Page 1

SERVICE MANUAL

(without price)

ELECTRONIC CASH REGISTER

QT-7300 (EX-963)

MAY. 2001

Page 2

CONTENTS

QT-7300 PAGE

1. EXPLANATION OF PRODUCT ................................................................... 1

1-1. General Description ................................................................................................... 1

1-2. System Overview........................................................................................................ 1

1-3. Major Component ....................................................................................................... 2

1-4. Specifications ............................................................................................................. 3

1-5. I/O Outlets ................................................................................................................... 5

2. DISASSEMBLY............................................................................................ 6

3. INSTALLATION ......................................................................................... 10

4. SYSTEM INSTALLATION.......................................................................... 11

4-1. CPU ............................................................................................................................ 11

4-2. DRAM......................................................................................................................... 11

4-3. HDD ............................................................................................................................ 12

4-4. Serial Ports................................................................................................................12

4-5. Parallel Port...............................................................................................................12

4-6. VGA ............................................................................................................................ 12

4-7. Ethernet ..................................................................................................................... 12

4-8. Cash Drawer.............................................................................................................. 13

4-9. Keyboard ................................................................................................................... 14

4-10. PS/2 Mouse ............................................................................................................... 14

4-11. External FDD ............................................................................................................. 14

4-12. Expansion Slot.......................................................................................................... 15

4-13. System O/S and Software Installation .................................................................... 15

4-14. Award BIOS Setup.................................................................................................... 16

4-15. Watchdog Function .................................................................................................. 28

4-16. Touch screen ............................................................................................................ 29

4-17. ETHERNET INTRODUCTION.................................................................................... 31

5. CIRCUIT EXPLANATIONS ........................................................................ 34

5-1. Explanations of each block ..................................................................................... 34

5-2. Block diagram........................................................................................................... 37

5-3. Jumper setting.......................................................................................................... 38

6. DIAGNOSTIC OPERATION....................................................................... 41

6-1. Diagnositc softwares ............................................................................................... 41

6-2. Customer display ..................................................................................................... 41

6-3. Drawer test ................................................................................................................ 45

6-4. Touch panel test ....................................................................................................... 46

7. TROUBLESHOOTING ............................................................................... 48

8. DATA SHEET............................................................................................. 50

8-1. Power Supply (100W) ............................................................................................... 50

9. CIRCUIT DIAGRAM ................................................................................... 51

10. PARTS LIST............................................................................................... 76

Page 3

1. EXPLANATION OF PRODUCT

1-1. General Description

The QT-7300 is a PC-based POS terminal which integrates SVGA, 12.1" LCD panel, Touch screen, Ethernet,

USB, multi I/O ports for wide range of PC peripherals and special PC technologies like watchdog timer together

with regular POS functionality like Cash Drawer interfaces all in a single system.

The QT-7300 features desktop free standing and wall mounting for a wide variety of applications. An unique cable

management device is also provided to trim the operation environment. In conformity to IPX1 standard, waterresistant system design is adopted. Designed by the PC and POS experts for the POS professionals, the QT7300 is virtually the ultimate solution for hospitality applications.

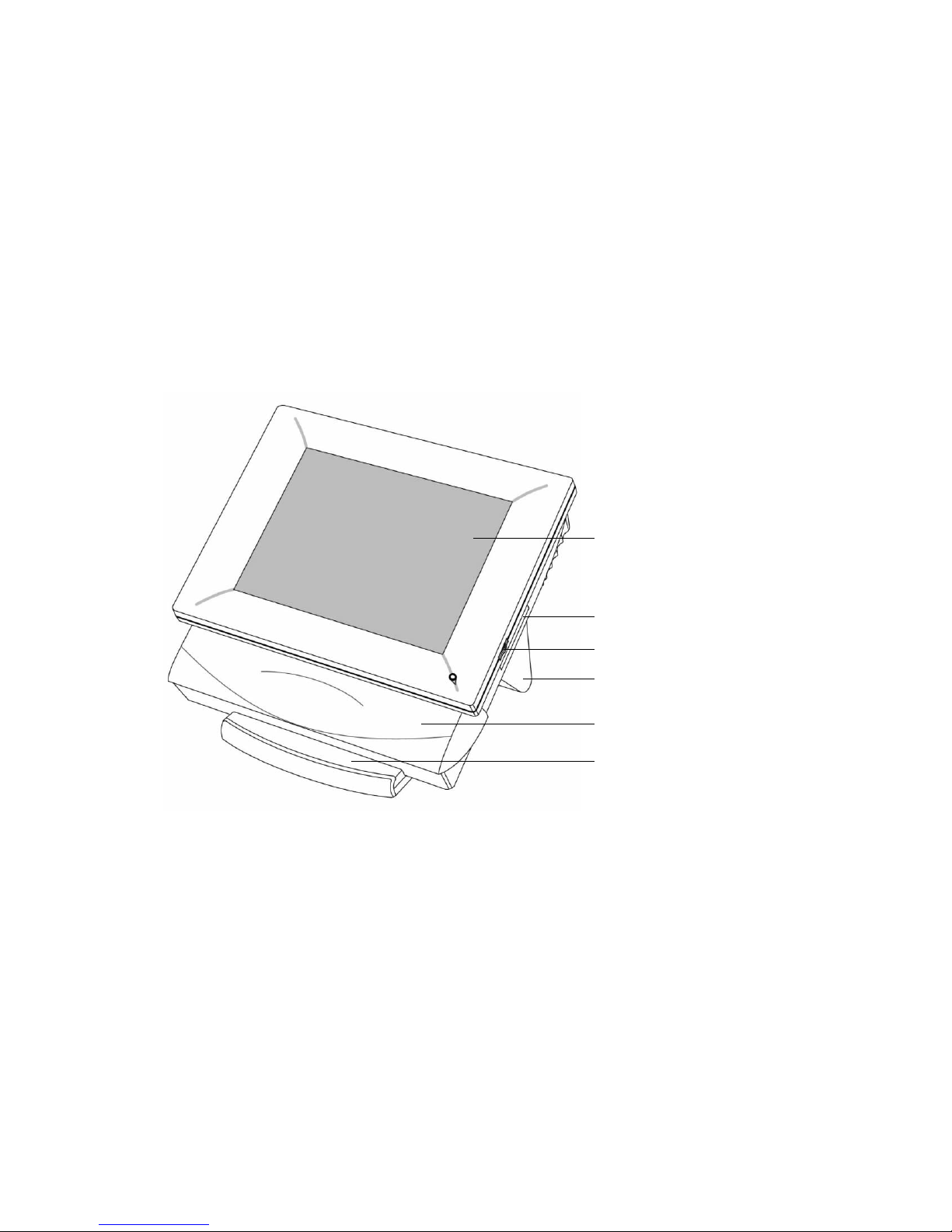

1-2. System Overview

Operator display with Touch screen

TFT color LCD

Side panel

LCD Display Contrast adjustment

Large Hinge cap (Large Hinge inside)

Cable management shroud

Main prop

— 1 —

Page 4

1-3. Major Component

1. Touchscreen: The QT7300 features a quick-response touchscreen for keyboardless operation. The

standard touch adapted in this computer is 12.1" analog resistive type Fujitsu touchscreen. Its durability is

10 million touches in life.

2. Flat panel: To provide the best visual resolution and viewing angle, the standard display panel adapted in

the QT7300 is 12.1" active-matrix TFT passive matrix flat panel.

3. Metal front compartment: The universal mounting design of the front metal compartment is able to mount

most brands of 12.1" flat panel and the EMI issue is also considered.

4. Touchscreen controller: The RS-232 touchscreen controller shares COM1.

5. Power supply: The power supply adapted in this computer is a super-slim 100W power which meets FCC/

VDE Class B specification.

6. System control board: The system engine used is SBC8360-4M. The controller combines both notebook

and industrial computer technology to most compact and stable computer.

7. Main prop: The main prop is made up by a inner metal piece with an outside plastic clothing. It consists of

a set of strong hinges to ensure the whole unit’s stability when a certain touch pressure is applied on the

touchscreen.

8. Cable management shroud: The shroud is made of the mixture of PC and ABS material. The only purpose

of this shroud is to hide the cables coming down from the bottom side of the chassis and to make the operation

environment look trimmed.

— 2 —

Page 5

1-4. Specifications

Core System (Motherboard)

• CPU: Celeron (566MHz)

• System Chipset: Intel 440BX

• BIOS: Award BIOS

• System Memory: 1 x 168-pin DIMM socket, 64MB standard, upgradable to 256MB(buffered)

• L2 Cache: Integrated in CPU

• Real Time Clock : ST M48T86PC1 with built-in battery lasting 10 years

• Expansion Slot: PC/104 and PCI expansion capability

• Watchdog timer: Generate a system reset. Software programmable time interval

I/O system

• Standard I/O: 3 x serial ports w/ power; jumper selectable

1 x parallel port, SPP/EPP/ECP

1 x external FDD Interface

1 x keyboard Interface

1 x P/S Mouse Interface

2 x USB Interface (*)

* Note: with fuse protection and complies with USB Spec. Rev. 1.1A

• Cash Drawer: 2 x

• Ethernet: 10/100 Base-T Ethernet Controller, RJ-45 connector

• Display controller: AGP interface controller with integrated 4MB SDRAM

• Dual independent display supports CRT(*) and LCD display

* Note: Applicable CRT is automatic horizontal frequency detective type only.

Built-in Peripherals

• 2.5" Hard disk (designed 10 GB )

• 12.1" Fujitsu analog resistive touch screen assigned RS-232 controller COM1

— 3 —

Page 6

System Specification

• 12.1" TFT LCD display, resolution 800 X 600

• IPX1 water resistant system

• Cable management shroud

• A versatile pedestal for 30 ° table standing and wall mounting

• Heat dispensing design

• One free slot for PCI expansion

• 100W power supply

• System cooling fan

• Dimension (main body size): 360 x 277 x 82 mm (W x H x D)

• Net Weight: 4.6 Kg

• Operating Temperature Range: 5 °C ~ 35 °C

• Relative Humidity: 5 % to 95 %, non-condensing

Note: 1) Specifications subject to change without notice.

2) The floppy disk drive, mouse and the P/C keyboard are designed for the engineers who are trained

to use them for installation of the QT-7300 POS terminal and are not recommended to use at

customer site as regular POS function in store hours. It may cause fail of the radiation regulation (ie.

FCC or CE).

