Page 1

QV-780B

INDEX

(KX-776B/NTSC)

APR. 1999

(without price)

R

Page 2

CONTENTS

SPECIFICATIONS ......................................................................................................................................1

WIRING AND BLOCK DIAGRAM..............................................................................................................3

POWER SUPPLY CIRCUIT OPERATION..................................................................................................4

ADJUSTMENT ...........................................................................................................................................5

1. Unit Adjustment ....................................................................................................................................5

1-1. Color parameters loading ............................................................................................................5

1-2. Scratch compensation .................................................................................................................6

1-3. Flash adjustment ..........................................................................................................................6

1-4. Flash check ...................................................................................................................................7

1-5. Current consumption ...................................................................................................................8

1-6. Clock reset ....................................................................................................................................8

1-7. Other test modes ..........................................................................................................................9

2. PCB K772-DA Adjustment ....................................................................................................................9

2-1. VCC1, VCC3 voltage check........................................................................................................10

2-2. VCC7, VEE3 adjustment.............................................................................................................10

2-3. Clock oscillation check ..............................................................................................................10

3. PCB K772-L Adjustment..................................................................................................................... 11

3-1. VCC1 adjustment and VCC2, VCC6, VEE2, VCC0 voltage check...........................................12

3-2. VCO free run frequency adjustment .........................................................................................12

3-3. Backlight drive voltage adjustment ..........................................................................................12

3-4. VCOM AC adjustment and VCOM DC coarse adjustment.......................................................13

3-5. Brightness voltage setting and contrast adjustment..............................................................13

3-6. Color adjustment ........................................................................................................................14

3-7. TINT adjustment..........................................................................................................................14

3-8. VCOM DC adjustment.................................................................................................................15

DISASSEMBLY ........................................................................................................................................16

PRINTED CIRCUIT BOARDS ..................................................................................................................22

TROUBLESHOOTING .............................................................................................................................26

EXPLODED VIEW ....................................................................................................................................28

PARTS LIST .............................................................................................................................................30

SCHEMETIC DIAGRAMS ........................................................................................................................36

Page 3

SPECIFICATIONS

Item Specification

Recording System Digital (JPEG base); PC Link software can be used to input images in CAM,

JPEG, TIFF and other format.

Recording Medium Memory card (2MB card included)

Memory Capacity FINE: 14 images (Minimum) (133KB compressed)

(2MB Card)/ NORMAL: 26 images (Minimum) (70KB compressed)

Computer Output image ECONOMY: 47 images (Minimum) (38KB compressed)

The above figures are approximations only. The actual number of images

depends on image subject matter.

Image Element 1/4-inch CCD (350,000 pixels)

Computer Output image 640 x 480 pixels

Lens Fixed focal point with macro position; F2, f = 3.94mm

Aperture F2, F8 switching/fixed

Focus Range NORMAL: 0.7m to ∞

MACRO: 14cm to 16cm (From surface of protective lens.)

Light Metering TTL center priority by CCD

Exposure Metering Program AE

Exposure Range EV +5 to 18

Exposure Correction –2EV to +2EV (1/4EV units)

Shutter CCD electronic shutter

Shutter Speed 1/8 to 1/4000 second

White Balance Automatic, WB1, WB2, WB3

Self-timer 2, 10 seconds

Recording Modes Single-image; Movie; Repeat; Panorama; Timer; Interval timer; Self-timer

Flash Modes AUTO, ON, OFF

Monitor 2.5-inch TFT low-glare color LCD; 84,480 pixels

Video Output NTSC

Input/Output Terminals

Clock January 1, 1998 00:00:00 to December 31, 2049 11:59:59 (Auto Calendar)

Power Supply

Power Consumption Approximately 6.4 W

Standard Battery Life This camera can be power using AA-size alkaline, lithium or Ni-MH batter-

DIGITAL OUT, VIDEO OUT, AC adaptor connector, memory card connector

Four batteries (AA-size alkaline, lithium or Ni-MH batteries)/AC adaptor (AD-C620)

ies. The battery life reference values given below indicate the amount of

time at standard temperature (25°C) until power automatically turns off due

to battery failure. They do not guarantee that batteries will perform the amount

of service indicated. Battery life is reduced by low temperatures and contin-

ued use.

Continuous Playback: Alkaline Batteries (LR6); Approx.180 minutes

Lithium Batteries (FR6); Approx. 290 minutes

AA-size Ni-MH; Approx.170 minutes

Continuous Recording: Alkaline Batteries (LR6); Approx. 630 shots

Lithium Batteries (FR6); Approx. 1,200 shots

AA-size Ni-MH; Approx. 780 minutes

•The above figures are approximations only.

•The above guidelines are based on the following battery types:

Alkaline: MX1500 (AA) DURACELL ULTRA

Lithium: Energizer

Ni-MH (Nickel-Metal Hydride): CASIO NP-H3

•Battery life varies with brand.

“Continuous Recording” is made without use of the camera’s flash.

Regardless of use of the camera’s flash, turning on and off the POWER

Switch, as well as other operating conditions may affect the above values.

— 1 —

Page 4

Dimensions 147(W) x 69(H) x 50(D) mm

Weight Approximately 290g (excluding batteries)

Standard Accessories Memory card; wrist strap; soft case; video cable; four LR6 alkaline batteries;

owner’s manual.

•The camera also has a lithium battery that powers its built-in clock.

When the power of this battery becomes weak, take the camera to your

CASIO Service Provider to have it replaced.

•The liquid crystal panel built into this camera is the product of precision

engineering, with an effective pixel rate of 99.99%. This also means,

however that 0.01% of the pixels can be expected to fail to light or to

remain lit at all times.

