CAT Delta 30, Delta 90 Service manual

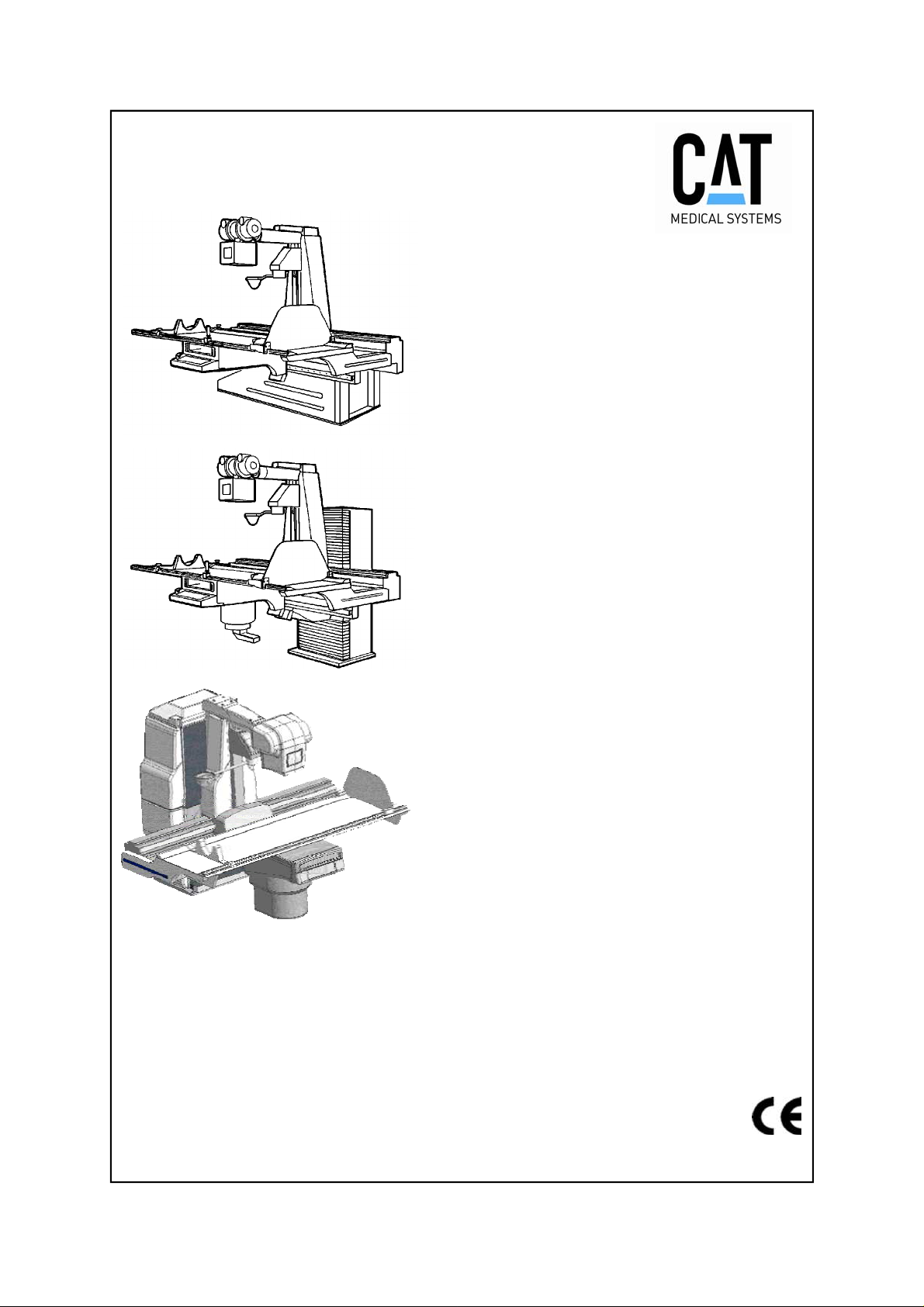

Remote-control table

DELTA 30

Remote-control table

DELTA 90

Remote-control table

DELTA 90 PLUS

Service manual

Service manual

Service manual

CAT MEDICAL SYSTEMS S.p.A. Via E. Amaldi 14. 00015 Monterotondo (RM)-ITALY

Tel: +39-06-90670300- Fax: +39-06-90670303 http://www.catmedical.com

MAN056 - rev.2 dated 10/05/2010

0051

CAT Medical Systems

Summary

Introduction

Consultation notes

Safety

II-III

IV

PART 1: MOVEMENT AND INSTALLATION

Chap. 1: MOVEMENT AND INSTALLATION 2

1.1: Packing characteristics …………………………………………………………………….

1.2: Disposal of the packing……………………………………………………………………..

1.3: Movement and lifting of the packing when crates are used….………….……………..

1.4: Movement and lifting of the individual units ……………………………………………...

1.5: Overall dimensions of the moving parts………………………………………………..

1.6: Positioning: characteristics of the room…………………………………………………..

1.7: Installation……………………………………………………………………………………

1.8: Fixing to the floor…………………………………………………………………………...

1.9: Leveling……………………………………………………………………………………..

1.10: Main column translator base assembly (only DELTA 90-90PLUS)………………...

1.11: X-ray tube column assembly……………………………………………………………..

1.12: Spot film device assembly………………………………………………………………...

1.13: Patient table assembly…………………………………………………………………….

……………2

…………....2

…………....3

…………....8

.………….10

…………..12

…………..13

…………..18

…………..19

…………..20

.….……...20

…………..21

…………..21

I

PART 2: SET -UP

Chap. 1: RAISING AND TILTING AXES SET-UP 2

1.1: Introduction………………………………………………………………………………….

1.2: Raising axis check (only DELTA 90-90PLUS)…………………………………………..

1.3: Tilting axis check…………………………………………………………………………….

Chap. 2: COLUMN TRANSLATOR SET-UP 6

Chap. 3: X-RAY TUBE COLUMN SET-UP 8

3.1: Introduction…………………………………………………………………………………..

3.2: X-ray tube raising check…………………………………………………………………....

Chap. 4: SPOT FILM DEVICE SETTING UP 9

4.1: Introduction………………………………………………………………………………….

4.2: Limit switch check……………………………………………………............

MAN056.pub

…………....2

…………....4

…………....5

…………....8

…………....8

…………....9

…………....9

Summary CAT Medical Systems

4.3: Film size detection...……………………………………………………………………….

4.4: Shutter opening ………………………..…………………………………………………..

4.5: Film edge offset check……………...………………………………………………….......

4.6: Shutters DELTA check……...……….……………………………………………………..

4.7: Photocell check……………..………………………………………………………………..

4.8: Final set-up…..………………..……………………………………………………………..

……………9

…………..11

…………..11

…………..12

.………….12

…………..13

PART 3: ELECTRICAL ADJUSTMENTS

Chap. 1:ELECTRICAL ADJUSTMENTS TO RAISING AND TILTING AXES FOLLOW-

ING COMPONENT REPLACEMENT 2

1.1: Introduction………………………………………………………………………………….

1.2: Raising axis calibration (DELTA 90-90PLUS only)…...………………………………..

1.3: Tilting axis calibration……………………………………………………………………...

Chap. 2: TRANSLATION UNIT CALIBRATION (column-spot film device) 18

2.1: Introduction………………………………………………………………………………….

2.2: Limit switch replacement……………….…………………………………………………..

2.3: Overtravel switch replacement……...…………………………………………………….

2.4: Inverter replacement…. ……………………………………………………………………

2.5: “Slave” control calibration…………………………………………………………………...

2.6: Replacement of the master potentiometer………………………………….

2.7: Replacement of the spot film device potentiometer……………………………………...

…………....2

…………....4

…………..10

…………..18

…………..19

…………..19

…………..19

…………..21

…………..21

…………..23

Chap. 3: SPOT FILM DEVICE UNIT CALIBRATION 26

3.1: Introduction………………………………………………………………………………….

3.2: Replacement of the cassette insertion and eject limit switches, replacement of the

cassette potentiometer ………………………………………………………........................

3.3: Replacement of “shutter” potentiometer ……………………………………………….

3.4: Replacement of “angle of incidence” potentiometer…………………………………..

3.5: Final setup of the spot film device and size calibration………………………………...

3.6: Offset calibration…………………………………………………………………………….

3.7: Shutters calibration………………………………………………………………………...

3.8: Photocell calibration………………………………………………………………………….

Chap. 4: X-RAY TUBE COLUMN CALIBRATION 36

4.1: Replacement of the parts inside the x-ray tube column………………………………..

4.2: Compressor………………………………………………………………………………...

4.3: X-ray tube rotation calibration…………………………………………………………….

4.4: X-ray tube rotation clutch adjustment…………………………………………………….

…………..26

…………..27

…………..31

…………..33

…………..34

…………..34

…………..35

…………..35

…………..36

…………..38

…………..39

…………..39

MAN056.pub

CAT Medical Systems Summary

Chap. 5: COLLIMATOR SET-UP 40

5.1: Introduction………………………………………………………………………………….

5.2: Axis X and axis Y shutter check…………………………………………………………

5.3: Iris calibration……………………………………………………………………….………..

……..……40

…….…….41

…………..42

PART 4: MECHANICAL ADJUSTMENTS

Chap. 1: MAIN UPRIGHT _ DELTA 90-90PLUS_ 2

1.1: Installation…………………………………………………………………………………….

1.2: Replacement of the raising motor…………………...…………………………………….

1.3: Removing and replacing protective bellows …………………………………………….

1.4: Replacement of the raising reduction gear……………………………………………….

1.5: Replacement of belts………………………………………………………………………

1.6: Replacement of the raising ball screws... ……………………………………………….

1.7: Replacement of the vertical movement sliding rollers…………………………………...

1.8: Replacement of the tilting rollers…………………………………………………………...

1.9: Replacement of the motor and/or tilting reduction gear………………………………..

Chap. 2: MAIN UPRIGHT_DELTA 30_ 9

2.1: Installation………………………………………………………………………………….

2.2: Replacement of the raising motor………………………………………………………...

2.3: Replacement of the raising reduction gear………………………………………………..

2.4: Replacement of belts..………………………………………………………………………

2.5: Replacement of the tilting ball screws…………………………………………………...

