Page 1

Martindale

USER INSTRUCTIONS: MAGNUM P2/P3 POWERED RESPIRATORS

Models covered

Power Units : M23/1000, M23/2000, M23/8500

Powered Respirator kits: M23/1000/CB, M23/2000/CB, M23/8500/CB

(Power Unit, 8-hour Battery and UK Charger)

Available Headpieces: See section 2 below

Before using the system it is essential that you read these instructions and ensure that the correct equipment has

been selected. Always be aware of the limitations of use of the equipment and that it is appropriate to the task.

1. WARNINGS

If these instructions are not followed or the unit is used incorrectly the system may not offer protection to EN12941/42 or EN 146.

Power units offer NO protection unless a main filter(s) is fitted.

In a power off situation the headpiece offers no respiratory protection and rapid CO2 build-up and oxygen depletion may also result. This is an

abnormal situation.

Power off is an abnormal situation regardless of whether a full hood, half suit or mask is used.

At high work rates the pressure inside the headpiece may become negative at peak inhalation.

The system should not be used in oxygen deficient or oxygen enriched atmospheres.

The user must ensure that the nature of the hazard is identified and that the system offers an adequate level of protection.

This unit should not be used where the nature of the hazard is unknown.

This unit is NOT intrinsically safe and therefore should not be used in explosive atmospheres

Be aware that the hose protrudes from the back of the headpiece and take care to avoid snagging.

In high wind velocities the assumed protection levels may not be achieved.

The full hood and half suit provide no protection against impact to head, face or eyes.

Respiratory protection will be reduced unless the hood is correctly fitted and properly maintained.

Do not confuse the markings on any filter which relate to standards other than EN12941 or EN12942 with the classification of this device when

used with that filter. The classification for EN12941 will begin with "TH" and for EN12942 will begin with "TM". Filters should only be fitted to the

power unit, do not attempt to fit them directly to a hood or helmet.

2. LIST OF PARTS , AVAILABLE HEADPIECES, APPROVALS / SPECIFICATION, NOMINAL AND ASSIGNED

PROTECTION FACTORS

kits Power Unit 8 hr Battery UK Charger Standard Class

M23/1000/CB

M23/2000/CB

M23/8500/CB M23/8500 M23SPB M23UIC EN12941/2

(1)

The M23/8500 and Full Facemask is approved with the full range of Martindale DIN 40 gas/combination filters.

(2)

The M23/8500 & TH2 headpieces are approved for use with the Fitta range of Combination Gas/Dust filters (M09A1P2) .

(3)

Optional 4 hour battery and charger available for the 2000 power units – M23P2/4B battery and M23P2/4BC charger.

(4)

All headpiece systems are to EN12941 or EN 146 with the exception of the Full facemask, which is to EN12942.

(5)

Note: Heavy Duty Battery M23HD4B and charger M23UIC are also available for use with the Magnum 1000 and will typically give durations of

12 hours+.

(6)

Note: Magnum 2000 only conforms to TH3 when used with M23P3/5 filters and M23LHF otherwise it conforms to TH2

(7)

Note: Nominal Protection factors of headpieces used with Magnum 1000 is 20

Nominal and Assigned Protection Factors for Headpiece/Power Unit kits

(Refer to Compatibility table below for suitable power units)

Headpiece code dust gases

Rigid Polycarbonate Visor with Saronex Hood M23RVSN 50

Flip up Polycarbonate Visor M23FUVN 50

Helmet with Flip-up Polycarbonate Visor M23HFUV 50

High Temperature Helmet with Clear Triacetate Flip up Visor M23HFUVHTT 50

High Temperature Helmet with Gold Polycarbonate Visor M23HFUVHTGP 50

Automatic Welding Visor M23AWSN 50

Fixed Shade Welding Visor M23FSWVN 50

Lightweight P3 Tyvek F Hood M23LHF 50/500* 50/500* 20/40* 20/40*

Full Hood M23FH/8 500 - 40 Half Suit M23HS/8 500 - 40 Full facemask with twin hose M23FF 2000 2000 40 40

(5)

M23/1000 M23P2/4B M23P2/4BC EN146 THP2

(3)

M23/2000 M23SPB M23UIC EN12941 TH2/TH3

(4)

NPF APF (UK)

(7)

(7)

(7)

(7)

(7)

(7)

(7)

(6)

(1)

TH3/TM3

(1,2)

(2)

TH2

dust gases

50 20 20

50 20 20

50 20 20

50 20 20

50 20 20

50 20 20

50 20 20

(1,2)

* Note NPF=500 & APF=40 when M23LHF is used with TH3P Filters (e.g. M23P3/5 or M23P3SL/6) and M23/2000 or 8500 otherwise the M23LHF

has NPF=50

(7)

& APF=20.

