Page 1

Page 2

TABLE OF CONTENTS

Safety Information I

Introduction 1-1

Functional Description and Specifications 2-1

Functional Descriptions 2-1

SURETEST Torque Calibration System 2-1

Roll cabinet 2-2

Front Panel 2-3

Rear Panel (Input/Output) 2-9

Torque Transducers 2-11

Specifications 2-12

SURETEST Torque Calibration System 2-12

Manual loader specifications 2-14

Setup and Programming 3-1

SURETEST Torque Calibration System Setup 3-1

Setting Up the Suretest System 3-2

Suretest Controls 3-3

Powering the Equipment 3-3

4-in-1 Transducer Select 3-4

Programming Setup 3-5

Setting up Date and Time 3-5

Setting Up High and Low Limits Alert 3-5

Programming AUTO CLEAR 3-6

DATA LIST Memory 3-7

Setting Up Printer/PC Ports 3-8

Selecting Printer/PC Ports 3-8

Setting Up Serial Communications 3-8

Torque Calibration System Setup 4-1

Testing Torque Wrenches and Drivers 4-1

Selecting a Transducer 4-1

Installing a Transducer 4-1

Dial and Bending Beam Torque Wrenches and Screwdrivers 4-2

Adjustable or Preset “Click” Wrenches and Screwdrivers 4-3

Testing Power Tools 4-4

Non-Impact Tools 4-4

Displaying Statistical Analysis 4-7

Displaying Statistical Analysis on LCD 4-7

Printing Statistical Analysis 4-8

Displaying or Downloading Data List 4-10

Displaying Data List on LCD 4-10

Downloading Data List to Printer 4-10

How to Use Analog Output (Rear Panel BNC Connector) 4-11

Calibration 5-1

Mounting Details 5-1

Quick Check 5-4

Torque Transducer Calibration 5-7

TABLE OF CONTENTS 1

Page 3

Suretest Indicator Torque Calibration 5-11

Gravitational Effects 5-14

Correction Factors on Test Weights 5-14

Gravitational Charts 5-14

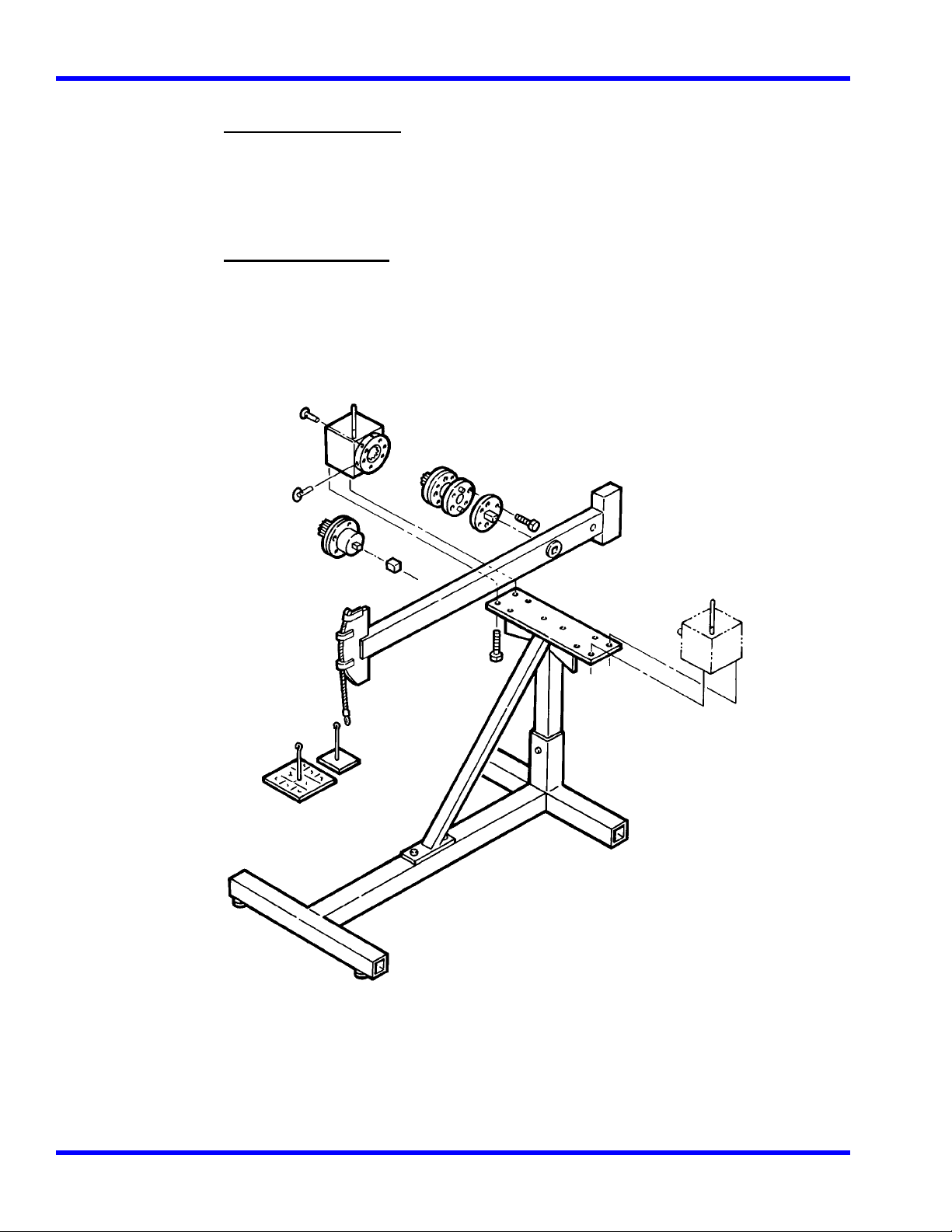

2000-600-02 Manual Loader 6-1

Application 6-1

Torque Tester/Calibrator 6-2

2000-600-02 Manual Loader 6-3

Loader Rear Panel Controls 6-5

Ball Handle Adaptor 6-6

4-in-1 Transducer (Accessory) 6-7

Extension Arm (Accessory) 6-8

Types of Loader Testing 6-9

Torque Driver Testing 6-9

Torque Multiplier Testing 6-9

Accessories A-1

SURETEST System Components and Inventory Control A-2

Optional Transducers and Accessories A-3

Calibration Accessories A-5

TABLE OF CONTENTS 2

Page 4

Using this Manual

This manual contains instructions for use and setup of the Suretest Torque Calibration

System. A table of contents and a table of illustrations are provided to make this manual

easy to use.

Some of the information shown in text or illustrations is obtained using optional

equipment.

Conventions

This section contains a list of conventions used in text.

Chapter References

Additional information in text is referenced by chapter number and section name.

Example:

For testing procedures refer to Chapter 4—Using the SURETEST System.

Equipment Damage

The possibility of damage to vehicle or equipment is introduced by a signal word

indicating this condition.

Example:

IMPORTANT

The connector on single transducer cables contains the EEPROM calibration memory

chip. Never attempt to remove the connector from the transducer. It is installed with a

permanent adhesive.

Safety Messages

Safety messages are provided to help prevent personal injury and equipment

damage. All safety messages are introduced by a signal word indicating the

hazard level. The types of safety messages are: Danger, Warning and Caution.

TABLE OF CONTENTS 3

Page 5

DANGER

Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury to the operator or to bystanders.

WARNING

Indicates a potential hazard which, if not avoided, could result in death or

serious injury to the operator or to bystanders.

CAUTION

Indicates a potential hazard which, if not avoided, may result in minor or

moderate injury to the operator or to bystanders.

The three-part message panel, used with safety messages, uses three different type styles

to further define the potential hazard:

• Normal type states the hazard,

• Bold type states how to avoid the hazard, and Warning.

• Italic type states the possible consequences of not avoiding the hazard.

Some safety messages contain visual symbols with signal words.

Example:

WARNING

Flying particles can discharge when applying torque.

• Users and bystanders must wear safety goggles.

• Always wear safety goggles when applying torque.

Flying particles can cause injury.

4

Page 6

Safety Information

Important Safety Instructions

This manual contains important safety and operating instructions for CDI SURETEST

Torque calibration system. Refer to the information in this manual often for safe

operation.

Read All Instructions

Read, understand and follow all safety messages and instructions in this manual and on

the test equipment. Safety messages in this section of the manual contain a signal word, a

three-part message.

The signal word indicates the level of hazard in a situation:

• Danger indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury to the operator or bystanders.

• Warning indicates a potentially hazardous situation which, if not avoided, could result

in death or serious injury to the operator or bystanders.

• Caution indicates a potentially hazardous situation which, if not avoided, may result in

moderate or minor injury to the operator or bystanders.

The three-part message uses three different type styles to further define the potential

hazard.

• Normal type states the hazard.

• Bold type states how to avoid the hazard.

• Italic type states the possible consequences of not avoiding the hazard.

SAVE THESE INSTRUCTIONS

WARNING

Risk of electric shock and fire.

• For indoor use only. Do not expose charger to rain or snow. Do not use in damp

locations.

• Replace defective cord immediately. Return to qualified service center for replacement.

Electric shock or fire can cause injury.

WARNING

Flying particles can discharge when applying torque.

• Users and bystanders must wear safety goggles.

• Always wear safety goggles when applying torque.

• Do not use this equipment with the power off. Always turn on the indicator and loader

so the torque and load values are indicated on the display. The safety relays only work

when the power is on. Flying particles can cause injury.

5

Page 7

WARNING

Risk of entanglement.

• When starting power tools, check for obstacles near your hand and anticipate the

reaction force by gripping the tool firmly.

• Do not wear loose clothing and jewelry while operating a power tool. Loose clothes

and jewelry can be caught in moving parts.

• Keep body parts away from rotating parts.

• Wear a protective hair covering to contain long hair and prevent contact with moving

parts.

• Do not overreach. Keep proper footing and balance at all times.

Entanglement can cause injury.

WARNING

Improper use can cause breakage.

• Read instructions before operating.

• Follow manufacturer’s instructions, safety precautions, and specifications when

operating tools. Broken equipment can cause injury.

WARNING

• Make sure all components, including, adaptors, extensions, drivers and sockets are rated

to match or exceed the torque or load being applied.

• Be sure the capacity of the SURETEST system matches or exceeds each application

before performing a procedure.

• Do not use the SURETEST system if it makes unusual noises, has loose parts, or shows

any other sign of damage. Have repairs performed at an Authorized Service Center

before use.

• Do not use chipped, cracked, or damaged sockets and accessories.

• Do not remove any labels. Replace any damaged label.

• Follow good, professional tool practices:

** Pull on a wrench handle ** do not push ** and adjust stance to prevent a possible

fall.

** Do not use extensions, such as a pipe, on a wrench handle.

• When using ratchets, make sure the direction lever is fully engaged in the correct

position.

• Never attempt to test an impact tool on this instrument.

• Always position the 40" arm over the front of the stand as shown. Never extend the test

arm behind the stand. The stand will tip over when weights are applied.

• Always be alert to the potential for personal injury that may be caused by excessive

torque applications, careless handling of heavy weights, and out-of-balance or unsafe

weight distribution.