…………....2

…………....2

…………....3

……………3

……………4

……………4

…………...6

……………7

……………8

…………....9

…………....9

……………9

……………9

…………..10

Chap. 3: COLUMN-SPOT FILM DEVICE TRANSLATOR UNIT 12

3.1: Dismantling of the patient table ………………………………………………………….

3.2: Replacement of master motor …..……………………………………………………....

3.3: Replacement of muster reduction gear……………………………………………………

3.4: Replacement of the slave motor………………………………………………………….

3.5: Replacement of the slave reduction gear………………………………………………..

3.6: Replacement of the table movement central chain…………………………………….

3.7: Replacement of the gear motor and drive pinions ……………………………………..

Chap. 4: TELESCOPIC COLUMN UNIT 16

4.1: Replacement of the motor…………………………………………………………………

4.2: Replacement of the ball screws…………………………………….…………………...

4.3: Replacement of the sliding rollers………………………………………………………….

MAN056.pub

…………..12

..………...12

…………..13

…………..13

…………..14

…………..14

…………..15

…………..16

…………..16

…………..17

Summary CAT Medical Systems

Chap. 5: HEAD ROTATION ARM UNIT 18

5.1: Clutch adjustment…………………………………………………………………………..

5.2: Replacement of the arm rotation bearings.……………………………………………..

Chap. 6: SPOT FILM DEVICE UNIT 19

6.1: Replacement of the cassette movement gear motor unit……………………………..

6.2: Replacement of the shutter gear motor unit………...…………………………………..

6.3: Replacement of the grid movement gear motor unit..………………………………….

6.4: Replacement of the flexible cable diam. 1.5..…………………………………………..

6.5: Replacement of the flexible cable diam. 3.2…………………….………………………

6.6: Replacement of the upper and/or lower sliding rollers………..……………………….

6.7: Dismantling and assembly of the mobile units……………….…………………………

Chap. 7: COMPRESSOR UNIT 23

7.1: Dismantling………………………………………………………………………………….

7.2: Replacement of the gear motor ……...………………………………………………….

7.3: Replacement of the chain…………...……………………….…………………………...

7.4: Replacement of the springs.………………………………………………………………

……..……18

…….…….18

…………..19

…………..19

…………..20

…………..20

…………..21

…………..21

…………..22

…………..23

…………..23

…………..23

…………..23

PART 5:TECHNICAL DOCUMENTATION AND

SUPPLIED MATERIAL

Chap.1: ELECTRICAL CONNECTIONS FOR SET-UP AND INTERFACING

2

1.1: List of digital inputs to be kept high during setting up…..……………………………... ……………2

Chap. 2: SPECIFICATIONS FOR INTERFACING TO OTHER EQUIPMENT 4

2.1: List of interface digital inputs……………………………………………………………….

2.2: List of interface digital outputs……………………………………………………………..

2.3: Connection for I.I. field on the RS013095 board…....…………………………………...

Chap. 3: TECHNICAL REFERENCE DOCUMENTS 7

Chap.4: MAINTENANCE MATERIAL NEEDED 8

……………4

…………....5

…………....6

MAN056.pub

CAT Medical Systems Summary

PART 6: FUNCTIONAL INTERLOCKS

Chap. 1: ENABLING AND INHIBITION SIGNALS 2

1.1: Checks when switching on..……………………………………………………………….

1.2: Raising (Delta 90-90 Plus only)…………………….…………………………………….

1.3: Lowering-tilting…….………………………………………………………………………...

1.4: Translation…………………………………………………………………………………...

1.5: Angle of incidence…………………………………………………………………………...

1.6: X-ray tube raising…………………………………………………………………………....

1.7: Patient table movement……………………………………………………………………..

1.8: Collimator: shutters and iris.………………………………………………………………...

Chap. 2: CHECKS CARRIED OUT ON THE SPOT FILM DEVICE 7

2.1: Cassette: insertion and eject………………………………………………………….

2.2: Shutters…………………..…………………………………………………………………...

2.3: Cassette rapid sequence…..……………………………………………………………….

Chap. 3: CHECKS CARRIED OUT ON THE FUNCTIONS 9

3.1: Tomography.………………………………………………………………………………….

3.2: Preparation..……………………………………………………………………………....

3.3: Radiography……………………………….…………………………………………………

3.4: Fluoroscopy…………………………………………….…………………………………..

3.5: TAB function……………………………………………..…………………………………

…………....2

…………....2

…………....3

……………4

……………4

……………5

……………5

……………6

…………....7

...………….8

………..…..8

………...….9

……………9

……………9

…………..10

..…………10

PART 7: MAINTENANCE

Chap.1: MAINTENANCE 2

1.1: Periodical maintenance operations…………………….………………………………...

1.2: Long periods of inactivity…………………………………………………………………...

1.3: List of reference documents for maintenance..…………………………………………..

PART 8: MAIN CONSOLLE SET-UP

Chap.1: GENERAL 2

Chap.2: COMPOSITION 3

Chap.3: WORKING MODALITIES 6

MAN056.pub

…………....2

…………....8

……………8

Summary CAT Medical Systems

Chap. 4: FUNCTION OF THE STATUS KEYS 7

Chap. 5: MULTIPLE FUNCTION KEYS 8

Chap. 6: “SPECIAL INFO” FUNCTION 9

Chap. 7: ALARM CODE INDIVIDUAL INHIBITION PROGRAM 11

Chap. 8: ANALOG JOYSTICK SET-UP FOR TABLE MOVEMENT 12

8.1: Analog joystick positioning procedure …………………………………………………... …………..13

Chap. 9: COLLIMATOR SHUTTERS MOVEMENT ADAPTATION TO THE OPERATOR

REQUIREMENTS 17

Chap. 10: PUSHBUTTON FUNCTION ALLOCATION 18

Chap. 11: CONSOLE KEY CONFIGURATION TABLE (CATWIN 2.2.2.0) 20

Chap. 12: GENERAL SET-UP 24

Chap. 13: DIAGNOSTIC FUNCTION FOR KEYBOARD AND LEDS CHECK 26

Chap. 14: TESTING CYCLE PROGRAMMING AND IMPLEMENTATION 27

MAN056.pub

CAT Medical Systems

Spare page.

MAN056-cover.pub

CAT Medical Systems

INTRODUCTION .

The DELTA 90 (90 Plus and 30) table described in this manual is a medical device, and was designed, manufactured and protected for radiological use on the human body.

The Service Manual is intended for anyone who has to carry out testing, setting up and maintenance operations on the DELTA 90-90PLUS and DELTA 30 Remote-control Tables. The contents

and the use of this manual presume appropriate mechanical, electromechanical and computer

knowledge. This manual is in no way a replacement for the training course, but it should be considered as a completion in training technicians, with appropriate technical-practical preparation, to carry

out interventions on the machine independently. CAT MEDICAL SYSTEMS S.p.A. is not responsible

for any modifications made to the machine by third parties and, consequently, to the manual subsequent to its issues.

The information contained in this manual is intended for the setting up of the machine and to provide

the necessary support in resolving any faults, enabling the technician to intervene by replacing faulty

parts or, in some cases, units.

The manual does not foresees the repair of faulty components. They must be returned to CAT MEDICAL SYSTEMS S.p.A., where they will be inspected and, if possible, repaired.

The DELTA 90 PLUS remote-control table is functionally the same as the DELTA 90 table, so all

the instruction for using for one of them, are valid also for the other one.

This document, and all the parts included therein, is property of CAT MEDICAL SYSTEMS S.p.A.; it

may not be copied, given to third parties or used in part or in full without the express written authorization of CAT MEDICAL SYSTEMS S.p.A.

MAN056-intro.pub Page I

Consultation notes CAT Medical Systems

CONSULTATION NOTES

Before to start any intervening on the table, carefully read this manual operating instructions, that

were written to ensure a rational and safe use of the machine.

Keep his manual in an well known and obvious place; it should be referred to whenever even the

slightest doubt occurs.

This manual should follow the entire life of the machine and be kept in any case for at least 10 (ten)

years.

For quick and rational reading, symbols have been used to indicate situations requiring maximum

attention, practical advice or simple information.

These symbols may be alongside a section of text (thus referring only to that section) or alongside

a figure (thus referring to the subject illustrated in the figure and to the relative text) .

ATTENTION! Pay maximum attention to the meaning of the symbols: their function is to

avoid repeating technical concepts or safety warnings, and they should therefore be considered as actual "memos". Refer to this page whenever any doubt arises as to their meaning.

Explanation of the symbols

ATTENTION! This indicates an important description regarding technical interventions,

dangerous conditions, safety warnings, precautionary advice and/or very important information.

FIRE DANGER

DANGER OF ELECTRIC SHOCK. During all operations requiring the removal of high volt-

age connections, take great care to avoid electric shock. Remember that high voltage cables can hold an electric charge or be directly connected to parts that hold an electric

charge even after the equipment has been switched off.

MACHINE STOPPED! Any operation highlighted by this symbol must only be carried out

with the machine stopped.

RISK OF RADIATION AND SAFETY PRECAUTIONS. It is dangerous for anyone to use

this equipment in any way without having received appropriate training, including the procedures for the use of X-rays, so as not to cause damage to the patient, the user and anyone

present in the X-ray room.

Page II MAN056-intro.pub

CAT Medical Systems Consultation notes

DANGER OF EXPLOSION. This equipment is not classified as anesthetic-proof and may

set inflammable anesthetics on fire. Inflammable products used for cleaning or disinfecting

the skin may also constitute a danger of explosion.

SPECIALIZED PERSONNEL! Any operation highlighted by this symbol must only be carried out by a specialized technician sent by the manufacturer or by personnel that have

attended a specific training course organized by the manufacturer.

MAN056-intro.pub Page III

Safety CAT Medical Systems

SAFETY.

ATTENTION

RISK OF RADIATION AND SAFETY PRECAUTIONS.

It is dangerous for anyone to use this equipment in any way without having received appropriate

training, including the procedures for the use of X-rays, so as not to cause damage to the patient ,

the user and anyone present in the X-ray room.

DANGER OF ELECTRIC SHOCK

During all operations requiring the removal of high voltage connections, take great care to avoid

electric shock.

Remember that high voltage cables can hold an electrical charge or be directly connected to parts

that hold an electrical charge even after the equipment has been switched off.

