Page 1

INSTALLATION, OPERATION, & MAINTENANCE MANUAL (IOM)

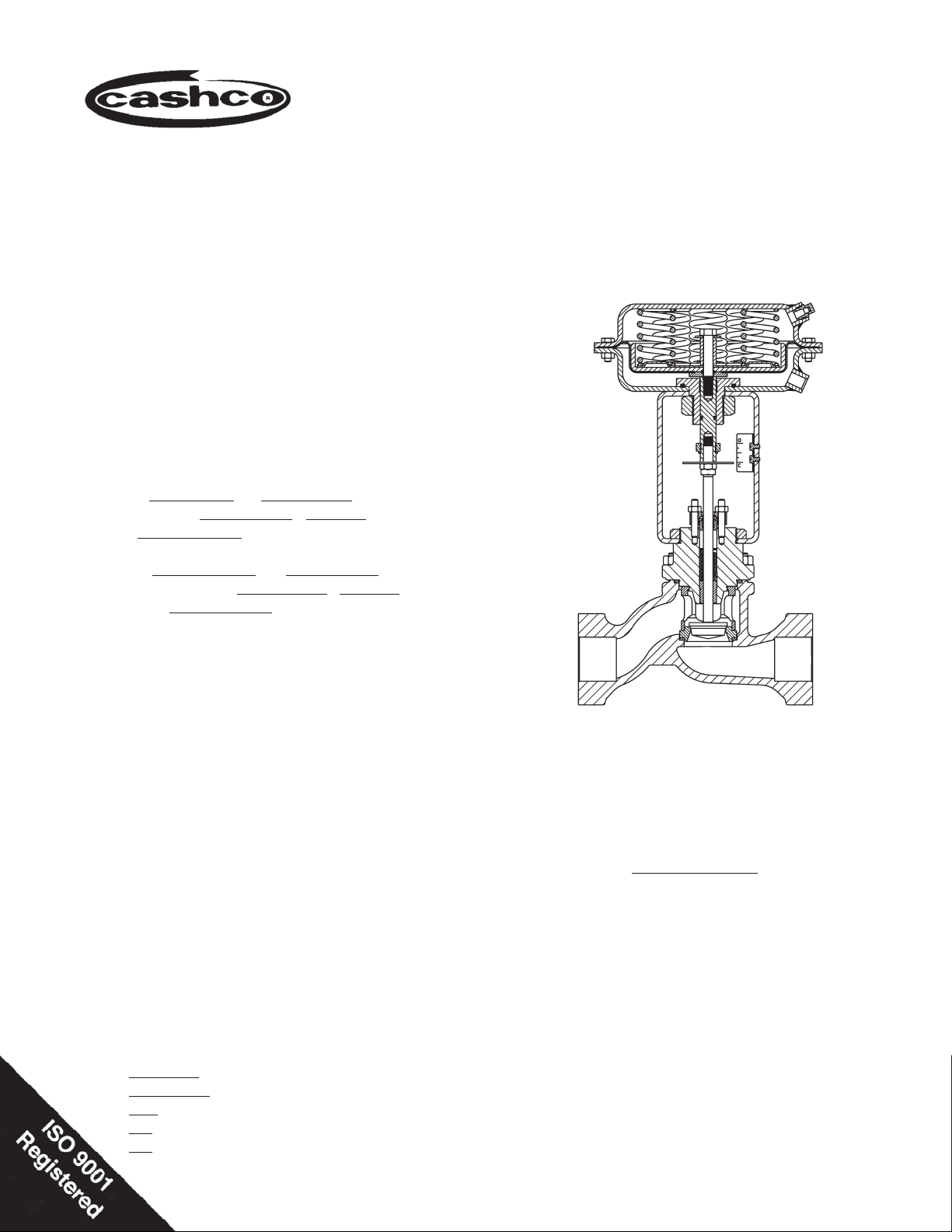

MODEL 964

GLOBE-STYLE

PNEUMATIC CONTROL VALVE UNIT

BODY IOM

SECTION l

I. DESCRIPTION AND SCOPE

The Model 964 is a pneumatically actuated, sliding

stem globe-style control valve. Sizes are 1/2",3/4",

1", 1-1/2", & 2". Available in Cast Iron and Cast Steel

body ma te ri als.

Failure position is determined by actuator for:

"D" = Direct action; on increasing air loading pressure,

the actuator stem extends. Fail-safe position is with

the stem retracted.

"R" = Reverse action; on increasing air loading pres-

sure, the actuator stem retracts. Fail-safe position is

with the stem extended.

IOM-964

12-13

The valve is designed primarily for general service

or utility applications such as steam, air, oil, gas and

water.

SECTION II

II. REFERENCES

Refer to Technical Bulletin 964-TB for complete

tech ni cal specifi cations of a Model 964 coupled with

either Cashco Actuator Model C27 or C53.

www.cashco.com/techbulletins/964.pdf

Refer to following Installation, Operation & Main te nance Manuals (IOM’s) for either actuator and/or

devices that maybe mounted to a Model 964:

Actuators: www.cashco.com/IOM/C27-C53.pdf

Positioners:

P/P: www.cashco.com/techbulletins/9540l.pdf

I/P: www.cashco.com/techbulletins/srd991.pdf

I/P: www.cashco.com/iom/PS2iom.pdf

Model 964

with ATO - FC Actuator

ABBREVIATIONS

ATC–FO – Air–to–Close, Fail Open

ATO–FC – Air–to–Open, Fail Close

CCW – Counter Clockwise

CW – Clockwise

D or DIR – Direct Acting

IAS – Instrument Air Supply

LOAD – Positioner Output Air Pressure

R or REV – Reverse Acting

SIG – Output Signal from Instrument

V – Vent

Page 2

SECTION III

CAUTION

For welded installations, all internal trim parts and

seals, must be removed from body prior to welding

into pipeline. The heat of fusion welding will dam age

non-metallic parts if not re moved. NOTE: This does

not apply to units equipped with extended pipe nip ples.

III. INSTALLATION

A. Orientation:

1. Recommended ori en ta tion when in stalled in

a hor i zon tal pipeline with the stem ver ti cal.

Valves may also be in stalled in ver ti cal pipe lines with stems hor i zon tal.

3. If pipe reducers are located before and/or after

the valve body, keep the reducers as close as

prac ti cal to the valve body; this is especially

important where the reducers are more than

one line size larger than the valve body size,

which is common in gaseous ser vice.

4. Clean the piping of all foreign debris, in clud ing

chips, weld scale, weld spatter, oil, grease,

sand or dirt prior to in stall ing the control valve.

This is an absolute re quire ment for valves

supplied with composition soft seats. System

start-up strain ers, for removal shortly after

initial start-up, are rec om mend ed.

