Page 1

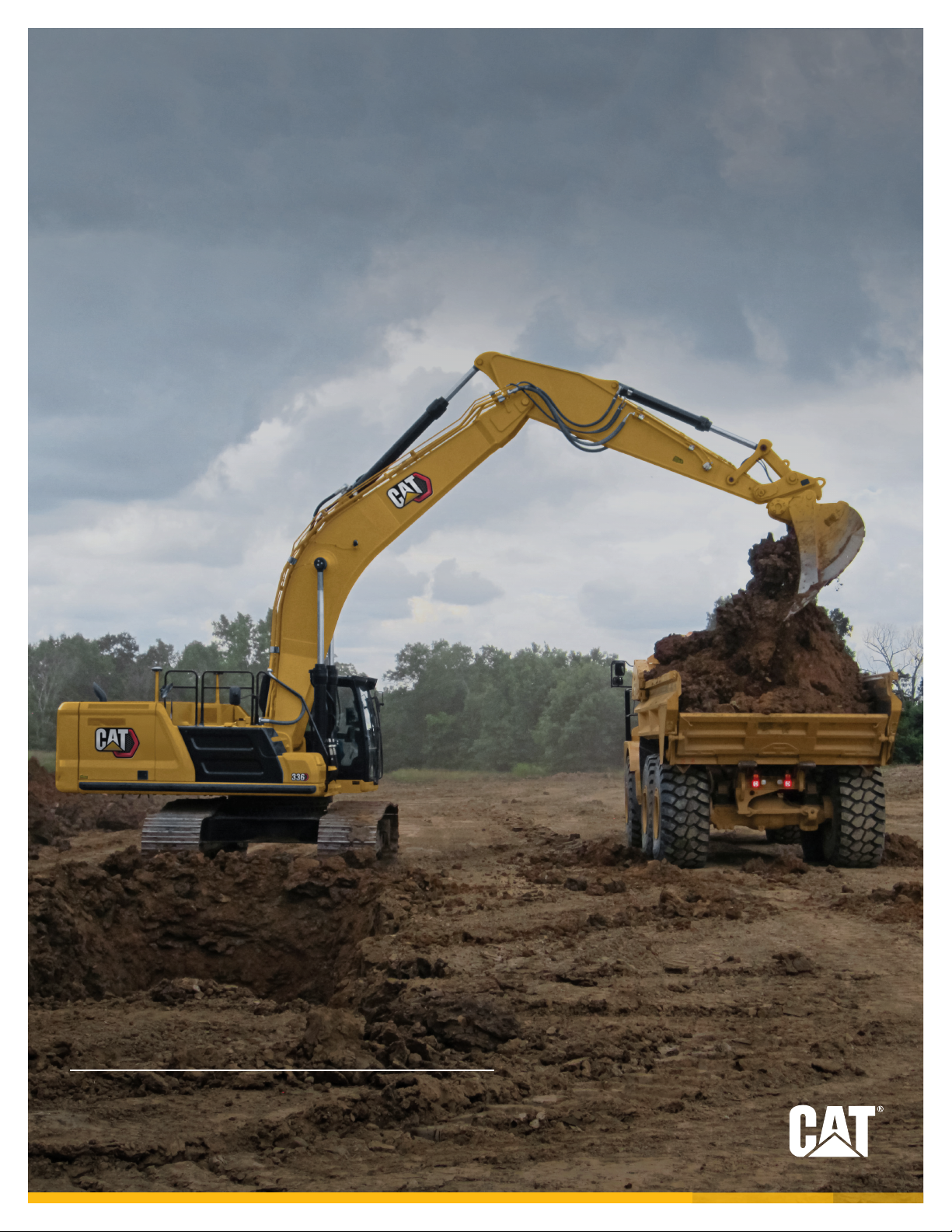

336

HYDRAULIC EXCAVATOR

Engine Power 232 kW (311 hp)

Operating Weight 37 200 kg (81,900 lb)

Cat® C9.3B Engine meets U.S. EPA Tier 4 Final, EU Stage V, and Japan 2014 emission standards.

Page 2

NEXT GENERATION EXCAVATORS

Cat® Next Generation Excavators offer you more choices than ever for your business.