DANGER OF EXPLOSION

This equipment is not classified as anesthetic-proof and may set inflammable anesthetics on fire. Inflammable products used for cleaning or disinfecting the skin may also constitute a

danger of explosion.

• Before using the radiological equipment, make sure that the protective screens are in-

stalled.

• The operator must not stand in the area occupied by moving parts of the equipment.

• All personnel not directly involved in the use of the equipment must leave the X-ray

room or stay behind the protective shields.

IMPORTANT !

DO ALWAYS WEAR THE DOSIMETRIC DEVICE.

Page IV MAN056-intro.pub

CAT Medical Systems

PART 1

Revisioni:

MOVEMENT

MOVEMENT

MOVEMENT

AND

AND

AND

INSTALLATION

INSTALLATION

INSTALLATION

DELTA 90, DELTA 90 PLUS, DELTA 30

Name of file Num. Date

MAN056 2 10/05/2010

DELTA 30: MAN005-1 1 1/09/1998

DELTA 90:MAN003-1 2 10/01/2003

MAN056-1.pub Page 1/22

PART1: Movement and installation CAT Medical Systems

1. MOVEMENT AND INSTALLATION.

Foreword:

On delivery of the machine, make sure (visually together with the courier) that none of the units have

been damaged in any way: if any damage is noted, this should be reported to the person responsible.

The Manufacturer is not responsible for damage caused by transport operations that do not comply

with the indications reported.

The units must be lifted and moved by means of a forklift truck only, except for the main upright

which is fitted with eye bolts for lifting from above. For lifting and movement in difficult conditions,

additional personnel must be used to control the movements to be made and avoid dangerous

situation.

Particular attention should be paid to protruding parts and to jerks, bumps and uneven surfaces,

etc...

1.1 PACKING CHARACTERISTICS.

The DELTA 90-90 PLUS and DELTA 30 are prepared for transport divided into functional units,

wrapped and protected in nylon and carton for long transports, and in particular conditions vacuum

bags with plastic and wooden crates are used.

1.2 DISPOSAL OF THE PACKING.

After unpacking, all the packing material must be disposed of in accordance with the current regulations for environment protection.

Page 2/22 MAN056-1.pub

CAT Medical Systems PART1: Movement and Installation

1.3 MOVEMENT AND LIFTING OF THE PACKING WHEN CRATES ARE USED.

The crates are marked with pictograms indicating the correct movements to be made.

The fork-positioning points are indicated with pictograms since the crates must be moved with a

forklift truck in a balanced load condition.

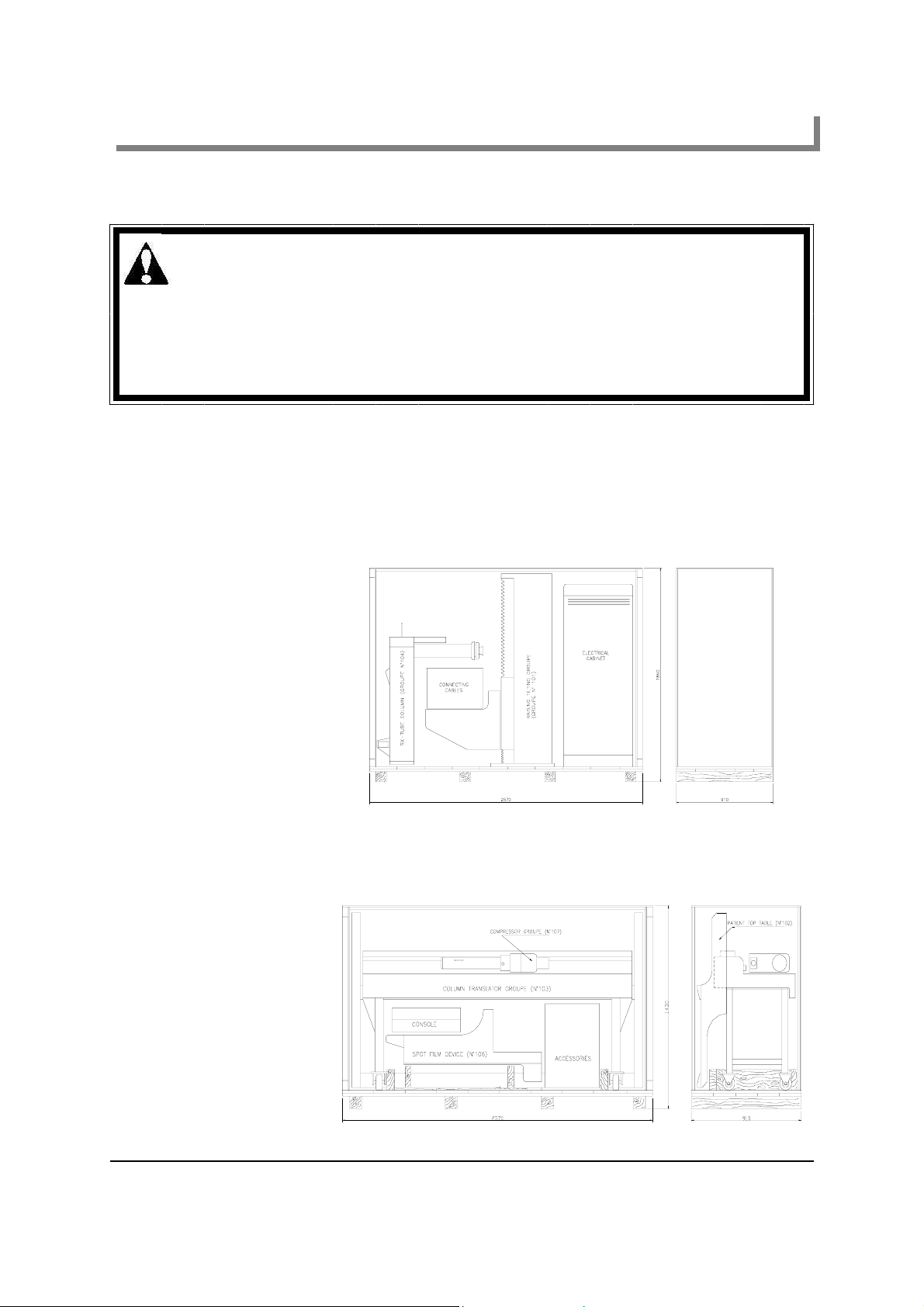

1.3.1 DELTA 90-90PLUS case:

The units that make up the DELTA 90-90PLUS are packed into two crates with the contents indicated

in the figures and with the dimensions and weights reported in the table below.

Crate1 (fig.1.1):

Electrical cabinet

Vertical upright

Connecting cables

X-ray tube column

Crate 2 (fig.1.2):

