Page 1

FOR YOUR PERMANENT FILE

OPERATION MANUAL

WRENCH MODEL NUMBER:

WRENCH SERIAL NUMBER:

For Warranty Claims, Contact CDI Torque Products

at (626) 965-0668.

LIMITED WARRANTY

The CDI Computorq II Electronic Torque Wrench

is backed by a one year warranty. This warranty

covers manufacturer defects and workmanship.

The warranty excludes misuse, abuse and normal

wear and tear. Exclusion is not allowed in some

states and may not apply. This warranty gives

you specific legal rights, and you may have other

rights, which vary from state to state.

cOMPUTORq II

TM

ELEcTRONIc

TORqUE WRENcH

IMPORTANT ENVIRONMENTAL NOTES:

1. This equipment may contain hazardous materials which can be

harmful to the environment.

2. Do not dispose of this equipment as municipal waste. Return it

to the distributor or a designated collection center.

Thank you for caring about our environment!

19220 SAN JOSE AVENUE • CITY OF INDUSTRY, CA 91748 • USA

(626) 965-0668

Find other ne torque products at WWW.CDITORQUE.COM

Form OM-C-CDI

Made in USA with US and Global Components

6/2010 Rev. C

Page 2

SAFETY MESSAGES

SAFETY MESSAGES

WARNING - Risk of ying particles

Over-torquing can cause breakage. Force

against flex stops on flex head can cause

head breakage. An out of calibration angle

wrench can cause part or tool breakage.

Broken hand tools, sockets or accessories

can cause injury. Excess force can cause crow

foot or flare nut wrench slippage.

READ THIS MANUAL COMPLETELY BEFORE

USING THE CDI COMPUTORQ II WRENCH

• To insure accuracy, work must not move in

angle mode.

• For personal safety and to avoid wrench

damage, follow good professional tool and

fastener installation practices.

• Periodic recalibration is necessary to

maintain tool accuracy.

USERS AND BYSTANDERS SHOULD ALWAYS

WEAR EYE PROTECTION

• Be sure all components, including

adapters, extensions, drivers and sockets

are rated to match or exceed the torque

being applied with tool.

• Observe all equipment, system and

manufacturer’s warnings, cautions and

procedures when using this wrench.

• Always use the correct size socket for the

fastener being torqued.

• Do not use damaged sockets, showing

signs of wear or cracks.

• Always replace damaged fasteners before

applying torque.

• Never use extensions, such as a pipe, on

the handle of the wrench.

• Always make sure the ratchet Forward/

Reverse Switch is fully engaged in the

correct position.

• Always verify that the wrench capacity

matches or exceeds each application before

proceeding.

• Always verify the calibration of the wrench

if you know or suspect its capacity has been

exceeded.

• Never force the head of ex head drives

against stops.

• Always pull - do not push - on the wrench

handle and adjust your stance to prevent a

possible fall while applying torque.

WARNING - Electrical Shock Hazard

• Electrical shock can cause injury.

• Plastic handle is not insulated.

• Do not use on live electrical circuits.

MAINTENANcE / SERVIcE

1. IMPORTANT - Service, repair and calibration are

to be performed by CDI Torque Products only.

Calibration by the user is recorded in the wrench

and voids factory certification.

2. The torque wrench’s internal mechanism is

permanently lubricated during assembly. Do not

attempt to lubricate the internal mechanism.

WARNING - To avoid damaging Computor II

Wrench

• Never operate wrench when powered OFF.

Always power wrench ON prior to applying

torque.

• Do not press ON key while torque is being

applied.

• Never use this wrench to loosen fasteners.

3. To safely clean the torque wrench, wipe with a damp

cloth. NEVER use solvents, thinners, or engine

cleaners of any kind. NEVER immerse the torque

wrench in liquids of any kind.

4. Store torque wrench in protective tube at its lowest

torque setting. Do not force handle below lowest

setting.