+ MORE MODEL OPTIONS

+ MORE STANDARD TECHNOLOGIES

+ MORE PRICE POINTS

Ready to help you make your business stronger, Cat Next Generation Excavators give you new ways to get the

most work done at the lowest cost – so you put more money in your pocket.

THE

®

CAT

MOVING THE STANDARD HIGHER

2

336 HYDRAULIC EXCAVATOR

336

The CAT 336 raises the bar for

efficiency and fuel economy in this

size class. With the industry’s highest

level of standard factory technology,

a cab made for operator comfort, plus

lower fuel and maintenance costs, the

336 will help make your operation more

productive and profitable.

Page 3

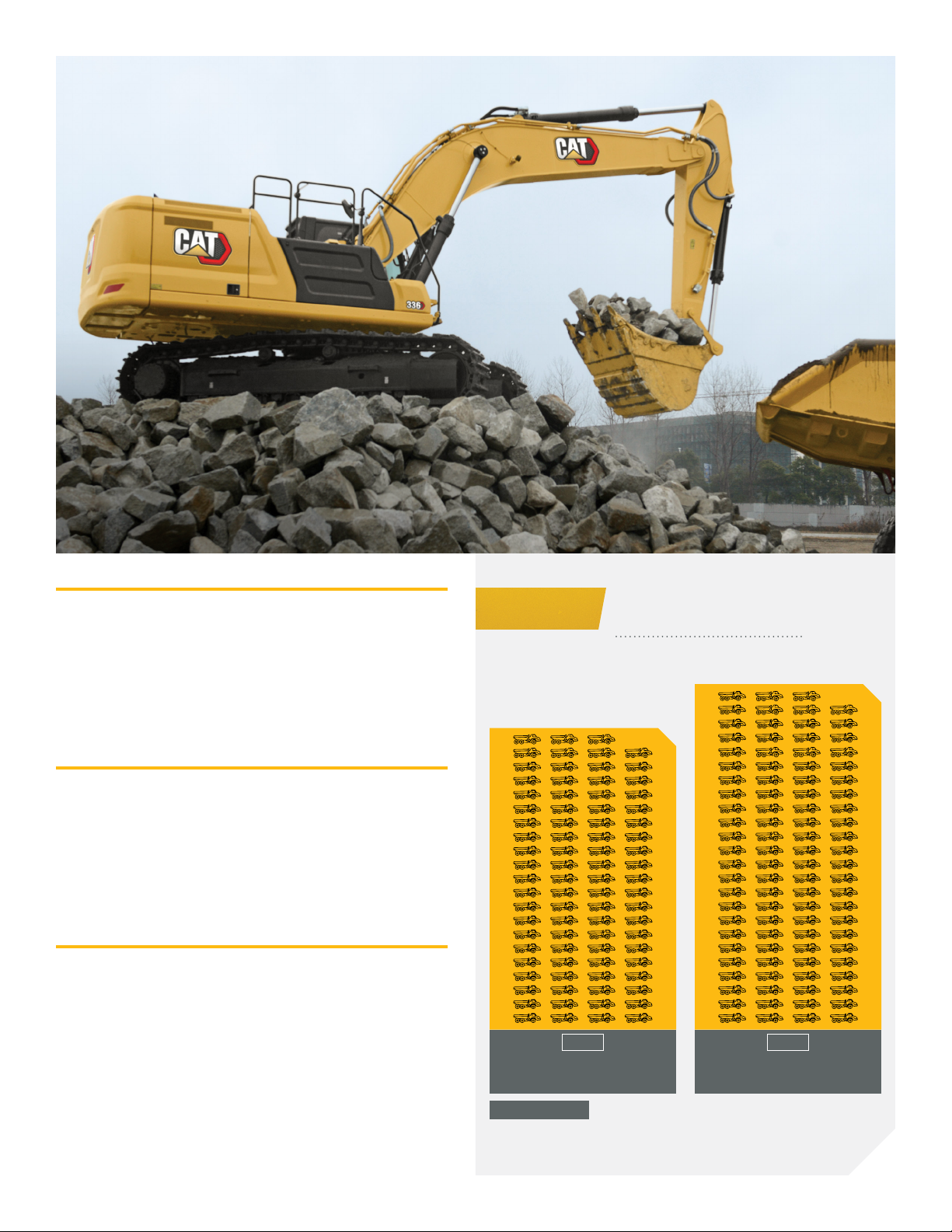

INCREASE OPERATING EFFICIENCY

UP TO 45%

The Cat 336 offers the industry’s highest level of standard

factory-equipped technology, including Cat GRADE with 2D,

GRADE with Assist, and PAYLOAD.

