Page 1

INSTALLATION, OPERATION & MAINTENANCE MANUAL (IOM)

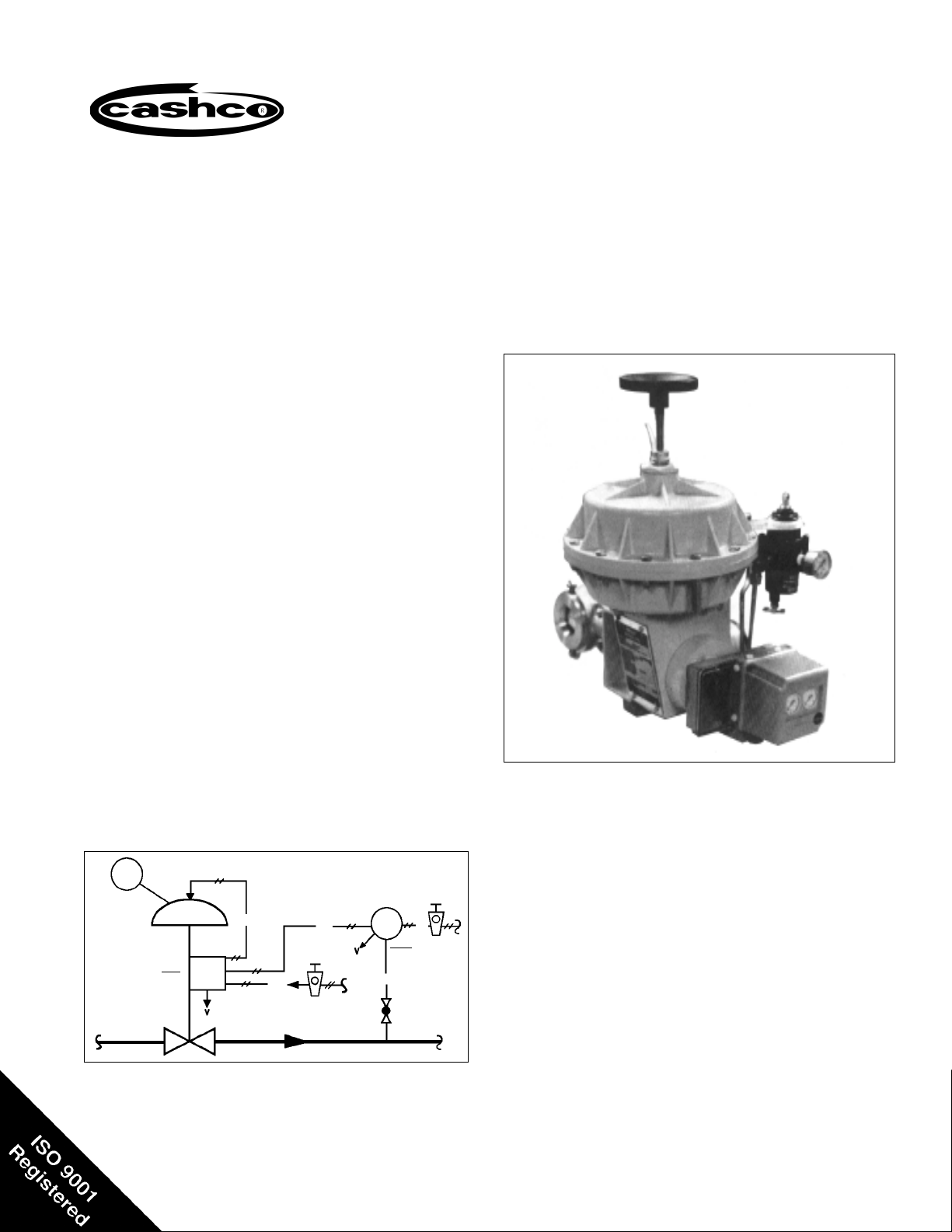

MODEL 9540R

P/P - PNEUMATIC POSITIONER FOR ROTARY VALVES

I. DESCRIPTION AND SCOPE

Model 9540R is a single acting, compact, force-balance, pneumatic positioner used together with a

rotary motion adapter baseplate for 90° rotary control

valves. This positioner is utilized to characterize the

relationship between valve stem position and the

system’s control signal. This design is only suitable for

nominal 3-15 psig (.21-1.0 Barg) input signals, or split

range variations thereof.

IOM-9540R

06-03

SECTION I

Each unit comes complete with a set of built-in gauges

within the internals, and a visual stem position indicator; the cover includes a clear see-thru panel to

monitor gauges. Gauges monitor input “SIG” and

output “LOAD”.

The Model 9540R P/P positioner may be utilized as an

alternate to the standard Model 9000R rotary P/P

positioner, with the following current Cashco product

models:

Ranger QCT

Premier EZO

Premier (unlined)

PCV

5-13 psig

SIG

15-3 psig

PC

REV.

PROCESS

P2 = 100 psig

IAS

P1 = 500 psig

3-15 psig

DIR.