Page 3

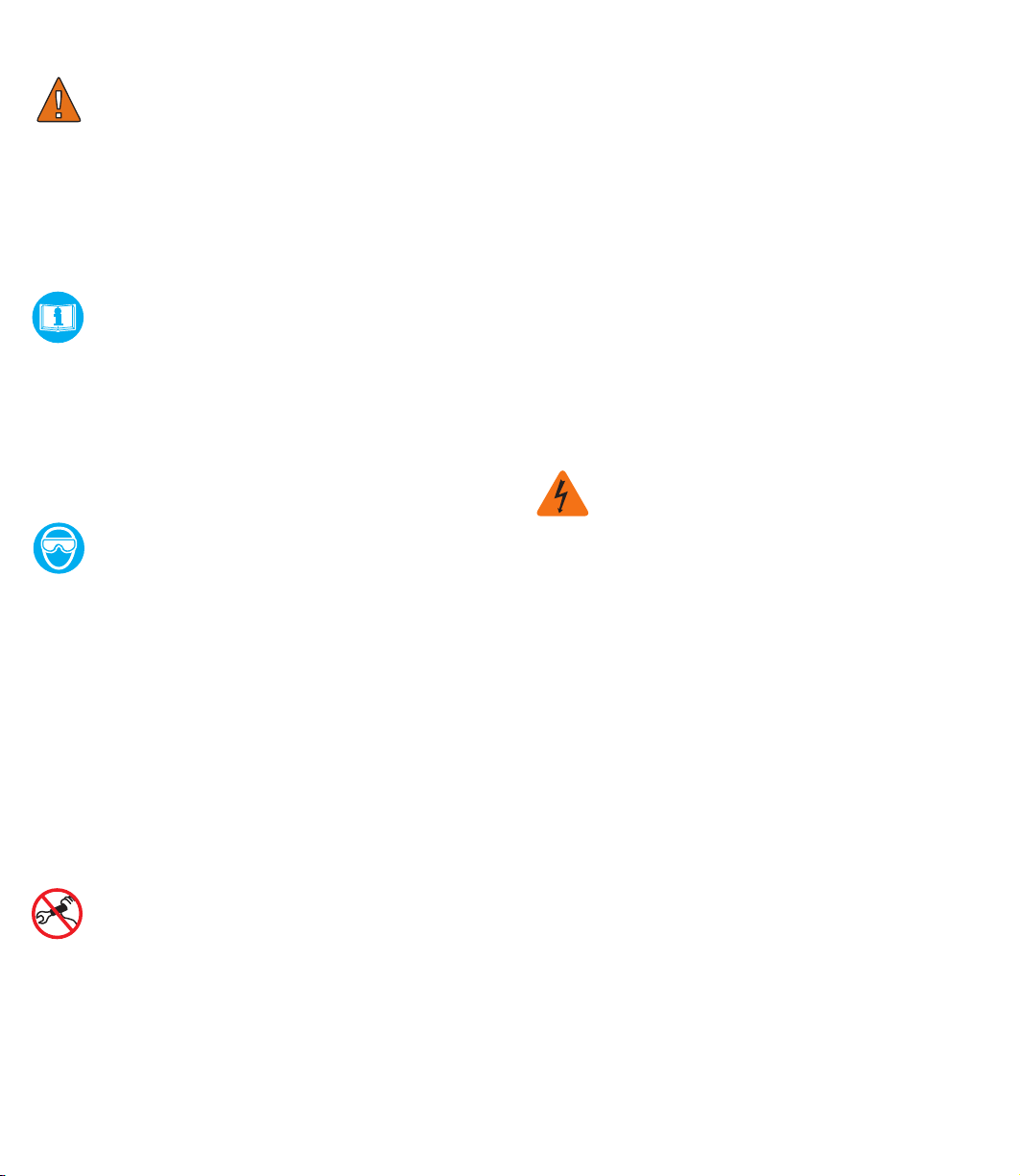

1

CLEAR

ZERO

dNm cmkg in-oz in-lb ft-lb

LO BAT

TRACK

PEAK

RECALL SETUP

AUTO POWER OFF

STORE

SEND

2

3 4

COMPUTORQ II

OVER

o.o. o.o

000

000

1

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

V

kEY PAd FUNcTIONS

000.0

000.0

171.5

000.0

171.5

000.0

171.5

000.0

171.5

ANALOG BAR GRAPH

A

SUPER TWIST LIQUID CRYSTAL DISPLAY

B

7 TORQUE UNITS (Ft.Lb., In.Lb., In.Oz., Nm, dNm,

C

MKG, CmKG

GREEN “GO” LIMIT LED

D

POWER ON/OFF

E

CLEAR LCD DISPLAY

F

ZERO TARE

G

ENTER (ACCEPT INFORMATION)

H

RECALL TORQUE DATA STORED IN MEMORY

I

OVER TORQUE “WARNING”

J

SPECIFIC TORQUE NUMBER IN MEMORY BEING

K

RECALLED AND SHOWN ON LCD

NUMBER OF TORQUE VALUES IN MEMORY

L

LOW BATTERY INDICATION

M

TRACK MODE

N

PEAK HOLD MODE

O

RED “OVER TORQUE” LIMIT LED

P

SCROLL UP (INCREASE VALUE DURING SET-UP)

Q

STORE DATA TO WRENCH

R

SEND DATA TO COMPUTER/DATA LOGGER/

S

PRINTER

SHIFT TO NEXT FLASHING DIGIT (DURING SET-UP)

T

SET-UP PARAMETERS

U

(TOLERANCE LIMIT/TORQUE UNIT)

AUDIO BUZZER

V

OPERATING INSTRUcTIONS

Please Note: There is an “off-on” slide switch located on

the right side of the wrench The wrench is shipped from

the factoiy with the switch in the “off” position. Before

use, slide the switch up or “on” Place the switch in the

“off” position only if the wrench is to be stored or not

used for a period of time. Otherwise, leave the switch in

the “on” position.

ELECTRONIC WRENCH SETUP

• TO TURN WRENCH “ON”

Press Button #1 (on/off).

Slide battery selector switch “Up” (on) or press Button

#1 (on/off) if slide switch is already in

the “Up” position.

The red and green lights will flash.

Zeros will flash and then be displayed on

the LCD along with the unit of torque measure.

The wrench is ready to use.

NOTE: If button #1 is pressed and held when first

turning the wrench “on”, the torque range capacity

and current software version of program will be

displayed. When first turning the wrench

on (sliding the switch “up”), the LCD will

ash “data good” then ash all zeros.

• TO CHANGE MODE OF OPERATION: “TRACK” OR

“PEAK”

1. Press Button #4 (set-up) one time.

Either “Track” or “Peak” will be ashing.

2. To change the mode, press Button #2 (store/send).

Continued pressing of Button #2 (store/send) will

toggle between “Track” and “Peak”

3. Press Button #3 (recall) to accept the

desired “ashing” mode change into

wrench memory.

• TO CHANGE UNIT OF TORQUE MEASURE: In.lb., In.oz.,

NM, dNM, MKG, CmKG, ft.lb.

1. Press Button #4 (set-up) two times.

The unit of measure will flash on the display.

