Page 1

DIAL TORQUE WRENCH

REPAIR, MAINTENANCE AND

TROUBLESHOOTING MANUAL

SUGGESTED PRICE $35.00

PART NUMBER: 21-220-01

ISSUED JANUARY, 2002

Page 2

TABLE OF CONTENTS

TITLE PAGE(S)

SAFETY INSTRUCTIONS – WARNING & CAUTION 1

CDI TORQUE TESTING EQUIPMENT Illustration 2

INTRODUCTION 3

CLEANING 3

LUBRICATION 3

REPAIR TOOLS REQUIRED 3

INSPECTION 4

CAUTION – Customer misuse 4

Types of Dial Wrenches 4

Precision Movement 4

Scale Pointer 5

Scale with electric Signal 5

Memory Pointer 6

ACCURACY VERIFICATION AND MINOR CALIBRATION

PROCEDURE

ASME B107.14M 7

ISO6789 8

Major Calibration 9/11

The push rod needs to be reset in the movement 9/10

CENTERING (Left or right adjustment) 10

DECREASING/INCREASING READING VALUE (forward or

backwards adjustment)

TROUBLESHOOTING 12

i

6/8

11

Page 3

REVISIONS –

The CDI Dial Wrench Torque Wrench Repair Manual was originated and first issued in

November 2001. The manual will be reviewed and revised as necessary to assure that it

contains the latest changes in product or repair changes. In between revisions, product

bulletins may be issued to assure any changes in product or repairs are supplied to

authorized repair facilities.

REV.

Date Issued

Effected Pages

Approved

January 2002

Written By: Donna E. Brunot

Photographs By: Gary Fitzhugh

ii

Page 4

CDI DIAL INDICATING (RIGID HOUSING) TORQUE WRENCH REPAIR,

MAINTENANCE AND TROUBLESHOOTING INSTRUCTIONS

SAFETY INSTRUCTIONS

Failure to follow WARNING instructions can cause personal injury to the operator.

Failure to follow CAUTION instructions can cause the equipment to fail or break in use.

! WARNING

Always wear Safety Glasses or goggles when using or repairing hand tools.

Read this manual completely before repairing torque wrenches.

DO NOT use or test a wrench that shows signs of damage (bent tubes, cracked or

broken parts) caused by misuse. Recommend replacement.

DO NOT use cheater extensions on the handles or tube to apply torque.

DO NOT exceed rated maximum torque.

Check all sockets or other test accessories for w ear, damage or cracks prior to their

use with torque wrenches. Do not exceed their rated maximum torque.

Always pull (DO NOT push) to apply torque. Adjust your stance to prevent a fall if

something should give suddenly.

Ratchet head torque wrenches must be checked for full (positive) engagement of the

ratchet in the direction of use prior to applying a load on the wrench. Broken or

slipping ratchets can cause injury.

CAUTION

Periodic recalibration is necessary to maintain accuracy.

Periodic examination and cleaning is necessary to maintain the wrench.