1

INCREASE FUEL EFFICIENCY

UP TO 15%

A precise combination of lower engine speed and large

hydraulic pump pressure and flow delivers more work

per unit of fuel.

2

LOWER MAINTENANCE COSTS

UP TO 20%

3

LOAD UP LOAD UP

WITHWITH

15%

MORE FUEL

EFFICIENCY

THAT’S 12 MORE TRUCKLOADS WITH THE

336 NEXT GENERATION EXCAVATOR.

Extended maintenance intervals increase uptime

and reduce costs.

1

Operator efficiency gains compared to traditional grading methods.

2

Compared to the 336F.

3

Compared to the 336F. Cost reduction based on 12,000 hours of operation.

336F 336

219 L (58 GAL) =

83 LOADED TRUCKS

SCENARIO:

83 LOADED TRUCKS × 15%

EFFICIENCY IMPROVEMENT =

12 ADDITIONAL TRUCKLOADS

Cat® Excavators loading Cat 730 trucks using

219 L (58 gal) of fuel each day.

336 HYDRAULIC EXCAVATOR

3

Page 4

WHAT WOULD YOU DO

STANDARD CAT

TECHNOLOGIES

GETS JOBS DONE FASTER

WITH LESS REWORK

Cat Technology gives you the edge. Operators of all experience

levels will dig, load, and grade with more confidence, speed,

and accuracy. The result?

Better productivity and lower costs.

4

336 HYDRAULIC EXCAVATOR

WITH 4.5 MORE WEEKS?

45

%

GAIN WITH TECHNOLOGY

means same amount of work done faster

4.5 WEEK GAIN

0

PREVIOUS YEAR:

USING TRADITIONAL GRADING METHODS

400 hours/year, grading with stakes and checkers

CURRENT YEAR:

