% of rated

Based on double kit excluding infrared safety beams

Assumes a 90° opening gate and optimum mounting position

Assumes full stroke of operator is used

VECTOR2 400 VECTOR2 500

Input voltage

Motor voltage

Motor power supply

Battery charger

Domestic

Light-industrial

Current consumption (mains)

Current consumption (motor at rated load)

Operator push force - maximum

Operator stroke

Piston extension / retraction speed

Typical gate opening time

Manual override

Maximum number of operations per day

Duty cycle - mains present

Operations in standby with 7Ah battery

Half day

Full day

Collision sensing

Controller solenoid output rating

Operating temperature range

Onboard receiver type

Receiver code storage capacity

Receiver frequency

Mass of unit packed (excluding battery)

Single kit

Double kit

220-240V AC ± 10%, 50Hz

12V DC

Battery driven (standard capacity - 7Ah)

CP84E - 800mA @ 13.8V

CP84SM - 2A @13.8V

60mA / 170mA

15A - max

250kgf

27mm/sec

Key release

100 / 250

25% / 50%

70

58

Electronic

2A DC

-15°C to +50°C

CENTURION code-hopping

multichannel

64 transmitter buttons

433MHz

400mm 500mm

<14 sec

<17 sec

8.5kg

14kg

9kg

15kg

Technical specifications

Page 14

Page 10

Control card

Power supply

Maximum motor current per channel 15A (fused)

Maximum input voltage 14.4V DC

Standby current draw 48mA

Maximum solenoid current draw 2A DC

Maximum aux output current 3A (PTC)

Collision detection Current sense and redundant optical

Position and trajectory Redundant optical

Temperature range -20°C to +60°C

Nominal input voltage

AC current draw (maximum)

Temperature Range

Max. continuous charging

current

7Ah, 12V, CP84E

(Domestic)

220-240V AC ±10% @ 50Hz

60mA

-20°C to +60°C

0.8A @ 13.8V

7Ah, 12V, CP84SM2A (Light

-industrial)

220-240V AC ±10% @ 50Hz

170mA

-20°C to +60°C

2.5A @ 13.8V

Boxed shipping weight

(excluding batteries):

Protection Level

7Ah, 12V, CP84E

(Domestic)

2.7kg

IP55

7Ah, 12V, CP84SM 2A

(Light-industrial)

2.6kg

IP55

Power supply, wall box and control card assembly

Page 15

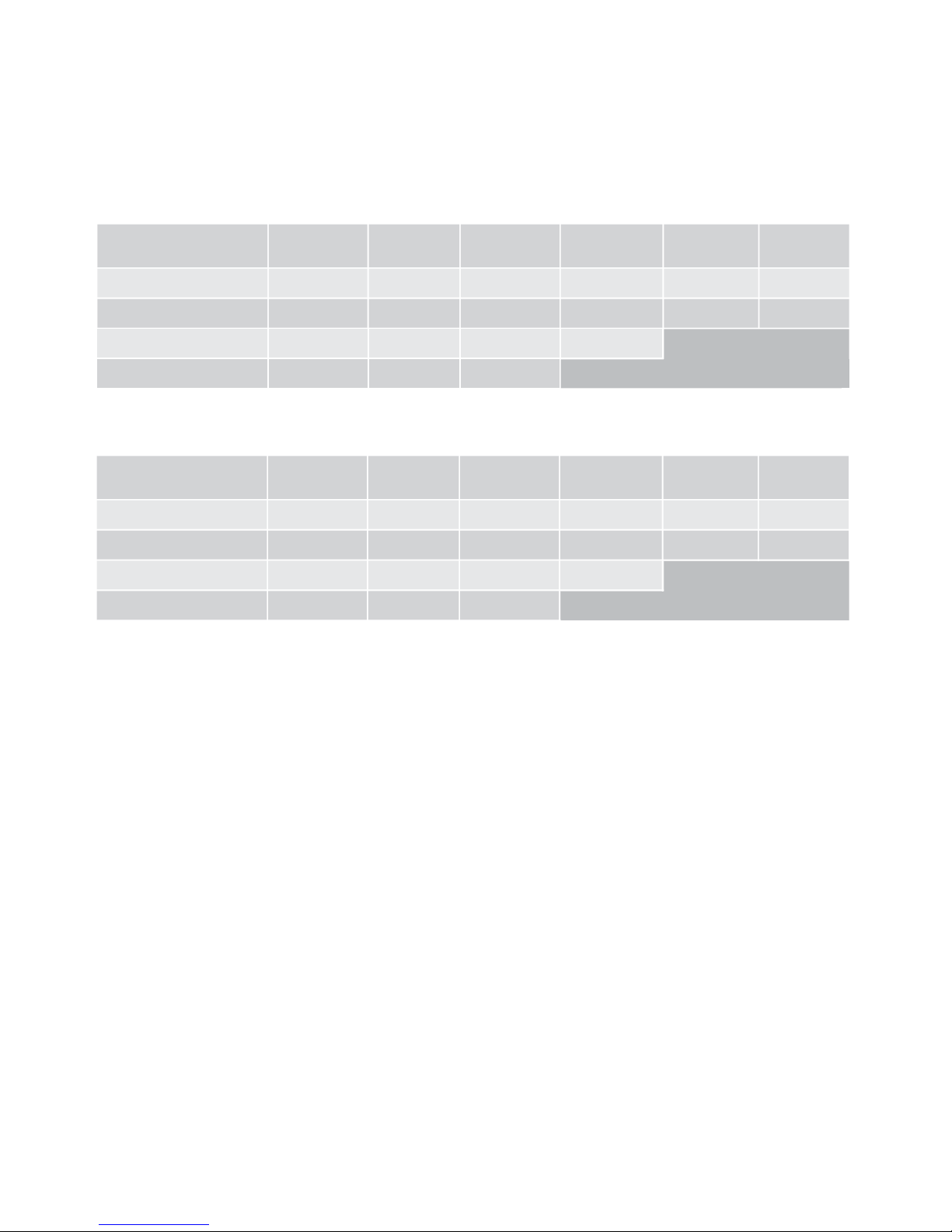

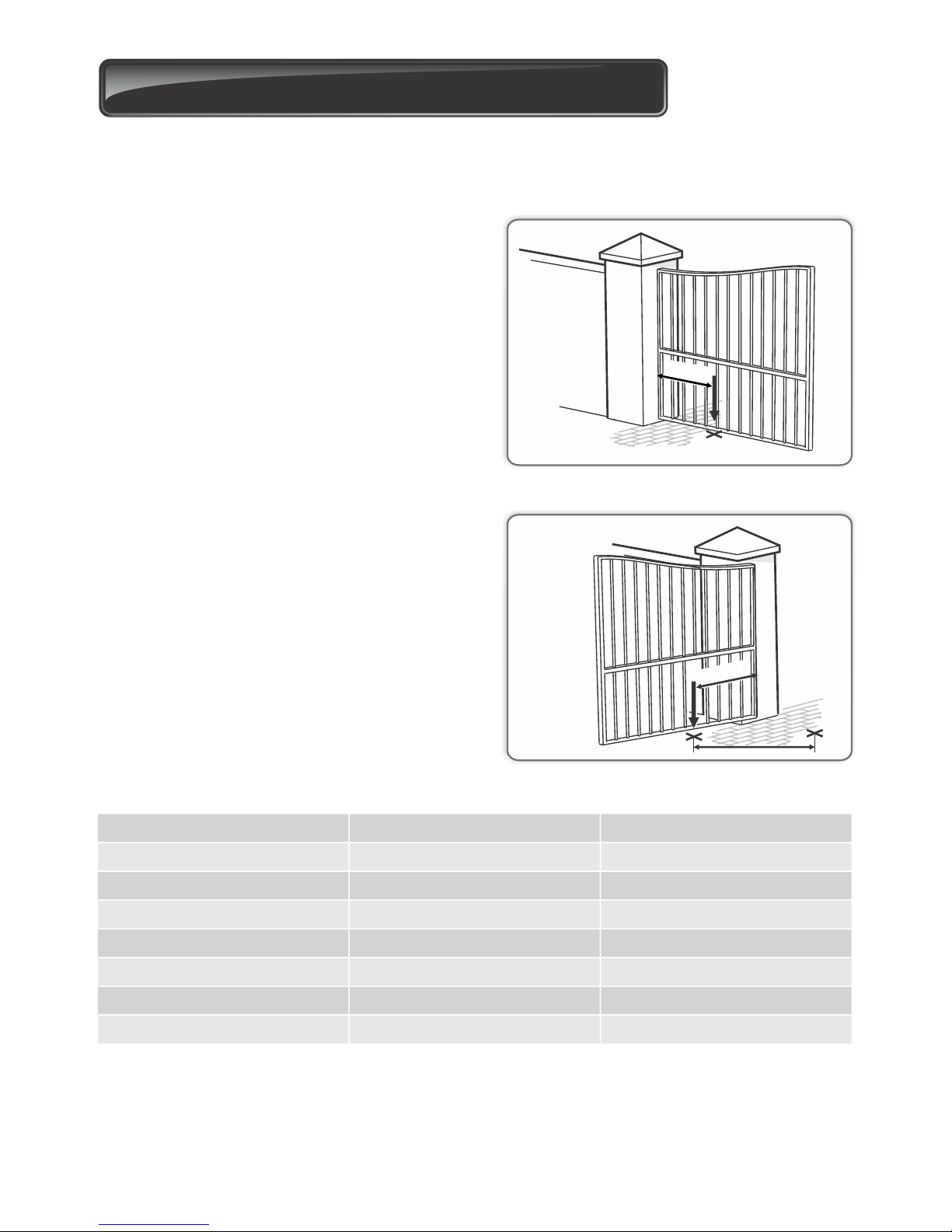

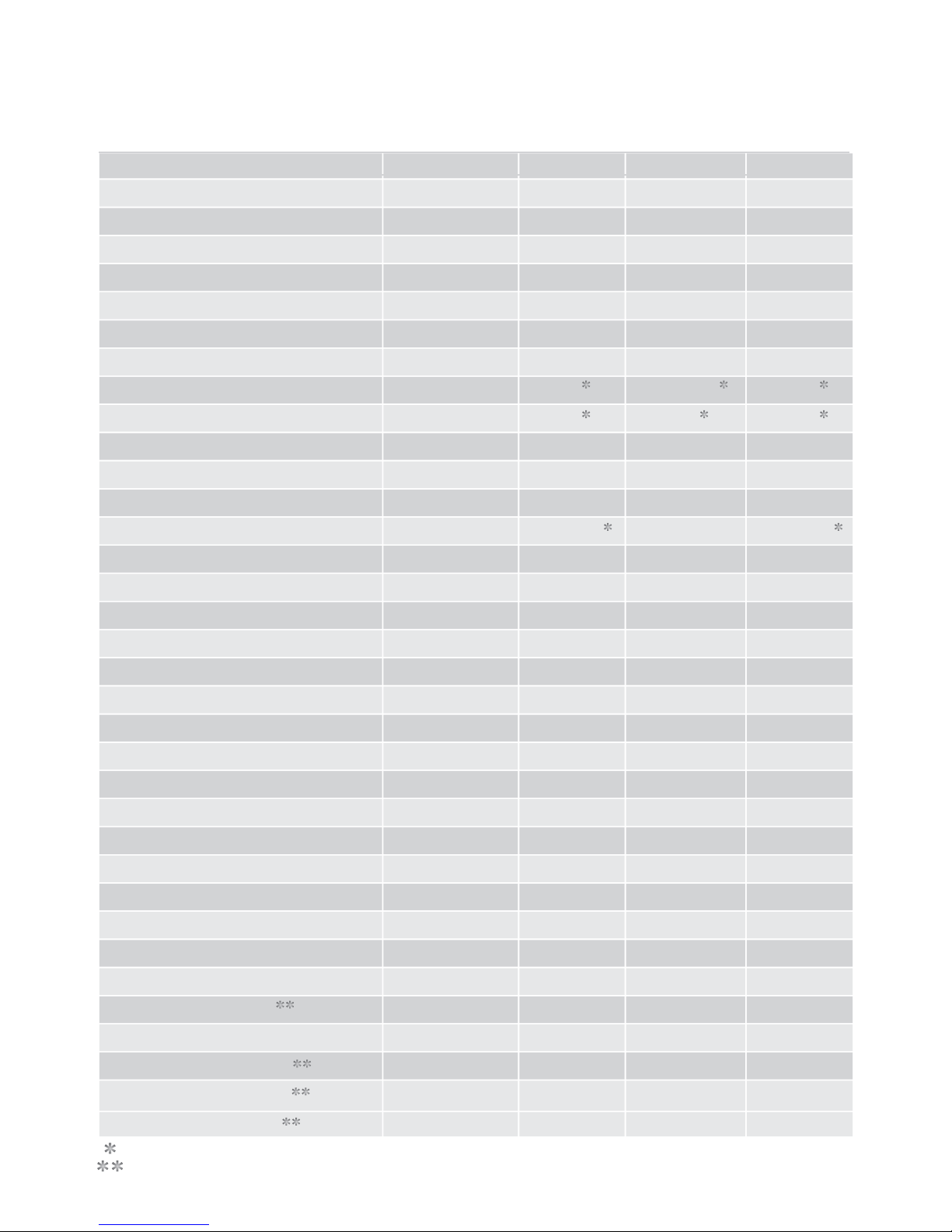

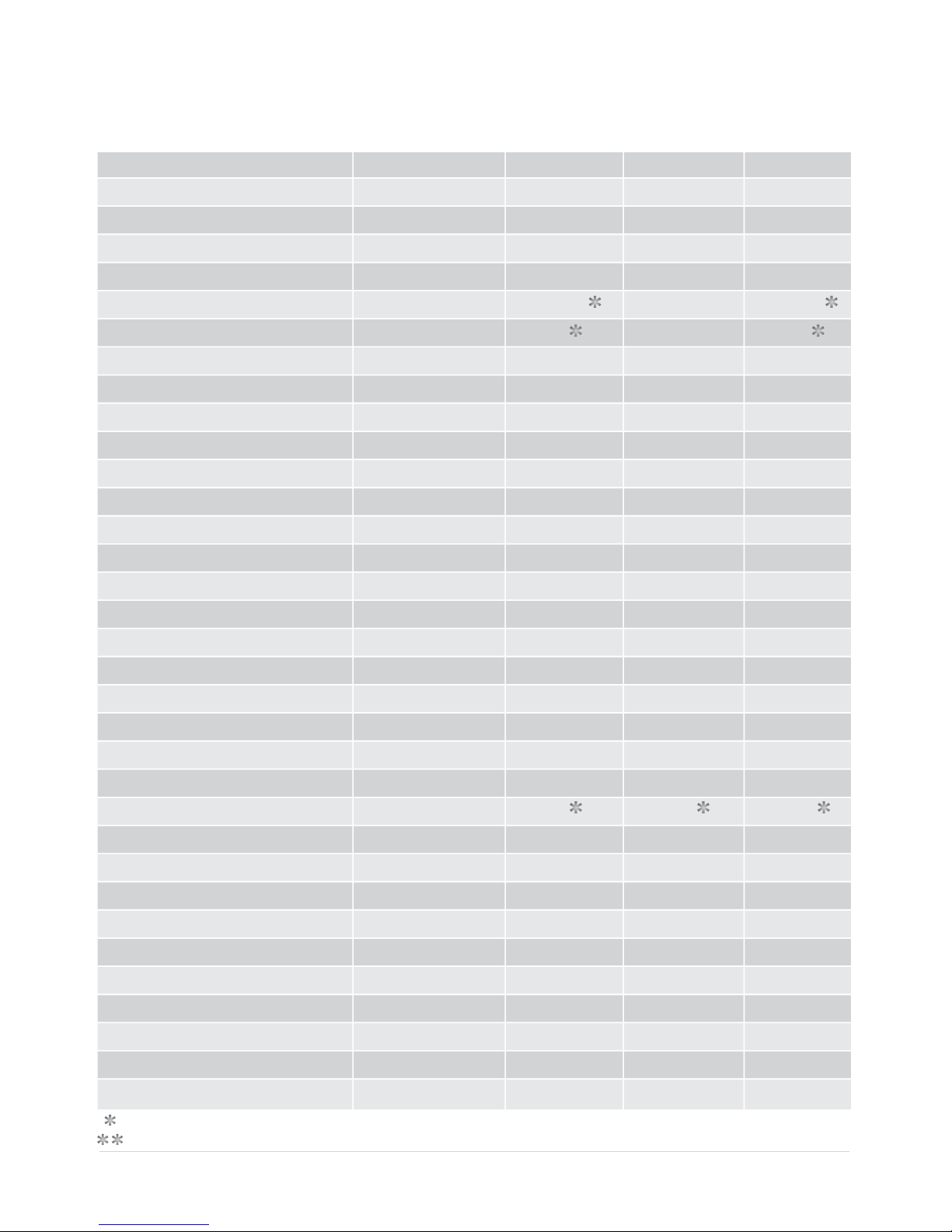

90° 750kg 750kg 750kg 550kg 410kg 310kg

100° 750kg 750kg 600kg 420kg 310kg 230kg

110° 750kg 500kg 320kg 220kg

120° 310kg 170kg 110kg

Gate swing angle Up to

1.5m

Up to

2m

Up to

2.5m

Upto

3m(#1)

Up to

3.5m(#1

Up to

4m(#1)

Maximum allowable gate mass for V500 operator:

(#1 - an electric lock must be fitted to secure gate in closed position)

Page 11

Allowable gate mass

90° 500kg 500kg 500kg 360kg 260kg 200kg

100° 500kg 500kg 388kg 160kg 190kg 150kg

110° 500kg 306kg 198kg 130kg

120° 180kg 100kg 65kg

Gate swing angle Up to

1.5m

Up to

2m

Up to

2.5m

Upto

3m(#1)

Up to

3.5m(#1)

Up to

4m(#1)

Maximum allowable gate mass for V400 operator:

(#1 - an electric lock must be fitted to secure gate in closed position)

Not

recommended

Not

recommended

Page 16

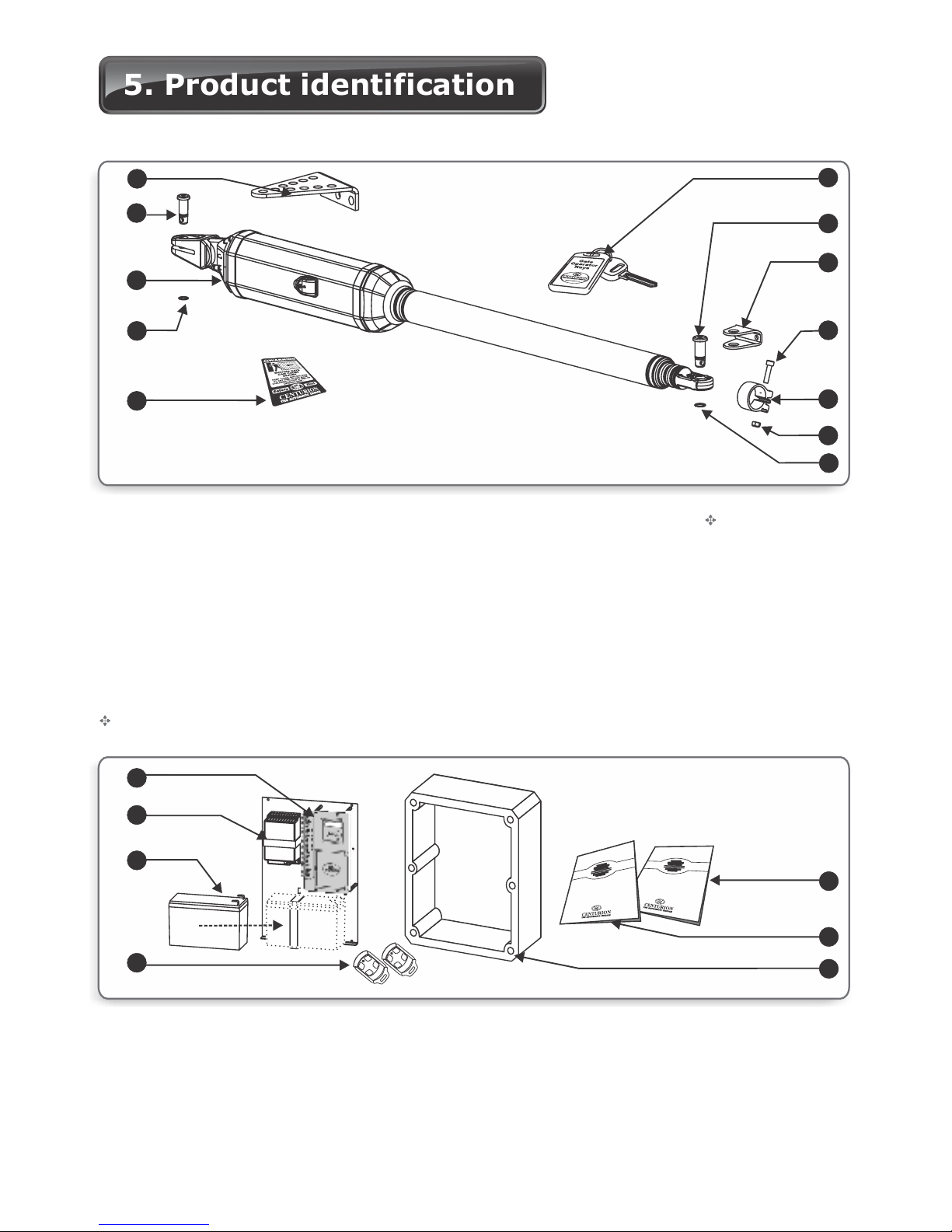

5. Product identification

1. VECTOR2 controller with built-in

receiver

2. Charger

3. 12V 7.2Ah Battery (user supplied -

not part of kit)

4. CENTURION transmitters

1

3

4

2

5

9

12

7

6

8

10

11

15

7.5

2

3

4

6

1

5

7

Page 12

1. Wall bracket (standard)

2. Wall bracket pin

3. VECTOR2 gate operator (complete

assembly)

4. 12mm snap ring

5. Gate warning decal

6. Gate bracket pin

7. Gate operator keys

8. Gate bracket

9. Stainless steel cap screw M6 x 25

10. Origin body

11. Stainless steel M6 nut

12. 14mm snap ring

Keys are specific to each operator-key number must be recorded.

