Page 1

SERVICE MANUAL

(without price)

ELECTRONIC CASH REGISTER

QT-2000 (EX-580)

JUNE 1997

C

7

8

9

4

5

6

1

2

3

0

00

¥

Page 2

CONTENTS

QT-2000 Page

1. GENERAL ............................................................................................................... 1

1-1. System chart.................................................................................................... 1

1-2. Device list (Option) .......................................................................................... 2

2. SPECIFICATIONS................................................................................................. 3

3. QT-2000 CONNECTOR LOCATIONS .................................................................... 8

4. INITIALIZE OPERATION ...................................................................................... 11

4-1. To initialize QT-2000 terminal........................................................................ 11

4-2. To initialize QT-2000 terminal(add/replace one QT-2000) ............................ 14

4-3. To flag clear QT-2000 terminal(INIT2, Restore from flash) ........................... 17

5. CIRCUIT EXPLANATION ..................................................................................... 18

5-1. Block diagram (MAIN PCB E580-1)............................................................... 18

5-2. Memory map.................................................................................................. 19

5-3. I/O address map ............................................................................................ 20

5-4. LSI Pin description......................................................................................... 21

5-5. Power down detection circuit......................................................................... 33

5-6. Option RAM circuit......................................................................................... 34

6. OPTION INSTALLATION...................................................................................... 35

6-1. Clerk key unit (CLK-K17,CLK-K18) ............................................................... 35

6-2. Rear display (QT-2060D)............................................................................... 36

6-3. MCR unit (QT-2046MC)................................................................................. 37

6-4. Multi drawer (MDL-8)..................................................................................... 38

7.IN / ON LINE .......................................................................................................... 39

7-1. C-In line (ARCNET) ....................................................................................... 39

7-2. On line ........................................................................................................... 42

1. Direct connection to PC ................................................................................. 42

2. MODEM system............................................................................................. 43

7-3. Kitchen printer connection ............................................................................. 44

8.DIAGNOSTIC OPERATION................................................................................... 47

9.ERROR CODE LIST .............................................................................................. 67

10.IC DATA ............................................................................................................... 73

11.PCB LAYOUT ...................................................................................................... 80

12.CIRCUIT DIAGRAM............................................................................................. 82

13. PARTS LIST...................................................................................................... 104

Page 3

1. GENERAL

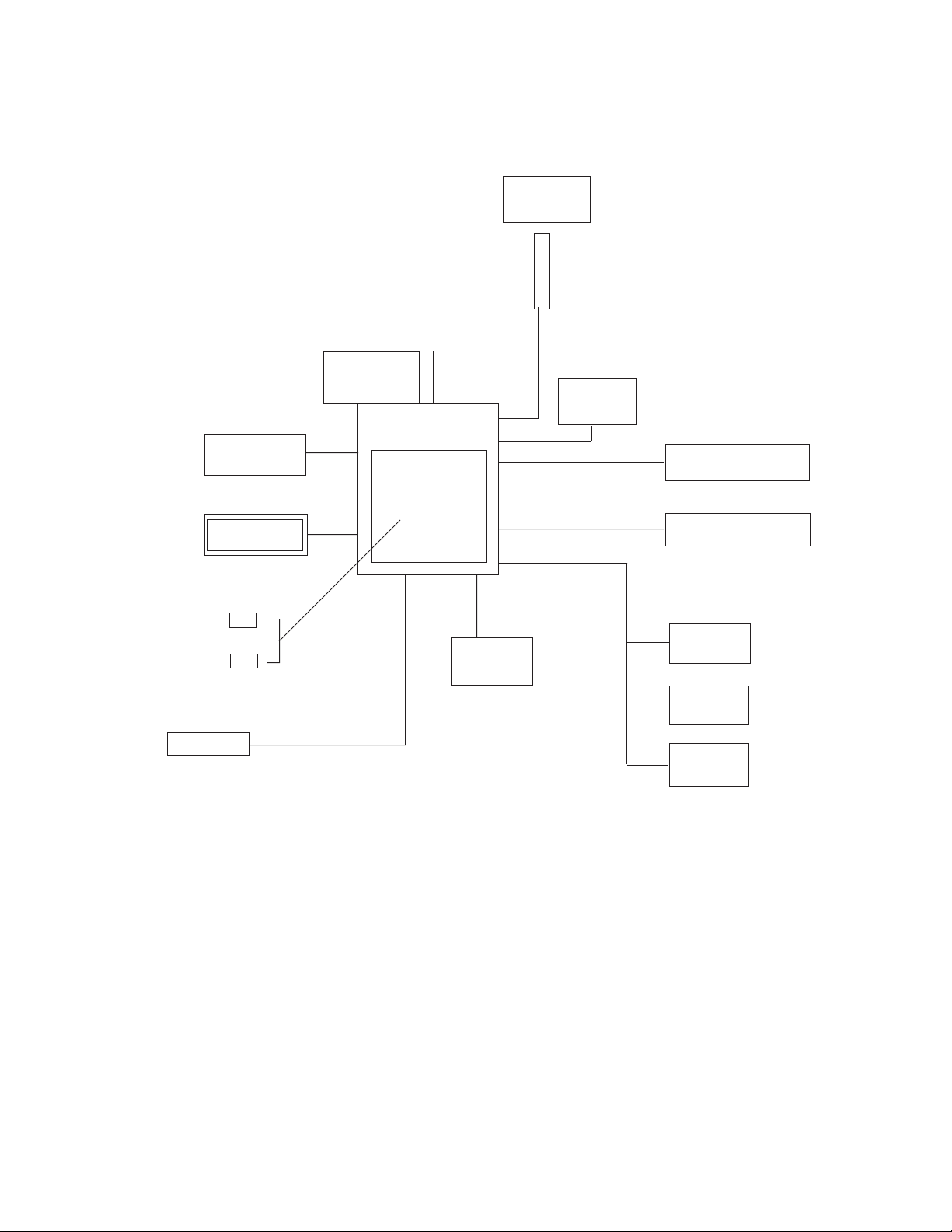

1-1. System chart

RAM610

4M bits

RAM530

1M bits

HHS-9

Scanner

QT-2046MC

MCR unit

MDL-8

Multi Drawer

2nd Display

QT-2000

Customer

Display

Pole

Cable SA-1062S

QT-2060D

Rear

Display

Clerk Key

CLK-K17 (6 clerk)

CLK-K18 (15 clerk)

QT-2063D

QT-2061S

KP-200 / KP-300

Kitchen Printer

SP-1200

Slip Printer

R/J Printer

TM-U950

TM-T85

TM-T88

SA-3015

TM-T85

UP-350

The QT-2000 has the following unique points:

(The system configuration is shown in the chart above.)

1. Separete R/J printer

2. Small foot-print and low-profile design

3. LCD display : Max. 2 LCD display

4. Flat keyboard menu holder : Max. 8 menu can be contorolled.

4 (direction) x 2 (holder)

5. Data backup function by EEPROM (Flash ROM)

6. Infrared communication interface

— 1 —

Page 4

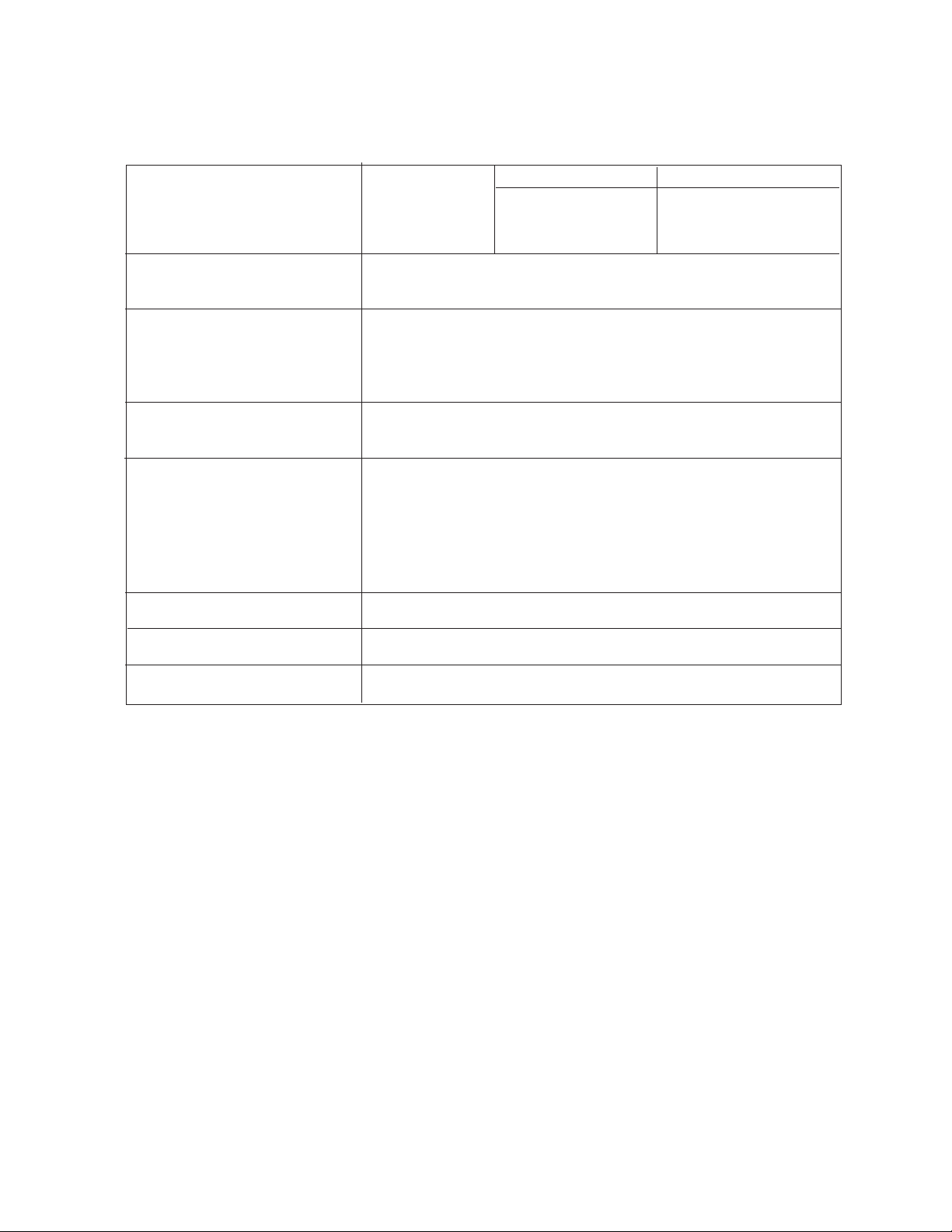

1-2. Device list (Option)

No. Model Name Device Name Note

Sheet holder

1 SH-KIT1 Sheet holder kit 2 holders (1st - 4th, 5th - 8th)

Kitchen Printer

2 KP-200 Kitichen printer

3 KP-300 Kitchen printer with auto cutter

Slip printer

4 SP-1200 Slip printer

R/J printer

5 SA-3015 R/J and slip printer TM-U950 Paper size : 70mm

Dot matrix printer

6 TM-T85 Receipt printer TM-T85 Paper size : 80mm

Thermal printer

7 UP-350 Receipt printer TM-T88 Paper size : 80mm

Thermal printer

8 PS-150/PS-170 AC adaptor for TM-T85 / UP-350

9 SA-3087TM Printer cable for TM-T85 / UP-350

(Cable length : 3 m)

Display

10 QT-2062D Second LCD display

11 QT-2060D Rear display

12 QT-2063D Customer display

13 QT-2061S Pole for QT-2063D

14 SA-1062S Expantion cable for QT-2063D

(Cable length : 5 m)

Multi drawer

15 MDL-8 Multi drawer kit Additional 1 drawer

Memory

16 RAM-610-10LL RAM chip 4 M bits chip

17 RAM-530-10 RAM chip 1 M bits chip

MCR

18 QT-2046MC Magnetic card reader

Clerk key

19 CLK-K17 Clerk key kit for 6 clerk

20 CLK-K18 Clerk key kit for 15 clerk

Hand held scanner

21 HHS-9 scanner RS-232C

— 2 —

Page 5

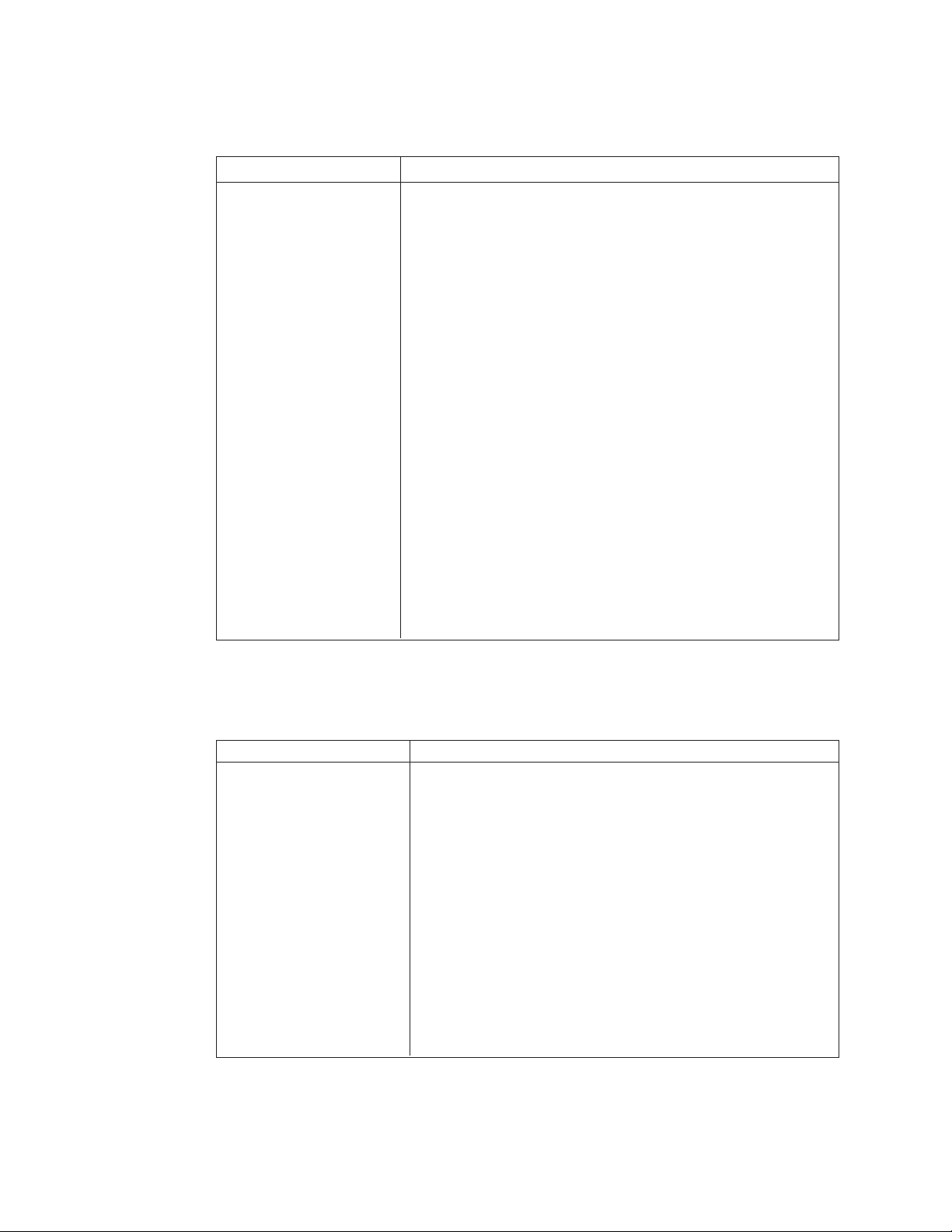

2. SPECIFICATION

2-1. QT-2000

120V 230V

Power consumption In operation Max.: 0.7A 0.4A

Stand-by Max.: 0.4A 0.3A

Mode SW OFF Max.: 0.3A 0.2A

Memory Standard: 384 KB

Max: 1MB

Memory protection Back up battery Lithium-Banadium battery VL3032/S6A

Back up period 30 days ( 25°C )

Battery life Replace every 5 years

Charging time 48 hours for full charge

Clock and calender Accuracy within ±30 sec./month ( 25 °C )

Auto calender Effective 2099 A.D.