— 2 —

Page 5

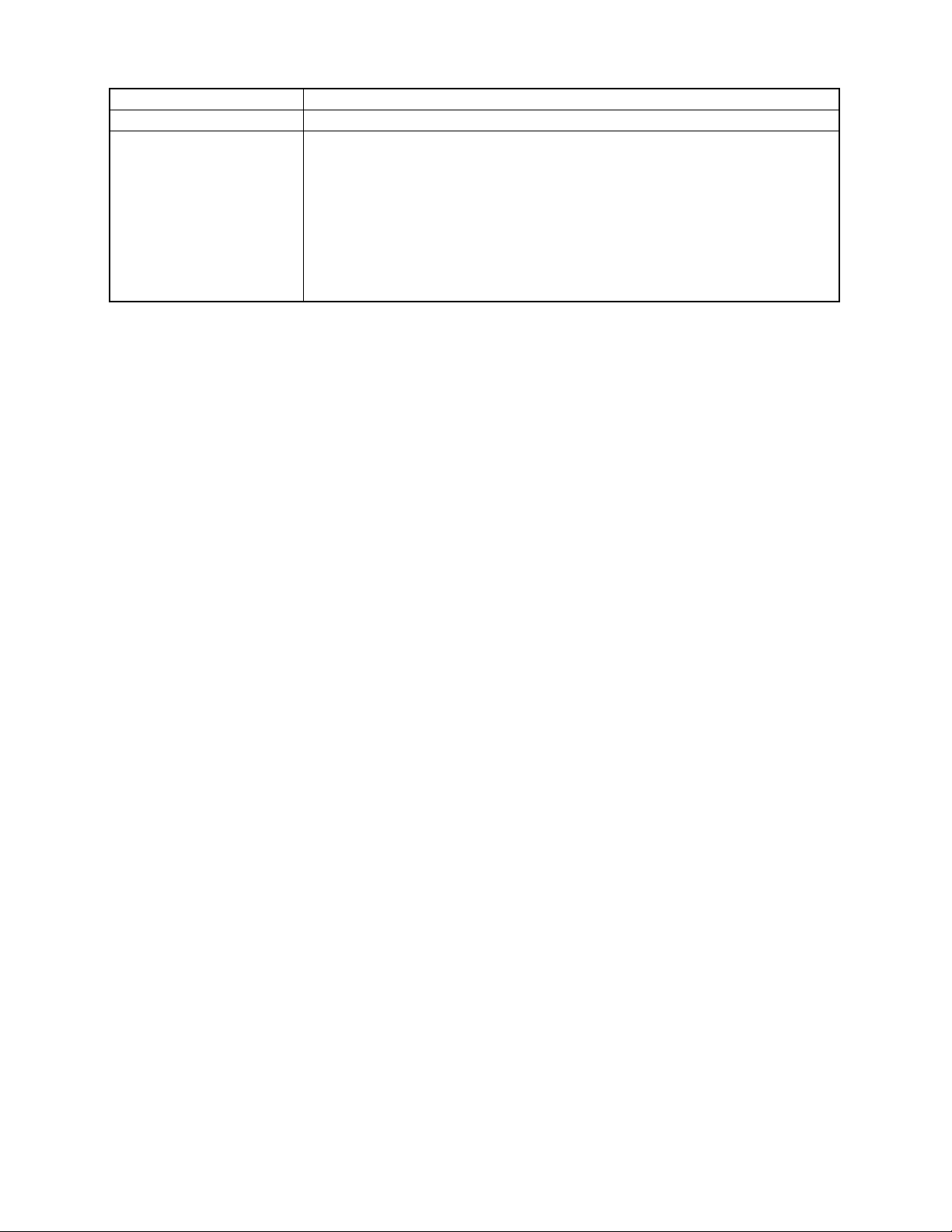

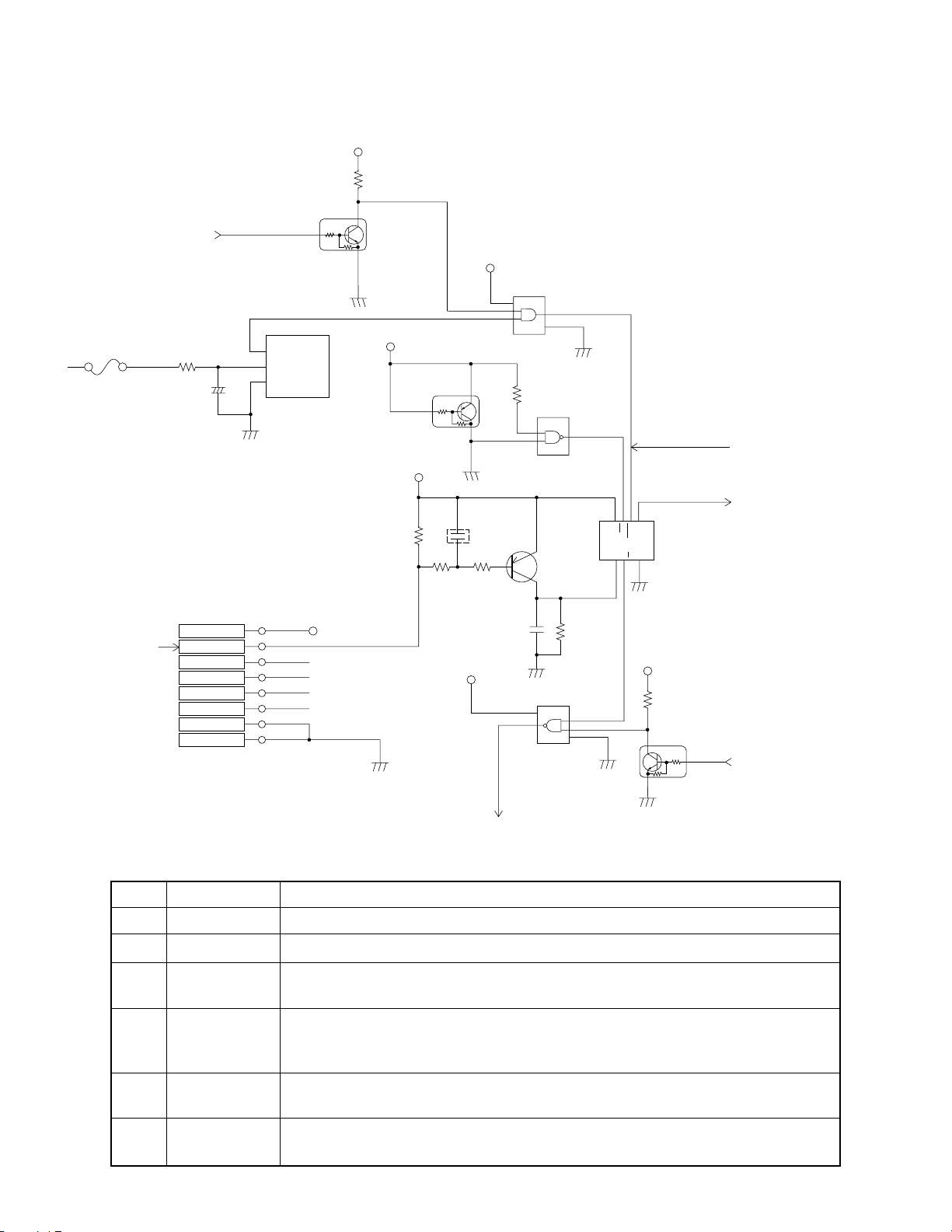

WIRING AND BLOCK DIAGRAM

Photo INT

Auto Iris Lens

Solenoid

CB-PCB

ICX098AK

15V

CCD

15V

-5.5V

Vdrv

CXD1267AN

3.5V

CXA2056Q

CDS+AGC

CXD2310R

ADC

3.5V

BR9040F

EEROM

T.G

3.3V

CXD2452R

20-pin

23-pin

8-pin

KEY-PCB

DA-PCB

60-pin

3.3V

YUV

Processor

CXD3120R

3.3V

3.0V

Switching

RS5C316A

RTC

UPD6466

OSD

MB91181

Detection

Switch

3.3V

MACO

3.2V

INTR

CFDET

Signal

Generator

Video

RS232C

EDO_

DRAM

Flash

Memory

3.3V

3.3V

3.3V

15.0V

-5.5V

5.0V

Battery Voltage

Voltage Controller

5V

VIDEO

RS232C

3.3V

CF

AC Adaptor

6.0V

10-pin

3.0V

4.5V

18.0V

12.0V

-10.5V

Transformer

5-pin

Battery voltage

GND

Battery voltage

GND

7-pin

Strobe Ass'y

Comparator

Photo

Sensor

Xenon Lamp

Battery

Voltage

Voltage Controller

Detection Sw.

(RSTW)

FUNC

button

LED

Chroma

IR3Y18A

Display Controller

CM7013L2

4.5V

3V

26-pin

BL

LCD module

High Voltage

Generator

5-pin

CA-PCB

Motor Driver

IRISA/IRISB

Battery Voltage

L-PCB

3.3V

7-pin

3.3V

— 3 —

Page 6

2 APO from Pin 202

of IC500

FU152 R590

C525

POWER SUPPLY CIRCUIT OPERATION

VCC1-1

3

1

2

Q580

IC584

1

OUT

VDD

GND

NC

NC

2

3

+

VCC1-1

5

4

Q582

VCC1-1

VCC1-1

IC586

5

VCC

1

4

2

3

GND

2

1

3

R585

IC582

1

2

7

6 Voltage detection signal

1 PON from

Key PCB

1

2

CN504

VCC3-1

PON

KEY0

KEY1

KEY2

SHTTER

GND

GND

Signal

PON

APO

2

Q588

3

C592

IC582

8

VCC

3

GND

IC588

R595

6

5

4

C590

R592

R593

1

2

3

4

VCC3-1

VCC1-1

1

R594

5

6

7

8

5 Power ON to Pin 1 of Q155

Operation

Power on/off signal (pulse) from Key PCB

Auto power off signal (pulse) from pin 202 of IC500

876

5

PR

CLR

VCC

CKDQ

123

4

VCC1-1

3

2

Q

GND

R579

Q583

3 POB to Pin193

of IC500

1

4 FACT from

Pin 195 of IC500

3

POB

Power on/off recognition signal to pin 193 of IC500

ON: H (VCC3) OFF: L (GND)

4

FACT

Forced power on signal from pin 195 of IC500

Forced ON: H (VCC3) OFF: L (GND)

ex. While writing to flash memory

5

Power On

Power on/off signal to pin 1 of Q155

ON: H (VCC1) OFF: L (GND)

6

Voltage

detection

Normal: H

Low voltage: L

— 4 —

Page 7

ADJUSTMENT

1. Unit Adjustment

Contents of the adjustment

(1) Color parameters loading

(2) Scratch compensation

(3) Flash adjustment

(4) Flash function check

(5) Current consumption check

(6) Clock reset

(7) Other test modes

Necessary equipments

(1) IBM PC/AT compatible computer

(2) Computer link cable

(3) Digital oscilloscope

(4) Stabilized power supply

(5) Ammeter

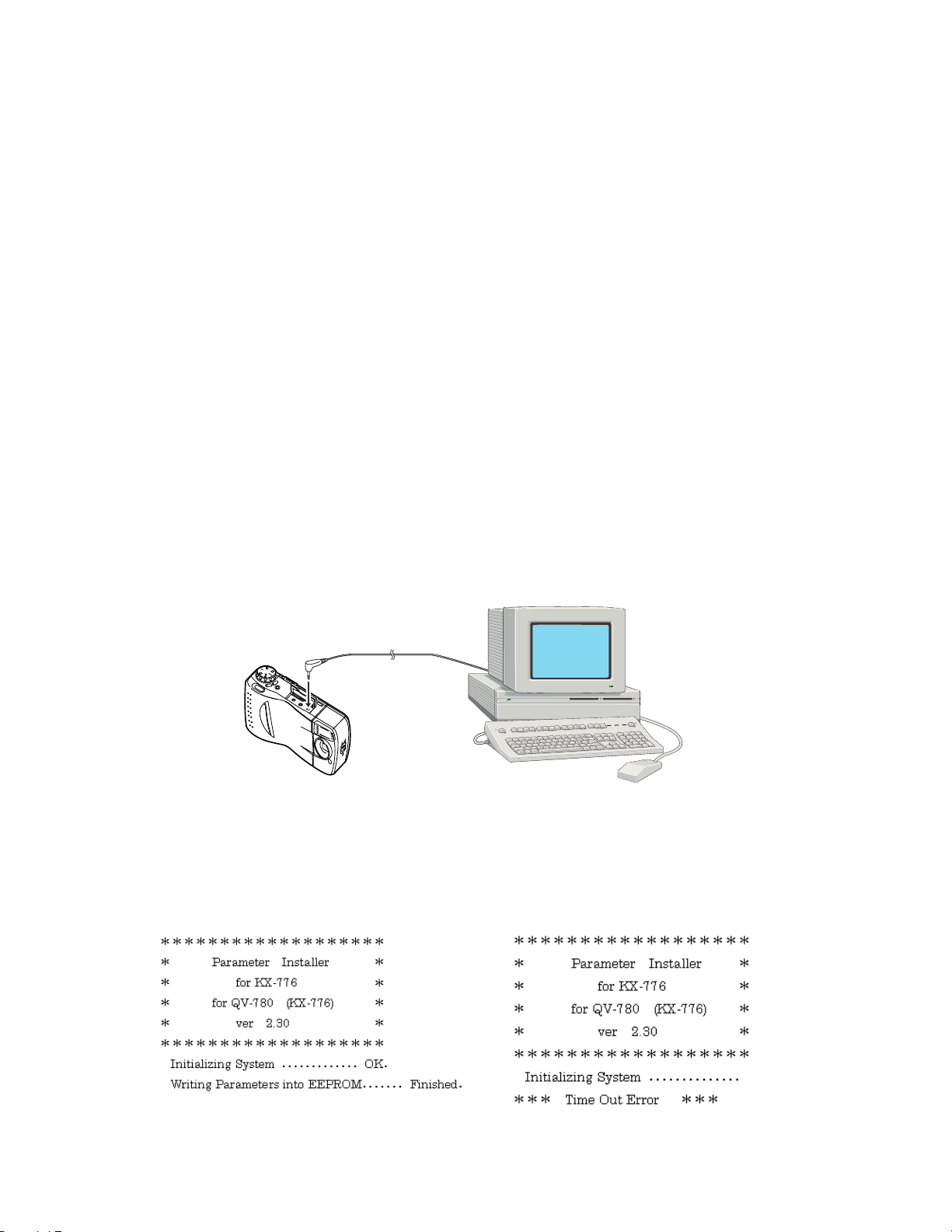

1-1. Color parameters loading

Perform the following procedures when you replaced Camera Unit.