USING CAT 336 WITH CAT TECHNOLOGY

220 hours/year, with standard Cat GRADE

10050150

HOURS

200

250

300

350

400

Page 5

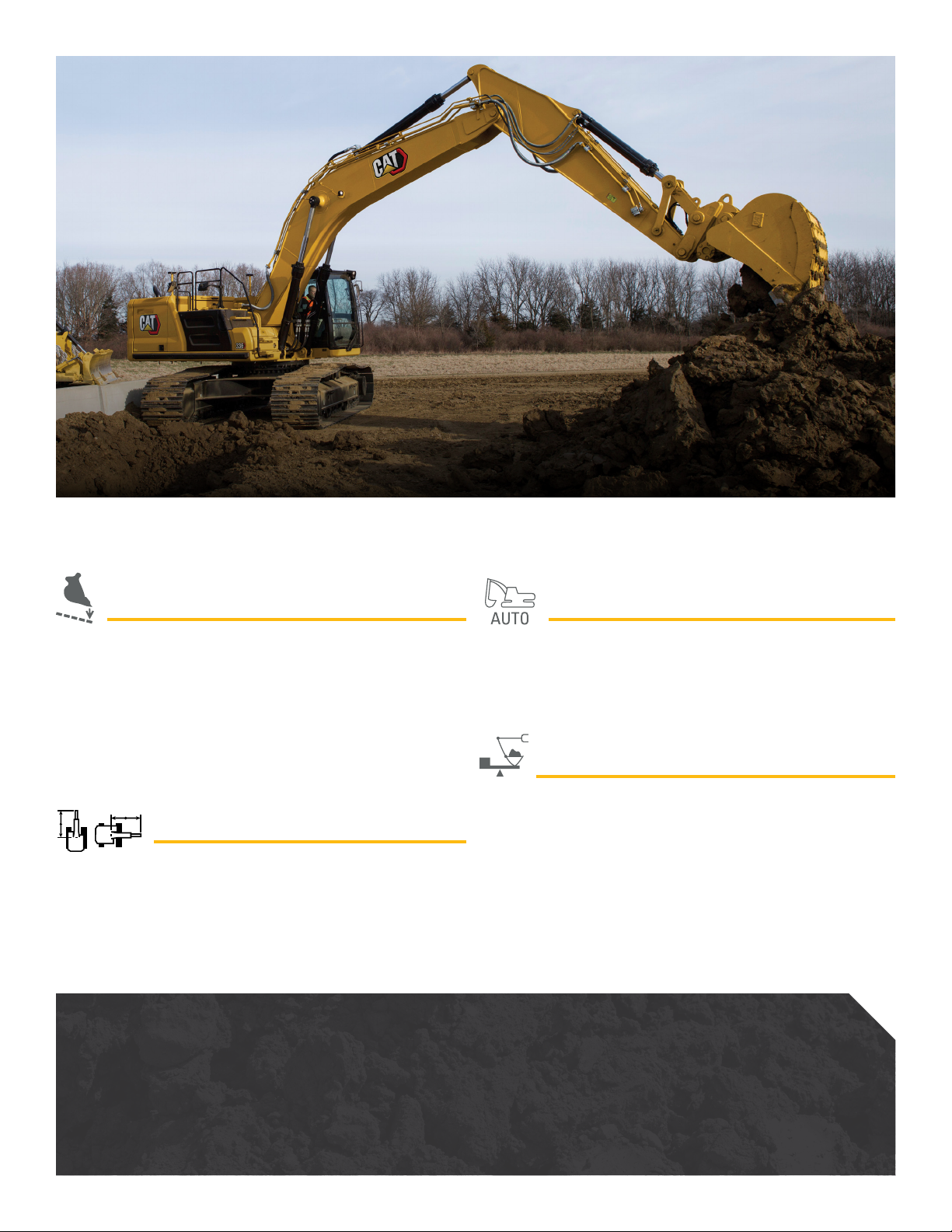

INCREASE EFFICIENCY UP TO 45%

WITH CAT TECHNOLOGY

STANDARD, SIMPLE-TO-USE TECHNOLOGIES INCLUDE:

STANDARD CAT GRADE WITH 2D STANDARD CAT GRADE WITH ASSIST

Cat GRADE with 2D helps operators reach grade faster. Operators

cut and fill to exact specifications without overcutting. You can

program up to four of your most commonly used target depth

and slope offsets so you can get to grade with ease – a real time

saver on the jobsite. Best of all, no grade checkers are needed so

the work area is safer.

STANDARD LIFT ASSIST

Lift Assist quickly calculates the actual load you are lifting

and compares it to the rated load the excavator is capable of

handling. Visual and auditory alerts tell you if you are within safe

working range or need to take action to avoid tipping.

Automated boom, stick, and bucket movements deliver more

accurate cuts with less effort. The operator simply sets the depth

and slope in the monitor and activates single-lever digging.

STANDARD CAT PAYLOAD

Cat PAYLOAD technology delivers precise load targets with

on-the-go weighing, which helps prevent over/underloading

and maximizes efficiency. Automated tracking helps manage

production and lower cost. You can even take payload data with

you. The monitor’s USB port lets you download your results from

one shift all the way up to 30 days of work so can manage your

progress without needing an internet connection or VisionLink®

subscription.

AVAILABLE OPTIONAL UPGRADES

Cat GRADE with Advanced 2D and Cat GRADE with 3D increase productivity and expand grading capabilities. GRADE with

Advanced 2D adds in-field design capabilities through an additional 254 mm (10 inch) high-resolution touchscreen monitor.

GRADE with 3D adds GPS and GLONASS positioning for pinpoint accuracy. Plus it’s easier than ever to connect to 3D services

like Trimble Connected Community or Virtual Reference Station with the excavator’s built-in communication technology.

336 HYDRAULIC EXCAVATOR

5

Page 6

CAT LINK TECHNOLOGY

TAKES THE GUESSWORK OUT OF MANAGING YOUR EQUIPMENT

CAT LINK telematics technology helps take the complexity out of managing your jobsites – by gathering data generated by your

equipment, materials, and people and serving it up to you in customizable formats.

