Page 1

MICROMETER ADJUSTABLE

“CLICK TYPE”

TORQUE WRENCH

REPAIR,

MAINTENANCE

AND

TROUBLESHOOTING

MANUAL

SUGGESTED PRICE $35.00

PART NUMBER: 21-201-01

ISSUED NOVEMBER , 2001

Page 2

TABLE OF CONTENTS

TITLE PAGE(S)

SAFETY INSTRUCTIONS – WARNING & CAUTION

1

CDI TORQUE TESTING EQUIPMENT - Illustration

2

INTRODUCTION 3

CLEANING 3

LUBRICATION 3

REPAIR TOOLS REQUIRED 3

OTHER REQUIRED MATERIALS 4

INSPECTION 4

CAUTION – Customer misuse

4

ACCURACY VERIFICATION AND MINOR CALIBRATION

PROCEDURE

4/8

MINOR CALIBRATION ADJUSTMENT 6/8

Handle Locking -Table 8

CALIBRATION ACCURACY CHECK - Illustration 8

MAJOR CALIBRATION AND REPAIR 8/14

To disassemble the tube 9

To recalibrate the wrench 9/14

Pawl Orientation Chart 10

Pawl Size - Table 11

Pawl Style Chart - Table 11

i

Page 3

TITLE PAGE(S)

Pawl Identification Code Example 11

Pawl Selection Chart - Table 12

Example #1 with Pawl Selection Chart - Table 13

Example #2 with Pawl Selection Chart - Table 14

To Disassemble and Check Parts 15/17

CAUTION – Positive Spring Pressure 17

To check for positive pressure on the spring 17

HANDLE/LOCK RING REPAIR 18/23

To disassemble the handle/lock ring 18/21

To assemble the handle/ lock ring 21/23

Handle Locking - Table 23

Calibration Instructions for Pre-Set Torque Wrenches 23/24

CDI Pre-Set Torque Wrench Ranges & Adjustment Tool Part Numbers 24

Troubleshooting 24

Micrometer Adjustable Torque Wrench Troubleshooting Matrix 25/26

ii

Page 4

REVISIONS –

The CDI Micrometer Adjustable Torque Wrench Repair Manual was originated and first

issued in November 2001. The manual will be reviewed and revised as necessary to

assure that it contains the latest changes in product or repair changes. In between

revision, product bulletins may be issued to assure any changes in product or repairs are

supplied to authorized repair facilities.