Environment Operating temperature 0°C ~ 40°C

Operating humidity 20% ~ 65%

Strorage temperature -20°C ~ 60°C

Storage humidity 10% ~ 80%

In the carton box : Storage temperature -20°C ~ 65°C

Storage humidity 10% ~ 80%

LCD display LCD life 15,000 hours

Back light Back light life 10,000 hours

Power prutection battery No function

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according

to the manufacture’s instructions.

VORSICHT !

Explosionsgefahr bei unsachgemäßem Austausch der Batterie.

Ersatz nur durch denselben oder einen vom

Hersteller empfohlenen gleichwertigen Typ.

Entsorgung gebrauchter Batterien nach

Angaben des Herstellers.

ADVARSEL !

Lithiumbatteri - Eksplosionsfare ved fejlagtig hándtering.

Udskiftning má kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandØren.

— 3 —

Page 6

2-2. Printer

2-2-1. Model name : SA-3015

Item Description

Printer name TM-U950

Power source +24V DC ±10%

Current consumprion R/J Average : Approx. 1.8A Max : Approx. 8A

Print method Serial impact dot-matrix printer

MCBF 5,000,000 lines (auto-cutter and stamp once every 15 lines)

Print speed 233 CPS ( 9x9 dots : High speed )

Charactor per line R/J : 30 (9x9), 40 (7x9)

Stamp size 42 x 20 mm (Print area)

Roll paper Type : Fine quality paper ( Single layer only)

Slip paper Type : Plane paper, Carbon copy paper,

Ink ribbon Type : ERC-31

Interface Serial RS-232C interface

Slip Average : Approx. 2.3A

Standby : 0.3A

311 CPS ( 7x9 dots : Low speed )

Slip : 66 (9x9), 88 (7x9)

Width : 69.5 ±0.5 mm

Paper diameter : 83 mm or less

Paper thickeness : 0.06 to 0.09 mm

Pressure-sensitive paper

Number of paper : Original + 4 copies

Dimension : 70x70 to 210x297mm (WxH)

Thickness : 0.09 to 0.36mm

Ribbon life : 7,000,000 characters (18 dots per charactor)

2-2-2. Model name : TM-T85

Item Description

Printer name TM-T85

Power source +24V DC ±7%

Current consumprion Average : Approx. 1.3A Max : Approx. 6.0A

Standby : Approx. 0.1A

Print method Line thermal printing method

MCBF 3,500,000 lines (font A printing)

Print speed 12 lines/sec. (1/6 inch line feed)

13 lines/sec. (1/9 inch line feed)

Charactor per line 42 digits (12x24), 56 digits (9x7), 21 digits (24x24)

Print width 72mm

Roll paper Type : Prescribed thermal paper

Width : 80mm

Paper diameter : 83 mm or less

Paper thickeness : 65±5µ m

Interface Serial RS-232C interface

— 4 —

Page 7

2-2-3. Model name : UP-350 (TM-T88)

Item Description

Printer name TM-T88

Power source +24V DC ±7%

Current consumprion Average : Approx. 1.5A Max : Approx. 5.0A

Print method Line thermal printing method

MCBF 10,000,000 lines (font A printing)

Print speed High speed : 16.5 lines/sec. (1/6 inch line feed)

Charactor per line 42 digits (12x24), 56 digits (9x7)

Print width 72.2 ±0.2mm

Roll paper Type : Prescribed thermal paper

Interface Serial RS-232C interface

2-3. Slip printer

Model name : SP-1200

Standby : Approx. 0.2A

Low speed : 11.8 lines/sec. (1/6 inch line feed)

Width : 79.5±0.5mm

Paper diameter : 83 mm or less

Item Description

Printer name Model 290

Power source +24V DC ±10%

Print method Dot print ( with built-in shuttle head)

MCBF 1,500,000 lines

Print speed Approx. 2.3 to 1.9 lines/sec.

Charactor per line Max. : 35 digits (5x7)

Slip paper Type : Prescribed thermal paper

Carbon copy paper

Pressure-sensitive paper

Width : 80x80 to 182x257mm (WxL)

Number of paper : Max. : 3 sheets (Original + 2 copies)

Thickness : Total thickness : 0.35mm

Nomal paper : 0.09 to 0.25mm

Copy paper :Base sheet : 0.07 to 0.2mm

Duplicate : 0.04 to 0.07mm

Carbon paper : Approx 0.035mm

Ink ribbon Type : ERC-27

Ribbon life : 1,500,000 characters

Interface Serial interface

— 5 —

Page 8

2-4. Kitchen printer

Model name : KP-300

Item Description

Printer name DP-617

Power source AC115V / AC230V

Current consumprion 30w

Print method Serial impact printing method

MCBF Printer mechanism : 2,500,000 lines

Print speed 2.4 lines/sec.

Character per line 40 digits 400 dots/line

Roll paper Width : 76mm

Ink ribbon RE-1

Interface RS-422 interface

Model name : KP-200

Item Description

Printer name DP-575

Power source AC115V / AC230V

Current consumprion 25w

Print method Serial impact printing method

MCBF Printer mechanism : 1,500,000 lines

Print speed 1.2 lines/sec.

Character per line 40 digits

Roll paper Width : 69mm

Ink ribbon RB-2

Interface RS-422 interface

Both direction printing

Head : 50,000,000 character

Paper diameter : 80mm or less

1 direction printing ( L to R )

Head : 50,000,000 character

Paper diameter : 80mm or less

2-5. Hand scanner

Model name : HHS-9

Item Description

Power supply +5.0 V DC ± 5%

Power consumption Max. 0.4 W

Rush current Max. 1.5 A

Operating temperrature 0 to 40°C

Operating humidity 10 to 90% RH (not to condence dew)

Reading width 65 mm

Reading resolution less than 0.125 mm (NW-7,CODE39,ITF,STF)

PCS value 0.45 or more

less than 0.15 mm (CODE93,CODE128)

(wavelength 660 nm, white bar reflectivity ≥ 85%)

— 6 —

Page 9

2-6. MCR

Model name : QT-2046MC

Item Description

Model Name ZU-M1242S4

Card feed Manual operation

Data read direction One way (from right to left)

Read/Write Read only

Magnetic card ISO 7810 , ISO7811

Magnetic stripe encode Track 1: ISO1(IATA) Track 2 : ISO2(ABA)

Size 90 mm (L) x 25 mm (W) x 24 mm (H)

Weight About 28 g (Mechanisn only)

Power supply 5 V DC ± 10%, 6.0 mA (typ.) 9.0 mA (max.)

Feed speed 10 to 1500 mm/sec.

Life of magnetic head 300,000 pass (min.)

Life of electric circuit 50,000 hours

Error rate 1/1,000 (max.)

— 7 —

Page 10

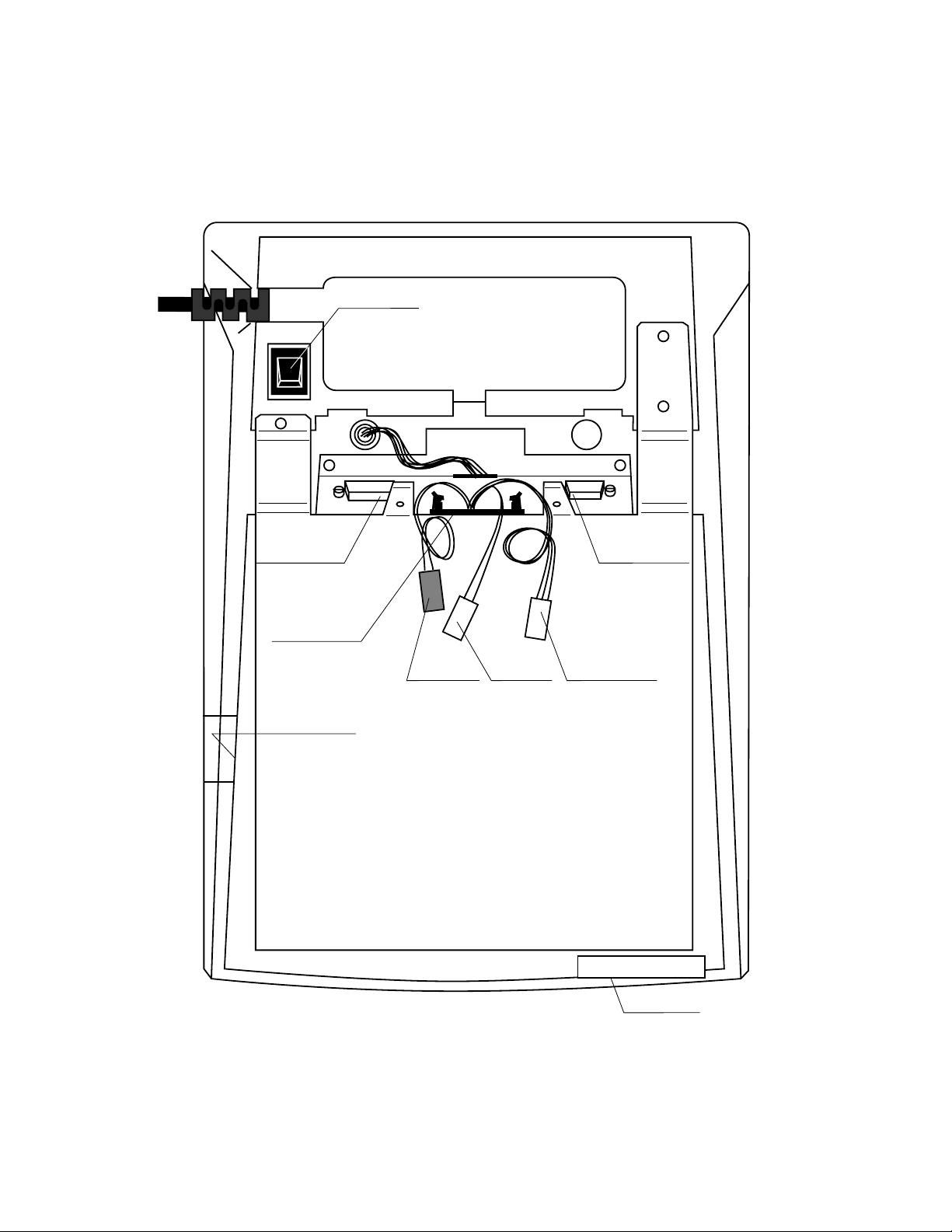

3. QT-2000 CONNECTOR LOCATIONS

3-1. QT-2000 connector location

Power switch

RS-232C Com1

Slip printer port

RS-232C Com3

Bottom view

RS-232C Com2

In-lineKP In-line

Drawer cable

Infrared port

Com 1 : for hand held scanner HHS-9

Com 2 : for R/J printer (UP-350, SA-3015 and TM-T85)

Com 3 : for MODEM or PC

Power switch : for service maintenance

Make sure off this switch when open the machine.

Because, the power is applied even if the mode swith is off.

— 8 —

Page 11

3-2. Interface pin asignment

Com1: Hand held scanner HHS-9 (Location : CN2 on E580-CNB)

Pin No. Description

1 TXD1

2 RXD1

3 RTS1

4 CTS1

5 DSR1

6 DTR1

7 GND

8 NC

9 VCC

10 NC

11 GND

12 NC

13 NC

14 NC

15 GND

Com2 : R/J printer (Location : CN1 on E580-CNB)

Pin No. Description

1 NC

2 RXD2

3 TXD2

4 DTR2

5 GND

6 DSR2

7 RTS2

8 CTS2

9 NC

Com3 : Modem / PC (Location : CN4)

Pin No. Description

1 CD3

2 RXD3

3 TXD3

4 DTR3

5 GND

6 DSR3

7 RTS3

8 CTS3

9 CI3

— 9 —

Page 12

Slip printer : SP-1200 (Location : CN10)

Pin No. Description

1 VCC

2 VCC

3 Sensor signal

4 NC

5 VP

6 VP

7 VP

8 VP

9 Busy signal

10 NACK signal

11 GNDP

12 GNDP

13 Data signal

14 GNDP

15 NC

16 Clock signal

17 Clear signal

18 Reset signal

19 GNDP

20 GNDP

Kitchen printer : KP-200, KP-300 ( Location : CN2)

Pin No. Description

1 TXD (Red wire)

2 RXD (Black wire)

In-line I/F : C In-Line (ARCNET) (Location : CN2)

Pin No. Description

3 RXD (Black wire)

4 TXD (Red wire)

Drawer I/F (Location : DW1)