6

Page 8

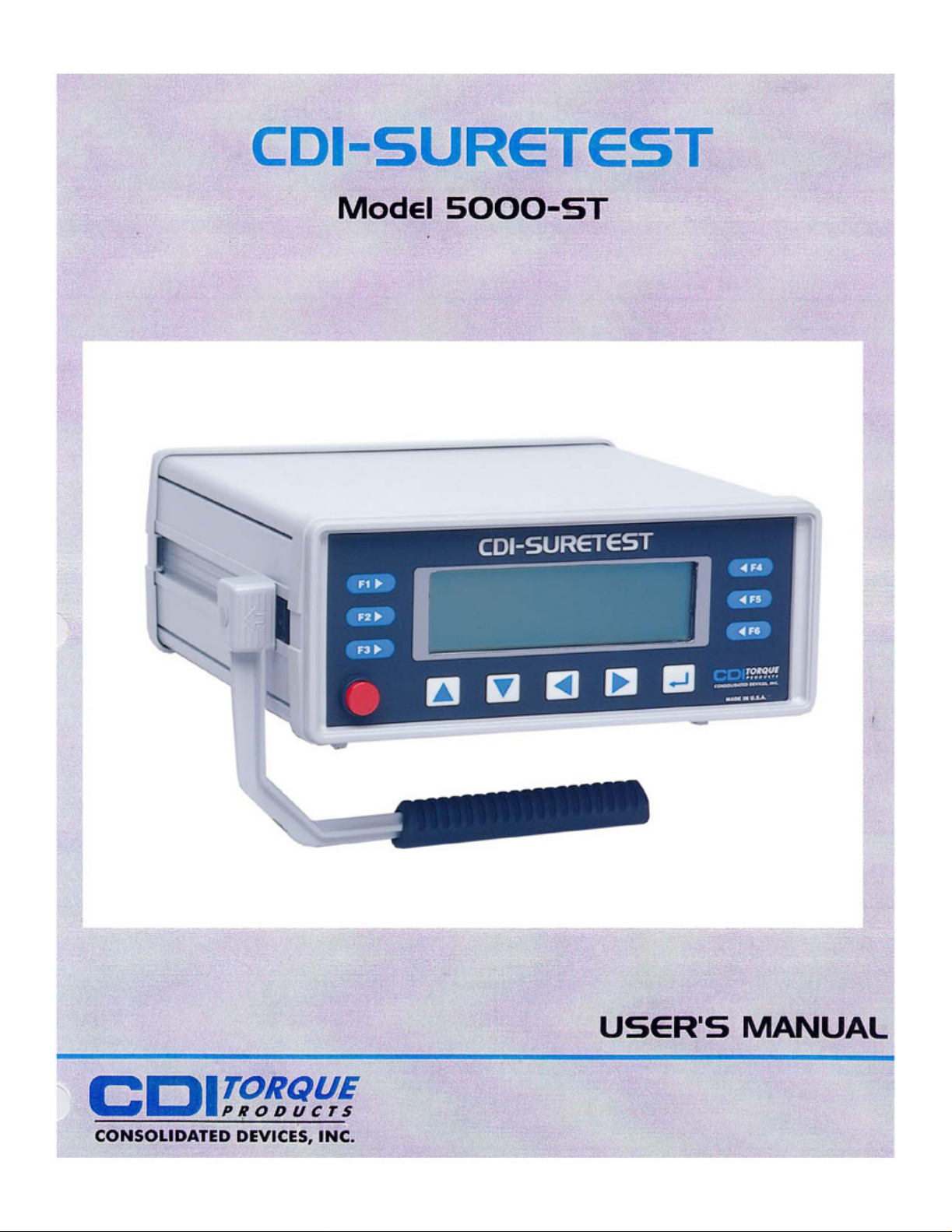

PRODUCT DESCRIPTION

CDI-SURETEST MODEL 5000-ST

The SURETEST is a laboratory grade instrument that provides

TORQUE measurements. Although designed as an independent

laboratory equipment, it can also be used in an integrated environment as

the principal component of a Torque Calibration System. The

SURETEST features versatile data acquisition capabilities including

measurement storage, retrieval, statistical analysis and automatic

downloading to an external printer/computer. A remote computer COM

port is available for PC interfacing.

Used with precision torque transducers, the SURETEST provides high

speed monitoring of static or dynamic torque inputs. Torque/force

transducers, purchased separately, are available in ranges from 15-200

in- oz, to 200-2000 ft-lb, and provide system readings with an accuracy

of +/- 0.25% of indicated value, or better. A special memory chip is

built into each torque/force transducer that identifies its range and

maintains its calibration between any other SURETEST with an

accuracy of +/- 0.5%. The SURETEST and its transducers may be

calibrated by using accessory precision bars and certified weights.

All readout of torque in ft-lb, in-lb, in-oz, Nm, dNm, cNm, mkg as well

as calibration, statistical analysis and set-up functions are reported on a

versatile 1.5” x 5.5” graphic dot matrix Liquid Crystal Display (LCD).

Set-up and calibration programming is entered using easy-to-use front

panel membrane keys. The number of keys is kept to a minimum. In

addition, concise menus and graphic symbols are used to guide the user

through all set-ups and operations. HIGH and LOW torque limits are

adjustable to give an audible alert. The user selects TRACK mode to

display torque values as they are applied, PEAK HOLD or POWER

TOOL modes to display the highest torque value applied, or FIRST

PEAK mode which captures the torque output at the “click” of a set-able

wrench or driver. CLEAR, STORE and SEND functions can be set up

for automatic or manual operation.

The SURETEST stores and recalls up to 3000 torque readings and does

statistical analysis on them for downloading to printer or computer. The

statistical report (print out) includes a simple histogram for process

monitoring. True RS-232 serial printer and separate RS-232 computer

COM ports are at the back of the unit

7

Page 9

CHAPTER 1

Introduction

The SURETEST is a laboratory grade instrument that provides

TORQUE measurements. Although designed as an independent digital

indicator, it can also be used in an integrated environment as the

principal component of a Torque Calibration System. The SURETEST

features versatile data acquisition capabilities including measurement

storage, retrieval, statistical analysis and automatic downloading to an

external printer/computer. A remote computer COM port is available for

PC interfacing.

Used with precision torque transducers, the SURETEST provides high

speed monitoring of static or dynamic torque inputs. Torque transducers,

purchased separately, are available in ranges from 15-200 in- oz, to 2002000 ft-lb, and provide system readings with an accuracy of ± 0.25% of

indicated value, or better. A special memory chip is built into each

torque transducer that identifies its range and maintains its calibration

between any other SURETEST with an accuracy of ± 0.5%. The

SURETEST and its transducers may be calibrated by using accessory

precision bars and certified weights.

All readout of torque in ft-lb, in-lb, in-oz, Nm, dNm, cNm, mkg as well

as calibration, statistical analysis and set-up functions are reported on a

versatile 1.5” x 5.5” graphic dot matrix Liquid Crystal Display (LCD).

Set-up and calibration programming is entered using easy-to-use front

panel membrane keys. The number of keys is kept to a minimum. In

addition, concise menus and graphic symbols are used to guide the user

through all set-ups and operations. HIGH and LOW torque limits are

adjustable to give an audible alert. The user selects TRACK mode to

display torque values as they are applied, PEAK HOLD or POWER

TOOL modes to display the highest torque value applied, or FIRST

PEAK mode which captures the torque output at the “click” of a set-able

wrench or driver. CLEAR, STORE and SEND functions can be set up

for automatic or manual operation.

The SURETEST stores and recalls up to 3000 torque readings and does

statistical analysis on them for downloading to printer or computer. The

statistical report (print out) includes a simple histogram for process

monitoring. True RS-232 serial printer and separate RS-232 computer

COM ports are at the back of the unit.

Page 10

FUNCTIONAL DESCRIPTIONS AND SPECIFICATIONS CHAPTER 2

The SURETEST operates directly from any AC power line between

120VAC to 220 VAC, 50–60 Hz without the need for switch selection. A

hard-wired lithium battery keeps the internal memory and date-time

clock operating for up to 10 years. The real time clock is fully year 2000

compliant.

The information in this manual is general. Operational features, procedures and

specifications may change without notice. CDI makes no claims as to the suitability of

this information for diverse user applications.

Page 11

FUNCTIONAL DESCRIPTIONS AND SPECIFICATIONS CHAPTER 2

CHAPTER 2

Functional Descriptions and Specifications

The SURETEST is CDI’s next generation Torque Measurement System. It provides

exceptional accuracy and ease of use. It is packaged in a compact, sturdy and attractive

housing unit which requires little room on a laboratory bench. The SURETEST is

typically used in conjunction with a Transducer and a Mechanical Loader.

Fig 2-1

Base Unit

The SURETEST monitors and displays the torque applied.

Transducer (Accessory)

Page 12

FUNCTIONAL DESCRIPTIONS AND SPECIFICATIONS CHAPTER 2

The loader accepts all SURETEST series single transducers directly. Use a 2000-500-02

adapter kit to mount the optional 2000-400-02 4-in-1 transducer. For additional

information refer to Appendix A–Accessories.

Loader

Use the 2000-600-02 Manual Loader for testing and calibrating all torque wrenches,

drivers, torque multipliers, non-impact pneumatic and electric nut runners. Loader

components are:

• Stand For Base Unit

• Safety Shield

• Hand Crank

• Transducer Mounting

Roll Cabinet

The roll cabinet features nine heavy duty drawers with ball bearing slides, locking wheels

and drawer locks. SURETEST accessories are stored in the roll cabinet which is fitted

with foam inserts for easy inventory control. The nine drawers are assigned and arranged

as shown in figure A-1 of Appendix A.

SURETEST Base Unit

This section describes the major hardware components of the SURETEST Base Unit,

including:

• Front Panel

• Rear Panel (Input/Output)

• SURETEST Torque Transducers.

Page 13

FUNCTIONAL DESCRIPTIONS AND SPECIFICATIONS CHAPTER 2

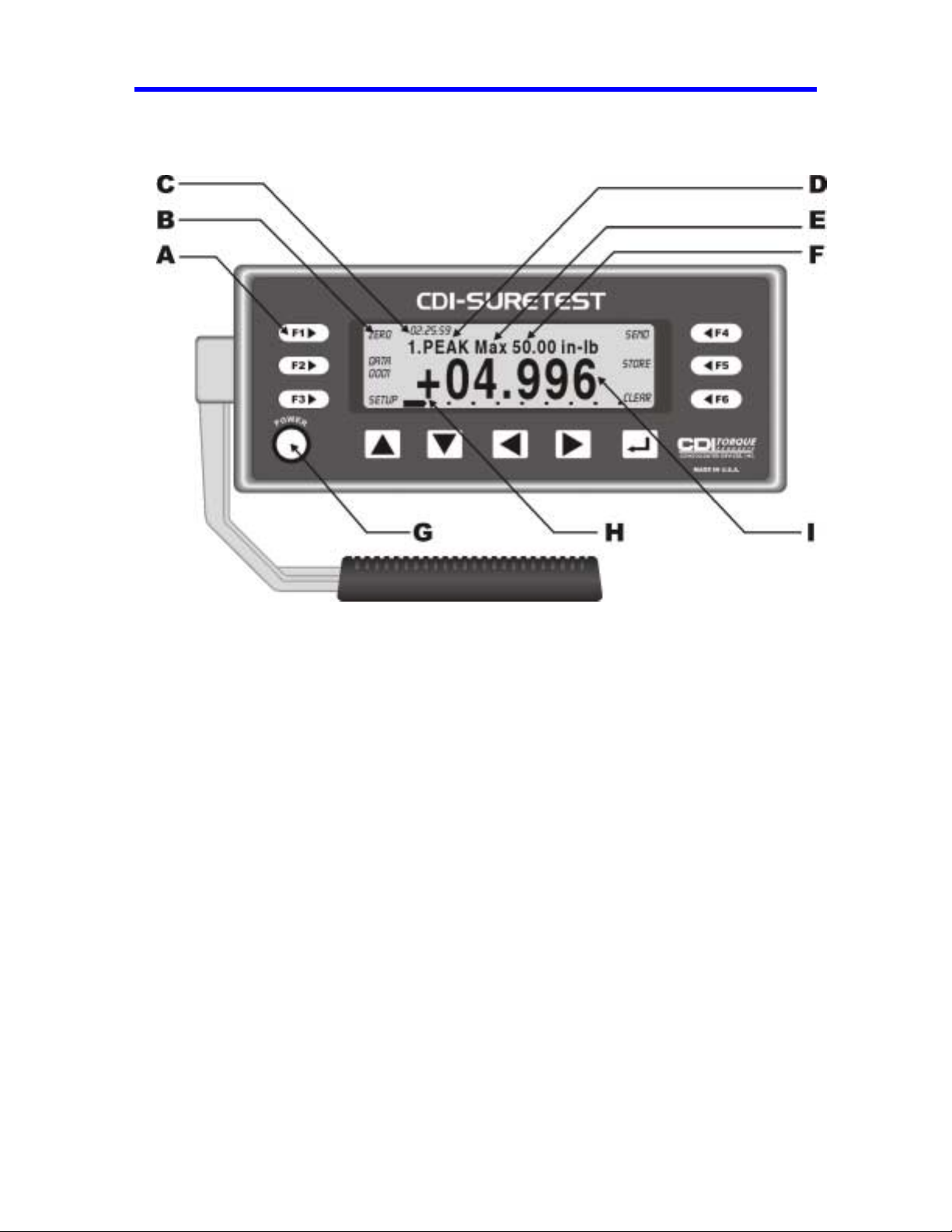

FRONT PANEL

Figure 2-3: SURETEST Front Panel

A- Membrane Function ( F1, F2, F3, F4, F5, F6 ),

And Cursor/Selection (Up, Down, Left, Right and Enter ) Keys.

B- Soft Key Menu: Zero, # Data Stored, Setup, Send, Store, Clear, Escape, Format.

C- Real Time Clock. HH:MM:SS

D- Modes: Track, Peak Hold, First Peak and Power tools.

E- Maximum Range of Transducer.

F- Engineering Units : Nm, dNm, Ncm, mkg, cmkg, ft.lb, in.lb, in.oz

G- Power: On/Off

H- Scroll Bar Each dot represents 10% of Full scale.