PRODUCT LINK

Product Link™ collects data automatically and accurately

from your assets – any type and any brand. Information such as

location, hours, fuel usage, productivity, idle time, maintenance

alerts, diagnostic codes, and machine health can be viewed

online through web and mobile applications.

VISIONLINK

Access information anytime, anywhere with VisionLink – and use

it to make informed decisions that boost productivity, lower costs,

simplify maintenance, and improve safety and security on your

jobsite. With different subscription level options, your Cat dealer

can help you configure exactly what you need to connect your

fleet and manage your business without paying for extras you

don’t want. Subscriptions are available with cellular or satellite

reporting (or both).

™

®

Remote Services is a suite of technologies that improve

your jobsite efficiency.

Remote Troubleshoot allows your Cat dealer to perform

diagnostic testing on your connected machine remotely,

pinpointing potential issues while the machine is in

operation. Remote Troubleshoot ensures the technician

arrives with the correct parts and tools the first time,

eliminating additional trips to save you time and money.

Remote Flash updates on-board software without a

technician being present, potentially reducing update

time by as much as 50%. You can initiate the update

when convenient, increasing your overall operating

efficiency.

Caterpillar releases products, services and technologies in each region at different time intervals. Please verify with your local Cat dealer for technology availability and specifications.

The Cat App helps you manage your assets – at any time – right from your

smartphone. You can see your fleet location, hours, and other information

you need to see. You will get critical alerts for required maintenance, and

you can even request service from your local Cat dealer.

6

336 HYDRAULIC EXCAVATOR

Page 7

CAB TAKES

THE HARD

OUT OF WORK

WE’VE GOT YOUR BACK.

BACK PAIN IS ONE OF THE MOST

COMMON REASONS PEOPLE MISS WORK.*

NEW CAB:

All controls are in front of the

operator. That means almost

no twisting is required.

Sites where excavators typically

work are rugged and challenging.

That’s why it’s important that the

336 cab protects the operator

as much as possible from the

fatigue, stresses, sounds, and

temperatures of the job.

OLD CAB: 2,000+ twists a year to reach controls

in back of cab that can strain your back.

ASSUME 1 TWIST PER HOUR

1 TWIST × 8-HOUR WORKDAY = 8 TWISTS PER DAY

8 TWISTS × 5 WORKDAYS PER WEEK = 40 TWISTS PER WEEK

40 TWISTS × 52 WEEKS PER YEAR = 2,080 TWISTS PER YEAR

* SOURCE: HTTPS://WWW.NINDS.NIH.GOV/DISORDERS/PATIENT-CAREGIVER-

EDUCATION/FACT-SHEETS/LOW-BACK-PAIN-FACT-SHEET

SEAT AND JOYSTICK CONSOLE REDUCE FATIGUE

Comfort and efficiency of movement keep operators productive and alert all shift long. The standard seat is wide

and adjustable for operators of virtually any size. The Deluxe cab package includes a heated air suspension seat;

the Premium seat is both heated and cooled.

336 HYDRAULIC EXCAVATOR

7

Page 8

TOUCHSCREEN MONITOR

Most machine settings can be controlled

through the high-resolution 10 inch

touchscreen monitor. It offers 42 languages

and is easy to reach from the seat – no

twisting or turning.

SMART SETTINGS

The Smart Mode automatically adjusts

engine and hydraulic power to meet work

demand with maximum fuel efficiency. Auto

Dig Boost increases power by up to 8% for

better bucket penetration, shorter cycle

times, and greater payloads.

CUSTOMIZABLE JOYSTICKS

Joystick function can be customized through

the monitor. Joystick pattern as well as

response can be set to match operator

preference. All preferences are saved

with the operator ID and restored at log in.

KEYLESS PUSH START

The 336 uses a keyless push-button engine

start. This adds security for the machine by

using Operator ID codes to limit and track

machine access. Codes can be entered

manually, via an optional Bluetooth® key

fob, or smartphone app.

8

336 HYDRAULIC EXCAVATOR

Page 9

A QUIET, SAFE WORKSPACE

BUILDS OPERATOR CONFIDENCE

ISO-CERTIFIED

ROPS CAB

The ISO-certified ROPS cab is soundsuppressed and sealed. The windows

and lower front profile of the machine

give outstanding visibility to the work

area without the strain of constantly

leaning forward.