(1) Set the QV-780 in “PLAY” mode.

(2) Connect the camera and a computer with a link cable.

To RS-232C

connector

Digital terminal

(3) Execute the following program on MS-DOS system.

PON776.EXE (for COM port 1)

(4) Loading is done successfully when computer monitor shows a message stating that loading is

completed.

When the loading is completed normally

.

When the loading is failed (example)

Note: After the loading, also perform the following Scratch compensation and Flash adjustment.

— 5 —

Page 8

1-2. Scratch compensation

“Scratch” is a black dot which appears dimly on a white screen. Three scratches are allowable on

350,000 pxels screen. Perform this adjustment after loading color parameters.

(1) Set the QV-780 in “REC” mode.

(2) Set the dial on “ ” (PANORAMA MODE).

(3) While pressing down the SHUTTER and DEL buttons, turn the power on.

LCD screen indicates “TEST MODE”.

(4) While TEST MODE is indicated on the LCD, select the dial on .

Press “MENU” and “ ” buttons simultaneously.

LCD indicates;

CLOCK RESET

STROBE ADJUST

DEFECT CORRECT

BATTERY CHECK

(5) Cover QV-780 lens so that the light does not go in the

camera.

(6) Using “+” or “–” buttons, select “DEFECT CORRECT” and

press the SHUTTER button to execute the program.

(7) Make sure that the small red square mark on LCD turns in

blue.

(8) Turn the POWER switch off.

As the compensation data is written in the EEPROM by the

POWER switch operation, do not forget to turn it off using

the switch.

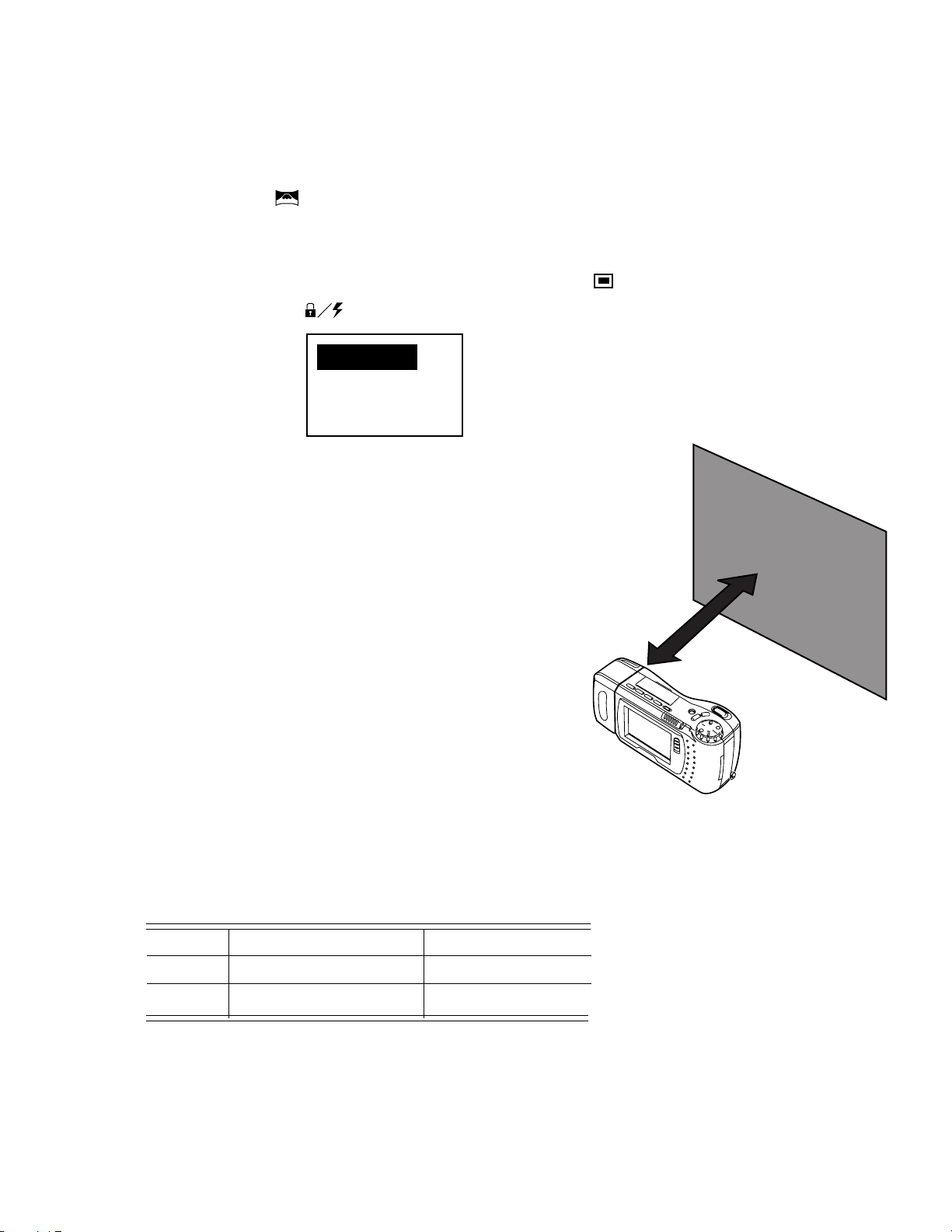

1-3.Flash adjustment

Perform this adjustment when you replaced the flash unit or

after color parameter loading.

Preparation and condition;

• Adjustments previously described should be completed.

• Distance between flash cover and gray paper should be one

meter.

• The adjustment must be done in a dark room.

• Use following gray paper for the testing.

Notes: •Use lighter color surface of the paper.

• Gray paper should be larger than the shooting area.

Code No. Name Specification

1904 5411 Superior Seamless Paper No. 22 (1.75 x 2.7 m)

1 meter

Gray paper

1904 5412 Superior Seamless Paper No. 22 (2.72 x 11 m)

Though these papers are available from Casio, large camera stores handle them.

— 6 —

Page 9

(1) Set the QV-780 in “REC” mode.

(2) Execute the test program.

• Set the dial on “ ” (PANORAMA MODE).

• While holding down the “SHUTTER” and “DELETE” buttons, turn the POWER on.

• While TEST MODE is indicated on the LCD, select the dial on .

Press “MENU” and “ ” buttons simultaneously.

LCD indicates;

CLOCK RESET

STROBE ADJUST

DEFECT CORRECT

BATTERY CHECK

(4) Use “+” or “–” buttons to select “STROBE ADJUST” and press the SHUTTER button.

(3) Shot a picture of the test paper.

(Flash indicator should be red before shooting.)

(5) Make sure that the flash icon turns from red to blue.

(If it does not turn into blue, IC531 might be faulty.)

(6) Turn the POWER switch off.

As the adjustment data is written in the EEPROM by the POWER switch operation, do not forget

to turn it off using the switch.

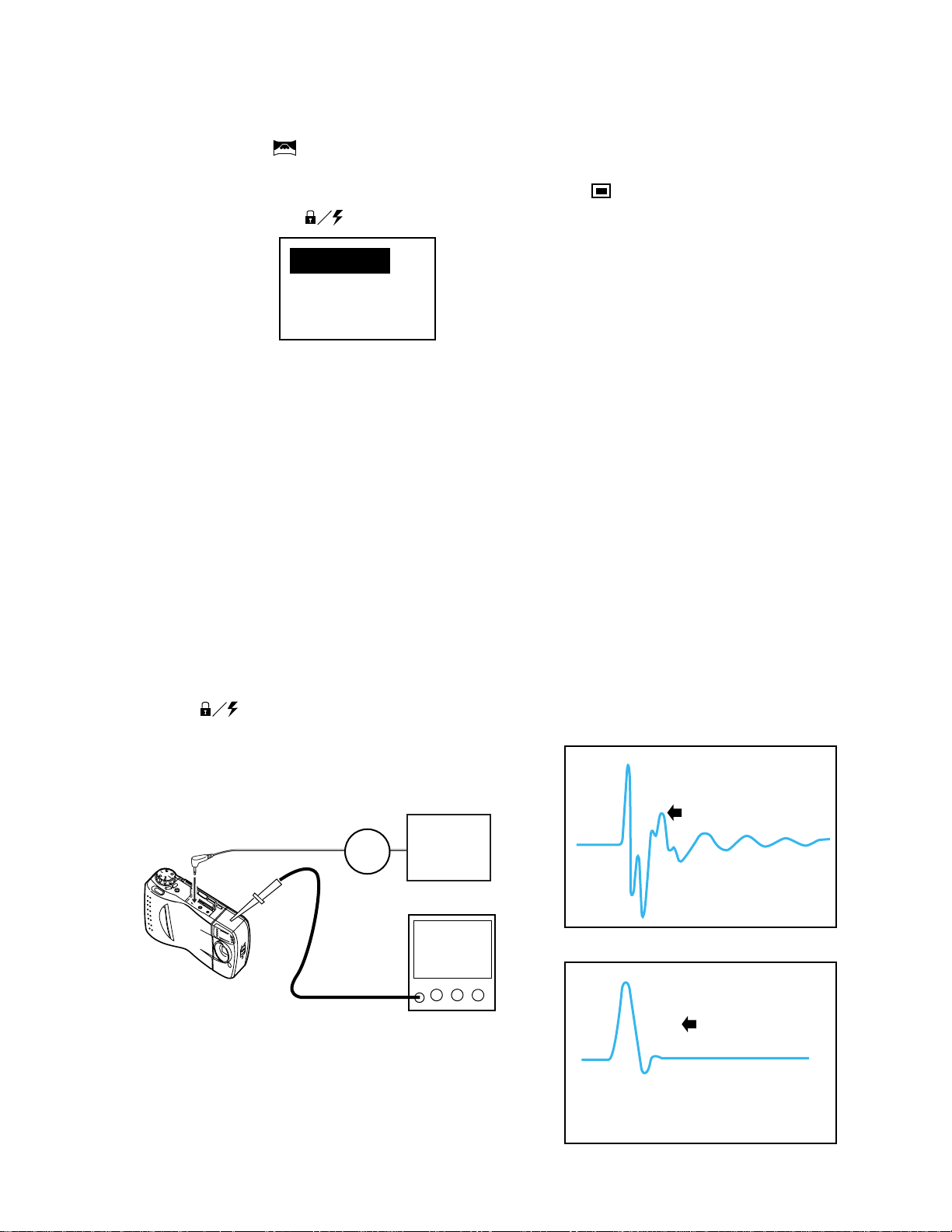

1-4.Flash check

This test is to make sure that the flash circuit is not affected by undesirable electric noise. Perform