I- Torque Reading: Full 5-digit readi ng Plus Sign (for dir ection)

Page 14

FUNCTIONAL DESCRIPTIONS AND SPECIFICATIONS CHAPTER 2

SURETEST DISPLAY

A 240 x 64 Full-featured Graphic LCD is used to provide versatile and clear displays of system

menus as well as measurements. Characters and symbols are displayed in different fonts:

• Maximum transducer range in the selected UNITS of measure.

• Statistical mean of all measurements in memory.

• The number of the present data memory location.

Front Panel Membrane Cursor and Function Keys

The SURETEST is supported by a powerful Graphic User Interface (GUI). Set up, Command, or

Control is done by selecting the appropriate Action Item on one of the provided Menus. Front

Panel Membra ne Cursor and Functio ns keys are defined to gui de the User in selecting an Action

Item.

There are 6 function (soft) keys:

the LCD.

To select an Action Item, the User simply presses a Function Key (F1-F6) to get to a Menu, uses

a Cursor Key to move to the Item, then hits ‘ENTER’ .

In addition to the

The GUI also provides P rompts to further a ssi st the user in navigating the Menus.

‘ENTER’ key, there are 4 Cursor Keys : UP , DOWN , LEFT , RIGHT .

F1 through F6. Their respective uses are clearly indicated on

Power Up Sequence

Upon power up, the SURETEST automatically performs Self-tests and displays the results. Any

detected non-functional hardware will be reported on the LCD. If a 4-in-1 transducer is

connected, the SURETEST performs ZEROTARE, then displays the following default menu

while continuously checking for any activity from an input transducer :

The user can either press F1 to display previously collected data (if any) or enter Setup Mode.

Any detected torque measurement will cause the SURETEST to enter Measurements mode where

the following menu is displayed:

Page 15

FUNCTIONAL DESCRIPTIONS AND SPECIFICATIONS CHAPTER 2

The SURETEST always returns to the default menu from the measurements mode in the event there is no

selection / input by the User. This serves as a reminder for more (input) measurements.

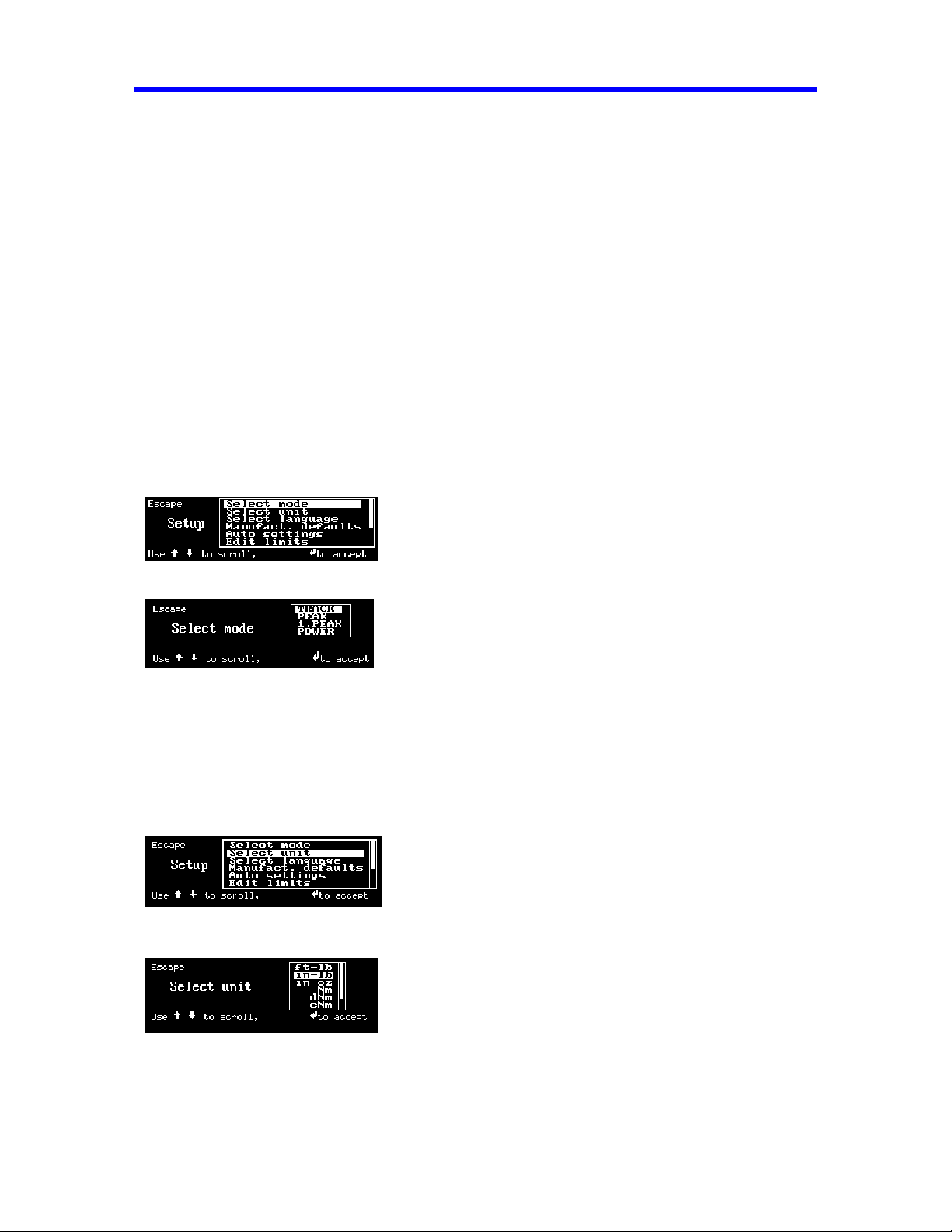

Setup Mode

The following Selections are available:

1. SELECT MODE

2. SELECT UNIT

3. SELECT LANGUAGE

4. MANUFACTURER’S DEFAULTS

5. AUTO SETTINGS

6. EDIT LIMITS

7. CLOCK ADJUST

8. CALIBRATION

9. EDIT P ARAMETERS

10. CDI INTERNAL

11. ABOUT

1. Select Mode

Selects either TRACK, PEAK HOLD, FIRST PEAK, or POWER mode.

• TRACK : In this mode, the SURETEST continually makes Torque Me asurements.

• PEAK : The SURETEST makes Torque Measurement at the Highest Peak.

• 1.PEAK : The SURETEST makes Torque Measurement at the First Peak.

• POWER : The SURETEST makes Torque Measurement at the Highest Peak at a faster rate.

2. Select Unit

Selects the following Torque units on LCD display:

Nm, dNm, cNm, mkg, ft-lb, in-lb, in-oz .

Page 16

FUNCTIONAL DESCRIPTIONS AND SPECIFICATIONS CHAPTER 2

3. Select Language

Selects either English, German (Deutsch), French (Francais), Spanish (Espanol),

or Portugue se (Portugues) .

4. Manufacturer’s Defaults:

A warning message is first displayed. Upon confirmation by the User, the Default Settings

will be loaded into the SURETEST.

5. Auto Settings

Sets up CLEAR, STORE, and SEND functions. There are 2 options: Automatic or Manual.

Selection: Automatic Clear, Automatic Store and Automatic Send data out (to RS-232 port).

Selection: Delay 9 seconds then clear the Display, Manual Store and Manual Send.

Selection: Automatic Clear, Automatic Store and Manual Send.

Page 17

FUNCTIONAL DESCRIPTIONS AND SPECIFICATIONS CHAPTER 2

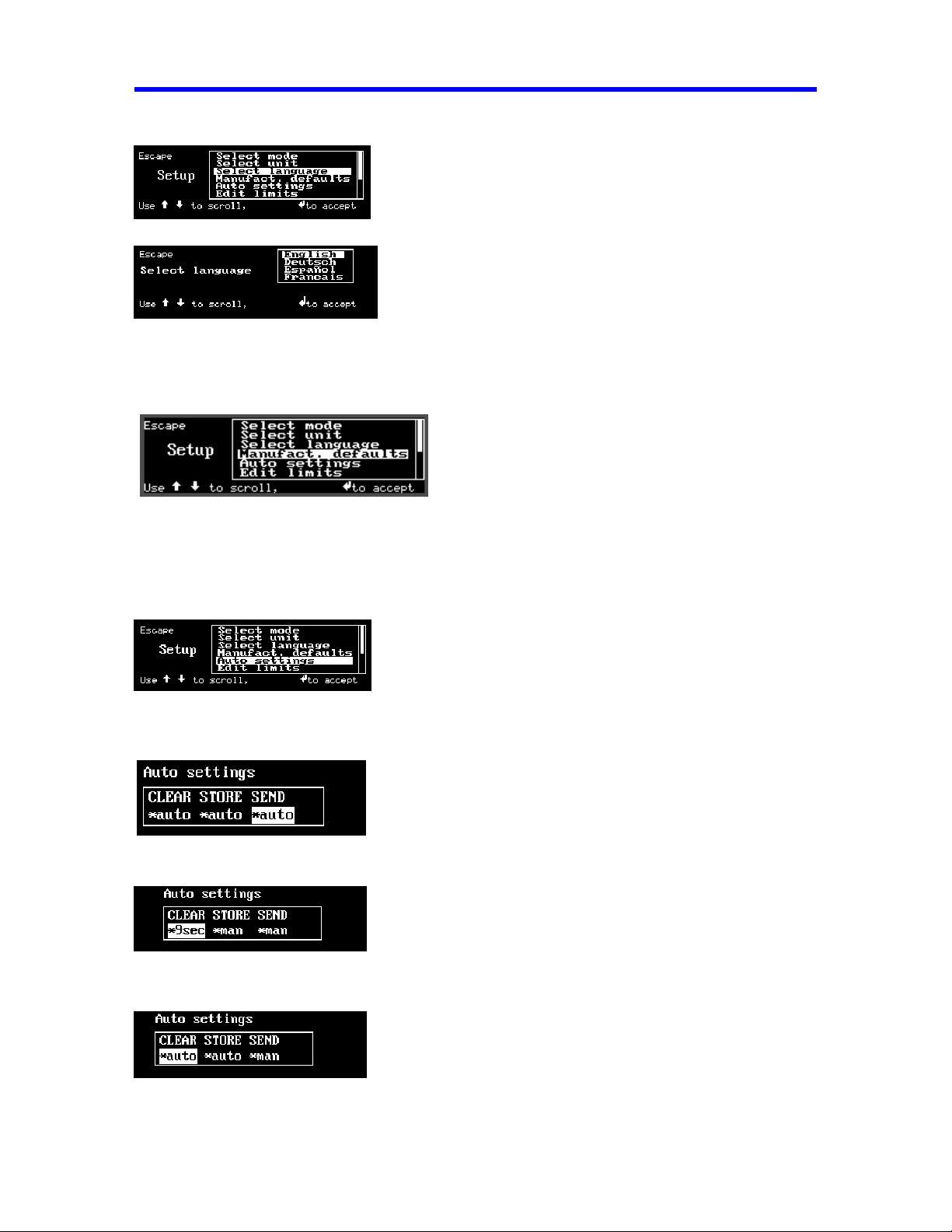

6. Edit Limits

Sets up high torque limit preset. (->) to go Down 1 line.

Sets up low torque limit preset. (<-) to go Up 1 line.

Use Up or Down cursor key to increment or decrement the respective value.

Use Left or Right cursor key to select digit.

Press ‘Save’ to activate the change. Press ‘Clear” to Clear All Limit set-up.

Press ‘Escape’ to Exit. Last setup is retained.

7. Clock Adjust

Edits DATE/TIME programming function.

To adjust the Clock, use LEFT or RIGHT cursor key to get to Day, Month, Year, Hour,

Minute, or Second field. Then use UP or DOWN cursor key to increment or decrement

the respective value.

Press and hold the cursor key to change the value quickly.

Press ‘ENTER’ to activate the change.