ATO-FC

P/P

LOAD

IAS

Figure 1: Typical Pressure Reducing Pneumatic

Control Loop – PCV with P/P Positioner

20 psig

Model 9540R Mounted on a

Cashco Ranger QCT Control Valve

IAS – Instrument Air Supply

PC – Pressure Controller

PCV – Pressure Control Valve

ATO-FC – Air-to-Open, Fail Close

ATC-FO – Air-to-Close, Fail Open

P/P – Pneumatic Input/Pneumatic Output

DIR – Direct Acting

REV– Reverse Acting

SIG – Controller Output Signal

V – Vent

CW – Clockwise Rotation

CCW – Counter-Clockwise Rotation

Page 2

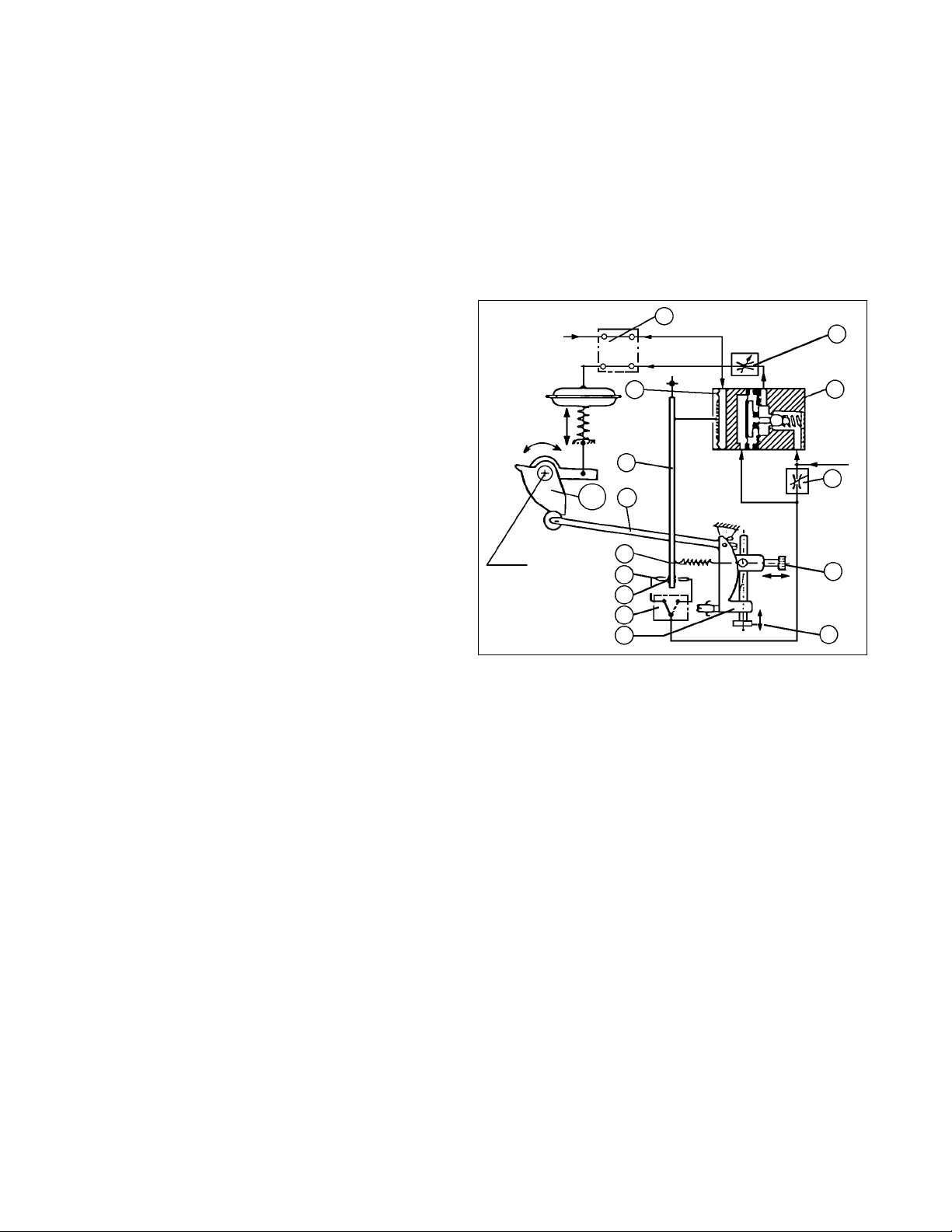

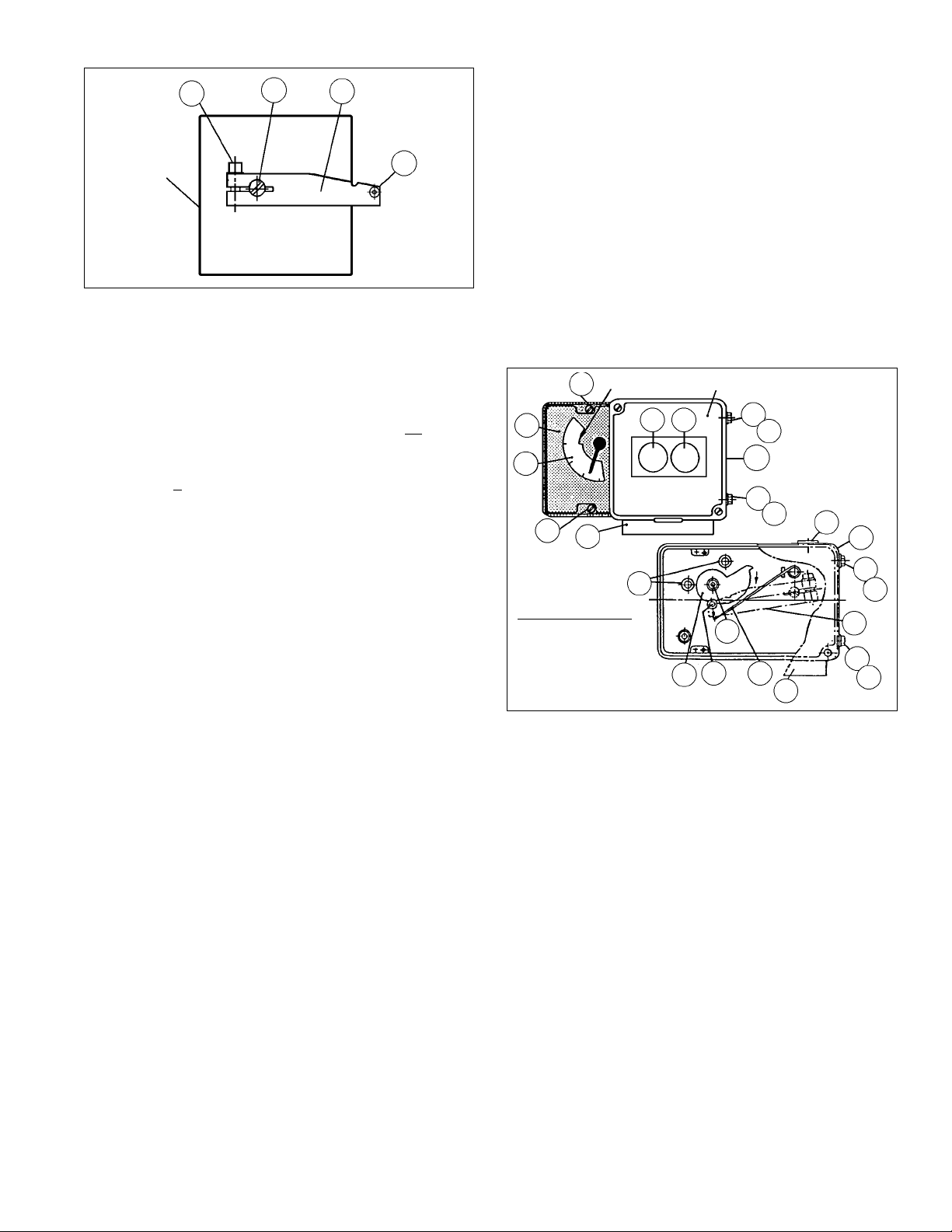

II. METHOD OF OPERATION (See Figure 2)

The positioner operates with the force balance

principle: the input signal “SIG” (3-15 psig) acts on the

input diaphragm (50). The stroke of the input

diaphragm is transferred to the flapper lever (38). The

resulting movement of the flapper varies the dynamic

pressure at the nozzle (51). This pressure acts on the

amplifier (53) and the change in output pressure

causes a movement of the valve’s rotary stem.

The rotary movement is back fed from the valve stem

(55), thru a characterization cam (24), to the feedback

lever (13) of the positioner, and transferred to the

stroke factor lever (19). The stroke factor lever (19) is

connected to the flapper lever (38) by means of a

range spring (41).

SECTION II

The normal factor set position of the bypass switch (3)

is “EIN” (ON) (pointer at 6 o’clock), and the positioner

will be operational. If the positioner bypass switch (3)

is set to the “AUS” (OFF) position (pointer at 9 o’clock),

the input signal “SIG” is supplied direct to the actuator;

i.e. the positioner is only practical for control valves

where the positioner action is “Direct” and the actuator

bench range is approximately equal to the 3-15 psig

“SIG”. Use of bench ranges with upper limits greater

than 15 psig will cause the control valve to not be able

to fully stroke when bypassed.

3

SIG

"LOAD"

Y

50

44

53

A force balance is created on the flapper lever (38)

when the force generated by the input diaphragm (50)

balances with the counter-force produced on the range

spring (41). This ensures that the valve stem position

is always characterized to the input signal.

Dynamic matching to the actuator (sensitivity, stability) is factory set by means of the throttle screw (42)

and the damping throttles (44). The stroke range and

zero are set by means of the stroke factor thumbscrew

(40) and the zero thumbscrew (39). The changeover

plate (15) is used to set either an increasing or

decreasing output pressure for an increasing input

signal, i.e. direct or reverse acting.