5. Field hydrostatic testing the com plet ed piping

system to 1-1/2 x CWP in psig indicated on the

nameplate, including the 964, is ac cept able.

If hydro test pressure exceeds the 1-1/2 x

CWP limit, the 964 must be re moved for such

testing. Before pres sur iza tion, the valve plug

should be lifted from the seat if of ATO-FC

action. Tighten packing as re quired.

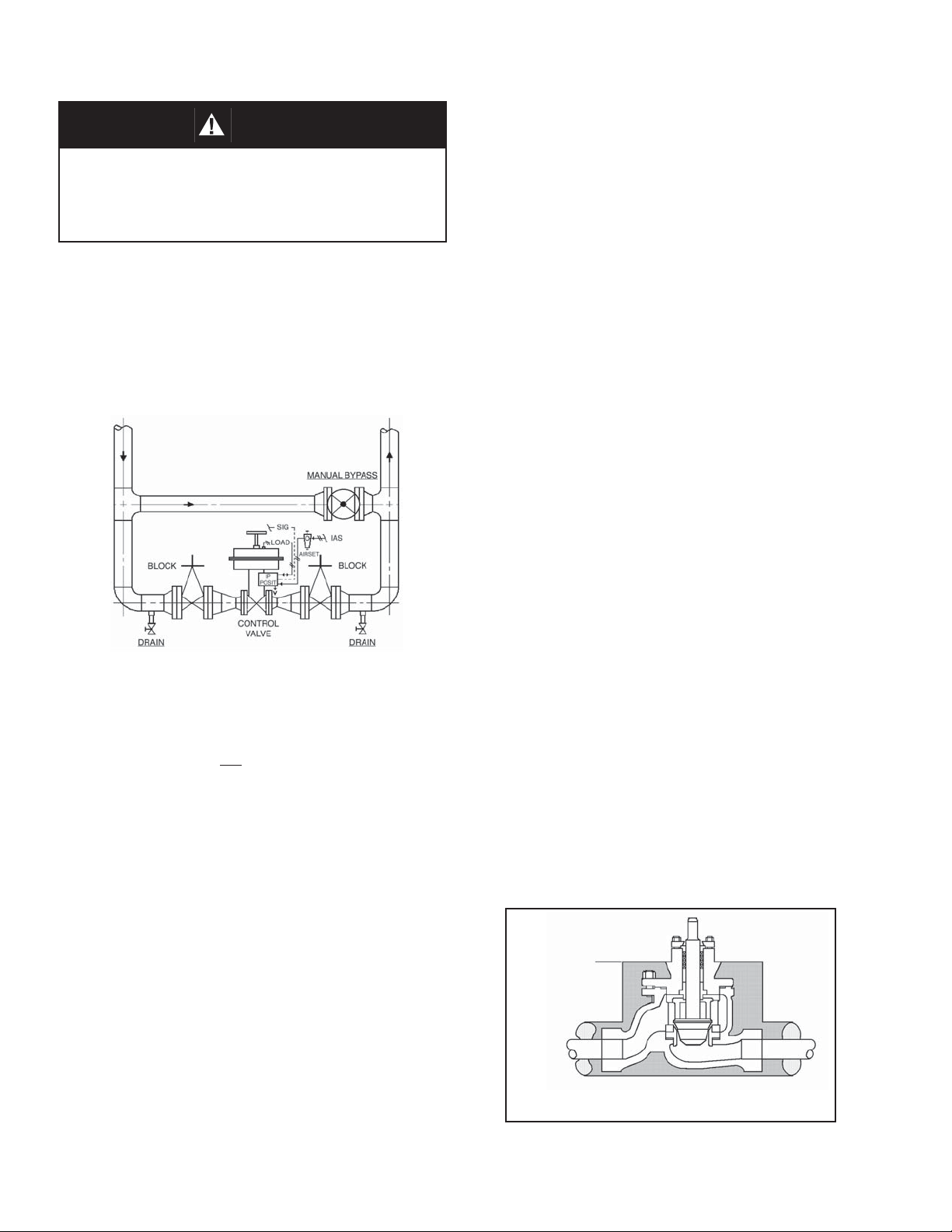

Figure 1: Typical Control Valve Station

2. Outdoors, all in stal la tions may be ori ent ed any

angle from hor i zon tal-to-vertical.

3. Valves are not recommended for in stal la tion

with the actuator oriented down wards..

B. Piping System:

1. It is recommended that the control valve unit

be in stalled with a double-block and bypass

as in di cat ed in Figure 1. This ar range ment is

rec om mend ed es pe cial ly where main te nance

will be done on the valve body while still installed in the pipeline.

2. Pipe unions are recommended for NPT

screwed or socket welded installations to al low

complete removal from sys tem. If re mov al

for main te nance is by cutting torch for socket

welded valves, leave suffi cient pipe nipple

space be tween the 964 body and the next

piping com po nent up or down stream to allow

socket weld couplings for re-in stal la tion.

6. In placing thread sealant on pipe ends prior

to en gage ment, ensure that excess ma te ri al

is removed and not allowed to enter the valve

upon start-up.

7. Flow Direction: Install so the fl ow direction

match es the arrow marked on the valve body.

8. For best performance, install in well drained

hor i zon tal pipe, properly trapped if a steam

service ap pli ca

tion.