A detailed table showing the exact classifications and protection levels is given in the headpiece instructions (024-001-692) supplied with each

headpiece which must be read in conjunction with these instructions.

750 MOD 8 11/05/07 Page 1 of 8 POWER UNITS

Centurion Safety Products Ltd. Howlett Way, Thetford, Norfolk, IP24 1HZ, UK

Tel. 0044 (0)1842 754266 Fax. 0044 (0)1842 765590

Page 2

Compatibility between Headpieces and Power Units:

Headpieces: Power Units:

Description Code 1000/2000 8500

Rigid Polycarbonate Visor with Saronex Hood M23RVSN

Flip up Polycarbonate Visor M23FUVN

Helmet with Flip-up Polycarbonate Visor M23HFUV

High Temperature Helmet with Clear Triacetate Flip up Visor M23HFUVHTT

High Temperature Helmet with Gold Polycarbonate Visor M23HFUVHTGP

Automatic Welding Visor M23AWSN

Fixed Shade Welding Visor M23FSWN

Full Facemask with Twin Hose M23FF x

Full Hood without airflow indicator M23FH/8 x

Half Suit without airflow indicator M23HS/8 x

Lightweight P3 Tyvek F M23LHF

3. APPLICATIONS AND LIMITATIONS

When used with filters M23P3/5, M23P2/5 or M23P3SL/6 the Magnum respirator will offer protection against dusts, particles, fumes and aerosols

(solid and liquid based) to the levels detailed.

No protection is given against gases or vapours.

The Magnum system should not be used where airborne concentration of contaminant exceeds the Assigned Protection Factor (APF) x the

Occupational exposure limit (OEL)

The system is recommended for use in the temperature range +5° to +35°C and in conditions where relative humidity does not exceed 90%.

Protection Factors

The efficiency of all types of respirators is classified by the protection factor rating system. There are two main classifications for protection factors,

these are:

Laboratory Protection Factor (also known as Nominal Protection Factor)

This is the minimum level of protection the equipment has to demonstrate for each of a panel of test subjects under laboratory conditions to gain

approval to the appropriate class of the performance standard.

Assigned Protection Factor (APF)

BS4275 or EN 529 acknowledges that laboratory performance is not always achievable in real use.

These figures are taken from BS4275: 1997 and are the minimum level of protection which it is calculated 95% of wearers who are trained in the use

of the equipment should achieve in practice, with well-maintained equipment. These figures are valid for use in the UK and may differ in other

countries.

For further information regarding protection factors please contact our technical advice service.

4. PREPARATION FOR USE

Battery

The power unit is fitted with a rechargeable battery pack, which requires charging before use. Ensure you are using the correct charger for your

battery pack (See Section 2).

Standard Charger (M23P2/4BC or M23HD4BC) –

When charging the battery connected to a Turbo unit the turbo unit must be turned off.

Plug the charger into an appropriate mains supply. Connect the battery charger plug to the charger socket on the battery pack. The LED indicator

will light if the charging circuit is satisfactory.

Batteries are supplied in a discharged condition, and must initially be charged for 20 hours before use. Subsequent charges only require 16 hours.

IOvercharging the batteries may permanently damage them.

Intelligent Charger (M23UIC) – This charger will charge all Magnum battery packs and will operate on both UK and European Voltages.

To change the mains plug from European to UK and vice versa unplug charger from mains and push up switch marked “Open” in the direction of

the arrow the plug should then pop out. Insert the replacement plug into the charger pushing firmly until it “clicks home” Batteries may be charged

on or off the turbo unit.

Batteries must be charged indoors at an ambient of between 10ºC and 30ºC. Do not cover charger.

Important : In excessive cold or warm environments the recharging device may suppress the charging current to standby level so the battery will

be not be charged. Never charge in a potentially explosive atmosphere.

To use : Plug the charger into the main power supply (100 – 240V AC – 50-60 HZ). When no battery is connected, the LED (Light emitting Diode)

indicators light on the front of the charger should not be lit.

When charging the battery connected to a Turbo unit the turbo unit must be turned off.

Plug the charging connector into the socket in the rear of the battery pack.

The RED LED indicator will flash for a few seconds indicating that the charger is checking the status of the battery pack. The RED LED should

then light continuously indicating that the battery is being charged.