III. MOUNTING TO SPRING DIAPHRAGM

ACTUATORS

A. The following text applies to the field mounting of

a positioner to a valve originally not supplied with

a shaft-end positioner. See Appendix A to remove

9000R.

B. Mounting Kit:

1. A factory-supplied field mounting kit must

be obtained. Request “Model 9540R P/P

Field Installation Kit” (FIK) and indicate the

following:

Figure 2: Single-Acting Positioner Functional Diagram

SECTION III

Travel

38

24

13

Valve

Stem

41

51

52

N

15

19

U

e. Desired characteristic; i.e. =%, linear

f. ATO-FC or ATC-FO action.

2. An airset with gauge is required. Request

separately from positioner KIT.

3. If a positioner indicating switch (by Bettis or

Proximity Controls) is shaft-end-mounted, the

use of the position switch(es) must be abandoned or replaced with probe-type proximity

switch(es) (“Go” Series 70) mounted on the

yoke. NOTE:

These units are available on

1” – 4” Rangers and 3” – 4” Premiers only.

C. Mounting Side:

"IAS"

42

39

40

a. Unit’s serial number

b. Product model; i.e. Ranger, Premier, or

Premier EZO

c. Valve body size

d. Actuator bench range

When viewed from the valve stem end, with the

actuator casing defined as upwards (above stem),

the position indication portion should be to the

“left”, and the positioner section should be to the

“right’.

IOM-9540R2

Page 3

D. Existing Control Valve Modifications:

1. Refer to IOM-48 or IOM-148 for instructions

for the rotary actuators used on Ranger QCT,

Premier EZO and Premier (unlined).

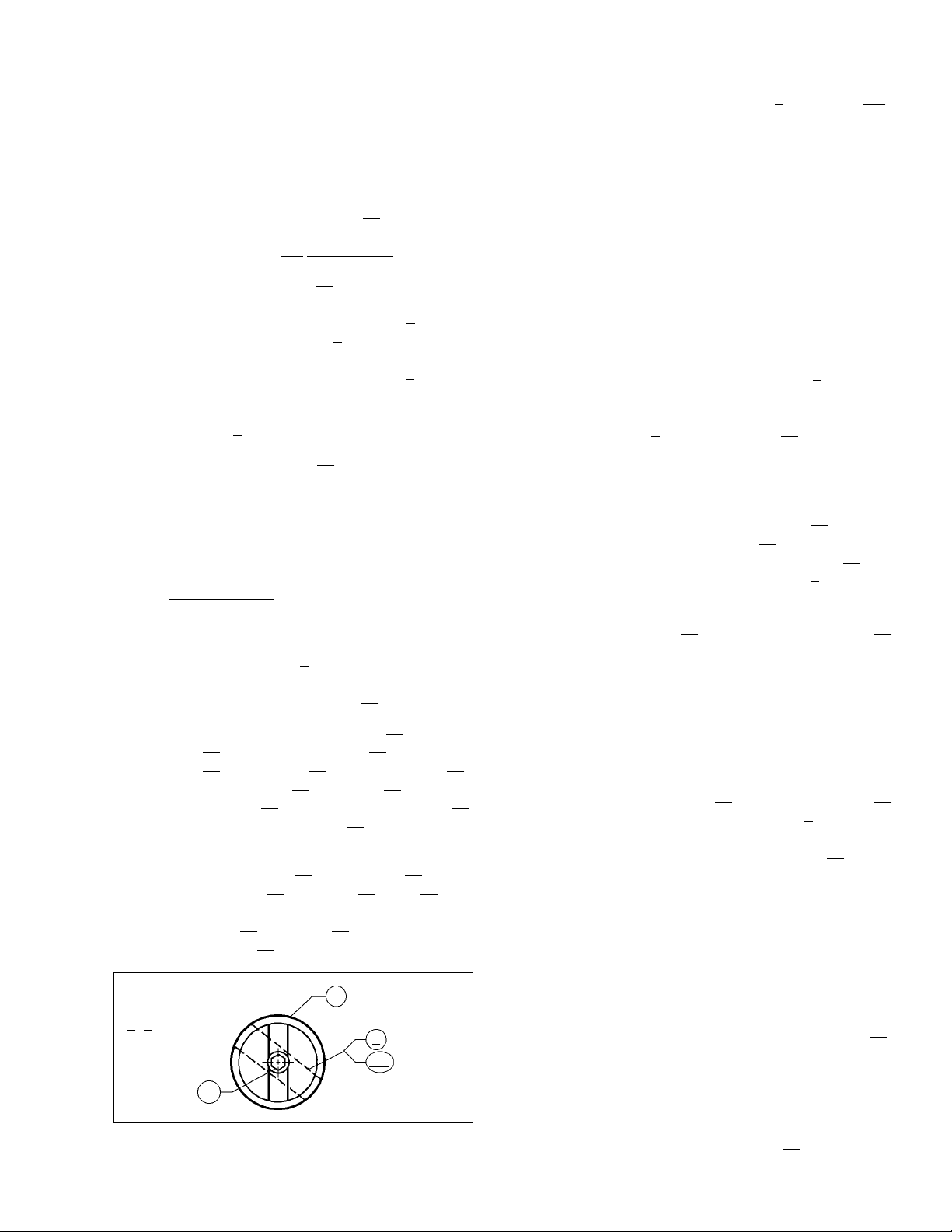

d. Position the new positioner spacer (17)

over the valve stem (7 - Ranger, 3.2 Premier) end, oriented as shown below in

Figure 2.5.

2. All indicated Item Numbers that are with

respect to IOM-48 or IOM-148 will be in parenthesis and underscored; i.e. (

32). All part Item

Numbers that are with respect to this

IOM-9520R are not underscored; i.e. (32).

NOTE:

If no handwheel (58) or adjusting screw

assembly is provided with the actuator, it is

recommended that the rod end (9) be uncoupled from the arms (5) by removal of bolt

(40). See IOM-48 or IOM-148. Use of air

loading into the actuator casing (1) is possible, but introduces safety considerations;

i.e. use “tools” and not “fingers” inside the arm

housing (4) area.

3. Remove cover plate (20).

4. Steps to change the mounting and stem interconnection between the valve end-of-shaft

and the positioner unit. These changes bring

the positioner into compliance with NAMUR

Standard VDI/VDE #3845.

