Page 1

INSTALLATION, OPERATION AND MAINTENANCE MANUAL (IOM)

I. DESIGN AND FUNCTION:

IOM-8900

09-10

8900 Series

Emergency Relief Vents

Pressure Only or Pressure/Vacuum

SECTION I

The 8900 Series is classifi ed as an Emergency Relief

Vent (ERV). The design allows it to be used as an

emergency pressure only vent or a pressure/vacuum

vent. This Series of Vents can be constructed as top

guided or hinged design. Depending on the pressure

requirement, vents can be assembled using a stack

of weights or springs to achieve the desired set point

pressure.

The 8900 Series can provide emergency pressure

and vacuum relief beyond that furnished by the

normal pressure/vacuum vent for atmospheric and

low pressure tanks, as well as providing a convenient

access for tank cleaning, inspection and repair.

Emergency Pressure Relief Vents provide relief from

excessive internal pressure which may be caused

by an abnormal condition, such as ruptured internal

heating coils, an external fi re or a failure of the tank

blanketing system. Some Models are also design to

provide emergency vacuum relief as a result of loss

of pressure casued by a break in the tank wall or a

nozzle being dislodged from the base of the tank or

sudden cooling of the tank.

The 8900 Series provides an effective vapor

tight seal when the tank is not under emergency

conditions. If the tank outbreathing requirements

exceed the capacity of the normal pressure relief

vent, under emergency conditions, the pallet opens

to allow escape of the vapors, preventing damage

to the tank due to excessive pressure. The intergal

vacuum vent allows high fl owing relief from the same

unit.

This vent design is rugged but light weight for easy

handling, inspection and maintenance. For Models

8910 and 8920 removal of the pallet assembly allows

unobstructed access to the inside of the tank. For

Models 8930 and 8940 use handle to raise the

weighted pallet assembly and gain access to the

inside of the tank.

Product Selection Guide

Vent Function Guiding Model

Pressure Relief

Pressure/Vacuum Relief 8920

Pressure Relief

Pressure/Vacuum Relief 8940

Top Guided

(Spring Loaded)

Hinged

8910

8930

Page 2

SECTION II

II. INSTALLATION:

CAUTION

When installing any Valve Concepts venting device,

any safety regulations and procedures appropriate to

the specifi c plant site must be understood and followed

in accordance with that facilities corporate legal and

advisory policies.

CAUTION

DO NOT attempt to change pressure settings, either by

adding additional weight to the pallet assembly or by

changing the spring compression without consulting

the factory.

Handle the 8900 Series carefully to insure seat

tightness. Units could be damaged by over tightening

the studs or mounting it on a tank nozzle fl ange that

is not horizontal.

Carefully inspect the relief vent to insure that

there are no packing materials inside or around

the vent housing.

Before placing the vent on the tank nozzle, the fl ange

face on the tank and the vent should be inspected.

The standard vent is supplied with fl at face fl anges

and can mate with 150# ASME or API 650 fl anges.

The connecting fl anges must be fl at within 0.015”

(.381 mm), clean and free of scratches, corrosion

and any tool marks.

Inspect the gasket and make sure it is compatible

for the service. It is recommended to use a full

faced gasket to avoid defl ection of the body fl ange.

The vent should be installed using a wire cables

or straps connected to the lifting lugs/eyebolts (39)

located around the fl ange base. This will prevent

any damage to the hood.

Lubricate all studs and nuts with an appropriate

thread lubricant. If stainless steel fasteners are

used, select an anti-seize lubricant such as molydisulfi de.

Align the gasket with the bolt circle of the fl ange.

Lower the vent body carefully on the nozzle fl ange;

keep the gasket between the fl anges. Install the

studs and tighten the nuts by hand.

Using an alternating star pattern, tighten all the

fasteners to one-half recommended torque - see

Table 1. Make sure that the fl anges are not distorted

and that the gasket is evenly compressed. Finish

tightening fasteners to torque values in Table 1.