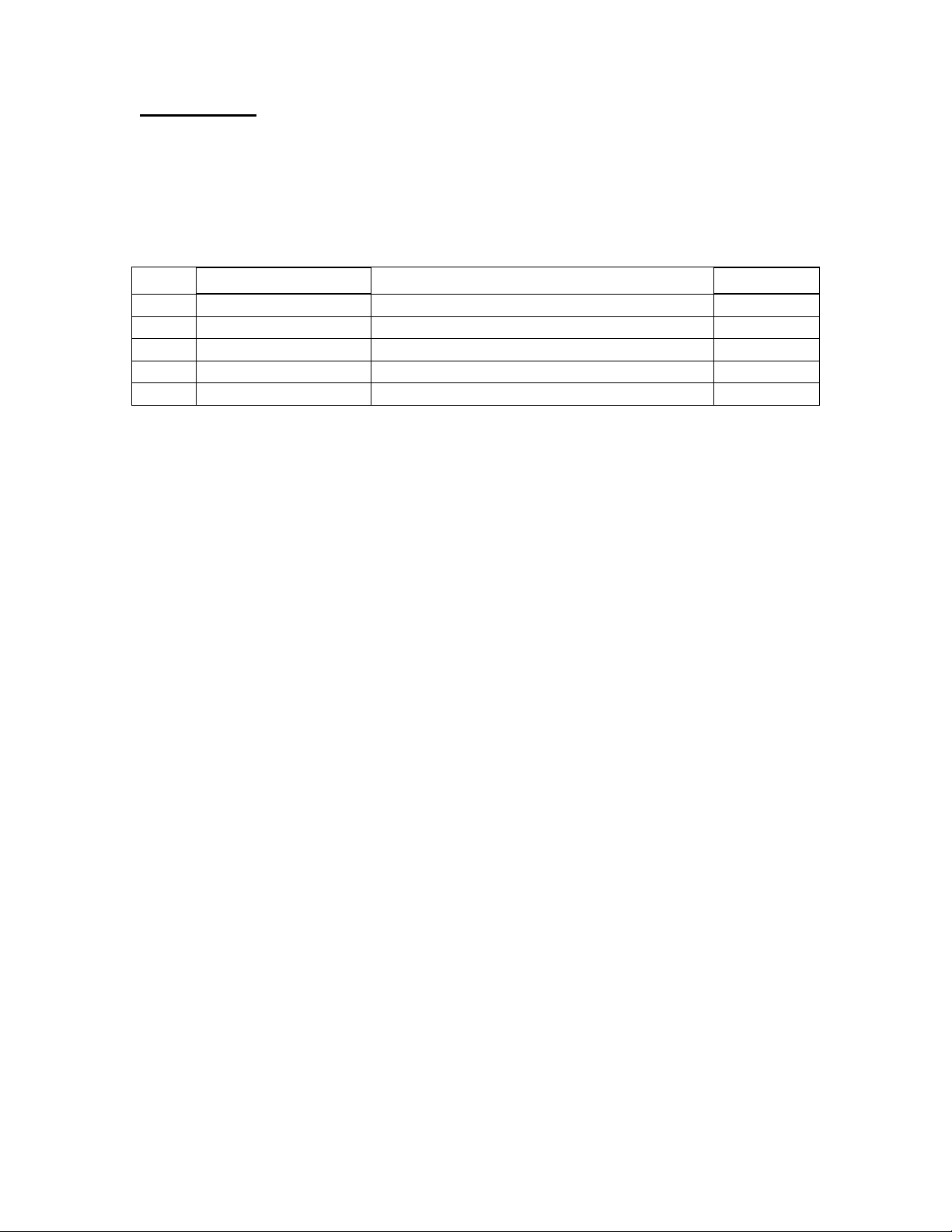

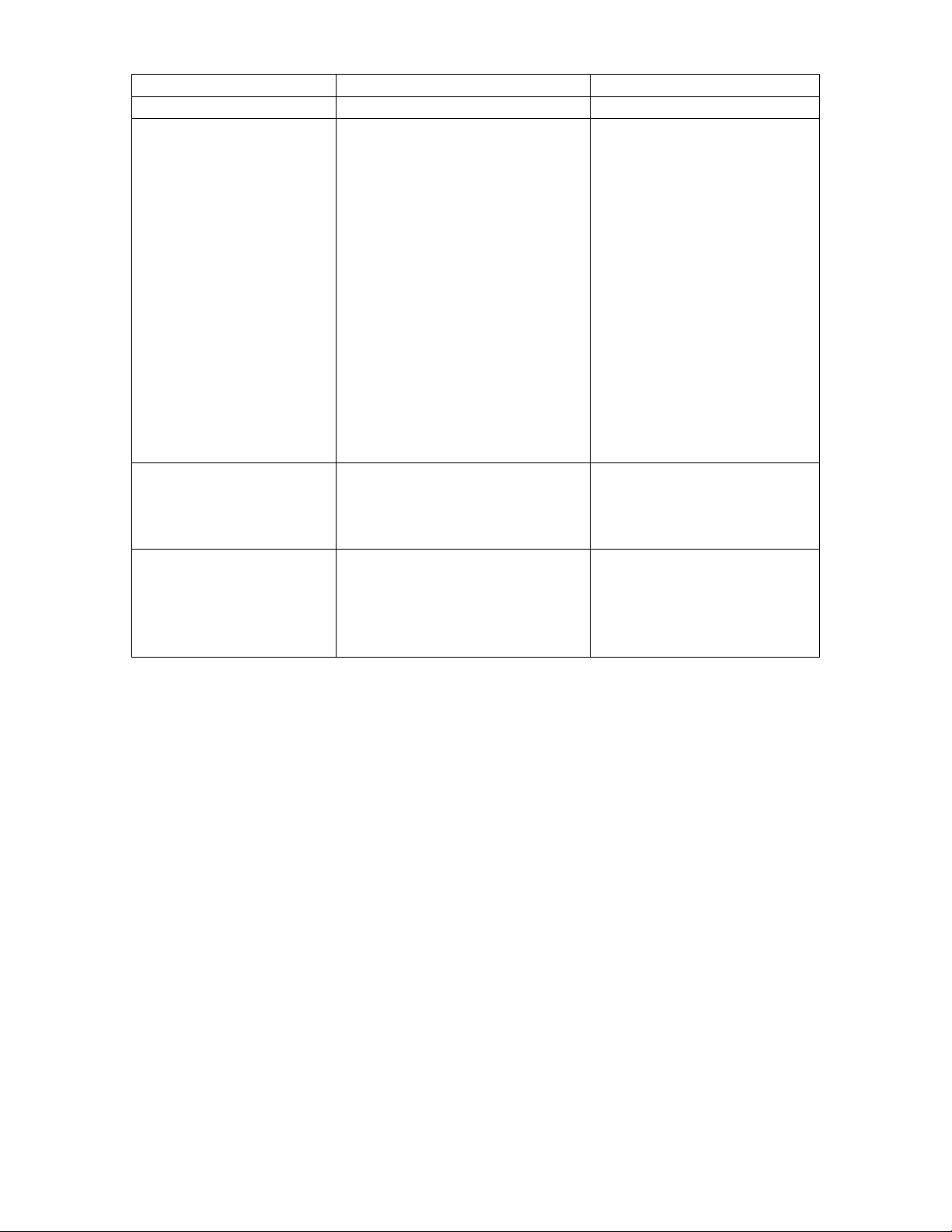

REV.

Date Issued

Affected Pages

Approved

November 2001

Written By: Donna E. Brunot

Photographs By: Gary Fitzhugh

iii

Page 5

CDI MICROMETER ADJUSTABLE AND PRE-SET TORQUE WRENCH

REPAIR, MAINTENANCE AND TROUBLESHOOTING INSTRUCTIONS

SAFETY INSTRUCTIONS

Failure to follow WARNING instructions can cause personal injury to the operator.

Failure to follow CAUTION instructions can cause the equipment to fail or break in use.

! WARNING

Always wear Safety Glasses or goggles when using or repairing hand tools.

Read this manual completely before repairing torque wrenches.

DO NOT use or test a wrench that shows signs of damage (bent tubes, cracked or

broken parts) caused by misuse. Recommend replacement.

DO NOT use cheater extensions on the handles or tube to apply torque.

DO NOT exceed rated maximum torque.

Check all sockets or other test accessories for wear, damage or crack prior to their

use with torque wrenches. Do not exceed their rated maximum torque.

Always pull (DO NOT push) to apply torque. Adjust your stance to prevent a fall if

something should give suddenly.

Ratchet head torque wrenches must be checked for full (positive) engagement of the

ratchet in the direction of use prior to applying a load on the wrench. Broken or

slipping ratchets can cause injury.

CAUTION

Periodic recalibration is necessary to maintain accuracy.

Periodic examination and cleaning is necessary to maintain the wrench

Page 1

Page 6

SURETEST

TORQUE

CALIBRATION

SYSTEM

MULTITEST

TORQUE

CALIBRATION

SYSTEM

ETT

ELECTRONIC

TORQUE

TESTER

Page 2

Page 7

INTRODUCTION

This manual covers the calibration, repair, maintenance and a troubleshooting guide to

identify and remedy problems that could occur with the CDI Torque Wrenches. Each

wrench model has an Exploded Illustration that lists the component parts and shows

assembly particulars. The exploded illustration must be used as a guide for assembling

CDI Torque Wrenches. CDI has a Service Center that performs repairs and calibration on

all of our products at the factory, plus a list of factory authorized repair/calibration

centers throughout the world. Contact CDI Service Center at (626) 965-0668 or

sales@cditorque.com for technical assistance on the repair or calibration of CDI Torque

Products.

CLEANING

Wipe all exterior parts with a dry, clean and lint free cloth. DO NOT USE any abrasive

or corrosive materials to clean any components of the CDI Torque Wrenches. After

assembly, a non-abrasive polishing agent applied with a dry, clean and lint free cloth may

be used to polish the chrome exterior parts.

LUBRICATION

Super Lube MULTI-Purpose Synthetic Lubrication with Teflon, CDI Part #10-

1000. NO SUBSTITUTES ALLOWED.

REPAIR TOOLS REQUIRED

Micrometer Adjustable Torque Wrenches

*

1

1

2

1

Torque Tester (range determined by the torque wrench to be tested)

Flat blade mini screwdriver (max. blade size .063 or 1.6mm)

End Cutter (modified jaws ground flat on top to allow rivet removal)

CDI Calibration Crank Handle (Pt. # 600-8-1 & 600-8-2) 7/16” & 3/8” hex

0 to 1” micrometer with tenth (.0000) increments

1 16 oz. hammer

1 40 to 200 In. Lb. CDI Torque Wrench

1 3/8” 6 Point Deep Socket

1 7/16” 6 Point Deep Socket

*We recommend that CDI torque testers are used to test the calibration accuracy of

CDI manufactured torque products.

CDI manufactures a complete line of torque testing equipment from moderately

priced testers to complete state of the art test systems used in metrology calibration

laboratories all over the world. Contact CDI Sales Department at (626) 965-0668 or

sales@cditorque.com

for the nearest distributor of CDI Torque Products.

Page 3

Page 8

OTHER REQUIRED MATERIALS

Torque Seal (Part # 10-1100)

INSPECTION

Inspect all wrenches repaired to determine that they are in an operational condition by

visually inspecting for worn, broken, cracked or damaged parts. Replace parts not found

to be in satisfactory condition.

CAUTION

Some torque wrenches are abused or damage beyond repair. The most common abuse is

using the wrench as a breaker bar to loosen a bolt or nut. This type of misuse is evident if

the tube or the drive is bent in the counterclockwise direction in relation to the tube or

marks from a cheater bar are on the tube or handle. DO NOT REPAIR the wrench if it

shows signs of this type of misuse. The component parts may be permanently damaged.

The SAFETY and INTEGRITY of the wrench could be impaired. Recommend that the

wrench be replaced.

ACCURACY VERIFICATION AND MINOR CALIBRATION PROCEDURE

This procedure is to be used to check the accuracy and, if necessary, perform a minor

adjustment on calibration. It must also be used after a major calibration.

There are two major international standards that establish torque wrench accuracy

requirements. They are ASME B107.14 M Hand Torque Tools (American Society of

Mechanical Engineers) and ISO 6789 Hand Torque Tools – Requirements and Test

Methods (International Organization for Standardization). Both standards are recognized

as established accuracy test methods and referenced in this section. ASME and ISO

standards are subject to review and changes. The repair manual will be reviewed and

revised periodically but may not reflect the latest revisions of the specifications listed

above.

ASME B107.14M

1. Preload the wrench by setting the wrench at 50% of full scale and operating three

times in the direction of the test.

2. Reset handle to 20% of full scale. Place square drive in tester. Adjust the loading

point of the tester until the load is being applied in the center of the handle.

Page 4

Page 9

3. Test the wrench three (3) times at 20% noting the accuracy error for each reading. Set

and test the wrench three (3) times at 60% and 100% of full scale noting the accuracy

error for each reading. If the readings are within the accuracy requirements for the

direction no calibration adjustment is required.

4. Test the torque wrench in the opposite direction, if required, by following steps 1

through 4 in that direction.

NOTE

The handle support MUST be at the center of the handle when the handle is adjusted to

20%, 60% of scale, and again at 100% of scale. Torque wrench readings, per industrial

(ASME B107.14M-1994) standards, have to be obtained by applying the load to the

center of the handle.

ISO6789

1. Preload the wrench by setting the wrench at 100% of full scale and operating five (5)

times in the direction of the test.

2. Reset handle to 20% of full scale. Place square drive in tester. Adjust the loading

point of the tester until the load is being applied in the center of the handle.