9. Valves are not to be direct buried un der ground.

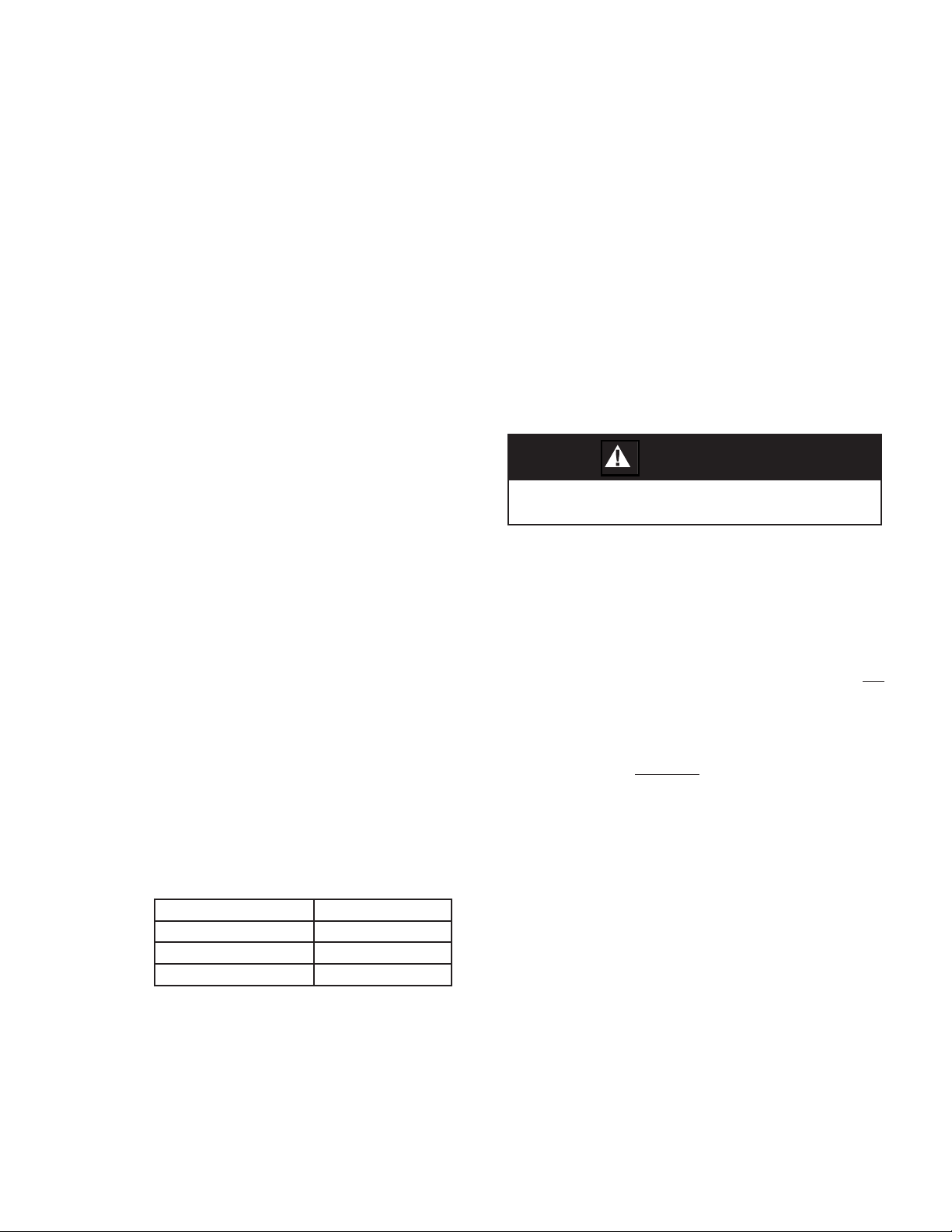

10. Insulation may be applied as in di cat ed in Figure 2. Drain age away from the packing area

must be ensured when fully in stalled, sealed

and lagged for outdoors in stal la tion.

Limit of

Bonnet

Insulation

Figure 2: Body Insulation

IOM-9642

Page 3

11. Undue piping stress/strain or bend ing

torques may not be trans mit ted thru the

valve body. One pipe (inlet or outlet) should

be an chored rig id ly for pip ing that is “hot” or

“cold” with respect to ambient tem per a ture;

the re main ing pipe (in let or out let) should

be sup port ed and guid ed to ensure uni di rec tion al ex pan sion/con trac tion.

C. Air Supply:

1. Use a desiccant dried, instrument quality

air supply. Such a supply is recommended

for outdoor installations, and is required in

areas of freezing weather conditions.

IV. START-UP

A. General:

1. Ensure that the Model 964 unit has been

prop er ly adjusted and cal i brat ed, in clud ing

the po si tion er, if in stalled.

2. Recommend startup to be in a “man u al”

mode. This pro ce dure assumes dou ble

block (iso la tion) and bypass valves for the

“control valve station”. See Fig ure 1.

3. Start with either of the two block valves

closed, with the other open. The bypass

valve should be closed. Pres sur ize sys tem,

if pos si ble/prac ti cal.

4. Back out the airset’s adjusting screw until

loose.

2. If air supply contains moisture and /or lubricating oil, the air should be fi ltered with

a coalescing type of fi lter prior to use in

stroking the actuator.

3. Failure to remove moisture will cause corrosion to the internals of the actuator casings.

4. Connections for the air supply are 1/4" female

NPT. Use a suitable pipe thread sealant

when installing the pipe or tube fi tting. DO

NOT allow sealant to enter the tube/pipe.

SECTION IV

CAUTION

DO NOT WALK AWAY AND LEAVE A MANUALLY CONTROLLED CONTROL VALVE UNATTENDED!

8. Confi rm that action of con trol ler and po si-

tion er - direct or reverse - are producing

the de sired re sponse in the con trol unit.

Con fi rm that the con trol valve “fail” po si tion

is as re quired.

9. Hereafter, the procedure as sumes that ac tu al

fl uid fl ow may be established. This may not

be practical / pos si ble in all cas es; if so, vary

procedure as re quired.

Always “heat” or “cool” down the system

pip ing SLOW LY by open ing the control valve

sta tion by pass valve in small in cre ments.

IOM-964

5. Turn on air supply pressure.

6. Adjust the air supply airset (fi l ter-reg u la tor)

to the proper lev el as in di cat ed as follows:

Bench Setting Airset Output

psig (Barg) psig (Barg)

5–15 (.34–1.0) 20 (1.4)

15–60 (1.0–4.1) 75 (5.2)

7. Place loop controller into “man u al” mode.

Vary setting from minimum - mid-range max i mum SIG output. Ob serve re sponse of

con trol valve unit to these chang es of input

SIG. The valve should fully stroke at the

vari a tion from min i mum SIG to max i mum

SIG; the mid-range SIG should have the

valve stem travel at/near 1/2 open.

10. With one of the control valve station block

valves still closed, and the loop con trol ler

still in “man u al” mode, open by pass valve

and vary fl ow rate man u al ly to ob serve the

re sponse of the con trol ler and control valve

unit to geth er.

11. Attempt to develop manual con trol of the

loop by opening/clos ing the man u al by pass

as re quired, or by manually con trol ling main stream fl ow as re quired.

12. When the control valve is partially open, crack

open slowly the closed block valve while

si mul ta neous ly clos ing the by pass valve.

Con tin ue this pro ce dure until the bypass is

closed and the block valves are both fully

open. The system is still under “man u

al”

3

Page 4

mode control, but all fl ow is pass ing through

the control valve.

13. Vary controller “manual” SIG output until

match ing the “au to mat ic” SIG output, then

V. MAINTENANCE

change the mode of the controller over to

“automatic”, and the loop will ex pe ri ence a

min i mum of upset con di tions, and will be in

au to mat ic control.

SECTION V

WARNING

SYSTEM UNDER PRES SURE. Prior to per form ing any

maintenance, isolate the valve/actuator from the sys tem

and relieve all pressure. Fail ure to do so could result in

personal injury.

A. General:

1. Maintenance procedures here in af ter are

based upon re mov al of the valve/ac tu a tor

unit from the pipe line where in stalled.