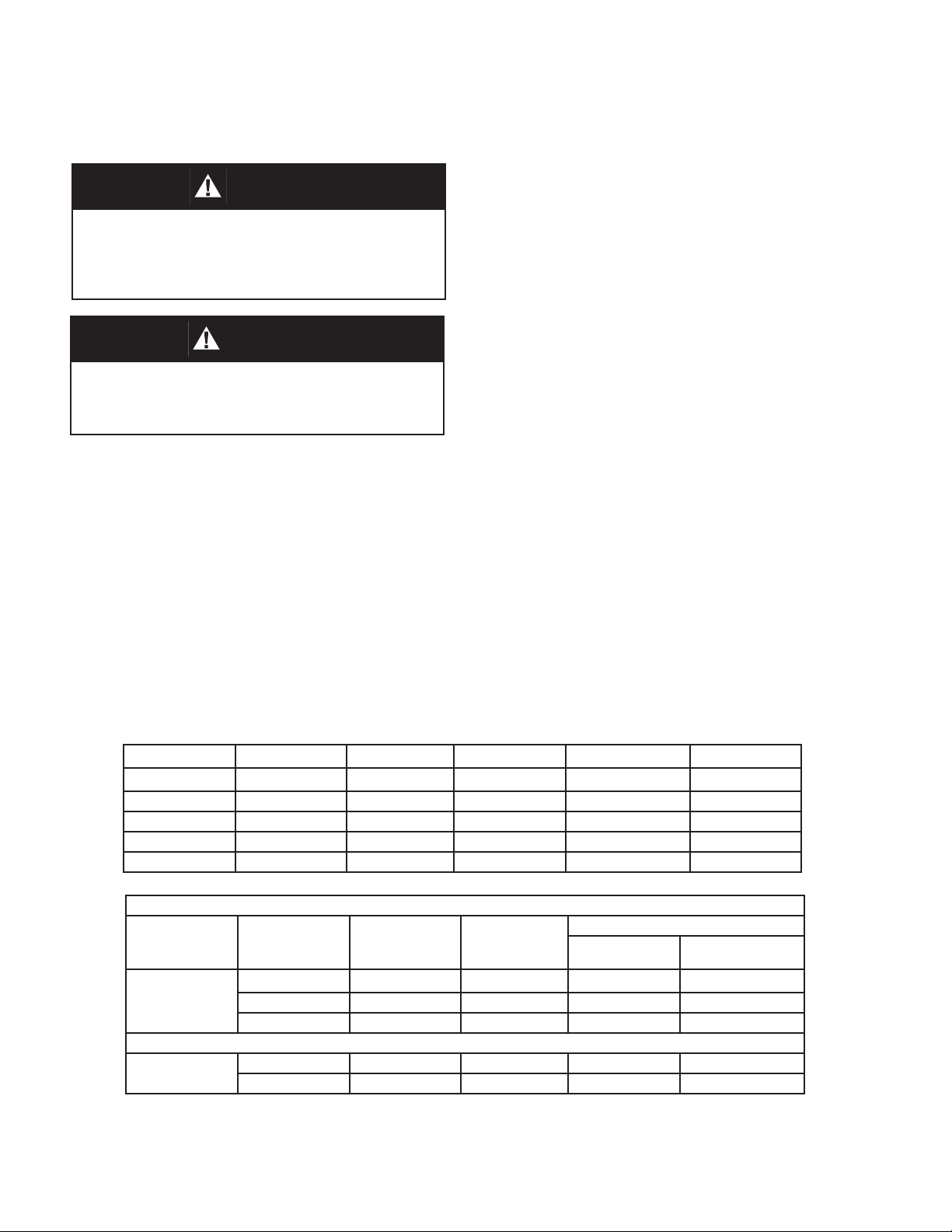

Gasket Dimensions

FLANGE TYPE O.D. in. I.D. in. B.C. in Bolt Hole in. Quantity

16” - 150# 23.50” 15.25’ 21.25” 1.13” 16

20 - 150#” 27.50” 19.25” 25.00” 1.25” 20

24” - 150# 32.00” 23.25” 29.50” 1.38” 20

20” - API 650 26.00” 19.25” 23.50” .75” 16

24” - API 30.00” 23.25” 27.50” .75” 20

TABLE 1

Flange

Type

150# ASME

API # 650

Size

16” 16 1.000 52 104

20” 20 1.125 63 110

24” 20 1.250 86 148

20” 20 0.625 35 53

24” 20 0.625 43 61

Qty

Holes

Bolt

(in)

(UNC)

Raised Face Flat Face

2

Torque (ft-lbs)

IOM-8900 Series

Page 3

III. MAINTENANCE:

SECTION III

The 8900 Series vents do not require any sort of

routine lubrication or adjustments, but should be

checked as part of a routine plant maintenance

program to confi rm that the vents are operating

properly. The ERV is a protection device and as

such will not normally cycle when in service.

In order to inspect the pallets and pallet diaphragms

for damage the vent must be removed from the tank

nozzle. Follow all safety guidelines your company

has to decommission a vent for inspection. Cashco/

Valve Concepts does not recommend that a vent be

removed from a tank in service due to the potental

of hazardous tank vapors or fl ammable tank vapors.

SECTION IV

IV. DISASSEMBLY of the 8910 and 8920 Guided - Spring Loaded Relief Vents:

See page 8 for a listing of parts. For Model 8910 (Figure 1) disregard item numbers 5 - 25, 28, 36, 40 - 60, 62

- 74 and 76. These parts are for vacuum service option for the Model 8920 and do not pertain to the pressure

only function of the 8910.

DISASSEMBLY FOR INSPECTION

To remove the vent from the tank nozzle, loosen

and remove the fl ange bolts and nuts from the tank

nozzle and fl ange seat (1). Attach lifting cables or

straps to the lifting lugs/eyebolts (39). Be sure to

utilize all lifting lugs in order to keep the unit stable

during lifting and transportion.

SPRING UNDER COMPRESSION. Relieve spring

com pres sion per following steps. Failure to do

so may result in fl ying parts that could cause

personal injury.

B. Removal of Vacuum Spring - 8920 Only:

WARNING

WARNING

SPRINGS UNDER COMPRESSION. Relieve spring

com pres sion per following steps. Failure to do so

may result in fl ying parts that could cause personal

injury.

A. Removal of Pressure Springs:

1. Place the vent fl ange (1) on a fl at work

surface. Measure the length of each compressed

spring (33) from the top surface of the pressure

pallet (3) to the top edge of the upper spring button

(34). Place a tag on each spring (33) and record

the height measurement for each. These values

will be required at re-assembly to reset the vent

spring pressure prior to installation.

2. Loosen and remove one “top” nut (35) from

each of the adjusting screws (31). Rotate remaining

nut (35) CCW evenly in 1/2” (13 mm) increments

to prevent unequal loads on the pallet/diaphragm

assembly. Continue this process until all nuts (35)

are removed.

3. Lift up to remove upper spring buttons (34)

(hole w/small I.D.) and springs (33).

1. Remove cap screws (28) from the weather

hood (11) and lift off upper spring canister (15).

Measure the length of the pallet stem (21), top edge

of stem to the top surface of the upper spring button

(14). Record this value. It will be required during reassembly to reset the vacuum range spring pressure

prior to installation.

Length of pallet stem ________

NOTE: DO NOT allow vacuum pallet assembly

(18) to fall as disassembly continues.

2. Rotate each nut (25) CCW one at a time to

remove and to release the compression of the spring

(16). NOTE: May need to grasp a section of the

threaded stem (21) with soft-jawed pliers to prevent

rotation of the pallet assembly (18). Maintain grip

on stem (21) while carefully lowering vacuum pallet

assembly (18) to rest on work surface below.

Lift up to remove upper vacuum spring button (14)

and spring (16).