— 4 —

Page 7

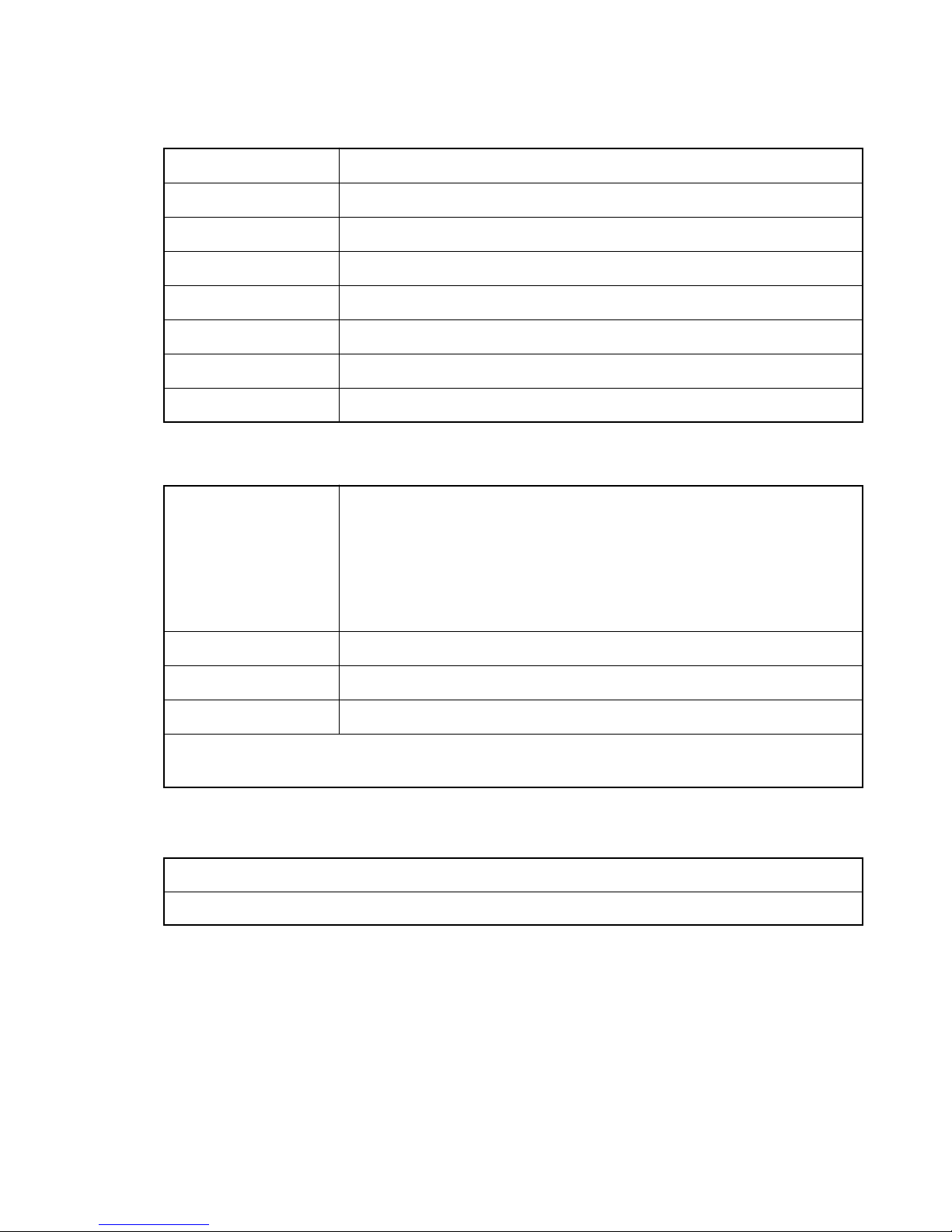

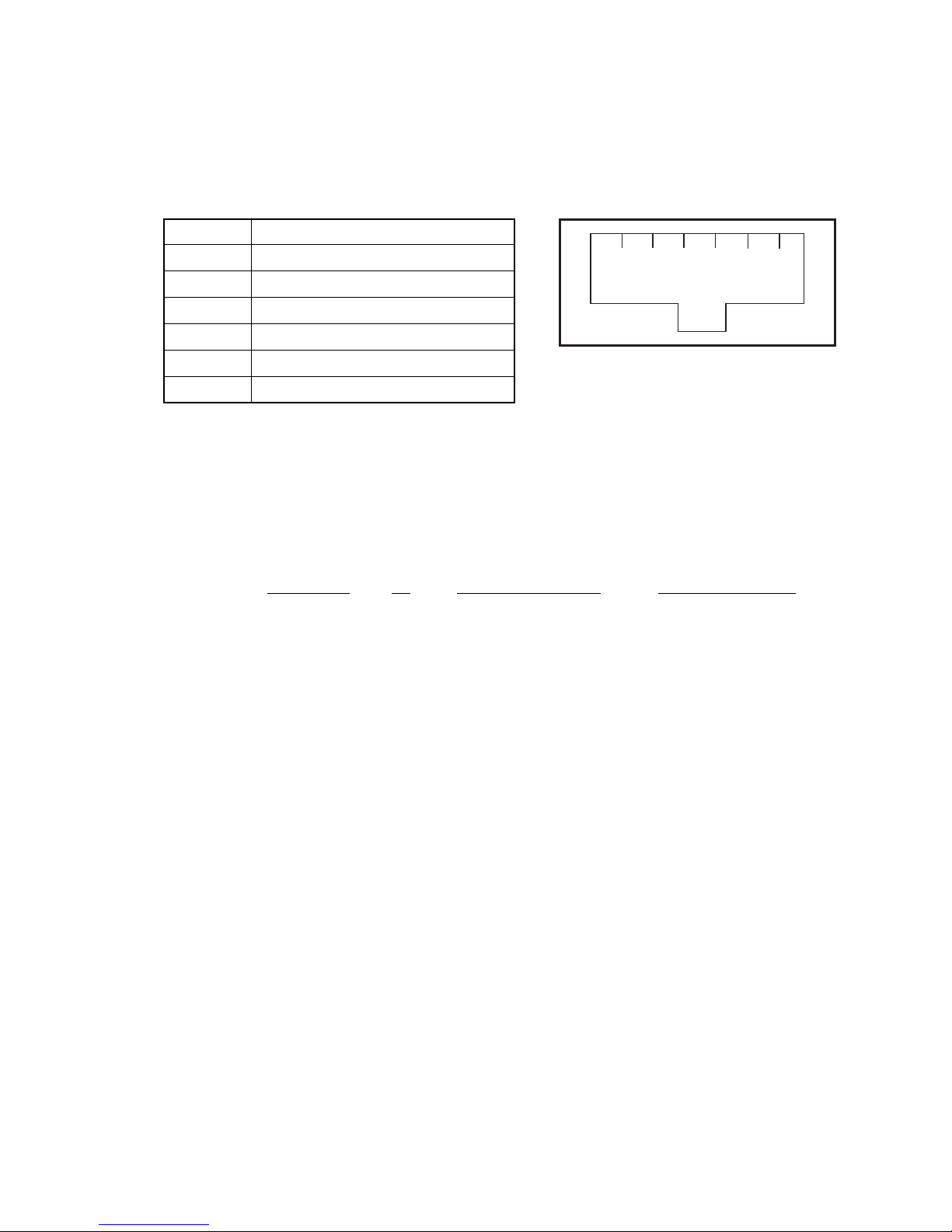

1-5. I/O Outlets

The following diagram shows the I/O arrangement of the QT-7300.

Bottom Panel

1 2 3 4 6 875

1) AC power switch

2) AC inlet

3) Ethernet 10/100 Base-T

4) Second VGA

5) Expansion slot

6) 3 X COM ports

7) 2X Cash Drawers

8) Parallel port

Side Panel

USB

NETVGACOM2COM3COM4PRN

100–230V

K/B

MOUSE FDD

COM1

DRW2 DRW1

4 1 2 3

1) External PS/2 Keyboard

2) External PS/2 mouse

3) External FDD

4) USB

— 5 —

Page 8

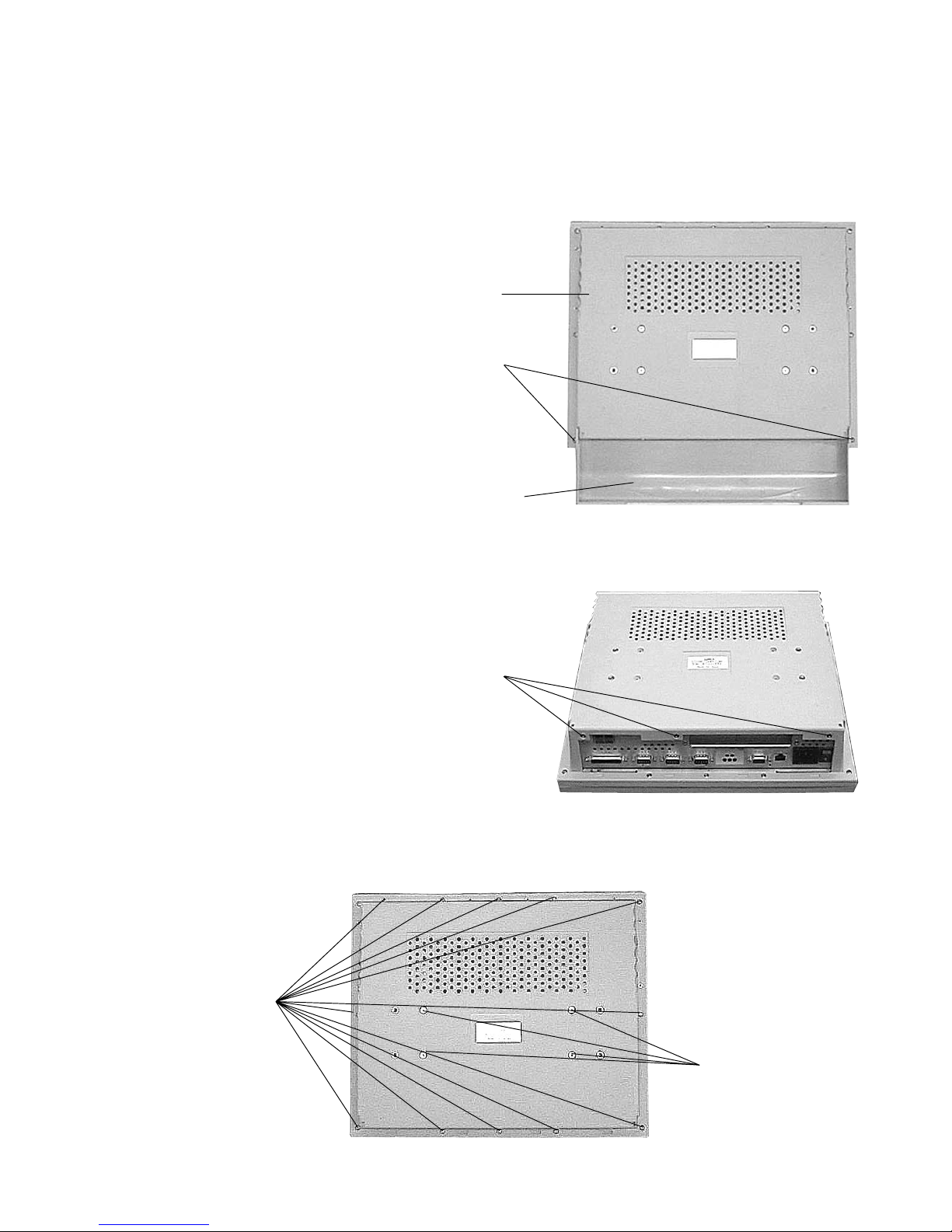

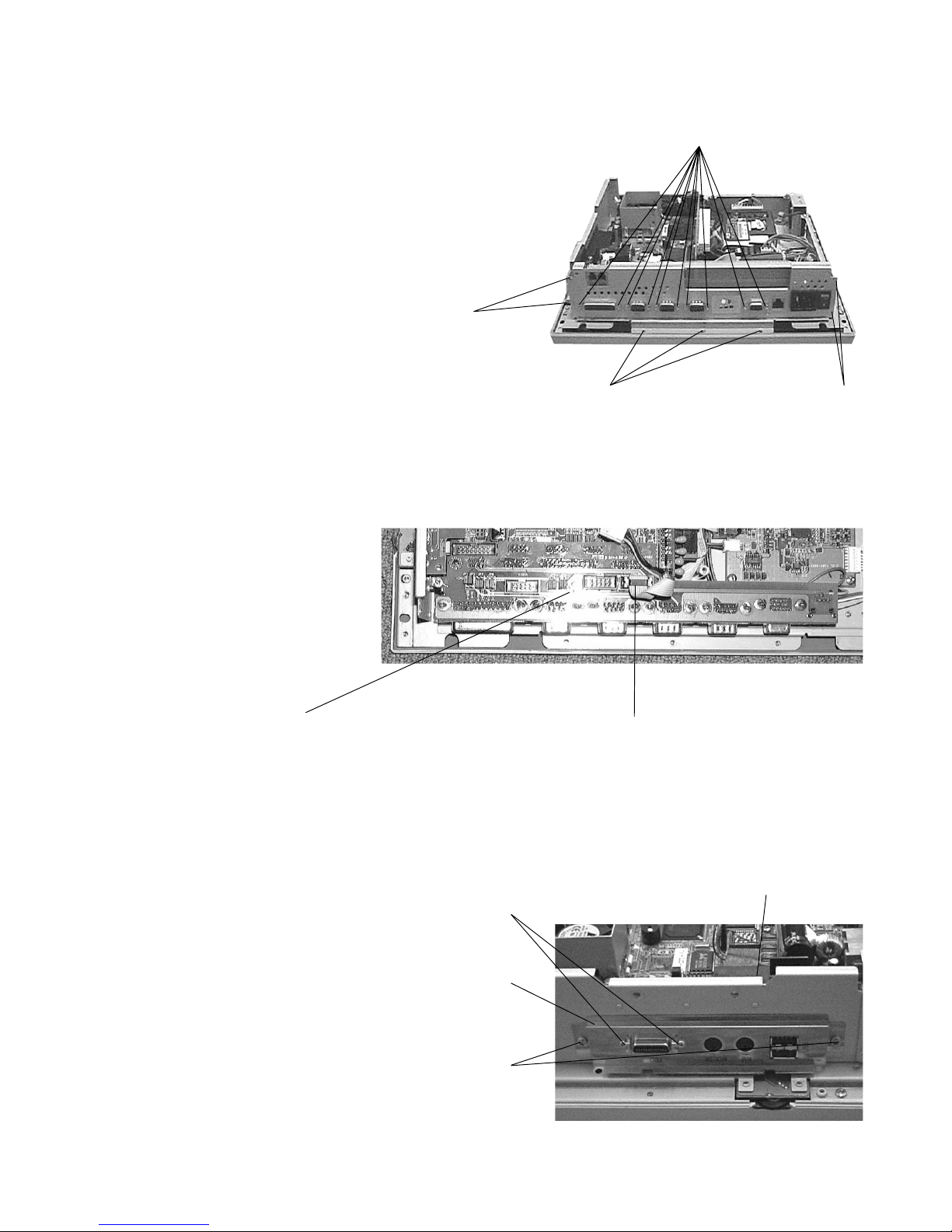

2. DISASSEMBLY

To open the case

1. Place the machine up side down.

2. Release the 2 screws of the case management

shroud. Then, remove the case management shroud

4 screws of the lower case.

The lower case

Release the 2 screws.

The case management shroud

3. Release the 3 screws of the lower case.

4. Release the 4 screws and the 12 screws of the lower

case.

Then, open the lower case.

Release the 12 screws.

Release the 3 screws.

Release the 4 screws.

— 6 —

Page 9

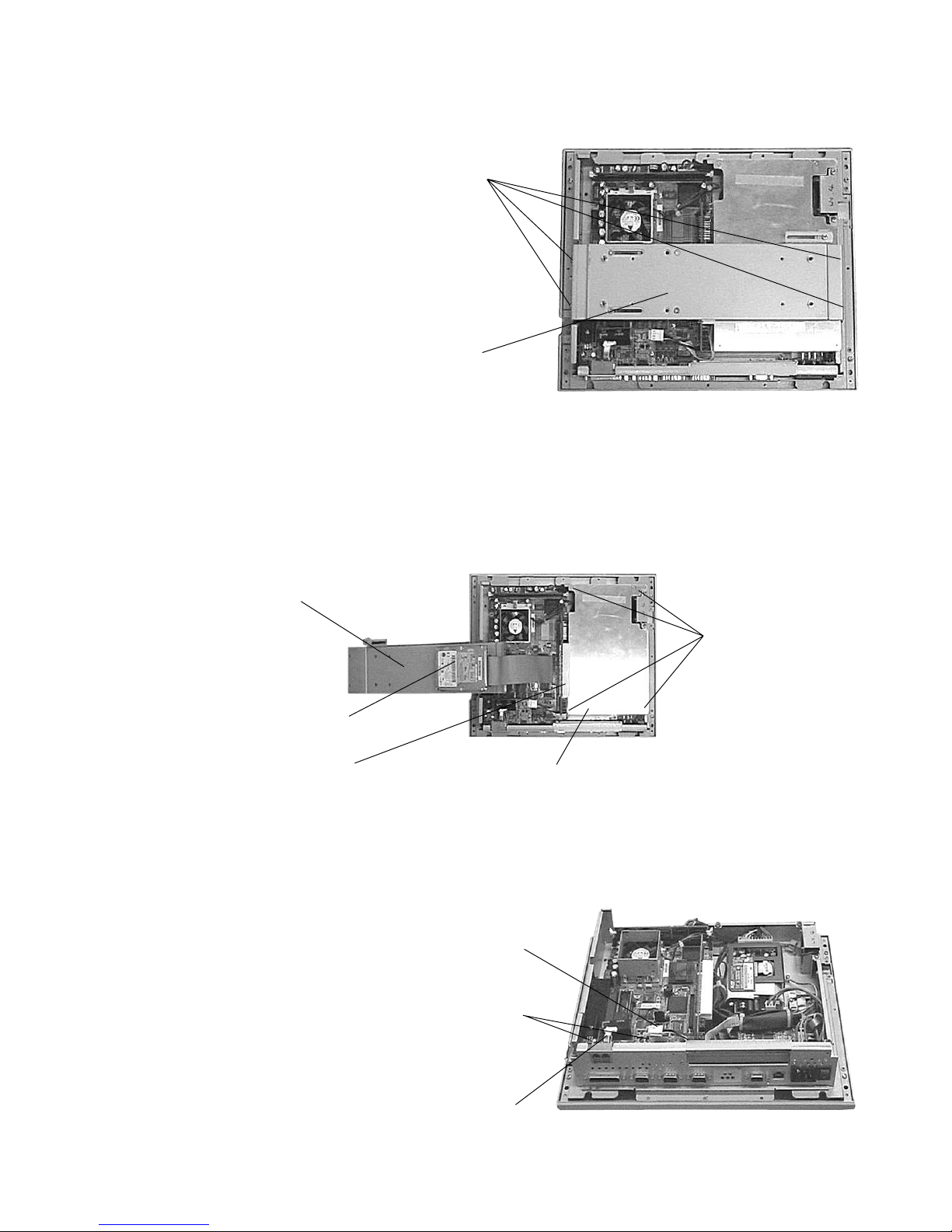

5. Release the 4 screws of the Metal rear bracket.

Then, remove the Metal rear bracket with the HDD

unit.