When the battery is fully charged the RED LED will go out and the GREEN LED will indicate. At this point the battery will be in “trickle charge”

mode, this will maintain the battery’s charge. The battery can be left permanently connected, if desired, until required for use.

Note : A new battery, a battery stored for a very long period or a battery that has been run completely flat so that is deeply discharged* may not

function correctly.

If when starting to charge such a battery the RED LED continues flashing for more than 10 seconds the charger has detected either a very deeply

discharged battery or a faulty battery.

750 MOD 8 11/05/07 Page 2 of 8 POWER UNITS

Centurion Safety Products Ltd. Howlett Way, Thetford, Norfolk, IP24 1HZ, UK

Tel. 0044 (0)1842 754266 Fax. 0044 (0)1842 765590

Page 3

Allow the charge to continue as the charger will try and trickle charge the battery up to a acceptable pre-set level before commencing the battery

charge, when the RED LED will continuously illuminate (this may take several hours) . If the charger refuses to charge the battery it may be faulty

– contact Centurion Safety Products for further help and assistance.

It is possible that a battery in this state may require several charge attempts to fully charge the battery.

*It is not recommended to deeply discharge a battery by running the power unit until the battery is completely flat since this may permanently

damage the battery.

If the power unit is to be stored without use for more than 3 months the battery must be detached from the power unit before storage.

5. FILTERS

5.1 General (Main Filter)

DUST FILTERS (particulate)

The filter(s) must be changed at regular intervals as determined by a competent person and must be changed when a drop in airflow is indicated

by either the electronic alarms or airflow indicator.

GAS/DUST FILTERS

The filter(s) must be changed at regular intervals as determined by a competent person and must be changed when a drop in airflow is indicated

by either the electronic alarms or air flow indicator or when any breakthrough of contaminate is detected by smell or taste.

GAS CANISTER

The Canisters(s) must be changed at regular intervals as determined by a competent person or when any breakthrough of contaminate is detected

by smell or taste.

We recommend the following MAXIMUM environmental contamination levels for filters as defined by EN 12941/2.

Class 1 Gas/Dust filters (e.g. M09A1/P2) = 500 ppm 200mg/m3

Class 2 Gas canisters (e.g. M23A2) = 1000ppm N/A

Class 2 Gas combination/Dust canisters (e.g. M23 A2B2/P3) = 1000ppm 100mg/m3

Dust filters TH2P (e.g. M23P2/5) = N/A 400mg/m3

Dust filters TH3P/TM3P (e.g. M23P3/5) = N/A 200mg/m3

MAGNUM 8500

2 or 3 Canisters(P3)

MAGNUM 2000

Cassette(P2)

MAGNUM 1000

Cassette(P2)

PRE-FILTERS AVAILABL E :

1

M23PF/10 (PARTICULATES ONLY) 2 M23PF/20 (PARTICULATES ONLY) 3 MO9PF ( PARTICULATES ONLY) *Pre-filters not available

2

2 or 3 Canisters(P3) 23 (Fitta)cartridge+adapters

# #

1

Cassette(P3)

1

# # #

1

3

3 Canisters(Din 40)

*

# = N/A

5.2 MAGNUM 1000, 2000 Power unit (M23/1000, M23/2000)

Pre-filters (General)

The pre-filter is an optional item, which sits in front of the main filter and removes coarse dust before it reaches the main filter.

Pre-filters, in themselves, do not offer any respiratory protection and hence must only be used in conjunction with a main filter.

The pre-filter should be changed immediately a drop in airflow is noticed.

Frequent changing of the pre-filter will maximise the life of the main filter.

Pre-filter Part number: M23PF/10 (For use with M23P2/5 & M23P3/5 filters only)

Pre-filter replacement

Outside surface of the power unit must be de-contaminated before changing the pre-filter

Open the front cover of the Power unit by easing open the right hand side.

Remove pre-filter with the minimum disturbance to the main filter.

Locate pre-filter on top of main filter centrally and without overlapping

Close the cover over the pre-filter/filter, taking care that it does not damage the filter media.

Press down on the centre of the cover until it snaps closed.

If a pre-filter is not used the main filter should be changed immediately the clogged filter alarm sounds/indicates or the air flow indicator, indicates

reduced airflow.

If a pre-filter is used it should be changed immediately the clogged filter alarm indicates or the airflow indicator, indicates reduced airflow.

(This may be more frequently than if a pre-filter is not used).