2. To change the unit of measure, press

Button #2 (store/send). Continue

pressing Button #2 (store/send) until

the unit of measure desired is blinking

on the LCD.

3. Press Button #3 (recall) to accept this change into the

wrench memory.

Page 4

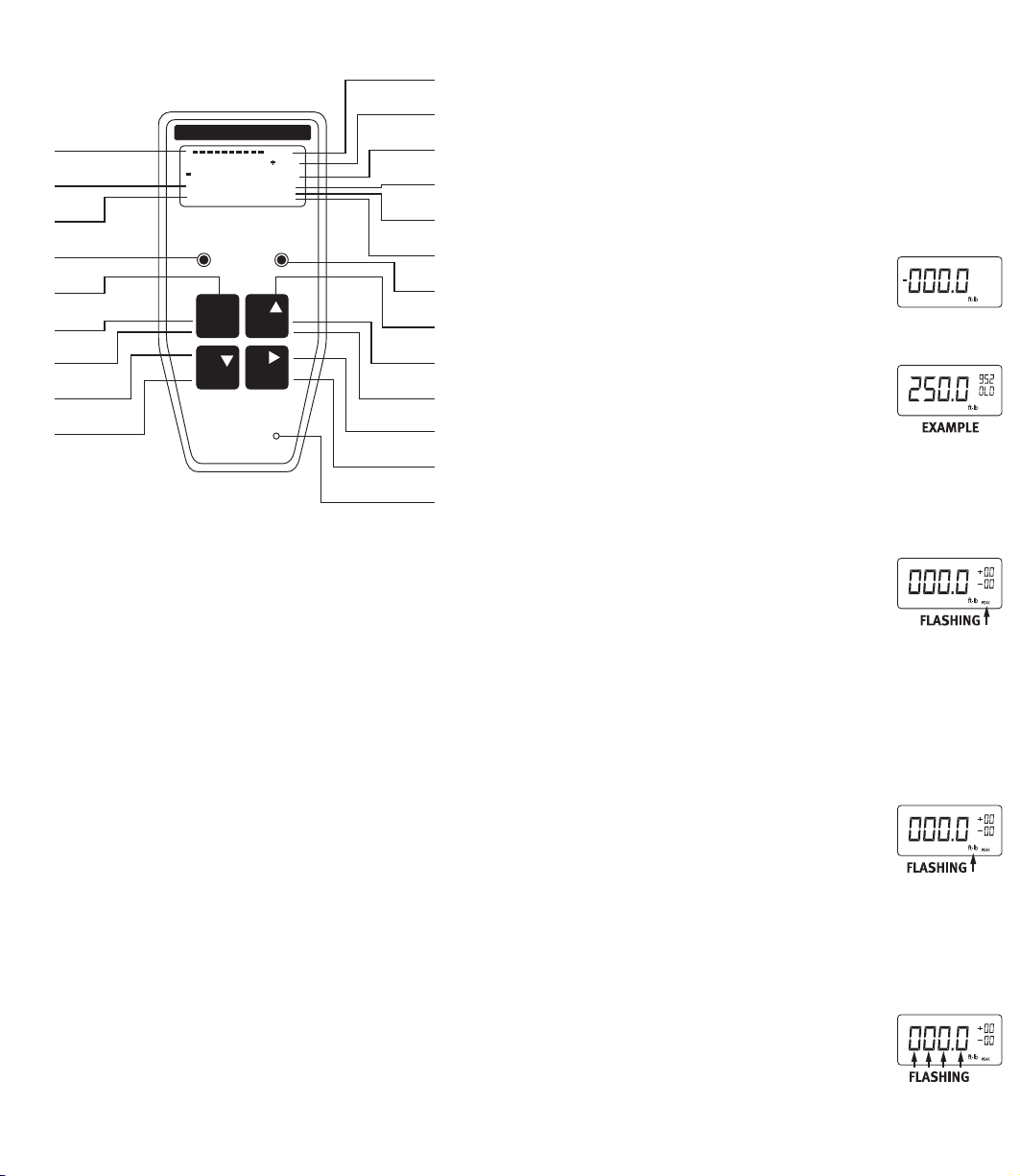

OPERATING INSTRUcTIONS

000.0

171.5

000.0

171.5

000.0

171.5

171.5

• TO SET A TARGET TORQUE VALUE:

1. Press Button #4 (set-up) three times.

The rst zero (0) on the digital display will blink.

2. To set a nominal target value into wrench memory,

press Button #2 (store/send). As this button is

repeatedly pressed, numbers zero through nine (0-9)

will be displayed.

3. When the correct number is displayed on the first

digit, press Button #4 (setup). This will “hold” that

number and cause the second digit to blink.

4. Again, press button #2 (store/send) until the value

desired is displayed (0-9).

5. Press Button #4 (set-up) to “hold” this value and

cause the third digit to blink.

6. Continue the same steps above to set the values for

the third and fourth digits.

7. After pressing Button #4 (set-up) on the last digit, the

decimal point will be blinking. This “point” can be

placed in three different locations by pressing Button

#2 (store/send). Press Button #4 (set-up) when the

decimal point is in the desired location.

• TO SET PERCENTAGES OF TOLERANCES:

1. Press Button #4 (set up), until the rst

digit of two in the upper right corner is

blinking.

2. This will be the rst of two digits in the (+) maximum

tolerance percentage. Again, as before, press Button

#2 (store/send) until the rst digit is set at the

FlASHING desired value. Press Button #4 (set-up)

to accept this value and move to the next blinking

number.