Release the 4 screws.

The Metal rear bracket with the HDD unit

6. Remove the Riser card from themother board.

Release the 4 screws of the Aluminum separator.

Then, remove the Aluminum separator.

The metal rear bracket with the HDD unit

HDD unit

Remove the Riser card. The Aluminum separator

7. Release the 2 screws of the Drawer drive board and

remove the power connector. Then, remove the

Drawer drive board.

Remove the power connector.

Release the 2 screws.

Releace the 4 screws.

The Drawer drive board

— 7 —

Page 10

8. Release the 7 screws of the connector panel and

release the 10 connector screws. Then, remove the

connector panel.

Remove 2 screws.

9. Remove the connector from the Touchscreen controller. Then remove the Multi-I/O conversion card.

Remove 10 connector screws.

Remove 3 screws. Remove 2 screws.

Remove the Multi-I/O

conversion card.

10.Release the 2 screws of the side connector cover

and the 2 connector screws. Then, remove the side

connector cover and the KB /Mouse/External FDD

conversion card.

Release the 2 connector screws.

The side connector cover

Release the 2 screws.

Remove the connector from the

Touchscreen controller.

The KB/Mouse/External FDD

conversion card

— 8 —

Page 11

11.Release the 9 screws of the Mother board.

Then, remove the Mother board.

1 2 3 4 56

7 8 9

— 9 —

Page 12

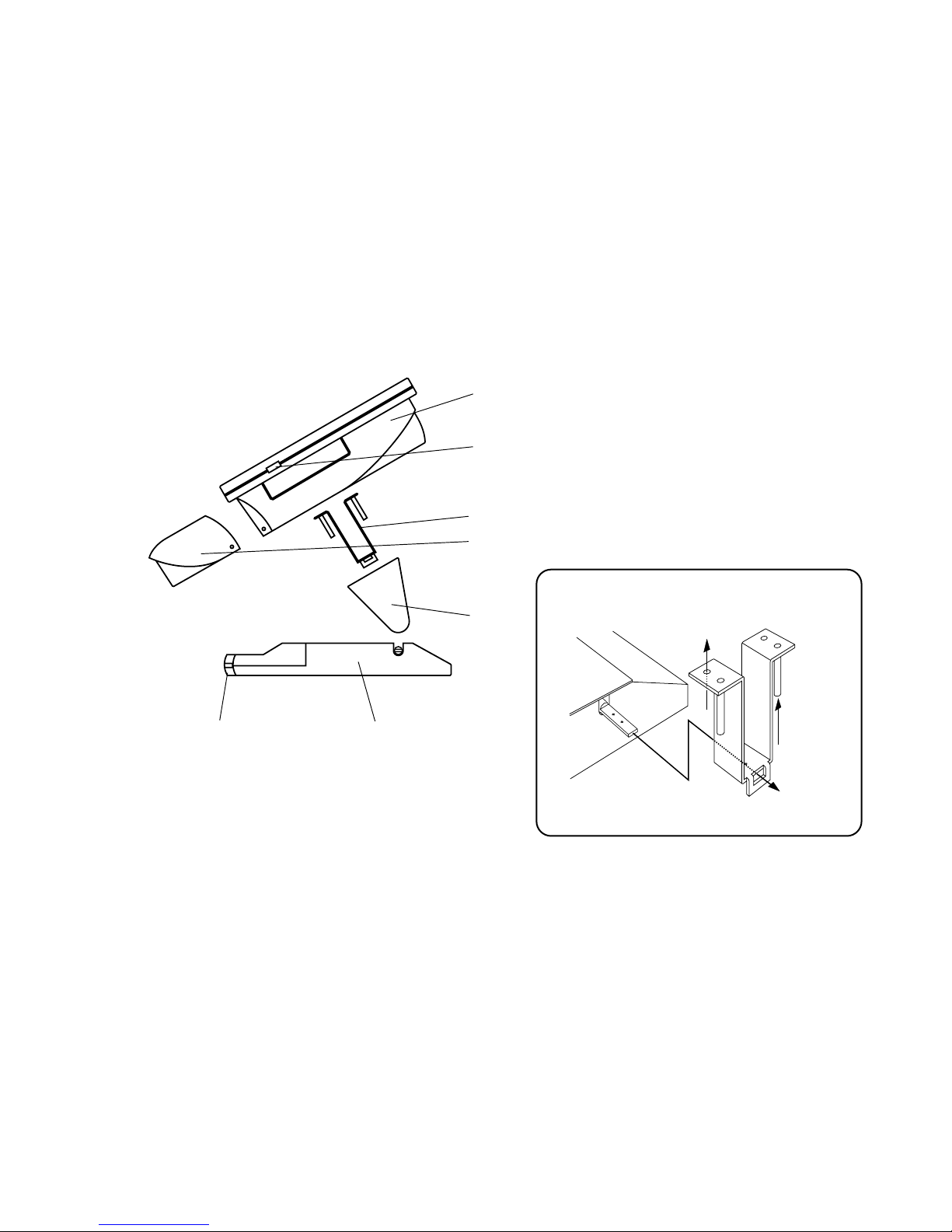

3. INSTALLATION

System main body

LCD Display Contrast adjustment

Large back metal fixtures

Cable management shroud

Large hinge caps

Main prop

Rubber Slip

1

2

3

4

5

6

7

1

2

3

4

5

67

Large back metal fixture

System

main

body

Large hinge

cap

Main

prop

Right or Left

side of main

prop

Unpacking

The QT-7300 along with its accessories are packed in carton box. After unpacking the carton, place the system

on a raised surface and carefully inspect the system for any damage that might have occurred during shipment.

If there are damaged or missing parts, contact your dealer immediately.

Hardware system installation procedure:

1. Attach large back metal fixture(s) to metal part of the main prop on both side with screws. Please refer the

figure “Large back metal fixture” on next page to attach metal fixture with correct direction.

2. Attach metal fixture and main prop to the system main body with screws.

3. Attach large hinge cap(s) to the metal fixture(s) with screws.

NOTES:

1. The QT-7300 do not equip any operating system. An operating system must be loaded first before installing

any software into the QT-7300.

2. Be sure to ground yourself to keep from any static charge when you install the internal components. Use a

grounding wrist strap and place all electronic components in any static-shielded devices. Most electronic

components are sensitive to the static electric charge.

3. Disconnect the power cord from the QT-7300 before any installation. Make sure both the system and the

external devices are turned off and the QT-7300 is properly grounded. The sudden surge of power could ruin

any sensitive components.

4. The brightness of the LCD panel display will decrease with use. However, hours of use will vary depending

on the application environment.

5.

Avoid using sharp objects to operate the touch-screen. Scratches on the touch-screen may cause malfunction

or non-function to the touch-screen

.

— 10 —

Page 13

4. SYSTEM INSTALLATION

This chapter describes the installation of the overall system of the QT-7300. See Chapter 4 for more details on

the motherboard in detail.

The QT-7300 has a Celeron/Pentium III based motherboard with a free PCI slot inside. It already builds in an

Intel Celeron CPU, 64MB of DRAM and a 2.5" HDD. These are all standard and the system is ready to play.

Variety of the I/O ports located at the bottom side and the right side of the chassis are available for customers

to connect external peripheral devices, such as a monitor, serial devices, parallel printer...etc. However, the

interface specification of the peripherals are vary depend on the manufactures and may not applicable to the QT7300 POS system. Please confirm list of the peripheral devices which are test by Casio as the QT-7300 POS

system before you choose the peripherals.

Note: Since all specification and quality of the system are assured by Casio as the QT-7300 POS system, any

local modification of the CPU, DRAM, HDD, jumper setting on the motherboard or system components

by customer will not be applicable for Casio’s guarantee or warranty unless modification are assured

or instructed by Casio.

4-1. CPU

The QT-7300 system already builds in a designated CPU in the socked on the motherboard.

QT-7300: Intel Celeron 566MHz on the motherboard SBC8360-4M

To maintain the CPU, follow the instructions below.

1. Pull the lever sideway away from the socket. Then, raise the lever up to a 90-degree angle.

2. Locate pin 1 at the corner of the CPU socket and align the CPU’s pin 1. Then place the CPU in the socket.

Check the notch on the corner of the CPU and the socket are properly aligned.

3. Press, the lever down to complete the installation. The CPU should always have a Heat Sink with thermal

sheet and a cooling fan attached to prevent overheating.

4. When a CPU is installed, the jumper settings on the motherboard are properly installed as factory default for

the QT-7300 (see Chapter 4 or 5 for CPU jumper settings).

4-2. DRAM

The QT-7300 provides 1 x 168-pin DIMM sockets and 64MB of SDRAM as standard. Maximum system memory

up to 128MB (unbuffered) / 256MB (buffered), respectively. To install the memory module, follow the instructions

below and check the list of DRAM memories tested as QT-7300.

1. The DIMM slots has 2 Notch Keys, so the DIMM memory module can fit in one direction.

2. Insert the DIMM memory module vertically into DIMM slot. Then push in.

3. The plastic clip at the side of the DIMM slot will automatically close.

The system is able to detect the new memory size automatically and it is not necessary to change the system

configuration after installation.

— 11 —

Page 14

4-3. HDD

The standard QT-7300 already builds in a 2.5" hard disk drive. To maintain the HDD, follow the installation

instructions below and check the list of HDD tested as the QT-7300.

1. Take out the screws, the IDE cable and remove the HDD.

2. Reinstall the new HDD on the bracket. The four rubber stands act as cushions to lessen the vibration which

usually causes damage to a mechanical device like a HDD.

3. Connect the IDE cable to the HDD. Match pin 1 of the HDD and the pin 1 of the cable.

4-4. Serial Ports

QT-7300 four onboard serial ports. Since the touch screen system requires one dedicated serial port interface

and COM1 is assigned for it, so that COM1 is not available for users. For the QT-7300, COM2 and COM4 are

RS-232, selected by jumpers. Each serial port is with +5V/+24V and +12V/+24V power capabilities on pin 1 and

pin 9, ready to accommodate a wide array of serial devices. COM2 to COM4 are all D-SUB 9-pin connectors.

4-5. Parallel Port

The printer interface is a 25-pin D-SUB connector located on the bottom side. To connect any parallel device,

just plug in the device connector to the 25pin D-SUB. There are variety of parallel port peripherals in the market

and interface specification vary depending on the peripherals. The peripherals which have been confirmed with

the QT-7300 terminals are listed in the Appendix and others may not be supported. Please confirm connectivity

of each peripherals before install to the customer site.

4-6. VGA

The QT-7300 has an analog RGB interface connector installed on the bottom side. It is able to connect to an

expansion CRT monitor, and the system can display on both the LCD display and the CRT individually or

simultaneously. However, as the LCD display adapted is of the resolution of 800 x 600, therefore, to support a

CRT monitor simultaneously, the CRT’s VGA resolution has to be set to 800 x 600, too. It can also support CRT

maximum resolution of up to 1600 x 1200 with 8bit on Dual-Display Mode colors. Also, an automatic horizontal

frequency detective type CRT is only approved.