Pin No. Description

1 Drive signal (Red wire)

2 Power (Black wire)

3 Sensor siglal (Brown wire)

— 10 —

Page 13

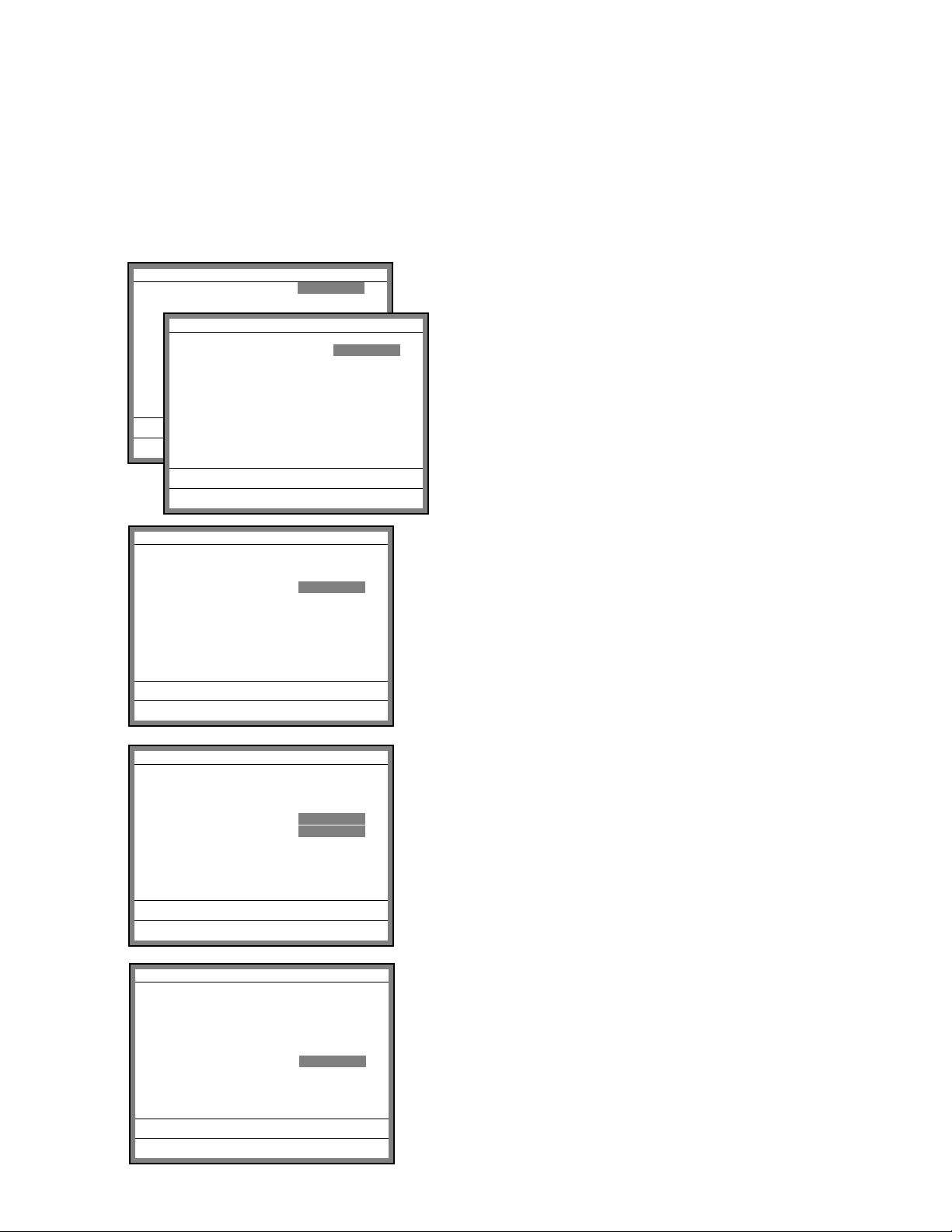

4. INITIALIZE OPERATION

1

4-1.To initialize QT-2000 terminal

Preparation:

1. All peripheral devices and QT-2000 terminals of this cluster should be turned off.

2. Connect all of the peripheral devices (such as printer, display etc.) to QT-2000 terminal.

3. Connect all QT-2000 terminals by in-line.

Operation:

Date 00-00-00

Time 12:34 00

ID Character MC #01

Date 97-12-15

Check System Master

Time 12:34 00

KP System Master

R/J/Order Printer SA-3015

ID Character MC #01

Slip Printer SA-3015

Check System Master

Rear Display No

KP System Master

Remote Display No

R/J/Order Printer SA-3015

OK? Yes

Slip Printer SA-3015

Rear Display No

Remote Display No

OK? YES

4. Turn on all peripheral devices of a QT-2000 terminal.

5. Turn on this QT-2000 terminal with pressing the left-most

key of the top row and release the key after buzzer sounds.

6. After releasing the key, enter 10000 (for Eu/Di)/20000 (U.S.)

and press the right part of the <ST> key.

7. Enter the current date (YY/MM/DD order) and time and

press the <Yes> key.

Date 97-12-15

Time 12:34 00

ID Character MC #01

Check System Master

KP System Master

R/J/Order Printer SA-3015

Slip Printer SA-3015

Rear Display No

Remote Display No

OK? YES

Date 97-12-15

Time 12:34 00

ID Character MC #01

Check System Master

KP System Master

R/J/Order Printer SA-3015

Slip Printer SA-3015

Rear Display No

Remote Display No

OK? YES

Date 97-12-15

Time 12:34 00

ID Character MC #01

Check System Master

KP System Master

R/J/Order Printer SA-3015

Slip Printer SA-3015

Rear Display No

Remote Display No

OK? YES

8. In ID character field, the auto-defined ID No. is shown.

We recommend that you should not change the value.

9. In these fields, you can select

“1.Master/2.Backup Master/3.Satellite.”

Please select one of these options and press the <Yes> key.

10. In this field, you can select, “1.Non/2.UP-350/3.SA-3015”

for R/J/Order printer.

Please select one of these options and press the <Yes> key.

— 11 —

Page 14

Date 97-12-15

Time 12:34 00

ID Character MC #01

Check System Master

KP System Master

R/J/Order Printer SA-3015

Slip Printer SA-3015

Rear Display No

Remote Display No

OK? YES

11. In this field, you can select, “1.Non/2.SA-3015/3.SP-1200”

for slip printer.

Please select one of these options and press the <Yes> key.

Date 97-12-15

Time 12:34 00

ID Character MC #01

Check System Master

KP System Master

R/J/Order Printer SA-3015

Slip Printer SA-3015

Rear Display No

Remote Display No

OK? YES

Date 97-12-15

Time 12:34 00

ID Character MC #01

Check System Master

KP System Master

R/J/Order Printer SA-3015

Slip Printer SA-3015

Rear Display No

Remote Display No

OK? YES

Date 97-12-15

Time 12:34 00

ID Character MC #01

Check System Master

KP System Master

R/J/Order Printer SA-3015

Slip Printer SA-3015

Rear Display No

Remote Display No

OK? YES

12. In these fields, you can select, “1.Yes/2.No” for rear display

and remote display.

Please select one of these options and press the <Yes> key.

13. Please confirm all of the field and if they are all right, press

the <Yes> key to proceed the next step.

INIT 97-12-17 12:34 000000

AUTO PGM Start YES

14. If you want to download program data from other terminal,

press the <Yes> key and proceed the next step.

If you don't need to download any program data, just press the

<No> key (the initialization of this terminal is completed).

Return to step 4 to initialize other terminals.

— 12 —

Page 15

Program copy from other terminal.

gpy

INIT 97-12-15 12:34 000000

Received Data All PGM

PGM Receive from MC #05

OK? YES

INIT 97-12-15 12:34 000000

Received Data All PGM

PGM Receive from MC #05

OK? YES

15. In this field, you can select the receiving contents as

“1.All Data (including totalizer)/2.All PGM (program only).”

16. In this field, you should enter the source ID number of

the data and press the <Yes> key.

INIT 97-12-15 12:34 000000

Received Data All PGM

PGM Receive from MC #05

OK? YES

17. Please confirm all of the fields and if they are all right,

press the <Yes> key to proceed downloading.

After completion of downloading, return to step 4 to initialize

other terminals.

— 13 —

Page 16

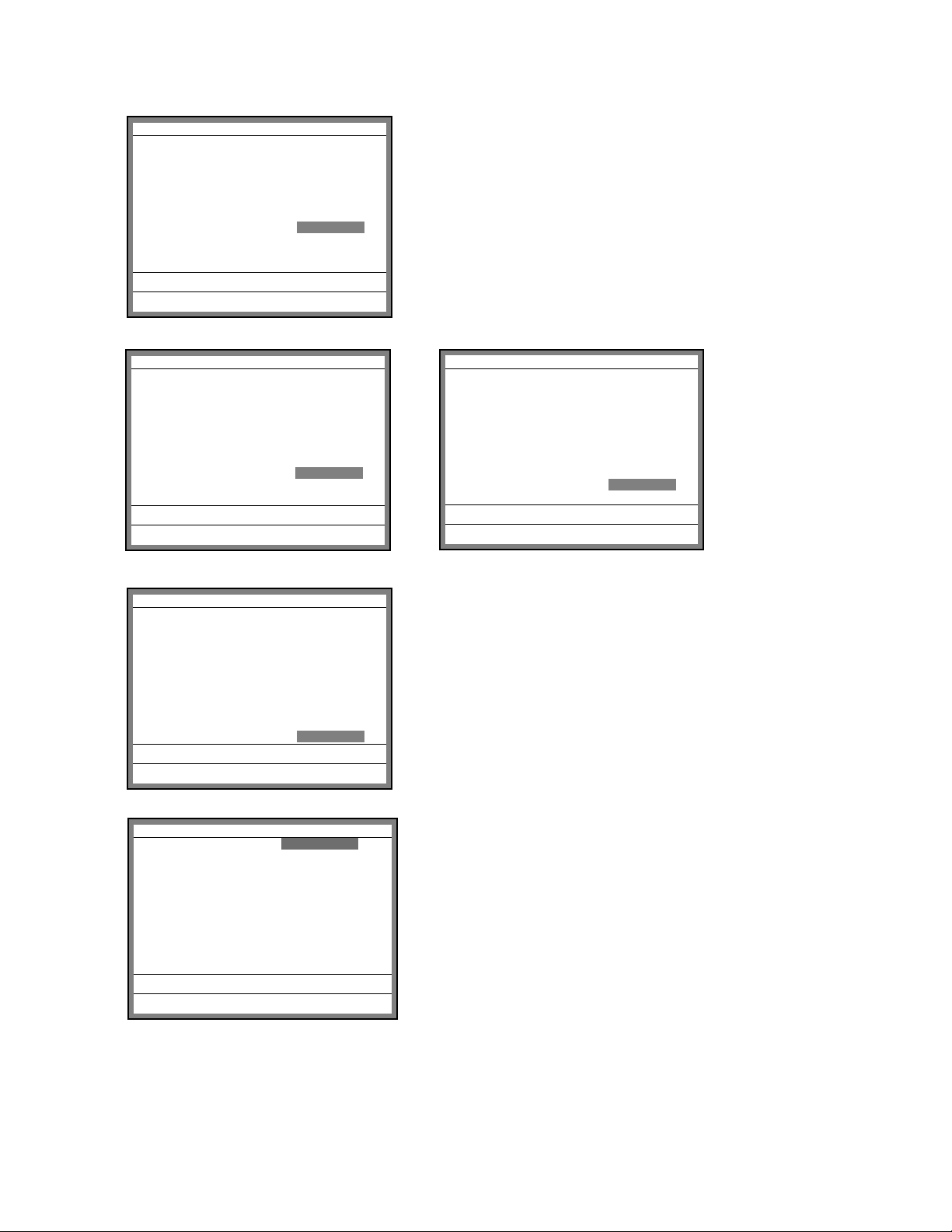

4-2. To initialize QT-2000 terminal (add/replace one QT-2000)

Preparation:

1. All peripheral devices and QT-2000 terminals of this cluster should be turned off.

2. Connect all of the peripheral devices (such as printer, display etc.) to this QT-2000 terminal.

3. Connect this QT-2000 terminal to in-line.

Operation:

Date 00-00-00

Time 12:34 00

ID Character MC #01

Check System Master

Date 97-12-15

KP System Master

Time 12:34 00

R/J/Order Printer SA-3015

Slip Printer SA-3015

ID Character MC #01

Rear Display No

Check System Master

Remote Display No

KP System Master

OK? Yes

R/J/Order Printer SA-3015

Slip Printer SA-3015

Rear Display No

Remote Display No

OK? YES

4. Turn on all peripheral devices of this QT-2000 terminal.

And turn on all QT-2000 except this terminal of the cluster.

5. Turn on this QT-2000 terminal with pressing the left-most

key of the top row and release the key after buzzer sounds.

6. After releasing the key, enter 10000 (for Eu/Di)/20000 (U.S.)

and press the right part of the <ST> key.

7. Enter the current date (YY/MM/DD order) and time and

press the <Yes> key.

Date 97-12-15

Time 12:34 00

ID Character MC #01

Check System Master

KP System Master

R/J/Order Printer SA-3015

Slip Printer SA-3015

Rear Display No

Remote Display No

OK? YES

8. In ID character field, the auto-defined ID No. is shown.

Please check if the same value is set in this field.

We recommend that you should not change the value.

Date 97-12-15

Time 12:34 00

ID Character MC #01

Check System Master

KP System Master

R/J/Order Printer SA-3015

Slip Printer SA-3015

Rear Display No

Remote Display No

OK? YES

Date 97-12-15

Time 12:34 00

ID Character MC #01

Check System Master

KP System Master

R/J/Order Printer SA-3015

Slip Printer SA-3015

Rear Display No

Remote Display No

OK? YES

9. In these fields, you can select

“1.Master/2.Backup Master/3.Satellite.”

Please choose former options and press the <Yes> key.

10. In this field, you can select, “1.Non/2.UP-350/3.TM-U950”

for R/J/Order printer.

1

Please choose former option and press the <Yes> key.

— 14 —

Page 17

Date 97-12-15

Time 12:34 00

ID Character MC #01

Check System Master

KP System Master

R/J/Order Printer SA-3015

Slip Printer SA-3015

Rear Display No

Remote Display No

OK? YES

11. In this field, you can select, “1.Non/2.SA-3015/3.SP-1200”

for slip printer.

Please choose former options and press the <Yes> key.

Date 97-12-15

Time 12:34 00

ID Character MC #01

Check System Master

KP System Master

R/J/Order Printer SA-3015

Slip Printer SA-3015

Rear Display No

Remote Display No

OK? YES

Date 97-12-15

Time 12:34 00

ID Character MC #01

Check System Master

KP System Master

R/J/Order Printer SA-3015

Slip Printer SA-3015

Rear Display No

Remote Display No

OK? YES

Date 97-12-15

Time 12:34 00

ID Character MC #01

Check System Master

KP System Master

R/J/Order Printer SA-3015

Slip Printer SA-3015

Rear Display No

Remote Display No

OK? YES

12. In these fields, you can select, “1.Yes/2.No” for rear display

and remote display.

Please choose former options and press the <Yes> key.

13. Please confirm all of the field and if they are all right, press

the <Yes> key to proceed the next step.

INIT 97-12-17 12:34 000000

AUTO PGM Start YES

14.If you want to download program dasa from other terminal,

press the <Yes> key to proceed the next step.

If you don’t need to download any program data, just press the

<No> key (The initialization is completed).

— 15 —

Page 18

Program copy from other terminal.

INIT 97-12-15 12:34 000000

Received Data All PGM

PGM Receive from MC #05

OK? YES

INIT 97-12-15 12:34 000000

Received Data All PGM

PGM Receive from MC #05

OK? YES

15. In this field, you can select the receiving contents as

“1.AllData (including totalizer)/2.All PGM (program only).”

16. In this field, you should enter the source ID number of

the data and press the <Yes> key.

INIT 97-12-15 12:34 000000

Received Data All PGM

PGM Receive from MC #05

OK? YES

17. Please confirm all of the fields and if they are all right,

press the <Yes> key to proceed downloading.