If after changing the pre-filter the clogged filter alarm sounds/indicates reduced airflow or the airflow indicator indicates reduced airflow.

Within a short period of time, the main filter should be changed as detailed (see Main filter).

750 MOD 8 11/05/07 Page 3 of 8 POWER UNITS

Centurion Safety Products Ltd. Howlett Way, Thetford, Norfolk, IP24 1HZ, UK

Tel. 0044 (0)1842 754266 Fax. 0044 (0)1842 765590

Page 4

Main filters

Part number: M23P2/5 or M23P2OD/5 THP2 /TH2P filters – for use with Magnum 1000 and 2000 Power Unit

Part Number: M23P3/5 TH3P filter – For use with Magnum 2000 Power Unit only

WARNING

Care should be taken when handling filters.

Do not touch the pleated paper filter medium.

Do not use filters with damaged paper filter medium.

Do not use filters after their expiry date.

Do not use filters with no or damaged filter seal.

Filters should be fitted as follows. :

Remove the front cover by easing open the right hand side.

Fit the filter squarely into the turbo unit.

Place pre-filter over filter (if used).

Close the cover over the filter, taking care that the cover does not touch the filter media.

Press down on the centre of the cover until it snaps closed.

MAGNUM 8500 Power unit M23/8500

Pre-filters (General)

The pre-filter is an optional item, which sits in front of the main filter and removes coarse dust before it reaches the main filter.

Pre-filters, in themselves, do not offer any respiratory protection and hence must only be used in conjunction with a main filter.

The pre-filter should be changed immediately a drop in airflow is noticed.

Frequent changing of the pre-filter will maximise the life of the main filter.

Pre-filter Part number: M23PF/20 (For use with M23P3SL/6 only)

Pre-filter replacement

Ensure that the main filter(s) are securely in place before commencing this operation.

Outside surfaces of both the power unit and the main filter(s) must be decontaminated before unscrewing the pre-filter retaining ring(s). Unscrew

the pre-filter retaining ring(s) and remove the contaminated pre-filter(s).

Replace the pre-filter(s) and re-fit the retaining ring(s).

Pre-filter Part number: M09PF ( for use with M09 Fitta filters only)

Pre-filter replacement

Ensure that the main filter(s) are securely in place before commencing this operation.

Outside surfaces of both the power unit and the main filter(s) must be de-contaminated before changing the pre-filter(s).

The louver forms a prefilter holder on each filter.

Lift the louver at the 2-pin catch, open it, and replace pre-filter in the recess on the top of the filter, ensuring that it lays flat.

Close the louver and secure it on the 2-pin catch ensuring that it is properly snapped shut.

If a pre-filter is not used the main filter should be changed immediately the clogged filter alarm sounds/indicates or the air flow indicator, indicates

reduced airflow.

If a pre-filter is used it should be changed immediately the clogged filter alarm indicates or the airflow indicator, indicates reduced airflow.

(This may be more frequently than if a pre-filter is not used).

If after changing the pre-filter the clogged filter alarm sounds/indicates reduced airflow or the airflow indicator indicates reduced airflow.

Within a short period of time, the main filter should be changed as detailed (see Main filter).

Main Particulate filters

Part number: M23P3SL/6 (Particulate Filters for Magnum 8500 power units)

Filters fitting:

Ensure that the rubber seal in the filter port of the power unit is present, in good condition and seated flat at the bottom of the threaded section.

Ensure that there is no visible damage to the filter; discard any damaged filters.

Screw the filter squarely into the power unit port until it is hand tight. Do not over tighten as this may damage the filter seal and impair efficiency.

Filter removal

The outside surfaces of both the power unit and the main filter must be decontaminated before unscrewing the main filter(s).

The power unit should be positioned so that the contaminated filters are facing downward, in order that any trapped material released by

unscrewing the filter does not fall into the filter port.

WARNING

Care should be taken when handling filters.

Do not touch the pleated paper filter medium.