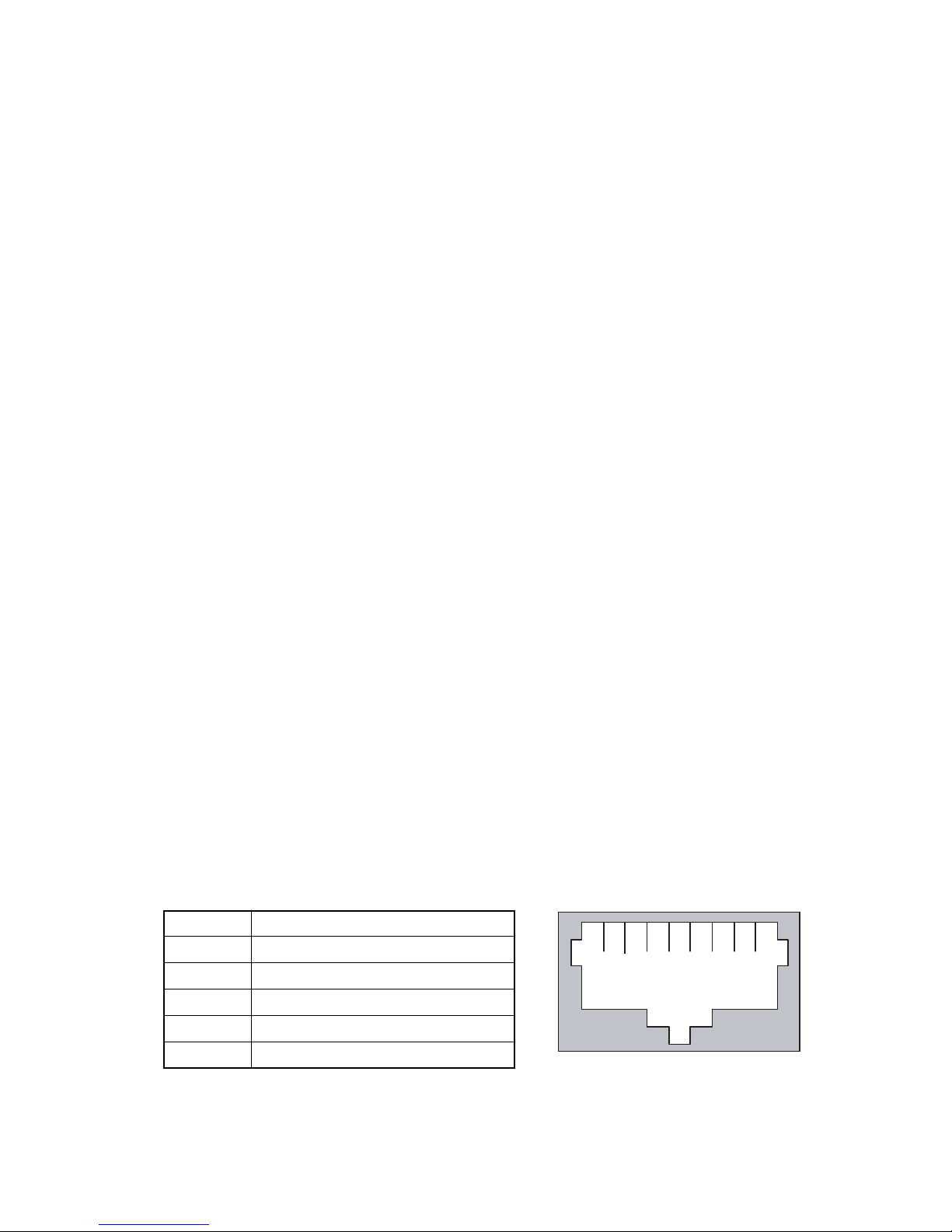

4-7. Ethernet

The QT-7300 provide a high performance Ethernet (RJ-45) interface. For network connection, just plug in one

end of cable of a 10/100-Base-T hub to the standard Ethernet phone jack. The pin assignment of the RJ-45 is

listed below;

RJ-45 Connector Pin Assignment

Pin Description

1 Tx+ (Data transmission positive)

2 Tx- (Data transmission negative)

3 Rx+ (Data reception positive)

6 Rx- (Data reception negative)

others Not use

15842736

RJ-45

— 12 —

Page 15

4-8. Cash Drawer

The QT-7300 provides two Cash Drawer interface. Cash Drawers are assigned as one of I/O in this system and

controlled by the Drawer port on the motherboard (SBC8360-4M).

The pin assignment for the Cash Drawer connector is as follows.

Cash Drawer connector Pin Assignment

Pin Description

1FG

146325

2 Out Switch

3 Read Switch

4 +24V

5NC

6 GND

4-8-1. Cash Drawer control Software Programming

The Cash Drawer is assigned as one of I/O device in the system. The I/O address assigned for the Cash Drawers

123h. The QT-7300 can support two Cash Drawers and each Cash Drawers can be controlled respectively by

output or input data to this I/O address. The open/close status of drawers also can be read by reading this I/O

address. Following is software programming method for Casio standard Cash Drawer model DL-2765, DL-2909

and DL-3615.

I/O Address Bit Output Data to Open Input data for status

Drawer A 123 0 01h FEh (open)

Drawer B 123 1 02h FDh (open)

Example program; < Drawer A open >

Out 123h, 01h : Drawer A open signal on

< 100 ms timer > : Open signal on 100 ms

Out 123h, 00h : Drawer A open signal off

Example program; < Read Drawer open status >

Input 220h : Read Drawer open status

If data is FFh: Drawer A , B closed

If data is FEh: Drawer A is open, Drawer B is closed.

If data is FDh: Drawer A is closed, Drawer B is open.

If data is FCh: Drawer A is open, Drawer B is open.

Note: 1) Drawer open signal on time is 100 ms.

2) Do not open Drawer A and B at same time (Output data 03). If two drawers were open at same time,

it may cause damage on system power supply.

— 13 —

Page 16

4-9. Keyboard

The QT-7300 provides a standard PS/2 keyboard connector located at the side panel. If the user would like to

use AT keyboard interface, a conversion cable is also provided to make this connection.

4-10. PS/2 Mouse

The QT-7300 has one PS/2 Mouse connector located at the right side. A simple plug-in will make the connection.

4-11. External FDD

The QT-7300 does not build in any floppy disk drive into the main system. Rather, it provides a FDD interface

located at the side panel. An external FDD cable is provided to connect a standard 3.5" FDD to the system for

system O/S and application software installation. Its pin position and pin assignment is listed as follows;

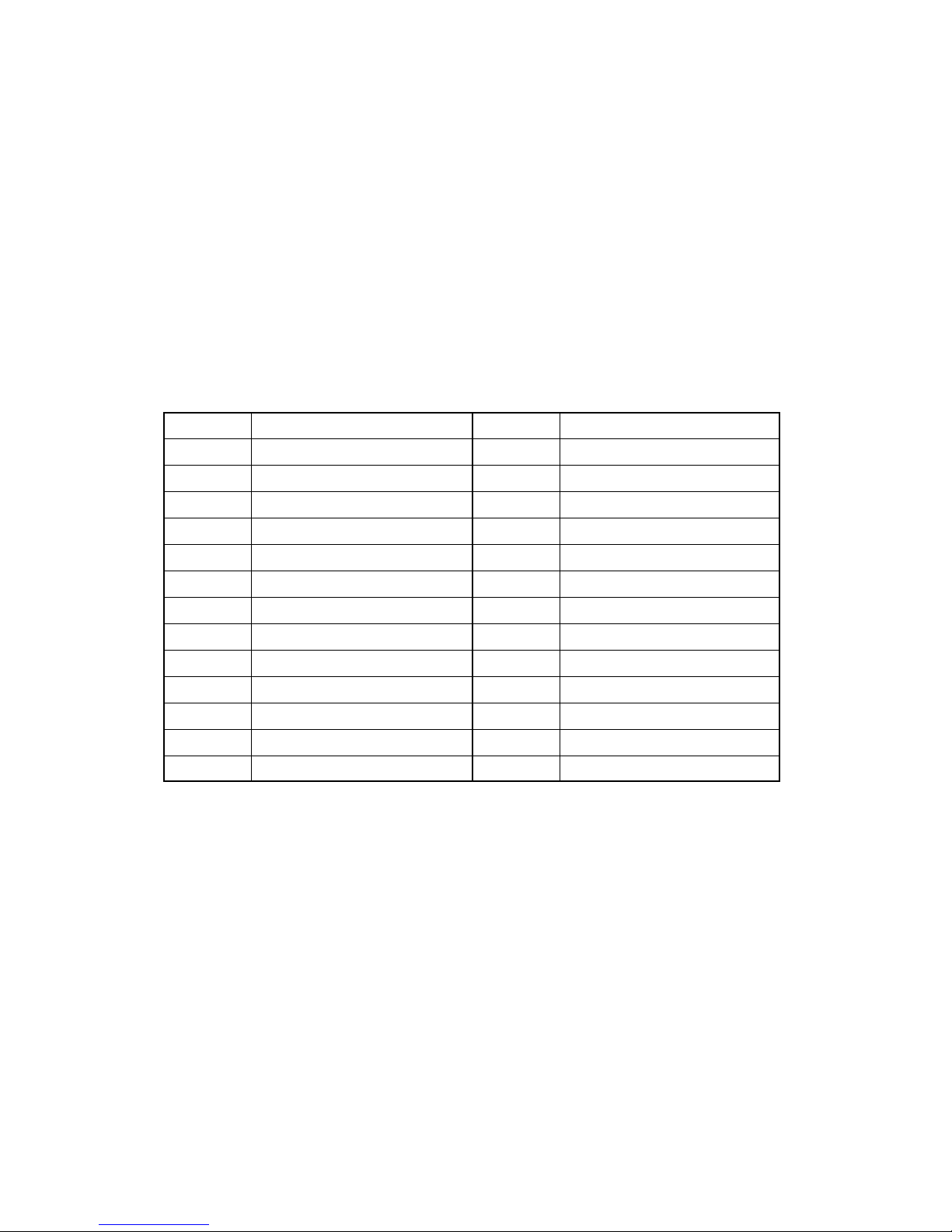

External FDD Pin Assignment

Pin Description Pin Description

P 1 SIDE1- P 14 WPTP 2 RDATA- P 15 TRK0P 3 GND P 16 GND

P 4 GND P 17 WGATEP 5 GND P 18 GND

P 6 WDATA- P 19 NC

P 7 REDWC- P 20 STEPP 8 NC P 21 DIRP 9 NC P 22 MOTE0P 10 DRVS0- P 23 NC

P 11 FDDDVcc P 24 DSKCHGP 12 FDDDVcc P 25 NC

P 13 INDEX- P 26 FDDDVcc

— 14 —

Page 17

4-12. Expansion Slot

The QT-7300 provides a free PCI expansion slot to accommodate a PCI device at a given time. The expansion

card can be plugged into the riser card which is plugged in the onboard PCI/ISA slot as standard. Due to the

compact space design, a half-size expansion card can be adapted. To use the PCI expansion, follow the

installation instructions below;

1. Unscrew the metal slip located inside the expansion outlet.

2. Plug a PCI card into the PCI slot on the riser card and fix the expansion card by screwing it to the metal front

compartment. All the connectors of the expansion card will come out from the expansion outlet on the bottom

side of the chassis for further cable connection.

4-13. System O/S and Software Installation

The QT-7300 is not equipped with any operating system. It builds in a 2.5" HDD as memory storage device. As

both devices are built in the system chassis, to load Win98/Win98SE or Win2000 O/S or application software

into the system, an external device is needed to act as a bridge. There are three major ways to load software

into the system.

1. Use an external FDD: Attach a 3.5" FDD to the external FDD port via the provided external FDD

cable. The 26-pin FDD connector is to be plugged in to the system FDD

connector; the 34-pin standard 3.5" FDD signal connector and the 4-pin FDD

power connector are to connect to the standard 3.5" FDD. Then, configure the

system BIOS setup and insert a 3.5" disk containing necessary software and

start the installation.

2. Use Ethernet: After install the O/S and necessary network utilities, download application

software from the network.

3. Use External CD-ROM/HDD: To use an external CD-ROM or HDD for software installation, an optional P-

IDE device is needed. The P-IDE device is a converter to convert the parallel

port to the IDE interface.

— 15 —

Page 18

4-14. Award BIOS Setup

>

Starting Award BIOS Setup

As POST executes, the following appears

Hit <DEL> if you want to run SETUP

Press <Del> to run Award BIOS Setup.

4-14-1. Award BIOS Setup Main Menu

When you enter the Award BIOS Setup Utility, the main menu will appear on the screen as follows. Use the arrow

keys to move among the items and press <Enter> to accept and enter into the sub-menu.

< Screen shows all default setting

ROM PCI/ISA BIOS (2A69KA5C)

CMOS SETUP UTILITY

AWARD SOFTWARE, INC.

STANDARD COMS SETUP

BIOS FEATURES SETUP

CHIPSET FEATURES SETUP

POWER MANAGEMENT SETUP

PNP/PCI CONFIGURATION SETUP

LOAD BIOS DEFAULTS

LOAD SETUP DEFAULTS

ESC : Quit

F10 : Save & Exit Setup

Time, Date, Hard Disk Type...

INTEGRATED PERIPHERALS

SUPERVISOR PASSWORD

USER PASSWORD

IDE HDD AUTO DETECTION

SAVE & EXIT SETUP

EXIT WITHOUT SAVING

↑ ↓ → ← : Quit

(Shift) F2 : Save & Exit Setup

— 16 —

Page 19

4-14-2. Setup

>

The Award BIOS Setup options described in this section are selected by choosing the appropriate high-level icon

from the Award BIOS Setup main menu selection screen.

Default setting for the QT-7300 is described in < > next to each option. ( i.e. <AUTO> )

4-14-2-1. Standard CMOS Setup

< Screen shows all default setting

ROM PCI/ISA BIOS (2A69KA5C)

STANDARD CMOS SETUP

AWARD SOFTWARE, INC.

Date (mm:dd:yy) : Tue, Oct 27 1999

Time (hh:mm:ss) : 18 : 56 : 41

HARD DISKS

Primary Master

Primary Slave

Secondary Master

Secondary Slave

Drive A : 1.44M, 3.5 in

Drive B : None

Video : EGA/VGA

Halt On : All Errors

ESC : Quit

F1 : Help

Type

: Auto

: None

: None

: None

SIZE

0

0

0

0

CYLS

0

0

0

0

↑ ↓ → ← : Select Item

(Shift) F2 : Change Color

HEAD

PRECOMP

0

0

0

0

PU/PD/+/- : Modify

LANDZ

0

0

0

0

BASE Memory

Extended Memory

Other Memory

Total Memory

0

0

0

0

SECTOR

0

0

0

0

:

:

:

:

MODE

AUTO

----

----

----

640K

64512K

384K

65536K

• Date, Day and Time Configuration

Select the Standard option. Select the Date and Time icon. The current values for each category are

displayed. Enter new values through the keyboard.

• Primary Master

• Primary Slave

• Secondary Master

< Auto>

< None>

< None>

• Secondary Slave

< None>

Select one of these hard disk drive icons to configure the drive named in the option. A scrollable screen

that lists all valid disk drive types is displayed. Select the correct type and press <Enter>. The Award

BIOS is able to detect the IDE drive parameters automatically and report them on this screen. To

enable this auto-detect function, just select the drive type Auto.