NOTE: If vent was not supplied with a fl ame screen

(5) remove lower spring button (14) and lower spring

canister (13). If vent included a fl ame screen, before

removing button (14) and canister (13), draw match

“marks” between fl ange face of the lower spring

canister (13) and weather hood (11).

IOM-8900 Series

3

Page 4

C. Removal of Pressure Pallet Assembly:

1. Rotate nut (35) CCW three revolutions

on each adjusting screw (31) to loosen connection

between adjusting screw and pallet guide (30).

Grasp adjusting screws (31) with hand and rotate

each one CCW to remove adjusting screws and

travel stops (37).

2. Remove lower spring buttons (32) (hole w/

large I.D.). NOTE: Not necessary to remove pallet

guides (30) or guide pin (75). (Factory installed with

Loctite - torqued to 15 ft-lbs.)

3. Carefully lift the pallet assembly (3) up off

the fl ange seat (1), so not to damage the seating

surface. Inspect the seat surface for any damage

including but not limited to nicks and corrosion. If

damage is found, the seat should be relapped

or remachined to smooth fi nish. If remachining

is required, contact Cashco/Valve Concepts for

assistance.

D. Inspection of Diaphragms:

1. Position the pressure pallet assembly (3) on

a work bench with the diaphragm (2) side face up.

3. According to stack orientation of the

diaphragms E.1 previous, lay new diaphragms (2) in

the pallet (3) groove. Align holes in diaphragm (2)

bolt circle over studs (29) in the pressure pallet (3).

4. Position diaphragm retainer ring (4) over

studs (29) resting fl at against the diaphragms (2).

Install 1 lock washer (26) and 1 nut (27) to each stud

(29), tighten to 5 ft. lbs. NOTE: Do not allow studs

(29) to rotate and protrude out the backside of the

pallet (3), end point of studs should be fl ush.

NOTE: For Model 8910 Vents proceed to IV. H.

For Vacuum Pallet:

1. Place threaded end of pallet stem ( 21) in a

soft-jaw vise with pallet (18) face up.

2. Remove the cotter pin (56), nut (24), lock

washer (23), and the fl at washer (22).

3. Remove vacuum pallet (18) and diaphragm

(19). Clean pallet (18), especially the pallet groove

and inspect for nicks or sctatches. NOTE: Vacuum

pressure set point will dictate the quantity and stack

orientation of diaphragms. Record diaphragm’s

stack orientation for re-assembly.

2. Inspect the diaphragms (2,19) on both

pallet assemblies (if applicable) for any signs of

damage. Damages may include but are not limited

to tears, crinkles/creases, and holes. If it is deemed

that the diaphragm(s) need to be replaced, proceed

with following steps to replace. If they are deemed

to be in good condition, inspect the vacuum seat

ring (8) for similar damages as for the fl ange seat

(1) seating surface. These include but are not

limited to nicks and corrosion. If damage is found,

the seat surface may be relapped. If relapping the

seating surface does not create a suitable seating

surface, a new seat ring is required. Contact your

local representative for assistance. Provide Serial

Number, Product Code & Set Point Pressure(s) to

place an order for parts.

E. Diaphragm Replacment:

For Pressure Pallet:

1. Remove hex nuts (27), lock washers (26),

and diaphragm retainer ring (4) from the pallet.

NOTE: Pressure set point will dictate the quantity

and stack orientation of diaphragms. Record

diaphragm’s stack orientation for re-assembly.

4. Install new diaphragm(s) (19) over short

threaded end of stem (21) onto retainer plate (20).

Apply a light coat of TFE paste on the top surface

of the last diaphragm (19) around the edge of the

center hole.

5. Place vacuum pallet (18) with the machined

groove facing down on the diaphragm (19). Apply a

light coat of TFE paste to short threaded end of stem

(21).

6. Install fl at washer (22), lock washer (23)

and nut (24) onto the protruding threads of the stem

(21). Use a torque wrench to tighten nut to 15 ft-lbs.

7. Insert cotter pin (56) thru small hole in the

stem (21) and wrap prongs around stem.

F. Vacuum Seat Ring Replacement:

- For ERV without Flame Screen:

NOTE: Installation of the pressure pallet diaphragms

should be completed prior to installation of the

vacuum seat ring.

2. Remove diaphragm (2). Clean the pressure

pallet (3), especially the pallet groove, and inspect

for nicks or scratches.

4

1. Re-Orient the pressure pallet assembly (3)

with vacuum seat ring (8) face down - use 4” x 4”

blocks as support. DO NOT ALLOW DIAPHRAGM

(2) OR RETAINER RING (4) TO REST ON THE

BLOCKS.

IOM-8900 Series

Page 5

2. Rotate cap screws (36) CCW to remove

weather hood (11). Remove screen (6). Around

the bolt circle of the weather collar (7) place match

“marks” to indicate the location of each weather

hood support (10).

3. Rotate each support (10) CCW and remove.

Rotate seat ring nuts (73) CCW to remove nuts,

lockwashers (74), weather collar (7) and gasket (5).

of pallet stem (21) protrude thru upper spring button

(14). With other hand, thread one jam nut (25) on to

pallet stem (21).

NOTE: Check to ensure that as the pallet assembly

(18) is lifted upwards that the vacuum seat ring (8)

is centered and aligned with vacuum pallet (18)

assembly.

WARNING

4. Re-Orient the pressure pallet assembly (3)

with the seat ring (8) face up, again resting on the

blocks. Rotate cap screw (9) CCW and remove seat

ring (8) and seat ring gasket (5).

6. Clean sealing surfaces on seat ring (8) and

both sides of pressure pallet (3).

7. Install new seat ring gasket (5). Position

seat ring (8) on gasket (5), align holes and thread

cap screws (9) into pallet using a star pattern and

tighten to 15 ft. lbs.

8. Re-Orient the pressure pallet assembly (3)

with the seat ring (8) face down, again resting on the

blocks. Position new gasket (5) and weather collar

(7) over cap screws (9).