this test whenever you changed wirings of the camera unit.

Conditions;

• Perform after the flash adjustment

• Use “ ” button to select Flash On.

• Apply 6.0 ± 0.1 [V] voltage on DC IN jack.

(1) Set the QV-780 in “REC” mode and press the shutter.

(2) Using a digital oscilloscope, monitor flash trigger pulse.

Voltage

A

Ammeter

Put oscilloscope probe

on Camera unit.

Regulator

DC6.0±0.1V

Digital oscilloscope

TIME: 1.0¨ µsec/div

VOLTS: 1V/div (AC)

Correct waveform

OK if this peak is shown

TIME: 1µsec/div

VOLTS: 1V/difv

NG waveform

2nd positive peak is not

shown.

— 7 —

TIME: 1µsec/div

VOLTS: 1V/difv

Page 10

(3) Set the QV-780 on “PLAY” mode and make sure that the picture taken is not too dark or too light.

(4) After the shot, flash is charged automatically. Observing the ammeter, make sure that the charging

current is less than 1.2 [A].

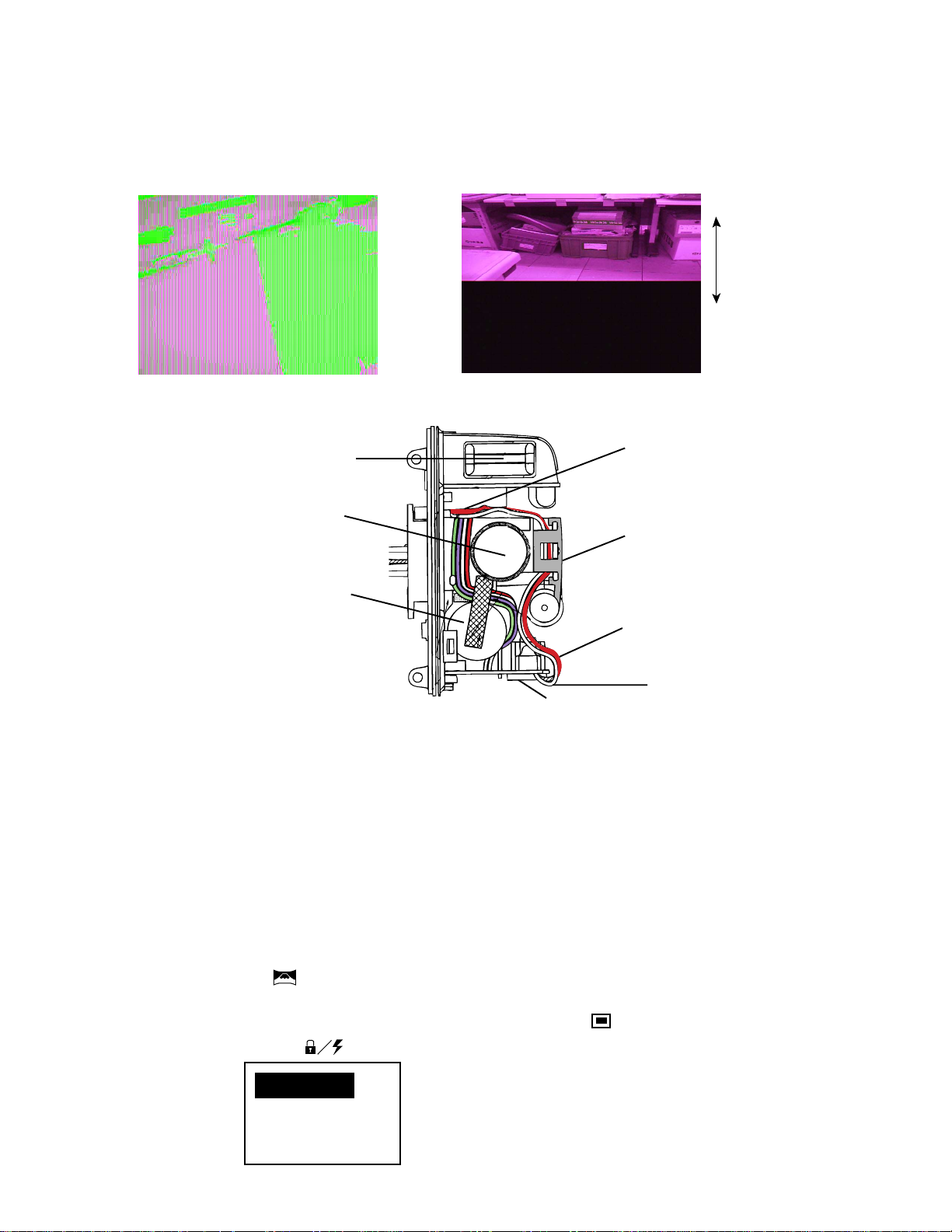

If the following pictures are taken, it may be caused by faulty wirings.

Shrinken

To solve this problem, install the wires as shown below.

Strobe

white wire in front. The

other four wires in the

back.

Lens

Removable

for correction

*Warning: Discharge

capacitor before operat-

Note: Red wire and

ing in accordance with

DISASSEMBLY proce-

Red wire

dure of page 19. There

is a risk of electric

shock.

1-5.Current consumption

Soldering

White wire

(1) Set the QV-780 in “REC” mode. After the flash circuit is fully charged, make sure that the current

consumption is less than 550 [mA] (for example, at PLAY mode, current consumption is 380 [mA]

when the flash is fully charged.

(2) Reduce the power supply voltage to 3.8 [V] and make sure that the low battery warning indicator

is shown.

1-6.Clock reset

Perform the following procedures when you replaced PCB K772-DA.

(1) Set the QV-780 in “REC” mode.

(2) Execute the test program.

• Set the dial on “ ” (PANORAMA MODE).

• While holding down the “SHUTTER” and “DELETE” buttons, turn the POWER on.

• While TEST MODE is indicated on the LCD, select the dial on .

Press “MENU” and “ ” buttons simultaneously.

LCD indicates;

CLOCK RESET

STROBE ADJUST

DEFECT CORRECT

BATTERY CHECK

— 8 —

Page 11

(3) Using “+” or “–” buttons, select “CLOCK RESET” and press the SHUTTER button to execute the

program.

1-7.Other test modes

(1) Set the QV-780 in “REC” mode.

(2) Execute the test program.

• While holding down the “SHUTTER” and “DELETE” buttons, turn the POWER on.

• While TEST MODE is indicated on the LCD, press “MENU” and “ ” buttons simultaneously.

LCD indicates;

BLACK

COLOR BAR

APO OFF

(3) Using [ + ] or [ – ] buttons, select a test mode then press “SHUTTER”.