3. Repeat the above procedure for the

second digit. When the desired digit is

displayed, press Button #4 (set-up). The

maximum tolerance is now entered.

4. The rst digit of the (-) minimum tolerance should

be ashing. Press Button #2 (store/send) to scroll

through numbers (0-9). Press Button #4 (set-up) to

accept this value and move to the second flashing

digit. Press Button #2 (store/send) to scroll through

numbers (0-9) until the second desired number is

displayed.

NOTE: Review the entire LCD at this time.

If everything is as desired, press Button #3

OPERATING INSTRUcTIONS

(recall) to accept all parameters into wrench memory.

These parameters will remain in memory until they are

changed.

EXAMPLE SET-UP

To set a 250 in.lb. Computorq II to a

nominal “target” value of 100 in.lbs. +/-2%

the following steps would be necessary:

1. Press Button #1 to turn the wrench “on”

( check to see if “peak” is active

2. Press Button #4 twice and verify if the active torque

units are in in. lbs.

3. Press Button #4 one more time to activate the rst

blinking “0”.

4. Press Button #2 until the number “1” is displayed.

5. Press Button #4 ve times to scroll through the three

remaining zeros and the decimal point placement.

6. Press Button # 4 one more time to scroll through

the rst zero of the (+) maximum

percentage. The second digit should be

blinking.

7. Press Button #2 until the number “2” is

displayed on the second digit.

8. Press Button #4 twice to the second digit of the (-)

minimum percentage.

9. Press Button #2 until the number ‘2” is displayed on

the second digit.

* Review Entire LCD at this time.

10. Press Button #3 to place all above parameters into

memory of wrench.

PLEASE NOTE: The wrench will sound an audible signal

and a green light will flash when the

applied torque to the wrench reaches the

lower acceptable torque limit of 98 in.lbs.

(100 in.lbs. - 2%). The green light and

audible tone will continue until the torque

value reaches the maximum preset limit of 102 in.lbs.