Column translator unit on

a support to be returned

Compressor unit

Patient table

Console, Spot film device

and Accessories

fig.1.1

fig.1.2

MAN056-1.pub Page 3/22

PART1: Movement and installation CAT Medical Systems

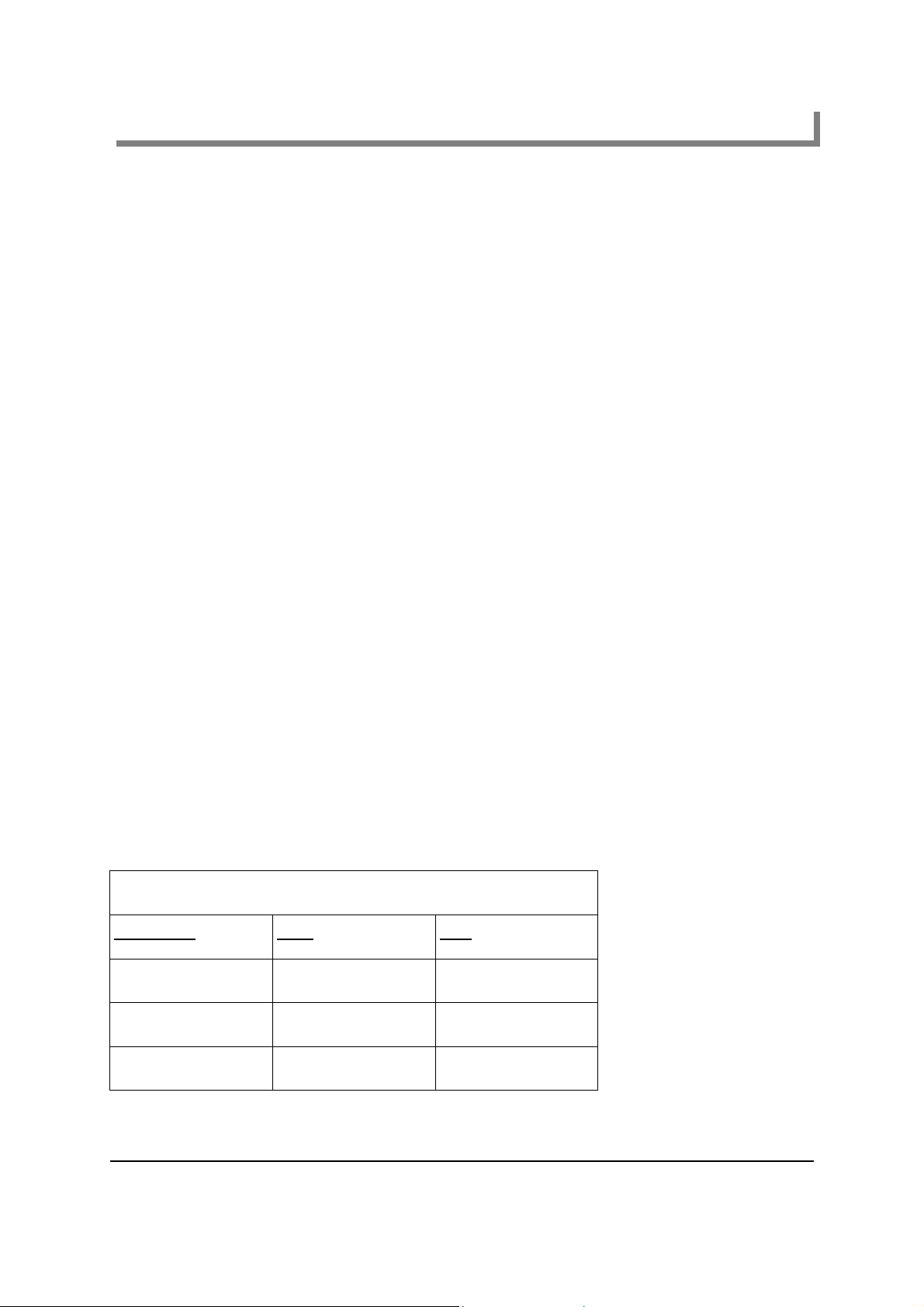

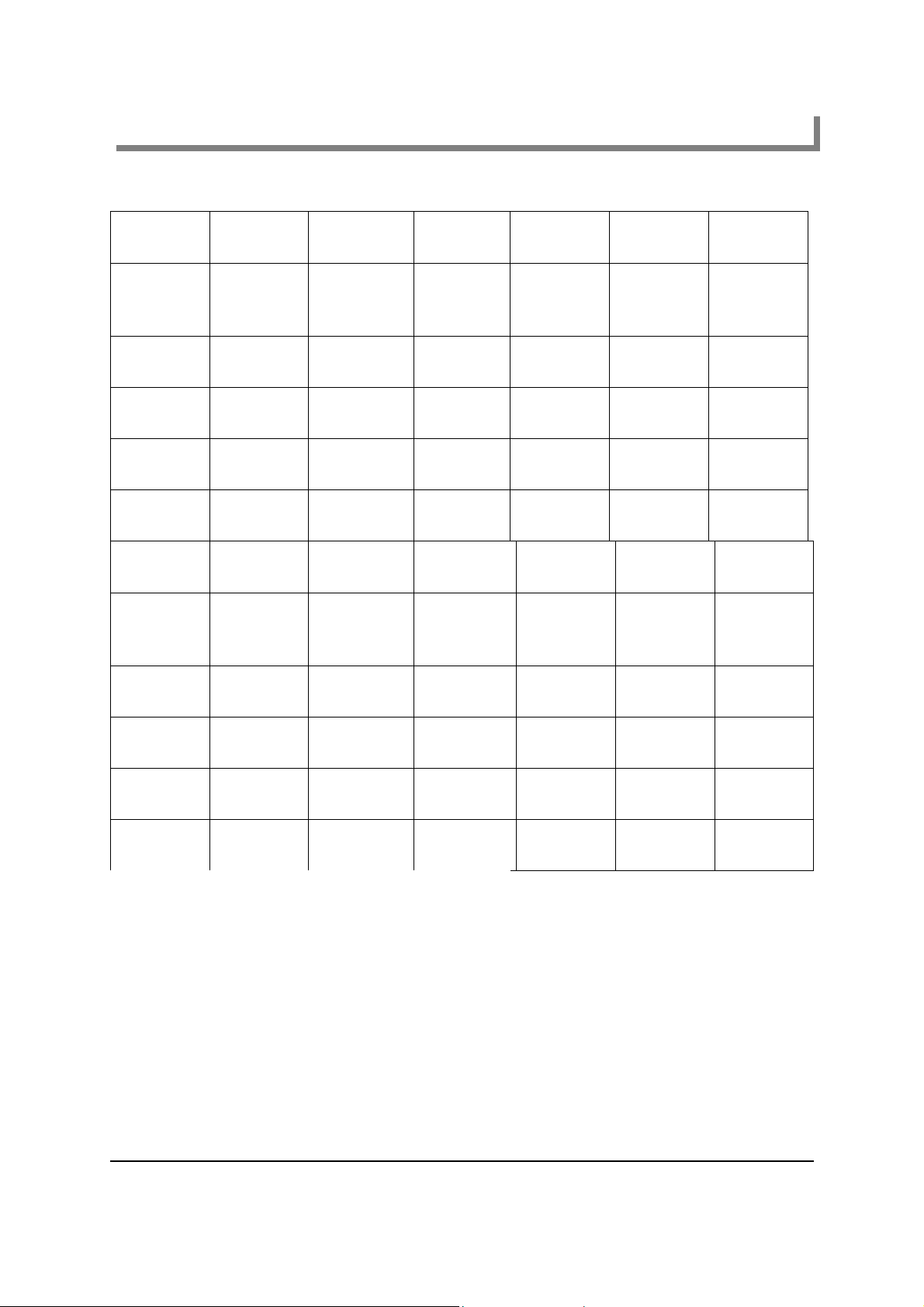

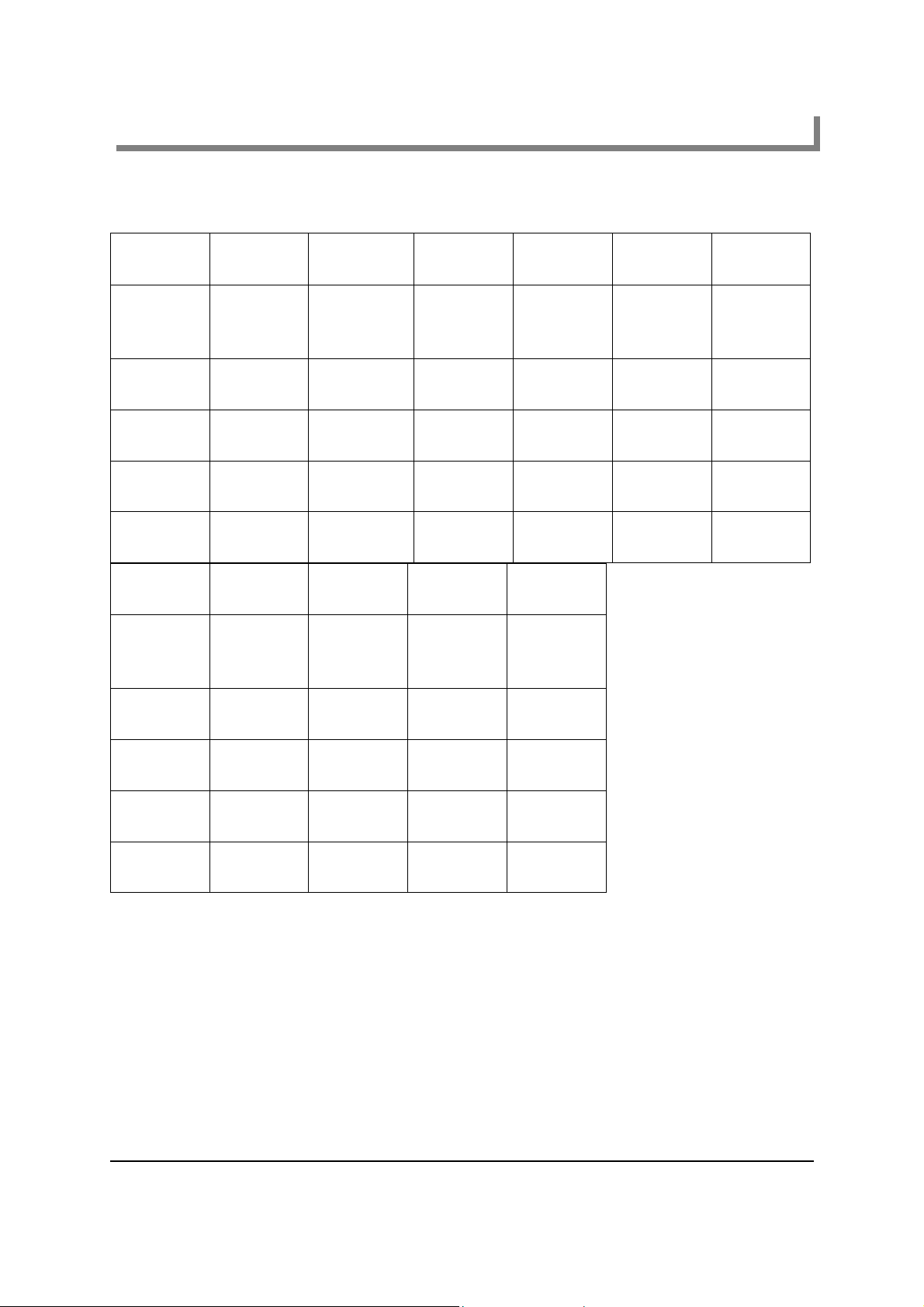

Table of packed weight and dimensions of the DELTA 90-90PLUS

PACKAGE

No.

DESCRIP

BASE

WIDTH

HEIGHT

WEIGHT

PACKAGE

No.

DESCRIP

1 2 3 4 5 6

Patient

table

Foot-rest

Shoulder-rest

Spot film

device

Compressor X-ray tube

column

Column

translator

Hand-grips

2450 780 1400 950 1250 2360

1300 340 620 200 600 800

250 380 640 340 1250 1000

70 12 71 19 84 265

7 8 9 10 11 12

Vertical upright

Compress.

band

Electrical

cabinet

Collimator Console I.I.

support

BASE

WIDTH

HEIGHT

WEIGHT

1380 430 600 350 600 1200

900 50 660 280 500 620

1800 120 1620 340 1100 640

535 4 173 12 23 30

LARGE CRATE: (2560x910x1900) 156 kg

SMALL CRATE: (2560x910x1470) 141 kg

All the dimensions are expressed in mm.

All the weights are expressed in Kg. and include the electrical cables.

Condition of the packed unit groups:

• The connecting cables protruding from the column and spot film device ducts are already the cor-

rect length and inside the sheath.

• The connecting cables between the electrical cabinet and the machine during transport are packed

in a crate.

• All the connections are complete inside each unit.

Page 4/22 MAN056-1.pub

CAT Medical Systems PART1: Movement and Installation

1.3.2 DELTA 30 case:

The units that make up the DELTA 30 are packed in one crate with contents indicated in the figures

and with the dimensions and weights reported in the table below.

Crate 1 (fig.1.3):

1. Main chassis.

2. Spot film device.

3. X-ray tube column.

4. Patient table

5. Compressor

6. Accessories.

fig.1.3

MAN056-1.pub Page 5/22

PART1: Movement and installation CAT Medical Systems

Table of packed weights and dimensions of the DELTA 30

PACKAGE

No.

DESCRIP.

BASE

WIDTH

HEIGHT

PESO

PACKAGE

No.

DESCRIP.

1 2 3 4 5 6

Patient table Foot-rest

Shoulder-rest

Spot film

device

Compressor X-ray tube

column

Main chassis

Hand-grips

2450 780 1400 950 1250 2360

1300 340 620 200 600 900

250 380 640 340 1250 1000

70 12 71 19 84 760

7 8 9 10

Compressor

band

Collimator Console I.I. (dig.)

support

BASE

WIDTH

HEIGHT

WEIGHT

430 350 600 1200

50 280 500 620

120 340 1100 640

4 12 23 30

CRATE: (2560x910x1900) Kg.250

All the dimensions are expressed in mm.