9. Using the “marks” per 2. previous, install the

weather hood supports (10) on the weather collar

and tighten to 15 ft-lbs.. On remaining cap screws,

install lock washers (74), nuts (73) and tighten to 15

ft-lbs..

10. Reposition the screen (6) around the

weather hood supports (10). Align holes in weather

hood (11) with holes in supports (10) and install cap

screws (36), torque to 15 ft-lbs. Install lower canister

(13) into weather hood (11).

11. From underside of pressure pallet (3)

assembly slide vacuum pallet (18) assembly threaded end of stem (21) fi rst, up through center

hole of lower canister (13).

12. Into the open end of the canister, install

lower spring button (14) and spring (16) over stem

(21) into the lower canister (13). Make sure that

lower spring coil rests inside the retainer groove of

the lower spring button (14).

13. Place upper spring button (14) on top of

vacuum spring (16). Make sure that top spring coil

rests inside the groove of the spring button.

SPRING UNDER COMPRESSION. Exercise caution to avoid accidental spring release. Vacuum

spring (16) is now under compression and the accidental release of force may result in fl ying parts

that could cause personal injury.

15. Continue to rotate jam nut (25) CW until

the height from the top of the pallet stem (21) to the

top of the upper spring button (14) is equal to the

value recorded per B.1. previous.

16. Thread a second jam nut (25) on pallet

stem (21). Secure tight against fi rst jam nut (25).

17. Place upper spring canister (15) over

vacuum spring (16), align bolt holes in canister

fl anges.

18. Insert cap screws (28) into fl ange bolt

holes and tighten snug - torque to 10 ft-lbs. NOTE:

DO NOT over tighten screws. Proceed to “H”.

G. Vacuum Seat Ring Replacement:

- For ERV with Flame Screen:

NOTE: Installation of the pressure pallet diaphragms

should be completed prior to installation of the

vacuum seat ring.

1. Orient the pressure pallet assembly (3) and

vacuum seat ring (8) face up. Note alignment of

the three cap screws in bottom of the lower spring

canister (13) with respect to the location of the cap

screws (9) around the weather collar (7). Place

match “marks” on fl ame screen (40) and on weather

collar (7) to indicate correct alignment of the fl ame

screen bolt holes during re-assembly of the fl ame

screen.

2. To dis-assemble fl ame screen from lower

spring canister (13) rotate three cap screws (28)

CCW and remove. NOTE: Support lower spring

canister (13) and lower spring button (14) from

below as cap screws are removed. They may fall

out of weather hood.

14. Place one hand on the upper spring button

(14) and compress the spring (16) until the threads

IOM-8900 Series

5

Page 6

3. Re-Orient the pressure pallet assembly (3)

with vacuum seat ring (8) face down - use 4” x 4”

blocks as support. DO NOT ALLOW DIAPHRAGM

(2) OR RETAINER RING (4) TO REST ON THE

BLOCKS.

4. Rotate cap screws (36) CCW to remove

weather hood (11). Remove screen (6). Around

the bolt circle of the weather collar (7) place match

“marks” to indicate the location of each weather

hood support (10).

5. Rotate each support (10) CCW and remove.

Rotate seat ring nuts (73) CCW to remove nuts,

lockwashers (74), weather collar (7), weather collar

(41) and fl ame screen (40).

6. Re-Orient the pressure pallet assembly (3)

with the seat ring (8) face up, again resting pressure

pallet on the blocks. Rotate cap screw (9) CCW and

remove seat ring (8) and seat ring gasket (5).

7. Clean sealing surfaces on seat ring (8) and

both sides of pressure pallet (3).

8. Install new seat ring gasket (5). Position

seat ring (8) on gasket (5), align holes and thread

cap screws (9) into pallet using a star pattern and

tighten to 15 ft. lbs.

9. Re-Orient the pressure pallet assembly (3)

with the seat ring (8) face down, again resting on the

blocks. Position fl ame screen (40), weather collar

gasket (41) and weather collar (7) over cap screws

(9). Ensure match marks are in alignment per G.1

and bolt holes.

14. From underside of pressure pallet assembly

slide vacuum pallet (18) assembly - threaded end of

stem (21) fi rst - up through the center hole of the

lower canister (13).

15. Install spring (16) over stem (21) and into

lower canister (13). Ensure that lower spring coil

rest inside the retainer groove of the lower spring

button (14).

16. Place upper spring button (14) on top of

vacuum spring (16). Make sure that top spring coil

rests inside the groove of the spring button.

17. Place one hand on the upper spring button

(14) and compress the spring (16) until the threads

of pallet stem (21) protrude thru upper spring button

(14). With other hand, thread one jam nut (25) on to

pallet stem (21).

NOTE: Check to ensure that as the pallet assembly

(18) is lifted upwards that the vacuum seat ring (8)

is centered and aligned with vacuum pallet (18)

assembly.

WARNING

SPRING UNDER COMPRESSION. Exercise caution to avoid accidental spring release. Vacuum

spring (16) is now under compression and the accidental release of force may result in fl ying parts

that could cause personal injury.

18. Continue to rotate jam nut (25) CW until

the height from the top of the pallet stem (21) to the

top of the upper spring button (14) is equal to the

value recorded per B.1. previous.

10. Using the “marks” per G.4. previous, install

the weather hood supports (10) on the weather collar

and tighten to 15 ft-lbs. On remaining cap screws

install lock washers (74), nuts (73) and tighten to 15

ft-lbs.

11. Reposition the screen (6) around the

weather hood supports (10). Align holes in weather

hood (11) with holes in supports (10) and install cap

screws (36), torgue to 15 ft-lbs.

12. With open end up, install lower spring

button (14) into lower canister (13) and position both

through the weather hood (11).Ensure alignment of

holes between fl ame screen (40), lower canister

(13) and lower spring button (14).