After completion of downloading, the initialization opera-tion

is finished.

— 16 —

Page 19

4-3. To flag clear QT-2000 terminal (INIT2, Restore from flash)

Preparation:

1. All peripheral devices and this QT-2000 terminal should be turned off.

2. Check the connection of all peripheral devices (such as printer, display etc.) of this

QT-2000 terminal.

3. Check the connection of this QT-2000 terminal to in-line.

Operation:

15-12-97 12:34

INIT

1.Flag Clear

2.Init2

3.Restore

0.00

Note:

Performing “Init 2” requires password “8888888888” and

performing “Restore” requires password “0000000000.”

4. Turn on all peripheral devices of this QT-2000 terminal.

5. Turn on this QT-2000 terminal with pressing the right-most

key of the top row and release the key after buzzer sounds.

6. After releasing the key, press the right part of the <ST> key.

7. Select "1.Flag Clear" and press the <Yes> key.

The flag clear operation is finished.

— 17 —

Page 20

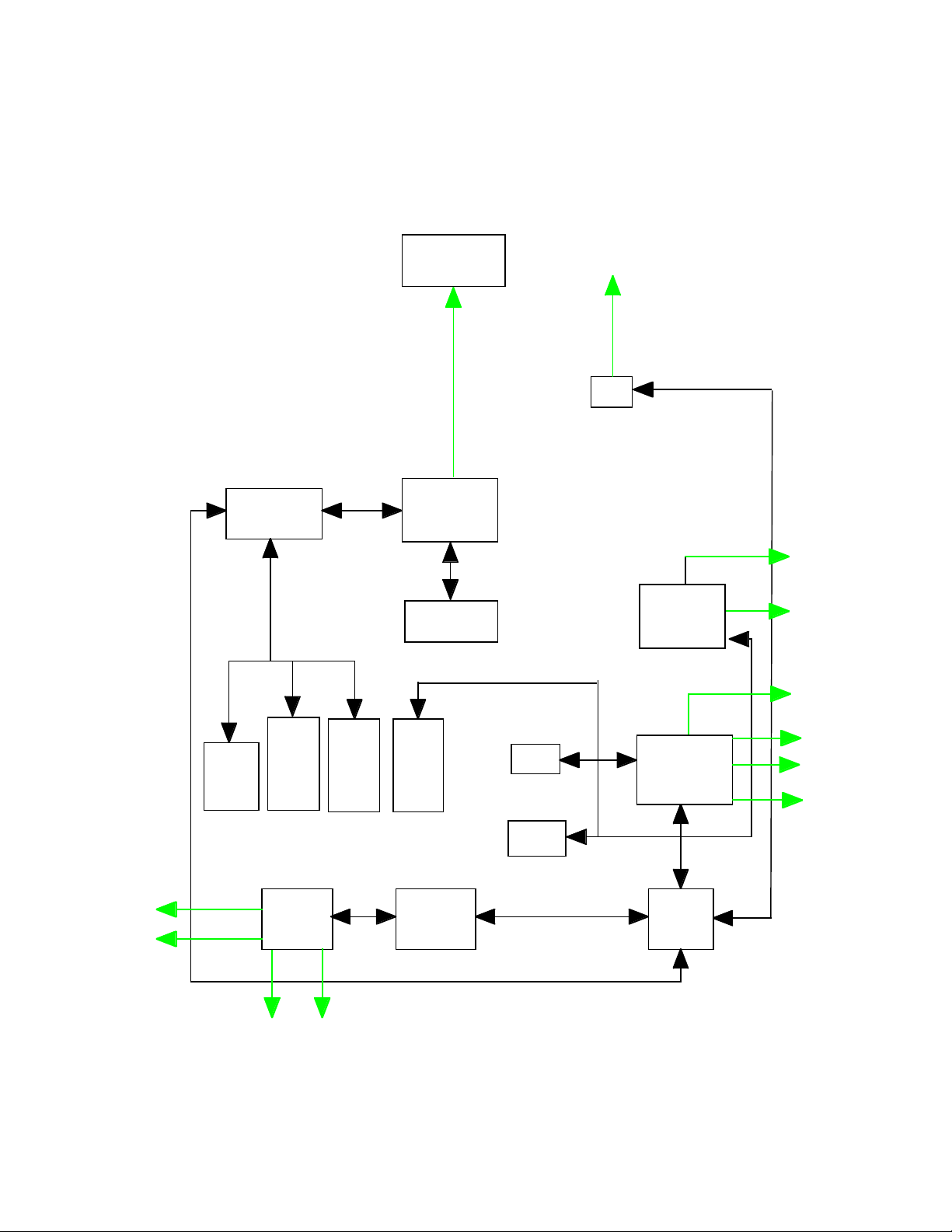

5. CIRCUIT EXPLANATION

y

y

y

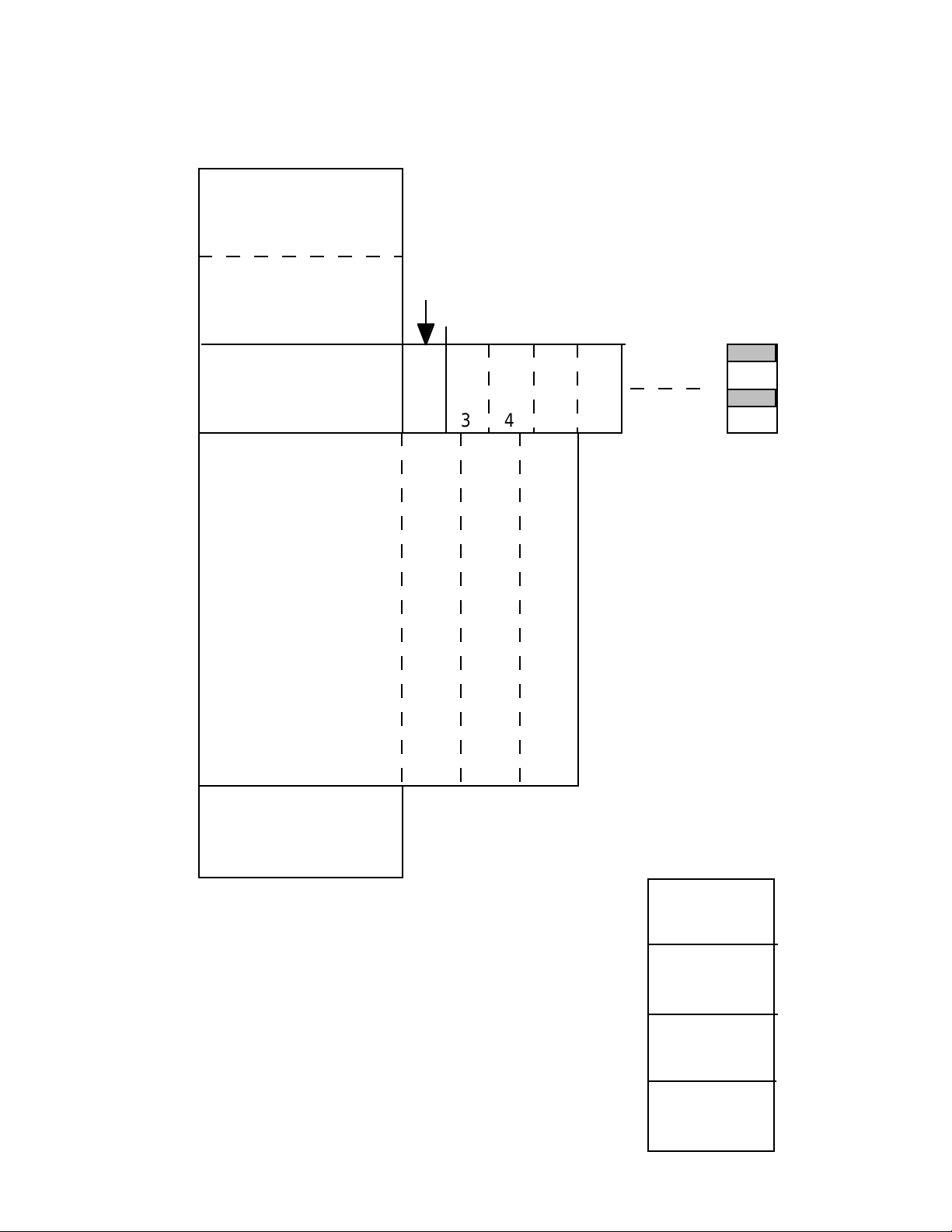

5-1. Block diagram (MAIN PCB E580-1)

MASS memory

control

IC36

GA4

LCD displa

IC26

Display

controller

IC20

Video RAM

IN-LINE

ARCNET

IC10

ARCNET

Controller

IC11

GA2

Drawer

Keyboard

Kitchen

Printer

IR I/F

COM3

Modem

IC43

1M

SRAM

IC35 IC39 IC31

4M

SRAM

IC33

UART

COM2

Printer

1M

SRAM

COM1

Scanner

1M

EP ROM

IC32

GA3

IC22

16M F-ROM

IC23

2M SRAM

IC12

GA1

Slip

Printer

Back

Displa

Remort

Displa

IC6

CPU

— 18 —

Page 21

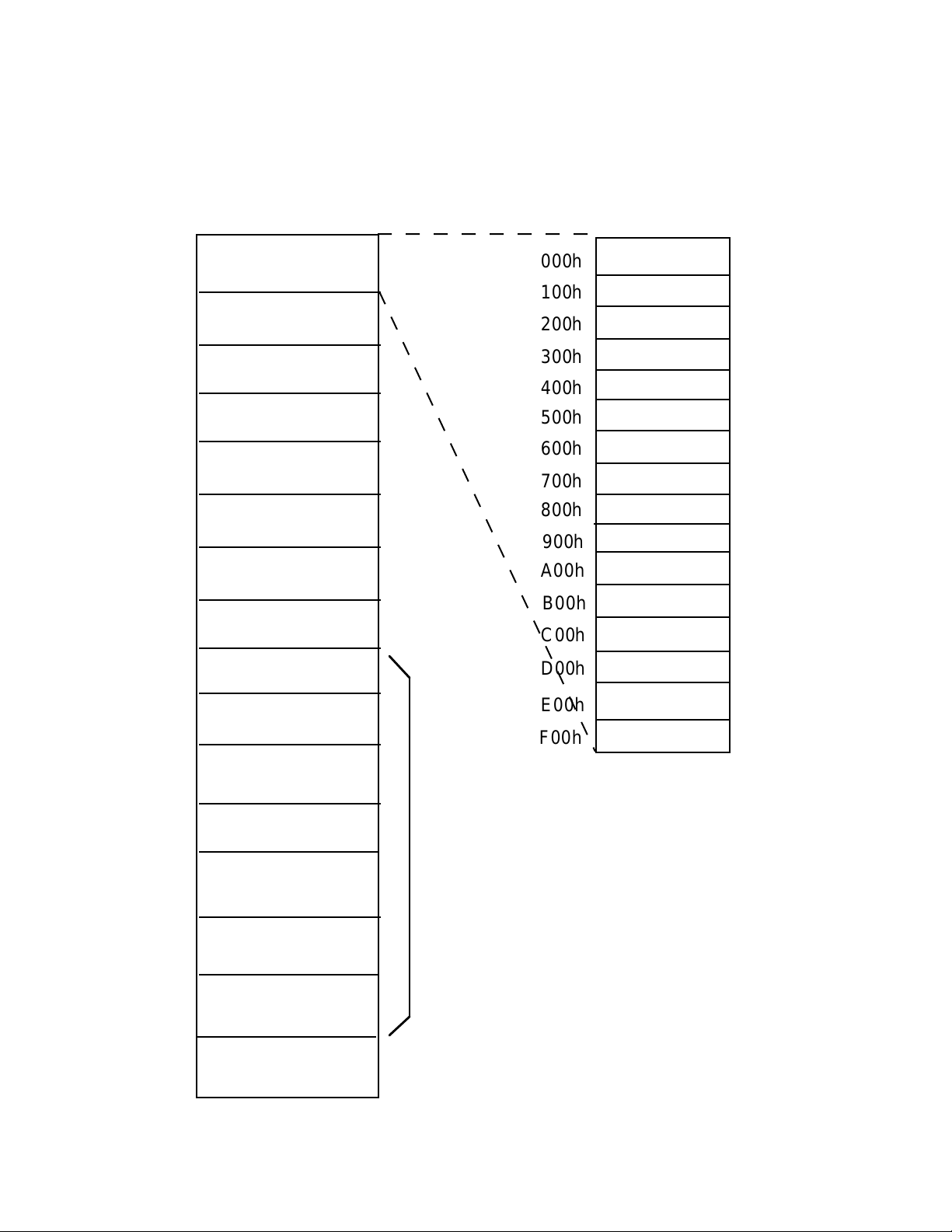

5-2. Memory map

00000h

20000h

40000h

60000h

80000h

SYSTEM RAM

2Mb x 1

RAM 1Mb x 1

16Mb FLASH ROM

Option RAM 1Mb

Option RAM 4Mb

2

1 3456

VRAM

256Kb x 2

Bank16

A0000h

C0000h

E0000h

FFFFFh

EP ROM

1Mb

Bank16 contents

40000h

VRAM

for LCD1

48000h

Control area

for LCD1

50000h

VRAM

for LCD2

— 19 —

Control area

for LCD2

58000h

Page 22

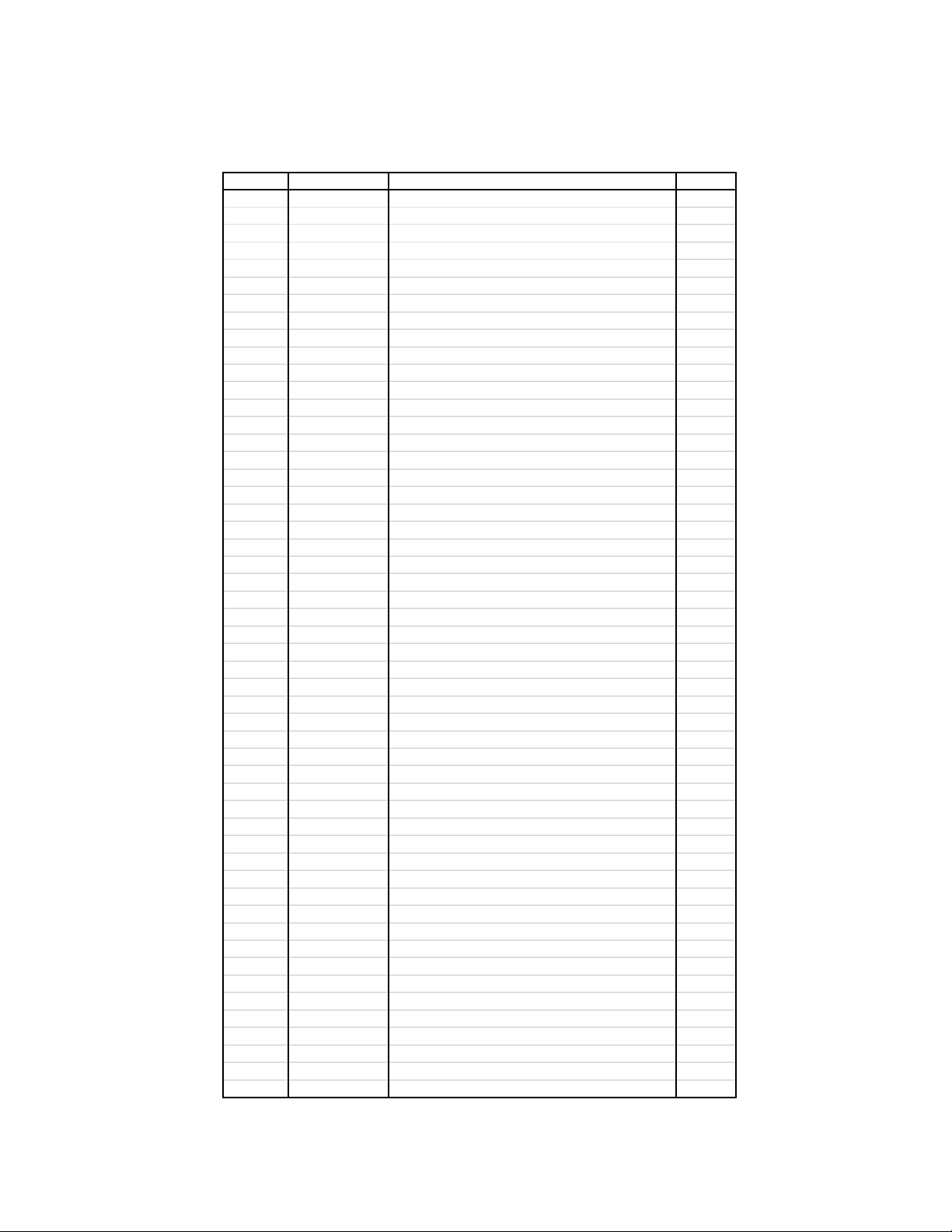

5-3. I/O Address map

W

W

Interrupt status port

There are 8 bits data for status per 1 port.