3. Test the wrench five (5) times at 20% noting the accuracy error for each reading. Set

and test the wrench five (5) times at 60% and 100% of full scale noting the accuracy

error for each reading. If the readings are within the accuracy requirements for the

test direction no calibration adjustment is required.

4. Test the torque wrench in the opposite direction, if required, by following steps 1

through 4 in that direction.

Page 5

Page 10

Minor Calibration Accuracy Adjustment

NOTE

A minor (handle) adjustment is used to adjust 20% of the scale reading. If the reading at

20% and 100% of scale are both either high or low to the required accuracy, a minor

adjustment may be used to bring the accuracy within torque specification. If the torque

wrench requires minor adjustment follow steps 5 through 8.

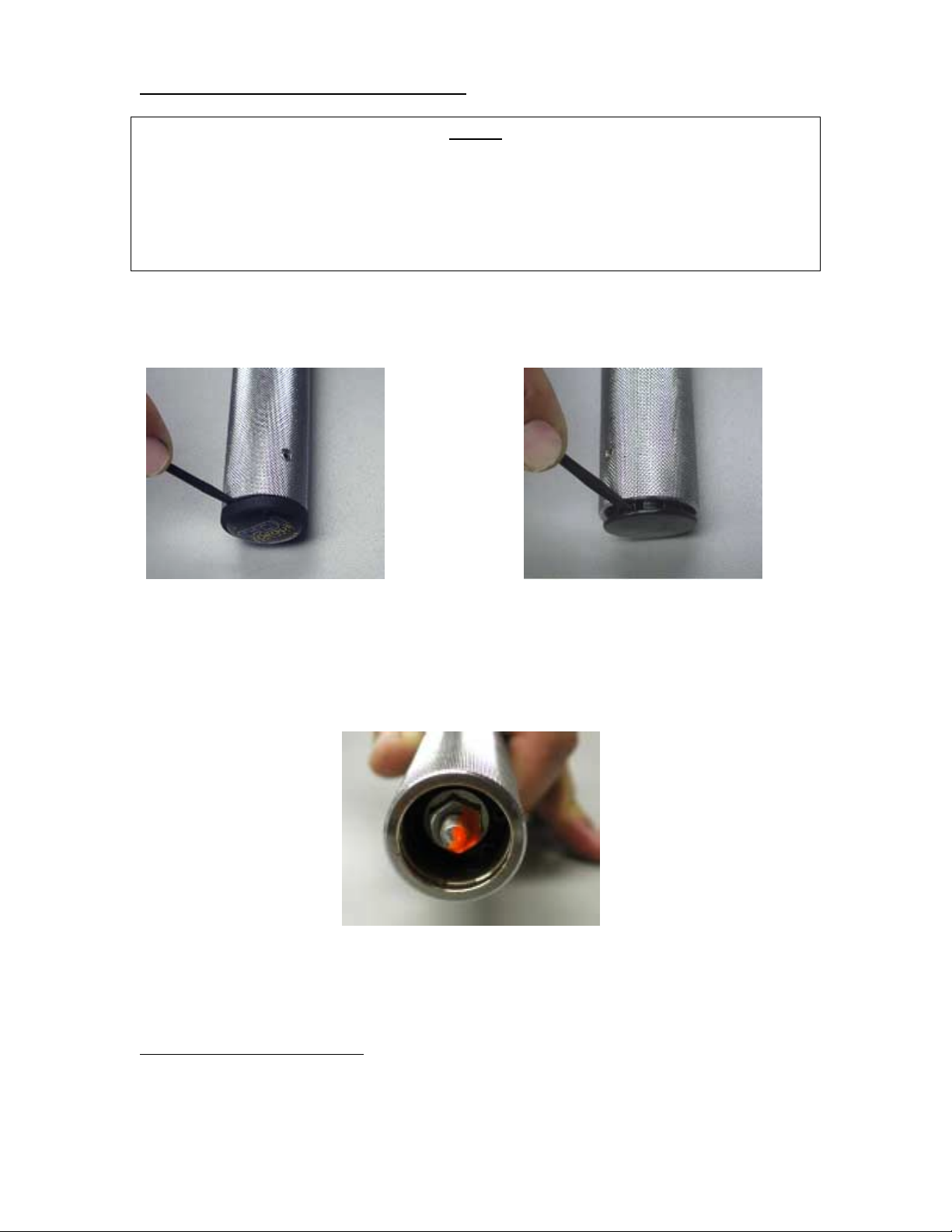

5. Set the handle at 120% of full scale. Remove the 2plug from the end of the handle.

OR

Plug Removal

6. Check the torque seal on the load screw. If removed or cracked, the wrench

calibration has been tampered with or the handle has been forced below its preset stop

point.

Handle End View

1

All torque wrenches with ¼” head drives must be calibrated at 100% of scale, not minimum (20%)

2

See section on handle/lock ri ng for particulars on button plug or FOD plug removal.

Page 6

Page 11

HANDLE/TUBE VIEW

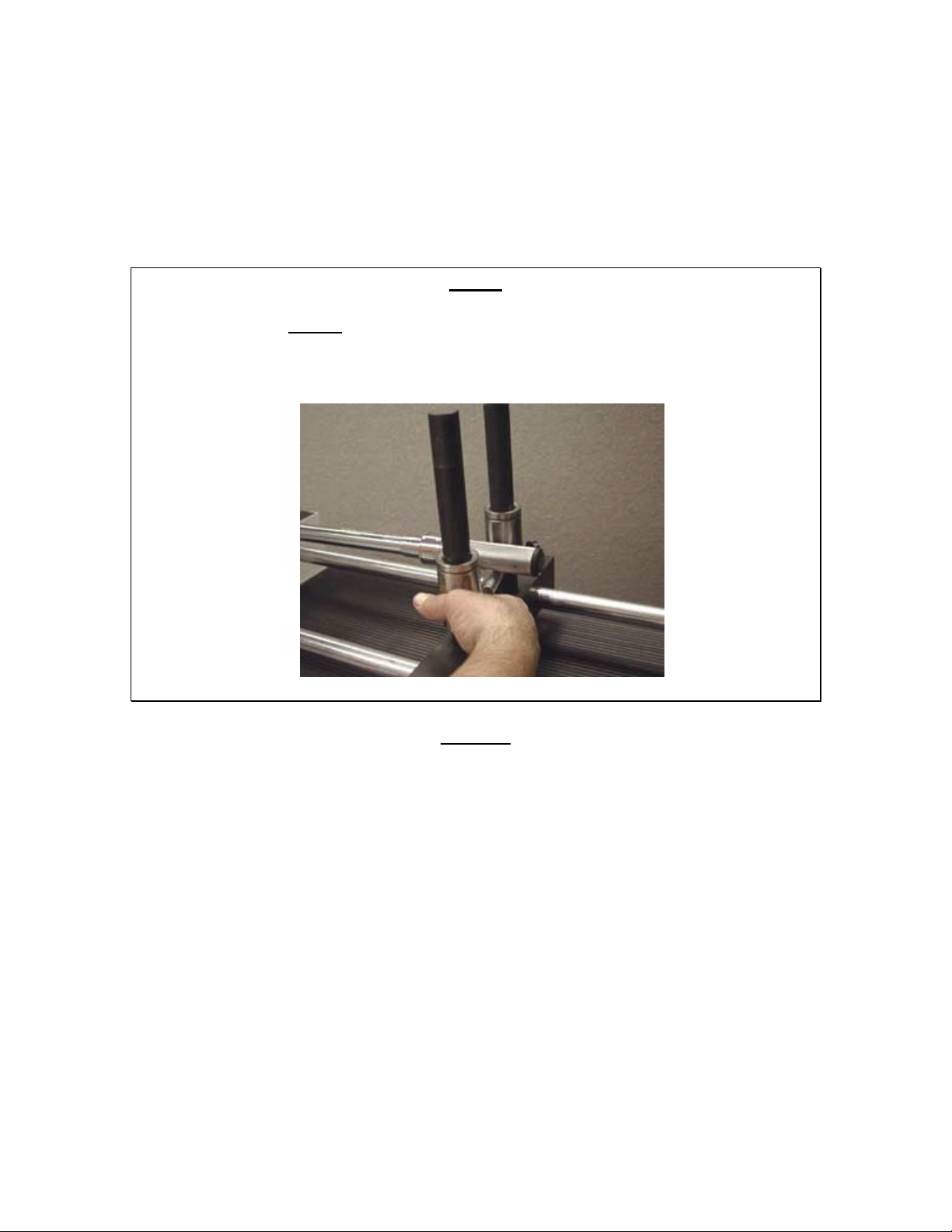

7. Pull the lock ring down and turn the handle until you reach the desired reading on the

tester as follows:

A.