(100 in.lbs. RED LIGHT + 2%). The red & green lights

will ash and intermittent tones will sound if the &

TONE torque value exceeds the maximum

percentage allowed. Loud audible tones

and flashing lights will continue even

when an over torque (of the range of the

wrench) condition occurs. The display

will then show “OVER” in small letters in the extreme

Page 5

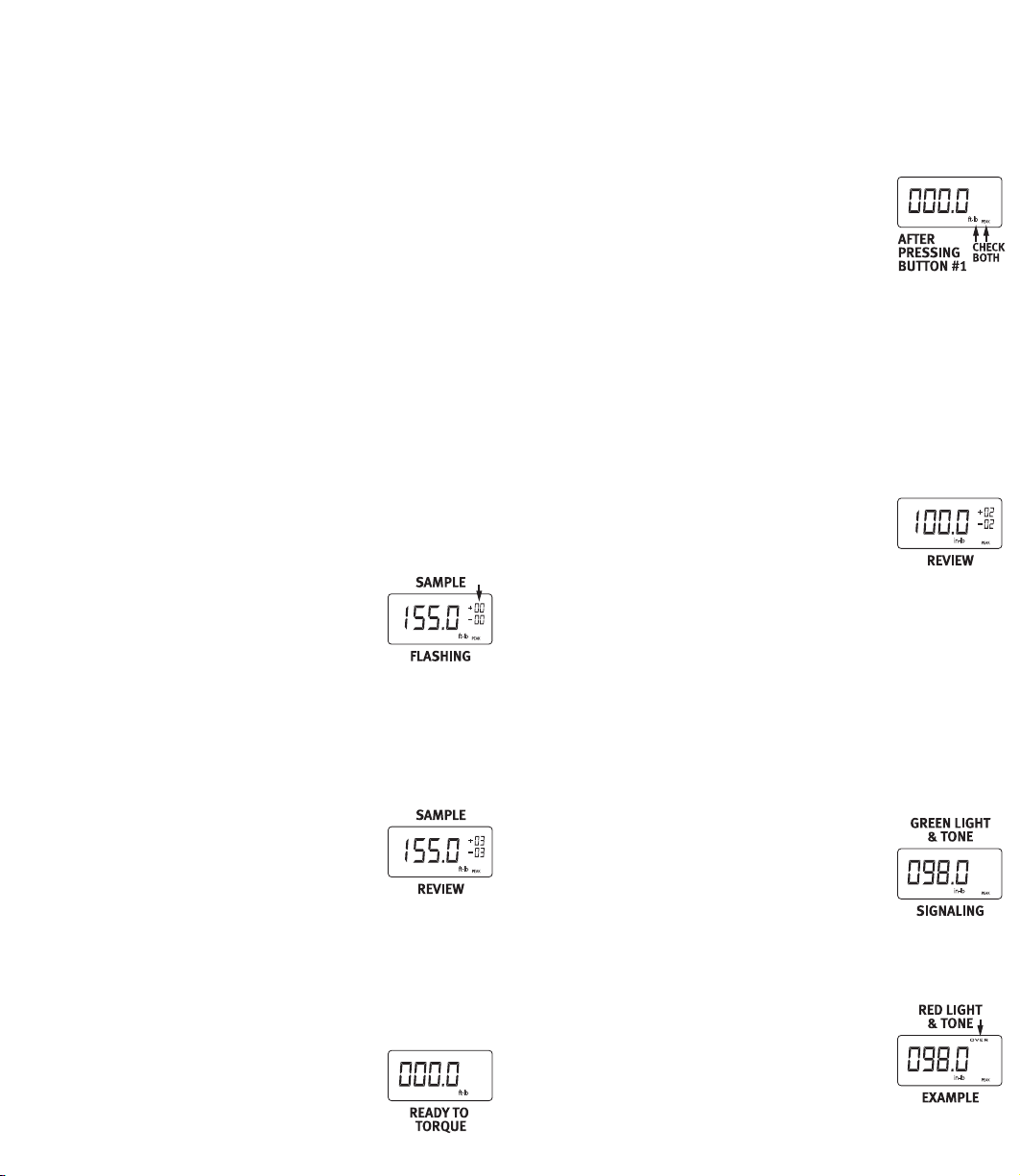

OPERATING INSTRUcTIONS

000.0

000.0

171.5

000.0

171.5

000.0

171.5

000.0

171.5

000.0

171.5

000.0

171.5

000.0

171.5

171.5

EXAMPLE upper right of the display. After

a over torque of 15% of the range of the

wrench, ‘OvEr” will be displayed on the

LCD. Damage may have already occurred.

ELECTRONIC WRENCH FUNCTIONS

• TO USE IN “TRACK” MODE OF OPERATION:

1. Turn wrench “on”. Check to see if wrench is in

“TRACK” mode

2. Place wrench on a fastener and apply a

force. The value on the LCD will rise with

the applied torque and then decrease when this force

is removed. Thus, the values will “track-up” and then

“track down”.

• TO USE IN “PEAK” MODE OF OPERATION:

1. Turn wrench “on”.

2. Refer to section “TO CHANGE MODE OF

OPERATION” if wrench is not in “PEAK”

mode.

3. Apply a force with the wrench, the

highest torque value will be held on the LCD.

• TO USE MEMORY FEATURE IN PEAK MODE OF

OPERATION:

1. Set up wrench to “Peak” mode of operation.

2. Load the wrench to correct applied torque desired.

Release the force applied. The maximum torque

(peak) will remain on the display.

NOTE: YOU NOW HAVE TWO OPTIONS

A. Press Button #2 (store/send) to store

this torque value into memory. The

display will clear to all zeros (000.0). The

number “001” will appear in the lower

right of the display. Repeat step 2 above

and then press Button #2 (store/send)

until the desired number of applied

torque values is reached.

B. Press Button #1 (clear/zero) and LCD will

clear...wrench is ready for new torque operation. No

value is stored in memory.

• TO RECALL DATA STORED IN MEMORY TO THE LCD:

1. Press Button #3 (recall). The torque values placed

in memory will appear on the digital display in the

OPERATING INSTRUcTIONS

reverse order that they were placed in

memory. Example: Last torque value

taken and placed into memory is first to

be recalled. The sequence number will

be displayed in the upper right of the

AFTER display (just above the total number of stored

torque values in memory).

2. Continued pressing of Button #3 (recall)

will scroll through all torque values in

memory.

• TO DOWNLOAD THE STORED DATA TO A

PRINTER OR COMPUTER:

Connect proper cable from printer, datalogger or

computer to wrench.

1. Press Button #3 (recall) at any time

during the torque sequence (see

above).

2. Then press Button #2 (store/send). The display will

show the values are being MEMORY

sent by indicating “SEnd” on the LCD

and will signal when all the data has

finished being transmitted by a audible

tone and the LCD display returning to the last torque

value left on the display.

3. If, after a single torque value has been taken, and you

wish to “send” this value to a peripheral, press and

hold Button #2 (store/send) for approx. 2 seconds.

A tone indicates completion of this function. If this

torque value also needs to be placed into memory,

press button #2 (store/send) once.

PLEASE NOTE: When downloading recalled memory to a

printer or computer, the data will be sent

and printed in the order torque values

were taken. Example: First value taken will

be first value printed.

* Please refer “INTERFACE CABLES”

section for proper cabling and “CALIBRATION

PROCEDURES” section for factory set parameters.

** If “Err” is displayed on the LCD during transmission

of torque data, the battery may need to be replaced.

Refer to the “BATTERIES” section for battery

replacement diagrams.

Page 6

OPERATING INSTRUcTIONS

ft-lb

PEAK

000.0

AFTER

PRESSING

BUTTON #1 TWICE

OPERATING INSTRUcTIONS

OPTIONS

A. After data is sent, or TO CLEAR MEMORY

ANYTIME, during this process press

Button #1 (clear/zero) TWICE in rapid

succession. An audible tone is sounded

indicating all stored data in memory will

be erased. The display will read “CLr”

and then all zeros.

PLEASE NOTE: Data being sent to a

printer or computer may be terminated

at any time by pressing Button # 2 (store

/ send).

B. To continue to add more values to the

existing memory, press Button #4

(set-up) and take more torque readings.

PLEASE NOTE:

A. To prevent stored torque values in memory from

being cleared erroneously, an operator must first

have recalled torque values on the LCD by pressing

Button #3 (recall) and then pressing Button #1

(clear/zero) twice.

B. While applying a load to the fastener, in “TRACK’

mode, care must be used by the operator to assure

that the applied torque is “held somewhat steady”

while Button #2 (store/send) is pressed. Computorq

II’s microprocessor will capture and store the values

on the display the instant Button #2 (store/send) is

pressed.

• TO TURN WRENCH “OFF”:

Press and hold Button #1 (clear / zero) for

approximately 2 seconds. An audible tone will signal

and the display will turn blank. If the wrench is to be

stored or not used for prolonged periods of time, slide

the ‘off-on” switch to the “off” position to conserve

battery life.