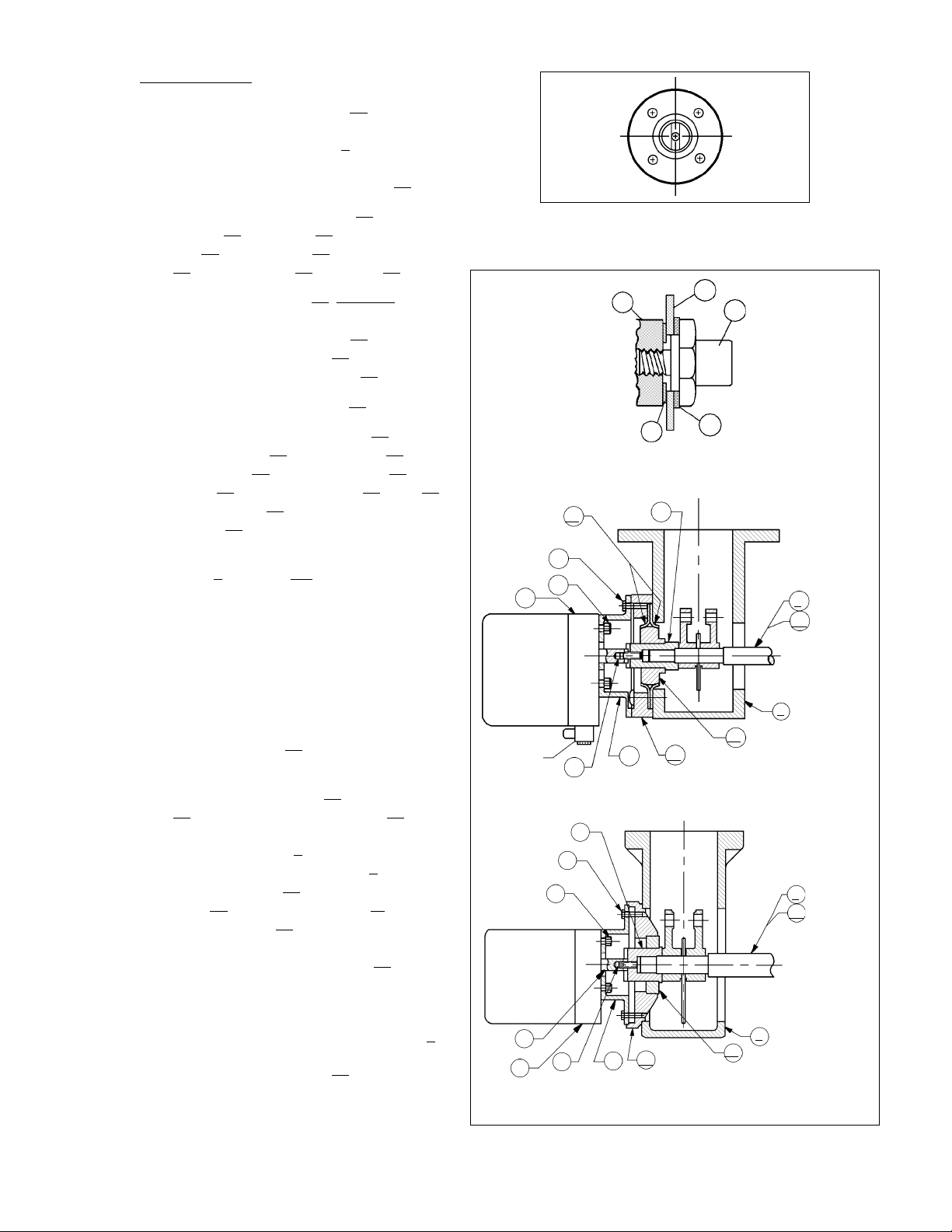

#48 Actuator: (See Figure 3)

a. Turn actuator handwheel CW to remove

stem windup torque. The linkage from the

actuator stem (9) will become slack. May

require 1-3 revolutions. This will ease

removal of cap screws (31).

b. Remove three cap screws (31), dial lens

(14), travel indicator dial (15), cover plate

(13), cap screw (32), travel indicator (16),

lock washer (55) and pin (51). Remove

bearing (18), both bearing flanges (19)

and indicator spacer (17).

c. Discard removed dial lens (14), travel

indicator dial (15), cap screw (32), travel

indicator (16), washer (55), pin (51) and

indicator spacer (17). Save only cover

plate (13), bearing (18) and both bearing

flanges (19) for re-use.

(Viewed looking

17

Actuator Casings

1, 2) on Topside

(

77

at Shaft end.)

Ranger

7

Premier

3.2

Figure 2.5: Spacer Orientation

e. Put Locktite #242 thread locking sealant,

or equal, onto the set screw (77). Engage

the set screw (77) into the tapped end of

the spacer (17), until the set screw (77) is

projecting out of the spacer (17)

3/16" – 1/4" (5 – 6 mm).

f. Position positioner baseplate (26) to

positioner mounting bracket (76) properly

oriented such that positioner baseplate

(26) bottom edge is parallel to the bottom

edge actuator arm housing (4). Opposite

side boltholes of bracket (76) must also

align with boltholes of actuator arm housing (4) and cover plate (13). Use four cap

screws (79) to secure the baseplate (26)

to the bracket (76). Place connected

parts (26, 76, 79) aside.

g. Position bearing flanges (19) with re-

tainer ball bearing (18) over the spacer

(17). Align the bearing flange (19) bolt

holes with the arm housing (4) bolt holes.

h. Position cover plate (13) over the bearing

flanges (19) aligning the cover plate (13)

bolt holes with those of the bearing

flanges (19). Hold cover plate (13) on

outer edge with fingers. NOTE:

Ensure

that the three tapped holes in the cover

plate (13) used to mount the bracket (76)

are near the 1 o'clock, 5 o'clock and 9

o'clock positions.

Engage three cap

screws (31) to secure spacer (17), bearing flanges (19) and cover plate (13)

securely to arm housing (4). NOTE

: It

may be necessary to rotate the actuator

manual handwheel operator (58) downwards, or alternately supply a small level

of air pressure (5-7 psig, .34 - .50 Barg) to

assist in aligning bolt holes for cap screws

(31). Do not tighten one cap screw (31)

until all three cap screws are partially

thread-engaged.

i. Position connected parts (26, 76, 79) of

Step 4f., above, with the bracket (76) up

and pressing against the cover plate (13),

engaging the tongue-and-groove joint

between the positioner baseplate rotary

shaft (32) and the spacer (17) with its

protruding set screw (77). Engage new

cap screws (78) to secure the bracket

(76) to the cover plate (13).

IOM-9540R

3

Page 4

#148 Actuator: (See Figure 3)

a. Turn actuator handwheel (

58) CW to remove stem windup torque. The linkage

from the actuator stem (9) will become

slack. May require 1-3 revolutions. This

will ease removal of cover plate (13).

b. Remove four cap screws (34), two cap

screws (31), dial lens (14), travel indicator

dial (15), cap screw (32), travel indicator

(16), lock washer (55) and pin (51).

c. Remove cover plate (13) carefully, prying

out with a screwdriver or similar instrument. Shaft-end bearing (18) may slide

out when cover plate (13) is removed;

otherwise, remove bearing (18).

d. Remove indicator spacer (17).

e. Discard removed dial lens (14), travel

indicator dial (15), coverplate (13), two

cap screws (31), travel indicator (16), cap

screw (32), indicator spacer (17), pin (51)

and washer (55). Save only four cap

screws (34) for re-use.

f. Position the spacer (17) over the valve

stem (7 Ranger, 3.2 Premier) end, oriented as shown in Figure 2.5.

g. Put Locktite #242 thread locking sealant,

or equal, onto the setscrew ( 77). Engage

the setscrew (77) into the tapped end of

the spacer (17), until the setscrew (77) is

projecting out of the spacer (17) 3/16"–

1/4" (5–6 mm).

h. Position bearing (18) over the spacer (17)

and push fully inwards.

i. Position cover plate (13) over bearing

(18) ensuring that cover plate (13) gets

properly centered and shouldered within

the arm housing (4). Align the four bolt

holes within the arm housing (4). Engage

the cap screws (34) to secure the cover

plate (13) to the arm housing (4), tightening cap screws (34) evenly. NOTE

: It may

be necessary to rotate the actuator

manual handwheel operator (58) downwards, or alternately supply a small level

of air pressure (5-7 psig), (0.35-0.50

Barg) to assist in properly shouldering the

cover plate (13) within the arm housing (4).

5. Rotate handwheel operator (58) until slack, or

release all air pressure from the actuator.

6. Position mounting bracket (76) onto the

positioner base plate (26) and secure with

78

79

26

POSITIONER

SUB-ASSY.