All the weights are expressed in Kg. and include the electrical cables.

Condition of the packed unit groups:

• The connecting cables protruding from the column an spot film device ducts are already of correct

length and inside the sheath.

• All the connections are complete inside each unit.

Page 6/22 MAN056-1.pub

CAT Medical Systems PART1: Movement and Installation

1.3.3 MOVEMENT INFORMATION NOTES:

• The conditions to which the contents must not be subjected and the weight are marked on each

crate.

• The fork-positioning points for the forklift truck are indicated on the packing.

• Lifting and movement must be carried out by means of a forklift truck, respecting the fork-

positioning points to ensure movement with a balanced load.

• The weight indicated on the crates is purely indicative.

• The equipment is wrapped in plastic inside the crates.

• On delivery of the machine make sure (visually together with the courier) that none of the units

have been damaged in any way: if any damage is noted, this should be reported to the person responsible; any damage to the crate could indicate damage to its contents.

• During movement and assembly of the machine, work shoes and gloves, and appropriate clothing

should be worn; the current accident-prevention regulations should in any case be carefully respected.

MAN056-1.pub Page 7/22

PART1: Movement and installation CAT Medical Systems

1.4 MOVEMENT AND LIFTING OF THE INDIVIDUAL UNITS.

After removing the crate packing, move the units according to the following indications:

1.4.1 DELTA 90-90PLUS case:

fig.1.4

Electrical cabinet: forklift truck required.

Procedure: insert the forks in the close-together points indicated on the long side of the nylon

wrapping.

Take care not to damage the adjustable feet.

X-ray Tube Column: forklift truck required.

Procedure: tilt the column and insert the forks close together under the base.

Move the column in a fixed and balanced load condition.

Main upright: forklift truck with lifting chains required or equivalent.

Procedure: raise the upright by means of the relative eye bolts and taking into account the

weight indicated on the packing.

Main translator column: (with packages on top)

Procedure: move using the support with wheels which must be removed when installation is

complete and kept for subsequent movement.

If the remaining packages are moved manually, each operator should not carry more than

25 Kg.

N.B.: After positioning the main upright, replace the eye bolts with the plugs provided to ensure protection against water infiltration.

Page 8/22 MAN056-1.pub

CAT Medical Systems PART1: Movement and Installation

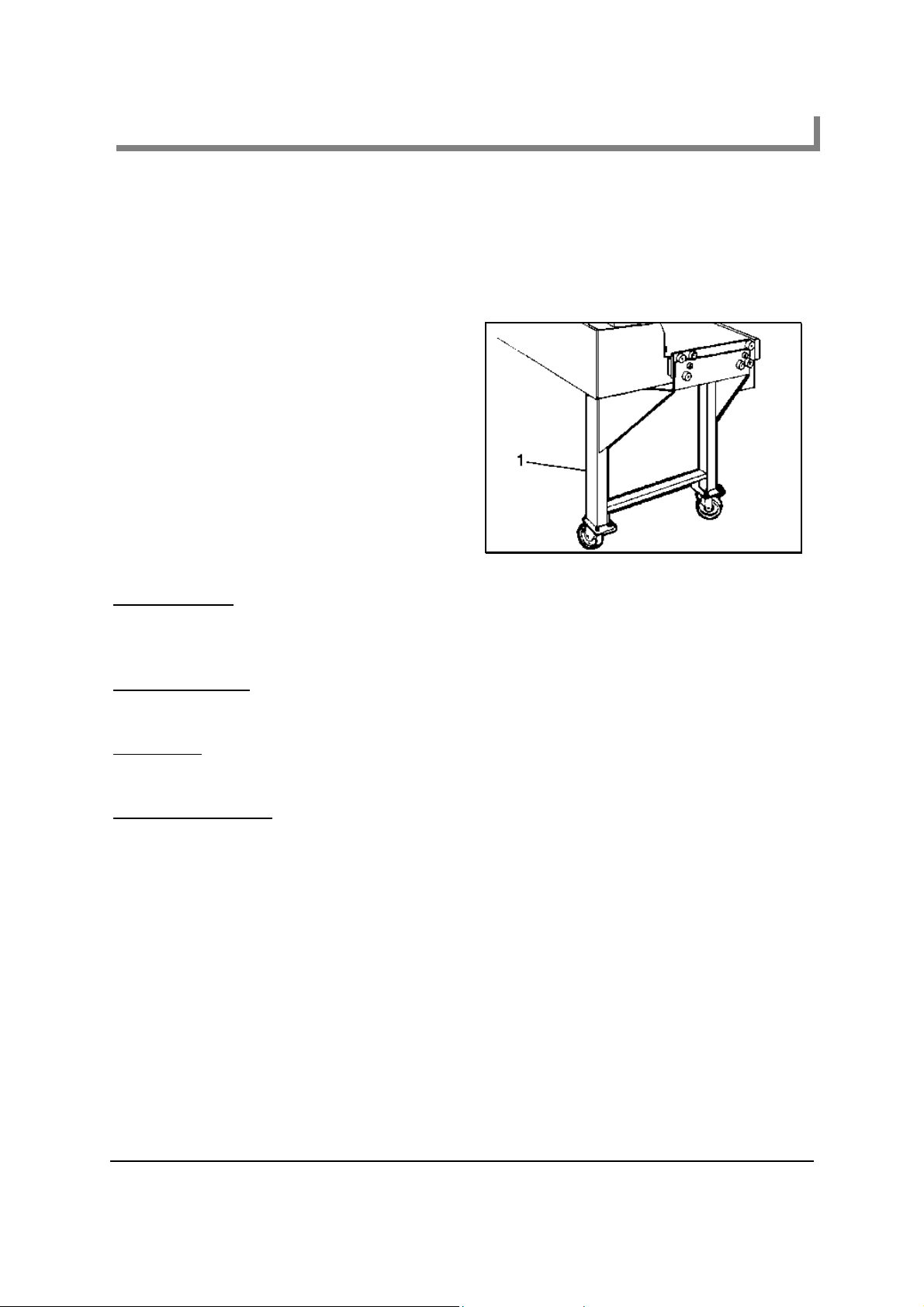

1.4.2 DELTA 30 case:

fig.1.5

X-ray Tube Column: forklift truck required.

Procedure: tilt the column and insert the forks close together under the base.

Move the column in a fixed and balanced condition.

Main chassis: forklift truck with lifting chains required or equivalent.

Procedure: raise the chassis by means of the relative eye bolts and taking into account the

weight indicated on the packing.

If the remaining packages are moved manually, each operator should not carry more than

25 Kg.

N.B.: After positioning the main chassis, replace the eye bolts with the plugs provided to ensure pro-

tection against water infiltration and tilting of the patient table during the movements to +90° and to –

30°.