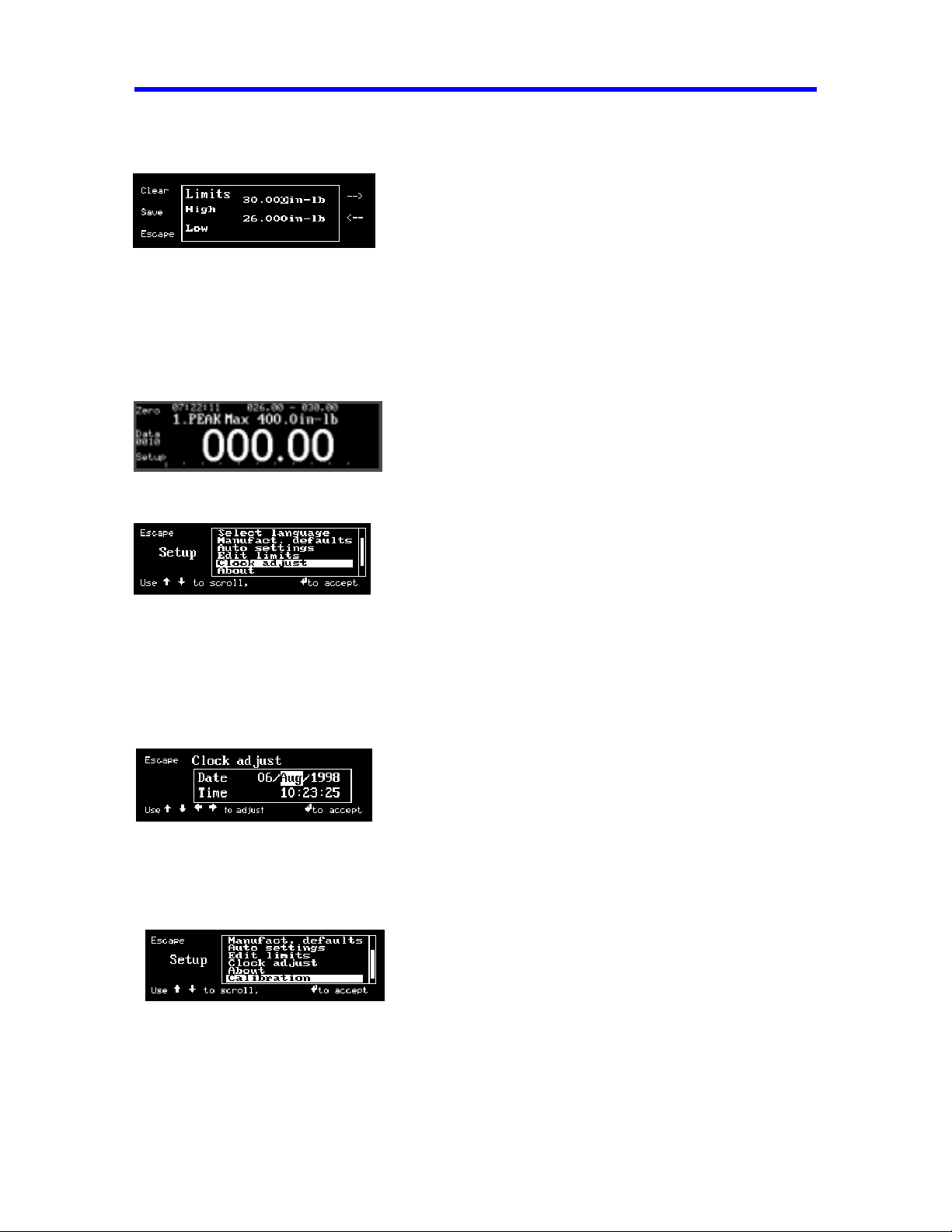

8. Calibration

This enables the User to perform calibration of the SURETEST. The procedures for both the

single and 4-in-1 transducers are in Chapter 5.

Page 18

FUNCTIONAL DESCRIPTIONS AND SPECIFICATIONS CHAPTER 2

9. EDIT PARAMETERS

Sets up serial protocol function.

Sets delay (in ms) per character upon printing.

Sets delay (in ms ) per Linefeed.

Minimum block-out with zero at 0.1% F.S. in Tracking Mode.

Minimum block-out with zero at 1.0% F.S. in Peak-Hold Mode.

10. CDI INTERNAL

For Manufacture r’s use only.

11. About

This provides relevant information regarding the CDI company, the software version, and the

serial number of the SURETEST device.

12. Other Features:

Provides manual ZERO TARE.

Stores present measurement to memory.

Recalls memory data to display.

Sends all memory data, statistical analysis and histogram to printer port.

Sends data list with or without date-time stamp to computer / printer.

Manually clears display in PEAK, FIRST PEAK, POWER TOOL modes.

Sets up memory clear options in RECALL mode.

Page 19

FUNCTIONAL DESCRIPTIONS AND SPECIFICATIONS CHAPTER 2

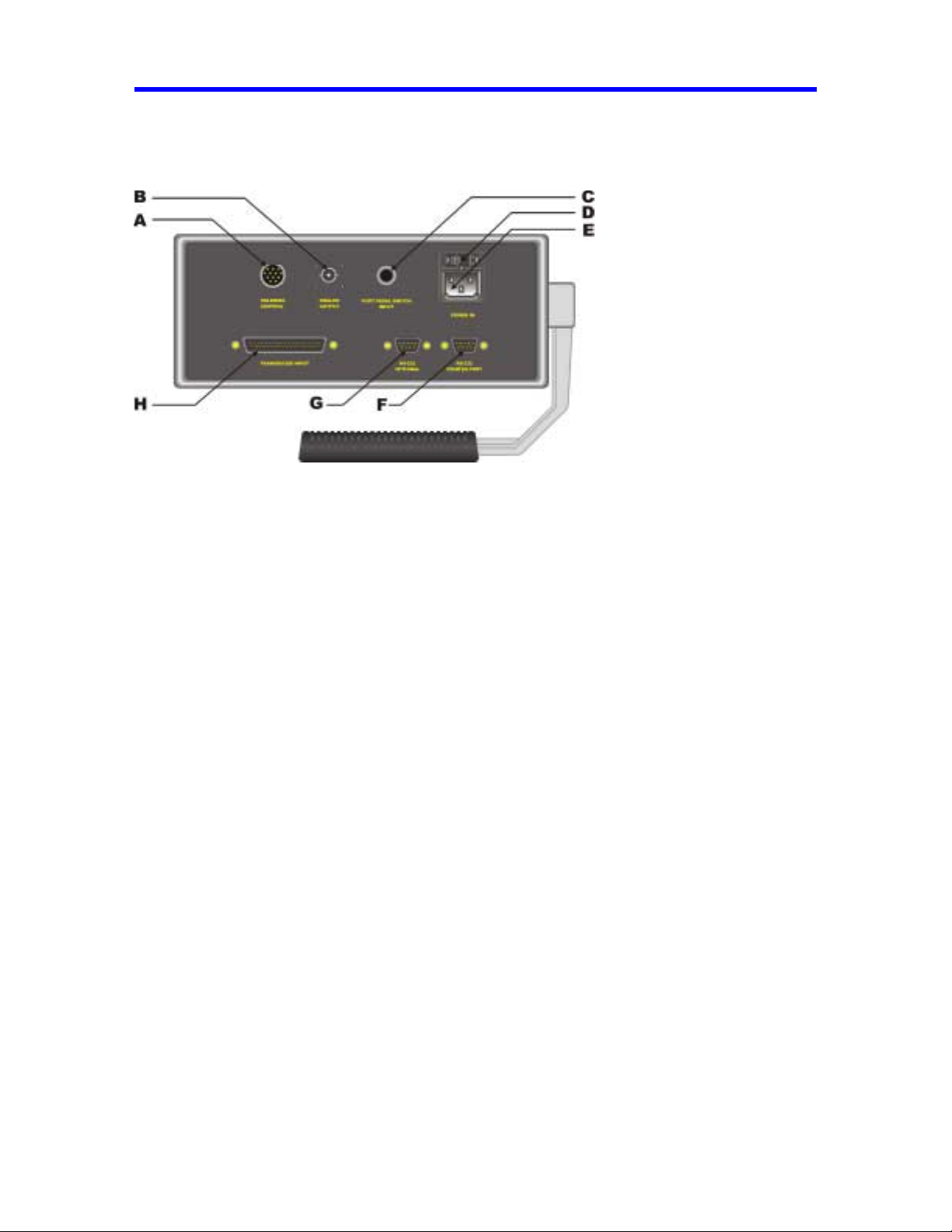

Rear Panel (Input/Output)

Figure 2-5: SURETEST Rear Panel

A- SOLENOID CONTROL (Hirose RM15TRD-12S)

PIN FUNCTION

10 Loader Relay Common

11 Loader Relay CCW Limit

12 Loader Relay CW Limit

B ANALOG OUTPUT (BNC)

Analog output provides a voltage level output that is directly proportional to transducer input,

from -1.8V (full scale counter clockwise) to +1.8V (full scale clockwise). Zero offset +/-100 mV.

Linearity +/-1% of reading. Maximum load = 5 mA.

When using the 4-in-1 transducer, zero output fluctuates until o ne of the transducers is

scan selected by applying 5% of full scale torque.

C- Foot Pedal Switch Input

D- Fuse Holder

Use AC fuse at specified rating only. ( 3.15 Amp).

E- INPUT AC VOLTAGE

Automatic Selection of any AC voltage from 100VAC to 230VAC, 50-60 Hz.

Page 20

FUNCTIONAL DESCRIPTIONS AND SPECIFICATIONS CHAPTER 2

F- PRINTER PORT (DB-9P)

PIN FUNCTION

2 Receive

3 Transmit

5 Ground

G- OPTIONAL (DB-9P)

PIN FUNCTION

2 Receive

3 Transmit

5 Ground

H- TRANSDUCER INPUT (DB-37S)

PIN FUNCTION

1 not used

2 ground

3 smart chip - bit 2

4 smart chip - bit 0

5 single xducer (-) signal

6 single xducer (+) signal

7 ground

8 4-in-1 xduce r (-) signal 2

9 4-in-1 xduce r (+) signal 2

10 ground

11 4-in-1 xducer (-) signal 4

12 4-in-1 xducer (+) signal 4

13 4-in-1 xducer LED 2

14 4-in-1 xducer LED 4

15 loader relay CW limit

16 not used

17 not used

18 ground

19 bridge excitation (+3V)

20 not used

21 smart chip - bit 3

22 smart chip - bit 1

23 ground

24 ground

25 4-in-1 xducer (-) signal 1

26 4-in-1 xducer (+) signal 1

27 ground

28 4-in-1 xducer (-) signal 3

29 4-in-1 xducer (+) signal 3

30 no transducer

31 4-in-1 xducer LED 1

32 4-in-1 xducer LED 3

33 loader relay CCW limit

34 loader relay common

35 Vcc (+5V@100 ma. max)

36 ground

37 bridge excitation (+3V)

Page 21

FUNCTIONAL DESCRIPTIONS AND SPECIFICATIONS CHAPTER 2

SURETEST Transducers

SURETEST transducers provide industry standard square drives. They feature a full

bridge strain-gauge @ 350 Ohms nominal. Full range output is 1500 uE, 9mV

(3mV/V @ 3.0V excitation).

Torque transducers use a built-in EEPROM memory chip that stores range identification

and calibration factors. Calibration of transducers is accomplished using precision torque

bars and certified weights. For additional information, refer to Chapter 5—Calibration.

After a transducer is calibrated, it provides ±0.5% system accuracy with any SURETEST

System. If the transducer and SURETEST are calibrated together, the system accuracy

increases to ±0.25%.

Transducer Dimensions/Transducer Torque Range

Calibration also results in a specified display resolution on the SURETEST. Display

resolution is dependent on the type o f transducer being used. The following table shows

display resolutions for the specified transducer with the force arm.

Display Resolution for Transducers

SURETEST torque transducers can withstand an overload of 110% of full range. The

SURETEST alarms, (audible beep and display "OVER" ) at 110% of rated capacity.

To protect the tool under test or to serve as a fastener installation torque preset alert, the

SURETEST produces a constant audible tone when the input torque exceeds the SET

LOW limit. It then produces a pulsating tone when the input torque exceeds the SET

HIGH limit.

The SURETEST Indicator ignores inputs less than 0.1% of full range in TRACK mode,

2% in PEAK HOLD mode, 7% in FIRST PEAK and POWER TOOL modes.

With the 4-in-1 transducer, the SURETEST System ignores inputs less than 2% of full

range after scan select.

Page 22

FUNCTIONAL DESCRIPTIONS AND SPECIFICATIONS CHAPTER 2

Specifications

SURETEST Torque Calibration System

System Accuracy

±0.25% of reading @ 25°C

(Suretest and transducer calibrated together)

SURETEST Transducers used with, but not calibrated to, another SURETEST provide a system

accuracy of ±0.5% of reading @ 25°C.

Temperature Drift

+0.03%/°C (+0.017%/°F)

Display Accuracy

±0.05% of reading @ 25°C

Temperature

Operating Temperature

10 to 32°C (50 to 90°F)

Storage

-20 to 50°C (-2 to 122°F)

Humidity

Up to 90%, Non-condensing

Temperature Drift

+0.011%/°C, (+0.006%/°F)

Dimensions

Width 10.5“

Height 4.5"

Depth* 10.5"

*Includes handle, feet and connectors

Weight

8 .4 lbs

Fuse:

Amperage, 3.15 amps

Data Storage/Recall w/Date Time Stamp

3,000 measurements

Statistical Analysis

Max, Min, Range, M ean, Sigma N, Sigma, Cp, Cpk

%Error, -NoGo, +NoGo, Histogram.