GAUGE

BLOCK

79

POSITIONER

SUB-ASSY.

32

77

26

Figure 2.8: VDI/VDE #3845

Positioner Mounting Bracket

32

28

24

27

Detail of Parts

23, 24, 27, 28, 32

76

17

13

19

77

MODEL 48 ACTUATORS

17

78

13

76

MODEL 148, 148X

ACTUATORS

Figure 3

23

18

18

RANGER

7

PREMIER

3.2

4

7

RANGER

3.2

PREMIER

4

IOM-9540R4

Page 5

13

31

Main

Positioner

Unit

21

17

Figure 4 - Rear View

four cap screws (79). The bracket should end

up with four holes to mount the positioner unit

and its baseplate (26) as shown in Figure 2.8.

7. Attach the baseplate and mounting bracket

(76) assembly to housing cover (13) using

four cap screws (78). Align baseplate (26) to

be parallel with bottom of valve's arm housing

(4). See III.C. NOTE:

Engage the tongueand-groove joint between the positioner

baseplate rotary shaft (32) and the spacer

(17) with its protruding set screw (77).

12. As shown in Figure 4, attach the feedback lever

(13) onto the positioner unit’s main shaft (17) by

hand-tightening socket cap screw (21). DO

NOT WRENCH TIGHTEN SCREW (21).

13. Remove the two plastic screws in the right side

of the main positioner unit where cap screws

(11) would be inserted. (See Figure 5.)

14. Begin to set the main positioner unit near its

final position on baseplate (26). Using needle

nose pliers grasp compensating spring (18)

and “hook” the end of the spring (18) under the

lower side of the feedback lever as indicated

in Figure 5.

Main Positioner

Unit

G2

11

12

WC

G2 = Air Supply "IAS"

G3 = Output "LOAD"

11

12

22

DC

A3

A3

"Notch"

G1

AB

33

26

8. Determine characterization cam's (24) proper

orientation as indicated in Figures 8 thru 15;

cut a spacer from wood or heavy cardboard to

the dimension “X” indicated.

NOTE:

Whether air-to-open (ATO) or air-toclose (ATC), Cashco's Ranger QCT, Premier

(unlined) or Premier EZO all rotate clockwise

(CW) to “close” valve, or counter clockwise

(CCW) to “open” valve, when viewed from

stem (7) end.

9. Place a thin film of adhesive, glue or pipe

thread sealant on the “back” side of cam (24)

to secure toothed lock washer (28) to cam

(24). Use post end screw (23) to correctly

align centers of these three parts (24, 27 &

28); do not allow the post-end screw (23) to

adhere to these parts.

10. Using the spacer of Step 8., position cam (24)

with adhered parts (27 & 28) up to the end of

positioner rotary shaft (32). Carefully screw-in

post-end screw (23) while holding cam (24) in

its approximate position. Hand-tighten postend screw (23) until certain that the washers

(27 & 28) have remained in alignment. (If

washers (27 & 28) are misaligned, the cam

(24) will not be able to be secured.)

11. Using the spacer of Step 6. above, wrenchtighten post-end screw (23) into a preliminary

position.

A1

Illustrated Position:

Ait to Close

Fail Open

24

31

17

18

AB

Figure 5

15. Position the positioner unit onto baseplate

(26), ensuring that the feedback lever’s (13)

roller is placed into contact with characterization cam (24) into the approximately proper

location. (See Figures 8 thru 15.)

16. Fasten the positioner unit to the baseplate

(26) inserting two cap screws (11) with lock

washers (12) thru the side of baseplate (26).

17. Remove the positioner cover (WC). Remove

plastic plug (33) from the upper edge of baseplate (26), allowing access to the socket cap

screw (21).

18. Press the stroke factor lever (19) (See Figure

6) of the positioner’s internals against the

travel stop pin (20) and hold firmly in place.

Using the #5 Allen wrench provided, tighten

socket cap screw (21) to the main shaft (17)

while holding the stroke factor lever (19).

Replace plastic plug (33).

11

12

13

11

12

IOM-9540R

5

Page 6

19. Install adapter block (AB) with four O-rings

(OR) to main positioner unit, with the connections oriented to the rear.

20. Install tubing fittings with acceptable thread

sealant and tubing from the unit’s 1/4” NPT

(female) “OUTPUT 1” port of the adapter

block (AB) up to the connection port of the

actuator casing. NOTE

- Thread Sealants: If

TFE tape is used, make sure that small pieces

of tape will not be “pinched off” and enter the

pneumatic internals. (Liquid thread sealants

are not recommended.)

21. Place temporary fittings and tubing so that the

positioner is able to be supplied with a 20-35

psig air supply to the “SUPPLY AIR” port of

the adapter block (AB). Supply pressure depends upon actuator bench setting; see Table

1. Using manual loader, connect a 3-15 psig

air source to the INPUT” (3-15 psig) “W” port

of the adapter block (AB).

Table 1

Actuator Bench Setting Supply Pressure, psig (Barg)

psig (Barg) Recommend Maximum

5-13 (.34-.90) 20 (1.4) 25 (1.7)

7.5-19.5 (.52-1.3) 27 (1.9) 30 (2.1)

10-26 (.69-1.8) 36 (2.5) 40 (2.8)

14-30 (.97-2.1) 44 (3.0) 45 (3.1)

(17) . If this occurs, the positioner unit must be

removed from the rotary baseplate (26). Using a

screwdriver, hand tighten the main shaft (17) by

turning CW (as viewed from main shaft (17) end)

as tightly as able while holding the stroke factor

lever (19) firmly against the travel stop pin (20).

23. Place decal (DC) onto indicator cover (22)

backside as indicated in Figure 5. Trim the decal

to remove the “120°” indication. Align the “0°”

position to the notch of the indicator cover (22);

the “0°”, “30°”, “60°” and “90°” tick-marks should

touch the outside arc of the clear portion of

indicator cover (22).

24. Check the valve’s actual position of the plug.

Place plastic red pointer (34) just barely onto

post-end screw (23). Calibrate pointer (34) to

indicator cover (22) by repositioning pointer (34)

as required. When calibration is satisfactory, press

pointer (34) firmly down over post-end screw (23).

25. Fasten clear indicator cover (22) into place using

two cap screws (A3).

26. Leave temporary air sources as installed for final

calibration, Section V, but turn off the air supply so

that no pressures are induced to the internals.

22. Slowly vary the pneumatic signal “SIG” input

and observe that the valve begins to stroke

from its failure (“LOAD” = 0 psig) position.

Observe the cam (24) to ensure that it appears

to be properly oriented. Fully stroke the valve

and observe for linkage interferences. Return

valve to closed position. Make a final

adjustment of the cam (24) using the spacer of

Step 6. Make sure that the cam follower (31)

does not enter the “valley” of the cam (24). (See

Figures 8-15.)

IMPORTANT NOTE:

If the feedback lever (13) is

turned forcibly against the travel stop pin (20), the

stroke factor lever (19) will be released from rigid

connection (unscrews) to the positioner main shaft

Figure 6

IOM-9540R6

Page 7

TABLE 2

Control Valve Positioner Plug Action Eckardt

Action/Fail Changeover Stem Travel With Signal Fail Action

Position Action Plate Setting Direction Increasing Position

ATO-FC Direct

ATC-FO Direct

ATC-FO Reverse

ATO-FC Reverse

N

U

N

U

N

U

N

U

TABLE 3

RANGE SPRING SELECTION

Input Product Product

"SIG" & Cam Color & Cam Color

psig Character P/N* Code Character P/N* Code

Light Olive

3-15 -08000- Yellow -08001- Green

Light Olive

3-9 -08000- Yellow Ranger - -08001- Green

Ranger - Light Linear Olive

9-15 =% -08000- Yellow or -08001- Green

Olive Premier Light

3-7 -08001- Green =% -08002- Gray

Olive Light

7-11 -08001- Green -08002- Gray

Olive Light

11-15 -08001- Green -08002- Gray

* Complete Cashco part number (P/N) is as shown in Figure 7. Table 3 indicates the

missing numbers of the complete P/N; general P/N = 830-69-5-_ _ _ _ _-00.