Page 1

Page 5

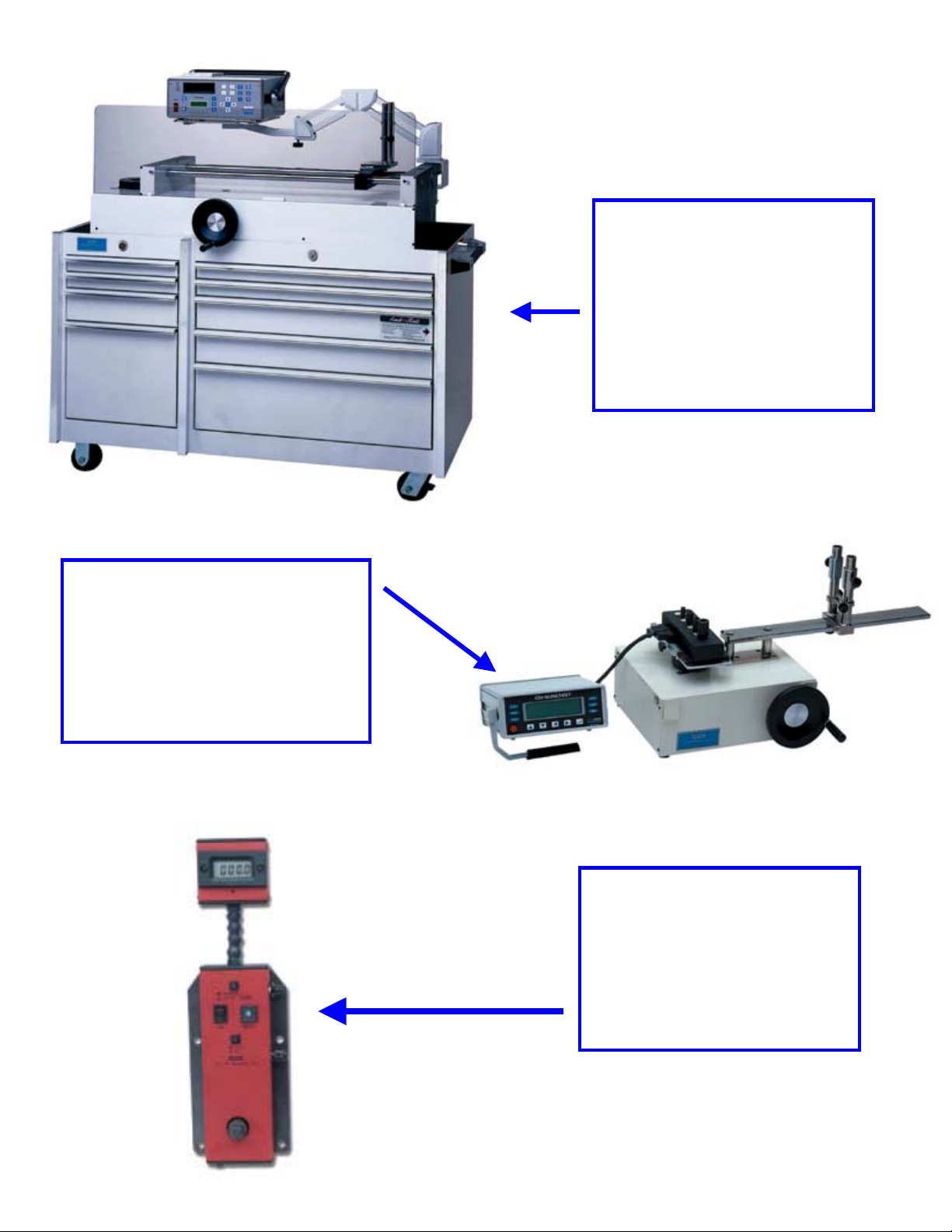

SURETEST

CALIBRATION

TORQUE

SYSTEM

MULTITEST

TORQUE

CALIBRATION

SYSTEM

ETT

ELECTRONIC

TORQUE

TESTER

Page 2

Page 6

INTRODUCTION

This manual covers the repair, maintenance and troubleshooting instructions to identify

and remedy problems that could occur with the CDI Dial Indicating Torque Wrenches.

Each wrench model has an Ex ploded Illustration that lists the component parts and shows

assembly particulars. The exploded illustration must be used as a guide for assembling

CDI Dial Indicating Torque Wrenches.

CDI has a Service Center that performs repairs and calibration on all of our products at

the factory, plus a list of factory authorized repair/calibration centers throughout the

world. Contact CDI Sales or Service Center at (626) 965-0668 or sales@cditorque.com

for technical assistance on the repair or calibration of CDI products.