FIGURE 3. PRODUCT IDENTIFICATION

FIGURE 3A. CONTROL BOX INCLUDING CHARGER AND CONTROLLER

5. User guide

6. Installation manual

7. Wall box

4

Page 17

2

3

Page 13

1. VECTOR2 wall adaptor kit packing leaflet

2. M10 Hexagon nuts

3. Wall adaptor plate

4. M10 x 20 Countersunk screw

FIGURE 3B. WALL ADAPTOR KIT

3

4

2

1

1

1. VECTOR2 high security kit packing leaflet

2. Padlock

3. Wall bracket (high security)

2

1

3

4

5

1. VECTOR2 securing plate (short)

2. VECTOR2 mechano kit packing leaflet

3. M10 x 35 Bolt

4. M10 x 35 Bolt

5. VECTOR2 securing plate (long)

1. VECTOR2 gate adaptor kit packing leaflet

2. M6x16 Countersunk cap screw

3. Gate bracket spreader plate

4. M6 Hexagon nuts

1

3

3

2

FIGURE 3C. HIGH SECURITY KIT

FIGURE 3D. MECHANO KIT

FIGURE 3E. GATE ADAPTOR KIT

Page 18

6. Required tools and equipment

Spanner - 17mm, 15mm, preferably socket set

Crimping tool and pin lugs

Hammer

Electric drilling machine

20mm hole saw

Screwdrivers - 6mm Philips, 3.5 Flat

Pliers

Connector block

2 x G-clamps

Masonry bits - 12mm; 10mm for wall mount brackets; steel bits 6.5mm/10.5mm

6mm pin punch

Angle grinder

Measuring tape

Hacksaw

5mm Allen key

Welding machine (including consumables and safety equipment

Soldering iron

Spirit level

Extension cord

Marking pen/chalk

Safety equipment (goggles, gloves, etc.)

Page 14

Page 19

7. Preparation of site

General considerations for the installation

Always recommend the fitment of additional safety equipment such as safety edges

and safety beams, for additional protection against entrapment or other mechanical

risks

Check that no pipes or electrical cables are in the way of the intended installation

Check that enough space is available for the gate operator with the gate in the required

open position. (See Figure 4 and 5)

Check the strength of the mounting pillar and fit a wall adaptor kit where needed

If the swing gate leaf is longer than 2.5m, ensure that a lock can be fitted

Never fit the operator on the outside of the gate, where the public has access to it

(Follow the instructions for an outward opening swing gate, if required.)

For greater security consider fitting an optional high security kit

Install the gate operator only if:

It will not pose a hazard to the public

There is sufficient clearance to a roadway and/or public thoroughfares

The installation will meet all municipal and/or local authority requirements once

completed

The gate mass, leaf width, allowable wind loading and application is within the operator

specifications (refer to the specification tables)

The gate is in good working order, meaning:

that it swings freely;

does not move on its own if left in any position;

each gate leaf is strong and rigid

It can be installed to have sufficient clearance between moving parts when opening and

closing to reduce the risk of personal injury and entrapment

Pushbuttons or key switches, when required, can be positioned so that the gate is in

line of sight of the operator

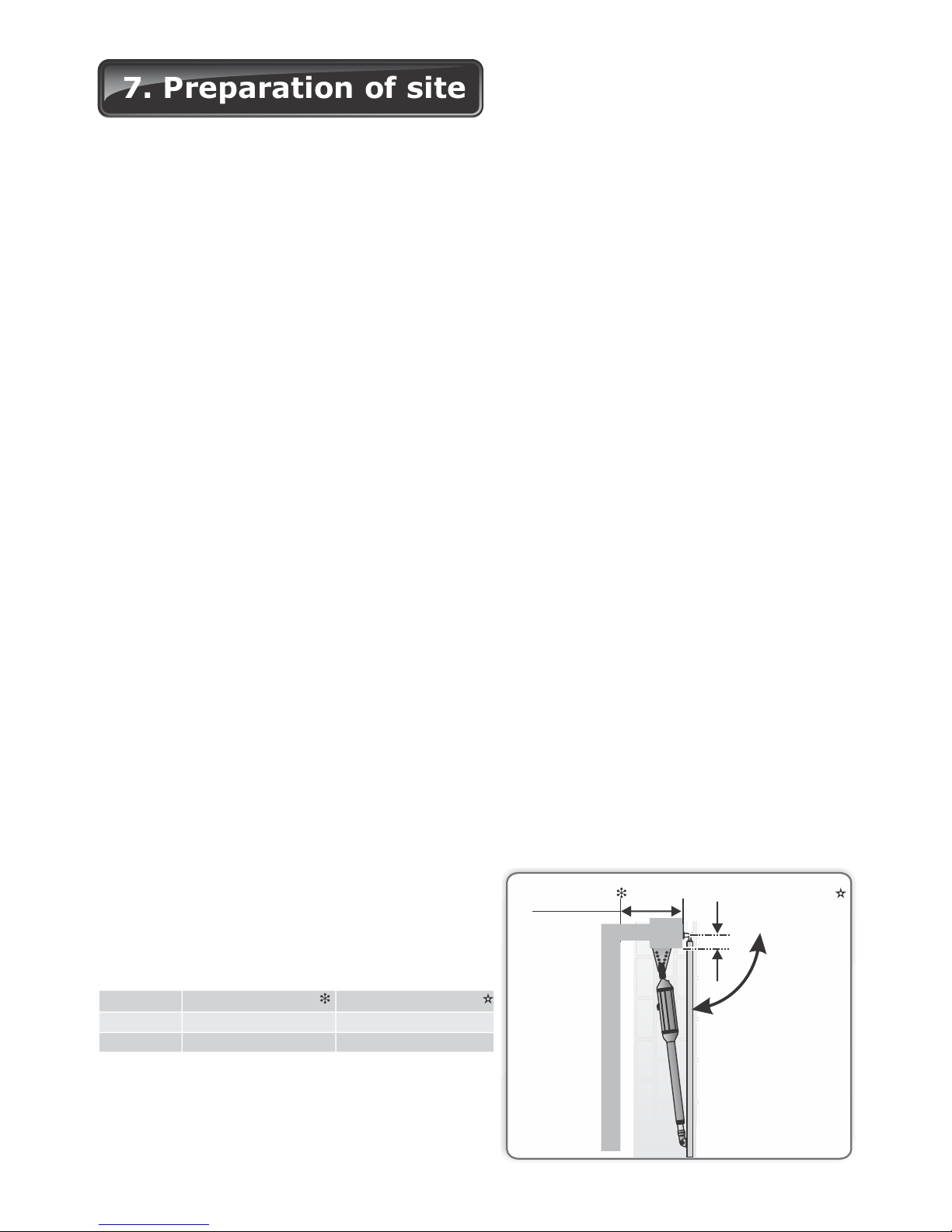

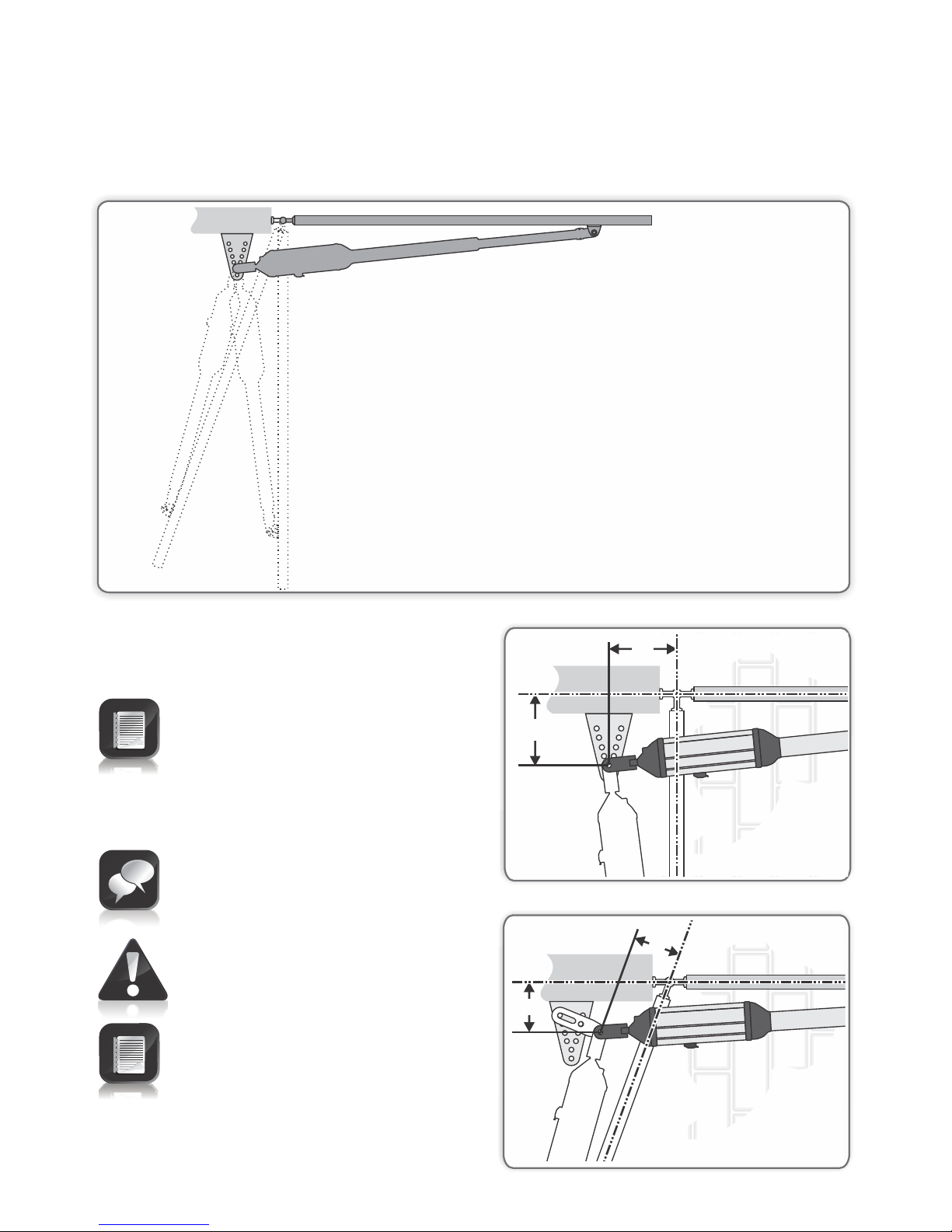

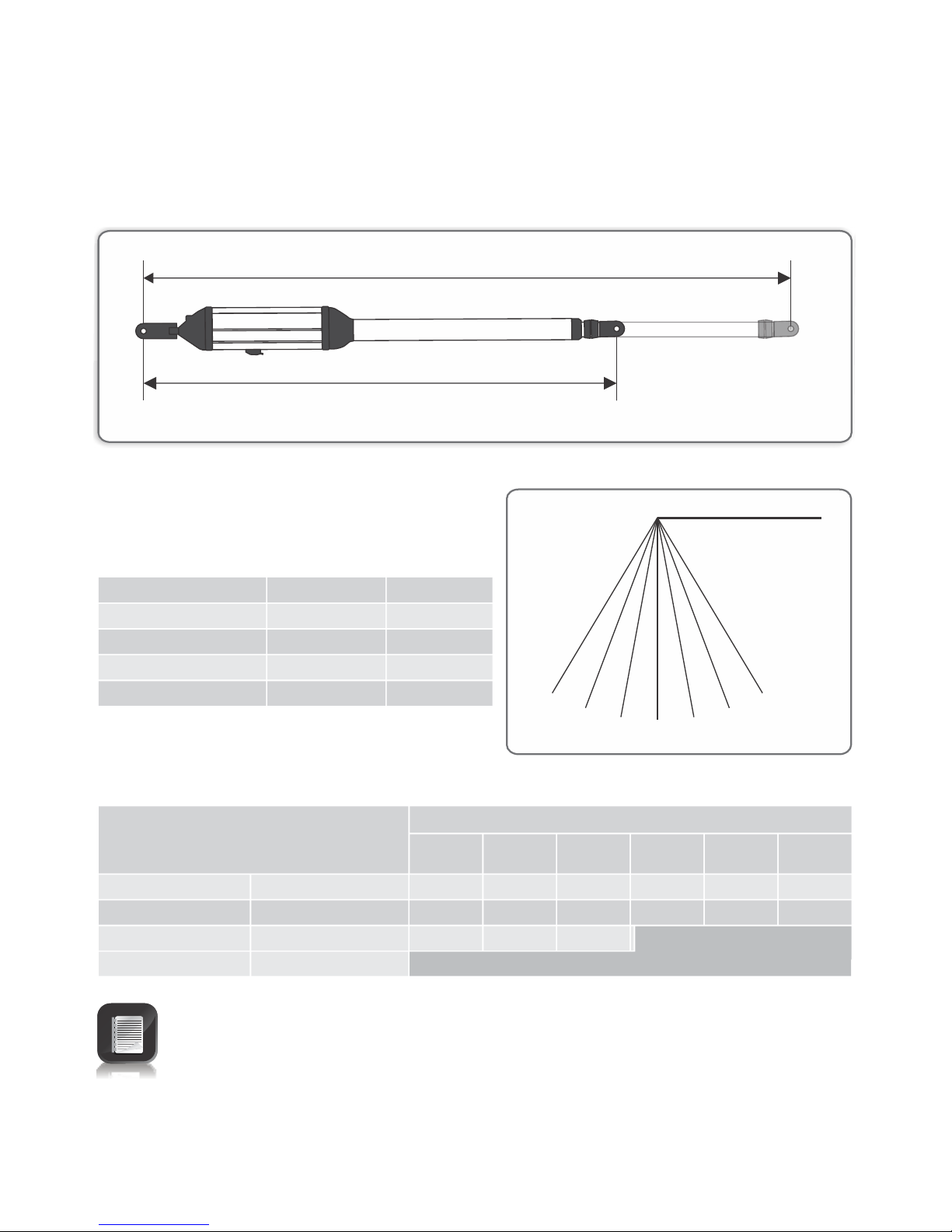

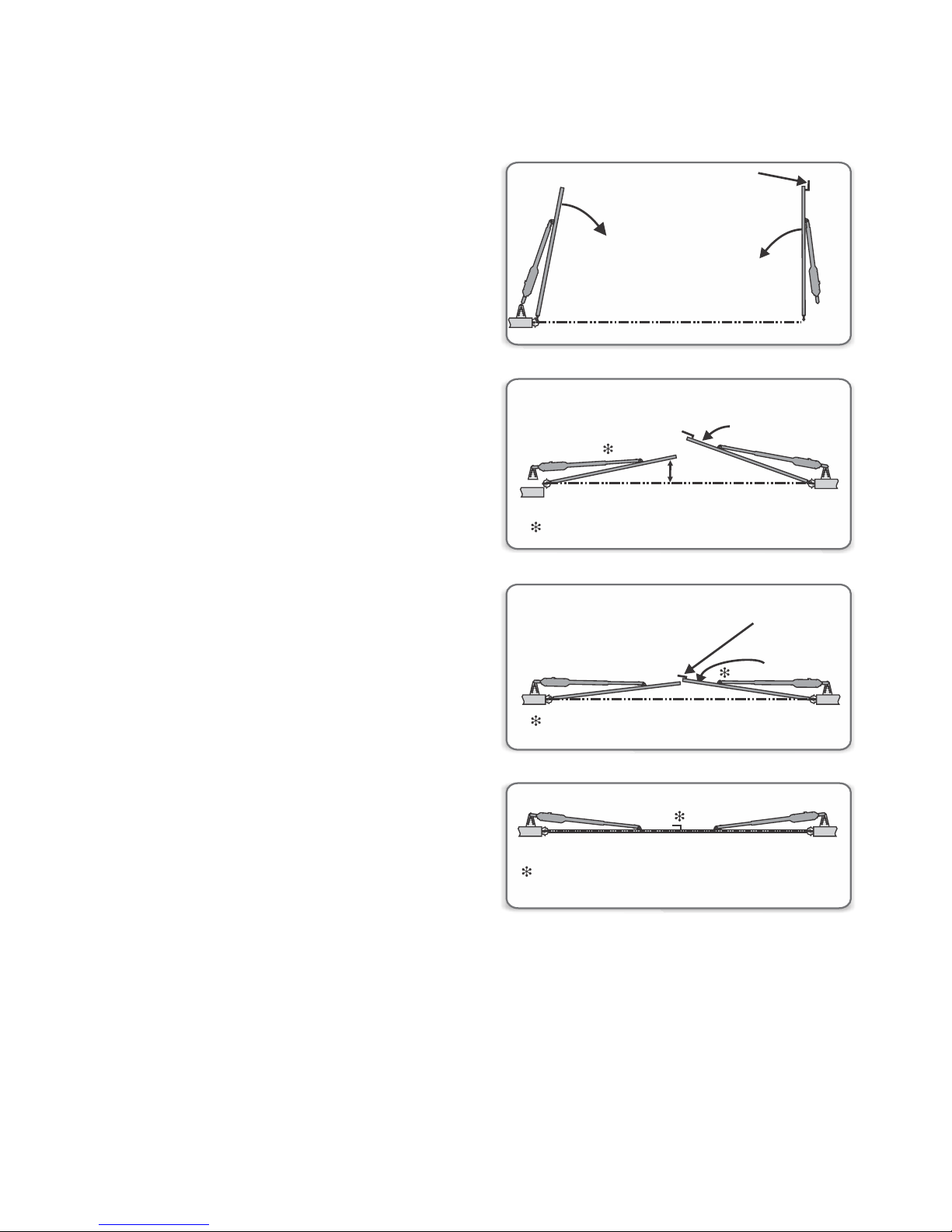

FIGURE 4

Page 15

Gate opening 90° or less

Gate opening

90° or less

Pillar (Maximum)Wall (minimum)

Operator

V400

150mm

150mm 250mm

V500 335mm

Wall (minimum) Pillar (maximum)

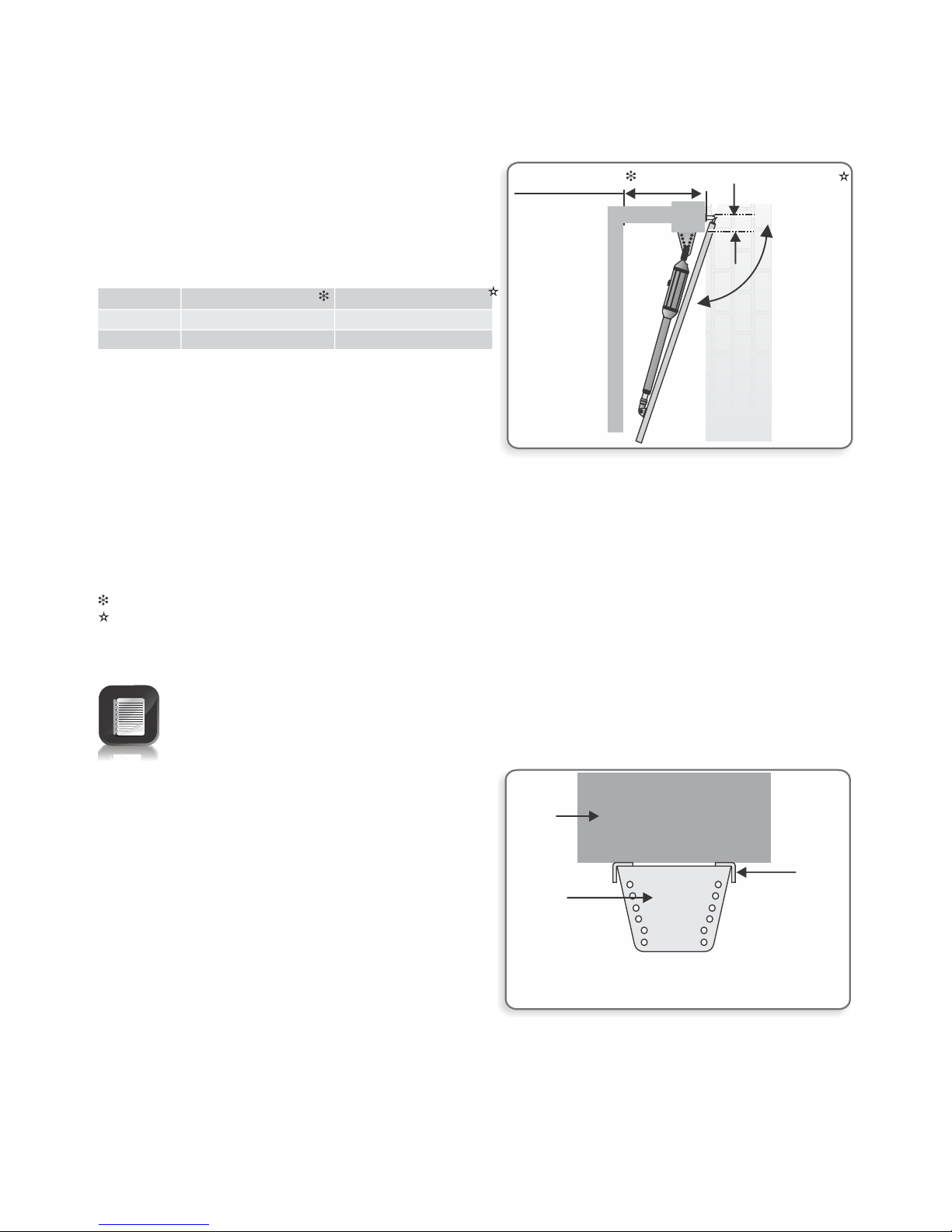

Page 20

Page 16

For reliable operation it is important to ensure that the way the operator is

secured to the wall takes into account the strength of the pillar, the size of the

gate, and how frequently the gate would be used:

Strength of the pillar

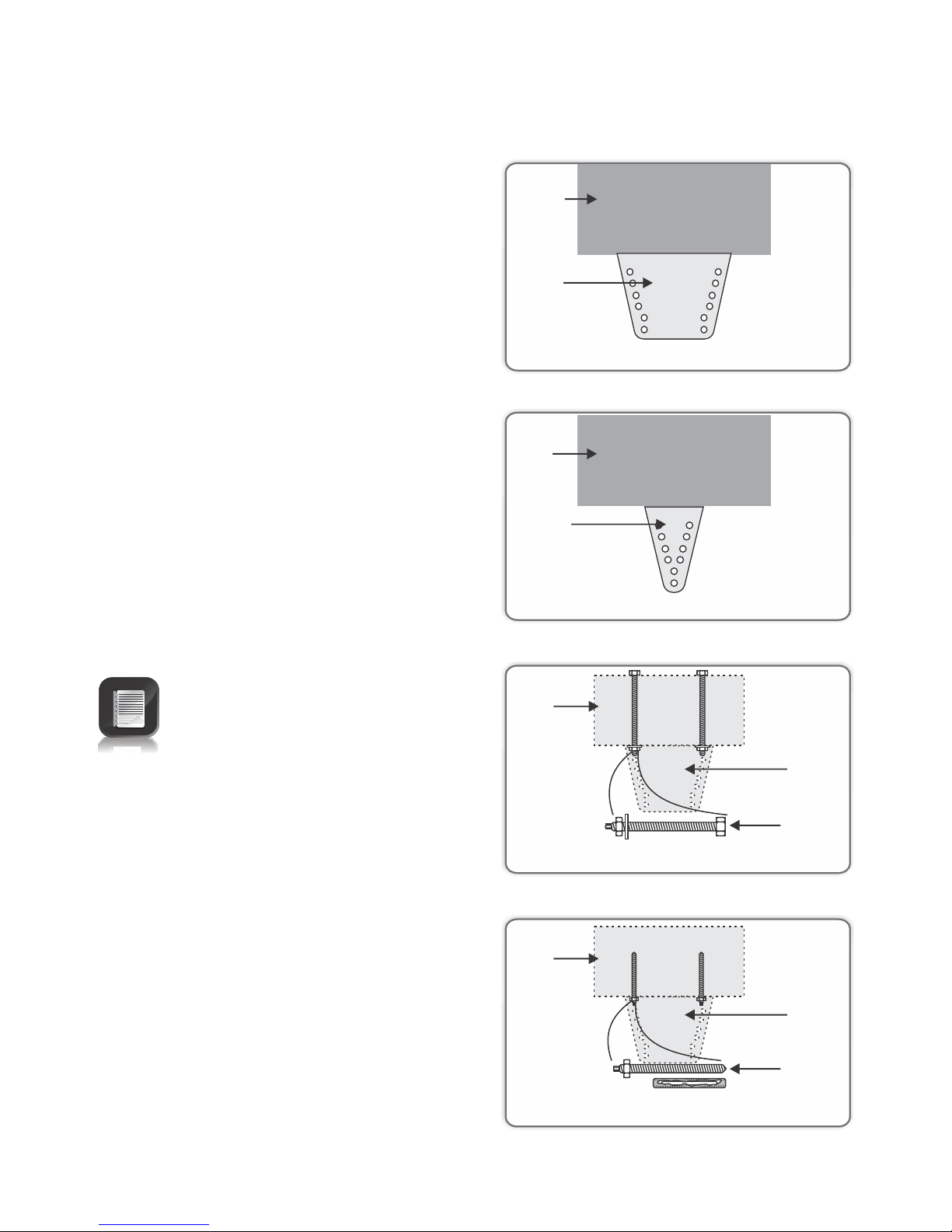

High Security Kit together with a Wall

Adaptor Kit

This mounting is highly recommended for all

light-industrial gates, or for heavy gates of any

length.

Alternatively it should be considered for use on

pillars of low or unknown strength.

Pillar

Best installation

FIGURE 6

Tables are based on gates shorter than 2.5m

For gates 2.5m to 3.0m long, reduce the maximum pillar thickness by 20mm

For gates 3.0m to 3.5m long, reduce the maximum pillar thickness by 40mm

For gates 3.5m to 4.0m long, reduce the maximum pillar thickness by 60mm

The typical minimum wall clearance required to fit the operator

The maximum allowable pillar thickness on which to fit the operator

Operator

V400

150mm

150mm 145mm

V500 210mm

Wall (minimum) Pillar (maximum)

Gate opening 110°

Wall (minimum)

Gate opening

110°

Pillar (maximum)

FIGURE 5

Wall

adaptor

(high

security)

Wall

adaptor

plate

Page 21

This mounting works well for heavy gates

shorter than about 2m in single household

domestic applications.

Alternatively it should be considered for use on

pillars of low or unknown strength.

High Security Kit

Works well

Standard bracket

This mounting means is typically used on light

to medium weight domestic gates that are

about 1.5m long, and that is mounted on

pillars of average strength.

Good

FIGURE 7

FIGURE 8

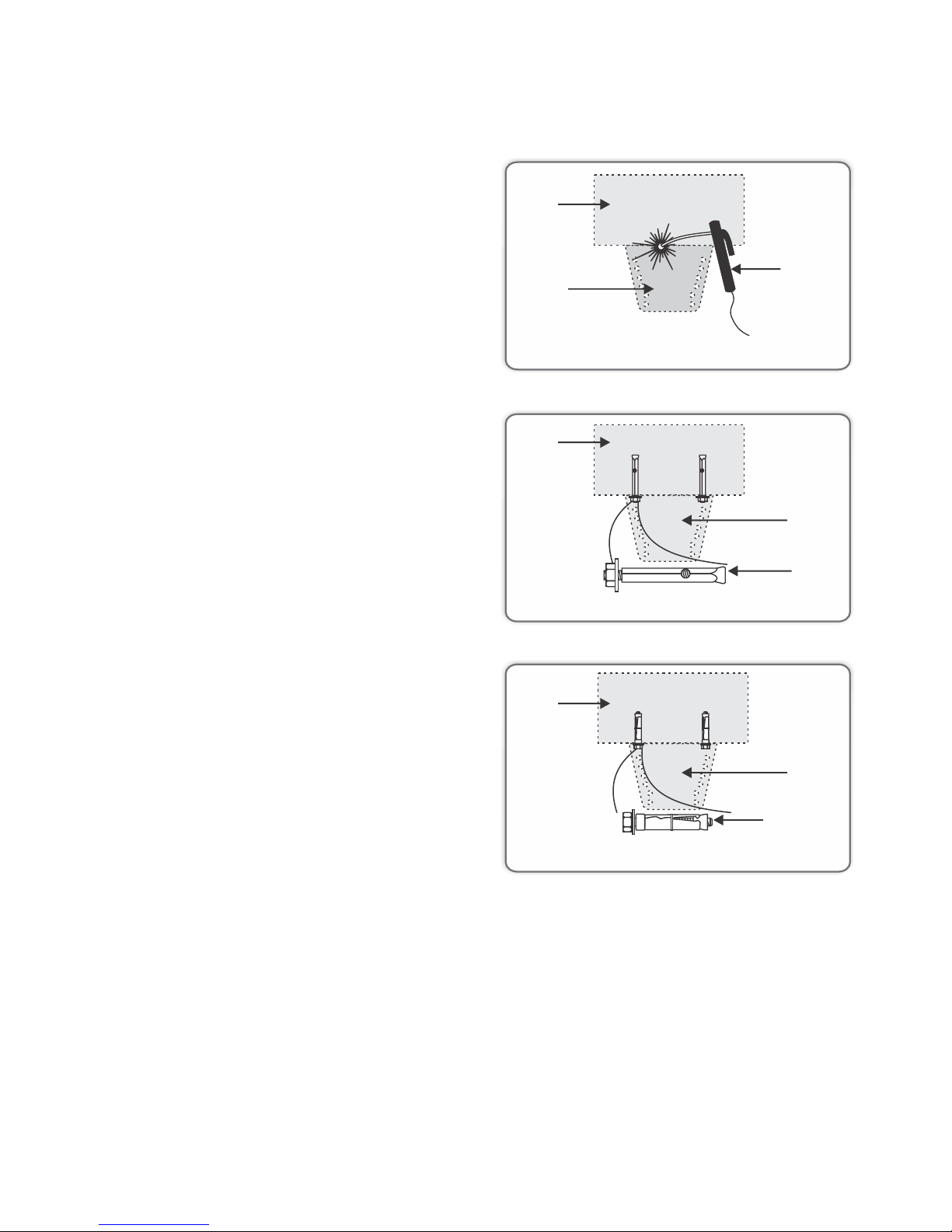

The means used to secure the

bracket to the pillar is as important

as the bracket itself

Through wall

Applications:

Prefabricated walling

For heavy gates operating frequently

Best

Works well

Chemical anchors

Applications:

Masonry pillars

Frequent use

FIGURE 9

FIGURE 10

Page 17

Pillar

Wall

adaptor

(high

security)

Pillar

Wall

adaptor

(standard)

Pillar

Through

wall bolt

Pillar

Chemical

anchors

Wall

adaptor

(high

security)

Wall

adaptor

(high

security)

Page 22

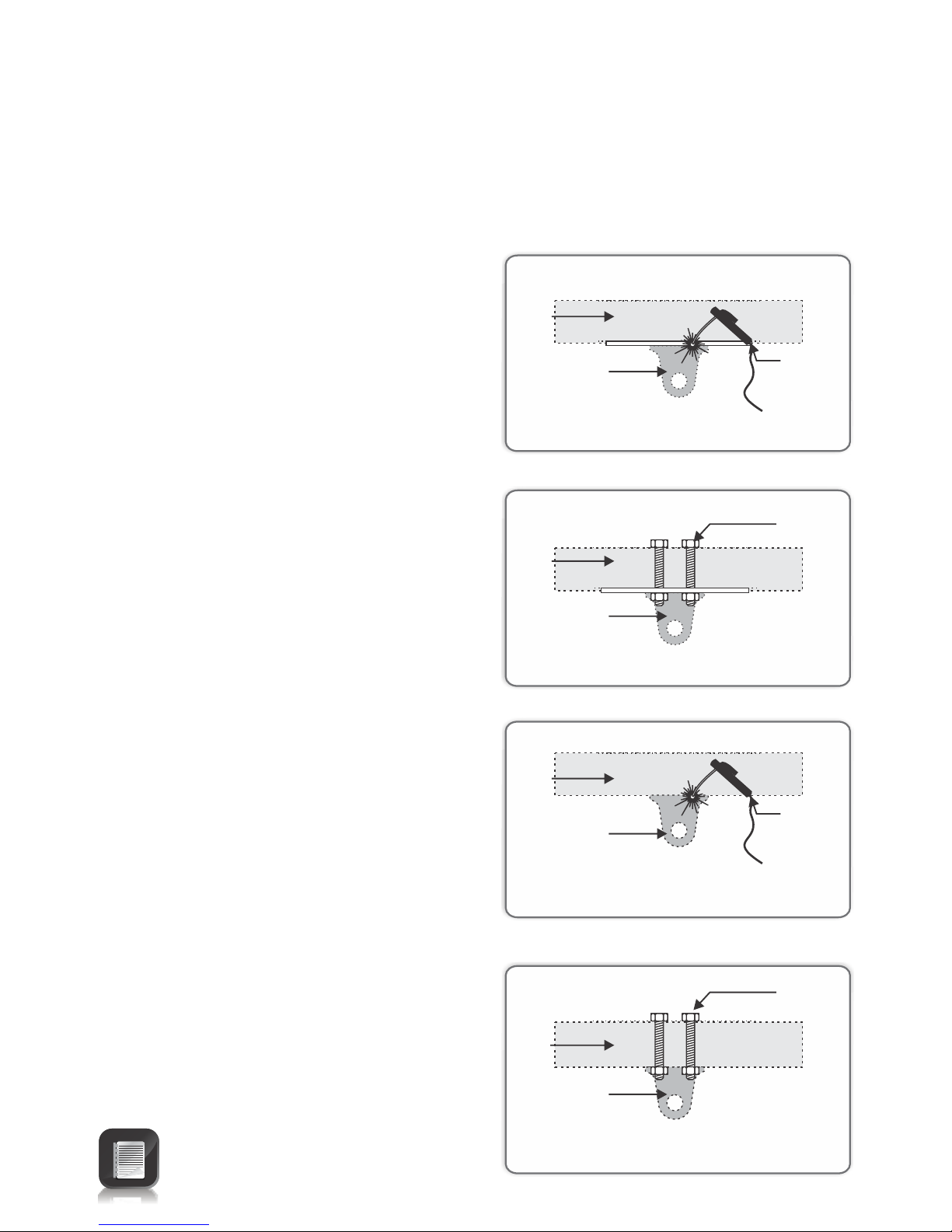

Page 18

Applications:

Lighter gates

Domestic

Welding

Sleeve anchors

Applications:

Lighter gates

Domestic

Applications:

Very light

Very domestic

RAWL Bolts

FIGURE 12

FIGURE 13

Works well

FIGURE 11

Ok

Not

recommended

Pillar

Welding

machine

Wall

adaptor

(high

security)

Sleeve

anchor

Pillar

Wall

adaptor

(high

security)

Wall

adaptor

(high

security)

Pillar

Rawl bolt

Page 23

Page 19

Applications:

Domestic

Medium gates

Frequent use

Welding

Strength of the gate and gate bracket

The gate adaptor kit both strengthens the connection to the gate, and also allows for more

flexibility when mounting the bracket to the gate:

Applications:

Light-industrial

Heavy gates

Frequent use

Welding Gate adaptor kit

Applications:

Domestic

Light gates

Infrequent use

Through bolts (High tensile)

Best

Very good

Through bolts Gate adaptor kit

Applications:

Light-industrial

Heavy gates

Frequent use

Good

Fair

Tek screws and mild steel bolts

are not recommended

FIGURE 14

FIGURE 15

FIGURE 16

FIGURE 17

Gate

Gate adaptor

Welding

machine

Gate

Gate adaptor

Through

bolts

Gate

Gate adaptor

Welding

machine

Gate

Gate adaptor

Through

bolts

Page 24

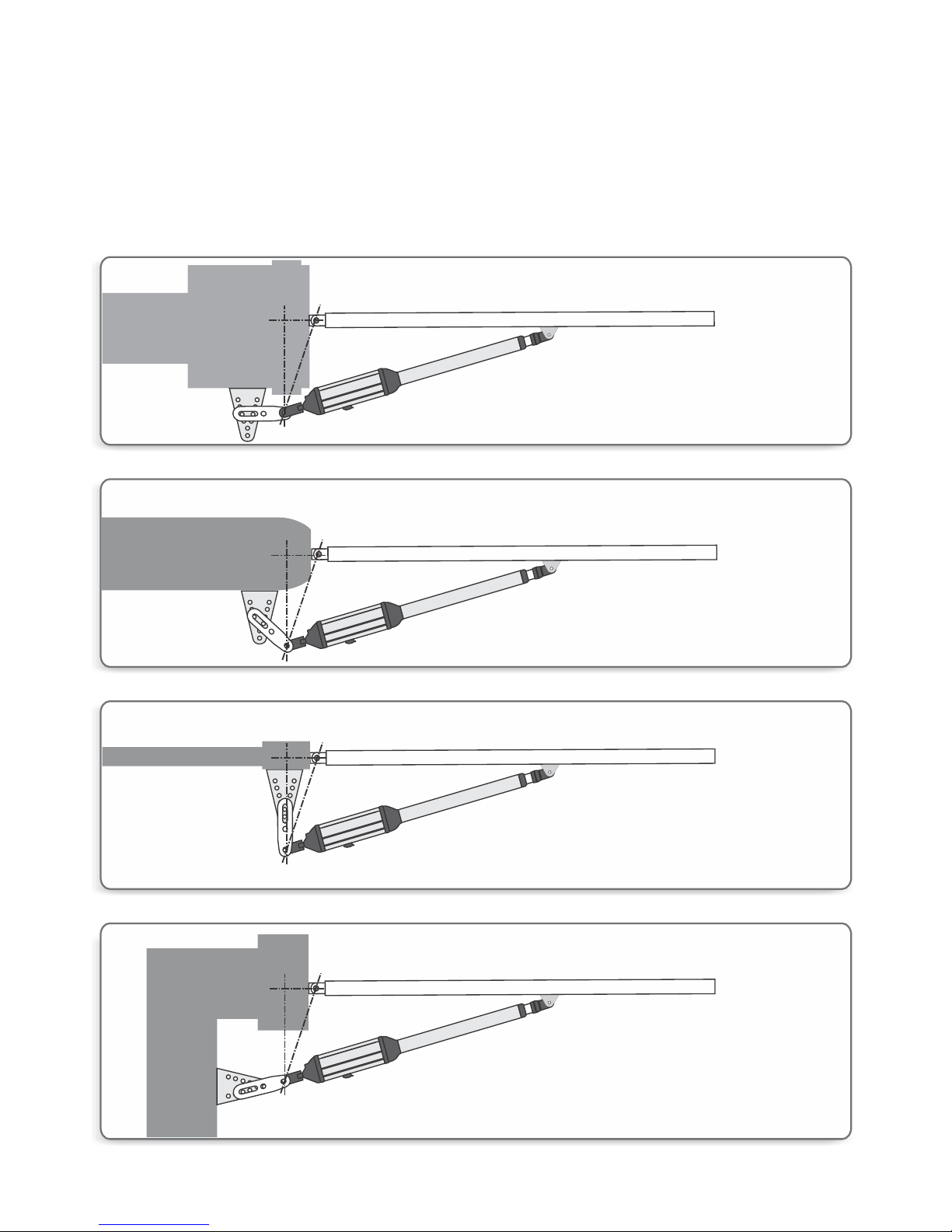

Page 20

The Mechano kit installation options

This kit is useful when fitting VECTOR2 to existing installations, and also makes adjustments

easier when doing new installations.