If there is a TARGET torque value with percentage

tolerances, the ten segment bar graph will show full

scale AT THE TARGET VALUE - not the wrenches’ full

scale.

EXAMPLE: 250 Ft.Lb. Wrench

set at 100 Ft.Lb. - Torquing in

Counter-Clockwise Direction

PLEASE NOTE:

A. The next time the wrench is turned “ON”, the same

parameters as last used will still be active until

changed.

B. If “Err” is displayed on the LCD (ashes at any time)

the wrench should be turned off and then on with NO

LOAD on the wrench. If “Err” continually appears on

the LCD after performing the above procedure, return

the wrench to the factory for evaluation.

IMPORTANT NOTICE: Please read all safety and

operational cautions and warnings contained in this

manual before using your electronic torque wrench

found at the beginning of this manual.

COMPUTORQ II is, in effect, a transducer. Torque

transducers are sensitive measuring instruments.

“Over Torquing” past the useable torque range of the

wrench may result in permanent damage. Always load

the wrench slowly and do not exceed the useable range

in any application.

• BAR GRAPH FUNCTION

A ten segment bar graph on the top of the LCD is a

reference for the operator of the relative position of

applied torque to the full range of the wrench. This is

whether in track or peak modes.

EXAMPLE: 250 Ft.Lb. Wrench -

Torquing in Clockwise Direction

Page 7

RS-232 cOMMUNIcATION

1

CLEAR

ZERO

STORE

SEND

2

RECALL SETUP

3 4

STORE

SEND

2

RECALL

SETUP

3

4

TRACK

ooo.o

o

TRACK

2.ooo

TRACK

ooo.o

2

2”

OFF ON

00 0 1

LINE FEED

CARRIAGE

RETURN

UNITS

BLANK

VALUE

SIGN

BLANK

SEQUENCE #

12 3 , 45 IN - LB

CR LF

+

INSTRUCTIONS LEGEND

LIGHT ON

BUZZER SOUNDS

INPUTTING THE LENGTH OF THE ADAPTOR

ACCEPTED

GO BACK TO MAIN MENU

CENTER OF SQUARE DRIVE TO

CENTER OF THE OPEN END.

BOX END OR FLARE NUT DRIVES

PRESS

PRESS + HOLD

UNITL

BUZZER SOUNDS

STORE

SEND

2

RECALL

SETUP

3

4

TRACK

ooo.o

o

TRACK

2.ooo

TRACK

ooo.o

2

2”

INSTRUCTIONS LEGEND

LIGHT ON

BUZZER SOUNDS

INPUTTING THE LENGTH OF THE ADAPTOR

ACCEPTED

GO BACK TO MAIN MENU

CENTER OF SQUARE DRIVE TO

CENTER OF THE OPEN END.

BOX END OR FLARE NUT DRIVES

PRESS

PRESS + HOLD

UNITL

BUZZER SOUNDS

1

cOMPUTORq IITM MOdELS

The Format Used for

Computorq II RS-232 Communication

ELECTRONIC WRENCH

50 & 250 In.Lb. Models • 50 Ft.Lb. Model

ELECTRONIC WRENCH

250, 600 & 1000 Ft.Lb. Models

Page 8

cALIbRATION PROcEdURES

1

o.o.o.o

cALIbRATION PROcEdURES

Due to the accuracy and the sensitivity of the

Computorq II electronic torque wrench, a mechanical

torque loader with a torque display (preferably

electronic) must be used for input torque. The loader is

necessary because the human hand cannot “push” or

“pull” on the wrench with enough stability for the torque

input to be an accurate value.

The calibration procedure must be done in both

directions (CW and CCW).

Please consider the following calibration precautions:

• Make sure the Computorq II is level (or horizontal

while in the loader. If not, side loading may affect the

true readings.

• Make sure the “reaction point” is in the center of the

grip or handle.

• Make sure the least amount of sockets and adapters

are used when mating to the calibration equipment.

• Check all sockets and adapters for “excessive play.”

This could result in false loads being applied and

shown on the display.

• Make sure the wrench is in the proper torque

engineering units prior to calibrating.

• Make sure the wrench mode of operation is in

“TRACK.” Refer to the “OPERATING INSTRUCTIONS”

section for proper setup.

* Accuracy

+/-1% From 20-100% of scale.

+/-1%, plus 5 increments, from 10-20% of scale.

Wrenches may be set up in 7 different torque

engineering units: ft. lb., in. lb., in. oz., nm, dNm,

mkg or cmkg. Refer to “TO CHANGE UNIT OF TORQUE

MEASURE” in the “OPERATING PROCDURES”.

Factory set parameters: Transmission data rate is 1200

baud; Communication protocol is RS 232 ASCII, 8

data bit, no parity. Other options are available, please

consult factory for additional information.

Please Note: Computorq II has an exclusive feature

— when using extensions or adapters, Computorq II’s

electronics can automatically compensate for these

extra lengths. Refer to the “PROCEDURES FOR USING

ADAPTERS” section.

COMPUTORQ II shown being Calibrated

on a Mechanical Loader.

SPECIFICATIONS

Product Torque Length Wt.

Code Drive Range Incr. In. Lbs.