CW to Close

CCW to Open

CW to Close

CCW to Open

CW to Close

CCW to Open

CW to Close

CCW to Open w/o Signal

Opens Closed

Closes Open

Opens Closed

Closes

Open

PART COLOR NO

NO. CODE COILS

light

830-69-5-08002-00 7 -1/4

830-69-5-08001-00 6 -3/4

830-69-5-08000-00 5 -3/4

gray

olive

green

light

yellow

Figure 7

RANGER QCT

Inner wall of

baseplate (26)

X

Signal = min

Output Load = min

Valve Position = closed

IOM-9540R

CHARACTERIZATION CAM SELECTION & ORIENTATION

VS. CONTROL VALVE ACTION –

RANGER & PREMIER PRODUCTS

RANGER QCT

31

Signal = min

Output Load = max

Valve Position = open

X ≈ 1/2" ≈ 12.7 mm

31

Characteristic: = %

Actuator Action: ATO-FC

Positioner Action: Direct

31

Signal = max

Output Load = max

Valve Position = open

24

Figure 8

Inner wall of

baseplate (26)

Figure 9

Characteristic: = %

Actuator Action: ATO-FC

Positioner Action: Reverse

X

24

31

Signal = max

Output Load = min

Valve Position = closed

7

Page 8

RANGER QCT

Inner wall of

baseplate (26)

24

X

RANGER QCT

Inner wall of

baseplate (26)

X

Signal = min

Output Load = min

Valve Position = open

Characteristic: = %

Actuator Action: ATC-FO

Positioner Action: Direct

Inner wall of

baseplate (26)

X

24

Signal = min

Output Load = min

Valve Position = closed

X ≈ 13/16"

X ≈ 18 mm

31

Figure 10 Figure 11

PREMIER EZO

or PREMIER

Characteristic: =%

X ≈ 5/64"

X ≈ 2 mm

31

31

Output Load = max

Valve Position = closed

RANGER QCT

Characteristic: Linear

24

31

Output Load = max

Valve Position = open

24

Signal = max

Actuator

Action:

ATO-FC

Positioner

Action:

Direct

Signal = max

=%

Signal = min

Output Load = max

Valve Position = closed

Characteristic: = %

Actuator Action: ATC-FO

Positioner Action: Reverse

PREMIER EZO

or PREMIER

Characteristic: =%

31

Signal = min

Output Load = max

Valve Position = open

24

X ≈ 1/2" ≈ 12.7 mm

31

Inner wall of

baseplate (26)

X ≈ 5/64"

X ≈ 2 mm

24

=%

31

Output Load = min

Valve Position = open

24

Signal = max

RANGER QCT

Characteristic: Linear

X

24

Actuator

Action:

ATO-FC

Positioner

Action:

Reverse

31

Valve Position = closed

Signal = max

Output Load = min

PREMIER EZO

or PREMIER

Characteristic: =%

31

Signal = min

Output Load = min

Valve Position = open

Figure12

Inner wall of

baseplate (26)

X

24

X ≈ 5/64"

X ≈ 2 mm

RANGER QCT

Characteristic: Linear

24

31

Output Load = max

Valve Position = closed

Actuator

Action:

ATC-FO

Positioner

Action:

Direct

Signal = max

Inner wall of

baseplate (26)

X

24

Signal = min

Output Load = max

Valve Position = closed

Figure 13

PREMIER EZO

or PREMIER

Characteristic: =%

X ≈ 5/64"

X ≈ 2 mm

31

Figure 15Figure 14

RANGER QCT

Characteristic: Linear

24

31

Output Load = min

Valve Position = closed

IOM-9540R8

Actuator

Action:

ATC-FO

Positioner

Action:

Reverse

Signal = max

Page 9

IV. BASIC ADJUSTMENTS/SETTINGS

A. Required Tools:

The following tools are required for the basic

adjustment:

1. Screwdriver

2. Open-end wrench - 6 mm

3. Feeler gauge 0.6 mm (.24 in)

4. Two test gauges - 30 psig (for 20 psig max

bench range); One test gauge - 30 psig, and

one test gauge - 60 psig (for 30 psig max

bench range)

5. Manual loader/airset

6. Open-end wrench - 10 mm

7. Needle nose pliers; small

8. #5 Allen wrench (5 mm) (provided)

B. Manual Bypass Setting: (See Figure 16)

1. There are two positions for the pneumatic

bypass switch (3) to be in:

“EIN” - Positioner is active (ON); this is the

factory set position.

“AUS” - Positioner is inactive (OFF), and the

input “SIG” is passed directly to the actuator,

bypassing the positioner internals.

2. “EIN” or “AUS” are labels cast into the baseplate (BP). To bypass, loosen the bypass

screw (2) CCW to release the bypass switch’s

(3) rotor; two full revolutions of the bypass

screw (2) will be required. Rotate the bypass

switch (3) CW 90° to move to bypass (AUS);

rotate CCW to activate the positioner (EIN).

The bypass switch (3) has a rib on its outer

edge that indicates the position of the bypass

switch (3). When adjustments are completed,

retighten bypass screw (2). DO NOT LEAVE

AT AN INTERMEDIATE POSITION; PLACE

AT “EIN” OR “AUS” ONLY.

SECTION IV

2. The “N” and “U” are labels cast into the

surface of the changeover plate (15). If necessary, to change action loosen CP screw (4) to

removal. Lift the changeover plate (15) and its

CP gasket (16) and replace them to align the

label with the arrow as desired. Replace and

re-tighten changeover plate screw (4).

3. If action of positioner unit is changed, the

characteristic cam (24) must be checked, as

re-orientation is normally required. See Section III for proper cam (24) shape and installation orientation. See Section III for steps to

follow in proper cam (24) installation.

D. Range Spring Selection:

1. Each positioner unit is supplied with a color

coded range spring (41). Figure 7 shows the

springs; alternate identification can be made

by counting the number of coils. The range

spring (41) to be utilized is indicated in Table 3.

2. To remove/change the range spring (41) see

Figure 17; hold stroke factor lever (19) against

the travel stop pin (20) and simultaneously

hold the zero thumbscrew (39). Using needle

nose pliers, remove the end of the range

spring (41) hooked to the flapper lever (38);

then remove the opposite end. Reverse the

procedure with the new/different range spring

(41). Always make sure that the range spring’s

(41) coils are closest to the flapper lever (38).

3. After removal/change of the range spring

(41), recalibration is required. See Section V.

NOTE:

hereafter have the two internal gauges removed.

C. Action Setting:

1. Refer to Table 2 to see the graphical indicated

position of the changeover plate (15). The

indicator arrow is located on the edge of the

baseplate (BP). There are two positions this

pneumatic switch (3) can be in:

“N” - Direct action

“U” - Reverse action

IOM-9540R

For picture clarity, all photographs

Figure 16

9

Page 10

V. CALIBRATION/ADJUSTMENTS

A. ZERO and STROKE Setting: (See Figure 17)

1. After settings of Section IV have been completed, place separate manual loaders to

supply the positioner with air (“IAS”) and

develop a variable 3-15 psig signal (“SIG”) as

the input.