NOTE: Secondary drives are not support.

• Drive A

• Drive B

< 1.44MB, 3.5inch>

< Not Installed >

Move the cursor to these fields via and select the floppy type. The settings are 360KB 5.25 inch, 1.2

MB 5.25 inch, 720KB 3.5 inch, 1.44 MB 3.5 inch, or 2.88 MB 3.5 inch.

• Video

<EGA/VGA>

The category selects the type of adapter used for the primary system modify that must match your video

display card and monitor.

— 17 —

Page 20

• Error Halt

>

<All errors>

The category determines whether the computer will stop if an error is detected during power up.

• Memory

The category is display-only which is determined by POST (Power On Self Test) of the BIOS.

4-14-2-2. BIOS Features Setup

< Screen shows all default setting

ROM PCI/ISA BIOS (2A69KA5C)

BIOS FEATURES SETUP

AWARD SOFTWARE, INC.

Virus Warning : Disabled

CPU Internal Cache : Enabled

External Cache : Enabled

CPU L2 Cache ECC Check : Enabled

Processor Number Feature : Enabled

Quick Power On Self Test : Enabled

Boot Sequence : A,C,SCSI

Video BIOS Shadow : Enabled

C8000-CBFFF Shadow : Disabled

CC000-CFFFF Shadow : Disabled

D0000-D3FFF Shadow : Disabled

D4000-D7FFF Shadow : Disabled

D8000-DBFFF Shadow : Disabled

DC000-DFFFF Shadow : Disabled

Swap Floppy Drive : Disabled

Boot Up Floppy Seek : Disabled

Boot Up NumLock Status : On

Gate A20 option : Fast

Typematic Rate Setting : Disabled

Typematic Rate (Chars/Sec) : 6

Typematic Delay (msec) : 250

LCD Type : (Type 8) 800x600 TFT

VGA Expansion (Full Screen) : Enable

Display Type During POST : Both

Display Type After POST : Both

Security Option : Setup

PCI/VGA Palette Snoop : Disabled

Assign IRQ for VGA : Enabled

OS Select for DRAM > 64MB : Non-OS2

Report No FDD for Win95 : Yes

ESC : Quit

F1 : Help

F5 : Old Values

F6 : Load BIOS Defaults

↑ ↓ → ← : Select Item

PU/PD/+/- : Modify

(Shift) F2 : Color

F7 : Load Setup Defaults

• Virus Warning

• CPU Internal Cache / External Cache

<Disabled>

< Enabled >

These two speed up memory access. However, it depends on the CPU/chipset design.

• CPU L2 Cache ECC Checking

When enabled, this allows ECC checking of the CPU's L2 cache.

• Quick Power On Self Test

• Boot Sequence

< A,C,SCSI >

This option sets the sequence of boot drives either floppy drive A or hard disk drive C or CDROM that

Award BIOS attempts to boot from after POST completes

• Swap Floppy Drive

This option enables the floppy swap function. The setting is Enable or Disable.

• Boot Up Floppy Seek

This option enables Award BIOS seek on floppy drive A before booting the system. The settings is

Enabled or Disabled.

• Boot Up NumLock Status

This option enables and disables the numberlock function of the keypad.

• Gate A20 option

< Fast >

< Enabled >

< Enabled >

< Disabled >

< Disabled >

< On >

— 18 —

Page 21

• Typematic Rate Setting

This determines the typematic rate of the keyboard.

< Disabled >

• Typematic Rate (Chars/Sec)

This option refers to the number of characters the keyboard can type per second.

• Typematic Delay (msec)

This option sets the display time interval from the first to the second character when holding a key.

• Security Option

This item allows you to limit access to the system and Setup, or just to Setup.

• PCI/VGA Palette Snoop

Some non-standard VGA display cards may not show colors properly.

• Assign IRQ for VGA

Enables or disables VGA's IRQ assignment.

• OS Select for DRAM > 64MB

This segment is specifically created for OS/2 when DRAM is larger than 64MB.

• Report No FDD for Win98/98SE/2000

This option allows Windows98/98SE/2000 to share IRQ6 (assigned to a floppy disk drive) with other

peripheral in cash the drive is not existing.

• Video ROM BIOS Shadow

Video shadowing increases the video speed by copying the video BIOS into RAM.

• C8000-CBFFF Shadow

• CC000-CFFFF Shadow

• D0000-D3FFF Shadow

< Setup >

< Enabled >

< 6 >

< 250 >

< Disabled >

< Non-OS2 >

< Yes >

< Enabled >

< Disabled >

< Disabled >

< Disabled >

• D4000-D7FFF Shadow

• D8000-DBFFF Shadow

• DC000-DFFFF Shadow

These options determine whether optional ROM will be copied t RAM by 16K byte or 32K byte per/unit.

OnBoard VGA Function

The following options allow the overriding of the VGA BIOS setting integrated in the core chipset of

SBC8360-4M.

• LCD Type

Although the system chipset already supports VGA and LCD alike, BIOS Features Setup still expands

this feature further with the option to set any of 15 LCD types.

• VGA Expansion (Full Screen)

This option allows you to enlarge application screens to full screen scale onto your display.

However this opton is not inversely compatible, rendering no change when applications screens have

resolutions larger than the display resolution.

• Display Type During POST

• Display Type After POST

This item configures the viewing area for the POST sequence. When configured to the incorrect display

setting or BOTH, it blankets the POST sequence from being viewed. If you select Default this option

is useless and follows the VGA BIOS setting.

< (Type 8) 800x600 TFT >

< Disabled >

< Disabled >

< Disabled >

< Enabled >

< Both >

< Both >

— 19 —

Page 22

4-14-2-3. Chipset Features Setup

>

< Screen shows all default setting

ROM PCI/ISA BIOS (2A69KA5C)

CHIPSET FEATURES SETUP

AWARD SOFTWARE, INC.

SDRAM RAS-to-CAS Delay : 3

SDRAM RAS Precharge Time : 3

SDRAM CAS Latency Time : Auto

SDRAM Precharge Control : Disabled

DRAM Data Integrity Mode : Non-ECC

System BIOS Cacheable : Disabled

Video BIOS Cacheable : Disabled

Video RAM Cacheable : Disabled

8 bit I/O Recovery Time : 1

16 bit I/O Recover Time : 1

CPU Warning Temperature : Disabled

Current System1 Temp : 35 °C/ 95 °F

Current System2 Temp : 0 °C/ 32 °F

Current CPU Temperature : 50 °C/112 °F

Current FAN1 Speed : 6136 RPM

Current FAN2 Speed : 0 RPM

Current FAN3 Speed : 0 RPM

Vcore : 1.68 V VTTP : 1.48 V

VCC : 3.32 V + 5 V : 5.18 V

+12 V : 12.28 V

Memory Hole At 15M-16M : Disabled

Passive Release : Enabled

Delayed Transaction : Disabled

AGP Aperture Size (MB) : 64

ESC : Quit

F1 : Help

F5 : Old Values

↑ ↓ → ← : Select Item

PU/PD/+/- : Modify

(Shift) F2 : Color

F6 : Load BIOS Defaults

F7 : Load Setup Defaults

• SDRAM RAS-to-CAS Delay

< 3 >

You can select RAS-to-CAS delay in HCLKs 2 or 3. The board designer should set the values in this

field, depending on the DRAM installed. Do not change the values in this field unless you change

specifications of the installed DRAM or installed CPU.

• SDRAM RAS Precharge Time

< 3 >

When synchronous DRAM is installed, the number of clock cycles of RAS precharge time depends on

the DRAM timing. Do not reset this field from the default value specified by system designer.

• SDRAM CAS Latency Time

You can select CAS latency time in HLCKs 2, 3 or Auto. The board designer should set the values in

this field, depending on the DRAM installed. Do not change the values in this field unless you change

specifications of the installed DRAM or installed CPU.

• SDRAM Precharge Control

• DRAM Data Integrity Mode

This option sets the data integrity mode of the DRAM installed in the system.

• System BIOS Cacheable

Selecting Enables allows caching of the system BIOS ROM at F0000h-FFFFh, resulting in better

system performance. However, if any program writes to this memory area, a system error may result.

• Video BIOS Cacheable

This item allows you to change the Video BIOS location from ROM to RAM. Video shadow wil increase

the video speed.

< Auto >

< Disabled >

< Non-ECC >

< Disabled >

< Disabled >

— 20 —

Page 23

• Video RAM Cacheable

< Disabled >

Selecting Enabled allows caching of the Video BIOS ROM at C0000h to C7FFFh, resulting in better

video performance. However, if any program writes to this memory area, a system error may result.

• 8 bit I/O Recovery Time

• 16 bit I/O Recover Time

< 1 >

< 1 >

The I/O recovery mechanism adds bus clock cycles between PCI-originated I/O cycles to the ISA bus.

This delay takes place because the PCI bus is so much faster than the ISA bus.

These two fields let you add recovery time (in bus clock cycles) for 16/8 - bit I/O.

• Memory Hole At 15M-16M

< Disabled >

You can reserve this area of system memory for ISA adapter ROM. When this area is reserved, it

cannot be cached. He user information of peripherals that need to use this area of system memory

usually discusses their memory requirements.

• Passive Release

< Enabled >

When enabled, CPU to PCI accesses are allows during passive release. Otherwise, the arbiter only

accept another PCI master access to local DRAM.

• Delayed Transaction

< Disabled >

The chipset has an embedded 32-bit posted write buffer to support delay transactions cycles. Select

Enabled to support compliance with PCI specification version 2.1.

• AGP Aperture Size (MB)

< 64 >

The field sets aperture size of the graphics. The aperture is portion of the PCI memory address range

dedicated for graphics memory address space. Host cycles that hit the aperture range are forwarded

to the AGP without any translation.

• CPU Warning Temperature

< Disabled >

This option lets you set the CPU temperature limit where the system will produce a warning indicating

CPU temperature has already exceeded.

• Current System1 Temp (35 °C/ 95 °F)

• Current System2 Temp (0 °C/ 32 °F)

• Current CPU Temperature (50 °C/112 °F)

These ready-only field reflect the function of the hardware thermal sensor that monitors the chio blocks

and system temperature to ensure the system is stable.

• Current FAN1 Speed (6136 RPM)

• Current FAN2 Speed (0 RPM)

• Current FAN3 Speed (0 RPM)

These option and ready-only field show the current speeds in RPM (revolution per minute) for the CPU

fan and chassis fan as monitored by the hardware monitoring IS.

• VCore (1.68 V) / VTTP (1.48 V) / VCC (3.32 V) / + 5 V (5.18 V) / +12 V (12.28 V)

These option and ready-only field show the current voltages in the voltage regulators and power supply

as monitored by the hardware monitoring IS.

— 21 —

Page 24

4-14-2-4. Power Management Setup

>

< Screen shows all default setting

ROM PCI/ISA BIOS (2A69KA5C)

POWER MANAGEMENT SETUP

AWARD SOFTWARE, INC.

ACPI function : Disabled

Power Management : User Define

PM Control by APM : Yes

Video off Method : V/H SYNC + Blank

Video off After : Standby

Modem Use IRQ : 3

Doze Mode : Disabled

Standby Mode : Disabled

Suspend Mode : Disabled

** Reload Global Timer Events **

IRQ[3-7,9-15],NMI Disabled

Primary IDE 0 : Disabled

Primary IDE 1 : Disabled

Secondary IDE 0 : Disabled

Secondary IDE 1 : Disabled

Floppy Disk : Disabled

Serial Port : Enabled

Parallel Port : Disabled

HDD Power Down : Disabled

Throttle Duty Cycle : 62.5%

PCI/VGA Act-Monitor : Disabled

Soft-Off by PWR-BTTN : Instant-Off

Wake Up on LAN : Enabled

IRQ 8 Break Suspend : Disabled

ESC : Quit

F1 : Help

F5 : Old Values

↑ ↓ → ← : Select Item

PU/PD/+/- : Modify

(Shift) F2 : Color

F6 : Load BIOS Defaults

F7 : Load Setup Defaults

• ACPI function

< Disabled >

This item allows you to enable/disable the Advanced Configuration and Power Management (ACPI).

• Power Management

This option allows you to select the type (or degree) of power saving for Doze, Standby

• PM Control by APM

< User Define >

< Yes >

If Advanced Power Management (ACPI) is installed on your system, selecting Yes gives better power

savings.

• Video off Method

< V/H SYNC + Blank >

Determines the manner in which the monitor is blanked.

• Video off After

< Standby >

As the system moves from lesser to grater power-saving modes, select the mode in which you want

the monitor to blank off.

• Modem Use IRQ

• Doze Mode

< 3 >

< Disabled >

After the selected period of system inactivity (1 minute to 1 hour), the CPU clock runs at slower speed

while all other devices still operate at full speed.

• Standby Mode

< Disabled >

After the selected period of system inactivity (1 minute to 1 hour), the fixed disk drive and the video shut

off while all other devices still operate at full speed.

• Suspend Mode

< Disabled >

After the selected period of system inactivity (1 minute to 1 hour), all devices except the CPU shut off.

— 22 —

Page 25

• HDD Power Down

After the selected period of drive inactivity (1 to 15 minute), the hard disk drive powers down while all

other devices remain active.

< Disabled >

• Throttle Duty Cycle

When the system enters Doze mode, the CPU clock runs only part of the time. You must select the

percent of time that the clock runs.

• PCI/VGA Act-Monitor

When Enabled, any vide activity restarts the global timer for Standby mode.

• Soft-Off by PWR-BTTN

This only works with system using an ATX power supply. It also allows user to define the type of soft

power OFF sequence the system will follow.

• Wake Up on LAN

All input signal on the network awakens the system from a soft-off state.

• IRQ 8 Break Suspend

You can turn on or off monitoring of IRQ8 (the Real Time Clock) so it does not awaken the system form

Suspend mode.

** Reload Global Timer Events **

When Enabled, an event occurring on each device listed below restarts the global time for Stanby

mode.