13. From below the pressure pallet assembly

(3) insert three cap screws to secure fl ame screen to

lower canister and spring button - tighten to 10 ft-lbs.

6

19. Thread a second jam nut (25) on pallet

stem (21). Secure tight against fi rst jam nut (25).

20. Place upper spring canister (15) over

vacuum spring (16), align bolt holes in canister

fl anges.

21. Insert cap screws (28) into fl ange bolt

holes and tighten snug - torque to 10 ft-lbs. NOTE:

DO NOT over- tighten cap screws.

H. Re-assemble Pallet to Flange Seat:

1. Lift pallet (3) sub-assembly up to a suffi cient

height to pass over tops of pallet guides (30). Lower

sub-assembly coming to rest on the fl ange seat (1).

NOTE: Check to ensure that as the pallet assembly

(3) is lowered, the fl ange seat (1) is centered and

aligned with pressure pallet (3) assembly.

IOM-8900 Series

Page 7

2. With open end up, place lower pressure

spring buttons (32) (hole with large I.D.) over pallet

guides (30) coming to rest on pressure pallet.

6. Place upper pressure spring buttons (34)

on springs (33), make sure springs are seated in the

spring button retaining groove.

3. Position travel stops (37) on top of pallet

guides (30) and thread adjusting screw (31) thru

stops and into top of pallet guides (30) hand tighten.

Make sure that adjusting screws (31) threads are

engaged fully into the pallet guides (30).

4. Rotate nuts (35) CW and wrench tighten

against travel stops (37).

5. Slide pressure springs (33) over adjusting

screws (31), make sure springs are seated in the

spring button retaining groove.

7. Thread one jam nut (35) CW onto each

adjusting screw (31). Recalling the values recorded

for the compressed height of each spring per A.1.

previous; continue to rotate jam nuts CW using a star

pattern until the height from the top of the pressure

pallet (3) to the top of the upper spring button (34) is

equal to the recorded value for each spring.

8. Thread a second jam nut (35) onto each

adjusting screw (31) tighten two nuts against each

other.

SECTION V

V. INSPECTION / DIAPHRAGM REPLACEMENT for 8930 and 8940 Hinged - Relief Vents:

See page 14 for a listing of parts. For Model 8930 (Figure 3) disregard item numbers 5 - 8, 10 - 16, 18 - 24, 28,

40, 56, and 73 - 74. These parts are for vacuum service option for the Model 8940 and do not pertain to the

pressure only function of the 8930.

To remove the vent from the tank nozzle, loosen

and remove the fl ange bolts and nuts from the tank

nozzle and fl ange seat (1). Attach lifting cables or

straps to the lifting lugs/eyebolts (39). Be sure to

utilize all lifting lugs in order to keep the unit stable

during lifting and transportion. Place the vent fl ange

(1) on a fl at work surface.

B. Diaphragm Replacment:

1. Remove hex nuts (27), lock washers (26),

and diaphragm retainer ring (4) from the pallet.

NOTE: Pressure set point will dictate the quantity

and stack orientation of diaphragm(s). Record

diaphragm’s stack orientation for re-assembly.

Model 8930 & 8940:

A. Inspection of Pressure Pallet Diaphragm:

1. Grasp handle (70), lift up to raise and open

the weighted pallet assembly.

2. Inspect the diaphragm(s) (2) on the

pressure pallet assembly for any signs of damage.

Damages may include but are not limited to tears,

crinkles/creases, and holes. If it is deemed that

the diaphragm need to be replaced, proceed with

following steps to replace. If the seating surface

(1) is damaged, the seat surface may need to be

relapped. If relapping the seating surface does not

create a suitable seating surface, a new fl ange seat

(1) is required. Contact your local representative for

assistance. Provide Serial Number, Product Code &

Set Point Pressure(s) to place an order for parts.

IOM-8900 Series

2. Remove diaphragm(s) (2). Clean the

pressure pallet (3), especially the pallet groove, and

inspect for nicks or scratches.

3. According to stack orientation of the

diaphragms B.1 previous, position new diaphragm(s)

(2) in the pallet (3) groove. Align holes in diaphragm

(2) bolt circle over the cap screws (49) in the pressure

pallet (3).

4. Position diaphragm retainer ring (4) over

cap screws (49). Install 1 lock washer (26) and 1 nut

(27) to each cap screw (49), tighten all nuts to 5 ft.

lbs.

5. Close the pressure pallet assembly. Return

to Section II for Installation.

7

Page 8

Model 8940:

A. Inspection/Replacement of Vacuum

Pallet Diaphragm:

SPRING UNDER COMPRESSION. Relieve spring

com pres sion per following steps. Failure to do

so may result in fl ying parts that could cause

personal injury.

1. Remove cap screws (28) from the weather

hood (11) and lift off upper spring canister (15).

Measure the length of the pallet stem (21), top edge

of stem to the top surface of the upper spring button

(14). Record this value. It will be required during reassembly to reset the vacuum range spring pressure

prior to installation.

WARNING

Length of pallet stem ________

7. Install new diaphragm(s) (19) over short

threaded end of stem (21) onto retainer plate (20).

Apply a light coat of TFE paste on the top surface

of the last diaphragm (19) around the edge of the

center hole.

8. Place vacuum pallet (18) with the machined

groove facing down on the diaphragm (19). Apply a

light coat of TFE paste to short threaded end of stem

(21).

9. Install fl at washer (22), lock washer (23)

and nut (24) onto the protruding threads of the stem

(21). Use a torque wrench to tighten nut to 15 ft-lbs.

10. Insert cotter pin (56) thru small hole in the

stem (21) and wrap prongs around stem.

B. Vacuum Seat Ring Replacement For ERV with Counter Weight Design:

NOTE: DO NOT allow vacuum pallet assembly

(18) to fall as disassembly continues.