0000h

1000h

2000h

3000h

4000h

5000h

6000h

7000h

8000h

9000h

A000h

B000h

C000h

Rererved

(INT Status)

System

System

System

System

System

Reserved

Reserved

ARCNET R/

Back light control

for LCD1

Back light control

for LCD2

COM3 select

I/O port

000h

100h

200h

300h

400h

500h

600h

700h

800h

900h

A00h

B00h

C00h

D00h

E00h

F00h

System

Port #1

Port #2

Port #3

Port #4

Port #5

Port #6

Port #7

Port #8

Port #9

Port #10

Port #11

Port #12

Port #13

Port #14

Port #15

Users Area

( 15 ports )

D000h

E000h

F000h

FFFFh

Flash bank W

Future

Future

Reserved

— 20 —

Page 23

5-4. LSI pin description

1. CPU (uPD70108HGC-16-3B6)

Pin No. Name Description In/Out

1 A18/PS2 Address bus (A18) / Processor status Ou t

2 A17/PS1 Address bus (A17) / Processor status Ou t

3 A16/PS0 Address bus (A16) / Processor status Ou t

4 A1 5 Address bus (A15) Ou t

5 VDD Power source 6 VDD Power source 7 GND GND 8 GND GND -

9 IC Internaly connect (GND) 1 0 A1 4 Address bus (A14) Out

1 1 A1 3 Address bus (A13) Out

1 2 A1 2 Address bus (A12) Out

1 3 A1 1 Address bus (A11) Out

1 4 NC Not used 1 5 A1 0 Address bus (A10) Out

1 6 A9 Address bus (A9) Ou t

1 7 A8 Address bus (A8) Ou t

18 AD7 Address / Data bus (AD7) In/Out

19 AD6 Address / Data bus (AD6) In/Out

20 AD5 Address / Data bus (AD5) In/Out

21 AD4 Address / Data bus (AD4) In/Out

22 AD3 Address / Data bus (AD3) In/Out

23 AD2 Address / Data bus (AD2) In/Out

24 AD1 Address / Data bus (AD1) In/Out

25 AD0 Address / Data bus (AD0) In/Out

2 6 NC Not used 2 7 NC Not used 28 NMI Non-maskable interrupt (GND) 29 INT Maskable interrupt In

30 CLK System clock (16MHz) In

31 GND GND 3 2 NC Not used 33 GND GND 34 GND GND 35 RESET Reset In

36 READY Ready signal In

37 _POLL Polling signal In

3 8 _INTAK Interrupt acknowedge Out

39 ASTB Address strobe Ou t

4 0 NC Not used 4 1 _BUFEN Buffer enable Ou t

4 2 BUF_R/W Buffer read/write enable Out

43 IO/_M IO / memory select signal Out

44 _WR Write strobe Out

45 HLDAK Hold acknowlege Ou t

4 6 NC Not used 4 7 HLDRQ Hold request In

4 8 _RD Read strobe Ou t

4 9 S/_LG Small / Large select (5V) 50 LBS0 Not used 51 A19/PS3 Address bus (A19) / Processor status Ou t

5 2 NC Not used -

— 21 —

Page 24

(

)

2. GA1(MN53040KSF1)

Pin No. Name Description In/Out

1 E49MX2 Sub clock 4.92MHz Ou t

2 SVSS GND -

3 EADB0 Address bus (EADB0) Ou t

4 EADB1 Address bus (EADB1) Ou t

5 EADB2 Address bus (EADB2) Ou t

6 EADB3 Address bus (EADB3) Ou t

7 EADB4 Address bus (EADB4) Ou t

8 EADB5 Address bus (EADB5) Ou t

9 SVSS GND 10 EADB6 Address bus (EADB6) Ou t

11 EADB7 Address bus (EADB7) Ou t

12 EADB8 Address bus (EADB8) Ou t

13 EADB9 Address bus (EADB9) Ou t

14 EADB10 Address bus (EADB10) O u t

1 5 VDD VCC In

16 EADB11 Address bus (EADB11) O u t

17 VSS GND 18 EADB12 Address bus (EADB12) O u t

19 EADB13 Address bus (EADB13) O u t

20 EADB14 Address bus (EADB14) O u t

21 EADB15 Address bus (EADB15) O u t

22 EADB16 Address bus (EADB16) O u t

23 SVSS GND 24 EROMDC Direction select signal Out

25 _EMRD Output enable signal for system RAM Out

26 _EXINT Interruput signal from GA2,3,4 In

27 _EMWR Memory write signal Out

2 8 _ECGA2 Chip select signal for GA2 Out

29 _ERSET Reset signal In

30 _ECRA0 Bank select signal for RAM Out

31 _ECRA1 Bank select signal for RAM Out

32 _ECRA2 Bank select signal for RAM Out

33 _ECRA3 Bank select signal for RAM Out

34 EADB17 Address bus (EADB17) O u t

35 EADB18 Address bus (EADB18) O u t

36 EADB19 Not used 3 7 E1MN4M VCC In

38 _ECR04 Chip enable for ROM Out

39 _ECR03 Chip enable for FROM Out

40 _ECR02 Chip enable for FROM Out

41 _ECR01 Chip enable for FROM Out

42 _ECR00 Chip enable for FROM Out

43 _EIREQ VCC In

4 4 EIASTB GND In

45 EIHDAK GND In

46 VSS GND 4 7 _EIACK Not used O u t

4 8 VDD VCC In

4 9 EIHDRQ Not used Out

50 EAD0 Address / Data bus

AD0

In/Out

— 22 —

Page 25

Pin No. Name Description In/Out

y

51 EAD1 Address / Data bus (AD1) In/Out

52 EAD2 Address / Data bus (AD2) In/Out

53 EAD3 Address / Data bus (AD3) In/Out

54 EAD4 Address / Data bus (AD4) In/Out

55 EAD5 Address / Data bus (AD5) In/Out

56 SVSS GND 57 EAD6 Address / Data bus (AD6) In/Out

58 EAD7 Address / Data bus (AD7) In/Out

5 9 EA8 Address bus (A8) In

6 0 EA9 Address bus (A9) In

61 EA10 Address bus (A10) In

62 EA11 Address bus (A11) In

63 EA12 Address bus (A12) In

64 EA13 Address bus (A13) In

65 EA14 Address bus (A14) In

66 EA15 Address bus (A15) In

67 ECPURS Reset signal Out

68 EREADY Ready signal Out

69 EA16 Address bus (A16) In

70 EA17 Address bus (A17) In

71 EA18 Address bus (A18) In

72 EA19 Address bus (A19) In

73 _EINTA Interrupt acknowledge signal from CPU In

74 EASTB Address strobe signal In

75 EINT Interrupt signal to CPU Out

76 EINMCK IO / Memory select signal Out

77 VSS GND 7 8 _EINSD Not used Out

7 9 VDD VCC In

8 0 _EINRD VCC In

8 1 ESDEND Not used Out

82 _EKPSD Send data to kitchen printer Out

83 _EKPRD Receive data from kitchen printer In

84 EKPEND RTS signal for kitchen printer Out

85 ESD Send data for COM1 Out

86 ERD Receive data for COM1 In

87 _ECI VCC In

8 8 _EDR DSR signal for COM1 In

89 _EER DTR signal for COM1 Out

9 0 _ECD VCC In

91 _ECS CTS signal for COM1 In

92 _ERS RTS signal for COM1 Out

9 3 E16MX1 Main system clock 16MHz In

9 4 E16MX2 Main system clock 16MHz Out

95 SVSS GND 96 ECPURC CLock signal from CPU In

97 ECPUCK CLock signal from CPU Out

9 8 _FBFEN Buffer enable signal In

99 TEST2 GND In

100 EIONM IO / Memor

selection signal from CPU In

— 23 —

Page 26

Pin No. Name Description In/Out

y

y

)