2. Owner should refer to Owner’s pro ce dures for

re mov al, handling and cleaning of non-re us able parts, i.e. gaskets, suitable sol vents, etc.

3. Valves supplied from the factory use a

gasket sealant, Federal Process Company,

PLS2, or equal. Owner may use such aids

provided the aids are com pat i ble with the

Owner’s fl uid.

4. All indicated Item Numbers that are with

re spect to the actuator assembly (AA) are

in pa ren the sis and un der scored; i.e (20).

All Item Num bers that are with respect to

the body assembly (BA) of a Model 964

are not un der scored; i.e. (32). Reference

with respect to the po si tion er is in double

parentheses; i.e. ((AP)).

5. Special care must be exhibited when

ro tat ing the stem (3) of the valve to

not mar that portion of the surface of

the stem (3) where it contacts with the

pack ing (6). To rotate the stem (3), use

the jam nuts (18) or grasp stem with softjawed pliers. NOTE: When using the jam

nuts (18) to rotate the stem (3), use the

upper jam nut to rotate the stem CW, and

the lower jam nut to rotate the stem CCW,

when viewed from above valve stem.

6. Hereafter, whenever text has the fol low ing

no ta tion, “(Note PA.)”, the fol low ing text is

to be ap plied;

“For ATO-FC reverse action units,

connect a temporary air source to the

actuator and pres sur ize to a level suf fi cient to initiate travel to ap prox i mate ly

mid-stroke.

7. Hereafter, whenever text has the fol low ing

no ta tion, “(Note RP.)”, the fol low ing text is

to be applied:

“For ATO-FC reverse action units, re lease all tem po rary air pressure.

B. Actuator Removal:

1. Secure the body (1) in a vise with the actuator as sem bly (AA) oriented ver ti cal ly. Place

matchmarks between the body (1) bon net

fl ange, the bonnet (2) fl ange, and the yoke

(3) to assist in fi nal ori en ta tion when the

body is dis as sem bled and/or the ac tu a tor

removed. If actuator has handwheel - see

Actuator IOM for removal instructions.

2. (Note PA.) Using blunt end tool, ham mer

rap the tool to loosen yoke nut (29) turning

CCW (viewed from above) ap prox i mate ly 2

rev o lu tions. Secure the ac tu a tor stem (6).

Loos en the stem jam nuts (18) by rotating

CW (viewed from above) one-at-a-time to

base of stem (3) threads.

3. Fully loosen any accessory de vic es that

are con nect ed to the stem (6) or (3) such

as ac ces so ry plate ((AP)) for po si tion

4. Loosen packing (6) by rotating nuts (15)

CCW 2-3 rev o lu tions. (Note RP.).

er.

IOM-9644

Page 5

NOTE: To fully disengage the actuator stem (6)

from the plug/stem (3) is a two-step pro ce dure.

Be aware of the valve’s stroke length as in di cat ed

on the name plate (40) before be gin ning dis en gage ment. During the dis en gage ment, mea sure

the dis tance ex tend ed, and stay at least 1/8" (3

mm) away from the full stroke length. Count and

record the number of rev o lu tions for each step in

the box below:

For Steps 5 and 6: Count the number of revolutions

to disengage plug/stem from actuator stem:

Step A. Step B.

TOTAL:

5. For ATO-FC Reverse Action Units:

a. (Note PA.)

b. Step A. Rotate plug/stem (3) CW (viewed

from above) to disengage the ac tu a tor

stem (6) from the plug/stem (3), while

holding the actuator stem (6). Record

the num ber of plug/stem rev o lu tions for

Step A above. When the dis en gage ment

reach es about 50% of full stroke trav el

Step A is com plet ed. (Note RP).

c. Step B. Support the actuator as sem-

bly (AA) from above. Fully loosen

yoke nut (29). Lift the actuator as sem bly (AA) up wards ap prox i mate ly

1/4"-3/8" (6-8 mm). Again, rotate plug/

stem (3) CW (viewed from above) to

dis en gage the ac tu a tor stem (6) from the

plug/stem (3) while holding the ac tu a tor

stem (6). Record the number of plug/

stem (3) rev o lu tions for Step B above.

This should allow the stems (6) (3) to

fully dis en gage.

NOTE: Take notice of the parts “dan gling

loosely” about the plug/stem (3), the order

of their lo ca tion and their proper orientation.

d. Fully raise the actuator assembly (AA)

from the valve body assembly (BA).

Re move cautiously to prevent dan gling

parts - position indicating washer (26),

ac ces so ry plate ((AP)), yoke nut (29) from fall ing.

6. For ATC-FO Direct Action Units:

a. Step A. Rotate plug/stem (3) CW (viewed

from above) to disengage the ac tu a tor

stem (6). Do not rotate the plug (3)

into the seat (11). Record the number

of plug/stem (3) rev o lu tions for Step

A above. When the dis en gage ment

reach es about 75% of full stroke travel,

Step A. is com plet ed.

b. Step B. Support the actuator as sem bly

(AA) from above. Fully loosen yoke nut

(29) and remove. Lift the actuator as sem bly (AA) upwards ap prox i mate ly 1/4" 3/8" (6-8 mm). Again, rotate plug/stem

(3) CW (viewed from above) to dis en gage the ac tu a tor stem (6) from the plug/

stem (3), while holding the actuator stem

(6). Record the number of plug/stem

rev o lu tions for Step B. This should allow the stems (6) (3) to fully disengage.

NOTE: Take notice of the parts “dangling

loosely” about the stem (3), the order of their

lo ca tion and their proper orientation.

c. Fully raise actuator assembly (AA) from

the valve body assembly (BA). Re move

cau tious ly to prevent dan gling parts – po si tion indicating washer (26), ac ces so ry

plate ((AP)), yoke nut (29) - from falling.

C. Actuator Replacement:

1. Secure body assembly (BA) in a vise with

the plug/stem (3) oriented ver ti cal ly. Push

plug/stem (3) down until the plug touches

the seating surface in the body.

2. Secure the actuator assembly (AA) from

above. Use matchmarks from B.1. previous

to assist with (BA) and (AA) alignment.

3. This procedure assumes that the bonnet (2)

has been bolted to the body (1), with stem

jam nuts (18) threaded on the plug/stem (3).

4. Lower actuator assembly (AA) until the plug/

stem (3) penetrates the opening in the yoke

(3). Re po si tion the “dangling parts” - yoke

nut (29), ac ces so ry plate ((AP)) or in di cat ing washer (26) - over threaded end of plug/

stem (3). Con tin ue to lower the actuator

assembly (AA) until there is ap prox i mate ly

1/4" (6 mm) space between the two stems

(6) (3).

IOM-964

5

Page 6

5. For ATC-FO: Connect a temporary air supply

hose that has an ad just able airset with gauge

to the ac tu a tor inlet to allow pres sur iza tion.