Do not use filters with damaged paper filter medium. M23P3SL/6

Do not use filters after their expiry date. FILTER

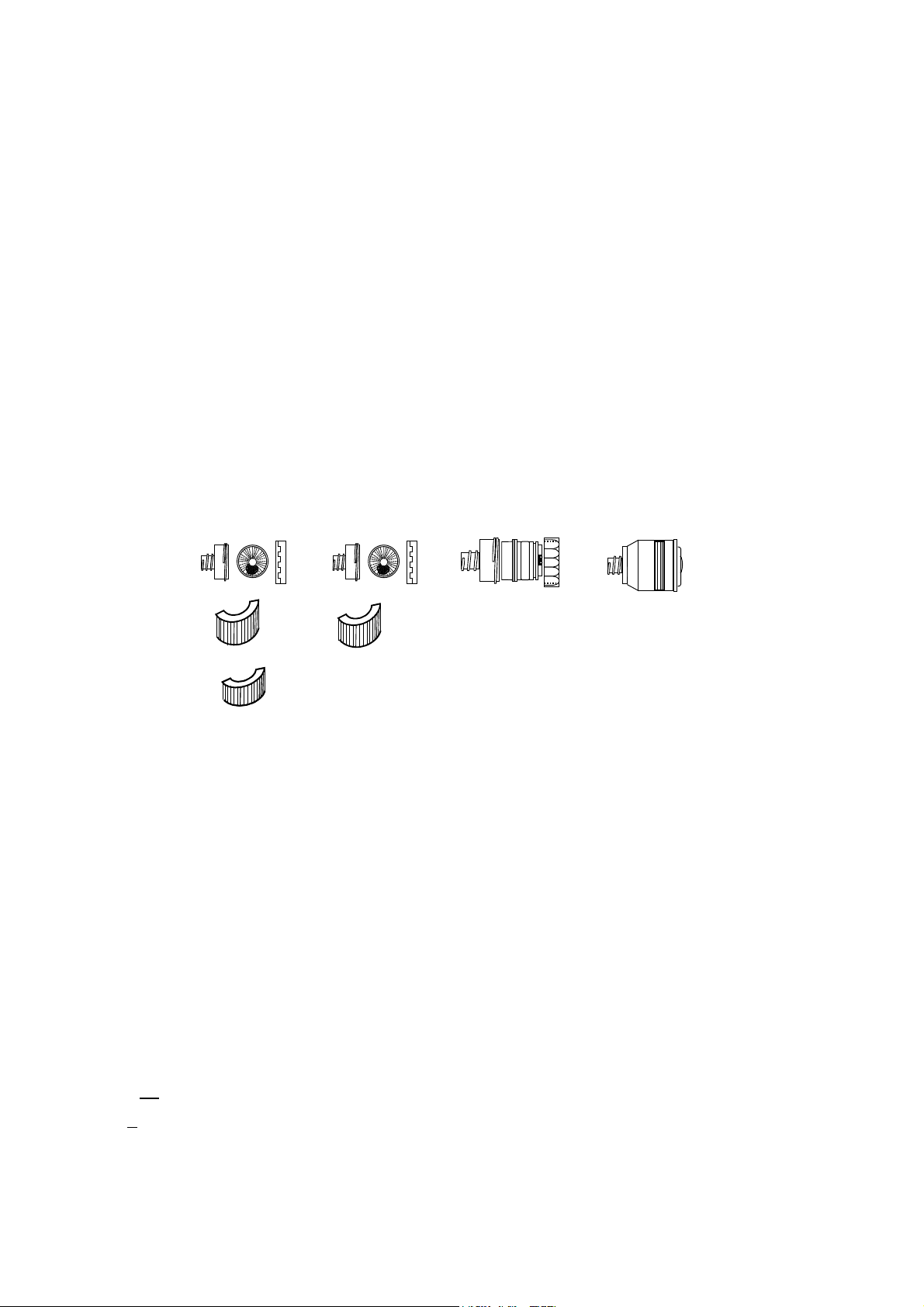

Fitta Combination Gas/Dust filters

(see diagram)

(for Magnum 8500 power unit only)

The following filters are available which can be used with the Magnum 8500 Unit and the range of TH2 headpieces and the M23LHF.

To use the Fitta range of filters as detailed below a cartridge holder Part number M22FH is required for each filter.

NB: 3 Combination Gas/Dust filters of the same type must be used.

If the centre Din 40 filter port is blanked off, the blank may be unscrewed with a coin. Cartridge holder base Filter Retaining ring

Part number Description

M09A1P2 (s) Organic Gas/ Dust

M09B1P2 (s)* Inorganic Gas / Dust

M09E1P2 (s)* Acid Gas / Dust

M09K1P2 (s)* Ammonia Gas/ Dust

* Discontinued

Filter fitting

Unscrew the retaining ring from the cartridge holder base and insert the filter with the louver facing outwards.

Ensure that the rubber-sealing ring on the filter rests against the rim of the base.