• IRQ[3-7,9-15],NMI

• Primary IDE 0

• Primary IDE 1

< 62.5% >

< Disabled >

< Instant-Off >

< Enabled >

< Disabled >

< Disabled >

< Disabled >

< Disabled >

• Secondary IDE 0

• Secondary IDE 1

NOTE: Secondary drives are not support.

• Floppy Disk

• Serial Port

• Parallel Port

< Disabled >

< Disabled >

< Disabled >

< Enabled >

< Disabled >

— 23 —

Page 26

4-14-2-5. PCI / Plug and Play Setup

>

PNP OS Installed : No

Resources Controlled By : Auto

Reset Configuration Data : Disabled Assign IRQ For USB : Enabled

< Screen shows all default setting

ROM PCI/ISA BIOS (2A69KA5C)

PNP/PCI CONFIGRATION

AWARD SOFTWARE, INC.

Onboard Ethernet BootROM : Disabled

ESC : Quit

F1 : Help

F5 : Old Values

F6 : Load BIOS Defaults

F7 : Load Setup Defaults

• PNP OS Installed

Select Yes the system operating environment is Plug-and-Play aware (e.g., Win98/98SE/2000).

• Resources Controlled By

The Award Plug and Play BIOS can automatically configure all the boot and Plug and Play-compatible

devices. If you select Auto, all the interrupt request (IRQ), DMA assignment, and used DMA field

disappear, as the BIOS automatically assigns them.

• Reset Configuration Data

Normally, you leave this field Disabled. Select Enabled to reset Extended System Configuration Data

(ESCD) when you exit Setup if you have installed a new add-on and system reconfiguration has caused

such a serious conflict that the operating cannot boot.

• IRQ 3 Assigned to

• IRQ 4 Assigned to

• IRQ 5 Assigned to

• IRQ 7 Assigned to

< No >

< Auto >

< Disabled >

< Legacy ISA >

< Legacy ISA >

< PCI/ISA PnP >

< Legacy ISA >

↑ ↓ → ← : Select Item

PU/PD/+/- : Modify

(Shift) F2 : Color

• IRQ 9 Assigned to

• IRQ 10 Assigned to

• IRQ 11 Assigned to

• IRQ 12 Assigned to

• IRQ 14 Assigned to

< PCI/ISA PnP >

< Legacy ISA >

< Legacy ISA >

< PCI/ISA PnP >

< PCI/ISA PnP >

— 24 —

Page 27

• IRQ 15 Assigned to

< PCI/ISA PnP >

When resources are controlled manually, assign each system interrupt as one of the following types,

depending on the type of device using the interrupt:

1. Legacy ISA Devices compliant with the original PC AT bus specification, requiring a specific

interrupt (such as IRQ4 for serial port 1).

2. PCI/ISA PnP Devices compliant with the Plug and Play standard, whether designed for PCI or ISA

bus architecture.

• DMA 0 Assigned to

• DMA 1 Assigned to

• DMA 3 Assigned to

• DMA 5 Assigned to

• DMA 6 Assigned to

• DMA 7 Assigned to

< PCI/ISA PnP >

< PCI/ISA PnP >

< PCI/ISA PnP >

< PCI/ISA PnP >

< PCI/ISA PnP >

< PCI/ISA PnP >

When resources are controlled manually, assign each system DMA channel as one of the following

types, depending on the type of device using the DMA channel:

Legacy ISA Devices compliant with the original PC AT bus specification, requiring a specific DMA

channel.

PCI/ISA PnP Devices compliant with the Plug and Play standard, whether designed for PCI or ISA bus

architecture.

• Used MEM base addr

< N/A >

Select a base address for the memory area used by any peripheral that requires high memory.

• Assign IRQ For USB

< Enabled >

This item allows you to assign IRQ for the USB interface.

• Onboard Ethernet BootROM

< Disabled >

The BIOS of SBC8360-4M includes Boot ROM for Novell.

— 25 —

Page 28

4-14-2-6. Integrated Peripheral Setup

>

ROM PCI/ISA BIOS (2A69KA5C)

< Screen shows all default setting

INTEGRATED PERIPHERALS

AWARD SOFTWARE, INC.

IDE HDD Block Mode : Enabled

UART Mode Select : Normal

IDE Primary Master PIO : Auto

IDE Primary Slave PIO : Auto

IDE Secondary Master PIO : Auto

IDE Secondary Slave PIO : Auto

IDE Primary Master UDMA : Auto

Onboard Parallel Port : 378H/IRQ7

Parallel Port Mode : SPP

IDE Primary Slave UDMA : Auto

IDE Secondary Master UDMA : Auto

IDE Secondary Slave UDMA : Auto

On-Chip Primary PCI IDE : Enabled

Onboard Parallel Port 3 : 3E8H/IRQ10

Onboard Parallel Port 4 : 2E8H/IRQ11

On-Chip Secondary PCI IDE : Enabled

USB Keyboard Support : Enabled

Init Display First : PCI/ISA

POWER ON Function :

Onboard FDC Controller : Enabled

Onboard Serial Port 1 : 3F8H/IRQ4

Onboard Serial Port 2 : 2F8H/IRQ3

BUTTON ONLY

ESC : Quit

F1 : Help

F5 : Old Values

↑ ↓ → ← : Select Item

PU/PD/+/- : Modify

(Shift) F2 : Color

F6 : Load BIOS Defaults

F7 : Load Setup Defaults

The four items related to the WDT describe the set up of the Watchdog Timer (WDT), please refer to the 4-15

for details.

• IDE HDD Block Mode

Block mode is also called block transfer, multiple commands, or multiple sector read/write. If your IDE

< Disabled >

hard drive supports block mode (most new drives do ), select Enabled for automatic detection of the

optional number of block read/write per sector the drive can support.

• IDE Primary Master PIO

• IDE Primary Slave PIO

• IDE Secondary Master PIO

• IDE Secondary Slave PIO

< Auto >

< Auto >

< Auto >

< Auto >

The four IDE PIO (Programmed Input/Output) field let you set a PIO mode (0-4) for each of four IDE

devices that the onboard IDE interface supports. Modes 0 though 4 provide successively increased

performance. In Auto mode, the system automatically determines the best mode for each device.

NOTE: Secondary drives are not support.

• IDE Primary Master UDMA

• IDE Primary Slave UDMA

• IDE Secondary Master UDMA

• IDE Secondary Slave UDMA

< Auto >

< Auto >

< Auto >

< Auto >

Ultra DMA/33 implementation is possible only if your IDE hard drive supports it and the operating

environment includes a DMA driver (Windows98 or a third-party IDE bus master driver). If your hard

drive and your system software both support Ultra DMA/33, select Auto to enable BIOS support.

NOTE: Secondary drives are not support.

— 26 —

Page 29

• On-Chip Primary PCI IDE

< Enabled >

• On-Chip Secondary PCI IDE

The integrated peripheral controller contain an IDE interface with support for two IDE channels. Select

Enabled to active each channel separately.

NOTE: Choosing Disabled for these options will automatically remove the IDE Primary Master/slave

PIO and/or IDE Secondary Master/Slave PIO items on the menu.

• USB Keyboard Support

Select Enabled if your system contains a USB controller and you have a USB keyboard.

• Init Display First

This item allows you to decide to active whether PCI/ISA or Onboard first.

• POWER ON Function

This option allows users to select the type of power ON sequence for the system to follow.

• Onboard FDC Controller

Select Enabled if your system has a floppy disk controller (FDC) installed on the system board and

you wish to use it. If you install an add-in FDC or the system has no floppy drive, select Disabled in

this field.

• Onboard Serial Port 1

• Onboard Serial Port 2

• Onboard Serial Port 3

• Onboard Serial Port 4

Select an address and corresponding interrupt for the serial ports

NOTE: Do not change this setting, since COM1 is assigned for the touch screen. It may cause system

problem.

< PCI/ISA >

< Enabled >

< BUTTON ONLY >

< Enabled >

< 3F8h, IRQ4 >

< 2F8h, IRQ3 >

< 3E8h, IRQ10 >

< 2E8h, IRQ11 >

< Enabled >

• UART Mode Select

The second serial port offers these infrared interface modes:

1. IrDA

2. ASKIR IrDA-compaliant serial infrared port

3. Normal (default value)

NOTE: The UART Mode Select will not appear on the menu once you disable the setting of Onboard

Serial Port 2.

When UART Mode Select is set ASKIR or IrDA, the options RxD, TxD Active and IR Transmittion delay

will appear.

• Onboard Parallel Port

Select a logical PRN port name and matching address for the physical parallel (printer) port.

NOTE: Choosing Disabled for this option will remove the Parallel Port Mode option on the menu.

• Parallel Port Mode

Select operating mode for the onboard parallel (printer) port. Select Normal unless your hardware and

software require one of the other modes offered in this field.

NOTE: Selecting EPP on this option will allow selection to the EPP Mode (EPP1.7, EPP1.9)

ECP mode selection will provide option for ECP Mode Use DMA.

Choosing ECP + EPP modes will provide selections for both EPP Mode select and ECP Mode

Use DMA.

• ECP Mode Use DMA

Select a DMA channel for the port.

• EPP Mode Select

Select EPP port type 1.7 or 1.9.

< Normal >

< 378h >

< Normal >

< 3 >

< EPP 1.7 >

— 27 —

Page 30

4-15. Watchdog Function

The QT-7300 features a system protective device, watchdog timer which can generate a CPU reset when the

system comes to a halt or failure. This function is to ensure the system's reliability during unattended operation.

The trigger sources for the watchdog contain both temperature over range and system failure. The system failure

may be caused by thunder, power glitch, radio interference, software bug or whatever reason.

To activate the watchdog timer, some program code similar to the following code has to be written to the system

running loops:

:

Loop: read (0x121) ; enable and trigger WDT

: ; interval time between triggers

if (END) GOTO END ; must be smaller than time-out

GOTO Loop ; period

END:

read (0x120) ; disable WDT

:

The time-out period ranges from 0.5 to 1000 seconds. If special settings for temperature or time-out are needed,

please refer to the utility diskette.

4-15-1. How to Use Watchdog Function

The user can read I/O Port 121H to enable Watchdog or disable it by reading I/O Port 120H.

Reset Watchdog - Read I/O Port 121H

Time_A - Read I/O Port 121H

Time_B - Read I/O Port 121H

Disable Watchdog - Read I/O Port 120H

** Time_B_Time_A < Time_Out Setting **

In system Run_Time, you must still have to read I/O Port 121H to reset the Watchdog timer.

If the system fails, the TSR should be stopped and Watchdog reset action will be activated.

— 28 —

Page 31

4-16. Touch screen

The QT-7300 is equipped with a quick-response touch screen that enables keyboard-less operation. To use the

touch screen, a related application program needs to be installed. This chapter provides all of the information

to install and use the software of the Fujitsu touch screen systems for Windows98 SE and Windows 2000.

4-16-1. System Requirements

The Fujitsu touch screen system requires a serial interface. COM1 is assigned for the touch screen system in

the QT-7300 system.

4-16-2. Installation

This section describes the installation procedure for the Windows Driver Disk.

There are two steps to install the touch screen drivers into the QT-7300 system.

Step 1 : Driver installation

Step 2 : Calibration

4-16-2-1. Driver installation

The accompanying Windows Driver Disk contains the following software:

1) For Windows 98 SE

(1) Run the "setup.exe" (Touch Panel Windows 98 Driver disk) file.

(2) Select "Primary install".

(3) Click "OK" button.

(4) Port setting window should open. Default condition is as below.

COM1, I/O address = 0x3f8, IRQ = 4

In the case that you want to use the touch panel as it is, click "OK" button.

(5) Restart the system.

Attention:

1) In the case that you need to use dual touch panels for a dual display condition, please select

"Secondary install" at step (2) when you install the second touch panel in addition.

2) In the case that you need to use dual touch panels for a dual display condition, please select

"Primary and Secondary install" at step (2) when you install the second touch panel at the same

time.

2) For Windows 2000

(1) Run the "setup.exe" (Touch Panel Windows 2000 Driver disk) file.

(2) Click "OK" button.

(3) Click "OK" button.

(4) Restart the system.

— 29 —

Page 32

4-16-2-1. Calibration

1) For Windows 98 SE and Windows 2000

(1) Insert Floppy disk into Floppy Disk Drive ("A:").

(2) Open "Explorer" <Click "Start", select" Programs" then select "Windows Explorer" >.

(3) Click Floppy Disk Drive ("A:") in "All Folders"

(4) Double Click "CALWIN(CALWIN.EXE)" then execute.

(5) Calibration Program. (Nine "+" marks will be shown on the display)

(6) Hit "+" marks (touch on the touch panel).

Color of "+" mark will be turned Black or Red by each touch, if touch is recognized.

(7) After touch all nine "+" marks, hit "Enter" key.

(8) Hit "Enter" key after "+" marks disappeared to finish.

Note at calibration :

1) You will be prompted to touch nine calibration points on the screen. Before you touch, position

yourself in front of the screen in 90-degree vertical angle against the screen.

2) Use sharp soft object (i.e. pen shaped plastic object) instead of your finger for accurate positioning.

3) Please do not use any hard sharp objects (i.e. knife, metal ballpoint pen), it may cause damage

on the touch screen panel.

4) Calibration data will be stored in the EEPROM on the touch screen controller board. You will not

need to calibrate at each system start by power on as long as data is stored in the EEPROM.

Why Calibration is Necessary?

The necessity for calibration is unique to the touch screen. Unlike mouse or keyboard applications where the

cursor is part of the image, a touch screen is a physical overlay with an independent coordinate system. Only

by knowing the position of the image can the PC software convert touch screen coordinates into image

coordinates.

Besides the differences among touch screens and controllers, calibration also compensates for the variation in

video image among displays. The image is affected by horizontal and vertical adjustments on the monitor and

by the physical mounting of the touch screen.

Additional calibration complications include image blooming, where bright-colored images expand, and the "pin

cushion" effect, which causes the corners of the display to be stretched. Poor display linearity can cause similarly

sized boxes to be larger at the edges of the screen than they are in the middle, or vice-versa. The displayed image

can also be tilted. Even changing video modes can affect the screen size.