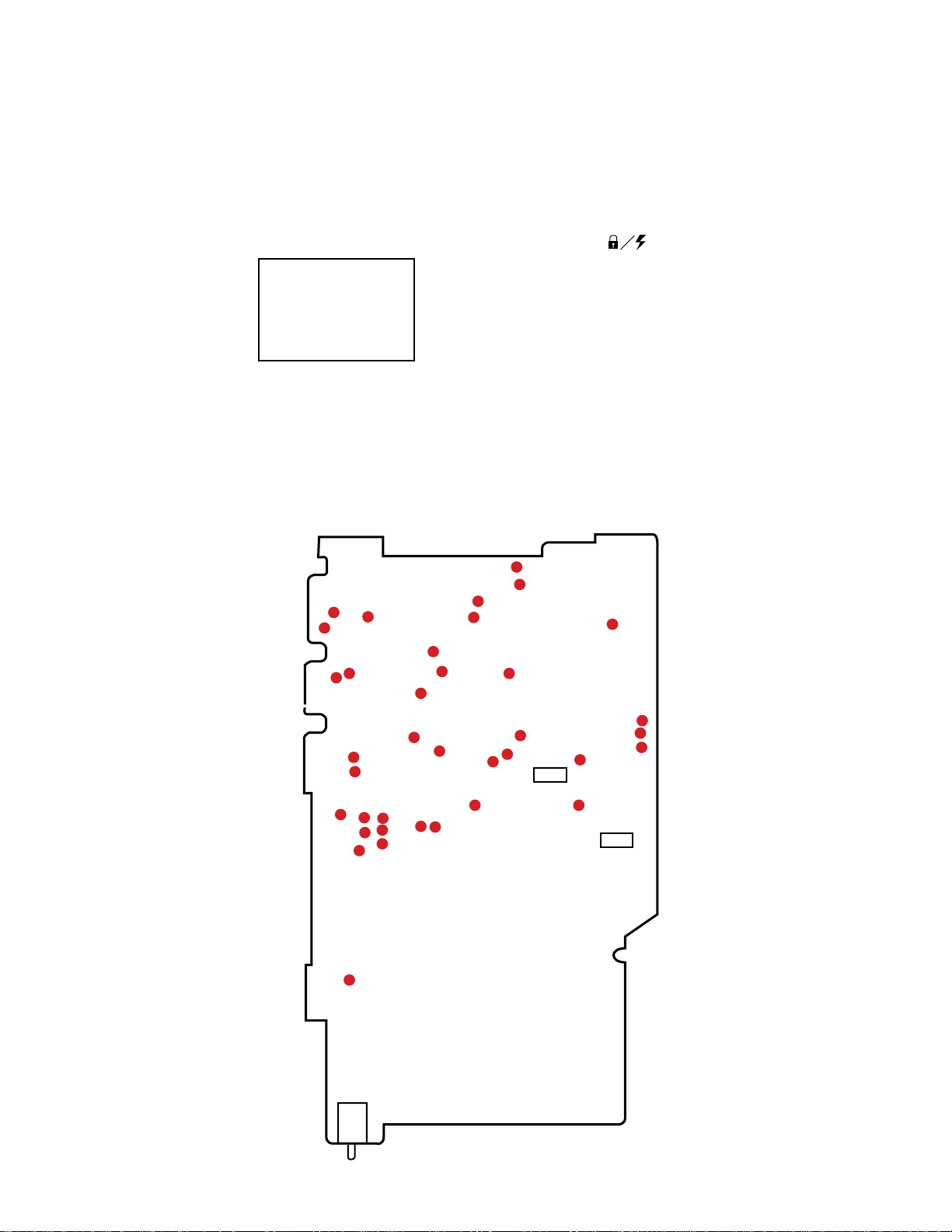

2. PCB K772-DA Adjustment

Contents of the adjustment

(1) VCC1, VCC3 checks

(2) VCC7, VEE3 adjustments

(3) Clock oscillation frequency check

Checkpoints

CP562

CP561

CP567

CP151

CP573

CP566

CP596 CP150

CP592

CP154

CP153

CP560

CP595

CP594

CP593

CP540

CP155

CP160

CP165

CP167

CP161

CP541

CP166

CP182

CP175

CP175

CP168

CP164

CP184

CP183

CP570

CP520

VR651

CP170

CP171

CP578

CP572

CP571

CP529

VR650

SW502

— 9 —

Page 12

2-1. VCC1, VCC3 voltage check

Apply 5.0 ± 0.05 [V] on check point CP150. (For normal check you can use an AC adaptor however,

when the camera is faulty, apply the above mentioned voltage.)

(1) At Power on;

VCC1 (CP164) ................. 3.2 ± 0.16 [V]

VCC5-1 (CP165) .............. 5.25 ~4.75 [V]

VCC5-2 (CP166) .............. 5.25~4.75 [V]

VCC3-1 (CP167) .............. 3.3 ± 0.17 [V]

VCC3-3 (CP168) .............. 3.3 ± 0.17 [V]

VCC3-4 (CP169) .............. 3.3 ± 0.17 [V]

(2) At Power off;

VCC3-1 (CP164) .............. 0 [V]

2-2.VCC7, VEE3 adjustment

Apply 5.0 ± 0.05 [V] on check point CP150. (For normal check you can use an AC adaptor however,

when the camera is faulty, apply the above mentioned voltage.)

(1) Adjust VR650 so that VCC7 (CP170) is 15.0 ± 0.45 [V].

(2) Adjust VR651 so that VEE3 (CP171) is -5.5 ± 0.2 [V].

2-3.Clock oscillation check

• Apply 3.2 ± 0.1 [V] on lithium battery terminal (CP578).

• Turn power off.

• Room temperature should be 25 ± 10 °C.

(1) Use quartz timer or frequency counter to measure clock frequency.

• Quartz timer; within ± 62 ppm

• Frequency counter (check point TC500 signal pad); 32.767 ± 0.002 [KHz}

(2) Current consumption; less than 1 [µA]

— 10 —

Page 13

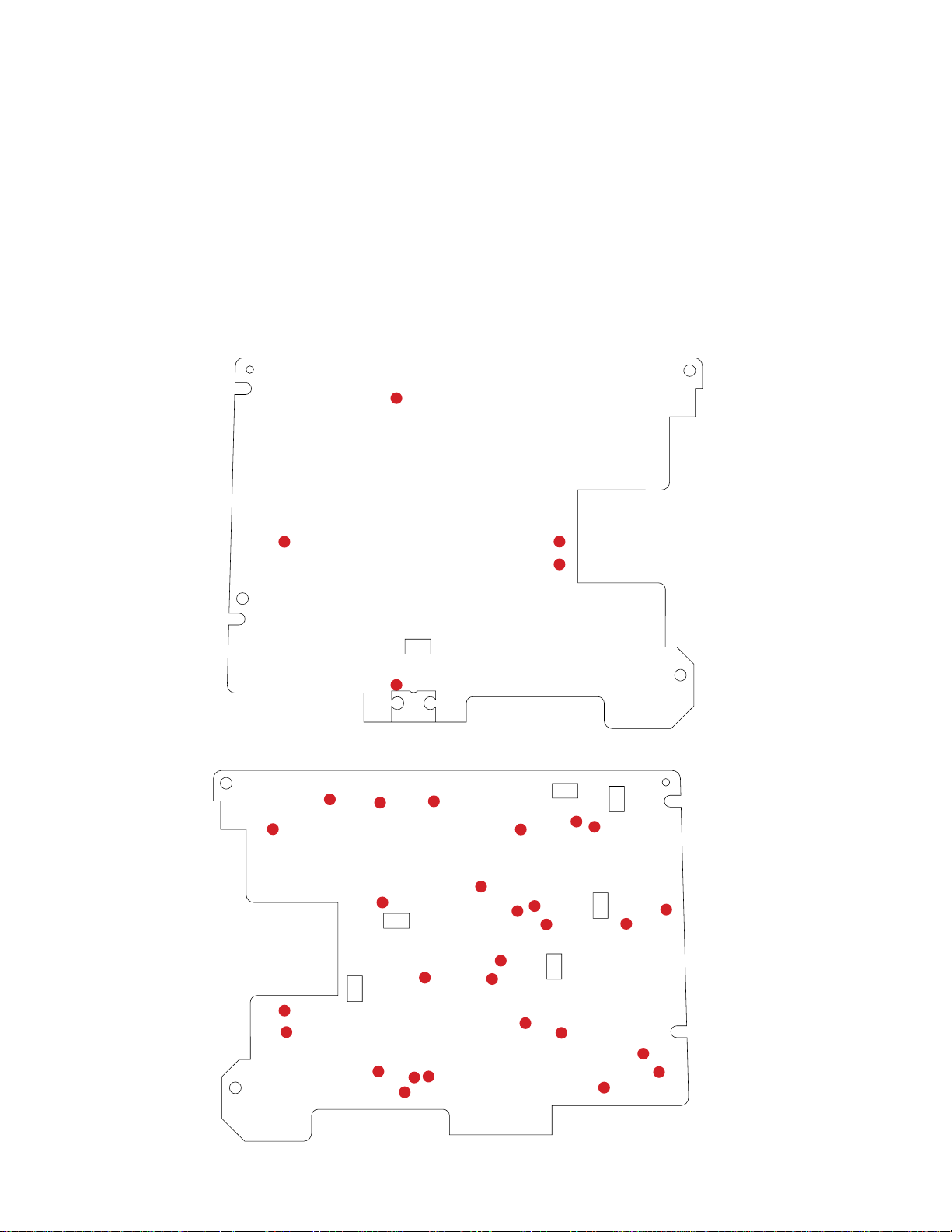

3. PCB K772-L Adjustment

Contents of the adjustment

(1) VCC1 adjustment and VCC2, VCC6, VEE2, VCC0 voltage check

(2) VCO free run frequency adjustment

(3) Backlight drive voltage adjustment

(4) VCOM AC adjustment and VCOM DC coarse adjustment

(5) Brightness voltage setting and contrast adjustment

(6) Color adjustment

(7) TINT adjustment

(8) VCOM DC fine adjustment

Check points

CP317

CP700

CP149

CP900

CP114 CP110

CP901

CP100

VR900

CP146

CP140

CP350

CP111

VR100

VR350

VR302

CP101

CP147

CP145

CP112

CP322

CP120

CP902

VR303

CP300

CP344

CP324

CP320 CP711

CP113

CP733

CP115

CP725

CP308

VR710

CP351

VR301

VR300

CP337

CP142

CP141

— 11 —

Page 14

3-1.VCC1 adjustment and VCC2, VCC6, VEE2, VCC0 voltage check

Apply 5.0 ± 0.05 [V] on check point CP101. (For normal check you can use an AC adaptor however,

when the camera is faulty, apply the above mentioned voltage.)

(1) Adjust VR100 so that VCC1 is 4.50 ± 0.02 [V]

(2) Check the following voltages.

VCC2 ...................... 11.5 ~ 12.5 [V]

VCC6 ...................... 17.5 ~ 19.5 [V]

VEE2....................... -9.5 ~ -11.5 [V]

VCC0 ...................... 2.8 ~ 3.2 [V]

(3) Turn the power off and make sure that all the voltages are 0 [V].

3-2.VCO free run frequency adjustment

• Show color bar in test mode.

• Apply 5.0 ± 0.05 [V] on check point CP101. (For normal check, AC adaptor can be used, however,

when the camera is faulty, apply the above mentioned voltage.)

• Connect check points CP725 (SYF) and CP115 (VCC0).

(1) Monitoring CP733 (HDB) with a frequency counter, adjust VR710 so that the frequency is 15.734 ±

0.1 [KHz].