ALL-AROUND

VISIBILITY

A standard rearview camera keeps

operators aware of their surroundings

at all times. An optional 360° visibility

feature is also available.

EASY ACCESS,

CONNECTIVITY

AND STORAGE

Convenience features include Bluetooth

integrated radio, USB ports for charging

and phone connectivity, 12V DC outlets

and AUX port, storage in rear, overhead

and console compartments, and cup

and bottle holders.

336 HYDRAULIC EXCAVATOR

9

Page 10

1,148 WAYS TO STAY SAFE.

SAFETY FEATURES

LOOK OUT FOR YOUR PEOPLE

AND YOUR EQUIPMENT

Routine maintenance checks can be performed faster, easier,

and safer with ground-level access to the air precleaner, the

fuel water separator, fuel tank water and sediment drains,

and cooling system coolant level check.

KEEP YOUR EXCAVATOR SECURE

Use your PIN code on the monitor, the optional Bluetooth

key fob, or your smartphone to enable the push-button start.

10

336 HYDRAULIC EXCAVATOR

SLIPPING IS ONE OF THE

FACT:

BIGGEST CONTRIBUTORS

TO WORKPLACE INJURIES.*

OUR ANTI-SKID PLATES FEATURE

1,000+

*SOURCE: HTTPS://WWW.OSHA.GOV/DTE/GRANT_MATERIALS/FY07/SH-16625-07/SLIPSTRIPSFALLS.PPT

INDIVIDUAL PERFORATIONS

FOR BETTER TRACTION

Page 11

PROTECTION IN

ALL DIRECTIONS

E-WALL SWING E-WALL FORWARD E-WALL CAB PROTECTION E-WALL CEILING E-WALL FLOOR

STANDARD 2D E-FENCE TECHNOLOGY

Whether you are using a bucket or hammer, standard 2D E-Fence automatically stops excavator motion using boundaries you set in the

monitor for the entire working envelope – above, below, sides and front. E-Fence protects equipment from damage and reduces fines

related to zoning or underground utility damage. Automatic boundaries even help prevent operator fatigue by reducing overswinging

and digging.

336 HYDRAULIC EXCAVATOR

11

Page 12

LOWER MAINTENANCE COSTS

UP TO 20%

With extended maintenance intervals, you get more done at a

lower cost compared to the 336F. Consolidated filter locations

make service faster. Hydraulic, air, and fuel tank filters have

increased capacity and longer life.

KEY MAINTENANCE COST REDUCTIONS INCLUDE:

+ Consolidated filter locations to reduce service time.

+ Oil and fuel filters with extended maintenance intervals.

+ Advanced air filter with double the dust holding capacity

of the previous filter.

WHAT WILL YOU DO

WITH YOUR SAVINGS?

REPLACE 50 FEWER FILTERS

OVER 12,000 HOURS OF OPERATION.

THAT SAVES YOU UP TO 20%

IN MAINTENANCE COSTS*

20%

* SOURCE: INTERNAL NEXT GENERATION PRODUCT SUPPORT

MAINTENANCE COST COMPARISON

12

336 HYDRAULIC EXCAVATOR

Page 13

INCREASE YOUR PRODUCTIVITY AND PROFIT

WITH CAT ATTACHMENTS

You can easily expand the performance of your machine by utilizing any of the variety of Cat Attachments.

Each Cat Attachment is designed to fit the weight and horsepower of Cat Excavators for improved

performance, safety, and stability.

BUCKETS

MULTI-PROCESSORS

GRAPPLES

QUICK COUPLERS

HYDRAULIC HAMMERS

RAKES

PREVENT HAMMER

WEAR AND TEAR

Turn on through

the monitor and

the hammer will

automatically stop

after 30 seconds of

continuous firing,

preventing both tool

and excavator from

overworking.

RIPPERS

ATTACHMENT

TRACKING

MADE EASY

The Cat PL161 Attachment

Locator is a Bluetooth device

that makes finding your

attachments and other gear

quick and easy. The excavator’s

onboard Bluetooth reader or

Cat App on your phone will

locate the device automatically.