Page 23

FUNCTIONAL DESCRIPTIONS AND SPECIFICATIONS CHAPTER 2

Printer Serial Output Port

Default: 9600 Baud Rate.

Serial Communications

RS-232 (true)

300—19.2K Baud

8 data bits

1 stop bit

no parity

Computer Serial COM Port (OPTIONAL)

Default: 19,200 Baud Rate.

RS-232 (True)

Analog Output

+(CW)/-(CCW) 1.8V at transducer full range linearity

±1% of reading

Loader Control Relays

Two, normally open, Form A, rated 12VDC @ 1/2A close contact at 110% CW or CCW of torque

transducer range. For additional information refer to Transducer and System specifications.

Display Capacity

(16 bit A/D), 5 digits, ±32,000 counts

Units of Measurement

Torque

ft-lb, in-lb, in-oz, Nm, dNm, cNm, mkg, cmkg

Torque Resolution

Refer to transducer range and display resolution tables in Functional Description of this chapter.

Accuracy

±0.2% of reading @ 25°C, within specified range, when used as prescribed with the 2000-600-02

Loader.

Range and Resolution

Refer to transducer range and display resolution tables in Functional Description of this chapter.

Temperature

Operating Temperature

10 to 32°C (50 to 90°F)

Storage

-20 to 50°C (-2 to 122°F)

Humidity

Up to 90% non-condensing

Temperature Drift

+0.02%/°C (+.011%/°F)

Page 24

SETUP AND PROGRAMMING CHAPTER 3

Manual Loader Specifications

Input Torque (Hand Crank)

8 ft lb maximum (without Motorized control).

Output Torque

2000 ft-lb ±20 degrees rotation maximum

Power Requirements (safety solenoids)

switching From 100 to 230VAC ±10%, @ 50-60 Hz.

Weight (including 2000-100-02 Roll Cab)

1500 lbs.

Optional Calibration Fixturing (Load bars and Weights)

±0.05% accuracy.

3-23

Page 25

SETUP AND PROGRAMMING CHAPTER 3

CHAPTER 3

SETUP AND PROGRAMMING

SURETEST TORQUE CALIBRATION SYSTEM SETUP

MANUAL LO ADER

2000-600-02

MANUAL MECHANICAL LOADER

REAR PANEL CONTROLS

SOLENOID CONTROL CABLE

2000-117

SURETEST

9502-610-02

A

C

D

B

SOLENOID

CONT ROL

TRANSDUC ER INPUT

ANALO G

OUTPUT

FOOT PEDAL SWITCH

INPU T

RS-23 2

OPTIONAL

G

H

I

POWER IN

RS-232

PRINTER PORT

PRINTER CABLE

2000-50-2

ANALOG OUTPUT

FOOT PEDAL SWITCH

950-87

POWER CABLES 110V/220 V AC

PA RT NUM BER :

2000-114 ( U.S.A. )

950-97 ( EUROPE )

950-96 ( AUSTRALIA )

950-95 ( U.K. )

J

SMART

4IN1 TR ANSDUCE R

2000-400-02

TRANSDUCER CABLE

2000-900-120

E

PRINTER

RS-232 COM PORT

F

P. C CABLE

SMART SINGLE TR ANSDUCER

2000-5-02 / 2000-6-02 / 2000-65-02 / 2000-7-02

2000-8-02 / 2000-10-02 / 2000-11-02 / 2000-12-02

2000-13-02 / 2000-14-02

Figure 3-1: SURETEST Torque Tester/Calibrator/Loader Setup

3-24

2000-50-1

K

P.C COMPUTER

RS-232 OPTIONAL

Page 26

SETUP AND PROGRAMMING CHAPTER 3

Back panel connections

A Manual Loader

B Solenoid control cable

C Suretest

D Smart 4-in-1 transducer

E Transducer cable

F Smart single transducer

G Analog Output

H Foot cable switch

I Power cables (110/220 VAC)

J Printer cable

K Personal computer cable

Note: Cable (K) can be connected to Printer Port too.

Setting Up the SURETEST Torque Calibration System

1. Position the roll cabinet on a level floor and lock the wheels.

2. Mount the indicator stand, part number 2000-111-0, to the Loader.

3. Mount the SURETEST base uint to the stand.

4. Connect the solenoid control cable between the Suretest and Loader.

5. Install the appropriate SURETEST transducer to the Loader drive.

6. Install two (2) quick release pins, part number 2000-195-12

7. Connect the transducer cable, part number 2000-900-120, between the Indicator and

transducer.

8. Select the appropriate AC voltage input at the rear of the Loader. Connect the AC power

cables to the Loader. For additional information refer to Chapter 6—Loader Rear Panel

Controls.

9. Install the safety shield to the front of the Loader.

10. Install the reaction pins into the reaction slide on the Loader.

11. Install two Linear ball bearing, part number 2000-173-11.

For testing procedures refer to Chapter 4—Using the Torque Tester.

3-25

Page 27

SETUP AND PROGRAMMING CHAPTER 3

SURETEST Base Unit Controls

Refer to the illustration below when performing the power-up and programming procedures.

Figure 3-2: SURETEST Controls

– SURETEST Graphic LCD Display

– Power Switch

– Front Panel Membrane Function Keys

Powering the Equipment

To power the equipment, press the power button on the front of the SURETEST.

• At POWER ON, the SURETEST performs self-test and momentarily displays the results on the

display.

• With no transducer installed, the display then reads:

• When applying power with the transducer connected, or when connecting a transducer while the

power is on, the display momentarily reads:

ZEROTARE prompt

3-26

Page 28

SETUP AND PROGRAMMING CHAPTER 3

4-in-1 Transducer Installation

When a 4-in-1 transducer is installed, the following is displayed:

All four transducers are scanned as indicated by their associated red LED indicators. To select

one of the transducers, apply at least 5% of its full range torque. To return to the scan mode, press

ENTER.

Single Transducer Installation:

When a single transducer is installed, the following is displayed:

The user can enter Setup mode then proceed to make Torque measurements.

3-27

Page 29

SETUP AND PROGRAMMING CHAPTER 3

Programming Setup

Setting up Date and Time

1. Press (Setup).

2. Scroll down to select Clock Adjust. Press ‘Enter’.

The display reads:

3. Use Left or Right Cursor to select the date/time element to be changed.

4. Increment or decrement the date/time element by repeatedly pushing Up or Down

Cursor. Push and hold Up or Down Cursor to change the display quickly.

5. Press ENTER to update date and time and to return to measurements mode.

Setting Up High and Low Limits Alert

Use SET HIGH and SET LOW to protect the tool under test or serve as a fastener

installation torque preset alert. The SURETEST produces a constant audible tone when

the input torque/force exceeds the SET LOW limit. It then produces a pulsating tone

when the input torque/force exceeds the SET HIGH limit.

It is important to program these limits if statistical analysis is to draw a histogram which

includes reporting out-of-limit parameters.

Changing transducers does not automatically change SET HIGH and SET LOW limits.

Setting High or Low Torque Limits

1. Press (Setup).

2. Scroll down to select Edit limits.

The display reads:

3-28

Page 30

SETUP AND PROGRAMMING CHAPTER 3

3. Press ‘Enter’. The display reads:

4. Press -> or <- to select Hi or Lo limit.

5. Use Left or Right Cursor to select a digit to be changed.

6. Increment or decrement the selected digit by pushing Up or Down Cursor. Push and

hold Up or Down Cursor to change the display quickly.

7. Select and change the next digi t using left and right D IGIT and up and down

Cursor. Continue until all digits are set.

8. Press (Save) to save and to return to measurements mode.

Set-up AUTO CLEAR

Use AUTO CLEAR to program the CLEAR, STORE and SEND functions for

automatic or manual operation. Use these functions in PEAK HOLD, POWER TOOL

and FIRST PEAK modes to STORE torque measurements to memory, CLEAR the

display, and SEND the last measurement captured on the display to the printer or PC.

Auto STORE and SEND are initiated at either AUTO or delayed CLEAR operations.

Use the manual modes to:

• Store the present reading by pushing STORE DATA,

• Clear a captured display by pushing MANUAL CLEAR, or

• Send a measurement to the printer/port by pushing SEND/AUTO SEND.

Use the automatic modes to:

• Store the last measurement, and/or

• Send the last measurement to the printer/port by initiating the auto or delayed

CLEAR function.

AUTO CLEAR can be programmed with a 1 to 9 second delay. Use this feature to

visually note the reading before the display clears. AUTO CLEAR with no delay stores,

prints and/or clears with no delay at the initiation of the next torque input

STORE DATA must be pressed to save the last reading. AUTO CLEAR must be

selected to use AUTO STORE and AUTO SEND.

3-29

Page 31

SETUP AND PROGRAMMING CHAPTER 3

To use the AUTO CLEAR, STORE, or SEND:

1. Press (Setup).

2. Scroll down to select Auto settings.

The display reads:

3. Press ‘Enter’. The display reads:

4. Use Right and Left Cursor to position the reverse-video (*) character under the

function being changed. To program:

CLEAR, press Up or Down Cursor to select "man" (manual clear), "auto"

(automatic), or (delayed automatic) from " 1Sec" to "9Sec" seconds.

STORE, press Up or Down Cursor to select "man" (manual) or "auto" (automatic).

SEND, press Up or Down Cursor to select "man" (manual) or "auto" (automatic).

5. Press ENTER save ‘Auto settings’ and to return to measurements mode.

DATA LIST Memory

When changing sensors, or when creating a new statistical data list, the data list memory

must be cleared. The entire memory list or any single memory location may be

selectively cleared. Clearing from the top of the list decrements the total number of

memory locations. Clearing from inside the list shifts all subsequently taken readings

down from that location and decrements the total number of memory locations.

3-30

Page 32

TORQUE CALIBRATION SYSTEM SETUP CHAPTER 4

Clear Single Memory Location

Use the procedure in this section to clear the a single memory location.

1. Press (Data) to enter data list display. The display reads:

2. Use the Up or Down Cursor to move to the current data. The units and present

memory location are given on the top line. The total number of memory locatio ns

is to the right -- separated by a forward slash (/). The bar graph to the right of the

data list indicates how far in the list the current data display is positioned.

+04.456 in-lb, Time: 23:19 Date: Feb 10, 1999

3. Press (DEL 1) to delete one data entry. The display automatically updates

(decrements by one) the total memory locations on the top line.

Clear All Memory Locations

Use the same above procedure fo r single memory location. Press (Clear) to

memory locations. The following warning appears:

clear all

Select “Yes” to clear all memory.

An audible alarm sounds momentarily. The SURETEST automatically returns to

measurements mode.

Setting Up Printer/PC Ports

The SURETEST is equipped with two RS-232 serial communications ports for use with

an external printer or personal computer. The transfer rate is programmable from 300 to

19.2K baud rate with 8 data bits, 1 stop bit and no parity. The recommended default is

19200 baud for Optional Port and 9600 for Serial Printer.

Communication setup as: (300 – 19200); 8 Data bits; 1 Stop Bit; No Parity

Connect the Printer port to a computer or printer. All (serial) communications will take

place under User’s command(s) Edit Parameters set-up mode.

4-1

Page 33

TORQUE CALIBRATION SYSTEM SETUP CHAPTER 4

CHAPTER 4

SURETEST TORQUE CALIBRATION SYSTEM SETUP

This chapter contains information on how to test, measure, and use the SURETEST

Torque Calibration System.

Testing Torque Wrenches and Drivers

To use the SURETEST Torque Calibration System for torque wrench testing, a

transducer of the appropriate range is fitted to the 2000-600-02 Manual Loader.

The Loader provides a stop that holds the torque wrench handle fixed and rotates the

transducer under the wrench drive. The system applies a precise, monitored torque to the

wrench. For additional information refer to Chapter 6—2000-600-02 Manual Loader.

Selecting a Transducer

When selecting a transducer, choose a single transducer that covers the low to high end

capacity of the torque wrench. Although possible, it is best not to change transducers

between calibration check points. For example: to test or calibrate a 20 to 100 ft lb

wrench, use the 2000-10-02 transducer, which covers the range between 10 and 125 ft lb.

Installing a Transducer

Install the transducer by lining up the red mark with the “TORQUE” label on the loader.

For additional information refer to 2000-600-02 Loader.

• Before changing or replacing transd ucers, adjust SET HIGH and SET LOW limits to

remain within the capacity of the tool under test. For additional information refer to

Chapter 3 Setting Up High and Low Limits Alert .