750 MOD 8 11/05/07 Page 4 of 8 POWER UNITS

Centurion Safety Products Ltd. Howlett Way, Thetford, Norfolk, IP24 1HZ, UK

Tel. 0044 (0)1842 754266 Fax. 0044 (0)1842 765590

Page 5

Replace the retaining ring and screw it up securely. Do not over tighten the ring.

The labelled portion of the filter and the louver protrude through the ring.

Ensure that the rubber seals in the filter ports of the power unit are present, in good condition and seated flat at the bottom of the threaded section.

Screw the holder(s) & filter(s) into the Din 40 ports of the power unit, hand tight only. Do not over tighten.

Filter removal

The outside surfaces of the power unit, holder and the filter(s) must be decontaminated before unscrewing the retaining ring(s).

The power unit should be positioned so that the contaminated filters are facing downward, in order that any trapped material released by

unscrewing the filter retainer does not fall into the filter holder.

Unscrew retaining ring of the holder, remove contaminated filter.

WARNING FITTED TO CARTRIDGE HOLDER

Care should be taken when handling filters.

Do not touch the filter medium.

Do not use filters with damaged filter medium.

Do not use filters after their expiry date.

Do not use filters that are not sealed in their bag.

FITTA COMBINATION FILTER

Din 40 Gas/Combination Gas/Particulate Canisters

The following filters are available for use with the Magnum 8500 Unit and the Full facemask.

NB: 3 filters of the same type must be used.

If the centre Din 40 filter port is blanked off, the blank may be unscrewed with a coin.

Part number Description

M23ABEK2/P3 Organic/Inorganic/Acid/Ammonia Gases and Dusts (Solid & Liquids)

M23A2/P3 Organic Gases and Dusts (Solid & Liquids)

M23B2/P3 Inorganic and Dusts (Solid & Liquids)

M23AX/P3 Organic Gases (with boiling points below 65 ºC and Dusts (Solid & Liquids)

M23A2 * Organic Gases

M23K2 * Ammonia Gases

M23A2B2/P3 * Organic/Inorganic Gases + Dusts (Solid & Liquids)

* Discontinued

NB Pre-filters cannot be used with the above Din 40 filters.

Canister fitting /Removal See M23P3SL/6.

(for Magnum 8500 power unit only)

WARNING

Care should be taken when handling filters.

Do not touch the filter medium.

Do not use filters with damaged filter medium.

Do not use filters after their expiry date.

Do not use filters with no or damaged filter seal caps.

6. AIR FLOW INFORMATION AND WARNING DEVICES

MAGNUM 1000 POWER UNIT

The Power unit is designed to exceed the requirements of EN 146 in that it will provide a flow rate of at least 140 litres/min for at least 4 hours

under all conditions, assuming a fully charged battery at start (MMDD = 4Hr). Typical Battery Life with M23P2/4B compact battery when fully

charged and run with Magnum 1000 Power Unit and appropriate filter and head piece is 8 Hrs (this will depend on various factors such as

condition of the filter, age of the battery etc.).

Once the battery has been charged and the correctly selected filter has been fitted the airflow should be checked before use.

AIR FLOW TEST

Principle of operation

The Airflow indicator is designed to be situated in the centre of the filtered air stream and as the air stream passes over the indicator, it causes it

to rise proportionally.

Indicated Airflow then can be read by means of a graduated scale situated on the body of the indicator.

Warnings and precautions

To ensure that your air flow indicator is maintained to give its optimum accuracy, the following precautions must be adopted: -

• When not in use, the indicator must be stored in conditions to prevent physical damage.

• When not in use, the indicator must be stored in conditions +5 to 35 degrees C @Rh<90%.

• When not in use, the indicator must be stored away from direct sunlight.

• The indicator must be kept clean and free from any contamination.

• No adjustments, alterations or additional markings must be made.

Method of use

Prior to use

• Visually inspect the Airflow indicator for any damage, contamination or distortion.

• Ensure that the battery pack fitted is in good condition and fully charged.

• Ensure a filter is fitted.

• Position Vertically the Magnum unit for testing. (See diagram I).

• Unlock the outlet ring (See diagram I) and remove Air hose (if attached) ensure that the outlet ring is in the UNLOCKED position at all

times during the air flow test.

• Switch unit on and allow to run for a minimum of 10secs.

• Locate Airflow indicator in the outlet ring with the letters of the graduated scale in the vertical and facing the front of the unit.

• Observe the airflow indicated from the graduated scale (See diagram II, III ). Ensure that when reading the scale your eye is level

750 MOD 8 11/05/07 Page 5 of 8 POWER UNITS

Centurion Safety Products Ltd. Howlett Way, Thetford, Norfolk, IP24 1HZ, UK

Tel. 0044 (0)1842 754266 Fax. 0044 (0)1842 765590

Page 6

with the top of the outlet ring.