SECONDARY

PULVERIZERS

VIBRATORY PLATE

THUMBSSHEARS

COMPACTORS

Save more time and energy

with the available work tool

recognition feature. A simple

shake of the attached tool

confirms its identity; it also

ensures all the attachment

settings are correct so you

can get to work quickly

and efficiently.

336 HYDRAULIC EXCAVATOR

13

Page 14

TECHNICAL SPECIFICATIONS

See cat.com for complete specifications.

ENGINE

Engine Model C9.3B

Engine Power – ISO 9249 232 kW 311 hp

Engine Power – ISO 14396 234 kW 314 hp

Bore 115 mm 5 in

Stroke 149 mm 6 in

Displacement 9.3 L 568 in³

HYDRAULIC SYSTEM

Main System – Maximum Flow – Implement 558 L/min (279 × 2 pumps)

147 gal/min (74 × 2 pumps)

Maximum Pressure – Equipment – Implement 35 000 kPa 5,076 psi

Maximum Pressure – Equipment – Lift Mode 38 000 kPa 5,511 psi

Maximum Pressure – Travel 35 000 kPa 5,076 psi

Maximum Pressure – Swing 29 400 kPa 4,264 psi

SWING MECHANISM

Swing Speed 8.75 rpm

Maximum Swing Torque 144 kN∙m 106,228 lbf-ft

WEIGHTS

Operating Weight 37 200 kg 81,900 lb

Long undercarriage, Reach boom, R3.9DB (12'10") stick, GD 2.27 m³

(2.97 yd³) bucket, 850 mm (33") triple grouser shoes, 6.8 mt (14,991 lb)

counterweight.

SERVICE REFILL CAPACITIES

Fuel Tank Capacity 600 L 158.5 gal

Cooling System 40 L 10.5 gal

Engine Oil (with filter) 32 L 8.5 gal

Swing Drive (each) 18 L 4.8 gal

Final Drive (each) 8 L 2.1 gal

Hydraulic System (including tank) 373 L 98.5 gal

Hydraulic Tank 161 L 42.5 gal

DEF Tank 80 L 21.1 gal

AIR CONDITIONING SYSTEM

The air conditioning system on this machine contains the fluorinated

greenhouse gas refrigerant R134a (Global Warming Potential = 1430).

The system contains 1.00 kg of refrigerant, which has a CO2 equivalent

of 1.430 metric tonnes.

DIMENSIONS

Boom Reach Boom 6.5 m (21'4")

Stick Reach Stick 3.9 m (12'10")

Bucket GDC 2.27 m³ (2.97 yd³)

Shipping Height (top of cab) 3170 mm 10'4"

Handrail Height 3160 mm 10'4"

Shipping Length 11 200 mm 36'8"

Tail Swing Radius 3530 mm 11'6"

Counterweight Clearance 1250 mm 4'1"

Ground Clearance 510 mm 1'8"

Track Length 5030 mm 16'6"

Track Length to Center of Rollers 4040 mm 13'3"

Track Gauge – Long Undercarriage 2590 mm 8'5"

Transport Width – 850 mm (33") Shoes 3440 mm 11'3"

WORKING RANGES AND FORCES

Boom Reach Boom 6.5 m (21'4")

Stick Reach Stick 3.9 m (12'10")

Bucket GDC 2.27 m³ (2.97 yd³)

Maximum Digging Depth 8200 mm 26'10"

Maximum Reach at Ground Level 11 730 mm 38'5"

Maximum Cutting Height 10 740 mm 35'2"

Maximum Loading Height 7490 mm 24'6"

Minimum Loading Height 1900 mm 6'2"

Maximum Depth Cut for 2440 mm (8'0")

Level Bottom

Maximum Vertical Wall Digging Depth 6360 mm 20'10"

Bucket Digging Force (ISO) 210 kN 47,160 lbf

Stick Digging Force (ISO) 144 kN 32,440 lbf

8060 mm 26'5"

14

336 HYDRAULIC EXCAVATOR

Page 15

STANDARD & OPTIONAL EQUIPMENT

Standard and optional equipment may vary. Consult your Cat dealer for details.