• If you must retain the statistical analysis, do not change SET HIGH and SET LOW

limits after changing the transducers and be careful not to exceed the wrench capacity.

The procedures provided are general. You may use or establish your own testing

procedures, techniques or standards.

4-1

Page 34

TORQUE CALIBRATION SYSTEM SETUP CHAPTER 4

Dial and Bending Beam Torque Wrenches and Screwdrivers

Be sure the SURETEST transducer is capable of handling the intended torque to avoid

damaging the transducer.

WARNING

Do not use this equipment with the power off. Always turn o n the Base Unit so the

torque values are indicated on the display.

1. T o program the SURETEST B ase Unit refer to Chapter 3 Set Up and Programming.

Use SET HIGH and SET LOW limit alert, data STORE, display CLEAR, printer

SEND and STATistical analysis features.

2. Press Setup then Select Unit to select the desired engineering unit of measure on the

display. It is easiest to match that of the tool under test.

3. Press Setup then Select Mode to select TRACK mode.

4. Install the tool onto the torque transducer-loader. Slowly apply clockwise (CW) to rque

using the Loader crank handle until the indicator displays the full scale torque for the

tool.

Release the torque and repeat twice again to exercise the tool and the transducer.

When applying torque by hand, make sure to hold the drive end of the tool perfectly in

line with the transducer drive to minimize side loading errors.

5. Remove the tool from the transducer-loader and press Zerotare.

6. Press Setup then Select Mode to select PEAK HOLD mode.

7. Reinstall the tool and apply CW torque to the first check point or calibration point

recommended by the manufacturer. If the point is not specified, use the desired working

torque or about 70% of full scale.

8. Read the tool display. The percentage difference between the Suretest and tool readings

should not be greater than the sum of their respective accuracies.

Example:

When tool accuracy is 4% and SURETEST System accuracy is 0.25%, readings should

be within ±4.25%.

9. Release the torque, CLEAR the display, and reapply torque for each of the remaining

check points recommended by the tool manufacturer. If no recommendation is available,

check at 20%, 40%, 60%, 80% and 100% of the tool’s full scale.

10. Repeat steps 4 through 9 in the counter clockwise (CCW) direction.

4-1

Page 35

TORQUE CALIBRATION SYSTEM SETUP CHAPTER 4

Adjustable or Preset “Click” Wrenches and Screwdrivers

Be sure the SURETEST transducer is capable of handling the intended torque to avoid

damaging the transd ucer. Always operate the system with the power on.

WARNING

Do not use this equipment with the power off. Always turn o n the Base Unit so the

torque values are indicated on the display.

1. To program the SURETEST Base Unit refer to Chapter 3–Set Up and Programming.

Use SET HIGH and SET LOW limit alert, data STORE, display CLEAR, printer SEND

and STATistical analysis features.

2. Press Select Unit to select the desired engineering unit of measure as displayed on the

display. It is easiest to match that of the tool under test.

3. Press Setup Select Mode to select TRACK mode.

4. Adjust the to ol for maximum “click” setting. Install the tool on the torque transducerloader. Slowly apply torque using the loader crank handle until the tool clicks or the

Suretest displays 100% of the full scale capacity for the tool. Release the torque and

repeat twice again to exercise the tool and the transducer.

When applying torque by hand, make sure to hold the drive end of the tool perfectly in

line with the transducer drive to minimize side loading errors.

5. Remove the tool from the transducer-loader and press Zerotare.

6. Press Setup then MODE to select FIRST PEAK mode.

When testing “click” screwdrivers, it may be easier to use the PEAK HOLD mode on

the SURETEST to capture the maximum ap p lied torque reading.

7. If featured, adjust the micrometer or preset knob on the tool to the first check point

recommended by the manufacturer, or the desired working torque, or approximately 70%

of its full scale torque.

8. Reinstall the tool and apply torque until the wrench “clicks.”

9. Release the torque and note the FIRST PEAK or PEAK HOLD reading. The

percentage difference between the Suretest reading and tool setting should not be gre ater

than the sum of their respective accuracies.

Example:

When the tool accuracy is 4%, and the SURETEST accuracy is 0.25%, then readings

should be within ±4.25%.).

10. CLEAR the display and reapply torque for each of the remaining check points

recommended by the tool manufacture. If no recommendation is available, test at

minimum torque, 60% and 100% of full scale.

11. Repeat steps 4 through 10 in the opposite direction, if required.

4-1

Page 36

TORQUE CALIBRATION SYSTEM SETUP CHAPTER 4

Testing Power Tools

The dynamic torque characteristic of a power tool and the static torque applied when

using a wrench usually result in different torque readings. Spinning electric and

pneumatic motor armatures contain inertia that produces a higher torque reading than

what is actually absorbed by a practical fastener. The difference is also due to individual

fastener installation characteristics that exhibit anywhere from a gradually increasing rundown torque, (soft-joint) to a free speed, sudden dead stop, (hard-joint). The way in

which a particular operator responds to the tool’s reaction forces can also be reflected in

the resulting torque measurements.

A joint rate simulator is required when testing a power tool to allow start-up rotation of

the tool’s armature. The simulator is experimentally adjusted to replicate the average

joint hardness of the intended work. Joint rate simulators that may be used with

transducers ranging from 50 in lb to 1000 in lb are:

• 50 in lb max, 1/4" internal square drive for use on 2000-6-02 transducer, part number

900-1-0 .

• 400 in lb max, for use on 2000-7-02 transducer, part number 900-2-0, or

• 1000 in lb max, for use on 2000-8-02 transducer, part number 900-3-0.

Be sure to operate any pneumatic or electrical power tool according to the manufacturer’s

recommendations.

Non-Impact Tools

Be sure the SURETEST transducer is capable of handling the intended torque to avoid

damaging the transd ucer. Always operate the system with the power on.

WARNING

Do not use this equipment with the power off. Always turn o n the Base Unit so the

torque values are indicated on the display.

1. To program the SURETEST Base Unit, refer to Chapter 3–Set Up and Programming in

this manual. Use SET HIGH and SET LOW limit alert, data STORE, display CLEAR,

printer SEND and STATistical analysis features.

2. Press Setup then select UNIT to select the desired engineering unit of measure as

displayed on the LCD display. It is easiest to match that of the tool under test.

3. Press Setup then MODE to select TRACK mode.

4. Adjust the power tool to the desired torque output, if possible.

5. Adjust the appropriate joint rate simulator assembly for the desired soft-hard

configuration.

6. Install the joint rate simulator onto the SURETEST transducer, as shown in Figure 4-1.

Secure the transducer set screw, if provided. Loosen the simulator load screw using the

appropriate hex or box wrench.

4-1

Page 37

TORQUE CALIBRATION SYSTEM SETUP CHAPTER 4

Figure 4-1: Power Tool T est Setup

A – Power Tool

B – Joint Rate Simulator

C – Transducer

7. Couple the power tool to the joint rate simulator using the appropriate accessory adaptors

and bit.

8. While holding the power tool drive perfectly in-line with the transducer drive, energize

the tool until its motor stalls or, if featured, the tool clutch slips.

9. Remove the power tool. Loosen the joint rate simulato r load screw.

10. Repeat steps 7 through 9 twice again t o exercise the to ol-simulator assembly and the

SURETEST transducer.

11. Remove the power tool from the loader-transducer and press Zerotare.

12. Press Select Mode to select POWER (TOOL) mode.

4-1

Page 38

TORQUE CALIBRATION SYSTEM SETUP CHAPTER 4

13. W hile holding the power tool drive perfectly in-line with the transducer drive, reinstall

the tool onto the simulator and energize the tool until its motor stalls or, if featured, the

tool clutch slips. Be careful not to add torque by turning the tool by hand.

14. Release the torque and note the Power tool reading on the display.

15. CLEAR the display.

16. Repeat steps 4 through 15 in the opposite direction, if required.

Given the variables typical of power tools and fastener joint dynamics, a number of

readings should be taken and averaged to best determine the accuracy and repea tability

for each tool.

4-1

Page 39

TORQUE CALIBRATION SYSTEM SETUP CHAPTER 4

Displaying Statistical Analysis

The SURETEST B ase Unit accumulates torque measurements in a data list. The list is

created with each AUTO or MANUAL data store entry. Statistical analysis is calculated

on the list, and if SET HIGH and SET LOW limits are established, draws a simple

histogram of the results. These features are very useful in statistical process control

(SPC) management. Statistical analysis can be previewed on the display or sent directly

to a printer/computer port. For additional information on setting up printer or PC ports,

refer to Chapter 3—Set Up and Programming in this manual.

Displaying Statistical Analysis

1. Press Data . Then Format .

Figure 4-2: Statistical Analysis Display

2. Repeatedly press Up or Down Cursor Key to scroll through the LCD display as shown:

Value: 0009

Mean: 07.559 in-lb

Min: 06.768 in-lb

Max: 08.206 in-lb

Range: 01.437 in-lb

SigmaN 00.526 in-lb

Sigma 00.558 in-lb

Cp: 0.3287

Cpk 0.2636

%Err 33.333%

-NoGo 1

+NoGo 2

3. Press Escape to return to measurements mode.

4-1

Page 40

TORQUE CALIBRATION SYSTEM SETUP CHAPTER 4

Printing Statistical Analysis

1. Press Data , then Press Format.

2. Press SEND to display the Print out menu.

Use Down key to select Send Statistics then press Enter to Print.

3. Press Escape to return to measurements mode.

SPC PRINT-OUT

_____________________

SPC listing

_____________________

PART NO.

_____________________

NAME

_____________________

STATISTICAL ANALYSIS

Time : 16/Nov/1998 14:23

** LIMIT DATA **

Set High: 254.85 in-lb

Set Low : 251.55 in-lb

0001 254.45 in-lb

0002 253.91 in-lb

H0003 254.89 in-lb

0004 252.89 in-lb

0005 253.42 in-lb

0006 253.31 in-lb

0007 252.40 in-lb

0008 252.49 in-lb

0009 252.61 in-lb

L0010 251.49 in-lb

4-1

Page 41

TORQUE CALIBRATION SYSTEM SETUP CHAPTER 4

** R E S U L T **

Data : 0010

Max : 254.89 in-lb

Min : 251.49 in-lb

Range : 3.4039 in-lb

Mean : 253.19 in-lb

Sig.n : 0.9755 in-lb

Sigma : 1.0283 in-lb

Cp : 0.5348

Cpk : 0.5317

%Err. : 20.000%

-NoGo : 0001

+NoGo : 0001

H I S T O G R A M

LSL :251.55 in-lb

USL :254.85 in-lb

DIV : 10

-NG0001:X

LSL --------------- A 0000:

B 0000:

C 0002:XX

D 0001:X

E 0001:X

F 0002:XX

G 0000:

H 0001:X

I 0001:X

J 0000:

USL ---------------+NG0001:X

Scale: X =01

A 251.55 in-lb<

B 251.88 in-lb<

C 252.20 in-lb<

D 252.53 in-lb<

E 252.86 in-lb<

F 253.20 in-lb<

G 253.53 in-lb<

H 253.85 in-lb<

I 254.19 in-lb<

J 254.51 in-lb<

254.85 in-lb

Figure 4-4: Sample Statistical Data Printout

4-1

Page 42

TORQUE CALIBRATION SYSTEM SETUP CHAPTER 4

Displaying or Downloading Data List

Torque measurements stored in the data list also include a date and time stamp . Fo r additional

information on setting up printer or PC ports, refer to Chapter 3—Set Up and Programming in this

manual.

Displaying Data List

1. Press DATA.

The display reads:

2. Torque Units of measure are displayed at top of the display with present memory

location/total memory locations to the right. Torque readings are to the left of the Time

and Date.

The selected reading is hightlighted.

3. Use Up and Down key to view the data list.

4. Press Escape to return to measurements mode.

Downloading Data List to Printer

1. Press DATA .

2. Press SEND .

The display reads:

Figure 4-5: Data Download Display.

3. To download the raw d a ta list, Select Send raw data then Press Enter.

4. To download the data list plus date-time stamp, press Down. To select

Send Data, Time/Date Then press Enter to print.

5. Press Escape to return to measurements mode.

4-1

Page 43

CALIBRATION CHAPTER 5

How to Use Analog Output (Rear Panel BNC Connector)

Analog Output on the SURETEST provides a real time voltage level that is

directly proportional to the torque applied to the transducer. It is useful for

direct driving equipment such as analog plotters and chart recorders, or

interfacing to a computer/controller with analog to digital (A/D) data acquisition

capability. Maximum output loading must be less than 5 mA.

The output varies between approximately +1.8 volts, full clockwise (CW) torque

applied and approximately -1.8 volts, full counter clockwise (CCW) torque

applied. Zero offset is within ±100 mv. Linearity is better than ±1% of

reading.