101 EWR Write strobe signal from CPU I n

102 EHLADK Hold acknowledge signal from CPU In

103 EHLDRQ Hold request signal to CPU Out

104 _ERD Read signal In

105 _E1WT VCC In

106 _E2WT VCC In

107 _EDCR1 Data clear signal for back display Out

108 VDD VCC In

10 9 _EDNK1 Data NACK signal for back display In

110 VSS GND 111 EDDDAT Data signal for back display Out

112 EDDCLK Clock signal for back display Out

11 3 _EDNK2 Data NACK signal for remort display In

114 _EDCR2 Data clear signal for remort display Out

115 ESPBSY Busy signal for slip printer In

116 _ESPNK NACK signal for slip printer In

117 ESLPCR Data clear signal for slip printer Out

118 EPRDAT Data signal for slip printer Out

119 EPRCLK Clock signal for slip printer Out

120 ERJBSY GND In

121 _ERJNK Interrupt signal from ARCNET controller In

12 2 _ERJCR Not used O ut

12 3 TEST1 GND In

12 4 E49MX1 Sub s

stem clock 4.91MHz In

3. GA2 (MN53020KSK)

Pin No. Name Description In/Out

1 VSS GND -

2 XO Clock signal Out

3 _K13 Key input data signal (K13) In

4 _K12 Key input data signal (K12) In

5 _K11 Key input data signal (K11) In

6 _K10 Key input data signal (K10) In

7 _K9 Key input data signal (K9) In

8 _K8 Key input data signal (K8) In

9 _K7 Key input data signal (K7) In

10 _K6 Key input data signal (K6) In

11 _K5 Key input data signal (K5) In

12 _K4 Key input data signal (K4) In

13 _K3 Key input data signal (K3) In

14 _K2 Key input data signal (K2) In

15 _K1 Key input data signal (K1) In

16 _K0 Key input data signal (K0) In

17 _KO11 Key common signal (KO11) Out

18 _KO10 Key common signal (KO10) Out

19 _KO9 Key common signal (KO9) Out

20 _KO8 Ke

common signal (KO8

Out

— 24 —

Page 27

Pin No. Name Description In/Out

g

21 _KO7 Key common signal (KO7) Out

22 _KO6 Key common signal (KO6) Out

23 _KO5 Key common signal (KO5) Out

24 _KO4 Key common signal (KO4) Out

25 _KO3 Key common signal (KO3) Out

26 VSS GND 27 _KO2 Key common signal (KO2) Out

28 _KO1 Key common signal (KO1) Out

29 _KO0 Key common signal (KO0) Out

30 _INTPWD Power down signal In

31 AD7 Address / Data bus (AD7) In/Out

32 AD6 Address / Data bus (AD6) In/Out

33 AD5 Address / Data bus (AD5) In/Out

34 AD4 Address / Data bus (AD4) In/Out

35 AD3 Address / Data bus (AD3) In/Out

36 AD2 Address / Data bus (AD2) In/Out

37 VSS GND 38 AD1 Address / Data bus (AD1) In/Out

39 VDD VDD In

40 AD0 Address / Data bus (AD0) In/Out

4 1 _CRAM0 Chip select signal for system RAM Out

4 2 _CRAM1 Chip select signal for system RAM Out

4 3 _CRAM2 Nit used Ou t

4 4 CPUCLK Clock signal from CPU In

45 ASTB Address strobe signal from CPU In

46 _WR Write signal from CPU In

47 _RD Read signal from CPU In

48 ICEASTB GND In

49 _RAM3 Bank select signal In

5 0 NC Not used 51 VSS GND 5 2 _CRAM3 Not used O u t

53 _RAM2 Bank select signal for RAM In

54 _RAM1 Bank select signal for RAM In

55 _RAM0 Bank select signal for RAM In

56 _RESET Reset signal Out

5 7 _CSGA2 Chip select signal In

58 _MEMWR Memory write signal In

59 _INT Initilize signal Out

6 0 _REFRESH Not used O ut

6 1 _MEMWRT Not used Ou t

62 RFSEL VCC In

6 3 ITEST2 GND In

6 4 ITEST1 GND In

6 5 DIP8 Not used In

6 6 DIP7 Not used In

6 7 CASHSW6 Clerk switch signal I n

6 8 CASHSW5 Clerk switch signal In

6 9 CASHSW4 Clerk switch signal In

7 0 CASHSW3 Clerk switch si

nal In

— 25 —

Page 28

Pin No. Name Description In/Out

71 CASHSW2 Clerk switch signal In

7 2 CASHSW1 Clerk switch signal In

73 _SLIPSEN Sensor signal from slip printer In

74 OBRCLK Not used Out

7 5 OBRDATA VCC In

76 VSS GND 7 7 _DR4 Not used Ou t

7 8 _DR3 Not used Ou t

7 9 _DR2 Drawer open signal (DR2) Out

8 0 _DR1 Drawer open signal (DR1) Out

81 DRS Drawer sensor signal In

82 TAIWANJ GN D In

83 TAIWANR GND In

84 VLDSEN GND In

85 JPEND GND In

8 6 _PWON Not used Ou t

8 7 VDD VDD In

88 BUZER Buzzer signal Out

89 VSS GND 90 OFF GND In

91 PGM GND In

92 RF GND In

93 REG1 GND In

94 REG2 GND In

95 X Sheet select switch signal In

96 Z Sheet select switch signal In

97 XZ2 Sheet select switch signal In

98 _NACK Not used Ou t

99 XI Clock signal In

10 0 NC Not used -

— 26 —

Page 29

4. GA3 (MN53020KSG)

Pin No. Name Description In/Out

1 VSS GND -

2 XO Clock signal Out

3 SVDD VCC In

4 _CLOCK Not used Ou t

5 _ENABLE Not used Out

6 WMF1 GND In

7 WMF2 GND In

8 WMF3 GND In

9 WMF4 GND In

1 0 WMF5 GND In

1 1 WMF6 GND In

1 2 WMF7 GND In

1 3 WMF8 GND In

1 4 WMF9 GND In

15 _CLD2 Card loading signal In

16 _RCL2 Data sampling clock In

17 _RDT2 Data signal In

18 _CLD1 Card loading signal In

19 _RCL1 Data sampling clock In

20 _RDT1 Data signal In

21 _RESET Reset signal In

22 ASTB Address strobe signal In

2 3 _BUFEN Buffer enable signal In

24 BUFNRW Buffer read/write signal In

25 _WR Write signal In

26 VSS GND 27 INT Initilize signal Out

28 AD0 Address / Data bus (AD0) In/Out

29 AD1 Address / Data bus (AD1) In/Out

30 AD2 Address / Data bus (AD2) In/Out

31 AD3 Address / Data bus (AD3) In/Out

32 SVSS GND 33 AD4 Address / Data bus (AD4) In/Out

34 AD5 Address / Data bus (AD5) In/Out

35 AD6 Address / Data bus (AD6) In/Out

36 AD7 Address / Data bus (AD7) In/Out

37 VSS GND 38 AB8 Address signal (A8) In

39 VDD VCC In

40 AB9 Adress signal (A9) In

41 AB10 Adress signal (A10) In

42 AB11 Adress signal (A11) In

43 AB12 Adress signal (A12) In

44 AB13 Adress signal (A13) In

45 AB14 Adress signal (A14) In

46 AB15 Adress signal (A15) In

47 _RD Read signal In

48 ICEASTB GND In

49 IOM IO/Memory select signal In

5 0 NC Not used -

— 27 —

Page 30

Pin No. Name Description In/Out

51 VSS GND 52 USD0 Data bus for USART (USD0) In/Out

5 3 USD1 Data bus for USART (USD1) In/Out

5 4 USD2 Data bus for USART (USD2) In/Out

5 5 USD3 Data bus for USART (USD3) In/Out

5 6 USD4 Data bus for USART (USD4) In/Out

5 7 USD5 Data bus for USART (USD5) In/Out

58 SVSS GND 5 9 USD6 Data bus for USART (USD6) In/Out

6 0 USD7 Data bus for USART (USD7) In/Out

61 TOUT Not used Ou t

62 CLK Clock signal for USART Out

63 ADB0 Not used O ut

6 4 _RXC1 Not used Ou t

65 TXRDY1 Ready signal for IrDA or Com3 In

66 RXRDY1 GND In

67 _USART1 CH1 select signal for USART Out

68 _TXC1 Send clock signal for CH1 Out

69 _RXC2 Not used O ut

70 TXRDY2 Ready signal for Com2 In

71 RXRDY2 GND In

72 _USART2 CH2 select signal for USART Out

7 3 _TXC2 Not used Out

74 _ST2 VCC In

7 5 _RT VCC In

76 VSS GND 7 7 _CD VCC In

78 _CI VCC In

79 T3 GND In

80 SELECT GND In

8 1 PEND GND In

8 2 _FAULT VCC In

8 3 BUSY GND In

8 4 NACK VCC In

8 5 CENTD7 Not used O ut

8 6 CENTD8 Not used O ut

8 7 VDD VCC In

8 8 CENTD6 Not used O ut

89 VSS GND 9 0 CENTD4 Not used O ut

9 1 CENTD5 Not used O ut

9 2 CENTD3 Not used O ut

9 3 CENTD2 Not used O ut

9 4 CENTD1 Not used O ut

95 _STROBE Not used Ou t

96 _INT Not used Ou t

97 T2 GND In

98 T1 GND In

99 XIN Clock signal In

10 0 NC Not used -

— 28 —

Page 31

5. GA4 (MN56020KSJ)

Pin No. Name Description In/Out

1 VSS GND -

2 MD2 Data signal for MASS memory (MD2) In / Out

3 MD3 Data signal for MASS memory (MD3) In / Out

4 MD4 Data signal for MASS memory (MD4) In / Out

5 MD5 Data signal for MASS memory (MD5) In / Out

6 MD6 Data signal for MASS memory (MD6) In / Out

7 MD7 Data signal for MASS memory (MD7) In / Out

8 SVSS GND -

9 MA0 Address signal for MASS memory (MA0) Out

10 MA1 Address signal for MASS memory (MA1) Out

11 MA2 Address signal for MASS memory (MA2) Out

12 MA3 Address signal for MASS memory (MA3) Out

13 MA4 Address signal for MASS memory (MA4) Out

14 MA5 Address signal for MASS memory (MA5) Out

15 SVSS GND 16 MA6 Address signal for MASS memory (MA6) Out

17 MA7 Address signal for MASS memory (MA7) Out

18 MA8 Address signal for MASS memory (MA8) Out

19 MA9 Address signal for MASS memory (MA9) Out

20 SVSS GND 21 MA10 Address signal for MASS memory (MA10) Out

22 MA11 Address signal for MASS memory (MA11) Out

23 MA12 Address signal for MASS memory (MA12) Out

24 MA13 Address signal for MASS memory (MA13) Out

25 VSS GND 26 MA14 Address signal for MASS memory (MA14) Out

27 MA15 Address signal for MASS memory (MA15) Out

28 MA16 Address signal for MASS memory (MA16) Out

29 _INT Initilize signal Out

30 _RESET Reset signal In

31 AB19 Address bus (AB19) In

32 AB18 Address bus (AB18) In

33 AB17 Address bus (AB17) In

34 AB16 Address bus (AB16) In

35 AB15 Address bus (AB15) In

36 AB14 Address bus (AB14) In

3 7 VSSI GND 38 AB13 Address bus (AB13) In

39 AB12 Address bus (AB12) In

40 AB11 Address bus (AB11) In

41 AB10 Address bus (AB10) In

4 2 AB 9 Address bus (AB9) In

4 3 AB 8 Address bus (AB8) In

44 AD7 Address / Data bus (AD7) In / Out

45 AD6 Address / Data bus (AD6) In / Out

46 AD5 Address / Data bus (AD5) In / Out

47 AD4 Address / Data bus (AD4) In / Out

48 AD3 Address / Data bus (AD3) In / Out

49 AD2 Address / Data bus (AD2) In / Out

50 VDD VCC In

— 29 —

Page 32

Pin No. Name Description In/Out

51 VSS GND 52 AD1 Address / Data bus (AD1) In /Out

53 AD0 Address / Data bus (AD0) In / Out

5 4 _RFSHOT Not used Ou t

55 ASTB Address strobe signal In

56 IOXM IO / Memory select signal In

57 BUFXRW Buffer read/write signal In

5 8 CPUCLK Clock signal from CPU I n

5 9 _BUFEN Buffer enable signal In

60 _WR Write signal In

61 _RD Read signal In

62 _RFSH GND In

63 ICEAST GND In

6 4 TEST GND In

65 RW1 Memory write enable signal Out

6 6 RW2 Not used Ou t

67 _OE1 Memory output enable signal Out

68 _OE2 Not used Out

69 _CE0 Chip enable for MASS memory Out

70 _CE1 Chip enable for MASS memory Out

71 _CE2 Chip enable for MASS memory Out

72 _CE3 Chip enable for MASS memory Out

73 _CE4 Chip enable for MASS memory Out

74 _CE5 Chip enable for MASS memory Out

75 VSS GND 76 _CE6 Chip enable signal (Not used) 77 _CE7 Chip enable signal (Not used) 78 _CE8 Chip enable signal (Not used) 79 _CE9 Chip enable signal (Not used) 80 _CE10 Chip enable signal (Not used) 81 _CE11 Chip enable signal (Not used) 82 _CE12 Chip enable signal (Not used) 83 _CE13 Chip enable signal (Not used) 84 _CE14 Not used 85 _CE15 Chip select signal for LCD display Out

86 LS0 GND In

87 VDDI VCC In

88 LS1 VCC In

89 LS2 GND In

9 0 IOLS0 GND In

9 1 IOLS1 GND In

9 2 IOLS2 GND In

9 3 IOLS3 GND In

94 SELECT GND In

95 _INTIN VCC In

96 CEIN GND In

9 7 CEOT Not used Out

98 MD0 Data signal for MASS memory (MD0) In / Out

99 MD1 Data signal for MASS memory (MD1) In / Out

100 VDD VCC In

— 30 —

Page 33

6. NETWORK DRIVER (COM20020BILJP)

Pin No. Name In/Out Status Status Status Description

of OFF of ON of ON

No Token Token

1 A0/MUX In L L Pulse

2 A1 In L L L

3 A2/ALE In L L L

Input. On a non-multiplexed bus,

these signals are dirctly connectoed to

the low bits of the host address bus.

On a multiplexed address/data bus,

A0/MUX is tied low, A1 is left open,

and A2 is tied to the address latch

enable signal of the host. A1 is

connectoed to an internal pull-up

resistor.

4 AD0 In/Out L Pulse Pulse

5 AD1 In/Out L Pulse Pulse

6 AD2 In/Out L Pulse Pulse

8 D3 In/Out L Pulse Pulse

9 D4 In/Out L Pulse Pulse

10 D5 In/Out L Pulse Pulse

11 D6 In/Out L Pulse Pulse

12 D7 In/Out L Pulse Pulse

Input/Output. On a non-multiplexed

bus, these signals are used as the

data lines for the device. On a

multiplexed address/data bus,

AD0~AD2 act as the address lines

(latched by ALE) and as the low data

lines for the device. D3~D7 are

always used for data only. These

signals are connected to internal pull-

up resistors.

7,12,14 GND Power GND GND GND

16 XTAL1 In L Pulse Pulse

17 XTAL2 In L Pulse Pulse

Signal ground.

An external crystal shoul be connected

to these pins. If an external TTL clock

is used instead, it must be connected

to XTAL1 with a 390 ohms pull-up

resistor, and XTAL2 should be left

floating.

18 PULSE1 Out L H Pulse

19 PULSE2 Out L L L

Output. In normal mode, these active

low signals carry the transmit data

information, encoded in pulse format,

from the COM20020 to the media

driver circuitry. When the device is in

backplane mode, the PULSE1 signal

driver is programmable (push/pull or

open-drain), while the PULSE2 signal

provides a clock with frequency of

crystal/4. PULSE1 is connected to a

week internal pull-up resistor in

backplane mode.

20 RXIN In L H Pulse

Receive input. This signal carries the

receive data information from the line

receiver circuitry to the COM20020.

21 TXEN Out L L Pulse

Transmit Enable output. This signal

used in backplane mode to enable the

line drivers for transmission. The

polarity of the signal is programmable

by grounding the PULSE2 pin. This

option is valid only in backplane mode.

23 RESET IN In L H H

Input. This active low signal issued by

the microcontroller executes a hard-

ware reset. It is used to activate the

internal reset circuitry within the

COM20020.

— 31 —

Page 34

Pin No. Name In/Out Status Status Status Description

of OFF of ON of ON

No token Token

24 INTR Out L H Pulse

Interrupt output. This active low signal

is generated by the COM20020 when

an enabled interrupt condition occurs.

INTR returns to its inactive state when

the interrupt status condition or the

corresponding interrupt mask bit is

reset.

25 CS In L H Pulse

Chip select input. This active low

signal issued by the microcontroller

selects the COM20020 for an access.

26 WR/DIR In L Pulse Pulse

Input. On a 68XX-like bus, this signal

is issued by the microcontroller as the

Read/Write signal to determine the

direction of data transfer. In this case,

a logic "1" selects a read operation,

while a logic "0" selects a write operation. In this case, data is actually

strobed by the DS signal. On an

80XX-like bus, this active low signal is

isuued by the microcontroller to

indicate a write operation. in this

case, a logic "0" on this pin, when the

COM20020 is accessed, enables data

from the data bus to be written to the

device.

27 RD/DS In L L Pulse

Read/ Data strobe signal input. On a

68XX-like bus, this active low signal is

issued by the microcontroller as the

data strobe signal to strobe the data

onto the bus. On a 80XX-like bus, this

active low signal is issued by the

microcontroller to indicate a read

operation. In this case, a logic "0" on

this pin, when the COM20020 is

accessed, enables data from the

device to the data bus to be read by

the microcontroller.

15,18 VCC Power GND +5V +5V

Power supply +5V.

— 32 —

Page 35

5-5. Power down detection circuit

IC48 : Detection IC

The power is supplied at CN16 from switching power supply unit.

When the VP voltage become more than 22V, the voltage appears at pin No.2 of IC48 through

the zener diode ZD2.

The detection IC outputs "High" signal from pin No.6 and its signal going to IC45.

Then, the signal "INTPWD" becomes "High" and going to GA2.

The GA2 outputs "Reset" signal and reset the all GAs.

— 33 —

Page 36

5-6. Option RAM circuit

Standard memory capacity : 384 KB

To expand the memory capacity, put the option RAM chip on RAM1 or RAM2 position

Its convination is as follows;

Memory capacity Standard RAM1 RAM2

(Location : IC39) (Location : IC35)

384KB 384KB Nil Nil

512KB 384KB RAM530 Nil

1MB 384KB RAM530 RAM610

RAM530 : 1Mbits RAM (CXK581000P-10L)

RAM610 : 4Mbits RAM (CXK584000P-10LL)

— 34 —

Page 37

6. OPTION INSTALLATION

6-1. Clerk key unit (CLK-K17,CLK-K18)

1. Cut off the cable cover from the bottom case.

2. Release the screw which is fixing the keyboard and take tke keyboard out.

Cut the cable cover.

3. Insart the cable of clerk key unit and connect to CN5 of Main PCB.

CN5

Wire clamp

4. Tighten the screw to mount the clerk key unit.

Screw here.

Note :

Hold the cable using a wire

clamp to prevent the cut of wire.