Figure 17

2. Recheck character cam (24) position carefully. Loosen post-end screw (23) and

retighten as required to maintain dimension

“X” spacing per Figures 8 thru 15. Valve may

need to be stroked to ‘full open” or “full closed”

position to allow measurement of “X”. (

Do not locate cam follower (31) in "valley” of

the equal % or linear cams (24) at either end

of stroke: follower (31) will always be slightly

out of the “valley

to ensure proper cam (24) orientation.

3. If the positioner has an input “SIG” of 3-15,

3-9, or 3-7 (i.e. full stroke is a 15 psig, 9 psig,

or 7 psig “SIG” respectively for DIRECT

action; zero stroke at a 15 psig, 9 psig, or 7

psig “SIG” respectively for REVERSE action),

skip Step 4. following, and go to Step 5.

4. If the positioner is split ranged for 9-15 or

11-15 psig “SIG” input (i.e. zero stroke is at a

9 psig or 11 psig “SIG” respectively for

DIRECT action; full stroke is at a 9 psig or 11

psig “SIG” respectively for REVERSE action),

then follow this procedure:

”.) Stroke valve thru full travel

SECTION V

NOTE:

c. See Figures 4 and 5. Remove plastic plug

(33). Loosen screw (21) securing the feedback lever (13) on the backside of the unit to

the main shaft (17) using the #5 (5 mm) metric

Allen wrench provided. Manually move the

stroke factor lever (19) away from the tip of the

stop pin (20) a distance of approximately 1/4”

- 3/8” using some form of spacer; i.e. folded

cardboard, etc. Re-tighten feedback lever (13)

to main shaft (17). Remove the temporary

spacer. Replace plastic plug (33).

d. Introduce an air supply (“IAS”) to the positioner

as required by Table 1.

e. Press the flapper lever (38) several times to

the left and right until the flappers are correctly

aligned.

f. Set the minimum input “SIG” with the manual

loader; i.e. 9 psig for 9-15 psig, 11 psig for 1115 psig.

g. Turn zero thumbscrew (39) CW, increasing

tension of range spring (41), until the actuator

begins to move away from its zero (shelf)

position. (If adjustment does not cause valve

response, turn off air supply (“IAS”) and return

to 4.c. above; increase the temporary spacer

thickness in increments of 1/8” and repeat

steps until the valve does move.) Care should

be taken to ensure that the stroke factor lever

(19) does not over-travel from the starting

point to the point where the stroke factor lever

(19) will hit the housing cover (WC), before

reaching its end position - approximately 39°

rotation.

h. Induce the maximum input “SIG” with the

manual loader; i.e. 15 psig for 9-15 psig or 1115 psig.

I. Turn the stroke factor thumbscrew (40) CW;

this shortens the valve stroke with respect to

the “SIG” change; i.e. less air pressure required to reach valve’s maximum stroke position. Once valve stem moves with each CW

adjustment of the stroke factor thumbscrew

(40), reverse to CCW rotation of stroke factor

thumbscrew (40) and precisely adjust up to

the maximum stroke position of the control

valve.

a. Shut off supply air (“IAS”; i.e. 0 psig).

b. Release all tension on range spring (41)

by turning zero thumbscrew (39) CCW.

j Repeat Steps e. and h. a minimum of three

times, as under this adjustment of Steps b.

and c. above, the STROKE and ZERO adjustments are mutually dependent; i.e. interacting.

IOM-9540R10

Page 11

k. If procedures of Step 4. above have been

completed, skip Step 5. following, and go

to next paragraph V.B.

5. Press the flapper lever (38) several times to

the left and right until the flappers are correctly

aligned.

a. Induce the minimum value of the input

signal (“SIG”) using a manual loader.

(This corresponds to the start of the valve’s

stroke.)

b. Turn the zero thumbscrew (39) either CW

or CCW until the actuator begins to cause

valve stem travel. Precisely adjust to the

point where travel just begins.

c. Induce the maximum value of the input

“SIG”. (This corresponds to the end of the

valve’s stroke.)

d. Turn the stroke factor thumbscrew (40)

first CCW until observing the shortening

of the valve’s stroke (less than 90°). Turn

the stroke factor thumbscrew (40) CW

until the valve travel (90°) is precisely at

its full stroke.

e. Recheck the ZERO and STROKE set-

tings. They should repeatable. Under this

procedure for adjustment, the ZERO and

STROKE calibrations are mutually independent (i.e. non-interacting, when the

feedback lever (13) and travel stop pin

(20) are properly installed and positioned).

B. Setting GAIN: (See Figure 18)

1. Increasing GAIN increases the sensitivity of

the positioner to change in the input “SIG”.

GAIN is normally factory set when mounted

by the factory, and should not require field

adjustment.

3. A change in GAIN is normally indicated when

instability/sluggishness shows up at steady

state operating conditions. If the positioner

output “LOAD” seems to rapidly oscillate (psstpsst-psst...), too much gain is present and

GAIN setting should be reduced until stability

is reached. If the positioner output “LOAD”

does not react to small changes in the “SIG”,

insufficient GAIN may be present; increase

GAIN until instability (psst-psst-psst...) is

present, then reduce as described previously.

This procedure allows the gain of the control

loop to match the dynamic requirements of

the control system.

4. Determine whether GAIN should increase or

decrease based on above text. To increase

GAIN, rotate throttle screw (42) CW; to decrease GAIN, rotate throttle screw (42) CCW.

To prevent over-adjustment, the throttle screw

(42) is located within the limiting screw (43).

This allows the throttle screw (42) to only be

adjustable a total of approximately one revolution from maximum to minimum. Thus, GAIN

should be adjusted slowly in very small increments.

5. If GAIN is adjusted, ZERO resetting may be

required. Repeat Procedure V.A.

C. Setting DAMPING: (See Figure 18)

1. Increase DAMPING introduces extra time constant to the output “LOAD” of the positioner.

DAMPING should be increased/decreased

depending on the time observed for the

positioner to respond to a large change in

input “SIG” during a non-steady state operating condition.

2. The open loop gain varies with the supply

IOM-9540R

“IAS” pressure, and the values represent linear amplification. Table 4 is a guide to the gain

available for each range spring (41) utilized:

TABLE 4

Supply Pressure Adjustable

psig (Barg) Range

20 (1.4) 150:1

27 (1.9) 140:1

36 (2.5) 124:1

44 (3.0) 113:1

Figure 18

11

Page 12

2. DAMPING is factory set, and normally requires minimal/no adjustment. However, if

determined as required, DAMPING is adjustable from a minimum-to-maximum ratio of

1:2.5. In its normal factory set position, the

damping screw (44) is set approximately flush

SECTION VI

with the amplifier housing (53); this position is

minimum DAMPING . As the damping screw

(44) is screwed CW - inwards, DAMPING

increases. DAMPING may be increased by

up to approximately three full revolutions of

the damping screw (44), which will represent

maximum DAMPING.

VI. MAINTENANCE

A. Adjustment of the Positioner: (See Figure 19)

1. Component adjustment is only required when

the positioner has been disassembled or subassemblies have been exchanged. All settings performed in order to match the positioner

to the actuator are described in Sections IV.

and V.