CAB STANDARD OPTIONAL

ROPS, sound suppression

High-resolution 203 mm (8") LCD

touchscreen monitor

High-resolution 254 mm (10") LCD

touchscreen monitor

Heated seat with air-adjustable suspension

(Deluxe only)

Heated and cooled seat with automatic

adjustable suspension (Premium only)

ENGINE STANDARD OPTIONAL

Cold start block heaters

Three selectable modes: Power, Smart, Eco

Automatic engine speed control

Up to 3300 m (10,830 ft) altitude capability

52° C (126° F) high-ambient cooling

capacity

Hydraulic reverse fan

–18° C (0° F) cold start capability

–32° C (–25° F) cold start capability

Double element air filter with

integrated precleaner

Remote disable

Biodiesel capability up to B20

HYDRAULIC SYSTEM STANDARD OPTIONAL

SmartBoom

Boom and stick regeneration circuit

Electronic main control valve

Heavy lift mode

Automatic hydraulic oil warm up

Reverse swing damping valve

Automatic swing parking brake

High performance hydraulic return filter

Two speed travel

Bio hydraulic oil capability

Combined two-way auxiliary circuit

Medium-pressure auxiliary circuit

Cooling circuit

Quick coupler circuit

Long undercarriage

Long Narrow undercarriage

Towing eye on base frame

6.8 mt (14,991 lb) counterweight

7.56 mt (16,667 lb) counterweight

600 mm (24") double grouser, HD double

grouser, triple grouser track shoes

700 mm (28") triple grouser track shoes

850 mm (33") triple grouser track shoes

For additional information, refer to the Technical Specifications brochures for the 336 GC and 336 models available at www.cat.com or your Cat dealer.

™

UNDERCARRIAGE AND STRUCTURES STANDARD OPTIONAL

Not all features are available in all regions. Please check with your local Cat dealer for specific offering availability in your area.

6.18 m (20'3") Mass boom

6.5 m (21'4") Reach boom

6.5 m (21'4") HD Reach boom

2.55 m (8'4") stick

2.8 m (9'2") stick

3.2 m (10'6") stick

3.2 m (10'6") HD stick

3.9 m (12'10") stick

3.9 m (12'10") HD stick

Maintenance-free 1,000 CCA batteries (×2)

Centralized electrical disconnect switch

LED chassis light, LH and RH boom lights,

cab lights

Cat Product Link

Cat GRADE with 2D

Cat GRADE with Advanced 2D

Cat GRADE with 3D

Cat GRADE with Assist

Cat PAYLOAD

Cat E-Fence

Lift Assist

Auto Dig Boost

Remote Services capability

Grouped location of engine oil and fuel filters

Scheduled Oil Sampling (S∙O∙SSM) ports

QuickEvac™ maintenance ready

Electric refueling pump with auto shutoff

Caterpillar One Key security system

Lockable external tool/storage box

Lockable door, fuel, and hydraulic tank locks

Lockable fuel drain compartment

Service platform with anti-skid plate

and recessed bolts

RH handrail and hand hold

(ISO 2867:2011 compliant)

Signaling/warning horn

Ground-level secondary engine shutoff switch

Rear and right-hand-sideview cameras

360° visibility

Boom lowering check valve

Stick lowering check valve

Cat Command remote control

BOOMS AND STICKS STANDARD OPTIONAL

ELECTRICAL SYSTEM STANDARD OPTIONAL

CAT TECHNOLOGY STANDARD OPTIONAL

SERVICE AND MAINTENANCE STANDARD OPTIONAL

SAFETY AND SECURITY STANDARD OPTIONAL

336 HYDRAULIC EXCAVATOR

15

Page 16

For more complete information on Cat products, dealer services and industry solutions, visit us on the web

at www.cat.com

© 2020 Caterpillar. All Rights Reserved.

VisionLink is a trademark of Trimble Navigation Limited, registered in the United States and in other countries.

Materials and specifications are subject to change without notice. Featured machines in photos may include

additional equipment. See your Cat dealer for available options.

CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Corporate Yellow”,

the “Power Edge” and Cat “Modern Hex” trade dress as well as corporate and product identity used herein,

are trademarks of Caterpillar and may not be used without permission.

www.cat.com www.caterpillar.com

Replaces AEXQ2358-03

AEXQ2358-04

Build Number: 07C

(Aus-NZ, Eur, Japan, N Am)

Loading...

Loading...