CLEANING

Wipe all ext erior parts with a dry, clean and lint free cloth. DO NOT USE any abrasive

or corrosive materials to clean any components of the CDI Dial Indicating Torque

Wrenches. A non-abrasive polishing agent applied with a dry, clean and lint free cloth

may be used to polish the chrome exterior parts.

LUBRICATION

None required.

REPAIR TOOLS REQUIRED

*

1

Torque Tester (range determined by the torque wrench to be tested)

Flat blade mini screwdriver (max. blade size .063 or 1.6mm)

1 Needle Nose Pliers

1 Dial Scale Assembly Tool

1 Pointer Tapping Tool

1 Dial Wrench Adjustment Tool (part # 600-2)

1 Screwdriver

• We recommend that CDI torque testers be used to test the calibration

accuracy of CDI manufactured torque products.

CDI manufactures a complete line of torque testing equipment from moderately

priced testers to complete state of the art test systems used in metrology calibration

laboratories all over the world. Contact CDI Sales or Service Center at (626) 9650668 or sales@cditorque.com.

Page 3

Page 7

INSPECTION

Inspect all wrenches repaired to determine that they are in an operational condition by

visually inspecting for worn, broken, cracked or damaged parts. Replace parts not found

to be in satisfactory condition.

CAUTION

Some customer’s abuse torque wrenches and damage them beyond repair. The most

common abuse is the placing of an extension or cheater bar on the handle end of the

wrench. This type of misuse is evident if the plate, handle or the drive is bent, or there are

cheater bar marks on the handle near the plate. DO NOT REPAIR the wrench if it shows

signs of this type of misuse. The component parts may be permanently damaged. The

SAFETY and INTEGRITY of the wrench could be impaired. Recommend that the

wrench be replaced.

Types of Dial Wrenches

There are three types of Dial Wrenches. They are:

♦ Plain Dial- A single pointer shows applied torque on the scale.

♦ Dial with Signal - Allows a pre-set torque value to be set on the wrench. When the set

torque value is applied a signal indicates that t he set torque value has been reached.

CDI produces dial wrenches that have an electric light or an el ectric light and audible

buzzer that is illuminated when the set torque value is reached.

♦ Dial with Memory Indicator – An auxiliary pointer is used to indicate the maximum

torque value applied to the wrench. The memory pointer remains at the highest

applied torque value until it is reset to zero.

Precision Movement

A precision movement controls dial wrench

accuracy. Damage to the movement cased by

misuse or abuse of the wrench can not be

repaired and must be replaced. Care must be

taken in the use and storage of dial wrenches,

as they are precision measuring instruments.

Page 4

Page 8

Scale Pointer

To repair loose scale pointer if removed from the

post.

1.) Take the scale pointer (orange) and align it to the

center of the square drive of the wrench.

2.) Place it in the center post in the center of the

scale.

3.) Align the scale pointer end point to the center of

the drive end of the wrench.

4.) Press into place.

5.) Tap it lightly to lock it into place with the

handle end of a plastic screwdriver or other

instrument. This will lock it into post.

The scale pointer (orange) end is slightly bent

upwards to allow the memory pointer (blue) to be

pushed by the scale pointer. If the scale pointer

(orange) end is not bent upwards or the scale

pointer (orange) end is touching the scale plate it

must be bent or replaced.

Scale with Electric Signal

To repair a wrench if the signal is not working on the wrench:

1.) Check/replace the battery first.

2.) Next, check the light bulb to assure it is screwed in and making contact.

3.) Remove the lens and remove the scale pointer (orange) from the wrench. Take a knife

and scrape the sides of the pointer (to assure better contact).

4.) Clean the contact on the scale.

5.) Check the wiring for broken wires or damaged wires.

6.) If the buzzer doesn’t work check the wiring connection to the battery.

If none of these remedies correct the problem, contact CDI Service Department, to return

the wrench to CDI for repair.