Slowly pressurize actuator to bring the ac tu a tor

stem (6) to with in 1/8" (3 mm) of reaching the

plug/stem (3).

6. With hand lift plug/stem (3) up to touch ac tu a tor

stem (6). Rotate plug/stem (3) CCW (viewed

from above) to en gage with ac tu a tor stem (6).

Use the total number of revs en gage ment

recorded in Step V.B. as the guide to control

engagement of the stems (6) (3). While en gag ing, rotate yoke nut (29) as able to help

stabilize top works, continue to pres sur ize the

ac tu a tor in 2-3 psi (.15-.20 Bar) in cre ments

in an al ter nat ing se quence with the distance

en gaged until the total num ber of revs engaged

is reached.

jam nuts (18) by rotating CCW (viewed from

plug end) while se cur ing the actuator stem

(6) with soft-jawed pliers.

8. Loosen stem packing (6) by turn ing nuts (15)

CCW to a point just short of dis en gage ment

from the threads.

9. While securing the actuator stem (6) by softjawed pliers, rotate the valve stem as sem bly

(3) CCW (viewed from plug end). Record the

number of rev o lu tions of dis en gage ment in

the box below:

Number of revolutions to disengage plug/stem as-

sembly from actuator stem.

10. Remove packing fl ange nuts (15) with CCW

ro ta tion.

7. Hand-tighten yoke nut (29) until fully po si tioned

with the yoke (3) sitting on the bonnet (2).

8. Secure “dangling parts” - ac ces so ry plate

((AP)) and indicating washer (26) - to ac tu a tor

stem (6) with stem jam nuts (18).

9. Ham mer rap yoke nut (29) until tight. (Release

tem po rary air source.)

D. Trim Removal and Re place ment:

1. Secure body (1) assembly (BA) in a vise with

actuator assembly (AA) di rect ed up wards.

Place match marks be tween the body (1) and

the bonnet (2).

2. Secure the actuator assembly (AA) with an

over head support capable of ver ti cal lift.

3. (Note PA.) Loosen all bonnet stud nuts (17)

(four nuts for 1/2" thru 1-1/2" sizes; six nuts

for 2" size).

4. Ensure actuator support is “taut”; i.e. hold ing

weight of actuator.

11. Partially withdraw plug/stem as sem bly (3).

Re move position in di ca ting washer (26), both

jam nuts (18), packing fl ange (4), pack ing

follower (5), and ac ces so ry plate ((AP)), if

installed.

12. Fully withdraw stem/plug as sem bly (3). For

1/2" thru 1-1/2" sizes, cage (10) may have

come loose see Step 6 above.

13. Using a sharp, hooked-end, pick-type tool,

hook and pull the packing rings (6) up and out

of the bonnet’s (2) packing bore individually.

Discard old packing (6).

CAUTION

Take extreme care to not mar internal wall surface of the

bonnet (2).

14. Using a sharp pointed tool, remove packing

washer (23) and packing spring (24).

15. Solvent clean all loose parts with suitable

solvent and let dry.

5. Remove all bonnet bolting nuts (17).

6. Lift the actuator assembly (AA), to geth er with

bon net (2) and stem as sem bly (3) vertically

out of the valve body (1). Lay the topworks

assembly down onto a work bench horizontally.

For 1/2" - 1-1/2" sizes, re move the cage (10)

and seat ring (11) from the body (1) cavity.

7. From the top works as sem bly, loosen the stem

16. For SIZES 1/2” thru 1-1/2", inspect guide

bushing (8) in-place, as the bushing (8) is

press fi t into the bonnet (2). If worn badly

or “scored”:

a. Remove bonnet (2) by removing yoke

nut (29).

b. Hydraulically press guide bushing (8)

“out” of bonnet (2); press “in” new

guide bushing (8).

c. Reinstall bonnet (2) back thru yoke (3),

and secure with yoke nut (29).

IOM-9646

Page 7

17. For SIZE 2", inspect guide bush ing (8) in-

place, as the bush ing (8) is press fi t into the

bonnet (2). If worn or “scored:

a. Remove bonnet (2) by re mov ing yoke nut

(29).

b. Remove retaining ring (9).

c. Hydraulically press guide bush ing (8)

“out”; press “in” new guide bushing (8)

into bon net (2).

d. Replace retaining ring (9).

e. Reinstall bonnet (2) back to geth er with ac-

tu a tor yoke (3), securing with yoke nut (29).