MAN056-1.pub Page 9/22

PART1: Movement and installation CAT Medical Systems

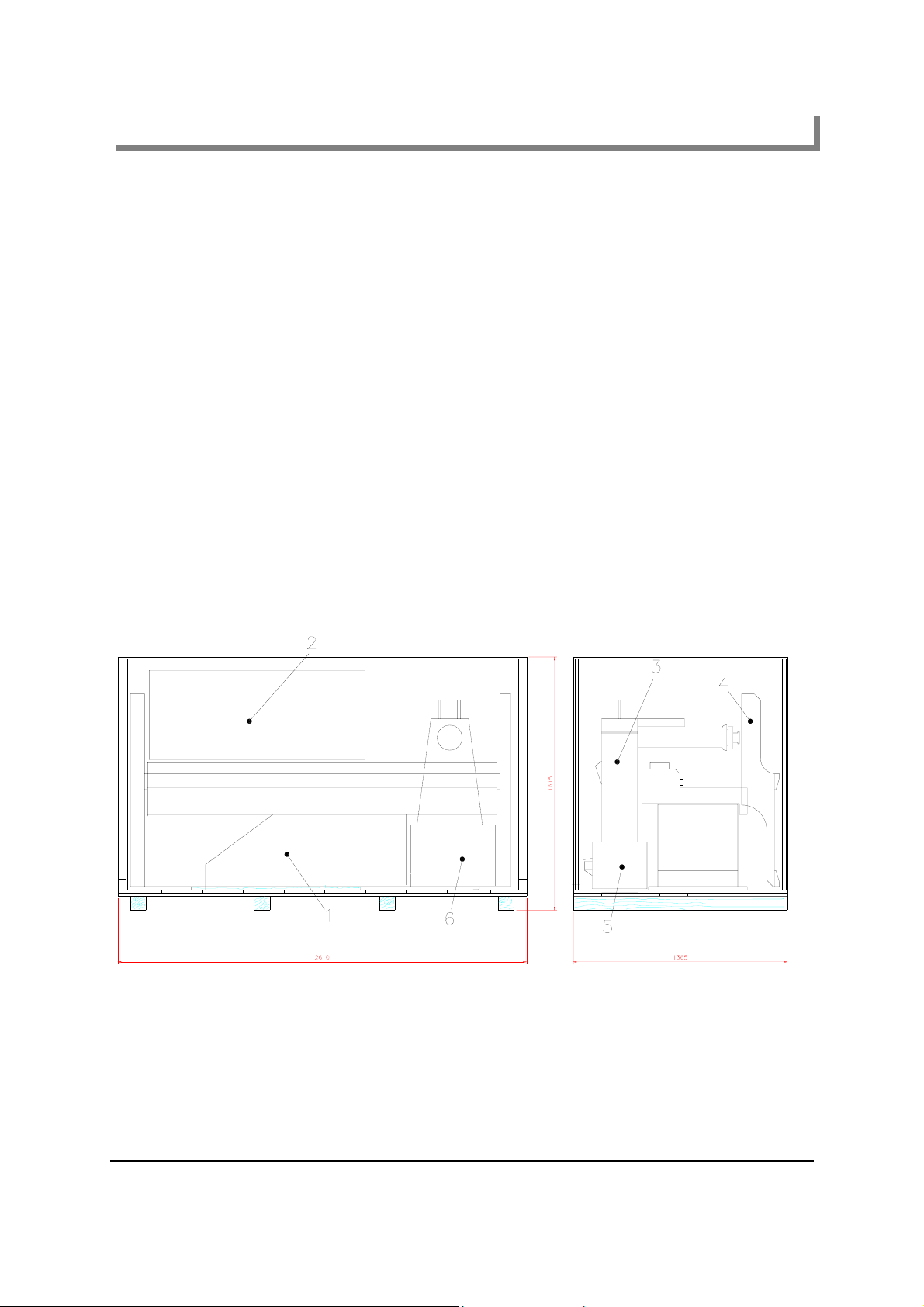

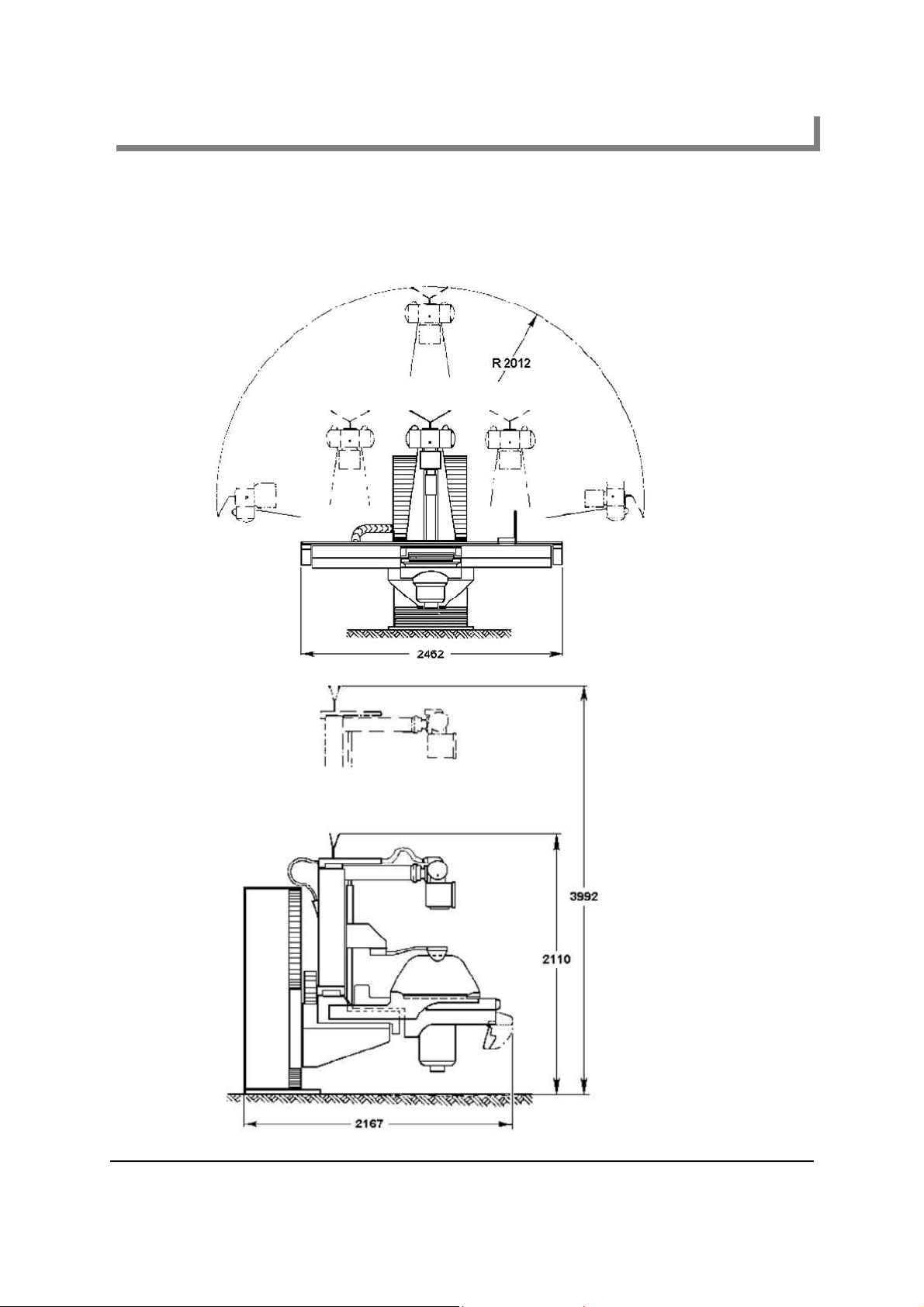

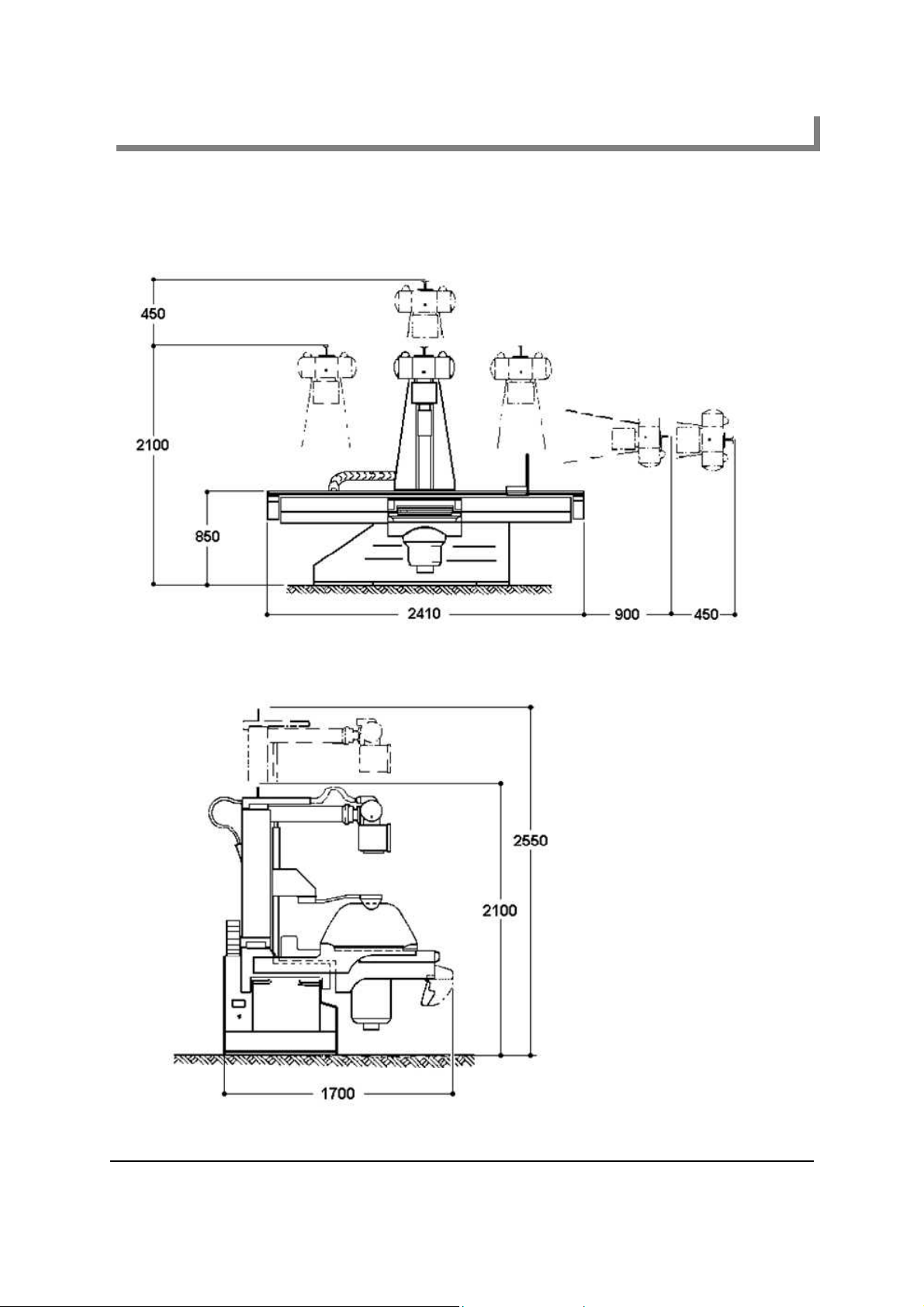

1.5 OVERALL DIMENSIONS OF THE MOVING PARTS.

1.5.1 DELTA 90-90PLUS case:

fig.1.6

fig.1.7

Page 10/22 MAN056-1.pub

CAT Medical Systems PART1: Movement and Installation

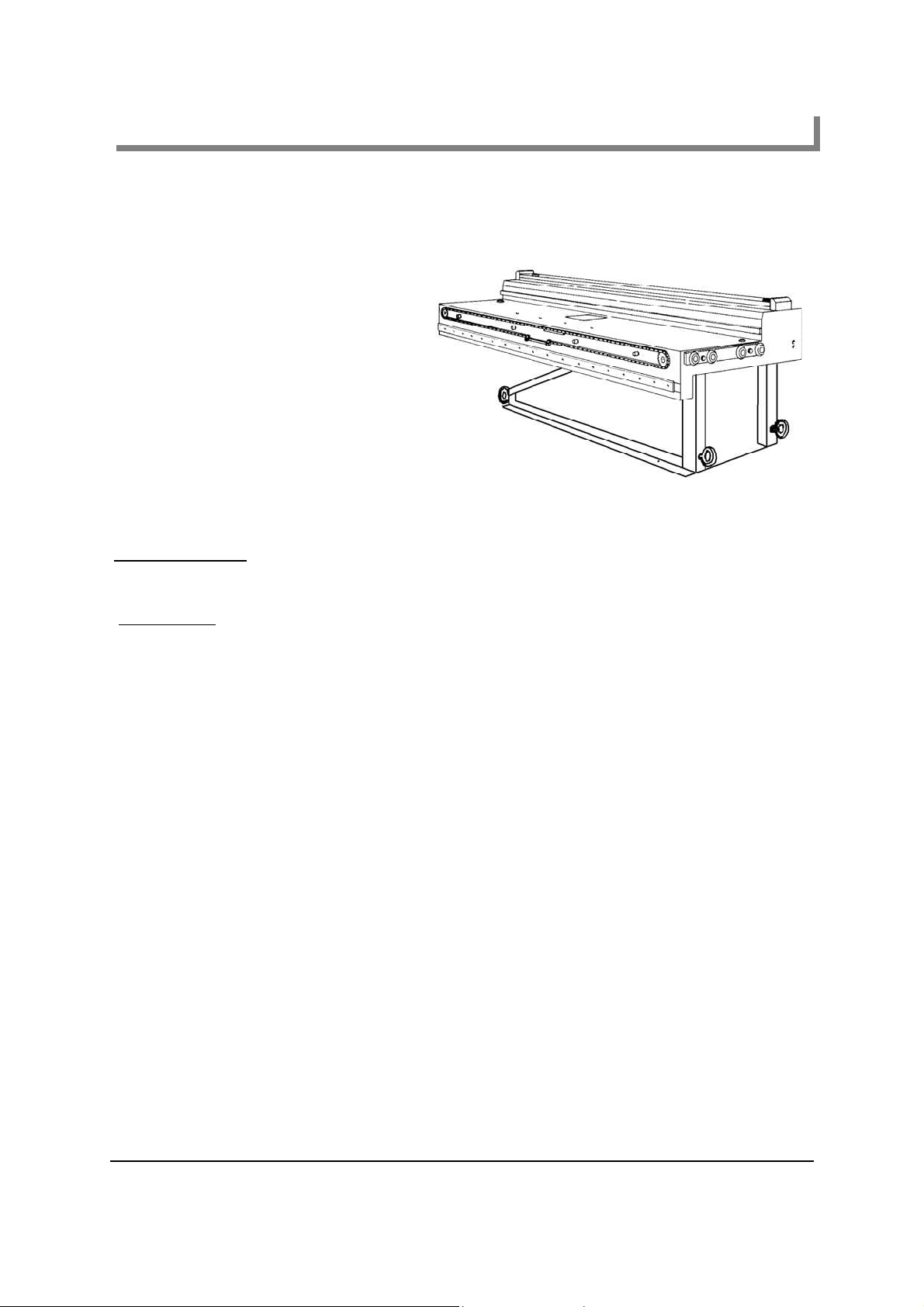

1.5.2 DELTA 30 case:

fig.1.9

fig.1.8

MAN056-1.pub Page 11/22

PART1: Movement and installation CAT Medical Systems

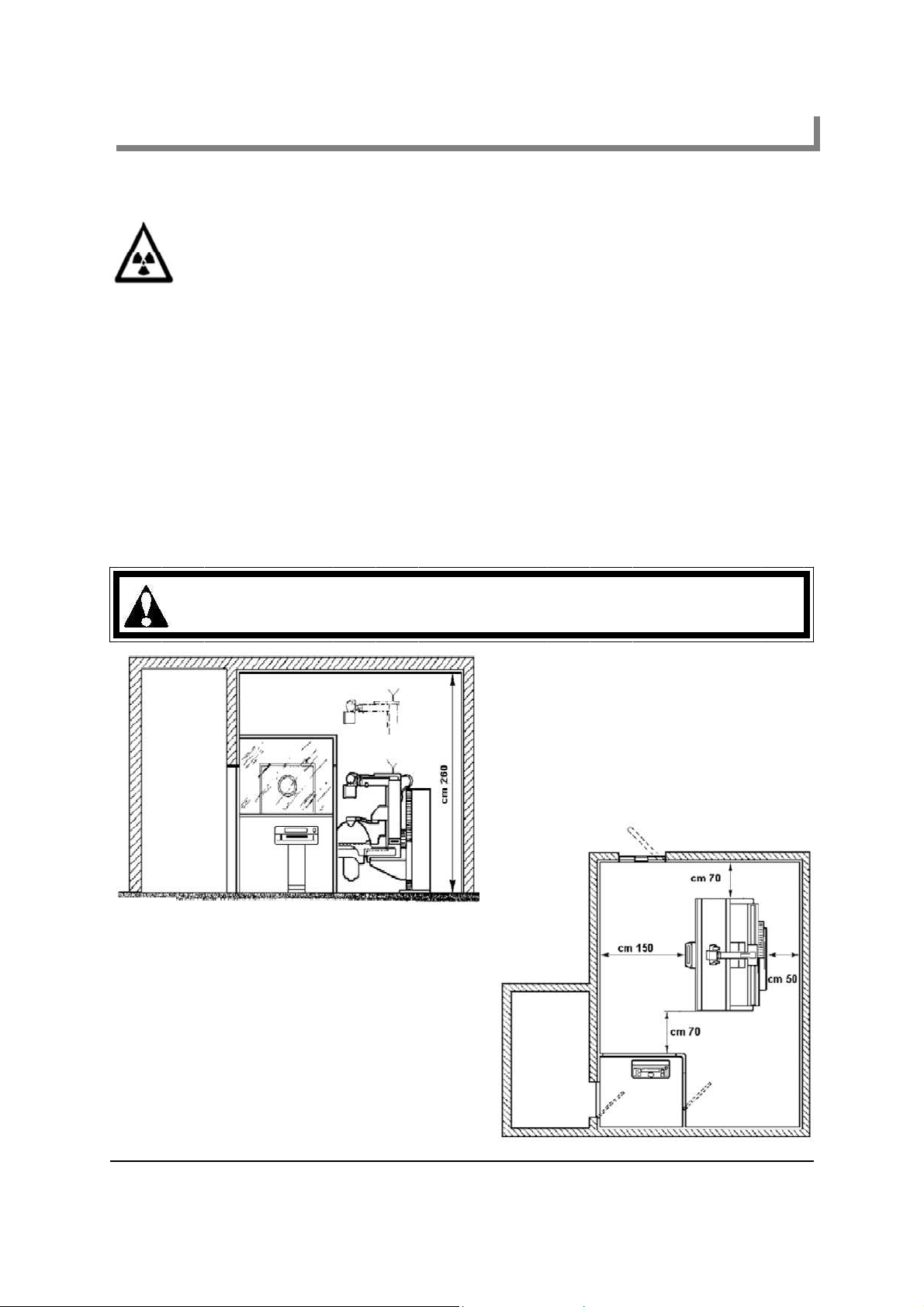

1.6 POSITIONING: CHARACTERISTICS OF THE ROOM.

Respecting the minimum requirements for machine positioning and functioning, always check

the following first: surrounding conditions, temperature, humidity, lighting, vibrations, dust,

radiation emissions and the cleanliness of the room where the machine will be installed.

DELTA 90 90PLUS, DELTA 30 must be installed in an appropriate room (with no infiltration

of water from the ceiling), with controlled temperature and degree of humidity, and with no

presence of gas mixtures that can constitute a danger of fire or explosion (e.g. Operating

rooms, or inflammable anesthetics) in strict accordance with the current regulations regarding

radiation emission (X-rays) (see example fig. 1.10 and 1.11).

A visual indicator must be positioned outside the room to warn that X-rays are being taken.

•Area occupied by the equipment: 4.8 sqm.

•Fig. 1.10 and 1.11 show the measurements (indicative) of the working spaces needed for

safe use and rational maintenance of the machine.

•Minimum dimensions of the room: 380x390x260(h) cm.

fig.1.10

The floor must be perfectly leveled, vibration-free and able to support the overall weight of

the machine (+4 people).

fig.1.11

Page 12/22 MAN056-1.pub

CAT Medical Systems PART1: Movement and Installation

1.7 INSTALLATION.

At this stage it is necessary to have a PC available with CATWIN software installed and to consult the