Perfect calibration cannot be achieved in all circumstances. For example, the user can encounter parallax

problems with a change in position, or because the present user is not the same stature as the person who

calibrated the screen.

When Re-calibration is Necessary?

Once calibrated, the touch screen will be ready to run automatically each time the system is restarted. Recalibration should only be necessary after moving or resizing the video image, or after changing either the touch

screen, controller, or monitor.

Refer calibration procedure based on your O/S system and re-calibrate if necessary.

— 30 —

Page 33

4-17. ETHERNET INTRODUCTION

4-17-1. Introduction

The QT-7300 is equipped with high performance Plug & Play Ethernet interface which is fully compliant with

IEEE802.3 standard, and consisting of RJ-45 connector .

4-17-2. Network Driver Installation under Windows98 Second Edition

This describes in detail the important steps when installing the SBC8360-4M network drivers under Win98SE.

IMPORTANT: During Win98SE installation, do not attempt to install your Sound Card & Network Adapter

hardware outright; doing so will install the older version of the device drivers within the Win98SE

setup program.

After completing the Win98SE installation, user must do the following action upon first-time entry into Win98SE:

1. Launch the Control Panel window

• Select the Start button at the bottom left corner of the screen then click on Settings.

• Choose Control Panel from the left and the following window appears on your display.

2. Access the System Properties window

• Double -click on System icon and then choose Device Manager from the menu.

• A new window will pop-up with Other Device represented by a "?" mark. Click this "?" mark and one

device marked with "?" appears on its subset device list. One device specifies the PCI Ethernet

Controller.

3. Enter the PCI Ethernet Controller Properties window

• Move the cursor to the PCI Ethernet Controller then double-click your left mouse button. The screen

then display the PCI Ethernet Controller Properties window.

4. Detect and specify the .INF network device driver path

• Click on Driver from the menu bar and a new screen appears with the Update Driver... button.

• Click on the this Update Driver... button and the Update Device Driver Wizard window appears.

Choose "Display a list of all drivers... " then click on the Next> button to proceed.

• Insert the EtherNet RTL8139 Disk II diskette (Disk ) into Drive A: and clock on Have Disk.

5. Capping the installation

• Enter the appropriate drive for your disk media (A:win98), and click on OK

• Click on OK ata the select Device dialog box.

• The Update Wizard display the message that it has found the driver. Click on Next> .

• Click on the Finish button to complete the installation of the PCI Ethernet Controller.

6. Provide Network Information

• Right after completing the network adapter installation, the system displays the network window

requiring you to fill up your computer's name, the workgroup it will appear in, and a short description

of it. Refer to the following screen.

• After filling up the items, press the Close button to exit.

7. Reboot the system

• Your system will now ask you whether you'd like to reset the computer. Click on the Yes button.

Note: We highly recommend that you reset the system in order for the new network driver to take

effect.

— 31 —

Page 34

4-17-3. Network Driver Installation under Windows 2000

This section describes in detail the important steps when installing the SBC8360-4M network drivers under

Windows 2000.

1. Select the Start button at the bottom left corner of the screen then click on Settings.

2. Choose Control Panel from the left and the following window appears on your display.

3. Double click on System icon

4. In the System Hardware dialog box, click on Device Manager.

5. Double click on Network Adapter.

6. Double click on Realtek RTL8139(A).... .

7. In the Driver Dialog Box, Click on Update Driver... .

8. In the Update Device Driver Wizard window, Click on Next.

9. Choose "Display a list of all drivers... ", then click on the Next button to proceed.

10. Insert the EtherNet RTL8139 Driver diskette (Disk 3) into Drive A: and clock on Have Disk.

11. Enter the appropriate drive for your disk media (A:win2000), and click on OK

12. Choose Realtek RTL8139 (A/B/C/8130) PCI Fast Ethernet NIC.

13. Click on Next at the select Device dialog box.

14. In the Start Device Installation window, click on Next.

15. In the Digital Signature Not Found window, click on Yes.

16. In the Confirm File Replace window, click on Yes.

17. Click on the Finish button to complete the installation of the PCI Ethernet Controller.

18. Right after completing the network adapter installation, the system displays the network window requiring

you to fill up your computer's name, the workgroup it will appear in, and a short description of it. Refer to the

following screen.

19. After filling up the items, press the Close button to exit.

20. Your system will now ask you whether you'd like to reset the computer. Click on the Yes button.

NOTE: We highly recommend that you reset the system in order for the new network driver to take effect.

— 32 —

Page 35

4-17-4. Setup and Diagnostic Test

Following software are provided in the Ethernet RTL8139 Drivers (Disk 3) floppy disk for setup and test the

Ethernet system.

Run RSET8139.EXE, a list of options including "View Current Configuration", "Set Up New Configuration",

"Run Diagnostic" and "Exit RSET8139" will appear.

NOTE: You should run this software under dos mode.

4-17-4-1. Configuration

View Current Configuration

View Current Configuration is an information display. It shows your PCI LAN board current configuration.

Set Up New Configuration

Set Up New configuration gives you complete control over the configuration of the LAN board. It lets you

set up the board in the computer while specifying parameters for a different computer. You can designate

the Node ID, the Manufacture's ID, Full-duplex mode, the BROM size and Flow control. Changing I/O base

and Interrupt in PCI system is not allowed.

4-17-4-2. Diagnostic Test

Run Diagnostic

Run Diagnostic lets you verify that your LAN Board is working correctly, a list of options including "Run

EEPROM Test", "Run Diagnostic On Board", "Run Diagnostic On network" and "Run Power Management

test".

— 33 —

Page 36

5. CIRCUIT EXPLANATIONS

5-1. Explanations of each block

System Major Parts

Refer to the following diagram to identify the major parts that make up the QT-7300.

1. Plastic front cover: The plastic front cover is made of the ABS material. An indicating LED is on the right

bottom side to indicate the power status.

2. Touch screen: The QT-7300 feature a quick-response touch screen for keyboard-less operation. The

standard touch is 12.1" analog resistive type Fujitsu touch screen. Its durability is 10 million touches in life.

3. LCD display: To provide the best visual resolution and viewing angle, the standard display adapted are 12.1"

TFT for the QT-7300.

4. LCD display back-light inverter: The back-light inverter is to provide the necessary power voltage to lighten

the LCD display.

5. Not available

6. Metal front compartment: The universal mounting design of the front metal compartment is able to mount

LCD display and the EMI is also considered.

7. System fan: In consideration of the system’s air flow, a system fan is installed to dispense the system heat

to stabilize the system

— 34 —

Page 37

8. System fan bracket: This fixture is made of aluminum alloy to hold the built-in system fan firmly.

9. Touch screen controller: RS-232 touch screen controller assigned for COM1.

10. Power supply: The power supply adapted in this system is a super-slim 100W power which meets FCC/VDE

Class B specification.

11. Motherboard: For the QT-7300 is Celeron/Pentium III based SBC8360-4M. It combine notebook technology

to make up a compact and stable system.

12. missing number

13. Hard Disk: The QT-7300 builds in a 2.5" hard disk.

14. Separator: An aluminum-made separator is provided to separate the expansion card from the main

components. It is also to provide better EMI protection and the system’s heat dispensing.

15. Metal rear bracket: The firm bracket is to hold the main body for stand and HDD inside.

16. Plastic rear cover: Made of ABS material and special heat dispensing design.

17. Side cover: Cover the external FDD, keyboard, mouse connectors and USB ports from dust or spill.

18. Back metal fixture: Connect the main prop to the main body of the system. The large set (standard) is used

for 30° table standing applications, the small set (optional) for wall mounting.

19. Main prop: Made up by a inner metal piece with an outside plastic clothing. It consists of a set of strong hinges

to ensure the whole unit’s stability when a certain touch pressure is applied on the touch screen.

20. Hinge caps: The large set (standard) is used to cover the large back metal fixtures for 30° table standing

applications, the small set (optional) for wall mounting.

21. Cable management shroud: Made of the mixture of ABS/PC material. Hide the cables coming down from

the bottom side of the chassis and to make the operation environment look trimmed.

— 35 —

Page 38

System Key Components

The following diagram shows system key components;

1. The main frame: It contains parts 1,2,3,4 and 5 listed on Section 2.1.

2. System fan bracket: It is to hold the built-in system fan

3. System fan: heat-dispensing system fan

4. System control board: Used to be the system engine is Celeron/Pentium III based SBC8360-4M for the QT-

7300. It is a compact and industrial-grade control board and is 100% PC compatible.

5. missing number

6. Hard disk: 2.5" notebook hard disk.

7. Riser card: The QT-7300 provides one free slot expansion capability. Either one PCI device (half-size card)

can be used at a given time.

8. KB/Mouse/External FDD conversion card:

9. Mylar insulator: An insulator is put under the power supply to ensure the power supply would not contact

the metal compartment to cause any short circuit.

10. Power supply: 65W high-efficiency power supply

11. Touch screen controller Fujitsu RS-232 touch screen controller

12. Aluminum separator

13. Multi-I/O conversion card: 3 x serial ports, 1 x parallel port, 1 x VGA, Ethernet and 2 x Drawer interface

14. Drawer interface card: It is to convert the onboard drawer ports functions to the system chassis.

— 36 —

Page 39

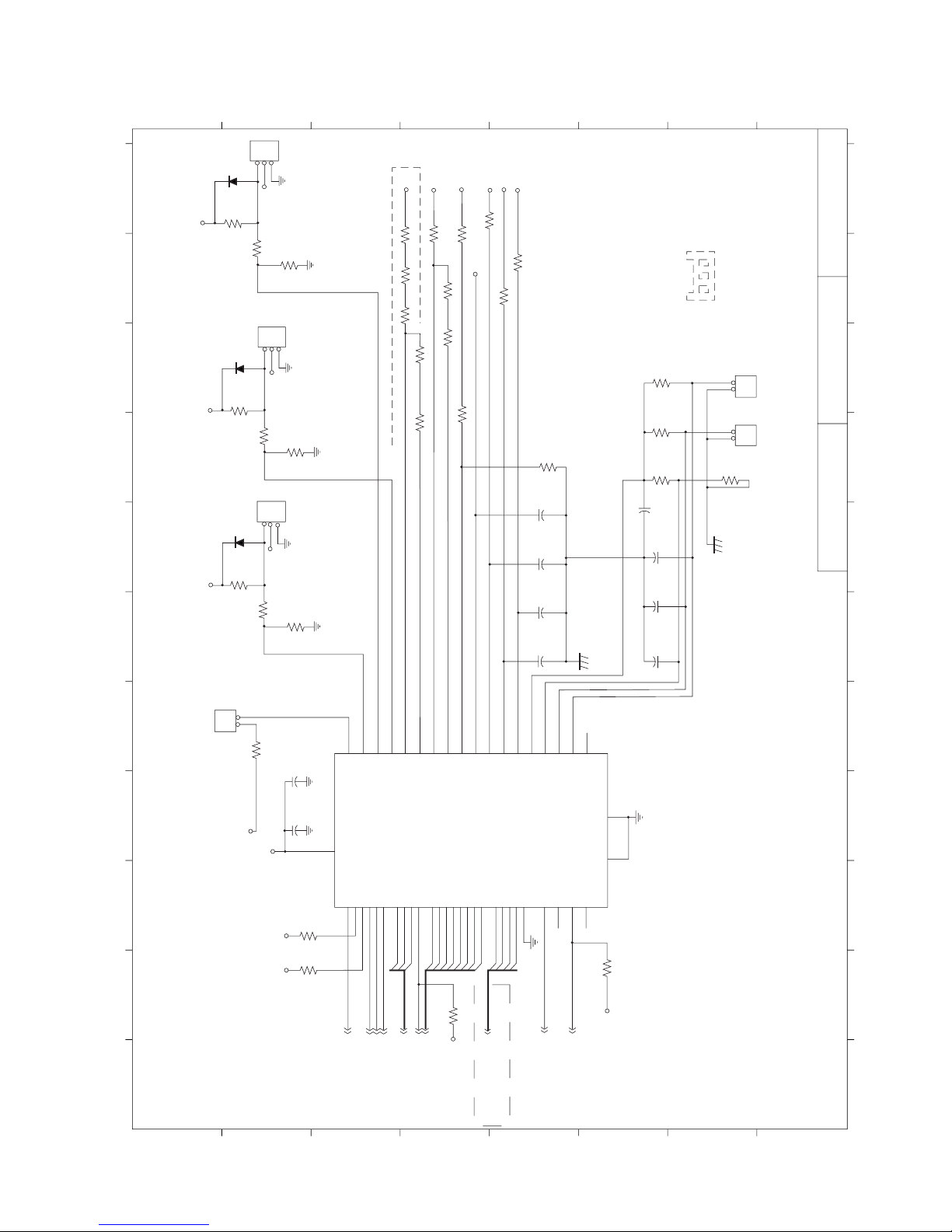

5-2. Block diagram

(1) QT-7300 System Diagram

<To Inverter>

<To TSCC>

+5V

Power Supply

GND

100 W

+5V

GND

+12V

5V/12V/GND

VR

LCD

convert

board

<LCD & Touch Screen>

<Relay Board>

LCD Cable

GND

+12V

+5V

EMI Filter

+5V

Inverter

GND

+12V

To COM1B

CN1 CN2

+5V

<From Power Supply>

GND

<Power Cable From Power Supply>

PISA

+5V

GND

+12V

+12V

GND

+5V

<To CDCC>

(2) QT-7300 system block diagram

VGA

C&T69030

EISA

Slot

AGP Bus

(66 MHz)

Ethernet

RTL8139C

Ultra DMA.33

IDE1

IDE2

CPU

Celeron Procesor

Host Bus (66/100 MHz)

North Bridge

82443BX

ISA Bus (33 MHz)

South Bridge

82371EB

(PIIX4)

FDD

FDD/KB/MOUSE

(66/100 MHz)