If the reading on the tester was below the accuracy limit for the value tested turn the

handle clockwise to increase the value. Release the lock ring. Repeat this test and

adjustment procedure until the torque reading is within the accuracy limits.

B. If the reading on the tester was above the accuracy limit for the value tested turn the

handle counterclockwise to decrease the value. Release the lock ring. Repeat this

test and adjustment procedure until the torque reading is within the accuracy limits.

Release the lock ring and check the value on the tester.

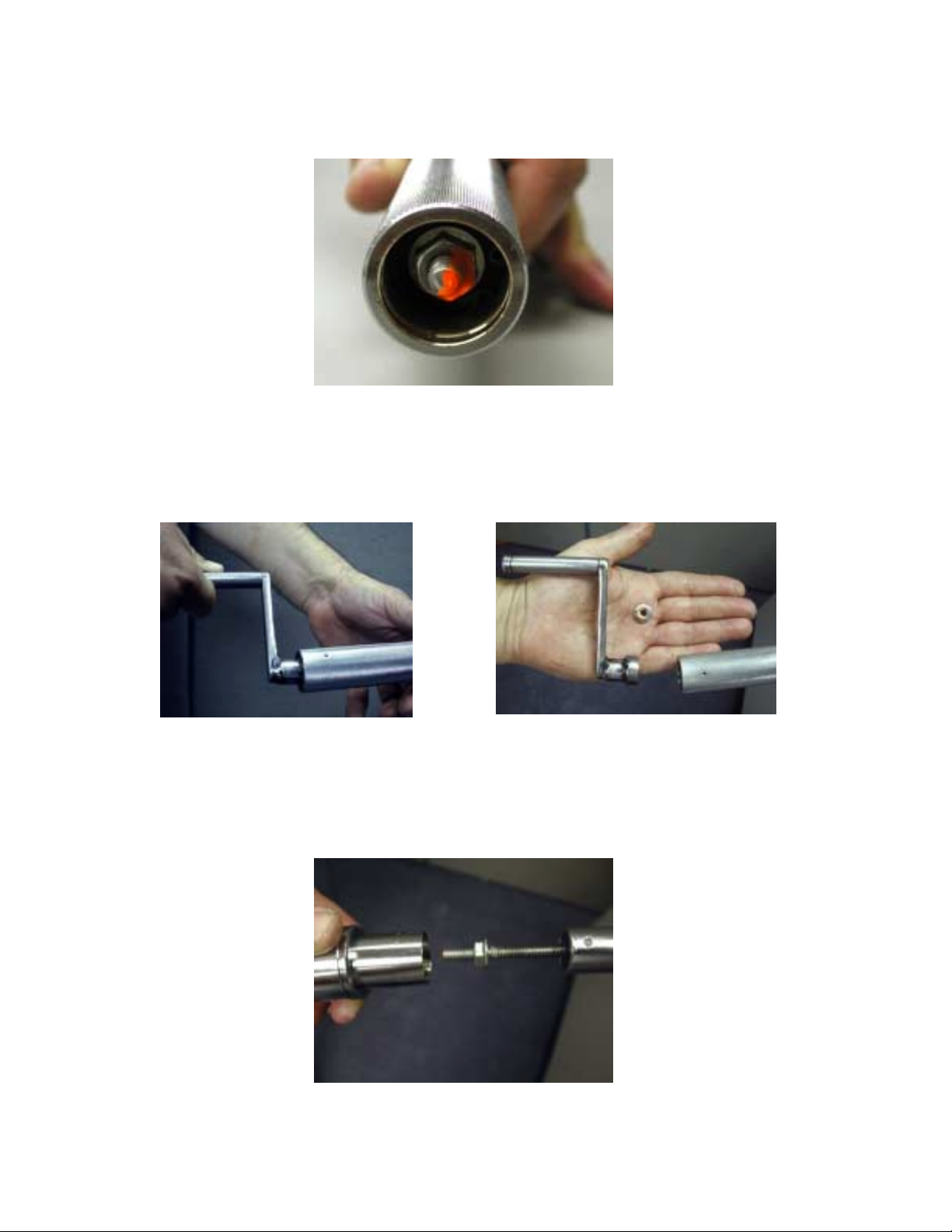

8. With the lock ring in the locked position and holding the wrench handle firmly to

prevent rotation of the handle, loosen the hex flange nut with the calibration crank

handle (approximately 2 full turns). Sometimes this will disengage the hex flange nut

from the screw and on other wrenches the hex flange nut will remain on the load

screw. The Torque seal will show a crack between the nut and screw. Remove the

loose torque seal from the nut and screw.

Loosening Nut

Page 7

Page 12

9. Pull the lock ring down, while applying a light force towards the wrench (to prevent

handle disengagement) and turn handle until handle “0” mark is aligned to the

centerline of the scale.

10. Tighten the hex flange nut (B) with a 200 in. lb. torque wrench as follows:

Handle Locking

Torque Wrench Ranges Hex Flange Nut Size Torque Ranges

50 in. lb. to 250 in. lb. 3/8” 35 to 40 in. lb.

75 ft. lb. to 1000 ft. lb. 7/16” 90 to100 in. lb.

11. Retest the wrench for accuracy (steps 1 through 4). If the wrench is not within

specified accuracy requirements repeat steps 5 through 10 or the wrench may require

a major calibration.

MAJOR CALIBRATION AND REPAIR

These instructions are to be used for the major calibration. Major calibration requires the

wrench to be partially disassembled from the front removing the ratchet or drive

mechanism, to inspect the internal component parts for contaminates, damage and/or

wear. Replacement parts are normally required. Each wrench model has an Exploded

Illustration that lists the component parts and shows assembly particulars. The exploded

illustration must be used as a guide for purchasing CDI Torque Wrench component parts.

Contact CDI Sales Department at (626) 965-0668 or sales@cditorque.com for

Exploded Illustrations for a particular torque wrench model and/or to purchase

component parts needed for repairs.

Page 8

Page 13

To disassemble the tube

1. Pull down the lock ring and unwind the handle of the wrench below 20% of scale

until it stops. This must be done to remove the pressure on the drive or ratchet head.

Prior to removal of the rivet and pivot pin required for a major calibration.

2. Remove the pivot pin rivet from the tube by using the modified end cutters. Push the

pivot pin out of the tube to release the head drive.

To recalibrate the wrench

1. Pull the head drive, secondary arm (if required), pawl and cam slowly out of the

wrench to prevent the pawl from 3loosing its orientation in the cam.

OR

3

If the pawl orientation in the slot of the cam is unknown rebuild the wrench without inserting the rivet

into the pivot pin and retest.

Page 9

Page 14

2. The orientation, size and style of the pawl in the wrench must be determined,

measured and noted so it can be found on the pawl selection chart. Use a micrometer

to measure the pawl and determine its

4

size and style.