(2) Disconnect CP725 and CP115 and make sure that signals of CP337 (CSY) and CP733 (HDB) are

synchronized.

QV-780

PCB K772A-L

Power

Supply

VCC0

SYF

(CP725)

CSY

(CP337)

HDB

(CP733)

CSY

HDB

Oscilloscope

Frequency

Counter

3-3.Backlight drive voltage adjustment

Apply 5.0 ± 0.05 [V] on check point CP101. (For normal check, AC adaptor can be used, however,

when the camera is faulty, apply the above mentioned voltage.)

(1) Adjust VR900 so that CP901 (VBL) is 11.5 ± 0.1 [V].

Also make sure that the current consumption is not abnormally large.

— 12 —

Page 15

3-4.VCOM AC adjustment and VCOM DC coarse adjustment

Power

Supply

Oscilloscope

22K

3.0±0.1

5.0±0.1V

Killer terminal

(CP308)

VB terminal

(CP324)

(L-PCB)

QV-780

VCC1

• Show color bar in test mode.

• Apply 5.0 ± 0.05 [V] on check point CP101. (For normal check, AC adaptor can be used, however,

when the camera is faulty, apply the above mentioned voltage.)

(1) Make sure that the oscillation level of VCOM output (CP351) is 6.0 ± 0.3 [V].

(2) Adjust VR350 so that the low level potential is 2.4 ± 0.2 [V].

QV-780

PCB K772A-L

Power

Supply

VCOM

(CP351)

Oscilloscope

2.4±0.2 [V]

0 [V]

3-5.Brightness voltage setting and contrast adjustment

• Show color bar in test mode.

• Apply 5.0 ± 0.05 [V] on check point CP101. (For normal check, AC adaptor can be used, however,

when the camera is faulty, apply the above mentioned voltage.)

(1) Via 22 kohm resistor apply VCC1 (CP113) voltage on killer terminal (CP308).

(2) Adjust BRIGHT VR (VR302) so that pedestal voltage of VB (CP324) signal is 5.0 ± 0.1 [V].

(3) Connect oscilloscope’s trigger terminal to FRP (CP711) for external trigger.

(4) Adjust VR303 so that potential between VB (CP324) signal’s pedestal and white peak is 3.0 ± 0.1 [V].

• Make sure that the waveforms are not distorted.

• After the adjustment, disconnect the voltage supply of the killer terminal.

• Do not turn BRIGHT VR until TINT and COLOR adjustments are completed.

— 13 —

Page 16

3-6.Color adjustment

• Perform this procedure together with TINT adjustment.

• Show color bar in test mode.

• Power supply voltage VCL 0 (CP101) = 5.0 ± 0.05 V(For normal check, AC adaptor can be used,

however, when the camera is faulty, apply the above mentioned voltage.)

• Apply 3.3V +/- 5% voltage on PW (CP146).

• Observing VB (CP324) waveform, adjust VR300 so that low voltage level between the first and the

second pulses and pedestal becomes –0.5 +/-0.1V.

(1) Perform this adjustment after contrast adjustment.

(2) Fix VB’s pedestal at 5.0 +/-0.1Vp-p by BRIGHT VR (VR302).

(3) Trigger with FRP (CP711).

-0.5±0.1 [V]

L-PCB

1234

Power

Supply

VB terminal

(CP324)

Oscilloscope

3-7.TINT adjustment

• Perform this adjustment with COLOR adjustment.

• Input signal: Standard signal. Input from VIDEO terminal (CP141). Should be 0.5Vp-p.

• Power supply voltage VCL0 (CP101) = 5.0 +/-0.05V (For normal check, AC adaptor can be used,

however, when the camera is faulty, apply the above mentioned voltage.)

• Apply 3.3V +/- 5% voltage on PW (CP146).

• Observing VB (CP324) waveform, adjust VR301 so that low voltage level between the pedestal

becomes 0.6 +/-0.1V.

(1) Perform this adjustment after Contrast adjustment

(2) Fix VB’s pedestal at 5.0 +/-0.1Vp-p by VRIGHT VR (VR302).

(3) Trigger with FRP (CP711).

0.6±0.1 [V]

L-PCB

123 4

Power

Supply

VB terminal

(CP324)

Oscilloscope

— 14 —

Page 17

3-8.VCOM DC adjustment

• Perform this adjustment when you replace the display module.

• No signal input

• BRIGHT VR: Maximum

• Apply 6.0 ± 0.1 [V] (DC in). (For normal check, AC adaptor can be used, however, when the camera

is faulty, apply the above mentioned voltage.)

(1) Adjustment VR350 if the display is flikered, dimmed or discolored with watching the LCD screen.

(2) If the adjustment cannot be done well, passing photosensor amp output signal through 60 Hz

band-pass filter, adjust VR350 to minimize the ripple of 60 Hz signal as shown below.

Photo diode

S1153

QV-780

Power supply

B.P.F.

Photosensor amp.

C2719

Oscilloscope

Adjust VR350

to minimize the

ripple.

— 15 —

Page 18

DISASSEMBLY

The following explains the disassembly procedure of QV-780. Numbers in the procedures correspond to the

part numbers on the exploded view.

Assembly can be done by the reverse order.

1. Remove the CompactFlash card by pushing the release lever.

2. Remove two screws j from the bottom of the camera.

3. Unscrew two screws f from the lens side of the case.

Note:Turn the lens as screws f are hidden by the Camera unit 1.

4. Remove three screws h and one screw i from the CompactFlash card compartment.

Note: Screw i is longer than the others. Do not misplace it when you assemble the camera.

i

— 16 —

Page 19

5. Prying the case R, remove the battery cover and CompactFlash card cover.

6. Unhook the upper part of Case/Upper R and open the case.

Unhook here

7. Desolder a lead wire from PCB Ass’y/Linear a and disconnect FPC from the connector CN514 on PCB

Ass’y/Digital. Separate Case/Upper R and Case/Lower E.

8. Remove two screws g and disconnect two connectors from PCB A’ssy/Digital then separate Camera

unit 1.

9. Remove two screws f from PCB Ass’y/Digital 2 and detach FPC from connector CN504.

— 17 —

Page 20

10.Lift up the buttom of the battery compartment and remove Holder/Battery 3 and PCB Ass’y/Digital.

Note: Before you remove Holder/Battery 3, be

sure that CompactFlash card release lever

is in upright position.

11.Take Knob/Selector 6 and PCB Ass’y/Key 5 off the case.

Note: Knob/Selector 6 can be removed by unscrewing two screws f from the bottom of the knob.

12.Peel Grip K then remove one screw h from Panel/Rear J.

Unclip the E-ring from Pin J.

Note: Peel Panel/Rear carefully off Case/Lower E as it is attached with adhesive tapes.

Removing LCD Unit

13.Remove four screws l from PCB Ass’y/Linear a.

— 18 —

Page 21

14.Lift up the stopper tab of connector CN700 and disconnect FPC cable. Also disconnect connector CN920.

15.Remove the BRIGHT knob T and take PCB Ass’y/Linear off the case.

Note: Be careful not to bend or break the LED on the other side of the PCB.

16.Remove Three screws l from BL ass’y _ then remove the BL ass’y.

Note: Do not touch BL ass’y with naked hand.

17.Remove Spacer ] and Display Ass’y [.

Note: Do not touch Display Ass’y with naked hand.

Camera Unit

18.Remove three screws h and m.

— 19 —

Page 22

19.Peel off the caution label.

Caution: Since high-voltage is applied on the circuits on Camera Unit, there is a risk of electric shock.

Before proceeding to the following steps, discharge 70 µF, 300 V capacitor with a 1.5 kohm,5 W cement

resistor.

1.5 kohm/5W

resistor

20.Remove two screws and disconnect two wires red and white.

21.Remove Strobe unit 1-3 .

22.Remove two screws from the gear.

Peel off the adhesive tape wrapped around the case shaft.

— 20 —

Page 23

23.Twisting the FPC cable and pulling out the connector throught the hole on the gear, pull the gear out.

24.Remove one screw l.

25.Disconnect FPC cables from the connectors CN200, CN201, and CN501 then remove CCD unit 1-2 .

— 21 —

Page 24

PCB K772-L

PRINTED CIRCUIT BOARDS

Top view

— 22 —

Page 25

PCB K772-L

Bottom view

— 23 —

Page 26

PCB K772-DA

Top view

— 24 —

Page 27

PCB K772-DA

Bottom view

— 25 —

Page 28

TROUBLESHOOTING

Problem Cause Solution

Display shows “DIAL” and

buttons do not work.

Display shows

CF

CF ERROR

FORMAT ➝ MENU

1. Dial key is placed in an odd place.

2. SW502 of DA assembly keeps

turning on.

1. Erroneous CF card data.

2. CF card hard drive error.

(Unable to execute Scan Disk or

format)

3. Broken circuit or broken connector on CF card of DA assembly

1. Turn the Dial key until it makes a

click sound, when there is no click

sound, click spring of key assembly may be broken or distorted.

2. Replace SW502.

1. Read P109 of Instruction Manual.

CF card can be handled the same

way as hard drive.

Try the actions noted below.

1) Set CF card to the PC using PC

card adapter.

2)Save the correct file in memory

file.

3) Execute “Scan Disk” on CF card

and correct the data of format.

4) Save the correct data than copy it

onto CF card.

2. Consult to technical support.

3. Replace connector of DA assembly.

Display shows

SYSTEM ERROR

CALL TECH

SUPPORT

Display shows

CF

NO CARD

Power will not turn on.

No display.

Flash not rechargeable/

will not flash

1. Bad connection between DA assembly and camera unit.

2. Erroneous EEPROM.

(exclude CF card)

1. No CF card.

2. Broken circuit or broken connector on CF card of DA assembly.

1. Memory card cover is open, or

SW502 is broken.

2. FU150 is broken.

3. Flat cable connecting DA assembly and L assembly is loose or

broken.