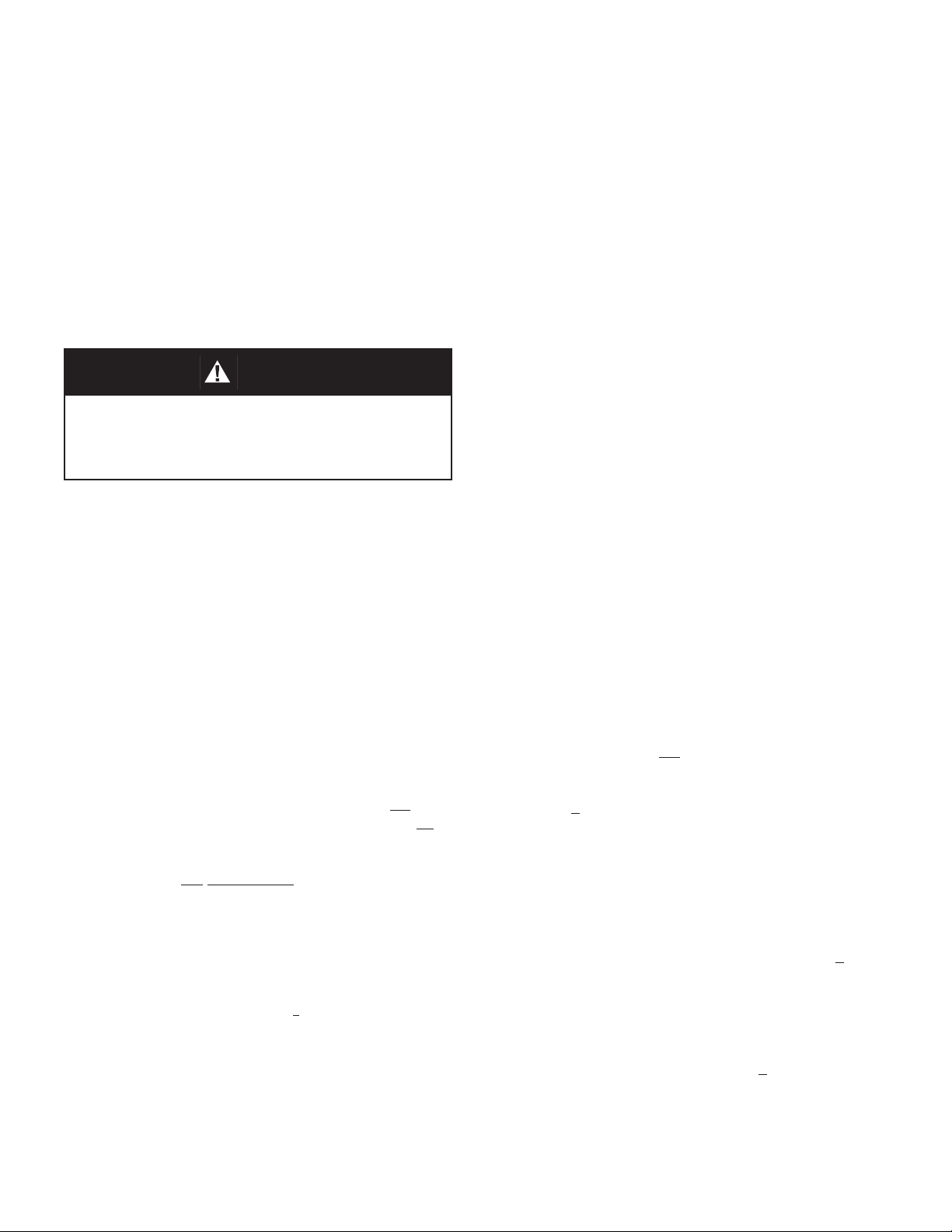

18. Examine cage (10), seat ring (11), plug/stem

(3) seat insert (27), seat retainer (28) and

gasket (13) for wear. Re place all worn parts.

Refer to Figure 3 for correct orientation of

composition seat parts.

19. Examine stem (3) in critical fi nish zone where

contact is made with the packing (6). It is desirable to restore the surface of the stem (3)

to a #8 Ra μ-in surface fi nish; metal removal

should not exceed 0.001-inch material. A

deeply scratched or pitted stem (3) should

be replaced.

25. For SIZES 1/2" - 1-1/2", lower packing spring

(24) into bonnet (2) pack ing bore.

For SIZE 2", fi rst slide packing stop (7) into

bonnet (2) packing bore followed by the packing spring (24).

26. Lower packing washer (23) into bonnet (2)

packing bore. Ensure that wash er (23) is

rest ing fl at on the packing spring (24).

27. Carefully place lower adapter (6.3) of packing ring set (6) over stem’s (3) threaded end,

properly oriented. Using the packing follower

(5), push the lower adapter into the bonnet’s

(2) packing bore.

20. Plug head of stem (3) assembly for metal

seated design may be hand lapped using

suitable lapping com pound. If hand lap ping

will not restore surface fi nish to an ac cept able

de gree, re place ment of stem (3) as sem bly

and seat ring (11) is rec om mend ed.

21. Examine the inner surface of the bonnet’s

(2) packing bore. It is desirable to restore

the surface of stuffi ng box to a #16 Ra μ-in

surface fi nish; metal removal should not ex-

ceed 0.001-inch material. If inner surface is

deeply scratched or pitted, bonnet (2) should

be replaced.

22. Examine packing follower (5) for corrosion.

Replace if signifi cantly corroded. Remove

follower bushing (25) from inside of packing

follower (5) and replace with new.

23. Remove gasket (12) (13), clean gas ket fac ing

sur fac es and replace with new gas ket (12) (13).

24. Place seat ring (11) [and cage (10) - for sizes

1/2" - 1-1/2"] into the body (1) cavity. Insert

the threaded end of stem (3) thru bonnet (2)

until it ap pears thru the top side. Place bonnet on body. (NOTE: The cage for 2" size

is integral with bonnet (2).)

Packing Orientation

28. Carefully place a packing ring (6.2) properly

oriented over the stem’s (3) end and push

into the packing bore similar to the adapter

(6.3). Repeat process for balance of rings.

29. Carefully place upper adapter (6.1) over

threaded end of stem (3).

30. Slide packing follower (5) with new follower

bushing (25) over threaded end of stem.

31. Place packing fl ange (4) over end of stem

(3) and over packing studs (14). Install both

jam nuts (18) on stem and rotate to bottom

of stem threads.

32. Slide indicating washer(26) and accessory

plate ((AP)), if installed, over threaded end

of stem (3).

33. Engage plug/stem (3) into ac tu a tor stem

(6) per the same number of rev o lu tions

recorded per D. Step 9.

34. Rotate both jam nuts (18) up tight against

position in di ca ting washer (26).

IOM-964

7

Page 8

35. Tighten packing nuts (15) evenly in ½ revolution increments, until the packing fl ange (4)

is resting evenly on the upper edge of the

bonnet (2) at the packing box. Snug both

nuts (15) tightly.

36. Raise actuator assembly (AA). (Note RP.)

Lower into body (1) over bonnet studs/bolts

(16). Align with match marks.

37. For ATO-FC action units, wiggle the ac tu a tor

as sem bly (AA) to assist in align ment.

38. For ATC-FO action units, pres sur ize ac tu a tor

to the “high er” number of the bench set range

in di cat ed on nameplate (12) plus 2 psig (.14

Barg); for 5-15 psig (.34-1.03 Barg) bench

setting, pres sur ize to 17 psig (1.17 Barg).

VI. CALIBRATION

This should “lift” the bonnet (2) and “seat”

the plug (3) fi rmly into the seat ring (11) for

align ment pur pos es. Wiggle the ac tu a tor

as sem bly (AA) to assist in align ment.

39. Wrench-tighten the bonnet bolt ing (16) (17) in

an al ter nat ing cross-pat tern in 1/4 rev o lu tion

in cre ments. Torque bonnet bolt ing to 30-35

ft/lbs (40-47 N-M) for sizes 1/2" - 1-1/2" , and

50-55 ft/lbs (66-73 N-M) for size 2"

40. For ATC-FO action units, release ac tu a tor

pres sure.

41. Hammer rap yoke nut (29) tight.

42. Calibrate unit per Section VI.

SECTION VI

A. General:

1. This section only covers cal i bra tion of the

control valve with Actuator Models C27/C53.

2. Positioner, if in stalled, requires ref er ence to

the spe cifi c positioner mod el IOM for prop er

cal i bra tion pro ce dure.

3. All indicated items numbers that are with re spect to IOM-C27-C53 will be in pa ren the sis

and un der scored; i.e. (20); those that reference

the po si tion er IOM will be in double paranthesis; i.e. ((AP)). All item numbers that are with

respect to this IOM-964 are not un der scored;

i.e. (3).

B. Procedure - Reverse Action, ATO-FC:

1. Reference the name plate (40) at tached to

the ac tu a tor yoke (3). De ter mine the bench

set ting of the in stalled range springs (10) from

the name plate (40); i.e. 5-15 psig (.34 -1.0

Barg), or 15-60 psig (1-4.1 Barg).