3 A major recalibration requires the selection of a new pawl. To find the correct pawl,

locate the pawl removed from the wrench on the pawl selection chart. This is the

starting point for selecting a new pawl

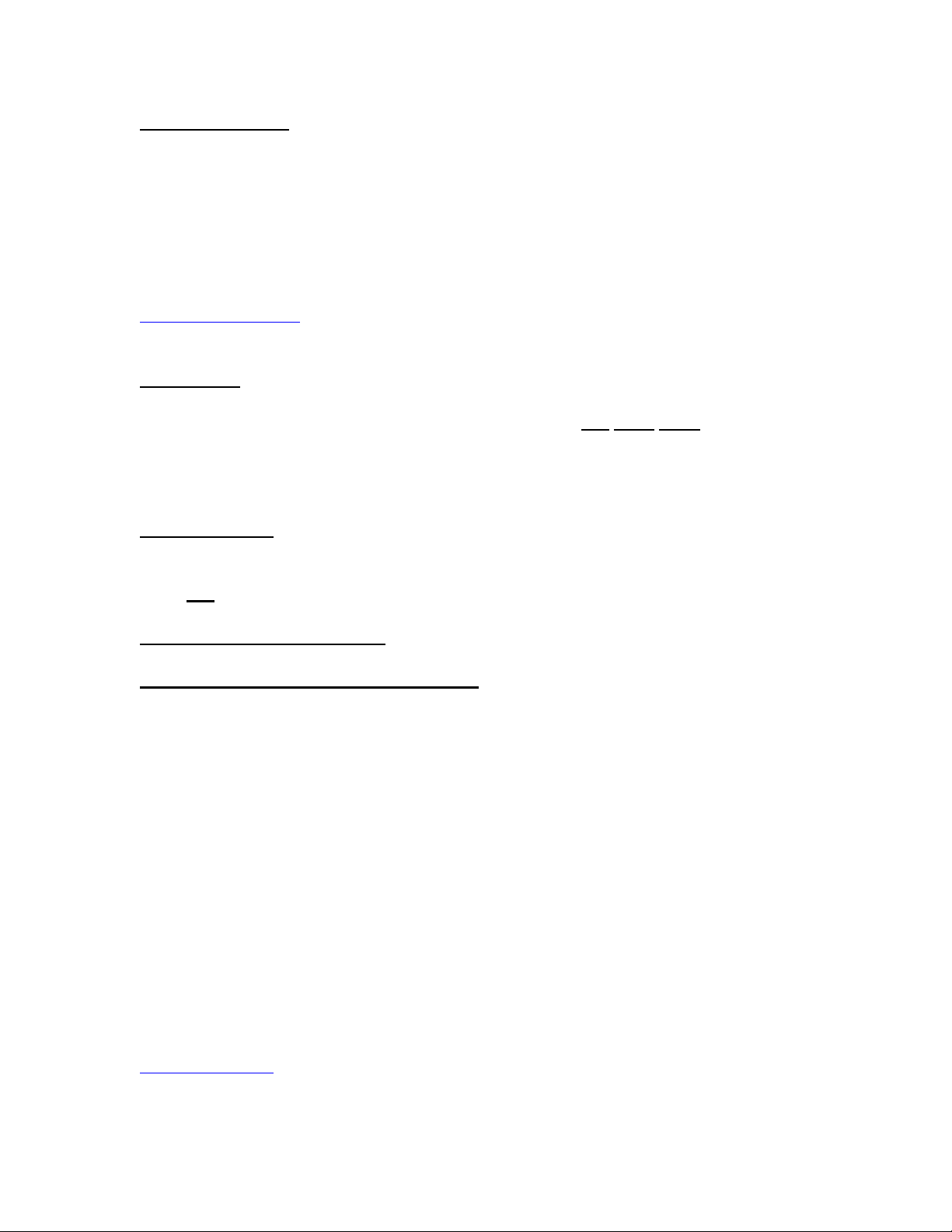

Pawl Orientation Chart

O = Square Pawl

All sides are the same no orientation to pawl slot required.

ARM

T = Tall

Taller side of

the pawl is

CAM perpendicular

to the cam slot

ARM

S = Short

Shorter side of

The pawl is

CAM perpendicular

to the cam slot

4

Due to the machining tolerances, pawl sizes sometimes do not corresponding exactly to the number in the

pawl selection chart. If this occurs choose the pawl on the chart closest to the pawl removed from the

wrench.

Page 10

Page 15

Pawl Size

There are six different pawl sizes available for calibrati on starting with pawl number “0”

with square cross sections. Metric sizes (mm) are in parentheses ().

SIZE

STYLE

A B C

0 - .250 x .250

(6.35) x (6.35)

1 - .250 x .244

(6.35 x 6.20)

2 .260 x .250

(6.60 x 6.35)

3 .260 x .245

(6.60 x 6.20)

4 .260 x .240

(6.60 x 6.10)

5 .260 x .235

.250 x 240

(6.35 x 6.10)

.250 x .235

(6.35 x 6.00)

.250 x .230

(6.35 x 5.85)

- .187 x .168

(6.60 x 6.00)

Style Chart

= Pawl with longer side .260 (6.60)

A

= Pawl with longer side .250 (6.35) or both sides .250 (6.35)

B

= Pawl with longer side .187 (4.75) or both sides .187 (4.75)

C

NOTE: Style “C” is used on wrenches up to a maximum scale of .250 in. lb.

PAWL IDENTIFICATION CODE EXAMPLE

ARM

3 T B size 3 ==== .250 x .235

↓↓↓↓ ↓↓↓↓ ↓↓↓↓ (6.35 x 6.00)

⇓

↓↓↓↓ of pawl is

⇔⇔⇔⇔ .235 (6.00) orientation perpendicular

CAM to the pawl slot)

B ==== pawl with longer

Metric sizes (mm) are in parentheses ().

⇓ .250 (6.35) =

⇓⇓

= size ↓↓↓↓ style ==== T ==== tall (longer side

==

side .250 (6.35)

.187 x .187

(4.75 x 4.75)

.187 x .183

(4.75 x 4.65)

.187 x .180

(4.75 x 4.57)

.187 x .176

(4.75 x 4.47)

.187 x .173

(4.75 x 4.40)

(4.75 x 4.27)

Page 11

Page 16

PAWL SELECTION CHART

STYLE

♦♦♦♦

A

.260

(6.60)

or

B

.250

(6.35)

TO DECREASE THE READING⇐⇐⇐⇐----------------⇒⇒⇒⇒TO INCREASE THE READING

SIZE & ORIENTATION

5T

A⇓⇓⇓⇓

.235

(6.00)

⇔⇔⇔⇔

4T

A⇓⇓⇓⇓

.240

(6.10)

⇔⇔⇔⇔

B⇓⇓⇓⇓

.230

(5.85)

⇔⇔⇔⇔

3T

A⇓⇓⇓⇓

.245

(6.20)

⇔⇔⇔⇔

B⇓⇓⇓⇓

.235

(6.00)

⇔⇔⇔⇔

2T

A⇓⇓⇓⇓

.250

(6.35)

⇔⇔⇔⇔

B⇓⇓⇓⇓

.240

(6.10)

⇔⇔⇔⇔

1T

B⇓⇓⇓⇓

.244

(6.20)

⇔⇔⇔⇔

0

B⇓⇓⇓⇓

B

⇔⇔⇔⇔

1S

.244⇓⇓⇓⇓

(6.20)

B

⇔⇔⇔⇔

2S

.240⇓⇓⇓⇓

(6.10)

B

⇔⇔⇔⇔

3S

.235⇓⇓⇓⇓

(6.00)

B

⇔⇔⇔⇔

4S

.230⇓⇓⇓⇓

(5.85)

B

⇔⇔⇔⇔

5S

Style C .187 (4.75)

for wrenches with a maximum scale up to 250 in. lb. ONLY.

♦♦♦♦

C⇓⇓⇓⇓

.168

(4.27)

⇔⇔⇔⇔

C⇓⇓⇓⇓

.173

(4.40)

⇔⇔⇔⇔

C⇓⇓⇓⇓

.176

(4.47)

⇔⇔⇔⇔

C⇓⇓⇓⇓

.180

(4.57)

⇔⇔⇔⇔

C⇓⇓⇓⇓

.183

(4.65)

⇔⇔⇔⇔

C⇓⇓⇓⇓

C

⇔⇔⇔⇔

.183⇓⇓⇓⇓

(4.65)

C

⇔⇔⇔⇔

.180⇓⇓⇓⇓

(4.57)

C

⇔⇔⇔⇔

.176⇓⇓⇓⇓

(4.47)

C

⇔⇔⇔⇔

.173⇓⇓⇓⇓

(4.40)

C

⇔⇔⇔⇔

.168⇓⇓⇓⇓

(4.27)

C

⇔⇔⇔⇔

NOTES

To increase or decrease the torque reading approximately 2% requires changing the

actual pawl size one location.