4. Flat cable connecting DA assembly and key assembly is loose or

broken.

1. LCD connector of BL connector is

open.

2. IC701 is broken or bad soldering.

1. IC531 is broken or bad soldering.

1. Reconnect the connector.

2. Execute DA assembly check program. If NG, replace.

1. Insert CF card

2. Replace connector or DA assembly.

1. Close memory card cover, or replace SW502.

2. Replace FU150.

3. Reinsert the flat cable or replace

the flat cable.

4. Reinsert the flat cable or replace

the flat cable.

1. Insert connectors.

If broken replace them.

2. Resolder or replace IC.

1. Refer to “Strobe adjustment”

— 26 —

Page 29

Problem

Cause

Solution

Display failure when

using flash

Cannot switch

between REC and

PLAY

Incorrect time.

Battery consumption is early.

1. Noise when strobe flashes.

1. Slide switch is broken or incorrectly

assembled.

1. Bad connection between DA assembly and camera unit.

2. Incorrect time data.

3. Lithium battery is dead.

4. Bad DA assembly.

1. Refer to P8, 29, 30, 31, and 112 of

Instruction Manual.

2. Current consumption is high.

3. Kept battery in the camera for a long

periods of time.

1. Refer to “Strobe operation check”

1. Replace switch or reassemble.

1. Reconnect connector.

2. Refer to “Reset time”. Set time.

3. Replace lithium battery.

4. Refer to “Clock oscillator frequency

check”

1. Battery life differs depending on manufacturers, types, temperatures, and

storage periods. The figures in the

Instruction Manual are approximations and are not guaranteed.

2. Refer to “Current consumption check”

3. Take the batteries out when not using

the camera for a long periods of time.

(Even when the power is turned off

minute currency (0.xx mA) is consumed.)

When switching

from PLAY to REC

LCD display turns

blue and keys do

not work. (Cannot

turn power off.)

Display failure.

(Flash not in use)

1. Bad connection between DA assembly and camera unit, or camera unit is

broken.

1. Bad connection between DS assembly and camera unit.

2. EEPROM data error.

3. Camera unit is broken.

1. Reconnect the connector, or replace

L case assy or CL unit or CAM case

unit.

1. Reconnect connectors.

2. Execute “Loading color parameters”

3. Replace L case assy or CL unit or

CAM case unit.