Page 5

Page 9

Memory Pointer

The memory pointer (blue) is designed to be pushed by the scale pointer (orange) and

indicate the point on the scale where the largest amount of torque was applied. It must

move freely with the scale pointer (orange). Check the memory pointer (blue) by turning

the knob until it meets the scale pointer (orange) in the clockwise position. Load the

wrench to the maximum scale. The memory pointer (blue) must be pushed by the scale

pointer (orange) all the way to full scale. Repeat this test in the opposite direction.

If the memory pointer (blue) slips over the scale pointer (orange), bend the blue pointer

downward so that the tip of the memory pointer will be moved by the scale pointer. Make

sure the memory pointer (blue) does not drag on the surface of the scale.

The Scale Pointers (orange) and the Memory Pointer Assembly (crystal, knob & blue

pointer) are available as repair parts.

ACCURACY VERIFICATION

This procedure is to be used to check the accuracy of a dial wrench.

There are two major international standards that establish torque wrench accuracy

requirements. They are ASME B107.14M Hand Torque Tools (American Society of

Mechanical Engineers) and ISO 6789 Hand Torque Tools – Requirements and Test

Methods (International Organization for Standards). Both standards are recognized as

established accuracy test methods and referenced in this section. ASME and ISO

standards are subject to review and changes. The repair manual will be reviewed and

revised periodically but may not reflect the latest revision of the specifications listed

above.

Page 6

Page 10

ASME B107.14M

1. Preload the wrench by loading the wrench three times in the direction of the test

(either clockwise or counterclockwise).

2. Set the pointer on th e zero increment of the scale. The pointer MUST be set in the

same plane as the testing will be performed (horizontal or vertical).

3. Load the wrench until the scale reads at 20% of full scale (example a 100 in. lb.

wrench would be tested at 20 in. lb., which is 20% of full scale). Repeat the test 2

more times. Record all three readings.

4. Load the wrench until the scale reads at 60% of full scale (example a 100 in. lb.

wrench would be tested at 60 in. lb., which is 60% of full scale). Repeat the test 2

more times. Record all three readings.

5. Load the wrench until the scale reads at 100% of full scale (example a 100 in. lb.

wrench would be tested at 100 in. lb., which is 100% of full scale). Repeat the test 2

more times. Record all three readings.

6. Preload the wrench by loading the wrench three times in the opposite direction of the

test already performed (either clockwise or counterclockwise).

7. Set the pointer on th e zero increment of the scale. The pointer MUST be set in the

same plane as the testing will be performed (horizontal or vertical).

8. Test the wrench in this direction by following steps 3 through 5. If all of the readings

are within the accuracy requirement no calibrati on adjustment is required. If they are

not see the section on calibration adjustment.

NOTE

Page 7

Page 11

Torque wrench readings MUST be obtained by applying force to the center of the handle

(per ANSI & ISO specifications).

ISO6789

1. Preload the wrench by loading the wrench five times in the direction of the test

(either clockwise or counterclockwise).

2. Set the pointer on the zero increment of the scale. The pointer MUST be set in the

same plane as the testing will be performed (horizontal or vertical).

3. Load the wrench until the scale reads at 20% of full scale (example a 100 in. lb.

wrench would be tested at 20 in. lb., which is 20% of full scale). Repeat the test 4

more times. Record all five readings.

4. Load the wrench until the scale reads at 60% of full scale (example a 100 in. lb.

wrench would be tested at 60 in. lb., which is 60% of full scale). Repeat the test 4

more times. Record all five readings.

5. Load the wrench until the scale reads at 100% of full scale (ex ample a 100 in. lb.

wrench would be tested at 100 in. lb., which is 100% of full scale). Repeat the test

4 more times. Record all five readings.

6. Preload the wrench by loading the wrench five times in the opposite direction of

the test already performed (either clockwise or counterclockwise).

7. Set the pointer on the zero increment of the scale. The pointer MUST be set in the

same plane as the testing will be performed (horizontal or vertical).