FIGURE 18. INSTALLATION WHEN THE PILLAR IS WIDE

FIGURE 19. INSTALLATION WHEN THE PILLAR IS AN IRREGULAR SURFACE

FIGURE 20. INSTALLATION ON A PALISADE FENCE

FIGURE 21. INSTALLATION ON AN ANGLED WALL

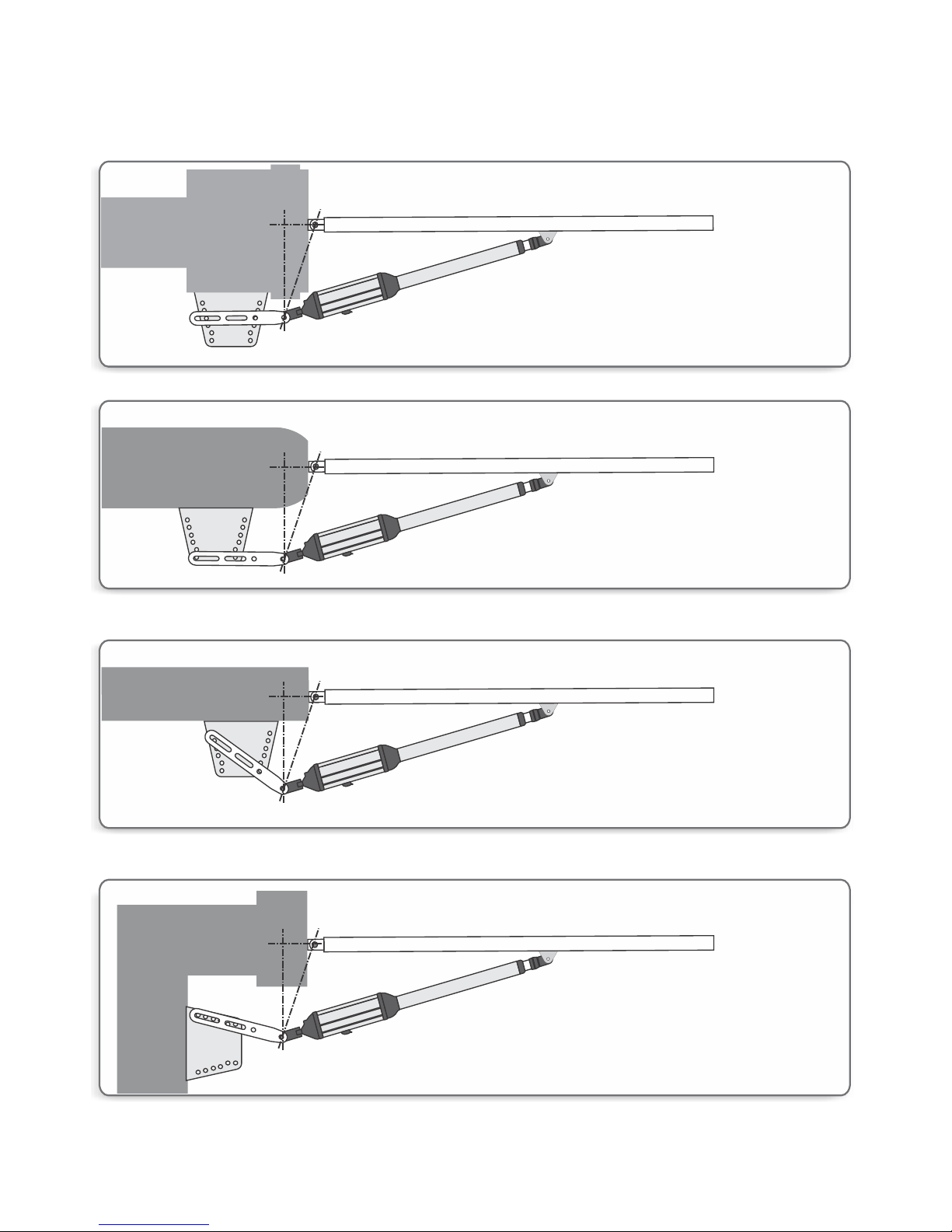

Page 25

Page 21

FIGURE 22. INSTALLATION WHEN THE PILLAR IS WIDE

FIGURE 23. INSTALLATION WHEN THE PILLAR IS IRREGULAR SURFACE

FIGURE 24. INSTALLATION ON A PALISADE FENCE

FIGURE 25. INSTALLATION ON AN ANGLED WALL

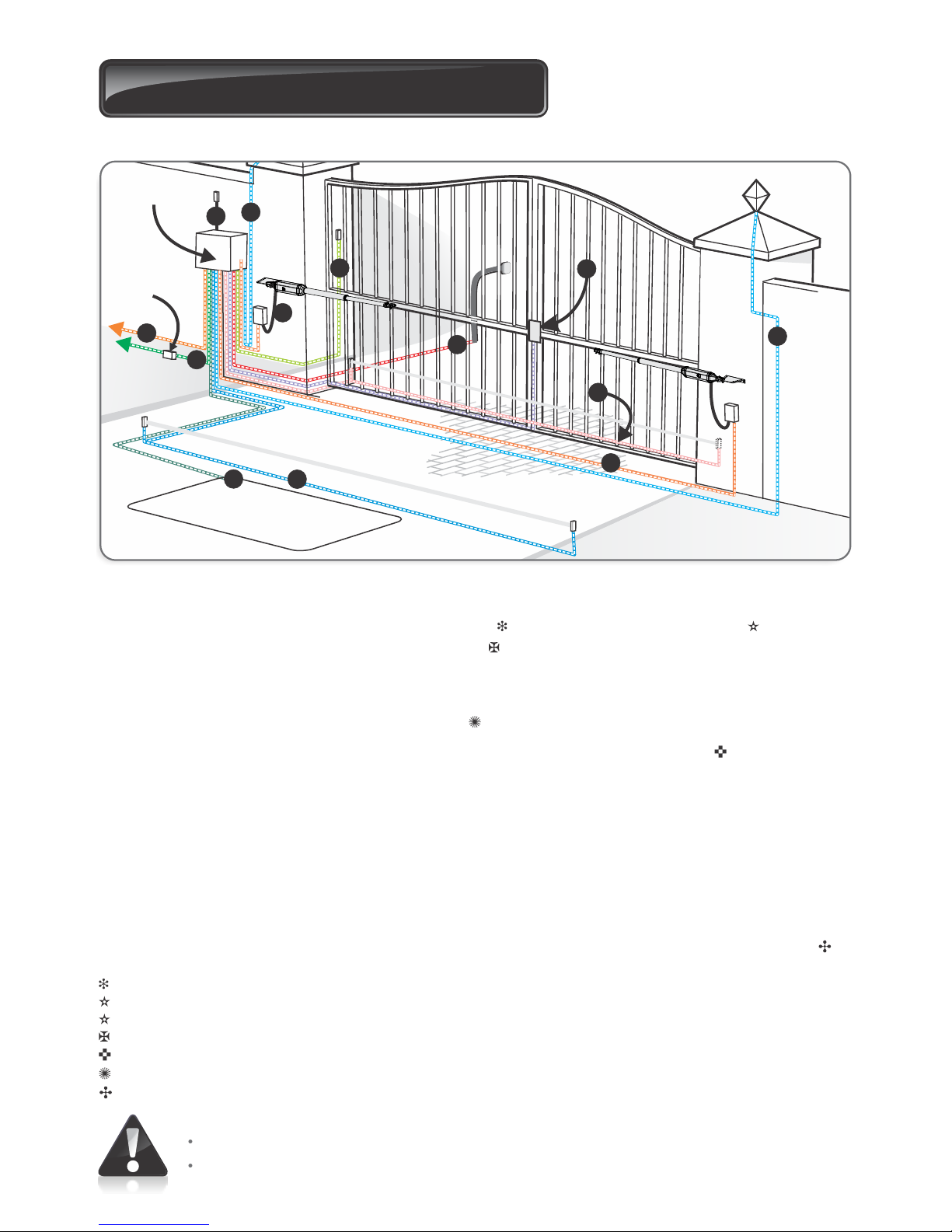

Page 26

8. Cabling requirements

To dwelling

Control

box

4

5

6

2

1

9

9

6

Beninca

Mains

isolator

switch

10

2

8

7

3

FIGURE 26. CABLING REQUIREMENTS

Page 22

Legend

1. 220-240V AC mains cable via mains isolator switch (3 core LNE 0,5mm²), or

low-voltage 16V AC battery charger supply (2 core 1,5mm²).

2. Intercom cable (n1 + 6 core) to house.

2

3. Master motor (MTR M) or Slave motor (MTR S) cable ( minimum, 2 core 2mm +

4 core 0,5mm² multi-stranded) see note

2

4. Optional radio receiver cable (3 core 0,5mm multi-stranded, optional)

2

5. Optional pedestrian key-switch (2 core 0,5mm multi-stranded).or Optional keypad (3

2

core 0,5mm multi-stranded).

2

6. Optional infrared beams or safety edge (3 core 0,5mm multi-stranded or 4 core

0.5mm² for CE compliance.)

7. Optional intercom cable (n2+2 core 0,5mm² multi-stranded) to gate station

8. Optional electric lock (2 core 0.5mm²)

9. Optional Pillar Light cable (3 core, size according to power reg.)

2

10. Optional ground loop for free-exit (1core 0.5mm multi-stranded - silicone-coated)

Mains isolator must be fitted less than 1m from controller

Increase cable thickness if Pillar Lights are to be installed.

Screened cable is always recommended to provide better protection against lightning - earth one end of screening.

Domestic charger only.

For optimum range an external receiver can be mounted on the wall.

CENTURION has available custom VECTOR2 cable order reference: CABLEVEC68

Consult manufacturer of loop detector for specific details

All cables must be routed in conduit unless underground cable is being used

Mains isolator must be less than 1m from the operator

Safety beams are always recommended

Page 27

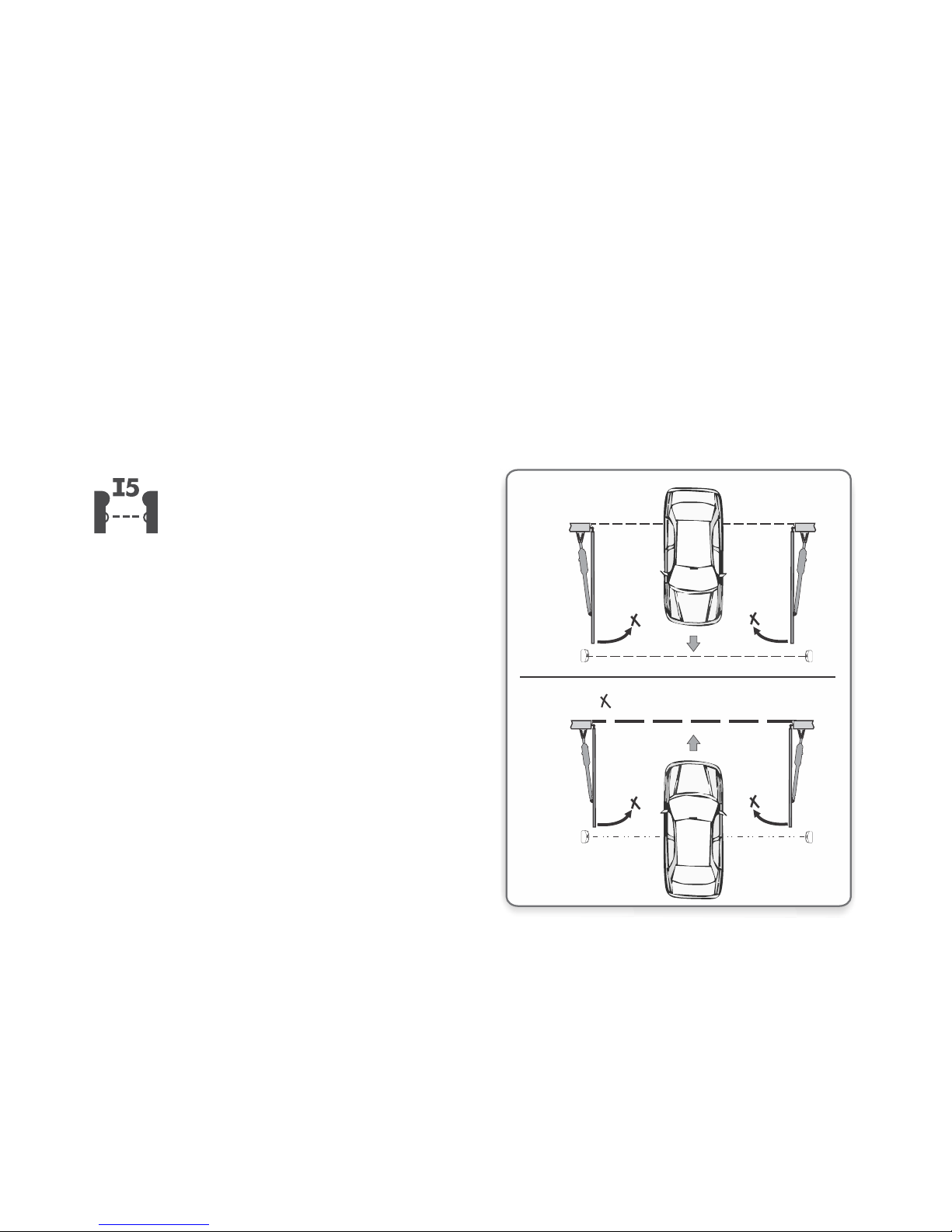

9. Operator installation

To simplify the installation process, it is recommended that the existing gate is

removed from the pillar before proceeding.

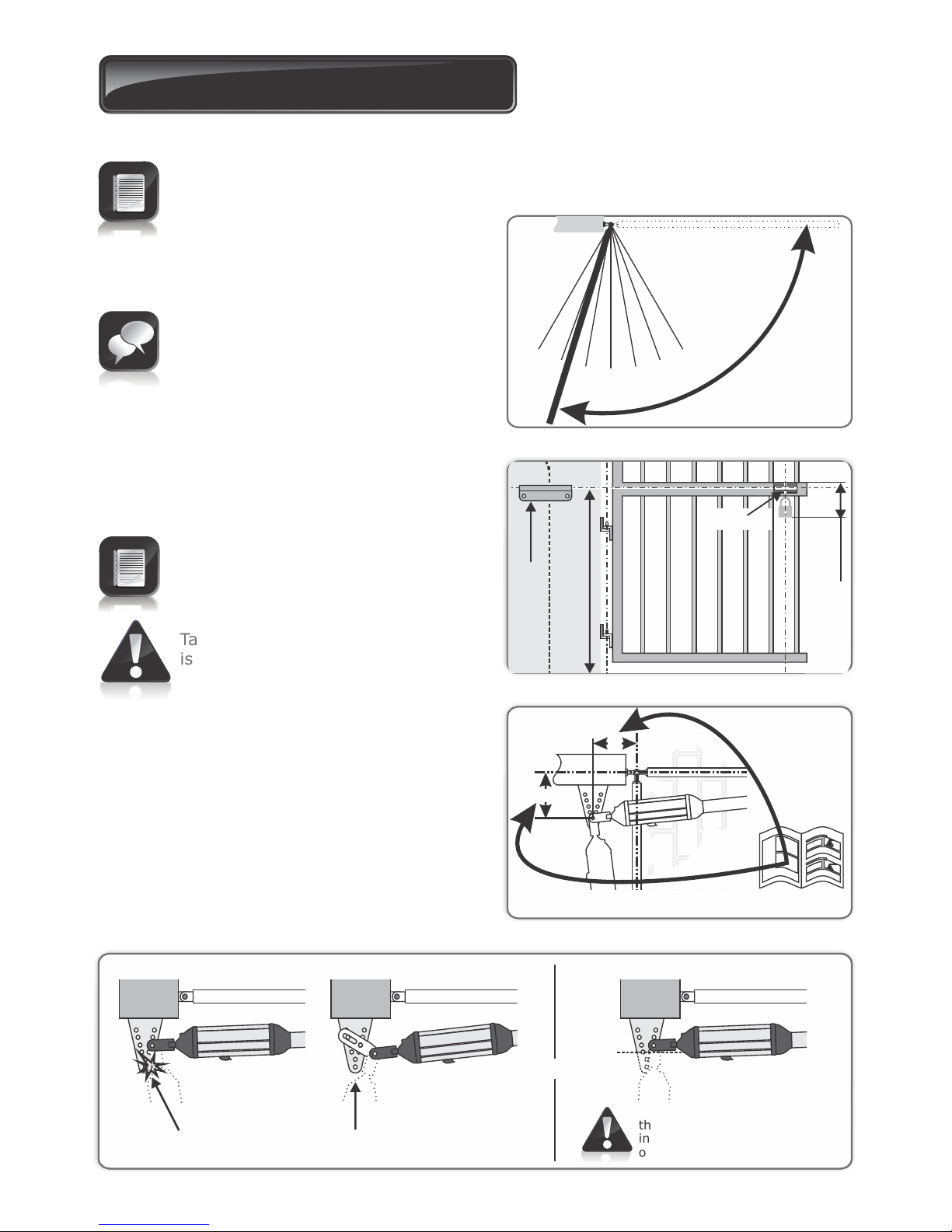

1. Determine gate opening angle and direction

of operator (inward or outward).

Alternatively the swing angle can be

determined more accurately with the

process detailed on page 33

120°

100°

110°

90°

80°

70°

60°

Open

Closed

Estimate

swing angle

2. Determine a suitable height for the wall

bracket.

The gate bracket must fit to a sturdy

point on the gate.

Consider using the optional gate

adaptor kit

Take care to make sure the operator

is mounted level

Wall Bracket

85mm

Gate Bracket

Minimum 125mm

3. Determine where to put the bracket

according to A and B values in the tables on

pages 28, 29, 31 and 32.

B

A

120°

110°

100°

90°

80°

70°

60°

Gate opening angle

0°

120°

110°

100°

90°

80°

70°

60°

Gate opening angle

0°

Use Mechano kit

Operator must not

foul against bracket

Take care to shorten

the wall bracket to prevent

interference with the

operator

FIGURE 27. ESTIMATE SWING ANGLE

FIGURE 28. GATE HEIGHT

FIGURE 29. BRACKET POSITION

FIGURE 30. BRACKET POSITION

Page 23

Or

Cut the bracket

Page 28

Page 24

FIGURE 31

FIGURE 32

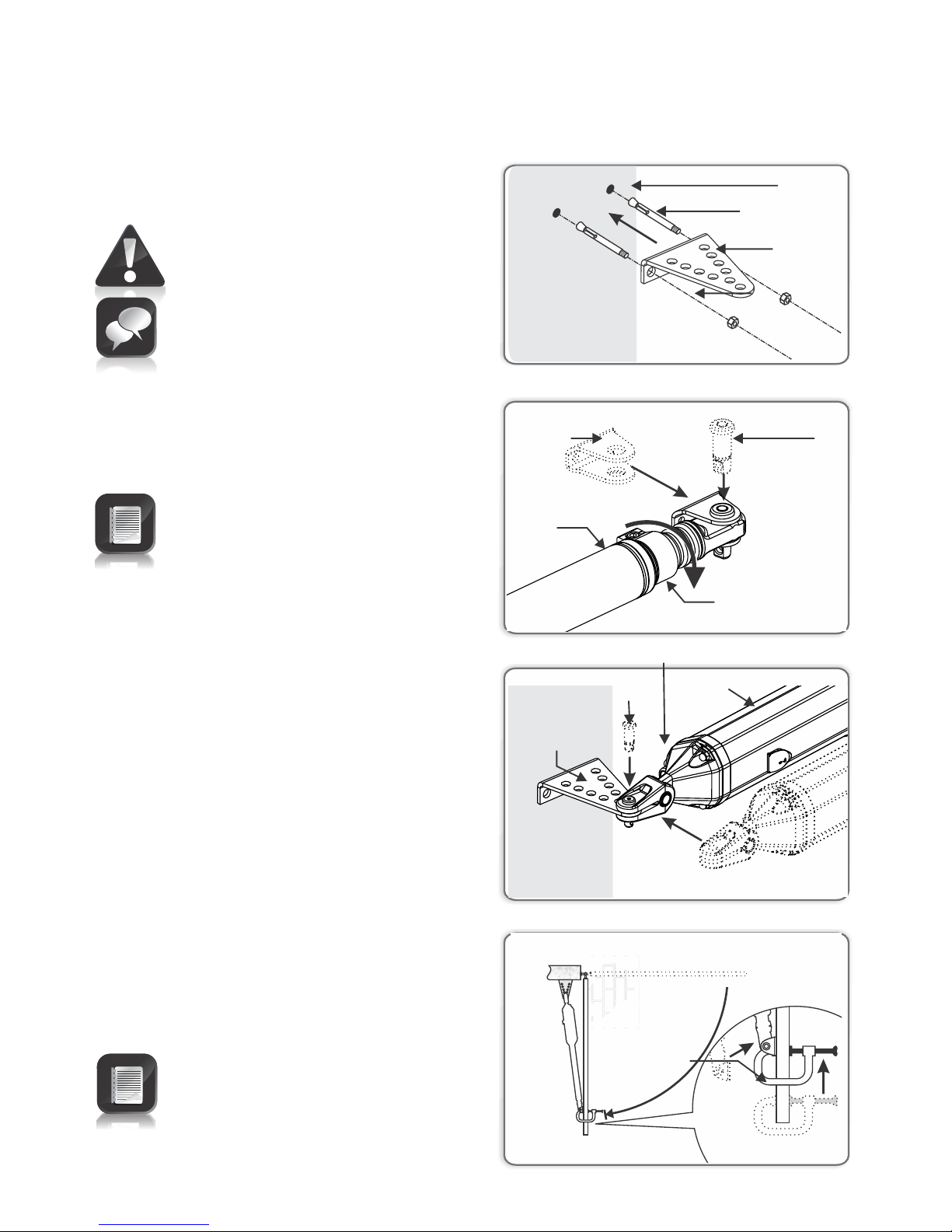

4. Secure the bracket to the wall with the

most appropriate means.

It is critical that the wall bracket is

securely mounted

See page 15 for site

considerations

Determine the gate

bracket position

One or two turns

5. Fit the gate bracket to the operator.

Start with the operator fully

retracted

Turn out the actuator tube one or

two turns

FIGURE 33

6. Fit the motor end of the operator to the

wall bracket.

7. Open the gate fully and temporarily clamp

the gate bracket to the gate.

The gate bracket must fit to a

sturdy point on the gate

Consider using the optional gate

adaptor kit. See page 13

FIGURE 34

Wall

adaptor

(Standard)

Wall

Mounting bolt

VECTOR2

unit

Pin

Gate

bracket

Wall

adaptor

(Standard)

VECTOR2

unit

Pin

G-clamp

Origin marker

Page 29

Page 25

FIGURE 37

FIGURE 35

8. Unlock the operator and swing the gate

closed.

9. Remove the pin and the operator from the

bracket, check that there are at least one

or two turns of the actuator before it is fully

extended.