2. Rotate each nut (25) CCW one at a time to

remove and to release the compression of the spring

(16). NOTE: May need to grasp a section of the

threaded stem (21) with soft-jawed pliers to prevent

rotation of the pallet assembly (18). Maintain grip

on stem (21) while carefully lowering vacuum pallet

assembly (18) to rest on work surface below.

Lift up to remove upper vacuum spring button (14)

and spring (16).

NOTE: If vent was not supplied with a fl ame screen

(5) remove lower spring button (14) and lower spring

canister (13). If vent included a fl ame screen, before

removing button (14) and canister (13), draw match

“marks” between fl ange face of the lower spring

canister (13) and weather hood (11).

3. Lift handle (70) up to raise the weighted

pallet assembly and remove the vacuum pallet

assembly (18).

4. Place threaded end of pallet stem ( 21) in a

soft-jaw vise with pallet (18) face up.

5. Remove the cotter pin (56), nut (24), lock

washer (23), and the fl at washer (22).

6. Remove vacuum pallet (18) and diaphragm

(19). Clean pallet (18), especially the pallet groove

and inspect for nicks or sctatches. NOTE: Vacuum

pressure set point will dictate the quantity and stack

orientation of diaphragms. Record diaphragm’s

stack orientation for re-assembly.

CAUTION

Use overhead support and sling to secure Counter

Weight. Failure to do so may result in falling parts

that could cause personal injury.

1. Attach sling and overhead support around

counter weight (58). Remove cotter pins (57) and

slide cables (17) off ends of pin (50).

2. Pull pin (50) out of pivot arm assembly

(46), spacers (51) and weight arm (47). Set counter weight assembly and parts aside.

3. Rotate nuts (55) CCW and remove. Push

hinge pin (52) through pivot arm assembly (46).

Lift pallet and vent hood assembly up to remove

from fl ange seat (1) assembly.

4. Proceed to Step D. or E.

C. Vacuum Seat Ring Replacement For ERV with Stack Weight Design:

1. Rotate top nuts (36) CCW and remove

nuts, lock washers (68) and fl at washers (67).

2. Lift up to remove stack of pressure weights

(64). Maintain stack orientation, do not remove or

add any weight that will change the factory calibarated pressure setpoint.

3. Rotate nuts (55) CCW and remove. Push

hinge pin (52) through pivot arm assembly (46).

Lift pallet and vent hood assembly up to remove

from fl ange seat (1) assembly.

8

IOM-8900 Series

Page 9

4. Rotate lower jam nuts (36) CCW two three revolutions to loosen from weather hood.

Rotate weight studs CCW and remove from top of

weatherhood.

11. From underside of pressure pallet (3)

assembly slide vacuum pallet (18) assembly threaded end of stem (21) fi rst, up through center

hole of lower canister (13).

4. Proceed to Step D. or E.

D. Vacuum Seat Ring Replacement:

- For ERV without Flame Screen:

1. Position the pressure pallet assembly (3)

with vacuum seat ring (8) face down - use 4” x 4”

blocks as support. DO NOT ALLOW DIAPHRAGM

(2) OR RETAINER RING (4) TO REST ON THE

BLOCKS.

2. Rotate cap screws (36) CCW to remove

weather hood (11). Remove screen (6). Around

the bolt circle of the weather collar (7) place match

“marks” to indicate the location of each weather

hood support (10).

3. Rotate each support (10) CCW and remove.

Rotate seat ring nuts (73) CCW to remove nuts,

lockwashers (74), weather collar (7) and gasket (5).

4. Re-Orient the pressure pallet assembly

(3) with the seat ring (8) face up, again resting on

the blocks. Rotate cap screw (9) CCW and remove

seat ring (8) and seat ring gasket (5).

6. Clean sealing surfaces on seat ring (8) and

both sides of pressure pallet (3).

7. Install new seat ring gasket (5). Position

seat ring (8) on gasket (5), align holes and thread

cap screws (9) into pallet using a star pattern and

tighten to 15 ft. lbs.

8. Re-Orient the pressure pallet assembly (3)

with the seat ring (8) face down, again resting on the

blocks. Position new gasket (5) and weather collar

(7) over cap screws (9).

9. Using the “marks” per 2. previous, install the

weather hood supports (10) on the weather collar

and tighten to 15 ft-lbs.. On remaining cap screws,

install lock washers (74), nuts (73) and tighten to 15

ft-lbs.

10. Reposition the screen (6) around the

weather hood supports (10). Align holes in weather

hood (11) with holes in supports (10) and install

studs/jam nuts or cap screws (36), torque to 15 ftlbs. Install lower canister (13) into weather hood

(11).

12. Into the open end of the canister, install

lower spring button (14) and spring (16) over stem

(21) into the lower canister (13). Make sure that

lower spring coil rests inside the retainer groove of

the lower spring button (14).

13. Place upper spring button (14) on top of

vacuum spring (16). Make sure that top spring coil

rests inside the groove of the spring button.

14. Place one hand on the upper spring button

(14) and compress the spring (16) until the threads

of pallet stem (21) protrude thru upper spring button

(14). With other hand, thread one jam nut (25) on to

pallet stem (21).

NOTE: Check to ensure that as the pallet assembly

(18) is lifted upwards that the vacuum seat ring (8)

is centered and aligned with vacuum pallet (18)

assembly.

WARNING

SPRING UNDER COMPRESSION. Exercise caution to avoid accidental spring release. Vacuum

spring (16) is now under compression and the accidental release of force may result in fl ying parts

that could cause personal injury.

15. Continue to rotate jam nut (25) CW until

the height from the top of the pallet stem (21) to the

top of the upper spring button (14) is equal to the

value recorded per A.1. previous.

16. Thread a second jam nut (25) on pallet

stem (21). Secure tight against fi rst jam nut (25).

17. Place upper spring canister (15) over

vacuum spring (16), align bolt holes in canister

fl anges.