8. Test the wrench in this direction by following steps 3 through 5. If all of the

readings are within the accuracy requirement no calibration adjustment is

required. If they are not see the section on calibration adjustment.

Page 8

Page 12

Major Calibration

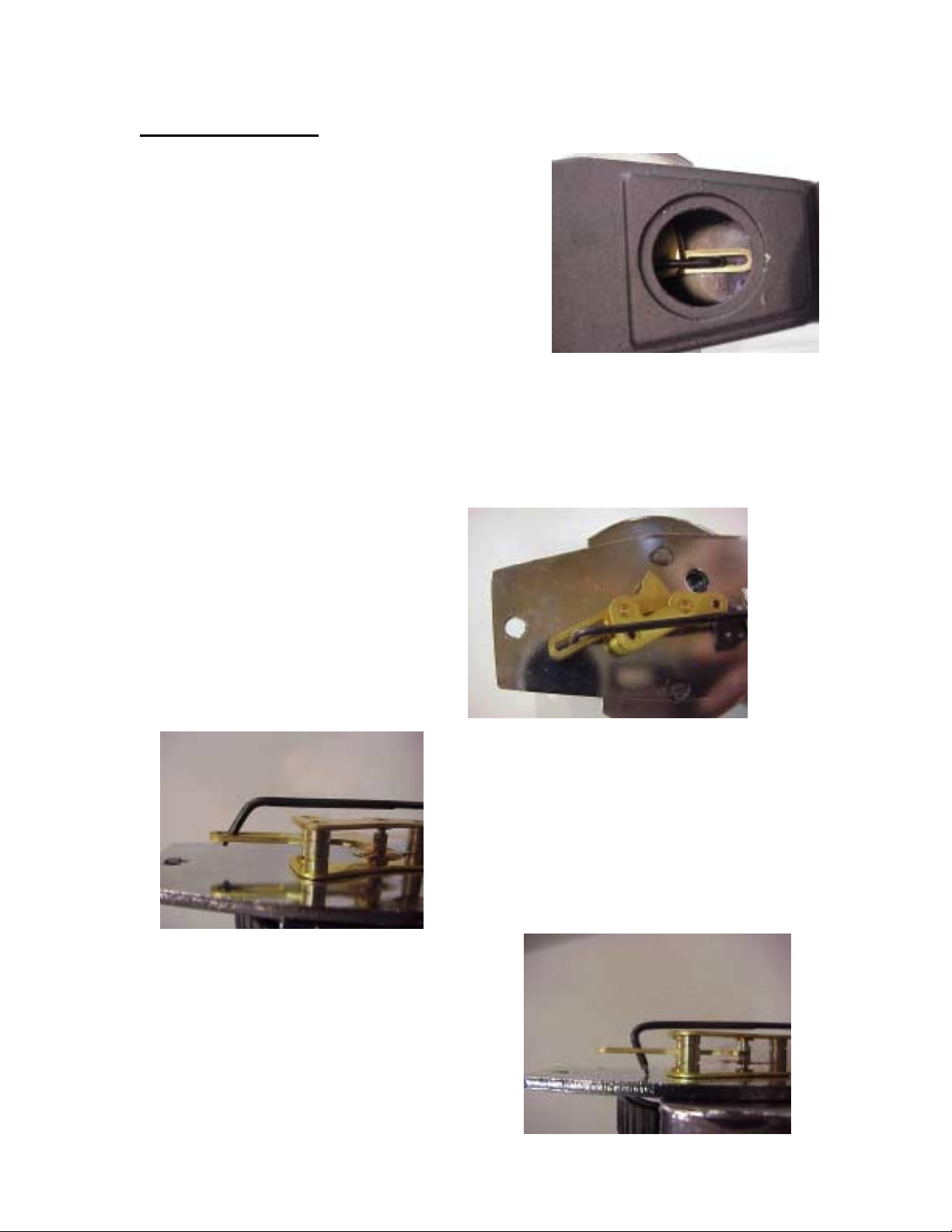

Turn the wrench over, with the dial facing down. On

the bottom of the case you will find a button plug.