If it becomes obvious that the

operator does not have enough

stroke, reduce either the A or B

distances by moving the wall

Be sure not to make the A and B

values less than allowed for in the

installation tables on page 28 and 29

In general:

Large B distances give good security and

good closing push force

Small A and small B will increase the

speed

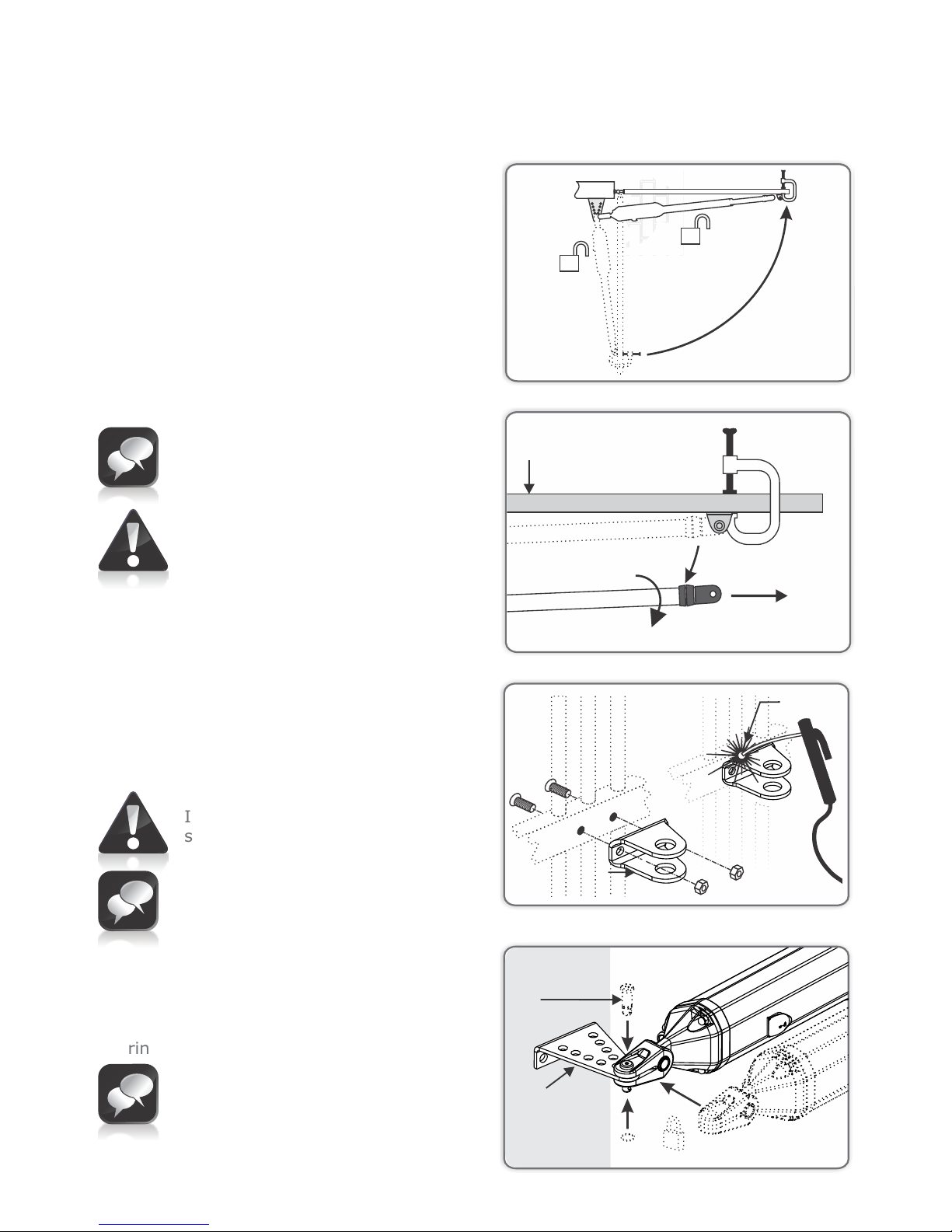

Fasten gate bracket to gate

ororor

10. Secure the gate bracket using the most

appropriate means.

It is critical that the gate bracket is

securely mounted

See page 15 for site considerations

FIGURE 38

11. Fit operator, wall bracket pins and snap

rings.

As an alternative to the snap ring, fit

a padlock

FIGURE 36

or

Gate

Gate adaptor

Welding

Wall adaptor

(standard)

Pin

Page 30

12. Fit operator, gate bracket pins and snap

rings.

Page 26

FIGURE 39

13.Unlock the operator and open the gate fully.

14. Slide the origin clamp along the actuator

tube, right up to the operator. Secure in

place with an Allen key and tighten

properly.

FIGURE 40

FIGURE 41

As an alternative to the snap ring, fit

a padlock

Adjust origin clamp

open

15. Attach warning decals to the gate as

shown.

1

1

or

Pin

Wall adaptor

(standard)

Padlock

VECTOR2

operator

Origin

marker

Page 31

For gates opening more than 90°

For gates opening 90° or less

Page 27

FIGURE 42

FIGURE 43

B

A

Inward swing gate Setup

Gate open

Gate open

Gate closed

FIGURE 44

B

A

For best security (but slower

operation) install with large B value

For fast operation (but less

security) install with small A and

small B values

Ensure that the gate does not

exceed the gate mass specifications

on page 11

Page 32

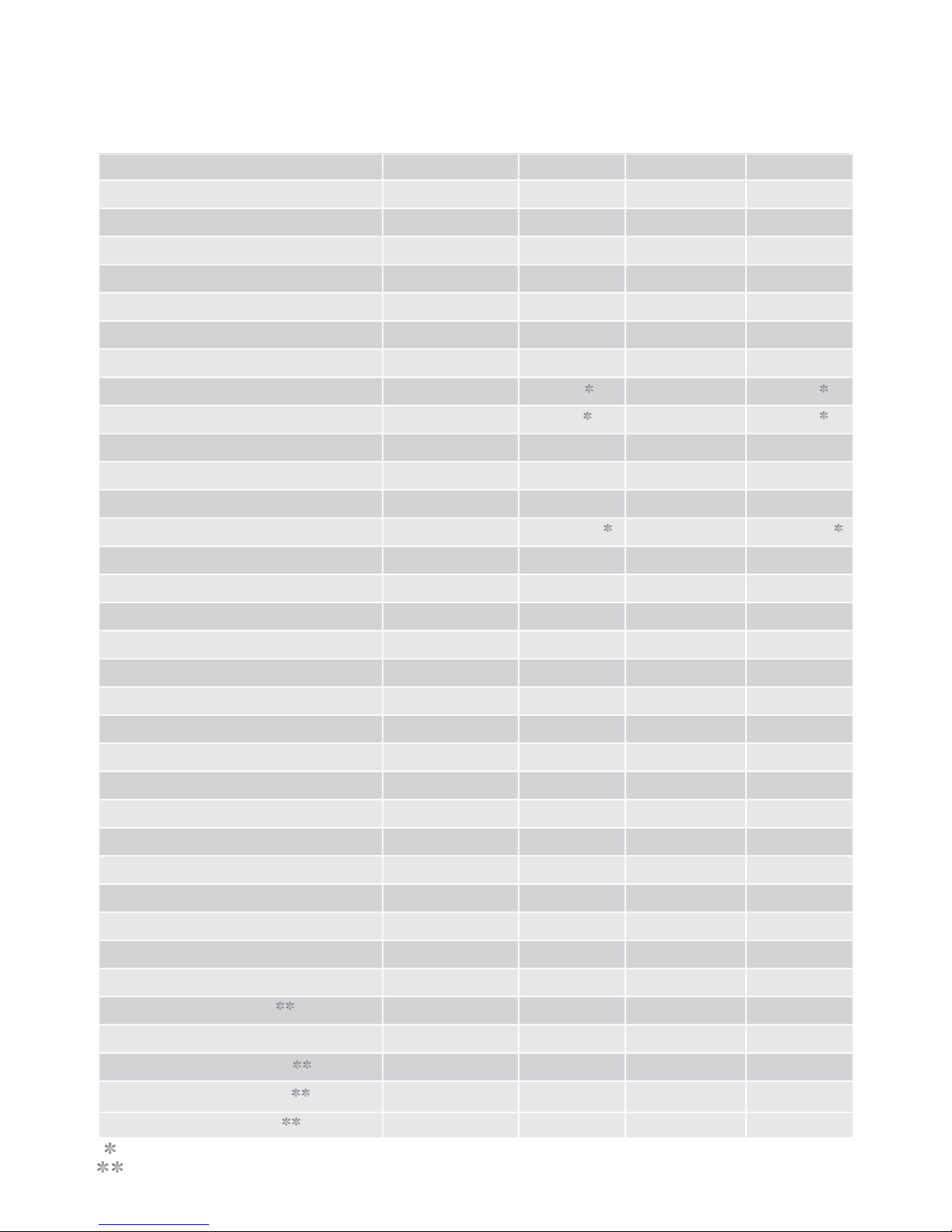

Page 28

FIGURE 45

FIGURE 46

1400mm Extended

1000mm Retracted1000mm Retracted1000mm Retracted

For V400 (400mm operator)

120°

100°

110°

90°

80°

70°

60°

Gate opening angle

0°

Gate swing angle

90° or less

100°

110°

120°

A Value

160

120

120

110

B Value

200

180

130

110

(Only for a 2.5m gate or shorter)

Recommended positions

Alternative positions

Gate swing

angle

60° - 90° or less

100°

110°

A+B should not

exceed

380mm

310mm

265mm

A and B must each be greater

Up

to1.5m

110mm

110mm

110mm

Up to

2m

110mm

110mm

110mm

Up to

2.5m

110mm

110mm

110mm

Up to

3m

120mm

120mm

Up to

3.5m

140mm

140mm

Up to

4m

160mm

160mm

Not recommended

110mm for A or B would ensure a 15mm clearance between the operator and

gate if the gate is 50mm thick

Page 33

Page 29

FIGURE 47

FIGURE 48

1600mm Extended

1100mm Retracted

For V500 (500mm operator)

120°

100°

110°

90°

80°

70°

60°

Gate opening angle

0°

Gate swing angle

90° or less

100°

110°

120°

A Value

205

165

144

115

B Value

250

215

180

150

(Only for a 2.5m gate or shorter)

Recommended positions

Alternative positions

110mm for A or B would ensure a 15mm clearance between the operator and

gate if the gate is 50mm thick

Gate swing

angle

60° - 90° or less

100°

110°

120°

A+B should not

exceed

460mm

400mm

340mm

285mm

A and B must each be greater

Up

to1.5m

110mm

110mm

110mm

Up to

2m

110mm

110mm

110mm

Up to

2.5m

110mm

110mm

110mm

Up to

3m

120mm

120mm

Up to

3.5m

140mm

140mm

Up to

4m

160mm

160mm

Not recommended

Page 34

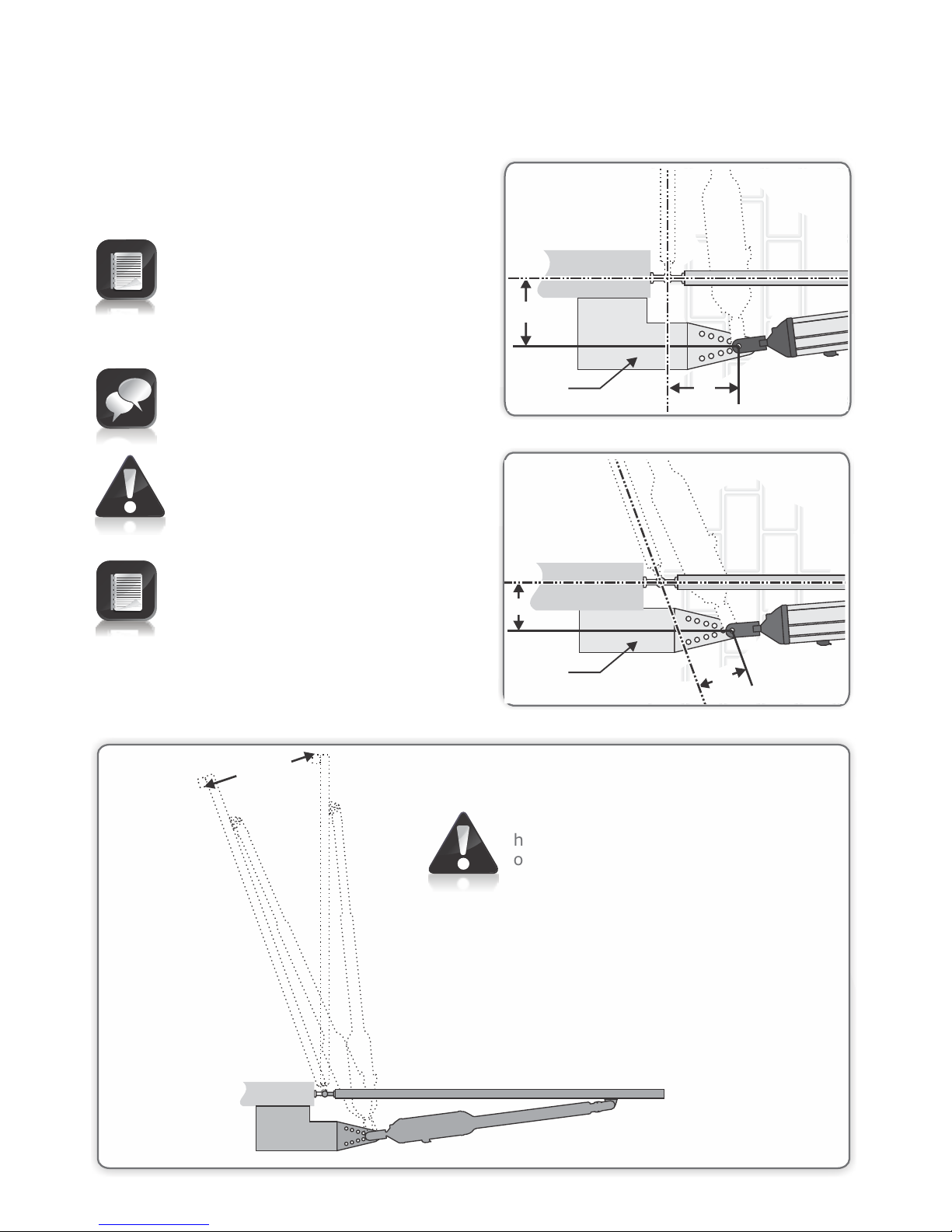

For gates opening 90° or less

FIGURE 51

FIGURE 49

For best security (but slower

operation) install with large B value

For fast operation (but less

security) install with small A and

small B values

Ensure that the gate does not

exceed the gate mass specifications

on page 11

For gates opening more than 90°

Endstop

see

Caution

Note

Gate closed

Gate open

Gate open

Outward swing gate Setup

B

A

B

A

Outward opening swing gates must

have physical endstops fitted in the

open position

FIGURE 50

Page 30

Make up

bracket

to suit

Make up

bracket

to suit

Page 35

Page 31

FIGURE 52

FIGURE 53

1400mm Extended

1000mm Retracted1000mm Retracted1000mm Retracted

For V400 (400mm operator)

120°

100°

110°

90°

80°

70°

60°

Gate opening angle

0°

Gate swing angle

90° or less

100°

110°

120°

A Value

173

145

120

106

B Value

191

160

130

114

(Only for a 2.5m gate or shorter)

Recommended positions

Alternative positions

110mm for A or B would ensure a 15mm clearance between the operator and

gate if the gate is 50mm thick

Gate swing

angle

60° - 90° or less

100°

110°

A+B should not

exceed

365mm

310mm

265mm

A and B must each be greater

Up

to1.5m

110mm

110mm

110mm

Up to

2m

110mm

110mm

110mm

Up to

2.5m

110mm

110mm

110mm

Up to

3m

120mm

120mm

Up to

3.5m

140mm

140mm

Up to

4m

160mm

160mm

Not recommended

Page 36

Page 32

FIGURE 54

FIGURE 55

1600mm Extended

1100mm Retracted

For V500 (500mm operator)

120°

100°

110°

90°

80°

70°

60°

Gate opening angle

0°

Gate swing angle

90° or less

100°

110°

120°

A Value

222

185

155

128

B Value

246

205

170

139

(Only for a 2.5m gate or shorter)

Recommended positions

Alternative positions

110mm for A or B would ensure a 15mm clearance between the operator and

gate if the gate is 50mm thick

Gate swing

angle

60° - 90° or less

100°

110°

120°

A+B should not

exceed

455mm

390mm

330mm

275mm

A and B must each be greater

Up

to1.5m

110mm

110mm

110mm

Up to

1.5m

110mm

110mm

110mm

Up to

2.5m

110mm

110mm

110mm

Up to

3m

120mm

120mm

Up to

3.5m

140mm

140mm

Up to

4m

160mm

160mm

Not recommended

Page 37

Page 33

10. Determine gate swing angle

1. Close the gate and measure a distance of

1m from the centreline of the gate hinge.

2. Make a mark on the ground.

1m

Use this procedure to accurately determine the gate opening angle:

3. Open the gate and measure a distance

along the gate a distance of 1m from the

centreline of the gate hinge.

4. Make a mark on the ground.

5. Measure the distance on the ground

between the two marks (Z).

6. Using this Z value, read off the gate

opening angle from the table below.

Step 1

Step 2

Step 3

Use gate swing angle of

60°

70°

80°

90°

100°

110°

120°

Value z from

1 000mm

1 075mm

1 218mm

1 351mm

1 474mm

1 587mm

1 687mm

To

1 075mm

1 218mm

1 351mm

1 475mm

1 587mm

1 687mm

1 732mm

1m

Z

FIGURE 56

FIGURE 57

Page 38

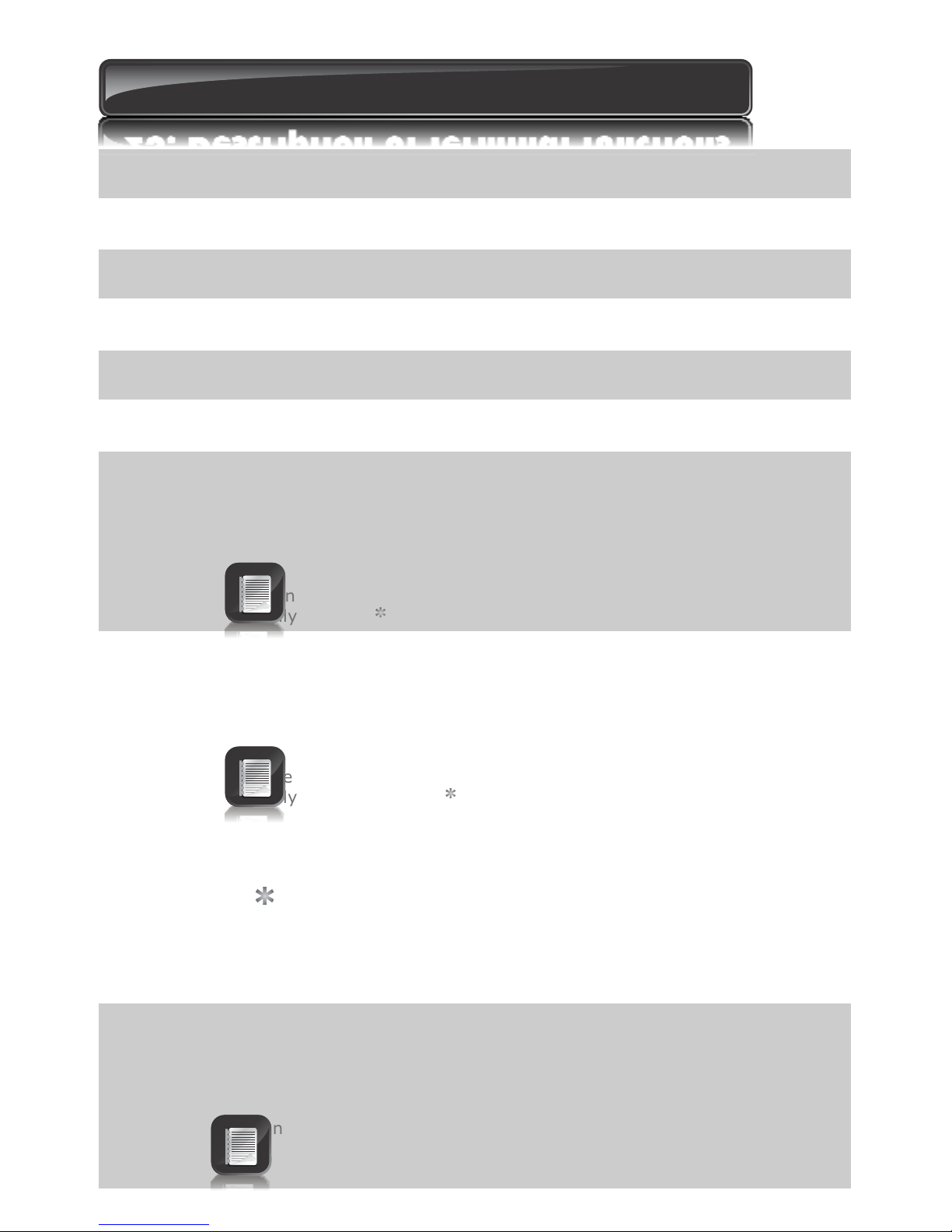

Page 34

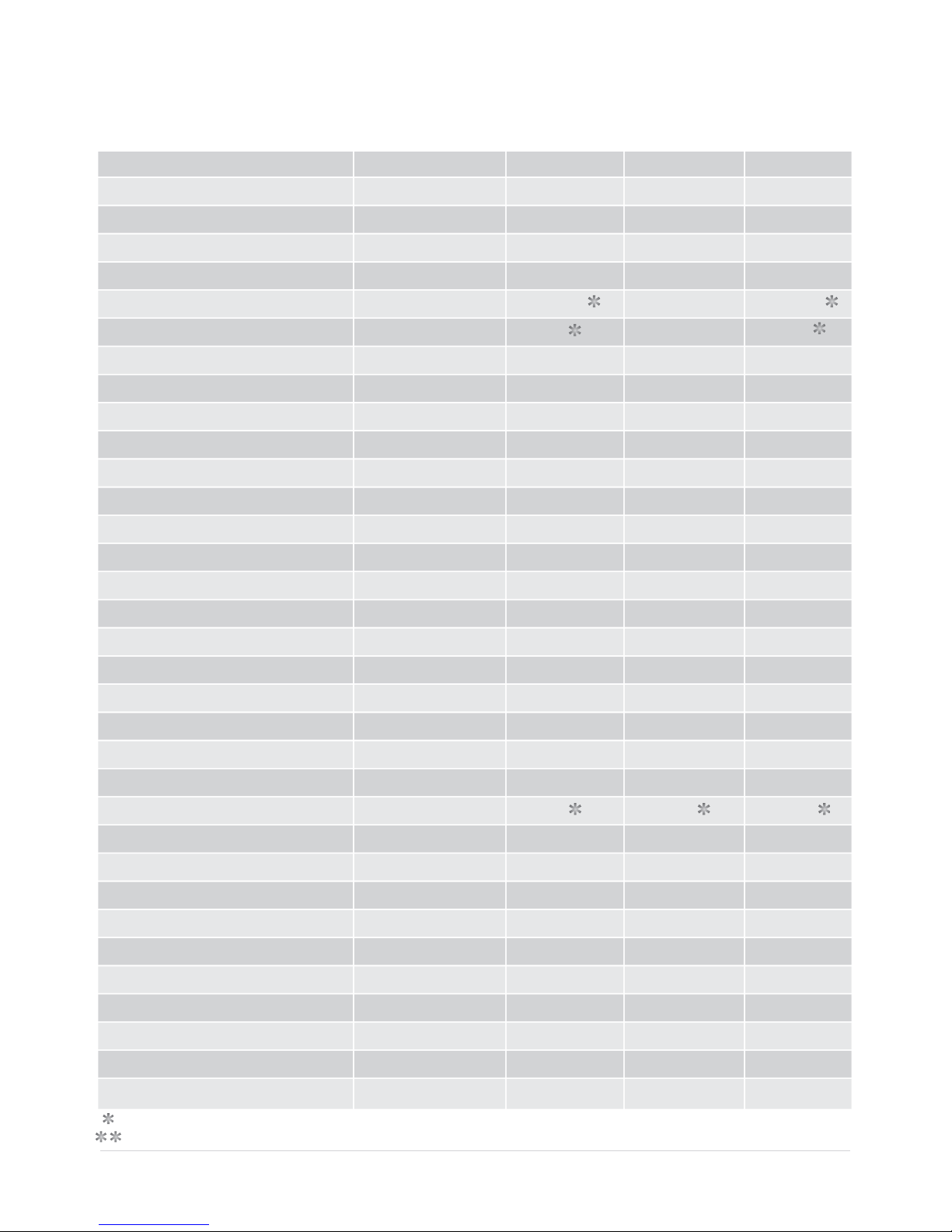

11. Allowable wind load

Wind speeds for which operator will still operate the gate (for V400 or V500 operators)

Value of A or B

dimension once

installed.