2. See Section IV.A. for a list of required tools.

necessary, loosen the AMPLIFIER mounting screws on the rear of the positioner

and align the amplifier (53) sub-assembly

accordingly; this will require removal of

the main positioner unit from the rotary

baseplate (26). )

e. Press the flapper lever (38) several times

alternately to the left and right, so that the

ball-and-socket mounted flappers (52) are

aligned parallel to the nozzles (51).

f. Press the flapper lever (38) to the left. Set

the clearance between the nozzle (51)

and the flapper (52) to 0.6 mm (0.024 in.)

with the aid of a feeler gauge by turning

the hexagonal adjuster (56) with 6 mm

wrench. Secure the nut against further

turning using sealing paint.

g. Connect the positioner as shown in the

test circuit in Figure 20. Provide an “IAS”

of 60-100 psig.

h. Press the flapper lever (38) to the left. If

the output does not rise to the level of the

supply air pressure, either leaks are

present or the flapper (52) is not correctly

aligned (repeat e. above).

Figure 19

3. If adjustments are made with the positioner

mounted on the control valve, the feedback

lever (13) on the main shaft (17) of the

positioner must be loosened. (See Section

III.D.11.-12.).

a. Set the changeover plate (15) to “N”.

b. Turn the throttling screw (42) CW to its

stops (maximum GAIN).

c. Unhook the range spring (41) from the

flapper lever (38).

d. Check that the flappers (52) are aligned

concentrically with the nozzles (51). (If

I. Hook the range spring (41) onto the flap-

per lever (38), and provide a mid-range (9

psig for 3-15 psig signal range, 6 for 3-9,

12 for 9-15, etc.) input “SIG” to port “Input

W” (3-15 psig) using a manual loader.

Test Gauge

Input

W

MANUAL

LOADER

AIRSET

SIG

Output

1

Supply

3-15 psig

Air

See Table 2

for pressure

required

Output

2

LOAD

Figure 20

IOM-9540R12

Test Gauge

IAS

IAS

Page 13

4. The following procedure must be observed in

order to achieve a no-feedback adjustment of

the ZERO and STROKE setting.

a. Press the stroke factor lever (19) against

the travel stop pin (20).

4. Turn the throttle screw (42) in again as far as

it goes CW.

5. Turn the limiting screw (43) in as far as it goes

CW; then back it out CCW about half a revolution.

b. Set the stroke factor thumbscrew (40) to

a high stroke factor (approximately 5/64”

before the upper stop).

c. Turn the zero thumbscrew (39) until the

output pressure is mid-range of “SIG”

span and make a note of this value.

d. Set the stroke factor thumbscrew (40)

to a low stroke factor (approximately

5/64” before the lower stop). The output

pressure may not vary by more than

±0.003 psig as compared with the setting

described in c. above.

e. In case of excessive deviations, the travel

stop pin (20) should be adjusted. Whenever the travel stop pin (20) is adjusted,

the settings described in b. to d. should be

repeated until the deviation is less than

±0.003 psig.

f. Seal the travel stop pin (20) with sealing

paint.

5. Return the changeover plate (15) to its original positioner if it was “U”. Re-tighten the

feedback (13) lever onto the main shaft (17) of

the positioner (see Section III.D.8. & 9.).

6. Secure the limiting screw (43) with sealing

paint.

C. Replacing the Amplifier: (See Figure 21)

1. Unhook the range spring (41) from the flapper

lever (38).

2. Unscrew and remove the amplifier (53) subassembly; the two amplifier mounting screws

are accessible from the rear of the positioner.

3. Install a new amplifier (53). Do not forget the

O-rings between the amplifier and the baseplate (BP) (air baffle). Before tightening, carefully align the mounting screws, position the

amplifier (53) in such a way that the flappers

(52) are concentrically aligned with the nozzles

(51).

4. Hook the range spring (41) onto the flapper

lever (38).

5. Perform a maintenance basic adjustment and

recalibrate per Section IV, V and VI.

6. Go thru a complete calibration/adjustment

procedure as described in Section V.

B. Cleaning the Throttle Screw: (See Figure 18)

1. Unscrew CCW the limiting screw (43). If you

can’t pull it out by hand, unscrew CCW the

throttle screw (42) and remove both by hand.

2. Pull the throttle screw (42) out of the limiting

screw (43).

3. Place the throttle screw (42) in solvent (e.g.

benzene) and blow through it carefully. It is

best to clean in an ultrasonic solvent bath.

IOM-9540R

Figure 21

13

Page 14

VII. TROUBLE SHOOTING GUIDE

1. Actuator does not respond to applied input signal.

Possible Causes Remedies

A. Amplifier defective A1. Replace amplifier (See VI.C.).

B. Pneumatic connections reversed B1. Check connections.

C. Feedback lever not tightened C1. Screw feedback lever tight (See III.D.9.).

D. Stroke factor lever is loose on the shaft D1. Tighten shaft.

E. Positioner mounted on the wrong side E1. Check mounting side in accordance with table in Section III.

F. Changeover plate in the wrong direction F1. Check setting in accordance with table in Section III.

2. Output pressure does not reach its maximum.

Possible Causes Remedies

A. Amplifier throttle dirty A1. Remove and clean throttle (See VI.B.).

B. Supply air too low B1. Check supply air pressure.

C. Flappers not parallel with nozzles C1. Align flappers (See VI.A.3.d.-f.).

D. Supply air filter dirty D1. Replace filter.

3. Actuator moves to end position.

SECTION VII

Possible Causes Remedies

A. Positioner mounted on wrong side A1. Check mounting side in accordance with table in Section III.

B. Feedback lever not tightened B1. Tighten feedback lever.

C. Stroke factor lever loose on shaft C1. Tighten shaft (See III.B.).

4. Unstable behavior; non-steady state in control loop.

Possible Causes Remedies

A. Amplification too high A1. Reduce amplification.

B. Gland friction on the valve too high B1. Loosen gland packing somewhat or replace.

C. Mislocated Cam C1. Loosen cam and relocate follower out of “valley” and

higher up on lobe.

5. Stroke range cannot be adjusted.

Possible Causes Remedies

A. Wrong range spring A1. Replace range spring (See IV.D.).

B. Positioner does not completely reduce B1. Check supply air pressure.

pressure B2. Check amplification.

B3. Adjust clearance between nozzle and flapper.

6. Positioner makes “buzzing” noise.

Possible Causes Remedies

A. Wrong action setting A1. Check the position of the bypass switch and the action.

Change as required.

IOM-9540R14

Page 15

REPAIR PARTS KITS

Kit A: Includes gaskets, O-rings and small parts.

Order P/N 295-08-5-07410-00

Kit B: Replacement pneumatic amplifier.

Order P/N 653-75-5-09542-00

APPENDIX A

Removal of Model 9000R P/P Positioner

1. Reference Section III.D. Existing Control Valve

Modifications, paragraphs 1. and 2.

2. Remove positioner unit (101) by removing four

socket cap screw (33).

3. Remove range spring (102).

4. Remove both machine screws (37).

5. Remove feedback pivot link shaft (74), both spacers

6. Install new cover plate (

7. Re-install both machine screws (37).

8. Discard unused parts at user’s discretion.

NOTES

(109), and feedback linkage assembly (73).

22), re-using socket cap

screws (33).

IOM-9540R

15

Page 16

Cashco, Inc.

P.O. Box 6

Ellsworth, KS 67439-0006

PH (785) 472-4461

FAX (785) 472-3539

www.cashco.com

E-mail: sales@cashco.com

Printed in U.S.A. IOM-9540R -dlb

exportsales@cashco.com

Loading...

Loading...