Remove it.

Through the button plug hole you will see the

movement and push rod (The push rod is the black

part that is bent through the loop in the brass

movement). Check the push rod to assure it is

centered to the wrench and level (not pushed down

touching the plate or out of the movements loop).

The push rod needs to be reset in the movement:

♦ If the push rod is pushed off center

and to one side of the wrench or the

other.

♦ If the push rod is bent down so far as to be

touching the plate.

♦ If the push rod is bent up so far as to be

coming out of the loop of the movement.

Page 9

Page 13

Use the Dial Wrench Adjusting Tool (Part #600-2)

and gently move the push rod until it is centered to

the channel and in the movement loop and not

touching the plate Next, perform an accuracy

check.

NOTE

The Dial Wrench Adjusting Tool (Part # 600-2) allows

adjustments to be made in small, slight movements.

The adjustments to the push rod must be made in very

small increments, generally not to exceed .010 (.26mm).

Test the wrench on a torque tester after each

incremental adjustment.

CENTERING (Left or Right Adjustment)

Centering adjustment is required, if the wrench failed th e accuracy check because it was

out in opposing directions (Example; +plus 4.5% in one direction and –4% in the

opposite direction) or near perfect in one direction and out in the opposite direction. To

center the push rod take the Dial Wrench Adjusting Tool (Part #602-2) and gently move

the push rod until it is moved slightly into the direction that the correction needs to be

made. An example of this would be a +plus 4.5% in one direction and –4% in the

opposite direction could be moved in the direction of the + plus reading. This would split

the tolerance between the two directions and center the wrench. Test the wrench to see if

the correction was enough to center the wrench readings so that both sides (CW & CCW)

are within specification requirements.

Page 10

Page 14

DECREASING/INCREASING READING VALUE (Forward or Backwards

Adjustment)

The second adjustment that can be made to a dial wrench is to decrease or increase the

reading values. To adjust the reading take the Dial Wrench Adjusting Tool (Part #600-2)

and gently move the push rod:

♦ Away from the movement (backward) to increase the reading values, if the wrench

values are reading low.

♦ Toward the movement forward) to decrease the reading values, if th e wrench values

are reading high.

If a slight movement of the push rod doesn’t

bring the wrench into calibration, the wrench

must be re-gaged. Do not bend the push rod so

that it is touching the plate or almost all the

way out of the movement loop. To re-gage the

case must be removed from the plate assembly.

After removing the case measure the distance

between the push rod bent end and the end of

the movement loop, with the inside diameter

end (blades) of a caliper.

Then loosen the screws on the channel. Every

0.010 increase or decrease of the distance will

change the reading value approximately 3 to 6 %.

After moving the push rod, tighten the channel

screws, re-assemble with the case and test the

readings.

Page 11

Page 15

TROUBLESHOOTING

CDI Dial Indicating Torque Wrenches generally do not require repair. They are sent

in, by users, for calibration. All adjustments are to be made as shown in the section on

Calibration.

The Troubleshooting Matrix is for CDI Di al Indi cating T orque Wren ch models only.

Refer to the Troubleshooting Matrix for problems that could occur to CDI Dial

Indicating Torque Wrenches and their remedy.

PROBLEM Remedy

Loose Pointer or disconnected pointer See Section III on Pointer Repair

Pointer or Memory Pointer rubs on scale. See Section III or V on Pointer and

Memory Pointer Repair

The memory pointer is not working. See Section III or V on Pointer and

Memory Pointer Repair

Signal on wrench does not work See Section IV Dial wrenches with a

signal.

Accuracy See Section VI on Calibration check

Re-Calibration See SectionVII

Page 12

Loading...

Loading...