18. Insert cap screws (28) into fl ange bolt

holes and tighten snug - torque to 10 ft-lbs. NOTE:

DO NOT over tighten screws.

Proceed to F. or G.

E. Vacuum Seat Ring Replacement:

- For ERV with Flame Screen:

NOTE: Installation of the pressure pallet diaphragms

should be completed prior to installation of the

vacuum seat ring.

IOM-8900 Series

9

Page 10

1. Orient the pressure pallet assembly (3) and

vacuum seat ring (8) face up. Note alignment of the

three cap screws (28) in bottom of the lower spring

canister (13) with respect to the location of the cap

screws (9) around the weather collar (7). Place

match “marks” on fl ame screen (40) and on weather

collar (7) to indicate alignment of the fl ame screen

bolt holes during re-assembly of the fl ame screen.

2. To dis-assemble fl ame screen from lower

spring canister (13) rotate three cap screws (28)

CCW and remove. NOTE: Support lower spring

canister (13) and lower spring button (14) from

below as cap screws are removed. They may fall

out of weather hood.

3. Re-Orient the pressure pallet assembly (3)

with vacuum seat ring (8) face down - use 4” x 4”

blocks as support. DO NOT ALLOW DIAPHRAGM

(2) OR RETAINER RING (4) TO REST ON THE

BLOCKS.

11. Reposition the screen (6) around the

weather hood supports (10). Align holes in weather

hood (11) with holes in supports (10) and install

studs/jam nuts or cap screws (36), torgue to 15 ftlbs.

12. With open end up, install lower spring

button (14) into lower canister (13) and position both

through the weather hood (11).Ensure alignment of

holes between fl ame screen (40), lower canister

(13) and lower spring button (14).

13. From below the pressure pallet assembly

(3) insert three cap screws (28) to secure fl ame

screen (40) to lower canister (13) and lower spring

button (14) - tighten to 10 ft-lbs.

14. From underside of pressure pallet assembly

slide vacuum pallet (18) assembly - threaded end of

stem (21) fi rst - up through the center hole of the

lower canister (13).

4. Rotate cap screws (36) CCW to remove

weather hood (11). Remove screen (6). Around

the bolt circle of the weather collar (7) place match

“marks” to indicate the location of each weather

hood support (10).

5. Rotate each support (10) CCW and remove.

Rotate seat ring nuts (73) CCW to remove nuts,

lockwashers (74), weather collar (7), weather collar

(41) and fl ame screen (40).

6. Re-Orient the pressure pallet assembly (3)

with the seat ring (8) face up, again resting pressure

pallet on the blocks. Rotate cap screw (9) CCW and

remove seat ring (8) and seat ring gasket (5).

7. Clean sealing surfaces on seat ring (8) and

both sides of pressure pallet (3).

8. Install new seat ring gasket (5). Position

seat ring (8) on gasket (5), align holes and thread

cap screws (9) into pallet using a star pattern and

tighten to 15 ft. lbs.

9. Re-Orient the pressure pallet assembly (3)

with the seat ring (8) face down, again resting on the

blocks. Position fl ame screen (40), weather collar

gasket (41) and weather collar (7) over cap screws

(9). Ensure match marks are in alignment per E.1

and bolt holes.

10. Using the “marks” per E.4. previous, install

the weather hood supports (10) on the weather collar

and tighten to 15 ft-lbs. On remaining cap screws

install lock washers (74), nuts (73) and tighten to 15

ft-lbs.

10

15. Install spring (16) over stem (21) and into

lower canister (13). Ensure that lower spring coil

rest inside the retainer groove of the lower spring

button (14).

16. Place upper spring button (14) on top of

vacuum spring (16). Make sure that top spring coil

rests inside the groove of the spring button.

17. Place one hand on the upper spring button

(14) and compress the spring (16) until the threads

of pallet stem (21) protrude thru upper spring button

(14). With other hand, thread one jam nut (25) on to

pallet stem (21).

NOTE: Check to ensure that as the pallet assembly

(18) is lifted upwards that the vacuum seat ring (8)

is centered and aligned with vacuum pallet (18)

assembly.

WARNING

SPRING UNDER COMPRESSION. Exercise caution to avoid accidental spring release. Vacuum

spring (16) is now under compression and the accidental release of force may result in fl ying parts

that could cause personal injury.

18. Continue to rotate jam nut (25) CW until

the height from the top of the pallet stem (21) to the

top of the upper spring button (14) is equal to the

value recorded per A.1. previous.

19. Thread a second jam nut (25) on pallet

stem (21). Secure tight against fi rst jam nut (25).

IOM-8900 Series

Page 11

20. Place upper spring canister (15) over

vacuum spring (16), align bolt holes in canister

fl anges.

21. Insert cap screws (28) into fl ange bolt

holes and tighten snug - torque to 10 ft-lbs. NOTE:

DO NOT over- tighten cap screws.

Proceed to F or G.

arm (47). Slip cables (17) over pin (50) ends and

install cotter pins (57).

G. Assemble Pallet Assembly & Stack

Weights to Flange Seat Assembly:

1. Place pallet assembly on fl ange seat (1).

Align pivot arm (46) with hinge (60) and insert hinge

pin (52). Install nut (55).

F. Assemble Pallet Assembly & Counter

Weight to Flange Seat Assembly:

1. Place pallet assembly on fl ange seat (1).

Align pivot arm (46) with hinge (60) and insert hinge

pin (52). Install nut (55).

2. Use overhead support and sling to lift

counter weight (58). Align hole in weight arm (47)

with pin hole in arm assembly (46). Press pin (50)

through arm assembly (46), spacers (51) and weight

2. Position stack weights (64) over studs on

top of jam nuts in vent hood (11). Maintain stack

orientation, do not remove or add any weight that

will change the factory calibrated pressure setpoint.

3. Install fl at washers ( 67), lock washers (68)

and hex nuts (36). Torque to 15 ft.-lbs.