Always select a pawl to the left ⇐⇐⇐⇐ of the actual pawl to decrease the wrench reading.

Always select a pawl to the right ⇒⇒⇒⇒ of the actual pawl to increase the wrench

reading.

There is an overlapping of pawl sizes. Style “A’” and “B” overlap from size 2T to

4T. Use style “A”

Metric sizes (mm) are in parentheses ().

, if available

.

Page 12

Page 17

EXAMPLE #1

The wrench reads approximately 5% low from nominal. Disassemble the wrench and

measure the pawl. It was .260 (6.60)⇓ X .245 (6.20)⇔, orientated with the longer side of

the pawl perpendicular to the cam slot. To find the correct pawl, locate the pawl removed

from the wrench on the pawl selection chart. This pawl is number 3TA on the chart. This

is the starting point for selecting a new pawl.

To increase the reading of the wrench 4% choose the pawl two places to the right of 3TA

(.260 (6.60)⇓ X .245 (6.20)⇔) which is 1TB (.250 (6.35)⇓ X .244 (6.20)⇔). This pawl

change should increase the wrench reading to within approximately 1% of nominal.

PAWL SELECTION CHART

STYLE

♦♦♦♦

5T

4T

3T

SIZE & ORIENTATION

Metric sizes (mm) are in parentheses ().

2T 1T

0

1S

2S

3S

4S

5S

.260

(6.60)

or

.250

(6.35)

A

B

A⇓⇓⇓⇓

.235

(6.00)

⇔⇔⇔⇔

A⇓⇓⇓⇓

.240

(6.10)

⇔⇔⇔⇔

B⇓⇓⇓⇓

.230

(5.85)

⇔⇔⇔⇔

A⇓⇓⇓⇓

✷✷✷✷

✷✷✷✷

.245

(6.20)

⇔⇔⇔⇔

B⇓⇓⇓⇓

.235

(6.00)

⇔⇔⇔⇔

A⇓⇓⇓⇓

.250

(6.35)

⇔⇔⇔⇔

B⇓⇓⇓⇓

.240

(6.10)

⇔⇔⇔⇔

.B⇓⇓⇓⇓

.244

(6.20)

⇔⇔⇔⇔

.B⇓⇓⇓⇓

B

⇔⇔⇔⇔

.244⇓⇓⇓⇓

(6.20)

B

⇔⇔⇔⇔

.240⇓⇓⇓⇓

(6.10)

B

⇔⇔⇔⇔

.235⇓⇓⇓⇓

(6.00)

B

⇔⇔⇔⇔

.230⇓⇓⇓⇓

(5.85)

B

⇔⇔⇔⇔

Page 13

Page 18

EXAMPLE #2

The wrench reads approximately 5% high from nominal. Disassemble the wrench and

measure the pawl. It was .250 (6.35)⇓ X .244 (6.20)⇔, orientated with the longer side of

the pawl perpendicular to the cam slot. To find the correct pawl, locate the pawl removed

from the wrench on the pawl selection chart. This pawl number is 1TA on the chart. This

is the starting point for selecting a new pawl.

To decrease the reading of the wrench 4% choose the pawl two places to the left of 1TB

(.250 (6.35)⇓ X .244 (6.20)⇔) which is 3TA (.260 (6.60)⇓ X .245 (6.20)⇔) or 3TB

(.250 (6.35)⇓ X .235 (6.00)⇔).

The recommended change would be to a Style “A”, if available. This pawl change should

decrease the wrench reading to within approximately 1% of nominal.

PAWL SELECTION CHART

STYLE

♦♦♦♦

5T

4T

3T

SIZE & ORIENTATION

Metric sizes (mm) are in parentheses ().

2T 1T

0

1S

2S

3S

4S

5S

.260

(6.60)

or

.250

(6.35)

A

B

A⇓⇓⇓⇓

.235

(6.00)

⇔⇔⇔⇔

A⇓⇓⇓⇓

.240

(6.10)

⇔⇔⇔⇔

B⇓⇓⇓⇓

.230

(5.85)

⇔⇔⇔⇔

A⇓⇓⇓⇓

✷✷✷✷

✷✷✷✷

.245

(6.20)

⇔⇔⇔⇔

B⇓⇓⇓⇓

.235

(6.00)

⇔⇔⇔⇔

A⇓⇓⇓⇓

.250

(6.35)

⇔⇔⇔⇔

B⇓⇓⇓⇓

.240

(6.10)

⇔⇔⇔⇔

B⇓⇓⇓⇓

.244

(6.20)

⇔⇔⇔⇔

B⇓⇓⇓⇓

B

⇔⇔⇔⇔

.244⇓⇓⇓⇓

(6.20)

B

⇔⇔⇔⇔

.240⇓⇓⇓⇓

(6.10)

B

⇔⇔⇔⇔

.235⇓⇓⇓⇓

(6.00)

B

⇔⇔⇔⇔

.230⇓⇓⇓⇓

(5.85)

B

⇔⇔⇔⇔

4. Check the pawl and pawl slot for worn or damaged edges. Choose the appropriate

pawl to increase⇒ or decrease⇐ the reading.

5. Go to page 15 and follow instructions 4 through 9 to calibrate.

OR

6. To disassemble, clean, inspect and re-lubricate go to page 14 and follow instructions

1 though 9.

Page 14

Page 19

To Disassemble and Check Parts

1. Rem ove all part s from t ube. Ex ami ne them for wear and/or dam age. Replace parts

as required. Clean and lubricate internal parts with Super Lube.

2. Assemble the parts according to the assembly blueprint requirements (spacers,

Thrust washers, flat washers & spring). Slide into the tube.

Page 15

Page 20

3. Place the cam on top of the spring, properly orientated to the pivot hole.

4. Select pawl as shown on pages 9 through 13. Lightly grease the pawl to hold it

into position in the cam. Place the pawl in the cam slot.

.

5. Place th e end of the drive head or arm carefully against the top of the pawl and

slide assembly back into the tube. Place pivot pin through the tube and head.

Page 16

Page 21

CAUTION

The wrench must always be assembled with some positive pressure on the spring. To

assure positive pressure, the pivot hole of the head must be pushed into alignment with

the pivot hole on the tube. Failure to assemble the wrench with positive pressure will

result in the wrench not being able to hold calibration.

To check for positive pressure on the spring

a) Place the pivot pin into the assembled wrench.

b) With the handle unwound to its lowest point (the handle stop), the wrench should be

at 5% to 10% of full scale (example a 250 ft/ lb. wrench should read 12.5 to 25 ft. lb.)

on a torque tester.

c) If the wrench does not click or reads below at 5% of full scale on a torque tester when

the handle is at its lowest position, disassemble and add more washers to increase the

pressure.

6. Pull the lock ring down and adjust the wrench up to the maximum scale value.

Cycle the wrench a minimum of 25 times in both directions (clockwise &

counterclockwise).

7. Pull the lock ring down and adjust the wrench down to minimum scale value.

8. Perform an accuracy verification and if required, a minor calibration adjustment.

9. After calibration, insert a new rivet into the pivot pin. Use a hammer to lock rivet

into pivot pin.

Page 17

Page 22

HANDLE/LOCK RING REPAIR

These instructions are to be used for the repair of the handles or lock rings. Calibration

does not require the handle to be disassembled.