specific tables (Ref. List of attached documents).

Operative stage.

1) Installation :

Position the crates close to the installation area, remove the plastic wrapping from the individual units,

which must be moved according to the indications in paragraph 1.3

DELTA 90-90 PLUS case:Position and fix the vertical upright to the ground as indicated in the follow-

ing paragraph 1.8. Place the electrical cabinet in position, lay the cables

connecting the cabinet to the vertical upright along their pre-arranged route,

and connect as shown in the specific tables.

DELTA 30 case: Position and fix the chassis to the ground as indicated in the following para-

graph 1.8. The DELTA 30 does not have an electrical cabinet apart from the

machine. All the electrical components are integrated in the main chassis.

Therefore, the two compartments front and rear of the main chassis that

contain the electrical components and electronic of control will be called

electrical cabinet.

The machine is supplied (unless specific otherwise) with connecting cables of different length that depends on the machine positioning inside the X-ray room.

As regards the connection of the cables of the X-ray tube column, the installer is advised to insert the

power and x-ray tube control cables with the machine completely dismantled and the generator cabinet

in its final position. The power cables must follow those of unit 2, (X-ray tube column) inserting them in

the flexible duct and making them 20cm shorter than XC11/12/13.

MAN056-1.pub Page 13/22

PART1: Movement and installation CAT Medical Systems

N.B. Only for the DELTA 90-90PLUS: check that the high voltage cables and anode start cables were

inserted preventively. Otherwise, it is necessary to install the cables, forming a not too tight loop between the compartment of the vertical upright and the entry into the flexible duct ( fig. 1.12), following

the pre-installed cables.

fig.1.12

Do not lock for any reason, any cable inserted in the sheath.