SECTION VI

VI. ORDERING INFORMATION:

NEW REPLACEMENT UNIT vs PARTS "KIT" FOR FIELD REPAIR

To obtain a quotation or place an order, please retrieve the Serial Number and Product Code that was

stamped on the metal name plate and attached to the unit. This information can also be found on the Bill of

Material (parts list) that was provided when unit was originally shipped.) (Serial Number typically 6 digits).

NEW REPLACEMENT UNIT:

PARTS "KIT" for FIELD REPAIR:

Contact your local Cashco, Inc., Sales Rep re sen ta tive with the Serial Number, Product code and the

pressure / vacuum settings. With this information

they can provide a quotation for a new unit including

a complete description, price and availability.

CAUTION

Do not attempt to alter the original construction of any

unit without assistance and approval from the factory.

All purposed changes will require a new name plate with

appropriate ratings and new product code to accomodate the recommended part(s) changes.

IOM-8900 Series

Contact your local Cashco, Inc., Sales Rep re sen ta tive with the Serial Number , Product code

and Pressure / Vacuum settings. Identify the

parts and the quantity required to repair the unit

from the Bill of Materials sheet that was provided

when unit was originally shipped.

NOTE: Those part numbers that have a quantity

indicated under "Spare Parts" in column "A”

refl ect minimum parts required for inspection

and rebuild, - "Soft Goods Kit". Those in column “B” include minimum trim replacement

parts needed plus those "Soft Goods" parts

from column "A".

If the "BOM" is not available, refer to the crosssectional drawings included in this manual for

part identifi cation and selection.

Local Sales Representative will provide quotation for appropriate Kit Number, Price and

Availability.

11

Page 12

MODEL 8910 PRESSURE ERV

Top Guided - Spring

Figure 1

12

ITEM NO. DESCRIPTION ITEM NO. DESCRIPTION

1. Flange Seat 23. Lock Washer

2. Press. Pallet Diaphragms * 24. Finsh Nut

3. Pressure Pallet 25. Jam Nut

4. Diaphragm Retainer (Press.) 26. Lock Washer

5. Seat Ring Gaskets * 27. Nut

6. Screen 28. Cap Screw

7. Weather Collar 29. Stud

8. Seat Ring 30. Pallet Guide

9. Cap Screw 31. Adjusting Screw

10. Weather Hood Support 32. Lower Press. Spring Button

11. Weather Hood 33. Pressure Spring

12. Rivet Nut 34. Upper Press. Spring Button

13. Lower Spring Canister 35. Jam Nut

14. Vacuum Spring Button 36. Cap Screw

15. Upper Spring Canister 37. Travel Stop

16. Vacuum Spring 38. Jam Nut

17. Stablizer Cable 39. Eye Bolt

18. Vacuum Pallet 40. Flame Screen

19. Vacuum Pallet Diaphragm * 41. Weather Collar Gasket *

20. Diaphragm Retainer (Vac.) 56. Cotter Pin

21. Pallet Stem 73. Seat Ring Nut

22. Flat Washer 74. Seat Ring Lock Washer

* Recommended Spare Parts 75. Pallet Guide Pin

61. Hinge Bolt (Not Shown)

IOM-8900 Series

Page 13

MODEL 8920 PRESSURE/VACUUM ERV

Top Guided - Spring

Figure 2

IOM-8900 Series

13

Page 14

MODEL 8930 PRESSURE ERV

Hinged Design

Figure 3

ITEM NO. DESCRIPTION ITEM NO. DESCRIPTION

1. Flange Seat 43. Pallet Swival

2. Press. Pallet Diaphragms * 44. Shoulder Screw - Pivo Clip

3. Pressure Pallet 45. Plain Washer - Pivo Clip

4. Diaphragm Retainer (Press.) 46. Pin Arm Assembly

5. Seat Ring Gaskets * 47. Weight Arm

6. Screen 48. Strap

7. Weather Collar 49. Cap Screw

8. Seat Ring 50. Pin - Counter Weight

9. Cap Screw 51. Spacer _ Weight Arm

10. Weather Hood Support 52. Hinge Pin

11. Weather Hood 53. Lock Washer - Pivot Clip

12. Rivet Nut 54. Cap Screw - Pivot Clip

13. Lower Spring Canister 55. Hex Nut - Hinge Pin

14. Vacuum Spring Button 56. Cotter Pin - Vacuum Pallet

15. Upper Spring Canister 57. Cotter Pin - Counter Wt. Pin

16. Vacuum Spring 58. Counter Weight (SST)

17. Stablizer Cable 59. Counter Weight (Lead)

18. Vacuum Pallet 60. Hinge

19. Vacuum Pallet Diaphragm * 61. Hinge Bolt

20. Diaphragm Retainer (Vac.) 62. Stud - Counter Weight

21. Pallet Stem - Vacuum 63. Lock Nut - Counter Weight

22. Flat Washer 64. Pressure Weight

23. Lock Washer 67. Flat Washer

24. Finish Nut 68. Lock Washer

25. Jam Nut - Canister 69. Set Screw - Slotted

26. Lock Washer 70. Handle

27. Nut 71. Handle Screws

28. Cap screw - Canister 72. Handle Lock Washer

36. Cap Screw - Weather Hood 73. Seat Ring Nut

38. Jam Nut - Lift Lug 74. Seat Ring Lock Washer

39. Eye Bolt 76. Vacuum Cover

40. Flame Screen

41. Weather Collar Gasket * * Recommended Spare Parts

14

IOM-8900 Series

Page 15

MODEL 8940 PRESSURE/VACUUM ERV

Hinged Design

Figure 4

IOM-8900 Series

15

Page 16

Valve Concepts, Inc./ Cashco, Inc.

607 W. 15th Street

Ellsworth, KS 67439

PH (785) 472-4461

FAX (785) 472-3539

www.cashco.com

email: vcisales@cashco.com

Printed in U.S.A. Series 8900

Loading...

Loading...