— 27 —

Page 30

MAIN BODY

46

EXPLODED VIEW

1

47

24

23

46

61

47

44

10

27

29

2

49

49

30

31

3

46

3-1

2-1

45

8

9

3-3

7

5-1

3-2

5

51

39

4

6

36

37

26

38

25

28

40

32

48

33

34

35

49

17

18

19

16

20

48

14

11

55

21

12

13

15

48

52

22

43

— 28 —

46

40-1

52

42

52

41

52

41-1

Page 31

CAMERA UNIT

54

53

48

1-1

1-2

48

1-3

48

52

1-10

1-9

1-11

1-7

— 29 —

1-4

1-5

1-6

1-8

Page 32

PARTS LIST

LINEAR PCB ASS'Y

Item Code No. Parts Name Specification Q R

Diodes

D110 2390 1820 CH IP DIODE 1SS355TE-17 1 C

D111 2390 1379 DIODE/SCHOTTKY MA729-(TX) 1 C

D112 2390 1379 DIODE/SCHOTTKY MA729-(TX) 1 C

D113 2390 1820 CH IP DIODE 1SS355TE-17 1 C

D140 2370 1396 L ED SLC-22DU3F 1 C

D700 2390 1820 CH IP DIODE 1SS355TE-17 1 C

D710 2390 1358 DIODE/VARICAP MA329-(TX) 1 C

D900 2390 1883 SCHOTTKY DIODE RB160L-40TE25 1 C

Oscillator

H300 2590 1239 CRYSTAL OSCILLATOR HC-49/U-S-A 1 C

Ics

IC100 2114 3654 IC MB3800PNF-G-BND-EF 1 C

IC130 2105 4501 IC/MOS RN5RL30AA-TR 1 C

IC300 2114 5804 IC IR3Y18A 1 C

IC350 2114 5805 IC NJM3414AV-TE1 1 C

IC700 2012 5744 LSI CM7013L2-T4N 1 C

IC701 2105 6397 IC TC74VHCT04AFT(EL) 1 C

IC900 2114 3654 IC MB3800PNF-G-BND-EF 1 C

IC920 7720 0700 IC TC7S02FU-TE85L 1 C

Transistors

Q100 2253 0308 TRANSISTOR 2SD1119-R(TX) 1 B

Q140 2259 1491 TRANSISTOR/DIGITAL UN5213-(TX) 1 B

Q141 2259 1491 TRANSISTOR/DIGITAL UN5213-(TX) 1 B

Q900 2253 0308 TRANSISTOR 2SD1119-R(TX) 1 B

Q901 2259 1491 TRANSISTOR/DIGITAL UN5213-(TX) 1 B

Q950 2253 0700 TRANSISTOR 2SK1485-T1 1 B

Switchs

SW140 3412 2080 SWITCH SSSS712-ZA 1 C

SW141 3412 2002 SWITCH SPVC2-1-T 1 C

Converter and Transformaers

T100 3065 0711 CONVERTER/DC-DC 6CA-01 1 B

T900 3012 1477 TRANSFORMER/INVERTER ETJ09K20AM 1 B

Variable resistors

VR100 2775 1470 CHIP SEMI-FIXED RESISTOR EVM-1XSX50B53 1 C

VR300 2775 1484 CHIP SEMI-FIXED RESISTOR EVM-1XSX50B24 1 C

VR301 2775 1484 CHIP SEMI-FIXED RESISTOR EVM-1XSX50B24 1 C

VR302 2775 0644 RESISTOR/SEMI-FIXED H0614D-10KB 1 C

VR303 2775 1484 CHIP SEMI-FIXED RESISTOR EVM-1XSX50B24 1 C

VR350 2775 1477 CHIP SEMI-FIXED RESISTOR EVM-1XSX50B14 1 C

VR710 2775 1484 CHIP SEMI-FIXED RESISTOR EVM-1XSX50B24 1 C

VR900 2775 1477 CHIP SEMI-FIXED RESISTOR EVM-1XSX50B14 1 C

Notes: Q - Quantity per unit

R - Rank

— 30 —

Page 33

DIGITAL PCB ASS'Y

Item Code No. Parts Name Specification Q R

Diodes

D151 2390 2506 DIODE RB060L-40-TE25 1 C

D155 2390 1379 DIODE/SCHOTTKY MA729-(TX) 1 C

D160 2390 2394 DIODE/SCHOTTKY U1FWJ44N-TE12L 1 C

D161 2390 1379 DIODE/SCHOTTKY MA729-(TX) 1 C

D170 2390 1379 DIODE/SCHOTTKY MA729-(TX) 1 C

D171 2390 1820 CIHP DIODE 1SS355TE-17 1 C

D510 2390 1379 DIODE/SCHOTTKY MA729-(TX) 1 C

D513 2390 1379 DIODE/SCHOTTKY MA729-(TX) 1 C

D530 2390 1176 CIHP DIODE MA152WK-(TX) 1 C

D660 2390 1820 CIHP DIODE 1SS355TE-17 1 C

Fuses

FU150 3632 0630 FUSE KE10 1 A

FU151 3632 0724 FUSE KE13 1 A

FU152 3632 0709 FUSE KE16 1 A

Oscillators

H500 2590 2720 CRYSTAL OSCILLATOR DSX-840GA-23.9M 1 C

H502 2590 2736 CRYSTAL OSCILLATOR CX-11F-14.3M 1 C

H530 2590 2722 CRYSTAL OSCILLATOR SPT2A-32KHZ 1 C

Ics

IC150 2114 5806 IC TK11232BMCL 1 C

IC152 2105 3374 IC/CMOS RS5RM5045A-T1 1 C

IC156 2105 6404 IC XC6375A311PR 1 C

IC400 2114 5808 LSI CXD3120R 1 C

IC500 2114 5809 LSI MB91181PMT-G 1 C

IC503 2114 5810 IC S-80930ALMP-DAT-T2 1 C

IC505 2012 6215 LSI LH5V4CTR 1 C

IC507 2012 5747 LSI MB81V16165B50LPFTN 1 C

IC510 2105 5712 IC TC7S04FU(TE85L) 1 C

IC515 2105 6378 IC MM1228XFBE 1 C

IC529 7911 0105 OP-AMP TA75S01F(TE85L) 1 C

IC530 7911 0105 OP-AMP TA75S01F(TE85L) 1 C

IC531 2105 6361 IC/MOS XC61AC2402MR 1 C

IC540 2012 5950 LSI UPD6466GS-514-E1 1 C

IC545 2105 6425 IC/MOS XC61AN3802MR 1 C

IC550 2105 6399 IC RS5C316A-E2 1 C

IC580 2105 5516 IC/CMOS TC7W126FU-TE12L 1 C

IC582 6571 0037 IC/L-MOS TC7W00FU(TE12L) 1 C

IC584 2114 5817 IC S-80936ANMP-DD0-T2 1 C

IC586 2105 3521 IC/CMOS TC7S08FU-TE85L 1 C

IC588 2105 5215 IC/CMOS TC7W74FU(TE12L) 1 C

IC651 2105 5999 IC XC6383F501MR 1 C

IC652 2114 5607 IC TK11830MTL 1 C

Jacks

JK150 3501 6755 JACK HEC3600-010120 1 C

JK510 3501 6538 JACK HSJ1169-012010 1 C

JK515 3501 5439 JACK HSJ1456-01-210 1 C

Transistors

Q155 2259 2715 TRANSISTOR/DIGITAL DTC144EETL 1 B

Q156 2259 2716 TRANSISTOR 2SC4617TLR 1 B

Q158 2114 5807 FET SI3441DV-T1 1 B

Q159 7101 5791 TRANSISTOR/DIGITAL DTA144EETL 1 B

Q169 2259 2716 TRANSISTOR 2SC4617TLR 1 B

Q507 2259 2715 TRANSISTOR/DIGITAL DTC144EETL 1 B

Q508 2259 2731 TRANSISTOR/DIGITAL DTA114EE-TL 1 B

Q510 2259 2731 TRANSISTOR/DIGITAL DTA114EE-TL 1 B

Notes: Q - Quantity per unit

R - Rank

— 31 —

Page 34

Item Code No. Parts Name Specification Q R

Q511 2259 2715 TRANSISTOR/DIGITAL DTC144EETL 1 B

Q515 2254 0448 FET 2SK1580-T1 1 B

Q520 2259 2716 TRANSISTOR 2SC4617TLR 1 B

Q521 2250 1579 TRANSISTOR 2SA1774TLR 1 B

Q522 2259 2716 TRANSISTOR 2SC4617TLR 1 B

Q539 2259 2715 TRANSISTOR/DIGITAL DTC144EETL 1 B

Q540 2250 1579 TRANSISTOR 2SA1774TLR 1 B

Q541 2251 0926 TRANSISTOR 2SB1412TLQ 1 B

Q543 2259 2716 TRANSISTOR 2SC4617TLR 1 B

Q580 2259 2715 TRANSISTOR/DIGITAL DTC144EETL 1 B

Q582 7101 5791 TRANSISTOR/DIGITAL DTA144EETL 1 B

Q583 2259 2715 TRANSISTOR/DIGITAL DTC144EETL 1 B

Q585 2259 2715 TRANSISTOR/DIGITAL DTC144EETL 1 B

Q588 2250 1579 TRANSISTOR 2SA1774TLR 1 B

Q650 2253 0308 TRANSISTOR 2SD1119-R(TX) 1 B

Q651 2259 2715 TRANSISTOR/DIGITAL DTC144EETL 1 B

Q652 2251 0930 CHIP TRANSISTOR 2SB1073-R(TX) 1 B

Q653 2259 2715 TRANSISTOR/DIGITAL DTC144EETL 1 B

Q660 2250 1579 TRANSISTOR 2SA1774TLR 1 B

Switch

SW502 3412 2002 SWITCH SPVC2-1-T 1 C

Variable resistors

VR650 2775 1491 CHIP SEMI-FIXED RESISTOR EVM-1XSX50B54 1 C

VR651 2775 1491 CHIP SEMI-FIXED RESISTOR EVM-1XSX50B54 1 C

KEY PCB ASS'Y

Item Code No. Parts Name Specification Q R

Diodes

D802 2390 2303 CHIP DIODE DA226U-T106 1 C

D803 2390 2303 CHIP DIODE DA226U-T106 1 C

Ic

IC600 2105 6398 IC LB1846M-TE-L 1 B

Switchs

SW800 2765 2193 VOLUME RK10J11F0001A 1 C

SW801 2254 0555 SWITCH ESE22MH4 1 B

SW802 3412 2068 SWITCH EVQPQHB55 1 C

SW803 3412 2068 SWITCH EVQPQHB55 1 C

SW804 3412 2068 SWITCH EVQPQHB55 1 C

SW805 3412 2068 SWITCH EVQPQHB55 1 C

SW806 3412 2068 SWITCH EVQPQHB55 1 C

SW807 3412 2068 SWITCH EVQPQHB55 1 C

SW808 3412 2068 SWITCH EVQPQHB55 1 C

SW809 3412 2068 SWITCH EVQPQHB55 1 C

SW810 3412 2068 SWITCH EVQPQHB55 1 C

SW811 3412 2081 SWITCH SPVC2-1-B 1 C

Notes: Q - Quantity per unit

R - Rank

— 32 —

Page 35

MAIN COMPONENT

Item Code No. Parts Name Specification Q R

1 6613 3215 CAMERA UNIT K240748*2 1 C

1-1 6613 3381 CASE/CAMERA R240158A-2 1 X

1-2 1014 9771 CCD UNIT LS-015D 1 B

1-3 1014 9897 STROBE UNIT CA-KX-776B 1 B

1-4 6613 3390 KNOB/FOCUS R340195-2 1 X

1-5 6613 3218 CASE ASSY/CAMERA K240752*2 1 X

1-6 6612 8480 TAPE K441232-1 1 X

1-7 6612 8490 TAPE K441233-1 1 X

1-8 6612 6050 COVER/SENSOR R340197-1 1 X

1-9 1014 9772 COVER/STROBE CA-KX-772A 1 X

1-10 6612 7050 INSULATION SEAL R440275-1 1 X

1-11 6613 3400 PANEL R240150-2 1 X

2 6614 0617 PCB ASSY/DIGITAL K341544*1 1 B

2-1 3502 2390 EJECTOR/CARD 55065-0005 1 C

3 6613 3221 HOLDER/BATTERY K340909*2 1 X

3-1 6614 0780 SPRING/BATTERY K441701-1 1 X

3-2 6614 0790 SPRING/BATTERY K441702-1 1 X

3-3 6614 0800 SPRING/BATTERY K441703-1 1 X

4 2012 5745 CF CARD SDCFB-2-200QV-T 1 X

5 6612 6969 PCB ASSY/KEY K340925*1 1 C

5-1 6612 6301 CABLE/JOINT R340174A-1 1 B

6 6613 3330 KNOB/SELECTOR R240130-2 1 X

7 6613 3520 COVER/CONNECTOR R240129-2 1 X

8 6612 6280 SHAFT R440245-1 1 X

9 6609 7530 LABEL K440064-1 1 X

10 6613 3300 BUTTON R240128-2 1 X

11 6613 3310 BUTTON R340164-2 1 X

12 6611 4340 ADHESIVE TAPE R440051-1 4 X

13 6613 3320 BUTTON R340165-2 1 X

14 5861 3649 E-RING ISB2805 1 X

15 6613 3291 CASE/LOWER R140037A-2 1 X

16 6612 8570 TAPE K441240-1 1 X

17 6614 0620 LABEL/RATING K441169-8 1 X

18 6613 3216 COVER/BATTERY K340908*2 1 B

19 6610 2531 LABEL/CAUTION K440205A-2 1 X

20 6614 0661 PANEL ASSY/REAR R240152A-4 1 X

21 6613 3250 GRIP K340962-2 1 X

22 6612 6260 PIN R340181-1 1 X

23 6613 3431 KNOB R340169A-2 1 X

24 6613 3440 PANEL/DISPLAY R240127-2 1 X

25 6613 3420 KNOB R240151-2 1 X

26 6611 4410 SPRING R440045-1 1 X

27 6612 2460 PLATE R440217-1 1 X

28 6613 3410 CASE/UPPER R140036-2 1 X

29 6612 6160 PLATE R440256-1 1 X

30 6603 8924 KNOB K3741D-1 1 X

31 6611 4390 HOLE/TRIPOD R340024-1 1 X

32 6612 6960 LABEL K441162-1 1 X

33 6612 6270 SHAFT R440253-1 1 X

34 6613 3231 COVER/CF R240136A-2 1 X

35 6613 3450 BLIND K441519-1 1 X

36 6612 8540 CUSHION K441237-1 1 X

37 2725 1340 DISPLAY ASSY COD25T2017LN 1 B

38 6612 8530 SHEET/INSULATION K441236-1 1 X

39 6612 6180 SPACER R440276-1 1 X

40 6614 0614 BL ASSY K340910*3 1 B

Notes: Q - Quantity per unit

R - Rank

— 33 —

Page 36

Item Code No. Parts Name Specification Q R

40-1 6612 8630 CABLE ASSY K441235*1 1 X

41 6614 0615 PCB ASSY/LINEAR K241157*1 1 B

41-1 6612 6310 CABLE/JOINT R340175-1 1 B

42 6612 7071 SPACER R440260A-1 1 X

43 6612 6190 SPACER R440257-1 1 X

44 5861 3591 NUT/HEXAGON M2 ZMC-3 2 C

45 5861 3589 SCREW M2X8 2 C

46 5860 0301 SCREW BT3 1.7X3.5 NI 5 C

47 5861 3111 SCREW PT3 1.7X5.5 Bk 2 C

48 5861 3746 SCREW PT3 1.7X3.5 BK 5 C

49 5860 9009 SCREW PT3 1.7X4.5 Bk 3 C

50 Not Used

51 5112 0906 SCREW BT3 1.7X5.0 NI 2 C

52 5860 1477 SCREW BT3 1.7X3.5 BK 13 C

53 5860 1498 SCREW PT3 1.7X3 BK 1 C

54 5112 0868 SCREW BT3 1.7X5.0 Bk 1 C

55 66128980 PLATE K441286-1 1 X

56 6612 8470 SHEET/INSULATION K441193-1 1 X

57 6612 6110 SPRING/DIAL R440244-1 1 X

Notes: Q - Quantity per unit

R - Rank

— 34 —

Page 37

Item Code No. Parts Name Specification Q R

58 5861 3578 STRAP ST-K775 1 X

59 1014 8773 CABLE/VIDEO VC-K723-FC 1 X

60 1014 9800 CASE/SOFT SC-772 1 X

61 3815 0796 LITHIUM BATTERY CR2016-CM1 1 C

62 3816 0266 LR6/ALKALINE BATTERIES LR6PA/2ST 2 -

Notes: Q - Quantity per unit

R - Rank

58

59

60

— 35 —

Page 38

PCB 772C-L

SCHEMATIC DIAGRAMS

— 36 —

Page 39

PCB 772C-DA

— 37 —

Page 40

KEY

— 38 —

Page 41

CASIO TECHNO CO.,LTD.

Overseas Service Division

Nishi-Shinjuku Kimuraya Bldg. 1F

5-25, Nishi-Shinjuku 7-Chome

Shinjuku-ku, Tokyo 160-0023, Japan

Loading...

Loading...