8500

85008500

8500

NB It is possible that the air flow of the power unit when fitted with a fully charged battery pack and a new or servicable filter/pre-filter will be such

that when the airflow indicator is located in the outlet ring (See diagram I) it will be expelled.

This is not a fault condition but an indication of airflow above the designed limits of the indicator, it is an indication of sufficient airflow.

If you have both replaced the filter and fully charged the battery and line B is still not visible the unit and battery should be returned to the

supplier.

AIRFLOW INDICATOR FITTING

Line B fully visible

Unit has sufficient airflow

Line B obscured/not visible

Battery flat or blocked filter

To check for a flat battery replace filter and retest

To check for blocked filter, charge battery and retest.

Once the battery has been charged and the filter has been fitted the airflow should be checked before each use and

when a change or suspected change in airflow conditions is detected.

MAGNUM 2000 POWER UNIT

The Power unit is designed to exceed the requirements of EN 12941 in that it will provide a flow rate of at least 140 litres/min for at least 4 hours

under all conditions, assuming a fully charged battery at start. (Minimum design duration = 4 hours).

Duration of up to 8 hours can be typically achieved dependent on various conditions.

The Power unit will give an audible and visual alarm when either the clogging of the filter causes the airflow to drop to the minimum design flowrate

or when the battery voltage drops to a level below which it could not safely power the Power unit. When either of these conditions occur a

frequently repeating audible bleep is emitted and in addition the yellow LED (Light emitting diode) on the top of the Power unit flashes if the filter is

clogged or the red LED flashes if the battery is low.

When either alarm condition occurs during use the wearer should leave the contaminated area immediately and replace the filter or recharge the

battery accordingly.

When first turning the unit on the alarm will beep to indicate the correct functioning of the alarm system. If the beep stops after a few seconds the

airflow is sufficient to proceed with using the unit.

MAGNUM 8500 POWER UNITS

The Magnum 8500 units are activated using a rotary control knob, which should be set to the correct setting as indicated on

the top of the unit. ( see diagram )

Counter clockwise setting for Headpieces/ Hoods/ Half Suits only.

Clock wise setting for the Full facemask only.

Centre setting for Power Off.

Top label

When used with TH2 Headpieces, TH3 Hood or Half Suit ( Counter clockwise setting)

The Power unit is designed to exceed the requirements of EN12941 in that it will provide a minimum design flow rate of at least 140 litres/min for

theTH2 Headpieces or 120 litres/min for the TH3 Hood / Half Suit for at least 4 hours under all conditions, assuming a fully charged battery at

start. (Minimum design duration = 4 hours). Typical battery duration depends on a number of factors but is usually around 8 Hrs.

024-001-750 MOD 8 11/05/07 Page 6 of 8 POWER UNITS

Centurion Safety Products Ltd. Howlett Way, Thetford, Norfolk, IP24 1HZ, UK

Tel. 0044 (0)1842 754266 Fax. 0044 (0)1842 765590

Page 7

The Power unit will give an audible and visual alarm when either the clogging of the filter(s) causes the airflow to drop to the minimum design flow

rate or when the battery voltage drops to a level below which it could not safely power the Power unit. When either of these conditions occur a

frequently repeating audible bleep is emitted and in addition the yellow LED on the top of the Power unit flashes if the filter is clogged or the red

LED flashes if the battery is low.

When either alarm condition occurs during use the wearer should leave the contaminated area immediately and replace the filter or recharge the

battery accordingly.

When first turning the unit on the alarm will beep to indicate the correct functioning of the alarm system. If the beep stops after a few seconds the

airflow is sufficient to proceed with using the unit.

When Used With Full facemask. ( clockwise setting )

The Power unit is designed to exceed the requirements of EN12942 TM3 in that it will provide a minimum design flow rate of at 95 litres/min

when used with a full-face mask. for at least 4 hours under all conditions, assuming a fully charged battery at start. (Minimum design duration =

4 hours). Typical battery duration depends on a number of factors but is usually around 8 Hrs.

The Power unit will give an audible and visual alarm when the battery voltage drops to a level below which it could not safely power the unit.

When this condition occurs a frequently repeating audible bleep is emitted and in addition the Red LED on the top of the Power unit flashes.