100mm

140mm

180mm

220mm

260mm

300mm

340mm

Up to

1.5m

94km/h

119km/h

138km/h

156km/h

171km/h

186km/h

199km/h

Up to

2m

66km/h

85km/h

101km/h

114km/h

126km/h

137km/h

147km/h

Up to

2.5m

48km/h

65km/h

78km/h

89km/h

99km/h

108km/h

116km/h

Up to

3m

44km/h

57km/h

67km/h

76km/h

84km/h

91km/h

98km/h

Up to

3.5m

41km/h

51km/h

60km/h

67km/h

74km/h

80km/h

86km/h

Up to

4m

37km/h

46km/h

53km/h

60km/h

65km/h

71km/h

76km/h

For a 25% covered gate: (Palisades, etc.) x 1.8m high

Gate lengths:

See page 23 or 24 for installation details

An electric lock must be fitted

Wind speeds for which operator will still operate the gate (for V400 or V500 operators)

Value of A or B

dimension once

installed.

100mm

140mm

180mm

220mm

260mm

300mm

340mm

Up to

1.5m

47km/h

59km/h

69km/h

78km/h

86km/h

93km/h

100km/h

Up to

2m

33km/h

43km/h

50km/h

57km/h

63km/h

68km/h

74km/h

Up to

2.5m

24km/h

32km/h

39km/h

44km/h

49km/h

54km/h

58km/h

Up to

3m

22km/h

28km/h

34km/h

38km/h

42km/h

46km/h

49km/h

Up to

3.5m

20km/h

26km/h

30km/h

34km/h

37km/h

40km/h

43km/h

Up to

4m

19km/h

23km/h

27km/h

30km/h

33km/h

35km/h

38km/h

For a 100% covered gate: (Fully clad gates, etc.) x 1.8m high

Gate lengths:

See page 23 or 24 for installation details

An electric lock must be fitted

Page 39

Page 35

12. Electrical setup

Secure control box to wall

1. Secure the control box to the wall using the

most appropriate means.

Step 1

Control box

Preferably mounted

At eye level

Be sure to position the wall box so as

not to cause any hazards during and

after the installation

Preferably mount the wall box:

Out of direct sunlight

At a comfortable working height

Away from garden sprinklers etc

To allow easy access even when

the gate is open

Figure 15 Wiring Diagram

Figure 15 Wiring DiagramFigure 15 Wiring Diagram

151515

151515

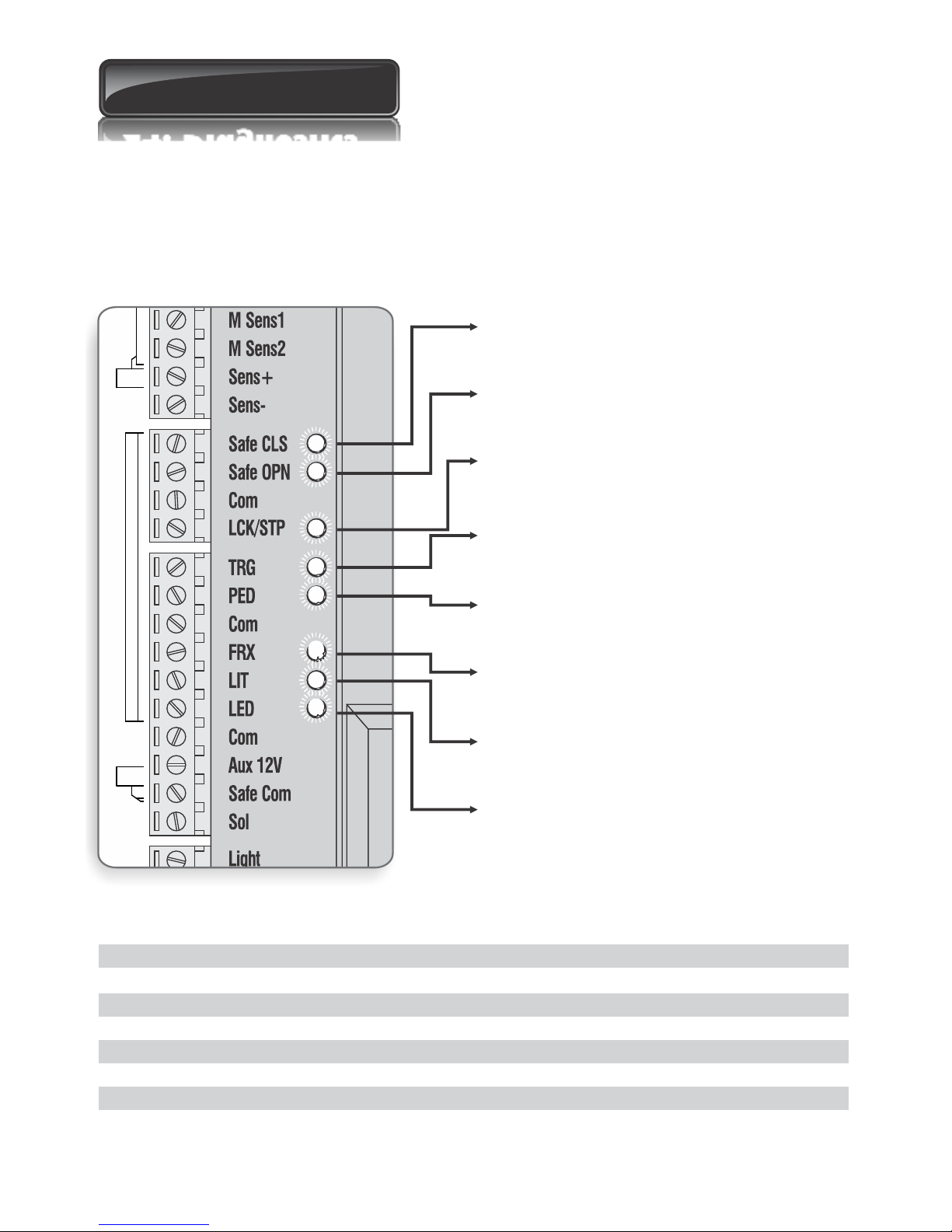

S Sens1

S Sens2

M Sens1

M Sense2

Sens+

Sens-

Saf CLO

Saf OPE

Com

LCK/STP

TRG

PED

Com

FRX

LIT

LED

Com

Aux 12V

Com Saf

Sol

Light

Light

Batt +

Bat -

MTR M+

MTR —

MTR S+

MTR S-

MASTER

SLAVE

BLACKBLACKBLACK

REDREDRED

BLUEBLUEBLUE

PURPLEPURPLEPURPLE

BLACKBLACKBLACK

REDREDRED

BLUEBLUEBLUE

PURPLEPURPLEPURPLE

BLACKBLACKBLACK

REDREDRED

BLUEBLUEBLUE

PURPLEPURPLEPURPLE

PURPLEPURPLEPURPLE

BLUEBLUEBLUE

MASTER

S Sens1

S Sens2

M Sens1

M Sense2

Sens+

Sens-

Saf CLO

Saf OPE

Com

LCK/STP

TRG

PED

Com

FRX

LIT

LED

Com

Aux 12V

Com Saf

Sol

Light

Light

Batt +

Bat -

MTR M+

MTR —

MTR S+

MTR S-

THIN PURPLE

THIN RED or GREY

THICK BLUE

THICK BLACK

THIN BLUE or ORANGE

THIN BLACK

SLAVE

S Sens1

S Sens2

M Sens1

M Sense2

Sens+

Sens-

Saf CLO

Saf OPE

Com

LCK/STP

TRG

PED

Com

FRX

LIT

LED

Com

Aux 12V

Com Saf

Sol

Light

Light

Batt +

Bat -

MTR M+

MTR —

MTR S+

MTR S-

THIN PURPLE

THIN RED or GREY

THICK BLUE

THICK BLACK

THIN BLUE or ORANGE

THIN BLACK

Wiring Diagram for Basic Operation

Wiring Diagram for Basic OperationWiring Diagram for Basic Operation

Page 36

Page 36Page 36

Page 37

Page 37Page 37

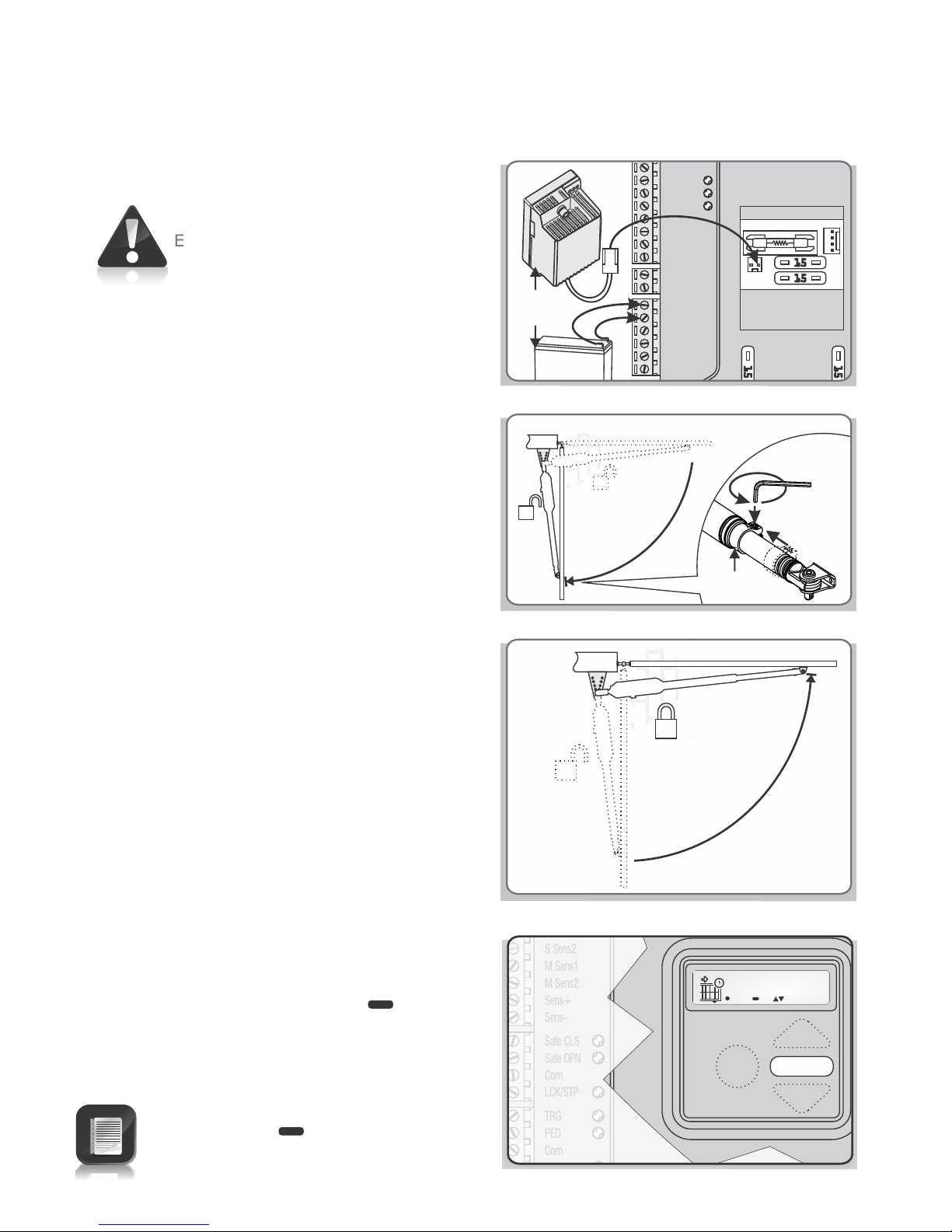

For wiring diagram see page 39/40

Connect all wiring

2. Connect all the cables as required to the

control card. See pages 36, 37, 38 and 39.

3. When wiring each operator back to the

controller housing, it is recommended to

mount a small junction box adjacent each

operator. Terminate the cable provided on

the operator into this junction box and then

route a new cable from the junction box to

the controller housing.

Junction

Box

1. Always check that the circuit breaker in the electrical panel is in the

OFF position, and that all high voltage circuits (more than 42.4V) are

completely isolated from the mains supply before doing any work.

2. Ensure that all low voltage systems (less than 42.4V) are suitably

protected from damage, by disconnecting all sources of power such

as chargers and batteries before doing any work.

3. All electrical work must be carried out according to the requirements

of all applicable local electrical codes. (It is recommended that a

licensed electrical contractor perform such work.)

FIGURE 58

FIGURE 59

FIGURE 60

It is recommended that the installer

tie off the harness in such a way so as

to allow for a 350mm loop between

the cable exit at the back of the

operator and either the mounting

bracket or junction box, to minimise

the flexing of the harness. If a sharp

bend is introduced to the cable

harness, or a loop that is less than

350mm in diameter, the resulting

cable fatigue may cause the actuators

to behave erratically or to stop

operating altogether

Page 40

Page 36

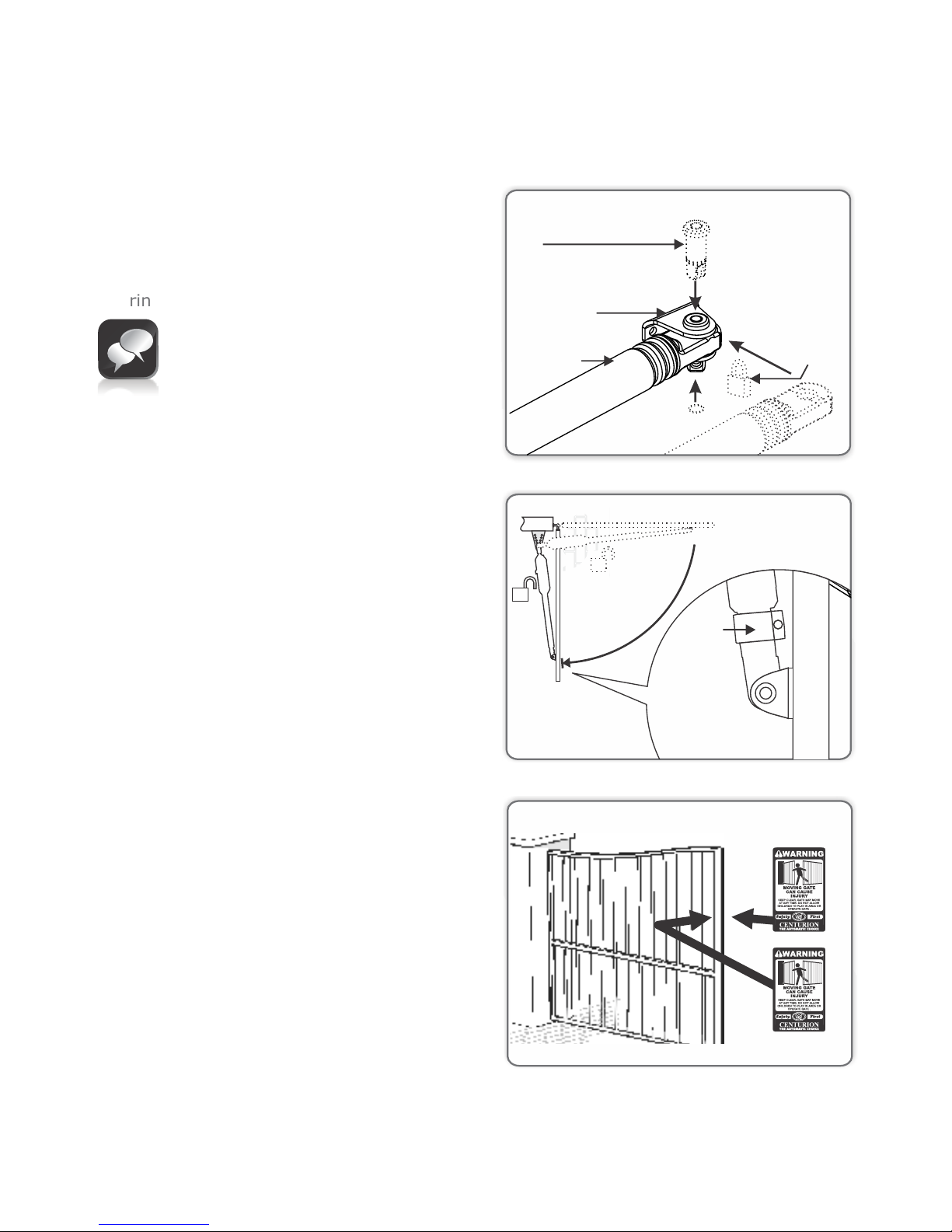

4. Check that the charger and battery are

connected to the controller.

Ensure the battery polarity is correct

5. Switch on the mains supply (via isolator).

6. Ensure that both the controller and charger

are effectively earthed for improved

lightning protection.

7. Check that the origin has been correctly set.

(See page 24).

8. Check that the gate is closed and the

operator is locked.

S Sens1

S Sens2

M Sens1

M Sens2

Sens+

Sens-

Safe CLS

Safe OPN

Com

LCK/STP

TRG

PED

Com

33333

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

AutoCloseAutoCloseAutoCloseAutoCloseAutoClose

9. If powering up the system ex-factory, it will

request for the operating PROFILE

(operating standard) to be set. Select from

the list the PROFILE that will suit the

specific region. With this set, the system

will automatically proceed to the limit

setup menu. Follow the onscreen

instructions to complete the setup

procedure.

If powering up with the PROFILE set but no

limits set, the system will

automatically proceed to the limit setup

menu. Follow the onscreen instructions to

complete the setup procedure.

If powering up at any stage after that, push

and hold the SETUP button ( ) for

3 seconds.

For more details about the PROFILE

(operating profile) – refer to page 53.