When used with the 4-in-1 transducer, zero output varies with the scan of the

four transducers. Select one of the four by applying at least 5% of its full range

torque to it. Press ENTER to return to scanning.

1. To program the SURETEST Base Unit, refer to Chapter 3—Set Up and

Programming. Use SET HIGH and SET LOW limit alert, data

STORE, display CLEAR, printer SEND and STATistical analysis

features.

2. Press Select Mode to select the TRACK mode.

3. Connect the recording or mo nitoring equipment to the ANALOG

OUTPUT port using a BNC coaxial connector.

4. With no torque applied, measure the ANALOG OUTPUT voltage and

adjust or program yo ur equipment for zero.

5. Apply full range torque to the transducer in the CW direction.

6. Measure the ANALOG OUTPUT voltage and adjust or program your

equipment to display the full range torque value.

7. Apply full range torque to the transducer in the CCW direction.

8. Measure the ANALOG OUTPUT voltage and adjust or program your

equipment to display the full range torque value.

CHAPTER 5

Calibration

The SURETEST Torque Calibration System is factory calibrated using

precision torque test arms, certified weights and laboratory grade

equipment. SURETEST series transducers must be p ositioned

horizontally, with torque applied within ±1 5 degrees of horizontal.

This chapter contains calibration instructions and information fo r the

SURETEST ystem.

5-42

Page 44

CALIBRATION CHAPTER 5

Annual calibration is recommended. Calibration by the user is

recorded in memory and voids factory certification. Contact your

authorized CDI sales representative for calibratio n and repair

services.

If extreme calibration precision is required , refer to Correction

Factors on Test Weights in this chapter.

Mounting Details

Single Transducer Mounting Detail for Calibration

Single transducer calibration requires the use of a reaction stand and

transducer calibration block.

As shown in Figure 5.1, the transducer is secured to the calibration

block with two quick release pins.

• Both pins must be installed for safety and stability of the mount.

• The white mark on the transducer is aligned in the up position.

Figure 5-1: Single Low Torque Transducer Mounting Detail

5-43

Page 45

CALIBRATION CHAPTER 5

Torque Under 250 ft lb

Mount the calibration block at the center of the stand with two 1/2-13 socket head cap

screws with test bars that are 10" or shorter. Install these screws using the supplied torque

wrench and 3/8-3/8 socket driver adapter. Use this configuration for up to 250 ft lb of

applied torque. A 1/2" to 3/8" reducer is required when mounting the 10" arm to

transducers having 3/8" drives.

Torque Over 250 ft lb

For torque calibration above 250 ft lb, the calibration block is moved to the left for CCW

loading and to the right for CW loading. The torque arm is always extended over the front

of the reaction bracket for both CW and CCW torque applications. In this configuration,

useful up to 2000 ft lb, the calibration block is secured to the stand using four 1/2-13

socket head cap screws, each torqued to 75 ft lb. For additional information refer to

Figure 5-2.

Figure 5-2: Single High Torque Transducer Mounting Detail

The 2000-12-02, 600 ft lb transducer, requires the 1-1/4" to 3/4" drive reducer, supplied, to couple to

the 40" test bar.

5-44

Page 46

CALIBRATION CHAPTER 5

WARNING

Always position the 40" arm over the front of the stand as shown. Never extend the test arm

behind the stand because the stand will tip over when we ights are applied.

The 40" test arm is coupled to the 2000-13-02, 1000 ft lb, and 2000-14-02, 2000 ft lb transducers

using a 1-1/4" drive adapter plate.

1. Remove the internal drive adapter plate and bottom plate from the transducer using the

torque wrench, ratchet head and 3/8-3/8 hex bit or 3/4" open end adapter supplied.

2. Remove separated adapter from calibration block.

3. Attach transducer to the calibration block so that red mark on transducer lines up with white dot in

left bottom corner on calibration block. Tighten six 1/2"-13 hex head bolts to 75 ft lb torque.

4. Attach the 1-1/4" drive adapter plate using six 1/2"x13 hex head bolts, each torqued to 75 ft lb

using the torque wrench, and 3/4” open end adapter, supplied.

5. After calibration, re-install the internal drive plate and bottom plate using appropriate 1/2"x13

screws, torquing them to 75 ft lb. Also re-install the separated adapter to the calibration block.

Appropriate hangers and weights are listed in the calibration check point table in this chapter.

Notice that the weight of the hanger is included in all measurements. The hanger must be removed

to set ZERO TARE on the Indicator.

4-in-1 Transducer Mounting Detail for Calibration

The 4-in-1 transducer mounts upright with integral transducers in the horizontal position. This

transducer may be mounted to a

• Wall using four 1/4" bolts torqued to 10 ft lb, or

• Sturdy table using a ri ght angle bracket. Refer to Figure 5-3.

Figure 5-3: 4-in-1 Transducer Mounting Detail

5-45

Page 47

CALIBRATION CHAPTER 5

The 4-in-1 transducer may also be mounted to the calibration stand, shown in Figure 5-2, using the

standoff fixture and bracket assembly. For this mounting configuration the two slide knobs must be

loosened and four 5/16-18 bolts attached to secure the 4-in-1 transducer to the bracket assembly.

Quick Check

WARNING

Always be alert to the potential for personal injury that may be caused by excessive

torque applications, careless handling of heavy weights, and out-of-balance or unsafe

weight distribution.

1. With the SURETEST ON, select TRACK mode, and select the UNITs of measure appropriate to

the transducer as specified in the calibration check point table in this chapter.

2. Install the transducer to be checked and allow a 5 minute warm up period to stabilize the electronic

circuits and transducer elements.

3. Transducers are mounted horizontally for calibration as instructed in Mounting Details in this

chapter. Mount the 4-in-1 transducer to a sturdy bench using the bracket provided. Mount single

transducers horizontally using the accessory stand and block. Attach the specified torque test bar,

wheel or butterfly, secured with its drive retention screw, and install the specified hanger for

clockwise (CW) torque application.

4. Apply and remove the full range torque for the transducer three times.

5. Remove the weights and hanger, but leave the arm attached, and press ZERO TARE.

6. At each of the check points specified for the transducer in the calibration check point

table (in this chapter), apply torque in the CW direction and verify the display readings are

within 0.25% of applied torque. If any reading is out of specification, proceed to Calibrating

SURETEST Torque Transduc e rs in this chapter.

7. Repeat Step s 3 through 6 in the co unter clockwise (CCW) direction.

When using the 2-1/2" or 5" test wheel, a small “S” hook is supplied to provide a positive zero bias

in the direction (CW or CCW) that the calibration is performed. Do not remove the “S” hook when

setting zero tare.

5-46

Page 48

CALIBRATION CHAPTER 5

Suggested Transducer Calibration Check Points, Bars, Hangers and Weights

(Sheet 1 of 2)

Part Bar Hanger Calibration Check Weights to Add Total

No. Ra nge Length Weight Points Points (n) = more than 1 Weight

2000-5-02

15-200 in oz 2.5" none 15.0 in oz 2 oz, 4 oz 6 oz

2.5" 1/2 lb 1 20.0 in oz 20.0 in oz none 1/2 lb

2.5" 1/2 lb 2 40.0 in oz 40.0 in oz 1/2 lb 1 lb

2.5" 1/2 lb 3 80.0 in oz 80.0 in oz 1/2 lb, 1 lb 2 lb

2.5" 1/2 lb 4 120.0 in oz 120.0 in oz 1/2 lb, (2) 1 lb 3 lb

2.5" 1/2 lb 5 200.0 in oz 200.0 in oz 1/2 lb, (2) 2 lb 5 lb

2000-6-02

4-50 in lb 5.0" 1/2 lb 4.0 in.lb 0.3 oz, 0.5 oz, 4 oz 0.8 lb

5.0" 1/2 lb 1 5.0 in lb 5.0 in lb 1/2 lb 1 lb

5.0" 1/2 lb 2 10.0 in lb 10.0 in lb 1/2 lb, 1 lb 2 lb

5.0" 1/2 lb 3 20.0 in lb 20.0 in lb 1/2 lb, 1 lb, 2 lb 4 lb

5.0" 1/2 lb 4 30.0 in lb 30.0 in lb 1/2 lb, 1 lb, (2) 2 lb 6 lb

5.0" 1/2 lb 5 50.0 in lb 50.0 in lb 1/2 lb, 1 lb, (4) 2 lb 10 lb

2000-65-02

15-150 in lb 5.0" 1/2 lb 1 15.0 in lb 15.0 in lb 1/2 lb, 2 lb 3 lb

5.0" 1/2 lb 2 30.0 in lb 30.0 in lb 1/2 lb, 1 lb, (2) 2 lb 6 lb

5.0" 1/2 lb 3 60.0 in lb 60.0 in lb 1/2 lb, 1 lb, (2) 5 lb 12 lb

5.0" 1/2 lb 4 90.0 in lb 90.0 in lb 1/2 lb, 2 lb, (3) 5 lb 18 lb

5.0" 1/2 lb 5 150.0 in lb 150.0 in lb 1/2 lb, (2) 2 lb, (5) 5 lb 30 lb

2000-7-02

30-400 in lb 10.0" 1/2 lb 30.0 in lb 1/2 lb, 2lb 3 lb

10.0" 1/2 lb 1 40.0 in lb 40.0 in lb 1/2 lb, 1 lb, 2 lb 4 lb

10.0" 1/2 lb 2 80.0 in lb 80.0 in lb 1/2 lb, 2 lb, 5 lb 8 lb

10.0" 1/2 lb 3 160.0 in lb 160.0 in lb 1/2 lb, (3) 5 lb 16 lb

10.0" 1/2 lb 4 240.0 in lb 240.0 in lb 1/2 lb, 1 lb, 2 lb, (4) 5 lb 24 lb

10.0" 1/2 lb 5 400.0 in lb 400.0 in lb 1/2 lb, 1 lb, (4) 2 lb, (6) 5 lb 40 lb

2000-8-02

80-1000 in lb 10.0" 7-1/2 lb 80.0 in lb 1/2 lb 8 lb

10.0" 7-1/2 lb 1 100.0 in lb 100.0 in lb 1/2 lb, 2 lb 10 lb

10.0" 7-1/2 lb 2 200.0 in lb 200.0 in lb 1/2 lb, 2 lb, (2)5 lb 20 lb

10.0" 7-1/2 lb 3 400.0 in lb 400.0 in lb 1/2 lb, 2 lb, (2)5 lb, (2)10 lb 40 lb

10.0" 7-1/2 lb 4 600.0 in lb 600.0 in lb 1/2 lb, 2 lb, (2)5 lb, (4)10 lb 60 lb

10.0" 7-1/2 lb 5 1000 in lb 1000 in lb 1/2 lb, 2 lb, (2)5 lb, (4)10 lb, (2)20 lb 100 lb

2000-10-02

10-125 ft lb 10.0" 7-1/2 lb 10 ft lb 1/2 lb, (2) 2 lb 12 lb

10.0" 15 lb 1 12.5 ft lb 12.5 ft lb none 15 lb

10.0" 15 lb 2 25.0 ft lb 25.0 ft lb (3) 5 lb 30 lb

10.0" 15 lb 3 50.0 ft lb 50.0 ft lb 5 lb, (2) 10 lb, 20 lb 60 lb

10.0" 15 lb 4 75.0 ft lb 75.0 ft lb (3) 5 lb, (2) 10 lb, (2) 20 lb 90 lb

10.0" 15 lb 5 125.0 ft lb 125.0 ft lb 5 lb, 10 lb, 20 lb, (2) 50 lb 150 lb

2000-11-02

20-250 ft lb 10.0" 15 lb 20.0 ft lb (2) 2 lb, 5 lb 24 lb

10.0" 15 lb 1 25.0 ft lb 25.0 ft lb 5 lb, 10 lb 30 lb

10.0" 15 lb 2 50.0 ft. lb 50.0 ft. lb 5 lb, (2) 20 lb 60 lb

10.0" 15 lb 3 100.0 ft. lb 100.0 ft. lb 5 lb, (2) 50 lb 120 lb

10.0" 15 lb 4 150.0 ft. lb 150.0 ft. lb 5 lb, (3) 20 lb, (2) 50 lb 180 lb

10.0" 15 lb 5 250.0 ft. lb 250.0 ft. lb 5 lb, (4) 20 lb, (4) 50 lb 300 lb

5-47

Page 49

CALIBRATION CHAPTER 5

Suggested Transducer Calibration Check Points, Bars, Hangers and Weights

(Sheet 2 of 2)