501CI-II 1/4” 5-50 in.lb. .01 in.lb. 13.5 1.5

2502CI-II 3⁄8” 25-250 in.lb. .1 in.lb. 14.9 2.0

502CF-II 3⁄8” 5-50 ft.lbs. .01 in.lb. 14.9 2.0

2503CF-II 1⁄2” 25-250 ft. lbs. .1 in.lb. 21.5 3.2

6004CF-II 3⁄4” 60-600 ft.lbs. .2 in.lb. 46.5 9.5

10005CF-II 1” 100-1000 ft.lb. .1 ft.lb. 74.0 19.0

Page 9

cALIbRATE cW dIREcTION cALIbRATE ccW dIREcTION

RECALL SETU P

3 4

STORE

SEND

2

RECALL SETU P

3 4

STORE

SEND

2

RECALL SETU P

3 4

STORE

SEND

2

RECALL SETU P

3 4

STORE

SEND

2

RECALL SETU P

3 4

RECALL SETU P

3 4

RECALL SETU P

3 4

STORE

SEND

2

RECALL SETU P

3 4

STORE

SEND

2

RECALL SETU P

3 4

STORE

SEND

2

RECALL SETU P

3 4

STORE

SEND

2

RECALL SETU P

3 4

RECALL SETU P

3 4

1

CLEAR

ZERO

STORE

SEND

2

RECALL SET UP

3 4

RECALL SET UP

3 4

RECALL SET UP

3 4

1

CLEAR

ZERO

STORE

SEND

2

RECALL SET UP

3 4

RECALL SET UP

3 4

RECALL SET UP

3 4

FIRST: Exercise the wrench to full scale 3 times in the CW direction

before calibration sequence begins.

LCD DISPLAY LCD DISPLAY

HOLD KEY FOR 3 SECONDS (BUZZER ON) FIRST DIGIT WILL BLINK

ENTER “CALIBRATE CW” CODE 5251 BY:

A/- PRESS KEY SCROLL UP TO (5) PRESS KEY SHIFT NEXT DIGIT

B/- PRESS KEY SCROLL UP TO (2) PRESS KEY SHIFT NEXT DIGIT

C/- PRESS KEY SCROLL UP TO (5) PRESS KEY SHIFT NEXT DIGIT

D/- PRESS KEY SCROLL UP TO (1) PRESS KEY SHIFT NEXT DIGIT

E/- PRESS KEY ACCEPTED CODE 5251

BUZZER WILL TURN ON AND

LCD WILL DISPLAY

FULLY UNLOAD WRENCH AND IN

CW DIRECTION UNTIL “LOAD” ON

LCD DISAPPEARS

AND DISPLAY SHOWS (“0--0” / “-00-”)

FULLY UNLOAD WRENCH AND

WAIT 10 SECONDS, THEN PRESS KEY

LCD WILL DISPLAY “ ”

KEEP AN EYE ON THE ELECTRONIC DISPLAY

LOAD TO FIRST VALUE

PRESS KEY TO ACCEPT

THE FIRST CALIBRATION POINT,

SET BY MANUFACTURER

FIRST: Exercise the wrench to full scale 3 times in the CCW direction

before calibration sequence begins.

HOLD KEY FOR 3 SECONDS (BUZZER ON) FIRST DIGIT WILL BLINK

ENTER “CALIBRATE CCW” CODE 5252 BY:

A/- PRESS KEY SCROLL UP TO (5) PRESS KEY SHIFT NEXT DIGIT

B/- PRESS KEY SCROLL UP TO (2) PRESS KEY SHIFT NEXT DIGIT

C/- PRESS KEY SCROLL UP TO (5) PRESS KEY SHIFT NEXT DIGIT

D/- PRESS KEY SCROLL UP TO (2) PRESS KEY SHIFT NEXT DIGIT

E/- PRESS KEY ACCEPTED CODE 5252

BUZZER WILL TURN ON AND

LCD WILL DISPLAY

FULLY UNLOAD WRENCH AND IN

CW DIRECTION UNTIL “LOAD” ON

LCD DISAPPEARS

AND DISPLAY SHOWS (“0--0” / “-00-”)

FULLY UNLOAD WRENCH AND

WAIT 10 SECONDS, THEN PRESS KEY

LCD WILL DISPLAY “ ”

KEEP AN EYE ON THE ELECTRONIC DISPLAY

LOAD TO FIRST VALUE

PRESS KEY TO ACCEPT

THE FIRST CALIBRATION POINT,

SET BY MANUFACTURER

BUZZER WILL TURN OFF AND ON 10 TIMES

LCD DISPLAY WILL COUNT DOWN

FROM 10 TO 0, AND DISPLAY “ ”

NOTE: DURING PROCESS, HOLD THE

WRENCH VERY STILL UNTIL “ ” IS DISPLAYED

LCD WILL DISPLAY “ ”

KEEP AN EYE ON THE ELECTRONIC DISPLAY

LOAD TO SECOND VALUE

PRESS KEY TO ACCEPT

THE SECOND CALIBRATION POINT,

SET BY MANUFACTURER

BUZZER WILL TURN OFF AND ON 10 TIMES

LCD DISPLAY WILL COUNT DOWN

FROM 10 TO 0, AND DISPLAY “ ”

NOTE: DURING PROCESS, HOLD THE

WRENCH VERY STILL UNTIL “ ”

IS DISPLAYED

NOTE: Follow the above directions as closely as possible. Please

be careful to “LOAD” the wrench ONLY during the indicated times -

overtorquing past the range of the wrench is very possible and could

cause damage without audio/visual indicators being active during

calibration.

NOTE: When “OK” is displayed after the second calibration check

point has been checked/adjusted, the LCD should then show the

torque presently being applied.