Page 14/22 MAN056-1.pub

CAT Medical Systems PART1: Movement and Installation

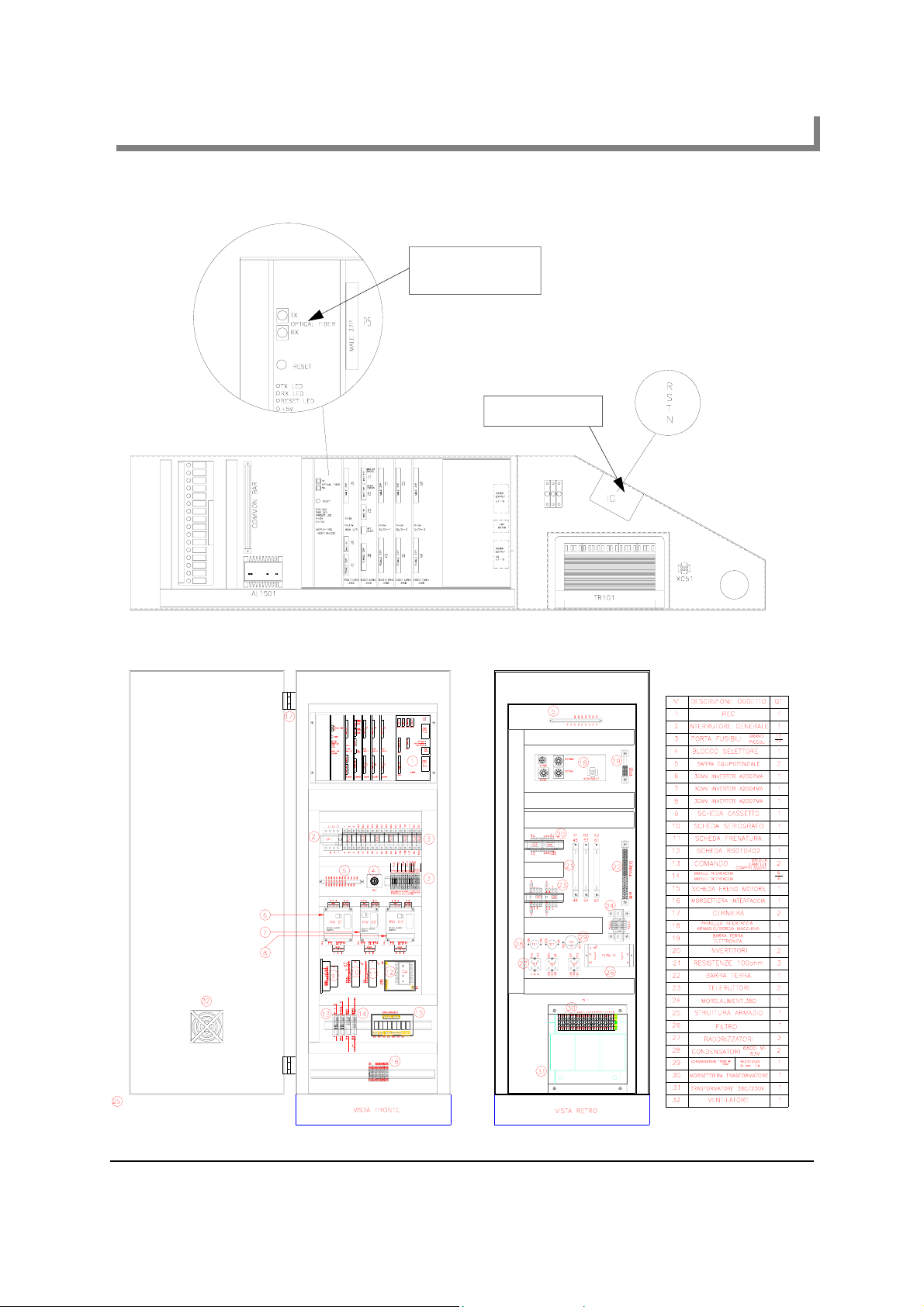

Connect the electrical cabinet to the main power supply as shown in fig.1.13 in case of DELTA 30 and

as shown in fig. 1.14 in case of DELTA 90-90PLUS.

CONNECTING

OPTICAL CABLE

POWER SUPPLY

fig.1.13: DELTA 30

fig.1.14: DELTA 90-90PLUS

MAN056-1.pub Page 15/22

PART1: Movement and installation CAT Medical Systems

Position and connect the Console as shown in the specific documentation (Ref. to Part 5 of this manual).

Attach the“ set up connectors” as indicated in part 5 of this manual (Tab.2).

Turn on the electrical cabinet by means of the main switch.

Press the“ Power On “ button on the console an command:

In case of DELTA 90-90 PLUS: lowering of the column translator by maintaining it in a horizontal position, till the minimum height from the ground.

If no anomalies are encountered, assemble the column translator and the column, spot film

device and patient table.

In case of DELTA 30:

check the tilting range –30°÷0° and the range +90°÷ 0°.

If no anomalies are encountered, assemble the column, spot film device and patient table.

If movement problems are encountered following the installation of the individual units, it is necessary

to proceed step by step checking the connections of the cables as specified below:

- Connect the PC with the CATWIN software installed to the optical fiber like in DELTA 90-90PLUS on

the micro-card inside the electronic rack, and in case of DELTA 30 as shown in fig.1.13. Turn on the

PC and launch the program using the PC keyboard, check whether the status inputs are configured

according to Table 1. part 5, if not check the service connectors referring to Table 2 part 5.

2) Cable Connection

Before connecting the cables to their respective connectors, check that all the contacts have

been perfectly inserted and locked to the connectors, thus obtaining a correct contact between the pins.

• Insert the cables in the pre-arranged positions, following the layout provided.

• First connect the cables of:

DELTA 90-90 PLUS case:

- vertical upright

- column translator

- column

- spot film device

- tube/collimator

DELTA 30 case:

- chassis

- spot film device

- tube/collimator

Page 16/22 MAN056-1.pub

CAT Medical Systems PART1: Movement and Installation

• It is however necessary to check the correct length of the tube/collimator cables, before forming the

external loop (X-ray column and collimator), which allows the cables to move up, down and follow

the rotation without any obstacles.

• The I.I. cables and the imaging system, if fitted, must be inserted in an orderly fashion and parallel

to each other, in order to prevent them from overlapping each other and detaching the sections of

the duct.

• It is indispensable that the length of the unit connecting cables be correctly arranged inside the

machine.

The cables must be left free to move inside cable guides, do not fix cables FOR ANY REASON with plastic lockers to pack cables inside cable guides.

MAN056-1.pub Page 17/22

PART1: Movement and installation CAT Medical Systems

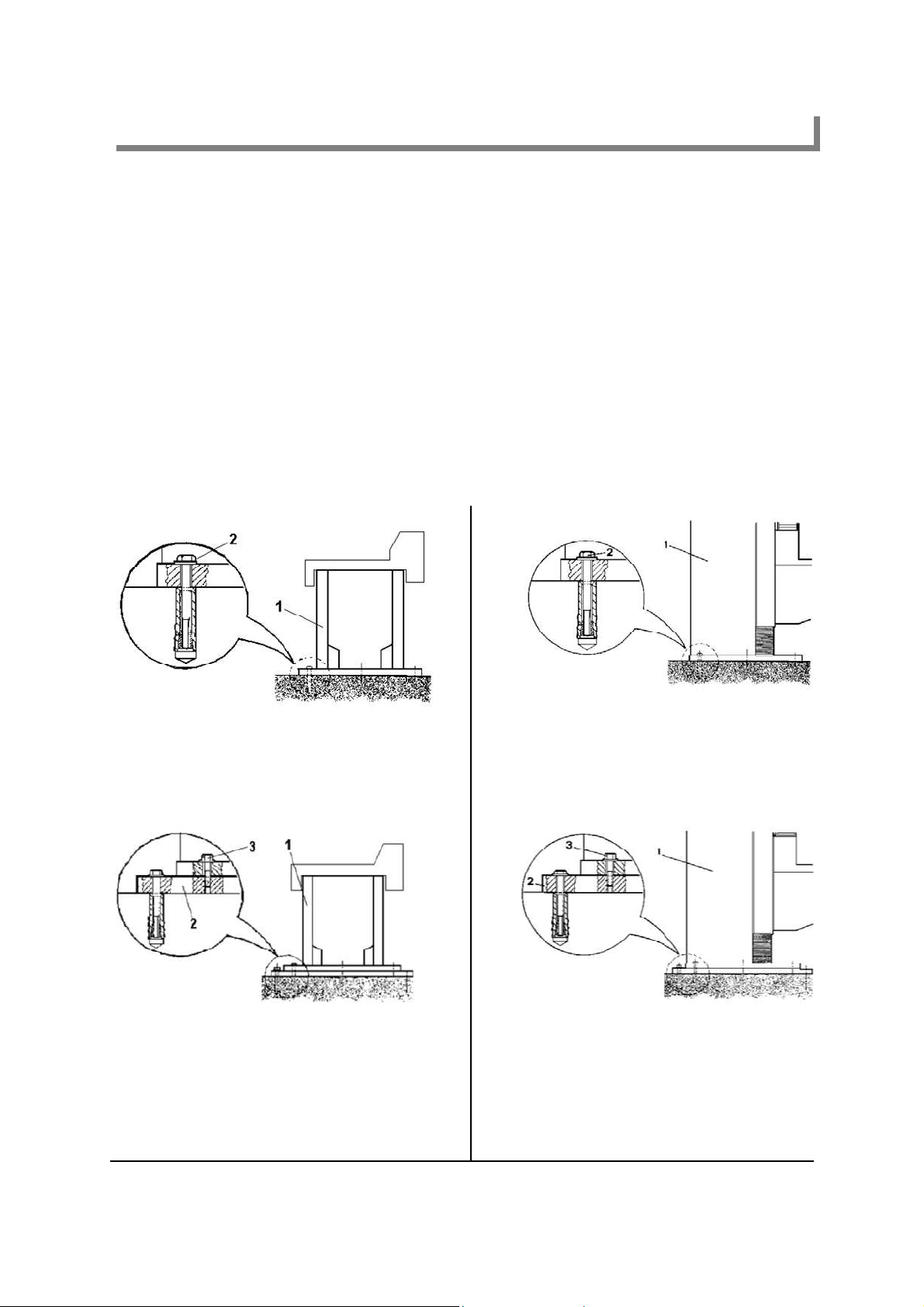

1.8 FIXING TO THE FLOOR.

To ensure good working results, the machine must be fixed to the floor since it has to function in to-

tally stable conditions and with no vibrations whatsoever.

Depending on the type of the floor, the fixing systems of the base (vertical upright for the DELTA 9090PLUS and chassis for the DELTA 30) can be:

A) Direct fixing by means of expansion bolts (fig.1.15), suggested only for the DELTA 30.

B) Fixing to a steel counter-plate previously fixed to the floor (fig.1.16).

C) Fixing to steel bars buried inside the floor.

The types of fixing B) and C) are suggested for the DELTA 90-90PLUS and are to be used for the

DELTA 30 if the load capacity of the floor is low.

DELTA 30 DELTA 90-90PLUS

1) Base

2) n° 6 Fischer

SL-M12 bolts (c.l. 8.8)

1) Base

2) Counter-plate

3) 6 M12x50 screws

fig.1.15

fig.1.16

1) Base

2) n° 6 Fischer

SL-M12 bolts (c.l. 8.8)

1) Base

2) Counter-plate

3) 6 M12x50 screws

fig.1.15

fig.1.16

Page 18/22 MAN056-1.pub

Loading...

Loading...