Part Bar Hanger Calibration Check Weights to Add Total

No. Ra nge Length Weight Points Points (n) = more than 1 Weight

2000-12-02

60-600 ft lb 40" 15 lb 1 60.0 ft lb 60.0 ft lb 1 lb, 2 lb 18 lb

40" 15 lb 2 120.0 ft lb 120.0 ft lb 1 lb, (2) 10 lb 36 lb

40" 15 lb 3 240.0 ft lb 240.0 ft lb 2 lb, 5 lb, 10 lb, (2) 20 lb 72 lb

40" 15 lb 4 360.0 ft lb 360.0 ft lb 1 lb, 2 lb, 10 lb, (4) 20 lb 108 lb

40" 15 lb 5 600.0 ft lb 600.0 ft lb 5 lb, (3) 20 lb, (2) 50 lb 180 lb

2000-13-02

100-1000 ft lb 40" 15 lb 1 100.0 ft lb 100.0 ft lb 5 lb, 10 lb 30 lb

40" 15 lb 2 200.0 ft lb 200.0 ft lb 5 lb, (2) 20 lb 60 lb

40" 15 lb 3 400.0 ft lb 400.0 ft lb 5 lb, (5) 20 lb 120 lb

40" 15 lb 4 600.0 ft lb 600.0 ft lb 5 lb, (2) 10 lb, (2) 20, (2) 50 lb 180 lb

40" 15 lb 5 1000.0 ft lb 1000.0 ft lb 5 lb, (4) 20 lb, (4) 50 lb 300 lb

2000-14-02

200-2000 ft lb 40" 50 lb 1 200.0 ft lb 200.0 ft lb (2) 5 lb 60 lb

40" 50 lb 2 400.0 ft lb 400.0 ft lb 20 lb, 50 lb 120 lb

40" 50 lb 3 800.0 ft lb 800.0 ft lb (2)5 lb, (4)20 lb, (2)50 lb 240 lb

40" 50 lb 4 1200.0 ft lb 1200.0 ft lb (2)5 lb, (5)20 lb (4)50 lb 360 lb

40" 50 lb 5 2000.0 ft lb 2000.0 ft lb (2)5 lb, (4)10 lb, (5)20 lb, (8)50 lb 600 lb

2000-400-02

4-50 in lb 5" 1/2 lb 4.0 in lb 0.3 oz, 0.5 oz, 4 oz 0.8 lb

(4-in-1) 5" 1/2 lb 1 5.0 in lb 5.0 in lb 1/2 lb 1 lb

5" 1/2 lb 2 10.0 in lb 10.0 in lb 1/2 lb, 1 lb 2 lb

5" 1/2 lb 3 20.0 in lb 20.0 in lb 1/2 lb, 1 lb, 2 lb 4 lb

5" 1/2 lb 4 30.0 in lb 30.0 in lb 1/2 lb, 1 lb, (2) 2 lb 6 lb

5" 1/2 lb 5 50.0 in lb 50.0 in lb 1/2 lb, 1 lb, (4) 2 lb 10 lb

30-400 in lb 10" 1/2 lb 30.0 in lb 1/2 lb, 2 lb 3 lb

10" 1/2 lb 1 40.0 in lb 40.0 in lb 1/2 lb, 1 lb, 2 lb 4 lb

10" 1/2 lb 2 80.0 in lb 80.0 in lb 1/2 lb, 1 lb, (3) 2 lb 8 lb

10" 1/2 lb 3 160.0 in lb 160.0 in lb 1/2 lb, (3) 5 lb 16 lb

10" 1/2 lb 4 240.0 in lb 240.0 in lb 1/2 lb,1 lb, 2 lb, (4) 5 lb 24 lb

10" 1/2 lb 5 400.0 in lb 400.0 in lb 1/2 lb,1 lb (4) 2 lb, (6) 5 lb 40 lb

80-1000 in lb 10" 7-1/2 lb 80.0 in lb 1/2 lb 8 lb

10" 7-1/2 lb 1 100.0 in lb 100.0 in lb 1/2 lb, 2 lb 10 lb

10" 7-1/2 lb 2 200.0 in lb 200.0 in lb 1/2 lb, 2 lb, (2)5 lb 20 lb

10" 7-1/2 lb 3 400.0 in lb 400.0 in lb 1/2 lb, 2 lb, (2)5 lb, (2)10 lb 40 lb

10" 7-1/2 lb 4 600.0 in lb 600.0 in lb 1/2 lb, 2 lb, (2)5 lb, (4)10 lb 60 lb

10" 7-1/2 lb 5 1000 in lb 1000 in lb 1/2 lb, 2 lb, (2)5 lb, (4)10 lb, (2)20 100 lb

20-250 ft lb 10" 15 lb 20.0 ft lb (2) 2 lb, 5 lb 24 lb

10" 15 lb 1 25.0 ft lb 25.0 ft lb 5 lb, 10 lb 30 lb

10" 15 lb 2 50.0 ft. lb 50.0 ft. lb 5 lb, (2) 20 lb 60 lb

10" 15 lb 3 100.0 ft. lb 100.0 ft. lb 5 lb, (2) 50 lb 120 lb

10" 15 lb 4 150.0 ft. lb 150.0 ft. lb 5 lb, (3) 20 lb, (2) 50 lb 180 lb

10" 15 lb 5 250.0 ft. lb 250.0 ft. lb 5 lb, (4) 20 lb, (4) 50 lb 300 lb

5-48

Page 50

CALIBRATION CHAPTER 5

Torque Calibrations

SURETEST New Transducer Calibration

Improper calibration can result in torque measurement errors. Follow these procedures precisely.

If an error is made in the procedure, turn the Suretest off and begin again. Users are responsible for

the results of their transducer calibration.

SURETEST series Torque transducers can only be calibrated using the SURETEST Base Unit.

Calibration data is calculated and then stored in the FLASH memory chip of the transducer by the

microcontroller in the Indicator.

WARNING

Always be alert to the potential for personal injury and equipment damage that may be

caused by excessive torque applications, careless handling of heavy weights, and out-ofbalance or unsafe weight distribution.

Equipment

• Precision test arms and certified calibration weights.

• Test stand.

Procedure

1. Turn the SURETEST ON. Refer to the calibration check point table in this chapter for the

transducer calibration check points, as well as the specified arms, hangers and weights.

2. Install the transducer being calibrated and allow a 5 minute warm up period to stabilize the

electronic circuits and transducer elements.

3. Mount the 4-in-1 transducer upright, drives horizontal, as shown in Figure 5-3, or mount

single transducers horizontally using the accessory stand and block as detailed in Figure 5-2.

Attach the specified torque arm, secured with the drive retention screw, and install the

specified hanger for clockwise (CW) torque application. Use the “S” hook on the 2-1/2" or 5" bars.

4. Apply and release full scale torque to the transducer three times in the CW direction, then remove

the weights and hanger. Leave the torque arm installed. Press Soft Key Setup to select Setup

Menu.

5. Use DOWN Cursor key to scroll down to Calibration Item. Press ‘ENTER’.

5-49

Page 51

CALIBRATION CHAPTER 5

6. Enter the following code into the display using the Cursor Keys: 5222

( Left / Right to select digit ; Up / Down = Increment / Decrement value ; ‘Enter’ to accept)

Calibration CW:

7. Select Calibrate CW. Press ‘ENTER’.

A warning is displayed.

Select ‘

8. Using the Up or Down Cursor keys, enter “

Using the Up or Down Cursor keys, enter “

9. Press ENTER. The disp lay reads:

Yes’. Press ‘Enter’ .

1” for a single transducer .

4” for the 4-in-1 transducer.

5-50

Page 52

CALIBRATION CHAPTER 5

Press F2 key and select the desired torque unit.

10. Using the Up and Down Cursor keys, enter the Full Scale value for the 4-in-1 transducer to calibrate.

Possible values are:

1 = 50 in-lb

2 = 400 in-lb

3 = 1000 in-lb

4 = 250 ft-lb

( For 4 in 1 Transd ucers display shows : CHECKING TRANSDUCER.)

Apply load until “ Full Scale [units] shows on display.

11. Press ENTER. To accept 50 in.lb Transducer.

Press any key to zerotare.

12. Press any key. The LCD displays:

13. Apply torque using the precision arm, hanger or certified weights listed as calibration point 1 in the

calibration check point table in this chapter. When the reading is stable, push and hold the Up or Down Cursor Keys

to get the correct torque value reading. Repeat the procedure for points 2,3,4, and 5 of the same table.

Apply 10% Torque = 5 in.lb

5-51

Page 53

CALIBRATION CHAPTER 5

13. P ress (Accept) to accept the calibration value (1

st

Cal point).

Apply 20% Torque = 10 in.lb

14. Press (Accept) to accept the calibration value (2

nd

Cal point) .

Apply 40% Torque = 20 in.lb

16. Press (Accept) to accept the calibration value (3

rd

Cal point) .

Apply 60% Torque = 30 in.lb

17. P r ess (Accept) to accept the calibration value (4

th

Cal point) .

Apply 100% Torque = 50 in.lb

18. P r ess (Accept) to accept the calibration value (5

th

Cal point) .

The display will show: Saving …. then show the Calibration table.

19. Remove all weights and the arm.

Press any key, go back to Select mode.

Calibration CCW:

(Go to step 7 then select CCW)

20. Select " Calibrate CCW” on the LCD display.

Apply and release full scale torque to the transducer three times in the CCW direction then

remove the weights and hanger, wait for about 15 seconds.

21. Repeat steps 12 through 19, applying al l torque in the counter clockwise (CCW) direction.

5-52

Page 54

CALIBRATION CHAPTER 5

22. All readings show minus sign (-). Press F1 twice to return to measurement mode.

SURETEST Indicator Calibration

WARNING:

Improper calibration can result in torque measurement errors. Follow these

procedures precisely. If an error is made in the procedure, turn the Suretest off and

begin again. Users are responsible for the results of their calibration.

Equipment

• Laboratory grade millivolt meter for calibration measurements capable of resolving 1/100

millivolts.

• Calibration fi xt ure as shown in Figure 5-2.

Calibration fixture Figure 5-2.

Procedure

1. With the power off, plug the calibration fixture into the TRANSDUCER INPUT

connector at the back of the SURETEST Base Unit.

2. Turn the power on. After initialization, the LCD display reads:

No Transducer Connected

3. Press Soft Key Setup to get to Setup Menu.

5-53

Page 55

CALIBRATION CHAPTER 5

Use DOWN Cursor key to scroll down to Calibration Item. Press ‘ENTER ’.

The display reads:

4. Enter the following code into the display using the Cursor Keys:

( Left / Right to select digit ; Up / Down = Increment / Decrement value ; ‘Enter’ to accept)

5111

Calibrate tester

Using a laboratory millivolt meter, measure the voltage across pin 2 (ground) and 19 (Gage

Excitation) of the calibration fixture.

The display reads:

Example:

3.0211 volts

Program the measured voltage into the SURETEST Base Unit using the Cursor Keys. (Use Up,

Down, Left and Right Cursor Keys to match the Suretest display to the millivolt-meter).

Then Press ‘Enter’ to accept.

5. Next, the display reads:

Short pins 5 and 6 together on the calibration fixture. Then hit Enter key.

6. Next, the display reads:

Remove the short between pins 5 and 6 of the calibration fixture.

5-54

Page 56

CALIBRATION CHAPTER 5

Using a laboratory millivolt meter, measur e the voltage across pins 5 and 6.

Example: 08.0622 mV

7. Program the measured voltage into the SURETEST Indicator as demonstrated in the example,

“+08.0622” by pushing and holding the Up or Down Cursor keys.

8. Press ENTER. The display momentarily reads:

SAVING...

9. Turn the power to OFF. Remove the calibration fixture.

5-55

Page 57

MANUAL LOADER CHAPTER 6

Gravitational Effects

Correction Factors on Test Weights

Weights used in torque calibration are affected by their acceleration due to:

• Altitude above or below sea level, and

• Latitude on earth between the equator and the poles.

Test bars are not affected by these conditions. The accuracy of torque wrenches

and testers does not change due to changes in geographic location. Only when

using weights must correction factors be considered. After an analysis is made

for a given location, it is often found that the correction factor is insignificant.

Two methods of correction are provided. They are:

• Correction factor for check point readings adjusts the calibration readings

without changing the ap plied weight.

• Correction factor for weights adjusts the weight applied without changing check

point readings. For additional information refer to Gravitational Charts in this

chapter.

Gravitational Charts

The charts in this section are taken from CRC Handbook of Chemistry and

Physics, 58th Edition. CRC Pr ess, Inc., 18901 Cranswood Parkway. Cleveland,

Ohio 44128.

Acceleration Due to Gravity for Sea Level at Various

Latitudes

Latitude, degrees Acceleration, cm/sec2 Latitude, degrees