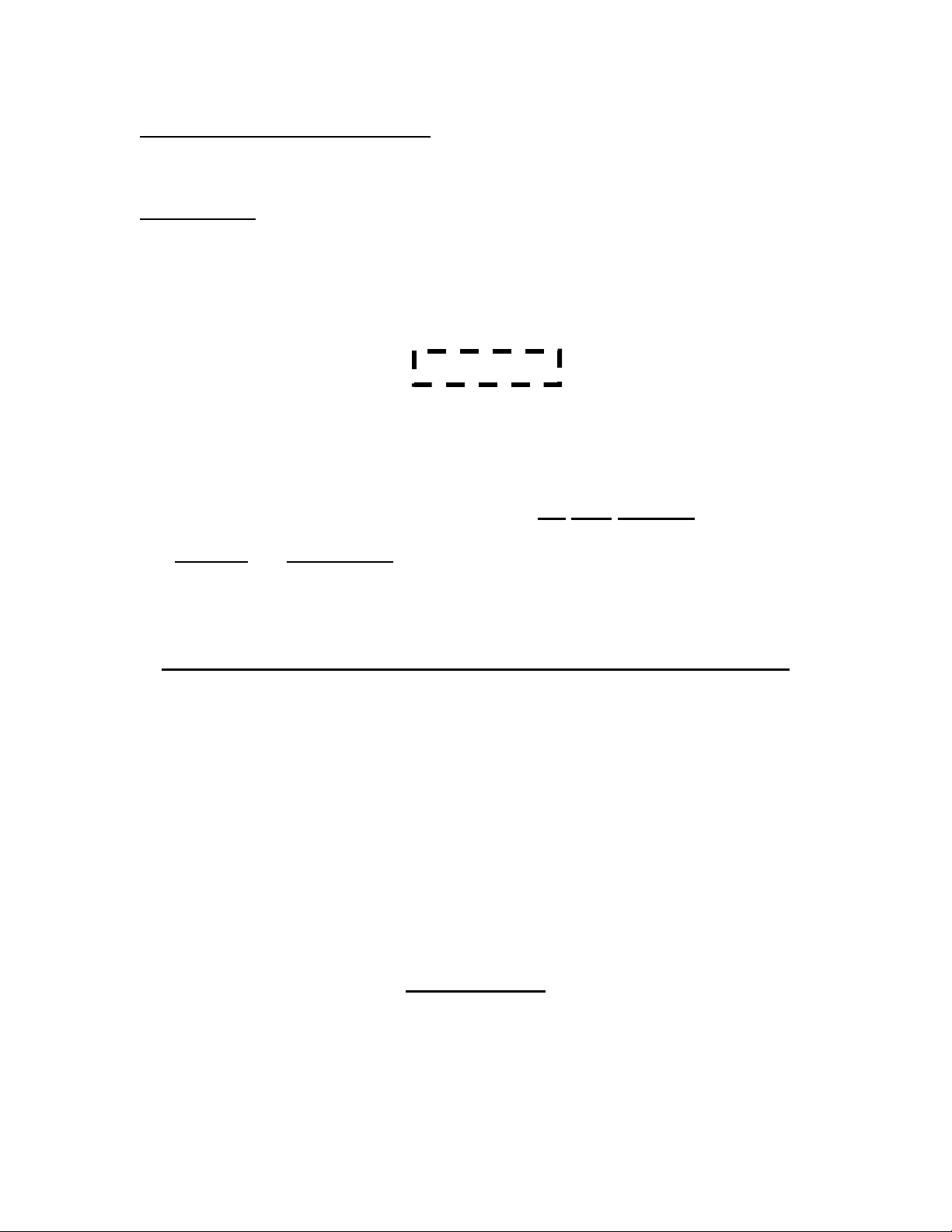

To Disassemble the Handle/Lock Ring

1. Remove the button or rubber plug with a flat blade mini screwdriver.

NOTE

There are two distinct end plugs for the torque wrenches.

They are:

• Steel button plug with a prongs, which requires 4 drops of adhesive (locktite 495) at

the top, bottom and sides.

⇐Steel Button

• Rubber plug that requires a groove inside of the handle end for installation.

A steel button plug may be placed into a handle end with a groove on the inside diameter.

A rubber plug may not be used on a handle without a groove on the inside of the handle.

Page 18

Page 23

2. Remove the Torque Seal from the screw and nut.

3. To disassemble the handle from the tube, remove the nut from the end of the wrench

using the calibration crank handle.

4. Next, remove the washer.

5. Pull the lock ring back to the unlock position (this releases the two balls from the

splines on the tube) and pull the handle off the tube.

Page 19

Page 24

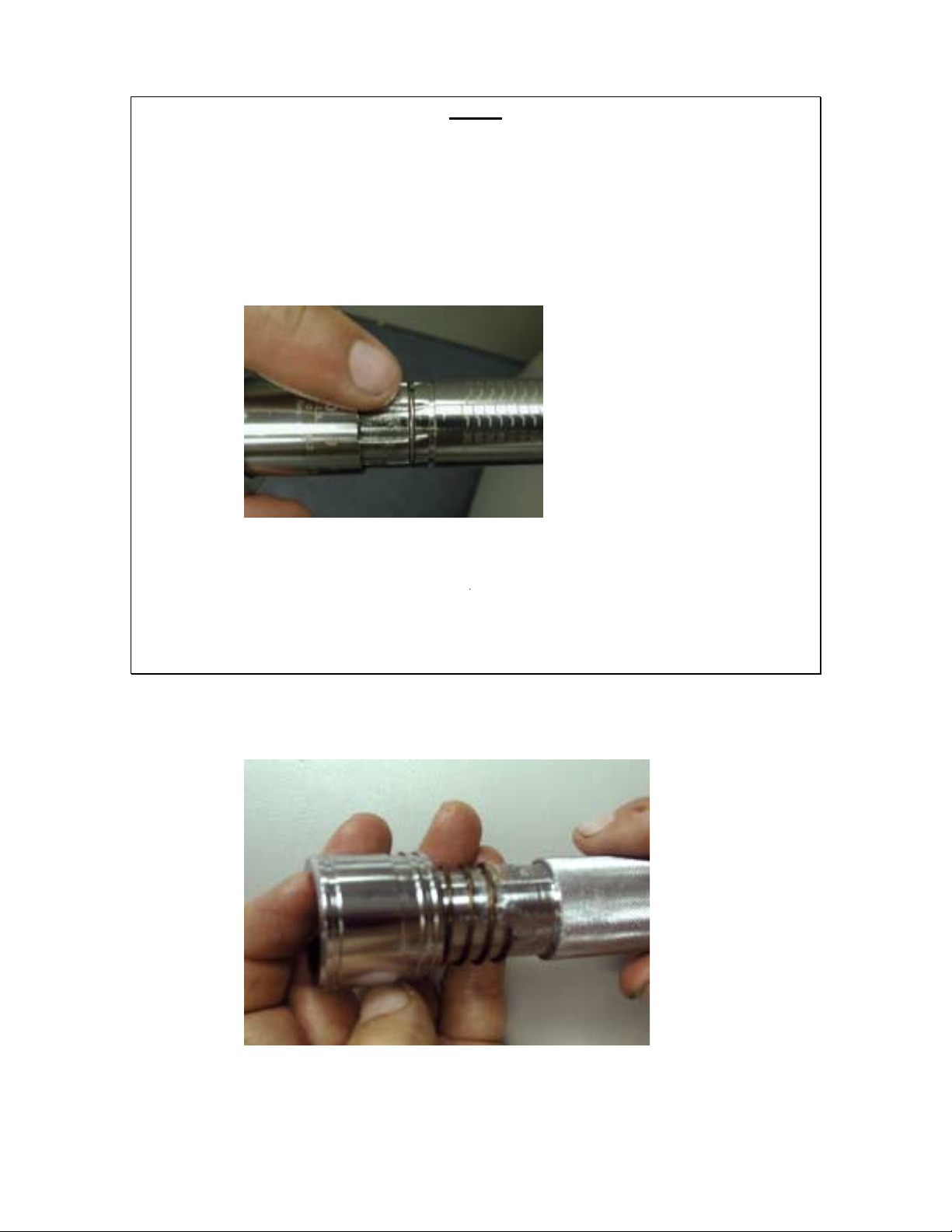

NOTE

There are two distinct metal handle styles for the CDI torque wrenches.

They are:

• A handle without a plastic bushing in the front. This model requires that the grooves

in the tube (between the splines and roll marking) have a spring rings in it. These are

wrenches that are from a maximum scale of 50 in. lb. to 250 in. lb

Spring Rings in tube

• A handle with a plastic bushing in the front. This handle requires the removal of the

spring ring from the groove in the tube (between the splines and roll marking).