When the alarm condition occurs during use the wearer should leave the contaminated area immediately and recharge the battery. The

electronic clogged filter low flow alarm is not enabled on the full-face mask setting. An airflow indicator is provided with the unit, which can be

used to check the flow prior to the use of the unit.

To check the airflow for full facemasks ensure that the filter and battery are fitted and turn the power unit on. The head piece hose should not

be fitted. Insert the airflow indicator into the outlet of the power unit with the letters on the label upright (See diagram I on page 6) and the label

facing toward the front of the unit (where the filter is fitted). If line A is fully visible then the unit has sufficient airflow. If line A is not visible

replace the filters. If you have both replaced the filter and fully charged the battery and line A is still not visible the unit and battery should be

returned to the supplier.

7. POWER UNIT FITTING

Ensure that the Power unit, Filter(s),air supply hose and headgear are not damaged, and that the battery is securely located in the Power unit.

Push the hose connector into the Power Unit outlet and twist the outlet collar to lock.

Turn on the Power unit and put the belt round the waist joining the buckles at the front.

8. HEADPIECE FITTING

Refer to the separate instructions supplied with the headpiece for fitting and maintenance instructions.

9. CLEANING, MAINTENANCE & STORAGE

Maintenance

Power unit - routine maintenance is limited to cleaning of the equipment and replacement of filters.

Cleaning

General - Avoid inhaling any dust during cleaning

Do not use abrasive cleaning agents or organic solvents to clean any surface.

To clean all external components wipe with a damp cloth dipped in warm soapy water. Dry with a soft, clean cloth.

Do not attempt to clean the filters, once fully loaded they must be replaced.

Do not immerse the power unit in water or allow water to enter the unit via the air outlet or inlet.

Storage

All equipment should be stored in a clean dry atmosphere (R.H. < 90%) within the temperature range -5°C to +55°C in the packaging provided.

It should be protected from direct sunlight and any material known to damage plastics, e.g. petrol and solvent vapours. Equipment should be

transported in the original packaging. If stored correctly this equipment has a shelf life of 5 years.

Disposal

Contaminated filters/pre filters should be disposed of in accordance with local Health & Safety Legislation.

10. WEEE

WEEE (Refers to Power unit, Battery and Charger ONLY)

THESE PRODUCTS SHOULD NOT BE DISPOSED OF IN GENERAL MUNICIPAL WASTE

1. The crossed-out wheeled bin symbol, with the solid bar, shown on this product, its packaging or instructions indicates that the product has

been manufactured after 13/8/05 and is subject to European Community directive 2002/96/EC, issued 27/1/03, on correct handling of

Waste Electronic and Electrical Equipment (WEEE).

2. WEEE cannot be disposed of as municipal waste and must be collected and disposed of separately. Appropriate public or private waste

collection systems defined by national and local regulations should be used.

3. The product may contain substances which could harm the environment or human health if disposed of incorrectly.

024-001-750 MOD 8 11/05/07 Page 7 of 8 POWER UNITS

Centurion Safety Products Ltd. Howlett Way, Thetford, Norfolk, IP24 1HZ, UK

Tel. 0044 (0)1842 754266 Fax. 0044 (0)1842 765590

Page 8

11. GUARANTEE

All Magnum Power Units are guaranteed free from any faults in materials or workmanship. Should any such faults develop within 12 months of

purchase then Centurion Safety Products Ltd will, at their discretion, repair or replace the unit without charge.

11. SPARES

Description Part Number

Shower resistant plastic shroud for 8500 unit M23PS

Comfort pad ( item 11 ) M23CP/L

Spare Standard Belt ( item 1 ) M23B

Plastic Belt (Wipe clean for decontamination) item 1 M23PB

DIAGRAM OF MAGNUM SYSTEM

1.Standard belt.

2.Comfort Pad.

3.Battery charger.

4. Gas/combination canister. 8. Filter.

EC Type-examination by : BSI Product Services, Maylands Avenue, Hemel Hempstead, Herts. HP2 4SQ

(Notified Body No 0086)

5. Small battery.

6. Large battery. 10. Hose.

7. Prefilter.

9. Outlet.

11. Large comfort pad.

12. 8500-type power unit with DIN 40 ports.

13. 1000/2000 type power unit fitted with hinged door.

024-001-750 MOD 8 11/05/07 Page 8 of 8 POWER UNITS

Centurion Safety Products Ltd. Howlett Way, Thetford, Norfolk, IP24 1HZ, UK

Tel. 0044 (0)1842 754266 Fax. 0044 (0)1842 765590

Loading...

Loading...