— 35 —

Page 38

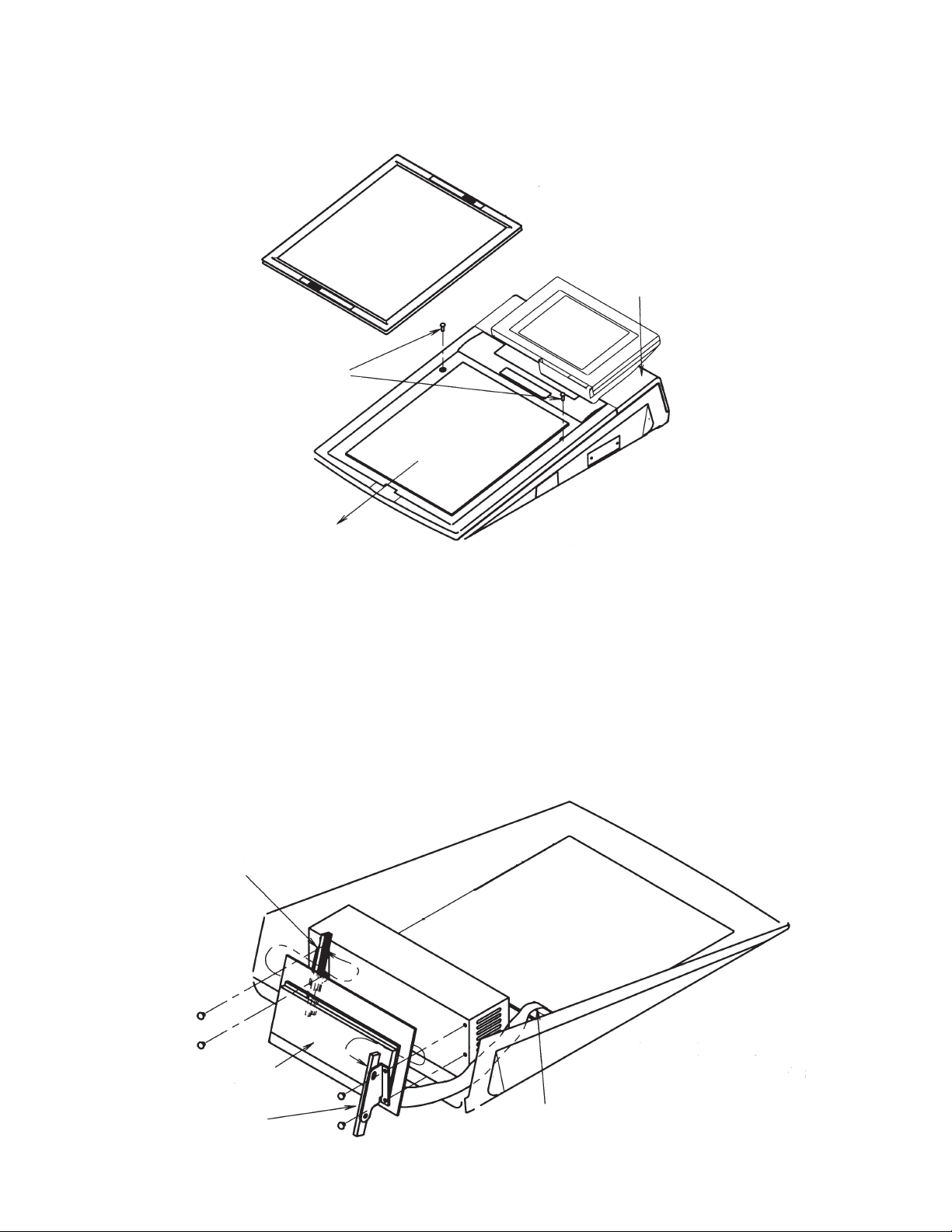

6-2. Rear Display (QT-2060D)

1. Release the screw which is fixing the keyboard and take tke keyboard out.

2. Remove the rear display window.

Rear display window

Release these screws

Slide the keyboard to the allow direction

3. Mount the display fixing plate (L).

4. Set the display PCB and display fixing plate (R), then tighten the screw.

5. Connect the display cable to CN15 of Main PCB.

Note :FG wire of the power code does not set behind displat PCB.

In case the FG wire is set behind the display PCB,the display might occurred flickering

problem.

Display fixing plate (L)

Display fixing plate (R)

CN15

— 36 —

Page 39

6-3. MCR Unit (QT-2046MC)

1. Release the screw which is fixing the keyboard and take tke keyboard out.

2. Remove the Main PCB and solder the connector which is in the QT-2046MC carton to the

location CN1 on Main PCB.

2. Mount the MCR unit on the lower case by screws and insart the cable to inside of the machine

from connector place.

4. Set the MAin PCB and connect the cable to CN1 on Main PCB.

Solder the connector here.

Cable for MCR is set

like this.

MCR mount stand

Screw here to mount

the MCR unit.

— 37 —

Page 40

6-4. Multi drawer (MDL-8)

1. Release the screw which is fixing the keyboard and take tke keyboard out.

2. Round the cable of connector sub ass'y for drawer to ferrite core as following figure.

2. Remove the Main PCB and mount the following pars.

3. Connect the connector for FG to FG plate.

LocationCode No. Name Specification Q'ty

Q9 22304151 Transistor 2SD1853 1

D16 23010127 Diode 1SR35-100A 1

62195096 Connector sub ass'y for drawer E32564-2(#24-800) 1

62214686 connector for FG E31553-17(#20-800) 1

30304055 Ferrite core L5T18X6X10 1

Not used 26004918 Carbon film resistor R-25-1K-J 1

Not used 26007313 Carbon film resistor R-25-10K-J 1

51501640 Screw 3x10 ZMC-3 2

Location for mounting parts

Sloder the connector

ass'y for drawer here.

Round the cable of drawer connector.

Mount the transistor and diode here.

— 38 —

Page 41

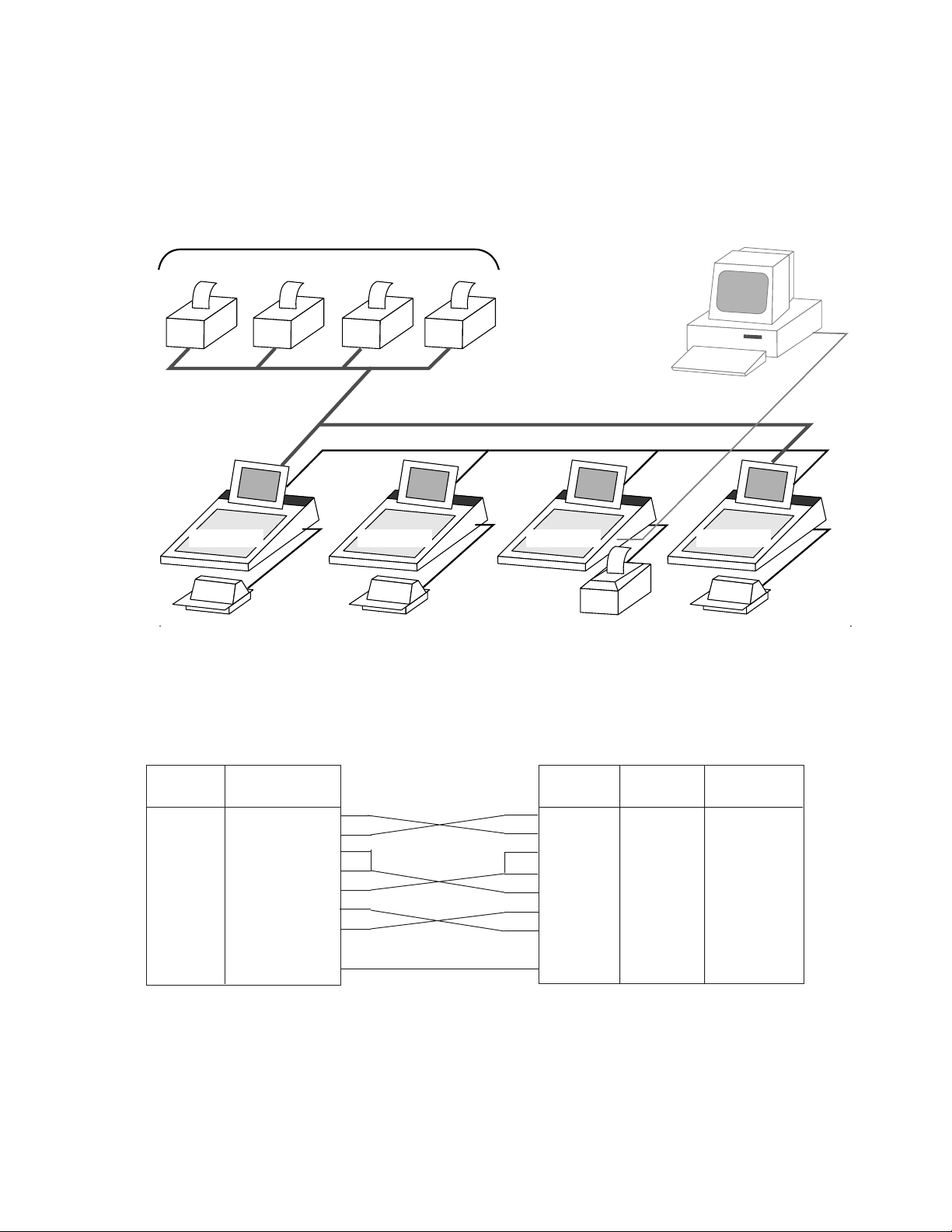

7. IN / ON LINE

7-1. C-In line (ARCNET)

1) C-In line connection diagram

The maximum C-In line cable length and the maximum connection unit will be varied by the in-line

communication speed as shown below list.

[C-In line cable wiring]

Install the I/O-PB-12 in

the PC.

Note: When the cluster has more than 8 QT-2000 terminals,

all printer should be local printer.

When the cluster has less than or equal to 8 QT-2000

terminals, remote printer is allowable.

PC

In-line

Total Length : A

QT2000-1

R/J

R/JR/J

QT2000-32QT2000-4QT2000-3QT2000-2

R/JR/J

C-In line communication speed Maximum Maximum

(Baud rate) connection unit cable length A ( m )

1.25 M bps 8 86

625 K bps 12 200

312.5 K bps 20 430

156.25 K bps 32 890

Note : This C-In line system needs a I/O-PB-12 in the PC.

— 39 —

Page 42

2) C-In line cable, Connector, and Terminater

C-In line cable

Code No. Parts name Specification

1904 4023 In-line cable IPEV-SLA0.5x1P

C-In line connector(ECR side)

Code No. Parts name Specification

3500 5820 In-line connector kit XLP-KIT-1

C-In line connector (PC side)

Code No. Parts name Specification

1904 4069 Connector DE-9PF-N10

1904 4070 Junction shell DE-C8-J9-F1

Terminater

Code No. Parts name Specification

2600 2516 Carbon film resistor R-25-100-J

3) Termination point

ECRPC

ECR ECR

Terminater(100 ohms)

Terminater(100 ohms)

— 40 —

Page 43

4) Cable connection diagram (PC and MasterECR)

Signal Pin Signal Pin

SD 1 SD 1

RD 3 RD 2

FG FG plate FG Disconnect

(PC side) (ECR side)

Termination 'R in series are connected at pins

1 and 4 of two connectors at both the ends of

3

the in-line cable.

Fold the shield and fasten by

wrapping copper tape.

5)Cable connection diagram (Master ECR and Satellite ECR)

Red

Red

In-line cable

Wrap bent shield wire

with Copper tape

Shield wire

Black

Black

Terminator (100 ohms)

[Connection between PC and Master ECR]

Red

Red

In-line cable

Wrap bent shield wire

with Copper tape

Shield wire

Black

Black

In-line connector

In-line connector

— 41 —

Page 44

7-2. ON-line

Only the RS-232C Com3 port can be connected with a modem or perssonal computer.

1. Direct connection to PC

1-1. Connection layout

Up to 4 kitchen printers

KP KP KP

KP

PC

QT2000QT2000QT2000QT2000

KP/M CHK/BM CHK/M KP/BM

Slip SlipSlip

Using Com3 port

1-2. Cable wiring

QT-2000 (Com3) PC

Pin No. Signal name Pin No. Pin No. Signal name

3 SD / TXD 3 2 SD

2 RD / RXD 2 3 RD

7 RS / RTS 7 4 RS

8 CS / CTS 8 5 CS

1 CD / DCD 1 8 CD

4 ER / DTR 4 20 ER

6 DR / DSR 6 6 DR

9 CI / RI - 22 CI

5 GND 5 7 GND

R/J

(DSUB9) (DSUB25)

RS-232C

— 42 —

Page 45

2. MODEM system

nals

MAX : 15 m

Use Com2 or

Com3 port

2-1. Connection layout

.

Note: When the cluster has more than 8 QT-2000 terminals,

PC

on-line

2-2. Cable wiring

all printer should be local printer.

When the cluster has less than or equal to 8 QT-2000

terminals, remote printer is allowable.

R/JR/J

R/J

QT2000-32QT2000-3QT2000-2QT2000-1

R/J

QT-2000 (Com2) MODEM (DSUB25)

Pin No. Signal name Pin No. Signal name

3 SD/ TXD 2 SD

2 RD / RXD 3 RD

7 RS / RTS 4 RS

8 CS / CTS 5 CS

1 CD / DCD 8 CD

4 ER / DTR 20 ER

6 DR / DSR 6 DR

9 CI / RI 22 CI

5 GND 7 GND

QT-2000 (Com3) MODEM (DSUB25)

Pin No. Signal name Pin No. Signal name

3 SD/ TXD 2 SD

2 RD / RXD 3 RD

7 RS / RTS 4 RS

8 CS / CTS 5 CS

1 CD / DCD 8 CD

4 ER / DTR 20 ER

6 DR / DSR 6 DR

9 CI / RI 22 CI

5 GND 7 GND

— 43 —

Page 46

7-3. Kitchen printer connection

The kitchen printer control system requires a kitchen printer control master ( and back up master)

for kitchen printer control.

Maimum connection number : Max. 4 kitchen printer

Max. 4 terminals

1) Connection layout

Up to 4 kitchen printers

KP KP KP

KP/M CHK/BM CHK/M KP/BM

Slip SlipSlip

2) Connector and cable

Cable

Code No. Parts name Specification

1904 4023 In-line cable IPEV-SLA0.5x1P

KP

MAX : 1,000 m

R/J

Up to 4 QT-2000 terminals

PC

RS-232C

QT2000QT2000QT2000QT2000

Connector (ECR side)

Code No. Parts name Specification

3500 5820 In-line connector kit XLP-KIT-1

Connector (KP side)

Code No. Parts name Specification

1904 4069 Connector DE-9PF-N10

1904 4070 Junction shell DE-C8-J9-F1

— 44 —

— 44 —

Page 47

3) Cable connection diagram (ECR and Kitchen printer)

Signal Pin Signal Pin

SD 1 SD 1

RD 2 RD 3

FG FG plate FG Disconnect

(ECR side) (KP side)

[Connection for Kitchen printer side]

Termination 'R in series are connected at pins

Solder the cable as above wiring.

1 and 4 of two connectors at both the ends of

3

the in-line cable.

[Connection for ECR side]

In-line cable

Wrap bent shield wire

with Copper tape

Shield wire

Terminator (100 ohms)

Fold the shield and fasten by

wrapping copper tape.