6. Remove the lock ring from the handle.

Page 20

Page 25

7. Remove the lock ring spring.

8. Remove the two small round balls (held with Super Lube to handle) from the inside

of the handle.

To assemble the handle/lock ring

1. Place Super Lube on the ball holes on handle. Place two balls in holes (Super Lube

will hold them in place).

Page 21

Page 26

2. Next, place lock ring spring on handle

3. Place lock ring on handle.

4. Pull the lock ring down into the unlock position while sliding the handle as far as it

will go onto the tube. Turn the handle until the six point flange nut on the load screw

is engaged into the handle’s twelve point insert. Release the lock ring to engage the

balls into the splines on the tube.

Page 22

Page 27

5. Next, set the handle on the lowest increment of the tube. Pull the lock ring down to

the unlock position and turn the handle until the top of the handle scale is lined up

with the lowest increment on the tube. Release the lock ring to engage balls into the

splines on the tube.

NOTE

The top of the handle must touch the increment line on the tube scale. When “0” is set,

the top of the handle cannot cover up the increment line on the tube scale or be below it.

6. If the center line of the tube is not lined up with the “0” on the handle, pull down on

the lock ring to unlock it, pull the handle back off of the flange nut on the tube screw

(approx. ¼”). Turn the handle to reset the flange nut into the handle insert so that the

“0” is lined up with the centerline of the tube scale. Release the lock ring and jiggle

the handle lightly left and right until the lock ring is fully engaged.

NOTE

Wrenches with maximum ranges from 50 in. lb. to 250 in. lb. require a lock washer on

the handle (see exploded illustration for lock washer part number). Do not reuse the lock

washer. Use a new lock washer when reassembling the handle to the tube.

7. Tighten the hex flange nut with a 200 in. lb. torque wrench as follows:

Page 23

Page 28

)

Handle Locking

Torque Wrench Ranges Hex Flange Nut Size Torque Ranges

50 in. lb. to 250 in. lb. 3/8” 35 to 40 in. lb.

75 ft. lb. to 1000 ft. lb. 7/16” 90 to 100 in. lb.

8. An accuracy and minor calibration adjustment must be performed after a handle is

assembled.

CALIBRATION INSTRUCTIONS FOR PRE-SET TORQUE WRENCHES

Pre-Set Torque Wrenches

REPAIR TOOLS REQUIRED

1 3/32” “T” Handle hex

1 CDI Adjusting Tool (see chart for correct part number)

LOCKING

PIN (6)

RECEPTACLE (3)

INTERCHANGEA

BLE HEAD (5)

HAND GRIP

ADJUSTING SCREW (4

BUTTON

PLUG (2)

LOCKING SCREW (1)

PRE-SET TORQUE WRENCH

1. Loosen locking screw (1) with the 3/32” T handled hex.

2. Remove Button Plug (2) from rubber handle end by bending a corner of the handle

end until the edge of the plug appears. Then remove the plug by lifting the edge.

3. Insert the interchangeable head (5) into the wrench receptacle until the locking pin (6)

is fully engaged with the corresponding receptacle hole (3).

NOTE

Some heads used in pre-set torque wrenches have lengths that vary. It is recommended

that pre-set torque wrenches be calibrated with the head that is to be used to assure the

greatest accuracy in calibration.

Page 24

Page 29

4. Place the wrench on a torque tester and turn adjustment screw (4) with a T handled

hex ( 1/8” or 3/32”) until the desired setting is on the torque tester when a load is

applied.

CDI Pre-Set (Click) Torque Wrench Ranges & Adjustment Tool Part Numbers

Part

Number

Torque Ranges Adjustment

Tool

Part #

in./ft. lb. dNM/NM. cmkg/mkg

5T-I 16-60 in. lb. 14-67 dNM 14-69 cmkg 600-45-01 3/32”

10T-I 36-108 in. lb. 40-122 dNM 42-124 cmkg 600-45-02 1/8”

10ST-I 84-300 in. lb. 95-338 dNM 110-385 cmkg 600-45-02 1/8”

10AT-I 84-300 in. lb. 95-338 dNM 110-385 cmkg 600-45-03 1/8”

50ST-I 10-50 ft. lb. 14-67 NM. 1.4-7 mkg. 600-45-03 1/8”

50T-I 10-50 ft. lb. 14-67 NM. 1.4-7 mkg. 600-45-03 1/8”

100ST-I 30-150 ft. lb. 41-200 NM. 4.1-20 mkg. 600-45-04 1/8”

100T-I 30-150 ft. lb. 41-200 NM. 4.1-20 mkg. 600-45-04 1/8”

200T-I 40-200 ft. lb. 55-270 NM. 5.5-27 mkg. 600-45-04 1/8”

300T-I 60-300 ft. lb. 82-400 NM. 8.2-40 mkg. 600-45-05 3/16”

600T-I 200-600 ft. lb. 275-800 NM. 27.5-135 mkg. 600-45-06 3/16”

5. Tighten the locking screw (1). Test wrenches setting three more times. If the readings

are correct, place torque seal into the locking screw (1) hex opening to prevent

tampering.

6. Place button plug (2) back into the handle end by inserting it into one side of the

opening then applying pressure with your finger until it is fully engaged.

TROUBLESHOOTING

The Pre-Set Torque Wrenches generally do not require repair. They are sent in for

calibration to the required use setting with the head or adapter chosen for use. All

adjustments are to be made as shown in the section on Pre-Set Torque Wrench

Calibration.

The Troubleshooting Matrix is for the Micrometer Adjustable Wrench models only.

Refer to the Troubleshooting Matrix for problems that could occur to the Micrometer

Adjustable Torque Wrenches and their remedy.

Hex

Size

Page 25

Page 30

Micrometer Adjustable Torque Wrench

Troubleshooting Matrix

PROBLEM CAUSE(s) REMEDY

Calibration accuracy at

20% of scale is out of

tolerance.

OR

Calibration accuracy at

20%, 60% and 100% of

scale is out of tolerance.

OR

Calibration accuracy at

60% and 100% of scale

is out of tolerance

When the lock ring is

released the handle goes

up and down the tube

without turning the

handle or the handle

doesn’t turn at all.

Handle and load screw

disassembled.

Lock Ring Doesn’t

Lock.

Lock ring is jammed or

doesn’t fall into lock

Wrench tampered with

(torque seal cracked or

missing)

OR

The handle is unwound below

the stop point. (torque seal

cracked or missing)

Check handle prior to adjusting to assure it is engaged to the adjusting screw.

Minor calibration

Adjustment.

OR

Handle disassembled handle

and reassembled wrong.

(torque seal cracked or

missing)

OR

If a minor calibration fails

to bring the 20% of scale

reading into tolerance or if

adjustment causes the 60%

or 100% of scale to fall out

of the tolerance a major

calibration is required.

Pawl and/or pawl slots worn or

damaged.

NOTE

NOTE

OR

NOTE

Check pawl and pawl slots

prior to a major calibration.

A major calibration.

The tube insert is stripped

Send to authorized repair

facility.

OR

No lubrication on torque load

screw.

See handle/lock ring repair

section to assemble.

The handle was turned without

releasing the lock ring. (the

Send to authorized repair

facility.

tube will show groove marks

through the splines)

Handle spring problem. Disassemble the

handle/lock ring and replace

Page 26

Page 31

position when released. lock ring spring.

PROBLEM CAUSE(s) REMEDY

The wrench does not

click.

The pawl is not in the pawl

slot.

OR

There is no pressure on the

pawl.

Disassemble wrench and

add washers to increase

pressure on pawl.

NOTE

When placing the

ratchet/head drive into the

tube to insert the pivot pin,

the drive pivot hole must be

pushed into the tube to align

the holes.

If there is no pressures

remove parts and add more

washers to increase pressure

on the pawl.

The wrench only clicks

in one direction or can

only be calibrated in one

direction.

The head drive and/or

secondary arm (if used) are not

in centerline.

Replace the head drive

and/or secondary arm (if

used).

The pawl double clicks. Check and replace as

needed head and/or

secondary arm (if used).

Check and replace the pawl,

as needed.

Page 27

Loading...

Loading...