2. Connect a temporary air supply with an in-line

ad just able airset regulator and gauge to the

lower actuator con nec tion. See Section IV. A.

6. for appropriate supply pressure. DO NOT

LOAD with any air pressure at this point.

3. To determine when stem/plug (3) begins to

lift out of the seat, touch the stem above the

packing studs with one fi nger. (Stem will begin

to move when actuator pressure exceeds

the spring load.)

4. Slowly pressurize the ac tu a tor to a pres sure

equal to the lower pres sure lev el of the bench

setting; i.e. for a 5-15 psig (.34 -1.0 Barg)

range, set pressure at 5 psig (.34 Barg). Take

note of pressure reading when the stem fi rst

begins to move.

5. If the loading pressure for the start of stem

movement is below the lower end of the

desired bench setting, then the com bined

stem (3, 6) length is too short.

a. Rotate both jam nuts (18) down to base of

threads on stem (3) and tighten together.

b. Increase pressure in the actuator to

approximately mid range of the bench

setting.

c. Rotate upper jam nut CW to increase

the combined stem length. DO NOT

allow actuator stem (6) to rotate in the

actuator.

d. Rotate upper jam nut CCW to hold indi-

cating washer (26) up against stem (6).

e. Release all pressure from the actuator

and repeat Step 4 previous.

6. If the loading pressure for the start of stem

movement is above the lower end of the

desired bench setting, then the com bined

stem (3, 6) length is too long.

a. Rotate both jam nuts (18) down to base of

threads on stem (3) and tighten together.

IOM-9648

Page 9

b. Increase pressure in the actuator to ap-

proximately mid range of the bench setting.

c. Rotate lower jam nut CCW to shorten the

combined stem length. DO NOT allow

actuator stem (6) to rotate in the actuator.

d. Rotate upper jam nut CCW to hold indicat-

ing washer (26) up against stem (6).

e. Release all pressure from the actuator

and repeat Step 4 previous.

7. After the opening set point pressure has been

established, rotate lower jam nut (18) CCW

up tight under the upper jam nut.

8. Release all pressure from the actuator.

6. for appropriate supply pressure. DO NOT

LOAD with any air pressure at this point.

3. To determine when stem/plug (3) makes

contact with the seat and travel stops, touch

the stem above the packing studs with one

fi nger. (Stem movement will stop when the

plug engages the seat.)

4. Slowly pressurize the ac tu a tor to a pres sure

equal to the upper pres sure lev el of the bench

setting; i.e. for a 5-15 psig (.34 -1.0 Barg)

range, set pressure at 15 psig (1.0 Barg).

Take note of the pressure reading when stem

travel actually stops.

9. Examine the location of the in di ca ting washer

(26) to the "C" mark on the in di ca tor plate

(23), mak ing sure to use the “top edge” of the

in di ca ting washer (26) as the ref er ence point.

Adjust indicator plate as needed.

10. Increase pressure in the actuator until the

indicating washer (26) is in alignment with the

"O" mark on the indicator plate.

11. To limit the up travel at the desired stroke

length, rotate the travel stop nut (52) CW and

secure to bottom of the attachment hub (4).

NOTE: Secure the actuator stem (6) by the

fl ats when rotating the travel stop nut.

NOTE: “Stroke” length is in di cat ed on the

name plate (40), and is the dis tance be tween

the “C” and “O” marks of the indicator plate

(23).

NOTE: The proper calibration of the ac tu a tor/

valve unit will occur when at the lower pressure

level of bench setting, the valve plug (3) will

just begin to travel from the "C" po si tion. At the

upper level of the bench setting, the actuator

pressure should be within ± 8% of the upper

bench setting for the designed stroke length.

12. Release all pres sure from actuator.

C. Procedure - Direct Action, ATC-FO:

1. Reference the name plate (40) at tached to

the ac tu a tor yoke (3). De ter mine the bench

set ting of the in stalled range springs (10) from

the name plate (40); i.e. 5-15 psig (.34 -1.0

Barg), or 15-60 psig (1-4.1 Barg).

5. If the loading pressure, when the stem movement stops, is below the upper end of the

desired bench setting, then the com bined

stem (3, 6) length is too long.

a. Rotate both jam nuts (18) down to base of

threads on stem (3) and tighten together.

b. Decrease pressure in the actuator to

approximately mid range of the bench

setting.

c. Rotate lower jam nut CCW to shorten the

combined stem length. DO NOT allow

actuator stem (6) to rotate in the actuator.

d. Rotate upper jam nut CW to hold indicat-

ing washer (26) up against stem (6).

e. Release all pressure from the actuator

and repeat Step 4 previous.

6. If the loading pressure when the stem move-

ment stops is above the upper end of the

desired bench setting, then the com bined

stem (3, 6) length is too short.

a. Rotate both jam nuts (18) down to base of

threads on stem (3) and tighten together.

b. Decrease pressure in the actuator to

approximately mid range of the bench

setting.

c. Rotate upper jam nut CW to increase the

combined stem length. DO NOT allow

actuator stem (6) to rotate in the actuator.

d. Rotate upper jam nut CCW to hold indicat-

ing washer (26) up against stem (6).

e. Release all pressure from the actuator

and repeat Step 4 previous.

7. After the closed set point pressure has been

established, rotate lower jam nut (18) CCW

up tight under the upper jam nut.

2. Connect a temporary air supply with an in-line

ad just able airset regulator and gauge to the

upper actuator con nec tion. See Section IV. A.

IOM-964

8. Increase pressure in the actuator to the upper

pressure level of the bench setting.

9

Page 10

9. Observe the location of the in di ca ting washer

(26) to the "C" mark on the in di ca tor plate

(23), mak ing sure to use the “top edge” of

the in di ca ting washer (26) as the ref er ence

point. Adjust indicator plate as needed.

10. Slowly release air pressure in the actuator

until the indicating washer (26) is in alignment

with the "O" mark on the indicator plate.

11. To limit the up travel at the desired stroke

length, rotate travel stop nut (52) CW and

secure to bottom of the attachment hub (4).

NOTE: Secure the actuator stem (6) by the

fl ats when rotating the travel stop nut.

NOTE: “Stroke” length is in di cat ed on the

name plate (40), and is the dis tance be tween

the “C” and “O” marks of the indicator plate

(23).

NOTE: The proper calibration of the ac tu a tor/

valve unit will occur when at the upper pressure level of bench setting, the valve plug (3)

will be in the "C" po si tion. At the lower level

of bench set the actuator pressure should

be within ± 8% of the lower bench setting

for the designed stroke length.