USB1 USB2

RTC DS12B887

CN2

DIO1A COM1B

PRN COM4 COM3 COM2 COM1 NETVGA

Drawer 1

Drawer 2

CDCC

PS/2USB

K/B

Multi I/O

North Bridge

82443BX

KCB

FDD COM2

IR LPT1 RS232/422/485

Super I/O 1

W83977TF-AW

COM1

ISA Bus (8.33 MHz)

Super I/O 2

W83877TF

— 37 —

COM3

COM4

BIOS

H/W M

DOC

WDT

PC/104

Page 40

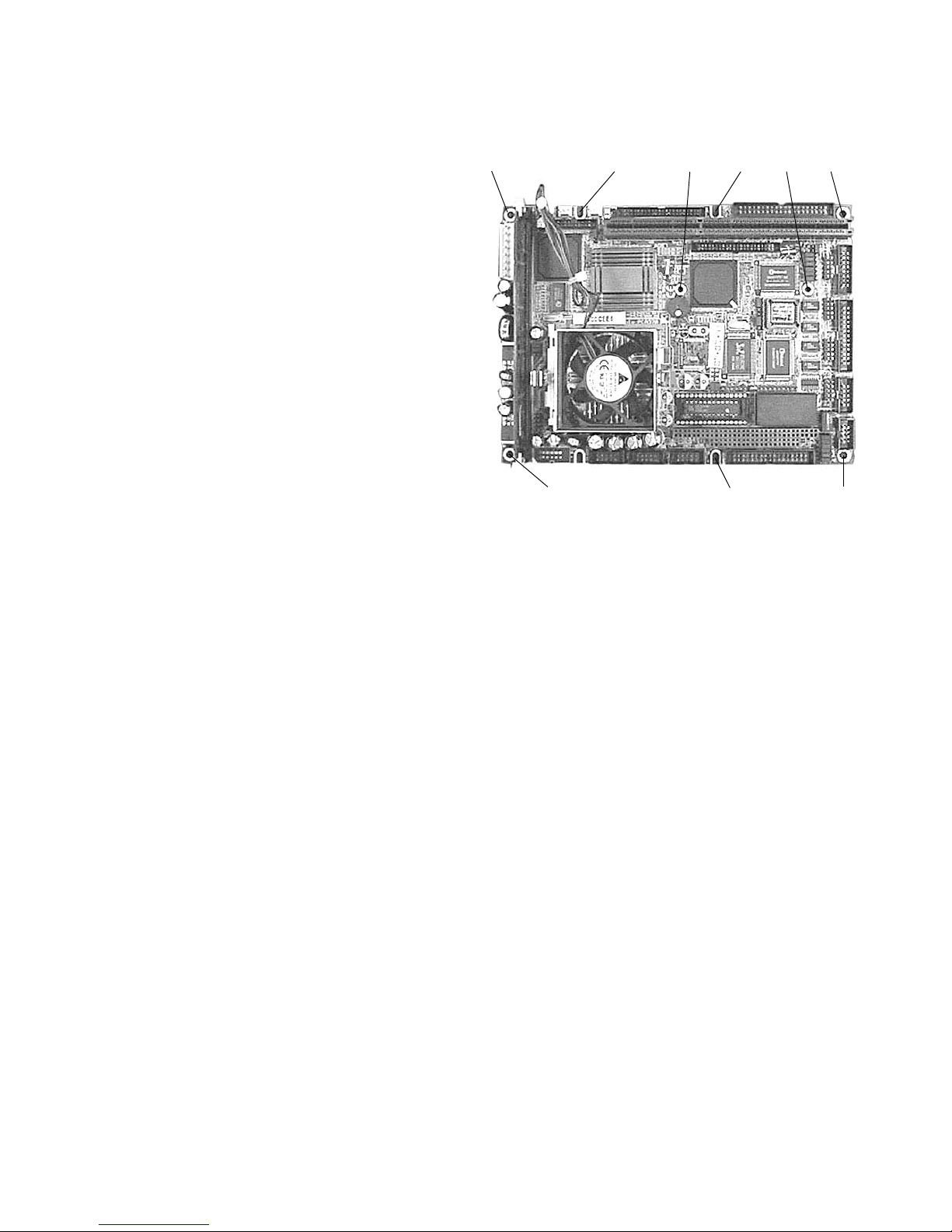

5-3. Jumper setting

The default setting of the mother board for QT-7300 is as follows:

SBC8360-4M Overview and Jumper switch

CN1

CN6

JP5

CN11

CN13

CN17

CN5

BIOS

JP13

JP11

JP12

JP10

CN22CN23CN24CN25

CN2

JP9

CN27

JP3

JP6

JP8

JP2

CN29

CN3

JP17 CN30 CN8JP4 JP7

PGA370

JP16

3

4

CN21 CN20 CN19 CN18

1

2

CN14

JP1

CN9 CN10 CN12

JP2

1

3

2

4

JP3, 9

1

2

3

JP8

1

3

5

JP10, 11, 12, 14, 15, 16

5

2

4

6

3

6

4

1

2

CN15

CN16

7

8

JP14

JP15

JP13

5

6

Multi I/O Board Jumper switch

JP1 JP7 JP6 JP5JP3

JP1, 3

1

2

3

2

4

6

JP5, 6, 7

1

3

5

— 38 —

Page 41

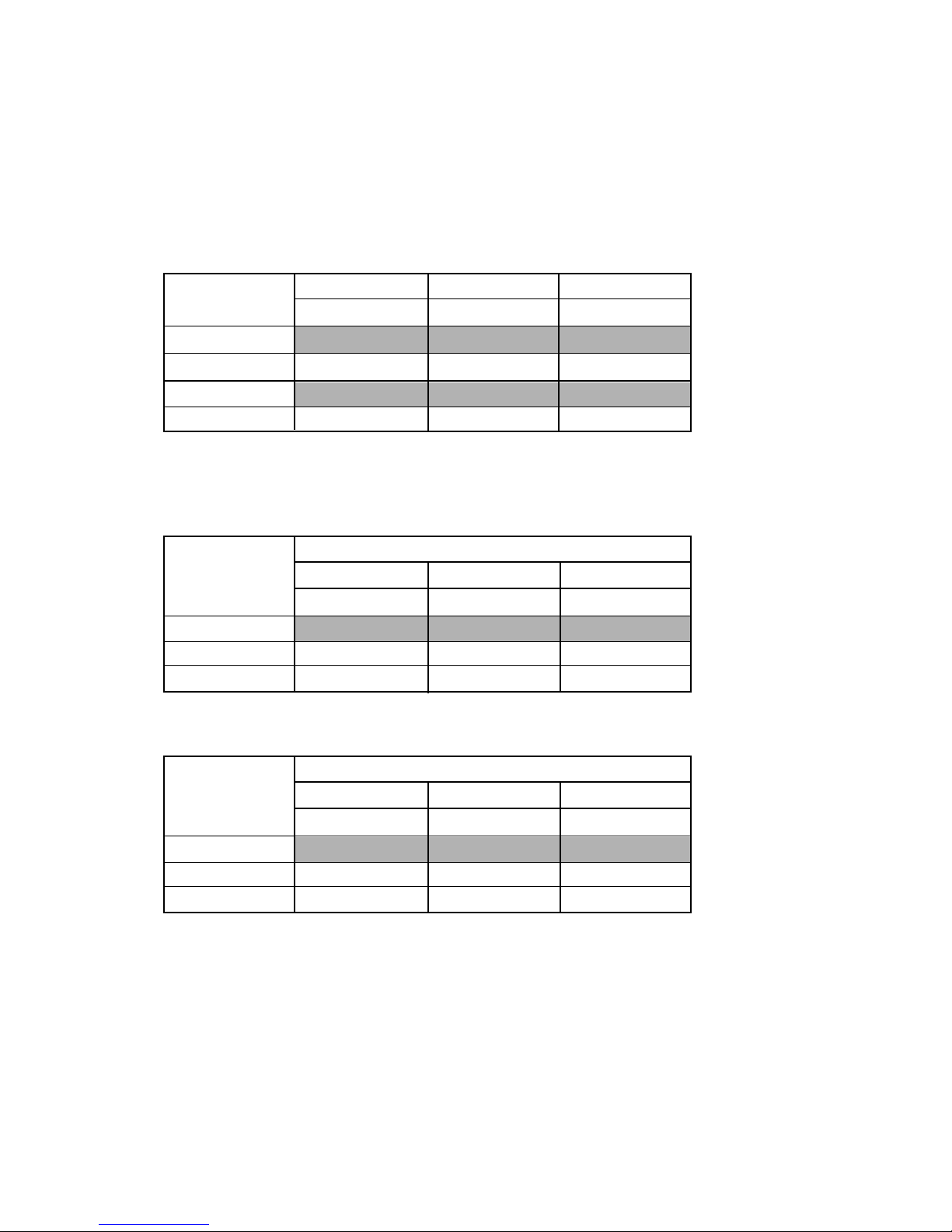

5-3-1. Jumper Settings

The SBC8360-4M is configured to match the needs of your application by proper jumper settings.

The following tables show the specification of the jumper settings. < : Default / “X”: Don’t Care >

Note: All specification and quality of the system are assured by Casio as the QT-7300, any local

modification of the jumper setting by customer will not be applicable for Casio’s guarantee or

warranty.

5-3-2. CMOS Clear Jumper: JP4

JP4

Clear CMOS SRAM data Short 1-2

Normal Operation Open

5-3-3. Watchdog Trigger Mode Setting: JP7

The watchdog timer is an indispensable feature of the SBC8360-4M. It has a sensitive error detection

function and a report function. When the CPU processing comes to a halt, the watchdog can generate an

NMI or resets the CPU.

Watchdog Function JP7

Activate NMI when Watchdog triggered 1-2

Reset system when Watchdog triggered 2-3

Disable OPEN

5-3-4. LCD display Power Level Setting (V

5V Panel Power Setting 1-2

3.3V Panel Power Setting 2-3

of CN11 and CN6) : JP9

DDM

JP9

— 39 —

Page 42

5-3-5. Serial Ports Settings: JP11, JP14, JP15

The SBC8360-4M provides four onboard serial ports, 4 x RS-232. COM2, COM3 and COM4 ports with

+5V/+24V and +12V/+24V power capabilities on Pin 1 and Pin 9 is ready to accommodate a wide array

of serial devices. The corresponding jumper settings are shown below.

<SBC8360-4M means the motherboard and MTIO means the Multi I/O board in the QT-7300. >

COM1: COM1 is assigned for the touch screen system and is not available for end user in this system.

COM2 ~ COM4:

Com2 Com3 Com4

JP14 JP11 JP15

Pin 1 = DCD 3-5 3-5 3-5

Pin 1 = +5V 1-3 1-3 1-3

Pin 9 = RI 4-6 4-6 4-6

Pin 9 = +12V 2-4 2-4 2-4

Multi I/O setting

COM2 ~ COM4:Pin 1 NOTE: Pin 1 does not have the +12V setting.

MTIO

Com2 Com3 Com4

JP5 JP6 JP7

Normal COM 3-5 3-5 3-5

+5V 3-5 3-5 3-5

+24V 1-3 1-3 1-3

COM2 ~ COM4:Pin 9 NOTE: Pin 9 does not have the +5V setting.

MTIO

Com2 Com3 Com4

JP5 JP6 JP7

Normal COM 4-6 4-6 4-6

+12V 4-6 4-6 4-6

+24V 2-4 2-4 2-4

— 40 —

Page 43

6. DIAGNOSTIC OPERATION

6-1. Diagnositc softwares

Use the following softwares for checking each block.

Mother board---------------------------------AMI Diag.5.42 (available in the market)

Customer display ---------------------------Diagnostic program built in the UNIT

Drawer -----------------------------------------drw.exe (available from Casio)

Touch panel ----------------------------------

For DOS;

medv10.com (Device Driver)

caldos.com (Calibration program)

For Windows 95

fidmour.drv (Device Driver)

vfidmd.386 (Device Driver)

fidmour.inf (Device Driver information file)

calwinr.exe (Calibration program)

For WindowsNT

fidtpntr.sys (Device Driver)

fidtpntr.inf (Device Driver information file)

calwinre.exe (Calibration program)

6-2. Customer display

Necessary tools

■ Loop back connector

■ Stabilized power supply

Preparations

■ In case of QT-7360D or QT-7362D

1 Connect a loop back connector (male type) to customer display’s D-SUB connector.

2 Apply +24 V to pin 1 and GND to pin 5 of the loop back connector.

3 Short circuit pins 2 and 3 (DSR-RXD), and pins 4 and 6 (TXD-DTR).

+ 24V

Short circuited

1

6

+ 24V (pin 1)

GND (pin 5)

QT-7360D or QT-7362D

GND

5

9

Short circuited

Loop back connector

— 41 —

Page 44

■ In case of QT-7363D

PCB

Loop back connector

AC adaptor jack

Display signal connector

1 Connect a loop back connector on Customer display stand unit.

2 Connect a testing customer display to Display signal connector.

3 Apply +24V DC to the AC adaptor jack.

CN3

5

9

TXD

DSR

RXD

DTR

4

8

3

7

2

6

1

PRINTER

5

9

4

8

3

7

2

6

1

HOST

Female

Male

5

9

4

8

3

7

2

6

1

5

9

4

8

3

7

2

6

1

Loop back connector

Sub PCB

Loop back connector circuit diagram

— 42 —

Page 45

Precautions

1 For checking QT-7363D, use customer display stand unit.

2 Turn the power off before connecting the customer display.

3 After the check, be sure to set the DIP switch correctly.

4 Also check rotating mechanism of the customer display.

Diagnose

1 Unscrew four screws and remove display panel.

Reset switch

ON

OFF

1

2

3

4

5

6

7

8

Initial position of DIP switch

DIP switch

Screws

Display tube

2 Apply power supply (AC adaptor).

3 Turn all the DIP switches on.

4 Push the reset switch. Diagnostic program starts and display shows;

— 43 —

Page 46

All dots off

All dots on

A vertical line moves from right to left.

1 2 3 4 5 6 7 8

1 1 1 1 1 1 1 1

— 44 —