Select the “limits” menu by pressing the

ENTER button ( ). Follow the onscreen instructions to complete the setup procedure

Light

Light

Batt +

Batt MTR M+

MTR M MTR S+

MTR S -

Com

FRX

LIT

LED

Com

Aux 12V

Com Saf

Sol

open

FIGURE 61

FIGURE 62

FIGURE 63

FIGURE 64

Setting the limits

Charger

Battery

Origin

marker

Page 41

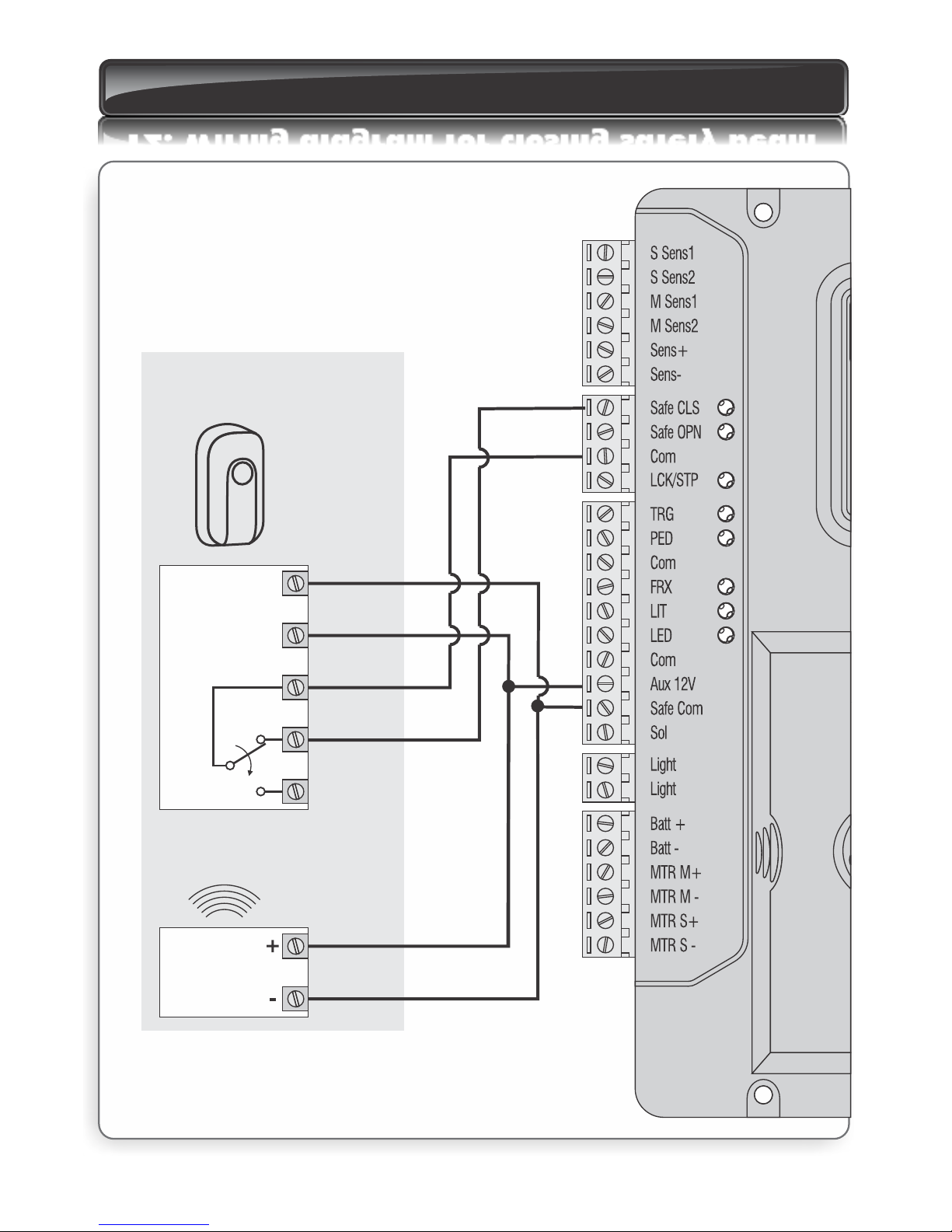

13. Wiring diagram for closing safety beam

IRB Tx

12V/24V +

12V/24V -

12V/24V -

IRB Receiver

COM

12V/24V +

NC

NO

Closing safety beam

FIGURE 65. WIRING OF SAFETY DEVICE

Page 37

Page 42

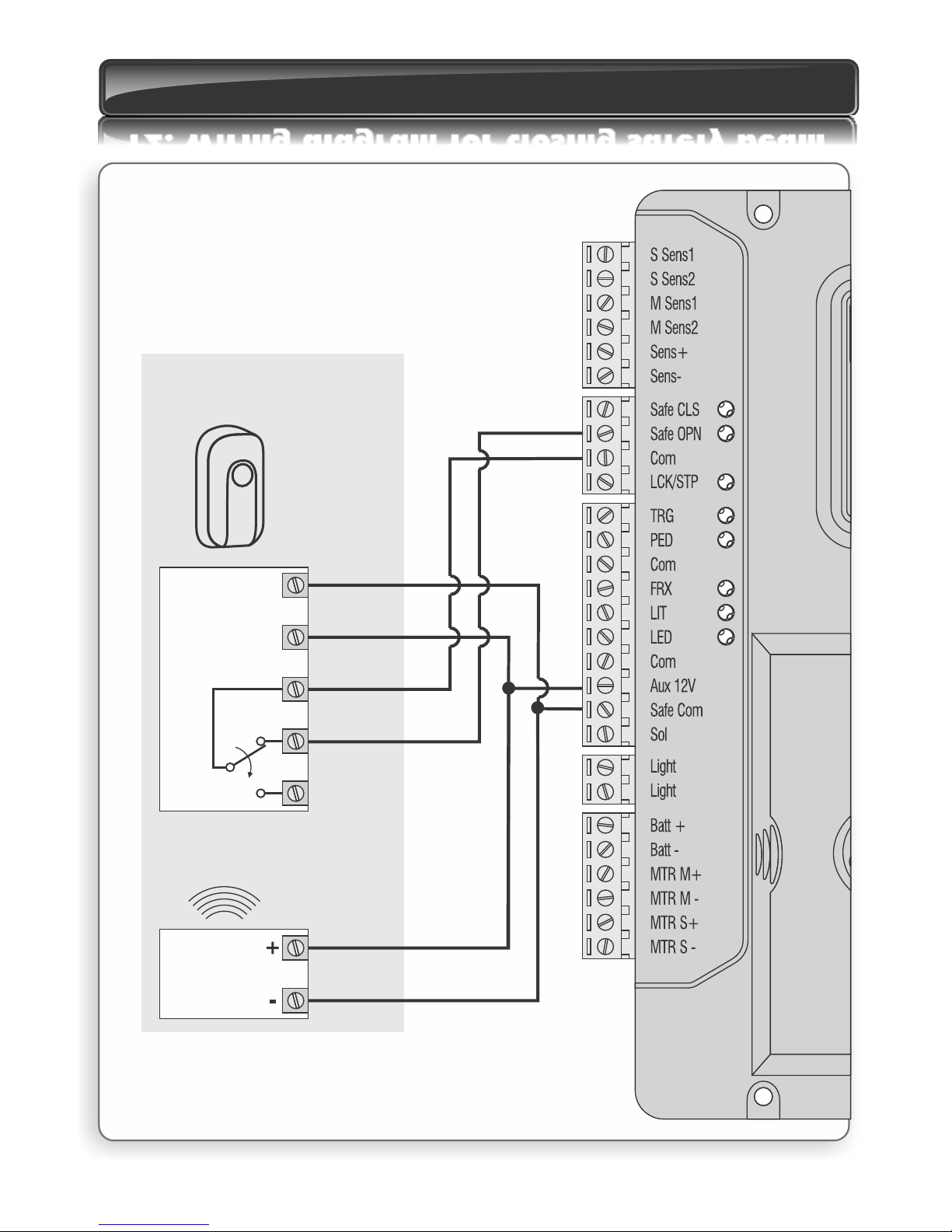

14. Wiring diagram for opening safety beam

IRB Tx

12V/24V +

12V/24V -

12V/24V -

IRB Receiver

COM

12V/24V +

NC

NO

Opening safety beam

FIGURE 66. WIRING OF SAFETY DEVICE

Page 38

Page 43

Refer to diagram only if external receiver is being used

and not the onboard receiver, disable onboard receiver - Menu 11

15. Wiring diagram for external

radio receiver and loop detector

Loop and loop detector

NEG

12V +

COM

NO

NC

Loop detector

Loop

Remote control circuitry

External radio receiver

FIGURE 67. WIRING OF OTHER INPUTS

Page 39

12V +

NEG

COM

NC

NO

Page 44

16. Wiring diagram for other inputs

Holiday Lockout

keyswitch/keypad

(normally-closed)

Pedestrian

keyswitch/keypad

(normally-open)

Pillar Light

pushbutton

(normally-open)

Status

LED

A

U

X

CENTURION

Solenoid

or strike lock

FIGURE 68. WIRING OF OTHER INPUTS

Page 40

Page 45

17. Wiring diagram for Master motor (MTRM)

S Sens1

S Sens2

M Sens1

M Sens2

Light

Light

Batt +

Batt MTR M+

MTR M MTR S+

MTR S -

Sens+

Sens-

Safe CLS

Safe OPN

Com

LCK/STP

TRG

PED

Com

FRX

LIT

LED

Com

Aux 12V

Safe Com

Sol

Thin purple

Thin red / grey

Thick blue

Thick black

Thin blue / orange

Thin black

Master motor (MTR M)Master motor (MTR M)Master motor (MTR M)

FIGURE 69. WIRING OF THE MASTER MOTOR

Page 41

Page 46

18. Wiring diagram for Slave motor (MTRS)

S Sens1

S Sens2

M Sens1

M Sens2

Light

Light

Batt +

Batt MTR M+

MTR M MTR S+

MTR S -

Sens+

Sens-

Safe CLS

Safe OPN

Com

LCK/STP

TRG

PED

Com

FRX

LIT

LED

Com

Aux 12V

Safe Com

Sol

Thin purple

Thin red / grey

Thick blue

Thick black

Thin blue / orange

Thin black

Slave motor (MTR S)Slave motor (MTR S)Slave motor (MTR S)

FIGURE 70. WIRING OF THE SLAVE MOTOR

Page 42

Page 47

19. Charger and Pillar Light connections

S Sens1

S Sens2

M Sens1

M Sens2

Light

Light

Batt +

Batt MTR M+

MTR M MTR S+

MTR S -

Sens+

Sens-

Safe CLS

Safe OPN

Com

LCK/STP

TRG

PED

Com

FRX

LIT

LED

Com

Aux 12V

Safe Com

Sol

220

-240V AC

Mains in

E

N

L

Protection fuse on

mains input to

charger (rating:

250mA slow blow)

Auxiliary

supply

Pillar

Light

Neutral

Live

N

L

E

N

L

E

N

L

E

N

L

E

N

L

E

N

L

E

N

L

E

N

L

E

N

L

E

N

L

E

N

L

E

N

L

E

N

L

E

N

L

E

N

L

E

Fuse protection

The following protection fuses are provided on the system:

Item

Main controller

Motor Circuit - fuse per channel

Light circuit

Auxiliary supply

CHARGER

Mains Input

Type

Automotive Fuse (25 x 7)

5 x 20mm

Electronic fuse - not replaceable

5 x 20mm

Rating

15A

3A Fast Blow

3A

250mA Fast Blow

To reset: Power off controller for at least 1 minute and re-apply power

FIGURE 71. CHARGER AND PILLAR LIGHT CONNECTIONS

Page 43

Page 48

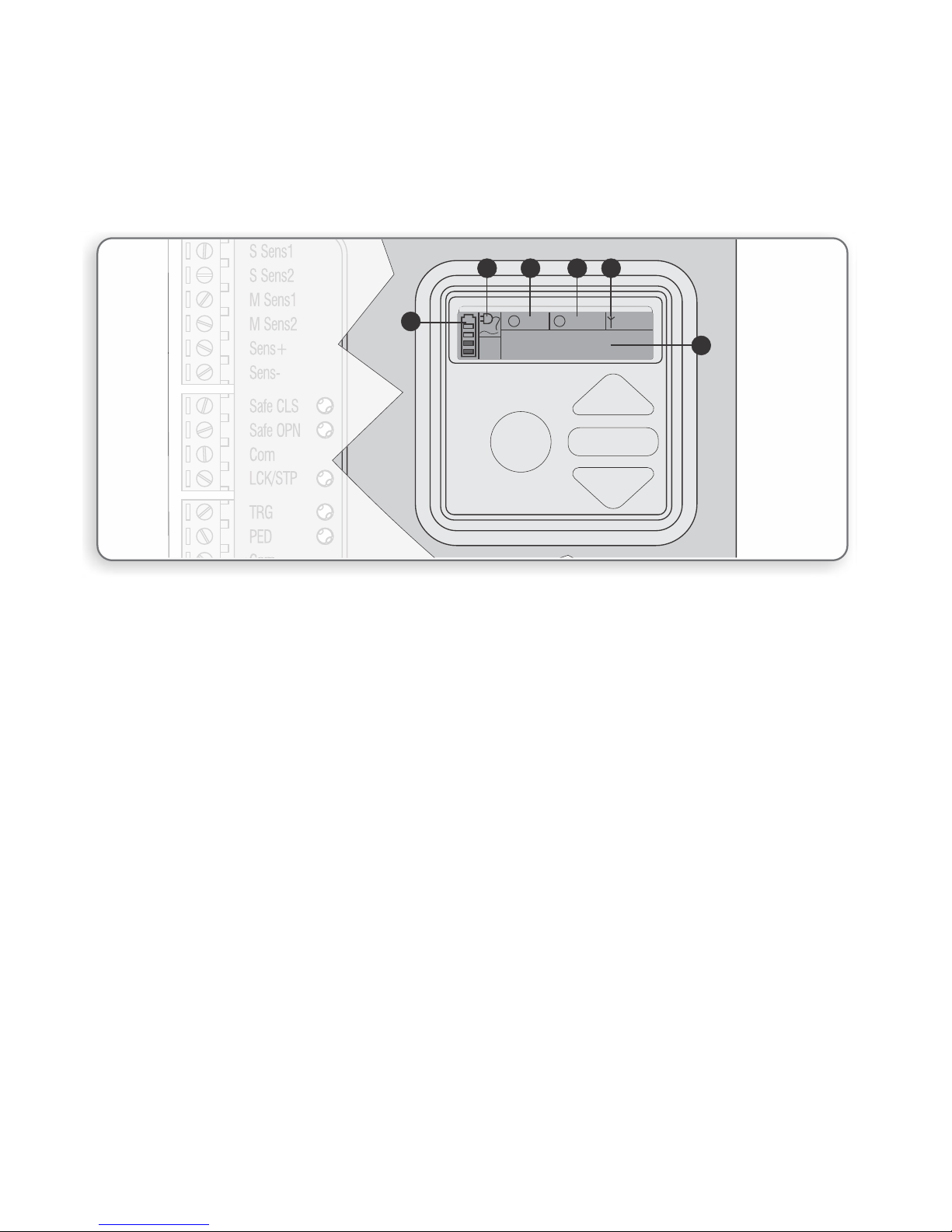

20. Setting up additional features

Figure 68 provides the full menu of features that can be set up on the system.

An explanation of each feature is provided in the section ‘Controller features’.

When setting up the VECTOR2 system via the LCD display, all the steps that have to be

followed are clearly provided via the display. It is only necessary to note the following:

1. To get into Setup Mode, press the (oblong) button for 3 seconds and follow the

instructions provided from there.

2. The buttons provided on the controller for navigating the system, are not marked

because at each step during the Setup, the function given to each button is provided

on the display.

3 When not in Setup Mode, ie Normal Mode, the (round) button is used as a TEST

button for operating the system. The up/down buttons are not used unless the

diagnostic screens have been selected to appear in Normal Mode, in which case these

buttons allow switching from one screen to the next.

For each feature a factory default setting has been programmed into the

controller. Referred to as an Operating Standard, these defaults have been

determined to suit the requirements of the specific region where the installation

is being carried out. It is only necessary to change a feature where the default

does not suit the installation. When selecting any feature in the menu, details of

the current setting stored in the controller are displayed

Refer to Table 1 on page 58 for the Schedule of Factory Defaults for each feature

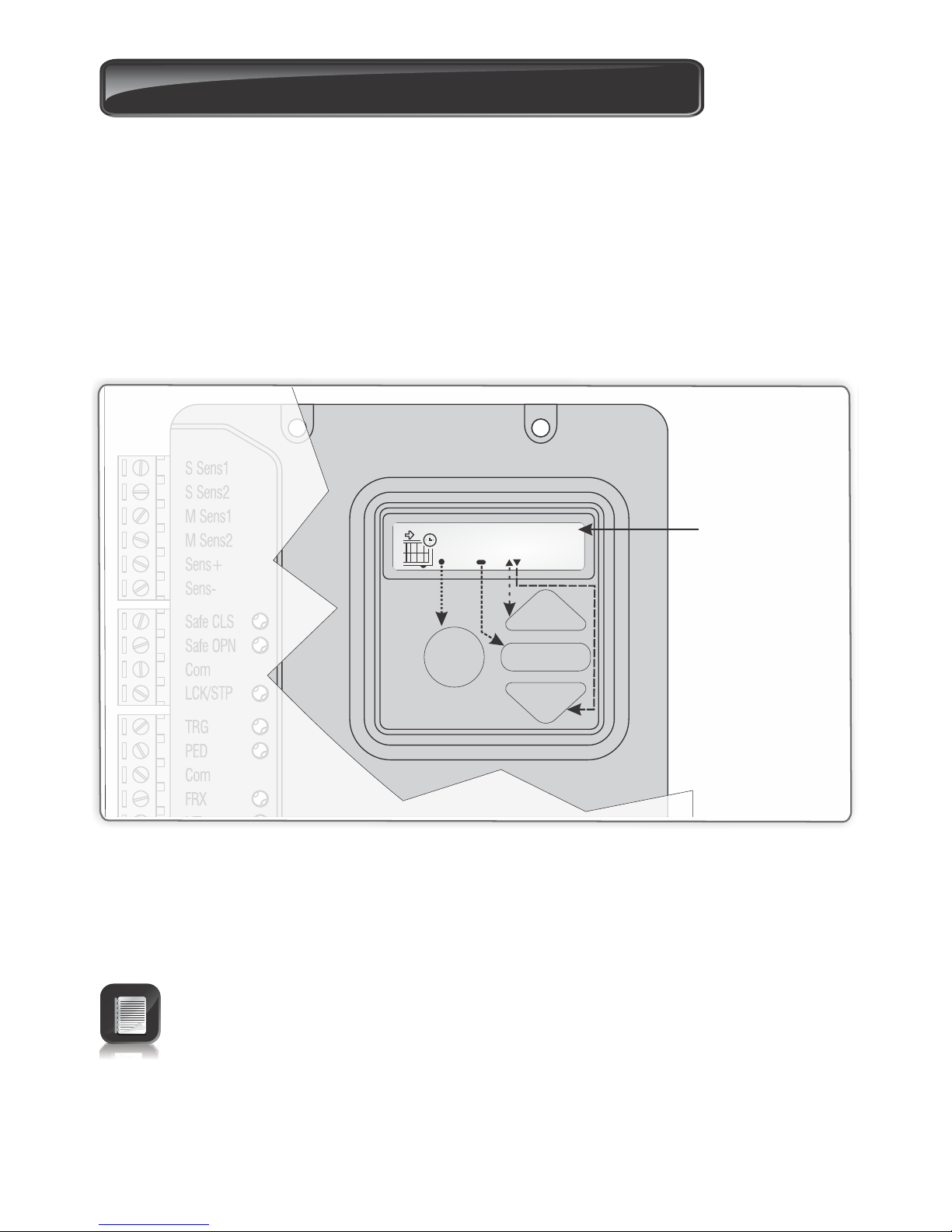

S Sens1

S Sens2

M Sens1

M Sens2

Sens+

Sens-

Safe CLS

Safe OPN

Com

LCK/STP

TRG

PED

Com

FRX

instructions provided from there.

because at each step during the Setup, the function given to each button is provided

on the display.

33333

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

Exit Go

Up/Dn

AutoCloseAutoCloseAutoCloseAutoCloseAutoClose

Menu LevelMenu LevelMenu Level

Page 44

FIGURE 68. VIEW OF CONTROLLER

Page 49

21. Menu navigation map

1. Setting limits 1.1. Setup wizard

2. Safety

2.1. MTRM Collision Force

2.2. MTRS Collision Force

2.3. Collision Count

2.1.1. MTRM Opening Collision

Force

2.1.2. MTRM Closing Collision

Force

2.2.1. MTRS Opening Collision

Force

2.2.2. MTRS Closing Collision

Force

3. Autoclose

3.1. Autoclose status

3.2. Autoclose timer

3.3. Autoclose override

3.4. Autoclose advanced

options

3.4.1. Autoclose fully open

3.4.2. Autoclose partly open

3.4.3. Autoclose partly closed

4. Modes of Operation

4.1. Operating Mode

4.1.1. Standard Mode

4.1.2. Condominium Mode

4.1.3. Reversing Mode

4.1.4. PLC

4.1.5. Deadman Control Mode

5. Run profile

5.1. Positive Close

5.1.1. Positive Close

Status

5.1.2. Positive Close

Type

5.1.3. Positive Close

Short Stop Value

5.1.4. Positive Close

Push Force

5.1.2.1. Short Stop

5.1.2.2. MTRM Only

5.1.2.3. MTRS Only

5.1.2.4. MTRM

and MTRS

Page 45

Page 50

Page 46

2.1.1. Leaf Delay Status

2.2.1. Leaf Delay Value

5.2 Leaf delay

5.2. Pre-open delay

5.3. Pre-close delay

5.4 Opening speed

5.5. Closing speed

5.6. Ramp-up distance

5.7. Ramp-down distance

5.8. TRG stop distance

5.9. IRB stop distance

5.10. Crawl distance

5.11. Torque limit

7. Pedestrian

7.1. Pedestrian open position

7.2. Pedestrian Autoclose time

7.3. Pedestrian pre-open delay

7.4. Pedestrian pre-close delay

6. Infrared beams

6.1. PIRAC control

6.2. IR beam test

6.3. IRBO=IRBC on

closing

6.4. IR beam alarms

6.1.1. PIRAC status

6.1.2. Stop on open

6.2.1. Status

6.2.2. Test beam

6.4.1. Ambush alarm

6.4.2. Break-in alarm

status

6.4.3. Alarm output

6.1.2.1. Stop on

open status

6.1.2.2. Stopping

distance

6.4.1.1. Ambush

alarm status

6.4.1.2. Broken IRB

time

8. Gate lock

8.1. Lock Enabled Status

8.2. Lock Type

8.3. Release Time

8.4. Pre-Release Time

8.5. Lock Location

8.6. Lock Drive (AC/DC)

Page 51

Page 47

10. Remote controls

Press button of valid transmitter (if menu locked)

10.1. Add remotes

10.2. Delete remotes

10.3. Edit remote button

10.4. Autolearn remotes

10.5. Tx menu locked

10.6. Onboard receiver enable/disable

10.2.1.Delete by ID

10.2.2.Delete button

10.2.3.Delete by button

9. Courtesy Light

9.1. Courtesy Light timer

9.2. Light profile

9.2.1. Courtesy Light

9.2.2. Pre-flash A

9.2.3. Pre-flash B

9.2.4. Pre-flash C

Page 52

Page 48

22. Controller features

Menu 2 - Safety (collision force)

Collision force

If the gate is obstructed, the internal collision circuitry will activate.

The response of the system to a collision will vary, depending on the profile

(operating standard, e.g. ZA,) selected. Responses can vary from the gate

stopping, to the gate reversing. The collision force can be set from minimum to

maximum in five discrete steps.