BUZZER WILL TURN OFF AND ON 10 TIMES

LCD DISPLAY WILL COUNT DOWN

FROM 10 TO 0, AND DISPLAY “ ”

NOTE: DURING PROCESS, HOLD THE

WRENCH VERY STILL UNTIL “ ” IS DISPLAYED

LCD WILL DISPLAY “ ”

KEEP AN EYE ON THE ELECTRONIC DISPLAY

LOAD TO SECOND VALUE

PRESS KEY TO ACCEPT

THE SECOND CALIBRATION POINT,

SET BY MANUFACTURER

BUZZER WILL TURN OFF AND ON 10 TIMES

LCD DISPLAY WILL COUNT DOWN

FROM 10 TO 0, AND DISPLAY “ ”

NOTE: DURING PROCESS, HOLD THE

WRENCH VERY STILL UNTIL “ ”

IS DISPLAYED

NOTE: Follow the above directions as closely as possible. Please

be careful to “LOAD” the wrench ONLY during the indicated times -

overtorquing past the range of the wrench is very possible and could

cause damage without audio/visual indicators being active during

calibration.

NOTE: When “OK” is displayed after the second calibration check

point has been checked/adjusted, the LCD should then show the

torque presently being applied.

Page 10

1

CLEAR

ZERO

RECALL SETUP

STORE

SEND

2

34

6.00’

6.00’

6.00’

o.o.o.o

OFF ON

E

F

G

H

I

P

Q

R

S

T

U

V

o.o.o.o

1

CLEAR

ZERO

STORE

SEND

2

RECALL SETUP

3 4

OFF ON

1

CLEAR

ZERO

STORE

SEND

2

RECALL SETUP

3 4

STORE

SEND

2

RECALL

SETUP

3

4

TRACK

ooo.o

o

TRACK

2.ooo

TRACK

ooo.o

2

2”

OFF ON

00 01

LINE FEED

CARRIAGE

RETURN

UNITS

BLANK

VALUE

SIGN

BLANK

SEQUENCE #

12 3 , 45 IN- LB

CR LF

+

INSTRUCTIONS LEGEND

LIGHT ON

BUZZER SOUNDS

INPUTTING THE LENGTH OF THE ADAPTOR

ACCEPTED

GO BACK TO MAIN MENU

CENTER OF SQUARE DRIVE TO

CENTER OF THE OPEN END.

BOX END OR FLARE NUT DRIVES

PRESS

PRESS + HOLD

UNITL

BUZZER SOUNDS

FEATURES INTERFAcE cAbLES

COMPUTORQ II TO

MITUTOYO PRINTER

COMPUTORQ II TO

SERIAL PRINTER (RS-232)

COMPUTORQ II

TO PC

COMPUTORQ II shown Connected

to Data Logger Interface.

6 PIN MALE

PLUG CONNECTOR

PLUG CONNECTOR

6 PIN MALE

6 PIN MALE

PLUG CONNECTOR

COMPUTORQ II features a Battery Conservation Switch

to Battery Life when the Wrench is not in use.

10 PIN FEMALE

CONNECTOR

25 PIN FEMALE

CONNECTOR

9 PIN FEMALE

CONNECTOR

Page 11

bATTERIES

STORE

SEND

2

RECALL

SETUP

3

4

TRACK

ooo.o

o

TRACK

2.ooo

TRACK

ooo.o

2

2”

BATTERY

BATTERY

LINE FEED

CARRIAGE

RETURN

UNITS

BLANK

VALUE

SIGN

BLANK

SEQUENCE #

123 ,45 IN-LB

CR LF

+

INSTRUCTIONS LEGEND

LIGHT ON

BUZZER SOUNDS

INPUTTING THE LENGTH OF THE ADAPTOR

ACCEPTED

GO BACK TO MAIN MENU

CENTER OF SQUARE DRIVE TO

CENTER OF THE OPEN END.

BOX END OR FLARE NUT DRIVES

PRESS

PRESS + HOLD

UNITL

BUZZER SOUNDS

cERTIFIcATION

REPLACEMENT LOCATION AND USE

A 9-volt alkaline battery is standard and provides

for approximately 60 hours of operation. A “LO-BAT”

indication on the display signals for replacement. There

are 10 -20 hours of wrench operation remaining, even

after “LO-BAT” is displayed. Batteries can be changed in

less than one minute.

PLEASE NOTE:

1. Have new and fresh batteries ready to install prior to

battery replacement.

2. A ashing “LO-BAT” indicates battery failure is

imminent. There are approximately 2 - 3 hours of

battery life remaining.

This torque wrench as calibrated at the factory, is

certified to meet the current ASME specification.

Additionally, all wrenches are calibrated on a torque

standard traceable to the National Institute of

Standards and Technology (N.I.S.T.).

To Convert Multiply

cONVERSION TAbLE

From To By

in. oz. in. lb. 0.06250

in. lb. in. oz. 16

in. lb. ft. lb. 0.08333

in. lb. cmkg 1.15212

in. lb. mkg 0.01152

in. lb. Nm 0.11298

in. lb. dNm 1.12984

ft. lb. in. lb. 12

50 & 250 In.Lb. Models

50 Ft.Lb. Model

250 & 1000 Ft.Lb. Models

ft. lb. mkg 0.13825

ft. lb. Nm 1.35581

dNm in. lb. 0.88507

dNm Nm 0.1

Nm dNm 10

Nm cmkg 10.1971

Nm mkg 0.10197

Nm in. lb. 8.85074

Nm ft. lb. 0.73756

cmkg in. lb. 0.86796

cmkg Nm 0.09806

mkg in. lb. 86.7961

mkg ft. lb. 7.23301

mkg Nm 9.80665

Page 12

NOTES

Loading...

Loading...