Red

Red

Black

Black

In-line connector

— 45 —

Page 48

4) Kitchen printer controll setting

DIP switch setting for kitchen printer model KP-200 and KP-300 are as follows;

When the the DIP switch is changed, it is necessary to make initilize the kitchen printer.

Otherwise, DIp switch status can not read the CPU inside the controll board.

To make initilize, pressing "LF" button and power on the machine.

SW No.

1

2

3

4

5

6

KP-200 Bottom view

Machine number setting Baud rate setting

Kitchen printer

machine number

1

2

3

4

DIP SW No. DIP SW No.

1

2

3

4

OFF

OFF

OFF

OFF

ON

OFF

OFF

OFF

OFF

ON

OFF

OFF

ON

ON

OFF

OFF

7

8

Baud rate

600

1200

2400

4800

9600

Function

Machine number

Baud rate

5

OFF

ON

OFF

ON

OFF

6

OFF

OFF

ON

ON

OFF

Factory setting

OFF

OFF

OFF

OFF

ON

ON

OFF

OFF

7

8

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

OFF

not used

}

KP-300 Bottom view

SW No.

1

2

Machine number

3

4

5

6

Baud rate

7

8

Machine number setting Baud rate setting

Kitchen printer

machine number

1

2

3

4

DIP SW No. DIP SW No.

1

2

3

4

OFF

OFF

OFF

OFF

ON

OFF

OFF

OFF

OFF

ON

OFF

OFF

ON

ON

OFF

OFF

— 46 —

Baud rate

600

1200

2400

4800

9600

Function

5

6

OFF

OFF

ON

OFF

OFF

ON

ON

ON

OFF

OFF

Factory setting

OFF

OFF

OFF

OFF

OFF

OFF

7

8

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

OFF

ON

ON

not used

}

Page 49

8.DIAGNOSTIC PROGRAM

1. Starting the diagnostic program

(1)While holding down the button on the upper left corner (9 on the standard keyboard sheet), turn the power on.

(2)Release the button when the cash register beeps a buzzer sound.

(3)Using 10-key pad, input [9][9][9][9][9][0][0][0][0][0] then press [SUB TOTAL].

Note: While in the diagnostic mode, use the right half of the SUB TOTAL button for [SUB TOTAL] operations.

2. List of the diagnoses

Command

code

1 Rear display n01

2 Remote display n02

3 RJ printer n03 RS-232C COM2 test

4 Slip printer n04

5 Keyboard n05 buttons 1 to 168 check

6 OBR n06 RS-232C COM1 test.

7 MCR n07 Use checker magnetic card.

9 Drawer n09

10 Buzzer n10

11 Switches 11

12 Clock n12

Device to be checked Operation Note

Use checker bar code.

13 ROM n13 EPROM (128kB) x 1

14 RAM n14 Read/Write check

15 RAM n15 Read check

16 MRAM n16 Read/write check

17 MRAM n17 Read check

20 Low-Inline nm20 Transmit check

21 Low-inline nm21 Receive check

25 Async online m25 Loop back test

30 Infrared port 30 Infrared port receive test

31 Infrared port n31 Infrared port transmit test

— 47 —

Page 50

Command

code

32 Standard LCD n32

33 Optional LCD n33

34 Flash memory 34 Read/Write/Clear test

38 ARCNET n38 ARCNET ID set

39 ARCNET n39 ARCNET baud rate, token

40 ARCNET 40 ARCNET token stop

41 ARCNET nm41 ARCNET data transmit

42 ARCNET nm42 ARCNET data receive

3. Diagnoses

(1) Dot/7-segment display test

Operation: [n][0][1][SUB TOTAL] (for the rear display)

Device to be checked Operation Note

[n][0][2][SUB TOTAL] (for the remote display)

n = Number of execution and should be within the range of 0 to 9.

If no number or “0” is input, the test continues endlessly.

To stop the test, press [ESC].

Display: <LCD> <Dot/7-segment>

ABCDEFGHIJKLMNOP

0,12,34,56,78,90,

abcdefghijkolmnop

12,34,56,78,90,1

Prints “END *01” when the test is finished.

RJ Print:

SUB DISP

Displays “END *01” when the test is finished.

SUB DISP *01

* Displays or prints 02 while testing a remote display.

*

01

Displays alternately

— 48 —

Page 51

(2) R/J Printer test (RS-232C COM2)

Prints B’s on RS-232C printer for specified times.

Operation: [n][0][3][SUB TOTAL]

n = Number of execution and should be within the range of 0 to 9.

If no number or “0” is input, the test continues endlessly.

To stop the test, press [ESC].

Display: <LCD> <Dot/7-segment>

R/J 03

R/J 03

R/J 03

R/J 03

END 03

R/J print:

R/J 03

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

BBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBBB

(3) Slip Printer test

Prints a test pattern on the slip printer for specified times and releases the slip.

Number of

execution

0

Dot/7-segment display indicates 0 only when

the test is continued from the “Dot/7-segment

display test.” When the test is performed

indipendently, the dot/7-segment display indicates nothing.

R/J Printer; TM-950 (2-sheet dot printer)

Partial cut (TM-950 printer prints “B” on the most significant digit)

Feed

Full cut (TM-950 printer prints “A” on the most significant digit)

0

TM-T85 (1-sheet thermal printer)

Operation: [n][0][4][SUB TOTAL]

n = Number of execution and should be within the range of 0 to 9.

If no number or “0” is input, the test continues endlessly.

To stop the test, press [ESC].

Display: <LCD> <Dot/7-segment>

slip 04

END 04

0

Slip print:

SLIP TEST PRINT

BBBBBBBBBBBBBBBBBBBBBBBB 8888888888

— 49 —

Dot/7-segment display indicates 0 only when

the test is continued from the “Dot/7-segment

display test.” When the test is performed

indipendently, the dot/7-segment display indicates nothing.

Release

0

Page 52

(4) Keyboard test

The display shows pressed button number when the key switch functions correctly.

Operation: [0][5][SUB TOTAL]

Press buttons and make sure that the pressed button number is displayed on the LCD.

Note:As [ESC] (button number159) button exits the diagnosis program, press [ESC] at the end.

Display: <LCD> <Dot/7-segment>

R/J Print:

KEY 05

KEY –– 26

KEY –– 27

KEY –– 28

KEY –– 29

KEY –––30

KEY 05

END 05

<Button numbers>

0

Dot/7-segment display indicates 0 only when

the test is continued from the “Dot/7-segment

display test.” When the test is performed

indipendently, the dot/7-segment display indicates nothing.

“END 05” will be displayed and

printed when [ESC] (button number

159) is pressed.

— 50 —

Press this button at the

end.

Page 53

(5) OBR test

Use only the checker bar code in which data 49401387 is written.

The program checks if the read data is 49401387.

Operation: [n][0][6][SUB TOT AL]

n = Number of execution and should be within the range of 0 to 9.

If no number or “0” is input, the test continues endlessly.

To stop the test, press [ESC].

Display: <LCD> <Dot/7-segment>

R/J Print:

OBR 06

OBR OK

OBR NG

FF4902580300562

END 06

OBR 06

OBR OK

OBR NG

When the read data is correct.

When the read data is incorrect.

Read data

0

When the read data is correct.

When the read data is incorrect.

0

Dot/7-segment display indicates 0 only

when the test is continued from the “Dot/

7-segment display test.” When the test

is performed indipendently, the dot/7segment display indicates nothing.

— 51 —

Page 54

(6) MCR test

Use only the checker magnet card.

Operation: [n][0][7][SUB TOTAL]

n = Number of execution and should be within the range of 0 to 9.

If no number or “0” is input, the test continues endlessly.

To stop the test, press [ESC].

Display: <LCD> <Dot/7-segment>

MCR 07

#1:OK #2:OK

#1:NG #2:NG

MCR#1

MCR#2

END 07

When the read data is incorrect, display indicates NG

and shows read data.

0

R/J Print:

MCR 07

#1:OK #2:OK

END 07

(7) Drawer test

Opens two drawers (multi drawer is optional) and shows open sensor status on the LCD.

Operation: [n][0][9][SUB TOTAL]

n = Number of execution and should be within the range of 0 to 9.

If no number or “0” is input, the test continues endlessly.

To stop the test, press [ESC].

“NG” when incorrect

Dot/7-segment display indicates 0 only when

the test is continued from the “Dot/7-segment

display test.” When the test is performed

indipendently, the dot/7-segment display indicates nothing.

Note: When MCR read error occurs, the display indicates “MCR READ ERR.”

0

Display: <LCD> <Dot/7-segment>

DRAWER 09

DRAWER: OPEN

END 09

R/J Print:

DRAWER 09

END 09

“NOT OPEN” when drawer does

not open

0

— 52 —

Dot/7-segment display indicates 0 only when

the test is continued from the “Dot/7-segment

display test.” When the test is performed

indipendently, the dot/7-segment display indicates nothing.

0

Page 55

(8) Buzzer test

Beep every 100 milliseconds. In one test, 2 buzzer sound.

Operation: [n][1][0][SUB TOT AL]

n = Number of execution and should be within the range of 0 to 9.

If no number or “0” is input, the test continues endlessly.

To stop the test, press [ESC].

Display: <LCD> <Dot/7-segment>

BUZZ 10

END 10

0

R/J Print:

BUZZ 10

END 10

(9) Switch test

Displays statuses of the switches and sensors of the connected devices.

Operation: [1][1][SUB TOTAL]

To stop the test, press [ESC].

Display: <LCD> <Dot/7-segment>

Keyboard Sheet 1 - 8

Not used

Not used

Slip paper sensor (0: slip inserted, 1: no slip inserted)

Drawer open sensor (0: close, 1: open)

Clerk key (00: not used, 01 - 15: clerk key no.)

No used

Dot/7-segment display indicates 0 only when

the test is continued from the “Dot/7-segment

display test.” When the test is performed

indipendently, the dot/7-segment display indicates nothing.

0

R/J Print:

STSW

0 0 0 0 0 0 1 00

END

STSW 11

END 11

11

11

0

Dot/7-segment display indicates 0 only when

the test is continued from the “Dot/7-segment

display test.” When the test is performed

indipendently, the dot/7-segment display indicates nothing.

— 53 —

Page 56

(10) Clock test

Operation: (1)Press [0][1][2][SUB TOTAL]

Display indicates date 99 12 31 MON, time 23 59 55.

If [1] is input instead of the first [0], the display shows the present time.

<LCD> <Dot/7-segment>

R/J Print:

CLOCK 12

99 12 31 MON

23 59 55

(2)Turn the power off.

(3)After for a while, turn the power on and

make sure that the time has been counted

while the register is off.

CLOCK 12

00 01 01 TUE

00 01 21

(4)Press [ESC] to exit from the program.

CLOCK 12

END 12

Counts up

Counts up

0

Dot/7-segment display indicates 0 only when

the test is continued from the “Dot/7-segment

display test.” When the test is performed

indipendently, the dot/7-segment display indicates nothing.

— 54 —

Page 57

(11) ROM test

Performs check sum test of the EPROM. Checks all the files written in the ROM and when an error occurs, the LCD

indicates the faulty file name and starting address of the file.

Operation: [n][1][3][SUB TOT AL]

n = Number of execution and should be within the range of 0 to 9.

If no number or “0” is input, the test continues endlessly.

To stop the test, press [ESC].

<LCD> <Dot/7-segment>

0

R/J Print:

ROM 13

config

cpyright

cmndrv.exe

ker.exe

tbox.exe

File names

Hndl580.exe

After the test, display indicates the result.

<LCD>

tbox.exe

hndl580.exe

diag580.exe

$tp.exe

config.env

ini.exe

ROM SUM CHECK OK

CREATE 97-04-17 11:53

Copywright (C) 1997

CASIO COMPUTER CO., LTD

All rights reserved.

ROM VER. AAFAB3075

END 13

Indicates “ESC” when the test is finished forcibly by [ESC].

0

ROM 13

config

cpyright

cmndrv.exe

fsys.exe

ker.exe

tbox.exe

hndl580.exe

diag580.exe

$tp.exe

config.env

ini.exe

ROM SUM CHECK OK

CREATE 97-04-17 11:53

Copyright (C) 1997

CASIO COMPUTER CO.,LTD

All rights reserved.

ROM VER. AAFAB 3075

END 13

Dot/7-segment display indicates 0 only when

the test is continued from the “Dot/7-segment

display test.” When the test is performed

indipendently, the dot/7-segment display indicates nothing.

— 55 —

Page 58

(12) RAM Read/Write test

Performs read after write test on RAM addresses 20000H to 3FFFF.

Operation: [n][1][4][SUB TOTAL]

n = Number of execution and should be within the range of 0 to 9.

If no number or “0” is input, the test continues endlessly.

To stop the test, press [ESC].

Display: <LCD> <Dot/7-segment>

R/J print:

RAM 14

RAM#2 OK

RAM#2 OK

RAM#2 OK

END 14

Number of execution.

Indicates “NG” when the

RAM is faulty.

0

Dot/7-segment display indicates 0 only when

the test is continued from the “Dot/7-segment

display test.” When the test is performed

indipendently, the dot/7-segment display indicates nothing.

0

RAM 14

RAM#2 OK

RAM#2 OK

“NG” when the RAM is

faulty

RAM#2 OK

END 14

(13) RAM Read test (memory backup test)

The program checks if RAM contents stored at the “RAM read/write test” are backed up after turning the power off.

Operation: (1)After the above “RAM Read/Write test”, turn the power off.

(2)After for a while, turn the power on then press [n][1][5][SUB TOTAL].

n = Number of execution and should be within the range of 0 to 9.

If no number or “0” is input, the test continues endlessly.

To stop the test, press [ESC].

Display: <LCD> <Dot/7-segment>

RAM 15

R/J print:

RAM#2 OK

RAM#2 OK

RAM#2 OK

END 15

Number of execution.

Indicates “NG” when the

RAM is faulty.

0

Dot/7-segment display indicates 0 only when

the test is continued from the “Dot/7-segment

display test.” When the test is performed

indipendently, the dot/7-segment display indicates nothing.

RAM 15

RAM#2 OK

RAM#2 OK

“NG” when the RAM is

faulty

RAM#2 OK

END 15

— 56 —

0

Page 59

(14) Mass RAM Read/Write test

Using the gate array and the CPU in QT-2000 circuit, the program performs RAM’s mass data (in 128k byte unit)

read after write test. The program does not diagnose VRAMs.

Operation: [n][1][6][SUB TOTAL].

n = Number of execution and should be within the range of 0 to 9.

If no number or “0” is input, the test continues endlessly.

To stop the test, press [ESC].

Display: <LCD> <Dot/7-segment>

RAM 16

MASS RAM CHIPS : m

m= bank number

0

MASS#m

Dot/7-segment display indicates 0 only when

the test is continued from the “Dot/7-segment

display test.” When the test is performed

indipendently, the dot/7-segment display indi-

R/J print:

MASS#m OK

END 16

or “NG”

Indicates “ESC” when

the test is finished

forcibly by [ESC].

0

cates nothing.

MASS 16

m= bank number