12. Release all pres sure from actuator.

IOM-96410

Page 11

SECTION VII

VII. TROUBLE - SHOOTING GUIDE

1. Valve is “jumpy” in stroking.

Possible Causes Remedies

A. Excess packing friction. A1.

B. Installed backwards. B. Install per fl ow arrow.

2. Valve makes “screeching” noise.

Possible Causes Remedies

A. Excess pressure drop. A. Bring pressure drop within design limits.

B. Guide bushing wear. B. Re place guide bushing.

C. Misalignment. C. Realign body-stem-actuator.

3. Valve exhibits “excess” vibration.

Possible Causes Remedies

A. Excess pressure drop. A. Bring pres sure drop within design limits.

B. Guide bushing wear. B. Re place guide bushing.

C. Excessive cavitation in liquid service. C1.

D. High outlet velocity. D1.

Realign body - stem - actuator.

A2.

Packing follower too tight for optional packing designs.

A3.

Install positioner.

A4.

Increase bench set by changing to stiffer actuator

range spring. Will require positioner if not installed.

May require different airset.

Change operation parameters to relieve causes of

C2.

cavitation.

Replace valve with valve equipped for cavi ta tional control.

Re duce fl ow rate and/or pressure drop.

D2.

Use multiple valves in series or parallel.

D3.

Increase outlet pipe size.

4. Valve exhibits “excess” seat leakage.

Possible Causes Remedies

A. Excess pressure drop. A. Re duce pres sure drop conditions.

B. Improper actuator bench setting. B1.

C. Metal seat design instead of composition seat

design.

D. Excess wear. D1.

E. Misalignment. E. Realign body - stem - actuator.

F. Composition seat failure. F1.

G. Seat ring gasket failure. G. Replace seat ring gasket.

IOM-964

Cali brate actuator-to-valve.

B2.

Assure proper engagement of actuator stem-to-valve

stem. Adjust as calibration dictates.

C. Convert valve to composition seat design.

Oversized valve op er at ing too close to seat; go to re-

D2.

duced trim.

D3.

Incorporate stellite trim.

D4.

Remove particulate.

Possible excess cavitation in liquid service. Change

D5.

operation parameters.

Re-lap plug-seat surface.

Replace soft seat.

F2.

Remove "dirty" portion of fl uid causing failure.

11

Page 12

5. Premature packing leakage.

Possible Causes Remedies

A.

Over-temperature. A1.

Bring process temperature to 450°F (232°C) or less.

A2.

Remove in su la tion along bonnet; al low di rect con tact

with ambient air.

B.

Misalignment. B. Realign body - stem - actuator.

C.

Wear. C1.

D.

Improper design for applied service. D1. Install alternate packing design.

Remove dirt/grit from fl uid.

C2.

Reduce cyclic travel.

6. Bonnet gasket leaking.

Possible Causes Remedies

A.

Improper bonnet bolting draw down.

A1.

Replace gasket and draw down bolting evenly in a

cross-pattern.

7. Body fl ange leakage.

Possible Causes Remedies

A.

Over-tightening fl ange bolting.

A1.

Loosen bolting, replace gasket, reinstall new fl ange

bolting.

A2.

Replace warped fl ang es.

B.

Improper pipe supports and anchors.

B.

Provide piping anchors and guides at control valve station. Restrain bending movements.

IOM-96412

Page 13

SECTION VIII

VIII. ORDERING INFORMATION

NEW REPLACEMENT UNIT vs PARTS "KIT" FOR FIELD REPAIR

To obtain a quotation or place an order, please retrieve the Serial Number and Product Code that was stamped

on the metal name plate and attached to the unit. This information can also be found on the Bill of Material

("BOM"), a parts list that was provided when unit was originally shipped. (Serial Number typically 6 digits).

Product Code typical format as follows: (last digit is alpha character that refl ects revision level for the product).

–

NEW REPLACEMENT UNIT:

Contact your local Cashco, Inc., Sales Rep re sen ta tive with the Serial Number and Product code.

With this information they can provide a quotation

for a new unit including a complete description,

price and availability.

CAUTION

Do not attempt to alter the original construction of any

unit without assistance and approval from the factory. All

purposed changes will require a new name plate with appropriate ratings and new product code to accommodate

the recommended part(s) changes.

–

7

PARTS "KIT" for FIELD REPAIR:

Contact your local Cashco, Inc., Sales Rep re sen ta tive with the Serial Number and Product code.

Identify the parts and the quantity required to repair

the unit from the "BOM" sheet that was provided

when unit was originally shipped.

NOTE: Those part numbers that have a quantity indicated

under "Spare Parts" in column "A” refl ect minimum

parts required for inspection and rebuild, - "Soft

Goods Kit". Those in column “B” include minimum

trim replacement parts needed plus those "Soft

Goods" parts from column "A".

If the "BOM" is not available, refer to the crosssectional drawings included in this manual for part

identifi cation and selection.

A Local Sales Representative will provide quotation

for appropriate Kit Number, Price and Availability.

NOTES

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be

construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to

modify or improve the designs or specifi cations of such product at any time without notice.

Cashco, Inc. does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any

Cashco, Inc. product remains solely with the purchaser.

IOM-964

13

Page 14

1/2"–1-1/2" Sizes MODEL 964

Figure 3: Composition Seat Ar range ment

IOM-96414

Page 15

2" Size MODEL 964

IOM-964

Item No. De scrip tion

1 Body

2 Bonnet

3 Plug & Stem Subassembly ‡

4 Packing Flange

5 Packing Follower

6 Packing ‡

7 Packing Stop (2" Size only)

8 Guide Bushing

9 Retaining Ring (2" Size only)

10 Cage

11 Seat Ring

12 Gasket - Body ‡

13 Gasket - Seat Ring ‡

Item No. De scrip tion

14 Packing Flange Stud

15 Packing Flange Nut

16 Studs - Body

17 Stud Nuts

18 Jam Nuts

23 Packing Washer

24 Packing Spring

25 Packing Follower (Bushing)

26 Indicating Washer

27 Seat Insert ‡

28 Seat Retainer

29 Yoke Nut

‡ Recommended replacement parts.

15

Page 16

Cashco, Inc.

P.O. Box 6

Ellsworth, KS 67439-0006

PH (785) 472-4461

Fax. # (785) 472-3539

www.cashco.com

email: sales@cashco.com

Printed in U.S.A. 964-IOM

Cashco GmbH

Handwerkerstrasse 15

15366 Hoppegarten, Germany

PH +49 3342 4243135

Fax. No. +49 3342 4243136

www.cashco.com

Email: germany@cashco.com

Cashco do Brasil, Ltda.

Al.Venus, 340

Indaiatuba - Sao Paulo, Brazil

PH +55 11 99677 7177

Fax. No.

www.cashco.com

Email: brazil@cashco.com

Loading...

Loading...