A sixth step will disable collision sensing entirely, allowing maximum force to

be achieved. Under this condition, the motor will continue running until it

stalls, at which point a collision will be detected.

Menu 3 - Autoclose

Autoclose status

When turned on, the Autoclose feature has the function of automatically closing

the gate after a preset Autoclose time. The Autoclose feature is automatically

turned on when the controller is set for Condiminium Mode of Operation

Autoclose time

The Autoclose time can be set anywhere from 1 to 255 seconds.

This level should only be used if additional safety measures are taken.

(e.g. infrared beams, sensitive edge, etc.). Collision force can be set

independently per direction of travel

Collision count

A counter monitors the number of collisions that the gate experiences before it

reaches the fully closed position. If the value exceeds the value set in the

Multiple Collision Counter the controller shuts down until the next valid

trigger is received. As indication, the status LED will flash four times every

two seconds. The Multiple Collision fault indication will continue to flash

indefinitely or until a valid trigger has been received

Autoclose Override

It is possible for the user to temporarily turn off Autoclose when the Mode of

Operation is Standard or Reversing. To activate Autoclose Override, the

Trg input must be activated and maintained for a period longer than the time

set for the Autoclose Override Time.

The gate response will be to start opening on the Trg trigger, and then to stop

as soon as the Autoclose Override feature is activated. On clearing of the Trg

input, the gate will continue opening until fully open. The Autoclose feature is

now off and the gate will remain open indefinitely.

The next signal received on Trg will clear the Autoclose Override feature,

close the gate, and set the Autoclose feature back to normal.

Autoclose Advanced Options

The conditions under which the gate will automatically close can be set within

the Advanced Autoclose options menu:

Autoclose on open - automatically close the gate if it has reached the fully

open position

Autoclose on partly open - automatically close the gate if it is stopped

while opening, but before reaching the fully opened position

Page 53

More than one advanced option can be selected

Menu 4 - Modes of Operation

It is possible to select the following Modes of Operation: Standard,

Condominium, Reversing, PLC and Deadman Control Mode (DCM). All

modes are triggered by closing a normally-open contact between the Trg input

terminal and the Com terminal.

Standard Mode

When stationary, a trigger impulse on Trg will cause the gate to either open or

close. On a moving gate, a trigger impulse on Trg will stop the gate. The next

impluse on Trg will cause the gate to reverse its direction of travel, i.e. the

action is start-stop-reverse.

Condominium Mode

A trigger impulse on Trg will open the gate under all conditions. If it were

closing, it will stop and reverse to open. In this Mode of Operation, the only

way to close the gate is with the Autoclose feature, which is automatically

activated when Condominium Mode is selected.

Reversing Mode

A trigger impulse on Trg will reverse the direction of a moving gate. If it were

closing, it will stop and immediately begin opening. If it were opening, it will

stop and immediately begin closing.

Autoclose on partly closed - automatically close the gate if it is stopped

while closing, but before reaching the fully closed position

Menu 5 - Run Profile

Positive Close Mode (PCM)

Setting Positive Close Mode to ON will allow the gate to drive up hard to the

closed endstop without causing the collision circuitry to operate. This feature

operates only during the last few millimetres of gate travel in closing mode.

Positive close type

PCM can be applied to one of the following:

Short Stop (further explanation follows)

Master motor (MTRM)

Slave motor (MTRS)

Both Master and Slave motors

Short stop

PCM applied to one gate is ideal for securely locking two gates to each other

without having to fit endstops. Typically, a 'mechanical' lip is fitted to one gate

which will push up against the other gate and via PCM keep pushing until the

gates are mechanically locked. To ensure that the gates do not close past their

desired end point, the gate (S) against which the gate (M) with the mechanical

lip pushes, can be preset to stop slightly short of its closed position. This is

referred to as the 'Short Stop' distance. If the 'Short Stop' distance is correctly

set, the gate (M) will engage with the S gate sufficiently before the closed

position and via the PCM, push the two gates into the fully closed position, but

not past.

Page 49

Page 54

Page 50

Line of gates when closed

M gate closes

slightly behind

S Gate (Leaf delay)

S Gate closes first

Mechanical lip

M Gate continues to close

“Short Stop”

S Gate stops slightly before closed position

If “Short Stop” is correctly set, PCM will cut off

when gates reach closed position, in line

Short Stop value

The Short Stop distance can be set

between 1mm and 40mm of piston

stroke

PCM push force

The amount of force applied by the

actuator when in PCM can be set as

a value from 1 to 15

Leaf delay

Leaf delay is used in cases where

one gate leaf must move before the

other. The most common need for

this arises when a mechanical 'lip' is

fitted to one of the gates. In a

double leaf installation, a leaf delay

can be set whereby the M motor will

open before the S motor, and the S

motor will close before the M motor

Leaf delay value

The leaf delay is based on piston

position, and can be adjusted from

3mm to 250mm of piston travel.

Pre-open delay

Allows a delay between a valid

trigger signal being received and

the gate commencing movement in

the opening direction. A warning

light can be set to activate during

this delay. (Refer to Pre-flash

modes of the feature ‘Pillar Light’,

for more details). This setting

applies to both motors

Pre-close delay

Allows a delay between a valid trigger signal being received and the gate

commencing movement in the closing direction. The delay will also occur if the

gate is set to close automatically. A warning light can be set to activate during

this delay. (Refer to Pre-flash modes of the feature ‘Pillar Light’, for more

details). This setting applies to both motors

Opening speed

Sets the maximum piston opening speed in millimeters per second.

This setting applies to both motors

Closing speed

Sets the maximum piston closing speed in millimeters per second. This setting

applies to both motors

Mechanical lip on

M Gate engages with S Gate

With PCM, Master Gate continues closing,

pushing the Slave Gate with it

FIGURE 69

FIGURE 70

FIGURE 71

FIGURE 72

Page 55

Page 51

Ramp-up distance

Sets the ramp-up distance in millimeters of travel of the piston when starting.

This setting applies to both motors

Ramp-down distance

Sets the ramp-down distance in millimeters of travel of the piston when

stopping. This setting applies to both motors

Crawl distance

Sets the final crawl distance in millimeters of travel of the piston when

reaching an endpoint. This setting applies to both motors

Push force limit

Sets the maximum push force delivered by the motors. The maximum setting

is a value of 15 and the minimum is four. This is useful in cases where limited

push force is required. This setting applies to both motors

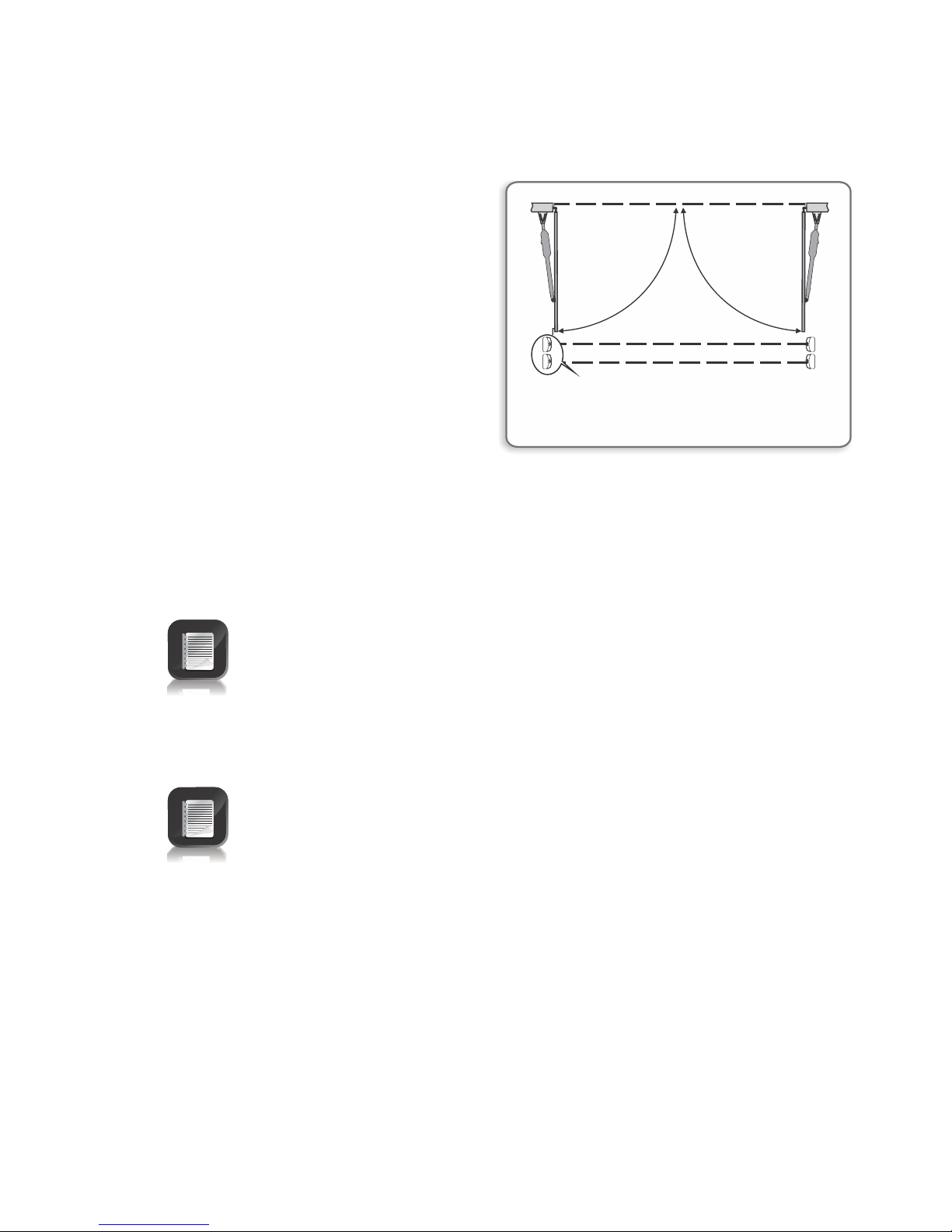

Menu 6 - IR beams

In a swing gate installation, in order to

provide protection for a person or

vehicle moving through the entrance,

it is necessary to have two sets of

beams, one across the driveway where

the gates are closed and another

where the gates are open. Both these

beams must be set as closing safety

beams, preventing the gate from

closing and stop the gates if they have

started to close.

However, across the line of the

driveway up to where the gates open,

it is also recommended to have

another set of safety beams to prevent

the gate from opening if they are

closed and stop if they are opening.

Two independent normally-closed

inputs are provided for opening and

closing safety beams.

Inside

closing beam

Outside

closing beam

FIGURE 73. TYPICAL CLOSING BEAM

INSTALLATION

Gates will not close

An interrupted closing beam will prevent the gates from closing and stop and

reverse the gates back to the open position if already opening. Vice- versa for a

closing beam.

Page 56

Page 52

PIRAC

The Passive-Infrared Autoclose

feature allows the gate to close

automatically, as soon as a vehicle

or pedestrian has passed through

the closing beam. This security

feature ensures that the gate stays

open for the minimum amount of

time possible.

If the Autoclose feature has been

enabled, the system will react in the

following way:

If the Autoclose feature has not been enabled then the gate will

remain open indefinitely. To close the gate the closing beam must be

interrupted or the trigger button must be pressed

Outside closing beam

Inside closing beam

Opening beam

IRBO = IRBC

(Combine inside closing beam with

opening beam = save on one beam)

When the gate is triggered to open and nothing moves through or interrupts

the closing beam, the gate will open fully and stay open for the period of time

determined by the Autoclose timer

However, if the closing beam is interrupted at any stage, while the gate is

opening or open, the gate will close immediately after the closing beam is

cleared

Safe output status

Automatically tests the safety beams before each gate cycle. (e.g. as required

by CE and UL325)

In order for this feature to work, the power supply negative of the beam

transmitter must be wired to the SAF COM terminal of the controller

IR beam test

Automatically tests the safety beams before each gate cycle. (e.g. as required

by CE.)

In order for this feature to work, the power supply negative of the beam

transmitter must be wired to the safe common terminal of the controller.

The time taken for the gate to open again after it has come to a stop is

approximately three seconds

Example:

Autoclose override time set to five seconds: Total time to temporarily

disable the PIRAC feature is approximately eight seconds

(5s + 3s = 8 seconds)

FIGURE 74

Additional beam functionality is provided:

Page 57

Page 53

IRBO=IRBC

Configures the opening beam to act as a closing beam while the gates are

closing. This allows one set of beams to be used across the line of the driveway

up to where the gates open.

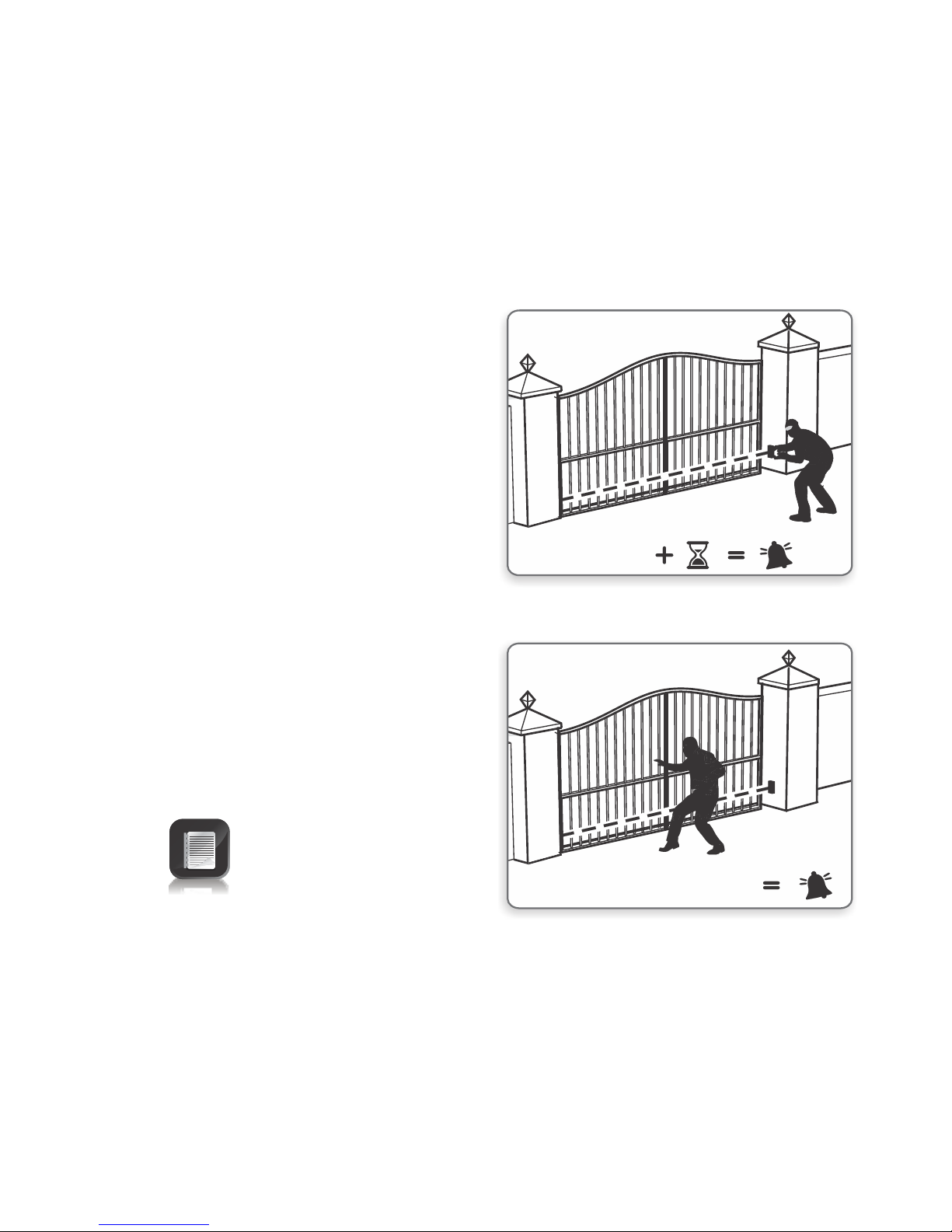

IR beam alarms

While the gate is fully closed, this feature allows the following alarms:

IR beam broken time

The time that the beams must be interrupted before the alarm is activated.

Break-in Alarm

Activates an alarm if the closing

beam on the outside of the

property is interrupted. The alarm

remains activated while the beams

are broken, and for a period of 30

seconds thereafter. This time is

fixed

If this alarm is used, it is

recommended that TWO

parallel closing beams are

used to reduce the chance of

false triggering

Intruder breaks beam

while loitering at gate

Alarm

FIGURE 76

Ambush Alarm

Activates an alarm if either the

opening or closing beams have

been continuously interrupted for

a predefined time. The alarm will

remain activated while the beams

are interrupted

For example, if a would-be

intruder covers the beams so that

when the gate is opened, the gate

will stay open, the system will

detect this beam override taking

place and set off an alarm

Alarm

Intruder

blocks beam

Adjustable

beam broken

time

FIGURE 75

Alarm output

The system can be configured to operate one of the following outputs

provided on the controller

Onboard buzzer – emits a continuous tone

Pillar / Courtesy Light contact (potential-free normally-open contact,

fuse protected – 5A)

Aux IO (this is an open collector drive, maximum current draw 3A, not fuse

protected)

Safety beam common (this is an open collector drive, maximum current

draw 3A, not fuse protected)

Status LED output (operate up to three LEDs in parallel or interface with

multi- LED driver card, CP78)

Page 58

Page 54

Menu 7 - Pedestrian Opening

This feature is associated with the Ped input on the controller. When activating

this input, the system will open the gate to the pedestrian open position, and

then automatically close after the Pedestrian Autoclose time lapses. If the Ped

connection to Com is maintained, then the gate will remain open, and when the

connection is broken, it will close after the Pedestrian Autoclose time has expired

The time taken for the gate to open to pedestrian is dependent on the pedestrian

pre-open delay and the time required for the gate to close from the pedestrian

position is dependent on the pedestrian pre-close delay

Pedestrian Open Position

Sets the maximum opening of the pedestrian gate in metres, in one

centimetre steps

Pedestrian Autoclose Time

Sets the Autoclose time in seconds after a Pedestrian Opening. This time can

be set from zero seconds to four minutes in one second steps.

Pedestrian Pre-open Delay

Sets the time delay between the pedestrian input being activated, and the

gate actually opening. This enhances safety in cases where the pedestrian has

to reach through the gate in order to activate the pedestrian input. A warning

light would typically be active during this delay. This delay can be set from

zero seconds to four minutes in one second steps

Pedestrian Pre-close Delay

Sets the time delay between the Pedestrian Autoclose timer expiring, and the

gate actually closing. A warning light would typically be active during this

delay. This delay can be set from zero seconds to four minutes in one second

steps

The warning light is any light wired to the Pillar Llight contacts, as

described in Menu 9

Menu 8 - Gate lock

An electric strike lock or magnetic lock can be connected to the control card,

allowing the gate to be locked when closed, open or both.

Lock enable status

Turns the lock functionality on or off

Lock type

Allows selection of either a solenoid strike lock, or a magnetic lock. A solenoid

strike unlocks when power is applied, while a magnetic lock unlocks when

power is removed

Release time

Sets the time period (in seconds) for which the lock remains released after the

gate has started moving

Page 59

Page 55

Menu 9 - Courtesy/Pillar Light

This feature is associated with the Light connections on the controller. Refer to

Section 16 of the manual for details on how to connect a pillar or security light to

the controller

The Pillar Light circuit has multiple functions:

It operates as a Courtesy Light and switches on for a selectable time period

every time the gate is activated

The Courtesy Light can also be turned on for the same time period by

momentarily connecting the Aux terminal to the Com terminal via a pushbutton

The Courtesy Light can also be turned on permanently by connecting the Aux

terminal to the Com terminal via a pushbutton, for three seconds. A short

pulse thereafter will switch the lights off. The status LED will flash once every

two seconds to indicate that the Courtesy Light is on permanently. The

abovementioned facility can also be achieved via a remote learned to the

system and mapped to the Courtesy Light function from within the remotes

menu

The gate will not open when using the Aux trigger input

When the Ped input is triggered, the Courtesy Light flashes for an adjustable

(1 to 255 seconds) pre-flash time, before the pedestrian gate opens

Courtesy Light time

The time that the Courtesy Light will remain activated can be set from four

seconds to ten hours in one second increments

Light profile

The Courtesy Light can be selected to operate according to one of the

following:

Courtesy Light as explained earlier

Pre-flashing Mode

If Pre-flashing Mode A, B or C is selected, the behaviour of the Courtesy

Light will be as follows:

Mode A will turn on the Courtesy Light only while the gate is moving

Mode B will flash the Courtesy Light during the pre-opening and preclosing delays, as well as while the gate is moving

Pre-release time

Sets the time period (in 0.1s increments) for which the lock releases BEFORE

the gate has started moving. This is useful in cases where premature gate

movement prevents the lock from releasing

Lock location

Specifies whether the gate is locked while closed, open or both

Lock drive

Specifies if the lock is to be powered by an AC or DC voltage. Selecting AC will

power the lock with a 50Hz square wave

Page 60

Page 56

Mode C will turn on the Courtesy Light during the pre-opening and preclosing delays, as well as while the gate is moving

In these pre-flashing modes, the timed Courtesy Light functionality is not

available

Menu 10 - General features

Operating standard

Regional operating standards can be set. Applying this setting will

automatically configure the controller settings to conform to the specific

region's standard (e.g. UL325 or CE)

Reset options

The controller settings can be reset through the reset options menu. Various

reset options are available: